INSTALLATION AND

OPERATION MANUAL

Packaged air-cooled water chillers

EUWAC5FBZW1

EUWAC8FBZW1

EUWAC10FBZW1

1

R

Q

D

M

N

15

G

F

E

H

12

O

P

J

K

I

L

L

27

B

A

C

A B C D E F G H I J K L M N O P Q R

EUWAC5FZ (mm) 243 311 243 1345 343 125 765 71 58 629 108 25 796 605 735 578 600 795

133

11

1

9

8

6

52

3

5

466

4

110

10712

7 2

1

2

EUWAC8FZ (mm) 163 800 162 1290 267 98 815 71 60 951 111 25 1125 605 288 975 600 1122

EUWAC10FZ (mm) 170 936 169 1395 292 127 857 71 60 1101 111 25 1275 605 286 1083 600 1272

2

3

500

800

200

250

3

200

CE - ATITIKTIES-DEKLARACIJA

CE - ATBILSTĪBAS-DEKLARĀCIJA

CE - VYHLÁSENIE-ZHODY

CE - UYUMLULUK-BİLDİRİSİ

CE - IZJAVA O SKLADNOSTI

CE - VASTAVUSDEKLARATSIOON

CE - ДЕКЛАРАЦИЯ-ЗА-СЪОТВЕТСТВИЕ

19 Direktive z vsemi spremembami.

20 Direktiivid koos muudatustega.

21 Директиви, с техните изменения.

22 Direktyvose su papildymais.

23 Direktīvās un to papildinājumos.

24 Smernice, v platnom znení.

25 Değiştirilmiş halleriyle Yönetmelikler.

Direktiivejä, sellaisina kuin ne ovat muutettuina.

10 Direktiver, med senere ændringer.

11 Direktiv, med företagna ändringar.

irányelv(ek) és módosításaik rendelkezéseit.

12 Direktiver, med foretatte endringer.

13

14 v platném znění.

15 Smjernice, kako je izmijenjeno.

16

17 z późniejszymi poprawkami.

18 Directivelor, cu amendamentele respective.

положително от <B> съгласно

<A> DAIKIN.TCF.003E1/04-2010

<B> KEMA (NB0344)

<C> 59276-KRQ/ECM95-4230

Daikin Europe N.V. je pooblaščen za sestavo datoteke s tehnično mapo.

Daikin Europe N.V. on volitatud koostama tehnilist dokumentatsiooni.

Daikin Europe N.V. е оторизирана да състави Акта за техническа конструкция.

Daikin Europe N.V. yra įgaliota sudaryti šį techninės konstrukcijos failą.

Daikin Europe N.V. ir autorizēts sastādīt tehnisko dokumentāciju.

Spoločnosť Daikin Europe N.V. je oprávnená vytvoriť súbor technickej konštrukcie.

**

21

**

22

**

23

**

24

Daikin Europe N.V. Teknik Yapı Dosyasını derlemeye yetkilidir.

**

25

**

**

20

19

súlade s osvedčením <C>.

<A>‘da belirtildiği gibi ve <C> Sertifikasına

göre <B> tarafından olumlu olarak

vērtējumam saskaņā ar sertifikātu <C>.

pagal Sertifikatą <C>.

Cертификата <C>.

değerlendirildiği gibi.

deklaruje na własną i wyłączną odpowiedzialność, że modele klimatyzatorów, których dotyczy niniejsza deklaracja:

declară pe proprie răspundere că aparatele de aer condiţionat la care se referă această declaraţie:

z vso odgovornostjo izjavlja, da so modeli klimatskih naprav, na katere se izjava nanaša:

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluvad kliimaseadmete mudelid:

m

r

o

x

18

19

20

17

CE - IZJAVA-O-USKLAĐENOSTI

CE - MEGFELELŐSÉGI-NYILATKOZAT

CE - DEKLARACJA-ZGODNOŚCI

CE - DECLARAŢIE-DE-CONFORMITATE

CE - ERKLÆRING OM-SAMSVAR

CE - ILMOITUS-YHDENMUKAISUUDESTA

CE - PROHLÁŠENÍ-O-SHODĚ

заявляет, исключительно под свою ответственность, что модели кондиционеров воздуха, к которым относится настоящее заявление:

erklærer under eneansvar, at klimaanlægmodellerne, som denne deklaration vedrører:

deklarerar i egenskap av huvudansvarig, att luftkonditioneringsmodellerna som berörs av denna deklaration innebär att:

erklærer et fullstendig ansvar for at de luftkondisjoneringsmodeller som berøres av denne deklarasjon innebærer at:

u

q

s

n

11

12

09

10

декларира на своя отговорност, че моделите климатична инсталация, за които се отнася тази декларация:

b

21

tamamen kendi sorumluluğunda olmak üzere bu bildirinin ilgili olduğu klima modellerinin aşağıdaki gibi olduğunu beyan eder:

visiška savo atsakomybe skelbia, kad oro kondicionavimo prietaisų modeliai, kuriems yra taikoma ši deklaracija:

ar pilnu atbildību apliecina, ka tālāk uzskaitīto modeĮu gaisa kondicionētāji, uz kuriem attiecas šī deklarācija:

vyhlasuje na vlastnú zodpovednosť, že tieto klimatizačné modely, na ktoré sa vzťahuje toto vyhlásenie:

w

t

v

k

22

23

24

25

instrukcjami:

conformitate cu instrucţiunile noastre

инструкции:

16 megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat előírás szerint használják:

17 spełniają wymogi następujących norm i innych dokumentów normalizacyjnych, pod warunkiem że używane są zgodnie z naszymi

18 sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiţia ca acestea să fie utilizate în

19 skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z našimi navodili:

20 on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:

21 съответстват на следните стандарти или други нормативни документи, при условие, че се използват съгласно нашите

s našim návodom:

22 atitinka žemiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mūsų nurodymus:

23 tad, ja lietoti atbilstoši ražotāja norādījumiem, atbilst sekojošiem standartiem un citiem normatīviem dokumentiem:

24 sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, že sa používajú v súlade

25 ürünün, talimatlarımıza göre kullanılması koşuluyla aşağıdaki standartlar ve norm belirten belgelerle uyumludur:

01 Directives, as amended.

02 Direktiven, gemäß Änderung.

03 Directives, telles que modifiées.

04 Richtlijnen, zoals geamendeerd.

05 Directivas, según lo enmendado.

06 Direttive, come da modifica.

*

**

21 Забележка * както е изложено в <A> и оценено

07 √‰ËÁÈÒv, fiˆ˜ ¤¯Ô˘Ó ÙÚÔÔÔÈËı›.

08 Directivas, conforme alteração em.

09 Директив со всеми поправками.

a(z) <C> tanúsítvány szerint.

16 Megjegyzés * a(z) <A> alapján, a(z) <B> igazolta a megfelelést,

Machinery 2006/42/EC

Electromagnetic Compatibility 2004/108/EC

Certifikatet <C>.

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat ilmastointilaitteiden mallit:

prohlašuje ve své plné odpovědnosti, že modely klimatizace, k nimž se toto prohlášení vztahuje:

izjavljuje pod isključivo vlastitom odgovornošću da su modeli klima uređaja na koje se ova izjava odnosi:

teljes felelőssége tudatában kijelenti, hogy a klímaberendezés modellek, melyekre e nyilatkozat vonatkozik:

j

c

y

h

13

14

15

16

acordo com as nossas instruções:

инструкциям:

instrukser:

förutsättning att användning sker i överensstämmelse med våra instruktioner:

disse brukes i henhold til våre instrukser:

08 estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) nor mativo(s), desde que estes sejam utilizados de

09 соответствуют следующим стандартам или другим нормативным документам, при условии их использования согласно нашим

10 overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore

11 respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under

mukaisesti:

12 respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at

13 vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme

14 za předpokladu, že jsou využívány v souladu s našimi pokyny, odpovídají následujícím normám nebo normativním dokumentům:

15 u skladu sa slijedećim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s našim uputama:

11 Information * enligt <A> och godkänts av <B> enligt

24 Poznámka * ako bolo uvedené v <A> a pozitívne zistené <B> v

23 Piezīmes * kā norādīts <A> un atbilstoši <B> pozitīvajam

22 Pastaba * kaip nustatyta <A> ir kaip teigiamai nuspręsta <B>

<B> i Świadectwem <C>.

de <B> în conformitate cu Certificatul <C>.

skladu s certifikatom <C>.

17 Uwaga * zgodnie z dokumentacją <A>, pozytywną opinią

18 Notă * aşa cum este stabilit în <A> şi apreciat pozitiv

19 Opomba * kot je določeno v <A> in odobreno s strani <B> v

20 Märkus * nagu on näidatud dokumendis <A> ja heaks

bedømmelse av <B> ifølge Sertifikat <C>.

hyväksynyt Sertifikaatin <C> mukaisesti.

souladu s osvědčením <C>.

12 Merk * som det fremkommer i <A> og gjennom positiv

13 Huom * jotka on esitetty asiakirjassa <A> ja jotka <B> on

14 Poznámka * jak bylo uvedeno v <A> a pozitivně zjištěno <B> v

15 Napomena * kako je izloženo u <A> i pozitivno ocijenjeno od

*

Not

25

kiidetud <B> järgi vastavalt sertifikaadile <C>.

strane <B> prema Certifikatu <C>.

Daikin Europe N.V. on valtuutettu laatimaan Teknisen asiakirjan.

Společnost Daikin Europe N.V. má oprávnění ke kompilaci souboru technické konstrukce.

Daikin Europe N.V. je ovlašten za izradu Datoteke o tehničkoj konstrukciji.

A Daikin Europe N.V. jogosult a műszaki konstrukciós dokumentáció összeállítására.

Daikin Europe N.V. ma upoważnienie do zbierania i opracowywania dokumentacji konstrukcyjnej.

**

13

Daikin Europe N.V. este autorizat să compileze Dosarul tehnic de construcţie.

**

**

**

**

**

14

15

16

17

18

Jean-Pierre Beuselinck

General Manager

Ostend, 1st of July 2010

CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE

CE - DECLARAÇÃO-DE-CONFORMIDADE

СЕ - ЗАЯВЛЕНИЕ-О-СООТВЕТСТВИИ

CE - OPFYLDELSESERKLÆRING

CE - DECLARACION-DE-CONFORMIDAD

CE - DICHIARAZIONE-DI-CONFORMITA

CE - ¢H§ø™H ™YMMOPºø™H™

declares under its sole responsibility that the air conditioning models to which this declaration relates:

CE - DECLARATION-OF-CONFORMITY

CE - KONFORMITÄTSERKLÄRUNG

a

CE - DECLARATION-DE-CONFORMITE

CE - CONFORMITEITSVERKLARING

Daikin Europe N.V.

01

declaración:

referencia la

erklärt auf seine alleinige Verantwortung daß die Modelle der Klimageräte für die diese Erklärung bestimmt ist:

déclare sous sa seule responsabilité que les appareils d'air conditionné visés par la présente déclaration:

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de airconditioning units waarop deze verklaring betrekking heeft:

declara baja su única responsabilidad que los modelos de aire acondicionado a los cuales hace

dichiara sotto sua responsabilità che i condizionatori modello a cui è r iferita questa dichiarazione:

‰ЛПТУВИ МВ ·ФОПВИЫЩИО‹ ЩЛ˜ В˘ı‡УЛ fiЩИ Щ· МФУЩ¤П· ЩˆУ ОПИМ·ЩИЫЩИОТУ Ы˘ЫОВ˘ТУ ЫЩ· ФФ›· ·У·К¤ЪВЩ·И Л ·ЪФ‡Ы· ‰‹ПˆЫЛ:

declara sob sua exclusiva responsabilidade que os modelos de ar condicionado a que esta declaração se refere:

e

05

i

06

g

07

p

08

EUWAC5FBZW1***, EUWAC8FBZW1***, EUWAC10FBZW1***,

d

02

f

03

l

04

* = , , -, 1, 2, 3, ..., 9, A, B, C, ..., Z

01 are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our

instructions:

daß sie gemäß unseren Anweisungen eingesetzt werden:

02 der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspr icht/entsprechen, unter der Voraussetzung,

03 sont conformes à la/aux norme(s) ou autre(s) document(s) normatif(s), pour autant qu'ils soient utilisés conformément à nos instructions:

04 conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig

onze instructies:

05 están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) nor mativo(s), siempre que sean utilizados de acuerdo con

∏ Daikin Europe N.V. Â›Ó·È ÂÍÔ˘ÛÈÔ‰ÔÙË̤ÓË Ó· Û˘ÓÙ¿ÍÂÈ ÙÔÓ ∆¯ÓÈÎfi Ê¿ÎÂÏÔ Î·Ù·Û΢‹˜.

A Daikin Europe N.V. está autorizada a compilar a documentação técnica de fabrico.

Компания Daikin Europe N.V. уполномочена составить Комплект технической документации.

Daikin Europe N.V. er autoriseret til at udarbejde de tekniske konstruktionsdata.

Daikin Europe N.V. är bemyndigade att sammanställa den tekniska konstruktionsfilen.

**

07

19 ob upoštevanju določb:

20 vastavalt nõuetele:

21 следвайки клаузите на:

22 laikantis nuostatų, pateikiamų:

23 ievērojot prasības, kas noteiktas:

24 održiavajúc ustanovenia:

25 bunun koşullarına uygun olarak:

10 under iagttagelse af bestemmelserne i:

11 enligt villkoren i:

12 gitt i henhold til bestemmelsene i:

13 noudattaen määräyksiä:

14 za dodržení ustanovení předpisu:

15 prema odredbama:

16 követi a(z):

nostre istruzioni:

Û‡Ìʈӷ Ì ÙȘ Ô‰ËÁ›Â˜ Ì·˜:

nuestras instrucciones:

06 sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle

07 В›У·И Ы‡МКˆУ· МВ ЩФ(·) ·ОfiПФ˘ıФ(·) ЪfiЩ˘Ф(·) ‹ ¿ППФ ¤ББЪ·КФ(·) О·УФУИЫМТУ, ˘fi ЩЛУ ЪФ¸fiıВЫЛ fiЩИ ¯ЪЛЫИМФФИФ‡УЩ·И

01 following the provisions of:

02 gemäß den Vorschriften der:

03 conformément aux stipulations des:

04 overeenkomstig de bepalingen van:

EN60335-2-40,

05 siguiendo las disposiciones de:

06 secondo le prescrizioni per:

07 Ì ًÚËÛË Ùˆv ‰È·Ù¿Íˆv Ùˆv:

da <B> secondo il Certificato <C>.

positivo de <B> de acordo com o Certificado <C>.

·fi ÙÔ <B> Û‡Ìʈӷ Ì ÙÔ ¶ИЫЩФФИЛЩИОfi <C>.

положительным решением <B> согласно

Свидетельству <C>.

henhold til Certifikat <C>.

06 Nota * delineato nel <A> e giudicato positivamente

07 ™ËÌ›ˆÛË * fiˆ˜ ηıÔÚ›˙ÂÙ·È ÛÙÔ <A> Î·È ÎÚ›ÓÂÙ·È ıÂÙÈο

08 Nota * tal como estabelecido em <A> e com o parecer

09 Примечание * как указано в <A> и в соответствии с

10 Bemærk * som anført i <A> og positivt vurderet af <B> i

17 zgodnie z postanowieniami Dyrektyw:

18 în urma prevederilor:

according to the Certificate <C>.

beurteilt gemäß Zertifikat <C>.

<B> conformément au Certificat <C>.

<B> overeenkomstig Certificaat <C>.

positivamente por <B> de acuerdo con el

Certificado <C>.

08 de acordo com o previsto em:

09 в соответствии с положениями:

01 Note * as set out in <A> and judged positively by <B>

02 Hinweis * wie in der <A> aufgeführ t und von <B> positiv

03 Remarque * tel que défini dans <A> et évalué positivement par

04 Bemerk * zoals vermeld in <A> en positief beoordeeld door

05 Nota * como se establece en <A> y es valorado

Daikin Europe N.V. is authorised to compile the Technical Construction File.

**

01

Daikin Europe N.V. har tillatelse til å kompilere den Tekniske konstruksjonsfilen.

**

**

**

**

**

08

11

12

09

10

Daikin Europe N.V. hat die Berechtigung die Technische Konstruktionsakte zusammenzustellen.

Daikin Europe N.V. est autorisé à compiler le Dossier de Construction Technique.

Daikin Europe N.V. is bevoegd om het Technisch Constructiedossier samen te stellen.

Daikin Europe N.V. está autorizado a compilar el Archivo de Construcción Técnica.

Daikin Europe N.V. è autorizzata a redigere il File Tecnico di Costruzione.

**

**

**

**

**

05

06

3PW61842-6

02

03

04

EUWAC5FBZW1

EUWAC8FBZW1

EUWAC10FBZW1

Packaged air-cooled water chillers

Installation and

operation manual

CONTENTS Page

Installing the unit ............................................................................ 1

Introduction ....................................................................................... 1

Options and features......................................................................... 2

Options ...................................................................................................... 2

Features..................................................................................................... 2

Technical specifications ............................................................................. 2

Electrical specifications ............................................................................. 2

Options and features ................................................................................. 2

Standard operation range.......................................................................... 2

Main components.............................................................................. 2

Selection of location .......................................................................... 3

Inspecting and handling the unit ....................................................... 3

Unpacking and placing the unit ......................................................... 3

Important information regarding the refrigerant used........................ 3

Checking the water circuit ................................................................. 4

Connecting the water circuit.............................................................. 4

Water charge, flow and quality.......................................................... 4

Piping insulation ................................................................................ 4

Field wiring ........................................................................................ 5

Parts table.................................................................................................. 5

Power circuit and cable requirements ........................................................ 5

Connection of the packaged air-cooled water chiller power supply........... 5

Point for attention regarding quality of the public electric power supply .... 5

Cable for flow switch.................................................................................. 5

How to continue................................................................................. 5

Operating the unit ........................................................................... 6

Introduction ....................................................................................... 6

Description ........................................................................................6

Function of the main components.............................................................. 6

Safety devices............................................................................................ 7

Measuring devices..................................................................................... 7

Internal wiring - Parts table........................................................................ 7

Before operation................................................................................ 8

Checks before initial start-up ..................................................................... 8

Water supply.............................................................................................. 8

Power supply connection and crankcase heating ...................................... 8

General recommendations ........................................................................ 8

Operation .......................................................................................... 8

Digital controller......................................................................................... 9

Working with the units.............................................................................. 10

Advanced features of the digital controller............................................... 13

BMS connection modbus ................................................................15

General description of Modbus................................................................ 15

Implemented error code........................................................................... 16

Defining the BMS setting ......................................................................... 16

Var iables database.................................................................................. 16

Troubleshooting ............................................................................... 17

Maintenance.................................................................................... 18

Important information regarding the refrigerant used .............................. 18

Maintenance activities ............................................................................. 18

Disposal requirements............................................................................. 19

Menu overview ................................................................................ 20

Annex I ............................................................................................21

Saturated temperature............................................................................. 21

Annex II ...........................................................................................21

Calculation of external pressure drop...................................................... 21

Annex III ..........................................................................................22

Fan characteristics................................................................................... 22

Thank you for purchasing this Daikin air conditioner.

The English text is the original instruction. Other languages are

translations of the original instructions.

This appliance is not intended for use by persons, including children,

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with

the appliance.

INSTALLING THE UNIT

READ THIS MANUAL ATTENTIVELY BEFORE STARTING

UP THE UNIT. DO NOT THROW THIS MANUAL AWAY.

KEEP IT IN YOUR FILES FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY DAIKIN WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE EQUIPMENT AND HAVE THEM INSTALLED BY A PROFESSIONAL.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

INTRODUCTION

The Daikin EUWAC-FBZW1 packaged air-cooled water chillers are

designed for indoor installation and used for cooling applications only.

The units are available in 3 standard sizes with nominal cooling

capacities ranging from 11.2 to 22.6 kW.

The EUWAC packaged air-cooled water chillers can be combined

with Daikin fan coil units or air handling units for air conditioning purposes.They can also be used for supplying water for process cooling.

The present installation chapter describes the procedures for

unpacking, installing and connecting the EUWAC units.

Installation and operation manual

1

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

OPTIONS AND FEATURES

–

–

Options and features

(3)

Refer to the engineering data book for the complete list of

specifications, options and features.

Options

■ Glycol application for chilled water temperature down to –10°C

or –5°C.

■ BMS-connection MODBUS (optional kit address card

EKAC10C)

■ Remote user interface (optional kit EKRUMCA). (Necessary to

additionally install kit address card EKAC10C.)

(1)

(1)

Features

■ Voltage free contacts

- general operation

- alarm

- operation compressor 1

■ Changeable remote inputs

Following functions can be assigned to a total of 1 digital input.

- remote start/stop

- dual setpoint

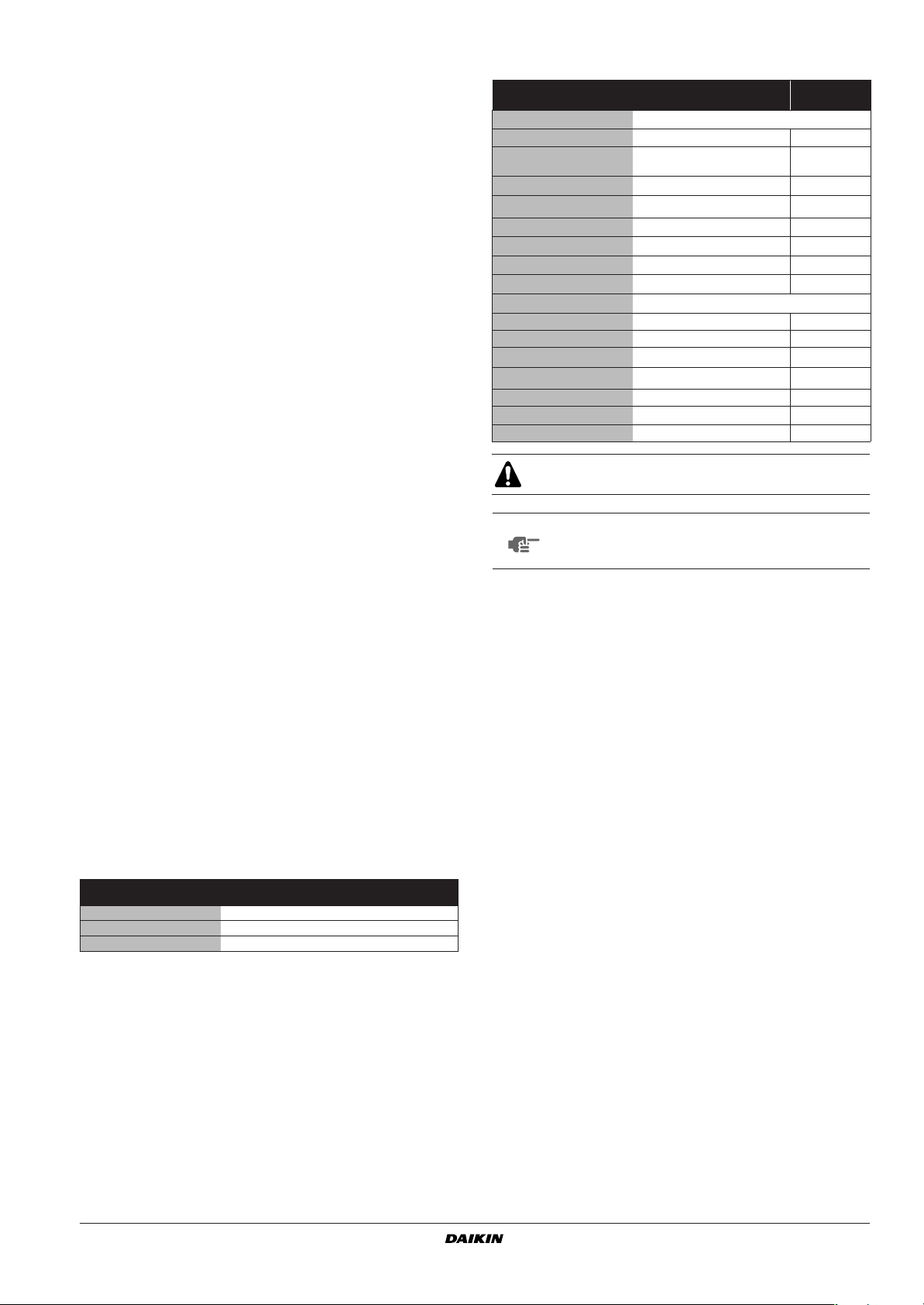

Technical specifications

Model EUWAC 5 8 10

Dimensions HxWxD

Weight

• Machine weight

• Operation weight

Connections

•Water inlet

•Water outlet FBSP 1”

•Water drain

Maximal E.S.P.

(*) E.S.P.=External Static Pressure

(*)

Electrical specifications

Model EUWAC 5 8 10

Power circuit

• Phase 3N~

•Frequency

•Voltage

•Voltage tolerance

(2)

1345x

(mm)

795x605

(kg)

164 224 261

(kg)

166 228 266

FBSP 1” FBSP 1” FBSP 1”

(mm)

(Pa)

25 25 25

100 150 150

1290x

1125x605

FBSP 1” FBSP 1”

(2)

(Hz)

(V)

(%)

50

400

±10

1395x

1275x605

Options

■ Glycol application for chilled water temperature down to –10°C

or –5°C. (**)

(**) Do not use internally Zinc-coated or galvanized steel pipes

for the additional waterpiping.

■ BMS-connection (MODBUS/J-BUS, BACNET)

■ Remote user controller (optional kit EKRUMCA)

Features

■ Lower ambient temperature operation (–10°C DB) due to

integrated head pressure control.

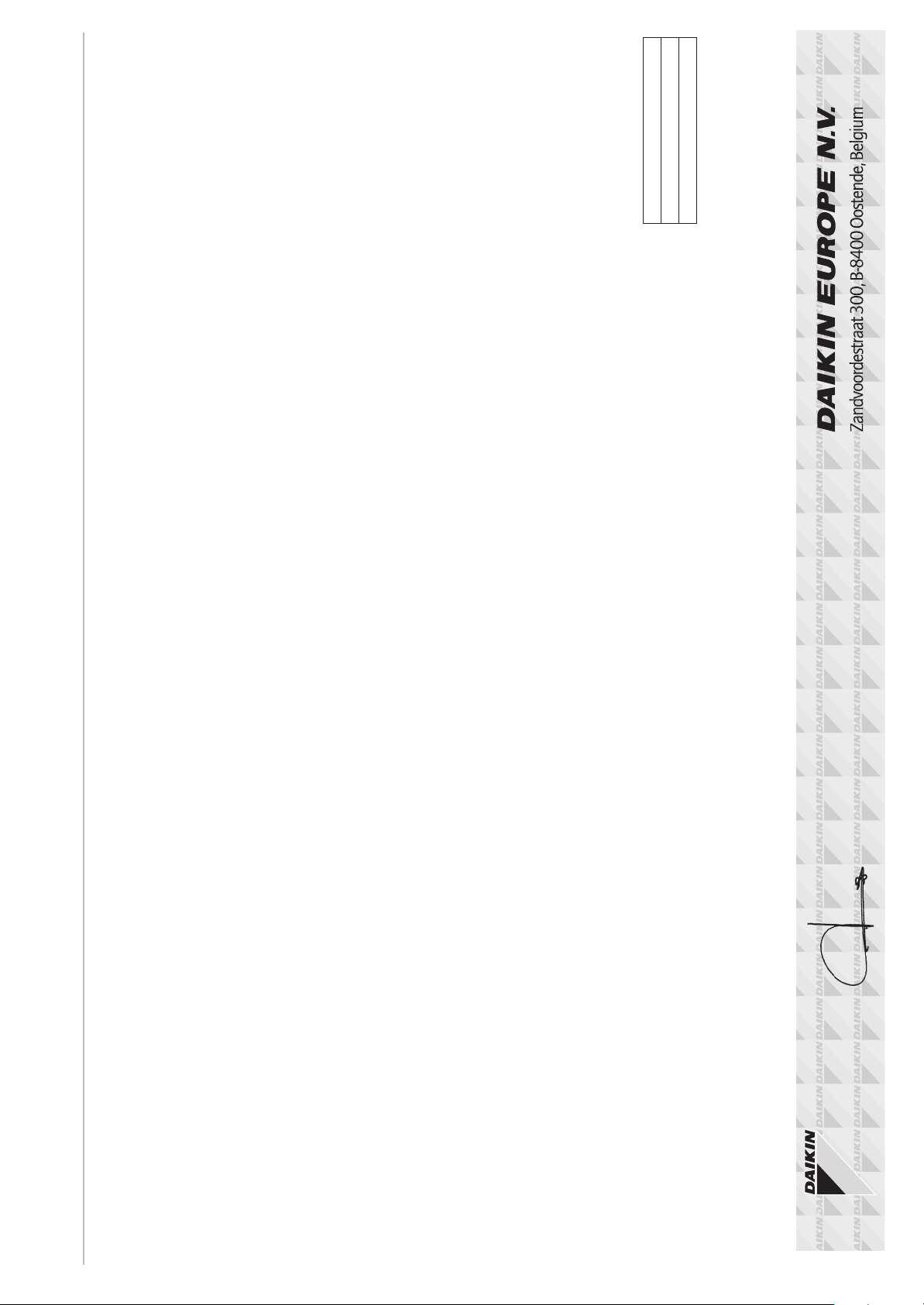

Standard operation range

A

50

43

40

40

36

0

10

20

A

B

C

D

E

F

C

ZL

ZH

–5–10–15–20 11 15

0

Standard operation range

Protect the water piping against water freezing during winter

period

Outdoor ambient temperature (°C DB)

Leaving water temperature evaporator (°C)

Glycol

Water

For nominal E.S.P. of 60 Pa (8 Hp) and of 72 Pa (10 Hp)

For E.S.P. of 150 Pa (8+10 Hp only)

EEFE

F

D

42125

B

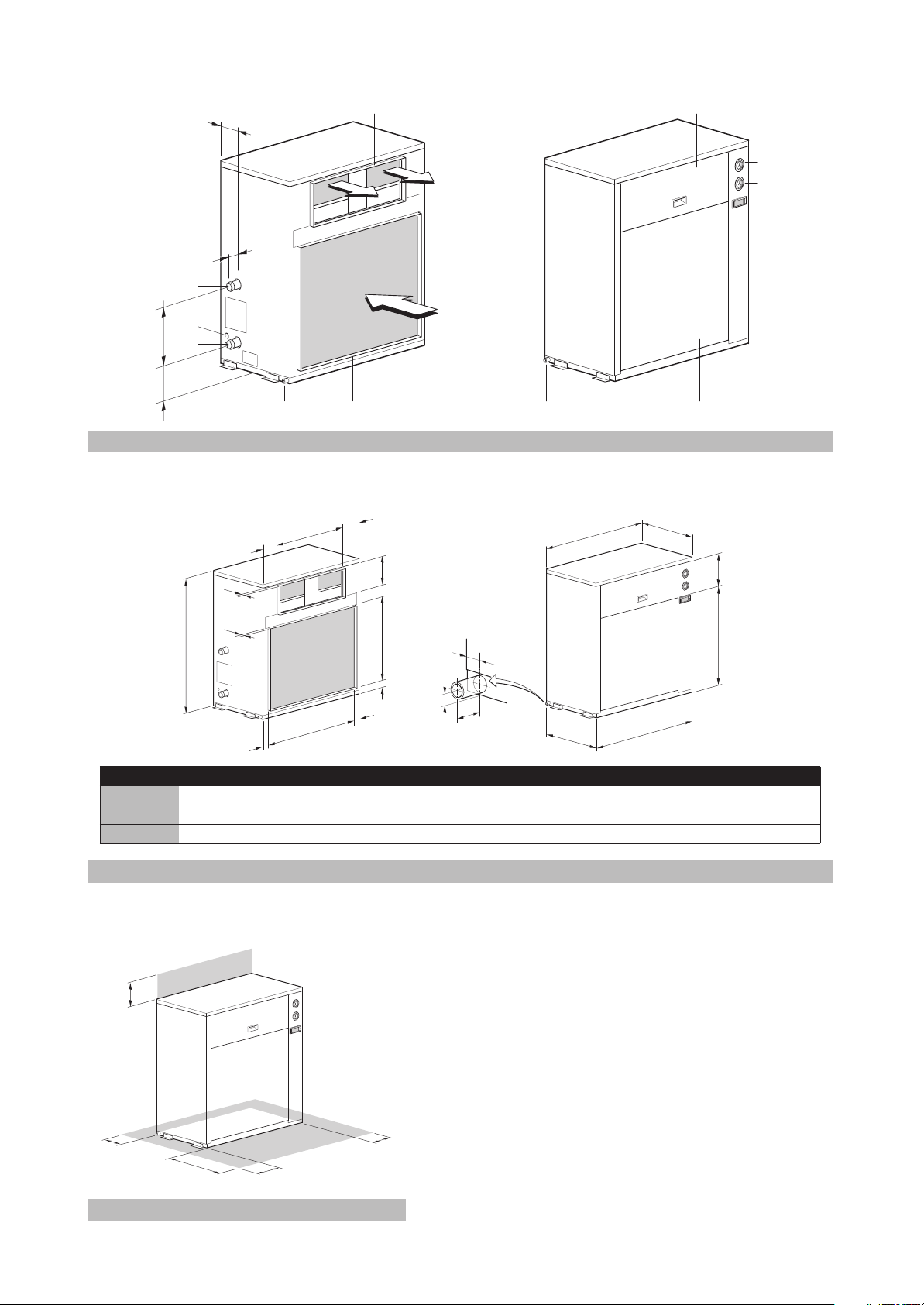

MAIN COMPONENTS (See figure 1)

1 Upper service plate

2 Lower service plate

3 Water inlet connection

4 Water outlet connection

5 Power supply intake

6 Digital controller

7 Drain outlet

8 Low pressure gauge (suction pressure)

9 High pressure gauge (discharge pressure)

10 Air inlet ducting flanges

11 Air outlet ducting flanges

12 Identification plate

(1) When EKAC10C is used in combination with remote user controller

EKRUMCA then it is not possible to use the BMS-connection MODBUS.

(2) Refer to the chapter “Operating the unit“ or engineering data book for the

complete list of specifications and options.

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

(3) Refer to the chapter “Operating the unit” or engineering data book for the

complete list of specifications and options.

Installation and operation manual

2

SELECTION OF LOCATION

UNPACKING AND PLACING THE UNIT

The EUWAC unit should be installed in a location that meets the

following requirements:

1 The foundation is strong enough to support the weight of the unit

and the floor is flat to prevent vibration and noise generation.

2 The space around the unit is adequate for servicing and the

minimum space for air inlet and air outlet is available. (See

figure 2 and figure 3.)

If several units are being installed side by side in parallel, the

minimum service space between them must be taken into

account.

3 There is no danger of fire due to leakage of inflammable gas.

4 Select the location of the unit in such a way that neither the

discharged air nor the sound generated by the unit disturb

anyone.

5 Make sure that the air inlet and outlet of the unit are not

positioned towards the main wind direction. Frontal wind will

disturb the operation of the unit. If necessary, use a windscreen

to block the wind.

6 Ensure that water cannot cause any damage to the location in

case it drips out of the unit (e.g. in case of a blocked drain pipe).

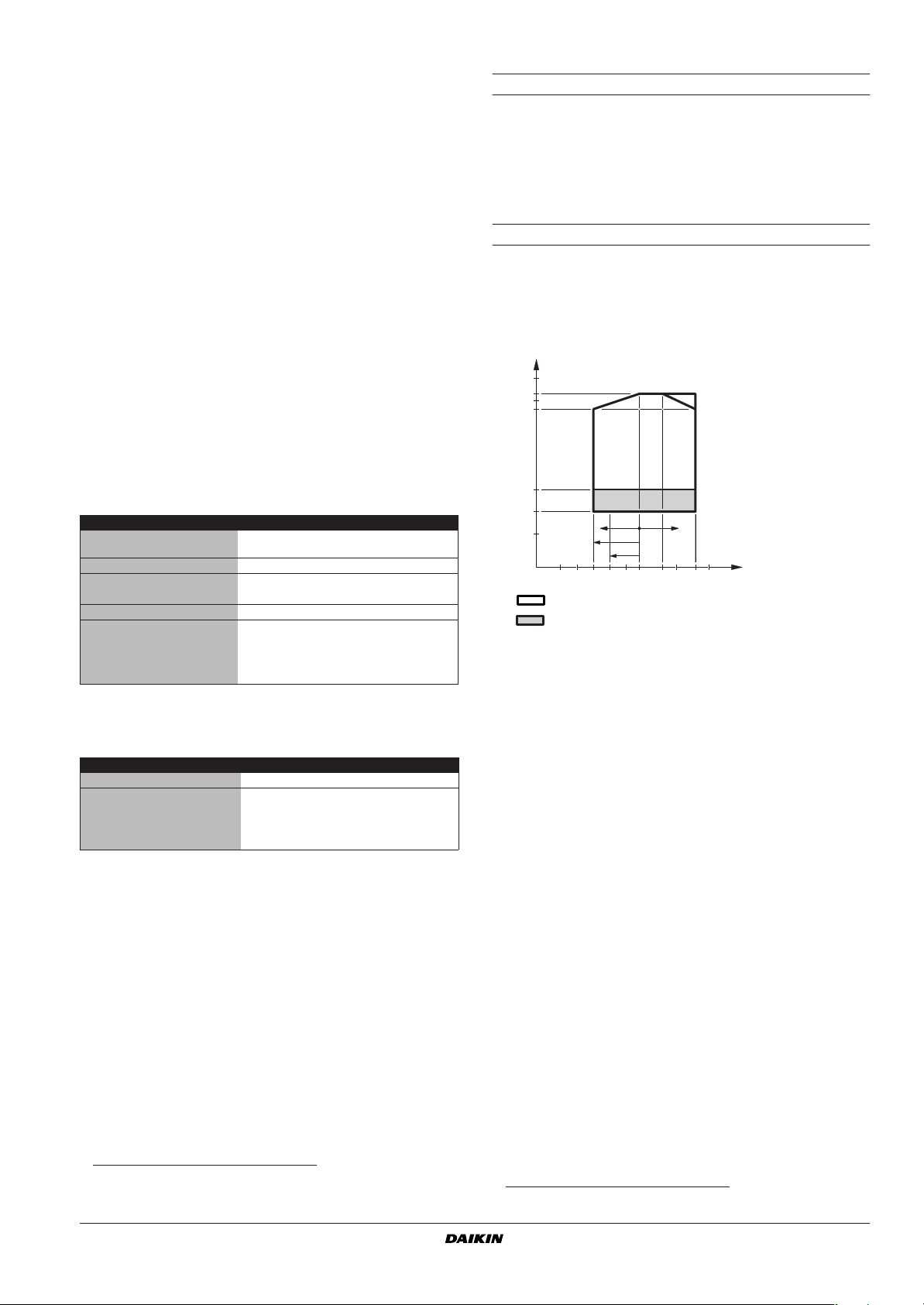

7 A drain is provided and there is

enough space to install a trap

75 mm

with a minimum fall of 75 mm

between the drain outlets of the

unit and the drain.

The equipment is not intended for use in a potentially explosive

atmosphere.

INSPECTING AND HANDLING THE UNIT

The EUWAC units are packed in a cardboard box and attached on a

wooden pallet.

At delivery, the package should be checked and any damage should

be reported immediately to the carrier claims agent.

When handling the unit, take into account the following:

1. Follow the instructions marked by the symbols on the package:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

Do not use straps to move the unit.

2. Lift the unit preferably with a fork-lift, a manual pallet mover or a

crane and belts.

3. When lifting the unit with a crane, always use protectors to prevent

belt damage and pay attention to the position of the unit’s centre of

gravity.

4. Bring the unit as close to its final installation position in its original

package to prevent damage during transport.

1 Cut the straps and remove the cardboard box from the unit.

2 Remove the four screws fixing the unit to the pallet.

3 Lift the unit from the pallet and place it on its installation position.

4 Connect the air inlet (lower part of the unit) to the air inlet

ducting and the air outlet (upper part of the unit) to the air outlet

ducting. Always provide a flexible connection between the

ducting flanges of the unit and the ducts to prevent vibrations

and noise generation.

Ensure that a protective guard is installed in front of

the air outlet to prevent that the fan blades be

touched. The protection must comply with relevant

European and national regulations.

NOTE

When connecting the unit to the ducting, a pressure

drop will be created and the air flow will be reduced.

The total external pressure drop may not exceed

100 Pa for the EUWAC5 and 150 Pa for the

EUWAC8+10. (For external pressure drop calculation,

refer to "Annex II" on page 21)

The fan pulley has been factory set to work with an

external static pressure of 0 to 150 Pa for the 8 and

10 Hp models. Other pulley settings are possible for

lowering the airflow and thus reducing the sound level

of the unit. But lowering the airflow may lead to

reduced performance (refer to "Troubleshooting" on

page 17).

Also refer to "Annex III" on page 22 for the fan

characteristics.

5 Fasten the unit in place using four anchor bolts.

6 Remove the upper and lower service plate.

7 Connect the drain outlet at one side to the drain. Provide a trap

with a minimum fall of 75 mm in the drain pipe to prevent that the

negative pressure, produced by the fan, disturbs the drain (refer

to figure in chapter "Selection of location" on page 3).

IMPORTANT INFORMATION REGARDING THE

REFRIGERANT USED

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type: R407C

(1)

GWP

value: 1652.5

(1)

GWP = global warming potential

The refrigerant quantity is indicated on the unit name plate.

Installation and operation manual

3

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

CHECKING THE WATER CIRCUIT

The EUWAC units are equipped with a water inlet and water outlet for

connection to a chilled water circuit. This circuit must be provided by

a licensed technician and must comply with all relevant European

and national regulations.

Before continuing the installation of the EUWAC, check the following

points:

1 A circulation pump must be provided in such a way that it

discharges the water directly into the evaporator. A voltage-free

contact is provided in the switch box to steer the pump.

2 A flow switch must be installed in the water outlet pipe to prevent

the unit from operating at a water flow which is too low. A

terminal is provided in the switch box for the electrical

connection of the flow switch.

3 A wire mesh strainer must be installed at the pump suction to

protect the pump and the heat exchanger from foreign matter.

The mesh size has to be between 0.5 and 1.5 mm.

4 Drain taps must be provided at all low points of the system to

permit complete drainage of the circuit during maintenance or in

case of shut down.

5 Air vents must be provided at all high points of the system. The

vents should be located at points which are easily accessible for

servicing. The water inlet pipe is specially designed to obtain a

complete air purge of the evaporator.

6 Provide adequate safeguards in the water circuit to make sure

that the water pressure will never exceed the maximum

allowable working pressure.

CONNECTING THE WATER CIRCUIT

The water quality must be in accordance with the specifications listed

in the table below.

circulating

water

Items to be controlled

pH at 25°C 6.8~8.0 6.8~8.0 corrosion + scale

Electrical conductivity [mS/m]

Chloride ion

Sulphate ion

M-alkalinity (pH4.8)

Total hardness

Calcium hardness

Silica ion

Items to be referred to

Iron [mg Fe/l] <1.0 <0.3 corrosion + scale

Copper [mg Cu/l] <1.0 <0.1 corrosion

Sulphide ion

Ammonium ion

Remaining chloride [mg Cl/l] <0.3 <0.3 corrosion

Free carbide

Stability index ——corrosion + scale

at 25°C

[mg Cl-/l]

2-

[mg SO

4

[mg CaCO3/l]

[mg CaCO3/l]

[mg CaCO3/l]

[mg SiO2/l]

[mg S2-/l]

[mg NH

[mg CO2/l]

+

4

<40 <30 corrosion + scale

<50 <50 corrosion

<50 <50 corrosion

/l]

<50 <50 scale

<70 <70 scale

<50 <50 scale

<30 <30 scale

not detectable not detectable corrosion

<1.0 <0.1 corrosion

/l]

<4.0 <4.0 corrosion

supply water

tendency if out

of criteria

The water pressure should not exceed the maximum working pressure of 10 bar.

NOTE

Provide adequate safeguards in the water circuit to

make sure that the water pressure will never exceed

the maximum allowable working pressure.

Piping connections (water inlet and outlet) must be made from the

right side of the water chiller. (See figure 1)

If air, moisture or dust get in the water circuit, problems may occur.

Therefore, always take into account the following when connecting

the water circuit:

1. Use clean pipes only.

2. Hold the pipe end downwards when removing burrs.

3. Cover the pipe end when inserting it through a wall so that no dust

and dirt enter.

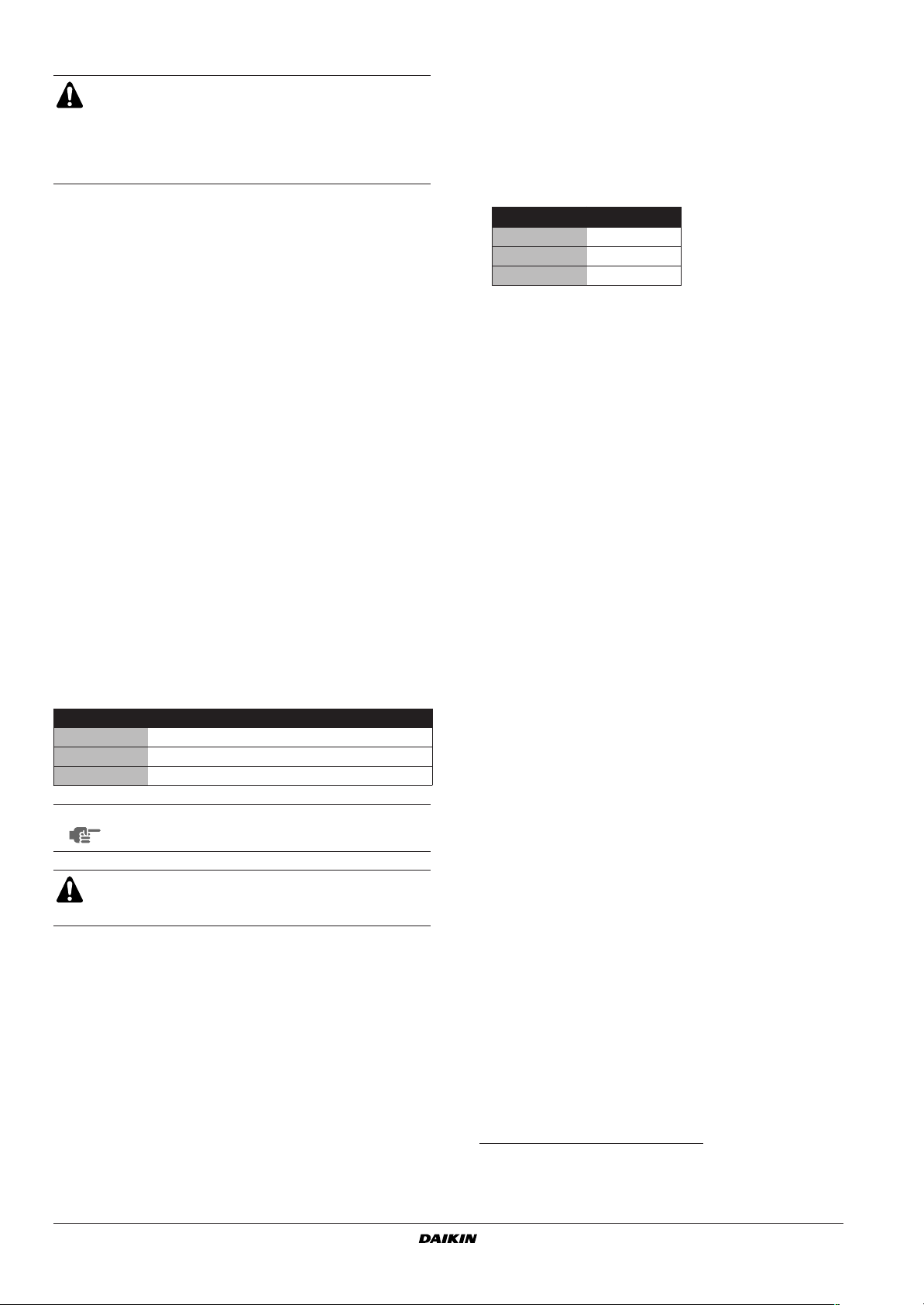

WATER CHARGE, FLOW AND QUALITY

To assure proper operation of the unit, a minimum water volume is

required in the system and the water flow through the evaporator

must be within the operation range, specified in the table below.

Minimum

EUWAC5 16 l/min 64 l/min

EUWAC8 23 l/min 92 l/min

EUWAC10 28 l/min 112 l/min

water flow

The minimum water volume v [kg] in the system should moreover full

fill the criteria below:

v > (Q / 2) x t / (C x y)

Q highest cooling capacity of the unit within the range of

application (kW)

t antirecycling timer of unit (AREC)/2(s)=120 s

C specific heat capacity of the fluidum (kJ/kg°C)=4.186 kJ/kg°C for

water

y steplength (°C)

standard setting=3°C

(refer to the chapter “Operating the unit” for adjustments)

Maximum

water flow

PIPING INSULATION

The complete water circuit, inclusive all piping, must be insulated to

prevent condensation and reduction of the cooling capacity. Take into

account the following points when insulating the piping:

1 Provide a separate insulation for the water inlet and the water

outlet piping.

2 Thoroughly insulate around the pipe connections.

3 Use Armaflex material with thickness of 9 mm.

Protect the water piping against water freezing during winter period

(e.g. by using a glycol solution).

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

Installation and operation manual

4

FIELD WIRING

All field wiring and components must be installed by a

licensed electrician and must comply with relevant European

and national regulations.

The field wiring must be carried out in accordance with the

wiring diagram supplied with the unit and the instructions

given below.

Parts table

L1,2,3 .................Live line

N.........................Neutral

F1,2,3U ..............Field fuses

H1P ....................Indication lamp alarm

H3P ....................Indication lamp operation compressor

KP ......................Pumpcontactor

PE ......................Main earth terminal

S9S ....................Switch for remote start/stop or dual setpoint

S10L...................Flowswitch

S11L...................Contact that closes if the pump is working

S12S ..................Main isolator switch

- - -......................Field wiring

Point for attention regarding quality of the public electric power supply

(2)

(1)

provided

max

at

max

■ This equipment complies with EN/IEC 61000-3-11

that the system impedance Z

is less than or equal to Z

sys

the interface point between the user's supply and the public system. It is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network

operator if necessary, that the equipment is connected only to a

supply with a system impedance Z

Z

(Ω)

max

EUWAC5 0.15

EUWAC8 0.06

EUWAC10 0.04

less than or equal to Z

sys

■ Equipment complying with EN/IEC 61000-3-12

Cable for flow switch

Be sure to interlock so that the compressor will not come into

operation unless the water pump is operated. For this purpose 2

spare terminals are provided in the switch box (refer to the wiring

diagram supplied with the unit).

HOW TO CONTINUE

.

Power circuit and cable requirements

1 The electrical power supply to the unit should be arranged so

that it can be switched on or off independently of the electrical

supply to other items of the plant and equipment in general.

2 A power circuit (see table below) must be provided for

connection of the packaged air-cooled water chiller. This circuit

must be protected with the required safety devices, i.e. a circuit

breaker, a slow blow fuse on each phase and an earth leak

detector.

Recommended fuses are mentioned on the wiring diagram

supplied with the unit.

Phase and frequency Voltage

EUWAC5 3N~ 50 Hz 400 V

EUWAC8 3N~ 50 Hz 400 V

EUWAC10 3N~ 50 Hz 400 V

NOTE

Select the power cable in accordance with relevant

local and national regulations.

Switch off the main isolator switch before making any

connections (switch off the circuit breaker and remove or

switch off the fuses).

Connection of the packaged air-cooled water chiller power supply

After installation and connection of the packaged air-cooled water

chiller, the unit should be checked and tested as described in

"Checks before initial start-up" on page 8 in the chapter "Before

operation".

1 Using the appropriate cable, connect the power circuit to the (N),

L1, L2 and L3 terminals of the unit as shown on the wiring

diagram.

2 Connect the earth conductor (yellow/green) to the earthing

terminal PE.

Installation and operation manual

5

(1) European/International Technical Standard setting the limits for voltage

changes, voltage fluctuations and flicker in public low-voltage supply

systems for equipment with rated current ≤75 A.

(2) European/International Technical Standard setting the limits for harmonic

currents produced by equipment connected to public low-voltage systems

with input current >16 A and ≤75 A per phase.

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

OPERATING THE UNIT

INTRODUCTION

This manual has been prepared to ensure adequate operation and

maintenance of the unit. It will tell you how to use the unit properly

and will provide help if problems occur. The unit is equipped with

safety devices, but they will not necessarily prevent all problems

caused by improper operation or inadequate maintenance.

In case of persisting problems contact your local Daikin dealer.

Before starting up the unit for the first time, make sure that

it has been properly installed. It is therefore necessary to

carefully read the chapter "Installing the unit" on page 1

and the recommendations listed in "Checks before initial

start-up" on page 8.

DESCRIPTION

The EUWAC packaged air-cooled water chillers are available in 3

standard sizes with nominal cooling capacities ranging from 11.2 to

22.6 kW. Each size is available in three phase 400 V+N 50 Hz.

(See figure 4)

1 Compressor (M1C)

2 Condenser coil

3 Condenser fan with motor (M11F) (only for EUWAC5)

4 Condenser fan (only for EUWAC8+10)

5 Condenser motor (M11F) (only for EUWAC8+10)

6 High pressure gauge

7 Low pressure gauge

8 Drier/filter

9 Thermostatic expansion valve

10 Evaporator

11 Water inlet connection

12 Water outlet connection

13 Switch box

14 Low-pressure switch (S4LP)

15 High-pressure switch (S1HP)

16 Digital controller

As the refrigerant circulates through the unit, changes in its state or

condition occur. These changes are caused by the following main

components:

■ Compressor

The compressor (M1C) acts as a pump and circulates the

refrigerant in the refrigeration circuit. It compresses the

refrigerant vapour coming from the evaporator at the pressure at

which it can easily be liquefied in the condenser.

■ Condenser

The function of the condenser is to change the state of the

refrigerant from gaseous to liquid. The heat gained by the gas in

the evaporator is discharged through the condenser to the

ambient air, and the vapour condenses to liquid. One fan

(EUWAC5) or two fans (EUWAC8+10) are used to accelerate

this process.

■ Filter

The filter installed behind the condenser removes small particles

from the refrigerant to prevent blockage of the expansion valve

and tubes.

■ Thermostatic expansion valve

The liquid refrigerant coming from the condenser enters the

evaporator via a thermostatic expansion valve. The valve

maintains a constant degree of suction superheat at the

evaporator outlet in order to ensure a maximum liquid refrigerant

has turned into gas.

■ Evaporator

The main function of the evaporator is to take heat from the

water that flows through it. This is done by turning the liquid

refrigerant, coming from the condenser, into gaseous

refrigerant.

■ Water in/outlet connection

The water inlet and outlet connections allow an easy connection

of the packaged air-cooled water chiller to the water circuit of the

air handling unit or industrial equipment.

Function of the main components (See figure 5)

1 Compressor

2 Condenser

3 Evaporator

4 Expansion valve

5 Filter

6 Low pressure switch

7 High pressure switch

8 Water inlet temperature sensor

9 Water outlet temperature sensor

10 Condenser fan motor

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

Installation and operation manual

6

Safety devices

Internal wiring - Parts table

In its standard version, the unit is equipped with the following safety

devices:

■ Overcurrent relay (general safety device)

The overcurrent relay (K4S) is located in the switch box of the

unit and protects the compressor motor in case of overload,

phase failure or too low tension. The relay is factory-set and may

not be adjusted. When activated, it must be reset manually.

■ High-pressure switch (general safety device)

The high-pressure switch (S1HP) is installed on the discharge

pipe of the unit and measures the condenser pressure (pressure

at the outlet of the compressor). When the pressure is too high,

the pressure switch is activated and the unit stops.

The switch is factory-set and may not be adjusted. The switch

resets automatically, but the controller needs to be reset

manually.

■ Low pressure switch (general safety device)

The low-pressure switch (S4LP) is installed on the suction pipe

of the unit and measures the suction pressure (pressure at the

inlet of the compressor). When the pressure is too low, the

pressure switch is activated and the unit stops.

The switch is factory set and may not be adjusted. The switch

resets automatically, but the controller needs to be reset

manually.

■ Reverse phase protector (general safety device)

The reverse phase protector (R1P) is installed in the switch box

of the unit. It prevents the compressor from running in the wrong

direction. If the unit does not start, two phases of the power

supply must be inverted.

■ Discharge thermal protector (general safety device)

The discharge thermal protector (Q*D) is activated when the

temperature of the refrigerant leaving the compressor becomes

too high. When the temperature returns to normal, the protector

resets automatically, but the controller needs to be reset

manually.

■ Fan motor thermal protector (part safety device)

The fan motor is equipped with a thermal protector (Q11F). The

protector is activated when the fan motor temperature becomes

too high.

When the temperature returns to normal, the protector resets

automatically.

■ Outlet water temperature sensor (general safety device)

The outlet water temperature sensor (R4T) measures the

temperature of the water at the water heat exchanger outlet. The

protection device shuts down the circuit when the temperature of

the chilled water becomes too low in order to prevent freezing of

the water during operation.

When the outlet water temperature returns to normal, the

protector resets automatically, but the controller needs to be

reset manually.

■ Additional interlock contact (general safety device)

To avoid that the unit could be started or run without water

circulating through the evaporator, an interlock contact (S10L) of

e.g. a flow switch must be switched in the start-up circuit of the unit.

Measuring devices

Checking the high and low pressure of the refrigerant circuit is necessary to ensure the proper operation of the unit and to guarantee that

the rated output will be obtained. The unit has therefore been

equipped with a high and low pressure gauge. Refer to the checklist

in the chapter "Switching the unit on" on page 10.

■ High pressure gauge

The high pressure gauge indicates the discharge pressure

(pressure at the outlet of the compressor).

■ Low pressure gauge

The low pressure gauge indicates the suction pressure

(pressure at the inlet of the compressor).

Refer to the internal wiring diagram sticker on the unit.

The abbreviations used are listed below:

A1P.................... PCB: Terminal unit

A2P............. ** ... PCB: Adress card (for optional BMS)

A3P.................... PCB: Fanspeed controller (5 Hp only)

A71P.................. PCB: power supply card

A72P.................. PCB: remote user interface

C1...................... Capacitor for fanmotor

E1H.................... Crankcase heater

F1,2,3U....... # .... Fuses

F5 ...............## .. Surge proof fuse

F5B.................... Fuse for control circuit

F7B.................... Fuse for fan circuit

F9B.................... Fuse for secondary of TR1

F8U.................... Surge-proof fuse

F9U............. ## .. Surge-proof fuse (for optional BMS)

H1P.............*..... Indication lamp alarm

H3P.............*..... Indication lamp operation compressor

K1M ................... Compressor contactor

K4S.................... Over current relay

K1A.................... Auxiliary relay for high pressure

K1F,K3F ............. Contactor for high speed selection of the fan motor

(8+10 Hp only)

K2F.................... Contactor for low speed selection of the fan motor

(8+10 Hp only)

KP............... *..... Pumpcontactor

M11F ................. Fan motor

M1C................... Compressor motor

PE...................... Main earth terminal

Q1D ................... Discharge thermal protector

Q11F.................. Fan thermal protector

R1P.................... Reverse phase protector

R3T.................... Inlet water temperature sensor

R4T.................... Outlet water temperature sensor

S1HP ................. High pressure switch

S4LP.................. Low pressure switch

S4PC ................. Head pressure switch for fanspeed control

(8+10 Hp only)

S9S............. *..... Switch for remote start/stop or dual setpoint

S10L ........... # .... Flowswitch

S11L ........... # .... Contact that closes if the pump is working

S12S........... # .... Main isolator switch

TR1.................... Transfo 230 V ➞ 24 V (30 VA) for power supply of

controllers

X1 ...................... Connector in terminal unit for digital inputs, analog

inputs, analog outputs and for power supply

controller

X2 ...................... Connector in terminal unit for digital outputs

Not included with standard unit

Not possible as option Possible as option

Obligatory # ##

Not obligatory * **

Installation and operation manual

7

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

BEFORE OPERATION

Checks before initial start-up

Make sure that the circuit breaker on the power supply

panel of the water chiller is switched off.

After the installation of the water chiller, check the following before

switching on the circuit breaker:

1 Field wiring

Make sure that the field wiring between the local supply panel

and the water chiller has been carried out according to the

instructions described in the chapter “Installing the unit”,

according to the wiring diagram and according to European and

national regulations.

2 Additional interlock contact

An additional interlock contact S11L should be provided (e.g.

flow switch or contact of pump motor contactor). Make sure that

it has been installed between the appropriate terminals (refer to

the wiring diagram supplied with the unit). S11L should be a

normal open contact.

3 Fuses or protection devices

Check that the fuses or the locally installed protection devices

are of the size and type specified in the chapter “Installing the

unit”. Make sure that neither a fuse nor a protection device has

been bypassed.

4 Earth wiring

Make sure that the earth wires have been connected properly

and that the earth terminals are tightened.

5 Internal wiring

Visually check the switch box on loose connections or damaged

electrical components.

6 Fixation

Check that the unit is properly fixed, to avoid abnormal noises

and vibrations when starting up the unit.

7 Damaged equipment

Check the inside of the unit on damaged components or

squeezed pipes.

8 Refrigerant leak

Check the inside of the unit on refrigerant leakage. If there is a

refrigerant leak, call your local Daikin dealer.

9 Oil leak

Check the compressor on oil leakage. If there is an oil leak, call

your local Daikin dealer.

10 Air inlet/outlet

Check that the air inlet and outlet of the unit is not obstructed by

paper sheets, cardboard, or any other material. Clean the inside

of the ducts and make sure that the air ducts are properly

installed.

11 Protective guard

Check that the protective guard(s) is (are) properly installed in

front of the air outlet(s).

12 Drain disposal

Check the proper operation of the drain. Pour some water into

the drain pan and check whether the water evacuates freely

through the drain.

Water supply

Fill the water piping, taking into account the minimum water volume

required by the unit. Refer to the chapter “Installing the unit”.

Make sure that the water is of the quality as mentioned in the chapter

“Installing the unit”.

Purge the air at the high points of the system and check the operation

of the circulation pump and the flow switch.

Power supply connection and crankcase heating

In order to avoid compressor damage, it is necessary to

switch on the crankcase heater for at least six hours

before starting the compressor after a long period of standstill.

To switch on the crankcase heater proceed as follows:

1 Switch on the circuit breaker on the local supply panel. Make

sure that the unit is “OFF”.

2 The crankcase heater is switched on automatically.

3 Check the supply voltage on the supply terminals L1, L2, L3, (N)

by means of a voltmeter. The voltage should correspond to the

voltage indicated on the identification label of the unit. If the

voltmeter reads values which are not within the ranges specified

in the technical data, check the field wiring and replace the

supply cables if necessary.

4 Check the LED on the reverse phase protector. If it lights up, the

phase order is correct. If not, switch off the circuit breaker and

call a licensed electrician to connect the wires of the power

supply cable in the correct phase order.

After six hours, the unit is ready for operation.

General recommendations

Before switching on the unit, read following recommendations:

1 When the complete installation and all necessary settings have

been carried out, close all front panels of the unit.

2 The service panel of the switch box may only be opened by a

licensed electrician for maintenance purposes.

OPERATION

The EUWAC units are equipped with a digital controller offering a

user-friendly way to set up, use and maintain the unit.

This part of the manual has a task-oriented, modular structure. Apart

from the first section, which gives a brief description of the controller

itself, each section or subsection deals with a specific task you can

perform with the unit.

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

Installation and operation manual

8

Digital controller

User interface

The digital controller consists of a numeric display, four labelled keys

which you can press and LEDs providing extra user information.

Figure - Digital controller

Figure - Remote user interface (optional kit)

Keys provided on the controller:

The function carried out when the user presses one or a combination

of these keys depends on the status of the controller and the unit at

that specific moment.

Keys digital

controller

AT

BU

A + BS

CC

DD

C + DR

Keys remote

interface

Main display Sensor readout menu Parameter selection menu Parameter setting menu

— Press once:

Press for 5 seconds:

To be able to access

DIRECT parameters

Press for 5 seconds:

A + B OR

Press once:

S

To be able to access USER

parameters (after entering

USER password)

Press for 5 seconds:

No effect on these units

Press once: Direct access to

readout menu sensor

(b01/b02/b03)

Press for 5 seconds:

Switch unit on/off in cooling

mode

Press once: Direct access to

readout menu sensor

(b01/b02/b03)

Press for 5 seconds:

Manually alarm reset in the

event of alarm

Select previous sensor

Return

—

Press once:

parameter

Press once:

Select next sensor

parameter

Press once:

Return

Press once:

Select parameter group or

parameter

—

Press once:

Select previous parameter

group or parameter

Press once:

Select next parameter group

or parameter

—

Press once:

Cancel and return

Press once:

Confirm and return

Press once:

Increase value

Press once:

Decrease value

Installation and operation manual

9

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

LEDs provided on the controller and remote interface:

Function during main display (not inside menu)

Remote

Leds digital controller

Led (green) Z Inlet water temperature.

P

Led (amber)

F

Led (amber)

G

H

L

M

&

é

Led (red) Y

Led (amber)

Led (amber)

Led (amber)

Led (amber)

interface

F

G

L

M

&

é

Main display

Not active.

Indicates that cooling mode is

active.

Indicates that the alarm is

active.

Indicates the status of the

pump

LED, indicates that at least

one compressor is active.

LED is on, indicates that

compressor 1 is active.

LED is flashing, indicates

compressor 1 startup request.

Not active.

When selecting a parameter group or parameter, different LEDs

related to the parameter group or parameter are displayed.

Example: The LEDs F and G are displayed when accessing a

parameter group or when accessing parameters directly.

NOTE

Temperature readout tolerance: ±1°C.

Legibility of the numeric display may decrease in direct

sunlight.

Direct and user parameters

The digital controller provides direct and user parameters. The direct

parameters are important for the everyday usage of the unit, e.g. to

adjust the temperature setpoint or to consult actual operational

information. The user parameters on the contrary provide advanced

features such as adjusting time delays.

Each parameter is defined by a code and a value. For example: the

parameter used to select local or remote on/off control has code

h07 and value 1 or 0.

For an overview of the parameters, refer to "Overview of the direct

and user parameters" on page 13.

Working with the units

This chapter deals with the everyday usage of the units. Here, you

will learn how to perform routine tasks, such as:

■ "Switching the unit on" on page 10 and "Switching the unit off"

on page 11,

■ "Adjusting the cooling temperature setpoint" on page 11,

■ "Consulting actual operational information" on page 11,

■ "Resetting alarms" on page 11,

■ "Resetting warnings" on page 12.

Switching the unit on

To switch the unit on in cooling mode, proceed as follows:

1 Press the D key for approximately 5 seconds, the G LED will

be displayed.

Then an initialization cycle is started, the L LED, the M LED, the &

LED will light up depending on the programmed thermostat function.

In case the & LED is flashing, it indicates that there is a

compressor 1 startup request. The compressor will start after the

timer has reached zero.

NOTE

2 When the unit is started up for the first time, or when the unit has

Cooling mode Minimum Nominal Maximum

Low pressure 3 bar 4 bar 6.5 bar

High pressure 7 bar 21 bar 24 bar

outdoor temperature

LW leaving water temperature

NOTE

If remote on/off control is enabled, refer to "Selecting

local or remote on/off control" on page 14.

been out of operation for a longer period, it is recommended to

go through the following checklist.

Condenser fan rotation

This check applies to the EUWAC8+10 units only.

As soon as the compressor and the condenser fan have started,

switch off the unit to stop them (refer to "Switching the unit off"

on page 11). Check if the fans turn in the right direction while

they are running out. The direction is indicated by an arrow on

the fan housing. If they run in the wrong direction, call your local

Daikin dealer.

Abnormal noise and vibrations

Make sure the unit does not produce any abnormal noises or

vibrations: check the fixations and piping. If the compressor

makes any abnormal noises, this may also be caused by an

overcharge of refrigerant.

Working pressure

It is important to check the high and low pressure of the

refrigerant circuit to ensure the proper operation of the unit and

to guarantee that the rated output will be obtained.

For reference, the average saturated temperature of R407C in

relation to the pressure readout can be found in "Annex I" on

page 21.

The pressures measured will vary between a maximum

and minimum value, depending on the water and outdoor

temperatures (at the moment of measurement).

( –5°C) ( 35°C) ( 38°C)

(LW 4°C) (LW 7°C) (LW 20°C)

Make sure that the lower service plate is in place when

carrying out the pressure measurements. If not, the

refrigerant will be cooled less in the condenser, which

results in an increase of the low and high pressure.

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

Installation and operation manual

10

Water leaks

Check the evaporator and the external water circuit on water

leaks.

Drain disposal

Put the service covers in place so that the unit is completely

closed, and start up the unit. After a few hours of operation,

check if the condensing water is evacuated properly through the

drain and that it does not flow over from the drain pan on the

floor.

It may happen that the drain pan outlet is obstructed or that the

condenser fans create a vacuum so that the condensing water

remains in the drain pan and flows over. In this case, the drain

disposal should be lowered. The level difference of 75 mm

indicated in the chapter “Installing the unit” is a minimum.

3 If the unit does not start after a few minutes, consult the actual

operational information available in the list of direct parameters.

Also refer to the chapter "Troubleshooting" on page 17.

NOTE

In case of remote on/off control (h07=1), it is recommended to install an on/off switch near the unit in

series with the remote switch. The unit can then be

switched off from either place.

Switching the unit off

To switch the unit off and cooling mode is active, proceed as follows:

1 Press the D key for approximately 5 seconds, the G LED will

be extinguished.

NOTE

If remote on/off control is enabled, refer to "Selecting

local or remote on/off control" on page 14.

How to consult and modify the direct parameters

For an overview of the menu structure, refer to "Menu overview" on

page 20.

1 Press B for 5 seconds in the main display.

The -/- parameter group is displayed.

2 Press the C or D key to select the required parameter

group.

3 Press the B key to enter the selected parameter group.

4 Press the C or D key to select the required parameter.

5 Press the B key to consult the selected parameter.

6 Press the C or D key to raise, respectively lower the

setting of the selected parameter. (Only valid for read/write

parameters.)

7 Press the B key to confirm the modified setting.

OR

Press the A key to cancel the modified setting.

8 Press the A key to return to the parameter group.

9 Press 2 times the A key to return to the main display.

If during the procedure no buttons are pressed for 30 seconds, the

displayed parameter code or value will start flashing. After another

30 seconds without pressing any buttons, the controller automatically

returns to the main display without saving any modified parameter.

How to consult the "sensor readout menu" parameters

For an overview of the menu structure, refer to "Menu overview" on

page 20.

The b01/b02/b03 parameters are part of the "sensor readout

menu".

1 Press the C or D key in the main display.

The b01 parameter is displayed.

In case no buttons are pressed, the value of the b01 sensor will

be displayed until C or D is pressed again to select

another parameter (b02 or b03).

2 Press the A key to return to the main display.

If during the procedure no buttons are pressed for 30 seconds, the

displayed parameter code or value will start flashing. After another

30 seconds without pressing any buttons, the controller automatically

returns to the main display.

Adjusting the cooling temperature setpoint

1 Modify the r1 cooling setpoint parameter.

This is a direct parameter, refer to "How to consult and modify the

direct parameters" on page 11.

NOTE

When dual setpoint is enabled (refer to "Selecting dual

setpoint control" on page 14).

Consulting actual operational information

The actual operational information that can be consulted in the list of

direct parameters consists of:

■ b01:Evaporator inlet water temperature,

■ b02:Evaporator outlet water temperature,

■ b03: Not used,

■ c10:Total running hours of the compressor 1,

■ c15:Total running hours of the pump.

NOTE

■ The parameters b01, b02 and b03 can also be

consulted by the "sensor readout menu". Refer to

"How to consult the "sensor readout menu"

parameters" on page 11.

■ To reset the timers of parameters c10, c11 and

c15 refer to "Resetting warnings" on page 12.

These are direct parameters, refer to "How to consult and modify the

direct parameters" on page 11.

Resetting alarms

When an alarm is detected, the following happens:

■ the alarm relay is energized,

■ the H LED is displayed

■ the display starts flashing, alternately showing the alarm code

and the inlet water temperature.

The following alarm codes may appear on the screen:

■ a1: indicates an anti-freeze alarm.

■ e1: indicates that the NTC probe used to measure the

■ e2: indicates that the NTC probe used to measure the

■ e3: indicates that the fuse for the evaporator heatertape (F4)

evaporator inlet water temperature is defective.

evaporator outlet water temperature is defective.

is blown or that there is a reverse phase error or that there

is a problem with the I/O PCB (A2P).

Installation and operation manual

11

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

In case the unit is equipped with freeze protection, it is

highly recommended to install the remote indicator

lamp alarm (H3P) (see wiring diagram supplied with

the unit). By doing so, breakdown of the fuse for the

evaporator heatertape (F4) will be detected sooner

and freezing of the circuit will be avoided during cold

weather.

■ ehs: indicates that the supply voltage is exceedingly high. In

this case contact a licensed electrician.

■ el1: indicates that there is a power supply error (example:

noise). In this case contact a licensed electrician.

■ el2: indicates that there is a power supply error (example:

noise). In this case contact a licensed electrician.

■ els: indicates that the supply voltage is exceedingly low. In this

case contact a licensed electrician.

■ epb: indicates that the EEPROM on the controller PCB inside

the unit is defective.

■ epr: indicates that the EEPROM on the controller PCB inside

the unit is defective.

■ fl: indicates that there was no sufficient water flow either

during the period of 15 seconds after the pump was

started or for 5 seconds while the compressor is active or

that the overcurrent protection of the pump is activated.

■ hp1: indicates that a high pressure switch, the discharge

thermal protection or the overcurrent protection of the

compressor motor is activated or that the NTC probe used

to measure the ambient temperature is defective.

fl + hp1

■

: indicates that there is most likely an RPP error or that the

F4 fuse is blown.

■ lp1: indicates that the low pressure switch is activated.

■ ter: indicates that there is a remote user interface

communication error.

■

:

communication failure between the digital controller of the

unit and the remote user interface. Confirm the correct

selection of parameter code h23. This should be default

setting 0 and confirm the correction installation according

to the installation manual of the remote user interface

EKRUMCA.

Resetting warnings

During normal operation, the display of the controller may start

flashing, alternately showing the inlet water temperature and the

following warning code:

■ hc1: indicates that the compressor 1 requires maintenance:

the total running hours of the compressor 1 (direct

parameter c10) has exceeded the setting of the timer

threshold for maintenance warning (user parameter

c14).

To reset the maintenance warning hc1, proceed as follows:

1 Consult c10 running hours of compressor 1.

This is a direct parameter, refer to "How to consult and modify

the direct parameters" on page 11.

2 When c10 parameter value is displayed, press the C and

D key simultaneously for 5 seconds. The value of the timer

becomes 0 and the warning is reset.

NOTE

Do not forget to carry out the required maintenance

activities after resetting the timers.

Besides resetting timer c10, it is also possible to reset

timer c15 (running hours of pump) in the same way.

NOTE

If the alarm codes fl and h1 are flashing alternately,

the alarm is most probably caused by the reverse

phase protector or by the fuse for evaporator heatertape (F4) that was blown.

To reset an alarm, proceed as follows:

1 Find the cause of shutdown and correct.

Refer to the chapter "Troubleshooting" on page 17.

2 If the alarm codes a1, fl, hp1 or lp1 appear on the display,

reset the alarm manually by pressing the E combination keys

C and D simultaneously for approximately 5 seconds.

In all other cases the alarm is reset automatically.

Once the alarm is reset, the error code and the H LED no longer

appears on the display. The controller continues its normal

operation, displaying the inlet water temperature.

EUWAC5~10FBZW1

Packaged air-cooled water chillers

4PW61657-1 – 07.2010

Installation and operation manual

12

Advanced features of the digital controller

This chapter gives an overview of the direct parameters and user

parameters provided by the controller. In the following chapter, you

will learn how you can set up and configure the unit using these

parameters.

Overview of the direct and user parameters

The list of direct parameters is accessible by pressing the B key

for approximately 5 seconds. Refer also to "How to consult and

modify the direct parameters" on page 11.

Parameter

group

-/- /23

Parameter

code

Description

Measurement unit

0=°C 1=°F

Default

value

Min Max Units

Read/

Write

User/

Direct

Modbus

Address

001 R/W U 5 D

-a- No user or direct parameters accessible

b01 Evaporator inlet water temperature 0.1°C R D 102 A

-b-

b02 Evaporator outlet water temperature 0.1°C R D 103 A

b03 Not used 0.1°C R D 104 A

Time delay between pump startup and

compressor startup

Time threshold between the unit

shutdown and the pump shutdown

Maintenance threshold for

maintenance warning (c10)

15 0 999 1 sec R/W U 238 I

00150 1 min R/W U 239 I

00100 x100 hours R/W U 241 I

-c-

c07

c08

c10 Total running hours of compressor 1 x100 hours R D 122 A

c14

c15 Total running hours of pump x100 hours R D 126 A

-d- No user or direct parameters accessible

-f- No user or direct parameters accessible

To activate remote on/off control

h07

0=not active

1=active

001 R/W U 15 D

(only in case p34=23)

To lock the controller keyboard

-h-

h09

0=lock

1=unlock

101 R/W U 16 D

h10 Serial address for BMS connection 1 1 200 R/W U 256 I

To select address card connection

h23

0=remote user interface connection

001 R/W U 11 D

1=MODBUS connection

Changeable digital input selection

S9S

-p- p34

0=no function

13=remote dual setpoint

23=remote on/off (only active in

23 0 27 R/W U 329 I

combination with h07)

DO NOT SELECT OTHER VALUES

7.0

7.0

(†)

25.0 0.1°C R/W D 41 A

(†)

25.0 0.1°C R/W D 55 A

-r-

r01

Cooling setpoint

12.0

r02 Cooling difference 3.0 0.3 19.9 0.1°C R/W D 42 A

r21

Cooling setpoint 2

(‡)

12.0

-t- No user or direct parameters accessible

f-r h99 Software release version R D 208 I

(*) D=digital, A=analog, I=integer.

(†) –2.0 and –7.0 only applicable for units with glycol applications.

(‡) Used in case dual setpoint is enabled in p09 or p34 and dual setpoint digital input is closed.

Parameter

(*)

type

Installation and operation manual

13

Packaged air-cooled water chillers

EUWAC5~10FBZW1

4PW61657-1 – 07.2010

How to consult and modify the user parameters

NOTE

For an overview of the menu structure, refer "Menu overview" on

page 20.

1 In case of digital controller, press the A and B keys for

2 Enter the correct password by using the C and D keys.

3 Press the B key to confirm the password and to enter the

4 Press the B key to consult the parameter settings (=s-p).

5 Press the C or D key to select the required parameter

6 Press the B key to enter the selected parameter group.

7 Press the C or D key to select the required parameter.

8 Press the B key to consult the selected parameter.

9 Press the C or D key to increase, respectively decrease

10 Press the B key to confirm the modified setting.

11 Press the A key to return to the parameter group.

12 Press 2 times the A key to return to the main display.

If during the procedure no buttons are pressed for 30 seconds, the

displayed parameter code or value will start flashing. After another

30 seconds without pressing any buttons, the controller automatically

returns to the main display without saving any modified parameter.

When user parameters are consulted, the direct

parameters are displayed as well.

approximately 5 seconds until O is displayed.

In case of remote user interface, push S once.