Page 1

ECFWEB6

ECFWER6

ECFWDER6

INSTALLATION AND

OPERATION MANUAL

Microprocessor controller for fan coils

Page 2

2

3

2

5

1

3 4 5 6 7 8 9

34 5 6 789

2

3

16.5°C 28.5°C

22.5°C

5

3

4

12

2

6 7 8

22

11

91011 12

130

86

9.3

7

19

24

93

4 5

7 86

22

11

105

90

7

0

22

11

2 x (ø5x8)

17.7

7

109

11

12

Page 3

13 16

13 16

14

14 17

15

19

17

19

20

18

15 18

20

21

4

2

21

Page 4

ECFWEB6

ECFWER6

ECFWDER6

T

ABLE OF CONTENTS

Main features .................................................................1

Main functions and equipment....................................... 1

Packing list.............................................................. 2

Control panel ..........................................................2

Temperature range .................................................2

LED indicators ........................................................2

Description of the operating modes........................ 3

Technical data and operation limits ........................5

Possible configurations.................................................. 7

Before installation ..........................................................9

ECFWEB6 installation instructions ................................9

Installation on the support and on the fan coil........9

ECFWER6 + ECFWDER6 installation instructions...... 10

Installation ............................................................10

Setting the microswitches ............................................10

Installing the air and water temperature probes...........11

Position of the air temperature probe ...................11

Position of the water temperature probe...............11

Installing the power contactor ......................................12

Wiring diagrams...........................................................12

Wiring parts table .................................................12

Read this manual attentively before starting up

the unit. Do not throw it away. Keep it in your

files for future reference.

Improper installation or attachment of

equipment or accessories could result in

electric chock, short-circuit, leaks, fire or other

damage to the equipment. Be sure only to use

accessories made by Daikin which are

specifically designed for the use with the

equipment and have them installed by a

professional.

If unsure of installation procedures or use,

always contact your Daikin dealer for advice

and information.

Microprocessor controller

for fan coils

Page

Installation and

operation manual

If options need to be installed, always refer to

the relevant manual of the option for additional

information.

M

AIN FEATURES

This controller is designed to control Daikin fan coil units.

■

ECFWEB6 Built-in for FWV and FWL

■

ECFWER6 Remote for FWV, FWL and FWM

■

ECFWDER6 Remote for FWD

M

AIN FUNCTIONS AND EQUIPMENT

■

Regulation of the air temperature via automatic

variation of the fan speed.

■

Regulation of the air temperature via ON/OFF switch

of the fan at a fixed speed.

■

Time function (only for ECFWEB6).

■

Regulation of the air temperature via control of ON/OFF

valves (on 2-pipe or 4-pipe systems).

■

Control of the electric heater as integration or

replacement of a heating circuit with delayed fan

stopping.

■

Cooling/Heating switching mode in following way:

■

Manual — on the controller

■

Manual — on the remote switch

■

Automatic — based on the water temperature

■

Automatic — based on the air temperature

■

The controller is also equipped with:

■

Free contacts for external enabling signal (i.e.:

reed contact, remote ON/OFF switch, proximity

contact etc.) that may enable or disable the unit.

(Closed contact = OFF; open contact= ON)

■

Free contacts for the centralized cooling/heating

switching system. (Closed contact = cooling,

open contact = heating)

■

Water temperature probe (white)

■

Air temperature probe (black)

Installation and operation manual

1

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 5

Part

(See figure 1)

ECFWEB6 ECFWER6 ECFWDER6

111

integrated in controller

Packing list

1

Controller 1 1 1

2

Manual 1 1 1

3

Cover plate left 1 0 0

4

Cover plate right 1 0 0

5

Support 1 0 0

6

Accessory bag

•wire clamp

•2 screws

•probe holder

7

Water probe 1 1 1

8

Air probe 1

9

Power interface 0 0 1

Control panel

Refer to figure 2 to catch the look of the controller.

1

Operation mode selector, to turn the fan coil on

and off, to choose the type of operating mode

(automatic or at fixed speed) and to control the

electric heating.

2

Operation LED indicating that cooling operation

mode is active (blue).

3

Cooling/Heating selector.

4

Operation LED indicating that heating operation

mode is active (red).

5

Thermostat to control the room temperature.

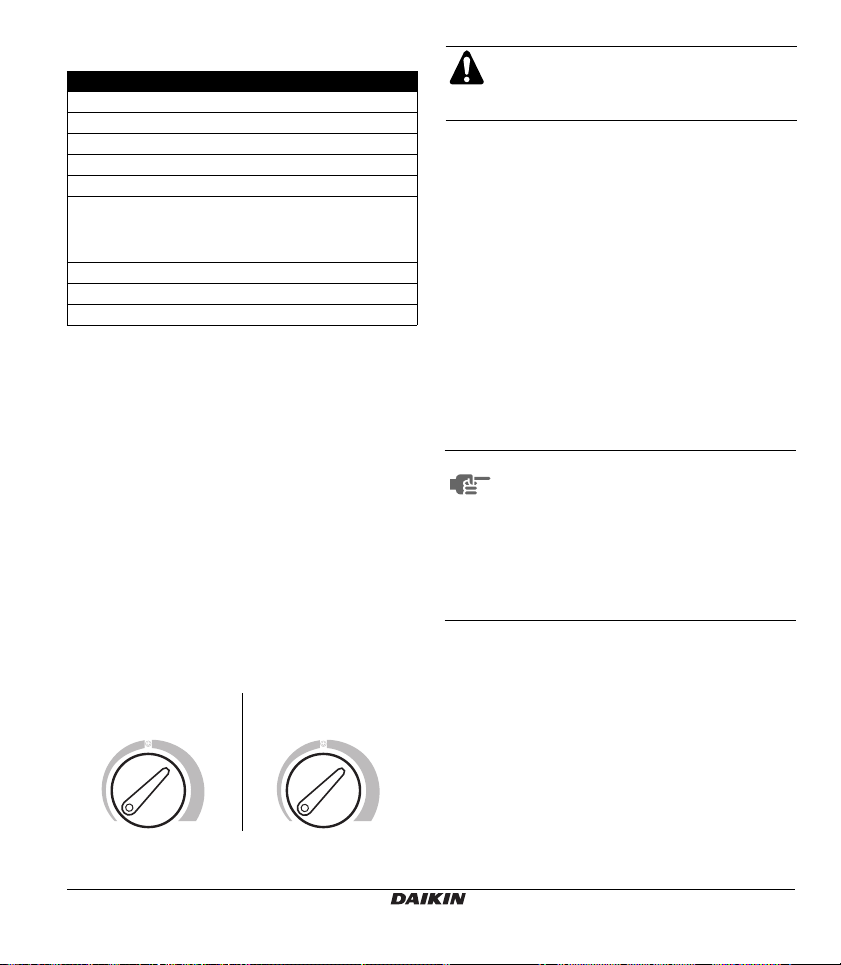

Temperature range

The print around the selector switch of the thermostat

represents temperature ranges from minimum, over

comfort, to maximum. The ranges refer to different

temperatures, depending on the selected operating

mode as illustrated in the figure below.

Cooling mode Heating mode

25°C

19°C31°C

20°C

14°C26°C

When automatic cooling/heating switching

mode based on the air temperature is running,

the temperature of the thermostat is as

illustrated in figure 3.

LED indicators

The various combinations in which the LED lights up

indicate procedures and operating status of the

controller.

■

Blue LED lit

running. The unit is running or waiting for an input

from the thermostat.

■

Red LED lit

running. The unit is running or waiting for an input

from the thermostat.

■

Blue and red LEDs lit

receive an enabling signal. The water temperature

does not enable the air cooling or heating functions

(see "Automatic cooling/heating switching mode

based on the water temperature" on page 3) or the

temperature of the air is within the neutral zone (see

"Automatic cooling/heating switching mode based on

the air temperature" on page 4).

NOTE

■

Double flashing of the blue LED

thermostat has sent an input to the unit for starting

cooling mode. It flashes when the room temperature

and the set cooling temperature are the same.

■

Double flashing of the red LED

thermostat has sent an input to the unit for starting

heating mode. It flashes when the room temperature

and the set heating temperature are the same.

The temperature of the air in the room can be seen at

any time on the thermostat range turning the knob of the

thermostat.

indicates that the cooling mode is

indicates that the heating mode is

indicates that the unit did not

To determine which operating mode is

selected when an enabling signal is

missing (blue and red LEDs are both lit),

turn the knob of the thermostat until one of

the two LEDs starts to flash and then

remains lit. This LED points out the

selected operating mode. Once the

operating mode has been established, turn

the thermostat back to the desired

position.

means that the

means that the

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

Installation and operation manual

2

Page 6

Description of the operating modes

D

O

Room thermostat with air temperature control

With the speed selector switch turned to , the fan

speed is switched automatically based on the difference

between the temperature set on the thermostat and the

room temperature.

With the selector switch turned to , , or the

ventilation mode is of the ON/OFF type.

Room thermostat with ON/OFF valve control for

2-pipe systems

With the speed selector switch turned to , the fan

speed is switched automatically based on the difference

between the temperature set on the thermostat and the

room temperature.

With the selector switch turned to , , or the

ventilation mode is of the ON/OFF type.

The water valve is shut off once the desired temperature

is reached

In cooling mode the fan continues at minimum speed,

even after the valve of the cooling circuit has shut off.

In heating mode the fan is stopped as soon as the valve

of the heating circuit is shut off.

Room thermostat with ON/OFF valve control for

4-pipe systems

Manual built-in cooling/heating switching mode

M

The controller is pre-arranged to operate manually in the

desired mode. It is enabled by pressing the selector key.

The blue (cooling) and red (heating) LEDs point out the

selected operating mode.

Manual remote cooling/heating switching mode

M

The controller is pre-arranged to operate manually and

remotely in the desired mode. This mode is carried out

by connecting the system to a remote switch. Use the

special terminals on the electronic PCB of the controller.

Automatic cooling/heating switching mode

based on the water temperature

H

2

The controller automatically selects the cooling or

heating mode based on the temperature of the water and

according to the following logic:

Water temperature <17°C — cooling mode is set

Water temperature >37°C — heating mode is set

Water temperature between 17°C and 37°C — the

system is disabled

For switching based on water temperature, the

supplied water probe needs to be installed.

See chapter "Position of the water temperature

probe" on page 11 for installation of the water

temperature probe.

With the speed selector switch turned to , the fan

speed is switched automatically based on the difference

between the temperature set on the thermostat and the

room temperature.

With the selector switch turned to , , or the

ventilation mode is of the ON/OFF type.

The water valve is shut off once the desired temperature

is reached

In cooling mode the fan continues at minimum speed

even after the valve of the cooling circuit has shut off.

In heating mode the fan is stopped as soon the valve of

the heating circuit is shut off.

Installation and operation manual

3

4PW17551-1

In this type of configuration, the input for the

centralised cooling/heating switching mode is

disabled.

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 7

Automatic cooling/heating switching mode

R

21

based on the air temperature

AI

The controller selects the cooling or heating mode based

on the temperature of the air compared to a neutral

temperature interval (neutral zone) centred on the set

value of the thermostat.

When this function is selected, the

temperature range of the thermostat refers to

the values indicated in figure 3, both for

cooling and for heating.

In this type of configuration, the input for the

centralised cooling/heating switching mode is

disabled.

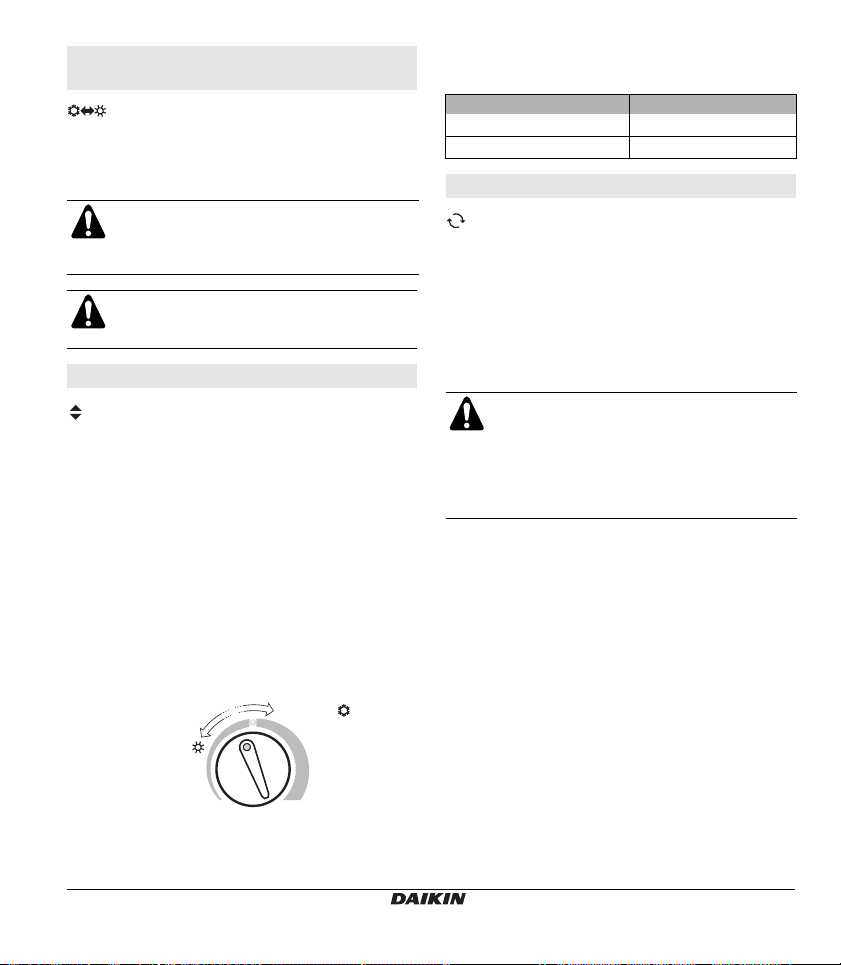

Selecting the range of the neutral zone

The neutral zone is a parameter related to the function

"automatic cooling/heating switching mode based on the

air temperature".

The neutral zone is a temperature interval astride the set

temperature. When the air is warmer than the top limit of

the neutral zone, the cooling mode is selected.

When the air is cooler than the lower limit of the neutral

zone, the heating mode is selected.

The following figure illustrates an example with:

Neutral zone = 5°C

Set room air temperature = 21°C

For temperatures above 23.5°C the cooling operating

mode is selected

For temperatures below 18.5°C the heating operating

mode is selected.

Neutral zone

<18.5°C =

>23.5°C =

21

°C21°C

On the controller, the range of the neutral zone is 2°C or

5°C and can be defined by setting microswitch number 4

(see "Setting the microswitches" on page 10).

Position of microswitch no. 4

Range of the neutral zone

ON 2°C

OFF 5°C

Time function

The time function is used to start the fan at medium

speed for 2 minutes at regular intervals (every 10

minutes) once the room temperature has reached the

level as set on the thermostat. It ensures the constant

monitoring of the air temperature in the room. It is only

used in summer and only if the enabling signal of the

water temperature probe is positive.

The time function cycle is also executed when the

controller is powered (first start-up or voltage reset).

The thermostat and the operating mode

selector switch are disabled when the time

function is in use.

The time function can be used only for units

without valves and only in summer.

The time function is not foreseen for the

ECFWER6 and ECFWDER6 versions.

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

Installation and operation manual

4

Page 8

Electric heater control

The thermostat controls an electric heater as integration

or replacement of a hot water heating system.

When the operating mode selector switch is turned

to and the electric heater is turned on, the fan runs

continuously at medium speed.

For safety reasons, the fan is turned off 2 minutes after

the electric heater is turned off, whether this occurs

when the desired air temperature is reached or when the

electric heater is turned off manually using the operating

mode selector.

■

During operation of the electric heater, the

fan runs at medium speed only.

■

During heating operation of 2-pipe system

units equipped with an electric heater and

motorised valves, only the electric heater

works.

Fan coil enabling system based on the water

temperature

The controller starts the unit according to the following

logic based on the water temperature that is detected by

a dedicated probe:

■

Water temperature <17°C: Cooling mode enabling

signal

■

Water temperature >37°C: Heating mode enabling

signal

In installations with electric heater control, the same

probe sends the enabling signal for the electric heater to

turn on according to the following logic:

■

Water temperature <37°C: Additional electric heater

enabling signal. (This enabling signal is sent only if

the operating mode selector switch is turned

to ).

■

Water temperature >39°C: The additional electric

heater is switched off.

For switching based on water temperature, the

supplied water probe needs to be installed.

See "Position of the water temperature probe"

on page 11 for installation of the water

temperature probe.

Technical data and operation limits

Warehouse temperatures –40°C~85°C

Operation temperatures 0°C~40°C

Accuracy of temperature probes ±0.5°C

Maximum current on terminal V1, V2

and V3 (fan speed)

Maximum current on terminal R and

V (valve and electric heater)

1.1 A

0.15 A

Installation and operation manual

5

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 9

NOTES

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

Installation and operation manual

6

Page 10

P

D

O

R

OSSIBLE CONFIGURATIONS

In this chapter we describe all possible configurations

(C1➞C18) for controlling the unit.

Select the configuration that best complies to the system

characteristics. Possible functions are combined in

various configurations and are defined by setting the

microswitches on the electronic PCB accordingly. Refer

to "Installation on the support and on the fan coil" on

page 9 and to "Setting the microswitches" on page 10.

To find the relation of the system characteristics with the

correct wiring diagram and the correct setting of the

microswitches to be used in function of the desired

control, combine the table on page 8 with the table at the

very end of this manual.

This table lists the following items for all possible

configurations:

■

activated functions

Room thermostat with air

temperature control

Room thermostat with ON-OFF

valve for 2-pipe systems

Room thermostat with ON-OFF

valve for 4-pipe systems

M

M

H

2

AI

Manual built-in cooling/heating

switching mode

Manual remote cooling/heating

switching mode

Automatic cooling/heating switching

mode based on the water

temperature

Automatic cooling/heating switching

mode based on the air temperature

Choice of the range of the neutral

zone

Operational enabling signal based

on the water temperature

Time function (not available for

ECFWER6 + ECFWDER6)

Electric heater control

■

system characteristics

Number of pipes (2 or 4)

Valve (✔ = present, — not present)

Electric heater (✔ = present, — not

present)

■

position of the microswitches

■

corresponding controllers

■

relevant reference to dedicated wiring diagram

()

■

other conventions for complete understanding of the

table:

with a number of units in parallel

1~ 1 phase

3~ 3 phase

Installation and operation manual

7

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 11

Characteristics List of functions activated

O

C1

Standard two pipe system

C2

Tw o pipe system – Remote switching mode

C3

Tw o pipe system – One valve

C4

Tw o pipe system – One valve – Remote switching mode

C5

Four pipe system – Two valves

C6

Four pipe system – Two valves – Remote switching mode

C7

Four pipe system

C8

Four pipe system – Remote switching mode

C9

Tw o pipe system – Electric heater

C10

Tw o pipe system – Electric heater – Remote switching mode

C11

Tw o pipe system – One valve – Electric heater

C12

Tw o pipe system – One valve – Electric heater – Remote

switching mode

C13

Tw o pipe systems – Automatic switching on water side

C14

Tw o pipe systems – One valve – Automatic switching mode on

water side

C15

Four pipe systems – Automatic switching on air side

C16

Four pipe systems – Two valves – Automatic switching on air

(b)(c)

side

C17

Tw o pipe systems – Electric heater – Automatic switching mode

on air side

C18

Tw o pipe systems – One valve – Electric heater – Automatic

switching mode on air side

(a) Electric heater control: during heating operation only the electric heater works

(b) In this type of configuration, the input for the centralised cooling/heating switching mode is disabled.

(c) For configurations with automatic cooling/heating switching mode based on the air temperature in cooling mode, the fan stops

when the valve shuts off. The enabling signal refers to heating mode only (the water probe is placed on the hot water branch.)

Cooling mode (fan) is always enabled apart from the water temperature (there is only one water temperature probe that is used

to avoid the fan from running with cold water inside the heat exchanger).

(a)

(b)

(b)

(a)(b)

(a)

(b)

(b)

M

MD

M

MD

M

MD

M

MD

M

MD

M

MD

H2O

H

2

AIR

AIR

AIR

AIR

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

Installation and operation manual

8

Page 12

BEFORE INSTALLATION

■ All field wiring and components must be

installed by a licensed electrician and must

comply with relevant local and national

regulations.

■ Before obtaining access to terminals, all

power circuits must be interrupted.

ECFWEB6 INSTALLATION INSTRUCTIONS

Built-in type controller

The controller has been specially designed for

FWV and FWL units; if used to control other

units, make sure its operation limits are

respected.

Installation on the support and on the fan coil

It is advisable to set the microswitches before installing

the controller, see paragraph "Setting the microswitches"

on page 10.

The controller can be installed on both sides of the unit

using a support and a cover plate.

Proceed as follows to install the controller.

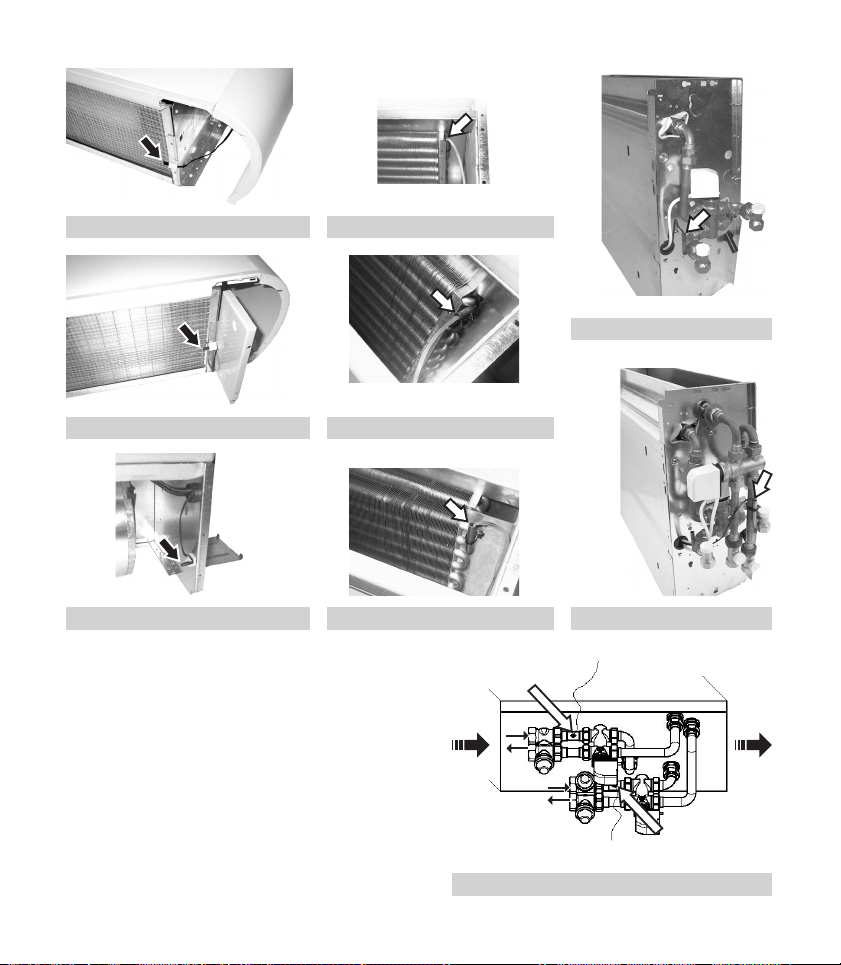

1 Unscrew the four screws hidden behind the hatches

at the end of the grid and remove the fan coil cabinet

(See figure 6).

2 Remove the blank plastic tabs from one of the two

slots of the support to be able to reach the "fast-on's"

of the controller (see figure 4). (The supplied cables

with fast-on's will need to pass through one of the

slots of the support, depending on whether the

controller is to be installed on the right hand or left

hand side of the unit).

1 Support

2 Blank tabs

3 Feed the cables of the probes if any, in one of the

slots of the support and secure the support and

controller together using the two screws supplied.

(See figure 10, it illustrates the installation of the

support and controller when the controller is to be

installed on the right hand side of the unit. If the

controller is to be installed on the left hand side of the

unit, the support is to be turned by 180° compared to

the drawing).

Ensure that all terminals required for the

electrical connections foreseen in the

configuration chosen (valve, electric heater,

external contacts, ...) can be accessed, even

after the support has been installed (see the

correct wiring diagram). If this is not the case,

remove the protective blank tabs from the

base of the support first.

4 Complete all electrical connections according to the

wiring diagrams.

5 Once the electrical connections have been

completed, it is advisable to execute the

autodiagnosis procedure to verify functioning of all

outputs before you finish installation of the controller

(outputs of the fan at various speeds, of the valves

and electric heaters if installed): Refer to the

paragraph "Installing the air and water temperature

probes" on page 11.

6 Assemble the controller-support unit on the fan coil

using the bayonet fittings (see figure 11).

7 Install the air temperature probe (black) and water

temperature probe (white) (see figures 13 unto 20)

following the instructions given in the paragraph

"Installing the air and water temperature probes" on

page 11.

8 Fit the cabinet back in place fix it with the four screws

and then insert the correct cover plate, as illustrated

in figure 12.

Installation and operation manual

9

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 13

ECFWER6 + ECFWDER6 INSTALLATION

INSTRUCTIONS

Remote type controller

Installation

It is advisable to set the microswitches before installing

the controller, see paragraph "Setting the microswitches"

on page 10.

The remote controller can be installed to a wall.

Proceed as follows to fit the controller.

1 Remove the controller lock screw and remove the

cover.

To facilitate its re-installation, be careful not to

modify the position of the 2 rotating knobs on

the controller cover (operating mode selector

switch and thermostat) and of the

corresponding potentiometers fit on the

electronic PCB.

2 Drill 2 holes in the wall where the controller shall be

installed, at the exact same position of the fixing slots

(5 x 8 mm) located on the control base (see figure 9).

3 Make the electric connections to the control terminal

board according to the wiring diagram of the selected

configuration.

4 By means of screws, fix the control base to the wall.

5 Reassemble the control cover part and make sure

the rotating knobs are in the same position as they

were upon disassembly. Secure the controller lock

screw back into place again.

6 Make the electric connections to the unit according to

the wiring diagram of the selected configuration.

When installing the ECFWDER6 controller,

always install the supplied power contactor

(see "Installing the power contactor" on

page 12).

SETTING THE MICROSWITCHES

1 Unscrew the controller lock screw from the bottom

side of the controller. Remove the front panel of the

controller.

To facilitate its re-installation, be careful not to

modify the position of the 2 rotating knobs on the

controller cover (operating mode selector switch

and thermostat) and of the corresponding

potentiometers fit on the electronic PCB.

2 Arrange the microswitches in the sequence

corresponding to one of the configurations explained

(see "Possible configurations" on page 7).

List of microswitches and their functions

(See figure 7)

Micros

witch

number

Function

cooling/heating

1

switching

cooling/heating

2

switching

automatic cooling/

heating switching

3

mode based on the

temperature of the

range of the neutral

zone for the automatic

4

cooling/heating mode

based on the air

temperature

valve presence on

5

hydraulic circuit

electric heater

6

presence

number of pipes of

7

the hydraulic circuit

Position

OFF ON

controller remote

manual automatic

air water

5°C 2°C

— ✔

— ✔

24

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

if the desired configuration does not include

the electric heaters control function and the

operating mode selector switch is turned to the

electric heater symbol, the fan coil will

continue to run with an automatic fan speed

and will regulate the air temperature by means

of the fan.

Installation and operation manual

10

Page 14

INSTALLING THE AIR AND WATER

TEMPERATURE

Position of the air temperature probe (black)

This chapter is valid for ECFWEB6 controllers only (FWV

and FWL units). For ECFW(D)ER6 controllers, the probe

is integrated in the controller itself.

Use the plastic adhesive probe-holder supplied with the

controller.

Refer to the following figures for installing the air probe:

■ Unit without supporting feet (figure 13)

■ Unit with supporting feet (figure 14)

■ Unit with front air intake (figure 15)

Position of the water temperature probe

(white)

NOTE

PROBES

■ The standard wires connected to the

water probe (1.5 m) are not shielded.

These wires are only intended to be

used inside the unit and need to be

installed away from the power supply

cable. Always use shielded cable if the

water probe wires can not be installed

away from the power supply cables.

■ The water probe cable can be

shortened if required.

■ Always use shielded cable to lengthen

the water probe cable.

■ The specifications of the shielded

cable are as follows:

- maximum length: 100 m

- minimum section: 0.5 mm

- the shield must be connected to

of the basic unit. Do not

connect the shield on the

controller side in order to avoid

electromagnetic interference.

■ For the electrical connection, refer to

the appropriate wiring diagram.

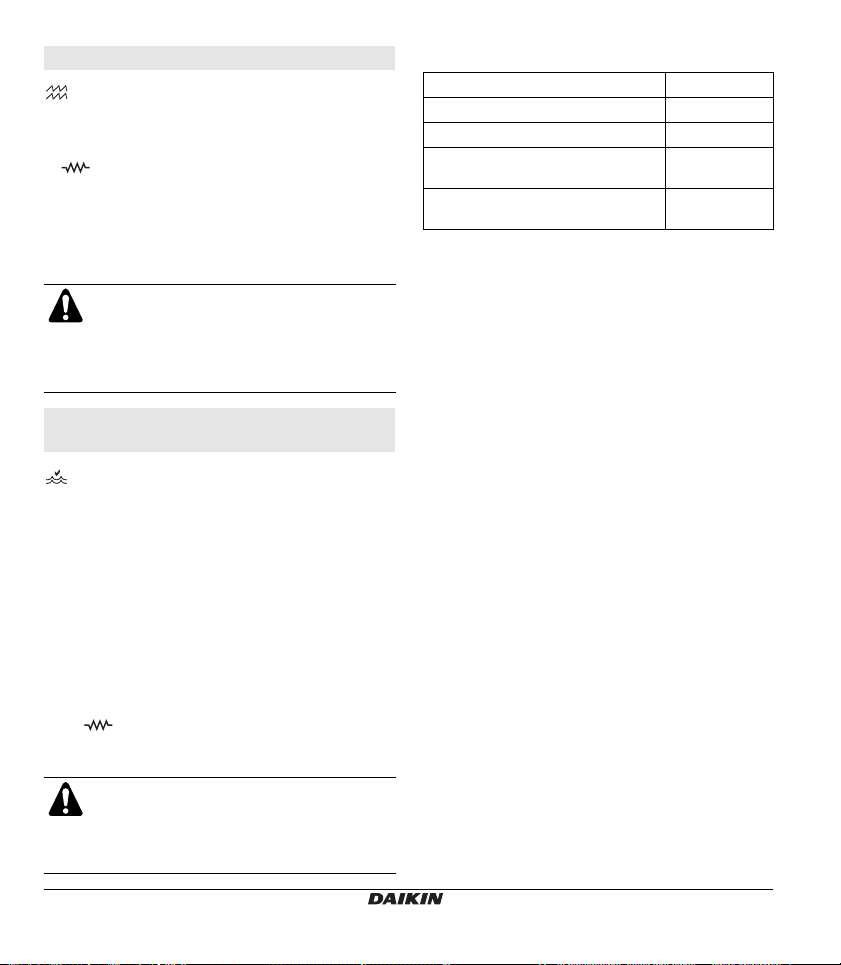

2

Position for FWV FWL FWM

Use the special copper probe-holder for the water

temperature probe and install it as described below.

■ For 2-pipe system units without valve, the water

temperature probe has to be placed on the heat

exchanger (see figure 16 and figure 17).

■ For 4-pipe system units without valve, the water

temperature probe has to be placed on the heat

exchanger of the heating circuit. (See figure 18)

■ For 2-pipe system units with valve, the water

temperature probe has to be placed on the valve inlet

(on the branch coming from the system). (See

figure 19).

■ For 4-pipe system units with valve, the water

temperature probe has to be placed on the heating

valve inlet (on the branch coming from the circuit).

(See figure 20).

Position for FWD

■ Valve fit on the left side, see figure 21.

4 Water probe for 4-pipe system

2 Water probe for 2-pipe system

Direction of the air

Direction of the waterflow

For 2-pipe system FWD units without valve,

the water probe has to be placed on the inlet

pipe of the heat exchanger.

For 4-pipe system FWD units without valve,

the water probe has to be placed on the inlet

pipe of the heating circuit heat exchanger.

Installation and operation manual

11

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 15

INSTALLING THE POWER CONTACTOR

This chapter is valid for FWD units only

The power interface permits to use ECFWDER6

microprocessor-based control panels on the whole range

of FWD units, even for models with current consumption

greater than 1 A.

The capacity of the power interface contacts is 16 A,

IP 30 rating.

Always install the power contactor.

Dimensions of the power interface are shown in figure 8.

Install the supplied DIN guide at the side of the FWD

unit, on the side opposite the hydraulic fittings. (See

figure 5).

Fit the power interface into place on the DIN guide.

Make the electrical connections according to the wiring

diagram.

WIRING DIAGRAMS

Once the configuration of the controller has been chosen

amongst those listed in the section "Possible

configurations" on page 7, combine the table on page 8

with the table at the very end of this manual to find the

wiring diagram indicated for the desired solution. The

wiring diagrams can also be found at the end of this

manual.

Each unit requires a switch (IL) on the power supply line

with a distance of at least 3 mm between the opening

contacts, and a suitable safety fuse (F).

Wiring parts table

V1.......... Minimum speed

V2.......... Medium speed

V3.......... Maximum speed

L............ Phase

PE ......... Earth

N ........... Neutral

RE......... Electric heater

V............ Valve

RM ........ Remote control

EX ......... Auxiliary contact

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

4PW17551-1

SW........ Water probe

SA......... Air probe

BK......... Black (maximum speed)

BU......... Blue (medium speed)

RD......... Red (minimum speed)

WH........ White (common)

BR......... Brown

GNYE.... Green/yellow

BL ......... Clear blue

F............ Fuse (field supply)

IL........... Line switch (field supply)

CN......... Wire terminal

RHC...... Remote cooling/heating selector switch

EXT....... External auxiliary contact

CRHC ... Centralised remote cooling/heating selector

EPIMSA6.

IPM ....... Power interface for FWD units

M........... Fan coil motor

VHC ...... Solenoid valve

VC......... Cooling solenoid valve

VH......... Heating solenoid valve

TSA....... Automatic safety thermostat

TSM ...... Safety thermal fuse

SC......... Cabling box

The code of the terminals on ECFWEB6 controllers can

be found on the rear side of the plastic support.

(closed contact = cooling;

open contact = heating) (field supply)

(closed contact = OFF; open contact = ON)

switch

Power interface for the control of 4 fan coils

.......... Ground

.... Electrical connections to be made by the

installer

.... Part of diagram valid only for the centralised

remote Cooling/Heating selector switch

(CRHC)

Installation and operation manual

12

Page 16

AUTODIAGNOSIS PROCEDURE

For checking the correct operational efficiency of the

controller when installing or for searching for possible

faults, all outputs can be operated manually (fan, valves,

electric heater) thanks to the autodiagnosis mode.

Proceed as follows to access the autodiagnosis mode

and to run the tests

1 Tu rn the operating mode selector switch to the "OFF"

position.

2 Tu rn the knob of the thermostat anti-clockwise until it

reaches the minimum temperature position.

3 Hold the cooling/heating selector pushed for at least

5 seconds. At this stage both LEDs light up.

4 Within 5 seconds, turn the knob of the thermostat

clockwise to the maximum temperature position. The

red LED switches off and the blue LED remains lit to

indicate that the autodiagnosis mode has been

accessed.

NOTE

If you wait more than 5 seconds before

turning the knob again, the autodiagnosis

mode will be automatically exited.

5 In the autodiagnosis mode, each position of the

operating mode selector switch corresponds to the

simulation of an output.

Position Output Terminals

Valve N-V

Minimum speed N-V1

Medium speed N-V2

Maximum speed N-V3

Electric heater

or second valve

N-RE

By running through the various positions of the

operating mode selector switch, the electronic

controller outputs can be checked one after the other

either by observing the related component (valve,

fan, electric heater) or by checking if the

corresponding terminals are powered at a voltage of

230 V.

NOTE

If the operating mode selector switch is not

moved for more than one minute, the

autodiagnosis mode is automatically

exited.

6 Exit the autodiagnosis mode by turning the operating

mode selector switch to the position.

Installation and operation manual

13

4PW17551-1

ECFWEB6+ECFWER6+ECFWDER6

Microprocessor controller for fan coils

Page 17

ECFWEB6

SA

1

ECFWEB6

SA

CRHC

L

N

L

N

2

ECFWEB6

SA

3

SW

SW

230V 1~ 50Hz

230V 1~ 50Hz

SW

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

FC66000633

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

IL

F

IL

F

FC66000634

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

FC66000635

CN

WH

4

BK

BU

RD

ILF

ILF

230V 1~ 50Hz

M

1~

CRHC

L

230V 1~ 50HzN

L

N

5

6

7

BR

L

BL

N

RHC

RM

EXT

RM

ECFWEB6

RM

RM

ECFWER6

3TW60016-1

CN

WH

4

BK

M

BU

1~

RD

WH

BK

M

BU

1~

RD

WH

BK

M

BU

1~

RD

WH

BK

M

BU

1~

RD

RHC

RM

RM

ECFWEB6

EXT

RM

RM

ECFWER6

2

C

3

1

4

2

5

3

13 L

14 N

15 L

16 N

EPIMSA6

POWER RELAY

3A 250V ~

POWER RELAY

3A 250V ~

POWER RELAY

3A 250V ~

5

6

7

L

22

19

4

20

21

26

23

3

24

25

30

27

2

28

29

34

31

1

32

33

N

CN

4

5

6

7

L

N

CN

4

5

6

7

L

N

CN

4

5

6

7

L

N

3TW60016-2

CN

WH

4

BK

M

5

BU

6

1~

RD

7

ILF

L

N

RHC

L

N

230V 1~ 50Hz

ILF

230V 1~ 50Hz

CRHC

L

N

VHC

BR

BL

RM

EXT

RM

ECFWEB6

RM

RM

ECFWER6

3TW60016-3

Page 18

ECFWEB6

4

ECFWEB6

SA

5

ECFWEB6

SA

6

SW

SW

SW

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

FC66000636

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

FC66000637

BK

V3

BU

V2

RD

V1

BR

L

GNYE

PE

WH

N

BL

N

RE

V

RM

RM

EX

EX

FC66000638

VCSAVH

VC

EXT

EXT

TSA

2

048

TS TS

EXT

TSA

2

048

TS TS

CN

WH

4

BK

M

BU

1~

RD

ILF

L

N

230V 1~ 50Hz

RHC

ILF

230V 1~ 50Hz

CRHC

L

N

RM

RM

ECFWEB6

BR

BL

RM

RM

ECFWER6

5

6

7

L

N

3TW

BK

BU

M

RD

1~

WH

RHC

RM

RETSM

61

SC

NLN

L

RM

ECFWEB6

RM

RM

ECFWER6

ILF

230V 1~ 50Hz

ILF

230V 1~ 50Hz

CRHC

L

N

L

N

3TW

BK

BU

M

RD

1~

WH

RHC

RM

RETSM

61

SC

NLN

L

RM

ECFWEB6

RM

RM

ECFWER6

ILF

230V 1~ 50Hz

ILF

230V 1~ 50Hz

CRHC

L

N

L

N

3TW

Page 19

ECFWER6

SA

SW

7

FC66000627

ECFWER6

SA

SW

CRHC

L

N

230V 1~ 50Hz

L

N

230V 1~ 50Hz

FC66000628

8

ECFWER6

SA

SW

9

FC66000629

CN

RM

RM

ECFWER6

WH

4

BK

5

6

7

L

N

M

BU

1~

RD

ILF

L

N

230V 1~ 50Hz

RHC

ILF

230V 1~ 50Hz

CRHC

L

N

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

EXT

RM

RM

ECFWEB6

3TW60026-1

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

IL

IL

RHC

F

F

RM

RM

ECFWEB6

EXT

RM

RM

ECFWER6

2

C

3

1

4

2

5

3

13 L

14 N

15 L

16 N

EPIMSA6

POWER RELAY

3A 250V ~

POWER RELAY

3A 250V ~

POWER RELAY

3A 250V ~

22

19

4

20

21

26

23

3

24

25

30

27

2

28

29

34

31

1

32

33

CN

WH

4

BK

5

6

7

L

N

CN

4

5

6

7

L

N

CN

4

5

6

7

L

N

CN

4

5

6

7

L

N

M

BU

1~

RD

WH

BK

M

BU

1~

RD

WH

BK

M

BU

1~

RD

WH

BK

M

BU

1~

RD

3TW60026-2

CN

RM

RM

ECFWER6

WH

4

BK

5

6

7

L

N

M

BU

1~

RD

ILF

L

230V 1~ 50Hz

N

RHC

ILF

230V 1~ 50Hz

CRHC

L

N

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VHC

EXT

RM

RM

ECFWEB6

3TW60026-3

Page 20

ECFWER6

SA

SW

10

FC66000630

ECFWER6

SA

SW

11

FC66000631

ECFWER6

SA

SW

12

FC66000632

CN

RM

RM

ECFWER6

WH

4

BK

5

6

7

L

N

M

BU

1~

RD

ILF

L

N

230V 1~ 50Hz

RHC

ILF

230V 1~ 50Hz

CRHC

L

N

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VC VH

EXT

RM

RM

ECFWEB6

3TW

CN

RM

RM

ECFWER6

WH

4

BK

5

6

7

L

N

M

BU

1~

RD

RHC

ILF

230V 1~ 50Hz

230V 1~ 50Hz

ILF

CRHC

L

N

L

N

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

EXT

TSA

61

2

048

TS TS

L

RM

RETSM

SC

NLN

RM

ECFWEB6

3TW

CN

RM

RM

ECFWER6

WH

4

BK

5

6

7

L

N

M

BU

1~

RD

RHC

ILF

230V 1~ 50Hz

230V 1~ 50Hz

ILF

CRHC

L

N

L

N

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VC

EXT

TSA

61

2

048

TS TS

L

RM

RETSM

SC

NLN

RM

ECFWEB6

3TW

Page 21

ECFWDER6

SA

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

EXT

SW

CRHC

L

N

230V 1~ 50Hz

L

N

230V 1~ 50Hz

13

UT66000279

ECFWDER6

SA

SW

1

C

2

V1

3

V2

C

4

V3

RM

RHC

IL

F

F

IL

RM

ECFWER6

RM

RM

ECFWER6

14 L

15 L

16 N

17 N

V3

V2

V1

IPM

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

M

1~

28

27

26

25

3TW60226-1

1

C

2

V1

3

V2

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VHC

EXT

4

V3

14 L

15 L

16 N

17 N

ECFWER6

C

V3

V2

V1

IPM

RM

RM

28

27

26

25

RM

RM

ECFWER6

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

RHC

M

1~

ILF

230V 1~ 50Hz

CRHC

L

N

14

UT66000280

ILF

230V 1~ 50Hz

3TW60226-2

L

N

Page 22

ECFWDER6

SA

SW

1

C

2

V1

3

V2

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VC VH

EXT

4

V3

14 L

15 L

16 N

17 N

ECFWER6

C

V3

V2

V1

IPM

RM

RM

28

27

26

25

RM

RM

ECFWER6

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

RHC

M

1~

ILF

230V 1~ 50Hz

ILF

230V 1~ 50Hz

CRHC

L

N

L

N

15

UT66000281

ECFWDER6

SA

SW

16

UT66000282

3TW60226-3

C

1

V1

2

V2

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

EXT

TSM

TSA

A2 1 3

TS TS

RE

4A1

2

NLN

L

3

C

V3

4

V3

V2

V1

14 L

15 L

16 N

IPM

17 N

RM

RM

ECFWER6

SC

28

27

26

25

RM

RM

ECFWER6

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

RHC

M

1~

ILF

230V 1~ 50Hz

230V 1~ 50Hz

ILF

CRHC

L

N

L

N

3TW60226-4

Page 23

ECFWDER6

SA

SW

17

UT66000313

ECFWDER6

SA

SW

1

C

2

V1

3

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VC

EXT

TSM

TSA

A1

A2 3 5

TS N

TSA

A1

A2 3 5

TS N

N L2 L3L1

EXT

TSM

N L2 L3L1

SC

SC

RE RE RE

2

1

L1

RE RE RE

2

1

L1

6

4

6

4

V2

4

V3

14 L

15 L

16 N

17 N

ECFWER6

1

C

2

V1

3

V2

4

V3

14 L

15 L

16 N

17 N

ECFWER6

C

V3

V2

V1

IPM

RM

RM

C

V3

V2

V1

IPM

RM

RM

28

27

26

25

28

27

26

25

RM

RM

ECFWER6

RM

RM

ECFWER6

CN

4

5

6

7

L

N

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

WH

BK

BU or GY

RD

RHC

RHC

M

1~

400V 3+N 50Hz

M

1~

400V 3+N 50Hz

ILF

230V 1~ 50Hz

IL

F

ILF

230V 1~ 50Hz

IL

F

CRHC

CRHC

L

N

L3

L2

L1

N

L

N

L3

L2

L1

N

18

UT66000314

Page 24

ECFWDER6

SA

SW

1

C

2

V1

3

V3

V2

V1

L

PE

N

N

N

RE

V

RM

RM

EX

EX

VC

EXT

TSM

TSA

RE

61

2

048

TS TS

L

SC

NLN

V2

4

V3

14 L

15 L

16 N

17 N

ECFWER6

C

V3

V2

V1

IPM

RM

RM

28

27

26

25

RM

RM

ECFWER6

CN

4

5

6

7

L

N

WH

BK

BU or GY

RD

RHC

M

1~

ILF

230V 1~ 50Hz

230V 1~ 50Hz

ILF

CRHC

L

N

L

N

19

UT66000283

3TW

Page 25

C1

FWV • FWL • FWM FWD

ECFWER6

ECFWEB6

12 76543

M

––2

✓

ECFWEB6

ECFWER6

612345 7 89101112 13141516 171819

✓

ECFWDER6

3~

1~

✓

✓

✓

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

MD

M

MD

M

MD

M

MD

M

MD

M

MD

H2O

H2O

AIR

AIR

2––

2–

✓

22–✓

4–✓

✓

4–

4––

4––

–

✓

2–✓

2 ✓✓

2 ✓✓

2––

✓

22–

4–––

✓

4–

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

C17

C18

AIR

AIR

2 ✓✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Page 26

Zandvoordestraat 300, B-8400 Oostende, Belgium

4PWEN17551-1

Loading...

Loading...