Page 1

OperatingGuide

ECLComfort310,applicationA361

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................5

2.1Beforeyoustart.....................................................5

2.2Identifyingthesystemtype.......................................9

2.3Mounting...........................................................10

2.4Placingthetemperaturesensors................................14

2.5Electricalconnections.............................................16

2.6InsertingtheECLApplicationKey..............................25

2.7Checklist............................................................32

2.8Navigation,ECLApplicationKeyA361.........................33

3.0Dailyuse.........................................................36

3.1Howtonavigate...................................................36

3.2Understandingthecontrollerdisplay..........................37

3.3Ageneraloverview:Whatdothesymbolsmean?...........40

3.4Monitoringtemperaturesandsystem

components........................................................41

3.5Influenceoverview................................................42

3.6Manualcontrol.....................................................43

3.7Schedule............................................................44

4.0Settingsoverview............................................45

5.0Settings...........................................................47

5.1IntroductiontoSettings..........................................47

5.2Flowtemperature..................................................48

5.3Returnlimit.........................................................53

5.4Flow/powerlimit.................................................57

5.5Optimization........................................................61

5.6Controlparameters................................................67

5.7Pumpcontrol.......................................................71

5.8Refillwater..........................................................74

5.9Application.........................................................79

5.10Alarm................................................................84

5.11Alarmoverview....................................................88

6.0Commoncontrollersettings..............................89

6.1Introductionto‘Commoncontrollersettings’................89

6.2Time&Date.........................................................90

6.3Holiday..............................................................91

6.4Inputoverview.....................................................93

6.5Log...................................................................94

6.6Outputoverride....................................................95

6.7Keyfunctions.......................................................96

6.8System...............................................................98

7.0Miscellaneous................................................105

7.1ECA30/31setupprocedures.................................105

7.2Overridefunction................................................113

7.3Severalcontrollersinthesamesystem......................116

7.4Frequentlyaskedquestions....................................119

7.5Definitions........................................................122

7.6Type(ID6001),overview.......................................126

7.7Automatic/manualupdateoffirmware.....................127

7.8ParameterIDoverview..........................................128

©Danfoss|2021.02AQ000086455681en-010402|1

Page 2

OperatingGuideECLComfort310,applicationA361

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisInstallationGuideisassociatedwithECLApplicationKeyA361

(ordercodeno.087H3804).

ThefunctionscanberealizedwithECLComfort310.

TheapplicationA361complieswithECLComfortcontroller310as

ofsoftwareversion1.10(visibleatstart-upofthecontrollerandin

‘Commoncontrollersettings’in‘System’).

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://heating.danfoss.com/.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

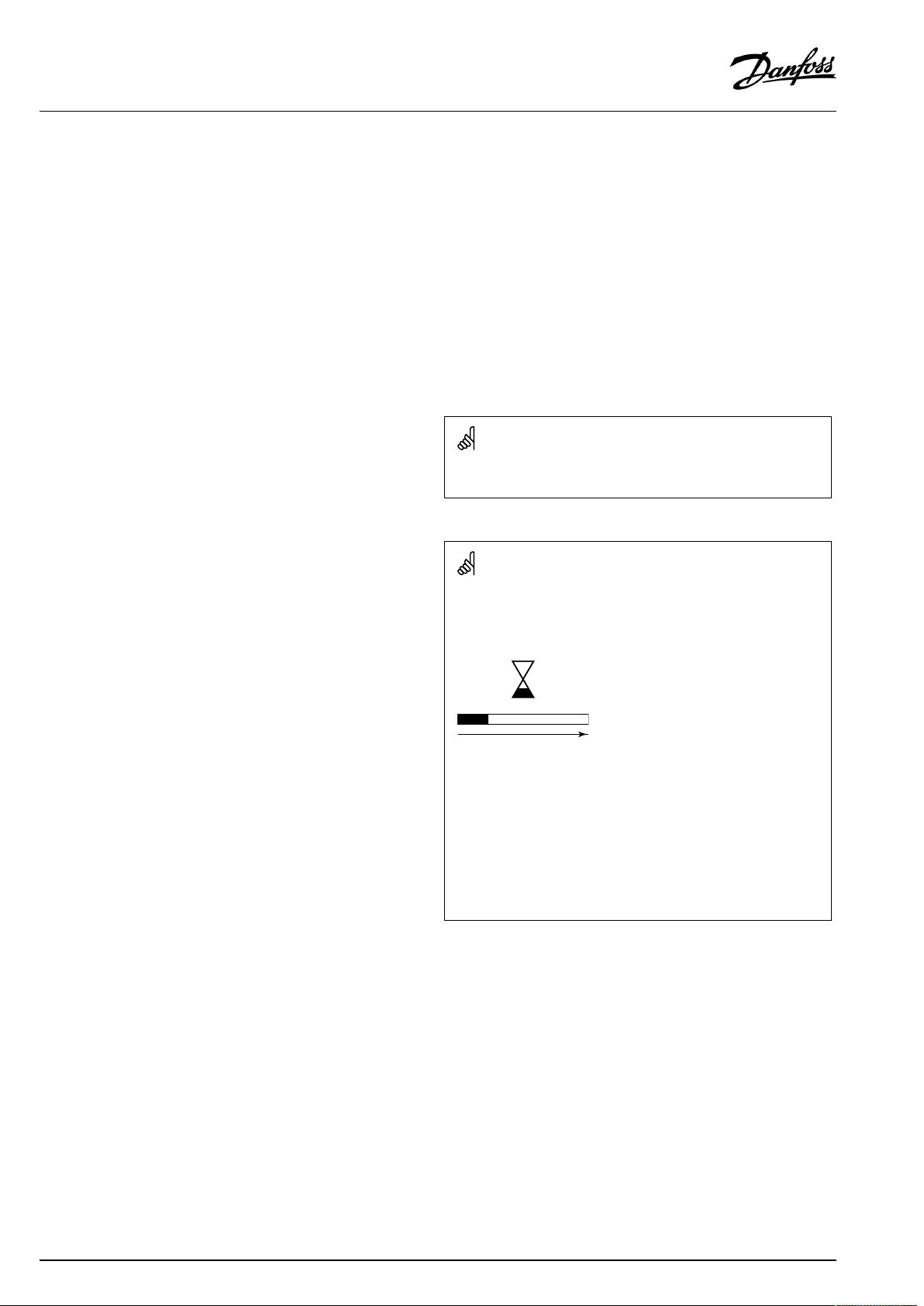

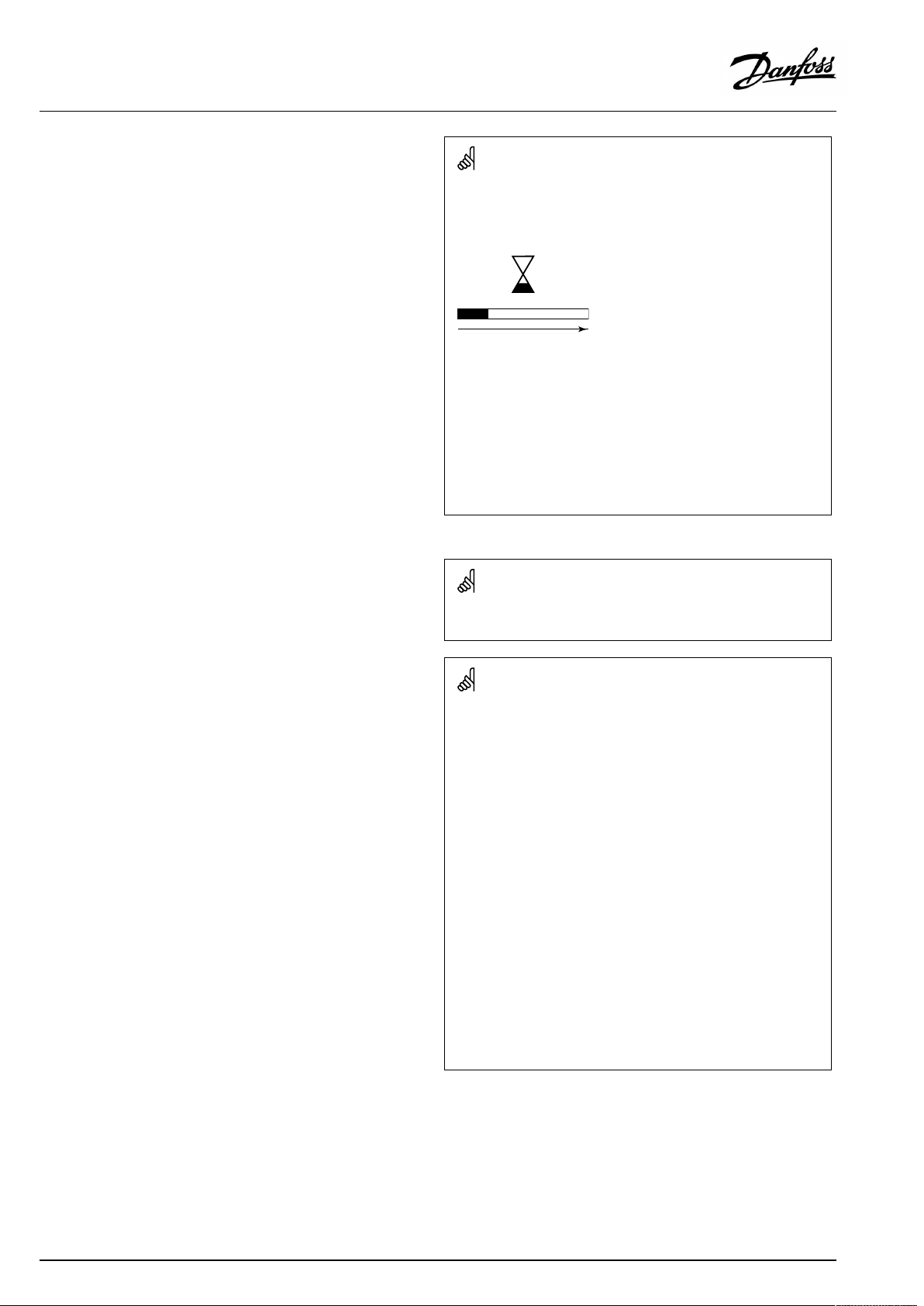

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

2|©Danfoss|2021.02

AQ000086455681en-010402

Page 3

OperatingGuideECLComfort310,applicationA361

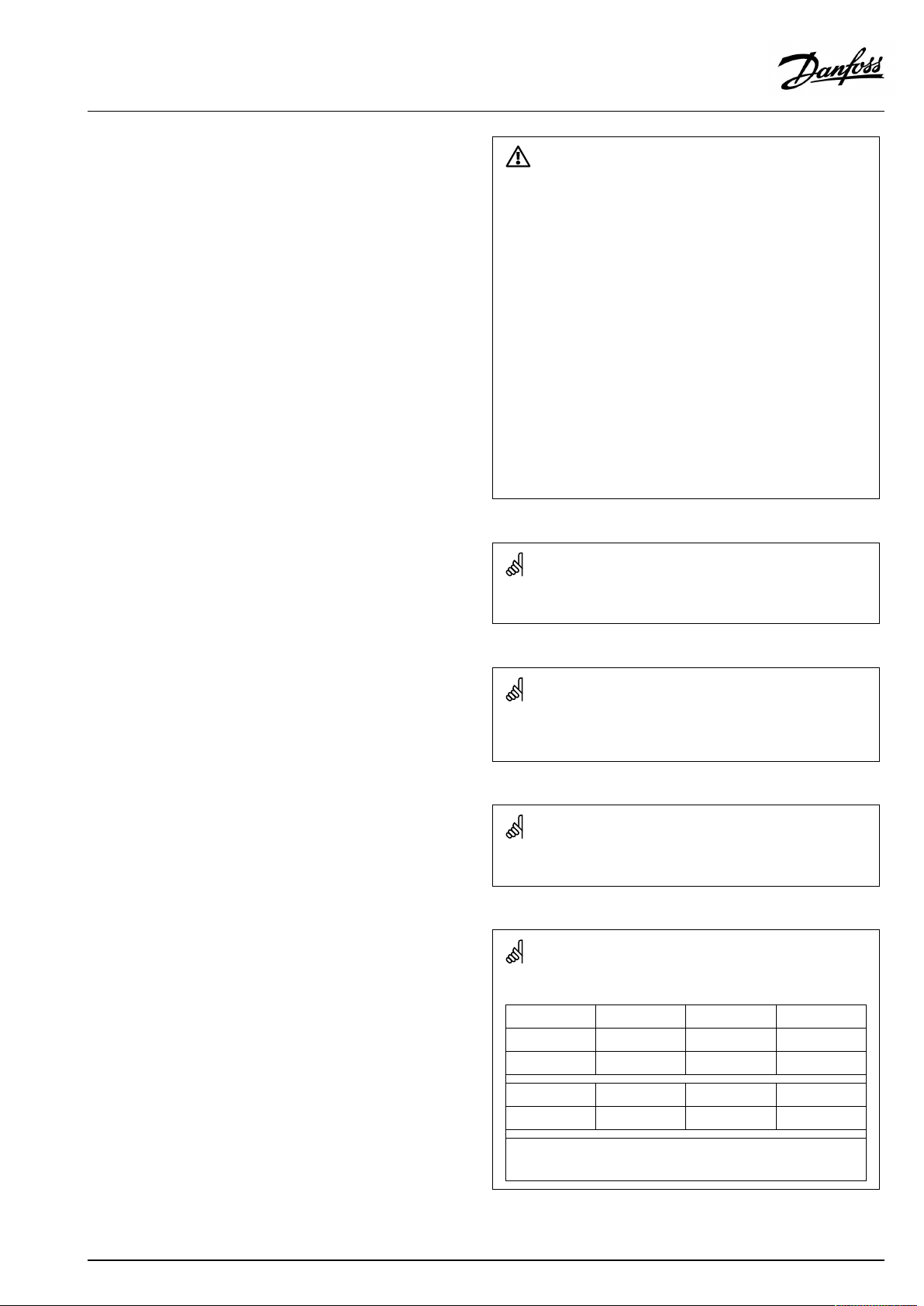

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1Parameterno.

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

2

Circuit2Parameterno.

AQ000086455681en-010402

174

©Danfoss|2021.02|3

Page 4

OperatingGuideECLComfort310,applicationA361

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thissymbolontheproductindicatesthatitmaynot

bedisposedofashouseholdwaste.

Itmustbehandedovertotheapplicabletake-back

schemefortherecyclingofelectricalandelectronic

equipment.

•Disposeoftheproductthroughchannelsprovided

forthispurpose.

•Complywithalllocalandcurrentlyapplicablelaws

andregulations.

4|©Danfoss|2021.02

AQ000086455681en-010402

Page 5

OperatingGuideECLComfort310,applicationA361

2.0Installation

2.1Beforeyoustart

TheapplicationA361.1isveryflexible.Thesearethebasic

principles:

Heating(circuit1and2):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS3(circuit1)and

S4(circuit2)arethemostimportantsensors.Thedesiredflow

temperaturesatS3andS4arecalculatedintheECLcontroller,

basedontheoutdoortemperature(S1).Thelowertheoutdoor

temperature,thehigherthedesiredflowtemperature.

Bymeansofaweekschedule,theheatingcircuitcanbein

‘Comfort’or‘Saving’mode(twodifferenttemperaturevaluesfor

desiredroomtemperature).

ThemotorizedcontrolvalvesM1(circuit1)andM2(circuit2)are

openedgraduallywhentheflowtemperatureislowerthanthe

desiredflowtemperatureandviceversa.

ThereturntemperaturesS5(circuit1)andS6(circuit2)tothe

districtheatingsupplyshouldnotbetoohigh.Ifso,thedesired

flowtemperaturecanbeadjusted(typicallytoalowervalue),thus

resultinginagradualclosingofthemotorizedcontrolvalves.

Inboiler-basedheatingsupplythereturntemperatureshouldnot

betoolow(sameadjustmentprocedureasabove).

Furthermore,thereturntemperaturelimitationcanbedependent

oftheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

ThecirculationpumpinquestionisONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalue.

Thestaticpressureonthesecondaryside(consumerside)can1)

bemeasuredasa0-10Vsignal(fromapressuretransmitter)or

2)beaswitchsignalfromapressureswitch.Incaseofatoolow

pressure,therefillwaterfunctionwillsupplementwithwaterfrom

thesupplyside.

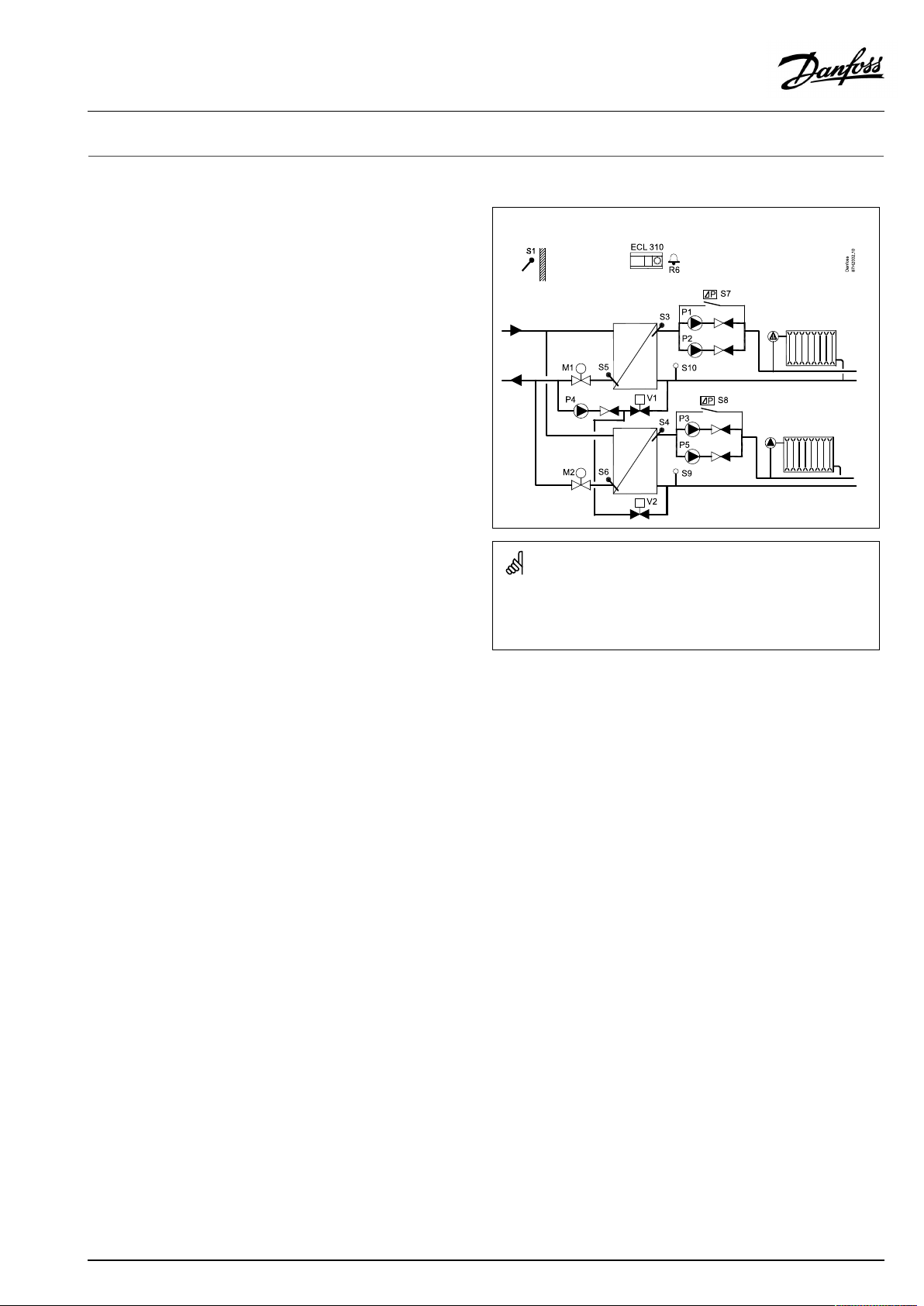

TypicalA361.1application:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S3

Flowtemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6Returntemperaturesensor,circuit2

S7

Differentialpressureswitch,circuit1

S8

Differentialpressureswitch,circuit2

S9

Pressuretransmitterorpressureswitch,circuit2

S10

Pressuretransmitterorpressureswitch,circuit1

P1

Circulationpump,circuit1

P2

Circulationpump,circuit1

P3

Circulationpump,circuit2

P4

Refillwaterpump

P5

Circulationpump,circuit2

M1

Motorizedcontrolvalve,circuit1

M2

Motorizedcontrolvalve,circuit2

V1

Solenoidvalve,circuit1,refillwatervalve

V2

Solenoidvalve,circuit2,refillwatervalve

R6

Relayoutput,alarm

AQ000086455681en-010402

©Danfoss|2021.02|5

Page 6

OperatingGuideECLComfort310,applicationA361

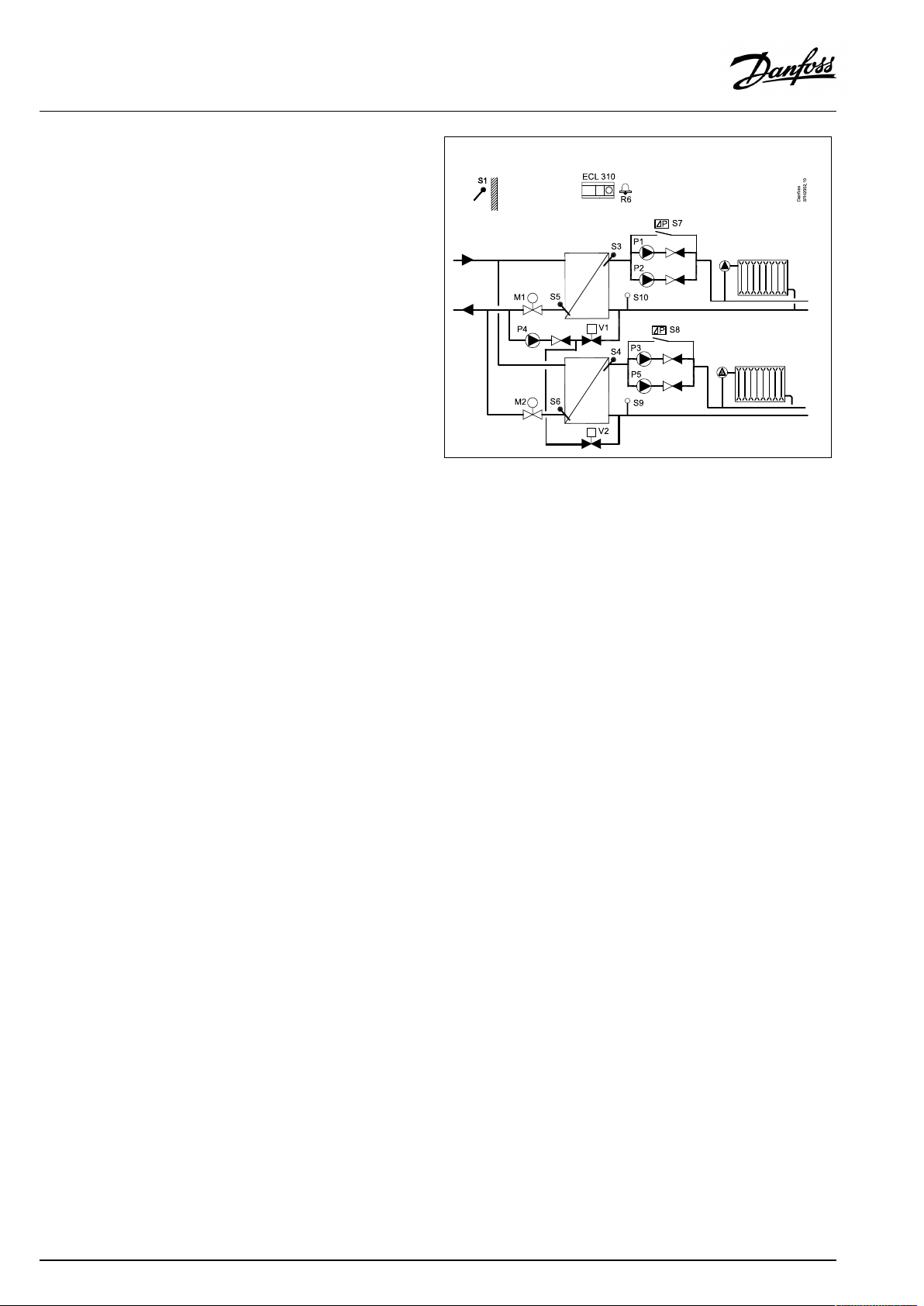

ApplicationA361.1ingeneral:

ThecirculationpumpsP1andP2(circuit1)/P3andP5(circuit2)

workinshiftaccordingtoaschedule.Onepumpisusedasspare

pumpandtheotherpumpisworking.Incaseofmalfunction

(missingdifferentialpressure)ofonepump,theotherpumpwill

takeover.Analarmwillbegeneratedandthedefectivepumpcan

beinspected/repaired.

Alarm(relay6)canbeactivatedif:

•Theactualflowtemperaturediffersfromthedesiredflow

temperature.

•Theactivatedcirculationpumpdoesnotgenerateapressure

difference.

•Therefillwaterfunctiondoesnotgenerateapressurewithin

apresettime.

ModbuscommunicationtoaSCADAsystemcanbeestablished.

M-buscommunicationenablesconnectiontofloworenergymeter.

Thecontrollercanlimitthefloworenergytoasetmaximumbut

alsoinrelationtotheoutdoortemperature.

Furthermore,theM-busdatacanbetransferredtotheModbus

communication.

TypicalA361.1application:

6|©Danfoss|2021.02

AQ000086455681en-010402

Page 7

OperatingGuideECLComfort310,applicationA361

TheapplicationA361.2isveryflexible.Thesearethebasic

principles:

Heating(circuit1and2):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS3(circuit1)and

S4(circuit2)arethemostimportantsensors.Thedesiredflow

temperaturesatS3andS4arecalculatedintheECLcontroller,

basedontheoutdoortemperature(S1).Thelowertheoutdoor

temperature,thehigherthedesiredflowtemperature.

Thesupplytemperature(S2)isusedto1)controltheS3andS4

temperaturesinrelationtotheS2temperatureor2)maximizethe

limitofthedesiredflowtemperature.

Thefactorysetting,wherethesupplytemperature(S2)determines

thedesiredflowtemperature,doesnotchangethedesiredflow

temperatureaccordingto‘Comfort’or‘Saving’mode.

However,ifthesupplytemperature(S2)determinesamax.

limitationofthedesiredflowtemperature,the‘Comfort’and

‘Saving’modewillhavetwodifferenttemperaturevaluesfor

desiredroomtemperature.

ThemotorizedcontrolvalvesM1(circuit1)andM2(circuit2)are

openedgraduallywhentheflowtemperatureislowerthanthe

desiredflowtemperatureandviceversa.

ThereturntemperaturesS5(circuit1)andS6(circuit2)tothe

districtheatingsupplyshouldnotbetoohigh.Ifso,thedesired

flowtemperaturecanbeadjusted(typicallytoalowervalue),thus

resultinginagradualclosingofthemotorizedcontrolvalves.

Inboiler-basedheatingsupplythereturntemperatureshouldnot

betoolow(sameadjustmentprocedureasabove).

Furthermore,thereturntemperaturelimitationcanbedependent

oftheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

ThecirculationpumpinquestionisONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalue.

Thestaticpressureonthesecondaryside(consumerside)can1)

bemeasuredasa0-10Vsignal(fromapressuretransmitter)or

2)beaswitchsignalfromapressureswitch.Incaseofatoolow

pressure,therefillwaterfunctionwillsupplementwithwaterfrom

thesupplyside.

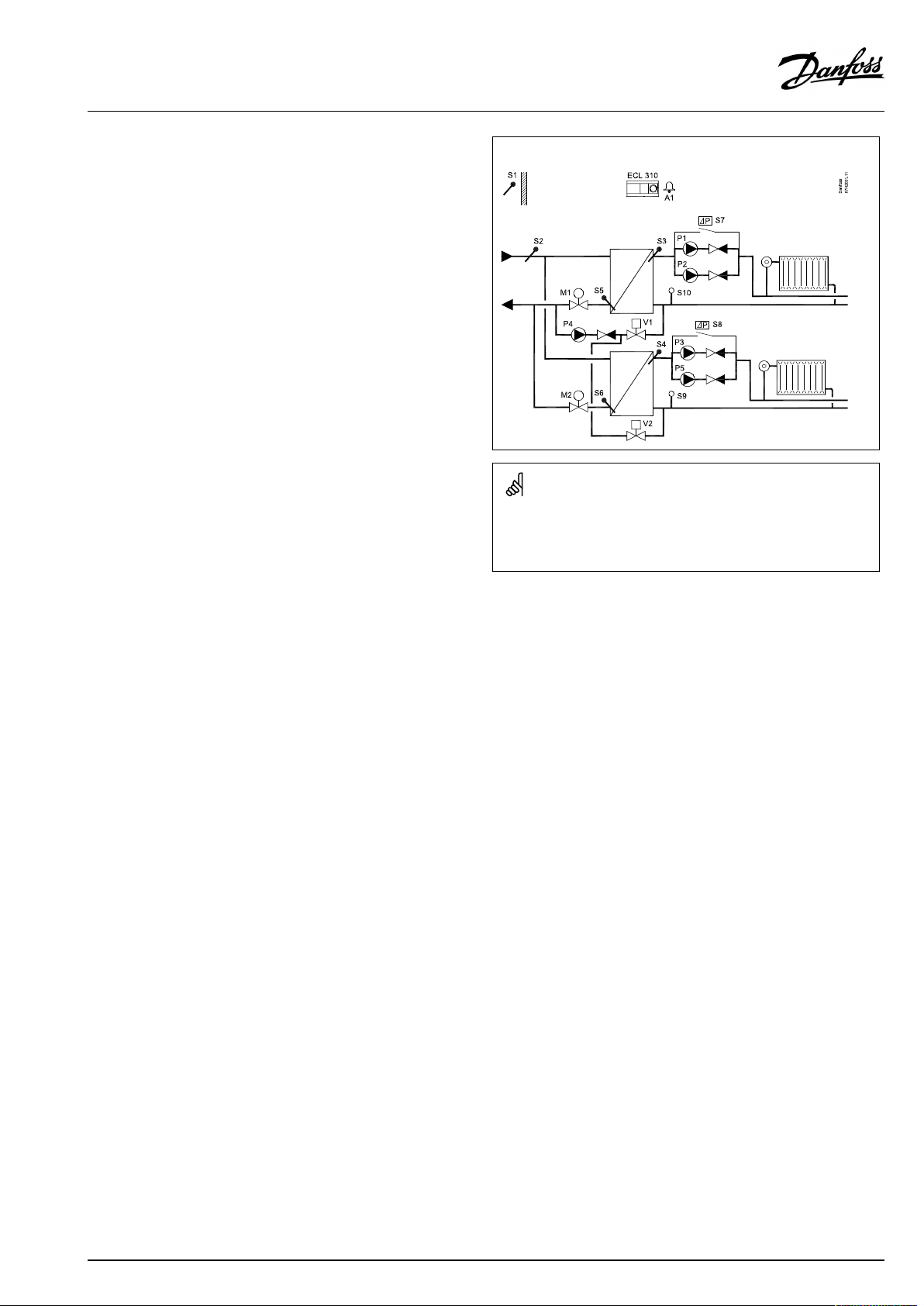

TypicalA361.2application:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S2

Supplyflowtemperaturesensor

S3

Flowtemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6Returntemperaturesensor,circuit2

S7

Differentialpressureswitch,circuit1

S8

Differentialpressureswitch,circuit2

S9

Pressuretransmitterorpressureswitch,circuit2

S10

Pressuretransmitterorpressureswitch,circuit1

P1

Circulationpump,circuit1

P2

Circulationpump,circuit1

P3

Circulationpump,circuit2

P4

Refillwaterpump

P5

Circulationpump,circuit2

M1

Motorizedcontrolvalve,circuit1

M2

Motorizedcontrolvalve,circuit2

V1

Solenoidvalve,circuit1,refillwatervalve

V2

Solenoidvalve,circuit2,refillwatervalve

R6

Relayoutput,alarm

AQ000086455681en-010402

©Danfoss|2021.02|7

Page 8

OperatingGuideECLComfort310,applicationA361

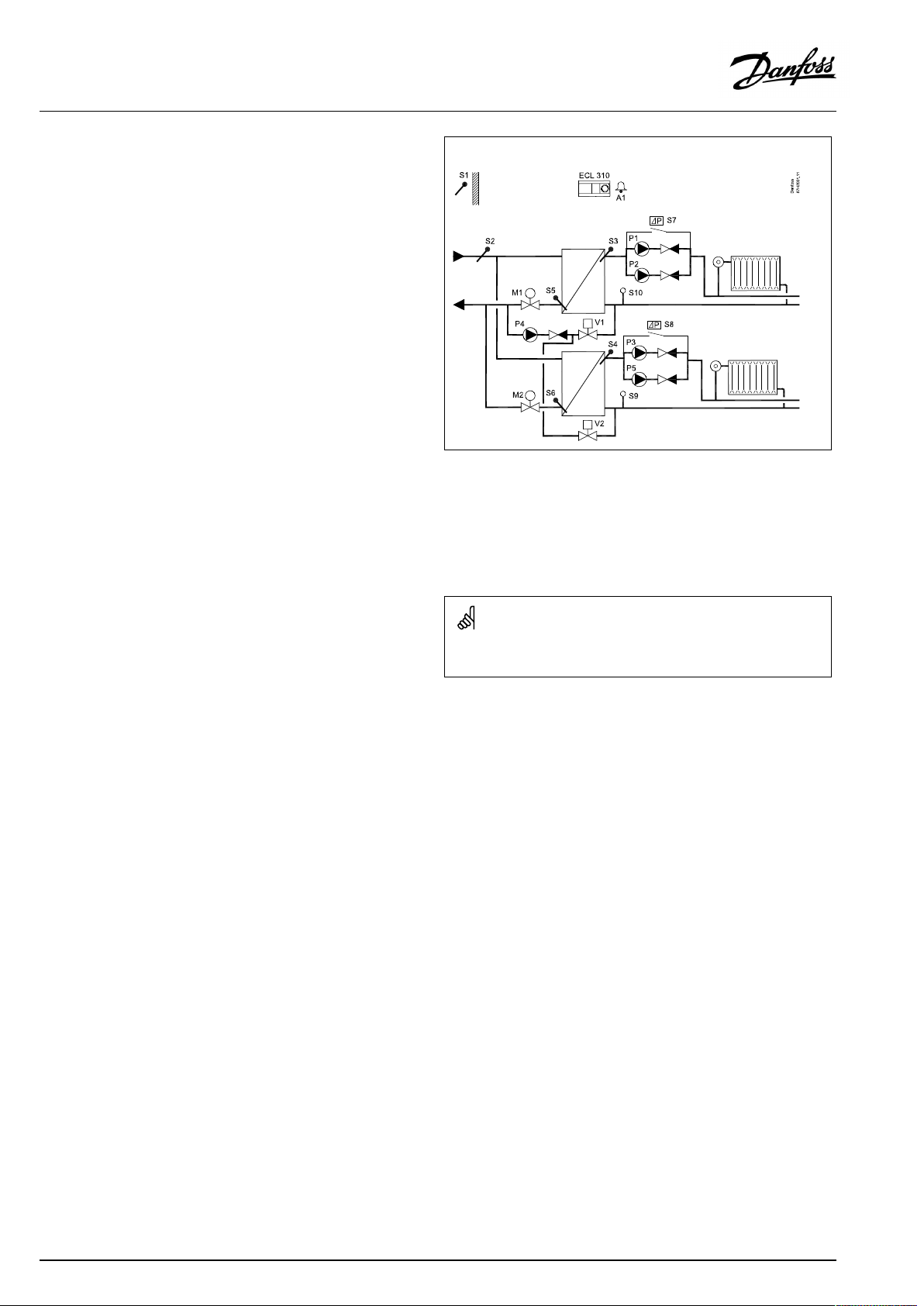

ApplicationA361.2ingeneral:

ThecirculationpumpsP1andP2(circuit1)/P3andP5(circuit2)

workinshiftaccordingtoaschedule.Onepumpisusedasspare

pumpandtheotherpumpisworking.Incaseofmalfunction

(missingdifferentialpressure)ofonepump,theotherpumpwill

takeover.Analarmwillbegeneratedandthedefectivepumpcan

beinspected/repaired.

Alarm(relay6)canbeactivatedif:

•Theactualflowtemperaturediffersfromthedesiredflow

temperature.

•Theactivatedcirculationpumpdoesnotgenerateapressure

difference.

•Therefillwaterfunctiondoesnotgenerateapressurewithin

apresettime.

ModbuscommunicationtoaSCADAsystemcanbeestablished.

M-buscommunicationenablesconnectiontofloworenergymeter.

Thecontrollercanlimitthefloworenergytoasetmaximumbut

alsoinrelationtotheoutdoortemperature.

Furthermore,theM-busdatacanbetransferredtotheModbus

communication.

TypicalA361.2application:

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

8|©Danfoss|2021.02

AQ000086455681en-010402

Page 9

OperatingGuideECLComfort310,applicationA361

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Thecirculationpump(s)inheatingcircuit(s)canbeplacedintheflow

aswellasthereturn.Placethepumpaccordingtothemanufacturer’s

specification.

AQ000086455681en-010402

©Danfoss|2021.02|9

Page 10

OperatingGuideECLComfort310,applicationA361

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

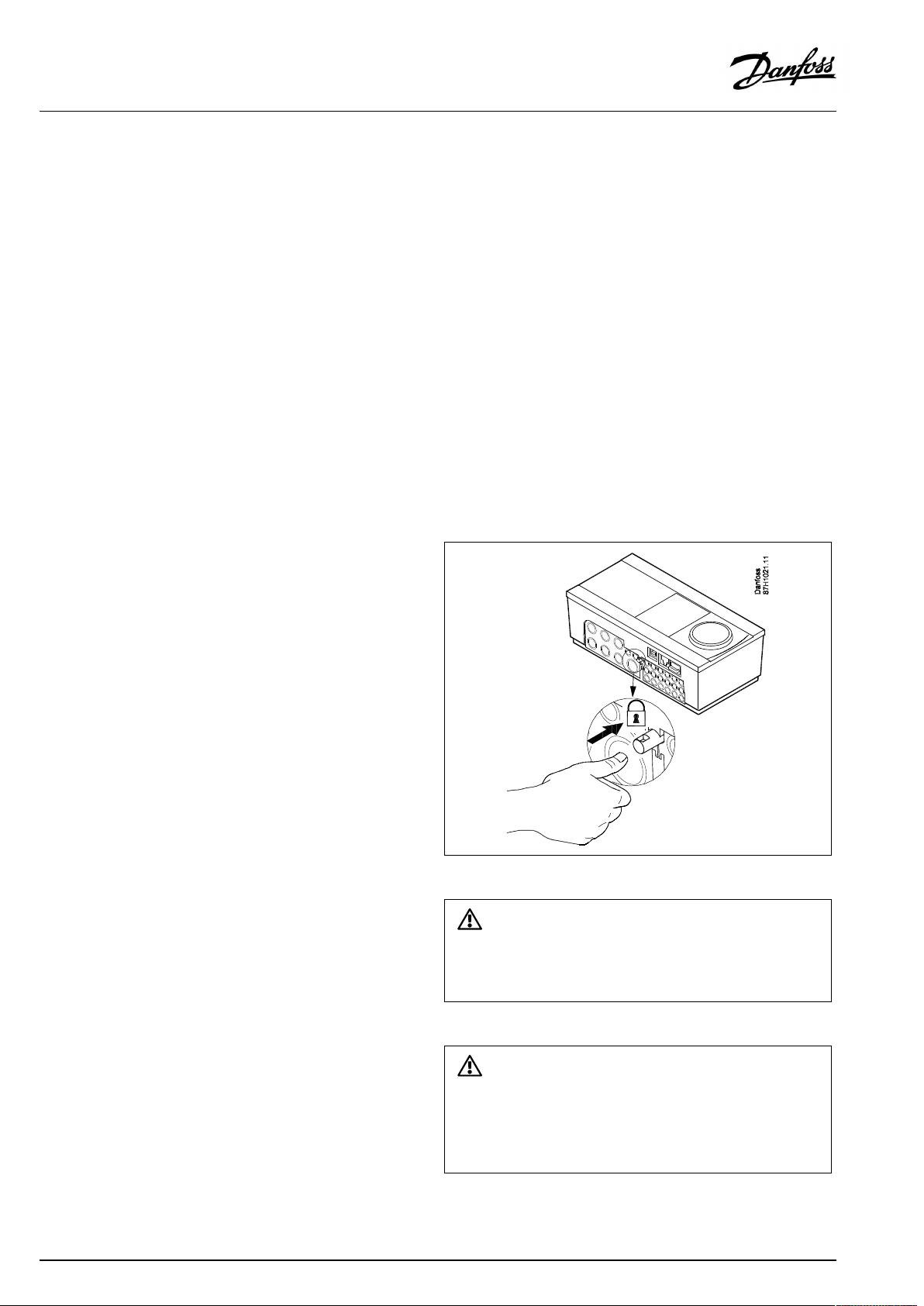

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

10|©Danfoss|2021.02

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

AQ000086455681en-010402

Page 11

OperatingGuideECLComfort310,applicationA361

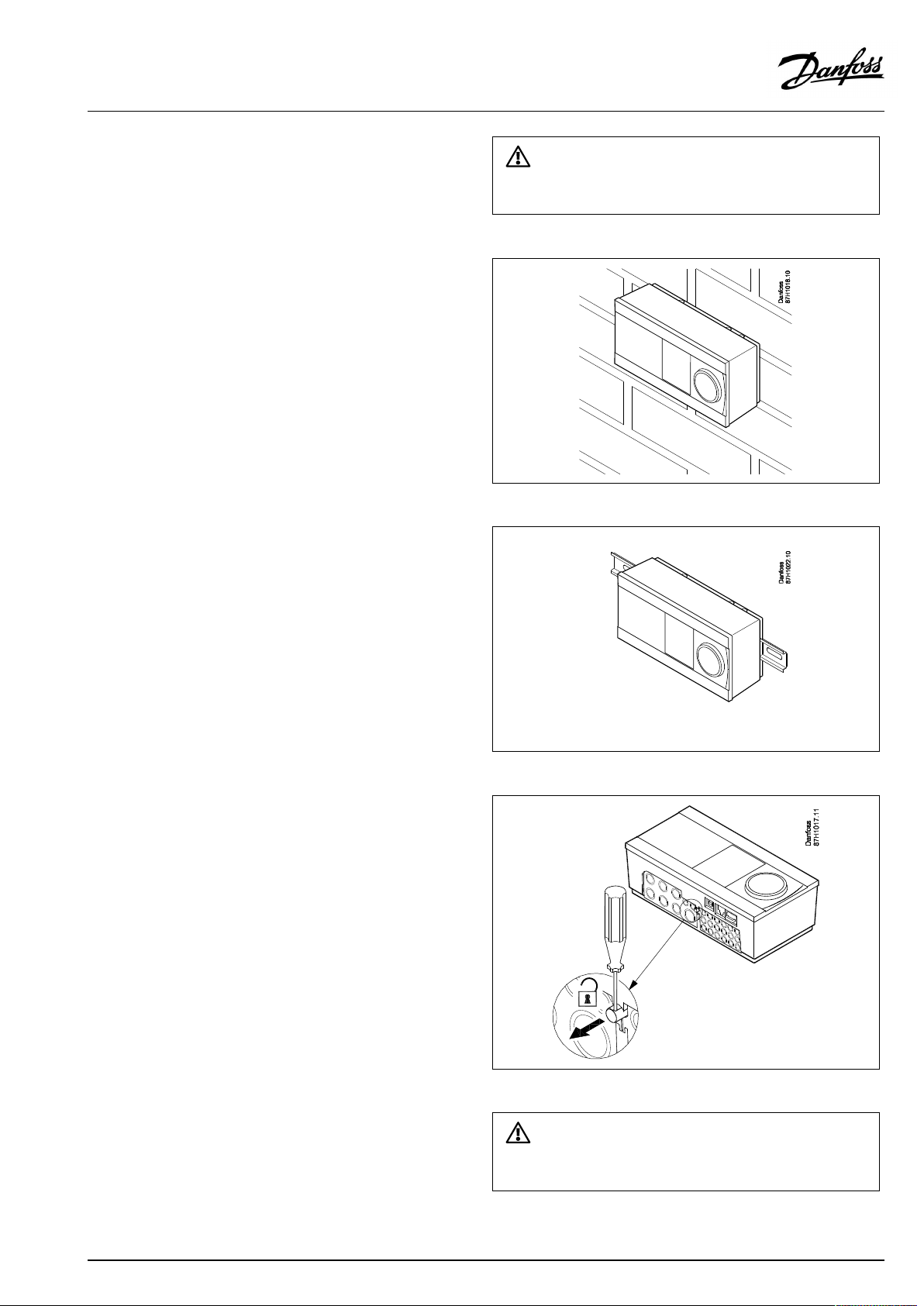

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

AQ000086455681en-010402

©Danfoss|2021.02|11

Page 12

OperatingGuideECLComfort310,applicationA361

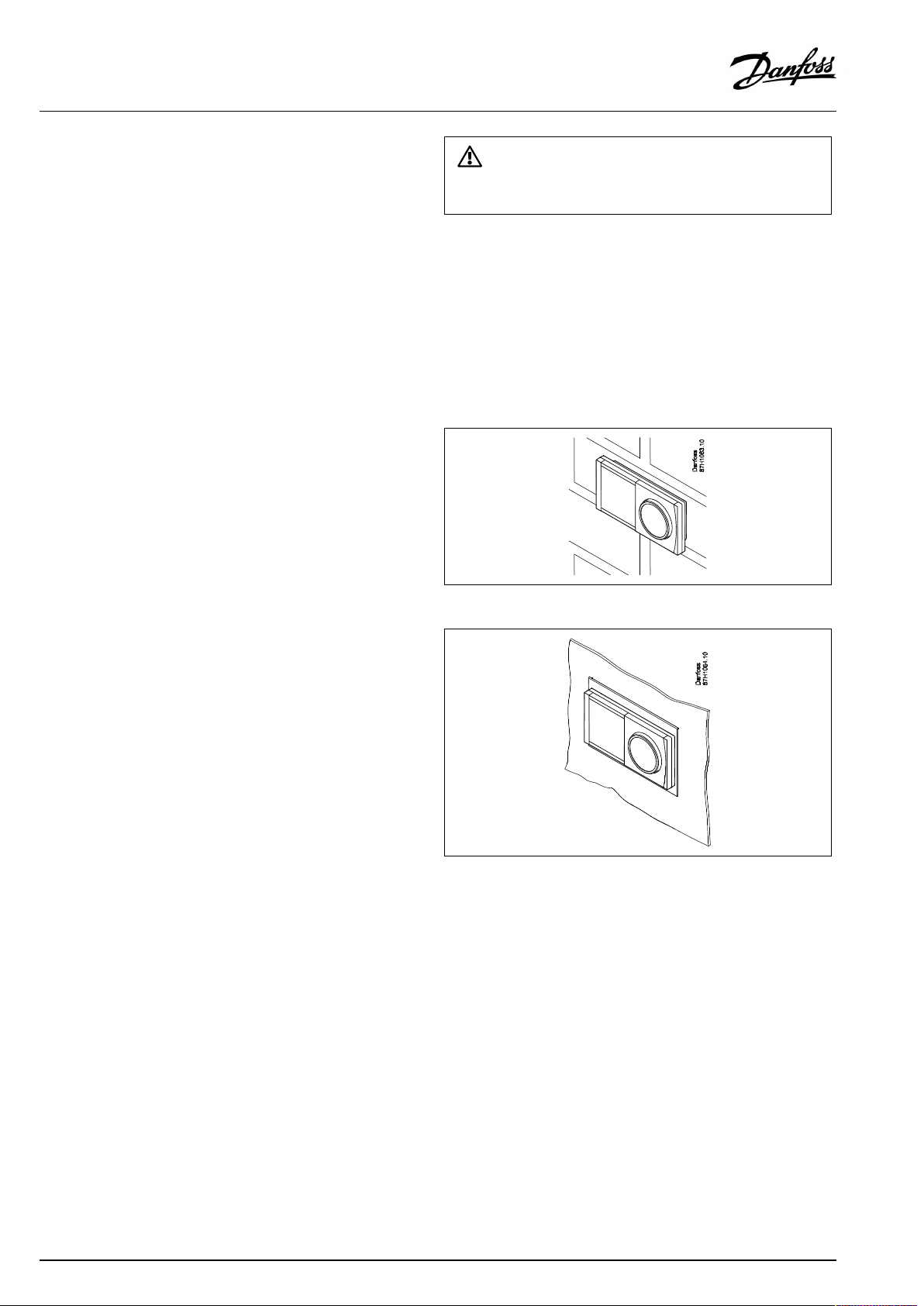

2.3.2MountingtheRemoteControlUnitsECA30/31

Selectoneofthefollowingmethods:

•Mountingonawall,ECA30/31

•Mountinginapanel,ECA30

Screwsandrawlplugsarenotsupplied.

Mountingonawall

MountthebasepartoftheECA30/31onawallwithasmooth

surface.Establishtheelectricalconnections.PlacetheECA30/

31inthebasepart.

BeforeremovingtheECLComfortcontrollerfromthebasepart,ensure

thatthesupplyvoltageisdisconnected.

Mountinginapanel

MounttheECA30inapanelusingtheECA30framekit(ordercode

no.087H3236).Establishtheelectricalconnections.Securethe

framewiththeclamp.PlacetheECA30inthebasepart.TheECA

30canbeconnectedtoanexternalroomtemperaturesensor.

TheECA31mustnotbemountedinapanelifthehumidity

functionistobeused.

12|©Danfoss|2021.02

AQ000086455681en-010402

Page 13

OperatingGuideECLComfort310,applicationA361

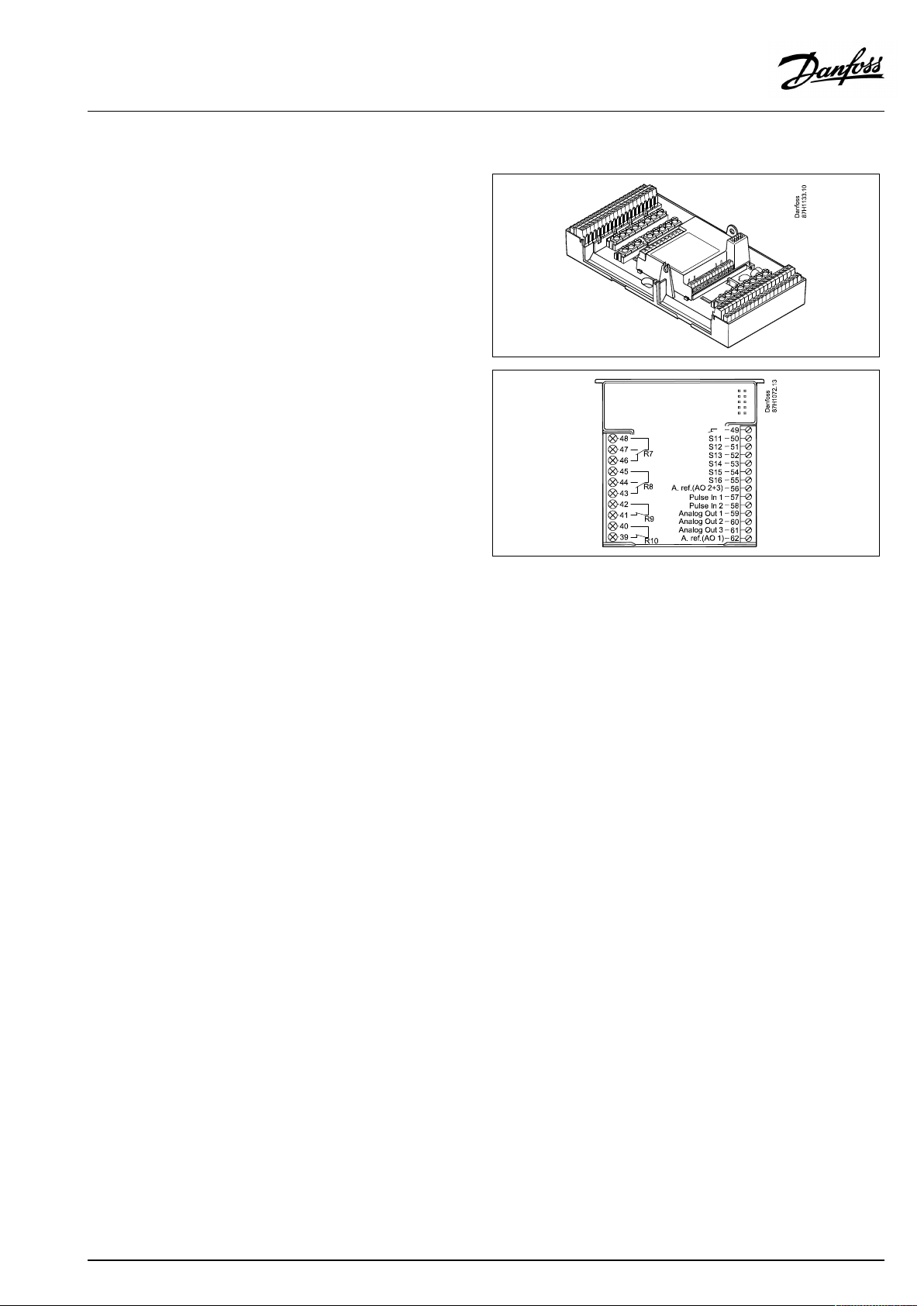

2.3.3MountingtheinternalI/OmoduleECA32

MountingoftheinternalI/OmoduleECA32

TheECA32module(ordercodeno.087H3202)mustbeinserted

intotheECLComfort310/310Bbasepartforadditionalinputand

outputsignalsinrelevantapplications.

TheconnectionbetweentheECLComfort310/310BandECA32

isa10-pole(2x5)connector.Theconnectionisautomatically

establishedwhentheECLComfort310/310Bisplacedonthe

basepart.

AQ000086455681en-010402

©Danfoss|2021.02|13

Page 14

OperatingGuideECLComfort310,applicationA361

2.4Placingthetemperaturesensors

2.4.1Placingthetemperaturesensors

Itisimportantthatthesensorsaremountedinthecorrectposition

inyoursystem.

Thetemperaturesensormentionedbelowaresensorsusedforthe

ECLComfort210/296/310serieswhichnotallwillbeneeded

foryourapplication!

Outdoortemperaturesensor(ESMT)

Theoutdoorsensorshouldbemountedonthatsideofthebuilding

whereitislesslikelytobeexposedtodirectsunshine.Itshouldnot

beplacedclosetodoors,windowsorairoutlets.

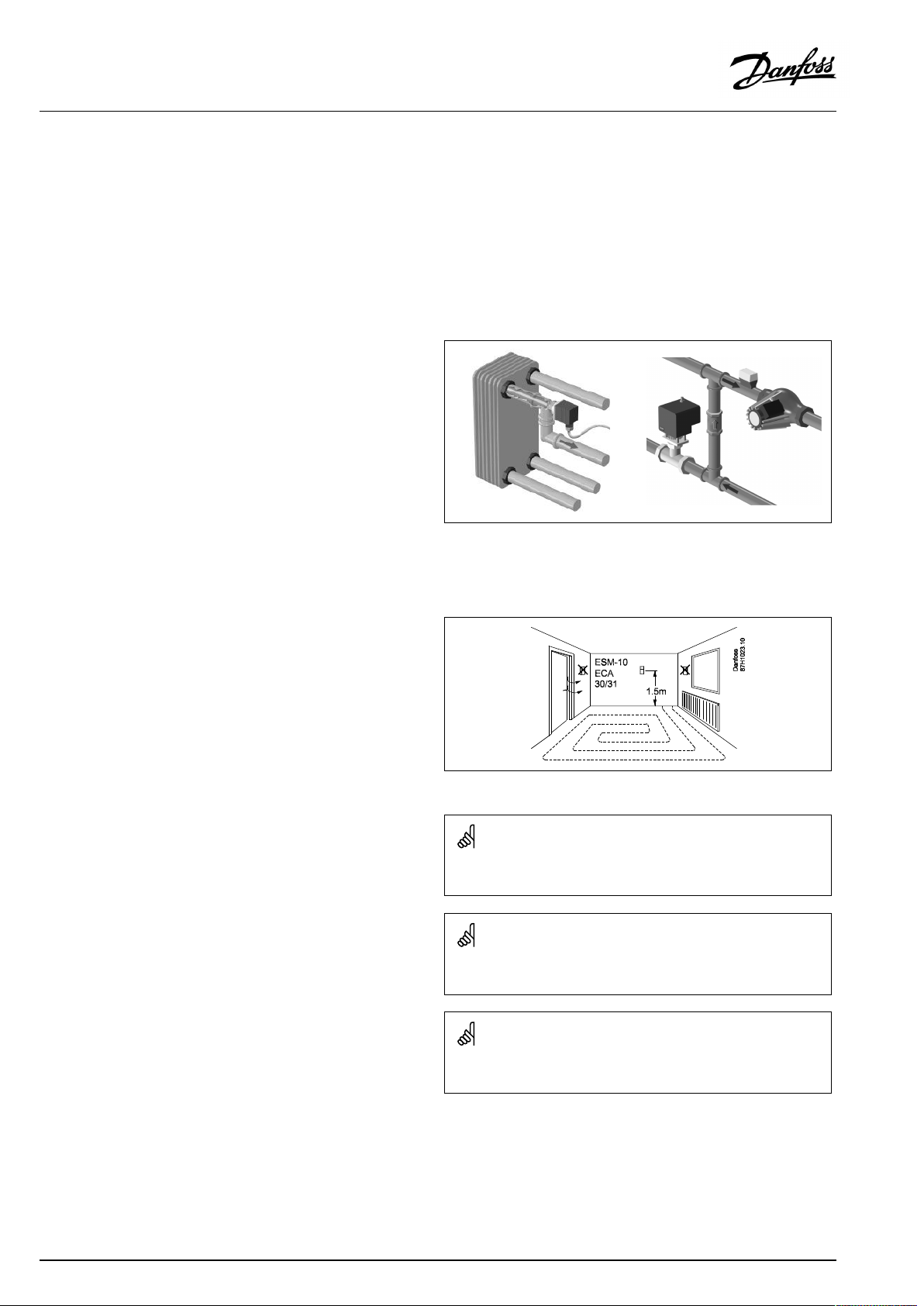

Flowtemperaturesensor(ESMU,ESM-11orESMC)

Placethesensormax.15cmfromthemixingpoint.Insystems

withheatexchanger,DanfossrecommendsthattheESMU-typeto

beinsertedintotheexchangerflowoutlet.

Makesurethatthesurfaceofthepipeiscleanandevenwhere

thesensorismounted.

Returntemperaturesensor(ESMU,ESM-11orESMC)

Thereturntemperaturesensorshouldalwaysbeplacedsothatit

measuresarepresentativereturntemperature.

Roomtemperaturesensor

(ESM-10,ECA30/31RemoteControlUnit)

Placetheroomsensorintheroomwherethetemperatureistobe

controlled.Donotplaceitonoutsidewallsorclosetoradiators,

windowsordoors.

Boilertemperaturesensor(ESMU,ESM-11orESMC)

Placethesensoraccordingtotheboilermanufacturer’s

specification.

Airducttemperaturesensor(ESMB-12orESMUtypes)

Placethesensorsothatitmeasuresarepresentativetemperature.

DHWtemperaturesensor(ESMUorESMB-12)

PlacetheDHWtemperaturesensoraccordingtothemanufacturer’s

specification.

Slabtemperaturesensor(ESMB-12)

Placethesensorinaprotectiontubeintheslab.

ESM-11:Donotmovethesensorafterithasbeenfastenedinorderto

avoiddamagetothesensorelement.

ESM-11,ESMCandESMB-12:Useheatconductingpasteforquick

measurementofthetemperature.

ESMUandESMB-12:Usingasensorpockettoprotectthesensorwill,

however,resultinaslowertemperaturemeasurement.

14|©Danfoss|2021.02

AQ000086455681en-010402

Page 15

OperatingGuideECLComfort310,applicationA361

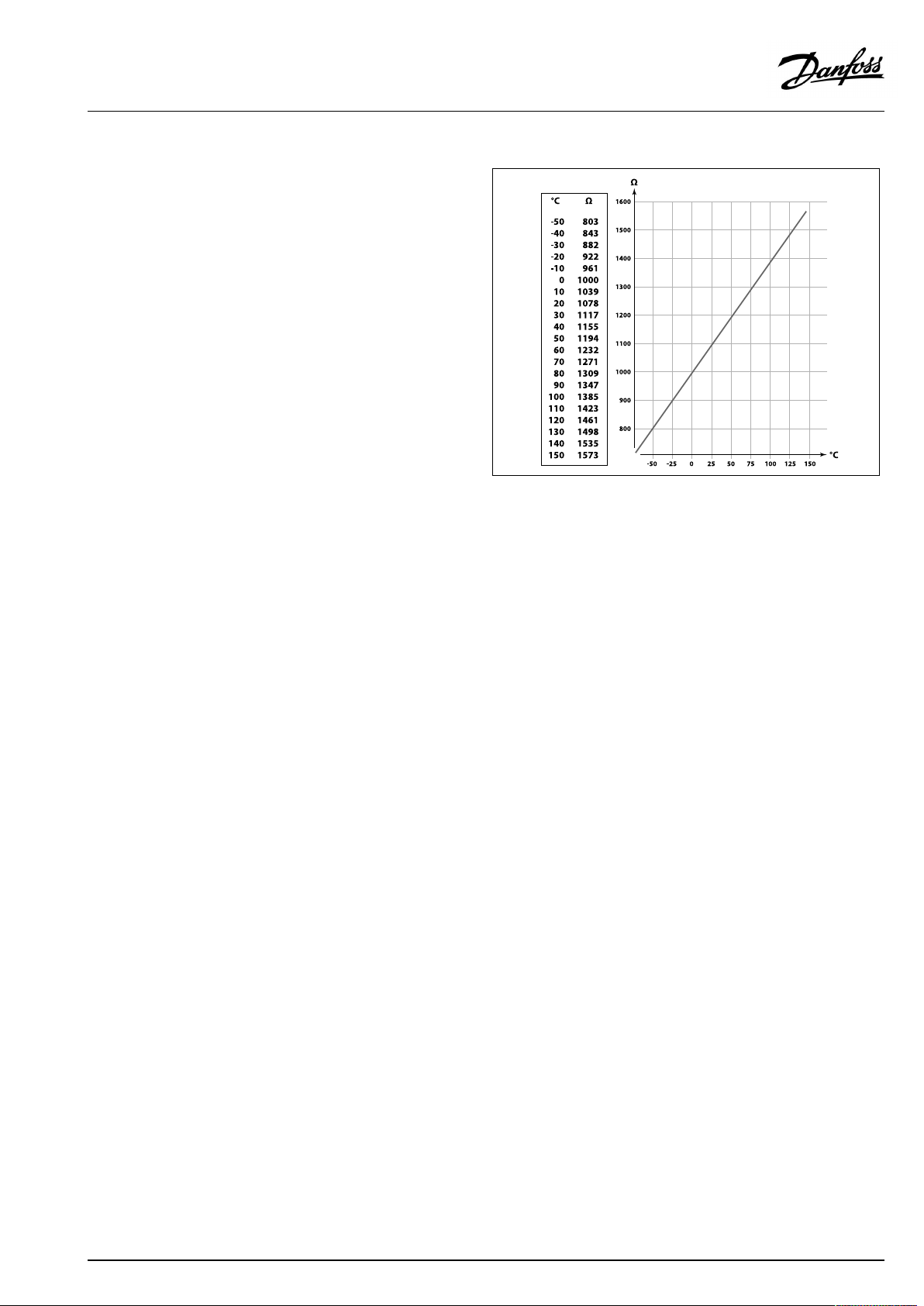

Pt1000temperaturesensor(IEC751B,1000Ω/0°C)

Relationshipbetweentemperatureandohmicvalue:

AQ000086455681en-010402

©Danfoss|2021.02|15

Page 16

OperatingGuideECLComfort310,applicationA361

2.5Electricalconnections

2.5.1Electricalconnections230Va.c.

Warning

ElectricconductorsonPCB(PrintedCircuitBoard)forsupplyvoltage,

relaycontactsandtriacoutputsdonothavemutualsafetydistanceof

minimum6mm.Theoutputsarenotallowedtobeusedasgalvanic

separated(voltfree)outputs.

Ifagalvanicseparatedoutputisneeded,anauxiliaryrelayis

recommended.

24Voltcontrolledunits,forexampleactuators,aretobecontrolledby

meansofECLComfort310,24Voltversion.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

16|©Danfoss|2021.02

AQ000086455681en-010402

Page 17

OperatingGuideECLComfort310,applicationA361

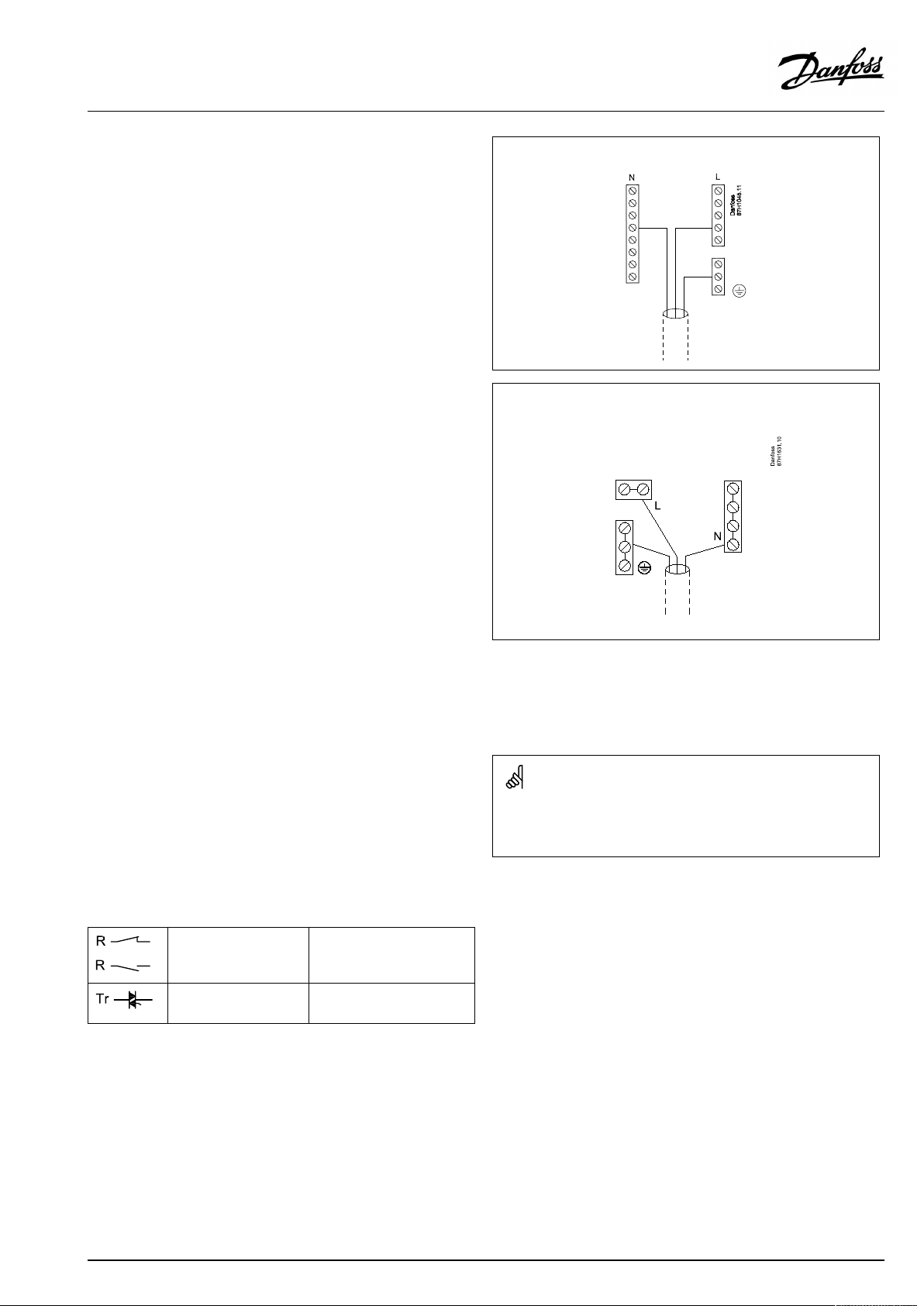

Thecommongroundterminalisusedforconnectionofrelevant

components(pumps,motorizedcontrolvalves).

ECL210/310

ECL296

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

Maximumloadratings:

Relayterminals

4(2)A/230Va.c.

(4Aforohmicload,2Afor

inductiveload)

Triac(=electronic

0,2A/230Va.c.

relay)terminals

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

AQ000086455681en-010402

©Danfoss|2021.02|17

Page 18

OperatingGuideECLComfort310,applicationA361

2.5.2Electricalconnections24Va.c.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

Maximumloadratings:

Relayterminals

Triac(=electronic

relay)terminals

4(2)A/24Va.c.

(4Aforohmicload,2Afor

inductiveload)

1A/24Va.c.

Donotconnect230Va.c.poweredcomponentstoa24Va.c.power

suppliedcontrollerdirectly.Useauxilliaryrelays(K)toseparate230

Va.c.from24Va.c.

18|©Danfoss|2021.02

AQ000086455681en-010402

Page 19

OperatingGuideECLComfort310,applicationA361

2.5.3Electricalconnections,safetythermostats,ingeneral

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

WhenSTisactivatedbyahightemperature,thesafetycircuitinthe

motorizedcontrolvalveclosesthevalveimmediately.

WhenST1isactivatedbyahightemperature(theTRtemperature),the

motorizedcontrolvalveisclosedgradually.Atahighertemperature

(theSTtemperature),thesafetycircuitinthemotorizedcontrolvalve

closesthevalveimmediately.

AQ000086455681en-010402

©Danfoss|2021.02|19

Page 20

OperatingGuideECLComfort310,applicationA361

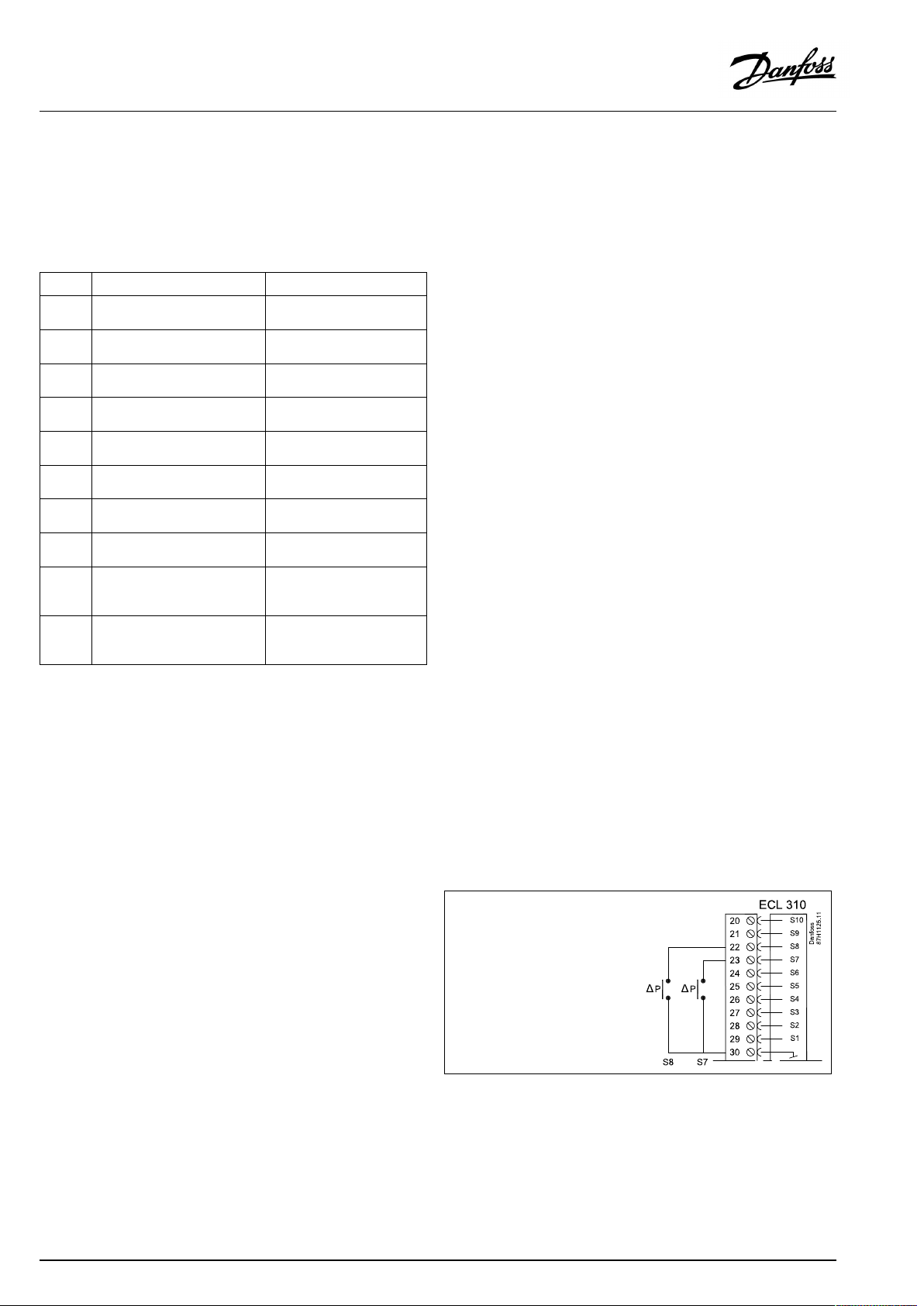

2.5.4Electricalconnections,Pt1000temperaturesensorsandsignals

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

sensorandinputconnections.

A361.1/A361.2:

Sensor

S1

S2

S3

S4

S5Returntemperaturesensor,

S6Returntemperaturesensor,

S7

S8

S9

S10

*

**

***

Description

Outdoortemperature

sensor*

Supplyflowtemperature

sensor**

Flowtemperaturesensor***,

circuit1

Flowtemperaturesensor***,

circuit2

circuit1

circuit2

Differentialpressureswitch,

circuit1

Differentialpressureswitch,

circuit2

Pressuretransmitter(0–10

Vor4–20mA)orpressure

switch,circuit2

Pressuretransmitter(0–10

Vor4–20mA)orpressure

switch,circuit1

Iftheoutdoortemperaturesensorisnotconnectedorthe

cableisshort-circuited,thecontrollerassumesthatthe

outdoortemperatureis0(zero)°C.

OnlyforapplicationA361.2.

Theflowtemperaturesensormustalwaysbeconnected

inordertohavethedesiredfunctionality.Ifthesensoris

notconnectedorthecableisshort-circuited,themotorized

controlvalvecloses(safetyfunction).

Recommendedtype

ESMT

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

Connectionof2differentialpressureswitches

20|©Danfoss|2021.02

AQ000086455681en-010402

Page 21

OperatingGuideECLComfort310,applicationA361

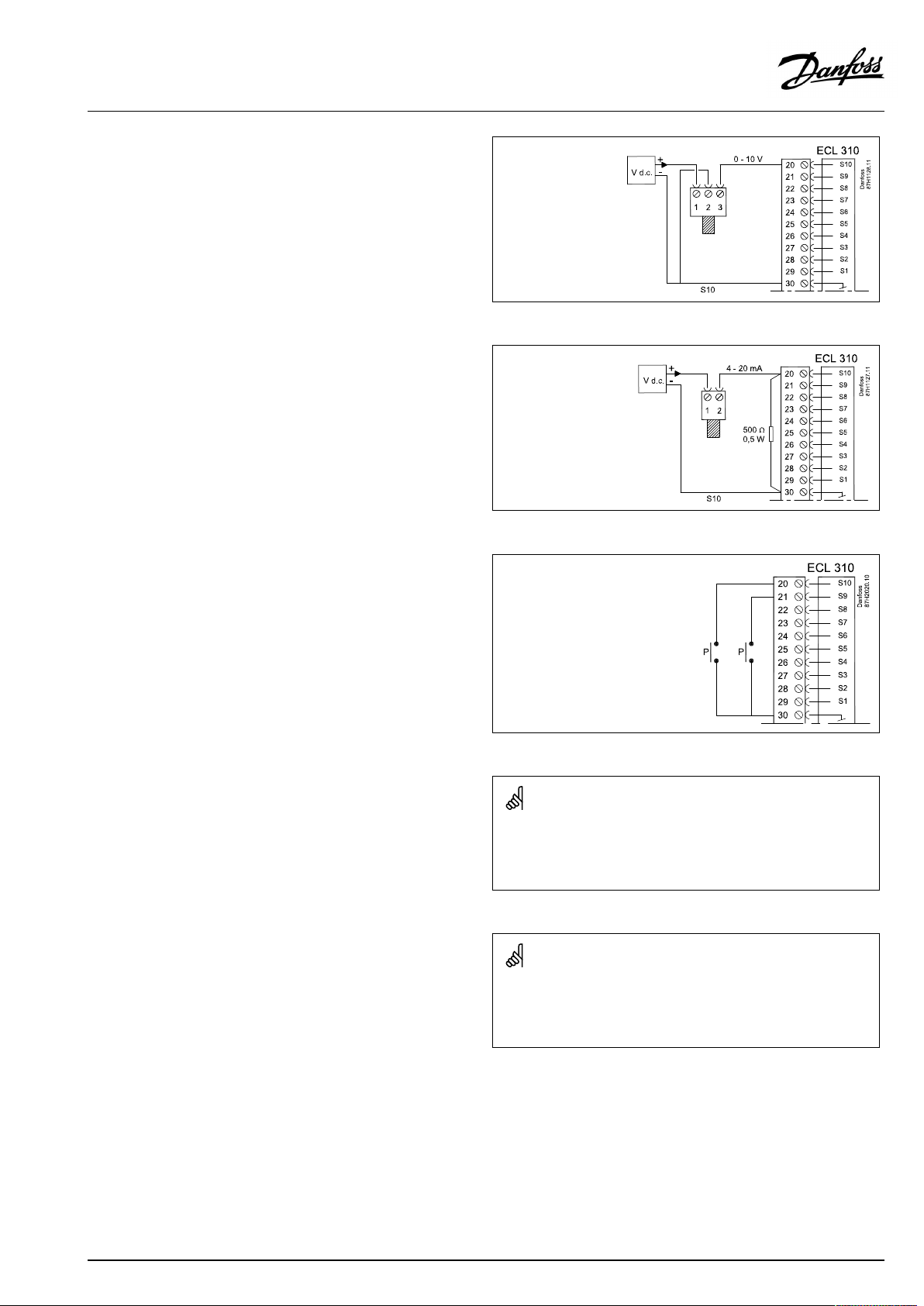

Connectionofapressuretransmitterwith0-10Voutput

ExampleofapressuretransmitterconnectiontoS10.Pressure

transmittercanbeconnectedinthesamewaytoS9.

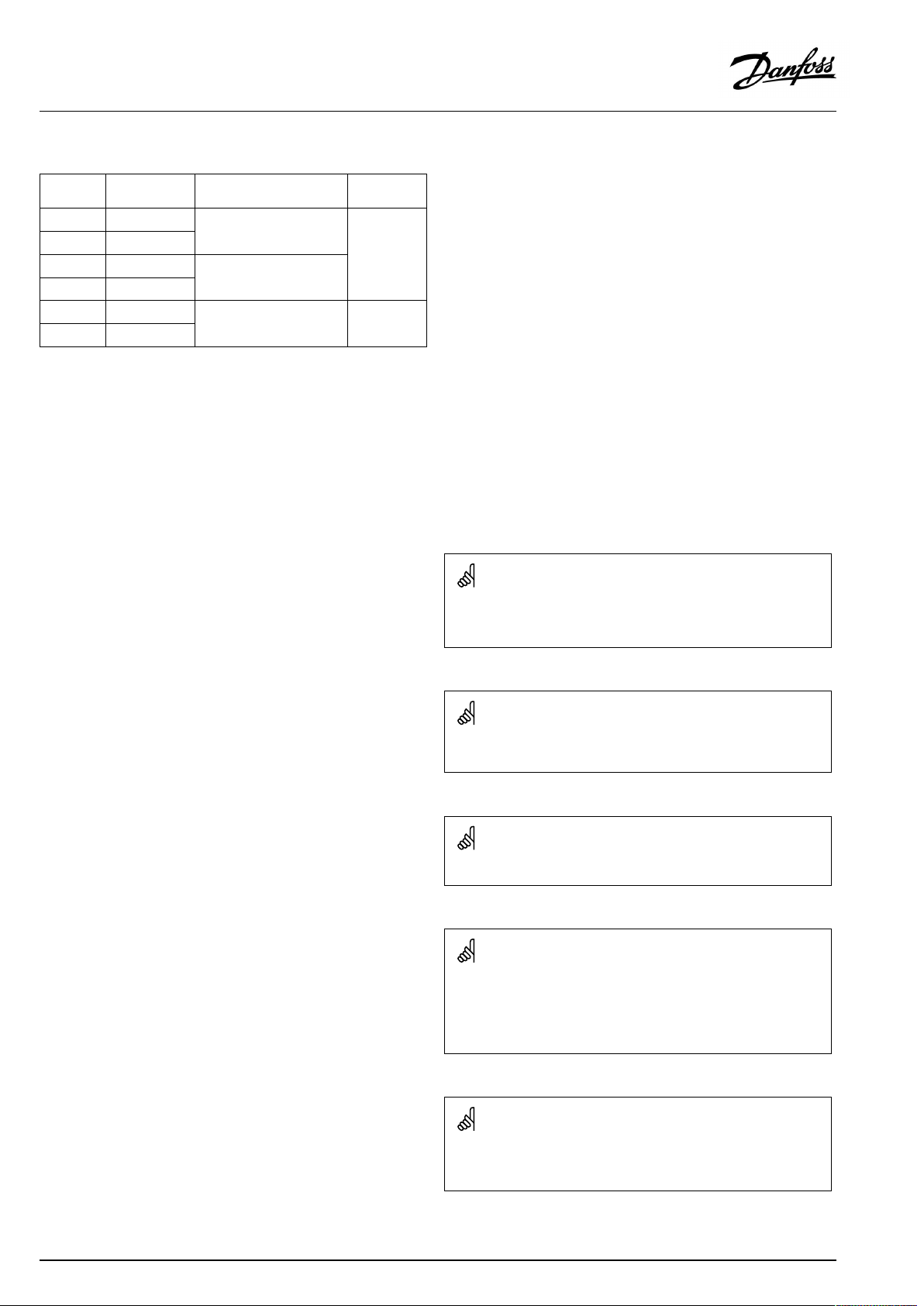

Connectionofapressuretransmitterwith4-20mAoutput

The4-20mAsignalisconvertedtoa2-10Vsignalbymeansofthe

500ohmresistor.

ExampleofapressuretransmitterconnectiontoS10.Pressure

transmittercanbeconnectedinthesamewaytoS9.

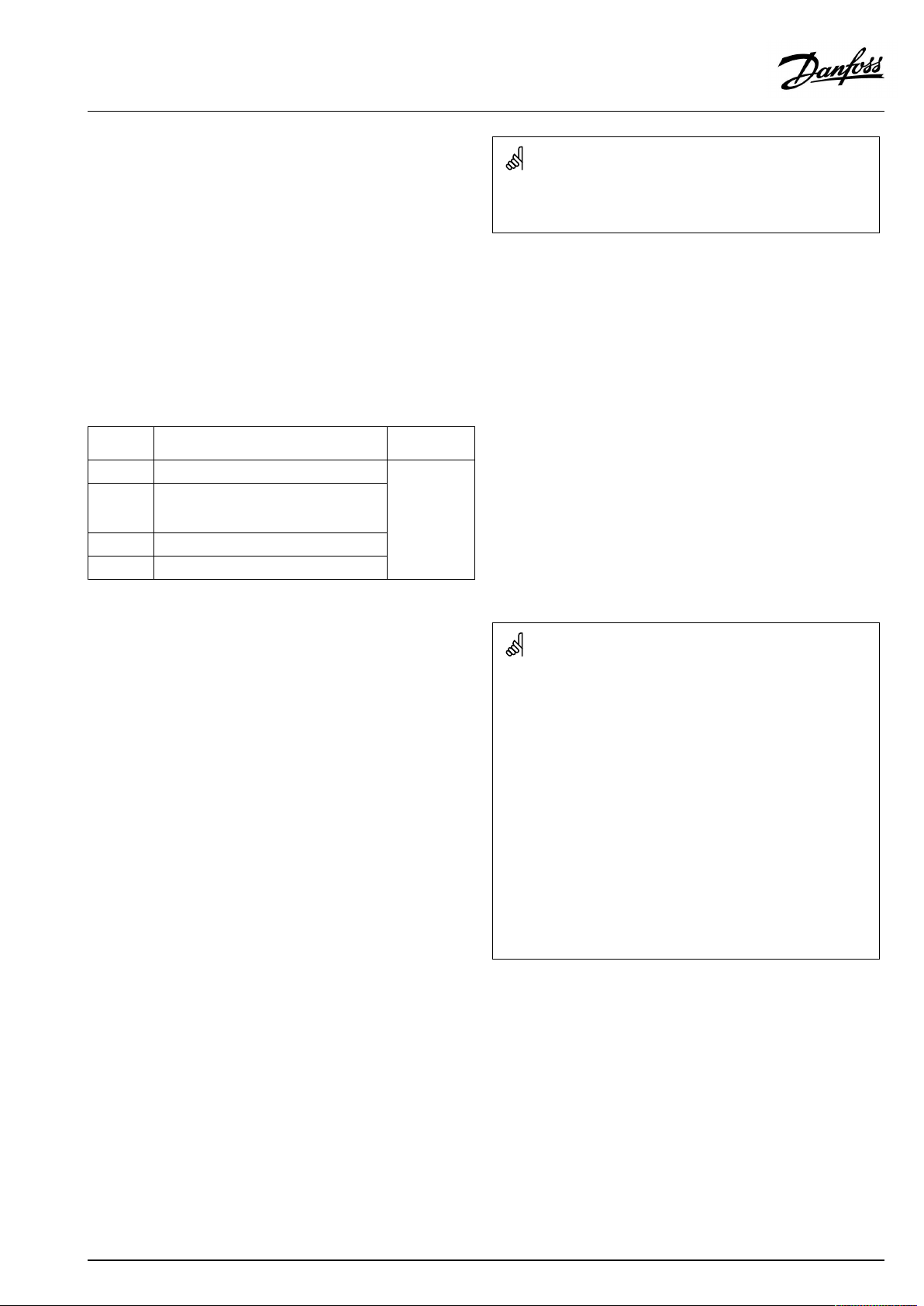

Connectionof2pressureswitches

Wirecrosssectionforsensorconnections:Min.0.4mm².

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus)

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

Wirecrosssectionforsensorconnections:Min.0.4mm².

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

AQ000086455681en-010402

©Danfoss|2021.02|21

Page 22

OperatingGuideECLComfort310,applicationA361

2.5.5Electricalconnections,ECA30/31

Terminal

ECL

Terminal

ECA30/31

30

31

4

1

322

333

4

5

*

Afteranexternalroomtemperaturesensorhasbeenconnected,

Description

Twistedpair

Twistedpair

Ext.roomtemperature

sensor*

Type

(recomm.)

Cable2x

twistedpair

ESM-10

ECA30/31mustberepowered.

ThecommunicationtotheECA30/31mustbesetupintheECL

Comfortcontrollerin'ECAaddr.'

TheECA30/31mustbesetupaccordingly.

AfterapplicationsetuptheECA30/31isreadyafter2–5min.A

progressbarintheECA30/31isdisplayed.

Iftheactualapplicationcontainstwoheatingcircuits,itispossible

toconnectanECA30/31toeachcircuit.Theelectricalconnections

aredoneinparallel.

Max.2ECA30/31canbeconnectedtoanECLComfort310controller

ortoECLComfort210/296/310controllersinamaster-slavesystem.

SetupproceduresforECA30/31:Seesection‘Miscellaneous’ .

ECAinformationmessage:

‘Applicationreq.newerECA’:

Thesoftware(firmware)ofyourECAdoesnotcomplywiththe

software(firmware)ofyourECLComfortcontroller.Pleasecontact

yourDanfosssalesoffice.

Someapplicationsdonotcontainfunctionsrelatedtoactualroom

temperature.TheconnectedECA30/31willonlyfunctionasremote

control.

22|©Danfoss|2021.02

AQ000086455681en-010402

Page 23

OperatingGuideECLComfort310,applicationA361

2.5.6Electricalconnections,master/slavesystems

Thecontrollercanbeusedasmasterorslaveinmaster/slave

systemsviatheinternalECL485communicationbus(2xtwisted

paircable).

TheECL485communicationbusisnotcompatiblewiththeECL

businECLComfort110,200,300and301!

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

Terminal

Description

Type

(recomm.)

30

Commonterminal

+12V*,ECL485communicationbus

31

*OnlyforECA30/31andmaster/

slavecommunication

32

B,ECL485communicationbus

33

A,ECL485communicationbus

Cable2x

twistedpair

ECL485buscable

MaximumrecommendedlengthoftheECL485busiscalculatedlike

this:

Subtract"TotallengthofallinputcablesofallECLcontrollersinthe

master-slavesystem"from200m.

Simpleexamplefortotallengthofallinputcables,3xECL:

1xECL

3xECL

3xECLReturntemp.sensor:

3xECLRoomtemp.sensor:

Total:

Outdoortemp.sensor:

Flowtemp.sensor:

15m

18m

18m

30m

81m

2.5.7Electricalconnections,communication

Electricalconnections,Modbus

ECLComfort210:Non-galvanicisolatedModbusconnections

ECLComfort296:GalvanicisolatedModbusconnections

ECLComfort310:GalvanicisolatedModbusconnections

AQ000086455681en-010402

MaximumrecommendedlengthoftheECL485bus:

200-81m=119m

©Danfoss|2021.02|23

Page 24

OperatingGuideECLComfort310,applicationA361

2.5.8Electricalconnections,communication

Electricalconnections,M-bus

ECLComfort210:Notimplemented

ECLComfort296:Onboard,non-galvanicisolated.Max.cable

length50m.

ECLComfort310:Onboard,non-galvanicisolated.Max.cable

length50m.

24|©Danfoss|2021.02

AQ000086455681en-010402

Page 25

OperatingGuideECLComfort310,applicationA361

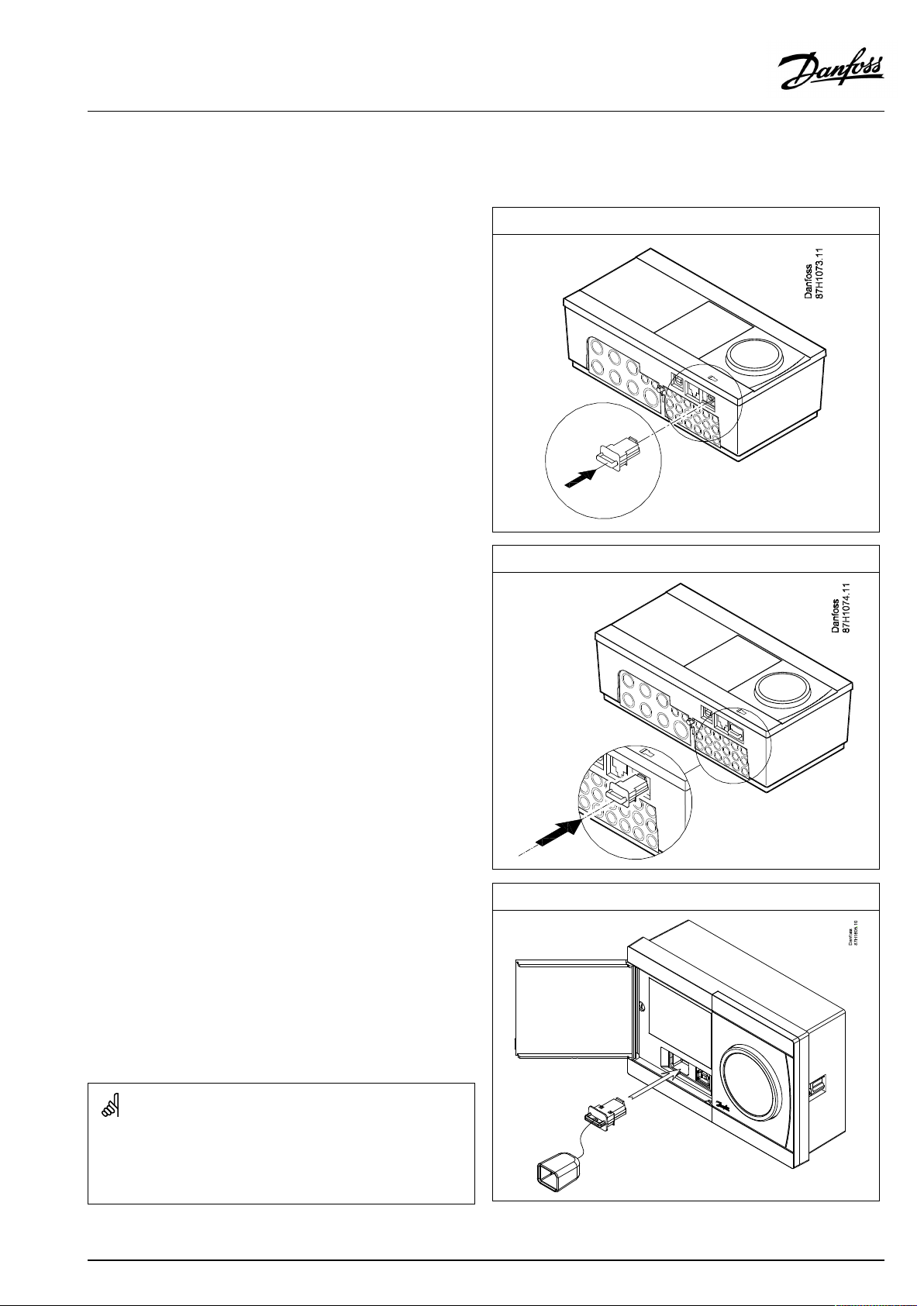

2.6InsertingtheECLApplicationKey

2.6.1InsertingtheECLApplicationKey

TheECLApplicationKeycontains

•theapplicationanditssubtypes,

•currentlyavailablelanguages,

•factorysettings:e.g.schedules,desiredtemperatures,

limitationvaluesetc.Itisalwayspossibletorecoverthefactory

settings,

•memoryforusersettings:specialuser/systemsettings.

Afterhavingpowered-upthecontroller,differentsituationsmight

beexisting:

1.Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

2.Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

3.Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

ECLComfort210/310

ECLComfort210/310

Usersettingsare,amongothers,desiredroomtemperature,desired

DHWtemperature,schedules,heatcurve,limitationvaluesetc.

Systemsettingsare,amongothers,communicationset-up,display

brightnessetc.

AQ000086455681en-010402

ECLComfort296

©Danfoss|2021.02|25

Page 26

OperatingGuideECLComfort310,applicationA361

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

26|©Danfoss|2021.02

AQ000086455681en-010402

Page 27

OperatingGuideECLComfort310,applicationA361

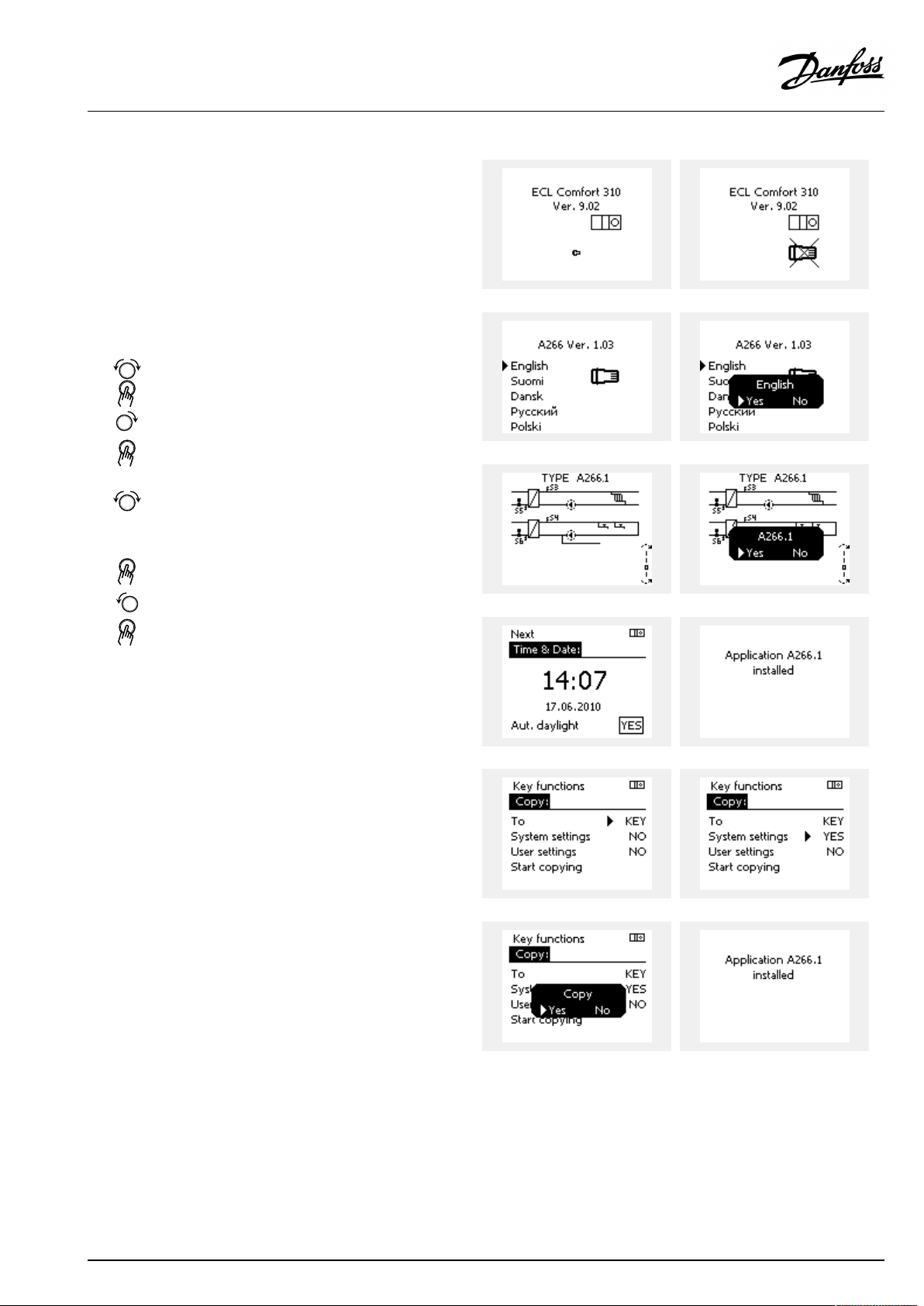

ApplicationKey:Situation1

Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

AnanimationfortheECLApplicationKeyinsertionisdisplayed.

InserttheApplicationKey.

ApplicationKeynameandVersionisindicated(example:A266

Ver.1.03).

IftheECLApplicationKeyisnotsuitableforthecontroller,a"cross"

isdisplayedovertheECLApplicationKey-symbol.

Action:Purpose:

Selectlanguage

Confirm

Selectapplication(subtype)

Somekeyshaveonlyoneapplication.

Confirmwith‘Yes’

Set'Time&Date'

Turnandpushthedialtoselectand

change'Hours' ,'Minutes','Date',

'Month'and'Year' .

Choose''Next'

Confirmwith‘Yes’

Goto‘Aut.daylight’

Choosewhether‘ Aut.daylight´*

shouldbeactiveornot

*‘Aut.daylight’istheautomaticchangeoverbetweensummer

andwintertime.

DependingonthecontentsoftheECLApplicationKey,procedure

AorBistakingplace:

A

TheECLApplicationkeycontainsfactorysettings:

Thecontrollerreads/transfersdatafromtheECLApplicationKey

toECLcontroller.

Examples:

YESorNO

Theapplicationisinstalled,andthecontrollerresetsandstartsup.

B

TheECLApplicationkeycontainschangedsystemsettings:

Pushthedialrepeatedly.

’NO’:

’YES*:

Ifthekeycontainsusersettings:

Pushthedialrepeatedly.

‘NO:

‘YES*:

*If‘YES’cannotbechosen,theECLApplicationKeydoesnot

containanyspecialsettings.

Choose‘Startcopying’andconfirmwith'Yes'.

AQ000086455681en-010402

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialsystemsettings(differingfromthefactory

settings)willbecopiedtothecontroller.

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialusersettings(differingfromthefactorysettings)

willbecopiedtothecontroller.

©Danfoss|2021.02|27

Page 28

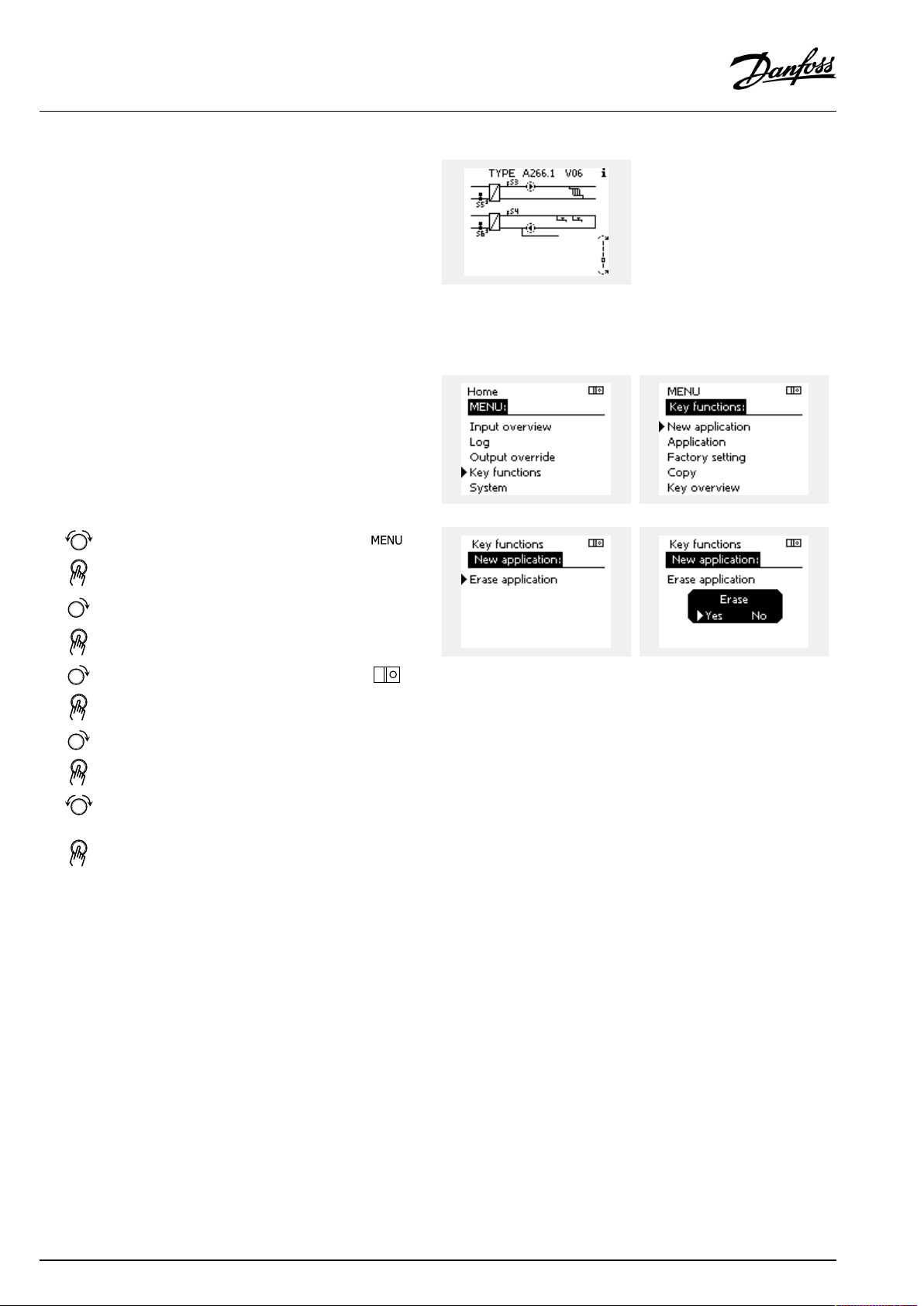

OperatingGuideECLComfort310,applicationA361

(Example):

The"i"intheupperrightcornerindicatesthat-besidesthefactory

settings-thesubtypealsocontainsspecialuser/systemssettings.

ApplicationKey:Situation2

Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

TochangetoanotherapplicationontheECLApplicationKey,the

currentapplicationinthecontrollermustbeerased(deleted).

BeawarethattheApplicationKeymustbeinserted.

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Choose‘Keyfunctions’

Confirm

Choose‘Eraseapplication’

Confirmwith‘Yes’

Thecontrollerresetsandisreadytobeconfigured.

Followtheproceduredescribedinsituation1.

Examples:

28|©Danfoss|2021.02

AQ000086455681en-010402

Page 29

OperatingGuideECLComfort310,applicationA361

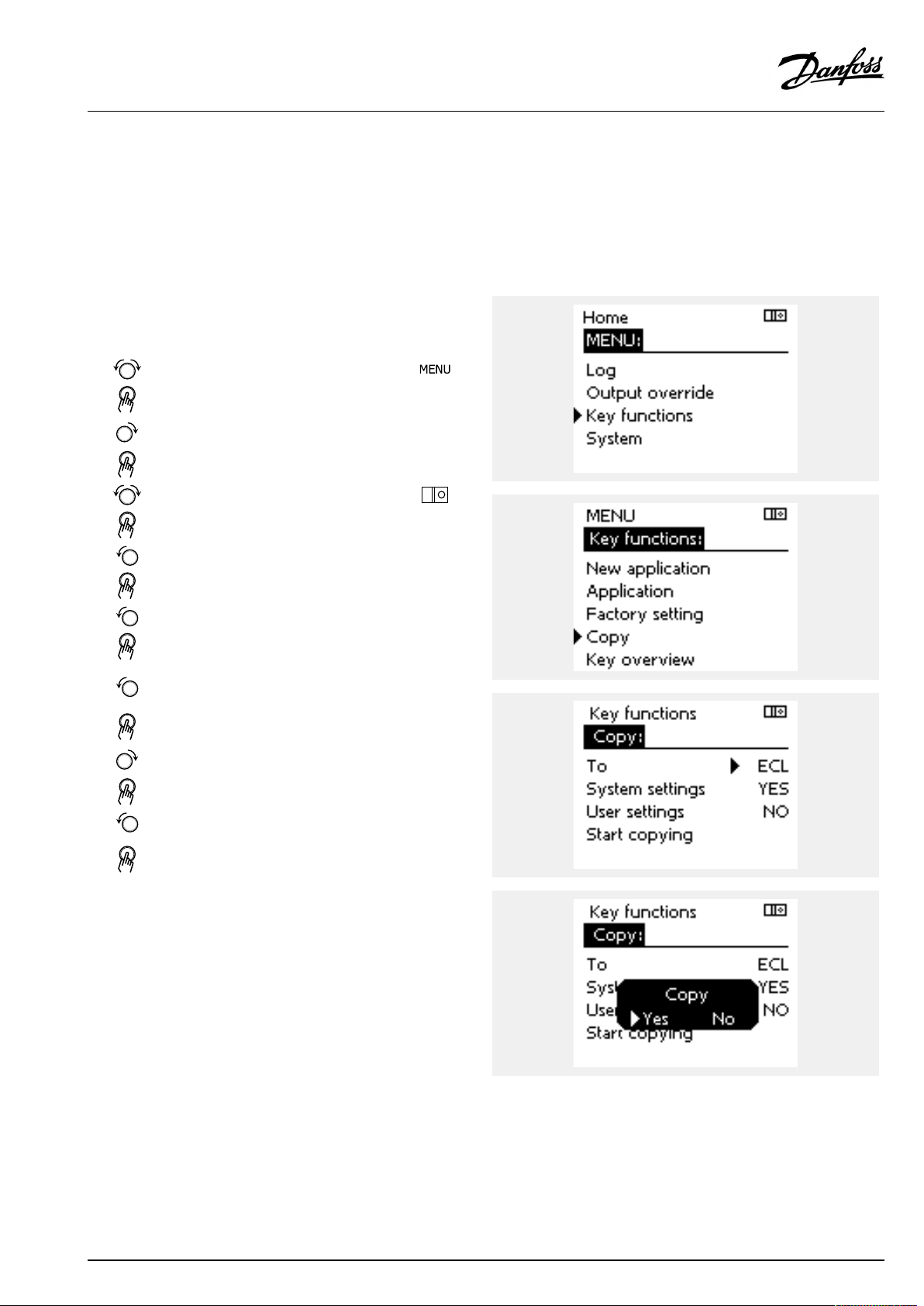

ApplicationKey:Situation3

Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

Thisfunctionisused

•forsaving(backup)ofspecialuserandsystemsettings

•whenanotherECLComfortcontrollerofthesametype(210,

296or310)mustbeconfiguredwiththesameapplicationbut

user/systemsettingsdifferfromthefactorysettings.

HowtocopytoanotherECLComfortcontroller:

Action:Purpose:

Choose‘MENU’

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose'Commoncontrollersettings'

Confirm

Goto‘Keyfunctions’

Confirm

Choose‘Copy’

Confirm

Choose‘To’ .

‘ECL’or‘KEY’willbeindicated.Choose

’ECL’orKEY’

Pushthedialrepeatedlytochoose

copydirection

Choose‘Systemsettings’or‘User

settings’

Pushthedialrepeatedlytochoose

‘Yes’or‘No’in‘Copy’ .Pushtoconfirm.

Choose‘Startcopying’

TheApplicationKeyorthecontroller

isupdatedwithspecialsystemoruser

settings.

Examples:

*

’ECL’or‘KEY’ .

**

‘NO’or‘YES’

*

‘ECL’:

‘KEY’:

**

‘NO’:

‘YES’:

AQ000086455681en-010402

DatawillbecopiedfromtheApplicationKeytothe

ECLController.

DatawillbecopiedfromtheECLControllertothe

ApplicationKey.

ThesettingsfromtheECLcontrollerwillnotbecopied

totheApplicationKeyortotheECLComfortcontroller.

Specialsettings(differingfromthefactorysettings)will

becopiedtotheApplicationKeyortotheECLComfort

controller.IfYEScannotbechosen,therearenospecial

settingstobecopied.

©Danfoss|2021.02|29

Page 30

OperatingGuideECLComfort310,applicationA361

Language

Atapplicationupload,alanguagemustbeselected.*

IfanotherlanguagethanEnglishisselected,theselectedlanguage

ANDEnglishwillbeuploadedintotheECLcontroller.

ThismakesserviceeasyforEnglishspeakingservicepeople,just

becausetheEnglishlanguagemenuscanbevisiblebychanging

theactualsetlanguageintoEnglish.

(Navigation:MENU>Commoncontroller>System>Language)

Iftheuploadedlanguageisnotsuitable,theapplicationmustbe

erased.UserandSystemsettingscanbesavedontheapplication

keybeforeerasing.

Afternewuploadwithpreferredlanguage,theexistingUserand

Systemsettingscanbeuploaded.

*)

(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

2.6.2ECLApplicationKey,copyingdata

Generalprinciples

Whenthecontrollerisconnectedandoperating,youcancheck

andadjustallorsomeofthebasicsettings.Thenewsettingscan

bestoredontheKey.

Factorysettingscanalwaysberestored.

HowtoupdatetheECLApplicationKeyaftersettingshave

beenchanged?

AllnewsettingscanbestoredontheECLApplicationKey.

Howtostorefactorysettinginthecontrollerfromthe

ApplicationKey?

PleasereadtheparagraphconcerningApplicationKey,Situation

1:Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

HowtostorepersonalsettingsfromthecontrollertotheKey?

PleasereadtheparagraphconcerningApplicationKey,Situation3:

Acopyofthecontrollerssettingsisneededforconfiguringanother

controller

Asamainrule,theECLApplicationKeyshouldalwaysremainin

thecontroller.IftheKeyisremoved,itisnotpossibletochange

settings.

Makeanoteofnewsettingsinthe'Settingsoverview'table.

DonotremovetheECLApplicationKeywhilecopying.Thedataon

theECLApplicationKeycanbedamaged!

ItispossibletocopysettingsfromoneECLComfortcontrollerto

anothercontrollerprovidedthatthetwocontrollersarefromthesame

series(210or310).

Furthermore,whentheECLComfortcontrollerhasbeenuploaded

withanapplicationkey,minimumversion2.44,itispossibletoupload

personalsettingsfromapplicationkeys,minimumversion2.14.

30|©Danfoss|2021.02

AQ000086455681en-010402

Page 31

OperatingGuideECLComfort310,applicationA361

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

AQ000086455681en-010402

©Danfoss|2021.02|31

Page 32

OperatingGuideECLComfort310,applicationA361

2.7Checklist

IstheECLComfortcontrollerreadyforuse?

Makesurethatthecorrectpowersupplyisconnectedtoterminals9and10(230Vor24V).

Makesurethecorrectphaseconditionsareconnected:

230V:Live=terminal9andNeutral=terminal10

24V:SP=terminal9andSN=terminal10

Checkthattherequiredcontrolledcomponents(actuator,pumpetc.)areconnectedtothecorrectterminals.

Checkthatallsensors/signalsareconnectedtothecorrectterminals(see'Electricalconnections').

Mountthecontrollerandswitchonthepower.

IstheECLApplicationKeyinserted(see'InsertingtheApplicationKey').

DoestheECLComfortcontrollercontainanexistingapplication(see'InsertingtheApplicationKey').

Isthecorrectlanguagechosen(see'Language'in'Commoncontrollersettings').

Isthetime&datesetcorrectly(see'Time&Date'in'Commoncontrollersettings').

Istherightapplicationchosen(see'Identifyingthesystemtype').

Checkthatallsettingsinthecontroller(see'Settingsoverview')aresetorthatthefactorysettingscomplywithyour

requirements.

Choosemanualoperation(see'Manualcontrol').Checkthatvalvesopenandclose,andthatrequiredcontrolled

components(pumpetc.)startandstopwhenoperatedmanually.

Checkthatthetemperatures/signalsshowninthedisplaymatchtheactualconnectedcomponents.

Havingcompletedthemanualoperationcheck,choosecontrollermode(scheduled,comfort,savingorfrostprotection).

32|©Danfoss|2021.02

AQ000086455681en-010402

Page 33

OperatingGuideECLComfort310,applicationA361

2.8Navigation,ECLApplicationKeyA361

Navigation,applicationsA361,circuit1and2(*application361.2only)

Home

IDno.

MENU

ScheduleSelectableSelectable

Settings

Flowtemperature

11178

11177

11300

11301

11302

11303

Returnlimit

Flow/powerlimitActualActual

Optimization

Controlpar.

11031

11032

11033

11034

11035

11036

11037

11085

11119

11117

11118

11116

11112

11113

11109

11115

11011

11012

11013

11014

11026

11021

11179

11174

11184

11185

11186

11187

Circuit1,HeatingCircuit2,Heating

Function

HeatcurveHeatcurve

Temp.max.

Temp.min.

Highsupp.TX2*

HighTmaxY2*

LowsupplyTX1*

LowTmaxY1*

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Infl.-max.

Infl.-min.

Adapt.time

Priority

LimitLimit

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Adapt.time

Filterconstant

Inputtype

Units

Autosaving

Boost

Ramp

Optimizer

Prestop

Totalstop

Cut-out

Motorpr.

Xp

Tn

Mrun

Nz

IDno.

11178

12177

12300

12301

12302

12303

12031

12032

12033

12034

12035

12036

12037

12085

12119

12117

12118

12116

12112

12113

12109

12115

12011

12012

12013

12014

12026

12021

12179

12174

12184

12185

12186

12187

Function

Temp.max.

Temp.min.

Highsupp.TX2*

HighTmaxY2*

LowsupplyTX1*

LowTmaxY1*

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Infl.-max.

Infl.-min.

Adapt.time

Priority

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Adapt.time

Filterconstant

Inputtype

Units

Autosaving

Boost

Ramp

Optimizer

Prestop

Totalstop

Cut-out

Motorpr.

Xp

Tn

Mrun

Nz

AQ000086455681en-010402

©Danfoss|2021.02|33

Page 34

OperatingGuideECLComfort310,applicationA361

Navigation,applicationA361,circuit1andcircuit2continued

Home

MENU

Settings

HolidaySelectableSelectable

Alarm

InfluenceoverviewDes.flowT

Pumpcontrol

Refillwater

Application

Temp.monitor.

Clearalarm

AlarmoverviewSelectableSelectable

IDno.

11314

11310

11313

11311

11312

11022

11327

11323

11321

11322

11320

11325

11326

11017

11023

11052

11077

11078

11093

11141

11142

11189

11147

11148

11149

11150

11315

11324

Circuit1,HeatingCircuit2,Heating

Function

Chan.-overtime

Retrytime

Stab.time

Change,duration

Changetime

Pexercise

PressurePressure

Inputtype

Time-out

Pressure,des.

Pressure,diff.

Pexercise

Valvedelay

No.ofpumps

Demandoffset

Mexercise

DHWpriority

PfrostT

PheatT

Frostpr.T

Ext.input

Ext.mode

Min.act.time

Upperdifference

Lowerdifference

Delay

Lowesttemp.

Circ.pumps

Refillwater

Returnlim.Returnlim.

Flow/powerlim.Flow/powerlim.

HolidayHoliday

Ext.overrideExt.override

BoostBoost

RampRamp

Slave,demand

Heatingcut-outHeatingcut-out

DHWpriorityDHWpriority

IDno.

12314

12310

12313

12311

12312

12022

12327

12323

12321

12322

12320

12325

12326

12023

12052

12077

12078

12093

12141

12142

12189

12147

12148

12149

12150

12315

12324

Function

Chan.-overtime

Retrytime

Stab.time

Change,duration

Changetime

Pexercise

Inputtype

Time-out

Pressure,des.

Pressure,diff.

Pexercise

Valvedelay

No.ofpumps

Mexercise

DHWpriority

PfrostT

PheatT

Frostpr.T

Ext.input

Ext.mode

Min.act.time

Upperdifference

Lowerdifference

Delay

Lowesttemp.

Circ.pumps

Refillwater

34|©Danfoss|2021.02

AQ000086455681en-010402

Page 35

OperatingGuideECLComfort310,applicationA361

Navigation,applicationA361,Commoncontrollersettings(*applicationA361.2only)

Home

MENU

Time&Date

HolidaySelectable

Inputoverview1

Inputoverview2

Log1(sensors)

Log2(sensors)

Outputoverride

Keyfunctions

SystemECLversion

OutdoorTLogtoday

SupplyT*Logyesterday

Heatingflow&des.

HeatreturnT&limitLog4days

Staticpressure

OutdoorTLogtoday

SupplyT*Logyesterday

Heatingflow&des.

HeatreturnT&limitLog4days

Staticpressure

NewapplicationEraseapplication

Application

FactorysettingSystemsettings

Copy

Keyoverview

Extension

Ethernet

M-busconfig

EnergyMeters

Display

Communication

Language

Commoncontrollersettings

IDno.

60058

60059

38

2048

2150

2151

2050

Function

Selectable

OutdoorT

SupplyT*

HeatflowT

HeatreturnT

Staticpressure

S7status

OutdoorT

SupplyT*

HeatflowT

HeatreturnT

Staticpressure

S8status

Log2days

Log2days

M1,P1,P2,M2,P3,P5,V1,V2,

P4,A1

Usersettings

Gotofactory

To

Systemsettings

Usersettings

Startcopying

Codeno.

Hardware

Software

Buildno.

Serialno.

MAC

Productionweek

Selectable

Selectable

Backlight

Contrast

Modbusaddr.

ECL485addr.

Servicepin

Ext.reset

Language

AQ000086455681en-010402

©Danfoss|2021.02|35

Page 36

OperatingGuideECLComfort310,applicationA361

3.0Dailyuse

3.1Howtonavigate

Younavigateinthecontrollerbyturningthedialleftorrightto

thedesiredposition().

Thedialhasabuilt-inaccellerator.Thefasteryouturnthedial,the

fasteritreachesthelimitsofanywidesettingrange.

Thepositionindicatorinthedisplay(

youare.

Pushthedialtoconfirmyourchoices().

Thedisplayexamplesarefromatwo-circuitapplication:One

heatingcircuit()andonedomestichot-water(DHW)circuit().

Theexamplesmightdifferfromyourapplication.

)willalwaysshowyouwhere

ExampleshowsECL210/310

Heatingcircuit():DHWcircuit();

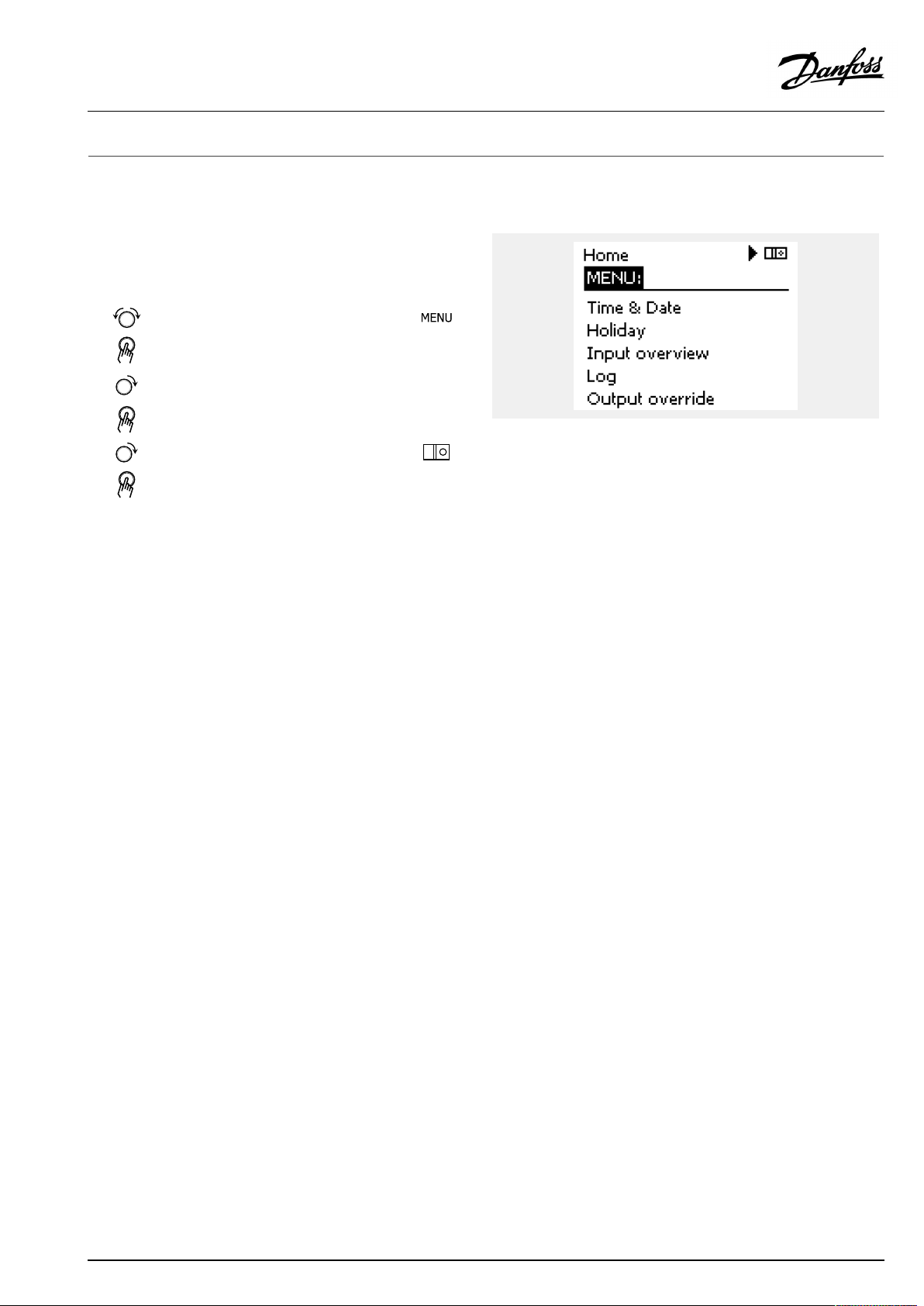

Somegeneralsettingswhichapplytotheentirecontrollerare

locatedinaspecificpartofthecontroller.

Toenter‘Commoncontrollersettings’:

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Examples:

Circuitselector

36|©Danfoss|2021.02

AQ000086455681en-010402

Page 37

OperatingGuideECLComfort310,applicationA361

3.2Understandingthecontrollerdisplay

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Choosingafavoritedisplay

Yourfavoritedisplayisthedisplayyouhavechosenasthedefault

display.Thefavoritedisplaywillgiveyouaquickoverviewofthe

temperaturesorunitsthatyouwanttomonitoringeneral.

Ifthedialhasnotbeenactivatedfor20min.,thecontrollerwill

reverttotheoverviewdisplayyouhavechosenasfavorite.

Toshiftbetweendisplays:Turnthedialuntilyoureachthedisplay

selector(

turntochooseyourfavoriteoverviewdisplay.Pushthedialagain.

)atthebottomrightsideofthedisplay.Pushthedialand

Heatingcircuit

Overviewdisplay1informsabout:

actualoutdoortemperature,controllermode,

actualroomtemperature,desiredroomtemperature.

Overviewdisplay2informsabout:

actualoutdoortemperature,trendinoutdoortemperature,

controllermode,max.andmin.outdoortemperaturessince

midnightaswellasdesiredroomtemperature.

Overviewdisplay3informsabout:

date,actualoutdoortemperature,controllermode,time,desired

roomtemperatureaswellasshowsthecomfortscheduleofthe

currentday.

Overviewdisplay4informsabout:

stateofthecontrolledcomponents,actualflowtemperature,

(desiredflowtemperature),controllermode,returntemperature

(limitationvalue),influenceondesiredflowtemperature.

ThevalueabovetheV2symbolindicates0–100%oftheanalogue

signal(0–10V).

Note:

Anactualflowtemperaturevaluemustbepresent,otherwisethe

circuit'scontrolvalvewillclose.

Overviewdisplay1:Overviewdisplay2:

Overviewdisplay3:Overviewdisplay4:

Exampleofoverviewdisplaywith

Influenceindication:

Example,favoritedisplay1in

A230.3,wheremin.desiredroom

temperatureisindicated(22.7):

Dependentonthechosendisplay,theoverviewdisplaysforthe

heatingcircuitinformyouabout:

•actualoutdoortemperature(-0.5)

•controllermode()

•actualroomtemperature(24.5)

•desiredroomtemperature(20.7°C)

•trendinoutdoortemperature(

)

•min.andmax.outdoortemperaturessincemidnight(

•date(23.02.2010)

•time(7:43)

•comfortscheduleofthecurrentday(0-12-24)

•stateofthecontrolledcomponents(M2,P2)

•actualflowtemperature(49°C),(desiredflowtemperature(31))

•returntemperature(24°C)(limitationtemperature(50))

AQ000086455681en-010402

)

©Danfoss|2021.02|37

Page 38

OperatingGuideECLComfort310,applicationA361

Settingthedesiredtemperature

Dependingonthechosencircuitandmode,itispossibletoenter

alldailysettingsdirectlyfromtheoverviewdisplays(seealsothe

nextpageconcerningsymbols).

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

Ifthetemperaturevalueisdisplayedas

"--"

thesensorinquestionisnotconnected.

"---"

thesensorconnectionisshort-circuited.

Settingthedesiredroomtemperature

Thedesiredroomtemperaturecaneasilybeadjustedinthe

overviewdisplaysfortheheatingcircuit.

Action:Purpose:

Examples:

Desiredroomtemperature

Confirm

Adjustthedesiredroomtemperature

Confirm

Thisoverviewdisplayinformsaboutoutdoortemperature,actual

roomtemperatureaswellasdesiredroomtemperature.

Thedisplayexampleisforcomfortmode.Ifyouwanttochange

thedesiredroomtemperatureforsavingmode,choosethemode

selectorandselectsaving.

20.5

21.0

38|©Danfoss|2021.02

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

AQ000086455681en-010402

Page 39

OperatingGuideECLComfort310,applicationA361

Settingthedesiredroomtemperature,ECA30/ECA31

Thedesiredroomtemperaturecanbesetexactlyasinthe

controller.However,othersymbolscanbepresentinthedisplay

(pleasesee'Whatdothesymbolsmean?').

WiththeECA30/ECA31youcanoverridethedesiredroom

temperaturesetinthecontrollertemporarilybymeansoftheoverride

functions:

AQ000086455681en-010402

©Danfoss|2021.02|39

Page 40

OperatingGuideECLComfort310,applicationA361

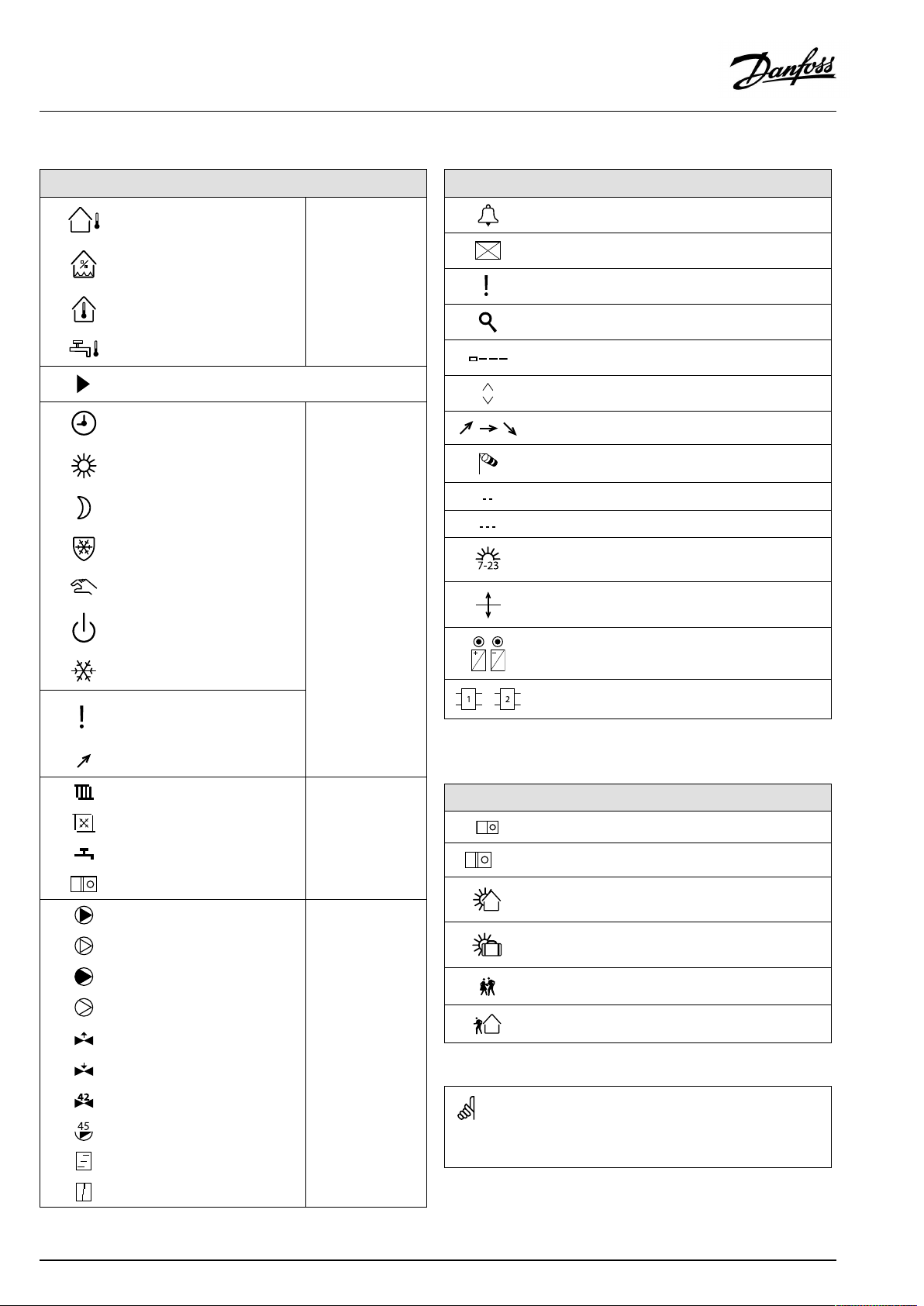

3.3Ageneraloverview:Whatdothesymbolsmean?

Symbol

Description

Outdoortemp.

Relativehumidityindoor

Roomtemp.

DHWtemp.

Positionindicator

Scheduledmode

Comfortmode

Savingmode

Frostprotectionmode

Manualmode

Standby

Coolingmode

Symbol

Temperature

Mode

Description

Alarm

Letter

Event

Monitoringtemperaturesensor

connection

Displayselector

Max.andmin.value

Trendinoutdoortemperature

Windspeedsensor

Sensornotconnectedornotused

Sensorconnectionshort-circuited

Fixedcomfortday(holiday)

Activeinfluence

Heatingactive(+)

Coolingactive(-)

Activeoutputoverride

Optimizedstartorstoptime

Heating

Cooling

DHW

Commoncontrollersettings

PumpON

PumpOFF

FanON

FanOFF

Actuatoropens

Actuatorcloses

Actuator,analoguecontrol

signal

Pump/fanspeed

DamperON

Circuit

Controlled

component

Numberofheatexchangers

Additionalsymbols,ECA30/31:

Symbol

InECA30/31onlythesymbolsthatarerelevanttotheapplicationin

thecontrolleraredisplayed.

Description

ECARemoteControlUnit

Connectionaddress(master:15,slaves:1-9)

15

Dayoff

Holiday

Relaxing(extendedcomfortperiod)

Goingout(extendedsavingperiod)

40|©Danfoss|2021.02

DamperOFF

AQ000086455681en-010402

Page 41

OperatingGuideECLComfort310,applicationA361

3.4Monitoringtemperaturesandsystemcomponents

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Heatingcircuit

Theoverviewdisplayintheheatingcircuitensuresaquick

overviewoftheactualand(desired)temperaturesaswellasthe

actualstateofthesystemcomponents.

Displayexample:

49°C

(31)

24°C

(50)

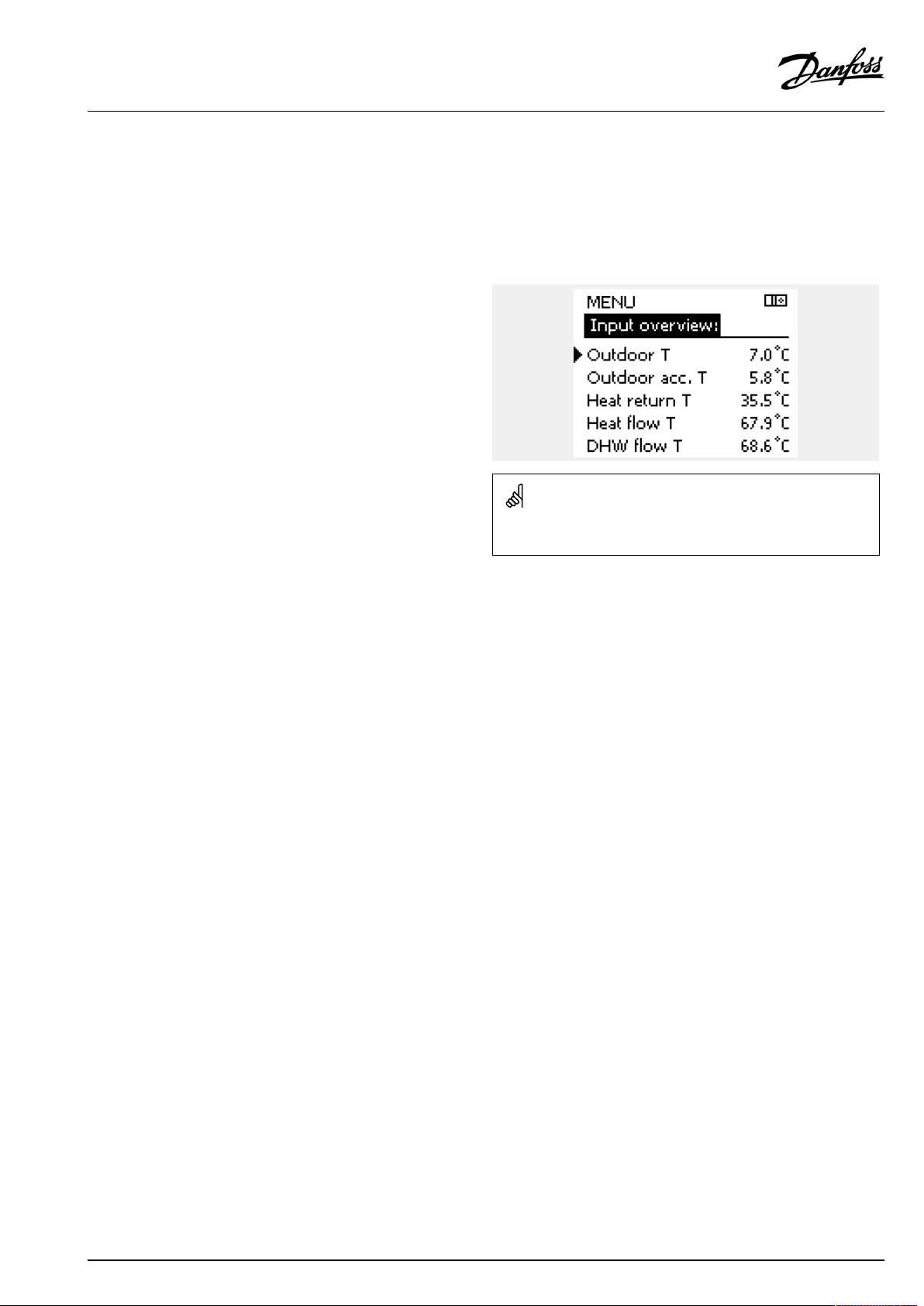

Inputoverview

Anotheroptiontogetaquickoverviewofmeasuredtemperatures

isthe'Inputoverview'whichisvisibleinthecommoncontroller

settings(howtoenterthecommoncontrollersettings,see

‘Introductiontocommoncontrollersettings’ .)

Asthisoverview(seedisplayexample)onlystatesthemeasured

actualtemperatures,itisread-only.

Flowtemperature

Desiredflowtemperature

Returntemperature

Returntemperaturelimitation

AQ000086455681en-010402

©Danfoss|2021.02|41

Page 42

OperatingGuideECLComfort310,applicationA361

3.5Influenceoverview

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Themenugivesanoverviewoftheinfluencesonthedesired

flowtemperature.Itdiffersfromapplicationtoapplicationwhich

parametersarelisted.Itcanbehelpfulinaservicesituationto

explainunexpectedconditionsortemperaturesamongothers.

Ifthedesiredflowtemperatureisinfluenced(corrected)byoneor

moreparameters,itisindicatedbyasmalllinewitharrow-down,

arrow-upordouble-arrow:

Arrow-down:

Theparameterinquestionreducesthedesiredflowtemperature.

Arrow-up:

Theparameterinquestionincreasesthedesiredflowtemperature.

Double-arrow:

Theparameterinquestioncreatesanoverride(e.g.Holiday).

Straightline:

Noactiveinfluence.

Intheexample,thearrowinthesymbolpointsdownwardsfor

'Roomlim. ' .Thismeansthattheactualroomtemperatureis

higherthanthedesiredroomtemperaturewhichagainresultsina

decreaseofthedesiredflowtemperature.

ExampleofoverviewdisplaywithInfluenceindication:

42|©Danfoss|2021.02

AQ000086455681en-010402

Page 43

OperatingGuideECLComfort310,applicationA361

3.6Manualcontrol

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Itispossibletomanuallycontroltheinstalledcomponents.

Manualcontrolcanonlybeselectedinfavoritedisplaysinwhich

thesymbolsforthecontrolledcomponents(valve,pumpetc.)are

visible.

Action:Purpose:

Choosemodeselector

Confirm

Choosemanualmode

Confirm

Choosepump

Confirm

SwitchONthepump

SwitchOFFthepump.

Confirmpumpmode

Choosemotorizedcontrolvalve

Confirm

Openthevalve

Stopopeningthevalve

Closethevalve

Examples:

ControlledcomponentsCircuitselector

Duringmanualoperation:

•Allcontrolfunctionsaredeactivated

•Outputoverrideisnotpossible

•Frostprotectionisnotactive

Stopclosingthevalve

Confirmvalvemode

Toleavemanualcontrol,usethemodeselectortoselectthe

desiredmode.Pushthedial.

Manualcontrolistypicallyusedwhencommisioningthe

installation.Thecontrolledcomponents,valve,pumpetc.,canbe

controlledforcorrectfunction.

AQ000086455681en-010402

Whenmanualcontrolisselectedforonecircuit,itisautomatically

selectedforallcircuits!

©Danfoss|2021.02|43

Page 44

OperatingGuideECLComfort310,applicationA361

3.7Schedule

3.7.1Setyourschedule

ThissectiondescribesthescheduleingeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.Insomeapplications,however,theremightbemore

thanoneschedule.Additionalschedulescanbefoundin‘Common

controllersettings’ .

Thescheduleconsistsofa7-dayweek:

=

M

Monday

=

T

Tuesday

=

W

Wednesday

=

T

Thursday

=

F

Friday

=

S

Saturday

=

S

Sunday

Theschedulewillday-by-dayshowyouthestartandstoptimesof

yourcomfortperiods(heating/DHWcircuits).

Changingyourschedule:

Action:

Purpose:

Choose'MENU'inanyoftheoverview

displays

Confirm

Confirmthechoice'Schedule'

Choosethedaytochange

Confirm*

GotoStart1

Confirm

Adjustthetime

Confirm

GotoStop1,Start2etc.etc.

Returnto'MENU'

Confirm

Choose'Yes'or'No'in'Save'

Confirm

Examples:

*Severaldayscanbemarked

Thechosenstartandstoptimeswillbevalidforallthechosendays

(inthisexampleThursdayandSaturday).

Youcansetmax.3comfortperiodsaday.Youcandeleteacomfort

periodbysettingstartandstoptimestothesamevalue.

44|©Danfoss|2021.02

Eachcircuithasitsownschedule.Tochangetoanothercircuit,goto

'Home',turnthedialandchoosethedesiredcircuit.

Thestartandstoptimescanbesetinhalf-hourly(30min.)intervals.

AQ000086455681en-010402

Page 45

OperatingGuideECLComfort310,applicationA361

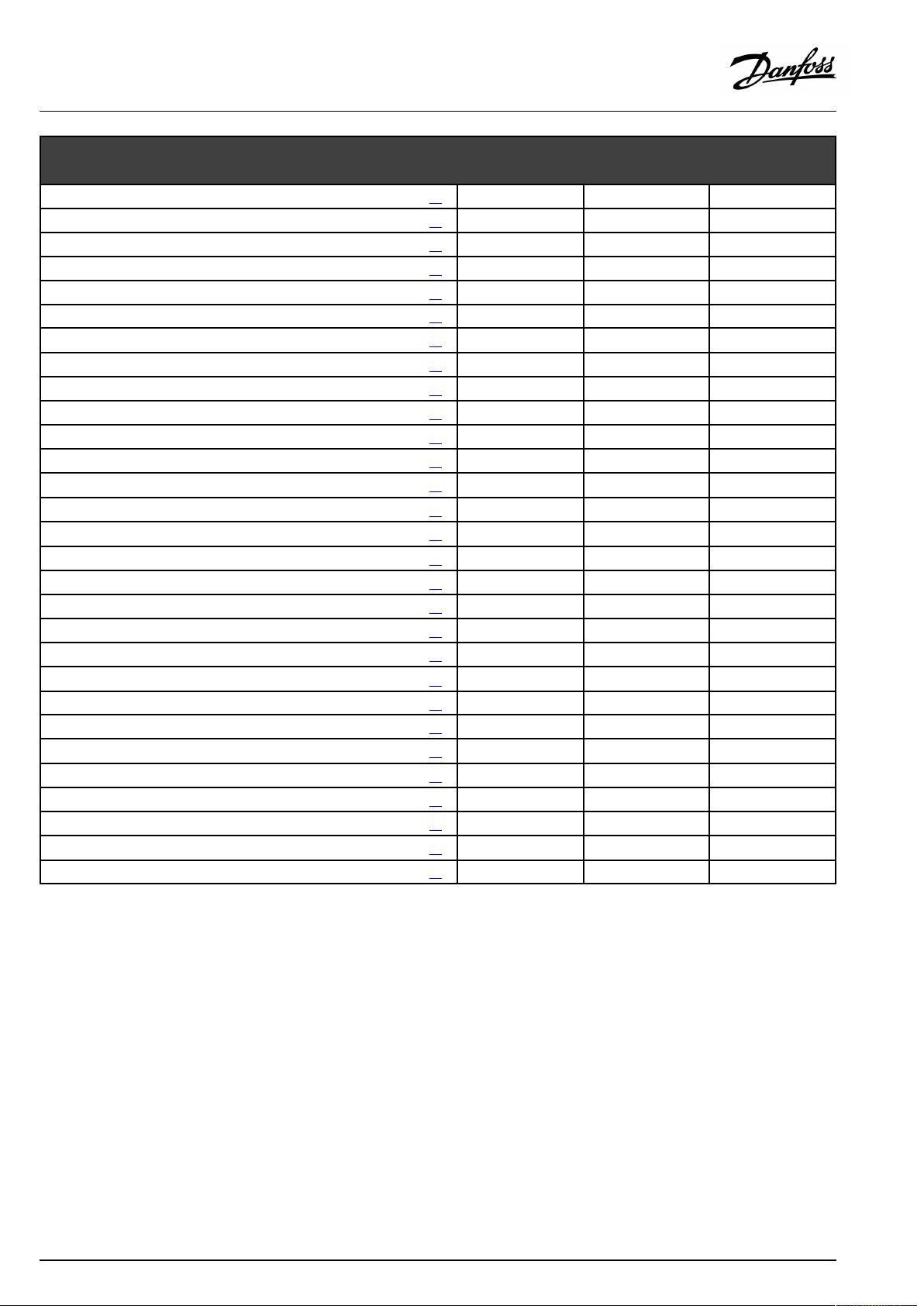

4.0Settingsoverview

Forfactorysettingsandsettingrange,seeappendix“ParameterIDoverview” .

ParametersindicatedwithanIDno.like"1x607"meanauniversalparameter.xstandsforcircuit/parametergroup.

SettingIDPage

Heatcurve

Heatcurve

Actual(actualfloworpower)

Pressure

Pressure,des.(desiredpressure)

Autosaving(savingtemp.dependentonoutdoortemp.)

Boost

Ramp(referenceramping)

Optimizer(optimizingtimeconstant)

Demandoffset

Totalstop

Pexercise(pumpexercise)

Mexercise(valveexercise)

Pre-stop(optimizedstoptime)

HighToutX1(returntemp.limitation,highlimit,X-axis)

LowlimitY1(returntemp.limitation,lowlimit,Y-axis)

LowToutX2(returntemp.limitation,lowlimit,X-axis)

HighlimitY2(returntemp.limitation,highlimit,Y-axis)

Infl.-max.(returntemp.limitation-max.influence)

Infl.-min.(returntemp.limitation-min.influence)

Adapt.time(adaptationtime)

DHWpriority(closedvalve/normaloperation)

PfrostT(circulationpump,frostprotectiontemp.)

PheatT(heatdemand)

Priority(priorityforreturntemp.limitation)

Frostpr.T(frostprotectiontemp.)

Inputtype

Limit(limitationvalue)

Adapt.time(adaptationtime)

Filterconstant

Units

HighlimitY2(flow/powerlimitation,highlimit,Y-axis)

LowlimitY1(flow/powerlimitation,lowlimit,Y-axis)

LowToutX2(flow/powerlimitation,lowlimit,X-axis)

HighToutX1(flow/powerlimitation,highlimit,X-axis)

Ext.input(externaloverride)

Ext.mode(externaloverridemode)

Upperdifference

1x01161

1x01262

1x01363

1x01463

1x01779

1x02164

1x022

1x02379

1x02665

1x031

1x032

1x033

1x034

1x035

1x036

1x037

1x05279

1x07780

1x07880

1x08556

1x09380

1x10958

1x111

1x11258

1x11359

1x115

1x11659

1x117

1x11860

1x11960

1x141

1x14281

1x147

Factorysettingsincircuit(s)

1

48

50

58

74

75

71

54

54

54

55

55

55

55

58

59

60

80

85

23

AQ000086455681en-010402

©Danfoss|2021.02|45

Page 46

OperatingGuideECLComfort310,applicationA361

SettingIDPage

Lowerdifference

Delay,example

Lowesttemp.

Motorpr.(motorprotection)

Temp.min.

Temp.max.

Summer,cut-out(limitforheatingcut-out)

Xp(proportionalband)

Tn(integrationtimeconstant)

Mrun(runningtimeofthemotorizedcontrolvalve)

Nz(neutralzone)

Min.act.time(min.activationtimegearmotor)

Highsupp.TX2(highvalueofsupplytemp.)

HighTmaxY2(highvalueofmaxlimitation)

LowsupplyTX1(lowvalueofsupplytemp.)

LowTmaxY1(lowvalueofmaxlimitation)

Retrytime

Change,duration

Changetime(changeovertime)

Stab.time(stabilizationtime)

Chan.-overtime(change-overtime)

Circ.pumps

Pexercise(pumpexercise)

Pressure,diff.(switchingdifference)

Time-out

Refillwater

Valvedelay

No.ofpumps

Inputtype

1x14885

1x14985

1x15086

1x174

1x17751

1x178

1x17966

1x18468

1x18569

1x18669

1x18769

1x18983

1x300

1x301

1x302

1x30352

1x310

1x311

1x31272

1x31372

1x31472

1x31586

1x320

1x322

1x323

1x32486

1x32576

1x326

1x327

Factorysettingsincircuit(s)

1

68

51

51

51

51

71

71

75

75

75

77

77

23

46|©Danfoss|2021.02

AQ000086455681en-010402

Page 47

OperatingGuideECLComfort310,applicationA361

5.0Settings

5.1IntroductiontoSettings

Descriptionsofsettings(parameter'sfunctions)aredividedinto

groupsasusedintheECLComfort210/296/310controller's

menustructure.Examples:"Flowtemperature" ,"Roomlimit"and

soon.Eachgroupstartswithageneralexplanation.

Thedescriptionsofeachparameterareinnumericorder,relatedto

theparameter'sIDnumbers.Youmightcomeacrossdifferences

betweentheorderinthisOperatingGuideandtheECLComfort

210/296/310controllers.

Someparameterdescriptionsarerelatedtospecificapplication

subtypes.Thismeansthatyoumightnotseetherelatedparameter

intheactualsubtypeintheECLcontroller.

Thenote"SeeAppendix… "referstotheAppendixattheendof

thisOperatingGuide,whereparameter'ssettingrangesandfactory

settingsarelisted.

Thenavigationhints(forexampleMENU>Settings>Returnlimit

…)covermultiplesubtypes.

AQ000086455681en-010402

©Danfoss|2021.02|47

Page 48

OperatingGuideECLComfort310,applicationA361

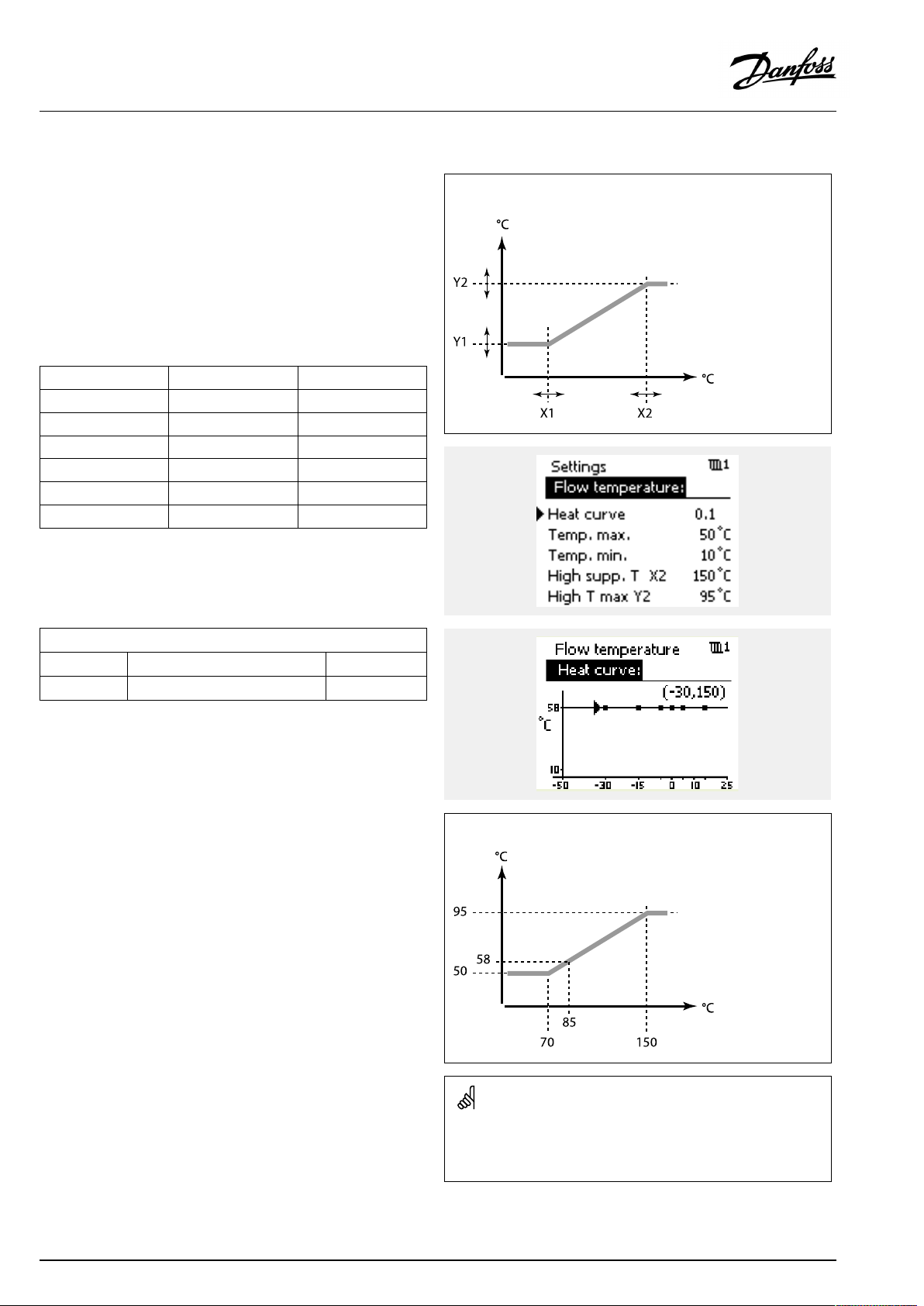

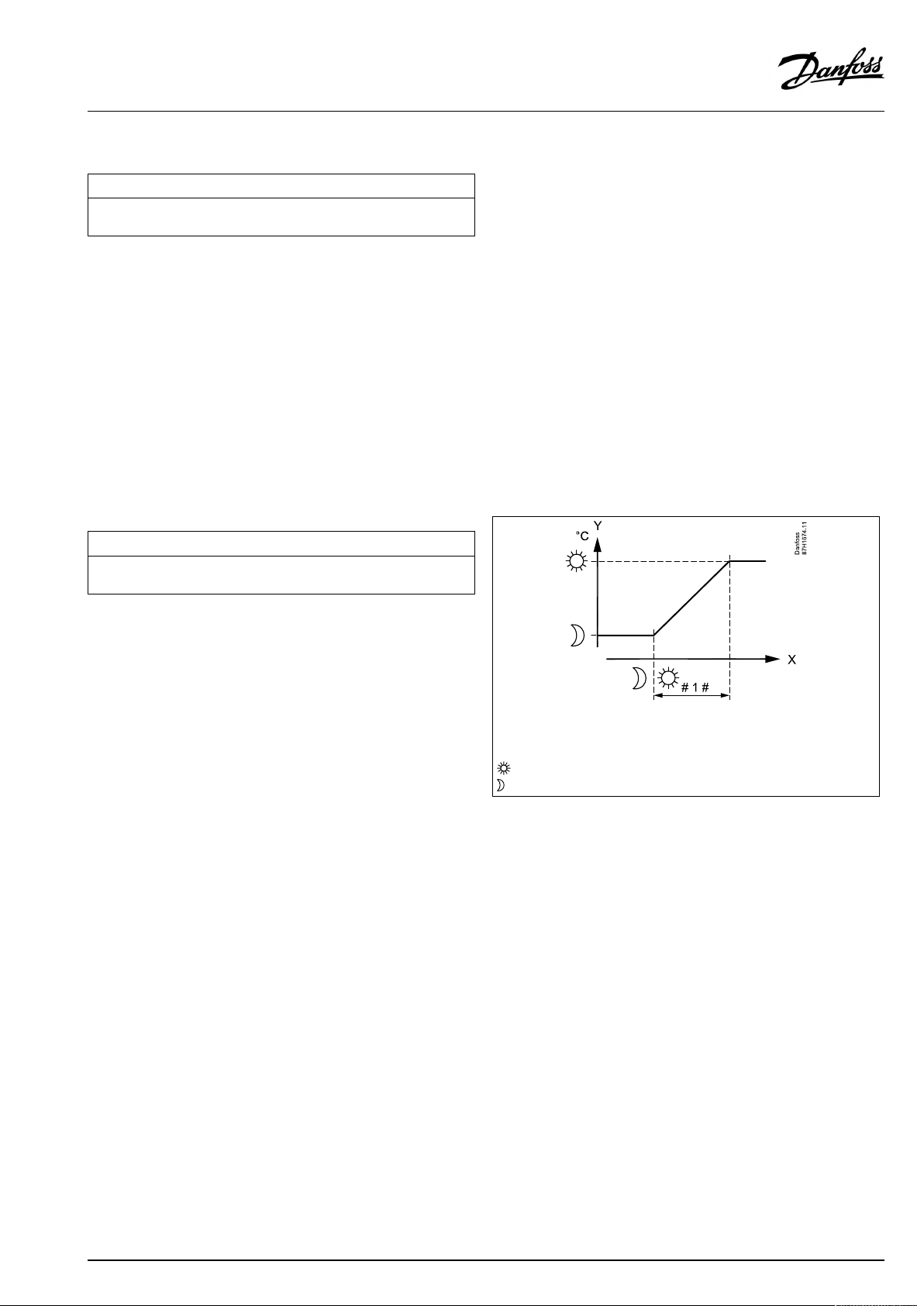

5.2Flowtemperature

TheECLComfortcontrollerdeterminesandcontrolstheflow

temperaturerelatedtotheoutdoortemperature.Thisrelationship

iscalledtheheatcurve.

Theheatcurveissetbymeansof6coordinatepoints.Thedesired

flowtemperatureissetat6pre-definedoutdoortemperature

values.

Theshownvaluefortheheatcurveisanaveragevalue(slope),

basedontheactualsettings.

Desiredflowtemperature

Outdoor

temp.

Desiredflowtemp.

A

BC

Your

settings

-30°C45°C75°C95°C

-15°C40°C60°C90°C

-5°C35°C50°C80°C

0°C32°C45°C70°C

5°C30°C40°C60°C

15°C25°C28°C35°C

A:Exampleforfloorheating

B:Factorysettings

C:Exampleforradiatorheating(highdemand)

MENU>Settings>Flowtemperature

Heatcurve

1

0.1...4.01.0

Theheatcurvecanbechangedintwoways:

1.Thevalueoftheslopeischanged(seeheatcurveexamples

onnextpage)

2.Thecoordinatesoftheheatcurvearechanged

Changethevalueoftheslope:

Pushthedialtoenter/changetheslopevalueoftheheatcurve

(example:1.0).

Whentheslopeoftheheatcurveischangedbymeansoftheslope

value,thecommonpointforallheatcurveswillbeadesiredflow

temperature=24.6°Catanoutdoortemperature=20°Canda

desiredroomtemperature=20.0°C.

Slopechanges

Coordinatechanges

Changethecoordinates:

Pushthedialtoenter/changethecoordinatesoftheheatcurve

(example:-30,75).

Theheatcurverepresentsthedesiredflowtemperaturesat

differentoutdoortemperaturesandatadesiredroomtemperature

of20°C.

Ifthedesiredroomtemperatureischanged,thedesiredflow

temperaturealsochanges:

(DesiredroomT-20)×HC×2.5

where"HC"istheHeatCurveslopeand"2.5"isaconstant.

48|©Danfoss|2021.02

Thecalculatedflowtemperaturecanbeinfluencedbythe‘Boost’and

‘Ramp’functionsetc.

Example:

Heatcurve:

Desiredflowtemp.:

Desiredroomtemp.:

Calculation(22–20)×1.0×2.5=

Result:

Thedesiredflowtemperaturewillbecorrectedfrom50°Cto55°C.

1.0

50°C

22°C

5

AQ000086455681en-010402

Page 49

OperatingGuideECLComfort310,applicationA361

Choosingaheatcurveslope

Theheatcurvesrepresentthedesiredflowtemperatureatdifferentoutdoortemperaturesandatadesiredroomtemperatureof20°C.

Thesmallarrows()indicate6differentoutdoortemperaturevaluesatwhichyoucanchangetheheatcurve.

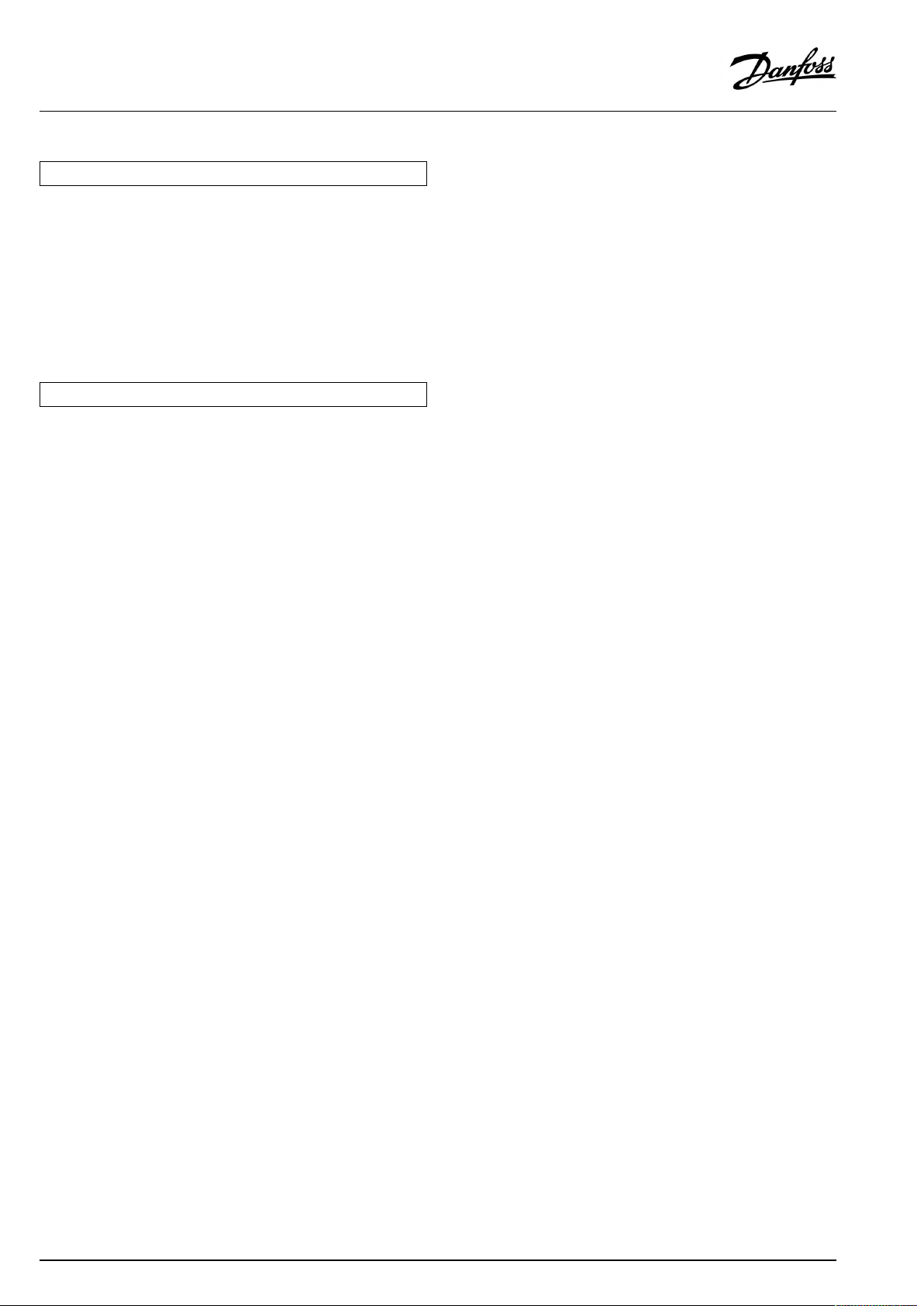

Max.limitationofthedesiredflowtemperature:

IntheapplicationA361.1themax.limitationvalueisselectable

in‘Temp.max. ’ .

Max.limitationofthedesiredflowtemperature:

IntheapplicationA361.2thedesiredflowtemperatureormax.

limitationvaluedependsonthesupplytemperature(S2).The

relationshipissetinthefoursettings‘Highsupp.TX2’ ,‘HighTmax

Y2’ ,‘LowsupplyTX1’and‘LowTmaxY1’ .

Whensettingtheheatcurvecoordinatesasdescribedinthe

section'A361.1’ ,thedesiredflowtemperaturecanbelimitedtoa

maximumaccordingtothesupplytemperature(S2).

AQ000086455681en-010402

©Danfoss|2021.02|49

Page 50

OperatingGuideECLComfort310,applicationA361

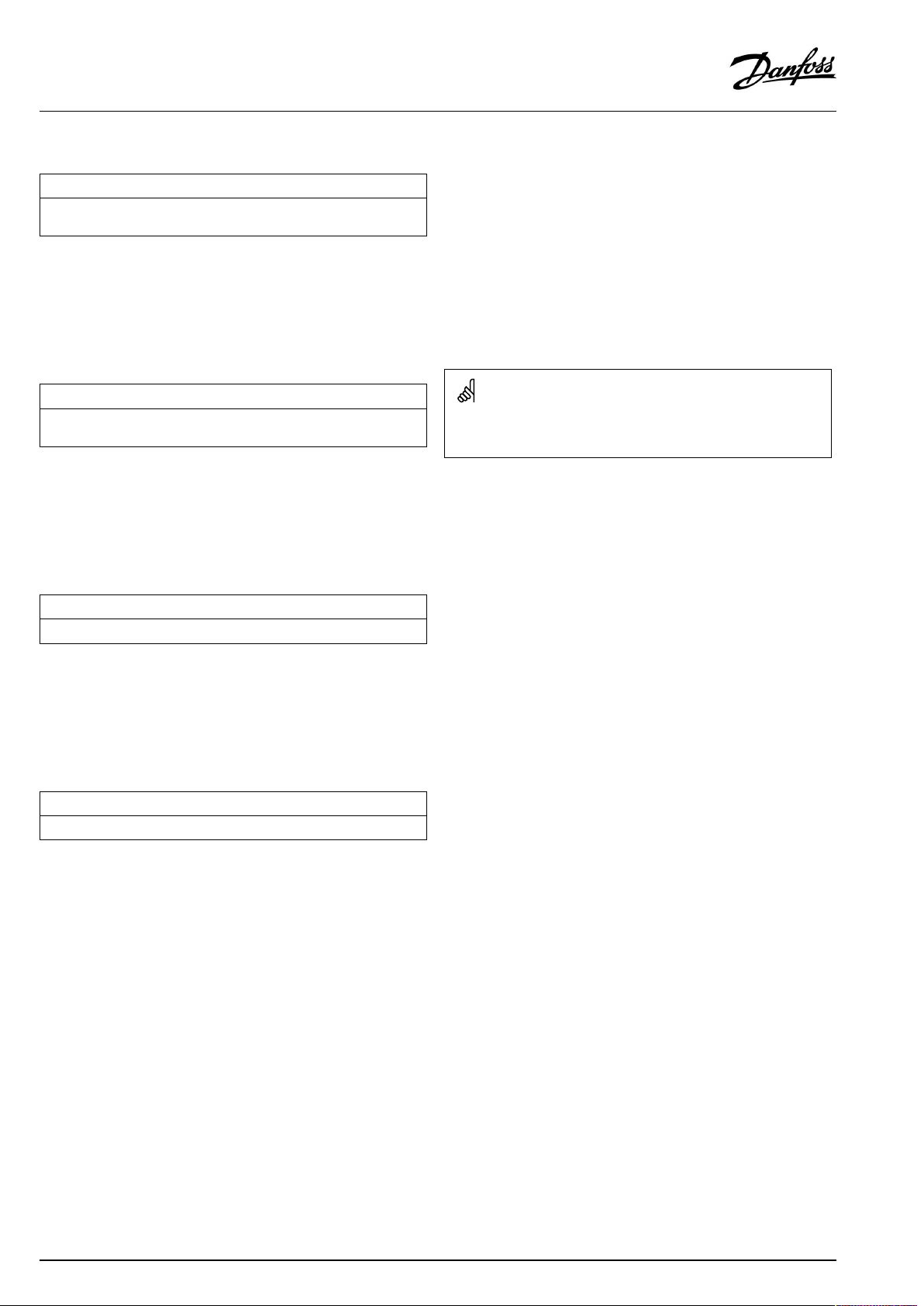

5.2.1A361.2

TheECLComfortcontrollerdeterminesandcontrolstheflow

temperaturerelatedtothesupplytemperature(S2).This

relationshipissetinthecontroller.

Theheatcurveissetinallcoordinatepointstothemax.desired

flowtemperature(150°C).Thedesiredflowtemperaturewill

alwaysbeinrelationtothesupplytemperature(S2).

Theshownvaluefortheheatcurveisanaveragevalue(slope),

basedontheactualsettings.

Outdoortemp.

FactorysettingY oursettings

-30°C150°C

-15°C150°C

-5°C150°C

0°C150°C

5°C150°C

15°C150°C

Adjustthedesiredflowtemperatureat-30,-15,-5,0,5,and15°C,

ifrequired.

MENU>Settings>Flowtemperature

Desiredflowtemperature

Supplytemp.(S2)

Heatcurve

CircuitSettingrange

1

Read-outonly

Factorysetting

Thefactorysetting(ageneraldesiredflowtemperatureof150°C)is

limitedtoamax.valuebasedonthesupplytemperature(S2)and

thesettingsinparameters‘Highsupp.TX2’ ,‘HighTmaxY2’ ,‘Low

supplyTX1’and‘LowTmaxY1’ .

Desiredflowtemperature

Supplytemp.(S2)

50|©Danfoss|2021.02

Theaboveheatcurveisanexampleofasupplytemperature(S2)of

85°C.Thedesiredflowtemperature(58°C)isbasedontheset-upof

therelationshipbetweenthesupplytemperature(S2)andthedesired

flowtemperature.

AQ000086455681en-010402

Page 51

OperatingGuideECLComfort310,applicationA361

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

MENU>Settings>Flowtemperature

Temp.min.

1x177

SeeAppendix“ParameterIDoverview”

Setthemin.flowtemperatureforthesystem.Thedesiredflow

temperaturewillnotbelowerthanthissetting.Adjustthefactory

setting,ifrequired.

MENU>Settings>Flowtemperature

Temp.max.

1x178

SeeAppendix“ParameterIDoverview”

Setthemax.flowtemperatureforthesystem.Thedesired

temperaturewillnotbehigherthanthissetting.Adjustthefactory

setting,ifrequired.

MENU>Settings>Flowtemperature

Highsupp.TX2(highvalueofsupplytemp.)

1x300

‘Temp.min.’isoverruledif'Totalstop'isactiveinSavingmodeor

'Cut-out'isactive.

‘Temp.min.’canbeoverruledbytheinfluencefromthereturn

temperaturelimitation(see'Priority').

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

Thesettingof‘heatcurve’ispossibleforheatingcircuitsonly.

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

SeeAppendix“ParameterIDoverview”

Setthehighvalueforthesupplytemperatureinrelationtothe

desiredmax.flowtemperature.Whenthesupplytemperatureis

abovethesetvalue,themax.limitationoftheflowtemperatureis

theY2value.Whenthesupplytemperatureisbelowthesetvalue,

themax.limitationoftheflowtemperaturewillbelower.

MENU>Settings>Flowtemperature

HighTmaxY2(highvalueofmaxlimitation)

1x301

SeeAppendix“ParameterIDoverview”

Setthehighvalueforthemax.limitationofthedesiredflow

temperature.

AQ000086455681en-010402

©Danfoss|2021.02|51

Page 52

OperatingGuideECLComfort310,applicationA361

MENU>Settings>Flowtemperature

LowsupplyTX1(lowvalueofsupplytemp.)

1x302

SeeAppendix“ParameterIDoverview”

Setthelowvalueforthesupplytemperatureinrelationtothe

desiredmax.flowtemperature.Whenthesupplytemperatureis

belowthesetvalue,themax.limitationoftheflowtemperatureis

theY1value.Whenthesupplytemperatureisabovethesetvalue,

themax.limitationoftheflowtemperaturewillbehigher.

MENU>Settings>Flowtemperature

LowTmaxY1(lowvalueofmaxlimitation)

1x303

SeeAppendix“ParameterIDoverview”

Setthelowvalueforthemax.limitationofthedesiredflow

temperature.

52|©Danfoss|2021.02

AQ000086455681en-010402

Page 53

OperatingGuideECLComfort310,applicationA361

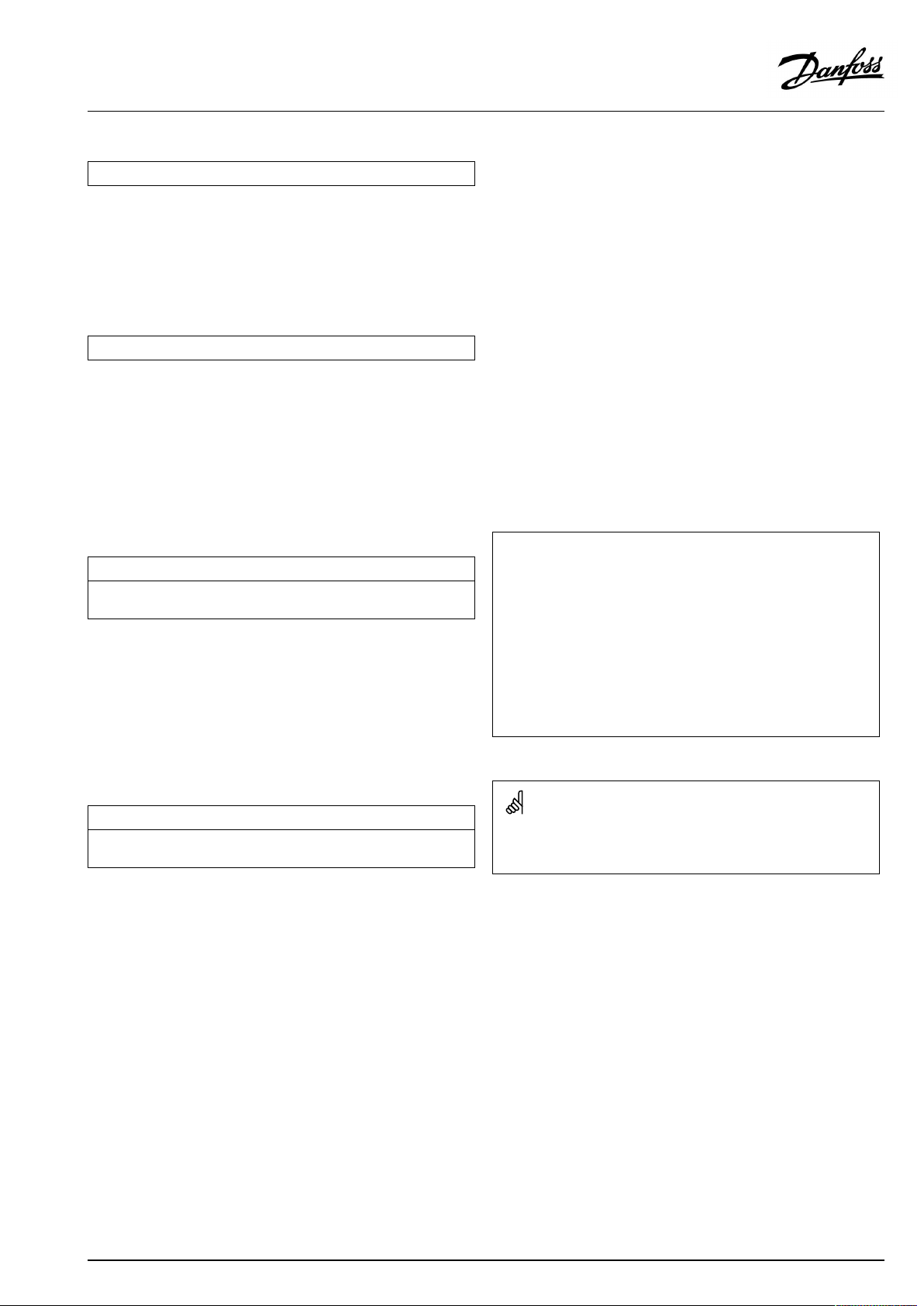

5.3Returnlimit

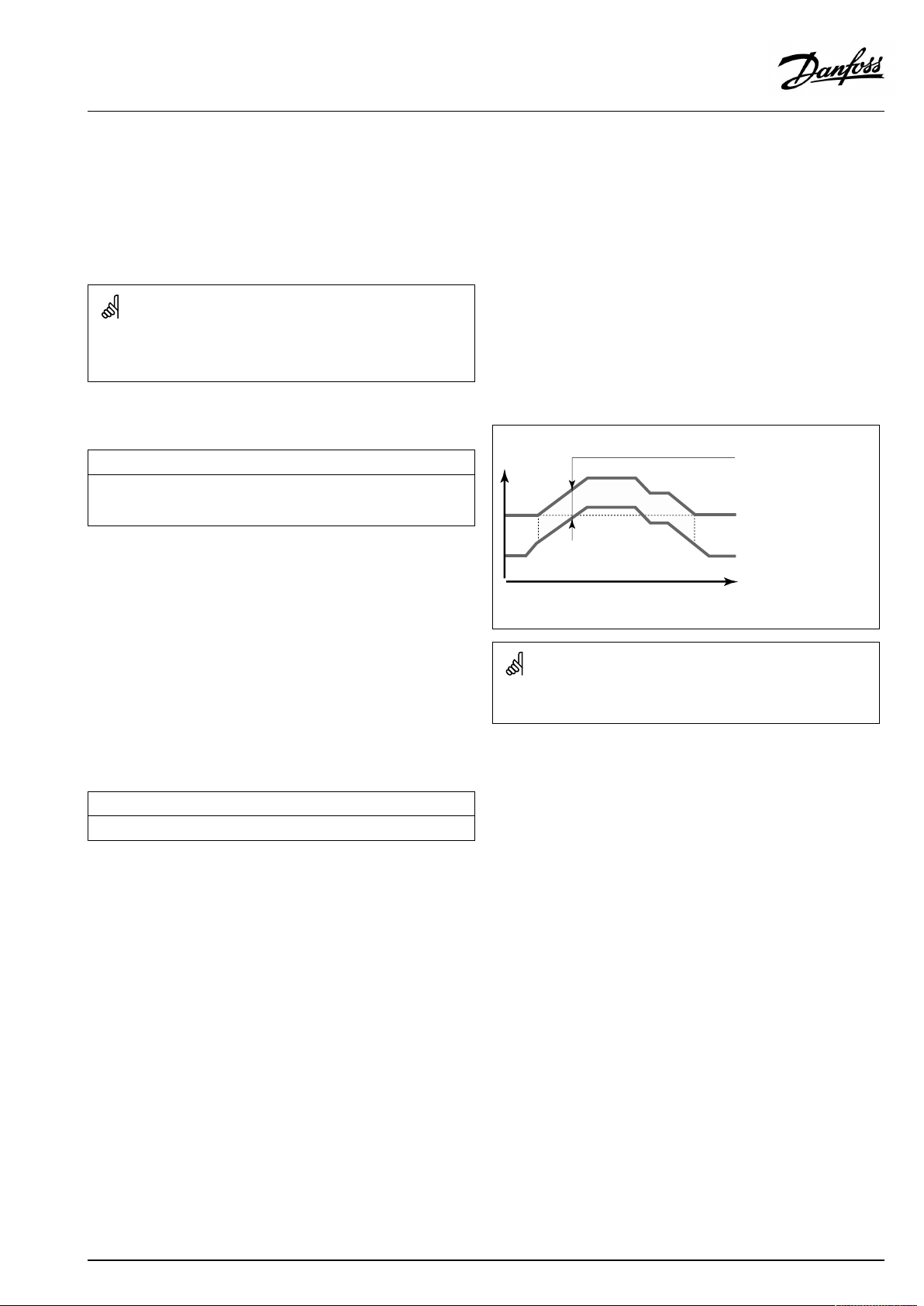

Thereturntemperaturelimitationisbasedontheoutdoor

temperature.Typicallyindistrictheatingsystemsahigherreturn

temperatureisacceptedatadecreaseinoutdoortemperature.The

relationshipbetweenthereturntemperaturelimitsandoutdoor

temperatureissetintwocoordinates.

Theoutdoortemperaturecoordinatesaresetin'HighToutX1'

and'LowToutX2' .Thereturntemperaturecoordinatesaresetin

'HighlimitY2'and'LowlimitY1' .

Thecontrollerautomaticallychangesthedesiredflowtemperature

toobtainanacceptablereturntemperaturewhenthereturn

temperaturefallsbeloworgetshigherthanthecalculatedlimit.

ThislimitationisbasedonaPIregulationwhereP('Infl.'factor)

respondsquicklytodeviationsandI('Adapt.time')responds

slowerandovertimeremovesthesmalloffsetsbetweenthe

desiredandactualvalues.Thisisdonebychangingthedesired

flowtemperature.

X

Y

#X1#

#X2#

#Y1#

#Y2#

=

Outdoortemperature

=

Limitationtemperature

=

HighTout(1x031)

=

LowTout(1x033)

=

Lowlimit(1x032)

=

Highlimit(1x034)

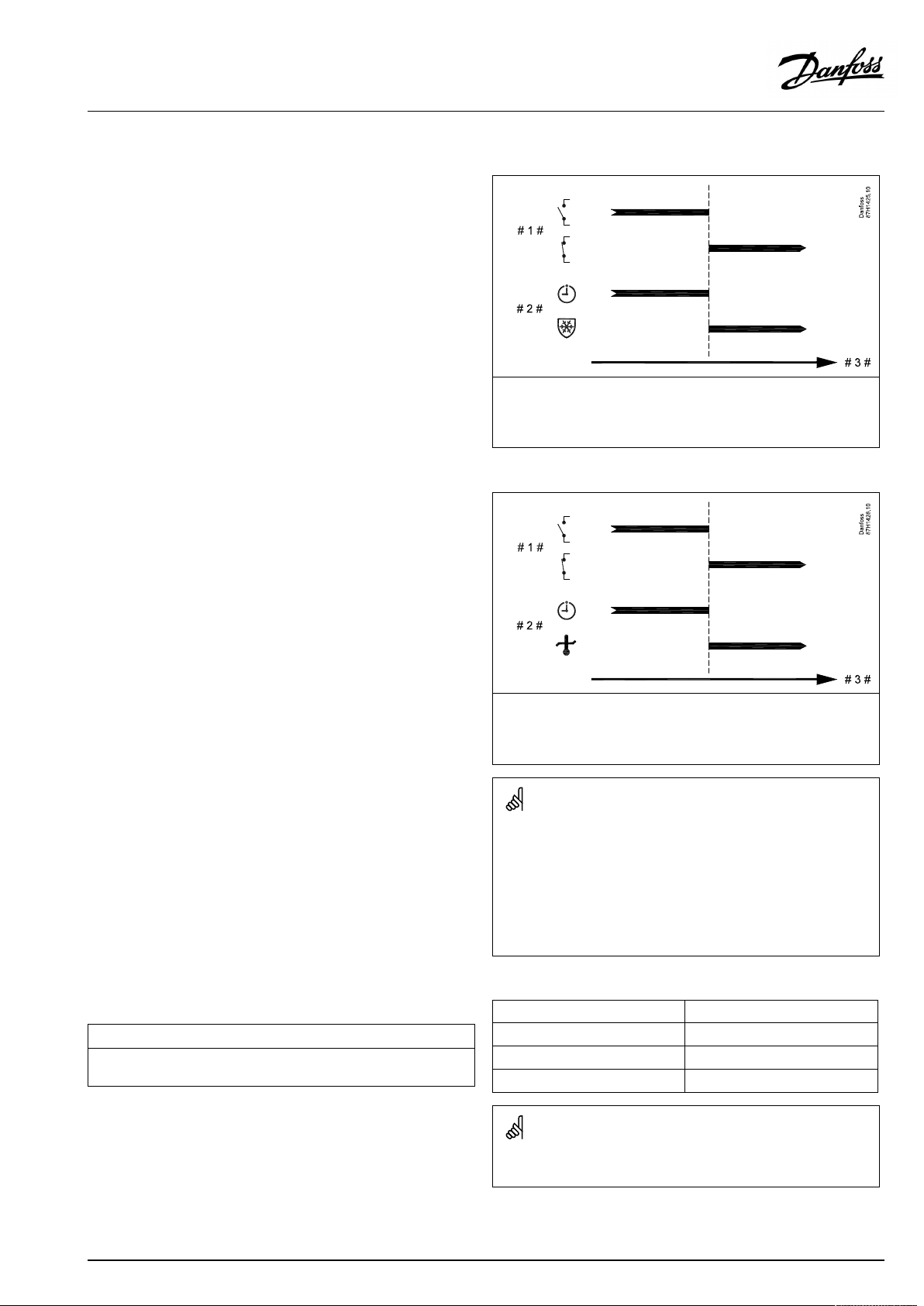

Example,maximumreturntemperaturelimitation;

returntemperaturegetshigherthanlimit

Thecalculatedlimitisshowninbrackets()inthemonitoringdisplay.

Seethesection"Monitoringtemperaturesandsystemcomponents" .

=

T

Temperature

=

Y

Temperature

=

X

Time

=

#1#

Returntemperature

=

#2#

Returntemperaturelimit

=

#3#

Desiredflowtemperature

=

#4#

Actionpoint

AQ000086455681en-010402

©Danfoss|2021.02|53

Page 54

OperatingGuideECLComfort310,applicationA361

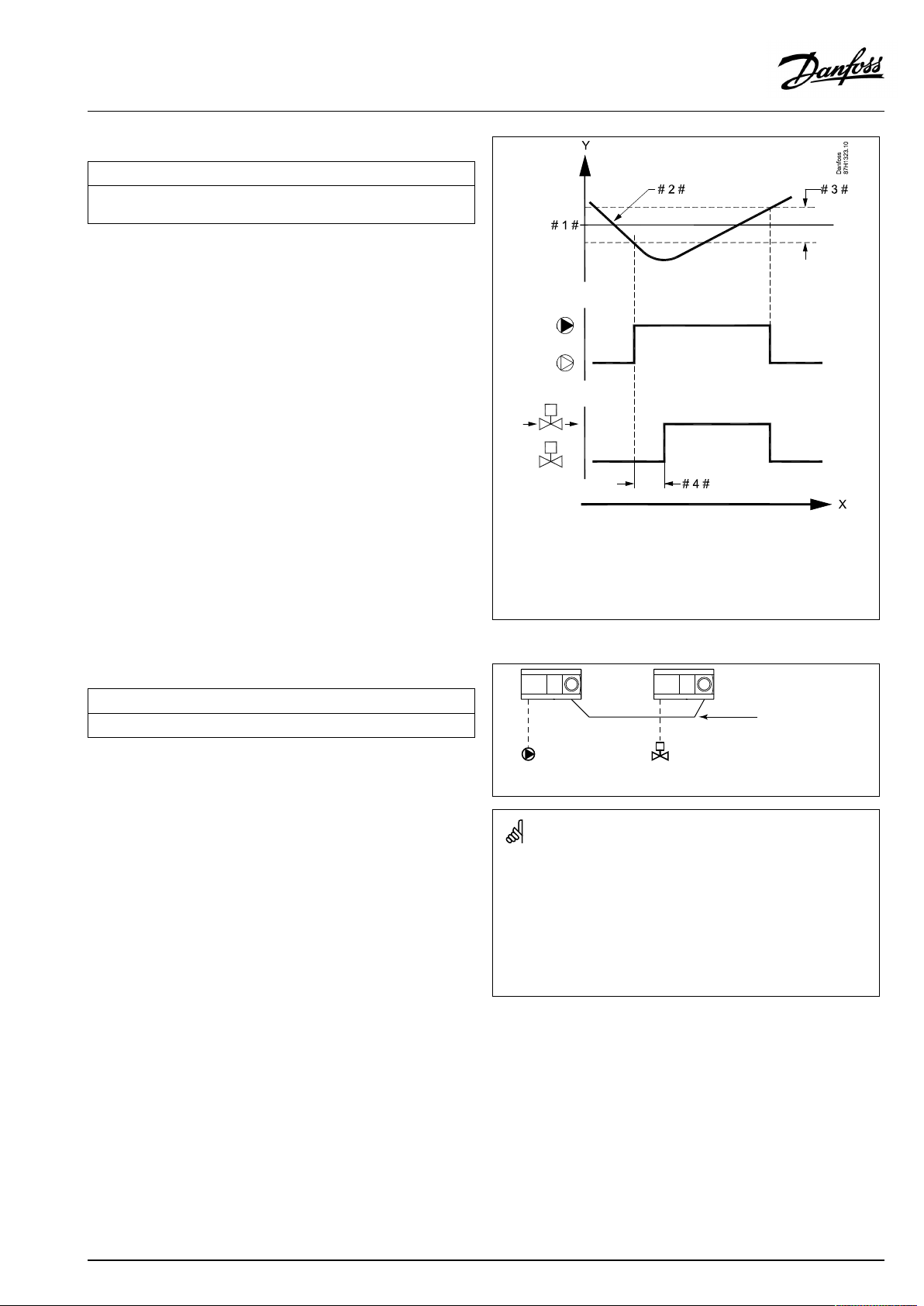

Example,minimumreturntemperaturelimitation;

returntemperaturegetslowerthanlimit

=

T

Y

X

#1#

#2#

#3#

#4#

Temperature

=

Temperature

=

Time

=

Returntemperature

=

Returntemperaturelimit

=

Desiredflowtemperature

=

Actionpoint

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

MENU>Settings>Returnlimit

HighToutX1(returntemp.limitation,highlimit,X-axis)

Settheoutdoortemperaturevalueforthelowreturntemperaturelimitation.

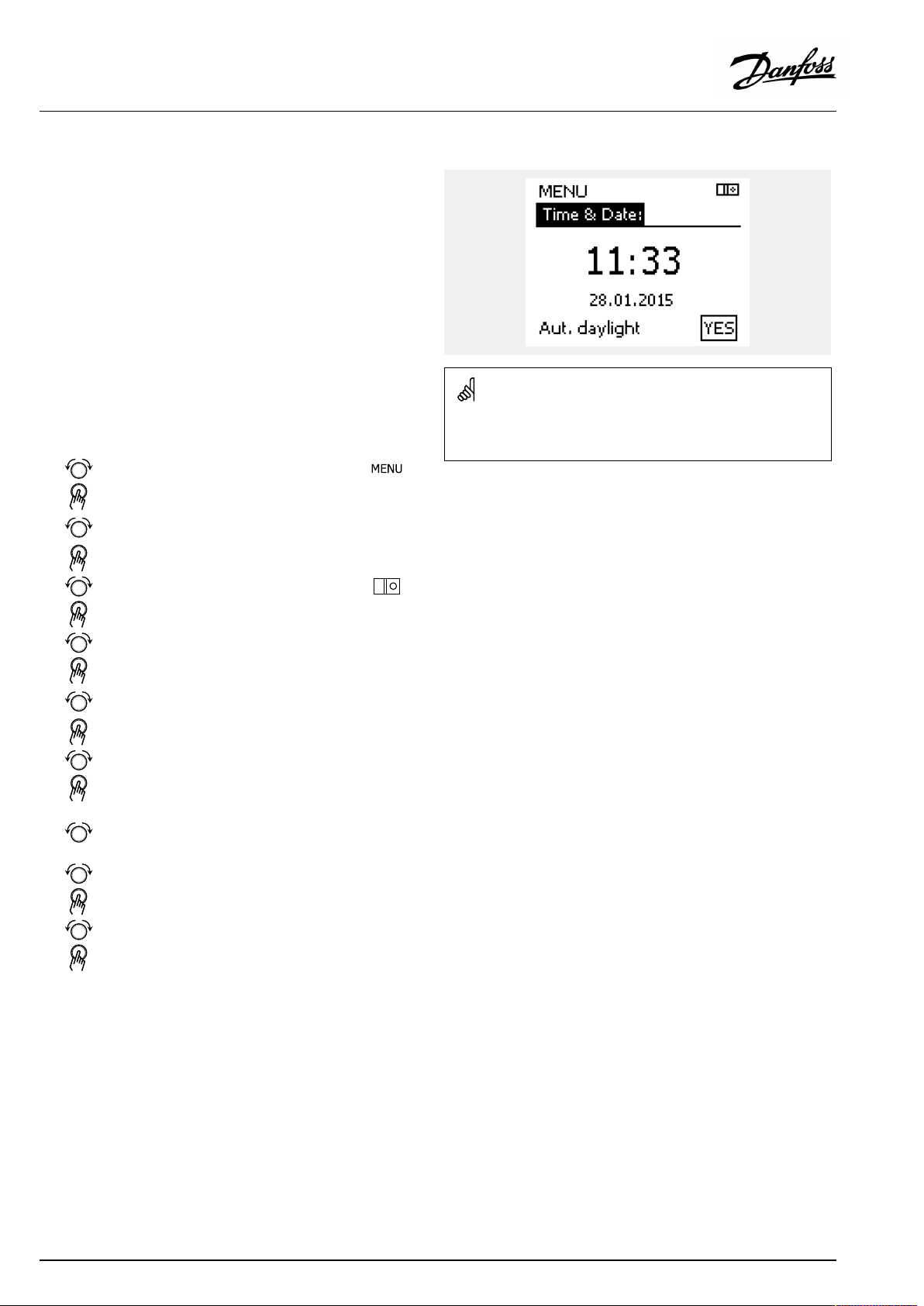

SeeAppendix“ParameterIDoverview”