Daikin DX17VSS181AA, DX17VSS series, DX17VSS241AA, DX17VSS301AA, DX17VSS361AA Installation Instructions Manual

AIR CONDITIONER

English

DX17VSS AIR CONDITIONING

INSTALLATION & SERVICE REFERENCE

Index

ImportAnt sAfety InstruCtIons ............................................. 1

shIppIng InspeCtIon .............................................................. 1

Codes & regulAtIons .......................................................... 2

feAtures..............................................................................2

preCAutIons for seleCtIng A loCAtIon ................................. 2

preCAutIons for InstAllAtIon ............................................... 3

InstAllAtIon CleArAnCes ...................................................... 3

rooftop InstAllAtIons .........................................................3

sAfety ConsIderAtIons.........................................................4

refrIgerAnt lInes ............................................................... 6

refrIgerAnt lIne ConneCtIons ............................................. 8

leAK testIng (nItrogen or nItrogen-trACed) ......................8

system stArt-up proCedure ................................................ 8

stArt-up proCedure detAIl .................................................. 9

eleCtrICAl ConneCtIons ...................................................... 9

AIr CondItIoner AdvAnCed feAture menu ........................... 30

wIrIng dIAgrAm ................................................................33

CApACItor .......................................................................... 34

troubleshootIng ............................................................... 36

settIng the mode dIsplAy .................................................. 41

7-segment dIsplAy ............................................................. 47

stArt up CheCKlIst ........................................................... 51

INSTALLATION INSTRUCTIONS

imPoRtant saFety instRuCtions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It is

the owner’s and installer’s responsibility to read and comply

with all safety information and instructions accompanying

these symbols. Failure to heed safety information increases

the risk of personal injury, property damage, and/or product

damage.

WARNING

HIGH VOLTAGE !

dIsConneCt All power before servICIng.

m

ultIple power sourCes mAy be present. fAIlure

to do so mAy CAuse property dAmAge, personAl

Injury or deAth.

WARNING

only personnel thAt hAve been trAIned to InstAll, Adjust, ser-

vICe or repAIr (hereInAfter, “servICe”) the equIpment speCIfIed

In thIs mAnuAl should servICe the equIpment. the mAnufACturer

wIll not be responsIble for Any Injury or property dAmAge ArIs-

Ing from Improper servICe or servICe proCedures. If you servICe

thIs unIt, you Assume responsIbIlIty for Any Injury or property

dAmAge whICh mAy result. In AddItIon, In jurIsdICtIons thAt re-

quIre one or more lICenses to servICe the equIpment speCIfIed In

thIs mAnuAl, only lICensed personnel should servICe the equIp-

ment. Improper InstAllAtIon, Adjustment, servICIng or repAIr of

the equIpment speCIfIed In thIs mAnuAl, or AttemptIng to InstAll,

Adjust, servICe or repAIr the equIpment speCIfIed In thIs mAnuAl

wIthout proper trAInIng mAy result In produCt dAmAge, property

dAmAge, personAl Injury or deAth.

shiPPing insPeCtion

Always keep the unit upright; laying the unit on its side or top

may cause equipment damage. Shipping damage, and subsequent investigation is the responsibility of the carrier. Verify

the model number, speci cations, electrical characteristics,

and accessories are correct prior to installation. The distributor

or manufacturer will not accept claims from dealers for transportation damage or installation of incorrectly shipped units.

Codes & Regulations

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility

of the installer. The manufacturer assumes no responsibility

for equipment installed in violation of any codes or regulations.

Rated performance is achieved after 72 hours of operation.

Rated performance is delivered at the specied airow. See

outdoor unit specication sheet for split system models or

product specication sheet for packaged and light commercial

models. Specication sheets can be found at www.daikin-

comfort.com for Daikin products. Within the website, please

select the products menu and then select the submenu for

the type of product to be installed, such as air conditioners,

to access a list of product pages that each contain links to

that model’s specication sheet.

The United States Environmental Protection Agency

(EPA) has issued various regulations regarding the introduction and disposal of refrigerants. Failure to follow

these regulations may harm the environment and can

lead to the imposition of substantial nes.

Should you have any questions please contact our local EPA

ofce.

If replacing one of the component of the system, the system

must be manufacturer approved and Air Conditioning, Heating

and Refrigeration Institute (AHRI) matched.

NOTE: The installation of an inverter air conditioner with

unmatched system units will not allow for proper operation.

NOTICE

Inverter A/C models CAn only be mAtChed wIth A CApeA** And

Chpe** A-CoIl. dAmAge resultIng from operAtIon wIth Any other

CombInAtIon Is not Covered by our wArrAntIes.

Outdoor inverter units are approved for operation above 0°F

in cooling mode with no additional kit necessary.

Damage resulting from operation of the unit in a structure

that is not complete (either as part of new construction or

renovation) is not covered by our warranties.

FeatuRes

This air conditioner is part of a system that uses inverter

technology to more efciently remove heat and achieve the

target cooling setting. System may ONLY be installed using

a ComfortNet™ thermostat with model number CTK04AE or

newer as part of the digital communicating system. The ComfortNet system reduces the number of required thermostat

wires, provides additional setup features and enhanced active

diagnostics. Due to components using inverter technology, the

air conditioner will not function properly if used with a CTK03,

02 or 01 ComfortNet thermostat.

PReCautions FoR seleCting a loCation

1. Choose a place solid enough to bear the weight and

vibration of the unit, where the operating sound will

not be amplied.

2. Choose a location where the hot air discharged

from the unit or the operating sound will not cause a

nuisance to the neighbours of the user.

3. Avoid places near a bedroom and the like, so that the

operating sound will cause no trouble.

4. There must be sufcient spaces for carrying the unit

into and out of the site.

5. There must be sufcient space for air passage and no

obstructions around the air inlet and the air outlet.

6. The site must be free from the possibility of ammable

gas leakage in a nearby place.

7. Do not install the air conditioner in the following

locations:

(a) Where a mineral oil mist or oil spray or vapor is produced,

for example, in a kitchen.

Plastic parts may deteriorate and fall off and thus may

result in water leakage.

(b) Where corrosive gas, such as sulfurous acid gas, is pro-

duced.

Corroding copper pipes or soldered parts may result in

refrigerant leakage.

(c) Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of the

control system and cause the unit to malfunction.

(d) Where ammable gas may leak, where there is carbon -

ber, or ignitable dust suspension in the air, or where vola-

tile ammables such as thinner or gasoline are handled.

Operating the unit in such conditions may result in a re.

NOTE: Cannot be installed suspended from ceiling or stacked.

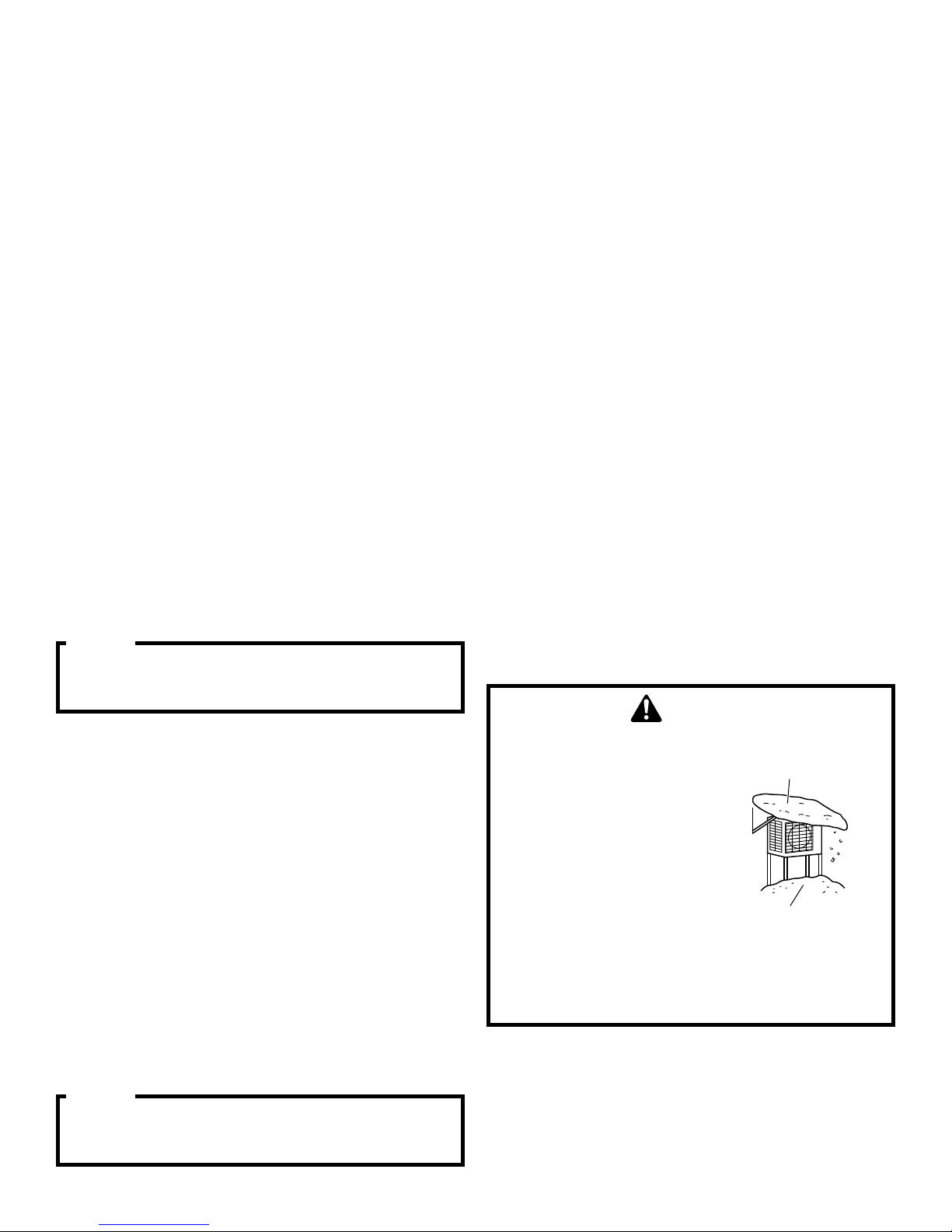

CAUTION

when operAtIng the AIr CondItIoner In

A low outdoor AmbIent temperAture,

be sure to follow the InstruCtIons

desCrIbed below.

•to prevent exposure to wInd, InstAll

the outdoor unIt wIth Its suCtIon

sIde fACIng the wAll.

•never InstAll the outdoor unIt At A

sIte where the suCtIon sIde mAy be

exposed dIreCtly to wInd.

•to prevent exposure to wInd, It Is

reCommended to InstAll A bAffle

plAte on the AIr dIsChArge sIde of

the outdoor unIt.

•In heAvy snowfAll AreAs, seleCt An

InstAllAtIon sIte where the snow

wIll not AffeCt the unIt.

• Construct a large

canopy.

• Construct a pedestal.

Install the unit high

enough off the ground

to prevent burying in

snow.

NOTICE

should use CtK04Ae or newer.

n

ot Approved for use wIth A CtK01, CtK02, CtK03,

CtK04Ad or older.

2

English

PReCautions FoR installation

• Check the strength and level of the installation ground

so that the unit will not cause any operating vibration or

noise after installed.

• Fix the unit securely by means of the foundation bolts.

(Prepare 4 sets of 3/8” or 7/16” foundation bolts, nuts and

washers; all separately available.)

• It is best to screw in the foundation bolts until their ends

are 1 inch from the foundation surface.

At ground oor level, the unit must be on a solid, level foun-

dation that will not shift or settle. To reduce the possibility

of sound transmission, the foundation slab should not be in

contact with or be an integral part of the building foundation.

Care should be taken to ensure the unit is installed away

from noise sensitive locations such as bedrooms, windows

and outdoor living areas. Ensure the foundation is suf cient

to support the unit. A concrete slab raised above ground level

provides a suitable base.

1”

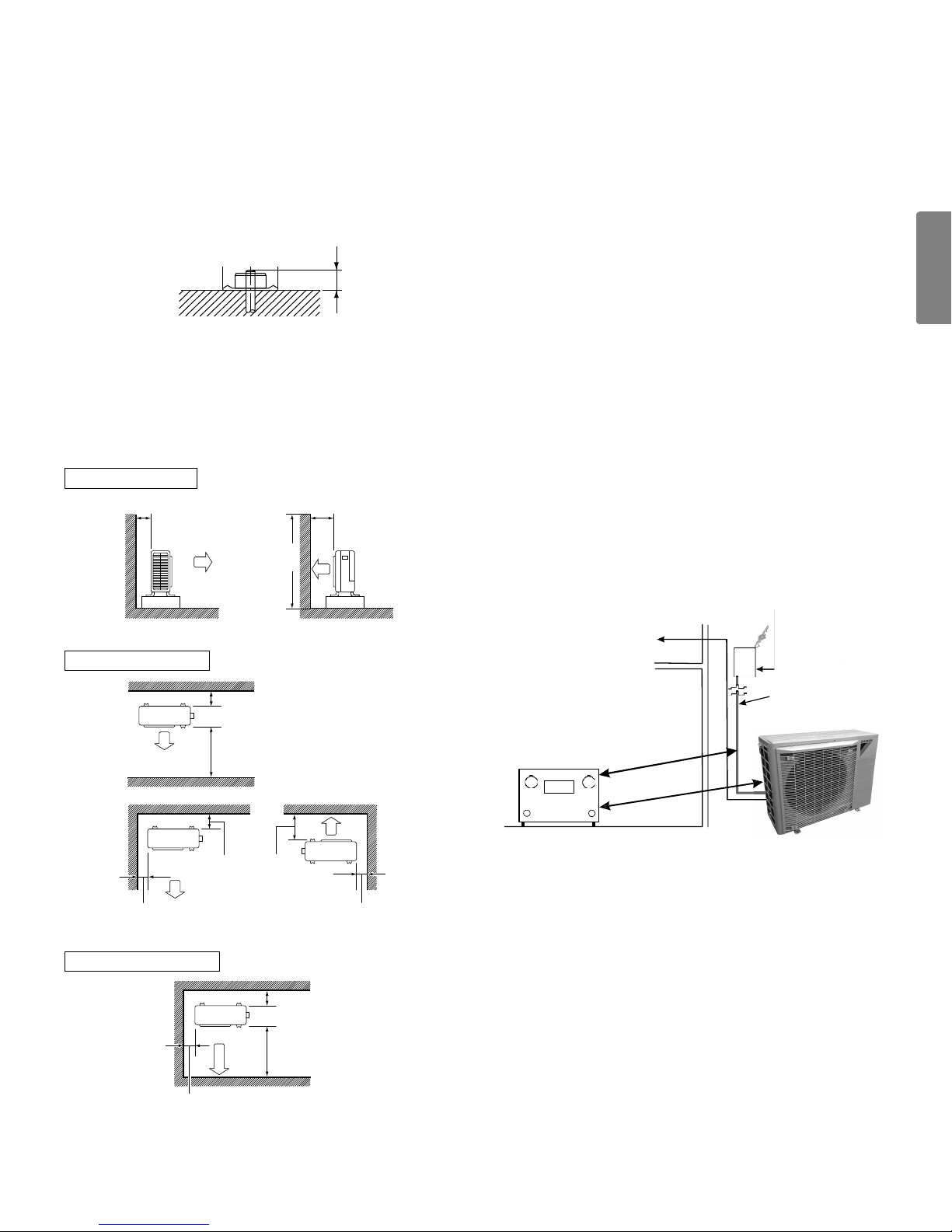

installation CleaRanCes

• Where a wall or other obstacle is in the path of the out-

door unit’s intake or exhaust air ow, follow the installation

space requirements below.

• For any of the below installation patterns, the wall height

on the outlet side should be 47” or less.

Wall facing one side

More than 4” More than 14”

Direction

of air

Walls facing two sides

47” or

less

Side view

More

than 4”

RooFtoP installations

If it is necessary to install this unit on a roof structure, ensure

the roof structure can support the weight and that proper

consideration is given to the weather-tight integrity of the roof.

Since the unit can vibrate during operation, sound vibration

transmission should be considered when installing the unit.

Vibration absorbing pads or springs can be installed between

the air conditioner unit legs or frame and the roof mounting

assembly to reduce noise vibration.

eleCtrICAl noIse

The unit should be well grounded so that potential effects of

electrical noise from the inverter to surrounding equipment

can be minimized.

When selecting an installation location, keep suf cient dis-

tance from the air conditioner unit and wiring to radios, per-

sonal computers, stereos, uorescent lamp, etc., as shown

in the following gure.

Circuit

To Indoor Unit and

Thermostat

Breaker

High voltage

power cable

More

than 14”

More

than 4”

More than 2” More than 2”

Walls facing three sides

More than 2”

More

than 14”

Top view

More than 4”

More than 14”

Top view

This unit can be located at ground oor level or on at roofs.

unit: inch

Radio, TV

(In.)

Placement to Minimize Electronic Noise

60” or more

60” or more

3

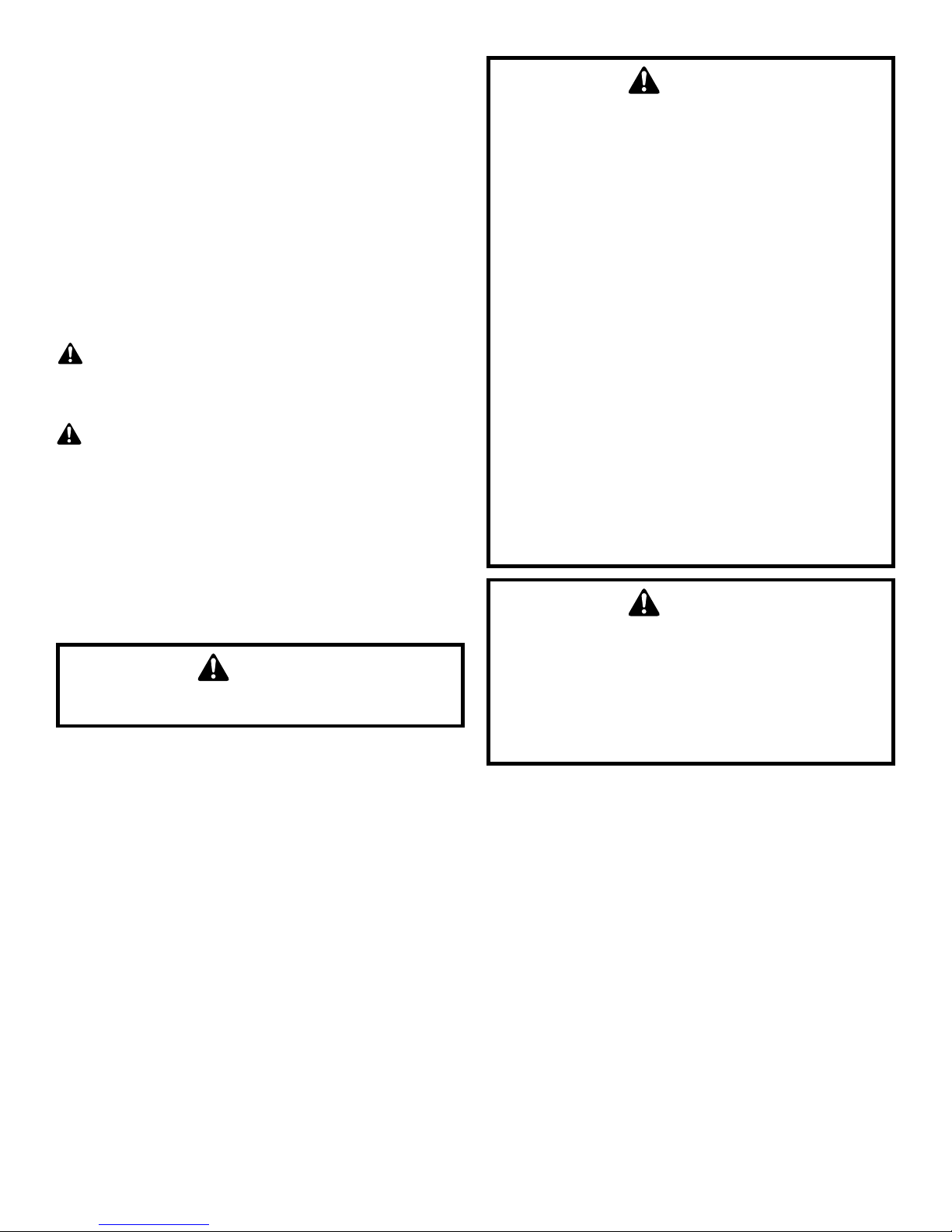

saFety ConsideRations

Read these Safety considerations for Installation carefully

before installing an air conditioner. After completing the installation, make sure that the unit operates properly during the

system start-up operation.

Instruct the customer on how to operate and maintain the unit.

Inform customers that they should store this Installation

Manual for future reference.

Always use a licensed installer or contractor to install this

product.

Improper installation can result in water or refrigerant leakage,

electrical shock, re, or explosion.

Meanings of WARNING, CAUTION, and NOTICE

Symbols:

WARNING .......

CAUTION ........

NOTICE .........

Indicates imminently or potentially

hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Indicates situations that may result

in equipment or property-damage

accidents only.

WARNING

refrIgerAnts Are heAvIer thAn AIr. they CAn “push out” the

oxygen In your lungs or In Any enClosed spACe. to AvoId pos-

sIble dIffICulty In breAthIng or deAth:

•never purge refrIgerAnt Into An enClosed room or spACe. by

lAw, All refrIgerAnts must be reClAImed.

•If An Indoor leAK Is suspeCted, thoroughly ventIlAte the AreA

before begInnIng worK.

•lIquId refrIgerAnt CAn be very Cold. to AvoId possIble frost

bIte or blIndness, AvoId ContACt And weAr gloves And goggles.

I

f lIquId refrIgerAnt does ContACt your sKIn or eyes, seeK

medICAl help ImmedIAtely.

•If refrIgerAnt gAs leAKs durIng InstAllAtIon, ventIlAte the

AreA ImmedIAtely. refrIgerAnt gAs wIll result In produCIng

toxIC gAs If It Comes Into ContACt wIth fIre. exposure to thIs

gAs wIll result In severe Injury or deAth.

•After CompletIng the InstAllAtIon worK, CheCK thAt the re-

frIgerAnt gAs does not leAK throughout the system.

•do not InstAll unIt In An AreA where flAmmAble mAterIAls Are

present due to rIsK of explosIons thAt wIll result In serIous

Injury or deAth.

•when InstAllIng the unIt In A smAll room, tAKe meAsures to

Keep the refrIgerAnt ConCentrAtIon from exCeedIng AllowAble

sAfety lImIts. exCessIve refrIgerAnt leAKs, In the event of An

ACCIdent In A Closed AmbIent spACe, Could result In oxygen

defICIenCy.

•AlwAys follow epA regulAtIons. never burn refrIgerAnt, As

p

oIsonous gAs wIll be produCed.

While these items will not cover every conceivable situation,

they should serve as a useful guide.

WARNING

to AvoId possIble Injury, explosIon or deAth, prACtICe sAfe

hAndlIng of refrIgerAnts.

WARNING

to AvoId possIble explosIon, use only returnAble (not dIspos-

Able) servICe CylInders when removIng refrIgerAnt from A

system.

•ensure the CylInder Is free of dAmAge whICh Could leAd to A

leAK or explosIon.

•ensure the hydrostAtIC test dAte does not exCeed 5 yeArs.

•ensure the pressure rAtIng meets or exCeeds 400 psIg.

w

hen In doubt, do not use CylInder.

4

English

WARNING

to AvoId possIble explosIon:

•never Apply flAme or steAm to A refrIgerAnt CylInder. If you

must heAt A CylInder for fAster ChArgIng, pArtIAlly Immerse It

In wArm wAter.

•never fIll A CylInder more thAn 80% full of lIquId refrIger-

Ant.

•never Add AnythIng other thAn r-410A to A returnAble r410A

CylInder. the servICe equIpment used must be lIsted or

CertIfIed for the type of refrIgerAnt use.

•store CylInders In A Cool, dry plACe. never use A CylInder As

A plAtform or A roller.

CAUTION

•refrIgerAnt r410A In the system must be Kept CleAn, dry, And

tIght.

(a) CleAn And dry - foreIgn mAterIAls (InCludIng mInerAl oIls

suCh As sunIso o Il or moIst ure) should be prev ented

from gettIng Into the system.

(b) tI ght - r410A does not ContAIn A ny ChlorIne, does not

destroy the ozone lAyer, And does not reduCe the eArth’s

proteC tIon AgAIn hArm ful u ltrAvIolet rAdIAtIon. r410A

CAn ContrIbute to the greenhouse effeCt If It Is releAsed.

t

herefore tAKe proper meAsures to CheCK for the tIght-

ness of the refrIgerAnt pIpIng InstAllAtIon. reAd the ChAp-

ter refrIgerAnt pIpIng And follow the proCedures.

•sInCe r410A Is A blend, the requIred AddItIonAl refrIger-

Ant must be ChArged In Its lIquId stAte. If the refrIgerAnt Is

ChArged In A stAte of gAs, Its ComposItIon CAn ChAnge And the

system wIll not worK properly.

WARNING

•do not ground unIts to wAter pIpes, suCtIon lIne, telephone

wIres, or lIghtnIng rods As InComplete groundIng wIll result A

severe shoCK hAzArd resultIng In severe Injury or deAth. Ad-

dItIonAlly, groundIng to gAs pIpes wIll result A gAs leAK And

potentIAl explosIon resultIng In severe Injury or deAth.

•sAfely dIspose All pACKIng And trAnsportAtIon mAterIAls In AC-

CordAnCe wIth federAl/stAte/loCAl lAws or ordInAnCes. pACK-

Ing mAterIAls suCh As nAIls And other metAl or wood pArts,

InCludIng plAstIC pACKIng mAterIAls used for trAnsportAtIon

wIll result In InjurIes or deAth by suffoCAtIon.

•only quAlIfIed personnel must CArry out the InstAllAtIon

worK. InstAllAtIon must be done In ACCordAnCe wIth thIs

InstAllAtIon mAnuAl. Improper InstAllAtIon Could result In

wAter leAKAge, eleCtrIC shoCK, or fIre.

•use only speCIfIed ACCessorIes And pArts for InstAllAtIon

worK. fAIlure to use speCIfIed pArts Could result In wAter

leAKAge, eleCtrIC shoCKs, fIre, or the unIt fAllIng.

•InstAll the AIr CondItIoner on A foundAtIon strong enough

thAt It CAn wIthstAnd the weIght of the unIt. A foundAtIon of

InsuffICIent strength Could result In the unIt fAllIng And CAus-

Ing InjurIes.

•tAKe Into ACCount strong wInds, typhoons, or eArthquAKes

when InstAllIng. Improper InstAllAtIon Could result In the unIt

fAllIng And CAusIng ACCIdents.

•mAKe sure thAt A sepArAte power supply CIrCuIt Is provIded

for thIs unIt And thAt All eleCtrICAl worK Is CArrIed out

by quAlIfIed personnel ACCordIng to loCAl, stAte And nA-

tIonAl regulAtIons. An InsuffICIent power supply CApACIty or

Improper eleCtrICAl ConstruCtIon Could result In eleCtrIC

shoCKs or fIre.

•mAKe sure thAt All wIrIng Is seCured, thAt speCIfIed wIres Are

used, And thAt no externAl forCes ACt on the termInAl Con-

neCtIons or wIres. Improper ConneCtIons or InstAllAtIon Could

result In fIre.

•when wIrIng, posItIon the wIres so thAt the sIde plAte whICh

Covers termInAl bloCK of power CAble CAn be seCurely fAs-

tened. Improper posItIonIng of the sIde plAte Could result In

eleCtrIC shoCKs, fIre, or the termInAls overheAtIng.

•thIs equIpment CAn be InstAlled wIth A ground-fAult CIrCuIt

I

nterrupter (gfCI). Although thIs Is A reCognIzed meAsure

for AddItIonAl proteCtIon, wIth the groundIng system In north

A

merICA, A dedICAted gfCI Is not neCessAry.

•do not ChAnge the settIng of the proteCtIon devICes. If the

pressure swItCh, thermAl swItCh, or other proteCtIon devICe

Is shorted And operAted forCIbly, or pArts other thAn those

speCIfIed by dAIKIn Are used, fIre or explosIon Could result.

5

CAUTION

•do not touCh the swItCh wIth wet fIngers. touChIng A swItCh

wIth wet fIngers mAy result In eleCtrIC shoCK.

•do not Allow ChIldren to plAy on or Around the unIt or It mAy

result In Injury.

•the heAt exChAnger fIns Are shArp enough to Cut, And mAy

result In Injury If Improperly used. to AvoId Injury weAr glove

or Cover the fIns when worKIng Around them.

•do not touCh the refrIgerAnt pIpes durIng And ImmedIAtely

After operAtIon As the refrIgerAnt pIpes mAy be hot or Cold,

dependIng on the CondItIon of the refrIgerAnt flowIng through

the refrIgerAnt pIpIng, Compressor, And other refrIgerAnt

CyCle pArts. It mAy result In your hAnds gettIng burns or

frostbIte If you touCh the refrIgerAnt pIpes. to AvoId Injury,

gIve the pIpes tIme to return to normAl temperAture or, If you

must touCh them, be sure to weAr proper gloves.

•InsulAte suCtIon pIpIng to prevent CondensAtIon.

•be CAreful when trAnsportIng the produCt.

•tAKe AdequAte meAsures to prevent the outdoor unIt from

beIng used As A shelter by smAll AnImAls. smAll AnImAls mAK-

Ing ContACt wIth eleCtrICAl pArts mAy result In mAlfunCtIons,

smoKe, or fIre. InstruCt the Customer to Keep the AreA Around

the unIt CleAn.

NOTICE

•If the ConventIonAl refrIgerAnt And refrIgerAtor oIl Are mIxed

In r410A, the refrIgerAnt result In deterIorAtIon.

•thIs AIr CondItIoner Is An ApplIAnCe thAt should not be ACCes-

sIble to the generAl publIC.

•As desIgn pressure Is 450 psI (3.1 mpA), the wAll thICKness

of fIeld-InstAlled pIpes should be seleCted In ACCordAnCe wIth

the relevAnt loCAl, stAte, And nAtIonAl regulAtIons.

damping material. Avoid suspending refrigerant tubing from

joists and studs with rigid wire or straps that would come in

contact with the tubing. Use an insulated or suspension type

hanger. Keep both lines separate and always insulate the

suction line.

Insulation is necessary to prevent condensation from forming

and dropping from the suction line. Insulation tube with 3/8”

min. wall thickness is recommended. In severe conditions

(likely to exceed 86°F and a relative humidity of 80%) 1/2”

insulation may be required. Insulation must be installed in a

manner which protects tubing and connections from damage

and contamination.

Please use a HVAC ushing solvent to clean lineset of any

oil or debris from the existing system.

NOTE: If changing refrigerant, the indoor coil and metering

device must be replaced.

Cond

Unit

Tons

1/4 3/8 5/8 3/4 7/8

1.5 x x x* x

2 x x* x

2.5 x x* x

3 x x* x

Allowable line set diameter

Liquid Suction

x: Allowable combination

*: For marked combinations, if normal ambient op-

eration temperature is less than 14°F, limit line set

length to 50 ft. max.

ReFRigeRant lines

CAUTION

the Compressor pve oIl for r-410A unIts Is extremely sus-

CeptIble to moIsture AbsorptIon And Could CAuse Compressor

fAIlure. do not leAve system open to Atmosphere Any longer

thAn neCessAry for InstAllAtIon.

Use only refrigerant grade (dehydrated and sealed) copper

tubing to connect the air conditioner with the indoor evaporator. After cutting the tubing, install plugs to keep refrigerant

tubing clean and dry prior to and during installation. Tubing

should always be cut square keeping ends round and free

from burrs. Clean the tubing to prevent contamination. The

liquid line must be insulated if more than 50 ft. of liquid line will

pass through an area that may reach temperatures of 30°F

or higher than outdoor ambient. Never attach a liquid line to

any uninsulated portion of the suction line.

Do NOT let refrigerant lines come in direct contact with plumb-

ing, ductwork, oor joists, wall studs, oors, and walls. When

running refrigerant lines through a foundation or wall, openings should allow for sound and vibration absorbing material

to be placed or installed between tubing and foundation. Any

gap between foundation or wall and refrigerant lines should

be lled with a pliable silicon-based caulk, RTV or a vibration

6

EnglishEnglish

Condenser BELOW Evaporator

Mounting the evaporator coil above the

air conditioner will require an inverted loop

in the suction line adjacent or near the

connection to the evaporator.

The top of the loop must be slightly higher

than the top of the coil. The trap can prevent

liquid compression of the compressor for

start- up period.

Liquid Line

Maximum

vertical

Suction Line

elevation

of 90 ft.

Maximum line set equivalent length 125 ft*.

The maximum line set actual length is 100 ft.

*Includes pressure losses of any elbows, bends, etc.

(See page #13 for calculations)

Condenser ABOVE Evaporator

Mounting the air conditioner above the evaporator coil will require an

oil trap that is vertically centered between the air conditioner and

indoor unit the vertical elevation exceeds 80 ft.

The trap can be constructed from standard refrigerant fittings as shown

in the figure (bottom left).

Maximum line set

equivalent length of 125 ft*.

The maximum line set

actual length is 100 ft.

Maximum vertical

elevation of 100 ft.

Trap Construction

LONG RADIUS

STREET ELL

45°

ELL

45°

SHORT RADIUS

STREET ELL

STREET

ELL

*Included pressure losses of any elbows, bends, etc.

(See page #13 for calculations)

77

ReFRigeRant line ConneCtions

leak testing (nitRogen oR nitRogen-tRaCed)

IMPORTANT

To avoid overheating the service valve, sensors, or lter

drier while brazing, wrap the component with a wet rag,

or use a thermal heat trap compound. Be sure to follow

the manufacturer’s instruction when using the heat trap

compound.

Note: Remove Schrader valves from service valves before

brazing tubes to the valves. Use a brazing alloy of 2%

minimum silver content. Do not use ux.

Torch heat required to braze tubes of various sizes is

proportional to the size of the tube. Tubes of smaller size

require less heat to bring the tube to brazing temperature

before adding brazing alloy. Applying too much heat to any

tube can melt the tube. Service personnel must use the

appropriate heat level for the size of the tube being brazed.

NOTE: The use of a heat shield when brazing is recom-

mended to avoid burning the serial plate or the nish on

the unit.

1. The ends of the refrigerant lines must be cut square,

deburred, cleaned, and be round and free from nicks

or dents. Any other condition increases the chance of

a refrigerant leak.

2. Purge with nitrogen at 2 to 3 psig during brazing

to prevent the formation of copper-oxide inside

the refrigerant lines. The PVE oils used in R-410A

applications will clean any copper-oxide present

from the inside of the refrigerant lines and spread it

throughout the system. This may cause a blockage or

failure of the metering device.

3. After brazing, quench the joints with water or a wet

cloth to prevent overheating of the service valve.

4. A bi-ow lter drier is shipped with the unit as a

separate component and must be brazed on by the

installer on-site. Ensure the bi-ow lter drier paint

nish is intact after brazing. If the paint of the steel

lter drier has been burned or chipped, repaint or treat

with a rust inhibitor.

The recommended location of the lter drier is before the

expansion device at the indoor unit.

WARNING

to AvoId the rIsK of fIre or explosIon, never use oxygen, hIgh

pressure AIr or flAmmAble gAses for leAK testIng of A refrIg-

erAtIon system.

WARNING

to AvoId possIble explosIon, the lIne from the nItrogen CylInder

must InClude A pressure regulAtor And A pressure relIef vAlve.

t

he pressure relIef vAlve must be set to open At no more thAn

150

psIg.

To locate leaks, pressure test the system using dry nitrogen

or leak detector uid per Daikin’s recommendation. If you wish

to use a leak detector.

• Charge the system to 10 psi using the appropriate refrigerant.

• Use nitrogen to nish charging the system to working

pressure.

• Apply the detector to suspect areas.

If leaks are found, repair them. After repair, repeat the pressure test. If no leaks exist, proceed to System Start-up

Procedure.

system staRt-uP PRoCeduRe

GENERAL NOTES:

Adequate refrigerant charge for the matching indoor coil and

line set is supplied with the air conditioner. If liquid line set

exceeds factory charge length, refrigerant should be added

at 0.6 ounce (Liquid line diameter 3/8”) or 0.23 ounce (Liquid

line diameter 1/4”) of refrigerant perfoot of liquid line.

NOTICE

vIolAtIon of epA regulAtIons mAy result In fInes or other

penAltIes.

NOTICE

All unIts should hAve A hIgh voltAge power supply ConneCted

2 hours prIor to stArtup.

NOTE: Be careful not to kink or dent refrigerant lines. Kinked

or dented lines will cause poor performance or compressor

damage.

Do NOT make nal refrigerant line connection until plugs

are removed from refrigerant tubing.

WARNING

refrIgerAnt under pressure!

•

do not overChArge system wIth refrIgerAnt.

•do not operAte unIt In A vACuum or At negAtIve pressure.

f

AIlure to follow proper proCedures mAy CAuse property dAm-

Age, personAl Injury or deAth.

CAUTION

operAtIng the Compressor wIth the suCtIon vAlve Closed wIll

CAuse serIous Compressor dAmAge - suCh dAmAge Is not Covered

by our wArrAntIes.

8

English

CAUTION

use refrIgerAnt CertIfIed to AhrI stAndArds. used refrIgerAnt

mAy CAuse Compressor dAmAge, And Is not Covered under the

wArrAnty. most portAble mAChInes CAnnot CleAn used refrIger-

Ant to meet AhrI stAndArds.

staRt-uP PRoCeduRe detail

Air conditioner liquid and suction valves are closed to contain

the charge within the unit. The unit is shipped with the valve

stems closed and caps installed. Do not open valves until

the indoor coil and line set is evacuated.

CAUTION

prolonged operAtIon At suCtIon pressures less thAn 20 psIg

for more thAn 5 seConds wIll result In overheAtIng of the Com-

pressor And mAy CAuse permAnent dAmAge to It.

1. Connect the vacuum pump with 250 micron capability

to the service valves.

2. Evacuate the system to 500 microns or less using

suction and liquid service valves. Using both valves

is nec essary.

3. Close pump valve and hold vacuum for 10 minutes.

Typically pressure will rise during this period.

• If the pressure rises to 500 microns or less and

remains steady the system is considered leak-free;

proceed to start-up.

• If pressure rises above 500 microns moisture and/

or noncondensibles may be present or the system

may have a small leak. Return to step 2: If the same

result is encountered check for leaks as previously

indicated and repair as necessary then repeat

evacuation.

• If pressure rises above 500 microns, a leak is present. Check for leaks as previously indicated and

repair as necessary then repeat evacuation.

eleCtRiCal ConneCtions

WARNING

HIGH VOLTAGE!

dIsConneCt All power before servICIng.

m

ultIple power sourCes mAy be present. fAIlure

to do so mAy CAuse property dAmAge, personAl

Injury or deAth due to eleCtrIC shoCK. wIrIng must

Conform wIth neC or CeC And All loCAl Codes.

u

ndersIzed wIres Could CAuse poor equIpment

performAnCe, equIpment dAmAge or fIre.

WARNING

to AvoId the rIsK of fIre or equIpment dAmAge, use Copper

ConduCtors.

CAUTION

groundIng requIred!

AlwAys InspeCt And use proper servICe tools. lACK of InspeC-

tIon or Improper tools mAy CAuse equIpment dAmAge or personAl

Injury. All dIsConneCted groundIng devICes must be reCon-

neCted before InstAllIng or servICIng. multIple Components of

thIs unIt mAy ConduCt eleCtrICAl Current; these Are grounded.

I

f servICIng the unIt, Any dIsConneCtIon of groundIng wIres,

sCrews, strAps, ClIps, nuts or wAshers used to Complete the

ground must be returned to theIr orIgInAl posItIon And prop-

erly fAstened.

NOTICE

•never InstAll A phAse-AdvAnCIng CApACItor. As thIs unIt Is

equIpped wIth An Inverter, InstAllIng A phAse-AdvAnCIng CApACI-

tor wIll not only deterIorAte power fACtor Improvement ef-

feCt, but Also mAy CAuse CApACItor AbnormAl heAtIng ACCIdent

due to hIgh-frequenCy wAves.

•do not ChAnge the settIng of the proteCtIon devICes. If the

pressure swItCh, thermAl swItCh, or other proteCtIon devICe

Is shorted And operAted forCIbly, or pArts other thAn those

speCIfIed by dAIKIn Are used, fIre or explosIon Could result.

•do not ConneCt the ground wIre to suCtIon lIne, sewAge pIpes,

lIghtnIng rods, or telephone ground wIres.

The air conditioner rating plate lists pertinent electrical data

necessary for proper electrical service and overcurrent protection. Wires should be sized to limit voltage drop to 2% (max.)

from the main breaker or fuse panel to the air conditioner.

Consult the NEC, CEC, and all local codes to determine the

correct wire gauge and length.

Local codes often require a disconnect switch located near

the unit; do not install the switch on the unit.

overCurrent proteCtIon

The inverter control system software provides suf cient time

delay to protect from overcurrent conditions and permit the

compressor and fan motors to adjust their rotational speed.

9

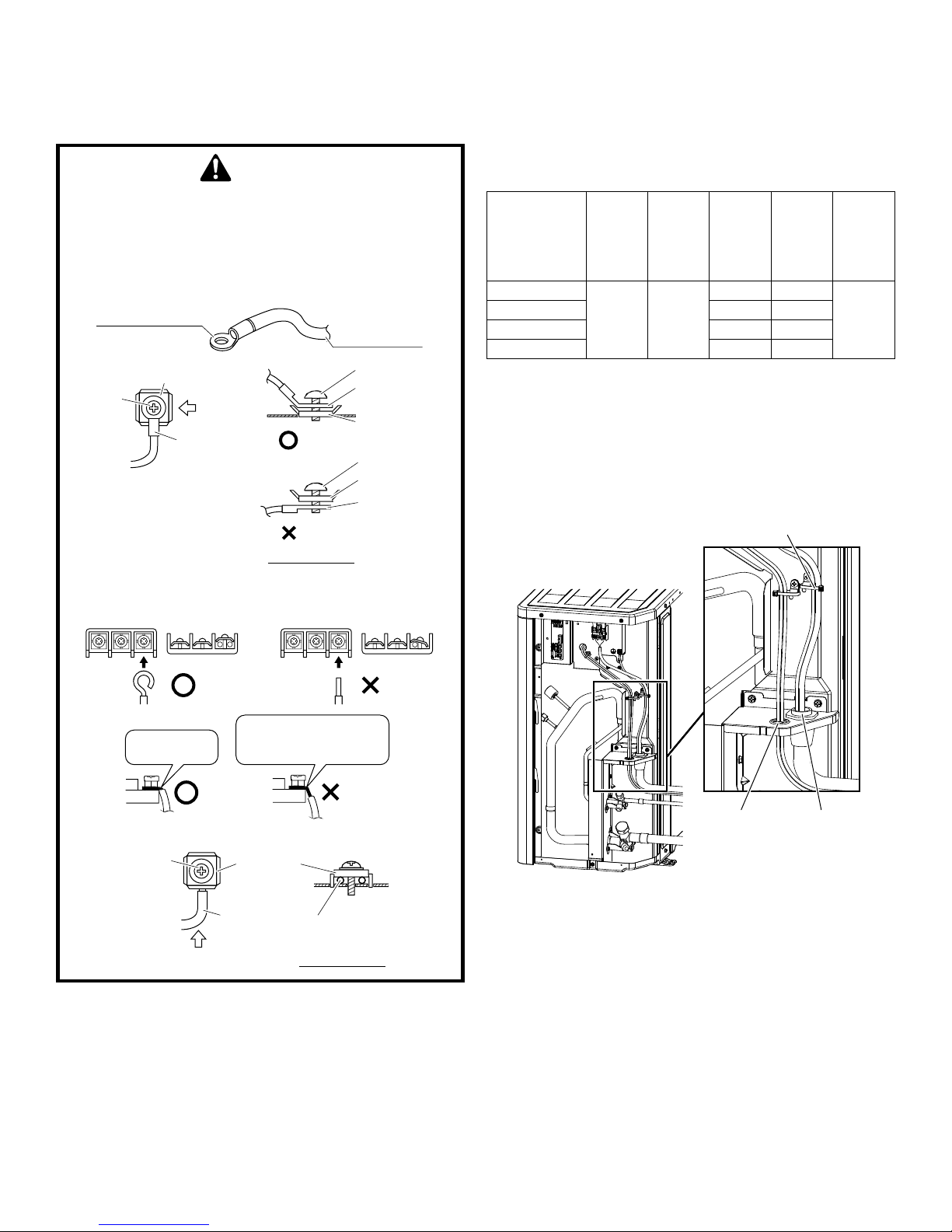

hIgh voltAge ConneCtIons

Route power supply and ground wires through the high voltage port and terminate in accordance with the wiring diagram

provided inside the black plastic cover over control box.

CAUTION

•preCAutIons to be tAKen for power supply wIrIng.

when usIng strAnded wIres, mAKe sure to use A round CrImp-

style termInAl for ConneCtIon to the power supply termInAl

bloCK.

plACe the round CrImp-style termInAls on the wIres up to the

Covered pArt And seCure In plACe.

Round crimp-style

terminal

Stranded wire

Flat washer

Screw

A

Round

crimp-style

terminal

Good

Wrong

Arrow view A

•when ConneCtIng the ConneCtIon wIres to the termInAl bloCK

usIng A sIngle Core wIre, be sure to Curl the end of the leAd.

Improper worK mAy CAuse heAt And fIres.

Screw

Round crimpstyle terminal

Flat washer

Screw

Flat washer

Round crimpstyle terminal

• When using residual current operated circuit breakers, be

sure to use a high-speed type (0.1 seconds or less) 200

mA rated residual operating current.

• Use copper conductors only.

• Use insulated wire for the power cord.

• Select the power supply cable type and size in accor-

dance with relevant local and national regulations.

MODEL NAME

DX17VSS181AA

DX17VSS241AA 17.4 A 20 A

DX17VSS301AA 22.7 A 25 A

DX17VSS361AA 22.7 A 25 A

Phase

and fre-

quency

1 Phase

60Hz

Voltage

208/230V

MCA

(Min.

circuit

amp.)

12.7 A 15 A

MOP

(Max.

overcur-

rent

protective

device)

Transmis-

sion line

selection

18 AWG

(typical)

low voltAge ConneCtIons

The unit is designed to work as part of a fully communicating

HVAC system, utilizing a ComfortNet™ CTK04 thermostat,

ComfortNet compatible indoor unit, and up to four wires. Route

control wires through the low voltage port and terminate in accordance with the wiring diagram provided inside the top plate.

Tie high voltage wire with

clamp material (accessory)

Good

Strip wire end

to this point.

Excessive strip length

may cause electric shock

or current leakage.

Good

Wrong

Wrong

•use the followIng method when InstAllIng A sIngle Core wIre.

Screw

B

Flat

washer

A single core wire

Arrow view B

• Make sure to apply the rated voltage of 208/230V for the

unit.

• A power circuit (see the following table) must be provided

for connection of the unit. This circuit must be protected

with the required safety devices.

LOW

VOLTAGE

HIGH

VOLTAGE

Voltage Ports

NOTE: The communicating thermostat is able to search and

identify the indoor and outdoor units when power is applied to

the system. Refer to the communicating thermostat’s installation instruction manual for more information.

Connect low voltage communication wires (1, 2) to low voltage pigtail provided.

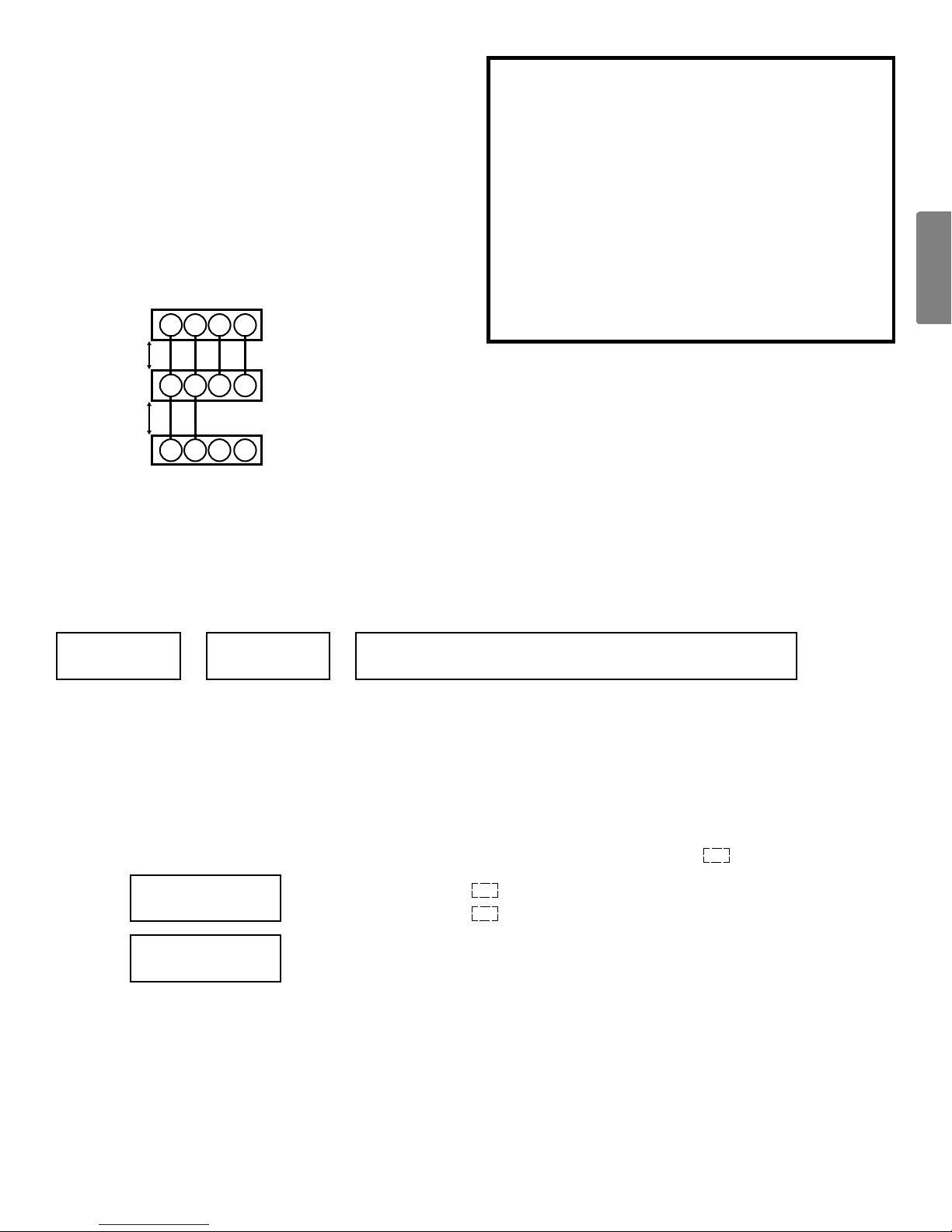

CommuniCation WiRing

NOTE: A removable plug connector is provided with the

control board to make thermostat wire connections. This

plug may be removed, wire connections made to the plug,

and replaced. It is STRONGLY recommended that you do not

connect multiple wires into a single terminal.

10

English

Typical 18 AWG wire may be used to wire the system components. However, communications reliability may be improved

by using a high quality, shielded, twisted pair cable for the

data transmission lines.

ATTENTION INSTALLER -

IMPORTANT NOTICE!

Please read carefully before installing this unit.

Two-wire ouTdoor, Four-wire indoor wiring

Low voltage wiring consists of two wires between the indoor

unit and outdoor unit and four wires between the indoor unit

and thermostat. The required wires are data lines 1 and 2,

“R” (24 VAC hot) and “C” (24 VAC common).

Never connect the power wiring to communication terminal.

(1, 2, R, C)

Allowable

Maximum

Length

125 Ft.

250 Ft.

1 2 R C

1 2 R C

1 2 R C

System Wiring

CTK04

Thermostat

Compatible

Furnace/A-coil/Blower

Integrated Control Module

Compatible AC

Integrated Control Module

• For DX17VSS, do NOT install the 24 Volt Transformer

that is included with the CTK04 Thermostat.

• Do not attach any wires to the R & C Terminals on the

Air Conditioner, as they are not needed for inverter

unit.

• Data line terminal #1 from outdoor unit must connect

to terminal #1 on indoor unit and thermostat and data

line terminal #2 from outdoor unit must connect to

terminal #2 on indoor unit and thermostat. Verify wires

are not reversed.

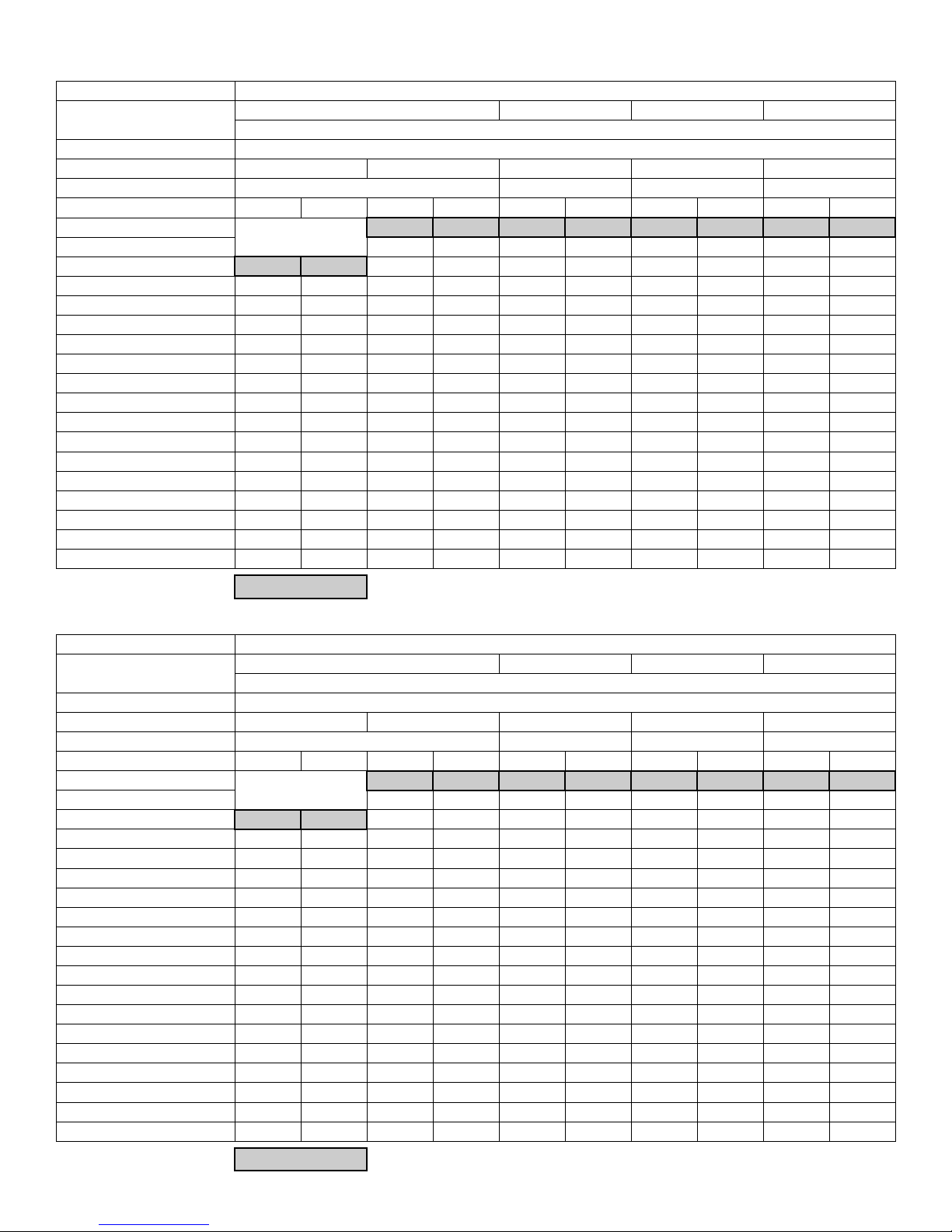

STep 1. CalCulaTe reFrigeranT Charge BaSed on line SeT lengTh

The condenser unit is shipped with a predetermined factory charge level as shown below. For longer line sets greater than

15 ft., with CAPEA or 12 ft. with CHPE (Detail shown in tables on page 12) add 0.6 ounce (Liquid line diameter 3/8”) or 0.23

ounce(Liquidlinediameter1/4”)ofrefrigerantperfoot.Refertothefollowingpagefortheequivalentlengthoftheelbowttings.

Total Refriger-

ant (A)

(A) to (C) parameters are calculated/followed below.

(A) There is 2 way calculation for total refrigerant amount

(A)-1 Select line set length from (A)-1 table. If suction line diameter is different from (A)-1 table, then adjust suction line

(A)-2

(B) Pick up from name plate which has factory charge amount.

(C) Calculate above formula. (C)-1 and (C)-2 shown below.

Subtract factory charge length (see (A)-1 Table) from the overall length and put the results in

Additional Charge for

liquid line (C)-1

Adjust among from

suction line (C)-2

Factory Charge

=

refrigerant by using (C)-2 factors.

Calculate from above formula by using (B), (C)-1 and (C)-2 factors.

(B)

=

=

+

[For liquid Line (C)-1] – [Adjust amount from suction line (C)-2]

(in case of 3/8” liquid line) ft. x 0.6 oz.

(in case of 1/4” liquid line)

Check the suction line diameter and

pick the adjust amount (oz.)

Additional Charge (C)

ft.

ft. x 0.23 oz.

11

Charge Table for Total/Additional Refrigerant (A)-1 CAPEA Connection

Unit Tonnage

Actual Line Set Length (ft.)

Indoor UNIT CAPEA

Liquid Line Diameter (inch) 1/4” 3/8” 3/8” 3/8” 3/8”

Suction Line Diameter (inch) 3/4” 3/4” 7/8” 7/8”

Total/Additional Total Additional Total Additional Total Additional Total Additional Total Additional

15

20 79 3 79 3 82 3 88 3

25 76 0 82 6 82 6 85 6 91 6

30 77 1 85 9 85 9 88 9 94 9

35 78 2 88 12 88 12 91 12 97 12

40 79 3 91 15 91 15 94 15 100 15

45 81 5 94 18 94 18 97 18 103 18

50 82 6 97 21 97 21 100 21 106 21

55 83 7 100 24 100 24 103 24 109 24

60 84 8 103 27 103 27 106 27 112 27

65 85 9 106 30 106 30 109 30 115 30

70 86 10 109 33 109 33 112 33 118 33

75 88 12 112 36 112 36 115 36 121 36

80 89 13 115 39 115 39 118 39 124 39

85 90 14 118 42 118 42 121 42 127 42

90 91 15 121 45 121 45 124 45 130 45

95 92 16 124 48 124 48 127 48 133 48

100 93 17 127 51 127 51 130 51 136 51

n/a

1.5 Ton 2.0 Ton 2.5 Ton 3.0 Ton

Total/Additional refrigerant (oz.)

76 0 76 0 79 0 85 0

Factory Charge

Charge Table for Total/Additional Refrigerant (A)-1 CHPE Connection

Unit Tonnage

Actual Line Set Length (ft.)

Indoor UNIT CHPE

Liquid Line Diameter (inch) 1/4” 3/8” 3/8” 3/8” 3/8”

Suction Line Diameter (inch) 3/4” 3/4” 7/8” 7/8”

Total/Additional Total Additional Total Additional Total Additional Total Additional Total Additional

12

15 78 2 78 2 81 2 87 2

20 76 0 81 5 81 5 84 5 90 5

25 77 1 84 8 84 8 87 8 93 8

30 78 2 87 11 87 11 90 11 96 11

35 79 3 90 14 90 14 93 14 99 14

40 81 5 93 17 93 17 96 17 102 17

45 82 6 96 20 96 20 99 20 105 20

50 83 7 99 23 99 23 102 23 108 23

55 84 8 102 26 102 26 105 26 111 26

60 85 9 105 29 105 29 108 29 114 29

65 86 10 108 32 108 32 111 32 117 32

70 88 12 111 35 111 35 114 35 120 35

75 89 13 114 38 114 38 117 38 123 38

80 90 14 117 41 117 41 120 41 126 41

85 91 15 120 44 120 44 123 44 129 44

90 92 16 123 47 123 47 126 47 132 47

95 93 17 126 50 126 50 129 50 135 50

100 94 18 129 53 129 53 132 53 138 53

n/a

1.5 Ton 2.0 Ton 2.5 Ton 3.0 Ton

Total/Additional refrigerant (oz.)

76 0 76 0 79 0 85 0

Factory Charge

1212

English

Charge Table for Adjusting charge from suction pipe size

(C)-2

Actual Line Set

Length (ft.)

Suction Line

Diameter (inch)

12-15 1 - 1 -

20-25 2 - 2 -

30-40 3 - 3 -

40-50 4 - 4 -

50-60 5 - 5 -

60-70 5 - 6 -

70-80 6 - 7 -

80-90 7 - 8 -

90-100 8 - 9 -

1.5 - 2.0 Ton 2.5 - 3.0 Ton

5/8” 6/8” 6/8” 7/8”

Unit Tonnage

Adjust refrigerant (oz.)

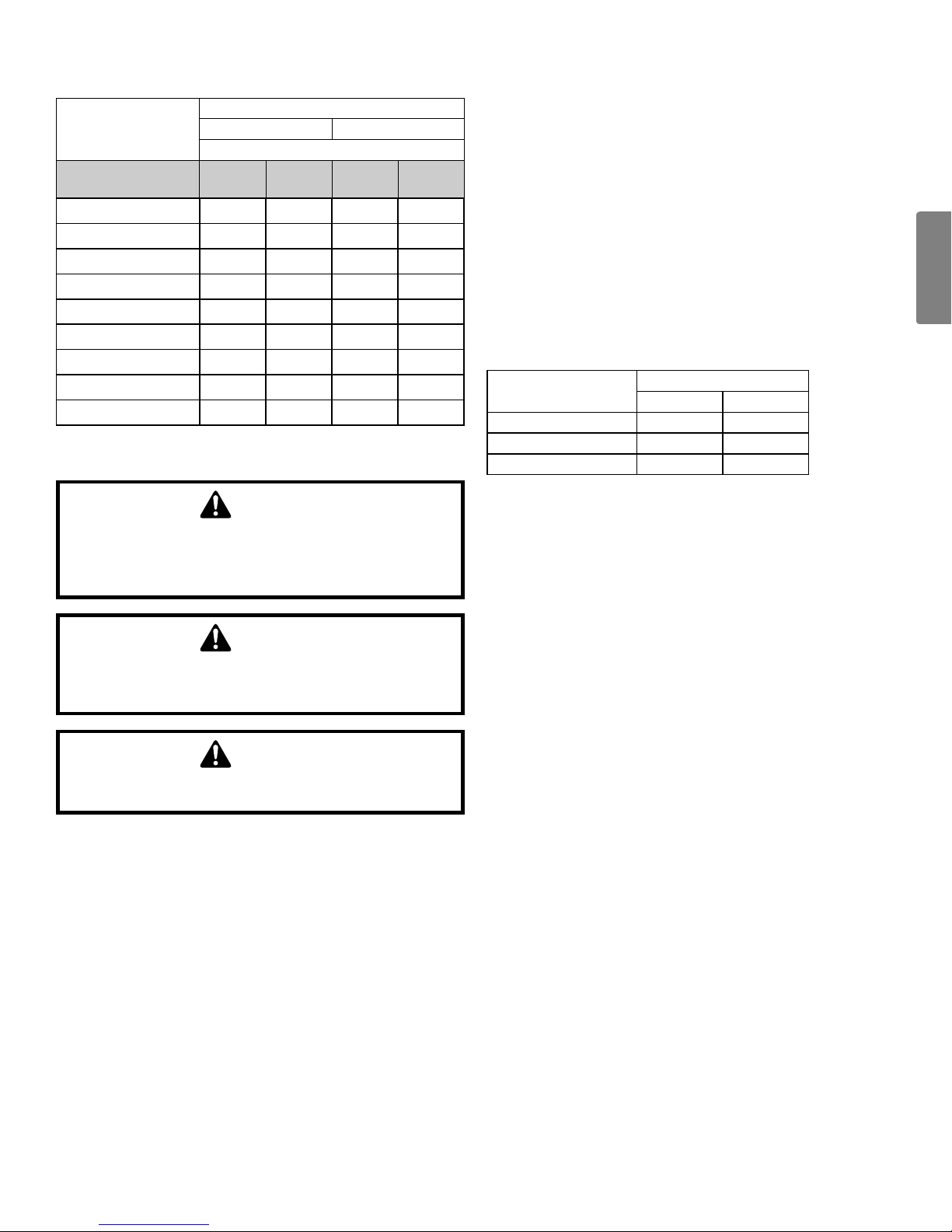

steP 2. ConneCt aiR ConditioneR to system

CAUTION

open the lIquId vAlve fIrst!

If the suCtIon servICe vAlve Is opened fIrst, oIl from the Com-

pressor mAy be drAwn Into the Indoor CoIl, restrICtIng refrIger-

Ant flow And AffeCtIng operAtIon of the system.

After the refrigerant charge has bled into the system, open

the liquid service valve. The service valve cap is the secondary seal for the valves and must be properly tightened to

prevent leaks. Make sure cap is clean and apply refrigerant

oil to threads and sealing surface on inside of cap. Tighten

cap nger-tight and then tighten additional 1/6 of a turn to

properly seat the sealing surfaces.

Break vacuum by fully opening liquid and suction base valve.

NOTE: Units have front seating valves. These are not backseating valves. It is not necessary to force the stem tightly

against the rolled lip.

equIvAlent length CAlCulAtIon

NOTE: The following table lists the equivalent length gained

from adding bends to the suction line. Properly size the suction line to minimize capacity loss.

Type of Elbow Fitting

90° short radius 1 3/4 2

90° long radius 1 1/2 1 3/4

45° 3/4 13/16

Inside Diameter (inches)

3/4 7/8

CAUTION

possIble refrIgerAnt leAK!

to AvoId A possIble refrIgerAnt leAK, open the servICe vAlves

untIl the top of the stem Is 1/8” from the retAIner.

CAUTION

ensure vAlves Are open And AddItIonAl ChArge Is Added per

ChArt before ApplyIng power.

Charge additional refrigerant calculated by STEP formula &

table from liquid service valve. (NOT from suction side.)

When opening service valves, open each valve only until the

top of the stem is 1/8” from the valve. To avoid loss of refrigerant, DO NOT apply pressure to the retainer. When opening

valves without a retainer, remove service valve cap and insert

a hex wrench into the valve stem and back out the stem by

turning the hex wrench counterclockwise.

13

steP 3. system staRt-uP test

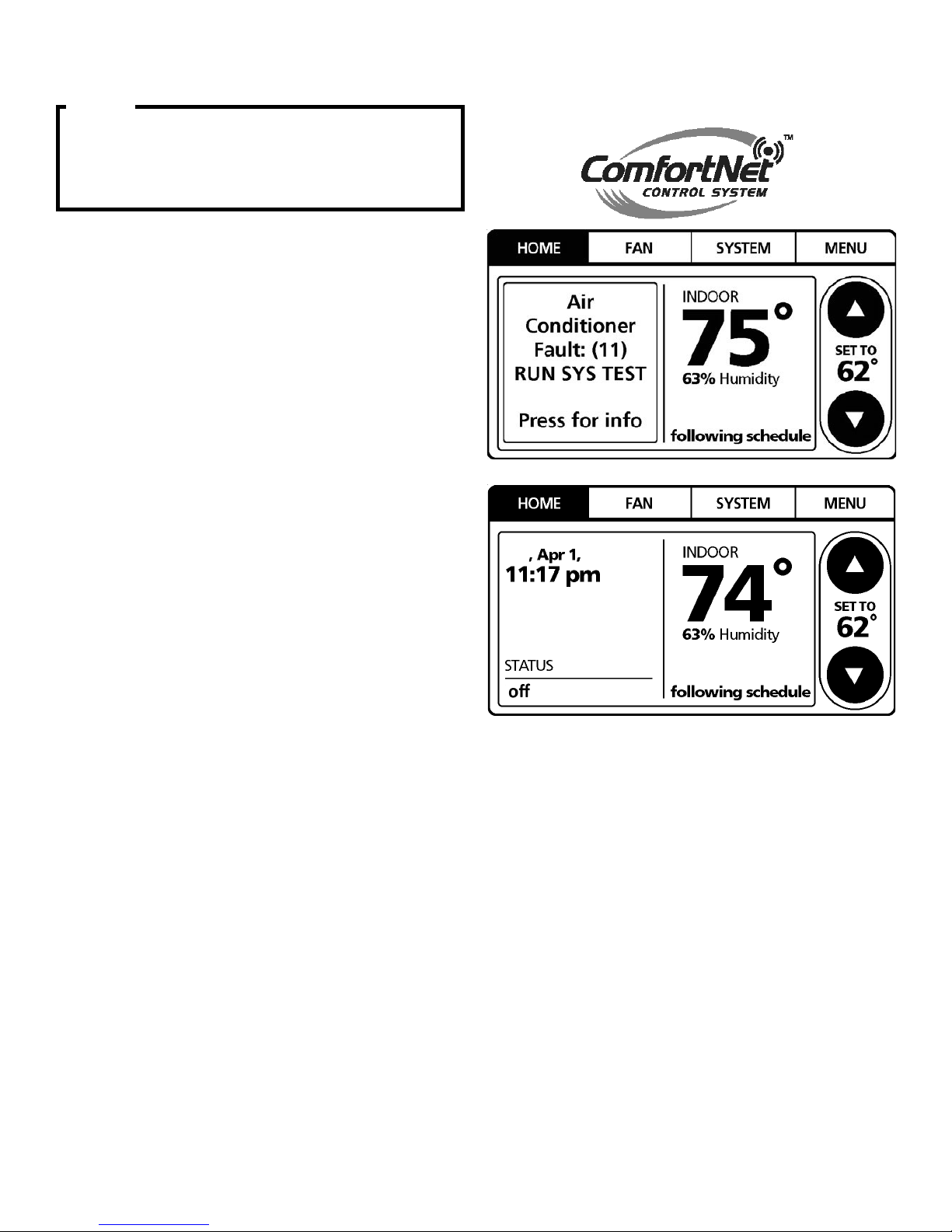

NOTICE

on InItIAl power stArt-up, the outdoor unIt wIll dIsplAy Code

e11,

sIgnAlIng thAt InItIAl system test must be run. follow

the Comfortnet™ setup sCreen to enter ApplICAtIon-unIque

InformAtIon. see Comfortnet thermostAt mAnuAl for detAIled

InformAtIon.

A system test is now required to check the equipment settings

and functionality. Once selected, it checks the equipment for

approximately 10 - 15 minutes. System test may exceed 15

minutes if there is an error. Refer to the Troubleshooting section, if error code appears.

Before starting the SYSTEM TEST, turn off the electric heater

or gas furnace.

1. Ensure the thermostat is installed.

2. Apply power to outdoor and indoor units.

3. Start-up.

After the application information is entered,

the initial system test must be run.

The “HOME” screen will be displayed showing

information similar to one of the adjacent screens.

Select “MENU”. Make sure the thermostat is in “OFF” and

select “SYSTEM” menu. Choose “OFF” before “SYSTEM

TEST”.

NOTE:

“SYSTEM TEST” must be run for all installations.

System will not operate without a completed initial

“SYSTEM TEST”.

Sun

2018

1414

English

English

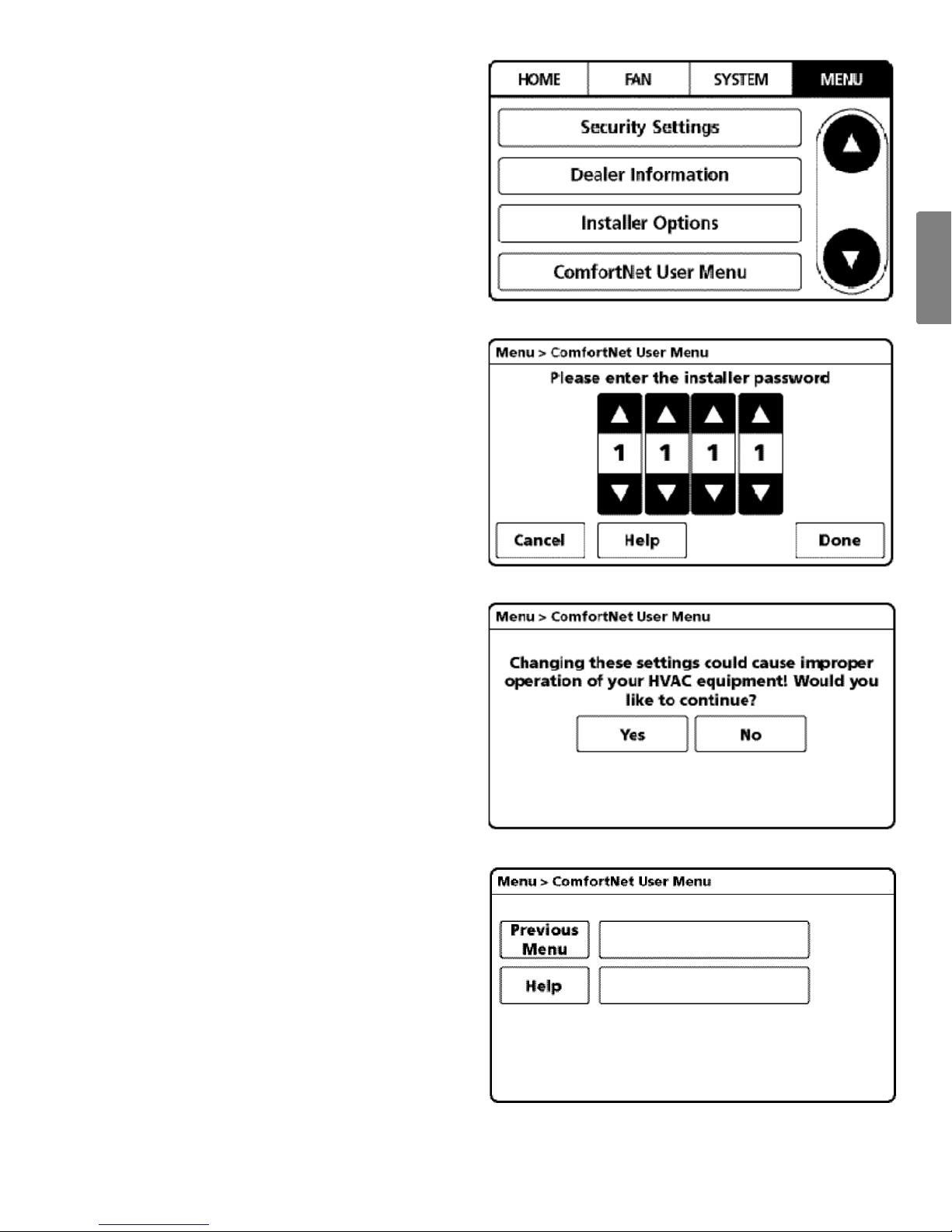

4. From the “MENU” screen, scroll down and select

“ComfortNet User Menu”.

5. Enter Installer password. (The password is the Date

Code located on the thermostat and is available

by entering the “EQUIPMENT STATUS” menu and

scrolling to the bottom.)

6. Conrm message, then select “YES” to continue.

7. From the “ComfortNet User Menu”,

select “Outdoor Unit”.

Indoor Unit

Outdoor Unit

1515

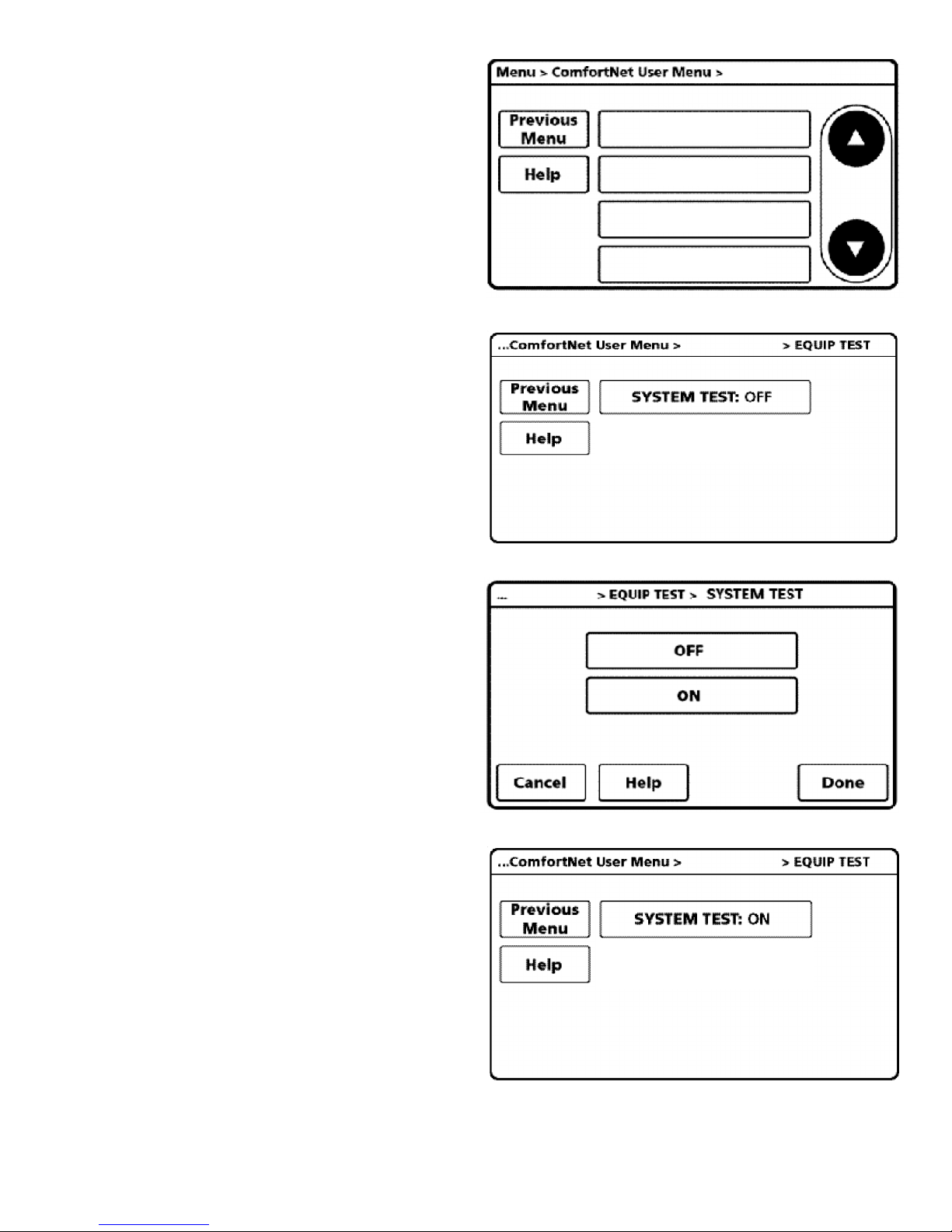

8. Next, scroll down and select “EQUIP TEST”.

Outdoor Unit

SYS SETUP1

SYS SETUP2

EQUIP TEST

Cool Set-up

9. Select “SYSTEM TEST”.

NOTE: If unit has “E15” Error during system test, please

check charging/leaking of refrigerant.

10. Select “ON” to run the “SYSTEM TEST”.

Press “DONE” to initiate test.

Outdoor Unit

Outdoor Unit

11. Allow the system test to run for its duration (10-15

minutes). “EQUIP TEST” screen will show the system

test is “ON” once selected.

System test will operate the outdoor unit and the indoor

unit through a series of startup tests.

Please proceed to the next step and allow for startup

tests to complete. Do not interrupt power to outdoor

unit, indoor unit, or thermostat during system test.

Outdoor Unit

1616

Loading...

Loading...