Daikin RHYKOMB33AA Operation manuals

Installation and operation

manual

ROTEX HPU hybrid gas boiler module

RHYKOMB33AA

Installation and operation manual

ROTEX HPU hybrid gas boiler module

English

Directivelor, cu amendamentele respective.

<A>

<B>

<C>

KIWA (NB0063)

—

177155_EMC2/03-2011

Direktive z vsemi spremembami.

Direktiivid koos muudatustega.

Директиви, с техните изменения.

Direktyvose su papildymais.

Direktīvās un to papildinājumos.

Smernice, v platnom znení.

18192021222324

Direktiver, med senere ændringer.

Direktiv, med företagna ändringar.

Direktiver, med foretatte endringer.

10111213141516

Directives, as amended.

Direktiven, gemäß Änderung.

deklaruje na własną i wyłączną odpowiedzialność, że urządzenia, których ta deklaracja dotyczy:

declară pe proprie răspundere că echipamentele la care se referă această declaraţie:

z vso odgovornostjo izjavlja, da je oprema naprav, na katero se izjava nanaša:

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluv varustus:

декларира на своя отговорност, че оборудването, за коeто се отнася тази декларация:

visiška savo atsakomybe skelbia, kad įranga, kuriai taikoma ši deklaracija:

ar pilnu atbildību apliecina, ka tālāk aprakstītās iekārtas, uz kurām attiecas šī deklarācija:

vyhlasuje na vlastnú zodpovednosť, že zariadenie, na ktoré sa vzťahuje toto vyhlásenie:

tamamen kendi sorumluluǧunda olmak üzere bu bildirinin ilgili olduǧu donanımının aşaǧıdaki gibi olduǧunu beyan eder:

17

18

19

20

21

22

23

24

25

megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat előírás szerint használják:

spełniają wymogi następujących norm i innych dokumentów normalizacyjnych, pod warunkiem że używane są zgodnie z naszymi instrukcjami:

sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiţia ca acestea să fie utilizate în conformitate cu

instrucţiunile noastre:

skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z našimi navodili:

on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:

съответстват на следните стандарти или други нормативни документи, при условие, че се използват съгласно нашите инструкции:

atitinka žemiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mūsų nurodymus:

tad, ja lietoti atbilstoši ražotāja norādījumiem, atbilst sekojošiem standartiem un citiem normatīviem dokumentiem:

sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, že sa používajú v súlade snašim

návodom:

161718192021222324

ürünün, talimatlarımıza göre kullanılması koşuluyla aşağıdaki standartlar ve norm belirten belgelerle uyumludur:

25

Directives, telles que modifiées.

010203040506070809

Değiştirilmiş halleriyle Yönetmelikler.

25

Direktiivejä, sellaisina kuin ne ovat muutettuina.

v platném znění.

Smjernice, kako je izmijenjeno.

irányelv(ek) és módosításaik rendelkezéseit.

z późniejszymi poprawkami.

17

Richtlijnen, zoals geamendeerd.

Directivas, según lo enmendado.

Direttive, come da modifica.

Οδηγιών, όπως έχουν τροποποιηθεί.

Directivas, conforme alteração em.

както е изложено в <A> и оценено положително от <B>

съгласно Сертификата<C>.

kaip nustatyta <A> ir kaip teigiamai nuspręsta <B> pagal

Sertifikatą<C>.

kā norādīts <A> un atbilstoši <B> pozitīvajam vērtējumam

saskaņā ar sertifikātu<C>.

ako bolo uvedené v <A> a pozitívne zistené <B> vsúlade

s osvedčením<C>.

<A>’da belirtildiği gibi ve <C>Sertifikasına göre <B>

tarafından olumlu olarak değerlendirildiği gibi.

Директив со всеми поправками.

21Забележка*

22Pastaba*

23Piezīmes*

24Poznámka*

25Not*

a(z) <A> alapján, a(z) <B> igazolta a megfelelést, a(z)

<C>tanúsítvány szerint.

zgodnie z dokumentacją <A>, pozytywną

opinią <B> i Świadectwem<C>.

aşa cum este stabilit în <A> şi apreciat pozitiv de<B>

în conformitate cu Certificatul<C>.

kot je določeno v <A> in odobreno s strani <B>

vskladu scertifikatom<C>.

nagu on näidatud dokumendis <A> ja heaks kiidetud

<B> järgi vastavalt sertifikaadile<C>.

16Megjegyzés*

17Uwaga*

18Notă*

19Opomba*

20Märkus*

Low Voltage 2014/35/EU

Gas Appliances 2009/142/EC

enligt <A> och godkänts av <B> enligt

Certifikatet<C>.

som det fremkommer i <A> og gjennom positiv

bedømmelse av <B> ifølge Sertifikat<C>.

jotka on esitetty asiakirjassa <A> ja jotka <B>

on hyväksynyt Sertifikaatin<C> mukaisesti.

jak bylo uvedeno v <A> a pozitivně zjištěno

<B> vsouladu sosvědčením<C>.

kako je izloženo u <A> i pozitivno ocijenjeno odstrane

Boiler Efficiency requirements 92/42/EEC

Electromagnetic Compatibility 2014/30/EU *

заявляет, исключительно под свою ответственность, что оборудование, к которому относится настоящее заявление:

erklærer under eneansvarlig, at udstyret, som er omfattet af denne erklæring:

deklarerar i egenskap av huvudansvarig, att utrustningen som berörs av denna deklaration innebär att:

erklærer et fullstendig ansvar for at det utstyr som berøres av denne deklarasjon innebærer at:

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat laitteet:

prohlašuje ve své plné odpovědnosti, že zařízení, k němuž se toto prohlášení vztahuje:

izjavljuje pod isključivo vlastitom odgovornošću da oprema na koju se ova izjava odnosi:

teljes felelőssége tudatában kijelenti, hogy a berendezések, melyekre e nyilatkozat vonatkozik:

09

10

11

12

13

14

15

16

estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) normativo(s), desde que estes sejam utilizados de

acordo com as nossas instruções:

соответствуют следующим стандартам или другим нормативным документам, при условии их использования согласно нашим инструкциям:

overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore instrukser:

respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under förutsättning att

användning sker i överensstämmelse med våra instruktioner:

respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at disse brukes i

henhold til våre instrukser:

vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme mukaisesti:

za předpokladu, že jsou využívány v souladu s našimi pokyny, odpovídají následujícím normám nebo normativním dokumentům:

08091011121314

u skladu sa slijedećim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s našim uputama:

15

ob upoštevanju določb:

vastavalt nõuetele:

следвайки клаузите на:

laikantis nuostatų, pateikiamų:

ievērojot prasības, kas noteiktas:

19202122232425

održiavajúc ustanovenia:

11Information*

12Merk*

13Huom*

bunun koşullarına uygun olarak:

delineato nel <A> e giudicato positivamente da<B>

secondo il Certificato<C>.

όπως καθορίζεται στο <A> και κρίνεται θετικά

από το <B> σύμφωνα με το Πιστοποιητικό<C>.

tal como estabelecido em <A> e com o parecer positivo

<B> prema Certifikatu<C>.

14Poznámka*

15Napomena*

de <B> de acordo com o Certificado<C>.

как указано в <A> и в соответствии сположительным

решением <B> согласно Свидетельству<C>.

som anført i <A> og positivt vurderet af <B> ihenhold til

Certifikat<C>.

Georg Blümel

Managing Director

1st of April 2016

declares under its sole responsibility that the equipment to which this declaration relates:

erklärt auf seine alleinige Verantwortung daß die Ausrüstung für die diese Erklärung bestimmt ist:

CE - DECLARATION-OF-CONFORMITY CE - DECLARACION-DE-CONFORMIDAD CE - DECLARAÇÃO-DE-CONFORMIDADE CE - ERKLÆRING OM-SAMSVAR CE - IZJAVA-O-USKLAĐENOSTI CE - IZJAVA O SKLADNOSTI CE - ATITIKTIES-DEKLARACIJA

CE - KONFORMITÄTSERKLÄRUNG CE - DICHIARAZIONE-DI-CONFORMITA CE - ЗАЯВЛЕНИЕ-О-СООТВЕТСТВИИ CE - ILMOITUS-YHDENMUKAISUUDESTA CE - MEGFELELŐSÉGI-NYILATKOZAT CE - VASTAVUSDEKLARATSIOON CE - ATBILSTĪBAS-DEKLARĀCIJA

CE - DECLARATION-DE-CONFORMITE CE - ΔHΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ CE - OVERENSSTEMMELSESERKLÆRING CE - PROHLÁŠENÍ-O-SHODĚ CE - DEKLARACJA-ZGODNOŚCI CE - ДЕКЛАРАЦИЯ-ЗА-СЪОТВЕТСТВИЕ CE - VYHLÁSENIE-ZHODY

CE - CONFORMITEITSVERKLARING CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE CE - DECLARAŢIE-DE-CONFORMITATE CE - UYGUNLUK-BEYANI

déclare sous sa seule responsabilité que l'équipement visé par la présente déclaration:

ROTEX

01

02

03

06Nota*

07Σημείωση*

08Nota*

09Примечание*

10Bemærk*

under iagttagelse af bestemmelserne i:

enligt villkoren i:

gitt i henhold til bestemmelsene i:

noudattaen määräyksiä:

za dodržení ustanovení předpisu:

prema odredbama:

követi a(z):

zgodnie z postanowieniami Dyrektyw:

101112131415161718

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de apparatuur waarop deze verklaring betrekking heeft:

declara bajo su única responsabilidad que el equipo al que hace referencia la declaración:

dichiara sotto la propria responsabilità che gli apparecchi a cui è riferita questa dichiarazione:

δηλώνει με αποκλειστική της ευθύνη ότι ο εξοπλισμός στον οποίο αναφέρεται η παρούσα δήλωση:

declara sob sua exclusiva responsabilidade que os equipamentos a que esta declaração se refere:

RHYKOMB33AA*,

08

* = , , 1, 2, 3, ..., 9

04

05

06

07

are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our instructions:

der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspricht/entsprechen, unter der Voraussetzung, daß sie gemäß

unseren Anweisungen eingesetzt werden:

sont conformes à la/aux norme(s) ou autre(s) document(s) normatif(s), pour autant qu'ils soient utilisés conformément à nos instructions:

conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig onze

instructies:

están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) normativo(s), siempre que sean utilizados de acuerdo con nuestras

instrucciones:

sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle nostre istruzioni:

είναι σύμφωνα με το(α) ακόλουθο(α) πρότυπο(α) ή άλλο έγγραφο(α) κανονισμών, υπό την προϋπόθεση ότι χρησιμοποιούνται

01020304050607

σύμφωνα με τις οδηγίες μας:

following the provisions of:

gemäß den Vorschriften der:

conformément aux stipulations des:

EN60335-2-102,

overeenkomstig de bepalingen van:

010203040506070809

în urma prevederilor:

as set out in <A> and judged positively by <B>

according to the Certificate<C>.

wie in <A> aufgeführt und von <B> positiv

beurteilt gemäß Zertifikat<C>.

tel que défini dans <A> et évalué positivement par <B>

conformément au Certificat<C>.

zoals vermeld in <A> en positief beoordeeld door <B>

siguiendo las disposiciones de:

secondo le prescrizioni per:

με τήρηση των διατάξεων των:

de acordo com o previsto em:

в соответствии с положениями:

01Note*

02Hinweis*

03Remarque*

04Bemerk*

overeenkomstig Certificaat<C>.

como se establece en <A> y es valorado

positivamente por <B> de acuerdo con el

05Nota*

Certificado<C>.

2P369568-4C

Table of contents

Table of contents

1 About the product 3

2 About the documentation 4

2.1 About this document.................................................................. 4

3 General safety precautions 4

3.1 About the documentation .......................................................... 4

3.1.1 Meaning of warnings and symbols.............................. 4

3.2 For the installer.......................................................................... 5

3.2.1 General ....................................................................... 5

3.2.2 Installation site ............................................................ 5

3.2.3 Water .......................................................................... 5

3.2.4 Electrical ..................................................................... 6

3.2.5 Gas ............................................................................. 6

3.2.6 Gas exhaust................................................................ 7

3.2.7 Local legislation .......................................................... 7

4 About the box 7

4.1 Gas boiler .................................................................................. 7

4.1.1 To unpack the gas boiler............................................. 7

4.1.2 To remove the accessories from the gas boiler.......... 8

5 About the units and options 8

5.1 Identification .............................................................................. 8

5.1.1 Identification label: gas boiler...................................... 8

5.2 Combining units and options ..................................................... 9

5.2.1 Possible options for the gas boiler.............................. 9

6 Preparation 11

6.1 Preparing the gas boiler installation .......................................... 11

7 Installation 11

7.1 Opening the units ...................................................................... 11

7.1.1 To open the gas boiler ................................................ 11

7.1.2 To open the switch box cover of the gas boiler........... 11

7.2 Mounting the gas boiler ............................................................. 11

7.2.1 To install the gas boiler............................................... 12

7.2.2 To install the condensate trap..................................... 12

7.3 Condensate pipe work............................................................... 13

7.3.1 Internal connections.................................................... 13

7.3.2 External connections................................................... 14

7.4 Connecting the water piping...................................................... 14

7.4.1 Connecting the water piping of the gas boiler............. 14

7.5 Connecting the electrical wiring................................................. 15

7.5.1 To connect the main power supply of the gas boiler... 15

7.5.2 To connect the communication cable between gas

boiler and indoor unit .................................................. 15

7.6 Connecting the gas piping......................................................... 16

7.6.1 To connect the gas pipe.............................................. 16

7.7 Connecting the boiler to the flue gas system ............................ 16

7.7.1 To change the gas boiler to 80/125 concentric

connection................................................................... 16

7.7.2 To change the 60/100 concentric connection to a

dual pipe connection ................................................... 17

7.7.3 Calculate the total piping length.................................. 17

7.7.4 Appliance categories and pipe lengths ....................... 18

7.7.5 Applicable materials.................................................... 19

7.7.6 Flue pipe position........................................................ 19

7.7.7 Insulation of the gas exhaust and air intake................ 20

7.7.8 Fitting a horizontal flue system ................................... 20

7.7.9 Fitting a vertical flue system........................................ 20

7.7.10 Plume management kit ............................................... 21

7.7.11 Flues in voids.............................................................. 21

7.8 Finishing the gas boiler installation ........................................... 21

7.8.1 To close the gas boiler................................................ 21

7.8.2 To install the cover plate............................................. 22

8 Configuration 22

8.1 Gas boiler ................................................................................... 22

8.1.1 Overview: Configuration............................................... 22

8.1.2 Basic configuration....................................................... 22

9 Operation 27

9.1 Overview: Operation................................................................... 27

9.2 Heating ....................................................................................... 27

9.3 Domestic hot water..................................................................... 27

9.4 Operation modes........................................................................ 27

10 Commissioning 28

10.1 To perform an air purge on the gas supply ................................ 28

10.2 To perform a test run on the gas boiler ...................................... 28

11 Maintenance and service 29

11.1 Maintenance safety precautions................................................. 29

11.1.1 Opening the gas boiler................................................. 29

11.2 To disassemble the gas boiler.................................................... 29

11.3 To clean the inside of the gas boiler........................................... 30

11.4 To assemble the gas boiler ........................................................ 31

12 Troubleshooting 31

12.1 General guidelines ..................................................................... 31

12.2 Precautions when troubleshooting ............................................. 31

12.3 Solving problems based on symptoms....................................... 32

12.3.1 Symptom: The burner does NOT ignite ....................... 32

12.3.2 Symptom: The burner ignites noisily............................ 32

12.3.3 Symptom: The burner resonates ................................. 32

12.3.4 Symptom: No space heating by the gas boiler ............ 32

12.3.5 Symptom: The power is reduced ................................. 32

12.3.6 Symptom: Space heating does NOT reach the

temperature.................................................................. 32

12.3.7 Symptom: No domestic hot water................................ 32

12.3.8 Symptom: Hot water does NOT reach the

temperature (no tank installed) .................................... 33

12.4 Solving problems based on error codes..................................... 33

12.4.1 Error codes: Overview ................................................. 33

13 Glossary 33

14 Technical data 35

14.1 Components ............................................................................... 35

14.1.1 Components: Gas boiler .............................................. 35

14.2 Wiring diagram ........................................................................... 36

14.2.1 Wiring diagram: Gas boiler .......................................... 36

14.3 Technical specifications ............................................................. 36

14.3.1 Technical specifications: Gas boiler............................. 36

1 About the product

Especially for UK:

The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and

installers. The purpose is to ensure that customers are provided with

the correct equipment for their needs, that it is installed,

commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the

requirements of the appropriate Building Regulations. The

Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for

future reference.

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

Installation and operation manual

3

2 About the documentation

a b

Installers are required to carry out installation, commissioning and

servicing work in accordance with the Benchmark Code of Practice

which is available from the Heating and Hotwater Industry Council

who manage and promote the Scheme. Visit http://

www.centralheating.co.uk for more information.

Approvals

British Gas Service listing:

RHYKOMB33AA*: G.C.N. 47-464-01

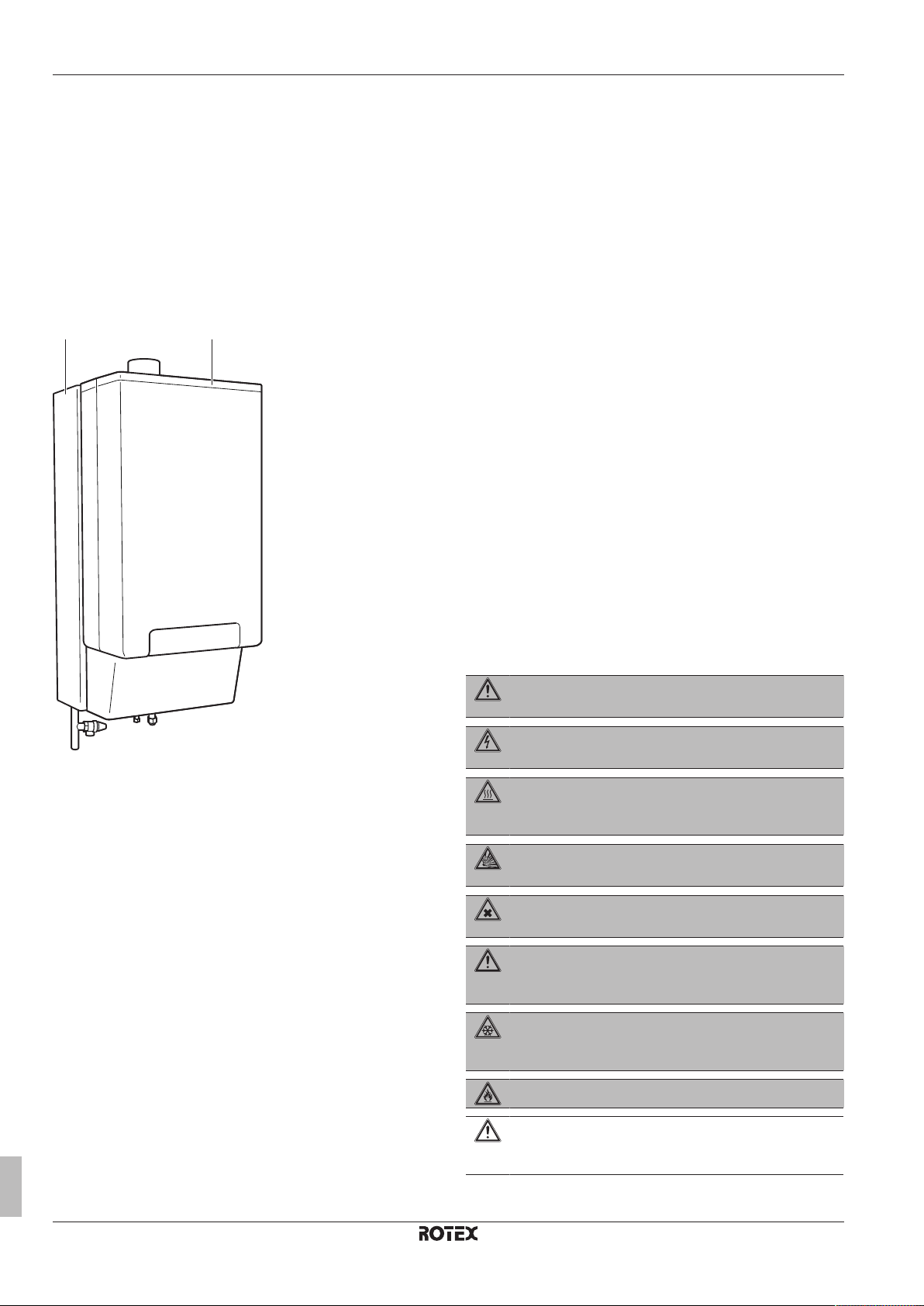

The product (hybrid system) is composed of two modules:

▪ heat pump module,

▪ gas boiler module.

These modules MUST always be installed and used together.

▪ Outdoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer reference guide:

▪ Preparation of the installation, reference data,…

▪ Format: Digital files on the ROTEX homepage

▪ Addendum book for optional equipment:

▪ Additional info about how to install optional equipment

▪ Format: Paper (in the box of the indoor unit) + Digital files on

the ROTEX homepage

Latest revisions of the supplied documentation may be available on

the regional ROTEX website or via your dealer.

The original documentation is written in English. All other languages

are translations.

3 General safety precautions

3.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and the installer reference guide must be

performed by an authorized installer.

a Heat pump module

b Gas boiler module

2 About the documentation

2.1 About this document

Target audience

Authorised installers

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the indoor unit)

▪ Heat pump module installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the indoor unit)

▪ Gas boiler module installation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the gas boiler unit)

3.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

DANGER: RISK OF POISONING

Indicates a situation that could result in poisoning.

WARNING

Indicates a situation that could result in death or serious

injury.

WARNING: PROTECT AGAINST FROST

Indicates a situation that could result in equipment or

property damage.

WARNING: FLAMMABLE MATERIAL

CAUTION

Indicates a situation that could result in minor or moderate

injury.

Installation and operation manual

4

ROTEX HPU hybrid gas boiler module

RHYKOMB33A

4P353068-1D – 2016.10

3 General safety precautions

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

Symbol Explanation

Before installation, read the installation and

operation manual, and the wiring instruction sheet.

Before performing maintenance and service tasks,

read the service manual.

For more information, see the installer and user

reference guide.

3.2 For the installer

3.2.1 General

If you are not sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by ROTEX.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the ROTEX documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminium fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information must be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

For Swiss market, domestic hot water operation should only be

prepared in combination with a tank. Instant domestic hot water by

the gas boiler is NOT allowed. Make the correct settings as

described in this manual.

Please follow following Swiss regulations and directives:

▪ SVGW-gas principles G1 for gas installations,

▪ SVGW-gas principles L1 for liquid gas installations,

▪ cautional instances regulations (e.g., fire regulation).

3.2.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the unit's weight and

vibration.

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

▪ Make sure walls sensitive to heat (e.g. wood) are protected by

suitable insulation.

▪ ONLY operate the gas boiler if a sufficient supply of combustion

air is ensured. In case of a concentric air/flue gas system

dimensioned according to the specifications of this manual, this is

fulfilled automatically and there are no other conditions for the

equipment installation room. This method of operation applies

exclusively.

▪ This gas boiler is NOT designed for room air dependent operation.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

▪ In bathrooms.

▪ In places where frost is possible. The ambient temperature around

the indoor unit should be >5°C.

3.2.3 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

Installation and operation manual

5

3 General safety precautions

NOTICE

Make sure water quality complies with EU directive

98/83EC.

Avoid damages caused by deposits and corrosion. To prevent

corrosion products and deposits, observe the applicable regulations

of technology.

Measures for desalination, softening or hardness stabilization are

necessary if the filling and top-up water have a high total hardness

(>3 mmol/l–sum of the calcium and magnesium concentrations,

calculated as calcium carbonate).

Using filling water and top-up water which does NOT meet the stated

quality requirements can cause a considerably reduced service life

of the equipment. The responsibility for this is entirely that of the

user.

3.2.4 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage categoryIII

condition, shall be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring must be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do not come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

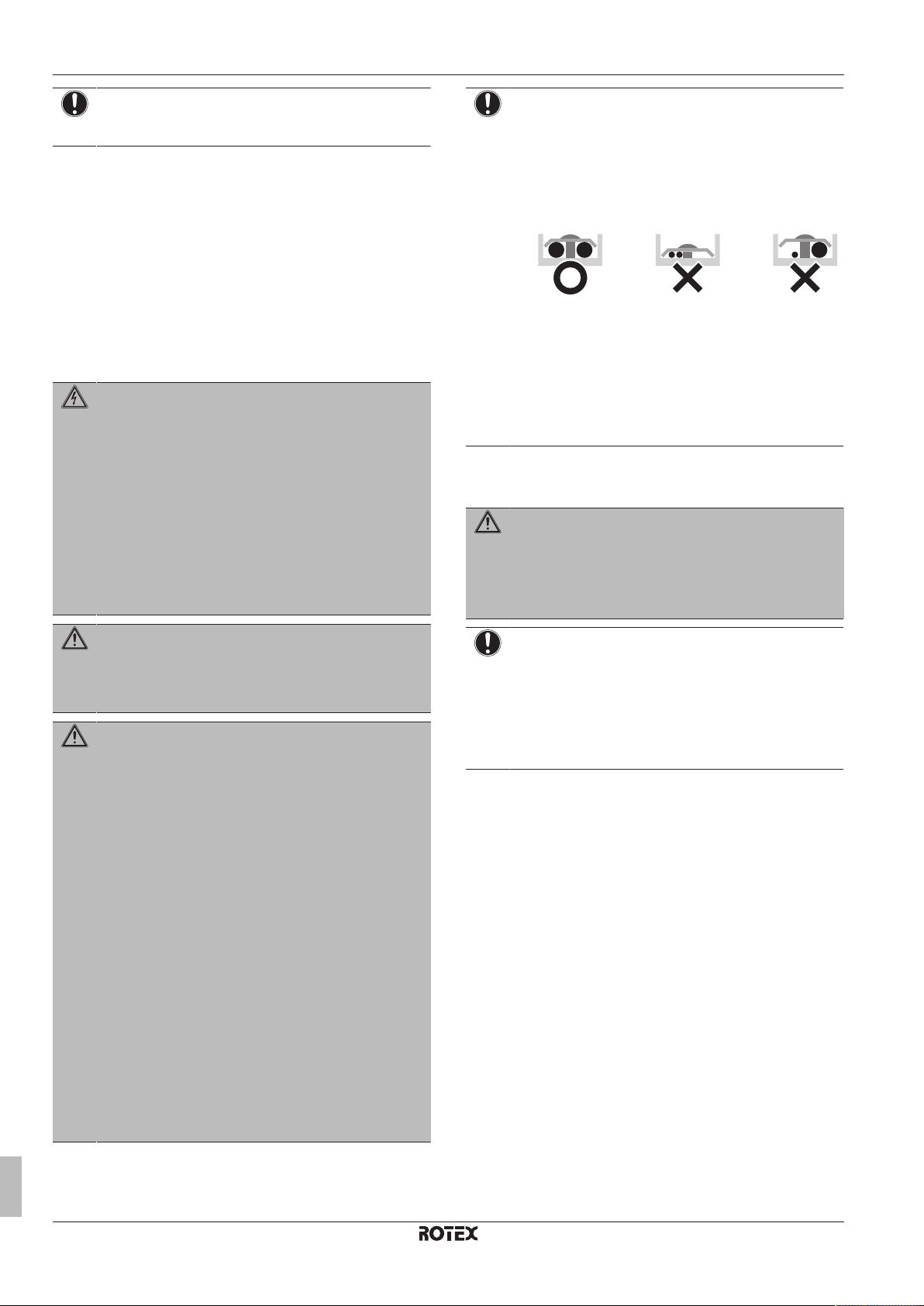

NOTICE

Precautions when laying power wiring:

▪ Do not connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure below.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1metre away from televisions or radios

to prevent interference. Depending on the radio waves, a distance of

1metre may not be sufficient.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

3.2.5 Gas

The gas boiler is factory‑set to:

▪ the type of gas quoted on the type identification plate or on the

setting type identification plate,

▪ the gas pressure quoted on the type identification plate.

Operate the unit ONLY with the gas type and gas pressure indicated

on these type identification plates.

Installation and adaptation of the gas system MUST be conducted

by:

▪ personnel qualified for this work,

▪ in compliance with valid gas installation related guidelines,

▪ in accordance with applicable regulations of the gas supply

company,

▪ In accordance with local and national regulations.

Boilers that use natural gas MUST be connected to a governed

meter.

Boilers that use liquid petroleum gas (LPG) MUST be connected to a

regulator.

The size of the gas supply pipe should under no circumstance be

less than 22mm.

Installation and operation manual

6

ROTEX HPU hybrid gas boiler module

RHYKOMB33A

4P353068-1D – 2016.10

4 About the box

1

2

The meter or regulator and pipe work to the meter MUST be

checked preferably by the gas supplier. This is to ensure that the

equipment works good and meets the gas flow and pressure

requirements.

DANGER

If you smell gas:

▪ call immediately your local gas supplier and your

installer,

▪ call the suppliers's number on the side of the LPG tank

(if applicable),

▪ turn off the emergency control valve at the meter/

regulator,

▪ do NOT turn electrical switches ON or OFF,

▪ do NOT strike matches or smoke,

▪ put out naked flames,

▪ open doors and windows immediately,

▪ keep people away from the affected area.

3.2.6 Gas exhaust

Flue systems must NOT be modified or installed in any way other

than as described in the fitting instructions. Any misuses or

unauthorized modifications to the appliance, flue or associated

components and systems could invalidate the warranty. The

manufacturer accepts no liability arising from any such actions,

excluding statutory rights.

It is NOT allowed to combine flue system parts purchased from

different suppliers.

▪ BS 6891: 1998 Installation of low pressure gas pipe-work

installation up to 35mm (RI)

▪ BS 7593: 1992 Code of practice for treatment of water in heating

systems

▪ BS 7671: 2001 Requirements for electrical installations, IEE

Wiring regulations

▪ BS 7074: 1 Code of practice for domestic and hot water supply

▪ EN12828 Central heating for domestic premises

Potable water: all seals, joints and compounds (including flux and

solder) and components used as part of the secondary domestic

water system MUST be approved by WRAS.

4 About the box

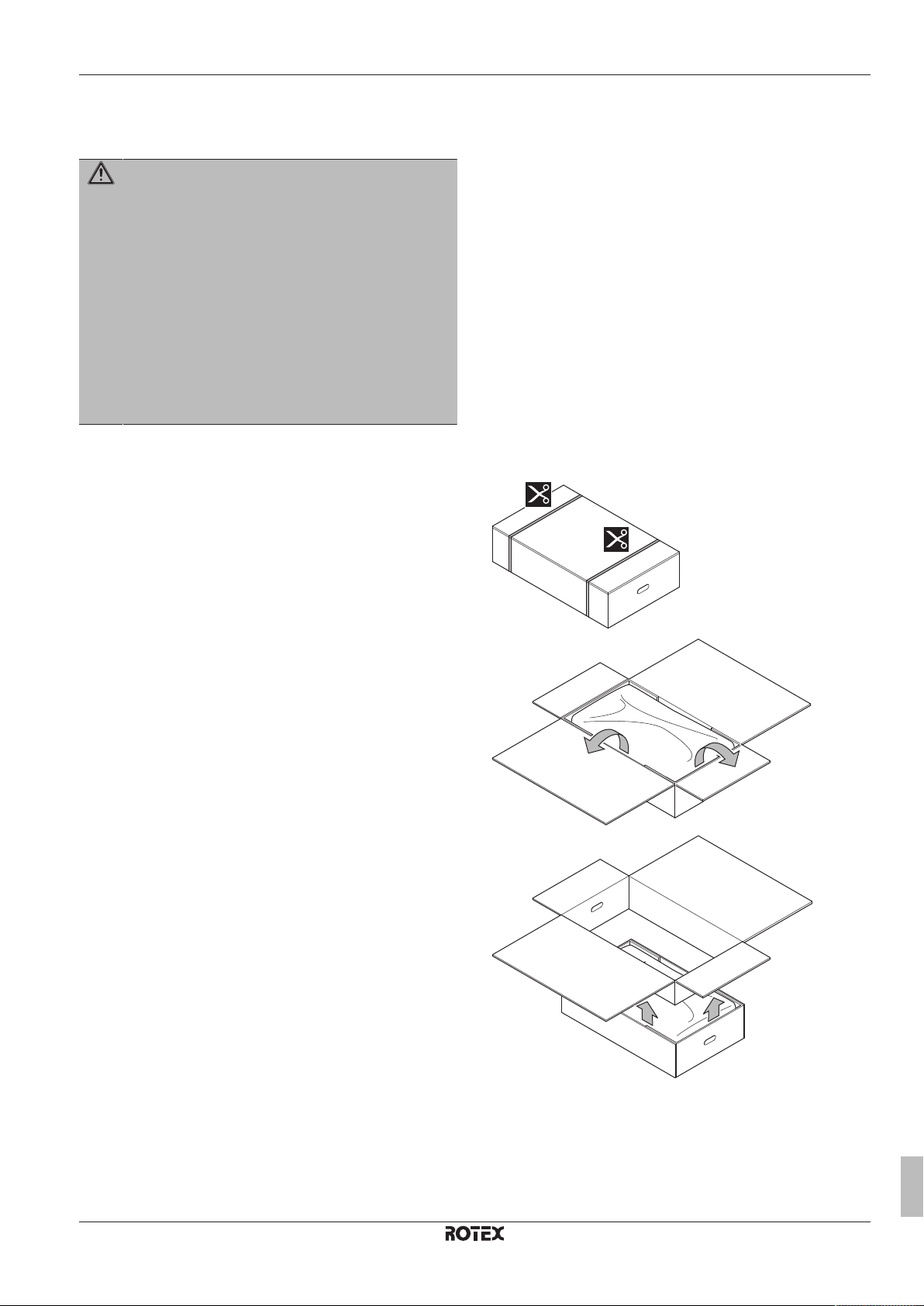

4.1 Gas boiler

4.1.1 To unpack the gas boiler

Before unpacking, move the gas boiler as close as possible to its

installation position.

3.2.7 Local legislation

See the local and national regulations.

Local regulations for UK

It is law that all gas appliances are installed by a gas safe registered

competent engineer and in accordance with the following

recommendations:

▪ Current Gas Safety (Installation and Use) Regulations

▪ All current building regulations

▪ Building Standards (Scotland) Consolidated

▪ This appliance MUST be installed in accordance with the Gas

(Safety and Use) Regulations, current Building Regulations,

Building Standards (Scotland), I.S.813 Installation of Gas

Appliances (Ireland), IEE Wiring Regulations (BS 7671), Health

and Safety Document No. 635 (Electricity at Work Regulations)

and Local Water Authority Bye Laws

▪ UK Water Regulations and Bye Laws

▪ Health & Safety

The installation MUST comply with the following British Standards

codes of practice:

▪ BS 5440: Flues and Ventilation for gas appliances of rated input

NOT exceeding 70kW (Part 1 Flues)

▪ BS 5440: Flues and Ventilation for gas appliances of rated input

NOT exceeding 70kW (Part 2 Air Supply)

▪ BS 5546: 2000 Installation of gas hot water supplies for domestic

purposes.

▪ BS 5549: 1990 Forced circulation hot water systems.

▪ BS 6700: 1997 Design, Installation, testing and maintenance of

services supplying hot water

▪ BS 6798: 2000 Specification for installation of gas fired hot water

boilers of rated input NOT exceeding 70kW

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

Installation and operation manual

7

5 About the units and options

a

b

c

a b c

No:

Anno:

Type:

NOx classe:

PIN:

G.C.:

SVGW:

Qnw(net)

PMW

kW

kW

kW

bar

Qn (net)

Pn

PMS

bar

°C

0063

2013

Tmax

Condensing boiler

b

i

j

a

c

d

e

f

k

l

m

n

o

p

q

r

s

g

h

5 About the units and options

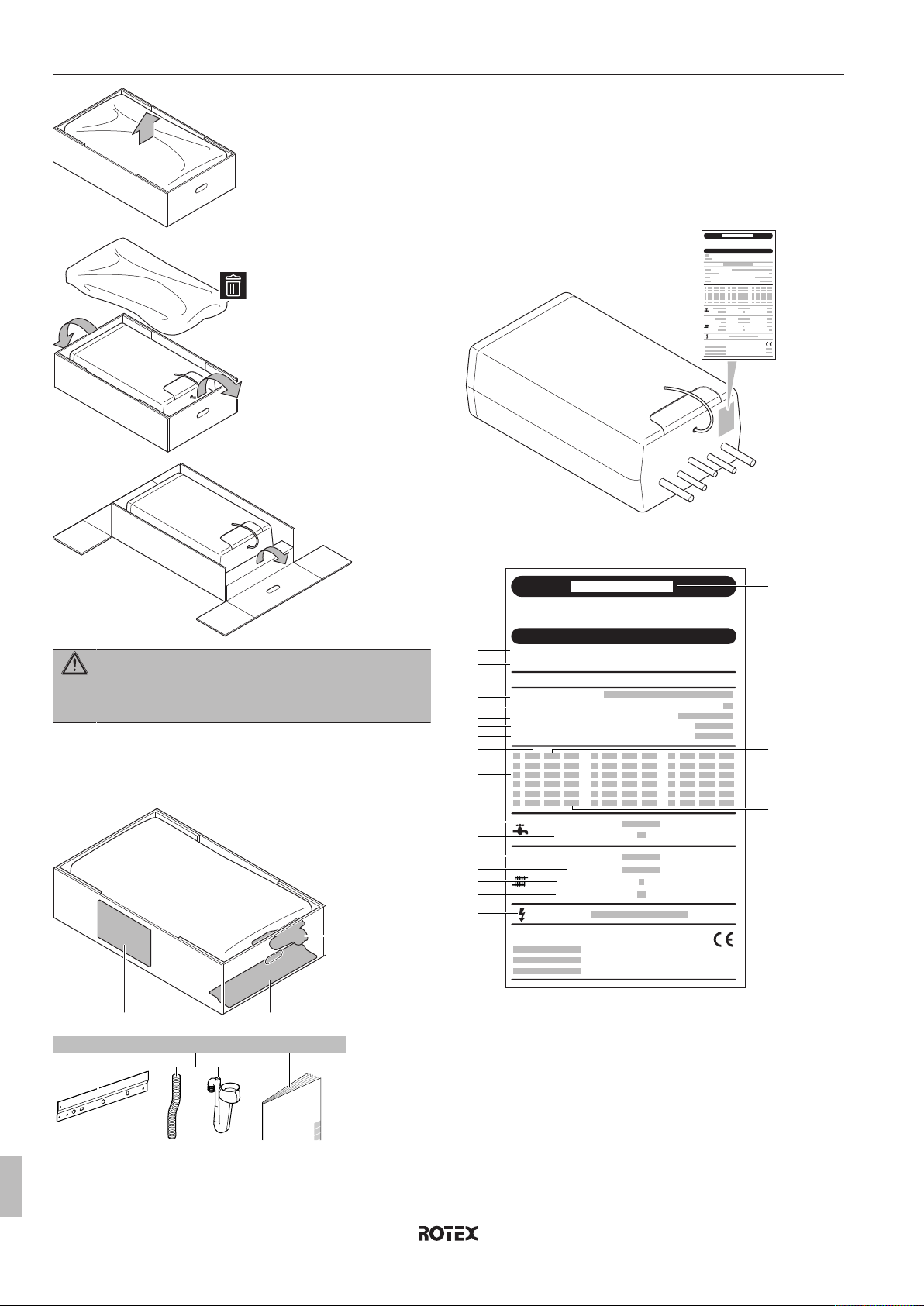

5.1 Identification

5.1.1 Identification label: gas boiler

Location

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

4.1.2 To remove the accessories from the gas boiler

1 Remove the accessories.

Installation and operation manual

a Mounting strip

b Condensate trap

c Installation manual and operation manual

8

Model identification

a Model

b Serial number

c Production year

d Appliance type

e NOx class

f PIN number: notified body reference

g Destination country

h Gas type

i Gas supply pressure (mbar)

j Appliance category

k Domestic hot water heat output (kW)

l Maximum domestic hot water pressure (bar)

m Heat output (space heating) (kW)

n Nominal power (kW)

o Maximum space heating pressure (bar)

p Maximum flow temperature (°C)

q Electrical supply

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

5 About the units and options

r GCN gas council number

s SVGW number

5.2 Combining units and options

5.2.1 Possible options for the gas boiler

Main options

Boiler cover plate (EKHY093467)

Cover plate to protect the gas boiler’s piping and valves.

For installation instructions, see the installation manual of the cover

plate.

Gas conversion kit G25 (EKPS076227)

Kit for the conversion of the gas boiler for use with gas type G25.

Gas conversion kit G31 (EKHY075787)

Kit for the conversion of the gas boiler for use with gas type G31

(propane).

Dual pipe conversion kit (EKHY090707)

Kit for the conversion of a concentric flue gas system to a dual pipe

system.

For installation instructions, see the installation manual of the dual

pipe conversion kit.

80/125 concentric connection kit (EKHY090717)

Kit for the conversion of 60/100 concentric flue gas connections to

80/125 concentric flue gas connections.

For installation instructions, see the installation manual of the

concentric connection kit.

Flue gas flap valve (EKFGF1A)

Non-return flap valve for use in multi-boiler flue gas systems. This

valve can only be used in systems using natural gas (G20, G25),

and CANNOT be used in systems using propane (G31).

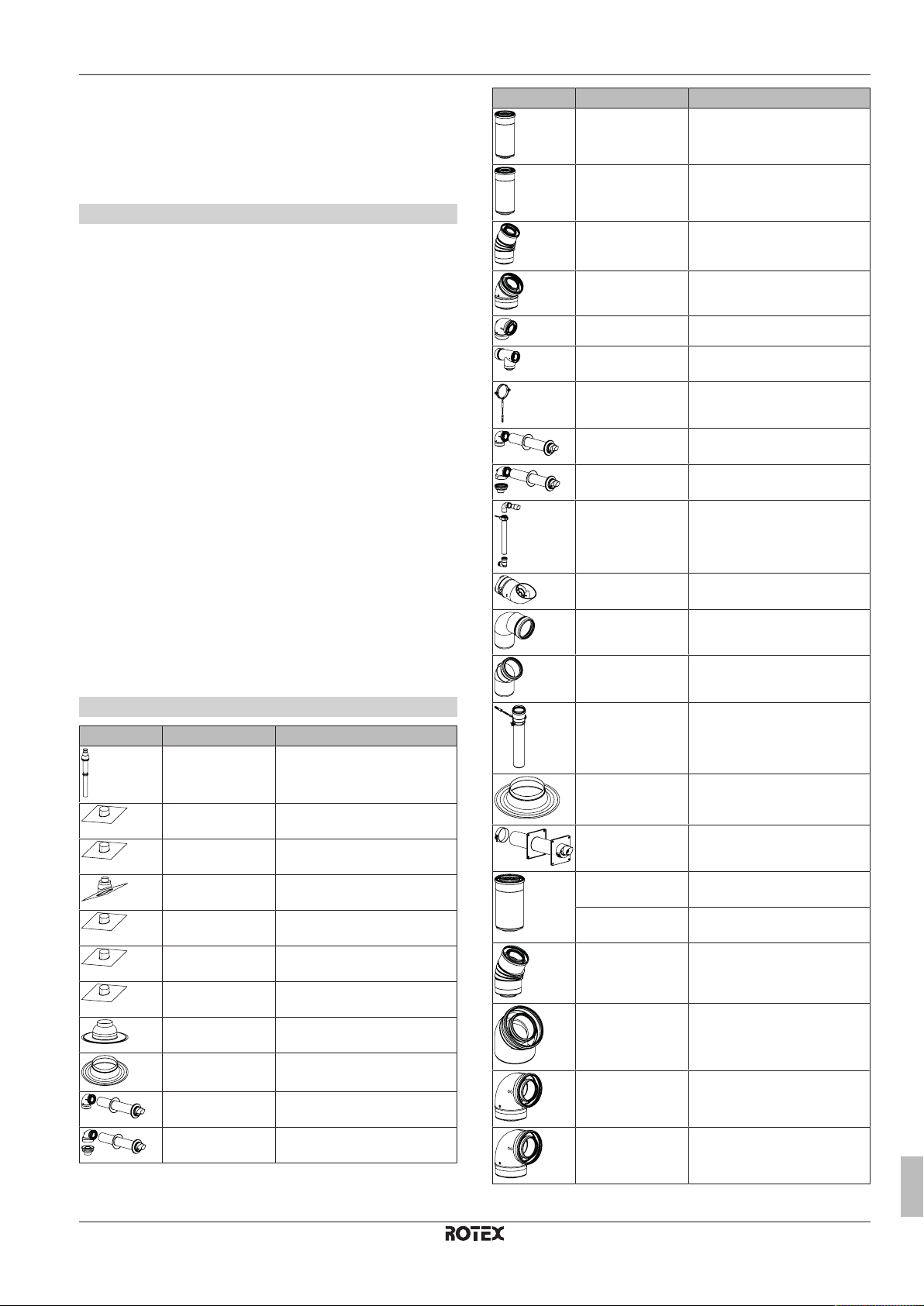

Accessories Part number Description

EKFGP4651 Extension PP/GLV

60/100×500mm

EKFGP4652 Extension PP/GLV

60/100×1000mm

EKFGP4664 Elbow PP/GLV 60/100 30°

EKFGP4661 Elbow PP/GLV 60/100 45°

EKFGP4660 Elbow PP/GLV 60/100 90°

EKFGP4667 Meas. tee with inspection panel

PP/GLV 60/100

EKFGP4631 Wall bracket Ø100

EKFGP1292 Wall terminal Kit PP/GLV

60/100

EKFGP1293 Wall terminal kit low profile PP/

GLV 60/100

EKFGP1294 Plume management kit 60 (UK

only)

EKFGP1295 Flue deflector 60 (UK only)

EKFGP1284 PMK elbow 60 90 (UK only)

EKFGP1285 PMK elbow 60 45° (2pieces)

(UK only)

Other options

Accessories Part number Description

EKFGP6837 Roof terminal PP/GLV 60/100

AR460

EKFGS0518 Weather slate steep Pb/GLV

60/100 18°-22°

EKFGS0519 Weather slate steep Pb/GLV

60/100 23°-17°

EKFGP7910 Weather slate steep PF 60/100

25°-45°

EKFGS0523 Weather slate steep Pb/GLV

60/100 43°-47°

EKFGS0524 Weather slate steep Pb/GLV

60/100 48°-52°

EKFGS0525 Weather slate steep Pb/GLV

60/100 53°-57°

EKFGP1296 Weather slate flat Aluminium

60/100 0°-15°

EKFGP6940 Weather slate flat Aluminium

60/100

EKFGP2978 Wall terminal kit PP/GLV

60/100

EKFGP2977 Wall terminal kit low profile PP/

GLV 60/100

EKFGP1286 PMK extension 60 L=1000

includes bracket (UK only)

EKFGW5333 Weather slate flat aluminium

80/125

EKFGW6359 Wall terminal kit PP/GLV

80/125

EKFGP4801 Extension PP/GLV

80/125×500mm

EKFGP4802 Extension PP/GLV

80/125×1000mm

EKFGP4814 Elbow PP/GLV 80/125 30°

EKFGP4811 Elbow PP/ALU 80/125 45°

EKFGP4810 Elbow PP/ALU 80/125 90°

EKFGP4820 Inspection elbow Plus PP/ALU

80/125 90° EPDM

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

Installation and operation manual

9

5 About the units and options

Accessories Part number Description

EKFGP6864 Roof Terminal PP/GLV 80/125

AR300 RAL9011

EKFGT6300 Weather slate steep Pb/GLV

80/125 18°-22°

EKFGT6301 Weather slate steep Pb/GLV

80/125 23°-27°

EKFGP7909 Weather slate steep PF 80/125

25°-45° RAL9011

EKFGT6305 Weather slate steep Pb/GLV

80/125 43°-47°

EKFGT6306 Weather slate steep Pb/GLV

80/125 48°-52°

EKFGT6307 Weather slate steep Pb/GLV

80/125 53°-57°

EKFGP1297 Weather slate flat aluminium

80/125 0°-15°

EKFGP6368 Tee flex 100 boiler connection

set 1

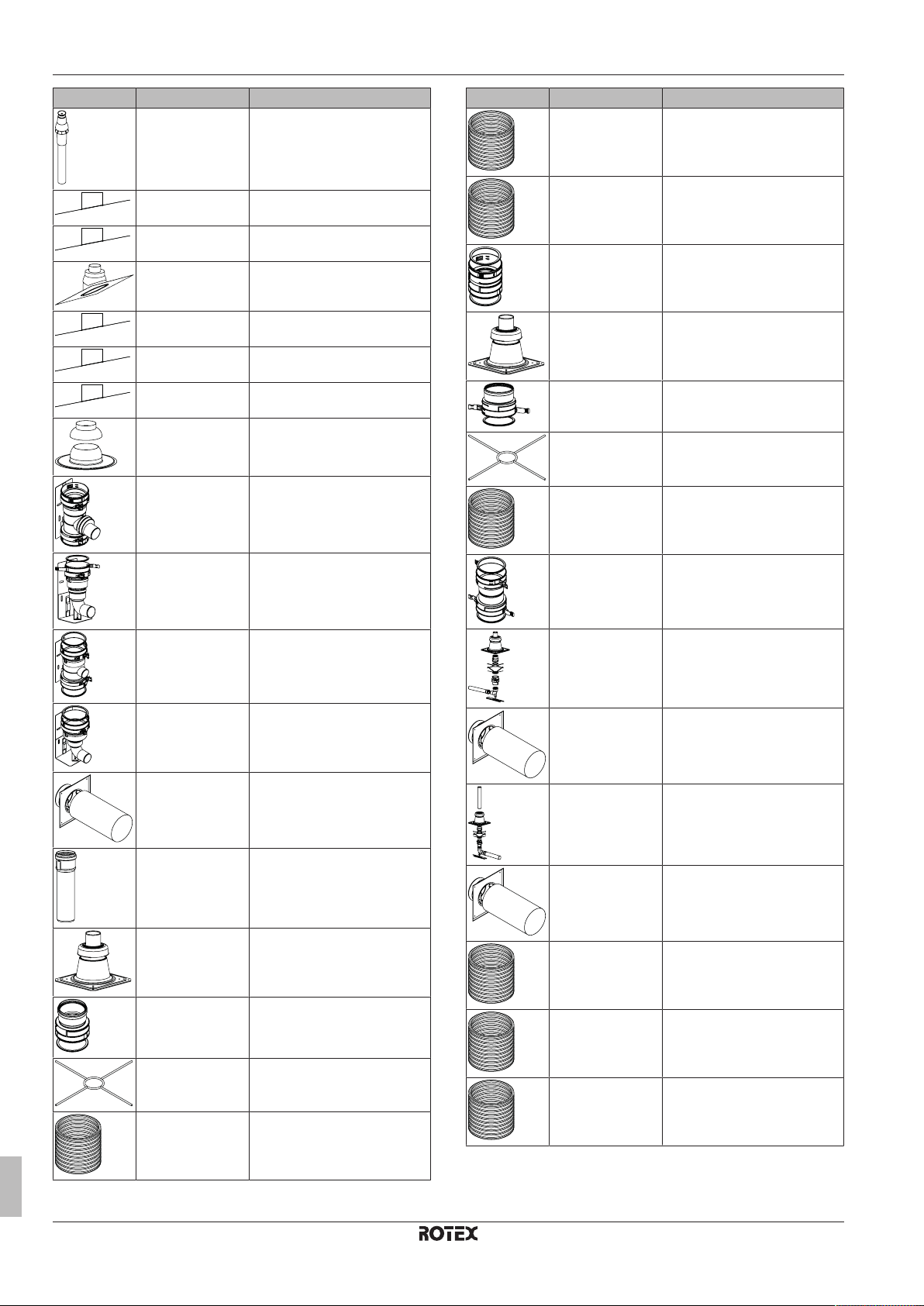

Accessories Part number Description

EKFGP6349 Extension flex PP100 L=15m

EKFGP6347 Extension flex PP100 L=25m

EKFGP6325 Connector flex-flex PP100

EKFGP5197 Chimney top PP 130 with

included flue pipe

EKFGS0252 Adapter flex-fixed PP130

EKFGP6353 Support bracket top inox Ø130

EKFGS0250 Extension flex PP130 L=130m

EKFGP6354 Flex 100-60 + support elbow

EKFGP6215 Tee flex 130 boiler connection

set 1

EKFGS0257 Flex 130-60 + support elbow

EKFGP4678 Chimney connection 60/100

EKFGP5461 Extension PP 60×500

EKFGP5497 Chimney top PP 100 with

included flue pipe

EKFGP6316 Adapter flex-fixed PP 100

EKFGP6366 Connector flex-flex PP130

EKFGP1856 Flex kit PPØ60-80

EKFGP4678 Chimney connection 60/100

EKFGP2520 Flex kit PP Ø80

EKFGP4828 Chimney connection 80/125

EKFGP6340 Extension Flex PP80 L=10m

EKFGP6344 Extension Flex PP80 L=15m

EKFGP6337 Support bracket top inox Ø100

EKFGP6346 Extension flex PP100 L=10m

Installation and operation manual

10

EKFGP6341 Extension Flex PP80 L=25m

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

6 Preparation

1

2

Accessories Part number Description

EKFGP6342 Extension Flex PP80 L=50m

EKFGP6324 Connector-flex-flex PP80

EKFGP6333 Spacer PP80-100

EKFGP4481 Fixation Ø100

EKFGV1101 Chimney connection 60/10

airintake Dn.80 C83

EKFGV1102 Connection set 60/10-60 Flue/

Air intake Dn.80 C53

EKFGW4001 ExtensionPBM-Air 80×500

EKFGW4002 ExtensionPBM-Air 80×1000

7 Installation

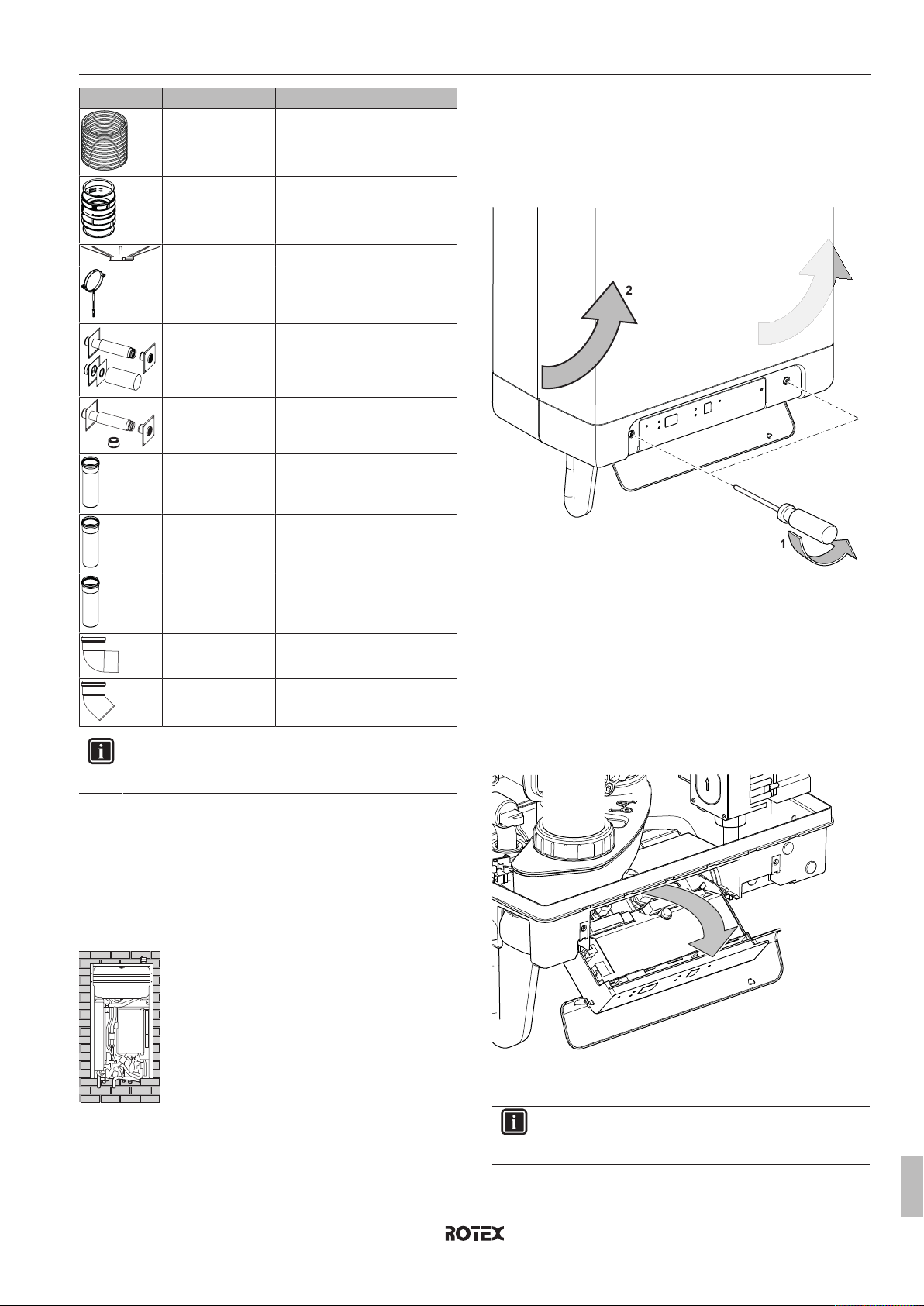

7.1 Opening the units

7.1.1 To open the gas boiler

EKFGW4004 ExtensionPBM-Air 80×2000

EKFGW4085 ElbowPPBM-Air8090°

EKFGW4086 ElbowPPBM-Air8045°

INFORMATION

For extra configuration options regarding the flue gas

system, visit http://fluegas.rotex-heating.com/.

6 Preparation

6.1 Preparing the gas boiler installation

Make sure that the hydrobox is already mounted to the wall.

1 Open the display cover.

2 Unscrew both screws.

3 Tilt the front panel towards you and remove the front panel.

7.1.2 To open the switch box cover of the gas boiler

1 Open the gas boiler, see "7.1.1 To open the gas boiler" on

page11.

2 Pull the boiler controller unit forwards. The boiler controller will

tip downwards to provide access.

It is recommended to first install:

▪ the water piping,

▪ the refrigerant piping,

▪ the electrical connection to the heat pump module.

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

7.2 Mounting the gas boiler

INFORMATION

Removing the top plate of the indoor unit makes it easier to

install the gas boiler.

Installation and operation manual

11

7 Installation

36kg

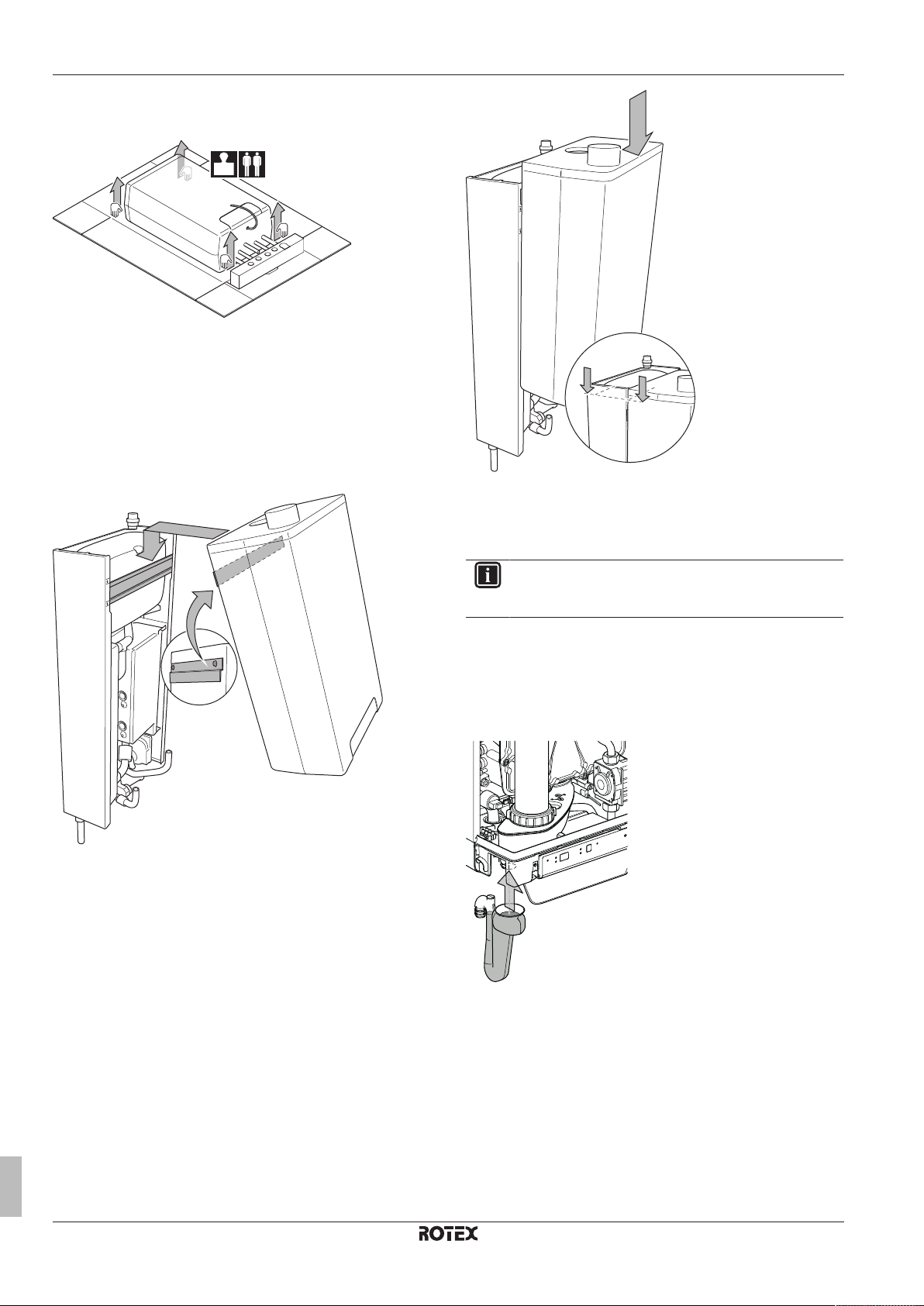

7.2.1 To install the gas boiler

1 Lift the unit from the package.

2 Remove the top plate from the indoor unit.

3 The bracket to mount the boiler on the heat pump module is

already mounted to the backside of the gas boiler.

4 Lift the boiler. One person lifts the gas boiler on the left side (left

hand on the top and right hand on the bottom) and another

person lift the gas boiler on the right side (left hand on the

bottom and right hand on the top).

5 Tilt the top of the unit at the position of the indoor unit mounting

bracket.

7 Make sure the gas boiler is fixed properly and well aligned with

the indoor unit.

6 Slide the boiler downwards to fix the boiler bracket onto the

indoor unit mounting bracket.

7.2.2 To install the condensate trap

INFORMATION

The boiler is provided with a 25mm flexible pipe on the

condensate trap.

Prerequisite: The boiler MUST be opened before installing the

condensate trap.

1 Fit the flexible tube (accessory) to the condensate trap outlet.

2 Fill the condensate trap with water.

3 Slide the condensate trap as far as possible upwards onto the

condensate drain connector below the gas boiler.

Installation and operation manual

12

4 Connect the flexible tube (where applicable with the overflow

pipe from the pressure relief valve) to the drain via an open

connection.

RHYKOMB33A

ROTEX HPU hybrid gas boiler module

4P353068-1D – 2016.10

Loading...

Loading...