Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Series ASC

Anti Spin Control Valve

powersolutions.danfoss.com

Page 2

Technical Information Series ASC Anti Spin Control Valve

Revision history Table of revisions

Date Changed Rev

March 2014 Converted to Danfoss layout - DITA CMS BA

July 2002 First edition AA

2 520L0525 • Rev BA • March 2014

Page 3

Technical Information

Series ASC Anti Spin Control Valve

Contents

Overview

Description..........................................................................................................................................................................................4

Features................................................................................................................................................................................................4

Further System Components.......................................................................................................................................................4

Sectional view

Circuit diagram

System schematic diagram

Technical specifications

General specifications.....................................................................................................................................................................8

General Technical Specifications

Pressure Limits................................................................................................................................................................................ 10

Hydraulic Fluids.............................................................................................................................................................................. 10

Temperature and Viscosity.........................................................................................................................................................10

Fluid and Filtration........................................................................................................................................................................ 11

Independent Braking System....................................................................................................................................................12

Reservoir............................................................................................................................................................................................12

Functional Description

General Description...................................................................................................................................................................... 13

ASC-Valve function........................................................................................................................................................................13

Application Considerations

Availability

Available Options...........................................................................................................................................................................16

Technical data

Pressure drop...................................................................................................................................................................................17

Remaining flow at maximum closed position.....................................................................................................................17

Spool stroke versus current........................................................................................................................................................18

Outline Dimensions

Technical data.............................................................................................................................................................................. 8

Fluid specifications.....................................................................................................................................................................9

520L0525 • Rev BA • March 2014 3

Page 4

Technical Information

Overview

Description

Features

Series ASC Anti Spin Control Valve

The Danfoss Anti Spin Control valve (ASC-valve) is used e.g. in a propel drive line. The flow provided by a

pump is split equally and ported to two propel motors, ensuring, both run at the same speed under all

load, pressure, flow, and vehicle steering conditions. This prevents wheel slip and provides optimum

vehicle traction. The ASC-valve concept allows therefore a wide variety of applications whenever equal

flow share is demanded.

The ASC-valve in conjunction with a SUSMIC S1X microprocessor as well as steering and speed sensors

combines the capabilities of modern digital electronics with the worldwide proven Danfoss hydrostatic

components, to enhance the machine performance and operation.

The microprocessor-based SUSMIC S1X provides software flexibility and is designed for the future. With

easy-to change parameters (in software) it is possible to make an individual setup for different machine

types.

Rugged design for mobile applications.

•

Two “remaining flow” options available.

•

Supply voltage 12 VDC or 24 VDC.

•

Easy to service.

•

Flexibility: 2 - 4 motors.

•

Active while steering.

•

Software optimization/adaption without hardware (orifice) changes.

•

Individual setup per software:

•

Selection of different steering modes

‒

Vehicle geometry

‒

Track width

‒

Wheel base

‒

Wheel diameter

‒

etc.

‒

Further System Components

S1X-16 G2 AMP K196 S1X Electronic w/o CAN

•

S1X-26 G2 AMP K196C S1X Electronic w CAN

•

4 520L0525 • Rev BA • March 2014

Page 5

L

B

A

P

M8

M7

X3

P001 968

Technical Information Series ASC Anti Spin Control Valve

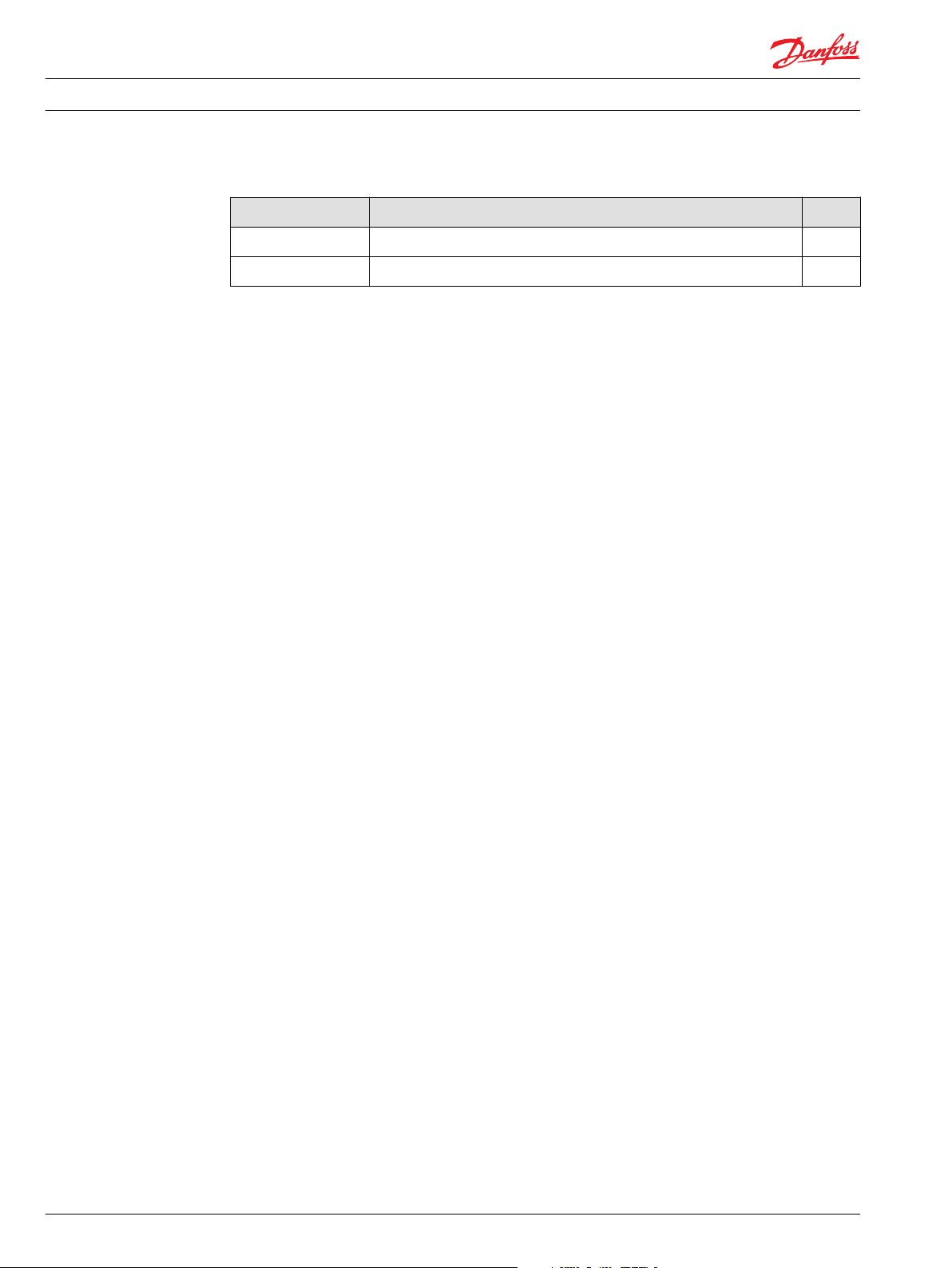

Sectional view

520L0525 • Rev BA • March 2014 5

Page 6

A

M7 X3

M8

B

P

L

P001 969

Technical Information Series ASC Anti Spin Control Valve

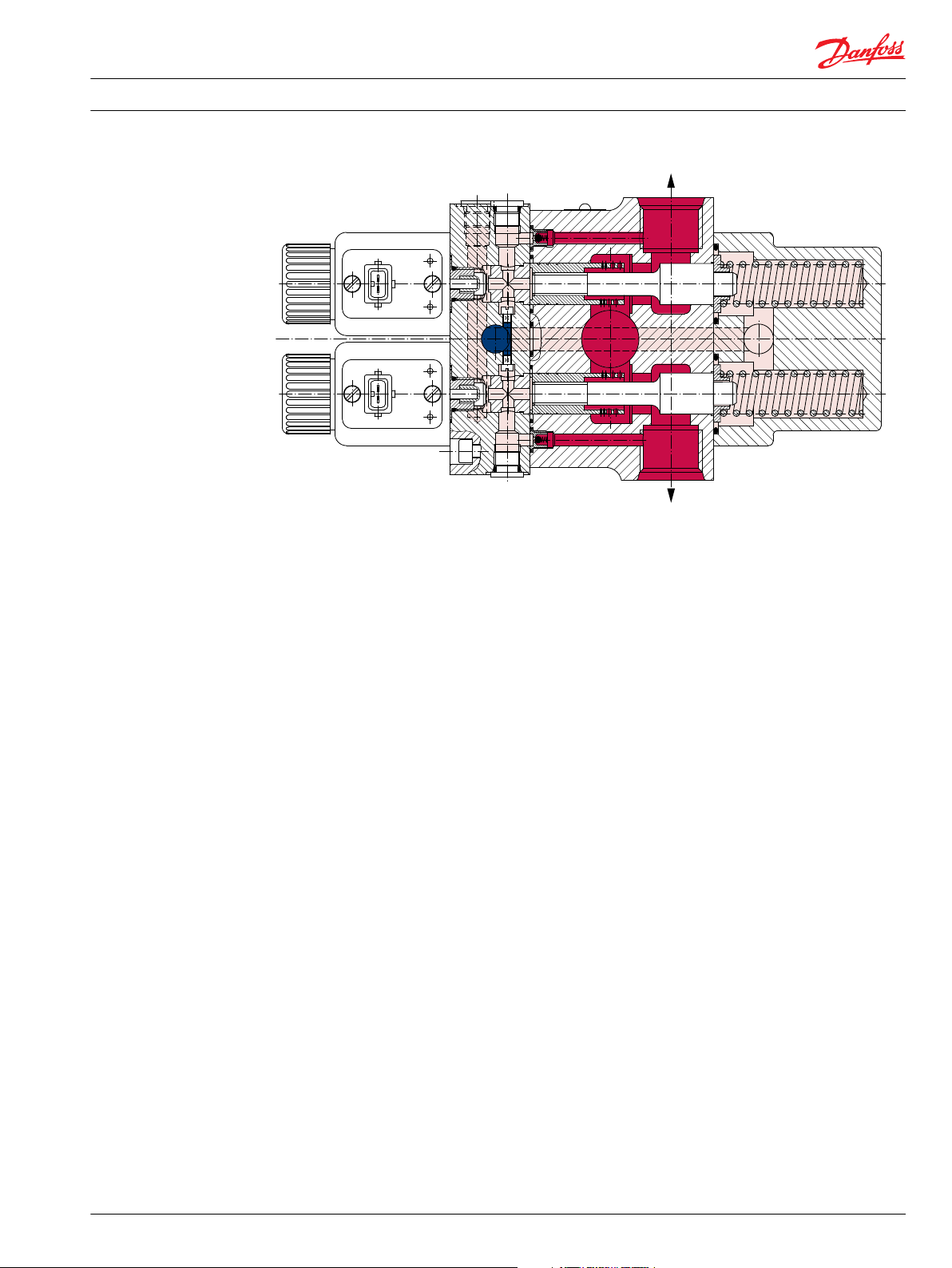

Circuit diagram

6 520L0525 • Rev BA • March 2014

Page 7

M

B P B

L

L2

L1

M2

M1

M4

M5

M3

A

A

S

P001 970

M8

X3

M7

ASC-valve

Technical Information

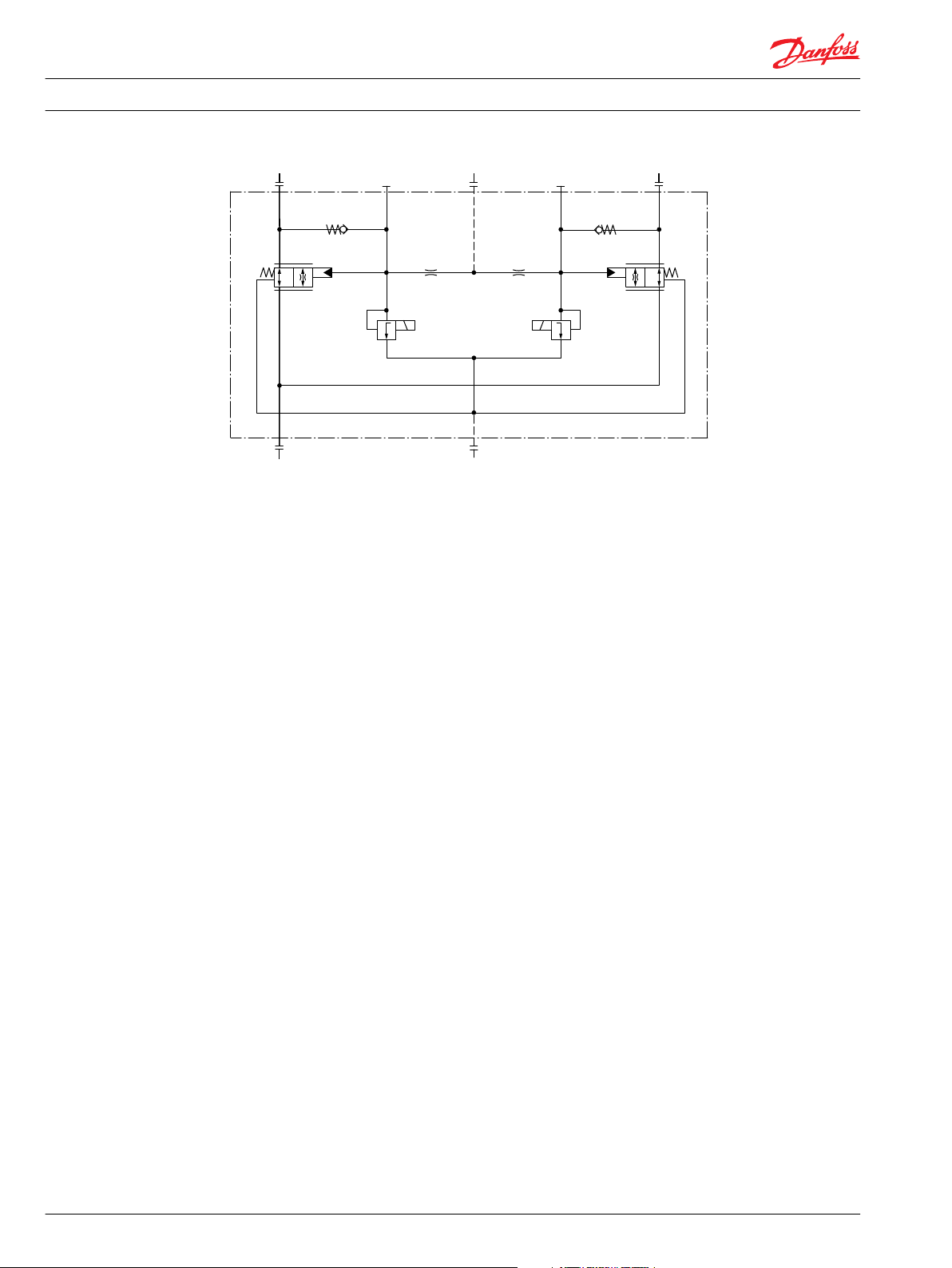

System schematic diagram

Series ASC Anti Spin Control Valve

Circuit Diagram – ASC-valve and System Components

Ports:

A, B = Main pressure ports M4, M5 = Gauge port - servo pressure

S = Suction port - charge pump M7, M8 = Gauge port - control pressure

L, L1, L2 = Case drain X3 = Control pressure supply port

M1, M2 = Gauge port for A and B

M3 = Gauge port - charge pressure

Above schematics show the function of a hydrostatic transmission using a Series 90 Axial Piston Variable

Displacement Pump with manual displacement control (MA) and two Fixed Displacement Hydraulic

Motors with brakes and brake valve, controled by an ASC-valve.

520L0525 • Rev BA • March 2014 7

Page 8

Technical Information Series ASC Anti Spin Control Valve

Technical specifications

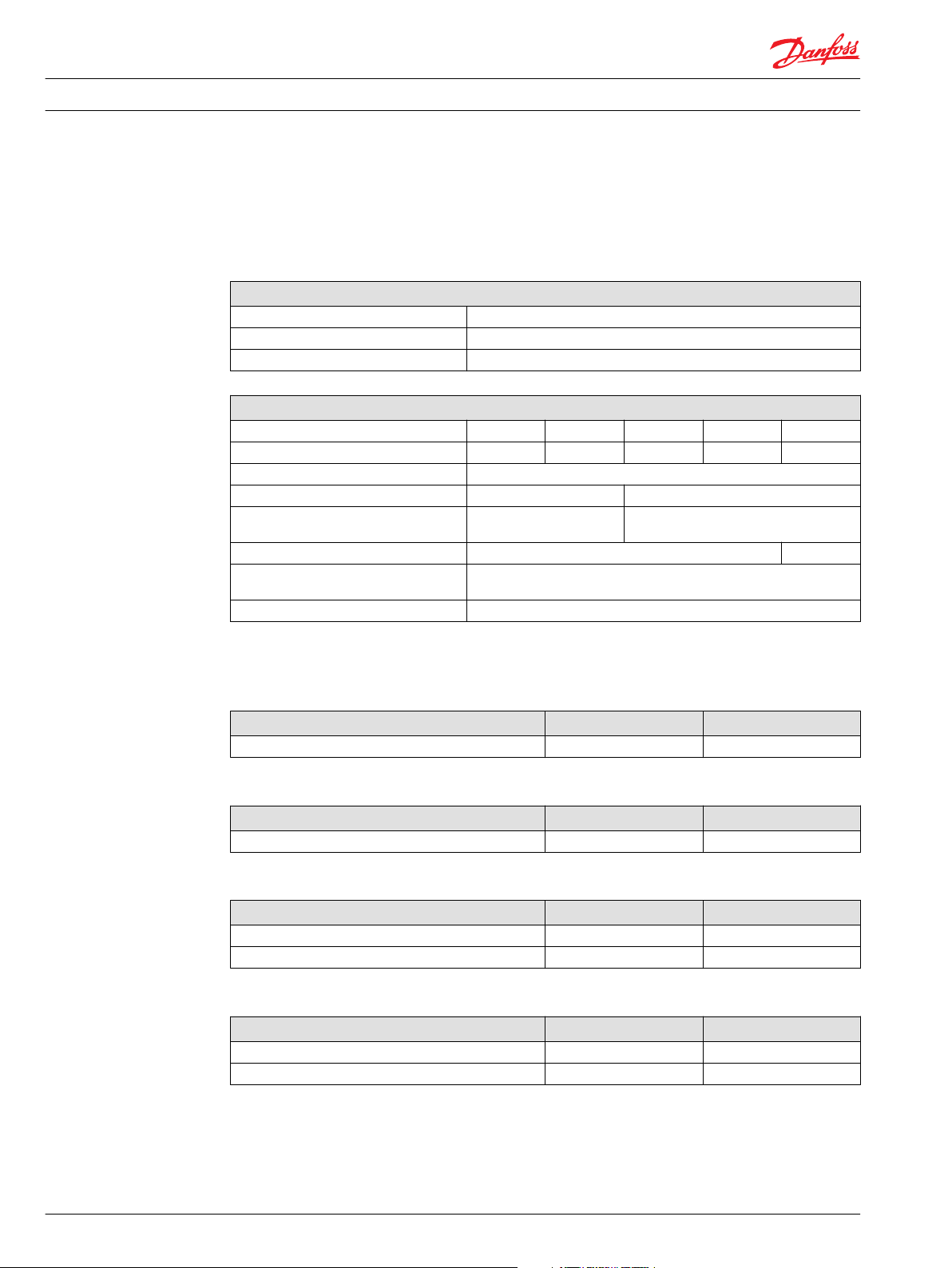

General specifications

Most specifications for the ASC-valve are listed below. For definitions of the various specifications, see the

related pages in this publication.

General specifications

Valve type Electrical proportional two-spool ASC-valve

Installation position Discretionary

Other system requirements Circuit overpressure protection, suitable reservoir

Specific Data

Order number 507 479 507 832 507 831 507 833 518 033

Voltage 12 V

Weight 7.85 kg [17.3 lb]

Maximum flow (at port P) 120 l/min [32 US gal/min] 60 l/min [16 US gal/min]

Remaining flow in closed position at 400

bar [5800 psi]

Case drain ports 1 2

Hydraulic pipe connections Main pressure ports: SAE flange + SAE straight thread O-ring boss.

Electric connections AMP Junior Timer, 12 VDC + 24 V

DC

24 V

DC

12 V

DC

24 V

DC

12 l/min [3.2 US gal/min] < 2 l/min [0.5 US gal/min]

Remaining port: SAE straight thread O-ring boss.

DC

24 V

DC

Technical data

Case pressure

bar [psi]

Maximum pressure 3.0 [44.0]

System pressure range

bar [psi]

Maximum pressure 480 [7000]

Control pressure

bar [psi]

Minimum control supply pressure (X3) 20 [290]

Maximum control supply pressure (X3) 30 [435]

Operating current

12 V

DC

Standby current 300 mA 150 mA

Required max. current 1200-1300 mA 600-650 mA

24 V

DC

8 520L0525 • Rev BA • March 2014

Page 9

Technical Information Series ASC Anti Spin Control Valve

Technical specifications

Fluid specifications

Temperature range*

Minimum -40 [-40] intermittent, cold start

Rated 104 [220]

Maximum 115 [240] intermittent

* At the hottest point, normally the case drain port.

Viscosity

Minimum 7 [49] intermittent

Recommended operating range 12-80 [70-370]

Maximum 1600 [7500] intermittent cold start

Cleanliness Level and βx-Ratio

Required fluid cleanliness level ISO 4406 Class 22/18/13

Recommended βx-ratio for suction filtration β

Recommended bx-ratio for charge pressure filtration β

Recommended inlet screen size for charge pressure

filtration

°C [°F]

mm2/s [SUS]

35-45

15-20

100 mm-125 mm

=75 (β10≥2)

=75 (β10≥10)

520L0525 • Rev BA • March 2014 9

Page 10

rab ]isp[

erusserpmumixaM 084 ]0007[

System Pressure Range

Technical Information

Series ASC Anti Spin Control Valve

General Technical Specifications

Pressure Limits

System pressure is the dominant operating variable affecting hydraulic unit life. High pressure, which

results from high load, reduces expected life in a manner similar to the affects of high load on other

mechanical assemblies such as engines and gear boxes.

Continuous pressure is the pressure at which the hydrostatic system could operate continuously and still

achieve acceptable hydrostatic life. This pressure level varies depending on operating speed, and on the

life requirements for a particular application. While most mobile applications require system pressure to

vary widely during operation, a “weighted average” pressure can be derived from a machine duty cycle.

(A duty cycle is a means of quantifying the pressure and speed demands of a particular system on a

percent time basis). Once a duty cycle has been determined or estimated for a specific application,

contact your Danfoss representative for system life ratings for the application.

Maximum pressure is the highest intermittent pressure allowed, and is the relief valve setting. It is

determined by the maximum machine load demand. For most systems, the load should move at this

pressure.

Maximum pressure is assumed to occur a small percentage of operating time, usually less than 2% of the

total. Both the continuous and maximum pressure limits must be satisfied to achieve the expected life.

Hydraulic Fluids

Temperature and Viscosity

Ratings and data are based on operating with hydraulic fluids containing oxidation, rust and foam

inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear, erosion and

corrosion of the internal components.

Fire resistant fluids are also suitable at modified operating conditions. Please see Danfoss literature

Hydraulic Fluids and Lubricants Technical Information for more information.

It is not permissible to mix hydraulic fluids. For more information contact your Danfoss representative.

The following hydraulic fluids are suitable:

Hydraulic Oil ISO 11 158 - HM (Seal compatibility and vane pump wear resistance per DIN 51 524-2

•

must be met)

Hydraulic Oil ISO 11 158 - HV (Seal compatibility and vane pump wear resistance per DIN 51 524-3

•

must be met)

Hydraulic Oil DIN 51 524-2 - HLP

•

Hydraulic Oil DIN 51 524-3 - HVLP

•

Automatic Transmission Fluid ATF A Suffix A (GM)

•

Automatic Transmission Fluid Dexron II (GM), which meets Allison C-3 and Catapillar TO-2 test

•

Automatic transmission Fluid M2C33F and G (Ford)

•

Engine Oils API Classification CD, SE and SF

•

Super Tractor Oil Universal (STOU) special agricultural tractor fluid

•

Temperature and viscosity requirements must be concurrently satisfied. The data shown in the tables

assume petroleum-based fluids are used.

The high temperature limits apply at the hottest point in the transmission, which is normally the case

drain. The system should generally be run at or below the rated temperature. The maximum temperature is

based on material properties and should never be exceeded.

10 520L0525 • Rev BA • March 2014

Page 11

C° ]F°[

muminiM 04- ]04-[ tratsdloc,tnettimretni

detaR 401 ]022[

mumixaM 511 ]042[ tnettimretni

)1

,tnioptsettohehttA

.tropniardesacehtyllamron

Temperature Range

1)

mm2s/ ]SUS[

muminiM 7 ]94[ tnettimretni

dednemmoceR

egnargnitarepo

08-21 ]073-07[

mumixaM 0061 ]0057[

tnettimretni

tratsdloc

Viscosity

Technical Information

Series ASC Anti Spin Control Valve

General Technical Specifications

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability to flow oil and transmit power; therefore temperatures should remain 16 °C [30 °F] above the pour

point of the hydraulic fluid. The minimum temperature relates to the physical properties of component

materials.

For maximum unit efficiency the fluid viscosity should remain in the recommended operating range. The

minimum viscosity should be encountered only during brief occasions of maximum ambient temperature

and severe duty cycle operation. The maximum viscosity should be encountered only at cold start.

Heat exchangers should be sized to keep the fluid within these limits. Testing to verify that these

temperature limits are not exceeded is recommended.

Fluid and Filtration

To prevent premature wear, it is imperative that only clean fluid enter the hydrostatic transmission

circuit. A filter capable of controlling the fluid cleanliness to ISO 4406 Class 22/18/13 or better under

normal operating conditions is recommended.

The filter may be located either on the inlet (suction filtration) or discharge (charge pressure filtration)

side of the charge pump. The selected filtration system must maintain a cleanliness level of 22/18/13 per

ISO 4406.

The selection of a filter depends on a number of factors including the contaminant ingression rate, the

generation of contaminants in the system, the required fluid cleanliness, and the desired maintenance

interval. Filters are selected to meet the above requirements using rating parameters of efficiency and

capacity.

Filter efficiency may be measured with a Beta ratio1) (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration,

a filter with a β-ratio within the range of β

For some open circuit systems, and closed circuits with cylinders being supplied from the same reservoir,

a considerably higher filter efficiency is recommended. This also applies to systems with gears or clutches

using a common reservoir. For these systems, a charge pressure or return filtration system with a filter βrotation in the range of β

Since each system is unique, the filtration requirement for that system will be unique and must be

determined by test in each case. It is essential that monitoring of prototypes and evaluation of

components and performance throughout the test program be the final criteria for judging the adequacy

of the filtration system.

Please see Danfoss literature Hydraulic Fluids and Lubricants Technical Information for more information.

1)

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the

number of particles greater than a given diameter (“x” in µm) upstream of the filter to the number of

these particles downstream of the filter.

= 75 (β10 ≥ 2) or better has been found to be satisfactory.

35-45

= 75 (β10 ≥ 10) or better is typically required.

15-20

520L0525 • Rev BA • March 2014 11

Page 12

ssenilnaelcdiulfderiuqeR

level

dednemmoceR bxoitar-

noitartlifnoitcusrof

b

54-53

(57= b01³ )2

dednemmoceR bxoitar-

erusserpegrahcrof

noitartlif

b

02-51

(57= b01³ )01

telnidednemmoceR

egrahcrofezisneercs

noitartliferusserp

001 m 521-m mm

Cleanliness Level and bx-Ratio

ISO 4406

Class 22/18/13

W

Technical Information

Series ASC Anti Spin Control Valve

General Technical Specifications

Independent Braking System

The loss of hydrostatic drive line power in any mode of operation (e.g., forward, reverse, or “neutral”

mode) may cause the loss of hydrostatic braking capacity. A braking system, redundant to the hydrostatic

transmission must, therefore, be provided which is adequate to stop and hold the system should the

condition develop.

Warning

Reservoir

The function of the reservoir is to remove air and to provide make up fluid for volume changes associated

with fluid expansion or contraction, possible cylinder flow, and minor leakage.

The reservoir should be designed to accommodate maximum volume changes during all system

operating modes and to promote deaeration of the fluid as it passes through the tank.

A minimum reservoir volume equal to 1/2 to 1 1/2 times charge pump flow/min is suggested. This allows

30 seconds fluid dwell for removing entrained air at the maximum return flow. This is usually adequate to

allow for a closed reservoir (no breather) in most applications. The reservoir outlet to the charge pump

inlet should be above the bottom of the reservoir to take advantage of gravity separation and prevent

large foreign particles from entering the charge inlet line.

The reservoir inlet (fluid return) should be positioned so that the flow to the reservoir is discharged below

the normal fluid level, and also directed into the interior of the reservoir for maximum dwell and efficient

deaeration.

12 520L0525 • Rev BA • March 2014

Page 13

L

B

A

P

M8

M7

X3

P001 968

Technical Information

Functional Description

General Description

ASC-Valve function

Series ASC Anti Spin Control Valve

The ASC-valve is used in anti slip systems for hydrostatic drive systems. It is possible to use this valve in

wheeled machines with up to 4 wheels driven individually. The ASC System is especially useful for

applications with fixed motors, but can also be combined with variable displacement motors.

The ASC System consists of a central digital controller Susmic S1X, speed sensors for each motor, the ASCvalve and steering sensors. It is important to note that in such system the amount of impulses per wheel

rotation should show the highest possible frequency resolution in order to be able to ensure a good

performance of the anti slip system.

The ASC-valve is of twin valve design and provides both motors with the required flow, generally these

are the 2 motors for one axle not mechanical connected. The input flow in P is divided and equally ported

to port A and B (see P001 968).

ASC-valve in neutral, no wheel slips

If for example the wheel connected to port “B” slips, the speed sensor detects this and sends a signal to

the Susmic S1X controller. The Susmic S1X controller then will provide current to the electric proportional

valve for port “B” and the spool in the ASC-valve closes the connection to port “B”, so a pressure drop

across this connection is build up equal to the pressure of the other wheel connected to port “A” minus

the pressure needed to drive wheel “B” (see P001 980). This limits the flow to wheel “B” and the wheel

stops to slip and runs at the same speed as the wheel connected to port “A”

520L0525 • Rev BA • March 2014 13

Page 14

L

B

A

P

M8

M7

X3

P001 980

L

B

A

P

M8

M7

X3

P001 995

Technical Information

Functional Description

Series ASC Anti Spin Control Valve

Wheel connected to port “B” slips, spool “B” 2/3 closed

If under extreme conditions and low speeds the wheel connected to port “B” continues to slip, spool “B”

will close completely and only the “remaining flow” will flow to

port “B” (see P001 995).

Wheel connected to port “B” at max slip, spool “B” completely closed.

14 520L0525 • Rev BA • March 2014

Page 15

Technical Information Series ASC Anti Spin Control Valve

Application Considerations

The following measures must be considered for proper anti spin function:

Remaining flow from the ASC-valve at maximum input current limits the minimum motor speed

•

(possible remaining motor slip).

Additional pressure limiter may be required if valve with low remaining flow at maximum input

•

current is used and valve is arranged in the return line of the motor.

When using more then one ASC-valve in an application either all valves must be placed in the supply

•

line of all motors or all valves must be placed in the return line of all motors.

Sum pressure for motors at downhill and deceleration condition must be considered.

•

Integrated loop flushing is not allowed because of potential sum pressure condition (high pressure

•

hydraulic fluid would be flushed out).

520L0525 • Rev BA • March 2014 15

Page 16

A

M7 X3

M8

B

P

LX L

P001 979

Technical Information

Availability

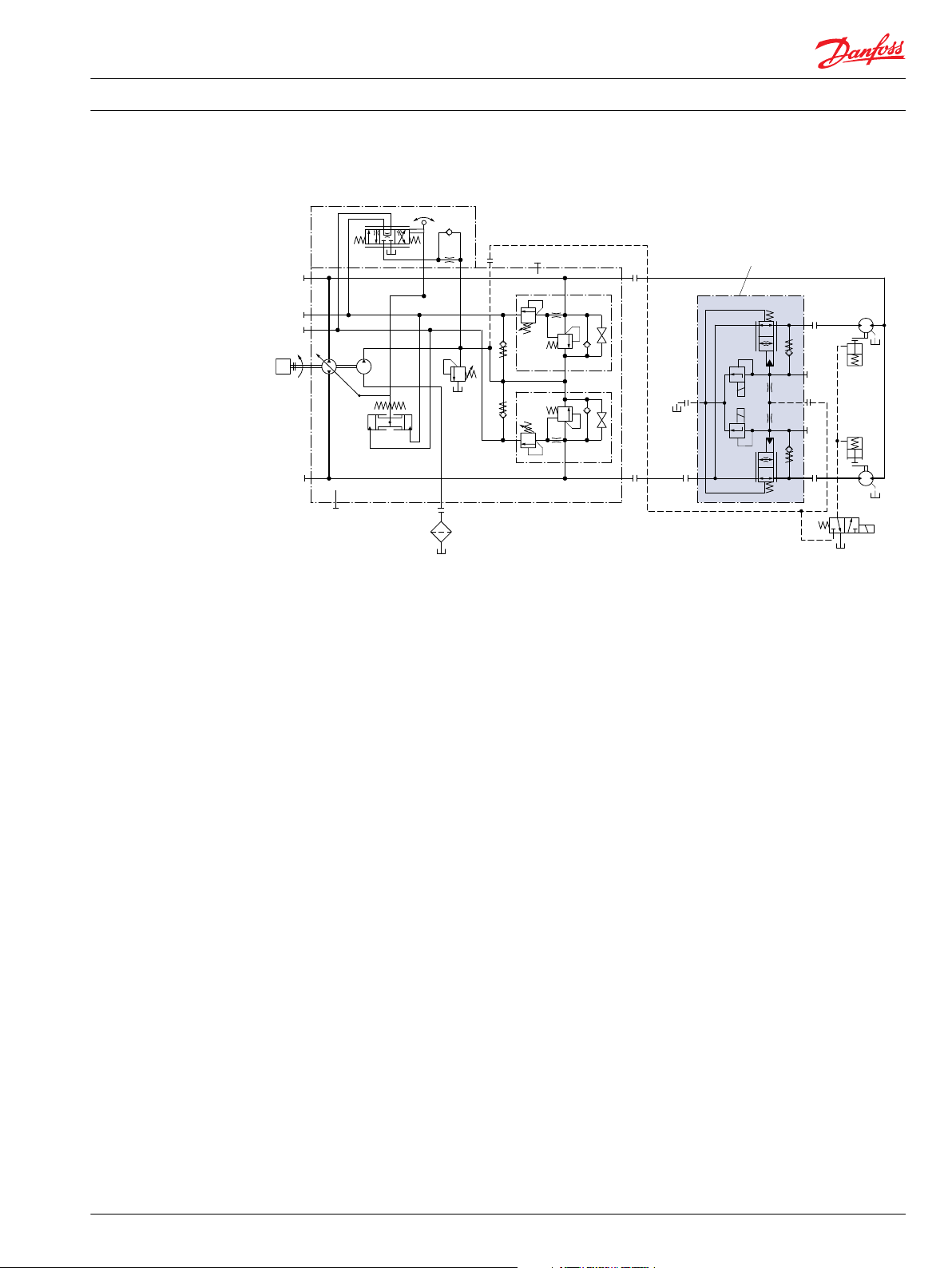

Available Options

Series ASC Anti Spin Control Valve

Typical ASC-valves with order numbers 507 479 (12 VDC) or 507 832 (24 VDC) with a remaining flow of 12

l/min [3.17 US gal/min] are used. These valves meet most application requirements. Please note, that due

to the 12 l/min [3.17 US gal/min] remaining flow at 400 bar [5800 psi] the spinning wheel cannot be

completely stoped.

If it is required that wheel slip is near zero at max closed position, the ASC-valves with a remaining flow of

< 2 l/min [0.5 US gal/min] at 400 bar [5800 psi] are recommended. Order numbers for such valves are 507

831 (12 VDC) or 507 833 (24 VDC) for a maximum flow of 60 l/min [16 US gal/min]. However, high sum

pressure risk at downhill condition is higher.

In some cases it may be demanded, that the ASC-valve remains in max closed position, if voltage/current

supply is lost. This is typically the case if the emergency stop button is hit. The ASC-valve with order

number 518 033 (24 VDC), 60 l/min [16 US gal/min] and remaining flow of < 2 l/min [0.5 US gal/min] at 400

bar [5800 psi] provides a separat LX port.

Scematic ASC-valve 518 033

In order to hold the ASC-valve in closed position this LX port may be closed by a solenoid valve which is

closed when not activated. This maintains the pressure acting on the main spool and keeps it closed.

Please note, that this causes the other spool to close as well. Carefully check the impact on the

application.

16 520L0525 • Rev BA • March 2014

Page 17

Output/or input flow at port A or port B l/min [US gal/min]

Pressure drop bar [psi]

P001 971E

0

0

1.0

2.0

3.0

4.0

5.0

0

[14.5]

[29.0]

[43.5]

[58.0]

[72.5]

20

[5.28]

40

[10.57]

60

[15.85]

80

[21.13]

Differential pressure bar [psi]

Remaining flow

l/min [US gal/min]

0 50

[725]

100

[1450]

150

[2175]

200

[2900]

250

[3625]

300

[4350]

350

[5075]

400

[5800]

P001972E

00

[0.53]

[1.06]

[1.59]

[2.11]

[2.64]

[3.17]

[3.70]

14

12

10

8

6

4

2

00

0.02[0.005]

[0.011]

[0.016]

[0.021]

[0.026]

[0.032]

[0.040]

[0.042]

[0.048]

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

Differential pressure bar [psi]

0 50

[725]

100

[1450]

150

[2175]

200

[2900]

250

[3625]

300

[4350]

350

[5075]

400

[5800]

P001994E

Remaining flow

l/min [US gal/min]

Technical Information

Technical data

Pressure drop

Series ASC Anti Spin Control Valve

The pressure drop versus flow at normal condition (anti spin function not active) from P to A respectively

from P to B and reverse is shown in below diagram at a viscosity of

28 mm2/s [70 SUS]. The flow entered in P is divided equally and ported to A and B.

Pressure drop versus flow

Remaining flow at maximum closed position

Although the ASC-valve is in maximum closed position (anti spin function is activated and running at

max slip condition) a remaining flow will allow the spinning wheel to slip. The remaining flow from P to A

respectively from P to B is shown in below diagrams at a viscosity of 28 mm2/s [70 SUS].

Remaining flow versus differential pressure for 507479 and 507832

Remaining flow versus differential pressure for 507831, 507833 and 518033

520L0525 • Rev BA • March 2014 17

Page 18

0 200 400

Current mA

Stroke mm [in]

600 800 1000 1200

0

2.00

4.00

6.00

8.00

10.00

12.00

14.00

0

[0.08]

[0.16]

[0.24]

[0.32]

[0.39]

[0.47]

[0.55]

P001 973E

min tolerance

max tolerance

mid tolerance

0 100 200

Current mA

Stroke mm [in]

300 400 500 600

0

2.00

4.00

6.00

8.00

10.00

12.00

14.00

0

[0.08]

[0.16]

[0.24]

[0.32]

[0.39]

[0.47]

[0.55]

P001 974E

min tolerance

max tolerance

mid tolerance

Technical Information Series ASC Anti Spin Control Valve

Technical data

Spool stroke versus current

Due to tolerance stack up the spool may start to close (start to shut off one motor) already at 200 mA or

may need 300 mA (24 VDC option). To make sure the valve is securely open when the anti spin function is

not needed, the standby current has to be limited to 300 mA for 12 VDC and 150 mA for 24 VDC.

These tolerances furthermore have an impact on the maximum spool closing position. The valve may

need 650 mA for 24 VDC respectively 1300 mA for 12 VDC to be at maximum closed position.

ASC-valve spool stroke versus current (all 12 VDC options)

ASC-valve spool stroke versus current (all 24 VDC options)

18 520L0525 • Rev BA • March 2014

Page 19

Ident-No.

Made in Germany

89.0

[3.50]

30.0

[1.18]

80.0

[3.15]

125.0

[4.92]

48.0

[1.89]

45.5

[1.79]

92.0

[3.62]

262.0

[10.30]

P001 978E

57.2

[2.25]

18.5

[0.73]

27.8

[1.09]

Drain port L

ISO 11926-1

0.5625-18 UNF-2B

[9/16-18 UNF-2B]

Control pressure supply X3

ISO 11926-1

0.5625-18 UNF-2B

[9/16-18 UNF-2B]

Gage port M7

control pressure for port A

ISO 11926-1

0.4375-20 UNF-2B

[7/16-20 UNF-2B]

Gage port M8

control pressure for port B

ISO 11926-1

0.4375-20 UNF-2B

[7/16-20 UNF-2B]

M10

18 [0.71] min.

full thread depth

Main port A

ISO 11926-1

1.0625-12 UN-2B

[1-1/16-12 UN-2B]

Main port B

ISO 11926-1

1.0625-12 UN-2B

[1-1/16-12 UN-2B]

45.0

[1.77]

89.0

[3.50]

96.8

[3.81]

19.7

[0.78]

73.5

[2.89]

A

A

B

B

A

M8

M7

P

L

M7

M7

M8

X3

Supply port P

DN 25 Typ III 40 MPa series

per ISO 6162 [SAE 1.00]

4 Thread: 0.4375-14UNC-2B

[7/16-14UNC-2B]

25 [1.00] min.

full thread depth

X

X

mm

[in]

AMP Junior Timer

A

M7 X3

M8

B

P L

Technical Information

Outline Dimensions

Series ASC Anti Spin Control Valve

ASC-valves 507479, 507832, 507831, 507833

Contact your Danfoss representative for specific installation drawings.

520L0525 • Rev BA • March 2014 19

Page 20

Ident-No.

Made in Germany

103.0

[4.06]

90.0

[3.54]

30.0

[1.18]

6.0

[0.24]

80.0

[3.15]

125.0

[4.92]

48.0

[1.89]

45.5

[1.79]

92.0

[3.62]

262.0

[10.30]

P001 975E

57.2

[2.25]

18.5

[0.73]

27.8

[1.09]

Drain port LX

ISO 11926-1

0.4375-20 UNF-2B

[7/16-20 UNF-2B]

Drain port L

ISO 11926-1

0.5625-18 UNF-2B

[9/16-18 UNF-2B]

Control pressure supply X3

ISO 11926-1

0.5625-18 UNF-2B

[9/16-18 UNF-2B]

Gage port M7

control pressure for port A

ISO 11926-1

0.4375-20 UNF-2B

[7/16-20 UNF-2B]

Gage port M8

control pressure for port B

ISO 11926-1

0.4375-20 UNF-2B

[7/16-20 UNF-2B]

M10

18 [0.71] min.

full thread depth

Main port A

ISO 11926-1

1.0625-12 UN-2B

[1-1/16-12 UN-2B]

Main port B

ISO 11926-1

1.0625-12 UN-2B

[1-1/16-12 UN-2B]

45.0

[1.77]

89.0

[3.50]

96.8

[3.81]

19.7

[0.78]

73.5

[2.89]

A

A

B

B

A

M8

M7LX

P

L

M7

M7

M8

X3

LX

LX

Supply port P

DN 25 Typ III 40 MPa series

per ISO 6162 [SAE 1.00]

4 Thread: 0.4375-14UNC-2B

[7/16-14UNC-2B]

25 [1.00] min.

full thread depth

X

X

mm

[in]

AMP Junior Timer

A

M7 X3

M8

B

P

LX L

Technical Information

Outline Dimensions

Series ASC Anti Spin Control Valve

ASC-valve 518033 with 2 case drain ports

Contact your Danfoss representative for specific installation drawings.

20 520L0525 • Rev BA • March 2014

Page 21

Technical Information Series ASC Anti Spin Control Valve

520L0525 • Rev BA • March 2014 21

Page 22

Technical Information Series ASC Anti Spin Control Valve

22 520L0525 • Rev BA • March 2014

Page 23

Technical Information Series ASC Anti Spin Control Valve

520L0525 • Rev BA • March 2014 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

520L0525 • Rev BA • March 2014 www.danfoss.com

Local address:

©

Danfoss A/S, 2014

Loading...

Loading...