Daikin EHS04P30A, EHSB04P30A, EHS08P30A, EHSB08P30A, EHS08P50A Installation manuals

...

Installation and maintenance

instructions

Indoor unit for air-water-heat pumps

Daikin Altherma integrated solar unit

Daikin Altherma

EHS(X/H)04P30A

EHS(X/H)B04P30A

EHS(X/H)08P30A

EHS(X/H)B08P30A

EHS(X/H)08P50A

EHS(X/H)B08P50A

EHS(X/H)16P50A

EHS(X/H)B16P50A

Installation and maintenance instructions

Daikin Altherma integrated solar unit

English

List of contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Observing instructions . . . . . . . . . . . . . . . . . . . . 3

1.2 Warning signs and explanation of symbols . . . . 3

1.2.1 Meaning of the warnings. . . . . . . . . . . . . . . . . . . . .3

1.2.2 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.3 Handling instructions. . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Avoid danger . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Instructions for operating safety . . . . . . . . . . . . . 4

1.5.1 Before working on the hydraulic system . . . . . . . . .4

1.5.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . .4

1.5.3 Working on cooling systems (heat pump) . . . . . . . .4

1.5.4 Site of installation . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5.5 Heating system and sanitary connection . . . . . . . .5

1.5.6 Requirements for the heating water . . . . . . . . . . . .5

1.5.7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5.8 Instructing the user/owner. . . . . . . . . . . . . . . . . . . .5

2 Product description. . . . . . . . . . . . . . . . . . . 6

2.1 Design and components . . . . . . . . . . . . . . . . . . 6

2.1.1 Top of unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.2 Device external and internal design Daikin

Altherma EHS(X/H)...P30A . . . . . . . . . . . . . . . . . . .7

2.1.3 Device external and internal design Daikin

Altherma EHS(X/H)B...P30A. . . . . . . . . . . . . . . . . .8

2.1.4 Device external and internal design Daikin

Altherma EHS(X/H)...P50A . . . . . . . . . . . . . . . . . . .9

2.1.5 Device external and internal design Daikin

Altherma EHS(X/H)B...P50A. . . . . . . . . . . . . . . . .10

3 Set-up and installation . . . . . . . . . . . . . . . 12

3.1 Dimensions and connections . . . . . . . . . . . . . . 12

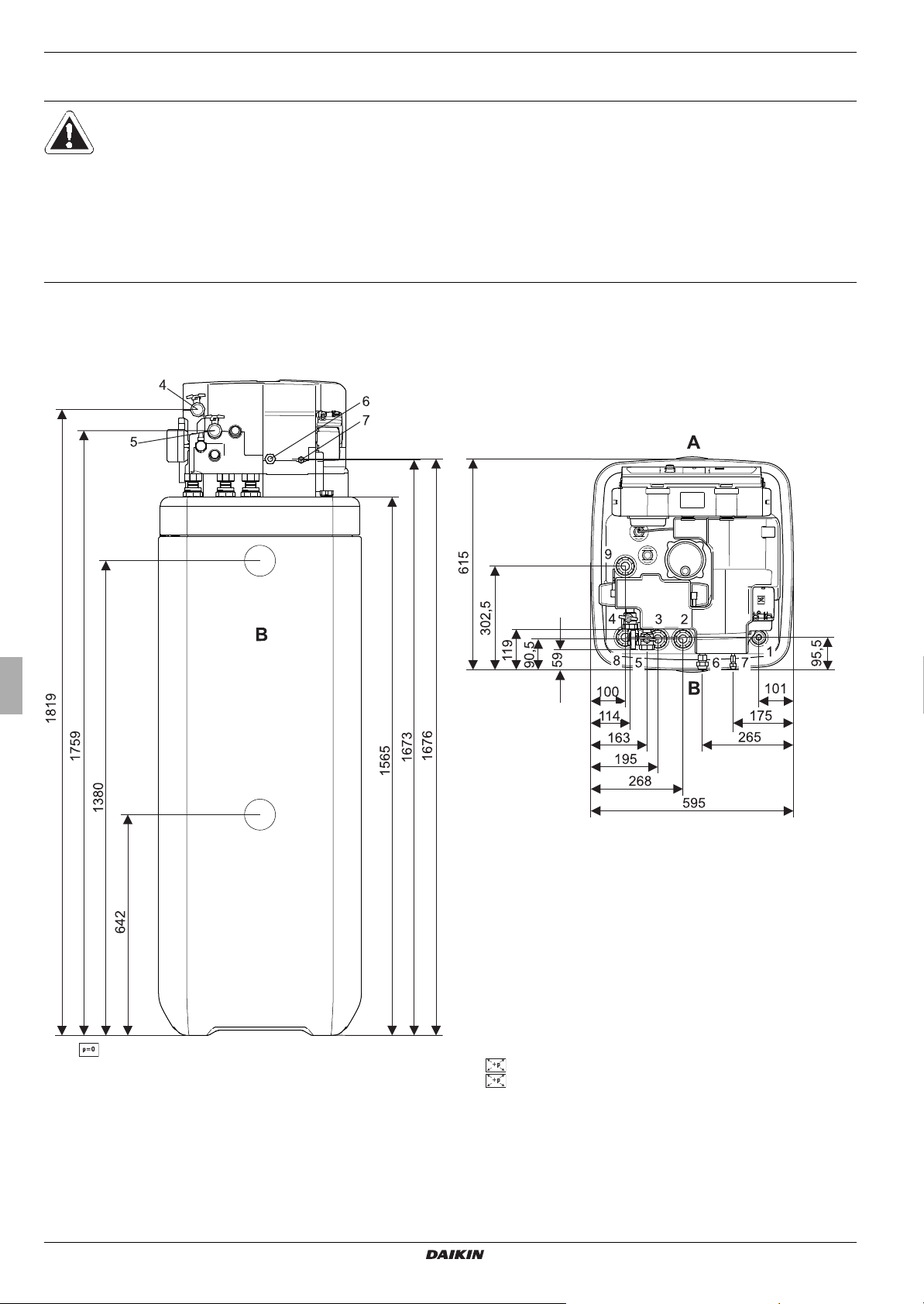

3.1.1 Daikin Altherma EHS(X/H)...P30A . . . . . . . . . . . .12

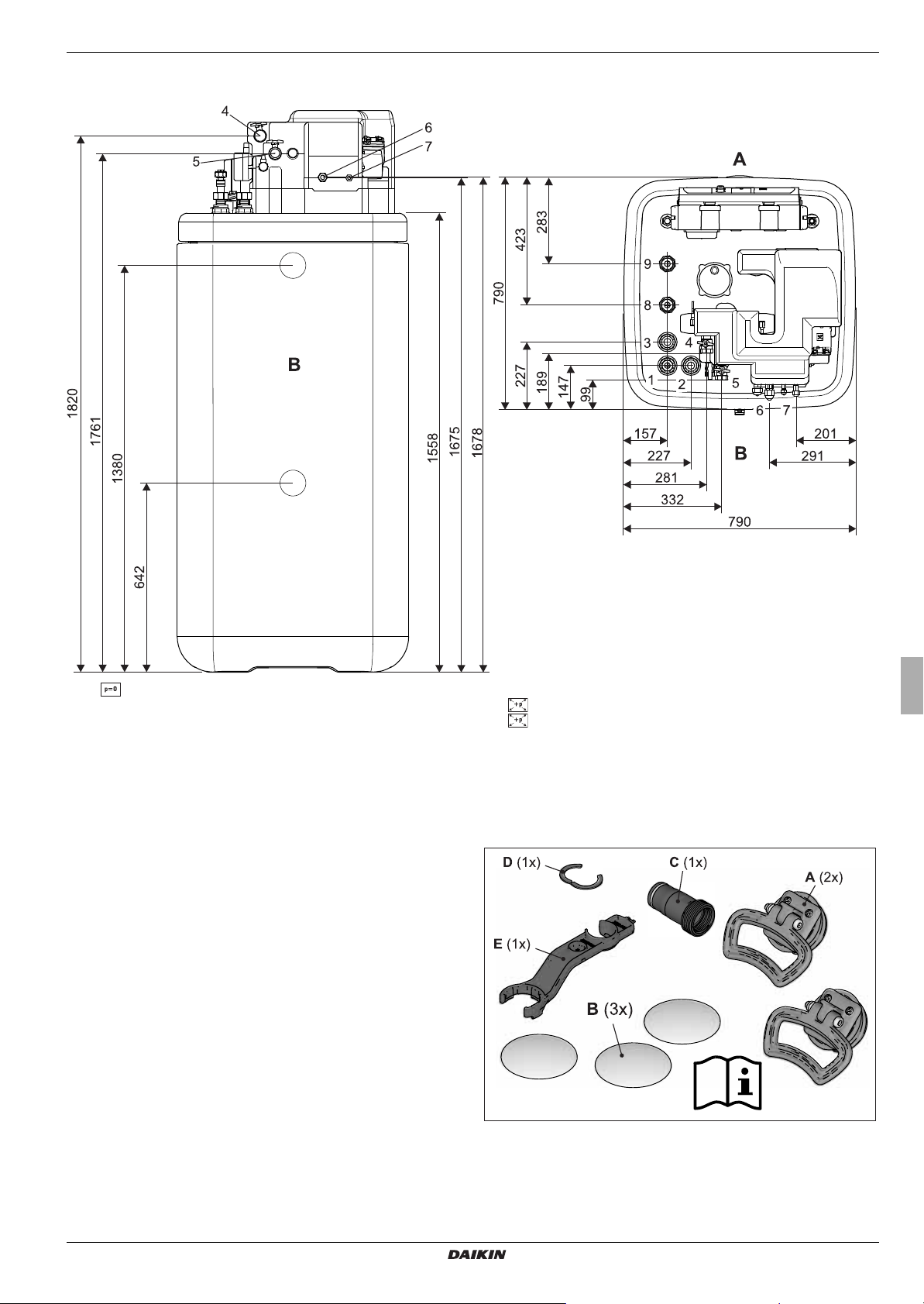

3.1.2 Daikin Altherma EHS(X/H)...P50A . . . . . . . . . . . .13

3.1.3 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . .13

3.2 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Water connection . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 Connecting hydraulic lines . . . . . . . . . . . . . . . . . .16

3.4 Electrical connection . . . . . . . . . . . . . . . . . . . . 16

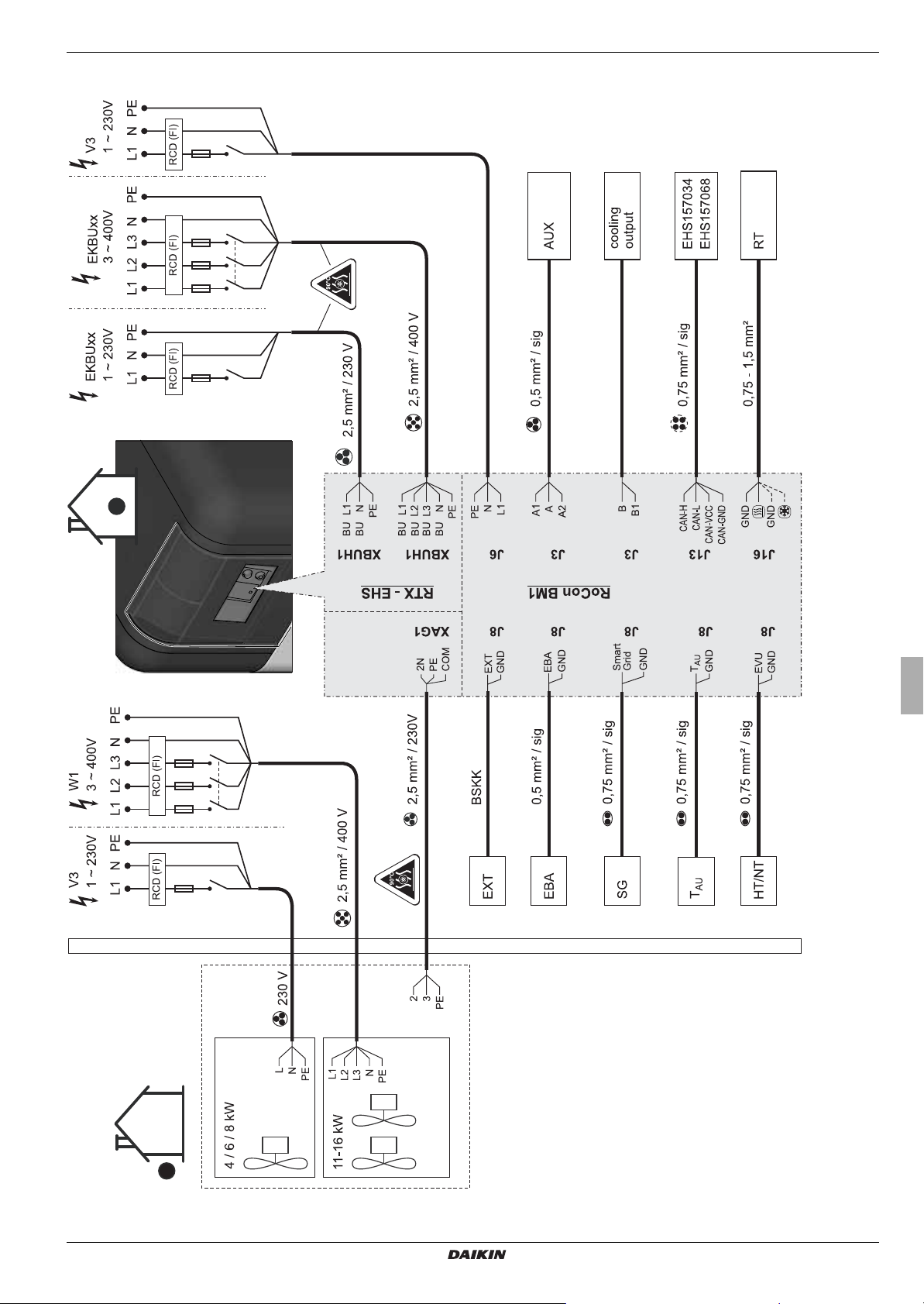

3.4.1 Overall connection plan Daikin Altherma

EHS(X/H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

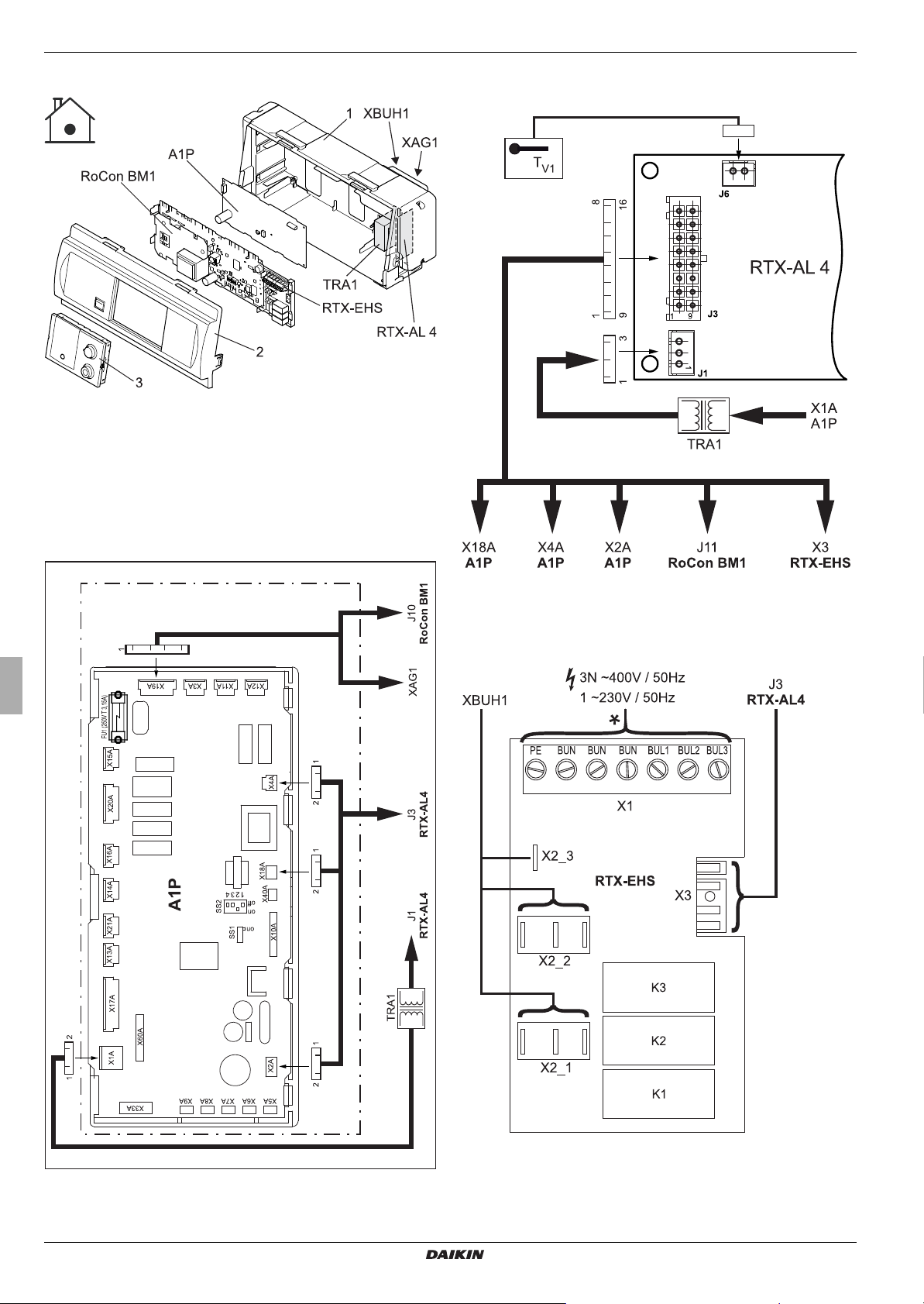

3.4.2 Position of the circuit boards. . . . . . . . . . . . . . . . .18

3.4.3 Connection assignment, circuit board A1P . . . . . .18

3.4.4 Terminal assignment for the RTX-AL4 circuit

board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4.5 Terminal assignment for the RTX-EHS circuit

board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

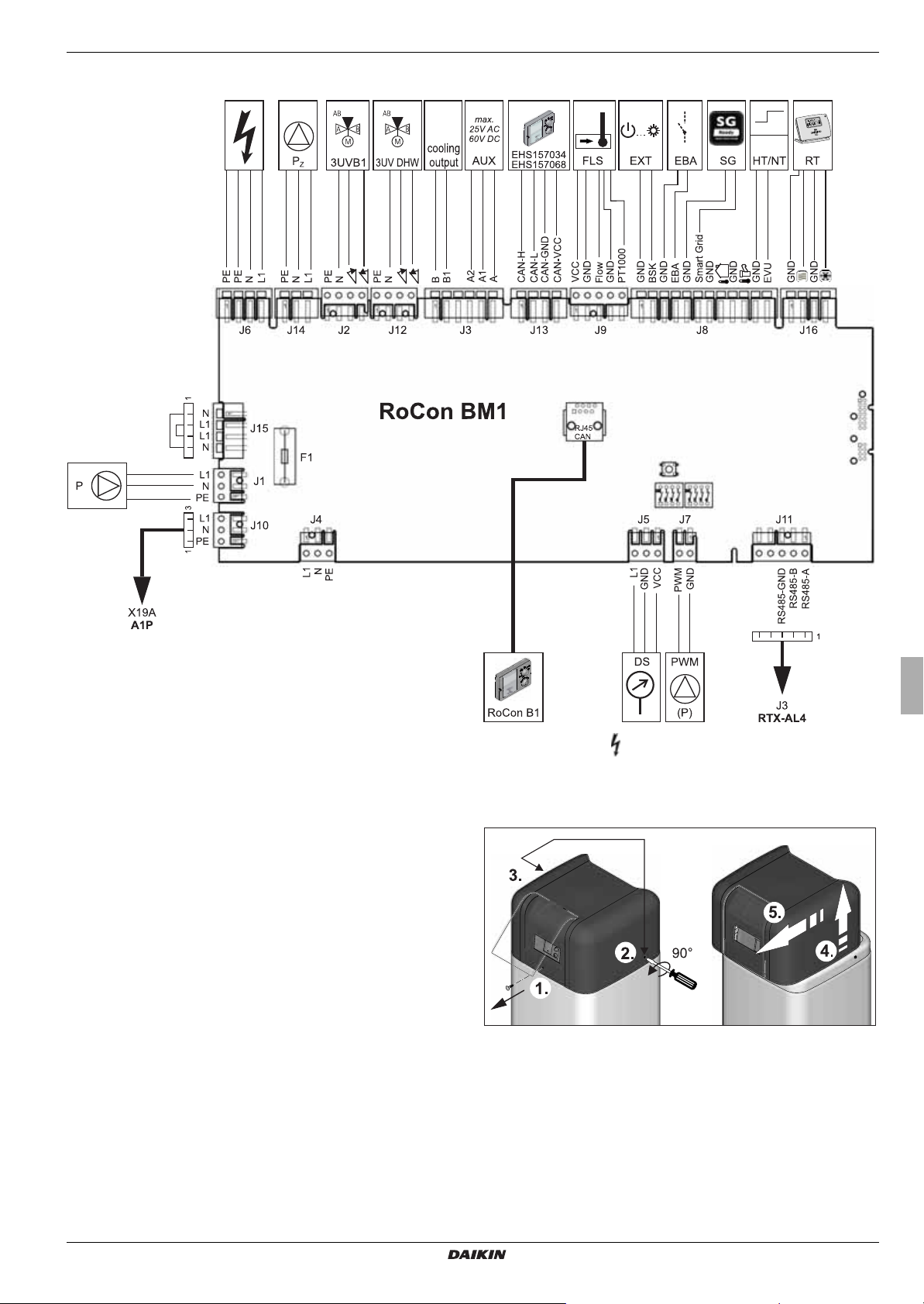

3.4.6 Connection assignment, circuit board

RoCon BM1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.7 Mains connection Daikin Altherma EHS(X/H). . . .19

3.4.8 Removing the protective cover . . . . . . . . . . . . . . .19

3.4.9 Opening the control housing and establishing

electrical connections . . . . . . . . . . . . . . . . . . . . . .20

3.4.10 Connection of ERLQ exterior heat pump unit . . . .20

3.4.11 Connection of external temperature sensor

RoCon OT1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.4.12 Connection of an external switching contact. . . . .21

3.4.13 External demand signal (EDS) . . . . . . . . . . . . . . .21

3.4.14 Connection of the electrical Daikin backup heater

(EKBUxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.4.15 Connection of the Daikin room thermostat . . . . . .22

3.4.16 Connection of the Daikin room controller

EHS157034. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.4.17 Connection of Daikin mixer module EHS157068 .23

3.4.18 Internet gateway Daikin EHS157056 . . . . . . . . . .23

3.4.19 Connection of the Daikin FWXV(15/20)AVEB. . . .23

3.4.20 Connection of the switching contact

(AUX output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.4.21 Low tariff mains connection (HT/NT). . . . . . . . . . 24

3.4.22 Connection intelligent controller

(Smart Grid - SG) . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.23 Symbols and legend keys on connection and

circuit diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 Laying coolant lines. . . . . . . . . . . . . . . . . . . . . 26

3.6 Pressure test and filling the coolant circuit . . . 27

3.7 Filling the system with water . . . . . . . . . . . . . . 27

3.7.1 Checking the water quality and adjusting the

pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.7.2 Filling the hot water heat exchanger . . . . . . . . . . 27

3.7.3 Filling the storage tank . . . . . . . . . . . . . . . . . . . . 27

3.7.4 Filling the heating system . . . . . . . . . . . . . . . . . . 27

4 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.1 Initial start-up. . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.3 Set the commissioning parameters. . . . . . . . . . . 28

4.1.4 Venting the internal heating circulation pump . . . 30

4.1.5 Activating the parameter [Air Purge] . . . . . . . . . . 30

4.1.6 Check minimum flow . . . . . . . . . . . . . . . . . . . . . . 30

4.1.7 Configuring Screed Program parameters

(only if necessary) . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 Re-commissioning. . . . . . . . . . . . . . . . . . . . . . 31

4.2.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5 Decommissioning . . . . . . . . . . . . . . . . . . . .32

5.1 Temporary shutdown . . . . . . . . . . . . . . . . . . . 32

5.1.1 Draining the storage tank . . . . . . . . . . . . . . . . . . 32

5.1.2 Draining the heating circuit and hot water circuit. 33

5.2 Final shutdown . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Service and maintenance . . . . . . . . . . . . . .35

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Removing the protective cover . . . . . . . . . . . . 35

6.3 Activities to be performed annually . . . . . . . . . 35

6.4 Filling and topping up the storage tank . . . . . . 37

6.5 Filling and topping up the heating system. . . . 38

7 Errors, malfunctions and messages . . . . .39

7.1 Deleting errors, correcting malfunctions,

deleting messages . . . . . . . . . . . . . . . . . . . . . 39

7.1.1 Current fault display . . . . . . . . . . . . . . . . . . . . . . 39

7.1.2 Read Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 Monitoring and configuration DIP Switch . . . . 50

7.5 Emergency operation . . . . . . . . . . . . . . . . . . . 51

8 Hydraulic system connection. . . . . . . . . . .52

9 Technical data . . . . . . . . . . . . . . . . . . . . . . .55

9.1 Equipment data . . . . . . . . . . . . . . . . . . . . . . . . 55

9.1.1 Daikin Altherma EHS(X/H)...P30A . . . . . . . . . . . 55

9.1.2 Daikin Altherma EHS(X/H)...P50A . . . . . . . . . . . 57

9.2 Characteristic lines . . . . . . . . . . . . . . . . . . . . . 58

9.2.1 Sensor characteristic lines . . . . . . . . . . . . . . . . . 58

9.2.2 Characteristic curves for pumps . . . . . . . . . . . . . 60

9.3 Tightening torque . . . . . . . . . . . . . . . . . . . . . . 60

9.4 Circuit diagram Daikin Altherma EHS(X/H). . . 61

10 List of keywords . . . . . . . . . . . . . . . . . . . . .62

11 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Installation and maintenance instructions

2

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

1Safety

1 x Safety

1.1 Observing instructions

These instructions are a >> Translation of the original

version

Please read this manual carefully and thoroughly before proceeding with the installation or modification of the heating

system.

These instructions are aimed at people who are authorised and

who have successfully completed a qualifying technical or skilled

manual training program for the particular work to be carried out

and who have participated in a professional development

seminar held by the appropriate responsible authority. This, in

particular, includes heating specialists and climate control techni

cians who have experience, as a result of their technical training

and their knowledge of the subject, of proper and appropriate installation and maintenance of heating, climate control and

cooling installations and heat pumps.

This manual provides all the necessary information for installation, start-up and maintenance, as well as basic information on

operation and settings. All parameters needed for trouble-free

operation have been configured at the factory. Please go through

the attached documents for a detailed description of operation

and control.

<< in your language.

Relevant documents

– Daikin Altherma EHS(X/H):

– Operating instructions for the user/owner

– Commissioning checklist

– Operating instructions for the RoCon HP control unit

– External unit for Daikin Altherma EHS(X/H); the associated

installation and operating instructions.

– When connecting to a Daikin solar system; the associated

installation and operating instructions.

– If a Daikin FWXV(15/20)AVEB is connected; the associated

installation and operating instructions.

– In the case of connection to a control component offered as

an accessory (room controller, mixer module etc.); the asso-

ciated installation and operating instructions.

The guides are included in the scope of supply for the individual

units.

1.2 Warning signs and explanation of symbols

1.2.1 Meaning of the warnings

Warnings in this manual are classified according into their severity and probability of occurrence.

DANGER!

Draws attention to imminent danger.

Disregarding this warning can lead to serious injury or

death.

CAUTION!

Indicates a situation which may cause possible

damage.

Disregarding this warning can lead to damage to

property and the environment.

This symbol identifies user tips and particularly useful

information, but not warnings or hazards.

-

Special warning signs

Some types of danger are represented by special symbols:

Electric power

Risk of burning or scalding

Risk of environmental damage

Danger of local freezing up

Health impairing or irritant materials

Prescribed temperature for continuous use

Danger of explosion

1.2.2 Validity

Some information in this manual has limited validity. The validity

is highlighted by a symbol.

Heat pump exterior unit ERLQ

Heat pump interior unit EHS(X/H)

FWXV(15/20)AVEB

Only valid for Daikin Altherma EHS(X/H) with cooling

function (see also section

Pay attention to the stipulated tightening torque (see

chapter 9.3 "Tightening torque")

Only applicable for the unpressurised system (Drain

Back)

Only applicable for the pressurised system

Valid/available only if a room regulator is connected

Valid/available only if a mixer module is connected

1.4)

WARNING!

Indicates a potentially dangerous situation.

Disregarding this warning can result in serious injury

or death.

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

1.2.3 Handling instructions

● Instructions on actions are shown as a list. Actions of which

the sequential order must be maintained are numbered.

Installation and maintenance instructions

3

1 x Safety

Results of actions are identified with an arrow.

Entry into a setting procedure

Exit from a setting procedure

1.3 Avoid danger

The Daikin Altherma EHS(X/H) is state-of-the-art and is built to

meet all recognised technical requirements. However, improper

use may result in serious physical injuries or death, as well as

property damage.

To prevent such risks, install and operate Daikin Altherma

EHS(X/H) only:

– as stipulated and in perfect condition,

– with an awareness of the safety and hazards involved.

This assumes knowledge and use of the contents of this manual,

the relevant accident prevention regulations and the recognised

safety-related and occupational medical rules.

WARNING!

This unit is not intended for use by persons (including

children) with impaired physical, sensory or mental

faculties or persons with insufficient experience and/or

expertise unless supervised by a person responsible

for ensuring their safety or are given instruction by this

person on how to use the unit.

Use as intended also involves compliance with maintenance and

inspection conditions. Spare parts must at least satisfy the technical requirements defined by the manufacturer. This is the case,

for example, with original spare parts.

1.5 Instructions for operating safety

1.5.1 Before working on the hydraulic system

● Work on the Daikin Altherma EHS(X/H) (such as setup,

servicing, connection and initial start-up) is only to be carried

out by persons who are authorised and who have success

fully completed qualifying technical or vocational training and

who have taken part in advanced training sessions recog

nised by the appropriate responsible authorities. This, in

particular, includes heating specialists and climate control

technicians who have experience, as a result of their

technical training and their knowledge of the subject, of

proper and appropriate installation and maintenance of

heating, climate control and cooling installations and heat

pumps.

● Switch off the external main switch before starting any work

on the Daikin Altherma EHS(X/H) and secure it against

unintentional switch-on.

● Seals must not be damaged or removed.

● Make sure that the safety valves comply with the require-

ments of EN 12828 when connecting on the heating side, and

with the requirements of EN

domestic water side.

● Only original Daikin replacement parts may be used.

12897 when connecting on the

-

-

1.4 Intended use

The Daikin Altherma EHS(X/H) may only be used for preparation

of warm water, as a room heating system, and depending on its

design, as a room cooling system. The Daikin Altherma

EHS(X/H) must be installed, connected and operated only ac

cording to the indications in this manual.

Only use of a suitable external unit approved by Daikin is permitted. The following combinations are permissible in this respect:

Internal unit External unit

Heating and

cooling (X)

EHSX04P30A EHSH04P30A

EHSXB04P30A EHSHB04P30A

EHSX08P30A EHSH08P30A

EHSXB08P30A EHSHB08P30A

EHSX08P50A EHSH08P50A

EHSXB08P50A EHSHB08P50A

EHSX16P50A EHSH16P50A ERLQ011CA(V3/W1)

EHSXB16P50A

B - Additional heat exchanger for the bivalent connection

Tab. 1 -1 Permissible combinations of Daikin exterior heat pump units

and Daikin Altherma EHS(X/H) internal units

Any other use outside the intended use is considered as improper. The operator alone shall bear responsibility for any resulting damage.

Heating only (H)

EHSHB16P50A

ERLQ004CAV3

ERLQ006CAV3

ERLQ008CAV3

ERLQ014CA(V3/W1)

ERLQ016CA(V3/W1)

-

1.5.2 Electrical installation

● Electrical installation may be carried out only by electrical

engineers and in compliance with the valid electro-technical

guidelines as well as the regulations of the relevant energy

supply company (EVU).

● Compare the mains voltage (~230 V, 50 Hz or ~400 V, 50 Hz)

indicated on the type plate with the supply voltage before

connecting to the mains.

● Before beginning work on live parts, disconnect all of the

systems circuits from the power supply (switch off main

switch, disconnect fuse) and secure against unintentional

restart.

● Equipment covers and service panels must be replaced as

soon as the work is completed.

1.5.3 Working on cooling systems (heat pump)

For work on stationary refrigeration systems (heat

pumps) and air conditioning systems, proof of expertise

is required in the European Community according to

the F-Gases Directive (EC) No. 303/2008.

–Up to 3 kg coolant fill quantity: Expert certificate

category II

–3 kg coolant fill quantity or over: Expert certifi-

cate category I

● Always wear safety goggles and protective gloves.

● When working on the coolant circuit, ensure that the

workplace is well ventilated.

● Never carry out work on the coolant circuit in closed rooms or

work pits.

● Do not let coolant come into contact with open fire, embers or

hot objects.

● Never allow coolant to escape into the atmosphere (high

pressure at the point of the leak).

Installation and maintenance instructions

4

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

1 x Safety

● When removing the service pipes from the filling connections,

never hold the connections in the direction of your body.

Residual coolant could escape.

● Components and spare parts must at least satisfy the

technical requirements defined by the manufacturer.

1.5.4 Site of installation

For safe and fault-free operation, it is necessary that the installation location of the Daikin Altherma EHS(X/H) fulfils certain criteria. Related information can be found in chapter 3.2.

Information on the installation site of other components can be

found in the associated documentation supplied with them.

1.5.5 Heating system and sanitary connection

● Create a heating system according to the safety requirements

12828.

of EN

● With sanitary connection, you must observe;

–EN 1717 - Protection of domestic water from contamina-

tion in domestic water installations and general requirements concerning safety equipment for the prevention of

domestic water contamination by back-flow

–EN 806 - Technical regulations for domestic water instal-

lations (TRWI)

– And, in addition, the country-specific legal regulations

1.5.7 Operation

The Daikin Altherma EHS(X/H):

● Do not operate until all installation and connection work is

completed.

● Only operate with a completely full storage tank (Level

indicator) and heating circuit.

● Operate at a maximum pressure of 3 bar.

● Only connect with a pressure reducer on the external water

supply (supply line).

● Only operate the with the specified quantity of coolant and the

type of coolant specified.

● Only operate if the protective cover is installed.

The specified servicing intervals should be adhered to and inspection work must be carried out.

1.5.8 Instructing the user/owner

● Before you hand over the Daikin Altherma EHS(X/H), explain

to the user/owner how to operate and check the system.

● Hand over the technical documentation (this document and

all supporting documents) to the user and advise him that

these documents must be made available at all times and be

stored in the immediate vicinity of the unit.

The connection of a solar installation, an electric heating rod or

an alternative heat generator may cause the storage temperature

to exceed 60

°C.

● For this reason you should fit scalding protection

(e.g. VTA32 + screw connection set 1") during installation.

If the Daikin Altherma EHS(X/H) is connected to a heating system

with steel pipes, radiators or non-diffusion-proof floor heating

pipes, slurry and swarf could enter the hot water storage tank and

cause blockages, local overheating or corrosion.

● To prevent possible damage, fit a dirt filter or sludge

separator into the heating return flow of the system.

– SAS 1

1.5.6 Requirements for the heating water

Observe the current technological regulations to prevent corrosion products and deposits.

Minimum requirements regarding the quality of filling and supplementary water:

– Water hardness (calcium and magnesium, calculated as

calcium carbonate): ≤

– Conductivity: ≤ 2700 μS/cm

– Chloride: ≤ 250 mg/l

– Sulphate: ≤ 250 mg/l

– pH value (heating water): 6,5 - 8,5

3 mmol/l

Using filling water and top-up water which does not meet the

stated quality requirements can cause a considerably reduced

service life of the equipment. The responsibility for this lies solely

with the operator.

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

5

2 x Product description

2 Product description

2.1 Design and components

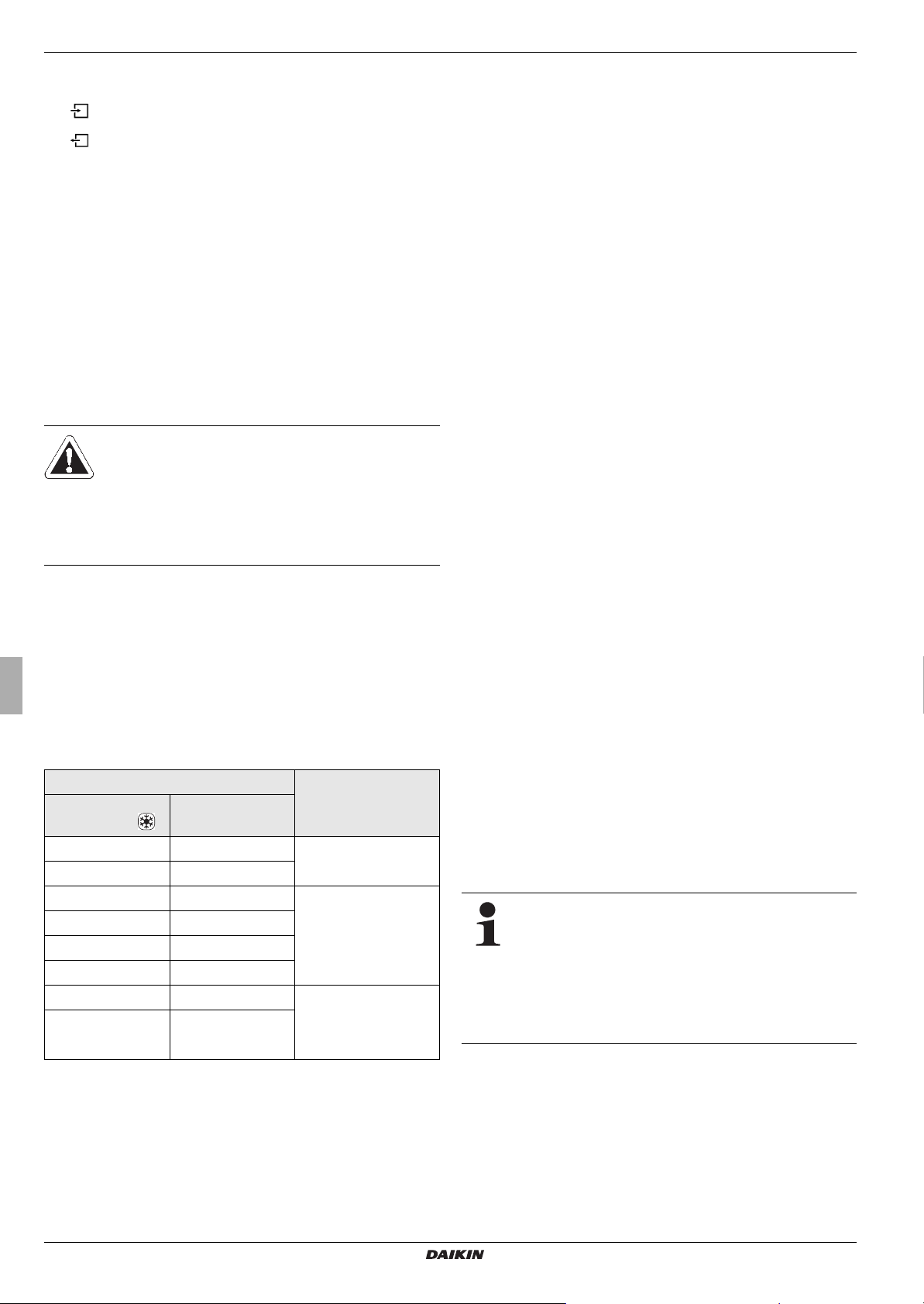

2.1.1 Top of unit

1 Solar - flow (1" IG)

2 Cold water flow (1" AG)

3 Hot water flow (1" AG)

4 Heating flow (1" AG)*

5 Heating return (1" AG)*

6 Circulation pump

7 Safety-pressure relief valve (heating circuit)

8 Automatic vent

17 Fill level indicator (tank water)

18 Daikin connection for electrical backup heater (R 1½" IG)

(Accessory)

30 Plate heat exchanger (PWT)

31 Connection coolant fluid line

Daikin Altherma EHS(X/H) 04P30A/08PxxA: Cu Ø 6.4 mm (1/4"),

Daikin Altherma EHS(X/H) 16P50A: Cu Ø 9.5 mm (3/8")

32 Connection to coolant gas line

Cu Ø 15,9 mm (5/8")

34 Ball cock (heating circuit)

35 Combined filling and draining valve (heating circuit)

37 Storage tank temperature sensor t

38 Connection diaphragm expansion vessel

DHW1

and t

DHW2

39 Controller housing with elect. terminal strip

3UVB1

3-way diverter valve (internal heat generator circuit)

3UV DHW

3-way diverter valve (hot water/heating)

DS pressure sensor

FLS (t

/ V1)

R1

Return flow temperature and flow sensor

tR2Return temperature sensor

t

V1, tV2

Feed temperature sensors

t

V, BH

Flow temperature sensor backup heater

Safety devices

Observe tightening torque!

AG Male thread

IG Female thread

* Ball cock (1" IG) is supplied with the equipment

Fig. 2-1 Structure and components Daikin Altherma EHS(X/H)

(top of unit)

Installation and maintenance instructions

6

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

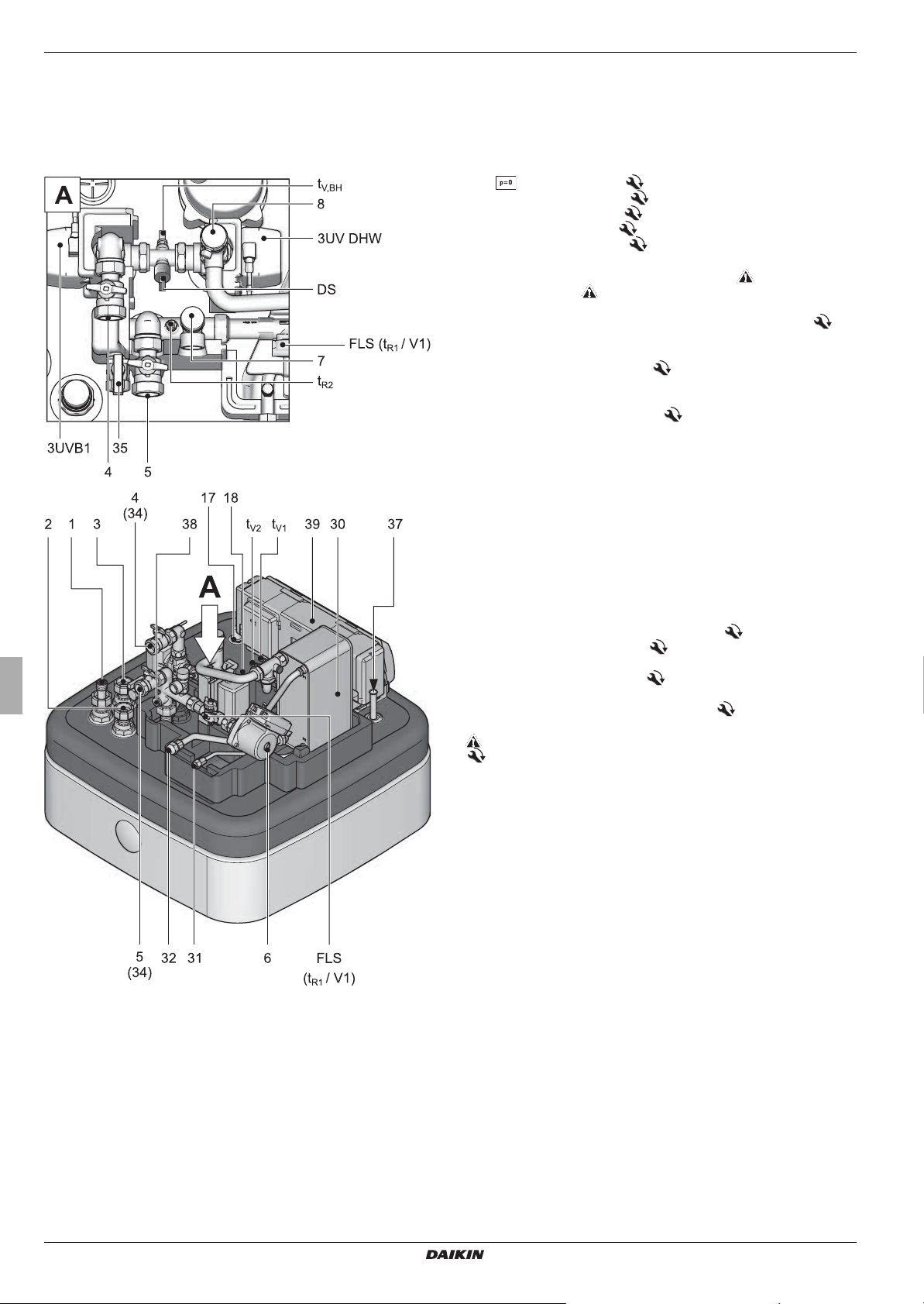

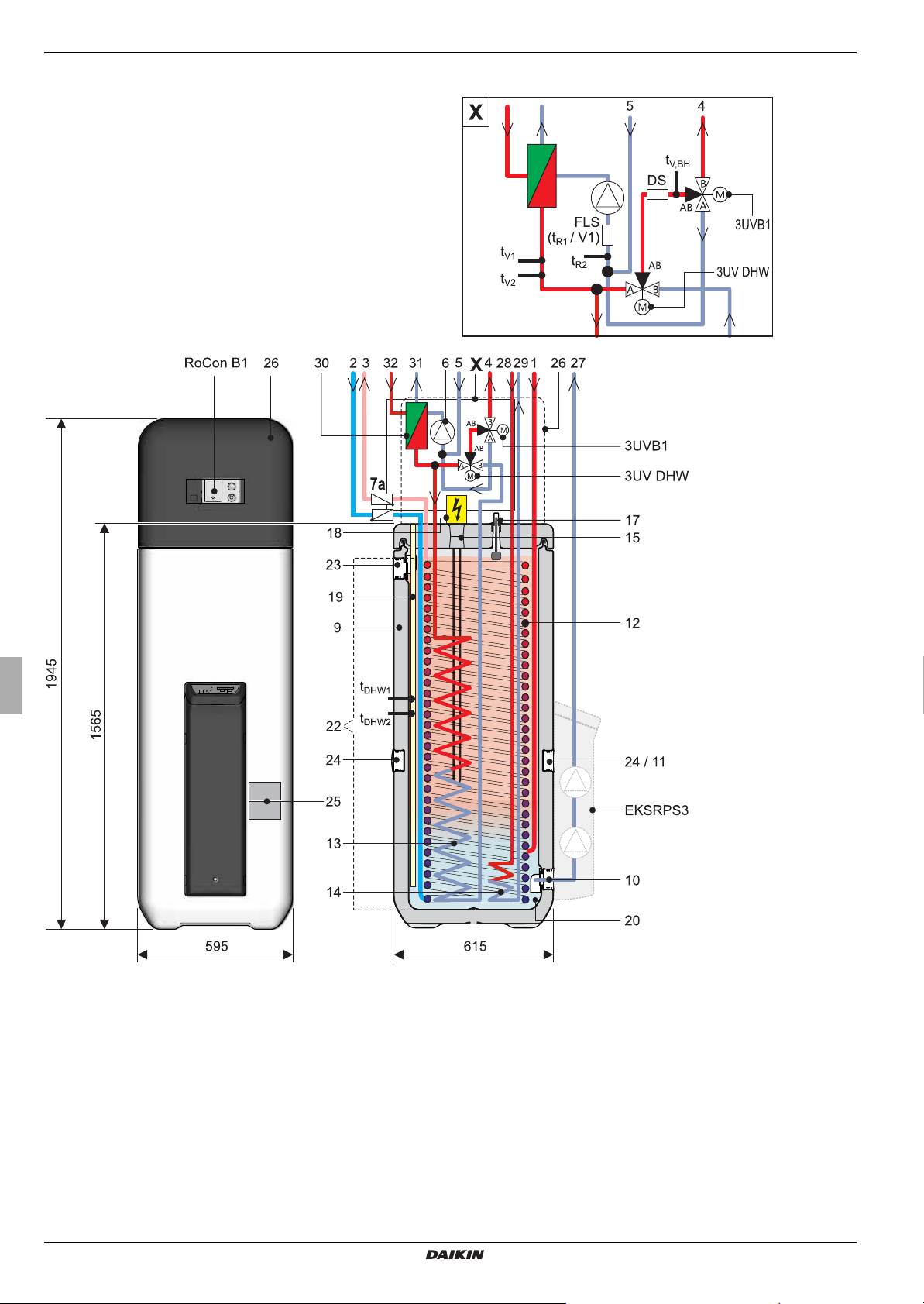

2.1.2 Device external and internal design Daikin Altherma EHS(X/H)...P30A

2 x Product description

Fig. 2-2 Design and components of the Daikin Altherma EHS(X/H)...P30A (external view and internal design)

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

For legend descriptions see tab. 2 -1

Installation and maintenance instructions

7

2 x Product description

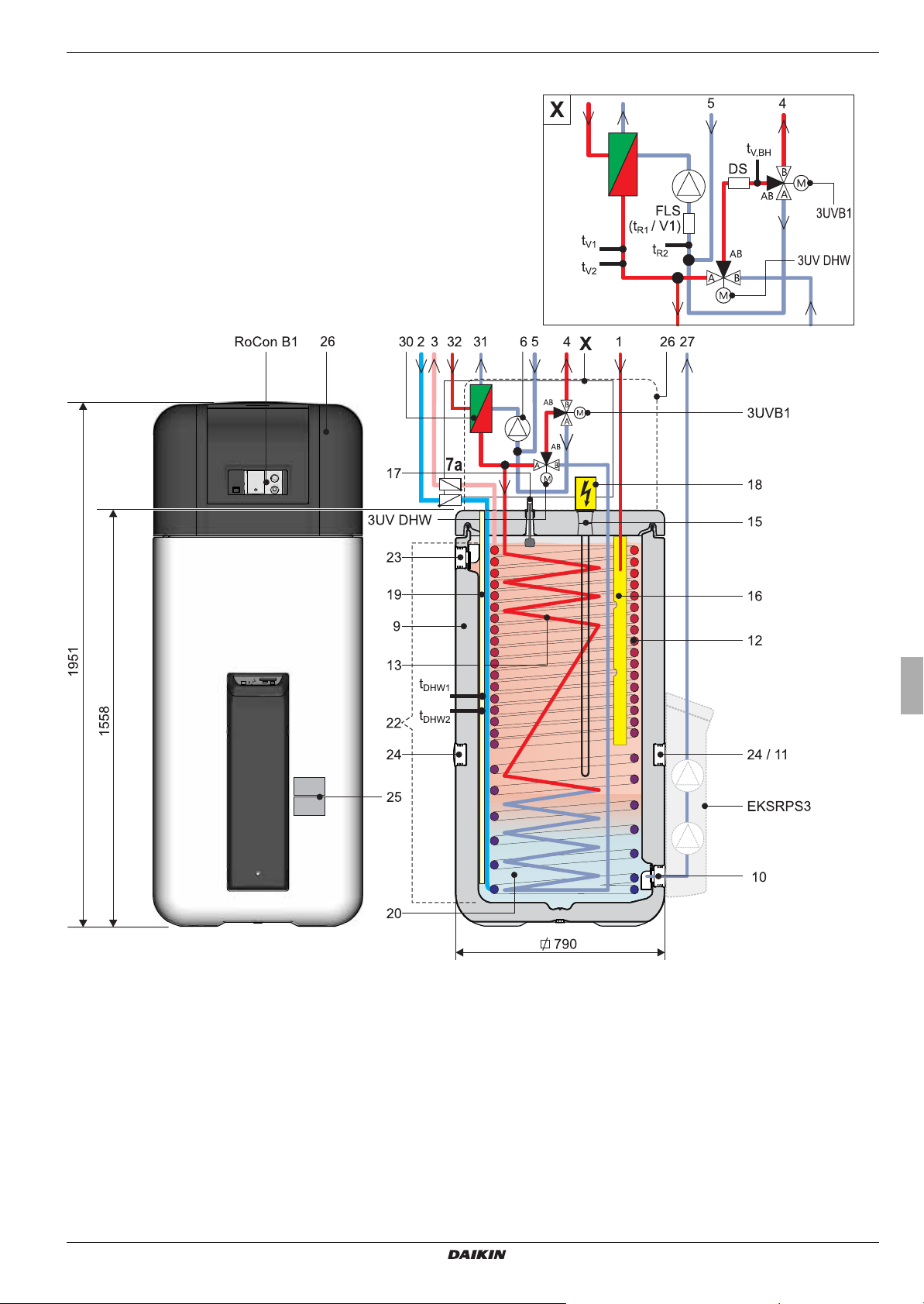

2.1.3 Device external and internal design Daikin Altherma EHS(X/H)B...P30A

Fig. 2-3 Design and components of the Daikin Altherma EHS(X/H)B...P30A (external view and internal design)

For legend descriptions see tab. 2 -1

Installation and maintenance instructions

8

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

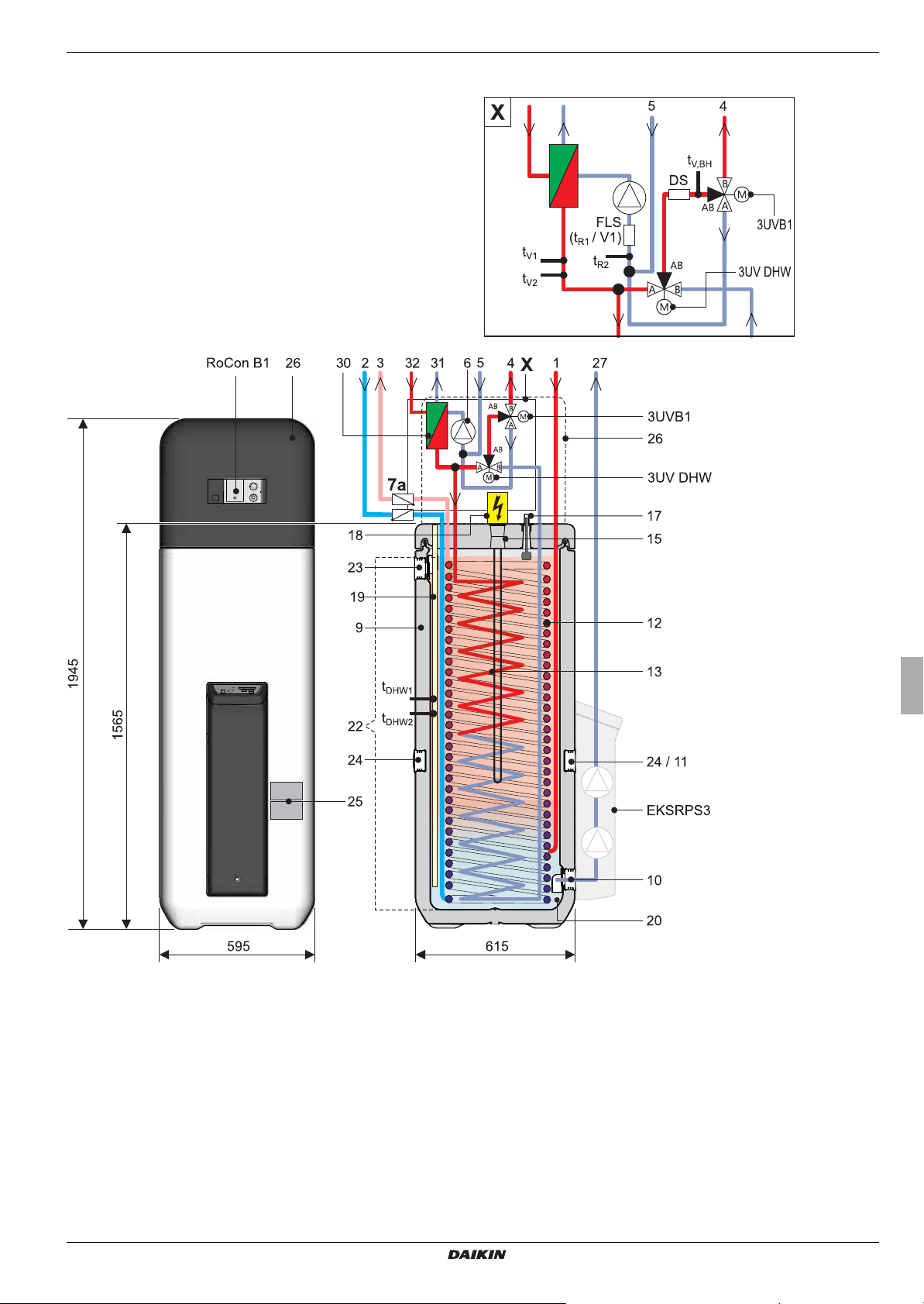

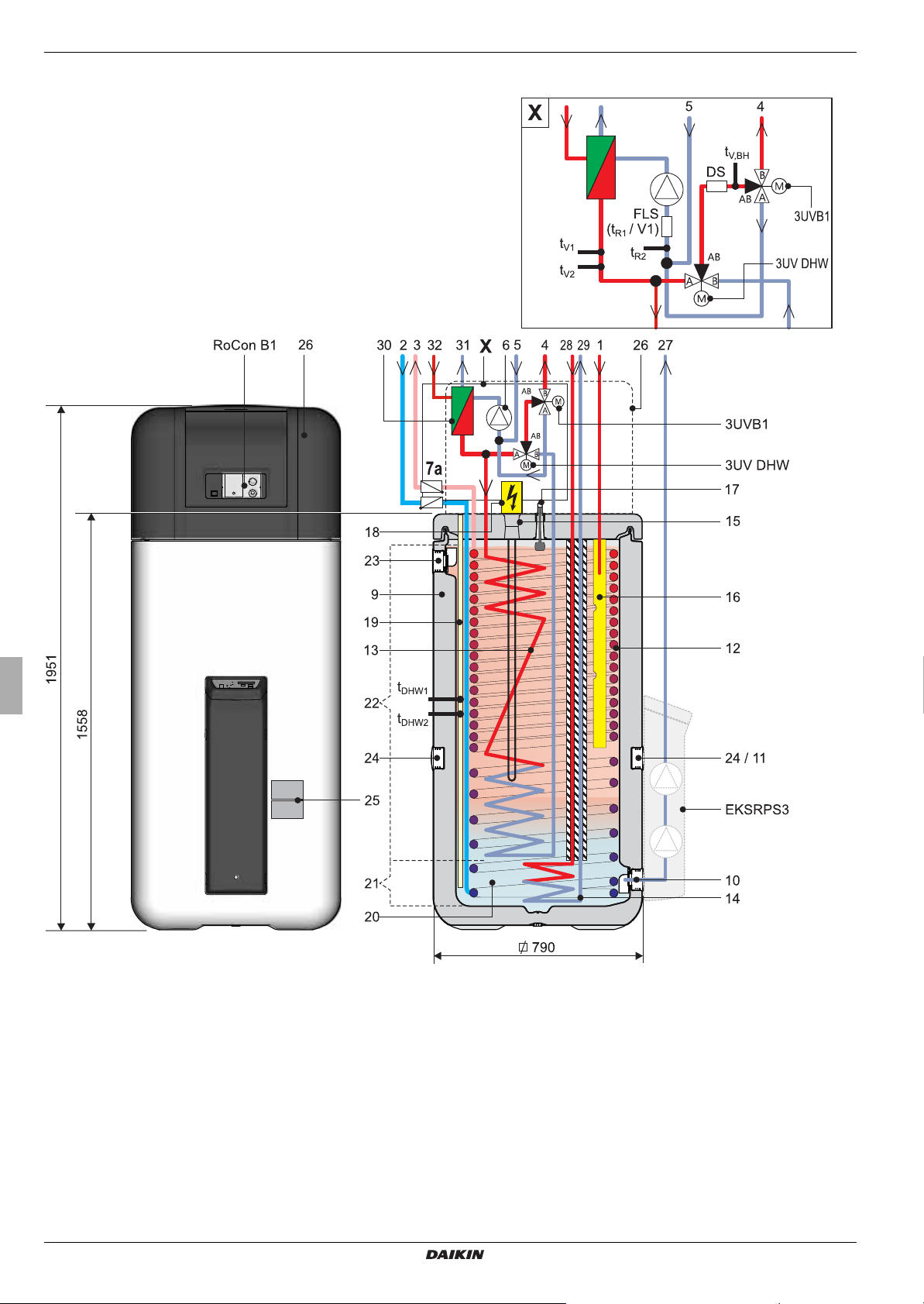

2.1.4 Device external and internal design Daikin Altherma EHS(X/H)...P50A

2 x Product description

Fig. 2-4 Design and components of the Daikin Altherma EHS(X/H)...P50A (external view and internal design)

For legend descriptions see tab. 2 -1

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

9

2 x Product description

2.1.5 Device external and internal design Daikin Altherma EHS(X/H)B...P50A

Fig. 2-5 Design and components of the Daikin Altherma EHS(X/H)B...P50A (external view and internal design)

For legend descriptions see tab. 2 -1

Installation and maintenance instructions

10

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

2 x Product description

1 Solar - flow or connection for addition-

al heat source(1" IG)

2 Cold water flow (1" AG)

3 Hot water flow (1" AG)

4 Heating flow (1" AG)*

5 Heating return (1" AG)*

6 Circulation pump

7a Recommended accessories:

Non-return valves (2 pcs.)

9 Storage tank (double walled jacket made

of polypropylene with PUR hard foam heat

insulation)

10 Filling and drainage connection or

Solar - return flow connection

11 Mount for solar R3 controller or handle

12 Heat exchanger (stainless steel) for drink-

ing water heating

13 Heat exchanger (stainless steel) for stor-

age tank charging or heating support

14 Heat exchanger (stainless steel) for pres-

surised solar storage tank charging

15 Connection for optional electrical backup

heater (R 1½" IG)

16 Solar inflow layering pipe

17 Fill level indicator (tank water)

18 Optional: Electrical backup heater (BUxx)

19 Submersible sensor sleeve for storage

tank temperature sensor t

20 Unpressurised storage tank water

DHW1

and t

DHW2

21 Solar zone

22 Hot water zone

23 Safety overflow connection

24 Mount for handle

25 Type plate

26 Protective cover

27 Solar - return

28 Solar - flow (3/4" IG)

(only type Daikin Altherma EHS(X/H)B)

29 Solar - return flow (3/4" IG)

(only type Daikin Altherma EHS(X/H)B)

30 Panel heat exchanger

31 Liquid-side coolant connection

Daikin Altherma EHS(X/H)

...04P30A/08PxxA:

Cu Ø 6.4 mm (1/4"),

Daikin Altherma EHS(X/H)...16P50A:

Cu Ø 9.5 mm (3/8")

32 Connection to coolant gas line

Cu Ø 15,9 mm (5/8")

3UVB1

3-way diverter valve (internal heat genera-

tor circuit)

3UV DHW

3 way diverter valve (hot water/heating)

DS Pressure sensor

FLS (t

t

/ V1)

R1

Return flow temperature and flow sensor

, t

DHW1

DHW2

Storage tank temperature sensor

tR2Return temperature sensor

t

V1, tV2

Feed temperature sensors

t

V, BH

Flow temperature sensor backup

heater

RoCon B1

Operating section Daikin Altherma

EHS(X/H) control unit

EKSRPS3B

Optional: Daikin R3 solar control and

pump unit

Safety devices

Observe tightening torque!

AG Male thread

IG Female thread

* Ball cock (1" IG) is supplied with the equip-

ment

Tab. 2 -1 Legend from fig 2-2 to fig 2-5

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

11

3 x Set-up and installation

3 Set-up and installation

WARNUNG

Cooling systems (heating pumps), climate control systems and heating devices that have been set up and installed incorrectly can both endanger life and health of people and be impaired in their function.

● Work on the Daikin Altherma EHS(X/H) (such as setup, servicing, connection and initial start-up) is only to be carried

out by persons who are authorised and who have successfully completed qualifying technical or vocational training

and who have taken part in advanced training sessions recognised by the relevant responsible authorities. These

include in particular certified heating engineers, qualified electricians and HVAC specialists, who because of their

professional training and expert knowledge, have experience in the professional installation and maintenance of

heating, cooling and air conditioning systems and heat pumps.

3.1 Dimensions and connections

3.1.1 Daikin Altherma EHS(X/H)...P30A

1 Solar - feed

2Cold water

3 Hot water

4 Heating feed

5 Heating return flow

6 Connection coolant gas line

Fig. 3-1 Connections and dimensions Daikin Altherma EHS(X/H)...P30A (general)

Installation and maintenance instructions

7 Connection coolant fluid line

8 Solar - feed flow (only Daikin Altherma EHS(X/H)(B) type)

9 Solar - return (only Daikin Altherma EHS(X/H)(B) type)

A Front

BBack

12

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

3.1.2 Daikin Altherma EHS(X/H)...P50A

3 x Set-up and installation

1 Solar - feed

2 Cold water

3 Hot water

4 Heating feed

5 Heating return flow

6 Connection coolant gas line

Fig. 3-2 Connections and dimensions Daikin Altherma EHS(X/H)...P50A (general)

7 Connection coolant fluid line

8 Solar - feed flow (only Daikin Altherma EHS(X/H)B type)

9 Solar - return (only Daikin Altherma EHS(X/H)B type)

A Front

BBack

3.1.3 Scope of delivery

– Daikin Altherma EHS(X/H)

– Bag of accessories (see figure 3-3)

A Handles (only required for

B Cover screen

Fig. 3-3 Content of bag of accessories

transport)

C Connection piece for safety

overflow

D Clamping piece

E Fitting spanner

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

13

3 x Set-up and installation

3.2 Set-up

CAUTION!

● Only erect the Daikin Altherma EHS(X/H) when a

sufficient ground load-bearing capacity, of

kg/m² plus safety margin, has been assured.

1050

The ground must be flat and level.

● Outdoor installation is not permitted.

● The electronic control system must not be

subjected to atmospheric factors under any

circumstances.

● The storage tank must not be exposed to

continuous direct sunlight, as the UV radiation

and the effects of the weather will damage the

plastic.

● The Daikin Altherma EHS(X/H) must be installed in

a manner protected from frost.

● Make sure that the supply company does not

provide corrosive domestic water.

– Suitable water treatment may be required.

WARNING!

The plastic wall of the storage tank on the Daikin Altherma EHS(X/H) may melt due to the effects of external heat (> 80 °C) and, in the extreme case, can

catch fire.

● Erect the Daikin Altherma EHS(X/H) only at a

minimum distance of 1 m to other heat sources

80 °C) (e.g. electric heater, gas heater, chimney)

(>

and flammable materials.

CAUTION!

If the Daikin Altherma EHS(X/H) is not erected with

sufficient distance beneath the solar flat collectors

(top edge of storage tank is higher than the lower edge

of the solar panel), the unpressurised solar system in

the outdoor area will be unable to drain completely.

● Erect the Daikin Altherma EHS(X/H) with a

DrainBack solar connection at a sufficient depth to

the flat solar panels (observe the minimum

gradient in the solar connecting lines).

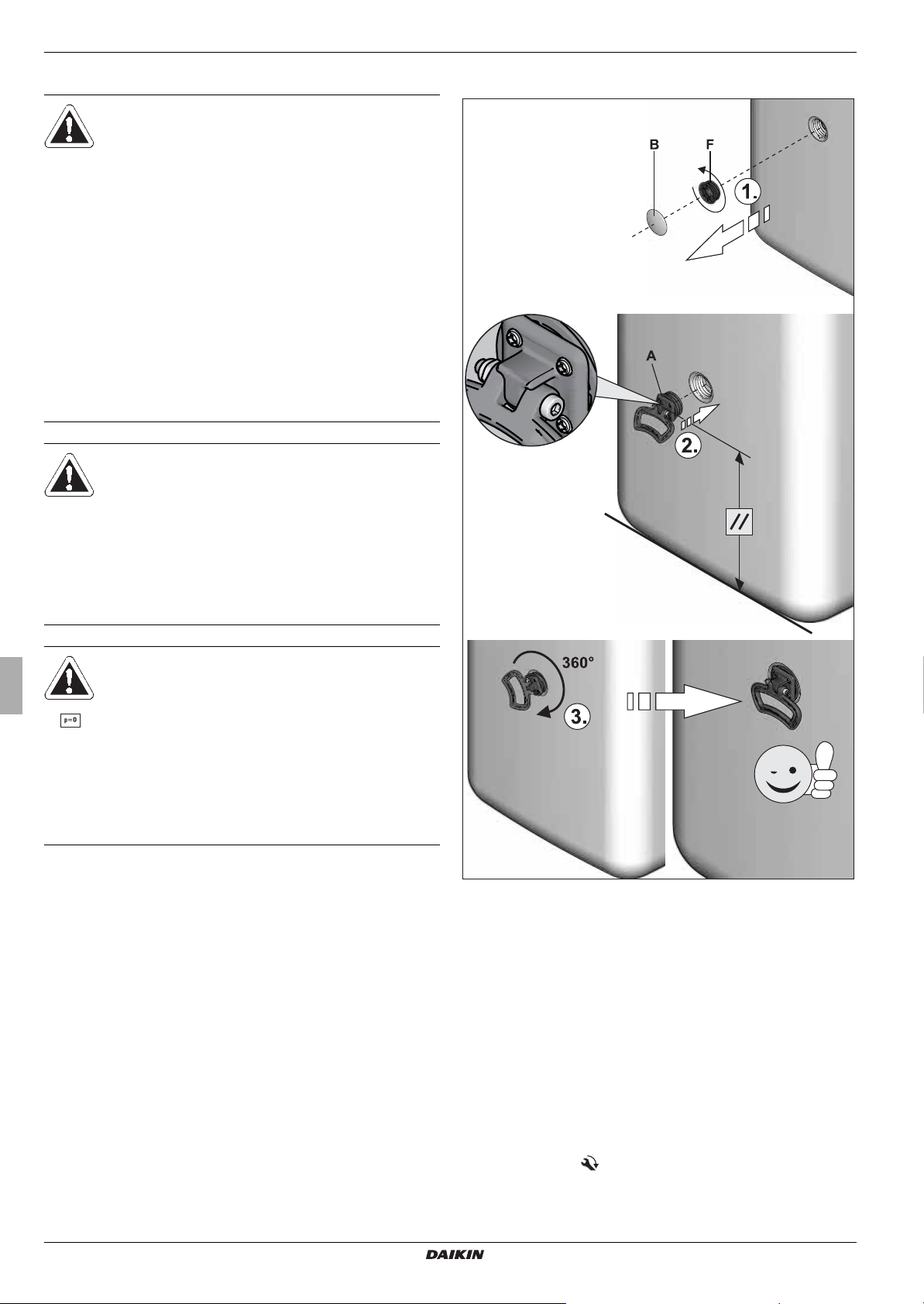

● Remove packing and dispose of it in an environment-friendly

manner.

● Remove the cover plates on the storage tank (figure 3-4,

item B) and unscrew the threaded pieces (figure 3-4, item F)

from the apertures on which the handles are to be mounted

(figure 2-2 to figure 2-5, item 24).

● Screw handles (figure 3-4, item A) into the threaded holes

that are now free.

A Handle

B Cover screen

Fig. 3-4 Attach handles

F Threaded piece

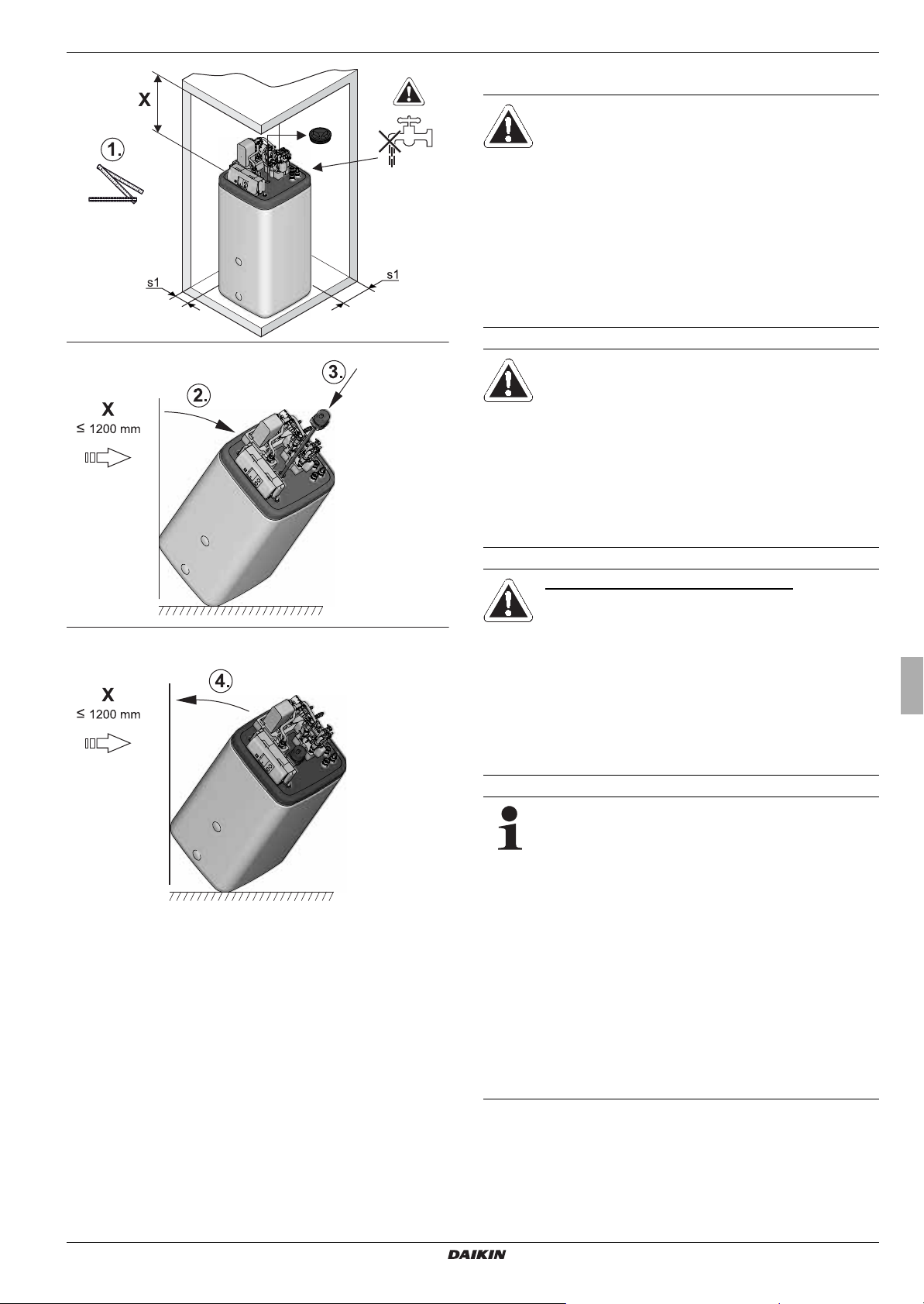

● Install the Daikin Altherma EHS(X/H) at the installation site.

– Recommended clearances (figure 3-5):

From the wall (s1): ≥ 200 mm.

From the ceiling (X): ≥ 1200 mm.

– Carefully transport the Daikin Altherma EHS(X/H), use the

handles.

– When setting up the unit in a cabinet, behind panels or in

other restricted conditions, sufficient ventilation (e.g.,

using ventilation gratings) must be ensured.

● If necessary, install the optional backup heater (EKBUxx) into

the Daikin Altherma EHS(X/H) (

figure 3-5).

Observe the assembly and operating manual supplied with

the accessory ( for tightening torque see chapter 9.3).

Installation and maintenance instructions

14

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

3 x Set-up and installation

3.3 Water connection

CAUTION:

If the Daikin Altherma EHS(X/H) is connected to a

heating system with steel pipes, radiators or non-diffusion-proof floor heating pipes, slurry and swarf could

enter the hot water storage tank and cause

blockages, local overheating or corrosion.

● Flush the feed pipes before filling the heat

exchanger.

● Rinse out the heat distribution network (in the

existing heating system).

● Install the dirt filter or sludge separator into the

heating return flow (see chapter

CAUTION:

If the Daikin Altherma EHS(X/H) is connected to a cold

water line, where steel pipes are used, chips can

enter the special steel corrugated pipe heat exchanger

and remain there. This can lead to contact corrosion

damage and subsequently to leakage.

● Flush the feed pipes before filling the heat

exchanger.

● Install contamination filter in the cold water feed

(see chapter

1.5.5).

1.5.5).

Fig. 3-5 Installation (shown using a Daikin Altherma EHS(X/H)...P50A

with integration of the optional back-up heater)

ONLY DAIKIN ALTHERMA EHS(X/H)B

CAUTION:

If the heat exchanger for charging the pressurised

solar system (figure 3-1/figure 3-2, item 8+9) has an

external heating unit (e.g. wood-burning boiler) con-

nected to it, an excessive flow temperature at these

connections can damage or destroy the Daikin Altherma EHS(X/H)B.

● The feed flow temperature of the external heater

should be limited to max. 95

°C.

In accordance with EN 12828 you must install a safety

valve at or in the immediate vicinity of the heat

exchanger, with which you can limit the maximum per

missible operating pressure in the heating system..

There should be no hydraulic blocking elements

between the heat generator and the safety valve.

Any steam or heating water which may escape must be

diverted by a suitable blow-off line with constant gradient in a frost-protected, safe and observable manner.

A diaphragm expansion vessel of adequate dimensions

and pre-set for the heating system must be connected

to the Daikin Altherma EHS(X/H). There should be no

hydraulic blocking elements between the heat genera

tor and the diaphragm expansion vessel.

Daikin recommends integrating a mechanical manometer for the filling of the heating system.

-

-

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

● For drinking water lines, comply with the EN 806 and

DIN 1988 stipulations.

● Install the Daikin Altherma EHS(X/H) near to the removal

point to dispense with the need for a circulation line. If a circulation line is absolutely essential, it must be installed in

accordance with the schematics in

chapter 8 "Hydraulic

Installation and maintenance instructions

15

3 x Set-up and installation

system connection".

3.3.1 Connecting hydraulic lines

Requirement: Optional accessories (e.g. Solar, backup heater)

mounted on the Daikin Altherma EHS(X/H) according to the

specifications of the instructions included.

● Check cold water pressure (maximum 6 bar).

– At higher pressure in the drinking water line, a pressure

reducer must be installed.

● Establish hydraulic connections at the Daikin Altherma

EHS(X/H).

– Position of the heating connections figure 3-1 / figure 3-2,

Dimensions to be taken from tab. 2 -1.

– Pay attention to the stipulated tightening torque (see

chapter 9.3 "Tightening torque").

– Design the lines as such that the sound attenuation cowl

can be applied without any problem following assembly.

– Connect the water for filling or refilling the heating system

as specified by EN 1717 to avoid contamination of drinking water by backwash.

● Connect the blow-off line to the safety over-pressure valve

and diaphragm expansion vessel in accordance with

12828.

EN

● Carefully insulate pipe lines against heat loss and so as to

avoid the formation of condensation (insulation thickness at

least 20

– Water shortage protection: The pressure and temperature

monitoring of the control unit safely switches off the Daikin

Altherma EHS(X/H) in the event of a water shortage. No addi

tional water shortage protection is needed in the construction.

– Avoid damages caused by deposits and corrosion:

Observe the relevant regulations of technology to prevent

creation of corrosion products and deposits.

Minimum requirements regarding the quality of filling and supplementary water:

– Water hardness (calcium and magnesium, calculated as

– Conductivity: ≤ 2700 μS/cm

– Chloride: ≤ 250 mg/l

– Sulphate: ≤ 250 mg/l

– pH value (heating water): 6,5 - 8,5

In the case of filling and top-up water with a high overall hardness

or other properties that deviate from the minimum requirements,

measures for the desalination, softening, hardness stabilisation

or other suitable conditioning measures are required to maintain

the required water quality.

mm).

calcium carbonate): ≤

3 mmol/l

● Connect the drain hose to the connection piece for the safety

overflow (figure 2-2 to figure 2-5, item 23).

– Use transparent drain hose (draining water must be visi-

ble).

– Connect the drain hose to an adequately dimensioned

waste water installation.

– Drain should not be lockable.

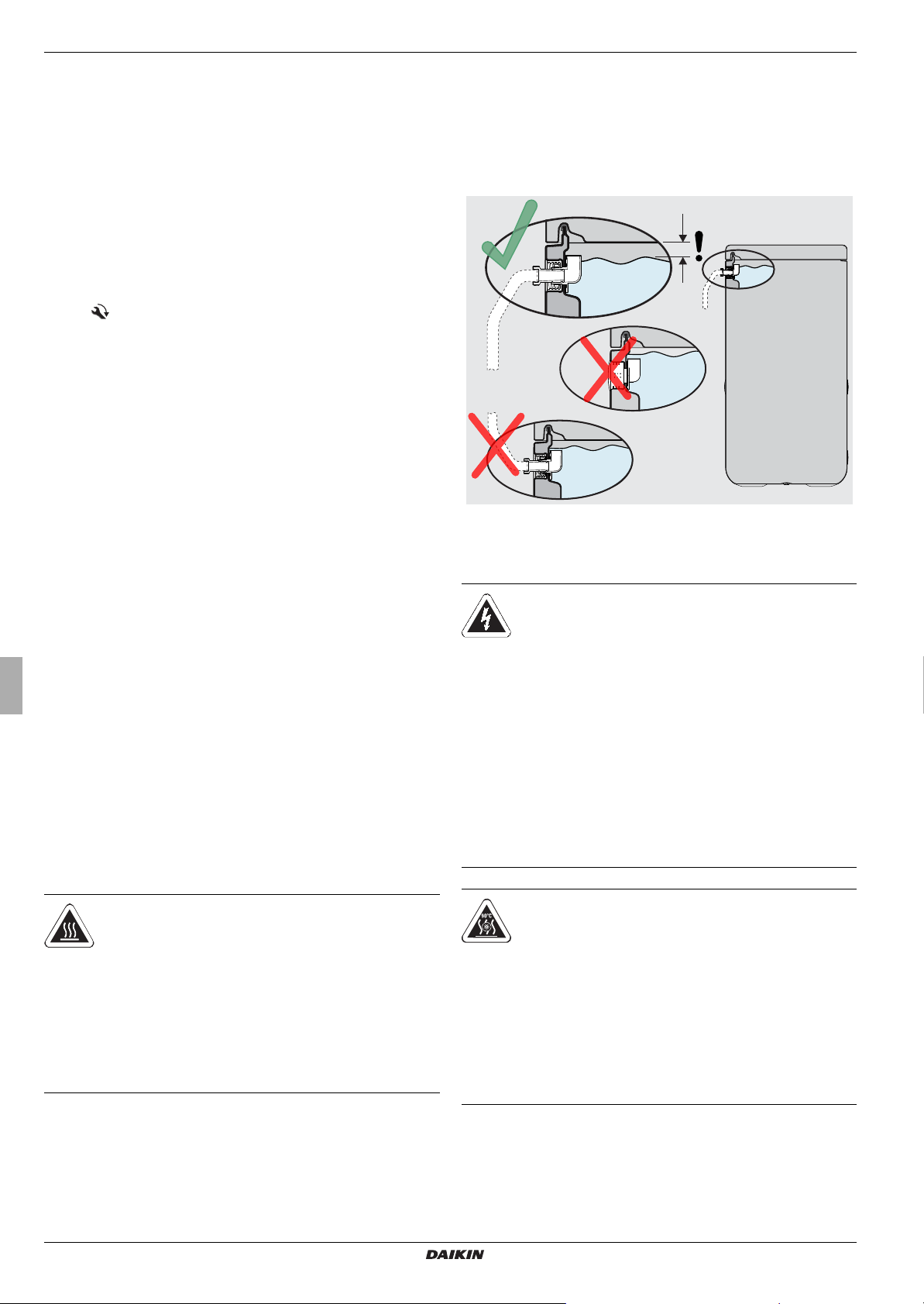

Fig. 3-6 Installation of drain hose at safety overflow

3.4 Electrical connection

-

WARNING!

Touching live parts can result in an electric shock

and lead to potentially fatal injuries and burns.

● Before beginning work on live parts, disconnect

all of the systems circuits from the power supply

(switch off main switch, disconnect fuse) and

secure against unintentional restart.

● The electrical connection and working on the

electrical components should only be performed

by electrical engineers in compliance with valid

standards and guidelines as well as the specifica

tions of the energy supply company.

● The equipment covers and maintenance

opening covers must be re-fitted immediately

after completion of the work.

-

WARNING!

There is a danger of scalding at hot water temperatures over 60 °C. This is possible, when solar energy is

used, with a connected external heating device, when

the Legionella protection is activated or when the domestic hot water target temperature is set higher than

60 °C. Only drain the storage tank container or heating

system

● Install scald protection (hot water mixer (e.g.

VTA32).

Installation and maintenance instructions

16

CAUTION:

Increased temperatures may arise in the control

housing of the Daikin Altherma EHS(X/H) during op

eration. This can result in currently-carrying wires

from reaching higher temperatures during operation

due to self-heating. For this reason, these lines must

have a temperature for continuous use of 90

°C.

● For the following connections, use only cables with

a long-term use temperature ≥ 90 °C:

– Exterior heat pump unit

– Optional: Electrical backup heater (EKBUxx)

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

-

3.4.1 Overall connection plan Daikin Altherma EHS(X/H)

3 x Set-up and installation

Fig. 3-7 Overall connection diagram - for electrical connection during device installation

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

17

3 x Set-up and installation

3.4.2 Position of the circuit boards

1 Control housing

2 Control panel

3 Control unit for the control

Fig. 3-8 Overview circuit boards (internal housing)

For further legend descriptions see tab. 3 -3

3.4.3 Connection assignment, circuit board A1P

The A1P circuit board comes pre-connected to the unit. No assembly or connection work is necessary on the A1P circuit board!

3.4.4 Terminal assignment for the RTX-AL4 circuit board

Fig. 3-10 Circuit board RTX-AL4 (interface)

3.4.5 Terminal assignment for the RTX-EHS circuit board

Fig. 3-9 Circuit board A1P (basic control of the heat pump)

Installation and maintenance instructions

18

Fig. 3-11 Circuit board RTX-EHS (backup heater)

Daikin Altherma integrated solar unit

Daikin Altherma EHS(X/H)

008.1420744 – 08/2014

3.4.6 Connection assignment, circuit board RoCon BM1

3 x Set-up and installation

Fig. 3-12 Circuit board RoCon BM1 (Basic control module)

3.4.7 Mains connection Daikin Altherma EHS(X/H)

A flexible cable for the mains connection is already connected internal to the device.

● Check the supply voltage (~230 V, 50 Hz).

● Disconnect the junction box of the domestic installation.

● Connect the cable for the mains connection on the Daikin

Altherma EHS(X/H) to the junction box of the domestic instal

lation via an all-pole disconnecting main switch to be installed

by the customer (separate isolator according to EN 60335-1).

Ensure that the polarity is correct.

The exterior unit and optional accessories must be connected

separately to the regulator on the Daikin Altherma EHS(X/H). To

do so, the cover panel of the Daikin Altherma EHS(X/H) must be

removed (see section

housing opened (see section 3.4.9).

3.4.8) and, if necessary, the control

Mains supply 230 V, 50 Hz

(Connection plan in this instruction manual)

3.4.8 Removing the protective cover

-

Fig. 3-13 Unscrew/loosen the screws, lift up the cover panel at the back

and pull forwards.

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Installation and maintenance instructions

19

3 x Set-up and installation

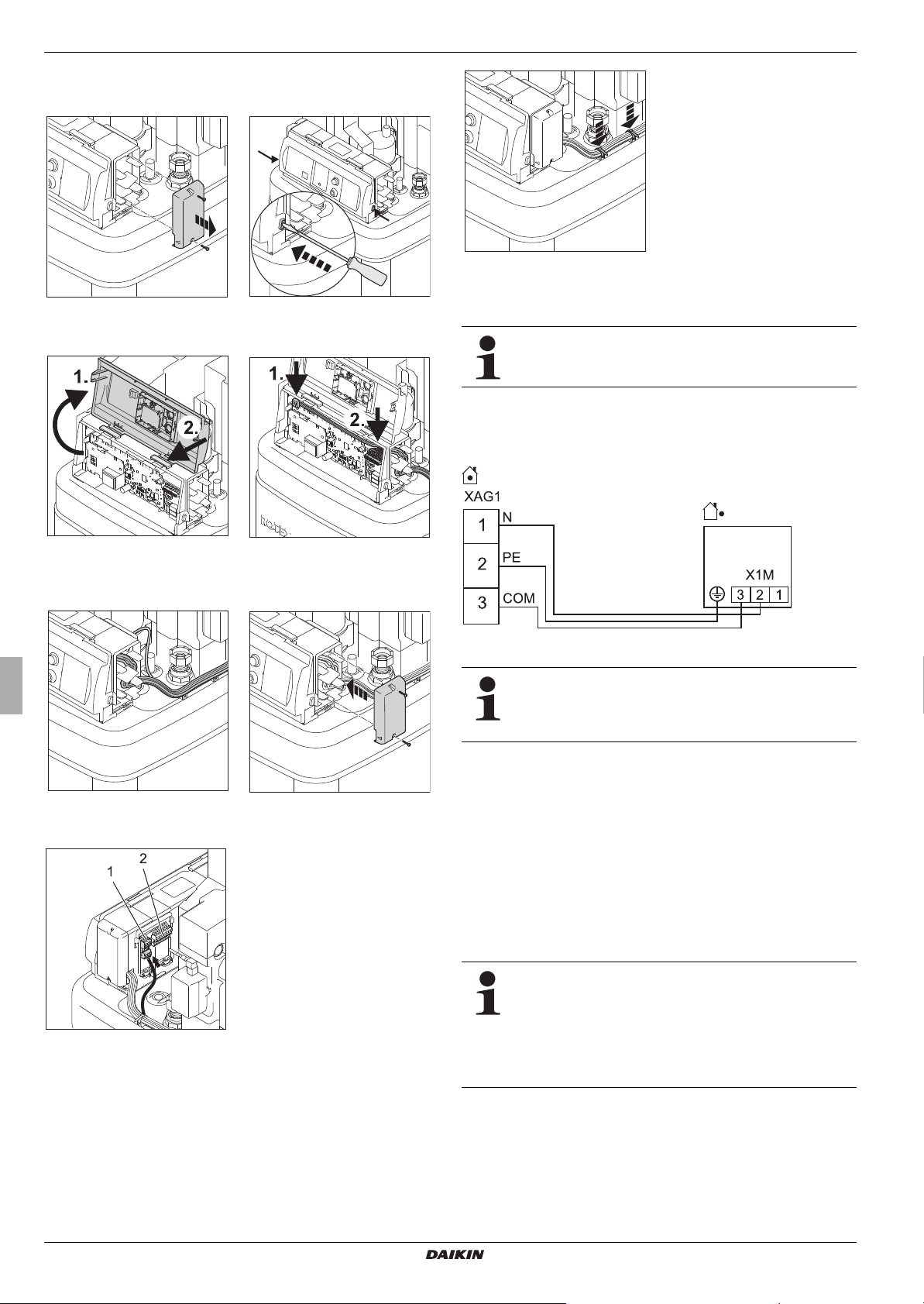

3.4.9 Opening the control housing and establishing electrical connections

Fig. 3-21 Fasten cabling on the storage container.

Fig. 3-14 Dismount right housing

cover.

Fig. 3-16 Open front panel and

place in assembly posi

tion.

Fig. 3-15 Unlock front panel.

Fig. 3-17 Route cabling into the

-

regulator and make the

electrical connections.

3.4.10 Connection of ERLQ exterior heat pump unit

This component has a separate manual attached,

including among other things instructions for installation

and operation.

● Dismount the protective cover (see section 3.4.8).

● Connect the exterior heat pump unit to the terminal strip

XAG1 (see figure 3-20, figure 3-22).

Fig. 3-22 Connection of exterior heat pump unit

When switching off the heat pump exterior unit using a

switching system prescribed by the energy supply company (EVU), the internal Daikin Altherma EHS(X/H)

device is not disconnected (see section

3.4.21).

Fig. 3-18 Lay cables in the right

housing cover.

Fig. 3-20 Make the electrical connections to the rear of the housing (see

section

3.4.1).

Fig. 3-19 Install the right housing

cover.

1 XAG1 Terminal block for exte-

rior unit

2 XBUH1 Terminal block for

backup heater

3.4.11 Connection of external temperature sensor RoCon OT1

The exterior heat pump unit of the Daikin Altherma EHS(X/H) has

a built-in exterior temperature sensor which is used to regulate

the inflow temperature depending on the weather, with frost pro

tection function.

Instead of the exterior temperature sensor built into the exterior

heat pump unit, the optional exterior temperature sensor RoCon

OT1 can also be used to regulate the inflow temperature de

pending on the weather, with frost protection function.

If the Daikin Altherma EHS(X/H) is used in a CAN bus

system as a master ("terminal function" for the remote

control of other data bus devices), the exterior temper

ature sensor RoCon OT1 must be connected directly

to the regulator RoCon HP on the master and not to

the remote controlled device (mixer circuit module

EHS157068 or a different heat generator).

-

-

-

Installation and maintenance instructions

20

Daikin Altherma EHS(X/H)

Daikin Altherma integrated solar unit

008.1420744 – 08/2014

Loading...

Loading...