Daikin EKSRPS4 Installation manuals

Operating and installation

instructions

Control and pump unit for solar systems for solar

systems

Operating and installation instructions

Control and pump unit for solar systems

English

EKSRPS4

1 x

Operating and installation instructions

2

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

List of contents

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Observing instructions . . . . . . . . . . . . . . . . . . . .4

2.2 Warning signs and explanation of symbols. . . . .4

2.3 Avoid danger. . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.5 Instructions for working safely. . . . . . . . . . . . . . .4

3 Product description . . . . . . . . . . . . . . . . . . .6

3.1 Design and components of the solar system . . .6

3.2 Brief description . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 System components . . . . . . . . . . . . . . . . . . . . . .7

3.3.1 Control and pump unit for solar systems

EKSRPS4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3.2 Filling and draining cock (KFE BA) for RPS4 . . . . 8

3.3.3 Regulating valve FlowGuard FLG . . . . . . . . . . . . . 8

3.3.4 Storage tank extension kit CON SX . . . . . . . . . . . 8

3.3.5 Storage tank extension kit 2 CON SXE. . . . . . . . . 8

4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 System concepts. . . . . . . . . . . . . . . . . . . . . . . . .9

4.1.1 Parallel connection . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.2 Serial connection. . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Installing the control and pump unit . . . . . . . . . .9

4.2.1 Installation pump unit. . . . . . . . . . . . . . . . . . . . . . 10

4.2.2 Installation FlowSensor, FlowGuard (optional) . . 11

4.2.3 Installing temperature sensor . . . . . . . . . . . . . . . 12

4.2.4 Preparing and fitting the control system . . . . . . . 12

4.2.5 Fit the covering hood. . . . . . . . . . . . . . . . . . . . . . 14

4.3 Linking several solar storage tanks. . . . . . . . . .15

6.3.10 Burner inhibit contact . . . . . . . . . . . . . . . . . . . . . . 30

6.4 Recommended settings . . . . . . . . . . . . . . . . . . 31

6.4.1 Standard parameter settings, recommended

setting ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2 Additional settings for your solar system . . . . . . . 32

6.4.3 Setting recommendation for the post-heating

via external heat sources or by the electrical

immersion heater, burner blocking contact . . . . . 33

6.4.4 Tips for optimised user behaviour . . . . . . . . . . . . 33

6.4.5 Domestic water hygiene . . . . . . . . . . . . . . . . . . . 33

7 Faults and malfunctions. . . . . . . . . . . . . . . 34

7.1 Display of events . . . . . . . . . . . . . . . . . . . . . . . 34

7.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 35

8 Hydraulic system connection . . . . . . . . . .37

8.1 Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.2 Connection of a pressure solar panel system . 39

9 Technical data. . . . . . . . . . . . . . . . . . . . . . .40

9.1 EKSRPS4 control and pump unit . . . . . . . . . . . 40

9.2 Sensor characteristics . . . . . . . . . . . . . . . . . . . 40

9.3 Connection allocation EKSRPS4 controller . . . 41

10 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

11 List of keywords . . . . . . . . . . . . . . . . . . . . . 43

5 Start-up and decommissioning . . . . . . . . .18

5.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.2 Decommissioning . . . . . . . . . . . . . . . . . . . . . . .19

5.2.1 Temporary shutdown. . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Final shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Control unit . . . . . . . . . . . . . . . . . . . . . . . . .21

6.1 Operating and display components . . . . . . . . .21

6.2 Operating mode of control system . . . . . . . . . .21

6.2.1 Pump operation . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.2 Booster function for high solar panel

temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Start optimisation. . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.4 Switch-on block functions . . . . . . . . . . . . . . . . . . 22

6.2.5 Pump kick function . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.6 Manual operation. . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.7 FlowSensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.8 Output calculation, maximum values,

and yield count . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.9 Speed regulation of the solar operating

pump PS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2.10 Total Reset Function . . . . . . . . . . . . . . . . . . . . . . 24

6.2.11 Frost protection function . . . . . . . . . . . . . . . . . . . 25

6.2.12 Leak protection function . . . . . . . . . . . . . . . . . . . 25

6.3 Adjustment and menu guide . . . . . . . . . . . . . . .25

6.3.1 Display during start-up. . . . . . . . . . . . . . . . . . . . . 26

6.3.2 Display during operation . . . . . . . . . . . . . . . . . . . 27

6.3.3 Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.4 Password input . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.5 Language selection . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.6 Setting and resetting parameters . . . . . . . . . . . . 29

6.3.7 Setting the mounting position of the solar

panel temperature sensor . . . . . . . . . . . . . . . . . . 29

6.3.8 Manual setting of the pump speed regulation . . . 30

6.3.9 Correction values for measuring points. . . . . . . . 30

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Operating and installation instructions

3

2 x Safety

2 Safety

2.1 Observing instructions

This manual is intended for authorised and trained technicians

who have experience in the proper installation and commissioning of solar systems on account of their technical training and

knowledge.

All necessary tasks for the installation, initial start-up, operation

and setting of the system are described in this manual. For detailed information regarding the connected components of your

heating system, please observe the respective documents.

Please read this manual carefully and thoroughly before proceeding with the installation and initial start-up or modification of

the system.

Relevant documents

Documents listed below are part of the technical documentation

of the Daikin solar system and therefore must be observed. The

documents are included in the scope of supply of the individual

components.

– Daikin V21P, V26P and H26P solar high-efficiency flat

solar panels: Installation instructions for on-roof, in-roof

and flat-roof mounting

– Daikin Hot water storage tank (EKHWP or Altherma

EHS(X/H): Operating and installation instructions

When connecting to an external heat generator or storage tank

which is not included in the scope of delivery, the individual associated operating and installation instructions apply.

2.2 Warning signs and explanation of symbols

Meaning of the warnings

Warnings in this manual are classified according into their severity and probability of occurrence.

Special warning signs

Some types of danger are indicated by special warning signs.

Electric power

Danger of explosion

Risk of burning or scalding

Order number

Notes related to Order numbers are identified by the cart symbol

.

Handling instructions

● Instructions on actions are shown as a list. Actions of which

the sequential order must be maintained are numbered.

Results of actions are identified with an arrow.

2.3 Avoid danger

Daikin solar installations are state-of-the-art and are built to meet

all recognised technical requirements. However, improper use

can lead to serious injuries or death, as well as causing material

damage. Install and operate only Daikin solar systems to avoid

danger:

– as stipulated and in perfect condition,

– with an awareness of the safety and hazards involved.

This assumes knowledge and use of the contents of this manual,

the relevant accident prevention regulations and the recognised

safety-related and occupational medical rules.

2.4 Intended use

DANGER!

Draws attention to imminent danger.

Disregarding this warning can lead to serious injury or

death.

WARNING!

Indicates a potentially dangerous situation.

Disregarding this warning can result in serious injury

or death.

CAUTION!

Indicates a situation which may cause possible

damage.

Disregarding this warning can lead to damage to

property and the environment.

This symbol identifies user tips and particularly useful

information, but not warnings or hazards.

The Daikin solar system may only be used for solar-supported

heating of hot water systems. The Daikin solar system must be

installed, connected and operated only according to the instructions in this manual.

Any other use outside the intended use is considered as improper. The operator alone shall bear responsibility for any resulting damage.

Use as intended also involves compliance with maintenance and

inspection conditions. Spare parts must at least satisfy the technical requirements defined by the manufacturer. This is the case,

for example, with original spare parts.

2.5 Instructions for working safely

Working on the roof

● Installation work on the roof may only be carried out by

authorised and trained persons (heating technicians, roofers,

etc.) under observance of the relevant Accident Prevention

Regulations.

● Material and tools must be secured against falling.

● Barriers must be erected to prevent persons from entering the

area below the roof where the work is being carried out.

Before working on the heating system

● All work on the heating system (such as installation,

connection and commissioning) may only be carried out by

authorised and trained heating technicians.

● Switch off the main switch and secure it against unintended

switching on when carrying out any work on the heating

system.

Operating and installation instructions

4

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

Electrical installation

● Electrical installation must be carried out only by qualified

electrical experts and in compliance with the valid electrotechnical guidelines as well as the regulations of the relevant

energy supply company (EVU).

● For the mains connection, use a separate EN 60335-1

disconnector for all-pole disconnection from the power mains

and a GFCI circuit breaker with a reaction time ≤ 0.2 s.

● Before completing the mains connection, compare the mains

voltage, indicated on the type plate (230 V, 50 Hz) with the

supply voltage.

● Before beginning work on live parts, disconnect them from the

power supply (switch off main switch, remove fuse) and

secure against unintentional restart.

● Equipment covers and service panels must be replaced as

soon as the work is completed.

Instructing the user/owner

● Before you hand over the heating system, explain to the

user/owner how to operate and check the heating system.

● Make a record of the handover by filling out and signing the

installation and instruction forms jointly with the user/owner.

2 x Safety

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Operating and installation instructions

5

3 x Product description

3 Product description

3.1 Design and components of the solar system

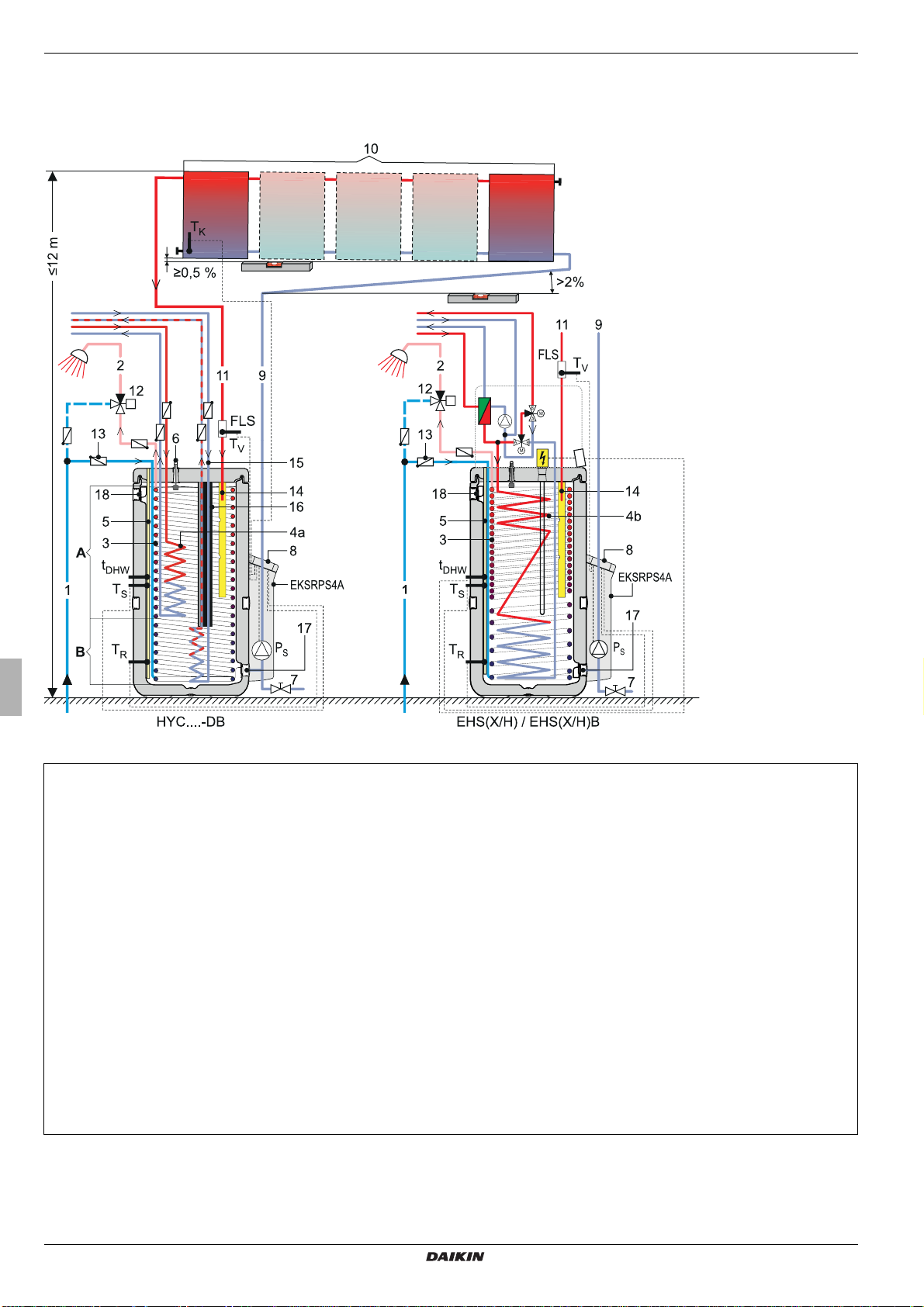

Fig. 3-1 Standard design of a Daikin solar system (Daikin recommends a double-sided connection)

1 Cold water connection line

2 Domestic water (hot) distribution line

3 Stainless steel corrugated heat exchanger for domestic water

(hot)

4a Stainless steel corrugated heat exchanger for storage tank charg-

ing

4b Stainless steel corrugated heat exchanger for storage tank charg-

ing and heating support

5 Submersion sleeve for storage, return temperature sensors

6 Fill level display

7 Filling and draining cock (KFE BA accessory)

8 Solar R4 controller

9 Solar return line (at the bottom on the solar panel)

10 Solar panel array

11 Solar flow line (at the top on the solar panel)

12 Thermal mixing valve (scalding protection, provided by customer)

13 Convection brake (accessory)

14 Solar flow layering pipe

15 Corrugated stainless steel heat exchanger for heating support

16 Thermal insulation sleeve for corrugated stainless steel heat ex-

changer for heating support

17 Solar return connection

18 Safety overflow connection

Tab. 3-1 Legend for fig. 3-1

A Zone with water for domestic use

B Solar zone

FLS Solar FlowSensor (flow measurement)

PSSolar operating pump

EKSRPS4

Control and pump unit for solar systems

t

Storage temperature sensor

DHW

TKSolar panel temperature sensor

TRSolar return flow temperature sensor

TSSolar storage tank temp. sensor

TVSolar flow temperature sensor

EHS(X/H)B

Solar tank with integrated interior heat pump device

HYC - DB

EKHWP energy storage

Operating and installation instructions

6

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

3 x Product description

3.2 Brief description

The Daikin solar system is a thermal solar system for supplying

hot water for consumption and solar support.

The Daikin EKSRPS4 Control and pump unit for solar

systems can only be installed and operated as part of a

Daikin Solar System (DrainBack) using the provided

installation material.

The prerequisite for problem-free operation in the

DrainBack system, is that the connection lines are

routed with a constant gradient (at least 2 %), and that

the bottom edges on the solar panels with double-sided

connections are mounted with a constant gradient to

the return connection, or, with same side connection,

are mounted horizontally.

Mode of operation

The V21P, V26P and H26P high-performance solar panels efficiently convert the sun’s radiation into heat. Hereby, the heat

transport media is normal tap water.

As soon as the solar collectors have reached a useful temperature level, the water of the heating jacket in the storage cylinder

(which is not under pressure) is pumped directly through the

collectors. With insufficient collector temperature, the circulation

pump is switched off and the system is drained automatically.

This operating mode has several advantages:

– High operational reliability, as there are no components that

could be damaged or fail (such as expansion vessel, safety

valve, venting valves, etc.).

– Excellent heat transfer and heat storage capacity (system

works without antifreeze agents).

– Minimum maintenance requirements.

– Frost proof.

– Without separate solar heat exchanger.

– No stagnation problems.

Electronic control

The fully electronic Daikin Solar R4 control system ensures optimum utilisation of the solar heat (hot consumption water generation, heating support) as well as the observance of all safety-relevant aspects. All parameters needed for trouble-free operation

have been preset at factory.

3.3 System components

3.3.1 Control and pump unit for solar systems EKSRPS4

Modular design

The system consists of several preassembled modules. Plug-in

technology and a high degree of pre-assembly ensure fast and

simple system installation.

Storage tank

The following storage tanks can be used for the Daikin solar

system:

– Daikin EKHWP (HYC): Thermally insulated, de-pressurised

plastic storage tank (with connection facility for a Daikin airwater heat pump).

– Daikin Altherma EHS(X/H) Solar storage tank with integrated

interior air-water heat pump device.

Construction, operating principle, commissioning, and

operation of other solar components are not described

in this manual. Detailed information about the components can be seen in the operating and installation

instructions of the individual units.

The handling instructions and descriptions in this

manual are valid for all Daikin storage tanks to be used

in conjunction with this solar system, even if only one

type is used for illustrative purposes. In the event of deviations from other storage tanks, a separate note is

provided.

Consists of:

1 Cover

2 Connection piping with circulation pump and solar operating pump

3 Daikin Solar R4-controller with storage tank temperature sensor,

return flow temperature sensor, solar panel temperature sensor

connecting cables, FlowSensor, 230 V mains connecting cable

(3 m)

4 Accessories pocket (6 fixing screws, 2 plastic plugs, 2 locking

screws, plug fitting and gasket)

5 Mounting material (retaining bracket for pump mounting, holding

bar and fixing bracket for controller)

6 Solar documentation

Fig. 3-2 Control and pump unit for solar systems (EKSRPS4)

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Operating and installation instructions

7

3 x Product description

3.3.2 Filling and draining cock (KFE BA) for RPS4

Fig. 3-3 KFE cock (optional)

3.3.3 Regulating valve FlowGuard FLG

For setting and display of flow rate of 2 - 16 l/min.

Consists of:

– FlowGuard FLG (a).

– 2x seals (b).

3.3.4 Storage tank extension kit CON SX

For connecting 2 EKHWP storage tanks.

Consists of:

– Return connection line (a).

– Flow distribution line (b).

Fig. 3-5 CON SX (optional)

Fig. 3-4 FlowGuard FLG (optional)

3.3.5 Storage tank extension kit 2 CON SXE

Extension kit for connecting an additional EKHWP storage tank.

Consists of:

– Return connection line (a).

– Flow distribution line (b).

Fig. 3-6 CON SXE (optional)

Operating and installation instructions

8

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

4 Installation

4 x Installation

4.1 System concepts

Daikin solar systems are usually built according to one of the following system concepts. Information concerning hydraulic

system incorporation with example schematics can be seen in

chapter 8 "Hydraulic system connection".

4.1.1 Parallel connection

Fig. 4-1 Solar panel field with a connection at each end

(recommended)

T

K

Fig. 4-2 Solar panel field with both connections at one end

(max. 3 solar panels)

4.1.2 Serial connection

As an alternative to the parallel mode described in this manual,

and if necessary, a maximum of 3 solar panels can be mounted

one above the other. Solar panels or solar panel fields mounted

one above the other must be connected in series (fig. 4-3).

1 Collector connector

2 Mounting rail

3 Solar panel securing hook

4 Solar panel

5 Return panel connection

6 Flow panel connection

7 Collector sealing cap

8 Roof penetration boxes for inflow/return flow

9 Solar return line

10 Solar flow line

11 Series panel connector

12 Solar panel array (2x 2 panels)

Tab. 4-1 Legend for fig. 4-3

4.2 Installing the control and pump unit

WARNING!

Live parts can cause an electric shock on contact and

cause life-threatening burns and injuries.

● Before beginning work on the boiler switching

panel or the solar controller, disconnect the

devices from the power supply (switch off fuse,

main switch) and secure against unintentional

restart.

● Electrical installations must always be carried out

by qualified electrical technicians in conformity

with the relevant electrical guidelines and the

regulations of the electric utilities company to

prevent hazards from damaged electric wiring.

● Comply with the relevant safety at work regulations.

DANGER!

Leaking gas in the immediate proximity of electrical

components can cause an explosion.

● The Control and pump unit for solar systems

EKSRPS4 and electrical components should not

be installed in locations where there is a danger of

flammable gas escaping.

● Pay attention to minimum distances from walls and

in shafts.

Fig. 4-3 Alternative solar panel arrangement

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Operating and installation instructions

9

4 x Installation

4.2.1 Installation pump unit

CAUTION!

Large volumes of water may come out of the solar

storage tank during installation.

● Mount the pump unit before filling the solar storage

tank (depressurised range) with water.

● If the pump unit is to be connected to solar storage

tank that is already in operation, the depressurised

storage area must first be drained.

Fig. 4-4 Work step 1 Fig. 4-5 Work step 2

Fig. 4-6 Work step 3

1x

007.16 054 99

4PW56022-1

MS

Fig. 4-10 Work step 7 Fig. 4-11 Work step 8

Fig. 4-12 Work step 9 Fig. 4-13 Work step 10

10. Prepare feed line

(VA 15 Solar) with sensor

cable and return line

(VA 18 Solar). Cut open

the twin heat insulation in

the middle.

11. Adapt the return line

(VA 18 Solar) accordingly

and route separately after

separating the twin thermal

insulation.

Click

Click

MS

100

710

ø3,5

<15 mm

Fig. 4-7 Work step 4

Fig. 4-8 Work step 5 Fig. 4-9 Work step 6

Fig. 4-14 Work step 11

12. Insert the pre-curved return

line (VA 18 Solar) into the

plug fitting on the pump

outlet pipe.

Fig. 4-15 Work step 12

13. Cut the flow line (VA Solar 15) to length on the storage tank

side and insert into the plug fitting on the solar flow connection

(see chapter 4.3 "Linking several solar storage tanks",

FlowSensor, work step 4).

Operating and installation instructions

10

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

CAUTION!

In the case of longer pipe runs with only a minimum

gradient, it is possible for water pockets to develop

due to thermal expansion of the plastic pipes between

the mounting points with siphon action:

● Use support troughs (TS).

● Always make sure that pipe runs have a

continuous gradient of at least 2 %.

4.2.2 Installation FlowSensor, FlowGuard (optional)

Note the direction of flow when installing the FlowSensor.

4 x Installation

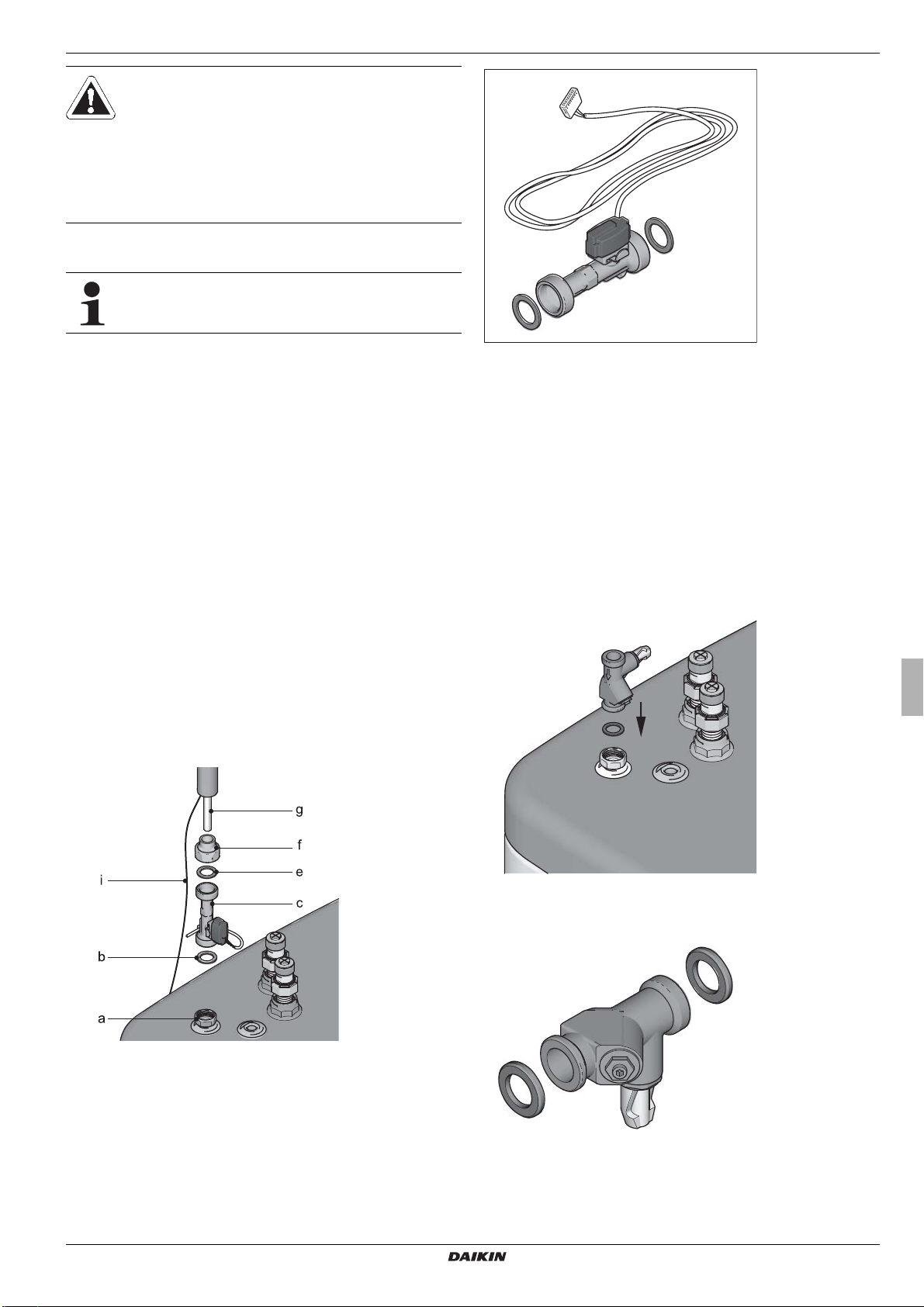

FlowSensor

The FlowSensor FLS 20 (fig. 4-17) is a measuring device that

simultaneously determines the flow rate in the solar panel and the

flow temperature. The measuring ranges are 0...20 l/min (flow

quantity) and 0...120 °C (inflow temperature). The measured

values are displayed on the Solar R4 control system.

By controlling the speed of the P

Solar R4 automatically adjusts the optimum flow quantity.

1. Insert the seal (b) on the solar flow connection (a) of the hot

water storage tank.

2. Screw the FlowSensor (c) onto the solar flow connection (a)

of the hot water storage tank.

3. Insert the seal (e) and fit the plug fitting (f) to the inlet to the

FlowSensor (c).

4. Shorten the flow line (g) (Ø 15 mm) to the required length and

insert into the plug fitting (f).

5. Lay FlowSensor cable between FlowSensor (c) and Solar R4

control unit.

6. Connect FlowSensor cable to FlowSensor (c) and to the Solar

R4 control system printed circuit board edge at position FLS

(4-pin, see fig. 4-23).

solar circulation pump, the

S

Fig. 4-17 FlowSensor FLS supplied with 3 m cable

FlowGuard

The FlowGuard FLG (fig. 4-19) is also available as an accessory.

It is a regulating valve with integrated flow indicator which can be

used to set the flow rate through the solar panel array.

The display range is 2...16 l/min.

1. Insert the seal in the flow connection (see fig. 4-18).

2. Mount the FlowGuard, and screw it tight.

3. Insert the seal and install the plug fitting into the input to the

FlowGuard.

4. Insert a prepared flow pipe into the plug fitting of the

FlowGuard.

Fig. 4-16 Mounting FlowSensor FLS

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Fig. 4-18 Work step 1+2

Fig. 4-19 Accessory FlowGuard FLG

Operating and installation instructions

11

4 x Installation

4.2.3 Installing temperature sensor

CAUTION!

On no account may the storage cylinder temperature

sensor of the boiler controller be inserted more than

75 cm into the sensor well. A sensor that is inserted

too deeply can lead to overheating of the consumption

water section, as well as a "hang-up" of the control unit

during the storage cylinder charging phase.

1. Bend over the contact springs on both sensors (return

temperature sensor, storage tank temperature sensor) and

insert into the sensor tube.

Fig. 4-22 Work step 4

4.2.4 Preparing and fitting the control system Requirements

– For electrical connections and consumable electrical materi-

als (cable, insulation, etc.), follow all valid country-specific

guidelines.

– For every fixed mains connection, use a separate

EN 60335-1 disconnector for all-pole disconnection from the

power mains and a GFCI circuit breaker with a reaction time

≤ 0.2 s.

a Solar return flow temperature sensor

b Solar storage tank temperature sensor

Fig. 4-20 Work step 1

2. Position the return flow temperature sensor in the sensor tube

at approx. 130 cm insertion depth (cable tie).

3. Position the storage cylinder temperature sensor in the

sensor tube at approx. 70 cm insertion depth (cable tie).

Permissible cable types at the terminal strip:

– Single core ≤ 2.5 mm

– Multi-core ≤ 2.5 mm

– Multi-core with wire end sleeves with insulating collar

≤ 1.5 mm

– Multi-core with wire end sleeves without insulating collar

≤ 2.5 mm

2

2

2

2

Fig. 4-21 Work step 2+3

4. Push the sealing plug into the well, and run the cables.

Operating and installation instructions

12

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

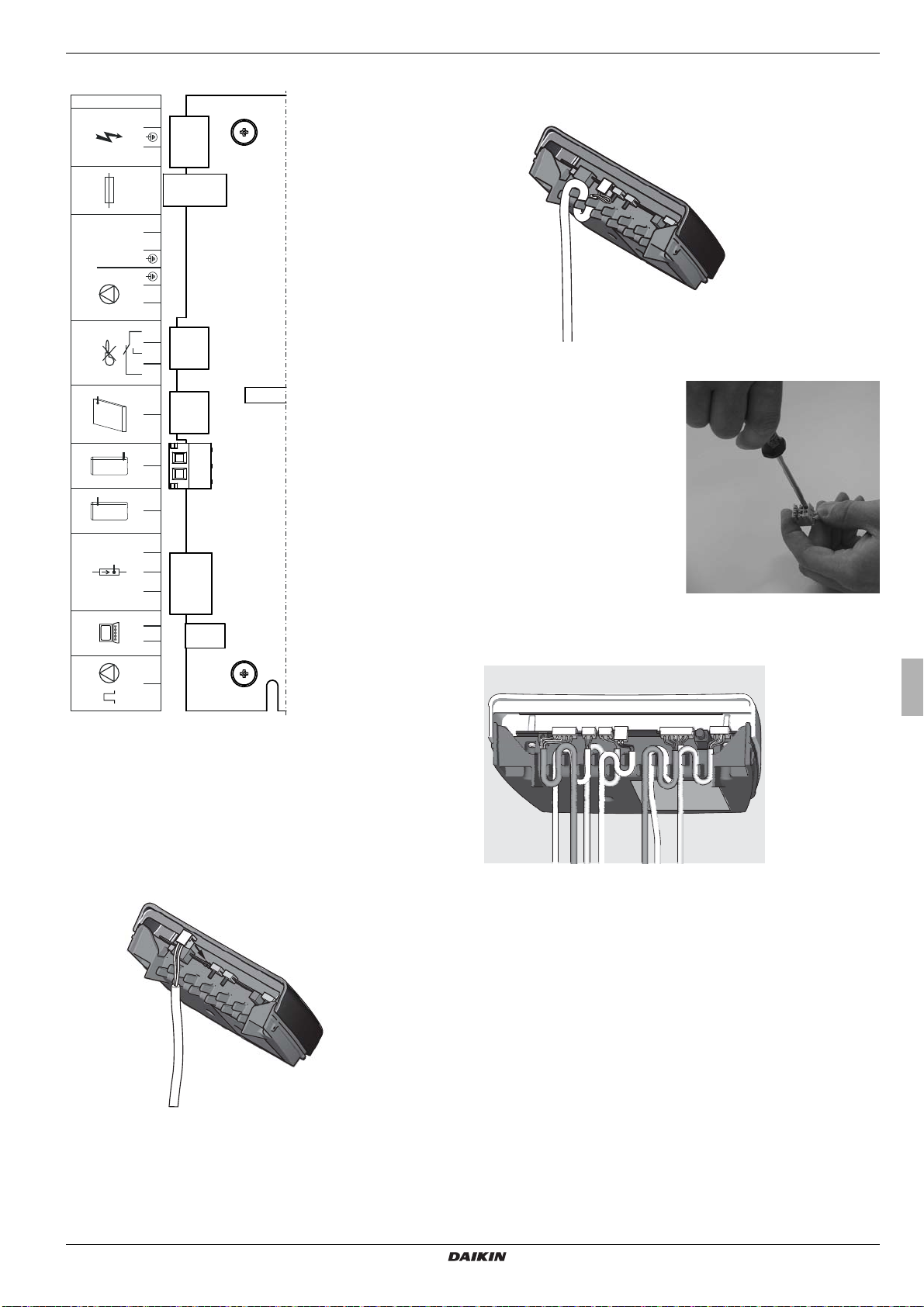

Electrical connection

007.16 108 99_00

NN LL11111113

POWERCONFPWM

T2A

250V

n.b.

P1 F1

4 x Installation

BSK

FLS TRTS TK

Fig. 4-23 Connection assignment

22222224

3

3

BSK Burner inhibit contact

CONF

Programming socket for

Software update

FLS FlowSensor

TS Storage cylinder temper-

ature sensor

TR Return flow temperature

sensor

TK Collector temperature

sensor

PSSolar operating pump

F1 Fuse

Power

Mains supply

1. Fix the cable supplied to the back of the control system using

the edge connectors. The connectors are polarised to prevent

errors. A connecting diagram is provided in the control unit

cover.

Fig. 4-25 Work step 2

3. Connect the solar panel

temperature sensor line

(integrated in the

connection line) to the plug

terminals.

Fig. 4-26 Work step 3

4. Insert the plug at the edge of the board on the controller, at

position TK (2-pin, see fig. 4-23).

Fig. 4-24 Work step 1

2. To ensure reliable tension relief, all cables should be run

through the respective labyrinths.

Daikin EKSRPS4

Daikin Control and pump unit for solar systems

008.1624644 – 07/2015

Fig. 4-27 Basic wiring: FlowSensor, storage tank, return, solar panel

sensor, pumps and mains wiring

Operating and installation instructions

13

4 x Installation

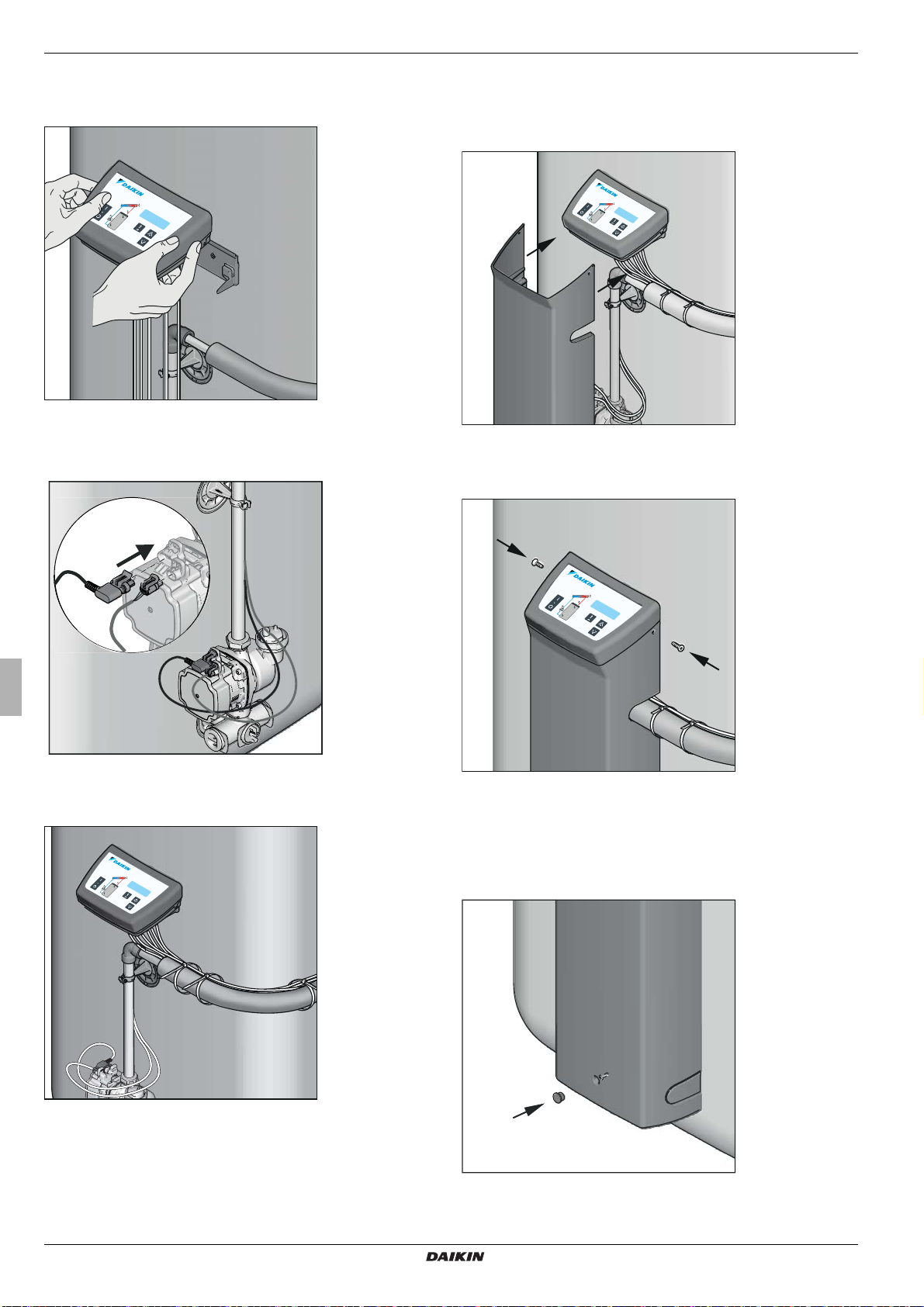

5. Suspend the controller from above in the fixing bracket.

– Make sure that the cable loops (as shown in fig. 4-27 and

fig. 4-28) point downwards.

Fig. 4-28 Work step 5

6. Cabling of the solar operating pump P

:

S

– Connect the pump cable to the solar operating pump P

4.2.5 Fit the covering hood

1. Slide the covering hood in position and align. Slide the

covering hood under the controller housing so that a constant

gap is produced round the controller.

Fig. 4-31 Work step 1

.

2. Screw the covering hood to the controller housing on both

S

sides using countersunk head screws.

Fig. 4-29 Work step 6

7. Lay the cable for the control system along the return line and

fix using cable ties.

Fig. 4-30 Work step 7

Fig. 4-32 Work step 2

3. Fix the covering hood to the storage tank connection bracket

that is located underneath. Carefully screw the self-tapping

fixing screw (pre-installed in the covering hood) over the

depression in the lower section of the housing front and then

insert the covering cap.

Fig. 4-33 Work step 3

Operating and installation instructions

14

Daikin Control and pump unit for solar systems

Daikin EKSRPS4

008.1624644 – 07/2015

Loading...

Loading...