Daikin UATYA-BBAY1, UATYA-BBC2Y1, UATYA-BBC3Y1 Installation manuals

Installation, use and

maintenance manual

Rooftop Packaged Unit

R-32 rooftop series – Base,

2-,3- and 4-damper versions

Made-To-Stock models

UATYA-BBAY1

UATYA-BBC2Y1

UATYA-BBC3Y1

Made-To-Order models

BASE

FC2

FC3

FC4

Installation, use and maintenance manual

Rooftop Packaged Unit

Montage- und Betriebsanleitung

Roof-Top-Monoblock-Einheit

Manuel d'installation, d'utilisation et d'entretien

Roof top unité de type monobloc

Handleiding voor installatie, gebruik en onderhoud

Eenheid monoblok-rooftop

Manual de instalación, uso y mantenimiento

Unidad monobloque Roof Top

Manuale installazione uso e manutenzione

Rooftop unità monoblocco

Εγχειρίδιο εγκατάστασης, χρήσης και συντήρησης

Μονάδα οροφής μονομπλόκ

Manual de instalação, uso e manutenção

Rooftop unidade monobloco

Návod k instalaci a údržbě

Rooftop monolitní jednotka

English

Deutsch

Français

Nederlands

Español

Italiano

ελληνικά

Português

Čeština

Telepítési, kezelési és karbantartási útmutató

Tetőtéri egység

Magyar

Contents

1 Introduction 7

1.1 Conformity 7

1.2 Description 7

1.2.1 Symbols 7

1.2.2 Labels 8

2 Safety 9

2.1 General safety precautions 9

2.1.1 Discharge of the safety valves 10

2.1.2 Emergency stop 10

2.2 Basic rules 11

2.2.1 Limits to the use – Minimum area of the conditioned space and maximum refrigerant charge 13

2.2.2 Refrigerant leak detector 15

2.2.3 Water ow rate at the heat exchangers 16

2.2.4 Water composition 16

2.2.5 Warnings concerning ammable refrigerants 17

2.3 Noise 23

2.4 Residual risks 23

2.5 Safety information on the refrigerant uid 24

2.5.1 Hazards and health consequences 24

3 Receiving the product and storage 25

3.1 Reception 25

3.2 Transport 25

3.3 Handling 26

4 Product description 28

4.1 Intended use 28

4.2 Unintended use 28

4.3 Control and safety devices 29

4.4 Principles of operation 29

4.5 Structure 29

4.6 Specications 29

4.7 Air system 30

4.7.1 Internal air fans 30

4.7.2 Flow rate sensor for fans 30

4.7.3 Dirty lter sensor 31

4.7.4 Air lters 31

4.7.5 Humidier 31

4.8 Control panel 32

4.8.1 Switch the unit on and o from the display. 32

4.8.2 Switch the unit on and o from external OK signal 32

4.8.3 Change of set points 33

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

3

4.8.4 Time band setup procedure 33

4.8.5 Change language 33

4.8.6 Change date and time 33

4.9 Wiring diagram 33

5 Installation 34

5.1 Dimensions and weight 34

5.2 Installation site 34

5.3 Installation 35

5.3.1 External positioning 35

5.3.2 Fitting of rain hoods 36

5.3.3 Anti-vibration mounts 36

5.3.4 Noise attenuation 37

5.3.5 Minimum distances 37

5.4 Hydraulic connections 38

5.4.1 Hot water coil connection 38

5.4.2 Condensate drain of the internal air coil 38

5.4.3 Condensate drain of the external air coil 39

5.4.4 Connection to the humidier 39

5.5 Electrical connections 40

5.6 Aeraulic connections 42

5.6.1 Return and supply ducts 42

5.6.2 Connection of the ducts 43

6 Commissioning 44

6.1 Preliminary operations 44

6.2 First starting 45

6.2.1 Preliminary checks 45

6.2.2 Functional tests 45

6.3 Calibration of safety components 46

6.4 Checks during operation 46

6.5 Alarms and malfunctions 47

6.5.1 General troubleshooting 47

6.6 Temporary stop 49

6.7 Stop for long periods of time 49

7 Maintenance 50

7.1 Adjustments 50

7.2 External cleaning 51

7.2.1 Cleaning traditional nned coils in Cu/Al 51

7.2.2 Installation site cleanness 52

7.3 Internal cleaning 52

7.3.1 Cleaning the unit 52

7.4 Periodic checks 53

7.5 Unscheduled maintenance 54

7.5.1 Special work 54

Translation from original instructions

Packaged Rooftop

We reserve the right to make changes without any prior notice.

4

UAT YA

4P645202-1

8 Decommissioning 55

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

5

THANK YOU

Thank you for choosing our product.

It is the result of many years’ experience and careful design and has been built with rst-class quality materials and

advanced technologies.

Declaration or certicate of conformity also guarantees that the equipment meets the requirements of the European

Machinery Safety Directive.

The quality level is constantly monitored, and therefore our products are synonymous with Safety, Quality and

Reliability.

Changes considered necessary for product improvement may be made to the stated data at any time without any

obligation to give prior notice.

Thank you again

Read this manual carefully before installing, testing or starting this unit.

Give this manual and all complementary documentation to the operator of the system who will be

responsible for keeping them so they are always available if needed.

The images and drawings contained herein are examples only.

Translation from original instructions

Packaged Rooftop

6

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

1 INTRODUCTION

1.1 Conformity

With regard to relevant regulations and directives, see the declaration of conformity that is an integral part of the

manual.

1.2 Description

1.2.1 Symbols

A description of the main symbols used in this manual and on the labels axed to the unit is given below.

Danger symbol; take extreme care.

Danger symbol; moving mechanical parts.

Danger symbol; live parts.

Warning symbol; important information

Note symbol; suggestions and advice

Danger sign: ammable gas.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

7

1.2.2 Labels

For the constructional features, available models and technical data, please refer to the Technical Catalogue.

The model, serial number, features, power supply voltage and so on are shown on the labels axed to the unit (the

following illustrations are shown only as an example).

The Manufacturer adopts a continuous development policy and, in this perspective, reserves the right

to make changes and improvements to the documentation and to the units without prior notice.

The Technical Catalogue, the labels placed directly on the unit and the various diagrams referred to

below, must be considered an integral part of this manual.

Do not remove or alter the labels placed on the unit.

Translation from original instructions

Packaged Rooftop

8

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

2 SAFETY

2.1 General safety precautions

Access to the area around the unit must be prevented by special guarding where this is positioned in a location that

is not protected and can be reached by unqualied persons.

The equipment operator is responsible for complying with regulatory obligations.

The equipment operator is the person who has actual control over the technical operation and free access, which

means the possibility of monitoring its components and their operation and the possibility of granting access to third

parties.

The equipment operator has the power to decide on technical modications, checks and repairs.

The equipment operator may give instructions to employees or to external companies for carrying out maintenance

and repair operations.

Access to the unit must be granted exclusively to technicians authorised by the equipment operator.

The equipment must be installed and maintained or repaired by sta and contractors who hold a relevant certicate

issued by a certication body. Within Europe, the certication body must be designated by a member state to certify

compliance with the requirements laid down in Regulation (EU) No 517/2014 of the European Parliament and of the

Council of 16 April 2014 on uorinated greenhouse gases and repealing Regulation (EC) No 842/2006 Text with EEA

relevance.

Any operator gaining access to the unit must be authorised and qualied as specied by Annex HH of IEC 60335-2-

40:2018, by local legislations and, with respect to europen standards, by EN 378-4 and EN 13133 ", additionally, they

must have proper knowledge to perform all the activities required throughout the service life of the machine.

Access to the unit requires that the closing panels, where tted, are removed.

On no account must unqualied personnel be allowed to enter the unit and no one should be allowed to enter before

the power to it has been turned o.

The user can interact with the unit only through the control and external OK signals.

Only authorised knowledgeable personnel may access the unit in compliance with safety in the workplace regulations.

At European level, refer to Council Directive 89/391/EEC of 12 June 1989 on the introduction of measures to

encourage improvements in the health and safety of workers at work.

Also, knowledge and understanding of the manual are indispensable for reducing risks and for improving the health

and safety of workers.

The operator must know what to do when faced with possible anomalies, malfunctions or conditions of danger to

himself or others, and in any case, he must comply with the following instructions:

Stop the unit immediately by using the emergency device.

Do not do anything that goes beyond your duties and technical knowledge.

Inform the manager immediately and do not take personal initiatives.

Before carrying out any work on the unit, make sure you have turned o the power supply to it. Refer

to the section on maintenance work.

Before work is started on the unit: check for potentially ammable atmospheres; Make sure there are

no possible ignition sources comply with the requirements specied by Annex HH of standard IEC

60335-2-40:2018, by local legislations, and, with respect to europen standards, by EN 378-4 and EN

13133", and by existing local regulations.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

9

In units with capacitors and/or inverters, certain components can remain live for several minutes even

after having turned o the main switch.

Wait 10 minutes before working on the electrical parts of the unit.

Circuits supplied from external sources (made with orange cable) can remain live even after the power

supply to the unit has been turned o.

Work on the unit only if there is sucient lighting for the type of work to be carried out.

Failure to comply with the instructions in this manual and any modications made to the unit without prior written

consent, will immediately void the warranty.

The law regulating the use of stratospheric ozone depleting substances prohibits the release of

refrigerant gases into the environment and obliges owners to recover and return them to the dealer or

take them to special collection centres at the end of their operational life.

The refrigerant contained in the refrigerant circuit is included among the substances subject to special

control regulations provided for by law and must therefore be disposed of as indicated above.

Particular care should be taken during maintenance operations in order to reduce refrigerant leaks as

much as possible.

2.1.1 Discharge of the safety valves

If present on the refrigerant circuit, installation requirements and/or national regulations lay down that the discharge

of the safety valves must be routed to the outside.

The conveying must be done with a pipe whose diameter must be at least that of the valve outlet, and the weight of

the pipe must not be borne by the valve.

Always direct the discharge to areas where the jet cannot cause harm to anyone.

Risk of burns following contact with hot and cold parts.

any material exhausted from the safety valves must be conveyed using pipes in compliance with

the national and/or European directives: the exhaust point must not be close to trap-doors, manhole

covers and any other opening where refrigerant may be contained; exhausted material must not

be conveyed close to fresh air inlets, doors or similar openings; exhausted material must not be

conveyed close to ignition sources, as dened in standard EN378-2.

It is responsibility of the installer to carry out a ammability risk assessment and a classication

of the danger zone at the site of installation, as required by standard EN378-3 and/or the national

regulations in place.

2.1.2 Emergency stop

In case of emergency, an immediate stop is carried out using the red disconnecting switch/master switch on the

electrical control panel by turning it to 0. When it is turned to 0, the disconnecting switch turns o the power to the

whole unit.

The main disconnect switch/master switch, used to electrically isolate the unit, is also intended for use

as an emergency device and it is only in an emergency that it should be used to stop the unit.

Except the case of an emergency stop, the unit must be stopped using its control software.

Translation from original instructions

Packaged Rooftop

10

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

2.2 Basic rules

All the units are designed and built in compliance with Directive 2014/68/EU of the European Parliament and of the

Council of 15 May 2014 on the approximation of the laws of the Member States relating to pressure equipment.

To ensure maximum safety, in order to prevent possible risks, follow the instructions below:

- this product contains pressurised vessels, live components, moving mechanical parts and very hot and cold

surfaces that, in certain situations, can pose a risk: all maintenance work must be carried out by skilled personnel

equipped with the necessary qualications in accordance with current regulations. Before carrying out any

operation, make sure that the personnel in charge has full knowledge of the documentation supplied with the unit.

- always have a copy of the documentation near the unit.

- The operations indicated in this manual must be integrated with the procedures indicated in the user instruction

manuals of the other systems and devices incorporated in the unit. The manuals contain all the necessary

information for safely managing the devices and the possible operating modes.

- use suitable protection (gloves, hard hat, protective glasses, safety shoes, etc.) for all maintenance or control

operations carried out on the unit.

- Do not wear loose clothing, ties, chains, watches, etc., which can get caught in the moving parts of the unit.

- always use tools and protective equipment in excellent condition.

- The compressors and delivery gas pipes are at high temperature. Therefore, when working in the immediate

vicinity, be careful to avoid touching any components of the unit without suitable protection.

- do not work in the discharge trajectory of the safety valves.

- if the units are positioned in unprotected places which can easily be reached by unqualied persons, suitable

protection devices must be installed.

- the user must consult the installation and use system manuals, incorporated and attached to this manual.

- there may be potential risks that are not obvious. Warnings and signals are therefore displayed on the unit.

- Do not remove the warnings.

It is expressly forbidden to:

- remove or disable the safety guards;

- tamper with and/or modify, even partially, the safety devices installed on the unit.

If there are alarm warnings and consequent tripping of the safety devices, the user must call in skilled maintenance

technicians to x the problem immediately.

An accident can lead to serious injury or death.

The safety devices must be tested according to the guidelines in this manual.

The manufacturer does not assume any liability for damage/injury to persons, pets or objects arising from the re-use

of individual parts of the unit for functions or assembly situations dierent from the original ones. Tampering with/

unauthorised replacement of one or more parts of the unit is prohibited.

The use of accessories, tools or consumables other than those recommended by the Manufacturer relieves the latter

from civil and criminal liability.

Deactivation and scrapping of the unit must be carried out only by suitably trained and equipped personnel.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

11

The units do not fall within the scope of Directive 2014/34/EU of the European Parliament and of

the Council, of 26 February 2014, on the approximation of the laws of the Member States relating to

equipment and protective systems intended for use in potentially explosive atmospheres.

Any operator gaining access to the unit must be authorised and qualied as specied by Annex HH

of IEC 60335-2-40:2018, by local legislations and, with respect to europen standards, by EN 378-4

and EN 13133 ", additionally, they must have proper knowledge to perform all the activities required

throughout the service life of the machine.

Translation from original instructions

Packaged Rooftop

12

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

2.2.1 Limits to the use – Minimum area of the conditioned space and maximum

[m²]

m

[kg]

refrigerant charge

Clause GG.9 of Annex GG within the standard IEC 60335-2-40:2018 (Household and similar electrical appliances Safety - Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidiers) denes the

charge limits based on the total conditioned space area and the ventilation requirements for ducted appliances using

A2L refrigerants. For full details refer to the standard IEC 60335-2-40:2018.

The minimum total conditioned room area "TA

accordance with following:

For units without hot gas post heating coil For units with hot gas post heating coil

m

Unit

Circuit 1 Circuit 2 Circuit 1 Circuit 2

UATYA25 7 - 20,7 8,3 - 24,4

UATYA30 10 - 29,6 11,3 - 33,5

UATYA40 12 - 35,5 13,7 - 40,6

UATYA50 15 - 44,4 17 - 50,4

UATYA60 18 - 53,3 21 - 62

UATYA70 18 - 53,3 21 - 62

UATYA80 23 - 68,1 26,9 - 79,6

UATYA90 24 - 71,1 28 - 83

UATYA100 28 - 82,9 32,3 - 95,7

UATYA110 30 - 88,8 34,7 - 102,8

UATYA120 36 - 106,6 41,2 - 122,1

UATYA140 19 19 56,3 23,1 23,1 68,4

UATYA150 19 19 56,3 23,1 23,1 68,4

UATYA160 23 23 68,1 27,9 27,9 82,6

UATYA180 25 25 74 25 25 74

UATYA190 25 25 74 25 25 74

[kg]

c

" of installed appliance with refrigerant charge "mc" (kg) shall be in

min

TA

min

2

m

m

[kg]

c

TA

min

2

m

No zoning dampers shall be installed in the rooms considered to determine the minimum room area

unless these zoning dampers can be fully opened by the control signal of the rooftop in case of a leak

If the refrigerant charge is adjusted on the eld, the minimum area must be re-evaluated in order to be always above

the result obtained through the following formula:

where

- m

is the refrigerant charge added on the eld in kg.

added

The sum “mc+m

" must be lower than 79,8 kg for each circuit.

added

The minimum area according to the area of the conditioned space is shown below

90

80

70

c

60

50

40

30

20

10

0

50

100 150 200 2500

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Fig. 1 Total min. installation area

Translation from original instructions

Packaged Rooftop

13

The unit is equipped with a refrigerant detection system that complies with Annex LL of the IEC 60335-2-40:2018,

which position has been checked according to test reported in Annex MM of IEC 60335-2-40:2018.

When the refrigerant detection system detects a leak, the following will be initiated by the unit:

• disable the compressor operation unless the compressors;

• Supply and return (if present) fan control will be set to to constant airow logic with a x airow value. The fans

will operate continuously even if time tables are set. This in order to not let the airow to go below "Q

" (see

min

below);

• Energize a dedicated relay in the electrical cabinet in order to fully open any external zoning dampers;

• Set the dampers (if installed on the appliance) in order to have a full intake of fresh air and a full expulsion of the

return air.

External zoning dampers, if present, must be connected to this relay in order to be open when a leak

is detected

Zoning dampers installed in rooms considered to determine the minimum room area must be

electrically powered at all times after installation, other than when servicing, to be eective for safety.

The refrigerant detection system and controls will maintain the above action until at least 5 min after the refrigerant

detection system has reset. Building re and smoke systems may override this function.

If the leak detector detects a leak, the above operations will be initiated even if the unit is turned OFF

by button, by BMS or by digital input.

In addition to what above another dedicated relay is present in the unit electrical cabinet and

connected directly to the leak detector alarm. This relay can be used to monitor the leak detector

alarm even in case of a unit control board fault.

The minimum circulation airow (Q

) circulated to the total conditioned space, expressed in m3⁄h, must be in

min

accordance with the following table:

For units without hot gas post heating coil For units with hot gas post heating coil

Unit

UATYA25 7 - 1368 8,3 - 1613

UATYA30 10 - 1954 11,3 - 2208

UATYA40 12 - 2345 13,7 - 2680

UATYA50 15 - 2932 17 - 3326

UATYA60 18 - 3518 21 - 4095

UATYA70 18 - 3518 21 - 4095

UATYA80 23 - 4495 26,9 - 5255

UATYA90 24 - 4691 28 - 5479

UATYA100 28 - 5472 32,3 - 6315

UATYA110 30 - 5863 34,7 - 6783

UATYA120 36 - 7036 41,2 - 8059

UATYA140 19 19 3713 23,1 23,1 4515

UATYA150 19 19 3713 23,1 23,1 4515

UATYA160 23 23 4495 27,9 27,9 5453

UATYA180 25 25 4886 25 25 4886

UATYA190 25 25 4886 25 25 4886

m

c

[kg] m3/h [kg] m3/h

Q

min

m

c

Whenever the ow, measured by the dierantial air presssure tranducer, falls below the values

reported in the table above, the airow alarm from dierential pressure transducer will be displayed on

the unit control and the unit will be stopped.

Q

min

The supply and return air shall be directly ducted to the conditioned space. Open areas such as false ceilings shall

not be used as a return air duct.

Translation from original instructions

Packaged Rooftop

14

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

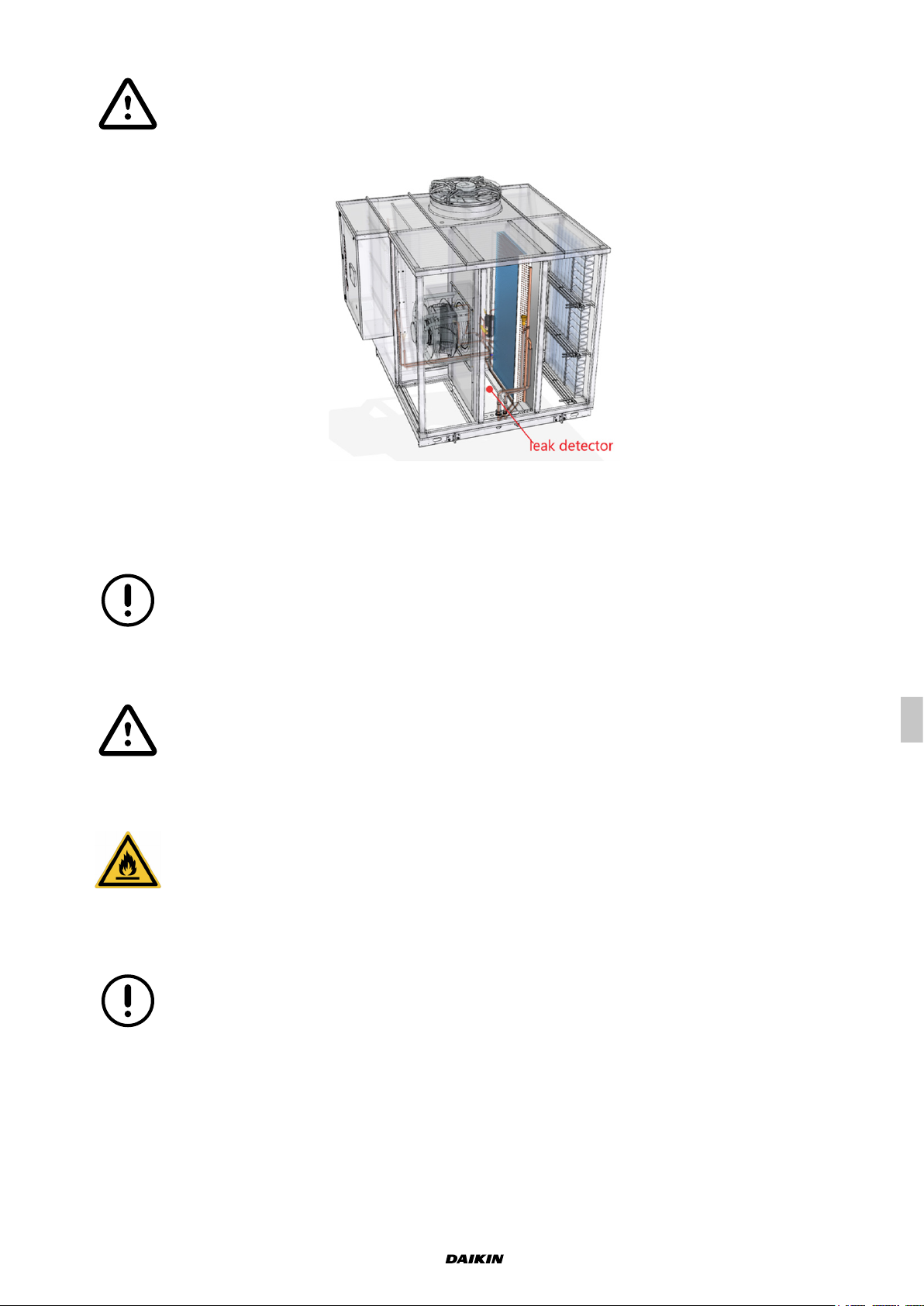

2.2.2 Refrigerant leak detector

This unit is equipped with a refrigerant leak detector for safety.

To be eective, the unit must be electrically powered at all times after installation, other than when

servicing.

A refrigerant leak detector is installed in the unit between the supply coil and the supply fan(s).

This device allows immediate detection of refrigerant leaks in order to start what reported in the above paragraph

“Limit to the use – This device allows immediate detection of refrigerant leaks in order to start what reported in the

above paragraph “Limit to the use – Minimum area required and maximum refrigerant charge”.

The detector has an internal self-testing routine. If this routine detects a fault the unit control will

automatically modify the supply and return (if present) fan control in order to set a constant airow

logic with a x airow value. This in order to not let the airow to go below Q

as dened in the

min

paragraph "Limit to the use – Minimum area required and maximum refrigerant charge”. The fans will

operate continuously even if time tables are set, in order to have always the minimum required airow.

In the unlike event that the airow is not able to reach the minimum airow level "Q

and the leak

min

detector is faulty, a dedicated relay in the electrical cabinet will be energized. This signal must be

used to warn the user that the airow is reduced (e.g. a buzzer and a ashing light).

Once the gas alarm of the leak detector system is released, the output is not reset even if the gas

concentration decreases. After detecting and repairing the leak spot, a manual reset of the alarm

can be operated. To reset the alarm output turn the power supply to the gas sensor o and on (e.g.

disconnecting and reconnecting its cable), if the alarm output will not be reset after this operation, it

means that leak has exceeded 10000 ppm, and the gas sensor has to be replaced.

The gas sensing part of the sensor has a designed life of 10 years. A countdown is set inside the

detector control and read by the unit control.

Six months before the expire of the countdown a warning message will appear on the unit HMI. If the

calibration will not be performed in time a warning message will appear on the unit HMI and the unit

control will operate as in case of a leak detector fault (see rst informative point of this paragraph).

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

15

2.2.3 Water ow rate at the heat exchangers

It is necessary to ensure that the water ow rate during operation is no higher than 1.5 times and no lower than 0.5

times the nominal ow rate of the unit stated in the Technical Catalogue.

In any case, refer to the specic Technical Catalogue for the allowed conditions for water ow in and

out of the exchangers.

2.2.4 Water composition

Dissolved substances in the water can cause corrosion in the heat exchangers.

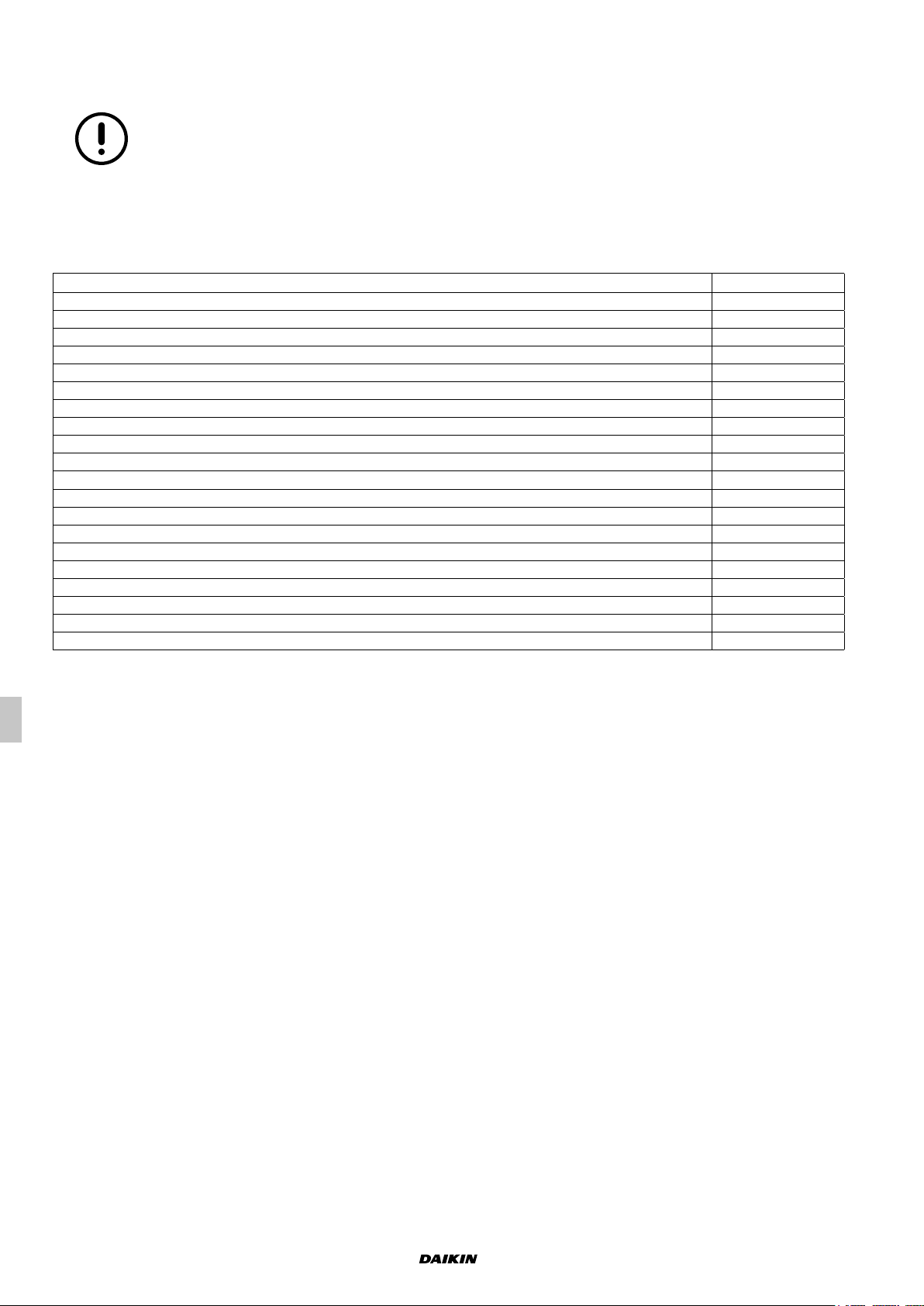

It is mandatory to make sure the parameters of the water comply with the following table:

Description Values

Total hardness 2,0 ÷ 6,0 °f

Langelier index - 0,4 ÷ 0,4

pH 7,5 ÷ 8,5

Electrical conductivity 10÷500 µS/cm

Organic elements -

Hydrogen carbonate (HCO3-) 70 ÷ 300 ppm

Sulphates (SO42-) < 50 ppm

Hydrogen carbonate / Sulphates (HCO3-/SO42-) > 1

Chlorides (Cl-) < 50 ppm

Nitrates (NO3-) < 50 ppm

Hydrogen sulphide (H2S) < 0,05 ppm

Ammonia (NH3) < 0,05 ppm

Sulphites (SO3), free chlorine (Cl2) < 1 ppm

Carbon dioxide (CO2) < 5 ppm

Metal cations < 0,2 ppm

Manganese ions (Mn++) < 0,2 ppm

Iron ions (Fe2+, Fe3+) < 0,2 ppm

Iron + Manganese < 0,4 ppm

Phosphates (PO43-) < 2 ppm

Oxygen < 0,1 ppm

ppm = mg/l

The use of water with values above the limits stated in the table will immediately void the warranty.

It is mandatory to include a system for eliminating possible organic substances in the water that could pass through

the lter and settle in the heat exchangers, which would lead to malfunctioning and/or breakage over time.

The use of water containing organic substances will immediately void the warranty.

Translation from original instructions

Packaged Rooftop

16

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

2.2.5 Warnings concerning ammable refrigerants

Units with mildly ammable refrigerants (A2L), such as R32, shall be installed in accordance with the

European standards and regulations and with the local regulations, where applicable.

The information below is provided in accordance with standard IEC 60335-2-40:2018 and its annexes

and clauses (here in after “Annex” and “Clause”) and it has been taken from the English version of the

standard, which is the document to be referenced.

(Annex DD.2) Do not use means to accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

The external unit shall be stored in a room without continuously operating ignition sources (for

example: open ames, an operating gas appliance or an operating electric heater).

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

(Annex DD.3.3) Qualication of workers

Any operation concerning the installation, maintenance, repair, disassembly and dismantling of the unit shall be

carried out by qualied personnel, in accordance with Annex HH to standard IEC 60335-2-40:2018, who hold a valid

certicate in compliance with the existing standards.

The above-mentioned operations include:

• breaking into the refrigerating circuit;

• opening of sealed components;

• opening of ventilated enclosures.

(Annex DD.4) Information on servicing

(Annex DD.4.2) Checks to the area

Prior to beginning work on systems containing ammable refrigerants, safety checks in the area are necessary

to ensure that the risk of ignition is minimised. For repair to the refrigerating system, DD.4.3 to DD.4.7 shall be

completed prior to conducting work on the system.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

17

Prior to beginning work on systems containing ammable refrigerants, safety checks in the area are necessary

to ensure that the risk of ignition is minimised. For repair to the refrigerating system, DD.4.3 to DD.4.7 shall be

completed prior to conducting work on the system.

(Annex DD.4.3) Work procedure

Work shall be undertaken under a controlled procedure so as to minimise the risk of a ammable gas or vapour being

present while the work is being performed.

(Annex DD.4.4) General work area

All maintenance sta and others working in the local area shall be instructed on the nature of the work being carried

out. Work in conned spaces shall be avoided.

(Annex DD.4.5) Checking for presence of refrigerant

The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician

is aware of potentially toxic and ammable atmospheres.

Ensure that the refrigerant or leak detection equipment being used is suitable for use with the refrigerant applicable

to the unit, i.e. non-sparking, adequately sealed or intrinsically safe.

(Annex DD.4.6) Presence of re extinguisher

If any hot work is to be conducted on the unit requiring an increase in the temperature of parts of the unit (e.g. brazing),

appropriate re extinguishing equipment shall be available to hand. Have a dry powder or CO2 re extinguisher

adjacent to the refrigerant charging area.

(Annex DD.4.7) No ignition sources

No person carrying out work in relation to a unit shall use any sources of ignition in such a manner that it may lead to

the risk of re or explosion. All possible ignition sources, including cigarette smoking, should be kept suciently far

away from the site of installation, repairing, removing and disposal of the unit, during which ammable refrigerant can

possibly be released to the surrounding space. Prior to work taking place, the area around the unit is to be surveyed

to make sure that there are no ammable hazards or ignition risks. “No Smoking” signs shall be displayed.

Translation from original instructions

Packaged Rooftop

18

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

(Annex DD.4.8) Ventilated area

Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting

any hot work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation

should safely disperse any released refrigerant and preferably expel it externally into the atmosphere.

(Annex DD.4.9) Checks to the refrigerating equipment

Where electrical components are being changed, they shall be t for the purpose and to the correct specication. At all

times the manufacturer’s maintenance and service guidelines shall be followed. If in doubt consult the manufacturer’s

technical department for assistance.

The following checks shall be applied to installations using ammable refrigerants (some parts are only applicable to

refrigerant containing units or components installed inside the building):

• the charge size is in accordance with the room size within which the refrigerant containing parts are installed;

• the ventilation machinery and outlets are operating adequately and are not obstructed;

• marking to the unit and components continues to be visible and legible. Markings and signs that are illegible shall

be corrected;

• refrigeration pipe or refrigerant containing components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing components, unless the components are

constructed of materials which are inherently resistant to being corroded or are suitably protected against being

so corroded.

(Annex DD.4.10) Checks to electrical components

Repair and maintenance to electrical components shall include initial safety checks and component inspection

procedures. If a fault exists that could compromise safety, then no electrical supply shall be connected to the circuit

until it is satisfactorily dealt with. If the fault cannot be corrected immediately but it is necessary to continue operation,

an adequate temporary solution shall be used. This shall be reported to the owner of the unit so all parties are

advised.

Initial safety checks shall include:

• that capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking;

• that no live electrical components and wiring are exposed while charging, recovering or purging the system;

• that there is continuity of earth bonding.

(Annex DD.5) Repairs to sealed components

(Annex DD.5.1)

During repairs to sealed components, all electrical supplies shall be disconnected from the unit being worked upon

prior to any removal of sealed covers, guards, etc.

If it is absolutely necessary to have an electrical supply to the unit during servicing, then a permanently operating

form of refrigerant leak detection shall be located at the most critical point to warn of a potentially hazardous situation.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

19

(Annex DD.5.2)

Particular attention shall be paid to the following to ensure that by working on electrical components, the casing is not

altered in such a way that the level of protection is aected.

This shall include damage to cables, excessive number of connections, terminals not made to original specication,

damage to seals, incorrect tting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the purpose of preventing the

ingress of ammable atmospheres. Replacement parts shall be in accordance with the manufacturer’s specications.

(Annex DD.5) Repairs to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the

permissible voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a ammable

atmosphere. The test apparatus shall be at the correct rating.

Replace components only with parts specied by the manufacturer. Other parts may result in the ignition of refrigerant

in the atmosphere from a leak.

(Annex DD.7) Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges or any other

adverse environmental eects. The check shall also take into account the eects of ageing or continual vibration from

sources such as compressors or fans.

(Annex DD.8) Detection of ammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching for or detection of refrigerant

leaks. A halide torch (or any other detector using a naked ame) shall not be used.

The following leak detection methods are deemed acceptable for systems containing ammable refrigerants.

Electronic leak detectors shall be used to detect ammable refrigerants, but the sensitivity may not be adequate, or

may need re-calibration (detection equipment shall be calibrated in a refrigerant-free area). Ensure that the detector

is not a potential source of ignition and is suitable for the refrigerant used.The leak detection system shall be set at

a percentage of the refrigerant LFL and it shall be calibrated to the refrigerant employed; the appropriate percentage

of gas (25% maximum) shall be conrmed.

Leak detection uids are suitable for use with most refrigerants but the use of detergents containing chlorine shall be

avoided as the chlorine may react with the refrigerant and corrode the copper pipe-work.

Note. Examples of leak detection uids are:

• bubble method;

• uorescent method agents.

If a leak is suspected, all naked ames shall be removed/extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be recovered from the system,

or isolated (by means of shut o valves) in a part of the system remote from the leak. Removal of refrigerant shall be

according to Annex DD.9.

Translation from original instructions

Packaged Rooftop

20

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

(Annex DD.9) Removal and evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose – conventional procedures shall

be used. However, it is important that best practice is followed since ammability is a consideration.

The following procedure shall be adhered to:

• remove refrigerant;

• purge the circuit with inert gas (optional for A2L);

• evacuate (optional for A2L);

• open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. For units containing ammable

refrigerants other than A2L the system shall be “ushed” with OFN to render the unit safe. This process may need to

be repeated several times. Compressed air or oxygen shall not be used for purging refrigerant systems.

For units containing ammable refrigerants, other than A2L refrigerants, refrigerants purging shall be achieved by

breaking the vacuum in the system with oxygen-free nitrogen and continuing to ll until the working pressure is

achieved, then venting to atmosphere, and nally pulling down to a vacuum. This process shall be repeated until no

refrigerant is within the system. When the nal oxygen-free nitrogen charge is used, the system shall be vented down

to atmospheric pressure to enable work to take place. This operation is absolutely vital if brazing operations on the

pipe-work are to take place.

(Annex DD.10) Charging procedures

In addition to conventional charging procedures, the following requirements shall be followed.

• Ensure that contamination of dierent refrigerants does not occur when using charging equipment. Hoses or lines

shall be as short as possible to minimise the amount of refrigerant contained in them.

• Cylinders shall be kept in an appropriate position according to the instructions.

• Ensure that the refrigerating system is earthed prior to charging the system with refrigerant.

• Label the system when charging is complete (if not already).

• Extreme care shall be taken not to overll the refrigerating system.

Prior to recharging the system it shall be pressure-tested with the appropriate purging gas. The system shall be leaktested on completion of charging but prior to commissioning. A follow up leak test shall be carried out prior to leaving

the site.

(Annex DD.11) Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with the unit and all its

detail. It is recommended good practice that all refrigerants are recovered safely. Prior to the task being carried out,

an oil and refrigerant sample shall be taken in case analysis is required prior to re-use of reclaimed refrigerant.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure, ensure that:

• mechanical handling equipment is available, if required, for handling refrigerant cylinders;

• all personal protective equipment is available and being used correctly;

• the recovery process is supervised at all times by a competent person;

• Label the system when charging is complete (if not already).

• recovery equipment and cylinders conform to the appropriate standards.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

21

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with instructions.

h) Do not overll cylinders (no more than 80 % volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been lled correctly and the process completed, make sure that the cylinders and the

equipment are removed from site promptly and all isolation valves on the equipment are closed o.

k) Recovered refrigerant shall not be charged into another refrigerating system unless it has been cleaned and

checked.

(Annex DD.12) Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be

dated and signed. For appliances containing ammable refrigerants, ensure that there are labels on the equipment

stating the equipment contains ammable refrigerant.

(Annex DD.13) Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is recommended good practice

that all refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery cylinders are employed.

Ensure that the correct number of cylinders for holding the total system charge are available. All cylinders to be used

are designated for the recovered refrigerant and labelled for that refrigerant (i.e. special cylinders for the recovery of

refrigerant). Cylinders shall be complete with pressure-relief valve and associated shut-o valves in good working

order. Empty recovery cylinders are evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions concerning the equipment that is at

hand and shall be suitable for the recovery of ammable refrigerants. In addition, a set of calibrated weighing scales

shall be available and in good working order. Hoses shall be complete with leak-free disconnect couplings and in

good condition. Before using the recovery machine, check that it is in satisfactory working order, has been properly

maintained and that any associated electrical components are sealed to prevent ignition in the event of a refrigerant

release. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery cylinder, and the relevant

waste transfer note arranged. Do not mix refrigerants in recovery units and especially not in cylinders.

If compressors or compressor oils are to be removed, ensure that they have been evacuated to an acceptable level

to make certain that ammable refrigerant does not remain within the lubricant. The evacuation process shall be

carried out prior to returning the compressor to the suppliers. Only electric heating to the compressor body shall be

employed to accelerate this process.

When oil is drained from a system, it shall be carried out safely.

Translation from original instructions

Packaged Rooftop

22

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

2.3 Noise

The starting of the unit, with activation of its components, emits a noise whose intensity varies depending on the

operating level.

The correct location choice and the correct installation prevent the unit causing annoying noise due to resonances,

reections and vibrations.

2.4 Residual risks

The unit uses technical means suitable for protecting people, animals and things against hazards that cannot

reasonably be eliminated or suciently reduced through design.

The presence of an operator is not required for normal operation of the unit. The change from the "OFF" state to

the "ON" state, and vice versa, of the unit can be carried out remotely or through the display, without having to enter

areas at risk.

Access restriction is part of correct installation to eliminate residual risks during normal operation.

Removal of the restrictions gives access to cold parts, hot parts and sharp edges.

When the electrical boxes and the electrical control panel are open, live parts can be accessed.

Instrument connection to the refrigerant circuit may cause the release of mildly ammable refrigerant.

Do not:

- remove or disable the safety guards;

- tamper with and/or modify, even partially, the safety devices installed on the unit.

In heat pump operation, during defrost cycles, the water drips onto the ground when the frost melts o the coils.

If the water is not properly drained, when the ambient temperatures are sub-zero, dangerous sheets of ice are formed.

Limit access to the area to prevent accidents.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

23

2.5 Safety information on the refrigerant uid

This product contains uorinated greenhouse gases included in the Kyoto protocol. Do not release these gases into

the atmosphere.

Type of refrigerant: R32.

GWP value: 677. Based on "IPCC Fifth Assessment Report".

GWP is the global warming potential.

The quantity of refrigerant uid is indicated in the unit’s data label. Periodic inspections are necessary to check for

refrigerant uid leaks in accordance with local and/or European regulations.

2.5.1 Hazards and health consequences

If accidentally released, rapid evaporation of the liquid can cause freezing.

In case of contact with the liquid:

- defrost the various part with water;

- remove clothing carefully;

- rinse thoroughly with water.

Contaminated clothing and shoes should be washed before reuse.

High vapour concentrations can cause headaches, dizziness, drowsiness and nausea, and may lead to

unconsciousness and cardiac arrhythmia.

If inhaled move the victim to fresh air. Articial respiration and/or oxygen may be necessary. Call a doctor immediately.

In case of contact with eyes, remove contact lenses. Rinse immediately with plenty of water, holding the eyelids open,

for at least 15 minutes.

The safety data sheet drawn up by the producer of the refrigerant can be obtained from the

manufacturer of the unit.

The refrigerants used in these units are classied as ASHRAE A2L and they are characterised by low

ammability (burning velocity < 10 cm/s). If refrigerant leaks out, it tends to stagnate in the bottom part

of the area where the leak has occurred.

Translation from original instructions

Packaged Rooftop

24

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

3 RECEIVING THE PRODUCT AND STORAGE

3.1 Reception

On receiving the unit, check that it is undamaged, bearing in mind that it left the factory in perfect condition.

Report any signs of damage immediately to the transporter and make a note of these on the Delivery Sheet before

signing it.

The relevant sales department or the manufacturer should be informed of the extent of the damage as soon as

possible.

The Customer must draw up a written and photographic report concerning any and all signicant damage.

Disposal of the packing material is the responsibility of the consignee and must be carried out in compliance with the

regulations in force in the country in which it is carried out.

3.2 Transport

The unit is sent from the factory using suitable vehicles, with correct locking in order to prevent any possibility of

movement whilst in transit by road that may damage it or cause accidents.

If there is to be trans-shipment to other vehicles to continue the journey, it is essential to adopt all necessary measures

for ensuring the correct safety conditions, with regard to the vehicles used and the anchorage, in order to prevent

damage.

If the unit is to be transported over uneven roads, the manufacturer must be informed beforehand so that suitable

measures can be taken in order to prevent damage to the unit.

If it is to be transported by container, make sure it is correctly anchored.

With reference to road, sea/ocean or air freight, refer to the ADR, IMDG, IATA codes, etc. in place at the time of

transport.

Before organising the freight, the Manufacturer shall notify the quantity and type of refrigerant lled in the machine.

Units with mildly ammable refrigerants (A2L) shall be hauled in accordance with the European

standards and regulations and the local regulations, where applicable.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

25

3.3 Handling

Before each unit handling operation, check that the lifting capacity of the machinery used is compatible with the

weight of the unit.

Handling must be carried out by adequately equipped qualied personnel.

In all lifting operations, make sure the unit is rmly secured in order to prevent accidental falls or

overturning.

Lifting must be carried out by qualied and authorised personnel taking the necessary precautions; if

carried out incorrectly, lifting can cause serious damage and physical injury.

The handling operations must be carried out slowly and sudden manoeuvres and knocks must be

avoided.

Do not, under any circumstances, stand or pass under or near the unit when it is lifted o the ground.

Use only the lifting system designed and prepared for the unit.

During unloading and positioning of the unit, great care must be taken to prevent sudden or violent manoeuvres, and

the components of the unit must not be used as lifting points.

Make sure the machinery and lifting ropes are of suitable size and capacity and strictly follow their operating

instructions. Use only equipment that is in excellent working order.

Check that the lifting equipment is of suitable size and capacity and strictly follow its operating instructions. Use only

equipment that is in excellent working order.

All work on the unit, including unpacking and connections, must be carried out with the unit resting on the ground.

Refer, in any case, to the lifting instructions provided with the unit.

A pallet is secured under the unit so that it can also be unloaded and handled with a suitable forklift truck.

If anti-vibration mounts are installed under the base of the unit, this must be done with the unit raised by no more than

200 mm from the ground and without putting any parts of the body under it.

Before sliding out the pallet, remove the screws xing it to the unit.

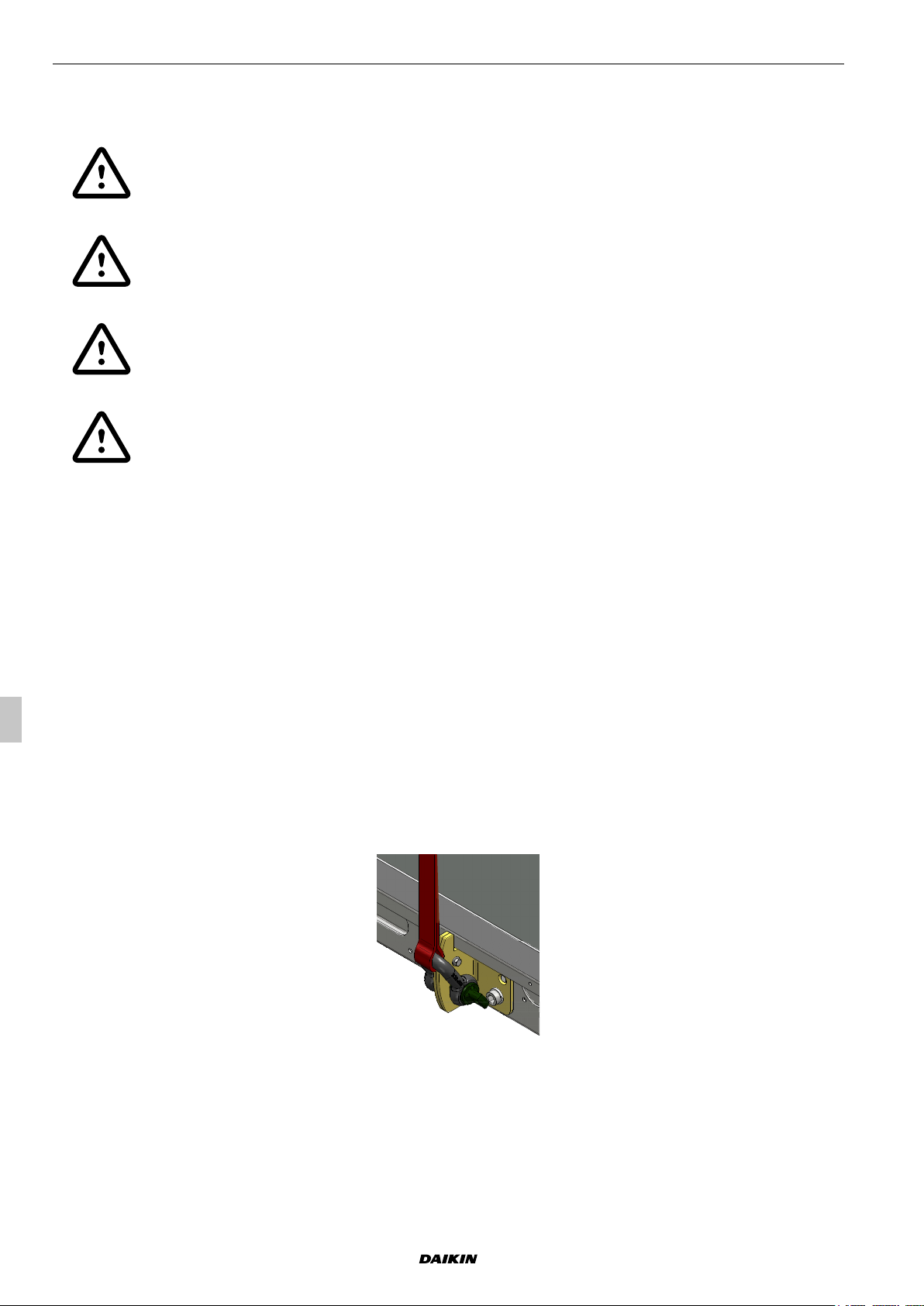

Use a 10 mm spanner to unscrew the screws that are visible through the slotted holes of the base.

Once the pallet has been removed, the unit must be lifted using only and exclusively slings and the yellow lifting

brackets xed to the base.

Use suitable shackles to fasten the slings to the lifting brackets.

Translation from original instructions

Packaged Rooftop

26

Fig. 2 Focus on the attachment of the sling to the lifting bracket

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

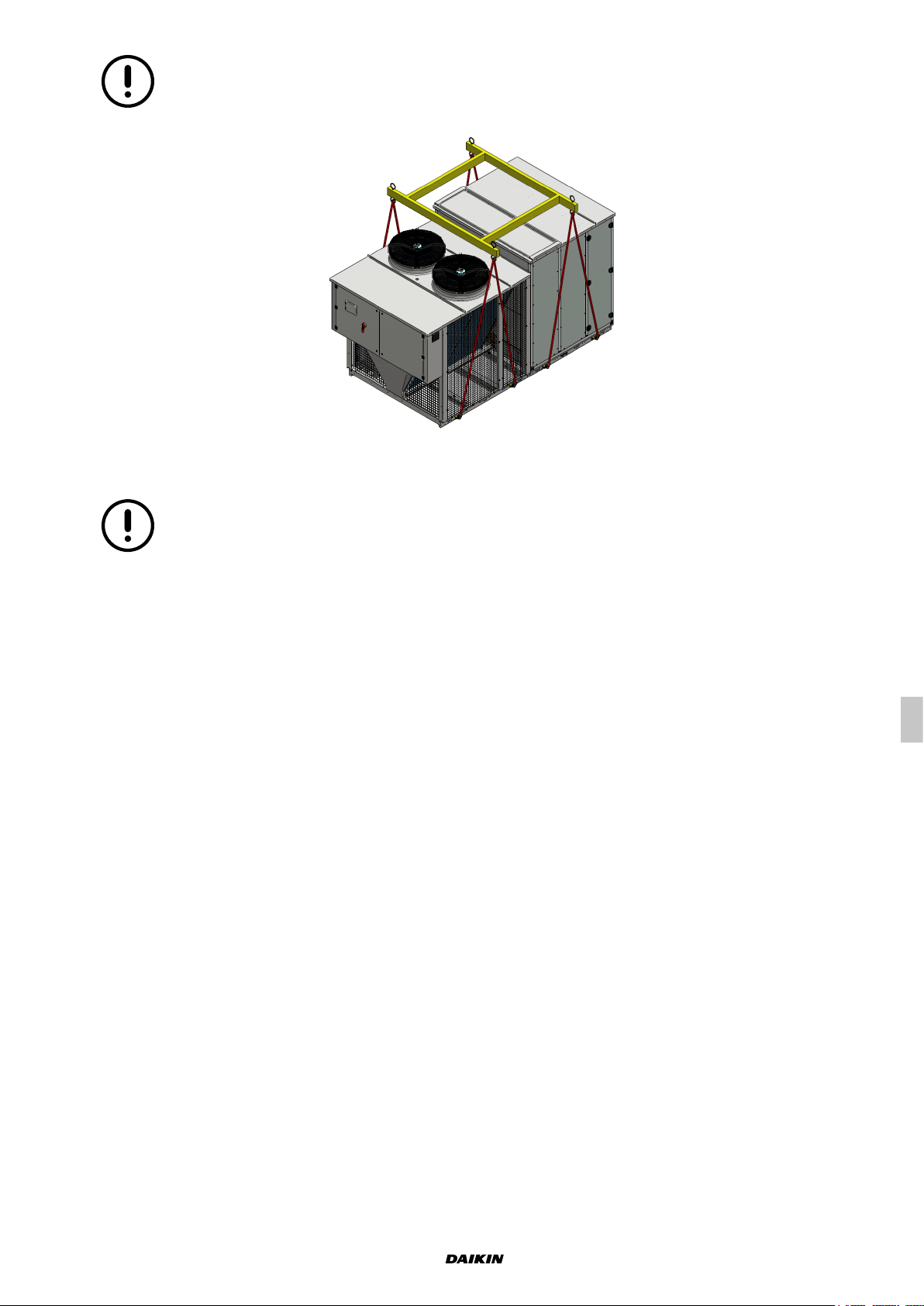

For lifting use all the brackets present in the unit.

Fig. 3 Lifting with slings

To prevent the slings from touching the unit, suitable protective devices must be placed on the upper

edges.

It is mandatory to use a lifting beam adjusted to the width of the unit in order to ensure lifting stability

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

27

4 PRODUCT DESCRIPTION

4.1 Intended use

These units are intended for air cooling / heating, generally used in air conditioning applications

These are high eciency, self-contained air conditioners, for both summer and winter use, that allow attainment of

complete thermo-hygrometric air handling and recovery of the heat dispersed for air renewal. They can be used in

both commercial and industrial applications that, besides having load variability, can be characterized by high latent

loads and need to guarantee optimum conditions for occupants.

Their use is recommended within the operating limits indicated in the Technical Catalogue.

4.2 Unintended use

The unit must not be used:

- in an explosive atmosphere;

- in a ammable atmosphere;

- in extremely dusty environments;

- in an environment that is not compatible with the stated IP protection rating;

- by untrained personnel;

- in a way that does not comply with the regulations in force;

- with incorrect installation;

- with power supply defects;

- with total or partial failure to comply with the instructions;

- with lack of maintenance and/or use of non-original spare parts;

- with inecient safety components.

- with modications or other work not authorised by the Manufacturer.

Translation from original instructions

Packaged Rooftop

28

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

4.3 Control and safety devices

The unit is integrally managed by an electronic microprocessor control that, through the various installed temperature

and pressure sensors, keeps its operation within the safety limits.

All the parameters involved with control of the unit are shown in the “Control Manual” that is an integral part of the

documentation of the unit.

All the parameters involved with control of the unit are shown in the “Operating Manual” that is an integral part of the

documentation of the unit.

The manual fully describes the logic with which the checks of the unit take place during the various operating stages.

The control and safety devices are shown in the Technical Catalogue.

4.4 Principles of operation

The basic operation of these units uses a reverse vapour compression cycle to change the thermo-hygrometric

conditions of the air in the interior environment. The simplest conguration works in total air recirculation.

The refrigeration cycle allows heat to be transferred from a uid at a lower temperature to a uid at a higher

temperature. The Roof Top units are equipped with one or more refrigerant circuits; in cooling mode, air is cooled -

and if necessary dehumidied - by a nned coil (evaporator); the removed heat is rejected to the outside by another

nned coil (condenser).

In addition to this, the heat pump versions allow the evaporator and condenser roles to be reversed, thereby providing

the heating function.

In addition to air ltration, other functions are possible, which vary depending on the conguration and the selected

accessories: partial air renewal, heat recovery from expelled air, thermodynamic recovery, humidication, additional

heating by means of burner, battery with hot water or electric heaters, free cooling / free heating.

4.5 Structure

Depending on the sizes, the structure is made of galvanized sheet-iron coated with epoxy polyester powder at 180°C,

which makes it highly resistant to weather conditions, or of extruded aluminium alloy proles connected with glass

bre reinforced nylon joints.

The base and cover are made of thick, epoxy polyester powder coated, galvanized sheet-iron.

The panelling is made with 25mm thick sandwich panels consisting of a 0.5 mm thick externally pre-painted

galvanized sheet-iron casing lled with polyurethane foam to guarantee the thermal and acoustic insulation of the unit.

Alternatively, the panels are insulated with closed-cell insulating matting or with rock wool, for the "heat generator"

section. The surface of the panels in contact with the treated air is made of galvanized sheet-iron to facilitate cleaning

and sanitizing operations.

The non-removable panels are xed to the structure with screws contained in nylon bushes with plug.

The removable panels are attached to the structure with nylon eccentrics or inserts and have handles to make them

easier to remove.

4.6 Specications

Direct expansion air conditioner with hermetic compressors, evaporating coil with centrifugal or radial fans and

condensing coil with axial fans.

The unit is made in two sections that are joined together but functionally separate. One section is for transferring the

energy absorbed from the treated interior environment into the atmosphere. The other section is for air handling and

allows air conditioning of the conned environment to be treated.

In congurations where air exchange is envisaged, heat recovery and free cooling/free heating can be managed.

For heating, there may be a gas heat generator, or a hot water coil or a group of electric heaters.

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Translation from original instructions

Packaged Rooftop

29

4.7 Air system

4.7.1 Internal air fans

Depending on the congurations, there may be only supply fans or also return fans in the units.

The fans are radial fans with reverse blades, with external rotor motor directly coupled to the impeller.

The radial fans are called "EC", with electronically commutated brushless motor. The fan is powered by mains AC

voltage, and speed control is obtained via DC 0-10V control signal coming from the microprocessor installed on the

unit. This makes it possible to set the air ow rate through the parameter being displayed.

The motors have alarm signalling, which includes thermal overload protection, overcurrent, undervoltage, absence

of one or more phases and seized rotor.

The EC fans are not provided with a contactor and are constantly live as soon as the main disconnect

switch of the unit is closed.

4.7.2 Flow rate sensor for fans

Units with "EC" fans are provided with a dierential pressure transducer that detects the pressure dierence between

the inside and the outside (upstream) of the intake nozzle. The air ow rate is proportional, for each fan/nozzle pair,

to the square root of the pressure dierence according to the equation:

where

- Q = total air ow [m3 / h]

- n = number of fans in the unit

- k = constant according to the fan nozzle

- ΔP = pressure dierence measured on the nozzle [Pa]

The dierential pressure value and the air ow rate can be shown directly on the display of the microprocessor that

carries out automatic control of the air ow rate.

Translation from original instructions

Packaged Rooftop

30

We reserve the right to make changes without any prior notice.

UAT YA

4P645202-1

Loading...

Loading...