Page 1

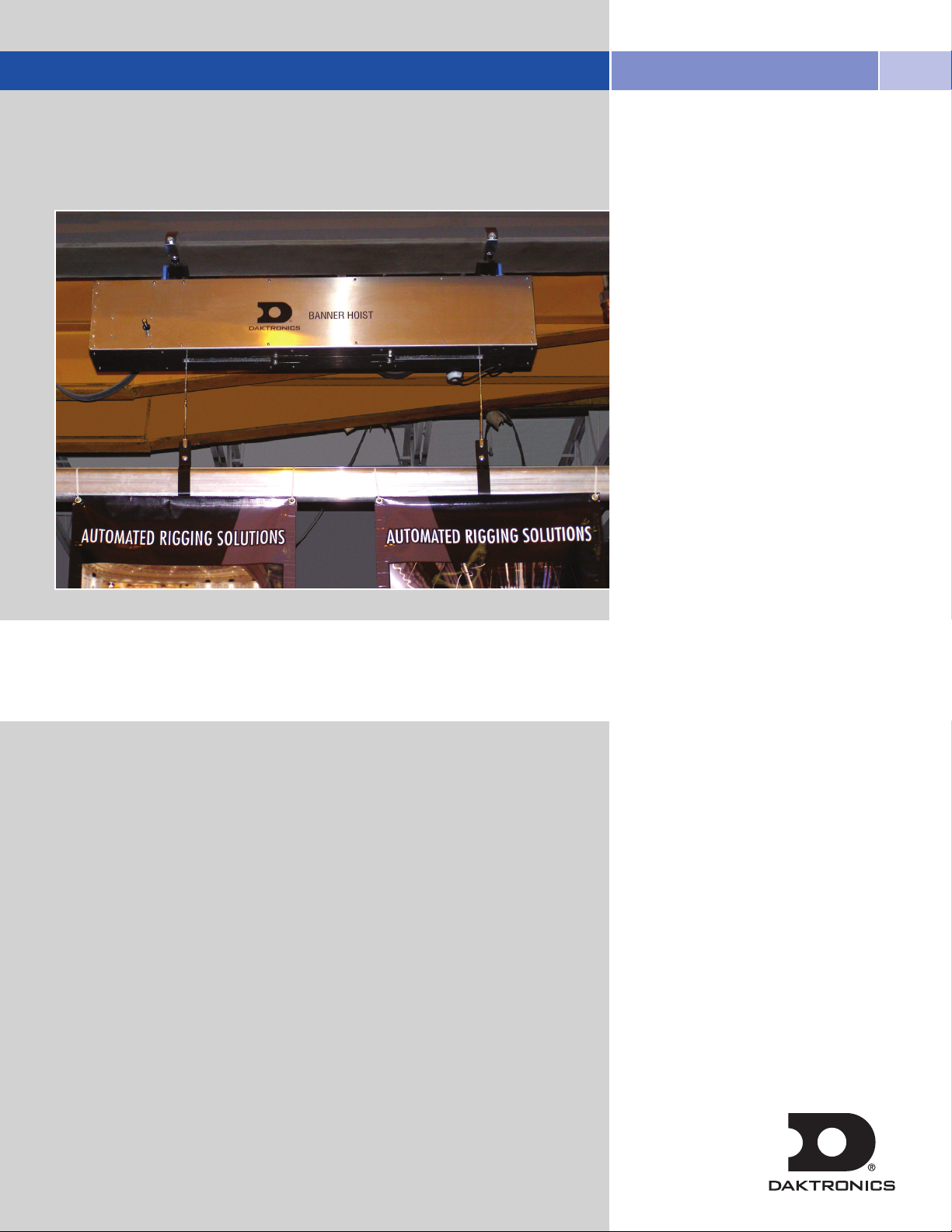

DBH-150

BANNER HOIST OPERATIONS & MAINTENANCE MANUAL

Page 2

Page 3

BANNER HOIST OPERATIONS & MAINTENANCE MANUAL

Daktronics Automated Rigging System

Manufacturer’s contact info

7200 Rawson Road

Victor, New York 14564 USA

tel 866-486-7835 585-924-5000

fax 585-924-0545

Daktronics Australia Pty Ltd

Unit 216, 354 Eastern Valley Way

Chatswood, NSW 2067,

ABN 53 131 659 455

tel +61 (2) 9417 3812

fax +61 (2) 9417 3868

email sales@daktronics.com

web site www.daktronics.com/rigging

DBH-150 Banner Hoist

Operations & Maintenance Manual

Rev 0 DD1979034 3 June 2011

Page 4

TABLE OF CONTENTS

01 SAFETY INFORMATION 1

02 GENERAL INFORMATION 3

03 GENERAL OPERATION/CONFIGURATION 5

Banner Hoist Remote

Powering On/Off 5

Raising/Lowering 5

Battery Maintenance 5

RF Tuning/Maintenance 6

04 MAINTENANCE/INSPECTION 7

Adjust & Inspect Banner Hoist

DBH-150 Limit Switch Operation & Adjustment 7

Initial Lower Limit Adjustment 8

Initial Upper Limit Adjustment 8

Mechanical Inspection 9

Electrical Inspection 10

Visual Inspection 10

05 WARRANTY INFORMATION 11

i

Page 5

01 SAFETY INFORMATION

Warnings, Cautions, and Notes

All Warning notes contained in this manual indicate information that may endanger personnel.

WARNING

The Daktronics rigging system is designed to raise and lower equipment under the rated hoist capacity ONLY.

Only trained and authorized personnel should be permitted to operate the Daktronics system. The unauthorized use,

alteration, or use for purposes other than those for which it was designed may cause injury to persons, damage to

the equipment, or create conditions which could lead to fatalities. All proper safety considerations must be observed.

While operating the Daktronics rigging system, a spotter must be used in conjunction with the user at all times. The

spotter must have a clear view of all moving elements while maintaining contact with the user. If an unsafe situation occurs, the

spotter must immediately signal the user to halt all movements until the environment is cleared of any person or obstruction.

All installation and maintenance involving the Daktronics drive unit itself or the main electrical control cabinets

will require trained personnel. Simple daily maintenance activities of the workstation may be carried out by the

operators, and in most cases will be all that is needed once installed.

Electrical Safety—General Warning

WARNING

Before working on any of the Daktronics hoists, the main electrical disconnect must be

turned off and locked out according to U.S.A. OSHA regulations 29 CFR 1910.147 or

Australian regulations AS 1418.1 Section 8.10.3.4.

The voltages used in the motor drive and master control panels can cause severe electrical

shock and/or burns. Extreme care is necessary at all times when working with the motor

drives. Only authorized personnel should carry out any installation, commissioning, or

maintenance of the electrical systems. All drive systems have been tuned at the factory

and will not require any additional alteration or adjustment by the owner’s personnel

unless specifically authorized by a Daktronics representative.

SAFETY INFORMATION

1

Page 6

2

Page 7

02 GENERAL INFORMATION

WARNING

The Daktronics hoist system is an automated rigging system, meaning that the load is not counter-weighted. Each

hoist can lift loads only up to the design capacity. Overloading will result in electrical overload protection shut

down of the hoist and possible damage to rigging components.

WARNING

The Daktronics Banner Hoists are not designed to raise and lower people.

These hoists should NEVER be used for this purpose.

The DBH-150 unit must only be used with a maximum load equal to the capacity stated for the

model below. Overloading the system may result in serious injury or an inoperable system

If it is necessary to operate a hoist from a location where the operator's view of the moving

load is obstructed, a second person must be used to observe the load and communicate to

the operator.

Dimensions of DBH-150 Unit

• Averageweightofself-containedhoistmoduleis88lb(39.9kg).

• Height=11.9"(303mm)

• Length=55.1"(1400mm)

•Width=9.9"(251.5mm)

DBH-150 Unit Overview

The Daktronics Banner Hoist is a chain-driven self-contained hoist platform that can be powered using single phase

120V 60Hz or 240V 50Hz electricity. The electricity powers the chain motor which rotates the drums, as well as the

power supply that in turn powers the RF receiver built into the hoist with 24 V DC power. It also controls the operation

of the chain motor and brakes.

The load is raised and lowered by the two available lift lines, utilizing “Zero-Fleet Angle” design architecture to ensure

that the cabling does not wind up on top of itself, protecting the cable and drum from wear.

Control over the unit is performed by utilizing the hand-held RF remote within line of sight of the hoist. It allows the

user to power on/off the unit, raise/lower the lift lines, and remotely program the RF remote to correspond to multiple

receivers, allowing one to control multiple banner hoists at once with one remote simultaneously. The RF remote

requres 2 AA alkaline batteries in order to operate.

GENERAL INFORMATION

3

Page 8

RF Controller

Limit Switch Nylon Drum

Motor Mounting ClipCable GuideElectrical Panel

Drum Chain Drive

Secondary Electric Brake

Drum Cable Keeper

Electrical Panel

Cable Guide Chain Drive

Specifications of DBH-150 Unit

Speed 0-20 ft/min (0.1 m/s)

Gross Lift Capacity 150 lb (68.03 kg)

Maximum Travel Standard travel 60' (18.2 m)

Number of Lift Lines 2 available

Electrical/HP Single Phase, 120V or 240V - 60 or 50HZ

Braking Primary & Secondary brakes are electromechanical type, rated at a minimum 150%

of full load (225 lb / 120.05 kg)

Control Wireless hand-held remote control

Mounting Standard units to be underhung horizontally.

Discuss special mounting requirements with Daktronics.

Cable&Drum 3/32"SteelWireRope

Covers Lightweight aluminum covers are standard for all unit

s

Product dimensions: Length: 55.1" (1400 mm)

Height: 11.9" (303 mm)

Width: 9.9" (251.5 mm)

Crated dimensions: Length: 67" (1702 mm)

Height: 22" (559 mm)

Width: 18" (457 mm)

Weight: 88 lb (39.9 kg)

Component Diagram

4

Page 9

03 GENERAL OPERATION/CONFIGURATION

BANNER HOIST REMOTE

The Banner Hoist System operates using a wireless remote

control that communicates with the hoist using radio wave

RF transmission. When operating the Banner Hoist system,

always have a clear line of sight to the hoist to minimize RF

interference and to promote safe operational use.

Powering On/Off

To power up the Banner Hoist, simply press the green

START button (Figure 1). To power it down, press the

red STOP button.

Raising/Lowering

To raise the Banner Hoist, simply press the UP button

and press the DOWN button.

Battery Maintenance

To replace the two AA alkaline batteries remove the

screw on the plastic back plate using a flat-head screw

Figure 1: Banner Hoist Remote front

driver (Figure 2).

Replace the batteries and screw the back plate into

proper position.

Figure 2: Banner Hoist Remote back

GENERAL OPERATION/CONFIGURATION

5

Page 10

RF Tuning/Maintenance

There are two ways to tune the remote and the hoist

assembly so that they synchronize. The first method is

through reprogramming the remote using the remote

interface plug (Figure 3) in conjunction with the

Copy Module #700PROC pendant (Figure 4) next

to the batteries. The second and less time consuming

method is through using the remote itself next to the

antenna receiver to program the receiver to respond

to the remote’s transmitting signal.

A. To program the receiver to respond to a

specific remote, first ensure the remote and

receiver are of the same model, and

operate on the same frequency band by

opening up the remote and receiver and

ensuring their frequency crystals match.

B. Place the remote as close as possible to the

receiver to avoid unnecessary interference.

C. Turn off the receiver’s power supply, then turn

it back on. Because the receiver is fed power

through the hoist itself, turn the hoist

assembly on and off.

D. Within 4 minutes of turning the Daktronics

Banner Hoist back on, press and hold the

STOP button. Continue holding and then press

and hold the DOWN button. While holding

the previous two buttons press the UP button

4 times, and release all the buttons when the

red LED light on the remote flashes. If done

correctly the remote and receiver on the hoist

should be synchronized.

E. It is possible to program multiple hoist receivers

to respond to one remote I.D. through this

programming method.

F. If the remote programming data has become

corrupt or access to the hoist receiver for

optimal remote synchronization is restricted, use

of the Copy Module #700PROC can allows

copying the programming data of one remote

into another remote, allowing that remote to

work with the equipment the source remote

is programmed to work with. (Copy Module

#700PROC sold optionally.)

G. If problems continue with the remote and/or the

receiver on the hoist, consult with Daktronics,

see manufacturing contact on the inside cover

of this manual.

Figure 3: Banner Hoist Remote Interface Plug

Figure 4: Copy Module #700PROC

6

Page 11

04 MAINTENANCE/INSPECTION

Figure 5: Rotary Limit Switch

Lower Overtravel

Limit Switch

Lower Normal

Limit Switch

Upper Normal

Limit Switch

Upper Overtravel

Limit Switch

ADJUST & INSPECT BANNER HOIST

After installation under normal circumstances, users

should never have to physically move the hoist assembly

or open it up for maintenance. It may become necessary

though to open up the side casing and check the cables

on the drum should they begin to run over themselves.

If the upper and lower limits of travel need changing,

it is necessary to open the smaller side panel near the

receiver antenna to gain access to the rotary limit switch.

DBH-150 Limit Switch Operation & Adjustment

The limit switch assembly is comprised of a fully enclosed

4-switch rotary mechanism attached to the hoist drum

shaft with a flexible coupling. As the drum shaft turns,

the switch mechanism rotates cams in one direction or

the other to actuate snap action switches by depressing

roller levers attached to each switch.

The upper and lower limits, both normal and over-travel,

are set from the factory for the maximum travel of the

hoist. After installation, it may be necessary to reset

these limits based on the height of the installation and

the desired travel distance. The limit switch assembly is

shown in Figure 5 and is located under the left most

front panel of the hoist where the wireless receiver

antenna protrudes. Remove this panel to gain access to

the limit switch assembly. It will be necessary to remove

the yellow plastic cover to make the switch adjustments.

As shown on Figure 6, the Rotary Limit Switch is

comprised of a Lower Over-travel Limit Switch, a Lower

Normal Limit Switch, an Upper Normal Limit Switch,

and an Upper Over-travel Limit Switch. The limit switches

are activated when the white cam wheel rotates into the

roller lever on the limit switch.

Figure 6: Rotary Limit Switch without cover

MAINTENANCE/INSPECTION

7

Page 12

Initial Lower Limit Adjustment

To initially adjust the lower limits, start by lowering the hoist

to the desired low limit height. Adjust the lower normal cam

wheel by turning the yellow set screw associated with the lower

normal limit switch (Figure 7) counterclockwise until it contacts

the back side of the roller lever on the switch, and actuates the

switch. Operate the hoist up and down into the limit to test.

Re-adjust the switch as necessary by rotating the yellow set screw

counterclockwise to raise the limit or clockwise to lower the limit.

Turning the adjustment screw ¼ turn will change the limit by

approximately9"(230mm).

Continue by setting the lower over-travel limit. Operate the hoist

until it actuates the lower normal limit and stops. Adjust the

lower over-travel cam wheel by rotating the yellow set screw

counterclockwise until it actuates the lower over-travel switch.

With the hoist power on and the hoist enabled from the remote

control, the main contactor (LC1) will de-energize. Once the

switch is actuated turn the yellow set screw ¼ turn clockwise.

The switch will deactivate and the main contactor will energize.

Thiswillgiveapproximately6"(150mm)ofover-traveldistance

beyond the normal lower limit.

Lower Overtravel

Limit Switch

Lower Normal

Limit Switch

Upper Normal

Limit Switch

Upper Overtravel

Limit Switch

Initial Upper Limit Adjustment

To initially adjust the upper limits, start by raising the hoist to the

desired high limit height. Adjust the upper normal cam wheel by

turning the yellow set screw associated with the upper normal

limit switch (Figure 7) clockwise until it contacts the front side of

the roller lever on the switch, and actuates the switch. Operate

the hoist up and down into the limit to test. Re-adjust the switch

as necessary by rotating the yellow set screw counterclockwise

to raise the limit or clockwise to lower the limit. Turning the

adjustment screw ¼ turn will change the limit by approximately

9"(230mm).Figure 8 illustrates the labels corresponding to

each screw.

Continue by setting the upper over-travel limit. Operate the hoist

until it actuates the upper normal limit and stops. Adjust the

upper over-travel cam wheel by rotating the yellow set screw

clockwise until it actuates the lower over-travel switch. With the

hoist power on and the hoist enabled from the remote control,

the main contactor (LC1) will de-energize. Once the switch is

actuated, turn the yellow set screw ¼ turn counterclockwise. The

switch should deactivate and the main contactor will energize.

Thiswillgiveapproximately6"(150mm)ofover-traveldistance

beyond the normal upper limit.

Once the limit switches are set, under normal operating

conditions they should not have to be reset. If the hoist is moved,

or the high or low limits do need to be reset for any reason, do

so by using the procedures above. When readjusting the limits,

make certain to reset the over-travel limits as well.

Figure 7: Adjustment Screw location

The upper cams will activate the

switches from the near side and the

lower cams will activate the switches

from the far side as shown.

LIMIT SWITCH INFORMATION TABLE

Limit Switch

Model

FRS-100 90 9 in. 228.6 mm

8

Set Screw

Turn Degree

Limit Change

Distance(")

Limit Change

Distance (mm)

Figure 8: Rotary Limit Switch Wire labels

Page 13

Figure 10:

Drive Chain

Figure 13: Cable Drum with Plastic Feed Guide

Figure 14: Cable Chain Clip

Figure 11:

Cable Guide

Chain A

Figure 12:

Cable Guide

Chain B

MECHANICAL INSPECTION

Inspection Schedule

Mechanical and electrical inspections shall be completed

in accordance with local regulations or every 5 years,

whichever comes sooner. Inspections shall be completed

by a competent person who is certified for field service.

All repairs shall also be inspected nd approved by a

competent person who is certified for field service prior

to the hoist being returned to service.

After usage over long periods of time, certain parts of

the Banner Hoist Assembly may become more audible

as certain components require periodical lubrication.

Examples of these parts of the assembly that could

end up requiring such inspection and maintenance

are shown on the illustrations to the left. Take into

consideration the environment of where the Banner Hoist

assembly will be installed to reduce the likelihood of

wear. On chain drives and acme parts, white lithium

grease should be used to lubricate (refer to

Figures 10-12).

Always ensure that when operating and performing

maintenance/inspection on the Banner Hoist system

that there is at least enough weight on the cables to

keep them taut. If the cables are allowed to become

slackened, the cable may become unwound from

the drum or for the cable to cross-over itself. Both

of these conditions present a safety hazard and will

depreciate the life of both the cable and the drum.

If a situation occurs where the cable has run over

the drum, simply lower the hoist to its lower limit and

pull the cabling outward, ensuring that the cabling

left on the drum is in line. Then with weight applied

raise the hoist to correctly rewind the cabling. Also

ensure that the cable is being correctly guided

through the Plastic Feed Guide (Figures 13,14)

while performing the rewinding. It may be necessary

to remove the front panel of the hoist to ensure

the cable is wound correctly on the drum. Should

additional problems or questions occur, do not

hesitate to call Daktronics for additional support.

Positioning of Drum Cable Keepers

Verify that the drum cable keepers are positioned

correctly as shown in Figure 15. The assemblies should

run parallel with the drum and contact the cables to

keep them in the drum grooves. If the plastic keeper part

is out of position, it should be relocated as shown. The

plastic keeper part is spring applied and should be free

to come off the drum. Lift the ends off the drum to ensure

the springs and resulting assembly are not binding.

Figure 15: Drum Cable keepers

MAINTENANCE/INSPECTION

9

Page 14

ELECTRICAL INSPECTION

Under normal conditions, the Daktronics Banner Hoist should

provide years of maintenance free service. Daktronics recommends

periodic electrical inspections for corrosion and wear, particularly

in high temperature and/or high humidity environments. Should

issues occur or if the hoist is exposed to water or other fluids,

immediately disconnect incoming power and contact Daktronics for

technical assistance.

Figure 16 shows the proper wiring for the Banner Hoist power

panel. If electrical issues are observed, this is where technical

assistance will focus.

Figure 17 displays the Banner Hoist RF Receiver and the

schematic of the wiring in the power panel in Figure 16 which

will be used as a reference when receiving technical assistance.

VISUAL INSPECTION

A quick visual inspection can provide valuable information about

how the hoist is operating and whether further maintenance is

required. Periodical visual inspections should be completed in

between scheduled maintenance inspections.

When visually inspecting the hoist, look for components that

have become loose or possible failures such as cracking in the

metal framework or other components. In addition, check for the

following:

· Cables should be tight around the drum, in the correct grooves

and not overlapping

· Cables should follow the correct path from the drum through the

cable guide assembly

· Chains are fitted properly around the sprockets

· Adequate lubrication on the chains and acme screw parts

· Intact wire terminations

· No frayed wires

· No visible corrosion or wear on or around the electrical

components

Figure 16: Banner Hoist Power Panel

10

Figure 17: Banner Hoist RF Receiver

Page 15

05 WARRANTY

This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the

Equipment. By accepting delivery of the Equipment, Purchaser agrees to be bound by and accept these terms and conditions.

All defined terms within the Warranty shall have the same meaning and definition as provided elsewhere in the Agreement.

DAKTRONICS WILL ONLY BE OBLIGATED TO HONOR THE WARRANTY SET FORTH IN THESE TERMS AND CONDITIONS

UPON RECEIPT OF FULL PAYMENT FOR THE EQUIPMENT.

1. Warranty Coverage

A. Daktronics warrants to the original end-user that the Equipment will be free from Defects (as defined below) in materials and

workmanship for a period of one (1) year (the “Warranty Period”). The warranty period shall commence on the earlier of: (i)

four weeks from the date that the equipment leaves Daktronics’ facility; or (ii) Substantial Completion as defined herein. The

warranty period shall expire on the first anniversary of the commencement date.

“Substantial Completion” means the operational availability of the Equipment to the Purchaser in accordance with the

Equipment’s specifications, without regard to punch-list items, or other non-substantial items which do not affect the operation of

the Equipment.

B. Daktronics’ obligation under this Warranty is limited to, at Daktronics’ option, replacing or repairing, any Equipment or part

thereof that is found by Daktronics not to conform to the Equipment’s specifications. Unless otherwise directed by Daktronics,

any defective part or component shall be returned to Daktronics for repair or replacement. Daktronics may, at its option,

provide on-site warranty service. Daktronics shall have a reasonable period of time to make such replacements or repairs and

all labor associated therewith shall be performed during regular working hours. Regular working hours are Monday through

Friday between 8:00 a.m. and 5:00 p.m. at the location where labor is performed, excluding any holidays observed by either

Purchaser or Daktronics.

C. Daktronics shall pay ground transportation charges for the return of any defective component of the Equipment. If returned

Equipment is repaired or replaced under the terms of this warranty, Daktronics will prepay ground transportation charges back

to Purchaser; otherwise, Purchaser shall pay transportation charges to return the Equipment back to the Purchaser. All returns

must be pre-approved by Daktronics before shipment. Daktronics shall not be obligated to pay freight for any unapproved

return. Purchaser shall pay any upgraded or expedited transportation charges.

D. Any replacement parts or Equipment will be new or serviceably used, comparable in function and performance to the

original part or Equipment, and warranted for the remainder of the Warranty Period. Purchasing additional parts or Equipment

from the Seller does not extend this Warranty Period.

E. Defects shall be defined as follows. With regard to the Equipment (excepting LEDs), a “Defect” shall refer to a material

variance from the design specifications that prohibit the Equipment from operating for its intended use. With respect to LEDs,

“Defects” are defined as LED pixels that cease to emit light. The limited warranty provided by Daktronics does not impose any

duty or liability upon Daktronics for partial LED pixel degradation. Nor does the limited warranty provide for the replacement

or installation of communication methods including but not limited to, wire, fiber optic cable, conduit, trenching, or for the

purpose of overcoming local site interference radio equipment substitutions.

WARRANTY

11

Page 16

THIS LIMITED WARRANTY IS THE ONLY WARRANTY APPLICABLE TO THE EQUIPMENT AND REPLACES ALL

OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

SPECIFICALLY, EXCEPT AS PROVIDED HEREIN, THE SELLER UNDERTAKES NO RESPONSIBILITY FOR THE QUALITY

OF THE EQUIPMENT OR THAT THE EQUIPMENT WILL BE FIT FOR ANY PARTICULAR PURPOSE FOR WHICH

PURCHASER MAY BE BUYING THE EQUIPMENT. ANY IMPLIED WARRANTY IS LIMITED IN DURATION TO THE

WARRANTY PERIOD. NO ORAL OR WRITTEN INFORMATION, OR ADVICE GIVEN BY THE COMPANY, ITS

AGENTS OR EMPLOYEES, SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS

LIMITED WARRANTY.

THIS LIMITED WARRANTY IS NOT TRANSFERABLE.

2. Exclusion from Warranty Coverage

The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for:

A Any damage occurring, at any time, during shipment of Equipment unless otherwise provided for in the

Agreement. When returning Equipment to Daktronics for repair or replacement, Purchaser assumes all risk of loss or

damage, and agrees to use any shipping containers that might be provided by Daktronics and to ship the Equipment

in the manner prescribed by Daktronics;

B. Any damage caused by the unauthorized adjustment, repair or service of the Equipment by anyone other than

personnel of Daktronics or its authorized repair agents;

C. Damage caused by the failure to provide a continuously suitable environment, including, but not limited to: (i)

neglect or misuse, (ii) a failure or sudden surge of electrical power, (iii) improper air conditioning or humidity control,

or (iv) any other cause other than ordinary use;

D. Damage caused by fire, flood, earthquake, water, wind, lightning or other natural disaster, strike, inability to

obtain materials or utilities, war, terrorism, civil disturbance or any other cause beyond Daktronics’ reasonable

control;

E. Failure to adjust, repair or replace any item of Equipment if it would be impractical for Daktronics personnel to

do so because of connection of the Equipment by mechanical or electrical means to another device not supplied

by Daktronics, or the existence of general environmental conditions at the site that pose a danger to Daktronics

personnel;

F. Any statements made about the product by salesmen, dealers, distributors or agents, unless such statements are in

a written document signed by an officer of Daktronics. Such statements as are not included in a signed writing do not

constitute warranties, shall not be relied upon by Purchaser and are not part of the contract of sale;

G. Any damage arising from the use of Daktronics products in any application other than the commercial and

industrial applications for which they are intended, unless, upon request, such use is specifically approved in writing

by Daktronics; or

H. Any performance of preventive maintenance.

3. Limitation of Liability

Daktronics shall be under no obligation to furnish continued service under this Warranty if alterations are made to the

Equipment without the prior written approval of Daktronics.

It is specifically agreed that the price of the Equipment is based upon the following limitation of liability. In no event

shall Daktronics (including its subsidiaries, affiliates, officers, directors, employees, or agents) be liable for any

12

Page 17

special, consequential, incidental or exemplary damages arising out of or in any way connected with the Equipment or otherwise,

including but not limited to damages for lost profits, cost of substitute or replacement equipment, down time, lost data, injury to

property or any damages or sums paid by Purchaser to third parties, even if Daktronics has been advised of the possibility of such

damages. The foregoing limitation of liability shall apply whether any claim is based upon principles of contract, tort or statutory

duty, principles of indemnity or contribution, or otherwise.

In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising

out of or in connection with this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by

the Purchaser. The Purchaser’s remedy in any dispute under this Warranty shall be ultimately limited to the Purchase Price of the

Equipment to the extent the Purchase Price has been paid.

4. Assignment of Rights

The Warranty contained herein extends only to the original end-user (which may be the Purchaser) of the Equipment and no

attempt to extend the Warranty to any subsequent user-transferee of the Equipment shall be valid or enforceable without the

express written consent of Daktronics.

5. Dispute Resolution

Any dispute between the parties will be resolved exclusively and finally by arbitration administered by the American Arbitration

Association (“AAA”) and conducted under its rules, except as otherwise provided below. The arbitration will be conducted

before a single arbitrator. The arbitration shall be held in Brookings, South Dakota. Any decision rendered in such arbitration

proceedings will be final and binding on each of the parties, and judgment may be entered thereon in any court of competent

jurisdiction. This arbitration agreement is made pursuant to a transaction involving interstate commerce, and shall be governed by

the Federal Arbitration Act.

6. Governing Law

The rights and obligations of the parties under this warranty shall not be governed by the provisions of the United Nations

Convention on Contracts for the International Sales of Goods of 1980. Both parties consent to the application of the laws of the

State of South Dakota to govern, interpret, and enforce all of Purchaser and Daktronics rights, duties, and obligations arising from,

or relating in any manner to, the subject matter of this Warranty, without regard to conflict of law principles.

7. Availability of Extended Service Agreement

For Purchaser’s protection, in addition to that afforded by the warranties set forth herein, Purchaser may purchase extended

warranty services to cover the Equipment. The Extended Service Agreement, available from Daktronics, provides for electronic

parts repair and/or on-site labor for an extended period from the date of expiration of this warranty. Alternatively, an Extended

Service Agreement may be purchased in conjunction with this warranty for extended additional services. For further information,

contact Daktronics Customer Support at 1-800-DAKTRONICS (1-800-325-8766).

WARRANTY

13

Page 18

Page 19

Daktronics

7200 Rawson Road Victor, New York 14564 USA

tel 866-486-7835 585-924-5000 fax 585-924-0545

www.daktronics.com/rigging email sales@daktronics.com

Copyright © 2011 Daktronics DD11979034 REV 0 3 June 2011

Loading...

Loading...