Dako Pascal User Manual [en, de, fr]

Pascal Handbook

Manuel de la chambre de pression Pascal

Pascal Handbuch

For In Vitro Diagnostic Use

Code No. S2800

(placeholder) 306163 091505

Copyright © 2005 DakoCytomation. All rights reserved.

This document may not be copied in whole or in part or reproduced in any other

media without the express written permission of DakoCytomation. Please note that

under copyright law, copying includes translation into another language.

2

Pascal Handbook

Table of Contents

Section 1.............................................................................................................................6

Unpacking and Installation...............................................................................................6

Inspect Packaging........................................................................................................6

Verify Contents.............................................................................................................6

Install the Pascal..........................................................................................................6

Connect Power.........................................................................................................7

Section 2.............................................................................................................................8

System Overview.............................................................................................................8

Principle and Intended Use..........................................................................................8

Symbols and Definitions...............................................................................................8

Audible Indicators and Error Messages .....................................................................10

Parts Description........................................................................................................10

Section 3...........................................................................................................................11

Operating Notes.............................................................................................................11

Section 4...........................................................................................................................13

Operating Instructions....................................................................................................13

Set Up ........................................................................................................................13

Programming..............................................................................................................13

Pascal Factory Settings..........................................................................................13

Pascal Factory Settings..........................................................................................13

Pascal Setting Limits..............................................................................................14

Start Program.............................................................................................................14

End Program..............................................................................................................15

Changing Factory Settings.........................................................................................15

Section 5...........................................................................................................................17

Maintenance...................................................................................................................17

Daily...........................................................................................................................17

Monthly.......................................................................................................................17

Pan, Gasket, Vent Nozzle and Weight...................................................................17

Heat Plate and Heat Sensor...................................................................................17

Body.......................................................................................................................17

Biannually...................................................................................................................18

Pascal Calibration Protocol....................................................................................18

Electrical Precautions.................................................................................................20

Service .......................................................................................................................20

Disposal .....................................................................................................................20

Troubleshooting .........................................................................................................20

Strong Target Retrieval performance.....................................................................20

Inconsistent/weak Target Retrieval performance...................................................21

Poor morphology....................................................................................................21

Adherence of specimen to glass slide....................................................................21

Specifications...........................................................................................................21

DakoCytomation Warranty.........................................................................................22

Pascal Handbook

3

Limitation of Liability...................................................................................................22

Appendix A.......................................................................................................................23

Pascal Quality Control Log.............................................................................................23

4

Pascal Handbook

How to use this handbook

This handbook, along with information contained on product labels, provides all the

information needed to operate and maintain the Pascal pressure chamber. Notes are set

off from the handbook text to highlight information.

Please pay close attention to the instructions that accompany the notes as well as the

standard laboratory practices outlined by your facility and local regulatory agencies.

Please use the system as intended. Improper use of Pascal may cause

damage to the system, inaccurate results, or potentially nullify warranties.

Translations of this handbook are available online at www.dakocytomation.com.

Introduction

The DakoCytomation Pascal pressure chamber is designed to control the parameters of

heat and pressure over time. Pascal was specifically engineered to pass strict laboratory

safety requirements. Quality control methods are provided to ensure consistent pre-set

pressure and temperature levels that can be monitored and recorded.

Pascal Quality Strips

Pascal Quality Strips are heat and pressure sensitive strips that allow the user to monitor

conditions inside the Pascal pressure chamber. The strip must register the proper color

(charcoal black) to ensure that optimum heat and pressure are achieved. The steam strip

can be dated and used as a record for laboratory and CAP inspections. Pascal Quality

strips can be reordered as DakoCytomation product code number S2801.

Pascal Handbook

5

Section 1

Unpacking and Installation

Inspect Packaging

Pascal and its accessories are delivered in one carton. If the instrument or accessories

have suffered any damage in transport, please inform your carrier immediately

Note Save shipping carton and components to simplify return in the event that service

is required.

Verify Contents

The Package contains:

Lid with Pressure Gauge and Hot Sticker

Weight (Petcock)

Pan and Gasket (removable)

Body with electric cord and programmable digital timer

Heat Shield

Pascal Quality Strips (S2801)

Note Pascal is a 110V–120V instrument. A step-down transformer is required for

laboratories using Pascal with a 220V–240V electrical source. This step-down transformer

is not supplied within the same box as Pascal.

.

Install the Pascal

1. Place the body of Pascal on a level surface suitable for laboratory instrumentation.

2. Position Pascal away from direct sunlight and sources of heat or cold.

3. Place the pan in the body. Make sure the outside of the pan is clean and that all

packaging has been removed.

4. Fit the rubber gasket in the top of the pan.

5. Place the heat shield in the center of the pan.

6. Place the weight (petcock) on the vent nozzle. Ensure that it is firmly in place.

7. Rest the lid on the pan until ready to use.

6

Pascal Handbook

Connect Power

Pascal is a 110V–120V instrument. In locations with 110– 120 V supply power, simply plug

the instrument into the appropriate outlet.

If the location supplies 220–240 V power, a step down isolation transformer is required

(dual winding, rated 1000 VA minimum, 50–60 Hz, 220–240 V input 110–120 V output

nominal 13A, with an IEC female output connector). An isolation transformer can be

connected with portable cord and plug to the main supply. Pascal is then connected to the

isolation transformer.

Do not operate Pascal with other types of high electrical demand equipment such as

incubators, microwave ovens, or refrigerators on the same circuit. This may affect the

performance of the instrument.

The main power switch is red and is located to the right of the operation panel on the front

of the instrument. This switch will illuminate in the ON position.

I = ON and O = OFF

Pascal Handbook

7

Section 2

System Overview

Principle and Intended Use

For in vitro diagnostic use. Pascal may be used for Target Retrieval of specimens on glass

microscope slides.

Pascal consists of a microprocessor controlled, bench top pressure chamber with lid.

Pascal allows for pressurized heating at temperatures above boiling but can also be used

at a variety of temperatures ranging from 37 ºC to 125 ºC

Symbols and Definitions

The following is a list of definitions for symbols and LED indicator lights that appear on the

Pascal operation panel located on the front of the instrument.

Display Set (button): Navigates users through the two programs SP1 and SP2. For

example, to advance from temperature and time settings for SP1 to temperature and time

settings for SP2, press Display Set.

Up and Down arrow (buttons): Adjusts the settings for temperature or time

Start/Stop (button): Starts and stops instrument based on the set temperature and time

functions.

SP1 (LED): Set Point 1 has two functional readouts on the digital display. The first SP1

display is the temperature at which Pascal can be set for operational use. The second

SP1 display is the time interval for which Pascal can be set to maintain the SP1

temperature.

8

Pascal Handbook

SP2 (LED): Set Point 2 has two functional readouts on the digital display. The first SP2

display is the temperature programmed to indicate that the chamber has cooled

sufficiently to permit the removal of contents. The second SP2 display is the time interval

at which the SP2 temperature is maintained before an audible alarm (beep) is sounded.

The purpose of the SP2 alarm is to standardize the time at which the contents in Pascal

should be removed from the instrument for cooling. This is a quality control function that

aids in consistency between runs.

SP Limit (LED): Set Point Limit is an internal temperature set point circuit breaker that

ensures the SP1 temperature will not exceed SP1+ SP Limit temperature; for example, if

SP1 = 125 ºC and SP limit = 10 ºC then a temperature of 135 ºC will automatically turn off

the heating element. This is a safety feature. For example, if an insufficient volume of

water is added to the system the temperature could rise beyond the SP1 temperature.

Actual (LED): Indicates that Pascal is in operation and the temperature on the digital

display is the current temperature in the chamber in degrees centigrade.

Symbols and Definitions

REF

Product/Reference

Number

Caution Statement of caution/warning, read instruction

Temperature

limitation

Indicates the product/catalog number

carefully

Indicates storage requirements range

EC REP

IVD

S N

EC Representative European Community Authorized Representative

In vitro diagnostic

medical device

Non sterile Indicates non-sterile product

Serial Number Indicates instrument serial number code

Consult

Instructions

Date of

Manufacture

Manufacturer Indicates the manufacturer identification

Disposal Separate collection for electrical and electronic

Clarifies for use as in vitro diagnostic only

Consult instruction manual for further explanation

Indicates the date the device was manufactured

equipment

Pascal Handbook

9

Audible Indicators and Error Messages

Audible alarm: An audible alarm will sound when Pascal reaches either the programmed

SP1 (Set Point 1) time and the SP2 (Set Point 2) temperatures. For quality control

purposes, the temperature and pressure can be recorded at these set points.

ERR: These letters will appear on the digital display if the instrument encounters a

technical issue such as the following:

The pan is not filled with a sufficient volume of water and therefore the heat and pressure

rise beyond normal limits.

The SP Limit may be set too low so that the normal temperature tolerance of the

instrument heats beyond the SP1 + SP Limit.

Heat Sensor fails.

Parts Description

Gasket: The rubber seal between the pan and the lid that enables an air-tight chamber.

Reorder code number SP99015.

Pan: The removable metal chamber that is placed within the body of Pascal. The pan

comes in contact with the heat sensor and the heat plate. Reorder code number SP99019.

Vent Nozzle: The part of the chamber lid where the weight (petcock) should be placed

prior to operation of Pascal.

Heat Shield: A circular, concave metal disc with perforations that should be placed in the

center of the pan prior to operation of Pascal.

Heat Sensor: A circular, spring-loaded device within the main body of Pascal that records

the actual temperature during operation.

Heat Plate: A large, metal disc area within the main body of Pascal surrounding the Heat

Sensor that heats the pan during operation.

10

Pascal Handbook

Section 3

Operating Notes

Pascal has been designed with many safety features unique from other pressure chamber

devices; however, when using heating and electrical equipment, basic precautions should

be used. This is a heating device under pressure. Please read the operating notes

carefully prior to operating the Pascal.

OPEN PASCAL LID CAUTIOUSLY

When there is resistance on the lid, do not open by force. Pressure in the

chamber may make the lid difficult to open. Tip the weight carefully to

release any residual pressure and make sure that the pressure in the pan

is at zero on the pressure gauge. Gently push down on the brown handle,

turn the lid counter clockwise, and slowly lift off the lid.

DO NOT OPERATE WITHOUT WATER IN THE PAN

** VERY IMPORTANT** Make sure there is deionized water in the pan. Do not turn on the

heat when the pan is empty. This can cause malfunction and jeopardizes the integrity of

the instrument.

CHECK THE WEIGHT PRIOR TO EACH USE

Make sure the weight (petcock) located on the vent nozzle is secure.

HANDLE WITH CARE

Dropping or roughly jolting Pascal will cause damage and deformation leading to

malfunctions.

DO NOT OPERATE NEAR A HEAT, FLAME OR GAS SOURCE

Never place the Pascal directly on a stove or other heating sources.

KEEP PASCAL CHAMBER BODY DRY

Remove foreign matter and water drops inside the body and on the outside of the chamber

pan. The heating plate, the sensor (inside the body) and the outside of the pan must be

dry and clean in order to work properly.

COOL DOWN AFTER EACH USE

In order to maintain consistency between runs, Pascal should be started at the same initial

temperature for each run. This can be done in a variety of ways. The user can cool the unit

down by adding cool water to the pan to bring the temperature down to 37 ºC, for

example. Alternatively, the instrument can be brought up to 80 ºC by setting SP1 to 80 ºC.

When the alarm sounds, the user can load the instrument, program the run parameters,

and start the run. This ensures consistency between runs. If only one run is performed per

day then this may not be an issue since the starting point will be close to the same each

day, i.e. ambient temperature.

Pascal Handbook

11

CHECK THE GASKET PERIODICALLY

Put the gasket check for Pascal on your monthly preventative maintenance list. The

gasket must be checked consistently for tears or damage. A replacement gasket can be

ordered with DakoCytomation code number SP99015. A relatively weak Pascal Quality

Strip color may indicate the need for a new Pascal gasket.

FILL THE UNIT WITH ONLY 500 mL FOR MOST APPLICATIONS.

Fill Pascal with deionized water. 500 mL is all that is required for most applications.

AVOID TOUCHING THE PAN OR LID WHEN IN USE – HOT!

When in use, the pan, the lid and the weight get very hot. Avoid touching

them. There is a hot sticker to warn that the lid is hot. The circular sticker

reads HOT at elevated temperatures.

12

Pascal Handbook

Section 4

Operating Instructions

Set Up

1. Familiarize yourself with Pascal and its parts prior to operating.

2. Adjust the pan by matching the pan handles with the body handles.

Note If the outside of the pan is wet, Pascal will make a cracking noise. Any water in the

body may cause malfunctions.

3. Fill the pan with 500 mL of deionized water for performing the standard Target Retrieval

procedure.

4. Ensure the heat shield is in the center of the pan.

5. Place 1 to 4 Tissue-Tek

Solution in the pan. Alternatively, use plastic Coplin jars. Fill each plastic Coplin jar with

50 mL of Target Retrieval Solution. Place slides intended for the Target Retrieval

procedure in the Tissue-Tek

6. Place a dry Pascal Quality Strip on top of the containers.

7. Position the lid on the pan and secure in place by aligning the OPEN arrow etched on

the lid’s surface with one of the white dots on the pan handle. Grip the lid handle and

rotate clockwise so that the CLOSE arrow is aligned with the white dot on the pan handle.

8. Place the weight (petcock) on the vent nozzle located on the Pascal chamber lid.

9. Turn the red main power switch to the ON position (I).

®

containers each filled with 250 mL of suitable Target Retrieval

®

containers or Coplin jars.

Programming

Pascal Factory Settings

Push the Display Set button to recall the following factory setting parameters on a new

instrument. These settings can be changed for individual applications. Refer to Changing

Factory Setting within this section for notes on making changes for specific applications.

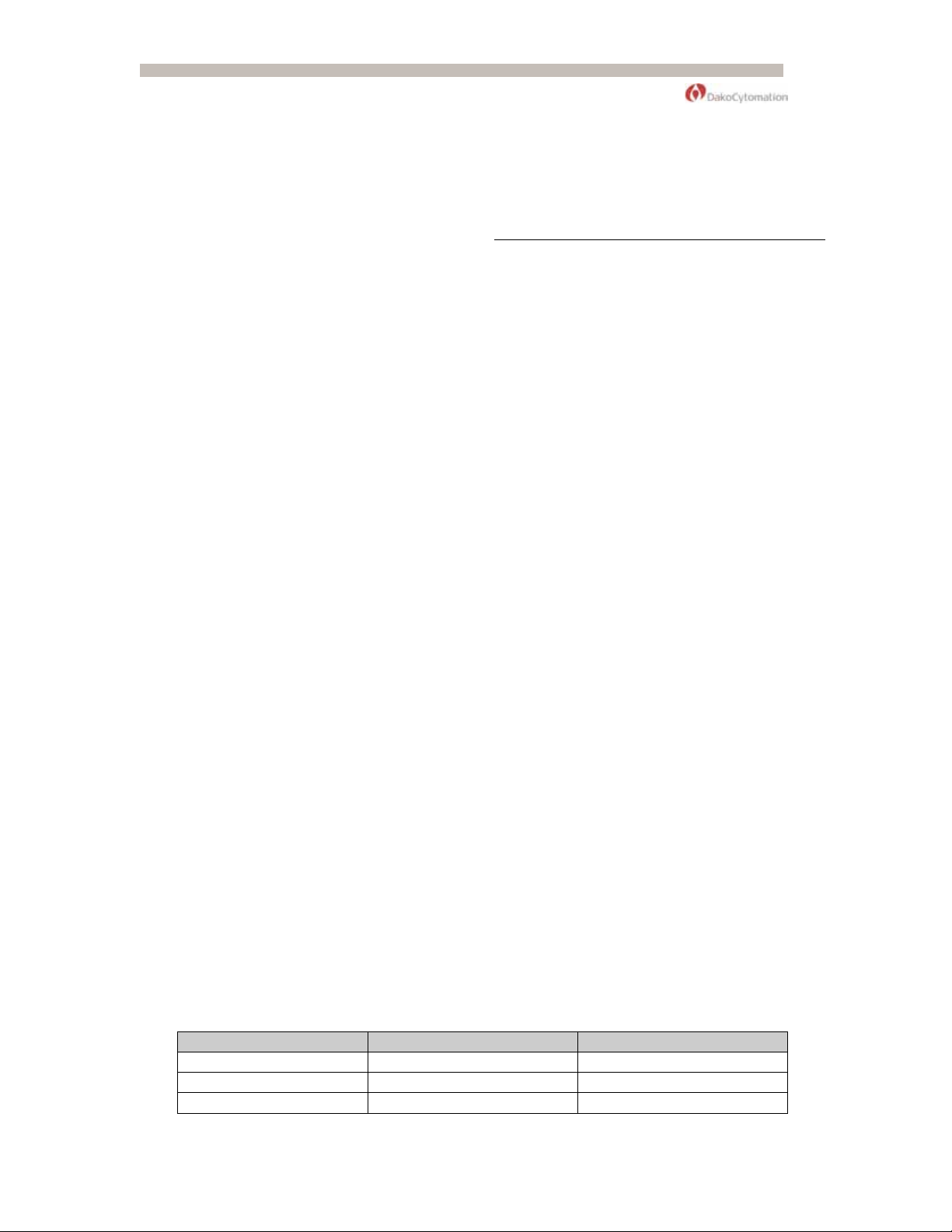

Pascal Factory Settings

Factory Settings Temperature Time

SP1 125 ºC 30 seconds

SP2 90 ºC 10 Seconds

SP Limit 10 ºC n/a

Pascal Handbook

13

Pascal Setting Limits

Minimum Maximum

SP Temperature 37 ºC 125 ºC

SP Time :01 second 98:59 minutes

These are the factory settings. SP1 and SP2 settings can be changed by the user.

DakoCytomation recommends performing Target Retrieval in Pascal at 120–125 ºC for

30 seconds–5 minutes. Recommended times may vary according to the application. Most

DakoCytomation applications recommend performing Target Retrieval in a pressure

chamber set at 125 ºC for 30 seconds.

Note The Pascal Quality Strip optimal performance (charcoal black color) is at 125 ºC and

relative pressure. Lower temperature and pressure will produce a lighter colored strip; this

should be consistent at the same temperature and pressure between runs.

Start Program

1. Press the Display Set button until the SP1 LED indicator illuminates.

2. Push the Start/Stop button to start the program.

3. Push the down arrow to display the actual temperature.

Note Both the Heat On light and Actual temperature light should be illuminated. The time

required to reach the temperature programmed depends on many variables such as the

voltage source and frequency, the number of bath/slides in the chamber, and the altitude

at which the instrument is operated.

Note Upon reaching the programmed temperature, the Heat On LED will turn off and the

timer will start counting down. The instrument will overshoot the programmed temperature

by approximately 2–3 ºC, and then will slowly come down to the programmed temperature.

When the digital timer reaches 0, the audible alarm will sound.

4. When the alarm sounds, press the Start/Stop button and the SP2 LED will illuminate.

5. For quality control, immediately record the temperature and pressure.

Note For quality control, immediately record the temperature and pressure. The pressure

will vary with contents within Pascal and the SP1 temperature setting. The temperature

may read +0–3 ºC above set SP1 temperature setting.

14

Pascal Handbook

End Program

1. When the temperature reaches the SP2 programmed temperature for the programmed

SP2 time limit, an audible beep will sound and all indicator-lights will be flashing. Press the

Start/Stop button to end the program. Confirm the pressure reads 0 psi, before unlocking

the Pascal lid.

Note If pressure is not at 0 psi when the SP2 audible alarm is reached but is low relative

to the pressure reached during the run, i.e. approximately 1-5 psi, the user should gently

tilt the weight (petcock) located on the lid to one side. This will release residual pressure

and enable a safe environment in which to open Pascal post run.

2. Slightly push down the lid and rotate counter-clockwise to the OPEN position. Turn the

On/Off switch to the Off position.

3. Check the Pascal Quality Strip for proper color (dark gray to charcoal black) and record

for quality control.

4. Remove container with slides and slowly rinse slides in running reagent grade water.

Slides should remain in the container while rinsing.

Note In order to maintain consistency between runs, Pascal should be started at the

same initial temperature for each run. This can be done in a variety of ways. The unit can

be cooled down by adding cool water to the pan to bring the temperature down to 37 ºC,

for example. Alternatively, the instrument can be brought up to 80 ºC by setting SP1 to

80 ºC. When the alarm sounds, load the instrument, program the run parameters and start

the run. This ensures consistency between runs. If only one run is performed per day, this

may not be an issue because the starting point will be close to the same each day, i.e.

ambient temperature.

Changing Factory Settings

1. Press the Display Set button until the SP1 LED illuminates. Use the up and down

arrows to set the SP1 temperature to the desired temperature. SP1 can be utilized

exclusively when the SP2 time is programmed at 0 minutes.

Note To speed up the time and temperature setting, push the second arrow while holding

the original direction arrow down.

Note Time Bypass feature: if Set Point 1 (SP1) time is programmed to 99:00 minutes,

Pascal will continuously maintain temperature without a time countdown. When using the

Time Bypass feature, the temperature cannot be set at greater than 100 ºC as a safety

precaution. If the bypass feature is set at 99:00 minutes at SP1, the SP2 function is

disabled.

2. Press the Display Set button again and use the up and down arrows to set the SP1

time to the desired program time.

Pascal Handbook

15

3. Press the Display Set button again until the SP2 LED illuminates. Use the up and down

arrows to set the SP2 temperature to the desired cool down temperature.

4. Press the Display Set button again and use the up and down arrows to set the SP2

time to the desired program time.

Note When Pascal has reached the SP1 temperature and time, the heating element will

turn off automatically and cannot be turned on again until after reaching an internal

temperature of 37 ºC. Also, the SP2 temperature will not be maintained when reached; the

alarm is only an indicator that the SP2 temperature has been reached.

5. Press the Display Set button until the SP Limit LED indicator illuminates. Use the up

and down arrows to set the SP Limit to the desired circuit breaker temperature setting.

16

Pascal Handbook

Section 5

Maintenance

Daily

The following maintenance procedures should be performed after each daily use of

Pascal:

Pour water out of pan.

Rinse pan with deionized water and dry.

Inspect gasket for wear.

Lid can be left on top of pan, but should be left slightly ajar.

Monthly

Preventative Maintenance should be performed once per month:

Pan, Gasket, Vent Nozzle and Weight

Remove the pan, gasket, lid, and weight and soak each in warm water with a mild

dish detergent. Abrasive powders or metal scrubbers will damage the surface and

may cause contamination. Wash thoroughly with a sponge and then dry well. To

protect against electrical hazards, do not immerse cord/plug or the body of Pascal

in water or a dishwasher.

Inspect gasket for wear. Do not pull or tear the gasket.

Inspect lid and pan for corrosion - especially where these parts come into contact with the

gasket.

If the vent nozzle becomes blocked with debris, clear the path with a toothpick or similar

device and wash clean.

Heat Plate and Heat Sensor

Wipe off anything stuck to the heat plate or heat sensor. Dry with a soft cloth.

Body

Wipe the surface lightly with a soft cloth soaked in warm water.

Be careful that water does not get into the body.

Pascal Handbook

17

Biannually

Pascal Calibration Protocol

Pascal calibration is performed at two temperatures. Both calibration points must be

performed for a complete Pascal calibration procedure. While the complete calibration

procedure is recommended every 6 months, it is also recommended to perform the room

temperature calibration prior to each use

Room Temperature Calibration

1. Plug Pascal into power supply

• Turn on the power switch located on the right side, next to the front panel.

2. Place 500 mL water into Pascal pan and equilibrate to room temperature for 15

20 minutes.

• This step is necessary in order to validate the starting temperature.

• Do not add warm water to speed up the process.

3. Read the temperature on the digital display.

4. Insert a calibrated thermometer in the Pascal pan containing 500 mL of water.

Compare the thermometer temperature reading to the digital display reading. If the

digital display matches the thermometer reading within 0.5 ºC then the instrument

should be considered within calibration limits for the Room Temperature

Calibration check point. Proceed to the High Temperature Calibration.

If the readings fail to match by greater than 0.5 ºC, adjust the digital reading by

following these steps:

• Turn the main power switch off.

• Turn it back on while pressing the Up

time.

• Confirm that all 6 LEDs are illuminated; this indicates that Pascal is in

calibration offset mode.

• Press the “Display Set” button one time.

• Use the Up

temperature read out will match the calibrated thermometer. Example: The

digital reading is 25 ºC, and the thermometer reading is 26 ºC. The action

required is to adjust the offset up by 1 ºC.

• Once the calibration is set press the “Display set” button two times to exit the

calibration mode.

High Temperature Calibration

1. Ensure that Pascal is set to factory settings for SP1, SP2, and SP Limit for the

High Temperature Calibration procedure. If Pascal settings have been changed

from factory specified settings refer to the Operating Instructions section in this

or Down arrow to adjust the offset so the digital

and Down arrows at the same

–

18

Pascal Handbook

manual for both the factory setting parameters and the instructions on changing

Pascal settings.

2. Place 500 mL water inside the Pascal pan followed by a 250 mL bath of water

containing a slide rack with 24 slides.

• Place a Steam Monitor Strip on the bath container.

• Close the Pascal lid and press the “Start/Stop” button.

3. When the SP1 temperature is reached and the alarm sounds verify the digital

display temperature is 126–128 ºC and chamber pressure is 21–23.4 pounds per

square inch (psi). If these parameters are within this range then the Pascal should

be considered to be within calibration limits for the High Temperature Calibration

check point. If the temperature and the pressure are not within the above range,

perform the following adjustment:

• Turn the power switch to the off position.

• Turn it back on while pressing the Up

time.

• Confirm all 6 LEDs are illuminated; this indicates that Pascal is in calibration

offset mode.

• Press the “Display Set” button one time.

• Adjust the digital display temperature reading by using Up

arrows to match the pressure that is displayed on the Pascal pressure gauge to

the corresponding temperature recorded on the Pressure-Temperature

Calibration Chart below.

• Note The arrow button may need to be pushed and held with consistent

pressure until the temperature changes. Work quickly as the

temperature and pressure are decreasing.

Pressure-Temperature Calibration Chart

and Down arrows at the same

or Down

Pressure Temperature Pressure Temperature

13.0 psi 118.0 ºC 18.9 psi 124.0 ºC

13.5 psi 118.5 ºC 19.5 psi 124.5 ºC

14.0 psi 119.0 ºC 20.0 psi 125.0 ºC

14.4 psi 119.5 ºC 20.5 psi 125.5 ºC

15.0 psi 120.0 ºC 21.0 psi 126.0 ºC

15.4 psi 120.5 ºC 21.6 psi 126.5 ºC

15.9 psi 121.0 ºC 22.2 psi 127.0 ºC

16.3 psi 121.5 ºC 22.8 psi 127.5 ºC

16.8 psi 122.0 ºC 23.4 psi 128.0 ºC

17.3 psi 122.5 ºC 23.9 psi 128.5 ºC

17.8 psi 123.0 ºC 24.5 psi 129.0 ºC

18.3 psi 123.5 ºC 25.1 psi 129.5 ºC

One pound force per square inch ( 1 psi) equates to 6.895 kPa (kiloPascals), conversion factor provided by United

Kingdom National Physical Laboratory.

4. Turn the Power off, and wait for Pascal to cool down to room temperature, i.e.

<27 °C. Cold water can be used to reduce the device’s temperature for this step.

Pascal Handbook

19

5. Repeat the High Temperature Calibration to verify that Pascal now falls within the

calibration limits specified in step 3 of the High Temperature Calibration procedure.

Electrical Precautions

Basic safety precautions should always be followed when using electrical equipment.

Read the following instructions:

To protect against electrical hazards, do not immerse cord/plug or the body of

Pascal in water or a dishwasher.

Unplug from outlet when not in use, and before cleaning.

Do not operate Pascal with a damaged cord or plug.

Do not let cord hang over edge of table or counter, or touch hot surfaces.

Do not place near a heat source, open flame or gas outlet.

Service

There are few user-serviceable parts such as the gasket, lid and pan. Refer all service to

qualified DakoCytomation service personnel.

Reference the DakoCytomation Warranty for further instructions.

Note Decontamination before returning for service is required.

A Pascal containing accumulated blood and/or other biological or chemical deposits must

be cleaned prior to shipment to the manufacturer/dealer for service. Refer to local or

regional regulations for decontamination requirements. DakoCytomation personnel cannot

perform this decontamination.

Disposal

Correct Disposal of this Product

(According to Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

applicable in the European Union and other European countries with separate collection

systems).

Contact DakoCytomation representative for disposal of the equipment at the end of its

working life. This product should not be mixed with other commercial waste for disposal.

Troubleshooting

Strong Target Retrieval performance

Reduce programmed time interval, i.e. if set at 5 minutes for a given temperature,

reduce time to 30 seconds to decrease stain intensity.

Alternatively, if time interval is already short, reduce programmed temperature.

Decrease antibody incubation time.

Increase antibody dilution.

20

Pascal Handbook

Inconsistent/weak Target Retrieval performance

Ensure the integrity of the gasket. Check to see if pressure is consistent between at least

three separate runs. If pressure is dropping relative to standard operation based on a

consistent program setting, replace the gasket.

Poor morphology

Reduce programmed time interval; i.e., if set at 5 minutes for a given temperature,

reduce time to 30 seconds to decrease time at high temperature which may affect

morphology within certain tissue types.

Use appropriate Target Retrieval Solutions. High pH buffers (i.e. pH 9.9) have a

tendency to be harsh on tissue specimens and can contribute to poor morphology.

Adherence of specimen to glass slide

Start retrieval program at a higher temperature; i.e., 80 ºC as opposed to lower

temperature such as ambient or 37 ºC. This has been shown to reduce tissue adherence

failure.

Use appropriate Target Retrieval Solutions. High pH buffers have a tendency to be harsh

on tissue specimens and can contribute to tissue adherence failure.

Ensure tissue sections are mounted on silanized slides or (+) charged slides.

Ensure that tissue sections were mounted from a waterbath not containing gelatin or other

adhesive product.

Ensure that sectioned slides have been baked for 1 hour at 60 °C before processing.

Specifications

Model: S2800 (110–120 volts)

Pan Capacity: 3.2 liters

Weight: 3.7 kg (8.18 lbs.)

CE Listed

Pascal Handbook

21

DakoCytomation Warranty

DakoCytomation warrants to Buyer that Pascal will be free, under

normal use and maintenance, from defects in material and workmanship for a

period of one (1) year from the date of delivery to the end-user. As Buyer’s

sole and exclusive remedy for any such defects, DakoCytomation will, at

its option, repair or replace without charge any unit which is found to be

so defective.

Limitation of Liability

DakoCytomation shall not be responsible under this warranty

for products found to be defective as a result of misuse, mishandling, or

neglect.

DakoCytomation MAKES NO OTHER WARRANTIES OTHER THAN THAT

SPECIFIED ABOVE, OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, AND ALL

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED BY DAKOCYTOMATION AND EXCLUDED FROM THE

TERMS OF SALE.

DakoCytomation, Inc.

6392 Via Real

Carpinteria, California 93013 USA

Tel 805 566 6655

Fax 805 566 6688

Technical Support 800 424 0021

Customer Service 800 235 5763

DakoCytomation Denmark A/S

Produktionsvej 42

DK-2600 Glostrup Denmark

Tel +45 4485 9500

Fax +45 4485 9595

www.dakocytomation.com

22

Pascal Handbook

Appendix A

Pascal Quality Control Log

Use the following quality control log to record settings such as pressure and temperature

to ensure consistent performance of the Pascal.

Pascal Handbook

23

Loading...

Loading...