Page 1

OperatingGuide

ECLComfort210/310,applicationA267

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................5

2.1Beforeyoustart.....................................................5

2.2Identifyingthesystemtype.......................................8

2.3Mounting...........................................................14

2.4Placingthetemperaturesensors................................18

2.5Electricalconnections.............................................20

2.6InsertingtheECLApplicationKey..............................26

2.7Checklist............................................................33

2.8Navigation,ECLApplicationKeyA267.........................34

3.0Dailyuse.........................................................38

3.1Howtonavigate...................................................38

3.2Understandingthecontrollerdisplay..........................39

3.3Ageneraloverview:Whatdothesymbolsmean?...........43

3.4Monitoringtemperaturesandsystem

components........................................................44

3.5Influenceoverview................................................45

3.6Manualcontrol.....................................................46

3.7Schedule............................................................47

4.0Settingsoverview............................................48

5.0Settings...........................................................50

5.1IntroductiontoSettings..........................................50

5.2Flowtemperature..................................................51

5.3Roomlimit..........................................................54

5.4Returnlimit.........................................................56

5.5Optimization........................................................62

5.6Controlparameters................................................69

5.7Application.........................................................73

5.8Heatcut-out........................................................83

5.9Tanktemperature..................................................86

5.10Anti-bacteria........................................................89

6.0Commoncontrollersettings..............................91

6.1Introductionto‘Commoncontrollersettings’................91

6.2Time&Date.........................................................92

6.3Holiday..............................................................93

6.4Inputoverview.....................................................95

6.5Log...................................................................96

6.6Outputoverride....................................................97

6.7Keyfunctions.......................................................98

6.8System.............................................................100

7.0Miscellaneous................................................107

7.1ECA30/31setupprocedures.................................107

7.2Overridefunction................................................115

7.3Severalcontrollersinthesamesystem......................118

7.4Frequentlyaskedquestions....................................121

7.5Definitions........................................................124

7.6Type(ID6001),overview.......................................128

7.7Automatic/manualupdateoffirmware.....................129

7.8ParameterIDoverview..........................................130

©Danfoss|2021.03AQ026486454993en-010401|1

Page 2

OperatingGuideECLComfort210/310,applicationA267

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisInstallationGuideisassociatedwithECLApplicationKeyA267

(ordercodeno.087H3816).

ThefunctionscanberealizedinECLComfort210aswellasECL

Comfort310.IftheA267keyisusedintheECLComfort310,the

functionalityremainsasintheECLComfort210.

TheapplicationA267complieswithECLComfortcontroller210

and310asofsoftwareversion1.11(visibleatstart-upofthe

controllerandin‘Commoncontrollersettings’in‘System’).

AdditionaldocumentationforECLComfort210andaccessoriesis

availableonhttp://heating.danfoss.com/.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

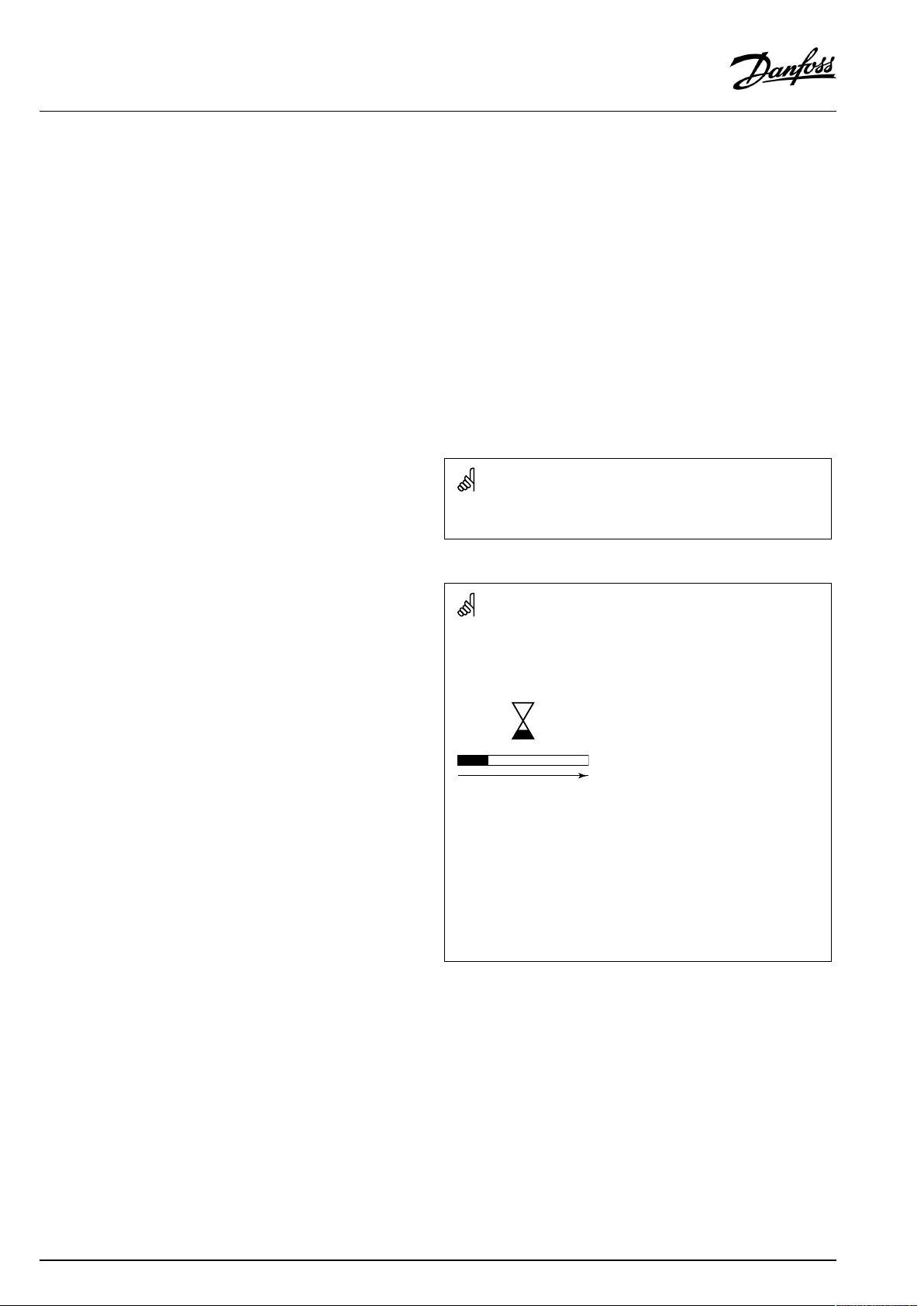

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

2|©Danfoss|2021.03

AQ026486454993en-010401

Page 3

OperatingGuideECLComfort210/310,applicationA267

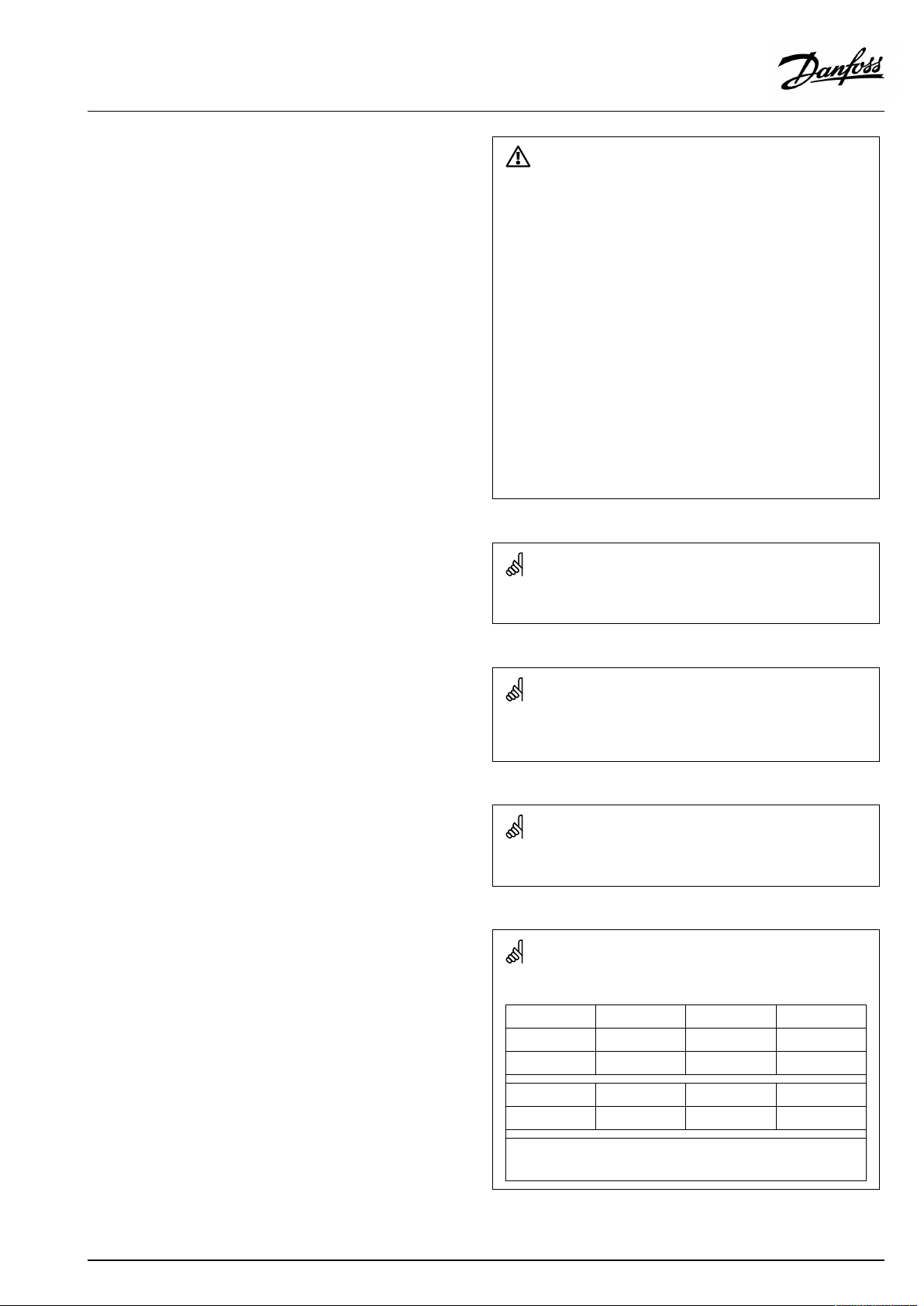

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

Circuit1Parameterno.

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

2

Circuit2Parameterno.

AQ026486454993en-010401

174

©Danfoss|2021.03|3

Page 4

OperatingGuideECLComfort210/310,applicationA267

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thissymbolontheproductindicatesthatitmaynot

bedisposedofashouseholdwaste.

Itmustbehandedovertotheapplicabletake-back

schemefortherecyclingofelectricalandelectronic

equipment.

•Disposeoftheproductthroughchannelsprovided

forthispurpose.

•Complywithalllocalandcurrentlyapplicablelaws

andregulations.

4|©Danfoss|2021.03

AQ026486454993en-010401

Page 5

OperatingGuideECLComfort210/310,applicationA267

2.0Installation

2.1Beforeyoustart

TheapplicationA267isveryflexible.Thesearethebasicprinciples:

Heating(circuit1):

Typically,theflowtemperatureisadjustedaccordingtoyour

requirements.TheflowtemperaturesensorS3isthemost

importantsensor.ThedesiredflowtemperatureatS3iscalculated

intheECLcontroller,basedontheoutdoortemperature(S1).

Thelowertheoutdoortemperature,thehigherthedesiredflow

temperature.Bymeansofaweekschedule(upto3‘Comfort’

periods/day),theheatingcircuit1canbein‘Comfort’or

‘Saving’mode(twodifferenttemperaturevaluesfordesiredroom

temperature).

ThemotorizedcontrolvalveM1isopenedgraduallywhenthe

flowtemperatureislowerthanthedesiredflowtemperatureand

viceversa.

Thereturntemperature(S5)tothedistrictheatingsupplyshould

notbetoohigh.Ifso,thedesiredflowtemperaturecanbeadjusted

(typicallytoalowervalue),thusresultinginagradualclosingofthe

motorizedcontrolvalve.

Furthermore,thereturntemperaturelimitationcandepend

ontheoutdoortemperature.Typically,thelowertheoutdoor

temperature,thehighertheacceptedreturntemperature.

Inboiler-basedheatingsupplythereturntemperatureshouldnot

betoolow(sameadjustmentprocedureasabove).

Ifthemeasuredroomtemperature(S7)doesnotequalthedesired

roomtemperature,thedesiredflowtemperaturecanbeadjusted.

Thecirculationpump(P1)isONatheatdemandoratfrost

protection.Thecirculationpump(P1)canbeswitchedOFF

whenheatingtheDHW(dependentpriority).Ifthesystemhas

achangeovervalve(P2)betweentheheatingandDHWheating

circuit,thecirculationpump(P1)isONwhenheatingtheDHW.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalue.

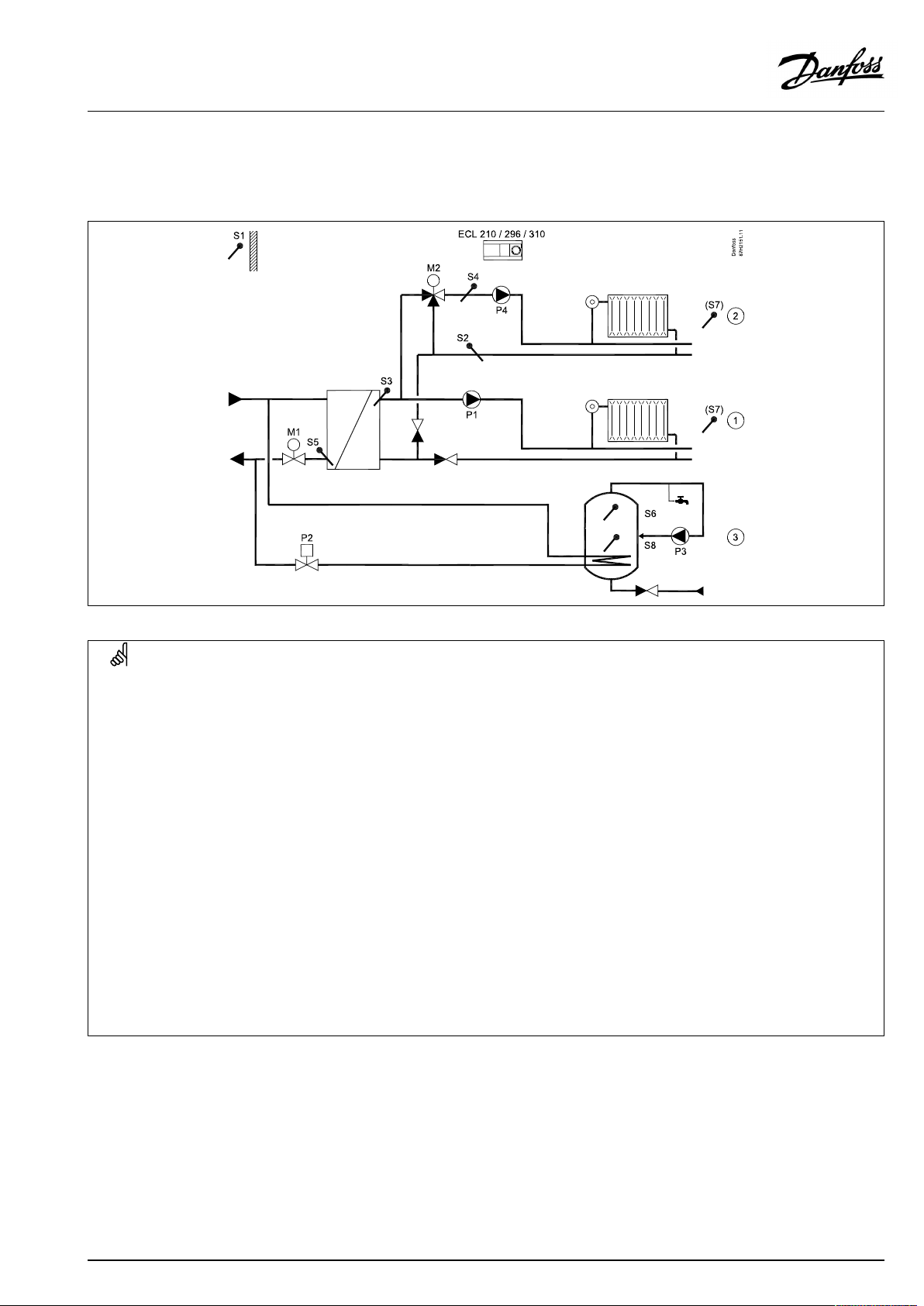

TypicalA267application:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

S1

Outdoortemperaturesensor

S2Returntemperaturesensor,circuit2

S3

Flowtemperaturesensor,circuit1

S4

Flowtemperaturesensor,circuit2

S5Returntemperaturesensor,circuit1

S6

DHWtanktemperaturesensor,upper

S7

Roomtemperaturesensor,circuits1and2

S8

DHWtanktemperaturesensor,lower

P1

Circulationpump,heating,circuit1

P2

DHWheatingpump,circuit3

P3

DHWcirculationpump,circuit3

P4

Circulationpump,heating,circuit2

M1

Motorizedcontrolvalve,circuits1and3

M2

Motorizedcontrolvalve,circuit2

AQ026486454993en-010401

©Danfoss|2021.03|5

Page 6

OperatingGuideECLComfort210/310,applicationA267

Heating(circuit2):

Thiscircuitworksaftersameprinciplesascircuit1.

TheflowtemperaturesensorS4isthemostimportantsensor.

Bymeansofaweekschedule(upto3‘Comfort’periods/day),the

heatingcircuit2canbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredroomtemperature).Themotorized

controlvalveM2controlsthecircuit.

Thereturntemperature(S2)enableslimitationasdescribed

previously.

IfthemeasuredroomtemperatureS7doesnotequalthedesired

roomtemperature,thedesiredflowtemperaturecanbeadjusted.

Thecirculationpump(P4)isONatheatdemandoratfrost

protection.

TheheatingcanbeswitchedOFFwhentheoutdoortemperatureis

higherthanaselectablevalue.

Heatingcircuit2canbeconnectedafterheatingcircuit1.Ifso,the

desiredflowtemperatureatS3canbeinfluencedbythedesired

flowtemperatureatS4.

Heatingcircuits1and2:

Theheatingcircuits1and2canusethesameroomtemperature

sensor(S7).However,eachheatingcircuitcanhaveanECA30,

RemoteControlUnit,inordertohaveseparateroomtemperature

signals.Anothersolution:UseS7foroneoftheheatingcircuitsand

ECA30fortheotherheatingcircuit.

A267.1examplea:

A267.1exampleb:

A267.1examplec:

6|©Danfoss|2021.03

AQ026486454993en-010401

Page 7

OperatingGuideECLComfort210/310,applicationA267

DomesticHotWater(DHW ,circuit3):

Bymeansofaweekschedule(upto3Comfortperiods/day),the

DHWcircuitcanbein‘Comfort’or‘Saving’mode(twodifferent

temperaturevaluesfordesiredDHWtemperature).

IfthemeasuredDHWtemperature(S6)islowerthanthedesired

DHWtemperature,theheatingcirculationpump(P1)canbe

switchedOFFandtheDHWheatingpump(P2)isswitchedON.The

motorizedcontrolvalve(M1)iscontrolledinordertomaintainthe

DHWheatingtemperatureatS3.

TheDHWheatingtemperatureistypically10-15degreeshigher

thanthedesiredDHWtemperature.

DHWtankwith1temperaturesensor:

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperature,theDHWheatingpump(P2)isswitched

OFF.Apost-runtimecanbeset.Themotorizedcontrolvalve(M1)

willhereaftermaintainthedesiredflowtemperatureintheheating

circuit.

DHWtankwith2temperaturesensors:

WhenthemeasuredDHWtemperature(S6)getshigherthanthe

desiredDHWtemperatureandthelowertemperature(atS8)gets

higherthanthecut-outtemperature,theDHWheatingpump(P2)

isswitchedOFF.Apost-runtimecanbeset.Themotorizedcontrol

valve(M1)willhereaftermaintainthedesiredflowtemperaturein

theheatingcircuit.

A267.1exampled:

A267.1examplee:

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

AQ026486454993en-010401

©Danfoss|2021.03|7

Page 8

OperatingGuideECLComfort210/310,applicationA267

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Thecirculationpump(s)inheatingcircuit(s)canbeplacedintheflow

aswellasthereturn.Placethepumpaccordingtothemanufacturer’s

specification.

A267.1,examplea

Indirectlyconnectedsystemwith2heatingcircuitsandsecondarilyconnectedDHWtankwithinternalheatexchanger(optionalDHW

priority).

8|©Danfoss|2021.03

AQ026486454993en-010401

Page 9

OperatingGuideECLComfort210/310,applicationA267

SpecialsettingsfortypeA267.1,examplea:

DHWcircuit(circuit3)

TheDHWheatingiscontrolledbymeansofDHWheatingpumpP2.

Navigation:IDno.:

MENU\Settings\Application:'Ch.-o.valve/P'

TheDHWtankisconnectedsecondarily.

MENU\Settings\Application:‘Tank,sec./prim. '

Recommendedsetting:

13051

13053

ON

OFF

AQ026486454993en-010401

©Danfoss|2021.03|9

Page 10

OperatingGuideECLComfort210/310,applicationA267

A267.1,exampleb

Indirectlyconnectedsystemwith2heatingcircuitsandsecondarilyconnectedDHWtankwithinternalheatexchanger(DHWpriority).

SpecialsettingsfortypeA267.1,exampleb:

DHWcircuit(circuit3)

TheDHWheatingiscontrolledbymeansofchangeovervalve*P2.

Navigation:IDno.:

MENU\Settings\Application:'Ch.-o.valve/P'

TheDHWtankisconnectedsecondarily.

MENU\Settings\Application:‘Tank,sec./prim. '

*

Thechangeovervalvecanbeofthistype:

DanfossAMZ113

Normalpowersupplied.Whenthecontrolvoltageisapplied(fromterminal12),thechangeovervalvechangesflowdirection.

13051

13053

Recommendedsetting:

OFF

OFF

10|©Danfoss|2021.03

AQ026486454993en-010401

Page 11

OperatingGuideECLComfort210/310,applicationA267

A267.1,examplec

Indirectlyconnectedsystemwith2heatingcircuitsandprimarilyconnectedDHWtankwithinternalheatexchanger(optionalDHW

priority).

SpecialsettingsfortypeA267.1,examplec:

DHWcircuit(circuit3)

TheDHWheatingiscontrolledbymeansofON/OFFvalve*P2.

Navigation:

MENU\Settings\Application:'Ch.-o.valve/P'

TheDHWtankisconnectedsecondarily.

MENU\Settings\Application:‘Tank,sec./prim.

*

Thechangeovervalvecanbeofthistype:

DanfossAMZ113

Normalpowersupplied.Whenthecontrolvoltageisapplied(fromterminal12),thechangeovervalvechangesflowdirection.

IDno.:

13051

13053

Recommendedsetting:

ON

ON

AQ026486454993en-010401

©Danfoss|2021.03|11

Page 12

OperatingGuideECLComfort210/310,applicationA267

A267.1,exampled

Indirectlyconnectedsystemwith2heatingcircuits(circuit2isconnectedassubcircuit)andsecondarilyconnectedDHWtankwith

internalheatexchanger(optionalDHWpriority).

SpecialsettingsfortypeA267.1,exampled:

Heatingcircuit1

Heatingcircuit1mustreceiveinformationaboutandreactonthedesiredflowtemperaturefromheatingcircuit2.

Navigation:IDno.:

MENU\Settings\Application:'Demandoffset'

*

Thedesiredflowtemperatureinheatingcircuit1is5Kabovethedesiredflowtemperatureinheatingcircuit2.

Heatingcircuit2

Heatingcircuit2isconnectedsecondarilyandmustsendinformationaboutitsdesiredflowtemperaturetoheatingcircuit1.

Navigation:IDno.:

MENU\Settings\Application:'SenddesiredT'

DHWcircuit(circuit3)

TheDHWheatingiscontrolledbymeansofDHWheatingpumpP2.

Navigation:IDno.:

MENU\Settings\Application:'Ch.-o.valve/P'

TheDHWtankisconnectedsecondarily.

MENU\Settings\Application:‘Tank,sec./prim. '

11017

12500

13051

13053

Recommendedsetting:

5K*

Recommendedsetting:

ON

Recommendedsetting:

ON

OFF

12|©Danfoss|2021.03

AQ026486454993en-010401

Page 13

OperatingGuideECLComfort210/310,applicationA267

A267.1,examplee

Indirectlyconnectedsystemwith2heatingcircuits(circuit2isconnectedassubcircuit)andprimarilyconnectedDHWtankwith

internalheatexchanger(optionalDHWpriority).

SpecialsettingsfortypeA267.1,examplee:

Heatingcircuit1

Heatingcircuit1mustreceiveinformationaboutandreactonthedesiredflowtemperaturefromheatingcircuit2.

Navigation:

MENU\Settings\Application:'Demandoffset'

*

Thedesiredflowtemperatureinheatingcircuit1is5Kabovethedesiredflowtemperatureinheatingcircuit2.

Heatingcircuit2

Heatingcircuit2isconnectedsecondarilyandmustsendinformationaboutitsdesiredflowtemperaturetoheatingcircuit1.

Navigation:

MENU\Settings\Application:'SenddesiredT'

DHWcircuit(circuit3)

TheDHWheatingiscontrolledbymeansofON/OFFvalve**P2/M3.

Navigation:

MENU\Settings\Application:'Ch.-o.valve/P'

TheDHWtankisconnectedsecondarily.

MENU\Settings\Application:‘Tank,sec./prim. '

**

Thechangeovervalvecanbeofthistype:

DanfossAMZ113

Normalpowersupplied.Whenthecontrolvoltageisapplied(fromterminal12),thechangeovervalvechangesflowdirection.

IDno.:

11017

IDno.:

12500

IDno.:

13051

13053

Recommendedsetting:

5K*

Recommendedsetting:

ON

Recommendedsetting:

ON

ON

AQ026486454993en-010401

©Danfoss|2021.03|13

Page 14

OperatingGuideECLComfort210/310,applicationA267

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

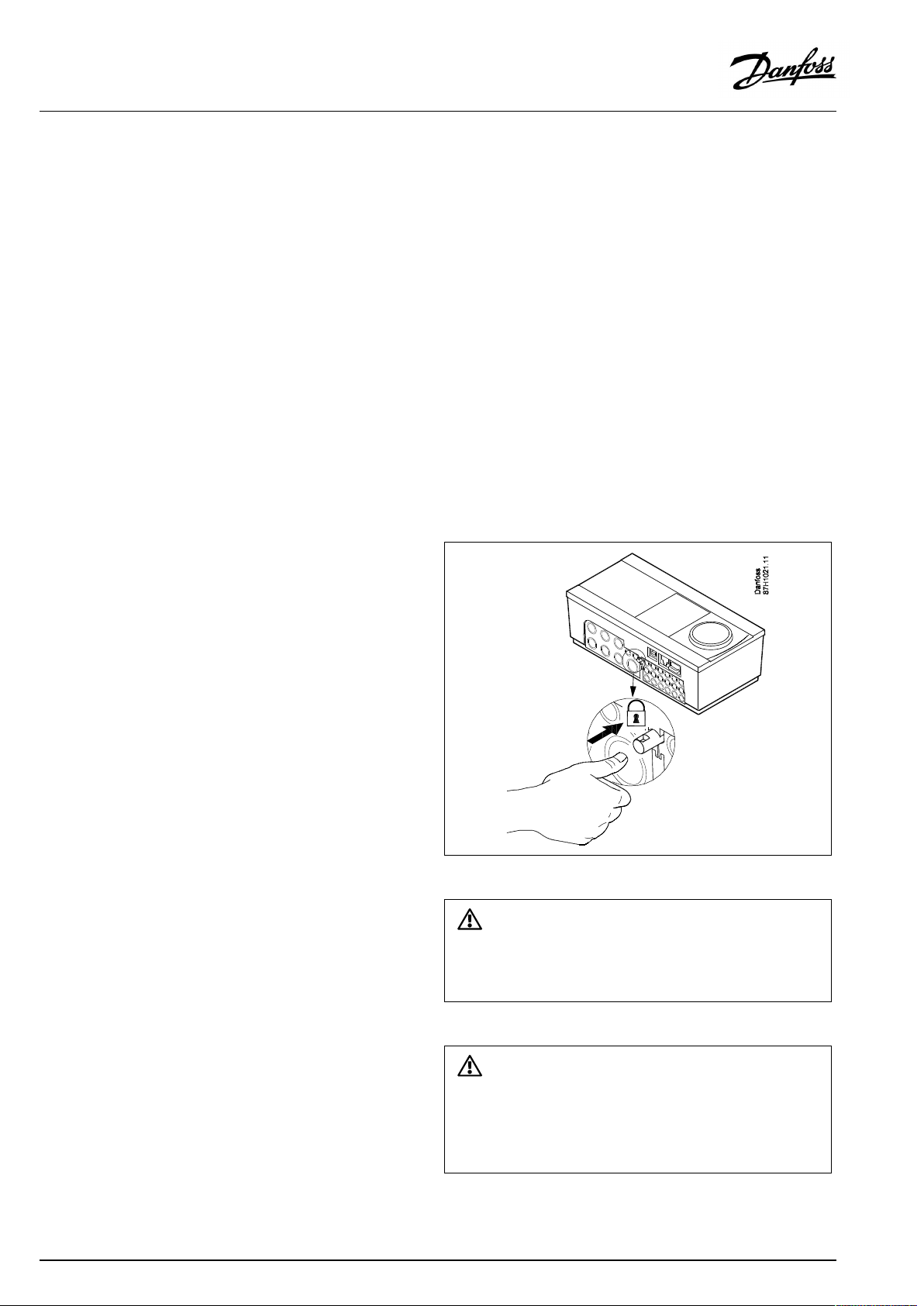

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

14|©Danfoss|2021.03

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

AQ026486454993en-010401

Page 15

OperatingGuideECLComfort210/310,applicationA267

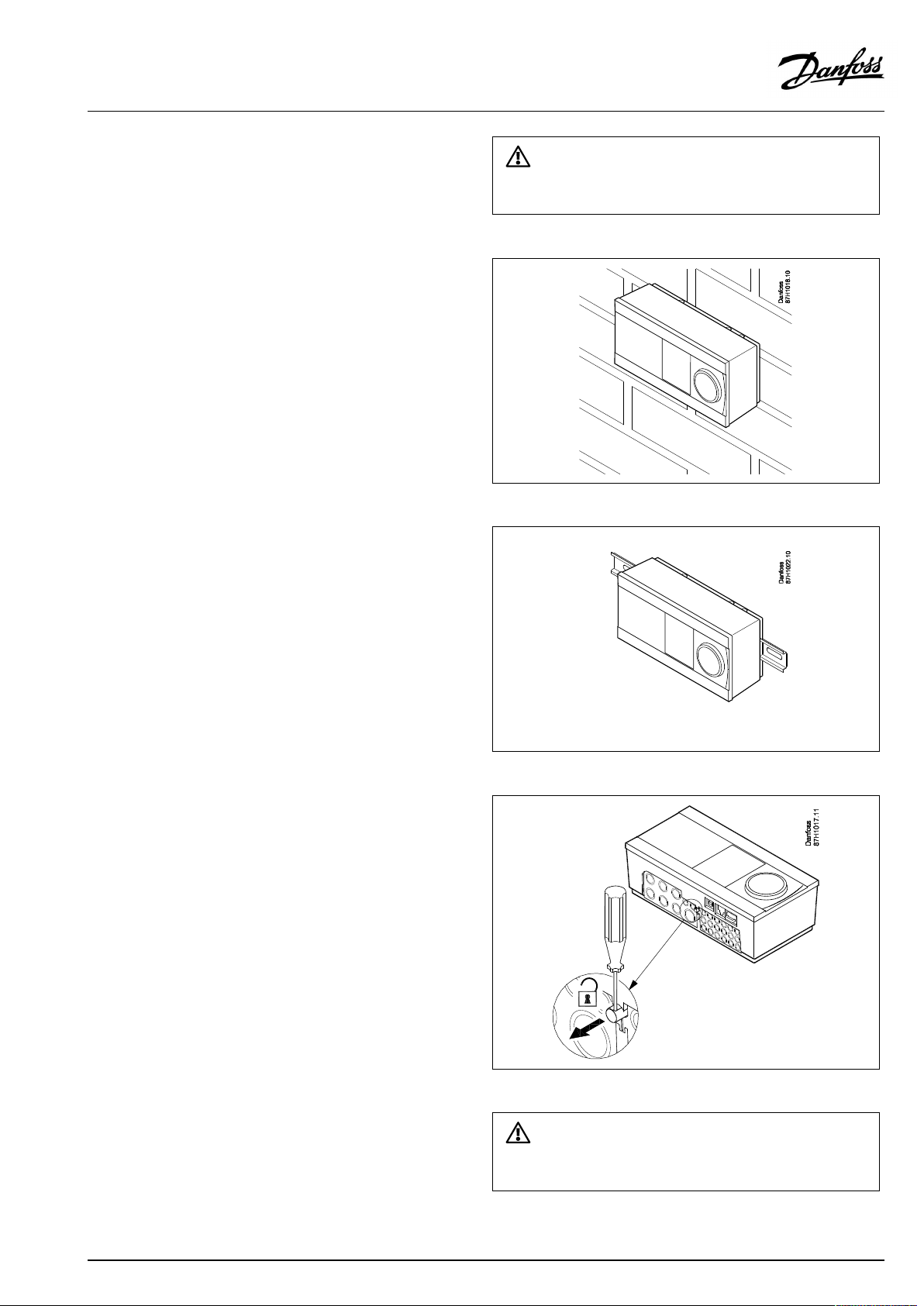

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

AQ026486454993en-010401

©Danfoss|2021.03|15

Page 16

OperatingGuideECLComfort210/310,applicationA267

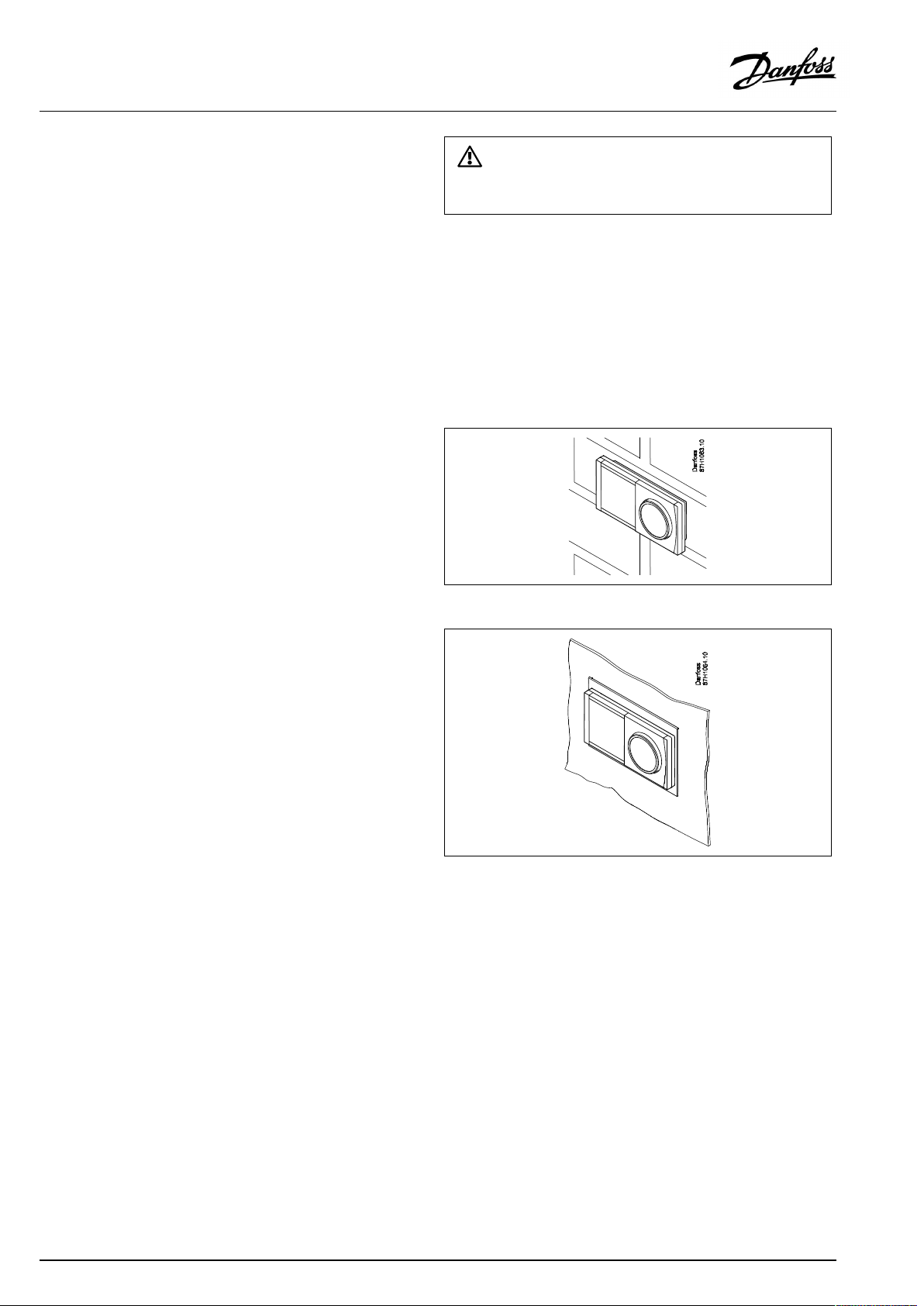

2.3.2MountingtheRemoteControlUnitsECA30/31

Selectoneofthefollowingmethods:

•Mountingonawall,ECA30/31

•Mountinginapanel,ECA30

Screwsandrawlplugsarenotsupplied.

Mountingonawall

MountthebasepartoftheECA30/31onawallwithasmooth

surface.Establishtheelectricalconnections.PlacetheECA30/

31inthebasepart.

BeforeremovingtheECLComfortcontrollerfromthebasepart,ensure

thatthesupplyvoltageisdisconnected.

Mountinginapanel

MounttheECA30inapanelusingtheECA30framekit(ordercode

no.087H3236).Establishtheelectricalconnections.Securethe

framewiththeclamp.PlacetheECA30inthebasepart.TheECA

30canbeconnectedtoanexternalroomtemperaturesensor.

TheECA31mustnotbemountedinapanelifthehumidity

functionistobeused.

16|©Danfoss|2021.03

AQ026486454993en-010401

Page 17

OperatingGuideECLComfort210/310,applicationA267

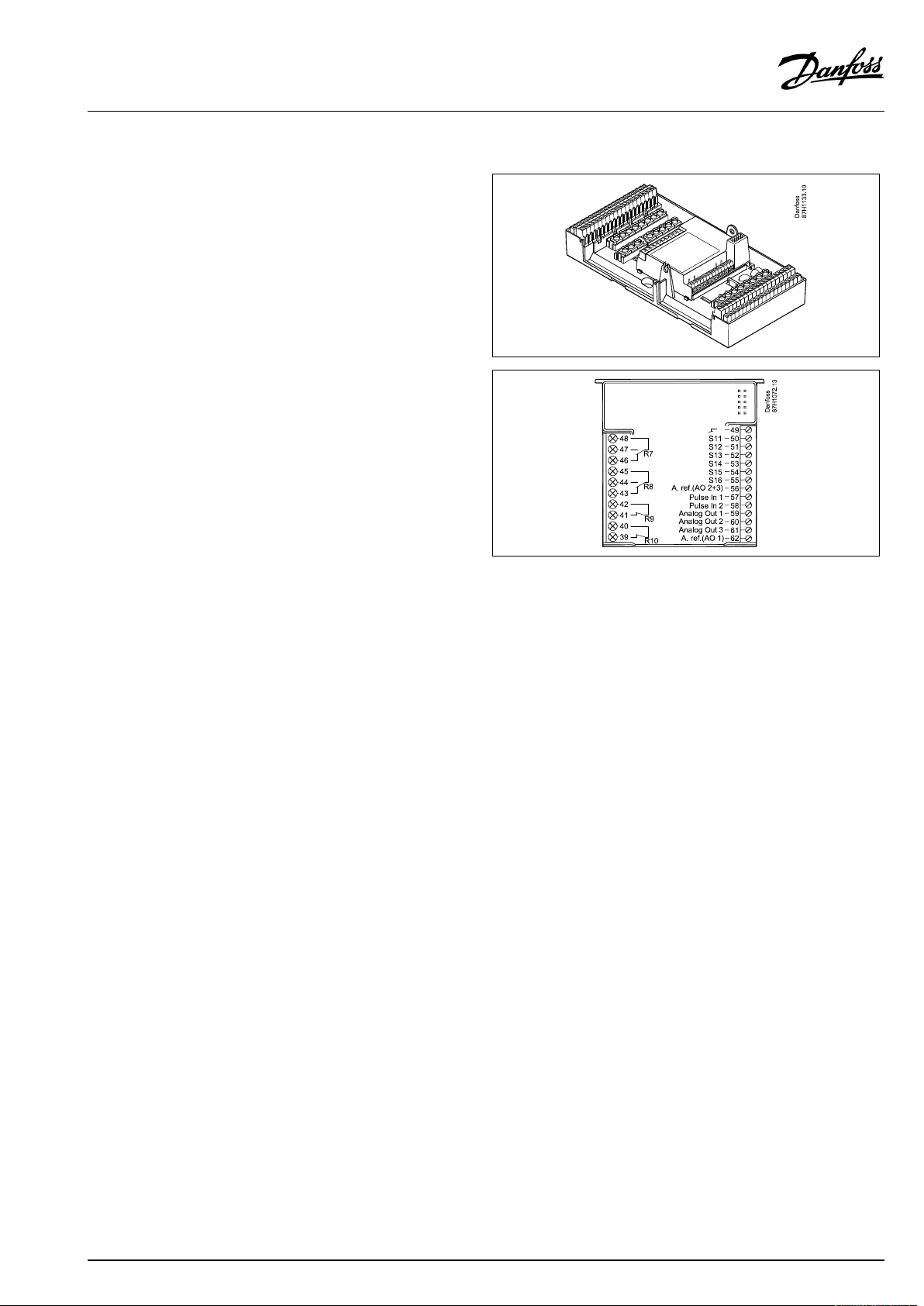

2.3.3MountingtheinternalI/OmoduleECA32

MountingoftheinternalI/OmoduleECA32

TheECA32module(ordercodeno.087H3202)mustbeinserted

intotheECLComfort310/310Bbasepartforadditionalinputand

outputsignalsinrelevantapplications.

TheconnectionbetweentheECLComfort310/310BandECA32

isa10-pole(2x5)connector.Theconnectionisautomatically

establishedwhentheECLComfort310/310Bisplacedonthe

basepart.

AQ026486454993en-010401

©Danfoss|2021.03|17

Page 18

OperatingGuideECLComfort210/310,applicationA267

2.4Placingthetemperaturesensors

2.4.1Placingthetemperaturesensors

Itisimportantthatthesensorsaremountedinthecorrectposition

inyoursystem.

Thetemperaturesensormentionedbelowaresensorsusedforthe

ECLComfort210/296/310serieswhichnotallwillbeneeded

foryourapplication!

Outdoortemperaturesensor(ESMT)

Theoutdoorsensorshouldbemountedonthatsideofthebuilding

whereitislesslikelytobeexposedtodirectsunshine.Itshouldnot

beplacedclosetodoors,windowsorairoutlets.

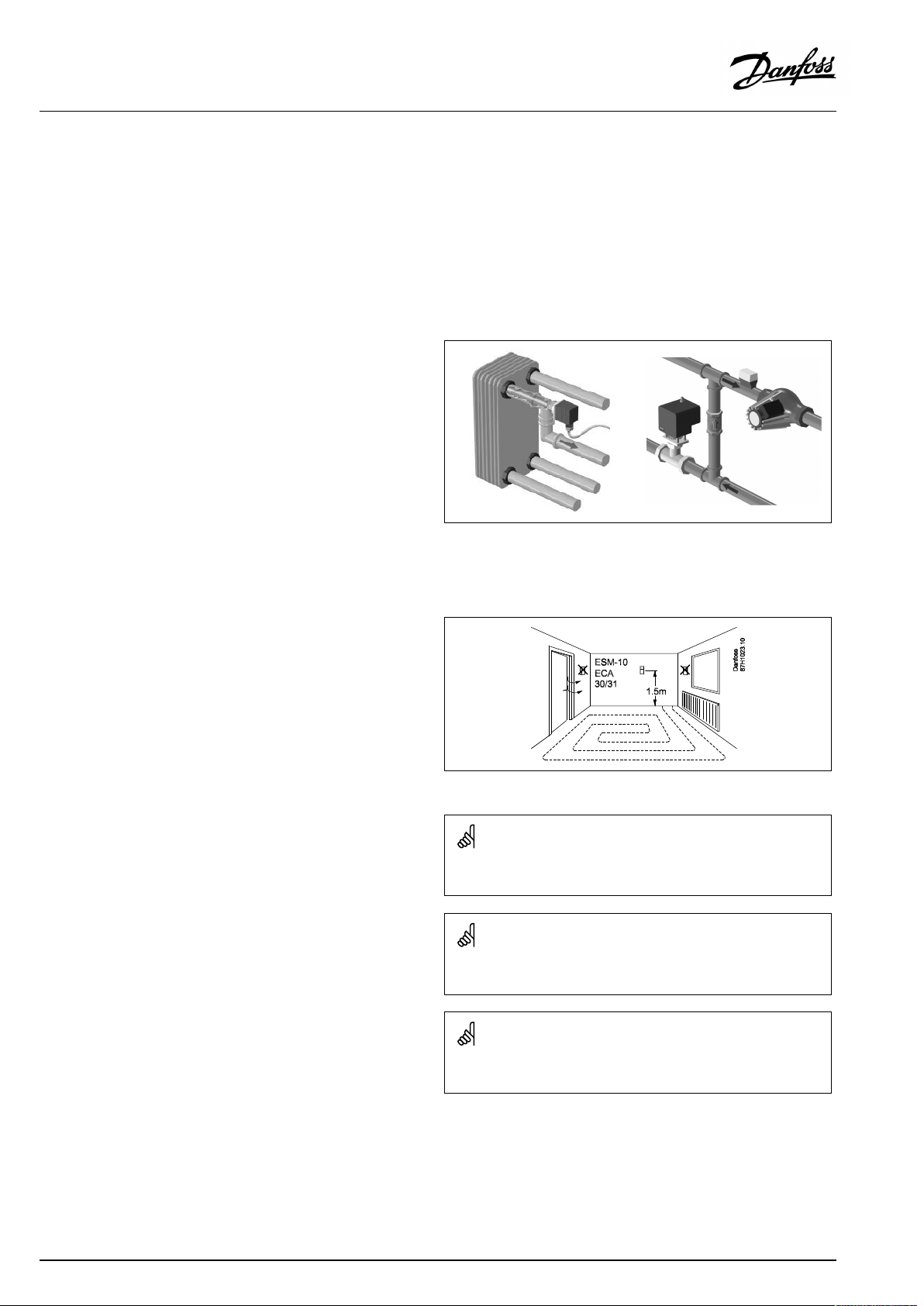

Flowtemperaturesensor(ESMU,ESM-11orESMC)

Placethesensormax.15cmfromthemixingpoint.Insystems

withheatexchanger,DanfossrecommendsthattheESMU-typeto

beinsertedintotheexchangerflowoutlet.

Makesurethatthesurfaceofthepipeiscleanandevenwhere

thesensorismounted.

Returntemperaturesensor(ESMU,ESM-11orESMC)

Thereturntemperaturesensorshouldalwaysbeplacedsothatit

measuresarepresentativereturntemperature.

Roomtemperaturesensor

(ESM-10,ECA30/31RemoteControlUnit)

Placetheroomsensorintheroomwherethetemperatureistobe

controlled.Donotplaceitonoutsidewallsorclosetoradiators,

windowsordoors.

Boilertemperaturesensor(ESMU,ESM-11orESMC)

Placethesensoraccordingtotheboilermanufacturer’s

specification.

Airducttemperaturesensor(ESMB-12orESMUtypes)

Placethesensorsothatitmeasuresarepresentativetemperature.

DHWtemperaturesensor(ESMUorESMB-12)

PlacetheDHWtemperaturesensoraccordingtothemanufacturer’s

specification.

Slabtemperaturesensor(ESMB-12)

Placethesensorinaprotectiontubeintheslab.

ESM-11:Donotmovethesensorafterithasbeenfastenedinorderto

avoiddamagetothesensorelement.

ESM-11,ESMCandESMB-12:Useheatconductingpasteforquick

measurementofthetemperature.

ESMUandESMB-12:Usingasensorpockettoprotectthesensorwill,

however,resultinaslowertemperaturemeasurement.

18|©Danfoss|2021.03

AQ026486454993en-010401

Page 19

OperatingGuideECLComfort210/310,applicationA267

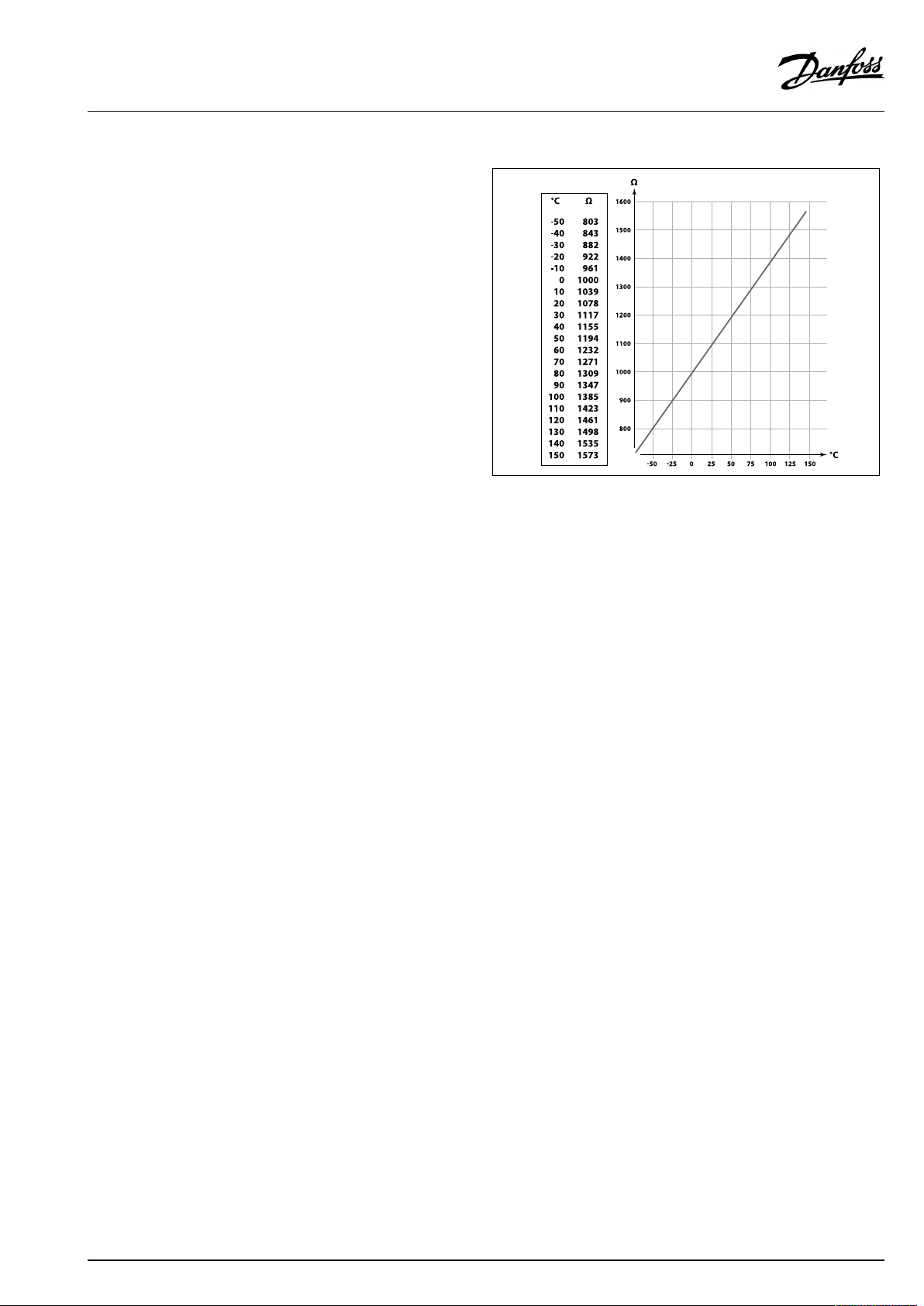

Pt1000temperaturesensor(IEC751B,1000Ω/0°C)

Relationshipbetweentemperatureandohmicvalue:

AQ026486454993en-010401

©Danfoss|2021.03|19

Page 20

OperatingGuideECLComfort210/310,applicationA267

2.5Electricalconnections

2.5.1Electricalconnections230Va.c.

Warning

ElectricconductorsonPCB(PrintedCircuitBoard)forsupplyvoltage,

relaycontactsandtriacoutputsdonothavemutualsafetydistanceof

minimum6mm.Theoutputsarenotallowedtobeusedasgalvanic

separated(voltfree)outputs.

Ifagalvanicseparatedoutputisneeded,anauxiliaryrelayis

recommended.

24Voltcontrolledunits,forexampleactuators,aretobecontrolledby

meansofECLComfort310,24Voltversion.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

20|©Danfoss|2021.03

AQ026486454993en-010401

Page 21

OperatingGuideECLComfort210/310,applicationA267

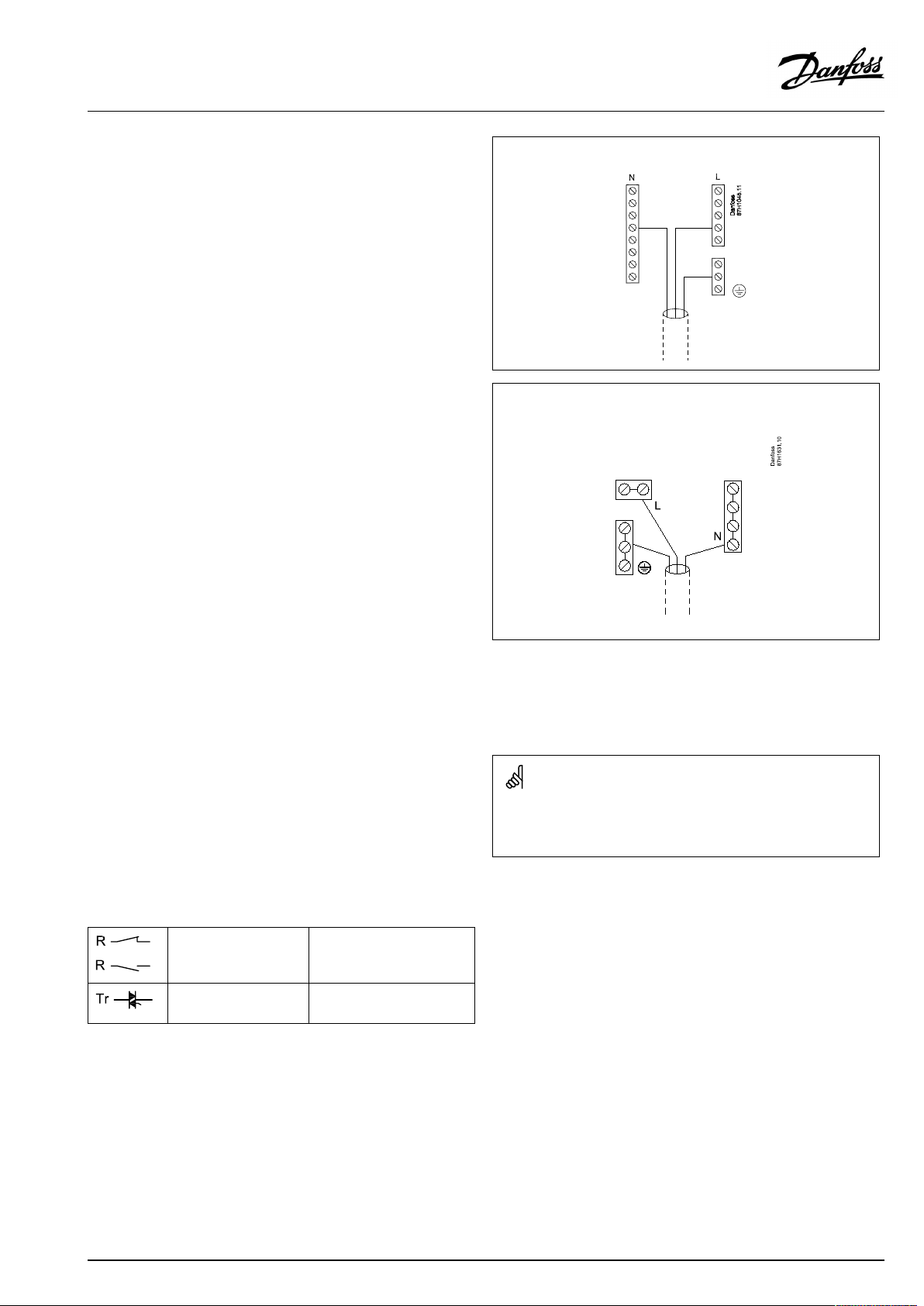

Thecommongroundterminalisusedforconnectionofrelevant

components(pumps,motorizedcontrolvalves).

ECL210/310

ECL296

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

Maximumloadratings:

Relayterminals

4(2)A/230Va.c.

(4Aforohmicload,2Afor

inductiveload)

Triac(=electronic

0,2A/230Va.c.

relay)terminals

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

AQ026486454993en-010401

©Danfoss|2021.03|21

Page 22

OperatingGuideECLComfort210/310,applicationA267

2.5.2Electricalconnections,Pt1000temperaturesensorsandsignals

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

sensorandinputconnections.

A267:

Sen-

Description

sor

S1

Outdoortemperature

Type

(recomm.)

ESMT

sensor*

S2Returntemperaturesensor,

heatingcircuit2

S3

Flowtemperaturesensor,

heatingcircuit1**

S4

Flowtemperaturesensor,

heatingcircuit2**

S5Returntemperaturesensor,

heatingcircuit1

S6

DHWtanktemperature

sensor,upper***

S7Roomtemperature

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESM-11/ESMB/

ESMC/ESMU

ESMB/

ESMU

ESM-10

sensor****,heatingcircuit1

and2

S8

DHWtanktemperature

sensor,lower

*

Iftheoutdoortemperaturesensorisnotconnectedorthe

ESMB/

ESMU

cableisshort-circuited,thecontrollerassumesthatthe

outdoortemperatureis0(zero)°C.Theoutdoortemperature

sensoriscommonforbothheatingcircuits.

**

Theflowtemperaturesensormustalwaysbeconnected

inordertohavethedesiredfunctionality.Ifthesensoris

notconnectedorthecableisshort-circuited,themotorized

controlvalvecloses(safetyfunction).

***

Thissensorisusedifonlyonetanktemperaturesensoris

required.

****

Onlyforroomtemperaturesensorconnection.Theroom

temperaturesignalcanalternativelybeavailablefroma

RemoteControlUnit(ECA30/31).See'Electricalconnections,

ECA30/31'.

22|©Danfoss|2021.03

Wirecrosssectionforsensorconnections:Min.0.4mm².

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

AQ026486454993en-010401

Page 23

OperatingGuideECLComfort210/310,applicationA267

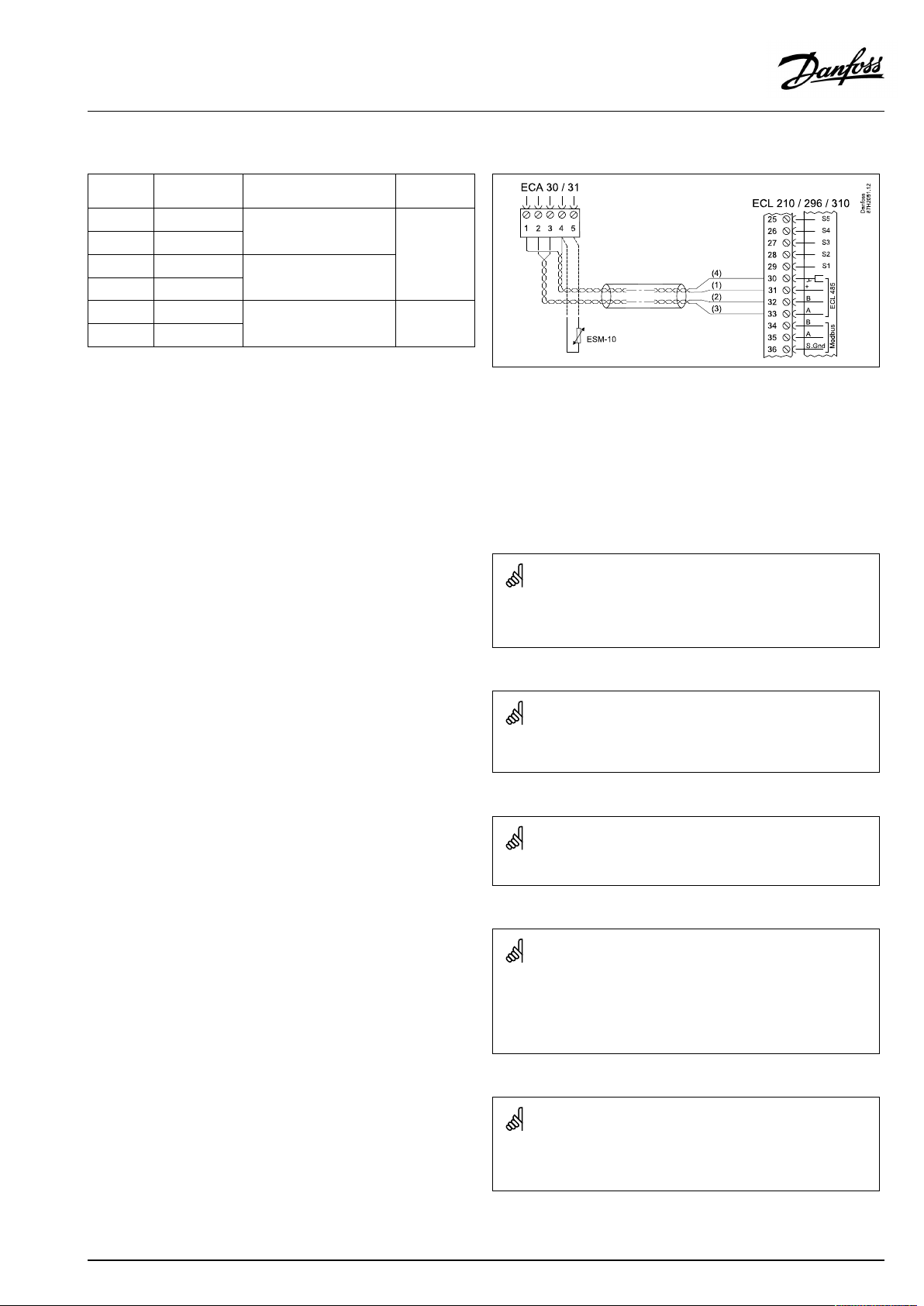

2.5.3Electricalconnections,ECA30/31

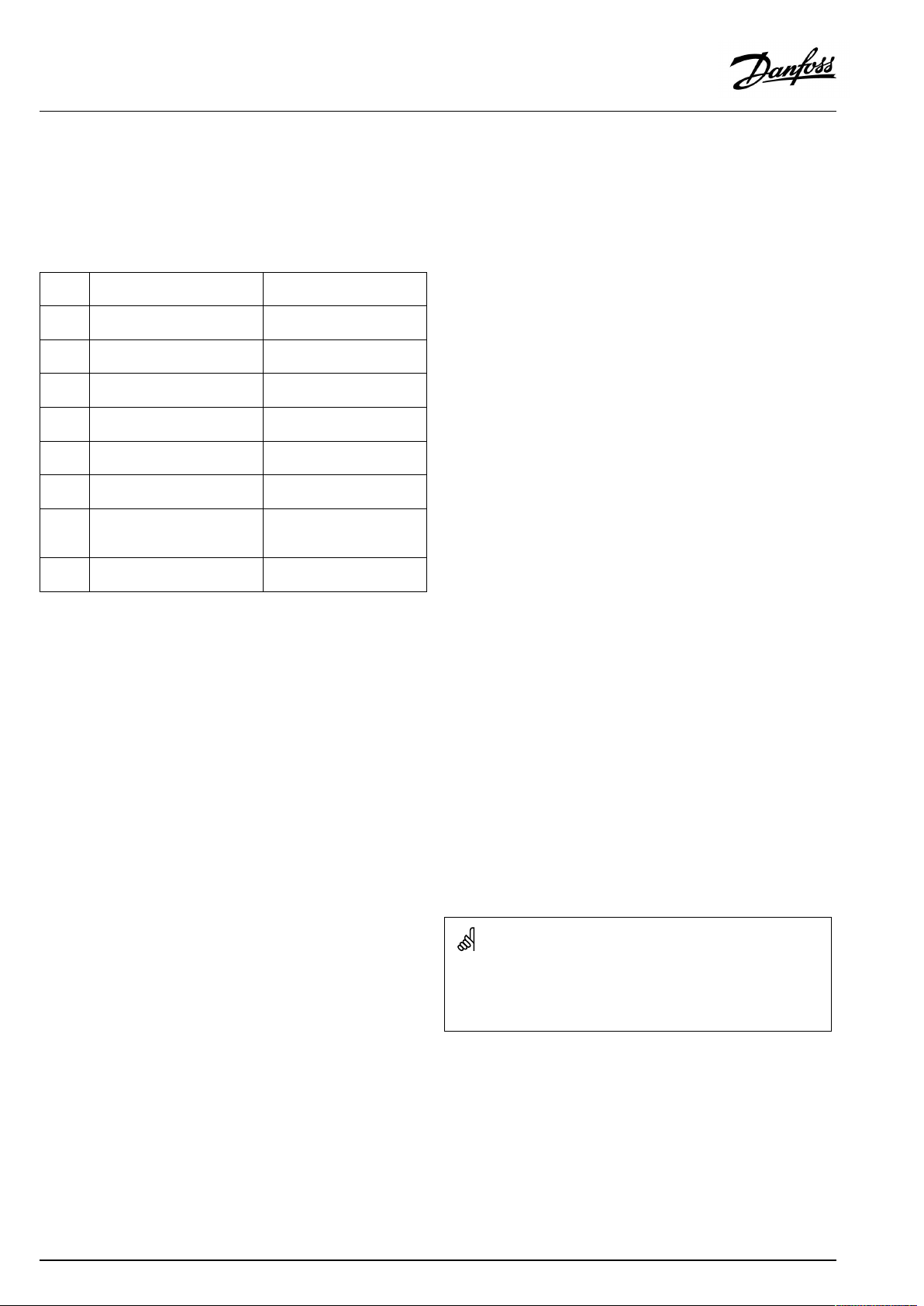

Terminal

ECL

Terminal

ECA30/31

30

31

4

1

322

333

4

5

*

Afteranexternalroomtemperaturesensorhasbeenconnected,

Description

Twistedpair

Twistedpair

Ext.roomtemperature

sensor*

Type

(recomm.)

Cable2x

twistedpair

ESM-10

ECA30/31mustberepowered.

ThecommunicationtotheECA30/31mustbesetupintheECL

Comfortcontrollerin'ECAaddr.'

TheECA30/31mustbesetupaccordingly.

AfterapplicationsetuptheECA30/31isreadyafter2–5min.A

progressbarintheECA30/31isdisplayed.

Iftheactualapplicationcontainstwoheatingcircuits,itispossible

toconnectanECA30/31toeachcircuit.Theelectricalconnections

aredoneinparallel.

Max.2ECA30/31canbeconnectedtoanECLComfort310controller

ortoECLComfort210/296/310controllersinamaster-slavesystem.

SetupproceduresforECA30/31:Seesection‘Miscellaneous’ .

ECAinformationmessage:

‘Applicationreq.newerECA’:

Thesoftware(firmware)ofyourECAdoesnotcomplywiththe

software(firmware)ofyourECLComfortcontroller.Pleasecontact

yourDanfosssalesoffice.

Someapplicationsdonotcontainfunctionsrelatedtoactualroom

temperature.TheconnectedECA30/31willonlyfunctionasremote

control.

AQ026486454993en-010401

©Danfoss|2021.03|23

Page 24

OperatingGuideECLComfort210/310,applicationA267

2.5.4Electricalconnections,master/slavesystems

Thecontrollercanbeusedasmasterorslaveinmaster/slave

systemsviatheinternalECL485communicationbus(2xtwisted

paircable).

TheECL485communicationbusisnotcompatiblewiththeECL

businECLComfort110,200,300and301!

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

Terminal

Description

Type

(recomm.)

30

Commonterminal

+12V*,ECL485communicationbus

31

*OnlyforECA30/31andmaster/

slavecommunication

32

B,ECL485communicationbus

33

A,ECL485communicationbus

Cable2x

twistedpair

ECL485buscable

MaximumrecommendedlengthoftheECL485busiscalculatedlike

this:

Subtract"TotallengthofallinputcablesofallECLcontrollersinthe

master-slavesystem"from200m.

Simpleexamplefortotallengthofallinputcables,3xECL:

1xECL

3xECL

3xECLReturntemp.sensor:

3xECLRoomtemp.sensor:

Total:

Outdoortemp.sensor:

Flowtemp.sensor:

15m

18m

18m

30m

81m

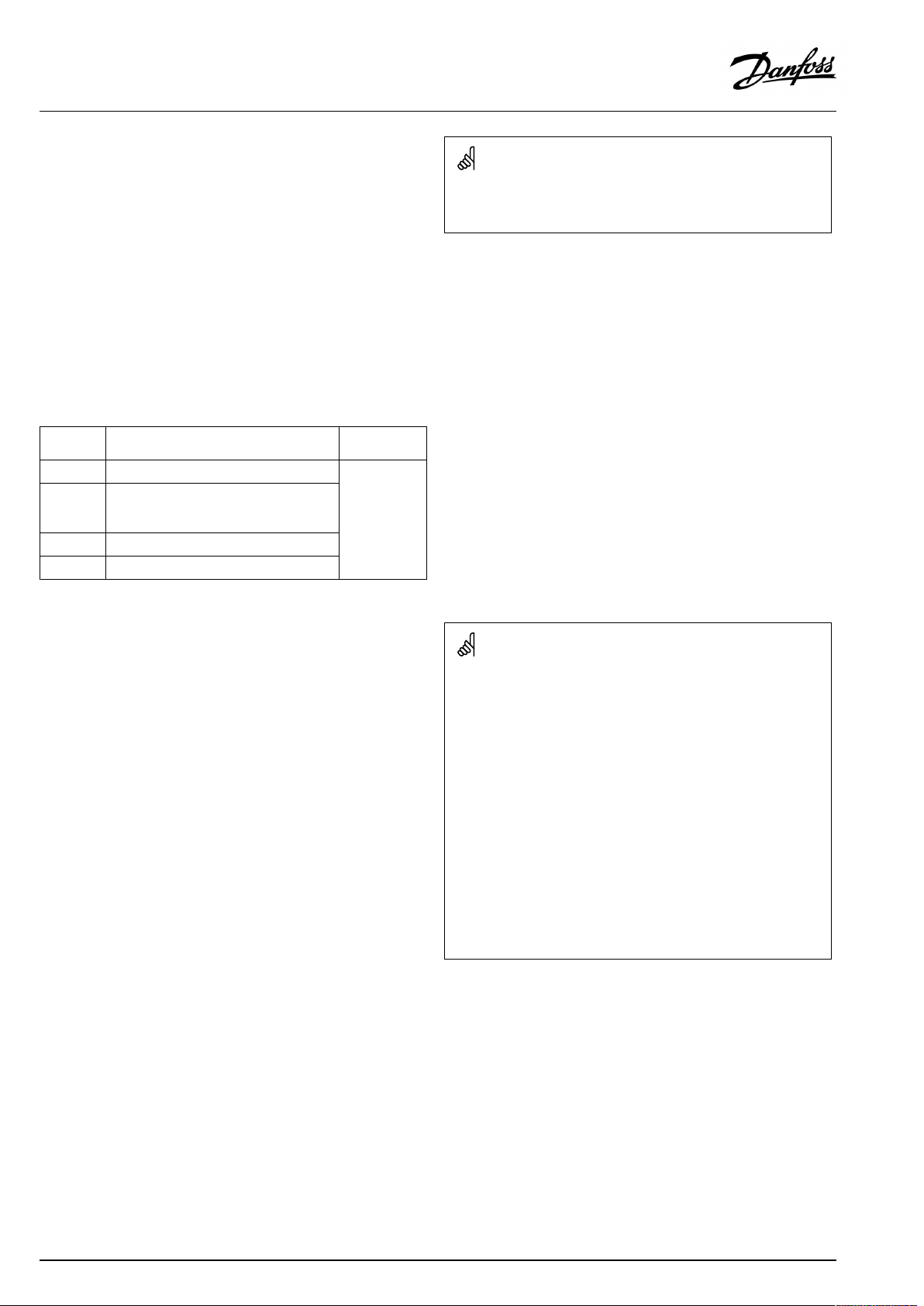

2.5.5Electricalconnections,communication

Electricalconnections,Modbus

ECLComfort210:Non-galvanicisolatedModbusconnections

ECLComfort296:GalvanicisolatedModbusconnections

ECLComfort310:GalvanicisolatedModbusconnections

24|©Danfoss|2021.03

MaximumrecommendedlengthoftheECL485bus:

200-81m=119m

AQ026486454993en-010401

Page 25

OperatingGuideECLComfort210/310,applicationA267

2.5.6Electricalconnections,communication

Electricalconnections,M-bus

ECLComfort210:Notimplemented

ECLComfort296:Onboard,non-galvanicisolated.Max.cable

length50m.

ECLComfort310:Onboard,non-galvanicisolated.Max.cable

length50m.

AQ026486454993en-010401

©Danfoss|2021.03|25

Page 26

OperatingGuideECLComfort210/310,applicationA267

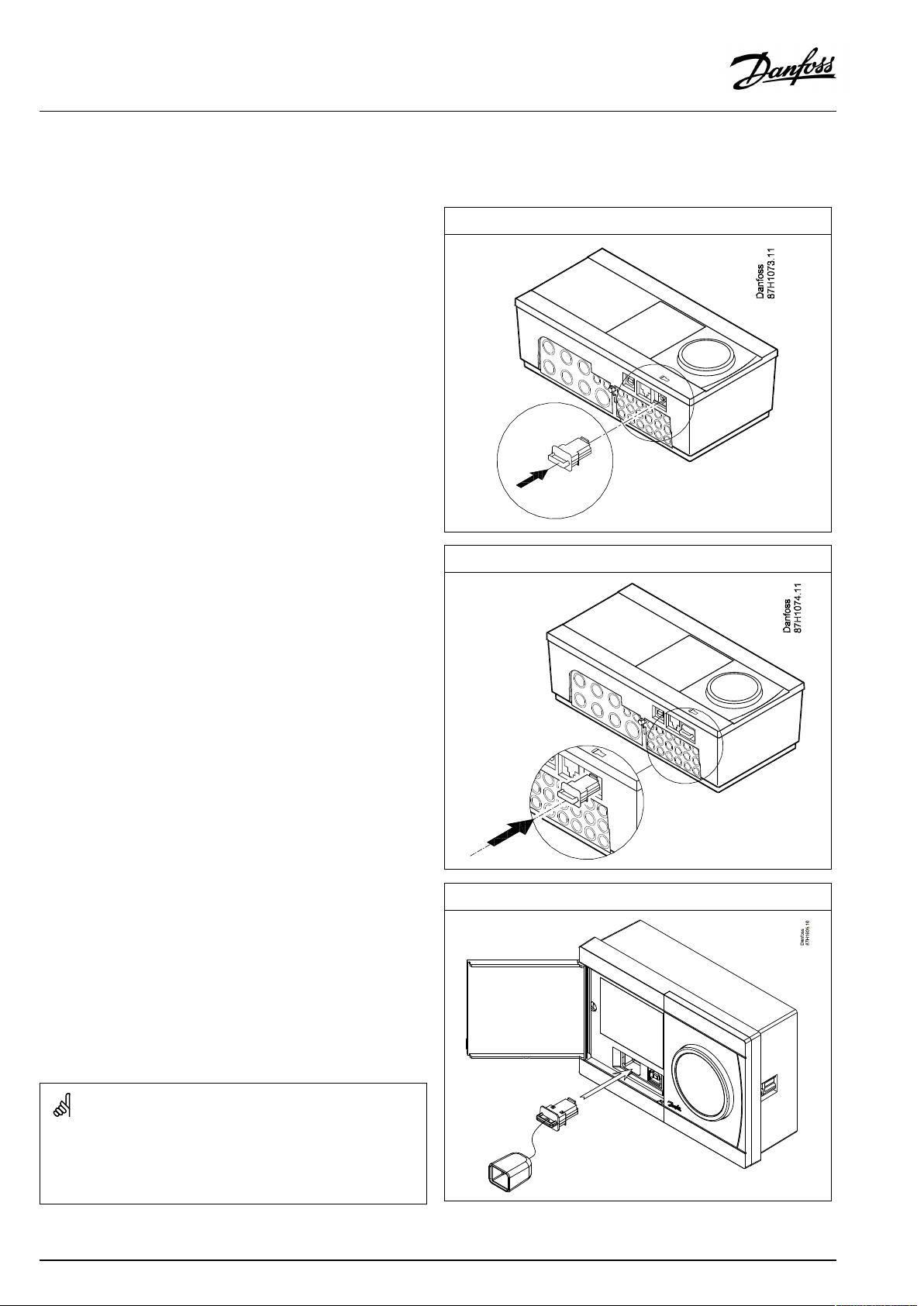

2.6InsertingtheECLApplicationKey

2.6.1InsertingtheECLApplicationKey

TheECLApplicationKeycontains

•theapplicationanditssubtypes,

•currentlyavailablelanguages,

•factorysettings:e.g.schedules,desiredtemperatures,

limitationvaluesetc.Itisalwayspossibletorecoverthefactory

settings,

•memoryforusersettings:specialuser/systemsettings.

Afterhavingpowered-upthecontroller,differentsituationsmight

beexisting:

1.Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

2.Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

3.Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

ECLComfort210/310

ECLComfort210/310

Usersettingsare,amongothers,desiredroomtemperature,desired

DHWtemperature,schedules,heatcurve,limitationvaluesetc.

Systemsettingsare,amongothers,communicationset-up,display

brightnessetc.

26|©Danfoss|2021.03

ECLComfort296

AQ026486454993en-010401

Page 27

OperatingGuideECLComfort210/310,applicationA267

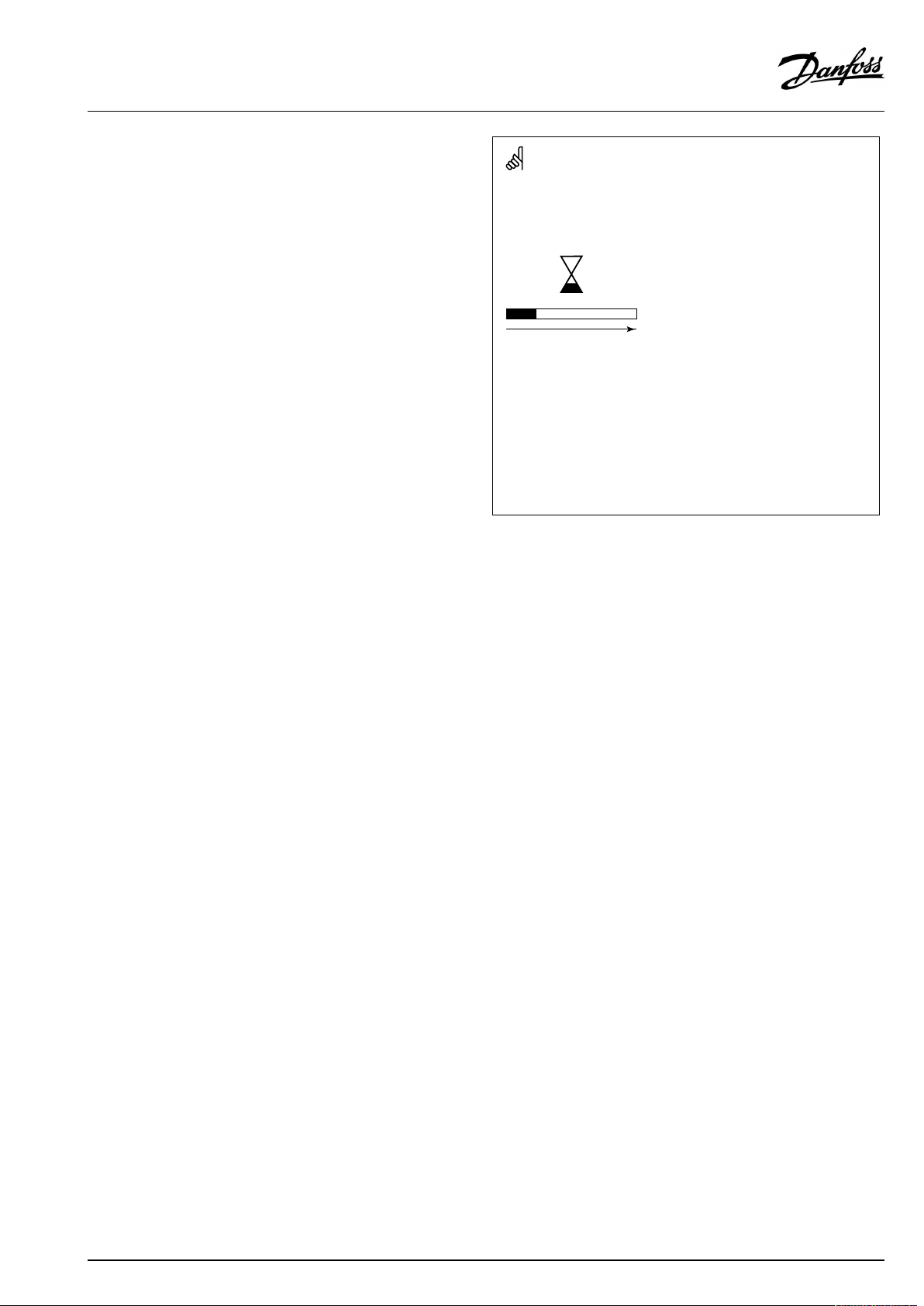

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

AQ026486454993en-010401

©Danfoss|2021.03|27

Page 28

OperatingGuideECLComfort210/310,applicationA267

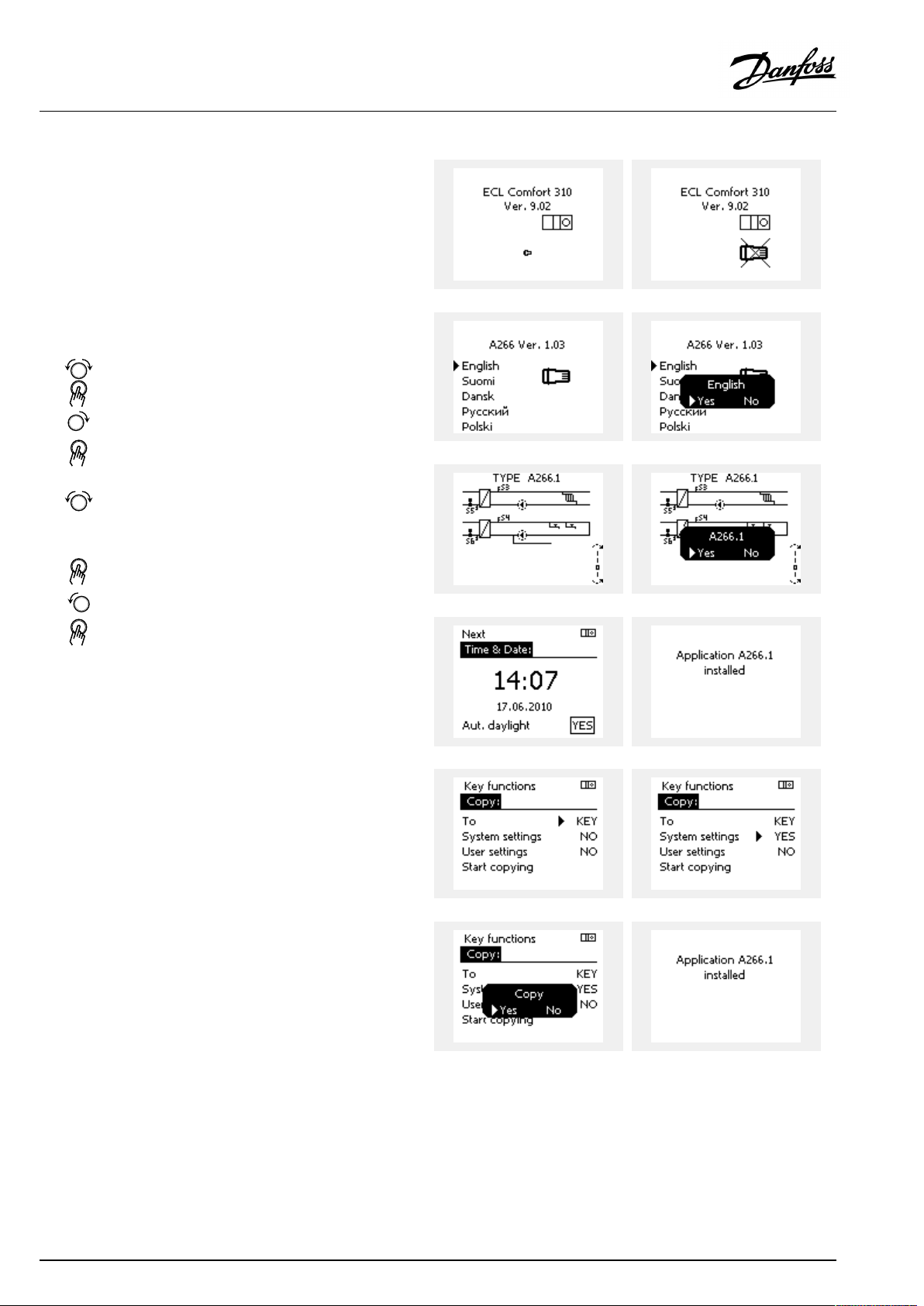

ApplicationKey:Situation1

Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

AnanimationfortheECLApplicationKeyinsertionisdisplayed.

InserttheApplicationKey.

ApplicationKeynameandVersionisindicated(example:A266

Ver.1.03).

IftheECLApplicationKeyisnotsuitableforthecontroller,a"cross"

isdisplayedovertheECLApplicationKey-symbol.

Action:Purpose:

Selectlanguage

Confirm

Selectapplication(subtype)

Somekeyshaveonlyoneapplication.

Confirmwith‘Yes’

Set'Time&Date'

Turnandpushthedialtoselectand

change'Hours' ,'Minutes','Date',

'Month'and'Year' .

Choose''Next'

Confirmwith‘Yes’

Goto‘Aut.daylight’

Choosewhether‘ Aut.daylight´*

shouldbeactiveornot

*‘Aut.daylight’istheautomaticchangeoverbetweensummer

andwintertime.

DependingonthecontentsoftheECLApplicationKey,procedure

AorBistakingplace:

A

TheECLApplicationkeycontainsfactorysettings:

Thecontrollerreads/transfersdatafromtheECLApplicationKey

toECLcontroller.

Examples:

YESorNO

Theapplicationisinstalled,andthecontrollerresetsandstartsup.

B

TheECLApplicationkeycontainschangedsystemsettings:

Pushthedialrepeatedly.

’NO’:

’YES*:

Ifthekeycontainsusersettings:

Pushthedialrepeatedly.

‘NO:

‘YES*:

*If‘YES’cannotbechosen,theECLApplicationKeydoesnot

containanyspecialsettings.

Choose‘Startcopying’andconfirmwith'Yes'.

28|©Danfoss|2021.03

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialsystemsettings(differingfromthefactory

settings)willbecopiedtothecontroller.

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialusersettings(differingfromthefactorysettings)

willbecopiedtothecontroller.

AQ026486454993en-010401

Page 29

OperatingGuideECLComfort210/310,applicationA267

(Example):

The"i"intheupperrightcornerindicatesthat-besidesthefactory

settings-thesubtypealsocontainsspecialuser/systemssettings.

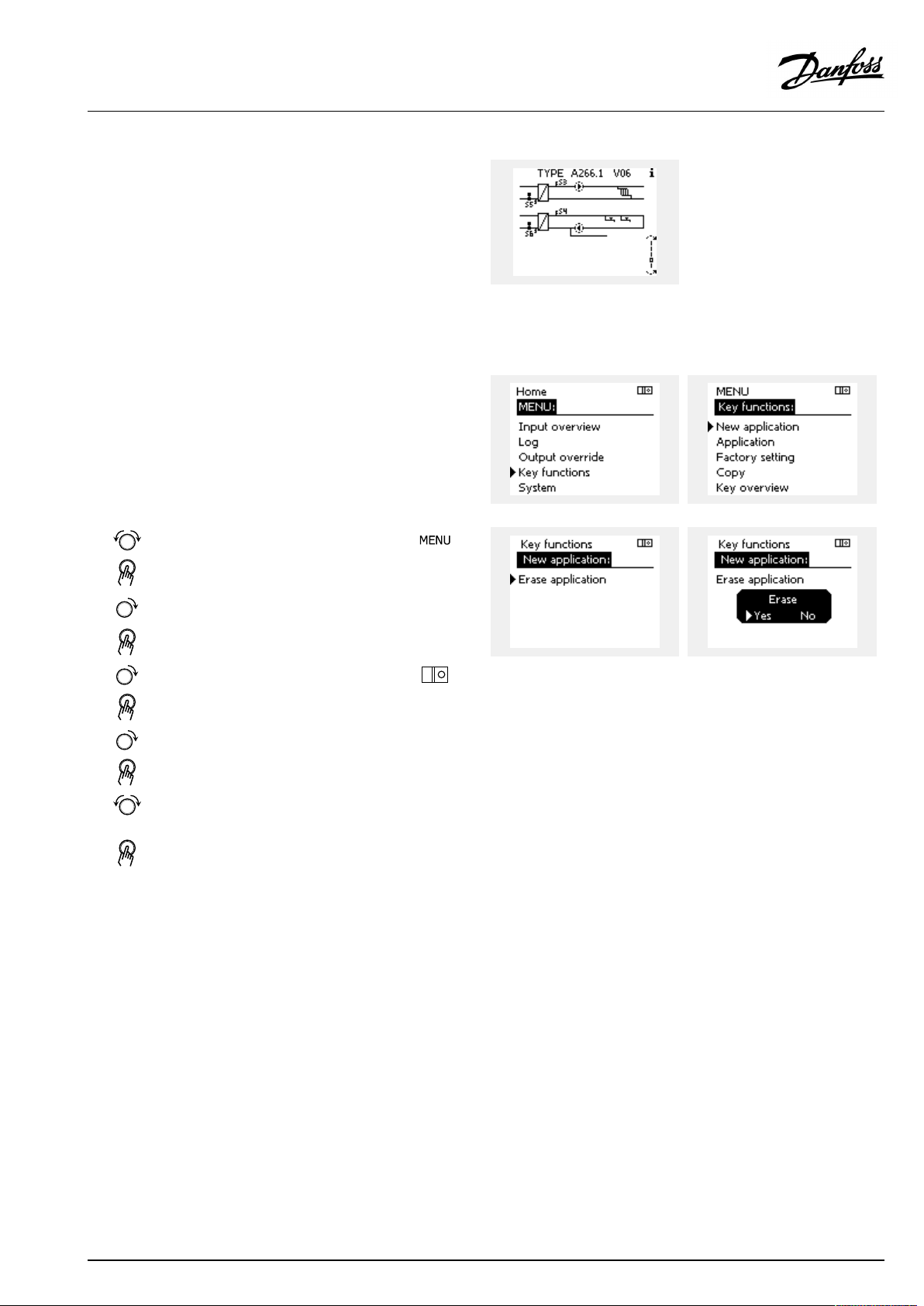

ApplicationKey:Situation2

Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

TochangetoanotherapplicationontheECLApplicationKey,the

currentapplicationinthecontrollermustbeerased(deleted).

BeawarethattheApplicationKeymustbeinserted.

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Choose‘Keyfunctions’

Confirm

Choose‘Eraseapplication’

Confirmwith‘Yes’

Thecontrollerresetsandisreadytobeconfigured.

Followtheproceduredescribedinsituation1.

Examples:

AQ026486454993en-010401

©Danfoss|2021.03|29

Page 30

OperatingGuideECLComfort210/310,applicationA267

ApplicationKey:Situation3

Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

Thisfunctionisused

•forsaving(backup)ofspecialuserandsystemsettings

•whenanotherECLComfortcontrollerofthesametype(210,

296or310)mustbeconfiguredwiththesameapplicationbut

user/systemsettingsdifferfromthefactorysettings.

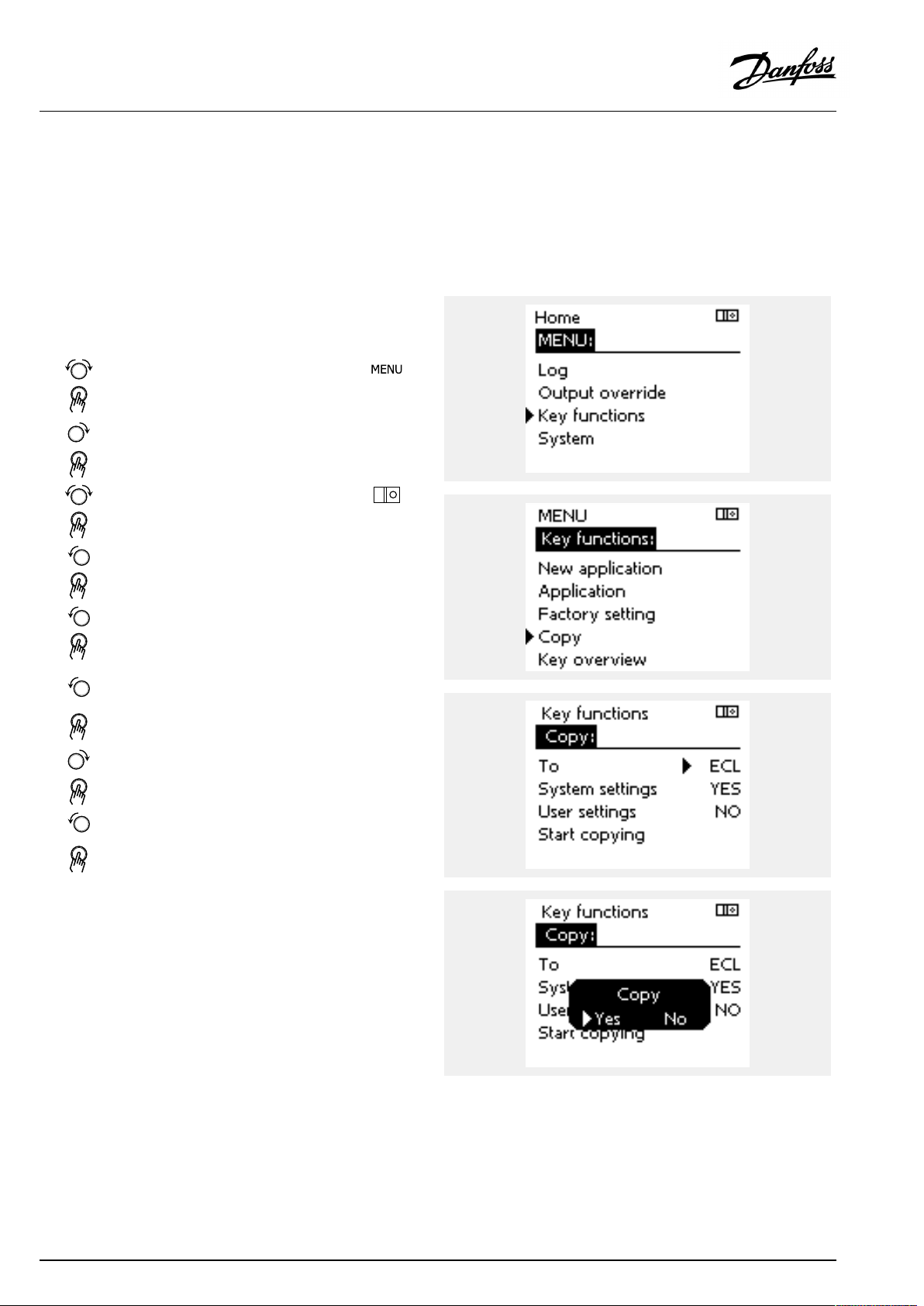

HowtocopytoanotherECLComfortcontroller:

Action:Purpose:

Choose‘MENU’

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose'Commoncontrollersettings'

Confirm

Goto‘Keyfunctions’

Confirm

Choose‘Copy’

Confirm

Choose‘To’ .

‘ECL’or‘KEY’willbeindicated.Choose

’ECL’orKEY’

Pushthedialrepeatedlytochoose

copydirection

Choose‘Systemsettings’or‘User

settings’

Pushthedialrepeatedlytochoose

‘Yes’or‘No’in‘Copy’ .Pushtoconfirm.

Choose‘Startcopying’

TheApplicationKeyorthecontroller

isupdatedwithspecialsystemoruser

settings.

Examples:

*

’ECL’or‘KEY’ .

**

‘NO’or‘YES’

*

‘ECL’:

‘KEY’:

**

‘NO’:

‘YES’:

30|©Danfoss|2021.03

DatawillbecopiedfromtheApplicationKeytothe

ECLController.

DatawillbecopiedfromtheECLControllertothe

ApplicationKey.

ThesettingsfromtheECLcontrollerwillnotbecopied

totheApplicationKeyortotheECLComfortcontroller.

Specialsettings(differingfromthefactorysettings)will

becopiedtotheApplicationKeyortotheECLComfort

controller.IfYEScannotbechosen,therearenospecial

settingstobecopied.

AQ026486454993en-010401

Page 31

OperatingGuideECLComfort210/310,applicationA267

Language

Atapplicationupload,alanguagemustbeselected.*

IfanotherlanguagethanEnglishisselected,theselectedlanguage

ANDEnglishwillbeuploadedintotheECLcontroller.

ThismakesserviceeasyforEnglishspeakingservicepeople,just

becausetheEnglishlanguagemenuscanbevisiblebychanging

theactualsetlanguageintoEnglish.

(Navigation:MENU>Commoncontroller>System>Language)

Iftheuploadedlanguageisnotsuitable,theapplicationmustbe

erased.UserandSystemsettingscanbesavedontheapplication

keybeforeerasing.

Afternewuploadwithpreferredlanguage,theexistingUserand

Systemsettingscanbeuploaded.

*)

(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

2.6.2ECLApplicationKey,copyingdata

Generalprinciples

Whenthecontrollerisconnectedandoperating,youcancheck

andadjustallorsomeofthebasicsettings.Thenewsettingscan

bestoredontheKey.

Factorysettingscanalwaysberestored.

HowtoupdatetheECLApplicationKeyaftersettingshave

beenchanged?

AllnewsettingscanbestoredontheECLApplicationKey.

Howtostorefactorysettinginthecontrollerfromthe

ApplicationKey?

PleasereadtheparagraphconcerningApplicationKey,Situation

1:Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

HowtostorepersonalsettingsfromthecontrollertotheKey?

PleasereadtheparagraphconcerningApplicationKey,Situation3:

Acopyofthecontrollerssettingsisneededforconfiguringanother

controller

Asamainrule,theECLApplicationKeyshouldalwaysremainin

thecontroller.IftheKeyisremoved,itisnotpossibletochange

settings.

Makeanoteofnewsettingsinthe'Settingsoverview'table.

DonotremovetheECLApplicationKeywhilecopying.Thedataon

theECLApplicationKeycanbedamaged!

ItispossibletocopysettingsfromoneECLComfortcontrollerto

anothercontrollerprovidedthatthetwocontrollersarefromthesame

series(210or310).

Furthermore,whentheECLComfortcontrollerhasbeenuploaded

withanapplicationkey,minimumversion2.44,itispossibletoupload

personalsettingsfromapplicationkeys,minimumversion2.14.

AQ026486454993en-010401

©Danfoss|2021.03|31

Page 32

OperatingGuideECLComfort210/310,applicationA267

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

32|©Danfoss|2021.03

AQ026486454993en-010401

Page 33

OperatingGuideECLComfort210/310,applicationA267

2.7Checklist

IstheECLComfortcontrollerreadyforuse?

Makesurethatthecorrectpowersupplyisconnectedtoterminals9and10(230Vor24V).

Makesurethecorrectphaseconditionsareconnected:

230V:Live=terminal9andNeutral=terminal10

24V:SP=terminal9andSN=terminal10

Checkthattherequiredcontrolledcomponents(actuator,pumpetc.)areconnectedtothecorrectterminals.

Checkthatallsensors/signalsareconnectedtothecorrectterminals(see'Electricalconnections').

Mountthecontrollerandswitchonthepower.

IstheECLApplicationKeyinserted(see'InsertingtheApplicationKey').

DoestheECLComfortcontrollercontainanexistingapplication(see'InsertingtheApplicationKey').

Isthecorrectlanguagechosen(see'Language'in'Commoncontrollersettings').

Isthetime&datesetcorrectly(see'Time&Date'in'Commoncontrollersettings').

Istherightapplicationchosen(see'Identifyingthesystemtype').

Checkthatallsettingsinthecontroller(see'Settingsoverview')aresetorthatthefactorysettingscomplywithyour

requirements.

Choosemanualoperation(see'Manualcontrol').Checkthatvalvesopenandclose,andthatrequiredcontrolled

components(pumpetc.)startandstopwhenoperatedmanually.

Checkthatthetemperatures/signalsshowninthedisplaymatchtheactualconnectedcomponents.

Havingcompletedthemanualoperationcheck,choosecontrollermode(scheduled,comfort,savingorfrostprotection).

AQ026486454993en-010401

©Danfoss|2021.03|33

Page 34

OperatingGuideECLComfort210/310,applicationA267

2.8Navigation,ECLApplicationKeyA267

Navigation,A267,circuits1,2and3

Home

MENU

Schedule

Schedulecirc.P

Settings

Flowtemperature

Tanktemperature

Roomlimit

Returnlimit

Optimization

Controlpar.

ApplicationA267

IDnos.

1117812178

11177

1118212182Infl.-max.((

1118312183

1101512015

1103112031

1103212032

1103312033

1103412034

1103512035

1103612036

1103712037

1108512085

1101112011

1101212012

1101312013

1101412014

1102612026

1102012020

1102112021

1117912179

11043

11174

1118412184

1118512185

1118612186

1118712187

1118912189

12177

13193

13195

13194

13152

13030

12174

FunctionCircuit1Circuit2Circuit3

(((

Heatcurve

Temp.max.

Temp.min.

Chargedifference

Startdifference

Stopdifference

Max.chargeT

Infl.-min.

Adapt.time

Limit

HighToutX1

LowlimitY1

LowToutX2

HighlimitY2

Infl.-max.

Infl.-min.

Adapt.time

Priority

Autosaving

Boost

Ramp

Optimizer

Prestop

Basedon

Totalstop

Cut-out

Paralleloperation

Motorpr.

Xp

Tn

Mrun

Nz

Min.act.time

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

((

(

((

((

((

((

((

((

(

(

(

(

(

(

34|©Danfoss|2021.03

AQ026486454993en-010401

Page 35

OperatingGuideECLComfort210/310,applicationA267

Navigation,A267.1,circuits1,2and3,continued

Home

MENU

Settings

Holiday

InfluenceoverviewDes.flowT

Application

Anti-bacteria

Des.DHWT

IDnos.

1101012010

11017

11050

1150012500

1102212022

1102312023

1105212052

1107712077

1107812078

1104012040

110931209313093

11141

111421214213142

1214113141

ApplicationA267

FunctionCircuit1Circuit2Circuit3

ECAaddr.

Demandoffset

Pdemand

SenddesiredT

Pexercise

Mexercise

DHWpriority

PfrostT

PheatT

Ppost-run

13051

13053

13055

13044

13045

13041

13500

13076

Ch.-o.valve/P

Tank,sec./prim.

Circ.Ppriority

Max.DHWtime

DHWdeact.time

DHWPpost-run

SenddesiredT

Circ.PfrostT

Frostpr.T

Ext.input

Ext.mode

Returnlim.

Roomlim.

Holiday

Ext.override

Anti-bacteria

ECAoverride

Boost

Ramp

Slave,demand

Heatingcut-out

DHWpriority

DHWinfluence

SCADAoffset

SCADAoverride

((

(

(

((

((

((

((

((

((

((

(

(

(

(

(

(

(

(

(((

(((

(((

(

(((

((

(

((

((

(((

(((

(

((

((

((

(

((

((

(

((

(

AQ026486454993en-010401

©Danfoss|2021.03|35

Page 36

OperatingGuideECLComfort210/310,applicationA267

Navigation,applicationA267,Commoncontrollersettings

Home

MENU

Time&Date

HolidaySelectable

Inputoverview1

Inputoverview2

Inputoverview3

Log1(sensors)

Log2(sensors)

Log3(sensors)

Outputoverride

OutdoorTLogtoday

RoomT.

FlowTanddesiredLog2days

ReturnT&limitLog4days

OutdoorTLogtoday

RoomT.

FlowTanddesiredLog2days

ReturnT&limitLog4days

TankTup.&des.Logtoday

TankTup.&low.Logyesterday

ApplicationsA267,Commoncontrollersettings

IDno.

Function

Selectable

OutdoorT

Outdooracc.T

RoomT

FlowT

ReturnT

OutdoorT

Outdooracc.T

RoomT

FlowT

ReturnT

TankupperT

TanklowerT

Logyesterday

Logyesterday

Log2days

Log4days

M1

P1

M2

P4

P2

P3

A267

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

36|©Danfoss|2021.03

AQ026486454993en-010401

Page 37

OperatingGuideECLComfort210/310,applicationA267

Navigation,applicationsA267.1,Commoncontrollersettings,continued

Home

MENU

Keyfunctions

SystemECLversion

ApplicationA267.1Commoncontrollersettings

IDno.

NewapplicationEraseapplication

Application

FactorysettingSystemsettings

Copy

Keyoverview

Extension

Ethernet

Portalconfig

M-busconfig

EnergyMeters

Rawinputoverview

Alarm

Display

Communication

Language

60058

60059

38

2048

2150

2151

2050

Function

Usersettings

Gotofactory

To

Systemsettings

Usersettings

Startcopying

Codeno.

Hardware

Software

Buildno.

Serialno.

Productiondate

Temp.monitor.

Backlight

Contrast

Modbusaddr.

ECL485addr.

Servicepin

Ext.reset

Language

A267.1

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

AQ026486454993en-010401

©Danfoss|2021.03|37

Page 38

OperatingGuideECLComfort210/310,applicationA267

3.0Dailyuse

3.1Howtonavigate

Younavigateinthecontrollerbyturningthedialleftorrightto

thedesiredposition().

Thedialhasabuilt-inaccellerator.Thefasteryouturnthedial,the

fasteritreachesthelimitsofanywidesettingrange.

Thepositionindicatorinthedisplay(

youare.

Pushthedialtoconfirmyourchoices().

Thedisplayexamplesarefromatwo-circuitapplication:One

heatingcircuit()andonedomestichot-water(DHW)circuit().

Theexamplesmightdifferfromyourapplication.

)willalwaysshowyouwhere

ExampleshowsECL210/310

Heatingcircuit():DHWcircuit();

Somegeneralsettingswhichapplytotheentirecontrollerare

locatedinaspecificpartofthecontroller.

Toenter‘Commoncontrollersettings’:

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Examples:

Circuitselector

38|©Danfoss|2021.03

AQ026486454993en-010401

Page 39

OperatingGuideECLComfort210/310,applicationA267

3.2Understandingthecontrollerdisplay

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Choosingafavoritedisplay

Yourfavoritedisplayisthedisplayyouhavechosenasthedefault

display.Thefavoritedisplaywillgiveyouaquickoverviewofthe

temperaturesorunitsthatyouwanttomonitoringeneral.

Ifthedialhasnotbeenactivatedfor20min.,thecontrollerwill

reverttotheoverviewdisplayyouhavechosenasfavorite.

Toshiftbetweendisplays:Turnthedialuntilyoureachthedisplay

selector(

turntochooseyourfavoriteoverviewdisplay.Pushthedialagain.

)atthebottomrightsideofthedisplay.Pushthedialand

Heatingcircuit

Overviewdisplay1informsabout:

actualoutdoortemperature,controllermode,

actualroomtemperature,desiredroomtemperature.

Overviewdisplay2informsabout:

actualoutdoortemperature,trendinoutdoortemperature,

controllermode,max.andmin.outdoortemperaturessince

midnightaswellasdesiredroomtemperature.

Overviewdisplay3informsabout:

date,actualoutdoortemperature,controllermode,time,desired

roomtemperatureaswellasshowsthecomfortscheduleofthe

currentday.

Overviewdisplay4informsabout:

stateofthecontrolledcomponents,actualflowtemperature,

(desiredflowtemperature),controllermode,returntemperature

(limitationvalue),influenceondesiredflowtemperature.

ThevalueabovetheV2symbolindicates0–100%oftheanalogue

signal(0–10V).

Note:

Anactualflowtemperaturevaluemustbepresent,otherwisethe

circuit'scontrolvalvewillclose.

Overviewdisplay1:Overviewdisplay2:

Overviewdisplay3:Overviewdisplay4:

Exampleofoverviewdisplaywith

Influenceindication:

Example,favoritedisplay1in

A230.3,wheremin.desiredroom

temperatureisindicated(22.7):

Dependentonthechosendisplay,theoverviewdisplaysforthe

heatingcircuitinformyouabout:

•actualoutdoortemperature(-0.5)

•controllermode()

•actualroomtemperature(24.5)

•desiredroomtemperature(20.7°C)

•trendinoutdoortemperature(

)

•min.andmax.outdoortemperaturessincemidnight(

•date(23.02.2010)

•time(7:43)

•comfortscheduleofthecurrentday(0-12-24)

•stateofthecontrolledcomponents(M2,P2)

•actualflowtemperature(49°C),(desiredflowtemperature(31))

•returntemperature(24°C)(limitationtemperature(50))

AQ026486454993en-010401

)

©Danfoss|2021.03|39

Page 40

OperatingGuideECLComfort210/310,applicationA267

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

Ifthetemperaturevalueisdisplayedas

"--"

thesensorinquestionisnotconnected.

"---"

thesensorconnectionisshort-circuited.

DHWcircuit

Overviewdisplay1informsabout:

actualDHWtemperature,controllermode,desiredDHW

temperatureaswellasthecomfortscheduleofthecurrentday.

Overviewdisplay2informsabout:

stateofthecontrolledcomponents,actualDHWtemperature,

(desiredDHWtemperature),controllermode,returntemperature

(limitationvalue),influenceondesiredDHWtemperature.

Dependentonchosendisplay,theoverviewdisplaysfortheDHW

circuitinformyouabout:

•actualDHWtemperature(50.3)

•controllermode(

)

•desiredDHWtemperature(50°C)

•comfortscheduleofthecurrentday(0-12-24)

•stateofthecontrolledcomponents(M1,P1)

•actualDHWtemperature(50°C),(desiredDHWtemperature(50))

•returntemperature(--°C)(limitationtemperature(30))

Settingthedesiredtemperature

Dependingonthechosencircuitandmode,itispossibletoenter

alldailysettingsdirectlyfromtheoverviewdisplays(seealsothe

nextpageconcerningsymbols).

Overviewdisplay1:Overviewdisplay2:

Exampleofoverviewdisplaywith

Influenceindication:

40|©Danfoss|2021.03

AQ026486454993en-010401

Page 41

OperatingGuideECLComfort210/310,applicationA267

Settingthedesiredroomtemperature

Thedesiredroomtemperaturecaneasilybeadjustedinthe

overviewdisplaysfortheheatingcircuit.

Action:Purpose:

Examples:

Desiredroomtemperature

Confirm

Adjustthedesiredroomtemperature

Confirm

Thisoverviewdisplayinformsaboutoutdoortemperature,actual

roomtemperatureaswellasdesiredroomtemperature.

Thedisplayexampleisforcomfortmode.Ifyouwanttochange

thedesiredroomtemperatureforsavingmode,choosethemode

selectorandselectsaving.

20.5

21.0

Overviewofsettingrangeandsettingsfordesiredroomtemperature:

Factorysetting

Frostprotection*

Mode

Comfort

Saving

Settingrange

5...40°C20°C

5...40°C16°C

5...40°C10°C

Settingthedesiredroomtemperature,ECA30/ECA31

Thedesiredroomtemperaturecanbesetexactlyasinthe

controller.However,othersymbolscanbepresentinthedisplay

(pleasesee'Whatdothesymbolsmean?').

*relatedtodesiredflowtemperature

Thesettingofthedesiredroomtemperatureisimportantevenifa

roomtemperaturesensor/RemoteControlUnitisnotconnected.

WiththeECA30/ECA31youcanoverridethedesiredroom

temperaturesetinthecontrollertemporarilybymeansoftheoverride

functions:

AQ026486454993en-010401

©Danfoss|2021.03|41

Page 42

OperatingGuideECLComfort210/310,applicationA267

SettingthedesiredDHWtemperature

ThedesiredDHWtemperaturecaneasilybeadjustedinthe

overviewdisplaysfortheDHWcircuit.

Action:Purpose:

DesiredDHWtemperature

Confirm

AdjustthedesiredDHWtemperature

Confirm

InadditiontotheinformationaboutdesiredandactualDHW

temperature,thetoday'sscheduleisvisible.

Thedisplayexampleindicatesthatthecontrollerisinscheduled

operationandincomfortmode.

Examples:

50

55

OverviewofsettingrangeandsettingsforDHWmodes:

Factorysetting

Frostprotection*

Mode

Comfort

Saving

Settingrange

10...150°C50°C

10...150°C10°C

5...40°C10°C

*relatedtodesiredflowtemperature

42|©Danfoss|2021.03

AQ026486454993en-010401

Page 43

OperatingGuideECLComfort210/310,applicationA267

3.3Ageneraloverview:Whatdothesymbolsmean?

Symbol

Description

Outdoortemp.

Relativehumidityindoor

Roomtemp.

DHWtemp.

Positionindicator

Scheduledmode

Comfortmode

Savingmode

Frostprotectionmode

Manualmode

Standby

Coolingmode

Symbol

Temperature

Mode

Description

Alarm

Letter

Event

Monitoringtemperaturesensor

connection

Displayselector

Max.andmin.value

Trendinoutdoortemperature

Windspeedsensor

Sensornotconnectedornotused

Sensorconnectionshort-circuited

Fixedcomfortday(holiday)

Activeinfluence

Heatingactive(+)

Coolingactive(-)

Activeoutputoverride

Optimizedstartorstoptime

Heating

Cooling

DHW

Commoncontrollersettings

PumpON

PumpOFF

FanON

FanOFF

Actuatoropens

Actuatorcloses

Actuator,analoguecontrol

signal

Pump/fanspeed

DamperON

Circuit

Controlled

component

Numberofheatexchangers

Additionalsymbols,ECA30/31:

Symbol

InECA30/31onlythesymbolsthatarerelevanttotheapplicationin

thecontrolleraredisplayed.

Description

ECARemoteControlUnit

Connectionaddress(master:15,slaves:1-9)

15

Dayoff

Holiday

Relaxing(extendedcomfortperiod)

Goingout(extendedsavingperiod)

DamperOFF

AQ026486454993en-010401

©Danfoss|2021.03|43

Page 44

OperatingGuideECLComfort210/310,applicationA267

3.4Monitoringtemperaturesandsystemcomponents

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Heatingcircuit

Theoverviewdisplayintheheatingcircuitensuresaquick

overviewoftheactualand(desired)temperaturesaswellasthe

actualstateofthesystemcomponents.

Displayexample:

49°C

(31)

24°C

(50)

DHWcircuit

TheoverviewdisplayintheDHWcircuitensuresaquickoverview

oftheactualand(desired)temperaturesaswellastheactualstate

ofthesystemcomponents.

Displayexample(heatexchanger):

50°C

(50)

(30)

Flowtemperature

Desiredflowtemperature

Returntemperature

Returntemperaturelimitation

Flowtemperature

Desiredflowtemperature

--

Returntemperature:sensornotconnected

Returntemperaturelimitation

Displayexamplewithheatexchanger:

Inputoverview

Anotheroptiontogetaquickoverviewofmeasuredtemperatures

isthe'Inputoverview'whichisvisibleinthecommoncontroller

settings(howtoenterthecommoncontrollersettings,see

‘Introductiontocommoncontrollersettings’ .)

Asthisoverview(seedisplayexample)onlystatesthemeasured

actualtemperatures,itisread-only.

44|©Danfoss|2021.03

AQ026486454993en-010401

Page 45

OperatingGuideECLComfort210/310,applicationA267

3.5Influenceoverview

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Themenugivesanoverviewoftheinfluencesonthedesired

flowtemperature.Itdiffersfromapplicationtoapplicationwhich

parametersarelisted.Itcanbehelpfulinaservicesituationto

explainunexpectedconditionsortemperaturesamongothers.

Ifthedesiredflowtemperatureisinfluenced(corrected)byoneor

moreparameters,itisindicatedbyasmalllinewitharrow-down,

arrow-upordouble-arrow:

Arrow-down:

Theparameterinquestionreducesthedesiredflowtemperature.

Arrow-up:

Theparameterinquestionincreasesthedesiredflowtemperature.

Double-arrow:

Theparameterinquestioncreatesanoverride(e.g.Holiday).

Straightline:

Noactiveinfluence.

Intheexample,thearrowinthesymbolpointsdownwardsfor

'Roomlim. ' .Thismeansthattheactualroomtemperatureis

higherthanthedesiredroomtemperaturewhichagainresultsina

decreaseofthedesiredflowtemperature.

ExampleofoverviewdisplaywithInfluenceindication:

AQ026486454993en-010401

©Danfoss|2021.03|45

Page 46

OperatingGuideECLComfort210/310,applicationA267

3.6Manualcontrol

ThissectiondescribesthefunctioningeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.

Itispossibletomanuallycontroltheinstalledcomponents.

Manualcontrolcanonlybeselectedinfavoritedisplaysinwhich

thesymbolsforthecontrolledcomponents(valve,pumpetc.)are

visible.

Action:Purpose:

Choosemodeselector

Confirm

Choosemanualmode

Confirm

Choosepump

Confirm

SwitchONthepump

SwitchOFFthepump.

Confirmpumpmode

Choosemotorizedcontrolvalve

Confirm

Openthevalve

Stopopeningthevalve

Closethevalve

Examples:

ControlledcomponentsCircuitselector

Duringmanualoperation:

•Allcontrolfunctionsaredeactivated

•Outputoverrideisnotpossible

•Frostprotectionisnotactive

Stopclosingthevalve

Confirmvalvemode

Toleavemanualcontrol,usethemodeselectortoselectthe

desiredmode.Pushthedial.

Manualcontrolistypicallyusedwhencommisioningthe

installation.Thecontrolledcomponents,valve,pumpetc.,canbe

controlledforcorrectfunction.

46|©Danfoss|2021.03

Whenmanualcontrolisselectedforonecircuit,itisautomatically

selectedforallcircuits!

AQ026486454993en-010401

Page 47

OperatingGuideECLComfort210/310,applicationA267

3.7Schedule

3.7.1Setyourschedule

ThissectiondescribesthescheduleingeneralfortheECLComfort

210/296/310series.Theshowndisplaysaretypicalandnot

applicationrelated.Theymightdifferfromthedisplaysinyour

application.Insomeapplications,however,theremightbemore

thanoneschedule.Additionalschedulescanbefoundin‘Common

controllersettings’ .

Thescheduleconsistsofa7-dayweek:

=

M

Monday

=

T

Tuesday

=

W

Wednesday

=

T

Thursday

=

F

Friday

=

S

Saturday

=

S

Sunday

Theschedulewillday-by-dayshowyouthestartandstoptimesof

yourcomfortperiods(heating/DHWcircuits).

Changingyourschedule:

Action:

Purpose:

Choose'MENU'inanyoftheoverview

displays

Confirm

Confirmthechoice'Schedule'

Choosethedaytochange

Confirm*

GotoStart1

Confirm

Adjustthetime

Confirm

GotoStop1,Start2etc.etc.

Returnto'MENU'

Confirm

Choose'Yes'or'No'in'Save'

Confirm

Examples:

*Severaldayscanbemarked

Thechosenstartandstoptimeswillbevalidforallthechosendays

(inthisexampleThursdayandSaturday).

Youcansetmax.3comfortperiodsaday.Youcandeleteacomfort

periodbysettingstartandstoptimestothesamevalue.

AQ026486454993en-010401

Eachcircuithasitsownschedule.Tochangetoanothercircuit,goto

'Home',turnthedialandchoosethedesiredcircuit.

Thestartandstoptimescanbesetinhalf-hourly(30min.)intervals.

©Danfoss|2021.03|47

Page 48

OperatingGuideECLComfort210/310,applicationA267

4.0Settingsoverview

Forfactorysettingsandsettingrange,seeappendix“ParameterIDoverview” .

ParametersindicatedwithanIDno.like"1x607"meanauniversalparameter.xstandsforcircuit/parametergroup.

SettingIDPage

Heatcurve

Extendedheatcut-outsetting

Extendedwintercut-outsetting

Day

Starttime

Duration

DesiredT

DesiredT(Desiredflowtemperature)

ECAaddr.(ECAaddress,choiceofRemoteControlUnit)

Autosaving(savingtemp.dependentonoutdoortemp.)

Boost

Ramp(referenceramping)

Optimizer(optimizingtimeconstant)

Adapt.time(adaptiontime)

Demandoffset

Basedon(optimizationbasedonroom/outdoortemp.)

Totalstop

Pexercise(pumpexercise)

Mexercise(valveexercise)

Actuator

Pre-stop(optimizedstoptime)

Con.T,re.Tlim.(Constanttemperaturemode,return

temperaturelimitation)

Limit(returntemp.limitation)

HighToutX1(returntemp.limitation,highlimit,X-axis)

LowlimitY1(returntemp.limitation,lowlimit,Y-axis)

LowToutX2(returntemp.limitation,lowlimit,X-axis)

HighlimitY2(returntemp.limitation,highlimit,Y-axis)

Infl.-max.(returntemp.limitation-max.influence)

Infl.-min.(returntemp.limitation-min.influence)

Adapt.time(adaptationtime)

Ppost-run

DHWPpost-run(DHWpump,post-run)

Paralleloperation

Max.DHWtime

DHWdeact.time(DHWdeactivationtime)

Pdemand

Ch.-o.valve/P(changeovervalve/pump)

DHWpriority(closedvalve/normaloperation)

1x00452

1x01073

1x01162

1x01263

1x01364

1x01464

1x015

1x01773

1x02065

1x02165

1x02273

1x023

1x02470

1x02666

1x02858

1x03058

1x03159

1x03259

1x03359

1x03460

1x03560

1x03660

1x03760

1x040

1x041

1x04366

1x044

1x045

1x050

1x051

1x05276

Factorysettingsincircuit(s)

1

51

84

84

89

89

90

90

54

74

74

74

74

75

75

75

23

48|©Danfoss|2021.03

AQ026486454993en-010401

Page 49

OperatingGuideECLComfort210/310,applicationA267

SettingIDPage

Tank,sec./prim.(Tanksecondarilyorprimarilyconnected)

Circ.Ppriority

Pchargedelay(Chargingpump,delayedstart)

Circ.PfrostT

PfrostT(circulationpump,frostprotectiontemp.)

PheatT(heatdemand)

Priority(priorityforreturntemp.limitation)

Frostpr.T(frostprotectiontemp.)

Ext.input(externaloverride)

Ext.mode(externaloverridemode)

Max.chargeT(maximumheating/chargingtemperature)

Motorpr.(motorprotection)

Temp.min.

Temp.max.

Summer,cut-out(limitforheatingcut-out)

Infl.-max.(roomtemp.limitation,max.)

Infl.-min.(roomtemp.limitation,min.)

Xp(proportionalband)

Tn(integrationtimeconstant)

Mrun(runningtimeofthemotorizedcontrolvalve)

Nz(neutralzone)

Min.act.time(min.activationtimegearmotor)

Chargedifference

Stopdifference

Startdifference

SenddesiredT

1x05376

1x05576

1x059

1x076

1x077

1x078

1x08561

1x09378

1x141

1x14279

1x15286

1x174

1x177

1x17853

1x17967

1x182

1x183

1x184

1x185

1x186

1x187

1x18972

1x19386

1x19486

1x19587

1x50081

Factorysettingsincircuit(s)

1

77

77

77

77

78

70

53

54

55

71

71

71

71

23

AQ026486454993en-010401

©Danfoss|2021.03|49

Page 50

OperatingGuideECLComfort210/310,applicationA267

5.0Settings

5.1IntroductiontoSettings

Descriptionsofsettings(parameter'sfunctions)aredividedinto

groupsasusedintheECLComfort210/296/310controller's

menustructure.Examples:"Flowtemperature" ,"Roomlimit"and

soon.Eachgroupstartswithageneralexplanation.

Thedescriptionsofeachparameterareinnumericorder,relatedto

theparameter'sIDnumbers.Youmightcomeacrossdifferences

betweentheorderinthisOperatingGuideandtheECLComfort

210/296/310controllers.

Someparameterdescriptionsarerelatedtospecificapplication

subtypes.Thismeansthatyoumightnotseetherelatedparameter

intheactualsubtypeintheECLcontroller.

Thenote"SeeAppendix… "referstotheAppendixattheendof

thisOperatingGuide,whereparameter'ssettingrangesandfactory

settingsarelisted.

Thenavigationhints(forexampleMENU>Settings>Returnlimit

…)covermultiplesubtypes.

50|©Danfoss|2021.03

AQ026486454993en-010401

Page 51

OperatingGuideECLComfort210/310,applicationA267

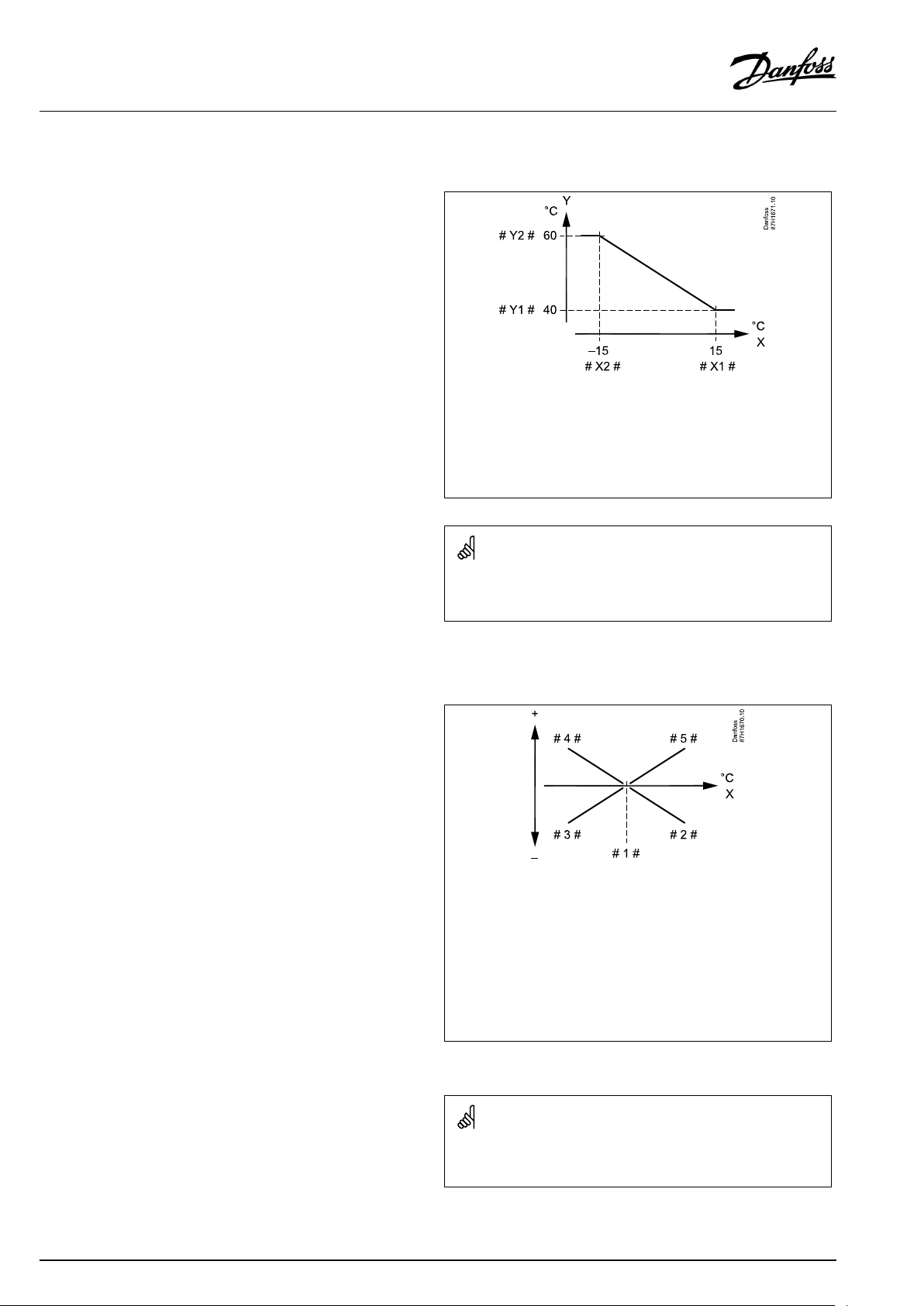

5.2Flowtemperature

TheECLComfortcontrollerdeterminesandcontrolstheflow

temperaturerelatedtotheoutdoortemperature.Thisrelationship

iscalledtheheatcurve.

Theheatcurveissetbymeansof6coordinatepoints.Thedesired

flowtemperatureissetat6pre-definedoutdoortemperature

values.

Theshownvaluefortheheatcurveisanaveragevalue(slope),

basedontheactualsettings.

Desiredflowtemperature

Outdoor

temp.

Desiredflowtemp.

A

BC

Your

settings

-30°C45°C75°C95°C

-15°C40°C60°C90°C

-5°C35°C50°C80°C

0°C32°C45°C70°C

5°C30°C40°C60°C

15°C25°C28°C35°C

A:Exampleforfloorheating

B:Factorysettings

C:Exampleforradiatorheating(highdemand)

MENU>Settings>Flowtemperature

Heatcurve

1

0.1...4.01.0

Theheatcurvecanbechangedintwoways:

1.Thevalueoftheslopeischanged(seeheatcurveexamples

onnextpage)

2.Thecoordinatesoftheheatcurvearechanged

Changethevalueoftheslope:

Pushthedialtoenter/changetheslopevalueoftheheatcurve

(example:1.0).

Whentheslopeoftheheatcurveischangedbymeansoftheslope

value,thecommonpointforallheatcurveswillbeadesiredflow

temperature=24.6°Catanoutdoortemperature=20°Canda

desiredroomtemperature=20.0°C.

Slopechanges

Coordinatechanges

Changethecoordinates:

Pushthedialtoenter/changethecoordinatesoftheheatcurve

(example:-30,75).

Theheatcurverepresentsthedesiredflowtemperaturesat

differentoutdoortemperaturesandatadesiredroomtemperature

of20°C.

Ifthedesiredroomtemperatureischanged,thedesiredflow

temperaturealsochanges:

(DesiredroomT-20)×HC×2.5

where"HC"istheHeatCurveslopeand"2.5"isaconstant.

AQ026486454993en-010401

Thecalculatedflowtemperaturecanbeinfluencedbythe‘Boost’and

‘Ramp’functionsetc.

Example:

Heatcurve:

Desiredflowtemp.:

Desiredroomtemp.:

Calculation(22–20)×1.0×2.5=

Result:

Thedesiredflowtemperaturewillbecorrectedfrom50°Cto55°C.

1.0

50°C

22°C

5

©Danfoss|2021.03|51

Page 52

OperatingGuideECLComfort210/310,applicationA267

Choosingaheatcurveslope

Theheatcurvesrepresentthedesiredflowtemperatureatdifferentoutdoortemperaturesandatadesiredroomtemperatureof20°C.

Thesmallarrows()indicate6differentoutdoortemperaturevaluesatwhichyoucanchangetheheatcurve.

TheECLComfort210/296/310controlstheDHWtemperature

accordingtothedesiredflowtemperatureforexampleunderthe

influenceofthereturntemperature.

ActualDHWtemp.

ThedesiredDHWtemperatureissetintheoverviewdisplay.

50.3:

50:

ActualDHWtemperature

DesiredDHWtemperature

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DesiredDHW

temp.

52|©Danfoss|2021.03

AQ026486454993en-010401

Page 53

OperatingGuideECLComfort210/310,applicationA267

MENU>Settings>Flowtemperature

DesiredT(Desiredflowtemperature)

WhentheECLComfortisinoverridemode,type"Const.T",thedesiredflow

temperaturecanbeset.

A"Const.T"relatedreturntemperaturelimitationcanalsobeset.SeeMENU

>Settings>Returnlimit>'Con.T,ret.Tlim. '

1x004

SeeAppendix“ParameterIDoverview”

MENU>Settings>Flowtemperature

Temp.min.

1x177

SeeAppendix“ParameterIDoverview”

Setthemin.flowtemperatureforthesystem.Thedesiredflow

temperaturewillnotbelowerthanthissetting.Adjustthefactory

setting,ifrequired.

Overridemode

WhenECLComfortisinScheduledmode,acontact(switch)signalcan

beappliedtoaninputinordertooverridetoComfort,Saving,Frost

ProtectionorConstanttemperature.Aslongasthecontact(switch)

signalisapplied,theoverrideisactive.

The"DesiredT"valuecanbeinfluencedby:

•temp.max.

•temp.min.

•roomtemp.limit

•returntemp.limit

•flow/powerlimit

‘Temp.min.’isoverruledif'Totalstop'isactiveinSavingmodeor

'Cut-out'isactive.

‘Temp.min.’canbeoverruledbytheinfluencefromthereturn

temperaturelimitation(see'Priority').

MENU>Settings>Flowtemperature

Temp.max.

1x178

SeeAppendix“ParameterIDoverview”

Setthemax.flowtemperatureforthesystem.Thedesired

temperaturewillnotbehigherthanthissetting.Adjustthefactory

setting,ifrequired.

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

Thesettingof‘heatcurve’ispossibleforheatingcircuitsonly.

Thesettingfor‘Temp.max. ’hashigherprioritythan‘Temp.min.’ .

AQ026486454993en-010401

©Danfoss|2021.03|53

Page 54

OperatingGuideECLComfort210/310,applicationA267

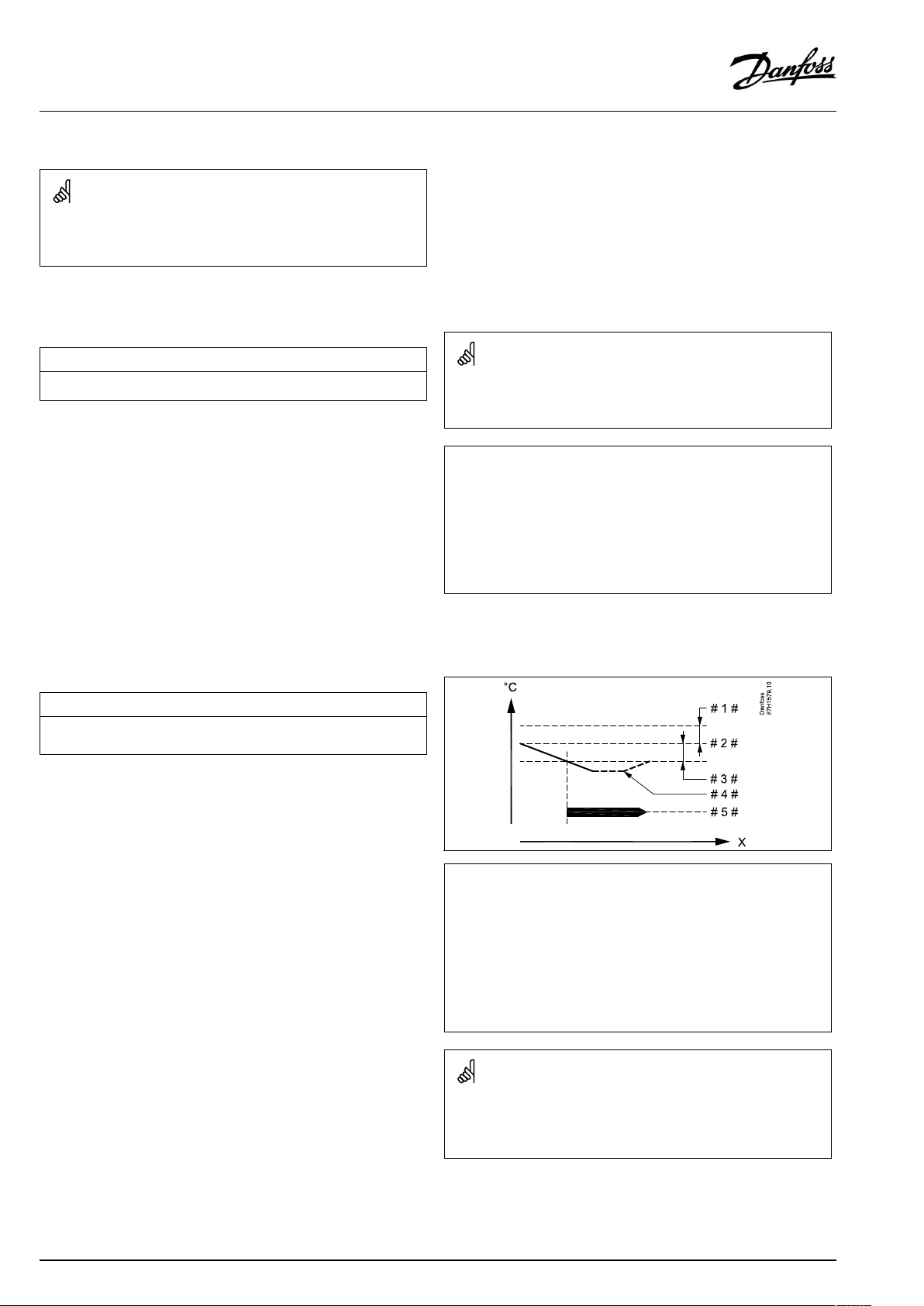

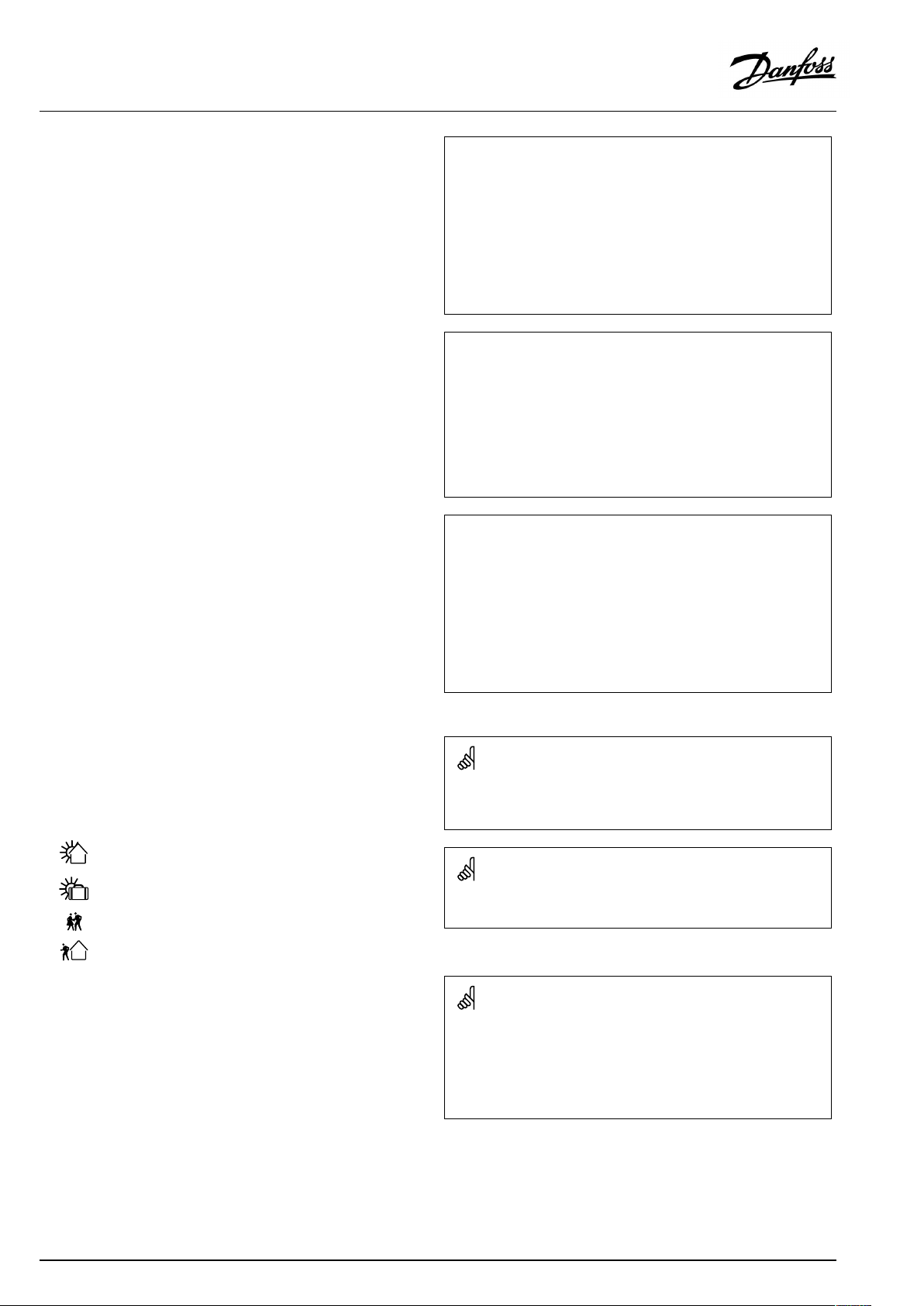

5.3Roomlimit

ThefollowingsectionisageneraldescriptionforRoom

temperaturelimitation.

Theactualapplicationmightnothavebothlimitationtypes.

Thissectionisonlyrelevantifyouhaveinstalledaroom

temperaturesensororaRemoteControlUnitforutilizingtheroom

temperaturesignal.

Inthefollowingdescriptionisreferredto"flowtemperature"in

general.

Thecontrolleradjuststhedesiredflowtemperaturetocompensate

forthedifferencebetweenthedesiredandtheactualroom

temperature.

Iftheroomtemperatureishigherthanthedesiredvalue,the

desiredflowtemperaturecanbereduced.

The'Infl.-max.'(Influence,max.roomtemp.)determineshow

muchthedesiredflowtemperatureshouldbereduced.

Usethisinfluencetypetoavoidatoohighroomtemperature.The

controllerwillallowforfreeheatgains,i.e.solarradiationorheat

fromafireplaceetc.

Iftheroomtemperatureislowerthanthedesiredvalue,thedesired

flowtemperaturecanbeincreased.

The'Infl.-min.'(Influence,min.roomtemperature)determines

howmuchthedesiredflowtemperatureshouldbeincreased.

Usethisinfluencetypetoavoidatoolowroomtemperature.This

coulde.g.becausedbywindysurroundings.

Atypicalsettingwillbe-4.0for'Infl.-max.'and4.0for'Infl.-min. '

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

MENU>Settings>Roomlimit

Adapt.time(adaptiontime)

Controlshowfasttheactualroomtemperatureadaptstothedesiredroom

temperature(Icontrol).

1x015

Theadaptationfunctioncancorrectthedesiredroomtemperature

withmax.8Kxheatcurveslopevalue.

SeeAppendix“ParameterIDoverview”

OFF:

Thecontrolfunctionisnotinfluencedbythe'Adapt.

time'.

Minor

Thedesiredroomtemperatureisadaptedquickly.

value:

Major

Thedesiredroomtemperatureisadaptedslowly.

value:

54|©Danfoss|2021.03

AQ026486454993en-010401

Page 55

OperatingGuideECLComfort210/310,applicationA267

MENU>Settings>Roomlimit

Infl.-max.(roomtemp.limitation,max.)

Determineshowmuchthedesiredflowtemperaturewillbeinfluenced

(decreased)iftheactualroomtemperatureishigherthanthedesiredroom

temperature(Pcontrol).

SeeAppendix“ParameterIDoverview”

0.0:

-2.0:

-5.0:

-9.9:

Noinfluence

Minorinfluence

Mediuminfluence

Maximuminfluence

1x182

=

X

#1#

#2#

#3#

Roomtemperature

=

Desiredroomtemperature

=

Negativeinfluence(1x082)whenactualroomtemp.getshigher

thandesiredroomtemp.

=

Positiveinfluence(1x083)whenactualroomtemp.getslowerthan

desiredroomtemp.

The‘Infl.-max.’and'Infl.-min. 'determinehowmuchtheroom

temperatureshouldinfluencethedesiredflowtemperature.

Ifthe‘Infl. ’factoristoohighand/orthe‘ Adapt.time’toolow,thereis

ariskofunstablecontrol.

Example

Theactualroomtemperatureis2degreestoohigh.

The‘Infl.-max.’issetto-4.0.

Theheatcurveslopeis1.8(see'Heatcurve'in'Flowtemperature').

Result:

Thedesiredflowtemperatureischangedby(2x-4.0x1.8)

–14.4degrees.

MENU>Settings>Roomlimit

Infl.-min.(roomtemp.limitation,min.)