Daikin E8.5064 V1 Installation manuals

E8.5064 V1

System Manager

Installation Manual

Please observe the safety instructions and

read through this manual carefully before

commissioning the equipment.

Safety information General information

General information

Safety information

Power connection regulations

Please note the connection conditions specified by your

local electrical power supply company and the VDE regulations.

Your heating control system may only be installed and serviced by appropriately authorised specialists.

E For fixed devices, a facility for mains disconnection in

accordance with EN 60335 must be installed in compliance

with the installation specifications (e.g. switch).

E The mains lines insulation must be protected against damage

caused by overheating (e.g. insulation hose).

E The minimum distance to installation objects in the vicinity

must be chosen so that the permitted ambient temperature is

not exceed during operation (see table - Technical Data).

E If the system is not installed properly, persons using it are at

put at risk of fatal or serious injury (electric shock).

Ensure the controller is de-energized prior to performing any

work on the controller!

Safety

Please read and keep in a safe place

Please read through these instructions carefully before installing or operating. Following the installation, pass the instructions on to the operator.

Warranty conditions

If the system is not installed, commissioned, serviced and

repaired properly, it will render the manufacturer's warranty

null and void.

Conversion

All technical changes are prohibited.

Transport

On receipt of the product, check that the delivery is complete. Report any transport damage immediately.

Storage

Store the product in a dry place. Ambient temperature: see

Technical data.

Important text passages

! Important information is highlighted by an

exclamation mark.

E This attention symbol indicates dangerous situations.

Note

! The operating manual describes the maximum

version of the controller, meaning that not all

statements are relevant for your device.

2

General information Description

General Notes

!

With regard to installation, operation, and maintenance,

the following instructions must be observed. This

device must only be installed by a specialist technician.

Improperly performed repairs can subject users to

considerable risks.

!

To comply with applicable regulations, the instructions

for assembly and operation must be readily available at

all times and must be handed over to the responsible

engineer when working on the device for his attention.

Description

Declaration of conformity

We the manufacturer declare the product E8.5064 is in

conformity with the fundamental requirements of the following directives and standards.

Directives:

– 2004/108/EC, 2006/95/EC

Standards:

– EN 60730-1, EN 60730-2-9

The manufacture is subject to the quality management

system in accordance with DIN EN ISO 9001.

Function

The device contains a number of functions and must be

set in accordance with use. The following functions are

mapped in the System Manager:

Cascade modulating HS

Cascade switching HS

Control of 2 HS or 2-stage HS via relay

Water heating, 2 mixed heating circuits, as well as 2

extra functions

Demand-related circulation pump control

Automatic toggle between summer and winter time

Activation of a timer is possible

3

Inhaltsverzeichnis General information

Inhaltsverzeichnis

General information 2

Safety information 2

Safety 2

General Notes 3

Description 3

Declaration of conformity 3

Function 3

Inhaltsverzeichnis 4

Installation 6

Assembly/Dismantling 6

Electrical Connection 7

Connecting instructions 7

Connection diagram 8

Terminal assignment 9

Power terminal assignments 10

Sensor terminal assignments 11

Remote controls 13

Operation-control module Merlin BM, BM 8,

Lago FB 13

Remote control FBR2 13

Sensor resistances FBR 14

DCF receiver 14

PC 14

Maximum delimiter 15

Telephone switch 15

Sensor values/characteristic curve 16

Sensors 17

Outside sensor AF (AFS) S 17

Immersion sensor KF (KFS) H/SPF (SPFS) F 17

Strap-on sensor VF (VFAS) v 17

System bus 18

The heating system 18

Bus ID 18

Input of the basic setting 18

Operation in normal mode 18

Operating elements 18

Ç Operating mode selection 19

Effect of the operating mode 19

Display in normal operation 20

Changing set values 21

Operating elements 21

Operating level 22

Areas 23

General 23

Display 23

User 23

Time programs 23

Expert 23

Expert FA (only for FA via BUS) 23

Levels 23

Installation 23

Hot water 23

Heating circuit I/II 23

Solar/MF 23

4

General information Inhaltsverzeichnis

Installation level 24

Commissioning procedure 24

Installation (selecting basic controller functions) 24

BUS-ID HS (- - - -) 25

HS 1 TYPE (primary heat generator type) 25

HS1 BUS (connection for HS) 25

HS 2 TYPE

(secondary heat generator type HS => A7) 25

STORAGE HS2 (heat accumulator for HS2) 25

BUFFER (heater buffer storage type) 26

HC FUNCTION

(heating circuit function selection) 26

CAP/STAGE (boiler output for each stage) 27

Auxiliary relay functions 28

RELAY FUNC 1 (function selection relay MF1) 28

T-MF1 SETP

(switching temperature relay MF1) 28

MF 1 HYST (hysteresis relay MF1) 28

F15 FUNCTION (sensor function F15) 31

BUS ID (heating circuit number): 31

5 K SENSORS/1 K SENSORS 31

Choice of installation 32

Schematic circuit diagrams hydraulic system 32

Installation 01 = E8.4034

=> Cascade controller for modulating HS 32

Terminal assignment 33

Installation 02 = E8.4834

=> Cascade controller for switching HS 34

Terminal assignment 35

Installation 03 = E8.3611 => 0 - 10 V Controller 36

Terminal assignment 37

Installation 04 = E8.0634

=> Standard controller with 2-stage HS 38

Terminal assignment 39

Installation 05 = 2HS controller

=> 2 HS cascade switched via relay 40

Terminal assignment 41

Service 42

Error Messages 42

Troubleshooting 43

Dimensions 45

Technical Data 46

Glossary 47

5

Assembly/Dismantling Installation

Installation

Installation

Assembly/Dismantling

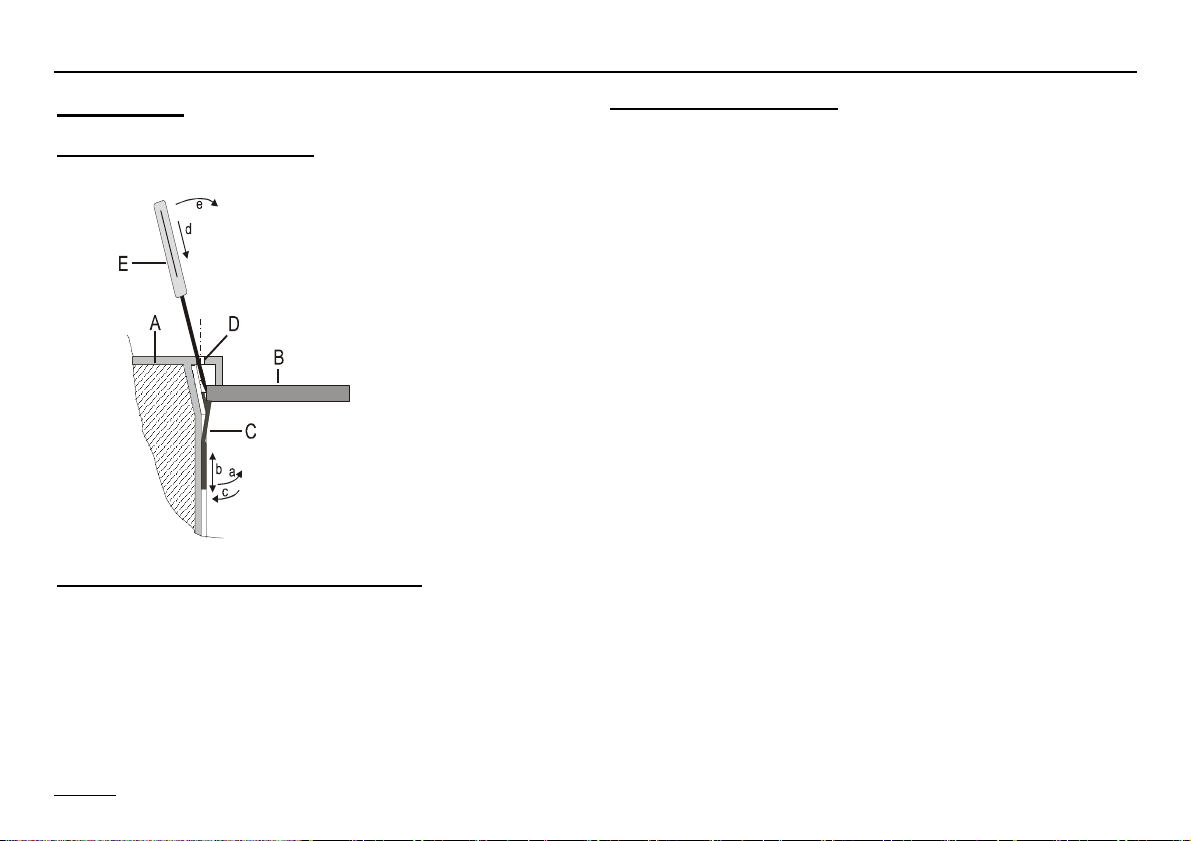

Sketch showing basic mode of operation:

A Controller, side view, cutaway view

B Control panel plate

C Mounting clamp

D Unlocking holes (see Chapter Changing set values)

E Sharp-pointed tool

Installing the controller:

1. Set the mounting clamp to the wall thickness of the control panel (at the left and right-hand side of the unit):

a. Pull the mounting clamp at the low away from the con-

troller wall (toothing).

b. In this condition, slide the mounting clamp down or up

until the distance from the edge of the unit corresponds to the thickness of the control panel wall.

Detent position 1 0.5 - 1.0 mm wall thickness

Detent position 5 5.0 mm wall thickness

c. Press the mounting clamp against the controller wall at

the low.

2. Press the controller into the control panel recess and

check that it is firmly secure. If the controller wobbles: Remove the controller and move the mounting clamps up.

6

Installation Electrical Connection

Removing the controller:

E Disconnect the unit from the power supply before

removing it.

d) Insert a sharp-pointed tool at an angle with respect to

the exterior wall into one of the unlocking holes (the

tool must be slid between mounting clamp and control

panel wall).

e) Lever the tool with respect to the unit exterior wall.

This causes the mounting clamp to release the control

panel wall.

Raise the unit slightly at the corresponding side and repeat

the procedure on the other side of the unit.

The unit can now be removed.

Electrical Connection

! After connecting or modifying the connections of

sensors and remote controls the controller must be

briefly switched off (mains switch/fuse). The function

of the controller is reconfigured in accordance with

the connected sensors the next time the controller is

switched on.

Note for installation in connection with digital room

device

When installing a digital room device, the heating circuitspecific set values are adjusted at the room device. These

values are automatically superceeded inside the controller.

! If during operation the digital room device is

separated from the BUS for a longer time period

(>5 min), the heating controller will continue to work

with its own set values.

In order to avoid damages in case of errors - for deviations

from relevant set values (such as maximum flow temperature for floor heaters) - we suggest the following proce-

Connecting instructions

E The controller is designed for an operating voltage of

230 V AC at 50 Hz. The burner contact is potential-free

and must always be connected in series with the

mechanical boiler thermostat (if present).

dure:

1. Installing the new heating controller

2. Set all values for heating controller

3. Install one digital room device

4. Set all values for digital room device

E Important: Bus lines and sensor lines must be laid

separately, away from mains cables!

7

Electrical Connection Installation

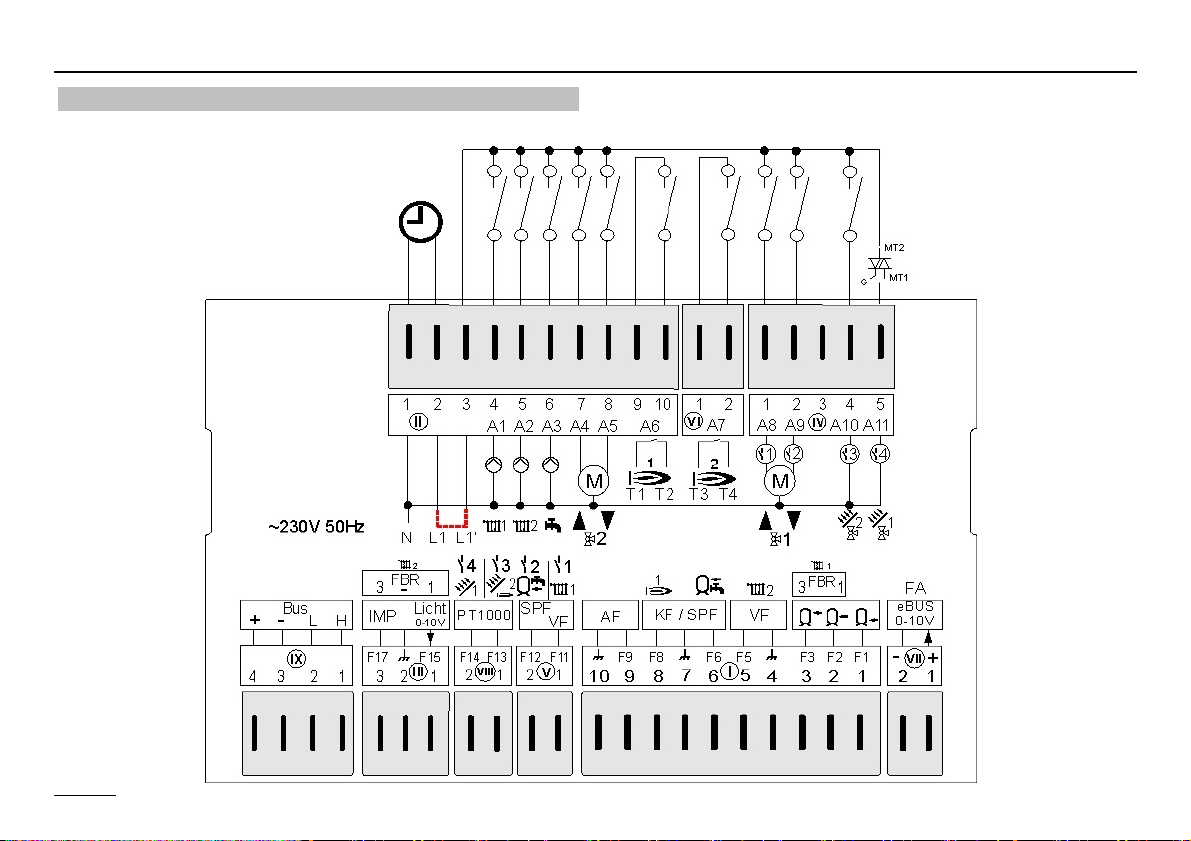

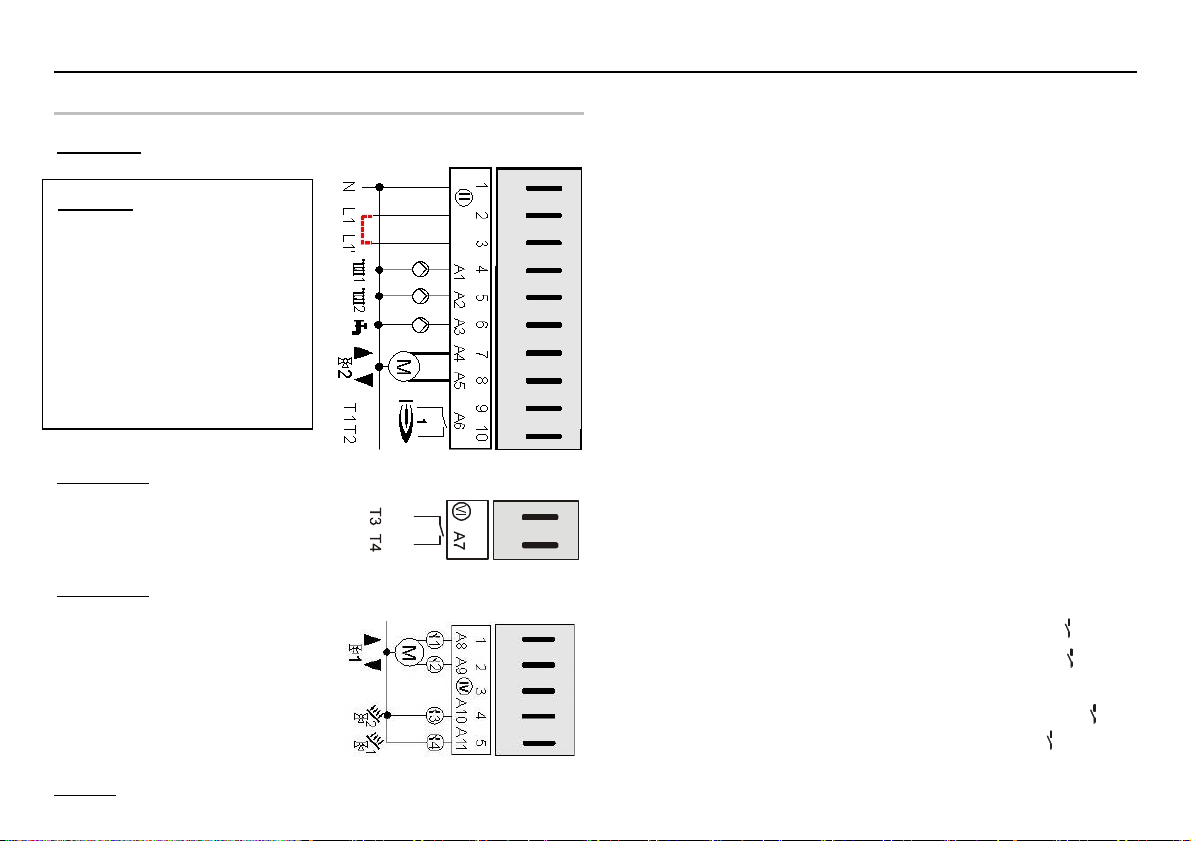

Connection diagram

~ 230 V; Relay switching capacity 2 (2) A, ~ 250 V

8

Installation Electrical Connection

Terminal assignment

Sensors

VII (1+2): eBUS (FA) or 0 - 10 V output

I (1,2,3+

low/middle/top

I (2+3+

I (2+

I (4+5): F5 = Flow sensor heating circuit 2

I (6+7): F6 = Storage tank sensor

I (7+8): F8 = Boiler sensor/header sensor

I (9+10): F9 = Outdoor sensor

V (1+

Multifunction relay sensor

V (2+

Multifunction relay sensor

VIII (1+

Multifunction relay sensor

VIII (2+

Multifunction relay sensor

III (1-3): FBR2 (FBR1) for heating circuit 2

): F1/F2/F3 = buffer storage tank

): FBR2 (FBR1) for heating circuit 1

): F2 = Room sensor for heating circuit 1

): F11 = Flow sensor heating circuit 1/

1

): F12 = Hot-water tank low/

2

): F13 = PT1000 => HS2/collector 2/

3

): F14 = PT1000 => Collector 1/

4

Mains

II (1): Neutral conductor, mains

II (2): Power supply, unit

II (3): Power supply, relay

II (4): A1 = Pump heating circuit 1

II (5): A1 = Pump heating circuit 2

II (6): A3 = Cylinder charging pump

II (7): A4 = Mixer motor heating circuit 2 on

II (8): A5 = Mixer motor heating circuit 2 to

II (9+10): A6 = Burner stage 1/HS 1

VI (1+2): A7 = Burner stage 2/HS 2/Solid fuel

IV (1): A8 = Mixer motor heating circuit 1 on/

Multifunction relay

1

IV (2): A9 = Mixer motor heating circuit 1 to/

Multifunction relay

2

IV (3): A10 = Collector pump 2/Switching valve to

solar tank 2/Multifunction relay

3

IV (4): A11 = Collector pump 1 (ON / OFF)

multifunction relay

4

III (1+2): F15 = 0-10V input/light sensor/

Room sensor for heating circuit 2

III (2+3): F17 = Pulse counter for output

measurement

IX (1+2): Data line CAN bus

IX (3+4): Power supply CAN bus

E Important: Bus lines and sensor lines must be laid separately, away from mains cables!

9

Electrical Connection Installation

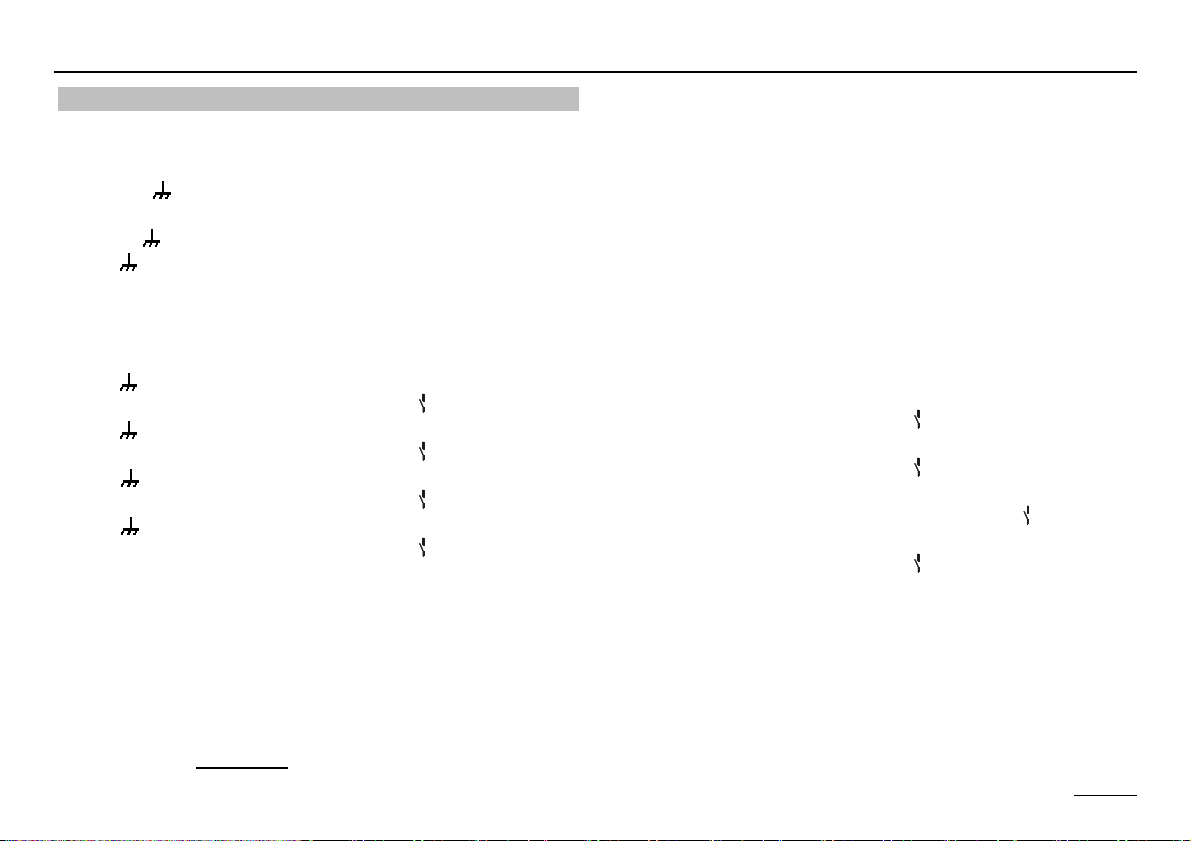

Power terminal assignments

Plug 2 [II]

Options

Provided no separate regulations for protecting the

relay apply, a bridge to

supply the relay must be

connected between terminals II 2 and II 3.

Plug 6 [VI]

Plug 4 [IV]

s

1

2

N: Neutral conductor, mains

L1: Power supply, unit

L1´: Power supply to relay

D 1: heating circuit pump HC 1

D 2: heating circuit pump HC 2

F: Storage tank charging pump

v: Mixer open, heating circuit 2

v: Mixer closed, heating circuit 2

H: Burner stage 1

H: Burner stage 1

H: Burner stage 2/HS2

H: Burner stage 2/HS2

v: Mixer heating circuit 1 open / Multifunction relay 1

v: Mixer heating circuit 1 close / Multifunction relay

Collector pump 2/Switching valve / Multifunction relay

Collector pump 1(ON / OFF) / Multifunction relay

2

3

4

10

Installation Electrical Connection

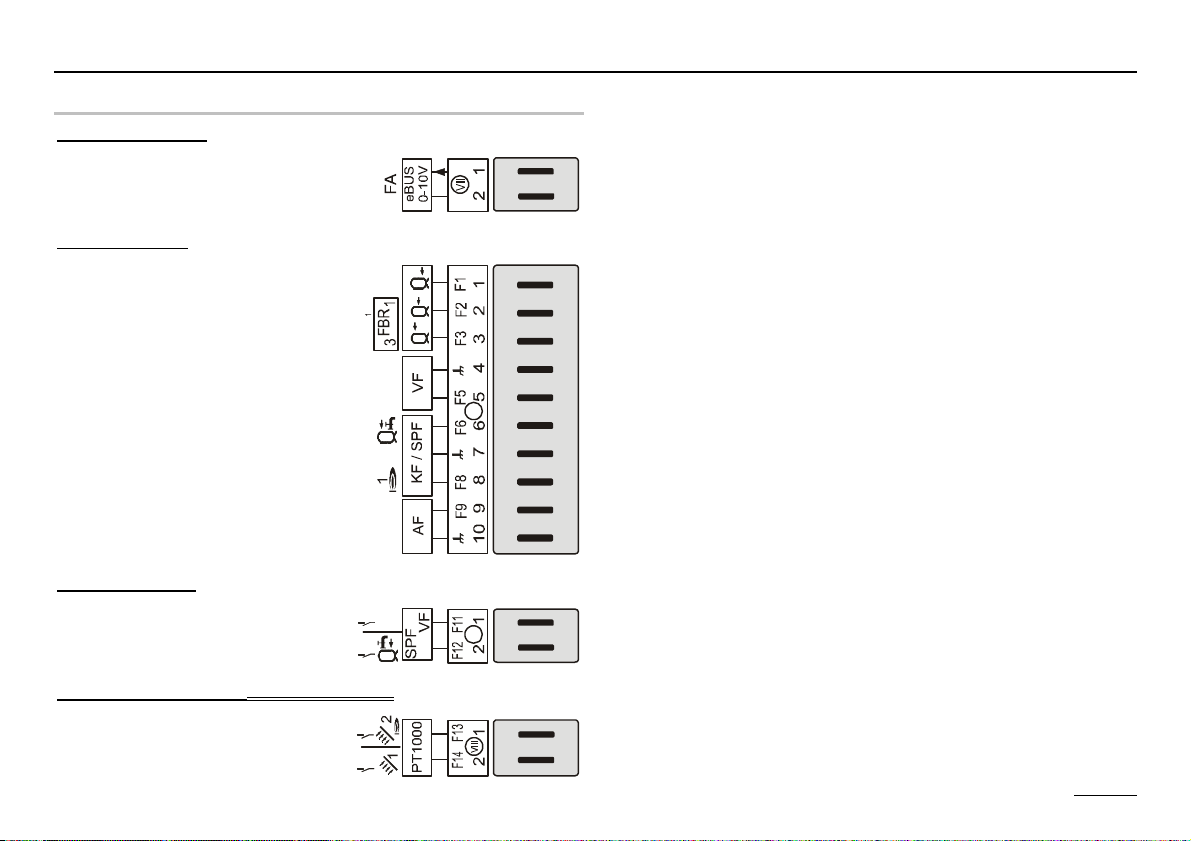

Sensor terminal assignments

Connector 7 [VII]

+

-

Connector 1 [I]

Pin 1: eBUS (FA) or 0 - 10 V output

Pin 2: (Ground BUS/0 - 10 V)

Pin 1: Buffer storage tank low sensor

Pin 2:

D

2

D

I

Buf. stor. tank middle sensor/FBR heat. circ. 1 (room sensor)

Pin 3:

Buf. stor. tank top, sensor/FBR heating circuit 1 (set value)

Pin 4: Flow sensor, heating circuit 2 (ground)

Pin 5: Flow sensor, heating circuit 2

Pin 6: Waste water sensor

Pin 7: Waste water and boiler sensor (ground)

Pin 8: Boiler sensor

Pin 9: Outdoor sensor

Pin 10: Outdoor sensor (ground)

Connector 5 [V]

12

Connector 8 [VIII] => PT 1000 sensor

3

4

1

D

V

Pin 1: Flow sensor heating circuit 1/sensor multifunction 1

Pin 2: Service water low sensor/sensor multifunction 2

Pin 1: Sensor HS2/Solar 2/Multifunction relay 3

Pin 2: Sensor Solar 1/Sensor multifunction relay 4

11

Electrical Connection Installation

Connector 3 [III]

Connector 9 [IX]

0-10V

Licht

-

D

III

IMP

HL

+

Pin 1: FBR heating circuit 2 (room sensor)/0 - 10 V IN/Light

Pin 2: FBR heating circuit 2 (ground)

Pin 3: FBR heating circuit 2 (set value)/Pulse counter for

output measurement

CAN Bus Pin 1 = H (Data)

CAN Bus Pin 2 = L (Data)

CAN Bus Pin 3 = - (ground, Gnd)

CAN Bus Pin 4 = + (12 V supply)

12

Installation Remote controls

Remote controls

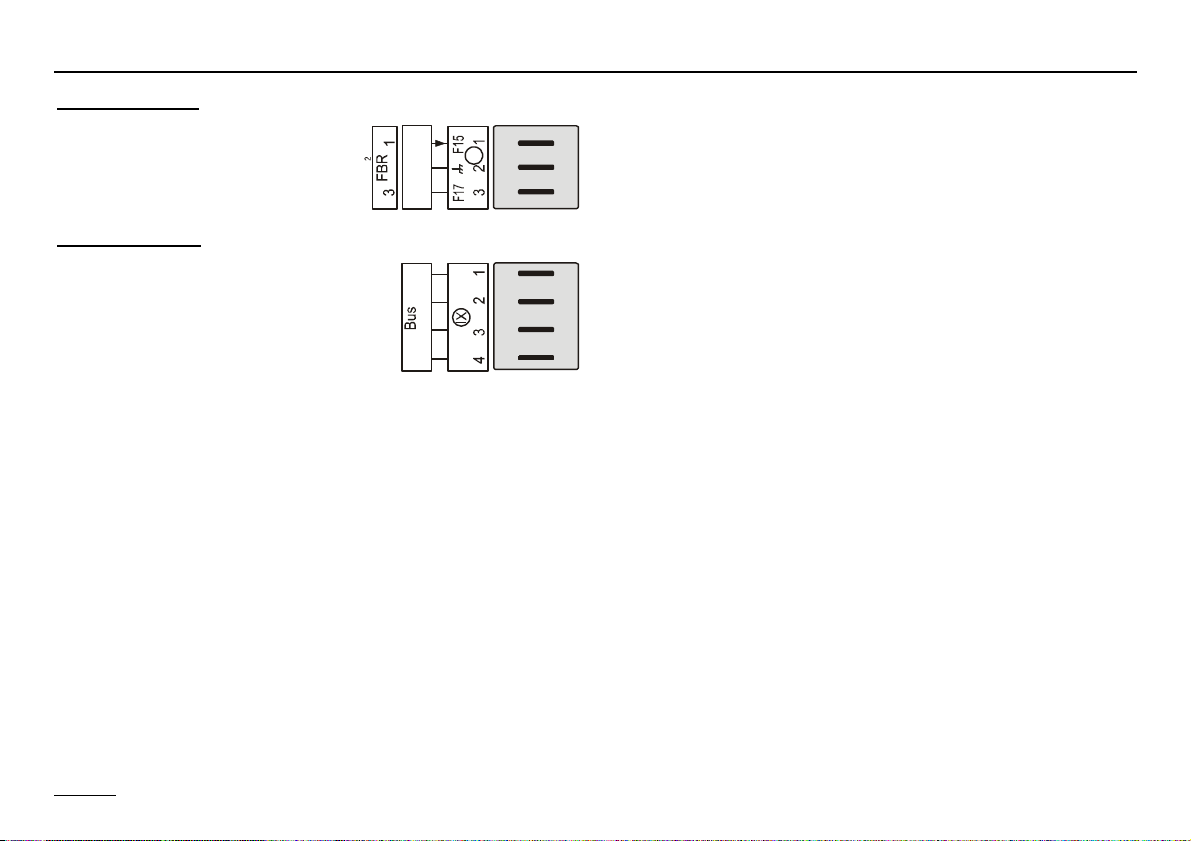

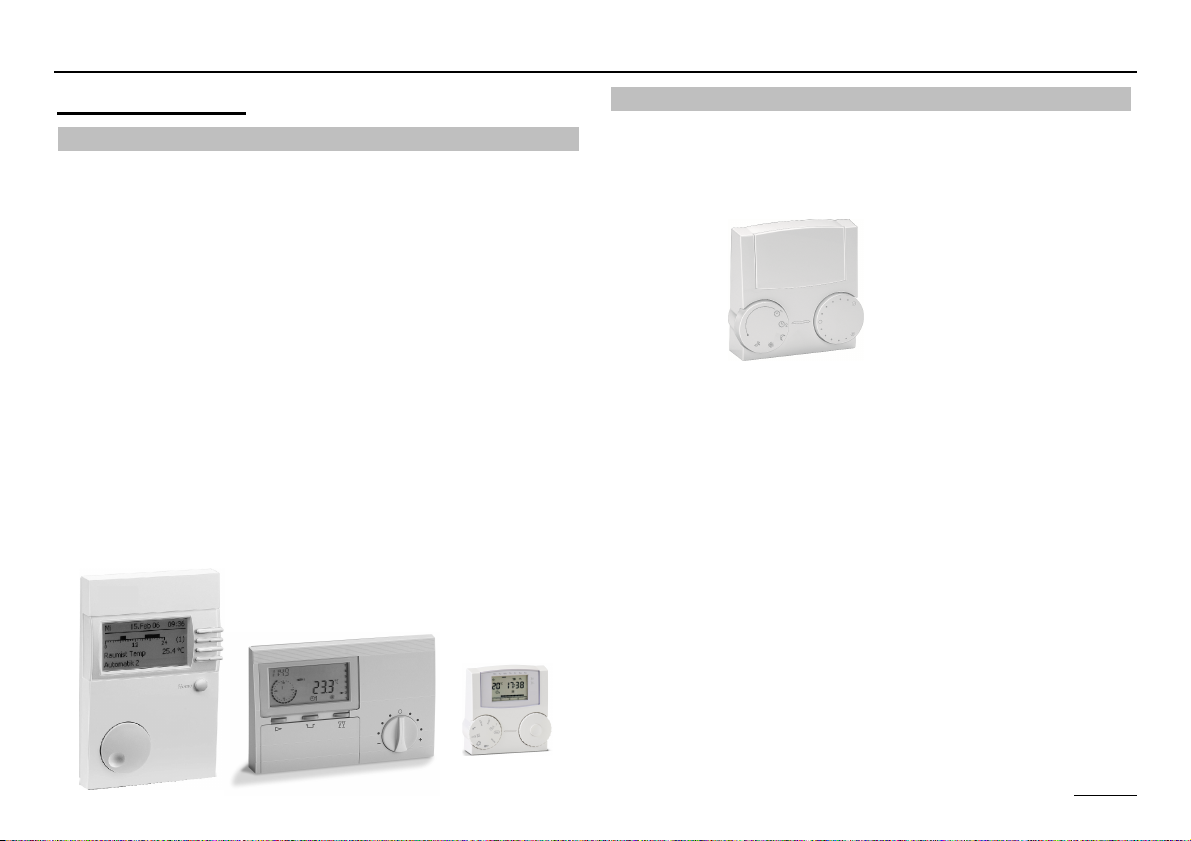

Operation-control module Merlin BM, BM 8, Lago FB

(Only for controller models with CAN-Bus connection)

Remote control FBR2

Electrical connection: HC1: Connector I; 2, Ground and 3

or HC2: Connector III; 1 - 3

Rotating switch for modifying room temperature setting

Electrical connection: Connector IX; 1 - 4

The controller permits connection of an operation-control

module BM for each heating circuit via a bus line. The operation-control module allows various operation-control

functions and monitoring functions for the system values to

be relocated to the main controlled zone – i.e. the living

room. This achieves maximum comfort and convenience.

Please refer to the technical description of the BM for a

precise description of the overall scope of functions.

Display of the system parameters

Entry of the heating circuit parameters

Room temperature control

Automatic adaptation of the heat slope (not Lago FB)

Adjusting range: (± 5 K)

Room control via the integrated room sensor

Rotating switch for selecting operating mode

i Standby/OFF (frost protection only)

q

Automatic mode (according to timer program 1 in

1

controller)

q

Automatic mode (according to timer program 2 in

2

controller)

C 24-hour night operation (reduction temperature)

B 24-hour daytime operation (comfort temperature)

F Summer mode (heating OFF, hot water only)

Depending on the version, your FBR supports a portion of the

following operating modes.

! The operating mode at the controller must be set to q.

The controller can also be operated with an FBR1.

13

Remote controls Installation

Installation location:

In reference/main living room of the heating circuit

(on an inside wall of the room).

Not in the vicinity of radiators or other heat dissipating

units.

Any, if the room sensor influence is switched off.

Installation:

Remove cap from underside of pedestal.

Secure the base at the installation location.

Connect the electrical connection cables.

Press the cap back on.

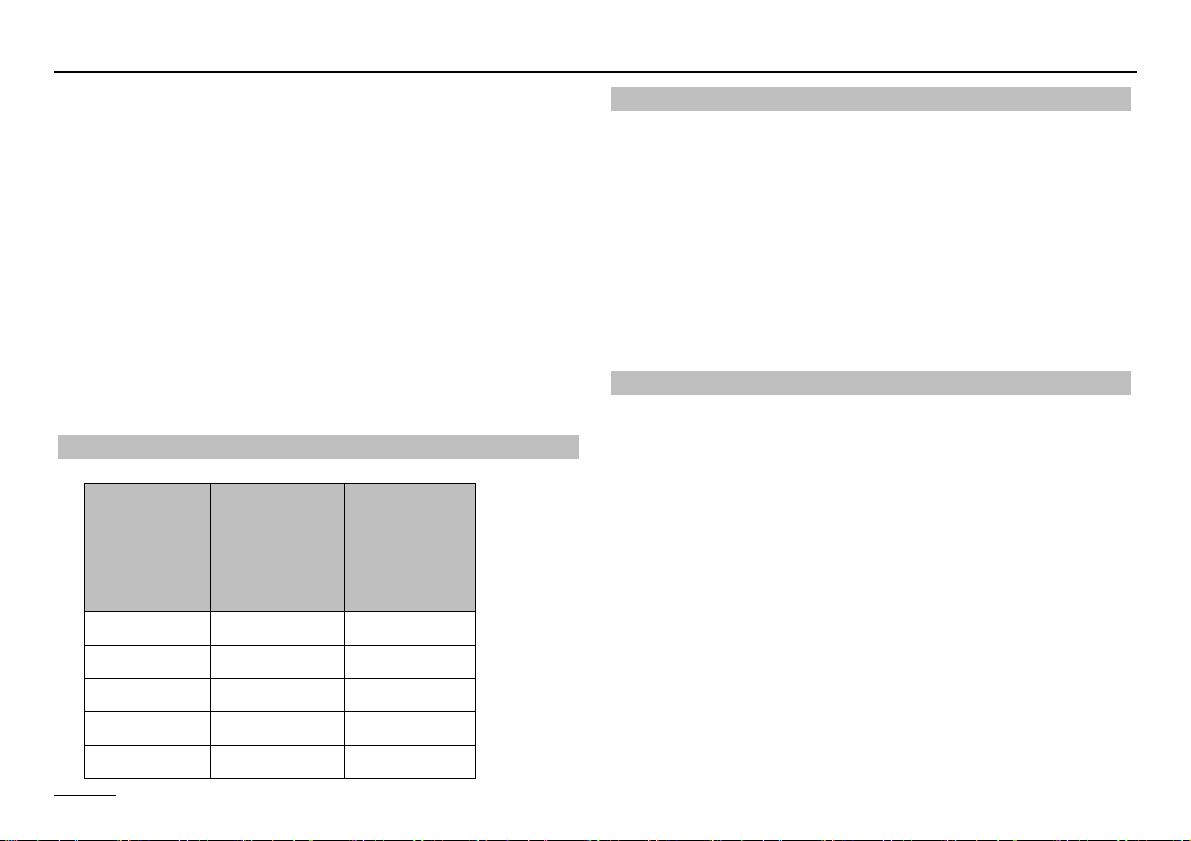

Sensor resistances FBR

Temperature FBR1

terminals 1-2

switch in position q

+10 °C 680 Ω 9950 Ω

+15 °C 700 Ω 7855 Ω

+20 °C 720 Ω 6245 Ω

+25 °C 740 Ω 5000 Ω

+30 °C 760 Ω 4028 Ω

FBR2

terminals 1-2

Room sensor

DCF receiver

Electrical connection: Connector VII; Terminal 1, 2

The controller can evaluate a eBUS DCF receiver on the

eBUS FA-Terminals.

If the DCF receiver is connected, the controller time is updated as soon as the DCF transmits a valid time on the

BUS.

If the time has not been corrected after max. 10 min, select

a different place of installation for the DCF (e.g. another

wall - not in proximity to TV devices, monitors or dimmers).

PC

All system-specific parameters can be set and interrogated

using the

ComfortSoft parameterisation software. The pa-

rameters can be saved, displayed graphically and evaluated on the PC at predefined intervals. T connect to a PC

you need the optical adapter or CoCo PC active, which also supports the sending of error messages by SMS and

the remote interrogation of controller data.

14

Installation Remote controls

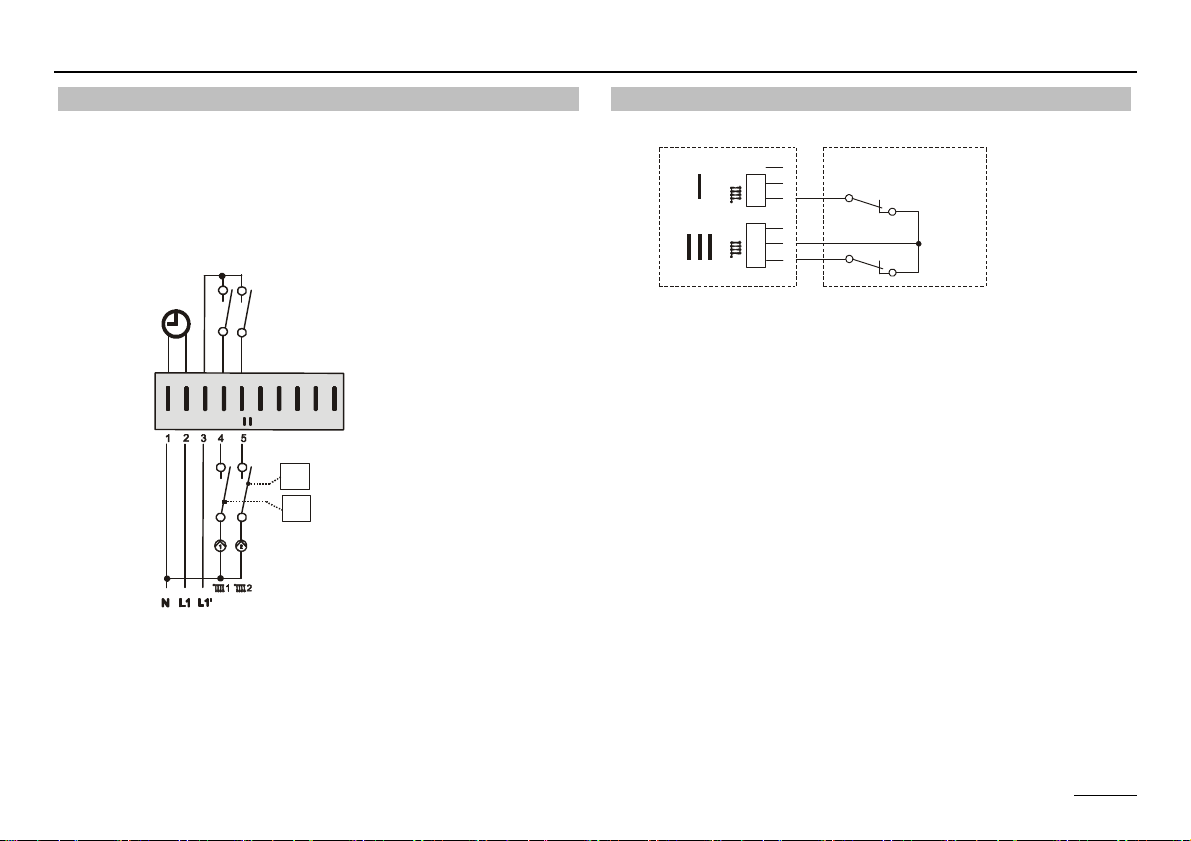

Maximum delimiter

If a maximum delimiter is required it must be connected

between the heating circuit pump and the pump controller

switch output.

Connector I, terminals 4 and 5

Telephone switch

12

FBR

1

FBR

3

1

1

3

32

1

32

The heating system can be switched to Heating mode h

with a telephone switch. The connection terminals of the

controller for the remote control FBR (see connection diagram) are used for installation. As soon as a short circuit

between terminal 3 of the FBR and ground (FBR terminal

2) is detected, the assigned heating circuit is switched to

T

T

heating mode. Additionally the hot water preparation is activated (only for controllers with hot water preparation).

When the short-circuit is eliminated, the controller once

again heats on the basis of the set heating program.

E If the heating circuit is controlled remotely by an

operating module, the telephone switch must be

connected at the operating module.

15

Loading...

Loading...