Page 1

Data sheet

Differential pressure relief controller

AVDA - internal thread, PN 10

AVDSA - internal thread, PN 16

Description

AVDA AVDSA

Ordering AVDA, AVDSA Controller

Example:

Differential pressure relief

controller, DN 15, kvs 1.9, PN 16,

setting range 0.05 - 0.5, t

int. thread

- 1x AVDSA DN 15 controller

Code No: 003N8204

max

130°C,

Picture Type DN

AVDA

AVDSA

AVDA and AVDSA are self-acting temperature

controllers used for constant flow control or

bypass control. Controller opens on rising

differential pressure.

The controller has a control valve, an actuator

with one control diaphragm and handle for

differential pressure setting.

For apartment block heating, district heating

plant and central heating systems.

Main data:

• DN 15, 20, 25

• kvs 1.9, 3.4, 5.5

• PN 10, 16

• Setting range:

0.1 - 1.2 bar (AVDA)

0.05 - 0.5 bar (AVDSA)

• Temperature:

- Circulation water / glycolic water up to 30%:

2 … 130 °C

• Connections: Int. thread

k

vs

m3/h

15 1.9

20 3.4 Rp ¾ 003N0039

25 5.5 Rp 1 003N0040

15 1.9

20 3.4 Rp ¾ 003N8205

25 5.5 Rp 1 003N8206

Setting range

PN

bar

10 0.1 - 1.2

16 0.05 - 0.5

Connection

- valve

Int. thread

ISO 7/1

Rp ½

Rp ½

Connection

Impulse

tube flare

7/16-20 UNF

7/16-20 UNF

Code No.

003N0038

003N8204

1)

2)

2)

1)

The code no. in cludes 2 impulse tube s (0.5 and 1.5 m) with tailpi eces.

2)

Available on r equest

Service kits

Picture Type designation for Code No.

Repair set

Two diaphragms, two O-rings, one rubber cone,

one tube of grease and eight valve cover screws

Brass-dipped nipple (two supplied as standard) AVDA, AVDSA 631X4700

Valve stuffing box AVDA, AVDSA 065F0006

Diaphragm housing

DH-SMT/SI VD.55. B1.02 © Danfoss 0 8/2006 1

DN 15 003N4006

DN 20 003N4007

DN 25 003N4008

AVDA 003N0065

AVDSA 003N0284

Page 2

Data sheet Differential pressure relief controllers AVDA (PN 10) and AVDSA (PN 16)

Technical data

Application principles

Nominal diameter DN 15 20 25

k

value m3/h 1.9 3.4 5.5

vs

Nominal pressure PN AVDA: 10, AVDSA: 16

Max. differential pressure bar

Medium Circulation water / glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature 2 … 130 oC

Materials

Valve body MS 58, hot-pressed, DIN 17660, W.No. 2.0402, CuZn40Pb2

Valve seat Cr Ni steel, DIN 17660, W.No. 1.4301

Valve cone NBR-rubber

Spindle Dezincing-free brass, BS 2874/CZ132

Diaphragm housing Zinc-cromated steel, DIN 1624, W.No. 1.0338

Diaphragm EPDM-rubber

7

Installation positions The valve body can be installed in any position.

A Danfoss FV strainer is recommended.

Impulse tubes have to be installed vertically

or horizontally onto the main pipe, never

downwards.

Needle valve can be installed between main pipe

and impulse tube, if necessary.

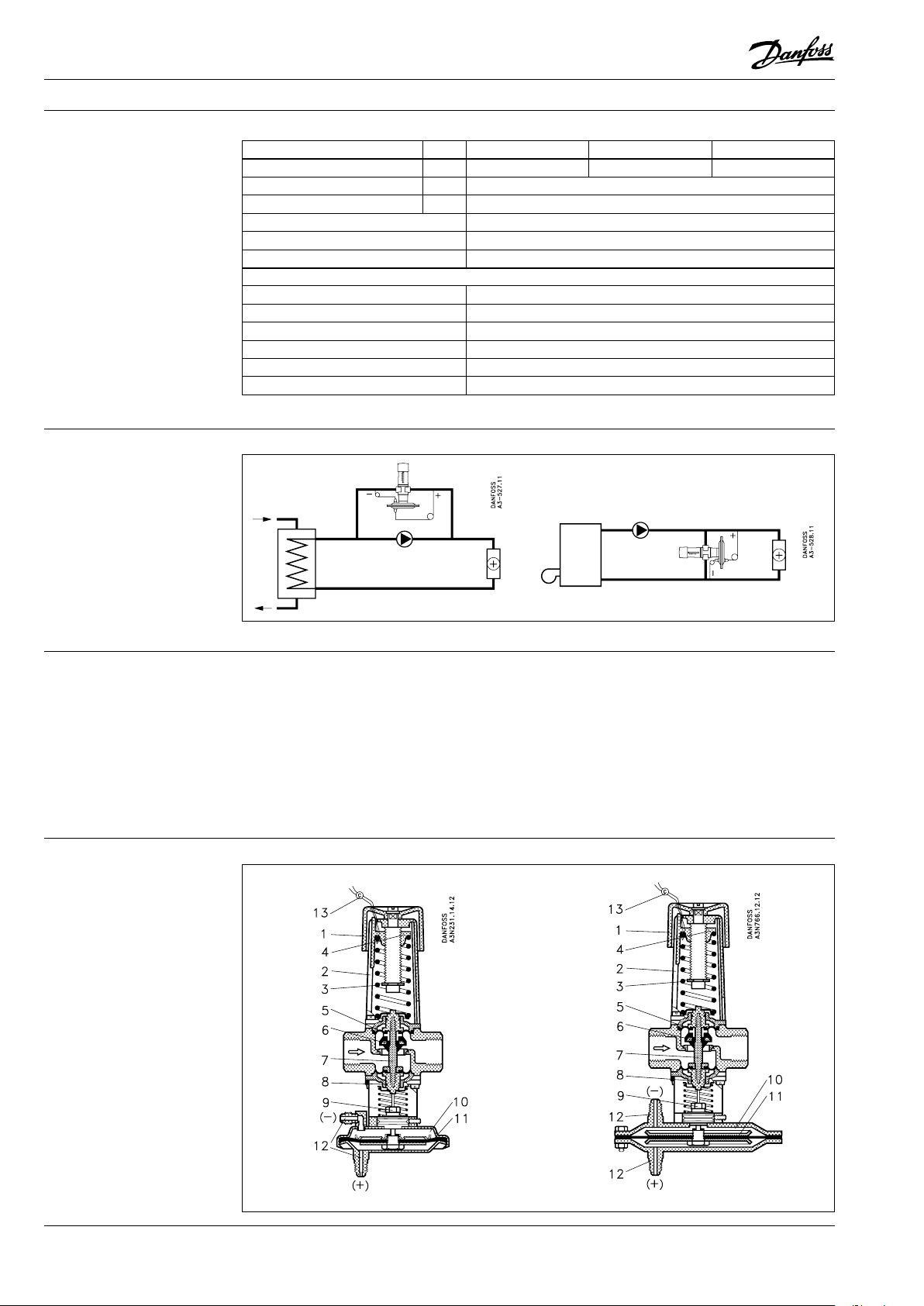

Design

1. Handle for differential

pressure setting

2. Spring housing

3. Setting spring

4. Spring guide

5. Diaphragm

6. Valve cone

7. Spindle

8. O-ring

9. O-ring gland

10. Diaphragm housing

11. Control diaphragm

12. Nipple for impulse tube

13. Lead seal

(+) impulse tube has to be connected to flow

line, (-) impulse tube has to be connected to

return line. Setting can be simplified by using

pressure indicators (manometers) placed close to

impulse tube connections.

By turning diaphragm housing downwards the

letter “RA” on valve housing must be oriented

upright.

AVDA AVDSA

2 VD.55. B1.02 © Danfoss 0 8/2006 DH-SMT/SI

Page 3

Data sheet Differential pressure relief controllers AVDA (PN 10) and AVDSA (PN 16)

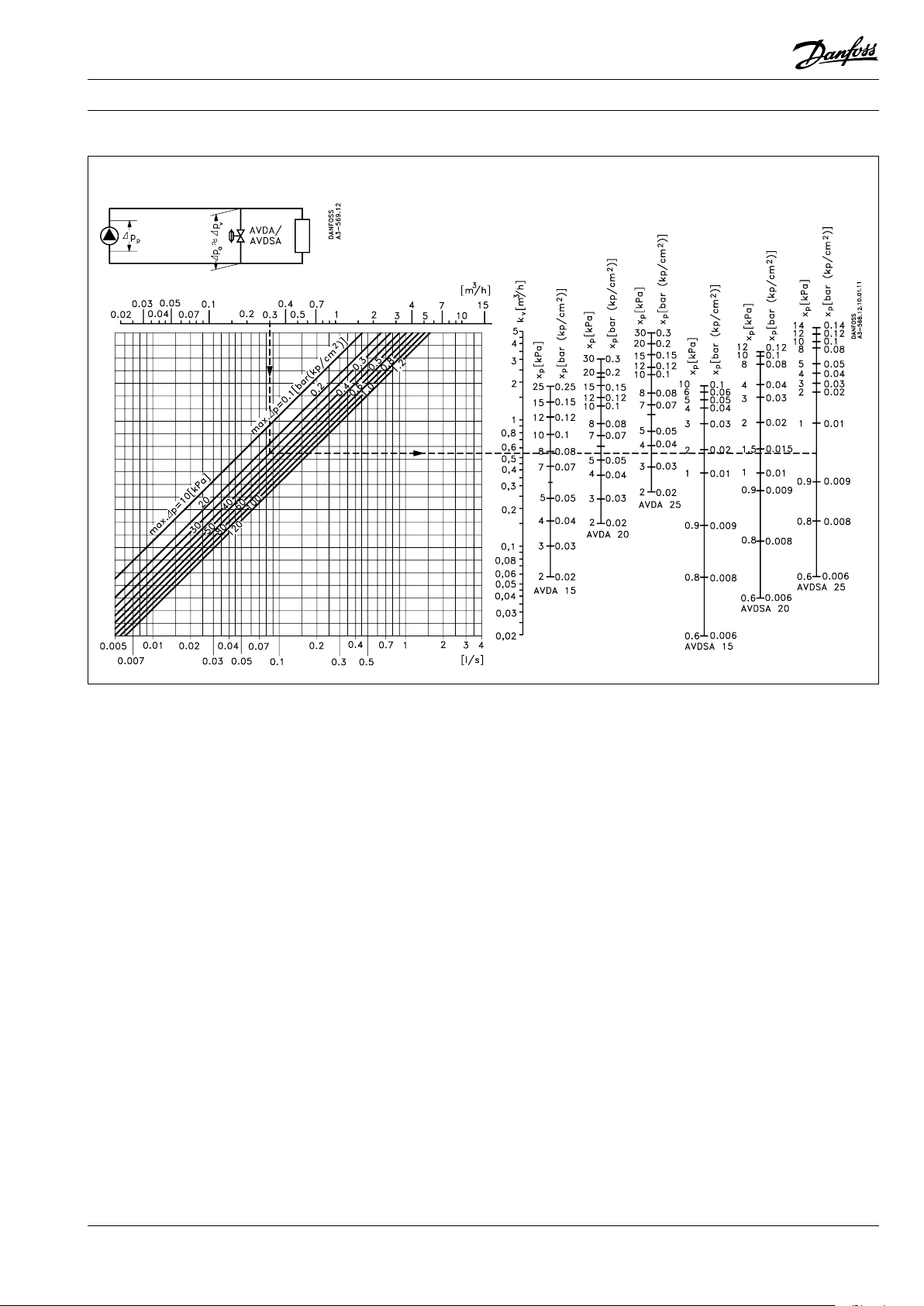

Sizing

Constant flow control

Example

Given

Assuming a pressure drop in the line from the

pump to and from the valve connections of nil

so that Δpp = Δpa = Δpv, the plant differential

pressure at max. load = 0.25 bar.

Condition

Maximum plant differential pressure with closed

radiator valves limited to 0.3 bar. Pump water

volume (Q) for this condition = 0.3 m3/h.

Required

A pressure relief control able to circulate a water

volume of at least 0.3 m3/h at Δpa = 0.3 bar and

which will remain closed under max. plant load,

Δpa = 0.25 bar.

Method

Locate the necessary water volume,

Q = 0.3 m3/h, on the horizontal axis in the

nomogram.

From the 0.3 m3/h point, take a vertical line up

to intersect the curve that gives the pressure at

which the valve must be completely open (here,

0,3 bar). From the intesection, take a horizontal

line to intersect the vertical axes on the right.

These axes give the pressure rise XP that is

necessary across the valve before it can give the

required capacity Q.

Since the pressure rise in this example is 0.3 -

0.25 = 0.05 bar, a valve where XP ≤ 0.05 bar could

be used, i.e. an AVDA 25.

This setting is therefore 0.25 bar, i.e. the valve is

closed when the differential pressure across it is

0.25 bar.

A pressure gauge can be used in making the

setting, or an approximate setting can be made

as shown in the associated installation example.

DH-SMT/SI VD.55. B1.02 © Danfoss 0 8/2006 3

Page 4

Data sheet Differential pressure relief controllers AVDA (PN 10) and AVDSA (PN 16)

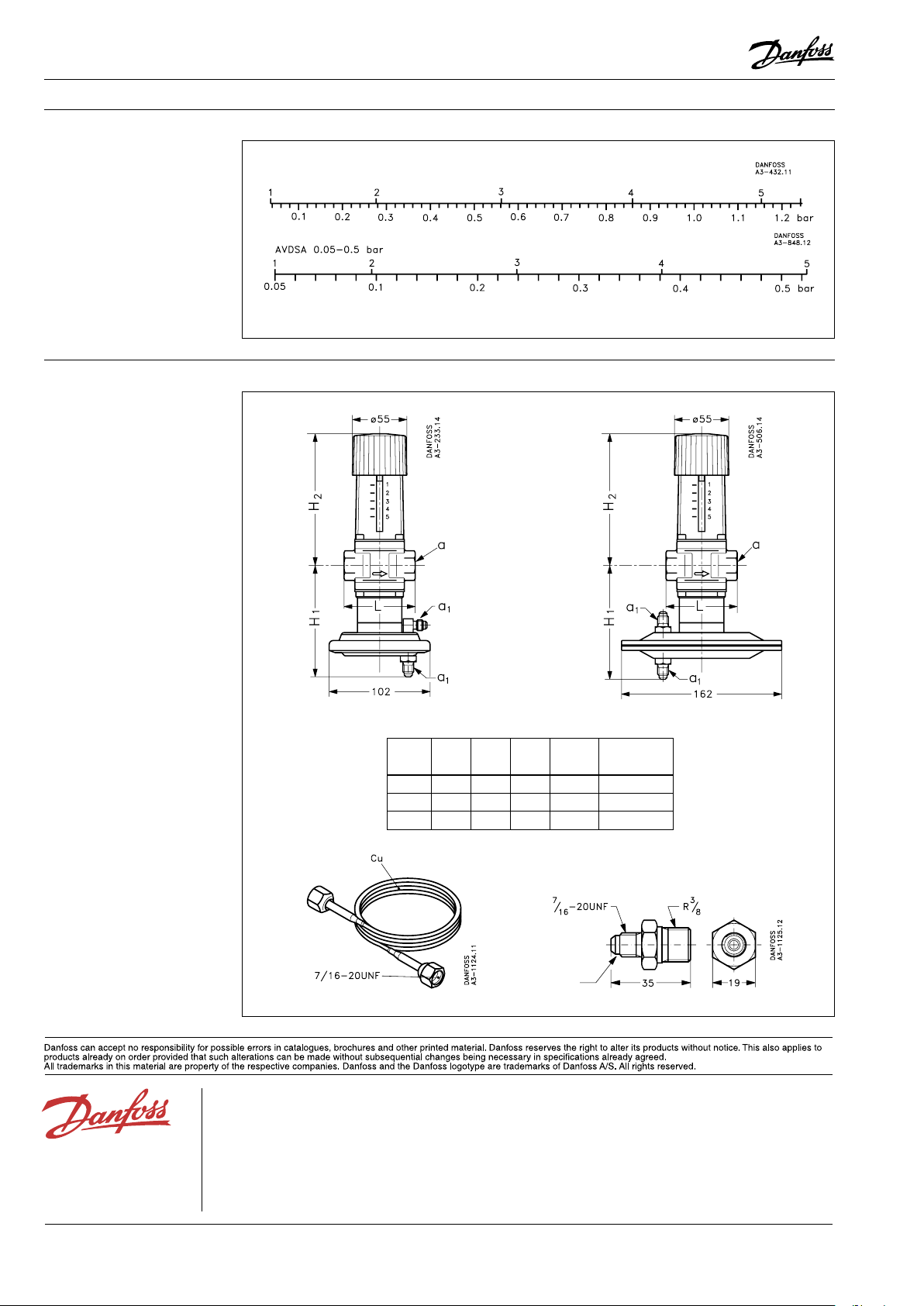

Settings

Dimensions

AVDA 0.1 - 1. 2 bar

Scale setting

Relation bet ween scale numbers and differential pressure.

The values given are indicative only.

AVDA AVDSA

H

H

1

Type

DN 15 112 133 72 Rp½ 7/16-20 UNF

DN 20 112 133 90 Rp¾ 7/16-20 UNF

DN 25 117 138 95 Rp1 7/16-20 UNF

Impulse tube Nipple

mm

2

mmL mmaISO 7/1

a1

flare

4 VD.55. B1.02 © Danfoss 0 8/2006 DH-SMT/SI

Loading...

Loading...