Daikin REYQ96TTJU, REYQ168TTJU, REYQ120TTJU, REYQ144TTJU, REYQ192TTJU Installation Manual

...

INSTALLATION MANUAL

System Air Conditioner

MODEL

REYQ72TTJU

REYQ96TTJU

REYQ120TTJU

REYQ144TTJU

REYQ168TTJU

REYQ192TTJU

REYQ216TTJU

REYQ240TTJU

REYQ264TTJU

REYQ288TTJU

REYQ312TTJU

REYQ336TTJU

REYQ360TTJU

REYQ384TTJU

REYQ408TTJU

REYQ432TTJU

REYQ456TTJU

REYQ72TYDN

REYQ96TYDN

REYQ120TYDN

REYQ144TYDN

REYQ168TYDN

REYQ192TYDN

REYQ216TYDN

REYQ240TYDN

REYQ264TYDN

REYQ288TYDN

REYQ312TYDN

REYQ336TYDN

REYQ360TYDN

REYQ384TYDN

REYQ408TYDN

REYQ432TYDN

REYQ456TYDN

English

Français

Español

3P362438-3H

Safety considerations

Read these Safety considerations for Installation carefully before installing an air conditioner or heat pump. After completing the installation, make sure that the unit operates properly

during the startup operation.

Instruct the customer on how to operate and maintain the

unit.

Inform customers that they should store this Installation

Manual with the Operation Manual for future reference.

Always use a licensed installer or contractor to install this

product.

Improper installation can result in water or refrigerant leak-

age, electrical shock, re, or explosion.

Meanings of DANGER, WARNING, CAUTION, and NOTE

Symbols:

DANGER ........ Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING ....... Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

CAUTION ........ Indicates a potentially hazardous

situation which, if not avoided,

may result in minor or moderate

injury. It may also be used to alert

against unsafe practices.

NOTE ........... Indicates situations that may result

in equipment or property-damage

accidents only.

INFORMATION ... This symbol identies useful tips

or additional information.

DANGER

• Refrigerant gas is heavier than air and replaces oxygen. A

massive leak will result in oxygen depletion, especially in

basements, and an asphyxiation hazard will result in seri-

ous injury or death.

• Do not ground units to water pipes, gas pipes, telephone

wires, or lightning rods as incomplete grounding will result

a severe shock hazard resulting in severe injury or death.

Additionally, grounding to gas pipes will result a gas leak

and potential explosion resulting in severe injury or death.

• If refrigerant gas leaks during installation, ventilate the

area immediately. Refrigerant gas will result in producing

toxic gas if it comes into contact with re. Exposure to this

gas will result in severe injury or death.

• After completing the installation work, check that the refrigerant gas does not leak throughout the system.

• Do not install unit in an area where ammable materials

are present due to risk of explosions that will result in seri-

ous injury or death.

• Safely dispose all packing and transportation materials

in accordance with federal/state/local laws or ordinances.

Packing materials such as nails and other metal or wood

parts, including plastic packing materials used for transportation will result in injuries or death by suffocation.

WARNING

• Only qualied personnel must carry out the installation

work. Installation must be done in accordance with this

installation manual. Improper installation could result in

water leakage, electric shock, or re.

• When installing the unit in a small room, take measures to

keep the refrigerant concentration from exceeding allowable safety limits. Excessive refrigerant leaks, in the event

of an accident in a closed ambient space, could result in

oxygen deciency.

• Use only specied accessories and parts for installation

work. Failure to use specied parts could result in water

leakage, electric shocks, re, or the unit falling.

• Install the air conditioner or heat pump on a foundation

strong enough that it can withstand the weight of the unit.

A foundation of insufcient strength could result in the unit

falling and causing injuries.

• Take into account strong winds, typhoons, or earthquakes

when installing. Improper installation could result in the

unit falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is carried

out by qualied personnel according to local, state and

national regulations. An insufcient power supply capacity

or improper electrical construction could result in electric

shocks or re.

• Make sure that all wiring is secured, that specied wires

are used, and that no external forces act on the terminal

connections or wires. Improper connections or installation

could result in re.

• When wiring, position the wires so that the control box

cover can be securely fastened. Improper positioning of

the control box cover could result in electric shocks, re, or

the terminals overheating.

• Before touching electrical parts, turn off the unit.

• This equipment can be installed with a Ground-Fault Cir-

cuit Interrupter (GFCI). Although this is a recognized measure for additional protection, with the grounding system in

North America, a dedicated GFCI is not necessary.

• Securely fasten the unit terminal cover (panel). If the

terminal cover/panel is not installed properly, dust or

water may enter the outdoor unit and could result in re or

electric shock.

• When installing or relocating the system, keep the refriger-

ant circuit free from substances other than the specied

refrigerant (R410A) such as air. Any presence of air or other foreign substance in the refrigerant circuit could result

in abnormal pressure rise or rupture, resulting in injury.

• Do not change the setting of the protection devices. If the

pressure switch, thermal switch, or other protection device

is shorted and operated forcibly, or parts other than those

specied by Daikin are used, re or explosion could result.

3P362438-3H Englishi

CAUTION

• Do not touch the switch with wet ngers. Touching a switch

with wet ngers may result in electric shock.

• Do not allow children to play on or around the unit or it

may result in injury.

• The heat exchanger ns are sharp enough to cut, and

may result in injury if improperly used. To avoid injury wear

glove or cover the ns when working around them.

• Do not touch the refrigerant pipes during and immediately

after operation as the refrigerant pipes may be hot or

cold, depending on the condition of the refrigerant owing through the refrigerant piping, compressor, and other

refrigerant cycle parts. It may result in your hands getting burns or frostbite if you touch the refrigerant pipes.

To avoid injury, give the pipes time to return to normal

temperature or, if you must touch them, be sure to wear

proper gloves.

• Install drain piping to proper drainage. Improper drain piping may result in water leakage and property damage.

• Insulate piping to prevent condensation.

• Be careful when transporting the product.

• Do not turn off the power immediately after stopping

operation. Always wait for at least 5 minutes before turning

off the power. Otherwise, water leakage may result.

• Do not use a charging cylinder. Using a charging cylinder

may cause the refrigerant to deteriorate.

• Refrigerant R410A in the system must be kept clean, dry,

and tight.

(a) Clean and Dry - Foreign materials (including mineral

oils such as SUNISO oil or moisture) should be prevented from getting into the system.

(b) Tight - R410A does not contain any chlorine, does

not destroy the ozone layer, and does not reduce the

earth’s protection again harmful ultraviolet radiation.

R410A can contribute to the greenhouse effect if it is

released. Therefore take proper measures to check

for the tightness of the refrigerant piping installation.

Read the chapter Refrigerant Piping and follow the

procedures.

• Since R410A is a blend, the required additional refrigerant must be charged in its liquid state. If the refrigerant is

charged in a state of gas, its composition can change and

the system will not work properly.

• The indoor unit is for R410A. See the catalog for indoor

models that can be connected. Normal operation is not

possible when connected to other units.

• Remote controller (wireless kit) transmitting distance can

be shorter than expected in rooms with electronic uores-

cent lamps (inverter or rapid start types). Install the indoor

unit far away from uorescent lamps as much as possible.

• Indoor units are for indoor installation only. Outdoor units

can be installed either outdoors or indoors. This unit is for

indoor use.

• Do not install the air conditioner or heat pump in the following locations:

(a) Where a mineral oil mist or oil spray or vapor is pro-

duced, for example, in a kitchen.

Plastic parts may deteriorate and fall off and thus may

result in water leakage.

(b) Where corrosive gas, such as sulfurous acid gas, is

produced.

Corroding copper pipes or soldered parts may result

in refrigerant leakage.

(c) Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of

the control system and cause the unit to malfunction.

(d) Where ammable gas may leak, where there is car-

bon ber, or ignitable dust suspension in the air, or

where volatile ammables such as thinner or gasoline

are handled. Operating the unit in such conditions

may result in a re.

• Take adequate measures to prevent the outdoor unit from

being used as a shelter by small animals. Small animals

making contact with electrical parts may result in malfunc-

tions, smoke, or re. Instruct the customer to keep the

area around the unit clean.

NOTE

• Install the power supply and transmission wires for the in-

door and outdoor units at least 3.5ft.(1m) away from tele-

visions or radios to prevent image interference or noise.

Depending on the radio waves, a distance of 3.5ft.(1m)

may not be sufcient to eliminate the noise.

• Dismantling the unit, treatment of the refrigerant, oil and

additional parts must be done in accordance with the

relevant local, state, and national regulations.

• Do not use the following tools that are used with conventional refrigerants: gauge manifold, charge hose, gas

leak detector, reverse ow check valve, refrigerant charge

base, vacuum gauge, or refrigerant recovery equipment.

• If the conventional refrigerant and refrigerator oil are

mixed in R410A, the refrigerant result in deterioration.

• This air conditioner or heat pump is an appliance that

should not be accessible to the general public.

• As design pressure is 478 psi (3.3 MPa), the wall thick-

ness of eld-installed pipes should be selected in accor-

dance with the relevant local, state, and national regulations.

Codes and Regulations

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility

of the installer. The manufacturer assumes no responsibility

for equipment installed in violation of any codes or regulations. Rated performance is achieved after 72 hours of operation.

3P362438-3H English ii

REYQ72TTJU

REYQ96TTJU

REYQ120TTJU

REYQ144TTJU

REYQ168TTJU

REYQ192TTJU

REYQ216TTJU

REYQ240TTJU

REYQ264TTJU

REYQ288TTJU

REYQ312TTJU

REYQ336TTJU

REYQ360TTJU

REYQ384TTJU

REYQ408TTJU

REYQ432TTJU

REYQ456TTJU

REYQ72TYDN

REYQ96TYDN

REYQ120TYDN

REYQ144TYDN

REYQ168TYDN

REYQ192TYDN

REYQ216TYDN

REYQ240TYDN

REYQ264TYDN

REYQ288TYDN

REYQ312TYDN

REYQ336TYDN

REYQ360TYDN

REYQ384TYDN

REYQ408TYDN

REYQ432TYDN

REYQ456TYDN

CONTENTS

VRVIV System air conditioner

Installation Manual

Safety considerations .....................................i

Codes and Regulations .................................. ii

1. Introduction ...........................................2

1.1. General information ................................. 2

1.2. Combination and options ........................ 2

1.3. Indoor capacity range .............................. 3

1.4. Scope of the manual ............................... 3

2. Accessories ...........................................3

2.1. Accessories supplied with this unit .......... 3

3. Overview of unit ....................................3

3.1. Opening the unit ...................................... 3

3.2. Technical and Electrical specications .... 4

3.3. Main components .................................... 4

4. Selecting an installation location ........4

4.1. General precautions on installation ......... 4

4.2. Weather related precautions ................... 4

4.3. Selecting a location in cold climates ....... 5

5. Dimensions and service space ............ 5

5.1. Dimensions of outdoor unit ..................... 5

5.2. Service space.......................................... 6

6. Inspecting, handling and unpacking

the unit ...................................................7

6.1. Inspection ................................................ 7

6.2. Handling .................................................. 7

6.3. Unpacking ............................................... 7

6.4. Installing the unit ..................................... 7

6.5. Method for removing shipping plate ........ 8

7. Refrigerant pipe size and allowable pipe

length .............................................................9

7.1. General information ................................. 9

7.2. Selection of piping material ..................... 9

7.3. Selection of piping size ........................... 9

7.4. Selection of refrigerant branch kits ........ 10

7.5. System piping (length) limitations ......... 11

8. Precautions on refrigerant piping ......14

8.1. Caution for brazing ................................ 14

8.2. Connecting the refrigerant piping .......... 14

8.3. Guidelines for handling stop valve......... 17

9. Field wiring ..........................................18

9.1. Power circuit, safety device and cable

requirements ......................................... 19

9.2. Wiring connection example for whole

system ................................................... 19

9.3. Leading wire procedure ......................... 19

9.4. Transmission wiring connection

procedure .............................................. 20

9.5. Power wiring connection procedure ...... 21

9.6. Procedure for Wiring Inside Units .......... 22

10. Air tight test and vacuum drying .......22

11. Pipe insulation ..................................... 23

12. Checking of device and installation

conditions ............................................24

13. Makingeldsettings ........................... 24

13.1. Accessing the push buttons on the

printed circuit board ............................... 24

13.2. Operating the push buttons and DIP

switches on the printed circuit board ..... 24

13.3. Connecting the PC congurator to the

outdoor unit ........................................... 26

14. Charging refrigerant ............................26

14.1. Precautions ........................................... 26

14.2. Calculating the additional refrigerant

charge ................................................... 26

14.3. Method for adding refrigerant ................ 28

15. Start-upandconguration .................32

15.1. Checks before initial start up ................. 32

15.2. Monitoring function and eld settings .... 33

15.3. Energy saving and optimum operation ... 36

15.4. Test operation ........................................ 39

15.5. Malfunction code list .............................. 40

16. Operation of the unit ........................... 44

17. Maintenance and service .................... 44

17.1. Maintenance introduction ...................... 44

17.2. Service precautions............................... 44

17.3. Service mode operation ........................ 44

18. Caution for refrigerant leaks ..............44

18.1. Introduction ...........................................44

19. Disposal requirements ........................45

The original instructions are written in English. All other

languages are translations of the original instructions.

1 3P362438-3H English

1. Introduction

1.1. General information

This installation manual concerns the VRV IV, full inverter driven, heat

pump system.

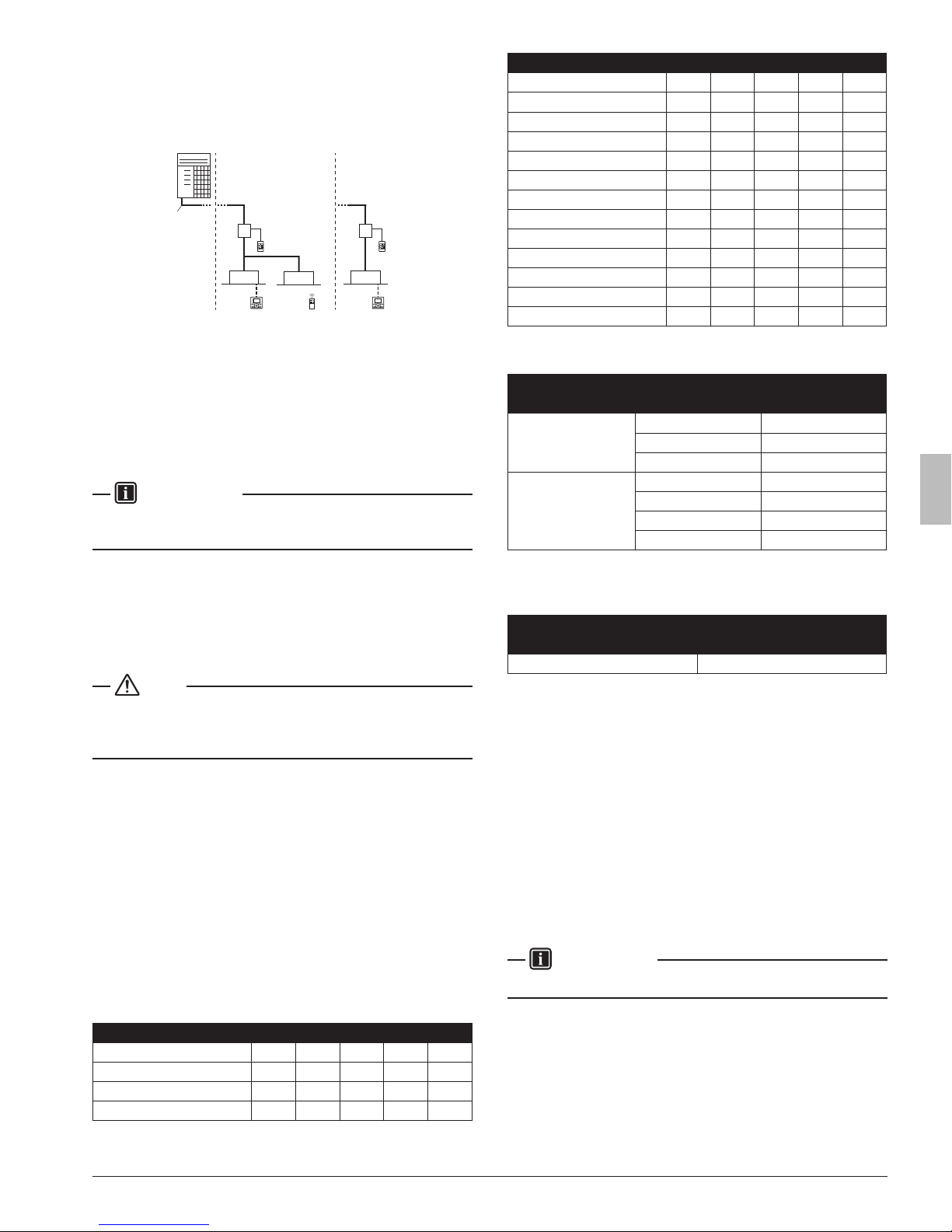

1

2

1 VRV IV Heat Recovery outdoor unit

2 Refrigerant piping

3 BS unit

4 VRV indoor unit

5 Cool/Heat selector (single BS unit only)

6 User interface (dedicated depending on indoor unit type)

7 User interface (wireless, dedicated depending on indoor unit

type)

INFORMATION

Not all combinations of indoor units are allowed. For guidance, see

1.2. Combination and options on page2.

1.2. Combination and options

The VRV IV heat recovery system can be combined with several types

of indoor units and is intended for R410A use only.

For an overview which units are available you can consult the product

catalogue for VRV IV.

NOTE

To be sure your system setup (outdoor unit + BS unit(s) + indoor

unit(s)) will work, you have to consult the latest technical engineering

data for VRV IV heat recovery.

An overview is given indicating the allowed combinations of indoor

units and outdoor units. Not all combinations are allowed. They are

subject to rules (combination between outdoor-indoor, single outdoor

unit use, multiple outdoor unit use, combinations between indoor

units, etc.) mentioned in the technical engineering data.

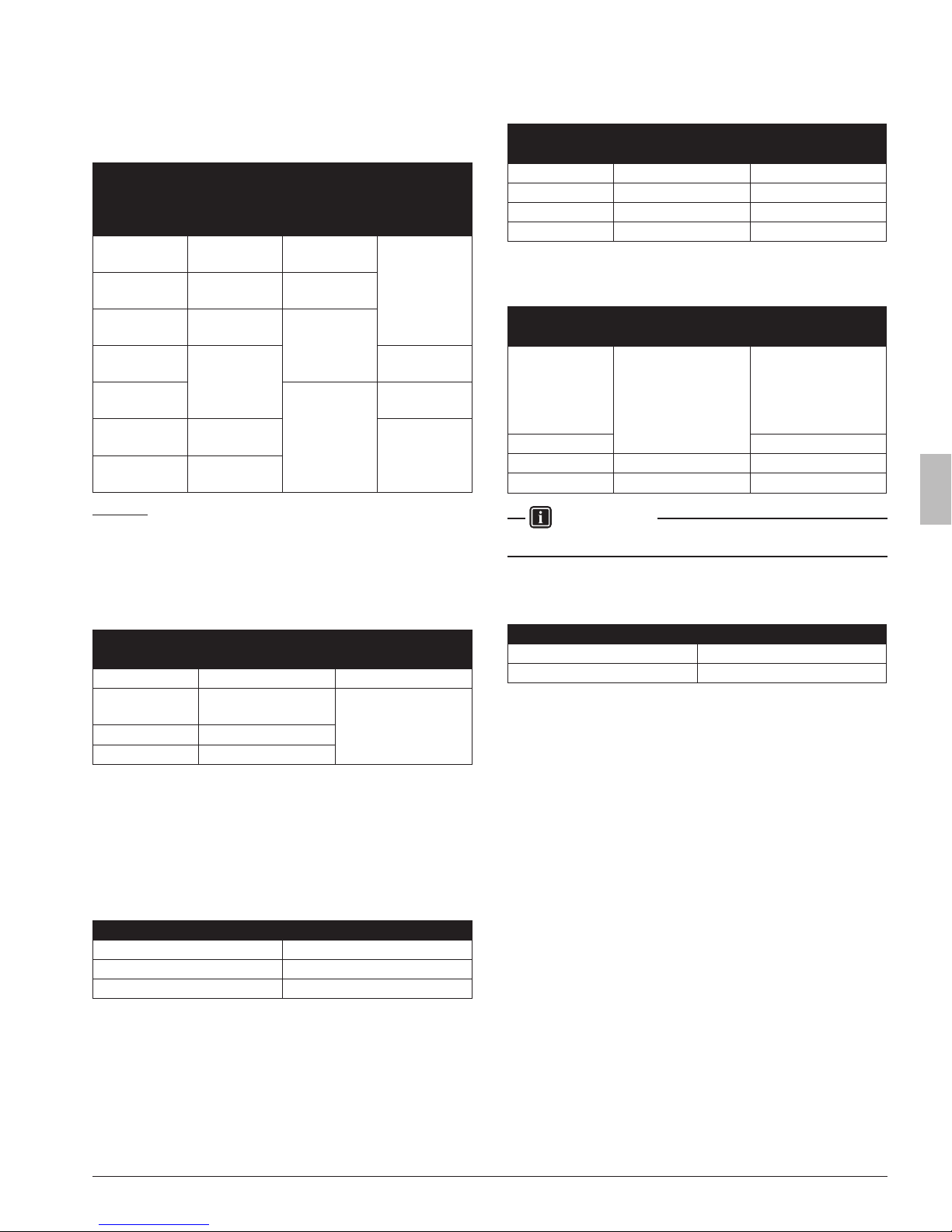

1.2.1. Indoor unit combinations

In general VRV indoor units can be connected to a VRV IV heat recovery system.

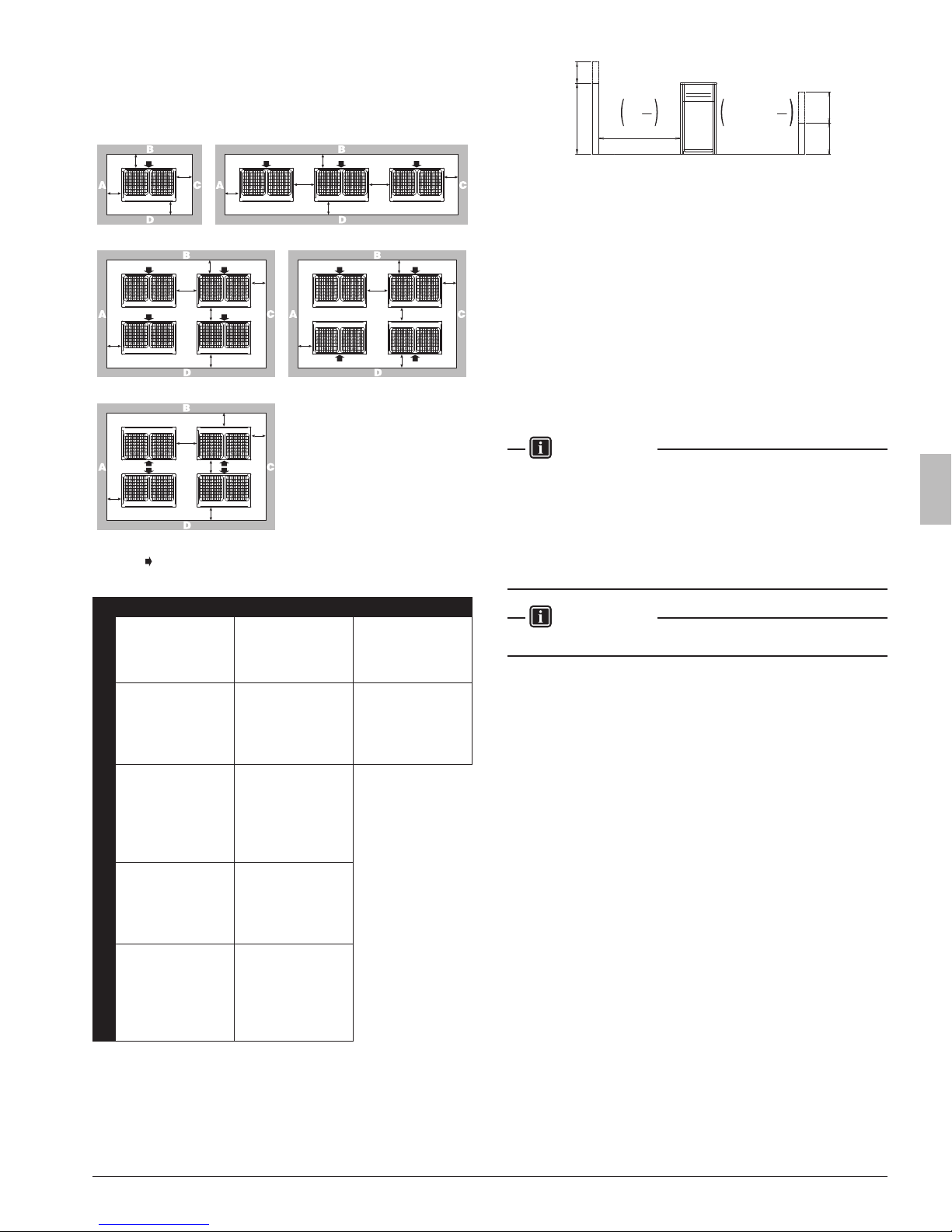

1.2.2. Outdoor unit combinations

Standard combinations for VRV IV heat recovery system are as

indicated in tables below and right, where REYQ192-456 consists of

several REYQ72-168 modules as indicated.

REYQ72TTJU/TYDN 1

REYQ96TTJU/TYDN 1

REYQ120TTJU/TYDN 1

REYQ144TTJU/TYDN 1

3

5

4

6

7

72 96 120 144 168

3

4

5

6

72 96 120 144 168

REYQ168TTJU/TYDN 1

REYQ192TTJU/TYDN 1 1

REYQ216TTJU/TYDN 1 1

REYQ240TTJU/TYDN 1 1

REYQ264TTJU/TYDN 1 1

REYQ288TTJU/TYDN 2

REYQ312TTJU/TYDN 1 1

REYQ336TTJU/TYDN 2

REYQ360TTJU/TYDN 3

REYQ384TTJU/TYDN 1 1 1

REYQ408TTJU/TYDN 1 1 1

REYQ432TTJU/TYDN 3

REYQ456TTJU/TYDN 2 1

To install the outdoor unit, the following optional parts are also required.

1 Refrigerant branching kit.

Description

REFNET header

REFNET joint

For the selection of the optimal branching kit, please refer to

7.4. Selection of refrigerant branch kits on page10.

2 Outdoor unit multi connection piping kit.

Number of outdoor units connected

2 3

BHFP26P100U BHFP26P151U

3 In order to control the cooling or heating operation from a central

location, the following option can be connected:

- Cool/Heat selector: KRC19-26A

- With optional xing box for the switch: KJB111A

- Centralized control devices (e.g., intelligent Touch Manager)

4 To instruct specic operation with an external input coming from a

central control the external control adaptor (DTA104A61/62) can

be used. Instructions (group or individual) can be instructed for low

noise operation and power consumption limitation operation.

5 For VRV IV heat recovery system it is also possible to make several

commissioning eld settings through a personal computer interface. For this option EKPCCAB* is required which is a dedicated

cable to communicate with the outdoor unit. The software for the

user interface program can be obtained from your local Daikin

sales ofce.

for 3 piping for 2 piping

KHRP25M33H9 KHRP26M22H9

KHRP25M72H9 KHRP26M33H9

KHRP25M73HU9 KHRP26M72H9

KHRP25A22T9 KHRP26A22T9

KHRP25A33T9 KHRP26A33T9

KHRP25M72TU9 KHRP26M72TU9

KHRP25M73TU9 –

Model name

INFORMATION

Refer to the technical engineering data for the latest option names.

23P362438-3H English

1.3. Indoor capacity range

Total capacity of indoor units needs to be within the specied range.

<Outdoor unit> <Total capacity index of indoor unit>

REYQ72TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 36-93

REYQ96TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 48-124

REYQ120TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 60-156

REYQ144TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 72-187

REYQ168TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 84-218

REYQ192TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 96-249

REYQ216TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 108-280

REYQ240TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 120-312

REYQ264TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 132-343

REYQ288TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 144-374

REYQ312TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 156-405

REYQ336TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 168-436

REYQ360TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 180-468

REYQ384TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 192-499

REYQ408TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 204-530

REYQ432TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 216-561

REYQ456TTJU/TYDN . . . . . . . . . . . . . . . . . . . . . 228-592

NOTE

Higher capacity than the above table can be selected, this may affect

heating and cooling capacity. For additional information see technical

engineering data.

1.4. Scope of the manual

This manual describes the procedures for handling, installing and

connecting the VRV IV heat recovery outdoor units. This manual has

been prepared to ensure adequate maintenance of the unit, and it will

provide help in case problems occur.

INFORMATION

The installation of the indoor unit(s) is described in the indoor unit

installation manual provided with the indoor units.

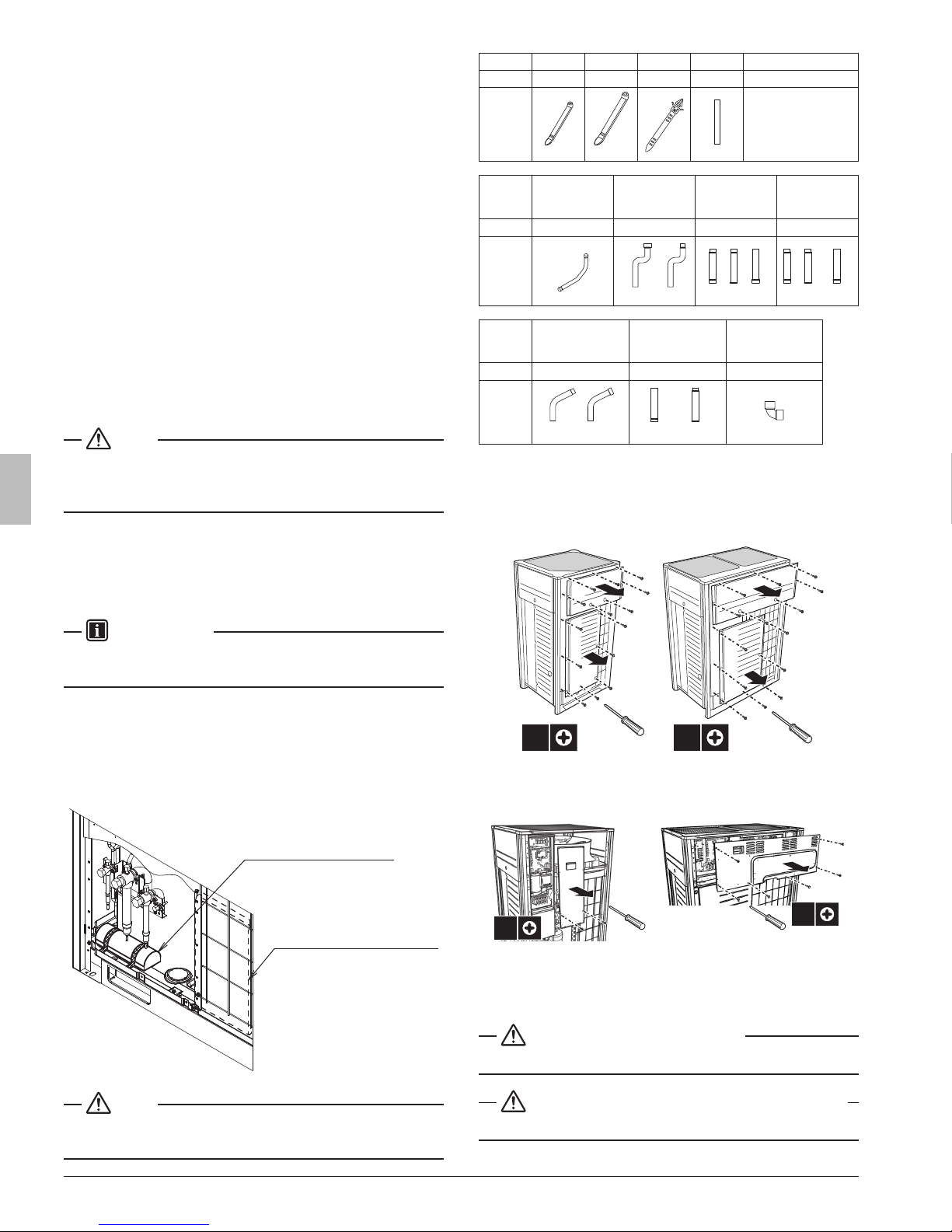

Name Clamp (1) Clamp (2) Clamp (3) Vinyl tube Manuals, etc.

Quantity 7 pcs. 1 pc. 1 pc. 5 pcs. 1 pc. each

• Operation Manual

• Installation Manual

Shape

(Small)

Name

Quantity 1 pc. 1 pc. 1 pc. 1 pc.

Shape

Name

Quantity 1 pc. 1 pc. 2 pcs.

Shape

Liquid side

accessory

High and low gas

side accessory

pipe (1)

pipe (1)

96-168T72T

(Large)

Liquid side

accessory

pipe (2)

168T72-144T 72,120T 144,168T96T 72T

High and low gas

side accessory

pipe (2)

72,96T 120-168T

• REQUEST FOR THE

Gas side

accessory

pipe (1)

L type

accessory joint

INDICATION label

(Installation records)

Gas side

accessory

pipe (2)

96,144,168T

120T

3. Overview of unit

3.1. Opening the unit

To gain access to the unit, front panels need to be opened as follows:

REYQ72TTJU/TYDN REYQ96-168TTJU/TYDN

2. Accessories

2.1. Accessories supplied with this unit

Conrm the following accessories are included. The storage location

of the accessories is shown in the gure below.

Accessories assy (piping)

Accessories assy (operation

and installation manual)

NOTE

Do not throw away any of the accessories until installation is complete.

They are needed for installation work.

14x14x

Once the front panel open, the electrical component box can be accessed by removing the control box cover as follows.

REYQ72TTJU/TYDN REYQ96-168TTJU/TYDN

6x

2x

For service purposes, the push buttons on the main printed circuit

board need to be accessed. To access these push buttons, the control

box cover does not need to be opened. See 13. Making eld settings

on page24.

DANGER: ELECTRICAL SHOCK

See Safety considerations on pagei.

DANGER: DO NOT TOUCH PIPING AND INTERNAL PARTS

See Safety considerations on pagei.

3 3P362438-3H English

3.2. TechnicalandElectricalspecications

Refer to the Engineering Data Book for the complete list of specications.

It is therefore recommended to install the equipment and electric wires

keeping proper distances away from stereo equipment, personal

computers, etc

3.3. Main components

For main components and function of the main components, refer to

the Engineering Data Book.

4. Selecting an installation location

WARNING

Be sure to provide for adequate measures in order to prevent that the

unit is used as a shelter by small animals.

Small animals making contact with electrical parts can cause malfunc-

tions, smoke or re. Please instruct the customer to keep the area

around the unit clean and clear.

In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

CAUTION

Appliance not accessible to the general public, install it in a secured

area, protected from easy access.

This unit, both indoor and outdoor, is suitable for installation in a commercial and light industrial environment.

4.1. General precautions on installation

Select an installation site that meets the following requirements:

• The foundation must be strong enough to support the weight of the

unit.

• Installation location is at to prevent vibrations and noise generation

and to have sufcient stability.

• The space around the unit is adequate for maintenance and servic-

ing (refer to 5.2. Service space on page6).

• The space around the unit allows for sufcient air circulation.

• There is no danger of re due to leakage of inammable gas.

• The equipment is not intended for use in a potentially explosive

atmosphere.

• Select the location of the unit in such a way that the sound generated by the unit does not disturb anyone, and the location is selected

according the applicable legislation.

• All piping lengths and distances have been taken into consideration

(refer to 7.5. System piping (length) limitations on page11).

• Take care that in the event of a water leak, water cannot cause any

damage to the installation space and surroundings.

• When installing the unit in a small room, take measures in order to

keep the refrigerant concentration from exceeding allowable safety

limits in the event of a refrigerant leak, refer to 18. Caution for refrig-

erant leaks on page44.

CAUTION

Excessive refrigerant concentrations in a closed room can lead to

oxygen deciency.

NOTE

The equipment described in this manual may cause electronic noise

generated from radio-frequency energy. The equipment complies

to specications that are designed to provide reasonable protection

against such interference. However, there is no guarantee that interference will not occur in a particular installation.

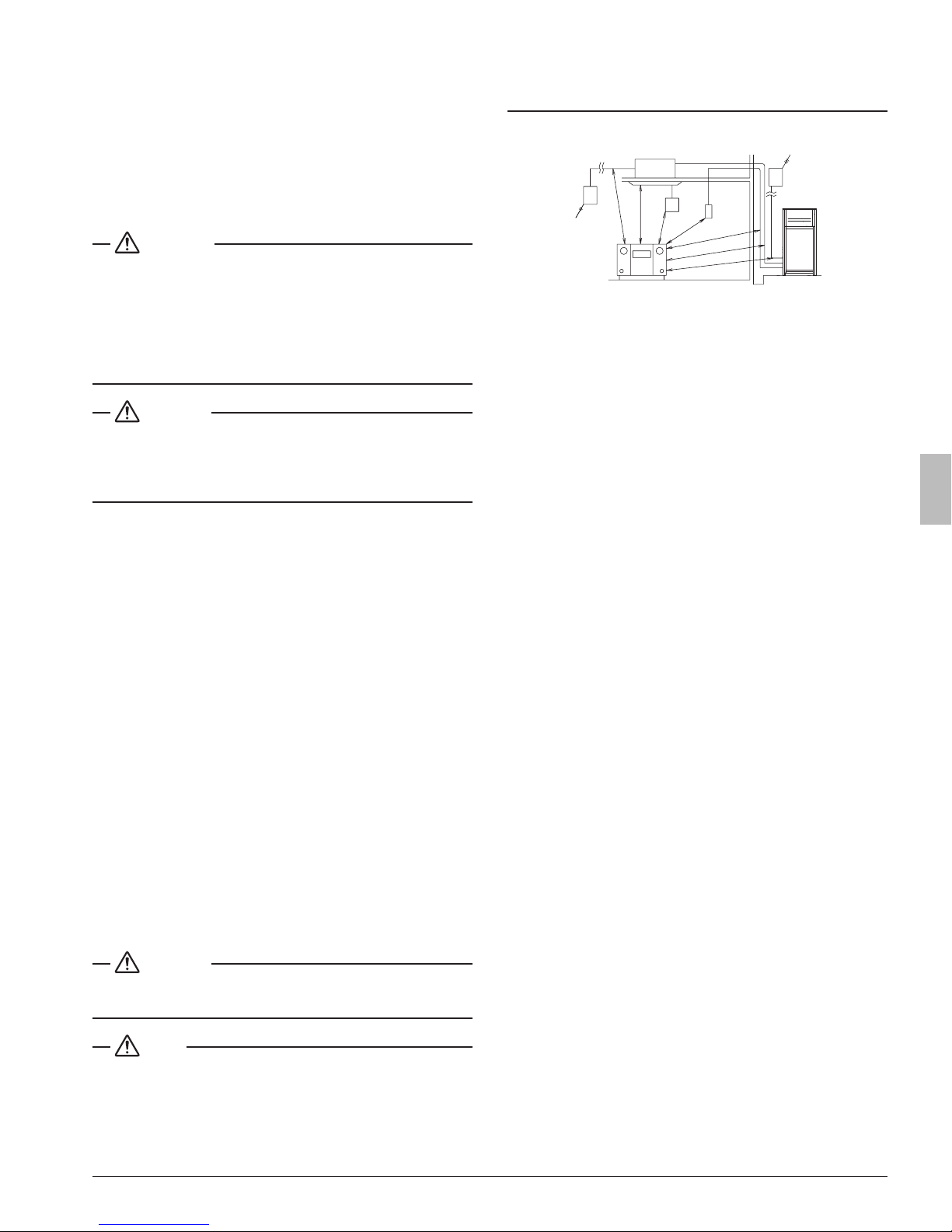

1

2

2

A

B

5

1 Indoor unit

2 Branch switch, overcurrent breaker

3 Remote controller

4 Cool/Heat selector

5 Personal computer or radio

A

≥ 60 in. (1500 mm)

B

≥ 40 in. (1000 mm)

An inverter air conditioner may cause electronic noise generated from

AM broadcasting. Examine where to install the main air conditioner

and electric wires, keeping proper distances away from stereo equipment, personal computers, etc.

Particularly for locations with weak reception, ensure there is a distance of at least 10 ft. (3 m) for indoor remote controllers, place power

wiring and transmission wiring in conduits, and ground the conduits.

• The refrigerant R410A itself is nontoxic, non-ammable and is safe.

If the refrigerant should leak however, its concentration may exceed

the allowable limit depending on room size. Due to this, it could be

necessary to take measures against leakage. Refer to 18. Caution

for refrigerant leaks on page44.

• Do not install in the following locations:

- Locations where sulfurous acids and other corrosive gases may

be present in the atmosphere. Copper piping and soldered joints

may corrode, causing refrigerant to leak.

- Locations where a mineral oil mist, spray or vapor may be present in the atmosphere. Plastic parts may deteriorate and fall off or

cause water leakage.

- Locations where equipment that produces electromagnetic

waves is found. The electromagnetic waves may cause the control system to malfunction, preventing normal operation.

- Locations where ammable gases may leak, where thinner,

gasoline and other volatile substances are handled, or where

carbon dust and other incendiary substances are found in the

atmosphere. Leaked gas may accumulate around the unit, caus-

ing an explosion.

• When installing, take strong winds, hurricanes or earthquakes into

account, improper installation may result in the unit turning over.

3

B

4

B

A

A

A

4.2. Weather related precautions

• Select a place where the rain can be avoided as much as possible.

• Be sure that the air inlet of the unit is not positioned towards the

main wind direction. Frontal wind will disturb the operation of the

unit. If necessary, use a screen to block the wind.

• Ensure that water cannot cause any damage to the location by

adding water drains to the foundation and prevent water traps in the

construction.

• Do not install the unit in areas where the air contains high levels of

salt such as that near the ocean.

43P362438-3H English

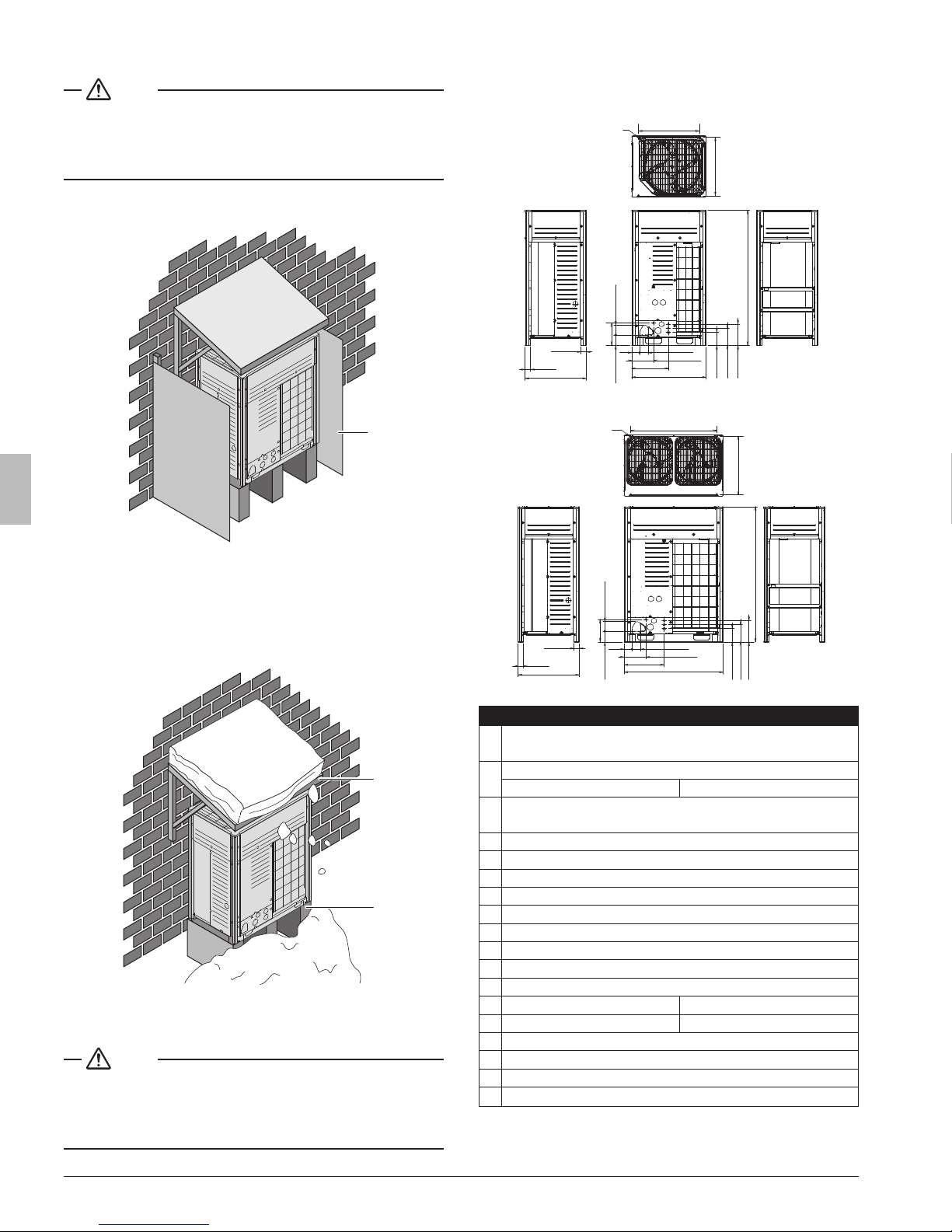

4.3. Selecting a location in cold climates

NOTE

• When operating the unit in a low outdoor ambient temperature, be

sure to follow the instructions described below.

• The following images are for reference only. For more details contact your local dealer.

To prevent exposure to wind and snow, install a bafe plate on the air

side of the outdoor unit:

1

5. Dimensions and service space

5.1. Dimensions of outdoor unit

REYQ72TTJU/TYDN

1

2

3

18

8

7

4

5

6

REYQ96-168TTJU/TYDN

10

9

1

11

12

13

15 16 17

14

2

3

1 Bafe plate

In heavy snowfall areas it is very important to select an installation site

where the snow will not affect the unit. If lateral snowfall is possible,

make sure that the heat exchanger coil is not affected by the snow

(if necessary construct a lateral canopy). Install the unit high enough

from the ground to prevent burying in snow.

1

2

1 Construct a large canopy.

2 Construct a pedestal.

NOTE

When operating the unit in a low outdoor ambient temperature with

high humidity conditions, make sure to take precautions to keep the

drainholes of the unit free by using proper equipment such as the optional drainpan heater. For more information contact your local dealer.

18

8

7

4

5

6

10

9

11

12

13

14

1615 17

Unit: in. (mm)

REYQ72TTJU/TYDN REYQ96-168TTJU/TYDN

1

2

9/16 (15) × 7/8 (22.5) × 4 oblong holes

30-3/16 (766) 42-3/8 (1076)

3

Foundation bolt hole

Pitch of foundation bolt holes

Pitch of foundation bolt holes

28-7/16-29 (722-737)

4 2-5/8 (67)

5 2-5/8 (67)

6 30-3/16 (767)

7 11-1/8 (282)

8 4-13/16 (122)

9 5-3/16 (132)

10 3-7/8 (98)

11 4-3/16 (107)

12 10-11/16 (272)

13 18-1/16 (458) 19-3/4 (502)

14 36-11/16 (932) 48-7/8 (1242)

15 6-9/16 (167)

16 8-9/16 (217)

17 10-1/2 (267)

18 66-11/16 (1694)

5 3P362438-3H English

5.2. Service space

1 2

The space around the unit is adequate for servicing and the minimum

space for air inlet and air outlet is available (refer to the gure below

and choose one of the possibilities).

b

a

a

c

a

a

d

3

b

e

f

a

a

d

c

b

e

d

e

c

4

b

e

d

a

a

b

c

5

b

e

f

a

a

d

ABCD Sides along the installation site with obstacles

Suction side

c

h2

<Front side> <Suction side>

h2

a

b +

2

or more

Service

space

or more

h1

+

2

h1

b

a 59 in. (1500 mm)

b 19-5/8 in. (500 mm)

• In case of an installation site where sides A+B+C+D have obstacles, the wall heights of sides A+C have no impact on service space

dimensions. Refer to the foregoing gure for impact of wall heights

of sides B+D on service space dimensions.

• In case of an installation site where only the sides A+B have ob-

stacles, the wall heights have no inuence on any indicated service

space dimensions.

• The installation space required on these drawings are for full load

heating operation without considering possible ice accumulation.

If the location of the installation is in a cold climate, then all dimensions above should be >19-5/8 in. (500 mm) to avoid accumulation

of ice in between the outdoor units.

INFORMATION

• The service space dimensions in above gure are based on cooling

operation at 95°F (35°C) ambient temperature (standard conditions).

• If the design outdoor temperature exceeds 95°F (35°C) or the

heat load exceeds maximum capacity in all the outdoor unit, take

an even large space on the intake shown in gure in 5.2. Service

space.

A+B+C+D A+B

a≥3/8 (10)

b≥11-3/4 (300)

1

c≥3/8 (10)

d≥19-5/8 (500)

a≥3/8 (10)

b≥11-3/4 (300)

2

c≥3/8 (10)

d≥19-5/8 (500)

e≥3/4 (20)

a≥3/8 (10)

b≥11-3/4 (300)

c≥3/8 (10)

3

d≥19-5/8 (500)

e≥3/4 (20)

f≥23-5/8 (100)

a≥3/8 (10)

b≥11-3/4 (300)

4

c≥3/8 (10)

d≥19-5/8 (500)

e≥3/4 (20)

a≥3/8 (10)

b≥19-5/8 (500)

c≥3/8 (10)

5

d≥19-5/8 (500)

e≥3/4 (20)

f≥35-7/16 (900)

a≥2 (50)

b≥3-7/8 (100)

c≥2 (50)

d≥19-5/8 (500)

a≥2 (50)

b≥3-7/8 (100)

c≥2 (50)

d≥19-5/8 (500)

e≥3-7/8 (100)

a≥2 (50)

b≥3-7/8 (100)

c≥2 (50)

d≥19-5/8 (500)

e≥3-7/8 (100)

f≥19-5/8 (500)

a≥2 (50)

b≥3-7/8 (100)

c≥2 (50)

d≥19-5/8 (500)

e≥3-7/8 (100)

a≥2 (50)

b≥19-5/8 (500)

c≥2 (50)

d≥19-5/8 (500)

e≥3-7/8 (100)

f≥23-5/8 (600)

a≥7-7/8 (200)

b≥11-3/4 (300)

a≥7-7/8 (200)

b≥11-3/4 (300)

e≥15-3/4 (400)

Unit: in.(mm)

INFORMATION

Further specications can be found in the Engineering Data Book.

63P362438-3H English

6. Inspecting, handling and unpacking the unit

6.1. Inspection

At delivery, the unit must be checked and any damage must be reported immediately to the carrier’s claims agent.

6.3. Unpacking

CAUTION

To avoid injury, do not touch the air inlet or aluminum ns of the unit.

6.2. Handling

1 When handling the unit, take into account the following:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

2 Choose beforehand the path along which the unit is to be brought

in.

3 Bring the unit as close as possible to its nal installation position in

its original package to prevent damage during transport.

2

4

2

4

1

4

3

3

1 Packaging material

2 Belt sling

3 Opening

4 Protector

4 Lift the unit preferably with a crane and 2 belts of at least 27 ft.

(8 m) long as shown in the gure above.

Always use protectors to prevent belt damage and pay attention to

the position of the unit’s center of gravity.

NOTE

Use a belt sling of ≤3/4 in. (20 mm) wide that adequately bears the

weight of the unit.

WARNING

Tear apart and throw away plastic packaging bags so that children will

not play with them. Children playing with plastic bags face danger of

death by suffocation.

1 Remove the 4 bolts xing the unit to its pallet.

2 Make sure that all accessories as mentioned in 2.1. Accessories

supplied with this unit on page3 are available in the unit.

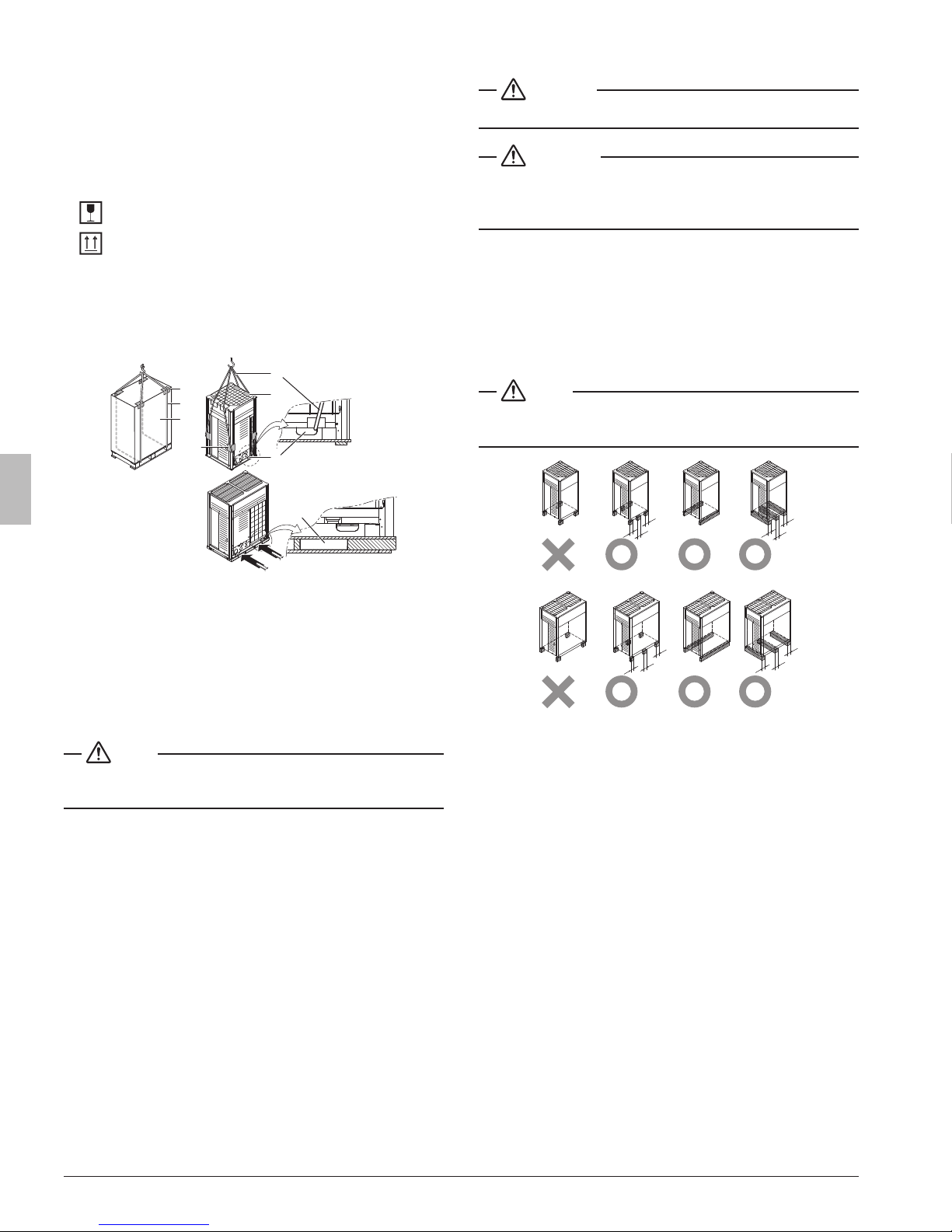

6.4. Installing the unit

Make sure the unit is installed level on a sufciently strong base to

prevent vibration and noise.

NOTE

When the installation height of the unit needs to be increased, do not

use stands to only support the corners.

A

≥3-7/8 in. (100 mm)

X Not allowed

O Allowed

A

A

A

A

A

A

A

A

A

A

A

A

A forklift can only be used for transport as long as the unit remains on

its pallet as shown above.

7 3P362438-3H English

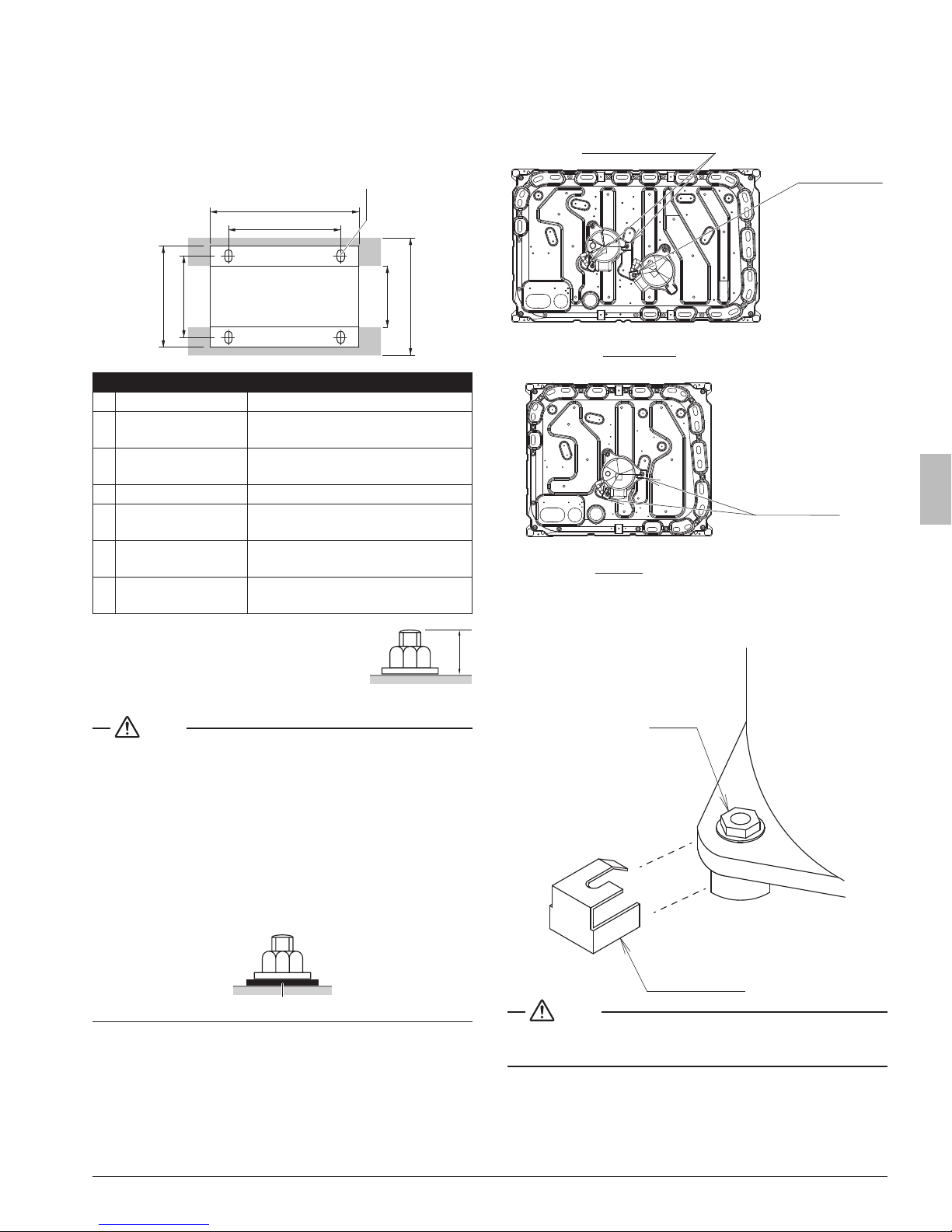

• The height of the foundation must at least be 5-7/8 in. (150 mm )

1

from the oor.

In heavy snowfall areas, this height should be increased, depending

on the installation place and condition.

• The unit must be installed on a solid longitudinal foundation (steel

beam frame or concrete) and make sure the base under the unit is

larger than the gray marked area.

6

7

3

4

2

5

Dimensionsforabovegure

1 Hole for foundation bolt

2 Inner dimension of

2

the base

Distance between

3

foundation bolt holes

f9/16 in. (15 mm) dia: 4 positions

24-7/8 in. (631 mm)

29 in. (729 mm)

4 Depth of unit 30-1/8 in. (765 mm)

Outer dimension of the

5

base

Longitudinal foundation

6

dimension

Distance between

7

foundation bolt holes

≥30-1/8 in. (765 mm)

72T type: 36-9/6 in. (930 mm)

96-168T type: 48-13/16 in. (1240 mm)

72T type: 30-3/16 in. (766 mm)

96-168T type: 42-3/8 in. (1076 mm)

• Fasten the unit in place using 4 foundation bolts

M12. It is best to screw in the foundation bolts

A

until their length remains 13/16 in. (20 mm)

above the foundation surface.

A=13/16 in. (20 mm)

NOTE

• There are restrictions on the refrigerant pipe connecting order

between outdoor unit in the case of the multi system.

See 1.2.2. Outdoor unit combinations on page2 for detail.

• When installing on a roof, make sure the roof oor is strong enough

and be sure to waterproof all work.

• Make sure the area around the machine drains properly by setting

up drainage grooves around the foundation.

• Drain water is sometimes discharged from the outdoor unit when it

is running.

• For anti-corrosion type, use nuts with resin washers. If the paint on

nut connections comes off, the anti-corrosion effect may decrease.

6.5. Method for removing shipping plate

The shipping plate installed over the compressor leg for protecting the

unit during transport must be removed. Proceed as shown in the gure

and procedure below.

Shipping plate

Shipping plate

Front

96-168T type

Shipping plate

Front

72T type

1 Remove shipping plates.

2 Be sure to tighten compressor xing bolts again. (9.1ft⋅lbf

(12.3N⋅m))

Bolt

Compressor

Resin washer

Shipping plate

NOTE

If the unit is operated with the shipping plate still attached, abnormal

vibration or noise may be generated.

83P362438-3H English

7.

Refrigerant pipe size and allowable pipe length

7.1. General information

NOTE

The refrigerant R410A requires strict cautions for keeping the system

clean, dry and tight.

• Clean and dry: foreign materials (including mineral oils or moisture)

should be prevented from getting mixed into the system.

• Tight: R410A does not contain any chlorine, does not destroy

the ozone layer, and does not reduce earth’s protection against

harmful ultraviolet radiation. R410A can contribute slightly to the

greenhouse effect if it is released. Therefore we should take special

attention to check the tightness of the installation.

7.2. Selection of piping material

NOTE

Piping and other pressure containing parts shall comply with the applicable legislation and shall be suitable for refrigerant. Use phosphoric

acid deoxidized seamless copper for refrigerant.

NOTE

• All eld piping must be installed by a licensed refrigeration technician and must comply with relevant local and national regulations.

• After piping work is complete, do not under any circumstances open

the stop valve until 9. Field wiring on page18 and 12. Checking of

device and installation conditions on page24 are complete.

• Do not use ux when brazing the refrigerant piping. Use the phosphor copper brazing ller metal (B-Cu93P-710/795 : ISO 3677)

which does not require ux. Flux has extremely negative effect on

refrigerant piping systems. For instance, if the chlorine based ux is

used, it will cause pipe corrosion or, in particular, if the ux contains

uorine, it will damage the refrigerant oil.

• Use only pipes which are clean inside and outside and which do not

accumulate harmful sulfur, oxidants, dirt, cutting oils, moisture, or

other contamination. (Foreign materials inside pipes including oils

for fabrication must be 0.14 gr/10 ft. (30 mg/10 m) or less.)

• Use the following items for the refrigerant piping.

Material : Jointless phosphor-deoxidized copper pipe.

Size : See 7.3. Selection of piping size to determine the correct

size.

Thickness : Select a thickness for the refrigerant piping which

complies with national and local laws.

• For piping work, follow the maximum tolerated length, difference in

height, and length after a branch indicated in the 7.5. System piping

(length) limitations.

• Outdoor unit multi connection piping kit and refrigerant branching

kit (sold separately) are needed for connection of piping between

outdoor units (in case of multi system) and piping branches.

• Use only separately sold items selected specically according to

the outdoor unit multi connection piping kit, the refrigerant branching kit selection in the 7.4. Selection of refrigerant branch kits.

7.3. Selection of piping size

Determine the proper size referring to following tables and reference

gure (only for indication).

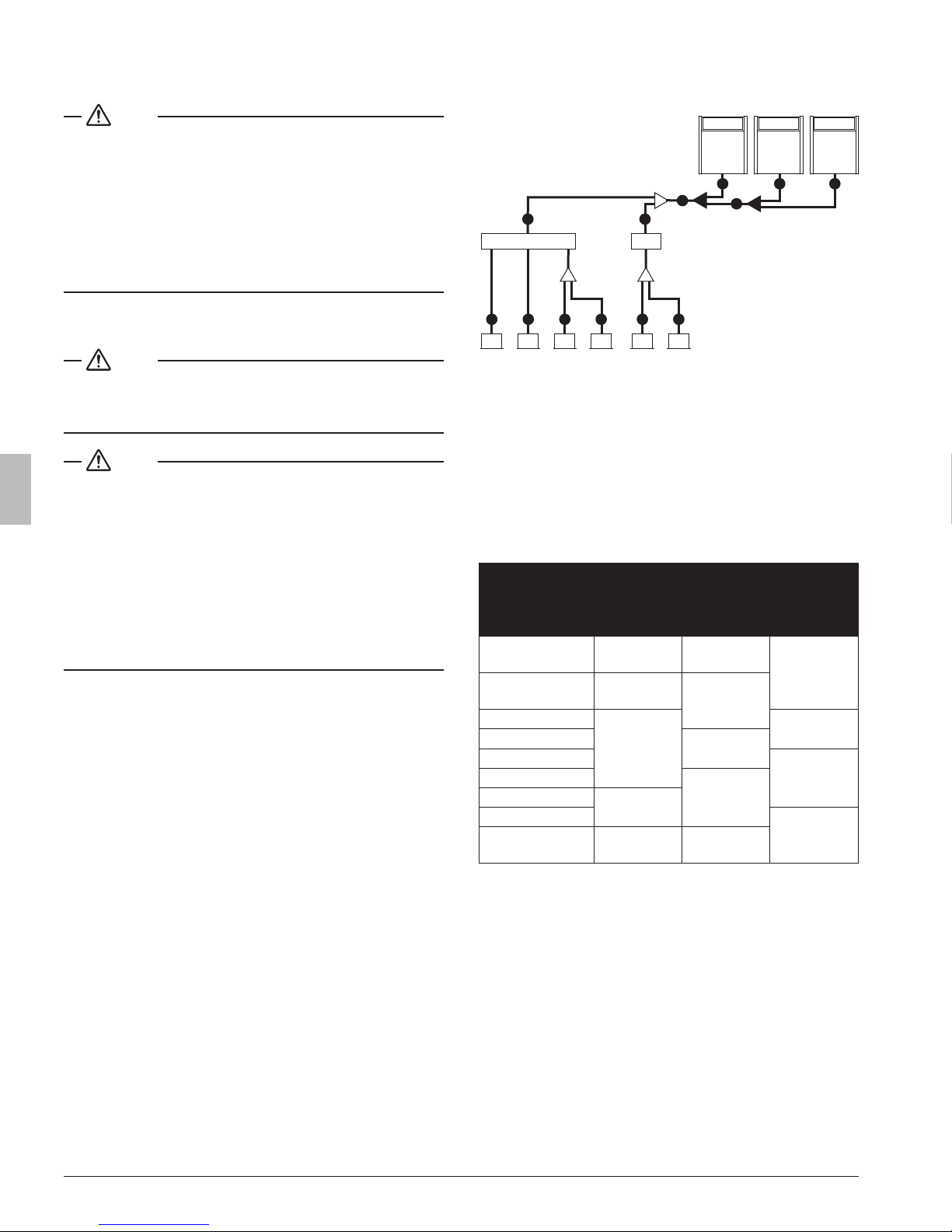

B B B

x

a

A

D

1

b

E

EE

5 6

43

1 Multi BS unit

2 Single BS unit

3-8 VRV indoor unit

a, b Refrigerant branching kit

x, y Outdoor unit multi connection piping kit

7.3.1. Pipingbetweenoutdoorunitand(rst)refrigerant

branch kit: A, B, C

Choose from the following table in accordance with the outdoor unit

total capacity type, connected downstream.

Outdoor unit

capacity type

REYQ72T type

REYQ96T type

REYQ120T type

REYQ144T type

REYQ168T type

REYQ192,216T type

REYQ240T type

REYQ264-336T type

REYQ360-456T type

Suction gas

D

2

b

E

7 8

pipe

3/4 in.

(19.1 mm)

7/8 in.

(22.2 mm)

1-1/8 in.

(28.6 mm)

1-3/8 in.

(34.9 mm)

1-5/8 in.

(41.3 mm)

E

E

Piping outer diameter size

High/Low

pressure gas

(15.9 mm)

(19.1 mm)

(22.2 mm)

(28.6 mm)

(34.9 mm)

C

pipe

5/8 in.

3/4 in.

7/8 in.

1-1/8 in.

1-3/8 in.

y

Liquid pipe

3/8 in.

(9.5 mm)

1/2 in.

(12.7 mm)

5/8 in.

(15.9 mm)

3/4 in.

(19.1 mm)

9 3P362438-3H English

7.3.2. Piping between refrigerant branch kits or refrigerant

branch kit and BS unit: D

Choose from the following table in accordance with the indoor unit

total capacity type, connected downstream. Do not let the connec-

tion piping exceed the refrigerant piping size chosen by the general

system model name.

Piping outer diameter size

Indoor unit

capacity index

< 54

54 ≤ × < 72

72 ≤ × < 111

111 ≤ × < 162

162 ≤ × < 230

230 ≤ × < 300

> 300

Example:

Downstream capacity for D = capacity index of (unit 3 + unit 4 + unit 5

+ unit 6)

Suction gas

pipe

5/8 in.

(15.9 mm)

3/4 in.

(19.1 mm)

7/8 in.

(22.2 mm)

1-1/8 in.

(28.6 mm)

1-3/8 in.

(34.9 mm)

1-5/8 in.

(41.3 mm)

High/Low

pressure gas

pipe

1/2 in.

(12.7 mm)

5/8 in.

(15.9 mm)

3/4 in.

(19.1 mm)

1-1/8 in.

(28.6 mm)

Liquid pipe

3/8 in.

(9.5 mm)

1/2 in.

(12.7 mm)

5/8 in.

(15.9 mm)

3/4 in.

(19.1 mm)

• For REFNET joints other than the rst branch (example REFNET

joint b - see 7.3. Selection of piping size), select the proper branch

kit model based on the total capacity index of all indoor units connected after the refrigerant branch.

Indoor unit

capacity index

< 72 KHRP25A22T9 KHRP26A22T9

72 ≤ × < 111

111 ≤ × < 246

≥246 KHRP25M73TU9 KHRP26M73TU9

• Concerning REFNET headers, choose from the following table in

accordance with the total capacity of all the indoor units connected

below the REFNET header.

Indoor unit

capacity index

< 72

72 ≤ × < 111

111 ≤ × < 230

≥230 KHRP25M73HU9 KHRP26M73H9

3 pipes 2 pipes

KHRP25A33T9 KHRP26A33T9

KHRP25M72TU9 KHRP26M72TU9

3 pipes 2 pipes

KHRP25M33H9

KHRP25M72H9 KHRP26M72H9

Kit name

Kit name

KHRP26M22H9:

maximum 4 indoor units

or

KHRP26M33H9:

maximum 8 indoor units

KHRP26M33H9

INFORMATION

Maximum 8 branches can be connected to a header.

7.3.3. Piping between refrigerant branch kit and indoor unit: E

Pipe size for direct connection to indoor unit must be the same as the

connection size of the VRV indoor unit.

Indoor unit

capacity index

07, 09, 12, 18 1/2 in. (12.7 mm) 1/4 in. (6.4 mm)

24, 30, 36, 42,

48, 54

72 3/4 in. (19.1 mm)

96 7/8 in. (22.2 mm)

Piping outer diameter size

Gas pipe Liquid pipe

5/8 in. (15.9 mm)

3/8 in. (9.5 mm)

7.4. Selection of refrigerant branch kits

For piping example, refer to 7.3. Selection of piping size on page9.

• When using REFNET joints at the rst branch from the outdoor unit,

choose from the following table in accordance with the capacity of

the outdoor unit (example: REFNET joint a - see 7.3. Selection of

piping size).

Outdoor unit capacity type Kit name

REYQ 72, 96T type KHRP25A33T9

REYQ 120-216T type KHRP25M72TU9

REYQ 240-456T type KHRP25M73TU9

• How to choose an outdoor multi connection piping kit (needed if the

outdoor unit capacity type is 192 or more). Choose from the following table in accordance with the number of outdoor units.

Number of outdoor units Branch kit name

2 BHFP26P100U

3 BHFP26P151U

103P362438-3H English

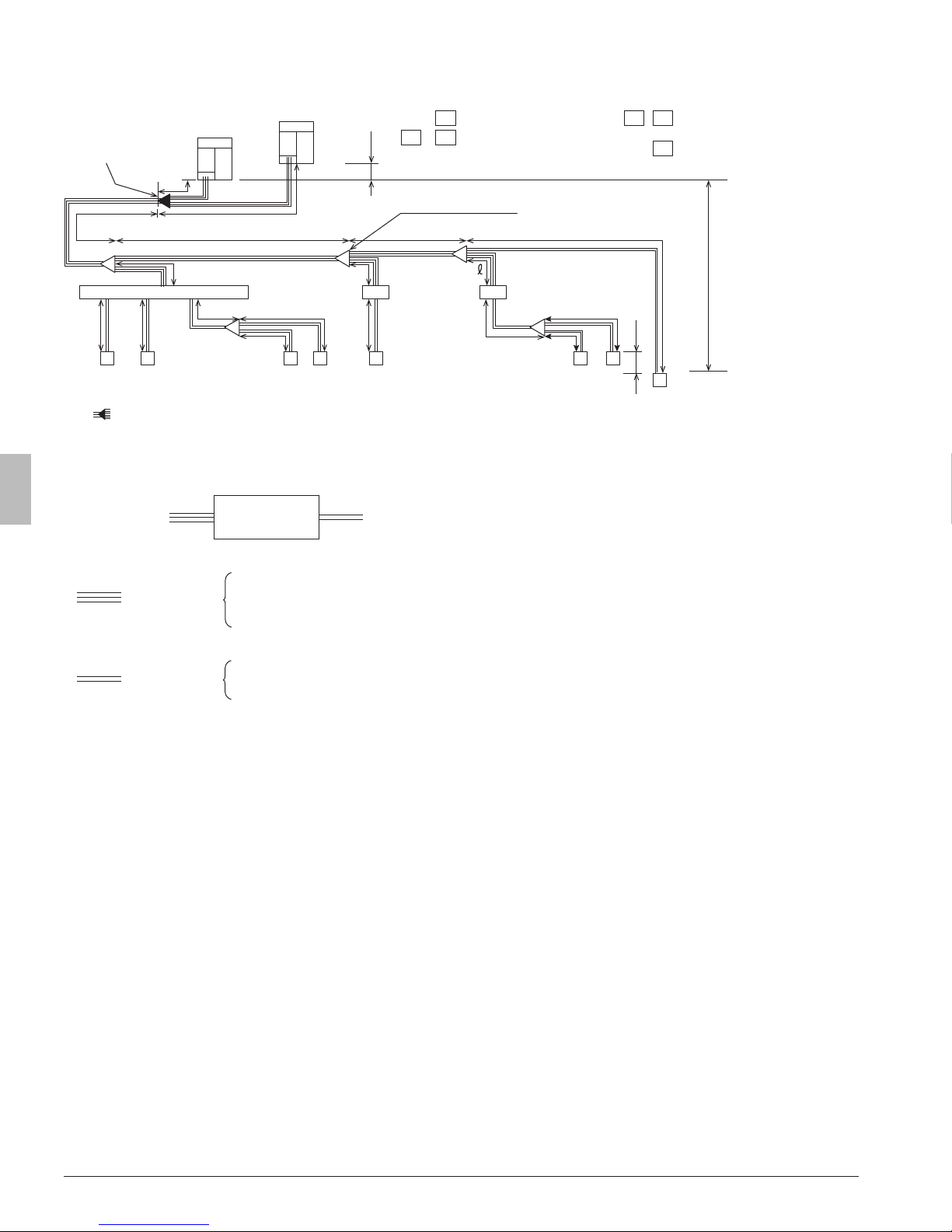

7.5. Systempiping(length)limitations

Outdoor unit

<Exampleofrefrigerantpiping(8indoorunitsareconnected)>

: BS unit (Multi BS)

First outdoor unit

multi connection

piping kit (*1)

a

A

e f

1 2

(*1) “ ” represents an outdoor unit multi connection piping kit.

The outdoor unit multi connection piping kit must always be installed horizontally, paying attention to the installation restrictions indicated in

“8.Precautions on refrigerant piping”.

<Exampleofconnection(8indoorunitsareconnected)>

Outdoor unit

side

(1)PipingfromtheoutdoorunittotheBSunit

(3 lines): 3 pipes

Outdoor unit

H3

r

b c

d

B-1 B-2 B-3

g

D

(1) (2)

BS unit

Suction gas pipe

High/Low pressure gas pipe

Liquid pipe

t

B

j

k

h

i

4 5 6 7

3

Indoor unit

B1

: BS unit (Single BS)

B3B2

,

REFNET joint (A-E)

C

m

side

E

n

1 7

o

: Indoor unit (cooling/heating

selectable)

8

: Indoor unit (cooling only)

(Note 4)

H1

p

8

H2

(2)PipingfromtheBSunittotheindoorunit,andfromtherefrigerantbranchkittothecooling-onlyindoorunit(Note1)

(2 lines): 2 pipes

Note 1: The 2-line gas pipe that is branched from the 3-line pipe and goes to the cooling-only indoor unit should be connected to the suction gas

pipe.

(Suction) gas pipe

Liquid pipe

11 3P362438-3H English

Loading...

Loading...