Daikin RKHH2E200AAV33, RKHH2E260AAV33, RKHH2E260PAAV33 Installation manuals

Installation Manual

Installation manual

Domestic Hot Water Heat Pump - Monobloc type

RKHH2E200AAV33

RKHH2E260AAV33

RKHH2E260PAAV33

Domestic Hot Water Heat Pump

Monobloc type

English

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 3

Installation Manual

4

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Table of contents

1 General safety precautions

.......... 5

1.1 About the documentation ......................... 5

1.1.1 Meaning of warnings and symbols 5

1.2 For the user ............................................. 5

1.3 For the installer ........................................ 6

1.3.1 General ...................................... 6

1.3.2 Installation site ............................ 6

1.3.3 Refrigerant ................................. 7

1.3.4 Water ..................................... 7

1.3.5 Electrical .................................... 8

1.4 Glossary ................................ ................. 9

2 Introduction

................................ 10

2.1 Units ..................................................... 10

2.2 Disclaimer ............................................. 10

2.3 Copyright .............................................. 10

2.4 Operating principle ................................. 10

2.5 Available versions and configurations ...... 11

3 Handling and transport

............... 11

4 Construction characteristics

....... 13

4.1 Technical characteristics ........................ 14

5 Important information

................. 16

5.1 Conformity with European regulations ..... 16

5.2 Degrees of protection provided by

enclosures ........................................ 16

5.3 Limitations of use ................................... 16

5.4 Operating limits ..................................... 16

5.5 Fundamental safety rules ....................... 16

5.6 Information on coolant used.................... 16

6 Installation and connections

....... 17

6.1 Preparation of the installation site ............ 17

6.2 Ventilation connection ............................ 17

6.2.1 Particular installation conditions .. 18

6.3 Device mounting and connection ............ 19

6.4 Water supply connections ...................... 19

6.4.1 Condense drain connections...... 20

6.5 Solar power system integration ............... 21

6.6 Electrical connections ............................ 22

6.6.1 Remote links............................. 22

6.7 Wiring diagram ...................................... 23

7 Commissioning ....................... 23

8 Operation and use

...................... 24

8.1 The User Interface ................................. 24

8.1.1 Interface keys and display ......... 24

8.1.2. Operating logic ......................... 25

8.1.3 Basic management ................... 25

8.2 Particular operations .............................. 31

8.2.1 List of equipment parameters ..... 32

9 Maintenance and cleaning

.......... 36

9.1 Resetting of safety equipment ................. 36

9.2 Quarterly inspections ............................. 37

9.3 Annual inspections ................................. 37

9.4 Cleaning of the ventilation filter ............... 37

9.5 Magnesium anodes ............................... 37

9.6 Emptying the boiler ................................ 37

10 Troubleshooting .................... 38

11 Disposal ................................. 38

12. Unit Fiche ................................... 39

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 5

1 General safety

precautions

1.1 About the documentation

• The original documentation was written in English.

All other languages are translations.

• The precautions described in this document cover

very important topics, follow them carefully.

• The installation of the system and all activities

described in the installation manual must be

performed by an authorized installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in serious

injury or death.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in

electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in

burning because of extreme hot or cold

temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in

explosion.

WARNING

Indicates a situation that could result in

serious injury or death.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor

or moderate injury.

NOTICE

Indicates a situation that could result in

equipment or property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol

Explanation

Before installation, read the installation

and operation manual, and the

wiring instruction sheet.

Before performing maintenance and

service tasks, read the service

manual.

For more information, see the installer

and user reference guide.

1.2 For the user

• If you are not sure how to operate the unit, contact

your installer.

• This appliance can be used by children aged 8

years or older and by people with reduced

physical, sensory or mental capabilities or lack of

experience and knowledge, if they are supervised

or have received sufficient instructions concerning

safe use of the appliance and they understand the

hazards involved. Children must not play with the

appliance. Cleaning and user maintenance must

not be carried out by children without supervision.

WARNING

To prevent electric shocks or fire:

- Do NOT rinse the unit.

- Do NOT operate the unit with wet hands.

- Do NOT place any objects containing

water on the unit.

NOTICE

- Do NOT place any objects or equipment

on top of the unit.

- Do NOT sit, climb or stand on the unit.

- Units are marked with the following symbol:

This means that electrical and electronic units must not

be mixed with unsorted household waste. Do NOT

try to dismantle the system yourself: the

dismantling of the system, treatment of the

refrigerant, of oil and of other parts must be carried

out by an authorized installer and must comply

with applicable legislation.

Units must be treated at a specialized treatment facility

for reuse, recycling and recovery. By ensuring this

unit is disposed of correctly, you will help to

prevent potential negative consequences for the

environment and human health. For more

information, contact your installer or local authority.

Installation Manual

6

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

1.3 For the installer

1.3.1 General

If you are not sure how to install or operate the unit,

contact your dealer.

NOTICE

Improper installation or attachment of

equipment or accessories can result in

electric shock, short-circuit, leaks, fire or

other damage to the equipment. Only use

accessories, optional equipment and

spare parts made or approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (in addition

to the instructions described in the Daikin

documentation).

CAUTION

Wear adequate personal protective

equipment (protective gloves, safety

glasses, …) when installing, maintaining

or servicing the system.

DANGER: RISK OF BURNING

• Do NOT touch the refrigerant piping,

water piping or internal parts during and

immediately after operation. These may

be too hot or too cold. Wait for the parts

to return to their normal temperature. If

you need to touch them anyway, wear

protective gloves.

• Do NOT touch any accidental leaking

refrigerant.

WARNING

Provide adequate measures to prevent the unit

from being used as a shelter by small animals.

Small animals that come into contact with

electrical parts can cause malfunctions, smoke

or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins

of the unit.

NOTICE

• Do NOT place any objects or equipment

on top of the unit.

• Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are

preferably carried out under dry weather

conditions to avoid water ingress.

In accordance with the applicable legislation, it may be

necessary to provide a logbook with the unit

containing at least: information on maintenance,

repair work, results of tests, stand-by periods, …

Also, following information (at least) must appear on the

unit where it can be read:

• Instructions for shutting down the system in case

of an emergency

• Name and address of fire department, police and

hospital

• Name, address and day and night telephone

numbers for obtaining service

In Europe, EN378 provides the necessary guidance for

this logbook.

1.3.2 Installation site

• Provide sufficient space around the unit for

servicing and air circulation.

• Make sure the installation site withstands the unit's

weight and vibration.

• Make sure the area is well ventilated. Do NOT

block any ventilation openings.

• Make sure the unit is level.

Do NOT install the unit in the following places:

• Potentially explosive atmospheres.

• In areas with machinery that emits

electromagnetic waves. Electromagnetic waves

may disturb the control system and cause the

equipment to malfunction.

• In areas with a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline),

carbon fibre, ignitable dust.

• In areas where corrosive gas (such as sulphurous

acid gas) is produced. Corrosion of copper pipes

or soldered parts may cause the refrigerant to

leak.

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 7

1.3.3 Refrigerant

If applicable. Consult the installation manual of your

application for more information.

WARNING

During tests, NEVER pressurize the unit with

a pressure higher than the allowed

maximum (as indicated on the nameplate

of the unit).

WARNING

Take sufficient precautions in case of

refrigerant leakage. If refrigerant gas

leaks, ventilate the area immediately.

Possible risks:

• Excessive refrigerant concentrations in a

closed room can lead to oxygen

deficiency.

• Toxic gas may be produced when

refrigerant gas comes into contact with

fire.

DANGER: RISK OF EXPLOSION

Pump-down – Refrigerant leakage. If you

want to pump-down the system, and

there is a leakage in the refrigerant

circuit:

• Do NOT use the unit's automatic pump-

down function, with which you can collect

all refrigerant from the system in the

outdoor unit. Possible consequence:

Self-combustion and explosion of the

compressor because of air entering the

operating compressor.

• Use a separate recovery system to

ensure that the unit's compressor does

NOT need to operate.

WARNING

Always recover the refrigerant. Do NOT throw

it out directly into the environment. Use a

vacuum pump to evacuate the

installation.

NOTICE

• To avoid compressor breakdown, do

NOT charge more than the specified

amount of refrigerant.

• When the refrigerant system needs to be

opened, refrigerant must be treated

according to the applicable legislation.

WARNING

Make sure there is no oxygen in the system.

Refrigerant may only be charged after

performing the leak test and the vacuum

drying.

• In case re-charge is required, consult the

nameplate of the unit. It mentions the type of

refrigerant and required amount.

• The unit is factory charged with refrigerant.

• Only use tools allowed for the refrigerant type

used in the system, this to ensure pressure

resistance and prevent foreign materials from

entering into the system.

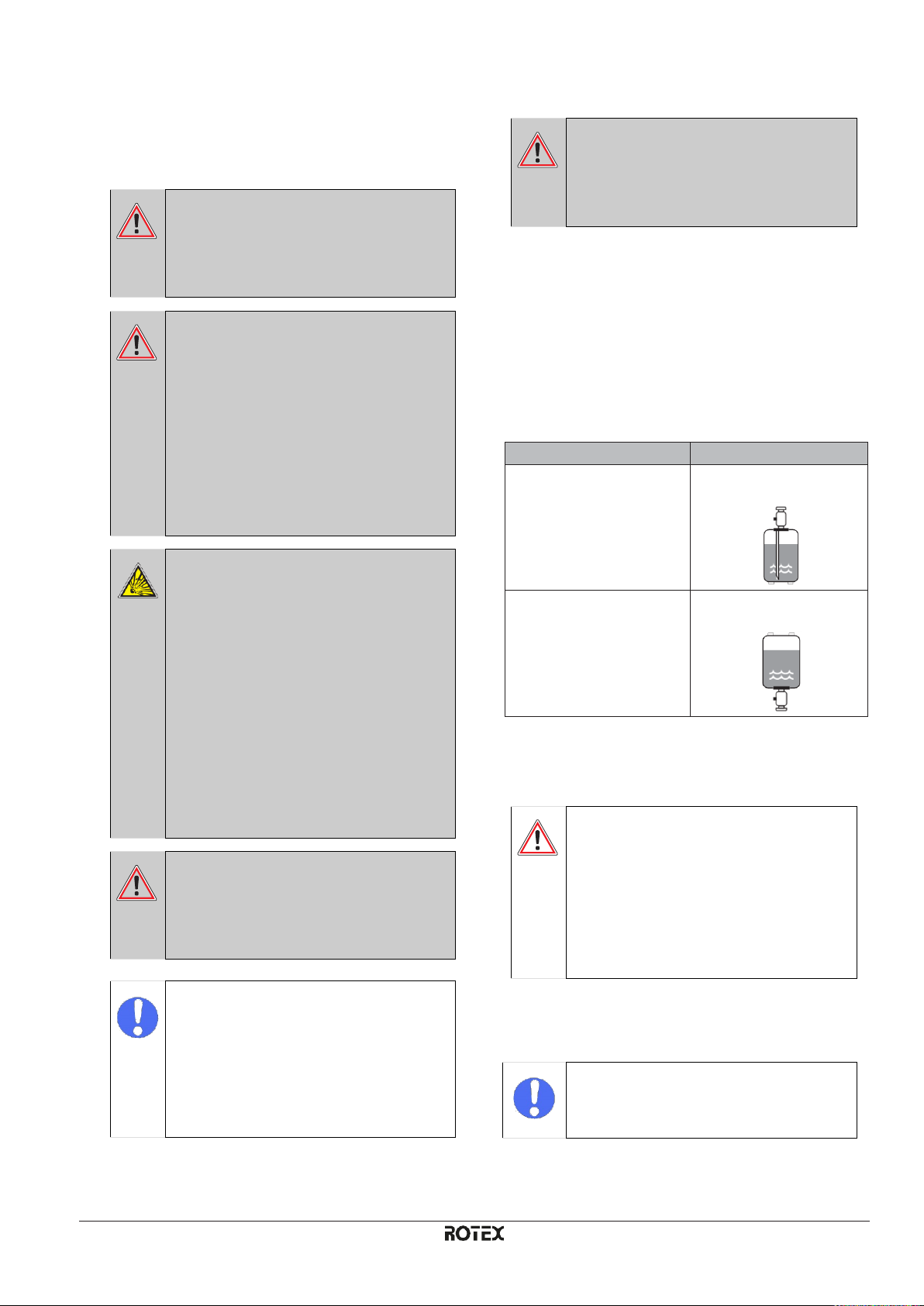

• Charge the liquid refrigerant as follows:

If

Then

A siphon tube is present

(i.e. the cylinder is

marked with "Liquid

filling siphon attached")

Charge with the cylinder

upright.

A siphon tube is NOT

present

Charge with the cylinder

upside down.

• Open refrigerant cylinders slowly.

• Charge the refrigerant in liquid form. Adding it in

gas form may prevent the unit from normal

operation.

CAUTION

When the refrigerant charging procedure is

done or when pausing, close the valve of

the refrigerant tank immediately. If the

valve is not closed immediately,

remaining pressure might charge

additional refrigerant. Possible

consequence: Incorrect refrigerant

amount.

1.3.4 Water

If applicable. Consult the installation manual of your

application for more information.

NOTICE

Make sure water quality complies with EU

directive 98/83 EC.

Installation Manual

8

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

1.3.5 Electrical

DANGER: RISK OF ELECTROCUTION

• Turn OFF all power supply before

removing the switch box cover,

connecting electrical wiring or touching

electrical parts.

• Disconnect the power supply for more

than 1 minute and measure the voltage

at the terminals of main circuit capacitors

or electrical components before

servicing. The voltage MUST be less

than 50 V DC before you touch electrical

components. For the location of the

terminals, consult the wiring diagram.

• Do NOT touch electrical components

with wet hands.

• Do NOT leave the unit unattended when

the service cover is removed.

WARNING

If NOT factory installed, a main switch or

other means for disconnection, having a

contact separation in all poles providing

full disconnection under overvoltage

category III condition, shall be installed in

the fixed wiring.

WARNING

• ONLY use copper wires.

• Make sure the field wiring complies with

the applicable legislation.

• All field wiring must be performed in

accordance with the wiring diagram

provided with the unit.

• NEVER squeeze bundled cables and

make sure they do not come into contact

with the piping or sharp edges. Make

sure no external pressure is applied to

the terminal connections.

• Make sure to install earth wiring. Do NOT

earth the unit to a utility pipe, surge

absorber, or telephone earth. Incomplete

earth may cause electrical shock.

• Make sure to use a dedicated power

circuit. NEVER use a power supply

shared by another appliance.

• Make sure to install the required fuses or

circuit breakers;

• Make sure to install an earth leakage

protector. Failure to do so may cause

electric shock or fire.

• When installing the earth leakage

protector, make sure it is compatible with

the inverter (resistant to high frequency

electric noise) to avoid unnecessary

opening of the earth leakage protector.

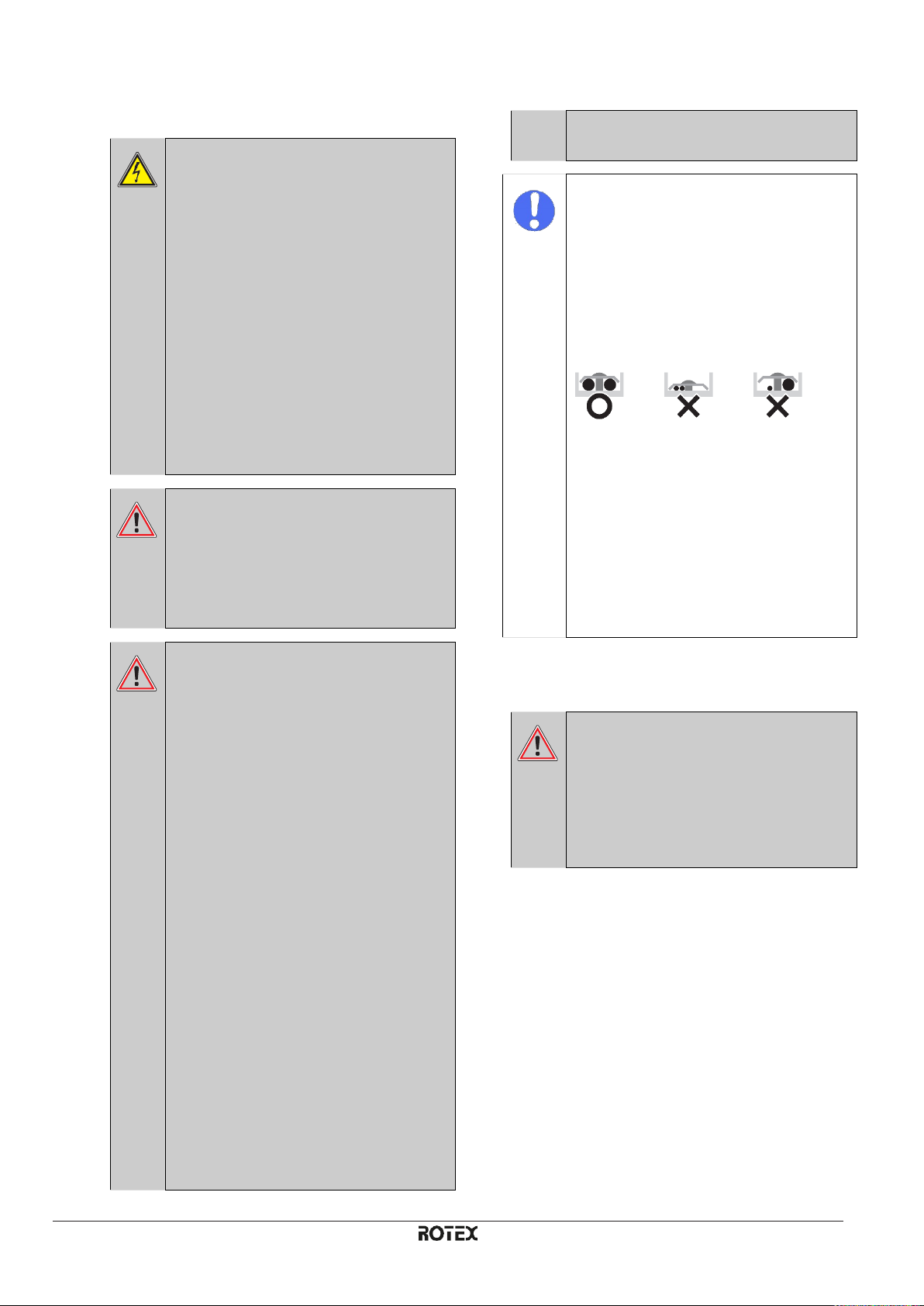

NOTICE

Precautions when laying power wiring:

• Do not connect wiring of different

thicknesses to the power terminal block

(slack in the power wiring may cause

abnormal heat).

• When connecting wiring which is the

same thickness, do as shown in the

figure below.

• For wiring, use the designated power

wire and connect firmly, then secure to

prevent outside pressure from being

exerted on the terminal board.

• Use an appropriate screwdriver for

tightening the terminal screws. A

screwdriver with a small head will

damage the head and make proper

tightening impossible.

• Over-tightening the terminal screws may

break them.

Install power cables at least 1 metre away from

televisions or radios to prevent interference.

Depending on the radio waves, a distance of 1

metre may not be sufficient.

WARNING

• After finishing the electrical work, confirm

that each electrical component and

terminal inside the electrical components

box is connected securely.

• Make sure all covers are closed before

starting the unit.

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 9

1.4 Glossary

Dealer

Sales distributor for the unit.

Authorized installer

Technical skilled person who is qualified to install the

unit.

User

Person who is owner of the unit and/or operates the

unit.

Applicable legislation

All international, European, national and local

directives, laws, regulations and/or codes that

are relevant and applicable to a certain unit or

domain.

Service company

Qualified company which can perform or coordinate

the required service to the unit.

Installation manual

Instruction manual designed for a certain unit or

application, explaining how to install, configure

and maintain it.

Operation manual

Instruction manual designed for a certain unit or

application, explaining how to operate it.

Accessories

Labels, manuals, information sheets and equipment

that are provided with the unit and need to be

installed according to the instructions in the

accompanying documentation.

Optional equipment

Equipment made or approved by Daikin that can be

combined with the unit according to the

instructions in the accompanying documentation.

Field supply

Equipment not made by Daikin that can be combined

with the unit according to the instructions in the

accompanying documentation.

Installation Manual

10

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

2 Introduction

This installation and maintenance manual is to be

considered an integral part of the present heat

pump (hereafter referred to as equipment).

The manual must be kept for future reference until the

heat pump itself has been dismantled. This manual

is intended for both the specialised installer

(installers – maintenance technicians) as well as

for the end user. It includes descriptions of the

installation modes to be complied with in order to

achieve a correct and safe operation of the

equipment, as well as methods of use and

maintenance.

This manual must accompany the equipment to its new

destination in case of sale or change of owner of

the equipment.

Before installing and/or using the equipment, read this

instruction manual carefully and pay attention to

chapter 0 (regarding safety) in particular.

The manual must be kept together with the equipment

and, in any case, it must always be at the disposal

of the qualified personnel in charge of installation

and maintenance.

The following symbols are used in the manual, to

ensure that you can rapidly find the most important

information:

Information on safety

Procedures to follow

Information/ Suggestions

2.1 Units

Dear Customer,

Thank you for purchasing this unit.

Our company has always paid a great deal of attention

to environmental problems and therefore uses

technologies and materials with a low

environmental impact to manufacture its units in

conformity with RAEE 2012/19/UE and RoHS

2011/65/UE community standards.

2.2 Disclaimer

The conformity of the content of these user instructions

with hardware and software has been submitted to

thorough verification. Regardless of this, it is still

possible for some non-compliances to occur;

therefore, no liability will be assumed for complete

conformity.

In the interest of achieving technical perfection, we

reserve the right to carry out modifications to the

equipment construction or to data at any time

whatsoever. We therefore do not accept any

liability claims whatsoever attributable to

instructions, figures, drawings or descriptions,

without prejudice to errors of any kind.

The Supplier shall not be held responsible for damages

attributable to misuse, improper use, or as a

consequence of unauthorised repairs or

modifications.

WARNING!

The equipment can be used by children aged

8 years or older as well as by people with

reduced physical, sensory or mental

abilities or by those who lack the

necessary experience or knowledge, if

they are supervised or after they have

received instructions relating to the safe

use of the equipment as well as

explanations relating to the use of such

equipment.

Children must not play with the equipment.

Cleaning and maintenance intended to be

carried out by the user must not be

performed by unsupervised children.

2.3 Copyright

These user instructions contain information protected

by copyright. It is forbidden to photocopy, duplicate,

translate or record these user instructions on

memory equipment, either in whole or in part,

without prior authorisation of Daikin. Any breaches

shall be subject to the payment of compensation

for any damage caused. All rights are reserved,

including those deriving from the issuing of patents

or the registration of utility models.

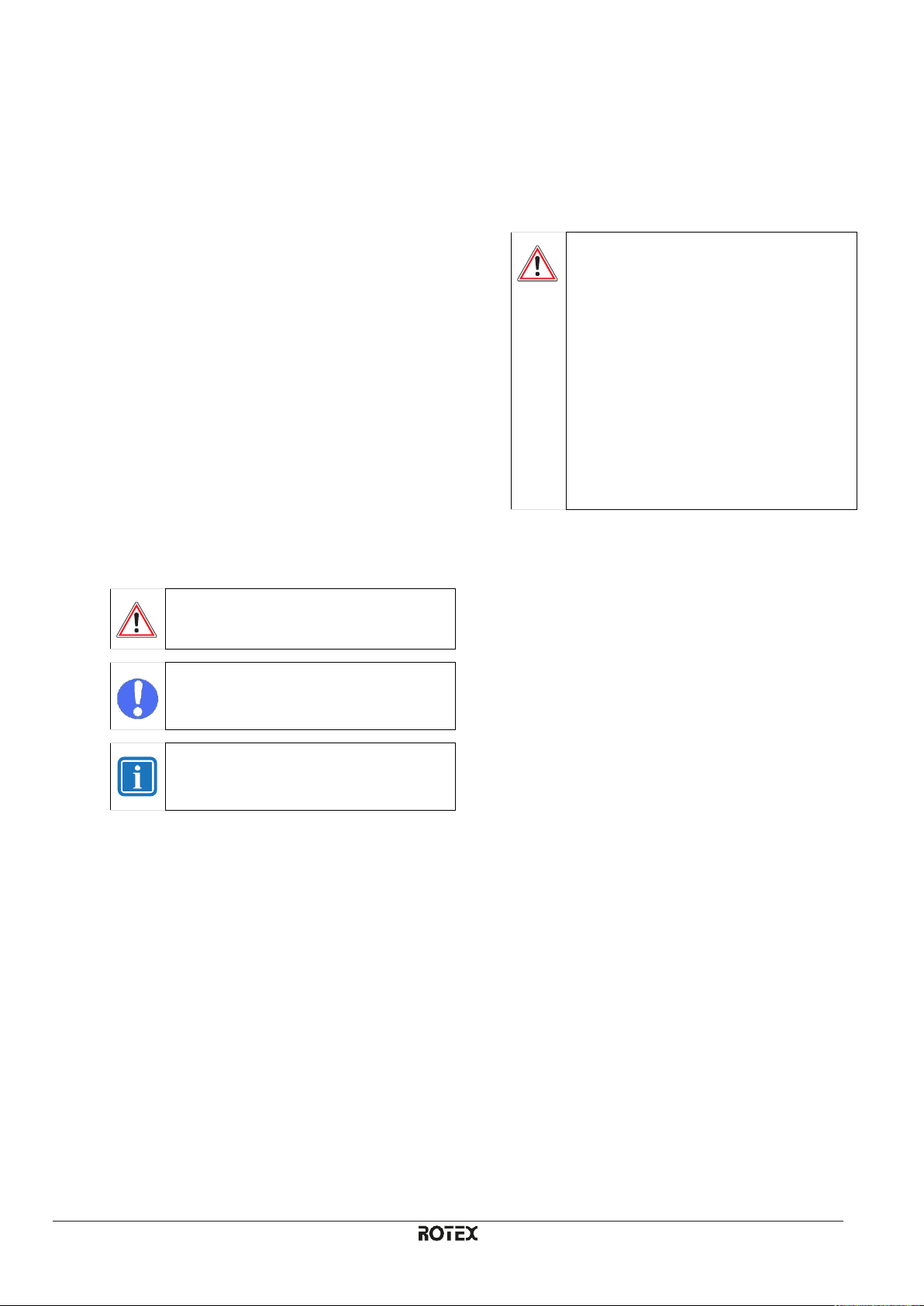

2.4 Operating principle

The equipment belonging to the 1.9 kW and 2.9 kW

series can produce domestic hot water and does

so mainly by using heat pump technology. A heat

pump can transfer thermal energy from a low

temperature source to one with a higher

temperature and vice versa (heat exchangers).

The equipment uses a water circuit consisting of a

compressor, an evaporator, a condenser and a

lamination valve; a liquid/gas coolant flows inside

this circuit (see paragraph 4.6).

The compressor creates a difference in pressure inside

the circuit, which creates a thermodynamic cycle

allowing the coolant fluid to be sucked in through

an evaporator, where the fluid itself evaporates at a

low pressure by absorbing heat. Next, it is

compressed and driven towards the condenser

where the fluid condenses at a high pressure

releasing the absorbed heat. When the fluids

leaves the condenser, it passes through the so-

called “lamination valve”, where it vaporises as it

loses pressure and because of the temperature. It

then re-enters the evaporator and the cycle is

repeated.

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 11

Fig. 1 – Operating principle

The operating principle of the equipment (Fig. 1):

I-II: The coolant fluid sucked in by the compressor flows

inside the evaporator and while it evaporates, it

absorbs the “ecological” heat given by the air.

At the same time, the ambient air is sucked into the

equipment by a fan; the air loses its heat by

passing over the finned-tube battery of the

evaporator;

II-III: The coolant gas passes through the compressor

and it undergoes an increase in pressure that

causes the temperature to rise; transforming the

gas into superheated steam;

III-IV: Inside the condenser, the coolant gas releases its

heat to the water inside the tank (boiler). This

exchange process enables the coolant to transform

from superheated steam into a liquid by

condensing at a constant pressure and undergoing

a lowering in temperature;

IV-I: The liquid coolant passes through the lamination

valve, it undergoes a sudden drop in both pressure

and temperature and it partially evaporates

bringing pressure and temperature back to its initial

conditions. The thermodynamic cycle can begin.

2.5 Available versions and

configurations

The heat pump is available as a 1.9 kW, which can be

set up in different configurations, depending on the

possible integrations with other heating sources

(e.g. solar thermal, biomass power, etc.).

Version

Configuration description

RKHH2E200AAV33

RKHH2E260AAV33

Air source heat pump for

the production of

domestic hot water

RKHH2E260PAAV33

Air source heat pump for

the production of

domestic hot water

suitable for use with

the solar power

system.

3 Handling and transport

The equipment is supplied in a cardboard box. It is

fastened to a pallet with three screws.

Use a fork-lift truck or a pallet truck in order to unload

the equipment: it is opportune for these to have a

load capacity of at least 250 Kg.

In order to loosen the

fixing screws more

easily, you can put

the packaged

equipment on a

horizontal position

on its back side.

The unpacking

operations must be

carried out carefully

to not damage the

equipment

enclosure, if the

unpacking is

carried out with

knives or cutters to

open the cardboard

packaging.

After having removed the packaging, check whether the

unit is intact. If in doubt, do not use the equipment

and seek help from authorised technical staff.

In conformity with the environmental protection

regulations, you should make sure that all

accessories supplied have been removed before

discarding the packaging.

WARNING!

Packaging items (staples, cardboard boxed,

etc.) should not be left within reach of

children, as this can lead to dangerous

situations.

(*) Note: at Daikin’s discretion, the type of packaging

may be subject to change.

It is opportune to protect the equipment from

atmospheric agents as long as it remains idle,

waiting to be used.

Ecological heat

Condenser

Air

Evaporator

Compressor

Lamination

valve

Tank

Cold water

Hot water

Electric heat

Installation Manual

12

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

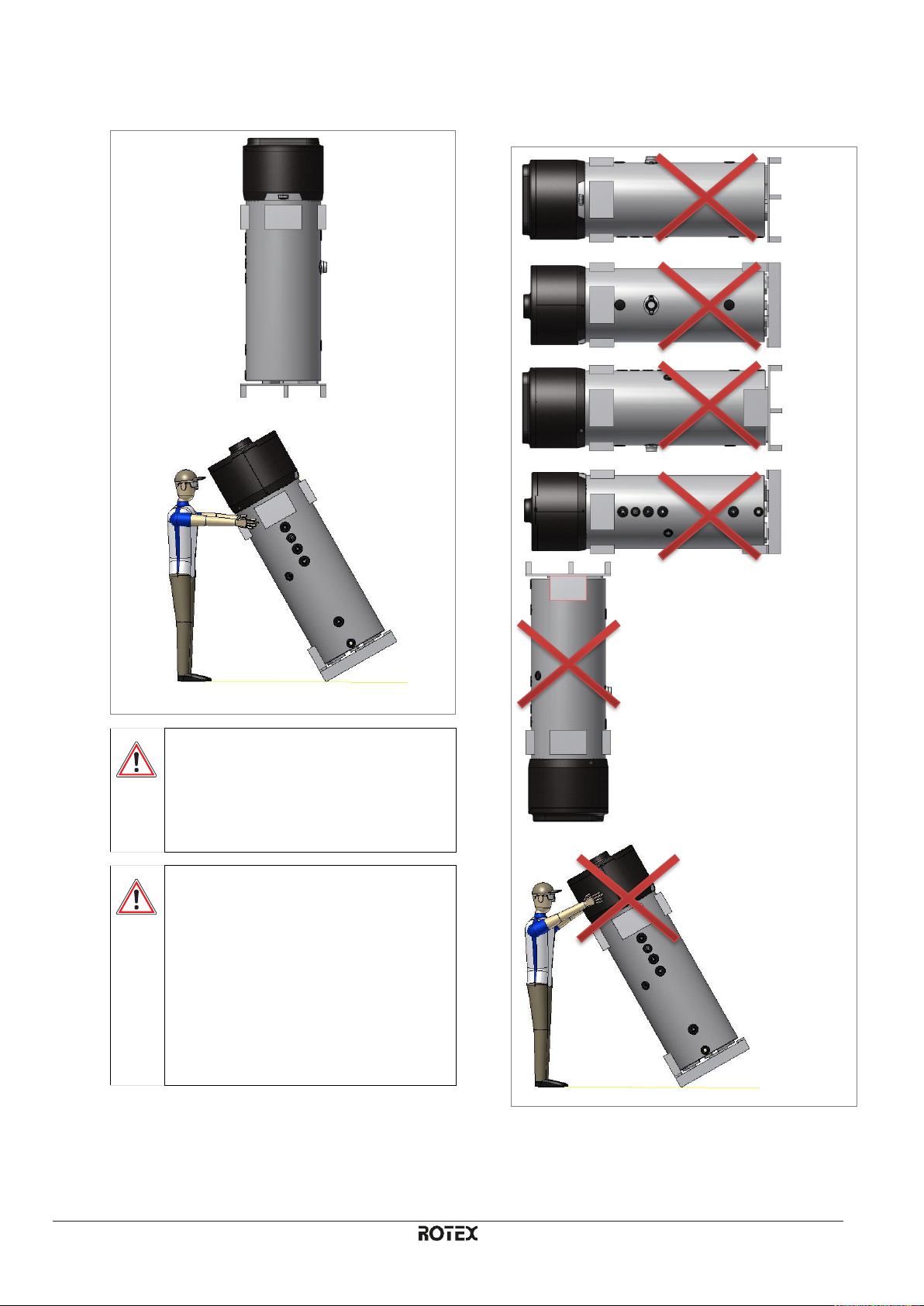

Positions permitted for transporting and handling:

WARNING!

During the unit handling and installation

stages, it is forbidden to put the upper

part of the device under any kind of stress

whatsoever due to the fact that it is not of

a structural nature.

WARNING!

The equipment can be transported

horizontally only during the last km,

following the instructions in the section

“Positions permitted for transporting and

handling” above and taking care of

positioning some supports on the lower

side of the boiler in order to not lean

against the upper part, which is not of a

structural nature. When transporting the

equipment horizontally, the display must

be facing up.

Positions that are not permitted for transporting and

handling purposes:

√

√

RKHH2E-(P)AAV33

ROTEX Domestic Hot Water Heat Pump

2018.8

Installation manual 13

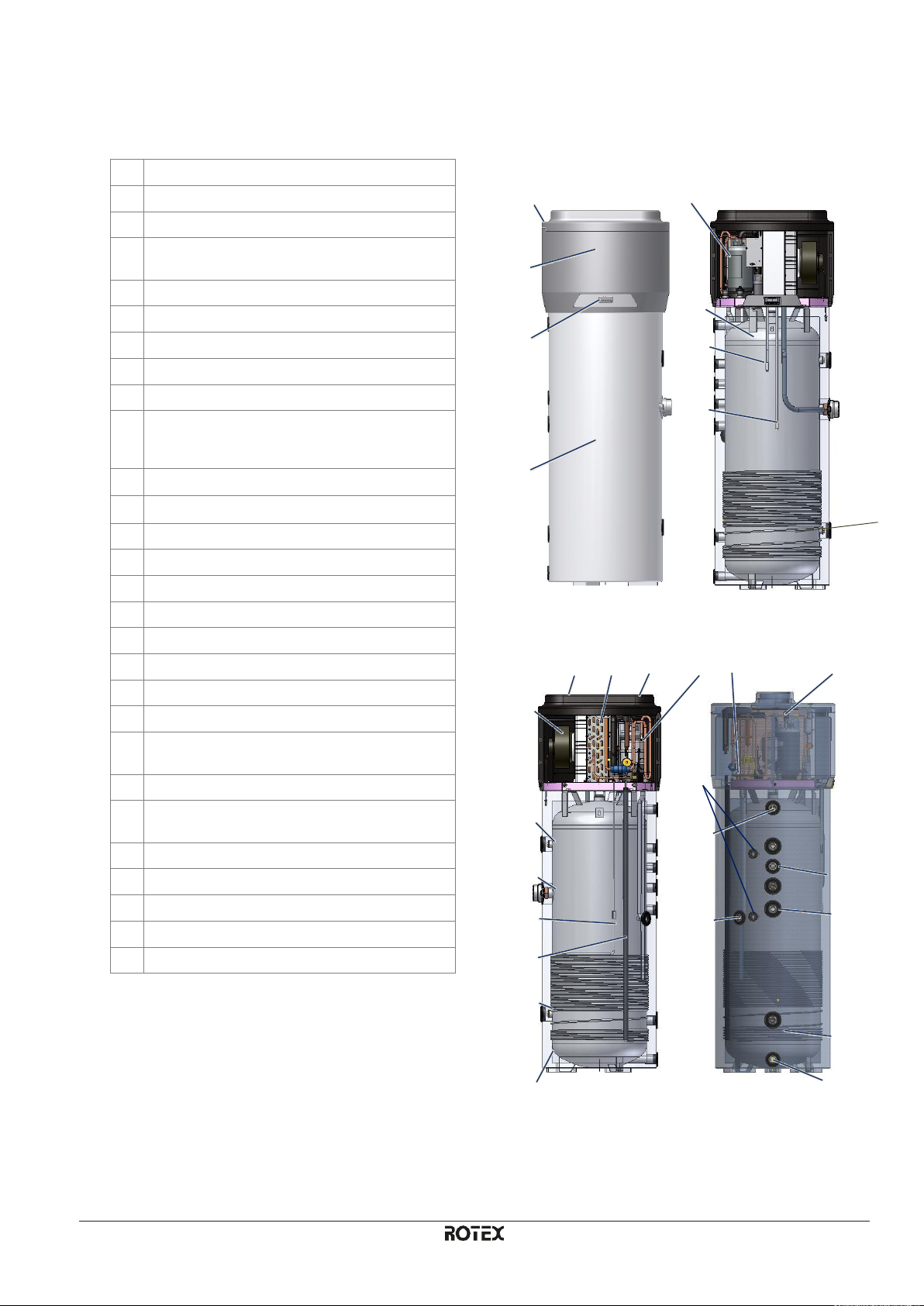

4 Construction characteristics

1

Heat pump.

2

Control panel.

3

Enclosure in embossed ABS.

4

Steel tank (boiler) enamelled according to UNI

standards (capacity: 200; 260 litres).

5

Upper boiler thermistor.

6

Lower boiler thermistor.

7

Coolant recharge.

8

Ambient air recirculation fan.

9

Lamination valve.

10

High-efficiency finned evaporator. The quantity

of fluid inside is regulated by an

appropriate thermostatic valve.

11

Air inlet ( 160 mm).

12

Air outlet ( 160 mm).

13

Hermetically-sealed rotary compressor.

14

Replaceable magnesium anode.

15

(1.5 kW – 230 W) Electric heating element

16

Condenser pump discharge line.

17

Condenser return.

18

Replaceable magnesium anode.

19

Hot water outlet connection joint (G 1”).

20

Recirculation fitting (G ¾”).

21

Inlet, coil fitting for solar thermal power system

(G 1”

1/4

; 1 m2 exchange surface).

22

Condensate drain (G 1/2”).

23

Outlet, coil fitting for solar thermal power

system (G 1”

1/4

; 1 m2 surface).

24

Cold water inlet connection joint (G 1”).

25

50 mm polyurethane insulation.

26

Automatic resetting safety pressure switch.

29

Air inlet filter.

30

½”G fitting for thermistor immersion sleeve

1

4

6

11

10

9

2

8

18

25

24

16

14

5

4

15

12

22

19

23

20

21

17

3

29 7 13

26

30

Loading...

Loading...