Data Sheet

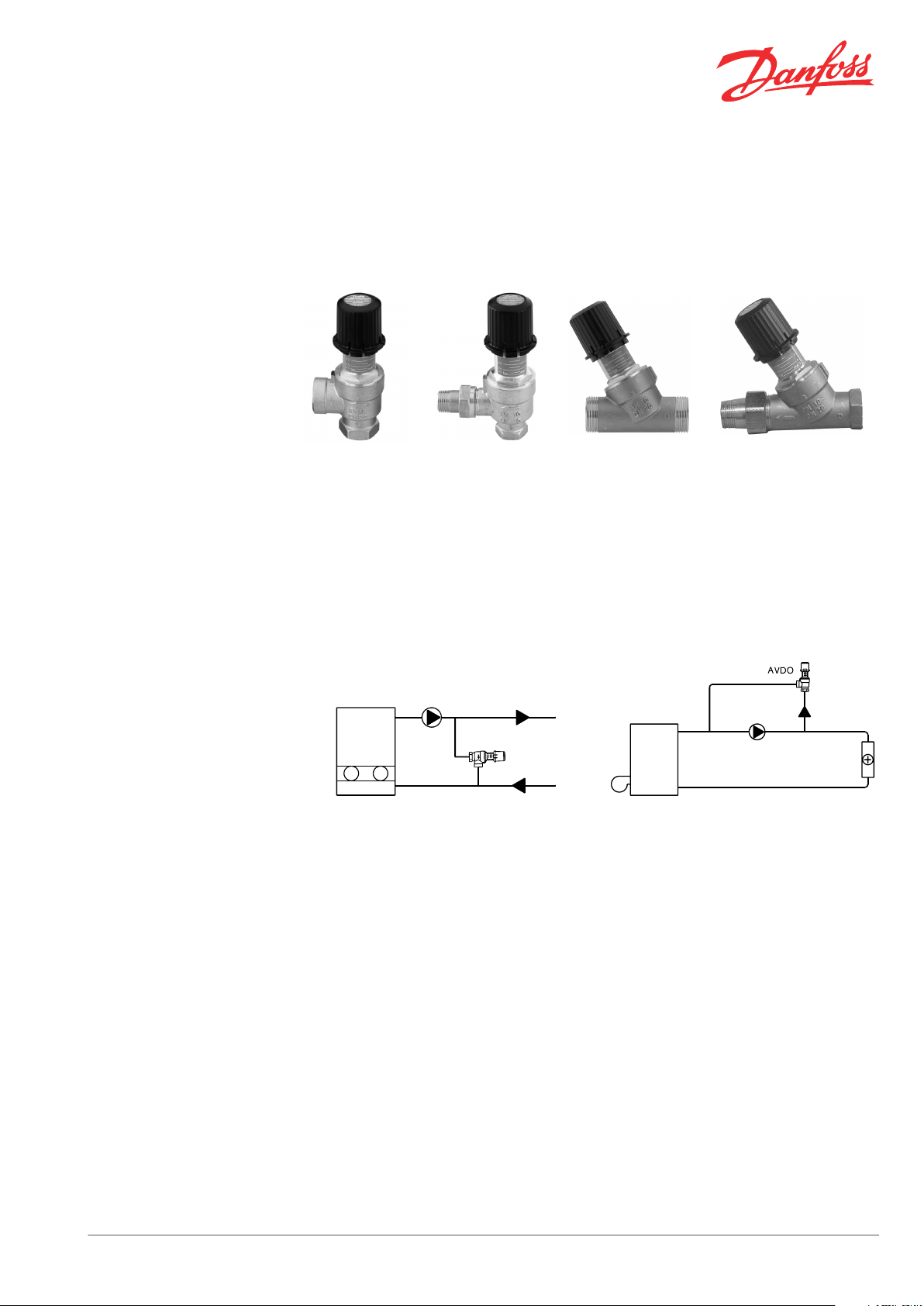

Automatic Bypass Control AVDO

Application

AVDO is a self-acting constant flow control

primarily used either to maintain minimum flow

rates through e.g. a low-capacity gas boiler or to

control the differential pressure in a central

heating system.

AVDO:

opens on rising differential pressure

▪

has a setting range of 0.05 - 0.5 bar

▪

Low-capacity gas boiler where maintenance of a min.

flow is required

is dimensioned for pressure stage PN 10,

▪

max. 120 °C

DN 15 and DN 20

▪

operates without impulse tubes

▪

On delivery valve housing is fit onto AVDO with

one of the following fittings: internal socket

thread, internal socket thread/nipple or external

thread for compression fittings.

Differential pressure control

Danfoss Heating Solutions VD55K902 © Danfoss 02/2011 1

Q

[m³/h]

∆P [bar]

Q

[m³/h]

∆P [bar]

Data Sheet Automatic Bypass Control AVDO

Ordering

Type Setting range, Connection Code no.

bar Inlet Outlet

AVDO 15

AVDO 20

AVDO 25

AVDO 15

AVDO 20

AVDO 25

AVDO 15

AVDO 20

AVDO 25

AVDO 15

AVDO 20

AVDO 25

1)

According to ISO 7/1

2)

According to ISO 228/1

0.05 - 0.5

0.05 - 0.5

0.05 - 0.5

0.05 - 0.5

Rp ½

Rp ¾

Rp 1

Rp ½

Rp ¾

Rp 1

G ¾ A

G 1 A

G 1 ¼ A

Rp ½

Rp ¾

Rp 1

1)

1)

1)

1)

1)

1)

2)

2)

2)

1)

1)

1)

R ½

R ¾

1)

R 1

R ½

R ¾

1)

R 1

G ¾ A

G 1 A

G 1 ¼ A

R ½

R ¾

1)

R 1

1)

1)

1)

1)

1)

1)

2)

2)

2)

003L6002

003L6007

003L6012

003L6003

003L6008

003L6013

003L6020

003L6025

003L6030

003L6018

003L6023

003L6028

Accessories (supplied in boxes of 10)

Copper tube fittings Code no.

AVDO 15

AVDO 20

Ø 16 x 1 013U0131

Ø 18 x 1 013U0132

Ø 18 x 1 013U0134

Ø 22 x 1 013U0135

AVDO 25 Ø 28 x 1 013U0140

Technical Data

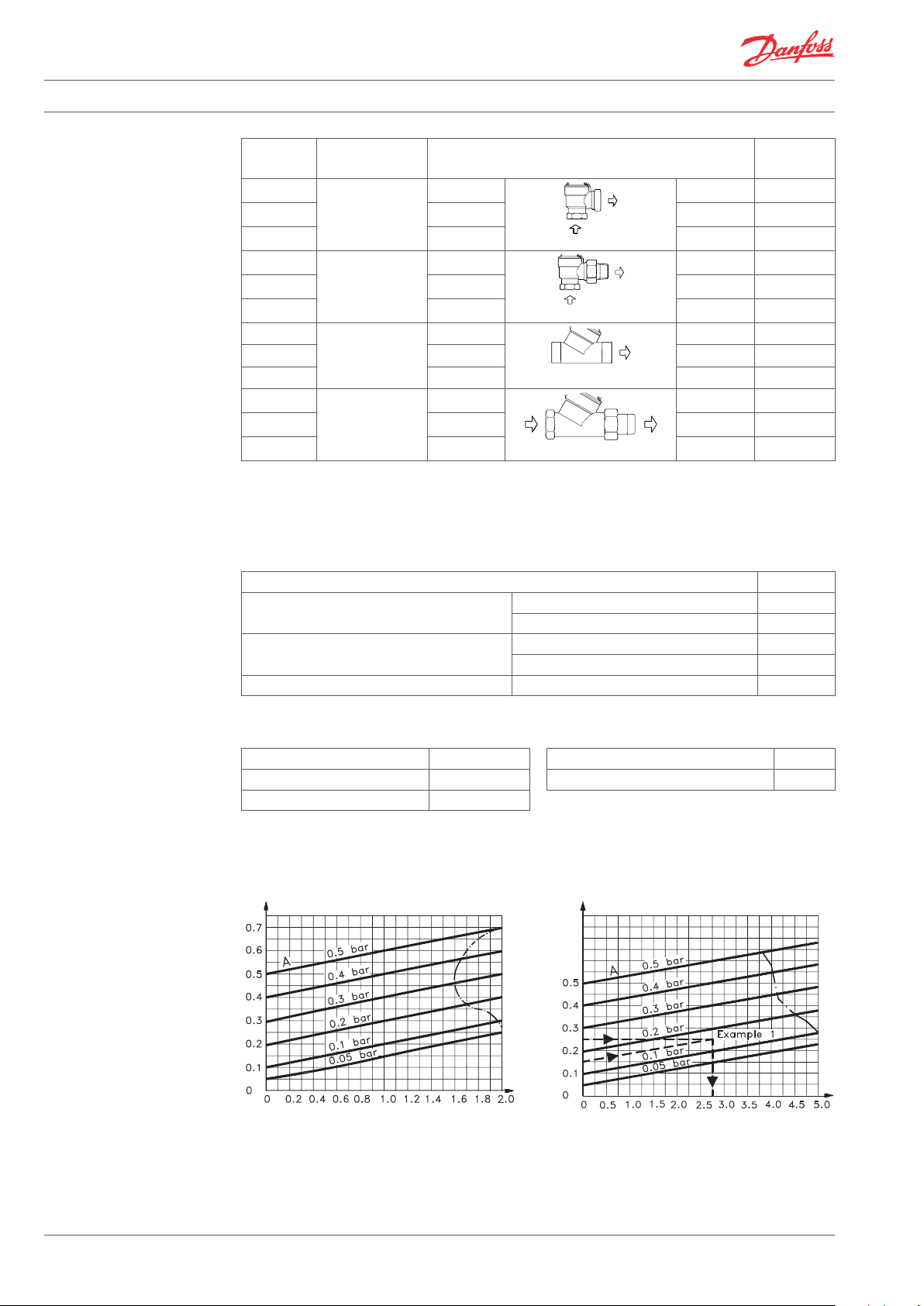

Capacities

Setting range: 0.05 - 0.5 bar

Max. differential pressure 0.5 bar

Max. flow temperature 120 °C

Max. leakage at closed valve 50 l/h

Operation pressure PN 10

AVDO 15 AVDO 25

2 VD55K902 © Danfoss 02/2011 Danfoss Heating Solutions

Q

[m³/h]

∆P [bar]

Data Sheet Automatic Bypass Control AVDO

AVDO 20

A = set opening pressure

∆P = ∆p for valve

– - – = Upper limit graph

for recommended

application area with

almost noiseless

installation.

Measurement conditions

according to ISO 3743.

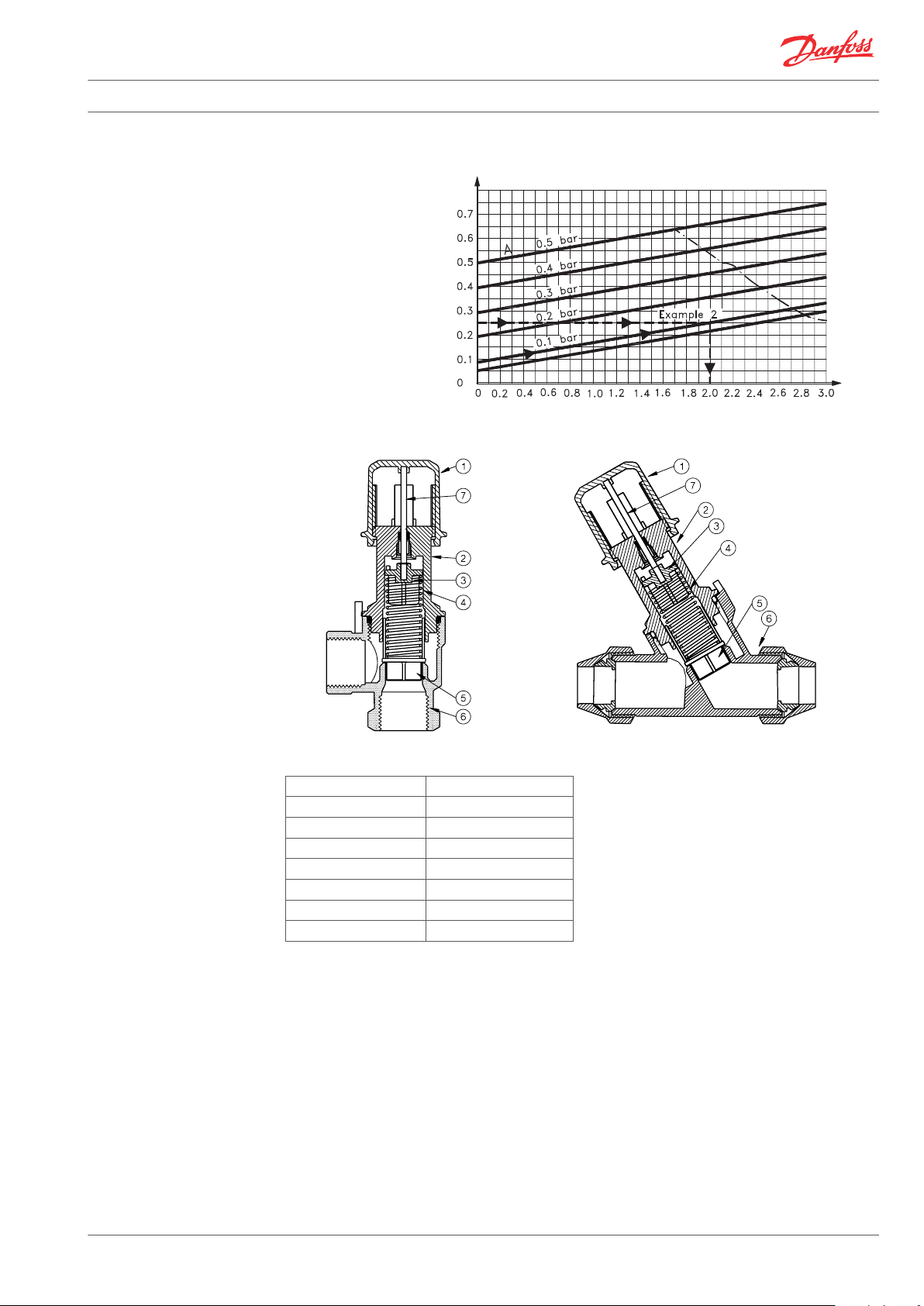

Design

Installation

Setting

Materials

Setting handle Pom-plast

1.

2. Base Ms 58

3. Spring guide PPS plastic

4. Spring Stainless steel

5. Valve cone PPS plastic

6. Valve body Ms 58, hot-pressed

7. Setting pin Stainless steel

O-rings EPDM

The valve body must be mounted with flow in

direction of the cast-in arrow.

The control is set by turning the setting dial.

AVDO has a setting scale on which the opening

pressure in bar or mwg can be directly read.

The differential pressures stated for a given

setting are indicative.

The scale gives the differential pressure across

the AVDO when it just begins to open.

Danfoss Heating Solutions VD55K902 © Danfoss 02/2011 3

1

1

Data Sheet Automatic Bypass Control AVDO

Sizing

Fig. 1 Fig. 2

Example 1:

Bypass control across heating system

Given:

System, see fig. 1.

▪

Insignificant pressure loss in pipe from

▪

boiler to bypass.

Pump characteristic, see fig. 2.

▪

0.15 bar system differential pressure at max.

▪

system load.

Required:

Bypass circulation beginning at 0.15 bar

▪

pump pressure.

Min. 2.0 m³/h boiler circulation.

▪

Seek:

A constant flow control that opens

▪

concurrently with falling load across the

system (closing radiator thermostats).

A constant flow control that ensures min. 2.0

▪

m³/h boiler circulation at min. system load.

Solution:

A 2.0 m³/h flow corresponds to a 0.25 bar

▪

pump pressure. On closing radiator

thermostats AVDO is to ensure min. 2.0 m³/h

circulation at 0.25 bar differential pressure

across AVDO. Choose AVDO 25 that

provides 2.75 m³/h at 0.25 bar differential

pressure across valve. Set AVDO on 0.15 bar

required opening pressure.

Example 2:

Bypass control across circulation pump

Given:

System, see fig. 3.

▪

-Pump characteristic, see fig. 4.

▪

Required:

Bypass circulation beginning at 0.1 bar

▪

pump pressure.

Max. system differential pressure at closed

▪

radiator thermostats must be limited to 0.25

bar.

Seek:

A constant flow control that opens

▪

concurrently with falling load across the

system (closing radiator thermostats).

A constant flow control that ensures max.

▪

system differential pressure not exceeding

0.25 bar at min. system load.

Solution:

The max. permissible differential pressure

▪

0.25 bar across system corresponds to a 1.8

m³/h water volume (fig. 4). At min. load

AVDO must ensure 1.8 m³/h pump bypass

circulation. In this example AVDO 20 must

be used - see "Capacity".- As circulation is

not to begin before differential pressure

across system has exceeded 0.1 bar, AVDO is

set on 0.1 bar - see "Setting.

Fig. 2

Fig. 4

1. Pump characteristic

4 VD55K902 © Danfoss 02/2011 Danfoss Heating Solutions

Data Sheet Automatic Bypass Control AVDO

Dimensions

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 1

DN Type

1)

a

1)

b

L3 L4 L5 H1 S1 S2

min max

15 AVDO 15 RP ½ R½ 40 69 33 83 112 28 30

20 AVDO 20 RP ¾ R ¾ 42 74 37 83 112 34 37

25 AVDO 25 RP 1 R 1 46 81 46 85 114 43 40

Fig.2

DN Type

1)

a

L3 L5 H1 S1

min max

15 AVDO 15 RP ½ 40 33 83 112 28

20 AVDO 20 RP ¾ 42 37 83 112 34

25 AVDO 25 RP 1 46 46 85 114 43

Danfoss Heating Solutions VD55K902 © Danfoss 02/2011 5

Data Sheet Automatic Bypass Control AVDO

Fig. 3

DN Type a, mm

2)

b

L1 L2 H1 S

min max

15 AVDO 15 15/16/18 G ¾ A 87 111 89 113 30

20 AVDO 20 18/22 G 1 A 93 120 90 114 37

25 AVDO 25 28 G 1¼ A 106 136 95 119 45

Fig. 4

DN Type

1)

a

1)

b

L1 L2 H1 S1 S2

min max

15 AVDO 15 RP ½ R½ 87 116 89 113 28 30

20 AVDO 20 RP ¾ R ¾ 93 125 90 114 34 37

25 AVDO 25 RP 1 R 1 106 141 95 119 43 40

1)

According to ISO 7/1

2)

According to ISO 228/1

6 VD55K902 © Danfoss 02/2011 Danfoss Heating Solutions

Data Sheet Automatic Bypass Control AVDO

Danfoss Heating Solutions VD55K902 © Danfoss 02/2011 7

Data Sheet Automatic Bypass Control AVDO

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

8 VD55K902 © Danfoss 02/2011 Danfoss Heating Solutions

Loading...

Loading...