Page 1

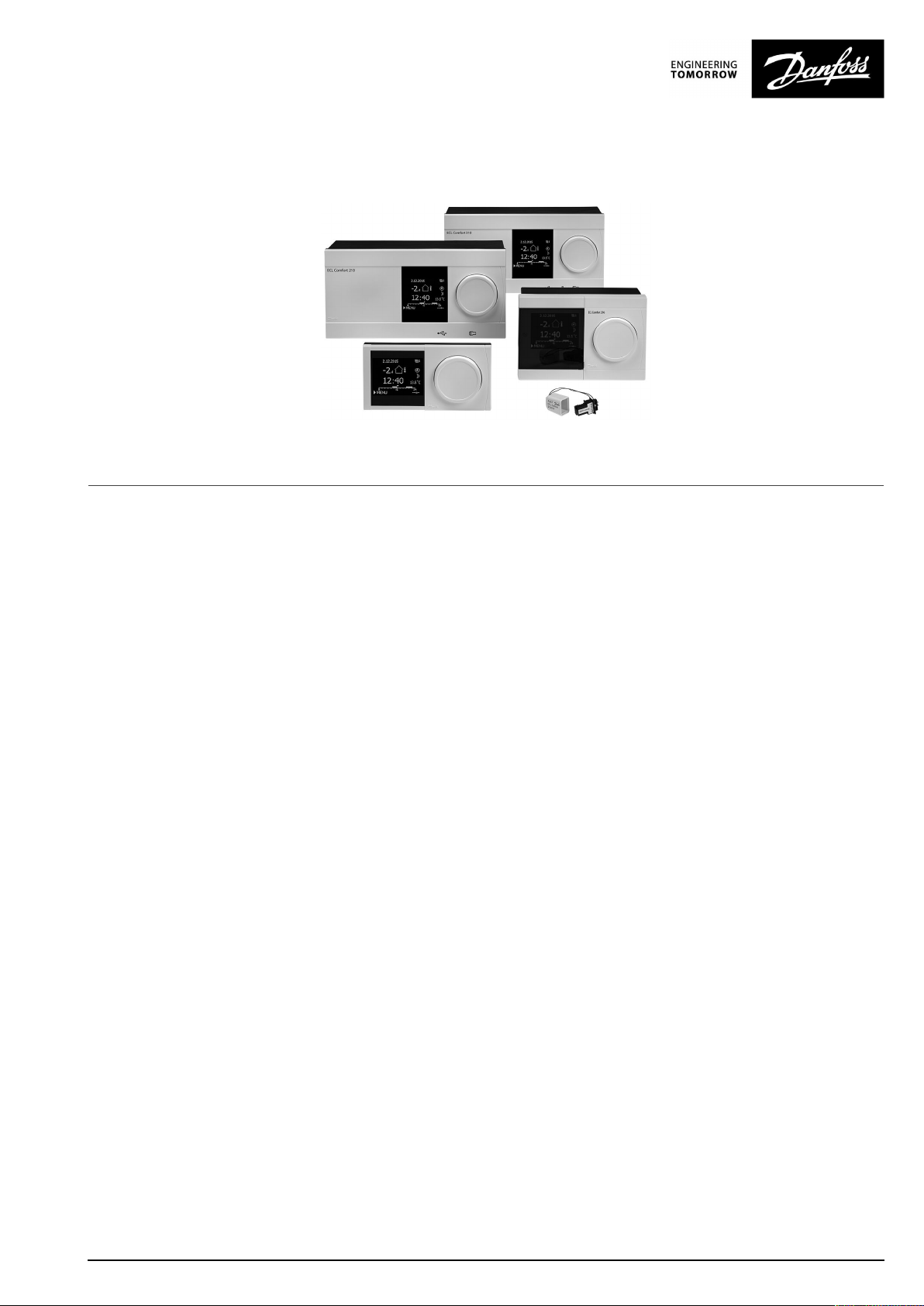

OperatingGuide

ECLComfort210/296/310,applicationA275/A375

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................7

2.1Beforeyoustart.....................................................7

2.2Identifyingthesystemtype......................................29

2.3Mounting...........................................................45

2.4Placingthetemperaturesensors................................48

2.5Electricalconnections.............................................50

2.6InsertingtheECLApplicationKey..............................59

2.7Checklist............................................................66

2.8Navigation,ECLApplicationKeyA275.........................67

3.0Dailyuse.........................................................79

3.1Howtonavigate...................................................79

3.2Understandingthecontrollerdisplay..........................80

3.3Ageneraloverview:Whatdothesymbolsmean?...........84

3.4Monitoringtemperaturesandsystem

components........................................................85

3.5Influenceoverview................................................87

3.6Manualcontrol.....................................................88

3.7Schedule............................................................89

4.0Settingsoverview............................................90

5.0Settings...........................................................93

5.1IntroductiontoSettings..........................................93

5.2Flow(boiler)temperature........................................94

5.3Tanktemperature..................................................98

5.4Roomlimit........................................................101

5.5Returnlimit.......................................................103

5.6Optimization......................................................108

5.7Boiler...............................................................114

5.8Controlparameters..............................................122

5.9Application.......................................................127

5.10Alarm..............................................................135

5.11Alarmoverview..................................................142

5.12Anti-bacteria......................................................143

6.0Commoncontrollersettings............................145

6.1Introductionto‘Commoncontrollersettings’..............145

6.2Time&Date.......................................................146

6.3Holiday............................................................147

6.4Inputoverview...................................................149

6.5Log.................................................................150

6.6Outputoverride..................................................151

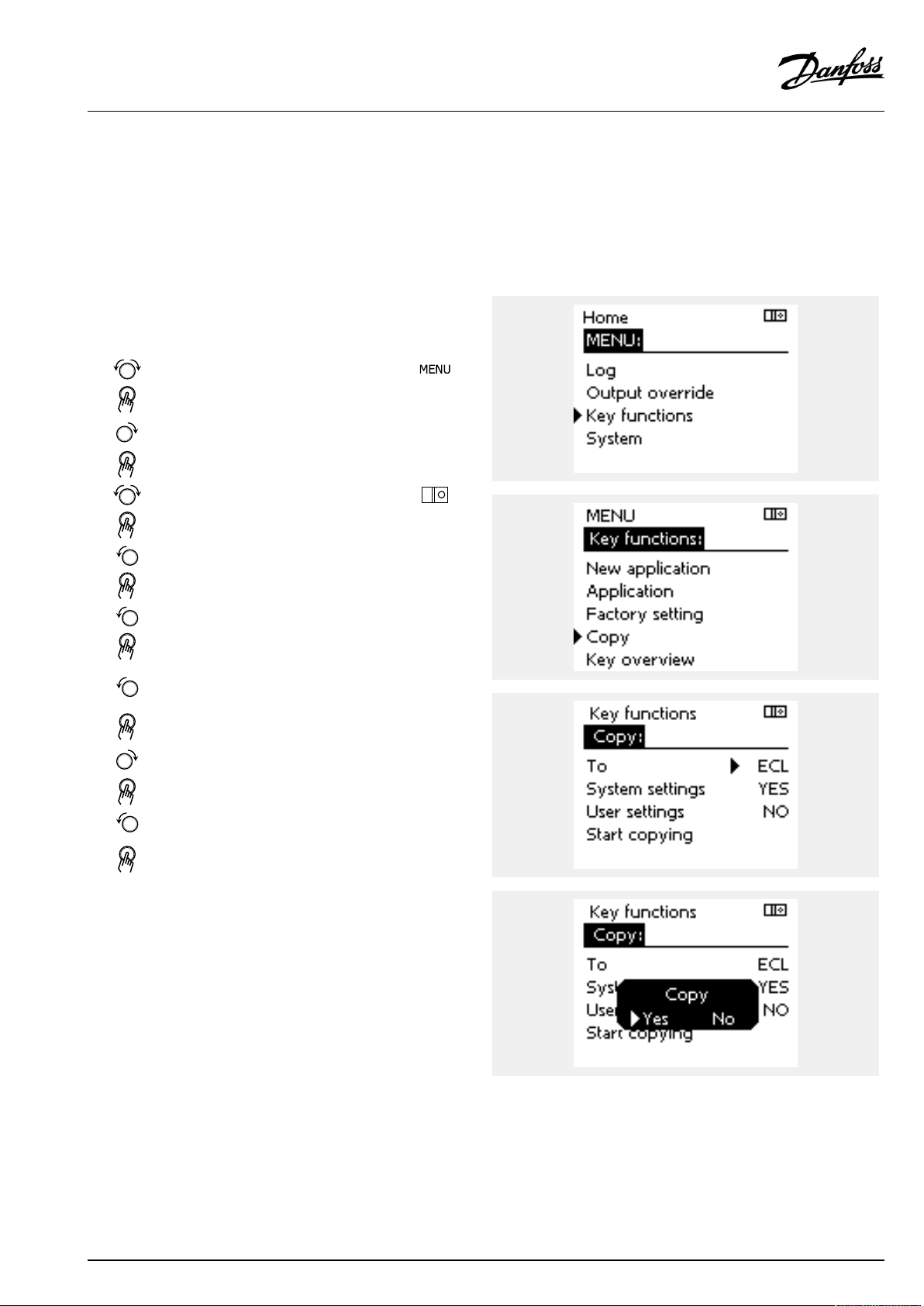

6.7Keyfunctions.....................................................152

6.8System.............................................................154

7.0Miscellaneous................................................161

7.1ECA30/31setupprocedures.................................161

7.2Overridefunction................................................169

7.3Severalcontrollersinthesamesystem......................172

7.4Frequentlyaskedquestions....................................175

7.5Definitions........................................................179

7.6Type(ID6001),overview.......................................183

7.7Automatic/manualupdateoffirmware.....................184

7.8ParameterIDoverview..........................................185

©Danfoss|2021.04AQ042286456873en-010501|1

Page 2

OperatingGuideECLComfort210/296/310,applicationA275/A375

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwithECLApplicationKeyA275

(ordercodeno.087H3814).

TheECLapplicationkeyA275containstwosetsofapplications:

•A275(subtypesA275.1,A275.2,A275.3)

•A375(subtypesA375.1,A375.2,A375.3,A375.4,A375.5).A375

subtypesonlyruninECL310.

SubtypesA275.1,A275.2andA275.3arefor1-burnersolutions.

SubtypesA375.1,A375.2andA375.3areformultipleburner

solutions.

SubtypesA375.4andA375.5arefor1-burnersolutions,inclusive

0-10Voltcontrolofburnertemperature.

Thefunctionscanberealizedin:

•ECLComfort210(A275)forsimplesolutionsor

•ECLComfort296(A275)forsimplesolutions,buthaving

advancedcommunication,suchasM-bus,Modbusand

Ethernet(Internet)communicationor

•ECLComfort310(A275/A375)foradvancedsolutions,e.g.

M-bus,ModbusandEthernet(Internet)communication.

FloworpowerlimitationviaM-busisnotusedinA275/A375.

TheapplicationA275complieswithECLComfortcontroller210

and310asofsoftwareversion1.11(visibleatstart-upofthe

controllerandin‘Commoncontrollersettings’in‘System’).

TheApplicationKeyA275alsocomplieswithECLComfort296

controllersasoffirmwareversion1.58.

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connectedforremotemonitoringandsetting.Thebuilt-inroom

temperaturesensorcanbeutilized.

ECLPortal,Internetbasedconnection,allowsECL296,310and

310Btobemonitoredandcontrolledremotelyviastandard

Internetbrowsers(forexampleInternetExplorer,GoogleChrome

andSafari).

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationexamplesandelectricalconnections.

AdditionaldocumentationforECLComfort210,296and310and

accessoriesareavailableonhttps://store.danfoss.com.

2|©Danfoss|2021.04

AQ042286456873en-010501

Page 3

OperatingGuideECLComfort210/296/310,applicationA275/A375

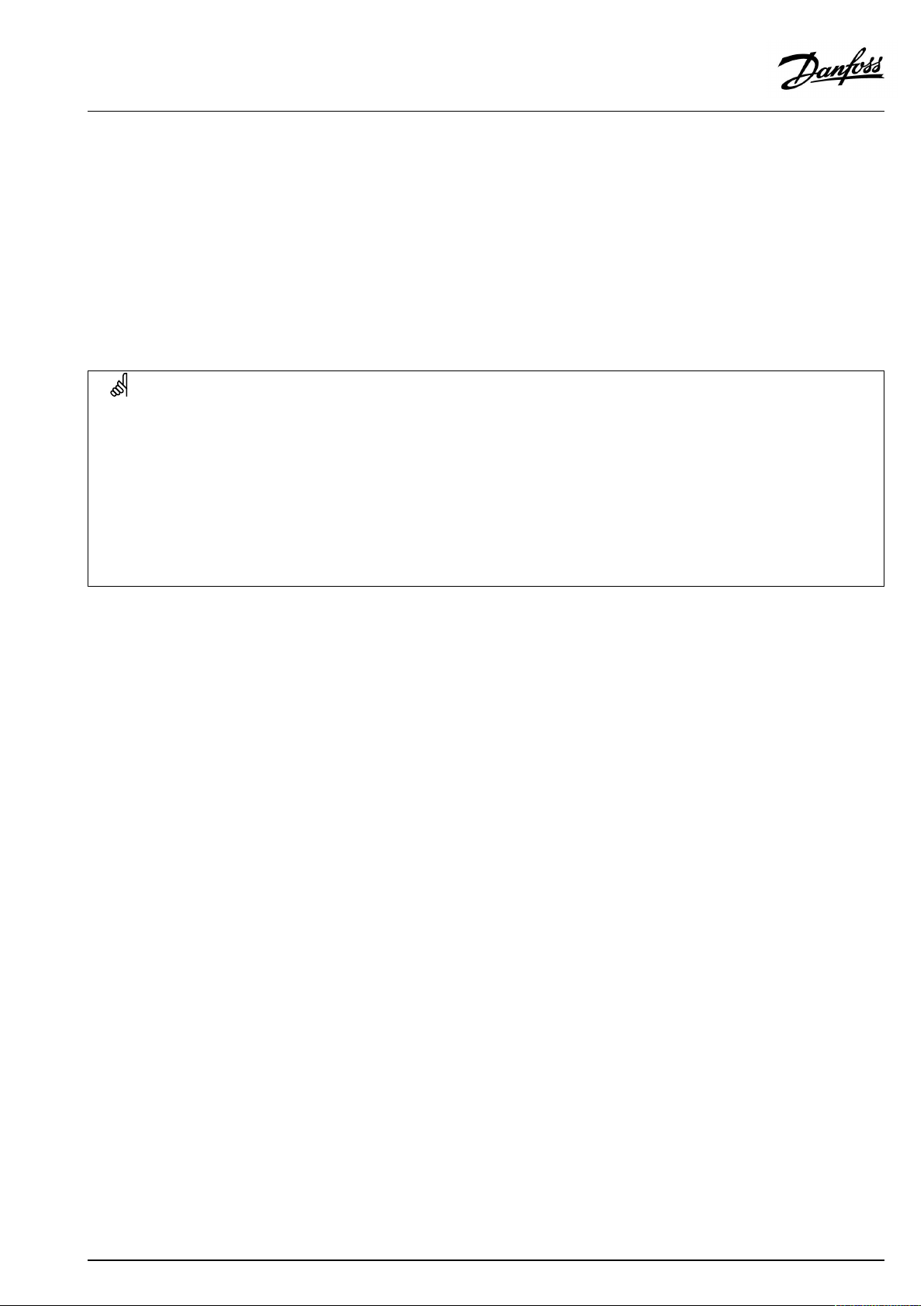

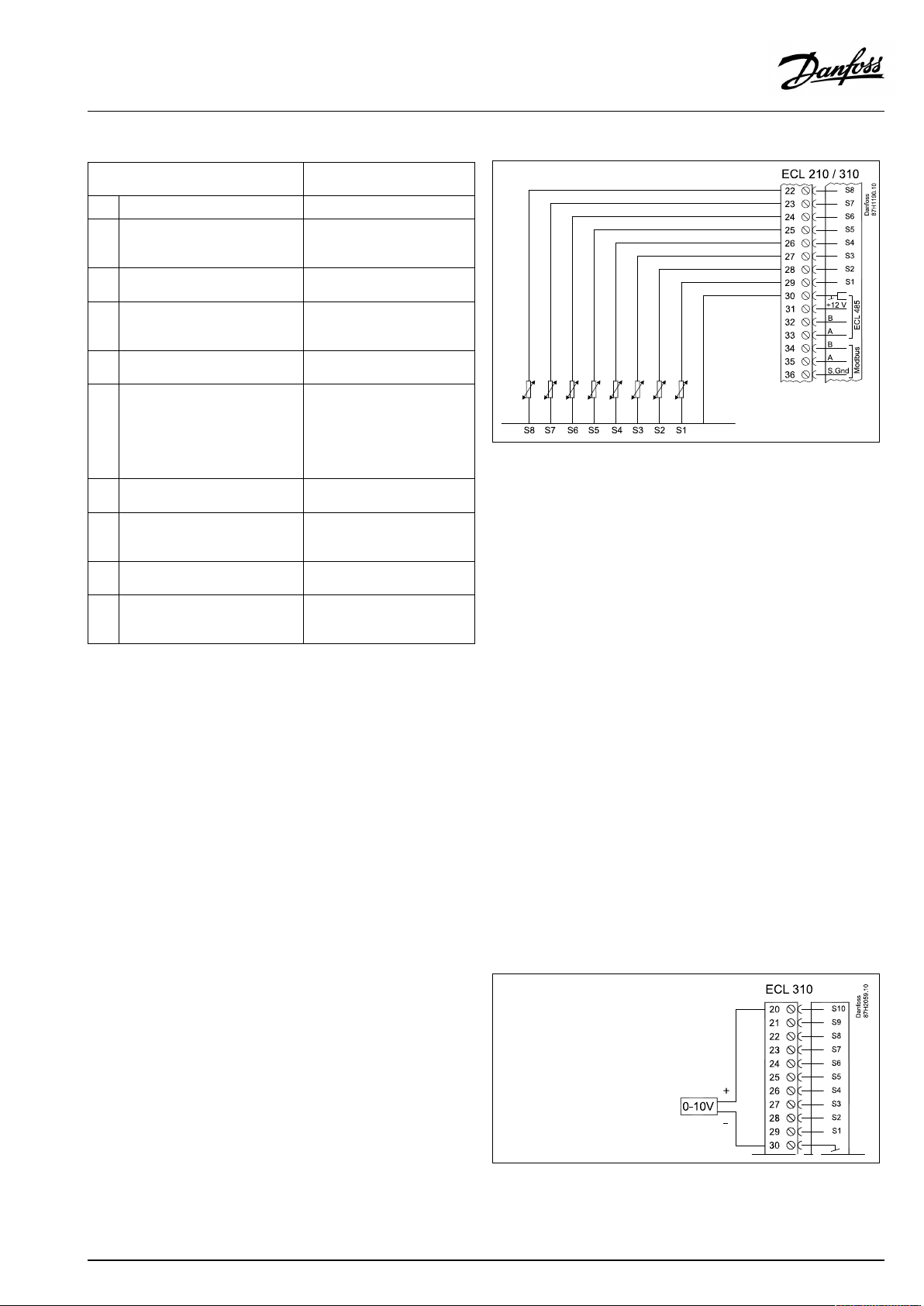

TogetherwiththeECLComfort310,theadditionalInternalI/O

moduleECA32(ordercodeno.087H3202)canbeusedforextra

datacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

•Digitalinput

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLTool".

Navigation:Danfoss.com>Serviceandsupport>Downloads>

Tools>Heating>ECLTool.

TheURLis:

https://www.danfoss.com/en/service-and-support/downloads/

TheInternalI/OmoduleECA32isplacedinthebasepartforECL

Comfort310.

ECLComfort210isavailableas:

•ECLComfort210,230volta.c.(087H3020)

•ECLComfort210B,230volta.c.(087H3030)

ECLComfort296isavailableas:

•ECLComfort296,230volta.c.(087H3000)

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(087H3040)

•ECLComfort310B,230volta.c.(087H3050)

•ECLComfort310,24volta.c.(087H3044)

TheB-typeshavenodisplayanddial.TheB-typesareoperatedby

meansoftheRemoteControlunitECA30/31:

•ECA30(087H3200)

•ECA31(087H3201)

BasepartsforECLComfort:

•forECLComfort210,230volt(087H3220)

•forECLComfort296,230volt(087H3240)

•forECLComfort310,230voltand24volt(087H3230)

AdditionaldocumentationforECLComfort210,296and310,

modulesandaccessoriesisavailableonhttp://heating.danfoss.com/

orhttp://store.danfoss.com.

DocumentationforECLPortal:Seehttp://ecl.portal.danfoss.com.

A275/A375navigationingeneral:

A275.1/A375.1/A375.4A275.2/A375.2A275.3/A375.3/A375.5

CircuitCircuitCircuit

11

AQ042286456873en-010501

2

1

23

©Danfoss|2021.04|3

Page 4

OperatingGuideECLComfort210/296/310,applicationA275/A375

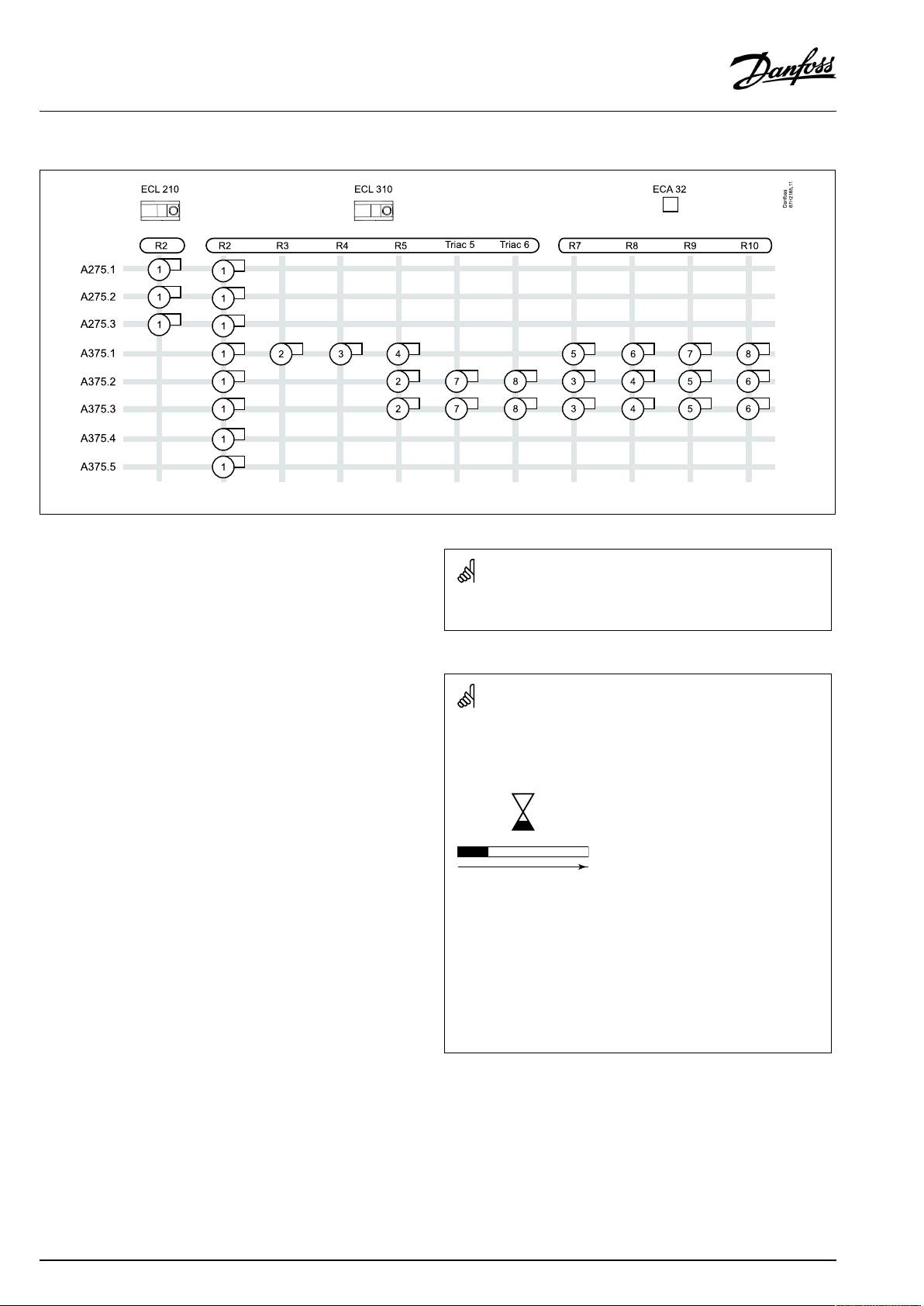

Burnercontroloverview:

R2–R10=relaynos.inECL/ECA32

Seethesection‘Electricalconnections’formoredetailedinformation.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

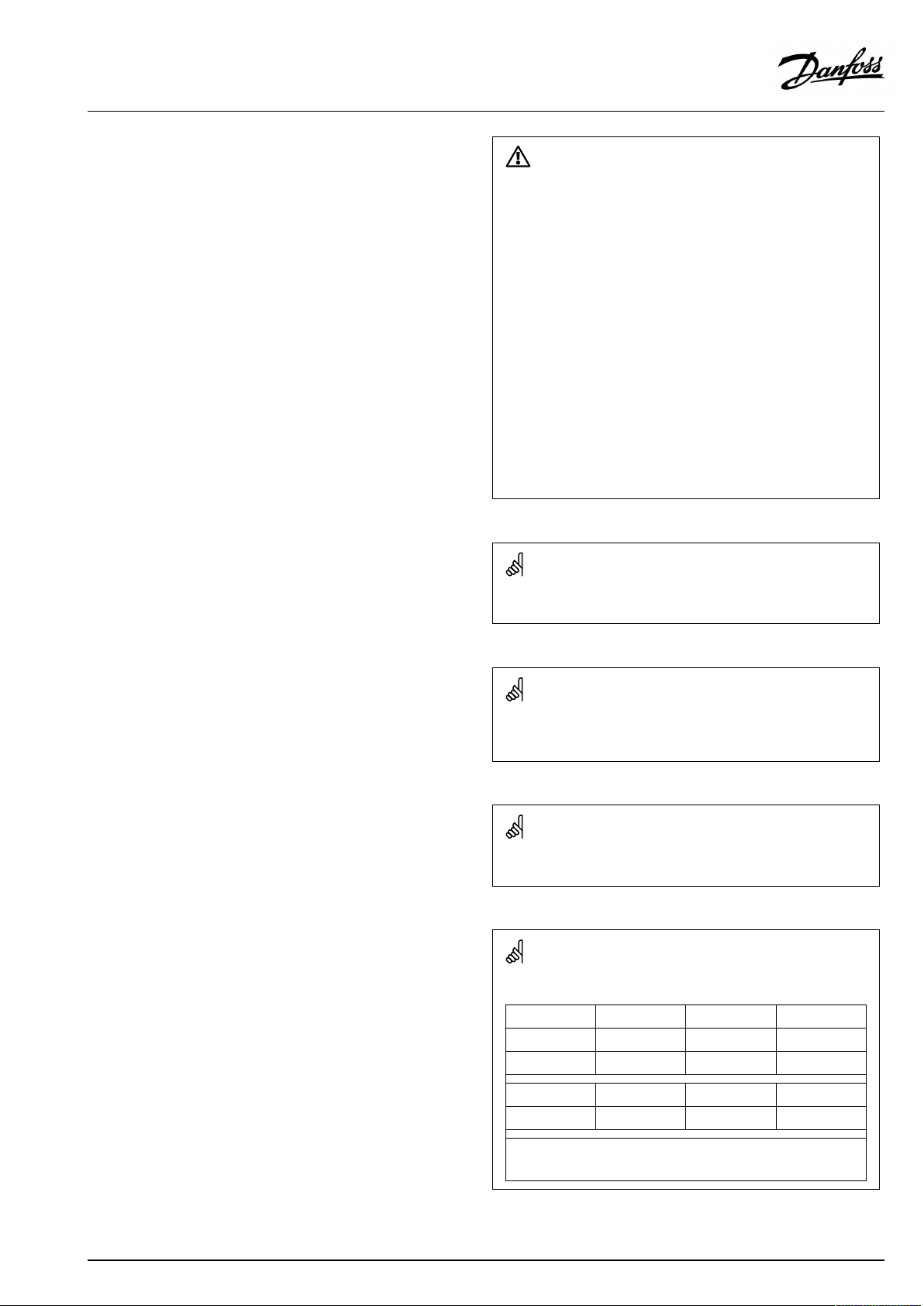

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

4|©Danfoss|2021.04

AQ042286456873en-010501

Page 5

OperatingGuideECLComfort210/296/310,applicationA275/A375

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

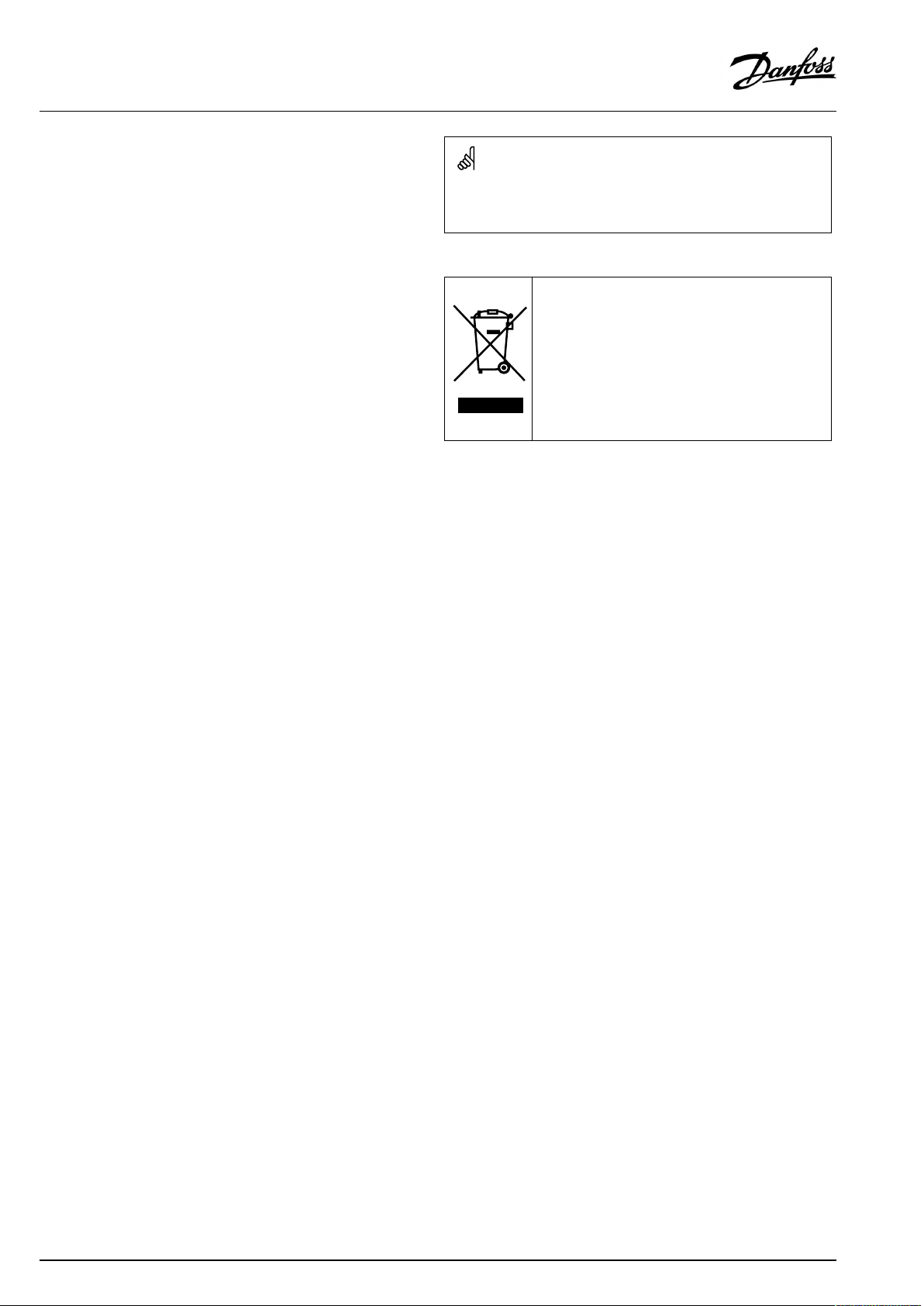

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1Parameterno.

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

2

Circuit2Parameterno.

AQ042286456873en-010501

174

©Danfoss|2021.04|5

Page 6

OperatingGuideECLComfort210/296/310,applicationA275/A375

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thissymbolontheproductindicatesthatitmaynot

bedisposedofashouseholdwaste.

Itmustbehandedovertotheapplicabletake-back

schemefortherecyclingofelectricalandelectronic

equipment.

•Disposeoftheproductthroughchannelsprovided

forthispurpose.

•Complywithalllocalandcurrentlyapplicablelaws

andregulations.

6|©Danfoss|2021.04

AQ042286456873en-010501

Page 7

OperatingGuideECLComfort210/296/310,applicationA275/A375

2.0Installation

2.1Beforeyoustart

TheapplicationA275.1isveryflexible.Thesearethebasic

principles:

Heating(circuit1):

Typically,theboilertemperatureisadjustedaccordingtoyour

requirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

theboilertemperature.ThedesiredboilertemperatureatS3is

calculatedintheECLcontroller,basedontheoutdoortemperature

(S1)andthedesiredroomtemperature.Thelowertheoutdoor

temperature,thehigherthedesiredboilertemperature.Theboiler

temperatureisalsotheflowtemperatureinthedirectconnected

heatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

TheburnerisswitchedONwhentheboilertemperatureis

lowerthanthedesiredboilertemperatureandswitchedOFF

whentheboilertemperatureishigherthanthedesiredboiler

temperature.AswitchingdifferencedeterminestheON/OFF

control.Furthermore,theboilerprotectionfunctionwillonly

switchONthecirculationpumpiftheboilertemperaturegets

aboveaminimumtemperature.AminimumON-timecanbesetfor

theburnerinordertoincreasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS7ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredboilertemperaturecanbeadjusted.

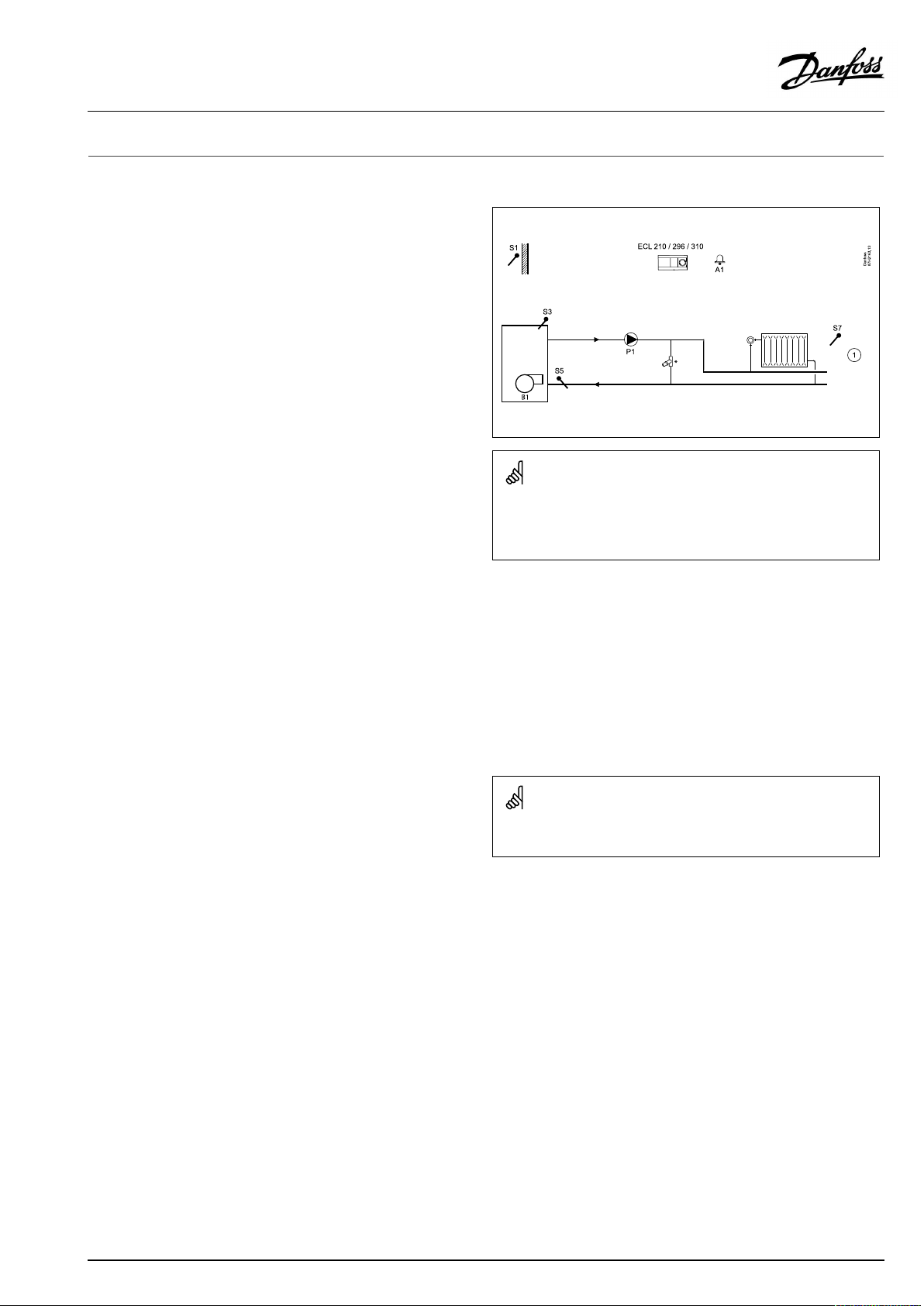

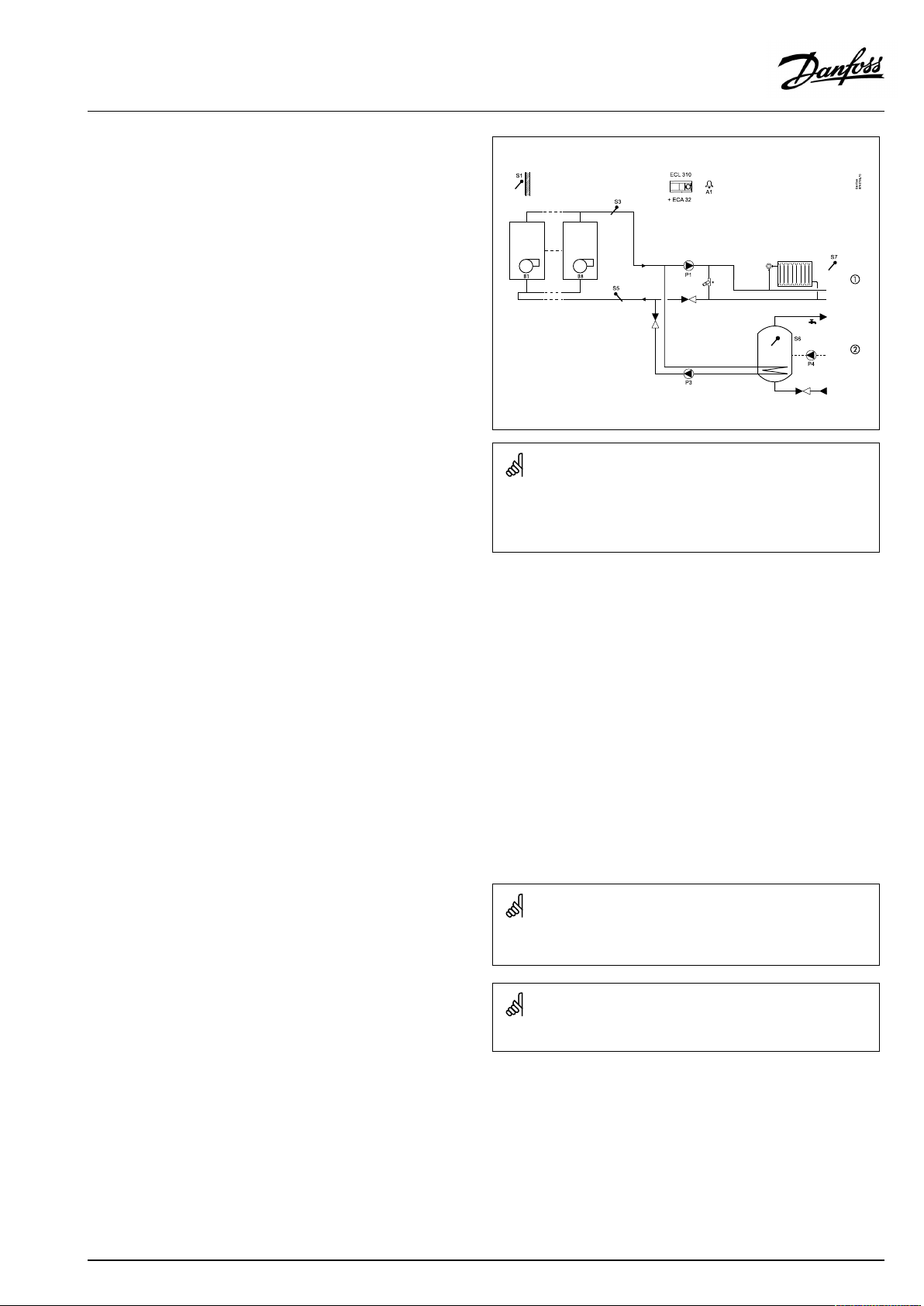

TypicalA275.1application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S3

(mandatory)Boilertemperaturesensor

S5Returntemperaturesensor

S7

Roomtemperaturesensor/ECA30

P1

Circulationpump

B1Burner

A1

Alarm

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFiftheoutdoortemperaturegets

higherthanasetvalue.

AQ042286456873en-010501

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

©Danfoss|2021.04|7

Page 8

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA275.2isveryflexible.Thesearethebasic

principles:

Heating(circuit1):

Typically,theboilertemperatureisadjustedaccordingtoyour

requirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

theboilertemperature.ThedesiredboilertemperatureatS3is

calculatedintheECLcontroller,basedontheoutdoortemperature

(S1)andthedesiredroomtemperature.Thelowertheoutdoor

temperature,thehigherthedesiredboilertemperature.Theboiler

temperatureisalsotheflowtemperatureinthedirectconnected

heatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

TheburnerisswitchedONwhentheboilertemperatureis

lowerthanthedesiredboilertemperatureandswitchedOFF

whentheboilertemperatureishigherthanthedesiredboiler

temperature.AswitchingdifferencedeterminestheON/OFF

control.Furthermore,theboilerprotectionfunctionwillonly

switchONthecirculationpumpiftheboilertemperaturegets

aboveaminimumtemperature.AminimumON-timecanbesetfor

theburnerinordertoincreasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS7ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredboilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFiftheoutdoortemperaturegets

higherthanasetvalue.

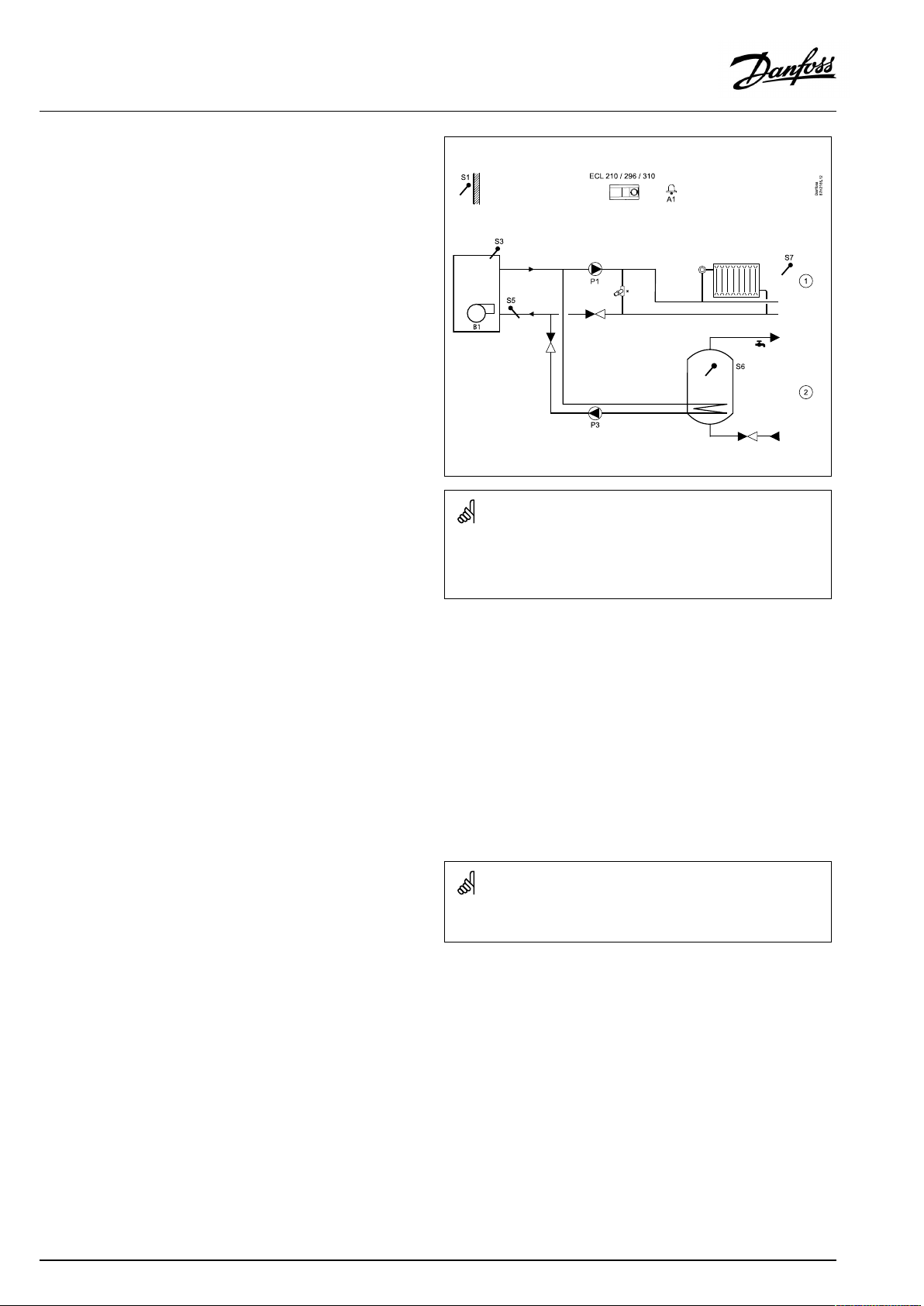

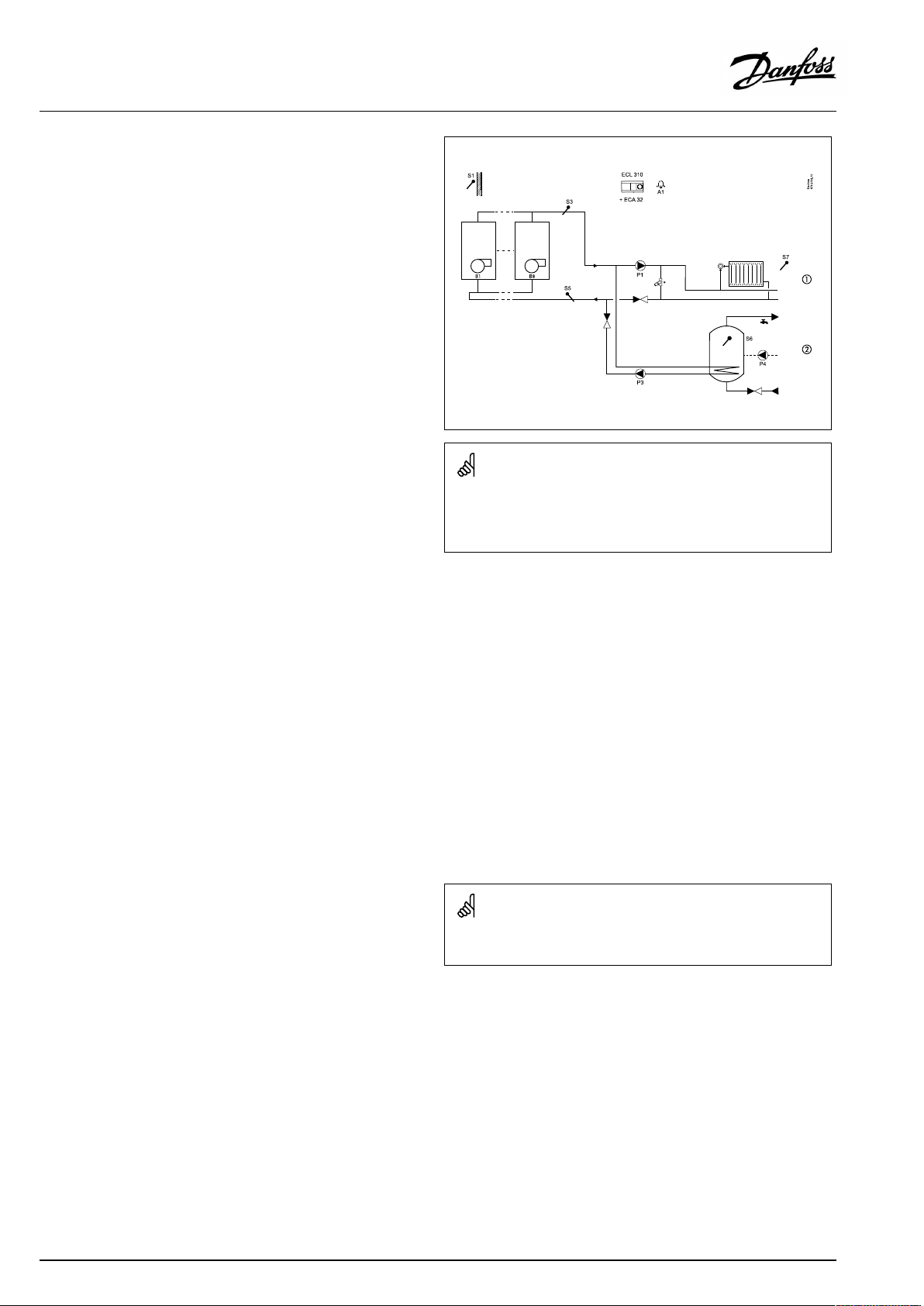

TypicalA275.2application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S3

(mandatory)Boilertemperaturesensor

S5Returntemperaturesensor

S6

DHWtanktemperaturesensor

S7

Roomtemperaturesensor/ECA30

P1

Circulationpump,heating

B1Burner

P3

DHWheatingpump

A1

Alarm

8|©Danfoss|2021.04

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

Page 9

OperatingGuideECLComfort210/296/310,applicationA275/A375

A275.2,basicprinciples,continued:

DHW(circuit2):

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theDHWheatingprocedurestarts:

•ThecirculationpumpP1intheheatingcircuitisswitchedOFF

•TheDHWheatingpumpP3isswitchedON

•ThedesiredboilertemperatureatS3isincreased.

Thedesiredboilertemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P3)isswitched

OFF.StartandstopdifferencesdeterminetheON/OFFcontrol.A

post-runtimecanbeset.

Ananti-bacteriafunctionisavailableforactivationontheselected

daysoftheweek.

TheDHWheatinghaspriority,i.e.pumpP3isONandpumpP1is

OFF.Iftheapplicationhasachangeovervalve(priorityvalve)for

theDHWheating,thecirculationpumpP1isstillONduringDHW

heating.

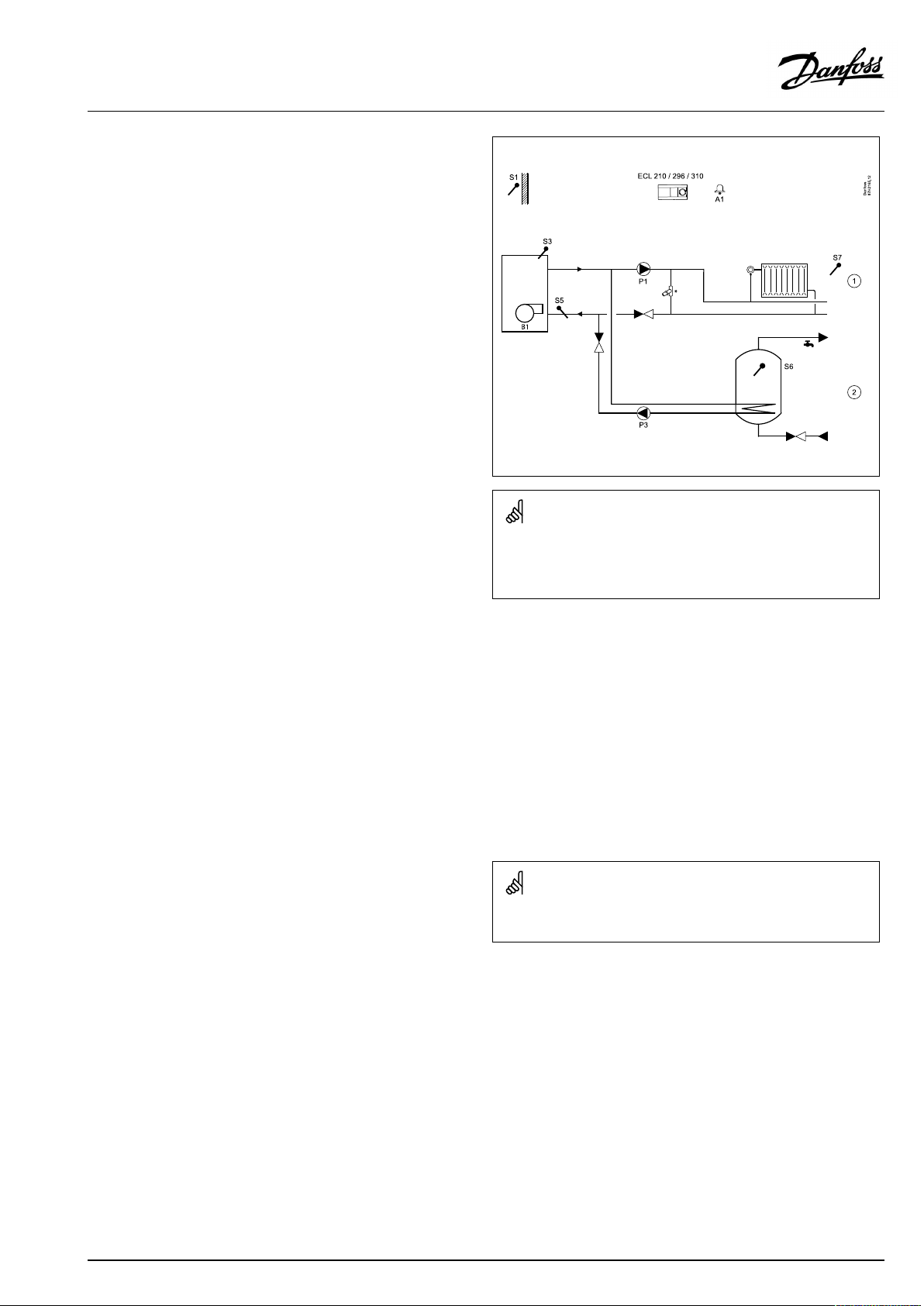

TypicalA275.2application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S3

(mandatory)Boilertemperaturesensor

S5Returntemperaturesensor

S6

DHWtanktemperaturesensor

S7

Roomtemperaturesensor/ECA30

P1

Circulationpump,heating

B1Burner

P3

DHWheatingpump

A1

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

©Danfoss|2021.04|9

Page 10

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA275.3isveryflexible.Thesearethebasic

principles:

Heating(circuit1):

Typically,theboilertemperatureisadjustedaccordingtoyour

requirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

theboilertemperature.ThedesiredboilertemperatureatS3is

calculatedintheECLcontroller,basedontheoutdoortemperature

(S1)andthedesiredroomtemperature.Thelowertheoutdoor

temperature,thehigherthedesiredboilertemperature.Theboiler

temperatureisalsotheflowtemperatureinthedirectconnected

heatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

TheburnerisswitchedONwhentheboilertemperatureis

lowerthanthedesiredboilertemperatureandswitchedOFF

whentheboilertemperatureishigherthanthedesiredboiler

temperature.AswitchingdifferencedeterminestheON/OFF

control.Furthermore,theboilerprotectionfunctionwillonly

switchONthecirculationpumpiftheboilertemperaturegets

aboveaminimumtemperature.AminimumON-timecanbesetfor

theburnerinordertoincreasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS7ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredboilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFiftheoutdoortemperaturegets

higherthanasetvalue.

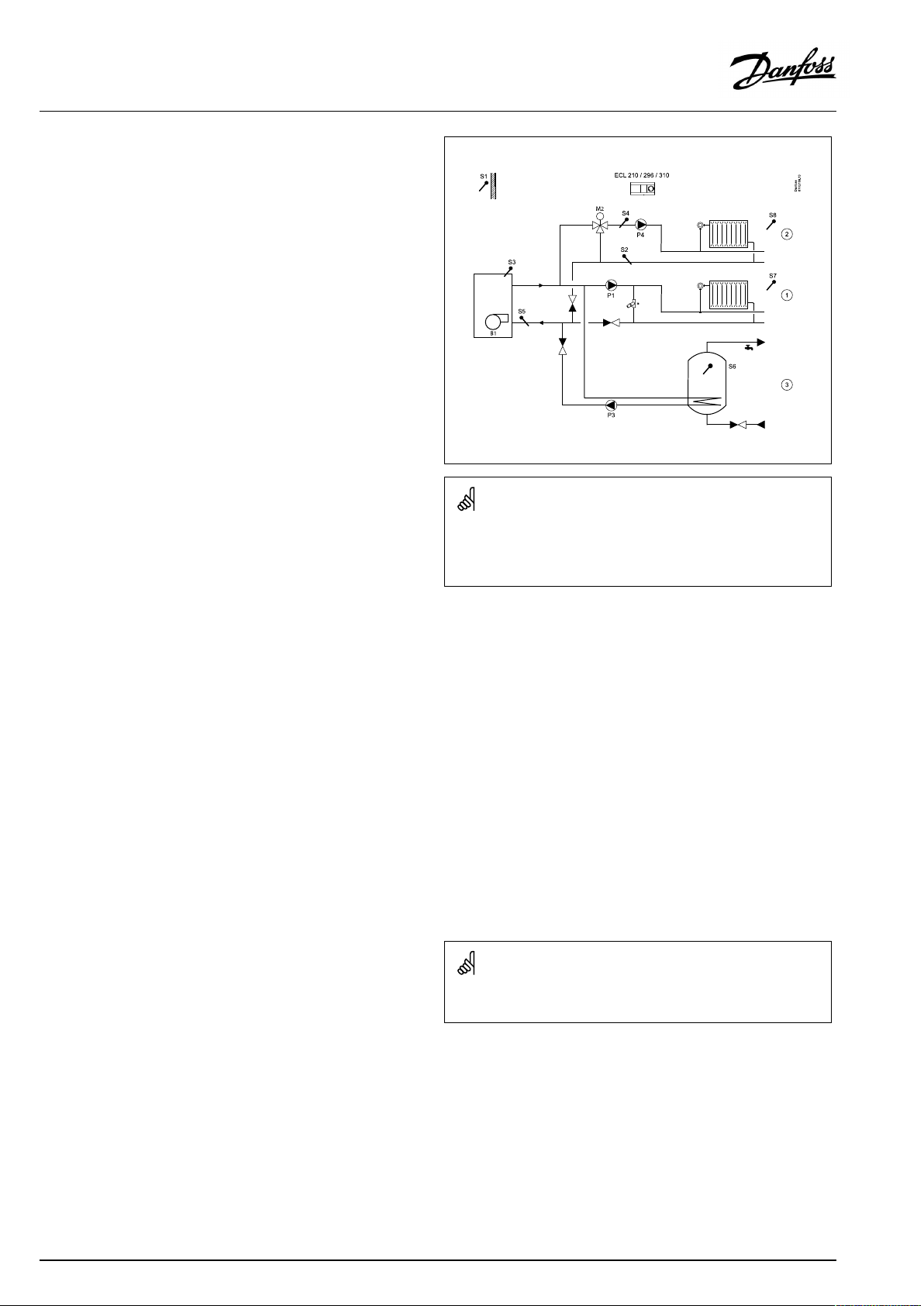

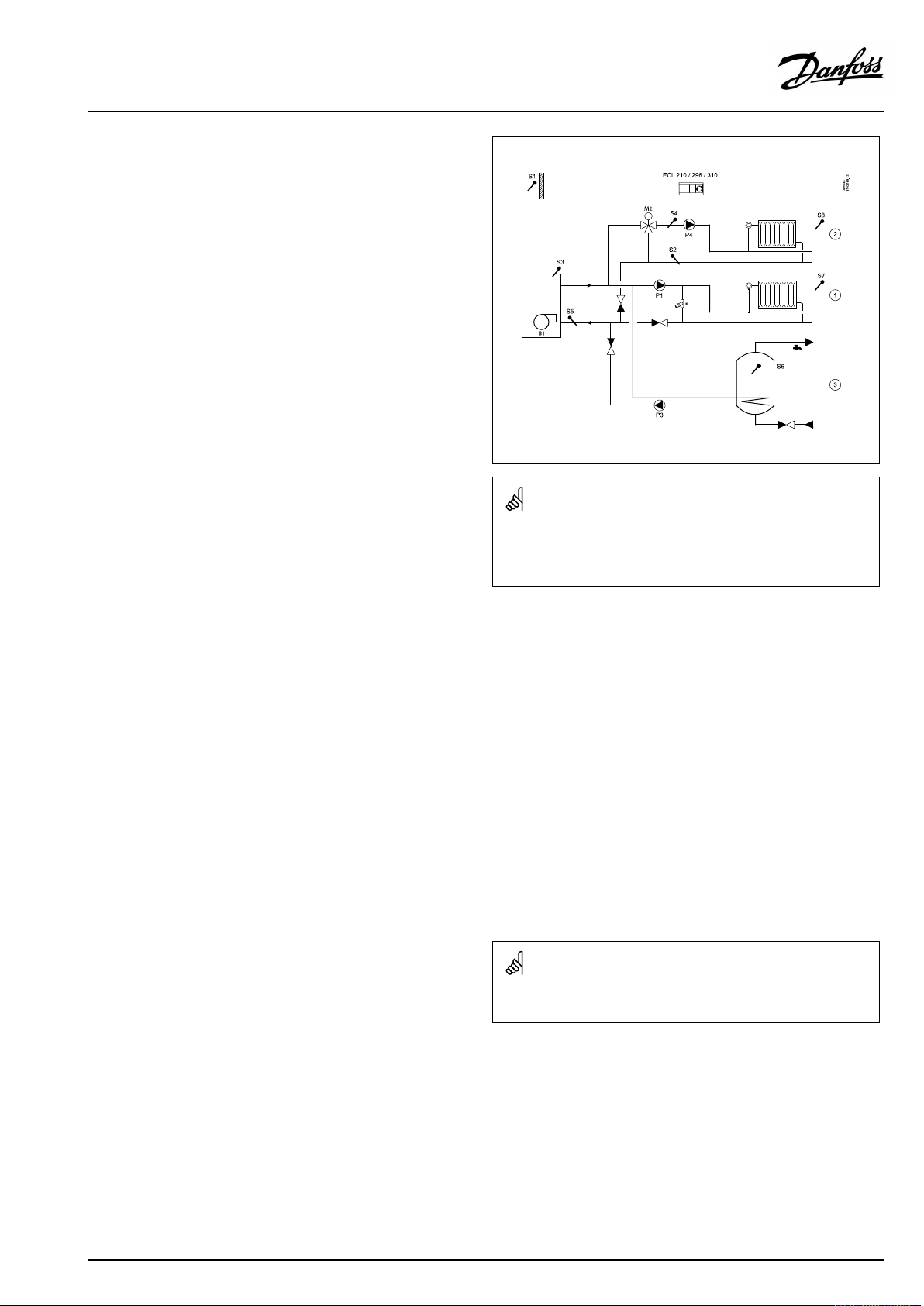

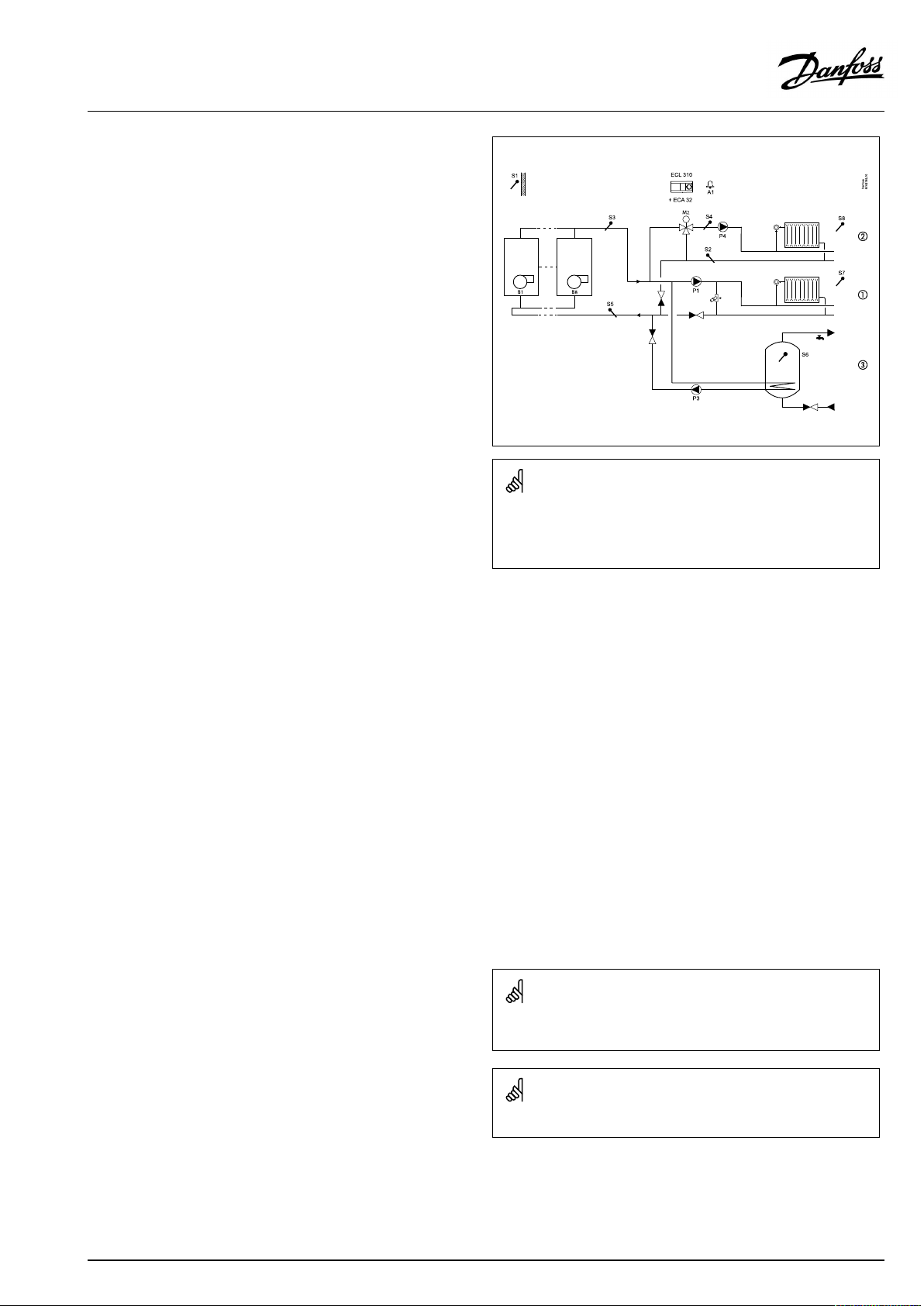

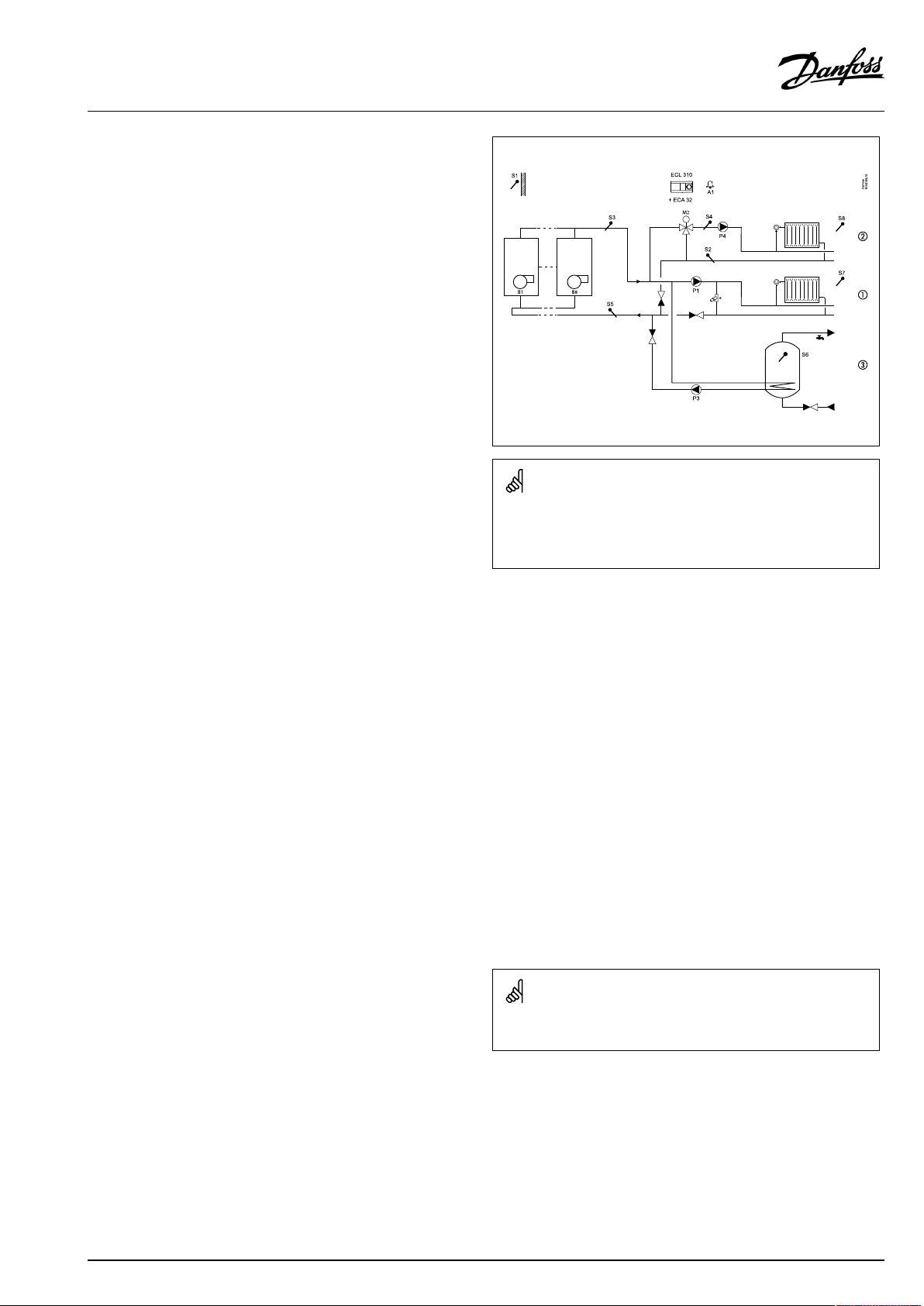

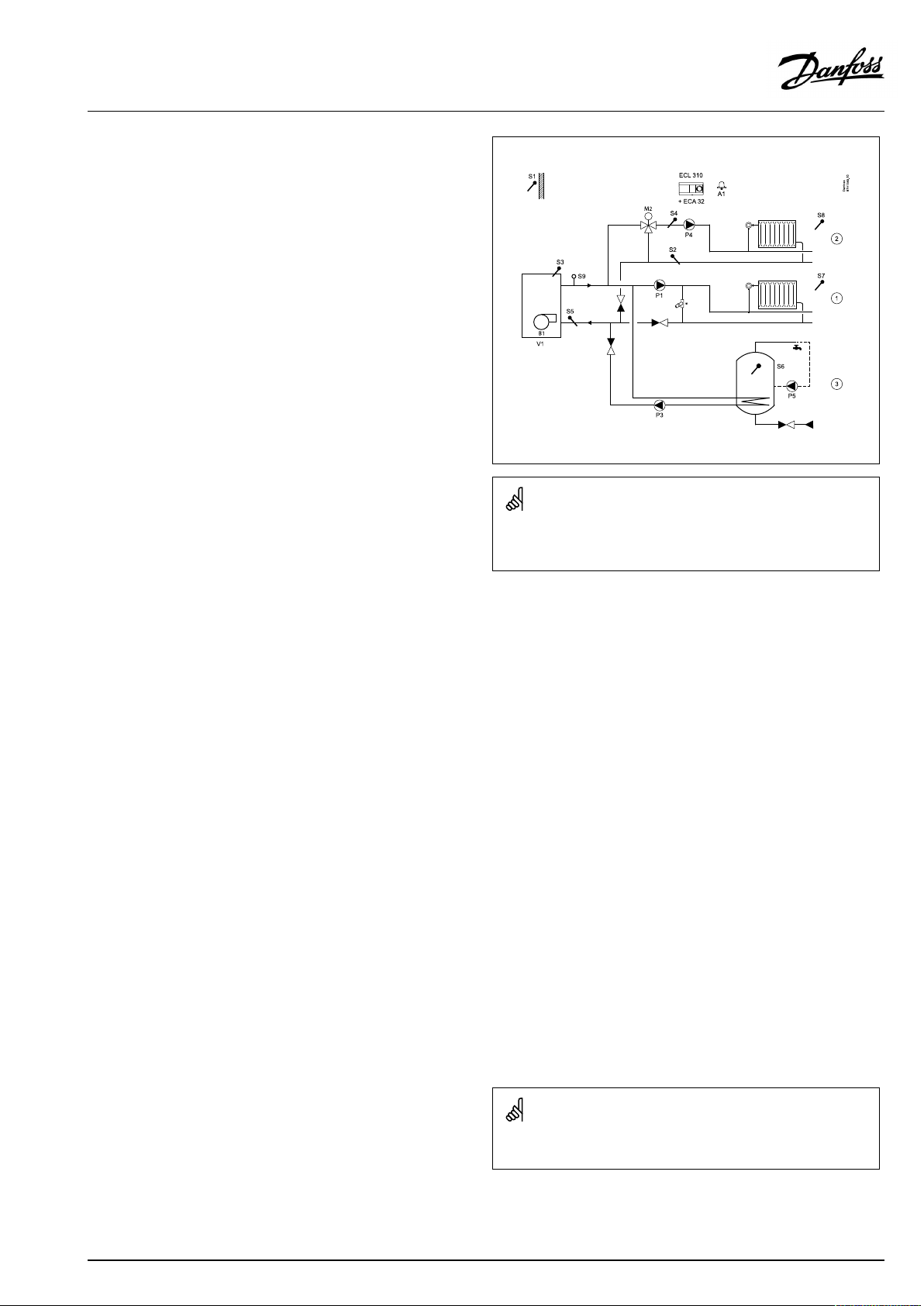

TypicalA275.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

(mandatory)Boilertemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6

DHWtanktemperaturesensor

S7

Roomtemperaturesensor/ECA30,circuit1

S8

Roomtemperaturesensor/ECA30,circuit2

M2

Motorizedcontrolvalve,circuit2

P1

Circulationpump,circuit1

B1Burner

P3

DHWheatingpump,circuit3

P4

Circulationpump,circuit2

10|©Danfoss|2021.04

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

Page 11

OperatingGuideECLComfort210/296/310,applicationA275/A375

A275.3,basicprinciples,continued:

Heating(circuit2):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS4isthemost

importantsensor.ThedesiredflowtemperatureatS4iscalculated

intheECLcontroller,basedontheoutdoortemperature(S1)and

thedesiredroomtemperature.Thelowertheoutdoortemperature,

thehigherthedesiredflowtemperature.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

ThemotorizedcontrolvalveM2isopenedgraduallywhentheflow

temperature,S4,islowerthanthedesiredflowtemperatureand

viceversa.

ThedesiredflowtemperatureatS4willtypicallydeterminethe

desiredboilertemperature(S3).

Thereturntemperature(S2)canbelimited.Ifso,thedesiredflow

temperatureatS4canbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

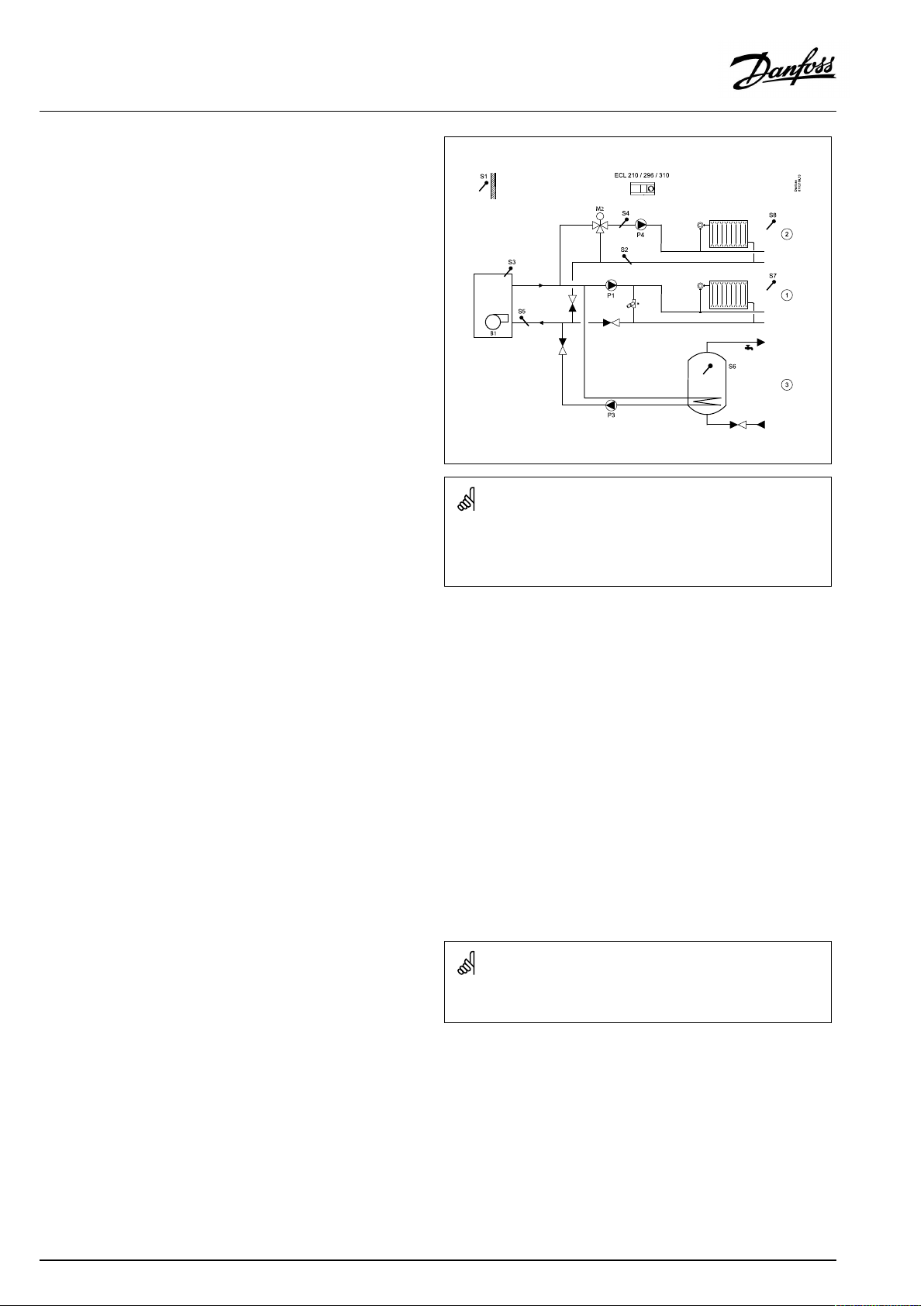

TypicalA275.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Ifthemeasuredroomtemperature(measuredbyS8ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredflowtemperaturecanbeadjusted.

Thecirculationpump(P4)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalueoraDHWheatingpriorityispresent.

Listofcomponents:

S1

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

(mandatory)Boilertemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6

DHWtanktemperaturesensor

S7

Roomtemperaturesensor/ECA30,circuit1

S8

Roomtemperaturesensor/ECA30,circuit2

M2

Motorizedcontrolvalve,circuit2

P1

Circulationpump,circuit1

B1Burner

P3

DHWheatingpump,circuit3

P4

Circulationpump,circuit2

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

©Danfoss|2021.04|11

Page 12

OperatingGuideECLComfort210/296/310,applicationA275/A375

A275.3,basicprinciples,continued:

DHW(circuit3):

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theDHWheatingprocedurestarts:

•ThecirculationpumpP1intheheatingcircuitisswitchedOFF

•TheDHWheatingpumpP3isswitchedON

•ThedesiredboilertemperatureatS3isincreased.

Thedesiredboilertemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P3)isswitched

OFF.StartandstopdifferencesdeterminetheON/OFFcontrol.A

post-runtimecanbeset.

Ananti-bacteriafunctionisavailableforactivationontheselected

daysoftheweek.

TheDHWheatinghaspriority,i.e.pumpP3isONandpumpP1is

OFF.Iftheapplicationhasachangeovervalve(priorityvalve)for

theDHWheating,thecirculationpumpP1isstillONduringDHW

heating.

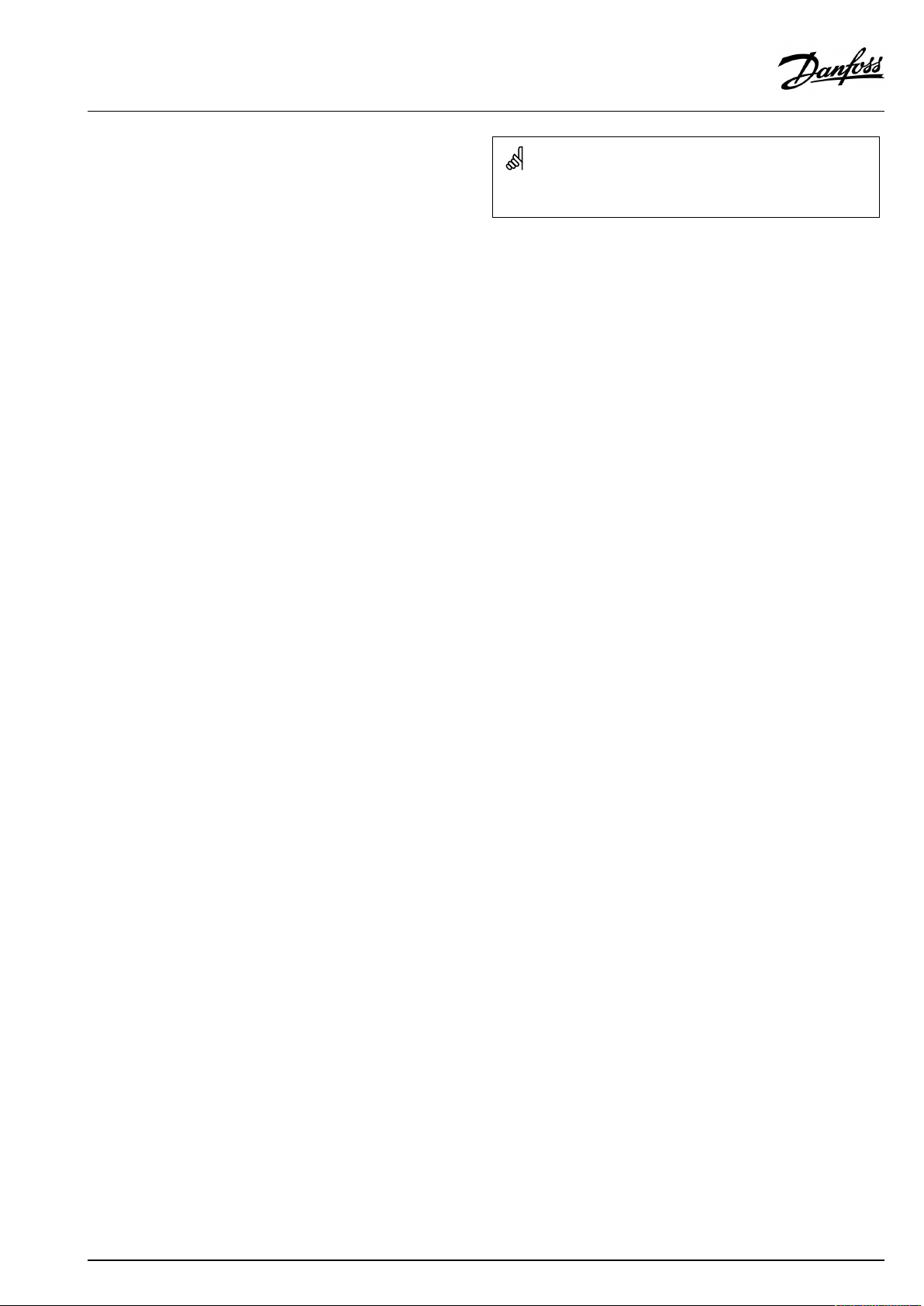

TypicalA275.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

(mandatory)Boilertemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6

DHWtanktemperaturesensor

S7

Roomtemperaturesensor/ECA30,circuit1

S8

Roomtemperaturesensor/ECA30,circuit2

M2

Motorizedcontrolvalve,circuit2

P1

Circulationpump,circuit1

B1Burner

P3

DHWheatingpump,circuit3

P4

Circulationpump,circuit2

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

12|©Danfoss|2021.04

AQ042286456873en-010501

Page 13

OperatingGuideECLComfort210/296/310,applicationA275/A375

ApplicationA275ingeneral:

UptotwoRemoteControlUnits,ECA30/31,canbeconnectedto

oneECLcontrollertocontroltheECLcontrollerremotely.

Exerciseofcirculationpumpsandcontrolvalveinperiodswithout

heatingdemandcanbearranged.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485bustoutilizecommonoutdoortemperaturesignal,timeand

datesignals.

SeveralECLcontrollers,internallyconnectedviaECL485bus,work

inMaster/Slaveconnection.InaMaster/Slavesystemmaximum

2ECA30/31canbepresent.

Unusedinput(fromS7andup)can,bymeansofanoverride

switch,beusedtooverridethescheduletoafixed'Comfort'or

'Saving'mode.

Modbuscommunication(ECL296andECL310)toaSCADAsystem

canbeestablished.

ECLPortal,Internetbasedconnection,allowsECL296,310and

310Btobemonitoredandcontrolledremotelyviastandard

Internetbrowsers(forexampleInternetExplorer,GoogleChrome

andSafari).

Heat-meters:

Upto5heat-meterscanbeconnectedtotheM-busterminals(ECL

296/310).

DatacanbetransferredtotheSCADAsystemviaModbusandTCP/

IPtotheECLPortal.

ModbuscommunicationtoaSCADAsystemcanbeestablished.

TheM-busdata(ECLComfort296/310)canfurthermorebe

transferredtotheModbuscommunication.

Alarm,A275.1andA275.2:

AlarmA1(relayR4)andthealarmsymbol(

•ifatemperaturesensororitsconnectiondisconnects/

shortcircuits.

Alarm,A275.3:

Thealarmsymbol(

•iftheactualflowtemperatureatS4(heatingcircuit2),differs

fromthedesiredflowtemperature.

•ifatemperaturesensororitsconnectiondisconnects/

short-circuits.

)canbeactivated:

)canbeactivated:

AQ042286456873en-010501

©Danfoss|2021.04|13

Page 14

OperatingGuideECLComfort210/296/310,applicationA275/A375

ApplicationA275ingeneral,continued:

Offsetadjustment

Ameasuredtemperaturecanbeoffsetadjusted,ifneeded.

(Navigation:MENU>Commoncontroller>System>Sensoroffset)

Inputconfiguration

Inputs(asfromS7andup),whicharenotpartoftheapplication

canbeconfiguredtobePt1000,0-10Volt,frequency(pulse

counter)ordigitalinput.ThisfeaturemakesitpossibleinECL296/

310tocommunicateextrasignals,suchastemperatures,pressures,

ON/OFFconditions,viaModbusandECLPortal.

TheconfigurationisdonebymeansoftheECLTool(freesoftware

fordownload)ordirectlyinadedicatedmenuintheECLPortalor

theconnectionforModbus(BMS/SCADA).

Applicationupload

Theapplicationuploadprocedureisthefollowingafterhaving

powereduptheECLComfortcontroller:

1.Inserttheapplicationkey

2.Selectlanguage,*1,*2

3.Selectsubtype(theInstallationGuideshowssubtypes)

4.SetTimeandDate

TheECLComfortcontrollerinstallstheapplication,initializesand

restarts.Outputrelaysareactivated/de-activated(click-sounds

fromthiscanbeheard).Thisalsomeansthat,forexample,

circulationpumpscanbeswitchedONandOFFshortly.

*1:Seealsosection"InsertingtheECLApplicationKey" .

*2:(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

Commissioning

WhentheselectedapplicationhasbeenuploadedtheECLComfort

controllerstartsinManualmode.Thiscanbeusedtoverifycorrect

connectionsof,forexample,temperature,pressureandflow

sensors.Alsoverifyingthecontrolledcomponents(valveactuators,

pumps,burneretc.)forcorrectfunctionalitycanbedone.

Theapplicationkeyisdeliveredwithfactorysettings.

Dependingonsystemtype,itmightbenecessarytochangesome

factorysettingsindividuallyforoptimizingthefunctionality.

Theapplicationkeymustbeinsertedforchangingsettings.

Power-down/power-up

WhenthepowersupplytotheECLComfortcontrolleris

disconnected(power-down),theoutputrelaysgotode-activated

position.

Thismeansthat,forexample,circulationpumpsandburnercanbe

switchedON.

SeetheelectricalconnectiondiagramsintheInstallationGuide.

Allrelaycontactsareshowninde-activatedsituation.Somerelay

contactsareclosed,somerelaycontactsareopen.

WhenthepowersupplytotheECLComfortcontrolleris

re-established(power-up),theoutputrelaysareactivated/

de-activated(click-soundsfromthiscanbeheard).Thisalsomeans

that,forexample,circulationpumpsandburnercanbeswitched

ONandOFFshortly.

ImportantforA275.3:

•Setthecorrectrunningtime"Mrun"oftheMotorizedControl

ValveM2.(Circuit2>MENU>Settings>Controlparameters

>Mrun).

14|©Danfoss|2021.04

AQ042286456873en-010501

Page 15

OperatingGuideECLComfort210/296/310,applicationA275/A375

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

AQ042286456873en-010501

©Danfoss|2021.04|15

Page 16

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA375.1isveryflexible.Thesearethebasic

principles:

TheapplicationsA375.1/A375.2/A375.3canON/OFFcontrolup

to8burnersteps.

InapplicationA375.1thefirst4burnerstepsarecontrolledby

relaysintheECL310.Thenext,max.4burnersteps,arecontrolled

byrelaysintheextensionmoduleECA32(placedinthebasepart

oftheECL310).

Heating(circuit1):

Typically,thecommonboilertemperatureisadjustedaccordingto

yourrequirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

thecommonboilertemperature.Thedesiredboilertemperature

atS3iscalculatedintheECLcontroller,basedontheoutdoor

temperature(S1)andthedesiredroomtemperature.Thelowerthe

outdoortemperature,thehigherthedesiredboilertemperature.

Theboilertemperatureisalsotheflowtemperatureinthedirect

connectedheatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

ThefirstburnerstepisswitchedONwhenthecommonboiler

temperatureislowerthanthedesiredboilertemperature.The

controllerobservesthecommonboilertemperatureandswitches

ONthenextburnerstepifthecommonboilertemperaturedoes

notincreasesatisfactorily.TheswitchingOFFprocedureofburner

stepsisviceversa.AswitchingdifferencedeterminestheON/OFF

control.

Theburnerscanbecontrolledin:

•fixedsequence(example:Always1-2-3-4-5)or

•automaticrotatingsequence(example:Firstperiod:1-2-3-4-5,

secondperiod:2-3-4-5-1,thirdperiod:3-4-5-1-2andsoon)

•semi-automaticrotatingsequence(example:Firstperiod:1,

2-3-4-5,secondperiod:1,3-4-5-2,thirdperiod:1,4-5-2-3and

soon)

Furthermore,theboilerprotectionfunctionwillswitchONthe

circulationpumpwhentheboilertemperaturegetsabovea

minimumvalue.AminimumON-timecanbesetfortheburnerin

ordertoincreasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

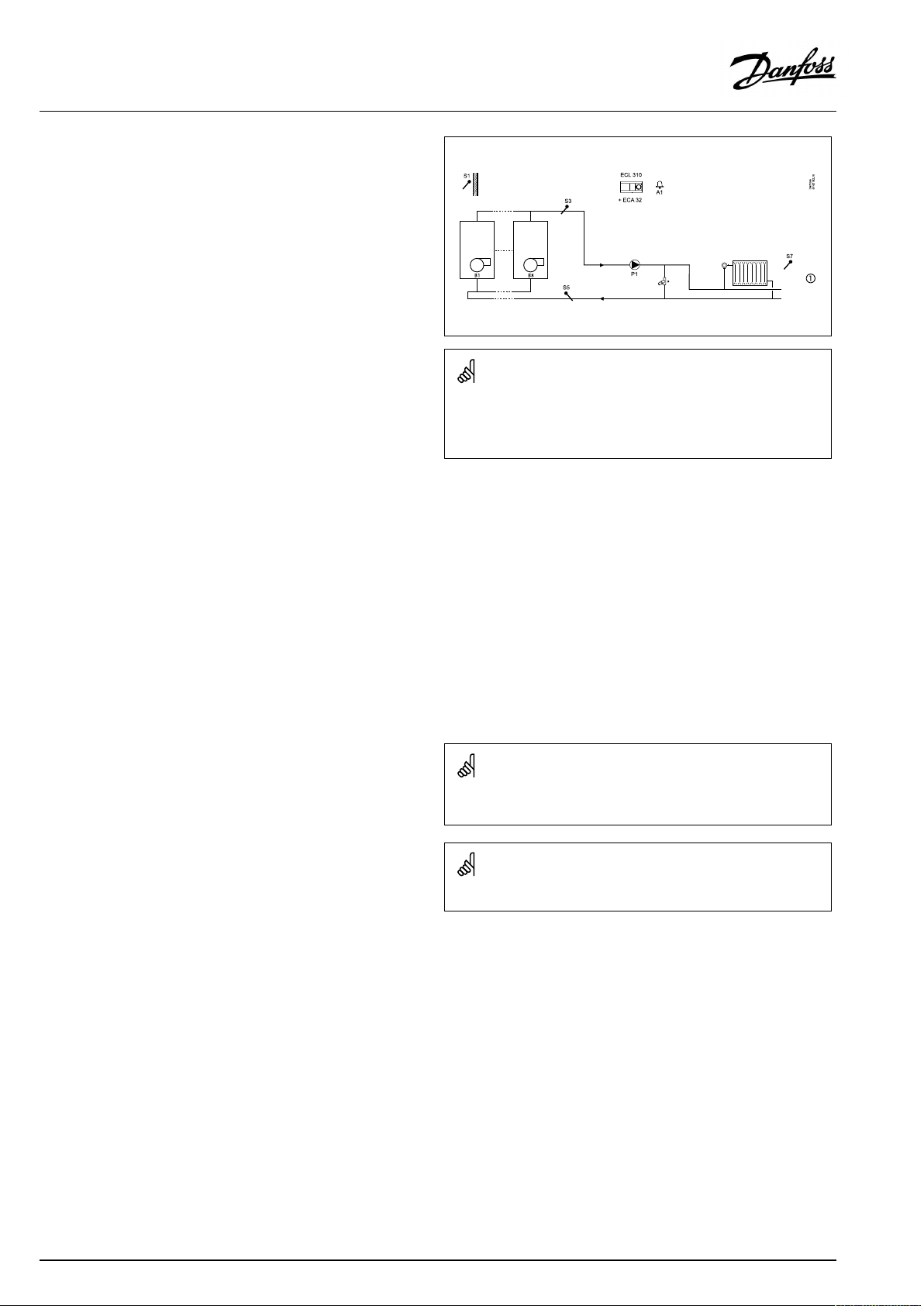

TypicalA375.1application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

S3

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

(mandatory)Commonboilertemperaturesensor

S5Returntemperaturesensor

S7

(S10)

P1

Roomtemperaturesensor/ECA30

(Externaltemperaturecontrol,notillustrated)

Circulationpump

B1–B8Burner1...8

A1

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

Boilersequencerotation/shifttakesplaceatmidnight.

Alarm

Ifthemeasuredroomtemperature(S7orRemotecontrolunitECA

30)doesnotequalthedesiredroomtemperature,thedesired

boilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanasetvalue.

Thedesiredcommonboilertemperaturecan,viaS10,becontrolled

bymeansofanexternalvoltageintherange0-10volt.

16|©Danfoss|2021.04

AQ042286456873en-010501

Page 17

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA375.2isveryflexible.Thesearethebasic

principles:

TheapplicationsA375.1/A375.2/A375.3canON/OFFcontrolup

to8burnersteps.

InapplicationA375.2thefirst2burnerstepsarecontrolledby

relaysintheECL310.Thenext,max.4burnersteps,arecontrolled

byrelaysintheextensionmoduleECA32(placedinthebasepartof

theECL310).Thelast,max.2burnerstepsarecontrolledbytriacs

intheECL310.Auxillaryrelaysmustbeconnectedtothetriacs.

Heating(circuit1):

Typically,thecommonboilertemperatureisadjustedaccordingto

yourrequirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

thecommonboilertemperature.Thedesiredboilertemperature

atS3iscalculatedintheECLcontroller,basedontheoutdoor

temperature(S1)andthedesiredroomtemperature.Thelowerthe

outdoortemperature,thehigherthedesiredboilertemperature.

Theboilertemperatureisalsotheflowtemperatureinthedirect

connectedheatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

ThefirstburnerstepisswitchedONwhenthecommonboiler

temperatureislowerthanthedesiredboilertemperature.The

controllerobservesthecommonboilertemperatureandswitches

ONthenextburnerstepifthecommonboilertemperaturedoes

notincreasesatisfactorily.TheswitchingOFFprocedureofburner

stepsisviceversa.AswitchingdifferencedeterminestheON/OFF

control.

Theburnerscanbecontrolledin:

•fixedsequence(example:Always1-2-3-4-5)or

•automaticrotatingsequence(example:Firstperiod:1-2-3-4-5,

secondperiod:2-3-4-5-1,thirdperiod:3-4-5-1-2andsoon)

•semi-automaticrotatingsequence(example:Firstperiod:1,

2-3-4-5,secondperiod:1,3-4-5-2,thirdperiod:1,4-5-2-3and

soon)

Furthermore,theboilerprotectionfunctionwillswitchONthe

circulationpumpwhentheboilertemperaturegetsabovea

minimumvalue.AminimumON-timecanbesetfortheburnerin

ordertoincreasetheboiler'sefficiency.

TypicalA375.2application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

S3

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

(mandatory)Commonboilertemperaturesensor

S5Returntemperaturesensor

S6

S7

(S10)

P1

DHWtanktemperaturesensor

Roomtemperaturesensor/ECA30

(Externaltemperaturecontrol,notillustrated)

Circulationpump,heating

B1–B8Burner1...8

P3

A1

DHWheatingpump

Alarm

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(S7orRemotecontrolunitECA

30)doesnotequalthedesiredroomtemperature,thedesired

boilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanasetvalue.

Thedesiredcommonboilertemperaturecan,viaS10,becontrolled

bymeansofanexternalvoltageintherange0-10volt.

AQ042286456873en-010501

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

Boilersequencerotation/shifttakesplaceatmidnight.

©Danfoss|2021.04|17

Page 18

OperatingGuideECLComfort210/296/310,applicationA275/A375

A375.2,basicprinciples,continued:

DHW(circuit2):

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theDHWheatingprocedurestarts:

•ThecirculationpumpP1intheheatingcircuitisswitchedOFF

•TheDHWheatingpumpP3isswitchedON

•ThedesiredboilertemperatureatS3isincreased.

Thedesiredboilertemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P3)isswitched

OFF.StartandstopdifferencesdeterminetheON/OFFcontrol.A

post-runtimecanbeset.

TheDHWcirculationpump(P4)hasaweekscheduleforupto3

ONperiodsperday.

Ananti-bacteriafunctionisavailableforactivationonselected

daysoftheweek.

TheDHWheatingcanhavepriority,i.e.pumpP3isONandpump

P1isOFF.Iftheapplicationhasachangeovervalve(priorityvalve)

fortheDHWheating,thecirculationpumpP1isstillONduring

DHWheating.

TypicalA375.2application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

S3

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

(mandatory)Commonboilertemperaturesensor

S5Returntemperaturesensor

S6

S7

(S10)

P1

DHWtanktemperaturesensor

Roomtemperaturesensor/ECA30

(Externaltemperaturecontrol,notillustrated)

Circulationpump,heating

B1–B8Burner1...8

P3

A1

DHWheatingpump

Alarm

18|©Danfoss|2021.04

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

Page 19

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA375.3isveryflexible.Thesearethebasic

principles:

TheapplicationsA375.1/A375.2/A375.3canON/OFFcontrolup

to8burnersteps.

InapplicationA375.3thefirst2burnerstepsarecontrolledby

relaysintheECL310.Thenext,max.4burnersteps,arecontrolled

byrelaysintheextensionmoduleECA32(placedinthebasepartof

theECL310).Thelast,max.2burnerstepsarecontrolledbytriacs

intheECL310.Auxillaryrelaysmustbeconnectedtothetriacs.

Heating(circuit1):

Typically,thecommonboilertemperatureisadjustedaccordingto

yourrequirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlyinordertomeasure

thecommonboilertemperature.Thedesiredboilertemperature

atS3iscalculatedintheECLcontroller,basedontheoutdoor

temperature(S1)andthedesiredroomtemperature.Thelowerthe

outdoortemperature,thehigherthedesiredboilertemperature.

Theboilertemperatureisalsotheflowtemperatureinthedirect

connectedheatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

ThefirstburnerstepisswitchedONwhenthecommonboiler

temperatureislowerthanthedesiredboilertemperature.The

controllerobservesthecommonboilertemperatureandswitches

ONthenextburnerstepifthecommonboilertemperaturedoes

notincreasesatisfactorily.TheswitchingOFFprocedureofburner

stepsisviceversa.AswitchingdifferencedeterminestheON/OFF

control.

Theburnerscanbecontrolledin:

•fixedsequence(example:Always1-2-3-4-5)or

•automaticrotatingsequence(example:Firstperiod:1-2-3-4-5,

secondperiod:2-3-4-5-1,thirdperiod:3-4-5-1-2andsoon)

•semi-automaticrotatingsequence(example:Firstperiod:1,

2-3-4-5,secondperiod:1,3-4-5-2,thirdperiod:1,4-5-2-3and

soon)

Furthermore,theboilerprotectionfunctionwillswitchONthe

circulationpumpwhentheboilertemperaturegetsabovea

minimumvalue.AminimumON-timecanbesetfortheburnerin

ordertoincreasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoo

high(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,

thedesiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

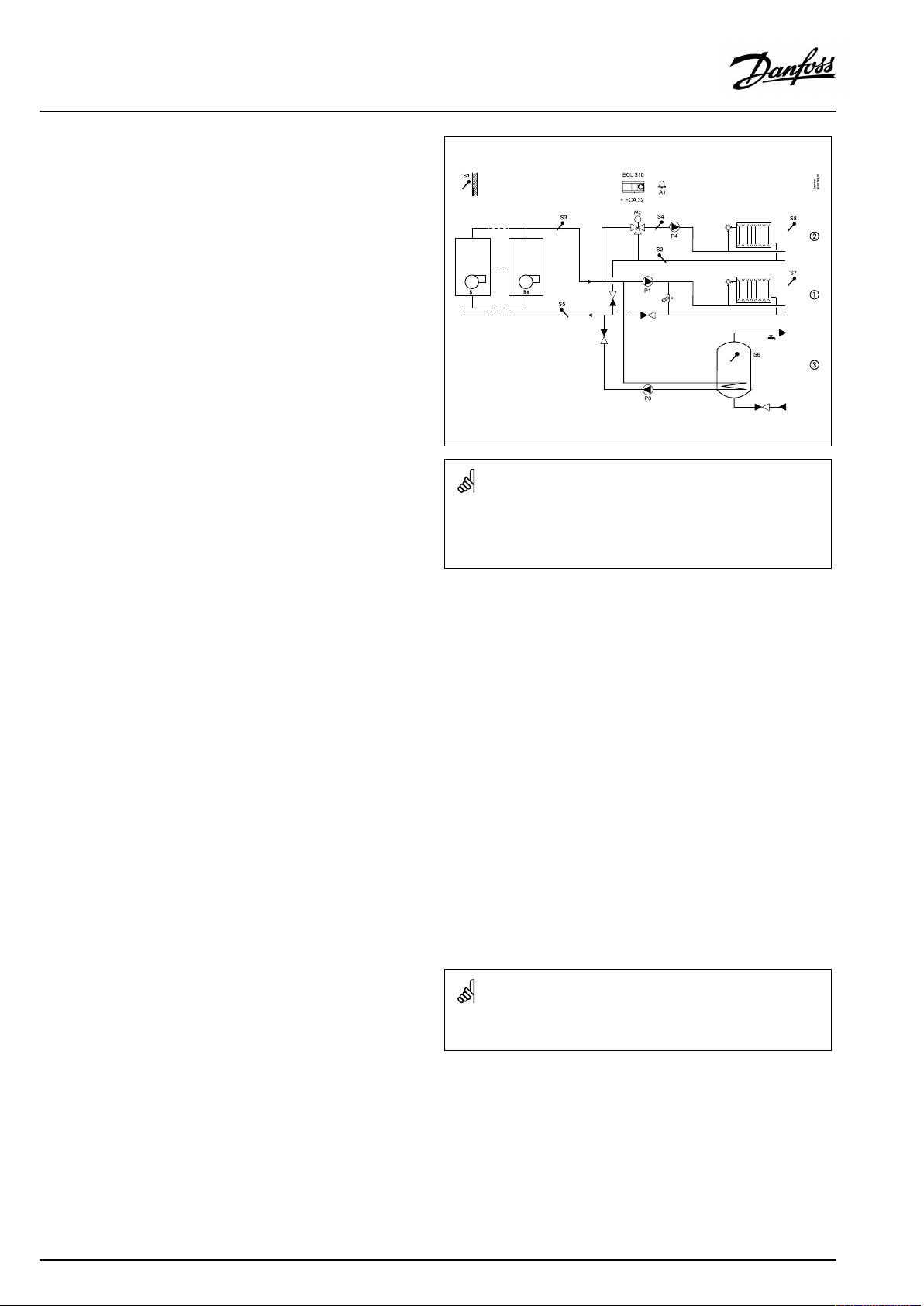

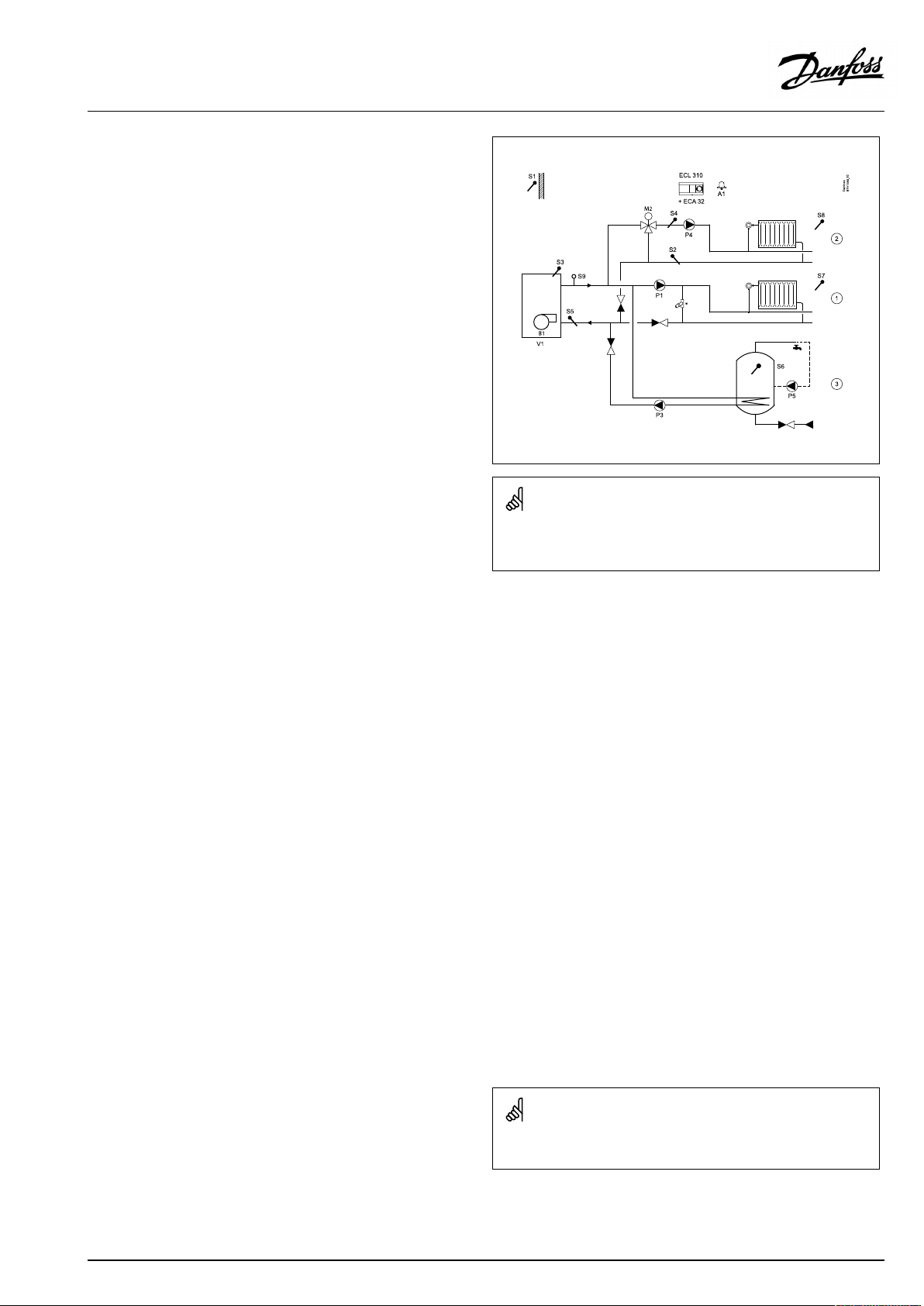

TypicalA375.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Commonboilertemperaturesensor,circuit1

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S7

S8

(S10)

M2

P1

Roomtemperaturesensor/ECA30,circuit1

Roomtemperaturesensor/ECA30,circuit2

(Externaltemperaturecontrol,notillustrated)

Motorizedcontrolvalve,circuit2

Circulationpump,circuit1

B1–B8Burner1...8

P3

A1

DHWheatingpump,circuit3

Alarm

Ifthemeasuredroomtemperature(S7orRemotecontrolunitECA

30)doesnotequalthedesiredroomtemperature,thedesired

boilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanasetvalue.

Thedesiredcommonboilertemperaturecan,viaS10,becontrolled

bymeansofanexternalvoltageintherange0-10volt.

AQ042286456873en-010501

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

Boilersequencerotation/shifttakesplaceatmidnight.

©Danfoss|2021.04|19

Page 20

OperatingGuideECLComfort210/296/310,applicationA275/A375

A375.3,basicprinciples,continued:

Heating(circuit2):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS4isthemost

importantsensor.ThedesiredflowtemperatureatS4iscalculated

intheECLcontroller,basedontheoutdoortemperature(S1).

Thelowertheoutdoortemperature,thehigherthedesiredflow

temperature.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedinordertoswitchOFF

theheating.

ThemotorizedcontrolvalveM2isopenedgraduallywhentheflow

temperature,S4,islowerthanthedesiredflowtemperatureand

viceversa.

ThedesiredflowtemperatureatS4willtypicallydeterminethe

desiredboilertemperature(S3).

Thereturntemperature(S2)canbelimited.Ifso,thedesiredflow

temperatureatS4canbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS8ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredflowtemperaturecanbeadjusted.

Thecirculationpump(P4)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalueoraDHWheatingpriorityispresent.

TypicalA375.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Commonboilertemperaturesensor,circuit1

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S7

S8

(S10)

M2

P1

Roomtemperaturesensor/ECA30,circuit1

Roomtemperaturesensor/ECA30,circuit2

(Externaltemperaturecontrol,notillustrated)

Motorizedcontrolvalve,circuit2

Circulationpump,circuit1

B1–B8Burner1...8

P3

A1

DHWheatingpump,circuit3

Alarm

20|©Danfoss|2021.04

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

Page 21

OperatingGuideECLComfort210/296/310,applicationA275/A375

A375.3,basicprinciples,continued:

DHW(circuit3):

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theDHWheatingprocedurestarts:

•ThecirculationpumpP1intheheatingcircuitisswitchedOFF

•TheDHWheatingpumpP3isswitchedON

•ThedesiredboilertemperatureatS3isincreased.

Thedesiredboilertemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P3)isswitched

OFF.StartandstopdifferencesdeterminetheON/OFFcontrol.A

post-runtimecanbeset.

Ananti-bacteriafunctionisavailableforactivationonselected

daysoftheweek.

TheDHWheatingcanhavepriority,i.e.pumpP3isONandpump

P1isOFF.Iftheapplicationhasachangeovervalve(priorityvalve)

fortheDHWheating,thecirculationpumpP1isstillONduring

DHWheating.

TypicalA375.3application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithrelayoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Commonboilertemperaturesensor,circuit1

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S7

S8

(S10)

M2

P1

Roomtemperaturesensor/ECA30,circuit1

Roomtemperaturesensor/ECA30,circuit2

(Externaltemperaturecontrol,notillustrated)

Motorizedcontrolvalve,circuit2

Circulationpump,circuit1

B1–B8Burner1...8

P3

A1

DHWheatingpump,circuit3

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

©Danfoss|2021.04|21

Page 22

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA375.4isveryflexible.Thesearethebasic

principles:

Heating(circuit1):

Typically,theboilertemperatureisadjustedaccordingtoyour

requirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlytomeasuretheboiler

temperature.ThedesiredboilertemperatureatS3iscalculatedin

theECLcontroller,basedontheoutdoortemperature(S1)andthe

desiredroomtemperature.Thelowertheoutdoortemperature,

thehigherthedesiredboilertemperature.Theboilertemperature

isalsotheflowtemperatureinthedirectconnectedheatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedtoswitchOFFthe

heating.

Theburneris,viarelayoutput2,switchedONwhentheboiler

temperatureislowerthanthedesiredboilertemperatureand

switchedOFFwhentheboilertemperatureishigherthanthe

desiredboilertemperature.Aswitchingdifferencedeterminesthe

ON/OFFcontrol.

Advancedboilercontrol:

1.A0-10VoltsignalfromtheinternalmoduleECA32canbe

appliedtotheboilerforsettingthedesiredboilertemperature.

2.A3-pointsignal,viaM3,canbeappliedtotheboilerforsetting

thedesiredboilertemperature.Itisrecommendedtoseparate

galvanicallytheECL'sM3outputfromtheboiler's3-pointinput.

Typically,thiscanbedonebymeansofSolid-Staterelays.

SeetheInstallationGuideforconnections.

TheboilerprotectionfunctionwillonlyswitchONthecirculation

pumpiftheboilertemperaturegetsaboveaminimum

temperature.AminimumON-timecanbesetfortheburnerto

increasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoohigh

(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,the

desiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS7ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredboilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

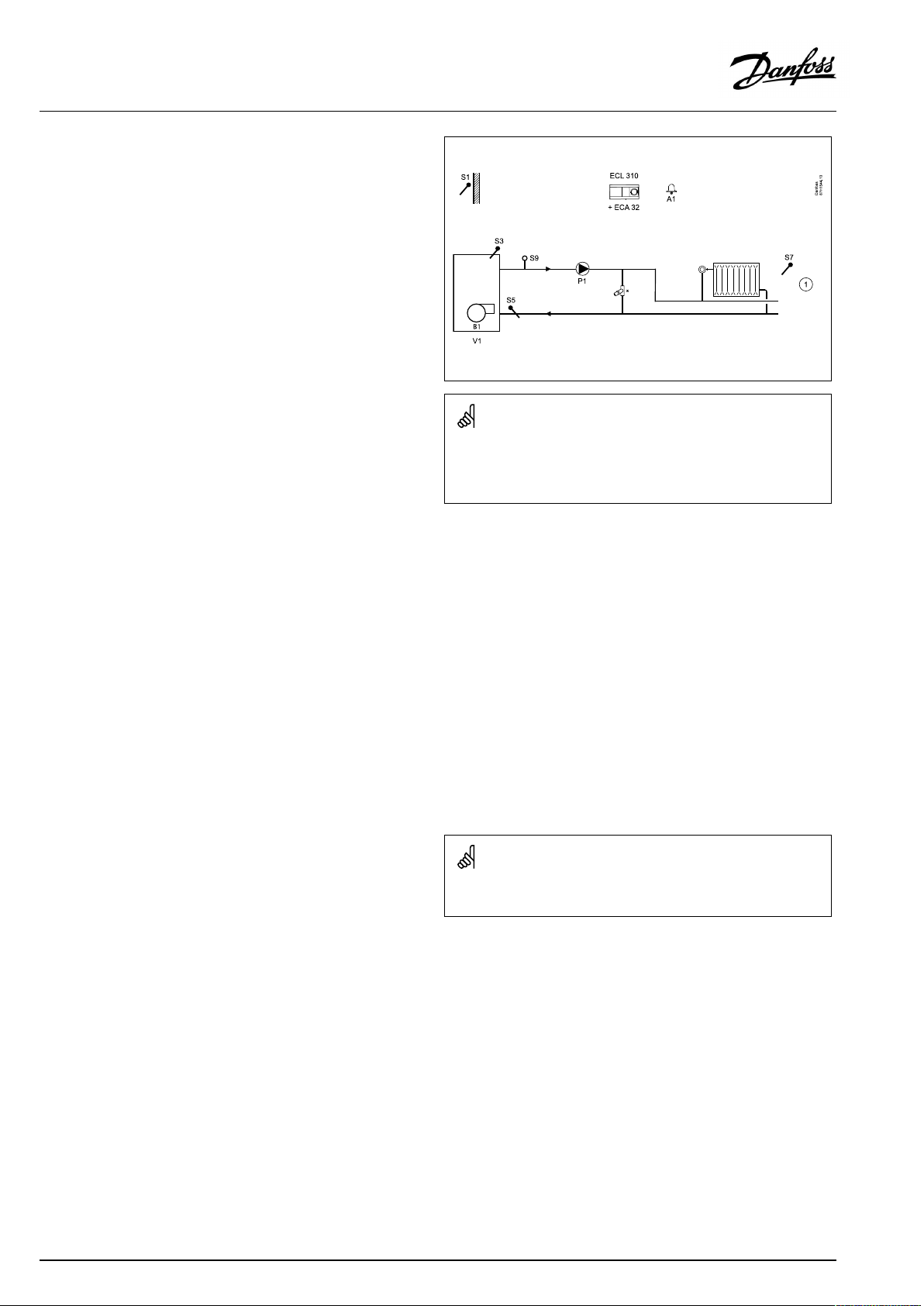

TypicalA375.4application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

S3

ElectroniccontrollerECLComfort310

Internalextensionmodulewithanalogoutputs

Outdoortemperaturesensor

(mandatory)Boilertemperaturesensor

S5Returntemperaturesensor

S7

Roomtemperaturesensor/ECA30

S9Pressuresensor

P1

B1

V1

M3

A1

Circulationpump

Burner,ON/OFFcontrol

Burner,0-10Vtemperaturecontrol

(notillustrated)3-pointcontrolofboilertemperature

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

TheheatingcanbeswitchedOFFiftheoutdoortemperaturegets

higherthanasetvalue.

A375.4canalsoruntheinstallationslikeA275.1,ex.aandex.b.

ThedifferencebetweenA375.4andA275.1is:

•A375.4hasadvancedboilercontrol

•A375.4canmeasurepressureviatransmitterandgenerate

alarm

22|©Danfoss|2021.04

AQ042286456873en-010501

Page 23

OperatingGuideECLComfort210/296/310,applicationA275/A375

TheapplicationA375.5isveryflexible.Thesearethebasic

principles:

Heating(circuit1):

Typically,theboilertemperatureisadjustedaccordingtoyour

requirements.TheboilertemperaturesensorS3isthemost

importantsensor.Itmustbeplacedcorrectlytomeasuretheboiler

temperature.ThedesiredboilertemperatureatS3iscalculatedin

theECLcontroller,basedontheoutdoortemperature(S1)andthe

desiredroomtemperature.Thelowertheoutdoortemperature,

thehigherthedesiredboilertemperature.Theboilertemperature

isalsotheflowtemperatureinthedirectconnectedheatingcircuit.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedtoswitchOFFthe

heating.

Theburneris,viarelayoutput2,switchedONwhentheboiler

temperatureislowerthanthedesiredboilertemperatureand

switchedOFFwhentheboilertemperatureishigherthanthe

desiredboilertemperature.Aswitchingdifferencedeterminesthe

ON/OFFcontrol.

Advancedboilercontrol:

1.A0-10VoltsignalfromtheinternalmoduleECA32canbe

appliedtotheboilerforsettingthedesiredboilertemperature.

2.A3-pointsignal,viaM3,canbeappliedtotheboilerforsetting

thedesiredboilertemperature.Itisrecommendedtoseparate

galvanicallytheECL'sM3outputfromtheboiler's3-pointinput.

Typically,thiscanbedonebymeansofSolid-Staterelays.

SeetheInstallationGuideforconnections.

TheboilerprotectionfunctionwillonlyswitchONthecirculation

pumpiftheboilertemperaturegetsaboveaminimum

temperature.AminimumON-timecanbesetfortheburnerto

increasetheboiler'sefficiency.

Thereturntemperature(S5)totheboilershouldnotbetoohigh

(condensingboiler)ortoolow(oilorgasfiredboiler).Ifso,the

desiredboilertemperaturecanbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Ifthemeasuredroomtemperature(measuredbyS7ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredboilertemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFiftheoutdoortemperaturegets

higherthanasetvalue.

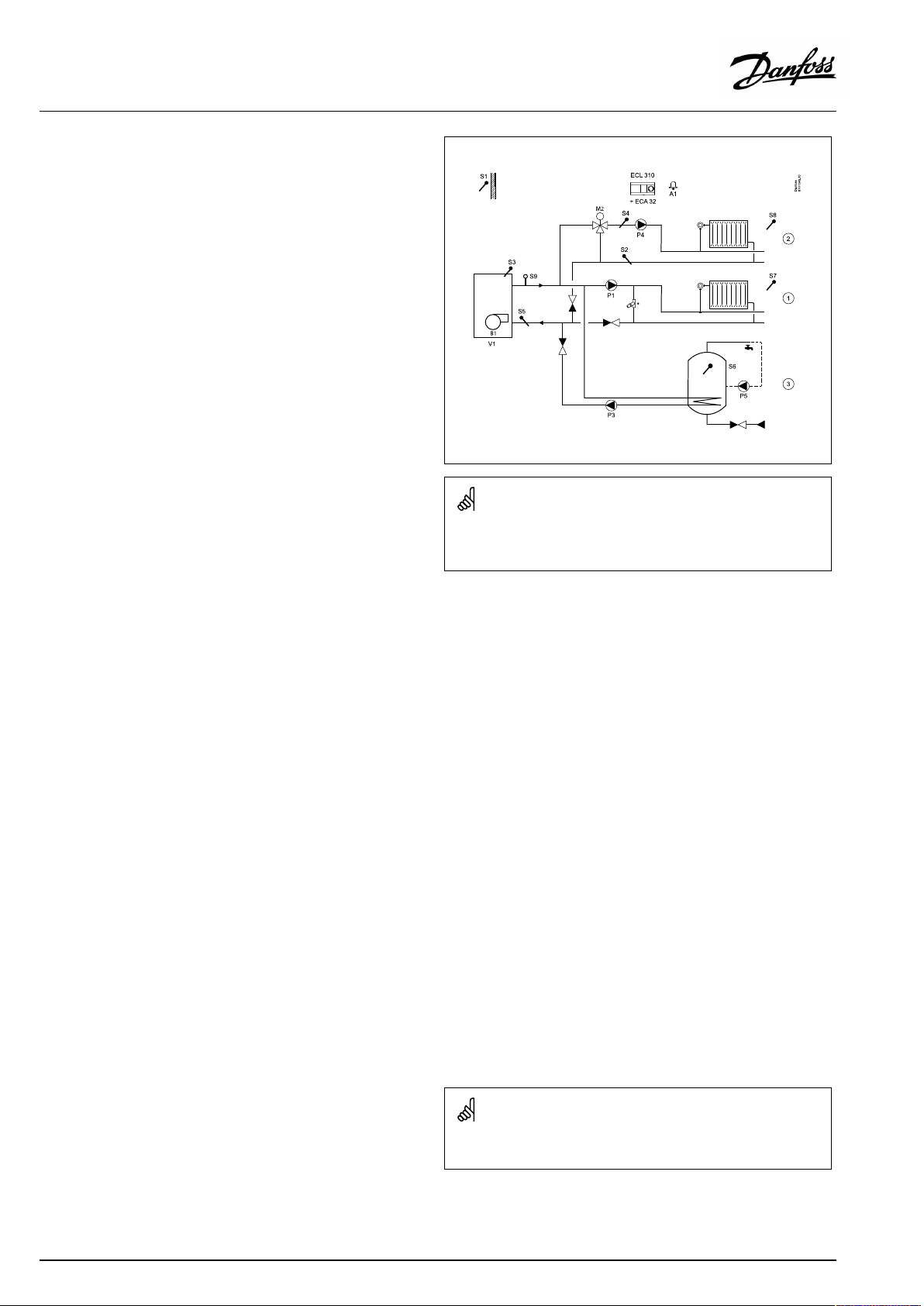

TypicalA375.5application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithanalogoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Boilertemperaturesensor

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor

S6

S7

S8

DHWtanktemperaturesensor

Roomtemperaturesensor/ECA30

Roomtemperaturesensor/ECA30,circuit2

S9Pressuresensor

P1

P3

P4

P5

B1

V1

M2

M3

A1

Circulationpump

DHWheatingpump

Circulationpump,circuit2

DHWcirculationpump

Burner,ON/OFFcontrol

Burner,0-10Vtemperaturecontrol

Motorizedcontrolvalve,circuit2

(notillustrated)3-pointcontrolofboilertemperature

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

©Danfoss|2021.04|23

Page 24

OperatingGuideECLComfort210/296/310,applicationA275/A375

A375.5,basicprinciples,continued:

Heating(circuit2):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS4isthemost

importantsensor.ThedesiredflowtemperatureatS4iscalculated

intheECLcontroller,basedontheoutdoortemperature(S1)and

thedesiredroomtemperature.Thelowertheoutdoortemperature,

thehigherthedesiredflowtemperature.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesforthedesiredroomtemperature).In'Saving'

modea'Totalstop'functioncanbeselectedtoswitchOFFthe

heating.

ThemotorizedcontrolvalveM2isopenedgraduallywhentheflow

temperature,S4,islowerthanthedesiredflowtemperatureand

viceversa.

ThedesiredflowtemperatureatS4willtypicallydeterminethe

desiredboilertemperature(S3).

Thereturntemperature(S2)canbelimited.Ifso,thedesiredflow

temperatureatS4canbedecreasedorincreased.

Furthermore,thereturntemperaturelimitationcanbedependent

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

TypicalA375.5application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Ifthemeasuredroomtemperature(measuredbyS8ortheremote

controlunitECA30)doesnotequalthedesiredroomtemperature,

thedesiredflowtemperaturecanbeadjusted.

Thecirculationpump(P4)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalueoraDHWheatingpriorityispresent.

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithanalogoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Boilertemperaturesensor

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor

S6

S7

S8

DHWtanktemperaturesensor

Roomtemperaturesensor/ECA30

Roomtemperaturesensor/ECA30,circuit2

S9Pressuresensor

P1

P3

P4

P5

B1

V1

M2

M3

A1

Circulationpump

DHWheatingpump

Circulationpump,circuit2

DHWcirculationpump

Burner,ON/OFFcontrol

Burner,0-10Vtemperaturecontrol

Motorizedcontrolvalve,circuit2

(notillustrated)3-pointcontrolofboilertemperature

Alarm

24|©Danfoss|2021.04

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

Page 25

OperatingGuideECLComfort210/296/310,applicationA275/A375

A375.5,basicprinciples,continued:

DHW(circuit3):

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theDHWheatingprocedurestarts:

•ThecirculationpumpP1intheheatingcircuitisswitchedOFF

•TheDHWheatingpumpP3isswitchedON

•ThedesiredboilertemperatureatS3isincreased.

Thedesiredboilertemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P3)isswitched

OFF.StartandstopdifferencesdeterminetheON/OFFcontrol.A

post-runtimecanbeset.

Ananti-bacteriafunctionisavailableforactivationontheselected

daysoftheweek.

TheDHWheatinghaspriority,i.e.pumpP3isONandpumpP1is

OFF.Iftheapplicationhasachangeovervalve(priorityvalve)for

theDHWheating,thecirculationpumpP1isstillONduringDHW

heating.

TypicalA375.5application:

*Pressurereliefvalve

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

A375.5canalsoruntheinstallationslikeA275.3,ex.a.-A275.3,

ex.g.

ThedifferenciesbetweenA375.5andA275.3are:

•A375.5hasadvancedboilercontrol

•A375.5hasalarmoutput(A1)

•A375.4canmeasurepressureviatransmitterandgenerate

alarm

Listofcomponents:

ECL310

ECA32

S1

ElectroniccontrollerECLComfort310

Internalextensionmodulewithanalogoutputs

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

S4

(mandatory)Boilertemperaturesensor

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor

S6

S7

S8

DHWtanktemperaturesensor

Roomtemperaturesensor/ECA30

Roomtemperaturesensor/ECA30,circuit2

S9Pressuresensor

P1

P3

P4

P5

B1

V1

M2

M3

A1

Circulationpump

DHWheatingpump

Circulationpump,circuit2

DHWcirculationpump

Burner,ON/OFFcontrol

Burner,0-10Vtemperaturecontrol

Motorizedcontrolvalve,circuit2

(notillustrated)3-pointcontrolofboilertemperature

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

intherelevantchaptersofthisguide.

AQ042286456873en-010501

©Danfoss|2021.04|25

Page 26

OperatingGuideECLComfort210/296/310,applicationA275/A375

ApplicationA375ingeneral:

UptotwoRemoteControlUnits,ECA30/31,canbeconnectedto

oneECLcontrollertocontroltheECLcontrollerremotely.

Exerciseofcirculationpumpsandcontrolvalveinperiodswithout

heatingdemandcanbearranged.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485bustoutilizecommonoutdoortemperaturesignal,timeand

datesignals.

SeveralECLcontrollers,internallyconnectedviaECL485bus,work

inMaster/Slaveconnection.InaMaster/Slavesystemmaximum

2ECA30/31canbepresent.

Unusedinput(fromS7andup)can,bymeansofanoverride

switch,beusedtooverridethescheduletoafixed'Comfort'or

'Saving'mode.

Modbuscommunication(ECL296andECL310)toaSCADAsystem

canbeestablished.

ECLPortal,Internetbasedconnection,allowsECL296,310and

310Btobemonitoredandcontrolledremotelyviastandard

Internetbrowsers(forexampleInternetExplorer,GoogleChrome

andSafari).

Heat-meters:

Upto5heat-meterscanbeconnectedtotheM-busterminals(ECL

296/310).

DatacanbetransferredtotheSCADAsystemviaModbusandTCP/

IPtotheECLPortal.

ModbuscommunicationtoaSCADAsystemcanbeestablished.

TheM-busdata(ECLComfort296/310)canfurthermorebe

transferredtotheModbuscommunication.

Alarm,A375:

AlarmA1(relayR6)andthealarmsymbol(

•ifatemperaturesensororitsconnectiondisconnects/

shortcircuits.

Alarm,A375.3andA375.5:

AlarmA1(relayR6)andthealarmsymbol(

•iftheactualflowtemperatureatS4(heatingcircuit2),differs

fromthedesiredflowtemperature.

Alarm,A375.4,A375.5:

AlarmA1(relayR6)andthealarmsymbol(

•ifthepressure,measuredbyS9,getshigherorlowerthanset

alarmvalues.

)canbeactivated:

)canbeactivated:

)canbeactivated:

26|©Danfoss|2021.04

AQ042286456873en-010501

Page 27

OperatingGuideECLComfort210/296/310,applicationA275/A375

ApplicationA375ingeneral,continued:

Offsetadjustment

Ameasuredtemperaturecanbeoffsetadjusted,ifneeded.

(Navigation:MENU>Commoncontroller>System>Sensoroffset)

Inputconfiguration

Inputs(asfromS7andup),whicharenotpartoftheapplication

canbeconfiguredtobePt1000,0-10Volt,frequency(pulse

counter)ordigitalinput.ThisfeaturemakesitpossibleinECL296/

310tocommunicateextrasignals,suchastemperatures,pressures,

ON/OFFconditions,viaModbusandECLPortal.

TheconfigurationisdonebymeansoftheECLTool(freesoftware

fordownload)ordirectlyinadedicatedmenuintheECLPortalor

theconnectionforModbus(BMS/SCADA).

Applicationupload

Theapplicationuploadprocedureisthefollowingafterhaving

powereduptheECLComfortcontroller:

1.Inserttheapplicationkey

2.Selectlanguage,*1,*2

3.Selectsubtype(theInstallationGuideshowssubtypes)

4.SetTimeandDate

TheECLComfortcontrollerinstallstheapplication,initializesand

restarts.Outputrelaysareactivated/de-activated(click-sounds

fromthiscanbeheard).Thisalsomeansthat,forexample,

circulationpumpscanbeswitchedONandOFFshortly.

*1:Seealsosection"InsertingtheECLApplicationKey" .

*2:(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

Commissioning

WhentheselectedapplicationhasbeenuploadedtheECLComfort

controllerstartsinManualmode.Thiscanbeusedtoverifycorrect

connectionsof,forexample,temperature,pressureandflow

sensors.Alsoverifyingthecontrolledcomponents(valveactuators,

pumps,burneretc.)forcorrectfunctionalitycanbedone.

Theapplicationkeyisdeliveredwithfactorysettings.

Dependingonsystemtype,itmightbenecessarytochangesome

factorysettingsindividuallyforoptimizingthefunctionality.

Theapplicationkeymustbeinsertedforchangingsettings.

Power-down/power-up

WhenthepowersupplytotheECLComfortcontrolleris

disconnected(power-down),theoutputrelaysgotode-activated

position.

Thismeansthat,forexample,circulationpumpsandburnercanbe

switchedON.

SeetheelectricalconnectiondiagramsintheInstallationGuide.

Allrelaycontactsareshowninde-activatedsituation.Somerelay

contactsareclosed,somerelaycontactsareopen.

WhenthepowersupplytotheECLComfortcontrolleris

re-established(power-up),theoutputrelaysareactivated/

de-activated(click-soundsfromthiscanbeheard).Thisalsomeans

that,forexample,circulationpumpsandburnercanbeswitched

ONandOFFshortly.

ImportantforA375.3andA375.5:

•Setthecorrectrunningtime"Mrun"oftheMotorizedControl

ValveM2.(Circuit2>MENU>Settings>Controlparameters

>Mrun).

AQ042286456873en-010501

©Danfoss|2021.04|27

Page 28

OperatingGuideECLComfort210/296/310,applicationA275/A375

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

28|©Danfoss|2021.04

AQ042286456873en-010501

Page 29

OperatingGuideECLComfort210/296/310,applicationA275/A375

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Thecirculationpump(s)inheatingcircuit(s)canbeplacedintheflow

aswellasthereturn.Placethepumpaccordingtothemanufacturer’s

specification.

AQ042286456873en-010501

©Danfoss|2021.04|29

Page 30

OperatingGuideECLComfort210/296/310,applicationA275/A375

A275applications:

SeetheInstallationGuide(deliveredwiththeapplicationkey)forapplicationexamplesandelectricalconnections.

A275.1,examplea

BoilerON/OFFcontrolforaheatingcircuit.

Thecomponentmarkedwith*isapressurereliefvalve.

A275.1,exampleb

BoilerON/OFFcontrolforaheatingcircuit.Theboilercircuitisequippedwithalowlossheader.

Thecomponentmarkedwith*isapressurereliefvalve.

A275.2,examplea

BoilerON/OFFcontrolforaheatingandaDHWcircuit.OptionalDHWpriority.

Thecomponentmarkedwith*isapressurereliefvalve.

AtDHWheatingP3isswitchedONandthedesiredboilertemperatureliesanumberofdegreesabovethedesiredDHWtemperature.

P1isswitchedOFF.

SpecialsettingsfortypeA275.2,examplea:

Navigation:

DHWcircuit(circuit2)

DHWheatingismanagedbypumpP3:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencethedesiredboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

Pleasenote:

If'Ch.-o.valve/P'in12051issettoOFF,P3willbeswitchedonatDHWheating.Thedesiredboilertemperaturewillstillliea

numberofdegreesabovethedesiredDHWtemperatureandP1willremainswitchedON.

A275.2,exampleb

BoilerON/OFFcontrolforaheatingandaDHWcircuit.DHWpriority.

Thecomponentmarkedwith*isapressurereliefvalve.

AtDHWheatingP3(changeovervalve)isactivatedandthedesiredboilertemperatureliesanumberofdegreesabovethedesiredDHW

temperature.

P1iscontinuouslyswitchedON.

SpecialsettingsfortypeA275.2,exampleb:

IDno.:

12051

12053

Recommendedsetting:

ON

OFF

Navigation:

DHWcircuit(circuit2)

DHWheatingismanagedbychangeovervalveP3/M1:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencethedesiredboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

30|©Danfoss|2021.04

IDno.:

12051

12053

Recommendedsetting:

OFF

OFF

AQ042286456873en-010501

Page 31

OperatingGuideECLComfort210/296/310,applicationA275/A375

SeetheInstallationGuide(deliveredwiththeapplicationkey)forapplicationexamplesandelectricalconnections.

A275.2,examplec

BoilerON/OFFcontrolforaheatingandaDHWcircuit.OptionalDHWpriority.Theboilercircuitisequippedwithalowlossheader.

Thecomponentmarkedwith*isapressurereliefvalve.

Thepumpintheboilercircuitisnotcontrolled.

AtDHWheatingP3isswitchedONandthedesiredboilertemperatureliesanumberofdegreesabovethedesiredDHWtemperature.

P1isswitchedOFF.

SpecialsettingsfortypeA275.2,examplec:

Navigation:IDno.:

DHWcircuit(circuit2)

DHWheatingismanagedbypumpP3:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencethedesiredboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

Pleasenote:

If'Ch.-o.valve/P'in12051issettoOFF,P3willbeswitchedonatDHWheating.Thedesiredboilertemperaturewillstillliea

numberofdegreesabovethedesiredDHWtemperatureandP1remainswitchedON.

A275.2,exampled

BoilerON/OFFcontrolforaheatingandaDHWcircuit.DHWpriority.Theboilercircuitisequippedwithalowlossheader.

Thecomponentmarkedwith*isapressurereliefvalve.

Thepumpintheboilercircuitisnotcontrolled.

AtDHWheatingP3(changeovervalve)isactivatedandthedesiredboilertemperatureliesanumberofdegreesabovethedesiredDHW

temperature.

P1isswitchedON.

SpecialsettingsfortypeA275.2,exampled:

12051

12053

Recommendedsetting:

ON

OFF

Navigation:

DHWcircuit(circuit2)

DHWheatingismanagedbychangeovervalveP3/M1:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencethedesiredboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

AQ042286456873en-010501

IDno.:

12051

12053

Recommendedsetting:

OFF

OFF

©Danfoss|2021.04|31

Page 32

OperatingGuideECLComfort210/296/310,applicationA275/A375

SeetheInstallationGuide(deliveredwiththeapplicationkey)forapplicationexamplesandelectricalconnections.

A275.3,examplea

BoilerON/OFFcontrolforadirectheatingcircuit(1),amixingcircuit(2)andaDHWcircuit(3).OptionalDHWpriority.

Thecomponentmarkedwith*isapressurereliefvalve.

Heatingcircuit2canalternativelybeafloorheatingcircuit.

AtDHWheatingP3isswitchedONandthedesiredboilertemperatureliesanumberofdegreesabovethedesiredDHWtemperature.

P1isswitchedOFF .Heatingcircuit2canbeclosedduringDHWheating.

SpecialsettingsfortypeA275.3,examplea:

Navigation:IDno.:

Heatingcircuit(circuit1)

Circuit1mustbeabletoreceiveaheatdemand(desiredflowtemperature)fromcircuit2:

MENU\Settings\Application:'Demandoffset'

**Thisvalueisaddedtotheheatdemandvaluefromcircuit2

Heatingcircuit(circuit2)

Circuit2mustbeabletosendaheatdemand(desiredflowtemperature)tocircuit1:

MENU\Settings\Application:'SenddesiredT'

Circuit2canbeclosedduringtheDHWheatingprocess:

MENU\Settings\Application:‘DHWpriority'

***Set'OFF'whennottobeclosed,set'ON'whentobeclosed

DHWcircuit(circuit3)

DHWheatingismanagedbypumpP3:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencetheboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

11017

12500

12052

13051

13053

Recommendedsetting:

3K**

ON

***

ON

OFF

32|©Danfoss|2021.04

AQ042286456873en-010501

Page 33

OperatingGuideECLComfort210/296/310,applicationA275/A375

SeetheInstallationGuide(deliveredwiththeapplicationkey)forapplicationexamplesandelectricalconnections.

A275.3,exampleb

BoilerON/OFFcontrolforadirectheatingcircuit(1),amixingcircuit(2)andaDHWcircuit(3).PartlyDHWpriority.

Thecomponentmarkedwith*isapressurereliefvalve.

Heatingcircuit2canalternativelybeafloorheatingcircuit.

AtDHWheatingP3(changeovervalve)isactivatedandthedesiredboilertemperatureisanumberofdegreesabovethedesiredDHW

temperature.

P1iscontinuouslyswitchedON.

Heatingcircuit2canbeclosedduringDHWheating.

SpecialsettingsfortypeA275.3,exampleb:

Navigation:IDno.:

Heatingcircuit(circuit1)

Circuit1mustbeabletoreceiveaheatdemand(desiredflowtemperature)fromcircuit2:

MENU\Settings\Application:'Demandoffset'

**Thisvalueisaddedtotheheatdemandvaluefromcircuit2

Heatingcircuit(circuit2)

Circuit2mustbeabletosendaheatdemand(desiredflowtemperature)tocircuit1:

MENU\Settings\Application:'SenddesiredT'

Circuit2canbeclosedduringtheDHWheatingprocess:

MENU\Settings\Application:‘DHWpriority'

***Set'OFF'whennottobeclosed,set'ON'whentobeclosed

DHWcircuit(circuit3)

DHWheatingismanagedbychangeovervalveP3/M1:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencetheboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

11017

12500

12052

13051

13053

Recommendedsetting:

3K**

ON

***

OFF

OFF

AQ042286456873en-010501

©Danfoss|2021.04|33

Page 34

OperatingGuideECLComfort210/296/310,applicationA275/A375

SeetheInstallationGuide(deliveredwiththeapplicationkey)forapplicationexamplesandelectricalconnections.

A275.3,examplec

BoilerON/OFFcontrolforadirectheatingcircuit(1),amixingcircuit(2)andaDHWcircuit(3).DHWpriority.

Thecomponentmarkedwith*isapressurereliefvalve.

Heatingcircuit2canalternativelybeafloorheatingcircuit.

AtDHWheating,P3(changeovervalve)isactivatedandthedesiredboilertemperatureisanumberofdegreesabovethedesiredDHW

temperature.

P1iscontinuouslyswitchedON.

Heatingcircuit2isclosedduringDHWheating.

SpecialsettingsfortypeA275.3,examplec:

Navigation:IDno.:

Heatingcircuit(circuit1)

Circuit1mustbeabletoreceiveaheatdemand(desiredflowtemperature)fromcircuit2:

MENU\Settings\Application:'Demandoffset'

**Thisvalueisaddedtotheheatdemandvaluefromcircuit2

Heatingcircuit(circuit2)

Circuit2mustbeabletosendaheatdemand(desiredflowtemperature)tocircuit1:

MENU\Settings\Application:'SenddesiredT'

Circuit2mustbeclosedduringtheDHWheatingprocess:

MENU\Settings\Application:‘DHWpriority'

DHWcircuit(circuit3)

DHWheatingismanagedbychangeovervalveP3/M1:

MENU\Settings\Application:'Ch.-o.valve/P'

ThedesiredDHWheatingtemperaturemustinfluencetheboilertemperature:

MENU\Settings\Application:‘Tank,sec./prim.'

11017

12500

12052

13051

13053

Recommendedsetting:

3K**

ON

ON

OFF

OFF

34|©Danfoss|2021.04

AQ042286456873en-010501

Page 35

OperatingGuideECLComfort210/296/310,applicationA275/A375