Daikin EHSX04P30D3, EHSX04P50D3, EHSH04P30D3, EHSX08P30D3, EHSX08P50D3 Operation manuals

...

Installation and operating manual

Daikin Altherma 3 R ECH₂O

EHSX(B)04P30D3

EHSX(B)04P50D3

EHSH(B)04P30D3

EHSX(B)08P30D3

EHSX(B)08P50D3

EHSH(B)08P30D3

EHSH(B)08P50D3

Installation and operating manual

Daikin Altherma 3 R ECH₂O

Installations- und Betriebsanleitung

Daikin Altherma 3 R ECH₂O

Manuel d'installation et de fonctionnement

Daikin Altherma 3 R ECH₂O

Montagehandleiding en gebruiksaanwijzing

Daikin Altherma 3 R ECH₂O

Manual de instalación y funcionamiento

Daikin Altherma 3 R ECH₂O

Manuale d'installazione e d'uso

Daikin Altherma 3 R ECH₂O

Manual de instalação e de operações

Daikin Altherma 3 R ECH₂O

Installations- och användarhandbok

Daikin Altherma 3 R ECH₂O

Příručka k instalaci a návod k obsluze

Daikin Altherma 3 R ECH₂O

English

Deutsch

Français

Nederlands

Español

Italiano

Portugues

Svenska

čeština

List of contents

List of contents

1 General safety precautions 3

1.1 Particular safety instructions ..................................................... 3

1.1.1 Observing the instructions .......................................... 3

1.1.2 Meaning of warnings and symbols.............................. 4

1.2 Safety instructions for installation and operation....................... 5

1.2.1 General ....................................................................... 5

1.2.2 Intended use ............................................................... 5

1.2.3 Installation room.......................................................... 6

1.2.4 Electrical installation ................................................... 6

1.2.5 Requirements for heating and storage water.............. 6

1.2.6 Heating system and sanitary connection .................... 7

1.2.7 Operation .................................................................... 7

1.3 Maintenance, troubleshooting and decommissioning ............... 7

1.4 Warranty conditions................................................................... 7

2 Product description 8

2.1 Design and components............................................................ 8

2.2 Function of the 3‑way changeover valves ................................. 10

3 Set-up and installation 11

3.1 Dimensions and connection dimensions ................................... 11

3.2 Transport and delivery............................................................... 12

3.3 Installing the heat pump ............................................................ 12

3.3.1 Selecting the installation site....................................... 12

3.3.2 Installing the device .................................................... 13

3.4 Preparing the device for installation .......................................... 13

3.4.1 Remove the front screen............................................. 13

3.4.2 Remove the protective cover ...................................... 14

3.4.3 Moving the switch box to the service position............. 14

3.4.4 Open the switch box ................................................... 14

3.4.5 Removing the bottom thermal insulation..................... 15

3.4.6 Opening the air purge valve........................................ 15

3.4.7 Aligning the connections of the heating inflow and

return flow ................................................................... 16

3.4.8 Making the hood opening............................................ 17

3.4.9 Installing the rotary switch of the controller................. 17

3.4.10 Securing the hood....................................................... 17

3.5 Installing optional accessories................................................... 18

3.5.1 Installation of electric backup heater (EKBUxx).......... 18

3.5.2 Installation of the external heat generator connection

set (EKBUHSWB) ....................................................... 18

3.5.3 Installation of the DB connection kit............................ 18

3.5.4 Installation of the P connection kit .............................. 18

3.6 Water connection ...................................................................... 19

3.6.1 Minimum water volume............................................... 19

3.6.2 Connecting hydraulic lines.......................................... 19

3.6.3 Connecting the drain................................................... 20

3.7 Electrical connection ................................................................. 20

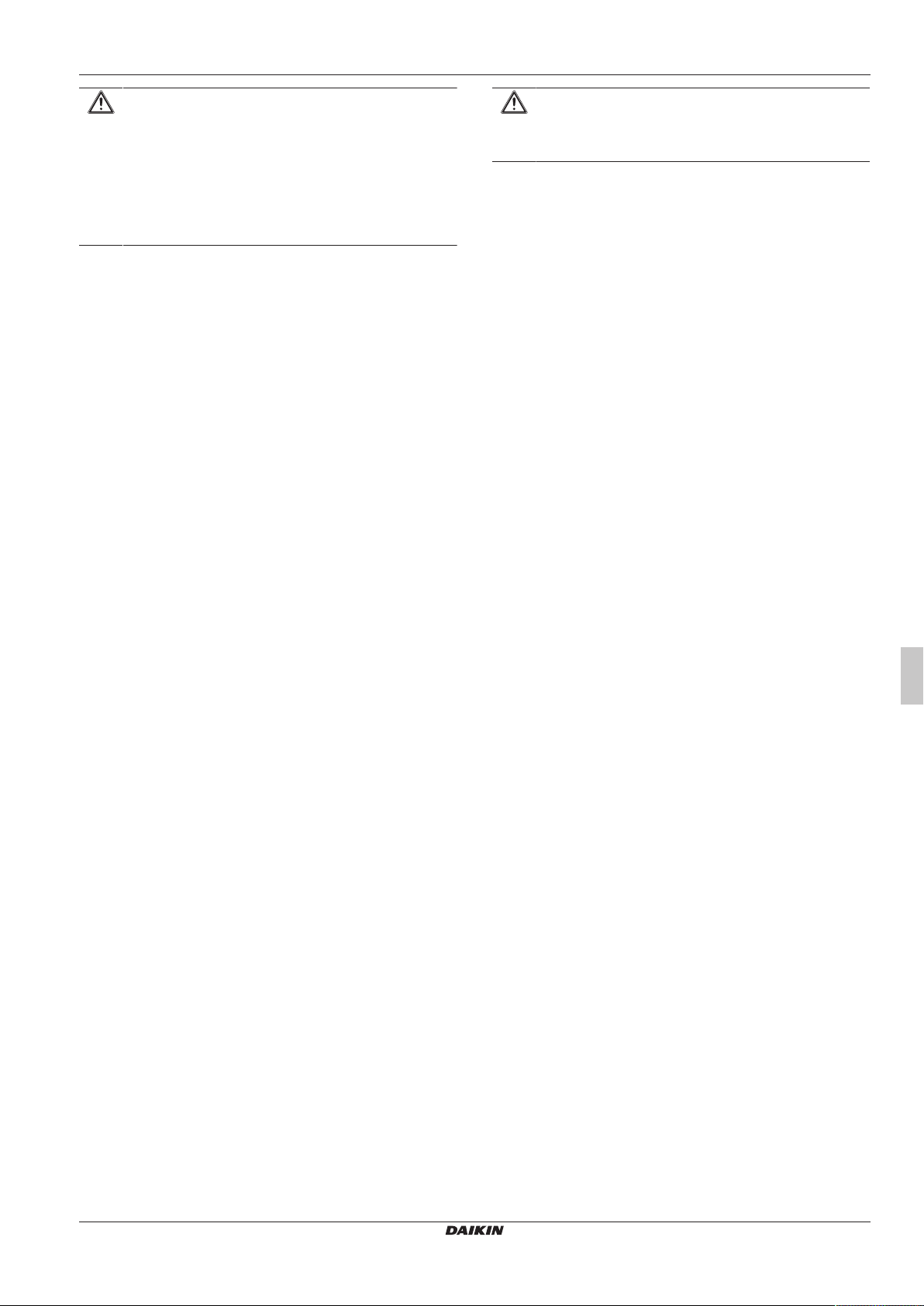

3.7.1 Overall connection diagram ........................................ 22

3.7.2 Position of the PCBs and terminal strips..................... 23

3.7.3 Mains connection........................................................ 23

3.7.4 General information on the electrical connection........ 23

3.7.5 Connecting the heat pump outdoor unit...................... 23

3.7.6 Connecting the outdoor temperature sensor

(optional) ..................................................................... 24

3.7.7 External switching contact .......................................... 24

3.7.8 EBA (external requirement request) ........................... 24

3.7.9 Connecting an external heat generator....................... 25

3.7.10 Connecting the room thermostat................................. 26

3.7.11 Connection of optional RoCon system components ... 26

3.7.12 Connecting the HP convector ..................................... 26

3.7.13 Connecting switching contacts (AUX outputs) ............ 27

3.7.14 Low rate mains connection (HT/NT) ........................... 27

3.7.15 Connecting an intelligent controller (Smart Grid - SG) 28

3.8 Connection for refrigerant.......................................................... 28

3.8.1 Laying refrigerant piping ............................................. 28

3.8.2 Pressure test and filling the refrigerant circuit.............. 28

3.9 Filling the system........................................................................ 29

3.9.1 Checking the water quality and adjusting the

manometer................................................................... 29

3.9.2 Filling hot water heat exchangers ................................ 29

3.9.3 Filling the storage tank................................................. 29

3.9.4 Filling the heating system ............................................ 29

4 Configuration 30

5 Check list for start-up 31

5.1 Requirements ............................................................................. 31

5.2 Commissioning at low ambient temperatures ............................ 31

5.3 Bleeding the hydraulic system.................................................... 31

5.4 Checking the minimum flow ....................................................... 32

5.5 Start screed drying (only if required) .......................................... 32

5.6 Commissioning checklist ............................................................ 32

5.7 Handover to the operating company .......................................... 33

6 Technical data 33

6.1 Information on the type plate...................................................... 33

6.2 Characteristic lines ..................................................................... 33

6.2.1 Sensor characteristic lines........................................... 33

6.2.2 Characteristic curves for pumps .................................. 34

6.3 Tightening torques...................................................................... 34

6.4 Minimum floor area and ventilation openings............................. 34

6.5 Electrical connection diagram .................................................... 36

6.6 Piping diagram for refrigerant circuit .......................................... 38

Installation and operating manual

2

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

1 General safety precautions

1.1 Particular safety instructions

1 General safety precautions

WARNING

Devices that have not been set up and

installed correctly can impair the

function of the device and/or cause

serious or fatal injury to the user.

▪ Work on the indoor unit (such as set-

up, servicing, connection and initial

commissioning) must only be carried

out by persons who are authorised

and who have successfully

completed qualifying technical or

vocational training, and who have

taken part in advanced training

sessions recognised by the relevant

responsible authorities for the specific

activity. These include, in particular,

certified heating engineers,

qualified electricians and HVAC

specialists who, because of their

professional training and expert

knowledge, have experience in the

professional installation and

maintenance of heating, cooling and

air conditioning systems as well as

hot water storage tanks.

WARNING

Disregarding the following safety

instructions may result in serious

physical injury or death.

▪ This device may only be used by

children aged 8 and above and by

persons with restricted physical,

sensory or mental capabilities or with

a lack of experience and knowledge if

they are under supervision or if they

have been instructed in the safe use

of the equipment and understand the

dangers arising from it. Children

must not play with the device.

Cleaning and user maintenance

must not be carried out by children

without supervision.

▪ Establish the power supply in

accordance with IEC60335‑1, via a

separate isolator that separates all

poles with a contact opening distance

and that provides full disconnection in

accordance with overvoltage

categoryIII.

▪ All electrical work must only be

carried out by electrically qualified

experts and with consideration of the

local and national regulations and the

instructions in this manual.

Ensure that a suitable electrical

circuit is used.

Insufficient load capacity of the

electrical circuit or improperly

executed connections can result in

electric shock or fire.

▪ The customer must install a pressure

relief device with a rated overpressure of less than 1.0MPa

(10bar). The connected drain line

must have a continuous gradient and

a free outlet in a frost-free

environment (see "3.3Installing the

heat pump"[412]).

▪ Water may drip out of the drain line of

the pressure relief device. The drain

opening must be left open to the

atmosphere.

▪ The pressure relief device must be

operated regularly in order to remove

scale deposits and to make sure it is

not blocked.

▪ The storage tank and hot water circuit

can be drained. The instructions in

"Temporary decommissioning" in the

reference manual for the fitter must

be complied with.

1.1.1 Observing the instructions

▪ The original documentation is written in German. All other

languages are translations.

▪ Please read this manual carefully and thoroughly before

proceeding with the installation or modification of the heating

system.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

3

1 General safety precautions

▪ The precautionary measures described in this document cover

very important topics. Follow them meticulously.

▪ The installation of the system, and all activities described in this

manual and the applicable documents for the installer must be

carried out by an approved installer.

Documentation set

This document is part of a documentation set of other applicable

documents. The complete set comprises:

▪ Installation manual for the indoor unit (format: paper – included in

the indoor unit scope of delivery)

▪ Operating manual for the indoor unit (format: paper – included in

the indoor unit scope of delivery)

▪ Operating manual for the heat pump (format: paper – included in

the indoor unit scope of delivery)

▪ Installation manual for the outdoor unit (format: paper – included

in the outdoor unit scope of delivery)

▪ Installation instructions for optional components (format: paper –

included in the scope of delivery of the respective component)

▪ Installer reference guide of the indoor unit (format: digital)

▪ Installer reference guide of the outdoor unit (format: digital)

The reference guides contain the complete set of technical data, a

detailed description of best practices and information on

maintenance, troubleshooting and decommissioning.

The digital documents and the latest editions of the supplied

documentation are available on the regional Daikin website or, on

request, from your dealer. The Daikin website is easy to access

using the QR code on your device.

Validity

Some information in this manual has limited validity. The validity is

highlighted by a symbol.

Heat pump outdoor unit

Heat pump indoor unit

FWXV-ATV3

Observe the specified tightening torque

Only applies to devices with unpressurised solar system

connection (DrainBack).

Only applies to devices with a bivalent solar system

connection (Biv).

Only applies to indoor units with cooling function

Handling instructions

1 Handling instructions are shown as a list. Actions where the

sequential order must be adhered to are numbered.

1.1.2 Meaning of warnings and symbols

Warnings in this manual are classified according into their severity

and probability of occurrence.

DANGER

Indicates an immediate danger.

Disregarding this warning can lead to serious injury or

death.

WARNING

Indicates a potentially dangerous situation.

Disregarding this warning may result in serious physical

injury or death.

CAUTION

Indicates a situation which may cause possible damage.

Disregarding this warning can cause damage to property

and the environment and result in minor injuries.

This symbol identifies user tips and particularly useful

information, but not warnings or hazards

Special warning signs

Some types of danger are represented by special symbols.

Electric current

Danger of explosion

Risk of burns or scalds

Risk of poisoning

Installation and operating manual

4

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

1 General safety precautions

1.2 Safety instructions for installation and operation

1.2.1 General

WARNING

Devices that have not been set up and

installed correctly can impair the

function of the device and/or cause

serious or fatal injury to the user.

▪ Work on the indoor unit (such as set-

up, servicing, connection and initial

commissioning) must only be carried

out by persons who are authorised

and who have successfully

completed qualifying technical or

vocational training, and who have

taken part in advanced training

sessions recognised by the relevant

responsible authorities for the specific

activity. These include, in particular,

certified heating engineers,

qualified electricians and HVAC

specialists who, because of their

professional training and expert

knowledge, have experience in the

professional installation and

maintenance of heating, cooling and

air conditioning systems as well as

hot water storage tanks.

▪ Switch off the external main switch

before starting any work on the

indoor unit and secure against being

switched on inadvertently.

▪ Do not leave any tools or other

objects below the hood of the device

after finishing installation or

maintenance work.

Avoid danger

The indoor unit conforms to the state of the art and meets all

recognised technical requirements. However, improper use can lead

to serious injuries or death, as well as causing material damage. To

prevent such risks, only install and operate the devices:

▪ as stipulated and in perfect condition,

▪ with an awareness of the safety and hazards involved.

This assumes knowledge and use of the contents of this manual, the

relevant accident prevention regulations and the recognised safetyrelated and occupational medical rules.

Before working on the hydraulic system

▪ Work on the system (such as set-up, connection and initial

commissioning, for example) must only be carried out by persons

who are authorised, who have successfully completed qualifying

technical or vocational training for the respective activity and who

have taken part in advanced training sessions recognised by the

relevant responsible authority.

▪ When carrying out any work on the system, switch off the main

switch and secure against being switched on inadvertently.

▪ Seals must not be damaged or removed.

▪ Make sure that the safety valves comply with the requirements of

EN 12828 when connecting on the heating side and with the

requirements of EN 12897 when connecting on the domestic

water side.

1.2.2 Intended use

The indoor unit may only be used for domestic hot water

preparation, as a room heating system and, depending on its design,

as a room cooling system.

The indoor unit must only be installed, connected and operated

according to the indications in these instructions.

Only the use of a suitable outdoor unit approved by the manufacturer

is permitted.

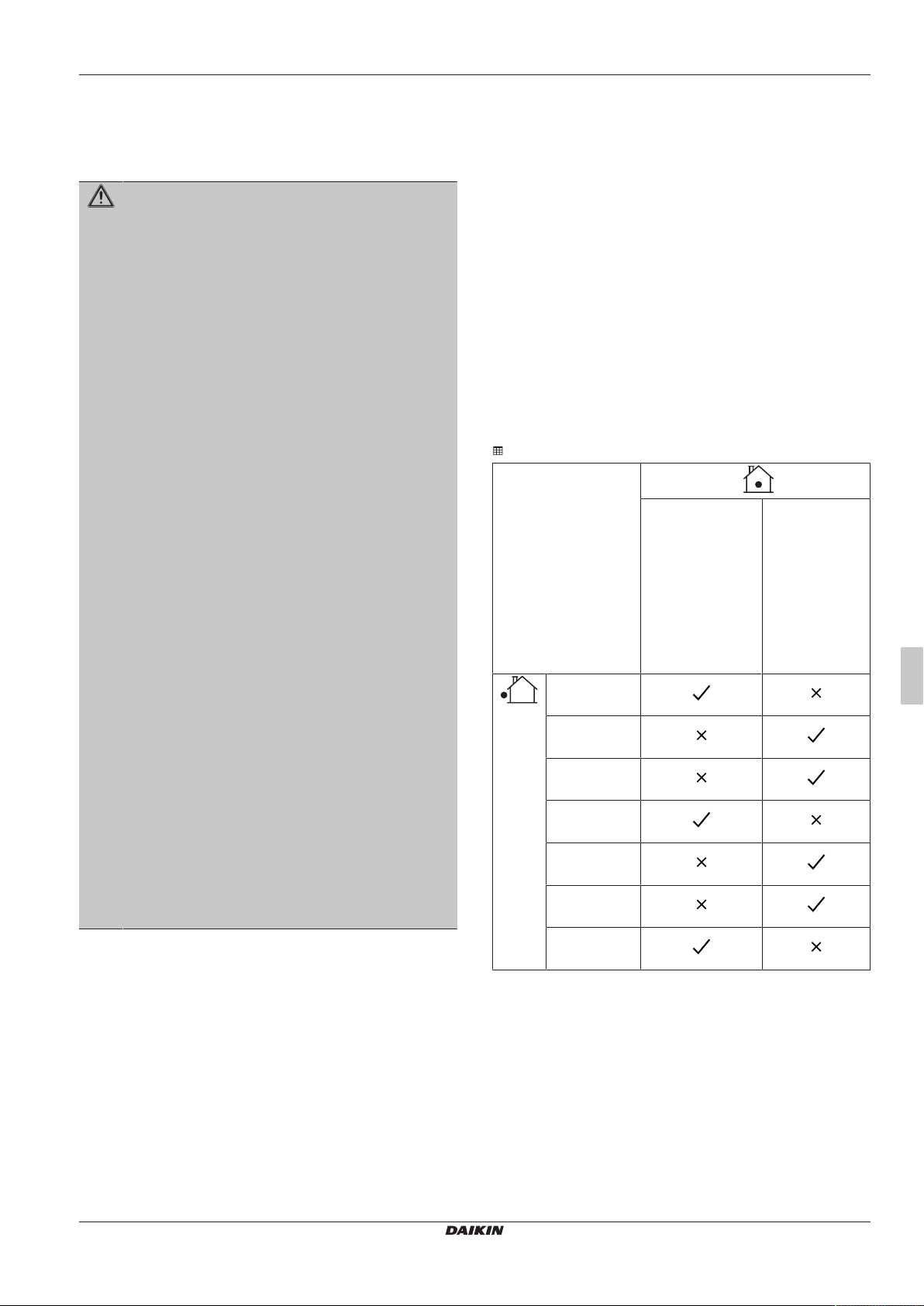

1‒1 Permissible combinations

EHSX04P30DA3

EHSX04P50DA3

EHSXB04P30DA3

EHSXB04P50DA3

EHSH04P30DA3

EHSHB04P30DA3

ERGA04DAV3

ERGA04EAV3

ERGA06DAV3

ERGA06EAV3

ERGA08DAV3

ERGA08EAV3

ERGA04DAV3A

ERGA04EAV3A

ERGA06DAV3A

ERGA06EAV3A

ERGA08DAV3A

ERGA08EAV3A

ERGA04DAV37

ERGA04EAV37

Any other use or use beyond the intended use is considered

improper use. The operator alone bears responsibility for any

resulting damage.

Intended use also includes compliance with the maintenance and

service conditions. Spare parts must at least satisfy the technical

requirements defined by the manufacturer. This is the case, for

example, with original spare parts.

EHSX08P30DA3

EHSX08P50DA3

EHSXB08P30DA3

EHSXB08P50DA3

EHSH08P30DA3

EHSH08P50DA3

EHSHB08P30DA3

EHSHB08P50DA3

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

5

1 General safety precautions

1.2.3 Installation room

WARNING

The plastic wall of the storage tank on

the indoor unit can melt under the

effects of external heat (>80°C) and, in

the extreme case, can catch fire.

▪ Only install the indoor unit at a

minimum clearance of 1m from other

heat sources (>80°C) (e.g. electrical

heater, oil heater, chimney) and

combustible materials.

CAUTION

▪ Only install the indoor unit if sufficient

load-carrying capacity of the ground

of 1050kg/m2 plus safety margin is

ensured. The ground must be flat,

horizontal and level.

▪ Outdoor set up is not permissible.

▪ Set-up in an explosion-risk

environment is not permissible.

▪ The electronic control system must

not be exposed to weather effects

such as rain and snow under any

circumstances.

▪ The storage tank may not be

exposed to continuous direct sunlight,

as the UV radiation and the effects of

the weather will damage the plastic.

▪ The indoor unit must be installed

protected from frost.

▪ Make sure that the supply company

does not provide corrosive domestic

water. Suitable water treatment may

be required.

▪ Always ensure the minimum distances from walls and other

objects ("3.1Dimensions and connection dimensions"[411]).

▪ Observe the special installation requirements of the R32

refrigerant (see "3.3.1Selecting the installation site"[412]).

CAUTION

▪ If a DrainBack solar heating

system is connected: Install the

indoor unit far enough under the solar

panels to allow complete emptying of

the solar heating system. (Follow the

instructions in the DrainBack solar

heating system manual.) An

insufficient height difference may lead

to destruction of the DrainBack solar

heating system.

▪ The indoor unit must not be operated

in rooms with ambient temperatures

of more than 40°C.

1.2.4 Electrical installation

▪ Electrical installations may only be carried out by electrical

technicians and in compliance with valid electrical guidelines as

well as the specifications of the responsible energy supply

company.

▪ Compare the mains voltage indicated on the nameplate with the

supply voltage before connecting to the mains.

▪ Before beginning work on live parts, disconnect them from the

power supply (switch off main switch, remove fuse) and secure

against unintentional restart.

▪ Device covers and service panels must be replaced as soon as

the work is completed.

1.2.5 Requirements for heating and storage water

Damage due to deposits and corrosion: observe the relevant

technical rules to avoid corrosion products and deposits.

Minimum requirements regarding the quality of filling and top-up

water:

▪ Water hardness (calcium and magnesium, calculated as calcium

carbonate): ≤3mmol/l

▪ Conductivity: ≤1500 (ideal ≤100)μS/cm

▪ Chloride: ≤250mg/l

▪ Sulphate: ≤250mg/l

▪ pH value: 6.5 – 8.5

Measures for desalination, softening or hardness stabilisation are

necessary if the filling and top-up water have a high total hardness

(>3 mmol/l – total of the calcium and magnesium concentrations,

calculated as calcium carbonate). We recommend the use of Fernox

KSK limescale and corrosion protector. For other properties

deviating from the minimum requirements, suitable conditioning

measures are necessary to maintain the required water quality.

Using filling water and top-up water which does not meet the stated

quality requirements can cause a considerably reduced service life

of the equipment. The responsibility for this lies solely with the

operator.

Installation and operating manual

6

INFORMATION

If an optional external heat generator is connected, these

minimum requirements also apply to the filling and

supplementary water for this heating circuit.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

1.2.6 Heating system and sanitary connection

▪ Create a heating system according to the safety requirements of

EN12828.

▪ The plumbing connection must comply with the requirements of

EN 12897. The requirements of the following must also be

observed:

▪ EN 1717 – Protection against pollution of potable water

installations and general requirements of devices to prevent

pollution by backflow

▪ EN61770 – Electric appliances connected to the water mains –

Avoidance of backsiphonage and failure of hose-sets

▪ EN 806 – Specifications for installations inside buildings

conveying water for human consumption

▪ and, in addition, the country-specific legislation.

During operation of the indoor unit with an auxiliary heat source, the

storage tank temperature may exceed 65°C, above all when solar

energy is used.

▪ For this reason, some form of scalding protection needs to be

included when you install the system (hot water mixing device,

e.g. VTA32).

INFORMATION

The domestic water quality must comply with the

EU Guideline 98/83 EC and the regionally-applicable

regulations.

If the indoor unit is connected to a heating system with steel pipes,

radiators or non-diffusion-proof floor heating pipes, sludge and chips

can enter the hot water storage tank and cause blockages, local

overheating or corrosion damage.

▪ To prevent possible damage, install a dirt filter or sludge separator

into the heating return flow of the system (SAS 1 or SAS 2).

▪ The dirt filter must be cleaned at regular intervals.

1.2.7 Operation

The indoor unit:

▪ Do not operate until all installation and connection work is

completed.

▪ Only operate with a completely full storage tank (check level

indicator) and heating circuit.

▪ Operate at a maximum pressure of 3bar.

▪ Only connect with a pressure reducer on the external water supply

(supply line).

▪ Only operate if the protective cover is installed.

The specified servicing intervals should be adhered to and

inspection work must be carried out.

1 General safety precautions

Thanks to the environmentally friendly design of the

indoor unit, we have established requirements to ensure

environmentally friendly disposal. Proper disposal in compliance

with the respective national regulations of the country of use is the

responsibility of the user/owner.

The designation of the product means that electrical and

electronic products may not be disposed of together with unsorted

domestic waste.

Proper disposal in compliance with the respective national

regulations of the country of use is the responsibility of the user/

owner.

▪ Disassembly of the system, handling of refrigerant, oil and other

parts may only be carried out by a qualified fitter.

▪ Disposal may only be carried out by an organisation that

specialises in reuse, recycling and recovery.

Further information is available from the installation company or the

responsible local authorities.

1.4 Warranty conditions

The legal guarantee conditions fundamentally apply. Our more

extensive warranty conditions can be found in the Internet. Ask your

suppliers if necessary.

Incorrect installation, commissioning and maintenance will void the

warranty. If you have any questions, please contact our customer

service.

Warranty claims can only be made if the annual maintenance work is

demonstrably carried out regularly according to the information in the

installer reference guide.

1.3 Maintenance, troubleshooting and decommissioning

Work for maintenance, troubleshooting and decommissioning must

not be carried out without knowledge of the relevant safety

precautions and in the event of disposal of the country-specific

guidelines. Please refer to the corresponding information in the

reference manual for the fitter.

Recommendations for disposal

We designed the indoor unit in an environmentally friendly manner.

During the disposal process, the only waste created is that which

can be used for material or thermal recycling. The materials used

that are suitable for recycling can be sorted into individual types.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

7

2 Product description

2 Product description

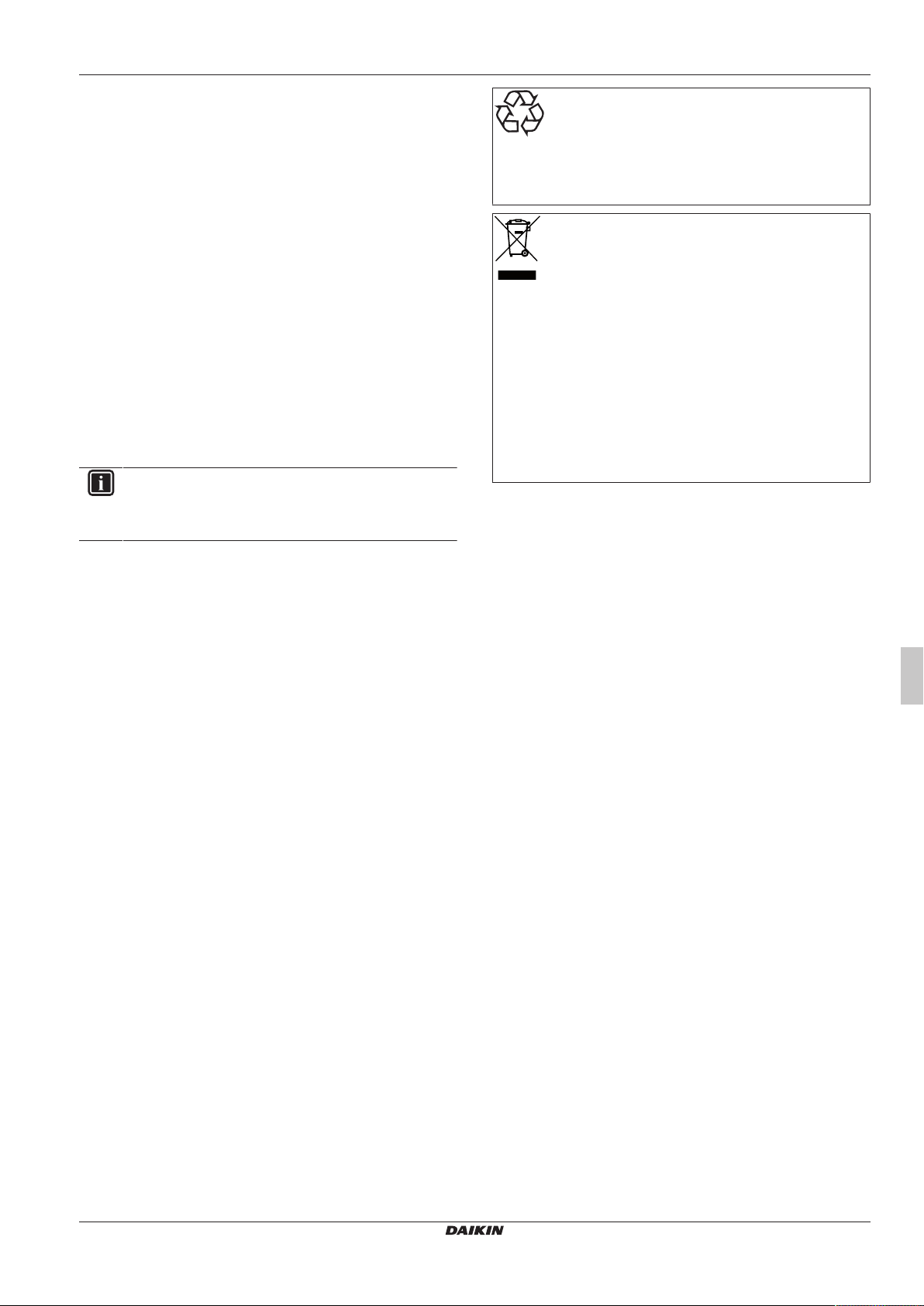

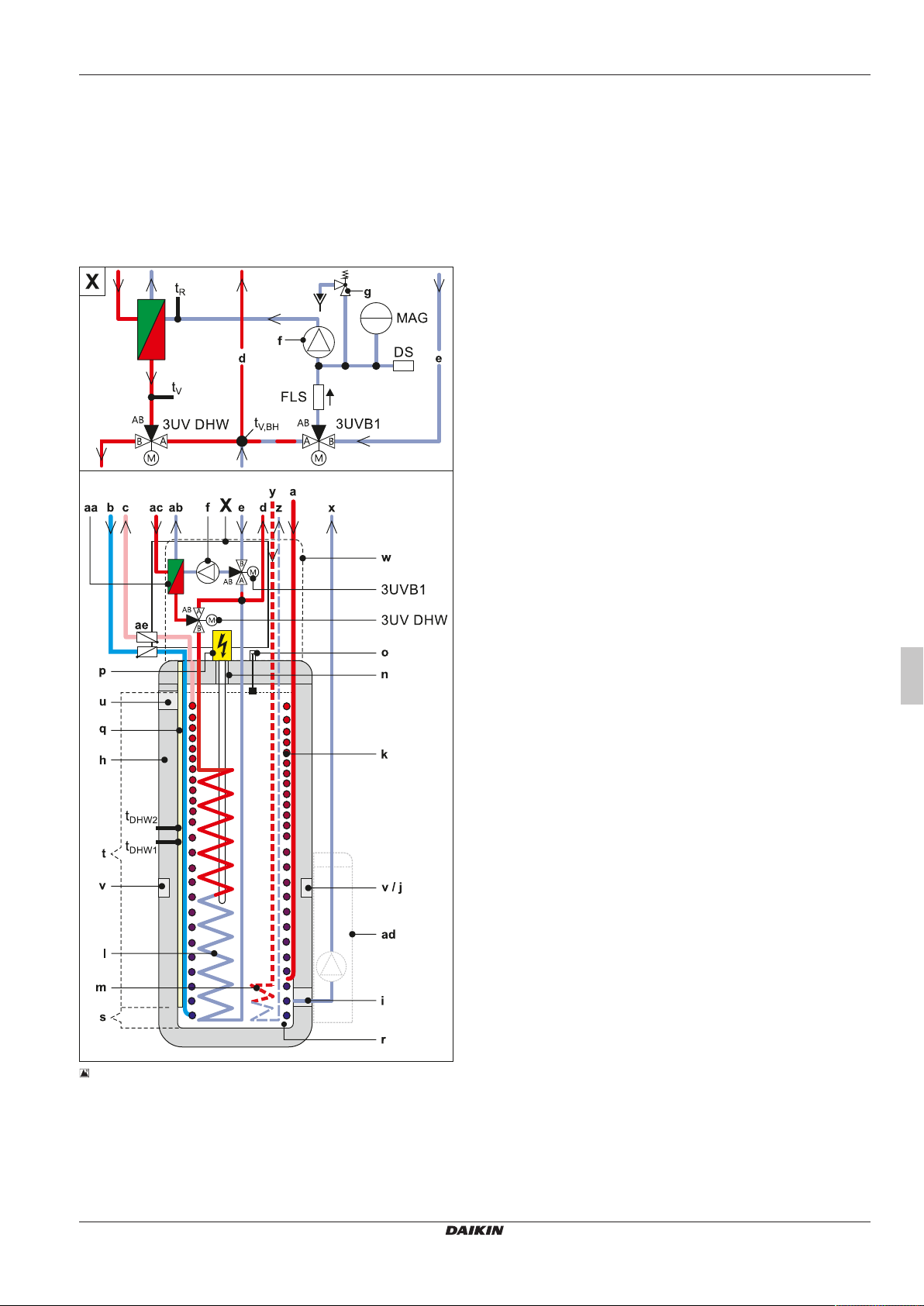

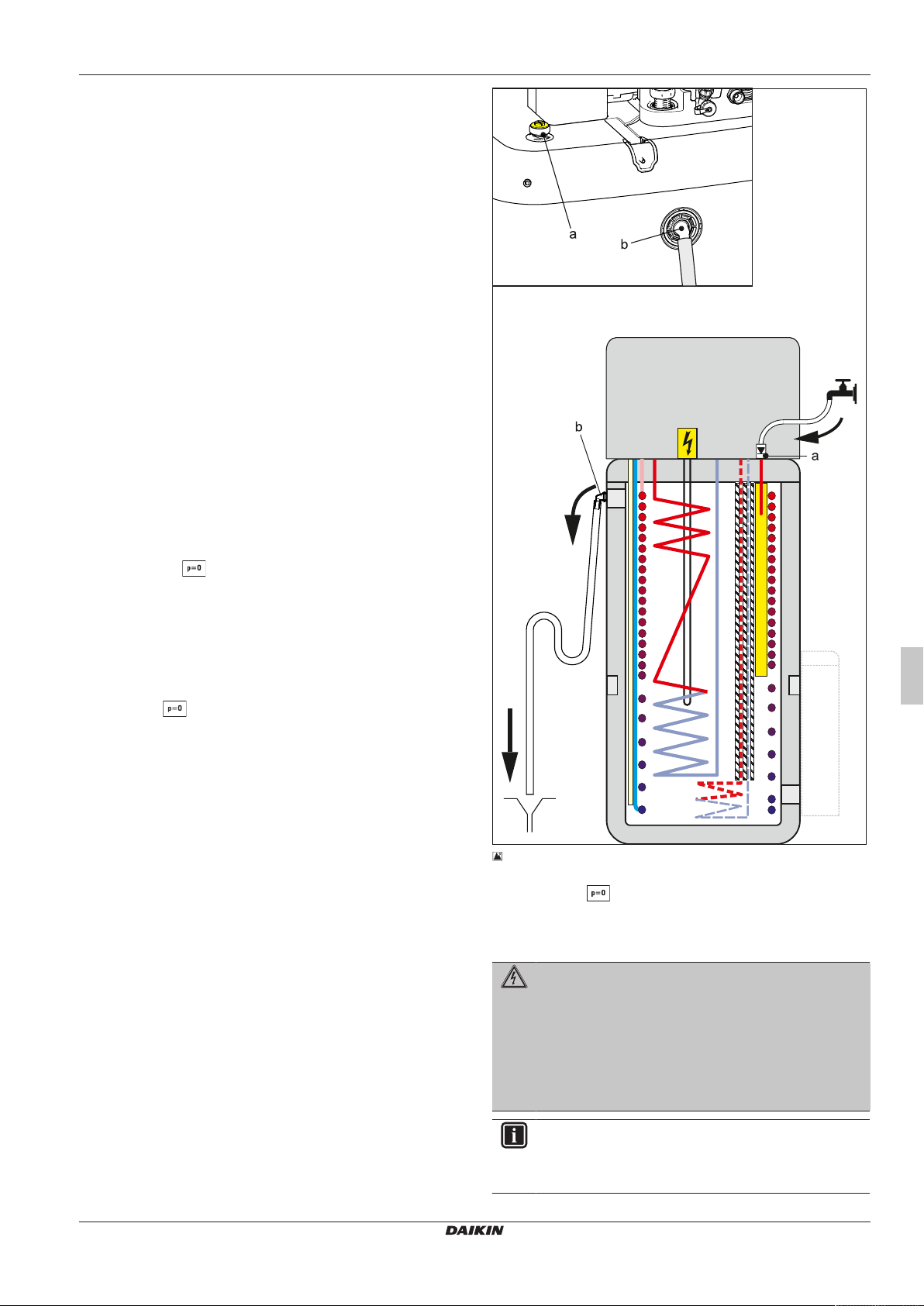

2.1 Design and components

Outside of the device

Upper side of the device

2‒1 Design and components – Outside of the device

a Status indicator

b Protective cover

c Mount for handle

d Filling and draining connection or solar return flow

connection

e Type plate

Installation and operating manual

8

2‒2 Design and components – Top of the device

a Solar flow

b Cold water connection

c Hot water

d Heating flow

e Heating return flow

f Circulation pump

g Pressure relief valve

h Automatic vent valve

i Connection for optional electrical backup heater EKBUxx

j Fill level indicator (tank water)

k Plate heat exchanger

l Connection for refrigerant fluid line

m Connection for refrigerant gas line

n Ball valve (heating circuit)

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

2 Product description

o Combined filling and draining valve (heating circuit)

p Storage tank temperature sensor

q Expansion vessel connection

r Switch box

s, t Manual air purge valves

3UVB1 3‑way changeover valve (internal heat generator circuit)

3UV DHW 3‑way changeover valve (hot water/heating)

DS Pressure sensor

FLS FlowSensor

tRReturn temperature sensor

t

Backup heater inflow temperature sensor

V,BH

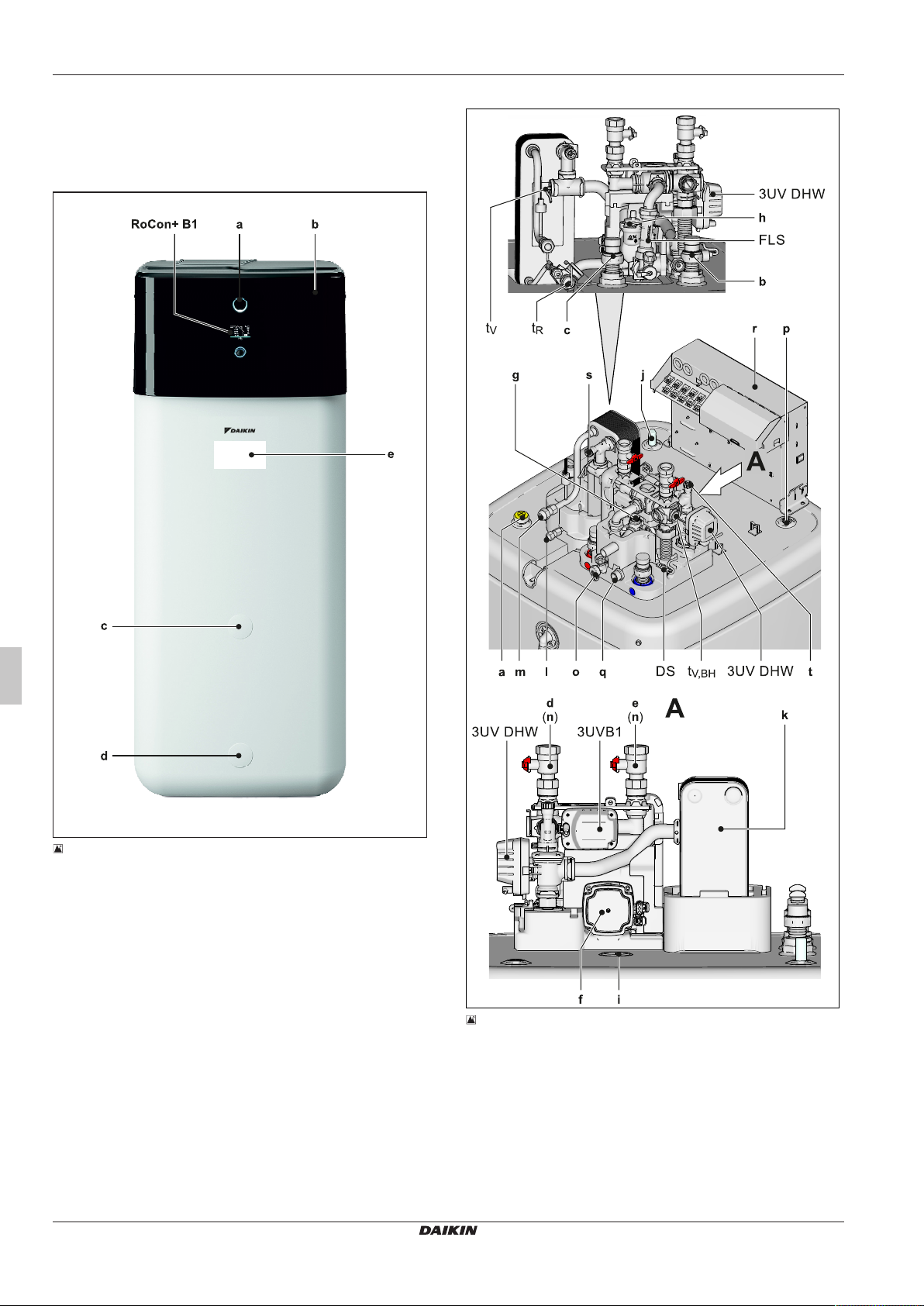

Internal structure…04P30D.../…08P30D...

h Storage tank (polypropylene, double-walled jacket with

PUR hard foam heat insulation)

i Filling and draining connection or solar return flow

connection

j Mount for solar controller or handle

k Heat exchanger (stainless steel) for domestic hot water

heating

l Heat exchanger (stainless steel) for storage tank

charging or heating support

m Biv heat exchanger (stainless steel) for charging with

external heat generator (e.g. pressurised solar system)

n Connection for optional electrical backup heater EKBUxx

o Fill level indicator (tank water)

p Optional: electric backup heater (EKBUxx)

q Submersible sensor sleeve for storage tank temperature

sensor t

r Pressureless storage tank water

DHW1

and t

DHW2

s Solar zone

t Hot water zone

u Safety overflow connection

v Mount for handle

w Protective cover

x Solar return flow

y Biv flow

z Biv return flow

aa Plate heat exchanger

ab Connection for refrigerant fluid line

ac Connection for refrigerant gas line

ad Optional: Solar control and pump unit

ae Circulation stop valve (accessory)

3UVB1 3‑way changeover valve (internal heat generator circuit)

3UV DHW 3‑way changeover valve (hot water/heating)

DS Pressure sensor

FLS FlowSensor

MAG Expansion vessel (field supply)

t

, t

DHW1

Storage tank temperature sensor

DHW2

tRReturn temperature sensor

t

Backup heater inflow temperature sensor

V,BH

2‒3 Design and components – Internal

structure ...04P30D.../...08P30D... (Biv)

a Solar flow

b Cold water connection

c Hot water

d Heating flow

e Heating return flow

f Circulation pump

g Pressure relief valve

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

9

2 Product description

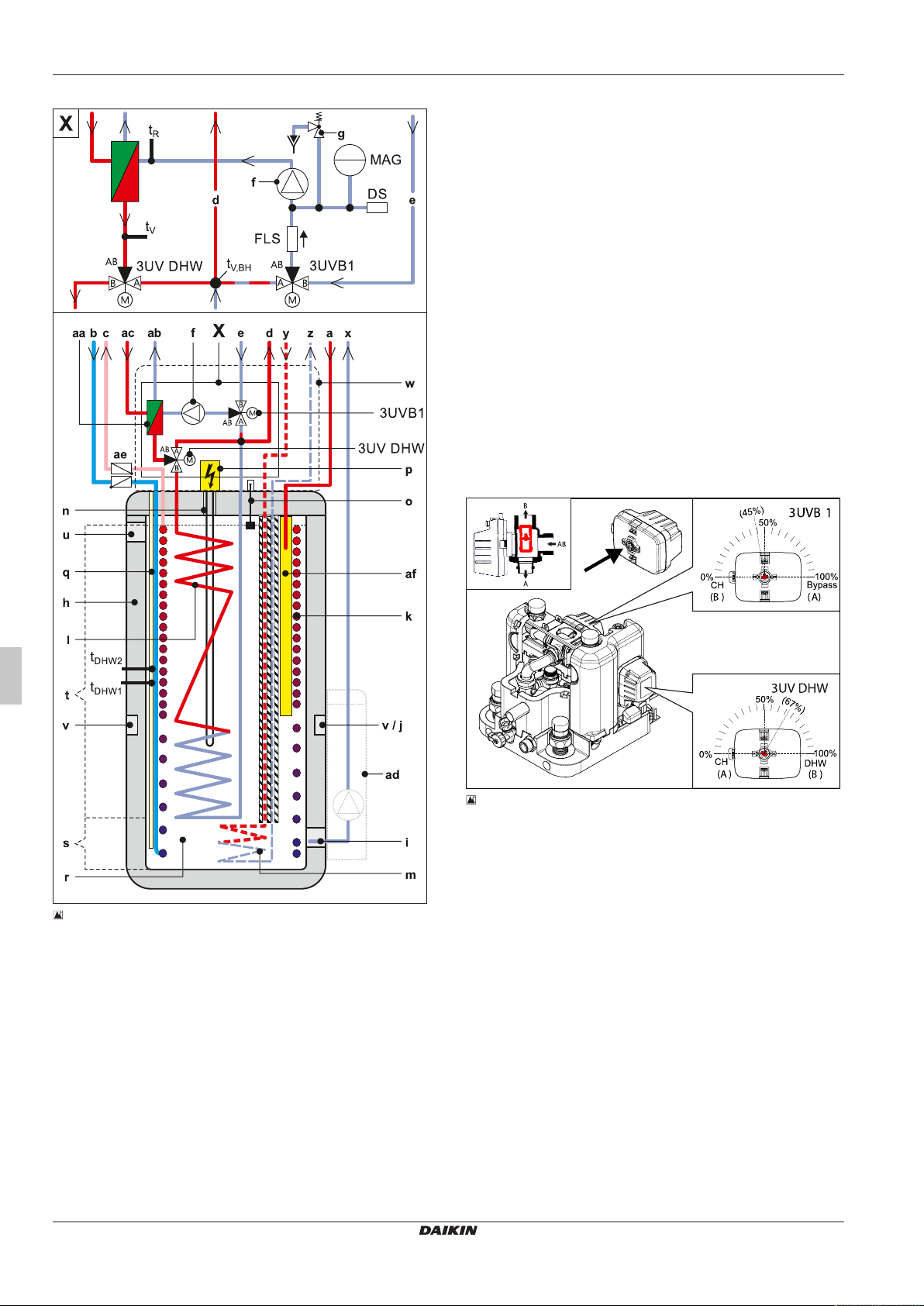

Internal structure…04P50D…/…08P50D...

p Optional: electric backup heater (EKBUxx)

q Submersible sensor sleeve for storage tank temperature

sensor t

r Pressureless storage tank water

s Solar zone

t Hot water zone

u Safety overflow connection

v Mount for handle

w Protective cover

x Solar return flow

y Biv flow

z Biv return flow

aa Plate heat exchanger

ab Connection for refrigerant fluid line

ac Connection for refrigerant gas line

ad Optional: Solar control and pump unit

ae Circulation stop valve (accessory)

af Solar flow layering pipe

3UVB1 3‑way changeover valve (internal heat generator circuit)

3UV DHW 3‑way changeover valve (hot water/heating)

DS Pressure sensor

FLS FlowSensor

MAG Expansion vessel (field supply)

t

, t

DHW1

Storage tank temperature sensor

DHW2

tRReturn temperature sensor

t

Backup heater inflow temperature sensor

V,BH

DHW1

and t

DHW2

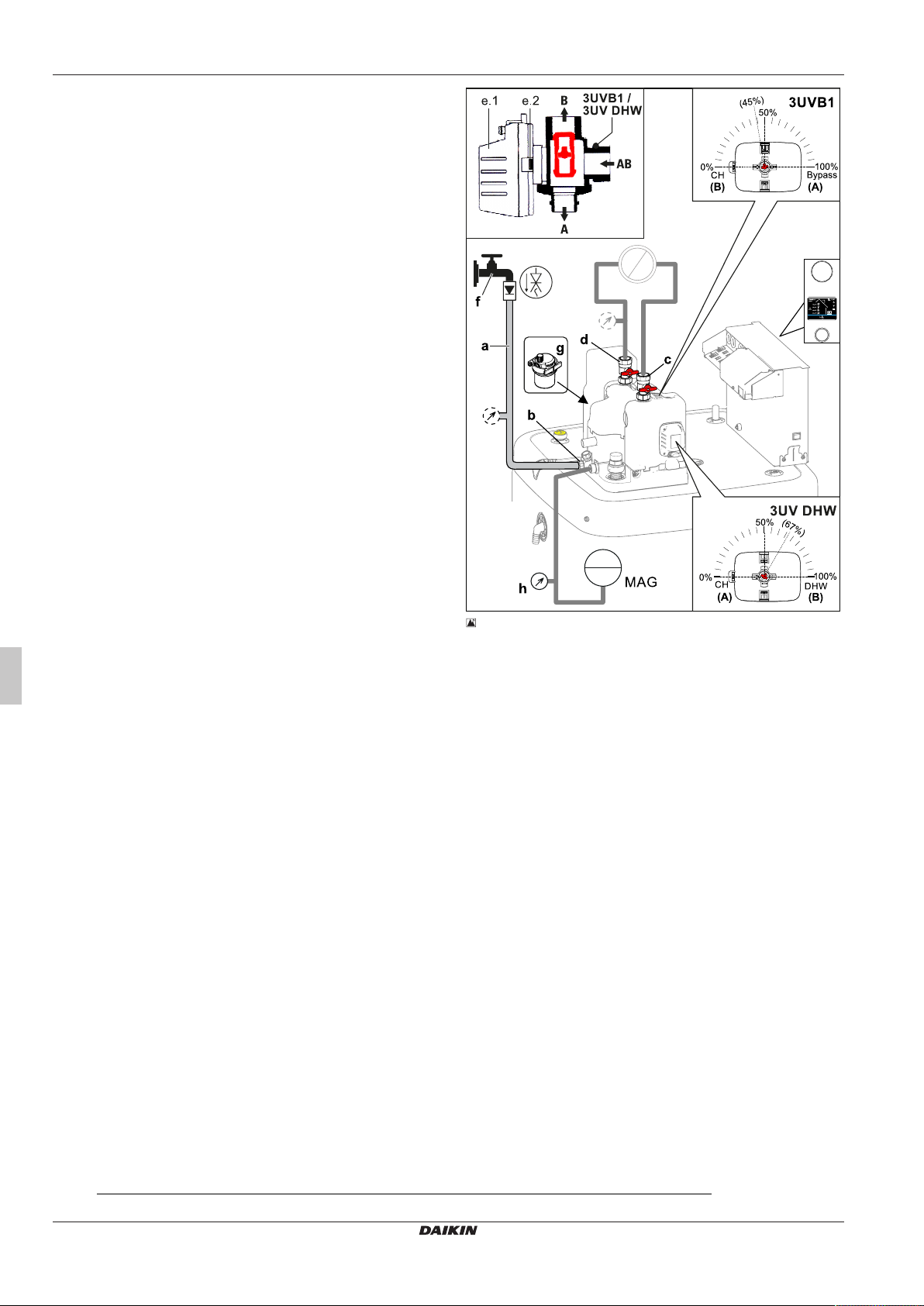

2.2 Function of the 3‑way changeover valves

2‒4 Design and components - Internal

structure ...04P50D/...08P50D… (Biv)

a Solar flow

b Cold water connection

c Hot water

d Heating flow

e Heating return flow

f Circulation pump

g Pressure relief valve

h Storage tank (polypropylene, double-walled jacket with

PUR hard foam heat insulation)

i Filling and draining connection or solar return flow

connection

j Mount for solar controller or handle

k Heat exchanger (stainless steel) for domestic hot water

heating

l Heat exchanger (stainless steel) for storage tank

charging or heating support

m Biv heat exchanger (stainless steel) for charging with

external heat generator (e.g. pressurised solar system)

n Connection for optional electrical backup heater EKBUxx

o Fill level indicator (tank water)

Installation and operating manual

10

2‒5 Function of 3‑way changeover valve

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3 Set-up and installation

3 Set-up and installation

WARNING

Cooling systems (heating pumps), climate control systems

and heating devices that have been set up and installed

incorrectly can both endanger human life and health and

be impaired in their function.

▪ Work on the indoor unit (such as set-up, repair,

connection and initial commissioning, for example)

must only be carried out by persons who are

authorised, who have successfully completed qualifying

technical or vocational training for the respective

activity and who have taken part in advanced training

sessions recognised by the relevant responsible

authority. These include, in particular, certified heating

engineers, qualified electricians and HVAC specialists

who, because of their professional training and expert

knowledge, have experience in the professional

installation and maintenance of heating, cooling and air

conditioning systems and heat pumps.

Incorrect set-up and installation would render the manufacturer's

guarantee for the unit void. If you have questions, please contact our

Technical Customer Service.

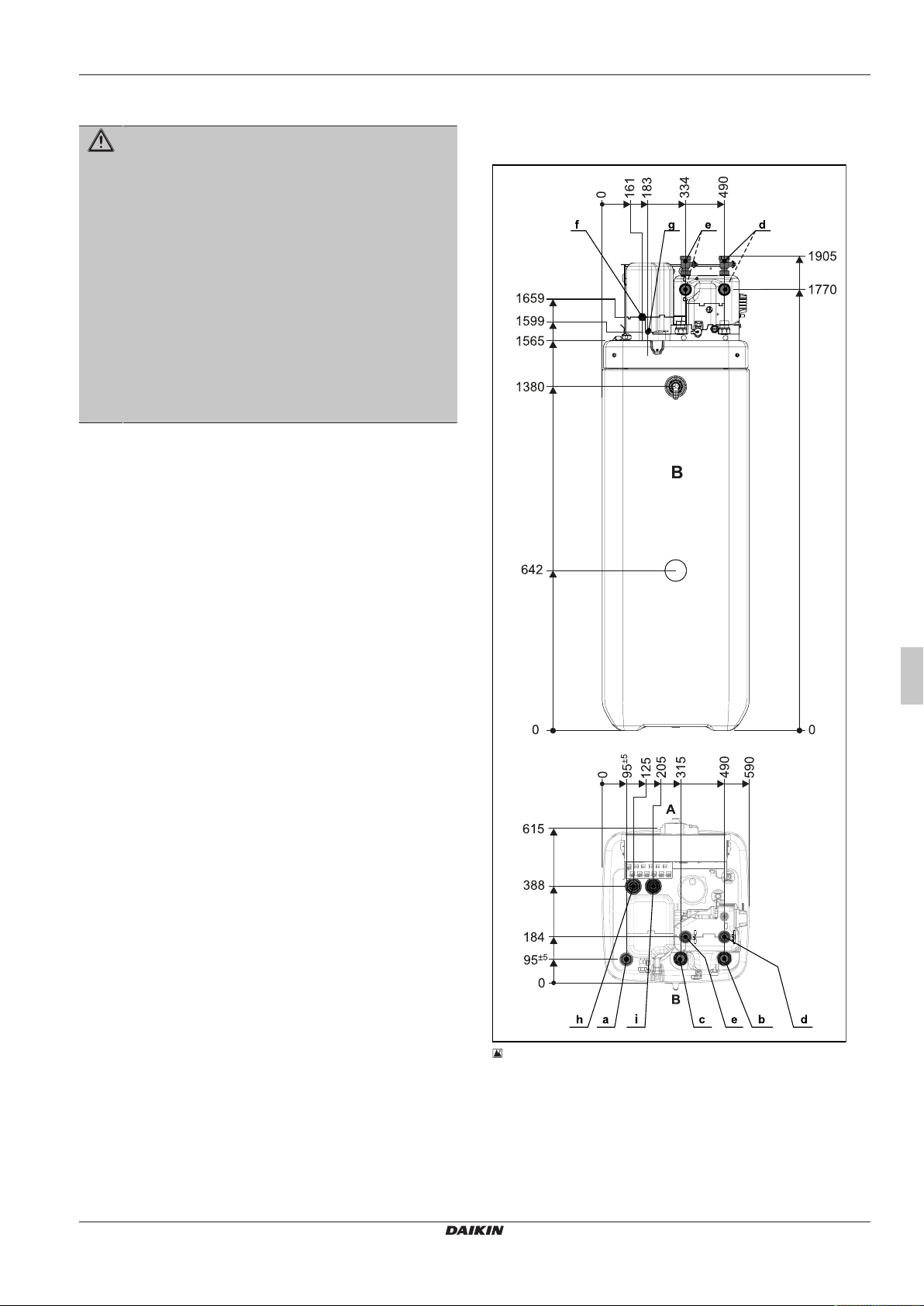

3.1 Dimensions and connection dimensions

Dimensions …04P30D.../…08P30D...

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3‒1 Dimensions …04P30D.../…08P30D...

a Solar flow

b Domestic cold water

c Hot water

d Heating flow

e Heating return flow

f Connection for refrigerant gas line

g Connection for refrigerant fluid line

h Biv flow (…Biv type only)

i Biv return flow (…Biv type only)

A front

B rear

Installation and operating manual

11

3 Set-up and installation

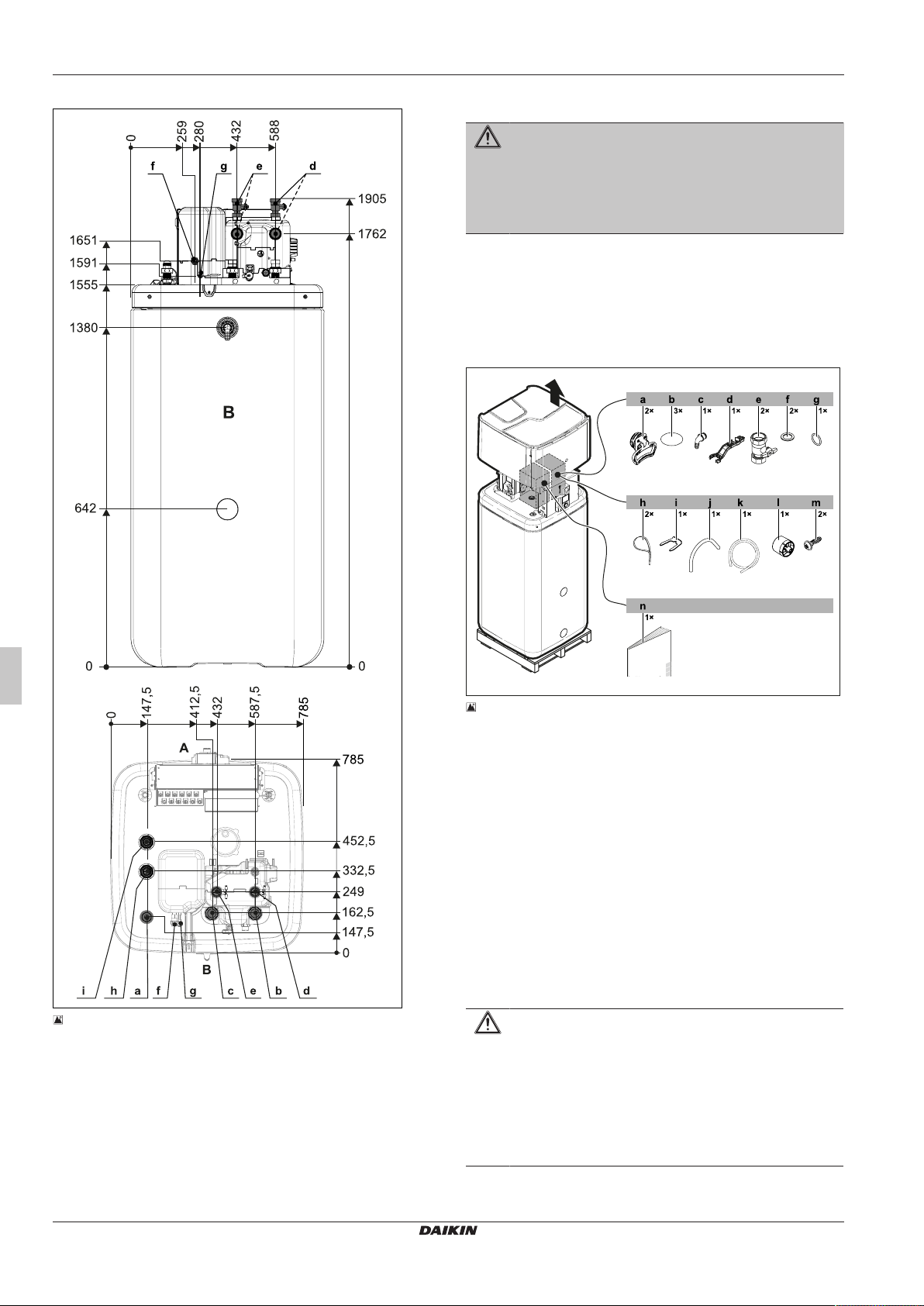

Dimensions …04P50D…/…08P50D…

3.2 Transport and delivery

WARNING

When unfilled, the indoor unit is top-heavy and could tip

over during transport, which could put persons in danger or

damage the device.

▪ Secure the indoor unit well, transport carefully, use the

handles.

The indoor unit is delivered on a pallet. All industrial trucks, such as

lifting trucks and forklift trucks, are suitable for transport.

Scope of delivery

▪ Indoor unit (pre-mounted),

▪ Bag of accessories,

▪ Document pack.

3‒2 Dimensions …04P50D…/…08P50D…

a Solar flow

b Domestic cold water

c Hot water

d Heating flow

e Heating return flow

f Connection for refrigerant gas line

g Connection for refrigerant fluid line

h Biv flow (…Biv type only)

i Biv return flow (…Biv type only)

A front

B rear

3‒3 Scope of delivery

a Handles (only required for transport)

b Cover screen

c Hose connecting piece for safety overflow

d Fitting spanner

e Ball valve

f Flat gasket

g O‑ring

h Cable tie

i Securing clip

j Venting hose

k Condensate drain hose

l Controller rotary switch

m Hood screws

n Document pack

For further accessories for the indoor unit, see price list.

3.3 Installing the heat pump

3.3.1 Selecting the installation site

CAUTION

If the total refrigerant charge in the system is ≥1.84kg, it is

essential to comply with additional requirements for

minimum footprint and minimum ventilation openings.

Observe "6.4 Minimum floor area and ventilation

openings"[434].

Information on the total refrigerant charge can be found on

the type plate of the outdoor unit. Please follow the

installation instructions.

The installation site of the indoor unit must meet the minimum

requirements below (see also "1.2.3Installation room"[46]).

Installation and operating manual

12

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3 Set-up and installation

Installation area

▪ The base must be level and smooth and have sufficient ground

load-bearing capacity of 1050kg/m² plus safety factor. Install a

pedestal if necessary.

▪ Observe the installation dimensions (see "3.1 Dimensions and

connection dimensions"[411]).

Minimum distance

DANGER: RISK OF BURNING/SCALDING

The plastic wall of the storage tank on the indoor unit can

melt under the effects of external heat (>80°C) and, in the

extreme case, can catch fire.

▪ Only install the indoor unit at a minimum clearance of

1 m from other heat sources (>80°C) (e.g. electrical

heater, oil heater, chimney) and combustible material.

CAUTION

If the indoor unit is not installed at a sufficient

distance below the flat solar panels (the top edge of the

storage tank is higher than the bottom edge of the solar

panels), the unpressurised solar system in the outdoor

area will not be able to drain completely.

▪ When a solar connection is used, install the indoor unit

low enough under the flat solar panels (observe the

minimum gradient of the solar connection lines).

Recommended minimum distances:

From the wall: (rear) ≥100mm, (sides) ≥500mm

From the ceiling: ≥1200mm, at least 480mm.

4 Carefully transport the indoor unit to the installation site, use the

handles.

Distances from the outdoor unit:

When selecting the installation location, the data in the table " 3‒1

"[413] must be taken into account.

3‒1

Maximum refrigerant piping length between the

indoor and outdoor units

Minimum refrigerant piping length between the

indoor and outdoor units

Maximum height difference between the indoor and

outdoor units

30m

3m

20m

3.3.2 Installing the device

WARNING

When unfilled, the indoor unit is top-heavy and could tip

over during transport, which could put persons in danger or

damage the device.

▪ Secure the indoor unit well, transport carefully, use the

handles.

Precondition

▪ The installation site complies with applicable country-specific

regulations and meets the minimum requirements described in

"3.3.1Selecting the installation site"[412].

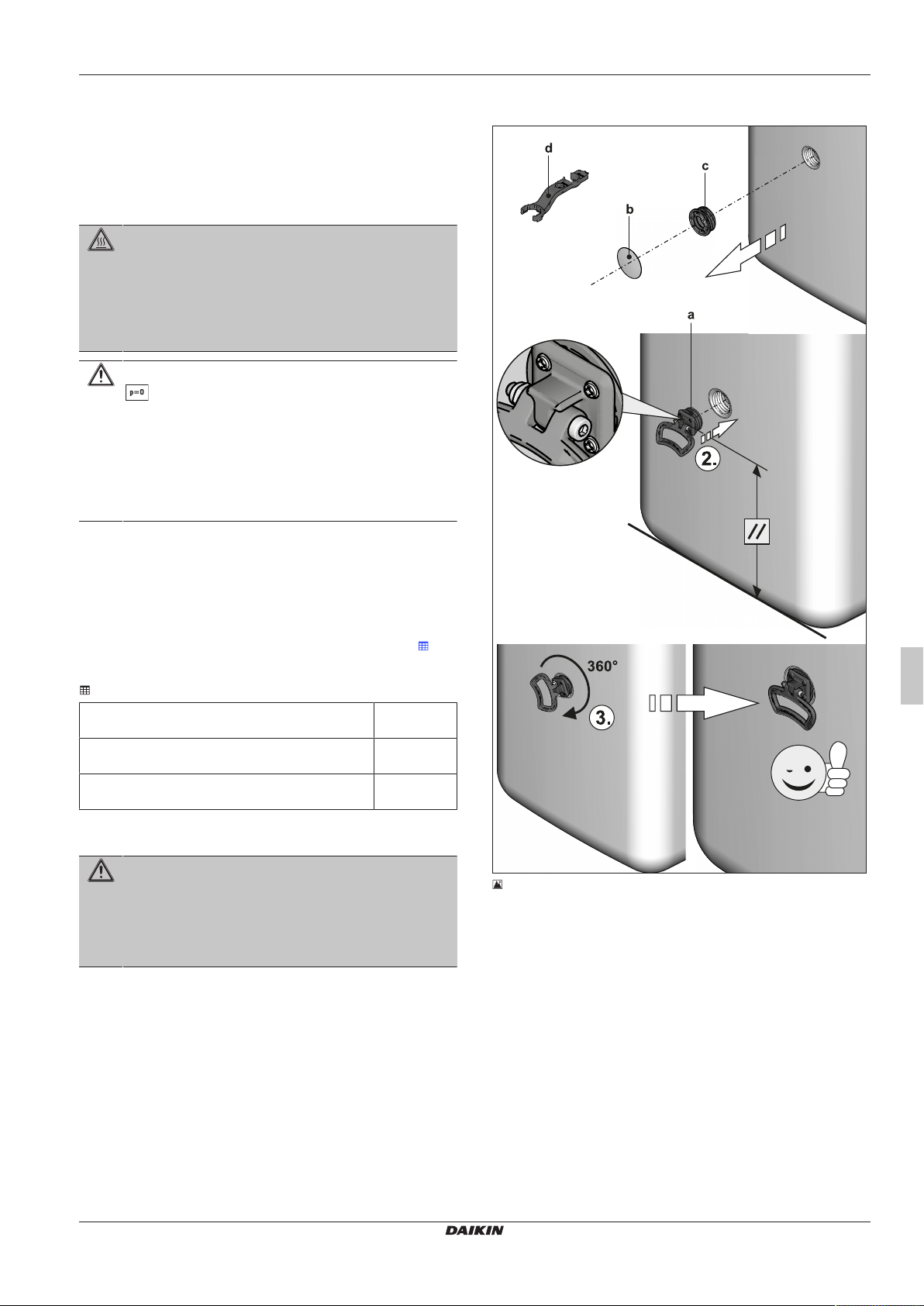

Set-up

1 Remove the packaging and dispose of it in an environmentally

sound manner.

2 Pull off the cover screens from the storage tank (item b) and

unscrew the threaded fittings (item c) from the openings at

which the handles are to be fitted.

3 Screw the handles (item a) into the now uncovered threaded

holes.

3‒4 Installing the handles

a Handle

b Cover screen

c Threaded piece

d Fitting spanner

5 Install the indoor unit at the installation site.

▪ When setting up the unit in a cabinet, behind panels or in other

restricted conditions, sufficient ventilation (e.g. using ventilation

gratings) must be ensured. If the total refrigerant charge in the

system is ≥1.84 kg, further requirements of the ventilation

openings must be met (see "6.4 Minimum floor area and

ventilation openings"[434]).

3.4 Preparing the device for installation

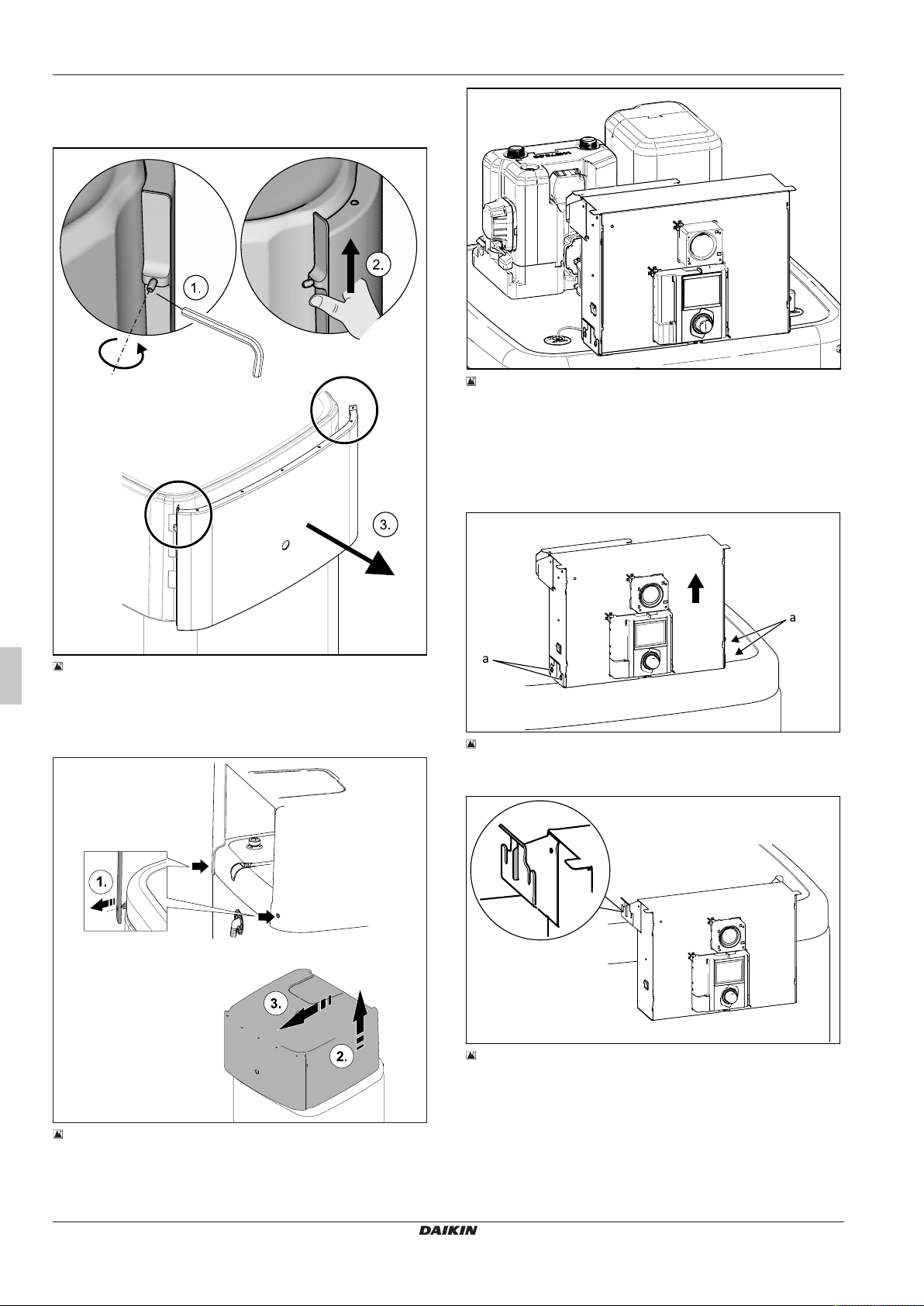

3.4.1 Remove the front screen

1 Undo the screws (1.).

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

13

3 Set-up and installation

2 Press the lateral holding burls upwards with your fingers (2.),

stem from above with the thumbs.

3 Remove the front screen to the front (3.).

3‒7 Without protective cover

3.4.3 Moving the switch box to the service position

To facilitate work on the hydraulics of the indoor unit, the switch box

can be moved to the service position.

1 Loosen the screws(a) of the holder of the switch box.

3‒5 Remove the front screen

3.4.2 Remove the protective cover

1 Unhook the protective cover from the rearward facing holding

burls (1.), lift at the back (2.) and remove to the front (3.).

3‒6 Remove the protective cover

3‒8 Moving the switch box to the service position

2 Remove the switch box from the front and insert it into the

bracket with the hooks on the rear brackets.

3‒9 Switch box in the service position

3.4.4 Open the switch box

To make the electrical connections, the switch box itself must be

opened. This can be done in both the normal and the service

position.

1 Loosen the front screw.

2 Push the cover upwards and pull it away to the front.

Installation and operating manual

14

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3‒10 Open the switch box

3 Hook in the cover on the switch box with the lateral hooks.

3 Set-up and installation

3‒12 Removing the top thermal insulation

a Side insulating element

b Rear insulating element

c Front insulating element

2 As required: Remove the bottom thermal insulation in the

following order:

▪ Pull the side insulating element off vertically (itema).

▪ Pull the rear insulating element off vertically (itemb).

3‒11 Hooking in the cover

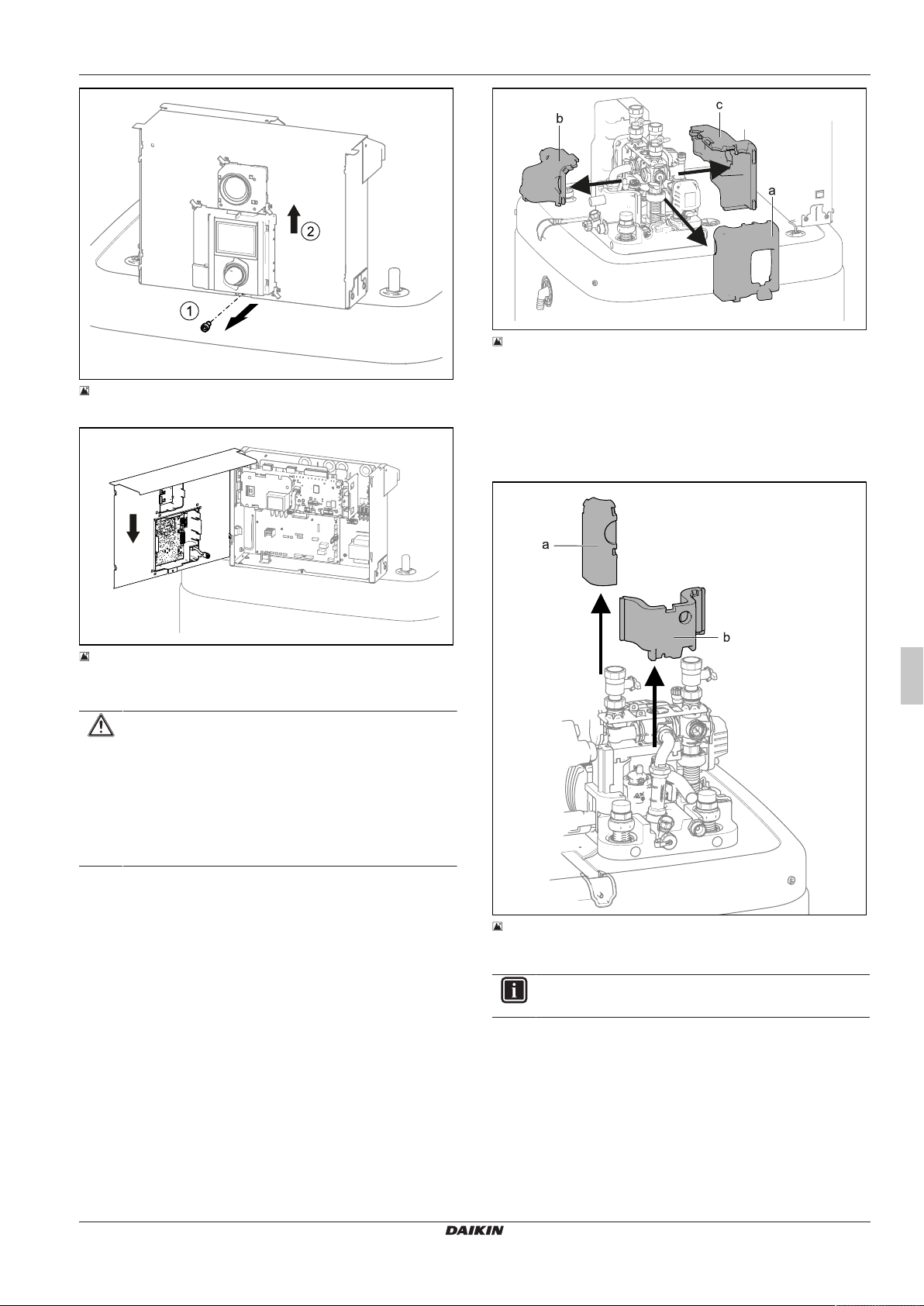

3.4.5 Removing the bottom thermal insulation

CAUTION

The thermal insulation consists of pressure-sensitive EPP

moulded parts that can be easily damaged if not handled

correctly.

▪ Only remove the thermal insulation in the order stated

below and in the stated directions.

▪ Do not use force.

▪ Do not use tools.

1 Remove the thermal insulation in the following order:

▪ Pull the side insulating element off horizontally (itema).

▪ Pull the rear insulating element off horizontally (itemb).

▪ Pull the front insulating element off horizontally (itemc).

3‒13 Removing the bottom thermal insulation

a Side insulating element

b Rear insulating element

INFORMATION

The thermal insulation is installed in reverse order.

3.4.6 Opening the air purge valve

1 Removing the thermal insulation (see "3.4.5 Removing the

bottom thermal insulation"[415]).

2 Open the air purge valve on the pump by one turn.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

15

3 Set-up and installation

3‒14 Opening the air purge valve

3.4.7 Aligning the connections of the heating inflow and return flow

CAUTION

When working on the hydraulics, pay attention to the

installation position of the O‑rings to avoid damaging them

and causing leaks.

▪ Always place O‑rings on the part to be inserted after

disassembly or before assembly (see " 3‒15

Hydraulic system plug connectors"[416]).

▪ The heating lines must be connected free of tension via

the plug connectors. Establish a suitable strain relief

especially when connecting with flexible lines (not open

to diffusion!) (see " 3‒28 Supporting rear-facing

hydraulic lines"[420]).

3‒16 Variants for aligning the heating infeed and return flow

The device is supplied with upwards aligned connections as

standard. The following conversion steps are required in order to

direct the connections to the rear out of the device:

1 Remove the protective cover and top thermal insulation

(see "3.4.2 Remove the protective cover" [4 14],

"3.4.5Removing the bottom thermal insulation"[415]).

2 Pull the two securing clips off the connection couplings (itemc).

3 Pull off the two connection couplings (itemb).

4 Remove the retaining plate (itema).

5 Pull off the sealing plug securing clip (itemd).

6 Pull out the sealing plug (iteme).

7 Turn the elbow (itemh) 90° to the rear.

8 Pull the securing clip off the manifold (itemg).

3‒15 Hydraulic system plug connectors

CAUTION

If the securing clips cannot be put on properly, the

couplings can be detached from their mountings to ensure

a very strong or continuous escape of liquid can occur.

▪ Before putting on a securing clip, make sure that the

securing clip engages in the coupling groove. To do so,

insert the coupling far enough into the mounting that

the groove is visible through the securing clip mounting.

▪ Insert the securing clip up to the end stop.

The connections of the heating inflow and return flow can be

directed upwards or backwards in order to adapt it optimally to the

structural conditions of the installation site.

Installation and operating manual

16

3‒17 Aligning the heating inflow and return flow connections

upwards

a Retaining plate

b Connection coupling

c Securing clip of the connection couplings

d Securing clip of the sealing plug

e Sealing plug

f Manifold

g Securing clip of the manifold

h Elbow

9 Carefully pull the manifold (item f) so far backwards out of its

horizontal mounting that the retaining plate (" 3‒18 Heating

inflow and return flow connections aligned to the rear" [4 17],

itema) can be pushed vertically in between.

10 Slide the retaining plate between the manifold and its horizontal

mounting, and insert the manifold (itemf) back into its mounting

through the middle hole of the retaining plate.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

11 Secure the manifold with securing clip (itemg) in its mounting

again.

12 Insert the two connection couplings (item b) through the

retaining plate into the lateral mountings.

13 Secure the two connection couplings with securing clips (itemc)

in their mountings.

14 Insert the sealing plug (iteme) in the upper mounting.

15 Secure the sealing plug with securing clip (itemd).

3 Set-up and installation

3‒20 Making the hood opening

3.4.9 Installing the rotary switch of the controller

1 Place the rotary switch on the rotary switch holder of the RoCon

+HP1 and press it on.

3‒18 Heating inflow and return flow connections aligned to the

rear

a Retaining plate

b Connection coupling

c Securing clip of the connection couplings

d Securing clip of the sealing plug

e Sealing plug

f Manifold

g Securing clip of the manifold

h Elbow

16 Cut out side openings in the thermal insulation (itema) using a

suitable tool.

3‒19 Cut-out in thermal insulation

a Side openings in the thermal insulation

3‒21 Putting on the rotary switch

3.4.10 Securing the hood

After the installation is fully completed:

1 Attach the screws for fixing the hood (accessory bag).

2 Place the front cover straight over the rotary switch of the

RoCon+ HP1. Press on the top and bottom until the front

screen is securely engaged again.

3.4.8 Making the hood opening

1 With the heating inflow and return flow directed upwards: Cut

the hood along the perforation with a suitable tool.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3‒22 Securing the hood

Installation and operating manual

17

3 Set-up and installation

3.5 Installing optional accessories

3.5.1 Installation of electric backup heater (EKBUxx)

INFORMATION

If the ceiling height is low, the storage tank must be tilted to

install the backup heater when empty. This must be done

before any further installation steps.

The indoor unit provides the option of installing an electrical auxiliary

heater (backup heater EKBUxx). For example, renewable energy

can be used as an additional heat source.

INFORMATION

A separate manual containing instructions about

installation and operation is included with this component.

3.5.2 Installation of the external heat generator connection set (EKBUHSWB)

The connection set for external heat generators must be installed to

control an electrical backup heater or another external heat

generator.

1 Open the housing by removing the screw.

2 Remove additional components from the housing (strain relief

clip, cable tie, grommet).

3 Attach the connection set to the switch box of the indoor unit.

To do this, insert the hooks (itema) of the connection set into

the slots of the switch box(item b); then press the connection

set downwards.

6 Guide the cable of the Ultra EHS PCB through the cable

grommet and connect it to the RoCon BM2C (see " 3‒38

Connection on the RTX-EHS PCB"[425]).

7 After the installation and the electrical connections (see

"3.6 Water connection" [4 19] or "3.7 Electrical

connection" [4 20]) have been completed, replace the cover

and close it with the screw.

3.5.3 Installation of the DB connection kit

The optional DB connection kit allows better access for connecting

the DrainBack pipe (solar feed).

3‒25 DB connection kit

a DB pipe connection (solar flow)

b FlowSensor (not part of the DB connection kit, but

included with EKSRPS4)

c Flow rate limiter (FlowGuard)

d

Solar flow connection on the storage tank

3‒23 Fitting the connection set

a Hooks

b Slot

4 Attach the grommet (item a) to the bushing between the

connection setand the switch box.

5 Attach the fastening rivet (itemb).

3.5.4 Installation of the P connection kit

The optional P connection kit for Biv device types allows better

access for connecting the flow and return flow lines of a pressurised

solar system or another external heat generator on the storage tank.

The kit contains two thermally insulated corrugated pipes that are

connected to the connections of the storage tank via a union nut. At

the other end of the corrugated pipes there is an adapter for different

connection sizes of the supply and return pipes.

3‒24 Cable gland

a Grommet

b Fastening rivet

Installation and operating manual

18

3‒26 P connection kit for Biv device types

a Connection for flow (red)

b Connection for return flow (blue)

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3 Set-up and installation

3.6 Water connection

Important information

CAUTION

If the indoor unit is connected to a heating system with

steel pipes, radiators or non-diffusion-proof floor heating

pipes, sludge and chips can enter the hot water storage

tank and cause blockages, local overheating or

corrosion damage.

▪ Rinse supply lines before filling the device.

▪ Rinse out the heat distribution network (in the existing

heating system).

▪ Install a dirt filter or sludge separator in the heating

return flow (see "1.2.6 Heating system and sanitary

connection"[47]).

CAUTION

If the indoor unit is connected to a cold water line where

steel pipes are used, chips can get into the stainless steel

corrugated pipe heat exchanger and remain there. This

can lead to contact corrosion damage and subsequently to

leakage.

▪ Flush the feed pipes before filling the heat exchanger.

▪ Install the dirt filter in the cold water supply (e.g. SAS 1

or SAS 2).

CAUTION: BIV only

If the heat exchanger for pressurised solar system

charging (see "3.1 Dimensions and connection

dimensions"[411], itemsh + i) is connected to an external

heater (e.g. wood burning boiler) the indoor unit can be

damaged or destroyed due to an excessively high flow

temperature at these connections.

▪ The flow temperature of the external heater should be

limited to max. 95°C.

CAUTION

Corrosion may be caused by air entering the heating water

network and by a quality of the heating water that does not

comply with the requirements in accordance with

"1.2.5 Requirements for heating and storage water" [4 6].

Corrosion products (particles) thus created may clog

pumps and valves and cause malfunctions.

▪ Device may not be connected by permeable, flexible

lines.

3.6.1 Minimum water volume

A water volume of at least 5 litres must be ensured in the heating

circuit. The internal water volume of the heat pump internal unit is

not included in this calculation.

INFORMATION

In critical applications or in rooms with high heating loads,

additional water volume may be required.

CAUTION

If several heating circuits are connected to the heat pump

indoor unit, it is important that the minimum water volume

is guaranteed even if only one heating circuit is open.

3.6.2 Connecting hydraulic lines

DANGER: RISK OF BURNING/SCALDING

There is a danger of scalding at hot water temperatures

over 65°C. This is possible when using solar energy if an

external heater is connected, the Legionella protection is

activated, or the target hot water temperature is set to be

greater than 65°C or if the Smart-Grid function is activated.

▪ Install scalding protection (hot water mixer device (e.g.

VTA32)).

INFORMATION

The indoor unit is equipped with a pressure sensor. The

system pressure in monitored electronically and can be

displayed with the device switched on.

Nevertheless, we recommend installing a mechanical

manometer between the indoor unit and the expansion

vessel, for example.

▪ Install the manometer so that it is easy to see when

filling.

Prerequisite: Optional accessories (e.g. solar, backup heater) are

mounted on the Daikin Altherma 3 R ECH2O as specified in the

enclosed instructions.

1 Check the cold water connection pressure (maximum 10bar).

▪ At higher pressure in the drinking water line, a pressure reducer

must be installed.

2 Fix the hydraulic block in place with a screwdriver.

INFORMATION

Any steam or heating water escaping from the safety valve

must be drained by a suitable blow-off line with constant

gradient in a frost-protected, safe and observable manner.

A expansion vessel suitably sized and preset for the

heating system must be connected to the Daikin Altherma

3 R ECH2O. There may not be any hydraulic blocking

elements between the heat generator and the diaphragm

expansion vessel.

We recommend installing a mechanical manometer for

filling the heating system.

▪ For potable water lines, observe the provisions of EN 806,

DIN 1988 and the additional applicable national regulations for

potable water installation.

▪ Install the indoor unit close to the withdrawal point to dispense

with the need for a circulation line. If a circulation line is

permissible and mandatory according to local regulations, it must

be installed according to the schematic diagrams in "Hydraulic

System Connection" in the reference manual for the fitter.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3‒27 Fix the hydraulic block in place when connecting to the top

(left) or to the rear (right)

Installation and operating manual

19

3 Set-up and installation

3 Make the hydraulic connections on the indoor unit.

▪ Refer to "3.1Dimensions and connection dimensions"[411] for

the position and dimension of the heater connections.

▪ Pay attention to the stipulated tightening torque (see

"6.3Tightening torques"[434]).

▪ Install the line so that the sound insulation hood can be

positioned easily after installation.

▪ Connect the water for filling or refilling the heating system as

specified by EN 1717/EN 61770 to avoid contamination of

drinking water by return flow.

▪ For rear-facing connections: Support hydraulic lines suitably

according to the spatial conditions.

3‒28 Supporting rear-facing hydraulic lines

4 Connect the blow-off line to the safety over-pressure valve and

expansion vessel in accordance with EN12828.

▪ Any steam or heating water that may escape must be drained

by a suitable blow-off line with constant gradient in a frostprotected, safe and observable manner.

▪ Install the line in such a way that the protective cover is simple

to put on after assembly.

▪ Check the seat of the drain hose on the safety pressure relief

valve. If necessary, connect and install a separate hose.

5 Connecting a expansion vessel.

▪ Connect a suitably dimensioned and preset expansion vessel

for the heating system. There may not be any hydraulic

blocking elements between the heat generator and the safety

valve.

▪ Position the expansion vessel in an easily accessible place

(maintenance, parts replacement).

3‒29 Mounting the expansion vessel

6 Carefully insulate pipework against heat loss and to avoid

condensation (insulation thickness at least 20mm).

▪ Water shortage protection: The pressure and temperature

monitoring of the controller shuts off and locks the indoor unit

safely if there is a shortage of water. No additional water shortage

protection is needed in the construction.

▪ Avoid damage caused by deposits and corrosion: see

"1.2.5Requirements for heating and storage water"[46]

3.6.3 Connecting the drain

1 Screw the hose connection piece for safety overflow (part of the

accessory bag) into the intended connection (" 2‒3 Design

and components – Internal structure ...04P30D.../...08P30D...

(Biv)"[49], itemu) and connect it with the drain hose.

▪ Use transparent drain hose (draining water must be visible).

▪ Connect the drain hose to an adequately dimensioned waste

water installation.

▪ Drain should not be lockable.

2 Attach the condensate drain hose (part of accessory bag) to its

connection on the cover.

3‒30 Connection of the overflow hose

a Hose connecting piece for safety overflow

b Condensate drain hose

3.7 Electrical connection

DANGER: RISK OF ELECTROCUTION

Touching live parts can result in an electric shock and

lead to potentially fatal injuries and burns.

▪ Before beginning work on live parts, disconnect all of

the circuits of the system from the power supply

(switch off external main switch, disconnect fuse) and

secure against unintentional restart.

▪ Establishment of the electrical connection and work on

electrical components should only be performed by

electrical technicians in compliance with valid

standards and guidelines as well as the specifications

of the energy supply company and the instructions in

this manual.

▪ The installation of earth leakage circuit breakers (GFCI)

is mandatory, as shown in the pictures of this

document.

▪ Never make constructional changes to connectors or

other electrical equipment components.

▪ Device covers and service panels must be replaced

as soon as the work is completed.

Installation and operating manual

20

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3 Set-up and installation

CAUTION

Increased temperatures can occur in the switch box of the

indoor unit during operation. This can result in currentlycarrying wires from reaching higher temperatures during

operation due to self-heating. For this reason, these lines

need to have a continuous use temperature of 90°C.

▪ For the following connections, only use cables with a

long-term use temperature ≥90°C: Heat pump outdoor

unit and optional: Electric backup heater (EKBUxx)

CAUTION

If the mains cable of the indoor unit is damaged, it must be

replaced by the manufacturer or his customer service or a

similarly qualified person to avoid hazards.

All electronic control and safety devices of the indoor unit are

connected ready for use and tested. Modifications on the electrical

installation are dangerous and prohibited. The operator alone bears

responsibility for any resulting damage.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

21

3 Set-up and installation

3.7.1 Overall connection diagram

3‒31 Overall connection diagram – for the electrical connection during the device installation (for the legend and pin assignment of the PCB,

see "6.5Electrical connection diagram"[436])

Installation and operating manual

22

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

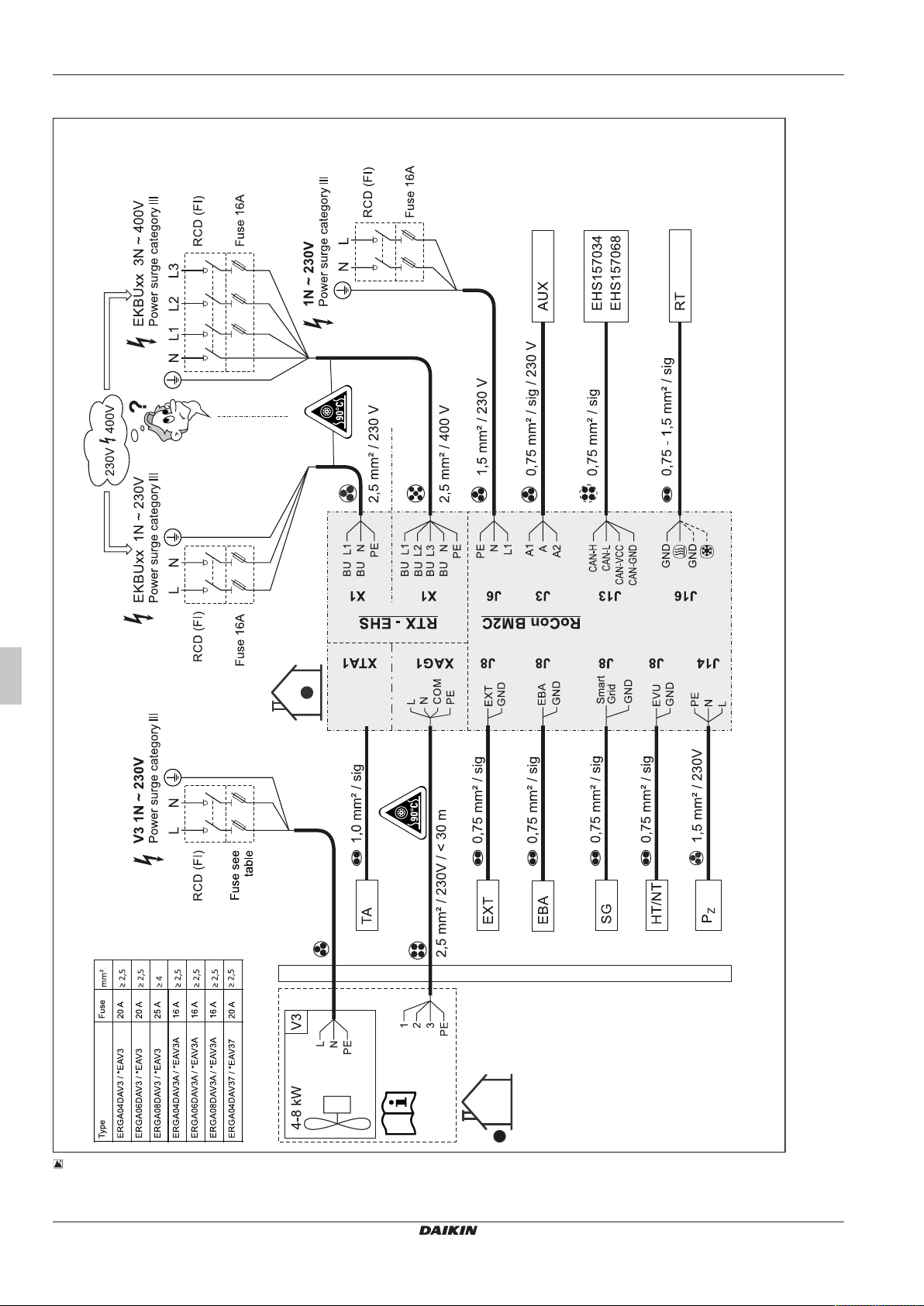

3.7.2 Position of the PCBs and terminal strips

3‒32 Position of the PCBs and terminal strips

a Switch box

b Switch box cover

A1P PCB (heat pump basic control)

RoCon+B1 Controller control panel

RoConBM2C PCB (basic controller module)

RTX-EHS PCB (backup heater)

X1 Terminal strip for backup heater mains connection

XAG1 Heat pump outdoor unit plug connection

XTA1 Outdoor temperature sensor terminal strip T

A

3 Set-up and installation

3‒33 Cable gland

6 Make electrical connections according to "3.7.1 Overall

connection diagram"[422] and the following sections.

7 Effective strain relief in the switch box by means of cable ties

must be ensured for all cables connected to the indoor unit and

their holding force checked.

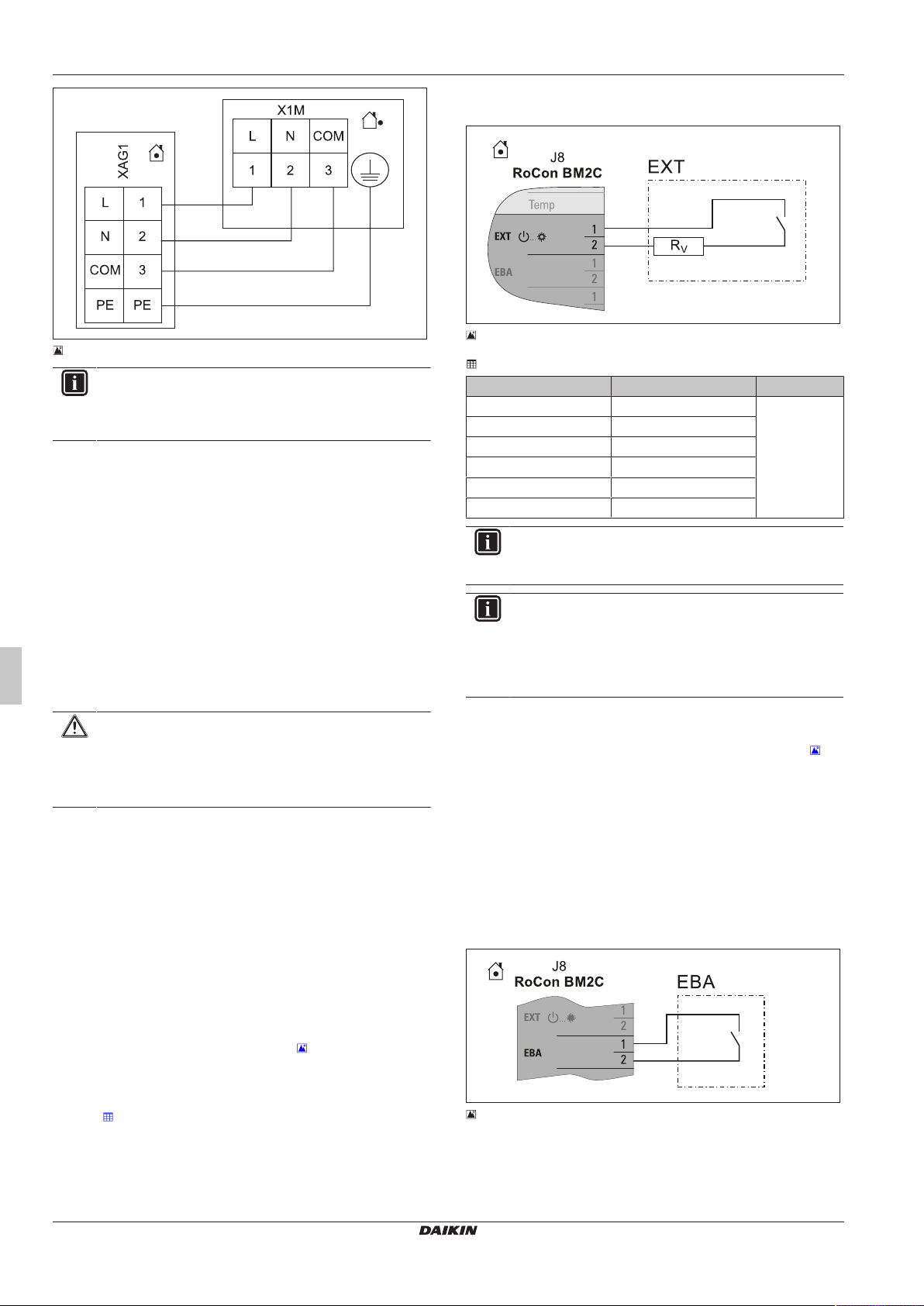

3.7.3 Mains connection

A flexible cable for the mains connection is already connected inside

the device.

1 Check the supply voltage (~230V, 50Hz).

2 Disconnect the junction box of the domestic installation.

3 Connect the cable for connecting the indoor unit to the mains to

the domestic installation's junction box (isolator according to

EN 60335-1) via an all-pole separating main switch to be

installed in the building. Ensure that the polarity is correct.

3.7.4 General information on the electrical connection

1 Check the supply voltage.

2 Set the mains switch to "Off".

3 Switch off the circuit breaker in the junction box of the domestic

power supply.

4 Open the switch box (see "3.4.4Open the switch box"[414]).

5 Insert the cable through one of the cable glands into the interior

of the switch box. When cutting and laying cables to be

connected, make sure that the switch box can be brought into

the service position without any tension.

3‒34 Establishing and checking the strain relief

8 After the installation is complete: Close the switch box again

and, if necessary, move it to the normal position.

3.7.5 Connecting the heat pump outdoor unit

INFORMATION

A separate manual containing instructions about

installation and operation is included with this component.

1 Follow the installation steps in "3.7.4General information on the

electrical connection"[423].

2 Connect the heat pump outdoor unit to the XAG1terminal strip.

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

23

3 Set-up and installation

When special functions (e.g. "Manual operation") are activated, the

input is not evaluated.

3‒35 Connecting the heat pump outdoor unit

INFORMATION

If the heat pump outdoor unit is shut off via a circuit

specified by the utility company, the indoor unit is not shut

off.

3.7.6 Connecting the outdoor temperature sensor (optional)

The heat pump outdoor unit has an integrated outdoor temperature

sensor that is used for weather-compensated inflow temperature

control with frost protection function. The weather-compensated

inflow temperature control can be further optimised with the optional

outdoor temperature sensor.

▪ Choose a location at about one third of the building height

(minimum distance from floor: 2 m) on the coldest side of the

building (north or north-east). Ensure that the location is not near

any external heat sources (flues, air ducts) or subject to direct

solar radiation.

▪ Place outdoor temperature sensors in such a way that the cable

exit points face downwards (prevents the ingress of humidity).

CAUTION

Laying the sensor and mains lines in parallel within an

installation conduit can lead to major malfunctions during

controlled operation of the indoor unit.

▪ Always lay the sensor line separately.

1 Connect the outdoor temperature sensor to a twin-core sensor

line (minimum diameter 1mm2).

2 Lay the sensor line to the indoor unit.

3 Follow the installation steps in "3.7.4General information on the

electrical connection"[423].

4 Connect the sensor line to terminal strip XTA1 (see

"3.7.2Position of the PCBs and terminal strips"[423]).

5 In the controller RoCon+ HP1 set the [Outside temperature

sensor] parameter to "On" [→ Main menu → Configuration

→Sensors].

3‒36 EXT switching contact connection

3‒2 Resistance values for evaluating the EXT signal

Operating mode Resistance R

Standby <680Ω ±5%

Heating 1200Ω

Reduce 1800Ω

Summer 2700Ω

Automatic 1 4700Ω

Automatic 2 8200Ω

INFORMATION

The input is not considered for resistance values greater

than the value for "Automatic 2".

INFORMATION

The [Heating support (HZU)] function integrated in the

RoCon+ HP1 controller (see the controller operating

instructions) makes it unnecessary to connect the EXT

connection to the burner blocking contact connection of the

solar system.

V

Tolerance

3.7.8 EBA (external requirement request)

By connecting the EBA switching contact to the indoor unit (" 3‒

37 EBA switching contact connection" [4 24]) and corresponding

parametrisation in its RoCon+HP1 controller, an external switching

contact can be used to generate a heat request. If the switching

contact is closed, the indoor unit switches to heating operation. The

flow temperature is regulated to the temperature set in the [Feed

temperature, heating mode] parameter [→ Main menu

→Configuration →Heating].

The EBA switching contact has priority over a request from the room

thermostat.

The switching contact is not evaluated in cooling operation, standby,

manual or summer mode. The heating limits are also ignored.

3.7.7 External switching contact

Connecting an external switching contact (" 3‒36 EXT switching

contact connection" [4 24]) enables the operating mode of the

indoor unit to be switched over.

The current operating mode is switched by a changing resistance

value (" 3‒2 Resistance values for evaluating the EXT

signal" [4 24]). The changeover of the operating mode is only

effective for a long as the external switching contact is closed.

The operating mode has an effect on the direct circuit of the indoor

unit as well as all other heating circuits connected to this device as

an option.

Installation and operating manual

24

3‒37 EBA switching contact connection

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

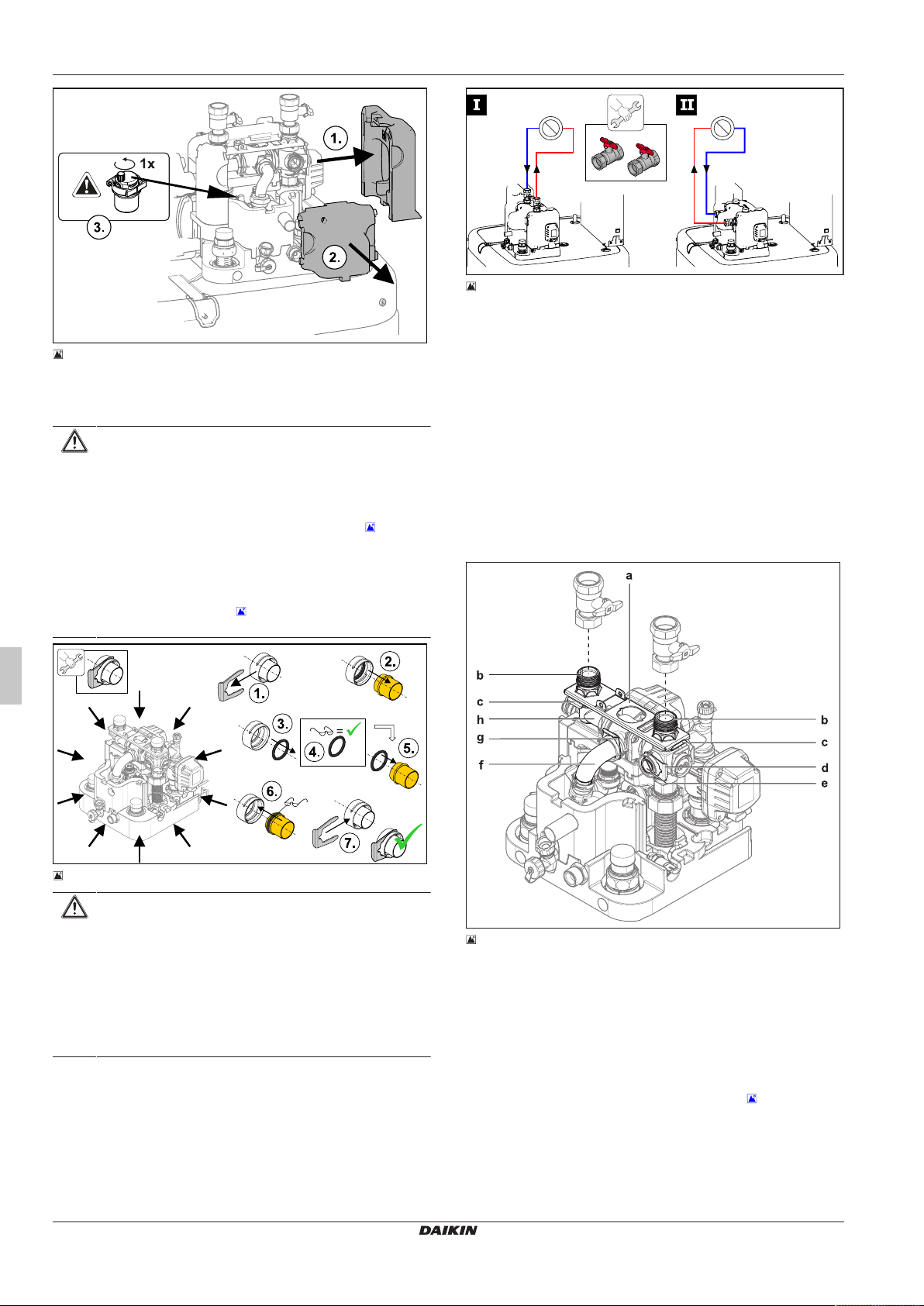

3.7.9 Connecting an external heat generator

INFORMATION

To connect an external heat generator, the connection set

for external EKBUHSWB heat generators must be installed

(see "3.5Installing optional accessories"[418]).

For heating support or as an alternative to an electric backup heater,

an external heat generator (e.g. gas- or oil-fired boiler) can be

connected to the indoor unit. To connect an external heat generator,

the connection set for external EKBUHSWB heat generators must

be installed (see "3.5Installing optional accessories"[418]).

The heat supplied by the external heat generator must be fed to the

unpressurised storage tank water in the hot water storage tank of the

indoor unit.

Implement the hydraulic connection according to one of the two

following options:

▪ unpressurised via the connections (solar flow and solar return

flow) of the hot water storage tank

▪ for ...Biv indoor unit device types, via the integrated

pressurised solar heat exchanger.

▪ Comply with the instructions on hydraulic connections (see

"1.2Safety instructions for installation and operation"[45])

▪ Examples of hydraulic connection (see "Hydraulic connection"

in the reference manual for the fitter).

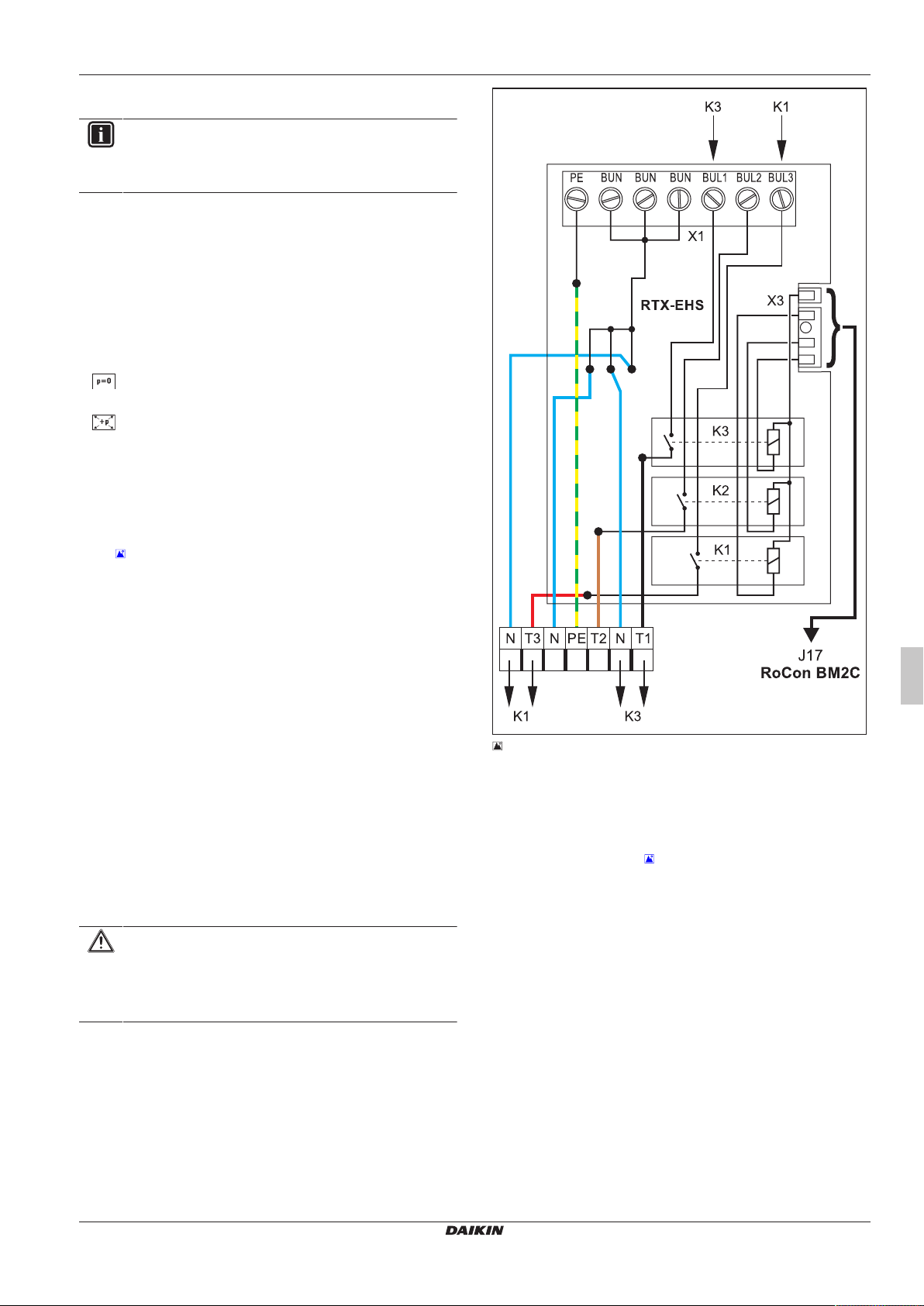

The external heat generator request is connected on PCB RTX-EHS

(see " 3‒38 Connection on the RTX-EHS PCB" [4 25]) via a

relay. Electrical connection to the indoor unit is possible as follows:

▪ External heat generator has a potential-free switching contact

connection for heat request:

▪ Connection to K3 if the external heat generator is responsible

for the domestic hot water preparation and the backup heating

(setting of the [Config. ext. heat source] parameter = DHW +

heating support [→Main menu →Settings →Ext. source])

or

▪ Connection to K1 and K3 if two external heat generators are

used (setting of the [Config. ext. heat source] parameter = Two

external heat generators [→ Main menu → Settings → Ext.

source]). In this case, K1 connects the external heat generator

(e.g. gas-fired or oil-fired boiler) for heating support and K3

connects the external heat generator (EKBUxx) for domestic

hot water preparation.

or

▪ Connection to AUX connection A (see "3.7.13 Connecting

switching contacts (AUX outputs)"[427])

▪ External heat generator can only be connected via mains voltage:

Connection (~230V, maximum load 3000W) to K1 and K3.

CAUTION

Danger of voltage flash-overs.

▪ The connections of the RTX-EHS PCB must not be

used simultaneously for connecting mains voltage

(~230V) and SELV ("Safety Extra Low Voltage").

3 Set-up and installation

3‒38 Connection on the RTX-EHS PCB

1 Refer to the external heat generator's respective installation

instructions for a suitable electrical connection.

2 Installing the connection set for external EKBUHSWB heat

generators (see "3.5Installing optional accessories"[418]).

3 Make suitable connections on the RTX-EHS PCB of the

connection set (see " 3‒38 Connection on the RTX-EHS

PCB"[425]).

4 Fix cables that are fed into the connection set from the outside

using the strain relief clips and cable ties included (see steps7

and 8 in "3.7.4 General information on the electrical

connection"[423]).

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

Installation and operating manual

25

3 Set-up and installation

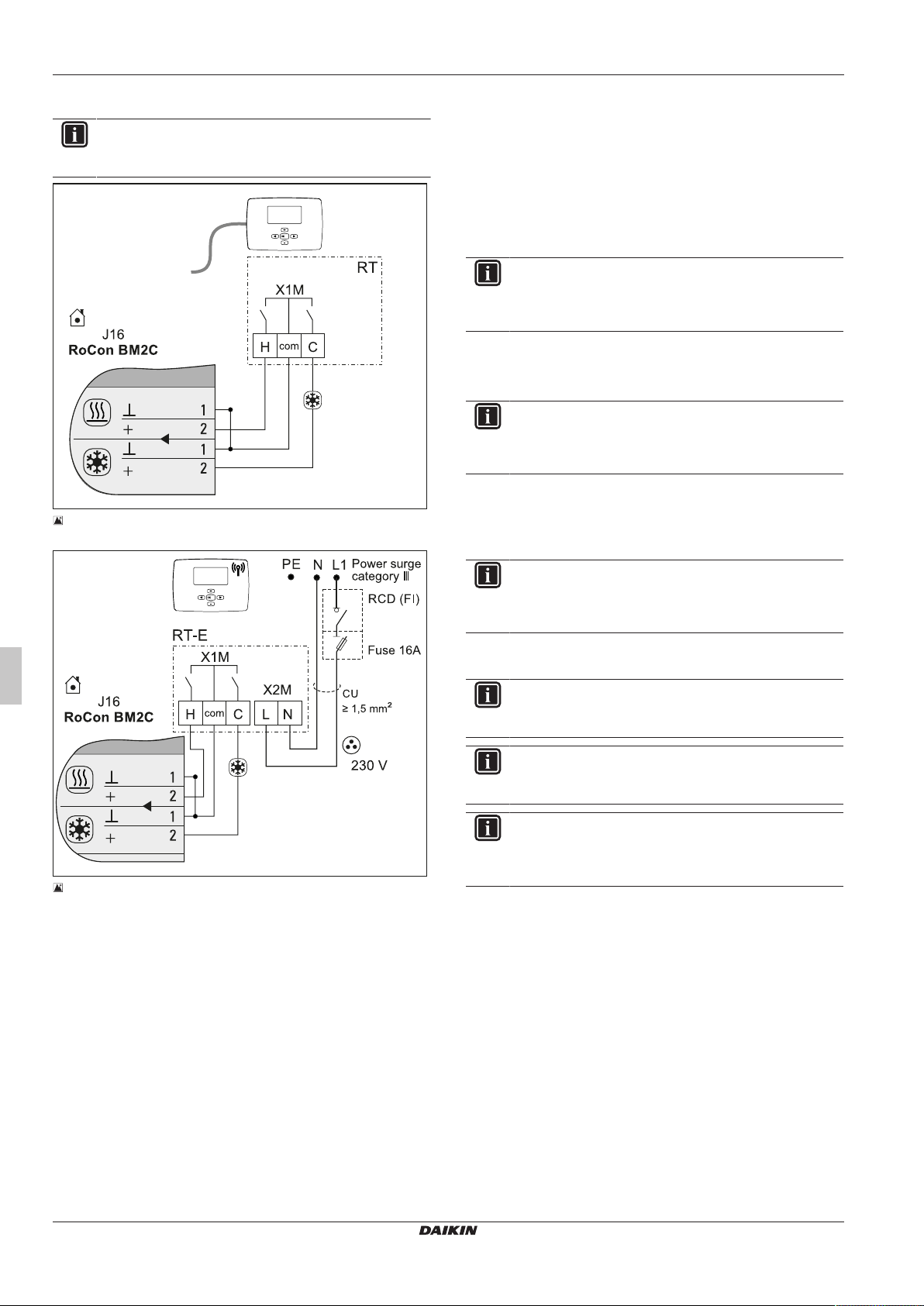

3.7.10 Connecting the room thermostat

INFORMATION

A separate manual containing instructions about

installation and operation is included with this component.

3‒39 Connection with wired room thermostat (RT = Daikin

EKRTW)

Ensure that mains, sensor and data bus lines are routed separately.

Use only cable ducts with separators or separate cable ducts spaced

at least 2cm apart. Line crossings are permissible.

A maximum of 16 devices with a total line length of up to 800m can

be connected in the entire RoCon system.

EHS157034 room controller

A separate EHS157034 room controller can be connected for each

heating circuit to enable remote adjustment of operating modes and

room target temperatures from another room.

INFORMATION

Separate installation instructions are included with this

component. See the enclosed control system manual for

instructions on setting and operation.

EHS157068 mixer module

The EHS157068 mixer module can be connected to the indoor unit

(J13 PCB connector) and is controlled by the electronic controller.

INFORMATION

Separate installation instructions are included with this

component. See the enclosed control system manual for

instructions on setting and operation.

EHS157056 Internet gateway

The controller can be connected to the internet with the optional

EHS157056 gateway. This enables remote control of the indoor unit

by mobile phones (by app).

3‒40 Connection with radio-controlled room thermostat (RT-E =

Daikin EKRTR)

3.7.11 Connection of optional RoCon system components

The optional RoCon devices must be connected to the indoor unit

via a 4-wire CAN bus cable (connection J13).

For this, we recommend shielded lines with the following

characteristics:

▪ Standardisation according to ISO 11898, UL/CSA type CMX

(UL444)

▪ PVC outer sheath with flame retardancy according to

IEC60332-1-2

▪ Up to 40 m, minimum cross-section 0.75mm2. Larger conductor

cross-section necessary with increasing length.

Commercially available junction boxes can be used to connect CAN

bus lines of several RoCon devices.

INFORMATION

Separate installation instructions are included with this

component. See the enclosed control system manual for

instructions on setting and operation.

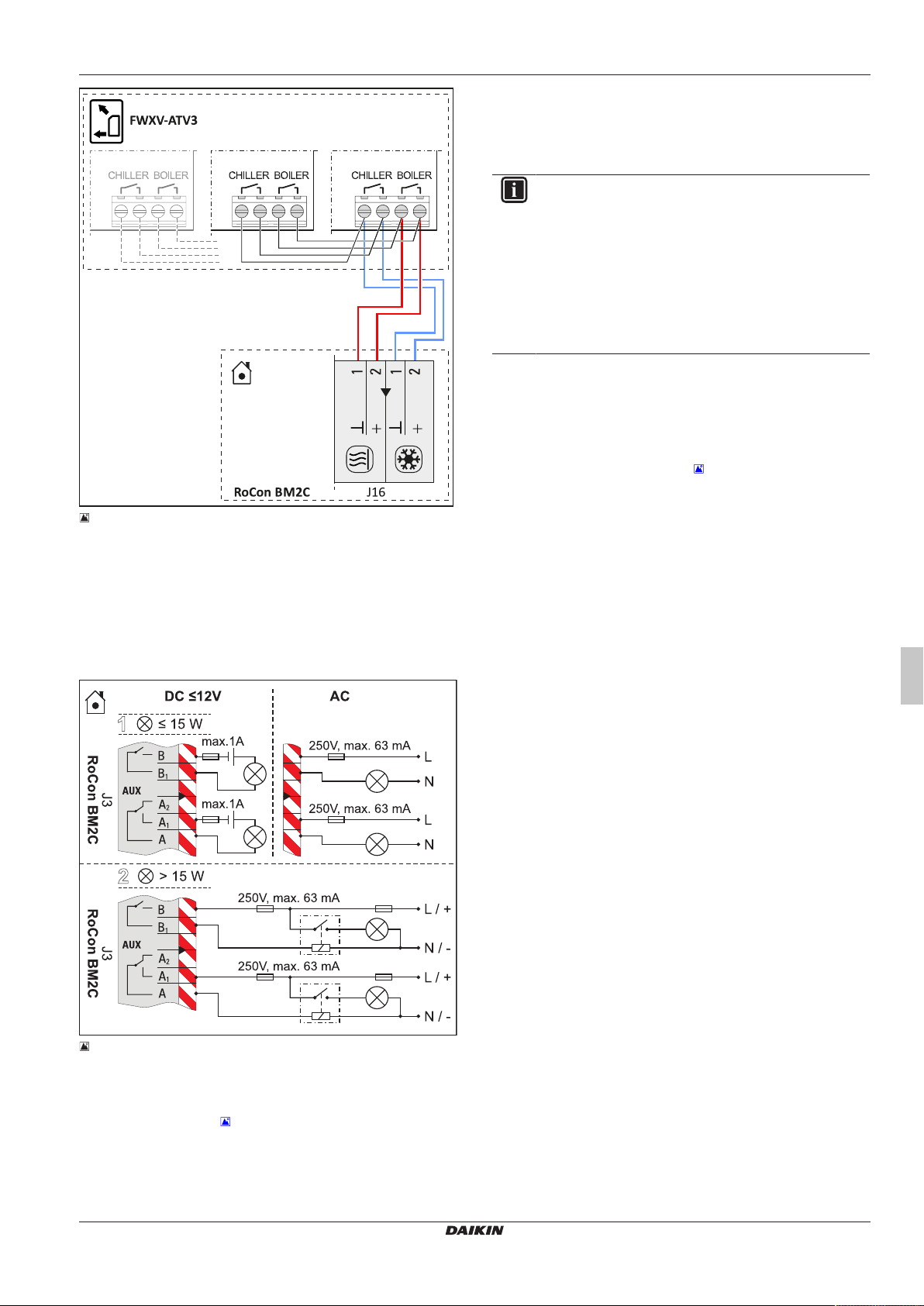

3.7.12 Connecting the HP convector

INFORMATION

Only the EKRTCTRL1 and EKWHCTRL(0/1) convector

controllers can be connected to the indoor unit.

INFORMATION

A separate manual containing instructions about

installation and operation is included with this component.

INFORMATION

When changing the operating mode (Heating/Cooling) on a

convector, all other convectors must either also be

changed or deactivated.

Installation and operating manual

26

Daikin Altherma EHS(X/H)(B)-D

Daikin Altherma 3 R ECH₂O

008.1451099_01 – 09/2020

3‒41 FWX(V/M)-AATV3 connection

3.7.13 Connecting switching contacts (AUX outputs)

The switching contacts (AUX outputs) can be used for various

parametrisable functions.

Switchover contact A-A1-A2 switches under the conditions set in

parameter [AUX switching function] [→ Main menu → Settings

→Inputs/Outputs] (see controller operating instructions).

3 Set-up and installation

Switchover contact A-A1-A2 can be used, for example, to control the

heat generators in bivalent heating systems consisting of an indoor

unit and an oil- or gas boiler. Examples of hydraulic system

integration are described in "Hydraulic connection" in the reference

manual for the fitter.

INFORMATION

If an A2 F or G-plus condensing boiler is connected, the

[AUX switching function ] and [AUX wait time] parameters

must be set according to the desired function [→ Main

menu →Settings →Inputs/Outputs].

See Operating instructions → chapter Parameter settings.

Precise information on the electrical connection and the

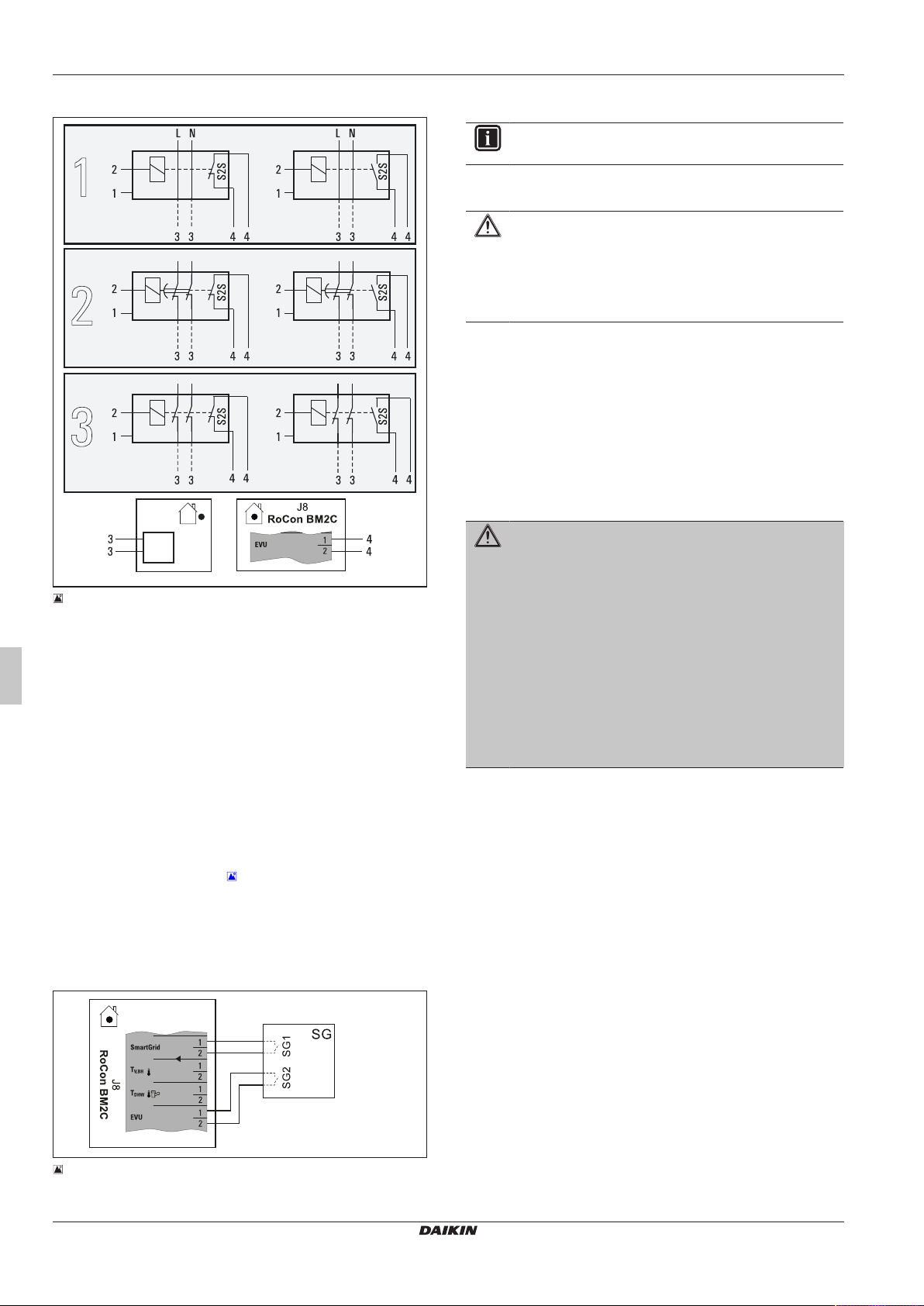

required parameter settings for such bivalent heating