Instruction

Disassembling and assembling

APP S 5.1-9.0 / APP S 674 5.1-9.0

ro-solutions.com

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

Table of Contents

1. Introduction

1. Introduction ....................................................................................................................................................................... 2

2. Disassembling the pump .............................................................................................................................................. 3

3. Assembling the pump .................................................................................................................................................... 7

4. Disassembling and assembling of the swash plate ...........................................................................................13

5. Disassembling and assembling of cylinder barrel and valve plate ..............................................................14

6. Disassembling and assembling of the ushing valve ......................................................................................15

7. How to replace the shaft seal.....................................................................................................................................15

8. Changing pistons ...........................................................................................................................................................16

8.1 Disassembling .................................................................................................................................................................16

8.2 Assembling .......................................................................................................................................................................18

9. Spare parts list APP S (674) 5.1-9.0 ...........................................................................................................................20

9.1 Exploded view APP S (674) 5.1-9.0 ...........................................................................................................................21

10. When should the pistons be replaced ....................................................................................................................22

This document covers the instructions for disassembling and assembling the axial piston pumps

APP S 5.1-9.0 / APP S 674 5.1-9.0

Important: It is essential that the pump is

serviced in conditions of absolute cleanliness.

For a better understanding of the pump, please

see the exploded view in item 9.

Note:

For disassembling and assembling it must be

possible to place the pump vertically with the

shaft pointing downwards. This can be done

with a distance block with a minimum height

of 50 mm.

Tools needed:

• 10 mm combination wrench

• 13 mm combination wrench

• Torque wrench

• 2 screwdrivers

• 1 press bush tool

• Adjustable pin wrench

• Distance block

Note:

This document covers dierent pump sizes.

Therefore the images shown in the instruction

may dier from your actual pump and parts,

however, the priciples of disassembling/

assembling will be the same.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 2

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

2. Disassembling the

pump

1. Disconnect the pump from the rest of the

system.

3. Carefully remove the stop bush ring and

the O-ring with a screwdriver.

2. Lubricate shaft with clean ltered water.

4. Using a 10 mm combination wrench,

unscrew the four bolts from shaft seal

cover.

WARNING!

While unscrewing the bolts with one

hand hold the shaft seal cover with the

other hand. This is done to ensure, the

cover does not pop out and damage the

ceramic ring.

© Danfoss | DCS (im) | 2021.02

5. Place two (!) bolts in threaded holes in the

shaft seal cover to remove it without

damaging the ceramic ring.

WARNING!

Be careful, the shaft has sharp edges.

180R9258 |AX073186502887en-000401 | 3

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

6. Remove ceramic ring from ange by

carefully pushing it from the back of the

sealing ring.

7. Wet the shaft with clean water.

8. Through the inlet port lever the shaft seal

with a screw driver between shaft seal and

spring. Use one hand to pull the shaft seal up.

WARNING:

Be careful not to scratch the shaft.

10. Carefully remove the spring by levering it

with two screwdrivers.

9. Carefully remove the shaft seal and

distance ring; the shaft has a sharp edge.

11. Turn pump upside down and place pump

on a distance block. Make sure there is

enough free space for the shaft beneath

the housing.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 4

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

12. Using a 13 mm combination wrench,

remove all the bolts on the mounting

ange except the two shown in item 13.

13. Unscrew the remaining two bolts. Turn

each bolt one round at the time to make

sure that the ange is removed as straight

upward as possible.

14. Remove end ange.

16. Remove the pistons one by one. Be careful

not to scratch the pistons. Tilt the retainer

plate to horizontal position for easy

removal of pistons, if required.

WARNING:

Do not use any tools.

15. Swash plate must be placed so that its

surface is not scratched. For further

disassembling of swash plate, see page 13.

17. Remove the retainer plate.

© Danfoss | DCS (im) | 2021.02

180R9258 |AX073186502887en-000401 | 5

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

19. Remove the retainer ball.

20. Pull the cylinder barrel straight upwards in

a continuous lift to ensure no damage of

house bearing. This can only be done if the

shaft seal is removed.

WARNING:

If the cylinder barrel is dropped or

lowered too fast into housing, the main

bearing/shaft bearing might be

damaged.

20. Remove the retainer guide and the spring.

21. Place cylinder barrel upside down. For

further disassembling of cylinder barrel

and valve plate see page 14.

© Danfoss | DCS (im) | 2021.02

22. Remove the port plate in the housing by

hand.

23. Remove, by hand, the pin.

Note: The following operation is only

necessary if O-ring on port ange is to be

changed.

180R9258 | AX073186502887en-000401 | 6

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

24. Turn the pump upside down.

25. If necessary, remove the remaining screws

in port ange by using a 13 mm

combination wrench.

3. Assembling the pump

WARNING:

Do not use silicone when assembling the

pump. Do not reuse disassembled O-rings;

they might be damaged. Always use new

O-rings.

1. Lubrication:

• To prevent seizing-up, lubricate all

threads with PTFE lubrication type.

• O-rings inside pump may be lubricated

only with clean ltered water.

• O-rings for port ange, mounting ange

and ushing valve must be lubricated.

• It is important to lubricate ALL parts to

be assembled with clean ltered water

(Especially all PEEK parts).

Important:

It is essential that the pump is serviced in

conditions of absolute cleanliness. All parts

must be absolute clean before mounting.

2. Place the housing with a drain holes

pointing upwards and insert pin for

positioning the port ange on housing.

© Danfoss | DCS (im) | 2021.02

3. Mount O-ring on port ange and lubricate

with water.

4. Position port ange by aligning pin hole

over pin.

5. Carefully press the port ange downwards.

Do not squeeze the O-ring. If the O-ring is

damaged, the pump will leak.

180R9258 |AX073186502887en-000401 | 7

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

6. Lubricate the treads with PTFE lubrication.

Insert screws on the port ange. Tighten

screws to a torque of 30 ± 3 Nm.

Guide pin

7. Turn pump upside down. Place a 10.5 mm

guide pin in port ange.

9. Ensure port plate is tted tightly against

the bottom.

Important: If valve plate is disassembled

from cylinder barrel, please see page 14

before continuing.

8. Lubricate and position port plate by using

the pin. Do not use force for this operation.

Distance block

10. Place the pump on a distance block. Make

sure, there is enough free space for the

shaft beneath the housing.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 8

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

11. Carefully lower cylinder barrel into the

housing.

WARNING:

If cylinder barrel is dropped or lowered

too fast into housing, main bearing and

shaft bearing might be damaged.

Replacement can only be done at

Danfoss, Nordborg.

12. Place the spring in cylinder barrel and

lubricate liners inside cylinder barrel with

water.

14. Lubricate retainer guide and position the

retainer ball.13. Lubricate and position the retainer guide.

16. Ensure it is oriented correctly.15. Position the retainer plate.

© Danfoss | DCS (im) | 2021.02

180R9258 |AX073186502887en-000401 | 9

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

17. Lubricate and position the pistons in the

retainer plate and cylinder barrel.

18. Lubricate the piston shoes. Tilt retainer

plate for easier placement of swash plate.

If the swash plate has been disassembled

from end ange, see page 13 for

assembling of swash plate. Remember to

place the pin in the housing.

19. Change and lubricate O-ring in end ange.

Position the end ange aligning pin hole

over the pin.

21. Screw in the rest of the bolts and tighten

all screws to the torque of 30 ± 3 Nm.

20. Lubricate and place two bolts in end

ange. Turn each bolt one round at a time

to ensure mounting ange is mounted as

straight downwards as possible. Be careful

not to squeeze the O-ring.

22. Lubricate and press new ceramic ring into

the shaft seal cover by using the press

bush tool.

WARNING:

Ensure that the face with rubber seal is

positioned against shoulder in shaft

seal ange.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 10

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

23. Remove old O-ring and place the new one

on shaft seal cover.

24. Place pump upside down to get access to

shaft. Position the distance ring.

26. Mount new shaft seal with the carbon seal

face pointing upwards.25. Lubricate shaft with clean ltered water.

© Danfoss | DCS (im) | 2021.02

27. Press seal down and at the same time turn

the seal clockwise until spring stops at

distance ring. Spring against distance ring

180R9258 |AX073186502887en-000401 | 11

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

28. Position the shaft seal cover on shaft. Be

careful not to damage the ceramic ring.

WARNING!

Be careful, the shaft has sharp edges.

29. Hold the cover down with one hand and

tighten the bolts with the torque

according to exploded view - page 17.

30. Lubricate the shaft with water before

mounting the stop bush.

32. Press stop bush in place by using the press

bush tool.

31. Mount O-ring and stop bush on shaft.

Ensure the gap with O-ring grove is

pointing in correct direction (towards

pump).

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 12

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

4. Disassembling and

assembling of the

swash plate

1. Unscrew centre bolt from swash plate and

remove the swash plate.

O-ring

2. Place two new pins in the end ange, if

needed. Change the O-ring in the end

ange. Remember to lubricate.

4. Lubricate centre bolt thread with a PTFE

lubricant type.3. Carefully align swash plate over pins.

6. Screw centre bolt into centre of swash

plate and tighten to 30 ±3 Nm. Finally

check the surface on the swash plate for

any marks or foreign particles.5. Position centre bolt.

© Danfoss | DCS (im) | 2021.02

180R9258 |AX073186502887en-000401 | 13

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

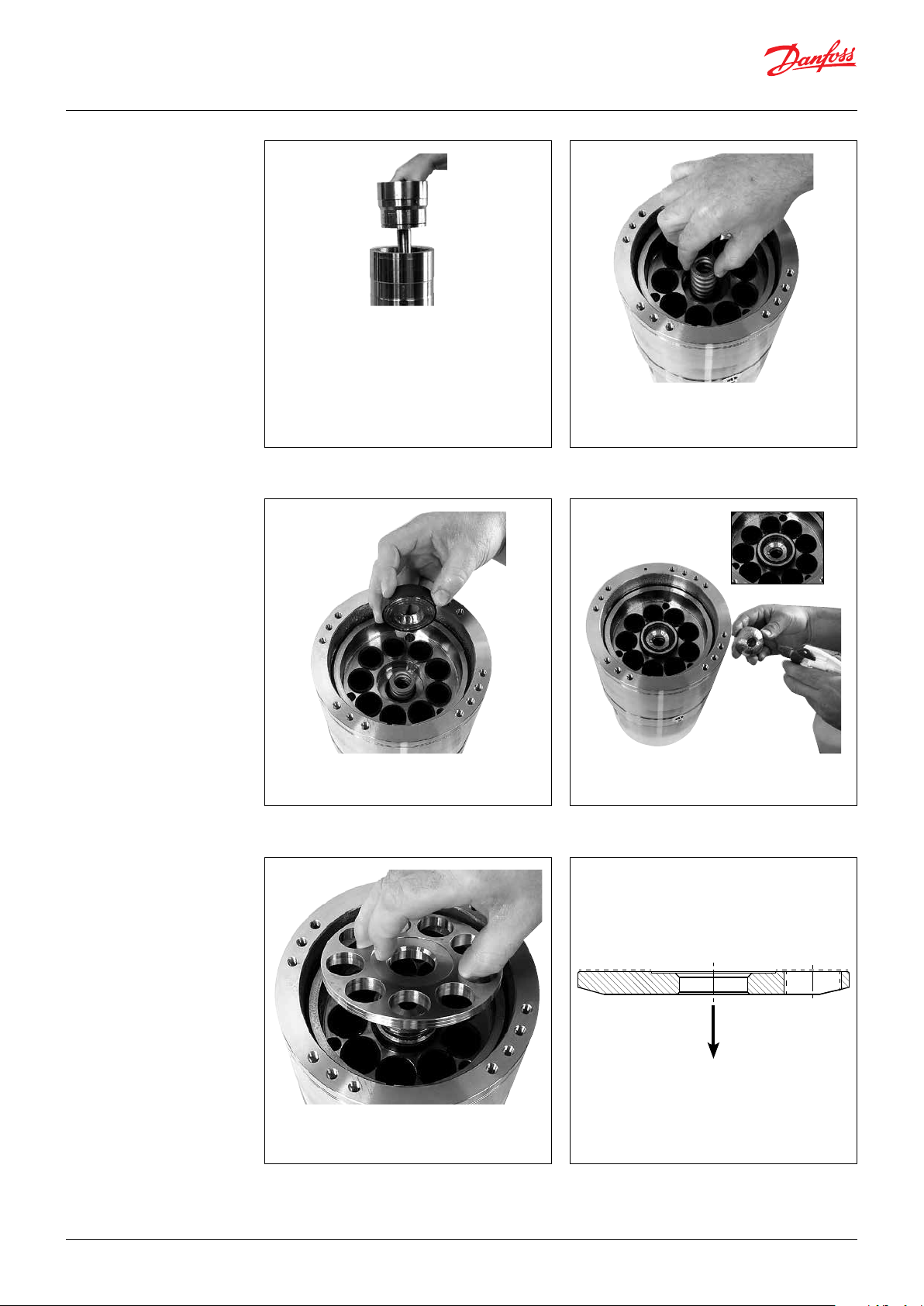

5. Disassembling and

assembling of cylinder

barrel and valve plate

1. Push a screwdriwer into the hole between

cylinder barrel and valve plate. Carefully

push downward the screwdriver so that it

makes a gap between cylinder barrel and

valve plate. Use this gap to put in another

screwdriver and loosen the valve plate

from the cylinder barrel.

O-ring

Back-up ring

O-ring

Back-up ring

2. Remove the O-rings and backup rings on

valve plate. If they have been removed

they can not be reused.

3. Mount the new back-up rings on the valve

plate rst and then mount the O-rings.

5. Lower the valve plate upside down on the

cylinder barrel.

4. Lubricate the new O-rings/back-up rings

and the liners in the cylinder barrel with

clean ltred water.

6. Press by hand valve plate into cylinder

barrel.

Cylinder barrel is now ready for mounting.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 14

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

6. Disassembling and

assembling of the

ushing valve

1. Unscrew the ushing valve

counterclockwise by using the pin wrench.

valve cone

3. It is important that if the spring is changed

it is located like on the picture. The end of

the spring must be against the shoulder of

the valve cone.

2. Remove the O-rings. If necessary, change

the valve cone, spring and plug.

4. Lubricate seals with clean ltered water

and lubricate thread with PTFE lubrication.

Screw it into the port ange. Tighten with

a torque of 30 Nm ±3 Nm.

7. How to replace the

shaft seal

© Danfoss | DCS (im) | 2021.02

Disassembling, please see Assembling, please see

Page 3 items 2 to 5 Page 10 item 19

Page 4 items 6 to 11 Page 11 items 20 to 25

Page 12 items 28 to 32

180R9258 |AX073186502887en-000401 | 15

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

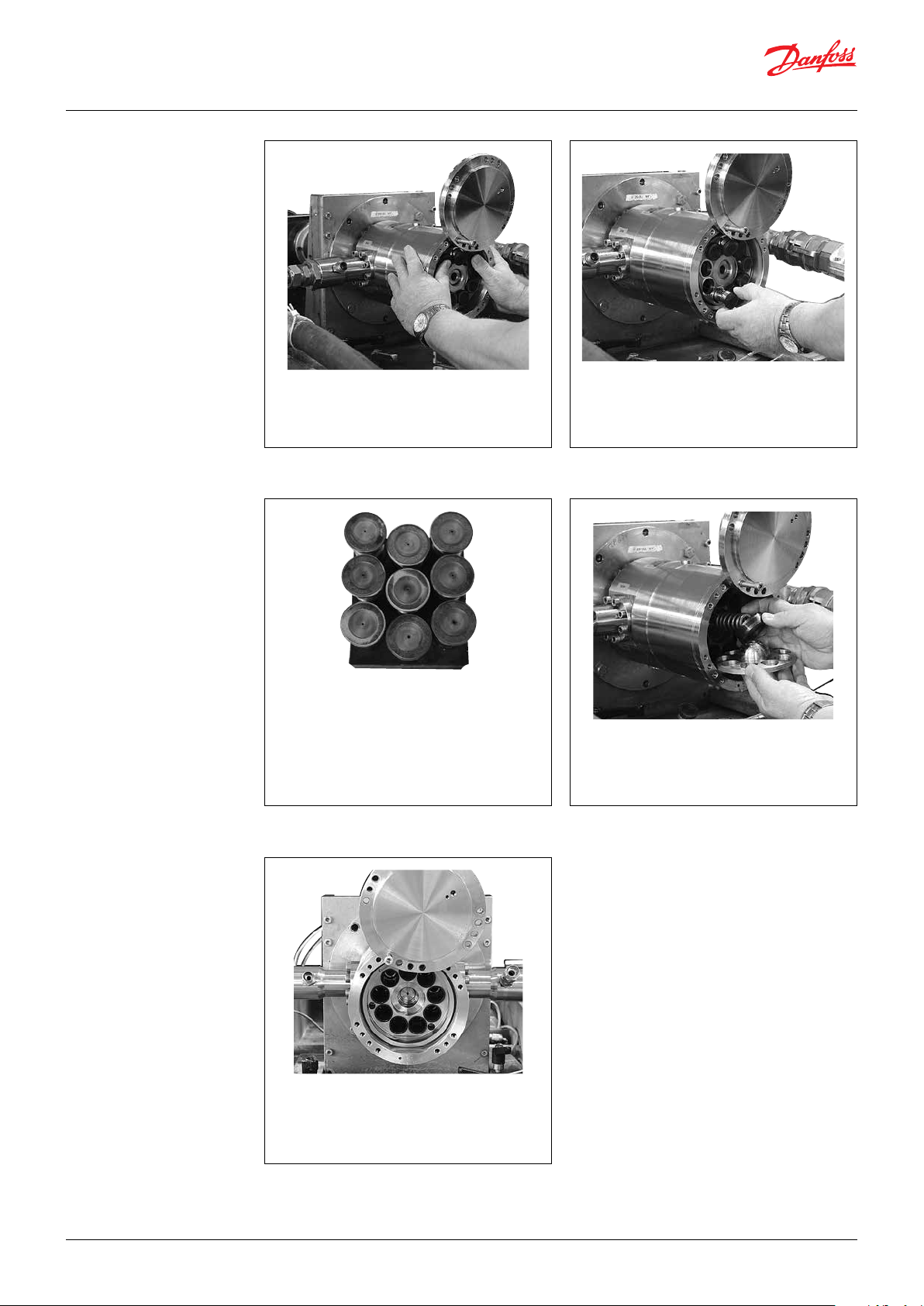

8. Changing pistons 8.1 Disassembling

To understand the pump design better, please

see the exploded view in item 9.

1. Disconnect the pump from the rest of the

system or close inlet valve.

2.

Loosen all screws on the pump except the

three screws as shown in the picture below.

Note: There is still water inside the pump.

3. A long M8 guide bolt can be mounted in

the top hole.

5. Remove the ange. The guide bolt must

remain mounted.

4. Unscrew the remaining three screws.

6. Carefully turn the ange and push it

backwards to make it rest on the housing

surface. Ensure not to scratch the swash

plate surface. The ange can also be

removed.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 16

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

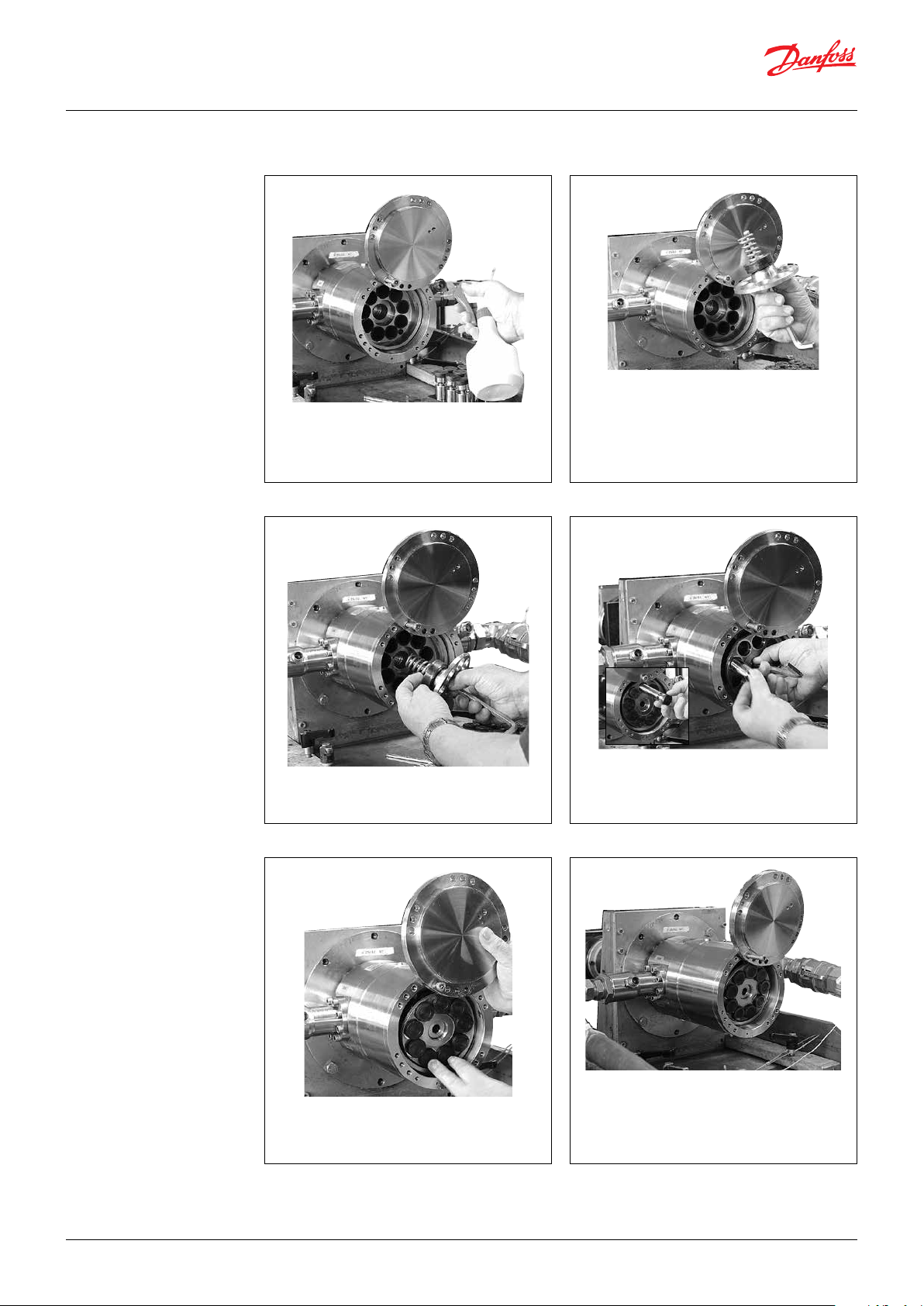

7. Adjust the retaining plate to be parallel to

the end ange.

9. WARNING:

Ensure that the piston shoes and the

piston surfaces are not damaged during

removal.

It is recommended to place the pistons

upside down on an even and clean base/

surface.

8. Carefully remove the pistons one by one.

10. Remove retainer plate, ball, guide and

spring.

© Danfoss | DCS (im) | 2021.02

12. Replace any worn parts.11. Inspect the piston liners.

180R9258 |AX073186502887en-000401 | 17

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

8.2 Assembling

1. Ensure liner and end of cylinder barrel are

wetted.

2.

Place retainer plate, ball, guide and spring

on the allen key.

WARNING!

Ensure right assembling and side of

retainer plate.

3. Carefully place all parts in the cylinder

barrel.

5. Place the retainer plate in an odd angle

corresponding to the orientation of the

swash plate.

4. Insert the pistons one by one. At the same

time keep the retainer plate in place with

the other hand.

6. Tilt the ange and replace the ange

O-ring.

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 18

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

7. Turn the ange and gently push it into the

housing.

9. Remove the guide bolt and mount the

remaining bolts.

11. Connect the pump to the rest of the

system.

8. Mount two screws as shown below and

tighten them.

10. Cross tighten the bolts to a torque of

30 Nm ± 3 Nm.

12. Bleed the pump before starting it up.

© Danfoss | DCS (im) | 2021.02

180R9258 |AX073186502887en-000401 | 19

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

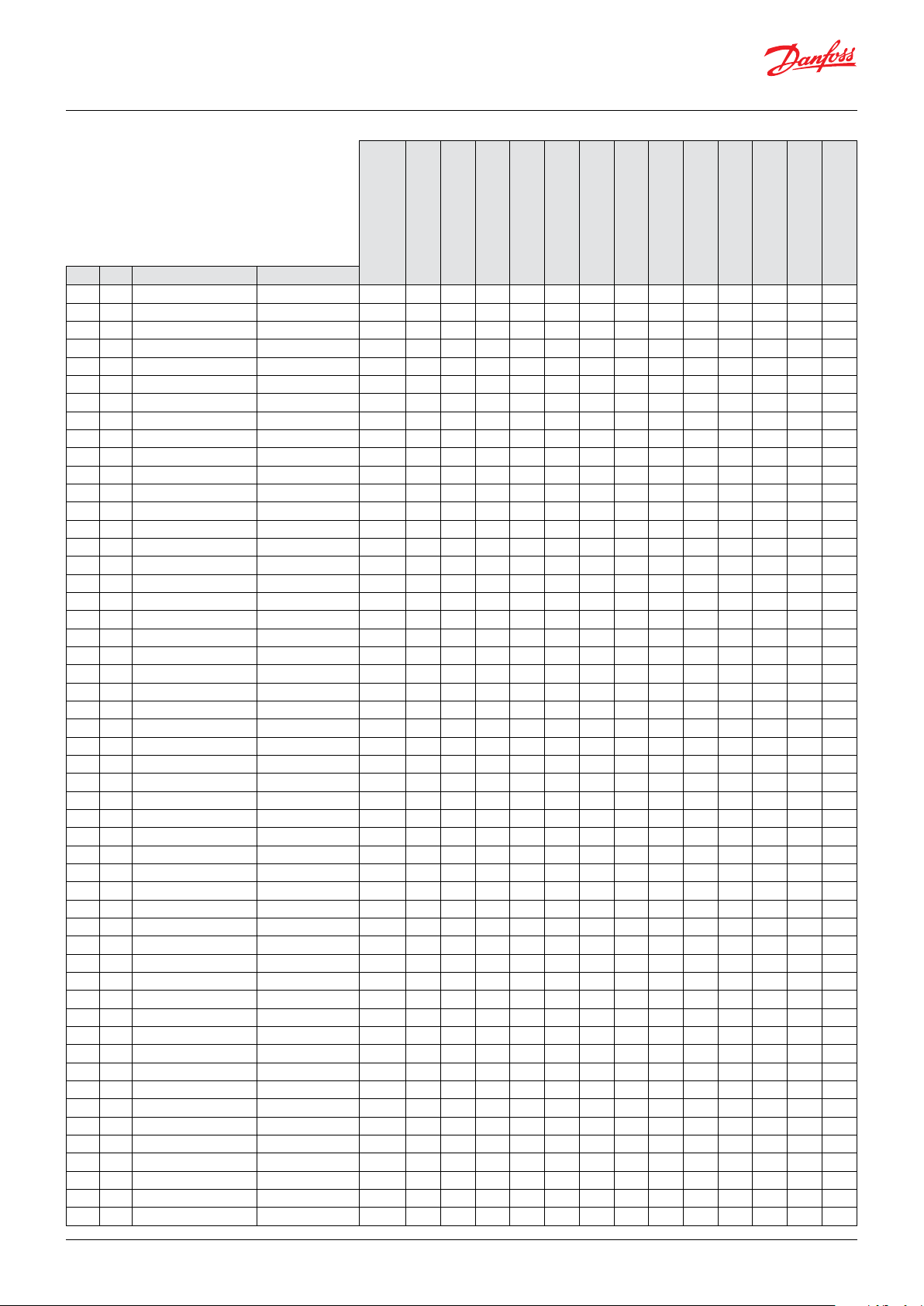

9. Spare parts list APP S (674) 5.1-9.0

)

3.1 Material certicate not traceable

²

)

PMI rapport not available

³

Pos. Qt y. Designation Material

1 1 Housing Super Duplex/PEEK X X

2 2 Pin AIS I 316

3 4 Bleeding plug, G1/4” Super Duplex X

4 4 O-ring NBR X

5 14 Screw M8x25 AI SI 316 X

9 1 O-ring NBR X

11 1 End ange Super Duplex X X X

12 1 Lifting eye Duplex

31 1 Swash plate Super Duplex X X X X X X

32 1 Screw M8x20 Super Duplex X X X X X X

34 2 Pin Super Duplex X X

61 1 Complete cylinder barrel X

(1) Cylinder barrel Super Duplex X

(1) Shaft Super Duplex X

(9) Bushing PEEK

62 1 Spring Duplex X X

64 1 Retainer ball Super Duplex X X

65 1 Retainer plate Super Duplex X X

66 9 Piston Super Duplex/PEEK X X

67 1 Key AIS I 316 X

71 1 Retainer guide Super Duplex/PEEK X X

91 1 Por t plate Super Duplex/PEEK X

92 1 Complete valve plate X

(1) Valve plate Super Duplex X

(9) Valve shoes Super Duplex X

93 9 Back-up ring PTFE X

94 9 O-ring NBR X

121 1 Port ange Super Duplex/PEEK X X

122 1 O-ring NBR X

123 1 O-ring NBR X

124 1 Shaft seal Hastelloy C4 X X

125 1 Cover for shaf t seal Super Duplex X X

126 1 Pin Super Duplex X X

127 4 Screw M6 x 16 AISI 316 X

128 14 Screw M8 x 90 AISI 316 X

129 1 Stop bush Polypropylene X

130 1 O-ring FPM X

131 2

132 2 O-ring EPDM X

133 16 Screw M8x25 AISI 316 X

140 1 Bearing PEEK

142 1 Stop for shaft seal Super Duplex X

144 4 Tailstock screw M12x60 AISI 316 X

145 4 Check nut M12 AISI 316 X

146 1 Eye bolt M8 AISI 1015

148 1 O-ring NBR

151 1 O-ring FPM X X

152 1 Valve cone Super Duplex X X

153 1 Spring Hastelloy C276 X

154 1 Plug/guide Super Duplex X X X

155 1 O-ring NBR X X

Cover for port connection

Instruction X X X X X X X X X X X X

AIS I 316

Pressure Containing Parts,

3.1 Material Certicate

Available and Traceable

Metallic Process Wet ted Parts,

PMI Rapport Available

180B4261 Seal & screw set

APP S (674) 5.1-9.0

180B4243 Shaft seal set

APP S (674) 5.1-9.0

180B4244 Cylinder barrel set

APP S (674) 5.1-9.0

180B4245 Valve plate set

APP S (674) 5.1-9.0

180B4246 Retainer set

APP S (674) 5.1-9.0

180B4247 Piston set

APP S (674) 5.1-9.0

180B4262 Swash plate set

APP S (674) 5.1

180B4263 Swash plate set

APP S (674) 6.5

180B4264 Swash plate set

APP S (674) 7.2

180B4248 Swash plate set

APP S (674) 8.2

180B4249 Swash plate set

APP S (674) 9.0

2)

X X

3)

3)

X

180B4250 Flushing valve set

APP S (674) 5.1-9.0

X

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 20

Instruction | Disassembling and assembling APP S 5.1-9.0 / APP S 674 5.1-9.0

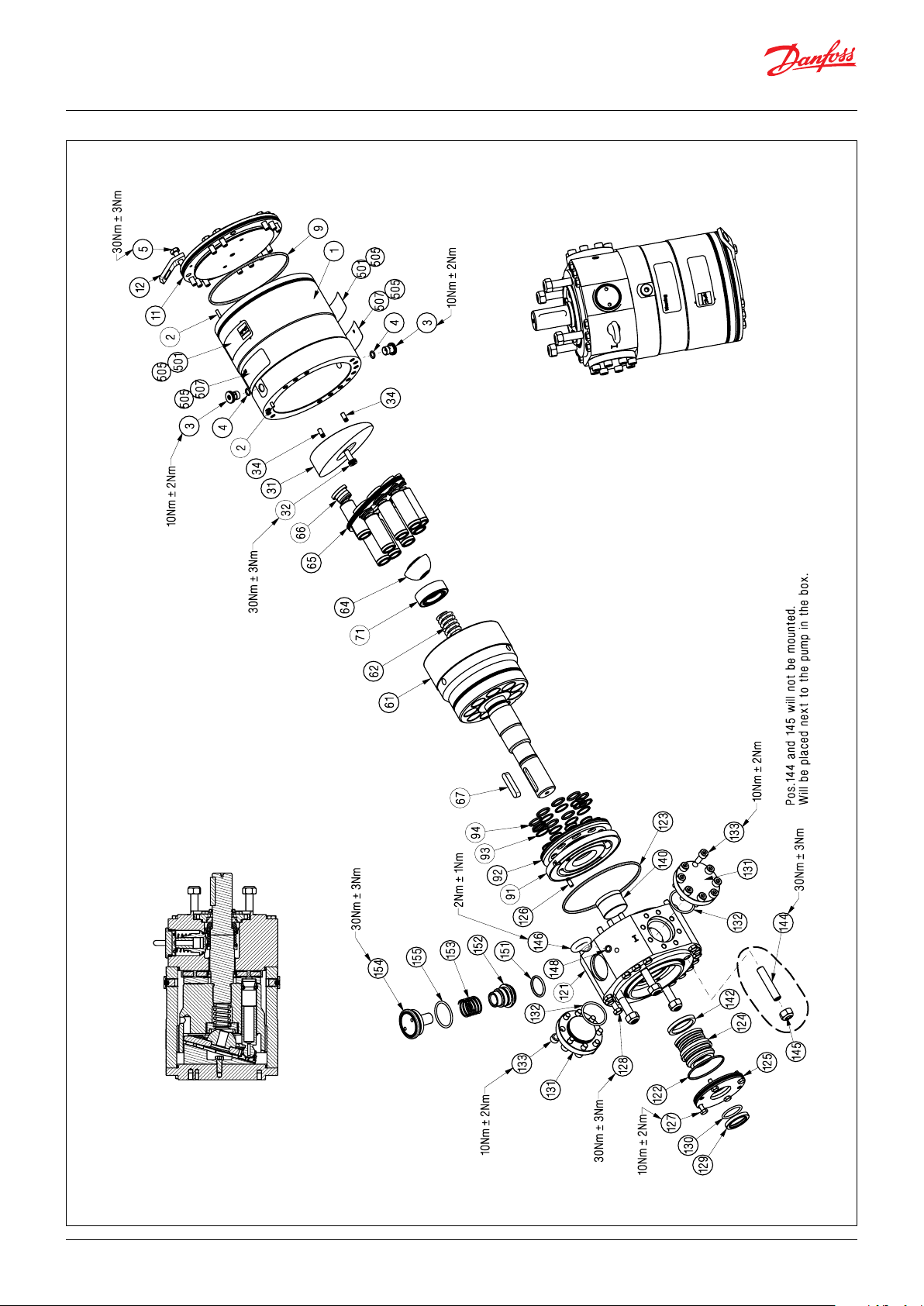

9.1 Exploded view

APP S (674) 5.1-9.0

© Danfoss | DCS (im) | 2021.02

180R9258 |AX073186502887en-000401 | 21

10. When should the pistons

be replaced

This section provides guidance on, how to

determine whether the parts of the pump are

worn and should be replaced. In case of doubt

- the pistons must be replaced. The pictures

below are meant as a guideline for evaluating

the wear of the sliding surface.

Note: If the pistons break down, the pump will

suer a disastrous breakdown.

1. Picture 1:

Cavitation of the piston shoes.|

New inspection is required in 3,000-4,000

hours.

3. Picture 3:

Cavitation of the piston shoes.

All pistons must be replaced within the

next 100-200 hours.

2. Picture 2:

Cavitation of the piston shoes.

All pistons must be replaced within the

next 500-1,000 hours.

4. Picture 4:

Abrasive wear of the piston shoes.

All pistons must be replaced immediately.

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2021.02

180R9258 | AX073186502887en-000401 | 22

Loading...

Loading...