Page 1

Data sheet

Pressure difference controller with integrated flow limiter

AB-PM DN 40-100

Description

AB-PM is a combined balancing valve.

It features 4 functions in one compact valve:

1. Differential pressure control

2. Flow limitation

3. Control valve with linear characteristic

4. Zone control

Reliable HVAC system with low total cost of

ownership:

Design:

• Easy, fast and flexible HVAC system design

Construction:

• Fast installation and easy setting

• Lower commissioning cost - no need for

balancing

• Faster project with staged handover

Operation:

• Perfect balance at all loads

• Guaranteed flow and p for users

• No problems caused by poor designed/

executed user installations

• Unoccupied zones do not impact other

AB-PM is ideal for staged installation and commissioning

users

• Flow verification and easy troubleshooting

Ordering AB-PM valve (including 2.5 m impulse tube (G ⁄ A), brass handle (003Z0695) impulse tube

connector (003L8151))

Picture

DN Connection Code No.

40 Ext thread (ISO228/1) G 2A 00 3Z1435

50 Ext.thread (ISO228/1) G 2½A 00 3Z1436

65

80 003Z1439

100 00 3Z144 0

Flange PN 16

003Z1438

Actuator

Typ e Power supply Code No.

AME435 QM

1)

For more inform ation see AME 435 QM datasheet

1)

24 VAC /DC 08 2H017 1

© Danfoss | 2018.01

Accessories

Picture Typ e To p ipe To va lve Code No.

Union connection

(CW617N) (1 pcs.)

Tail piece welding

(W.Nr. 10308)(1 pcs.)

Tailpiece welding INOX

(W. Nr. 1.4404) (1 pcs.)

R1½ DN40 003Z0279

R2 DN50 003Z0278

Weld

Weld

DN40 003Z0270

DN50 003Z0276

DN40 003Z12 75

DN50 00 3Z1276

VD.HR.D1.02 | 1

Page 2

Data sheet AB-PM DN 40-100

Ordering

Spare parts

Typ e Comments Code No.

Handle AB-PM (brass handle for spindle fixation) DN 40 -100 003Z0695

1.5 m 003L 8152

Impulse tube, with O-rings

Plastic impulse tube with connectors and adapters (industry pack) 10 pcs order quantity 003Z0689

Adapter large G .-R .; G 1/16 003Z0691

Plug for connecting impulse tube

Plug for connecting impulse tube on other valves (US standard) G 1⁄16-4⁄16-20 UNF-2B 00 3L8176

O-ring for impulse tube (set of 10 pcs) 2.90 × 1.78 0 03L8175

Plug for impulse tube connection ASV-I/M (set of 10 pcs) G1⁄16 A 00 3L8174

Needle plug set (1 pcs.) 003Z0100

Ext plug set (1 pcs.) 003 Z0106

Measuring needle, set (1 pcs.) 003 Z0107

Elbow test plug extension (1 pcs.) 003Z3944

Straight test plug extension (1 pcs.) 003Z3945

Straight plug extension set 003Z3946

2.5 m 003Z0690

5 m 003L 8153

3/8” – 1/16” 003L5042

¾” – 1/16” 003 Z0109

¼” – 1/16 003L 8151

Technical data

Nominal diameter DN 40 50 65 80 100

Qnom factory setting (∆pr 25 kPa) l/h 5000 6500 16800 19600 21000

Min. differential pressure (∆pa), Factory setting 1)kPa 42 60

Setting range

Nominal maximal pressure

Max. pressure drop 4

Control valve characteristics Linear

Shut-off leakage rate Acc. to ISO 5208 class A - no visible leakage

CV stroke mm 10 10 15 15 15

Connection

Connection actuator Danfoss standard

Flow medium

Medium temperature °C –10 … 120

Materials in water

Body Cast iron EN -GJL 250 (GG 25)

Membrane and O-rings EPDM

Springs W.Nr. 1.4568, W.Nr. 1.4310

Cone (Pc)

Seat (Pc) /(Cv) W.Nr. 1.4305

Cone (Cv) CuZn40Pb3 -CW 614N

Screw Stainless steel (A2)

Flat gasket NBR

Sealing agent (for test plugs) Dimenthcrylate Ester

1)

For other set tings see table 6

2)

Factory se tting see fig. 13 and 14

3)

Regardless of t he setting, the valve can modu late below 1 % of set flow.

2) 3)

Flow% 40 -100

∆p setting 0-20 turns 0-40 turns

bar

External thread (ISO

228/1) G2A

Water and water mixture for closed heating and cooling systems

according to plant type I for DIN EN 14868. When used in plant

Type II for DIN EN 14868 appropriate protec tive measures are

taken. The requirements of VDI 2035, part 1 + 2 are observed.

16 (PN16)

Flange (EN 1092-2)

CuZn40Pb3 -CW 614N,

W.Nr. 1.4305

2 | VD.HR.D1.02

© Danfoss | 2018.01

Page 3

Data sheet AB-PM DN 40-100

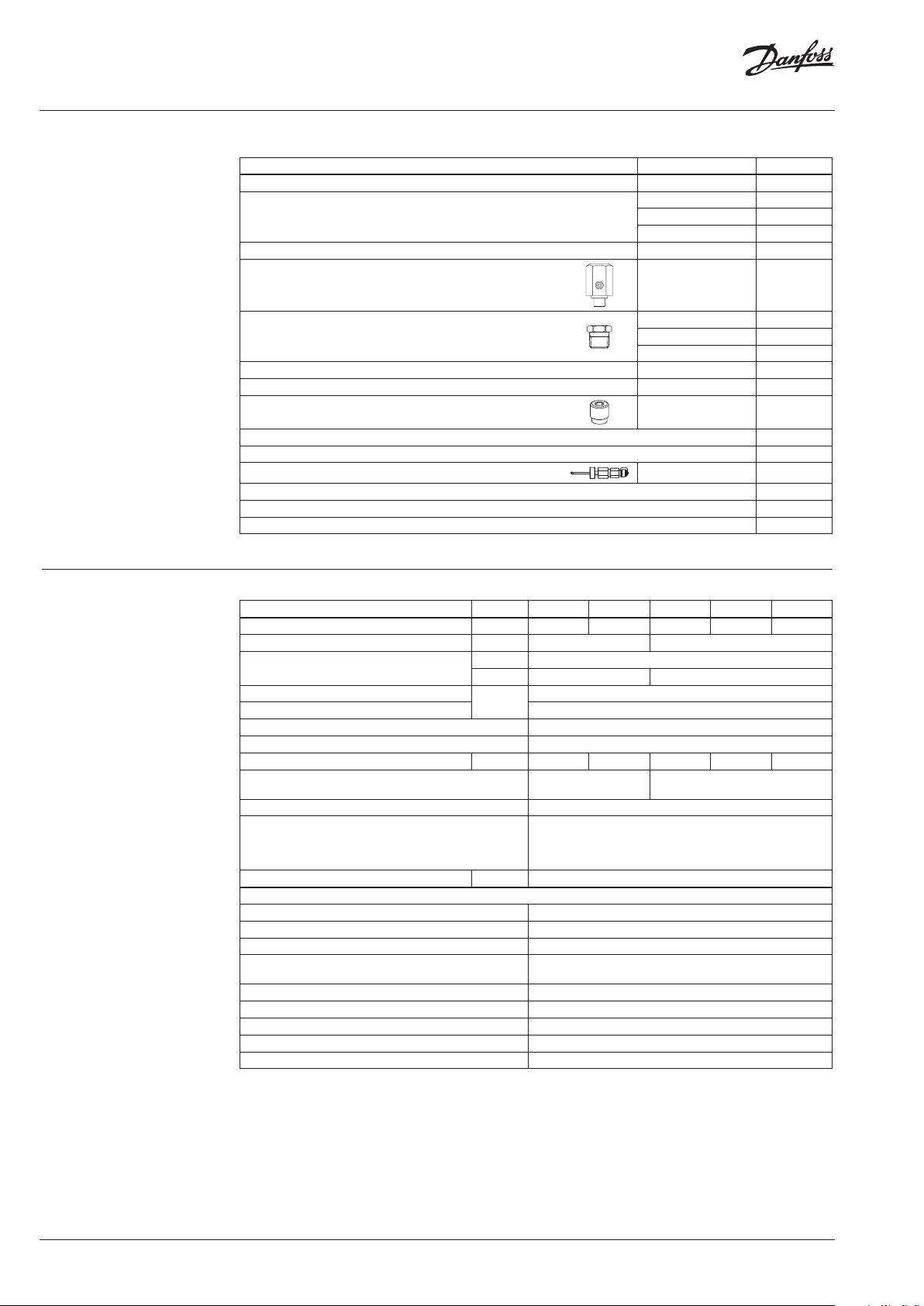

Mounting AB-PM DN 40-100 should be mounted in the

return pipe. The arrow on the valve body should

correspond with the flow direction of the

medium. The impulse tube should be connected

to the supply pipe using the included ¼”-/”

adaptor (003L8151).

Alternatively, the impulse tube can be connected

to a partner valve, such as ASV-BD or MSV-F2 1).

Using a partner valve offers additional service/

troubleshooting functions such as flow

verification, shut-off etc.

If the impulse tube is connected to the supply

pipe the AB-PM functions as a differential

pressure controller with flow limitation. The

impulse tube can also be connected to the

return pipe (upstream from the AB-PM) or to

the red test plug with adapter 003Z0691. In

that case the AB-PM will function as a pressure

independent control valve with 100% authority.

1)

For informatio n on partner valve see ASV a nd MSV-F2 datasheet

Impulse tube connection

DPCV

003L8151

Impulse tube connected to flow

PIBCV

003L8151

Impulse tube connected to return

PIBCV

003L8151

003Z0691

Commissioning

Service and trouble

shooting

When filling the system make sure to open the

supply valve before opening the return valve.

The pressure on the upper side of the membrane

(impulse tube) should always be higher than the

pressure on the lower side of the membrane (at

the valve)

Flush the impulse tube and ensure the HVAC

system is de-aired before starting the system.

For the setting procedure please refer to the

operating instructions enclosed with the

product.

It is recommended that an FV filter be installed in

the system supply pipe.

The valve can be manually shut off for service

purposes, up to 16 Bar.

AB-PM is equipped with 3 test plugs for flow

verification, service and trouble shooting.

+

Alternative

Fig. 1 AB-PM can be connected to flow or return with

impulse tube

Please check the following if the valve does not

function correctly:

1. Is the flow direction through the valve correct?

2. Is the impulse tube fitted correctly and are any

test plugs open?

3. Is the valve shut-off open? (see operating

instructions)

4. Is the available pressure big enough?

© Danfoss | 2018.01

VD.HR.D1.02 | 3

Page 4

Data sheet AB-PM DN 40-100

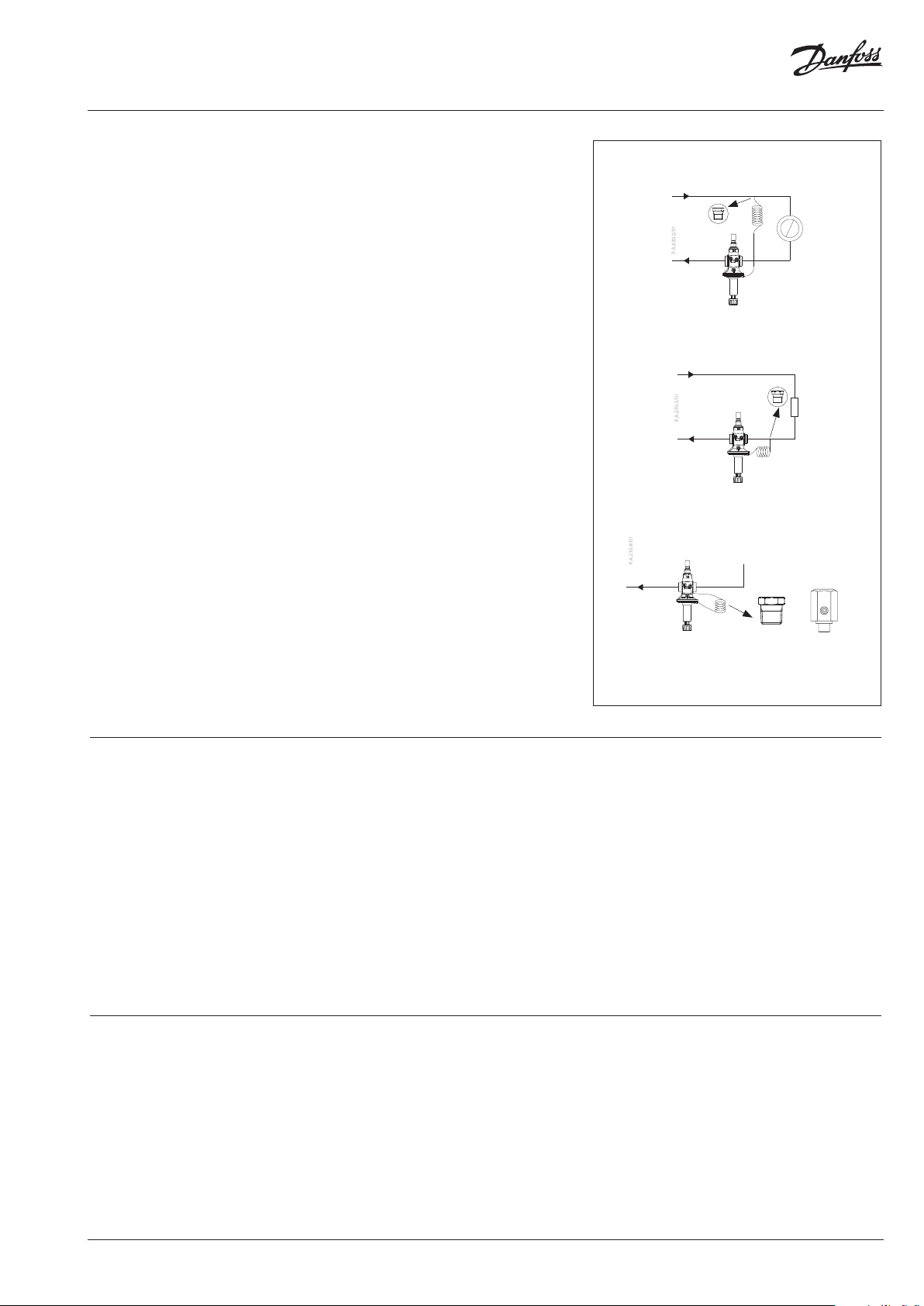

Application

-variable flow systems

Zone 1

Zone 3

Zone 2

Zone 6

Zone 5

Heating/

cooling

Zone 4

station

Fig. 2 Staged commissioning – 1st stage : ensuring Δp and flow for each zone

AB-PM DN 40 to 100 is the ideal solution for

applications where a so called staged installation,

Typical applications are shopping malls and shell

& core office buildings.

hand over and commissioning is used. In such

cases, the 1st stage is installation of backbone

piping without terminal units. AB-PM is used as

DPCV with flow limitation, ensuring the specified

The AB-PM ensures the required flow for each

zone and maintains hydronic balance in the

system.

design pressure and flow to each zone. The 2nd

stage is then the installation of terminal units.

4 | VD.HR.D1.02

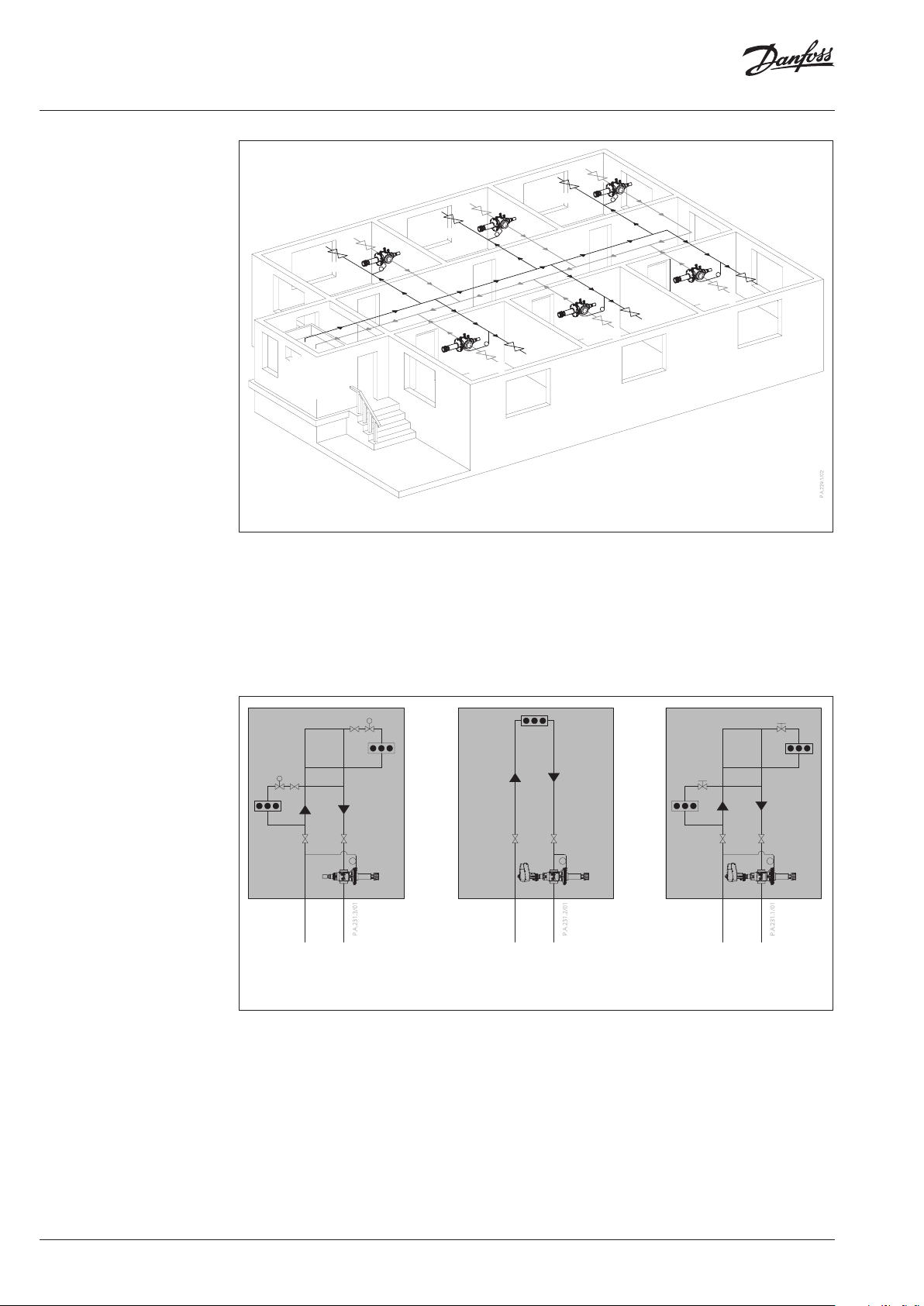

DPCV: several fancoils with

individual room control

Fig. 3 Staged commissioning – 2nd stage : Installation of terminal units

PIBCV: zone control for

one terminal unit

In the 2nd stage of commissioning the installation

of terminal units can be done. Optionally the

AB-PM can be changed from differential pressure

controller to pressure independent control valve.

This allows flexibility when designing the zones.

If only one terminal unit is used in the zone, the

AB-PM as a PIBCV can be used to control that

unit and no additional valves are needed.

DPCV: Zone control

for several fancoils

© Danfoss | 2018.01

Page 5

Data sheet AB-PM DN 40-100

Flow verification /trouble

shooting

Differential pressure legend

To verify that an installation functions per the

design specifications the AB-PM (DN 40-100) has

test plugs that allow measuring of the pressure

difference ∆pr or ∆pcv across the valve. In this

way the pressure difference and flow can be

verified for handover or troubleshooting.

At handover of the base building when the HVAC

design conditions are specified but components

are not yet installed in the zone, the differential

pressure and flow for the valve and loop can

only be verified by installing a bypass with the

same dp as specified for the zone. For quick hand

over, without flow verification, the calculated dp

can be pre-set on the valve for the dp and flow

demand of the loop.

In the 2nd stage of commissioning when the

HVAC system has been installed in the zone, the

differential pressure and flow can be verified for

handover and troubleshooting.

The differential pressure can be measured using

the following methods:

003L8151

DPCV: Measure differential pressure from AB-PM

to installed partner valve (∆pr =p0 − p1).

PIBCV: Measure the differential pressure across

the control valve (∆Pcv =p1 − p2).

To calculate the flow below formulas are used:

DPCV:

∆pr=p0 − p

Q=kvcv × √p

1

r

PIBCV:

∆pCv=P1 − P

2

Q=kvcv × √pcv

For kvcv values see datasheet “AB-QM flow

checker DN 40-250”

For trouble shooting the available pressure can

be verified, Closing the AB-PM valve fully and

measuring p0 – p2.

Verifying the pressure and flow can be done

by using Danfoss PFM or other dp measuring

devices (select valve type: AB-QM)

P1-P

3

P1-P

2

3

-P

0

=P

a

∆p

∆p

v

Q = needed desi gn flow for the loop

Δpr = needed dif ferential pressure for the l oop

Δpv = differe ntial pressure on AB-PM

Δpa = min. needed d ifferential pressure ove r

bo th AB-PM and loop

Δpa = Δpv + Δp

r

-P

=P

∆p

1

0

r

Fig. 4 Differential pressure legend

Sizing AB-PM is to be sized based on the needed flow

(Q) and the needed differential pressure drop for

the zone (pr).

Max flow /∆pr for all sizes are presented in the

sizing guide in fig. 5.

When pipe dimension has been selected, specific

sizing, selection and setting can be identified

based on Q and ∆pr in fig. 6-10.

Alternatively table 1-5 can be used for AB-PM

sizing as well.

Flow

direction

P

P

3

ΔpV = p1 − p3

Δpr = p0 − p1 (as DPCV)

Δpcv = p1 − p2 (as PIBCV for f low validation)

∆pa = p0 − p

3

1

P

2

P0-P

P

0

1

For needed flow and differential pressure

outside specified in graphs and tables, setting

can be calculated by linear distribution of

setting.

For minimum needed available differential

pressure (∆pa ) at Q nominal see table 6.

© Danfoss | 2018.01

VD.HR.D1.02 | 5

Page 6

Data sheet AB-PM DN 40-100

13000

60

Q [l/h]

∆pr[kPa]

55000

60

FLOW [L/H]

ΔPr [kPa]

Sizing graph - ΔP/ max. flow

50000

45000

40000

35000

30000

25000

20000

15000

10000

5000

AB-PMHP DN 10-32

0

10 15 20 25 30 35 40 45 50 55

1)

See datasheet AB-PM

DN 10-32

Fig. 5

DN 100

DN 80

DN 65

DN 50

DN 40

1)

Sizing

Example 1

Given : Design flow to zone

4200 l/h, pressure drop over

the zone at design flow 25 kPa.

Solution: AB-PM DN 40 is

selected. ∆p setting is kept

at factory setting and flow

limitation is changed to 80 %.

AB-PM will control differential

pressure of 25 kPa when

design flow is achieved and

the flow to the zone will be

limited to 4200 l/h

DN 40

12000

11000

10000

9000

100 %

8000

7000

6000

5000

Example 1

4000

3000

2000

90 %

80 %

70 %

60 %

50 %

40 %

10 15 20 25 30 35 40 45 50 55

Fig. 6

DN 40 Flow limitation on Δp factory setting

Δpr

[kPa]

Table 1

40% 50% 60% 70% 80% 90%

10 4600 5520 6348 7084 7728 8280 9200

15 4000 4800 5520 616 0 6720 7200 8000

20 3300 3960 455 4 5082 5544 5940 6600 9200

25 2500 3000 3450 3850 4200 4500 5000 8000 10200

30 2070 2310 2520 2700 3000 6600 920 0 1110 0

35 5000 8000 10200 119 00

40 3000 6600 9200 1110 0

45 5000 8000 1020 0

50 315 0 6600 9200

55 5000 8000

60 3150 6600

5 turns

10 tur ns 15 tu rns

Factory

setting

100%

/0 turns 5 turns 10 tu rns 15 tu rns 20 turns

Q [l/ h]

20 turns

∆p setting [kPa]

6 | VD.HR.D1.02

© Danfoss | 2018.01

Page 7

Data sheet AB-PM DN 40-100

16000

60

Q [l/h]

∆pr[kPa]

60

Q [l/h]

∆pr[kPa]

Sizing

DN 50

15000

14000

13000

12000

100 %

11000

90 %

10000

80 %

9000

70 %

8000

60 %

7000

50 %

6000

40 %

5000

4000

3000

10 15 20 25 30 35 40 45 50 55

Fig. 7

DN 50 Flow limitation on Δp factory setting

Δpr

[kPa]

Table 2

40% 50% 60% 70% 80% 90%

10 5520 6750 7920 9030 10 080 1107 0 12000

15 478 4 5850 6864 7826 8736 9594 10 400

20 3910 4781 5610 6396 714 0 7841 8500 12000

25 3656 4290 4891 5460 5996 6500 1040 0 1309 5

30 3085 3444 3782 4100 8500 116 40 14155

35 6500 10 088 12825 15390

40 410 0 8245 114 00 1415 5

45 6305 9880 1282 5

50 3977 8075 114 00

55 6175 9880

60 3895 8075

5 turns 10 tu rns 15 tu rns 20 turns

Factory

setting

100%

/0 turns 5 turns 10 tu rns 15 tu rns 20 turns

Q [l/ h]

∆p setting [kPa]

DN 65

30000

28000

26000

24000

100 %

22000

90 %

20000

80 %

18000

70 %

16000

14000

60 %

12000

50 %

10000

8000

40 %

6000

10 15 20 25 30 35 40 45 50 55

Fig.8

DN 65 Flow limitation on Δp factory setting

Δpr

[kPa]

Table 3

40% 50% 60% 70% 80% 90%

10 8432 111 60 14136 1736 0 198 40 22320 24800

15 7616 100 80 1276 8 156 80 1792 0 2016 0 22400

20 6732 8 910 112 86 138 60 158 40 1782 0 1980 0 24800

25 7560 9576 1176 0 134 40 15 120 16 800 22400 25840

30 6075 7695 9450 108 00 1215 0 135 00 198 00 23560 27740

35 6650 760 0 8550 9500 168 00 21280 25840 29450

40 13500 18810 23560 27 740

45 9500 15960 21280 25840

50 12825 18810 23560

55 9025 15960 2128 0

60 12825 18810

20 turns 30 turns 40 tur ns10 tur ns

Factory

setting

∆p setting [kPa]

100%

/0 turns 10 tu rns 20 turns 30 turns 40 turns

Q [l/ h]

© Danfoss | 2018.01

VD.HR.D1.02 | 7

Page 8

Data sheet AB-PM DN 40-100

51000

60

Q [l/h]

∆pr [kPa]

60

Q [l/h]

∆pr[kPa]

Sizing

DN 80

41000

39000

37000

35000

33000

31000

100 %

29000

27000

90 %

25000

80 %

23000

70 %

21000

60 %

19000

50 %

17000

15000

40 %

13000

11000

9000

10 15 20 25 30 35 40 45 50 55

Fig. 9

DN 80 Flow limitation on Δp factory setting

Δp

r

[kPa]

Table 4

40% 50% 60% 70% 80% 90%

10 1512 0 18113 2079 0 23373 25956 28350 3150 0

15 13536 16 215 18612 20924 23237 25380 28200

20 11616 13915 15972 1795 6 19941 217 80 2420 0 315 00

25 9408 1127 0 1293 6 14543 16150 17640 1960 0 28200 35000

30 9504 10 685 11866 12960 144 00 24200 3150 0 376 00

35 19600 28200 35000 40000

40 14400 24200 31500 376 00

45 19600 28200 35000

50 14400 24200 31500

55 19600 28200

60 14400 24200

20 turns 30 turns 4 0 turns10 tur ns

Factory

setting

∆p setting [kPa]

100%

/0 turns 10 tu rns 20 turns 30 turns 40 turns

Q [l/ h]

DN 100

49000

47000

45000

43000

41000

39000

37000

35000

100 %

33000

90 %

31000

29000

80 %

27000

70 %

25000

23000

60 %

21000

50 %

19000

17000

40 %

15000

13000

11000

10 15 20 25 30 35 40 45 50 55

Fig . 10

DN 10 0 Flow limitation on Δp factory setting

Δpr

[kPa]

Table 5

40% 50% 60% 70% 80% 90%

10 16470 2 0130 23607 26901 30012 32940 36600

15 14490 177 10 20769 23 667 26404 28980 32200

20 12150 14 850 17415 19 845 2 2140 24300 27000 36600

25 13545 154 35 1722 0 1890 0 21000 32200 40600

30 114 80 126 00 14000 27000 36600 44400

35 21000 32200 40600 48000

40 14000 27000 36600 44400

45 21000 32200 40600

50 14000 27000 36600

55 21000 32200

60 14000 27000

10 tur ns 20 tur ns 30 turns 40 turns

Factory

setting

∆p setting [kPa]

100%

/0 turns 10 tu rns 20 turns 30 turns 40 turns

Q [l/ h]

8 | VD.HR.D1.02

© Danfoss | 2018.01

Page 9

Data sheet AB-PM DN 40-100

Min. differential pressure

(Δpa)

Nominal diameter ≤Factory setting ∆p setti ng

≤100% /0 turns

DN40 42 52 63 74 85

DN50 42 52 63 74 85

DN65 60 72 83 94 105

DN80 60 72 83 94 105

DN100 60 72 83 94 105

Table 6

1)

If applicati on requires less dpr, for valve will be h igher so flow validation a cross valve is needed in order to incr ease.

5 turns

(pr >= 20 kPa )

Setting The AB-PM valves are factory preset to min. ∆p

setting with 100% flow.

For changing the setting please use the

following procedure:

Setting the desired differential pressure:

the setting on the AB-PM can be changed by

turning the setting spindle to allow higher

differential pressure. Turning the spindle

clockwise increases the setting; turning it

counter clockwise reduces the setting.

If the setting is not known, turn the spindle fully

clockwise. With this the setting on AB-PM is at

maximum value within setting range. Now turn

the spindle backwards a number of times (n)

as described in Fig. 13 or 14 until the required

differential pressure setting is obtained.

1)

10 tu rns

(pr >= 25 kPa )

pa [kPa]

15 tu rns

(pr >= 30 kPa )

20 turns

(pr >= 35 kPa )

The calculated flow can be adjusted easily with

a standard tool. The presetting scale indicates

values from 100 % flow to 40 %. Clock wise

turning would decrease the flow value while

counter clock wise would increase it.

Danfoss recomm ends a presetting/fl ow from 40 % to 100 %.

Factory pr esetting is 100 %.

DN Wrench

40-50 50

65-100 42

Design

1. Shut off knob

2. Differential pressure setting

spindle

3. Membrane

4. DP cone

5. Seat

6. Valve body

7. Control valve cone

8. Locking screw

9. Scale

10. Stuffing box

11. Spindle

12. Impulse tube

13. Brass handle

Fig. 11 Setting of differential pressure is done with

standard tool

Adjusting the flow limitation:

To give lower flow than factory setting the

% scale on the AB-PM need to be adjusted

according to sizing diagrams (figure 6 to 10).

one turn

is 10%

Max. 25 Nm

Fig. 12 Setting of flow limitation with standard tool

DN 40 50

5 5

Factory presetting DN 40-50

∆p setting min. setting (0 turns)

Flow % 10 0%

n Δp setting

(turns)

0 turns

… …

20 turns Max. setting

Min. setting

(factory setting)

© Danfoss | 2018.01

Do not turn the sp indle more than 20 turns as it will b ecome disengaged.

Fig. 13 AB-PM DN 40-50

VD.HR.D1.02 | 9

Page 10

Data sheet AB-PM DN 40-100

Design

1. Shut off knob

2. Differential pressure setting

spindle

3. Membrane

4. DP cone

5. Seat

6. Valve body

7. Control valve cone

8. Locking screw

9. Scale

10. Stuffing box

11. Spindle

12. Impulse tube

13. Brass handle

n

(turns)

0

… …

40 Max. setting

Factory presetting DN 65 -100

∆p setting min. setting (0 turns)

Flow % 10 0%

65 80 100

DN

42 13 23

Δp setting

Min. setting (factory

setting)

65 80 100

DN

Do not turn the sp indle more than 40 turns as it wil l become disengaged.

Fig. 14 AB-PM DN 65-100

DPCV PIBCV

AB-PM is a combined automatic balancing valve.

It works as differential pressure controller (DPCV)

or pressure independent control valve (PIBCV),

flow limiter and zone controller/control valve.

As DPCV it keeps a constant differential pressure

over the control loop and when installed as a

PIBCV it keeps the pressure constant over the

control valve ensuring it full authority.

Higher pressure acts on the lower side of the

control membrane (3) via an impulse tube (12)

while the lower pressure in the return pipe acts

on the upper side of the membrane (use either

membrane or diaphragm. Do not mix these

two, it will help clarity). When available pressure

increases at partial loads, the membrane closes

and thus keeps the differential pressure stable.

The control part of AB-PM is working as a

flow limiter. This enables to set a required

combination of the design flow as well as the

needed ∆p. By presetting the AB-PM, the flow

rate is defined based on the pressure demand of

the loop or terminal unit.

With an actuator mounted on the valve, AB-PM

can be used as a zone valve. When the AB-PM is

converted to a PICV it can be used, together with

an actuator, as a full authority control valve with

either a linear or a logarithmic characteristic.

10 | VD.HR.D1.02

© Danfoss | 2018.01

Page 11

Data sheet AB-PM DN 40-100

Dimensions

1

H

2

H

L

1

3

H

b

AB-PM DN 40, 50

L

H

Typ e

DN40 110

DN50 130 G 2 ½ (ISO228/1) 7. 8

1

H

1

168 273 280

L

1

H

1

2

mm

AB-PM + AME 435 QM

H

3

G 2 (ISO228/1) 6.9

b

Weight

(kg)

3

H

a

2

H

© Danfoss | 2018.01

AB-PM DN 65-100

Typ e

L

H

H

1

1

H

2

mm

AB-PM + AME 435 QM

3

(EN 1092-2)

a

Weight

(kg)

DN 65 290 218 388 330 185 41

DN 80 310 223 393 335 200 46

DN 10 0 350 239 451 350 220 64

VD.HR.D1.02 | 11

Page 12

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet AB-PM DN 40-100

Tender text

AB-PM DN 40-100 is a combined differential pressure controller for dynamic hydronic balance.

•

The valve should be able to ensure hydronic balance for each zone with one or more terminal units.

•

Valve shall have flexible functionality as either DPCV or PIBCV.

• The valve can be connected to either flow or return pipe via impulse tube

• With impulse tube connected to flow, the valve should keep differential pressure across the

branch by membrane driven controller.

•

With impulse tube connected to the return, the valve should control the flow on every terminal unit

• Valve should have shut-off function.

• Valve should have possibility to mount actuator without effecting presetting.

• Valve should have variable setting. Setting value should allow to set a combination of needed

differential pressure and flow for zone.

• Setting should be lockable to prevent unauthorized change.

• Control valve should have metal to metal sealing to ensure sufficient performance of differential

pressure control at low flows.

• Shut-off service function should be possible to do with hand or a tool. The Dp controller should

have soft sealing to ensure suficient closing in case of zero flow

• Valve should be delivered with min. 2.5 m impulse tube. Diameter of impulse tube should not be

bigger than 1.2 mm.

• Valve should be delivered in reliable packaging for safe transport and handling.

Product characteristics:

a) Pressure class: PN16

b) Max. pressure drop across AB-PM: 4 bar

c) Temperature range: –10 … 120 °C

d) Connections size: DN 40-100

e) Connection type: External tread ISO 228/1 (DN 40, DN50 ), Flange EN1092-2 (DN 65-100)

f) Installation: in return pipe with connection via impulse tube to flow or return pipe

g) Setting range: Flow: 40-100%, ∆p setting : 0-20 turns (DN40, DN50), 0-40 turns (DN65-DN100)

h) Nom. flow at factory setting (∆pr 25 kPa): 5000l/h (DN40), 6500 l/h (DN50), 16800 l/h (DN65),

19600 (DN80), 21000 (DN100)

i) Minimum differential pressure across valve and zone at factory setting 45 kPa (DN40, DN50),

60 kPa (DN65-100)

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

12 | VD.HR.D1.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2018.01

Loading...

Loading...