Page 1

Data sheet

AB-QM 4.0 / AB-QM Pressure Independent Control

Valves (PICV) DN 15-250

The AB‑QM valve equipped with an actuator is a control valve with full authority and an automatic balancing func tion / flow limitation. Typical applications

are: Temperature control with permanent automatic balancing on terminal units (chillers, air‑handling units, fan coils, induction units, radiation panels and

heat exchangers). Without an actuator is a flow limiter e.g for one‑pipe systems.

Description

The Danfoss AB-QM is a Pressure Independent

Control Valve (PICV) that combines high

accuracy and durability with market leading

user-friendliness. The design of the AB-QM is

fully geared towards making your project run on

time and on budget while delivering the most

efficient HVAC system.

Pressure independent valves are control valves

with an automatic balancing function. An

in-built pressure controller keeps a constant

differential pressure over the control valve,

ensuring full authority and automatic flow

limitation. By combining two functions in one,

control and automatic hydronic balance, Danfoss

PICVs provide a cost-efficient solution for the

challenges faced by forward-looking designers

of HVAC systems.

The Danfoss AB-QM delivers the lowest total cost

of ownership because:

• Precise flow limitation ensures always

the right flow at the right time, ensuring

minimized pumping energy

• Full range from DN15 to DN250 for flows up to

407 m3/h

• Available with internal and external thread for

universal applicability

• Danfoss’ durability test ensures the AB-QM

has best-in-class resistance to scaling and

clogging

• Easy troubleshooting because of the always

visible setting and the ability to measure flow

through test plugs

• Minimum hysteresis for stable and precise

temperature control

• Future-ready with a range of smart actuators,

ready for data driven and optimized HVAC 4.0

© Danfoss | 2022.03 AI309581732428en-030402 | 1

Page 2

Data sheet AB-QM DN 15-250

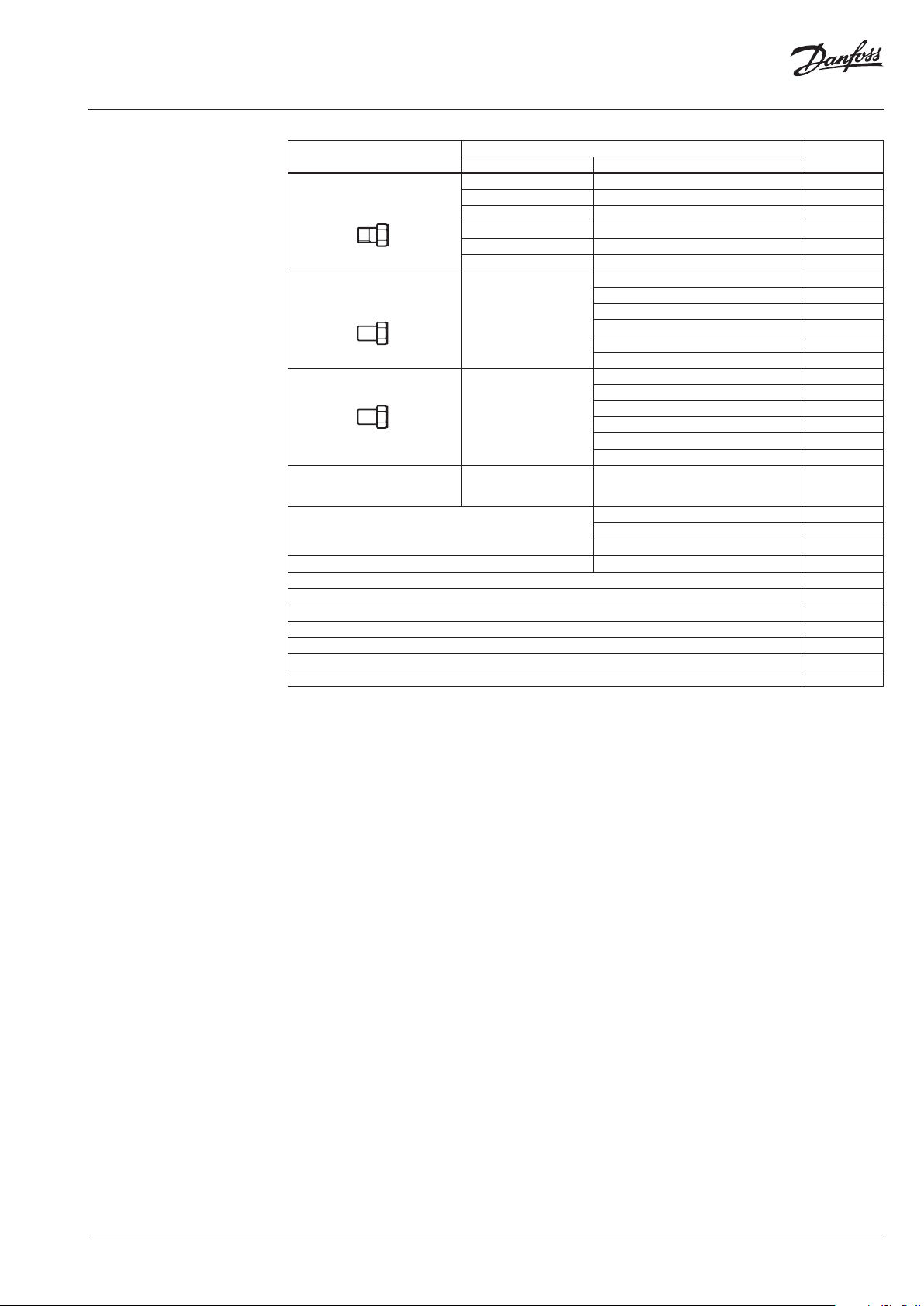

Ordering

AB‑QM 4.0 threaded version (with test plugs and without test plugs) - External thread

With test

plugs

Code No. Code No.

003Z8200 003Z8220

003Z8203 003Z8223

Picture DN

15 LF 200

15 650 003Z 8201 003 Z8221

15 HF 1,200 003Z8202 003Z8222

20 1,100

20 HF 1,900 003Z8204 003Z8224

Typ e

Q

(l/h)

nom.

Ext. thread

(ISO 228/1)

G ¾A

G 1A

AB‑QM threaded version (with test plugs and without test plugs) - External thread

Typ e

Q

Picture DN

25 1,700

25HF 2,70 0 ‑ 003Z1224

32 3,200

32 HF 4,000 ‑ 003Z1225

40 7,500 G 2 A 003Z0770

50 12,500 G 2 ½ A 003Z0771

* AB‑QM D N 15‑32 w/o TP can not be upgraded to ver sion with TP

nom.

(l/h)

Ext. thread

(ISO 228/1)

G 1 ¼A

G 1 ½A

-

With test

plugs

Code No. Code No.

00 3Z1214 0 03Z1204

00 3Z1215 003Z1205

Without test

plugs

Without test

plugs

*

AB‑QM 4.0 threaded version (with test plugs and without test plugs) - Internal thread

With test

plugs

Code No. Code No.

003Z8300 003Z8320

003Z8303 003Z8323

Picture DN

15 LF 200

15 650 003Z8301 003 Z8321

15 HF 1,200 003Z8302 003Z 8322

20 1,100

20 HF 1,900 003Z8304 003Z8324

Typ e

Q

(l/h)

nom.

Int. thread

(I SO 7/1)

Rp ½

Rp ¾

AB‑QM flanged version

Picture DN

50 12,500

65 20,000 003Z0773

65 HF 25,000 003Z0793

80 28,000 003Z0 774

80 HF 40,000 003Z0794

100 38,000 003Z0775

100 H F 59,000 003Z0795

125 90,000 003Z0705

125 HF 110,000 003Z0715

150 145,000 003Z070 6

150 HF 190,000 003Z0716

200 200,000 003Z0707

200 HF 270,000 0 03Z0717

250 300,000 003Z0708

250 HF 370,000 0 03Z0718

Q

(l/h)

nom.

Flange

connection

(E N 1092-1)

PN 16

Code No.

003Z0772

Without test

plugs

2 | AI309581732428en-030402 © Danfoss | 2022.03

Page 3

Data sheet AB-QM DN 15-250

Ordering (continuous)

Accessories & spare parts

Typ e

Union connection

(C W617N )

(1 pc s.)

Tailpiece welding

(W. Nr. 1.0308)

(1 pc s.)

Tailpieces for soldering

(CW614N )

(2 nuts, 2 gaskets, 2 soldering plugs

Handle AB-QM

(necessar y accessory if installing valve without actuator)

Shut off accessories DN15 -32

Stem heater for AB-QM DN 40-100 / AME 435 QM

Stem heater for AB-QM DN 125, 150 / AME 55 QM / AME 655

Elbow test plug extension (1 pcs.)

Straight test plug extension (1 pcs.)

Straight plug extension set (1 pcs.)

AB-QM 4.0 DN15 EPP insulation

AB-QM 4.0 DN20 EPP insulation

To pipe To val ve

R / DN 15 003Z0232

R / DN 20 003Z0233

R 1 DN 25 0 03Z0234

R 1 / DN 32 003Z0235

R 1/

R 2

Weld.

Weld.

15×1 mm DN 15 0 65Z7017

Comments

DN 40

DN 50

DN 15 003Z0226

DN 20 0 03Z0227

DN 25 0 03Z0228

DN 32 003Z0229

DN 40

DN 50

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50

DN 40 -100

DN 125-15 0

DN 200 -250

Code No.

003Z0279

003Z0278

003Z0270

003Z0276

00 3Z1271

00 3Z1272

003Z1273

00 3Z1274

00 3Z1275

00 3Z1276

003Z0695

003Z0696

003Z0697

003Z0230

065Z0 315

065Z7022

003Z3944

003Z3945

003Z3946

003 Z7810

00 3Z 7811

AI309581732428en-030402 | 3© Danfoss | 2022.03

Page 4

Data sheet AB-QM DN 15-250

Technical data

AB‑QM 4.0 (threaded version) AB‑QM (threaded version)

Nominal diameter DN 15 LF 15 15 HF 20 20 HF 25 25 HF 32 32 HF 40 50

Q

Flow range

Setting range

Diff. pressure

3), 4)

nom

Q

high

1), 2)

∆p

∆p

Pressure stage PN 25 16

Control range 1:1000

Control valve’s characteristic Linear (could be converted by actuator to equal percentage)

Leakage rate with recommended

actuators

For shut off function Acc. to ISO 5208 class A - no visible leakage

Flow medium

Medium temperature

Storage and transport temp. -40 … +70

Stroke mm 4 4.5 10

ext. thread (ISO 228/1) G ¾ A G 1 A G 1¼ A G 1½ A G 2 A G

Connection

int. thread (ISO 7/1) Rp ½ Rp ½ Rp ½ Rp ¾ Rp ¾ -

actuator M30 x 1.5 Danfoss standard

Materials and medium

Valve bodies DZR Brass

Membranes and O-rings EPDM

Shutter guide PPSU N/A

Shutter DZR Brass -

Materials in

the medium

Springs W.Nr.1. 4310 W.Nr.1.4310, W.Nr. 1.4568

Spring support PPSU -

Cone (Pc) - W.Nr. 1.4305 CW 614N, W.Nr.1.4305

Cone (Cv) PPSU CW 614N

Seat (Pc) - EPDM W.Nr. 1. 4305

Seat (Cv) DZR Brass W.Nr. 1.4305

Screw - Stainless steel A2

Materials out

of medium

1)

Factory se tting of the valve is done at no minal setting range.

2)

Regardless o f the setting, the valve can mo dulate below 1 % of set flow.

3)

When set above 100 % , minimum starting pressu re needed is higher, see figu res in the ().

4)

At min diffe rential pressure valve reache s at least 90% of nominal f low. Declaration of perf ormance is available upo n request.

Plastic parts ABS PA POM

Insert parts and outer

screws

*) If the medium te mperature when using AB‑ QM DN 15‑32 is below 2 ° C, than ice forming on the spi ndle must be prevented, ther e fore valve and actuator shou ld be insulated.

ForAB‑Q M DN40‑100 stem heaters must be used: Co de 065B2171, 065Z0315 or 065Z7022.

According suitabil ity and usage especia lly in not oxygen tight sy stems please mind the instruc tions given by the coolant pro ducer.

Pc ‑ pressure control ler part

Cv ‑ Control valve part

(100 %)

3)

min

max

1)

200 650 1.200 1.100 1.900 1.700 2.700 3.200 4.000 7.50 0 12 .50 0

l/h

200 650 1.200 1.10 0 1.90 0 1. 870 2.970 3.520 4.400 7. 500 12 .50 0

% 10-10 0 20 -110 40 -100

kPa

16 16 25 16 25 20 (25) 35 (40) 25 (30) 35 (40) 30

600

IEC 60534- 4:2007 class IV IEC 60534- 4:2007 class III

Water and water mixture for closed heating and cooling systems according to plant type I for DIN WN 14868. When used in Plant

type II for DIN EN 14868 appropriate protective measures are taken. The requirements of VDI 2035, part 1+2 are observed

°C

-10 … +95 (-10*) + 2 … 120

- CW 614N, W.Nr. 1.4310, W.Nr. 1.4401

Grey iron EN-GJL-250

(GG25)

2 ½

A

4 | AI309581732428en-030402 © Danfoss | 2022.03

Page 5

Data sheet AB-QM DN 15-250

Technical data (continuous)

AB‑QM (flanged version)

Nominal diameter DN 50 65 65 HF 80 80 HF 10 0 100 HF

Q

Flow range

Setting range

Diff. pressure

3) ,5)

nom

Q

high

1), 2)

∆p

∆p

Pressure stage

Control range Acc. to standard IEC 534 control range is high as Cv characteristic is linear. (1:1000)

Control valve’s characteristic Linear (could be converted by actuator to equal percentage)

Leakage rate with recommended

actuators

For shut off function

Flow medium

Medium temperature

Storage and transport temp. –40 … 70

Stroke

Connection

flange PN 16

actuator Danfoss standard

Materials in the water

Valve bodies Grey iron EN-GJL-250 (GG25)

Membranes/ Bellow EPDM

O-rings EPDM

Springs W.Nr. 1.4568, W.Nr. 1.4310

Cone (Pc) CuZn40Pb3 - CW 614N, W.Nr. 1.4305

Seat (Pc) W.Nr. 1.4305

Cone (Cv) CuZn40Pb3 - CW 614N

Seat (Cv) W.Nr. 1.43 05

Screw Stainless Steel (A2)

Flat gasket NBR

1)

(100 %)

12,500 20,000 25,000 28,000 40,000 38,000 59,000

min

max

12,500 20,000 25,000 28,000 40,000 38,000 59,000

l/h

40 -100

600

kPa

%

30 60 30 60 30 60

PN 16

max. 0.05 % of Q

nom

Acc. to ISO 5208 class A - no visible leakage

Water and water mixture for closed heating and cooling systems according to plant type

I for DIN EN 14868. When used in plant Type II for DIN EN 14868 appropriate protective

measures are taken. The requirements of VDI 2035, part 1 + 2 are obser ved.

°C

mm

10 15

−10 ... +120

1)

Factory set ting of the valve is done at

nominal setting range.

2)

Regardless of the set ting, the valve

can modulate b elow 1 % of set flow.

3)

When set above 100 %, minim um

starting pre ssure needed is higher,

see figure s in the ().

4)

In case AB‑QM is used ab ove 400 kPa

differential pressure contact D anfoss

design center to assur e proper

design.

5)

At min differential p ressure valve

reaches at lea st 90% of nominal

flow. Declarat ion of performance is

available upon request.

Pc ‑ pressure controll er part

Cv ‑ Control valve part

Nominal diameter DN 125 125 H F 150 150 H F 200 200 HF 250 250 HF

Flow range

Setting range

Diff. pressure

3),

4),

5)

Q

nom

Q

high

2)

∆p

∆p

(100 %)

3)

min

max

1)

90,000 110,000 145,000 190,000 200,000 270,000 300,000 370,000

l/h

100,000 120,000 160,000

209,000

% 40 -110

40 (60) 60 (80) 40 (60) 60 (80) 45 (65) 60 (80) 45 (65) 60 (80)

kPa

600 600

600

600 600 600 600 600

220,000

300,000 330,000 407,000

Pressure stage PN 16

Control range 1:1000

Control valve’s characteristic Linear (could be conver ted by actuator to equal percentage)

Leakage rate with recommended

actuators

max.0.01 % of Q

nom

Water and water mixture for closed heating and cooling systems according to plant type

Flow medium

I for DIN EN 14868. When used in plant Type II for DIN EN 14868 appropriate protective

measures are taken. The requirements of VDI 2035, part 1 + 2 are obser ved.

Medium temperature

Storage and transport temp. –40 … 70

°C

−10 ... +120

Stroke mm 30

Connection

flange PN 16

actuator Danfoss standard

Materials in the water

Valve bodies Grey iron EN-GJL-250 (GG 25)

Membranes/ Bellow W.Nr.1. 4571 EPDM

O-rings EPDM

Springs W.Nr.1. 4401 W.Nr.1. 4310

Cone (Pc) W.Nr.1.4404NC W.Nr.1.4021

Seat (Pc) W.N r.1.40 27

Cone (Cv) W.Nr.1.4404NC W.Nr.1.4021

Seat (Cv) W. Nr.1.4027

Screw W.Nr.1.1181

Flat gasket Graphite gasket Non asbestos

AI309581732428en-030402 | 5© Danfoss | 2022.03

Page 6

Data sheet AB-QM DN 15-250

Actuators overview

AB‑QMDN 15‑32

NovoCon® S

NovoCon® S is a high accuracy multi-functional field bus actuator, specifically designed for use in

combination with the Pressure Independent Balancing Control Valve type AB-QM in sizes from

DN15LF-32 HF. The actuator with AB-QM is used to control water supply to fan coil units, chilled

beams, induction units, small re-heaters, re-coolers, AHU’s and other terminal units for zone control,

in which heating/ chilled water is the controlled medium.

Typ e Speed Power supply Control signal Communication protocol Enclosure Cod e No.

NovoCon® S

3/6/12/24

s/mm

24 V ac/dc

0-10 V, 2-10V,

0-20mA, 4 -20mA

BACnet MS/TP,

Modbus RTU

IP 54 (IP40 if mounted

upside down)

003Z8504

AME(V) 110/120 NL

The AME 110 and 120 are high precision modulating gear actuators that can be mounted on the

AB-QM for precise control. They have a calibration function so the travel of the actuator always

matches the stroke of the AB-QM perfectly. The actuator is suitable for both linear and logarithmic

characteristics. The AME(V) 110/120 fits to AB-QM DN 15 LF to DN 32 HF.

Typ e Speed Feedback signal Power supply Control signal Enclosure Code No.

AMV 110 NL 24 s/mm No

AMV 110 NL 24 s/mm No 082H8058

AME 110 NLX 24 s/mm Yes 082H8060

AME 120 NL 12 s /mm No

AME 120 NL 12 s /mm No 082H8059

24 V ac

3 point

IP 42

0-10 V, 2-10V,

0-20mA, 4 -20mA

082H8056

082H8057

AME 13 SU/SD

The AME 13 is a precision gear actuator that has a built-in spring that will close the valve (Spring Down,

SD) or open the valve (Spring Up, SU) if the power on the actuator is lost. The characteristic can be set

to Logarithmic or Linear with a dip switch. The AME 13 SU/SD fits to AB-QM DN 15 LF to DN32HF.

Typ e

AME 13 SU-1

AME 13 SD-1 Spring to close 082H5007

Speed

14 s/

mm

Spring Power supply Control signal Feedback signal

Spring to open

24 V ac

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2 -10V IP 54

Enclosure

Code No.

082H5006

Cables

1 meter 082F1081

5 meter 082F1082

10 me ter 082F1083

Code No.

AME 113

The AME 113 are modulated controlled gear actuators that has a build in battery operated function

that opens or closes the valve if the power on the actuator is lost. The AME 113 has a logarithmic

characteristic. They have a calibration function so the travel of the actuator always matches the stroke

of the AB-QM valve. The AME 113 fits to AB-QM DN 15 LF to DN 32 HF.

Typ e

AME 113 NL SD

AME 113 NL SU Opens the valve 082H5008

AME 113 NLX SD Closes the valve

AME 113 NLX SU Opens the valve 082H5001

Speed

Safety function Power supply Control signal Feedback signal

Closes the valve

15 s/

mm

24 V ac/dc 0-10 V

-

0-10 V

Enclosure

IP 54

Code No.

082H5007M

082H5000

ABNM‑A5

The ABNM is a thermal modulating actuator. It can be used to modulate the AB-QM if speed or

precision is not the first concern. ABNM has either a Logarithmic (LOG) or a Linear (LIN) characteristic

which should be chosen to fit the application. It is available in Normally Open (NO) and Normally

Closed (NC) versions, as well as in 24V DC and AC . The ABNM-A5 fits to AB-QM DN 15 LF to DN 32 HF.

Typ e N O/NC LOG/LI N Supply voltage Stroke Full stroke time Enclosure Code No.

ABNM-A5 NC LOG

ABNM-A5 NC LIN 5 mm 08 2F1161

ABNM-A5 NC LOG 6.5 mm 08 2F1162

ABNM-A5 NO LO G 6.5 mm 08 2F11 63

ABNM-A5 NC LIN 6.5 mm 08 2F11 64

ABNM-A5 NO LIN 6.5 mm 0 82F116 5

ABNM-A5 NC LOG

ABNM-A5 NO LO G 6.5 mm 08 2F11 67

Note: ABN & ABNM A5 w ith 5mm stroke are only able to op en AB‑QM DN 25‑32 90%.

24 V ac

24 V dc

5 mm

3-5 min IP 54

6.5 mm 0 82F 1166

08 2F116 0

TWA‑Q

TWA-Q is a thermal actuator that is used for On/Off applications, where control precision and speed

are not prioritized. It is available in Normally Open (NO) and Normally Closed (NC) versions and in 24

and 230 Volt. TWA-Q has a position indicator to show if it is open or closed. The TWA-Q fits to AB-QM

DN 15 LF to DN 32 HF.

Typ e NC/NO Voltage Stroke Full stroke time

TWA-Q NC 230V AC 5 mm

TWA-Q NO 230V AC 5 mm 08 2F1601

TWA-Q NC 24V AC/DC 5 mm 0 82F1602

TWA-Q NO 24V AC/DC 5 mm 0 82F160 3

1)

at room tempe rature.

<3 min. IP 54

1)

Enclosure

Code No.

082 F1600

6 | AI309581732428en-030402 © Danfoss | 2022.03

Page 7

Data sheet AB-QM DN 15-250

Actuators overview

AB‑QMDN 40‑100

NovoCon® M

NovoCon® M is a high accuracy multi-functional field bus actuator, specifically designed for use in

combination with the NovoCon Pressure Independent Balancing Control Valve type NovoCon AB-QM

in sizes from

DN 40-100, please see separate data sheet. The NovoCon® M actuator with AB-QM is used in air

handling units AHU, chillers and distribution station applications.

Typ e Speed Power supply Control signal Communication protocol Enclosure Code No.

NovoCon® M 3/6/12/24 s/mm 24 V ac/dc

AME 435 QM

The AME 435 QM is a high precision modulating gear actuator that can be mounted on the AB-QM for

precise control. It has a calibration function, so the travel of the actuator always matches the stroke of

the AB-QM perfectly. The actuator is suitable for both linear and logarithmic characteristics. The AME

435 QM fits to AB-QM DN 40 to DN 100 HF.

Typ e Speed Power supply Control signal Feedback signal Enclosure Code No.

AME 435 QM 7.5/15 s/mm 24 V ac/dc

AME 25 SU/SD

The AME 25 SU/SD is a precision gear actuator that has a built-in spring that will close the valve (Spring

Down, SD) or open the valve (Spring Up, SU) if the power on the actuator is lost. The characteristic

can be set to Logarithmic or Linear with a dip switch. The AME 25 SU/SD fits to AB-QM DN 40 to

DN100HF.

Typ e Speed Power supply Control signal Feedback signal Enclosure Code No.

AME 25 SD

AME 25 SU

Please consider adapter is needed 003Z0694

15 s/mm 24 V ac

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V,

0-20mA, 4 -20mA

BACnet MS/TP, Modbus

RTU

0-10 V, 2 -10V IP 54 082 H0171

0-10 V, 2 -10V IP 54

IP 54 0 03Z8540

082H3038

082H3041

Actuators overview

AB‑QMDN 125‑150

AME 55 QM

AME 55 QM and AME 655-1 actuators are used with pressure independent balancing and control valve

typeAB-QM DN125 and DN 150.

Typ e Speed Power supply Control signal Feedback signal Enclosure Code No.

AME 55 QM 8 s/mm

24 V ac

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2 -10V IP 54

082H3078

AM E 655‑1

Typ e Speed Power supply Control signal Feedback signal Enclosure

AM E 655-1 2/6 s/mm 24 V ac/dc

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V, 0-20mA,

4-20mA

IP 54

Code No.

082 H5010

AME 658 SU/SD‑1

AME 658 SU/SD-1 actuator is used together with pressure independent balancing and control valves

type AB-QM DN 125 and DN 150. The AME 658 SU/SU-1 is a precision gear actuator that has a built-in

spring that will close the valve (Spring Down, SD) or open the valve (Spring Up, SU) if the power on the

actuator is lost. The characteristic can be set to Logarithmic or Linear with a dip switch.

Typ e Speed Power supply Control signal Feedback signal Enclosure

AME 658 SU-1

AME 658 SD-1

All actuato rs type “‑1” are UL certified .

4/6 s/mm 24 V ac/dc

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V, 0-20mA,

4-20mA

IP 54

Code No.

082H5012

082H5011

NovoCon® L

NovoCon® L is a high accuracy multi-functional fieldbus actuator, specifically designed for use in

combination with the Pressure Independent Control Valve type AB-QM in sizes from DN 125-150 used

in air handling units AHU, chillers and distribution station applications. NovoCon® L SU/SD has a builtin a spring that will close the valve (Spring Down, SD) or open the valve (Spring Up, SU) if the power on

the actuator is lost.

Typ e Speed Power supply Control signal Communication protocol Enclosure Code No.

NovoCon® L

NovoCon® L SU 003Z8 561

NovoCon® L SD 003Z8562

3/6/12/24 s/mm 24 V ac/dc

0-10 V, 2-10V,

0-20mA, 4 -20mA

BACnet MS/TP, Modbus

RTU

003Z8560

IP 54

AI309581732428en-030402 | 7© Danfoss | 2022.03

Page 8

Data sheet AB-QM DN 15-250

Actuators overview

AB‑QMDN 200‑250

AME 685‑1

AME 685-1 are used together with large pressure independent balancing and control valves type ABQM DN 200 and DN 250.

Typ e Speed Power supply Control signal Feedback signal Enclosure

AM E 685 -1 3/6 s/mm 24 V ac/dc

NovoCon® XL

NovoCon® XL is a high accuracy multi-functional fieldbus actuator, specifically designed for use in

combination with the Pressure Independent Control Valve type AB-QM in sizes from DN 200- 250

used in air handling units AHU, chillers and distribution station applications.

Typ e Speed Power supply Control signal Communication protocol Enclosure

NovoCon® XL 3/6/12/24 s/mm 24 V ac/dc

In case other t ypes of actuators are n eeded please contact our l ocal sales representative.

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V,

0-20mA, 4 -20mA

0-10 V, 2-10V, 0-20mA,

4-20mA

BACnet MS/TP, Modbus

RTU

Code No.

IP 54 003Z8563

Code No.

IP 54 003Z8563

Presetting

DN 15‑32

The calculated flow can be adjusted easily

without using special tools.

The change of presetting (factory setting is 100%

(10) follow steps below:

1. Remove the blue protective cap or the

mounted actuator

2. Raise the pointer (DN 25-32)

DN 15 ‑ 32

DN 15, 20

0 - 10

DN 40 ‑ 100

3. Turn the pointer (clockwise to decrease) to the

new setting

4. Press pointer back into lock position

(DN 25-32) the presetting scale indicates

values from 100% flow to 0% (DN 25-32) and

10-0 (DN 15-20). Clockwise turning would

decrease the flow value while counter clock

wise would increase it.

DN 25, 32

0 - 100 %

Max 25Nm

Note: 1 turn = 10 %

DN 125‑250

+

–

Setting 60 %

+

–

Note:

1 turn = 5 %

8 | AI309581732428en-030402 © Danfoss | 2022.03

Page 9

Data sheet AB-QM DN 15-250

Service DN 15‑32

For the service shut off function, it is

recommended to install the valve in the supply

water pipe.

DN 40‑10 0

For the service shut-off function, the valve can

be installed in either supply or return pipe.

Valves are equipped with manual shut-off for

isolating function up to 16 bar.

Tender text

A pressure independent balancing and control valve with a linear control characteristic that is

independent of the available pressure and setting. Make: Danfoss AB-QM or equivalent.

The pressure independent valve should have the following features:

• Automatic flow limitation function

• Membrane driven design for reduced clogging risk

• Modulating below 1% of set flow, regardless of the setting

• Maximum flow clearly marked on the valve

• Authority of 1 at all settings

• Ability to close against 16 Bar of differential pressure.

• Linear control characteristic

• Linear setting

• Control ratio 1:1000

• Test plugs for pump optimization and flow verification for DN 15-250. Available in the range from

DN 10 – 250 from one supplier.

• Option to change the characteristic from linear to equal percentage at all sizes by adjusting

actuator settings.

• Leakage rate of no visible leakage (IEC 60534-4:2007 class IV) for DN 15 - DN 20 in combination with

recommended actuator

• Leakage of 0.05 % of the Q

recommended actuator

• Leakage of 0.01 % of the Q

recommended actuator

• Flow measurements (AB-QM DN 15, 20) according to BS7350:1990

DN 125‑250

For the service shut-off function, the valve can

be installed in either supply or return pipe.

For shut-off set the valve to 0%.

for DN 25 - DN 100 (IEC 60534-4:2007 class III) in combination with

nom

for DN 125 - DN 250 (IEC 60534-4:2007 class IV) in combination with

nom

Insulation

L H

DN

15 113 62 56 68

20 12 0 62 60 75

H

1

2

mm

D

Fire class

E (EN 13501-1),

B2 (DIN 4102)

AI309581732428en-030402 | 9© Danfoss | 2022.03

Page 10

Data sheet AB-QM DN 15-250

Dimensions

2

H

ext. (ISO 228/1)

1

H

L

b

int. (ISO 7/1)

A

L

2

Length Height Threaded Welde d

DN

external internal H

1

H

2

L (mm) b L (mm) b (mm)

A

(mm)

15 65 G ¾A 75 Rp ½ 38.2 65.2 120 139 42.6

20 82 G 1A 85 Rp ¾ 43.9 67. 2 143 166 49.4

2

H

b

L

A

H

b

1

H

2

A

(mm) (mm)

2

L

3

L

2

DN

1

H

L

Length Height Threaded Welded

L

(mm)

25 10 4 G 1 ¼ 39.2 82.6 174 188 71 79

32 130 G 1 ½ 48.7 93.8 207 214 90 79

L

2

L

3

A

H

H

DN 25, 32

DN

DN 15, 20

TWA‑ Q ABNM A5

AME/AMV 110NL,

120 NL, AMI 140

NovoCon S AME 13 SU

H (mm) external internal

15 110 .8 9 7.8 131. 3 130 .1 210.7 0.56 0.59

20 112 99 132. 5 131.3 212.1 0.75 0.73

25 117 124 155 153 233.9

32 128 13 6 166 16 4 245

10 | AI309581732428en-030402 © Danfoss | 2022.03

A

Valve weight

(kg)

1.45

2.21

Page 11

Data sheet AB-QM DN 15-250

Dimensions (continuous)

L

1

1

H

b

2

H

3

H

1

3

H

H

a

2

H

L

1

AB-QM DN 40, 50 AB-QM + AME 435 QM

L

H

H

DN

1

1

mm

H

2

40 11 0 170 174 280 G 2 6.9

50 13 0 170 174 280 G 2 ½ 7.8

1

H

2

H

3

b

(ISO 228/1)

Weight

AB-QM DN 50-100 AB-QM + AME 435 QM

L1H1H2H

kg

DN

mm

50 230 170 174 280 165 14. 2

65 290 220 172 330 185 38.0

80 310 225 17 7 335 20 0 45.0

100 350 240 187 350 220 5 7.0

1

H

a

2

H

3

a

(EN 1092-2)

a

Weight

(kg)

L

1

L

1

AB-QM DN 125 AB-QM DN 150

L1H1H

DN

400 234 532 250 85.3

125

480 308 465 285 138

150

2

mm

a

(EN 1092-2)

Weight

(kg)

AI309581732428en-030402 | 11© Danfoss | 2022.03

Page 12

Data sheet AB-QM DN 15-250

Dimensions (continuous)

505

AB-QM DN 125 + AME 55 QM

1

H

AB-QM DN 150 + AME 55 QM

a

541

3

H

2

H

L

1

AB-QM DN 200, 250

Typ e

DN 200 600 434 483 784 340 219

DN 250 730 430 533 789 405 342

L1H1H2H

AB-QM DN 200, 250 + AME 685-1 & NovoCon XL

mm

3

a

(EN 1092-2)

Weight

(kg)

© Danfoss | DCS-SGDPT/SI | 2022.0312 | AI309581732428en-030402

Loading...

Loading...