Page 1

OperatingGuide

ECLComfort310,applicationA319

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................6

2.1Beforeyoustart.....................................................6

2.2Identifyingthesystemtype.......................................9

2.3Mounting...........................................................11

2.4Placingthetemperaturesensors................................15

2.5Electricalconnections.............................................17

2.6InsertingtheECLApplicationKey..............................28

2.7Checklist............................................................35

2.8Navigation,ECLApplicationKeyA319.........................36

3.0Dailyuse.........................................................40

3.1Howtonavigate...................................................40

3.2Understandingthecontrollerdisplay..........................41

3.3Ageneraloverview:Whatdothesymbolsmean?...........44

3.4Monitoringtemperaturesandsystem

components........................................................45

3.5Influenceoverview................................................46

3.6Manualcontrol.....................................................47

3.7Schedule............................................................48

4.0Settingsoverview............................................49

5.0Settings...........................................................51

5.1IntroductiontoSettings..........................................51

5.2Flowtemperature..................................................52

5.3Returnlimit.........................................................55

5.4Controlparameters................................................59

5.5Application.........................................................65

5.6Tanktemperature..................................................72

5.7Alarm................................................................75

5.8Alarmoverview....................................................78

7.0Miscellaneous..................................................95

7.1ECA30/31setupprocedures...................................95

7.2Overridefunction................................................103

7.3Severalcontrollersinthesamesystem......................106

7.4Frequentlyaskedquestions....................................109

7.5Definitions........................................................112

7.6Type(ID6001),overview.......................................116

7.7Automatic/manualupdateoffirmware.....................117

7.8ParameterIDoverview..........................................118

6.0Commoncontrollersettings..............................79

6.1Introductionto‘Commoncontrollersettings’................79

6.2Time&Date.........................................................80

6.3Holiday..............................................................81

6.4Inputoverview.....................................................83

6.5Log...................................................................84

6.6Outputoverride....................................................85

6.7Keyfunctions.......................................................86

6.8System...............................................................88

©Danfoss|2021.06AQ152886470424en-010601|1

Page 2

OperatingGuideECLComfort310,applicationA319

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwiththeECLApplicationKey

A319(codeno.087H3831)

TheECLApplicationKeyA319containstwosubtypes:

•A319.1:Heatingsupply,directlyfrombuffer

•A319.2:asA319.1,butwithmixingcircuitafterthebuffer

SeetheInstallationGuideforelectricalconnections.

ThedescribedfunctionsarerealizedinECLComfort310whichalso

allowsM-bus,ModbusandEthernet(Internet)communication.

TheApplicationKeyA319complieswithECLComfort310

controllersasofsoftwareversion1.11(visibleatstart-upofthe

controllerandin'Commoncontrollersettings'in'System').

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connected.

TheapplicationA319workswithadditionalInternalI/Omodules:

•TheextensionmoduleECA32gives0-10Voltsignalforspeed

controlofchargingandcirculationpumps

•TheextensionmoduleECA35gives0-10Voltsignalforspeed

controlofchargingandcirculationpumps.ECA35canalso

givePWM*signalforspeedcontrolofchargingandcirculation

pumps.

TheECLComfort310workswitheitheroneECA32oroneECA

35.TheInternalI/Omoduleinquestionisplacedinthebasepart

oftheECLComfort310.

*PWM=PulseWidthModulation

TogetherwiththeECLComfort310theadditionalInternalI/O

modulescanalsobeusedforextradatacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLTool".

Navigation:Danfoss.com>Products&Solutions>DistrictHeating

andCooling>T ools&Software>ECLTool.

TheURLis:

https://www.danfoss.com/en/service-and-support/downloads

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(codeno.087H3040)

•ECLComfort310B,230volta.c.(codeno.087H3050)

•ECLComfort310,24volta.c.(codeno.087H3044)

TheB-typehasnodisplayanddial.

TheB-typeisoperatedbymeansoftheremotecontrolunit

ECA30/31:

•ECA30(codeno.087H3200)

•ECA31(codeno.087H3201)

2|©Danfoss|2021.06

AQ152886470424en-010601

Page 3

OperatingGuideECLComfort310,applicationA319

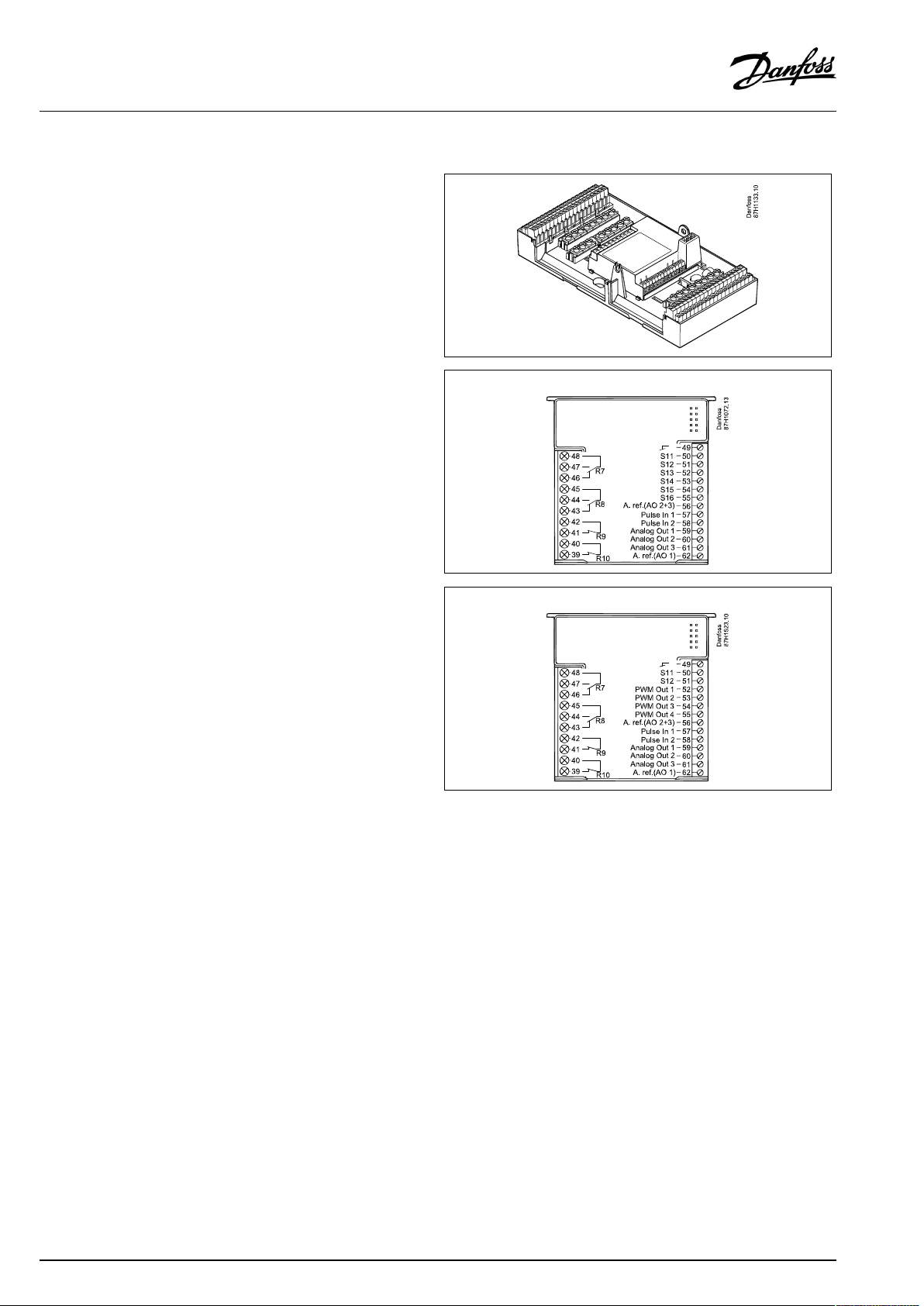

InternalI/Omodules:

•ECA32(codeno.087H3202)

•ECA35(codeno.087H3205)

BasepartforECLComfort310,230voltand24volt:(codeno.

087H3230).

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://danfoss.com/.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

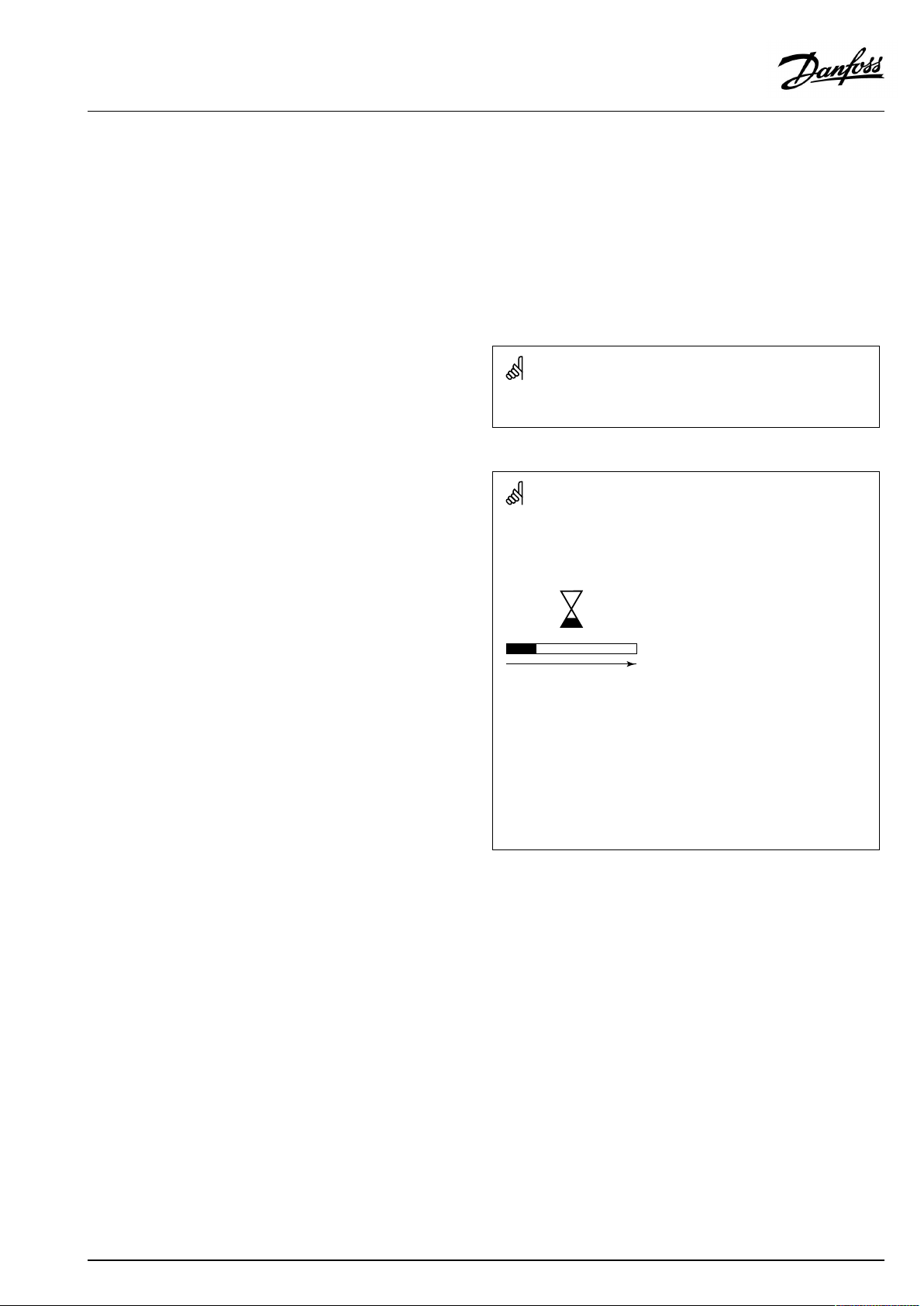

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

AQ152886470424en-010601

©Danfoss|2021.06|3

Page 4

OperatingGuideECLComfort310,applicationA319

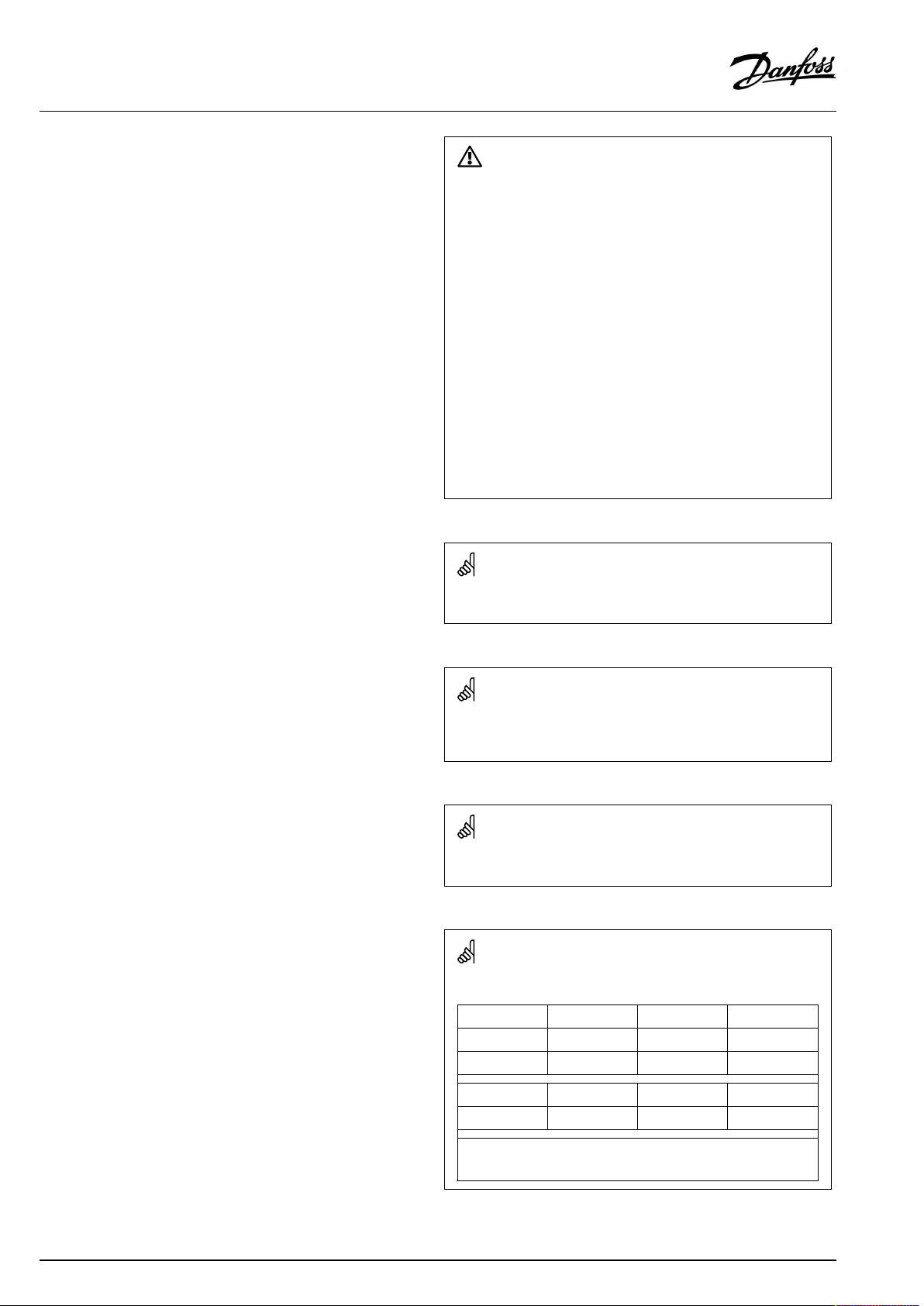

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1Parameterno.

4|©Danfoss|2021.06

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

2

Circuit2Parameterno.

174

AQ152886470424en-010601

Page 5

OperatingGuideECLComfort310,applicationA319

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thissymbolontheproductindicatesthatitmaynot

bedisposedofashouseholdwaste.

Itmustbehandedovertotheapplicabletake-back

schemefortherecyclingofelectricalandelectronic

equipment.

•Disposeoftheproductthroughchannelsprovided

forthispurpose.

•Complywithalllocalandcurrentlyapplicablelaws

andregulations.

AQ152886470424en-010601

©Danfoss|2021.06|5

Page 6

OperatingGuideECLComfort310,applicationA319

2.0Installation

2.1Beforeyoustart

TheECLapplicationkeyA319contains2subtypes:A319.1and

A319.2.

Theseheatingbasedapplicationsareveryflexible.

ThebasicprinciplesforapplicationA319.1:

Temperaturecontrolofbuffer

ThebuffertemperatureS6isadjustedaccordingtoyour

requirements.ThesupplytemperaturesensorS2,thebuffer

temperaturesensorsS6andS8andthechargingtemperature

sensorS3arethemostimportantsensorsandmustbeconnected.

ThedesiredbuffertemperatureatS6iscalculatedintheECL

controller,basedonthedemandfromtheheatingcircuit

(consumer).ThisdemandisaresultoftheoutdoortemperatureS1,

theheatcurveandadesiredroomtemperature.Acompensation

fortheheatlossbetweenbuffertankandconsumercanbeset

as"Demandoffset" .

ThechargingtemperatureatS3isbasedonthedesiredbuffer

temperatureatS6andachargingdifference.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

buffertemperature'+'Startdifference').

Anexample:60°C+(-7)=53°C

2.X1isswitchedON

3.M1opensinordertoincreasethesupplytemperatureS2

4.P2isswitchedONwhensupplytemperatureS2getshigher

than('Desiredbuffertemperature'+'Pumpstartdiff. ').

Example:60°C+3K=63°C

V2startswithminimumspeed,forexample20%

5.M1controlsthechargingtemperatureatS3

6.V2increasesthespeedaslongasthechargingtemperatureis

equaltothedesiredchargingtemperature.

Stopbufferchargingprocess:

1.BuffertemperatureS6temperaturegetshigherthan('Desired

buffertemperature'+'Startdifference)

AND

LowerbuffertemperatureS8getshigherthan('Desiredbuffer

temperature'+'Stopdifference).

Anexample:S6temperaturehigherthan(60°C+(-7)=53°C)

AND(60°C+(-4)=56°C)

2.P2isswitchedOFF ,respecting'Char.Ppost-run'.V2changes

to0%.

NOTE:Post-runisnotrespectedifchargingtemperatureS3islower

thandesiredchargingtemperature.

3.X1isswitchedOFF

4.M1closesormaintainsthedesiredtemperatureatS3.

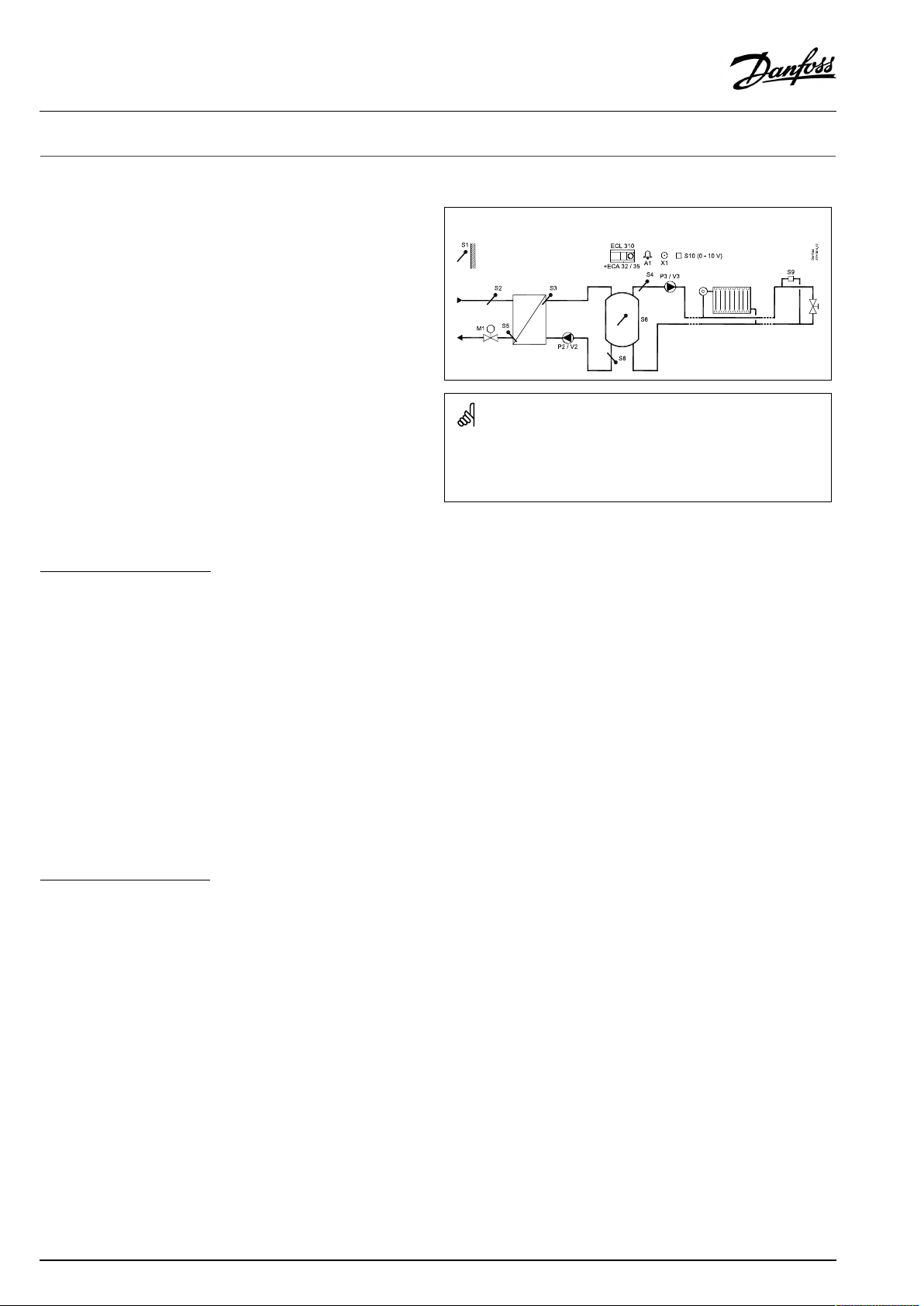

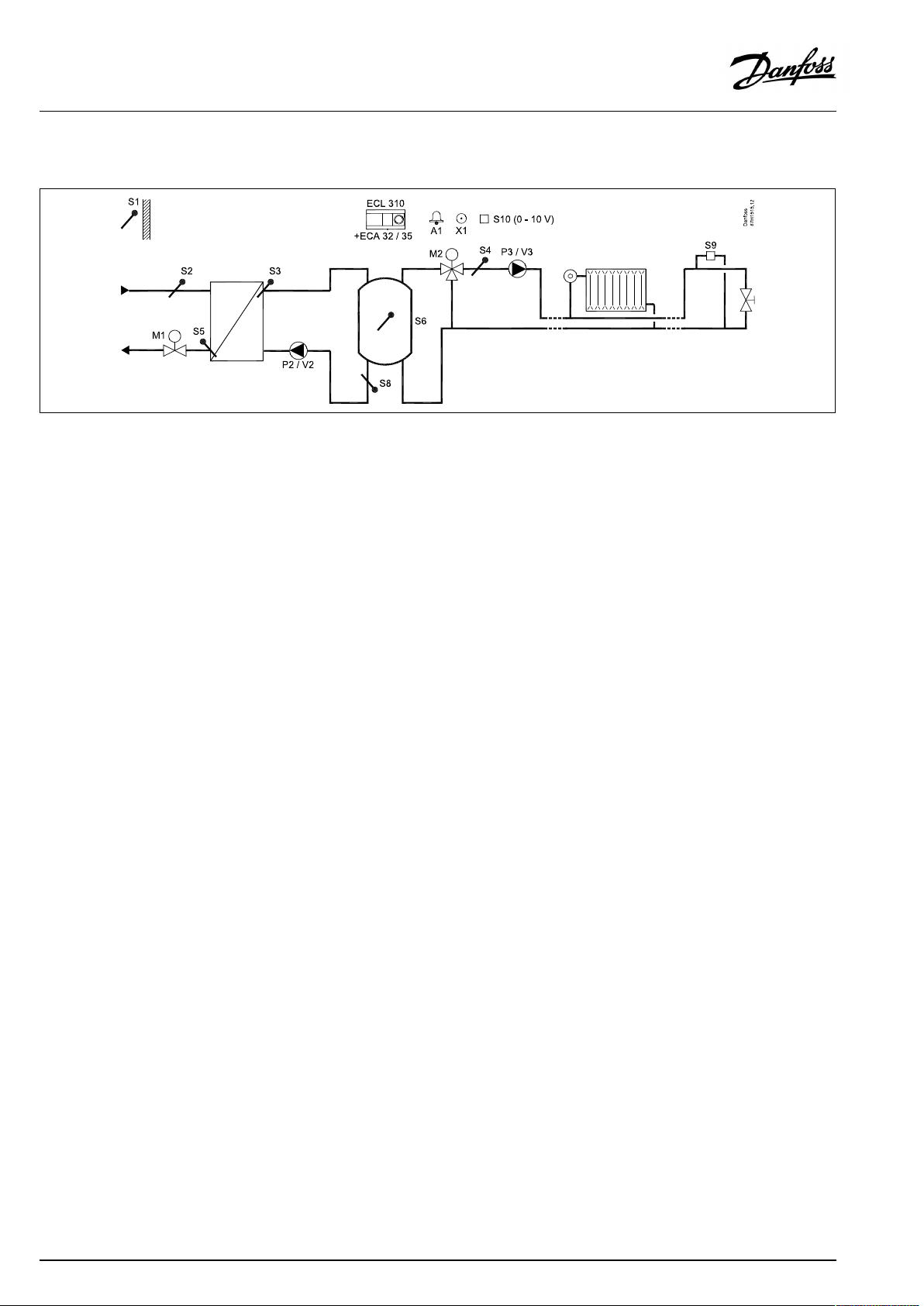

TypicalA319.1application:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

S1

S2

S3

S4

S5Returntemperaturesensor

S6

S7

S8

S9

S10

P2

V2

P3

V3

M1

X1

A1

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

Outdoortemperaturesensor

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(monitoringonly)Flowtemperaturesensor

(mandatory)Upperbuffertemperaturesensor

notused

(mandatory)Lowerbuffertemperaturesensor

Pressuredifferencetransmitter(0-10V)

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

Motorizedcontrolvalve(3-pointcontrolled)

Heatdemandsignal

Alarm

6|©Danfoss|2021.06

AQ152886470424en-010601

Page 7

OperatingGuideECLComfort310,applicationA319

Bymeansofaweekschedule,thecircuitcanbein‘Comfort’or

‘Saving’mode(twovaluesforthedesiredroomtemperature).In

'Saving'modetheheatingcanbereducedorswitchedofftotally.

Themotorizedcontrolvalve(M1)isopenedgraduallywhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredchargingtemperatureatS3canbe

adjusted(typicallytoalowervalue);thisresultsinagradualclosing

ofthemotorizedcontrolvalve.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

TheON-OFFoutputX1isONatheatingdemand.

ThecirculationpumpP3isONatheatingdemandoratfrost

protection.

Unusedinputcan,bymeansofanoverrideswitchorrelaycontact,

beusedforoverridingthescheduletoafixed'Comfort' ,'Saving',

'Frostprotection'or'Constanttemperature'mode.

UptotwoRemoteControlUnits,ECA30/31canbeconnectedto

oneECLcontrollerinordertocontroltheECLcontrollerremotely.

The'Frostprotection'modemaintainsaselectabletemperature,

forexample10°C.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485businordertoutilizecommonoutdoortemperaturesignal,

timeanddatesignals.TheECLControllersintheECL485bus

systemcanworkasmasterandslaves.

AlarmA1(=relay6)canbeactivatedif:

•theactualchargingtemperaturediffersfromthedesiredcharge

temperature

•thesupplytemperaturedoesnotreachthenecessarylevel

•atemperaturesensororitsconnectiondisconnects/short

circuits.(See:Commoncontrollersettings>System>Raw

inputoverview)

Pressuredifferencecontrol(optional):

ThecirculationpumpP3/V3can,asanalternativetoON-OFF

control,bespeedcontrolledbymeansofa0-10voltsignalora

PWMsignal.ThedesiredpressuredifferenceatS9canbesetforthe

speedcontrolprocedure.

AQ152886470424en-010601

©Danfoss|2021.06|7

Page 8

OperatingGuideECLComfort310,applicationA319

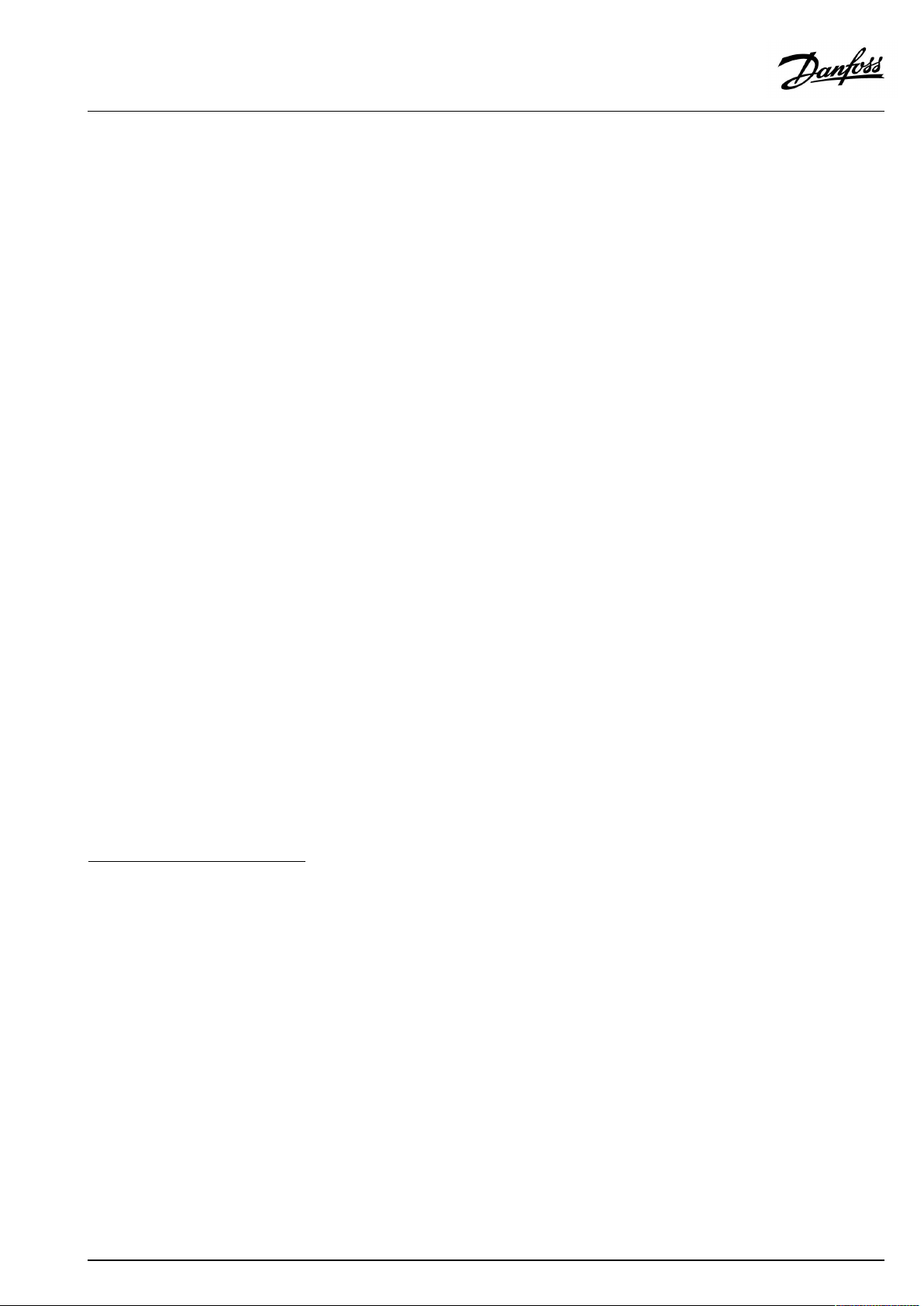

ThebasicprinciplesforapplicationA319.2:

TheapplicationA319.2workslikeA319.1andwiththeseadditional

features:

Themotorizedcontrolvalve(M2)isopenedgraduallywhenthe

flowtemperatureS4islowerthanthedesiredflowtemperature

andviceversa.

TypicalA319.2application:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S1

S2

S3

S4

Outdoortemperaturesensor

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(mandatory)Flowtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S10

P2

V2

P3

V3

(mandatory)Upperbuffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

Pressuredifferencetransmitter(0-10V)

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

M2

X1

A1

Motorizedcontrolvalve(3-pointcontrolled)

Motorizedcontrolvalve(3-pointcontrolled)

Heatdemandsignal

Alarm

8|©Danfoss|2021.06

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

AQ152886470424en-010601

Page 9

OperatingGuideECLComfort310,applicationA319

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Thecirculationpump(s)inheatingcircuit(s)canbeplacedintheflow

aswellasthereturn.Placethepumpaccordingtothemanufacturer’s

specification.

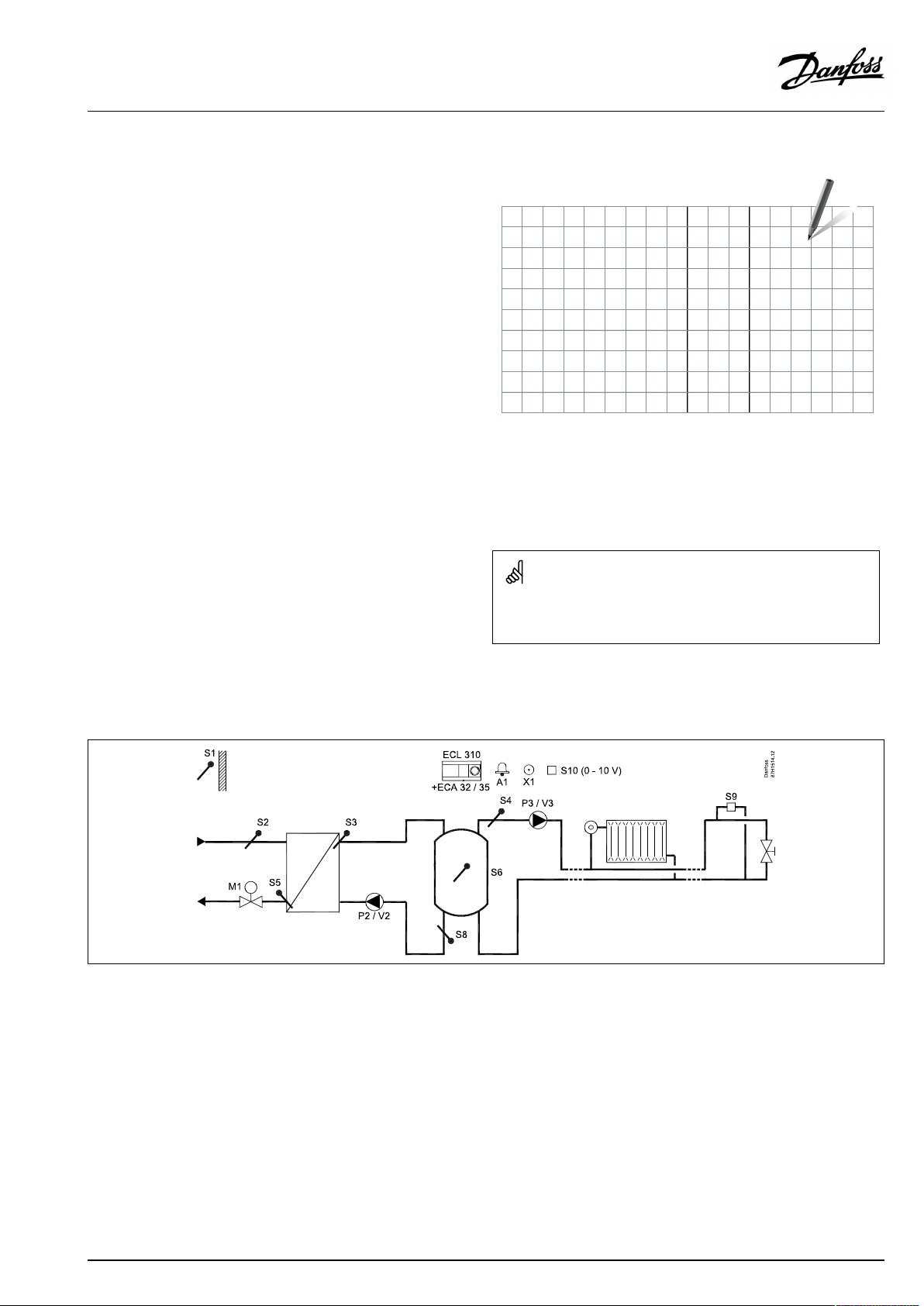

A319.1,ex.a

Chargingcontrolofbuffertemperatureandheatingsupplydirectlyfrombuffer.Controlofpressuredifference.

Sensoradvice:

SensorS3,S6andS8mustbeconnected.Ifnot,thechargingprocesswillnotwork.

IfpressuredifferencesensorS9isnotconnected,thespeedcontrolofP3/V3isnotinaction.

AQ152886470424en-010601

©Danfoss|2021.06|9

Page 10

OperatingGuideECLComfort310,applicationA319

A319.2,ex.a

Chargingcontrolofbuffertemperatureandheatingsupplyfrombufferviamixingcircuit.Controlofpressuredifference.

Sensoradvice:

SensorS3,S4,S6andS8mustbeconnected.Ifnot,thechargingprocesswillnotwork.

IfpressuredifferencesensorS9isnotconnected,thespeedcontrolofP3/V3isnotinaction.

10|©Danfoss|2021.06

AQ152886470424en-010601

Page 11

OperatingGuideECLComfort310,applicationA319

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

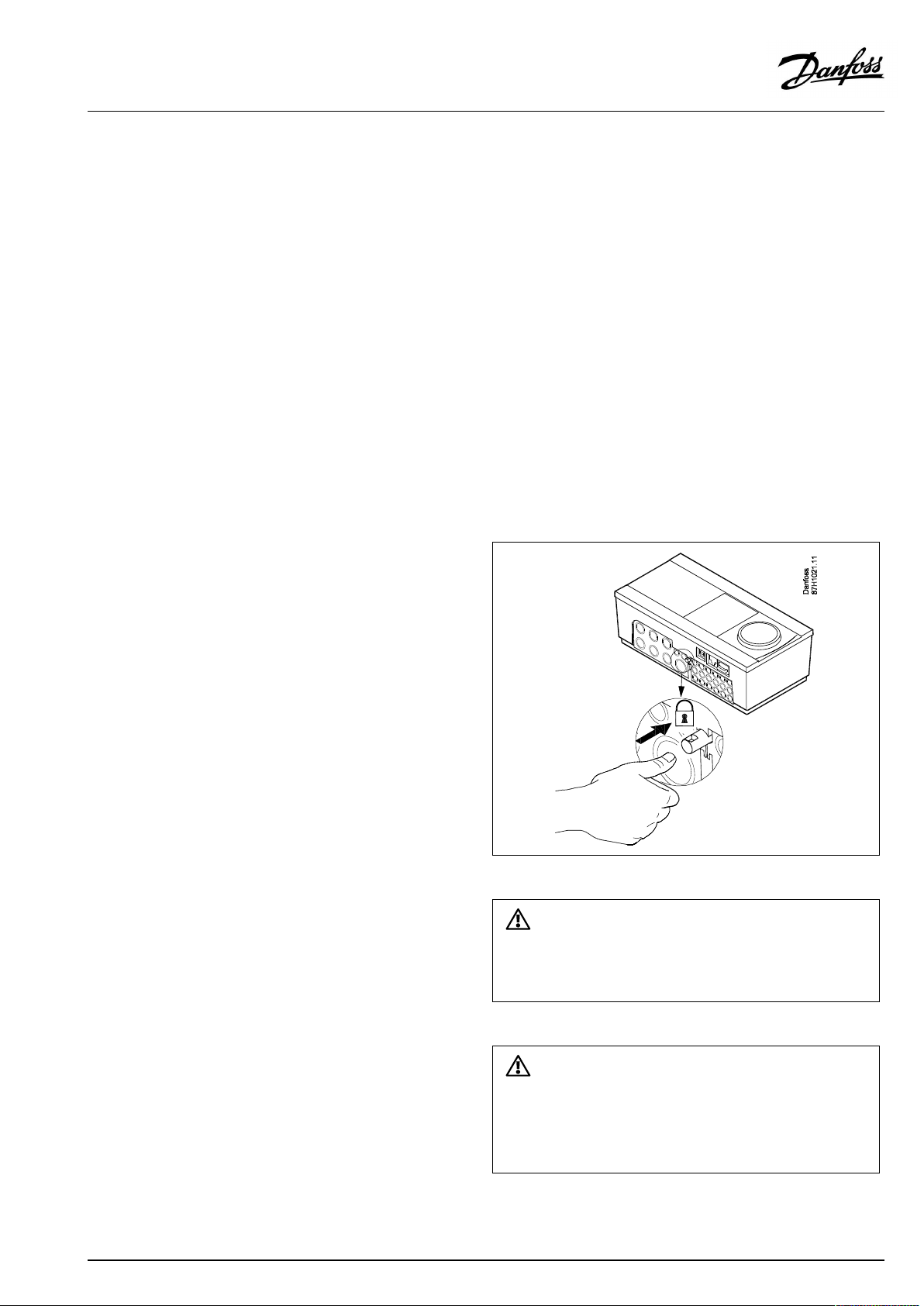

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

AQ152886470424en-010601

©Danfoss|2021.06|11

Page 12

OperatingGuideECLComfort310,applicationA319

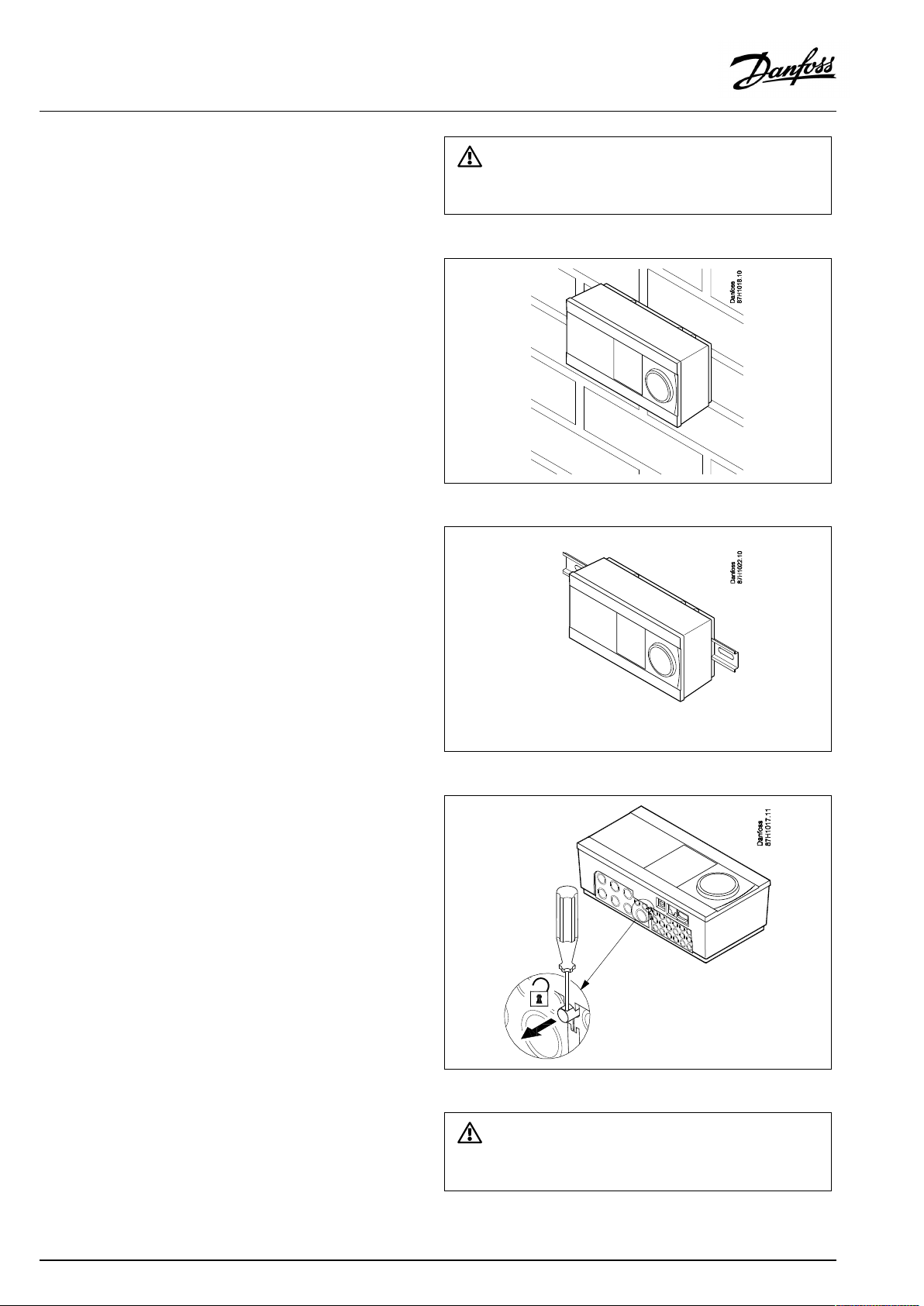

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

12|©Danfoss|2021.06

AQ152886470424en-010601

Page 13

OperatingGuideECLComfort310,applicationA319

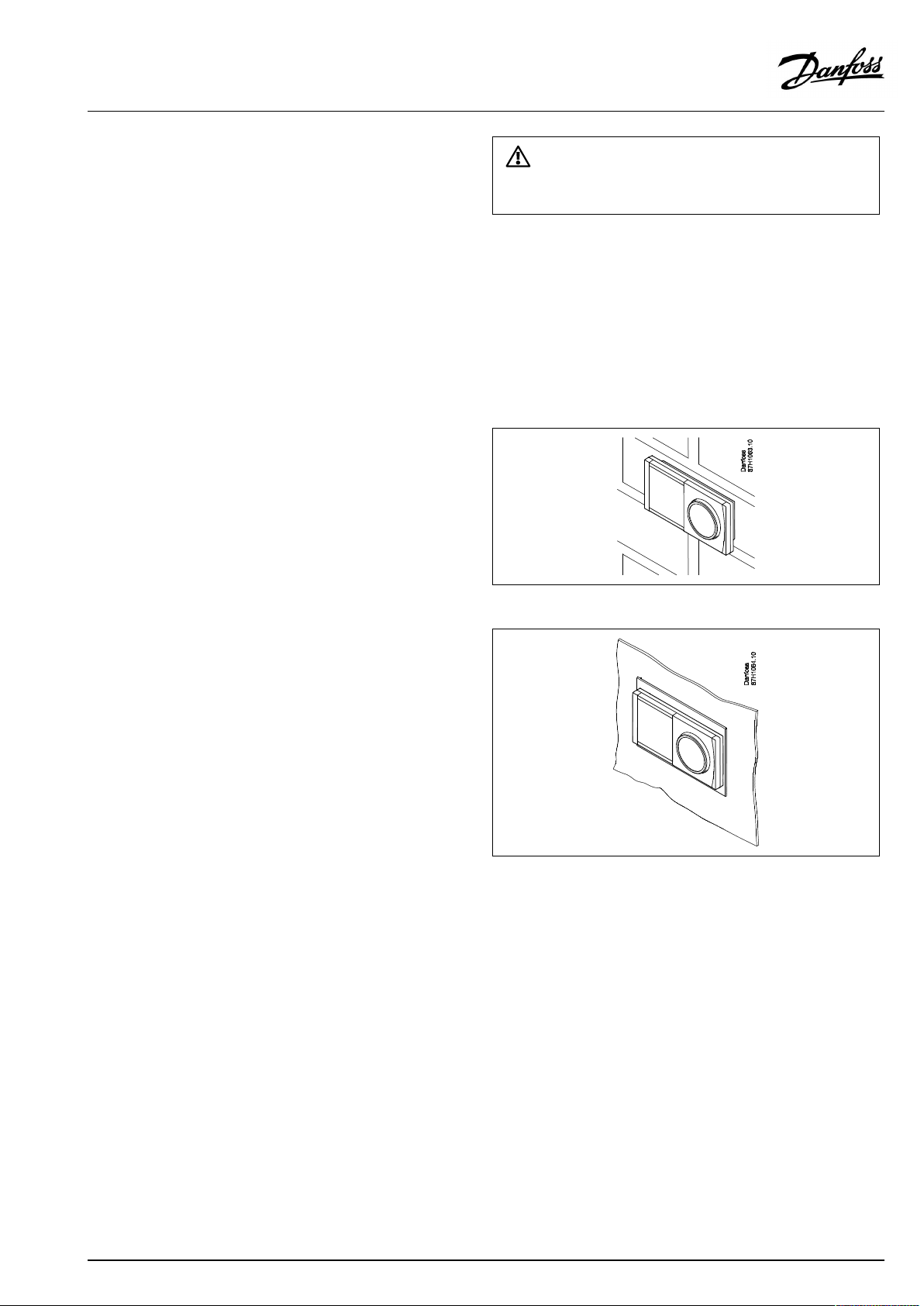

2.3.2MountingtheRemoteControlUnitsECA30/31

Selectoneofthefollowingmethods:

•Mountingonawall,ECA30/31

•Mountinginapanel,ECA30

Screwsandrawlplugsarenotsupplied.

Mountingonawall

MountthebasepartoftheECA30/31onawallwithasmooth

surface.Establishtheelectricalconnections.PlacetheECA30/

31inthebasepart.

BeforeremovingtheECLComfortcontrollerfromthebasepart,ensure

thatthesupplyvoltageisdisconnected.

Mountinginapanel

MounttheECA30inapanelusingtheECA30framekit(ordercode

no.087H3236).Establishtheelectricalconnections.Securethe

framewiththeclamp.PlacetheECA30inthebasepart.TheECA

30canbeconnectedtoanexternalroomtemperaturesensor.

TheECA31mustnotbemountedinapanelifthehumidity

functionistobeused.

AQ152886470424en-010601

©Danfoss|2021.06|13

Page 14

OperatingGuideECLComfort310,applicationA319

2.3.3MountingtheinternalI/OmoduleECA32orECA35

TheECA32module(ordercodeno.087H3202)orECA35module

(ordercodeno.087H3205)canbeinsertedintotheECLComfort

310/310Bbasepartforadditionalinputandoutputsignalsin

relevantapplications.

ECA32

ECA35

14|©Danfoss|2021.06

AQ152886470424en-010601

Page 15

OperatingGuideECLComfort310,applicationA319

2.4Placingthetemperaturesensors

2.4.1Placingthetemperaturesensors

Itisimportantthatthesensorsaremountedinthecorrectposition

inyoursystem.

Thetemperaturesensormentionedbelowaresensorsusedforthe

ECLComfort210/296/310serieswhichnotallwillbeneeded

foryourapplication!

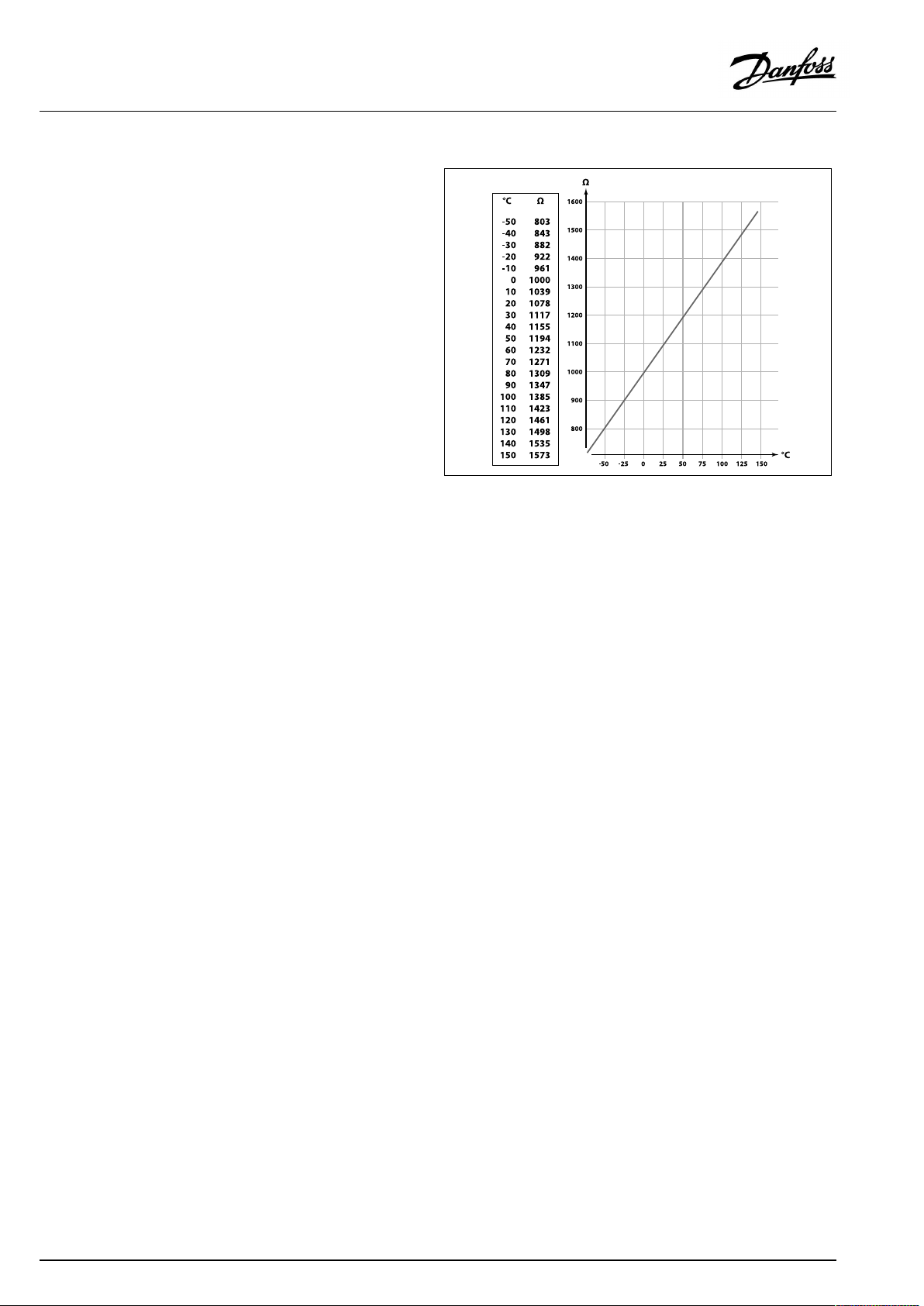

Outdoortemperaturesensor(ESMT)

Theoutdoorsensorshouldbemountedonthatsideofthebuilding

whereitislesslikelytobeexposedtodirectsunshine.Itshouldnot

beplacedclosetodoors,windowsorairoutlets.

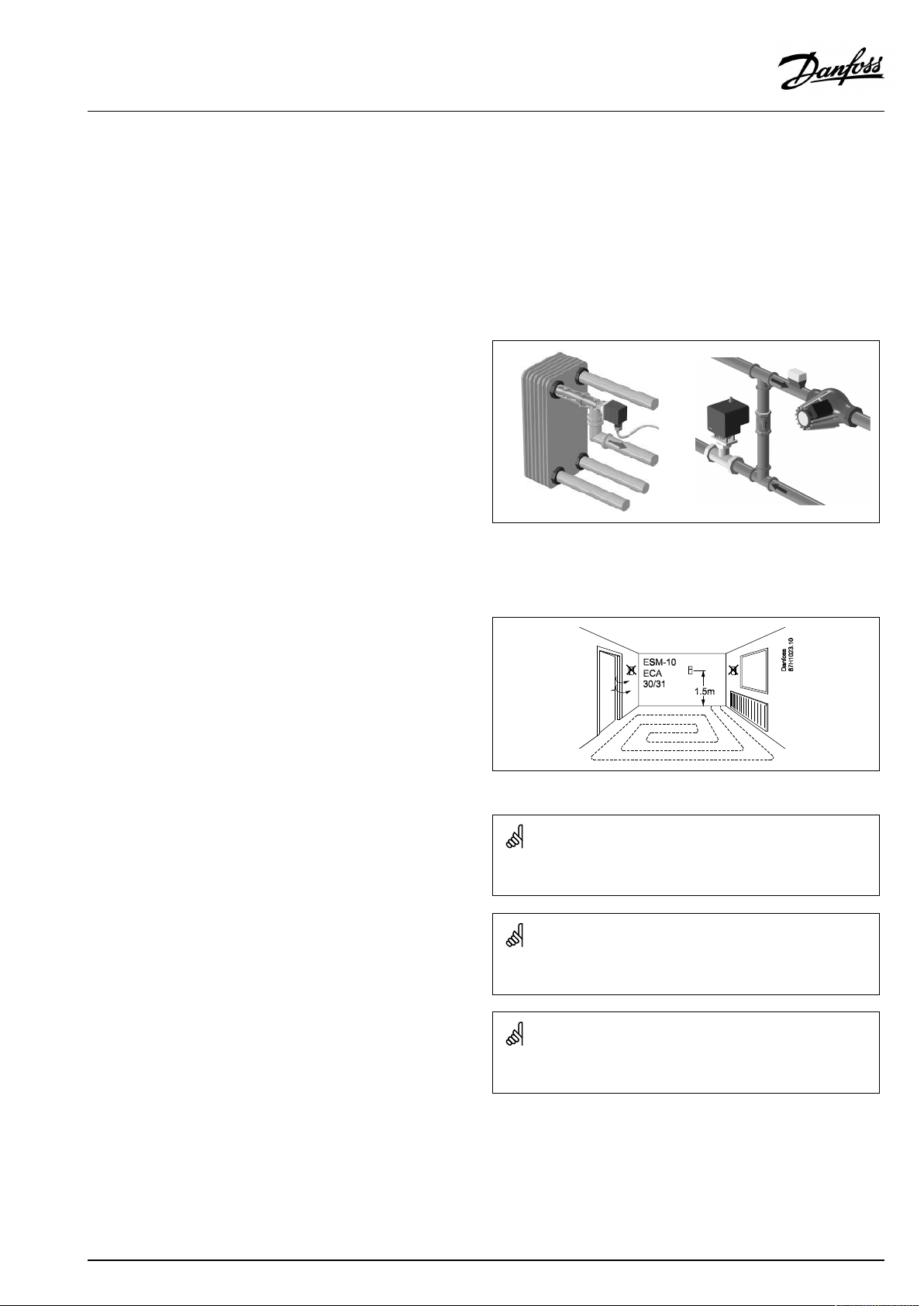

Flowtemperaturesensor(ESMU,ESM-11orESMC)

Placethesensormax.15cmfromthemixingpoint.Insystems

withheatexchanger,DanfossrecommendsthattheESMU-typeto

beinsertedintotheexchangerflowoutlet.

Makesurethatthesurfaceofthepipeiscleanandevenwhere

thesensorismounted.

Returntemperaturesensor(ESMU,ESM-11orESMC)

Thereturntemperaturesensorshouldalwaysbeplacedsothatit

measuresarepresentativereturntemperature.

Roomtemperaturesensor

(ESM-10,ECA30/31RemoteControlUnit)

Placetheroomsensorintheroomwherethetemperatureistobe

controlled.Donotplaceitonoutsidewallsorclosetoradiators,

windowsordoors.

Boilertemperaturesensor(ESMU,ESM-11orESMC)

Placethesensoraccordingtotheboilermanufacturer’s

specification.

Airducttemperaturesensor(ESMB-12orESMUtypes)

Placethesensorsothatitmeasuresarepresentativetemperature.

DHWtemperaturesensor(ESMUorESMB-12)

PlacetheDHWtemperaturesensoraccordingtothemanufacturer’s

specification.

Slabtemperaturesensor(ESMB-12)

Placethesensorinaprotectiontubeintheslab.

ESM-11:Donotmovethesensorafterithasbeenfastenedinorderto

avoiddamagetothesensorelement.

ESM-11,ESMCandESMB-12:Useheatconductingpasteforquick

measurementofthetemperature.

ESMUandESMB-12:Usingasensorpockettoprotectthesensorwill,

however,resultinaslowertemperaturemeasurement.

AQ152886470424en-010601

©Danfoss|2021.06|15

Page 16

OperatingGuideECLComfort310,applicationA319

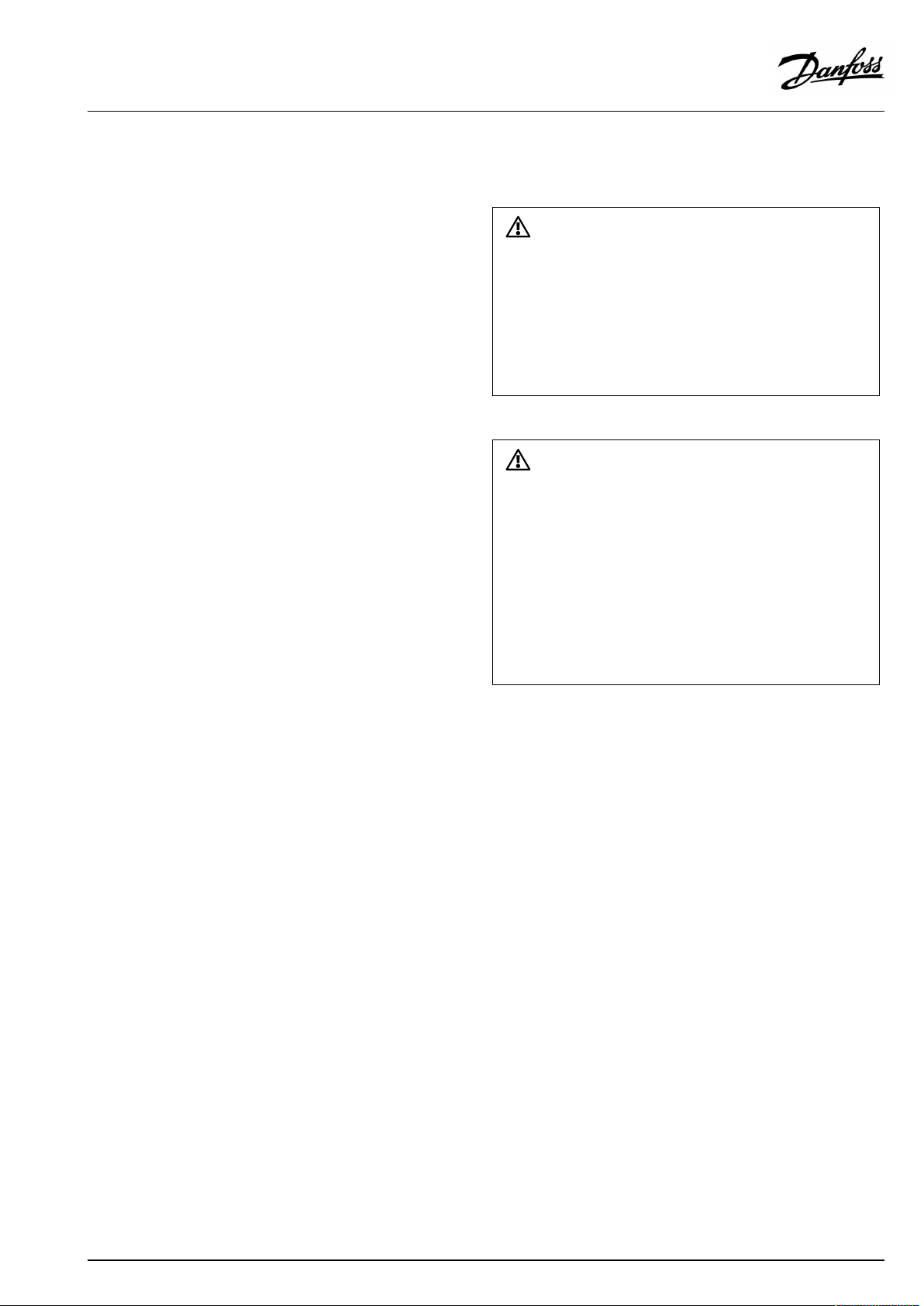

Pt1000temperaturesensor(IEC751B,1000Ω/0°C)

Relationshipbetweentemperatureandohmicvalue:

16|©Danfoss|2021.06

AQ152886470424en-010601

Page 17

OperatingGuideECLComfort310,applicationA319

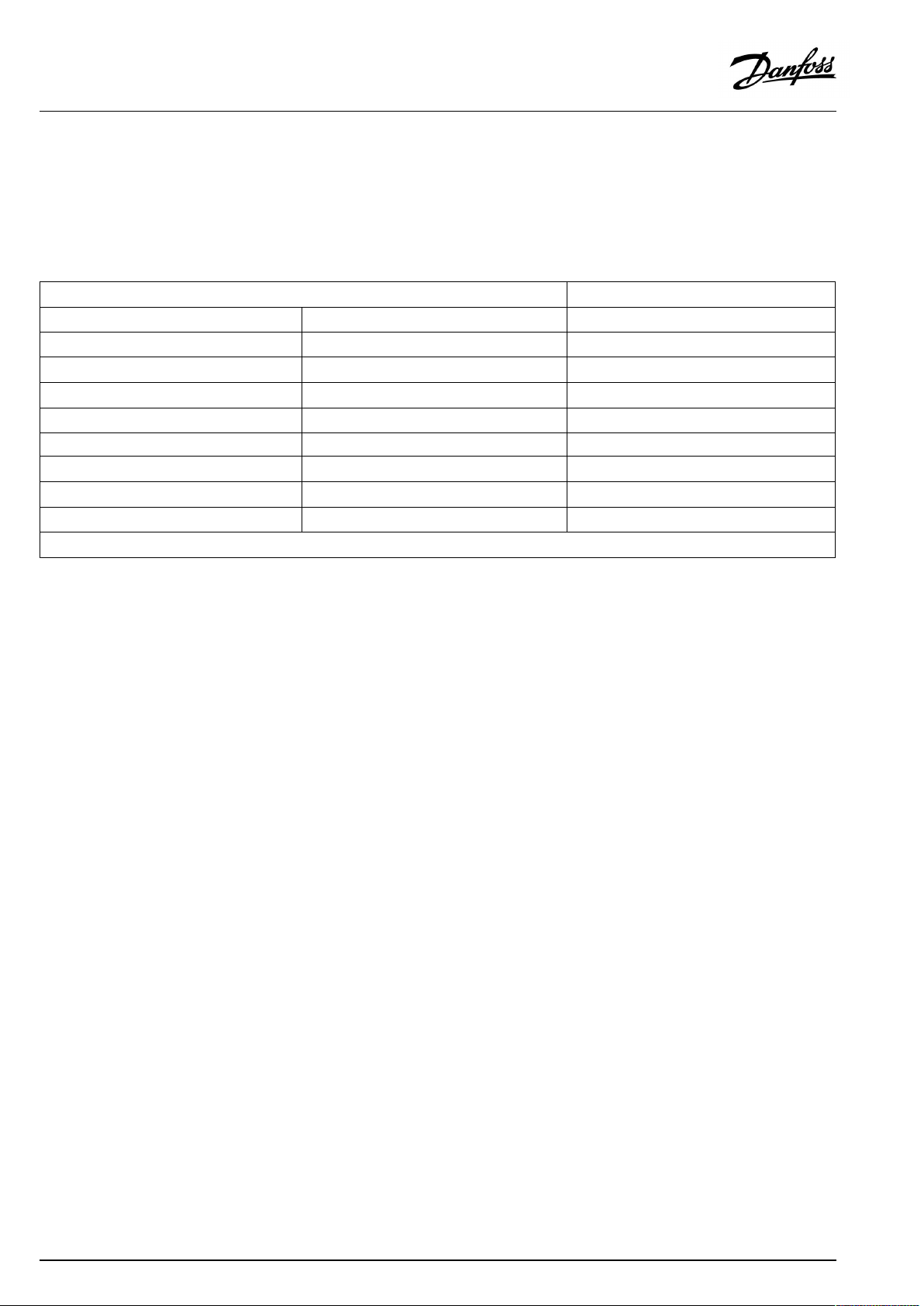

2.5Electricalconnections

2.5.1Electricalconnections230Va.c.

Warning

ElectricconductorsonPCB(PrintedCircuitBoard)forsupplyvoltage,

relaycontactsandtriacoutputsdonothavemutualsafetydistanceof

minimum6mm.Theoutputsarenotallowedtobeusedasgalvanic

separated(voltfree)outputs.

Ifagalvanicseparatedoutputisneeded,anauxiliaryrelayis

recommended.

24Voltcontrolledunits,forexampleactuators,aretobecontrolledby

meansofECLComfort310,24Voltversion.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

AQ152886470424en-010601

©Danfoss|2021.06|17

Page 18

OperatingGuideECLComfort310,applicationA319

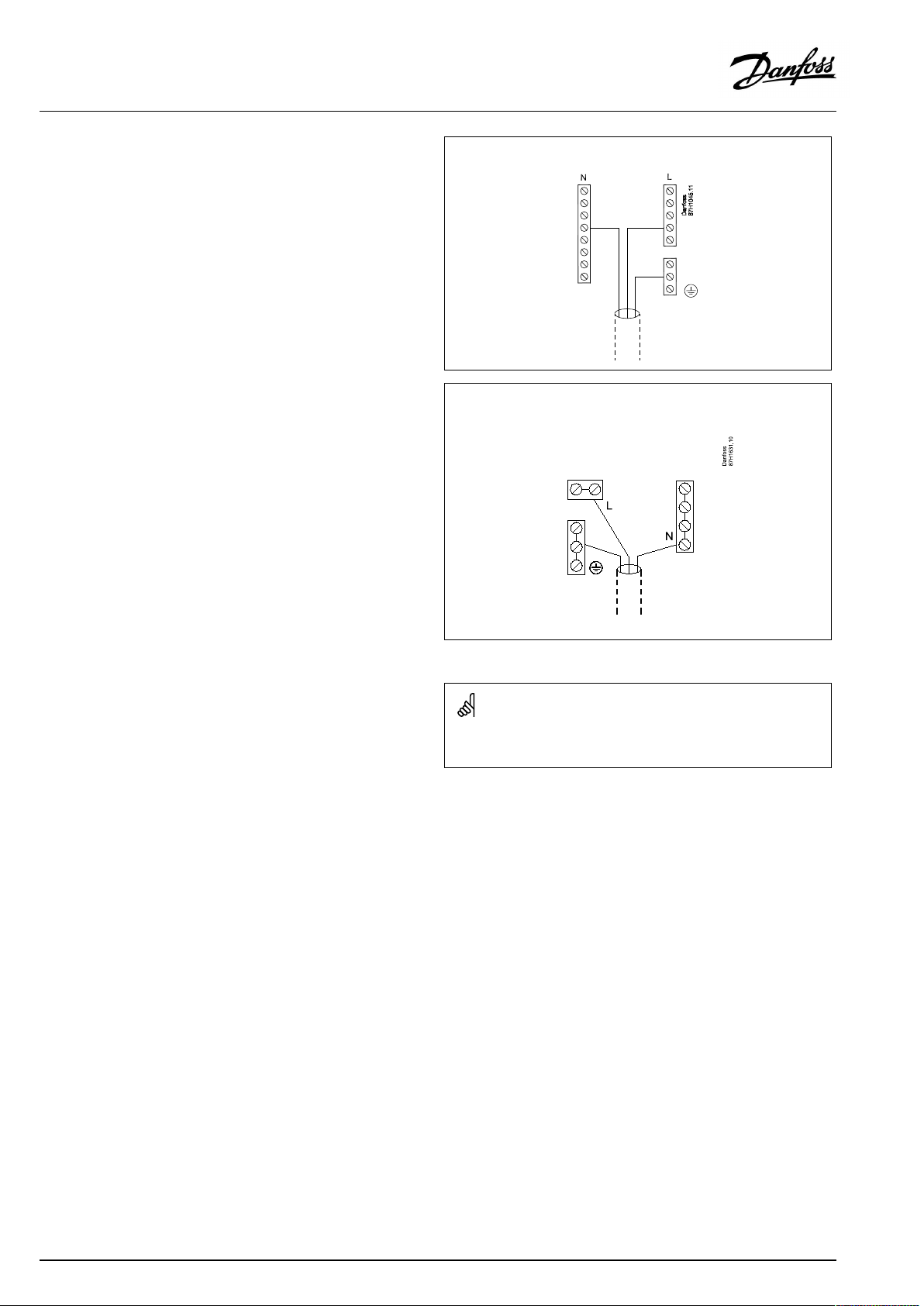

Thecommongroundterminalisusedforconnectionofrelevant

components(pumps,motorizedcontrolvalves).

ECL210/310

ECL296

Factoryestablishedjumpersinthebasepart:

5to8,9to14,Lto5andLto9,Nto10

18|©Danfoss|2021.06

AQ152886470424en-010601

Page 19

OperatingGuideECLComfort310,applicationA319

2.5.2Electricalconnections,230Va.c.,powersupply,pumps,motorizedcontrolvalvesetc.

Connections,ingeneral.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)forapplicationspecificconnections.

Maximumloadratings:

Relayterminals

4(2)A/230Va.c.

(4Aforohmicload,2Aforinductiveload)

Triac(electronicrelay)terminals

0,2A/230Va.c.

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

2.5.3Electricalconnections,24Va.c.,powersupply,pumps,motorizedcontrolvalvesetc.

Connections,ingeneral.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)forapplicationspecificconnections.

Maximumloadratings:

Relayterminals

4(2)A/24Va.c.

(4Aforohmicload,2Aforinductiveload)

Triac(electronicrelay)terminals

1A/24Va.c.

Donotconnect230Va.c.poweredcomponentstoa24Va.c.power

suppliedcontrollerdirectly.Useauxilliaryrelays(K)toseparate230

Va.c.from24Va.c.

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

AQ152886470424en-010601

©Danfoss|2021.06|19

Page 20

OperatingGuideECLComfort310,applicationA319

Electricalconnections,ECA32/ECA35

Connections,ingeneral.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)forapplicationspecificconnections.

Maximumloadratings:

Terminals

ECA32ECA35

PWMOut1(52)

PWMOut2(53)

PWMOut3(54)

PWMOut4(55)

AnalogOut1(59)AnalogOut1(59)47kΩ*

AnalogOut2(60)AnalogOut2(60)47kΩ*

AnalogOut3(61)AnalogOut3(61)47kΩ*

*Thevalueisaminimum.

5kΩ*

5kΩ*

5kΩ*

5kΩ*

20|©Danfoss|2021.06

AQ152886470424en-010601

Page 21

OperatingGuideECLComfort310,applicationA319

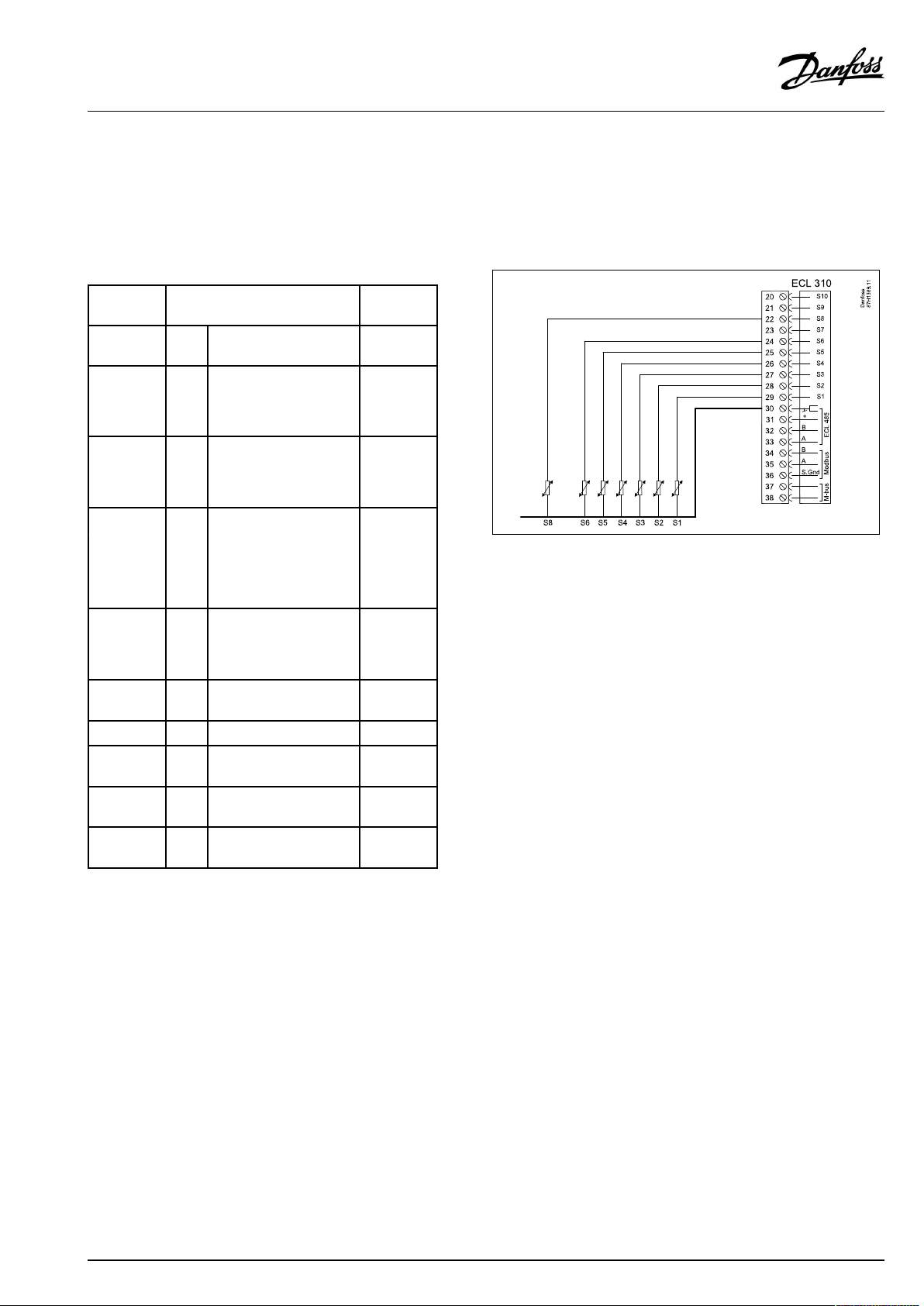

2.5.4Electricalconnections,Pt1000temperaturesensors

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

A319

TerminalSensor/description

29and30

28and30

27and30

26and30

25and30

24and30

23and30

22and30

21and30

20and30

S1

Outdoortemperature

sensor*

S2

Supplytemperature

sensor

S3

Chargingtemperature

sensor**

A319.1:

S4

Flowtemperature

sensor,monitoring

A319.2:

Flowtemperature

sensor

S5Returntemperature

sensor

S6

Upperbuffer-tank

temperaturesensor

S7

notused

S8

Upperbuffer-tank

temperaturesensor

S9

Pressuredifference

transmitter(0-10V)

S10

0-10Voltasdesired

temperature

Type

(recom.)

ESMT

ESM-11/

ESMB/

ESMC/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

ESMB/

ESMU

ESMB/

ESMU

Temperaturesensorsmustbeconnectedinordertohavethe

desiredfunctionality.

*

Iftheoutdoortemperaturesensorisnotconnectedorthe

sensorcableisshort-circuited,thecontrollerassumesthat

theoutdoortemperatureis0(zero)°C.

**

Ifthesensorisnotconnectedorthesensorcableis

short-circuited,themotorizedcontrolvalvecloses(safety

function).

Factoryestablishedjumper:

30tocommonterminal.

AQ152886470424en-010601

©Danfoss|2021.06|21

Page 22

OperatingGuideECLComfort310,applicationA319

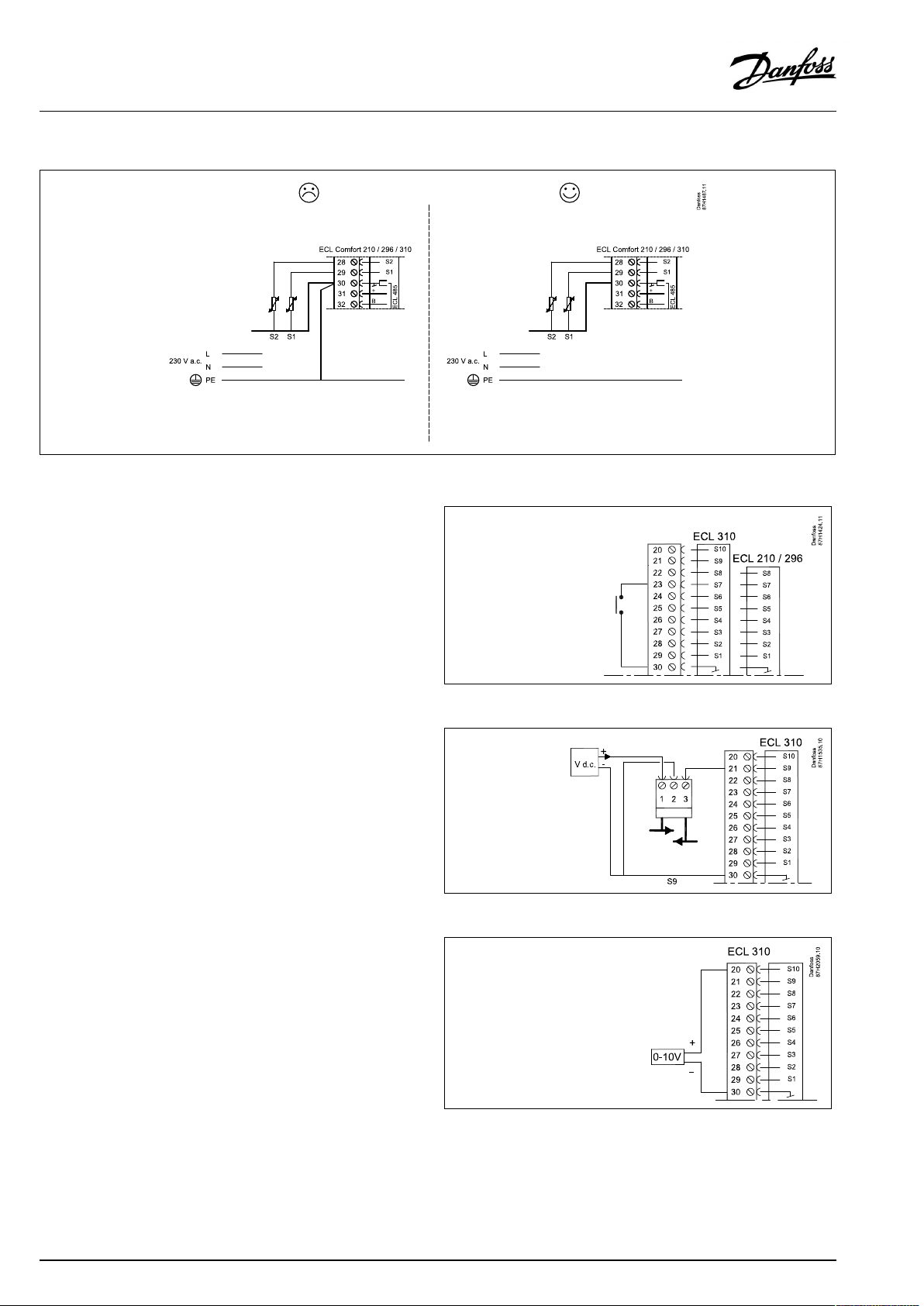

Inputconnnections

Exampleofoverridecontact,connectedtoS7:

(ignoreECL210)

ConnectionofinputS9:

Pressuredifferencetransmitter,0-10Volt

ConnectionofinputS10:

Controlvoltagefordesiredtemperature

22|©Danfoss|2021.06

AQ152886470424en-010601

Page 23

OperatingGuideECLComfort310,applicationA319

Connectionofswitchforexternaloverride

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

Wirecrosssectionforsensorconnections:Min.0.4mm².

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

AQ152886470424en-010601

©Danfoss|2021.06|23

Page 24

OperatingGuideECLComfort310,applicationA319

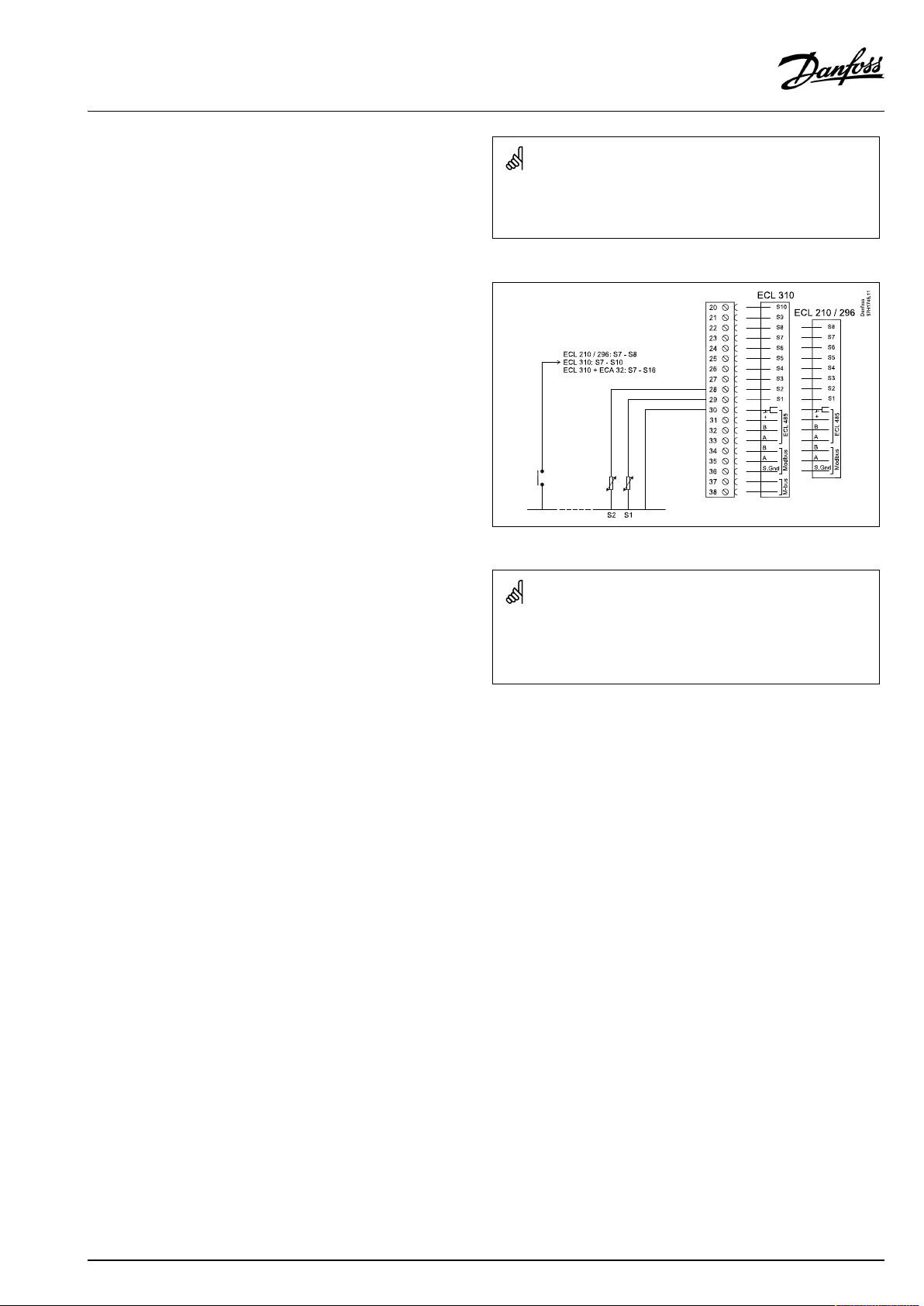

2.5.5Electricalconnections,ECA30/31

Terminal

ECL

Terminal

ECA30/31

30

31

4

1

322

333

4

5

*

Afteranexternalroomtemperaturesensorhasbeenconnected,

Description

Twistedpair

Twistedpair

Ext.roomtemperature

sensor*

Type

(recomm.)

Cable2x

twistedpair

ESM-10

ECA30/31mustberepowered.

ThecommunicationtotheECA30/31mustbesetupintheECL

Comfortcontrollerin'ECAaddr.'

TheECA30/31mustbesetupaccordingly.

AfterapplicationsetuptheECA30/31isreadyafter2–5min.A

progressbarintheECA30/31isdisplayed.

Iftheactualapplicationcontainstwoheatingcircuits,itispossible

toconnectanECA30/31toeachcircuit.Theelectricalconnections

aredoneinparallel.

Max.2ECA30/31canbeconnectedtoanECLComfort310controller

ortoECLComfort210/296/310controllersinamaster-slavesystem.

SetupproceduresforECA30/31:Seesection‘Miscellaneous’ .

ECAinformationmessage:

‘Applicationreq.newerECA’:

Thesoftware(firmware)ofyourECAdoesnotcomplywiththe

software(firmware)ofyourECLComfortcontroller.Pleasecontact

yourDanfosssalesoffice.

Someapplicationsdonotcontainfunctionsrelatedtoactualroom

temperature.TheconnectedECA30/31willonlyfunctionasremote

control.

24|©Danfoss|2021.06

AQ152886470424en-010601

Page 25

OperatingGuideECLComfort310,applicationA319

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

AQ152886470424en-010601

©Danfoss|2021.06|25

Page 26

OperatingGuideECLComfort310,applicationA319

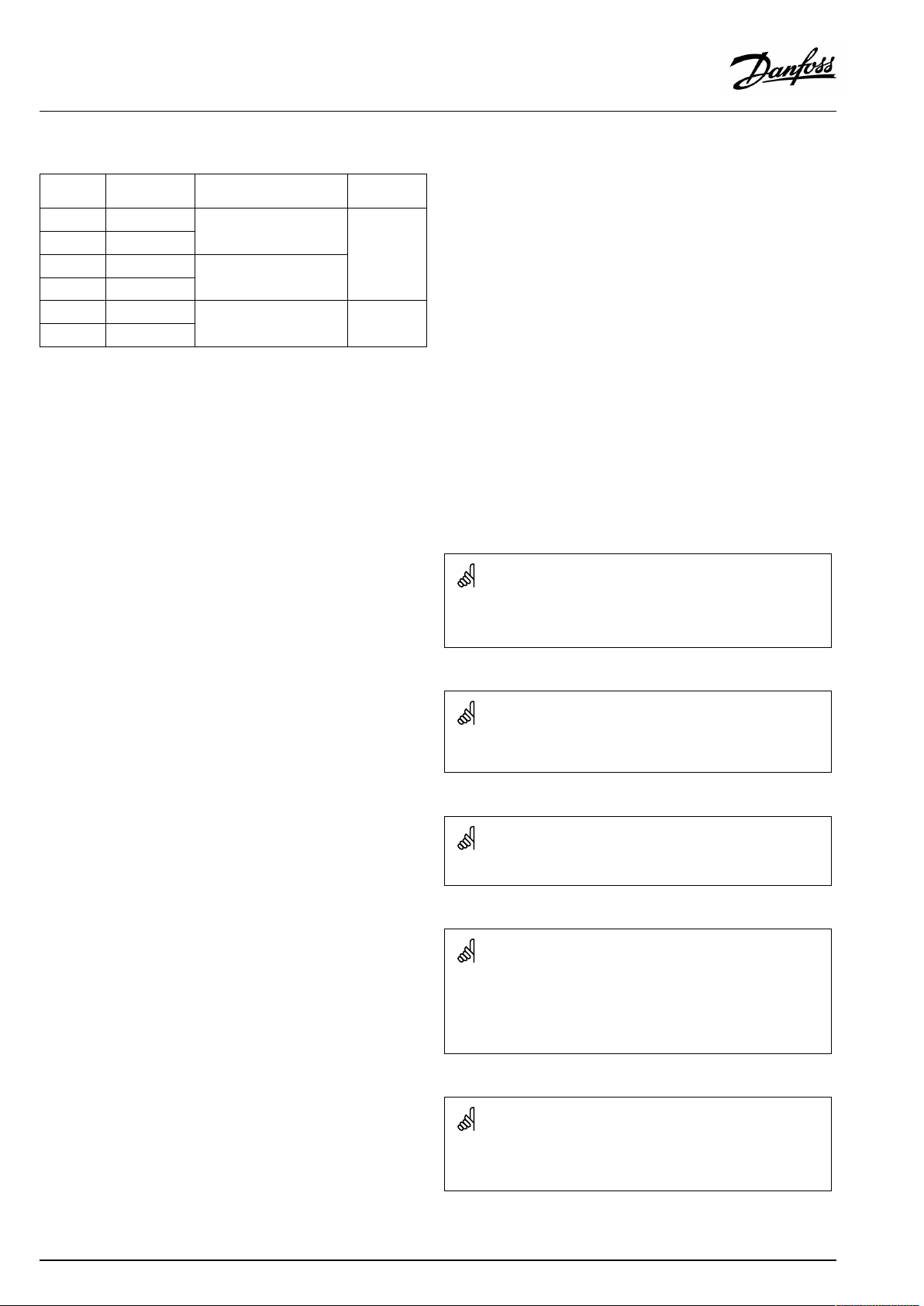

2.5.6Electricalconnections,master/slavesystems

Thecontrollercanbeusedasmasterorslaveinmaster/slave

systemsviatheinternalECL485communicationbus(2xtwisted

paircable).

TheECL485communicationbusisnotcompatiblewiththeECL

businECLComfort110,200,300and301!

Terminal

Description

Type

(recomm.)

30

Commonterminal

+12V*,ECL485communicationbus

31

*OnlyforECA30/31andmaster/

slavecommunication

32

B,ECL485communicationbus

33

A,ECL485communicationbus

Cable2x

twistedpair

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

ECL485buscable

MaximumrecommendedlengthoftheECL485busiscalculatedlike

this:

Subtract"TotallengthofallinputcablesofallECLcontrollersinthe

master-slavesystem"from200m.

Simpleexamplefortotallengthofallinputcables,3xECL:

1xECL

3xECL

3xECLReturntemp.sensor:

3xECLRoomtemp.sensor:

Total:

MaximumrecommendedlengthoftheECL485bus:

200-81m=119m

Outdoortemp.sensor:

Flowtemp.sensor:

15m

18m

18m

30m

81m

26|©Danfoss|2021.06

AQ152886470424en-010601

Page 27

OperatingGuideECLComfort310,applicationA319

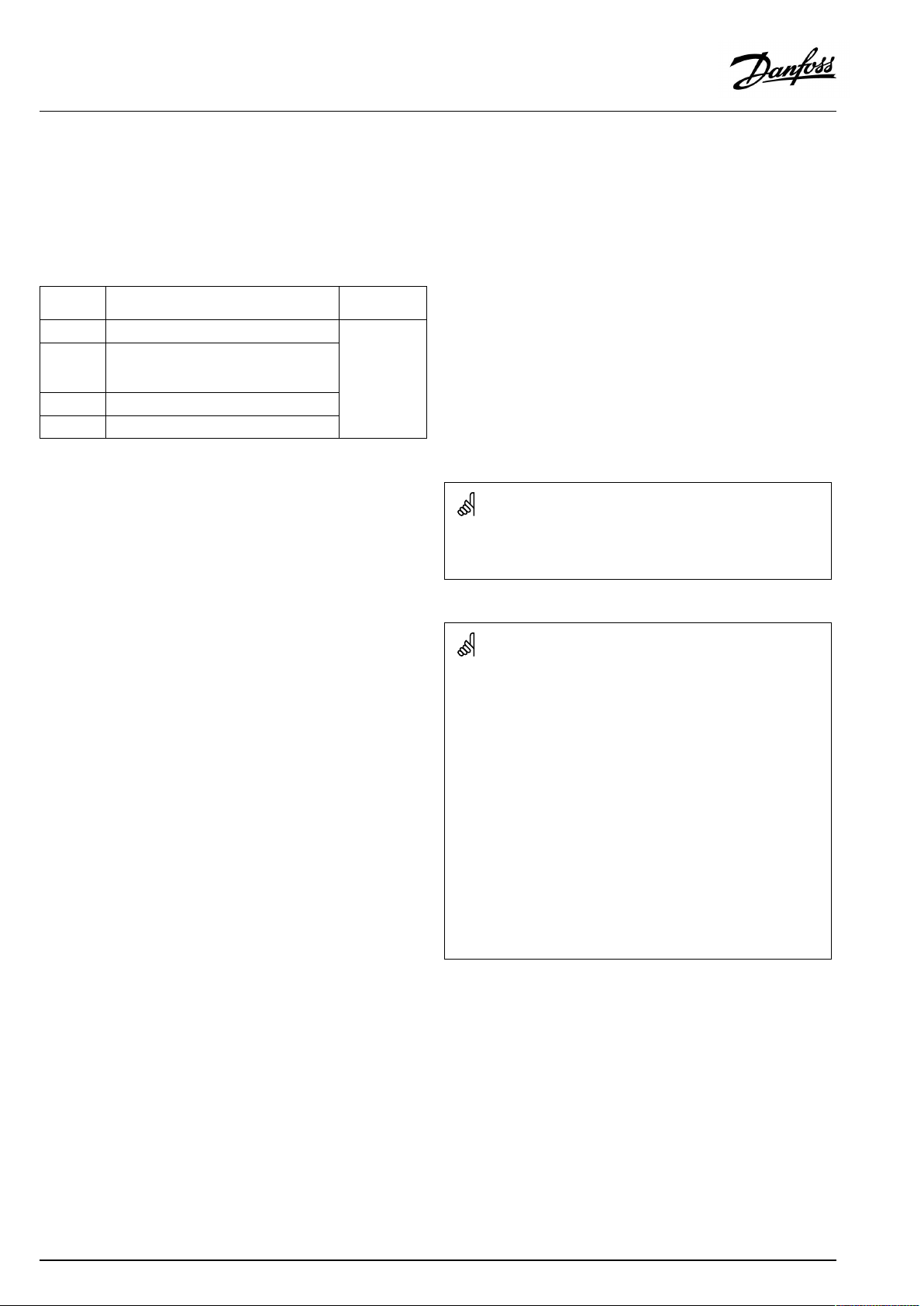

2.5.7Electricalconnections,communication

Electricalconnections,Modbus

ECLComfort210:Non-galvanicisolatedModbusconnections

ECLComfort296:GalvanicisolatedModbusconnections

ECLComfort310:GalvanicisolatedModbusconnections

Electricalconnections,M-bus

ECLComfort210:Notimplemented

ECLComfort296:Onboard

ECLComfort310:Onboard

Example,M-busconnections

(ECLComfort296/310and310Bonly)

AQ152886470424en-010601

©Danfoss|2021.06|27

Page 28

OperatingGuideECLComfort310,applicationA319

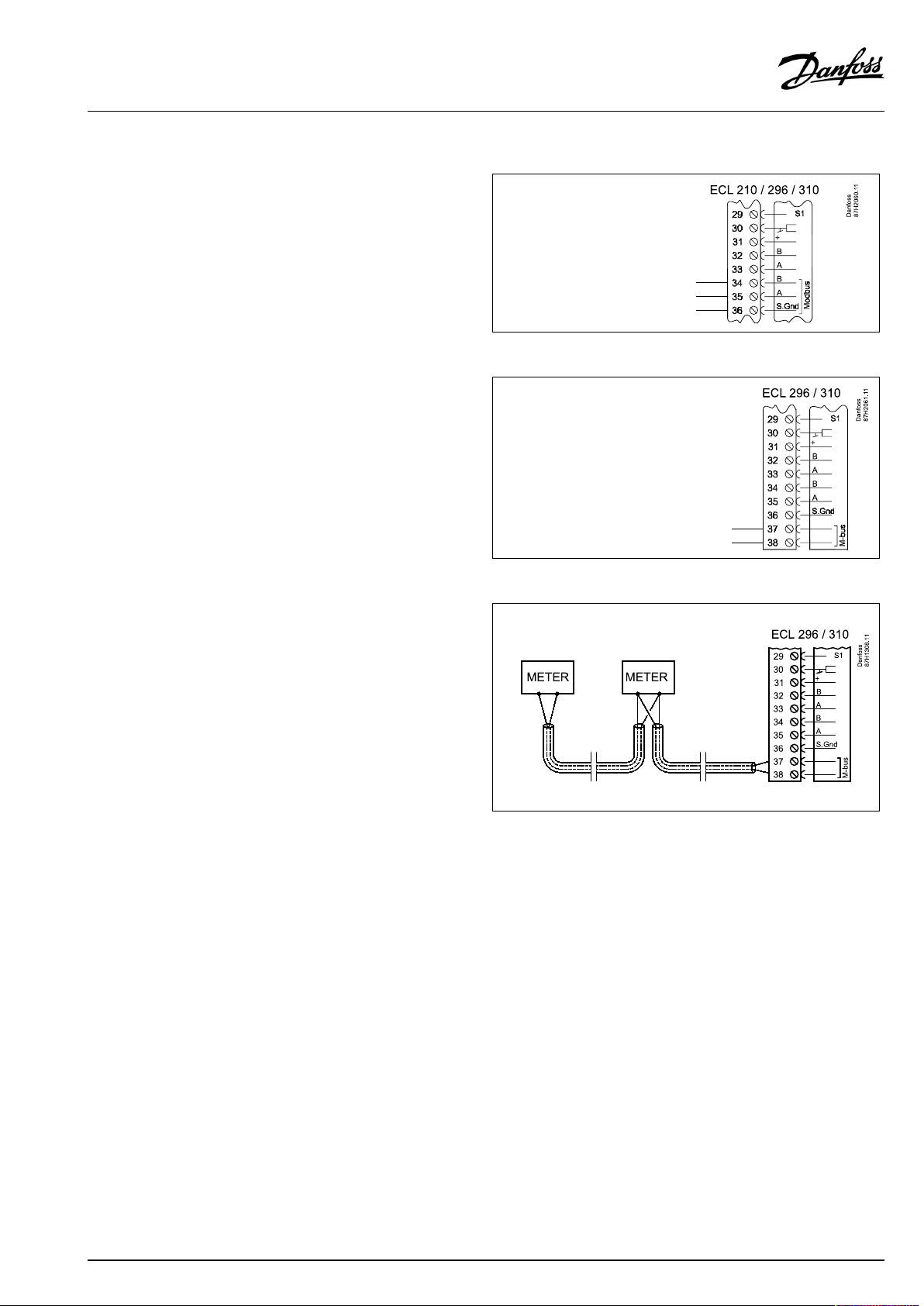

2.6InsertingtheECLApplicationKey

2.6.1InsertingtheECLApplicationKey

TheECLApplicationKeycontains

•theapplicationanditssubtypes,

•currentlyavailablelanguages,

•factorysettings:e.g.schedules,desiredtemperatures,

limitationvaluesetc.Itisalwayspossibletorecoverthefactory

settings,

•memoryforusersettings:specialuser/systemsettings.

Afterhavingpowered-upthecontroller,differentsituationsmight

beexisting:

1.Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

2.Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

3.Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

ECLComfort210/310

ECLComfort210/310

Usersettingsare,amongothers,desiredroomtemperature,desired

DHWtemperature,schedules,heatcurve,limitationvaluesetc.

Systemsettingsare,amongothers,communicationset-up,display

brightnessetc.

28|©Danfoss|2021.06

AQ152886470424en-010601

Page 29

OperatingGuideECLComfort310,applicationA319

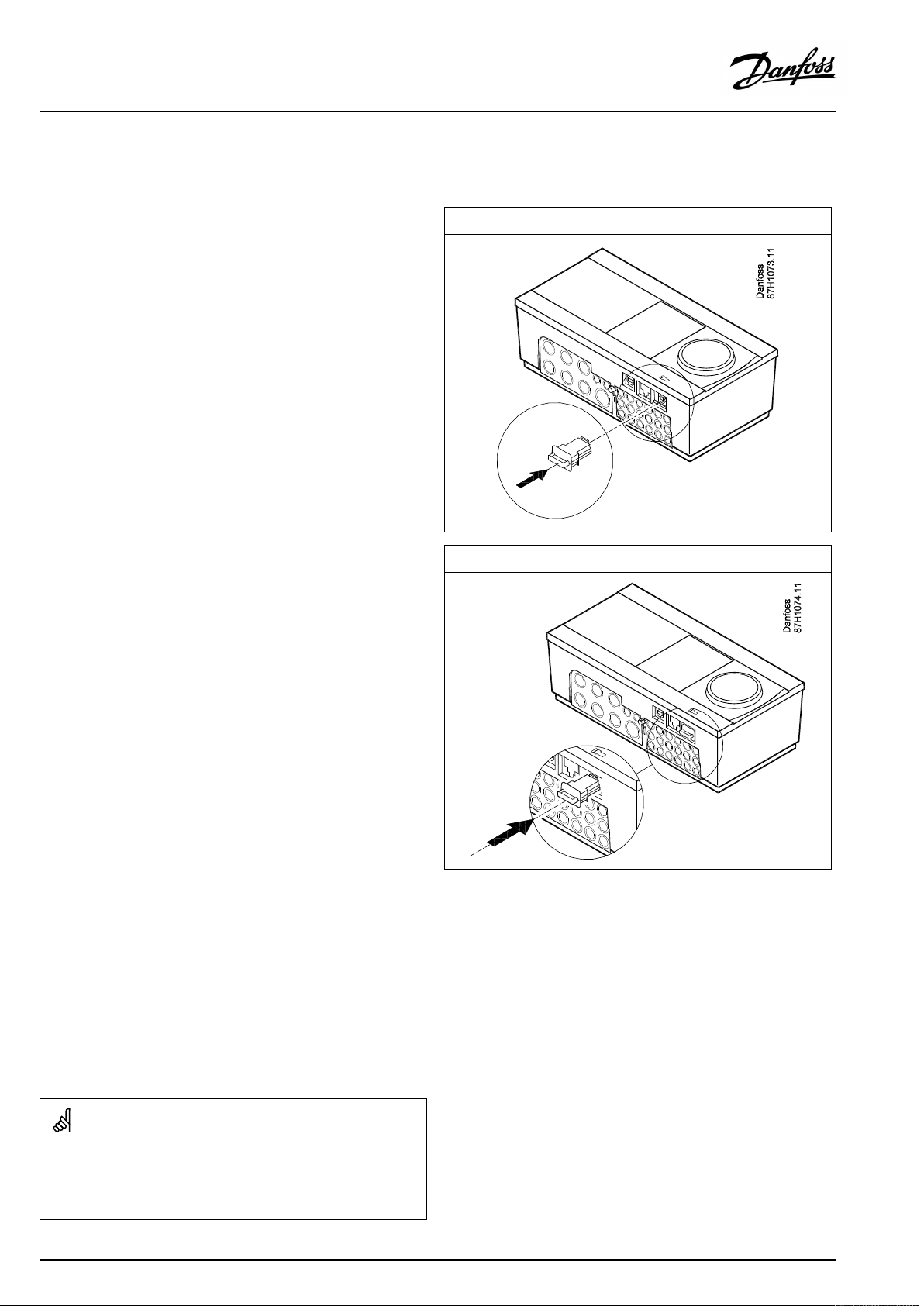

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

AQ152886470424en-010601

©Danfoss|2021.06|29

Page 30

OperatingGuideECLComfort310,applicationA319

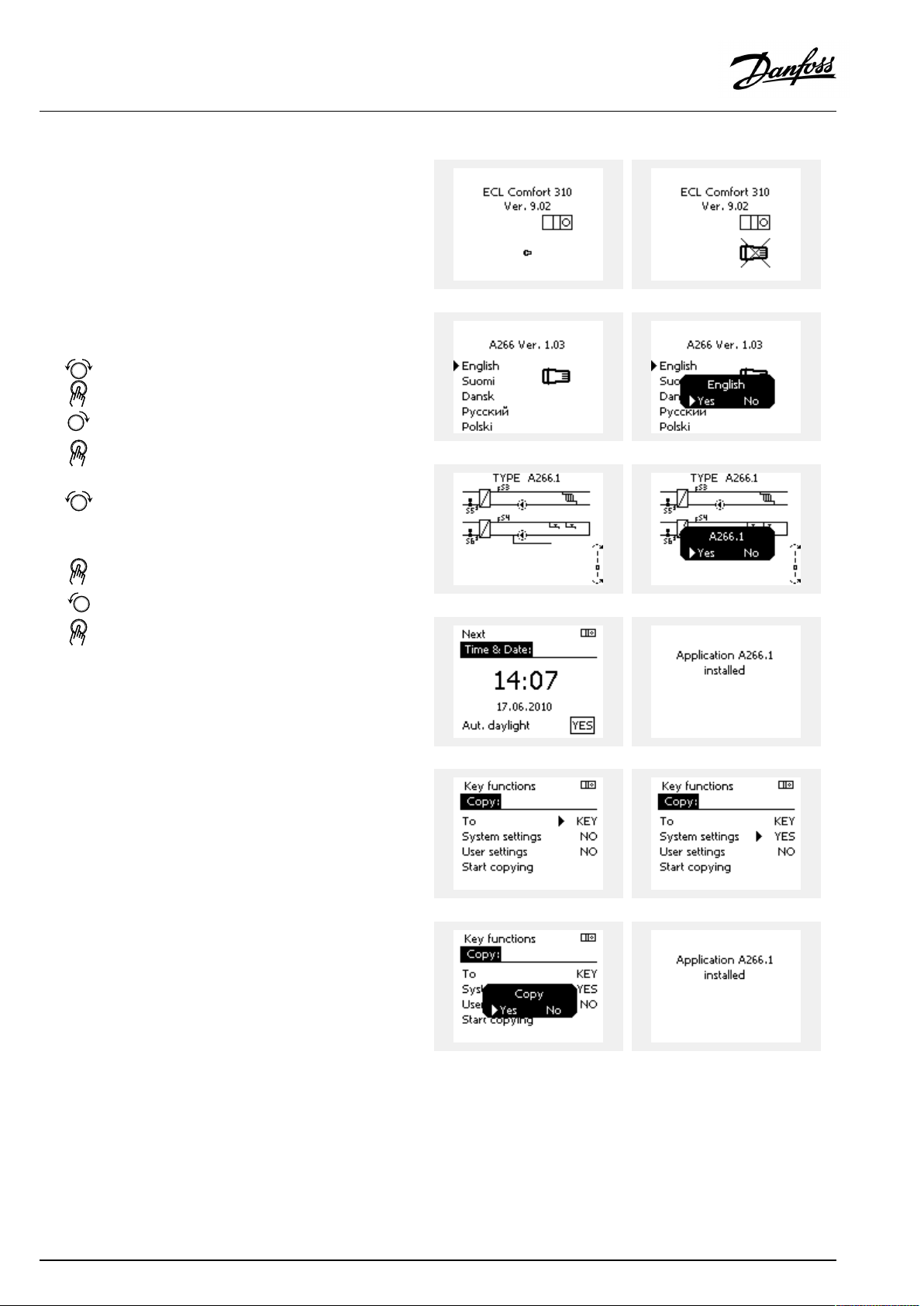

ApplicationKey:Situation1

Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

AnanimationfortheECLApplicationKeyinsertionisdisplayed.

InserttheApplicationKey.

ApplicationKeynameandVersionisindicated(example:A266

Ver.1.03).

IftheECLApplicationKeyisnotsuitableforthecontroller,a"cross"

isdisplayedovertheECLApplicationKey-symbol.

Action:Purpose:

Selectlanguage

Confirm

Selectapplication(subtype)

Somekeyshaveonlyoneapplication.

Confirmwith‘Yes’

Set'Time&Date'

Turnandpushthedialtoselectand

change'Hours' ,'Minutes','Date',

'Month'and'Year' .

Choose''Next'

Confirmwith‘Yes’

Goto‘Aut.daylight’

Choosewhether‘ Aut.daylight´*

shouldbeactiveornot

*‘Aut.daylight’istheautomaticchangeoverbetweensummer

andwintertime.

DependingonthecontentsoftheECLApplicationKey,procedure

AorBistakingplace:

A

TheECLApplicationkeycontainsfactorysettings:

Thecontrollerreads/transfersdatafromtheECLApplicationKey

toECLcontroller.

Examples:

YESorNO

Theapplicationisinstalled,andthecontrollerresetsandstartsup.

B

TheECLApplicationkeycontainschangedsystemsettings:

Pushthedialrepeatedly.

’NO’:

’YES*:

Ifthekeycontainsusersettings:

Pushthedialrepeatedly.

‘NO:

‘YES*:

*If‘YES’cannotbechosen,theECLApplicationKeydoesnot

containanyspecialsettings.

Choose‘Startcopying’andconfirmwith'Yes'.

30|©Danfoss|2021.06

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialsystemsettings(differingfromthefactory

settings)willbecopiedtothecontroller.

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialusersettings(differingfromthefactorysettings)

willbecopiedtothecontroller.

AQ152886470424en-010601

Page 31

OperatingGuideECLComfort310,applicationA319

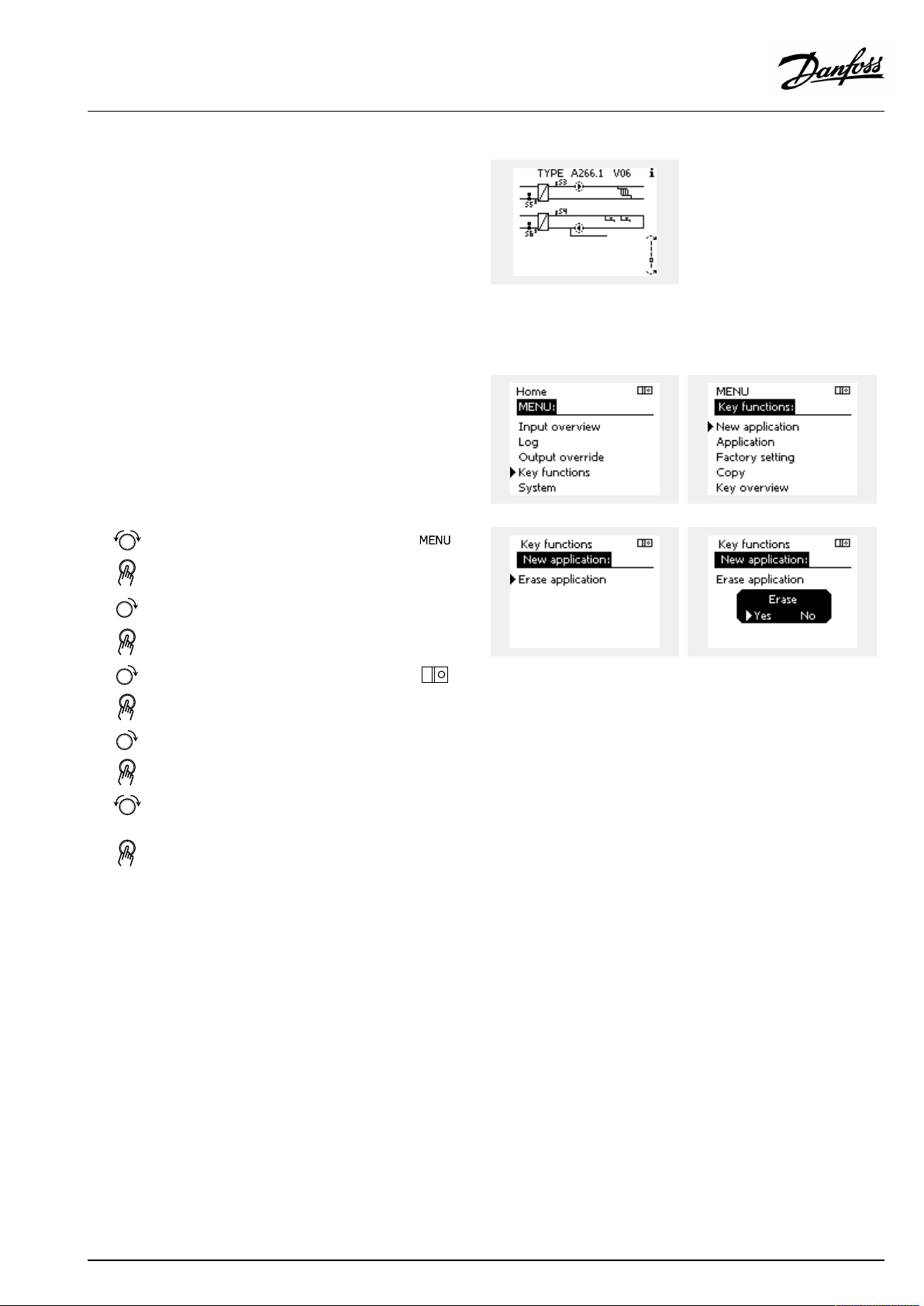

(Example):

The"i"intheupperrightcornerindicatesthat-besidesthefactory

settings-thesubtypealsocontainsspecialuser/systemssettings.

ApplicationKey:Situation2

Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

TochangetoanotherapplicationontheECLApplicationKey,the

currentapplicationinthecontrollermustbeerased(deleted).

BeawarethattheApplicationKeymustbeinserted.

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Choose‘Keyfunctions’

Confirm

Choose‘Eraseapplication’

Confirmwith‘Yes’

Thecontrollerresetsandisreadytobeconfigured.

Followtheproceduredescribedinsituation1.

Examples:

AQ152886470424en-010601

©Danfoss|2021.06|31

Page 32

OperatingGuideECLComfort310,applicationA319

ApplicationKey:Situation3

Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

Thisfunctionisused

•forsaving(backup)ofspecialuserandsystemsettings

•whenanotherECLComfortcontrollerofthesametype(210,

296or310)mustbeconfiguredwiththesameapplicationbut

user/systemsettingsdifferfromthefactorysettings.

HowtocopytoanotherECLComfortcontroller:

Action:Purpose:

Choose‘MENU’

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose'Commoncontrollersettings'

Confirm

Goto‘Keyfunctions’

Confirm

Choose‘Copy’

Confirm

Choose‘To’ .

‘ECL’or‘KEY’willbeindicated.Choose

’ECL’orKEY’

Pushthedialrepeatedlytochoose

copydirection

Choose‘Systemsettings’or‘User

settings’

Pushthedialrepeatedlytochoose

‘Yes’or‘No’in‘Copy’ .Pushtoconfirm.

Choose‘Startcopying’

TheApplicationKeyorthecontroller

isupdatedwithspecialsystemoruser

settings.

Examples:

*

’ECL’or‘KEY’ .

**

‘NO’or‘YES’

*

‘ECL’:

‘KEY’:

**

‘NO’:

‘YES’:

32|©Danfoss|2021.06

DatawillbecopiedfromtheApplicationKeytothe

ECLController.

DatawillbecopiedfromtheECLControllertothe

ApplicationKey.

ThesettingsfromtheECLcontrollerwillnotbecopied

totheApplicationKeyortotheECLComfortcontroller.

Specialsettings(differingfromthefactorysettings)will

becopiedtotheApplicationKeyortotheECLComfort

controller.IfYEScannotbechosen,therearenospecial

settingstobecopied.

AQ152886470424en-010601

Page 33

OperatingGuideECLComfort310,applicationA319

Language

Atapplicationupload,alanguagemustbeselected.*

IfanotherlanguagethanEnglishisselected,theselectedlanguage

ANDEnglishwillbeuploadedintotheECLcontroller.

ThismakesserviceeasyforEnglishspeakingservicepeople,just

becausetheEnglishlanguagemenuscanbevisiblebychanging

theactualsetlanguageintoEnglish.

(Navigation:MENU>Commoncontroller>System>Language)

Iftheuploadedlanguageisnotsuitable,theapplicationmustbe

erased.UserandSystemsettingscanbesavedontheapplication

keybeforeerasing.

Afternewuploadwithpreferredlanguage,theexistingUserand

Systemsettingscanbeuploaded.

*)

(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

2.6.2ECLApplicationKey,copyingdata

Generalprinciples

Whenthecontrollerisconnectedandoperating,youcancheck

andadjustallorsomeofthebasicsettings.Thenewsettingscan

bestoredontheKey.

Factorysettingscanalwaysberestored.

HowtoupdatetheECLApplicationKeyaftersettingshave

beenchanged?

AllnewsettingscanbestoredontheECLApplicationKey.

Howtostorefactorysettinginthecontrollerfromthe

ApplicationKey?

PleasereadtheparagraphconcerningApplicationKey,Situation

1:Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

HowtostorepersonalsettingsfromthecontrollertotheKey?

PleasereadtheparagraphconcerningApplicationKey,Situation3:

Acopyofthecontrollerssettingsisneededforconfiguringanother

controller

Asamainrule,theECLApplicationKeyshouldalwaysremainin

thecontroller.IftheKeyisremoved,itisnotpossibletochange

settings.

Makeanoteofnewsettingsinthe'Settingsoverview'table.

DonotremovetheECLApplicationKeywhilecopying.Thedataon

theECLApplicationKeycanbedamaged!

ItispossibletocopysettingsfromoneECLComfortcontrollerto

anothercontrollerprovidedthatthetwocontrollersarefromthesame

series(210or310).

Furthermore,whentheECLComfortcontrollerhasbeenuploaded

withanapplicationkey,minimumversion2.44,itispossibletoupload

personalsettingsfromapplicationkeys,minimumversion2.14.

AQ152886470424en-010601

©Danfoss|2021.06|33

Page 34

OperatingGuideECLComfort310,applicationA319

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

34|©Danfoss|2021.06

AQ152886470424en-010601

Page 35

OperatingGuideECLComfort310,applicationA319

2.7Checklist

IstheECLComfortcontrollerreadyforuse?

Makesurethatthecorrectpowersupplyisconnectedtoterminals9and10(230Vor24V).

Makesurethecorrectphaseconditionsareconnected:

230V:Live=terminal9andNeutral=terminal10

24V:SP=terminal9andSN=terminal10

Checkthattherequiredcontrolledcomponents(actuator,pumpetc.)areconnectedtothecorrectterminals.

Checkthatallsensors/signalsareconnectedtothecorrectterminals(see'Electricalconnections').

Mountthecontrollerandswitchonthepower.

IstheECLApplicationKeyinserted(see'InsertingtheApplicationKey').

DoestheECLComfortcontrollercontainanexistingapplication(see'InsertingtheApplicationKey').

Isthecorrectlanguagechosen(see'Language'in'Commoncontrollersettings').

Isthetime&datesetcorrectly(see'Time&Date'in'Commoncontrollersettings').

Istherightapplicationchosen(see'Identifyingthesystemtype').

Checkthatallsettingsinthecontroller(see'Settingsoverview')aresetorthatthefactorysettingscomplywithyour

requirements.

Choosemanualoperation(see'Manualcontrol').Checkthatvalvesopenandclose,andthatrequiredcontrolled

components(pumpetc.)startandstopwhenoperatedmanually.

Checkthatthetemperatures/signalsshowninthedisplaymatchtheactualconnectedcomponents.

Havingcompletedthemanualoperationcheck,choosecontrollermode(scheduled,comfort,savingorfrostprotection).

AQ152886470424en-010601

©Danfoss|2021.06|35

Page 36

OperatingGuideECLComfort310,applicationA319

2.8Navigation,ECLApplicationKeyA319

Navigation,A319.1andA319.2,circuits1and2

Home

MENU

Schedule

Schedule,Circ.pu.

Settings

A319

A319.1A319.2

CircuitCircuit

IDnos.

Weekplan,max.3comfort

periods/day

Factorysettings:

00.00-08.00,08.00-16.00,

16.00-24.00

Weekplan,max.3comfort

periods/day

Factorysettings:

00.00-08.00,08.00-16.00,

16.00-24.00

FlowtemperatureHeatcurve((

11178

11177

11004

Tanktemperature12195Startdifference((

12194

12371

12004

Returnlimit

Controlpar.1

Controlpar.2

12031

12032

12033

12034

12035

12036

12037

12080

12028

1218413184

1218513185

1218613186

1218713187

1218913189

1218414184

1218514185

12186

1218714187

12189

14165

14167

14171

Function

Temp.max.

Temp.min.

Ext.desiredT

DesiredT

Stopdifference

Pumpstartdiff.

DesiredT

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Infl.-max.

Infl.-min.

Adapt.time

Delay

Con.T,ret.Tlim.

Xp

Tn

Mrun

Nz

Min.act.time

Xp

Tn

Mrun

Nz

Min.act.time

Voutmax.

Voutmin.

Reverseout

1

((

((

((

((

((

((

2

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

(((

(((

(((

((

((

((

1

(

(

2

36|©Danfoss|2021.06

AQ152886470424en-010601

Page 37

OperatingGuideECLComfort310,applicationA319

Navigation,A319.1andA319.2,circuits1and2,continued

Home

MENU

Settings

Holiday

Alarm

Influenceoverview

Des.flowT

A319

A319.1A319.2

CircuitCircuit

IDnos.

Controlpar.3

11558

11184

11185

11187

11165

11167

11171

Application11500SenddesiredT((

11077

11021

1109312093

11141

12141

1114212142

12017

12054

12042

ChargeT

SupplyT

Alarmoverview

Holiday

Ext.override

SCADAoffset

Ext.desiredT

Slave,demand

SCADAoverride

Returnlimit

12147

12148

12149

12150

12340

Function

Pressure,diff.

Pressurediff.des.

Xp

Tn

Nz

Voutmax.

Voutmin.

Reverseout

PfrostT

Totalstop

Frostpr.T

Ext.input

Ext.mode

Demandoffset

Cont.Tcontrol

Char.Ppost-run

Upperdifference

Lowerdifference

Delay

Lowesttemp.

Delay

ChargeT

SupplyT

Tsensordefect

1

((

((

((

((

((

((

((

((

((

((

((((

((((

((((

((

((

((((

((

((((

223

((

((

((

((

((

((

((

((

((

((

((

((

((

((

AQ152886470424en-010601

©Danfoss|2021.06|37

Page 38

OperatingGuideECLComfort310,applicationA319

Navigation,A319,Commoncontrollersettings

Home

MENU

Time&Date

ScheduleSelectable

Inputoverview

Log

Outputoverride

Keyfunctions

OutdoorTLogtoday

FlowT&desiredLogyesterday

Pressure,diff.&des.

ChargeT&des.Log4days

ReturnT&limit

SupplyT

TankTup&des.

TankTup&low.

NewapplicationEraseapplication

Application

FactorysettingSystemsettings

Copy

Keyoverview

IDno.

Commoncontrollersettings

Function

Selectable

OutdoorT

FlowT

ChargeT

SupplyT

Prim.returnT

TankupperT

TanklowerT

Pressure,diff.

Ext.desiredT

Log2days

M1

V2

P2

M2(A319.2only)

V3

P3

X1

A1

Usersettings

Gotofactory

To

Systemsettings

Usersettings

Startcopying

38|©Danfoss|2021.06

AQ152886470424en-010601

Page 39

OperatingGuideECLComfort310,applicationA319

Navigation,A319,Commoncontrollersettings,continued

Home

MENU

SystemECLversion

Extension

Ethernet(ECLComfort310only)

Portalconfig(ECLComfort310only)

M-busconfig(ECLComfort310only)

EnergyMeters

(ECLComfort310only)

Rawinputoverview

Alarm

Display

Communication

Language

IDno.

Commoncontrollersettings

Function

Codeno.

Hardware

Software

Serialno.

Productiondate

Addresstype

ECLportal

Portalstatus

Portalinfo

5998

Command

5997

Baud

6000

M-busaddress

6002

Scantime

6001

Type

EnergyMeter1....5

S1-S10(S1-S18whenECA32/35isinstalled)

32:

Tsensordefect

60058

Backlight

60059

Contrast

2048

ECL485addr.

38

Modbusaddr.

39

Baud

2150

Servicepin

2151

Ext.reset

2050

Language

AQ152886470424en-010601

©Danfoss|2021.06|39

Page 40

OperatingGuideECLComfort310,applicationA319

3.0Dailyuse

3.1Howtonavigate

Younavigateinthecontrollerbyturningthedialleftorrightto

thedesiredposition().

Thedialhasabuilt-inaccellerator.Thefasteryouturnthedial,the

fasteritreachesthelimitsofanywidesettingrange.

Thepositionindicatorinthedisplay(

youare.

Pushthedialtoconfirmyourchoices().

Thedisplayexamplesarefromatwo-circuitapplication:One

heatingcircuit()andonedomestichot-water(DHW)circuit().

Theexamplesmightdifferfromyourapplication.

)willalwaysshowyouwhere

ExampleshowsECL210/310

Heatingcircuit():DHWcircuit();

Somegeneralsettingswhichapplytotheentirecontrollerare

locatedinaspecificpartofthecontroller.

Toenter‘Commoncontrollersettings’:

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Examples:

Circuitselector

40|©Danfoss|2021.06

AQ152886470424en-010601

Page 41

OperatingGuideECLComfort310,applicationA319

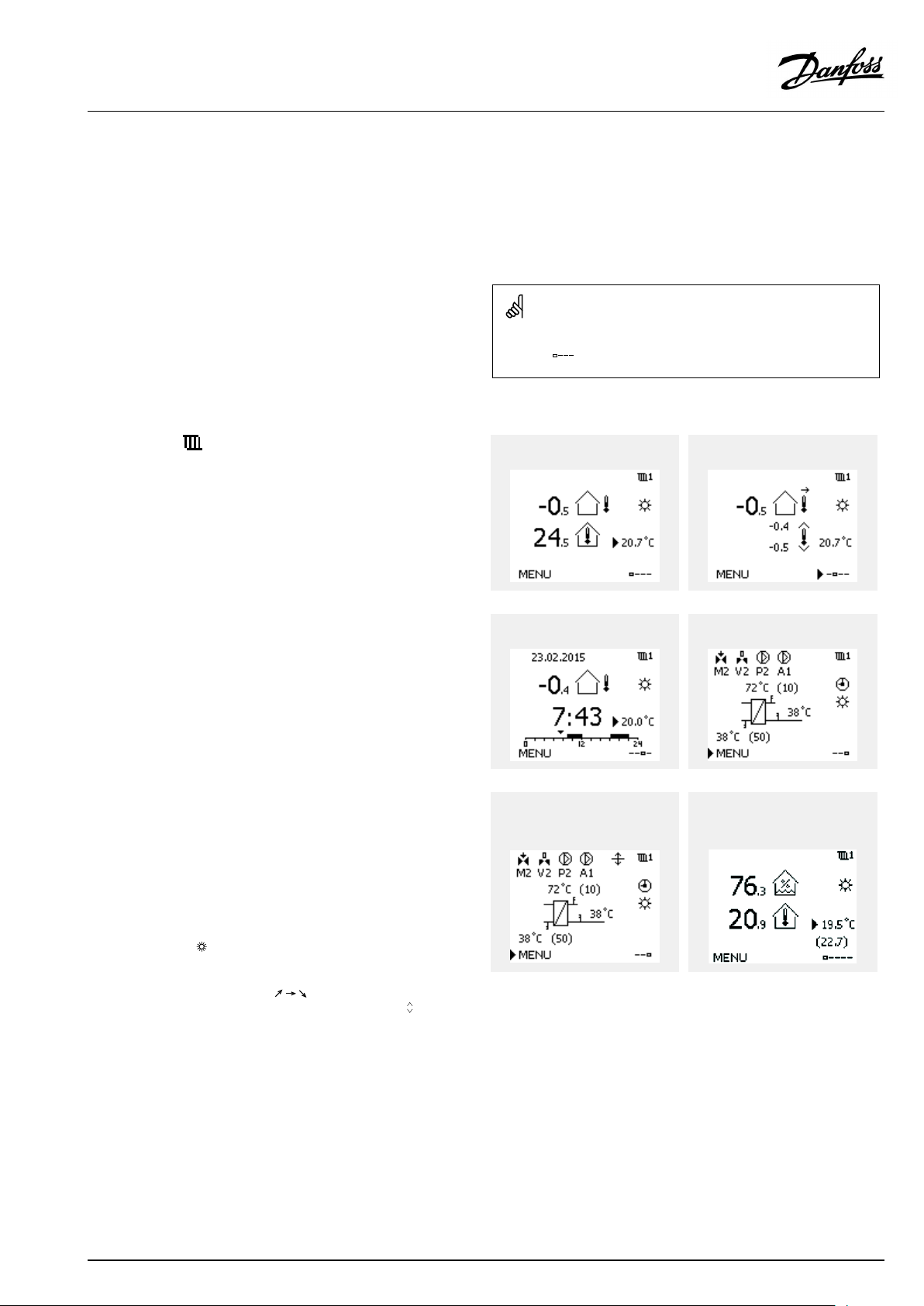

3.2Understandingthecontrollerdisplay

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Choosingafavoritedisplay

Yourfavoritedisplayisthedisplayyouhavechosenasthedefault

display.Thefavoritedisplaywillgiveyouaquickoverviewofthe

temperaturesorunitsthatyouwanttomonitoringeneral.

Ifthedialhasnotbeenactivatedfor20min.,thecontrollerwill

reverttotheoverviewdisplayyouhavechosenasfavorite.

Toshiftbetweendisplays:Turnthedialuntilyoureachthedisplay

selector(

turntochooseyourfavoriteoverviewdisplay.Pushthedialagain.

)atthebottomrightsideofthedisplay.Pushthedialand

Heatingcircuit

Overviewdisplay1informsabout:

actualoutdoortemperature,controllermode,

actualroomtemperature,desiredroomtemperature.

Overviewdisplay2informsabout:

actualoutdoortemperature,trendinoutdoortemperature,

controllermode,max.andmin.outdoortemperaturessince

midnightaswellasdesiredroomtemperature.

Overviewdisplay3informsabout:

date,actualoutdoortemperature,controllermode,time,desired

roomtemperatureaswellasshowsthecomfortscheduleofthe

currentday.

Overviewdisplay4informsabout:

stateofthecontrolledcomponents,actualflowtemperature,

(desiredflowtemperature),controllermode,returntemperature

(limitationvalue),influenceondesiredflowtemperature.

ThevalueabovetheV2symbolindicates0–100%oftheanalogue

signal(0–10V).

Note:

Anactualflowtemperaturevaluemustbepresent,otherwisethe

circuit'scontrolvalvewillclose.

Overviewdisplay1:Overviewdisplay2:

Overviewdisplay3:Overviewdisplay4:

Exampleofoverviewdisplaywith

Influenceindication:

Example,favoritedisplay1in

A230.3,wheremin.desiredroom

temperatureisindicated(22.7):

Dependentonthechosendisplay,theoverviewdisplaysforthe

heatingcircuitinformyouabout:

•actualoutdoortemperature(-0.5)

•controllermode()

•actualroomtemperature(24.5)

•desiredroomtemperature(20.7°C)

•trendinoutdoortemperature(

)

•min.andmax.outdoortemperaturessincemidnight(

•date(23.02.2010)

•time(7:43)

•comfortscheduleofthecurrentday(0-12-24)

•stateofthecontrolledcomponents(M2,P2)

•actualflowtemperature(49°C),(desiredflowtemperature(31))

•returntemperature(24°C)(limitationtemperature(50))

AQ152886470424en-010601

)

©Danfoss|2021.06|41

Page 42

OperatingGuideECLComfort310,applicationA319

Settingthedesiredtemperature

Dependingonthechosencircuitandmode,itispossibletoenter

alldailysettingsdirectlyfromtheoverviewdisplays(seealsothe

nextpageconcerningsymbols).

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

Ifthetemperaturevalueisdisplayedas

"--"

thesensorinquestionisnotconnected.

"---"

thesensorconnectionisshort-circuited.

Settingthedesiredroomtemperature

Thedesiredroomtemperaturecaneasilybeadjustedinthe

overviewdisplaysfortheheatingcircuit.

Action:Purpose:

Examples:

Desiredroomtemperature

Confirm

Adjustthedesiredroomtemperature

Confirm

Thisoverviewdisplayinformsaboutoutdoortemperature,actual

roomtemperatureaswellasdesiredroomtemperature.

Thedisplayexampleisforcomfortmode.Ifyouwanttochange

thedesiredroomtemperatureforsavingmode,choosethemode

selectorandselectsaving.

20.5

21.0

42|©Danfoss|2021.06

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

AQ152886470424en-010601

Page 43

OperatingGuideECLComfort310,applicationA319

Settingthedesiredroomtemperature,ECA30/ECA31

Thedesiredroomtemperaturecanbesetexactlyasinthe

controller.However,othersymbolscanbepresentinthedisplay

(pleasesee'Whatdothesymbolsmean?').

WiththeECA30/ECA31youcanoverridethedesiredroom

temperaturesetinthecontrollertemporarilybymeansoftheoverride

functions:

AQ152886470424en-010601

©Danfoss|2021.06|43

Page 44

OperatingGuideECLComfort310,applicationA319

3.3Ageneraloverview:Whatdothesymbolsmean?

Symbol

Description

Outdoortemp.

Relativehumidityindoor

Roomtemp.

DHWtemp.

Positionindicator

Scheduledmode

Comfortmode

Savingmode

Frostprotectionmode

Manualmode

Standby

Coolingmode

Symbol

Temperature

Mode

Description

Alarm

Letter

Event

Monitoringtemperaturesensor

connection

Displayselector

Max.andmin.value

Trendinoutdoortemperature

Windspeedsensor

Sensornotconnectedornotused

Sensorconnectionshort-circuited

Fixedcomfortday(holiday)

Activeinfluence

Heatingactive(+)

Coolingactive(-)

Activeoutputoverride

Optimizedstartorstoptime

Heating

Cooling

DHW

Commoncontrollersettings

PumpON

PumpOFF

FanON

FanOFF

Actuatoropens

Actuatorcloses

Actuator,analoguecontrol

signal

Pump/fanspeed

DamperON

Circuit

Controlled

component

Numberofheatexchangers

Additionalsymbols,ECA30/31:

Symbol

InECA30/31onlythesymbolsthatarerelevanttotheapplicationin

thecontrolleraredisplayed.

Description

ECARemoteControlUnit

Connectionaddress(master:15,slaves:1-9)

15

Dayoff

Holiday

Relaxing(extendedcomfortperiod)

Goingout(extendedsavingperiod)

44|©Danfoss|2021.06

DamperOFF

AQ152886470424en-010601

Page 45

OperatingGuideECLComfort310,applicationA319

3.4Monitoringtemperaturesandsystemcomponents

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Heatingcircuit

Theoverviewdisplayintheheatingcircuitensuresaquick

overviewoftheactualand(desired)temperaturesaswellasthe

actualstateofthesystemcomponents.

Displayexample:

49°C

(31)

24°C

(50)

Inputoverview

Anotheroptiontogetaquickoverviewofmeasuredtemperatures

isthe'Inputoverview'whichisvisibleinthecommoncontroller

settings(howtoenterthecommoncontrollersettings,see

‘Introductiontocommoncontrollersettings’ .)

Asthisoverview(seedisplayexample)onlystatesthemeasured

actualtemperatures,itisread-only.

Flowtemperature

Desiredflowtemperature

Returntemperature

Returntemperaturelimitation

AQ152886470424en-010601

©Danfoss|2021.06|45

Page 46

OperatingGuideECLComfort310,applicationA319

3.5Influenceoverview

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Themenugivesanoverviewoftheinfluencesonthedesired

flowtemperature.Itdiffersfromapplicationtoapplicationwhich

parametersarelisted.Itcanbehelpfulinaservicesituationto

explainunexpectedconditionsortemperaturesamongothers.

Ifthedesiredflowtemperatureisinfluenced(corrected)byoneor

moreparameters,itisindicatedbyasmalllinewitharrow-down,

arrow-upordouble-arrow:

Arrow-down:

Theparameterinquestionreducesthedesiredflowtemperature.

Arrow-up:

Theparameterinquestionincreasesthedesiredflowtemperature.

Double-arrow:

Theparameterinquestioncreatesanoverride(e.g.Holiday).

Straightline:

Noactiveinfluence.

Intheexample,thearrowinthesymbolpointsdownwardsfor

'Roomlim. ' .Thismeansthattheactualroomtemperatureis

higherthanthedesiredroomtemperaturewhichagainresultsina

decreaseofthedesiredflowtemperature.

ExampleofoverviewdisplaywithInfluenceindication:

46|©Danfoss|2021.06

AQ152886470424en-010601

Page 47

OperatingGuideECLComfort310,applicationA319

3.6Manualcontrol

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Itispossibletomanuallycontroltheinstalledcomponents.

Manualcontrolcanonlybeselectedinfavoritedisplaysinwhich

thesymbolsforthecontrolledcomponents(valve,pumpetc.)are

visible.

Action:Purpose:

Choosemodeselector

Confirm

Choosemanualmode

Confirm

Choosepump

Confirm

SwitchONthepump

SwitchOFFthepump.

Confirmpumpmode

Choosemotorizedcontrolvalve

Confirm

Openthevalve

Stopopeningthevalve

Closethevalve

Examples:

ControlledcomponentsCircuitselector

Duringmanualoperation:

•Allcontrolfunctionsaredeactivated

•Outputoverrideisnotpossible

•Frostprotectionisnotactive

Stopclosingthevalve

Confirmvalvemode

Toleavemanualcontrol,usethemodeselectortoselectthe

desiredmode.Pushthedial.

Manualcontrolistypicallyusedwhencommisioningthe

installation.Thecontrolledcomponents,valve,pumpetc.,canbe

controlledforcorrectfunction.

AQ152886470424en-010601

Whenmanualcontrolisselectedforonecircuit,itisautomatically

selectedforallcircuits!

Manualcontrolof0–10Volt/PWMcontrolledpumpspeed:

TheV1andV2symbolshaveavalue(in%)whichcanbechanged.

The%valueiscorrespondingtoavoltage/PWMintherange0–10

Volt/0-100%PWM.

©Danfoss|2021.06|47

Page 48

OperatingGuideECLComfort310,applicationA319

3.7Schedule

3.7.1Setyourschedule

ThissectiondescribesthescheduleingeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.Insomeapplications,however,theremightbemore

thanoneschedule.Additionalschedulescanbefoundin‘Common

controllersettings’ .

Thescheduleconsistsofa7-dayweek:

=

M

Monday

=

T

Tuesday

=

W

Wednesday

=

T

Thursday

=

F

Friday

=

S

Saturday

=

S

Sunday

Theschedulewillday-by-dayshowyouthestartandstoptimesof

yourcomfortperiods(heating/DHWcircuits).

Changingyourschedule:

Action:

Purpose:

Choose'MENU'inanyoftheoverview

displays

Confirm

Confirmthechoice'Schedule'

Choosethedaytochange

Confirm*

GotoStart1

Confirm

Adjustthetime

Confirm

GotoStop1,Start2etc.etc.

Returnto'MENU'

Confirm

Choose'Yes'or'No'in'Save'

Confirm

Examples:

*Severaldayscanbemarked

Thechosenstartandstoptimeswillbevalidforallthechosendays

(inthisexampleThursdayandSaturday).

Youcansetmax.3comfortperiodsaday.Youcandeleteacomfort

periodbysettingstartandstoptimestothesamevalue.

48|©Danfoss|2021.06

Eachcircuithasitsownschedule.Tochangetoanothercircuit,goto

'Home',turnthedialandchoosethedesiredcircuit.

Thestartandstoptimescanbesetinhalf-hourly(30min.)intervals.

AQ152886470424en-010601

Page 49

OperatingGuideECLComfort310,applicationA319

4.0Settingsoverview

Forfactorysettingsandsettingrange,seeappendix“ParameterIDoverview” .

ParametersindicatedwithanIDno.like"1x607"meanauniversalparameter.xstandsforcircuit/parametergroup.

SettingIDPage

Heatcurve

Ext.desiredT—(ECLComfort310)

Pressure,diff.

DesiredT(Desiredflowtemperature)

DesiredT(Desiredflowtemperature)

Demandoffset

Totalstop

Con.T,re.Tlim.(Constanttemperaturemode,return

temperaturelimitation)

HighToutX1(returntemp.limitation,highlimit,X-axis)

LowlimitY1(returntemp.limitation,lowlimit,Y-axis)

LowToutX2(returntemp.limitation,lowlimit,X-axis)

HighlimitY2(returntemp.limitation,highlimit,Y-axis)

Infl.-max.(returntemp.limitation-max.influence)

Infl.-min.(returntemp.limitation-min.influence)

Adapt.time(adaptationtime)

Char.Ppost-run(Chargingpump,post-run)

Cont.Tcontrol(Continuedtemperaturecontrol)

PfrostT(circulationpump,frostprotectiontemp.)

Delay

Frostpr.T(frostprotectiontemp.)

Ext.input(externaloverride)

Ext.mode(externaloverridemode)

Upperdifference

Lowerdifference

Delay,example

Lowesttemp.

Voutmax.

Voutmin.

Reverseout

Temp.min.

Temp.max.

Xp(proportionalband)

Tn(integrationtimeconstant)

Mrun(runningtimeofthemotorizedcontrolvalve)

Nz(neutralzone)

Min.act.time(min.activationtimegearmotor)

Stopdifference

Startdifference

1x00453

1x00472

1x01765

1x02165

1x02856

1x03156

1x032

1x033

1x034

1x035

1x036

1x03758

1x04266

1x05466

1x07767

1x08058

1x09367

1x141

1x14268

1x14775

1x14876

1x14976

1x150

1x16561

1x16761

1x171

1x17754

1x178

1x18462

1x18562

1x18662

1x18763

1x18963

1x19472

1x19573

Factorysettingsincircuit(s)

1

52

52

60

57

57

57

57

57

67

77

61

54

2

AQ152886470424en-010601

©Danfoss|2021.06|49

Page 50

OperatingGuideECLComfort310,applicationA319

SettingIDPage

Delay

Pumpstartdiff.

SenddesiredT

Pressurediff.des.(Pressuredifference,desired)

1x340

1x371

1x50070

1x55863

Factorysettingsincircuit(s)

1

77

74

2

50|©Danfoss|2021.06

AQ152886470424en-010601

Page 51

OperatingGuideECLComfort310,applicationA319

5.0Settings

5.1IntroductiontoSettings

Descriptionsofsettings(parameter'sfunctions)aredividedinto

groupsasusedintheECLComfort210/296/310controller's

menustructure.Examples:"Flowtemperature" ,"Roomlimit"and

soon.Eachgroupstartswithageneralexplanation.

Thedescriptionsofeachparameterareinnumericorder,relatedto

theparameter'sIDnumbers.Youmightcomeacrossdifferences

betweentheorderinthisOperatingGuideandtheECLComfort

210/296/310controllers.

Someparameterdescriptionsarerelatedtospecificapplication

subtypes.Thismeansthatyoumightnotseetherelatedparameter

intheactualsubtypeintheECLcontroller.

Thenote"SeeAppendix… "referstotheAppendixattheendof

thisOperatingGuide,whereparameter'ssettingrangesandfactory

settingsarelisted.

Thenavigationhints(forexampleMENU>Settings>Returnlimit

…)covermultiplesubtypes.

AQ152886470424en-010601

©Danfoss|2021.06|51

Page 52

OperatingGuideECLComfort310,applicationA319

5.2Flowtemperature

TheECLComfortcontrollerdeterminesandcontrolstheflow

temperaturerelatedtotheoutdoortemperature.Thisrelationship

iscalledtheheatcurve.

Theheatcurveissetbymeansof6coordinatepoints.Thedesired

flowtemperatureissetat6pre-definedoutdoortemperature

values.

Theshownvaluefortheheatcurveisanaveragevalue(slope),

basedontheactualsettings.

Slopechanges

Outdoortemp.

(factorysettings)Yoursettings

-30°C75°C

-15°C70°C

-5°C65°C

0°C60°C

5°C60°C

15°C60°C

MENU>Settings>Flowtemperature

Desiredtemperature:

Heatcurve

CircuitSettingrange

1

0.1...4.01.0

Theheatcurvecanbechangedintwoways:

1.Thevalueoftheslopeischanged(seeheatcurveexamples

onnextpage)

2.Thecoordinatesoftheheatcurvearechanged

Example:

Heatcurve:

Desiredflowtemp.:

Desiredroomtemp.:

Calculation(22–20)×1.0×2.5=

Result:

Thedesiredflowtemperaturewillbecorrectedfrom50°Cto55°C.

Factorysetting

1.0

50°C

22°C

5

Changethevalueoftheslope:

Pushthedialtoenter/changetheslopevalueoftheheatcurve

(example:1.0).

Whentheslopeoftheheatcurveischangedbymeansoftheslope

value,thecommonpointforallheatcurveswillbeadesiredflow

temperature=24.6°Catanoutdoortemperature=20°C

Changethecoordinates:

Pushthedialtoenter/changethecoordinatesoftheheatcurve

(example:-30,75).

Theheatcurverepresentsthedesiredflowtemperaturesat

differentoutdoortemperaturesandatadesiredroomtemperature

of20°C.

Ifthedesiredroomtemperatureischanged,thedesiredflow

temperaturealsochanges:

(DesiredroomT-20)×HC×2.5

where"HC"istheHeatCurveslopeand"2.5"isaconstant.

52|©Danfoss|2021.06

AQ152886470424en-010601

Page 53

OperatingGuideECLComfort310,applicationA319

Externalsignalfordesiredflowtemperature

Avoltage(0-10V)canbeappliedtotheinputterminalS10in

ordertodeterminethedesiredflowtemperature.

ThemeasuredvoltageoninputS10mustbeconvertedtoa

temperaturevaluebythecontroller.Whenthevoltagegetshigher,

thedesiredflowtemperatureincreases.

Thefollowingsettingssetupthescaling.

MENU>Settings>Flowtemperature

Ext.desiredT—(ECLComfort310)

CircuitSettingrange

1

Theactualdesiredflowtemperatureisindicatedbytheunit°C.

Read-outonly

Factorysetting

Read-out:

--:

°C:

Externalvoltagesignalisnotconnected..

Externalvoltagesignalconvertedtodesiredflow

temperature.

Pushthedialtoseethegraphandenterthevaluesetsfortheinput

voltage(1and10volt)anddisplayeddesiredflowtemperature.

Example:Relationshipbetweeninputvoltageanddisplayeddesiredflow

temperature

Desiredflowtemp.(°C)

Volt

Thisexampleshowsthat1voltcorrespondsto10.0°Cand10volt

correspondto100°C.

Desiredflowtemperature:

10...120°C

Fixedvoltagesettings:1Vand10V

Factorysettings:

(1,10)and(10,100)

Thismeansthatthe‘Desiredflowtemperature’is10°Cat1.0V

and100°Cat10V.

Typically,thehigherthevoltage,thehigherthedisplayeddesired

flowtemperature.

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

Theexternalvoltagesignalmustbehigherthan1.0Vinorderto

activatetheoverride.

AQ152886470424en-010601

©Danfoss|2021.06|53

Page 54

OperatingGuideECLComfort310,applicationA319

MENU>Settings>Flowtemperature

DesiredT(Desiredflowtemperature)

WhentheECLComfortisinoverridemode,type"Const.T",thedesiredflow

temperaturecanbeset.

A"Const.T"relatedreturntemperaturelimitationcanalsobeset.SeeMENU

>Settings>Returnlimit>'Con.T,ret.Tlim. '

1x004

SeeAppendix“ParameterIDoverview”

MENU>Settings>Flowtemperature

Temp.min.

1x177

SeeAppendix“ParameterIDoverview”

Setthemin.flowtemperatureforthesystem.Thedesiredflow

temperaturewillnotbelowerthanthissetting.Adjustthefactory

setting,ifrequired.

Overridemode

WhenECLComfortisinScheduledmode,acontact(switch)signalcan

beappliedtoaninputinordertooverridetoComfort,Saving,Frost

ProtectionorConstanttemperature.Aslongasthecontact(switch)

signalisapplied,theoverrideisactive.

The"DesiredT"valuecanbeinfluencedby:

•temp.max.

•temp.min.

•roomtemp.limit

•returntemp.limit

•flow/powerlimit

‘Temp.min.’isoverruledif'Totalstop'isactiveinSavingmodeor

'Cut-out'isactive.

‘Temp.min.’canbeoverruledbytheinfluencefromthereturn

temperaturelimitation(see'Priority').

MENU>Settings>Flowtemperature

Temp.max.

1x178

SeeAppendix“ParameterIDoverview”

Setthemax.flowtemperatureforthesystem.Thedesired

temperaturewillnotbehigherthanthissetting.Adjustthefactory

setting,ifrequired.

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

Thesettingof‘heatcurve’ispossibleforheatingcircuitsonly.

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

54|©Danfoss|2021.06

AQ152886470424en-010601

Page 55

OperatingGuideECLComfort310,applicationA319

5.3Returnlimit

Thereturntemperaturelimitationisbasedontheoutdoor

temperature.Typicallyindistrictheatingsystemsahigherreturn

temperatureisacceptedatadecreaseinoutdoortemperature.The

relationshipbetweenthereturntemperaturelimitsandoutdoor

temperatureissetintwocoordinates.

Theoutdoortemperaturecoordinatesaresetin'HighToutX1'

and'LowToutX2' .Thereturntemperaturecoordinatesaresetin

'HighlimitY2'and'LowlimitY1' .

Thecontrollerautomaticallychangesthedesiredflowtemperature

toobtainanacceptablereturntemperaturewhenthereturn

temperaturefallsbeloworgetshigherthanthecalculatedlimit.

ThislimitationisbasedonaPIregulationwhereP('Infl.'factor)

respondsquicklytodeviationsandI('Adapt.time')responds

slowerandovertimeremovesthesmalloffsetsbetweenthe

desiredandactualvalues.Thisisdonebychangingthedesired

flowtemperature.

X

Y

#X1#

#X2#

#Y1#

#Y2#

=

Outdoortemperature

=

Limitationtemperature

=

HighTout(1x031)

=

LowTout(1x033)

=

Lowlimit(1x032)

=

Highlimit(1x034)

Example,maximumreturntemperaturelimitation;

returntemperaturegetshigherthanlimit

Thecalculatedlimitisshowninbrackets()inthemonitoringdisplay.

Seethesection"Monitoringtemperaturesandsystemcomponents" .

=

T

Temperature

=

Y

Temperature

=

X

Time

=

#1#

Returntemperature

=

#2#

Returntemperaturelimit

=

#3#

Desiredflowtemperature

=

#4#

Actionpoint

AQ152886470424en-010601

©Danfoss|2021.06|55

Page 56

OperatingGuideECLComfort310,applicationA319

Example,minimumreturntemperaturelimitation;

returntemperaturegetslowerthanlimit

=

T

Y

X

#1#

#2#

#3#

#4#

Temperature

=

Temperature

=

Time

=

Returntemperature

=

Returntemperaturelimit

=

Desiredflowtemperature

=

Actionpoint

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

MENU>Settings>Returnlimit

Con.T,re.Tlim.(Constanttemperaturemode,return

temperaturelimitation)

The"Con.T ,ret.Tlimit"isthereturntemperaturelimitationvaluewhenthe

circuitissettooverridemodetype"Const.T"(=Constanttemperature).

SeeAppendix“ParameterIDoverview”

Value:Setthereturntemperaturelimitation

1x028

56|©Danfoss|2021.06

AQ152886470424en-010601

Page 57

OperatingGuideECLComfort310,applicationA319

MENU>Settings>Returnlimit

HighToutX1(returntemp.limitation,highlimit,X-axis)

Settheoutdoortemperaturevalueforthelowreturntemperaturelimitation.

SeeAppendix“ParameterIDoverview”

ThecorrespondingYcoordinateissetin'LowlimitY1' .

MENU>Settings>Returnlimit

LowlimitY1(returntemp.limitation,lowlimit,Y-axis)

Setthereturntemperaturelimitationreferringtotheoutdoortemperature

valuesetin'HighToutX1' .

SeeAppendix“ParameterIDoverview”

ThecorrespondingXcoordinateissetin'HighToutX1' .

MENU>Settings>Returnlimit

LowToutX2(returntemp.limitation,lowlimit,X-axis)

Settheoutdoortemperaturevalueforthehighreturntemperature

limitation.

1x031

1x032

1x033

SeeAppendix“ParameterIDoverview”

ThecorrespondingYcoordinateissetin'HighlimitY2'.

MENU>Settings>Returnlimit

HighlimitY2(returntemp.limitation,highlimit,Y-axis)

Setthereturntemperaturelimitationreferringtotheoutdoortemperature

valuesetin'LowToutX2' .

SeeAppendix“ParameterIDoverview”

ThecorrespondingXcoordinateissetin'LowToutX2' .

MENU>Settings>Returnlimit

Infl.-max.(returntemp.limitation-max.influence)

Determineshowmuchthedesiredflowtemperaturewillbeinfluencedifthe

returntemperatureishigherthanthesetlimit.

SeeAppendix“ParameterIDoverview”

Influencehigherthan0:

Thedesiredflowtemperatureisincreased,whenthereturn

temperaturegetshigherthanthesetlimit.

1x034

Example

1x035

Thereturnlimitisactiveabove50°C.

Theinfluenceissetto0.5.

Theactualreturntemperatureis2degreestoohigh.

Result:

Thedesiredflowtemperatureischangedby0.5x2=1.0degree.

Influencelowerthan0:

Thedesiredflowtemperatureisdecreased,whenthereturn

temperaturegetshigherthanthesetlimit.

AQ152886470424en-010601

©Danfoss|2021.06|57

Page 58

OperatingGuideECLComfort310,applicationA319

MENU>Settings>Returnlimit

Infl.-min.(returntemp.limitation-min.influence)

Determineshowmuchthedesiredflowtemperaturewillbeinfluencedifthe

returntemperatureislowerthanthecalculatedlimit.