Page 1

Models

BB-2102

BB-2126

BB-2104

BB-2146

BB-2106

BB-2147

BB-2108

BB-2154

BB-2124

BB-2156

Daktronics Tuff Sport®

Four-Sided Basketball

LED Scoreboards

Display Manual

ED-13248 Rev 6 – 7 February 2013

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4746

www.daktronics.com

Page 2

Page 3

Please fill in the information below for your display; use it for reference when

calling Daktronics for assistance.

Scoreboard Serial No. __________________________________________

Scoreboard Model No. __________________________________________

Date Installed _________________________________________________

ED-13248

Product 1237

Rev 6 – 7 February 2013

DAKTRONICS, INC.

Copyright 2003-2013

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retrieval systems – without written permission of the publisher.

All Sport®, PanaView®, Tuff Sport®, and UniView® and are trademarks of Daktronics, Inc.

Page 4

Page 5

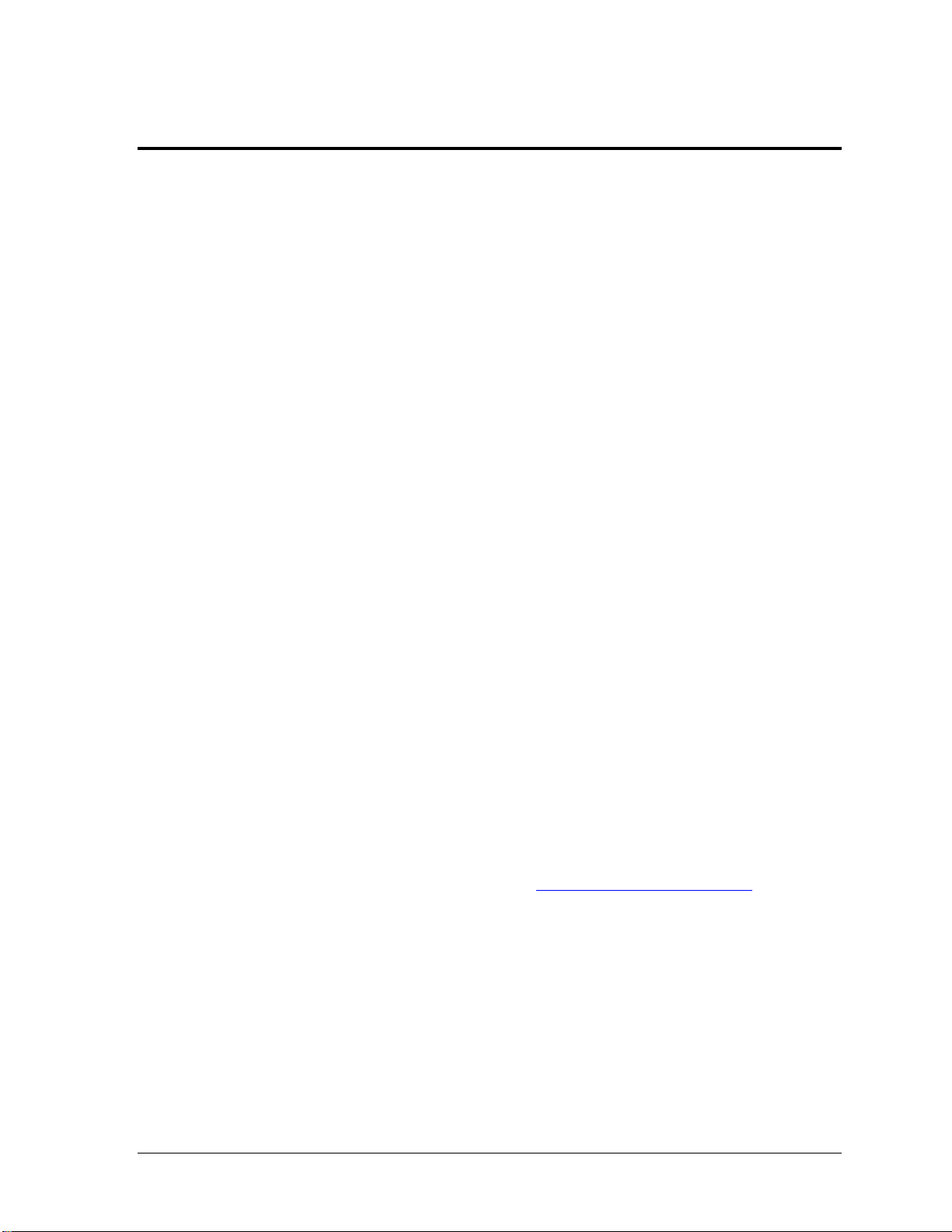

Table of Contents

Section 1: Introduction ............................................................................................................................ 1

1.1 Scoreboard Controllers ........................................................................................................... 1

1.2 Scoreboard Label ..................................................................................................................... 2

1.3 Model Number ........................................................................................................................ 2

1.4 Resources .................................................................................................................................. 2

1.5 Daktronics Nomenclature ...................................................................................................... 3

1.6 Product Safety Approval........................................................................................................ 3

Section 2: Specifications .......................................................................................................................... 5

Section 3: Mechanical Installation ........................................................................................................ 7

3.1 Lifting the Scoreboard ............................................................................................................ 7

3.2 Four-Sided Scoreboard Suspension Options ....................................................................... 8

Static Mounting ................................................................................................................ 8

Electric Hoist System ....................................................................................................... 9

3.3 Assembly Overview.............................................................................................................. 10

3.4 Frame Assembly .................................................................................................................... 10

BB-2146 and BB-2147 ..................................................................................................... 10

3.5 Optional Lower Ad Panel Attachment............................................................................... 11

3.6 Mounting Scoreboard Sections to the Frame ..................................................................... 11

BB-2146 and BB-2147 ..................................................................................................... 11

3.7 Optional Top Ad Panel or Message Center Attachment ................................................. 12

3.8 Optional Ad Panels on Message Centers ........................................................................... 12

3.9 Attaching Corner Shrouds ................................................................................................... 13

3.10 Attaching Suspension Cables .............................................................................................. 13

Section 4: Electrical Installation .......................................................................................................... 15

4.1 Installation Overview ........................................................................................................... 15

4.2 Power/Signal Connections Between Sections ................................................................... 16

4.3 Main Power Connection ....................................................................................................... 18

Grounding ....................................................................................................................... 18

4.4 Power-On Self-Test (POST) ................................................................................................. 18

Radio Settings ................................................................................................................. 19

4.5 Main Signal Connection ....................................................................................................... 19

Section 5: Maintenance & Troubleshooting ...................................................................................... 21

5.1 Troubleshooting Table .......................................................................................................... 21

5.2 Component Location & Access ........................................................................................... 23

5.3 Replacing Digits .................................................................................................................... 24

PanaView ........................................................................................................................ 24

UniView .......................................................................................................................... 25

5.4 LED Drivers ........................................................................................................................... 26

Replacing a Driver ......................................................................................................... 28

Setting the Driver Address ........................................................................................... 28

Multiple Drivers ............................................................................................................. 28

5.5 Segmentation and Digit Designation .................................................................................. 29

Table of Contents i

Page 6

5.6 Schematics .............................................................................................................................. 29

5.7 Suspension System Periodic Inspections ........................................................................... 29

Static System ................................................................................................................... 29

Hoist System ................................................................................................................... 29

5.8 Replacement Parts List ......................................................................................................... 30

5.9 Daktronics Exchange and Repair & Return Programs ..................................................... 31

Exchange Program ......................................................................................................... 31

Repair & Return Program ............................................................................................. 32

Daktronics Warranty and Limitation of Liability ...................................................... 32

Section 6: Scoreboard Options ............................................................................................................. 33

6.1 Horns ...................................................................................................................................... 33

Adjusting Horn Volume ................................................................................................ 33

6.2 Radio Control ......................................................................................................................... 33

6.3 Visual Horn Indicator (VHI) ................................................................................................ 33

6.4 Changeable Captions ............................................................................................................ 34

6.5 Double Bonus Indicators ...................................................................................................... 34

6.6 Time Outs Left (TOL) Digits ................................................................................................ 34

6.7 Team Name Message Centers ............................................................................................. 34

Section 7: TNMC Troubleshooting & Maintenance ........................................................................ 35

7.1 Display Overview ................................................................................................................. 35

7.2 Initialization Information at Startup ................................................................................... 36

7.3 Display Troubleshooting Table ........................................................................................... 36

7.4 Power & Signal Summary .................................................................................................... 37

7.5 Component Locations & Access .......................................................................................... 37

7.6 Display Drivers ...................................................................................................................... 37

Diagnostic LEDs ............................................................................................................. 38

Replacing a Driver ......................................................................................................... 38

7.7 Modules .................................................................................................................................. 39

Replacing Modules ........................................................................................................ 39

7.8 Power Supplies ...................................................................................................................... 40

Replacing a Power Supply ............................................................................................ 40

7.9 Display Maintenance ............................................................................................................ 40

7.10 Replacement Parts List ......................................................................................................... 40

Appendix A: Mechanical Specification Drawings ................................................................................. 41

Appendix B: Electrical Specification Drawings ..................................................................................... 43

Appendix C: Scoreboard Options ............................................................................................................. 45

Appendix D: Schematic Drawings ............................................................................................................ 47

Appendix E: Additional Reference Drawings ........................................................................................ 49

Appendix F: Hoist Suspension Systems ................................................................................................. 51

Appendix G: Daktronics Warranty and Limitation of Liability .......................................................... 53

ii Table of Contents

Page 7

1

Section 1: Introduction

This manual explains the installation and maintenance of Daktronics Tuff Sport® Four-Sided Indoor

Basketball LED Scoreboards. For additional information regarding the safety, installation, operation,

or service of these displays, refer to the telephone numbers listed in Section 5.9. This manual is not

specific to a particular installation.

Important Safeguards:

Please read and understand all instructions before beginning the installation process.

Do not drop control equipment or allow it to get wet.

Do not disassemble control equipment or electronic controls of the display; failure to

follow this safeguard will make the warranty null and void.

Disconnect display power when not in use or when servicing.

Disconnect display power before servicing power supplies to avoid electrical shock.

Power supplies run on high voltage and may cause physical injury if touched while

powered.

Do not modify the scoreboard structure or attach any panels or coverings to the

scoreboard without the express written consent of Daktronics, Inc.

Project-specific information takes precedence over any other general information found in

this manual.

1.1 Scoreboard Controllers

Daktronics four-sided Tuff Sport scoreboards are designed for use with the All Sport® 5000

series control consoles. This console uses keyboard overlays (sport inserts) to control numerous

sports and scoreboard models. Refer to the following manual for operating instructions:

All Sport 5000 Series Control Console Operation Manual (ED-11976)

This control console manual is available online at www.daktronics.com/manuals.

Introduction

Page 8

1.2 Scoreboard Label

BB

Basketball

Figure 1: Display ID Label

-13

indoor scoreboards, 120 V, PanaView® digits

-14

indoor scoreboards, 230 V, PanaView® digits

-15

indoor scoreboards, 120 V, UniView® digits

-16

indoor scoreboards, 230 V, UniView® digits

Figure 2: Daktronics Drawing Label

Serial and model numbers of a Daktronics scoreboard can be found on the ID label on the

display, similar to that shown in Figure 1.

Please list the model number, display serial number, and the date this display became

operational in the blanks provided on the second page of this manual. When calling

Daktronics customer service, please have this information available to ensure the request is

serviced as quickly as possible.

1.3 Model Number

Daktronics scoreboards are differentiated by their model numbers and two-letter prefixes for

each sport. Most Daktronics scoreboards also carry a two-number suffix that refers to indooroutdoor status, power supply, and digit color.

1.4 Resources

Figure 2 illustrates a Daktronics drawing

label. The drawing number is located in the

lower-right corner of a drawing. This manual

refers to drawings by listing the last set of

digits and the letter preceding them. In the

example, the drawing would be referred to

as Drawing C-325405.

Reference Drawing:

System Riser Diagram ............................................................................Drawing C-325405

Daktronics identifies manuals by the DD or ED number located on the cover page of each

manual. For example, this manual would be referred to as ED-13248.

2 Introduction

Page 9

3

Main Component Labels

Part Type

Part Number

Individual circuit board

0P-XXXX-XXXX

Assembly; a collection of circuit boards

0A-XXXX-XXXX

Wire or cable

W-XXXX

Fuse

F-XXXX

Transformer

T-XXXX

Metal part

M-XXX

Fabricated metal assembly

0S-XXXXXX

Specially ordered part

PR-XXXXX-X

Accessory Labels

Component

Label

Termination block for power

or signal cable

TBXX

Grounding point

EXX

Power or signal jack

JXX

Power or signal plug for the

opposite jack

PXX

Figure 3: Typical Label

1.5 Daktronics Nomenclature

Most components within this display carry a white label that lists the part number of the unit.

If a component is not found in the Replacement Parts List in Section 5.8, use the label to order

a replacement. Figure 3 illustrates a typical label. The part number is in bold.

Following the Replacement Parts List is the Daktronics Exchange Policy and the Repair &

Return Program. Refer to these instructions if replacing or repairing any display component.

1.6 Product Safety Approval

Daktronics Tuff Sport scoreboards are ETL-listed, tested to CSA standards and CE-labeled for

indoor use. Contact Daktronics with any questions regarding the testing procedures.

Note: The four-sided scoreboards detailed in this manual are designed to be suspended

above players or spectators, and that creates serious liability considerations. It is

imperative that the roof support system be able to bear the weight of the scoreboard and

all other attachments. Consequently, a licensed engineer must certify the roof support

system. Suspension cables and hoist or attachment structures must also be designed and

certified by a licensed engineer.

Daktronics is not responsible for structures and suspension systems designed or installed

by others.

Introduction

Page 10

Page 11

Model

Dimensions:

Height, Width, Depth

Uncrated

Weight

Watts

Amps

120/230 VAC

Driver #

& Address

BB-2102

4'-2" H, 10'-10" W, 10'-10" D

(1270 mm, 3302 mm, 3302 mm)

780 lb

354 kg

[840 lb

381 kg]

800 W

[1200 W]

6.7 / 3.5 A

[10 / 5.2 A]

A1 17

BB-2104

6'-2" H, 10'-10" W, 10'-10" D

(1880 mm, 3302 mm, 3302 mm)

1020 lb

463 kg

[1080 lb

490 kg]

800 W

[1200 W]

6.7 / 3.5 A

[10 / 5.2 A]

A1 17

BB-2106

4'-2" H, 12'-10" W, 12'-10" D

(1270 mm, 3912 mm, 3912 mm)

900 lb

408 kg

[960 lb

435 kg]

800 W

[1200 W]

6.7 / 3.5 A

[10 / 5.2 A]

A1 17

BB-2108

6'-2" H, 12'-10" W, 12'-10" D

(1880 mm, 3912 mm, 3912 mm)

1200 lb

544 kg

[1260 lb

572 kg]

800 W

[1200 W]

6.7 / 3.5 A

[10 / 5.2 A]

A1 17

BB-2124

6'-2" H, 12'-10" W, 12'-10" D

(1880 mm, 3912 mm, 3912 mm)

1220 lb

553 kg

[1280 lb

581 kg]

1600 W

[2000 W]

13.3 / 7 A

[16.7 / 8.7 A]

A1 17

A2 14

BB-2126

4'-2" H, 12'-10" W, 12'-10" D

(1270 mm, 3912 mm, 3912 mm)

900 lb

408 kg

[960 lb

435 kg]

800 W

[1200 W]

6.7 / 3.5 A

[10 / 5.2 A]

A1 17

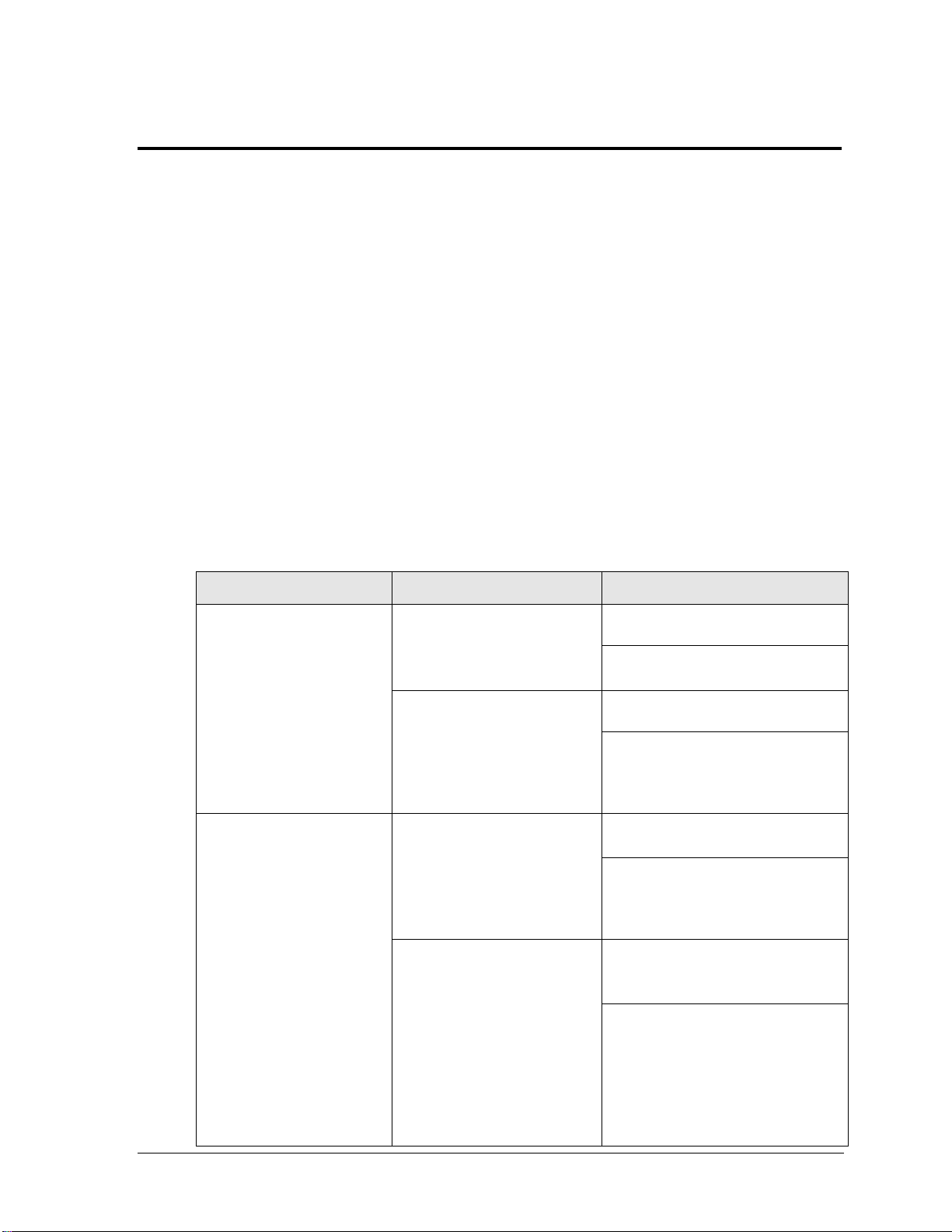

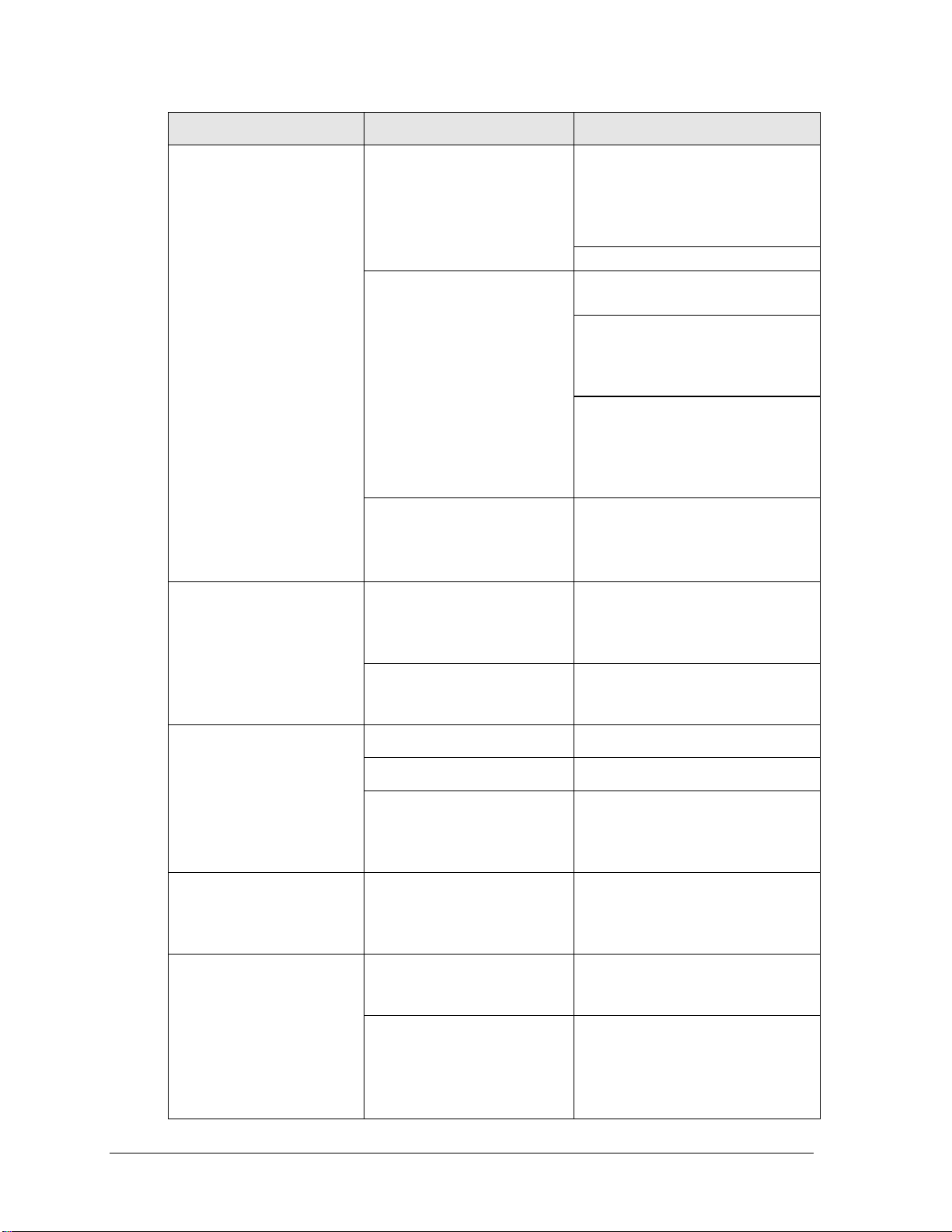

Section 2: Specifications

The chart on the following pages details all of the mechanical specifications, circuit specifications, and

power requirements for each display in this manual. Models are listed in alphanumeric order.

Notes:

1) All displays require a 120 VAC, 15 A circuit; models with 230 VAC power are also available.

2) Values in [Brackets] indicate scoreboards with Team Name Message Centers (TNMC).

3) Dimensions include corner shrouding and flooring.

4) Optional sheet metal flooring adds 100 lb (45 kg) to total weight.

Specifications 5

Page 12

Model

Dimensions:

Height, Width, Depth

Uncrated

Weight

Watts

Amps

120/230 VAC

Driver #

& Address

*BB-2146

8'-8" H, 12'-10" W, 12'-10" D

(2642 mm, 3912 mm, 3912 mm)

2750 lb

1247 kg

[2810 lb

1274 kg]

7488 W

[7888 W]

62.4 / 32.6 A

[65.7 / 34.3 A]

A1 17

*BB-2147

8'-8" H, 12'-10" W, 12'-10" D

(2642 mm, 3912 mm, 3912 mm)

2000 lb

907 kg

[2060 lb

934 kg]

4144 W

[4544 W]

34.5 / 18 A

[38 / 19.8 A]

A1 17

BB-2154

6'-2" H, 10'-10" W, 10'-10" D

(1880 mm, 3302 mm, 3302 mm)

1080 lb

490 kg

[1140 lb

517 kg]

1400 W

[1800 W]

11.7 / 6.1 A

[15 / 7.8 A]

A1 17

BB-2156

6'-2" H, 12'-10" W, 12'-10" D

(1880 mm, 3912 mm, 3912 mm)

1260 lb

572 kg

[1320 lb

599 kg]

1400 W

[1800 W]

11.7 / 6.1 A

[15 / 7.8 A]

A1 17

* These displays are composed of scoreboards and LED message centers. Refer to the SS Series 20mm

Indoor Scoreboard Message Centers Installation & Operation Manual (DD1564453) for more

information about message center specifications, operation, and troubleshooting.

6 Specifications

Page 13

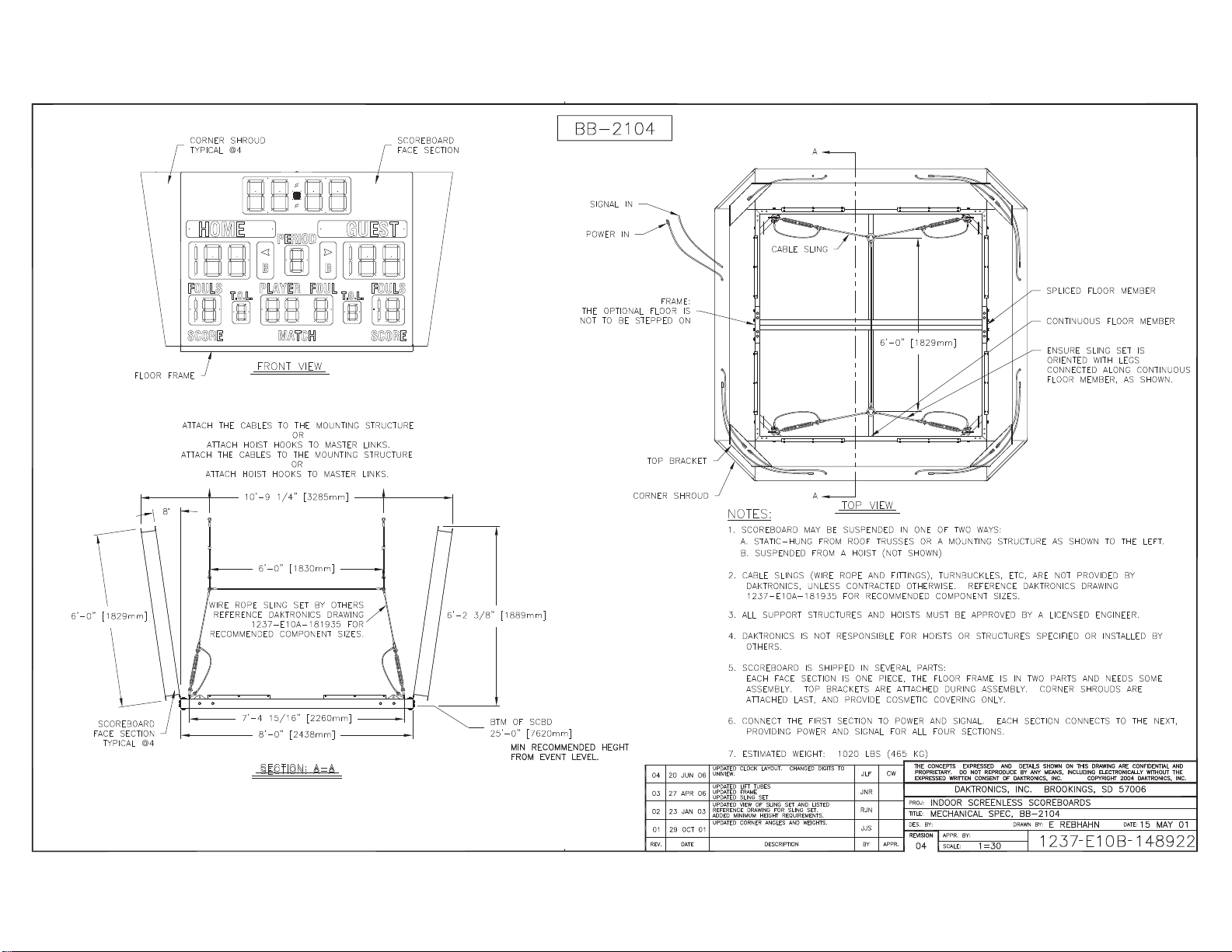

Section 3: Mechanical Installation

Mechanical installation consists of lifting and permanently mounting the scoreboard and any optional

advertising panels or message centers. The mechanical specification drawings listed in Appendix A

show measurements, cable attachment points, and mounting weights for each scoreboard model.

Be sure that the installation complies with local building codes.

Note: Daktronics does not assume any liability for any installation derived from the information

provided in this manual or installations designed and installed by others.

Below is a general overview of the entire installation process. Each step is detailed in the sections that

follow, and the instructions are presented in the general order in which events should occur.

1. Plan and install the hoist or static-suspension structure.

2. Provide power circuit(s) and outlet(s) at the scoreboard location.

3. Provide a power outlet at the control location.

4. Route signal cable from the control location to the scoreboard location, and install the

junction box (if the system is not controlled by radio).

5. Assemble the scoreboard frame.

6. Attach the lower ad panel supports to the frame, if required, and mount the lower

ad panels.

7. Mount the scoreboard sections to the frame and join them at the top.

8. Route and connect all power cords and signal cables around the top of the scoreboard.

9. Mount the upper ad panels or message centers, if required.

10. Mount ad panels atop the message center, if required.

11. Make power and signal connections between message center sections and/or power

connections for backlit ad panels, if required.

12. Attach the corner shrouds.

13. Lift the scoreboard assembly and static-mount, or lower the hoist and attach it to the

scoreboard assembly.

14. Make the final power and signal hookup to each tier of the display (scoreboard tier,

backlit ad panel tier, message center tier).

3.1 Lifting the Scoreboard

Daktronics Tuff Sport scoreboards are shipped equipped with a single eyebolt for lifting the

display into place. The eyebolt is located in the center of the top of the scoreboard cabinet.

Daktronics indoor scoreboards use 3/8" eyebolts. Use the single eyebolt at the top of the

scoreboard section only to lift the display into position for assembly.

Note: Eyebolts are intended for lifting only. Do not attempt to permanently support the

display by its eyebolt. Daktronics assumes no liability for damages resulting from

incorrect setup or lifting methods.

Mechanical Installation 7

Page 14

3.2 Four-Sided Scoreboard Suspension Options

The method by which the scoreboard is to be suspended must be determined at the time of

purchase. There are two primary methods of installing a center-hung scoreboard: creating a

static-hung system or using a hoist. Each method has its own benefits and drawbacks. Refer

to the suspension publication, DD1627665, in Appendix F, and call Daktronics for help in

making the best choice for your installation.

Note: Do not attach items to the scoreboard without prior approval.

To properly review and approve a proposed attachment, Daktronics requires information on

the size, weight, and method by which the item will be attached to the scoreboard.

(Engineering time to review attachments will be charged at a "time and expenses" rate.)

Static Mounting

Static-mounted displays are typically hung with two or four static cables. Two cables may be

used when mounting the scoreboard below a large beam or when the display is centered

between a pair of beams. Four cables are used to further distribute weight.

Note: For either method, the mounting cables must be symmetrically distributed to

maintain a level and a square configuration.

Cable assemblies must have a strength greater than six times the actual load. All other rigging

components must be sized within the working load limits published by the component

manufacturer.

Note: Daktronics strongly recommends that only components from reputable domestic

suppliers be used to permanently suspend the scoreboard.

Remove immediately and do not use any assemblies that show evidence of excessive wear or

broken wires as defined by the component manufacturer.

Follow these procedures for installation:

1. Have a structural engineer certify that the building can safely support the additional

display loading and that the connection points are designed to safely carry the

scoreboard weight.

2. Attach the cable sling to the scoreboard assembly while it is on the arena floor.

3. Hang ends that attach to the ceiling over the sides of the scoreboards. If an end is too

short, attach a rope to the end temporarily so it can be returned from the top.

4. The scoreboard can be lifted into place in a number of different ways.

Note: It is the installer's responsibility to ensure that the installation is safe and that

the display meets OSHA or local regulations.

8 Mechanical Installation

Page 15

Lifting Method Example: A common method of temporarily lifting the scoreboard is to use a

pair of chain-lift motors mounted on the ceiling. Secure prior approval from the facility

management regarding location and acceptable loads for each rigging point.

1. Attach the chain hoist hooks to the sling master link, or sling to the corner lift tubes.

Be sure the angle of the sling is greater than 45°.

2. Use the chain hoist to lift the scoreboard to the appropriate height.

3. From the lift, retrieve the sling cables draped over the sides of the scoreboard and

attach them to the appropriate locations in the ceiling.

4. Connect to power outlets (and signal junction boxes, if required) in the ceiling.

5. Level the scoreboard by adjusting the turnbuckle on the sling.

6. Lower the scoreboard weight onto the slings.

7. Remove the chain motors.

Electric Hoist System

Installing an electric hoist system is more complex and may expose the customer to greater

liability. Publication SL-03610 in Appendix F discusses recommended minimum hoist

specifications and points that must be considered when selecting a hoist system.

A building engineer must review and approve the combined weight of the

scoreboard, hoist, and a minimum impact factor of 15 percent.

The hoist must be accessible for periodic inspections and maintenance as required by

ANSI and OSHA.

Note: Records of periodic inspections must be on file to be accessible for OSHA

(refer to Section 5.7).

Electrical service and control wiring must be run to the hoist location.

Additional structures in the ceiling are often required to accommodate the hoist.

If an existing hoist is to be used, or if a hoist is to be purchased directly by the end

user, the user assumes all responsibility and liability for the hoist system.

The hoist must be inspected and certified in writing by the hoist manufacturer,

manufacturer's representative, or other qualified hoist inspector.

Daktronics will inspect hoists installed by Daktronics.

Daktronics will certify the scoreboard weight but will require a liability waiver

signed by the customer before the scoreboard is shipped.

Once the hoist is installed according to the specifications of the hoist manufacturer

and the building engineer, refer to Section 3.10 for more information about attaching

the scoreboard to the hoist.

WARNING!

Never ride in or work on or below the scoreboard while the hoist is powered up.

Daktronics recommends having an audible horn warning to indicate that the hoist

system is ON.

Never operate the hoist system during public events or when people are below the

scoreboard.

When running the hoist, the operator must have an unobstructed view from ceiling to

floor (to ensure free scoreboard travel). Hoist operators should be trained according

to the hoist manufacturer's specifications.

Mechanical Installation 9

Page 16

3.3 Assembly Overview

The assembly kit includes the following:

Floor frame – 2 halves, 2 side splice plates, and 4 top & bottom splice plates

Corner shrouds @ 4

Shroud brackets @ 8

Top corner brackets @ 4

Assorted bolts, nuts, washers, and screws

In addition to the scoreboard pieces, an installation may also include:

Upper and lower ad panels

A message center at the top or bottom of the scoreboard

Each scoreboard face section is one piece and must be attached to the structural frame.

The frame is shipped in two parts and requires some assembly. Corner shrouds, which

provide cosmetic covering only, are attached to the display last.

Ad panels may simply be painted metal cabinets that do not need power, or they may be

backlit, requiring a 120 V circuit. An LED message center requires power as well as signal

wiring. The scoreboard itself requires power and signal wiring. The scoreboard tilts outward

at approximately 10°, while the ad panels or message centers are vertical (except for BB-2146

and BB-2147, where the opposite is true). Refer to Section A-A shown on the mechanical

specification drawings in Appendix A.

3.4 Frame Assembly

Reference Drawing:

Optional 4-Side Canvas Assembly ......................................................... Drawing A-173611

Field Assembly; 8' x 8' Bolted Frame ....................................................Drawing B-1101988

Field Assembly; 10' x 10' Bolted Frame ................................................Drawing B-1102115

Field Assembly; 10' x 10' SS Bolted Frame ..........................................Drawing B-1102140

The scoreboard frame is shipped in two sections (refer to Drawings B-1101988 and B-1102115

in Appendix E). Note that each section has two corners with a brace across the corner and

two corners without a brace. The lift tubes in the braced corners will be on the top side. An

optional sheet metal floor may be attached to the top side of the frame sections during

manufacturing.

1. Lay out the two sections with the unbraced sides facing each other and the corner lift

tubes facing up.

2. Connect the sections together in the middle using

3. Attach all six section splice plates using

the sides, while two smaller splice plates will go on both the top and bottom.

Note: If an optional canvas was ordered, attach it to the bottom of the frame using the

provided hook and loop fastener strips and self-drilling screws. Refer to DWG-

173611 in Appendix C for more information on this option.

1

/2" hardware.

1

/2" hardware. Two splice plates will go on

BB-2146 and BB-2147

For BB-2146 and BB-2147 models, refer to Drawing B-1102140. These models include LED

message centers that require additional “kickers” for support.

10 Mechanical Installation

Page 17

3.5 Optional Lower Ad Panel Attachment

Reference Drawing:

Bottom 4-Side Ad Panel Mounting ......................................................... Drawing A-107664

This step is required only if the scoreboard has ad panels or auxiliary scoreboard displays to

be attached to the bottom. Refer to Drawing A-107664 in Appendix C.

Support brackets are attached to the bottom of the frame, and the ad panel sections are to be

attached to these brackets. The support brackets are designed to be able to support the weight

of the whole scoreboard while sitting on the arena floor.

Note: The bottom ends of the supports should extend about 1/16" beyond the bottom of

the lower ad panels so that the scoreboard's weight is not resting on the ad panels.

1. Raise the assembled frame and support it on sturdy blocks or stands.

2. There are four holes in each corner of the frame on the bottom side. Secure a support

bracket in all four corners using 3/8" hardware.

3. Attach the rear flanges of the ad panels to the support brackets with

3

/8" hardware.

3.6 Mounting Scoreboard Sections to the Frame

Reference Drawing:

4-Side Installation Details ....................................................................... Drawing A-154598

Top 4-Side, Mounting ........................................................................... Drawing B-1102472

Each side of the frame has two mounting angles to which the bottom of each scoreboard

section will be attached. The tops of the scoreboard sections will be joined at their corners by

brackets. Refer to Drawing A-154598 in Appendix E for an illustration of the parts used in

this procedure.

1. Lift one scoreboard section into place on the frame, with the mounting angles inside

the bottom channel of the scoreboard section.

2. Align the holes along the bottom of the scoreboard's rear flange with the

threaded inserts on the mounting angles, and install the 1/4" bolts as shown in

Detail A of Drawing A-154598.

3. Ask for assistance as needed to support the scoreboard section and prevent it from

tipping as the second section is lifted into place adjacent to the first and secured to

the frame.

4. Join the two scoreboard sections at their common top corner using a top bracket and

3

/8" hardware as shown in Detail B of Drawing A-154598. Once the two sections are

joined, they will not require additional support during assembly.

5. Attach the third scoreboard section to the frame at the bottom and to the second

section at the top corners.

6. Attach the fourth scoreboard section to the frame at the bottom and to the third

section at the top corners.

1

/4"

BB-2146 and BB-2147

In addition to being attached to mounting angles on the bottom of the frame and to each

other with top corner brackets, two LED message centers will be connected to support

“kickers” via angle brackets and 1/2" hardware. Refer to Drawing B-1102472.

Mechanical Installation 11

Page 18

3.7 Optional Top Ad Panel or Message Center Attachment

Reference Drawing:

Top 4-Side Ad Panel Mounting ............................................................... Drawing A-107665

Note: Make sure all power and signal wires are connected on top of the scoreboard

before mounting an ad panel/message center – it will be very difficult to make these

connections once upper display tiers have been added. Refer to Section 4.2.

Drawing A-107665 in Appendix E illustrates the parts used in this procedure. The ad panels

or the message centers are attached to the top of the scoreboard with mounting strips, and

then joined at the top with brackets.

1. Attach the mounting strips to the top of the scoreboard. The mounting strips are

fitted with 1/4" threaded inserts. Two mounting strips are required for each ad

panel/message center.

a. Position a mounting strip inside the top channel of the scoreboard section,

aligned with the holes in the rear flange.

b. Use the

scoreboards. The tapered washers allow the ad panels/message centers to be

supported in a vertical position while the scoreboard remains tilted out 10°.

2. Lift one ad panel/message center into place atop the scoreboard section, and align

the holes along the bottom of the rear flange with the threaded inserts in the

mounting strips.

3. Insert and tighten

4. Ask for assistance as needed to support the ad panel/message center section and

prevent it from tipping as the second ad panel/message center is lifted into place

adjacent to the first and secured to the frame.

5. Join the two ad panel/message center sections at their common top corner using a

top bracket and 3/8" hardware. Once the two sections are joined at the top, they will

not require additional support during assembly.

6. Attach the third ad panel/message center section to the mounting strips on the top of

the scoreboard and to the second section at the top corners.

7. Attach the fourth ad panel/message center section to the mounting strips on the top

of the scoreboard and to the third section at the top corners.

1

/4" bolts and tapered washers to attach the mounting strips to the

1

/4" bolts along the rear flange of the ad panel.

3.8 Optional Ad Panels on Message Centers

Repeat the mounting procedures detailed in the section above, with one major difference:

the ad panels and message centers are both vertical and do not require the alignment angle

change provided by the tapered washers, and therefore tapered washers will not be used. +

12 Mechanical Installation

Page 19

3.9 Attaching Corner Shrouds

Reference Drawing:

4-Side Installation Details ....................................................................... Drawing A-154598

Note: Make sure all power and signal wires are connected on top of the scoreboard

before attaching the corner shrouds. Refer to Section 4.2.

The corner shrouds are metal panels that cover the outside corners of the four-sided assembly

and hide the wiring between sections. Separate shrouds are provided for each display tier.

Refer to Detail C of Drawing A-154598 in Appendix E for corner shroud installation details.

1. Position and attach angle brackets to the side channel of each scoreboard, ad panel, or

message center section with the #10 screws provided.

2. Position each corner shroud across the appropriate corner and mark the locations of

the holes on the angle brackets.

3. Drill

4. Secure the corner shrouds to the corners with the #10 screws provided.

5

/32" holes as a guide for the screws.

3.10 Attaching Suspension Cables

Reference Drawings:

Sling Set: Standard 10' Square 4-Side Scoreboards ............................. Drawing A-181903

Sling Set: Standard 8' Square 4-Side Scoreboards ............................... Drawing A-181935

Sling Set: Standard 10' 4-Side Scoreboards .......................................... Drawing A-268195

The roof of the facility and any structures fabricated for suspending the scoreboard, as well as

the suspension cable slings, must be designed by or inspected and approved by a qualified

engineer. Drawing A-181903 and Drawing A-181935 in Appendix E show recommended

component specifications of cable slings (these are not typically provided by Daktronics).

Note: Refer to Drawing A-268195 for BB-2146 and BB-2147 models.

If the scoreboard is to be static mounted, that is, suspended from fixed cables without a hoist:

1. Attach the cables to the four lift tubes on the corner braces of the frame. The cables

may be connected together to make two attachment points, or all four cables may

attach to the roof trusses or the mounting structure.

2. Hang the top ends of the cables over the sides of the scoreboard to get them out of the

way yet keep them accessible when hooking up.

3. Lift the scoreboard using an appropriate means, such as a chain hoist, to the correct

suspension height.

4. Attach the top ends of the cables to the previously prepared mounting points.

5. Remove the temporary lifting apparatus and level the scoreboard by adjusting the

turnbuckles built into the slings.

Mechanical Installation 13

Page 20

If the scoreboard is to be suspended from a hoist:

1. Attach the cable sling to the four lift tubes on the corner braces of the frame.

2. Lower the hoist cables and attach them to the master links.

3. Raise the scoreboard 1-2' (305-610 mm) from the floor, and level the scoreboard by

adjusting the turnbuckles built into the slings.

4. The hoist installer must set upper and lower primary limits and all safety limits.

Daktronics recommends maintaining a minimum of 2' (610 mm) between the

scoreboard and the nearest obstruction.

WARNING! Never raise or lower the scoreboard with personnel or equipment underneath!

14 Mechanical Installation

Page 21

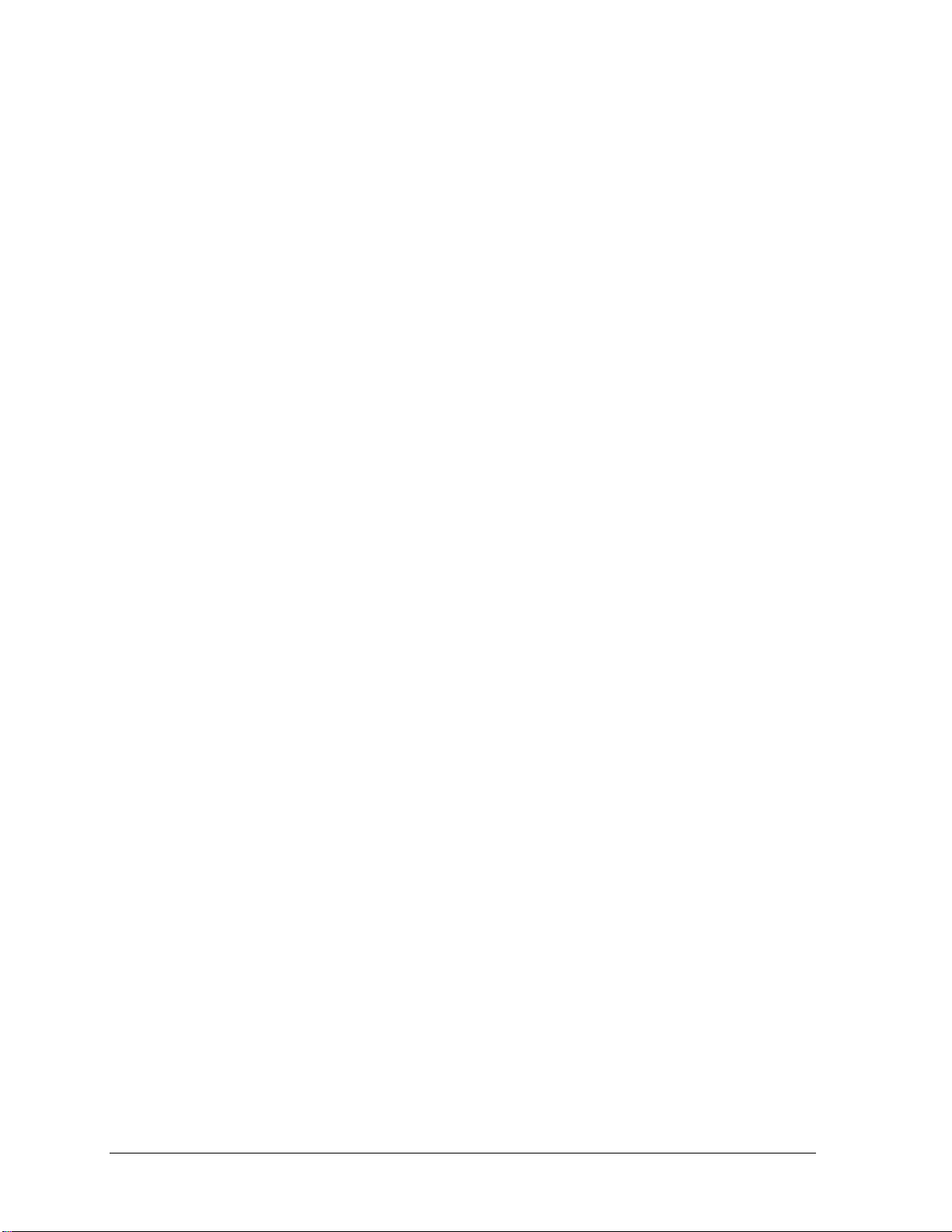

Figure 4: Wired Installation

Section 4: Electrical Installation

CAUTION: Only qualified individuals should access the electrical components of the display and its

associated equipment. It is the responsibility of the electrical contractor to ensure that all electrical

work meets or exceeds local and national codes.

Daktronics engineering staff must approve all changes or the warranty will be void.

4.1 Installation Overview

Electrical installation for four-sided scoreboards involves routing power and control signal

wiring through separate conduit or wire ways to the scoreboard location, as well as routing

power and signal wiring from section to section.

The diagram shown in Figure 4 illustrates a typical wired setup between the first scoreboard

section and the control system. Daktronics part numbers are shown in parentheses.

Note: Control signal cable and some junction boxes are not provided as part of this

system and can be purchased locally or from Daktronics.

Electrical Installation 15

Page 22

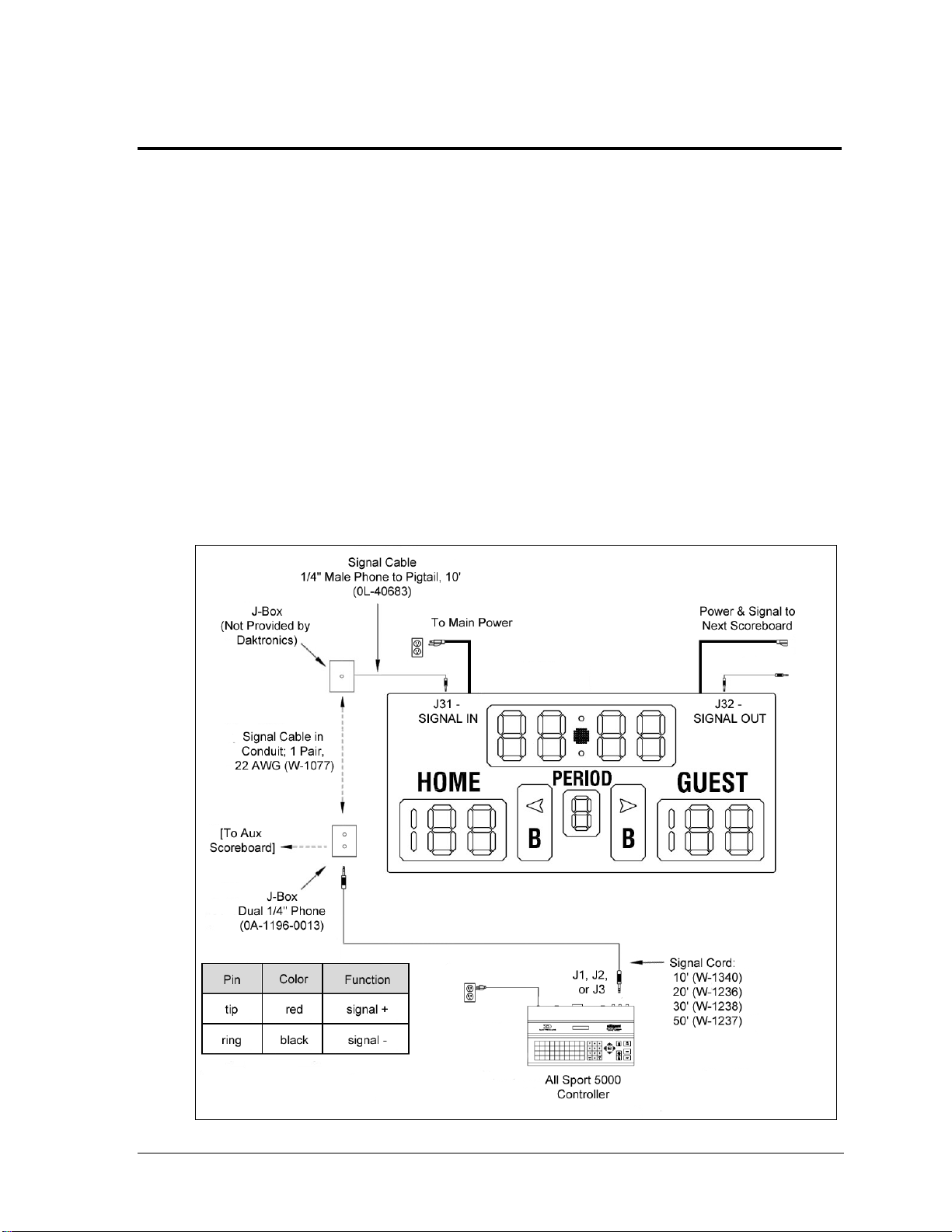

Figure 5: Wireless Installation

The diagram shown in Figure 5 illustrates a typical wireless setup between the first

scoreboard section and the control system. Refer to Section 6.2 for more information about

the wireless radio option.

4.2 Power/Signal Connections Between Sections

Reference Drawing:

Note: Be sure to make sectional power connections before connecting main power! It is also

recommended that these connections are made before the corner shrouds or optional top ad

panels/message centers are mounted into place.

16 Electrical Installation

Ad Panel/Message Center Hookup Overview, 4-Side ............................ Drawing A-154599

Connection Diagram; 4-Sided SS20i Series Displays ............................ Drawing A-822860

Page 23

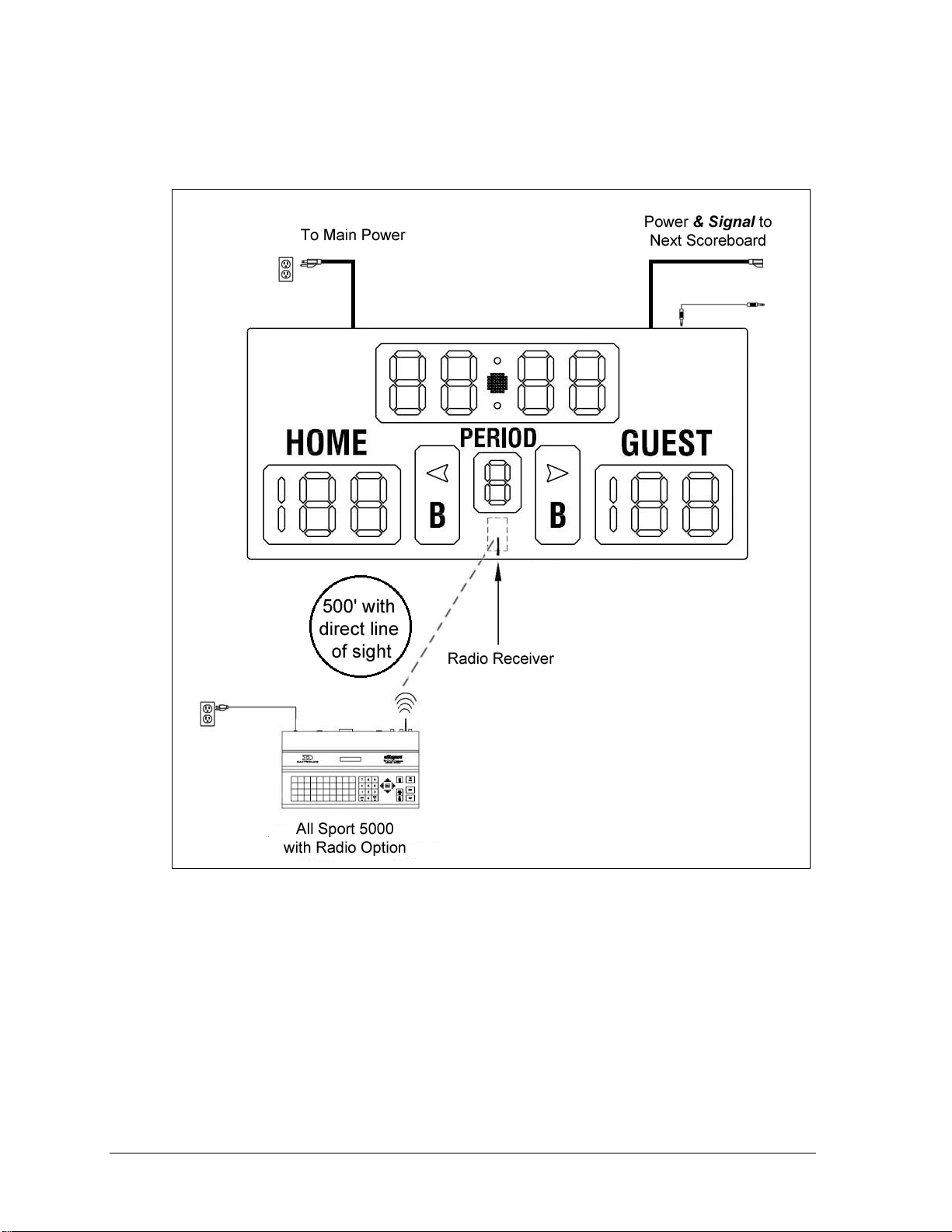

Figure 6: Scoreboard Power & Signal Connection, Top View

Scoreboard power and signal connectors are located on top of the scoreboard cabinet.

Input cables should be routed to the left, and output cables should be routed to the

right (as viewed from the front). The scoreboard section that will receive main

power/signal is designated “Face A”; all other sections are named in relation to it.

Power and signal flows to the right around the display from face output to face input.

Figure 7 shows the power and signal flow between sections. Main power and signal are

terminated last (refer to Sections 4.3 and 4.5, respectively).

Backlit ad panel and message center connectors are located on the sides of the

cabinets. Inputs are on the left, and outputs are on the right (as viewed from the front).

Each message center requires its own power input, while backlit ad panels may be

daisy-chained together for power, like scoreboards. Message center signal connections

use 6-pin RJ45 quick connect cables; main signal may be wired or wireless.

Refer to Drawing A-154599 in Appendix E for connection details of power and signal

from one backlit ad panel or message display section to the next. Refer to Drawing

A-822860 for additional message center connection details.

Electrical Installation 17

Page 24

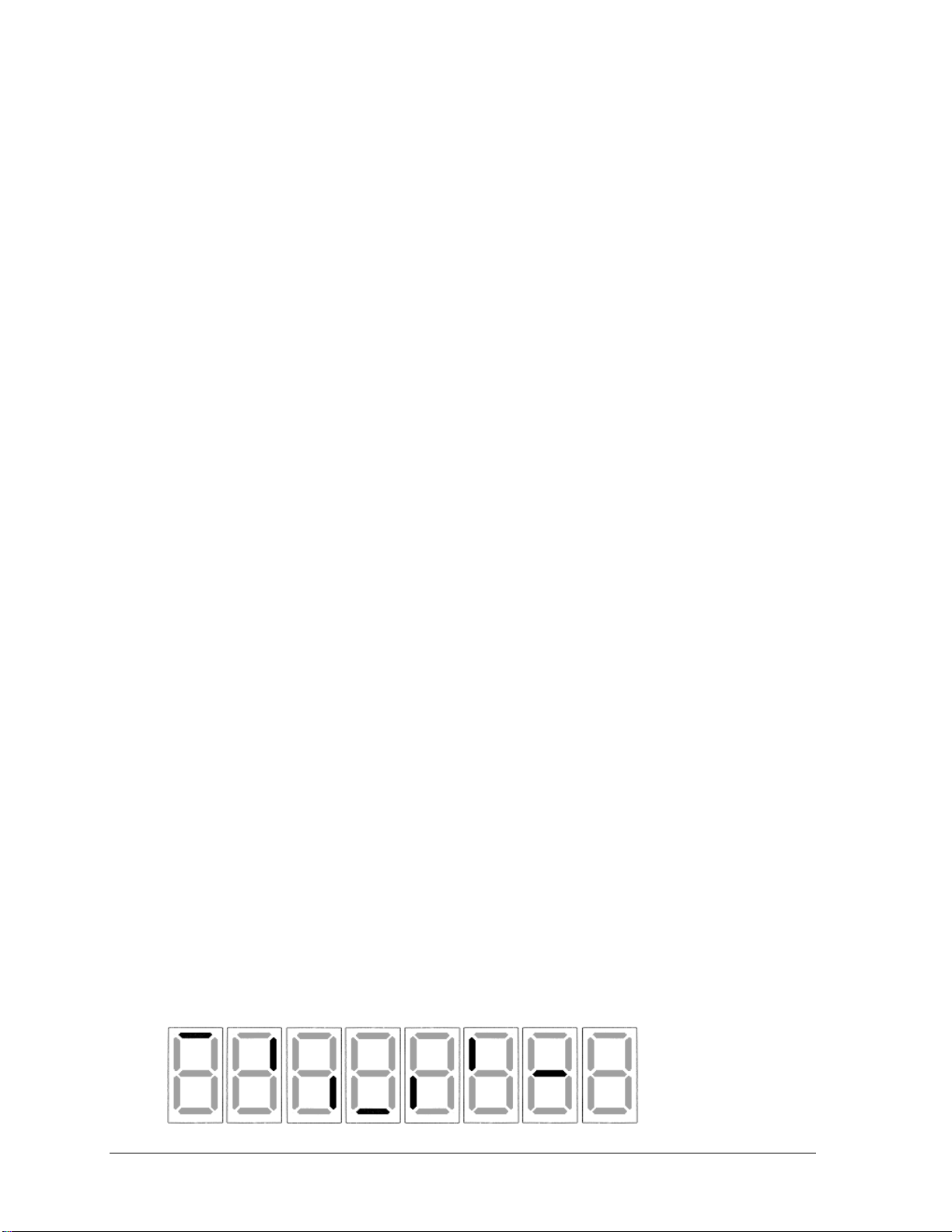

Figure 7: Digit Segment POST

Note: Standard power cords and signal cables are about 10' (3 m) long. If a hoist is used

for this installation, all main power/signal cables must be long enough to allow the

display to be lowered. An optional sheet metal floor may contain the cables when the

scoreboard is raised. If the scoreboard is static-mounted, the cables only need to be long

enough to provide service. Neatly tie excess lengths out of the way.

4.3 Main Power Connection

Note: Be sure to make sectional power connections before connecting main power!

Each scoreboard section includes two 120 VAC power cords: one for Power In and one for

Power Out.

1. Install a grounded 120 VAC receptacle near the scoreboard/backlit ad panel location

(each message center will require its own power receptacle). Try to mount it so that

the power cord is easily accessible to plug in and hidden from view, such as centered

above the display.

2. Determine which scoreboard/backlit ad panel section is closest to the grounded

receptacle, and plug in its power cord.

The control console requires a 120 VAC receptacle and uses less than 1 A of power.

Displays operating on 230 VAC are also available, and they are shipped equipped with

universal power plugs.

Grounding

Connect the scoreboard to earth ground. Proper grounding assures reliable equipment

operation and protects the equipment against damaging electrical disturbances and lightning.

Daktronics recommends a resistance-to-ground of 10 ohms or less. The electrical contractor

performing the electrical installation can verify ground resistance. Daktronics Sales and

Service personnel can also provide this service. The grounding connection on the power

cord‟s three-prong plug connects to the shell of the scoreboard.

Note: The customer must properly ground the outlet according to local and national

codes. Failure to ground the outlet voids the warranty for the scoreboard.

4.4 Power-On Self-Test (POST)

The scoreboard performs a self-test each time that power is turned on and the control console

is powered off or not attached to the scoreboard. If the control console is attached and

powered on, the self-test does not run, and data from the control console is displayed on the

scoreboard after a brief period of time. Each scoreboard self-test pattern will vary depending

on the scoreboard model, the number of drivers and types of digits. Figure 7 shows an

example of the LED bar test pattern that each digit performs.

18 Electrical Installation

Page 25

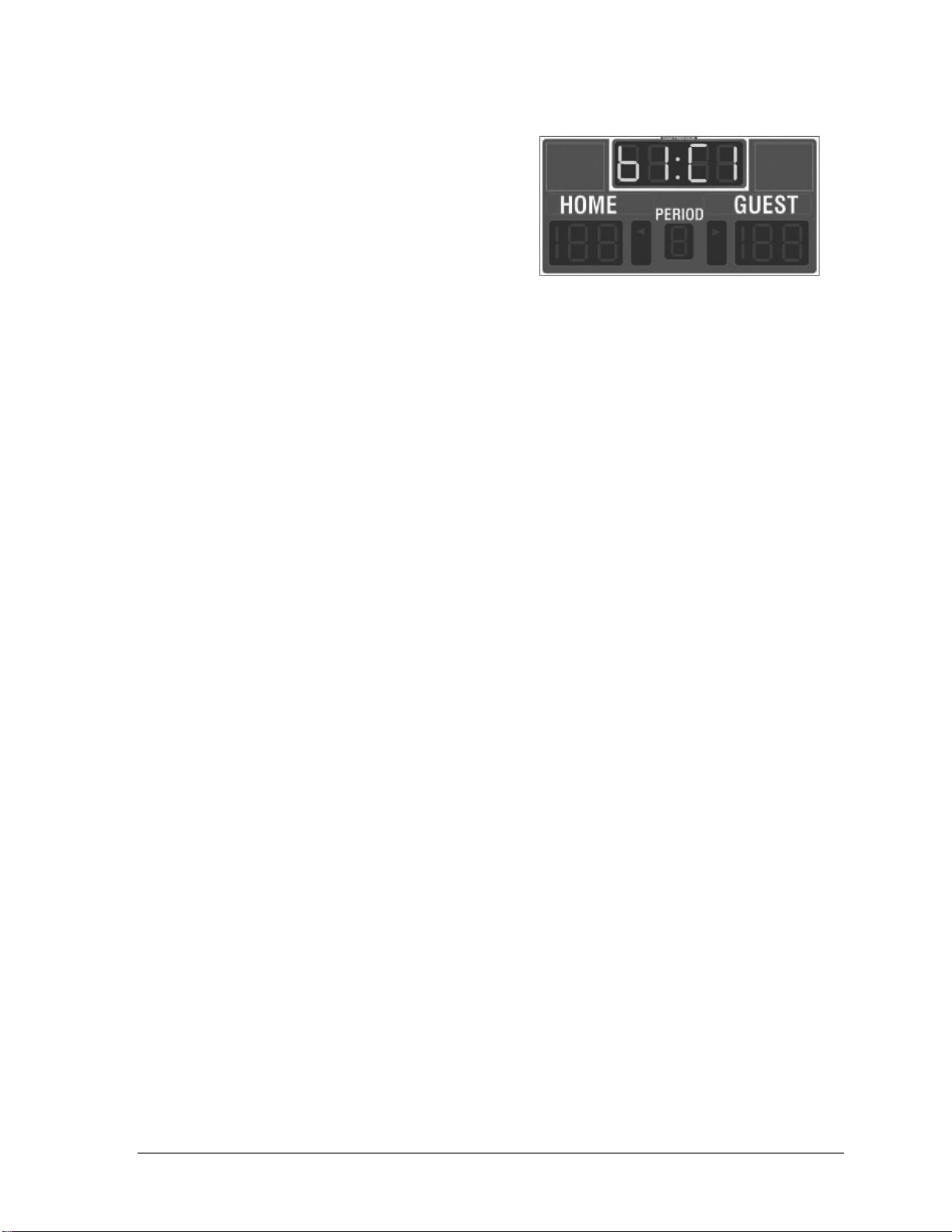

Figure 8: Radio Settings in Clock Digits

Radio Settings

If a radio receiver is installed (see Section 6.2),

the radio broadcast settings (“b1”) and the

channel settings (“C1”) will be displayed in the

Home and Guest or clock digits (Figure 8)

during the POST. These values must match the

settings in the control console (refer to the

appropriate control console manual listed in

Section 1.1).

4.5 Main Signal Connection

Signal installation (for systems without radio control) requires routing control cable from the

scoreboard control console to a signal junction box (J-box) near the display. Refer to Drawing

A-28124 and Drawing A-125316 in Appendix E for signal wire connection.

Note: For message center signal installation, including for BB-2146 and BB-2147 models,

refer to the SS Series 20mm Indoor Scoreboard Message Centers Installation &

Operation Manual (DD1564453).

1. At a minimum, use a paired, 22 AWG shielded cable (Daktronics part # W-1077) and

connect the cable to a dual

Using a dual J-box for separate Main and Auxiliary scoreboards lets operators control

several displays with one controller, and they can also switch jacks to control

individual boards using multiple controllers.

2. Install a J-box near the scoreboard location. Try to mount it so that the signal cable is

easily accessible to plug in and hidden from view, such as centered above the display.

3. Route signal cable from the J-box on the control console end to the J-box at the

display end.

4. Install the

1

/4" phone plug (Daktronics part # 0L-40683) to the display end of the

cable. Be sure to connect the cable shielding only in the J-box on this end.

5. Insert the plug into the J31 - SIGNAL IN jack located on the top of the scoreboard

section closest to the J-box.

6. Connect a signal cable from the J-box on the control console end to the J1, J2, or J3

jack on the back of the All Sport 5000 console.

If using a Main Clock Start/Stop Switch (Daktronics part # 0A-1166-0003), connect it

to the J4 jack on the All Sport 5000 console.

1

/4" J-box at the control console end.

Electrical Installation 19

Page 26

Page 27

Problem

Possible Cause

Solution/Items to Check

Scoreboard doesn’t light

and console doesn’t work

No power to the scoreboard

Check that the main circuit breaker

for the scoreboard is on.

Check that the scoreboard is

receiving 120 (or 230) VAC power.

No power to console

Ensure the console is plugged into a

120 (or 230) VAC power supply.

Swap the console with one known to

work correctly, and enter the proper

sport code to test. Replace console

if necessary.

Scoreboard digits don’t light,

but console works

No wired signal from console

Check that the scoreboard is

receiving 120 (or 230) VAC power.

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.4).

No radio signal from console

Cycle power to the scoreboard and

watch for radio receiver broadcast/

channel settings (see Section 4.4).

Check that the green POWER and

amber RADIO IN RANGE indicators

on the radio receiver in the

scoreboard light up when the control

console is powered on. Keep the

console between 20 to 500 feet from

the scoreboard.

Section 5: Maintenance & Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair work on the scoreboard.

2. Allow only qualified service personnel access to internal display electronics.

3. Disconnect power when not using the scoreboard.

5.1 Troubleshooting Table

The table below lists potential problems with the scoreboard and indicates possible causes

and corrective actions. This list does not include every symptom that may be encountered,

but it does present several of the most common situations that may occur.

Many of the solutions offered below provide references to other sections within this manual

or to supplemental product manuals with further detail on how to fix the problem.

If a problem occurs that is not listed or that cannot be resolved using the solutions in the

following table, contact Daktronics using the information provided in Section 5.9.

Maintenance & Troubleshooting 21

Page 28

Problem

Possible Cause

Solution/Items to Check

Move the console 20-30 feet from

the scoreboard and test again.

Verify that both the console and

scoreboard antennae are securely

tightened and in a vertical position.

Replace the radio receiver.

No signal to driver

Check that the scoreboard is

receiving 120 (or 230) VAC power.

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.4).

Swap the driver with one known to

work correctly and with the same

part number to verify the problem.

Replace if necessary (see Section

5.4).

No power to driver

Check that the green DS1 LED on

the driver is always lit up when the

scoreboard is powered on

(see Section 5.4).

Scoreboard digits light, but

not in the correct order

Incorrect sport code

Ensure the correct sport code is

being used for the scoreboard

model. Refer to the control console

operation manual (see Section 1.1).

Incorrect driver address

Check that the scoreboard driver(s)

are set to the correct address(es)

(see Section 5.4).

Scoreboard digits light,

console works, but no

display on scoreboard

No wired signal from console

(See solution on previous page)

No radio signal from console

(See solution on previous page)

Bad/damaged wiring

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.4).

Scoreboard works, but some

LEDs always stay on

Short in digit or indicator circuit

Swap the digit/indicator with one

known to work correctly to verify the

problem. Replace if necessary (see

Section 5.3).

Scoreboard works, but some

LEDs do not light or they

blink

Bad connection

Verify the power/signal connector on

the back of the digit circuit board is

secure (see Section 5.3).

Bad digit or driver

Swap the digit/driver with one known

to work correctly to verify the

problem. Replace if necessary

(see Section 5.3 for digits or

Section 5.4 for drivers).

22 Maintenance & Troubleshooting

Page 29

Problem

Possible Cause

Solution/Items to Check

Scoreboard works, but some

digits do not light

Bad digit or driver

(see solution on previous page)

Incorrect sport code

(see solution on previous page)

Incorrect driver address

(see solution on previous page)

Wrong console controlling

scoreboard

Another console’s radio signal could

be transmitting to the scoreboard.

Radio interference

There may be other radio

transmissions in the area that

overpower the console. If it is not

possible to disable the interfering

device, It may be necessary to run a

wired signal connection instead.

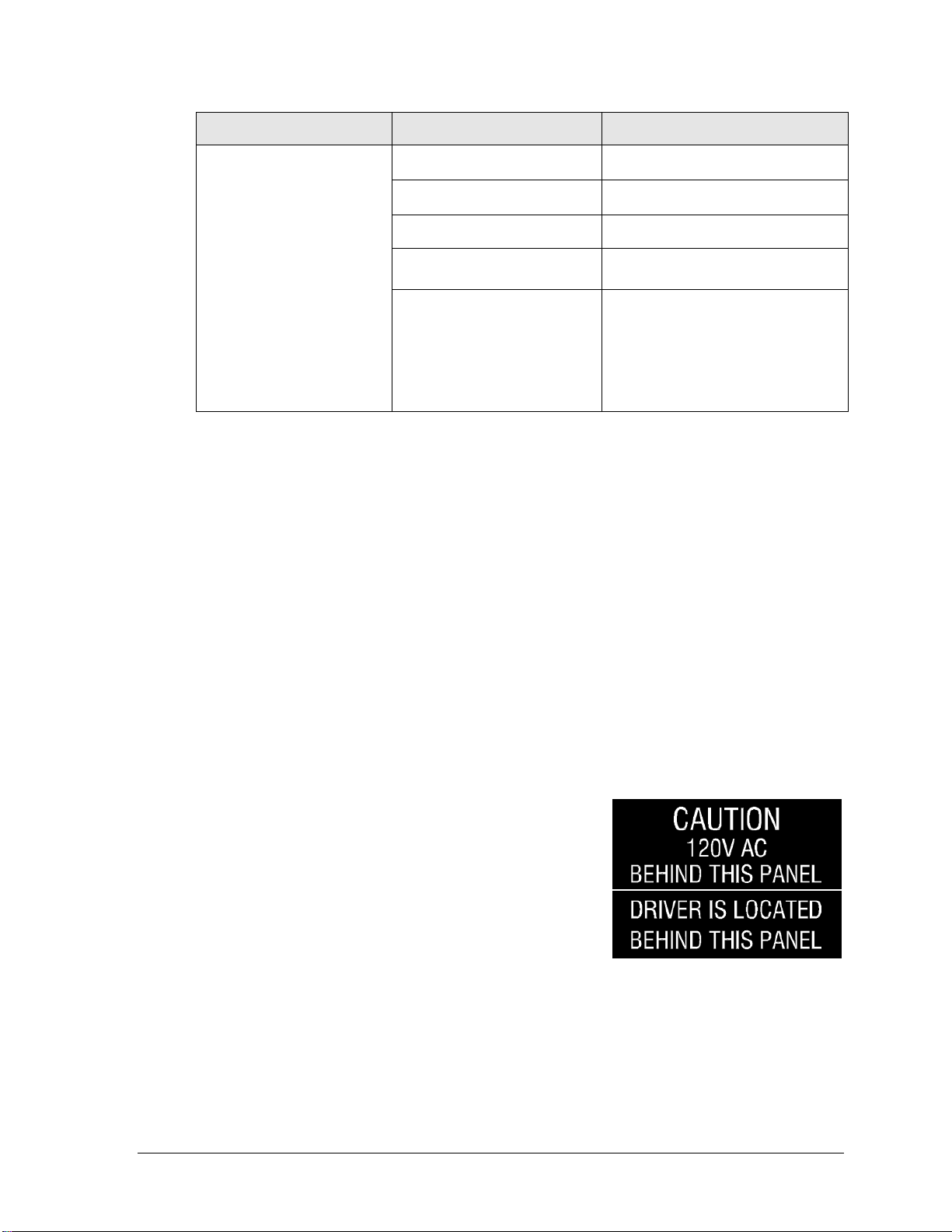

Figure 9: Power Warning Label

Note: For message center maintenance and troubleshooting for BB-2146 and BB-2147 models,

refer to the SS Series 20mm Indoor Scoreboard Message Centers Installation & Operation

Manual (DD1564453).

5.2 Component Location & Access

All Tuff Sport indoor basketball displays are front-access scoreboards, meaning that internal

electronic components and digits are reached by opening a face panel, an access door, or a

digit panel on the front of the display.

Digit panels are typically held in place on the scoreboard face by two screws. To remove a

digit, simply unfasten the screws and carefully lift it from the cabinet. The power/signal plug

can then be removed from the connector on the back of the digit to completely free the digit

and access internal components.

Remove non-digit access panels by unfastening the top, side or bottom screws holding it in

place. Some panels are hinged and swing open when the screws are removed or loosened.

Component location varies with each scoreboard model,

but drivers and power and signal components are

typically mounted inside the scoreboard behind a digit

panel. To locate the driver(s), look for a warning label

similar to that shown in Figure 9.

Refer to the electrical and signal specification drawings in

Appendix B for model-specific component layouts and

access locations.

Maintenance & Troubleshooting 23

Page 30

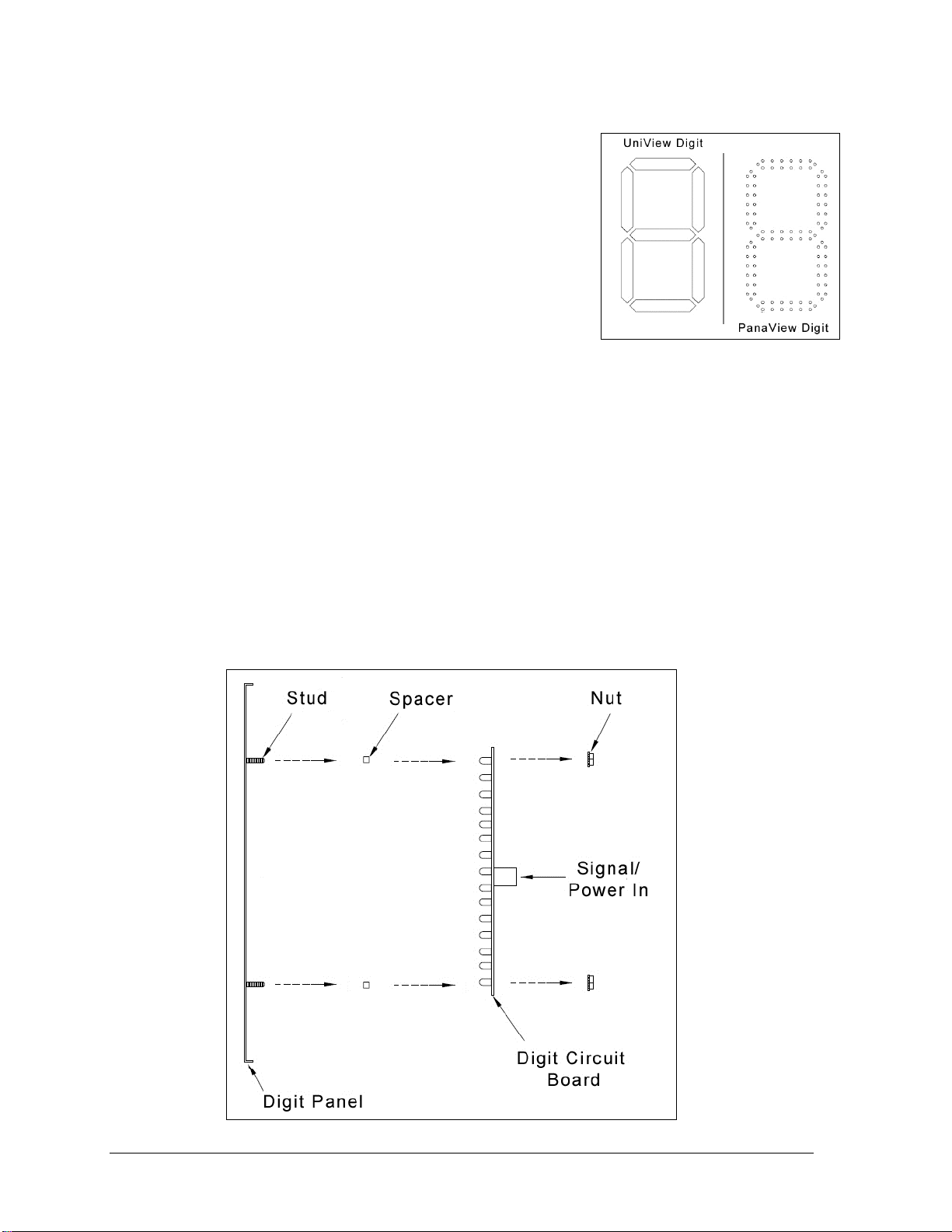

Figure 10: Digit Types

Figure 11: PanaView Digit Assembly

5.3 Replacing Digits

LEDs are embedded in a circuit board that is mounted to the

back of the digit panel. Do not attempt to remove individual

LEDs. In the case of a malfunctioning LED or digit segment,

replace the entire digit circuit board.

The process of replacing digits varies by whether it is a

PanaView digit or UniView digit (Figure 10).

PanaView

To replace a PanaView digit circuit board (Figure 11):

1. Open the digit panel as described in Section 5.2.

2. Disconnect the power/signal connector from the back of the digit by squeezing

together the locking tabs and pulling the connector free.

3. Use a

4. Position a new digit over the studs (making sure the small plastic spacers are still in

5. Reconnect the power/signal connector.

6. Secure the digit panel to the display with the two screws, then power up and test the

9

/32" nut driver to remove the nuts securing the digits to the inside of the panel,

and then lift the digit off the stud inserts.

place) and tighten the nuts.

Note: This is a keyed connector and it will attach in one way only. Do not attempt to

force the connection.

display to see if changing the digit has resolved the problem.

24 Maintenance & Troubleshooting

Page 31

Figure 12: UniView Digit Assembly

UniView

To replace a UniView digit circuit board (Figure 12):

1. Open the digit panel as described in Section 5.2.

2. Disconnect the power/signal connector from the back of the digit by squeezing

together the locking tabs and pulling the connector free.

3. Use a

4. Position a new digit over the standoffs, and tighten the nuts. It may be necessary to

5. Reconnect the power/signal connector.

6. Secure the digit panel to the display with the two screws, then power up and test the

9

/32" nut driver to remove the nuts securing the digits to the aluminum

standoffs, and then lift the digit off the standoff/diffuser assembly.

also tighten the standoffs if they became loose while removing the nuts.

Note: This is a keyed connector and it will attach in one way only. Do not attempt to

force the connection.

display to see if changing the digit has resolved the problem.

Maintenance & Troubleshooting 25

Page 32

Figure 13: Driver Enclosure Location & Components

5.4 LED Drivers

In each scoreboard, one or more LED drivers perform the task of switching LEDs on and off.

LED drivers are located inside of a driver enclosure. Refer to Figure 13 to view the location

and components of a Tuff Sport driver enclosure.

All scoreboards in this manual use 16-column drivers (Figure 13). Some scoreboard models

contain more than one driver to accommodate all of the digits and indicators. Refer to the

electrical and signal specifications in Appendix B to determine the type and number of

drivers for a particular scoreboard model.

Each driver has numerous connectors providing power and signal inputs and outputs to the

scoreboard digits and indicators. The table on the following page shows the function of these

connectors for a 16-column driver:

26 Maintenance & Troubleshooting

Page 33

Connector #

Function

1-16

Output to digits and indicators

17

Control signal

18

Control for horn

19

Address

LED

Color

Function

Operation

Summary

DS1

Green

Power

Steady on

DS1 will be on and steady to indicate the driver

has power.

DS2

Red

Signal RX

Steady on

or blinking

DS2 will be on or blinking when the driver is

receiving a signal and off when there is no signal.

DS3

Amber

Status

Blinking

DS3 will be blinking at one second intervals to

indicate the driver is running.

Figure 14: Driver Status Indicators

Refer to Drawing A-126174 in Appendix E for detailed driver pin out/switch specifications.

When troubleshooting driver problems, three LEDs labeled DS1, DS2, and DS3, provide the

following diagnostic information:

Note: While it is necessary to have the scoreboard powered on to check the LED driver

status indicators, always disconnect scoreboard power before servicing.

Maintenance & Troubleshooting 27

Page 34

Figure 15: Address Jack J19

Replacing a Driver

If the driver status indicators do not appear to be working correctly, it may be necessary to

replace the driver.

1. Open the digit panel or scoreboard face panel as described in Section 5.2.

2. Disconnect all connectors from the driver by squeezing together the locking tabs and

pulling the connectors free.

Note: It may be helpful to label the cables to know which cable goes to which

connector when reattaching the driver.

3. Remove the wing nuts securing the driver to the driver tray.

4. Carefully lift the driver from the display and place it on a clean, flat surface.

5. Position a new driver over the screws and tighten the nuts.

6. Reconnect all power/signal connectors.

Note: The connectors are keyed and will attach in one way only. Do not attempt to

force the connections.

7. Ensure the driver is set to the correct address (refer to Setting the Driver Address).

8. Close and secure the access panel, then power up and test the scoreboard to see if

changing the driver has resolved the problem.

Setting the Driver Address

Since the same LED drivers can be used for many

scoreboard models, each driver must be set to receive

the correct signal input, or address, for the model

being used. This address is set with jumper wires in a

12-pin plug which mates with jack J19 on the driver

(Figure 15).

It may be possible to reuse the same address plug

from the driver that was replaced. If not, first refer to

the specifications table in Section 2 to find the correct

driver address(es) for a particular scoreboard model.

Then refer to Drawing A-115078 in Appendix E for a

listing of the wire/pin connections for driver

addresses 1 – 128.

Multiple Drivers

Scoreboards that require multiple drivers operate using a master/slave driver configuration.

Master and slave drivers function identically, but slave units lack the power/signal

termination blocks. The two drivers have been designed to simply plug into one another, and

this is done at the factory, so no additional on-site connection is necessary.

If it appears as though only a certain group of digits on the scoreboard is not functioning,

there may be a problem with the slave driver(s) or the power/signal connection from the

other driver(s).

28 Maintenance & Troubleshooting

Page 35

Model

Drawing Title

Drawing Number

BB-2102 BB-2146

BB-2104 BB-2147

BB-2106 BB-2154

BB-2108 BB-2156

BB-2126

Schematic- 16V 1 Driver- 120 or 230VAC

A-158348

BB-2124

Schematic, 16V 2 Driver, 120 or 230 VAC

B-158859

5.5 Segmentation and Digit Designation

In each digit, certain LEDs always go on and off together. These groupings of LEDs are called

segments. Drawing A-38532 in Appendix E details which connector pin is wired to each digit

segment and the wiring color code used throughout the display.

The electrical and signal specification drawings in Appendix B specify the driver connectors

controlling the digits. Numbers shown in hexagons in the upper half of each digit indicate

which connector is wired to that digit.

5.6 Schematics

For advanced scoreboard troubleshooting and repair, it may be necessary to consult the

schematic drawings. Located in Appendix D, schematic drawings show detailed power and

signal wiring diagrams of internal display components such as drivers, horn interface cards,

and transformers as well as optional components like TNMCs and radio receivers.

5.7 Suspension System Periodic Inspections

Suspension systems need to be inspected periodically. Listed below are instructions and

information about such inspections.

Static System

A static-hung system should be inspected one year after initial installation and once every

five years thereafter.

Inspect cable assemblies for broken wires, crushes, or kinks.

Inspect components, per manufacturer's recommendations, for deformations.

Inspect the four-sided scoreboard for any loose or missing bolts.

Inspect the attachment bracket for loose bolts or cracks in members or welds.

Check torque on all wire rope clips.

Hoist System

Hoist systems must be inspected annually per OSHA requirements. Some local governing

bodies require more frequent inspections. See the hoist manufacturer's manual for inspection

procedures.

Inspect cable assemblies for broken wires, crushes, or kinks.

Inspect connections for loose bolts or cracks in members or welds.

Be sure to document all inspections. Any irregularities must be addressed immediately.

For installation problems, call the original installer; for hoist problems, contact the hoist

Maintenance & Troubleshooting 29

manufacturer.

Page 36

Description

Daktronics Part #

Horn, 120V with capacitor

0A-1152-0332

Main clock, start/stop switch

0A-1166-0003

Shot clock, start/stop switch

0A-1196-0031

LED driver, 16-column

0P-1150-0126

16 V AC LED VHI

0P-1150-0233

PanaView Digit, 7” red LED, 7-seg

0P-1230-0048

PanaView Digit, 7” amber LED, 7-seg

0P-1230-0049

PanaView Digit, 7” red LED, 2-seg

0P-1230-0058

PanaView Digit, 7” amber LED, 2-seg

0P-1230-0059

PanaView Digit, 10” red LED, 7-seg

0P-1230-0050

PanaView Digit, 10” amber LED, 7-seg

0P-1230-0051

PanaView Digit, 10” red LED, 2-seg

0P-1230-0060

PanaView Digit, 10” amber LED, 2-seg

0P-1230-0061

PanaView Digit, 13” red LED, 7-seg

0P-1230-0052

PanaView Digit, 13” amber LED, 7-seg

0P-1230-0053

PanaView Digit, 13” red LED, 2-seg

0P-1230-0062

PanaView Digit, 13” amber LED, 2-seg

0P-1230-0063

PanaView B-Bonus Indicator, Amber

0P-1150-0217

PanaView Arrow, Red, 3”

0P-1150-0185

PanaView Arrow, Amber, 3”

0P-1150-0164

PanaView Colon, Red

0P-1230-0070

PanaView Colon, Amber

0P-1230-0071

UniView Digit, 7” Red LED, 7-seg

0P-1230-0023

UniView Digit, 7” Amber LED, 7-seg

0P-1230-0024

UniView Digit, 7” Red LED, 2-seg

0P-1230-0031

UniView Digit, 7” Amber LED, 2-seg

0P-1230-0032

UniView Digit, 10” Red LED, 7-seg

0P-1230-0025

UniView Digit, 10” Amber LED, 7-seg

0P-1230-0026

UniView Digit, 10” Red LED, 2-seg

0P-1230-0033

UniView Digit, 10” Amber LED, 2-seg

0P-1230-0034

UniView Digit, 13” Red LED, 7-seg

0P-1230-0027

UniView Digit, 13” Amber LED, 7-seg

0P-1230-0028

UniView Digit, 13” Red LED, 2-seg

0P-1230-0035

UniView Digit, 13” Amber LED, 2-seg

0P-1230-0036

UniView 1 Position Indicator, Red

0P-1230-0037

UniView 3 Position Indicator, Red & Amber

0P-1230-0038

UniView B-Bonus Indicator & Arrow, Amber

0P-1230-0039

UniView Colon, Red

0P-1230-0068

UniView Colon, Amber

0P-1230-0069

Transformer, 120P/16S, 6.3 A

T-1066

Cable, 20' phone plug

W-1236

Cable, 50' phone plug

W-1237

Cable, 30' phone plug

W-1238

Cable, 10' phone plug

W-1340

5.8 Replacement Parts List

Refer to the following table for Daktronics scoreboard replacement parts.

30 Maintenance & Troubleshooting

Page 37

Market Description

Customer Service Number

Schools (including community/junior colleges), religious

organizations, municipal clubs and community centers

877-605-1115

Universities and professional sporting events, live events

for auditoriums and arenas

866-343-6018

5.9 Daktronics Exchange and Repair & Return Programs

Exchange Program

The Daktronics Exchange Program is a quick, economical service for replacing key

components in need of repair. If a component fails, Daktronics sends a replacement part to

the customer who, in turn, returns the failed component to Daktronics. This not only saves

money but also decreases equipment downtime. Customers who follow the program

guidelines explained below will receive this service.

Before Contacting Daktronics

Identify these important numbers:

Display Serial Number: _________________________________________________________

Display Model Number: _________________________________________________________

Job/Contract Number: __________________________________________________________

Date Installed: _________________________________________________________________

Daktronics Customer ID Number: ________________________________________________

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service.

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part being replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. The defective or unused parts must be returned to Daktronics within 5 weeks of

initial order shipment.

If any part is not returned within five (5) weeks, a non-refundable invoice will be

presented to the customer for the costs of replenishing the exchange parts inventory

with a new part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of

nature or causes other than normal wear and tear.

Maintenance & Troubleshooting 31

Page 38

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Refer to the appropriate market number in the chart listed on the previous page.

Fax: 605-697-4444

2. Receive a case number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend using packing „peanuts‟

when shipping.

4. Enclose:

name

address

phone number

the case number

a clear description of symptoms

Shipping Address

Daktronics Customer Service

[Case #]

201 Daktronics Drive, Dock E

Brookings, SD 57006

Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix G. The Warranty

is independent of Extended Service agreements and is the authority in matters of service,

repair, and display operation.

32 Maintenance & Troubleshooting

Page 39

Section 6: Scoreboard Options

6.1 Horns

Daktronics Tuff Sport scoreboards are equipped with a 120 VAC vibrating horn mounted

behind the scoreboard face. The horn sounds automatically when the period clock counts

down to zero, or when manually triggered by the operator using the control console.

Installation of an optional 12 VDC horn is detailed in Drawing A-148960 in Appendix C.

Louder trumpet horns are also available. Contact Daktronics for information and pricing.

Adjusting Horn Volume

CAUTION: The scoreboard horn is a 120 VAC device. Turn off the power to the scoreboard

before adjusting the horn.

The volume for the electronic, buzzer-type horn is set at its maximum level at the factory. If

the horn is too loud, reduce its volume by adjusting the setscrew mounted in the front of the

horn. A plastic tip on the screw touches the horn's diaphragm, reducing the volume. Turn the

screw clockwise and test the volume by operating the horn from the scoreboard control

console. Continue adjusting and testing until the desired volume level is obtained.

Note that with the noise of spectators, the horn will not seem as loud as when it is being

tested in an empty area, so be sure to set the volume according to the acoustics of the facility.

6.2 Radio Control

Radio control is an option for Daktronics Tuff Sport scoreboards. The system provides

scoreboard control via a 2.4 GHz, extra-high frequency FM signal.

The radio transmitter and receiver are not standard equipment. This setup requires a control

console equipped with a radio transmitter as well as a radio receiver plugged into the

driver/power enclosure and mounted internally to the front panel of the scoreboard.

For additional information about this option, contact a Daktronics representative; for

complete information on setting up radio communication control, refer to the Gen V Radio

Installation Manual (ED-13831) or the Gen VI Radio Installation Manual (DD2362277),

both available online at www.daktronics.com/manuals.

6.3 Visual Horn Indicator (VHI)

In addition to the horn, Daktronics offers both incandescent and LED visual horn indicators

that light up when the buzzer sounds. To install the VHI, users must tap into the existing

horn wiring to provide power and signal. For more information about installing the VHI

options, refer to the Visual Horn Indicator Installation Instructions (ED-13397) or the

BB-2133 LED Indicator Installation Instructions (ED-13806). Both manuals are available

online at www.daktronics.com/manuals.

Scoreboard Options 33

Page 40

6.4 Changeable Captions

Team name and statistics caption kits contain hardware for one caption only and consist of an

upper caption retainer, a lower caption retainer, a changeable caption panel and screws.

The standard HOME and GUEST captions are applied directly to the face of the scoreboard.

Team name captions are on changeable panels that fit into retainers mounted above and

below the standard captions. If these retainers are not already present, attach the retainers

included with the caption kit.

Refer to Drawing A-150021 in Appendix C for changeable caption installation instructions.

6.5 Double Bonus Indicators

All of the clock/score basketball scoreboards in this manual have the option to include

double-bonus indicators, which are factory installed. This option is illustrated in the electrical

and signal specification drawings in Appendix B for each scoreboard model.

6.6 Time Outs Left (TOL) Digits

Certain scoreboards have the option to add a time outs left (TOL) digit for both the home and

guest teams. These digits are installed by simply unscrewing the blank face panel, connecting

and securing the digit, and manually applying the “T.O.L.” caption. Refer to Drawing A-

149030 in Appendix C for more information.

6.7 Team Name Message Centers

Refer to Section 7 for more information about Team Name Message Centers.

34 Scoreboard Options

Page 41

Matrix Size

Number of

Modules

Pixel Spacing

Active Display Area

Weight*

8x48

3

19 mm (0.75")

6" x 36" (152 mm x 914 mm)

15 lb (7 kg)

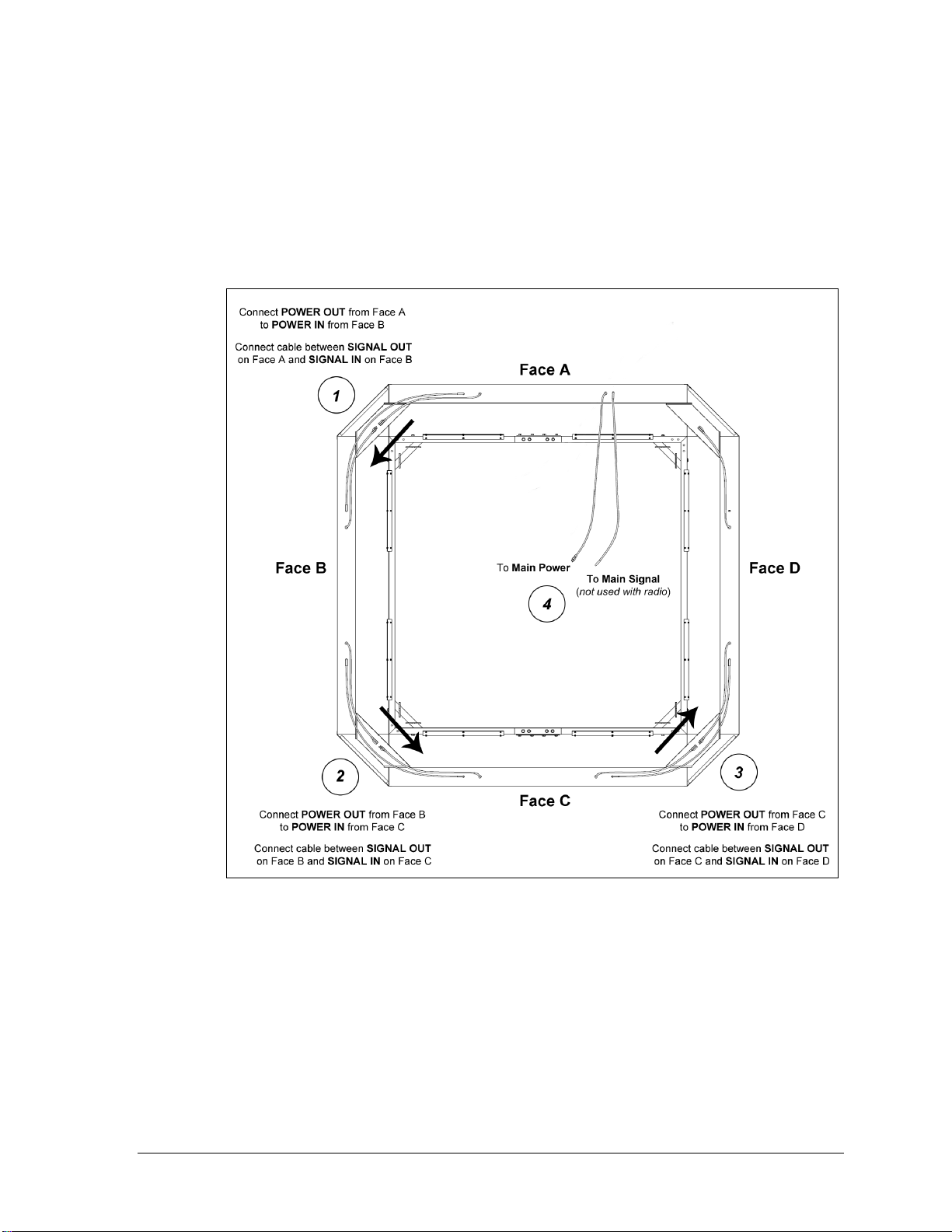

Figure 16: Basketball Scoreboard with TNMCs

TNMC

Section 7: TNMC Troubleshooting & Maintenance

IMPORTANT NOTES:

1. Always disconnect scoreboard power before doing any repair/maintenance work on the

message centers.

2. Permit only qualified service personnel to access internal display electronics.

3. Disconnect power when not using the scoreboard.

7.1 Display Overview

Team Name Message Centers (TNMCs) are programmable LED displays that allow users to

show custom Home and Guest names or messages of ~15 characters on the scoreboard in

place of static vinyl captions. TNMCs are typically ordered factory-installed, but they may

also be field-mounted after the scoreboard is in place. Characters are shown on one line using

single- or double-stroke fonts.