Page 1

Installation guide

ATEX

Type Designation

ENGLISH

Danfoss Industrial refrigeration standard

products are primary designed to be used

148R9541

with common “industrial” refrigerants like

ammonia, CO₂, and halocarbons, however

specific valve types can be used to HC

refrigerants (flammable).

European Directives

If not specifically mentioned all Industrial

Refrigeration valves comply with the

relevant European Directives like the

Pressure Equipment Directive (97/23/CE).

ATEX directive: (94/9/CE)

The ATEX directive specifies the

requirements for equipment intended for

use in potentially explosive atmospheres.

Danfoss Industrial Refrigeration products

have been verified according to this

directive.

The products are divided into 3 main

groups:

I) Products which are (type) approved

to be used in potentially explosive

atmospheres (zone 2, zone 1 or zone 0).

(Table 1, group F)

These products are marked and are

available with “Certificate of

Conformance” acc. ATEX

II) Products which can be used in

potentially explosive atmospheres, but

are not covered by the scope of the

ATEX directive.

(Table 1, group A, B, C and D)

These products are available with

“Manufactures Declaration” according

to ATEX.

Note: Due to material compatibility

specific product type / code no. has

to be used for HC refrigerants. (E.g.

components with O-rings. see table 1,

group D)

III) Products which have an ignition source.

These products must not be used in

potentially explosive atmospheres.

(Table 1, group E)

These products are available with

“Manufactures Declaration” according

to ATEX.

Installation

General remarks

For safety reasons, the installation must

take place under the supervision of an

© Danfoss | DCS (ms) | 2021.01 AN070586420248en-000501 | 1

authorised person taking account of local

safety instructions, for flammable fluids,

and advisories.

The handling of valves and their controls

must be done by staff trained in all

technical aspects of their operation.

Before installation the pipes must be

depressurised and purged (empty of its

fluid) in order to avoid any danger to the

operator.

In ATEX zone, check that the pipes are

connected to the earth (grounded).. Do not

use insulating pipes (PVC…)

– Check that the valves are suitable for

the actual refrigerant.

Note: Type designation “xxxE”, are used

for products containing O-rings, and are

suitable for flammable (HC) refrigerants.

– Check that the valves are suitable for

the actual zone.

Commission

Before putting valve into operation, check

that:

– The working conditions are compatible

with the details given on the

identification plate , this instruction

notice and the manufacturer’s details

(technical data sheet, price list

catalogue, advisory service).

– All electrical connections have been

properly made.

– Installation is tight after the assembly.

Maintenance

– Maintenance and repair work must be

carried out by qualified personnel.

– The pipe must be depressurized and

purged (emptied of its fluid) in order

to avoid any danger to the operator.

If the installation has carried fluids

which are dangerous in themselves if

in contact with the outside atmosphere

(inflammable, corrosive, toxic,

explosive..)

– All operations must be performed using

suitable protective (clothing, gloves,

mask…).

– Where a control uses an external energy

source, it is essential to isolate this

source before any operation.

Warning:

When used in an ATEX zone,

electrostatic charges may be present

inside the valve. The user is responsible

for taking all precautions to avoid this

risk.

Safety

As well as the indications given in the

preceding paragraphs of this notice, it is

imperative that the following instructions

be followed:

– This notice must be available on site

where valves are installed.

– Personnel carrying out any intervention

on the valve must be qualified for the

task. In ATEX zone, the personnel must

be educated in the risks of explosion,

and should have received specific ATEX

training.

– In case the forwarded media would

be an explosive atmosphere (deliberate

internal explosive) or should it cause an

explosive atmosphere in case of

external leakage, the user must check

the tightness of the installation after

assembling, after a faulty operation

or on a periodic basis undernormal

conditions

– It is the responsibility of the user to

check after the installation of the

valve that there is no leakage. Especially

in case of deliberate internal explosive

atmospheres.

– Internal rules and legislation current

in the country concerned with respect

to health and safety at work must be

applied and respected.

– The valve and its control must not

undergo any modification without prior

approval from our advisory service.

Danfoss is not responsible for any

damage which may be caused by the

use of parts, accessories or controls

which are not original Danfoss parts

– Hot or cold parts of the valve which

present a danger to the operator must

be protected.

– In ATEX zone, the valve and its control

must be cleaned regularly to avoid the

accumulation of dust.

– In ATEX zone do not mount valves at

open ends of lines.

148R9541

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

Page 2

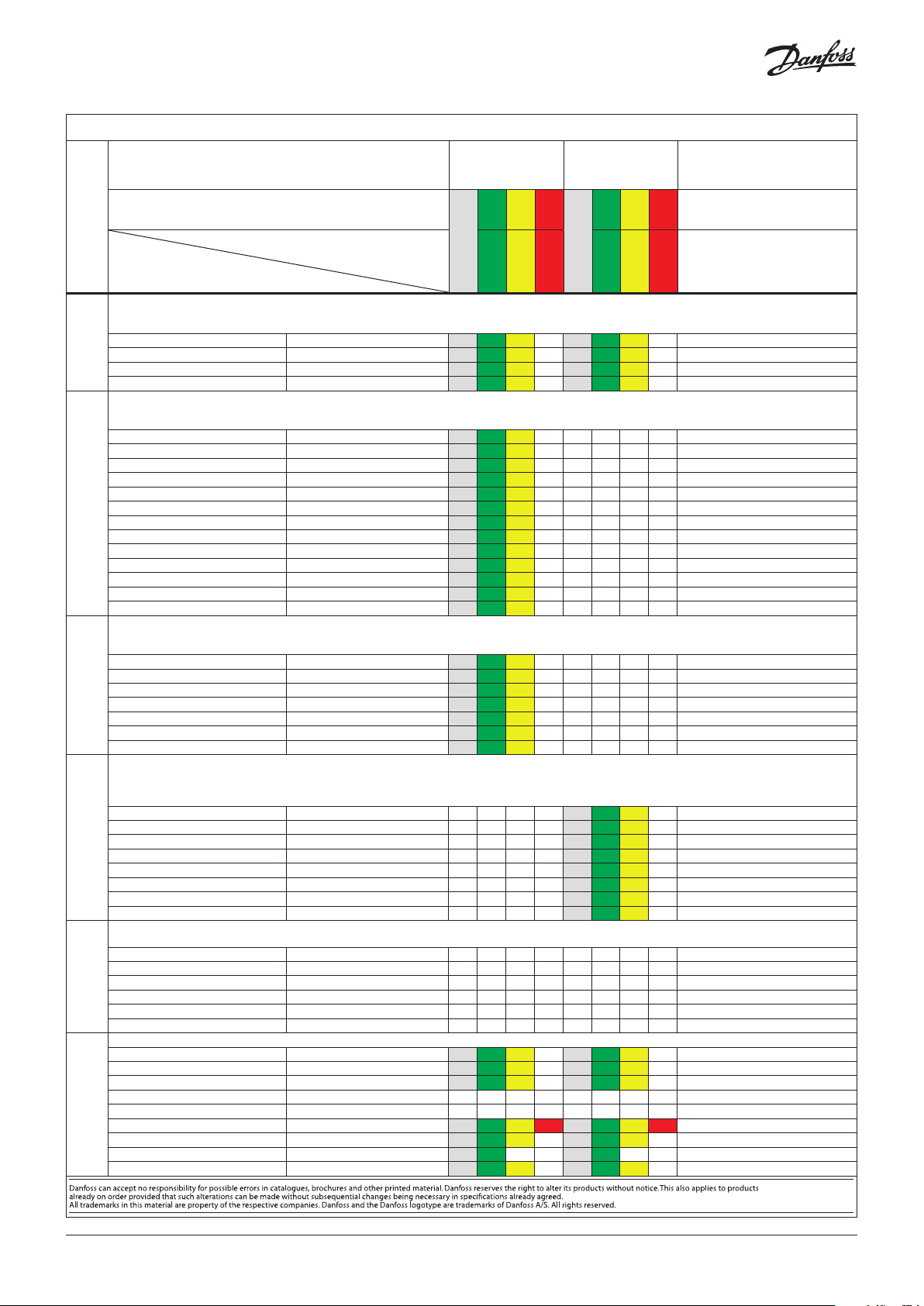

Classification of Danfoss Industrial Refrigeration products

Product groups - ATEX requirements

Hazardous area

Group

ATEX Equipment group II

“Non-flammable”

refrigerants

(Ammonia, CFC,HCFC,

HFC,CO₂)

Zone 2

Zone 1

Flammable refrigerants

(Propane, Butane,

Iso-butane, Propylene,

ethane)

Zone 0

Zone 2

Zone 1

Table 1

Comments

Zone 0

Component type

Component which can be used to all refrigeraqnts

and - cannot be mounted with any electrically pilots / equipment

and - have no ignition sources

Stop Valves SVA-HS, X1 X X X - X X X -

A

Filters FIA FIA X X X - X X X Check Valves NRVS X X X - X X X Check Valves NR VA X X X - X X X -

Component which can be used to Ammonia, CO₂, CFC, HCFC, HFC refrigerants

and - cannot be mounted with any electrically pilots / equipment

and - have no ignition sources

Stop Valves SVA-ST, LT X X X - - - - Regulating Valves - REG REG X X X - - - - Stop Check Valves SCA SCA X X X - - - - Overflow valve OFV X X X - - - - Check Valves CHV X X X - - - - -

B

Float Valves HFI X X X - - - - Float Valves SV X X X - - - - Pilots for ICS Valves CVP, CVPP X X X - - - - Safety Valves SFA X X X - - - - Safety Valves SFV X X X - - - - Safety Valves BSV X X X - - - - Change Over Valves for Safety Valves DSV X X X - - - - Safety Valves POV X X X - - - - -

Component which can be used to Ammonia, CO₂, CFC, HCFC, HFC

refrigerants and - can be mounted with electrically pilots / equipment

and - have no ignition sources

Main Valves (control valves) ICS 1 ICS 3 X X X - - - - Main Valves (control valves) PM1 PM3 PML PMLX X X X - - - - -

C

Modulating liquid level regulators PMFH X X X - - - - Pilots for ICS Valves EVM X X X - - - - Electrically operated expansion valve AK VA X X X - - - - Solenoid Valves EVRS X X X - - - - Solenoid Valves EVRA X X X - - - - -

Component with special sealing material for HC-refrigerants ( Probane,

Butane, Iso-butane and Propylene)

and - can be mounted with electrically pilots / equipment

and - have no ignition sources

Main Valves (control valves) ICS 3E - - - - X X X Modulating liquid level regulators PMFHE - - - - X X X -

D

Modulating liquid level regulators SV3E - - - - X X X Pilots for ICS Valves CVPE-L, CVPE-M - - - - X X X Pilots for ICS Valves CVCE - - - - X X X Pilots for ICS Valves EVME - - - - X X X Safety Valves SFAE - - - - X X X Safety Valves BSVE - - - - X X X -

Component not to be used in hasadas areas

Components in this group has an ignition source

Motor Valves ICM - - - - - - - Motor Valves MRV / MEV - - - - - - - -

E

Level controls 38E, AKS48 - - - - - - - Electronic regulators EKC 2.., EKC 3.. - - - - - - - “Standard” coils all - - - - - - - Pilots CVQ, CVPM - - - - - - - -

Electrically component to be used in hasadas areas

RT-Safety pressure control RTE X X X - X X X - Ex II 3 G EEx ia IIC T6

RT-Differential pressure control RTE X X X - X X X - Ex II 3 G EEx ia IIC T6

RT-Thermostats RTE X X X - X X X - Ex II 3 G EEx ia IIC T6

KPE-Safety pressure control KPE - - - - X X - - Ex II 3 G EEx nL IIC T6

F

MP 55E-Differential pressure control MP 55E - - - - X X - - Ex II 3 G EEx nL IIC T6

MBS Pressure transmittere MBS 42xx X X X X X X X X Ex II 1 G EEx ia II T4 - T6

EX Coils BP X X X - X X X - Ex II 2 G EEx m II T4

EX Coils “ “ X X - - X X - - Ex II 3 G EEx nA II T3

Gas detector GD X X X - X X X - Ex II 2 G EEx d IIB + H2 T3 –T6

Category 3

Category 2

Outside catagory / zone

Note: Only EX approved coils, if any coils are used

Note: Only EX approved coils, if any coils are used

Category 1

Outside catagory / zone

Category 3

Category 2

Category 1

© Danfoss | DCS (ms) | 2021.012 | AN070586420248en-000501

Loading...

Loading...