DAIKIN R-410A OPERATION MANUAL

EDUS 391004 - N

Installation

AMERICASAMERICAS

EDUS391004-N

Installation of

Outdoor Units

1. Center of Gravity .........................................................................................2

1.1 460V ............................................................................................................. 2

1.2 208/230V ...................................................................................................... 5

2. Foundation Drawing ....................................................................................8

3. REFNET Pipe System.................................................................................9

3.1 Layout Example............................................................................................ 9

3.2 Field Refrigerant Piping.............................................................................. 11

3.3 REFNET Joints and Headers ..................................................................... 12

4. REFNET Pipe System...............................................................................14

4.1 REFNET Joint (Branch Kit) ........................................................................ 14

4.2 REFNET Header (Branch Kit) .................................................................... 18

4.3 Outdoor Unit Multi Connection Piping Kit ................................................... 22

5. Installation .................................................................................................43

5.1 RXYQ72~360PBYD (Heat Pump, 460V)

RXYQ72~360PBTJ (Heat Pump, 208/230V).............................................. 43

5.2 REYQ72~120PBYD (Heat Recovery, 460V)

REYQ72~144PBTJ (Heat Recovery, 208/230V)........................................ 67

5.3 REYQ144~336PBYD (Heat Recovery, 460V)

REYQ168~336PBTJ (Heat Recovery, 208/230V)...................................... 89

6. Field Setting ............................................................................................112

6.1 460V ......................................................................................................... 112

6.2 208/230V .................................................................................................. 120

Installation of Outdoor Units 1

Center of Gravity EDUS391004-N

4D058650B

4D058651B

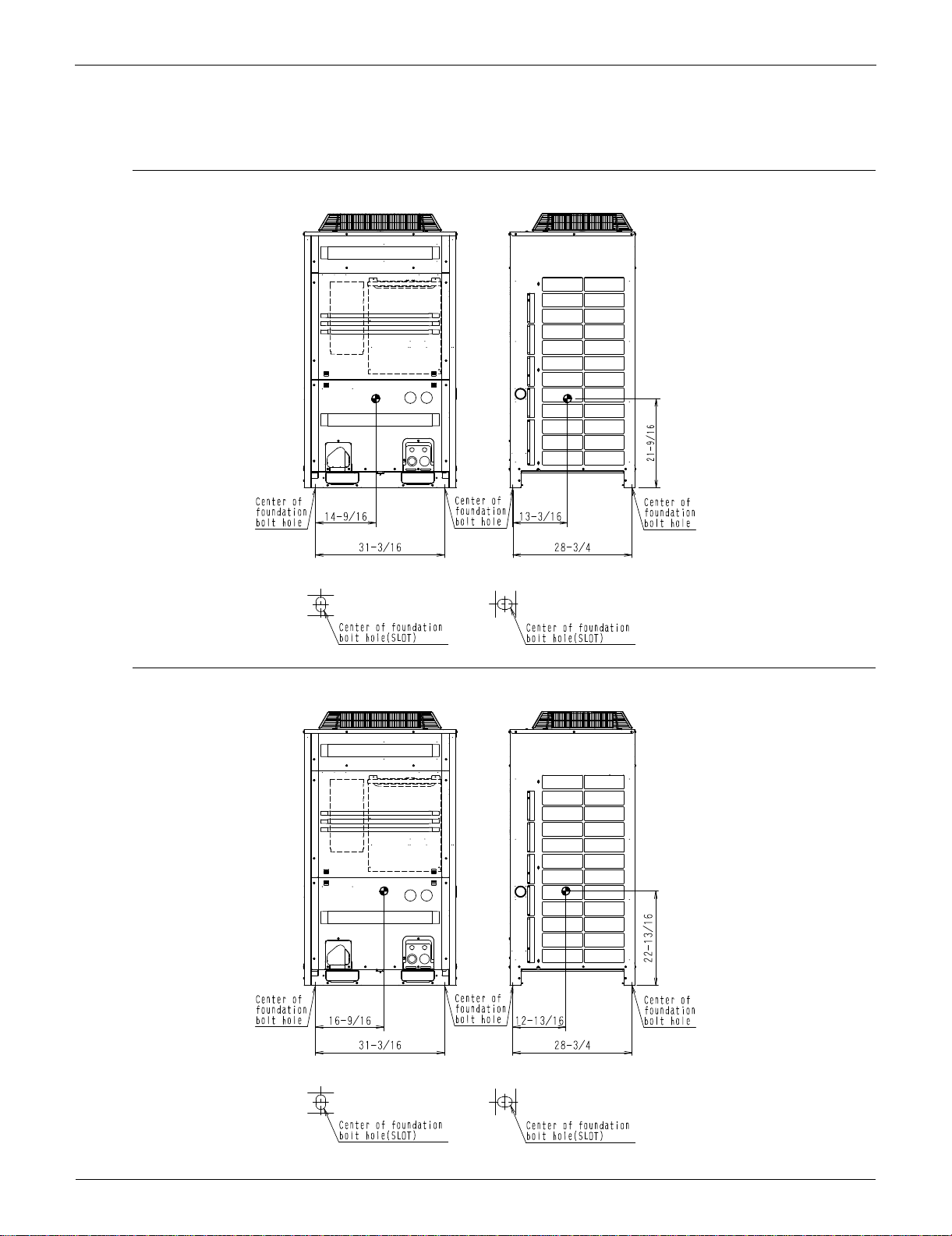

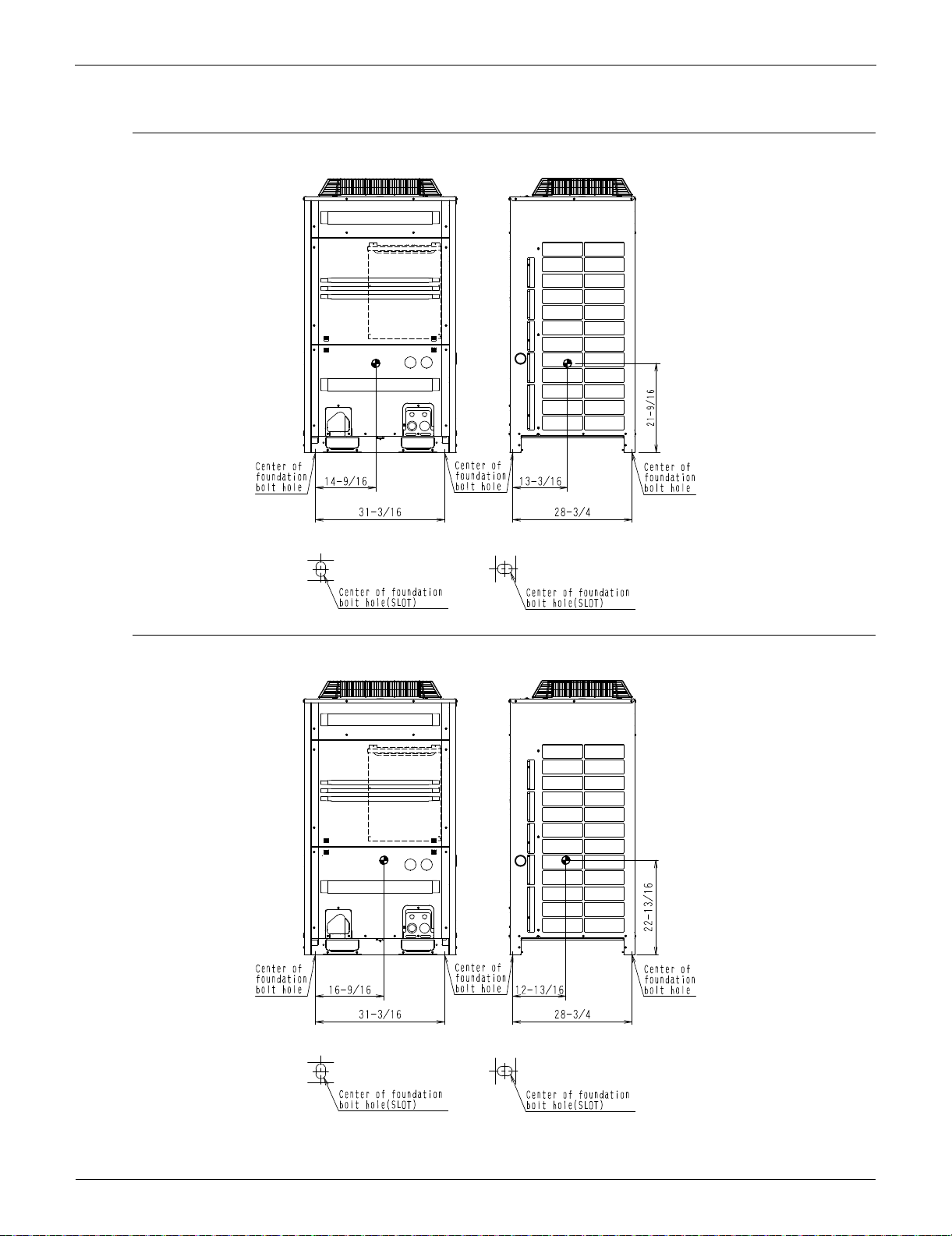

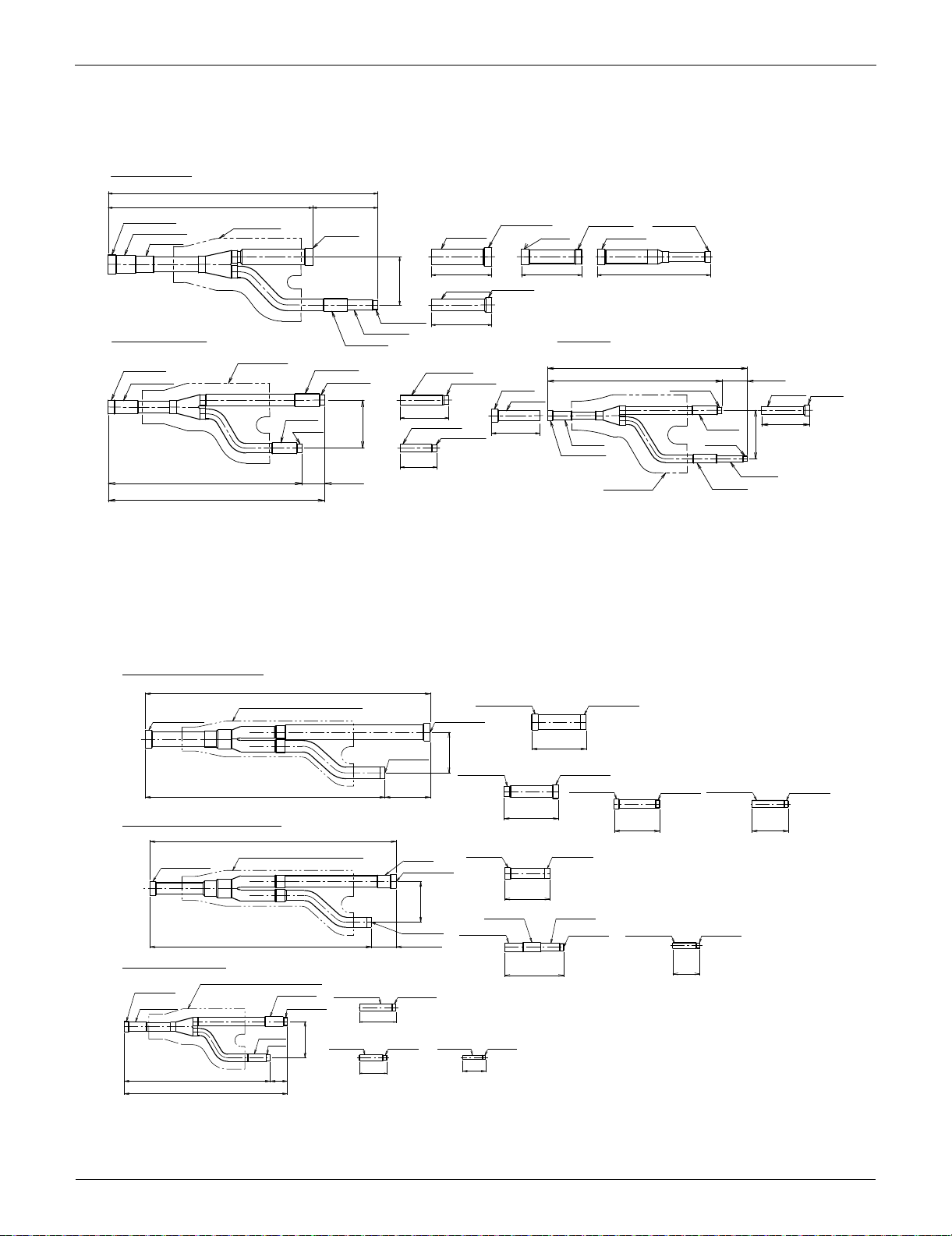

1. Center of Gravity

1.1 460V

REMQ72PBYD

REMQ96PBYD / REMQ120PBYD

2 Installation of Outdoor Units

EDUS391004-N Center of Gravity

4D070791

4D070790

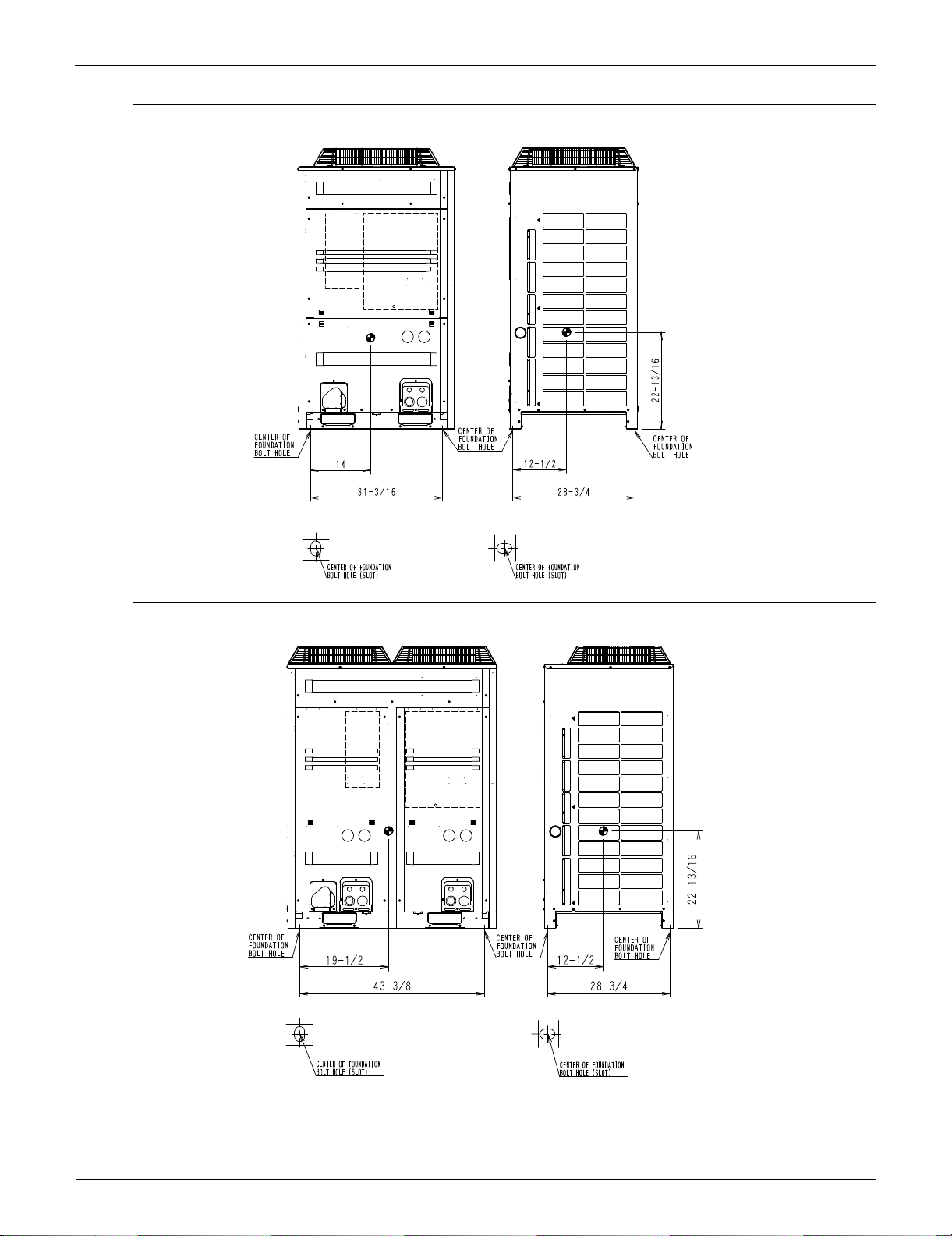

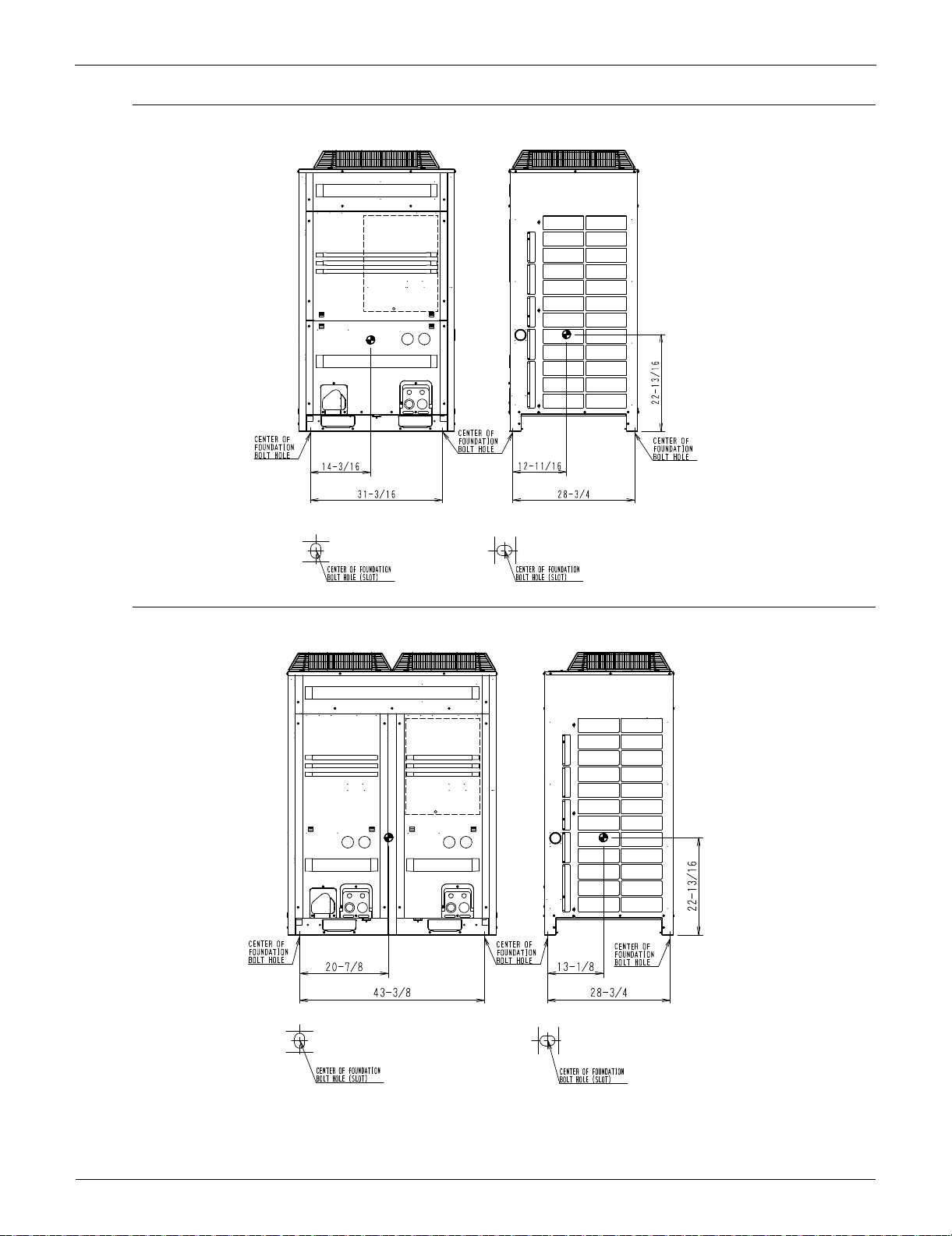

RXYQ72PBYD

RXYQ96PBYD / RXYQ120PBYD

Installation of Outdoor Units 3

Center of Gravity EDUS391004-N

4D058652B

REYQ72PBYD / REYQ96PBYD / REYQ120PBYD

4 Installation of Outdoor Units

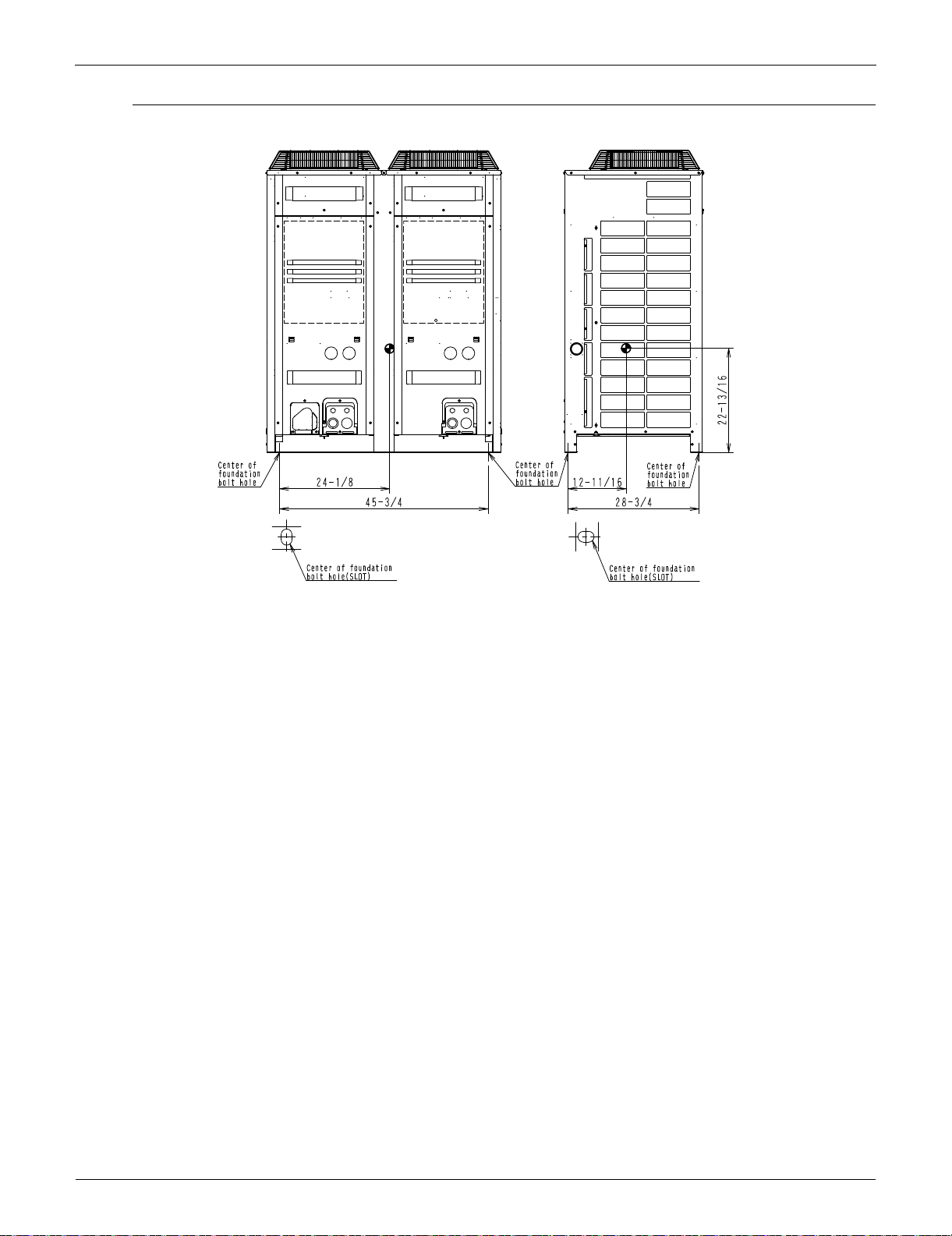

EDUS391004-N Center of Gravity

4D060193C

4D060194C

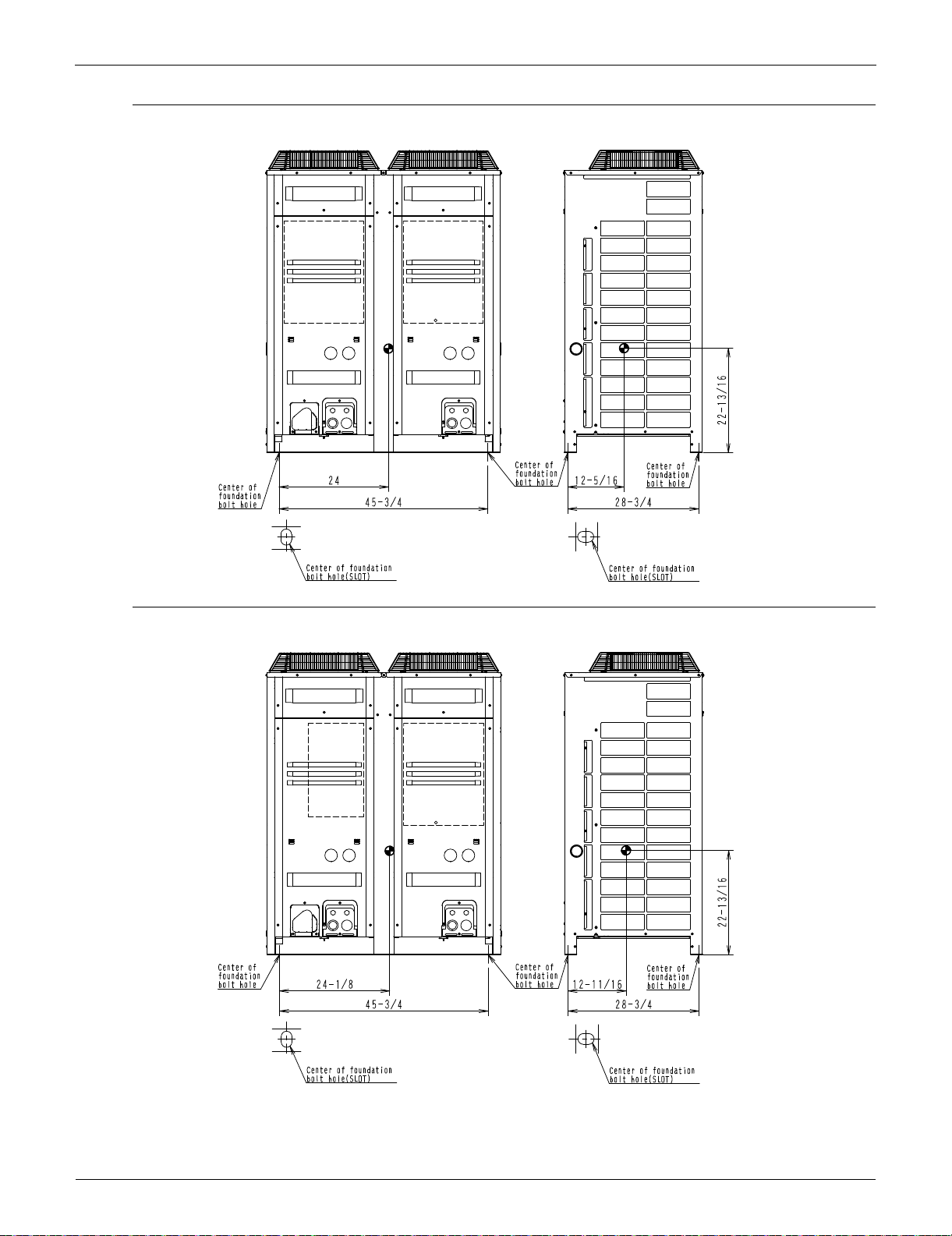

1.2 208/230V

REMQ72PBTJ

REMQ96PBTJ / REMQ120PBTJ

Installation of Outdoor Units 5

Center of Gravity EDUS391004-N

4D070509

4D070510

RXYQ72PBTJ

RXYQ96PBTJ / RXYQ120PBTJ

6 Installation of Outdoor Units

EDUS391004-N Center of Gravity

4D060196A

4D060195B

RXYQ144PBTJ / REYQ144PBTJ

REYQ72PBTJ / REYQ96PBTJ / REYQ120PBTJ

Installation of Outdoor Units 7

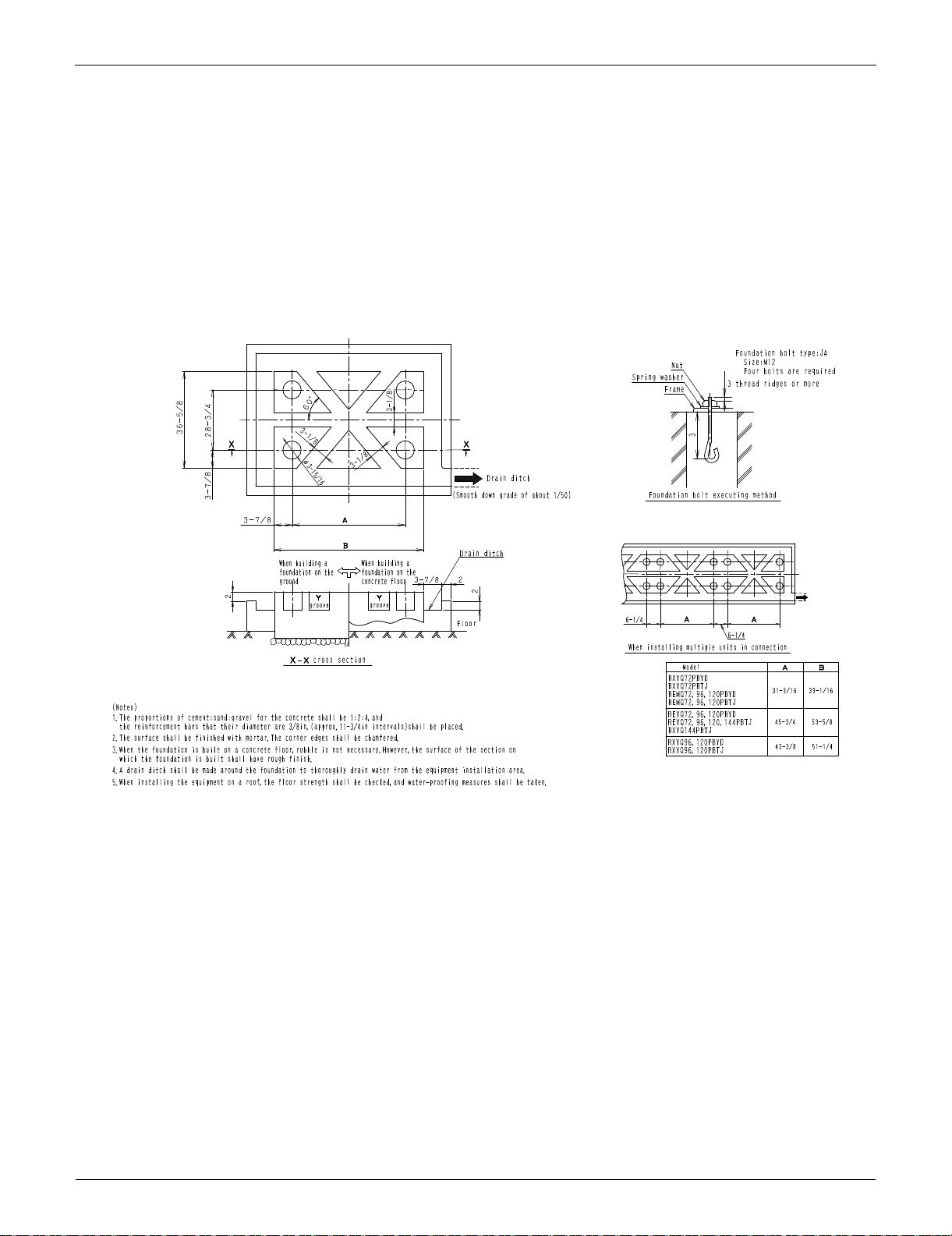

Foundation Drawing EDUS391004-N

3D058655B

2. Foundation Drawing

460V

RXYQ72PBYD / RXYQ96PBYD / RXYQ120PBYD

REYQ72PBYD / REYQ96PBYD / REYQ120PBYD

REMQ72PBYD / REMQ96PBYD / REMQ120PBYD

208/230V

RXYQ72PBTJ / RXYQ96PBTJ / RXYQ120PBTJ / RXYQ144PBTJ

REYQ72PBTJ / REYQ96PBTJ / REYQ120PBTJ / REYQ144PBTJ

REMQ72PBTJ / REMQ96PBTJ / REMQ120PBTJ

8 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

3. REFNET Pipe System

3.1 Layout Example

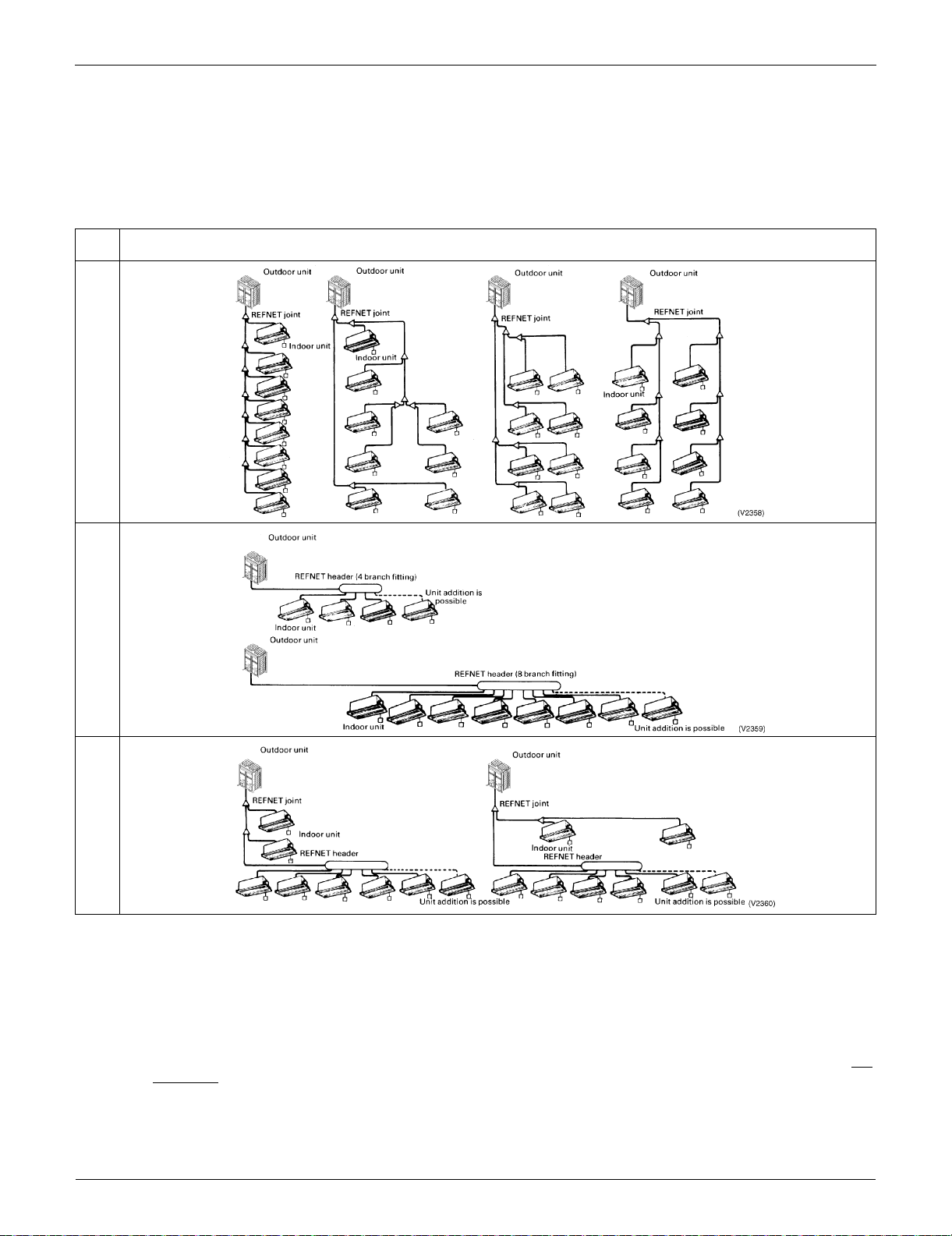

3.1.1 Heat Pump System

Use of the particular branch fitting appropriate to each individual unit type not only permits the pipes to be laid

with ease but also increases the reliability of the system as a whole.

Type of

fitting

Line branch fitting

(Pipes containing REFNET joints only)

Sample systems

headers only)

Header branch fitting

(Piping consists of REFNET

and joints)

Mixed branch fittings

(Piping including both headers

Units can be added by connecting them directly to the REFNET header or REFNET joint. Further branches cannot be

included in the system below the REFNET header branch.

NOTES:

1. When the capacity ratio of the indoor system to the outdoor unit is more than 100% and when all the indoor units are in operation at

the same time, the rated capacity of each unit will be somewhat reduced.

2. Special purpose REFNET pipe components must be used for all the pipe work. For further details concerning choosing components,

see VRVIII REFNET and Piping Selection Rules.

3. The Daikin REFNET kits are supplied with insulation intended to fit over the main body of the REFNET joint after installation of the

REFNET kit is complete.

4. IMPORTANT: In applications where the REFNET kits are installed in an environment requiring fire-rated materials to be used, it is

necessary for the installer to obtain from a third party supplier and to utilize, for insulation, fire-rated materials that meet all

applicable building codes and other requirements. The factory-provided insulation that is supplied with the REFNET kit should be

discarded in a manner meeting all applicatble laws.

Installation of Outdoor Units 9

REFNET Pipe System EDUS391004-N

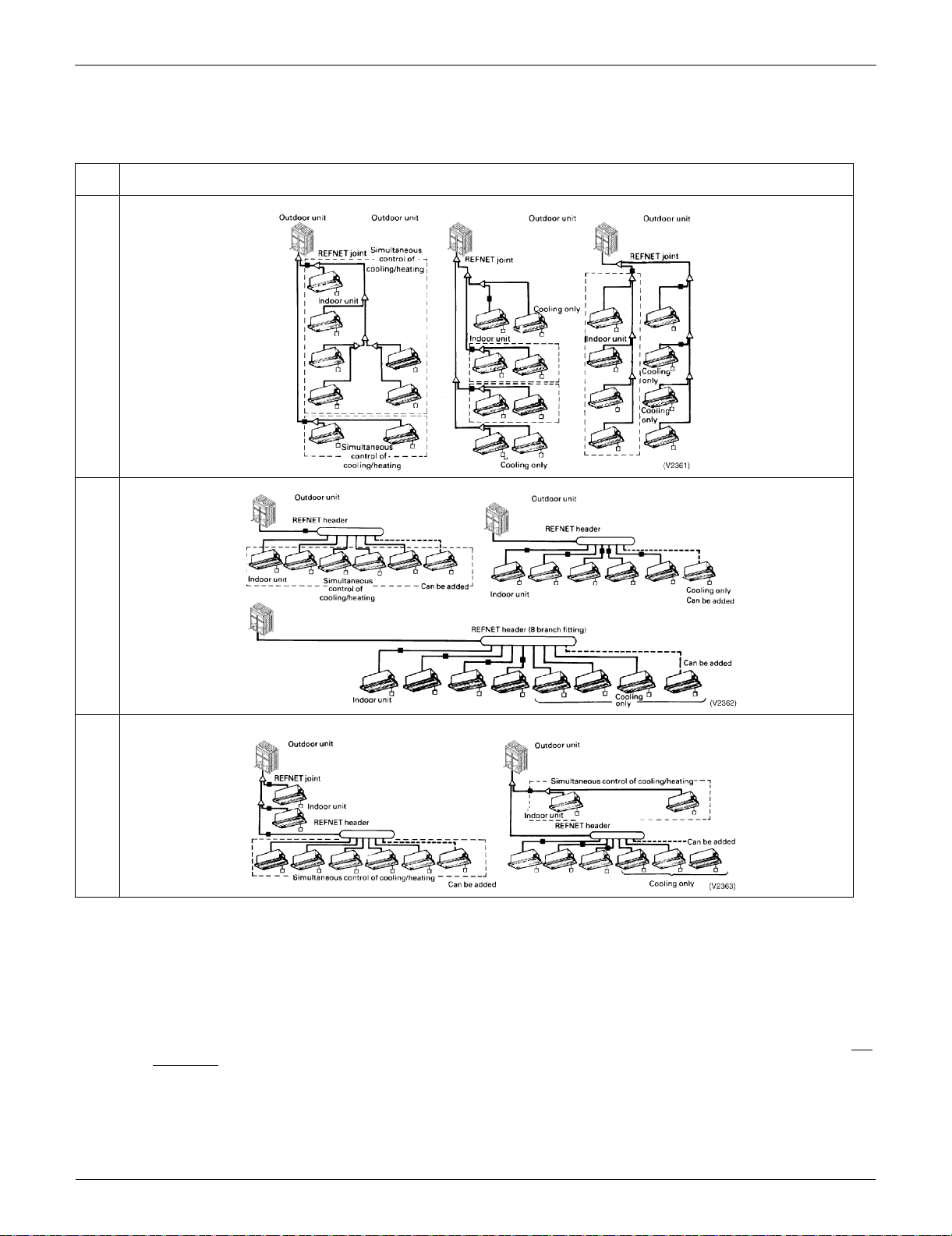

3.1.2 Heat Recovery System

Use of the particular branch fitting appropriate to each individual unit type not only permits the pipes to be laid

with ease but also increases the reliability of the system as a whole.

Type of

fitting

Distribution by REFNET jointsDistribution by REFNET header

Sample systems

and headers

Combination of REFNET joints

Units can be added by connecting them directly to the REFNET header or REFNET joint. Further branches cannot be

included in the system below the REFNET header branch.

NOTES:

1. When the capacity ratio of the indoor system to the outdoor unit is more than 100% and when all the indoor units are in operation at

the same time, the rated capacity of each unit will be somewhat reduced.

2. Special purpose REFNET pipe components must be used for all the pipe work. For further details concerning choosing components,

see VRVIII REFNET and Piping Selection Rules.

3. The Daikin REFNET kits are supplied with insulation intended to fit over the main body of the REFNET joint after installation of the

REFNET kit is complete.

4. IMPORTANT: In applications where the REFNET kits are installed in an environment requiring fire-rated materials to be used, it is

necessary for the installer to obtain from a third party supplier and to utilize, for insulation, fire-rated materials that meet all

applicable building codes and other requirements. The factory-provided insulation that is supplied with the REFNET kit should be

discarded in a manner meeting all applicatble laws.

10 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

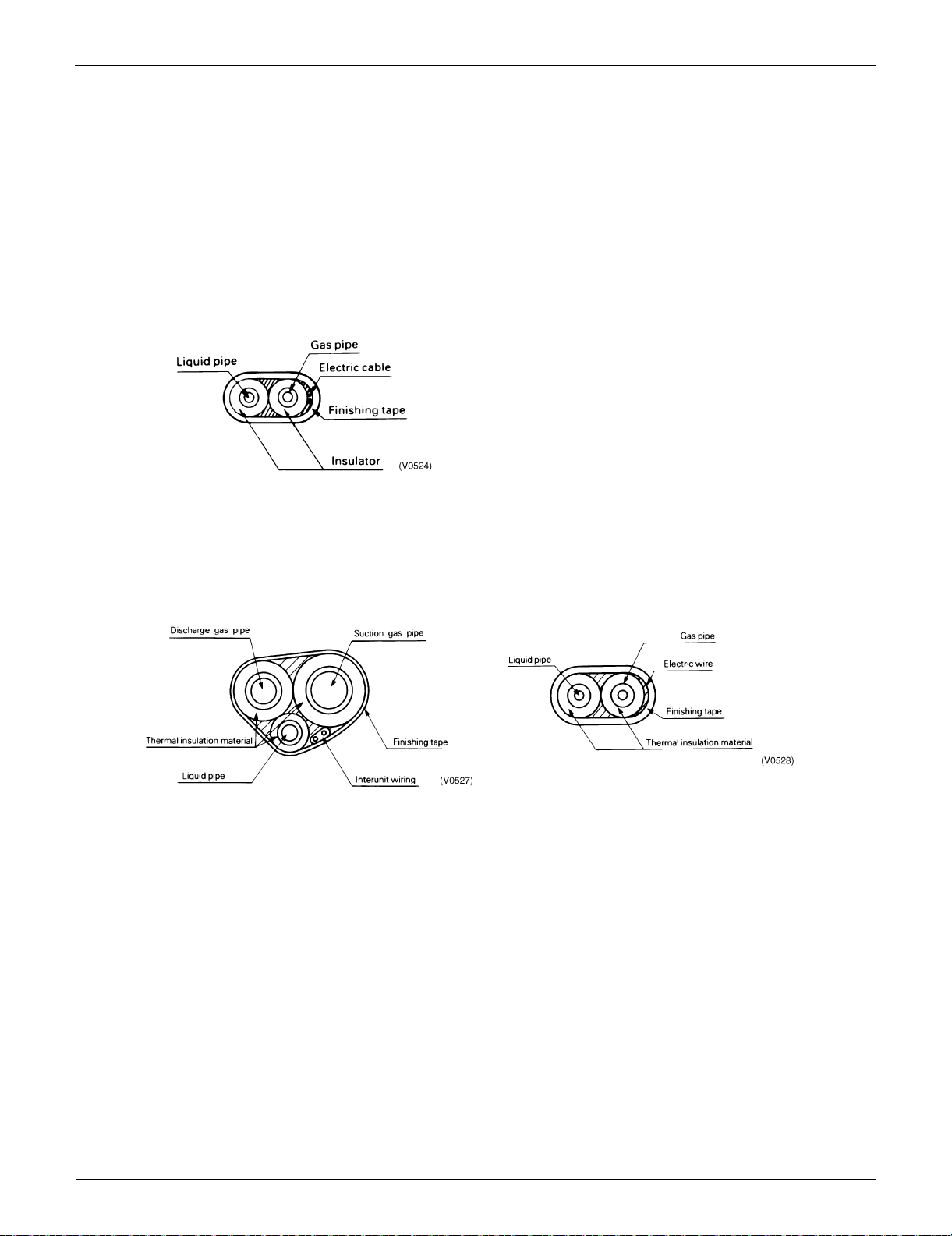

3.2 Field Refrigerant Piping

3.2.1 Heat Pump Series

1. The following materials should be used for all refrigerant piping.

Materials: Deoxidized phosphorous seamless copper pipe or equivalent

2. The tips for insulation

Both Gas, Liquid piping must be insulated.

Materials: Glass fiber or heat resistant polyethylene foam.

Thickness: 1/2 inch or more

Insulation of both liquid and gas pipe

3.2.2 Heat Recovery Series

Suction, Discharge Gas piping, liquid piping must be insulated.

Example of thermal insulation work.

3 piping section (between outdoor unit and Branch Selector

unit)

2 piping section (between Branch Selector unit and indoor

unit)

Installation of Outdoor Units 11

REFNET Pipe System EDUS391004-N

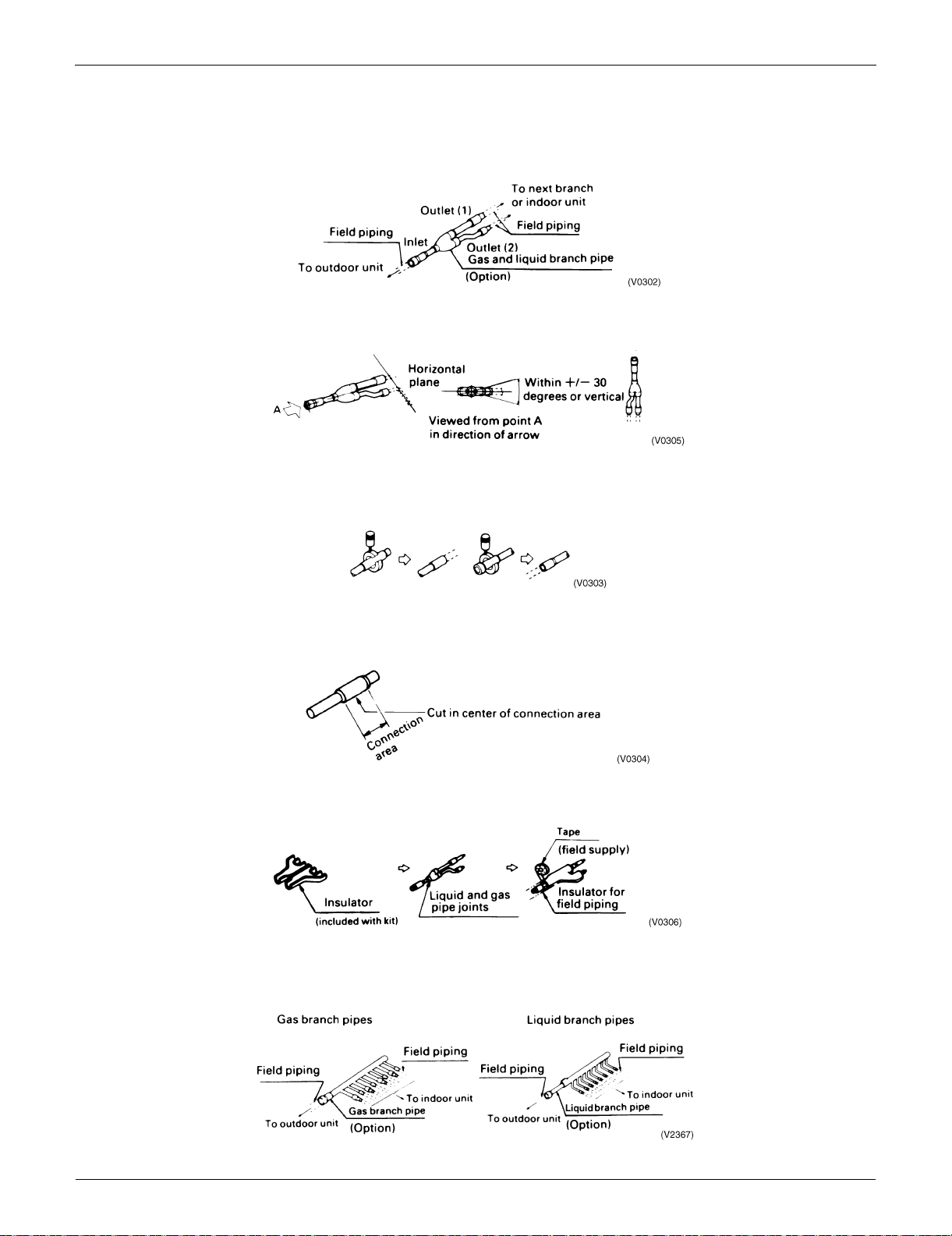

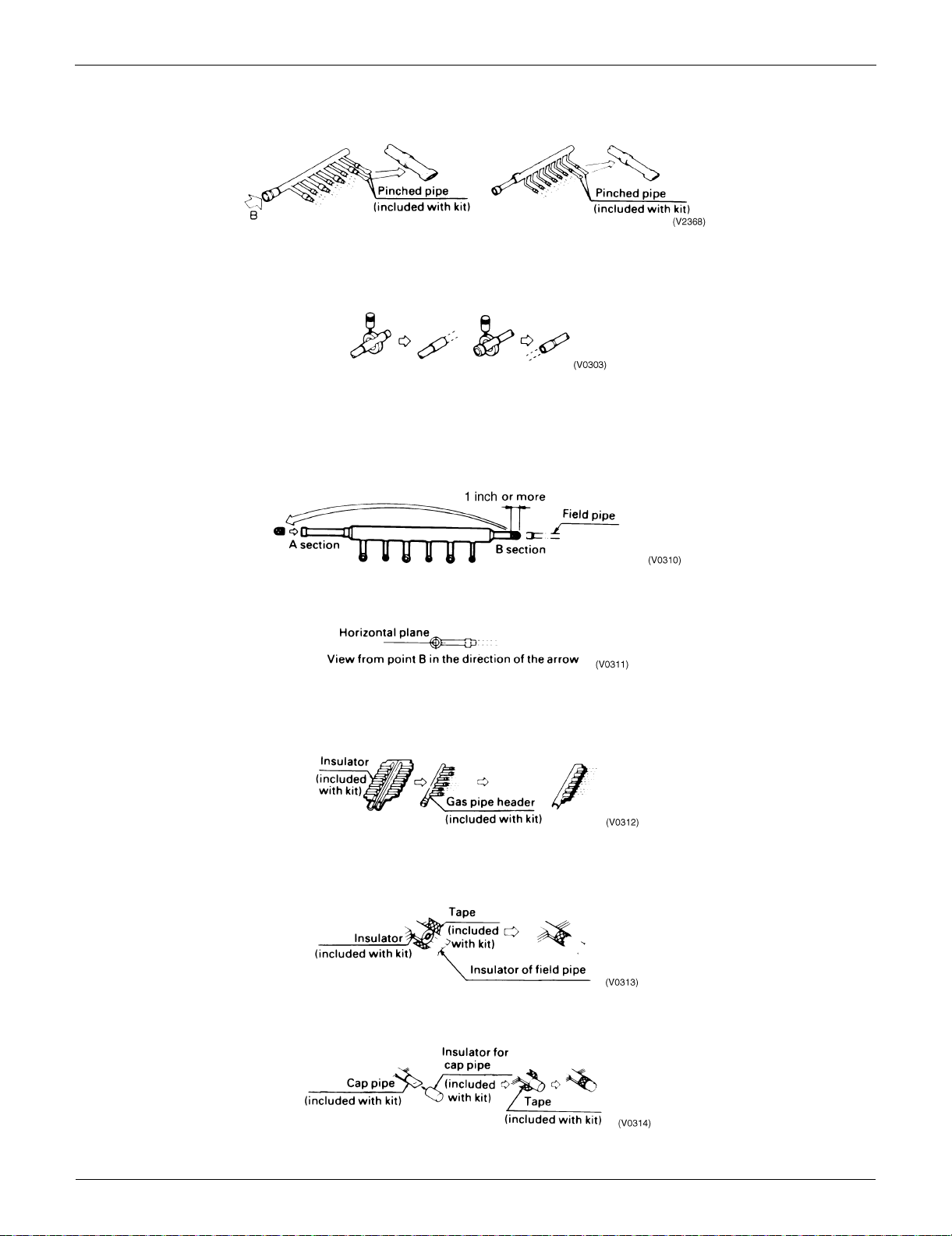

3.3 REFNET Joints and Headers

3.3.1 REFNET Joints

For gas and liquid branch pipes

Make sure that all branch pipes are fitted such that they branch either horizontally or vertically.

When the size of the selected field piping is different from that of branch pipe then the connecting section should be

cut with a pipe cutter as shown in the figure below.

When you are cutting an inlet or outlet pipe with a pipe cutter make sure that you make the cut in the center of the

connection area.

Branch pipes must be insulated in accordance with the handbook which comes with each kit.

3.3.2 REFNET Header

12 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

When the number of indoor units to be connected to the branch pipes is less than the number of branch pipes

available for connection then cap pipes should be fitted to the surplus branches.

When the size of the selected field piping is different from that of branch pipe then the connecting section should be

cut with a pipe cutter as shown in the figure below.

When field piping is connected to the B section of the inlet/outlet pipe on the outdoor unit side of the liquid pipe

header.

Cut the B section with a pipe cutter as shown below and connect it to the A section.

Connect the flared section of the field pipe to the B section.

Fit the branch pipe so that the branch lies in a horizontal plane.

The branch pipe must be insulated in accordance with the instruction manual which comes with each kit.

1.Use the insulator included in the kit to insulate the header.

2. Joints between insulators included in the kit and those already applied to the field piping should be sealed with the tape which is also

included in each kit.

3. Any cap pipes should also be insulated using the insulator provided with each kit and then taped as described above.

Installation of Outdoor Units 13

REFNET Pipe System EDUS391004-N

Gas Side

1/2

5/8

3/4

5/8

5/8

1/2

3/8

3/8

3/8

9-13/16

11-7/16

(1-9/16)

1/4

1/4

3-5/32

1/2

3-5/32

(1-21/32)

Insulation

Insulation

Liquid Side

D3K03622D

13-5/16

7/8

3/4

5/8 3/4

3-15/16

3-5/32

14-31/32

(unit: in)

Gas Side

Insulation

Insulation

Liquid Side

D3K03623B

7/8

3/4

3/4

5/8

1/2

3/8

3/8

3/8

10-1/4

11-13/16

3-5/32

1/4

(1-9/16)

1/4

5/8

3-5/32

1/2

(1-1/2)

12-11/16

1

7/8

3/4

7/8

3-15/16

3-15/16

14-3/16

Liquid Side

Gas Side

Insulation

Insulation

D3K04887A

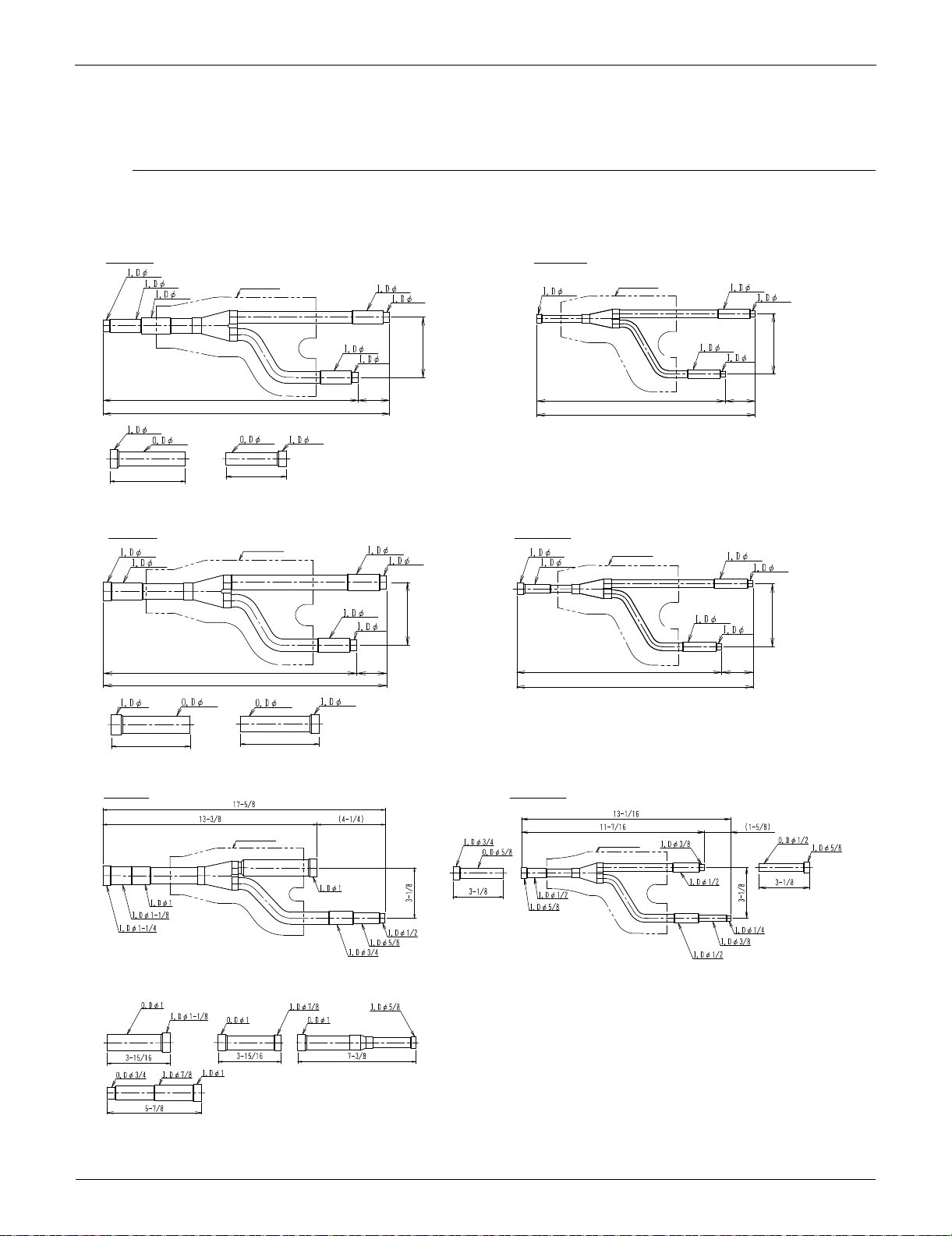

4. REFNET Pipe System

4.1 REFNET Joint (Branch Kit)

RXYQ72~360PBYD (460V)

RXYQ72~360PBTJ (208/230V)

KHRP26A22T

KHRP26A33T

KHRP26M72TU

14 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

LIQUID SIDE JOINT

GAS SIDE JOINT

I. D. 1/2

24-3/4

I. D. 3/4

O. D. 1-3/8

THERMAL INSULATION

3-9/16

I. D. 1/2

I. D. 1/4

THERMAL INSULATION

I. D. 7/8

O. D. 5/8

I. D. 3/4

1-15/16

(1-1/2)

14-1/8

3-1/8

12-6/8

I. D. 3/8

I. D. 1-1/8

20-3/4 (3-15/16)

4-3/4

I. D. 5/8

4-3/4

O. D. 7/8

I. D. 1-1/8

I. D. 1-3/8

I. D. 5/8

O. D. 1/2

I. D. 1-3/8

I. D. 7/8

O. D. 3/8

I. D. 5/8

3-15/16

O. D. 7/8

2-3/8

O. D. 5/8

3-1/8

I. D. 1/2

3-1/8

D3K05572A

KHRP26M73TU

Installation of Outdoor Units 15

REFNET Pipe System EDUS391004-N

D3K03626B

(unit: in)

Suction gas side

Discharge gas side

Liquid side

Insulation

Insulation

Insulation

1/2

1/2

5/8

3/4

13-5/16

14-31/32

1-21/32

1-9/16

1-9/16

1/2

5/8

5/8

5/8

3/4

3-5/32

1/2

3-5/32

3-5/32

3-5/32

3/8

1/2

2-3/8

5/8

5/8

3/8

3/8

3/8

3/8

1/4

1/4

3/8

11-13/16

13-3/8

1/2

1/2

11-7/16

9-13/16

D3K03627B

3/4

Suction gas side

Discharge gas side

Liquid side

Insulation

Insulation

Insulation

1

3-15/16

12-11/16

14-3/16

14-7/16

10-1/4

11-13/14

16-1/16

1-21/32

1-9/16

7/8

7/8

5/8

5/8

5/8

3/4

3/4

1/2

1-1/2

3/4

7/8

5/8

5/8

3-15/16

1/2

1/2

1/2

3/8

3/8

1/4

1/4

3/8

3/4

3/8

3-5/32

3-5/32

3-5/32

REYQ72~336PBYD (460V)

REYQ72~336PBTJ (208/230V)

KHRP25A22T

KHRP25A33T

16 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

D3K04888B

Liquid sideDischarge gas side

Insulation

Insulation

Insulation

Suction gas side

17-5/8

13-3/8 (4-1/4)

I. D. φ1-1/4

I. D. φ1-1/8

I. D. φ1

I. D. φ1

I. D. φ1/2

3-1/8

I. D. φ5/8

I. D. φ3/4

O. D. φ1

I. D. φ1-1/8

O. D. φ1

3-15/16

O. D. φ3/4

I. D. φ7/8

3-15/16

3-15/16 7-3/8

I. D. φ7/8

O. D. φ1

I. D. φ5/8

I. D. φ7/8

I. D. φ3/4

I. D. φ3/4

I. D. φ5/8

12-11/16

14-3/16

I. D. φ5/8

I. D. φ1/2

3-1/8

(1-1/2)

O. D. φ5/8

I. D. φ1/2

3-1/8

I. D. φ3/8

O. D. φ1/2

2-3/8

I. D. φ3/4

O. D. φ5/8

3-1/8

13-1/16

11-7/16 (1-5/8)

I. D. φ1/2

I. D. φ5/8

I. D. φ3/8

I. D. φ1/2

I. D. φ1/4

I. D. φ3/8

I. D. φ1/2

3-1/8

O. D. φ1/2

I. D. φ5/8

3-1/8

DISCHARGE GAS SIDE JOINT

LIQUID SIDE JOINT

SUCTION GAS SIDE JOINT

21-3/8

O. D. 5/8

3-15/16

O. D. 3/8

I. D. 1/2

19-1/4

3-1/83-15/16

O. D. 7/8

I. D. 3/8

I. D. 7/8

I. D. 1-3/8

I. D. 3/4

(3-15/16)

3-9/16

O. D. 5/8

I. D. 5/8

I. D. 3/4

I. D. 1-1/8

24-3/4

THERMAL INSULATION

I. D. 1-1/8

I. D. 1-1/8

O. D. 1

2-3/8

4-3/4

I. D. 1/2

I. D. 3/4

I. D. 3/4

I. D. 7/8

2-3/8

20-3/4

(2-3/16)

3-1/8

12-6/8

14-1/8

(1-1/2)

O. D. 1/2

I. D. 5/8

I. D. 3/8

I. D. 1-3/8

O. D. 1/2

I. D. 1/2

I. D. 1-1/8

I. D. 1

I. D. 1/2

I. D. 1/4

I. D. 3/4

THERMAL INSULATION

1-15/16

I. D. 5/8

5-1/8

O. D. 7/8

O. D. 3/4

3-9/16

THERMAL INSULATION

O. D. 1-3/8

4-3/4

I. D. 5/8

3-1/8

D3K05573A

KHRP25M72TU

KHRP25M73TU

Installation of Outdoor Units 17

REFNET Pipe System EDUS391004-N

D3K03629C

(unit: in)

Gas Side

Liquid Side

Insulation

I. D. φ 3/4

I. D. φ 5/8

3-5/32

Insulation

3 - I. D. φ 1/2

I. D. φ 7/8

O. D. φ 3/4

I. D. φ 1/2

O. D. φ 1/2

I. D. φ 5/8

I. D. φ 5 / 8

5-29/32

14-31/32

3-15/16

2-3/8

3-5/32

4-23/32

2 × 2-3/8 = 4-23/32

I. D. φ 3/8

2-3/8

3 - I. D. φ 1/4

I. D. φ 1/4

I. D. φ 3/8

3-21/32

2 × 2-3/8 = 4-23/32

16-5/32

2-3/85-1/8

3-1/32

1-9/16

O. D. φ 1/4

I. D. φ 3/8

× 2

× 2

D3K03630C

Gas Side

Liquid Side

Insulation

Insulation

I. D. φ 3/4

I. D. φ 5/8

6-23/32

5-23/32

4-23/32 4-23/32

2 × 2-3/8 = 4-23/32

4-23 /3210-7/16

8-1/16

3-15/16

24-7/32

2 - I. D. φ 1/2

I. D. φ 1/2

O. D. φ 1/2

I. D. φ 5/8

I. D. φ 5/8

I. D. φ 1

O. D. φ 7/8

I. D. φ 5/8

I. D. φ 3/4

I. D.

φ

7/8

5 - I. D. φ 1/2

3-3/16

4-3/4

3-5/32

6 - I. D. φ 3/8

6 - I. D. φ 1/4

2 - I. D. φ 1/4

2-3/8

3-21/32

5-29/32

20-3/32 2-3/8

1-9/16

3-1/32

26-3/8

I. D. φ 1/2

I. D. φ 3/8

5 × 2-3/8 = 11-13/16

O. D. φ 1/4

I. D. φ 3/8

× 2

× 2

D3K03631C

Gas Side Liquid Side

Insulation

Insulation

I. D. φ 1-1/8

I. D. φ 1

I. D. φ 1-1/4

3 - I. D. φ 3/4

3 - I. D. φ 5/8

7-9/32

10-7/16

29-23/32

2 × 6-5/16 = 12-19/32

2 × 6-5/16 = 12-19/32 2-3/8 2-3/8

3 - I. D. φ 1/2

O. D. φ 1/2

I. D. φ 5/8

3-5/32

3 - I. D. φ 1/2

2 - I. D. φ 1/2

6 - I. D. φ 3/8

6 - I. D. φ 1/4

2 - I. D. φ 1/4

2-3/8

3-21/32

I. D. φ 3/4

O. D. φ 1/4

I. D. φ 5/8

O. D. φ 5/8

I. D. φ 3/8

1-9/16

3-5/32

I. D. φ 1/2

3-9/32

5-1/2

4-27/32

6-13/16

3 - I. D. φ 5/8

5 × 2-3/8 = 11-13/16

14-3/16 2-3/8

25-31/32

3-1/32

× 2

× 2

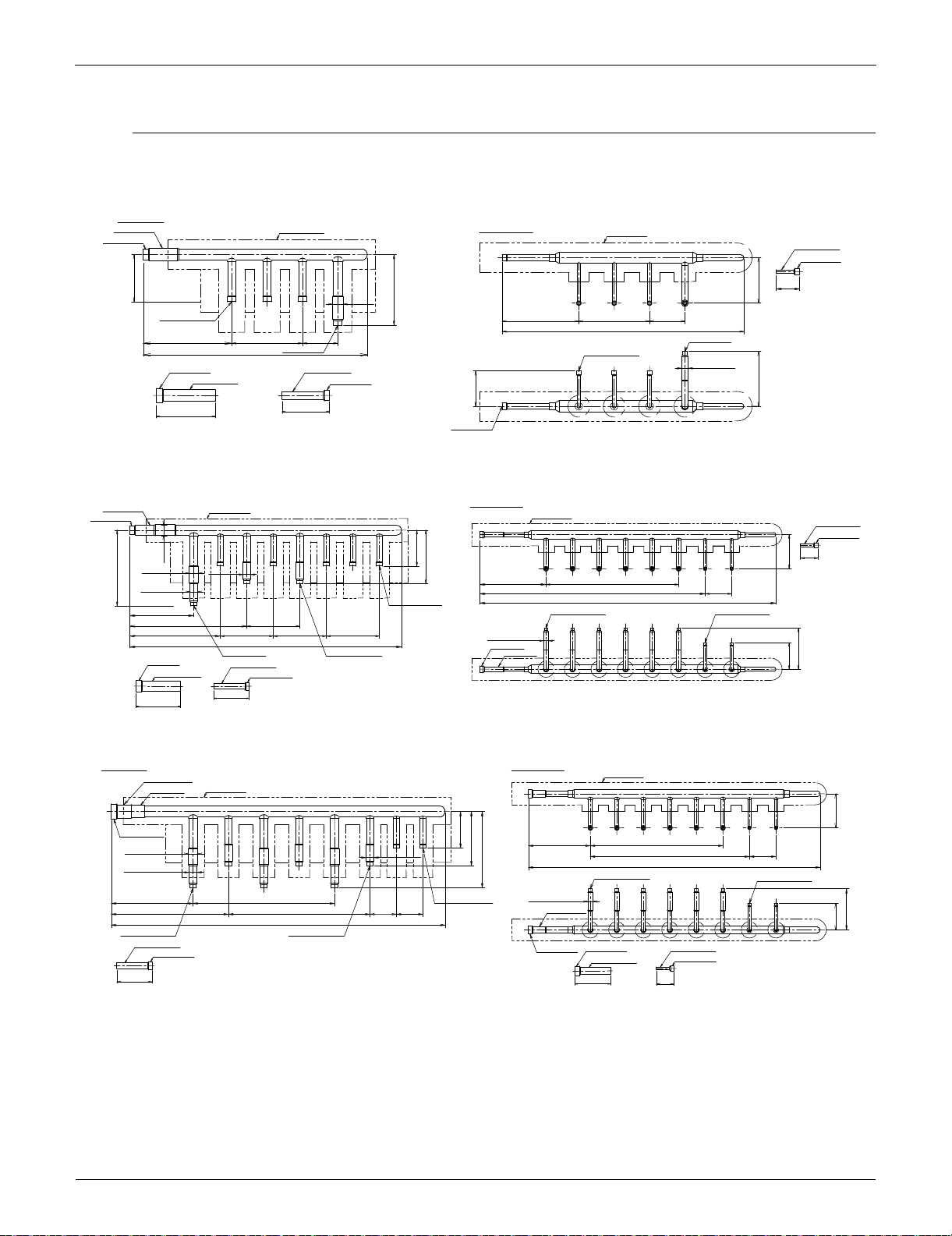

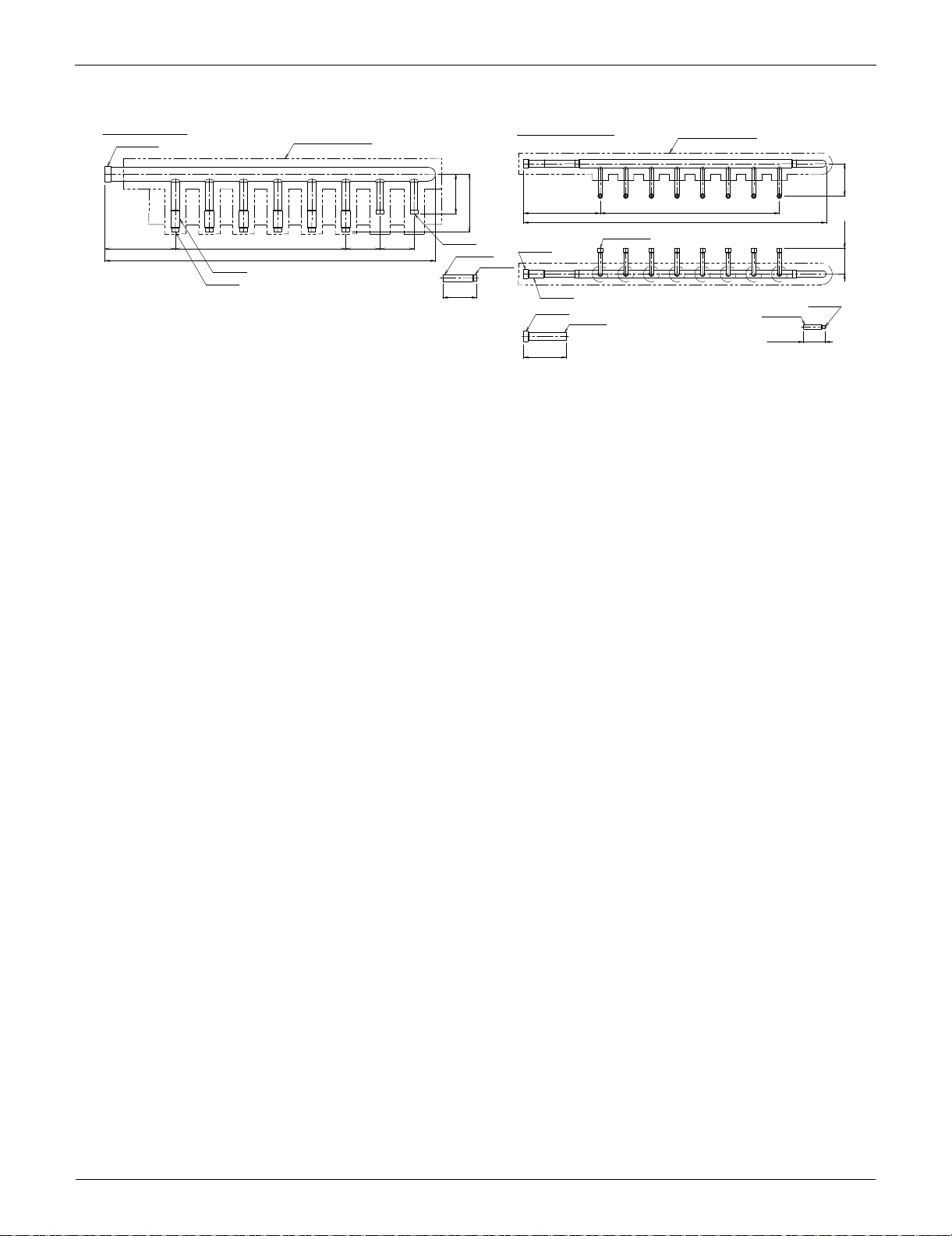

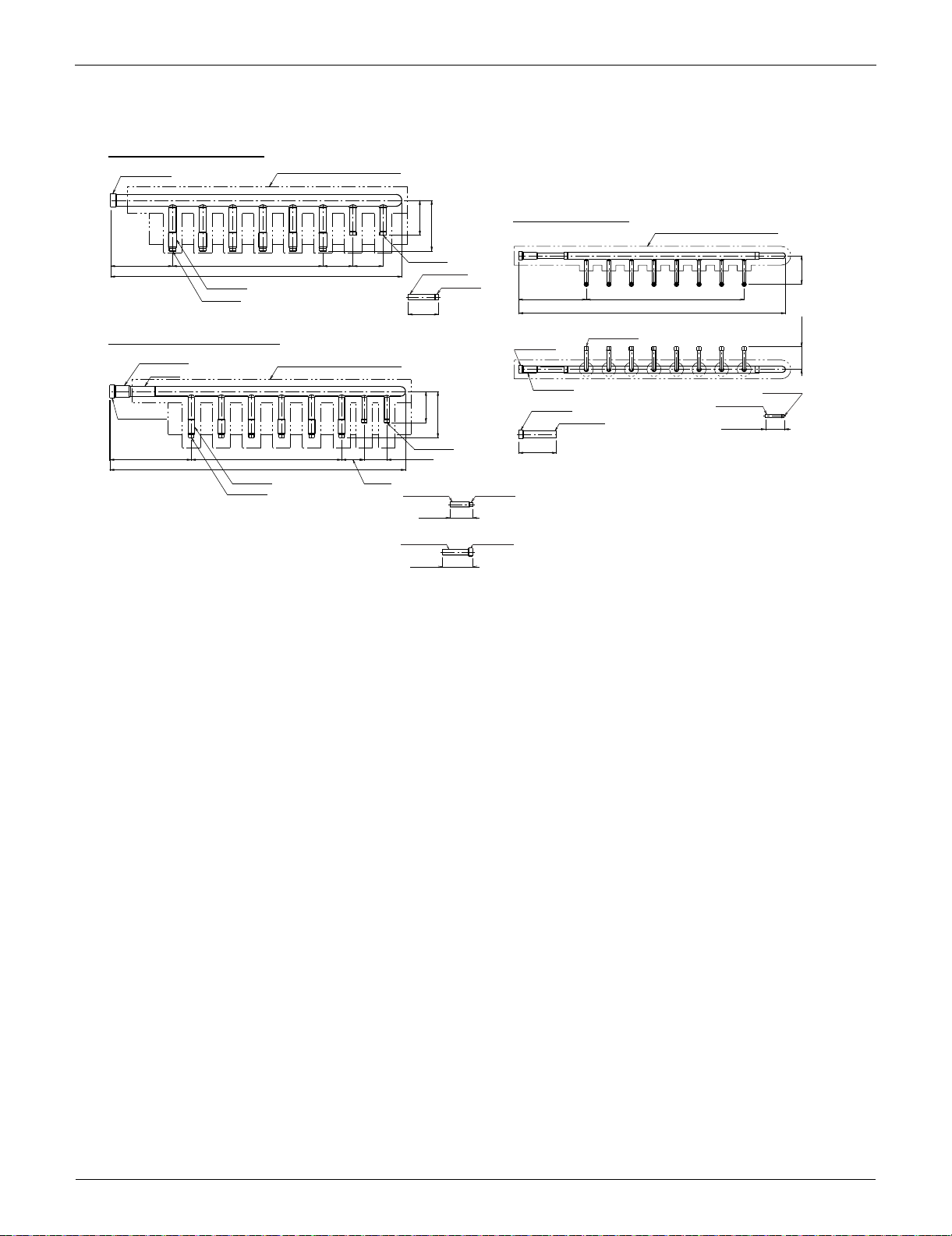

4.2 REFNET Header (Branch Kit)

RXYQ72~360PBYD (460V)

RXYQ72~360PBTJ (208/230V)

KHRP26M22H

KHRP26M33H

KHRP26M72H

18 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

D3K05574

I. D. 1-3/8

6-1/2 5×3-1/8=15-3/4

Thermal Insulation

Thermal Insulation

30-1/2

I. D. 3/4

I. D. 5/8

3-1/8 3-1/8

3-11/16

5-5/16

I. D. 5/8

7-1/16

I. D. 3/4

I. D. 5/8

I. D. 7/8

O. D. 3/4

O. D. 3/8

I. D. 1/4

1-15/16

O. D. 5/8

I. D. 1/2

3-1/8

× 6

× 6

7×2-3/8=16-1/2

27-15/16

32-3/8

8 - I. D. 3/8

3-15/16

Gas Side Header Liquid Side Header

KHRP26M73HU

Installation of Outdoor Units 19

REFNET Pipe System EDUS391004-N

D3K03633D

I. D. φ 3/4

I. D. φ 5/8

6-23/32

5-23/32

10-7/16

4-23 /32

4-23/32

24-7/32

4-23/32

8-1/16

2 × 2-3/8 = 4-23/32

I. D. φ 1/2

I. D. φ 5/8

I. D. φ 3 /4

I. D. φ 5/8

I. D.

φ

7 /8

2 - I. D. φ 1/2

5 - I. D. φ 1/2

O. D. φ 1/2

I. D. φ 5/8

3-5/32

3-3/16

4-3/4

I. D. φ 5/8

I. D. φ 5/8

I. D. φ 1/2

I. D. φ 3/8

O. D. φ 5/8

3-5/32

I. D. φ 3/4

I. D. φ 3/8

I. D. φ 1/2

6 - I. D. φ 3/8

3-3/16

4-3/4

6-23/32

I. D. φ 3/8

I. D. φ 3/4

I. D. φ 3/8

7-3/32

25-19/32

I. D. φ 1/2

I. D. φ 1/2

7 × 2-3/8 = 16-17/32

6 - I. D. φ 1/4

5-29/32

2 - I. D. φ 1/4

20-3/32 2-3/8

2-3/8

3-21/32

1-9/16

3-1/32

26-3/8

O. D. φ 1/4

I. D. φ 3/8

5 × 2-3/8 = 11-13/16

× 5

× 2

3-17/32

O. D. φ 3/8

I. D. φ 1/2

× 3

(unit:in)

Suction gas side

HP/LP gas side

Insulation

Insulation

Insulation

Liquid side

D3K03634D

I. D. φ 1-1/4

7-9/32

10-7/16

29-23/32

I. D.

φ

1-1/8

I. D.

φ

1

2 × 6-5/16 = 12-19/32

2 × 6-5/16 = 12-19/32

2-3/8 2-3/8

3 - I. D. φ 1/2

3 - I. D. φ 1/2

3 - I. D. φ 5/8

3 - I. D. φ 3/4

2 - I. D. φ 1/2

O. D. φ 1/2

I. D. φ 5/8

3-5/32

3-9/32

4-27/32

6-13/16

I. D. φ 1/2

8-19/32

27-3/32

I. D. φ 3/8

I. D. φ 3/8

I. D. φ 3/8

5-1/2

25-31/32

2-3/8

3-1/32

14-3/16

O. D. φ 3/8

I. D. φ 5/8

I. D.

φ

1/2

O. D. φ 5/8

3-17/32

3-5/32

I. D. φ 1/2

I. D. φ 3/4

3-7/32

4-27/32

6-13/16

I. D. φ 5/8

I. D. φ 3/4

I. D. φ 7/8

I. D. φ 1

7 × 2-3/8 = 16-17/32

I. D. φ 1/2

5 × 2-3/8 = 11-13/16

6 - I. D. φ 3/8

6 - I. D. φ 1/4

2 - I. D. φ 1/4

O. D. φ 1/4

2-3/8

3-21/32

1-9/16

I. D. φ 3/8

3 - I. D. φ 5/8

× 2

× 2

× 3

× 2

3-5/32

I. D. φ 3/4

O. D. φ 5/8

3-5/32

I. D. φ 5/8

O. D. φ 1/2

Suction gas side

HP/LP gas side

Insulation

Insulation

Insulation

Liquid side

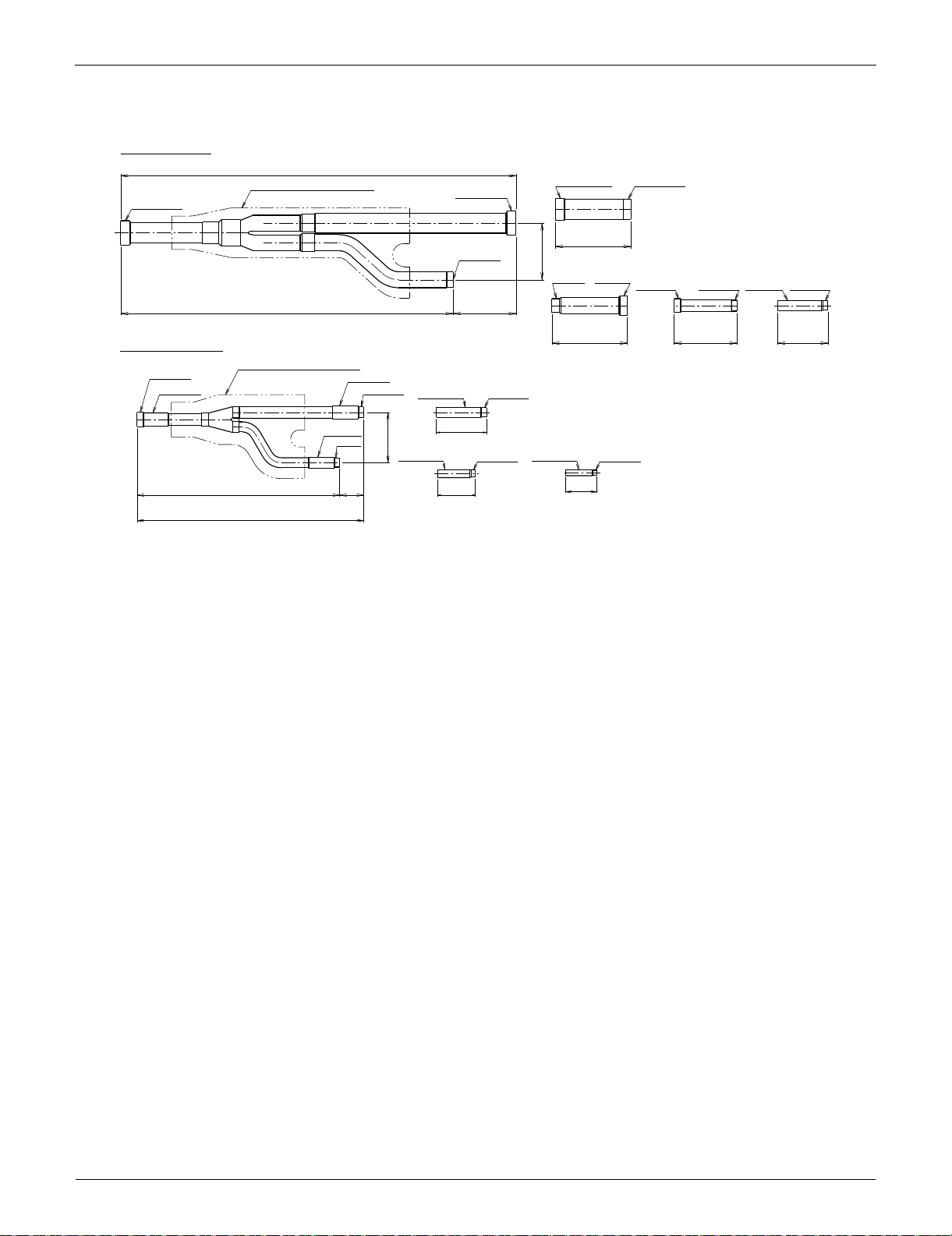

REYQ72~336PBYD (460V)

REYQ72~336PBTJ (208/230V)

KHRP25M33H

KHRP25M72H

20 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

SUCTION GAS SIDE HEADER

DISCHARGE GAS SIDE HEADER

× 6

× 6

× 6

× 6

LIQUID SIDE HEADER

O. D. 3/4

7 × 2-3/8 = 16-1/2

8-9/16

I. D. 5/8

O. D. 5/8

I. D. 5/8

30-15/16

6-1/2

3

I. D. 1/4

30-1/2

3-1/4

I. D. 1/2

27-15/16

15-3/4

1-15/16

I. D. 1-1/4

3-1/8

I. D. 1-3/8

8-I. D. 3/8

7-1/16

I. D. 3/4

5 × 3-1/8 = 15-3/4

I. D. 5/8

2-3/8

5-5/16

THERMAL INSULATION

O. D. 3/8

4-13/16

I. D. 1/2

I. D. 1-1/8

I. D. 7/8

I. D. 1/2

THERMAL INSULATION

O. D. 5/8

THERMAL INSULATION

I. D. 3/4

2-3/8

2-3/8

O. D. 1/2

3-15/16

3-1/8

I. D. 3/4

3-1/8

3-11/16

I. D. 1

I. D. 3/8

2-3/8

3-1/8

I. D. 5/8

D3K05575

KHRP25M73HU

Installation of Outdoor Units 21

REFNET Pipe System EDUS391004-N

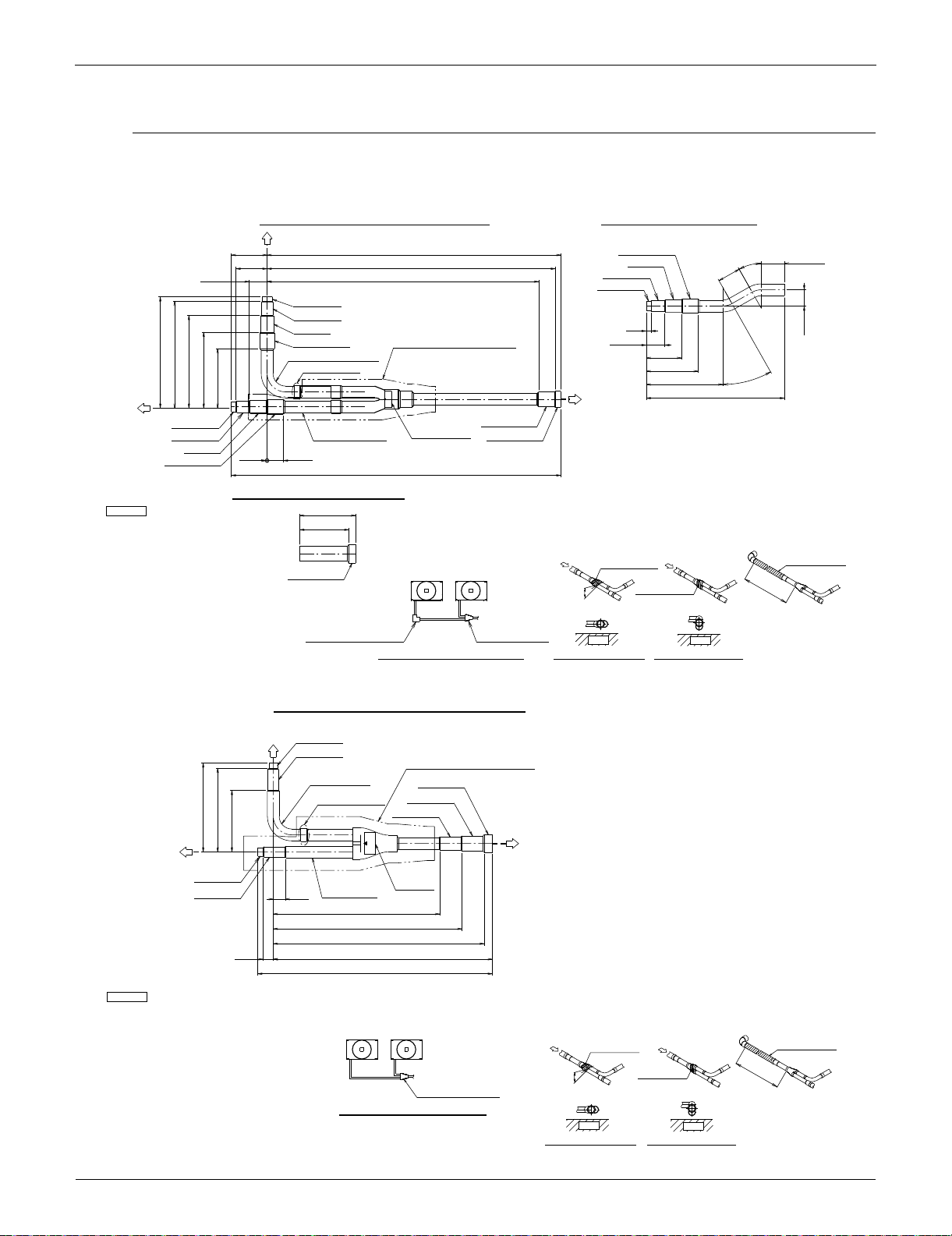

to Outdoor Unit A

GAS-SIDE JOINT + GAS-SIDE REDUCER (1)

1-3/8

1/16

5-1/16

Gas-Side Reducer

I. D. φ 3/4

I. D. φ 7/8

I. D. φ 1

I. D. φ 1-1/8

3/8

24-7/16

Local Brazing

1-9/16

24-15/16

30˚

1-15/16

Caution Label

30˚

1-15/16

1-9/16

7-7/8

2-5/8

Gas-Side Joint

9-1/16

3-1/16

23-1/16

1-3/8

9-7/16

6-1/2

3

6-7/16

11-3/4

27-15/16

4-7/16

to Outdoor

Unit B

I. D. φ 3/4

I. D. φ 7/8

I. D. φ 1-1/8

I. D. φ 1

INSULATION MATERIAL

FOR GAS-SIDE JOINT

I. D. φ 1-1/8

I. D. φ 1-1/4

to Indoor

Unit

4-3/16

4-3/4

GAS-SIDE REDUCER (2) (φ 1-1/4)

I. D. φ 1-1/2

to Indoor Unit

Outdoor Unit A

Gas-Side Joint

Layout Drawing (Upper-Side)

Outdoor Unit B

Elbow

(Field Supplied Parts)

ARROW VIEW A

Ground

ARROW VIEW B

Ground

×

View 2 ×

Caution Label

B

HORIZON

Caution Label

View 1

A

±15˚

or Less

View 3

Straight Length

19-11/16in or more

(Length 4-3/4in or More)

Local Piping

GAS-SIDE JOINT : 1

LIQUID-SIDE JOINT : 1

GAS-SIDE REDUCER (1) : 1

GAS-SIDE REDUCER (2) : 1

GAS-SIDE REDUCER (3) : 1

GAS-SIDE REDUCER (7) : 1

GAS-SIDE REDUCER (9) : 1

LIQUID-SIDE REDUCER (1) : 1

LIQUID-SIDE REDUCER (3) : 1

LIQUID-SIDE REDUCER (5) : 1

INSULATION MATERIAL FOR GAS-SIDE JOINT : 1

INSULATION MATERIAL FOR LIQUID-SIDE JOINT : 1

INSULATION MATERIAL FOR GAS-SIDE PIPE : 1

INSULATION MATERIAL FOR LIQUID-SIDE PIPE : 1

INSTALLATION MANUAL

GAS-SIDE REDUCER (3) (φ 1)

I. D. φ 1-1/8

I. D. φ 1

I. D. φ 7/8

I. D. φ 3/4

NOTE)

1. "- - - -" in the figure show field supply piping.

2. About size of connection pipe refer the "engineering data of VRV III".

3. In case of install this kit observe follow conditions.

· Do not tilt the joint more than ±15˚.

Install the joint horizontally so that the caution label attached to joint

comes to the top.

· Do not install the joint vertically why it may cause the malfunction of

outdoor unit.

· Make sure the piping up to the joint is straight for more than 19-11/16in.

Do not bend the field piping within this range. If a straight field piping

more than 4-3/4in is connected, more than 19-11/16in of straight section

can be ensured.

Accessory

3D060136

5/8

Local Brazing

4-7/16

LIQUID-SIDE JOINT + LIQUID-SIDE REDUCER (1)

10

11-3/16

Liquid-Side

Joint

12-7/16

8-13/16

11-5/8

Caution

Label

3-1/4

Liquid-Side

Reducer (1)

4-3/4

INSULATION MATERIAL

FOR LIQUID-SIDE JOINT

9/16

to Outdoor

Unit A

to Outdoor

Unit B

to Indoor Unit

I. D. φ 3/8

I. D. φ 3/8

I. D. φ 1/2

I. D. φ 7/8

I. D. φ 3/4

I. D. φ 5/8

I. D. φ 1/2

to Indoor Unit

Liquid-Side Joint

Layout Drawing (Upper-Side)

A

HORIZON

Caution Label

View 1

±15˚

or Less

ARROW VIEW A

Ground

View 2 ×

Caution Label

B

ARROW VIEW B

Ground

×

Straight Length

19-11/16in or more

View 3

(Length 4-3/4in or More)

Local Piping

NOTE) 1. "- - - -" in the figure show field supply piping.

2. About size of connection pipe refer the "engineering data of VRV III".

3. In case of install this kit observe follow conditions.

· Do not tilt the joint more than ±15˚.

Install the joint horizontally so that the caution label attached to joint comes to the top.

· Do not install the joint vertically why it may cause the malfunction of outdoor unit.

· Make sure the piping up to the joint is straight for more than 19-11/16in. Do not bend

the field piping within this range.

If a straight field piping more than 4-3/4in is connected, more than 19-11/16in of

straight section can be ensured.

GAS-SIDE JOINT : 1

LIQUID-SIDE JOINT : 1

GAS-SIDE REDUCER (1) : 1

GAS-SIDE REDUCER (2) : 1

GAS-SIDE REDUCER (3) : 1

GAS-SIDE REDUCER (7) : 1

GAS-SIDE REDUCER (9) : 1

LIQUID-SIDE REDUCER (1) : 1

LIQUID-SIDE REDUCER (3) : 1

LIQUID-SIDE REDUCER (5) : 1

INSULATION MATERIAL FOR GAS-SIDE JOINT : 1

INSULATION MATERIAL FOR LIQUID-SIDE JOINT : 1

INSULATION MATERIAL FOR GAS-SIDE PIPE : 1

INSULATION MATERIAL FOR LIQUID-SIDE PIPE : 1

INSTALLATION MANUAL

Accessory

Outdoor Unit BOutdoor Unit A

3D060135

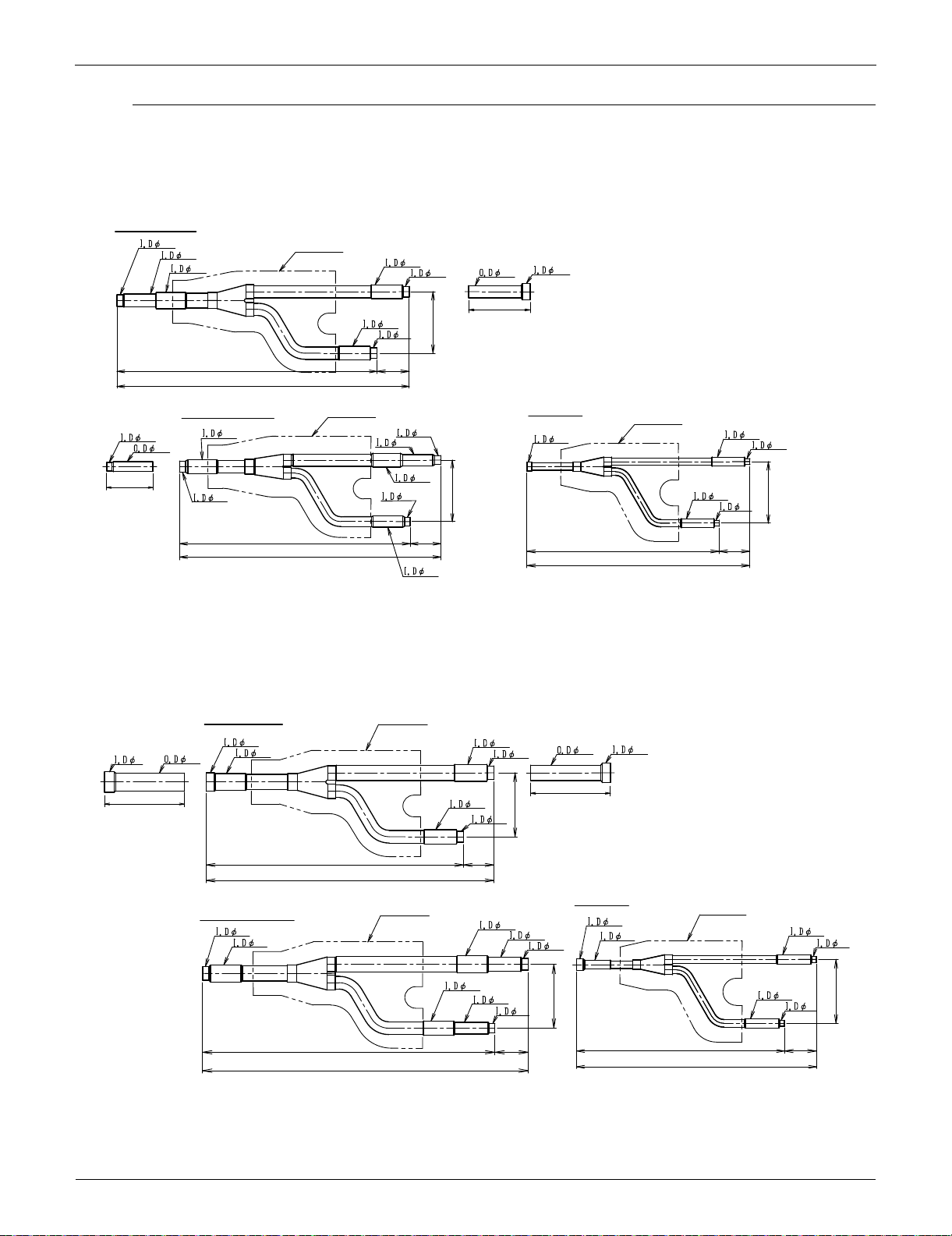

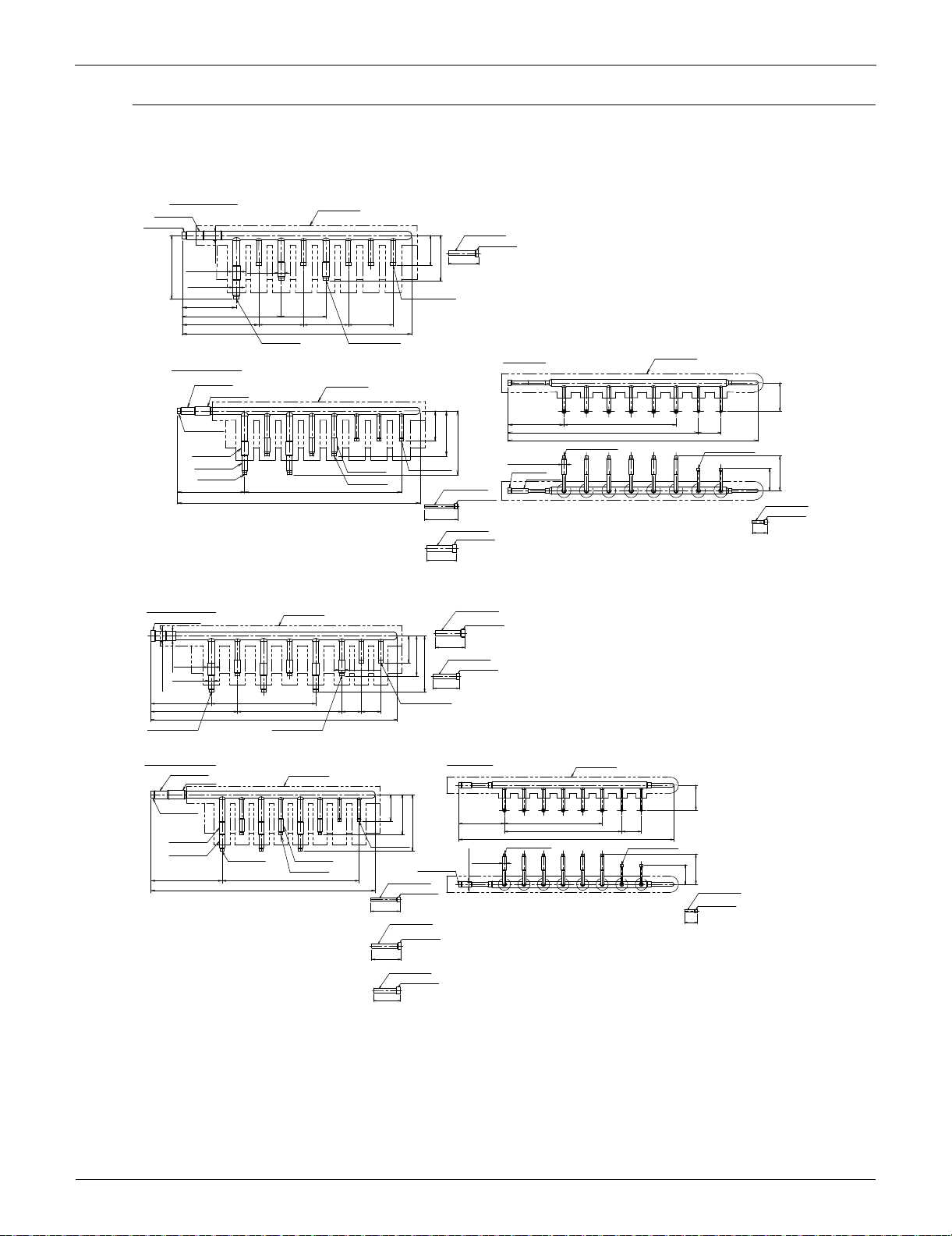

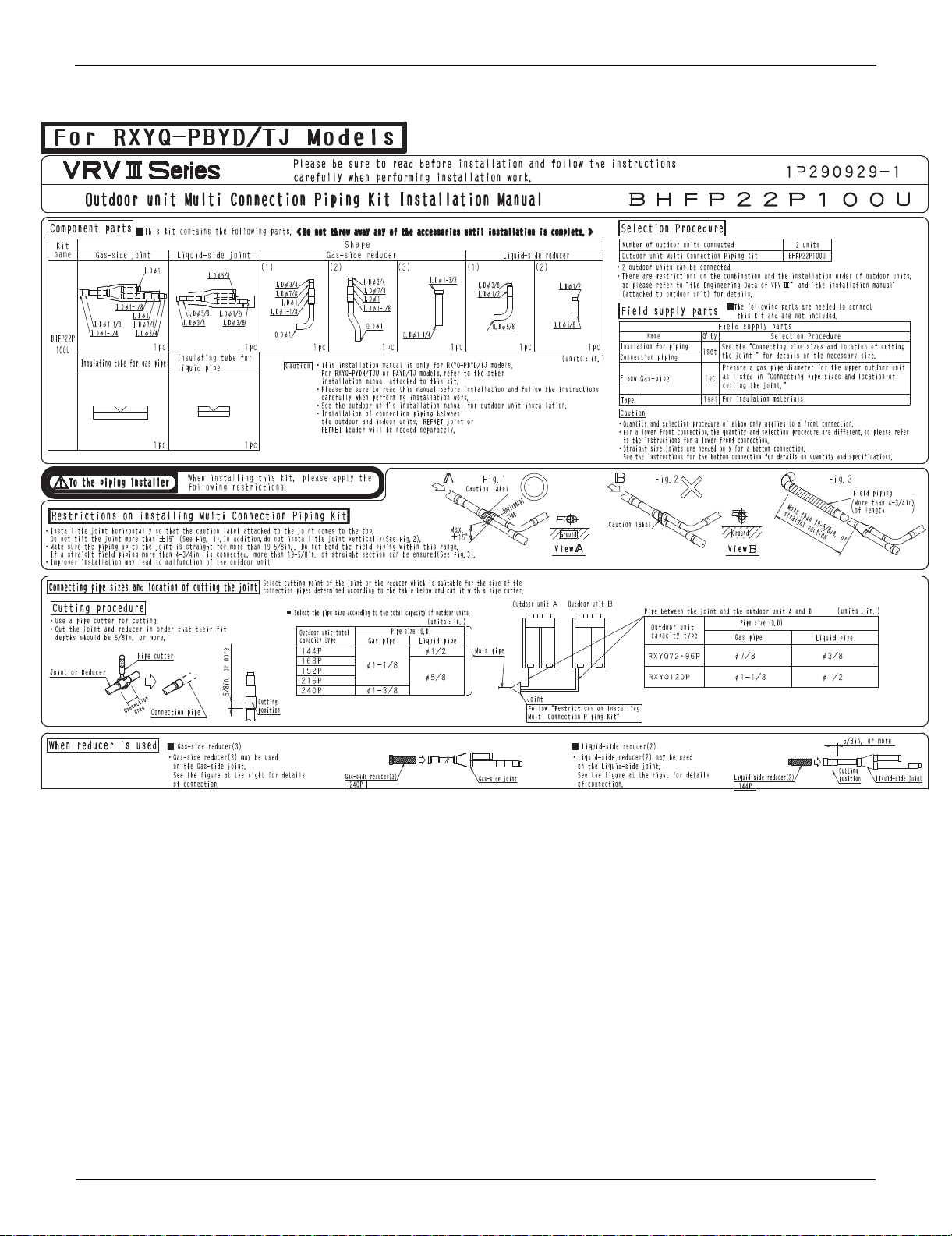

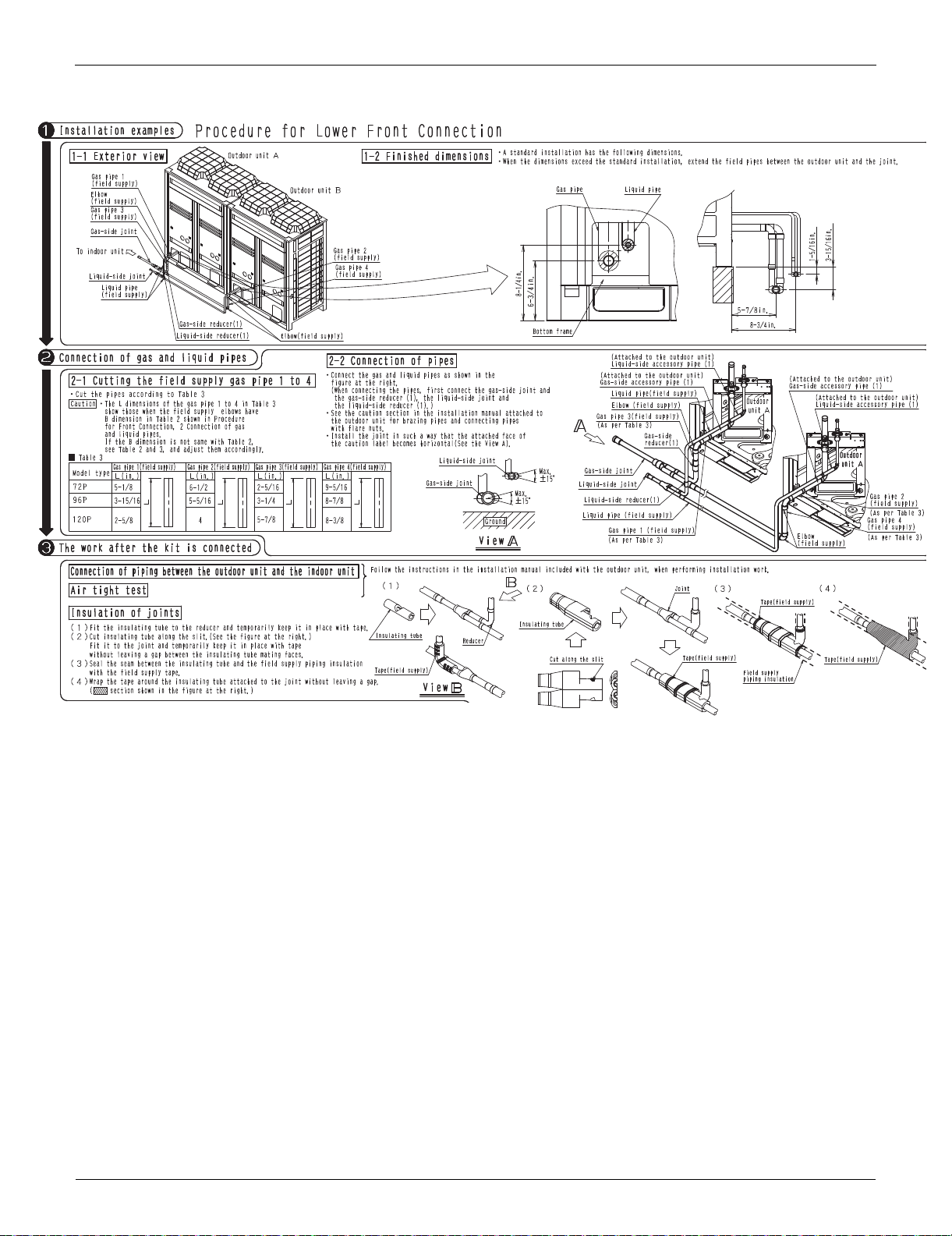

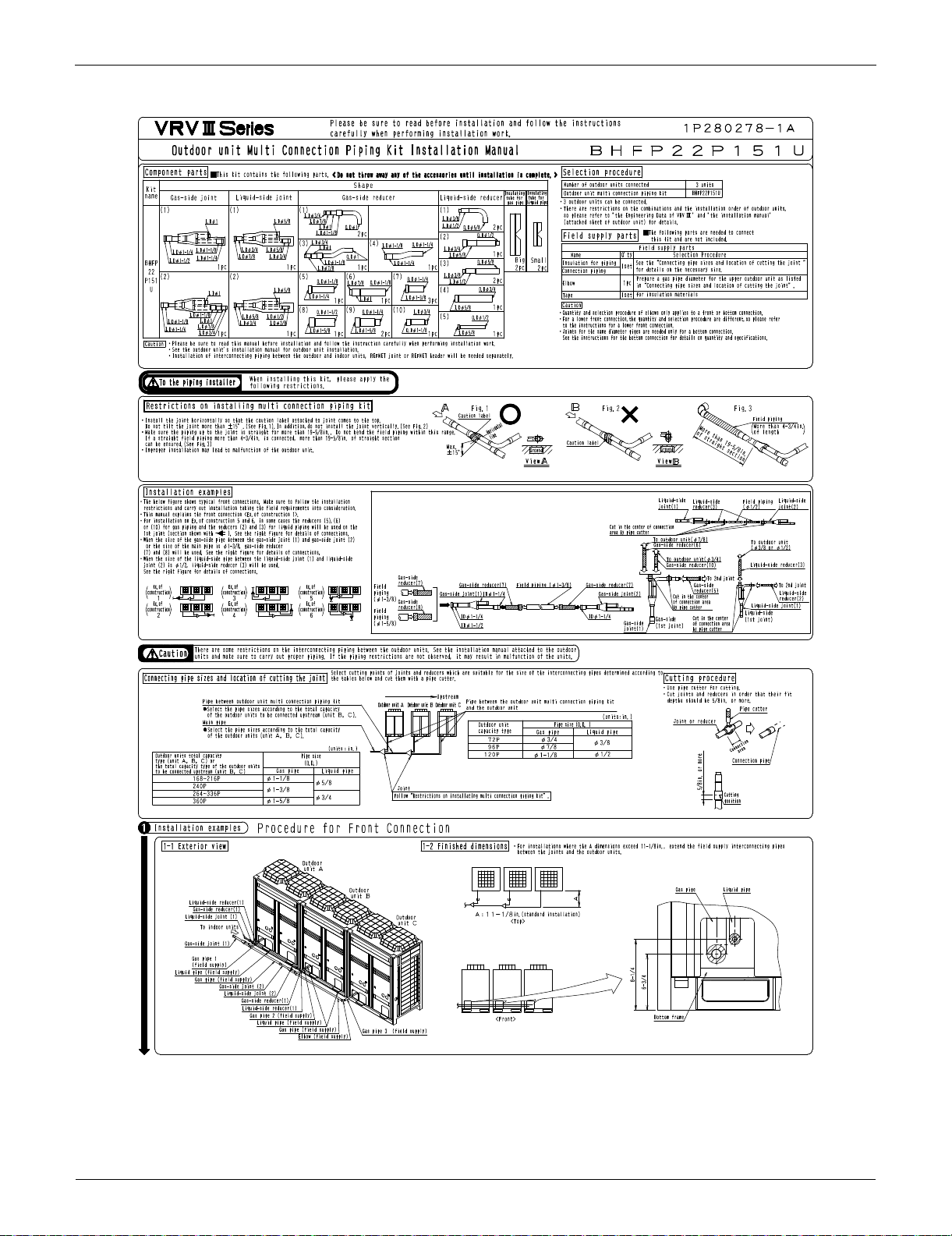

4.3 Outdoor Unit Multi Connection Piping Kit

RXYQ144~240PBYD (460V)

RXYQ168~240PBTJ (208/230V)

BHFP22P100U

22 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

Installation of Outdoor Units 23

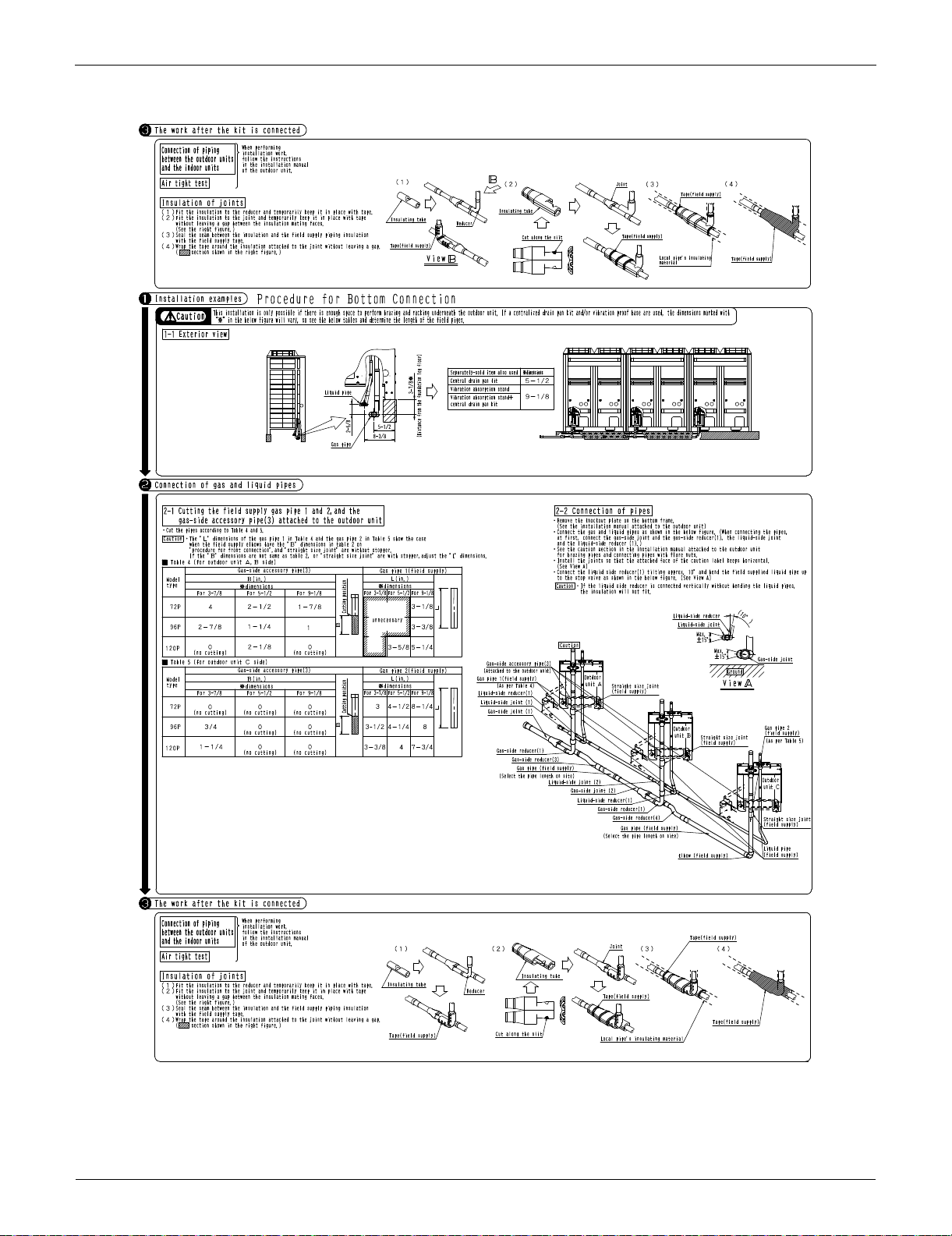

1P218719

REFNET Pipe System EDUS391004-N

24 Installation of Outdoor Units

1P218720

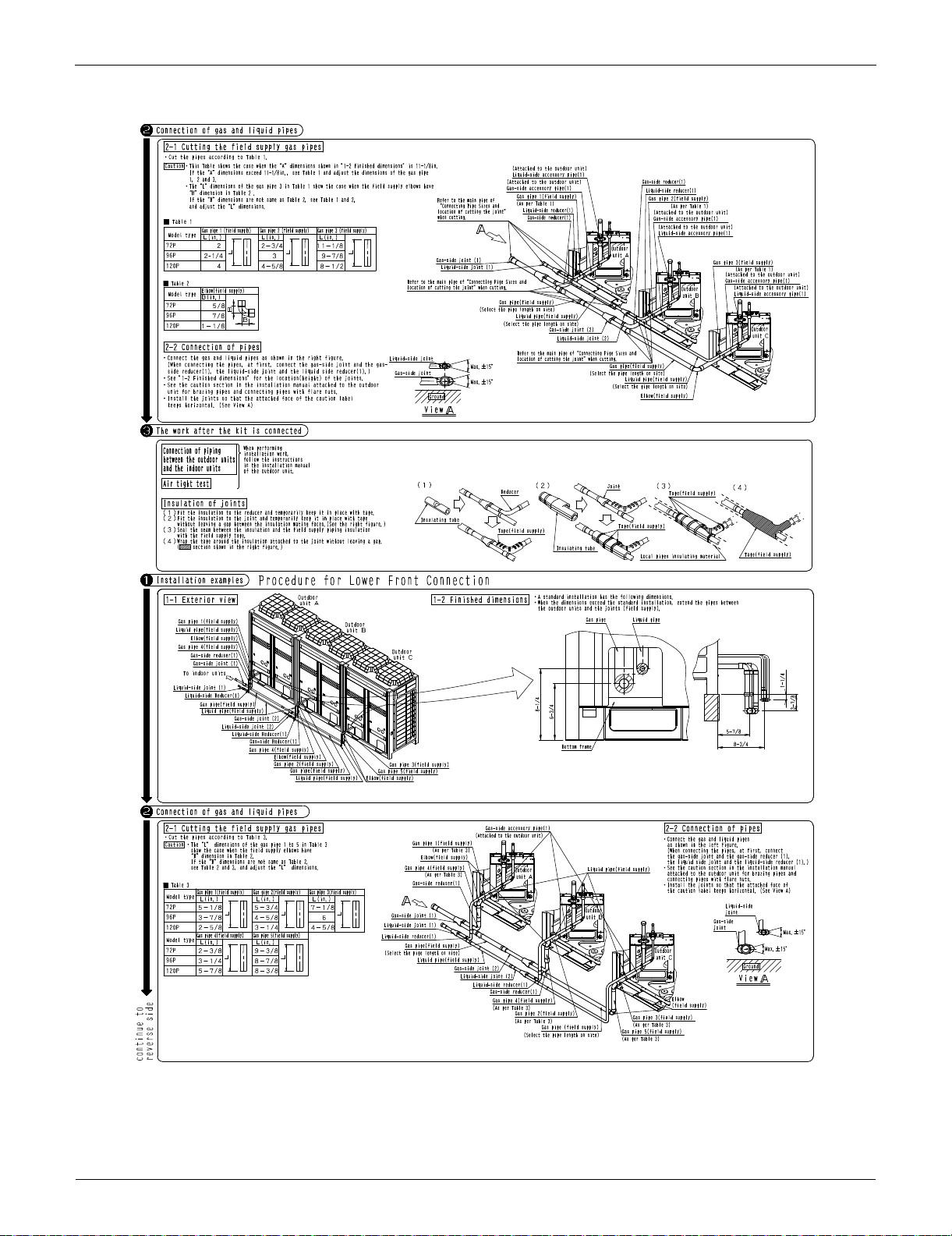

EDUS391004-N REFNET Pipe System

Installation of Outdoor Units 25

1P218720

REFNET Pipe System EDUS391004-N

3D071077

3D071076

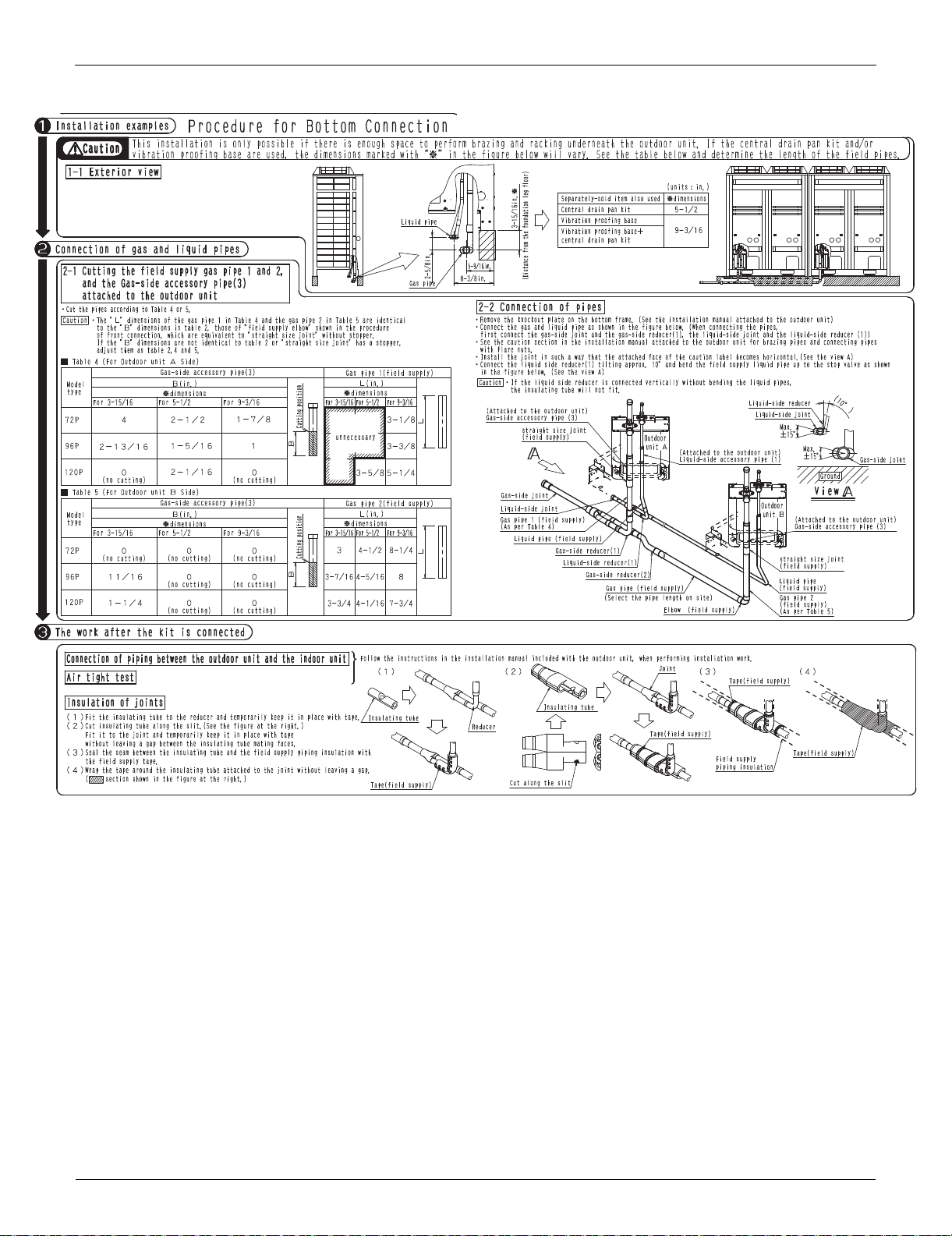

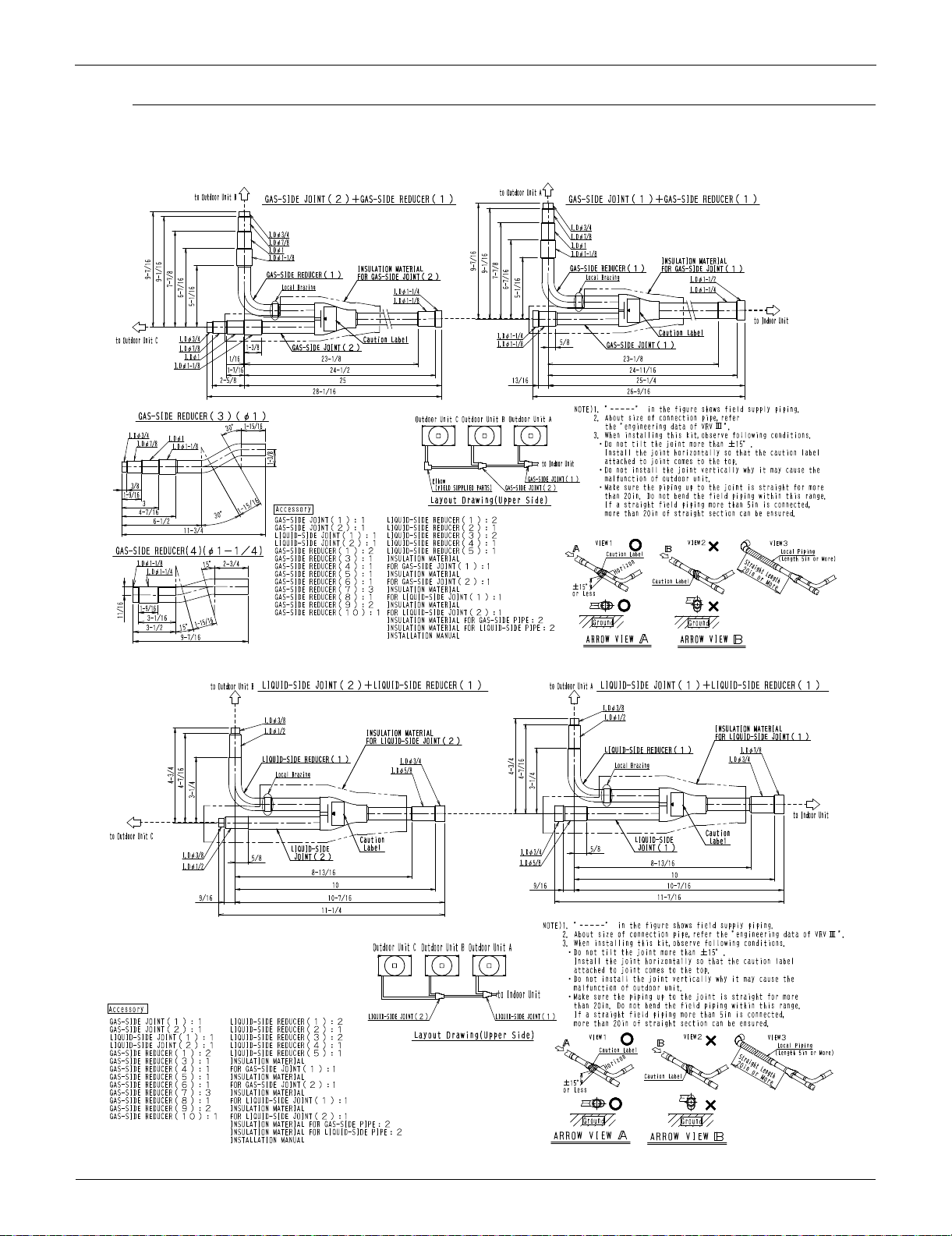

RXYQ264~360PBYD (460V)

RXYQ264~360PBTJ (208/230V)

BHFP22P151U

26 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

1P280278A

Installation of Outdoor Units 27

REFNET Pipe System EDUS391004-N

1P280278A

28 Installation of Outdoor Units

EDUS391004-N REFNET Pipe System

1P280279

Installation of Outdoor Units 29

Loading...

Loading...