Daikin EHSH04P30D3, EHSX04P30D3, EHSX04P50D3, EHSH08P30D3, EHSX08P30D3 Operation manuals

...Page 1

Operating instructions

Controller RoCon+ HP1

EHSH(B)04P30D3

EHSX(B)04P30D3

EHSX(B)04P50D3

EHSH(B)08P30D3

EHSX(B)08P30D3

EHSH(B)08P50D3

EHSX(B)08P50D3

EHSH(B)04P30D2

EHSX(B)04P30D2

EHSH(B)08P30D2

EHSH(B)08P50D

EHSX(B)04P50D

EHSX(B)08P50D

ETSH(B)16P30D

ETSX(B)16P30D

ETSH(B)16P50D

ETSX(B)16P50D

Operating instructions

Controller RoCon+ HP1

English

Page 2

List of contents

List of contents

1 General safety precaution 3

1.1 Particular safety instructions ..................................................... 3

1.1.1 Observing the instructions .......................................... 3

1.1.2 Meaning of warnings and symbols.............................. 4

1.2 Safety instructions for installation and operation....................... 4

1.2.1 General ....................................................................... 4

1.2.2 Intended use ............................................................... 4

2 Product description 5

2.1 Temporary shutdown................................................................. 5

3 Operation 6

3.1 General...................................................................................... 6

3.2 Display and operating elements ................................................ 6

3.2.1 Status indicator ........................................................... 6

3.2.2 Display ........................................................................ 6

3.2.3 Rotary button .............................................................. 6

3.2.4 Start screen................................................................. 6

3.3 Operating concept ..................................................................... 8

3.3.1 Navigating in the menu ............................................... 8

3.3.2 Help function ............................................................... 8

3.3.3 Navigating in lists and selecting list entries................. 8

3.3.4 Setting setpoints ......................................................... 9

3.3.5 Setting the times ......................................................... 9

3.3.6 Calendar function........................................................ 9

3.3.7 Setting the time programs........................................... 10

3.3.8 External operation....................................................... 11

4 Function 11

4.1 Operating mode......................................................................... 11

4.2 User........................................................................................... 12

4.2.1 Room temperature target setting ................................ 12

4.2.2 Room temperature reduced setting ............................ 12

4.2.3 Room temperature absent setting............................... 12

4.2.4 Hot water temperature, target setting ......................... 12

4.2.5 Unscheduled domestic hot water preparation............. 13

4.3 Time program ............................................................................ 13

4.3.1 Temporary time programs........................................... 13

4.3.2 Permanent time programs .......................................... 13

4.3.3 Time program reset..................................................... 14

4.4 Settings ..................................................................................... 14

4.4.1 Display settings........................................................... 14

4.4.2 System ........................................................................ 14

4.4.3 External heat sources ................................................. 14

4.4.4 Inputs/Outputs............................................................. 15

4.4.5 Intelligent storage tank management.......................... 16

4.5 Configuration ............................................................................. 16

4.5.1 Access rights (technician code) .................................. 16

4.5.2 Sensors....................................................................... 16

4.5.3 HC config. ................................................................... 16

4.5.4 Heating........................................................................ 17

4.5.5 Cooling........................................................................ 18

4.5.6 Hot water..................................................................... 19

4.5.7 Additional program...................................................... 19

4.5.8 Configuration Wizard .................................................. 21

4.5.9 Parameter reset .......................................................... 21

4.6 Information ................................................................................ 21

4.6.1 Current ........................................................................ 21

4.6.2 Overview ..................................................................... 22

4.6.3 Values ......................................................................... 22

4.6.4 Water pressure ........................................................... 22

4.7 Error .......................................................................................... 22

4.8 Terminal .................................................................................... 22

4.8.1 Selecting the terminal address.................................... 23

4.8.2 Bus scan for terminal function..................................... 23

4.9 Statistics ..................................................................................... 23

4.9.1 Month ........................................................................... 23

4.9.2 Total ............................................................................. 23

5 Initial commissioning 24

5.1 Configuration Wizard.................................................................. 24

5.2 Menu navigation in the Configuration Wizard............................. 24

6 Parameter overview 25

6.1 Menu: Operating mode............................................................... 25

6.2 Menu: User................................................................................. 25

6.3 Menu: Time program .................................................................. 25

6.4 Menu: Settings ........................................................................... 26

6.5 Menu: Configuration ................................................................... 26

6.6 Menu: Information ...................................................................... 27

6.7 Menu: Error ................................................................................ 27

6.8 Menu: Terminal .......................................................................... 27

6.9 Menu: Statistics .......................................................................... 27

7 Parameter settings 28

7.1 Explanation of the parameter tables........................................... 28

7.2 Operating mode.......................................................................... 28

7.3 User............................................................................................ 29

7.3.1 Menu: Room temperature target.................................. 29

7.3.2 Menu: Reduce room temperature ................................ 29

7.3.3 Menu: Room temperature absent ................................ 29

7.3.4 Menu: Hot water temperature, target ........................... 29

7.3.5 Menu: 1x Hot water...................................................... 30

7.4 Time program ............................................................................. 30

7.5 Settings ...................................................................................... 31

7.5.1 Menu: Display settings................................................. 31

7.5.2 Menu: System .............................................................. 32

7.5.3 Menu: External heat source ......................................... 33

7.5.4 Menu: Inputs/Outputs................................................... 33

7.5.5 Menu: Intelligent Storage Mgmt ................................... 36

7.6 Configuration .............................................................................. 37

7.6.1 Menu: Sensors............................................................. 37

7.6.2 Menu: Heating circuit config......................................... 38

7.6.3 Menu: Heating.............................................................. 38

7.6.4 Menu: Cooling.............................................................. 40

7.6.5 Menu: Hot water........................................................... 41

7.6.6 Menu: Additional programs .......................................... 42

7.7 Information ................................................................................. 43

7.7.1 Overview ...................................................................... 43

7.7.2 Values .......................................................................... 44

7.7.3 Water pressure ............................................................ 45

7.8 Error ........................................................................................... 45

7.9 Terminal ..................................................................................... 45

7.10 Statistics ..................................................................................... 46

7.11 Configuration Wizard .................................................................. 46

8 Errors and faults 47

8.1 Emergency operation ................................................................. 47

8.2 Manual operation........................................................................ 47

8.3 Error protocol.............................................................................. 47

8.4 Error screen................................................................................ 48

8.5 Error codes................................................................................. 48

9 Mixer module 48

9.1 Mixer module start screen (terminal function) ............................ 49

9.2 Mixer valve parameter overview................................................. 49

9.3 Mixer module parameter settings ............................................... 50

10 Glossary 51

11 User-specific settings 52

11.1 Timers ........................................................................................ 52

11.2 Parameters ................................................................................. 53

11.3 Data bus addresses ................................................................... 53

List of keywords 54

Operating instructions

2

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 3

1 General safety precaution

1 General safety precaution

1.1 Particular safety instructions

WARNING

Heating devices that are not set up and

installed correctly can impair the

function of the heating device and/or

cause serious or fatal injury to the user.

▪ Work on the heat generator (such as

set-up, servicing, connection and

initial start-up) must only be carried

out by persons who are authorised

and who have successfully

completed qualifying technical or

vocational training and who have

taken part in advanced training

sessions recognised by the relevant

responsible authorities for the specific

activity. They include, in particular,

certified heating engineers, qualified

electricians and HVAC specialists

who, because of their professional

training and their expert

knowledge, have experience in the

professional installation and

maintenance of heating systems, oil

and gas installations and hot water

storage systems.

▪ Only operate the heat generator

when it is in perfect condition with the

protective hood closed.

WARNING

Disregarding the following safety

instructions may result in serious

physical injury or death.

▪ This device may only be used by

children aged 8 and above and by

persons with restricted physical,

sensory or mental capabilities or with

a lack of experience and knowledge if

they are under supervision or if they

have been instructed in the safe use

of the equipment and understand the

dangers arising from it. Children

must not play with the device.

Cleaning and user maintenance

must not be carried out by children

without supervision.

▪ Establish the power supply in

accordance with IEC60335‑1, via a

separate isolator that separates all

poles with a contact opening distance

and that provides full disconnection in

accordance with overvoltage

categoryIII.

▪ All the electrical work must only be

carried out by electrically qualified

experts and with consideration of the

local and national regulations, and

the instructions in this manual. Check

that a suitable electrical circuit is

being used. Insufficient load capacity

of the electrical circuit or improperly

executed connections can result in

electric shock or fire.

1.1.1 Observing the instructions

▪ The original documentation is written in German. All other

languages are translations.

▪ Please read this manual carefully and thoroughly before

proceeding with the installation or modification of the heating

system.

▪ The precautionary measures described in this document cover

very important topics. Follow them meticulously.

▪ The installation of the system, and all activities described in this

manual and the applicable documents for the installer must be

carried out by an approved installer.

Documentation set

This document is part of a documentation set of other applicable

documents. The complete set comprises:

▪ Installation manual for the Daikin Altherma indoor unit –

subsequently referred to as "indoor unit " (format: paper –

included in the indoor unit scope of delivery)

▪ Operating manual for the indoor unit (format: paper – included in

the indoor unit scope of delivery)

▪ Operating manual for the heat pump (format: paper – included in

the indoor unit scope of delivery)

▪ Installation manual for the outdoor unit (format: paper – included

in the outdoor unit scope of delivery)

▪ Installation instructions for optional components (format: paper –

included in the scope of delivery of the respective component)

▪ Installer reference guide of the indoor unit (format: digital)

▪ Installer reference guide of the outdoor unit (format: digital)

▪ Operating instructions for controller RoCon HP, EHS157034,

EHS157068 (status 04/2017) (format: digital)

The reference guides contain the complete set of technical data, a

detailed description of best practices and information on

maintenance, troubleshooting and decommissioning.

The digital documents and the latest editions of the supplied

documentation are available on the regional Daikin website or, on

request, from your dealer. The Daikin website is easy to access

using the QR code on your device.

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

3

Page 4

1 General safety precaution

1.1.2 Meaning of warnings and symbols

Warnings in this manual are classified according into their severity

and probability of occurrence.

DANGER

Indicates an immediate danger.

Disregarding this warning can lead to serious injury or

death.

WARNING

Indicates a potentially dangerous situation.

Disregarding this warning may result in serious physical

injury or death.

CAUTION

Indicates a situation which may cause possible damage.

Disregarding this warning can cause damage to property

and the environment and result in minor injuries.

This symbol identifies user tips and particularly useful

information, but not warnings or hazards

Special warning signs

Some types of danger are represented by special symbols.

Electric current

1.2.2 Intended use

The RoCon+ HP1 controller may only be used in the indoor units

specified on the title page that are approved for the control system.

The RoCon+ HP1 controller must only be operated in accordance

with the specifications in these instructions.

Any other use or use beyond the intended use is considered

improper use. The operator alone bears responsibility for any

resulting damage.

For any work on the equipment that extends above and beyond the

operation of the regulating system, the details provided in the

supplementary documents must be observed, particularly with

regard to safety instructions.

Documentation

The technical documentation included in the scope of supply is a

constituent part of the equipment. It must be stored in such a way

that it can be consulted at any time by the operator or technicians.

Risk of burns or scalds

General description

1 Handling instructions are shown as a list. Actions where the

sequential order must be adhered to are numbered.

[Language]: Parameters are shown in square brackets.

"Operating mode", "Deutsch": Available menu names and parameter

setting options are shown in quotation marks.

[→ Main menu]: The position of menus and functions is shown in

square brackets with →.

1.2 Safety instructions for installation and operation

1.2.1 General

▪ For any work on the equipment that extends above and beyond

the operation of the regulating system, the details provided in the

supplementary documents must be observed, particularly with

regard to safety instructions.

Avoid danger

The indoor unit conforms to the state of the art and meets all

recognised technical requirements. However, improper use can lead

to serious injuries or death, as well as causing material damage.

To avoid hazards, only operate the indoor unit:

▪ as stipulated and in perfect condition,

▪ with an awareness of the safety and hazards involved.

This assumes knowledge and use of the contents of this manual, all

applicable documents, the relevant accident prevention regulations

as well as the recognised safety-related and occupational health

rules.

Display representation of the RoCon+HP1 controller

Certain screen displays or menu items may deviate from those

shown in these instructions depending on the national or equipment

variant of the indoor unit or the user status logged onto the

controller.

Operating instructions

4

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 5

2 Product description

2 Product description

INFORMATION

The RoCon+HP1 controller is part of the indoor unit.

It consists of the switching panel RoCon BM2C PCB to

which the actuators and sensors as well as other

components in the regulating system are connected and

the RoCon+B1 control panel.

These operating instructions only explain the functions and

possible settings of the controller. More information on the

switch box and other equipment components can be found

in the supplementary documents.

The electronic, digital controller is able to automatically control all

heating and hot water functions for a direct HC, a storage loading

circuit and also further HCs via optionally connectible mixer

modules, depending on the heating device.

It performs all safety management for the indoor unit. This executes

a safety switch-off in the event of a water shortage or undefined

operating states. A corresponding error message shows the operator

all the information regarding fault causes.

All function settings for the indoor unit and the optional RoCon

devices that are connected via the data bus are undertaken with the

control elements of the integrated RoCon+ B1 control panel and

shown on the plain text display with coloured backlighting.

The following additional, optional devices can be connected to the

indoor unit via the controller data bus:

▪ RoConU1 (EHS157034) room station

▪ RoConM1 (EHS157068) mixer module

In addition, the RoCon+ HP1 controller has a freeze-up protection

function for the direct HC and the storage tank charging circuit as

well as an automatic function for heating support (integration of an

auxiliary heat source such as a wood-burning boiler or solar system).

The potential-free AUX switching contact can be used to carry out

different control functions in conjunction with external devices

(request from an external heat generator, changeover to bivalent

operation, external status indicator, etc.).

In addition, it also has several inputs for assessing external control

contacts (external operating mode switching or heat request, Smart

Grid and low rate EVU functions

The optional outdoor temperature sensor installed on the north side

of the building can be used to further optimise the weathercompensated leaving water temperature control.

If the optional RoCon G1 (EHS157056) gateway is installed and

connected to the Internet, the indoor unit can be conveniently

monitored and operated by remote control using a mobile phone

(app).

Initial commissioning of the heating system is described in the

installation instructions for the indoor unit.

Certain menu items of the RoCon+ HP1 controller are only

accessible to the heating expert. This security measure ensures that

no undesirable malfunctions arise during operation of the system

through incorrect settings.

All settings for the assigned HC can be made with the RoConU1

(EHS157034) room station in the same way as on the control panel.

If the terminal function is activated, all operating possibilities that are

available on the integrated control panel are available with the

exception of certain special functions (e.g. manual operation).

After appropriate assignment, a connected RoConM1 (EHS157068)

mixer module is also operated using the RoCon+ B1 control panel

and/or the RoConU1 (EHS157034) room station.

(1)

).

2.1 Temporary shutdown

CAUTION

A heating system that is shut down can freeze in the event

of frost and may suffer damage.

▪ Drain the heating system that is shut down if there is

danger of frost.

▪ If the heating system is not drained, the power supply

must be ensured and the external main switch must

remain switched on if there is a danger of frost.

If the heat pump is not required for a lengthy period, it can be

temporarily decommissioned.

However, we recommend not to disconnect the system from the

power supply but merely to switch it to "Standby mode"

The system is then protected from frost. The pumps and valve

protection functions are active.

If it is not possible to guarantee the power supply when there is

danger of frost,

▪ completely drain the indoor unit on the water side, or

▪ apply suitable antifreeze measures to the connected heating

system and hot water storage tank (e.g. draining).

INFORMATION

If there is only a risk of frost for a few days when the power

supply is not reliable, it is not necessary to empty the

indoor unit due to the very good thermal insulation,

provided that the storage tank temperature is regularly

monitored and does not fall below +3°C.

However, this provides no freeze-up protection for the

connected heat emitter.

(1)

The energy supply company (EVU) sends signals that are used for controlling the power mains utilisation and that have an influence on the

cost of the power and availability.

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

5

Page 6

3 Operation

3 Operation

3.1 General

DANGER: RISK OF ELECTROCUTION

If electrical components come into contact with water, this

can cause an electric shock as well as cause potentially

fatal burns or injuries.

▪ The displays and keys of the controller must be

protected against the effects of moisture.

▪ To clean the controller, use a dry cotton cloth. The use

of aggressive cleaning agents and other fluids can

cause damage to devices or lead to electric shock.

INFORMATION

The heat pump makes the most effective use of energy at

the lowest possible return and hot water target

temperatures.

If an external heat generator (e.g. the optional backup

heater) is activated at target leaving water temperatures

above 50°C, the efficiency (COP) of the heat pump can

deteriorate (depending on the outside temperature).

3.2 Display and operating elements

3.2.1 Status indicator

The LEDs of the status indicator light up or flash to indicate the

operating mode of the device.

3‒1 Status indicator

LED Mode Description

Flashes blue Standby The device is not in operation.

Lights up blue Operation The device is in operation.

Flashes red Error An error has occurred. For further

details, see "8Errors and

faults"[447].

3.2.2 Display

During normal operation the display is deactivated (completely dark).

The activity of the system is indicated by the status indicator. Each

press of the rotary button (turn, press or hold) activates the display

with the start screen.

If the start screen is active and no user input is made for

60 seconds, the display is deactivated. If no input is made by the

user at any other point in the menu for 120seconds, the system

returns to the start screen.

3.2.3 Rotary button

CAUTION

Never operate the operating elements of the controller with

a hard, pointed object. This can cause damage and can

cause the controller to malfunction.

The rotary button can be used to navigate in the respective level, to

select or change the setting value and to accept this change with a

short key press.

3‒1 RoCon+B1 display and operating elements

1 Status indicator

2 Display

3 Rotary button

3‒2 Function of the rotary button

Action Result

Turning Select menu, select setting, make setting

Press Confirm selection, accept setting, execute

function.

Press for 2sec. Exit menu

3.2.4 Start screen

The start screen provides an overview of the current operating status

of the system. From the start screen, any operation of the rotary

switch (turn, press or hold down) leads to the Main menu.

Operating instructions

6

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 7

3‒2 Display position on the start screen

3‒3 Display icons on the start screen

Item Icon Explanation

1 Date and time

2 Error message

3 Operation

Item Icon Explanation

10 Operating mode: Standby

Operating mode: Reduce

Operating mode: Heating

Operating mode: Cooling

Operating mode: Summer

Operating mode: Automatic 1

Operating mode: Automatic 2

Operating mode: Emergency

11 Special program: Party

Special program: Absent

Special program: Holiday

Special program: Public holiday

3 Only with connected room unit: Room

temperature

4 Hot water temperature

5 Underfloor heating leaving water temperature

Convector heating leaving water temperature

Radiator heating leaving water temperature

6 Outside temperature

7 Pressure in the HC

8 Storage tank without heating rod

Storage tank with connected heating rod (off)

Storage tank with connected heating rod (on)

9 No outdoor unit detected

Outdoor unit present, compressor off

Outdoor unit present, compressor on

Special program: 1 x hot water

Special program: Screed

Special program: Ventilation

12 Quiet mode On

13 Operating mode: Heating

Operating mode: Cooling

Operating mode: Hot water

Operating mode: Defrost

Operating mode: No request

14 Ext External operating mode switched (Burner

blocking contact or Room thermostat)

INFORMATION

If the local control panel is used as a remote controller for

a mixer module, both the standard screen and the menu

structure are changed (see "9Mixer module"[448]).

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

7

Page 8

3 Operation

3.3 Operating concept

The operating concept of the controller allows quick navigation in the

menu:

▪ Clear display of information

▪ Straightforward selection of parameters

▪ Setting of setpoints and programs.

The basics of the operating concept are described in detail below

using a few examples. The operation of special functions follows the

same principle and is described in the corresponding sections if

required in "4Function"[411].

3.3.1 Navigating in the menu

From the start screen, any operation of the rotary switch (turn, press

or hold down) leads to the main menu. The menu view consists of an

upper area for the menu icons of the various submenus and the

lower menu bar. The Back and Help icons are displayed in the menu

bar. Use the rotary button to switch between the icons (including the

icons in the menu bar). Multi-page menus are indicated by the page

break arrow. Use the rotary button to switch between the menu icons

on the different menu pages.

3‒3 Example: Elements in a two-page menu

1 Back icon

2 Menu bar

3 Menu icon

4 Page change arrow (for multi-page menus)

5 Help icon

Example: In the "Statistics" menu, change [→Main menu]:

1 Turn the rotary button clockwise until the "Statistics" icon (on

the second menu page) turns blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The "Statistics" submenu is called up

3.3.2 Help function

A help text is available for each menu icon.

3‒4 Help function

Example: Calling up the help text for the "Hot water" menu and

stopping the help function again [→Main menu →User]:

1 Turn the rotary button clockwise until the help icon in the menu

bar turns blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The help function becomes active, the "?" symbol is

displayed on the last menu icon.

3 Turn the rotary button anticlockwise until the "?" symbol

appears on the "Hot water" icon.

4 Briefly press the rotary button to confirm ("OK").

Result: The help text for the "Hot water" is displayed.

5 Briefly press the rotary button to confirm ("OK").

Result: Exits the help text level.

6 Turn the rotary button clockwise until the help icon in the menu

bar turns blue.

7 Briefly press the rotary button to confirm ("OK").

Result: The help function is terminated.

3.3.3 Navigating in lists and selecting list entries

Lists exist as pure information lists or can be used to select a list

entry. Turning the rotary button switches between the list entries.

Multi-page lists are indicated by the page break arrow. Turn the

rotary button to switch between the list entries of the different pages.

In the case of selection lists, the currently selected list entry is

indicated by a tick. Click "OK" to select another list entry. The

corresponding setting is then accepted and the list is exited.

Operating instructions

8

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 9

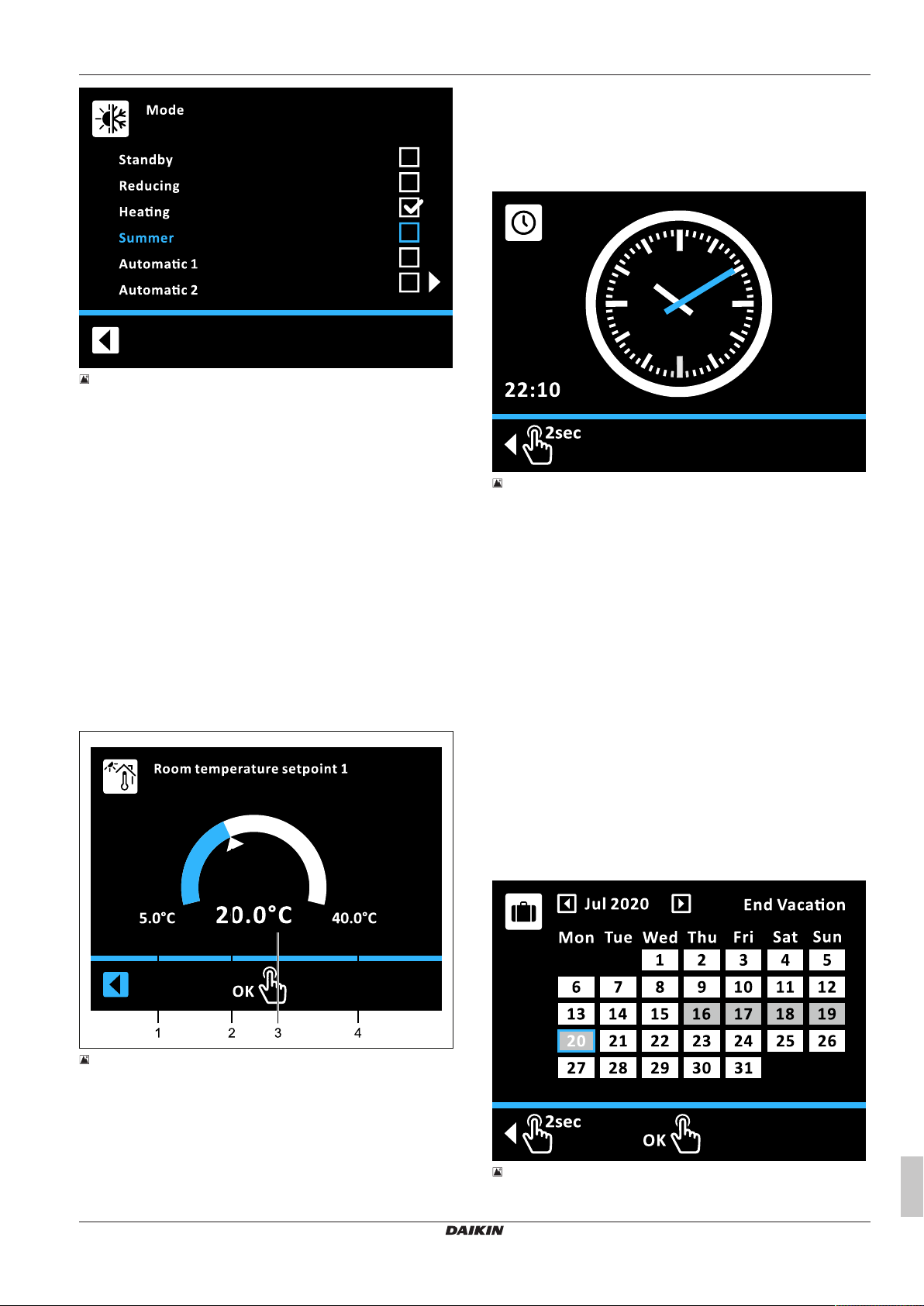

3‒5 List with selected list entry

Example: Switch the operating mode to "Summer" [→Main menu

→Operating mode]

1 Turn the rotary button clockwise until the "Summer" list entry is

displayed in blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The box is ticked in the "Summer" list entry.

3 Turn the rotary button anticlockwise until the Back icon turns

blue.

4 Briefly press the rotary button to confirm ("OK").

Result: The setting is saved and the setting level is exited.

3.3.4 Setting setpoints

The setpoint of a parameter can be changed within the displayed

scale. Click "OK" to save the new value. Press and hold the rotary

button to exit the setting level without saving. For some parameters

there is an "Off" setting in addition to values on the scale. This

setting can be selected by turning the rotary button anticlockwise

after the minimum value of the scale has been reached.

3 Operation

2 Briefly press the rotary button to confirm ("OK").

Result: The setting is saved and the setting level is exited.

3.3.5 Setting the times

The clock function is used to set the current time.

3‒7 Setting the times

Example: Set the time to 16:04 [→ Main menu → Settings

→Display →Time]:

1 Turn the rotary button clockwise until the circle is displayed in

blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The hour hand is displayed in blue.

3 Turn the rotary button clockwise until 16:00 is displayed.

4 Briefly press the rotary button to confirm ("OK").

Result: The minute hand is displayed in blue.

5 Turn the rotary button clockwise until 16:04 is displayed.

6 Briefly press the rotary button to confirm ("OK").

Result: The Confirm icon in the menu bar is displayed in blue.

7 Briefly press the rotary button to confirm ("OK").

Result: The setting is saved and the setting level is exited.

3‒6 Display of the parameter setting

1 Minimum value

2 Default value

3 Currently selected value

4 Maximum value

Example: Set [Room temperature target 1] to 22°C [→ Main menu

→User →Room →Room temperature target 1]:

1 Turn the rotary button clockwise until 22°C is displayed.

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

3.3.6 Calendar function

The calendar function is used to set the current date or the "Holiday"

and "Public holiday" time programs. The calendar function allows the

selection of a time period for the time programs.

3‒8 Setting the period with the calendar function

Operating instructions

9

Page 10

3 Operation

Example: Set [Holiday] from 16 July2020 – 20July 2020 [→Main

menu →Time program →Holiday]:

1 Turn the rotary button clockwise until the month selection is

Jul2020.

2 Briefly press the rotary button to confirm ("OK").

Result: 1July is shown with a blue border.

3 Turn the rotary button clockwise until 16July is highlighted in

blue.

4 Briefly press the rotary button to confirm ("OK").

Result: 16July is shown on a grey background.

5 Turn the rotary button clockwise until 20July is highlighted in

blue.

6 Briefly press the rotary button to confirm ("OK").

Result: The setting is saved and the setting level is exited.

When a new holiday period is set, the previously set holiday period

is automatically deleted. Alternatively, the holiday setting can also be

reset.

Example: Reset the holiday setting [→Main menu →Time program

→Holiday]:

1 Turn the rotary button clockwise until the month selection is

displayed in blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The last selected day of the holiday is displayed with a

blue border.

3 Turn the rotary button anticlockwise until all days are shown in

white.

4 Briefly press the rotary button to confirm ("OK").

Result: The holiday setting is reset and the setting level is

exited.

3.3.7 Setting the time programs

The time program function is used to set permanent time programs

(see "4.3.2Permanent time programs"[413]). This allows the daily

setting of 3switching cycles. The times can be entered separately

for each individual weekday or in blocks of "Monday to Friday",

"Saturday to Sunday" and "Monday to Sunday". The selected

switching cycles are highlighted in grey (" 3‒9 Time program

function with overview level (left) and setting level (right)" [410]) in

the overview level of the respective program.

3‒4 Structure of the permanent time programs

Time period Switching cycle

Single day of the week (Monday,

Tuesday ...)

Working week (Monday to

Friday)

Weekend (Saturday to Sunday) 1. 06:00 to 22:00

Entire week (Monday to Sunday) 1. 06:00 to 22:00

1. 06:00 to 22:00

2. xx:xx to xx:xx

3. xx:xx to xx:xx

1. 06:00 to 22:00

2. xx:xx to xx:xx

3. xx:xx to xx:xx

2. xx:xx to xx:xx

3. xx:xx to xx:xx

2. xx:xx to xx:xx

3. xx:xx to xx:xx

INFORMATION

Time settings for a switching cycle in a weekday or block

program will also be accepted for other time periods as

long as they are for the same weekdays.

▪ The starting time in the first switching cycle is changed

from 06:00 am to 05:00 am for the individual weekday

"Monday". In the period "Monday to Friday" and

"Monday to Sunday", the first switching cycle is

automatically changed from 06:00 to 05:00.

3‒9 Time program function with overview level (left) and setting

level (right)

Example: For the [Heating circuit auto. 1] program, set switch cycles

1 and 2 for Monday to Friday [→Main menu →Time program →HC

auto 1]:

1 Turn the rotary button clockwise until the "Settings" icon is

displayed in blue.

2 Briefly press the rotary button to confirm ("OK").

Result: Display changes to setting level with blue flashing

period selection.

3 Turn the rotary switch clockwise until the required time period is

displayed.

4 Briefly press the rotary button to confirm ("OK").

Result: The display changes to the input window for the start

time of the first switching cycle.

5 Briefly press the rotary button to confirm ("OK").

Result: Input window for start time of the first switching cycle

flashes blue.

6 Turn the rotary button clockwise until the required start time is

displayed.

7 Briefly press the rotary button to confirm ("OK").

Result: The display changes to the input window for the end

time of the first switching cycle.

8 Turn the rotary button clockwise until the required end time is

displayed.

9 Briefly press the rotary button to confirm ("OK").

Result: The display changes to the input window for the start

time of the second switching cycle.

10 Briefly press the rotary button to confirm ("OK").

Result: Input window for the start time of the second switching

cycle flashes blue.

11 Turn the rotary button clockwise until the required start time is

displayed.

12 Briefly press the rotary button to confirm ("OK").

Result: The display changes to the input window for the end

time of the second switching cycle.

13 Turn the rotary button clockwise until the required end time is

displayed.

14 Briefly press the rotary button to confirm ("OK").

Result: The display changes to the input window for the start

time of the third switching cycle.

Operating instructions

10

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 11

4 Function

15 Turn the rotary button clockwise until the Confirm icon turns

blue.

Result: The display changes to the Confirm icon.

16 Briefly press the rotary button to confirm ("OK").

Result: The programming is saved.

Result: The setting level is exited.

Result: Selected switching cycles are highlighted in grey.

17 Turn the rotary button anticlockwise until the Back icon turns

blue.

18 Briefly press the rotary button to confirm ("OK").

Result: The menu is exited

3.3.8 External operation

In addition to operation via the integrated RoCon+ HP1 controller,

the system can also be adjusted and operated via external devices.

Operation via the Internet

An optional (RoCon G1 (EHS157056)) gateway can be used to

connect the RoCon+ HP1 controller to the Internet. This enables

remote control of the RoCon+HP1 by mobile phone (using an app).

Operation via the room station

It can also be operated via the optional RoCon U1 (EHS157034)

room station. The operating elements and instructions for use are

described in the "Daikin RoCon HP, EHS157034, EHS157068

Operating Instructions " (available in digital form). All application

instructions are also valid for the indoor unit.

4 Function

The system fully automatically controls the operation of the room

heating, room cooling and domestic hot water preparation on the

sanitary side on the basis of the specifications set in the RoCon

+HP1 controller. The functions that can influence system operation

are described below.

Some of the functions and parameters described are restricted by

access rights and can only be set by a heating specialist (see

"4.5.1Access rights (technician code)"[416]).

4.1 Operating mode

[→Main menu →Operating mode]

This menu is used to select the operating mode for operating the

device. The current operating mode is indicated by a corresponding

symbol on the start screen.

Standby operating mode (Standby)

NOTICE

A heating system that is not protected against frost can

freeze in the event of frost and thus be damaged.

▪ Drain the heating system on the water side if there is a

danger of frost.

▪ If the heating system is not drained, the power supply

must be ensured and the mains switch must remain

switched on if there is a risk of frost.

In this operating mode, the indoor unit is switched to standby mode.

The freeze-up protection function remains unchanged. In order to

maintain this function, the system must not be disconnected from the

mains.

All controllers integrated in the RoCon system via the CAN bus are

primarily also switched to the "Standby" operating mode.

INFORMATION

In the "Standby" operating mode, the heat pump and the

optionally connected backup heater are disconnected from

the power supply (energy-saving mode) if the following

conditions are met:

▪ the outdoor temperature sensor is connected and

correctly parametrised in the system configuration

▪ the outside temperature is more than 8°C

▪ there is no heating request

▪ the freeze-up protection function is not active in any

connected HC and

▪ the indoor unit has been switched on for at least

5minutes.

Reduce operating mode

Reduced heating operation (lower room target temperature)

according to the set reduction temperature in the [Reduce room

temperature] parameter (see "4.2User"[412]).

Domestic hot water preparation according to the target leaving water

temperatures and switching cycles in the [Hot water auto. 1] hot

water time program (see "4.2User"[412]).

Heating operating mode

Heating, cooling operation according to the room target temperature

set in the [Room temperature target 1] parameter (see

"4.2User"[412]).

A connected outdoor temperature sensor (weather-compensated

leaving water temperature control), a connected RoCon U1

(EHS157034) room station or a connected room thermostat also

influence the target leaving water temperature.

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

11

Page 12

4 Function

Domestic hot water preparation according to the target leaving water

temperatures and switching cycles in the [Hot water auto. 1] hot

water time program (see "4.2User"[412]).

Summer operating mode

Only domestic hot water preparation according to the set target

temperatures and switching cycles is carried out in the [Hot water

auto. 1] hot water time program (see "4.2User"[412]).

All controllers integrated in the RoCon system via the CAN bus are

primarily also switched to the "Summer" operating mode.

Automatic 1 operating mode (time program)

Automatic heating and setback mode according to the permanent

time programs (see "4.3Time program"[413]):

▪ [Heating circuit auto. 1]

▪ [Hot water auto. 1]

Automatic 2 operating mode (time program)

Automatic heating and setback mode according to the permanent

time programs (see "4.3Time program"[413]):

▪ [Heating circuit auto. 2]

▪ [Hot water auto. 2]

INFORMATION: Switching contact for external

operating mode changeover

A potential-free switching contact connected to the "Ext"

terminals on connection J8 of the indoor unit and wired

with a resistor can also be used to change over from an

external device (e.g. modem, ...). See " 4‒1 Resistance

values for evaluating the EXT signal"[412].

In this case, the switching contact functionality is

dependent on the parameter [Func. burner blocking

contact]:

▪ [Func. burner blocking contact] = "Resistance

values" (default setting): Evaluation of the resistance

values.

▪ [Func. burner blocking contact] = "Burner blocking

contact": Evaluation as a burner blocking contact. If the

switching contact is closed, the external heat generator

has priority.

4‒1 Resistance values for evaluating the EXT signal

Operating mode Resistance Tolerance

Standby <680Ω ±5%

Heating 1200Ω

Reduce 1800Ω

Summer 2700Ω

Automatic 1 4700Ω

Automatic 2 8200Ω

INFORMATION

The resistances specified in " 4‒1 Resistance values for

evaluating the EXT signal" [4 12] in a tolerance field of

5%. Resistances outside this tolerance field are interpreted

as an open input. The heat generator switches back to the

previously active operating mode.

The input is not considered for resistance values greater

than the value for "Automatic 2".

If several switching contacts are connected to the indoor

unit (e.g. smart grid, room thermostat), the associated

functions may have a higher priority than the external

mode switching. The operating mode requested by the

EXT switching contact is then possibly not activated or is

only activated later.

Besides these operating modes, different temporary time programs

(see " 4‒2 Overview of temporary time programs" [4 12]) are

available that are carried out with priority after activation.

4‒2 Overview of temporary time programs

Temporary heating

program

Party Time program "4.3Time pro-

Absent

Public holiday

Holiday

Screed Configuration "4.5.7Additional

INFORMATION

If a temporary heating program (Party, Absent, Public

holiday, Holiday, Screed) is started during the selected

operating mode, control is carried out primarily according

to the settings for this time program.

Setting/activation in

the menu

Information

gram"[413]

program"[419]

4.2 User

[→Main menu →User]

The most important target temperatures and functions are set for the

user in this menu.

4.2.1 Room temperature target setting

[→Main menu →User →Room]

The room target temperatures for room heating in heating operation

are defined in this menu. The available setpoints (1-3) belong to the

respective cycle (1-3) of the [Heating circuit auto. 1] and [Heating

circuit auto. 2] time programs.

Further explanations and possible settings for this menu can be

found in "7.3User"[429].

4.2.2 Room temperature reduced setting

[→Main menu →User →Reduce]

The room target temperatures for room heating in Reduced mode

are defined in this menu. The reduced operation is carried out by the

"Reduce" operating mode or by the "Heating circuit auto. 1" and

"Heating circuit auto. 2" time programs.

Further explanations and possible settings for this menu can be

found in "7.3User"[429].

4.2.3 Room temperature absent setting

[→Main menu →User →Absent]

The room target temperature for room heating in Absence mode are

defined in this menu. The absence operation is carried out by the

"Absent" or "Holiday" time programs.

Further explanations and possible settings for this menu can be

found in "7.3User"[429].

4.2.4 Hot water temperature, target setting

[→Main menu →User →Hot water]

The hot water target temperatures for domestic hot water

preparation are defined in this menu. The available setpoints (1-3)

belong to the respective cycle (1-3) of the "Hot water auto. 1" and

"Hot water auto. 2" time programs.

Further explanations and possible settings for this menu can be

found in "7.3User"[429].

Operating instructions

12

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 13

4 Function

4.2.5 Unscheduled domestic hot water preparation

[→Main menu →User →1x load]

By starting this function, the hot water can be heated up to the [Hot

water temperature target 1] target temperature at any time. The

heating up is carried out with priority and independent of other

heating programs. After this temporary function has elapsed, the

controller automatically jumps back to the previously active operating

mode.

Possible settings for this menu can be found in "7.3User"[429].

4.3 Time program

[→Main menu →Time program]

Various freely adjustable permanent time programs are available for

convenient and individual room and hot water temperature control.

Temporary time programs are also available, which override the

permanent time programs or the currently set operating mode for the

duration of their validity.

4.3.1 Temporary time programs

INFORMATION

The following temporary time programs can be cancelled

at any time due to the manual changing of the operating

mode.

Party

[→Main menu →Time program →Party]

The program runs from activation until the end of the set period.

During this time, the HC is controlled to the temperature set in the

[Room temperature target 1] parameter. If the [Automatic 1] or

[Automatic 2] time program is active, the heating cycle is extended

or started prematurely. The domestic hot water preparation is not

affected.

Absent

[→Main menu →Time program →Absent]

The program runs from activation until the end of the set period.

During this time, the HC is controlled to the room target temperature

in the [Room temperature absent] parameter. The domestic hot

water preparation is not affected.

Holiday

[→Main menu →Time program →Holiday]

A calendar function can be used to enter a time period of absence.

During this time, the HC is continuously controlled (24 h per day) to

the room target temperature set in the [Room temperature absent]

parameter. This program is not started if the Standby operating

mode is active on the set start date.

Public holiday

[→Main menu →Time program →Public holiday]

A calendar function can be used to enter a time period of presence.

During this time, regulation is carried out exclusively according to the

settings for "Sunday" in [Heating circuit auto. 1] and [Hot water auto.

1].

4.3.2 Permanent time programs

For the connected HCs and the storage tank charging circuit, time

programs control the HC and hot water temperatures or the

operating times of the circulation pump according to the specified

switching cycles. The switching cycles are saved in time blocks for

which different target temperatures can be set.

The saved time program can be changed at any time. For a better

overview, it is recommended to write down and safely store the

programmed switching cycles ("11.1Timers"[452]).

Heating circuit auto. 1 and Heating circuit auto. 2

[→Main menu →Time program →HC auto 1/HC auto 2]

The time programs for the HC can be parametrised in these menus.

Three switching cycles can be set per day, to which the [Room

temperature target 1/2/3] parameters are assigned. Outside the

switching cycles, it is controlled to the [Reduce room temperature]

setpoint. The entry can be made separately for each individual

weekday or in week segments.

Hot water auto. 1 and Hot water auto. 2

[→Main menu →Time program →DHW auto 1/DHW auto 2]

The time programs for the domestic hot water preparation can be

parametrised in these menus. Three switching cycles can be set per

day, to which the [Hot water temperature, target 1/2/3] parameters

are assigned.

Outside of the switching cycles, it is controlled to the minimum

adjustable setpoint (see "7.3.4 Menu: Hot water temperature,

target"[429]).

Circulation program

[→Main menu →Time program →Circulation]

A time program for an optionally connected circulation pump can be

parametrised in this menu. 3 switching cycles per day can be set.

INFORMATION

Use of circulation lines not permitted in France!

Sound program

INFORMATION

During quiet mode, the output in room heating and room

cooling operation decreases so that it may no longer be

possible to achieve pre-set target temperature values. This

program can therefore only be set by the installer.

In this menu, a time program can be parametrised for various stages

of the heat pump quiet mode. 3 switching cycles with a resolution of

15 minutes can be set. A separate entry for each weekday is

possible. Format: (on) hh:mm – hh:mm (off)

Also, the cycles from Monday to Friday, Saturday to Sunday and

Monday to Sunday can be parametrised.

A noise level can be assigned to each switching cycle:

▪ 0 – no noise reduction,

▪ 1 – low noise reduction,

▪ 2 – medium noise reduction,

▪ 3 – maximum noise reduction.

Factory settings

The permanent time programs are preset according to the following

factory settings.

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

13

Page 14

4 Function

4‒3 Factory setting of the permanent time programs

Switching cycle 1 Switching cycle 2 Switching cycle 3

Time period On Off On Off On Off

Room heating

Temperature setting [Room temperature target 1]: 20°C [Room temperature target 2]: 20°C [Room temperature target 3]: 20°C

[Reduce room temperature]: 10°C

"Heating circuit auto. 1"

Monday – Friday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

"Heating circuit auto. 2"

Monday – Friday 06:00 08:00 16:00 22:00 - - : - - - - : - -

Saturday, Sunday 07:00 23:00 - - : - - - - : - - - - : - - - - : - -

Domestic hot water preparation

Temperature setting [Hot water temperature target 1]:

48°C

"Hot water auto. 1"

Monday – Sunday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

"Hot water auto. 2"

Monday – Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

"Circulation program"

Monday – Friday 05:00 21:00 - - : - - - - : - - - - : - - - - : - -

Saturday, Sunday 06:00 22:00 - - : - - - - : - - - - : - - - - : - -

Monday – Sunday - - : - - - - : - - - - : - - - - : - - - - : - - - - : - -

[Hot water temperature target 2]:

"Sound program"

48°C

[Hot water temperature target 3]:

48°C

4.3.3 Time program reset

[→Main menu →Time program →TP reset]

This menu can be used to reset the time programs to factory

settings. To do this, select the respective time programs and then

confirm the selection with the Confirm button on the second menu

page.

4.4 Settings

[→Main menu →Settings]

The basic settings of the controller and the system are made in this

menu. This includes the integration of optional and external

components. Depending on the access authorisation (user or

expert), different parameters are available.

4.4.1 Display settings

[→Main menu →Settings →Display]

This menu can be used to set the following parameters: Language,

date, time, LCD brightness and LCD illumination time.

Further explanations and possible settings for this menu can be

found in "7.5Settings"[431].

INFORMATION

Increasing the brightness of the LCD display beyond the

factory-set value will reduce the life of the display.

4.4.2 System

[→Main menu →Settings →System]

This menu combines basic parameters of the heating system.

Further explanations and possible settings for this menu can be

found in "7.5.2Menu: System"[432].

4.4.3 External heat sources

[→Main menu →Settings →Ext. source]

This menu can be used to configure the integration of an optional

external heat source.

The heat supplied by an alternative heat generator (WEZ) must be

fed to the unpressurised cylinder water in the hot water tank of the

indoor unit.

▪ On use of the optional EKBUxx backup heater, this is carried out

due to the design installation situation.

▪ When using an alternative WEZ (e.g. gas- or oil-fired boiler), this

can be hydraulically integrated:

▪ unpressurised via the connections (solar feed and solar return)

of the hot water storage tank or

▪ with Daikin Altherma EHS…B… and ETS…B… device types,

via the integrated pressure solar heat exchanger

The setting of the [Config. ext. heat source] parameter determines

whether and which additional heat generator (WEZ) is available for

domestic hot water preparation (DHW) and heating support (HZU).

▪ No external heat source

▪ Optional backup heater

▪ External heat source for DHW and heating support: Alternative

WEZ provides domestic hot water preparation and heating

support. To request the WEZ, relay K3 is switched for connections

X1-L1 and XBUH1-T1 on the RTX-EHS PCB.

▪ External heat source for DHW or HZU: Alternative WEZ 1

(optional EKBUxx backup heater) provides domestic hot water

preparation and alternative WEZ 2 provides heating support. To

request the WEZ 1, relay K3 (connections X1-L1 and XBUH1-T1)

is switched on the RTX-EHS PCB and to request the WEZ 2, relay

K1 (connections X1-L3 and XBUH1-T3) is switched on the RTX-

Operating instructions

14

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 15

4 Function

EHS PCB. Heed warning notice! The operation of an additional

alternative WEZ is also influenced by the settings of the

[Bivalence function] and [Bivalence temperature] parameters.

Further explanations and possible settings for this menu can be

found in "7.5.3Menu: External heat source"[433].

4.4.4 Inputs/Outputs

[→Main menu →Settings →Inputs/Outputs]

This menu can be used to adjust parameter for inputs and outputs of

the controller PCB to optimise the system controller individually.

Smart grid

WARNING

There is a danger of scalds at hot water target

temperatures over 65°C. This is possible because the

utility company (EVU) is entitled to control current draw

optimised according to supply and demand in the

definitions for Smart Grid.

Such forced charging can cause the hot water target

temperature in the hot water tank to exceed 65°C.

This storage tank charging is carried out even when

"Standby" operating mode is set.

▪ Install scald protection in the hot water distribution line.

To use this function, a special electricity meter with SG receiver to

which the heat pump must be connected is required.

As soon as the function is activated by the [Smart grid] parameter,

the heat pump is set to an operating mode as per the following table

depending on the utility company signal.

4‒4 Use of the SG signal

(1)

Signal

EVU SG Hot water Heating

1 0 --- No operation

0 0 Normal Normal

0 1 low Switch-on re-

1 1 Very low Switch-on com-

AUX switching function

Setting the [AUX switching function] parameter determines the

switching conditions for the potential-free AUX switching contact

(toggle switch output A). This switching contact can be used to

control an external heat generator, for example.

Electricity

costs

Effect on

operation

commendation,

and storage

tank setpoint

temperature

value is in-

creased de-

pending on the

[Smart grid

mode] para-

meter.

mand and stor-

age tank set-

point temperat-

ure is set to

70°C.

installations

(2)

No operation

Normal

operation

Switch-on recommendation,

and target leav-

ing water tem-

perature is in-

creased de-

pending on the

[Smart grid

mode] para-

meter.

Switch-on com-

mand for stor-

age tank char-

ging

(2)

(3)

If one of the switching conditions is fulfilled, the potential-free

switching contact is switched after the time set in the [AUX wait time]

parameter.

AUX switching contact (toggle switch output A) is not switched if

the switch function is deactivated. [AUX switching function]

parameter = "Inactive".

AUX switch contact (toggle switch output A) is switched when one

of the following conditions is set:

▪ Storage tank temperature (T

) ≥ [Switching threshold TDHW

dhw

(AUX)] parameter value.

▪ if an error is pending.

▪ Outside temperature <[Bivalence temperature] parameter value.

▪ Heat request for domestic hot water preparation.

▪ Heat request for room heating or cooling requirement.

▪ Heat request for room heating or domestic hot water preparation.

▪ "Cooling" operating mode active.

Interlink function

Setting the [Interlink function] parameter = "On" provides the option

that the indoor unit includes two different leaving water temperature

setpoints in the controller.

This applies to both weather-compensated control and control

according to a fixed target leaving water temperature (see

"4.5Configuration"[416]).

One possible application is, for example, the additional integration of

an HP convector in a surface heating and cooling system.

Prerequisite: 2 switching contacts (e.g. room thermostats) are

connected to the plug connection J16 of the indoor unit.

▪ [Interlink function] parameter = "Off": Deactivated

▪ [Interlink function] parameter = "On": Evaluation of the heating and

cooling switching contacts at plug connection J16 on the

RoConBM2C PCB:

Activation of cooling operation only by switching the operating

mode to "Cooling" (see "4.1 Operating mode" [4 11]). [Room

thermostat] parameter must be set to "Yes".

1 Open switching contacts: Only freeze-up protection active

2 "Heating" or "Automatic 1" / "Automatic 2" operating mode

active during the switching cycles in day mode.

▪ Closed heating switching contact = IL1: It is controlled to the

normal target leaving water temperature according to the

parameter settings for [Heating].

▪ Closed cooling switching contact = IL2: It is controlled to the

increased target leaving water temperature (normal target

leaving water temperature + value of the [Interlink temperature

increase] parameter). Priority if both switching contacts are

closed!

3 "Cooling" operating mode active.

▪ Closed heating switching contact = IL1: It is controlled to the

normal target leaving water temperature according to the

parameter settings in level [Heating circuit config.] > [Cooling].

▪ Closed cooling switching contact = IL2: It is controlled to the

reduced target leaving water temperature (normal target leaving

water temperature – value of the [Interlink temperature

increase] parameter). Priority if both switching contacts are

closed!

Further explanations and possible settings for this menu can be

found in "7.5.4Menu: Inputs/Outputs"[433].

(1)

Switching contacts at input J8 of the RoConBM2C PCB closed(1) or open(0).

(2)

No freeze-up protection function

(3)

When the charging process is completed, heating is carried out according to the settings for the respective HC. Heating support from the HC

active if [Heating support (HZU)] parameter = "On".

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Operating instructions

15

Page 16

4 Function

4.4.5 Intelligent storage tank management

[→Main menu →Settings →ISM]

If the storage temperatures are high enough, the energy in the

storage tank can be used for room heating. This can either increase

comfort ([Continuous heating] function) or make it possible to use

energy from an external heat source, e.g. solar, when heating is

required ([Heating support (HZU)] function).

Continuous heating

The activated Continuous heating function ([Continuous heating]

parameter = "On") allows uninterrupted heating even during

defrosting of the evaporator. This enables high comfort to be

guaranteed, even with rapidly reacting heating systems (e.g.

convectors).

Heating support (HZU)

If the heating support ([Heating support (HZU)] parameter = "On") is

activated, the energy in the built-in storage tank of the indoor unit is

used to perform the heating function. If the storage tank temperature

is sufficiently high, the heat generation by the heat pump remains

out of operation.

The minimum required storage tank temperature (T

calculated as follows:

T

= Currently active hot water target temperature

HZUmin

(1)

+hysteresis

a) Switch-on condition:

Tdhw>T

+4 K and Tdhw>Information parameter [Feed

HZUmin

temperature, target]+1K

If the switch-on condition is fulfilled, heat is taken from the storage

tank and this is used to supply the heating system.

b) Switch-off condition:

Tdhw<T

or Tdhw<Information parameter [Feed temperature,

HZUmin

target] (see "7.7.2Values"[444])

If the switch-off condition is met, heating support from the hot water

storage tank is ceased, and the heat pump takes over heating

operation.

The [Heating support power] parameter limits the maximum power

that can be taken. The [Heating support max. temp.] parameter limits

the maximum temperature that can enter the heating system.

Further explanations and possible settings for the parameters in this

menu can be found in "7.5.5Menu: Intelligent Storage Mgmt"[436].

HZUmin

) is

4.5 Configuration

[→Main menu →Configuration]

This menu can be used to optimally adapt the operating

characteristics of the system to the system structure and the needs

of the users. Additional programs facilitate commissioning.

Depending on the access authorisation (user or expert), different

parameters are available.

4.5.1 Access rights (technician code)

[→Main menu →Configuration →Access]

Certain functions and parameters in the controller are restricted by

access rights and are not visible to the user. To gain access to it, the

specialist code must be entered.

4‒1 Setting the access code

Example: Set code 3090 (example only, this is not a valid access

code) [→Main menu →Configuration →Access]:

1 Turn the rotary button clockwise until the first input field is

displayed in blue.

2 Briefly press the rotary button to confirm ("OK").

Result: The first input field flashes blue.

(2)

3 Turn the rotary button clockwise until 3 is displayed.

4 Briefly press the rotary button to confirm ("OK").

Result: The second input field is displayed in blue.

5 Turn the rotary button clockwise until the third input field is

displayed in blue.

6 Briefly press the rotary button to confirm ("OK").

Result: The third input field flashes blue.

7 Turn the rotary button clockwise until 9 is displayed.

8 Briefly press the rotary button to confirm ("OK").

Result: The fourth input field is displayed in blue.

9 Turn the rotary button clockwise until the Confirm icon turns

blue.

10 Briefly press the rotary button to confirm ("OK").

Result: The code is checked and the setting level is exited.

4.5.2 Sensors

[→Main menu →Configuration →Sensors]

Optional sensors are activated and configured in this menu.

Pressure setpoints for the water side can be defined.

Further explanations and possible settings for the parameters in this

menu can be found in "7.6.1Menu: Sensors"[437].

4.5.3 HC config.

[→Main menu →Configuration →HC config]

This menu is used to adjust the basic functionality of the HC.

Further explanations and possible settings for the parameters in this

menu can be found in "7.6.2Menu: Heating circuit config."[438].

Weather-compensated leaving water temperature control

If the weather-compensated leaving water temperature control is

active, the leaving water temperature ([Feed temperature, target]

parameter) is determined automatically according to the set heating/

cooling curve depending on the outside temperature.

(1)

Information parameter [Hot water temperature, target] (see "7.3.4Menu: Hot water temperature, target"[429])

(2)

[Heating support hysteresis] parameter setting (see "7.5.5Menu: Intelligent Storage Mgmt"[436])

Operating instructions

16

Daikin RoCon+ HP1

Controller RoCon+ HP1

008.1447899_01 – 08/2020

Page 17

4 Function

This function is activated in the delivery condition. It can only be

deactivated (fixed value control) or reactivated with a technician

code.

If the RoConU1 (EHS157034) room station is also connected to the

RoCon+ HP1, the target temperatures are controlled according to

the weather and room temperature [Room influence]) parameter.

This function can only be configured using the technician code.

Contact your heating expert in this regard.

This function is activated or deactivated via the [Weathercompensated] parameter in the "Configuration" menu.

▪ [Weather-compensated] parameter = "Weather-compensated":

Weather-compensated leaving water temperature control

according to the settings made in the [Heating] and [Cooling]

menus.

▪ [Weather-compensated] parameter = "Feed temperature, fixed":

Control based on fixed target temperature

▪ For heating operation: [Feed temperature, heating mode]

parameter or [Feed temperature, reducing mode] parameter

▪ For cooling operation: [Feed temperature, cooling mode]

parameter

INFORMATION

The weather-compensated leaving water temperature

control has no influence on the target leaving water

temperature in the case of a hot water circuit request.

With mixer module connected

The setting of the heating/cooling curves and the activation of the

weather-compensated leaving water temperature control for the

assigned HC are carried out in the same way as described above.

The assigned HC can be operated as a:

▪ Mixer add-on

The outside temperature of the outdoor temperature sensor

connected to the indoor unit external temperature sensor is

transmitted to the mixer module via the CAN bus.

or as a

▪ Mixer add-on with zone control

A separate outdoor temperature sensor must be connected to the

mixer module. The assigned HC is controlled according to the

outside temperature relevant for this zone.

If the terminal function is activated, the mixer module can be

operated and the settings for the assigned HC undertaken via the

RoCon+B1 control panel of the indoor unit.

In conjunction with the RoCon U1 (EHS157034) room station, the

mixer module can also control the assigned HC completely

autonomously and independently of the heat generator.

Further explanations and possible settings for this menu can be

found in "7.6Configuration"[437].

Freeze-up protection function

The integrated heating circulation pump is switched on at an external

temperature below the [Frost protection temperature] parameter

value in order to prevent the heating system from freezing.

In addition, the feed, storage and connected room temperature

sensors are also constantly monitored. If the temperature measured

by one of these sensors falls below 7°C (below 5°C at room

temperature), the antifreeze function is also activated.

If the heating leaving water temperature falls below 7°C, the heat

pump heats until the heating leaving water temperature reaches at

least 12°C.

The function is ended if the external temperature rises above the set

[Frost protection temperature] parameter value+1K and also there is

no other activation condition.

INFORMATION

Operation of the heat pump can be shut off completely for

a limited period of time by the utility company if the

following low-tariff functions are activated:

[HT/NT function] parameter = "Switch all off" or [Smart grid]

parameter = "On"

These situations can be recognised if, in the [→ Main

menu → Information → Overview] menu in the operating

data field "Ext" the "High rate" or "SG1" value is displayed.

4.5.4 Heating

[→Main menu →Configuration →Heating]

This menu is used to configure heating times and target leaving

water temperatures for heating operation.

Heating curve

INFORMATION: Overheating and moisture protection

In the event of malfunction, the underfloor heating system,

the screed or the floor structure could be damaged due to

overheating.

▪ Prior to initial commissioning, set the maximum

temperature limit in the RoCon+HP1 controller ([Max.

feed temperature] parameter) to the maximum

permissible system temperature before the screed

drying starts.

▪ Connect an overheating protection switch (in the

building) at the "EXT" plug connection to external mode

switch-over so that the indoor unit is switched to

"Standby" or "Summer" mode. If the [Room thermostat]

parameter = "Yes" or [Interlink function] parameter =

"On", the overheating protection switch must be

connected so that the room thermostat's switching

contact is interrupted.

▪ If the underfloor heating is also used for room cooling,

the connection notes in the above point also apply to

the connection of a moisture protection switch in the

building.

The heating curve is used to adapt the leaving water temperature to

the characteristics of the building independent of the respective

outside temperature (weather-compensated leaving water

temperature control, see "4.5 Configuration" [4 16]). Generally

speaking, the slope of the heating curve describes the ratio of the

leaving water temperature change to the external temperature

change.

The heating curve is valid within the limits of the minimum and

maximum temperatures set for the respective HC. Deviations may