Daikin SERHQ020BAW1, SERHQ032BAW1, SEHVX20BAW, SEHVX32BAW, SEHVX40BAW Installer reference guide

...

Installer and user

reference guide

Split packaged air-cooled water chiller

SERHQ020BAW1

SERHQ032BAW1

SEHVX20BAW

SEHVX32BAW

SEHVX40BAW

SEHVX64BAW

Installer and user reference guide

Split packaged air-cooled water chiller

English

Table of contents

Table of contents

1 General safety precautions 3

1.1 About the documentation .......................................................... 3

1.1.1 Meaning of warnings and symbols.............................. 3

1.2 For the user ............................................................................... 4

1.3 For the installer.......................................................................... 4

1.3.1 General ....................................................................... 4

1.3.2 Installation site ............................................................ 4

1.3.3 Refrigerant .................................................................. 5

1.3.4 Brine............................................................................ 5

1.3.5 Water .......................................................................... 6

1.3.6 Electrical ..................................................................... 6

2 About the documentation 6

2.1 About this document.................................................................. 6

2.2 Installer and user reference guide at a glance .......................... 7

For the installer 7

3 About the box 7

3.1 Overview: About the box ........................................................... 7

3.2 Outdoor unit............................................................................... 8

3.2.1 To unpack the outdoor unit ......................................... 8

3.2.2 To handle the outdoor unit.......................................... 8

3.2.3 To remove the accessories from the outdoor unit....... 8

3.3 Indoor unit ................................................................................. 8

3.3.1 To unpack the indoor unit ........................................... 8

3.3.2 To handle the indoor unit ............................................ 9

3.3.3 To remove the accessories from the indoor unit......... 9

4 About the units and options 9

4.1 Overview: About the units and options...................................... 9

4.2 Identification .............................................................................. 9

4.2.1 Identification label: Outdoor unit ................................. 10

4.2.2 Identification label: Indoor unit .................................... 10

4.2.3 About the outdoor unit................................................. 10

4.2.4 About the indoor unit................................................... 10

4.2.5 About combining units and options............................. 10

4.2.6 Operation range .......................................................... 10

4.3 Combining units and options ..................................................... 11

4.3.1 Possible options for the split system........................... 11

4.4 System layout............................................................................ 11

5 Preparation 11

5.1 Overview: Preparation............................................................... 11

5.2 Preparing the installation site .................................................... 11

5.2.1 Installation site requirements of the outdoor unit ........ 11

5.2.2 Installation site requirements of the indoor unit .......... 12

5.3 Preparing refrigerant piping....................................................... 13

5.3.1 Refrigerant piping requirements.................................. 13

5.3.2 To select the piping size ............................................. 13

5.3.3 About the piping length ............................................... 13

5.4 Preparing water piping .............................................................. 13

5.4.1 Water circuit requirements .......................................... 13

5.4.2 Formula to calculate the expansion vessel pre-

pressure ...................................................................... 15

5.4.3 To check the water volume and expansion vessel

pre-pressure................................................................ 15

5.4.4 Changing the pre-pressure of the expansion vessel... 16

5.4.5 To check the water volume: Examples ....................... 16

5.5 Preparing electrical wiring ......................................................... 16

5.5.1 About preparing electrical wiring................................. 16

5.5.2 About electrical compliance ........................................ 16

5.5.3 Cable requirements..................................................... 17

5.5.4 Safety device requirements ........................................ 17

6 Installation 17

6.1 Overview: Installation ................................................................. 17

6.2 Opening the units ....................................................................... 17

6.2.1 About opening the units ............................................... 17

6.2.2 To open the outdoor unit.............................................. 17

6.2.3 To open the indoor unit ................................................ 18

6.2.4 To open the electrical component box of the outdoor

unit ............................................................................... 18

6.2.5 To open the electrical component box of the indoor

unit ............................................................................... 18

6.3 Mounting the outdoor unit........................................................... 18

6.3.1 About mounting the outdoor unit.................................. 18

6.3.2 Precautions when mounting the outdoor unit............... 19

6.3.3 To provide the installation structure ............................. 19

6.3.4 To provide drainage ..................................................... 19

6.4 Mounting the indoor unit............................................................. 19

6.4.1 About mounting the indoor unit .................................... 19

6.4.2 Precautions when mounting the indoor unit................. 19

6.4.3 To provide the installation structure ............................. 19

6.5 Connecting the refrigerant piping ............................................... 20

6.5.1 Precautions when connecting the refrigerant piping .... 20

6.5.2 To braze the pipe end .................................................. 20

6.5.3 Using the stop valve and service port .......................... 21

6.5.4 To connect the refrigerant piping to the outdoor unit ... 21

6.5.5 To connect the refrigerant piping to the indoor unit ..... 23

6.6 Checking the refrigerant piping .................................................. 23

6.6.1 About checking the refrigerant piping .......................... 23

6.6.2 Precautions when checking the refrigerant piping ....... 24

6.6.3 Checking refrigerant piping: Setup............................... 24

6.6.4 To check for leaks: Pressure leak test ......................... 24

6.6.5 To perform vacuum drying ........................................... 24

6.6.6 To insulate the refrigerant piping ................................. 24

6.7 Charging refrigerant ................................................................... 25

6.7.1 About charging refrigerant ........................................... 25

6.7.2 Precautions when charging refrigerant ........................ 25

6.7.3 To determine the additional refrigerant amount ........... 25

6.7.4 To charge refrigerant ................................................... 25

6.7.5 Checks after charging refrigerant................................. 25

6.7.6 To fix the fluorinated greenhouse gases label ............. 26

6.8 Connecting water piping............................................................. 26

6.8.1 About connecting the water piping............................... 26

6.8.2 Precautions when connecting the water piping............ 26

6.8.3 To connect the water piping......................................... 26

6.8.4 To fill the water circuit .................................................. 26

6.8.5 To insulate the water piping ......................................... 27

6.9 Connecting the electrical wiring.................................................. 27

6.9.1 About connecting the electrical wiring.......................... 27

6.9.2 Precautions when connecting the electrical wiring ...... 27

6.9.3 Field wiring: Overview.................................................. 28

6.9.4 About the electrical wiring ............................................ 28

6.9.5 To route and fix the power supply................................ 29

6.9.6 To connect the power supply of the outdoor unit ......... 29

6.9.7 To connect the power supply and transmission

cables........................................................................... 31

6.9.8 Guidelines when knocking out knockout holes ............ 31

6.9.9 To install the user interface.......................................... 31

6.9.10 To install optional equipment ....................................... 32

7 Configuration 32

7.1 Overview: Configuration ............................................................. 32

7.2 Making field settings................................................................... 32

7.2.1 About making field settings

7.2.2 Field setting components ............................................. 33

7.2.3 To access the field setting components....................... 33

7.2.4 To access mode 1 or 2 ................................................ 33

7.2.5 To use mode 1 ............................................................. 34

7.2.6 To use mode 2 ............................................................. 34

7.2.7 Mode 1: Monitoring settings......................................... 34

7.2.8 Mode 2: Field settings.................................................. 34

7.2.9 Field settings on the user interface .............................. 35

.......................................... 32

Installer and user reference guide

2

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

1 General safety precautions

7.3 Switching between cooling and heating .................................... 40

8 Commissioning 40

8.1 Overview: Commissioning......................................................... 40

8.2 Precautions when commissioning ............................................. 41

8.3 Checklist before commissioning the outdoor unit...................... 41

8.4 Checklist before commissioning the indoor unit ........................ 41

8.5 Final check ................................................................................ 42

8.6 About the test run ...................................................................... 42

8.6.1 To display the temperature on the remote controller .. 43

8.6.2 To test space heating/cooling ..................................... 43

8.7 Correcting after abnormal completion of the test run ................ 43

8.8 Checklist handover to the user.................................................. 43

8.9 To complete the model fill-in ..................................................... 43

9 Maintenance and service 44

9.1 Overview: Maintenance and service ......................................... 44

9.2 Maintenance safety precautions................................................ 44

9.2.1 To prevent electrical hazards...................................... 44

9.3 About service mode operation................................................... 44

9.3.1 To use vacuum mode ................................................. 44

9.3.2 To recover refrigerant ................................................. 44

9.4 Checklist for yearly maintenance of the indoor unit................... 45

10 Troubleshooting 45

10.1 Overview: Troubleshooting........................................................ 45

10.2 Error codes: Overview ............................................................... 45

11 Disposal 46

12 Technical data 46

12.1 Overview: Technical data .......................................................... 46

12.2 Service space: Outdoor unit ...................................................... 46

12.3 Service space: Indoor unit ......................................................... 47

12.4 Piping diagram: Outdoor unit..................................................... 48

12.5 Piping diagram: Indoor unit ....................................................... 49

12.6 Wiring diagram: Outdoor unit .................................................... 50

12.7 Wiring diagram: Indoor unit ....................................................... 50

12.8 Technical specifications: Outdoor unit....................................... 51

12.9 Field settings on the user interface – overview ......................... 52

12.10 Field settings on the outdoor unit .............................................. 54

12.11 ESP curve: Indoor unit .............................................................. 55

For the user 55

13 About the system 55

13.1 System layout ............................................................................ 55

14 User interface 56

15 Before operation 56

17.2.3 Recommended maintenance and inspection cycles .... 65

18 Troubleshooting 65

18.1 Error codes: Overview ................................................................ 66

19 Relocation 66

20 Disposal 66

21 Glossary 67

1 General safety precautions

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and in the installer reference guide MUST be

performed by an authorised installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING

Indicates a situation that could result in death or serious

injury.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate

injury.

16 Operation 57

16.1 Operation range ........................................................................ 57

16.2 Quick start-up ............................................................................ 57

16.3 Operating the system ................................................................ 58

16.3.1 About the clock ........................................................... 58

16.3.2 About operating the system ........................................ 59

16.3.3 Space cooling operation ............................................. 59

16.3.4 Space heating operation ............................................. 59

16.3.5 Other operation modes ............................................... 60

16.3.6 Schedule timer ............................................................ 60

16.3.7 Operating the optional demand PCB .......................... 64

16.3.8 Operating the optional external control adapter .......... 64

16.3.9 Operating the optional remote controller..................... 64

17 Maintenance and service 64

17.1 About the refrigerant.................................................................. 65

17.2 After-sales service and warranty ............................................... 65

17.2.1 Warranty period .......................................................... 65

17.2.2 Recommended maintenance and inspection .............. 65

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol Explanation

Before installation, read the installation and

operation manual, and the wiring instruction sheet.

Before performing maintenance and service tasks,

read the service manual.

For more information, see the installer and user

reference guide.

Installer and user reference guide

3

1 General safety precautions

1.2 For the user

▪ If you are NOT sure how to operate the unit, contact your installer.

▪ This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved. Children shall

NOT play with the appliance. Cleaning and user maintenance

shall NOT be made by children without supervision.

WARNING

To prevent electric shocks or fire:

▪ Do NOT rinse the unit.

▪ Do NOT operate the unit with wet hands.

▪ Do NOT place any objects containing water on the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

▪ Units are marked with the following symbol:

This means that electrical and electronic products may NOT be

mixed with unsorted household waste. Do NOT try to dismantle

the system yourself: the dismantling of the system, treatment of

the refrigerant, of oil and of other parts must be done by an

authorized installer and must comply with applicable legislation.

Units must be treated at a specialized treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences

for the environment and human health. For more information,

contact your installer or local authority.

▪ Batteries are marked with the following symbol:

This means that the batteries may NOT be mixed with unsorted

household waste. If a chemical symbol is printed beneath the

symbol, this chemical symbol means that the battery contains a

heavy metal above a certain concentration.

Possible chemical symbols are: Pb: lead (>0.004%).

Waste batteries must be treated at a specialized treatment facility

for reuse. By ensuring waste batteries are disposed of correctly,

you will help to prevent potential negative consequences for the

environment and human health.

1.3 For the installer

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information MUST be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.3.1 General

If you are NOT sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

Installer and user reference guide

4

1.3.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the weight and vibration

of the unit.

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

1 General safety precautions

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

1.3.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are NOT

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case recharge is required, see the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

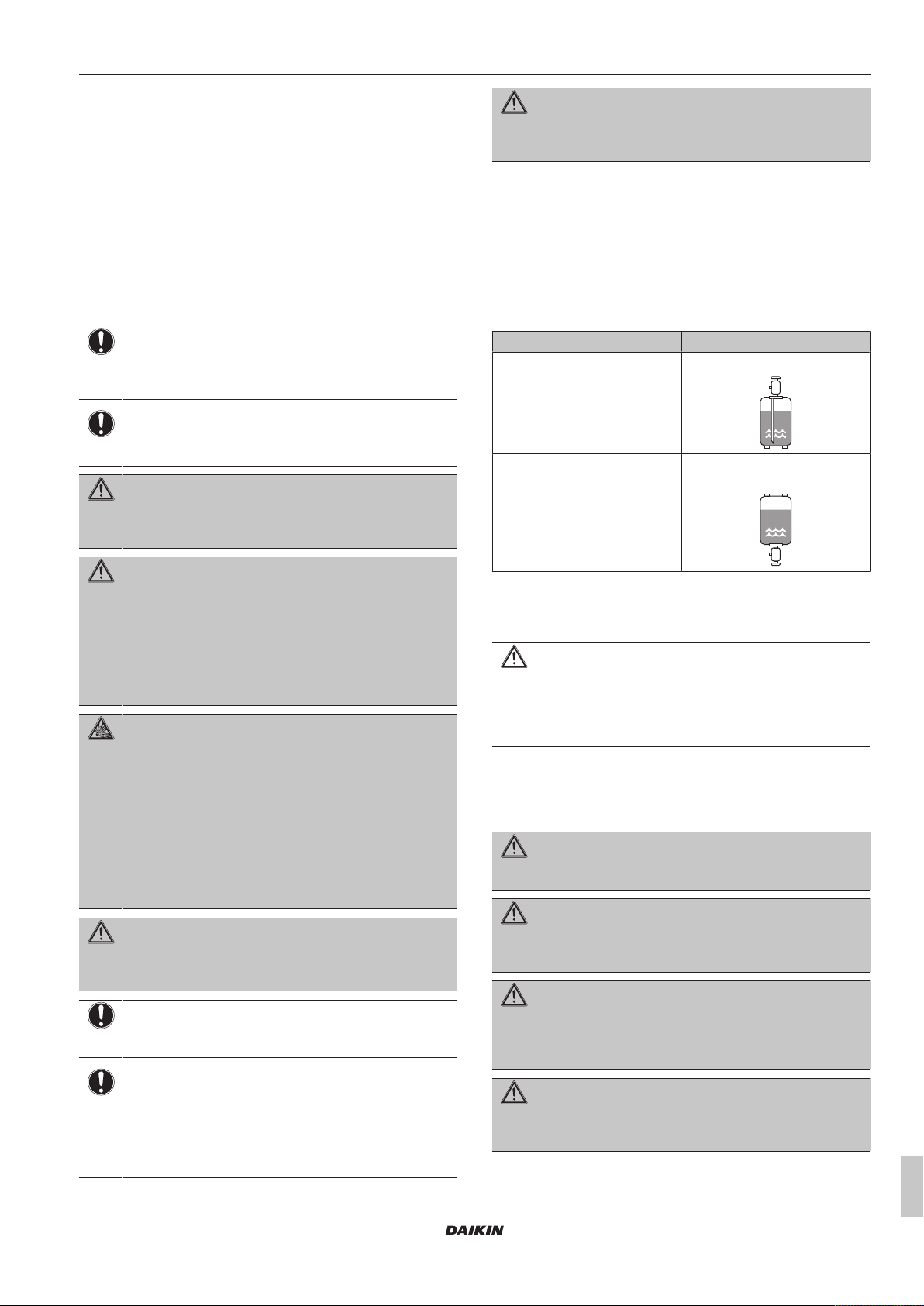

▪ Charge the liquid refrigerant as follows:

If Then

A siphon tube is present

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside

Charge with the cylinder upright.

down.

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage. If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit. Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

WARNING

ALWAYS recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant MUST be treated according to the applicable

legislation.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is NOT closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

1.3.4 Brine

If applicable. See the installation manual or installer reference guide

of your application for more information.

WARNING

The selection of the brine MUST be in accordance with the

applicable legislation.

WARNING

Take sufficient precautions in case of brine leakage. If

brine leaks, ventilate the area immediately and contact

your local dealer.

WARNING

The ambient temperature inside the unit can get much

higher than that of the room, e.g. 70°C. In case of a brine

leak, hot parts inside the unit can create a hazardous

situation.

WARNING

The use and installation of the application MUST comply

with the safety and environmental precautions specified in

the applicable legislation.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

Installer and user reference guide

5

2 About the documentation

1.3.5 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

1.3.6 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1 minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, MUST be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring MUST be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do NOT come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

CAUTION

When connecting the power supply, the earth connection

must be made before the current-carrying connections are

established. When disconnecting the power supply, the

current-carrying connections must be separated before the

earth connection is. The length of the conductors between

the power supply stress relief and the terminal block itself

must be as such that the current-carrying wires are

tautened before the earth wire is in case the power supply

is pulled loose from the stress relief.

NOTICE

Precautions when laying power wiring:

▪ Do NOT connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure above.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1 m away from televisions or radios to

prevent interference. Depending on the radio waves, a distance of

1m may not be sufficient.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

2 About the documentation

2.1 About this document

INFORMATION

Make sure that the user has the printed documentation and

ask him/her to keep it for future reference.

Target audience

Authorised installers + end users

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the outdoor unit)

Installer and user reference guide

6

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

3 About the box

b

a

▪ Installation and operation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the indoor unit)

▪ Installer and user reference guide:

▪ Preparation of the installation, reference data,…

▪ Detailed step-by-step instructions and background information

for basic and advanced usage

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

For installation of the heat pump unit (location, piping, and wiring),

refer to the installation and operation manual of the RXYQ*.

INFORMATION

First read the indoor unit manual, and only then the

outdoor unit manual.

2.2 Installer and user reference guide at a glance

Chapter Description

General safety

precautions

About the documentation What documentation exists for the

About the box How to unpack the units and remove

About the units and

options

Preparation What to do and know before going

Installation What to do and know to install the

Configuration What to do and know to configure the

Operation Operation of the units

Commissioning What to do and know to commission the

Hand‑over to the user What to give and explain to the user

Maintenance and service How to maintain and service the units

Troubleshooting What to do in case of problems

Disposal How to dispose of the system

Technical data Specifications of the system

Field settings table Table to be filled in by the installer, and

Glossary Definition of terms

Safety instructions that you must read

before installing

installer

their accessories

▪ How to identify the units

▪ Possible combinations of units and

options

on‑site

system

system after it is installed

system after it is configured

kept for future reference

For the installer

3 About the box

3.1 Overview: About the box

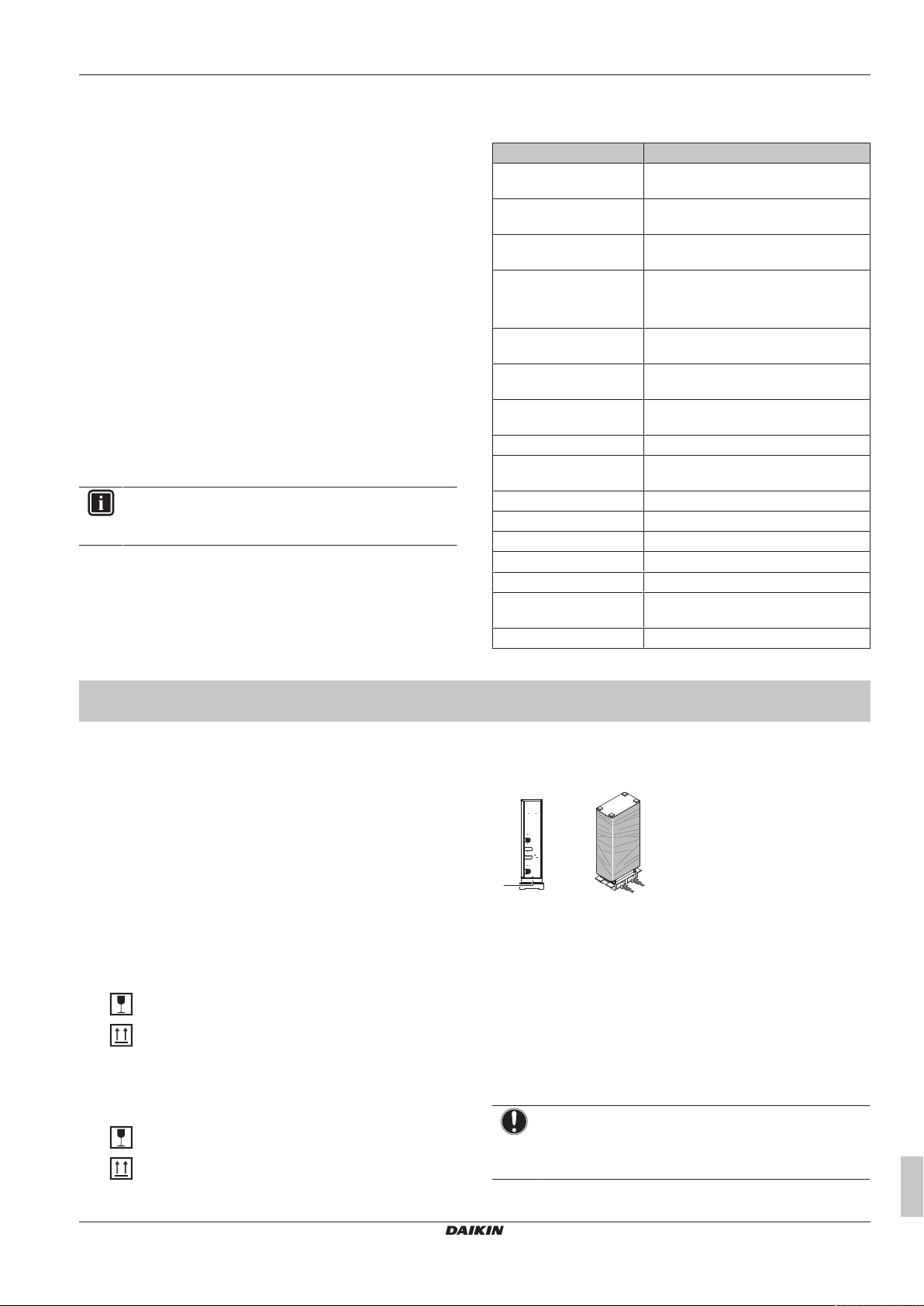

This chapter describes what you have to do after the boxes with the

outdoor and indoor unit are delivered on-site.

Keep the following in mind:

▪ At delivery, the unit MUST be checked for damage. Any damage

MUST be reported immediately to the claims agent of the carrier.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

▪ When handling the unit, take into account the following:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

▪ Prepare the path along which you want to bring the unit inside in

advance.

▪ When handling the unit, take into account the following:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

▪ Prepare the path along which you want to bring the unit inside in

advance.

a Opening

b Forklift

▪ A forklift can only be used for transport as long as the unit remains

on its pallet as shown above.

▪ A forklift can only be used for transport as long as the unit remains

on its pallet as shown above.

▪ If a forklift is to be used, preferably transport the unit with pallet

first, then pass the forklift arms through the large rectangular

openings on the bottom of the unit.

▪ Once at final position, unpack the unit and pass the forklift arms

through the large rectangular openings on the bottom of the unit.

NOTICE

Cover the forklift arms with a cloth to prevent damaging the

unit. If the paint on the bottom frame peels off, the anticorrosion effect may decrease.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

Installer and user reference guide

7

3 About the box

1 2

a

d e

c

b

d

a

a

c

b

c

b

c

b

c

f

f

1× 1× 1× 1×1× 1× 1×

ea c d f g

b

3.2 Outdoor unit

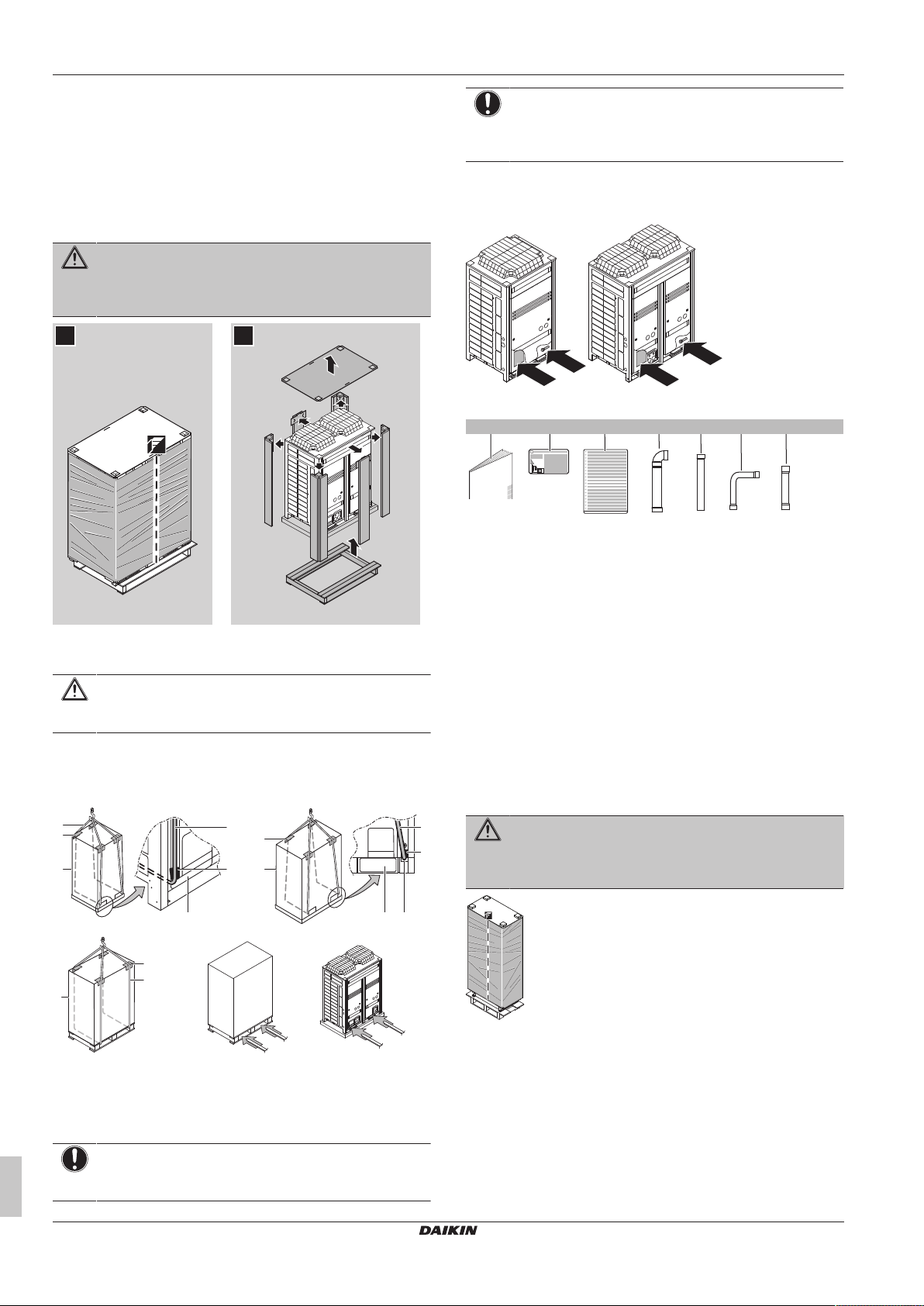

3.2.1 To unpack the outdoor unit

Remove the packaging material from the unit:

▪ Take care not to damage the unit when removing the shrink foil

with a cutter.

▪ Remove the 4 bolts fixing the unit to its pallet.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

NOTICE

Cover the forklift arms with a cloth to prevent damaging the

unit. If the paint on the bottom frame peels off, the anticorrosion effect may decrease.

3.2.3 To remove the accessories from the outdoor unit

Make sure that all accessories are available in the unit.

a General safety precautions

b Fluorinated greenhouse gases label

c Multilingual fluorinated greenhouse gases label

d Gas side accessory pipe

e Gas side accessory pipe

f Liquid side accessory pipe

g Liquid side accessory pipes

3.2.2 To handle the outdoor unit

CAUTION

To avoid injury, do NOT touch the air inlet or aluminium

fins of the unit.

▪ Lift the unit preferably with a crane and 2belts of at least 8m long

as shown in the figure below. Always use protectors to prevent

belt damage and pay attention to the position of the unit's centre

of gravity.

Installer and user reference guide

8

a Packaging material

b Belt sling

c Protector

d Large opening

e Small opening (40×45)

f Forklift

NOTICE

Use a belt sling of ≤20mm wide that adequately bears the

weight of the unit.

3.3 Indoor unit

3.3.1 To unpack the indoor unit

Remove the packaging material from the unit:

▪ Take care not to damage the unit when removing the shrink foil

with a cutter.

▪ Remove the 4 bolts fixing the unit to its pallet.

▪ Take care not to drop the unit when removing it from the pallet. Lift

the unit with at least 2installers.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

4 About the units and options

1 2

b

a

8×

a d ec

1×

b

1× 1×

f g

h

2×

1× 1×1×/2×

i

2×

j k

3×2×

l

2×

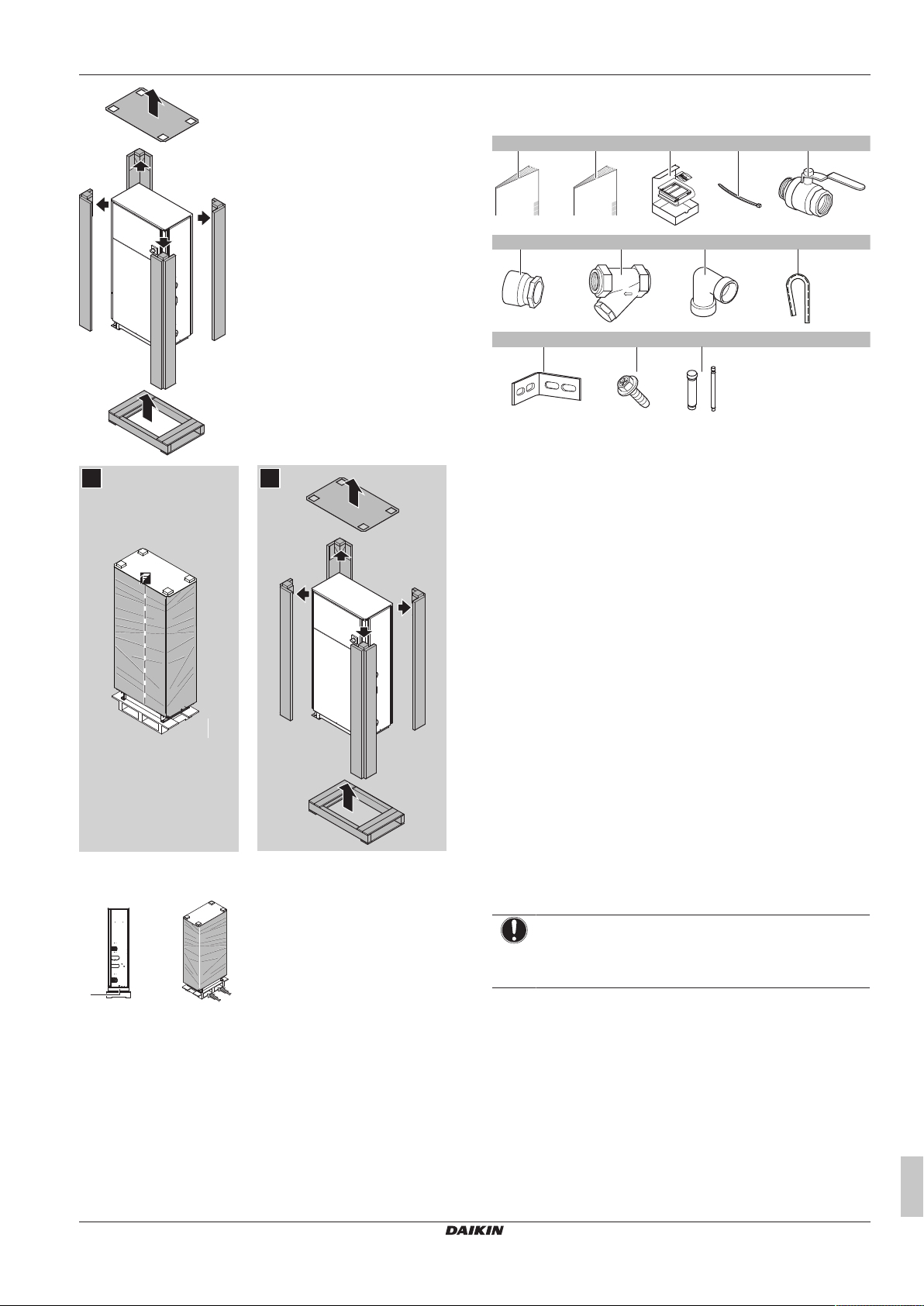

3.3.3 To remove the accessories from the indoor unit

a General safety precautions

b Installation manual and operation manual (panel 3)

c User interface (panel 3)

d Tie wraps (panel 3)

e Shut-off valves (panel 3)

f Threaded connection (panel 3) (1× for SEHVX20+32BAW,

2× for SEHVX40+64BAW)

g Filter (panel 3)

h Elbow (panel 3)

i Black grommet (2×)

j L-shaped support (2×)

k M5 screws (3×)

l Accessory pipes (Ø12.7→Ø9.52 and Ø25.4→Ø28.6)

3.3.2 To handle the indoor unit

a Opening

▪ A forklift can only be used for transport as long as the unit remains

on its pallet as shown above.

b Forklift

4 About the units and options

4.1 Overview: About the units and options

This chapter contains information about:

▪ Identifying the outdoor unit

▪ Identifying the indoor unit

▪ About the outdoor unit

▪ About the indoor unit

▪ Combining the split system with options

▪ Where the outdoor and indoor units fit in the system layout

4.2 Identification

NOTICE

When installing or servicing several units at the same time,

make sure NOT to switch the service panels between

different models.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

Installer and user reference guide

9

4 About the units and options

43

–5

0

0 5 20 25

LWE

T

A

A B

4.2.1 Identification label: Outdoor unit

Location

Model identification

Example: SE RH Q 020 BA W1

Code Explanation

SE Special European model

RH Outdoor/low water temperature

Q R410A refrigerant

020 Capacity class

BA Model series

W1 Power supply: 3P, 400V

4.2.2 Identification label: Indoor unit

4.2.4 About the indoor unit

This installation manual concerns the inverter heat pump chilling unit

with separate hydro module. The unit is intended for indoor

installation and can be combined with VRV outdoor units

(SERHQ020+032BAW1) for air conditioning purposes, or it can be

used for supplying water for process cooling applications.

The units are available in 4 standard sizes with nominal capacities

ranging from 16.8 to 63 kW.

The unit is designed to work in heating mode at ambient

temperatures from –15°C to 35°C and in cooling mode at ambient

temperatures from –5°C to 43°C.

The main component is the water heat exchanger.

The indoor unit is connected to the outdoor unit by field refrigerant

piping and the compressor in the outdoor unit circulates refrigerant

into the heat exchangers.

▪ In cooling mode, the refrigerant transports the heat taken from the

water heat exchanger to the air heat exchanger where the heat is

released to the air.

▪ In heating mode, the refrigerant transports the heat taken from the

air heat exchanger to the water heat exchanger where the heat is

released to the water.

4.2.5 About combining units and options

This packaged air-cooled water chiller can be combined with fan coil

units and is intended for R410A use only.

The indoor unit can be combined with fan coil units and is intended

for R410A use only.

Location

Model identification

Example: SE HVX 20 BA W

Code Explanation

SE Special European model

HVX Indoor unit / Floor-standing

20 Capacity class

BA Model series

W Power supply: 3P, 400V

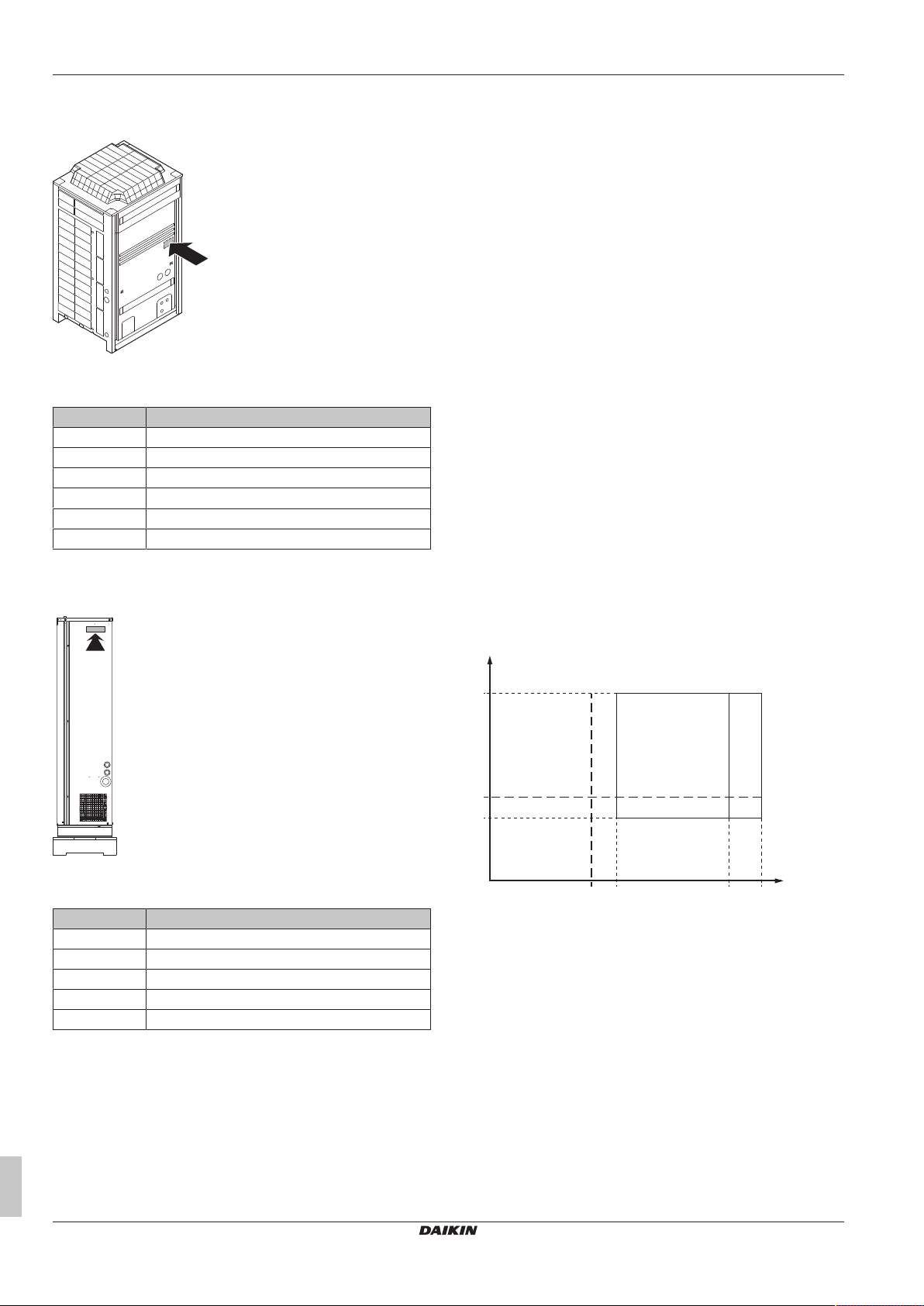

4.2.6 Operation range

Cooling

TAAmbient temperature (°CDB)

LWE Leaving water evaporator temperature (°C)

A Standard water operation range

B Pull down area

4.2.3 About the outdoor unit

SERHQ outdoor units are designed for outdoor installation and are

meant to be combined with SEHVX indoor units.

The outdoor units are designed to work in heating mode at ambient

temperatures from –15°C WB to 35°C WB and in cooling mode at

ambient temperatures from –5°CDB to 43°CDB.

Installer and user reference guide

10

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

5 Preparation

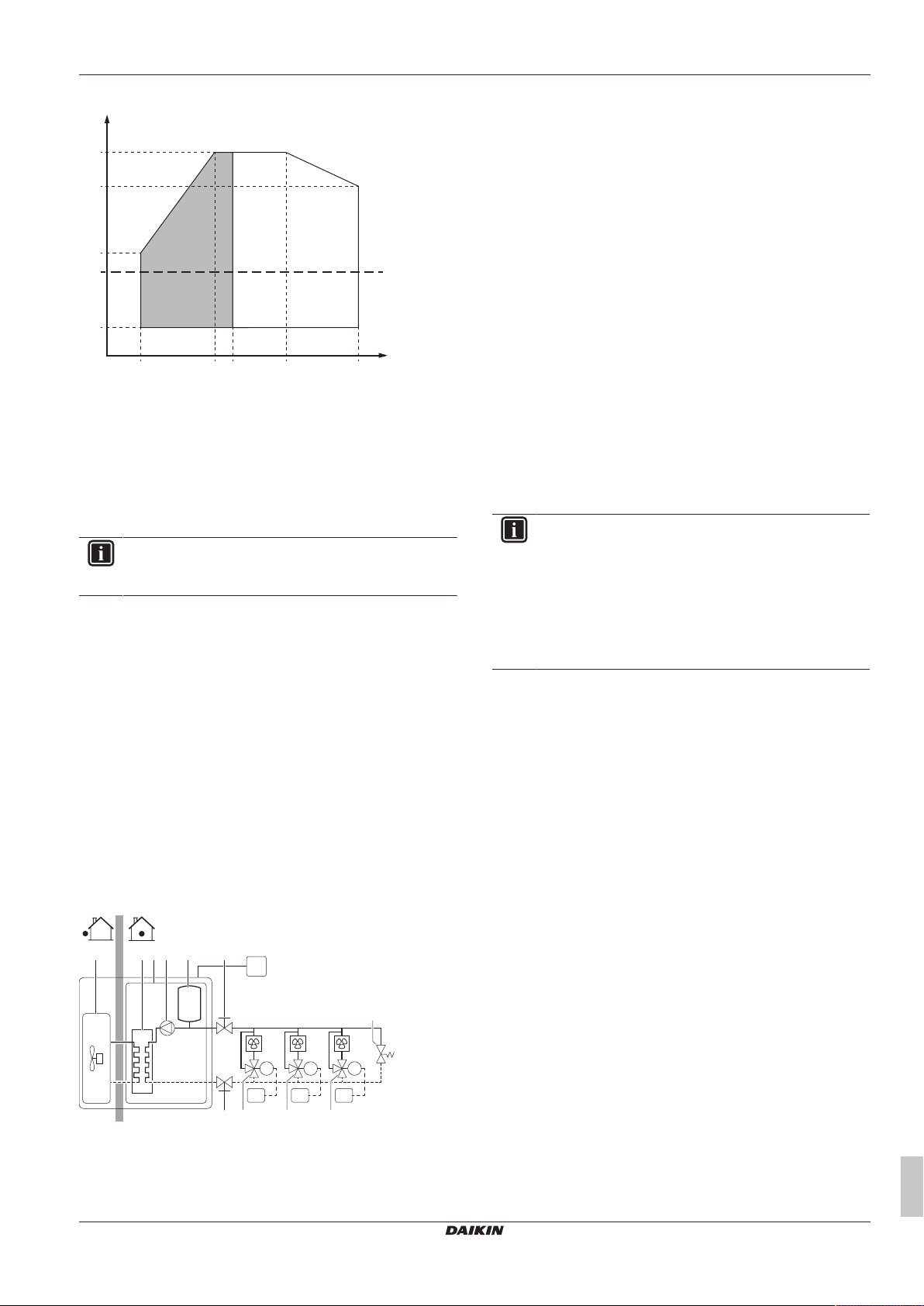

0

35

25

5

–15

5 (EWC) 20 25 35 50

LWC

T

A

A B

RC

RT1M1RT2M2RT3

M3

FC1 FC2 FC3

a c e f

f

g g g

h

db

Heating

TAAmbient temperature (°CDB)

LWC Leaving water condenser temperature (°C)

EWC Entering water condenser temperature (°C)

A Pull up area

B Standard water operation range

4.3 Combining units and options

4.3.1 Possible options for the split system

INFORMATION

Refer to the technical engineering data for the latest option

names.

Remote controller (EKRUAHTB)

A second remote controller to control the unit from 2 locations.

Demand PCB (EKRP1AHTA)

To enable the power saving consumption control by digital inputs

you must install the demand PCB.

For installation instructions, see the installation manual of the

demand PCB. In case of SEHVX40+64BAW, 2 sets of this option

are required.

External control adaptor (DTA104A62)

To instruct specific operation with an external input coming from a

central control, the external control adaptor can be used. Instructions

(group or individual) can be given for low noise operation and power

consumption limitation operation. In case of SEHVX40+64BAW, 2

sets of this option are required.

4.4 System layout

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

a Outdoor unit

b Indoor unit

c Plate heat exchanger

d Pump

e Expansion vessel

f Shut-off valve

g Motorized valve

h Bypass valve

FC1…3 Fancoil unit (field supply)

RC User interface

RT1…3 Room thermostat

5 Preparation

5.1 Overview: Preparation

This chapter describes what you have to do and know before going

on-site.

It contains information about:

▪ Preparing the installation site

▪ Preparing the refrigerant piping

▪ Preparing the water piping

▪ Preparing the electrical wiring

5.2 Preparing the installation site

5.2.1 Installation site requirements of the outdoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Service space requirements. See the "Technical data"

chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the weight and vibration

of the unit.

▪ Make sure the unit is level.

▪ Select a place where rain can be avoided as much as possible.

▪ Take care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

▪ Select the location of the unit in such a way that the sound

generated by the unit does not disturb anyone, and the location is

selected according the applicable legislation.

▪ During installation, avoid the possibility that anybody can climb on

the unit or place objects on the unit.

▪ All piping lengths and distances have been taken into

consideration (see "5.3.3About the piping length"[413]).

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

Installer and user reference guide

11

5 Preparation

b

c

a

a

b

c

d

c

d

≥1500

≥1500

a

d

e

b

(mm)

f

c

≥1000≥1000

≥1000

≥1500

≥1500

≥1000

b

c

≥1500≥1500

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

CAUTION

Appliance NOT accessible to the general public, install it in

a secured area, protected from easy access.

This unit is suitable for installation in a commercial and

light industrial environment.

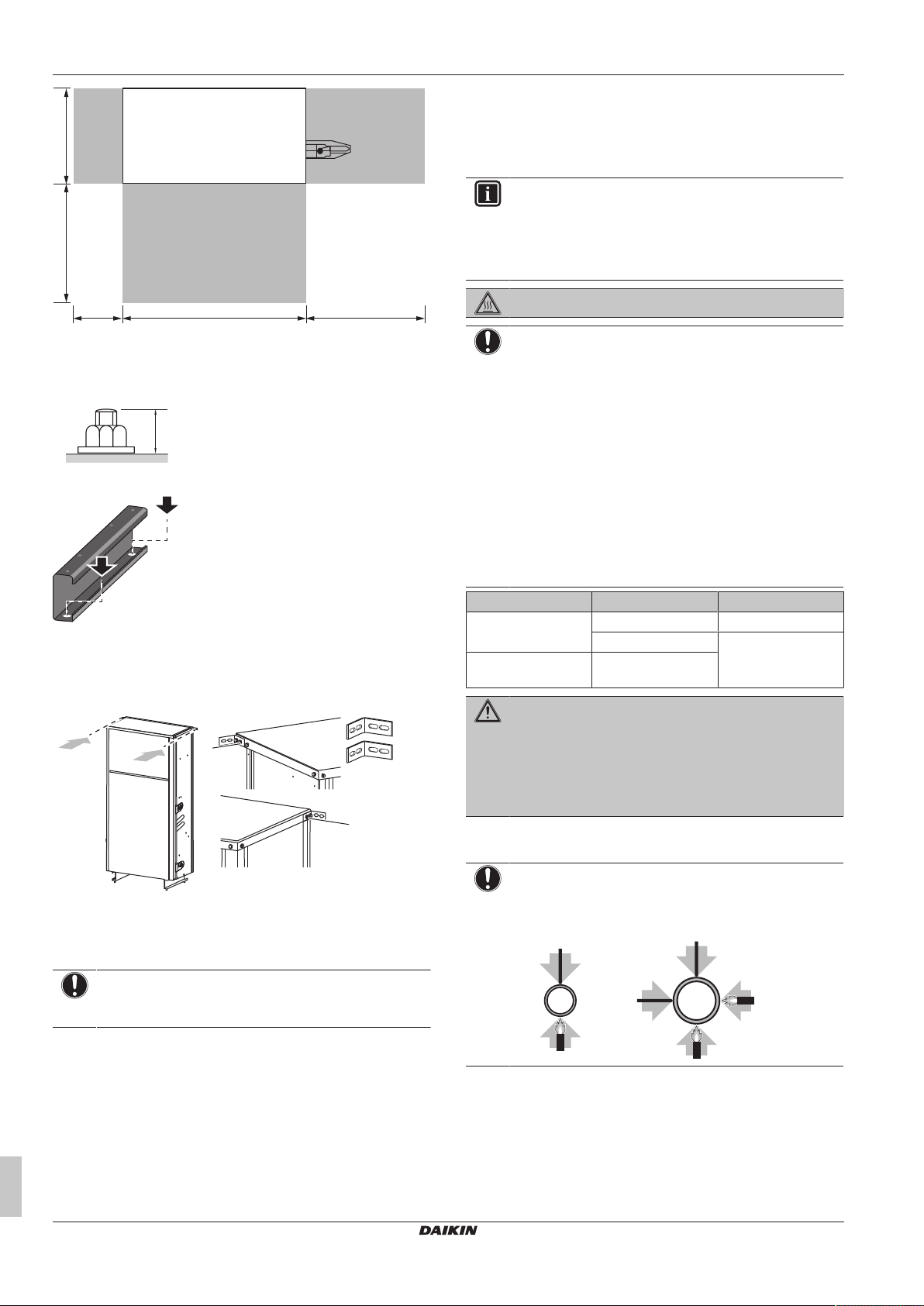

▪ When installing, take strong winds, typhoons or earthquakes into

account, improper installation may result in the unit turning over.

▪ Be sure that the air inlet and outlet of the unit is not positioned

towards the main wind direction. Frontal wind will disturb the

operation of the unit. If necessary, use a screen to block the wind.

▪ Ensure that water cannot cause any damage to the location by

adding water drains to the foundation and prevent water traps in

the construction.

▪ In heavy snowfall areas, select an installation site where snow will

not affect the operation of the unit.

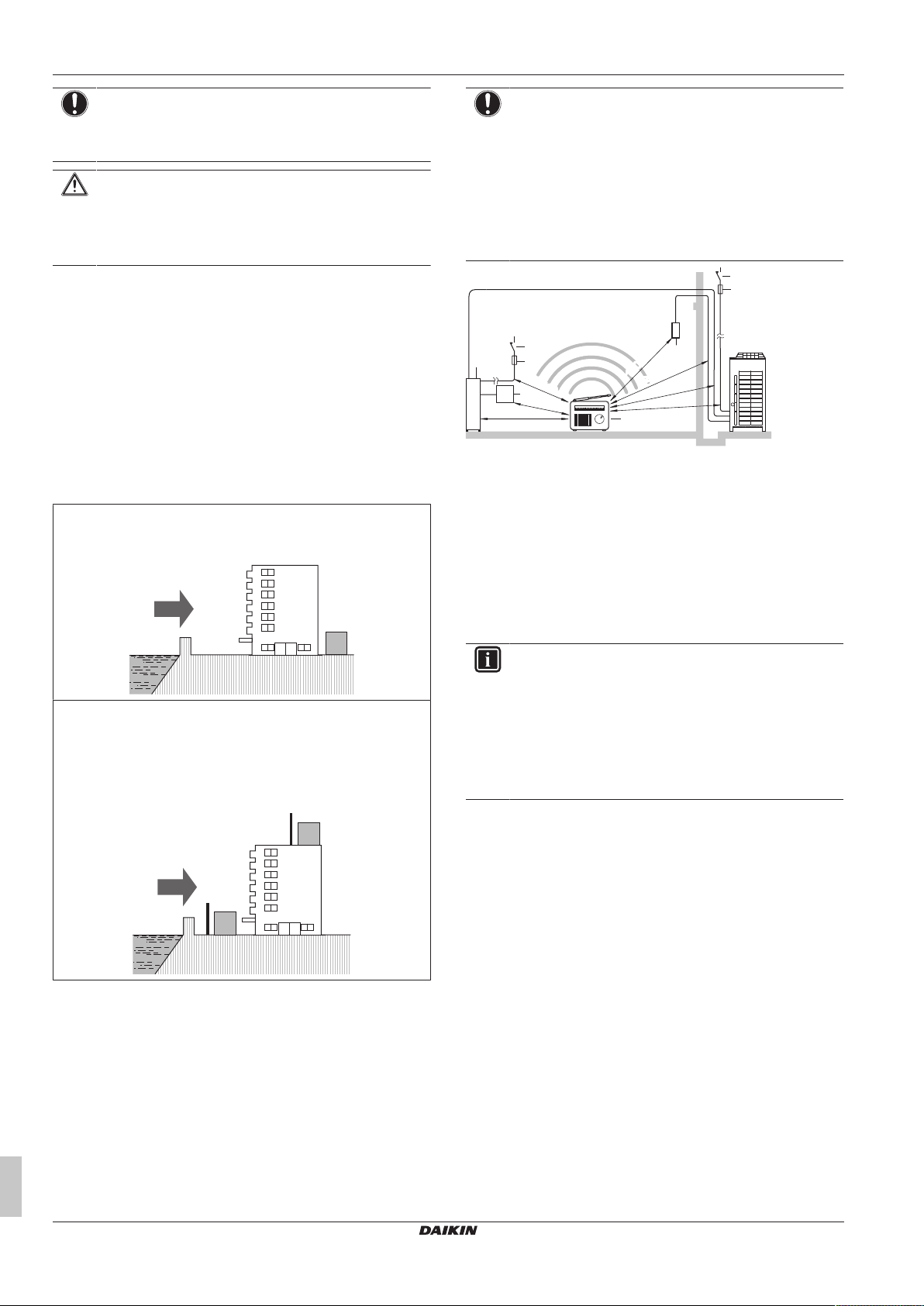

Seaside installation. Make sure the outdoor unit is NOT directly

exposed to sea winds. This is to prevent corrosion caused by high

levels of salt in the air, which might shorten the life of the unit.

Install the outdoor unit away from direct sea winds.

Example: Behind the building.

NOTICE

The equipment described in this manual may cause

electronic noise generated from radio-frequency energy.

The equipment complies to specifications that are

designed to provide reasonable protection against such

interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment and

electric wires keeping proper distances away from stereo

equipment, personal computers, etc.

a Personal computer or radio

b Fuse

c Earth leakage breaker

d Cool/heat selector

e User interface

f Indoor unit

▪ In places with weak reception, keep distances of 3m or more to

avoid electromagnetic disturbance of other equipment and use

conduit tubes for power and transmission lines.

If the outdoor unit is exposed to direct sea winds, install a

windbreaker.

▪ Height of windbreaker≥1.5×height of outdoor unit

▪ Mind the service space requirements when installing the

windbreaker.

a Sea wind

b Building

c Outdoor unit

d Windbreaker

Installer and user reference guide

12

5.2.2 Installation site requirements of the indoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Service space requirements. See the "Technical data"

chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the weight and vibration

of the unit.

▪ Make sure the unit is level.

▪ Select the location of the unit in such a way that the sound

generated by the unit does not disturb anyone, and the location is

selected according the applicable legislation.

▪ Take care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

▪ During installation, avoid the possibility that anybody can climb on

the unit or place objects on the unit.

▪ All piping lengths and distances have been taken into

consideration (see "5.3.3About the piping length"[413]).

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

5 Preparation

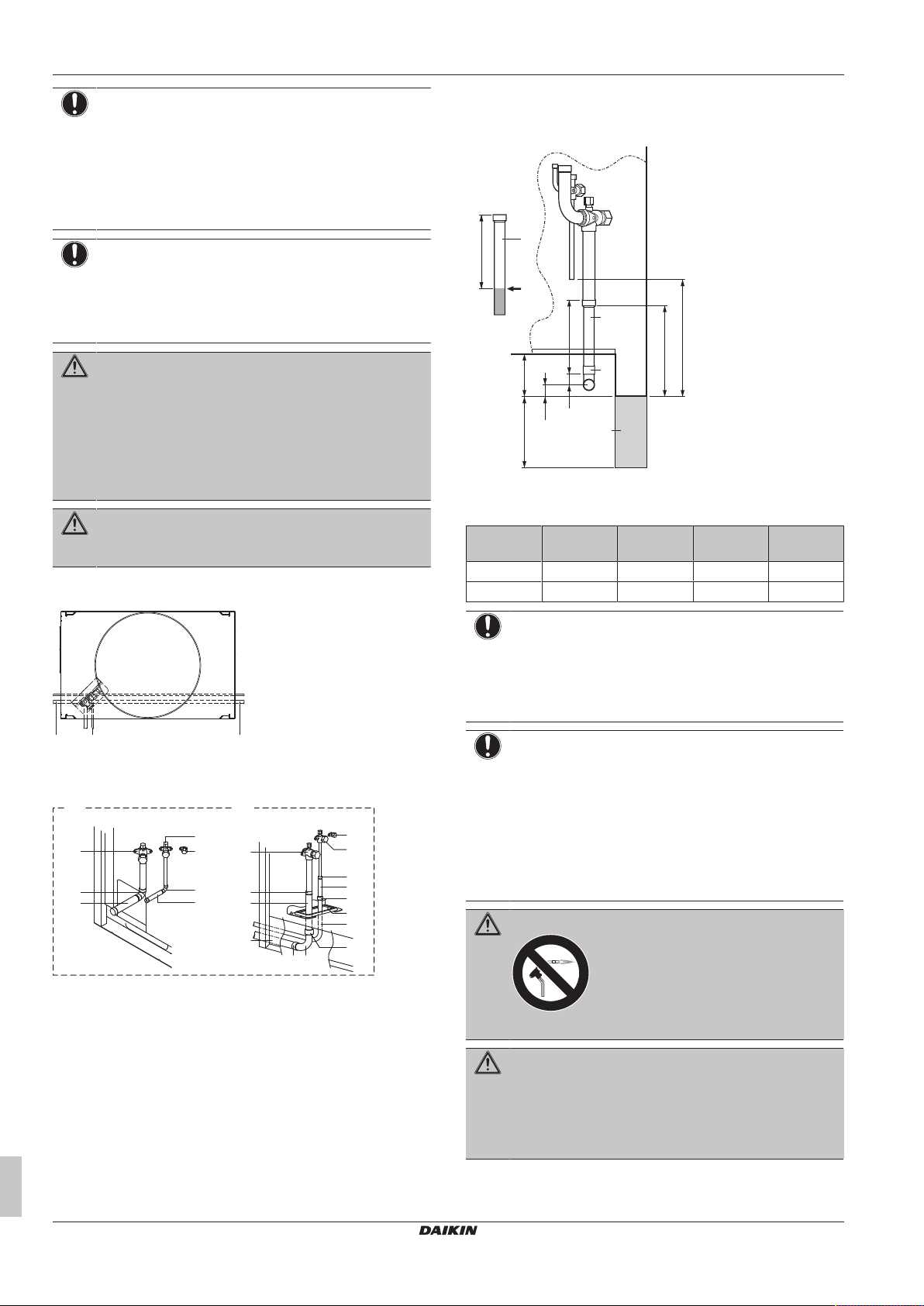

G

L

G1

L2

G2

L1

1

2

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

CAUTION

Appliance NOT accessible to the general public, install it in

a secured area, protected from easy access.

This unit is suitable for installation in a commercial and

light industrial environment.

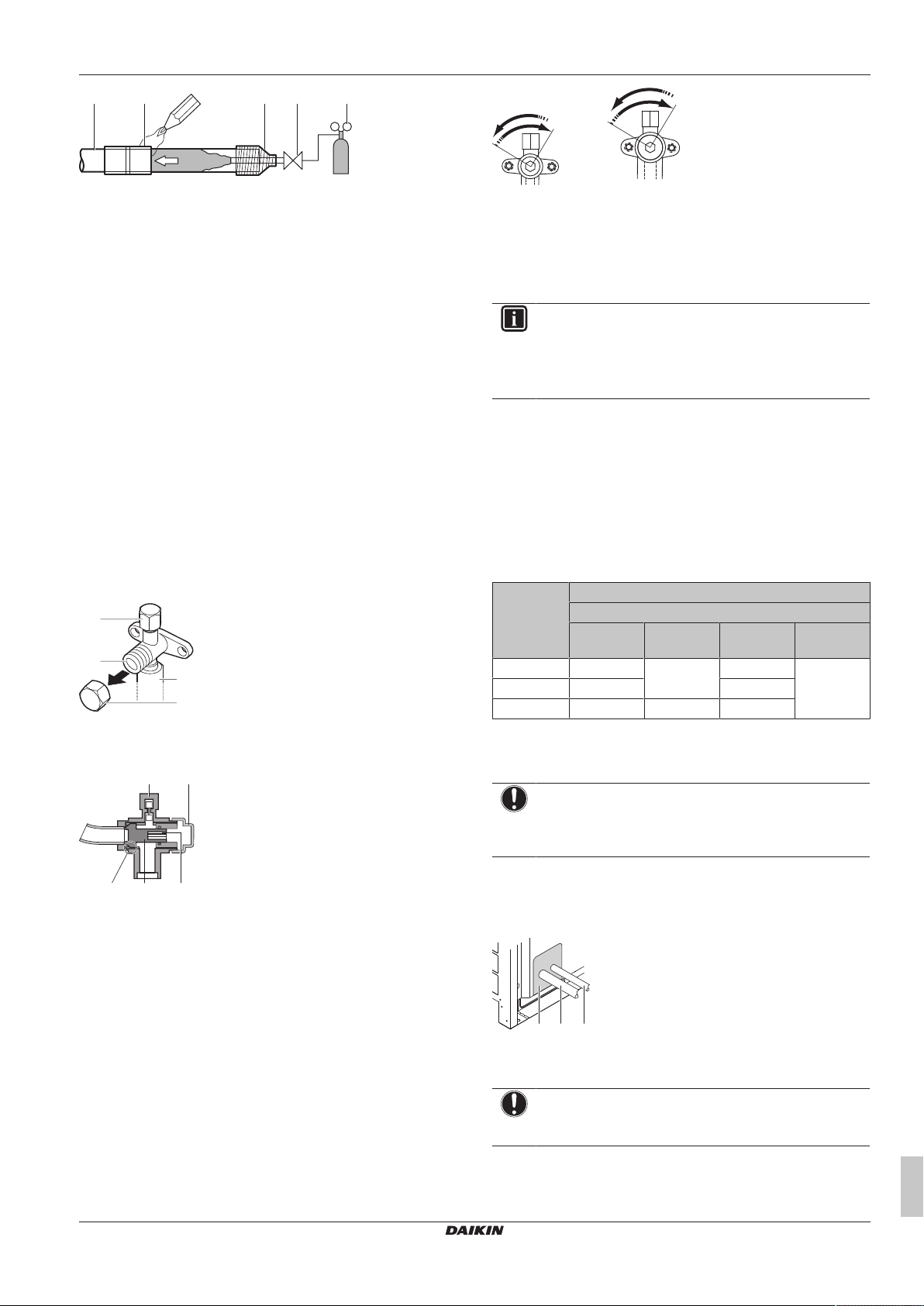

5.3 Preparing refrigerant piping

5.3.1 Refrigerant piping requirements

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

▪ Temper grade: use piping with temper grade in function of the

pipe diameter as listed in table below.

Pipe Ø Temper grade of piping material

≤15.9mm O (annealed)

≥19.1mm 1/2H (half hard)

▪ All piping lengths and distances have been taken into

consideration (see "5.3.3About the piping length"[413]).

▪ The pipe thickness of the refrigerant piping shall comply with the

applicable legislation. The minimal pipe thickness for R410A

piping must be in accordance with the table below.

Pipe Ø Minimal thickness t

6.4mm/9.5mm/12.7mm 0.80mm

15.9mm 0.99mm

19.1mm/22.2mm 0.80mm

28.6mm 0.99mm

34.9mm 1.21mm

41.3mm 1.43mm

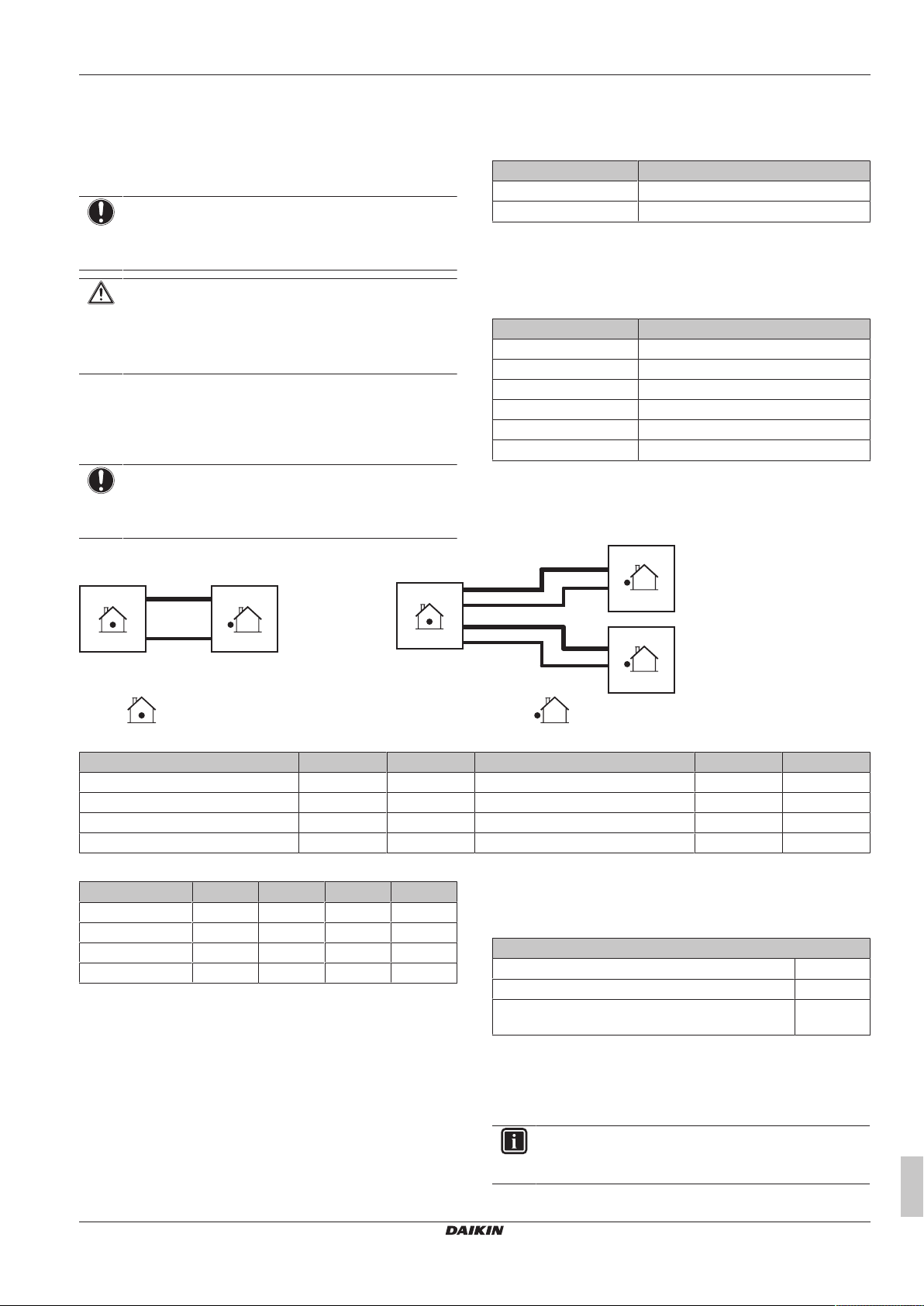

5.3.2 To select the piping size

Determine the proper size using the following tables and reference

figure (only for indication).

Indoor unit Outdoor unit

▪ Piping connection sizes

Indoor unit Gas Liquid Outdoor unit Gas Liquid

SEHVX20BAW Ø25.4mm Ø12.7mm 1× SERHQ020BAW1 Ø22.2mm Ø9.52mm

SEHVX32BAW Ø25.4mm Ø12.7mm 1× SERHQ032BAW1 Ø28.6mm Ø12.7mm

SEHVX40BAW Ø25.4mm Ø12.7mm 2× SERHQ020BAW1 Ø22.2mm Ø9.52mm

SEHVX64BAW Ø25.4mm Ø12.7mm 2× SERHQ032BAW1 Ø28.6mm Ø12.7mm

▪ Field piping sizes

Indoor unit G/G1 L/L1 G2 L2

SEHVX20BAW Ø28.6mm Ø9.52mm — —

SEHVX32BAW Ø28.6mm Ø12.7mm — —

SEHVX40BAW Ø28.6mm Ø9.52mm Ø28.6mm Ø9.52mm

SEHVX64BAW Ø28.6mm Ø12.7mm Ø28.6mm Ø12.7mm

If the hydro module connections do not match the diameter of the

specified piping requirements, the piping diameter requirements

must be met using reducers/expanders (field supply) on the hydro

module connections.

If the indoor unit connections do not match the diameter of the

specified piping requirements, the piping diameter requirements

must be met using reducers/expanders (field supply) on the indoor

unit connections.

Other diameters (mm sizes) can also be used if the required pipe

sizes (inch sizes) are not available, taking the following into account:

▪ select the pipe size nearest to the required size,

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

▪ use the suitable adapters for the change-over from inch to mm

pipes (field supply).

5.3.3 About the piping length

Maximum piping length and height difference

Maximum allowable piping length 30m

Height difference between indoor and outdoor unit <10m

Height difference between outdoor unit 1 and outdoor

unit 2 (if applicable)

0m

5.4 Preparing water piping

5.4.1 Water circuit requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

Installer and user reference guide

13

5 Preparation

a

b

a

c

d

b

NOTICE

In case of plastic pipes, make sure they are fully oxygen

diffusion tight according to DIN 4726. The diffusion of

oxygen into the piping can lead to excessive corrosion.

▪ Connecting piping – Legislation. Make all piping connections in

accordance with the applicable legislation and the instructions in

the "Installation" chapter, respecting the water inlet and outlet.

▪ Connecting piping – Force. Do NOT use excessive force when

connecting the piping. Deformation of the piping can cause

malfunctioning of the unit.

▪ Connecting piping – Tools. Only use appropriate tooling to

handle brass, which is a soft material. If NOT, pipes will get

damaged.

▪ Connecting piping – Air, moisture, dust. If air, moisture or dust

gets into the circuit, problems may occur. To prevent this:

▪ Only use clean pipes

▪ Hold the pipe end downwards when removing burrs.

▪ Cover the pipe end when inserting it through a wall, to prevent

dust and/or particles from entering the pipe.

▪ Use a decent thread sealant to seal connections.

Capacity class Minimum required flow rate

20 23 l/min

32 36 l/min

40 46 l/min

64 72 l/min

▪ Field supply components – Water pressure and temperature.

Check that all components in the field piping can withstand the

water pressure and water temperature.

▪ Drainage – Low points. Provide drain taps at all low points of the

system in order to allow complete drainage of the water circuit.

▪ Non-brass metallic piping. When using non-brass metallic

piping, insulate the brass and non-brass properly so that they do

NOT make contact with each other. This to prevent galvanic

corrosion.

▪ Shut-off valves. Two shut-off valves are delivered with the unit.

Install them as shown in the following figure.

NOTICE

If the bend is not used during installation, replace it with an

extension (5cm long for a 1¼"filter, and 6 cm long for a

2"filter) to ensure proper cleaning operation of the filter.

NOTICE

Be sure to install the filter properly. Failure to install or

incorrect installation will damage the plate heat exchanger

permanently.

▪ Drain taps. Drain taps must be provided at all low points of the

system to permit complete drainage of the circuit. A drain valve is

provided inside the unit.

▪ Air vents. Provide air vents at all high points of the system, which

must also be easily accessible for servicing. An automatic air

purge valve is provided inside the unit. Check that this air purge

valve is NOT tightened too much, so that automatic release of air

from the water circuit is possible. Refer to field setting[E‑04] in

Field settings on the remote controller.

▪ Air vents. Provide air vents at all high points of the system, which

must also be easily accessible for servicing. An automatic air

purge valve is provided inside the unit. Check that this air purge

valve is NOT tightened too much, so that automatic release of air

from the water circuit is possible. Refer to field setting[E‑04] in

"7.2.9Field settings on the user interface"[435].

▪ Water pressure. Take care that the components installed in the

field piping can withstand the water pressure (maximum 3 bar +

static pressure of the pump). Refer to ESP curve: Outdoor unit.

▪ Water pressure. Take care that the components installed in the

field piping can withstand the water pressure (maximum 3 bar +

static pressure of the pump). Refer to ESP curve: Indoor unit.

WARNING

▪ For correct operation of the system, a regulating valve

must be installed in the water system. The regulating

valve is to be used to regulate the water flow in the

system (field supply).

▪ Selecting a flow outside the curves can cause

malfunction or damage to the unit. Also refer to the

Technical specifications.

▪ The maximum water piping temperature is 50°C according to

safety device setting.

▪ Always use materials which are compatible with the water used in

the system and with the materials used in the unit. (The unit piping

fittings are made of brass, the plate heat exchangers are made of

stainless steel 316 plates brazed together with copper and the

optional pump housing is made of cast iron.)

▪ Select the piping diameter in relation to the required water flow

and available external static pressure (ESP) of the pump. See the

following table for the recommended water piping diameter.

Capacity class Water piping diameter

20+32 1-1/4"

40+64 2"

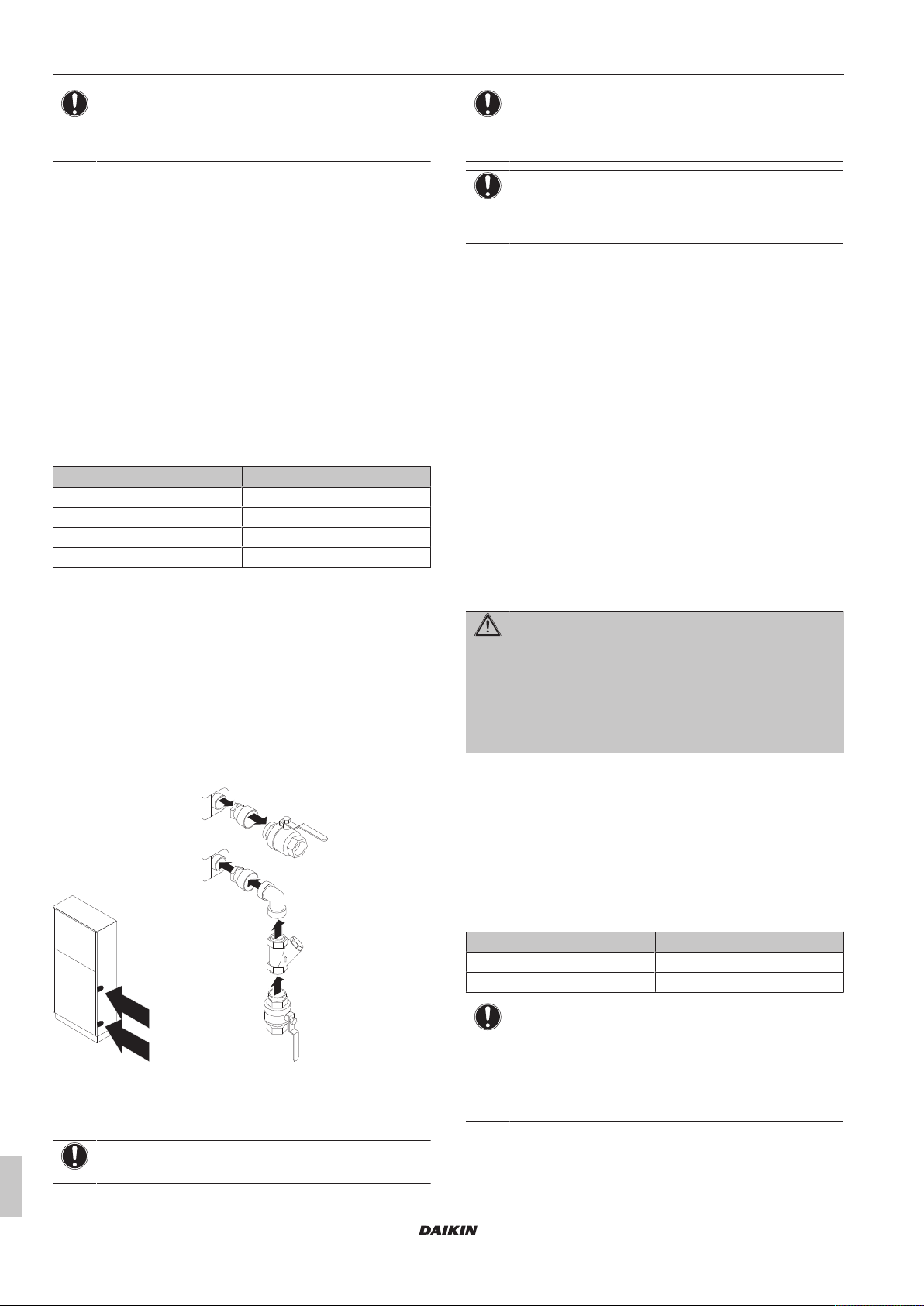

a Adapter piece (on the inlet only in case of

SEHVX40+64BAW)

b Shut-off valve

c Bend

d Filter

NOTICE

Before mounting the bend, attach the filter to it.

Installer and user reference guide

14

NOTICE

It is strongly recommended to install an additional filter on

the water circuit. Especially to remove metallic particles

from the field water piping, it is advised to use a magnetic

or cyclone filter which can remove small particles. Small

particles can damage the unit and will not be removed by

the standard filter of the unit.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

5 Preparation

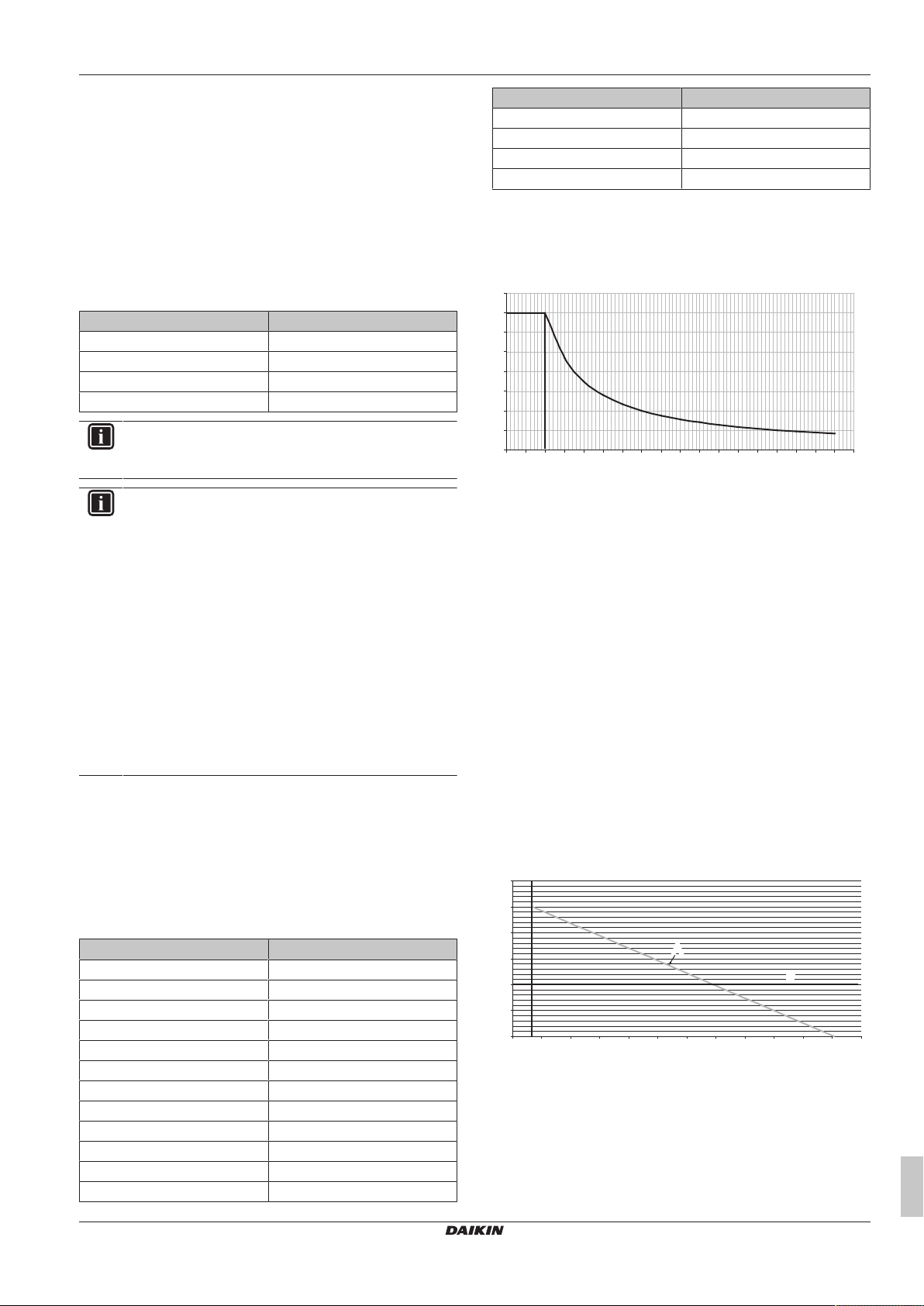

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5

9

a

b

0

0.5

1

1.5

2

2.5

3

0 50 100 150 200 250 300 350 400 450 500 550 600

A

B

33

b

a

5.4.2 Formula to calculate the expansion vessel pre-pressure

The pre-pressure (Pg) of the vessel depends on the installation

height difference (H):

Pg=0.3+(H/10) (bar)

5.4.3 To check the water volume and expansion vessel pre-pressure

The unit has an expansion vessel of 12 litre with a default prepressure of 1bar.

Minimum water volume

Model Minimum total water volume (l)

20 76

32 110

40 152

64 220

INFORMATION

In critical processes, or in rooms with a high heat load,

extra water might be required.

INFORMATION

The temperature step difference can be modified using

settings [A‑02] and [F‑00]. This has an impact on the

minimum water volume required when the unit operates in

cooling.

By default, the unit is set to have a water temperature

difference of 3.5 K which allows it to operate with the

minimum volume mentioned in the previous table.

However, if a smaller temperature differential is set, as in

the case of process cooling applications where

temperature fluctuations must be avoided, a larger

minimum water volume will be required.

To ensure proper operation of the unit when changing the

values of setting [F‑00] (for cooling mode), the minimum

water volume has to be corrected. If this volume exceeds

the range allowed in the unit, an additional expansion

vessel or a buffer tank must be installed in the field piping.

Example:

To illustrate the impact on the system when modifying the setting

[F‑00], we will consider a unit with a minimum allowable water

volume of 66l. The unit is installed 5m below the highest point in

the water circuit.

Assuming that the setting [F‑00] is changed from 5°C (default value)

to 0°C. From the below table we see that 5°C corresponds to a

temperature differential of 3.5K and 0°C to 1K, which is actually the

lowest value we can set.

[F‑00] value (°C) Temperature differential (K)

0 1

1 1.5

2 2

3 2.5

4 3

5 3.5

6 4

7 4.5

8 5

9 5.5

10 6

11 6.5

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

[F‑00] value (°C) Temperature differential (K)

12 7

13 7.5

14 8

15 8.5

The water volume correction factor according to the curve shown in

the below graph is 3.5; this means that the minimum volume will be

3.5 times larger.

Correction factor curve for minimum water volume

a Water volume correction factor

b Temperature differential (K)

When multiplying 64 l by the correction factor, we get 224 l, which

will be the minimum water volume allowed in the installation if a

temperature differential of 1K is used.

Now it is very important to check that for the height difference of the

system, the volume in the system is less than the maximum allowed

value at that pre-pressure (Pg). If we take a look at the curve, for

1bar of pre-pressure, the maximum volume allowed is 350l.

The total volume in the system will definitely be larger after adding

the internal volume of the unit. In this case, some pre-pressure can

be applied or an additional expansion vessel or buffer tank must be

installed in the field piping.

The default value of pre-pressure (Pg) is for a height difference of

7m.

If the height difference of the system is lower than 7 m AND the

volume in the system is less than the maximum allowed value at that

pre-pressure (Pg) (see graph), then NO pre-pressure (Pg)

adjustment is required.

Maximum water volume

Use the following graph to determine the maximum water volume for

the calculated pre-pressure.

a Pre-pressure (bar)

b Maximum water volume (l)

A System

B Default

If the total water volume in the entire circuit exceeds the maximum

allowed water volume (see graph), an additional expansion vessel

must be installed in the field piping.

Installer and user reference guide

15

5 Preparation

a

5.4.4 Changing the pre-pressure of the expansion vessel

NOTICE

Only a licensed installer may adjust the pre-pressure of the

expansion vessel.

The default pre-pressure of the expansion vessel is 1bar. When it is

required to change the pre-pressure, take following guidelines into

account:

▪ Only use dry nitrogen to set the expansion vessel pre-pressure.

▪ Inappropriate setting of the expansion vessel pre-pressure will

lead to malfunction of the system.

Changing the pre-pressure of the expansion vessel should be done

by releasing or increasing nitrogen pressure through the Schrader

valve of the expansion vessel.

WARNING

▪ If the power supply has a missing or wrong N-phase,

equipment might break down.

▪ Establish proper earthing. Do NOT earth the unit to a

utility pipe, surge absorber, or telephone earth.

Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the

cables do NOT come in contact with sharp edges or

piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires,

extension cords, or connections from a star system.

They can cause overheating, electrical shock or fire.

▪ Do NOT install a phase advancing capacitor, because

this unit is equipped with an inverter. A phase

advancing capacitor will reduce performance and may

cause accidents.

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

a Schrader valve

5.4.5 To check the water volume: Examples

Example 1

The unit is installed 5m below the highest point in the water circuit.

The total water volume in the water circuit is 250l.

No actions or adjustments are required.

Example 2

The unit is installed at the highest point in the water circuit. The total

water volume in the water circuit is 420l.

Actions:

▪ Because the total water volume (420 l) is more than the default

water volume (340l), the pre-pressure must be decreased.

▪ The required pre-pressure is:

Pg = (0.3+(H/10))bar = (0.3+(0/10))bar = 0.3bar

▪ The corresponding maximum water volume is approximately 490l

(see graph).

▪ Because 420 l is lower than 490 l, the expansion vessel is

appropriate for the installation.

5.5 Preparing electrical wiring

5.5.1 About preparing electrical wiring

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

WARNING

ALWAYS use multicore cable for power supply cables.

5.5.2 About electrical compliance

This equipment complies with:

▪ EN/IEC 61000‑3‑11 provided that the system impedance Z

less than or equal to Z

at the interface point between the user's

max

supply and the public system.

▪ EN/IEC 61000‑3‑11 = European/International Technical

Standard setting the limits for voltage changes, voltage

fluctuations and flicker in public low-voltage supply systems for

equipment with rated current ≤75A.

▪ It is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator if

necessary, that the equipment is connected only to a supply

with a system impedance Z

less than or equal to Z

sys

max

▪ EN/IEC 61000‑3‑12 provided that the short-circuit power Ssc is

greater than or equal to the minimum Ssc value at the interface

point between the user's supply and the public system.

▪ EN/IEC 61000‑3‑12 = European/International Technical

Standard setting the limits for harmonic currents produced by

equipment connected to public low-voltage systems with input

current >16A and ≤75A per phase.

▪ It is the responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network operator if

necessary, that the equipment is connected only to a supply

with a short-circuit power Ssc greater than or equal to the

minimum Ssc value.

Outdoor unit Z

(Ω) Minimum Ssc value

max

(kVA)

SERHQ020BAW1 0.27 838

SERHQ032BAW1 0.24 873

is

sys

.

Installer and user reference guide

16

Indoor unit Z

(Ω) Minimum Ssc value

max

(kVA)

SEHVX20BAW 0.27 820

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

6 Installation

4×

4×

Indoor unit Z

(Ω) Minimum Ssc value

max

(kVA)

SEHVX32BAW 0.24 874

SEHVX40BAW 0.25 1639

SEHVX64BAW 0.22 1747

The local wiring power cord must comply with IEC60245.

The wiring type in protected pipes must be H05VV; H07RN-F must

be used in unprotected pipes.

5.5.3 Cable requirements

Item Cable

bundle

1 PS Indoor unit power supply 4+GND

2 LV Communication cable between indoor

3 LV Standard remote controller (F1/F2) 2

4 LV Secondary remote controller (F1/F2)

5 LV Thermostat ON/OFF signal

6 LV Thermostat cooling/heating signal

7 LV Operation ON signal

8 LV Operation OFF signal

9 HV Cooling/heating output 2 0.3 A

10 HV Operation ON/OFF output 2 0.3 A

11 HV Error output 2 0.3 A

12 HV Water piping heater output 2 1 A

13 HV Pump ON/OFF output 2 0.3 A

unit and outdoor unit

(a) Optional

(b) Refer to the nameplate on the unit or to the technical data

book.

(c) Minimum cable section 0.75mm2.

(d) Minimum cable section 1.5mm2.

PS Power supply

LV Low voltage

HV High voltage

Description Required

(a)

(a)

(a)

(a)

(a)

number of

conductors

(d)

2

2

2

2

2

2

Maximum

running

current

(b)

(d)

(c)

(c)

(c)

(c)

(c)

(c)

5.5.4 Safety device requirements

The power supply must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage protector in accordance with the applicable legislation.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table below.

6 Installation

6.1 Overview: Installation

This chapter describes what you have to do and know on-site to

install the system.

Typical workflow

Installation typically consists of the following stages:

1 Mounting the outdoor unit.

2 Mounting the indoor unit.

3 Connecting the refrigerant piping.

4 Checking the refrigerant piping.

5 Charging refrigerant.

6 Connecting the water piping.

7 Connecting the electrical wiring.

6.2 Opening the units

6.2.1 About opening the units

At certain times, you have to open the unit. Example:

▪ When connecting the electrical wiring

▪ When maintaining or servicing the unit

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover

is removed.

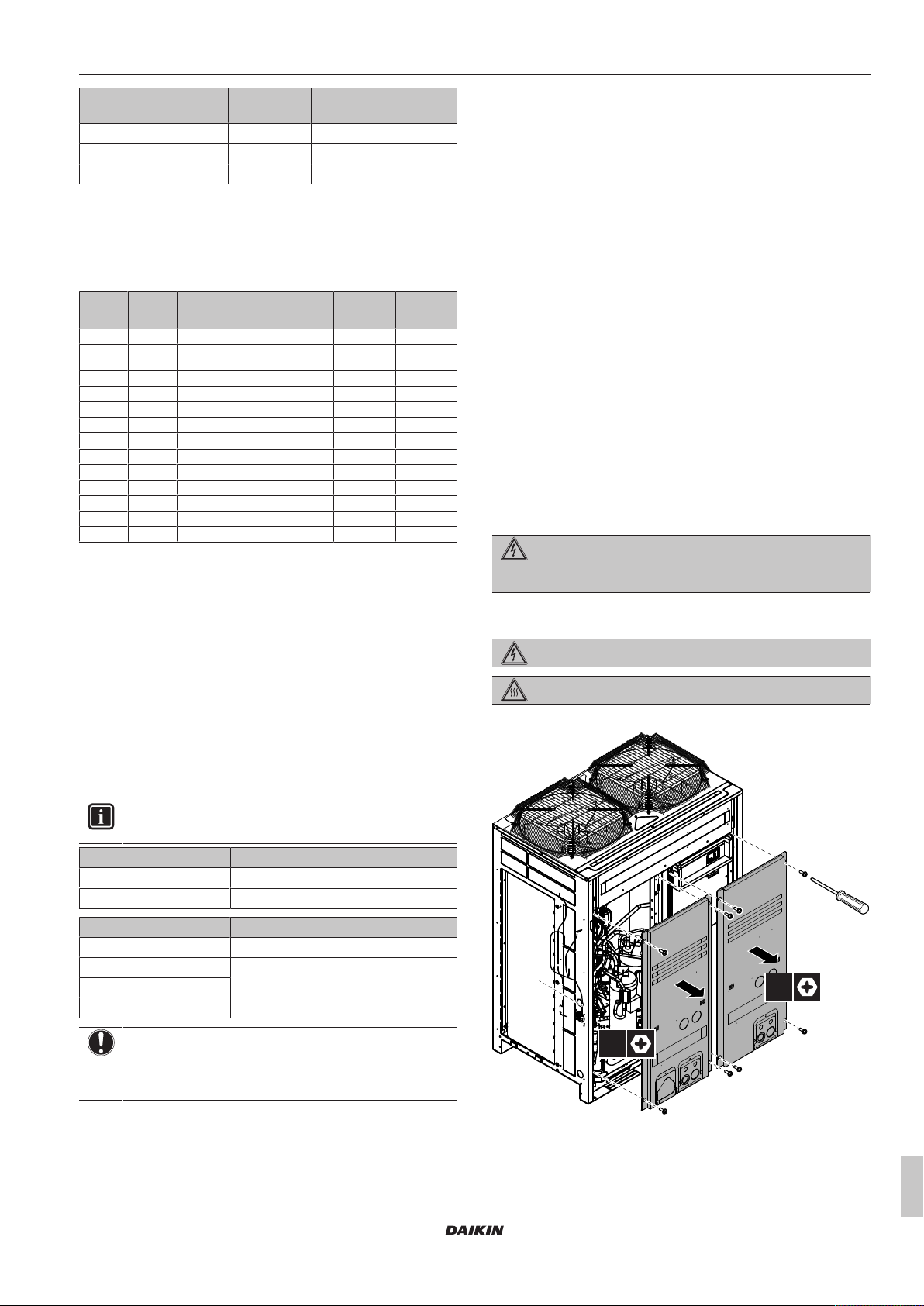

6.2.2 To open the outdoor unit

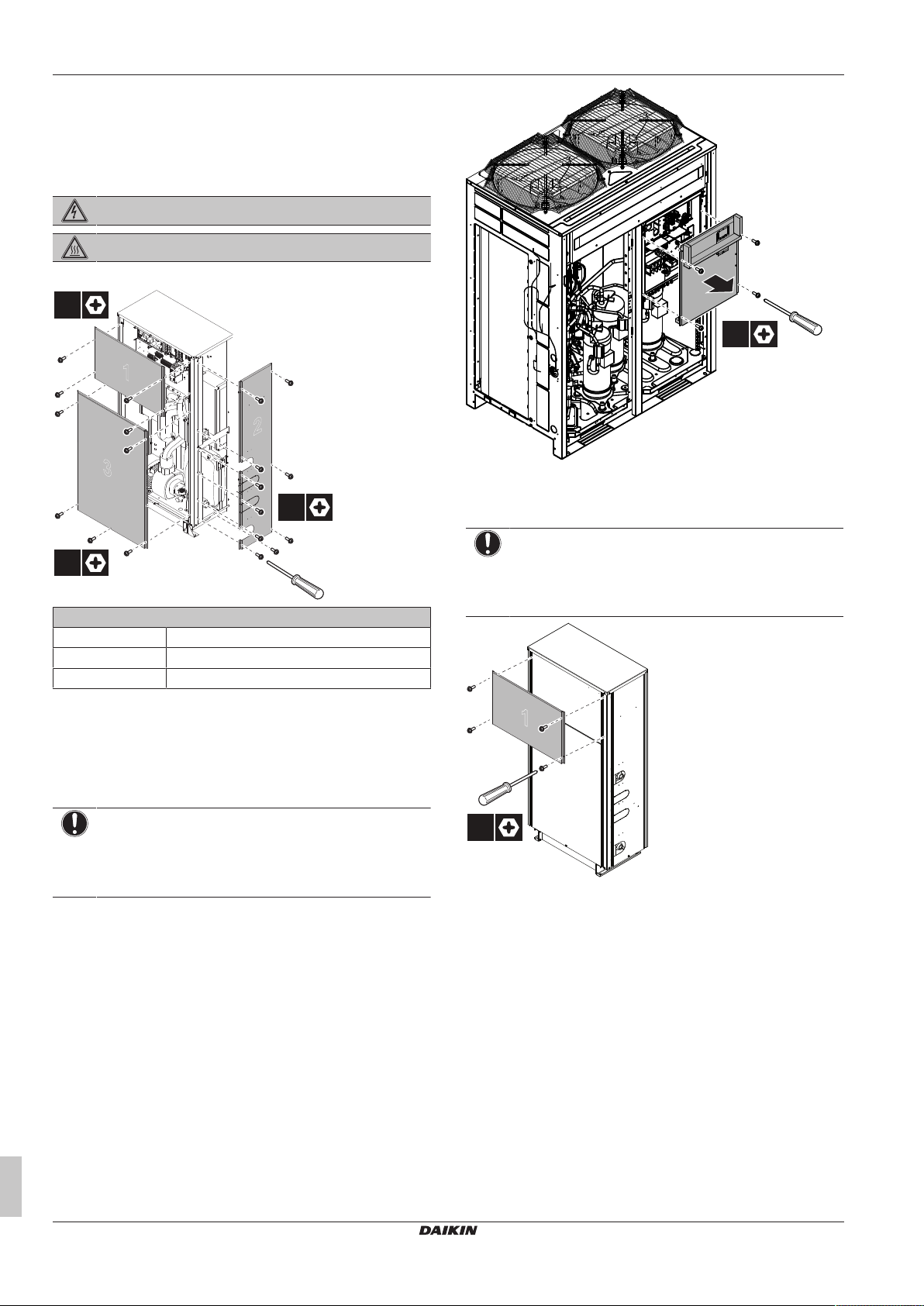

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

To gain access to the unit, front plates need to be opened as follows:

INFORMATION

Multi units are standard combinations.

Outdoor unit Recommended fuses

SERHQ020BAW1 32A

SERHQ032BAW1 40A

Indoor unit Recommended fuses

SEHVX20BAW 6A

SEHVX32BAW 10A

SEHVX40BAW

SEHVX64BAW

NOTICE

When using residual current operated circuit breakers, be

sure to use a high-speed type 300 mA rated residual

operating current.

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

Once the front plates open, the electrical component box can be

accessed. See "6.2.4 To open the electrical component box of the

outdoor unit"[418].

Installer and user reference guide

17

6 Installation

1

3

2

10×

5×

4×

4×

1

4×

For service purposes, the pushbuttons on the main PCB need to be

accessed. To access these pushbuttons, the electrical component

box cover does not need to be opened. See "7.2.3To access the

field setting components"[433].

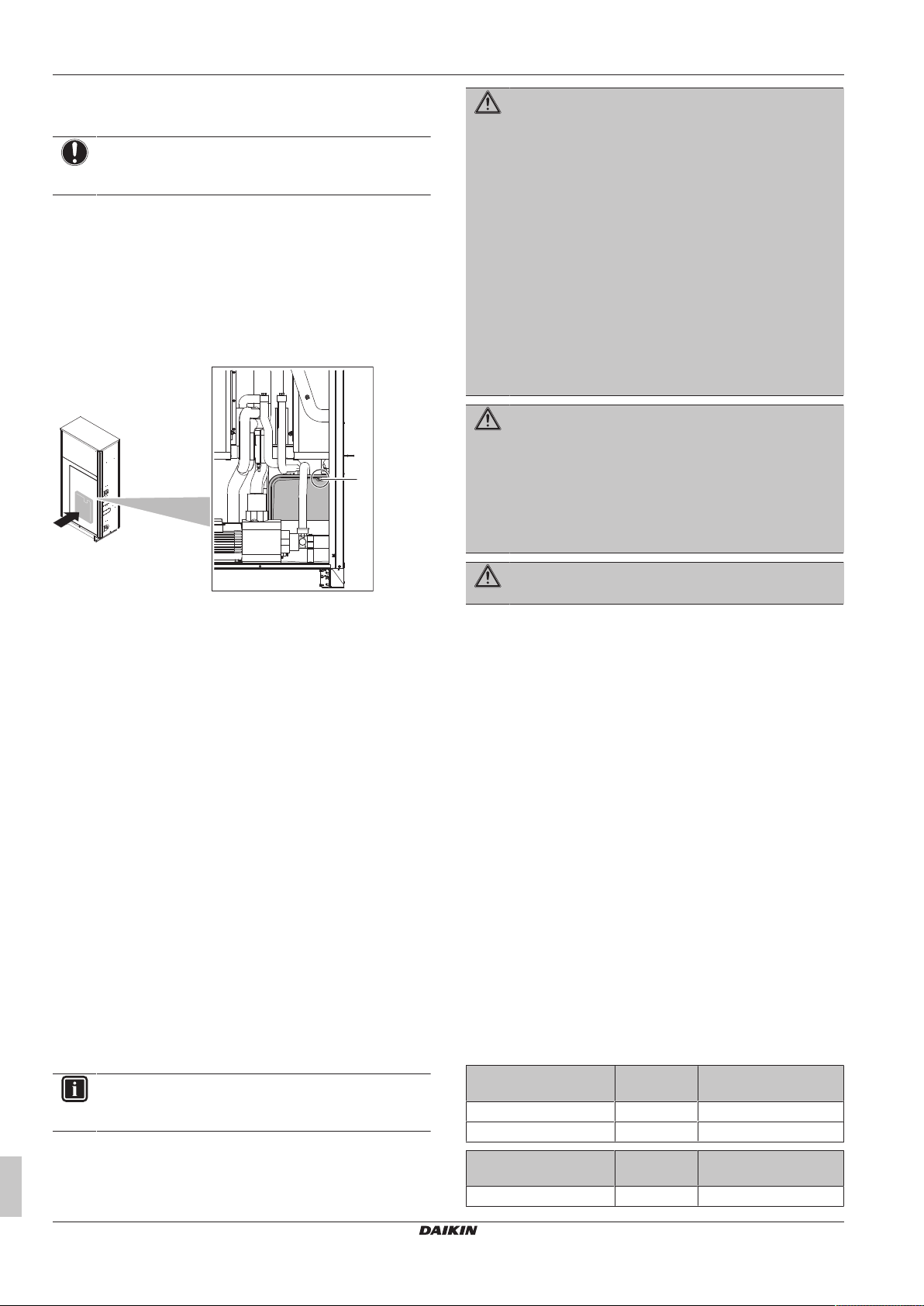

6.2.3 To open the indoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

To gain access to the unit, front plates need to be opened as follows:

6.2.5 To open the electrical component box of the indoor unit

Panel

1 Electrical parts of the indoor unit

2 Indoor unit (side panel)

3 Indoor unit (front panel)

Once the front plates open, the electrical component box can be

accessed. See "6.2.5 To open the electrical component box of the

indoor unit"[418].

6.2.4 To open the electrical component box of the outdoor unit

NOTICE

Do NOT apply excessive force when opening the

electronic component box cover. Excessive force can

deform the cover, resulting in entering of water to cause

equipment failure.

NOTICE

Do NOT apply excessive force when opening the

electronic component box cover. Excessive force can

deform the cover, resulting in entering of water to cause

equipment failure.

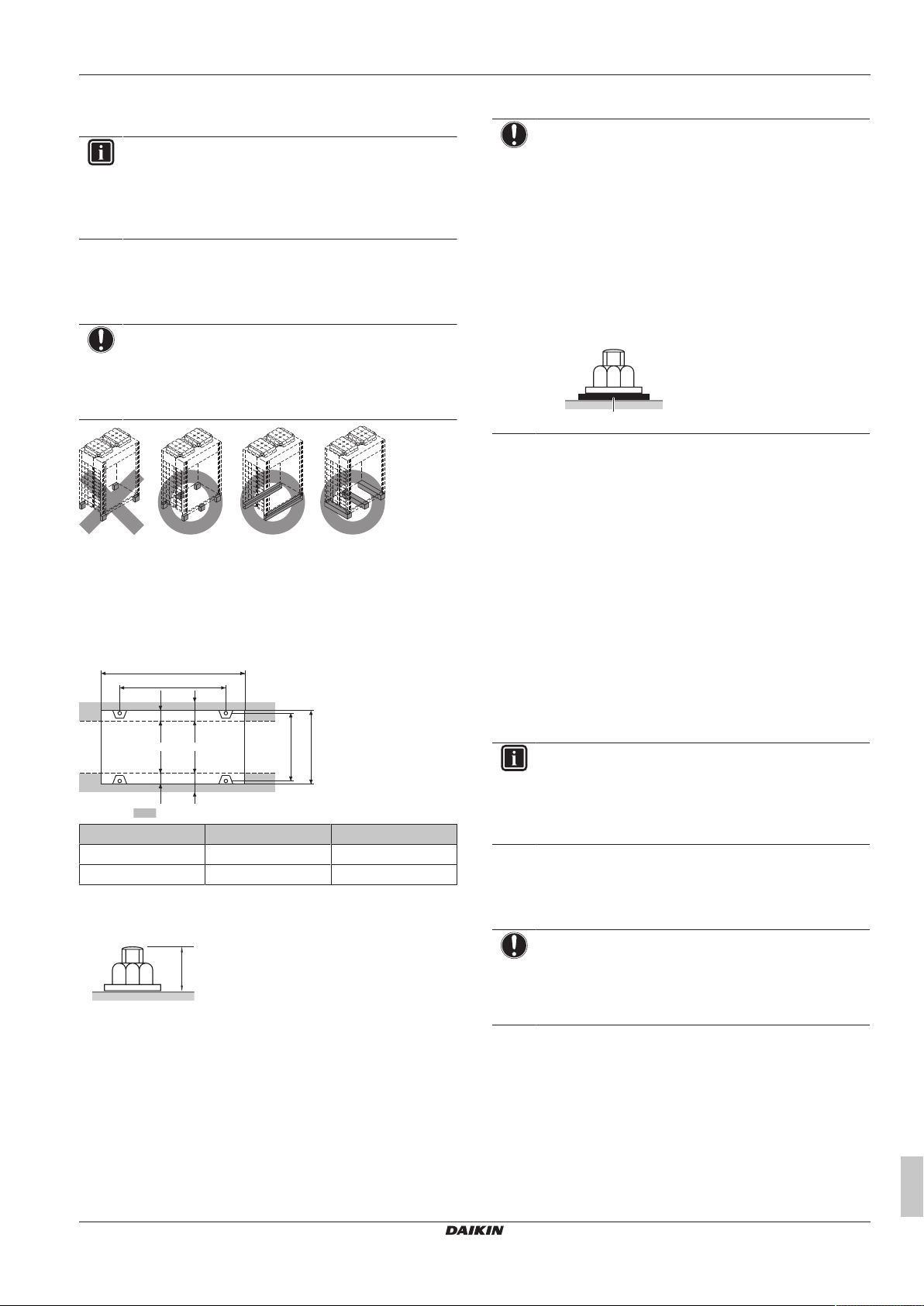

6.3 Mounting the outdoor unit

6.3.1 About mounting the outdoor unit

When

You have to mount the outdoor and indoor unit before you can

connect the refrigerant and water piping.

Typical workflow

Mounting the outdoor unit typically consists of the following stages:

1 Providing the installation structure.

2 Installing the outdoor unit.

3 Providing drainage.

Installer and user reference guide

18

SERHQ020~032BAW1 + SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1C – 2019.11

6 Installation

722-737

≥67≥67