Daikin FCQ45EVA, FCQ24EVA, RZQ45LVA, FBQ20EVA, FBQ24EVA Service Manual

...

Service

Manual

RZQ Series

Heat Pump R410A 60Hz

RZQ20 / 24 / 36 / 45LVA

RZQ45 / 48MYL

SiME281501E

TopAir RZQ Series

ED Reference

For items below, please refer to Engineering Data.

No. Item ED No. Page Remarks

1 Specification EDTW281313A P. 9-22

2 Option List EDTW281313A P. 70-72

SiME281501E

Heat Pump

R410A 60Hz

1. Introduction ............................................................................................iv

1.1 Safety Cautions ....................................................................................... iv

1.2 Used Icons ............................................................................................ viii

Part 1 General Information ........................................................... 1

1. Model Name of Indoor / Outdoor Units ...................................................2

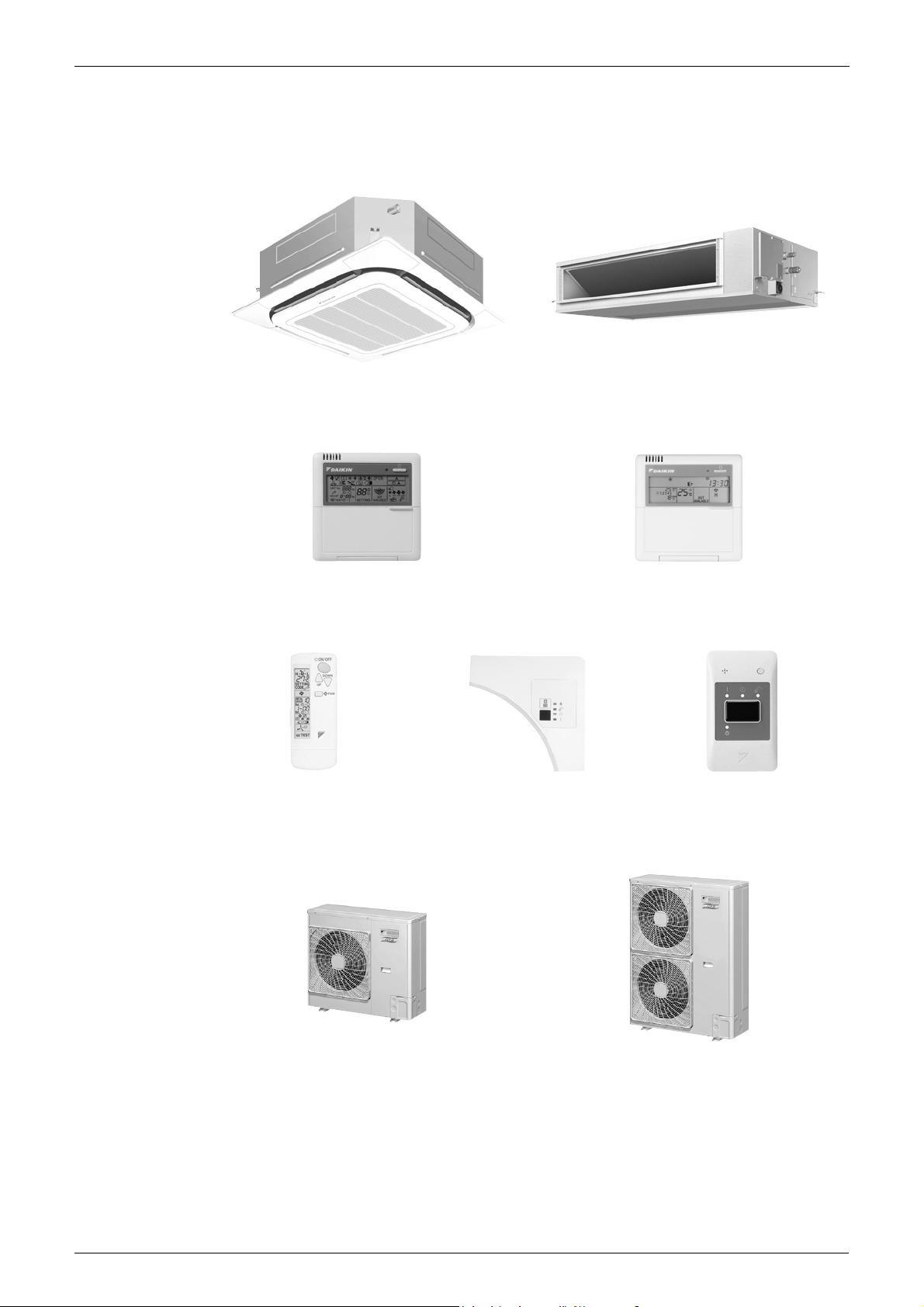

2. External Appearance...............................................................................3

Part 2 Functions ............................................................................4

1. Functions.................................................................................................5

Part 3 Remote Controller .............................................................. 6

1. Wired Remote Controller.........................................................................7

1.1 Applicable Models ....................................................................................7

1.2 Names and Functions ..............................................................................8

1.3 MAIN/SUB Setting when Using 2 Remote Controllers ...........................11

1.4 Centralized Control Group No. Setting...................................................12

2. Wireless Remote Controller ..................................................................13

2.1 Applicable Models ..................................................................................13

2.2 Names and Functions ............................................................................13

2.3 Address and MAIN/SUB Setting.............................................................15

3. Service Mode ........................................................................................17

3.1 BRC1C61/BRC1D61 ..............................................................................17

Part 4 Function and Control........................................................ 19

1. Functions of Main Components and Thermistors .................................20

2. Function Outline ....................................................................................23

2.1 Indoor Unit..............................................................................................23

3. Operation Flow Chart ............................................................................25

3.1 Cooling / Dry Operation..........................................................................25

3.2 Heating Operation ..................................................................................26

i Table of Contents

SiME281501E

4. Function Details ....................................................................................27

4.1 Indoor Unit..............................................................................................27

4.2 Outdoor Unit ...........................................................................................32

Part 5 Field Setting ..................................................................... 48

1. Test Operation ......................................................................................49

1.1 Check Items before the Test Operation .................................................49

1.2 Test Operation........................................................................................49

2. Field Setting from Remote Controller....................................................51

2.1 Wired Remote Controller........................................................................51

2.2 Wireless Remote Controller ...................................................................52

2.3 Setting Contents and Code No. for Indoor Units ....................................53

2.4 Setting Contents and Code No. for Outdoor Units .................................57

3. Field Setting from Outdoor Unit PCB ....................................................60

3.1 Location of DIP Switch and BS Button...................................................60

3.2 Field Setting for Outdoor Unit.................................................................61

4. Emergency Operation ...........................................................................67

4.1 Forced Operation ...................................................................................67

4.2 Emergency Operation when the Remote Controller is Lost ...................68

Part 6 Service Diagnosis............................................................. 69

1. Maintenance Inspection ........................................................................71

1.1 Overview ................................................................................................71

2. Symptom-based Troubleshooting .........................................................74

2.1 Overview ................................................................................................74

2.2 Equipment does not Operate .................................................................75

2.3 Indoor Unit Fan Operates, but Compressor does not Operate ..............76

2.4 Cooling / Heating Operation Starts but Stops Immediately ....................77

2.5 After Unit Shuts Down, It cannot be Restarted for a While ....................78

2.6 Equipment Operates but does not Provide Cooling ...............................80

2.7 Equipment Operates but does not Provide Heating...............................81

2.8 Equipment Discharges White Mist .........................................................82

2.9 Equipment Produces Loud Noise or Vibration .......................................83

2.10 Equipment Discharges Dust ...................................................................84

2.11 Remote Controller LCD Displays "88" ....................................................84

3. Troubleshooting by LED Indications .....................................................85

3.1 Troubleshooting by LED on the Indoor Unit ...........................................85

3.2 Troubleshooting by LED on Outdoor Unit PCB......................................85

4. Troubleshooting by Remote Controller .................................................86

4.1 Procedure of Self-diagnosis by Remote Controller ................................86

4.2 Error Codes and Description ..................................................................89

4.3 Safety Devices .......................................................................................90

4.4 Error of External Protection Device ........................................................91

4.5 Indoor Unit PCB Abnormality .................................................................92

4.6 Drain Water Level System Abnormality..................................................93

4.7 Indoor Unit Fan Motor Abnormality ........................................................95

4.8 Swing Flap Motor Abnormality / Lock.....................................................96

4.9 Abnormal Power Supply Voltage............................................................98

4.10 Drain System Abnormality ......................................................................99

4.11 Capacity Setting Abnormality ...............................................................100

Table of Contents ii

SiME281501E

4.12 Transmission Error between Indoor Unit PCB and Fan PCB ...............101

4.13 Thermistor Abnormality ........................................................................103

4.14 Combination Error between Indoor Unit PCB and Fan PCB ................104

4.15 Humidity Sensor System Abnormality ..................................................105

4.16 Room Temperature Thermistor in Remote Controller Abnormality ......106

4.17 Outdoor Unit PCB Abnormality.............................................................107

4.18 High Pressure Abnormality (Detected by the High Pressure Switch)...108

4.19 Low Pressure Abnormality ...................................................................110

4.20 Compressor Motor Lock .......................................................................112

4.21 Outdoor Unit Fan Motor Abnormality....................................................114

4.22 Electronic Expansion Valve Abnormality ..............................................116

4.23 Discharge Pipe Temperature Control Error ..........................................119

4.24 High Pressure Switch System Abnormality ..........................................121

4.25 Thermistor System Abnormality ...........................................................122

4.26 Pressure Sensor Abnormality...............................................................123

4.27 Outdoor Unit PCB Abnormality.............................................................124

4.28 Radiation Fin Temperature Rise ..........................................................126

4.29 DC Output Overcurrent ........................................................................128

4.30 Electronic Thermal (Time Lag) .............................................................130

4.31 Stall Prevention (Time Lag)..................................................................132

4.32 Transmission Error between Control and Inverter PCB .......................134

4.33 Transmission Error between Control and Inverter PCB .......................135

4.34 Open Phase or Power Supply Voltage Imbalance ...............................137

4.35 Radiation Fin Thermistor (R10T) or Related Abnormality ....................138

4.36 Defective Capacity Setting ...................................................................139

4.37 Refrigerant Shortage (Error).................................................................140

4.38 Refrigerant Shortage ............................................................................141

4.39 Power Supply Voltage Abnormality ......................................................142

4.40 Transmission Error between Indoor Unit and Outdoor Unit .................143

4.41 Transmission Error between Indoor Unit and Remote Controller.........146

4.42 Transmission Error between MAIN Remote Controller

and SUB Remote Controller.................................................................147

4.43 Field Setting Switch Abnormality ..........................................................148

4.44 Centralized Address Setting Error ........................................................150

4.45 Transmission Error between Indoor and Outdoor Unit /

Piping and Wiring Mismatch / Refrigerant Shortage ............................151

4.46 Check ...................................................................................................152

Part 7 Appendix......................................................................... 166

1. Wiring Diagrams..................................................................................167

1.1 Indoor Units ..........................................................................................167

1.2 Outdoor Units .......................................................................................169

iii Table of Contents

SiME281501E Introduction

1. Introduction

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “ Warning” and “ Caution”. The “ Warning”

items are especially important since they can lead to death or serious injury if they are not

followed closely. The “ Caution” items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

About the pictograms

This symbol indicates the item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates the prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates the action that must be taken, or the instruction.

The instruction is shown in the illustration or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer.

1.1.1 Cautions Regarding Safety of Workers

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for repair.

Working on the equipment that is connected to the power supply may cause an

electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas is discharged during the repair work, do not touch the

discharged refrigerant gas.

The refrigerant gas may cause frostbite.

Warning

When disconnecting the suction or discharge pipe of the compressor at the

welded section, evacuate the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it may

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas may generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor may cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging the

power cable plug.

Plugging or unplugging the power cable plug to operate the equipment may

cause an electrical shock or fire.

iv

Introduction SiME281501E

Warning

Be sure to wear a safety helmet, gloves, and a safety belt when working at a

high place (more than 2 m). Insufficient safety measures may cause a fall

accident.

In case of R410A refrigerant models, be sure to use pipes, flare nuts and tools

for the exclusive use of the R410A refrigerant.

The use of materials for R22 refrigerant models may cause a serious accident

such as a damage of refrigerant cycle as well as an equipment failure.

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water may cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shocks.

Be sure to turn OFF the power switch and unplug the power cable when

cleaning the equipment.

The internal fan rotates at a high speed, and cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

Be sure to check that the refrigerating cycle section has cooled down enough

before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room may cause oxygen deficiency.

v

SiME281501E Introduction

1.1.2 Cautions Regarding Safety of Users

Warning

Be sure to use parts listed in the service parts list of the applicable model and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances, since it may cause an electrical shock,

excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and follow the local

technical standards related to the electrical equipment, the internal wiring

regulations, and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work may cause an

electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and outdoor

units. Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

When wiring between the indoor and outdoor units, make sure that the terminal

cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable may cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable

may damage the cable.

Do not mix air or gas other than the specified refrigerant (R410A / R22) in the

refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leaking point and repair it

before charging the refrigerant. After charging refrigerant, make sure that there

is no refrigerant leak.

If the leaking point cannot be located and the repair work must be stopped, be

sure to perform pump down and close the service valve, to prevent the

refrigerant gas from leaking into the room. The refrigerant gas itself is

harmless, but it may generate toxic gases when it contacts flames, such as fan

and other heaters, stoves and ranges.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment may fall and cause injury.

vi

Introduction SiME281501E

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert

the plug into a power outlet securely.

If the plug has dust or loose connection, it may cause an electrical shock or fire.

Be sure to install the product correctly by using the provided standard

installation frame.

Incorrect use of the installation frame and improper installation may cause the

equipment to fall, resulting in injury.

Be sure to install the product securely in the installation frame mounted on the

window frame.

If the unit is not securely mounted, it may fall and cause injury.

When replacing the coin battery in the remote controller, be sure to disposed

of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Caution

Installation of a leakage breaker is necessary in some cases depending on the

conditions of the installation site, to prevent electrical shocks.

For unitary type

only

For unitary type

only

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If the combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if the parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections may cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame may cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding may cause an electrical shock.

vii

SiME281501E Introduction

Caution

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 M or higher.

Defective insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Defective drainage may cause the water to enter the room and wet the furniture

and floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water may enter the room and

wet the furniture and floor.

1.2 Used Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

icon is described in the table below:

Icon Type of

Note:

Caution

Warning

For unitary type

only

Description

Information

Note A “note” provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution A “caution” is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get

an unexpected result or has to restart (part of) a procedure.

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or

in this manual, where he/she will find additional information on a

specific topic.

viii

SiME281501E

Part 1

General Information

1. Model Name of Indoor / Outdoor Units ...................................................2

2. External Appearance...............................................................................3

1 General Information

SiME281501E Model Name of Indoor / Outdoor Units

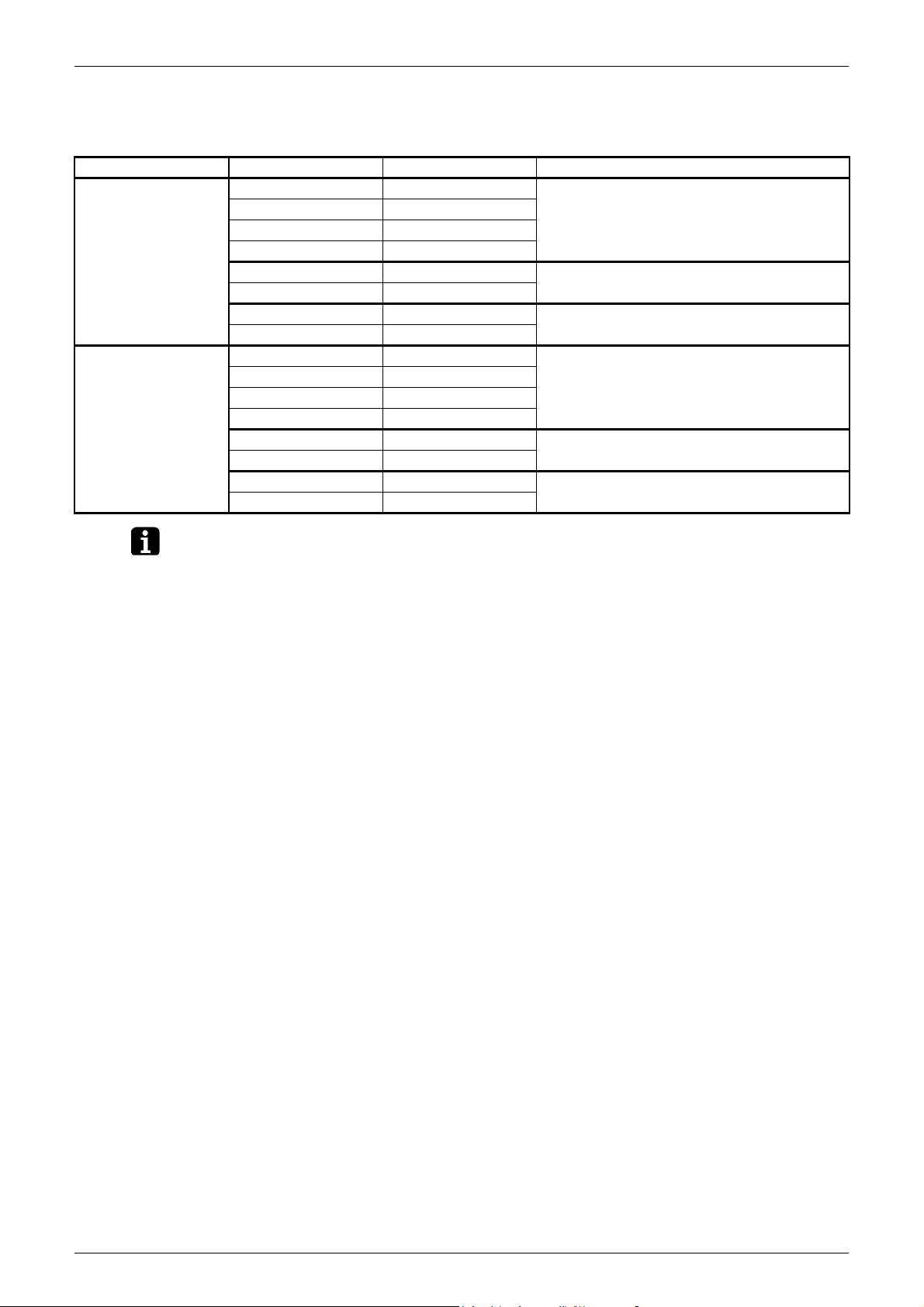

1. Model Name of Indoor / Outdoor Units

Model series Indoor unit Outdoor unit Power supply intake

FCQ20EVA RZQ20LVA

Ceiling Mounted

Cassette Type

(Round Flow)

Duct Connection

Middle and High Static

Pressure Type

FCQ24EVA RZQ24LVA

FCQ36EVA RZQ36LVA

FCQ45EVA RZQ45LVA

FCQ36EVA RZQ36LVA

FCQ45EVA RZQ45LVA

FCQ36EVA RZQ36LVA

FCQ45EVA RZQ45LVA

FBQ20EVA RZQ20LVA

FBQ24EVA RZQ24LVA

FBQ36EVA RZQ36LVA

FBQ45EVA RZQ45LVA

FBQ36EVA RZQ36LVA

FBQ45EVA RZQ45LVA

FBQ45EVA RZQ45MYL

FBQ48EVA RZQ48MYL

Outdoor unit: 1 phase, 220V, 60Hz

Outdoor unit: 3 phase, 220V, 60Hz

Outdoor unit: 3 phase, 380V, 60Hz

Indoor unit: 1 phase, 220V, 60Hz

Outdoor unit: 1 phase, 220V, 60Hz

Indoor unit: 1 phase, 220V, 60Hz

Outdoor unit: 3 phase, 220V, 60Hz

Indoor unit: 1 phase, 220V, 60Hz

Outdoor unit: 3 phase, 380V, 60Hz

Note: : New model or changed model

General Information 2

External Appearance SiME281501E

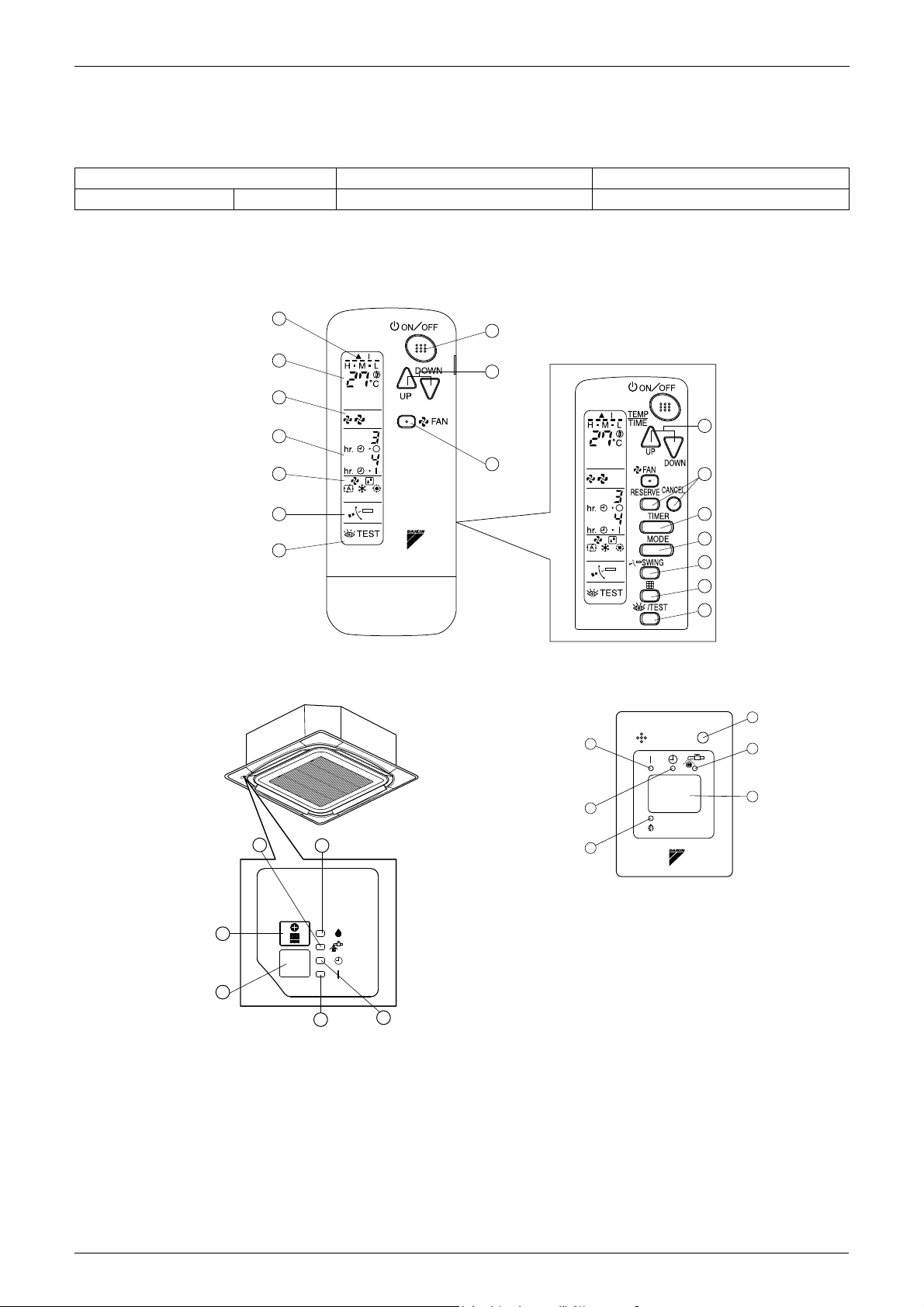

2. External Appearance

Indoor unit

FCQ FBQ-DA

Wired

remote controller

Wireless

remote controller

Outdoor unit

BRC1C61 BRC1D61

BRC7F632F (for FCQ)

BRC4C62 (for FBQ-DA)

Signal receiver unit

(for FCQ)

Signal receiver unit

(for FBQ-DA)

RZQ20LVA

RZQ24LVA

3 General Information

RZQ36LVA

RZQ45LVA

RZQ45MYL

RZQ48MYL

SiME281501E

Part 2

Functions

1. Functions.................................................................................................5

Functions 4

Functions SiME281501E

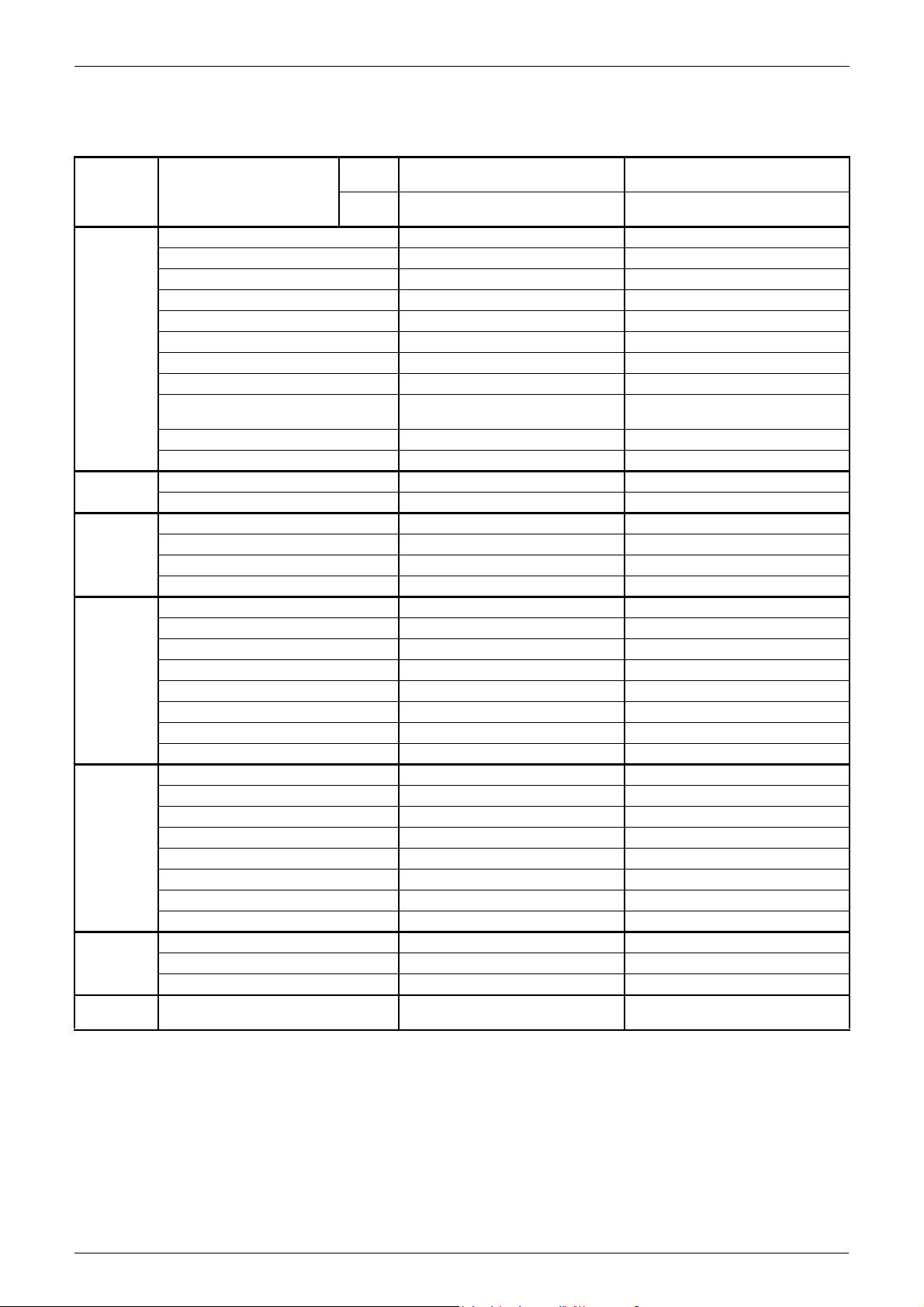

1. Functions

Indoor

Items Features

Comfort Auto swing —

Swing pattern selection —

Draft prevention function (heating) —

Switchable fan speed (2 step) (2 step)

Auto airflow rate — —

High fan speed mode — —

Program “Dry”

High ceiling application —

Two selectable temperature-sensors

(1)

Hot start (after defrost)

Year-round cooling applicable

Remote

controller

Cleanliness Anti-bacterial air filter (4)

Work &

servicing

Control

features

Options High-efficiency filter

Others Anti corrosion treated heat exchanger

Weekly schedule timer (3)

On/Off timer (5)

Mould-proof air filter — —

Silver ion anti-bacterial drain pan

Mould-proof drain pan — —

Drain pump mechanism —

Pre-charged for up to 30 m (2)

Long-life filter (4)

Filter sign

Ceiling soiling prevention —

Low gas pressure detection (2)

Emergency operation

Self-diagnosis function

Auto-restart

Auto cooling/heating changeover

Control by 2 remote controllers

Group control by 1 remote controller

External command control

Centralized remote control

Interlock control

DIII-NET communication standard

Ultra long-life filter —

Fresh air intake kit —

(2)

unit

Outdoor

unit

FCQ20-45EVA FBQ20-48EVA

RZQ20-45LVA

RZQ45-48MYL

RZQ20-45LVA

RZQ45-48MYL

Note: : Functions exist.

— : No functions

1 : Applicable when wired remote controller is used

2 : For the outdoor units

3 : Applicable when BRC1D61 is used

4 : Option

5 : Applicable when BRC1C61 is used

5 Functions

SiME281501E

Part 3

Remote Controller

1. Wired Remote Controller.........................................................................7

1.1 Applicable Models ....................................................................................7

1.2 Names and Functions ..............................................................................8

1.3 MAIN/SUB Setting when Using 2 Remote Controllers ...........................11

1.4 Centralized Control Group No. Setting...................................................12

2. Wireless Remote Controller ..................................................................13

2.1 Applicable Models ..................................................................................13

2.2 Names and Functions ............................................................................13

2.3 Address and MAIN/SUB Setting.............................................................15

3. Service Mode ........................................................................................17

3.1 BRC1C61/BRC1D61 ..............................................................................17

Remote Controller 6

Wired Remote Controller SiME281501E

1. Wired Remote Controller

1.1 Applicable Models

Model Series FCQ-EV FBQ-EV

Remote Controller Heat Pump BRC1C61

Wired Remote Controller with Weekly

Schedule Timer

BRC1D61

7 Remote Controller

SiME281501E Wired Remote Controller

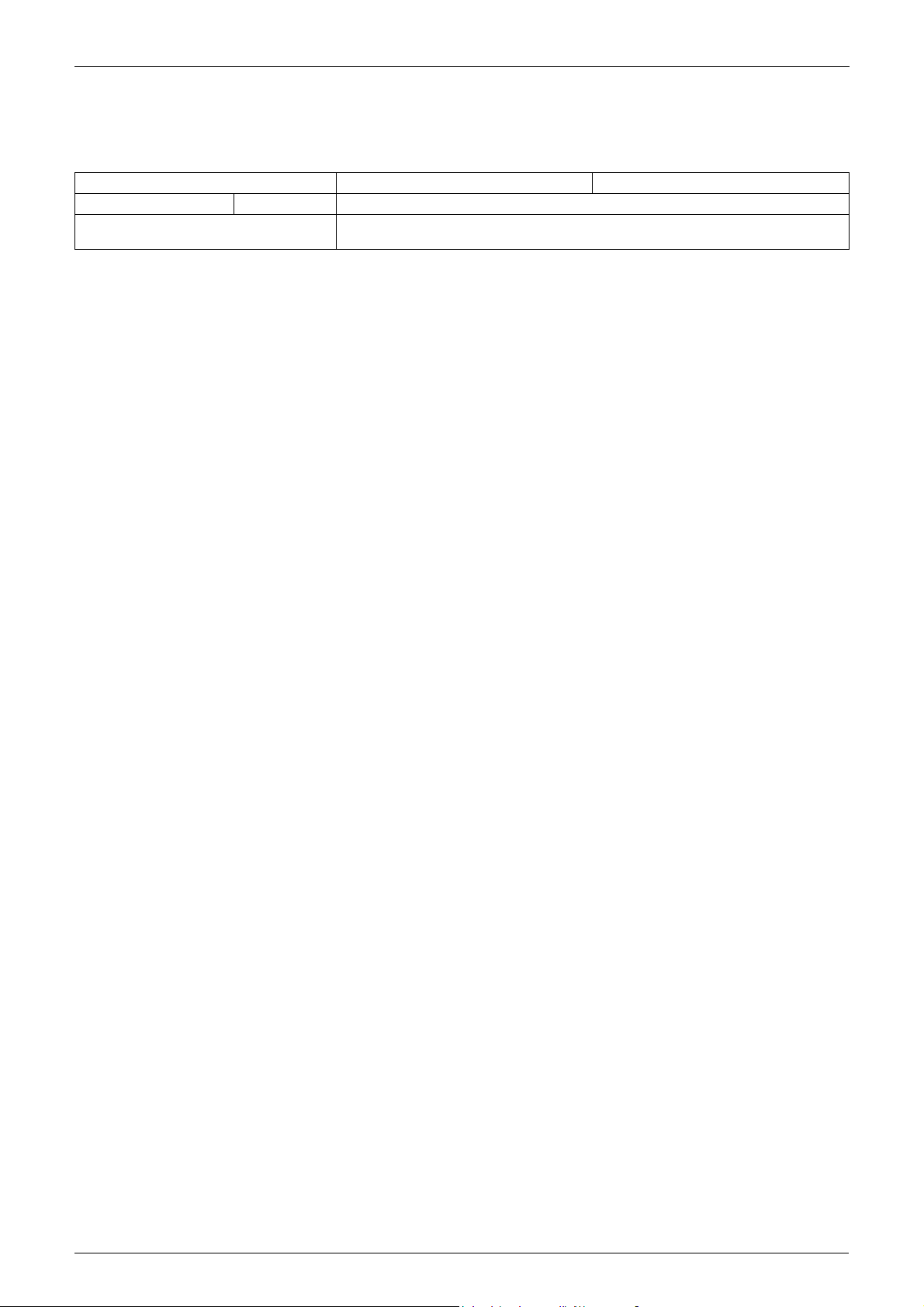

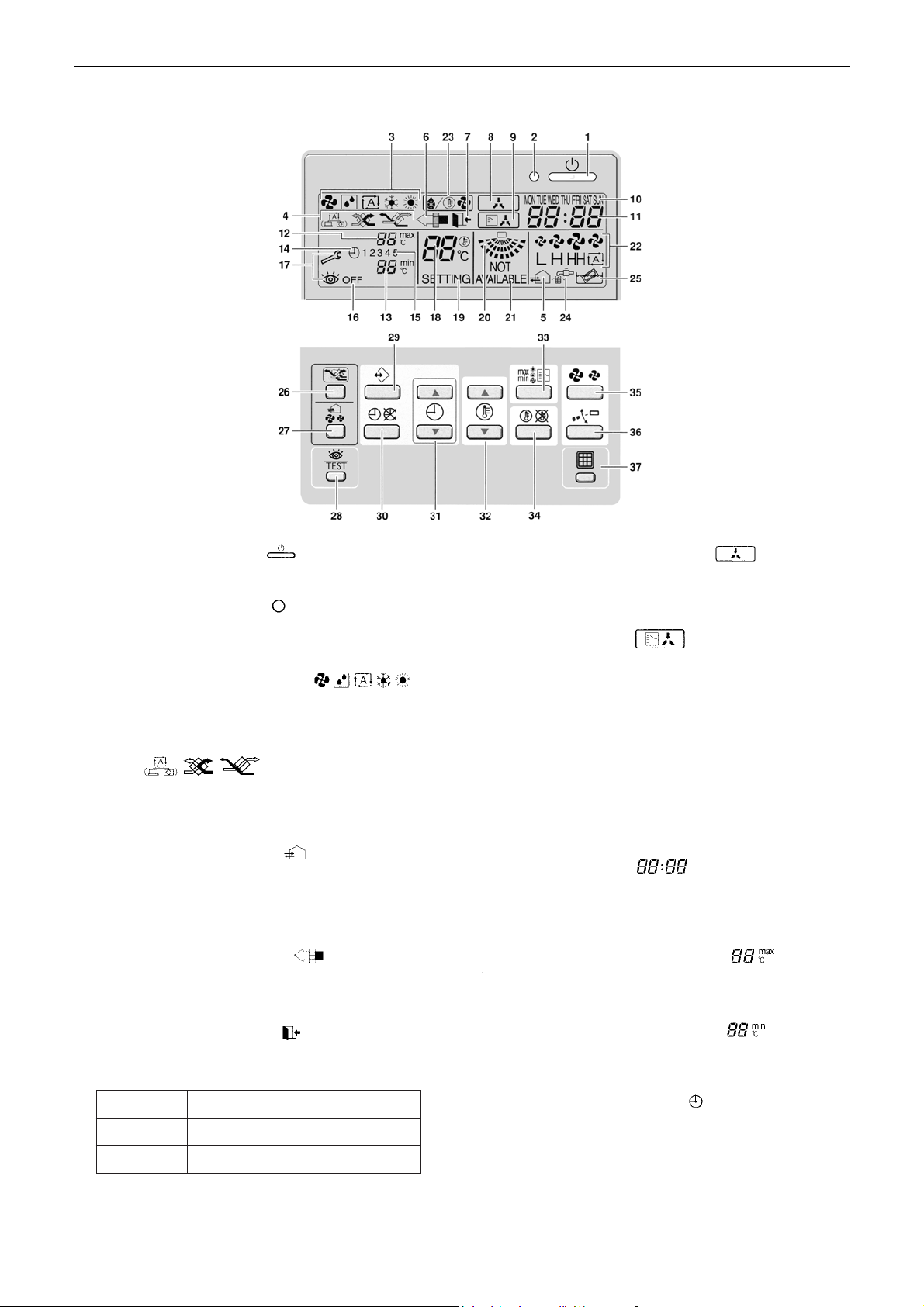

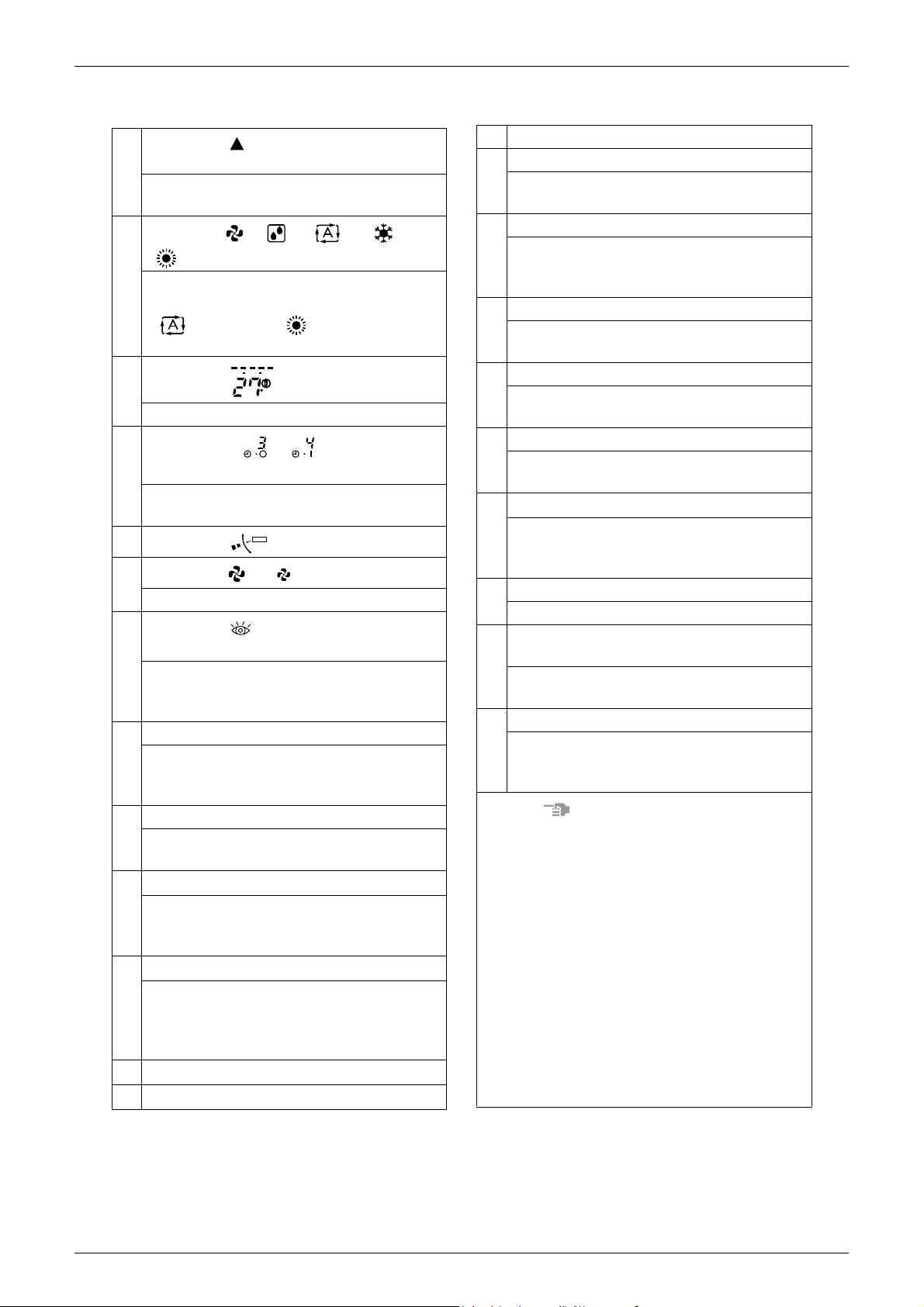

hr

hr

C

C: 3PA59583-16Z

2

10

11

3

1

4

5

6

7

8

14

15

16

17

18

19

20

21

22

12

9

13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

ON/OFF BUTTON

Press the button and the system will start.

Press the button again and the system will stop.

OPERATION LAMP (RED)

The lamp lights up during operation.

DISPLAY “ ” (UNDER CENTRALIZED

CONTROL)

When this display shows, the system is UNDER

CENTRALIZED CONTROL.

DISPLAY “ ” “ ” “ ” “ ”

(VENTILATION/AIR CLEANING)

This display shows that the total heat exchange

and the air cleaning unit are in operation

(These are optional accessories).

DISPLAY “ ” “ ” “ ” “ ” “ ”

(OPERATION MODE)

This display shows the current OPERATION

MODE. For cooling only type, “ ” (Auto)

and “ ” (Heating) are not installed.

DISPLAY “

TEST” (INSPECTION/TEST

OPERATION)

When the INSPECTION/TEST OPERATION

BUTTON is pressed, the display shows the

system mode is in.

DISPLAY “ ” (PROGRAMMED TIME)

This display shows the PROGRAMMED TIME

of the system start or stop.

This display shows the set temperature.

DISPLAY “ ” (FAN SPEED)

DISPLAY “ ” (SET TEMPERATURE)

This display shows the set fan speed.

DISPLAY “ ” (AIRFLOW FLAP)

DISPLAY “ ”(TIME TO CLEAN AIR FILTER)

If that particular function is not available, pressing

the button may display the words “NOT

AVAILABLE” for a few seconds.

When running multiple units simultaneously the

“NOT AVAILABLE” message will only be appear

if none of the indoor units is equipped with the

function. If even one unit is equipped with the

function, the display will not appear.

DISPLAY

“ ” (DEFROST)

NON-FUNCTIONING DISPLAY

TIMER MODE START/STOP BUTTON

TIMER ON/OFF BUTTON

INSPECTION/TEST OPERATION BUTTON

This button is used only by qualified service

persons for maintenance purposes.

PROGRAMMING TIME BUTTON

Use this button for programming “START and/or

STOP” time.

TEMPERATURE SETTING BUTTON

Use this button for SETTING TEMPERATURE.

FILTER SIGN RESET BUTTON

FAN SPEED CONTROL BUTTON

Press this button to select the fan speed,

HIGH or LOW, of your choice.

OPERATION MODE SELECTOR BUTTON

Press this button to select OPERATION MODE.

AIRFLOW DIRECTION ADJUST BUTTON

NOTE

• For the sake of explanation, all indications are shown

on the display in the above figure contrary to actual

running situations.

1.2 Names and Functions

1.2.1 BRC1C61

Remote Controller 8

Wired Remote Controller SiME281501E

1 ON/OFF BUTTON

Press the ON/OFF button to start or stop the system.

2 OPERATION LAMP

The operation lamp lights up during operation or

blinks if an error occurs.

3 OPERATION MODE ICON

These icons indicate the current operation mode

(FAN, DRY, AUTOMATIC, COOLING, HEATING).

4 VENTILATION MODE ICON

These icons indicate the current ventilation mode

(Heat Reclaim Ventilator only) (AUTOMATIC, HEAT

EXCHANGE, BYPASS).

5 VENTILATION ICON

The ventilation icon appears when the ventilation is

adjusted with the ventilation amount button (Heat

Reclaim Ventilator only). Simultaneously, the ventilation

amount is indicated by the fan speed icon (see 22).

6 AIR CLEANING ICON

This icon indicates that the air cleaning unit (option) is

operational.

7 LEAVE HOME ICON

The leave home icon shows the status of the leave

home function.

ON

FLASHING

OFF

Leave home is enabled

Leave home is active

Leave home is disabled

8 EXTERNAL CONTROL ICON

This icon indicates that another controller with higher

priority is controlling or disabling your installation.

9 CHANGE-OVER UNDER CENTRALIZED

CONTROL ICON

This icon indicates that the change-over of the

installation is under centralized control assigned to

another indoor unit or optional cool/heat selector

connected to the outdoor unit (= main remote

controller).

10 DAY OF THE WEEK INDICATOR

MON TUE WED THU FRI SAT SUN

The day of the week indicator shows the current week

day (or the set day when reading or programming the

schedule timer).

11 CLOCK DISPLAY

The clock display indicates the current time (or the

action time when reading or programming the

schedule timer).

12 MAXIMUM SET TEMPERATURE

The maximum set temperature indicates the

maximum set temperature when in limit operation.

13 MINIMUM SET TEMPERATURE

The minimum set temperature indicates the minimum

set temperature when in limit operation.

14 SCHEDULE TIMER ICON

This icon indicates that the schedule timer is enabled.

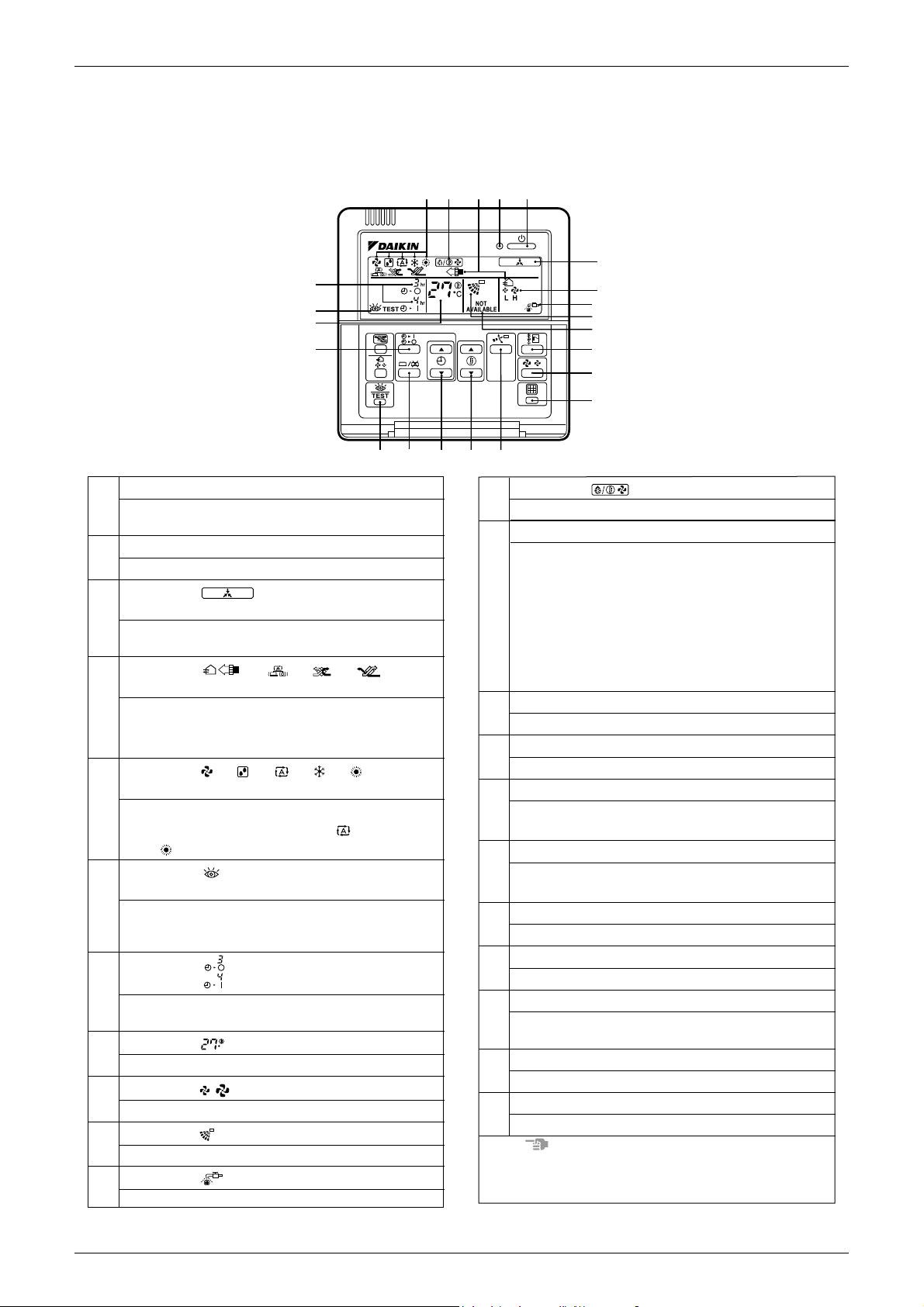

1.2.2 BRC1D61

9 Remote Controller

C: 3P107422-3D

SiME281501E Wired Remote Controller

15 ACTION ICONS 1 2 3 4 5

These icons indicate the actions for each day of the

schedule timer.

16 OFF ICON

OFF

This icon indicates that the OFF action is selected

when programming the schedule timer.

17 INSPECTION REQUIRED and

These icons indicate that inspection is required.

Consult your installer.

18 SET TEMPERATURE DISPLAY

This indicates the current set temperature of the

installation (not shown in LIMIT operation or in FAN or

DRY mode).

19 SETTING

SETTING

Not used, for service purposes only.

20 AIRFLOW DIRECTION ICON

This icon indicates the airflow direction (only for

installations with motorised airflow flaps).

21 NOT AVAILABLE

is displayed whenever a non-installed option

is addressed or a function is not available.

NOT

AVAILABLE

NOT

AVAILABLE

22 FAN SPEED ICON

This icon indicates the set fan speed.

23

DEFROST/HOTSTART MODE ICON

This icon indicates that the defrost/hotstart mode is

active.

24

AIR FILTER CLEANING TIME ICON

This icon indicates the air filter must be cleaned.

Refer to the manual of the indoor unit.

25 ELEMENT CLEANING TIME ICON

This icon indicates the element must be cleaned

(Heat Reclaim Ventilator only).

26

VENTILATION MODE BUTTON

The ventilation mode button operates the Heat

Reclaim Ventilator; refer to the Heat Reclaim

Ventilator manual for more details.

27 V

ENTILATION AMOUNT BUTTON

This button sets the ventilation amount; refer to the

Heat Reclaim Ventilator manual for more details.

28

INSPECTION/TEST OPERATION BUTTON

Not used, for service purposes only.

TEST

29 PROGRAMMING BUTTON

This button is a multi-purpose button.

Depending on the previous manipulations of the user,

the programming button can have various functions.

30

SCHEDULE TIMER BUTTON

This button enables or disables the schedule timer.

31 TIME ADJUST BUTTON

These buttons are used to adjust the clock or, when in

programming mode, to adjust the programmed action

time. Both buttons have an auto-repeat function.

32 TEMPERATURE ADJUST BUTTONS

These buttons are used to adjust the current setpoint

or, when in programming mode, to adjust the

programmed setpoint temperature (step = 1˚C). Both

buttons are also used to adjust the day of the week.

33 OPERATION CHANGE/MIN-MAX BUTTON

This button is a multi-purpose button. Depending on

the previous manipulations of the user, it can have

following functions.

1 select the operation mode of the installation

(FAN, DRY, AUTOMATIC, COOLING, HEATING)

2 toggle between minimum temperature and

maximum temperature when in limit operation

34 SETPOINT/LIMIT BUTTON

This button toggles between setpoint, limit operation

or

OFF (programming mode only).

35

FAN SPEED BUTTON

This button toggles between L (Low), H (High), HH

(very High), (Automatic).

36 AIRFLOW DIRECTION ADJUST BUTTON

This button enables to adjust the airflow direction.

37 AIR FILTER CLEANING TIME ICON RESET

BUTTON

This button is used to reset the air filter cleaning time

icon.

max

min

L H

HH

Remote Controller 10

3P107422-3D

Wired Remote Controller SiME281501E

Upper part of the

remote controller

Lower part of the

remote controller

S

M

S

M

The switch is set to MAIN (factory

setting)

Set the switch to SUB.

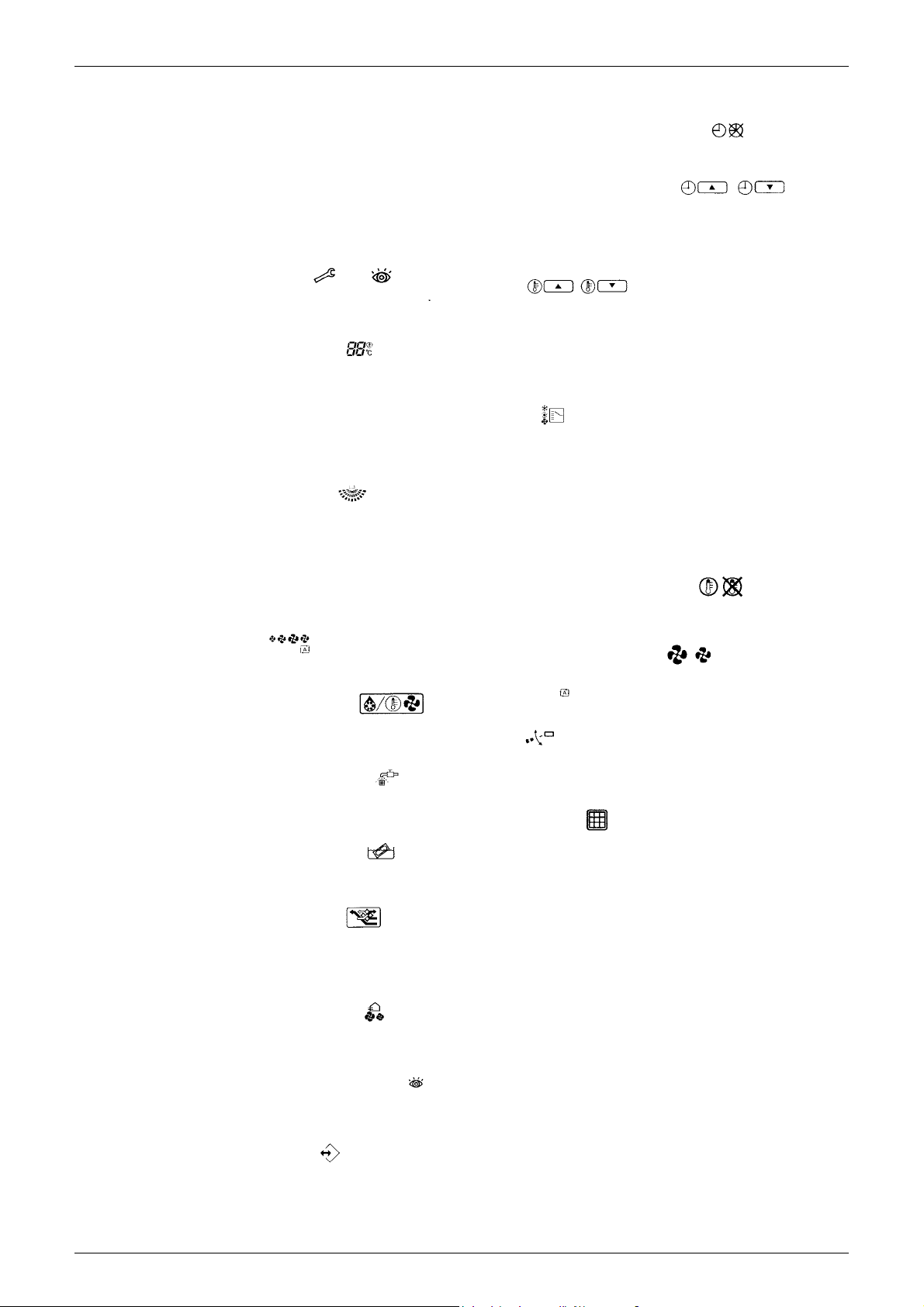

1.3 MAIN/SUB Setting when Using 2 Remote Controllers

Situation

The MAIN/SUB setting is necessary when 1 indoor unit is controlled by 2 remote controllers. When you use 2

remote controllers (control panel and separate remote controller), set one to MAIN and the other to SUB.

Setting

The remote controllers are set at factory to MAIN, so you only have to change 1 remote controller from MAIN

to SUB. To change a remote controller from MAIN to SUB, proceed as follows:

1.3.1 BRC1C61/BRC1D61

Step Action

1 Insert a flathead screwdriver into the recess between the upper and lower part of the remote

controller, as shown in the illustration below. Gently pry off the upper part of the controller, working

from the 2 possible positions.

2 Turn the MAIN/SUB changeover switch on the PCB to “S”.

11 Remote Controller

SiME281501E Wired Remote Controller

TEST

TEST

4

1,5

3

2

Group No.

Mode No.

Field Setting

Mode

4

1,5

3

2

Group No.

Mode No.

Field Setting

Mode

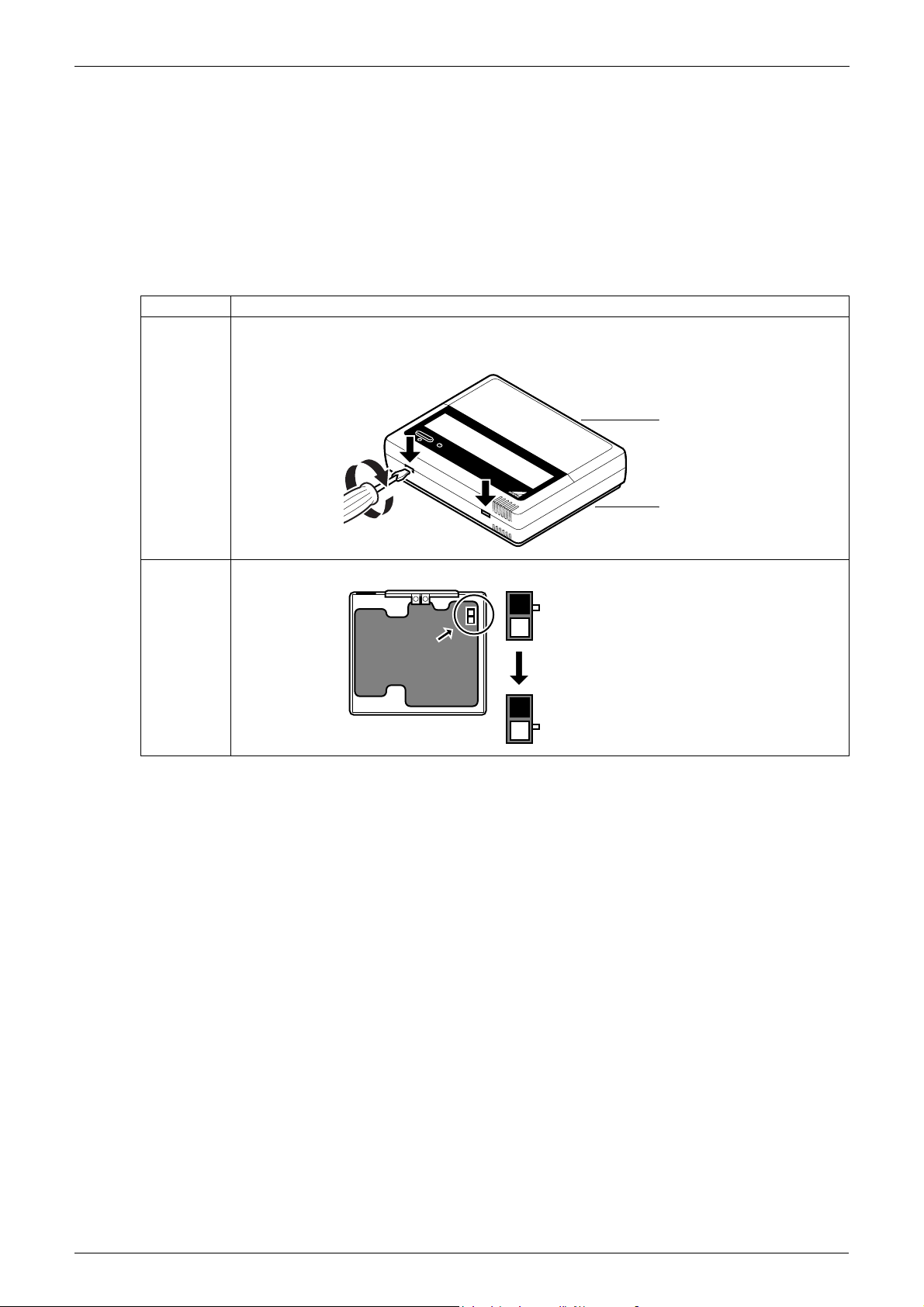

1.4 Centralized Control Group No. Setting

1.4.1 BRC1C61/BRC1D61

In order to conduct the centralized remote control using the central remote controller and the unified ON/OFF

controller, Group No. settings should be made by group using the operating remote controller.

Make Group No. settings for centralized remote control using the operating remote controller.

1. While in normal mode, press and hold the “ ” button for 4 seconds or more to set the system to "Field

Setting Mode".

2. Select the Mode No. “00” with the “ ” button.

3. Use the “ ” button to select the Group No. for each group.

(Group numbers increase in the order of 1-00, 1-01, ... 1-15, 2-00, ... 4-15.)

4. Press the “ ” button or the “ ” button to set the selected group No.

5. Press the “ ” button to return to the Normal Mode.

BRC1C61

BRC1D61

Note:

For setting Group No. of Heat Reclaim Ventilator and wiring adaptor for other air conditioners, etc., refer to

the installation manual attached.

NOTICE

Enter the Group No. and installation place of the indoor unit into the attached installation table. Be sure to

keep the installation table with the operation manual for maintenance.

Remote Controller 12

Wireless Remote Controller SiME281501E

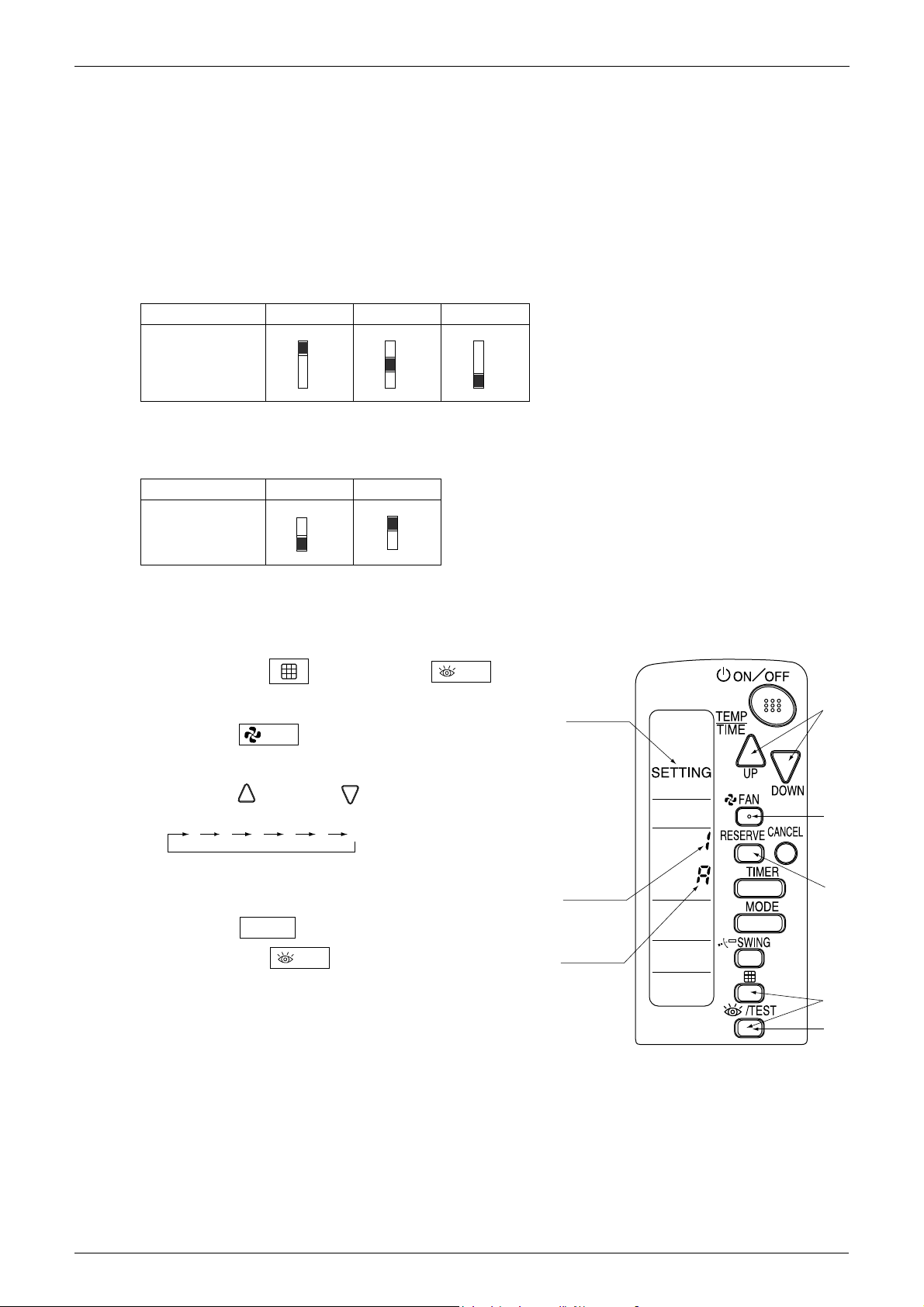

1-1

1-2

8

10

13

11

12

15

14

16

17

9

1

3

4

6

2

5

7

19

23

22

18

20

21

20

21

23

18

22

19

2. Wireless Remote Controller

2.1 Applicable Models

Model Series FCQ FBQ-DA

Remote Controller Heat Pump BRC7F632F BRC4C62

2.2 Names and Functions

3P107422-11J

Receiver

FCQ-K/KA

FBQ-DA (separate type)

3P107422-21S

13 Remote Controller

3P107422-11J

SiME281501E Wireless Remote Controller

MHL

C

hr.

hr.

•

•

•

•

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

This display shows the current

OPERATION MODE. For cooling only type,

“ ” (Auto) and “ ” (Heating) are not

installed.

DISPLAY “ ” (SIGNAL

TRANSMISSION)

This lights up when a signal is being

transmitted.

DISPLAY “ ”

(PROGRAMMED TIME)

DISPLAY “ ”

(SET TEMPERATURE)

This display shows the set temperature.

This display shows PROGRAMMED TIME

of the system start or stop.

DISPLAY “ ” (AIRFLOW FLAP)

DISPLAY “ ” “ ” (FAN SPEED)

The display shows the set fan speed.

DISPLAY “ TEST ”

(INSPECTION/TEST OPERATION)

When the INSPECTION/TEST

OPERATION BUTTON is pressed, the

display shows the system mode is in.

ON/OFF BUTTON

Press the button and the system will start.

Press the button again and the system will

stop.

FAN SPEED CONTROL BUTTON

Press this button to select the fan speed,

HIGH or LOW, of your choice.

TEMPERATURE SETTING BUTTON

Use this button for SETTING

TEMPERATURE (Operates with the front

cover of the remote controller closed.)

PROGRAMMING TIMER BUTTON

Use this button for programming “START

and/or STOP” time. (Operates with the

front cover of the remote controller

opened.)

TIMER MODE START/STOP BUTTON

TIMER RESERVE/CANCEL BUTTON

AIRFLOW DIRECTION ADJUST BUTTON

OPERATION MODE SELECTOR BUTTON

Press this button to select OPERATION

MODE.

FILTER SIGN RESET BUTTON

Refer to the section of MAINTENANCE in

the operation manual attached to the

indoor unit.

INSPECTION/TEST OPERATION BUTTON

This button is used only by qualified service

persons for maintenance purposes.

EMERGENCY OPERATION SWITCH

This switch is readily used if the remote

controller does not work.

RECEIVER

This receives the signals from the remote

controller.

OPERATING INDICATOR LAMP (Red)

This lamp stays lit while the air

conditioner runs. It blinks when the unit

is in trouble.

TIMER INDICATOR LAMP (Green)

This lamp stays lit while the timer is set.

AIR FILTER CLEANING TIME

INDICATOR LAMP (Red)

Lights up when it is time to clean the air

filter.

DEFROST LAMP (Orange)

Lights up when the defrosting operation

has started. (For cooling only type this

lamp does not turn ON.)

For the sake of explanation, all indications

are shown on the display in Figure 1 contrary

to actual running situations.

Fig. 1-2 shows the remote controller with the

front cover opened.

If the air filter cleaning time indicator lamp

lights up, clean the air filter as explained in

the operation manual provided with the

indoor unit.

After cleaning and reinstalling the air filter

press the filter sign reset button on the

remote controller. The air filter cleaning time

indicator lamp on the receiver will go out.

The Defrost Lamp will blink when power is

turned ON. This is not an error.

DISPLAY “ ” “ ” “ ” “ ”

“ ” (OPERATION MODE)

NOTES

Remote Controller 14

C: 3P107422-11J

Wireless Remote Controller SiME281501E

1 2 3

1 2 3

1 2 3

S

M

S

M

Mode

Address

Multiple

setting

3

2

4

1

5

/TEST

FAN

UP

DOWN

123456

RESERVE

/TEST

2.3 Address and MAIN/SUB Setting

Introduction

To set the wireless remote controller, you have to set the address for:

The receiver of the wireless remote controller

The wireless remote controller.

Setting the Address for the Receiver

The address for the receiver of the wireless remote controller is factory setting to 1. To change this setting,

proceed as follows:

Set the wireless address switch (SS2) on the PCB according to the table below.

Unit No. No. 1 No. 2 No. 3

Wireless address

switch (SS2)

When using both a wired and a wireless remote controller for 1 indoor unit, the wired controller should be set

to MAIN. Therefore, set the MAIN/SUB switch (SS1) of the receiver to SUB.

For FCQ, FBQ

MAIN/SUB MAIN SUB

MAIN/SUB

switch (SS1)

Setting the Address for the Wireless Remote Controller

The address for the wireless remote controller is factory setting to 1. To change this setting, proceed as

follows:

1. Hold down the “ ” button and the “ ”

button for at least 4 seconds to get the Field Setting mode.

(Indicated in the display area in the figure at right.)

2. Press the “ ” button and select a multiple setting

(A/b). Each time the button is pressed the display

switches between “A” and “b”.

3. Press the “ ” button or “ ” button to set the address.

Address can be set from 1 to 6, but set it to 1 ~ 3 and to

same address as the receiver. (The receiver does not

work with address 4 ~ 6.)

4. Press the “ ” button to enter the setting.

5. Hold down the “ ” button for at least 1 second to

quit the Field Setting mode and return to the normal

display.

15 Remote Controller

SiME281501E Wireless Remote Controller

Multiple Settings A/b

When the indoor unit is being operating by external control (central remote controller, etc.), it sometimes does

not respond to ON/OFF and temperature setting commands from this remote controller. Check what setting

the customer wants and make the multiple setting as shown below.

Remote controller FCQ FBQ

Multiple

setting

A: Standard All items displayed.

b: Multi

System

Remote controller

display

Operations remain

displayed shortly after

execution.

Movement when the operation is controlled

by the other air conditioners and equipment

When operation changeover, temperature

setting or the like is carried out from the

remote controller, the indoor unit rejects the

instruction.

(Signal receiving sound “peeh” or “pickpick-pick”)

As a result, a discrepancy between the

operation state of the indoor unit and the

indication of the remote controller display

occurs.

Since the indication of the remote controller

is turned OFF, no discrepancy such as

mentioned above occurs.

To control other air

conditions and units

Commands other than ON/

OFF and temperature

setting accepted.

(1 LONG BEEP or 3

SHORT BEEPS emitted)

All commands accepted (2 SHORT

BEEPS)

For other than

on left

Remote Controller 16

Service Mode SiME281501E

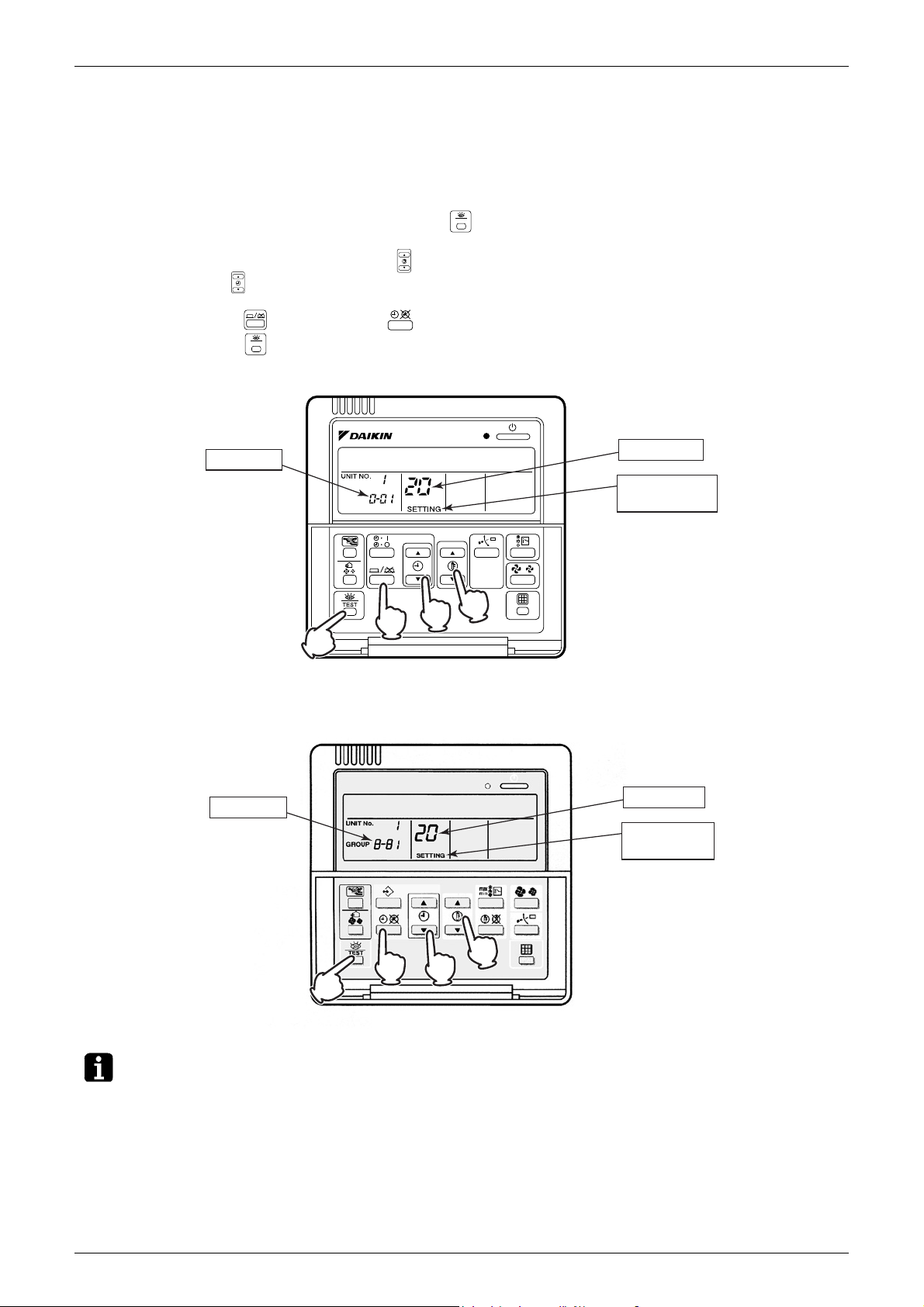

2

7

6

3

4

5

3

1

Unit No.

Second

Code No.

First

Code No.

Mode No.

Field

Setting

Mode

UNIT NO.

past error

code

CODE

SETTING

Error history

: Newest

: Oldest

1

3

∼

∗ "00" displayed for 4 and subsequent.

UNIT No.

Thermistor type

Temperature

SETTING

3. Service Mode

3.1 BRC1C61/BRC1D61

3.1.1 Display Service Data

1. Enter the field setting mode.

Press the INSPECTION/TEST button for 4 seconds or more.

2. Enter the service mode.

After having entered the field setting mode, press the INSPECTION/TEST button for 4 seconds or more.

3. Select the mode No.

Set the desired mode No. with the up/down temperature setting button.

4. Select the unit No.

Select the indoor unit No. set with the time mode START/STOP button.

5. Select the desired error history No. or thermistor data No. with “ ” or “ ” button.

6. Each data displays (Refer to the table below display)

7. Return to the normal operation mode.

Press the INSPECTION/TEST button once.

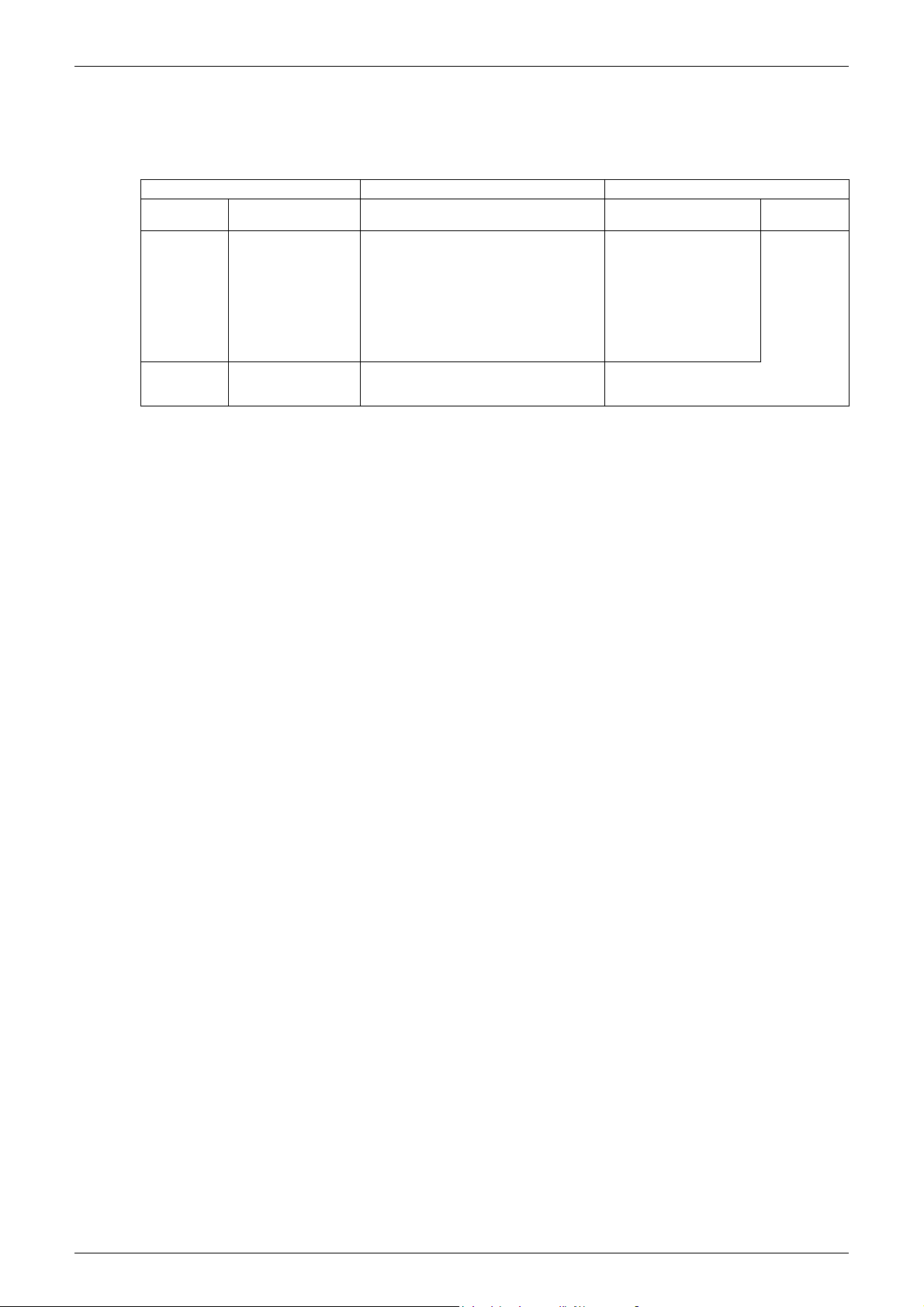

Mode No. Function Content and Operation Method Example of Remote Controller Display

40 Error History You can change the history with the

41 Thermistor Data

Display

programming time up-down button.

Select the display thermistor with

the programming time up-down

button

Display thermistor

00: Room temperature thermistor in

remote controller

01: Suction air thermistor

02: Heat exchanger thermistor

17 Remote Controller

SiME281501E Service Mode

2

6

5

3

4

5

3

1

Unit No.

Second

Code No.

First

Code No.

Mode No.

Field

Setting

Mode

Mode No.

Field Setting Mode

5

5

Second Code No.

First Code No.

3

1, 2, 6

SETTING

UNIT No.

UNIT No.

CODE

Fan

speed

1 : Low

3 : High

Airflow direction

SETTING

0: Upper

4: Lowest

UNIT No.

CODE

SETTING

Field setting No.

No. after change

3.1.2 Service Setting

1. Enter the field setting mode.

Press the INSPECTION/TEST operation button for 4 seconds or more.

2. Enter the maintenance mode.

After having entered the field setting mode, press the INSPECTION/TEST operation button for a minimum

of 4 seconds.

3. Select the mode No.

Set the desired mode No. with the up/down temperature setting button.

4. Select the unit No.

Select the indoor unit No. set with the time mode START/STOP button.

5. Carry out the necessary settings for each mode. (Only mode 43 possible for wireless remote controller)

• In case of Mode 43

Press timer ON/OFF button to decide the forced Fan ON.

• In case of Mode 44

Set “Fan speed” with fan speed control button and “Airflow direction” with airflow direction adjusting

button, then press timer ON/OFF button to decide.

In case of Mode 45

•

Select the changed unit No. with “ ” or “ ” button, then press timer ON/OFF button to decide.

6. Return to the normal operation mode.

Press the INSPECTION/TEST operation button once.

Mode No. Function Content and Operation Method Example of Remote Controller Display

43 Forced Fan ON Turns the fan ON for each unit

individually.

44 Individual Setting Sets fan speed and airflow direction for

each unit individually when using group

control.

Settings are made using the “airflow

direction adjust” and “fan speed adjust”

buttons.

45 Unit No. Change Changes unit No.

Set the unit No. after changing with the

programming time up-down button.

Remote Controller 18

SiME281501E

Part 4

Function and Control

1. Functions of Main Components and Thermistors .................................20

2. Function Outline ....................................................................................23

2.1 Indoor Unit..............................................................................................23

3. Operation Flow Chart ............................................................................25

3.1 Cooling / Dry Operation..........................................................................25

3.2 Heating Operation ..................................................................................26

4. Function Details ....................................................................................27

4.1 Indoor Unit..............................................................................................27

4.2 Outdoor Unit ...........................................................................................32

19 Function and Control

SiME281501E Functions of Main Components and Thermistors

3D058951C

Indoor heat exchanger

R2T

R3T R5T

Indoor unit

R1T

Stop valve

(with service port 5/16'' flare)

Accumulator

(C) Four way valve

FilterFilter

S1NPH

S1PH

(A) Compressor

Outdoor unit

(B)

Electronic

expansion valve

Outdoor unit

heat exchanger

Pressure

sensor

(high/low)

Pressure

switch

(high)

Gauge port

(5/16'' flare)

R6T

R3T

R4T

R1T

∗

R10T

R5T

R2T

∗This thermistor is near the el. compo. box.

Compressor

accumulator

Field piping φ 9.5

C1220T-O

Field piping φ 15.9

C1220T-O

1. Functions of Main Components and Thermistors

FCQ20EVA / FBQ20EVA + RZQ20LVA

FCQ24EVA / FBQ24EVA + RZQ24LVA

Function and Control 20

Functions of Main Components and Thermistors SiME281501E

3D060254C

Indoor heat exchanger

Accumulator

(C) Four way valve

FilterFilter

S1NPH

S1PH

(A) Compressor

Indoor unit

Outdoor unit

Stop valve

(with service port 5/16'' flare)

(B)

Electronic

expansion valve

Outdoor unit

heat exchanger

Pressure

sensor

(high/low)

Pressure

switch

(high)

Gauge port

(5/16'' flare)

R2T

R3T R5T

R1T

R6T

R3T

R2T

R4T

R1T

∗

R10T

R5T

∗This thermistor is near the el. compo. box.

Field piping φ 9.5

C1220T-O

Field piping φ 15.9

C1220T-O

FCQ36EVA / FBQ36EVA + RZQ36LVA

FCQ45EVA / FBQ45EVA + RZQ45LVA

FCQ45EVA / FBQ45EVA + RZQ45MYL

FCQ48EVA / RBQ48EVA + RZQ48MYL

21 Function and Control

Loading...

Loading...