Daikin PGDK, PGMK Operation manuals

English

Deutsch

Français

Nederlands

156077 PGDK

156075 PGMK

06/2019

Italiano

Español

Português

Ελληνικά

j zyk polskię

156077 PGDK

156075 PGMK

Read manual before use!

English

Observe all safety information!

Keep manual for future use!

About these operating instructions

1 About these operating instructions

These operating instructions describe the pump assembly with and without

mixer (also referred to as "product" in these operating instructions).

These operating instructions are part of the product.

• You may only use the product if you have fully read and understood these

operating instructions.

• Verify that these operating instructions are always accessible for any type

of work performed on or with the product.

• Pass these operating instructions as well as all other product-related documents on to all owners of the product.

• If you feel that these operating instructions contain errors, inconsistencies, ambiguities or other issues, contact the manufacturer prior to using

the product.

There operating instructions are protected by copyright and may only be

used as provided for by the corresponding copyright legislation. We reserve

the right to modifications.

The manufacturer shall not be liable in any form whatsoever for direct or consequential damage resulting from failure to observe these operating instructions or from failure to comply with directives, regulations and standards and

any other statutory requirements applicable at the installation site of the product.

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

2

Information on safety

2 Information on safety

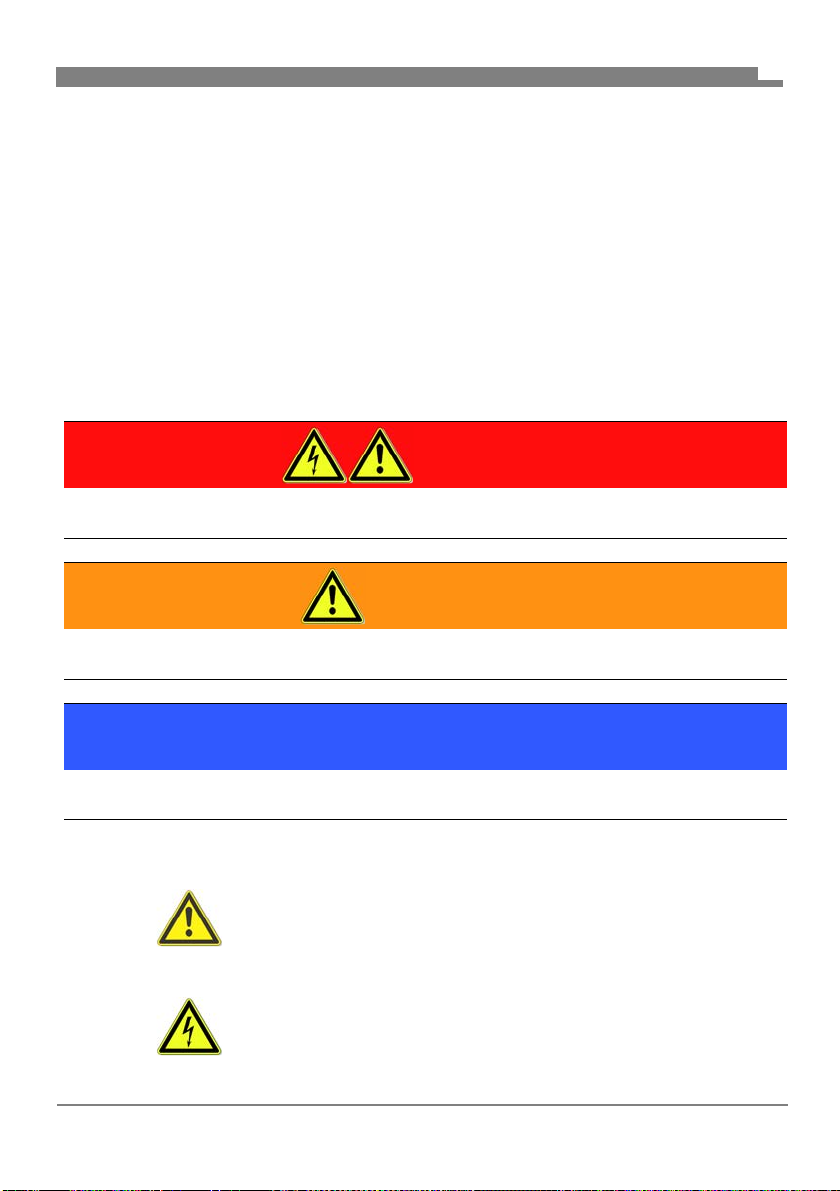

2.1 Safety messages and hazard categories

These operating instructions contain safety messages to alert you to potential hazards and risks. In addition to the instructions provided in these operating instructions, you must comply with all directives, standards and safety

regulations applicable at the installation site of the product. Verify that you are

familiar with all directives, standards and safety regulations and ensure compliance with them prior to using the product.

Safety messages in these operating instructions are highlighted with warning

symbols and warning words. Depending on the severity of a hazard, the

safety messages are classified according to different hazard categories.

DANGER

DANGER indicates a hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided,

can result in serious injury or equipment damage.

EN

NOTICE

NOTICE indicates a hazardous situation, which, if not avoided, can

result in equipment damage.

In addition, the following symbols are used in these operating instructions:

This is the general safety alert symbol. It alerts to injury hazards or equipment da

tions in conjunction with this symbol to help avoid possible

death, injury or equipment damage.

This symbol alerts to hazardous electrical voltage. If this

symbol is used in a safety message, there is a hazard of

electric shock.

mage. Comply with all safety instruc-

FA PG - 06/2019 - 008.15 442 99_02 - EN

3

Information on safety

2.2 Intended use

This product may only be used to circulate the following liquids in intrinsically

safe, sealed, thermal heating systems:

• Heating circuit water as per VDI 2035

• Water/glycol mixtures with a maximum admixture of 20 %

Any use other than the application explicitly permitted in these operating

instructions is not permitted and causes hazards.

Verify that the product is suitable for the application planned by you prior to

using the product. In doing so, take into account at least the following:

• All directives, standards and safety regulations applicable at the installation site of the product

• All conditions and data specified for the product

• The conditions of the planned application

In addition, perform a risk assessment in view of the planned application,

according to an approved risk assessment method, and implement the

appropriate safety measures, based on the results of the risk assessment.

Take into account the consequences of installing or integrating the product

into a system or a plant.

When using the product, perform all work and all other activities in conjunction with the product in compliance with the conditions specified in the operating instructions and on the nameplate, as well as with all directives, standards and safety regulations applicable at the installation site of the product

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

4

Information on safety

2.3 Predictable incorrect application

The product must never be used in the following cases and for the following

purposes:

• Use with drinking water

• Use with adherent, corrosive or flammable fluids

• Operation in systems with temperatures exceeding 110 °C

(for example, solar systems)

2.4 Qualification of personnel

Only appropriately trained persons who are familiar with and understand the

contents of these operating instructions and all other pertinent product documentation are authorized to work on and with this product.

These persons must have sufficient technical training, knowledge and experience and be able to foresee and detect potential hazards that may be

caused by using the product

All persons working on and with the product must be fully familiar with all

directives, standards and safety regulations that must be observed for performing such work.

2.5 Personal protective equipment.

Always wear the required personal protective equipment. When performing

work on and with the product, take into account that hazards may be present

at the installation site which do not directly result from the product itself.

EN

2.6 Modifications to the product

Only perform work on and with the product which is explicitly described in

these operating instructions. Do not make any modifications to the product

which are not described in these operating instructions.

FA PG - 06/2019 - 008.15 442 99_02 - EN

5

Transport and storage

3 Transport and storage

The product may be damaged as a result of improper transport or storage.

NOTICE

DAMAGE TO THE PRODUCT

• Verify compliance with the specified ambient conditions during transport or

storage of the product.

• Use the original packaging when transporting the product.

• Store the product in a clean and dry environment.

• Verify that the product is protected against shocks and impact during transport and storage.

Failure to follow these instructions can result in equipment damage.

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

6

Product description

4 Product description

The product is a pre-assembled, tightness-tested and heat-insulated pump

assembly.

The universal insulation allows for the installation of virtually any standard circulation pump (with G1

reworking of the insulation.

The second ball valve in the return line lets you replace the pump without

draining the system.

In addition, the system is modular so that the flow line can be mounted at the

left or the right side. Optional temperature probes Ø 6 mm can be mounted

to all ball valves.

1

/

connection and a length of 180 mm) without major

2

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

7

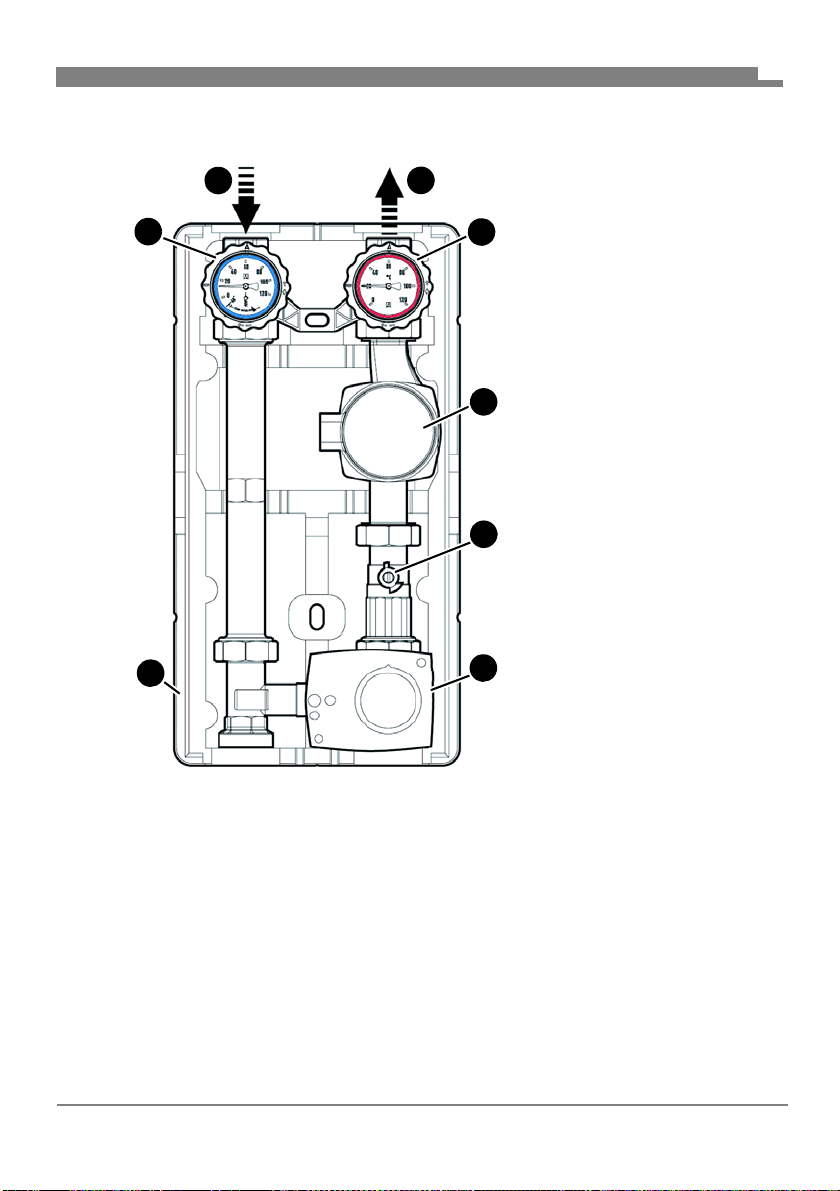

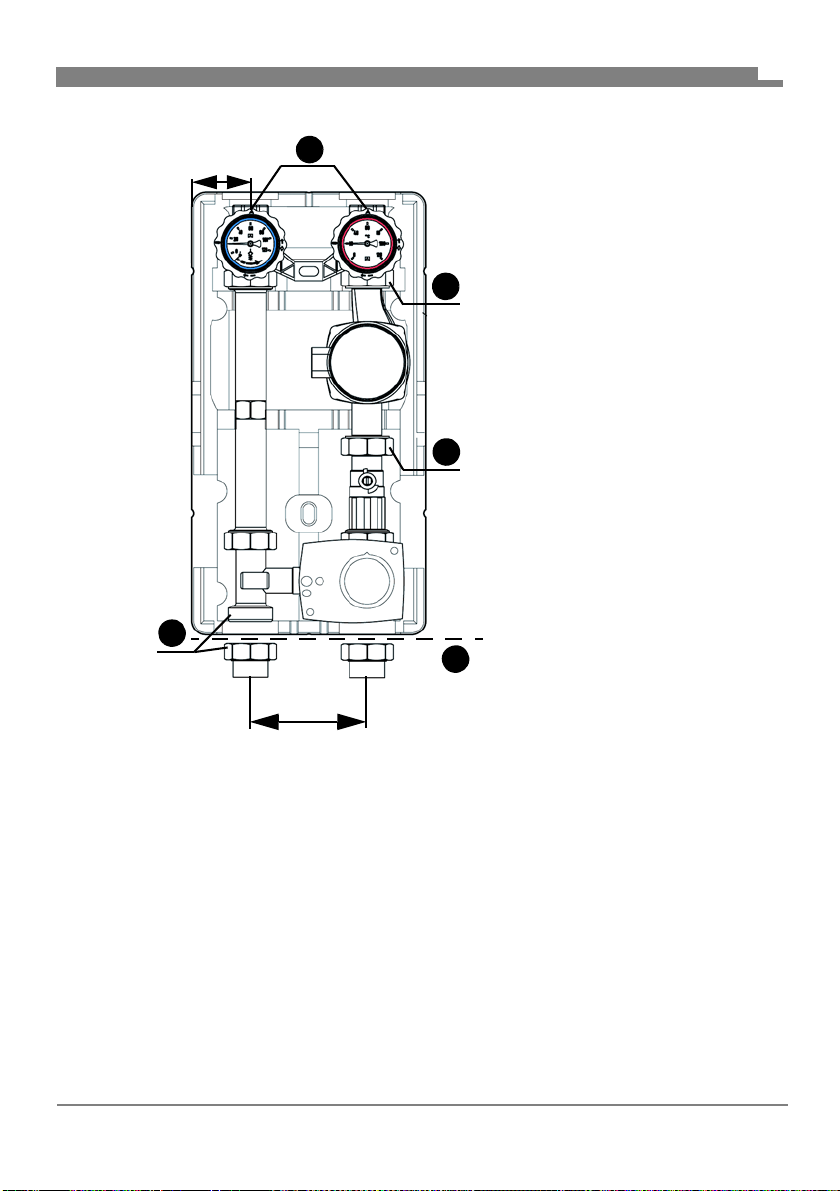

4.1 Overview

1

2

B

C

D

E

F

A

Product description

1. Return

2. Flow

A. Ball valve, can be shut off,

B. Ball valve, can be shut off,

C. Circulation pump (various

D. Ball valve

E. 3-way mixer with actuator

F. Insulation

EN

with thermometer blue

and gravity brake

with thermometer red

manufacturers)

Fig. 1: PrimoTherm® components

FA PG - 06/2019 - 008.15 442 99_02 - EN

8

Product description

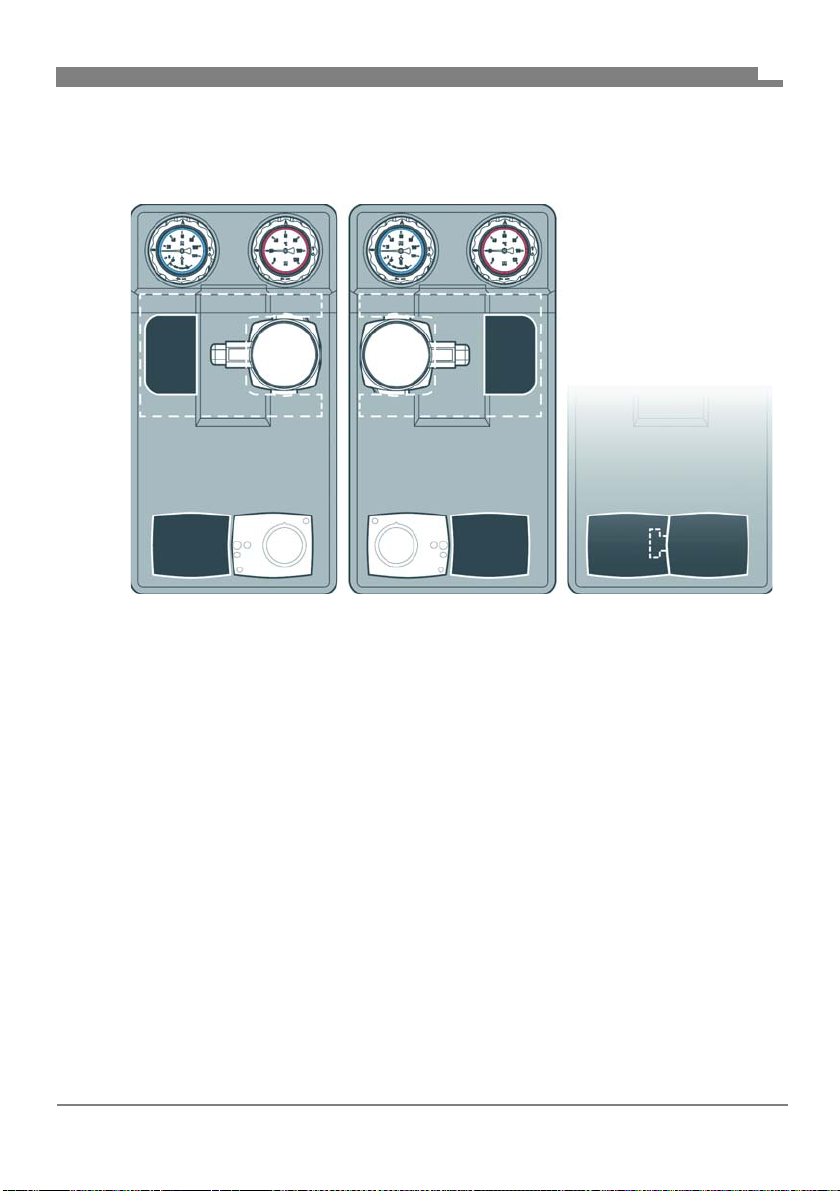

4.2 Versions

The variable insulation can be used for applications with flow at the left and

flow at the right.

Fig. 2: Flow right (left figure)

Fig. 3: Flow left (centre figure)

Fig. 4: Without actuator (right figure)

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

9

Product description

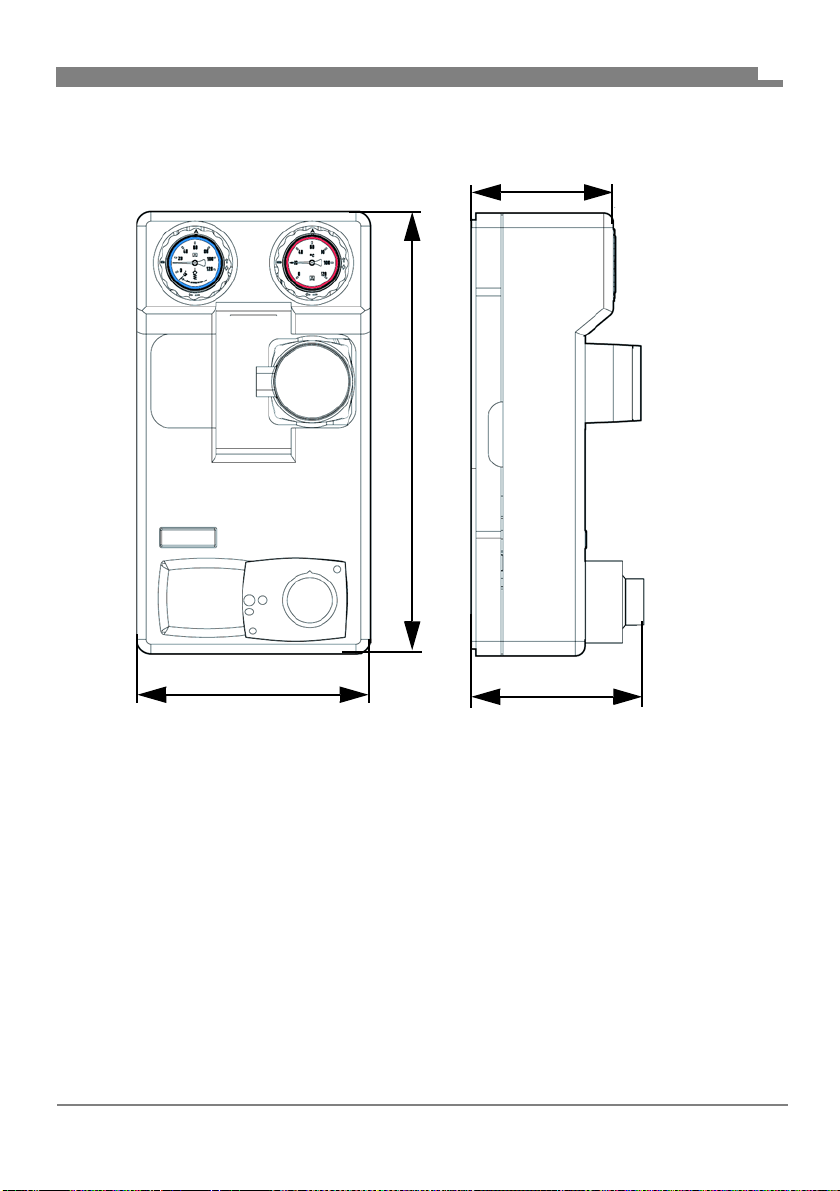

Approx. 250

Approx.

Approx. 475

Approx. 152

4.3 Dimensions and connections

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

10

Product description

B

1

B

B

A

Approx. 125

Approx. 60

A. G1

B. G1½

EN

4.4 Approvals, conformities, certifications

See operating instructions of the manufacturer of the circulation pump for versions with circulation pump.

FA PG - 06/2019 - 008.15 442 99_02 - EN

11

Product description

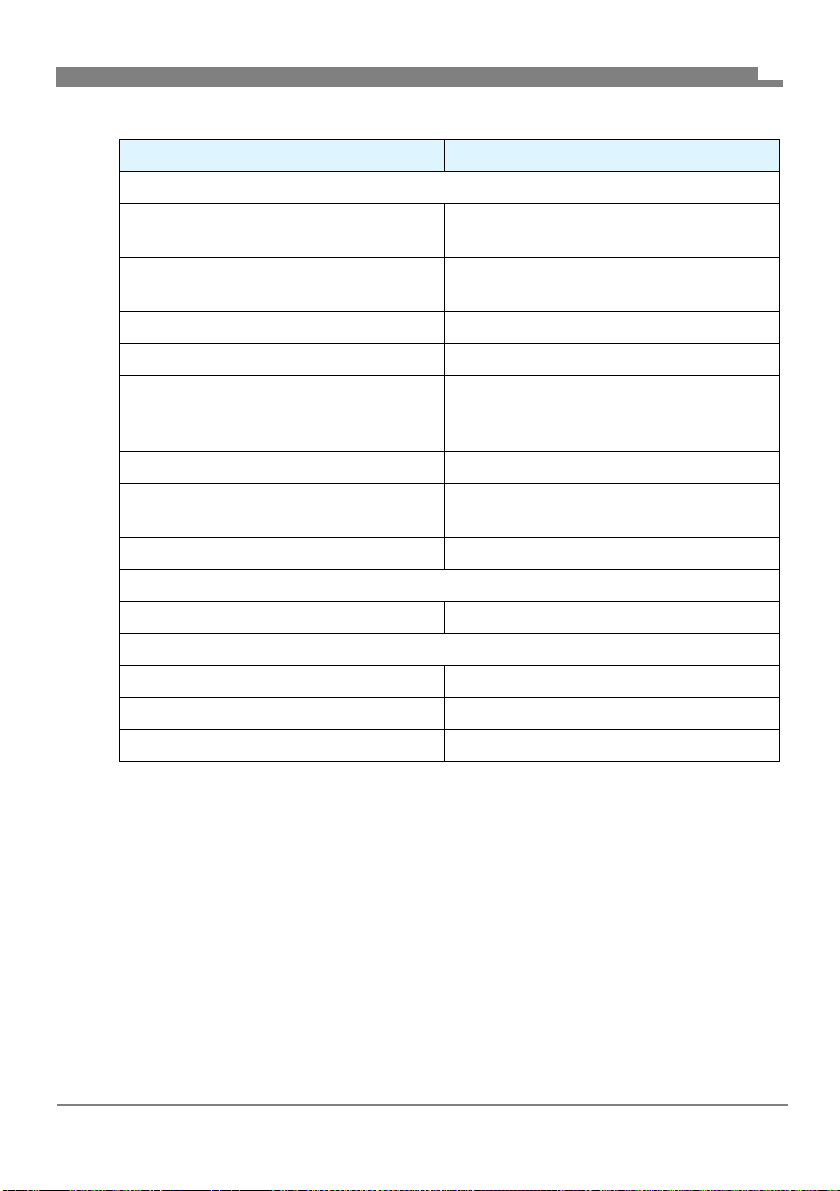

4.5 Technical specifications

Parameter Value

General specifications

Dimensions with insulation

(W x H x D)

Weight Approx. 5.5 kg with mixer

Material of fittings Brass

Insulation material Polypropylene EPP

System pressure Max. 10 bar

Axis distance 125 mm

System connections Boiler R1

Flow coefficient Kvs 4.8 m

Operating temperature range

Medium Max. 110 °C

Pressure loss

Flow line Flow coefficient Kvs = 6.9 m

Return line Flow coefficient Kvs = 6.7 m

Total: Flow coefficient Kvs = 4.8 m

250 x 475 x 152 mm

Approx. 7.2 kg without mixer

(observe maximum pressure of

circulation pump used)

1

/

2

Heating circuit Rp1

3

/h

3

/h

3

/h

3

/h

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

12

Mounting

5 Mounting

WARNING

BURNS CAUSED BY HOT LIQUID

Water in heating systems is under high pressure and can have temperatures of

more than 100 °C.

• Verify that the heating water has cooled down before opening the system and

mounting the product.

Failure to follow these instructions can result in death, serious injury or

equipment damage.

5.1 Preparing mounting

Verify that the product is mounted in such a way that no external forces

can act on the components after it has been installed.

Verify that the product is not overheated by welding or soldering work per-

formed on the system.

- Install the product after completion of such welding or soldering work.

Verify that the nominal pressure of the product corresponds to the speci-

fication value of the system.

Verify that the liquid in the system and the application area of the product

are compatible.

Verify that the pipes are thoroughly flushed prior to installation of the prod-

uct.

- Impurities such as weld beads, hemp or metal chips cause leaks of the

product.

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

13

Mounting

B

A

C

B

D

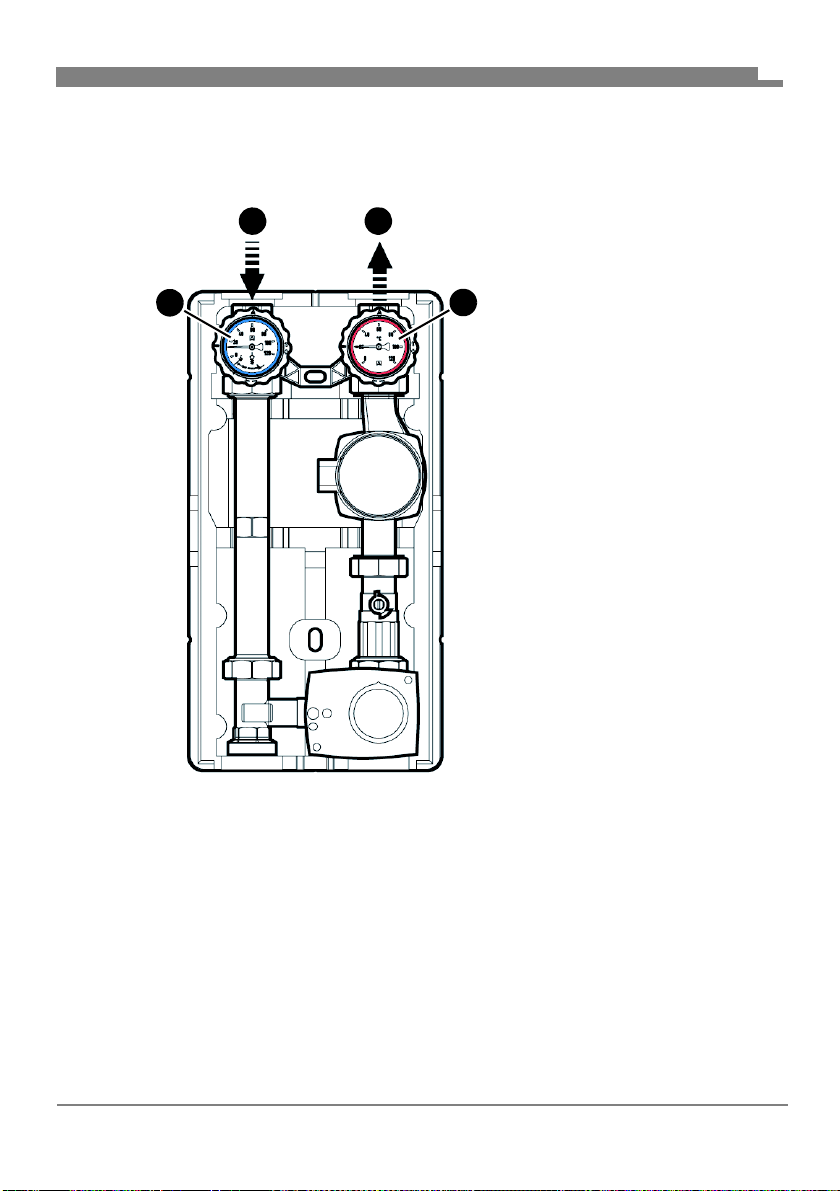

5.1.1 Interchanging flow/return

Unless otherwise specified, all information in these operating instructions

relates to the installation type "flow right".

EN

A. Return

B. Flow

C. Red thermometer ball

valve

D. Blue thermometer ball

valve

Fig. 5: Flow right (condition as supplied)

FA PG - 06/2019 - 008.15 442 99_02 - EN

14

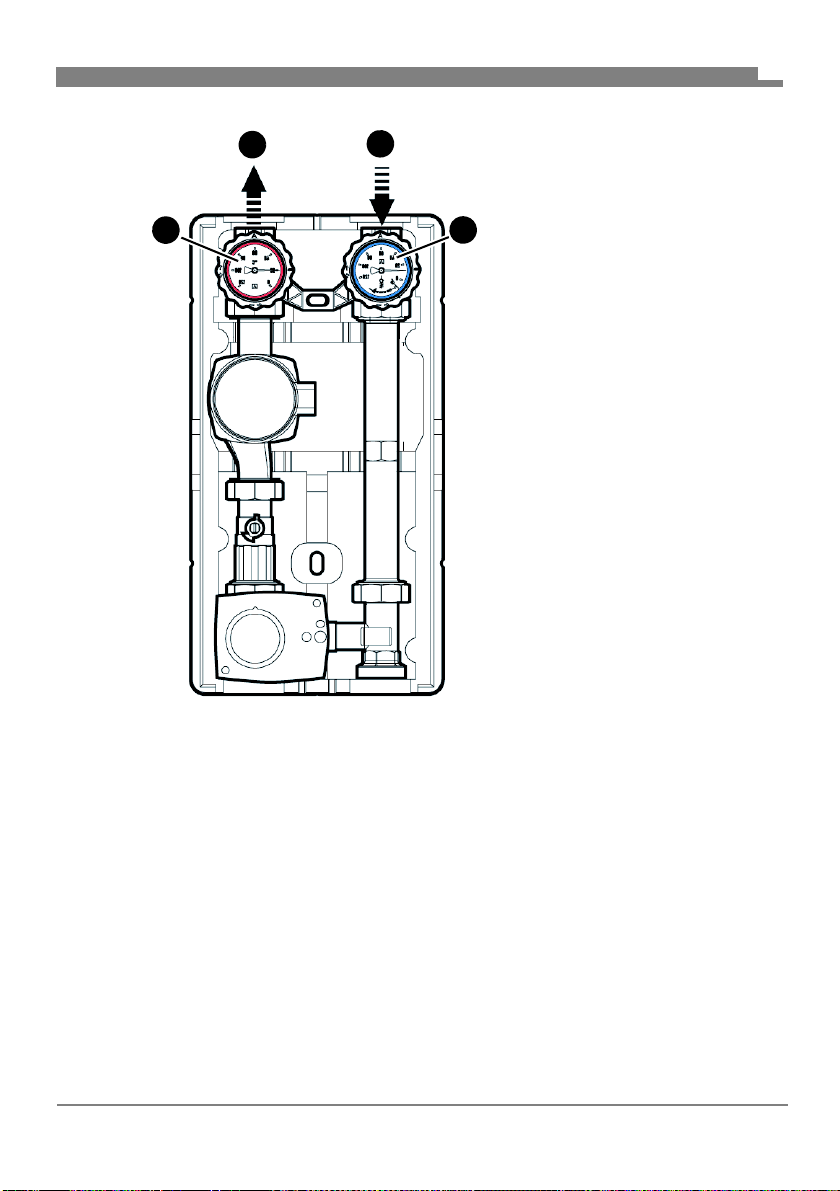

Mounting

D

A

A

B

C

D

EN

A. Flow

B. Return

C. Blue thermometer ball

valve

D. Red thermometer ball

valve

Fig. 6: Flow left

FA PG - 06/2019 - 008.15 442 99_02 - EN

15

Mounting

EN

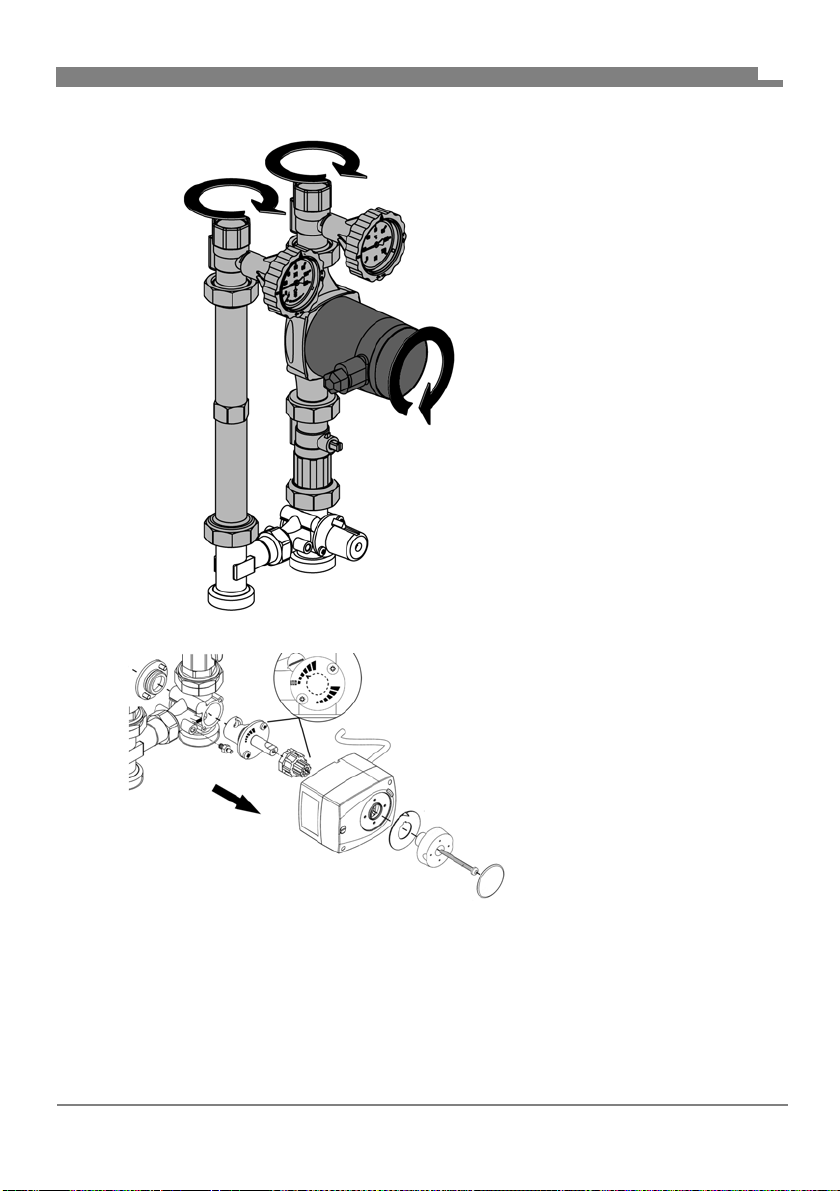

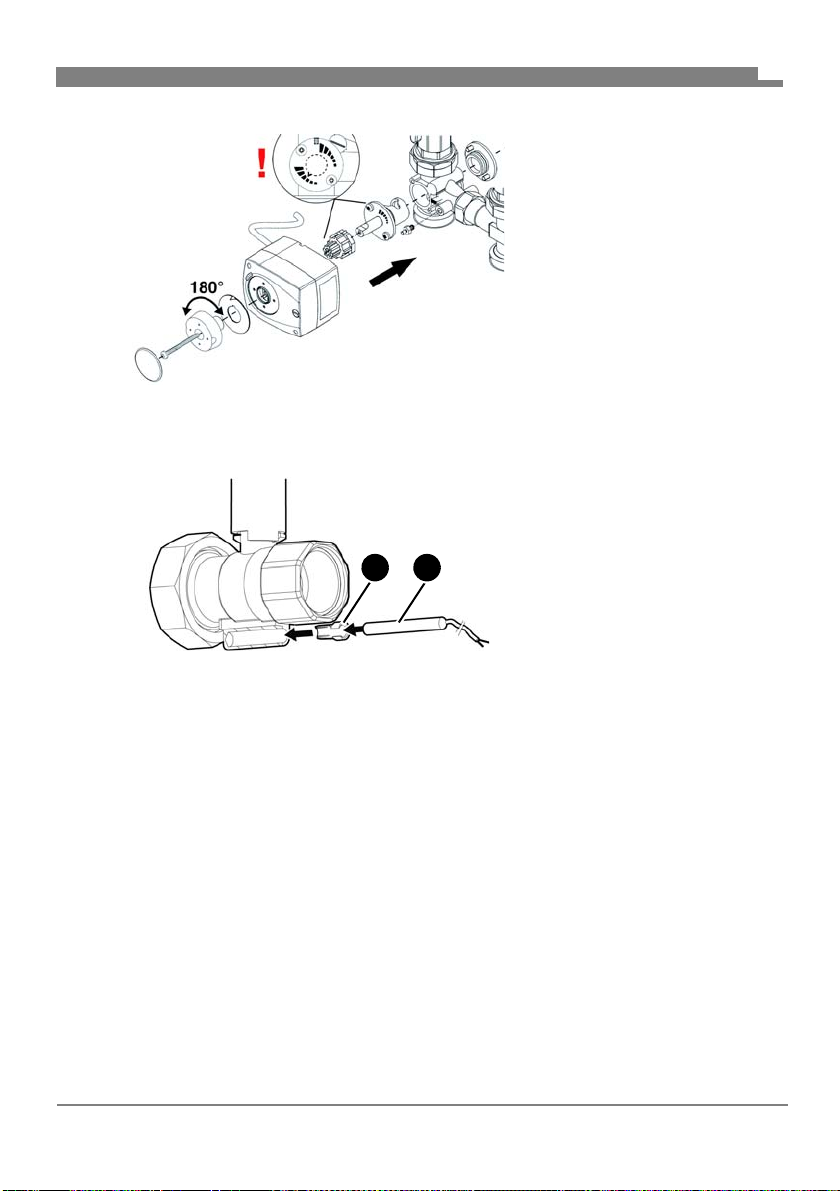

1. Interchange left and right

lines.

2. Turn the pump head.

3. Change the actuator.

- Flow right

4. Uninstall the actuator.

FA PG - 06/2019 - 008.15 442 99_02 - EN

16

Mounting

A B

5. Re-install the actuator.

- Flow left

6. Fit the upper insulation.

5.1.2 Mounting the temperature probe (optional)

Depending on the type of the

temperature probe (B), it may

be necessary to shorten the

ferrule (A).

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

17

Mounting

5.2 Mounting the product

5.2.1 Mounting the product to a module manifold

NOTICE

MECHANICAL LOADS AND STRESS

• Verify that the product is not subjected to mechanical loads and stress when

connecting the product.

• If necessary, install a corrugated pipe compensator to compensate for

mechanical stress or tension.

Failure to follow these instructions can result in equipment damage.

1. Remove the insulation.

2. Screw the pump assembly to module manifold.

3. Screw the pipes of the heating circuit to the top connections (no

mechanical stress).

4. Fit the complete insulation.

5.2.2 Wall mounting

EN

NOTICE

MECHANICAL LOADS AND STRESS

• Verify that the product is not subjected to mechanical loads and stress when

mounting the product to the wall.

Failure to follow these instructions can result in equipment damage.

FA PG - 06/2019 - 008.15 442 99_02 - EN

18

Mounting

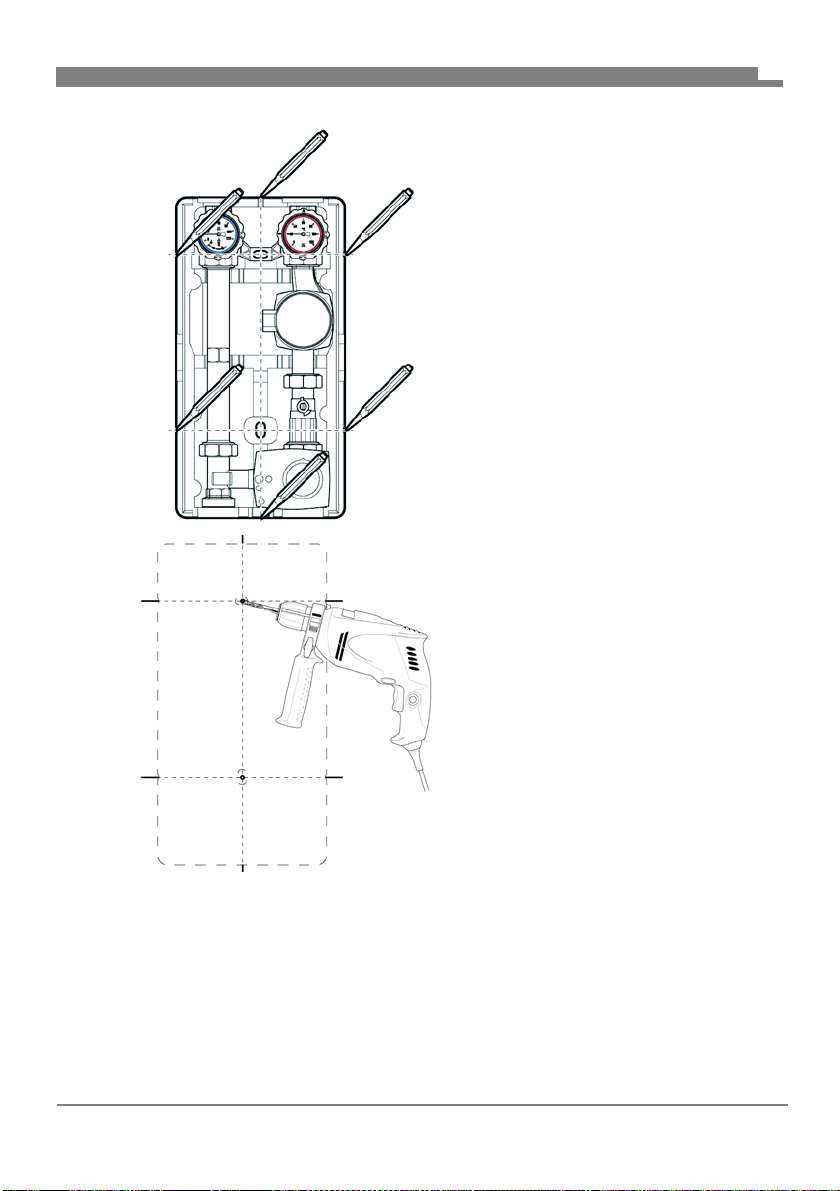

EN

1. Remove the upper insulation.

2. Hold the product to the wall and

align it with a level.

3. Draw six marks.

4. Interconnect the opposing marks.

5. Drill holes (Ø 10 mm) at the position of the two centre marks.

6. Insert the enclosed dowels.

7. Screw the long hanger bolt into

the top hole.

8. Screw the short hanger bolt into

the bottom hole.

9. Fit the product with the bottom insulation and secure it with a washer and

a nut.

10.Connect the pipes of the heating circuit to the connections of the fittings

(no mechanical stress).

11.Fit the upper insulation.

FA PG - 06/2019 - 008.15 442 99_02 - EN

19

Mounting

5.3 Electrical connection

DANGER

ELECTRIC SHOCK

• Verify that the degree of protection against electric shock (protection class,

double insulation) is not reduced by the type of electrical installation.

Failure to follow these instructions will result in death or serious injury.

DANGER

ELECTRIC SHOCK CAUSED BY LIVE PARTS

• Disconnect the mains voltage supply before performing the work and ensure

that it cannot be switched on.

• Verify that no hazards can be caused by electrically conductive objects or

media.

Failure to follow these instructions will result in death or serious injury.

1. Connect the circulation pump and the actuator in accordance with the

instructions of the manufacturer.

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

20

Commissioning

6 Commissioning

6.1 Commissioning the product

Verify that the thermometer ball valves are in 0° setting.

1. Perform a pressure test.

2. Check all screwed connections for tightness.

3. Set to ball valves to 45° position for filling of the system.

4. Fill the system and apply pressure.

5. Set the ball valves to 0° position.

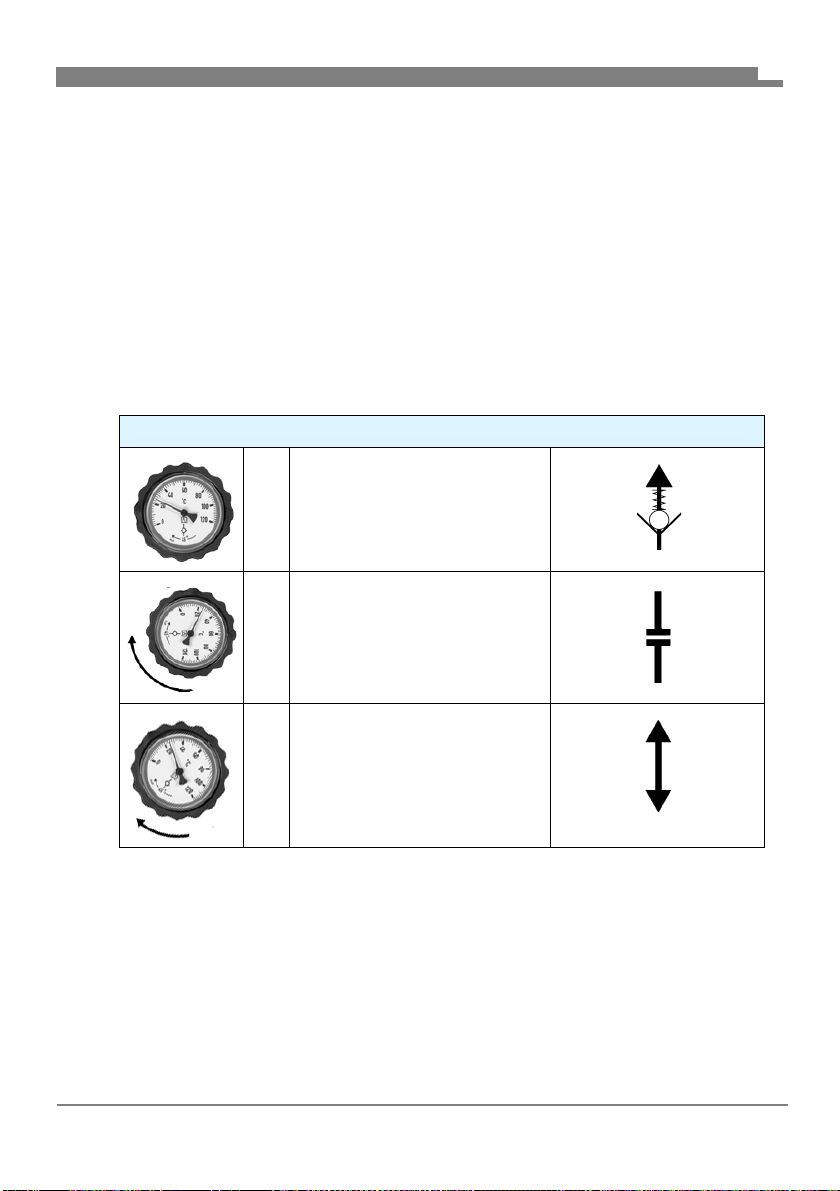

6.1.1 Thermometer ball valves

Thermometer ball valves

0° Normal operation:

Gravity brake active

90 ° Maintenance:

Ball valve closed

EN

45 ° Commissioning, filling, vent-

ing, flushing:

Both ends open (gravity

brake not active)

7 Operation

Proper operation is only possible if the thermometer ball valves and the ball

valves are open (0° setting, see chapter "Thermometer ball valves").

FA PG - 06/2019 - 008.15 442 99_02 - EN

21

Maintenance

8 Maintenance

8.1 Maintenance intervals

When Activity

Monthly Perform a visual inspection of the heating system

and verify tightness.

If required Replace the circulation pump.

8.2 Maintenance activities

DANGER

ELECTRIC SHOCK CAUSED BY LIVE PARTS

• Disconnect the mains voltage supply before performing the work and ensure

that it cannot be switched on.

Failure to follow these instructions will result in death or serious injury.

8.2.1 Replacing a defective circulation pump

1. Close the red thermometer ball valve and the ball valve in the pump line

(90° setting).

2. Replace the circulation pump (see instructions of the manufacturer of

the pump).

3. Open the thermometer ball valve and the ball valve (0° setting).

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

22

Troubleshooting

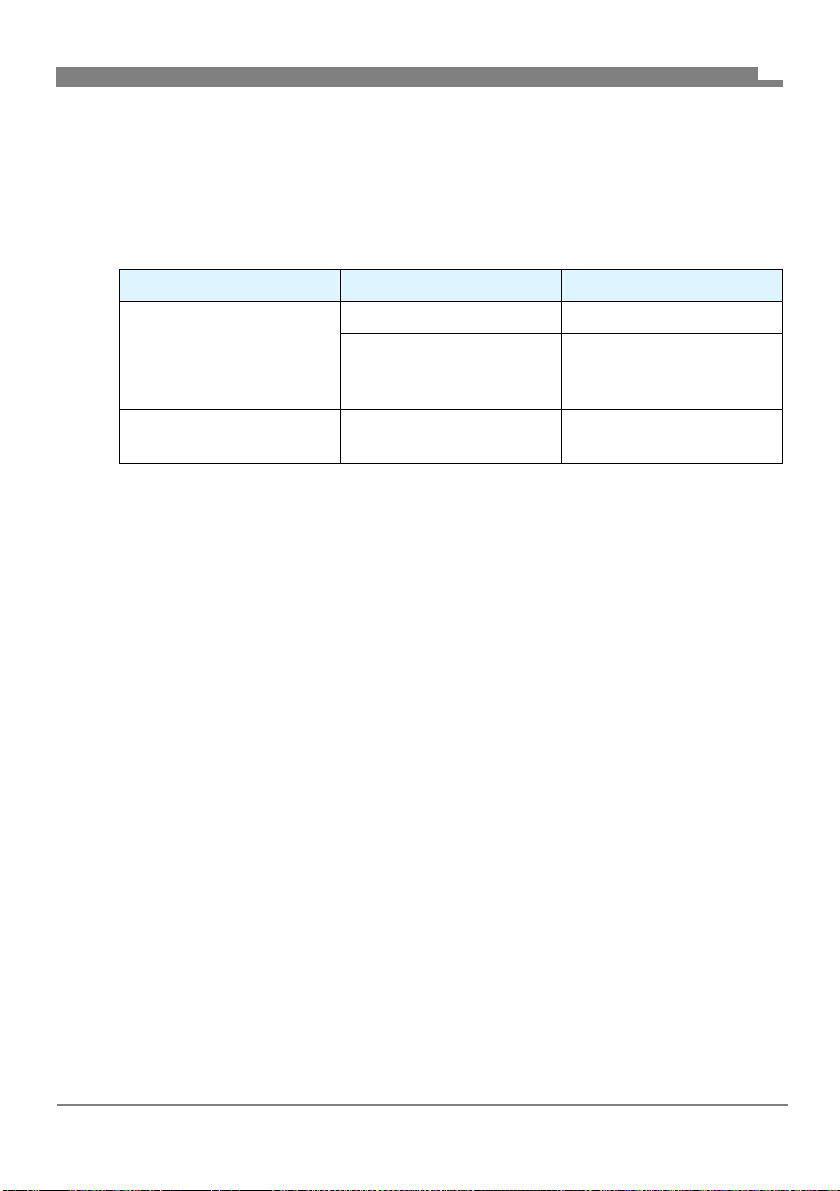

9 Troubleshooting

Any malfunctions that cannot be removed by means of the measures

described in this chapter may only be repaired by the manufacturer.

Also observe the corresponding instructions of the manufacturer in the case

of malfunctions of the circulation pump or the actuator.

Problem Possible reason Repair

Noise in the system Air in the system Vent the system

Circulation pump not

properly adjusted

Other malfunctions - Contact the AFRISO

Verify correct adjustment of the circulation

pump

service hotline

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

23

Decommissioning, disposal

10 Decommissioning, disposal

Dispose of the product in compliance with all applicable directives, standards

and safety regulations.

Electronic components must not be disposed of together with the normal

household waste.

1. Disconnect the product from mains.

2. Dismount the product (see chapter "Mounting", reverse

sequence of steps).

3. Dispose of the product.

11 Returning the device

Get in touch with us before returning your product.

12 Warranty

See our terms and conditions at www.daikin.com or your purchase contract

for information on warranty.

EN

FA PG - 06/2019 - 008.15 442 99_02 - EN

24

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

__________________________

156077 PGDK

156075 PGMK

Vor Gebrauch lesen!

Deutsch

Alle Sicherheitshinwei

se beachten!

Für künftige Verwendung aufbewahren!

Über diese Betriebsanleitung

1 Über diese Betriebsanleitung

Diese Betriebsanleitung beschreibt die Pumpengruppe mit und ohne

Mischer (im folgenden auch „Produkt“).

Diese Betriebsanleitung ist Teil des Produkts.

• Sie dürfen das Produkt erst benutzen, wenn Sie die Betriebsanleitung

vollständig gelesen und verstanden haben.

• Stellen Sie sicher, dass die Betriebsanleitung für alle Arbeiten an und mit

dem Produkt jederzeit verfügbar ist.

• Geben Sie die Betriebsanleitung und alle zum Produkt gehörenden

Unterlagen an alle Benutzer des Produkts weiter.

• Wenn Sie der Meinung sind, dass die Betriebsanleitung Fehler, Widersprüche oder Unklarheiten enthält, wenden Sie sich vor Benutzung des

Produkts an den Hersteller.

Diese Betriebsanleitung ist urheberrechtlich geschützt und darf ausschließlich im rechtlich zulässigen Rahmen verwendet werden. Änderungen vorbehalten.

Für Schäden und Folgeschäden, die durch Nichtbeachtung dieser Betriebsanleitung sowie Nichtbeachten der am Einsatzort des Produkts geltenden

Vorschriften, Bestimmungen und Normen entstehen, übernimmt der Hersteller keinerlei Haftung oder Gewährleistung.

DE

FA PG - 06/2019 - 008.15 442 99_02 - DE

2

Loading...

Loading...