Page 1

INSTALLATION

MANUAL

CEILING CASSETTE

R22 SPLIT TYPE AIR CONDITIONER

MODELS

FHC20JEV1K RD20JEV1K

FHC25JEV1K RD25JEV1K

FHC30JEV1K RD30JEV1K

FHC40JEV1K RD40JEV1K

RD40JEY1K

FHC50JEV1K RD50JEY1K

R22 Split Type Air Conditioner

Installation Manual

English

IM-CKE-0412(0)-DAIKIN

Part No.: R08019037616

Page 2

Page 3

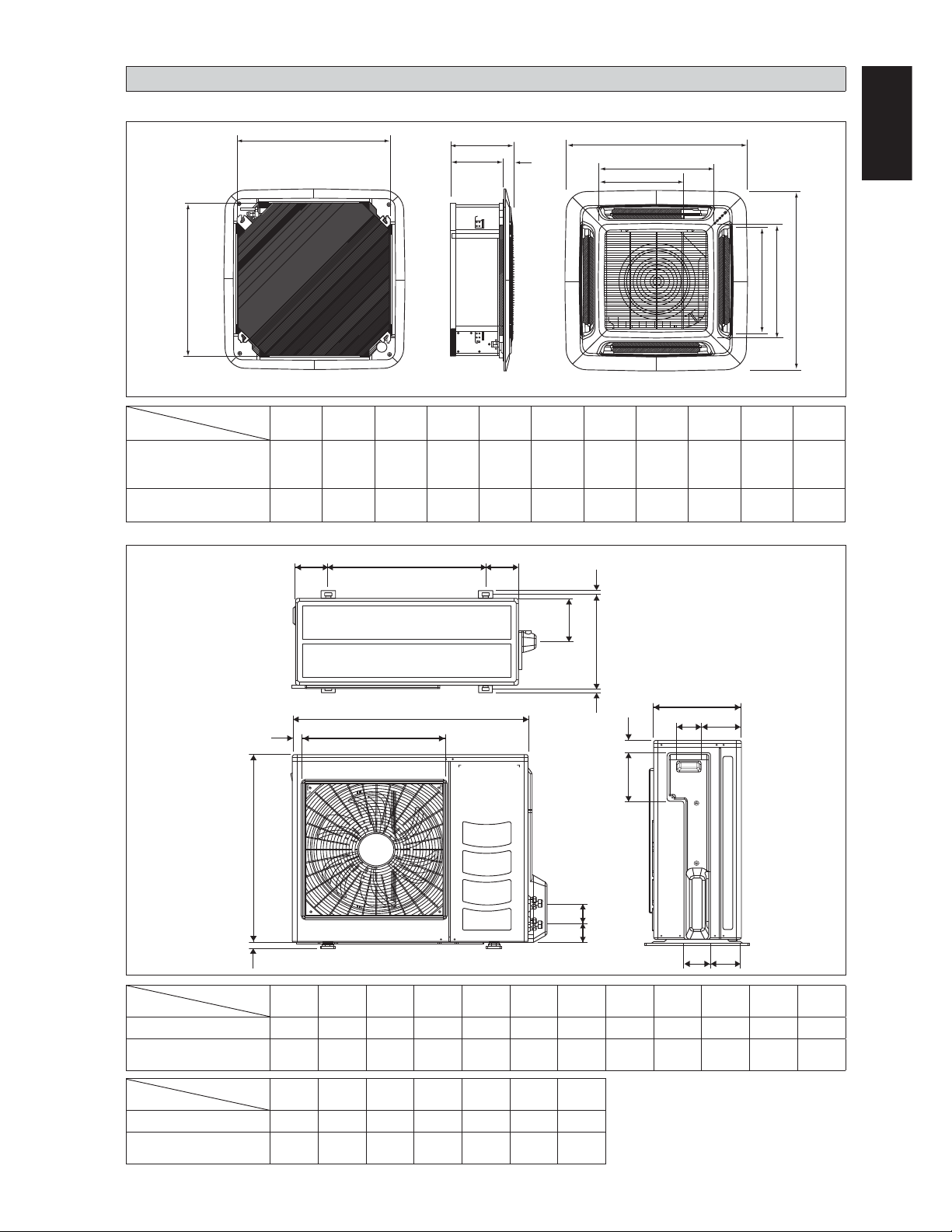

Indoor Unit

OUTLINE AND DIMENSIONS

B

C

D

E

F

H

K

English

A

Dimension

Model

FHC20JEV1K

FHC25JEV1K

FHC30JEV1K

FHC40JEV1K

FHC50JEV1K

Outdoor Unit

J

I

G

All dimensions are in mm

ABCDE FGHI J K

820 820 340 300 40 990 990 627 627 607 430

820 820 375 335 40 990 990 627 627 607 430

L

O

KL

A

D

N

M

QN

F

All dimensions are in mm

C

HG

Original Instruction

E

BP

RS

IJ

Model

Dimension

ABCDE FGHI J KL

RD20JEV1K 855 628 328 520 179 46 93 149 101 113 603 126

RD25JEV1K

RD30JEV1K

Dimension

Model

855 730 328 520 179 46 93 149 101 113 603 126

MNO P Q R S

RD20JEV1K 164 15 34 23 362 73 75

RD25JEV1K

RD30JEV1K

164 15 34 23 362 73 75

1

Page 4

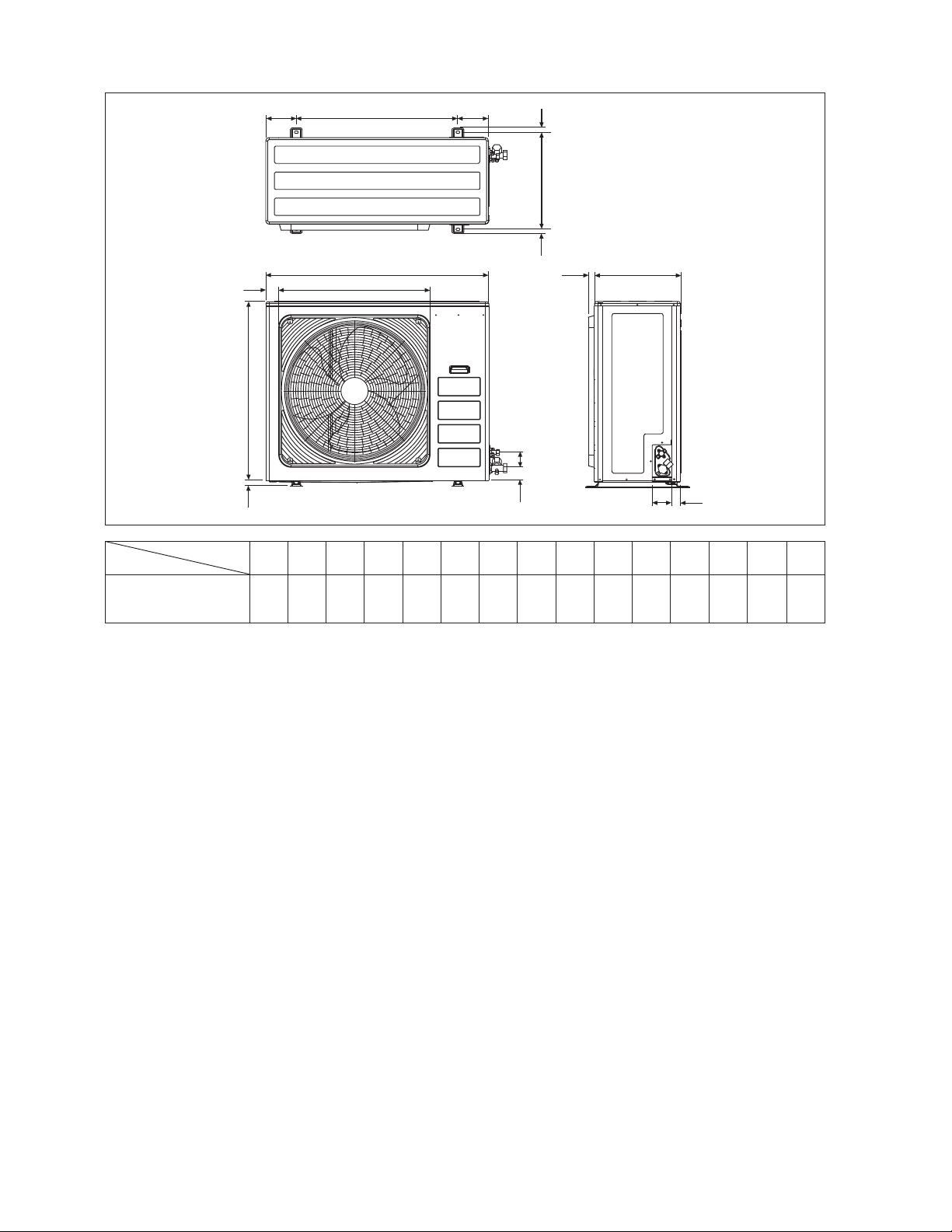

Outdoor Unit

Model

Dimension

RD40JEV1K

RD40JEY1K

RD50JEY1K

IJJ

M

NN

A

K

B

L

D

MADE IN MALAYSIA

EF

O

All dimensions are in mm

C

G

H

ABCDE FGHI J KLMNO

1030 826 400 410 57 72 90 40 746 142 60 26 448 22 28

2

Page 5

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air

conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for

commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

! WARNING ! CAUTION

Installation and maintenance should be performed by

•

qualified persons who are familiar with local code

and regulation, and experienced with this type of

appliance.

All field wiring must be installed in accordance with

•

the national wiring regulation.

Ensure that the rated voltage of the unit corresponds to

•

that of the name plate before commencing wiring work

according to the wiring diagram.

The unit must be GROUNDED to prevent possible

•

hazard due to insulation failure.

All electrical wiring must not touch the refrigerant

•

piping, or any moving parts of the fan motors.

Confirm that the unit has been switched OFF before

•

installing or servicing the unit.

Disconnect from the main power supply before servicing

•

the air conditioner unit.

DO NOT pull out the power cord when the power is

•

ON. This may cause serious electrical shocks which

may result in fire hazards.

•

Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending on

the type and source of the electrical waves, static may

be heard even when more than 1m away}.

Please take note of the following important points when

installing.

Do not install the unit where leakage of flammable

•

gas may occur.

If gas leaks and accumulates around the unit, it

may cause fire ignition.

Ensure that the drainage piping is connected

•

properly.

If the drainage piping is not connected properly,

it may cause water leakage which will dampen

the furniture.

Do not overcharge the unit.

•

This unit is factory pre-charged. Overcharge

will cause over-current or damage to the

compressor.

Ensure that the unit’s panel is closed after service or

•

installation.

Unsecured panels will cause the unit to operate

noisily.

•

Sharp edges and coil surfaces are potential locations

which may cause injury hazards. Avoid from being in

contact with these places.

•

Before turning off the power supply, set the remote

controller’s ON/OFF switch to the “OFF” position to

prevent the nuisance tripping of the unit. If this is not

done, the unit’s fans will start turning automatically when

power resumes, posing a hazard to service personnel or

the user.

•

Do not install the units at or near doorway.

•

Do not operate any heating apparatus too close to the air

conditioner unit or use in room where mineral oil, oil

vapour or oil steam exist, this may cause plastic part to

melt or deform as a result of excessive heat or chemical

reaction.

•

When the unit is used in kitchen, keep flour away from

going into suction of the unit.

•

This unit is not suitable for factory used where cutting oil

mist or iron powder exist or voltage fluctuates greatly.

•

Do not install the units at area like hot spring or oil refinery

plant where sulphide gas exists.

•

Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors respectively.

•

IMPORTANT : DO NOT INSTALL OR USE THE

AIR CONDITIONER UNIT IN A LAUNDRY

ROOM.

•

Don’t use joined and twisted wires for incoming power

supply.

•

The equipment is not intended for use in a potentially

explosive atmosphere.

English

3

Page 6

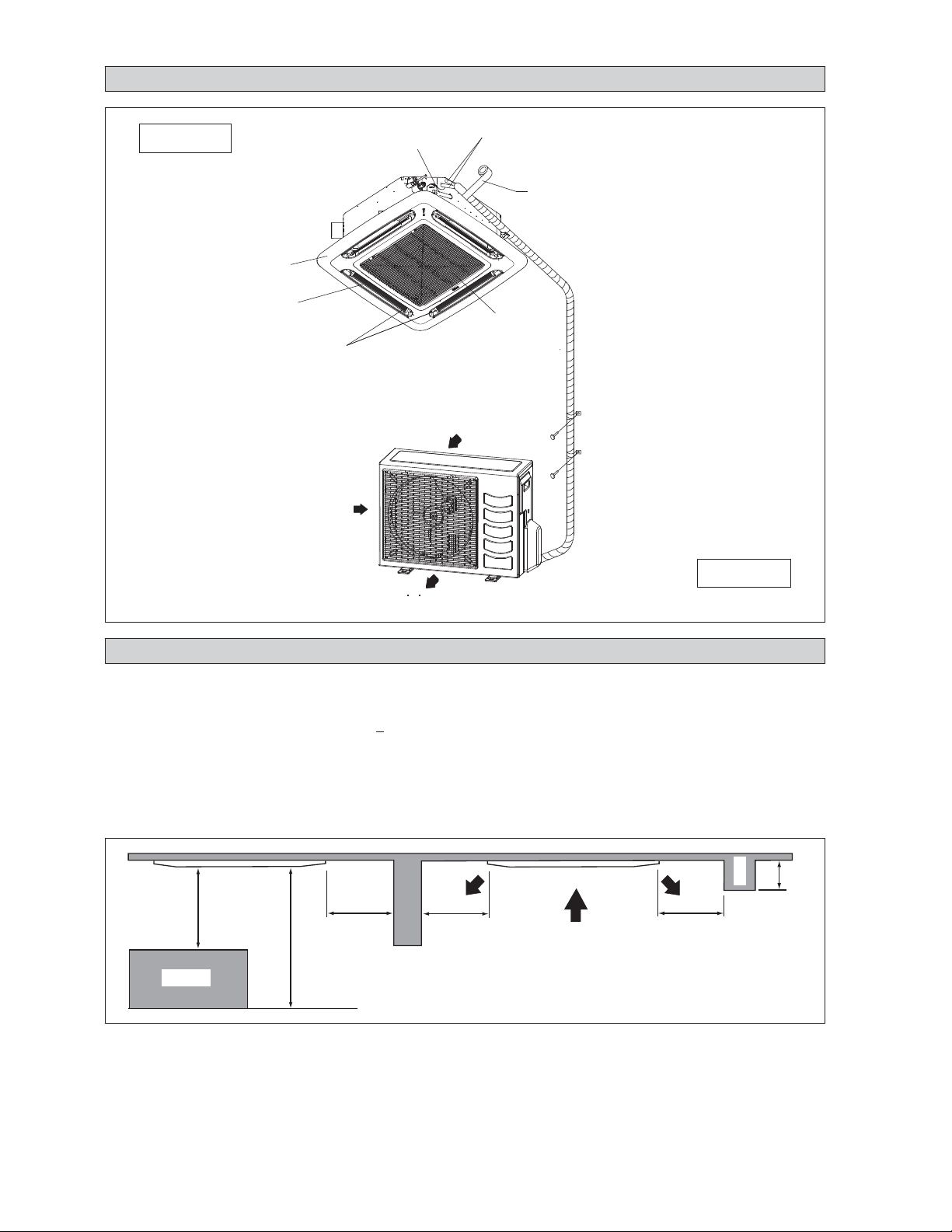

INSTALLATION DIAGRAM

Indoor Unit

Front Panel

Air Filter

(behind the grille)

Air Discharge Louver

Air Intake

Drain Piping

Air Discharge

Thermal Insulation

Wrap the insulated pipe with the

À nishing tape from bottom to top

Air Intake Grille

Air Intake

Outdoor Unit

INSTALLATION OF THE INDOOR UNIT

Preliminary Site Survey

Be sure to read this manual before installing the air-conditioner indoor unit.

•

Voltage supply Á uctuation must not exceed +10% of rated voltage. Electricity supply lines must be independent of

welding transformers which can cause high supply Á uctuation.

•

Ensure that the location is convenient for wiring, piping and drainage.

•

Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

•

Do not move the unit from packaging while moving, until it reaches the installation site. Use safe material or protection

plates when unpacking it or lifting it to avoid damage or scratches to the unit.

Beam

1m or more

Obstacle

0.5m or more 0.5m or more 0.5m or more

3m or more

Floor

0.3m or less

4

Page 7

•

Ensure a location where:

a)

Drainage can be done easily.

b)

Convenient for wiring and piping.

c)

Which have enough space for installation and service work.

d)

Where no risk of flammable gas leakage.

e)

When free from any obstacles in path of cool air discharge and warm air return and must allow spreading of air

throughout the room (near the center of the room).

f)

Must be provided clearance for indoor unit from the wall and obstacles as shown in figure below.

g)

The installation place must be strong enough to support a load 4 times the indoor unit weight to avoid amplifying

noise and vibration.

h)

The installation place (hanging ceiling surface) must be assuring levelness and the height in the ceiling is 350mm or

more.

i)

The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

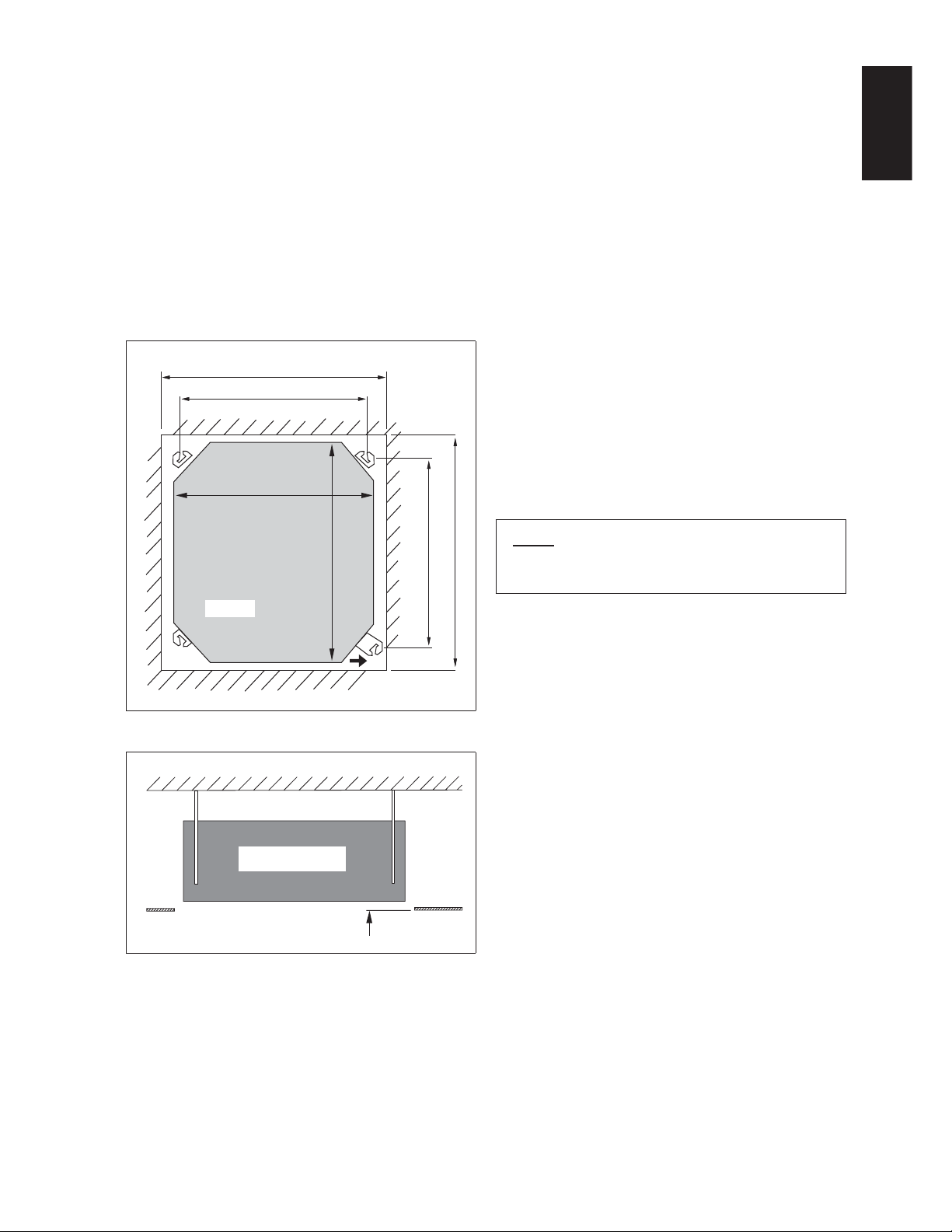

Unit Installation

•

Measure and mark the position for the hanging rod.

Ceiling Opening Site = 890mm

Hanging Rod Site = 790mm

Unit size 820mm

Drill the hole for the angle nut on the ceiling and fix the

hanging rod.

•

The installation template is extended according to

temperature and humidity. Check on dimensions in use.

•

The dimensions of the installation template are the same

as those of the ceiling opening dimensions.

Before ceiling laminating work is completed, be sure to

•

fit the installation template to the indoor unit.

English

Unit Hanging

Unit

Indoor Unit

Unit size 820mm

Hanging rod size = 621mm

Piping Direction

Ceiling

Board

30 mm

NOTE

Be sure to discuss the ceiling drilling work with the

installers concerned.

Ceiling Opening Site = 890mm

•

Confirm the pitch of the hanging rod is 770mm x 622mm

sharp.

•

Hold the unit and hang it on the hanging rod with the nut

and washer.

•

Adjust the unit height to 30mm between the indoor unit

bottom surface and the ceiling surface.

•

Confirm with a level gauge that the unit is installed

horizontally and tighten the nut and bolt to prevent unit

falling and vibration.

•

Open the ceiling board along the outer edge of the paper

installation template.

5

Page 8

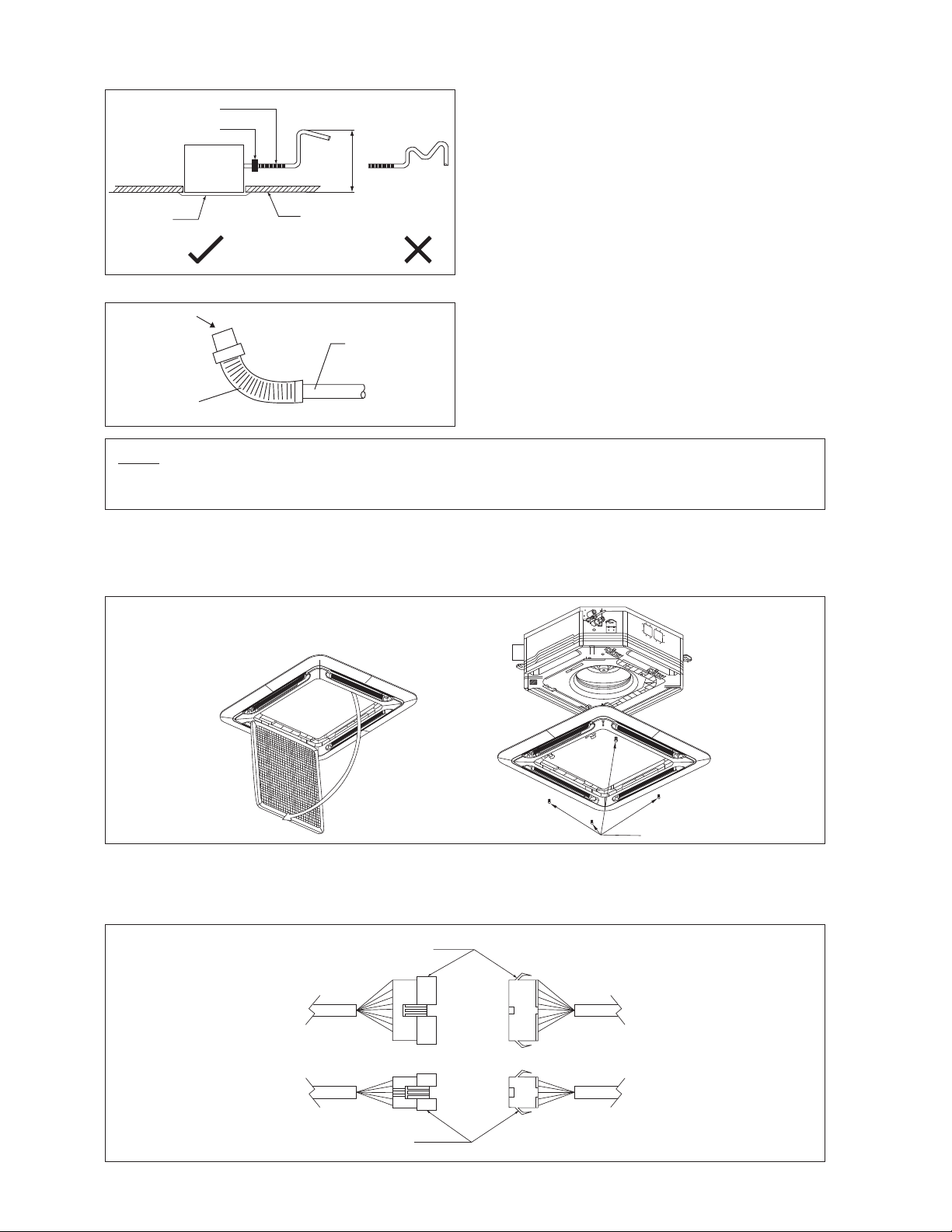

Avoid installing the drain pipe in upward gradient after

Drain Piping Work

Flexible Hose

Pipe Clamp

•

the drain connection.

Ensure the height of drain pipe from ceiling is 700mm or

•

less if it is necessary to increase the height of drain pipe

to prevent water leak.

Avoid installing the drain pipe in up and down slope to

•

prevent reversed water flow.

During the drain pipe connection, be careful not to exert

•

extra force on the drain connector at indoor unit.

The outside diameter of the drain connection at the

•

Panel

Indoor

Unit

700.0mm or less

Ceiling

flexible drain hose is 20mm.

Be sure to execute heat insulation (polyethylene foam

•

with thickness more than 8mm) on the drain piping to

Drain Test

Feed Water

Main Drain Pipe

avoid the condensed water dripping inside the room.

Connect the main drain pipe to the flexible drain hose.

•

Feed water from flexible drain hose to check the piping

•

for leakage.

When the test is completed, connect the flexible drain

•

Flexible Drain Hose

hose to the drain connector on the indoor unit.

NOTE

This Indoor Unit uses a drain pump for condensed water drainage. Install the unit horizontally to prevent water leakage

or condensation around the air outlet.

Panel Installation

The front panel can only be fitted in one direction, follow the piping direction. (Follow piping arrow sticker on front

•

panel)

Be sure to remove the installation template before installing the front panel.

•

Open

Screw

•

Open the air intake grille by pulling back the catchers and removing it together with filter from panel.

•

Install the front frame panel onto the indoor unit by 4 screws and tighten it completely to prevent cool air leakage.

•

Connect the LED wire and air swing wire to the indoor unit.

•

The air swing connector must put inside the control box after connected.

LED Wire

From Front

Panel

From Unit

Control Box

Air Swing Wire

6

Page 9

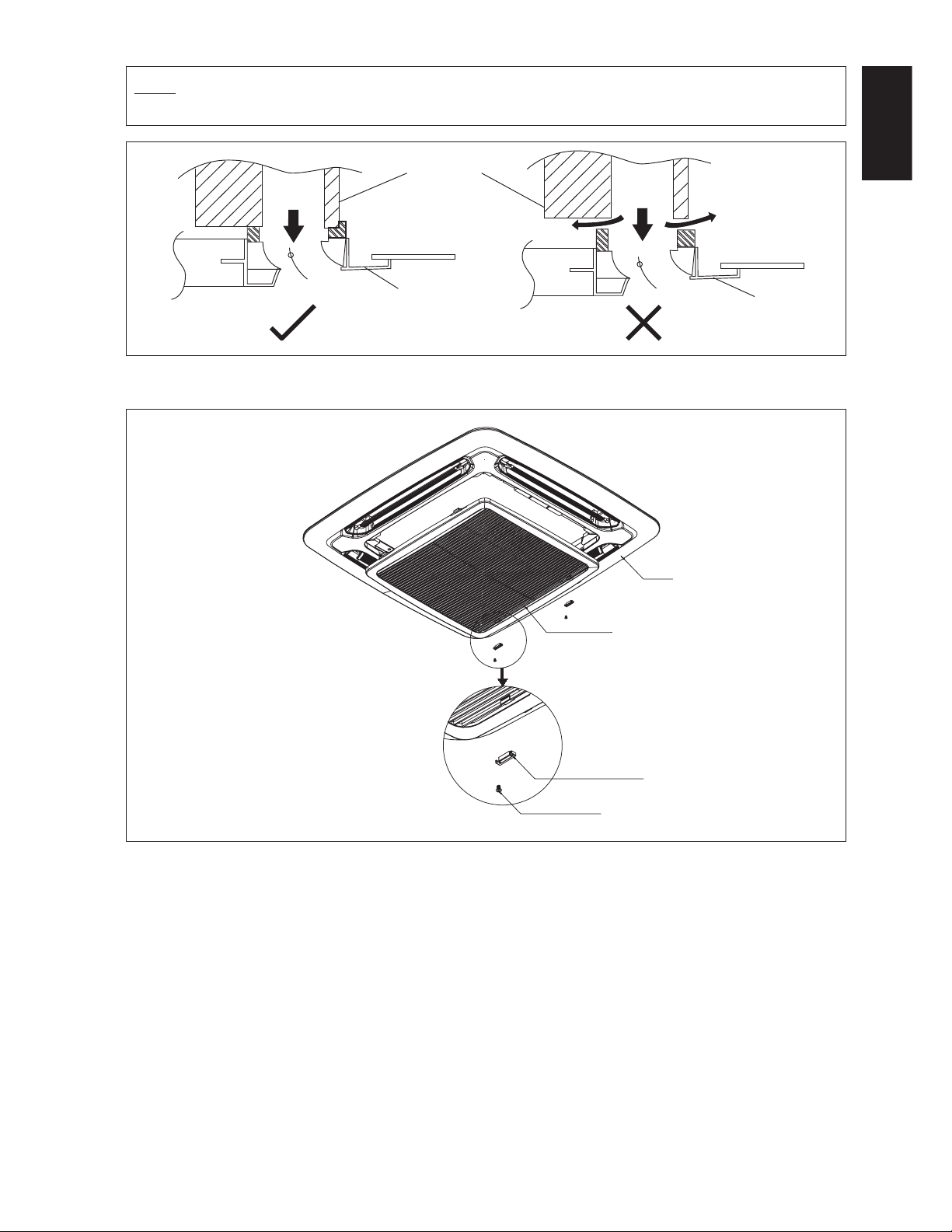

NOTE

Install the front frame panel À rmly to prevent cool air leakage which will cause condensation and water dripping.

Indoor Unit

Cool

Air

Cool

Air

Air Leak

English

Ceiling Board

Air Leak

Panel

Cover Lock Grille (The moving part protection for user direct touching)

Cover lock grille must be installed as the figure below.

Intake Grille

Ceiling Board

Panel

Frame

Cover Lock Grille

(2pcs)

Screw 4 x 6

(2pcs)

If the unit need to be service, steps below shall be followed:

1.

ConÀ rm that the unit had been switched off before servicing the unit.

2.

Use screwdriver to unlock the screw on the cover lock grille.

3.

Remove the cover lock grille and open the intake grille for the service purpose.

4.

Install the intake grille and screw the cover lock grille after service and make sure the unit is proper install.

7

Page 10

Wires Installation

Figure A

Figure A and Figure B shows the location of cover wire in indoor unit.

Steps to install power supply wires and wires from outdoor unit.

1.

Remove wire cover by removing 2 screws as shown in Figure C.

2.

Wires will go through the hole as shown in Figure D and E respectively without crossing the height of the hole.

3.

After that, wire cover will be assembled back to close the wire.

Figure B Figure C

Figure D Figure E

8

Page 11

INSTALLATION OF THE OUTDOOR UNIT

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to achieve maximum

cooling capacity, the location selected for outdoor unit should fulfill the following requirements:

Install the condensing (outdoor) unit in a way such that the hot air distributed by the outdoor condensing unit cannot be drawn

•

in again (as in the case of short circuit of hot discharge air). Allow sufficient space for maintenance around the unit.

Ensure that there is no obstruction of air Á ow into or out of the unit. Remove obstacles which block air intake or

•

discharge.

The location must be well ventilated, so that the unit can draw in and distribute plenty of air thus lowering the condensing

•

temperature.

English

A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

•

A place protected from the direct sunlight. Otherwise use an awning for protection, if necessary.

•

The location must not be susceptible to dust or oil mist.•

! CAUTION

Do not install the unit at altitude over 2000m for both indoor and outdoor.•

9

Page 12

INSTALLATION CLEARANCE

Outdoor units must be installed such that there is no short circuit of the hot discharge air or obstruction to smooth air Á ow.

•

Select the coolest possible place where intake air should not be hotter than the outside temperature (refer to operating

range).

AB

Air

Inlet

Obstacle

All Model

Minimum Distance (mm)

Air

Discharge

Obstacle

ABCD

300 1000 300 500

C

Obstacle

D

MADE IN MALAYSIA

Service

Space

Obstacle

REFRIGERANT PIPING

Allowable Pipe Length and Elevation

If the pipe is too long, both the capacity and reliability of the unit will drop. As the number of bends increases, resistance to

the Á ow of refrigerant system increases, thus lowering cooling capacity. As a result, the compressor may become defective.

Always choose the shortest path and follow the recommendations as tabulated below:

R22 Units

Model

Indoor FHC20JEV1K FHC25JEV1K FHC30JEV1K FHC40JEV1K FHC40JEV1K FHC50JEV1K

Outdoor RD20JEV1K RD25JEV1K RD30JEV1K RD40JEV1K RD40JEY1K RD50JEY1K

Max. allowable length, m 40 40 5050 50 45

Max. allowable elevation, m 20 20 30 30 30 25

Liquid pipe size, mm/(in) 6.35

(1/4")

Gas pipe size, mm/(in) 15.88

(5/8")

9.52

(3/8")

15.88

(5/8")

9.52

(3/8")

15.88

(5/8")

9.52

(3/8")

19.05

(3/4")

9.52

(3/8")

19.05

(3/4")

9.52

(3/8")

19.05

(3/4")

NOTE

Be sure to add the proper amount of additional refrigerant, failure to do so may result in reduced performance.

Remark: The refrigerant pre-charged in the outdoor unit is for the piping length up to 7.5m.

10

Page 13

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If any pipings, evaporator or condenser had been exposed or had been

•

opened for 15 seconds or more, the system must be vacuumed. Generally, do not remove plastic, rubber plugs and brass

nuts from the valves, fittings, tubings and coils until it is ready to connect suction or liquid line into valves or fittings.

If any brazing work is required, ensure that the nitrogen gas is passed through coil and joints while the brazing work is

•

being done. This will eliminate soot formation on the inside walls of the copper tubings.

Cut the pipe stage by stage, advancing the blade of the pipe cutter slowly. Extra force and deep cut will cause more distortion

•

on the pipe and thus extra burr. See Figure I.

Remove burrs from cut edges of the pipes with remover

•

as shown in Figure II. This will avoid unevenness on the

flare faces which will cause gas leak. Hold the pipe on

top position and burr remover at lower position to prevent

metal chips from entering the pipe.

Insert the flare nuts, mounted on the connection parts

•

Figure I

Cutting Copper Tube

1/4t

of both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface

•

Figure II

of the swaging block is determined by the flaring tool.

Refer Figure III.

Fix the pipe firmly on the flare die. Match the centers of

•

Remove Burr

both the flare die and the flaring punch, and then tighten

the flaring punch fully.

Piping Connection To The Units

Align the center of the piping and tighten the flare nut

•

sufficiently with fingers. Refer Figure IV.

Finally, tighten the flare nut with the torque wrench until

•

the wrench clicks.

When tightening the flare nut with the torque wrench,

•

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe connection are insulated by closed

•

cell polyurethane.

Pipe Size (mm/in) Torque, Nm/(ft-lb)

6.35 (1/4") 18 (13.3)

9.52 (3/8") 42 (31.0)

12.70 (1/2") 55 (40.6)

15.88 (5/8") 65 (48.0)

19.05 (3/4") 78 (57.6)

Figure III

Swaging Block

Figure IV

Copper Tube

Flare Joint

Indoor Piping

D

A

Flared Tube

Flare Nut

English

Ø Tube, D A (mm)

Inch mm

Imperial

(Wing-nut Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Rigid

(Clutch Type)

11

Spanar

Torque Wrench

Page 14

ELECTRICAL WIRING CONNECTION

IMPORTANT :

* These values are for information only. They should be checked and selected to comply with local and/or

national codes and regulations. They are also subject to the type of installation and size of conductors.

** The appropriate voltage range should be checked with data label on the unit.

FHC20JEV1K - RD20JEV1K

FHC25JEV1K - RD25JEV1K

COMP

L1

Outdoor Unit

Terminal Block

N1

L

N

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Indoor Unit

Terminal Block

COMP

L

N

Interconnection Cable

Power Supply

Cable

Model Indoor FHC20JEV1K FHC25JEV1K

Outdoor RD20JEV1K RD25JEV1K

Voltage range** Indoor

Outdoor

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

220-240V/1Ph/50Hz + !

220-240V/1Ph/50Hz + !

2.5

3

1.0

4

4

3

1.0

4

Recommended time delay fuse* A 20 25

FHC30JEV1K - RD30JEV1K

Indoor Unit

Terminal Block

COMP

L

N

Interconnection Cable

Power Supply Cable

Outdoor Unit

COMP

Terminal Block

L

N

L

N

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor FHC30JEV1K

Outdoor RD30JEV1K

Voltage range** Indoor

Outdoor

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

220-240V/1Ph/50Hz + !

220-240V/1Ph/50Hz + !

4

3

2.5

4

Recommended time delay fuse* A 30

12

Page 15

FHC40JEV1K - RD40JEV1K

L

N

S

R

Outdoor Unit

COMP

Terminal Block

L

N

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Indoor Unit

Terminal Block

Power Supply Cable

COMP

L

N

Interconnection Cable

Model Indoor FHC40JEV1K

Outdoor RD40JEV1K

Voltage range** Indoor

Outdoor

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

220-240V/1Ph/50Hz + !

220-240V/1Ph/50Hz + !

4.0

3

2.5

4

Recommended time delay fuse* A 35

FHC40JEV1K - RD40JEY1K

English

Interconnection Cable

Power Supply Cable

COMP

L

N

Outdoor Unit

Terminal Block

R

S

T

N

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Indoor Unit

Terminal Block

COMP

L

N

Model Indoor FHC40JEV1K

Outdoor RD40JEY1K

Voltage range** Indoor

Outdoor

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

220-240V/1Ph/50Hz + !

308-415V/3N~/50Hz + !

2.5

5

2.5

4

Recommended time delay fuse* A 15

13

Page 16

FHC50JEV1K - RD50JEY1K

Indoor Unit

Terminal Block

COMP

L

N

Interconnection Cable

Power Supply Cable

Outdoor Unit

COMP

Terminal Block

L

N

R

S

T

N

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor FHC50JEV1K

Outdoor RD50JEY1K

Voltage range** Indoor

Outdoor

Power supply cable size* mm

Number of conductors

Interconnection cable size* mm

Number of conductors

2

2

220-240V/1Ph/50Hz + !

308-415V/3N~/50Hz + !

2.5

5

2.5

4

Recommended time delay fuse* A 16

•

All wires must be firmly connected.

•

Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

•

The connecting wire between the indoor unit and the outdoor unit must be clamped on the wire clamps.

•

The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

•

Make sure no external pressure is applied to the terminal connectors and wires.

•

Make sure all the covers are properly fixed to avoid any gap.

•

Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

Attach insulation sleeve

Round crimp-style terminal

Use the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

•

Over tightening can damage the terminal screw.

•

Do not connect wire of different gauge to same terminal.

•

Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

•

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Electric wire

Do not connect wires

of different gauges.

14

Page 17

VACUUMING AND CHARGING

Vacuuming is necessary to eliminate all moisture and air from the system. The series II Outdoor Unit is provided with flare

valve fittings.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with refrigerant,

Allen key

Flare nut

Refrigerant Piping

the indoor unit and the refrigerant connection pipes must be

air-purged because the air containing moisture that remains in the

refrigerant cycle may cause malfunction of the compressor.

Remove the caps from the valve and the service port.

•

Connect the center of the charging gauge to the vacuum

•

pump.

Connect the charging gauge to the service port of the 3-way

•

Service Port

Outdoor Unit 3 ways valve

valve.

Start the vacuum pump. Evacuate for approximately 30

•

minutes. The evacuation time varies with different vacuum

pump capacity. Confirm that the charging gauge needle has

LOW PRESSURE GAUGE

-760mmHg

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

moved towards -760mmHg.

Caution

•

If the gauge needle does not move to -760mmHg, be sure to

check for gas leaks (using the refrigerant detector) at flare type

connection of the indoor and outdoor unit and repair the leak

before proceeding to the next step.

•

Close the valve of the changing gauge and stop the vacuum

pump.

•

On the outdoor unit, open the suction valve (3 way) and liquid

valve (2 way) (in anti-clockwise direction) with 4mm key for

hexagon sacked screw.

HANDLE LO

CHARGE HOSE

LIQUID VALVE

GAS VALVE

(3-WAY)

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

VACUUM PUMP

ADAPTER FOR

COUNTER FLOW

PREVENTION

CHECK VALVE

CONFIGURATION OF AIR

PURGE BY CHARGING

Charge Operation

This operation must be done by using a gas cylinder and a precise

weighing machine. The additional charge is topped-up into the

outdoor unit using the suction valve via the service port.

•

Remove the service port cap.

•

Connect the low pressure side of the charging gauge to the

suction service port center of the cylinder tank and close the

high pressure side of the gauge. Purge the air from the service

hose.

•

Start the air conditioner unit.

•

Open the gas cylinder and low pressure charging valve.

•

When the required refrigerant quantity is pumped into the unit,

close the low pressure side and the gas cylinder valve.

•

Disconnect the service hose from service port. Put back the

service port cap.

LOW PRESSURE GAUGE

-760mmHg

HANDLE LO

CHARGE HOSE

LIQUID VALVE

GAS VALVE

(3-WAY)

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

CHECK VALVE

CONFIGURATION OF AIR

PURGE BY CHARGING

English

ADDITIONAL CHARGE

The refrigerant is pre-charge in the outdoor unit. If the piping length is less than 7.5m, then additional charge after

vacuuming is not necessary. If the piping length is more than 7.5m then use the additional charge value as indicated in the

table.

Additional refrigerant charge [g] per additional 1m length as tabulated

Cooling only

Model

Additional charge [g/m] 19 38 55 65 65 54

Example:

FHC25JEV1K & RD25HEV1K with 13m piping length, additional piping length is 5.5m. Thus,

Additional charge = 5.5[m] x 38[g/m]

= 209[g]

Indoor FHC20JEV1K FHC25JEV1K FHC30JEV1K FHC40JEV1K FHC40JEV1K FHC50JEV1K

Outdoor RD20JEV1K RD25JEV1K RD30JEV1K RD40JEV1K RD40JEY1K RD50JEV1K

15

Page 18

SPECIAL PRECAUTIONS WHEN CHARGING UNIT WITH SCROLL COMPRESSORS

These precautions are intended for use with Scroll compressors only with R22 refrigerants but are not applied to others

competitive Scroll compressors.

Scroll compressors have a very high volumetric efficiency and quickly pump a deep vacuum if there is insufficient refrigerant

in the system or if refrigerant is added too slowly. Operation with low suction pressure will quickly lead to very high discharge

temperatures. While this process is happening, the scrolls are not being well lubricated – scrolls depend on the oil mist in the

refrigerant for lubrication. A lack of lubrication leads to high friction between the scroll flanks and tips and generates additional

heat. The combination of heat of compression and heat from increased friction is concentrated in a small localized discharge

area where temperatures can quickly rise to more than 300ÝC. These extreme temperatures damage the Scroll spirals and the

orbiting Scroll bearing. This damage can occur in less than one minute especially on larger compressors. Failure may occur

in the first few hours or the damage done during field charging may show up some time later.

Other typical field charging problems include undercharging, overcharging, moisture or air in the system etc. In time each

one of these problems can cause compressor failure.

Minimal equipment is required for field charging. The minimum equipment required to do a satisfactory job is:-

Set of service gauges1. Vacuum gauge4.

Hoses2. Scales5.

Vacuum pump3. Thermometer6.

The proper refrigerant charge should follow the volume as recommended by manufacturer and recommendation should be

followed by the installer.

Charging procedures – Single phase compressors

1.

Evacuate the system to -760mmHg. To reduce evacuation time, use short, large diameter hoses and connect to unrestricted

service ports on the system. Quality of vacuum cannot be determined by time – a reliable vacuum gauge must be used.

(etc. electronic vacuum gauge)

Turn the refrigerant cylinder upside down, purge the charging hose and charge liquid through the liquid line charging port

until refrigerant no longer Á ows or until the correct charge has been weighed in. If additional charge is required start the

system and slowly bleed liquid into the suction side until the system is full.

It recommends charging liquid in a CONTROLLED manner into the suction side until the system is full.

This recommendation does not hold true for reciprocating compressors where liquid charging into the suction side could

cause severe damage.

Carefully monitor the suction and discharge pressures – ensure that the suction pressure does not fall below 25 psig (1.7 bar)

at any time during the charging process.

Dip-pipe

Invert cylinder

without dip-pipe

Liquid withdrawal

! CAUTION

Manifold Gauge will show cylinder pressure rather than suction pressure if the cylinder valve and Manifold

•

valve “A” are both open.

There are many ways of charging liquid in a “controlled manner” into the

suction side:-

Use valve A on the manifold gauge set

1.

Use the valve on the refrigerant cylinder

2.

Charge through a Shredder valve

3.

Use a hose with a Shredder valve depressor

4.

Charge into the suction side at some distance from the compressor

A

5.

All of the above

6.

16

Page 19

Charging procedures – Three phase compressors

2.

The fundamental procedure is the same as for single phase models but the compressor can run in the wrong direction on

starting.

If this happens reverse any two phases and start again. Short term reverse rotation will not damage the compressor.

All Specter compressors have internal discharge temperature protectors which are very effective in preventing dangerously

high discharge temperatures during charging. The protection module will trip and lock the compressor out for 30 minutes.

It is not normally necessary to wait 30 minutes for the module to reset. When the compressor has cooled down the module

can be reset by breaking the power supply to the control circuit. Very often the serviceman does not understand why the

module tripped and uses a jumper wire to bypass it. He continues to charge the system and removes the jumper when

charging is complete. The compressor may or may not run with the protector back in the circuit but it is certain that the

compressor has been damaged and premature failure is inevitable.

OPTIONAL FUNCTIONS

Short Duct SpeciÀ cation

The indoor unit is provided with air discharge and air intake “knock-out” hole for duct connection. However the connection

•

of the short duct for air discharge is possible on only one side.

The use of short duct for air discharge will improve airflow distribution if there is an obstruction (such as a lighting fixture)

•

or in a long, narrow room or an L-shaped room. It also use for air conditioning of two rooms simultaneously.

Possible Direction For Air Discharge And Air Intake

Air DischargeAir Discharge

Possible Opening Dimension For Duct Connection

50 50 50 50 50 10

10

90

207020

PCD Ø140

Ø100

English

115 20 115

Air Discharge Air Discharge

Air Intake

Air Discharge Knock Out Hole Air Intake Knock

Out Hole

NOTE

Avoid using the short duct on which the air discharge grille can be completely closed, to prevent evaporator

•

freezing.

In order to prevent condensation forming, be sure that there is sufficient thermal insulation and no leakage of cool air

•

when installing the short duct.

Keep the introduction of fresh air intake within 20% of total air Á ow. Also provide a chamber and use a booster fan.

•

Sealing Material

It is possible to seal one of the four air discharge outlet. (sealing two or more air discharge outlet could cause a

•

malfunction)

Remove the front panel and insert the sealing material into the air discharge outlet on the indoor unit to seal the air

•

outlet.

The sealing material is the same length as the longer air discharge outlet. If it is desired to seal the shorter air discharge

•

outlet, cut the sealing material to shorten it.

•

Push the sealing material in about 10mm beyond the bottom surface of the indoor unit so that it does not touch the air

louver. Be sure not to push the sealing material in any farther than about 10mm.

17

Page 20

INDICATOR LIGHTS

FAULT DIAGNOSIS

Wireless Controller

When there is infrared remote control operating signal, the signal receiver on indoor unit will make a <beep> for signal

acceptance conÀ rmation.

Wired Controller

If there is any abnormal condition detected, wired controller will blink the error code.

Event Power LED Timer LED Other LEDs Error Code

1. Room Sensor Open or Short Blink 1 time - Blink Fan Blink E1

2. Indoor Coil Sensor Open Blink 2 times - Blink Sleep Blink E2

3. Outdoor Coil Sensor Open Blink 3 times - Blink Dry Blink E3

4. Compressor Overload /

Indoor Coil Sensor Short /

Outdoor Coil Sensor Short

5. Low Refrigerant Charge/Gas Leak/Outdoor

Abnormal

6. Water Pump Fault - Blink 2 times Blink Cool & Fan Blink E6

7. Outdoor Coil Sensor Exist (MS model) - Blink 5 times Blink Cool & Heat Blink E7

8. Hardware Error (tact switch pin short) - Blink 6 times Blink Heat, Cool,

- Blink 1 time Blink Cool Blink E4

- Blink 3 times Blink Cool & Dry Blink E5

Blink E8

follow by Fan, Dry

NOTE

Power LED = Cool/Dry/Fan LED, turns on in these modes

The unit will not detect sensor missing when the compressor is ON

Call your dealer immediately when this error happen

OPERATING RANGE

COOLING

Outdoor

DB (°C)

54

52

19

14

19 23 Indoor WB (°C)

DB = Dry Bulb WB = Wet Bulb

18

Page 21

OVERALL CHECKING

Ensure that:

•

The unit has been mounted solidly and rigid in

1)

position.

The piping and connections are leak-proof after the

2)

charging.

3)

Proper wiring has been installed.

•

Drainage check

– pour some water into the left side of the drain pan (the

drainage is at the right side of the unit).

•

Test run:

1)

Conduct a test run on the unit after having perform the

water drainage test and the gas leakage test.

2)

Check the following items:

a)

Is the electrical plug inserted firmly into the socket?

b)

there any abnormal sounds from the unit?

Is

c)

Is there any abnormal vibrations on the unit or the

piping?

he drainage of water smooth?

d)

Is t

Confirm that:

•

The condenser fan is running. Check the warm air

1)

blowing from the condensing unit.

The evaporator blower is running and discharge cool

2)

air.

The suction (low side) pressure is as recommended.

3)

The remote controller incorporates a 3-minute delay

4)

protection in the circuit, whereby the outdoor condensing

unit requires about 3 minutes delay before it can start

operating.

PHASE PROTECTOR (OPTIONAL)

The unit with Scroll Compressor can only rotate in one direction. For this reason, a protective device (phase protector) is fitted

to prevent incorrect wiring of the electrical phases. When the three phases are not connected correctly, the phase protector

operates, and the unit will not start. This device is located in the control box of the outdoor unit.

The following table shows the LED indicator light for phase protector under normal operation and fault conditions.

English

Description

Normal operation

Reverse phase

T phase missing

S phase missing

R phase missing

S &T phase missing

Overload

Sensor missing

ON

LED

+

+

PW

(Red)

P_R

(Yellow)

P_S

(Yellow)

P_T

(Yellow)

Actions

-

Switch off the unit. Check the 3 phase wiring.

Switch off the unit. Check the 3 phase wiring.

Switch off the unit. Check the 3 phase wiring.

Switch off the unit. Check the 3 phase wiring.

+

Switch off the unit. Check the 3 phase wiring.

High discharge temperature. Check the refrigerant system.

Switch off the unit. Plug in sensor.

OFF

Fast Blink

NOTE

1. “+” indicates additional functions for PP01 phase protector.

2. When R phase missing, no LED or buzzer will indicate the error, but relay 71 and relay 81 will cut off.

19

Page 22

SERVICE AND MAINTENANCE

Service Parts Maintenance Procedures Period

Indoor Air Filter Remove any dust adhering to the À lter by using a vacuum cleaner

1.

or wash in lukewarm water (below 40°C) with a neutral cleaning

detergent.

Rinse the À lter well and dry before placing it back onto the unit.

2.

Do not use gasoline, volatile substances or chemicals to clean the À lter.

3.

At least every

2 week.

More frequently

if necessary.

Indoor Unit Clean any dirt or dust on the grille or panel by wiping it with a soft

Indoor Fan Check for any abnormal noise.1. When necessary

1.

cloth soaked in lukewarm water (below 40°C) and a neutral detergent

solution.

Do not use gasoline, volatile substances or chemicals to clean the indoor

2.

unit.

At least every

2 week.

More frequently

if necessary.

! CAUTION

Avoid direct contact of any coil treatment cleaners on plastic part. This may cause plastic part to deform

•

as a result of chemical reaction.

TROUBLESHOOTING

For any enquiries on spare parts, please contact your authorized dealer. If any malfunction of the air

conditioner unit is noted, immediately switch off the power supply to the unit. Check the following fault

conditions and causes for some simple troubleshooting tips.

Fault Causes / Action

The compressor does not start operate after 3 minutes

1. Protection against frequent starting. Wait for 3 to 4

from starting the air conditioner unit.

The air conditioner unit does not operate.2. Power failure, or the fuse need to be replaced.

minutes for the compressor to start operating.

-

-

The power plug is disconnected.

-

It is possible that your delay timer has been set

incorrectly.

The air flow is too low.3. The air filter is dirty.

Discharge air flow has bad odor.4. Odors may be caused by cigarettes, smoke particles,

Condensation on the front air grille of the indoor unit.5. This is caused by air humidity after an extended long

Water flowing out from the air conditioner unit.6. Switch off unit and call local dealer/serviceman.-

-

-

The air suction and discharge are clogged.

-

The regulated temperature is not high enough (applicable

for auto fan mode only).

perfume etc. which might have adhered onto the coil.

period of operation.

-

The set temperature is too low, increase the temperature

setting and operate the unit at high fan speed.

If the fault persists, please call your local dealer / serviceman.

20

Page 23

Page 24

In the event that there is any conflict in the interpretation of this manual and any translation of the same in any language,

•

the English version of this manual shall prevail.

The manufacturer reserves the right to revise any of the specification and design contain herein at any time without prior

•

notification.

P.O.Box 18674, Galleries 4, 11th Floor,

Downtown Jebel Ali, Dubai, UAE.

Zandvoordestraat 300, B-8400 Oostende,

Belgium

Loading...

Loading...