Page 1

INSTALLATION AND MAINTENANCE MANUAL

Serie

PORTABLE

Edition

R00

Models

ADP-12FX-A3

ADP-

12F/CX-A3

Page 2

Content

Operation Notices

The Refrigerant

Safety Warning ........................................................................................................2

Operation Environment ............................................................................................3

Part's Name .............................................................................................................4

Operation Guide

Operation Introduction for Control Panel .................................................................5

Use for air conditioner .............................................................................................7

Using the remote control .........................................................................................8

Buttons on Remote Controller .................................................................................9

Introduction for Icons on Display Screen .................................................................9

Introduction for Buttons on Remote Controller .......................................................10

Function Introduction for Combination Buttons .....................................................12

Replacement of Batteries in Remote Controller .....................................................

Maintenance

Clean and Maintenance.........................................................................................13

Malfunction

Malfunction analysis ..............................................................................................15

Installation Notice

Installation Precaution ...........................................................................................18

Preparation before Installation ...............................................................................19

Installation

Install Wire Hook ...................................................................................................20

Removing Collected Water ...................................................................................21

Installation in a double-hung sash window(Optional)............................................24

Installation in a sliding sash window(Optional)......................................................27

Installation and Disassembly of Heat Discharge Pipe ...........................................30

Attached Sheet

Operation Test .......................................................................................................33

Electric Schematic Diagram...................................................................................34

Specialist’s Manual

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Frequency band(s) in which the radio equipment operates: 2400MHz-2483.5MHz

Maximum radio-frequency power transmitted in the frequency band(s) in which the radio equipment

operates:20dBm

This marking indicates that this product should not be disposed with other household wastes

throughout the EU. To prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse of material resources. To return your used device, please use the return and collection systems or

contact the retailer where the product was purchased. They can take this product for environmental safe recycling.

R290: 3

........................................................................................................1

12

................................................................................................35

Page 3

Explanation of Symbols

DANGER

WARNING

CAUTION

N OTIC E

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates important but not hazard-related information,

used to indicate risk of property damage.

Indicates a hazard that would be assigned a signal word

WARNING or CAUTION.

Exception Clauses

Manufacturer will bear no responsibilities when personal injury or

property loss is caused by the following reasons.

1.Damage the product due to improper use or misuse of the product;

2.Alter, change, maintain or use the product with other equipment without abiding

by the instruction manual of manufacturer;

3.After verification, the defect of product is directly caused by corrosive gas;

4.After verification, defects are due to improper operation during transportation of

product;

5.Operate, repair, maintain the unit without abiding by instruction manual or related

regulations;

6.After verification, the problem or dispute is caused by the quality specification or

performance of parts and components that produced by other manufacturers;

7.The damage is caused by natural calamities, bad using environment or force

majeure.

Page 4

Appliance filled with flammable gas R290.

Before install and use the appliance, read the owner’s manual first.

Before install the appliance, read the installation manual first.

Before repair the appliance, read the service manual first.

The Refrigerant

To realize the function of the air conditioner unit, a special refrigerant circulates in

the system. The used refrigerant is the fluoride R290, which is specially cleaned.

The refrigerant is flammable and inodorous. Furthermore, it can leads to explosion

under certain conditions.

Compared to common refrigerants, R290 is a nonpolluting refrigerant with no harm

to the ozonosphere. The influence upon the greenhouse effect is also lower. R290

has got very good thermodynamic features which lead to a really high energy

efficiency. The units therefore need a less filling.

Please refer to the nameplate for the charging quantity of R290.

WARNING

Appliance filled with flammable gas R290.

Appliance shall be installed, operated and stored in a room with a floor area larger

than 11 m .

The appliance shall be stored in a room without continuously operating ignition sources .

(for example: open flames, an operating gas appliance or an operating electric heater.)

The appliance shall be stored in a well-ventilated area where the room size corresponds

to the room area as specified for operation.

The appliance shall be stored so as to prevent mechanical damage from occurring.

Ducts connected to an appliance shall not contain an ignition source.

Keep any required ventilation openings clear of obstruction.

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

Servicing shall be performed only as recommended by the manufacturer.

Should repair be necessary, contact your nearest aut

Any repairs carried out by unqualified personnel may be dangerous.

Compliance with national gas regulations shall be observed.

Read specialist’s manual.

2

horized Service Centre.

1

Page 5

Safety Warning

● This appliance can be used by children aged from 8 years and

above and persons with reduced physical,sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

nerdlihc yb edam eb ton llahs ecnanetniam resu dna gninaelC

without supervision.Children shall not play with the appliance.

● Before operation, please confirm whether power specification

complies with that on nameplate.

● Before cleaning or maintaining the air conditioner, please turn off

air conditioner and pull out the power plug.

● Make sure the power cord hasn’t been pressed by hard objects.

● Do not pull or drag the power cord to pull out the power plug or

move the air conditioner.

● Do not insert or pull out the power plug with wet hands.

● Please use the grounded power. Make sure the gounding is reliable.

● If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualified person

in order to avoid a hazard.

● If abnormal condition occurs (e.g. burned smell), please

disconnect power at once and then contact local dealer.

● When nobody is taking care of the unit, please turn it off and

remove the power plug or di

● Do not splash or pour water on air conditioner. Otherwise, it may

cause short circuit or damage to air conditioner.

If drainage hose is used, ambient temperature can't be lower than

●

0 .

Otherwise, it will cause water leakage to air conditioner.

● Prohibit operating heating equipment around the air conditioner.

● Prohibit operating the unit in the bathroom or laundry room.

● Far away from fire source, inflammable and explosive objects.

● Children and disabled people are not allowed to use the

unit without supervision.

● Keep children from playing or climbing on the air conditioner.

● Do not put or hang dripping objects above the air conditioner.

● Do not repair or disassemble the air conditioner by yourself.

● Prohibit inserting any objects into the air conditioner.

● Do not through sundries into the air duct. If there are sundr

into the air duct, please contact the professionals to deal with it.

● Do not use an extension cord.

sconnect power.

ies get

2

Page 6

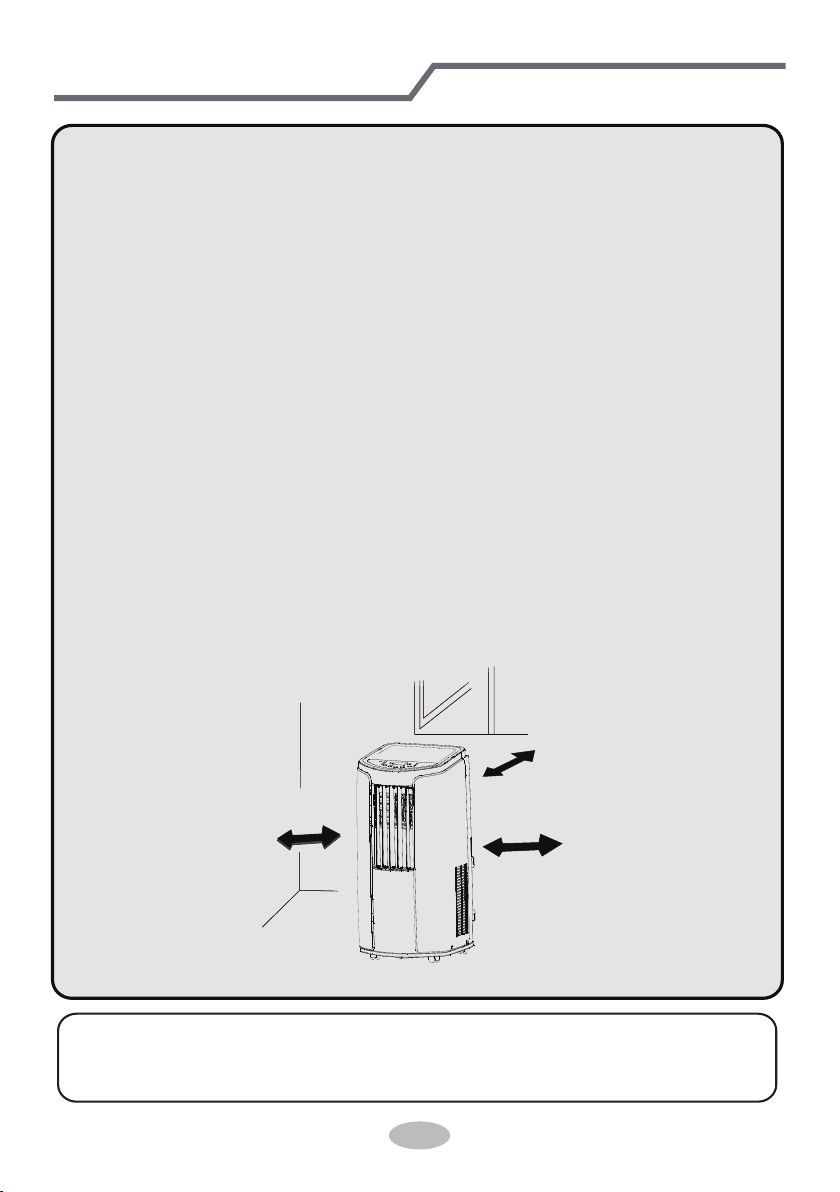

Operation Environment

● The air conditioner must be operated within the temperature range:

16°C ~ 35°C.

● The appliance is for indoor use only.

● The appliance must be positioned so that the plug is accessible.

● This air conditioner can only be used for family, not for

commercial industry.

● Reserved space around the air conditioner should be 12″(30cm)

at least.

● Do not operate the air conditioner at humid environment.

● Please keep air inlet and air outlet clean, no obstacles.

● During operation, close doors and windows to improve cooling effect.

● Please put the air conditioner at smooth and flat ground for operation

to avoid noise and vibration.

● This air conditioner is equipped with castors. Castors should slide

at smooth and flat ground.

● Prohibit inclining or turning over the air conditioner. If there’s abnor-

mity, please disconnect power immediately and contact dealer.

● Avoid direct sunshine.

30cm

30cm

Note:

Graphics in this manual are only for reference. Please refer to actual products

for specific details.

30cm

3

Page 7

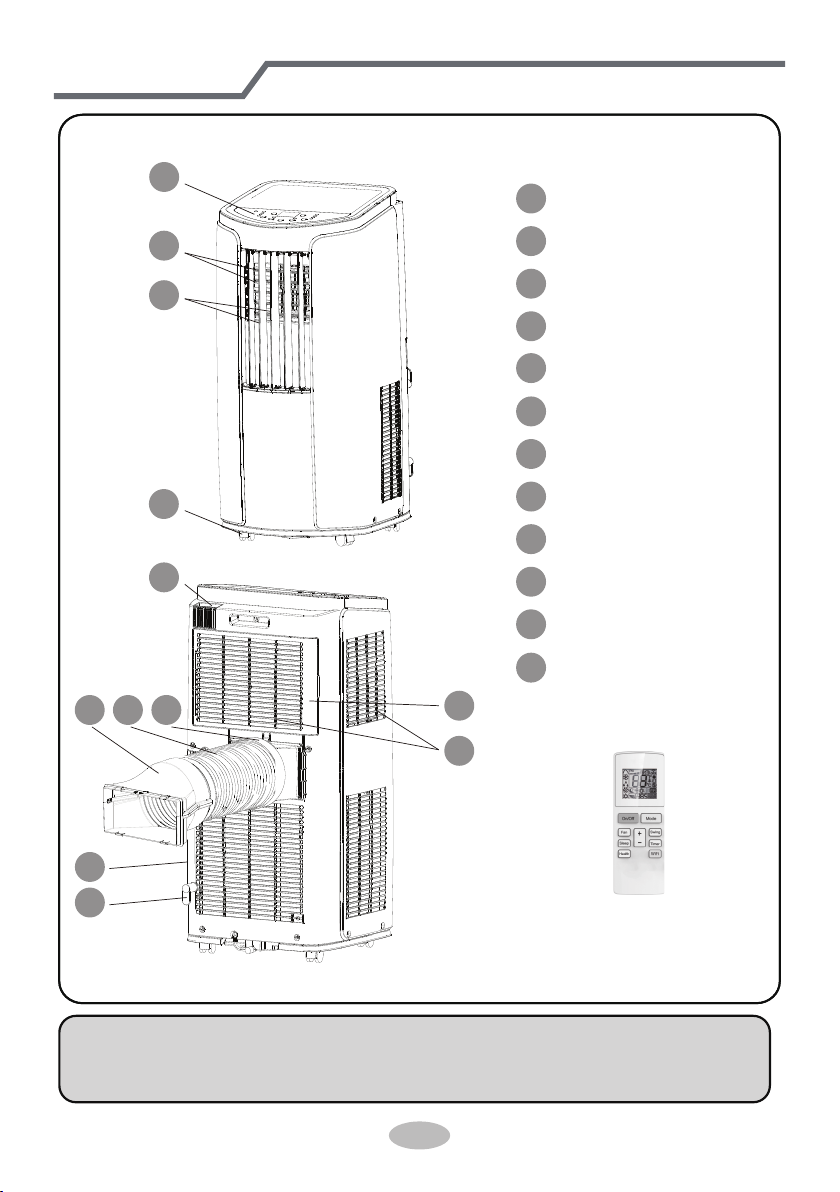

Part's Name

1

2

3

4

1

Controller panel

2

Guide louver

Swing louver

3

Castor

4

5

Wire-fixing hook

Plug of power cord

6

Filter

7

8

Air inlet

9

Joint A

12

9

10

11

6

5

NOTICE:

Installation accessories can't be discarded.

4

10

Heat discharge pipe

11

Joint B+C

12 Remote controller hook

7

8

Remote controller

Page 8

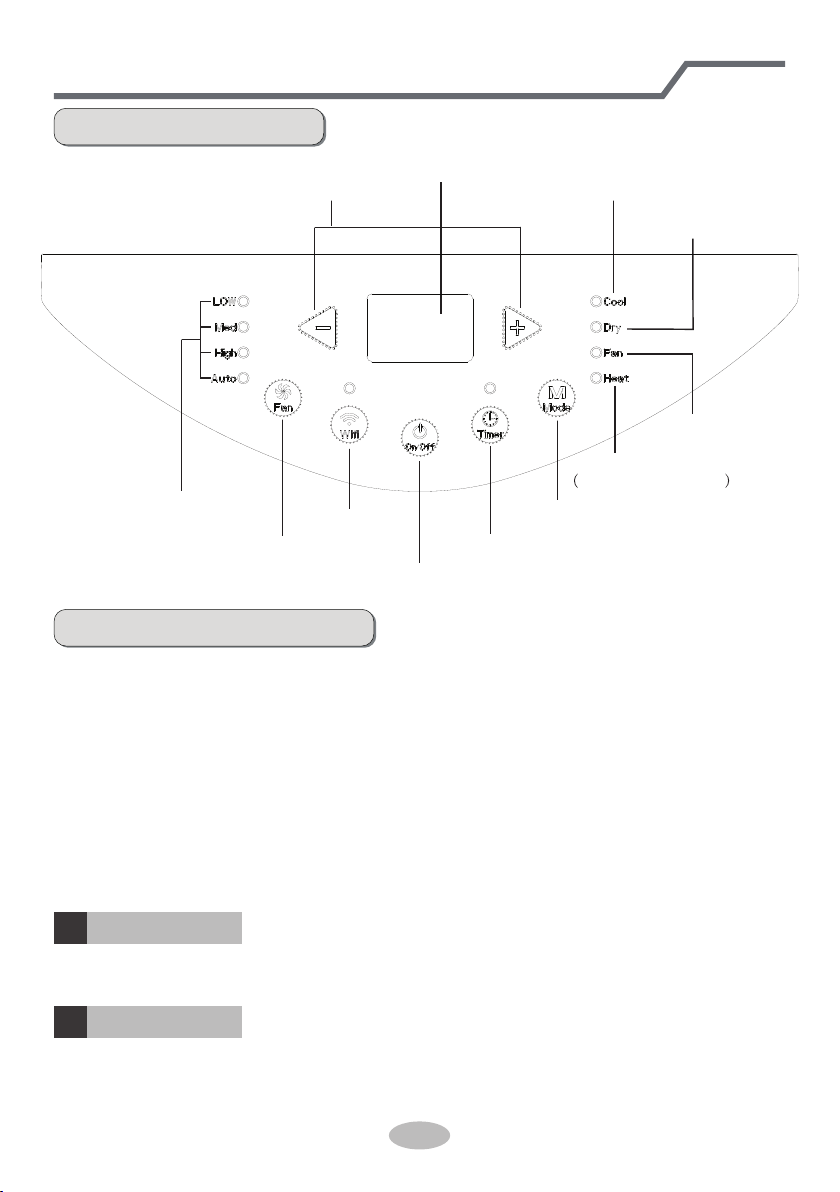

Operation Introduction for Control Panel

Name of control panel

+ / - button

Fan speed indicator

Fan button

Dual-8 nixie tube

nottub ifiW

Timer button

ON/OFF button

Cool mode indicator

Dry mode indicator

Fan mode indicator

Heat mode indicator

Cool&Heat Unit only

Mode button

Operation of control panel

NOTICE:

●

After putting through the power, the air conditioner will give out a sound. After

that, you can operate the air conditioner by the control panel.

●

Under ON status, after each pressing of the button on control panel, the air

conditioner will give out a sound. Meanwhile, corresponding indicator on control

panel will be bright.

●

Under OFF status, dual-8 nixie tube on control panel won’t display.

Under ON status, dual-8 nixie tube on control panel will display set temperature

under cooling mode and Heating mode (Cool&Heat Unit only), while it won’t display

under other modes.

ON/OFF button

1

Pressing this button can turn on or turn off the air conditioner.

+ / - button

2

Under cooling mode, press “+” or “-” button to increase or decrease set temperature by

1°C. Set temperature range is 16°C~30°C. Under auto, drying or fan mode, this

button is invalid.

5

Page 9

Operation Introduction for Control Panel

Mode button

3

Press this button and the mode will circulate according to below sequence:

Cool→Dry→Fan→Heat Cool&Heat Unit only

Cool: Under this mode, cooling mode indicator is bright. Dual-8 nixie tube displays

°C

set temperature. Temperature setting range is 16

Dry: Under this mode, drying mode indicator is bright. Dual-8 nixie tube won’t

display.

Fan: Under this mode, the air conditioner only blow fan. Fan indicator is bright.

Dual-8 nixie tube won’t displa

Heat Cool&Heat Unit only : Under this mode, heating mode indicator is bright.

Fan button

4

Press this button and the fan speed will circulate as “low speed→ medium speed →

high speed→ auto fan→ low speed”.

Timer

5

Press timer button to enter into timer setting mode. Under this mode, press " "

-

or " " button to adjust the timer setting. Timer setting will increase or decrease

0.5 hour by pressing " " or " " button within 10 hours, while timer setting will

increase or decrease 1 hour by pressing " " or " " button beyond 10 hours.

After timer setting is finished, the unit will display temperature if there’s no

operation for 5s. If timer function is started up, the upper indicator will keep the

display status. Others, it won’t be displayed. Under timer mode, press timer button

again to cancel timer mode.

+

y.

Dual-8 nixie tube displays set temperature. Temperature

setting range is 16°C~30°C.

+

~30°C.

+

-

Wifi button

6

After the unit is powered up, press WIFI button to turn on or off WIFI function.

Press and hold the button for 10s to reset WIFI function.

6

Page 10

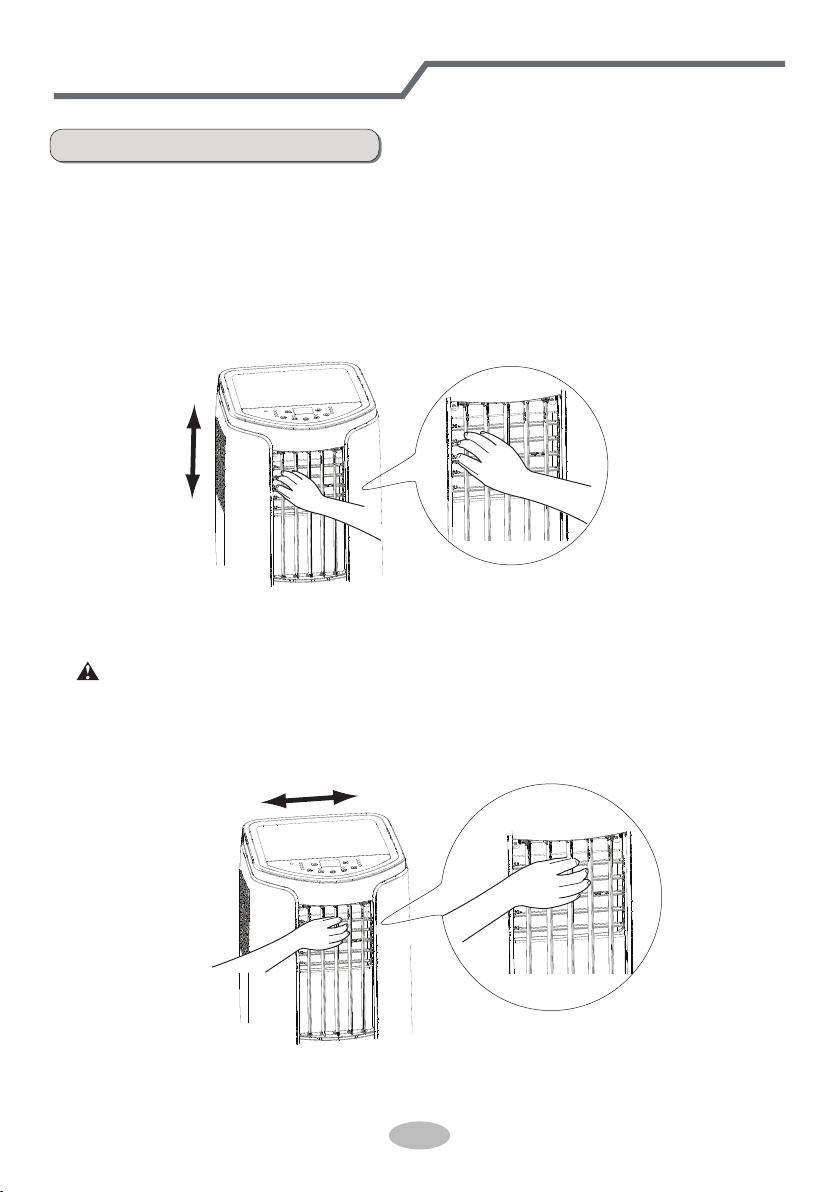

Use for air conditioner

To change air flow direction

1. Up/down air flow direction

• Hold the horizental louvers as shown in the diagram and adjust the air flow

direnction.

• Do not adjust the horizontal louvers to the lowest or the highest position in the

COOL or DRY mode with the fan speed set to Low for an extended period of

time, Condensation may form on the louvers.

2. Left/right air flow direction Hold the vertical louver as shown in the diagram

and adjust the air flow direction.

CAUTION:

• Do not adjust the vertical louvers to the extreme left or right in the COOL or

DRY mode with the fan speed set to Low for an extended period of time.

Condensation may form on the louvers.

7

Page 11

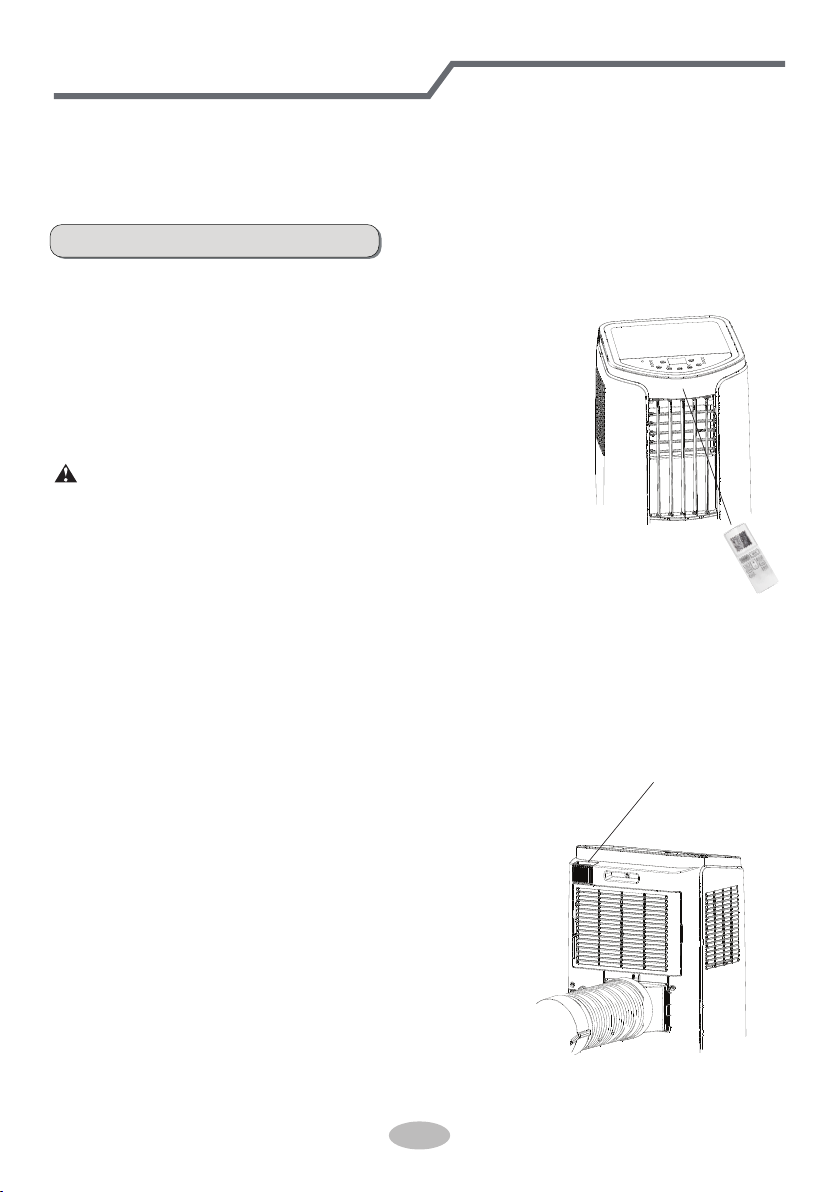

Using the remote control

This is a general use remote controller, it could be used for the air conditioners

with multifunction; For some function, which the model doesn't have, if press the

corresponding button on the remote controller that the unit will keep the original

running status.

How to use the remote control

Point the remote control toward the Signal receiver

and press the desired button. The unit generates

a beep when it receives the signal.

• Make sure nothing, such as curtains, blocks the

signal receiver window.

• The signal effective distance is 8m.

CAUTION:

• Do not expose the receiver window to direct sunlight.

This may adversely affect its operation.

• Use of certain fluorescent lamp in the same room

may interfere with transmission of the signal.

• Do not leave the remote control in direct sunlight

or near a heater. Protect the remote control from

moisture and shock.

To prevent the remote control from being

misplaced, hook it to the unit when not in

use.

When attached, to remove the remote control from

the unit, lift the remote control up slightly and pull it

out.

8

Remote control hook

Page 12

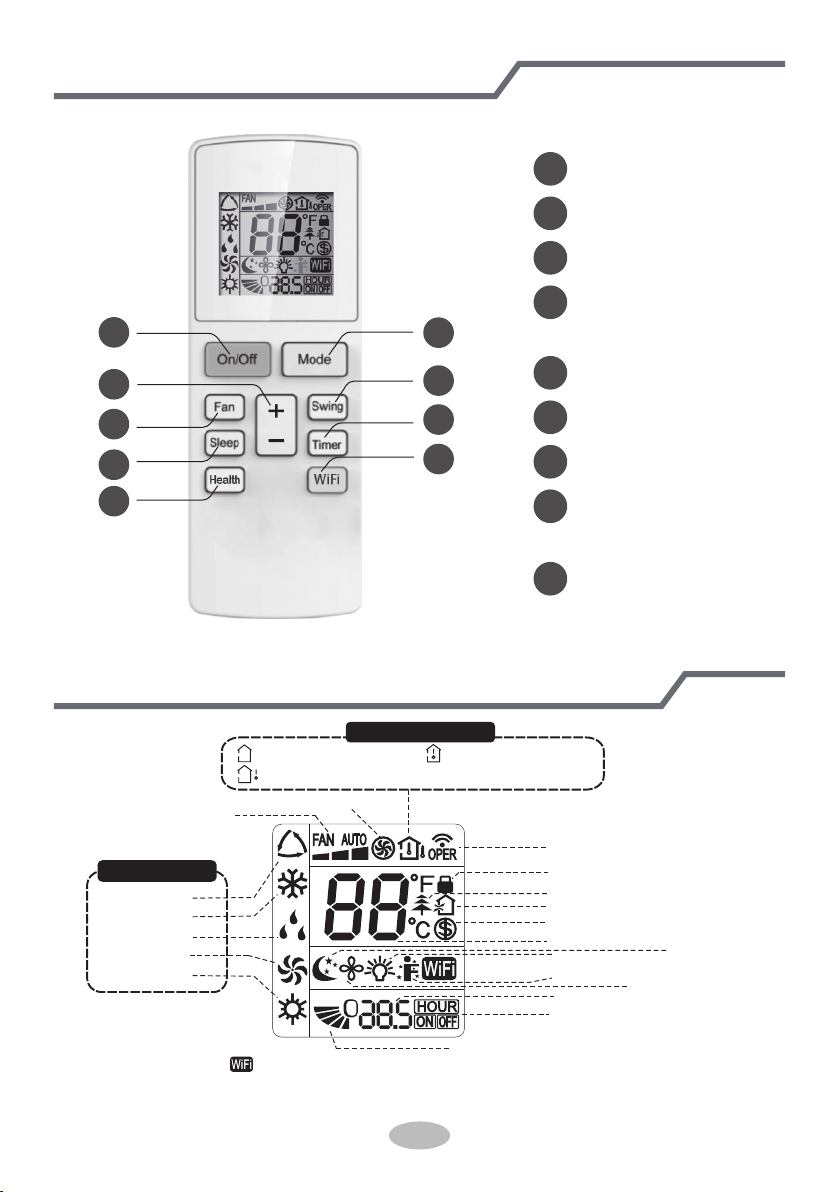

Buttons on remote controller

1

3

5

2

4

7

On/Off button

1

Mode button

2

+ / - button

3

Swing button

4

(This function is not applicable

for this model. )

Fan button

5

Sleep button

6

6

9

8

Timer button

7

Health button

8

(This function is not applicable

for this model. )

WiFi button

9

Introduction for icons on display screen

Temp. display type

:Indoor ambient temp.

Up & down swing

Send signal

Child lock

health function

ventilation operation

8℃ heating function

Set temperature

Light function

I feel function

Set time

TIMER ON /TIMER OFF

X-fan mode

Set fan speed

Operation mode

Auto mode

Cool mode

Dry mode

Fan mode

Heat mode

NOTICE:

:Set temp.

:Outdoor ambient temp.

Turbo mode

“

” This is a general remote controller. Some models have this function while some

do not. Please refer to the actual models.

Sleep mode

9

Page 13

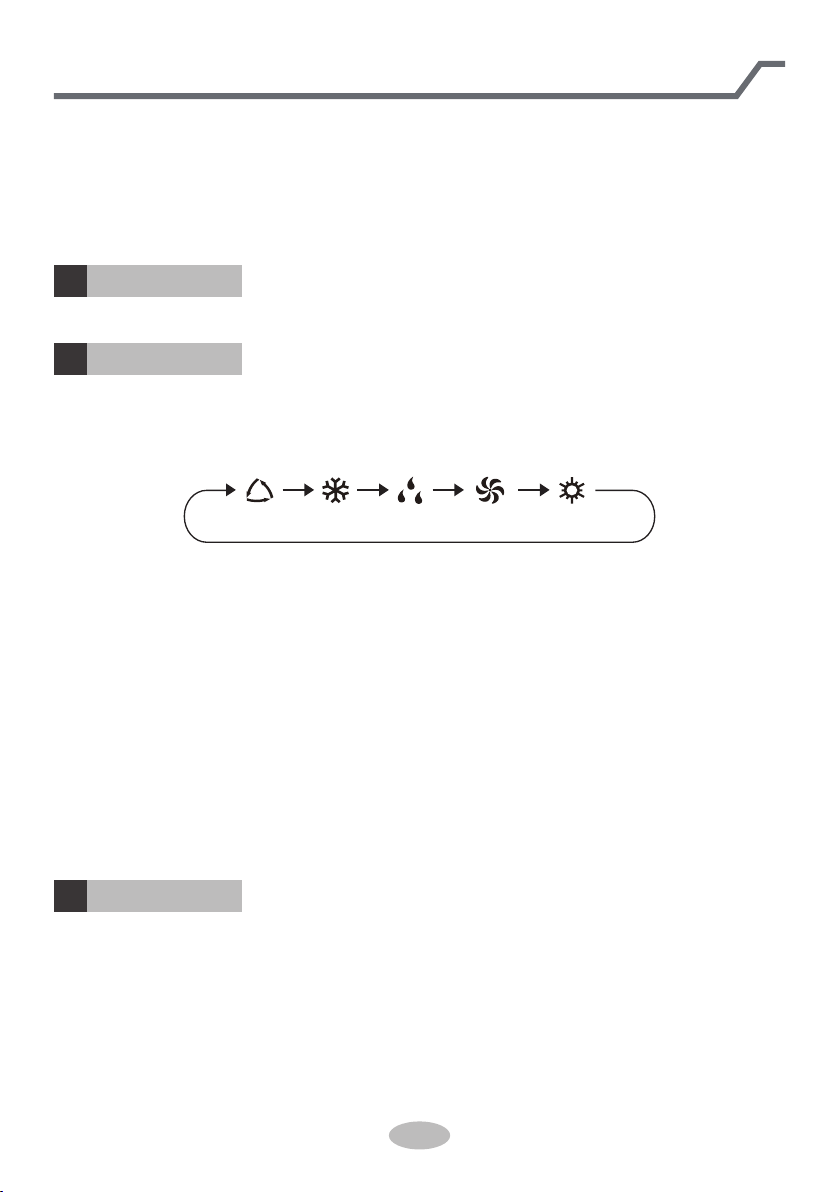

Introduction for buttons on remote controller

Note:

● This is a general use remote controller, it could be used for the air conditioners

with multifunction; For some function, which the model doesn't have, if press

the corresponding button on the remote controller that the unit will keep the

original running status.

ON/OFF button

1

Press this button to turn on the unit. Press this button again to turn off the unit.

MODE button

2

Press this button can your required operation mode in turn. Corresponding indicator

will be on.

Dry HeatCoolAuto

● Auto: Under this mode, the unit will operate automatically according to ex-factory

setting. In this case, set temperature cannot be adjusted.

● Cool: Under this mode, air conditioner operates under cooling mode. Cooling

indicator will be on. Press “Fan Speed” button can adjust the fan speed.

● Dry: Under this mode, the unit runs in low fan speed for dehumidification and the

corresponding indicator is on; under dry mode, the fan speed cannot be adjusted.

●

Fan Only: Under this mode, air conditioner will not cool or heat, only blow wind.

Fan indicator will be on. Press “Fan Speed” button can adjust the fan speed.

● Heat: Under this mode, air conditioner operates under heating mode. Press “Fan

Speed” button can adjust the fan speed.(Cooling only unit won’t receive heating

mode signal. If setting heat mode with remote controller, press ON/OFF button

can’t start up the unit).

Fan

Only

+ / - button

3

●

Pressing “+” or “-” button once will increase or decrease set temperature by 1°F(°C).

Hold “+” or “-” button for 2s, set temperature on remote controller will change

quickly.

Release the button after your required set temperature is reached.

●

Under timer setting status, after each pressing of “+” or “-” button, time will increase

or decrease 0.5h . Hold “ + ” or “-” button, 2s later, time displayed on dual-8 nixie

tube will change quickly. Loosen the button until the time is reached to your set

time.

10

Page 14

Introduction for buttons on remote controller

Swing button

4

Press this button to turn “ON” & “OFF” swing.

Fan button

5

This button is used for setting Fan Speed in the sequence that goes from AUTO,

, , to then back to Auto.

NOTE: There are 3 speeds for the Fan Speed of this model.

Sleep button

6

Press this button to go into the Sleep operation mode. Press it again to cancel this

function. This function is available in COOL, HEAT (Only for models with heating

function) mode to maintain the most comfortable temperature for you.

Timer button

7

Under ON status, press this button to set timer OFF; Under OFF status, press

this button to set timer ON.

Press this button once and the characters of HOUR ON (OFF) will

displayed. Meanwhile, press “+” button or “-” button to adjust timer setting (time

will change quickly if holding “+” or “-” button). Time setting range is 0.5~24hours.

Press this button again to confirm timer setting and the characters of HOUR ON

(OFF)will stop flashing.

If the characters are flashing but you haven’t press timer button,timer setting status

will be quit after 5s.If timer is confirmer, press this button again to cancel timer.

(This function is not applicable for this model. )

Auto

Speed 1 Speed 2

Speed 3

ash to be

Health button

8

Press this button to achieve the on and off of healthy and scavenging functions in

LCD displays " ". Press the button for the second time to start healthy and

scavenging functions simultaneously; LCD displays " " and " ". Press this

button for the third time to quit healthy and scavenging functions simultaneously.

Press the button for the fourth t ime to start healthy function; LCD display " ".

Press this button again to repeat the operation above.

●

This function is applicable to partial of models.

(This function is not applicable for this model. )

11

Page 15

Introduction for buttons on remote controller

WiFi button

9

Press " WiFi " button to turn on or turn off WiFi function. When WiFi function is

turned on, the " WiFi " icon will be displayed on remote controller; Under status of

unit off, press "Mode" and " WiFi " buttons simultaneously for 1s, WiFi module will

restore to factory default setting.

This function is only available for some models.●

Function introduction for combination buttons

Temperature display switchover function

Under OFF status, press "-" and "Mode" buttons simultaneously to switch temperature display between °C and °F

Light function

Under switch-on or switch-off state, you may hold "+"and "FAN" buttons

simultaneously to set the lamp on or off and send the code. After being energized

the lamp is defaulted on.

Replacement of batteries in remote controller

1. Press the back side of remote controller marked

the cover of battery box along the arrow direction.

2. Replace two 7# (AAA 1.5V) dry batteries, and

make sure the position of "+" polar and "-" polar

are correct.

Reinstall the cover of battery box.3.

signal sender battery

reinstall

remove

Cover of battery box

NOTICE

● The distance between signal sender and receiving window should be no

more than 8m, and there should be no obstacles between them.

● As the signal will be interfered in the room with electronic fluorescent lamp,

conversion fluorescent lamp or wireless phone, please get closer to the air

conditioner when using the remote controller.

●●Replace new batteries of the same model when replacement is required.

When you don’t use remote controller for a long time, please take out the

batteries.

12

Page 16

Clean and Maintenance

WARNING:

● Before cleaning the air conditioner, please turn off the unit and disconnect

power. Otherwise, it may cause electric shock.

● Do not wash air conditioner with water. Otherwise, it may cause electric

shock.

● Do not use volatile liquid (such as thinner or gas) to clean the air conditioner.

Otherwise, it may damage the appearance of air conditioner.

Clean outer case and grille

Clean outer case:

If there's dust on the surface of outer case, please use soft towel

to wipe it. If the outer case is very dirty (such as grease), please

use neutral abluent to wipe it.

Clean grille: Use cleaner or soft brush to clean it.

1. Remove the filter

a. Press the clasp as shown in the fig, and then remove the filter 1;

b. Pull out the filter 2.

filter 2

clasp

filter 1

2. Clean filter

Use cleaner or water to clean the filter. If the filter is very dirty (such as grease),

use warm water 40℃ melted with neutral abluent to clean it and then put at shady

place to dry it.

3. Install filter

After the filer is cleaned and dried, reinstall it well.

NOTICE:

● The filter should be cleaned about once every three months. If there's much dust

in the operation environment, you can increase clean frequency.

● Do not dry the filter with fire or hair drier. Otherwise, it may be deformed or catch

fire.

13

Page 17

Clean and Maintenance

NOTICE

dust in the operation environment, you can increase clean frequency.

Clean heat discharge pipe

Remove the heat discharge pipe from air conditioner, clean and dry it , and then

reinstall it. (For the method of installation and removal , please refer to the

instruction for "Installation and disassembly of heat discharge pipe").

Checking before use-season

1. Check whether air inlets and air outlets are blocked.

2. Check whether plug and socket are in good condition.

4. Check whether batteries are installed in remote controller.

5. Check whether joint, window bracket and heat discharge pipe are installed tightly.

6. Check whether heat discharge pipe is damaged.

Checking after use-season

1. Disconnect power supply.

3. Remove dust and sundries on the air conditioner.

4.

Eliminate accumulated water in chassis (refer to the section of "Drainage way"

for details).

5. Check whether window bracket is damaged or not. If yes, please contact dealer.

Long-time storage

If you don't use the air conditioner for a long time, please maintain it by following

steps for good performance:

● Make sure there's no accumulated water in chassis and the heat discharge pipe is

disassembled.

● Pull out the plug and wrap the power cord.

● Clean the air conditioner and pack it well to prevent dust.

Notice for recovery

● Many packing materials are recyclable materials. Please deal with them through

local recycle bin.

● If you want to throw away the air conditioner, please contact local division or

consultant service center for the correct disposal method.

14

Page 18

Malfunction analysis

Please check below items before asking for maintenance. If the malfunction still

Phenomenon Troubleshooting Solution

Air conditioner

can't operate

Poor cooling

(heating)

Air conditioner

can't receive

signal from

remote controller or remote

controller is

not sensible.

● Power failure?

● Is plug loose?

● Whether the air switch is trip ped off or fuse is burnt?

● Is there's malfunction for the

circuit?

● Whether the unit is restarted up

after stopping immediately?

● Is the power too low?

●

●

Whether the set temperature is

proper?

● Whether door and window are

closed?

● Whether the unit is interfered

seriously (such as static pres sure, unstable voltage)?

● Whether remote controller is

within the receiving range?

● Whether it's blocked by obst acles?

● Is sensitivity of remote contr oller low?

● Wait after power recovery.

● Reinsert the plug.

● Ask professional person to

replace air switch or fuse.

● Ask professional person to

replace circuit.

● Wait for 3min, and then turn

on the unit again.

●

Wait after voltage is resumed.

● Adjust the temperature.

● Close door and window.

● Please pull out the plug. Ins ert the plug after about 3min,

and then turn on the unit.

●

The receiving range of remote

controller is 8m. Do not exce ed this range.

● Remove the obstacles.

● Check the batteries of remote

controller. If the power is low,

please replace the batteries.

lamp in the room?

15

● Move the remote controller

close to air conditioner.

●

and try it again.

Page 19

Malfunction analysis

Phenomenon Troubleshooting Solution

No air blowed

out from air

conditioner

Set temperature can't be

adjusted.

There's off

● Whether air outlet or air inlet is

blocked?

● Under heating mode, whether

indoor temperature ireaches

set temperature?

● Whether heating mode is sta rted up just now?

● Whether evaporator is defros ted? (observe it by pulling out

● Whether the unit operates un der auto mode?

● Whether the required temper ature exceeds the temperature

setting range?

the room, such as furniture,

cigarette etc.

● Eliminate the obstacles.

● The unit will stop blowing

fan after reaching set

temperature.

● In order to prevent cold air,

air conditioner will delay for a

while to be started up, which

is the normal phenomenon.

● It's the normal phenomenon.

Air conditioner is defrosting.

will resume operation.

● Temperature can't be adjus ted

under auto mode.

● Temperature set ting range: 16°C-30°C .

source.

There's abnormal sound during operation

You can heard

sound

You can heard

the sound of

"PAPA"

● Whether the unit is interfered

by thunder, radio, etc?

● Whether the unit is turned on

or turned off just now?

● Whether the unit is turned on

or turned off just now?

16

● Disconnect power, put thro ugh the power again, and

then turn on the unit again.

rigerant inside the air condit ioner, which is the normal

phenomenon.

● Heat expansion or shrinkage

for the panel due to change

of temperature, which cause

friction sound.

Page 20

Malfunction analysis

Malfunction code

ERROR

CODE

F0

F1

F2

F4

E8

H3

H8

Troubleshooting

Please contact qualified professionals for service.

Please contact qualified professionals for service.

Please contact qualified professionals for service.

Please contact qualified professionals for service.

1.Check if the unit is under high-temperature

and high-humidity environment; if ambient

temperature is too high, power off the unit and

then energize it for operation after the ambient

temperature drops to 35℃below.

2. Check if the evaporator and condenser are

blocked by some objects; if yes, take away the

objects, power off the unit and then energize

it for operation.

3. If the malfunction still occur, please contact

our after-sales service center.

1. Pour out the water inside chassis.

2. If "H8" still exits, please contact professional

person to maintain the unit.

WARNING

●

If there're following phenomenon, please turn off the air conditioner and discon-

nect the power immediately, and then contact dealer immediately.

→ Power cord is overheating or damaged.

→ Abnormal sound during operation.

→ Water leakage

● If operate the air conditioner under abnormal condition, it may cause malfunc-

17

Page 21

Installation Precaution

WARNING:

● Observe all governing codes and ordinances.

● Do not use damaged or non-standard power cord.

● Be caution during installation and maintenance. Prohibit incorrect operation

to prevent electric shock, casualty and other accidents.

Selection of installation location

Basic requirement

Installing the unit in the following places may cause malfunction. If it is unavoidable,

consult the local dealer:

objects spread in the air.

2. The place with high-frequency devices (such as welding machine, medical equipment).

3. The place near coast area.

4. The place with oil or fumes in the air.

5. The place with sulfureted gas.

6. Other places with special circumstances.

7. It’s not allowed to be installed on the unstable or motive base structure (such as truck) or

in the corrosive environment (such as chemical factory).

Requirement of air conditioner

1. Air inlet should be far away from obstacles and do not put any objects near air outlet.

Otherwise, it will affect the radiation of heat discharge pipe.

2. Select a location where the noise and outflow air emitted by the outddor unit will not affect

neighborood.

3. Please try your best to keep far away from fluorescent lamp.

4.The appliance shall not be installed in the laundry.

Requirements for electric connection

Safety precaution

1. Must follow the electric safety regulations when installing the unit.

2. According to the local safety regulations, use qualified power supply circuit.

3. For appliances with type Y attachment,the instructions shall contain the substance of

the following.If the supply cord is damaged,it must be replaced by the manufacturer, its

service agent or similarly qualified persons in order to avoid a hazard.

4. Properly connect the live wire, neutral wire and grounding wire of power socket.

5. Be sure to cut off the power supply before proceeding any work related to electricity and

safety.

6. Do not put through the power before finishing installation.

7. The air conditioner is first class electric appliance. It must be properly grounding with

specialized grounding device by a professional. Please make sure it is always grounded

effectively, otherwise it may cause electric shock.

8. The yellow-green wire or green wire in air conditioner is grounding wire, which can't be

used for other purposes.

9. The grounding resistance should comply with national electric safety regulations.

10. The appliance shall be installed in accordance with national wiring regulations.

18

please

Page 22

11. metsys ylppus-rewop fo eulav ecnadepmi ,11-3-00016 CEI htiw ecnailpmoc ni eb oT

connected to product must be less than or eq ual to the allowable maximum value

of |Zsys| in the following sheet:

GPC12AL-K5NNA3C

GPH12AL-K5NNA3C

0.12

Preparation before Installation

NOTICE: Check if the accessories are available before installation.

Accessory list

joint A joint B joint C

wire hook

Drain connector

heat discharge pipe

screw

drainage pip

remote control

battery

(AAA 1.5V)

pipe hooppipe clip rubber plug

user's manual

Optional

Window panel

Exhaust cover

Extension panel

Window kit BracketRain guardInsect guard net

Tools needed for installation

cross screwdriver

gauge

straight screwdriver

Adjustment panel

scissors

19

screw

sponge A sponge B

saw

pencil

Page 23

Install Wire Hook

● Assemble the wire hook at the back of the unit with screws (the direction of wire

direction of wire hook is upward

wire hook

screw

direction of wire hook is downward

● Wind the power cord around the wire hook.

20

Page 24

Removing Collected Water

There are 2 ways to remove collected water:

Use the continuous drainage option from the lower hole.

1

NOTICE:

■

Instructions for drainage pipe installation.

1. Fix the drainage pipe clip on the right of rear side plate near drainage port with

a screw.

2. Remove the rubber plug at drainage port.

When using the continuous drainage option from the bottom hole, install

drainage pipe as follow before using, otherwise poor drainage will affect

normal operation of the unit.

drainage pipe clip

drainage port

screw

drainage port

3. Put the drainage pipe into drainage port and screw it up, and then bind it with

pipe hoop.

pipe hoop

rubber plug

drainage pipe clip

drainage pipe

drainage port

pipe hoop

21

Page 25

Removing Collected Water

■ Drainage way as follows.

1. In Cool, Dry or Heat mode operating, the condensation water will be drained to

the chassis.

2. When the chassis is full with water, the buzzer will give out 8 sounds and "H8" is

displayed to remind user to discharge water:

● Move the unit to a suitable place for discharging water; do not tilt the unit and

keep it horizontal during moving;

● Take the drainage pipe from the clip and pull out the rubber plug on the

drainage pipe to discharge water;

● After full water protection is eliminated and the compressor has been stopped

for 3 minutes, the unit will resume operation.

22

Page 26

Removing Collected Water

Use the continuous drainage option from the middle hole

NOTICE:

1. Remove the continuous drain cap 1 by turning it counter clockwise then remove

the rubber stopper 2 from the spout.

Water can be automatically emptied into a floor drain by attaching 14mm inner

diameter hose (not included).

2. Screw the drain connector to(included

in the package) the spout by turning

clockwise.

ATTENTION:

When using continuous drainage option from the middle hole, place portable

on a level surface and make sure garden hose is clear of any obstructions

and is directed downward. Placing portable on an uneven surface or

improper hose installation may result in water filling up the chassis and

causing the unit to shut off. Empty water in the chassis if shut off occurs,

then check portable location and hose for proper setup.

3. Insert the drainage hose into

drain connector.

23224

Page 27

Installation in a double-hung sash window(Optional)

1. Connect the rain guards to the insect guard net.

Insert all three projections on each rain guard into the holes in the insect guard net.

Side “A” will now be at the top, as indicated in the diagram.

Insect guard net

Hole

Rain guard

Projection

"A"

2. Attach the guard combined above to the window panel.

Push the insect guard net firmly to ensure that its four projections fit into the holes

in the window panel.

Side “A” will now be at the top, as indicated in the diagram.

Projection

"A"

Window panel

3. Cut the sponge A (adhesive type) to the proper length and attach it to the

window stool and to the bottom of sash.

Sponge A

4. Attach the window panel to the window stool.

Make sure that the exhaust cover is attached to the window panel.

Inner width of the window:20.5"(520mm)

Use the window panel.

Page 28

Installation in a double-hung sash window(Optional)

The window panel cannot be installed in windows less than 20.5" (520mm) wide,

as you will be unable to shut the exhaust cover.

(1) Open the window sash and place the window panel on the window sill.

(2) Secure the window panel to the window stool with screws.

Exhaust cover

Window panel

Cut

20.5"

Inner width of the window:20.5" (520mm)- 38.5" (980mm)

Use the window panel and the adjustment panel.

(1) Open the window sash and place the window panel on the window sill.

(2) Slide the adjustment panel to fit the window frame width.

(3) Secure the window panel to the sill with screws.

Adjustment panel

20.5" - 38.5"

Inner width of the window:38.5" (980mm) - 59" (1500mm)

Use the window panel, the adjustment panel and the extension panel.

(1) Open the window sash and place the window panel on the window sill.

(2) Slide the adjustment and extension panels to fit the window frame width.

(3) Secure the window panel to the window sill with screws.

Extension panel

Adjustment panel

38.5" - 59"

25

Page 29

Installation in a double-hung sash window(Optional)

5. Close the window sash securely against the Window panel.

6. Stuff the sponge B between the glass and the window to prevent air and insects

from getting into the room.

7. Attach the bracket with a screw.(Recommended)

Bracket

Please lay a tabular material underneath the window panel in case you could

not attach the rain guard or the window adapter properly due to the deep

window sill.

26

Page 30

Installation in a sliding sash window

(Optional)

1. Connect the rain guards to the insect guard net.

Insert all three projections on each rain guard into the holes in the insect guard net.

Side “A” will now be at the top, as indicated in the diagram.

"A"

Insect guard net

Hole

Projection

Rain guard

2. Attach the guard combined above to the window panel.

Push the insect guard net firmly to ensure that its four projections fit into the holes

in the window panel.

Side “A” will now be at the top, as indicated in the diagram, when it is installed in

the window.

Window panel

"A"

Projection

3. Cut the sponge A (adhesive type) to the proper length and attach it to the

window frame and to the side of sash.

Sponge A

4. Install the window panel into the window frame.

Make sure that the exhaust cover is attached to the window panel.

Inner height of the window:20.5"(520mm)

Use the window panel.

27

Page 31

Installation in a sliding sash window

(Optional)

The window panel cannot be installed in windows less than 20.5" (520mm) high,

as you will be unable to shut the exhaust cover.

(1) Open the window sash and place the window panel on the window frame.

(2) Secure the window panel to the window frame with screws.

Exhaust cover

Window panel

20.5"

Cut

Inner height of the window:20.5" (520mm)- 38.5" (980mm)

Use the window panel and the adjustment panel.

(1) Open the window sash and place the window panel on the window frame.

(2) Slide the adjustment panel to fit the window frame height.

(3) Secure the window panel to the window frame with screws.

Adjustment panel

20.5" - 38.5"

Inner height of the window:38.5" (980mm) - 59" (1500mm)

Use the window panel, the adjustment panel and the extension panel.

(1) Open the window sash and place the window panel on the window frame.

(2) Slide the adjustment and extension panels to fit the window frame height.

(3) Secure the window panel to the window frame with screws.

Extension panel

Adjustment panel

38.5"- 59"

28

Page 32

Installation in a sliding sash window

5. Close the window sash securely against the Window panel.

6. Stuff the foam seal B between the glass and the window to prevent air and insects

from getting into the room.

(Optional)

7. Attach the bracket with a screw.(Recommended)

Bracket

Please lay a tabular material underneath the window panel in case you could

not attach the rain guard or the window adapter properly due to the deep

window sill.

29

Page 33

Installation and Disassembly of Heat Discharge Pipe

Install heat discharge pipe

1. Rotate joint A and joint B clockwise into the two ends of heat discharge pipe.

clockwise

clockwise

joint A

heat discharge pipe

2. Insert joint A of heat

discharge pipe (the

side with "TOP" is

upwards) into the

groove until you

hear a sound.

3. Lead the exhaust hose outdoors.

4. Slide and open the exhaust cover on the

window panel, and attach the window

adapter. (Optional)

clasp

groove

joint B+C

the side with "TOP" is upwards

30

Page 34

Installation and Disassembly of Heat Discharge Pipe

Note of Installingheat discharge pipe

correct correct

correct

wrong

● The length of the heat discharge pipe is less than 1m. It is recommended to

use it with shortest length.

When installing,heat discharge pipe should be as flat as possible. Don’t prolong

the pipe or connect it with other

heat discharge pipe.

31

Page 35

Installation and Disassembly of Heat Discharge Pipe

should not be over 130cm from floor).

would easily cause malfunction.)

Disassemble heat discharge pipe

2. Remove joint B+C from1. Remove joint A:

Press the clasp and lift joint A upwards to outdoors.

remove it.

clasp

upwards

joint A

disassemble

32

joint B+C

Page 36

Installation and Disassembly of Heat Discharge Pipe

3. Remove the window adapter.

Pull out and remove the window

adapter by pushing down two

“PUSH” markings, and slide and

close the exhaust cover in the

window panel. (Optional)

"PUSH"

"PUSH"

Operation Test

● Put through the power supply and then press ON/OFF button on remote contro ller to start the unit.

● Press mode button to select auto, cooling, drying, fan or heating function, and

then check if the unit operates normally.

● If ambient temperature is below 16°C, the unit can't operate in cooling mode.

33

Page 37

Electric Schematic Diagram

The Electric schematic diagram are subject to change without notice. Please refer

to which one on the unit.

GPC12AL-K5NNA3C:

WATER MOTOR

YEGN

PE

DISP2

DISP1

AP2

DISPLAY

BOARD

ROOM TEMP.

M3

RD

SENSOR

BU

ROOM

N1

WATER1

DISP2

DISP1

WIFI

AP4

WIFI

MODULE

GPH12AL-K5NNA3C:

WATER MOTOR

YEGN

PE

DISP2

DISP1

AP2

DISPLAY

BOARD

ROOM TEMP.

SENSOR

M3

BU

RD

ROOM

N1

WATER

DISP2

DISP1

WIFI

AP4

WIFI

MODULE

TUBE TEMP.

RT2RT1

MAIN BOARD

HIGH-WP

BK

WATER LEVEL

SWITCH

TUBE TEMP.

SENSOR

RT2RT1

TUBE

MAIN BOARD

HIGH-WP

BK

WATER LEVEL

SWITCH

SENSOR

TUBE

AP1

BK

AP1

BK

RT3

SA

YEGN

PE

OUTTUBE TEMP.

SENSOR

RT3

OUTTUBE

SA

YEGN

PE

OUTTUBE TEMP.

SENSOR

OUTTUBE

OFAN

M2

RD

CAP.

C3

DOWN FAN

MOTOR

OFAN

M2

RD

CAP.

C3

DOWN FAN

MOTOR

BN

RECEIVER

BOARD

AP3

REC

BN

RECEIVER

BOARD

AP3

REC

AC-L

K201

RD

N2

AC-L

K201

RD

COMP

FAN

M1

CAP.

C2

UP FAN

MOTOR

VALVE

4-WAY

4YV

COMP

FAN

M1

CAP.

C2

UP FAN

MOTOR

4WAY

POWER

BN(BK)

L

BU(WH)

N

YEGN(GN)

PE

BU

N3

C

YEGN

COMP.

COMP

R(M)

S

CAP.

YE

RD

RD

YEGN

PE

BN

N3

COMP.

R(M)

RD

RD

YEGN

PE

BN

C1

BN(BK)

BU(WH)

YEGN(GN)

PE

BU

COMP

CAP.

C1

PE

POWER

L

N

C

YEGN

S

YE

PE

34

Page 38

Specialist’s Manual

Aptitude requirement for maintenance man(repairs should be done only

be specialists).

a. All the work men who are engaging in the refrigeration system should bear the

valid certification awarded by the authoritative organization and the qualification for

dealing with the refrigeration system recognized by this industry.

b. It can only be repaired by the method suggested by the equipment’s manufacturer.

If it needs other technician to maintain and repair the appliance, they should be

supervised by the person who bears the qualification for using the flammable refrigerant.

Safety preparation work before installation

The safety must be inspected before maintaining the appliances with the flammable

refrigerant for reducing the flammable hazard to the lowest.

Work shall be undertaken under a controlled procedure so as to minimise the risk of a

flammable gas or vapour being present while the work is being performed.

Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching

for or detection of refrigerant leaks. A halide torch (or any other detector using a naked flame)

shall not be used.

Environment checking

All maintenance staff and others working in the local area shall be instructed on the

nature of work being carried out. Work in confined spaces shall be avoided. The area

around the workspace shall be sectioned off. Ensure that the conditions within the area

have been made safe by control of flammable material.

The area shall be checked with an appropriate refrigerant detector prior to and during

work, to ensure the technician is aware of potentially toxic or flammable atmospheres.

Ensure that the leak detection equipment being used is suitable for use with all applicable

refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

No person carrying out work in relation to a refrigeration system which involves

exposing any pipe work shall use any sources of ignition in such a manner that it may lead

to the risk of fire or explosion. All possible ignition sources, including cigarette smoking,

should be kept sufficiently far away from the site of installation, repairing, removing and

disposal, during which refrigerant can possibly be released to the surrounding space.

Prior to work taking place, the area around the equipment is to be surveyed to make sure

that there are no flammable hazards or ignition risks. “No Smoking” signs shall be displayed.

If any hot work is to be conducted on the refrigeration equipment or any associated

parts, appropriate fire extinguishing equipment shall be available to hand. Have a dry

powder or CO

Ensure that the area is in the open or that it is adequately ventilated before breaking

into the system or conducting any hot work. A degree of ventilation shall continue during

the period that the work is carried out. The ventilation should safely disperse any released

refrigerant and preferably expel it externally into the atmosphere.

2 fire extinguisher adjacent to the charging area.

35

Page 39

Specialist’s Manual

Refrigeration equipment Checking

Where electrical components are being changed, they shall be fit for the purpose and

to the correct specification. At all times the manufacturer’s maintenance and service

guidelines

for assistance.

The following checks shall be applied to installations using flammable refrigerants:

The actual refrigerant charge is in accordance with the room size within which the

refrigerant containing parts are installed;

The ventilation machinery and outlets are operating adequately and are not obstructed;

If an indirect refrigerating circuit is being used, the secondary circuit shall be checked

for the presence of refrigerant;

Marking to the equipment continues to be visible and legible. Markings and signs that

are illegible shall be corrected;

Refrigeration pipe or components are installed in a position where they are unlikely to

be exposed to any substance which may corrode refrigerant containing components,

unless the components are constructed of materials which are inherently resistant to

being corroded or are suitably protected against being so corroded.

Electrical devices checking

Repair and maintenance to electrical components shall include initial safety checks

and component inspection procedures. If a fault exists that could compromise safety, then

no electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If the

fault cannot be corrected immediately but it is necessary to continue operation, an

adequate temporary solution shall be used. This shall be reported to the owner of the

equipment so all parties are advised.

Initial safety checks shall include:

That capacitors are discharged: this shall be done in a safe manner to avoid possibility

of sparking;

That no live electrical components and wiring are exposed while charging, recovering

or purging the system;

That there is continuity of earth bonding.

Repairs to sealed components

During repairs to sealed components, all electrical supplies shall be disconnected from

the equipment being worked upon prior to any removal of sealed covers, etc. If it is

absolutely necessary to have an electrical supply to equipment during servicing, then a

permanently operating form of leak detection shall be located at the most critical point

to warn of a potentially hazardous situation.

Particular attention shall be paid to the following to ensure that by working on electrical

components, the casing is not altered in such a way that the level of protection is affected.

This shall include damage to cables, excessive number of connections, terminals not made

to original specification, damage to seals, incorrect fitting of glands, etc.

shall be followed. If in doubt, consult the manufacturer’s technical department

36

Page 40

Specialist’s Manual

Ensure that the apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded to the point that they no

longer serve the purpose of preventing the ingress of flammable atmospheres.

Replacement parts shall be in accordance with the manufacturer’s specifications.

NOTE : The use of silicon sealant can inhibit the effectiveness of some types of leak

detection equipment. Intrinsically safe components do not have to be isolated prior to

working on them.

Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure,

vibration, sharp edges or any other adverse environmental effects. The check shall

also take into account the effects of aging or continual vibration from sources such

as compressors or fans.

Leak detection methods

The following leak detection methods are deemed acceptable for all refrigerant systems.

Electronic leak detectors may be used to detect refrigerant leaks but, in the case of

flammable refrigerants, the sensitivity may not be adequate, or may need re-calibration.

(Detection equipment shall be calibrated in a refrigerant-free area.) Ensure that the

detector is not a potential source of ignition and is suitable for the refrigerant used.

Leak detection equipment shall be set at a percentage of the LFL of the refrigerant and

shall be calibrated to the refrigerant employed, and the appropriate percentage of gas

(25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of

detergents containing chlorine shall be avoided as the chlorine may react with the

refrigerant and corrode the copper pipe-work.

If a leak is suspected, all naked flames shall be removed/extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be

recovered from the system, or isolated (by means of shut off valves) in a part of the system

remote from the leak. For appliances containing flammable refrigerants, oxygen free

nitrogen (OFN) shall then be purged through the system both before and during the

brazing process

Removal and evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose –

conventional procedures shall be used. However, for flammable refrigerants it is important

that best practice is followed since flammability is a consideration. The following procedure

shall be adhered to:

remove refrigerant;

purge the circuit with inert gas;

evacuate;

purge again with inert gas;

open the circuit by cutting or brazing.

37

Page 41

Specialist’s Manual

The refrigerant charge shall be recovered into the correct recovery cylinders.

For appliances containing flammable refrigerants, the system shall be “flushed” with

OFN to render the unit safe. This process may need to be repeated several times.

Compressed air or oxygen shall not be used for purging refrigerant systems.

For appliances containing flammable refrigerants, flushing shall be achieved by

breaking the vacuum in the system with OFN and continuing to fill until the working

pressure is achieved, then venting to atmosphere, and finally pulling down to a vacuum.

This process shall be repeated until no refrigerant is within the system.

When the final OFN charge is used, the system shall be vented down to atmospheric

pressure to enable work to take place. This operation is absolutely vital if brazing operations

on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and that

ventilation is available.

Charging procedures

In addition to conventional charging procedures, the following requirements shall be followed.

– Ensure that contamination of different refrigerants does not occur when using charging

equipment. Hoses or lines shall be as short as possible to minimise the amount of

refrigerant contained in them.

– Cylinders shall be kept upright.

– Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

– Label the system when charging is complete (if not already).

– Extreme care shall be taken not to overfill the refrigeration system.

Prior to recharging the system, it shall be pressure-tested with the appropriate purging gas.

The system shall be leak-tested on completion of charging but prior to commissioning.

A follow up leak test shall be carried out prior to leaving the site.

Decommissionin

Before carrying out this procedure, it is essential that the technician is completely

familiar with the equipment and all its detail. It is recommended good practice that all

refrigerants are recovered safely. Prior to the task being carried out, an oil and refrigerant

sample shall be taken in case analysis is required prior to re-use of reclaimed refrigerant.

It is essential that electrical power is available before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure, ensure that:

mechanical handling equipment is available, if required, for handling refrigerant cylinders;

all personal protective equipment is available and being used correctly;

the recovery process is supervised at all times by a competent person;

recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from

various parts of the system.

g

38

Page 42

Specialist’s Manual

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with manufacturer's instructions.

h) Do not overfill cylinders. (No more than 80 % volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been filled correctly and the process completed, make sure

that the cylinders and the equipment are removed from site promptly and all isolation

valves on the equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system unless it

has been cleaned and checked.

Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of

refrigerant. The label shall be dated and signed. For appliances containing flammable

refrigerants, ensure that there are labels on the equipment stating the equipment contains

flammable refrigerant.

Recovery

When removing refrigerant from a system, either for servicing or decommissioning,

it is recommended good practice that all refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant

recovery cylinders are employed. Ensure that the correct number of cylinders for holding

the total system charge are available. All cylinders to be used are designated for the

recovered refrigerant and labelled for that refrigerant (i.e. special cylinders for the recovery

of refrigerant). Cylinders shall be complete with pressure-relief valve and associated

shut-off valves in good working order. Empty recovery cylinders are evacuated and,

if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions

concerning the equipment that is at hand and shall be suitable for the recovery of all

appropriate refrigerants including, when applicable, flammable refrigerants. In addition, a

set of calibrated weighing scales shall be available and in good working order. Hoses shall

be complete with leak-free disconnect couplings and in good condition. Before using the

recovery machine, check that it is in satisfactory working order, has been properly

maintained and that any associated electrical components are sealed to prevent ignition

in the event of a refrigerant release. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct

recovery cylinder, and the relevant waste transfer note arranged. Do not mix refrigerants

in recovery units and especially not in cylinders.

If compressors or compressor oils are to be removed, ensure that they have been

evacuated to an acceptable level to make certain that flammable refrigerant does not

remain within the lubricant. The evacuation process shall be carried out prior to returning

the compressor to the suppliers. Only electric heating to the compressor body shall be

employed to accelerate this process. When oil is drained from a system, it shall be

carried out safely.

39

Page 43

Eurofred S.A.

Marqués de Sentmenat 97

08029 Barcelona

www.eurofred.es

Loading...

Loading...