Page 1

Auto Racing Display

Model CH-1024H

Installation, Maintenance &

Troubleshooting Manual

ED-5891

ED-5891

Project #1081

Rev. 8 – 16 November, 1999

Copyright © 1999 Daktronics, Inc.

All rights reserved. While every precaution

has been taken in the preparation of this

manual, the publisher assumes no

responsibility for errors or omissions. No part

of this book covered by the copyrights hereon

may be reproduced or copied in any form or

by any means - graphic, electronic, or

mechanical, including photocopying, taping,

or information storage and retrieval systems without written permission of the publisher.

DAKTRONICS, INC.

Communication Solutions

Through Technology

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4400 or (800) 843-9879 Fax 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 2

Page 3

Table of Contents

Section 1: Introduction..................................................................................................1-1

1.1 How To Use This Manual ........................................................................................1-1

1.2 Display Overview.....................................................................................................1-1

Section 2: Installation..................................................................................................2-1

2.1 General System.........................................................................................................2-1

2.2 Beam And Footing Selection....................................................................................2-2

2.3 Display Mounting.....................................................................................................2-2

2.4 Electrical Installation................................................................................................2-3

2.4.1 Control Signal Cable....................................................................................2-3

2.4.2 Power Wiring...............................................................................................2-3

Section 3: Maintenance & Troubleshooting..............................................................3-1

3.1 Lamp Replacement...................................................................................................3-1

3.2 Lamp Drivers............................................................................................................3-1

3.3 Digit Segmentation...................................................................................................3-2

3.4 Schematic .................................................................................................................3-2

3.5 Troubleshooting........................................................................................................3-2

3.6 Replacement Parts....................................................................................................3-3

3.7 Daktronics Exchange/Repair & Return Programs....................................................3-3

Table of Contents i

Page 4

Page 5

Section 1: Introduction

1.1 How to Use This Manual

This manual is designed to explain installation and maintenance of the CHTS-1024H display

system. Details for display maintenance are also given. Setup of other control equipment or

operation of the CHTS-300 timing console are not covered in this manual. For questions

regarding the safety, installation, operation or service of this system, please refer to the

telephone numbers listed on the cover page of this manual.

ΚImportant Safeguards:

1. Read and understand these instructions before installing.

2. Do not drop the control console or allow it to get wet.

3. Be sure the display is properly grounded with a ground rod at the display location.

4. Disconnect power to the display when it is not in use.

5. Disconnect power when servicing the display.

6. Do not modify the display structure or attach any panels or coverings to the

scoreboard without the express written consent of Daktronics, Inc.

The box below illustrates Daktronics drawing numbering system. The drawing number

Α7087-P08A-69945≅ is how Daktronics identifies individual drawings. This number is

located in the bottom right corner of the drawing. The manual refers to drawings by the last

set of digits and the letter preceding them. In the example, the drawing would be referred to

as Drawing A-69945. All reference drawings are inserted at the end of the first section which

references them.

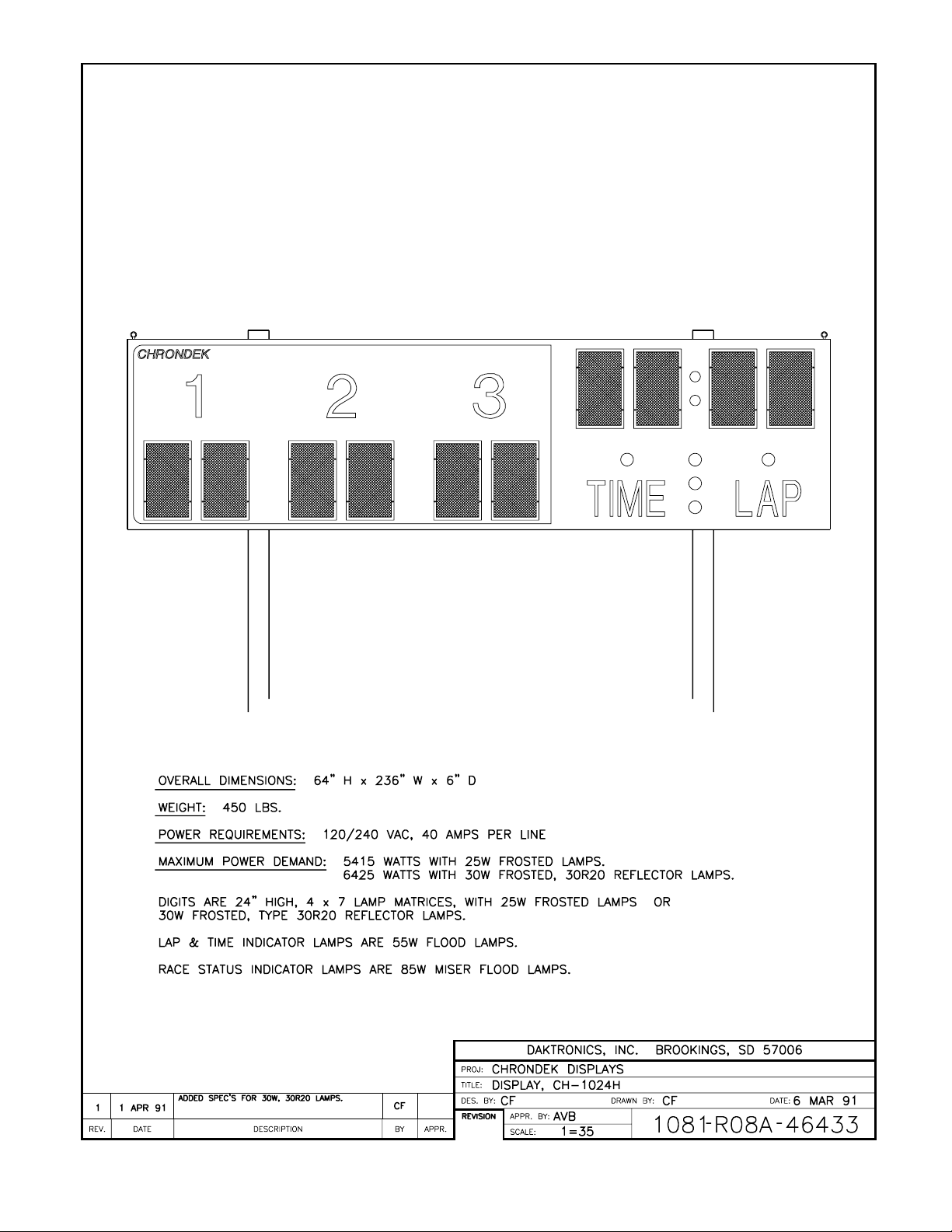

1.2 Display Overview

Reference Drawing: Display, CH-1024H ..................................... Drawing A-46433

Drawing A-46433 shows a Daktronics CH-1024H display. When used with the Daktronics

CHTS-300 timing console, the Daktronics CH-1024H display will show the lap number or lap

time and the first three car positions on the display.

Introduction 1-1

Page 6

Page 7

Section 2: Installation

2.1 General System

Reference Drawings: Driver Enclosure, Power & Signal............... Drawing A-37915

Mounting Instructions.................................. Drawing A-38856

System Layout ............................................ Drawing A-46448

Footing and Beams..................................... Drawing A-46451

Electrical Installation................................... Drawing A-46458

Component Locations................................. Drawing A-46464

Color Code, 25-Pin J-Box ........................... Drawing A-47207

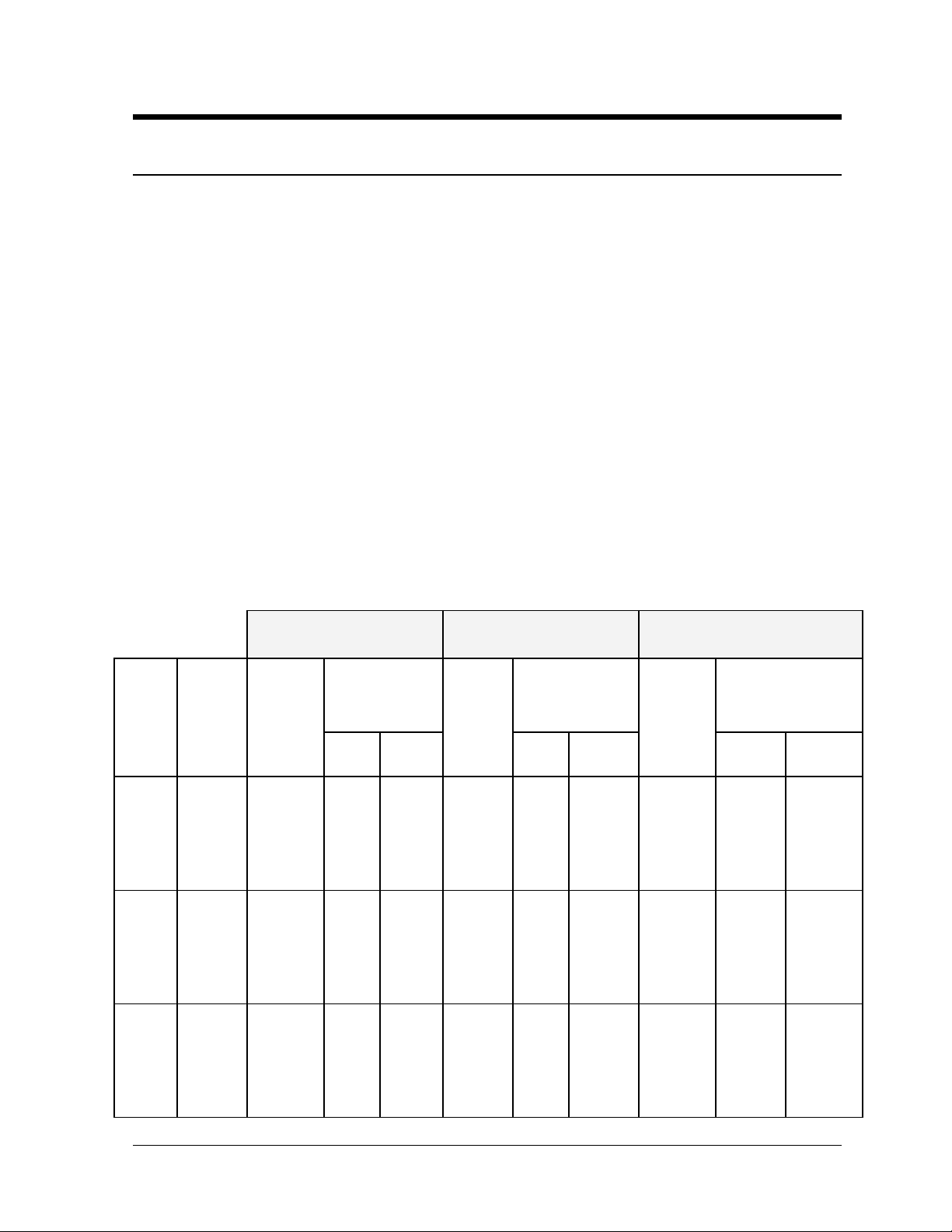

Refer to Drawing A-46448 for the general system layout. The general procedure for

installing the CH-1024H display is as follows:

• Select beam and footing recommendations from the table below.

• Dig the footing holes to install beams and footings.

• Route power and signal cables to the display and control locations.

• Mount the displays to the beams as described in Drawings A-38856 and A-46451,

and in Sections 2.2 and 2.3.

• Route power and signal wires into the displays as described in Drawings A-37915, A-

46458, A-46464, and A-47207, and in Section 2.4.

BEAM AND FOOTING RECOMMENDATIONS

DIST

TO

BTM

SCBD

8

12

16

20

24

28

8

12

16

20

24

28

8

12

16

20

24

28

DSG

WIND

VELOC

(MPH)

80

100

Installation 2-1

SCOREBOARDS

BEAM

REQUIRED

(2 EA)

W6X12

W6x15.5

W6x20

W8x24

W8x28

W8x35

W6x15.5

W6x16

W8x20

9

W8x24

0

W8x28

W8x35

W6x15.5

W8x17

W8x24

W8x28

W8x35

W12x53

FOOTINGS

DIAM

(FT)

3.00

3.25

3.50

4.50

4.50

5.00

3.00

3.50

4.00

4.25

4.25

5.50

3.00

3.50

4.25

4.50

4.75

5.25

DEPTH

(FT)

5.00

5.50

6.50

6.50

7.00

7.50

5.50

6.00

7.00

7.50

8.00

8.00

6.00

6.50

7.50

8.00

8.50

9.00

SCOREBOARDS W/

42" ADV PANEL

BEAM

REQUIRED

(2 EA)

W8x15

W8x24

W8x28

W8x35

W8x35

W12x53

W8x17

W8x28

W8x35

W12x36

W12x40

W12x53

W8x24

W8x35

W12x31

W12x36

W12x40

W12x53

FOOTINGS

DIAM

(FT)

3.25

4.50

5.00

5.00

5.25

6.00

4.00

5.50

5.50

5.00

6.00

6.00

5.00

5.25

5.25

6.00

6.00

6.00

DEPTH

(FT)

6.00

7.00

7.50

8.00

8.50

9.00

6.50

7.00

8.00

9.00

9.00

10.00

6.50

8.00

9.00

9.25

10.00

11.00

SCBD W/ 42" ADV

PANEL & MESSAGE BRD

BEAM

REQUIRED

(2 EA)

W8x17

W12x22

W12x27

W12x36

W12x45

W12x50

W8x20

W12x27

W12x31

W12x36

W12x45

W12x50

W12x19

W12x27

W12x36

W12x45

W12x50

W12x58

FOOTINGS

DIAM

(FT)

4.50

5.25

5.25

5.50

6.00

6.00

4.75

6.00

6.00

6.25

6.25

6.25

5.00

6.50

6.50

6.00

6.00

6.00

DEPTH

(FT)

6.00

7.00

8.00

8.50

9.00

10.00

6.50

7.50

8.50

9.00

10.00

11.00

7.00

8.00

9.00

10.00

11.00

12.00

Page 8

These footing recommendations are based on an allowable soil bearing pressure of 300 psf

vertically and 300 psf/ft of depth horizontally. However, these recommendations are

suggestions only and each installation should be treated individually. Be sure that the

installation complies with local codes and is suitable for particular soil and wind conditions.

Daktronics assumes no responsibility for structures installed by others.

A note about beam nomenclature: For a typical beam, W6x16 for example, "W" stands for

"Wide-Flange Beam". The first number (6) is the approximate front to rear dimension of the

beam in inches. The second number (16) is the weight per foot in pounds. This numbering is

a standard in the steal industry. Widths are from 4.00 to 10.00 inches in the chart above.

2.2 Beam And Footing Selection

Reference Drawing: Footing and Beams......................................Drawing A-46451

The above contains recommendations for beams and footings. The distance in the first

column is from the ground to the bottom of the CH-1024H display, regardless if one or two

extra sections, such as an ad panel and/or message center, are added to the CH-1024H scoring

display. The second column is wind velocities that are likely to occur at the display location

in miles per hour.

The beams listed are W-section (wide flange) beams which provide maximum wind load

strength for the weight and cost of the beams. Decide how high you want your display and

what sort of wind it will be subject to. Read across the table to the appropriate column for

your display; these are the beams and footings that are recommended. Drawing A-46451

shows a typical installation of beams and footings.

The calculations for footing diameters and depths are based on the assumption that footings

are in undisturbed soils, not fill soils, with a lateral bearing capacity of 300 psf/ft of depth

horizontally. However, these recommendations are suggestions only and each installation

must comply with local codes and be suitable for the particular soil and wind conditions.

Daktronics recommends that W-section grade 36 steel be used for beam, and that 28-day

(strength 3000 psi) concrete be used for footings. Daktronics assumes no responsibility for

structures installed by others.

2.3 Display Mounting

Reference Drawing: Mounting Instructions...................................Drawing A-38856

Drawing A-38856 shows the typical mounting for your display.

Note: The bolts that secure the display sections do not go through the beams, but run along

the sides of the beam, clamping the display to the beams.

A mounting kit with mounting angles and 2" hardware are provided to mount your display.

Position the display against the mounting beams and secure the bottom of the display to both

beams as shown. Next, secure the top of the display. Once mounting angles are attached, the

display may be slid up or down to the desired height. Once positioned as desired, tighten all

bolts.

2-2 Installation

Page 9

2.4 Electrical Installation

2.4.1 Control Signal Cable

Reference Drawings: Driver Enclosure, Power & Signal... Drawing A-37915

Component Locations ..................... Drawing A-46464

Color Code, 25-Pin J-Box................ Drawing A-47207

For the display, two conductors of 24 AWG are needed. For distances up to 600 ft. or

22 AWG, up to 1000 ft. are required. Daktronics has 24 AWG direct burial cable,

Daktronics part no. W-1105 with 6 conductors, and 22 AWG cable that must be

pulled through the conduit before burial, Daktronics part no. W-1077 with 2

conductors.

At the control location, mount the signal J-box to a convenient location. Route the

cables and connect them to the wires leading from the connector in the cover,

according to the table below and Drawing A-47207.

At the display, open the hinged access door covering the lamp driver enclosure as

shown in Drawing A-46464. Remove the cover from the lamp driver enclosure. See

Drawing A-37915 for an illustration of the components inside the enclosure.

Connect the signal wires to TB31 as indicated in the table below.

Signal Connections

2.4.2 Power Wiring

Installation 2-3

Control End

J-Box

Terminal no.

14 Red/Wht

15 Grn/Wht

*Auxiliary display(s) require(s) a different output number(s). Consult your CHTS300 console manual.

Reference Drawings: Driver Enclosure, Power & Signal... Drawing A-37915

A 120/240 VAC circuit (two hot lines, one neutral, plus a ground) must be run into a

load center. See Drawing A-46458. When equipped with 30W lamps, this display is

capable of drawing a maximum of 40 amps on line 1 and 14 amps on line 2 when

lighted.

Route four "hot", two "neutral", and one "ground" wire, 12 AWG from the load center

(Drawing A-46458) to the driver enclosure (Drawing A-37915) in the display.

Connect the ground wire to terminal E41. Connect the two neutral wires to TB41-3

and TB41-4. Connect the hot wires to the load center and the display as in the

example below.

Wire Color

Electrical Installation ....................... Drawing A-46458

Output

No.

1*

Display End

TB31

Terminal no.

1 (+)

2 (-)

Page 10

Note: Breaker numbers are examples only. Breaker numbers may be assigned as

required. The objective is to have TB41-1 and TB41-2 on line 1. TB41-5 and TB416 should be on line 2.

Load Center

Breaker No.

1

2

3

4

Display Terminal

No.

TB41-1

TB41-2

TB41-5

TB41-6

2-4 Installation

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Section 3: Maintenance & Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before any repair or maintenance work is done on

the CH-1024H display!

2. Any access to internal display electronics must be made by qualified

service personnel.

3. Disconnect power when the CH-1024H display is not in use.

3.1 Lamp Replacement

Reference Drawing: Digit Service..............................................Drawing A-27674

The primary service required by the CH-1024H display is to replace burned-out lamps. See

Drawing A-27674 for how to access the digit lamps for replacement. Standard replacement

lamps for the digits are 120V, 25W frosted medium base and may be obtained at your local

store or directly from Daktronics, part number DS-1029. Some displays may be equipped

with 120V, 30W reflector type 30R20 lamps, Daktronics part number DS-1126.

The Lap/Time indicators use 120V, 55W clear flood lamps, type 55PAR38, Daktronics part

number DS-1101.

The Status indicators use 120V, 85W flood lamps, type 85PAR38. The Daktronics part

numbers are as follows:

• Amber - Daktronics Part No. DS-1184

• Green - Daktronics Part No. DS-1185

• Red - Daktronics Part No. DS-1186

Do not use lamps larger than those originally installed in the display. Using higher powered

lamps will likely cause fuse failures in the display and could exceed the current levels that the

display's circuits can safely handle.

3.2 Lamp Drivers

Reference Drawing: Multiplex Controllers..................................Drawing A-37070

Component Location.................................Drawing A-46464

In the scoreboard, the task of switching lamps on and off is performed by the lamp drivers.

Drawing A-46464 in Section 2 shows the location of the lamp driver in the display.

Drawing A-37070 shows the lamp driver and the fuses located in it.

The lamp driver has 22 connectors providing power and signal inputs to the circuit and

outputs to the digits.

Maintenance & 3-1

Troubleshooting

Page 20

Connector No. Function

1-16 Output to digits

17 Signal input

18 Power input for outputs 1-8

19 Power input (120V) for driver logic

20 Power input for outputs 9-16 (120V)

24 Dim option selector

Drawing A-46464 in Section 2 shows the numbers on the digits that refer to the lamp driver

output connector wired to each digit

3.3 Digit Segmentation

Reference Drawing: Segments, 4x7 Lamp Matrix Digit.............Drawing A-37685

In a digit, certain lamps always go on and off together. These groupings of lamps are known

as segments. Each digit can have up to eight segments, referred to by letters A through H.

Drawing A-37685 shows which connector pin number is wired to each digit segment and the

wiring color code used throughout the display.

3.4 Schematic

Reference Drawing: Schematic, Power & Signal.......................Drawing A-38788

Driver Enclosure, Power & Signal.............Drawing A-37915

Drawing A-38788 shows the power and signal inputs into the display and to the lamp driver.

The component numbers correspond to those shown in Drawing A-37915 in Section 2.

3.5 Troubleshooting

This section lists some symptoms that may be encountered with the scoreboard. For these

symptoms, possible cause and corrective actions are indicated. This list does not include

every possible problem, but does represent some of the more common situations that may

occur.

Symptom/Condition Possible Cause or Corrective Action

One lamp won’t light • Burned-out lamp

Scoreboard will not light. • Console not connected or poor connection.

• No power to the control console.

• No power to the scoreboard.

• Bad relay or poor relay connection in signal

circuit.

• Driver logic fuse (F17) blown.

• P17, P19 or P20 unplugged.

Half of the scoreboard will not light. • Circuit breaker tripped at service panel.

• Driver malfunction.

• Poor signal contact at main power connection.

• Driver logic fuse blown

Garbled display. • Control console malfunction.

3-2

Maintenance & Troubleshooting

Page 21

• Internal lamp driver malfunction.

Digit will not light. • Fuse blown in driver.

• Black wire to the digit is broken.

• Poor contact at driver connector.

Segment will not light. • Lamps are burned out.

• Driver malfunction (bad triac).

• Broken wire between lamp driver and digit.

• Poor contact at driver connector.

Segment stays lit. • Driver malfunction (bad triac).

• Broken wire behind digit

If a problem is observed in one digit, the cause may be isolated by swapping plugs on the

driver (connect the plug from the digit into a different jack). If the same digit shows the same

problem, the cause may be in the digit or the wiring. If the problem moves to another digit,

then the cause is probably an internal driver problem.

Use a volt meter at driver inputs to determine if power is being supplied to the driver. An

ohmmeter can be helpful in finding broken wires and bad connections. Internal electronic

problems must be corrected by Daktronics or by an authorized service center.

3.6 Replacement Parts

Part Name or Description Type

Lamp Driver

J-Box, CHTS-300 Timer

Fuse, Lamp Driver, 10A

Fuse, Driver Logic, 1/2A

Digit Lampbank, 24"4x7

S-1064-02

Socket, Med. Base

X-1046

Lamp, 25W Frosted

DS-1029

Lamp, 30W Reflector

Lamp, 55W Clear Flood

Lamp, 85W Amber Flood

Lamp, 85W Green Flood

Lamp, 85W Red Flood

AGC-10

AGC-1/2 F-1000

30R20

55PAR38 DS-1101

85PAR38 DS-1184

85PAR38 DS-1185

85PAR38 DS-1186

Part Number

0A-1033-0122

0A-1067-0056

F-1006

DS-1126

3.7 Daktronics Exchange/Repair & Return Programs

To serve customers’ repair and maintenance needs, Daktronics offers both an exchange and a

repair and return program. The exchange program reduces down time by providing timely

replacement of key components. This service is provided to qualified customers who follow

the program guidelines explained below. It is our pleasure to provide this service to ensure

you get the most from your Daktronics products. Please call our Help Desk (1-800 / 843-

9879) if you have any questions regarding the exchange program or any other Daktronics

service.

Maintenance & 3-3

Troubleshooting

Page 22

When you call the Daktronics Help Desk, a trained service technician will work with you to

solve the equipment problem. You will work together to diagnose the problem and determine

which exchange replacement part to ship. If, after you make the exchange, the equipment still

causes problems, please contact our Help Desk immediately.

If the replacement part fixes the problem, package the defective part in the same packaging the

replacement part arrived in, fill out and attach the enclosed UPS shipping document and

RETURN THE PART TO DAKTRONICS. (You may use the same box and packing the

exchange part was sent in.) This will speed up the transaction and alleviate confusion when

the failed component arrives at Daktronics. (Daktronics expects immediate return of the

exchange part if it does not solve the problem.) For most equipment, you will be invoiced for

the replacement part at the time it is shipped. This invoice is due when you receive it.

Daktronics reserves the right to refuse equipment that has been damaged due to acts of nature

or causes other than normal wear and tear.

If the defective equipment is not shipped to Daktronics within 30 working days from the

invoice date, it is assumed you are purchasing the replacement part and you will be invoiced

for it. This second invoice represents the difference between the exchange price and the

purchase price of the equipment. This amount is due when you receive the second invoice. If

you return the exchange equipment after 30 working days from invoice date, you will be

credited for the amount on the second invoice minus a restocking fee.

≅To avoid a restocking charge, please return the defective equipment within 30 days from the

invoice date.

Daktronics also offers a Repair and Return program for items not subject to exchange.

Where to Send: To return parts for service, contact your local representative prior to

shipment to acquire a Return Material Authorization Number (RMA#). If you have no local

representative, call the Daktronics Help Desk for the RMA#. This will expedite the receiving

process.

Packaging for Return: Package and pad the item well so that it will not be damaged in

shipment. Electronic components such as printed circuit boards should either be installed in an

enclosure or should be put in an anti-static bag before boxing. Please enclose your name,

address, phone number and a clear description of symptoms.

Mail: Daktronics, Inc., Customer Service

PO Box 5128

331 32nd Avenue

Brookings, SD 57006

Phone: Daktronics Help Desk: 1-800/843-9879

or 1-605/697-4400

Customer Service Fax: 1-605-697-4444

e-mail: helpdesk@daktronics.com

3-4

Maintenance &

Troubleshooting

Page 23

Page 24

Page 25

Page 26

Loading...

Loading...