Daikin ERYQ006ABV3, ERYQ005ABV3, ERYQ007ABV3, ERYQ005A, ERYQ006A Service Manual

...

ESIE06-03

434

5

What is in this part? This part contains the following chapters:

Chapter See page

1–General Outline: Altherma 1–3

2–Specifications 1–15

1

Part 1

System Outline

3–Functional Diagrams 1–21

4–Piping Diagrams 1–27

5–Switch Box Layout 1–33

6–Wiring Diagrams 1–39

7–PCB Layout 1–51

Part 1 – System Outline 1–1

1

ESIE06-03

1–2 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

Part 1

1 General Outline: Altherma

1.1 What Is in This Chapter?

Introduction This chapter contains the following information on the Altherma:

P Outlook and dimensions

P Installation and service space

P Componentss

P Physical limitations and limits of operation

General outline This chapter contains the following general outlines:

General outline See page

1.2–ERYQ005~007AAV3N: Outlook and Dimensions 1–4

1.3–EKHBH007A***: Outlook and Dimensions 1–6

1.4–EKHBX007A***: Outlook and Dimensions 1–8

1.5–EKSWW150~300V3: Outlook and Dimensions - Service Space 1–10

1.6–ERYQ005~007AAV3N: Installation and Service Space 1–12

1.7–EKHBH(X)007A: Installation and Service Space 1–12

1.8–Physical Limitations and Limits of Operation 1–14

Part 1 – System Outline 1–3

1

General Outline: Altherma ESIE06-03

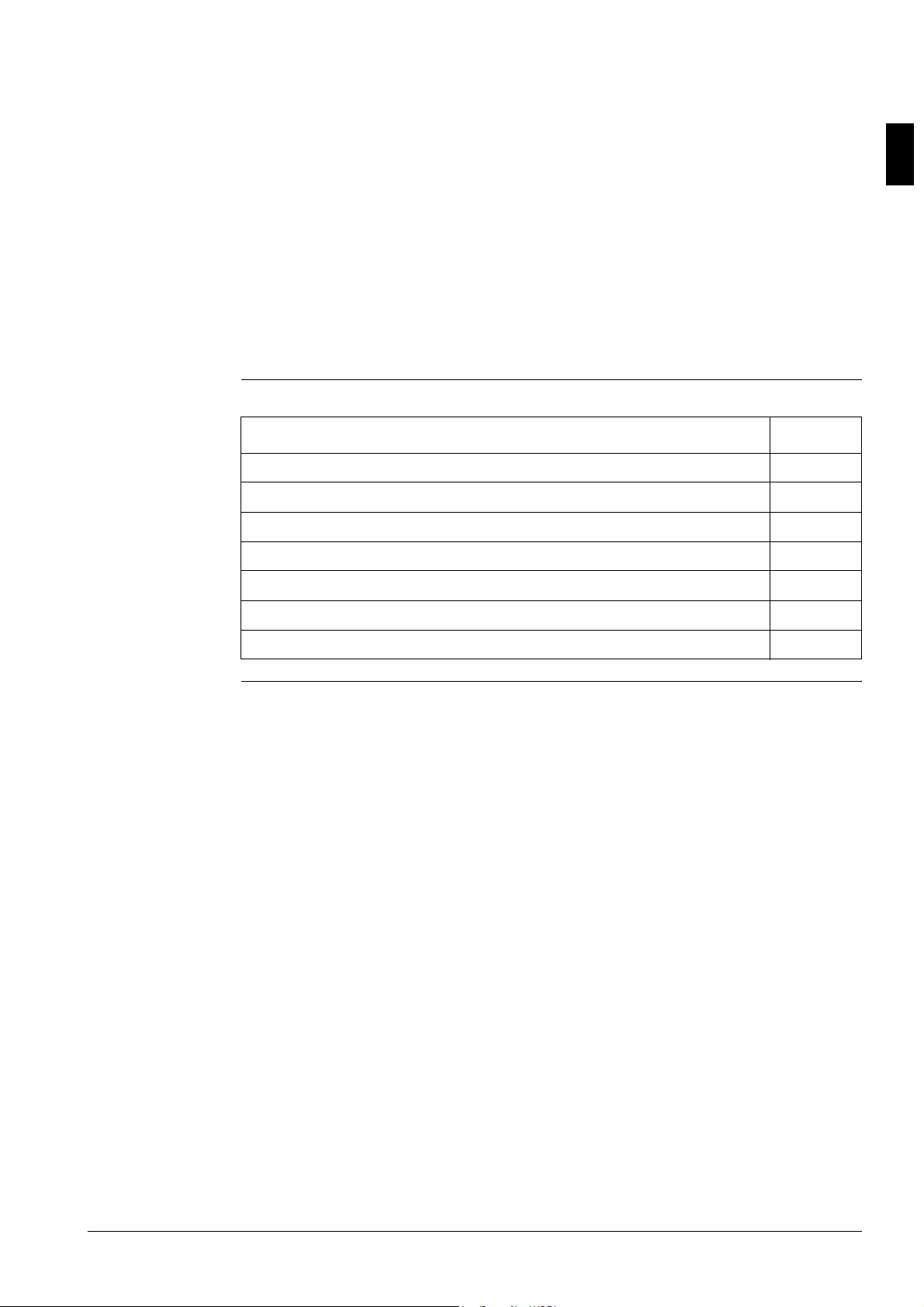

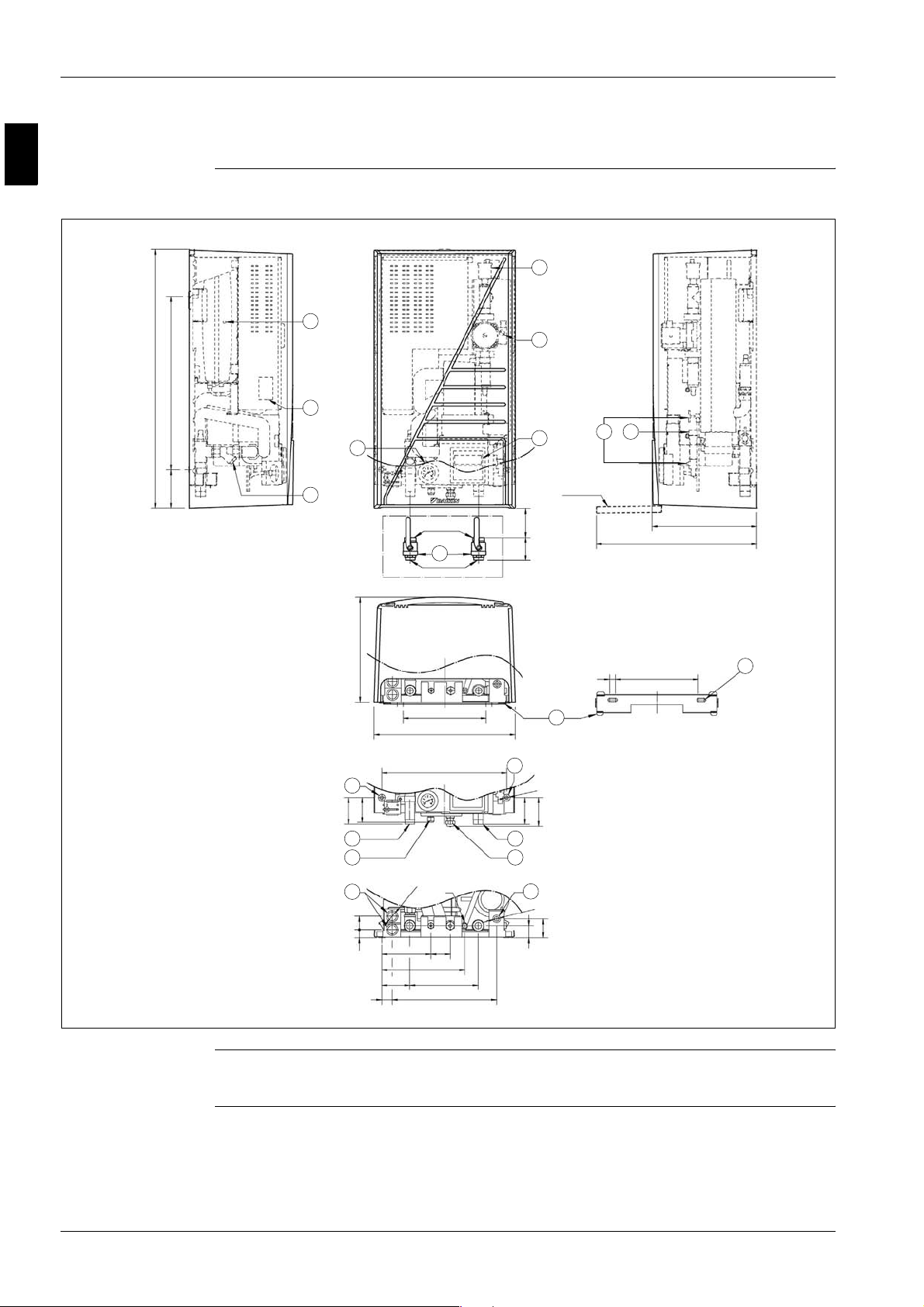

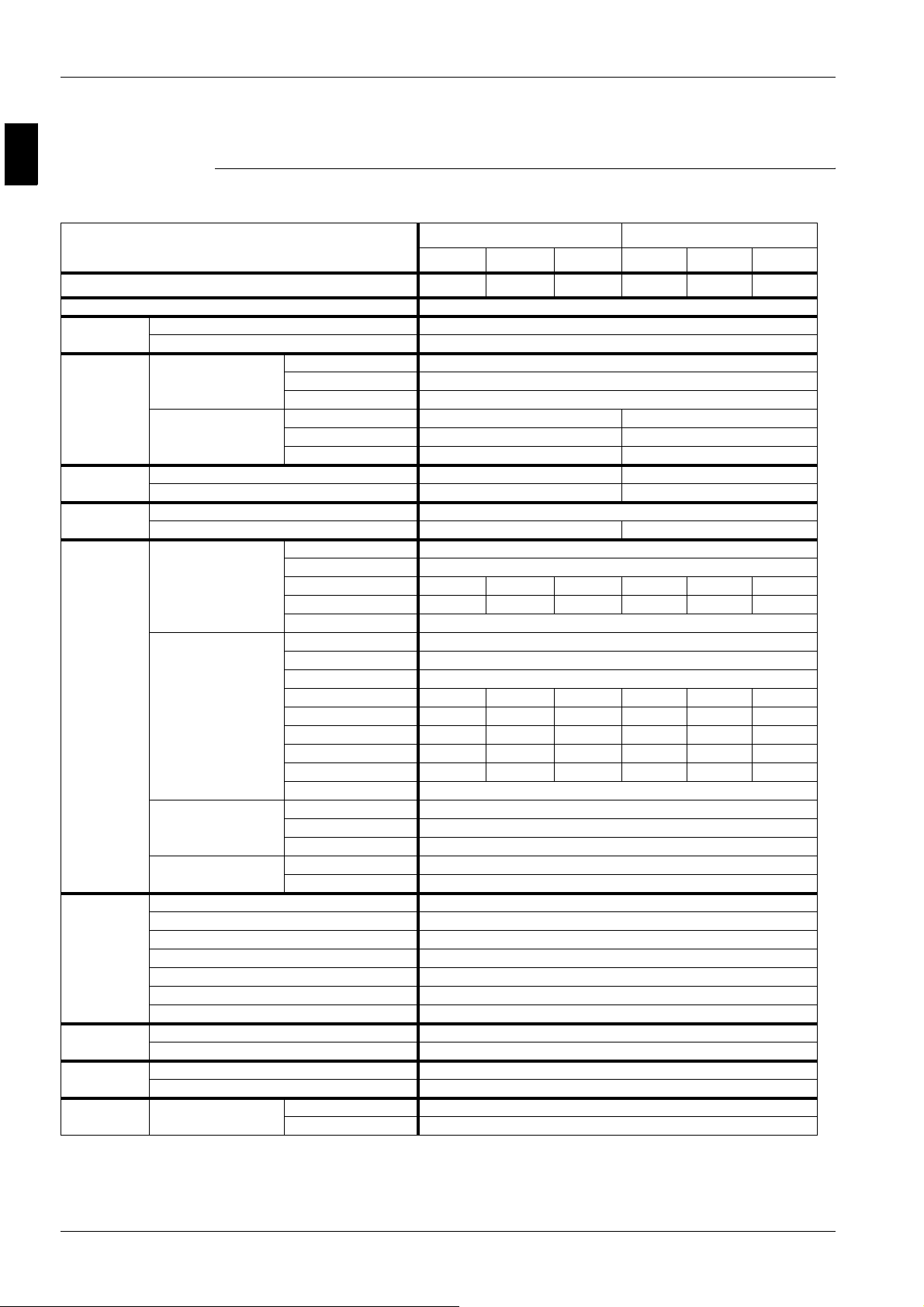

1.2 ERYQ005~007AAV3N: Outlook and Dimensions

Outlook and

dimensions

The illustration below shows the outlook and the dimensions of the unit (mm).

9

825 78

325

124

2

36

300

330

350

25

10

10

580

1

Installation and

service space

In case of removing stop

valve cover

2 3 4 5

8

7

89 64

155 18

160

6

30

See page 1–12.

1–4 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

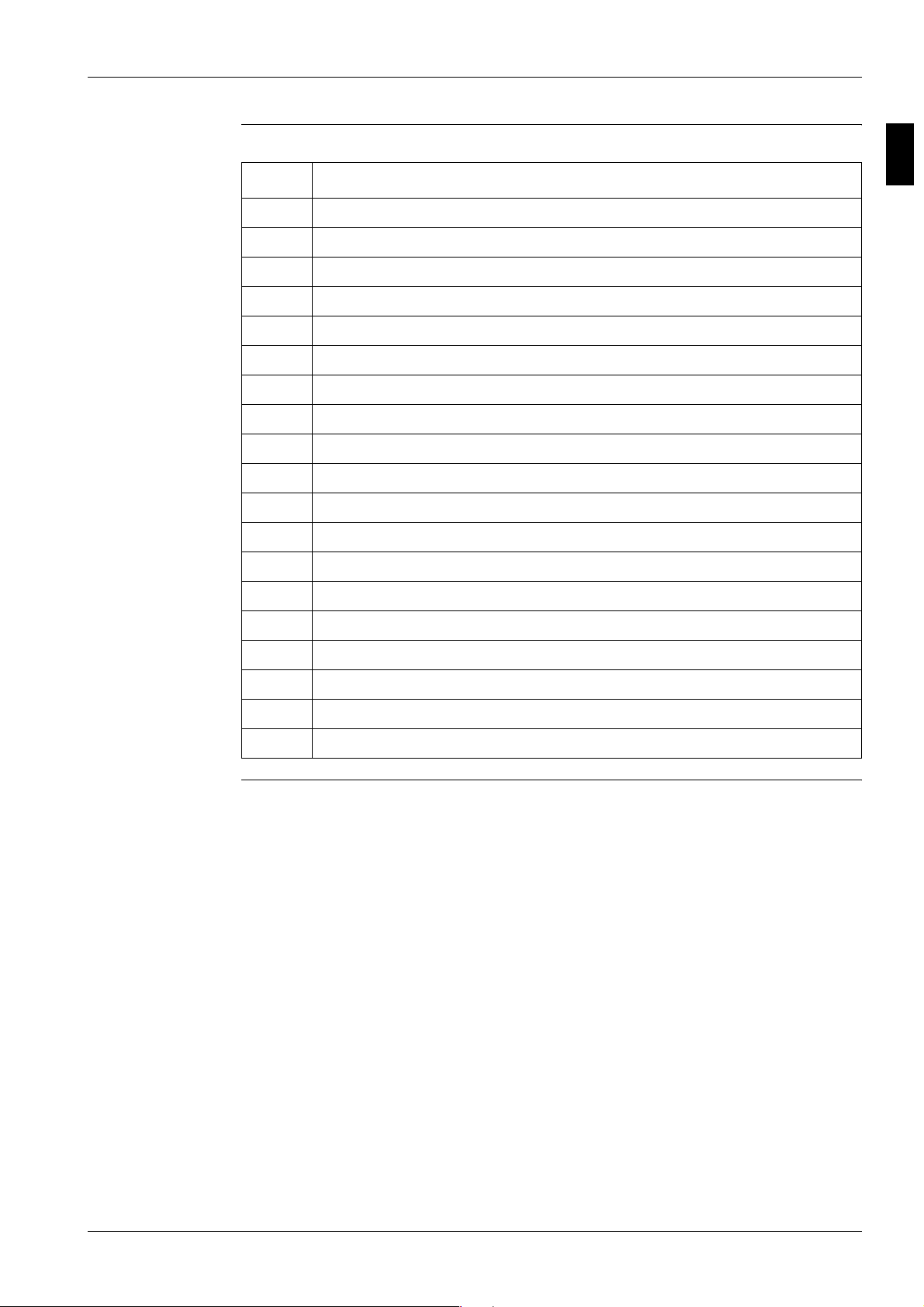

Components The table below contains the different components of the unit.

No. Component

1 Brand name label

2 Name plate

3 Wiring inlet

4 Terminal strip with earth terminal

5 Outdoor air temperature thermistor

6 Gas stop valve (φ15.9CuT)

7 Service port

8 Liquid stop valve (φ6.4CuT)

9 Drain outlet (I.D. φ15.9 hose for connection)

10 4-holes for anchor bolts (M8 or M10)

Part 1 – System Outline 1–5

1

General Outline: Altherma ESIE06-03

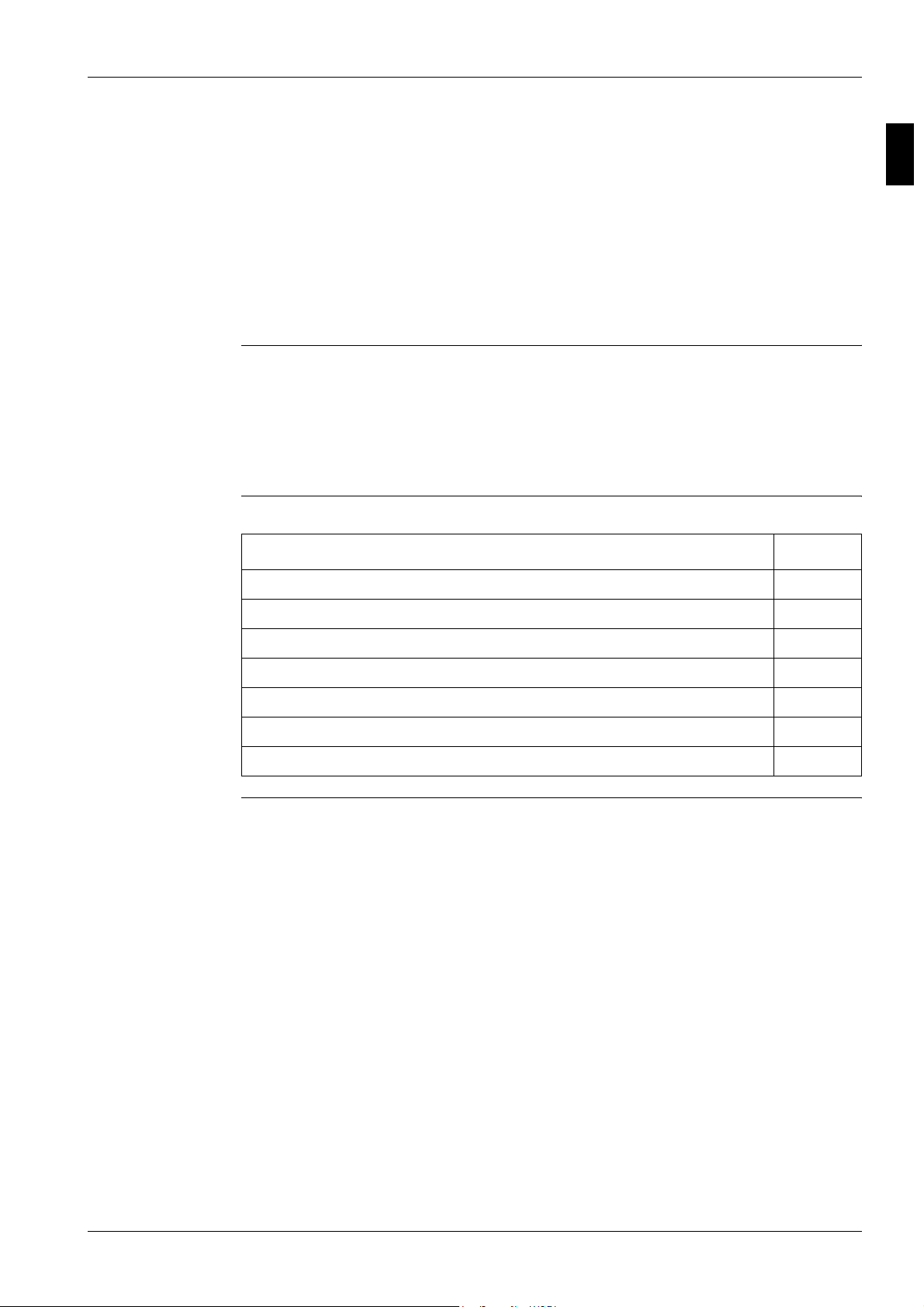

1.3 EKHBH007A***: Outlook and Dimensions

Outlook and

dimensions

The illustration below shows the outlook and the dimensions of the unit (mm).

7

8

1

895

600133

18

9

10

11

1’ Female BSP

14

1’ Male BSP

2

80 ≥100

6

Service door

(CLOSED) 361

(OPEN) 553

Installation and

service space

See page 1–13.

361

20

286

487

431

16

3

13

5

2xØ 30

46

28

170 67

287

23697

36036

16

12

2xØ 12

4

93

Ø 16

19

100

15

65

42

286

16

12

Ø

2x

1–6 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

Components The table below contains the different components of the unit.

No. Component

1 Pump + switch for speed setting

2 Remocon

3 Water IN connection 1e M BSP

4 Water OUT connection 1e M BSP

5 Power supply intake (+ sanitary warm water tank)

6 Drain/fill valve

7 Air purge

8 Expansion vessel + nipple

9 Blow off valve

10 Pressure gauge

11 Wa terfilte r

12 Suction pipe connection φ15.9 flare connection

13 Liquid pipe connection φ9.52 flare connection

14 Shut off valves (delivered with unit)

15 Thermistor connection (+ sanitary warm water tank)

16 Holes for fixation

17 Blow off drain

18 Switchbox connection terminals

19 Wallbracket

Part 1 – System Outline 1–7

1

General Outline: Altherma ESIE06-03

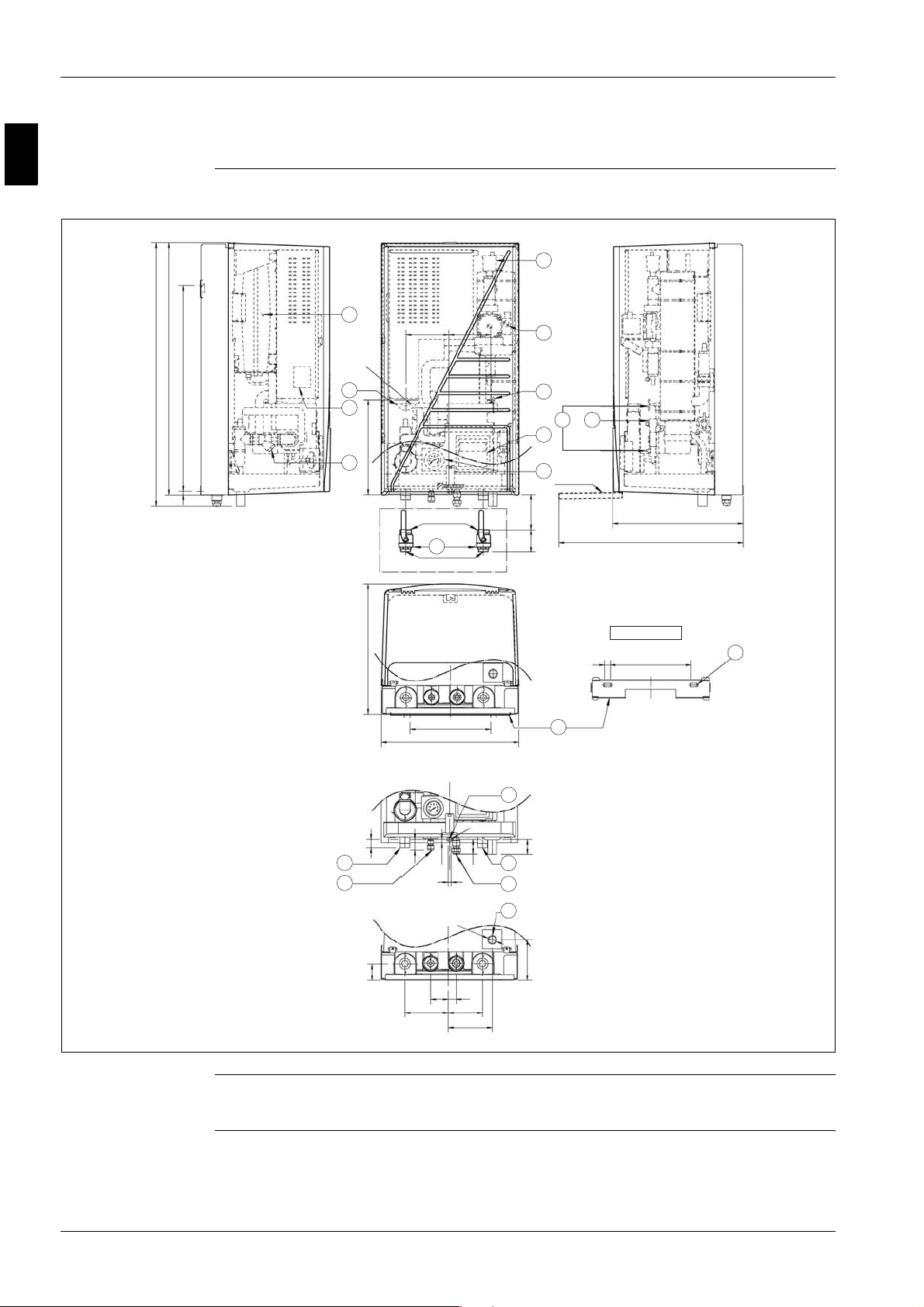

1.4 EKHBX007A***: Outlook and Dimensions

Outlook and

dimensions

The illustration below shows the outlook and the dimensions of the unit (mm).

7

8

895

936

731

Ø 46

5

18

337

11

13

461

152 148

1' Female BSP

14

1' Male BSP

286

487

286

487

1

15

9

6

2

10

Service door

≥125

80

20

(CLOSED) 461

(OPEN) 653

Dimensions wallbracket

286

16

2xØ 12

19

Installation and

service space

See page 1–13.

16

40

62

153 122

Ø 12

12

53

10

Ø

32

28

156

54

4

12

17

144

31

3

13

58

1–8 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

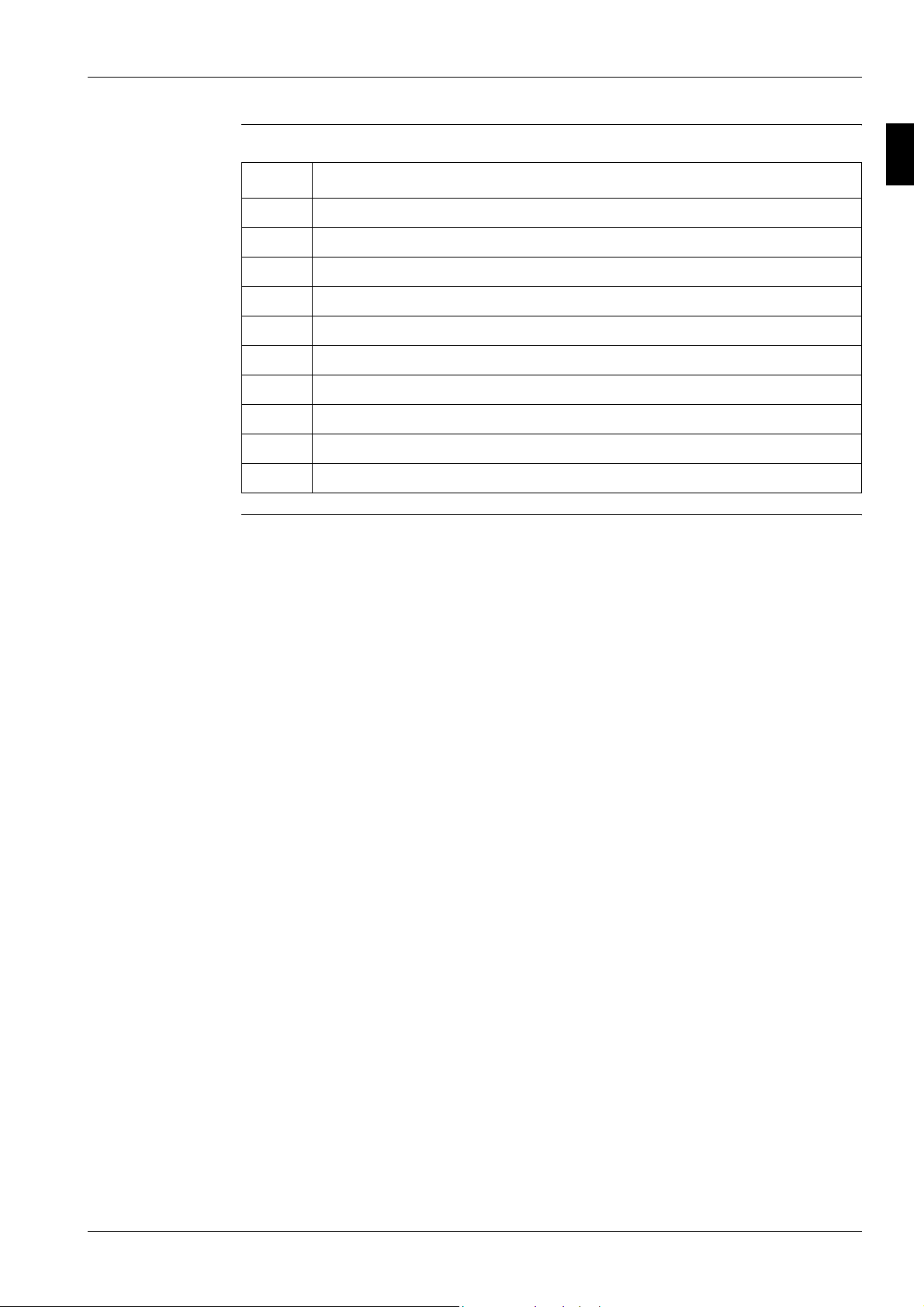

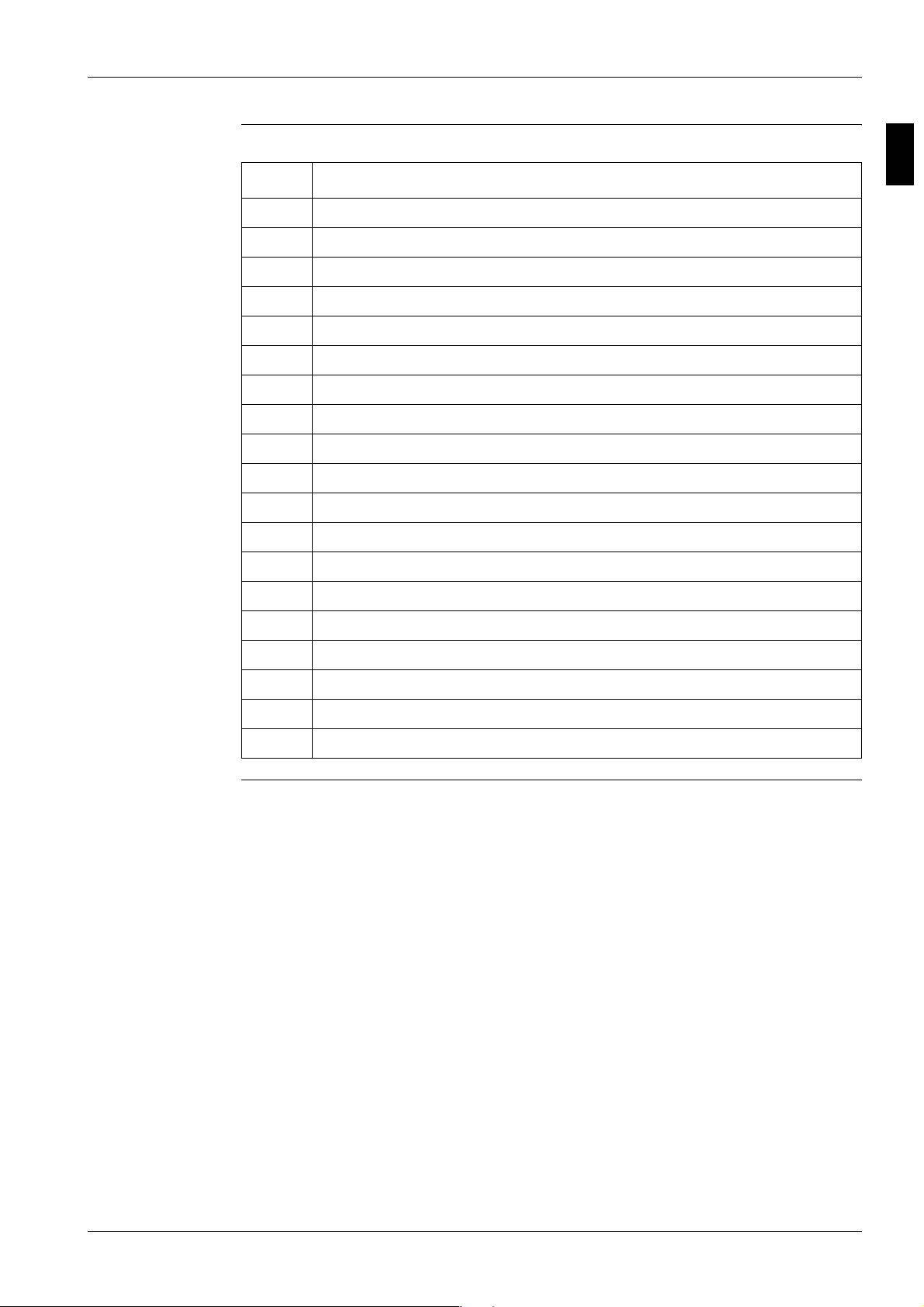

Components The table below contains the different components of the unit.

No. Component

1 Pump + switch for speed setting

2 Remocon

3 Water IN connection 1e M BSP

4 Water OUT connection 1e M BSP

5 Power supply intake (+ sanitary warm water tank)

6 Drain/fill valve

7 Air purge

8 Expansion vessel + nipple

9 Blow off valve

10 Pressure gauge

11 Wa terfilte r

12 Suction pipe connection φ15.9 flare connection

13 Liquid pipe connection φ9.52 flare connection

14 Shut off valves (delivered with unit)

15 Thermistor connection (+ sanitary warm water tank)

16 Holes for fixation

17 Blow off drain

18 Switchbox connection terminals

19 Wallbracket

Part 1 – System Outline 1–9

1

General Outline: Altherma ESIE06-03

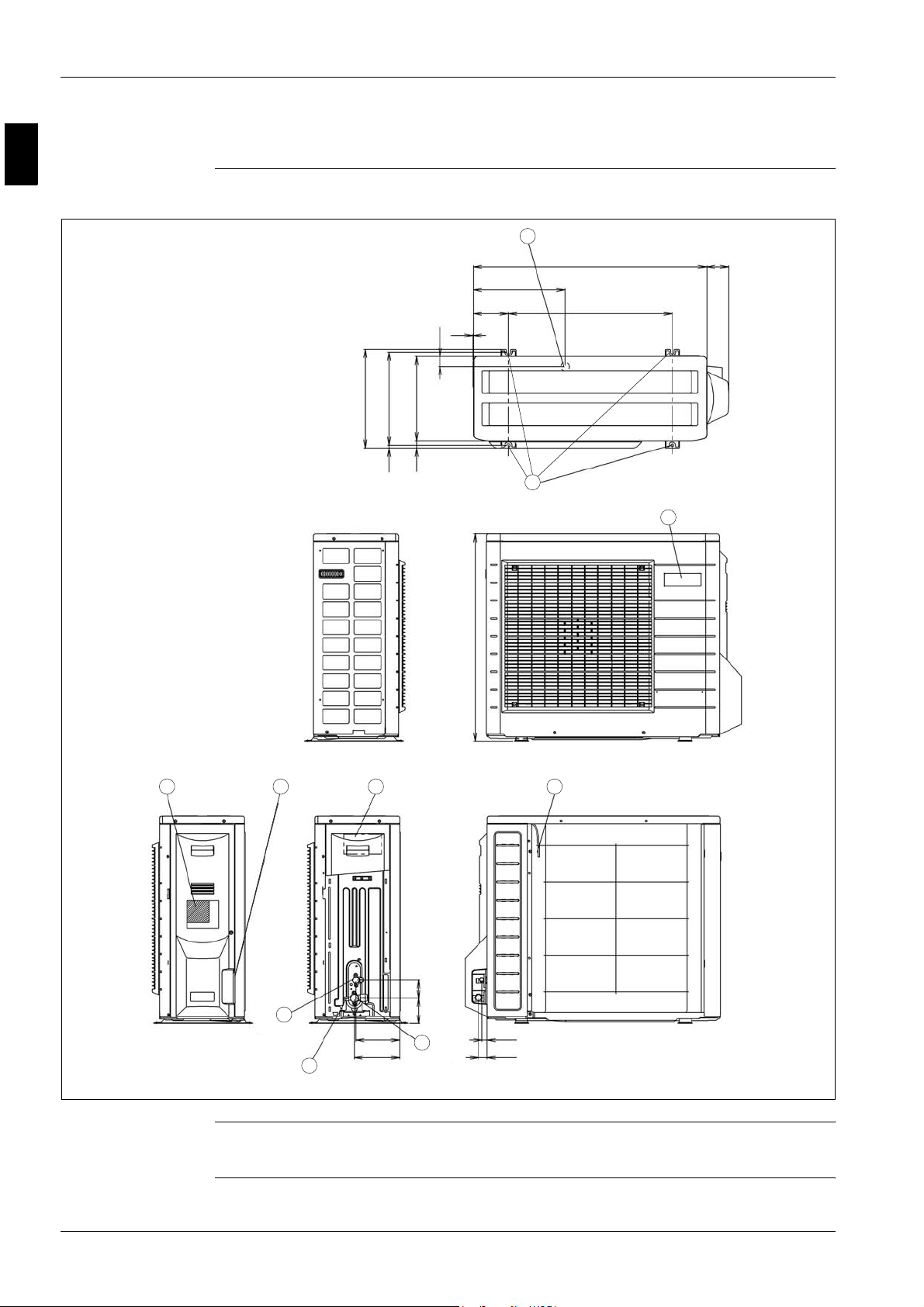

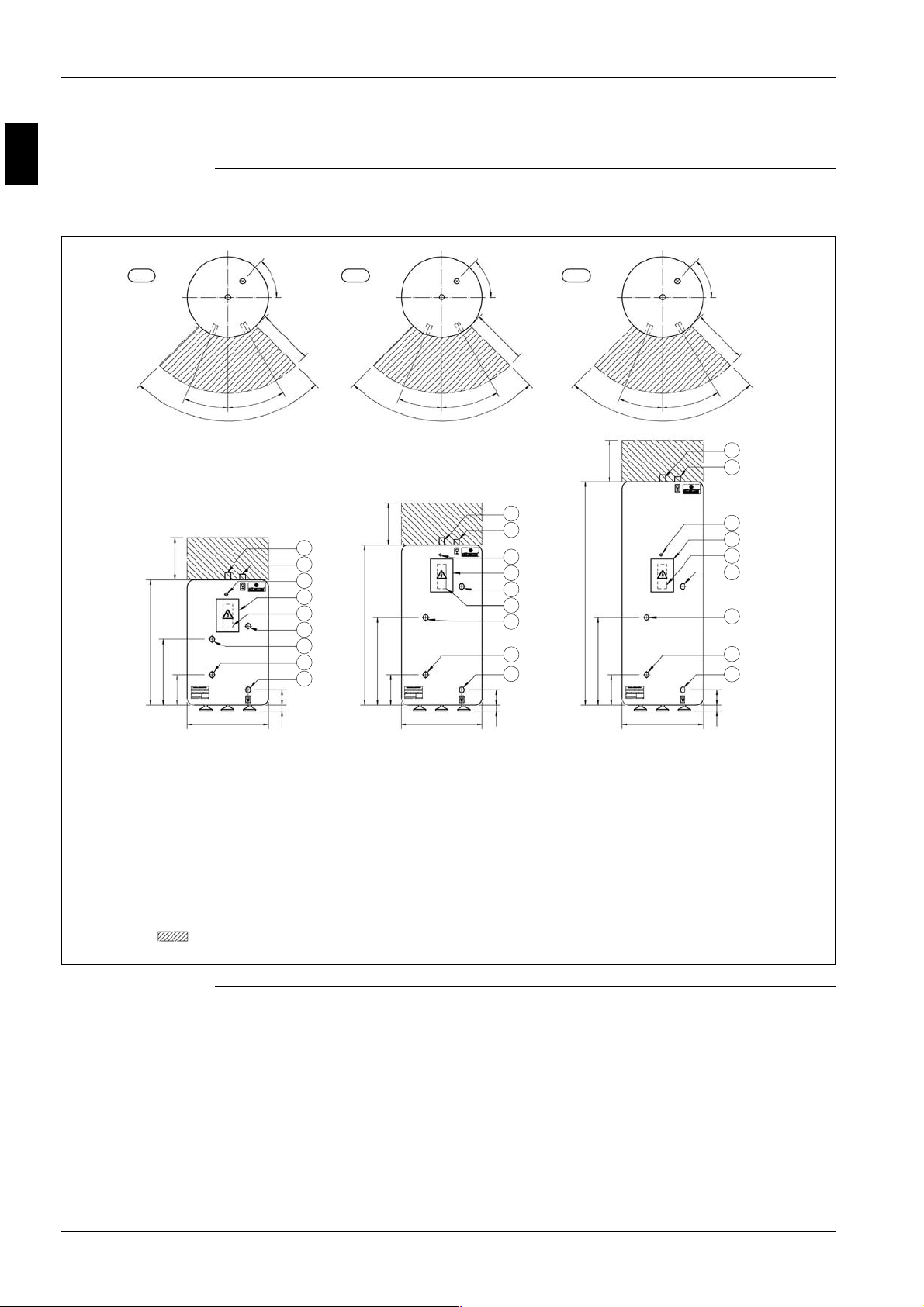

1.5 EKSWW150~300V3: Outlook and Dimensions - Service Space

Outlook and

dimensions Service space

150 L 200 L 300 L

The illustration below shows the outlook and the dimensions of the unit (mm).

47°

400

°

23

30

°

90°

23

°

90°

300

8

300

2

9

6

7

3

900

4

5

475

220

1

1150

630

220

47°

400

30°

23

°

90°

300

8

2

9

6

3

1600

7

4

5

1

630

220

47°

400

30°

8

2

9

6

7

3

4

5

1

580

Required service space

around the tank

0-40 110

580

0-40 110

580

0-40 110

1–10 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

Components The table below contains the different components of the unit.

No. Component

1 Water mains IN female 3/4’ BSP

2 Water mains OUT female 3/4’ BSP

3 Thermistor connection female 1/2’ BSP

4 Flow (from Hydro-box) female 3/4’ BSP

5 Return (to Hydro-box) female 3/4’ BSP

6 Switchbox

7Clixon

8 Connection female 1/2’ BSP

9 Power entrance

Part 1 – System Outline 1–11

1

General Outline: Altherma ESIE06-03

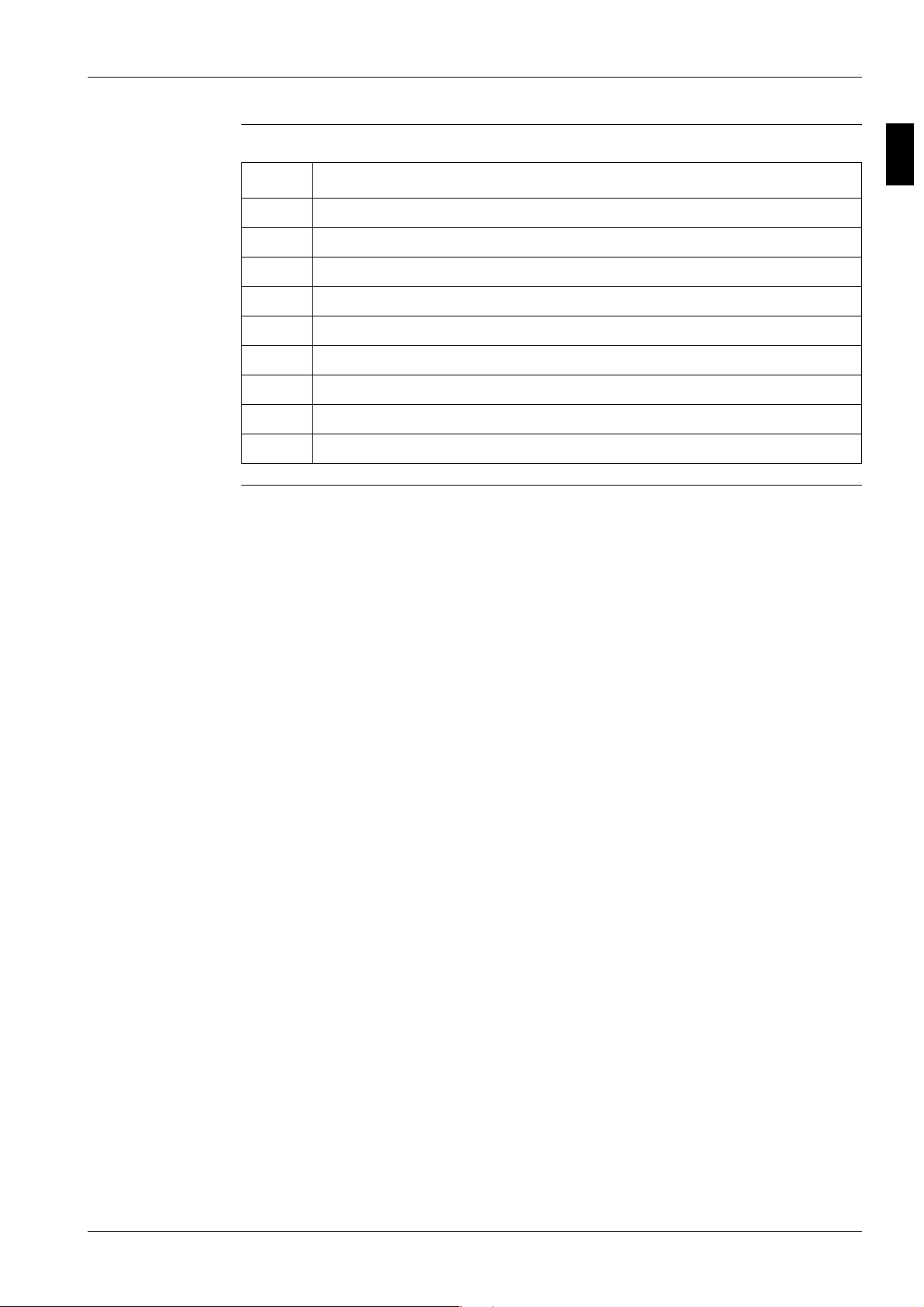

1.6 ERYQ005~007AAV3N: Installation and Service Space

Installing near a

wall or obstacle

Wall facing one side

(unit: mm)

Walls facing two

sides (unit: mm)

P Where a wall or other obstacle is in the path of the outdoor unit air intake or exhaust airflow, follow

the installation guidelines below.

P For any of the installation patterns below, the wall height on the exhaust side should be 1200 mm

or less.

<1200

>100

>100

>50

>350

>350

>50

Walls facing three

sides (unit: mm)

Remark:

P Back to back: 300 mm

P Front to front: 5000 mm

>50

>100

>350

1–12 Part 1 – System Outline

ESIE06-03 General Outline: Altherma

314

5

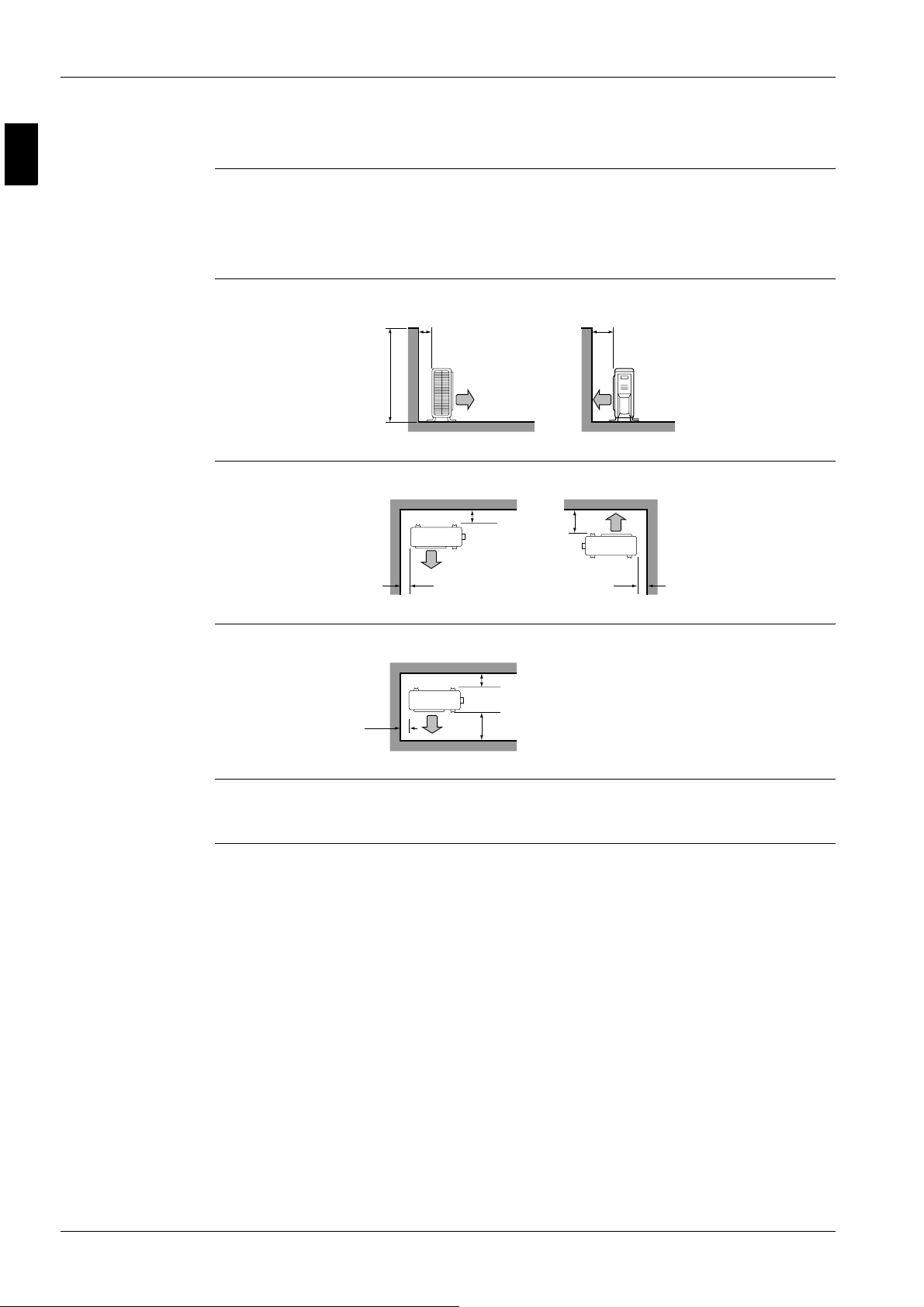

1.7 EKHBH(X)007A: Installation and Service Space

EKHBH The illustration below shows the minimum service space for service and ventilation.

B

A

250

≥ 200

500

≥ 400

172

460

AB

Setup 1 ≥ 200 ≥ 400

Setup 2 ≥ 350 ≥ 200

EKHBX The illustration below shows the minimum service space for service and ventilation.

B

A

250

≥ 200

500

≥ 400

235

460

AB

Setup 1 ≥ 200 ≥ 400

Setup 2 ≥ 350 ≥ 200

Part 1 – System Outline 1–13

1

General Outline: Altherma ESIE06-03

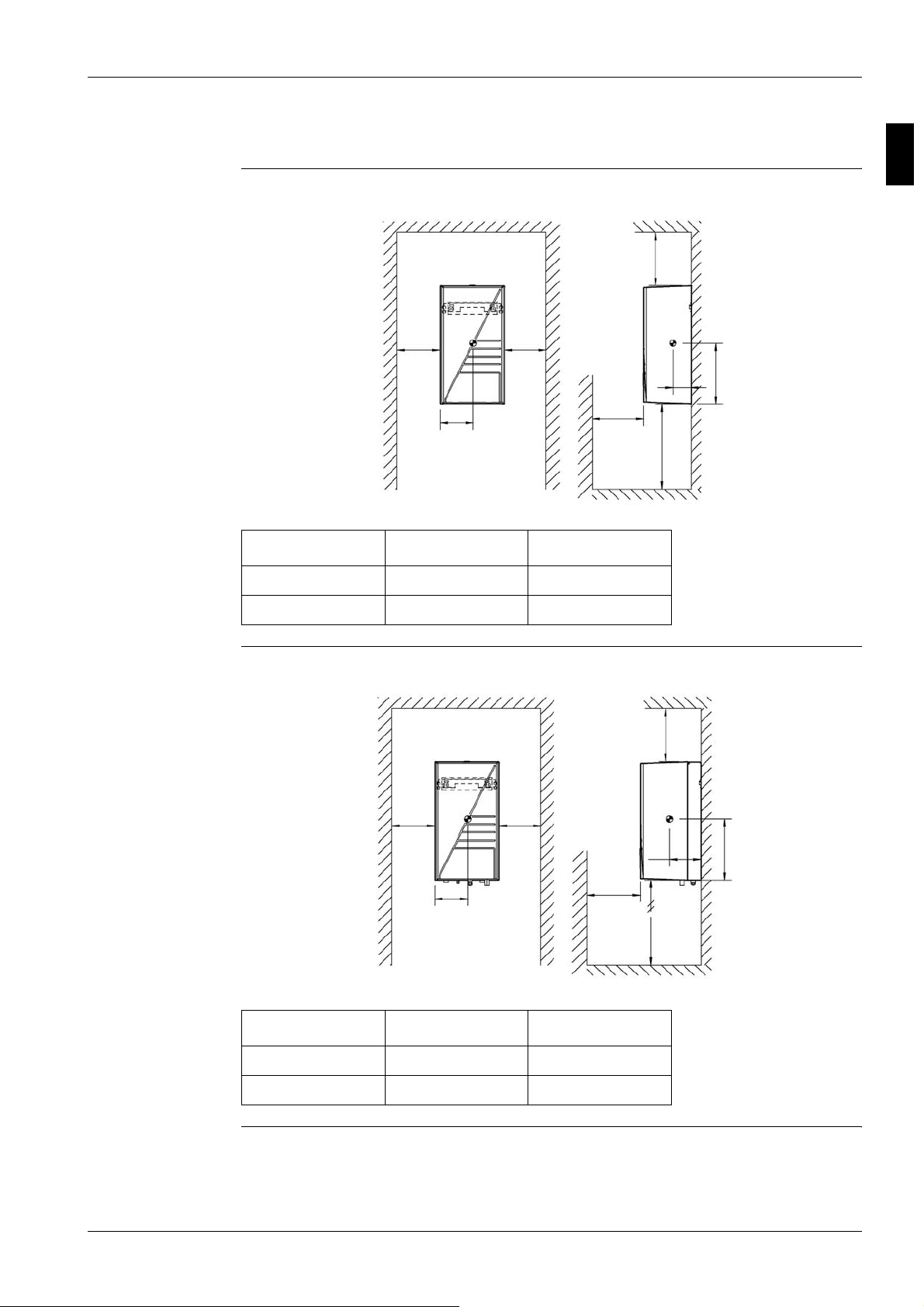

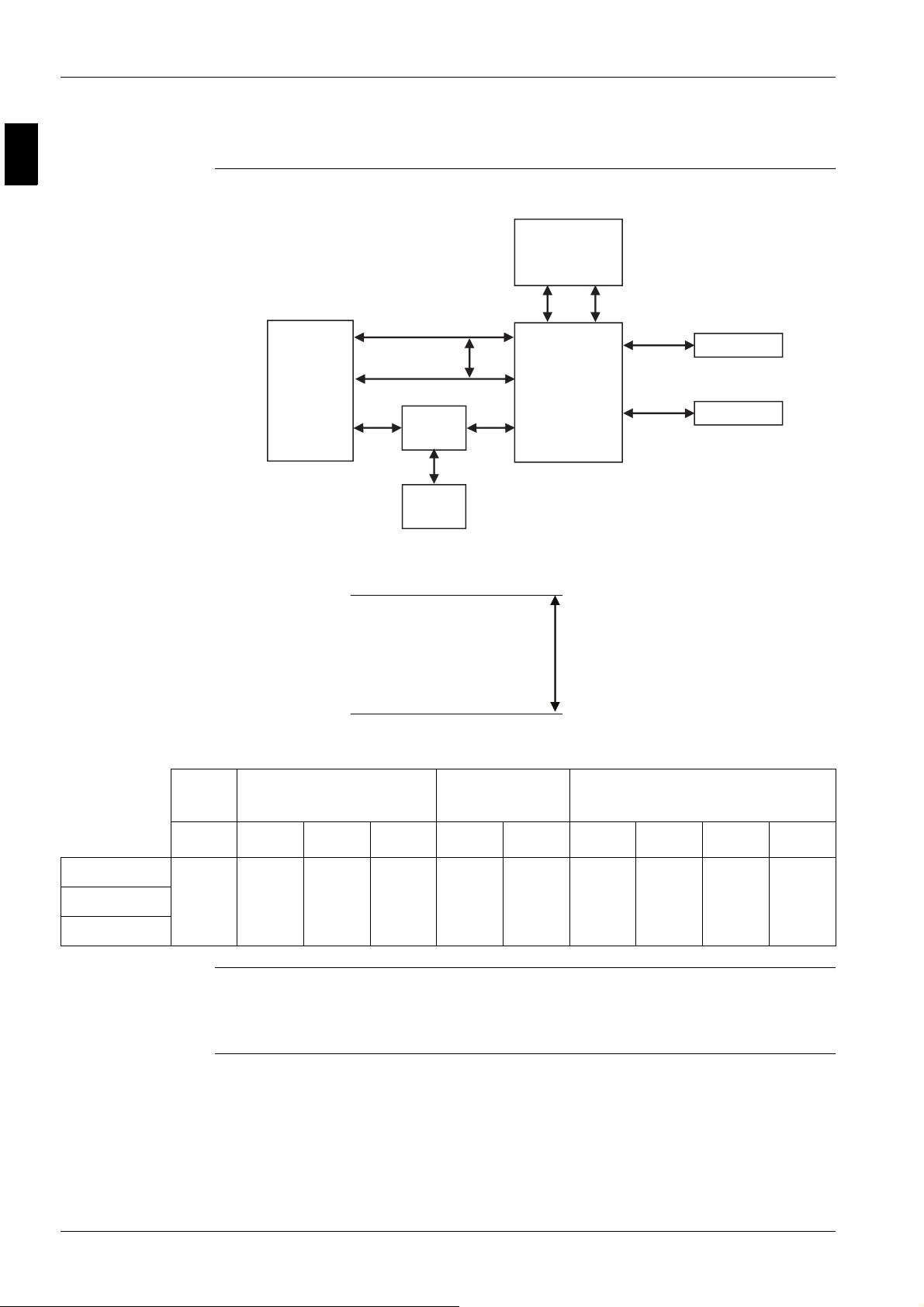

1.8 Physical Limitations and Limits of Operation

Distance between

components

The illustrations and table below show the limitations.

A

G

H

Sanitary

tank

Allowable heigth:

indoor

F

3 way

valve

D

Heat

emitters

BC

OUTDOOR

E

INDOOR

Total system : ≤ 20 m

I

Thermostat

J

2 way valve

outdoor

Piping

R410A

ABCDE FGH I J

ERYQ005ABV3

ERYQ006ABV3

ERYQ007ABV3

Remark E: 123-wiring in/outdoor

3 < A ≤

30m

F: Power supply booster + Q2L safety

G: Thermistor cable supplied with the sanitary tanks is 12 m in length. May not be changed!

Piping water Power supply Communication

≤ 3 m ≤ 10 m

depend

on instal-

lation

depend

on instal-

lation

depend

on instal-

lation

(outdoor unit can be above

or below the hydro-box)

depend

12 m > 0.05 m

on instal-

lation

depend

on instal-

lation

1–14 Part 1 – System Outline

ESIE06-03 Specifications

314

5

Part 1

2 Specifications

2.1 What Is in This Chapter?

Introduction This chapter contains the following information:

P Technical specifications

P Electrical specifications

Altherma This chapter contains the following specifications:

Specifications See page

2.2–ERYQ005~007 1–16

2.3–EKHBH and EKHBX 1–18

2.4–EKSWW150~300V3/Z2 1–20

Part 1 – System Outline 1–15

1

Specifications ESIE06-03

2.2 ERYQ005~007

Technical

specifications

The table below contains the technical specifications.

Specification ERYQ005~007

Casing

Dimensions

Weight

Packing Material EPS, CARTON

Heat exchanger Specifications Length 845 mm

Fan Type Propeller

Compressor Quantity 1

Operation range (see Altherma

operation manual)

Sound level (nominal) Heating Sound power (5/6/7) 64/64/66 dBA

Sound level (night quiet) Sound pressure —

Refrigerant Type R410A

Colour Ivory white

Material Polyester painted galvanised steel

Packing Height 797 mm

Width 960 mm

Depth 390 mm

Unit Height 735 mm

Width 825 mm

Depth 300 mm

Machine weight 56 kg

Gross weight 61 kg

Weight 5 kg

Nr. of rows 2

Fin pitch 1.8 mm

Nr. of passes —

Face area —

Nr. of stages 32 m²

Tube type Hi-Xa(8)

Fin Type WF fin

Treatment Anti-corrosion treatment (PE)

Discharge direction Horizontal

Quantity 1

Air flow rate (nominal at 230 V) Heating high —

Heating low —

Cooling high —

Cooling low —

Motor Quantity 1

Output 53 W

Motor Model 2YC63BXD#C

Type Hermetically sealed swing compressor

Output 1920 W

Heating Min. -20°C DB

Max. 25°C DB

Cooling Min. 7°C WB

Max. 20°C WB

Sanitary water Min. -20°C DB

Max. 43°C DB

Sound pressure (5/6/7) 48/48/52 dBA

Cooling Sound power 63/64/66 dBA

Sound pressure (5/6/7) 47/47/53 dBA

Charge 1.7 kg

Control Expansion valve (electronic type)

Nr. of circui ts 1

1–16 Part 1 – System Outline

ESIE06-03 Specifications

314

5

Specification ERYQ005~007

Refrigerant oil Type FVC50K

Charged volume 0.75 l

Piping connections Liquid Type Flare connection

Diameter (OD) 6.35 mm

Gas

Drain Quantity 1

Piping length Min. 3 m

Additional refrigerant charge 0.02 IF > 10 m

Installation height difference max. 15 m

Max. interunit level difference 20 m

Defrost method Reverse cycle

Defrost control Sensor for outdoor heat exchanger temperature

Capacity control method Inverter controlled

Standard accessories Item Installation manual, drain plug

Quanti ty 1

Type Flare connection

Diameter (OD) 15.9 mm

Type Socket

Diameter (OD) 18 mm

Max. 30 m

Equivalent —

Chargeless —

Electrical

specifications

The table below contains the electrical specifications.

Specification ERYQ00

Power supply Name V1

Phase 1

Frequency 50 Hz

Volt age 220 V-240 V

Voltage range Minimum -10% (V)

Maximum +10% (V)

Current Nominal running current Cooling —

Heating —

Starting current Cooling 11 A

Heating 11 A

Maximum running current Cooling 16.25 A

Heating 18 A

Recommended fuses 20 A

Wire connections For power supply Quantity 3

Remark —

For connection with hydro-box Quantity 4

Remark Included earth wiring

Part 1 – System Outline 1–17

1

Specifications ESIE06-03

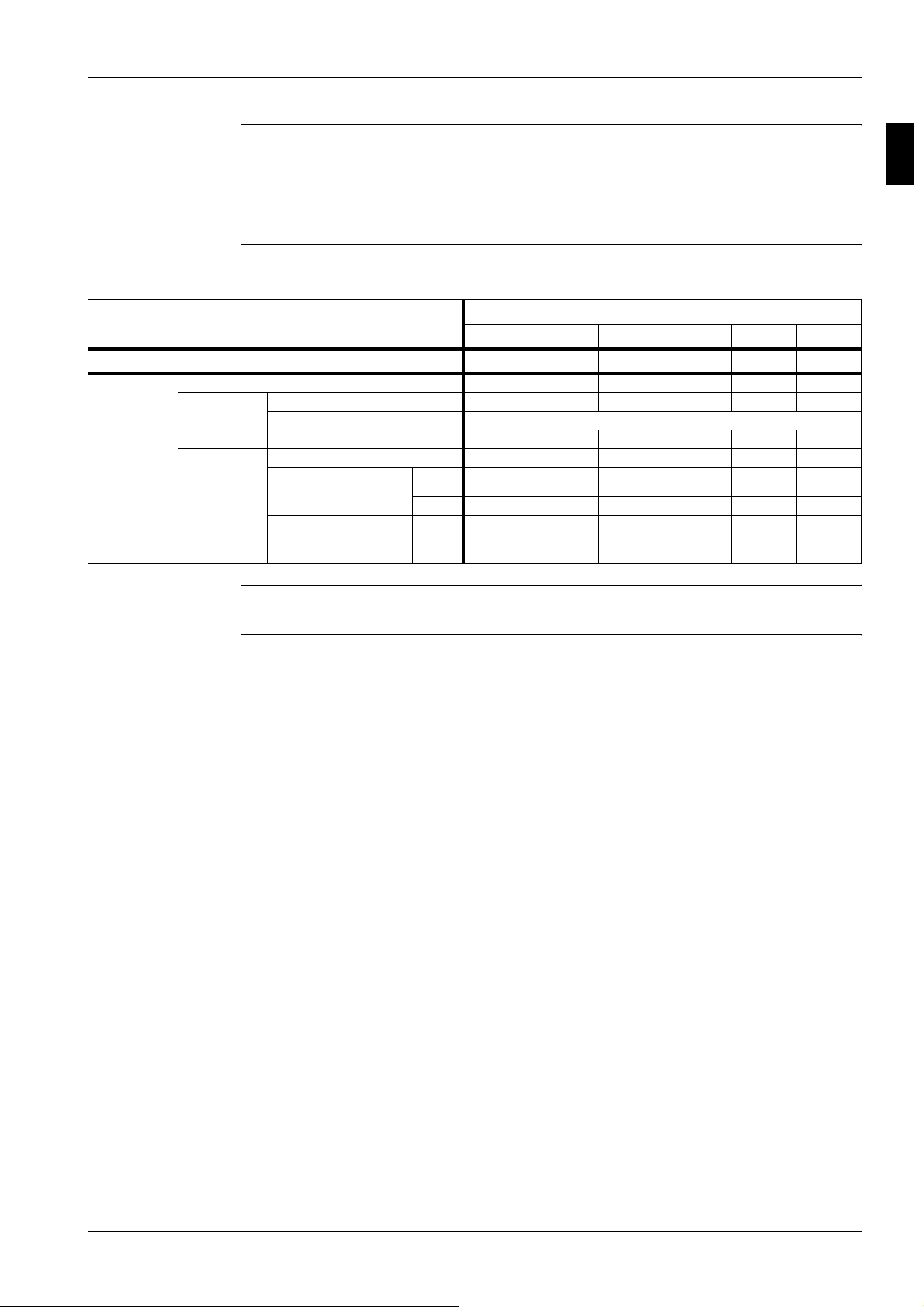

2.3 EKHBH and EKHBX

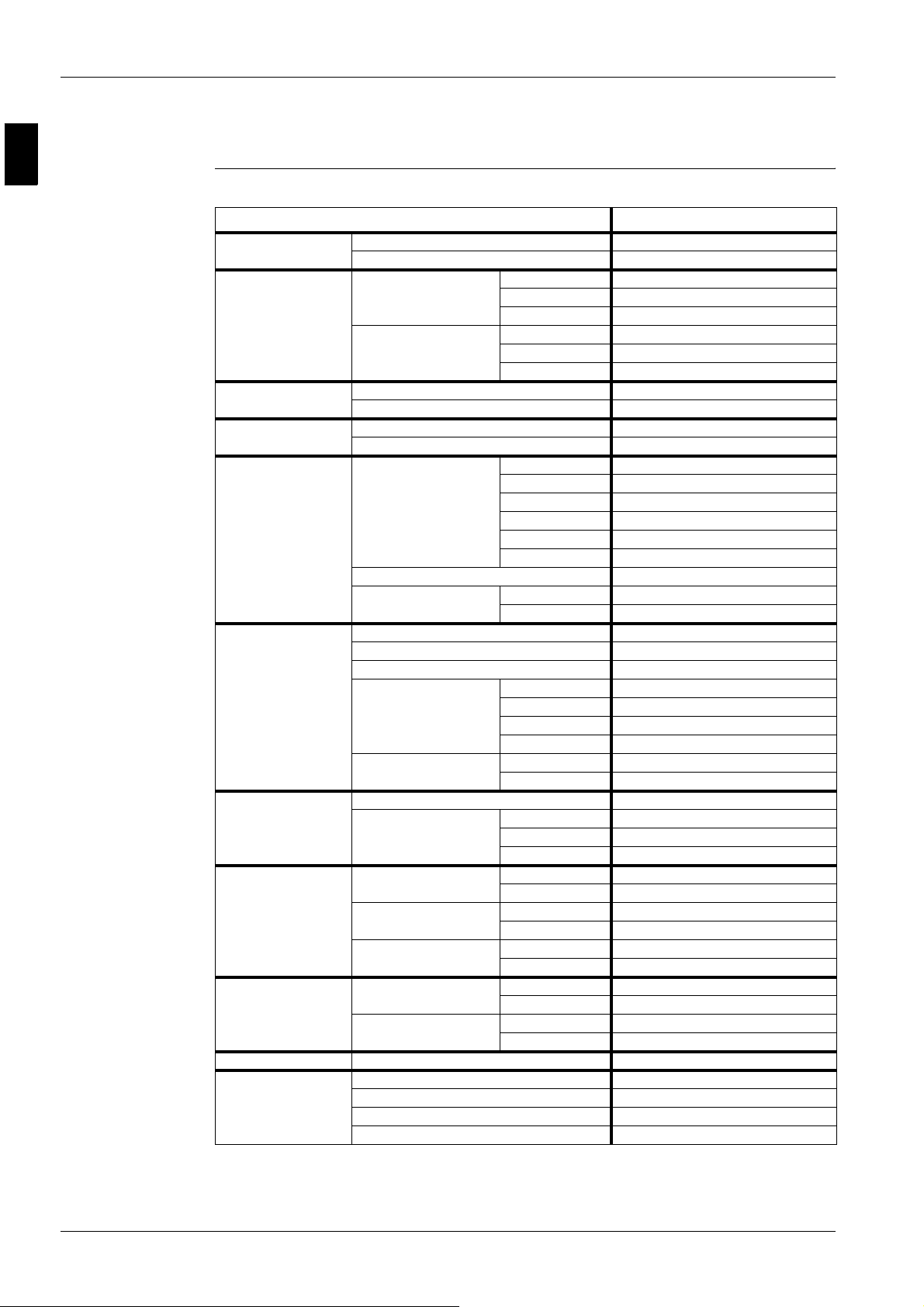

Technical

The table below contains the technical specifications.

specifications

Specification EKHBH* EKHBX*

EKHBH007A* EKHBH007A* EKHBH007A* EKHBX007* EKHBX007* EKHBX007*

Outdoor units ERYQ005A ERYQ006A ERYQ007A ERYQ005A ERYQ006A ERYQ007A

Nominal input (indoor only without electric heater) 230 W

Casing Colour RAL9010

Material E poxy polyester painted galvanised steel

Dimensions Packing Height 1225 mm

Width 660 mm

Depth 595 mm

Unit Height 895 mm 936 mm

Width 487 mm 487 mm

Depth 361 mm 461 mm

Weight Machine weigth 55 kg 65 kg

Gross weight 65 kg 75 kg

Packing Material EPS/Wood/Carton/PS (straps)

Weight 10 kg 10 kg

Main components Pump Type Water cooled

Nr. of speed 3

Nominal ESP unit Cooling — — — 49.9 kPa 46.5 kPa 44.4 kPa

Nominal ESP unit Heating 46.5 kPa 40.1 kPa 29.0 kPa 46.5 kPa 40.1 kPa 29.0 kPa

Power input 130 W

Water side Heat exchanger Type Brazed plate

Quantity 1

Water volume 0.67 l

Water flow rate Min. 12 l/min 12 l/min 12 l/min 12 l/min 12 l/min 12 l/min

Water flow rate Nom. Cooling — — — 14.7 l/min 16.5 l/min 17.6 l/min

Water flow rate Nom. Heating 16.5 l/min 19.6 l/min 24.2 l/min 16.5 l/min 19.6 l/min 24.2 l/min

Water flow rate Max. Cooling — — — — — —

Water flow rate Max. Heating — — — — — —

Insulation material Polyurethane foam

Expansion vessel Volume 10 l

Max. water pressure 3 bar

Pre-pressure 1 bar

Water filter Diameter perforations 1 mm

Material Brass

Water circuit Piping connections diameter 1” MBSP

Piping 1” MBSP

Safety valve 3

Manometer Yes

Drain valve/Fill valve Yes

Shut off valve Yes

Air purge valve Yes

Refrigerant ciruit Gas side diameter 15.9 mm

Liquid side diameter (2)

Sound level Sound pressure 27 dBA

Sound power —

Operation range Waterside Cooling 7~20°C

Heating 30~55°C

1–18 Part 1 – System Outline

ESIE06-03 Specifications

314

5

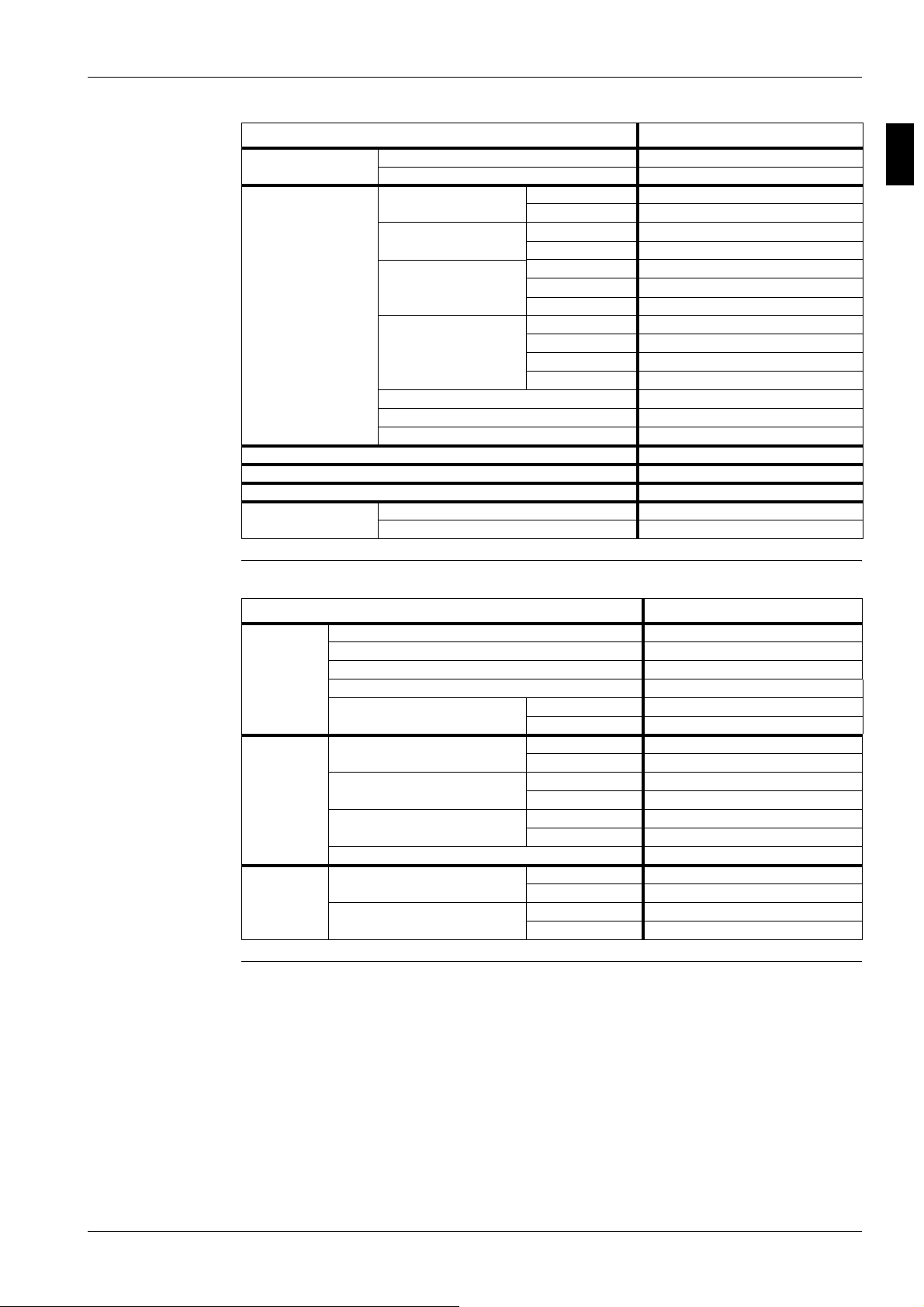

Notes: 1 The sound pressure level is measured via a microphone at a certain distance from the unit. It is a relative value, depending on

the distance and acoustic environment:

2 (2):

P ERYQ-models: 6.35 mm

P EKHB-models: 9.52 mm (flare connection)

Electrical

The table below contains the electrical specifications.

specifications

Specification EKHBH* EKHBX*

EKHBH007A* EKHBH007A* EKHBH007A* EKHBX007* EKHBX007* EKHBX007*

Outdoor units ERYQ005A ERYQ006A ERYQ007A ERYQ005A ERYQ006A ERYQ007A

Electric heater Type 3V3 6V3 6W1 6T1 9W1 9T1

Power supply Phase 1~ 1~ 3N~ 3~ 3N~ 3~

Frequency 50 Hz

Voltage 230 V 230 V 400 V 230 V 400 V 230 V

Current Running current 13 A 26 A 8.6 A 15 A 13 A 23 A

Zmax. List No

Text — 0.25 + j0.15 — — — —

Zmax. electric heater + booster

heater (EKSWW* models)

List — — No

Text 0.25 + j0.15 0.17 + j0.10 — — — —

requirements

—No

requirements

requirements

Out of scoop No

Out of scoop No

requirements

requirements

Out of scoop

Out of scoop

Notes: 1

Electric heater has 2 capacity steps except for the 3V3 model which has only 1 capacity step.

Part 1 – System Outline 1–19

1

Specifications ESIE06-03

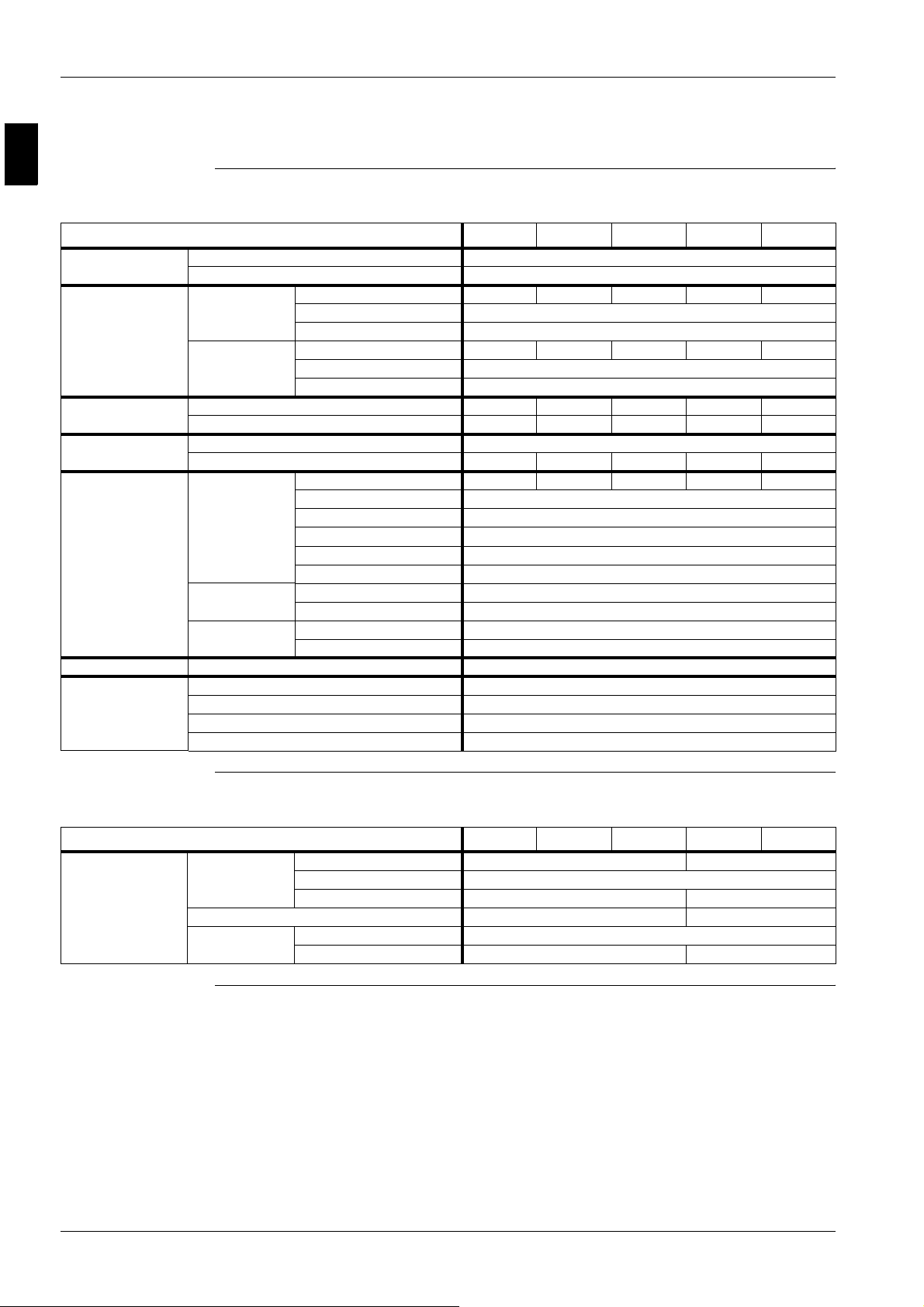

2.4 EKSWW150~300V3/Z2

Technical

The table below contains the technical specifications.

specifications

Specification EKSWW150V3 EKSWW200V3 EKSWW300V3 EKSWW200Z2 EKSWW300Z2

Casing Colour Neutral white

Material Epoxy-coated mild steel

Dimensions Packing Height 950 mm 1200 mm 1650 mm 1200 mm 1650 mm

Width 600 mm

Depth 600 mm

Unit Height 900 mm 1150 mm 1600 mm 1150 mm 1600 mm

Width 580 mm

Depth 580 mm

Weight Machine weigth 37 kg 45 kg 59 kg 45 kg 59 kg

Gross weight 40 kg 49 kg 64 kg 49 kg 64 kg

Packing Material EPS/Carton

Weight 3 kg 4 kg 5 kg 4 kg 5 kg

Main components Tank Water volume 150 l 200 l 300 l 200 l 300 l

Material Stainless steel (DIN 1.4521)

Max. temperature 85°C

Max. water pressure 10 bar

Insulation Material Polyurethane foam

Insulation Min. thickness 40 mm

Heat exchanger Quantity 1

Material Stainless steel (DIN 1.4401)

Booster heater Quantity 1

Capacity 3 kW

Temperature sensor Cable length 12 m

Piping connections Water inlet H/E Diameter 3/4” FBSP (inch)

Water outlet H/E Diameter 3/4” FBSP (inch)

Cold water in Diameter 3/4” FBSP (inch)

Hot water out Diameter 3/4” FBSP (inch)

Electrical

The table below contains the electrical specifications.

specifications

Specification EKSWW150V3 EKSWW200V3 EKSWW300V3 EKSWW200Z2 EKSWW300Z2

Unit Power supply Phase 1~ 2~

Frequency 50 Hz

Voltage 230 V 400 V

Nominal running current 13 A 7.5 A

Fuse Size 20 A

Phase 1~ 2~

1–20 Part 1 – System Outline

ESIE06-03 Functional Diagrams

314

5

Part 1

3 Functional Diagrams

3.1 What Is in This Chapter?

Introduction This chapter contains the following information:

P Overview complete system

P Electrical connection diagram

P Pipe connection diameters.

Functional

diagrams

This chapter contains the following functional diagrams:

Functional diagram See page

3.2–Complete System 1–22

3.3–Electrical Connection Diagram 1–24

3.4–Pipe Connection Diameters 1–25

Part 1 – System Outline 1–21

1

Functional Diagrams ESIE06-03

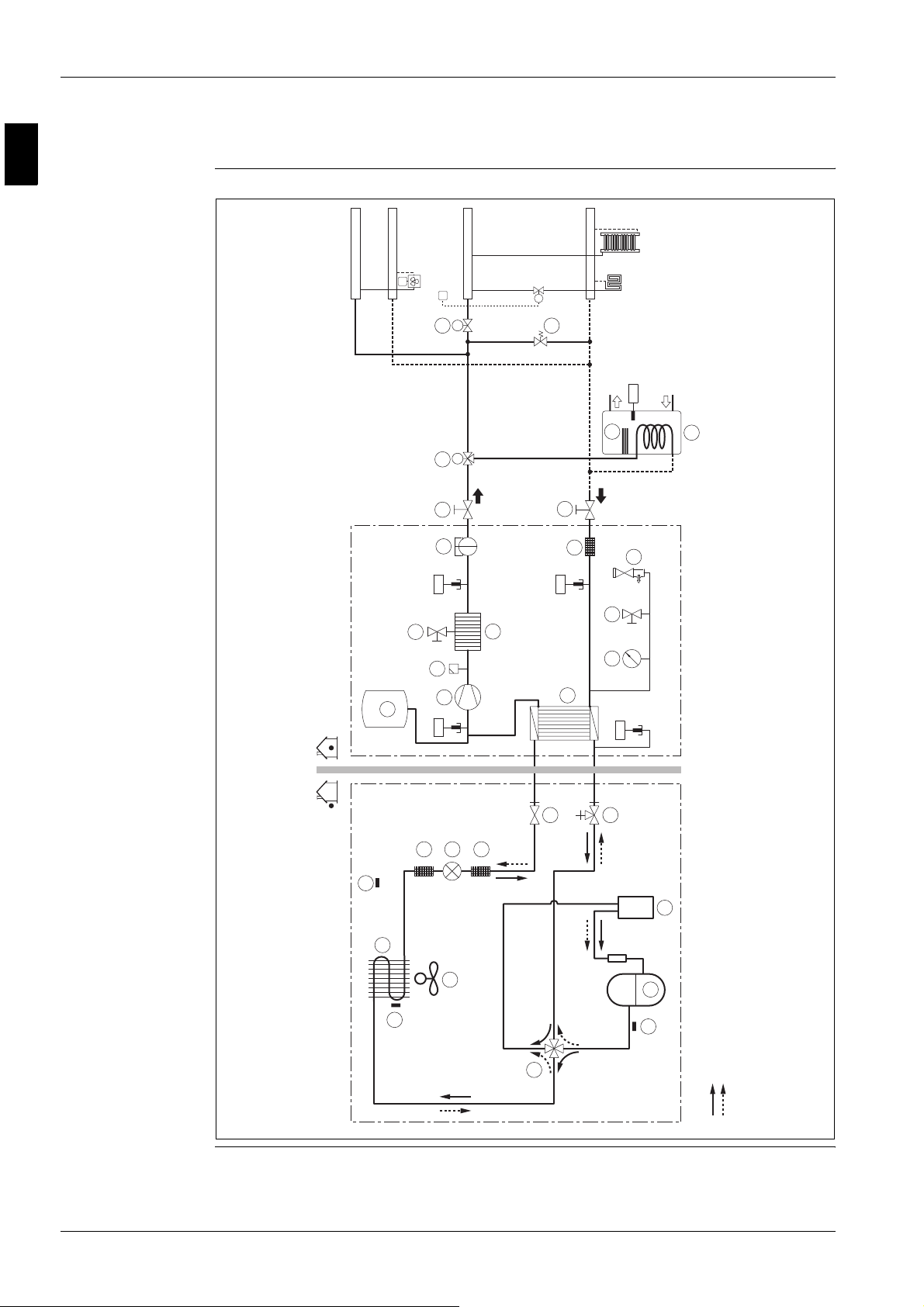

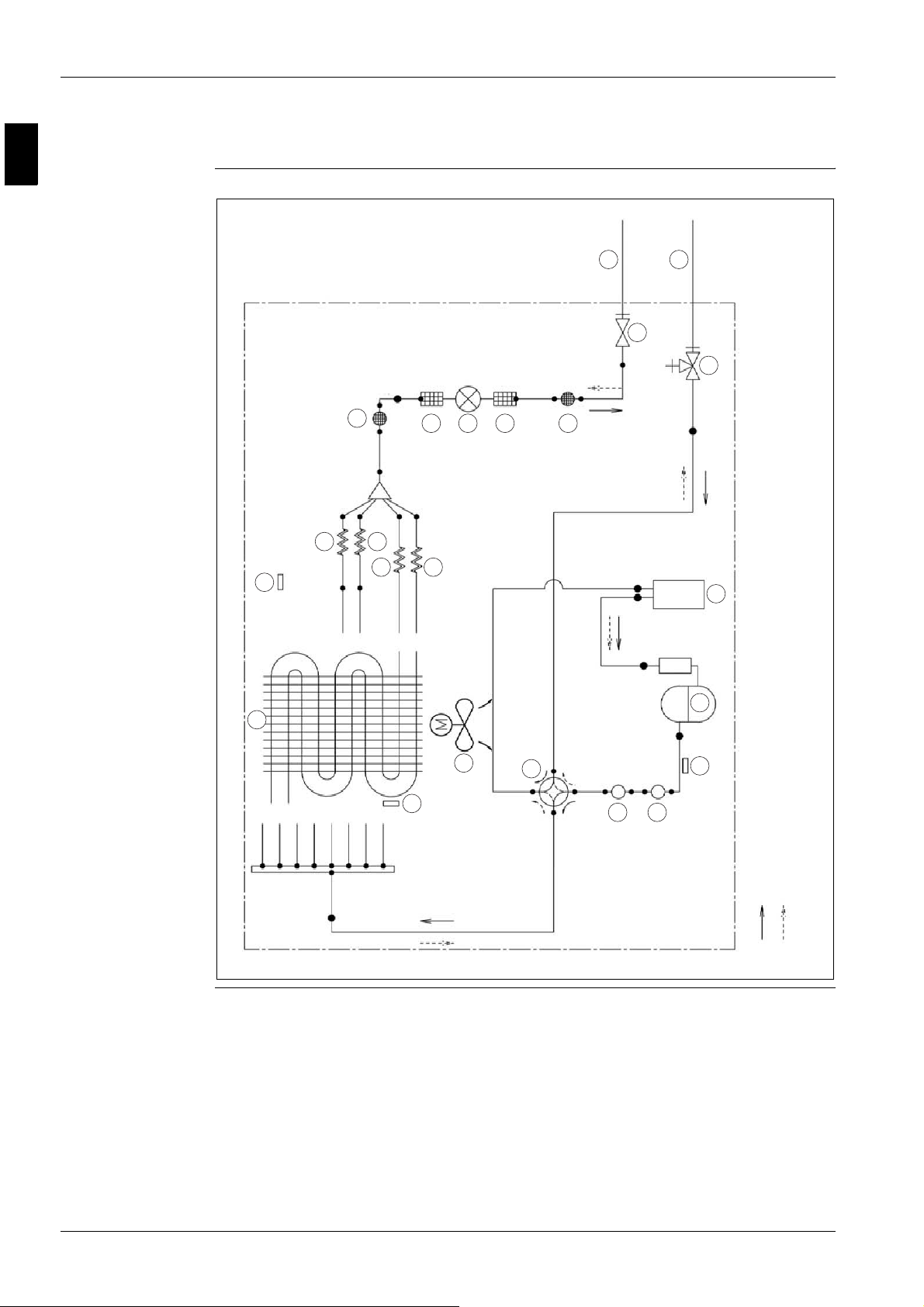

3.2 Complete System

T1

FCU1

T1

M1

M

M

19 24 27

17

t >

R2T

16

15

R1T

14

t >

13

18

28

t >

R5T

25

20

5

t >

R4T

O

2

2

H

2221

R3T

23

t >

26

7

5

6

5

1

2

M

4

3

12

8

9

10

11

cooling

heating

refrigerant flow

1–22 Part 1 – System Outline

ESIE06-03 Functional Diagrams

314

5

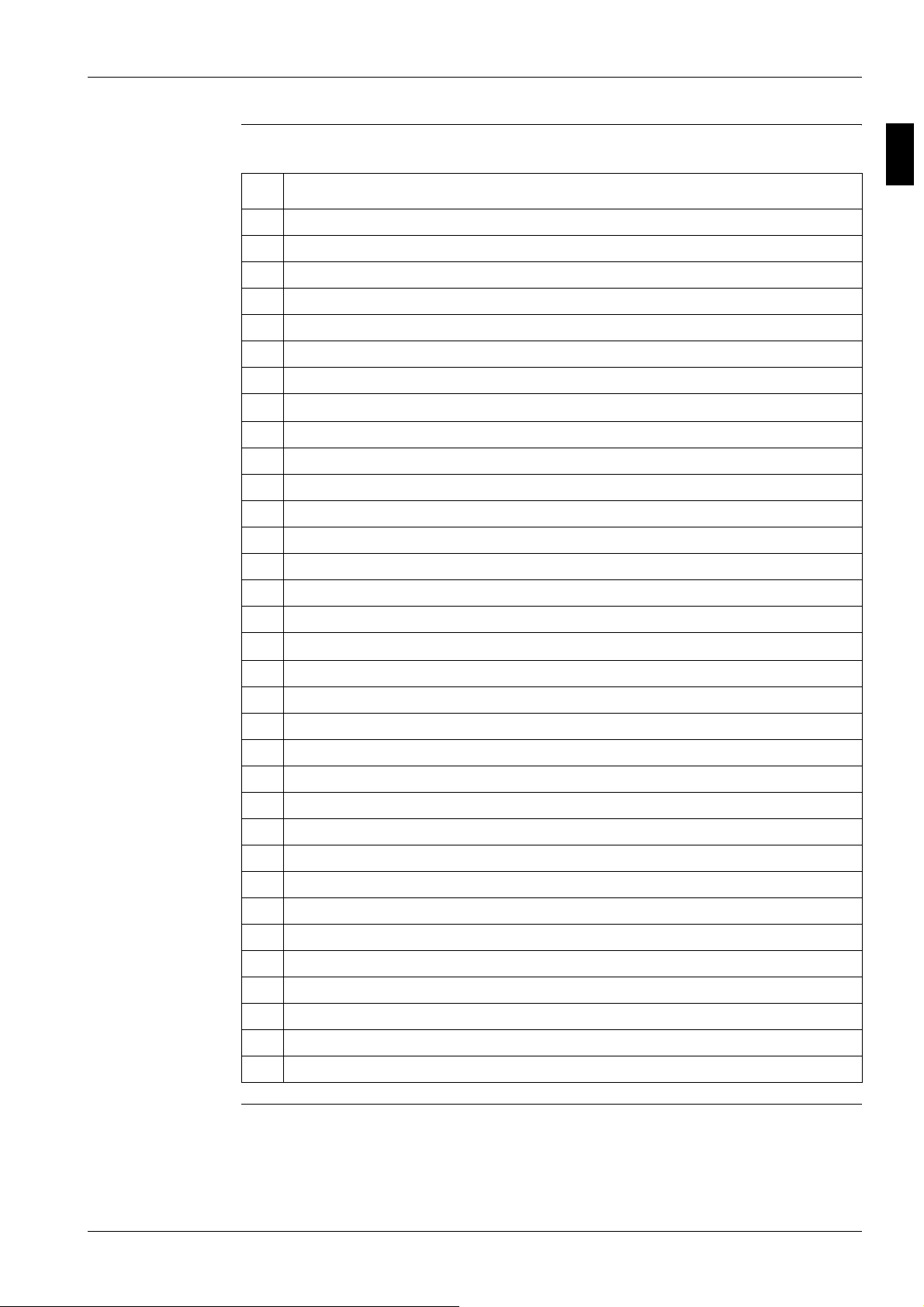

Components The table below contains the different components of the functional diagrams.

No. Name

1 Outdoor air temperature thermistor

2 Heat exchanger

3 Heat exchanger thermistor

4 Propeller fan

5Filter

6 Expansion valve

7 Liquid stop valve

8

Gas stop valve with service port

9 Accumulator

10 Compressor

11 Discharge pipe thermistor

12 4-way valve ON: heating

13 Expansion vessel

14 Pump

15 Air purge valve

16 Drain valve

17

Flow switch

18 Backup heater

19 Outlet

20 Inlet

21 Manometer

22 Fill and drain valve

23 Pressure relief valve

24 3-way valve for sanitary water tank

25 Booster heater

26 SWW tank

27 2-way valve for cooling mode

28 By-pass valve

R1T Outlet water Heatexchanger thermistor

R2T Outlet water Backup heater thermistor

R3T Refrigerant water thermistor

R4T Inlet water thermistor

R5T Sanitary water tank thermistor

Part 1 – System Outline 1–23

1

Functional Diagrams ESIE06-03

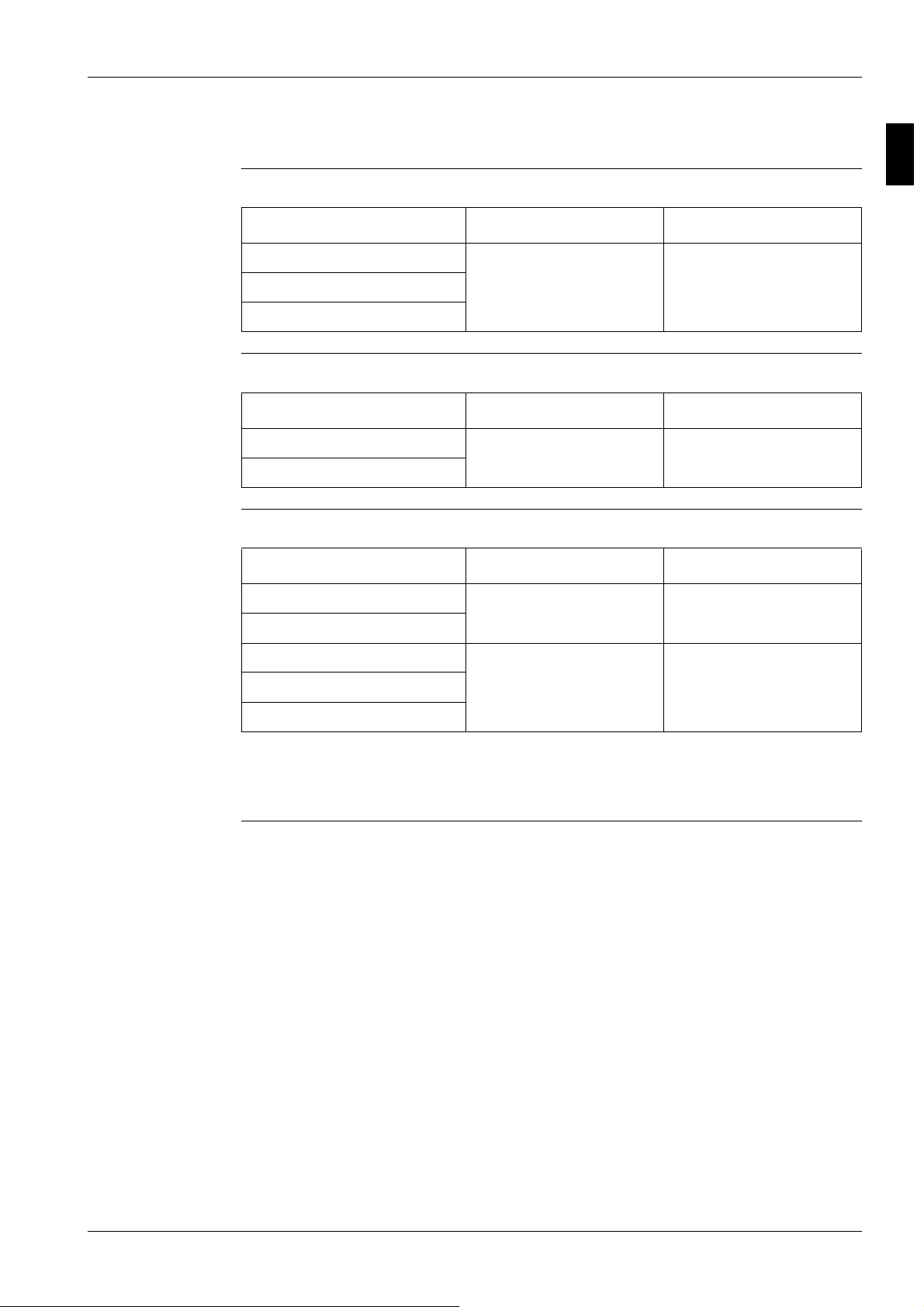

3.3 Electrical Connection Diagram

Standard parts

Power Supply

unit power supply: 230V + earth

backup heater power supply (3/6/9kW): 400V or 230V + earth

Optional power supply:

booster heater power supply(3kW): 400V or 230V + earth

3 core

3 core

Optional parts

SANITARY

TANK

Power supply

booster heater

Q2L - Clixon

booster heater

R5T - Thermistor

water temperature

5 core

5Gx2.5

230V or 400V

2 core

signal

Thermistor cable

NOTE: min. distance

to power cable = 3cm

3 or 4 core

OUTDOOR UNIT

X1M:L-N-earth

X2M:1-2-3-earth

<10m:4Gx1.5

<10m:4Gx2.5

F1B

F2B

X1M:7-8-earth X1M:13-15-17-23

X1M:21-22

X9A (PCB A1P)

4 core

X1M:9-10-11-earth

NO valve: X1M:16-18

NO valve: X1M:14-18

X1M:19-20

HYDRO-BOX

user

interface

For more details

please check unit wiring diagram

Field supply

4 core

230V

2 core

230V

Room thermostat

A3P (optional)

2way valve

M2S (EKHBX units)

for cooling mode

3way valve

M3S (when EKSWW is installed)

1–24 Part 1 – System Outline

ESIE06-03 Functional Diagrams

314

5

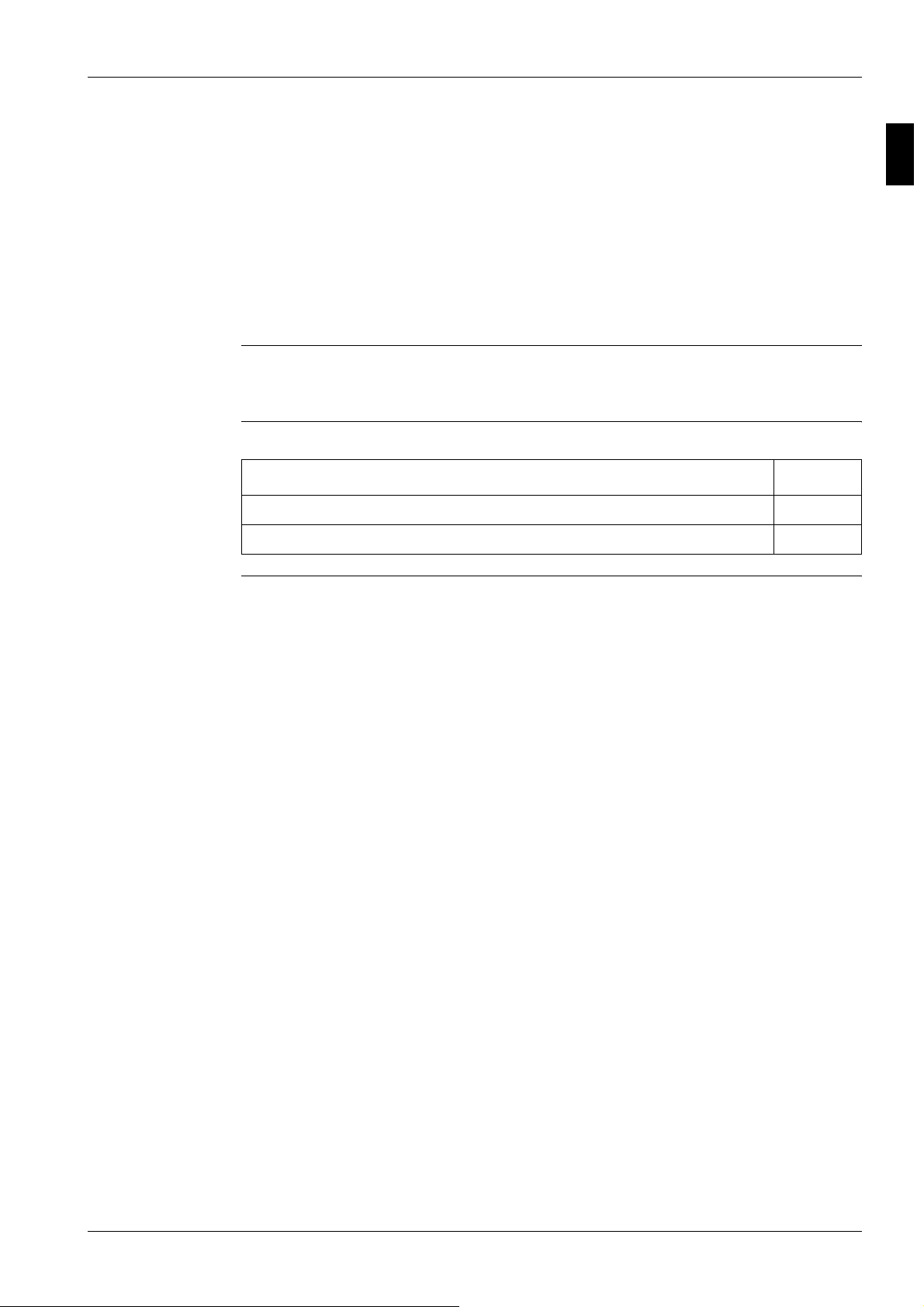

3.4 Pipe Connection Diameters

Outdoor units The table below contains the refrigerant pipe connection diameters.

Model ∅ Gas pipe (flare) ∅ Liquid pipe (flare)

ERYQ005ABV3 15.9 mm 6.4 mm

ERYQ006ABV3

ERYQ007ABV3

Hydro-box The table below contains the refrigerant pipe connection diameters.

Model ∅ Gas pipe (flare) ∅ Liquid pipe (flare)

EKHBH007A 15.9 mm 6.4 mm

EKHBX007A

Hydro-box + water

side

The table below contains the water inlet/outlet connection diameters.

Model ∅ Gas pipe (flare) ∅ Liquid pipe (flare)

EKHBH007A 1 inch

EKHBX007A

EKSWW150 3/4 inch

EKSWW200

EKSWW300

1: MBSP = male British standard pipe

2: FBSP = female British standard pipe

(MBSP)

(FBSP)

1

2

1 inch

(MBSP)

3/4 inch

(FBSP)

Part 1 – System Outline 1–25

1

Functional Diagrams ESIE06-03

1–26 Part 1 – System Outline

ESIE06-03 Piping Diagrams

314

5

Part 1

4Piping Diagrams

4.1 What Is in This Chapter?

Introduction This chapter contains the following information:

P Piping diagrams

Piping diagrams This chapter contains the following piping diagrams:

Functional diagram See page

4.2–ERYQ005~007 1–28

4.3–EKHBH(X) 1–30

Part 1 – System Outline 1–27

1

Piping Diagrams ESIE06-03

4.2 ERYQ005~007

11

(6.4 CuT)

11

(15.9 CuT)

10

12

6.4 CuT

6.4 CuT

4

5

6.4 CuT

8

9

6

7

3

19

7.9 CuT 4.0 CuT

7.9 CuT 4.0 CuT

4.0 CuT

4.0 CuT

12.7 CuT

6.4 CuT

8

7

6.4 CuT

12.7 CuT

13

12.7 CuT

1

7.9 CuT

7.9 CuT

7.9 CuT

7.9 CuT

7.9 CuT12.7 CuT

7.9 CuT

7.9 CuT

18

2

7.9 CuT

17

7.9 CuT

7.9 CuT

16

12.7 CuT 12.7 CuT

Outdoor Unit

15 14

16

cooling

heating

refrigerant flow

1–28 Part 1 – System Outline

ESIE06-03 Piping Diagrams

314

5

Components The table below contains the different components of the functional diagrams.

No. Name

1 Heat exchanger

2 Heat exchanger thermistor

3 Capillary Tube 1

4 Capillary Tube 2

5 Capillary Tube 3

6 Capillary Tube 4

7 Muffler with filter

8Filter

9 Motor operated valve

10 Liquid stop valve

11 Field piping

12 Gas stop valve with service port

13 Accumulator

14 Compressor

15 Discharge pipe thermistor

16 Muffler

17 4-way valve on: heating

18 Propeller fan

19 Outdoor air temperature thermistor

Part 1 – System Outline 1–29

1

Piping Diagrams ESIE06-03

4.3 EKHBH(X)

WATER SIDE

R4T

FIELD INSTALLATION

t >

INLET

2

OUTLET

2

FIELD INSTALLATION

5

1

43

OPTION

BACKUP HEATER

4

10

R2T

t >

9

8

7

R1T

t >

6

REFRIGERANT SIDE

WATER INLET

EVAPORATOR

CONDENSOR

t >

R3T

: COOLING (EKHBX)

: HEATING (EKHBX + EKHBH)

REFR. OUT

OVERVIEW

WATER

REFR.

REFR. IN

WATER OUTLET

SIDE

SIDE

REFR. IN

OUTDOOR UNIT

REFR. OUT

1–30 Part 1 – System Outline

Loading...

Loading...