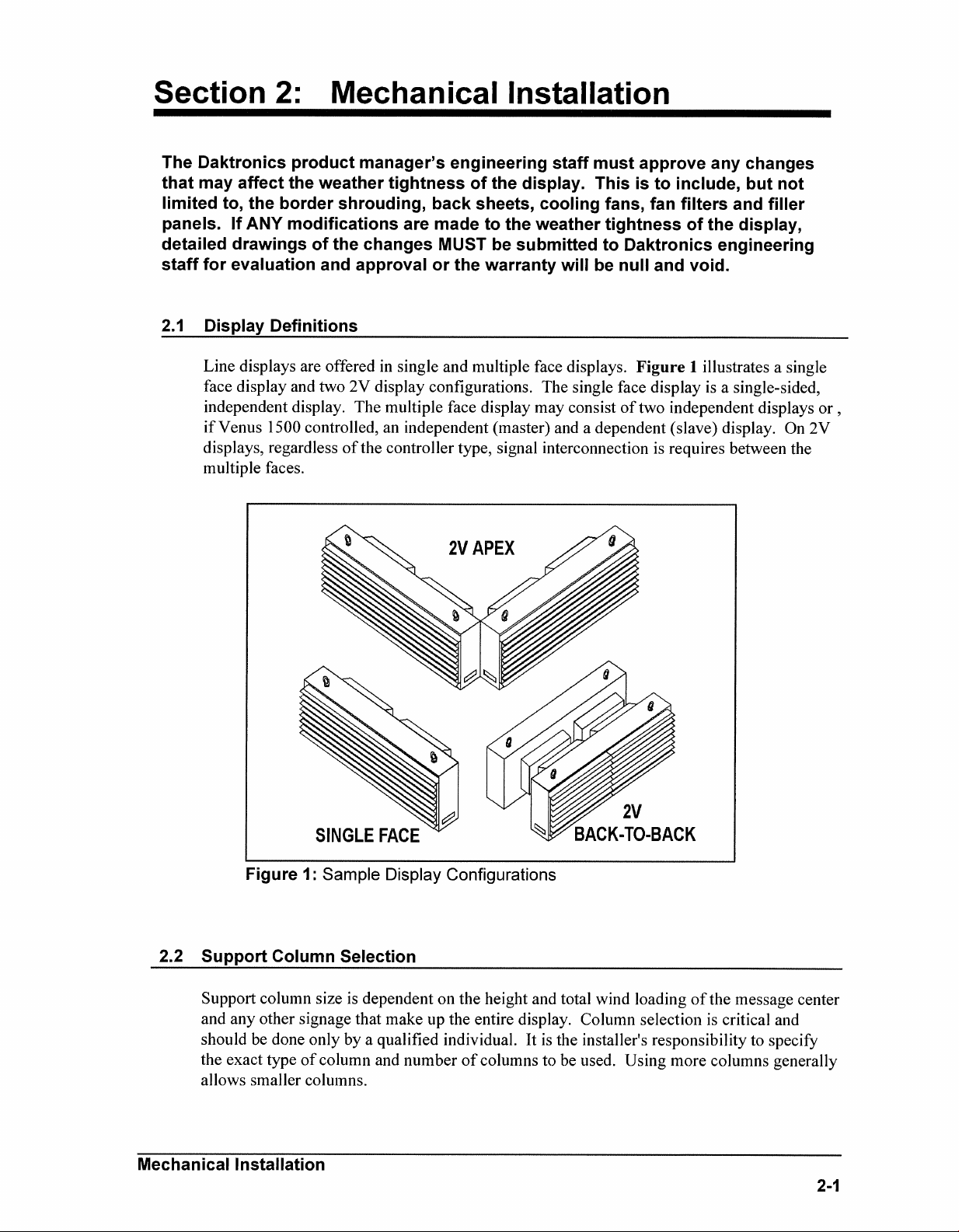

Page 1

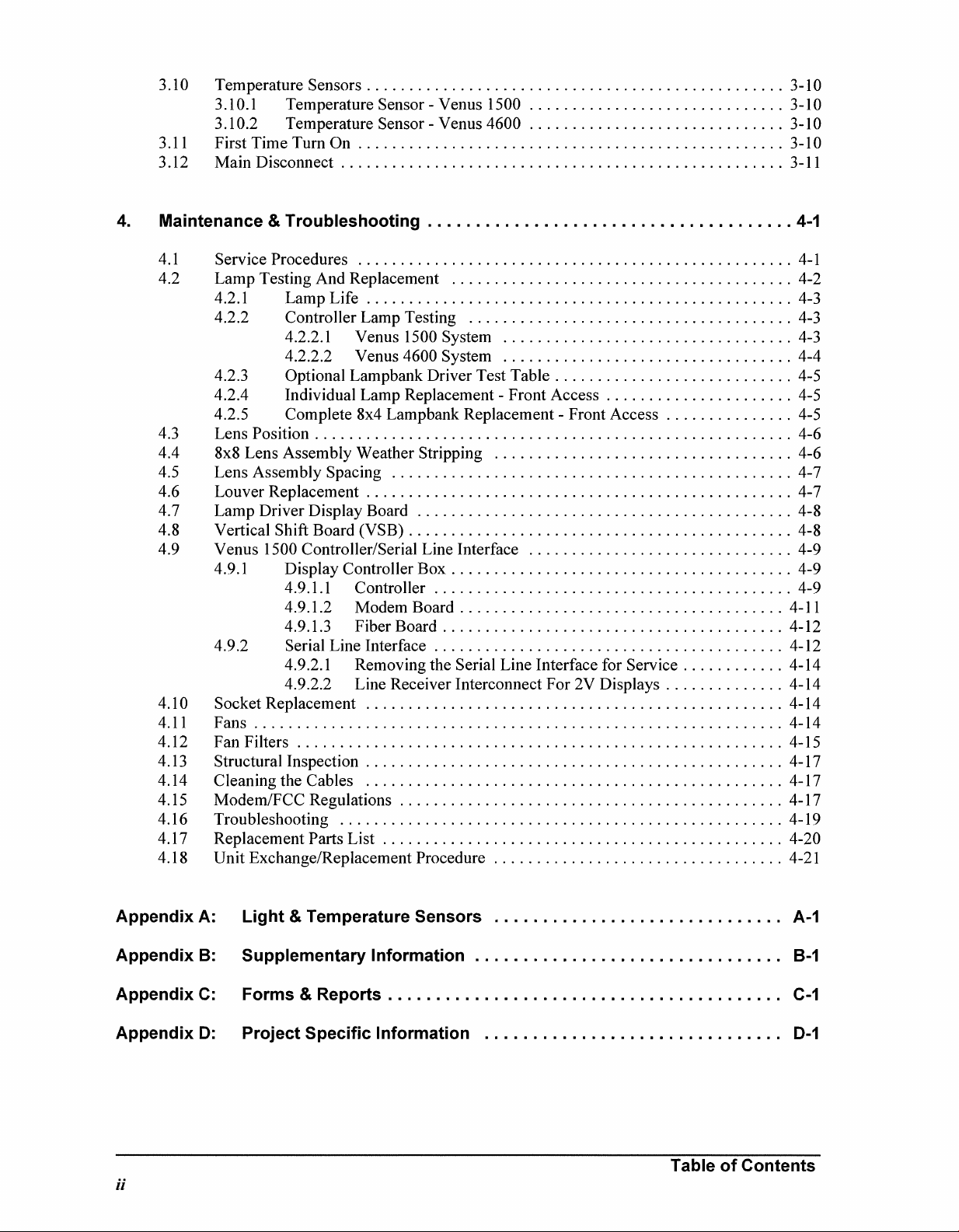

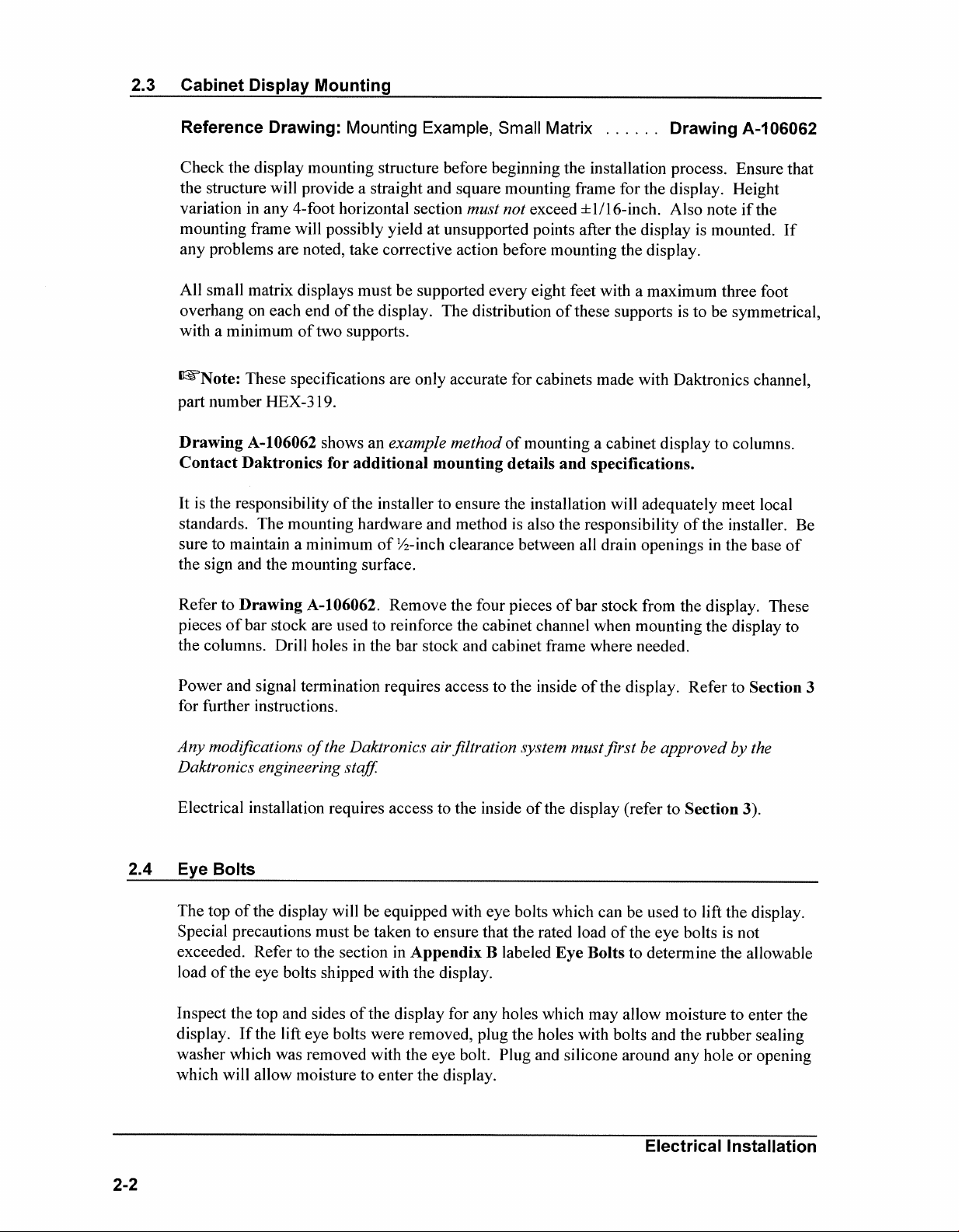

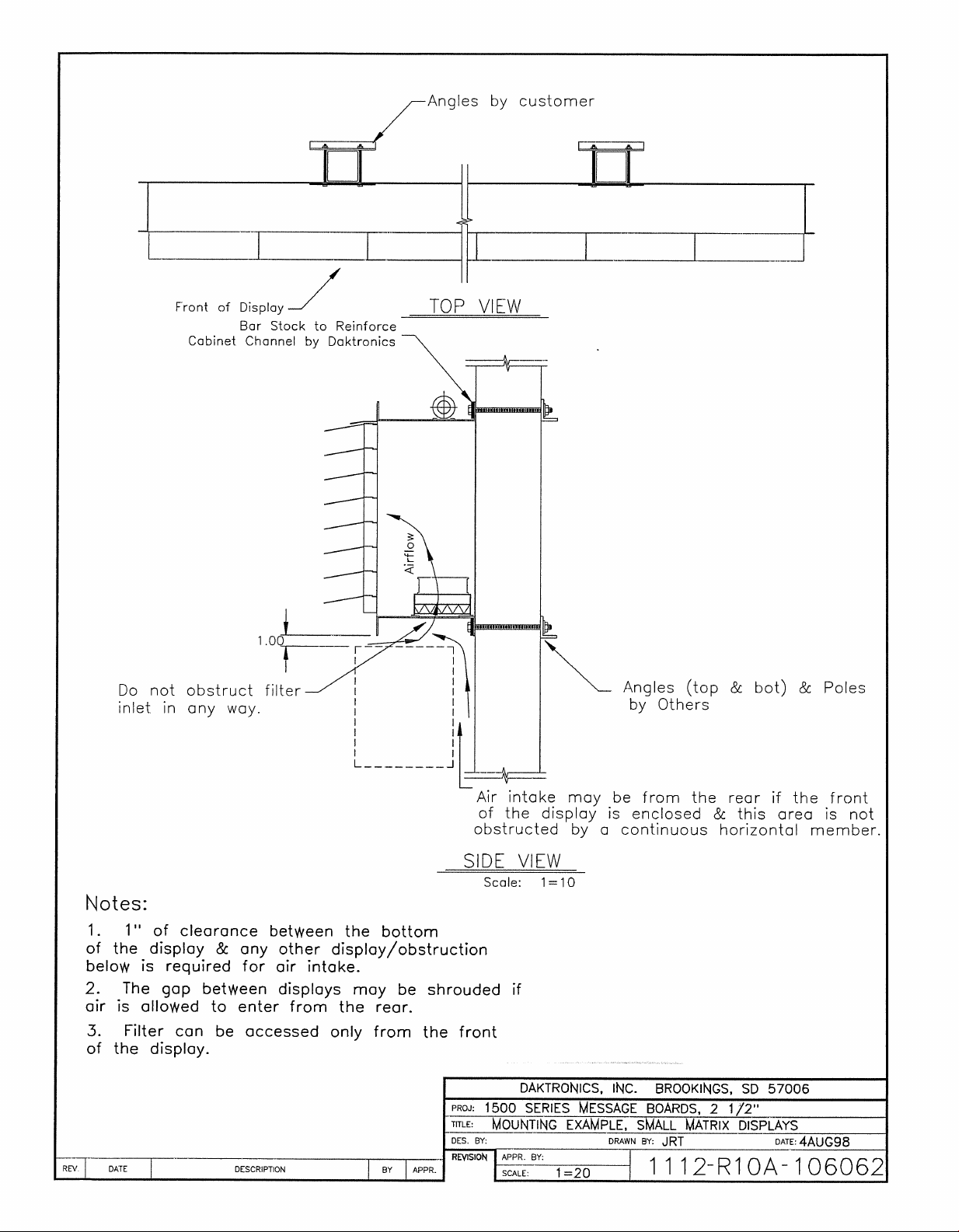

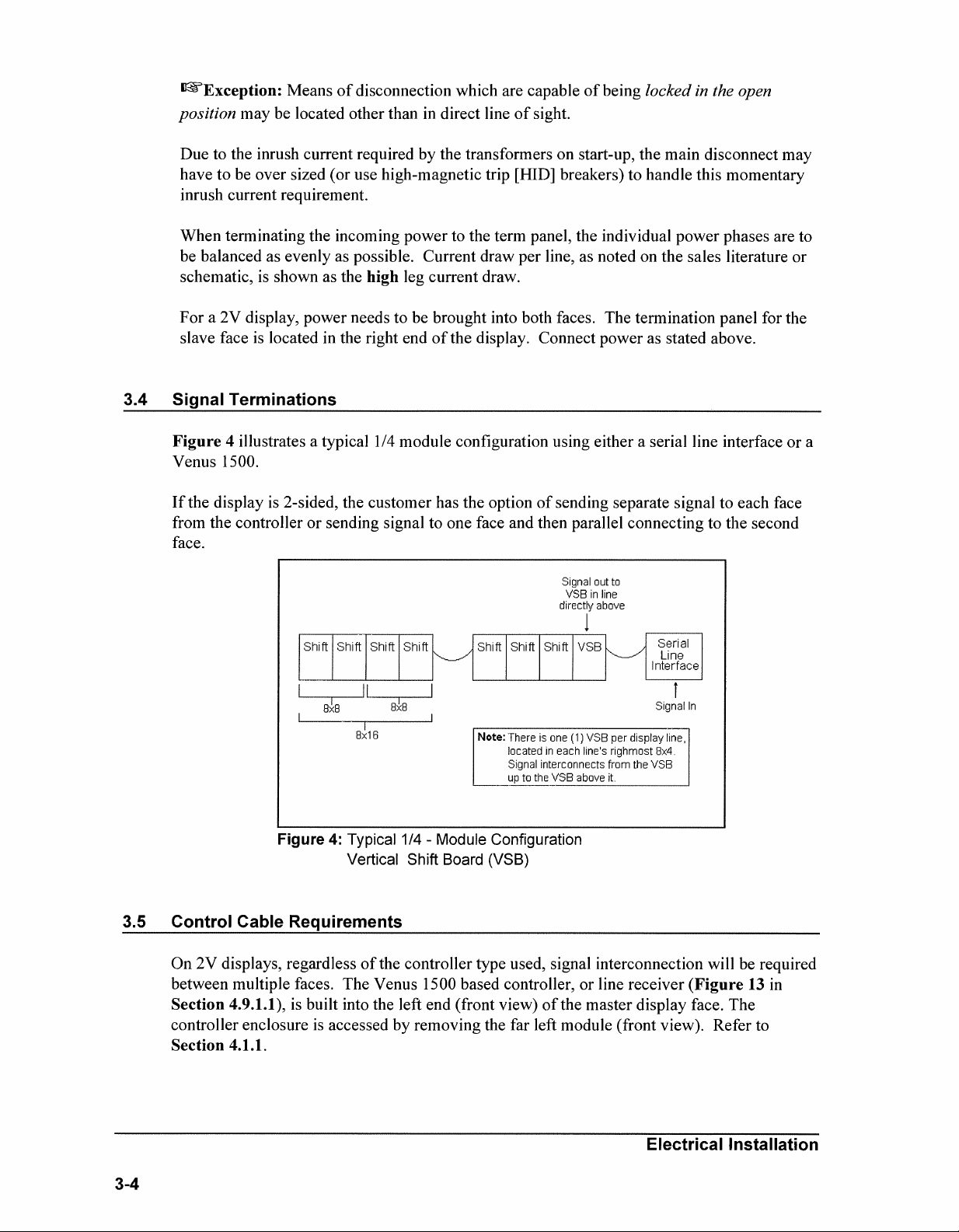

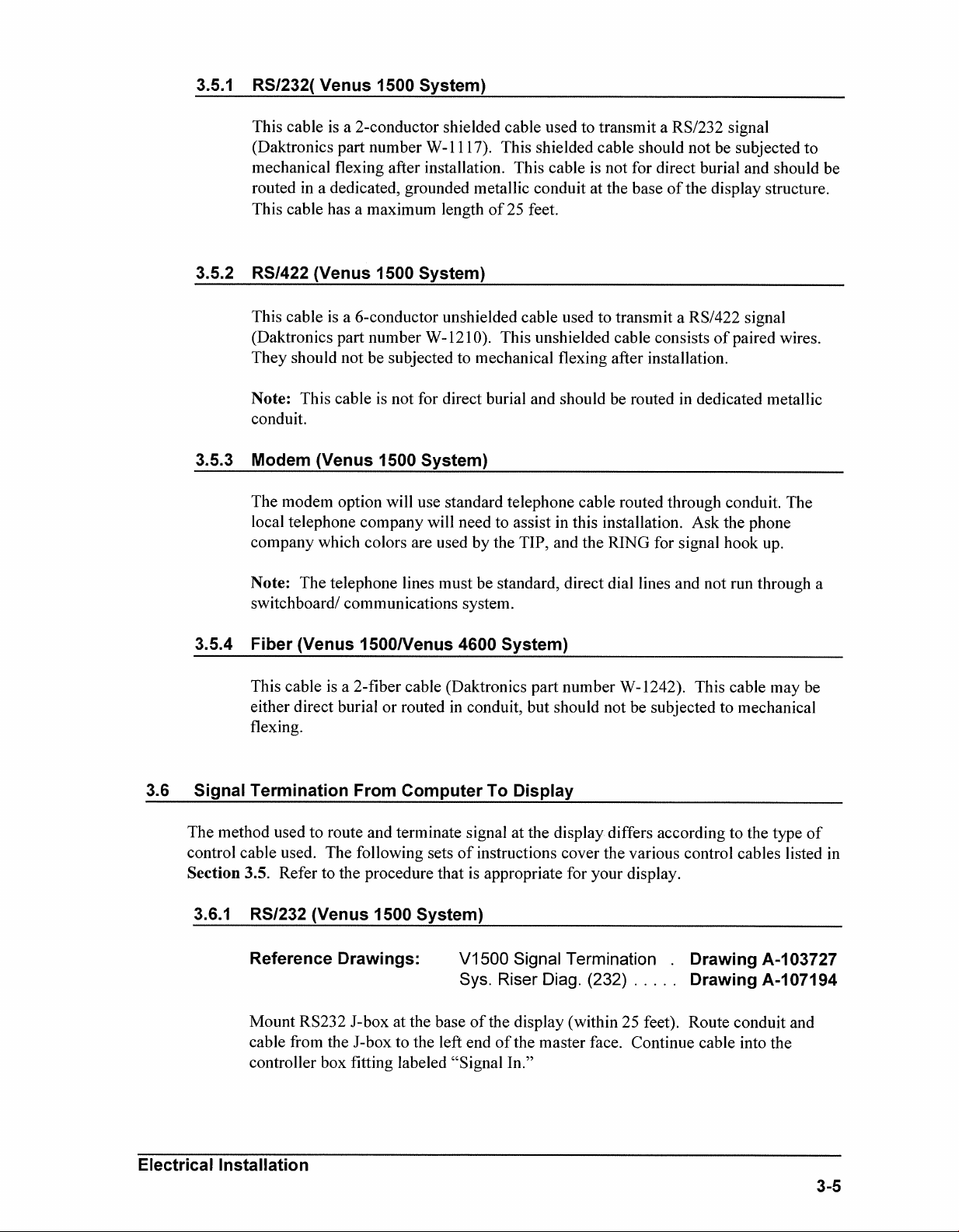

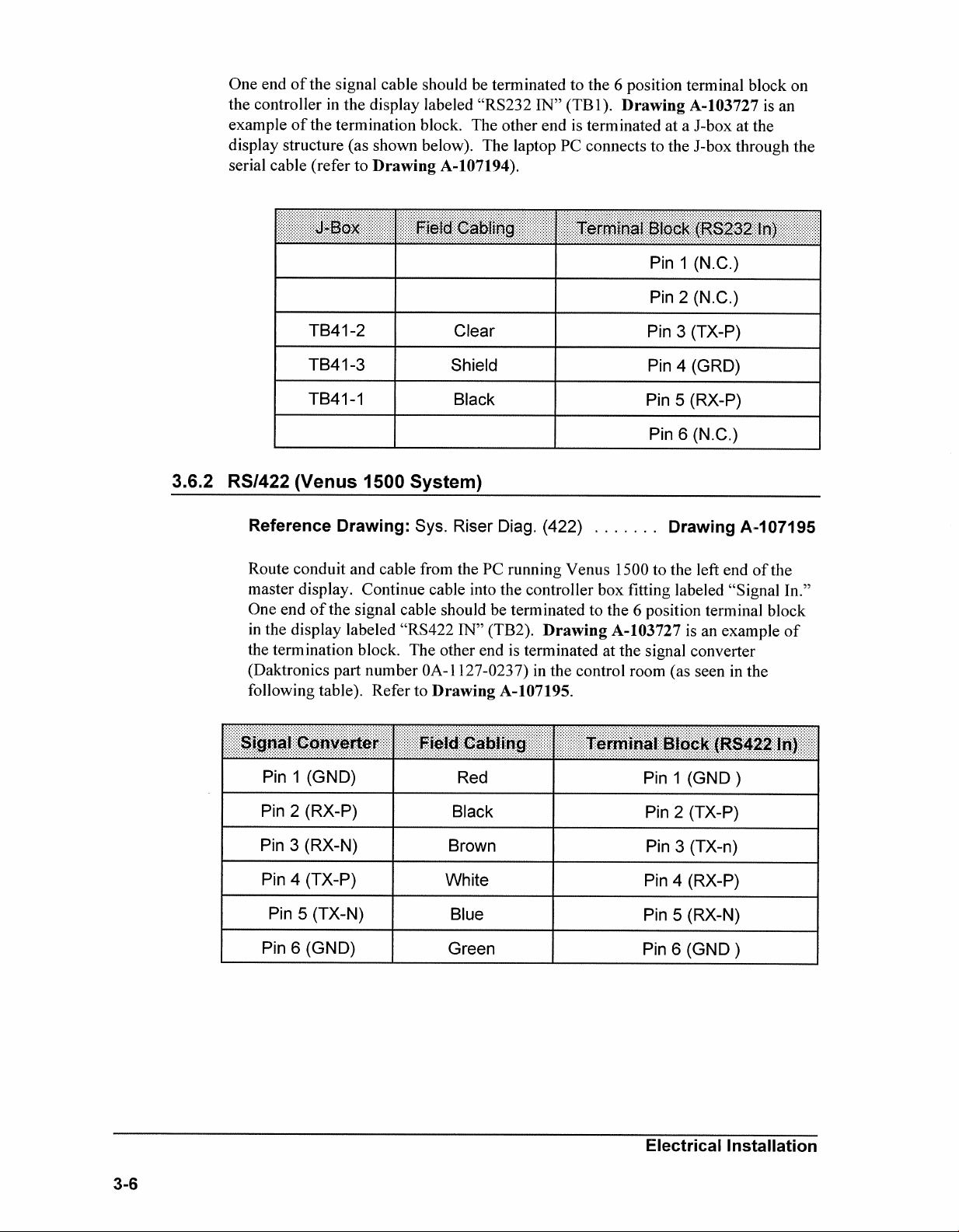

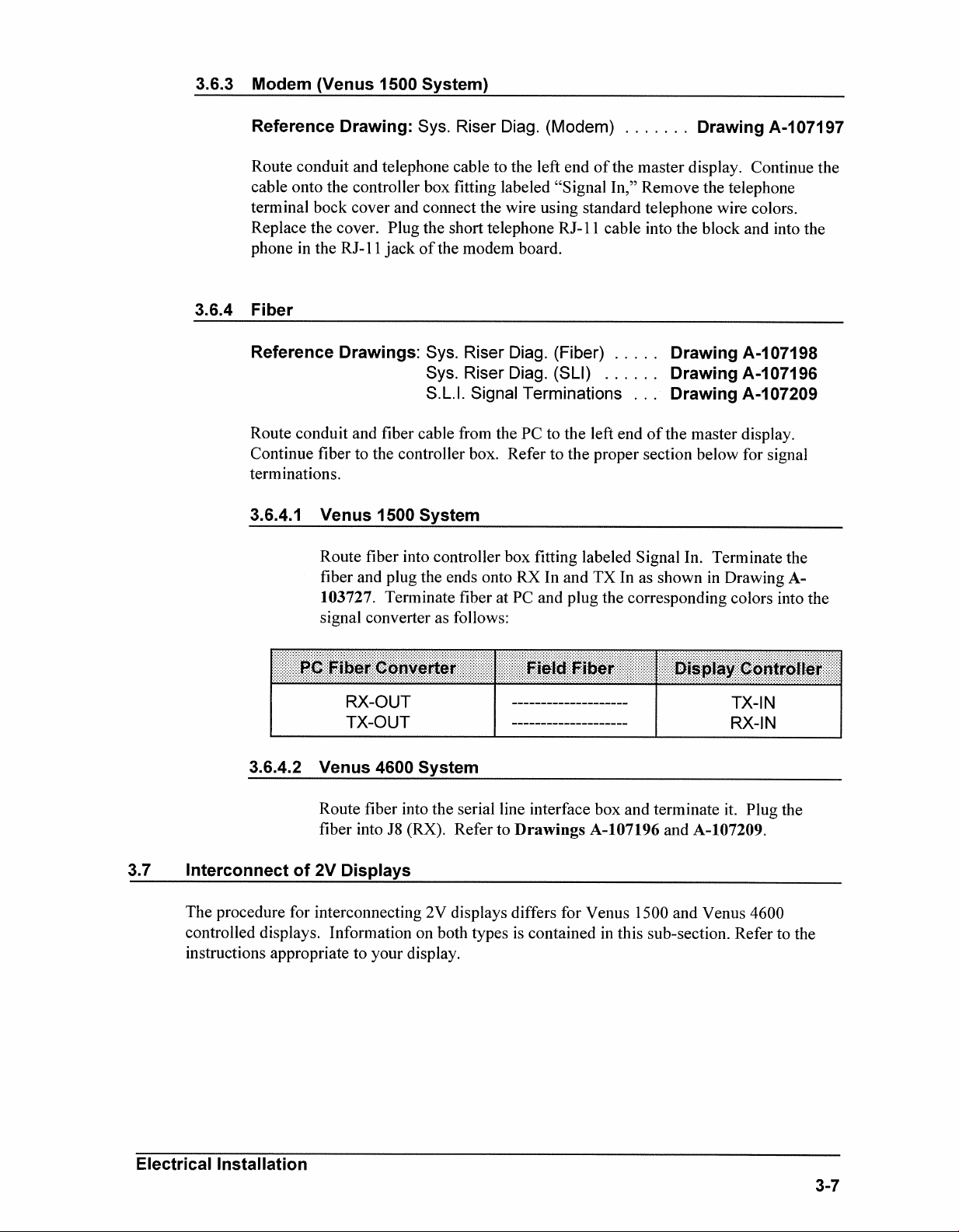

Page 2

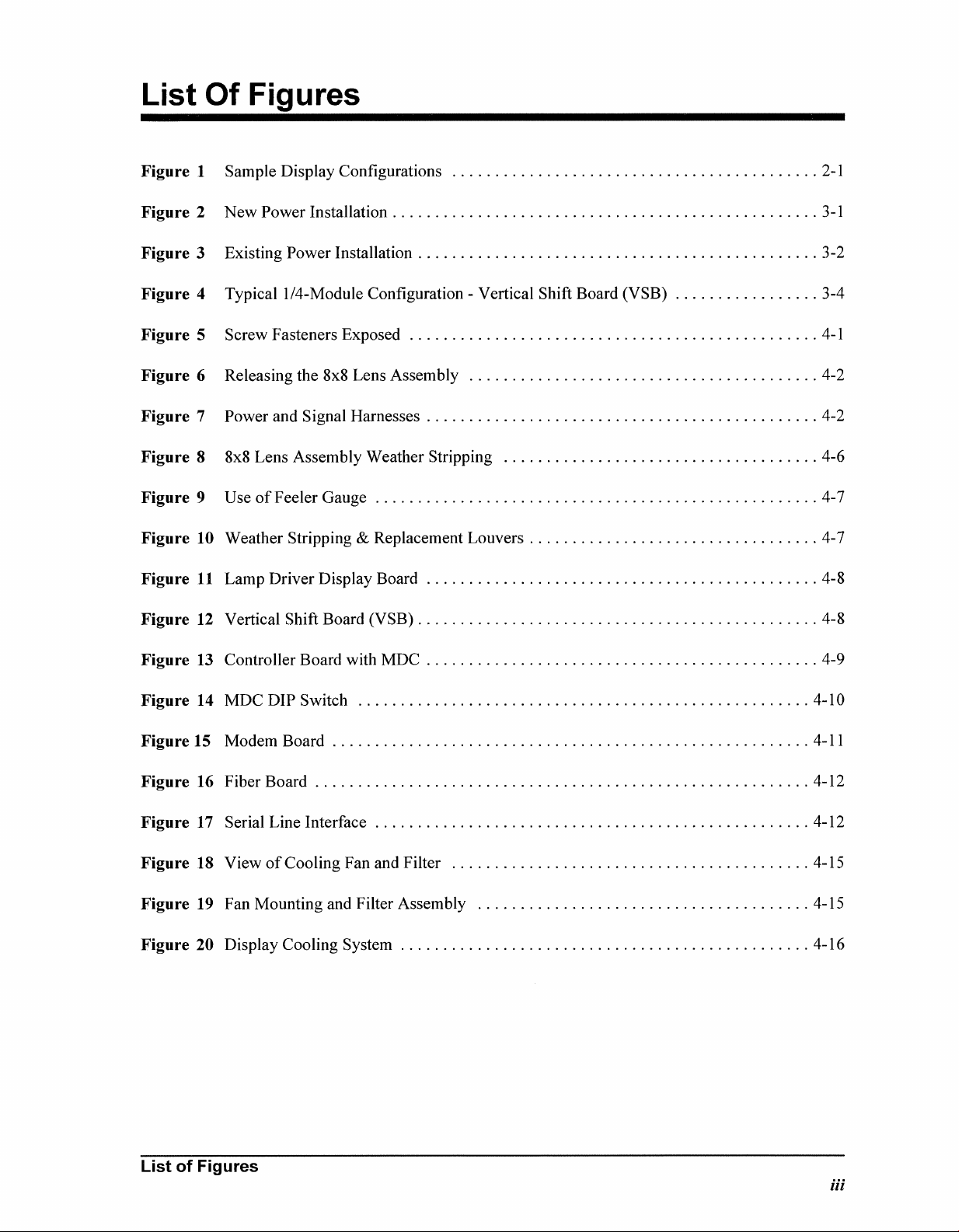

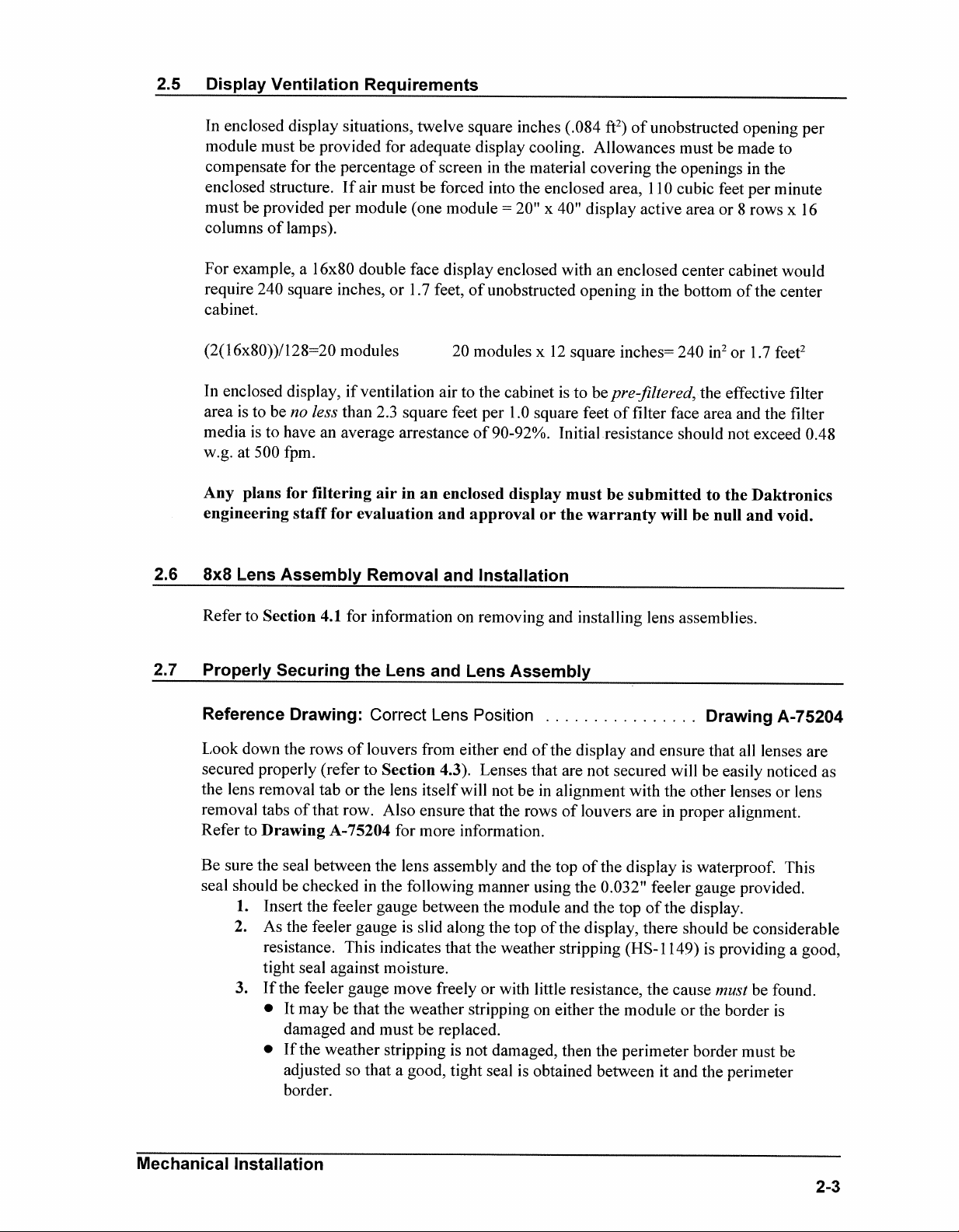

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

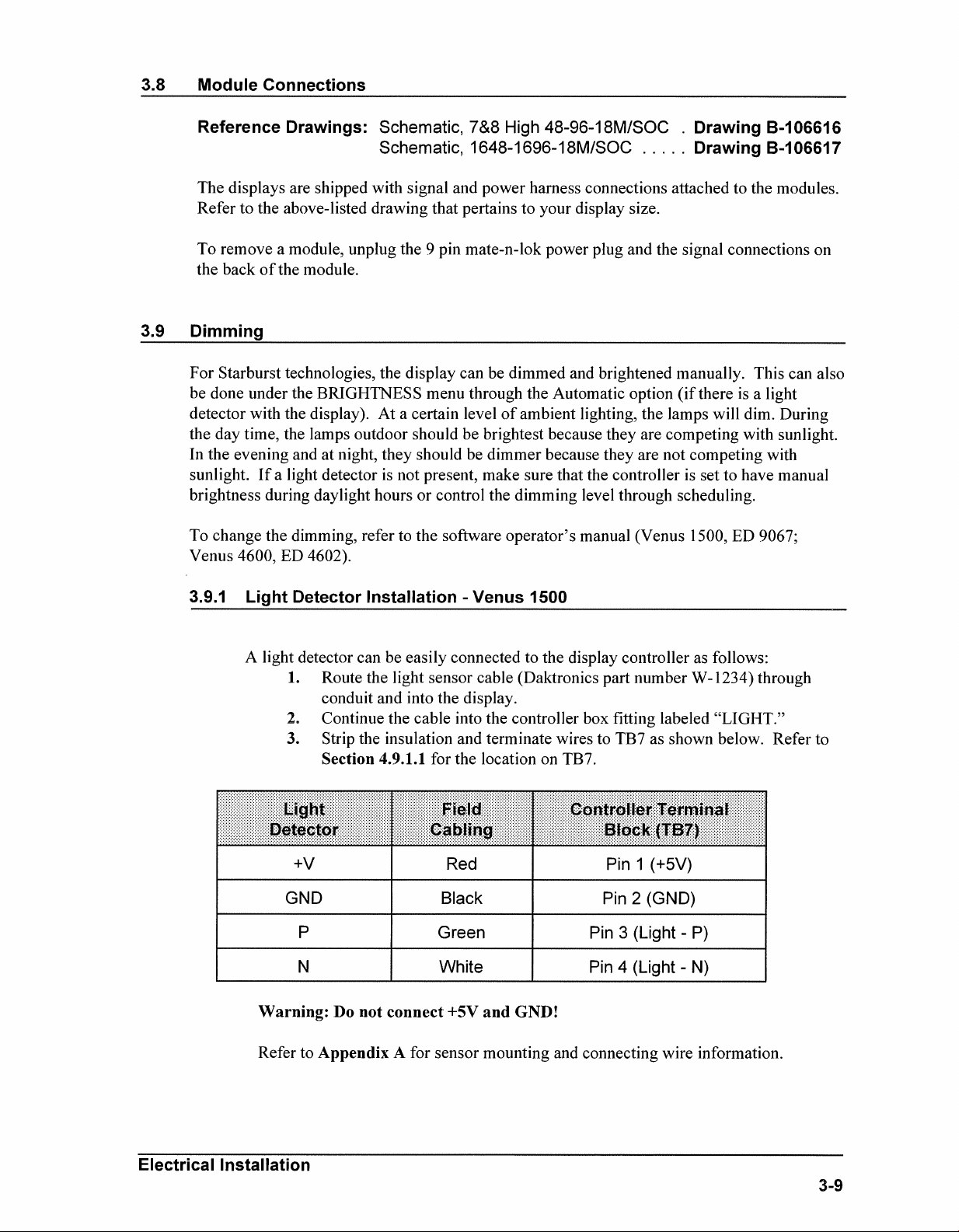

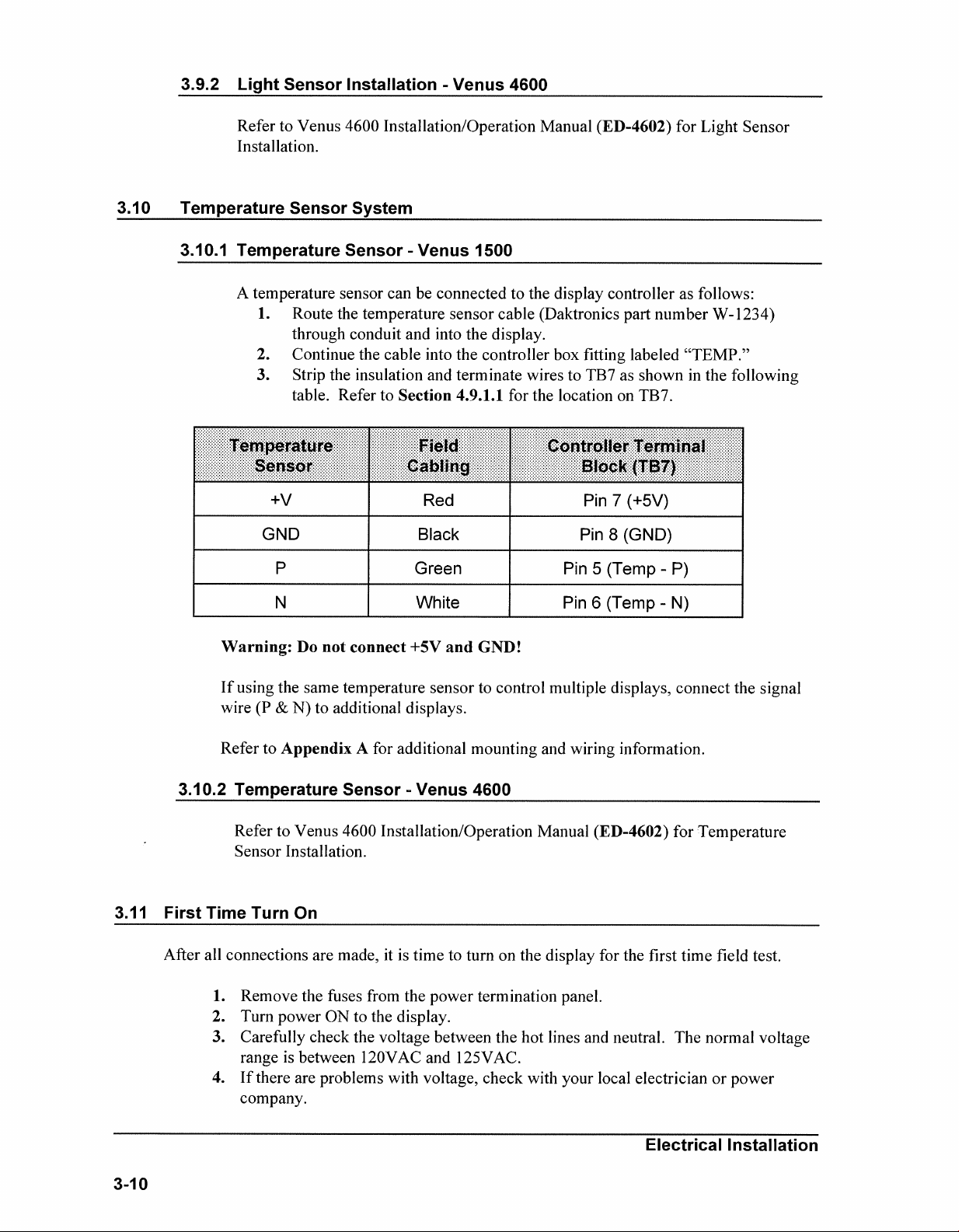

The Temperature Sensor is mounted separately and requires a location away from the influence of

chimneys, air conditioners, vents, tar roofs, concrete, and parking lots which can cause abnormal

temperature fluctuations. Usually a separation of at least 20-30 feet horizontally and 8 feet vertically is

required to achieve this. Locations where air movement is restricted are also unsatisfactory.

A first-choice sensor location is a north eave or northern exposure away from direct sun light and above

grass. This location gives extra stability and accuracy to the sensor because of the added shading usually

obtained on a northern exposure.

The second choice for locating a temperature sensor is on the display itself, or somewhere on the display

structure. A light-colored display is preferred in this application. Location of the sensor should be above,

below, or on a northern edge of the display to try to keep the sensor shaded. If mounting above the

display, a minimum height above of 6 feet is required. If mounting below the display, a minimum of 8 feet

above ground and a minimum of 1 foot between sensor and display is required. Greater accuracy is

obtained if there is grass below the sign rather than concrete or some other material.

A 2 pair, individually shielded cable (Belden 5594, Dak. P.N. W-1234) is used to connect the sensor to the

display controller. Maximum length is 1000 feet.

Directions

1. Run ½" conduit from the sensor location to the controller where the sensor cable is to be attached.

The cable must be routed thru ½" metal conduit which should be earth grounded to help protect

the sensor and controller from lightning damage.

2. Power down the controller where the sensor cable is to be attached.

3. Connect the cable to the temperature sensor terminal block as follows:

RED = V+ BLK = GND

GRN = P WHT = N

4. Install the mesh screen with the four screws enclosed.

5. Connect the cable to the display controller as described in the controller installation manual.

6. Power up the controller.

Page 64

Page 65

Page 66

Page 67

Eyebolts

Almost every display that leav es D ak tronics is equipped w ith ey ebolts for lifting the display . There are

two standard sizes of eyebolts: ½″ and A″.

Load Increase Factor: The load increases as the lift angle (θ) decreases. The allowable load on the

eyebolts also decreases with the lift angle due the bending stress on the eyebolts. In sum, the smaller

the angle between the cable and the top of the display, the lighter the sign must be to safely lift it. Do

NOT attempt to lift the display when the lift angle is less than 30 degrees.

Horizontal Load Angle

Angle Factor (L/H)

90 1.00

60 1.155 90 2600 2600 4000 4000

50 1.305 60 1500 1299 3300 2858

45 1.414 45 650 460 1000 707

30 2.00 30 520 260 800 400

θθθθ

½”

Line Weight/ Line Weight/

Load Anchor Load Anchor

A

A”

AA

ED7244 Copyright 1996-2001

Rev. 4 – 14 March 2001 Daktronics, Inc.

Page 68

Min.

A B C D E No.

Wx Wy Wz

1/4 1 3/4 1-3/16 25/32 21 600 2,000 Blank 1/4-20 7/8 400 100 80

3/8 1-1/4 1 1-21/32 1-3/16 23 2,100 5,000 Blank 3/8-16 1-1/8 1,400 350 250

1/2 1-1/2 1-3/16 2-1/16 1-13/32 25 3,900 9,200 Blank 1/2-13 1-11/32 2,600 650 520

9/16 1-5/8 1-9/32 2-13/16 1-17/32 26 4,500 11,830 Blank 9/16-12 1-3/8 3,000 750 600

5/8 1-3/4 1-3/8 2-1/2 1-11/16 27 6,000 14,700 Blank 5/8-11 1-9/16 4,000 1,000 800

3/4 2 1-1/2 2-13/16 1-13/16 28 9,000 21,700 Blank 3/4-10 1-5/8 6,000 1,500 1,200

7/8 2-1/4 1-11/16 3-1/4 2-1/16 29 10,000 30,000 Blank 7/8-9 1-13/16 6,600 1,670 1,330

1 2-1/2 1-13/16 3-9/16 2-5/16 30 12,000 39,400 Blank 1-8 2-1/16 8,000 2,000 1,600

1-1/2 3-1/2 2-9/16 5-1/2 3-5/32 34 27,000 91,300 Blank 1-1/2-6 3 17,800 4,500 3,600

Proof

Load

(lbs.)

Min.

Break

Load

(lbs.)

Stocked

Min.

Eff.

Thrd.

Length

Line Loads

A. Do not use eyebolts on angular lifts unless absolutely necessary. For angular lifts, the shoulder pattern

eyebolt is preferred.

B. Load should always be applied to eyebolts in the plane of the eye, not at some angle to this plane.

C. Shoulder eyebolts must be properly seated (should bear firmly against the mating part), otherwise the

working loads must be reduced to those indicated for regular eyebolts. A washer or spacer may be

required to put the plane of the eye in the direction of the load when the shoulder is seated.

D. No load greater than the safe working load listed in the data table should be used.

E. To obtain the greatest strength from the eyebolt, it must fit reasonably tight in its mounting hole to prevent

accidental unscrewing due to twist of cable.

F. Eyebolts should never be painted or otherwise coated when used for lifting. Such coatings may cover

potential flaws in the eyebolt.

G. To attain the safe working loads listed for regular eyebolts, 90% of the thread length must be engaged.

Copyright 1996-2001 ED-7244

Daktronics, Inc. Rev. 4 – 14 March 2001

Page 69

Page 70

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 71

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 72

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 73

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 74

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 75

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 76

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 77

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 78

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 79

Maintenance Checklist

1½ Inch and 2½ Inch Displays

This form can be used as both as a maintenance guide and a record of maintenance performed. Store these forms in

maintenance file as they are completed. Each form is designed to cover one year of maintenance.

Circle the operational year to which this form applies 1 2 3 4 5 6 7 8 9 10

Maintenance Procedures

1. Check fans at 1,500 hour intervals to ensure proper operation. With display power off, clean dust from blades and

spin the blades with a pen or pencil to make sure the bearings are free and the fan is still 'in balance.

2. Check the filters at 1,500 hour intervals. Check the filter for excessive dust/dirt buildup and for damage, such as

holes, which may allow unfiltered air into the display.

3. Check line and lamp voltage every 4,500 hours or whenever a significant change occurs in the area that could

affect line voltage. Refer to the Electrical Installation section of the Installation and Maintenance Manual for more

information.

4. At least once each 9,000 operational hours check the inside of the display, including the circuit boards, for signs of

water intrusion such as water stains. Water may enter the display due to any of the following:

• Loose or deteriorating weather stripping.

• Loosened fasteners which allow gaps to open between panels.

• Weak seals around hardware, such as eye bolts, on the top of the display.

5. At least once each 9,00 operational hours inspect the paint and check for signs of corrosion on the structure. Pay

special attention to footings, structural tie points and ground rods. Fasteners should be tightened or replaced as

required.

Operation Hours Perform Above

Steps Numbered

1,500 Hrs

3,000 Hrs

4,500 Hrs

6,000 Hrs

7,500 Hrs

9,500 Hrs

* Day 83

* Day 62

* Day 166

** Day 125

* Day 249

** Day 187

* Day 332

** Day 250

* Day 415

** Day 312

* Day 498

** Day 365

1,2

1,2

1,2,3

1,2

1,2

1,2,3,4,5

* Assuming the display is operated 18 hours per day

and is turned off when not in use.

** Assuming the display is operated 24 hours per day.

Consult the Installation and Maintenance Manual for additional

Maintenance Details.

Date Performed Checked By

DF-1866

Rev. 3 – 24 October 2001

DAKTRONICS, INC.

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail helpdesk@daktronics.com

Page 80

Send 1 Copy (Front and Back of t his Inst allation Quality

Installation Quality

Checklist to the Daktronics Address below.

Checklist

1½ Inch and 2½ Inch Displays

This checklist is intended to serve as a general guide during display

installation. If this display is to operate in a dependable manner it

must be installed properly. Date and initial each of the following

tasks as they are completed. Because each installation site is

unique, the tasks below may not necessarily be in the order in

which they should be performed. If product quality concerns arise

during check off, please note them on the back of this form or

contact Daktronics Customer Service.

OK box if acceptable.

!!!!

OK Rej Initial Date

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

Rej box if a deficiency is noted & correction is required.

!!!!

Inspect the display & all crates & boxes for any damage as they are unloaded at the site.

Note any shipping damage on this form or notify Daktronic s

Review the installation manual & installation procedures with the installation crew prior to

beginning the installation work. Stress the importance of water tightness at all points.

Check the display mounting structure to ensure a straight & square mounting frame for the

display. The height variation in any 4 foot horizontal should not exceed ¼ inch. This check

should be done well in advance of the scheduled installation to allow for repairs if necessary.

Mount the display as per the engineering plan & shop drawing. If the display is shipped in

sections, ensure that the sections were bolted together vertically & horizontally.

If eyebolts are removed, plug the holes with bolts & the rubber water sealing washer which

was removed with the eyebolt. Plug & silicone around any hole or openings in the top of the

display.

Inspect the top & side front shr ouds for weather ti ght ness. If the shroudi ng has been field

attached, ensure it was done per the engineering drawing. All shroud overlaps must be

siliconed.

Note that there are drain holes in the bottom on the display. There should be a minimum of

½ inch clearance between these holes & any mounting surface.

Check the spacing between modules of sectional displays with the 0.032 feeler gauge. Also

check the weather stripping tightness with the feeler gauge (0M-69133).

Check the lens to see if they are secured properly & that the rows of louvers are in proper

alignment with each other. Ensure that all lampbanks are secured properly & all lamps are

the focal point of the reflector.

During assembly of sectional displays, check the interconnect ribbon cables at the splice

locations to ensure they are not pinched.

Use electrical contact cleaner (Daktronics part number CH-1015) to clean the 16 & 20 pin

connectors any time a ribbon cable is removed during installation. Use electrical contact

lubricant & protector (CH-1019) to protect the connector from moisture.

Ensure that all electrical entrance connections are watertight.

Ensure that each load center is properly earth grounded as per National Electrical Code.

Refer to the grounding information in the Electrical Installation section of the manual.

Ensure that the supply voltage rating matches the voltage rating of the display.

Ensure that all cooling fans are operational after the initial fire up of the display.

Daktronics Customer Service

P.O. Box 5128

Brookings, SD 57006-51285

Contract/Work

Order Number: __________________

Display

Serial Number: __________________

Display

Description: ____________________

________________________

DF-1859

Rev. 6 – 10 March 2000 Page 1 of 2

Page 81

OK Rej Initial Date

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

I certify that all items listed above have been checked and approved.

_________________________________________ _____________________________________________

Signature of Installer Date Signature of Owner/Owner Rep Date

Owner’s signature signifies they have been shown the installation checklist and the periodic maintenance located in the manuals.

The owner also understands the importance or air filter and fan maintenance. When customer service receives this completed

form, they will send the first set of replacement air filters to the customer at no charge.

Comments

Items rejected and later corrected, and the person

Return one copy of the installation checklist to Daktronics at the address listed on the front of this form!

Customer Service will Route Copies to the Following:

1 Copy – Customer Service File 1 Copy – Project Manager File

1 Copy – Product Manager

DF-1859

Rev. 6 – 10 March 2000 Page 2 of 2

Monitor display voltage per the Line Voltage and 24-Hour Monitoring instructions in the

Electrical Installation section of the manual. Fill out and complete both copies of DF-1796

(Display Power Report). Send one copy of the form to Daktronics customer service & keep

one copy of the report for your records.

Ensure that the display controller is set to have the lamp level on bright during the daylight

hours.

If any modifications have been made to the Daktronics air filtration system, ensure that these

changes have bee n approved by the Daktronics Engineering Staff.

If displays are mounted back to back inside a center cabinet, adequate clearance must be

provided between the rain shields to provide for proper air flow to all ventilation fans.

Ensure that this clearance has been approved by the Daktronics Engineering staff.

In enclosed display situations, ensure that 12 square inches of unobstructed opening is

provided for each module. Allowances must be made to compensate for the percentage of

screen or any other material covering the ventilation opening in the enclosed structure.

Ensure that all wiring clears the bottom of the display by a minimum of ½” and is not in

contact with any sharp edges.

Ensure that the backsheets of rear access displays are removable and are not obstructed by

conduit or support structure members.

On displays with bottom ventilation, 2 ½” of clearance between the bottom of the display &

any other display/obstruction is required for air intake & filter mainenance.

making the correc tion

Page 82

Send 1 Copy (Front and Back of t his Inst allation Quality

Installation Quality

Checklist to the Daktronics Address below.

Checklist

1½ Inch and 2½ Inch Displays

This checklist is intended to serve as a general guide during display

installation. If this display is to operate in a dependable manner it

must be installed properly. Date and initial each of the following

tasks as they are completed. Because each installation site is

unique, the tasks below may not necessarily be in the order in

which they should be performed. If product quality concerns arise

during check off, please note them on the back of this form or

contact Daktronics Customer Service.

OK box if acceptable.

!!!!

OK Rej Initial Date

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

Rej box if a deficiency is noted & correction is required.

!!!!

Inspect the display & all crates & boxes for any damage as they are unloaded at the site.

Note any shipping damage on this form or notify Daktronic s

Review the installation manual & installation procedures with the installation crew prior to

beginning the installation work. Stress the importance of water tightness at all points.

Check the display mounting structure to ensure a straight & square mounting frame for the

display. The height variation in any 4 foot horizontal should not exceed ¼ inch. This check

should be done well in advance of the scheduled installation to allow for repairs if necessary.

Mount the display as per the engineering plan & shop drawing. If the display is shipped in

sections, ensure that the sections were bolted together vertically & horizontally.

If eyebolts are removed, plug the holes with bolts & the rubber water sealing washer which

was removed with the eyebolt. Plug & silicone around any hole or openings in the top of the

display.

Inspect the top & side front shr ouds for weather ti ght ness. If the shroudi ng has been field

attached, ensure it was done per the engineering drawing. All shroud overlaps must be

siliconed.

Note that there are drain holes in the bottom on the display. There should be a minimum of

½ inch clearance between these holes & any mounting surface.

Check the spacing between modules of sectional displays with the 0.032 feeler gauge. Also

check the weather stripping tightness with the feeler gauge (0M-69133).

Check the lens to see if they are secured properly & that the rows of louvers are in proper

alignment with each other. Ensure that all lampbanks are secured properly & all lamps are

the focal point of the reflector.

During assembly of sectional displays, check the interconnect ribbon cables at the splice

locations to ensure they are not pinched.

Use electrical contact cleaner (Daktronics part number CH-1015) to clean the 16 & 20 pin

connectors any time a ribbon cable is removed during installation. Use electrical contact

lubricant & protector (CH-1019) to protect the connector from moisture.

Ensure that all electrical entrance connections are watertight.

Ensure that each load center is properly earth grounded as per National Electrical Code.

Refer to the grounding information in the Electrical Installation section of the manual.

Ensure that the supply voltage rating matches the voltage rating of the display.

Ensure that all cooling fans are operational after the initial fire up of the display.

Daktronics Customer Service

P.O. Box 5128

Brookings, SD 57006-51285

Contract/Work

Order Number: __________________

Display

Serial Number: __________________

Display

Description: ____________________

________________________

DF-1859

Rev. 6 – 10 March 2000 Page 1 of 2

Page 83

OK Rej Initial Date

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

!" !"

I certify that all items listed above have been checked and approved.

_________________________________________ _____________________________________________

Signature of Installer Date Signature of Owner/Owner Rep Date

Owner’s signature signifies they have been shown the installation checklist and the periodic maintenance located in the manuals.

The owner also understands the importance or air filter and fan maintenance. When customer service receives this completed

form, they will send the first set of replacement air filters to the customer at no charge.

Comments

Items rejected and later corrected, and the person

Return one copy of the installation checklist to Daktronics at the address listed on the front of this form!

Customer Service will Route Copies to the Following:

1 Copy – Customer Service File 1 Copy – Project Manager File

1 Copy – Product Manager

DF-1859

Rev. 6 – 10 March 2000 Page 2 of 2

Monitor display voltage per the Line Voltage and 24-Hour Monitoring instructions in the

Electrical Installation section of the manual. Fill out and complete both copies of DF-1796

(Display Power Report). Send one copy of the form to Daktronics customer service & keep

one copy of the report for your records.

Ensure that the display controller is set to have the lamp level on bright during the daylight

hours.

If any modifications have been made to the Daktronics air filtration system, ensure that these

changes have bee n approved by the Daktronics Engineering Staff.

If displays are mounted back to back inside a center cabinet, adequate clearance must be

provided between the rain shields to provide for proper air flow to all ventilation fans.

Ensure that this clearance has been approved by the Daktronics Engineering staff.

In enclosed display situations, ensure that 12 square inches of unobstructed opening is

provided for each module. Allowances must be made to compensate for the percentage of

screen or any other material covering the ventilation opening in the enclosed structure.

Ensure that all wiring clears the bottom of the display by a minimum of ½” and is not in

contact with any sharp edges.

Ensure that the backsheets of rear access displays are removable and are not obstructed by

conduit or support structure members.

On displays with bottom ventilation, 2 ½” of clearance between the bottom of the display &

any other display/obstruction is required for air intake & filter mainenance.

making the correc tion

Page 84

Page 85

Loading...

Loading...