Daikin REYQ8PY1B, REYQ10PY1B, REYQ12PY1B, REYQ14PY1B, REYQ16PY1B Installation manuals

INSTALLATION MANUAL

System air conditioner

REYQ8PY1B

REYQ10PY1B

REYQ12PY1B

REYQ14PY1B

REYQ16PY1B

Installation manual

III

VRV

Conditionneur d’air VRV

Sistema de acondicionador de aire VRV

Condizionatore d’aria a sistema VRV

Κλιìατιστικü ìε σýστηìα VRV

Airconditioner met VRV

System air conditioner

Installationsanleitung

III

VRV

System Klimaanlage

Manuel d’installation

III

System

Manual de instalación

Manuale di installazione

Εγχειρßδιο εγκατÜστασηò

Installatiehandleiding

III

Systeem

III

III

III

English

Deutsch

Français

Español

Italiano

ΕλληνικÜ

Nederlands

Manual de instalação

III

Ar condicionado VRV

Рóêоводство по монтажó

Кондиционер системы VRV

Montaj elkitabý

III

VRV

System Klima

System

III

Portugues

Рóссêий

Türkçe

DAIKIN.TCF.024

TNO

0510260101

Umeda Center Bldg., 4-12, Nakazaki-Nishi 2-chome,

Kita-ku, Osaka, 530-8323 Japan

Low Voltage 2006/95/EC

Machinery Safety 98/37/EC

REYQ8PY1, REYQ10PY1, REYQ12PY1, REYQ14PY1, REYQ16PY1,

REYQ18PY1, REYQ20PY1, REYQ22PY1, REYQ24PY1, REYQ26PY1, REYQ28PY1, REYQ30PY1, REYQ32PY1,

REYQ34PY1, REYQ36PY1, REYQ38PY1, REYQ40PY1, REYQ42PY1, REYQ44PY1, REYQ46PY1, REYQ48PY1,

REYQ8PY1B, REYQ10PY1B, REYQ12PY1B, REYQ14PY1B, REYQ16PY1B,

REMQ8PY1, REMQ10PY1, REMQ12PY1, REMQ14PY1, REMQ16PY1,

BSVQ100PV1, BSVQ160PV1, BSVQ250PV1,

Electromagnetic Compatibility 89/336/EEC

Noboru Murata

Manager Quality Control Department

1st of April 2007

DAIKIN INDUSTRIES, LTD.

RXYQ5PY1(E), RXYQ8PY1(E), RXYQ10PY1(E), RXYQ12PY1(E), RXYQ14PY1(E), RXYQ16PY1(E), RXYQ18PY1(E),

RXYQ20PY1(E), RXYQ22PY1(E), RXYQ24PY1(E), RXYQ26PY1(E), RXYQ28PY1(E),

RXYQ30PY1(E), RXYQ32PY1(E), RXYQ34PY1(E), RXYQ36PY1(E), RXYQ38PY1(E),

RXYQ40PY1(E), RXYQ42PY1(E), RXYQ44PY1(E), RXYQ46PY1(E), RXYQ48PY1(E),

RXYQ50PY1(E), RXYQ52PY1(E), RXYQ54PY1(E),

EN60335-2-40,

3P177868-1C

<

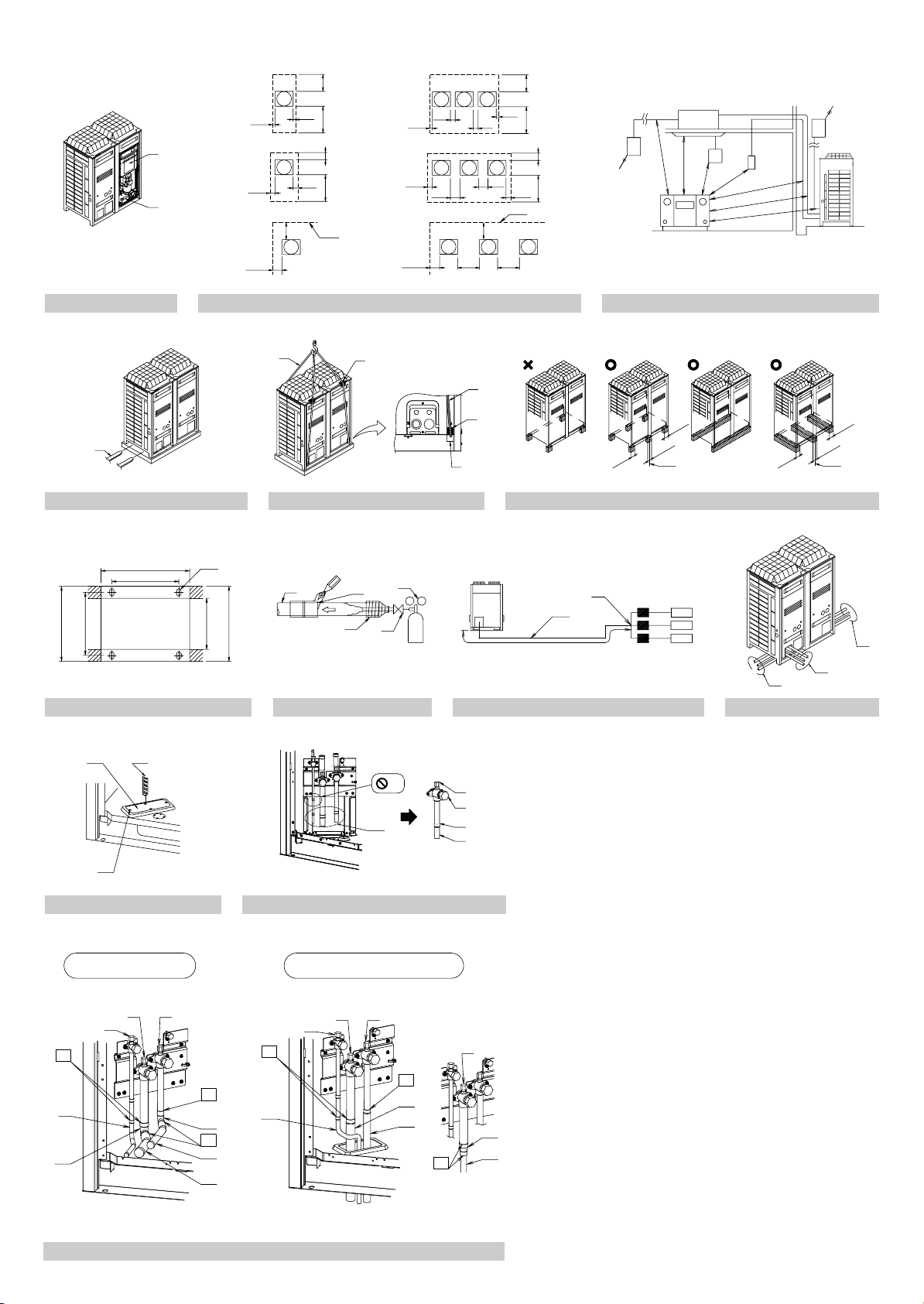

If installed as a single unit

(Pattern 1)

1

≥10

≥10

1

(Pattern 2)

≥50

1

≥50

2

(Pattern 3)

≥300

>

≥300 ≥300

4

≥500

3

≥100

4

≥500

3

2

(Pattern 1)

≥10

(Pattern 2)

≥50

(Pattern 3)

<

When installed in serial

≥10

1

≥20

≥100

≥20

≥100

1

≥300

>

≥500

≥50

2

4

3

≥100

≥500

1

2

2

4

3

≥1500

5

≥1000

≥1000

3

≥1000

4

≥1500

≥1500

≥1500

(mm)

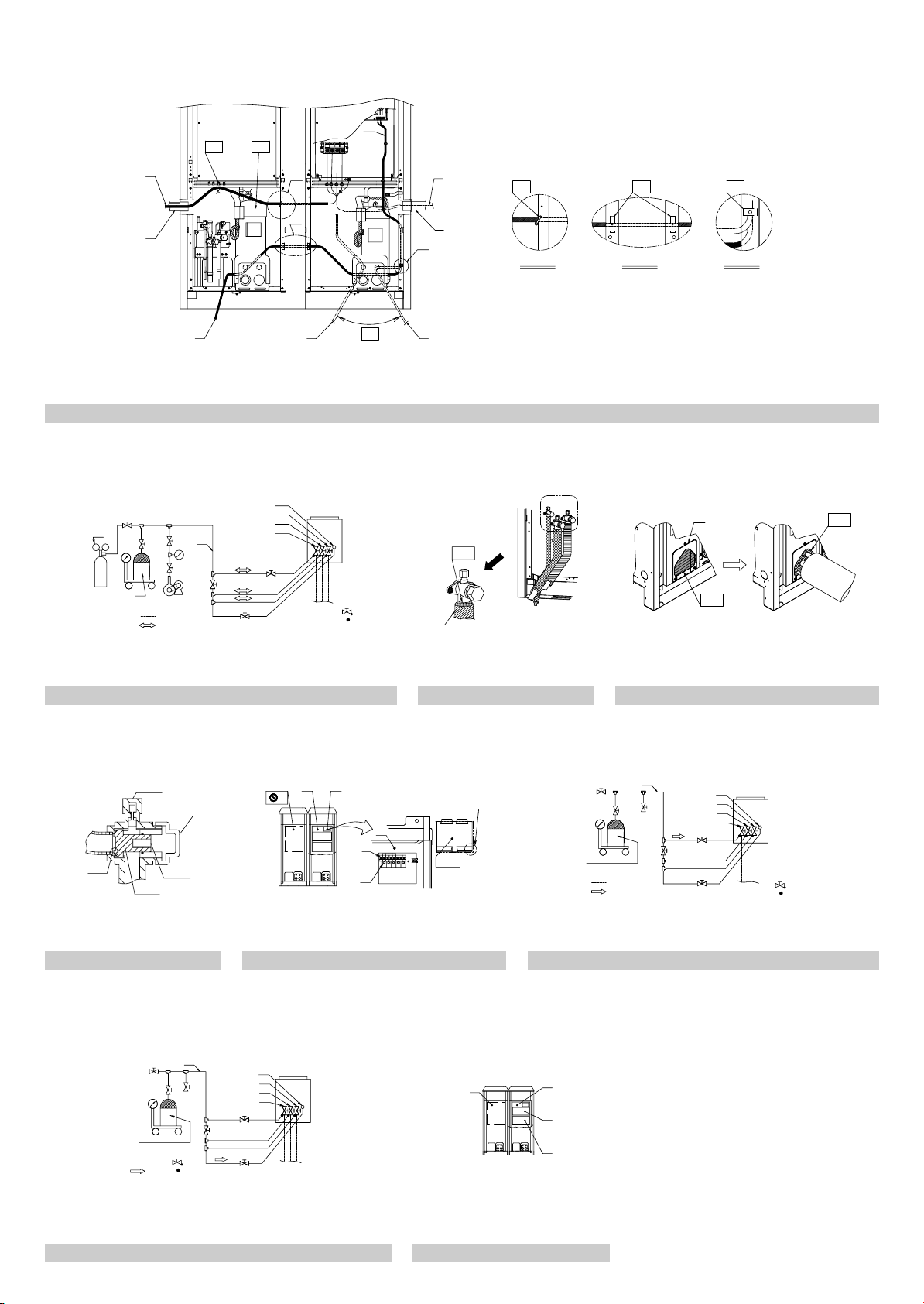

figure 1

figure 4

2

765

figure 7

729

1

≥400 ≥400

figure 3

12

3

4

figure 2

≥200

1

1

2

≥200

1

2

1

100

≥

4

1300

1162

1

631

3

figure 5

1

3

4

3

765

≥

4

6

2

5

3

figure 6

1

2

100

≥

100

≥

55

100

≥

56

3

100

≥

100

≥

3

2

1

figure 8

figure 9

figure 10

1

2

3

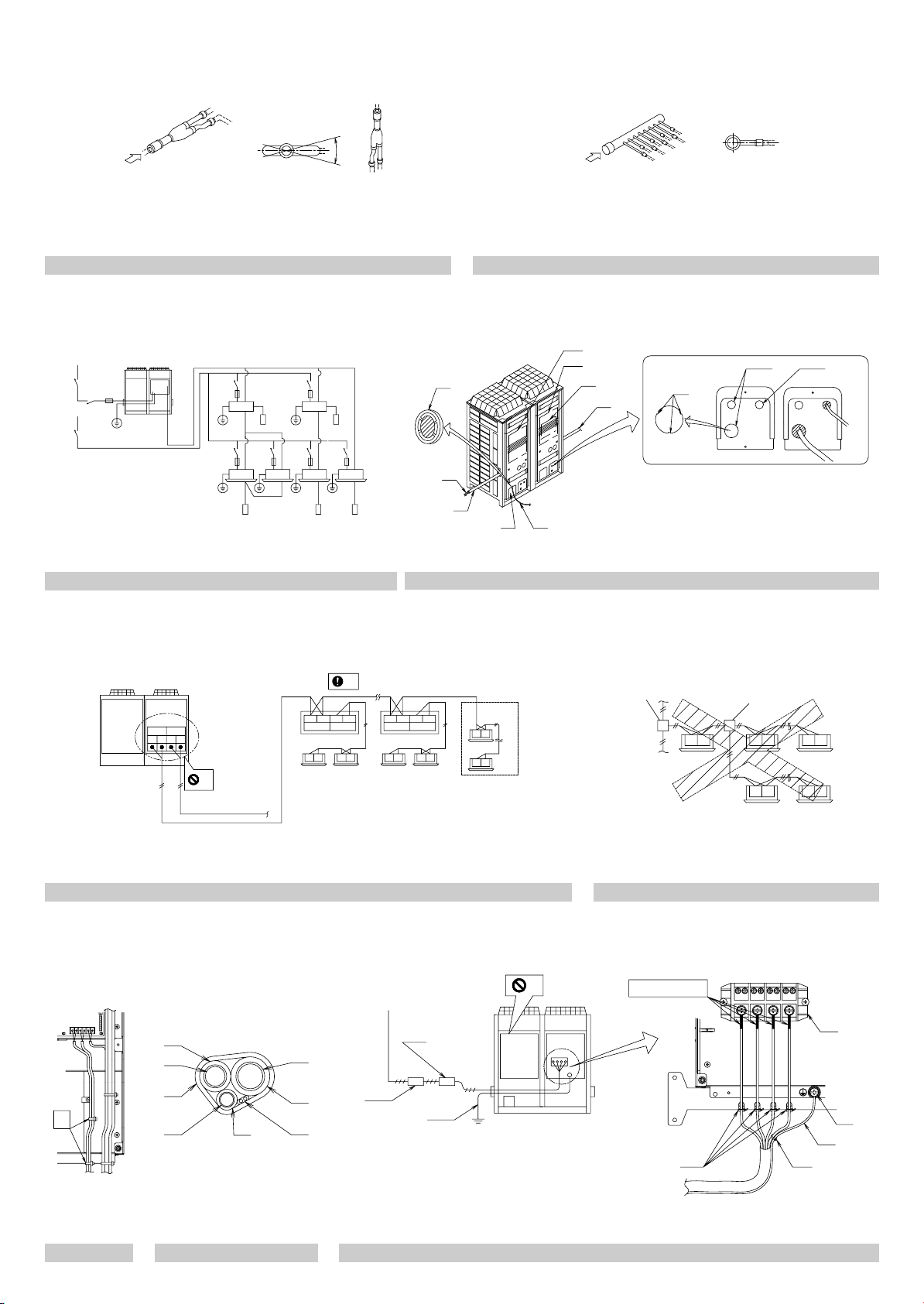

figure 11 figure 12

1

3

7

6

5

8

8

8

9

13

14

8

12

11

10

2

5

4

1

6

3

2

4

6

5

7

17

6

8

15

16

8

18

15

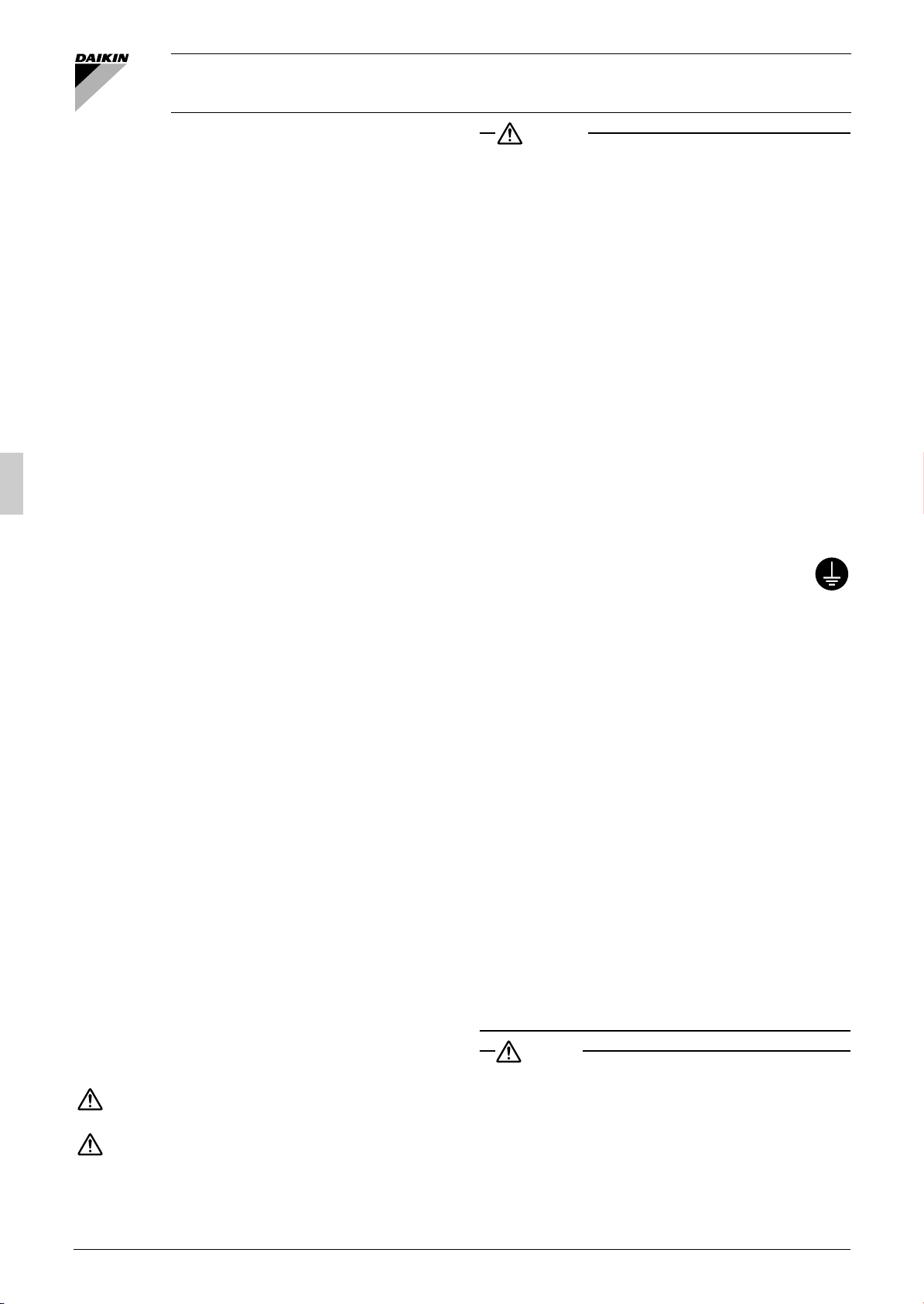

figure 13

34

A

1

2

5

B

1

2

figure 14

1

2

3

1

2

figure 17

figure 15

5

4

9

9

10

6

3

4

8

7

8

7

65

15

14

1

2

3

4

11

12

8

12

13

figure 18

12

A1P

TO IN/D UNIT

TO OUT/D UNIT

F1 F2 F1 F2

5

F1 F2 F1 F2

TO IN/D UNIT

TO OUT/D UNIT

6

F1F2F1

3

7

F2

F1 F2 F1 F2

TO IN/D UNIT

TO OUT/D UNIT

6

F1F2F1

F2

7

8

F1

F2

F1

F2

4

1

2

F1 F2 F1 F2F1 F2

F1 F2 F1 F2

figure 19

1

(A1P)

4

1

5

2

figure 21 figure 23

3

figure 22

4

2

4

2

6

figure 20

7

1

3

65

4

8

L1 L2 L3 N

9

10

4

11

11

11

1

12

3

A

9

10

8

13

14 14

figure 24

2

B

2

C

Part A Part B Part C

45 7

7

8

14

9

1

3

2

4

: 18

: 19

6

13

5

11

10

12

15

6

:

16

()

:

17

1

1

3

2

2

figure 25

figure 28

figure 26 figure 27

1

1

2

5

3

4

4

23

8

5

6

1

2

7

3

9

2

:

13

:

14

10

8

11

4

5

6

7

:

12

15

()

:

16

figure 29 figure 30

3

1

2

: 13

: 14

10

: 15

()

: 16

4

11

5

6

7

9

8

12

2

1

3

4

figure 31

figure 32

3P201178-4B EM07A013

(0705) HT

REYQ8PY1B

REYQ10PY1B

REYQ12PY1B

REYQ14PY1B

REYQ16PY1B

CONTENTS

1. FIRST OF ALL ......................................................................... 1

1-1. Safety considerations........................................................ 1

1-2. Special notice of product................................................... 2

1-3. Disposal requirements ...................................................... 2

2. INTRODUCTION...................................................................... 2

2-1. Combination...................................................................... 2

2-2. Standard supplied accessories ......................................... 3

2-3. Option accessory .............................................................. 3

2-4. Technical and Electrical specifications .............................3

2-5. Main components.............................................................. 3

3. SELECTION OF LOCATION ................................................... 3

4. INSPECTING AND HANDLING THE UNIT ............................. 4

5. PLACING THE UNIT................................................................ 4

6. REFRIGERANT PIPING.......................................................... 4

6-1. Selection of piping material and Refrigerant

branching kit...................................................................... 4

6-2. Protection against contamination when installing pipes.... 4

6-3. Pipe connection ................................................................ 5

6-4. Connecting the refrigerant piping...................................... 5

6-5. Example of connection...................................................... 6

7. FIELD WIRING ........................................................................ 9

7-1. Power circuit, safety device and cable requirements........ 9

7-2. Wiring Connection Example for Whole System ................ 9

7-3. Leading wire Procedure .................................................... 9

7-4. Transmission Wiring Connection Procedure................... 10

7-5. Power Wiring Connection Procedure.............................. 10

7-6. Procedure for Wiring Inside Units ................................... 10

8. AIR TIGHT TEST AND VACUUM DRYING........................... 11

9. PIPE INSULATION ................................................................ 11

10. CHECKING OF DEVICE AND

INSTALLATION CONDITIONS .............................................. 12

11. ADDITIONAL REFRIGERANT CHARGE AND

CHECK OPERATION ............................................................ 12

11-1. Before working.............................................................. 12

11-2. Procedure of Adding Refrigerant charging and check

12. ONSITE SETTINGS............................................................... 16

13. TEST RUN ............................................................................. 16

14. CAUTION FOR REFRIGERANT LEAKS ............................... 16

operation ....................................................................... 13

13-1. Before test run............................................................... 16

13-2. Test Run........................................................................16

13-3. Checks After Test Run.................................................. 16

1. FIRST OF ALL

• This document is an installation manual for the Daikin REYQ-P

Series VRV Inverter. Before installing the unit, read this manual

thoroughly, and following the instructions contained in it.

After installation, do a test run to make sure the unit runs properly,

and then explain how to operate and take care of the unit to the

customer, using the operation manual.

Lastly, make sure the customer keeps this manual, along with the

operation manual, in a safe place.

1-1 Safety considerations

Please read these “Safety considerations” carefully before installing

air conditioning unit and be sure to install it correctly. The safety precautions listed here are divided into two categories.

In either case, important safety information is listed which must be

read carefully.

Warning ........Failure to observe a warning may result in death

or serious injury.

Caution.........Failure to observe a caution may result in injury

or damage to the unit.

These too might lead to serious injury depending on the circumstances.

VRV

III

System air conditioner

Warning

• Ask your dealer or qualified personnel to carry out installation

work. Do not try to install the machine yourself.

Improper installation may result in water leakage, electric

shocks or fire.

•

Perform installation work in accordance with this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• When installing the unit in a small room, take measures against to

keep refrigerant concentration from exceeding allowable safety

limits in the event of refrigerant leakage.

Excessive refrigerant in a closed ambient can lead to oxygen deficiency. Contact your dealer for more information.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in water leakage,

electric shocks, fire or the unit falling.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the unit falling

and causing injuries.

• Carry out the specified installation work after taking into account

strong winds, typhoons or earthquakes.

Improper installation work may result in the unit falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this

unit and that all electrical work is carried out by qualified personnel according to local and national regulations and this installation

manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

• Be sure to establish an earth.

Do not earth the unit to a utility pipe, arrester or telephone earth.

Incomplete earth may cause electrical shock or fire.

A high surge current from lightning or other sources may cause

damage to the air conditioner.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks or fire.

• Before touching electrical parts, turn off the power.

Failure to turn off the power may result in electric shocks.

• Make sure that all wiring is secured, the specified wires are used,

and no external forces act on the terminal connections or wires.

Improper connections or installation may result in the terminals

overheating or fire.

• When wiring the power supply and connecting the remote controller wiring and transmission wiring, position the wires so that the

EL.COMPO.BOX lid can be securely fastened.

Improper positioning of the EL.COMPO.BOX lid may result in

electric shocks or fire.

• If the refrigerant gas leaks during installation, ventilate the area

immediately.

Toxic gas may be produced if the refrigerant gas comes into contact with fire.

• After completing the installation work, check that the refrigerant

gas does not leak.

Toxic gas may be produced if the refrigerant gas leaks into the

room and comes into contact with a source of fire, such as a fan

heater, stove or cooker.

• Do not directly touch the refrigerant leaked from refrigerant piping

connections.

Frostbite may be caused.

• Do not allow children to mount on the outdoor unit, or avoid

placing any object on it. Falling or tumble may result in injury.

Caution

• While following the instructions in this installation manual,

install drain piping in order to ensure proper drainage and insulate piping in order to prevent condensation.

Improper drain piping may result in water leakage and property

damage.

• Install the indoor, BS and outdoor units, power supply wiring and

connecting wiring at least 1 meter away from televisions or radios

in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not be

sufficient enough to eliminate the noise.)

Installation manual

1 English

• The indoor and BS unit should be installed as far away from fluorescent lighting as possible.

Remote controller (wireless kit) transmitting distance can result

shorter than expected in rooms with electronic fluorescent lamps

(inverter or rapid start types).

• Do not install the air conditioner in the following locations:

(a) where a mineral oil mist or an oil spray or vapor is produced,

for example in a kitchen.

Plastic parts may deteriorate and fall off or result in water leakage.

(b) where corrosive gas, such as sulfurous acid gas, is produced.

Corroding copper pipes or soldered parts may result in refrigerant leakage.

(c) near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of the control system and result in a malfunction of the unit.

(d) where flammable gas may leak, where there are carbon fiber

or ignitable dust suspensions in the air, or where volatile flammables such as thinner or gasoline are handled.

Operating the unit in such conditions may result in fire.

(e) Locations where small animals might build nests inside the unit.

If small animals enter and come in contact with electrical parts,

this can cause malfunctions, smoke, and fire.

4

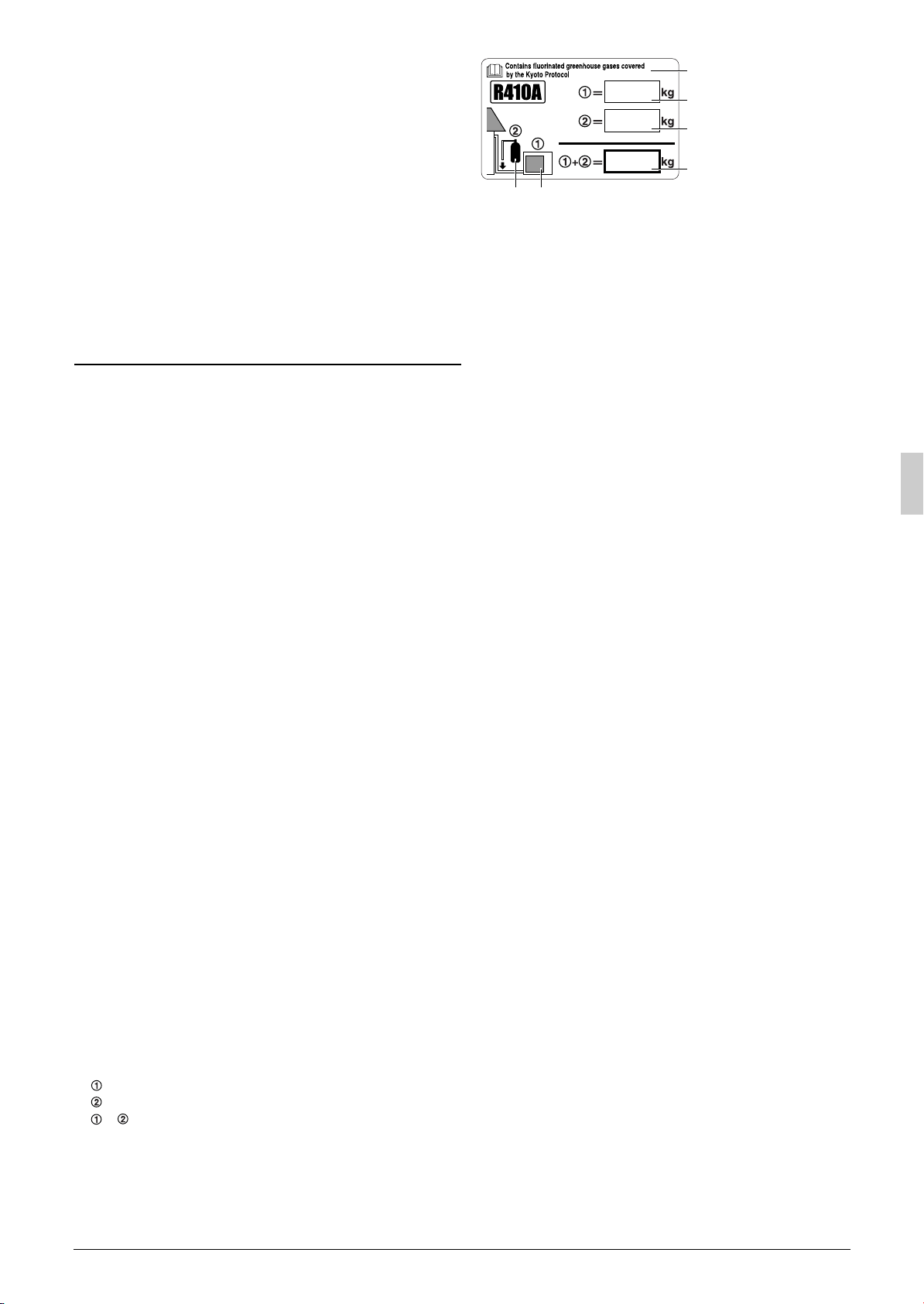

1 factory refrigerant charge

of the product : see unit

name plate

1

2 additional refrigerant

2

amount charged in the field

3 total refrigerant charge

3

4 Contains fluorinated

5

6

(2)

In case of multiple outdoor systems, only 1 label must be adhered,

greenhouse gases covered

by the Kyoto Protocol

5 outdoor unit

6 refrigerant cylinder and

manifold for charging

(2)

mentioning the total factory refrigerant charge of all outdoor units

connected on the refrigerant system.

[DESIGN PRESSURE]

Since design pressure is 4.0MPa or 40bar (for R407C units : 3.3MPa

or 33bar), the wall thickness of pipes should be more carefully selected

in accordance with the relevant local and national regulations.

1-2 Special notice of product

[CLASSIFICATION]

This air conditioner comes under the term “appliances not accessible

to the general public”.

[EMC CHARACTERISTICS]

VRVIII System is a class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

[REFRIGERANT]

VRVIII System use R410A refrigerant.

• The refrigerant R410A requires strict cautions for keeping the sys-

tem clean, dry and tight.

Read the chapter “REFRIGERANT PIPING” carefully and follow

these procedures correctly.

A.Clean and dry

Foreign materials (including mineral oils such as SUNISO oil or

moisture) should be prevented from getting mixed into the system.

B.Tight

Take care to keep the system tight when installing.

R410A does not contain any chlorine, does not destroy the

ozone layer, and does not reduce the earth’s protection against

harmful ultraviolet radiation.

R410A can contribute slightly to the greenhouse effect if it is

released.

• Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state. If the refrigerant is

charged in a state of gas, its composition changes and the system

will not work properly.

Limit by the total maximum refrigerant charge

The total maximum refrigerant charge of a VRVIII system must be

below 100kg, this to be in accordance with CE requirement

(EN60335-2-40 standard).

This means that in case the total maximum refrigerant charge of the

system (factory and additional charge) is equal to or more than

100kg you must divide your multiple outdoor system into smaller

independent systems, each containing less than 100kg refrigerant

charge.

For factory charge, refer to the unit name plate.

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type : R410A

(1)

value : 1975

GWP

(1)

GWP = global warming potential

Please fill in with indelible ink,

Q the factory refrigerant charge of the product,

Q the additional refrigerant amount charged in the field and

Q + the total refrigerant charge on the refrigerant charge label

supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the service cover).

1-3 Disposal requirements

Dismantling of the unit, treatment of the refrigerant, oil and eventual

other parts, should be done in accordance with the relevant local and

national regulations.

2. INTRODUCTION

• REYQ-P series are designed for outdoor installation and used for

cooling and heating aplications. The REYQ8-16P system is exclusive unit for single outdoor unit system. The unit can not use for

independent unit of multi outdoor unit system.

With this system, rated cooling capacity from 22.4kW to 45.0kW

and rated heating capacity from 25.0kW to 50.0kW can be

achieved.

• The BS units that combined with REYQ-P system for changing

the refrigerant flow to indoor units are BSVQ100, 160, 250P type

only. To combine with other type BS unit will cause malfunction.

• The indoor units that combined with REYQ-P system for air conditioning are Daikin VRV series indoor units that compatible with

R410A. To learn which indoor units are compatible with R410A,

refer to the product catalogs. To combine with other refrigerant

indoor unit will cause malfunction.

2-1 Combination

• The indoor units can be installed in the following range.

Outdoor unit

〈

〉〈

REYQ8PY1B ....................................... 100 ~ 260

REYQ10PY1B ..................................... 125 ~ 325

REYQ12PY1B ..................................... 150 ~ 390

REYQ14PY1B ..................................... 175 ~ 455

REYQ16PY1B ..................................... 200 ~ 520

• If the total capacity of the connected indoor units exceeds the

capacity of the outdoor unit, cooling and heating performance

may drop when running the indoor units. See the capacity table in

the Engineering Data Book for details.

Total capacity of indoor units

〉

English 2