Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Concrete Pumps

Series 90

powersolutions.danfoss.com

Page 2

Technical Information Series 90 Concrete Pumps

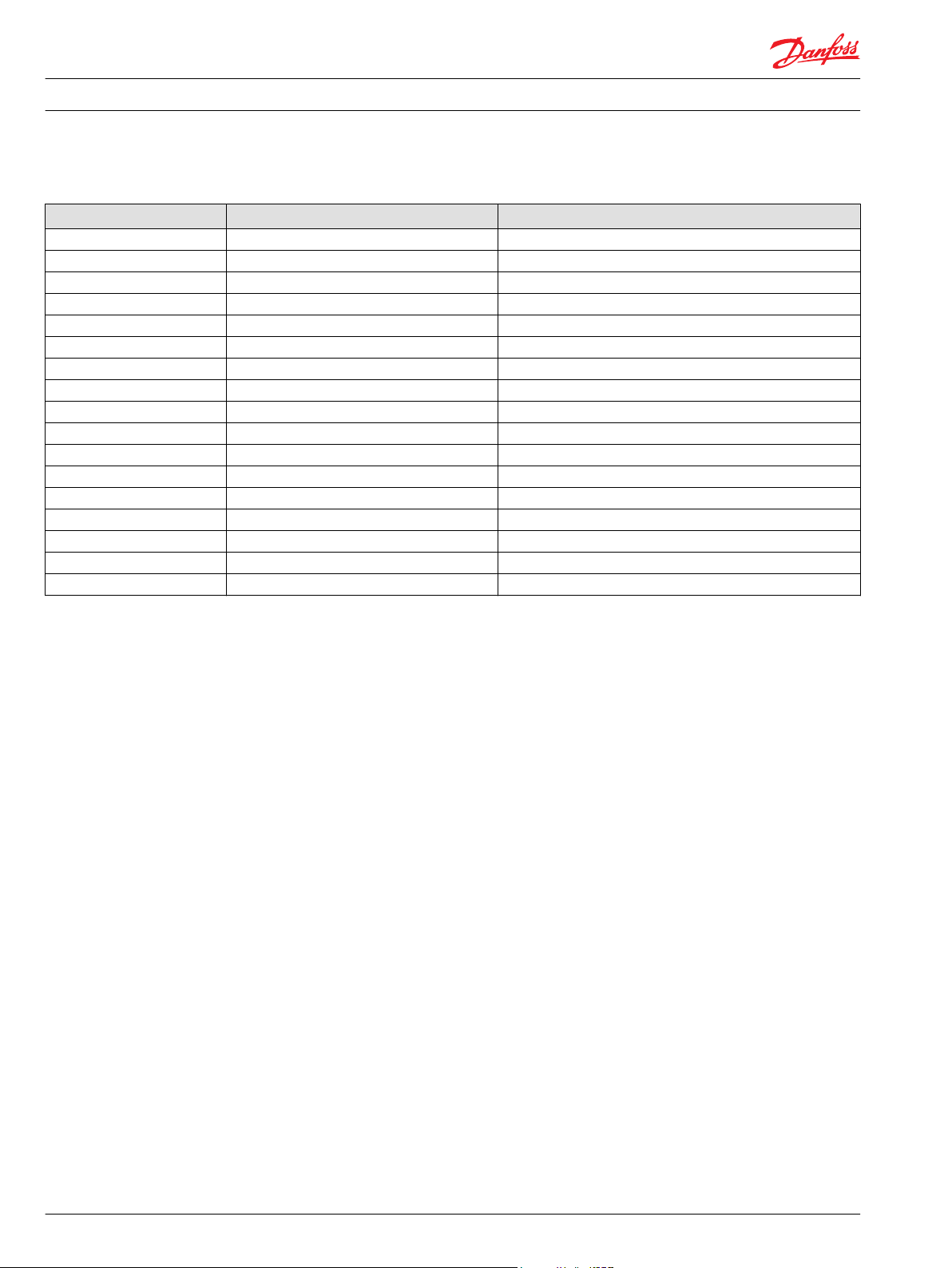

Revision history Table of revisions

Date Changed Rev

February 2016 minor edits - new installation drawings 0202

June 2014 Converted to Danfoss layout – DITA CMS BA

February 2014 First Edition AA

2 BC00000360en-US • Rev 0202 • February 2016

Page 3

Technical Information

Contents

General Description

Technical specifications

Operating Parameters

System Design Parameters

Master Model Code

Control Options

Features and Options

Installation Drawings

Series 90 Concrete Pumps

Series 90 Concrete Pumps.............................................................................................................................................................4

General Specifications.................................................................................................................................................................... 5

Features and Options......................................................................................................................................................................5

Operating Parameters.....................................................................................................................................................................6

Fluid Specifications..........................................................................................................................................................................6

Overview..............................................................................................................................................................................................7

Input Speed........................................................................................................................................................................................ 7

System Pressure................................................................................................................................................................................7

Servo Pressure................................................................................................................................................................................... 7

Charge Pressure................................................................................................................................................................................ 8

Case Pressure..................................................................................................................................................................................... 8

External Shaft Seal Pressure..........................................................................................................................................................8

Temperature and Viscosity........................................................................................................................................................... 9

Filtration System.............................................................................................................................................................................10

Filtration Options...........................................................................................................................................................................10

Suction filtration – Option S................................................................................................................................................. 10

Fluid Selection.................................................................................................................................................................................10

Reservoir............................................................................................................................................................................................11

Case Drain.........................................................................................................................................................................................11

Pump Life..........................................................................................................................................................................................11

Understanding and Minimizing System Noise....................................................................................................................11

Sizing Equations............................................................................................................................................................................. 12

Mounting Flange Loads...............................................................................................................................................................12

Accumulator.................................................................................................................................................................................... 13

High Pressure Signal Output Port X10................................................................................................................................... 13

Master Model Code....................................................................................................................................................................... 14

Hydraulic Displacement Control (HDC), Option HD; H9..................................................................................................17

Operation.....................................................................................................................................................................................17

Features and Benefits..............................................................................................................................................................17

Pump output flow direction vs. control pressure.........................................................................................................18

Multi-Function Valves...................................................................................................................................................................19

Overpressure protection........................................................................................................................................................19

Bypass Function........................................................................................................................................................................ 19

Auxiliary Mounting Pads............................................................................................................................................................. 20

Mating pump requirements................................................................................................................................................. 20

Displacement Limiter................................................................................................................................................................... 21

Shaft Torque.....................................................................................................................................................................................22

Shaft Availibility and Torque Ratings......................................................................................................................................22

Charge Pump...................................................................................................................................................................................23

Charge pump sizing/selection.............................................................................................................................................23

Charge pump flow and power curves...............................................................................................................................24

Loop Flushing Valve......................................................................................................................................................................25

Frame Size 130................................................................................................................................................................................ 27

Frame Size 180................................................................................................................................................................................ 29

BC00000360en-US • Rev 0202 • February 2016 3

Page 4

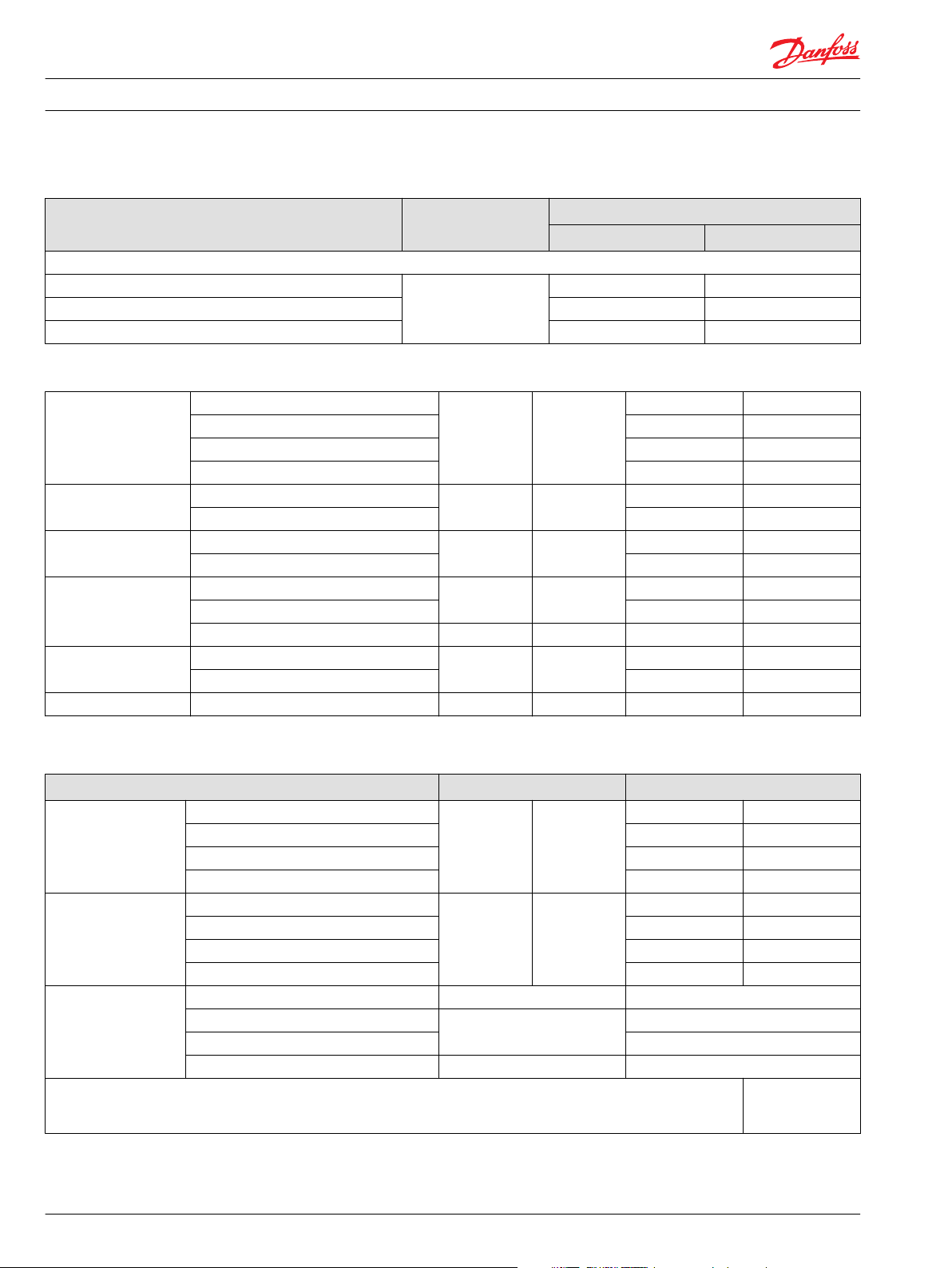

M3

S

X2

X1

P108958

TA

M5

M4

TB

S (B)

S (A)

P

M10

L1

L2

CW

2

1

flow out

M2

X9 (M22)

X9 (3/4)

X8 (M22)

X8 (3/4)

M1

X 10

M12

B

T

A

M3

S

X2 X1

TA

M5

M4

TB

S (B)

S (A)

P

M10

L1

L2

CW

2

1

M2

X9 (M22)

X9 (3/4)

X8 (M22)

X8 (3/4)

M1

X 10

M12

B

T

A

X12

X11

A

N

X3(M11)

N

X12

X11

flow out

A

X3(M11)

Technical Information Series 90 Concrete Pumps

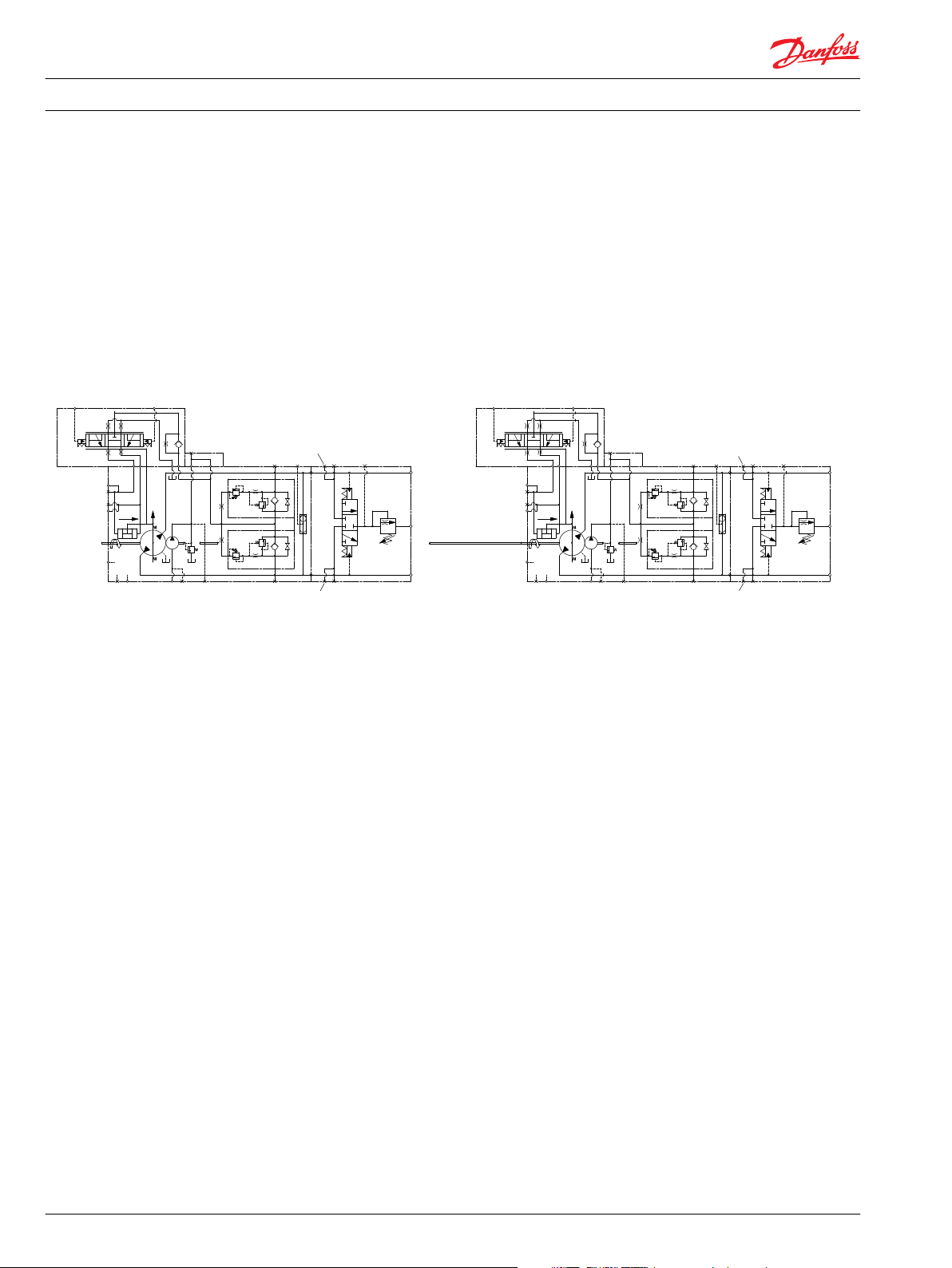

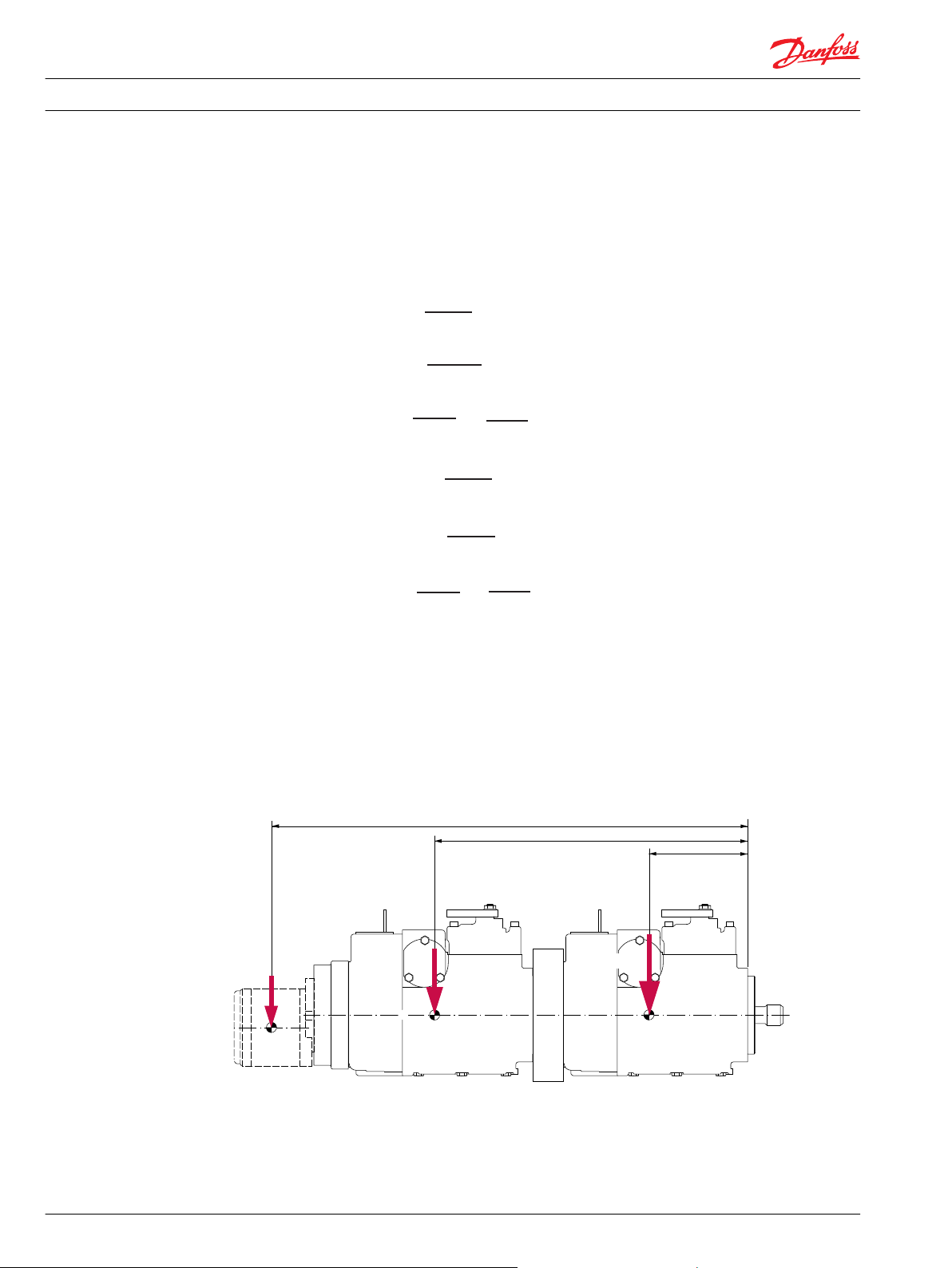

General Description

Series 90 Concrete Pumps

The S90 concrete pumps are designed for 2 cylinder concrete pump applications. This Technical

Infomation only describes concrete pump specific information - General information about Series 90

pumps can be found in Series 90 Axial Piston Pumps Technical Information 520L0603.

The concrete pump system can be built up as Series 90 single or tandem pumps. Each pump can be

equipped with a loop flushing valve (LFV).

System Schematic

4 BC00000360en-US • Rev 0202 • February 2016

Page 5

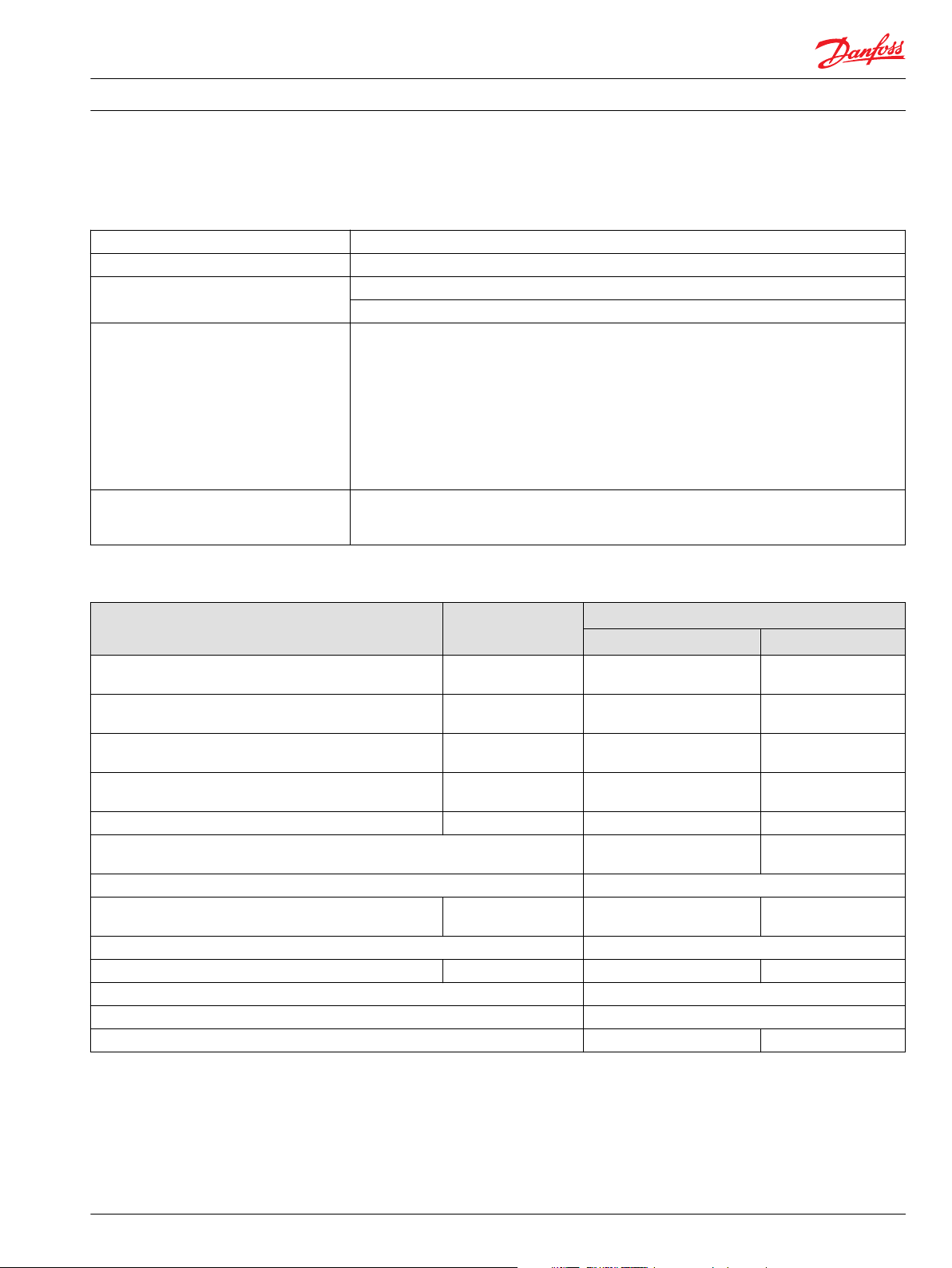

Technical Information Series 90 Concrete Pumps

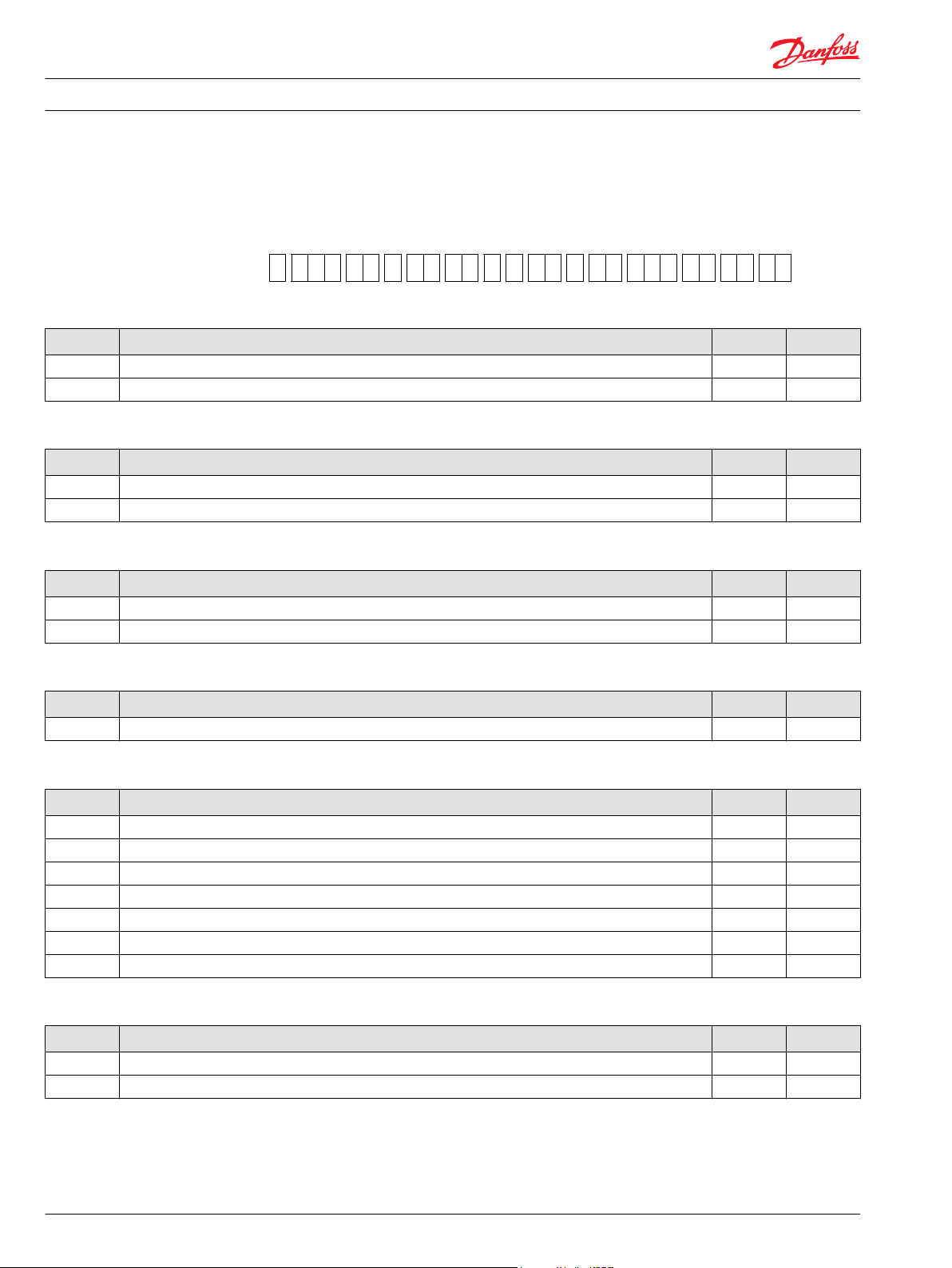

Technical specifications

General Specifications

Design Axial piston pump of cradle swashplate design with variable displacement

Direction of rotation Clockwise, counterclockwise

Pipe connections Main pressure ports: ISO split flange boss

Remaining ports: SAE straight thread O-ring boss

Recommended installation position Pump installation position is discretionary, however the recommended control position is on the top

or at the side, with the top position preferred.

Vertical input shaft installation is acceptable.

If input shaft is at the top 1 bar case pressure must be maintained during operation.

The pump housing must be filled with hydraulic fluid under all conditions; including after a long

period of shutdown. Before operating the machine, ensure the pump housing and case drain lines are

free of air.

Recommended mounting for a multiple pump stack is to arrange the highest power flow towards the

input source.

Consult Danfoss for nonconformance to these guidelines.

Auxiliary cavity pressure Will be inlet pressure with internal charge pump. For reference see Operating Parameters on page 6.

Will be case pressure with external charge supply.

Please verify mating pump shaft seal capability.

Features and Options

Feature Unit Frame

130 180

Displacement cm³/rev.

[in³]/rev.

Flow at rated speed (theoretical) l/min.

[US gal/min.]

Torque at maximum displacement (theoretical) N•m/bar

[lbf•in/1000 psi]

Mass moment of inertia of rotating components kg•m²

[slug•ft²]

Weight (with control opt. MA) kg [lb] 88 [195] 136 [300]

Mounting (per ISO 3019-1) Flange

Rotation

Main ports: 4-bolt split-flange

(per SAE J518 code 62)

Main port configuration Twin port

Case drain ports (SAE O-ring boss) UNF thread (in.) 1.3125–12 1.625–12

Other ports SAE O-ring boss

Shafts Splined, and tapered shafts available

Auxiliary mounting SAE-A, B, C, D SAE-A, B, C, D, E

mm

[in]

130

[7.93]

403

[106]

2.07

[1260]

0.023

[0.0170]

152-4 (SAE D)

31.75

[1.25]

180

[10.98]

468

[124]

2.87

[1750]

0.0380

[0.0280]

Flange

165-4 (SAE E)

31.75

[1.25]

BC00000360en-US • Rev 0202 • February 2016 5

Page 6

Technical Information Series 90 Concrete Pumps

Technical specifications

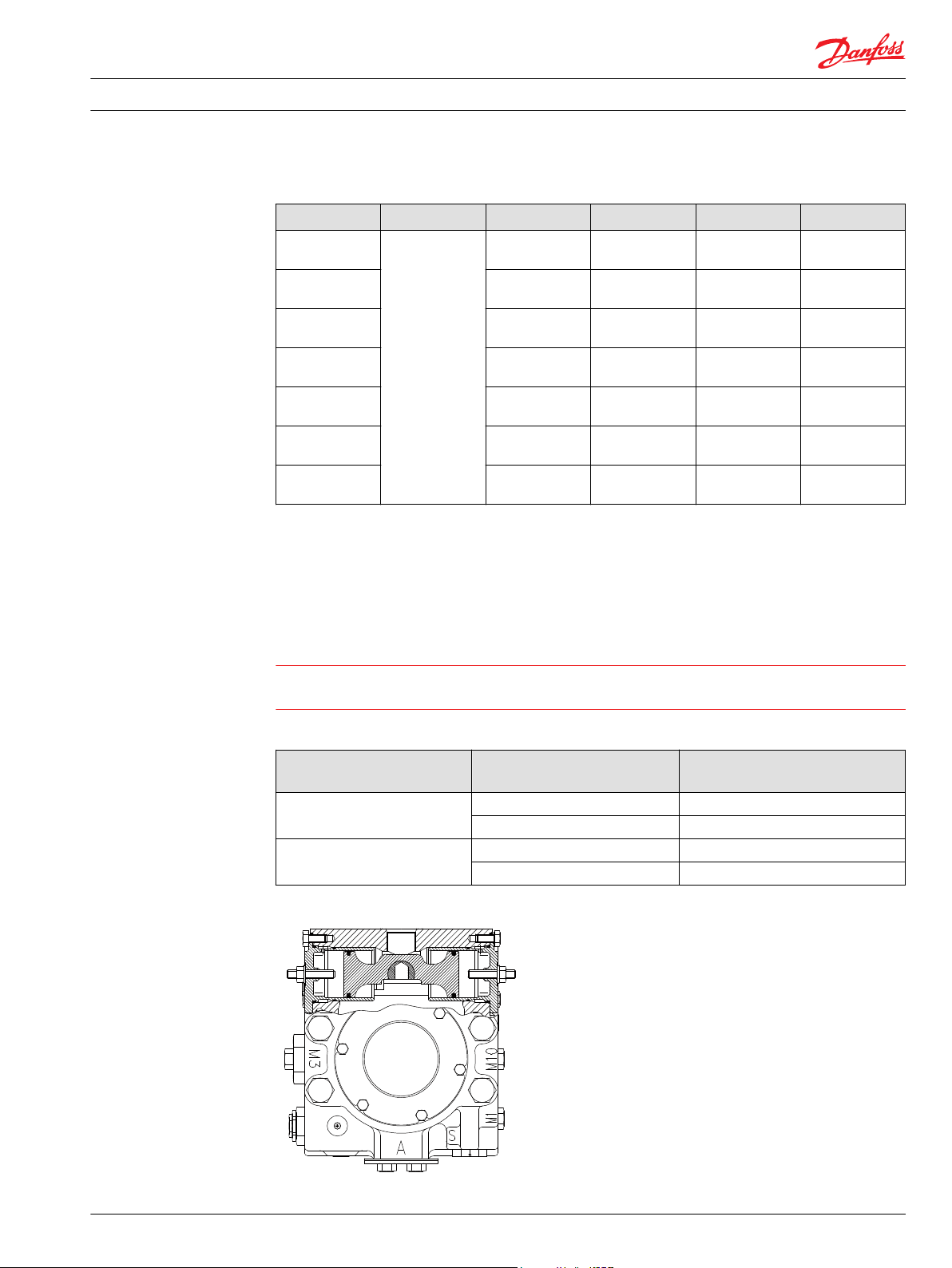

Operating Parameters

Parameter Unit Frame

130 180

Input speed

Minimum min-1(rpm) 500 500

Rated Speed 3100 2600

Maximum 3400 2850

Operating parameters

System pressure Maximum working pressure bar [psi] 450 [6525]

Maximum pressure 480 [6960]

Maximum low loop 45 [650]

Minimum low loop pressure 10 [145]

Charge pressure Minimum bar [psi] 18 [261]

Maximum 34 [493]

Control pressure Minimum (at corner power for HDC) bar [psi] 14 [203]

Maximum 40 [580]

Charge pump inlet

pressure

Case pressure Rated bar [psi] 3.0 [44]

Lip seal external pressure Maximum bar [psi] 0.4 [5.8]

Rated bar (absolute) [in Hg vacuum] 0.7 [9]

Minimum (cold start) 0.2 [24]

Maximum bar [psi] 4.0 [58]

Maximum 12 [174]

Fluid Specifications

Feature Unit

Viscosity Intermittent

Minimum 7 [49]

Recommended range 12-80 [66-370]

Maximum 1600 [7500]

Temperature

range 2)

Minimum (cold start) 3) °C [°F] -40 [-40]

Recommended range 60-85 [140-185]

Rated 104 [220]

Maximum intermittent

Filtration

(recommended

minimum)

Cleanliness per ISO 4406-1999 22/18/13

Efficiency (charge pressure filtration) β-ratio β

Efficiency (suction and return line filtration) β

Recommended inlet screen mesh size µm 100 – 125

1)

Intermittent = Short term t < 1min per incident and not exceeding 2 % of duty cycle based load-life

2)

At the hottest point, normally case drain port

3)

Cold start = Short term t < 3min, p ≤ 50 bar [725 psi], n ≤ 1000 min-1(rpm)

1)

1)

mm2/s [SUS] 5 [42]

115 [240]

= 75 (β10 ≥ 10)

15-20

= 75 (β10 ≥ 2)

35-45

T000 129E

6 BC00000360en-US • Rev 0202 • February 2016

Page 7

Technical Information

Operating Parameters

Overview

Input Speed

Series 90 Concrete Pumps

This section defines the operating parameters and limitations for Series 90 pumps with regard to input

speeds and pressures. For actual parameters, refer to the operating parameters for each displacement.

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits the pump's ability to maintain adequate flow for lubrication and power

transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Operating conditions between Rated speed and Maximum speed should be restricted to less than full

power and to limited periods of time.

For more information consult Pressure and Speed Limits, BLN-9884, when determining speed limits for a

particular application.

System Pressure

Servo Pressure

System pressure is the differential pressure between high pressure system ports. It is the dominant

operating variable affecting hydraulic unit life. High system pressure, which results from high load,

reduces expected life. Hydraulic unit life depends on the speed and normal operating, or weighted

average, pressure that can only be determined from a duty cycle analysis.

Application pressure is the high pressure relief or pressure limiter setting normally defined within the

order code of the pump. This is the applied system pressure at which the drive-line generates the

maximum calculated pull or torque in the application.

Maximum working pressure is the highest recommended Application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure is the highest allowable Application pressure under any circumstance. Application

pressures above maximum working Pressure will only be considered with duty cycle analysis and factory

approval.

Pressure spikes are normal and must be considered when reviewing maximum working pressure.

Minimum low loop pressure must be maintained under all operating conditions to avoid cavitation.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

Servo pressure is the pressure in the Servo-system needed to position and hold the pump on stroke. It

depends on system pressure and speed.

At minimum servo pressure the pump will run at reduced stroke depending on speed and pressure.

Minimum servo pressure at corner power holds the pump on full stroke at max speed and max pressure.

Maximum servo pressure is the highest pressure typically given by the charge pressure setting.

BC00000360en-US • Rev 0202 • February 2016 7

Page 8

C

C

Technical Information

Operating Parameters

Charge Pressure

Series 90 Concrete Pumps

An internal charge relief valve regulates charge pressure. Charge pressure supplies the control with

pressure to operate the swashplate and to maintain a minimum pressure in the low side of the

transmission loop. The charge pressure setting listed in the order code is the set pressure of the charge

relief valve with the pump in neutral, operating at 1800 min-1 [rpm], and with a fluid viscosity of 32 mm2/s

[150 SUS]. Pumps configured with no charge pump (external charge supply) are set with a charge flow of

30 l/min. [7.93 US gal/min.] and a fluid viscosity of 32 mm2/s [150 SUS].

The charge pressure setting is referenced to case pressure. Charge pressure is the differential pressure

above case pressure.

Minimum charge pressure is the lowest pressure allowed to maintain a safe working condition in the

low side of the loop. Minimum control pressure requirements are a function of speed, pressure, and

swashplate angle, and may be higher than the minimum

charge pressure shown in the Operating parameters tables.

Maximum charge pressure is the highest charge pressure allowed by the charge relief adjustment, and

which provides normal component life. Elevated charge pressure can be used as a secondary means to

reduce the swashplate response time.

At normal operating temperature charge inlet pressure must not fall below rated charge inlet pressure

(vacuum).

Minimum charge inlet pressure is only allowed at cold start conditions. In some applications it is

recommended to warm up the fluid (e.g. in the tank) before starting the engine and then run the engine

at limited speed.

Maximum charge pump inlet pressure may be applied continuously.

Case Pressure

External Shaft Seal Pressure

Under normal operating conditions, the rated case pressure must not be exceeded. During cold start

case pressure must be kept below maximum intermittent case pressure. Size drain plumbing accordingly.

Auxiliary Pad Mounted Pumps. The auxiliary pad cavity of S90 pumps configured without integral

charge pumps is referenced to case pressure. Units with integral charge pumps have auxiliary mounting

pad cavities referenced to charge inlet (vacuum).

Caution

Possible component damage or leakage

Operation with case pressure in excess of stated limits may damage seals, gaskets, and/or housings,

causing external leakage. Performance may also be affected since charge and system pressure are

additive to case pressure.

In certain applications the input shaft seal may be exposed to external pressure. In order to prevent

damage to the shaft seal the maximum differential pressure from external sources must not exceed 0.4

bar (5.8 psi) over pump case pressure. The case pressure limits of the pump must also be followed to

ensure the shaft seal is not damaged.

Caution

Regardless of the differential pressure across the shaft seal, the shaft seal has been known to pump oil

from the external source (e. g. gear box) into the pump case.

8 BC00000360en-US • Rev 0202 • February 2016

Page 9

Technical Information Series 90 Concrete Pumps

Operating Parameters

Temperature and Viscosity

Temperature

The high temperature limits apply at the hottest point in the transmission, which is normally the motor

case drain. The system should generally be run at or below the quoted rated temperature.

The maximum intermittent temperature is based on material properties and should never be

exceeded.

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability of oil to flow and transmit power; therefore temperatures should remain 16 °C [30 °F] above the

pour point of the hydraulic fluid.

The minimum temperature relates to the physical properties of component materials.

Size heat exchangers to keep the fluid within these limits. Danfoss recommends testing to verify that

these temperature limits are not exceeded.

Viscosity

For maximum efficiency and bearing life, ensure the fluid viscosity remains in the recommended range.

The minimum viscosity should be encountered only during brief occasions of maximum ambient

temperature and severe duty cycle operation.

The maximum viscosity should be encountered only at cold start.

BC00000360en-US • Rev 0202 • February 2016 9

Page 10

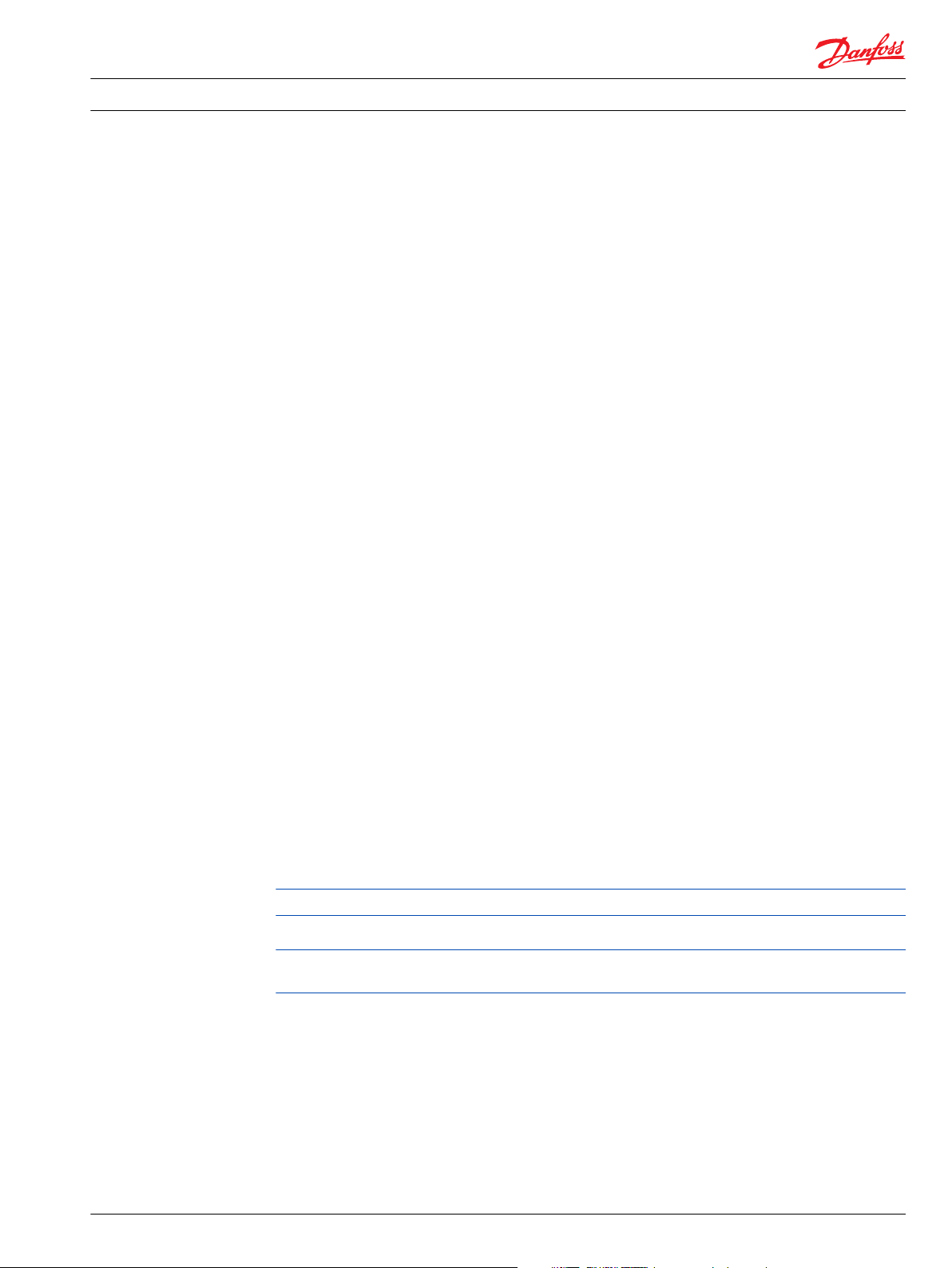

Charge pump

Filter

Hydraulic fluid reservoir

Adjustable

charge pressure relief valve

To pump case

To low

loop and

control

Manometer

P102 003E

C

Technical Information

System Design Parameters

Filtration System

Filtration Options

Series 90 Concrete Pumps

To prevent premature wear, ensure only clean fluid enters the hydrostatic transmission circuit. A filter

capable of controlling the fluid cleanliness to ISO 4406 class 22/18/13 (SAE J1165) or better, under normal

operating conditions, is recommended.

These cleanliness levels can not be applied for hydraulic fluid residing in the component housing/case or

any other cavity after transport.

Filter efficiency can be measured with a Beta ratio (βX). For suction filtration, a filter with a β-ratio within

the range of β

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number

of particles greater than a given diameter (“x” in microns) upstream of the filter to the number of these

particles downstream of the filter.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information,

520L0467 for more information.

= 75 (β10 ≥ 2) or better has been found to be satisfactory.

35-45

Fluid Selection

Suction filtration – Option S

Suction filtration is the only option available for concrete pumps.

The suction filter is placed in the circuit between the reservoir and the inlet to the charge pump, as

shown below.

The use of a filter contamination monitor is recommended.

Suction filtration

Caution

Clogged filters can cause cavitation, which damages the charge pump. We recommend a filter bypass

with a filter bypass sensor to prevent damage due to blocked suction filters.

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion, and corrosion of pump components.

Never mix hydraulic fluids of different types.

10 BC00000360en-US • Rev 0202 • February 2016

Page 11

Technical Information

System Design Parameters

Reservoir

Case Drain

Series 90 Concrete Pumps

The hydrostatic system reservoir should accommodate maximum volume changes during all system

operating modes and promote de-aeration of the fluid as it passes through the tank. A suggested

minimum total reservoir volume is 5⁄8 of the maximum charge pump flow per minute with a minimum

fluid volume equal to ½ of the maximum charge pump flow per minute. This allows 30 seconds fluid

dwell for removing entrained air at the maximum return flow. This is usually adequate to allow for a

closed reservoir (no breather) in most applications.

Locate the reservoir outlet (charge pump inlet) above the bottom of the reservoir to take advantage of

gravity separation and prevent large foreign particles from entering the charge inlet line. A 100-125 μm

screen over the outlet port is recommended. Position the reservoir inlet (fluid return) to discharge below

the normal fluid level, toward the interior of the tank. A baffle (or baffles) will further promote de-aeration

and reduce surging of the fluid.

All single S90 pumps are equipped with multiple drain ports. Port selection and case drain routing must

enable the pump housing to maintain a volume of oil not less than half full and normal operating case

pressure limits of the unit are maintained. Case drain routing and design must consider unit case pressure

ratings.

A case drain line must be connected to one of the case outlets to return internal leakage to the system

reservoir.

Do not over torque the fitting on case drain port L2 (located on the side cover). The proper torque is 100

N•m [74 lbf•ft] maximum. Over torquing the fitting may change the neutral position of the swashplate.

Pump Life

Pump life depends on several factors, such as speed, pressure, and swashplate angle. For detailed

product life calculation, please contact your Danfoss representative.

Understanding and Minimizing System Noise

Noise is transmitted in fluid power systems in two ways: as fluid borne noise, and structure borne noise.

Fluid-borne noise (pressure ripple or pulsation) is created as pumping elements discharge oil into the

pump outlet. It is affected by the compressibility of the oil, and the pump's ability to transition pumping

elements from high to low pressure. Pulsations travel through the hydraulic lines at the speed of sound

(about 1400 m/s [4600 ft/sec] in oil) until there is a change (such as an elbow) in the line. Thus, amplitude

varies with overall line length and position.

Structure born noise is transmitted wherever the pump casing connects to the rest of the system. The

way system components respond to excitation depends on their size, form, material, and mounting.

System lines and pump mounting can amplify pump noise.

Follow these suggestions to help minimize noise in your application:

Use flexible hoses.

•

Limit system line length.

•

If possible, optimize system line position to minimize noise.

•

If you must use steel plumbing, clamp the lines.

•

If you add additional support, use rubber mounts.

•

Test for resonants in the operating range; if possible avoid them.

•

BC00000360en-US • Rev 0202 • February 2016 11

Page 12

Output f ow Q = (l/min..)

Inp ut torque M = (N•m)

Inp ut power P = = (kW)

SI units Vg= Displacement per revolution

(cm3/rev)

∆p = pO- pi(system pressure)

(bar)

n = Speed (min-1(rpm))

ηv= Volumetric eff cien cy

ηm= Mechanical eff cien cy

ηt= Overall eff ciency (ηv• ηm)

Vg• n • η

v

1000

Vg• ∆p

20 • π • η

m

Q •∆p

600 • η

t

M • n • π

30 000

g

= Displacement per revolution

(in3/rev)

∆p = pO- pi(system pressure)

(psi)

n = Speed (min-1(rpm))

ηv= Volumetric eff cien cy

ηm= Mechanical eff cien cy

ηt= Overall eff ciency (ηv• ηm)

Output f ow Q = (US gal/min..)

Inp ut torque M = (lbf•in)

Inp ut power P = = (hp)

Vg• n • η

v

231

Vg• ∆p

2 • π • η

m

Q •∆p

1714 • η

t

M • n • π

198 000

First stageSecond stage

Third

stage

P108 511E

L1

L2

L3

F2 F1

F3

Technical Information

System Design Parameters

Sizing Equations

Series 90 Concrete Pumps

The following equations are helpful when sizing hydraulic pumps. Generally, the sizing process is

initiated by an evaluation of the machine system to determine the required motor speed and torque to

perform the necessary work function. Refer to Selection of drive line components, BLN-9885, for a more

complete description of hydrostatic drive line sizing. First, the motor is sized to transmit the maximum

required torque. The pump is then selected as a flow source to achieve the maximum motor speed.

Mounting Flange Loads

Adding tandem mounted auxiliary pumps and/or subjecting pumps to high shock loads may result in

excessive loading of the mounting flange.

Applications which experience extreme resonant vibrations or shock may require additional pump

support. The overhung load moment for multiple pump mounting may be estimated using the formula

below.

Overhung load example

12 BC00000360en-US • Rev 0202 • February 2016

Estimated maximum and rated acceleration factors for some typical applications are shown in the table

below.

Page 13

R

= g • GR(W1L1+ W2L2+ ... + WnLn)

S

= g • GS(W1L1+ W2L2+ ... + WnLn)

R

= Rated load moment N•m

S

= Shock load moment N•m

2

R

= Calculation factor for rated (vibratory) acceleration (G’s)*

S

= Calculation factor for maximum shock acceleration (G’s)*

MR= GR(W1L1+ W2L2+ ... + WnLn)

MS= GS(W1L1+ W2L2+ ... + WnLn)

Based on US units

W = Weight of pump [lb]

L = Distance from mounting f ange [in]

to pump center of gravity

Where:

MR= Rated load moment N•m

MS= Shock load moment N•m

HP A

HP B

Port X10: HP Out

P108721

Technical Information

System Design Parameters

Series 90 Concrete Pumps

Allowable overhung load moment values are shown in the following table.

Allowable overhung load moments

Frame size Rated moment (MR) Shock load moment (MS)

N•m lbf•in N•m lbf•in

130 3160 28 000 10 730 95 000

180 6070 54 000 20 600 182 000

Accumulator

Typical for concrete pump systems is a significant pressure drop on the low pressure side. The gage port

M3 can be used to conncet an accumulator on to the system. The accumulator has to be connected to

port M3. The volume size of the accumulator has to be at least 1.6 liters or larger. The preliminary charge

pressure is at least 2 bar.

High Pressure Signal Output Port X10

This port provides a high pressure signal from side A or B of the working loop controlled by a 2-wayshuttle valve within the endcap.

This port can be used for a torque limiter control.

BC00000360en-US • Rev 0202 • February 2016 13

Page 14

M J G F

L

T

H Y Z

K

S90

Size

R

P

N

W

Technical Information Series 90 Concrete Pumps

Master Model Code

Master Model Code

R - Type and Rotation

Code Description 130 180

R Right Hand [CW] O O

L Left Hand [CCW] O O

Size

Code Description 130 180

130 130 cc [7.93 in³] max. displacement per revolution O

180 180 cc [10.98 in³] max. displacement per revolution O

M - Controls

Code Description 130 180

HD HDC, standard porting, 6 - 18 bar (88 - 264 PSI), UNF thread ports O O

H9 Standard porting, 6.0-18.0 bar (88-264 psi), metric thread ports O

P - High Pressure Regulation

Code Description 130 180

D high pressure relief valves for port A and B (240-350 bar) O O

J - Auxiliary Mounting Pad

Code Description 130 180

AB SAE-A with sealed cover, 9 teeth coupling O O

BB SAE-BB with sealed cover, 15 teeth coupling O O

BC SAE-B with sealed cover, 13 teeth coupling O O

CD SAE-C with sealed cover, 4 bolt adapter, 14 teeth coupling, (2) ½-13 UNC O O

DE SAE-D with sealed cover, 13 teeth coupling O O

EF SAE-E with sealed cover, 13 teeth coupling O

NN no auxiliary mounting pad O O

G - Endcap Ports

Code Description 130 180

8C twin ports with high pressure shuttle valve, HD measurement port, UNF thread ports, loop flushing valve O O

9C twin ports with high pressure shuttle valve, HD measurement port, metric thread ports, loop flushing valve O

14 BC00000360en-US • Rev 0202 • February 2016

Page 15

Technical Information Series 90 Concrete Pumps

Master Model Code

N - Filtration

Code Description 130 180

S suction filtration O O

K suction filtration with metric port O

F - Displacement Limitation

Code Description 130 180

C no limiters, only for 180 cc O

M limitation both sides, only for 180 cc O

3 no limiters O

4 limitation both sides O

E limitation both sides, spec. servo cylinder with gage ports O O

L - Shaft Options

Code Description 130 180

C8 splined shaft, 27 teeth, pitch = 16 / 32 O O

F1 splined shaft, 13 teeth, pitch = 8 / 16 O O

D5 Splined shaft, W50x2x30x24x9g per DIN 5480 O

H - Charging System

Code Description 130 180

F nominal flow = 26 cc / rev O

H nominal flow = 34 cc / rev O O

J nominal flow = 47 cc / rev O

T - Control Orifice Options

Code Description

HDC

inlet P drain TA drain TB servo A servo B 130 180

00 n/o 1.3 1.3 n/o n/o O O

W - Special Hardware Features

Code Description 130 180

GBA CP15 +0,5° valve plate O

NNN 180cc: CP15 +0,5° valve plate O

250cc: CP15 +0,5° valve plate , nested T- bar springs

GCE CP15 +1,5° valve plate, metric ports, special plate retainer O

GCF CP15 +1,5° valve plate, metric ports O

BC00000360en-US • Rev 0202 • February 2016 15

Page 16

Technical Information Series 90 Concrete Pumps

Master Model Code

Y - High Pressure Setting A

Code Description 130 180

32 320 bar O O

35 350 bar O O

Z - High Pressure Setting B

Code Description 130 180

32 320 bar O O

35 350 bar O O

K - Charge Pressure Setting

Code Description 130 180

20 20 bar O O

22 22 bar O O

24 24 bar O O

26 26 bar O O

28 28 bar O O

30 30 bar O O

32 32 bar O O

34 34 bar O O

16 BC00000360en-US • Rev 0202 • February 2016

Page 17

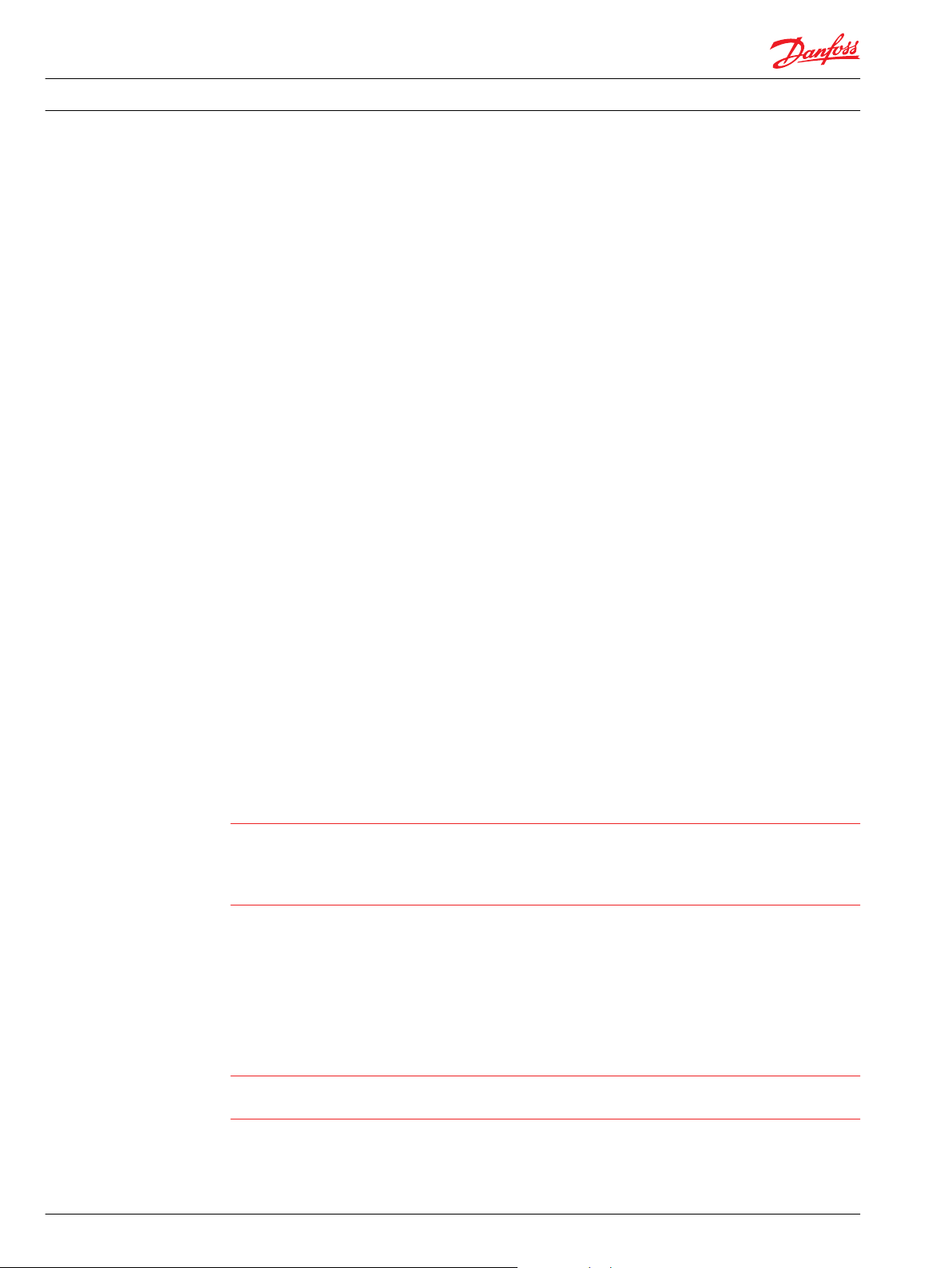

W

M5 M4

T

P

Feedback

from

swashplate

X2

X1

P102029

Technical Information

Series 90 Concrete Pumps

Control Options

Hydraulic Displacement Control (HDC), Option HD; H9

Warning

Avoid designing a system which puts swashplate into full stroke when control operation is blocked by

contamination.

Operation

The hydraulic displacement control uses a hydraulic input signal to operate a 4-way servo valve, which

ports hydraulic pressure to either side of a double acting servo piston. The servo piston tilts the cradle

swashplate, thus varying the pump's displacement from full displacement in one direction to full

displacement in the opposite direction.

The control has a mechanical feedback mechanism which moves the servo valve in relation to the input

signal and the angular rotation of the swashplate. The hydraulic displacement control is designed so the

angular position of the swashplate (pump displacement) is proportional to the hydraulic input signal

pressure. Due to normal operating force changes, the swashplate tends to drift from the position preset

by the machine operator. Drift, sensed by feedback linkage system connecting the swashplate to the

control valve, activates the valve to supply pressure to the servo piston, maintaining the swashplate in its

preset position.

Features and Benefits

The hydraulic displacement control is a high gain control: With only small change of the input signal,

•

the servo valve moves to a full open position porting maximum flow to the servo cylinder.

Internal mechanical stops on the servo valve allow rapid changes in input signal pressure without

•

damaging the control mechanism.

Precision parts provide repeatable, accurate displacement settings with a given input signal.

•

The swashplate is coupled to a feedback mechanism. The control valve drains the ends of the servo

•

piston when an input signal is not present.

Benefits:

Simple - low cost design.

•

Pump returns to neutral after prime mover shuts down.

•

Pump returns to neutral if there is a loss of input signal pressure or if there is a loss of charge pressure.

•

Hydraulic displacement control schematic

BC00000360en-US • Rev 0202 • February 2016 17

Page 18

T

M4 P

M5

T

P102 030

X1 X2

W

"0"

Signal pressure

Displacement

100 %

a b

-b -a

100 %

P102 031E

Technical Information

Control Options

Series 90 Concrete Pumps

Cross-section

Warning

Maximum allowable signal pressure is 60 bar [870 psi]. Exceeding allowable signal pressure will cause

damage to the control.

Hydraulic signal pressure range

a 6 ± 0.5 bar [88 ± 6 psi]

b 18 ± 0.5 bar [264 ± 6 psi]

Stroking time from A to B

130cc 300 ms

180cc 300 ms

Pump displacement vs. signal pressure

Pump output flow direction vs. control pressure

Pump output flow direction vs. control pressure

Input shaft rotation CW CCW

Control pressure to port X1 X2 X1 X2

Port A flow (M1) Out In In Out

Port B flow (M2) In Out Out In

Servo cylinder (side) M5 (2) M4 (1) M5 (2) M4 (1)

Refer to Installation Drawings on page 27, for port locations.

18 BC00000360en-US • Rev 0202 • February 2016

Page 19

TA

TB

S (B)

S (A)

P

CW

2

1

flow out

(M22)

(3/4)

(M22)

(3/4)

X12

X11

A

M3

S

X2

X1

M5

M4

M10

L1

L2

M2

X9

X9

X8

X8

M1 X 10

M12

B

T

A

N

X3(M11)

Charge

pressure

relief valve

Multifunction valve

Multifunction valve

To control

Servo piston

Servo piston

Port A

Port B

C

Bypass hex

adjustment

P108961

Servo pressure

relief valves

A

B

Technical Information

Series 90 Concrete Pumps

Features and Options

Multi-Function Valves

Overpressure protection

Series 90 concrete pumps are only designed with high pressure relief valves.

The relief valve is built into the multi-function valve located in the pump endcap. The high pressure relief

valve system in the Series 90 provides an advanced design of overpressure protection.

Because the relief valves open only during extremely fast pressure spike conditions, heat generation is

minimized during the short time that they might be open. The relief response is approximately 20 ms

whether used with or without the pressure limiter function.

HPRVs are factory set at a low flow condition. Any application or operating condition which leads to

elevated HPRV flow will cause a pressure rise with flow above a valve setting. Consult factory for

application review. Excessive operation of the HPRV will generate heat in the closed loop and may cause

damage to the internal components of the pump.

Multifunction valve, pressure regulation

Bypass Function

In some applications it is desirable to bypass fluid around the variable displacement pump when pump

shaft rotation is either not possible or not desired. For example, an inoperable vehicle may be moved to a

service or repair location or winched onto a trailer without operating the prime mover. To provide for

this, Series 90 pumps are designed with a bypass function.

The bypass is operated by mechanically rotating the bypass hex on both multifunction valves three (3)

turns counterclockwise (CCW). This connects working loop A and B and allows fluid to circulate without

rotating the pump and prime mover.

BC00000360en-US • Rev 0202 • February 2016 19

Page 20

Ø P

0

-0.05

[+0.000]

[-0.002]

F

min.

Minimum spline

engagement

D

B

max.

E

Mounting flange

(Ref)

Coupling

0.8 [0.03] R

preferred

P102 015E

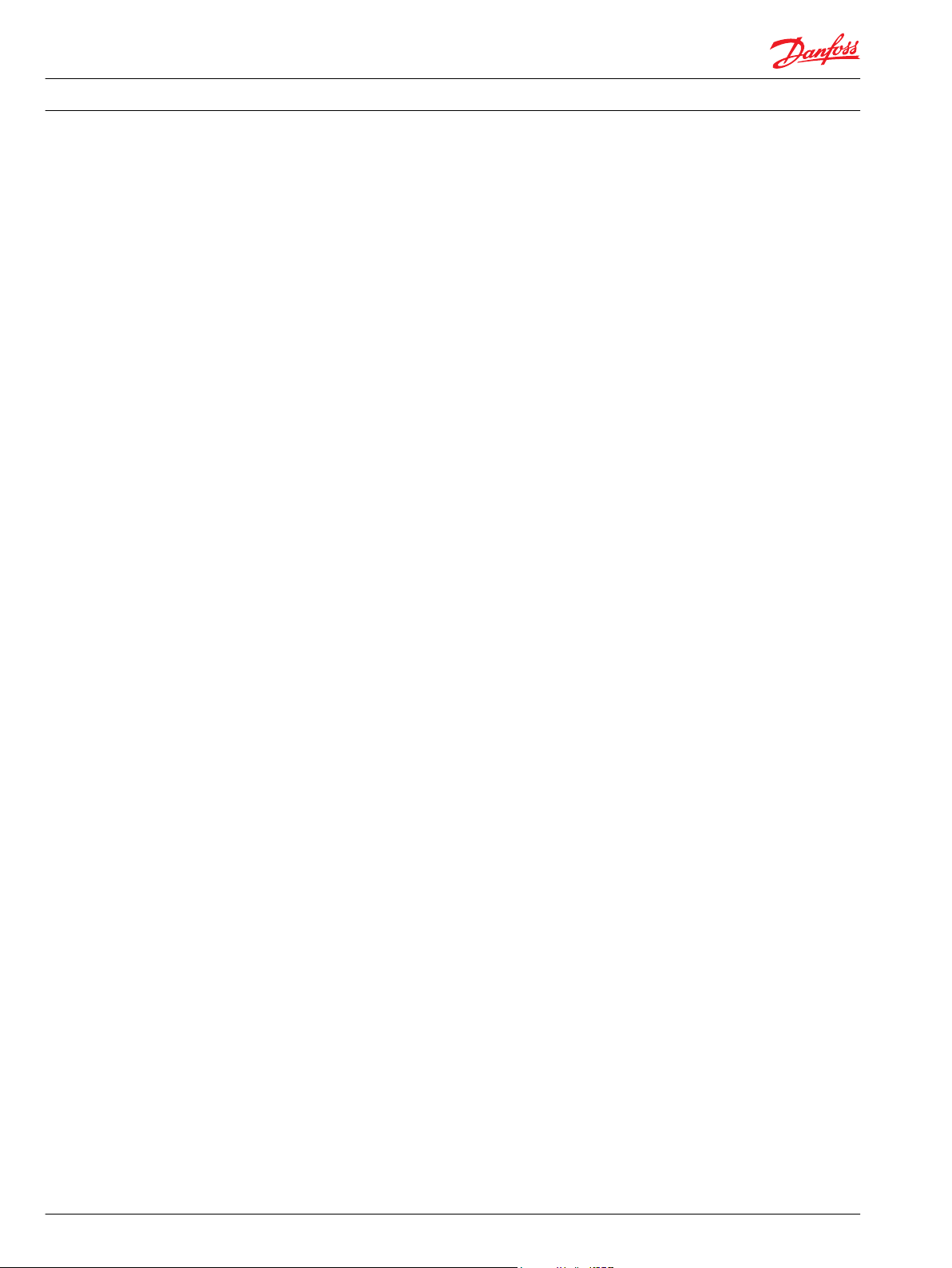

Technical Information Series 90 Concrete Pumps

Features and Options

Auxiliary Mounting Pads

Auxiliary mounting pad specifications

Mounting pad Option code Spline coupling Frame size/Maximum torque N•m [lbf•ft]

130 180

SAE A AB 9T 16/32 106 [78] 120 [89]

SAE B BC 13T 16/32 334 [246] 324 [239]

SAE B-B BB 15T 16/32 368 [271] 368 [271]

SAE C CD 14T 12/24 741 [546] 628 [463]

SAE D DE 13T 8/16 741 [546] 1070 [789]

SAE E EF 13T 8/16 n/a 1070 [789]

SAE E EG 27T 16/32 n/a 1220 [900]

Mating pump requirements

The accompanying drawing provides the dimensions for the auxiliary pump mounting flange and shaft.

Pump mounting flanges and shafts with the dimensions noted below are compatible with the auxiliary

mounting pads on the Series 90 pumps. An O-ring is required when a pump is bolted to an aux pad. Refer

to outline drawings for more details and O-ring dimensions.

Auxiliary pump mounting flange and shaft

20 BC00000360en-US • Rev 0202 • February 2016

Page 21

W

P108 705E

Side 2

Technical Information

Features and Options

Displacement Limiter

Series 90 Concrete Pumps

Auxiliary pump dimensions

Flange size Units P diameter B maximum D F minimum

SAE A mm [in] 82.55

[3.25]

SAE B 101.6

[4.00]

SAE B-B 101.6

[4.00]

SAE C 127.0

[5.00]

SAE D 152.4

[6.00]

SAE E

13 teeth

SAE E

27 teeth

165.1

[6.50]

165.1

[6.50]

All Series 90 pumps are designed with optional mechanical displacement (stroke) limiters.

The maximum displacement of the pump can be set independently for forward and reverse using the

two adjustment screws.

7.4

[0.29]

10.7

[0.42]

10.7

[0.42]

14.3

[0.56]

14.3

[0.56]

18.0

[0.71]

18.0

[0.71]

32

[1.26]

41

[1.61]

46

[1.81]

56

[2.20]

75

[2.95]

75

[2.95]

75

[2.95]

13.5

[0.53]

14.2

[0.56]

16.1

[0.63]

18.3

[0.72]

20.8

[0.82]

20.8

[0.82]

27.0

[1.06]

Warning

Adjusting the displacement limiter with the machine running may result in leakage. If backed out too far,

the adjustment screw will come completely out of its threaded bore.

Displacement limiter location

Pump rotation Displacement limiter mounted on

servo side

Right [CW] 1 A

2 B

Left [CCW] 1 B

2 A

Displacement limitation at high

pressure side

Displacement limiter

BC00000360en-US • Rev 0202 • February 2016 21

Page 22

Technical Information

Features and Options

Series 90 Concrete Pumps

Shaft Torque

Frame size Lock nut wrench size and torque Adjusting screw

wrench size

internal hex

130 17 mm 48 N•m [35 lbf•ft] 5 mm 8.8 cm³/rev [0.53 in³/rev]

180 19 mm 125 N•m [92 lbf•ft] 6 mm 12.5 cm³/rev [0.76 in³/rev]

Approximate displacement change

per revolution of adjusting screw

The servo cylinders are equipped with gage port X11 and X12. These ports provide the possibility to

connect the servo system of the pump to the system loop. This feature connects the high pressure lines

with the servo system over check valves and provides a smooth concrete flow.

Shaft torque and spline lubrication

The rated torque is a measure of tooth wear and is the torque level at which a normal spline life of 2x109

shaft revolutions can be expected. The rated torque presumes a regularly maintained minimum level of

lubrication via a moly-disulfide grease in order to reduce the coefficient of friction and to restrict the

presence of oxygen at the spline interface. It is also assumed that the mating spline has a minimum

hardness of Rc 55 and full spline depth. The rated torque is proportional to the minimum active spline

length.

Maximum torque ratings are based on torsional fatigue strength considering 100.000 full load reversing

cycles. However, a spline running in oil-flooded environment provides superior oxygen restriction in

addition to contaminant flushing. The rated torque of a flooded spline can increase to that of the

maximum published rating. A flooded spline would be indicative of a pump driven by a pump drive or

plugged into an auxiliary pad of a pump.

Maintaining a spline engagement at least equal to the Pitch Diameter will also maximize spline life. Spline

engagements of less than ¾ Pitch Diameter are subject to high contact stress and spline fretting.

Shaft torque for tapered shafts

The rated torque is based on the contact pressure between the shaft and hub surfaces with poor surface

contact areas. With an increased quality of the contact areas, the contact pressure between the shaft and

hub is increased and allows higher torque to be transmitted.

When a key is used for orientation of the hub on the shaft in conjunction with poor quality contact

surfaces, the transmitted torque will drop significantly. This is due to the key carrying the torque, which

limits the shaft torque carrying capability.

Maximum torque rating is based on an ideal contact area of 100 % and the retaining nut properly

torqued. This allows for the highest contact pressure between the shaft and the hub.

Shaft Availibility and Torque Ratings

Alignment between the mating spline's pitch diameters is another critical feature in determining the

operating life of a splined drive connection. Plug-in, or rigid spline drive installations can impose severe

radial loads on the shafts. The radial load is a function of the transmitted torque and shaft eccentricity.

Increased spline clearance will not totally alleviate this condition; but, increased spline clearance will

prevent mechanical interference due to misalignment or radial eccentricity between the pitch diameters

of the mating splines. Spline life can be maximized if an intermediate coupling is introduced between the

bearing supported splined shafts.

For multiple pump installations, consider load of the entire pump stack. All torques are additive. Include

charge pumps loads when calculating torques.

22 BC00000360en-US • Rev 0202 • February 2016

Page 23

First stageSecond stageThird

stage

for the first pumpM

e

1

second pump

for the M

e

2

next pumpfor the M

e

3

Input torqueM

e

P102 014E

Technical Information

Series 90 Concrete Pumps

Features and Options

Through torque diagram

Refer to the outline drawings for shaft dimensions.

Torque required by auxiliary pumps is additive. Ensure requirements don't exceed shaft torque ratings.

Shaft availability and maximum input torque - splined shafts

Option code Customer end Frame size/Maximum torque N•m [lbf•ft]

130 180

C8 27T 16/32 2693 [1986] 3125 [2304]

F1 13T 8/16 2303 [1700] 2303 [1700]

D5 W50x2x30x24x9g

-

3788 [2794]

Charge Pump

Charge flow is required on all Series 90 pumps applied in closed circuit installations. The charge pump

provides flow to make up internal leakage, maintain a positive pressure in the main circuit, provide flow

for cooling and filtration, replace any leakage losses from external valving or auxiliary systems, and to

provide flow and pressure for the control system.

Many factors influence the charge flow requirements. These factors include system pressure, pump

speed, pump swashplate angle, type of fluid, temperature, size of heat exchanger, length and size of

hydraulic lines, control response characteristics, auxiliary flow requirements, hydrostatic motor type, etc.

Unusual application conditions may require a more detailed review of charge pump sizing. Charge

pressure must be maintained at a specified level under all operating conditions to prevent damage to the

transmission. Danfoss recommends testing under actual operating conditions to verify this.

Charge pump sizing/selection

In most applications a general guideline is that the charge pump displacement should be at least 10% of

the total displacement of all components in the system. Unusual application conditions may require a

more detailed review of charge flow requirements. Refer to Selection of Drive line Components BLN-9885,

for a detailed procedure.

System features and conditions which may invalidate the 10% guideline include (but are not limited to):

Continuous operation at low input speeds (< 1500 min-1 (rpm))

•

High shock loading

•

Excessively long system lines (> 3m [9.8 ft])

•

Auxiliary flow requirements

•

Use of low speed high torque motors

•

High flushing flow

•

BC00000360en-US • Rev 0202 • February 2016 23

Page 24

80

70

60

50

40

30

20

10

3

6

9

12

15

21

18

500 1000 2000 3000 4000 4500

Speed min¯¹ (rpm)

US gal/min

l/min

17 cm • 1.03 in /Rev

14 cm • 0.86 in /Rev

34 cm • 2.07 in /Rev

3

3

26 cm • 1.60 in /Rev

3

3

3

20 cm • 1.2 in /Rev

3

3

3

3

3

0

0

47 cm • 2.9 in /Rev

3

3

90

24

65 cm • 3.9 in /Rev

3

3

P102 012E

Technical Information Series 90 Concrete Pumps

Features and Options

Contact your Danfoss representative for application assistance if your application includes any of these

conditions.

Available charge pump sizes and speed limits

Code Charge pump size

cm³ [in³]

F 26 [1.60] (only for 130cc) 3300

H 34 [2.07] 3100

J 47 [2.82] (only for 180cc) 2600

Charge pump flow and power curves

Charge pressure: 20 bar [350 psi]

Case drain: 80 °C (8.2 cSt) 180 °F (53 SUS)

Reservoir temperature: 70 °C (11 cSt) 160 °F (63 SUS)

Charge pump output flow

Rated speed

min-1 (rpm)

24 BC00000360en-US • Rev 0202 • February 2016

Page 25

3

2

1

6

500 1000 2000 3000

4000

4500

HP

kW

34 cm •

2.07 in /rev

26 cm

•

1.60 in /rev

20 cm

•

1.2 in /rev

17 cm

•

1.03 in /rev

14 cm

•

0.86 in /rev

11 cm

•

0.69 in /rev

5

4

3

2

1

4

0

0

3

3

3

3

3

3

Speed min (rpm)

-1

47 cm

•

2.9 in /rev

3

65 cm

•

3.9 in /rev

3

7

5

P102 013E

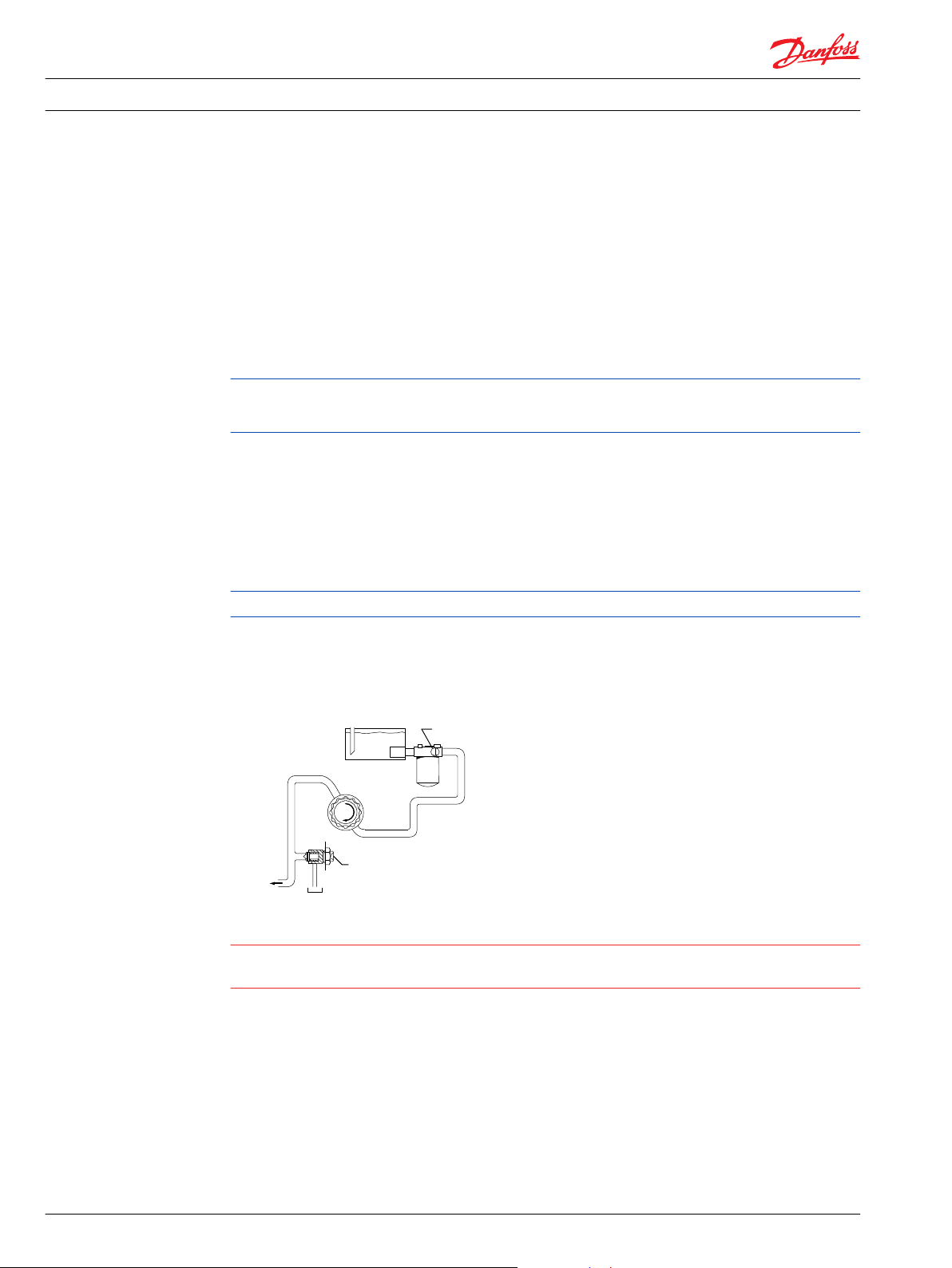

100

[26.4]

delta p - bar [psi]

0

0

Flow - l/min [gal/min]

P108687

Set Minimum

Set 12 bar/15 l/min

Set 22 bar/15 l/min

Set 30 bar/15 l/min

Set 37 bar/15 l/min

10

[145]

20

[290]

30

[435]

40

[580]

50

[725]

60

[870]

70

[1015]

200

[52.8]

300

[79.3]

P108688

A

B

T

M12

Technical Information

Features and Options

Series 90 Concrete Pumps

Charge pump power requirements

Loop Flushing Valve

For cooling and cleaning the fluid of the concrete pump system a loop flushing valve is available. This

valve is mounted directly on to the pump. To order a concrete pump with a loop flushing valve contact

your Danfoss representative.

Flushing characteristic (80°C) Manifold block

Loop Flushing Valve Schematic

BC00000360en-US • Rev 0202 • February 2016 25

Page 26

Technical Information Series 90 Concrete Pumps

Features and Options

Loop Flushing Valve Setting Capability

Loop flushing factory setting: 15 L/min to 22bar

The flushing valve is adjustable within the shown range.

26 BC00000360en-US • Rev 0202 • February 2016

Page 27

P108959

X12

L1

M4

X1

X2

M2

X9

M5

X11

X10

B

S

A

M12

X8

M1

M10

L2

M3

X3/M11

N

X8

X9

T

Charge pressure

relief valve

Displacement limiter screw

Displacement limiter seal nut

188 ± 1.2

132 ± 1.2

15.05 ± 0.5

25 ± 0.5

15.05 ± 0.5

91 ± 0.8

121.17 ± 1.2

176.6 ± 1.2

299.2 ± 1.2

128 ± 1.2

317 ± 1.2

300.2 ± 1.2

97 ± 0.8

48.8 ± 0.8

77 ± 0.15

117.6 ± 0.8

128 ± 1.2

95 ± 1.2

4 ± 0.5

300.2 ± 1.2

299.7 ± 1.2

166.8 ± 1.2

300.2 ± 1.2

290.9 ± 1.2

217.9 ± 1.2

209.3 ± 1.2

95 ± 1.2

299.7 ± 1.2

294.7 ± 1.2

209.3 ± 1.2

145.6 ± 1.2

102.1 ± 0.8

117.6 ± 0.8

86.6 ± 0.8

86.8 ± 0.8

5.2 ± 0.5

86.6 ± 0.8

77 ± 0.15

Multi-Function valve

system pressure B

Multi-Function valve

system pressure A

Technical Information Series 90 Concrete Pumps

Installation Drawings

Frame Size 130

Ports and port dimensions

Further dimensions can be found in Series 90 Axial Piston Pumps Technical Information 520L0603

BC00000360en-US • Rev 0202 • February 2016 27

Page 28

Technical Information Series 90 Concrete Pumps

Installation Drawings

Port description

Port Description Port Size UNF

A/B System Ports -

S Charge Inlet ISO 11926-1, 1-1/16-12

M2 System B Gauge ISO 11926-1, 9/16-18

M1 System A Gauge ISO 11926-1, 9/16-18

X9 System B Gauge ISO 11926-1, ¾-16/ISO 11926-1, 7/8-14

X8 System A Gauge ISO 11926-1, ¾-16/ISO 11926-1, 7/8-14

L1/L2 Case Drain ISO 11926-1, 1-5/16-12

T Case Drain ISO 11926-1, 7/8-14

M4/M5 Servo Gauge ISO 11926-1, 9/16-18

M3 Charge Pressure Gauge, accumulator ISO 11926-1, 9/16-18

X3/M11 Charge Gauge ISO 11926-1, 9/16-18

X1/X2 Control Signal Pressure Inlet ISO 11926-1, 9/16-18

X10 High Pressure Signal Output ISO 11926-1, 9/16-18

X11/X12 External Control Inlet DIN 3852-1, M22 x 1,5

M10 Charge Inlet Gauge ISO 11926-1, 9/16-18

M12 Charge Flush Gauge ISO 11926-1, ¾-16

N Case gauge ISO 11926-1, 9/16-18

28 BC00000360en-US • Rev 0202 • February 2016

Page 29

P108960

X12

L1

M4

X1

X2

M2

X9

M5

X11

X10

B

S

A

M12

X8

M1

M10

L2

M3

X3/M11

N

X8

X9

T

Charge pressure

relief valve

Displacement limiter screw

Displacement limiter seal nut

215 ± 1.2

159 ± 1.2

15.05 ± 0.5

25 ± 0.5

15.05 ± 0.5

92 ± 0.8

130.8 ± 0.1

211.3 ± 1.2

326.7 ± 1.2

7 ± 0.5

155 ± 1.2

337.9 ± 1.2

352.9 ± 1.2

120 ± 1.2

56 ± 0.8

93 ± 0.15

144.7 ± 1.2

155 ± 1.2

123 ± 1.2

25 ± 0.5

335.9 ± 1.2

326.9 ± 1.2

185.6 ± 1.2

93 ± 0.15

326.9 ± 1.2

321.9 ± 1.2

254.6 ± 1.2

228 ± 1.2

123 ± 1.2

35 ± 0.8

326.9 ± 1.2

315.9 ± 1.2

228 ± 1.2

152.1 ± 1.2

108.6 ± 0.8

144.7 ± 1.2

111 ± 0.8

111 ± 0.8

13 ± 0.5 79 ± 0.8

Multi-Function valve

system pressure B

Multi-Function valve

system pressure A

Technical Information Series 90 Concrete Pumps

Installation Drawings

Frame Size 180

Ports and port dimensions

Further dimensions can be found in Series 90 Axial Piston Pumps Technical Information 520L0603

BC00000360en-US • Rev 0202 • February 2016 29

Page 30

Technical Information Series 90 Concrete Pumps

Installation Drawings

Port description

Port Description Port size Metric Port size UNF

A/B System Ports - -

S Charge Pump Inlet M48 ISO 11926-1, 1-1/16-12

M2 System B Gauge M22 ISO 11926-1, 9/16-18

M1 System A Gauge M22 ISO 11926-1, 9/16-18

X9 System B Gauge M22 ISO 11926-1, ¾-16/DIN 3852-1, M22 x 1,5

X8 System A Gauge M22 ISO 11926-1, ¾-16/DIN 3852-1, M22 x 1,5

L1/L2 Case Drain M42 ISO 11926-1, 1 5/8-12

T Case Drain M22 ISO 11926-1, 7/8-14

M4/M5 Servo Gauge M14 ISO 11926-1, 9/16-18

M3 Charge Pressure Gauge M22 ISO 11926-1, 9/16-18

X3/M11 Charge Gauge M14 ISO 11926-1, 9/16-18

X1/X2 Control Signal Pressure Inlet M14 ISO 11926-1, 9/16-18

X10 High Pressure Signal Output M14 ISO 11926-1, 9/16-18

X11/X12 External Control Inlet M22 DIN 3852-1, M22 x 1,5

M10 Charge Inlet Gauge M14 ISO 11926-1, 9/16-18

M12 Charge Flush Gauge M14 ISO 11926-1, ¾-16

N Case Gauge M14 ISO 11926-1, 9/16-18

30 BC00000360en-US • Rev 0202 • February 2016

Page 31

Technical Information Series 90 Concrete Pumps

BC00000360en-US • Rev 0202 • February 2016 31

Page 32

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

BC00000360en-US • Rev 0202 • February 2016 www.danfoss.com

Local address:

©

Danfoss A/S, 2016

Loading...

Loading...