Daikin RMXS48LVJU, BPMKS048A2U, BPMKS049A3U, CTXS07LVJU, FDXS09LVJU User Manual

...

Service

Manual

Multi-Split 8-Zone

Heat Pump Systems

RMXS-L Series

SiUS181305E

[Applied Models]

Inverter Multi : Heat Pump

Heat Pump Systems

Heat Pump

Outdoor Unit

RMXS48LVJU

Branch Provider (BP) Unit

BPMKS048A2U

BPMKS049A3U

SiUS181305E

Multi-Split 8-Zone

RMXS-L Series

Indoor Unit

CTXS07LVJU FDXS09LVJU FFQ09LVJU

CTXS07JVJU FDXS12LVJU FFQ12LVJU

CTXS09HVJU CDXS15LVJU FFQ15LVJU

CTXS12HVJU CDXS18LVJU FFQ18LVJU

FTXS15LVJU CDXS24LVJU

FTXS18LVJU

FTXS24LVJU

The removal procedure for each model is separately bound. Refer to page 239 for the booklet number of

applicable model.

Table of Contents i

SiUS181305E

Safety Considerations ..................................................................... vii

Part 1 List of Functions ................................................................... 1

1. Functions.....................................................................................................2

1.1 Outdoor Unit ................................................................................................. 2

1.2 Indoor Unit.................................................................................................... 3

Part 2 Specifications........................................................................ 5

1. Specifications ..............................................................................................6

1.1 Outdoor Unit ................................................................................................. 6

1.2 Branch Provider (BP) Unit ............................................................................ 6

1.3 Indoor Unit.................................................................................................... 7

Part 3 Printed Circuit Board

Connector Wiring Diagram .................................................. 13

1. Outdoor Unit..............................................................................................14

1.1 RMXS48LVJU ............................................................................................ 14

2. Branch Provider (BP) Unit.........................................................................17

2.1 BPMKS048A2U, BPMKS049A3U .............................................................. 17

3. Indoor Unit................................................................................................18

3.1 CTXS07LVJU ............................................................................................. 18

3.2 CTXS07JVJU, CTXS09/12HVJU ............................................................... 20

3.3 FTXS15/18/24LVJU ................................................................................... 22

3.4 FDXS09/12LVJU, CDXS15/18/24LVJU ..................................................... 24

3.5 FFQ09/12/15/18LVJU ................................................................................ 26

4. Wired Remote Controller...........................................................................27

4.1 BRC1E72 ................................................................................................... 27

5. Wireless Remote Controller ......................................................................28

5.1 BRC7E830 ................................................................................................. 28

Part 4 Refrigerant Circuit............................................................... 30

1. Refrigerant Circuit .....................................................................................31

1.1 Outdoor Unit ............................................................................................... 31

1.2 Branch Provider (BP) Unit .......................................................................... 32

2. Functional Parts Layout ............................................................................33

3. Refrigerant Flow for Each Operation Mode...............................................35

3.1 Cooling Operation ...................................................................................... 35

3.2 Heating Operation ...................................................................................... 36

3.3 Cooling Oil Return Operation ..................................................................... 37

3.4 Heating Oil Return Operation & Defrost Operation .................................... 38

ii Table of Contents

SiUS181305E

Part 5 Function ............................................................................... 39

1. Operation Mode ........................................................................................41

2. Basic Control.............................................................................................42

2.1 Normal Operation ....................................................................................... 42

2.2 Compressor PI Control............................................................................... 42

2.3 Electronic Expansion Valve PI Control....................................................... 43

2.4 Cooling Operation Fan Control................................................................... 44

3. Special Control..........................................................................................45

3.1 Startup Control ........................................................................................... 45

3.2 Oil Return Operation .................................................................................. 46

3.3 Defrosting Operation .................................................................................. 48

3.4 Pump-down Residual Operation ................................................................ 48

3.5 Restart Standby.......................................................................................... 49

3.6 Stopping Operation .................................................................................... 49

4. Protection Control .....................................................................................50

4.1 High Pressure Protection Control............................................................... 50

4.2 Low Pressure Protection Control................................................................ 51

4.3 Discharge Pipe Temperature Protection Control........................................ 52

4.4 Inverter Protection Control ......................................................................... 53

4.5 Freeze-up Protection Control ..................................................................... 54

4.6 Dew Condensation Prevention Control ...................................................... 55

5. Other Control.............................................................................................56

5.1 Demand Control ......................................................................................... 56

5.2 Heating Operation Prohibition Control........................................................ 56

6. Branch Provider (BP) Unit Control ............................................................57

6.1 Branch Provider (BP) Unit Command Conversion ..................................... 57

6.2 Branch Provider (BP) Unit Electronic Expansion Valve Control................. 58

6.3 SH Control in Cooling Operation ................................................................ 60

6.4 SC Control in Heating Operation................................................................ 61

6.5 Heat Exchanger Isothermal Control in Heating Operation ......................... 61

7. Function of CTXS, FTXS, CDXS, FDXS Series........................................62

7.1 Temperature Control .................................................................................. 62

7.2 Airflow Direction Control (CTXS/FTXS Series Only) .................................. 63

7.3 Fan Speed Control for Indoor Unit ............................................................. 65

7.4 Program Dry Operation .............................................................................. 66

7.5 Automatic Operation................................................................................... 67

7.6 Thermostat Control..................................................................................... 68

7.7 NIGHT SET Mode ...................................................................................... 69

7.8 ECONO Operation ..................................................................................... 69

7.9 HOME LEAVE Operation ........................................................................... 70

7.10 INTELLIGENT EYE Operation ................................................................... 72

7.11 Inverter POWERFUL Operation ................................................................. 73

7.12 Clock Setting .............................................................................................. 74

7.13 WEEKLY TIMER Operation ....................................................................... 75

7.14 Other Functions.......................................................................................... 81

8. Function of FFQ Series .............................................................................82

8.1 Drain Pump Control.................................................................................... 82

Table of Contents iii

SiUS181305E

8.2 Thermostat Sensor in Remote Controller................................................... 84

8.3 Freeze Prevention Control ......................................................................... 86

8.4 Hot Start Control (In Heating Operation Only)............................................ 86

Part 6 Test Operation and Field Settings ...................................... 87

1. Test Operation ..........................................................................................88

1.1 Procedure and Outline ............................................................................... 88

1.2 Operation when Power is Turned On ......................................................... 90

1.3 Branch Provider (BP) Unit .......................................................................... 91

1.4 RA Indoor Unit: CTXS, FTXS, CDXS, FDXS Series .................................. 93

1.5 SA Indoor Unit: FFQ Series........................................................................ 94

2. Field Settings ............................................................................................96

2.1 Outdoor Unit ............................................................................................... 96

2.2 RA Indoor Unit: CTXS, FTXS, CDXS, FDXS Series ................................ 110

2.3 SA Indoor Unit: FFQ Series...................................................................... 113

Part 7 Remote Controller ............................................................. 121

1. CTXS07JVJU, CTXS09/12HVJU ............................................................122

2. CTXS07LVJU, FTXS15/18/24LVJU........................................................124

3. FDXS09/12LVJU, CDXS15/18/24LVJU ..................................................126

4. FFQ09/12/15/18LVJU .............................................................................128

4.1 <BRC1E72> Wired Remote Controller..................................................... 128

4.2 <BRC7E830> Wireless Remote Controller .............................................. 134

Part 8 Troubleshooting................................................................. 136

1. Troubleshooting with LED ....................................................................... 138

1.1 Outdoor Unit ............................................................................................. 138

1.2 Branch Provider (BP) Unit ........................................................................ 143

1.3 Indoor Unit................................................................................................ 144

2. Service Check Function ..........................................................................145

2.1 CTXS, FTXS, CDXS, FDXS Series.......................................................... 145

2.2 FFQ Series ............................................................................................... 148

3. Error Codes and Description...................................................................154

4. Troubleshooting for CTXS, FTXS, CDXS, FDXS Series......................... 156

4.1 Indoor Unit PCB Abnormality ................................................................... 156

4.2 Freeze-up Protection Control or Heating Peak-cut Control...................... 158

4.3 Fan Motor or Related Abnormality ........................................................... 160

4.4 Thermistor or Related Abnormality........................................................... 164

4.5 Check for CTXS, FTXS, CDXS, FDXS Series ......................................... 165

5. Troubleshooting for FFQ Series..............................................................167

5.1 Indoor Unit PCB Abnormality ................................................................... 167

5.2 Drain Level Control System Abnormality.................................................. 168

5.3 Fan Motor or Related Abnormality ........................................................... 169

5.4 Drain System Abnormality........................................................................ 170

5.5 Thermistor or Related Abnormality........................................................... 171

5.6 Remote Controller Thermistor Abnormality .............................................. 172

iv Table of Contents

SiUS181305E

5.7 Signal Transmission Error between Remote Controller and Indoor Unit.. 173

5.8 Signal Transmission Error between MAIN Remote Controller and

SUB Remote Controller............................................................................ 174

5.9 Field Setting Abnormality ......................................................................... 175

6. Troubleshooting for Branch Provider (BP) Unit.......................................176

6.1 Electronic Expansion Valve Abnormality.................................................. 176

6.2 Branch Provider (BP) Unit PCB Abnormality............................................ 177

6.3 Branch Provider (BP) Liquid or Gas Pipe Thermistor Abnormality........... 178

6.4 Signal transmission Error between Indoor Unit and

Branch Provider (BP) Unit ........................................................................ 179

6.5 Tran sm ission Error b et ween Outdoor Un it and

Branch Provider (BP) Unit ........................................................................ 181

6.6 Check for Branch Provider (BP) Unit........................................................ 182

7. Troubleshooting for Outdoor Unit............................................................183

7.1 Outdoor Unit PCB Abnormality................................................................. 183

7.2 Actuation of High Pressure Switch ........................................................... 184

7.3 Actuation of Low Pressure Sensor ........................................................... 186

7.4 Compressor Motor Lock ........................................................................... 188

7.5 Outdoor Fan Motor Abnormality............................................................... 189

7.6 Moving Part of Electronic Expansion Valve (Y1E, Y3E) Abnormality....... 190

7.7 Discharge Pipe Temperature Abnormality ............................................... 192

7.8 Refrigerant Overcharged.......................................................................... 193

7.9 Outdoor Temperature Thermistor (R1T) Abnormality .............................. 194

7.10 Discharge Pipe Thermistor (R2T) Abnormality......................................... 195

7.11 Suction Pipe Thermistor (R3T, R5T) Abnormality .................................... 196

7.12 Outdoor Heat Exchanger Thermistor (R4T) Abnormality ......................... 197

7.13 Outdoor Liquid Pipe Thermistor (R7T) Abnormality ................................. 198

7.14 Subcooling Heat Exchanger Gas Pipe Thermistor (R6T) Abnormality..... 199

7.15 High Pressure Sensor Abnormality .......................................................... 200

7.16 Low Pressure Sensor Abnormality ........................................................... 201

7.17 Outdoor Unit PCB Abnormality................................................................. 202

7.18 Radiation Fin Temperature Rise .............................................................. 203

7.19 Inverter Compressor Abnormality............................................................. 204

7.20 Inverter Current Abnormality .................................................................... 205

7.21 Compressor Start-up Error ....................................................................... 206

7.22 High Voltage of Capacitor in Main Inverter Circuit ................................... 207

7.23 Radiation Fin Thermistor Abnormality ...................................................... 208

7.24 Low Pressure Drop due to Refrigerant Shortage or Electronic Expansion

Valve Abnormality .................................................................................... 209

7.25 Power Supply Insufficient or Instantaneous Failure ................................. 211

7.26 Check Operation is not Conducted .......................................................... 212

7.27 Signal transmission Error between Indoor Unit and Outdoor Unit in the Same

System ..................................................................................................... 213

7.28 Excessive Number of Indoor Units ........................................................... 214

7.29 Address Duplication of Central Remote Controller................................... 215

7.30 Transmission Error between Centralized Remote Controller

and Indoor Unit......................................................................................... 216

7.31 System is not Set yet................................................................................ 218

7.32 System Abnormality, Refrigerant System Address Undefined................. 219

Table of Contents v

SiUS181305E

7.33 Check for Outdoor Unit............................................................................. 220

8. Thermistor Resistance / Temperature Characteristics............................224

9. Pressure Sensor .....................................................................................226

10.Method of Replacing Inverter’s Power Transistors Modules ...................227

Part 9 Appendix ............................................................................ 229

1. Piping Diagrams......................................................................................230

1.1 Outdoor Unit ............................................................................................. 230

1.2 Branch Provider (BP) Unit ........................................................................ 231

1.3 Indoor Unit................................................................................................ 232

2. Wiring Diagrams......................................................................................234

2.1 Outdoor Unit ............................................................................................. 234

2.2 Branch Provider (BP) Unit ........................................................................ 235

2.3 Indoor Unit................................................................................................ 236

3. Removal Procedure (Booklet No.) ..........................................................239

Legends

Ta Outdoor temperature

Tb Outdoor heat exchanger temperature

Tc High pressure equivalent saturation temperature

Tdi Discharge pipe temperature

Te Low pressure equivalent saturation temperature

Tfin Radiation fin temperature

Tl Liquid pipe temperature

Tp Value of compressor port temperature calculated by Tc and Te, and suction superheated

degree

Tr Room thermistor temperature

Ts Set temperature

Ts1 Suction pipe temperature 1

Ts2 Suction pipe temperature 2

Tsh Subcooling heat exchanger gas pipe temperature

Tt Target temperature

HTdi Value of discharge pipe temperature (Tdi) compensated with outdoor temperature

SC Difference between the heat exchanger temperature and liquid pipe temperature of each

indoor unit

SH Difference between the heat exchanger temperature and gas pipe temperature of each

indoor unit

Pc High pressure sensor detection value

Pe Low pressure sensor detection value

vi Table of Contents

Safety Considerations

WARNING

CAUTION

1. Safety Considerations

Read these SAFETY CONSIDERATIONS carefully before

repairing air conditioners and heat pumps. After completing

repairs, check if the unit operates properly. All electrical

repairs and work must be carried out by qualified personnel

in accordance local, state, and national regulations. Follow

all instructions that are listed under each hazard sign

(DANGER, WARNING, CAUTION, NOTE) as they are

important for ensuring safety.

DANGER .............. Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING ............ Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION ............. Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

NOTE ................... Indicates situations that may result

in equipment or property-damage

accidents only.

1.1 During Repairs

• Do not start or stop the air conditioner or heat pump

operation by plugging or unplugging the power cord.

Plugging or unplugging he power cord to operate or

disconnect the equipment could cause an electrical

shock or fire.

• Wear a safety helmet, gloves, and a safety belt when

working at an elevated height of more than 6.5ft (2m).

Insufficient safety measures could cause a fall

resulting in a injury.

• Use only pipes, flare nuts, tools, and the other

materials designed specifically for R410A refrigerant

systems. Never use tools or materials designed for

R22 refrigerant systems on an R410A refrigerant

system. Doing so could cause a serious accident or

an equipment failure.

• If the installation platform or frame has corroded,

have it replaced. A corroded platform or frame could

cause electrical shock or fire.

• When relocating equipment, make sure that the new

installation site has sufficient strength to withstand

the weight of the equipment. If the installation site

does not have sufficient strength and if the

installation work is not conducted securely, the

equipment could fall and cause injury.

• Disconnect power before disassembling the

equipment for repairs. Working on the equipment

that is connected to a power supply could cause an

electric shock. If it is necessary to supply power to

the equipment to conduct repairs or to inspect the

circuits, do not touch any electrically charged

sections of the equipment.

• Prior to disconnecting the suction or discharge pipe

of the compressor at welded sections, pump-down

the refrigerant gas completely. If there is gas or oil

remaining inside the compressor, the refrigerant gas

or oil can discharge when the pump is being

disconnected and it could cause an injury.

• If refrigerant gas is discharges during repair work,

do not touch the discharged refrigerant gas. The

refrigerant gas could cause frostbites.

• If refrigerant gas leaks during repair or service,

ventilate the area immediately. Refrigerant gas could

produce toxic gas if it comes into contact with

flames.

• The step-up capacitor supplies high-voltage

electricity to the electrical components of the

outdoor unit. Discharge the capacitor completely

before conducting repair work. A charge capacitor

could cause an electrical shock.

• When relocating equipment, keep the refrigerant

circuit free from all substances other than the

specified refrigerant, such as air. Any presence of

air or other foreign substance in the refrigerant

circuit could cause an abnormal pressure rise or

rupture, resulting in injury.

• Check the unit foundation for damage on a continual

basis, especially if it has been in use for a long time.

If left in a damaged condition, the unit could fall and

cause injury.

• Do not repair the electrical components with wet

hands. Working on the equipment with wet hands may

cause an electrical shock.

• Do not clean the air conditioner or heat pump by

splashing water on it. Washing the unit with water may

cause an electrical shock.

• Equipment must be grounded when carrying out

repairs in a humid or wet place to avoid electrical

shocks.

• Turn off the power when cleaning the equipment to

prevent internal fans (that rotate at high speed) from

starting suddenly, as they may cause injury.

• Do not tilt the unit when removing it. The condensate

water inside the unit may spill and wet furniture and

floors.

Safety Considerations vii

Safety Considerations

WARNING

WARNING

CAUTION

DANGER

WARNING

CAUTION

NOTE

• Do not touch the refrigerant pipes during and

immediately after operation for any repair work as

the refrigerant pipes may be hot or cold, depending

on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other

refrigerant cycle parts. Your hands may suffer burns

• All welding and cutting operations must be done in a

well-ventilated place. Welding and cutting

operations done in an enclosed room may cause

deficiency in oxygen in the enclosed room.

• Dismantling of the unit, disposal of refrigerant, oil,

and additional parts, should be done in accordance

with the relevant local, state, and national

regulations.

1.2 After Repairs

• Use an exclusive power circuit for the equipment.

Insufficient circuit amperage capacity could cause

an electrical shock or fire.

• Use specified cable to connect indoor and outdoor

units. Make the connections securely, and route the

cable properly so that there is no force pulling the

cable a the connection terminals. Improper

connections could cause excessive heat generation

or fire.

1.3 Inspections after Repairs

• If the unit has a power cable plug and it is dirty, clean

the plug before securely inserting it into a power

outlet. If the plug has a loose connection, tighten it or

it could cause electrical shock or fire.

• If the power cable and lead wires have scratches or

are deteriorated, replace them. Damaged cable and

wires could cause an electrical shock, excessive

heat generation, or fire.

• Do not use a joined power cable or extension cable,

or share the same power outlet with other electrical

appliances as it could cause an electrical shock,

excessive heat generation, or fire.

• Check if parts and wires are mounted and connected

properly and if the connections at the soldered or

crimped terminals are secure. Improper installation

and connection could cause and electrical shock,

excessive heat generation, or fire.

• Measure the insulation resistance after the repair.

The resistance must be 1M or higher. Faulty

insulation could cause an electrical shock.

• Securely fasten the outdoor unit terminal cover

(panel). If the terminal cover/panel is not fastened

properly, dust or water could enter the outdoor unit

causing fire or electric shock.

• Do not damage or modify the power cable. Damaged

or modified power cables could cause an electrical

shock or fire. Placing heavy items on the power

cable could damage the cable.

• Do not charge air or gas other than the specified

refrigerant to the refrigerant system. If air enters the

refrigerant system, it could cause excessive high

pressure resulting in equipment damage and injury.

• If refrigerant gas leaks, locate the leaking point and

repair it before charging refrigerant. After charging

the refrigerant, check for refrigerant leaks. If the

leaking pint cannot be located and the repair work

must be stopped, perform a pump-down. Close the

service valve to prevent the refrigerant gas from

leaking into the room. the refrigerant gas itself is

harmless, but it could generate toxic gases if it

comes into contact with flames.

• After replacing the battery in the remote controller,

dispose of the old battery to prevent children from

swallowing it. If a child swallows the battery, consult

with a doctor immediately.

• Check the drainage of the indoor unit after the repair.

Faulty drainage may cause the water to enter the

room resulting in wet floors and furniture.

1.4 Safety for Users

• Never attempt to modify the equipment. Doing so will

cause electrical shock, excessive heat generation, or

fire.

• Never remove the fan guard of the unit while the unit

is operating. A fan rotating at high speed without the

fan guard is very dangerous.

• Before cleaning the unit, stop the operation of the

unit by turning the power off or by pulling the power

cord out from its socket. Otherwise, an electrical

shock or injury may result.

• Do note wipe the controller operation panel with

benzene, thinner, chemical dust cloths, or similar.

The panel may get discolored or the coating can peel

off. if it is extremely dirty, soak a cloth in a waterdiluted neutral detergent, squeeze it well, and wipe

the panel clean. Then wipe it with another dry cloth.

viii Safety Considerations

Safety Considerations

Safety Considerations ix

SiUS181305E

Part 1

List of Functions

1. Functions.....................................................................................................2

1.1 Outdoor Unit ................................................................................................. 2

1.2 Indoor Unit.................................................................................................... 3

1 List of Functions

SiUS181305E Functions

1. Functions

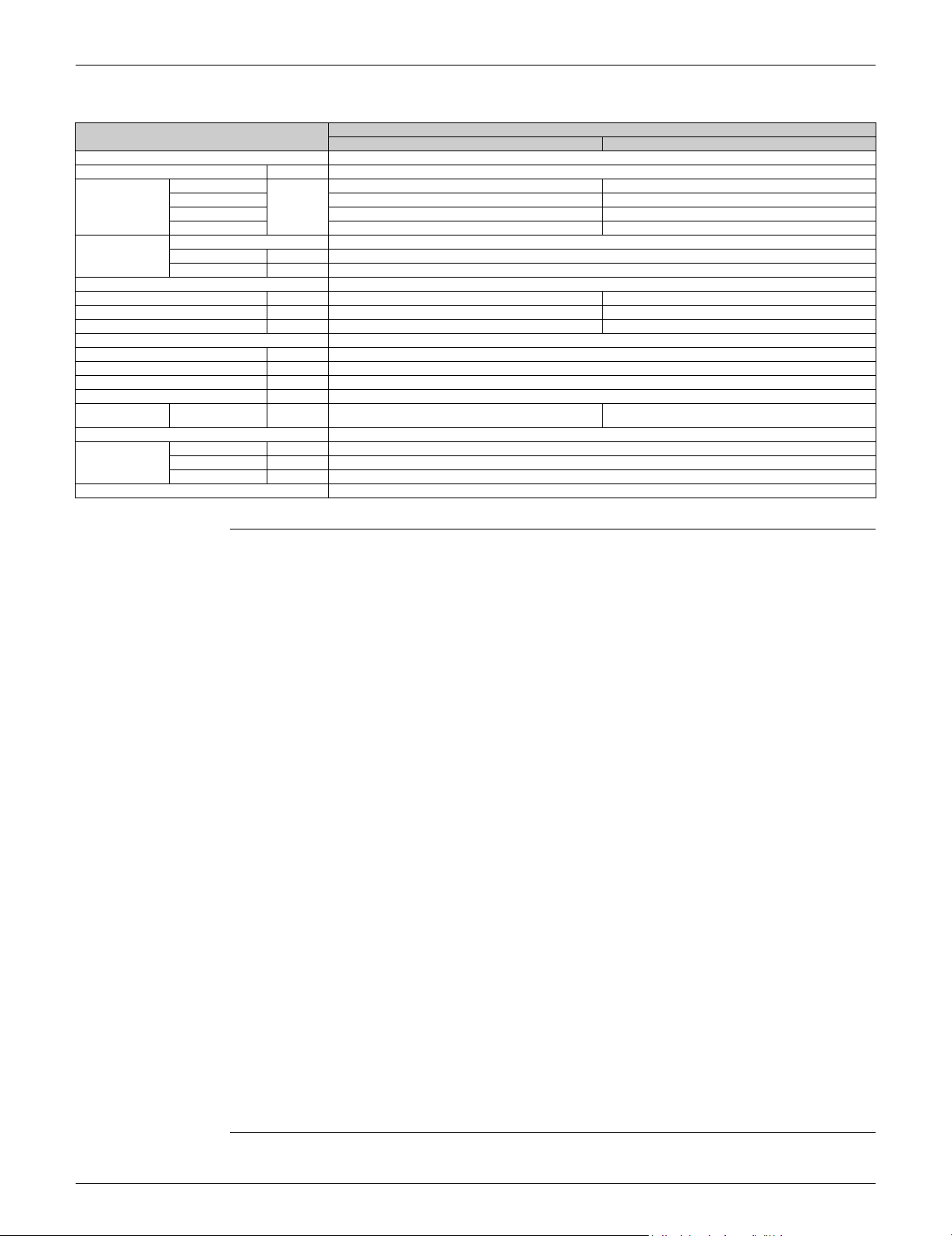

1.1 Outdoor Unit

Category Functions

Basic

Function

Compressor Oval scroll compressor Wipe-clean flat panel —

Comfortable

Airflow

Comfort

Control

Operation

Lifestyle

Convenience

Inverter (with inverter power control)

Operation limit for cooling (°CDB)

Operation limit for cooling (°FDB)

Operation limit for heating (°CWB)

Operation limit for heating (°FWB)

PAM control — Air filter (prefilter) —

Swing compressor — Washable grille —

Rotary compressor — Filter cleaning indicator —

Reluctance DC motor Good-sleep cooling operation —

Power-airflow louver (horizontal blade) — Timer WEEKLY TIMER operation —

Power-airflow dual louvers — 24-hour ON/OFF timer —

Power-airflow diffuser — 72-hour ON/OFF timer —

Wide-angle fins (vertical blades) — NIGHT SET mode —

Vertical auto-swing (up and down) — Worry Free

Horizontal auto-swing (right and left) — Self-diagnosis (digital, LED) display

3-D airflow — Wiring error check function

COMFORT AIRFLOW operation — Automatic test operation

Auto fan speed — Memory function

Indoor unit quiet operation —

NIGHT QUIET mode (automatic) Flexibility Multi-split / split type compatible indoor unit —

OUTDOOR UNIT QUIET operation (manual) Flexible power supply correspondence —

INTELLIGENT EYE operation — High ceiling application —

Quick warming function Chargeless —

Hot-start function — Either side drain (right or left) —

Automatic defrosting Power selection —

Automatic operation —

Program dry function — Remote

Fan only —

New POWERFUL operation (non-inverter) —

Inverter POWERFUL operation — Dlll-NET compatible (adaptor) (option) —

Priority-room setting — Remote

COOL / HEAT mode lock — Wired —

HOME LEAVE operation —

ECONO operation —

Indoor unit ON/OFF button —

Signal receiving sign —

R/C with back light —

Temperature display —

–5

~ 46

23

~ 115

–15

~ 15.5

~ 60

Category Functions

RMXS48LVJU

Health &

Clean

5

(Reliability &

Durability)

Control

Controller

Air-purifying filter —

Photocatalytic deodorizing filter —

Air-purifying filter with photocatalytic

deodorizing function

Titanium apatite photocatalytic

air-purifying filter

Longlife filter —

Auto-restart (after power failure) —

Anti-corrosion treatment of outdoor heat

exchanger

°F/°C changeover R/C temperature display

(factory setting: °F)

5-room centralized controller (option) —

Remote control adaptor

(normal open pulse contact) (option)

Remote control adaptor

(normal open contact) (option)

Wireless —

Note: : Available

— : Not Available

RMXS48LVJU

—

—

—

—

—

List of Functions 2

Functions SiUS181305E

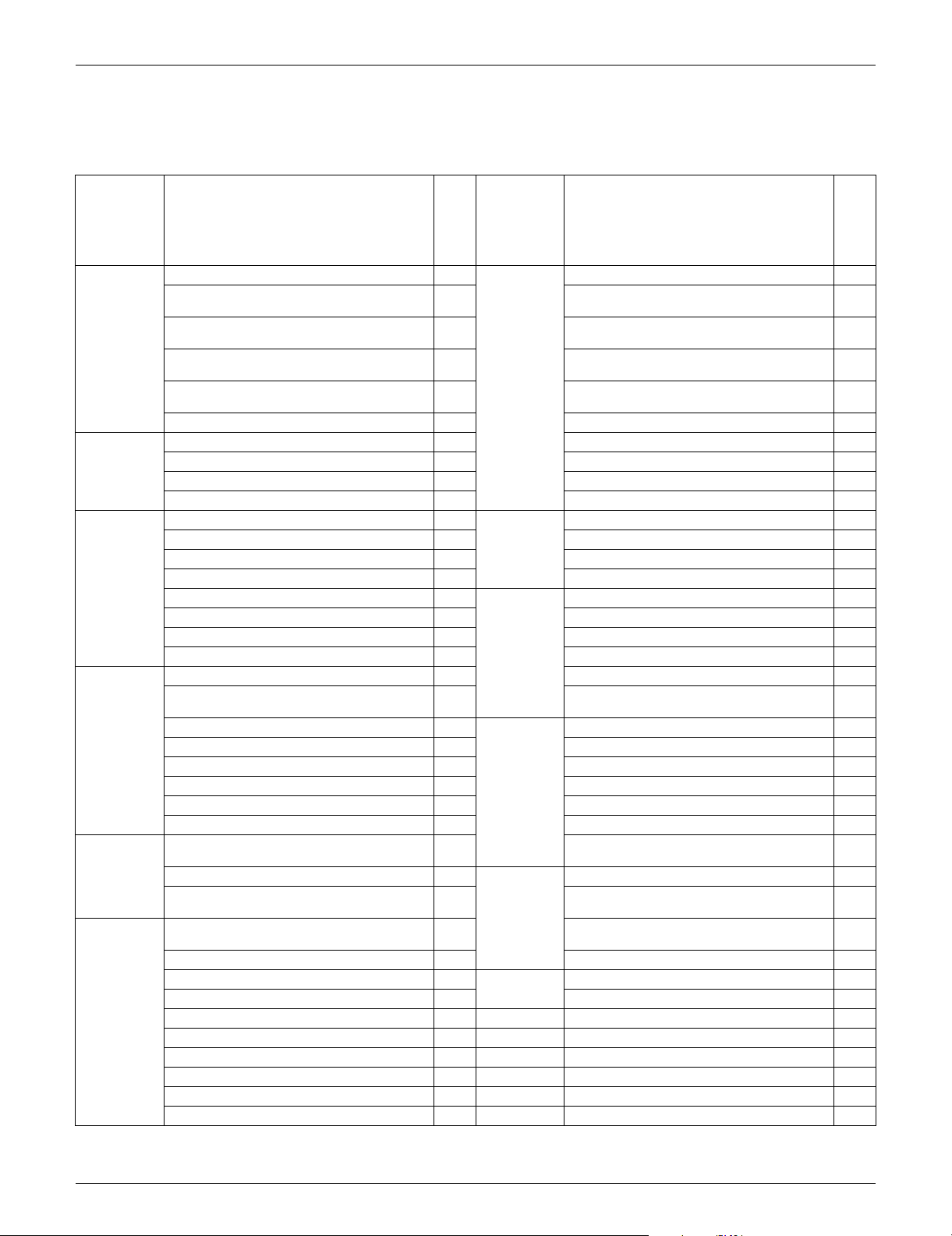

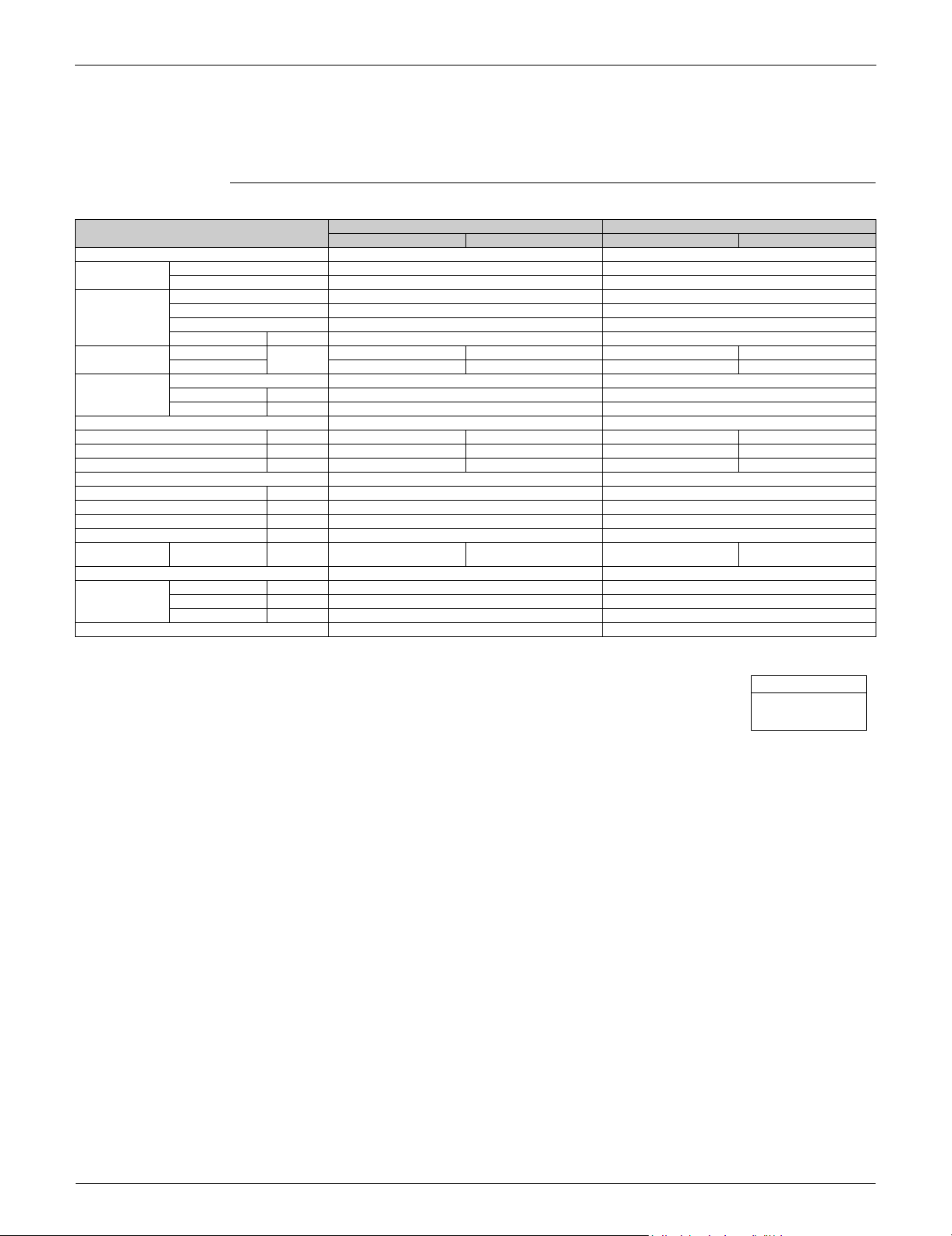

1.2 Indoor Unit

Category Functions

CTXS07LVJU

Basic Function Inverter (with inverter power control)

Operation limit for cooling (°CDB) — — — — — —

Operation limit for cooling (°FDB) — — — — — —

Operation limit for heating (°CWB) — — — — — —

Operation limit for heating (°FWB) — — — — — —

PAM control ——————

Compressor Oval scroll compressor — — — — —

Swing compressor — — — — — —

Rotary compressor ——————

Reluctance DC motor — — — — — —

Comfortable

Airflow

Comfort Control Auto fan speed —

Operation Automatic operation

Lifestyle

Convenience

Power-airflow louver (horizontal blade) — — — — — —

Power-airflow dual louvers ———

Power-airflow diffuser ——————

Wide-angle fins (vertical blades) ———

Vertical auto-swing (up and down) ——

Horizontal auto-swing (right and left) ———

3-D airflow ———

COMFORT AIRFLOW operation — ———

Indoor unit quiet operation —

NIGHT QUIET mode (automatic) — — — — — —

OUTDOOR UNIT QUIET operation (manual) —

INTELLIGENT EYE operation ———

Quick warming function — — — — — —

Hot-start function

Automatic defrosting ——————

Program dry function

Fan only

New POWERFUL operation

(non-inverter)

Inverter POWERFUL operation —

Priority-room setting — — — — — —

COOL / HEAT mode lock — — — — — —

HOME LEAVE operation — ————

ECONO operation — —

Indoor unit ON/OFF button 1

Signal receiving sign 1

R/C with back light

Temperature Display — — — — — —

——————

Note: : Available

CTXS07JVJU

CTXS09/12HVJU

FTXS15/18/24LVJU

2

FDXS09/12LVJU

CDXS12/18/24LVJU

FFQ09/12/15/18LVJU

— : Not Available

3 List of Functions

SiUS181305E Functions

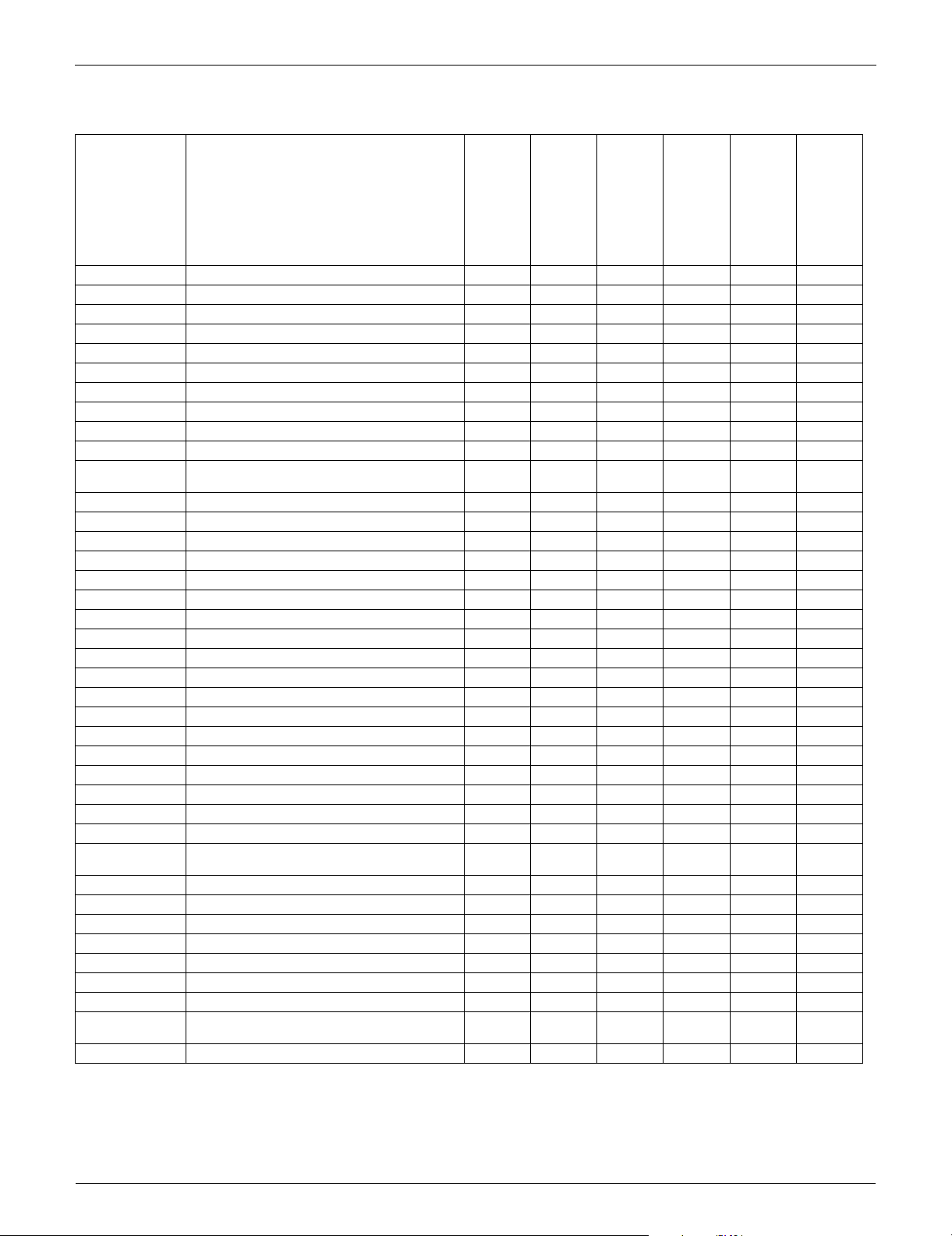

Category Functions

CTXS07LVJU

Health &

Clean

Timer WEEKLY TIMER operation — ——2

Worry Free

(Reliability &

Durability)

Flexibility Multi-split / split type compatible indoor unit — — ——

Remote

Control

Remote

Controller

Air-purifying filter

Photocatalytic deodorizing filter

Air-purifying filter with photocatalytic

deodorizing function

Titanium apatite photocatalytic

air-purifying filter

Longlife filter (option) — — ———

Air filter (prefilter)

Wipe-clean flat panel ———

Washable grille — — ———

Filter cleaning indicator — —

Good-sleep cooling operation — —

24-hour ON/OFF TIMER —

72-hour ON/OFF TIMER

NIGHT SET mode

Auto-restart (after power failure)

Self-diagnosis (digital, LED) display

Wiring error check function — —

Automatic test operation — — ———

Memory function — — — ———

Anticorrosion treatment of outdoor heat

exchanger

Flexible power supply correspondence — — ———

High ceiling application — — — ———

Chargeless — — — ———

Either side drain (right or left) ———

Power selection — — — ———

°F/°C changeover R/C temperature display

(factory setting: °F)

5-room centralized controller (option)

Remote control adaptor

(normal open pulse contact) (option)

Remote control adaptor

(normal open contact) (option)

DIII-NET compatible (adaptor) (option)

Wireless

Wired (option)

——————

——

—

—

— — ———1

—

CTXS07JVJU

CTXS09/12HVJU

—

FTXS15/18/24LVJU

FDXS09/12LVJU

CDXS12/18/24LVJU

FFQ09/12/15/18LVJU

— ———

— ———

———

—

———

— ———

—

— ———

— ———

2

—

—

—

Note: : Available

— : Not Available

1: With wireless remote controller

2: With wired remote controller

List of Functions 4

SiUS181305E

Part 2

Specifications

1. Specifications ..............................................................................................6

1.1 Outdoor Unit ................................................................................................. 6

1.2 Branch Provider (BP) Unit ............................................................................ 6

1.3 Indoor Unit.................................................................................................... 7

5 Specifications

SiUS181305E Specifications

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

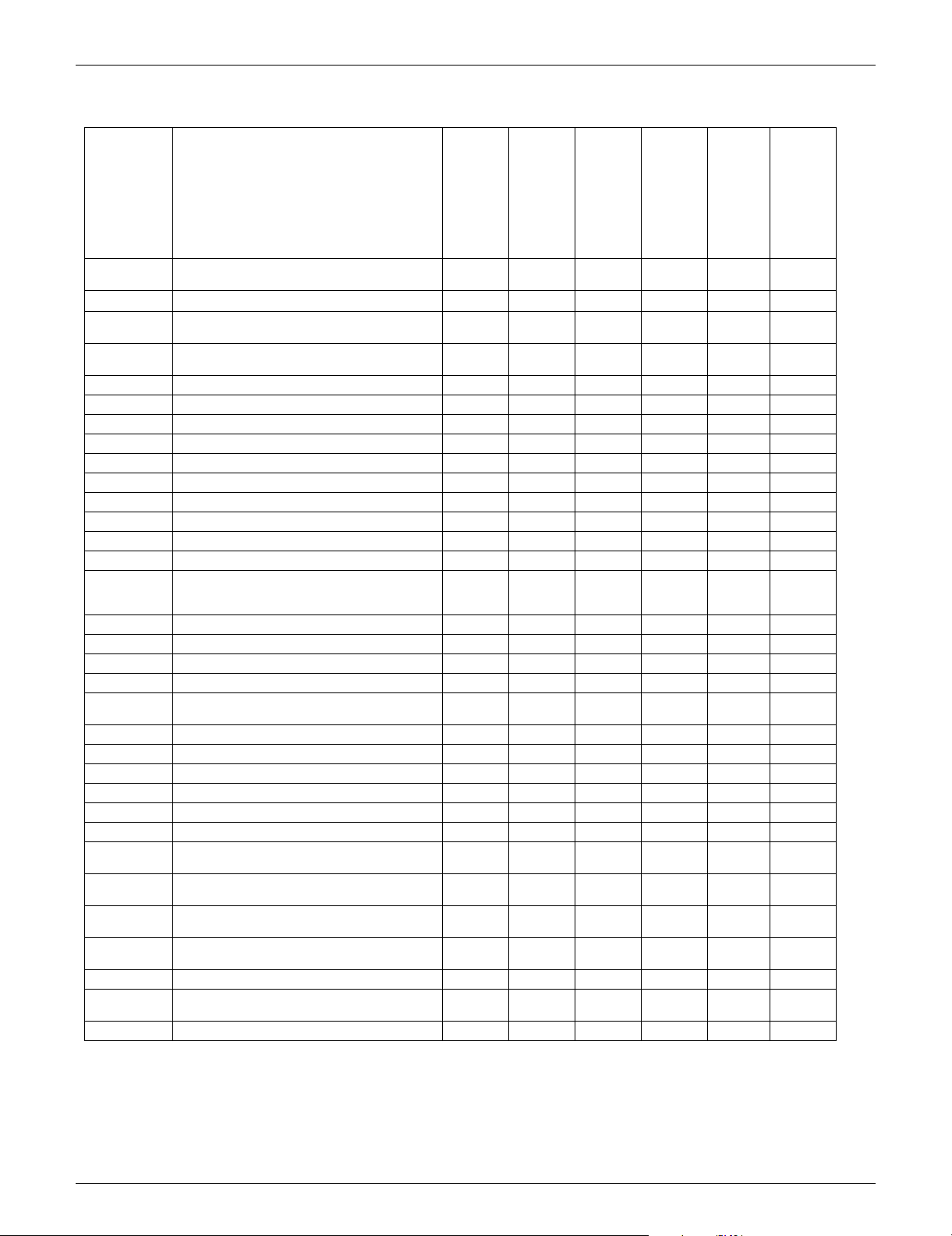

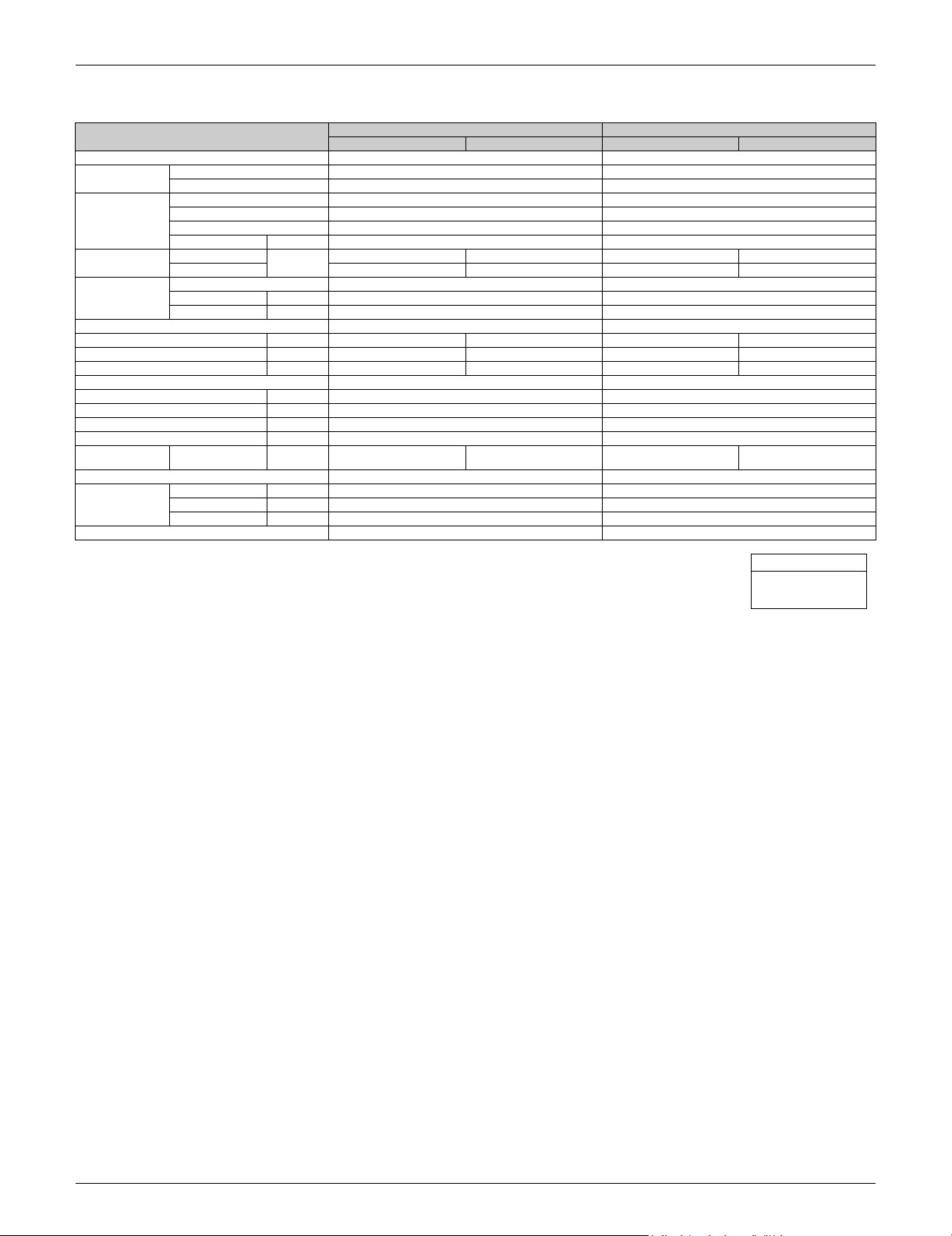

1. Specifications

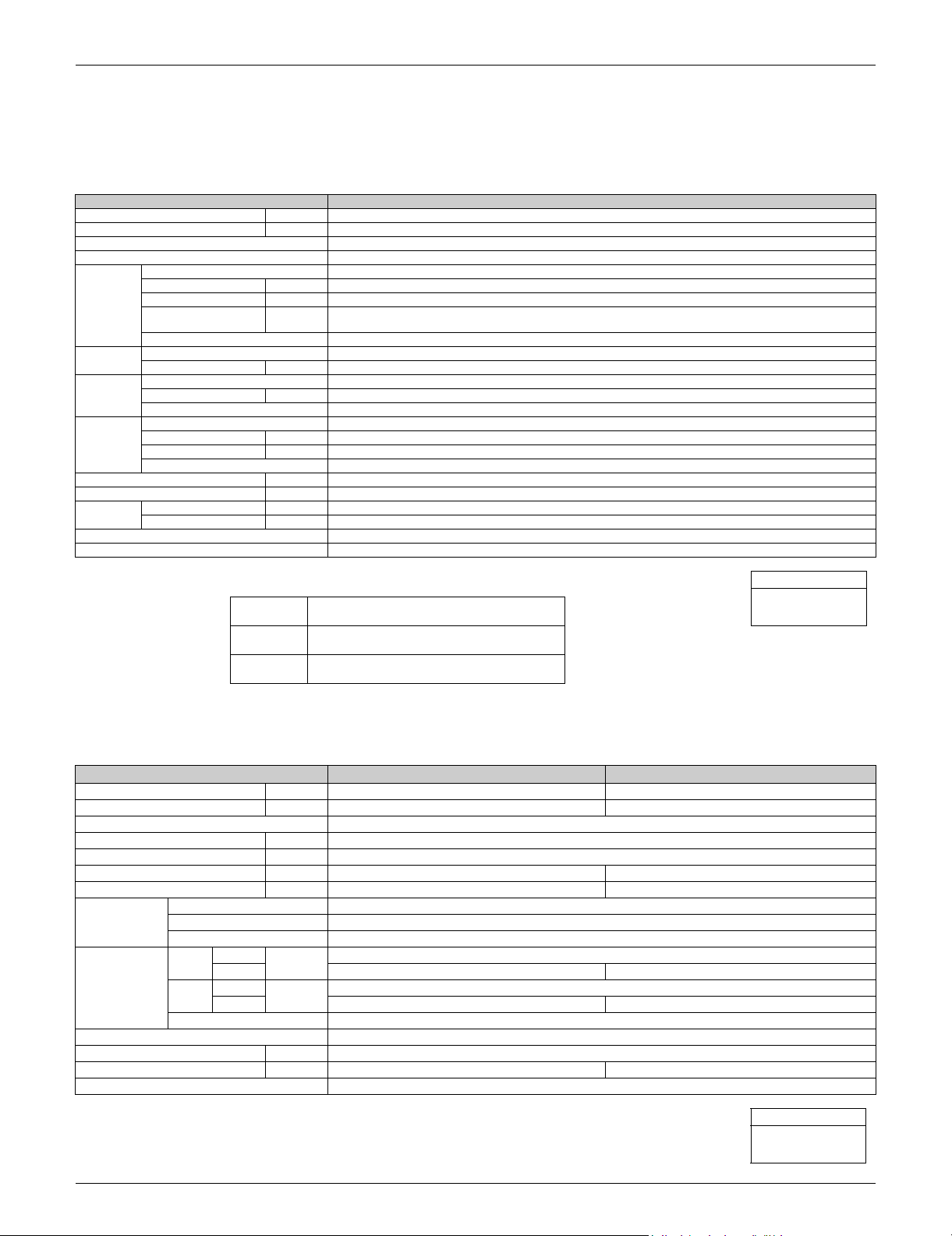

1.1 Outdoor Unit

60 Hz, 208 - 230 V

Model RMXS48LVJU

Cooling Capacity Btu/h 48,000

Heating Capacity Btu/h 54,000

Casing Color Ivory White

Heat Exchanger Cross Fin Coil

Compressor

Refrigerant

Oil

Refrigerant

Fan

Dimensions (H × W × D) in. (mm) 52-15/16 × 35-7/16 × 12-5/8 (1,345 × 900 × 320)

Weight (Mass) Lbs (kg) 283 (129)

Piping

Connection

Defrost Method Reverse Cycle Defrosting

Drawing No. 4D080735

Type Hermetically Sealed Scroll Type

Piston Displacement

Number of Revolutions r.p.m 6,480

Motor Output

(2.2 kW / 60 rps)

Starting Method Direct on line

Model DAPHNE FVC68D

Charge L (floz) 1.7 (57.5)

Type R-410A

Charge Lbs (kg) 8.8 (4.0)

Control Electronic Expansion Valve

Type Propeller Fan

Motor Output kW 0.070 × 2

Airflow rate cfm 3,740

Drive Direct Drive

Liquid in. (mm) 3/8 ( 9.5) C1220T (Flare Connection)

Gas in. (mm) 3/4 ( 19.1) C1220T (Brazing Connection)

3

/h

ft

kW 3.0

791.5

Note:

The data are based on the conditions shown in the table below.

Cooling

Heating

Piping

Length

Indoor ; 80°FDB (26.7°CDB) / 67°FWB (19.4°CWB)

Outdoor ; 95°FDB (35°CDB)

Indoor ; 70°FDB (21.1°CDB)

Outdoor ; 47°FDB (8.3°CDB) / 43°FWB (6.1°CWB)

O.U. – BP : 16.4 ft (5 m), BP – I.U. : 9.8 ft (3 m)

Level Difference: 0 ft (0 m)

1.2 Branch Provider (BP) Unit

60 Hz, 208 - 230 V

Model BPMKS048A2U BPMKS049A3U

Power Consumption W 10 10

Running Current A 0.05 0.05

Refrigerant Type R-410A

Dimensions (H × W × D) in. (mm) 7-1/16 × 11-9/16 [26-11/16]* ×13-3/4 (180 × 294 [678]* × 350)

Packaged Dimensions (H × W × D) in. (mm) 10-1/8 × 29-1/16 × 16-13/16 (257 × 738 × 427)

Weight (Mass) Lbs (kg) 18 (8) 20 (9)

Gross Weight (Gross Mass) Lbs (kg) 27 (12) 29 (13)

Number of Wiring

Connections

Piping Connection

(Flare)

Heat Insulation Both Liquid and Gas Pipes

Min. Combination Btu/h 7,000

Max. Combination Btu/h 48,000 62,000

Drawing No. 4D080441

Power Supply 3 (including ground wiring)

O.U. – BP 2 (for DIII transmission)

BP – I.U. 4 (including ground wiring)

O.U. side

Liquid

I.U. side 1/4 ( 6.4) × 2 1/4 ( 6.4) × 3

O.U. side

Gas

I.U. side 5/8 ( 15.9) × 2 5/8 ( 15.9) × 3

Drain Drain Processingless

in. (mm)

in. (mm)

3/8 ( 9.5) × 1

5/8 ( 15.9) × 1

Specifications 6

Note:

[ ]* : including auxiliary piping length

Specifications SiUS181305E

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

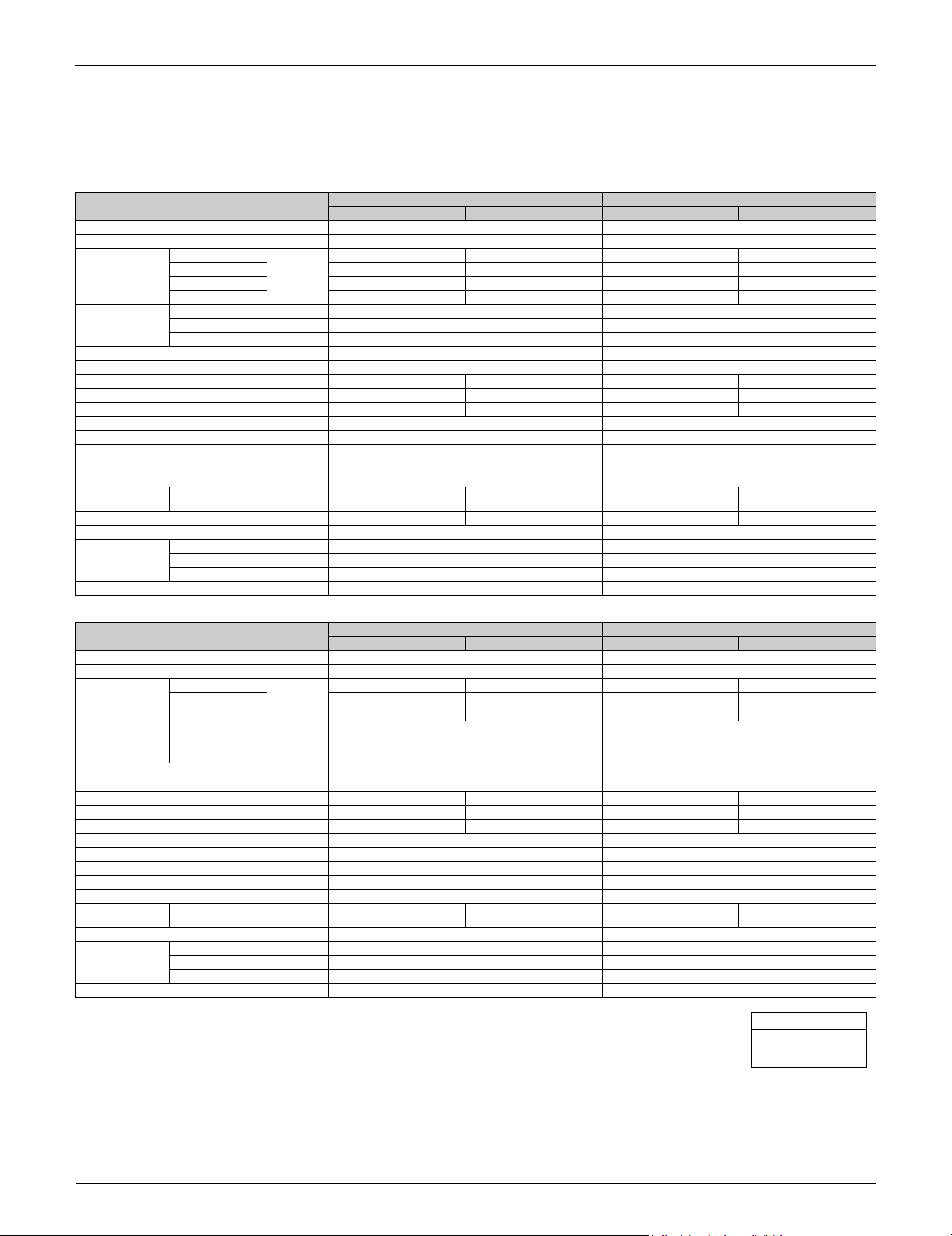

1.3 Indoor Unit

CTXS, FTXS Series

60 Hz, 208 - 230 V

Model

Rated Capacity 7 kBtu/h Class 7 kBtu/h Class

Front Panel Color White White

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.09 - 0.08 0.11 - 0.10 0.18 0.2

Power Consumption (Rated) W 18 - 18 21 - 21 40 45

Power Factor (Rated) % 96.2 - 97.8 91.8 - 91.3 96.6 97.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-5/8 × 31-1/2 × 8-7/16 (295 × 800 × 215) 11-7/16 × 31-5/16 × 9-3/8 (290 × 795 × 238)

Packaged Dimensions (H × W × D) in. (mm) 14-7/16 × 34-1/4 × 10-13/16 (366 × 870 × 274) 13-5/16 × 33-1/16 × 11 (338× 840 × 280)

Weight (Mass) Lbs (kg) 20 (9) 20 (9)

Gross Weight (Gross Mass) Lbs (kg) 29 (13) 29 (13)

Sound Pressure

Level

Sound Power Level dB 54 54 – –

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping Connection

Drawing No. 3D075490 3D066156A

H

M 261 (7.4) 290 (8.2) 335 (9.5) 357 (10.1)

L 194 (5.5) 233 (6.6) 283 (8.0) 314 (8.9)

SL 145 (4.1) 219 (6.2) – –

Type Cross Flow Fan Cross Flow Fan

Motor Output W 23 40

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 38 / 32 / 25 / 22 38 / 33 / 28 / 25 44 / 40 / 35 / – 44 / 39 / 34 / –

Liquid in. (mm)

Gas in. (mm) 3/8 (9.5)

Drain in. (mm) 5/8 (16.0)

cfm

(m³/min)

Cooling Heating Cooling Heating

332 (9.4) 350 (9.9) 388 (11.0) 400 (11.3)

CTXS07LVJU CTXS07JVJU

1/4 (6.4)

1/4 ( 6.4)

3/8 ( 9.5)

11/16 ( 18.0)

Model

Rated Capacity 9 kBtu/h Class 12 kBtu/h Class

Front Panel Color White White

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.18 0.2 0.18 0.2

Power Consumption (Rated) W 40 45 40 45

Power Factor (Rated) % 96.6 97.8 96.6 97.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-7/16 × 31-5/16 × 9-3/8 (290 × 795 × 238) 11-7/16 × 31-5/16 × 9-3/8 (290 × 795 × 238)

Packaged Dimensions (H × W × D) in. (mm) 13-5/16 × 33-1/16 × 11 ( 338 × 840 × 280) 13-5/16 × 33-1/16 × 11 ( 338 × 840 × 280)

Weight (Mass) Lbs (kg) 20 (9) 20 (9)

Gross Weight (Gross Mass) Lbs (kg) 29 (13) 29 (13)

Sound Pressure

Level

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping Connection

Drawing No. 3D062870A 3D062871A

H

M 335 (9.5) 357 (10.1) 335 (9.5) 357 (10.1)

L 283 (8.0) 314 (8.9) 283 (8.0) 314 (8.9)

Type Cross Flow Fan Cross Flow Fan

Motor Output W 40 40

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L dB(A) 44 / 40 / 35 44 / 39 / 34 45 / 41 / 36 45 / 40 / 35

Liquid in. (mm)

Gas in. (mm)

Drain in. (mm)

cfm

(m³/min)

Cooling Heating Cooling Heating

388 (11.0) 400 (11.3) 388 (11.0) 400 (11.3)

CTXS09HVJU CTXS12HVJU

1/4 (

6.4)

6.4)

1/4 (

3/8 ( 9.5) 3/8 ( 9.5)

11/16 ( 18.0) 11/16 ( 18.0)

7 Specifications

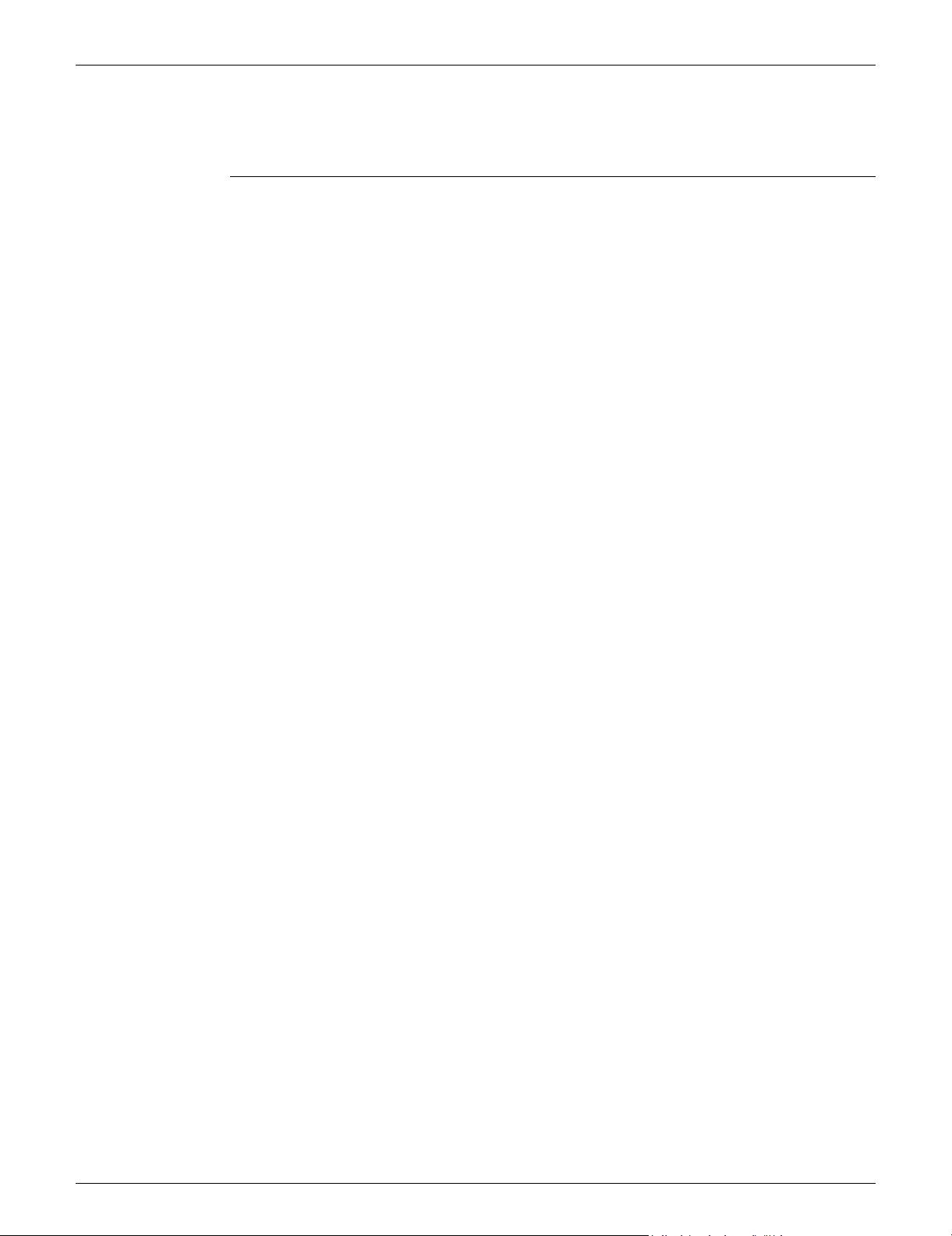

SiUS181305E Specifications

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

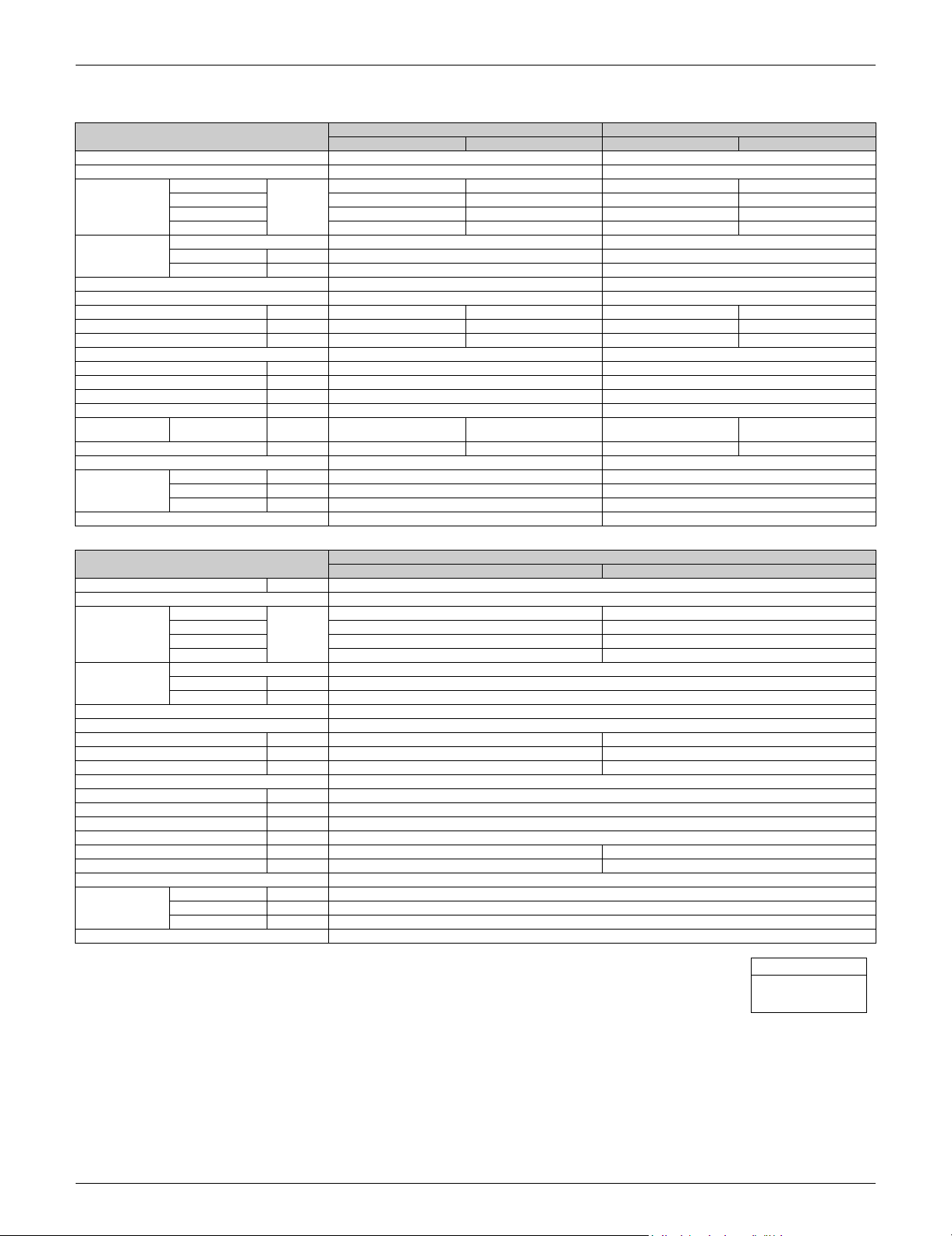

60 Hz, 208 - 230 V

Model

Rated Capacity 15 kBtu/h Class 18 kBtu/h Class

Front Panel Color White White

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward Right, Left, Horizontal, Downward

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.31 - 0.29 0.31 - 0.29 0.32 - 0.30 0.32 - 0.30

Power Consumption (Rated) W 38 - 38 38 - 38 38 - 38 38 - 38

Power Factor (Rated) % 58.9 - 57.0 58.9 - 57.0 57.1 - 55.1 57.1 - 55.1

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 13-3/8 × 41-5/16 × 9-3/4 (340 × 1,050 × 248) 13-3/8 × 41-5/16 × 9-3/4 (340 × 1,050 × 248)

Packaged Dimensions (H × W × D) in. (mm) 16-7/8 × 45-11/16 × 13 (429 × 1,160 × 331) 16-7/8 × 45-11/16 × 13 (429 × 1,160 × 331)

Weight (Mass) Lbs (kg) 31 (14) 31 (14)

Gross Weight (Gross Mass) Lbs (kg) 44 (20) 44 (20)

Sound Pressure

Level

Sound Power Level dB 61 59 62 61

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D075043 3D075044

H

M 477 (13.5) 505 (14.3) 484 (13.7) 526 (14.9)

L 385 (10.9) 417 (11.8) 385 (10.9) 431 (12.2)

SL 360 (10.2) 371 (10.5) 360 (10.2) 399 (11.3)

Type Cross Flow Fan Cross Flow Fan

Motor Output W 48 48

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 45 / 40 / 35 / 32 43 / 38 / 33 / 30 46 / 41 / 36 / 33 45 / 40 / 35 / 32

Liquid in. (mm) 1/4 (6.4) 1/4 (6.4)

Gas in. (mm) 1/2 (12.7) 1/2 (12.7)

Drain in. (mm) 5/8 (16.0) 5/8 (16.0)

cfm

(m³/min)

Cooling Heating Cooling Heating

568 (16.1) 593 (16.8) 583 (16.5) 625 (17.7)

FTXS15LVJU FTXS18LVJU

Model

Rated Capacity Btu/h 24 kBtu/h Class

Front Panel Color White

Airflow Rate

Fan

Air Direction Control Right, Left, Horizontal, Downward

Air Filter Removable / Washable / Mildew Proof

Running Current (Rated) A 0.57 - 0.51 0.57 - 0.51

Power Consumption (Rated) W 69 - 68 69 - 68

Power Factor (Rated) % 58.2 - 58.0 58.2 - 58.0

Temperature Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 13-3/8 × 41-5/16 × 9-3/4 (340 × 1,050 × 248)

Packaged Dimensions (H × W × D) in. (mm) 16-7/8 × 45-11/16 × 13 (429 × 1,160 × 331)

Weight (Mass) Lbs (kg) 31 (14)

Gross Weight (Gross Mass) Lbs (kg) 46 (21)

Sound Pressure Level (H / M / L / SL) dB(A) 51 / 44 / 37 / 34 48 / 42 / 37 / 34

Sound Power Level dBA 67 64

Heat Insulation Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D075045

H

M 494 (14.0 ) 572 (16.2)

L 350 (9.9) 445 (12.6)

SL 328 (9.3) 403 (11.4)

Type Cross Flow Fan

Motor Output W 48

Speed Steps 5 Steps, Quiet, Auto

Liquid in. (mm) 1/4 (6.4)

Gas in. (mm) 5/8 (15.9)

Drain in. (mm) 5/8 (16.0)

cfm

(m³/min)

Cooling Heating

643 (18.2) 699 (19.8)

FTXS24LVJU

Specifications 8

Specifications SiUS181305E

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

CDXS, FDXS Series

60 Hz, 208 - 230 V

Model

Rated Capacity 9 kBtu/h Class 12 kBtu/h Class

External Static Pressure inAq (Pa) 0.12 (30) 0.12 (30)

Airflow Rate

Fan

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.58 - 0.52 0.58 - 0.52 0.58 - 0.52 0.58 - 0.52

Power Consumption (Rated) W 72 - 72 72 - 72 72 - 72 72 - 72

Power Factor (Rated) % 59.7 - 60.2 59.7 - 60.2 59.7 - 60.2 59.7 - 60.2

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 7-7/8 × 27-9/16 × 24-7/16 (200 × 700 × 620) 7-7/8 × 27-9/16 × 24-7/16 (200 × 700 × 620)

Packaged Dimensions (H × W × D) in. (mm) 10-13/16 × 36-5/16 × 30-1/4 (274 × 923 × 768) 10-13/16 × 36-5/16 × 30-1/4 (274 × 923 × 768)

Weight (Mass) Lbs (kg) 47 (21) 47 (21)

Gross Weight (Gross Mass) Lbs (kg) 64 (29) 64 (29)

Sound Pressure

Level

Sound Power Level dB 51 51 51 51

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D075493 3D075494

H

M 280 (7.9) 280 (7.9) 280 (7.9) 280 (7.9)

L 260 (7.4) 260 (7.4) 260 (7.4) 260 (7.4)

SL 235 (6.7) 235 (6.7) 235 (6.7) 235 (6.7)

Type Sirocco Fan Sirocco Fan

Motor Output W 62 62

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L dB(A) 35 / 33 / 31 35 / 33 / 31 35 / 33 / 31 35 / 33 / 31

Liquid in. (mm) 1/4 (6.4) 1/4 (6.4)

Gas in. (mm) 3/8 (9.5) 3/8 (9.5)

Drain in. (mm) VP20 (O.D. 1-1/32 (26), I.D. 25/32 (20)) VP20 (O.D. 1-1/32 (26), I.D. 25/32 (20))

cfm

(m³/min)

Cooling Heating Cooling Heating

305 (8.6) 305 (8.6) 305 (8.6) 305 (8.6)

FDXS09LVJU FDXS12LVJU

Model

Rated Capacity 15 kBtu/h Class 18 kBtu/h Class

External Static Pressure inAq (Pa) 0.16 (40) 0.16 (40)

Airflow Rate

Fan

Air Filter Removable / Washable / Mildew Proof Removable / Washable / Mildew Proof

Running Current (Rated) A 0.79 0.79 0.79 0.79

Power Consumption (Rated) W 172 172 172 172

Power Factor (Rated) % 94.4 94.4 94.4 94.4

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 7-7/8 × 35-7/16 × 24-7/16 (200 × 900 × 620) 7-7/8 × 35-7/16 × 24-7/16 (200 × 900 × 620)

Packaged Dimensions (H × W × D) in. (mm) 10-1/2 × 43-9/16 × 29-9/16 (266 × 1,106 × 751) 10-1/2 × 43-9/16 × 29-9/16 (266 × 1,106 × 751)

Weight (Mass) Lbs (kg) 60 (27) 60 (27)

Gross Weight (Gross Mass) Lbs (kg) 75 (34) 75 (34)

Sound Pressure

Level

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping

Connections

Drawing No. C: 3D075721 C: 3D075722

H

M 388 (11.0) 388 (11.0) 388 (11.0) 388 (11.0)

L 353 (10.0) 353 (10.0) 353 (10.0) 353 (10.0)

SL 297 (8.4) 297 (8.4) 297 (8.4) 297 (8.4)

Type Sirocco Fan Sirocco Fan

Motor Output W 130 130

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 37 / 35 / 33 / 31 37 / 35 / 33 / 31 37 / 35 / 33 / 31 37 / 35 / 33 / 31

Liquid in. (mm) 1/4 (6.4) 1/4 (6.4)

Gas in. (mm) 1/2 (12.7) 1/2 (12.7)

Drain in. (mm) VP20 (O.D. 1-1/32 (26), I.D. 25/32 (20)) VP20 (O.D. 1-1/32 (26), I.D. 25/32 (20))

cfm

(m³/min)

Cooling Heating Cooling Heating

424 (12.0) 424 (12.0) 424 (12.0) 424 (12.0)

CDXS15LVJU CDXS18LVJU

9 Specifications

SiUS181305E Specifications

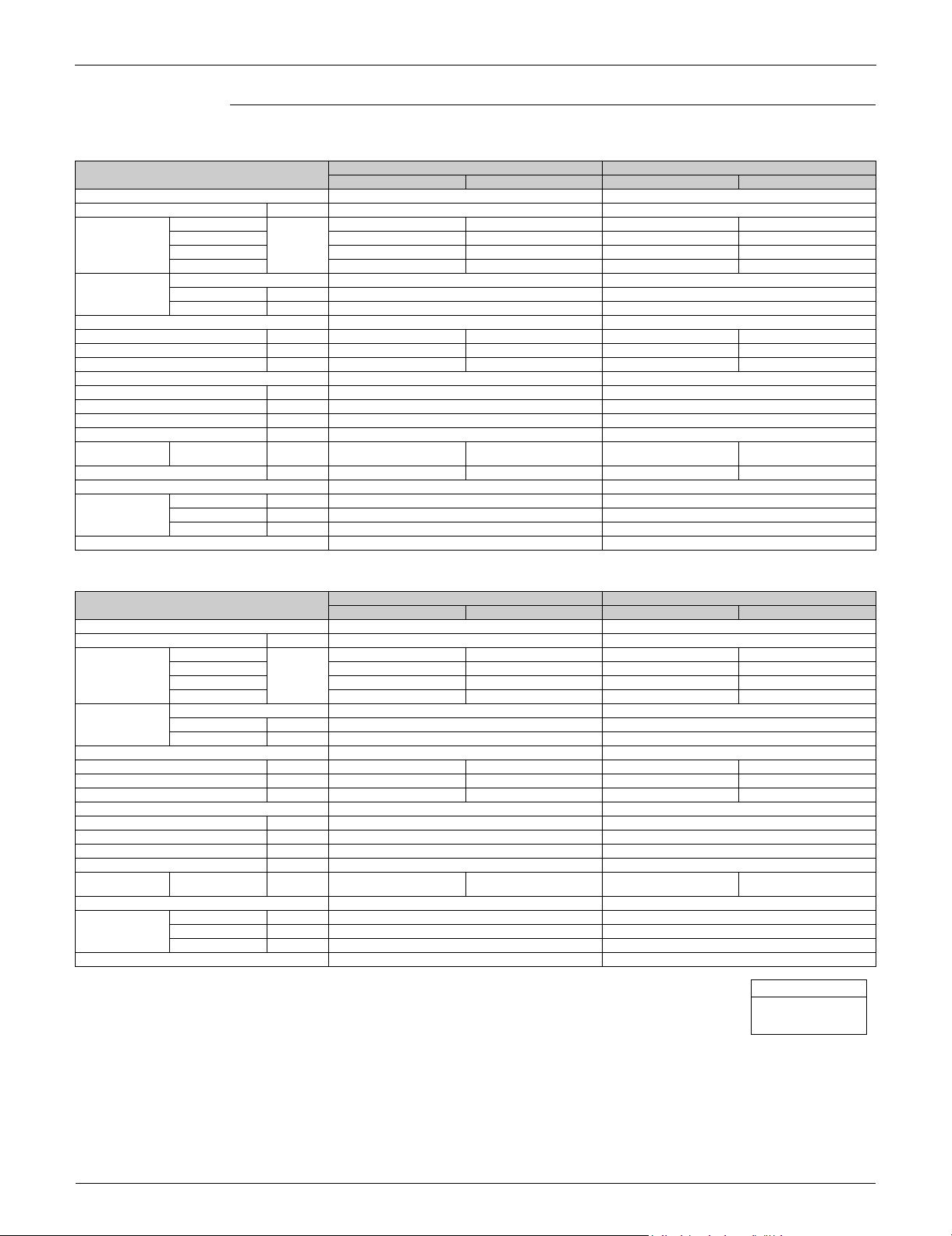

60 Hz, 208 - 230 V

Model

Rated Capacity 24 kBtu/h Class

External Static Pressure inAq (Pa) 0.16 (40)

Airflow Rate

Fan

Air Filter Removable / Washable / Mildew Proof

Running Current (Rated) A 0.79 0.79

Power Consumption (Rated) W 160 160

Power Factor (Rated) % 90.3 92.8

Temperature Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 7-7/8 × 43-5/16 × 24-7/16 (200 × 1,100 × 620)

Packaged Dimensions (H × W × D) in. (mm) 10-1/2 × 52-1/16 × 30-1/4 (266 × 1,323 × 768)

Weight (Mass) Lbs (kg) 66 (30)

Gross Weight (Gross Mass) Lbs (kg) 84 (38)

Sound Pressure

Level

Heat Insulation Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D080590

H

M 523 (14.8) 523 (14.8)

L 477 (13.5) 477 (13.5)

SL 395 (11.2) 395 (11.2)

Type Sirocco Fan

Motor Output W 130

Speed Steps 5 Steps, Quiet, Auto

H / M / L / SL dB(A) 38 / 36 / 34 / 32 38 / 36 / 34 / 32

Liquid in. (mm) 1/4 (6.4)

Gas in. (mm) 5/8 (15.9)

Drain in. (mm) VP20 (O.D. 1-1/32 (26), I.D. 25/32 (20))

cfm

(m³/min)

Cooling Heating

565 (16.0) 565 (16.0)

CDXS24LVJU

Specifications 10

Specifications SiUS181305E

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

FFQ Series 60 Hz, 208 - 230 V

Model

Rated Capacity 9 kBtu/h Class 12 kBtu/h Class

Remote Controller

Decoration Panel

Airflow Rate

Fan

Air Direction Control Horizontal, Downward Horizontal, Downward

Running Current (Rated) A 0.44 0.38 0.47 0.42

Power Consumption (Rated) W 87 76 98 89

Power Factor % 85.8 87.0 91.3 91.8

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-1/4 × 22-5/8 × 22-5/8 (285 × 575 × 575) 11-1/4 × 22-5/8 × 22-5/8 (285 × 575 × 575)

Packaged Dimensions (H × W × D) in. (mm) 14-9/16 × 27-1/16 × 26-9/16 (370 × 687 × 674) 14-9/16 × 27-1/16 × 26-9/16 (370 × 687 × 674)

Weight (Mass) Lbs (kg) 38.6 (17.5) 38.6 (17.5)

Gross Weight (Gross Mass) Lbs (kg) 46 (21) 46 (21)

Sound Pressure

Level

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D080626 3D080627

Wired BRC1E72 BRC1E72

Wireless BRC7E830 BRC7E830

Model BYFQ60B8W1U BYFQ60B8W1U

Color White White

Dimensions (H × W × D) 2-5/32 × 27-9/16 × 27-9/16 (55 × 700 × 700) 2-5/32 × 27-9/16 × 27-9/16 (55 × 700 × 700)

Weight (Mass) Lbs (kg) 6 (2.7) 6 (2.7)

H

L 230 (6.5) 230 (6.5) 230 (6.5) 230 (6.5)

Type Turbo Fan Turbo Fan

Motor Output W 55 55

Speed Steps 2 Steps 2 Steps

H / L dB(A) 36.0 / 29.5 36.0 / 29.5 38.5 / 29.0 38.5 / 29.0

Liquid in. (mm)

Gas in. (mm)

Drain in. (mm) VP20 (O.D.

cfm

(m³/min)

Cooling Heating Cooling Heating

318 (9.0) 318 (9.0) 353 (10.0) 353 (10.0)

FFQ09LVJU FFQ12LVJU

)

(

6.4

(

9.5)

(26) / I.D.

(20)) VP20 (O.D.

25/32

1-1/32

1-1/32

1/4

3/8

(

1/4

(

3/8

(

26) / I.D.

6.4

9.5)

)

(

20))

25/32

11 Specifications

SiUS181305E Specifications

Conversion Formulae

kcal/h = kW × 860

Btu/h = kW × 3412

cfm = m³/min × 35.3

60 Hz, 208 - 230 V

Model

Rated Capacity 15 kBtu/h Class 18 kBtu/h Class

Remote Controller

Decoration Panel

Airflow Rate

Fan

Air Direction Control Horizontal, Downward Horizontal, Downward

Running Current (Rated) A 0.57 0.52 0.71 0.65

Power Consumption (Rated) W 112 103 140 130

Power Factor % 86.1 86.0 85.5 86.2

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H × W × D) in. (mm) 11-1/4 × 22-5/8 × 22-5/8 (285 × 575 × 575) 11-1/4 × 22-5/8 × 22-5/8 (285 × 575 × 575)

Packaged Dimensions (H × W × D) in. (mm) 14-9/16 × 27-1/16 × 26-9/16 (370 × 687 × 674) 14-9/16 × 27-1/16 × 26-9/16 (370 × 687 × 674)

Weight (Mass) Lbs (kg) 38.6 (17.5) 38.6 (17.5)

Gross Weight (Gross Mass) Lbs (kg) 46 (21) 46 (21)

Sound Pressure

Level

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping

Connections

Drawing No. 3D080628 3D080629

Wired BRC1E72 BRC1E72

Wireless BRC7E830 BRC7E830

Model BYFQ60B8W1U BYFQ60B8W1U

Color White White

Dimensions (H × W × D) 2-5/32 × 27-9/16 × 27-9/16 (55 × 700 × 700) 2-5/32 × 27-9/16 × 27-9/16 (55 × 700 × 700)

Weight (Mass) Lbs (kg) 6 (2.7) 6 (2.7)

H

L 283 (8.0) 283 (8.0) 353 (10.0) 353 (10.0)

Type Turbo Fan Turbo Fan

Motor Output W 55 55

Speed Steps 2 Steps 2 Steps

H / L dB(A) 42.5 / 31.5 42.5 / 31.5 46.0 / 37.5 46.0 / 37.5

Liquid in. (mm)

Gas in. (mm)

Drain in. (mm) VP20 (O.D.

cfm

(m³/min)

Cooling Heating Cooling Heating

424 (12.0) 424 (12.0) 530 (15.0) 530 (15.0)

FFQ15LVJU FFQ18LVJU

)

(

6.4

(

12.7)

(26) / I.D.

(20)) VP20 (O.D.

25/32

1-1/32

1-1/32

1/4

1/2

(

1/4

(

12.7)

1/2

(

26) / I.D.

)

6.4

(

20))

25/32

Specifications 12

SiUS181305E

Part 3

Printed Circuit Board

Connector Wiring Diagram

1. Outdoor Unit..............................................................................................14

1.1 RMXS48LVJU ............................................................................................ 14

2. Branch Provider (BP) Unit.........................................................................17

2.1 BPMKS048A2U, BPMKS049A3U .............................................................. 17

3. Indoor Unit................................................................................................18

3.1 CTXS07LVJU ............................................................................................. 18

3.2 CTXS07JVJU, CTXS09/12HVJU ............................................................... 20

3.3 FTXS15/18/24LVJU ................................................................................... 22

3.4 FDXS09/12LVJU, CDXS15/18/24LVJU ..................................................... 24

3.5 FFQ09/12/15/18LVJU ................................................................................ 26

4. Wired Remote Controller...........................................................................27

4.1 BRC1E72 ................................................................................................... 27

5. Wireless Remote Controller ......................................................................28

5.1 BRC7E830 ................................................................................................. 28

13 Printed Circuit Board Connector Wiring Diagram

SiUS181305E Outdoor Unit

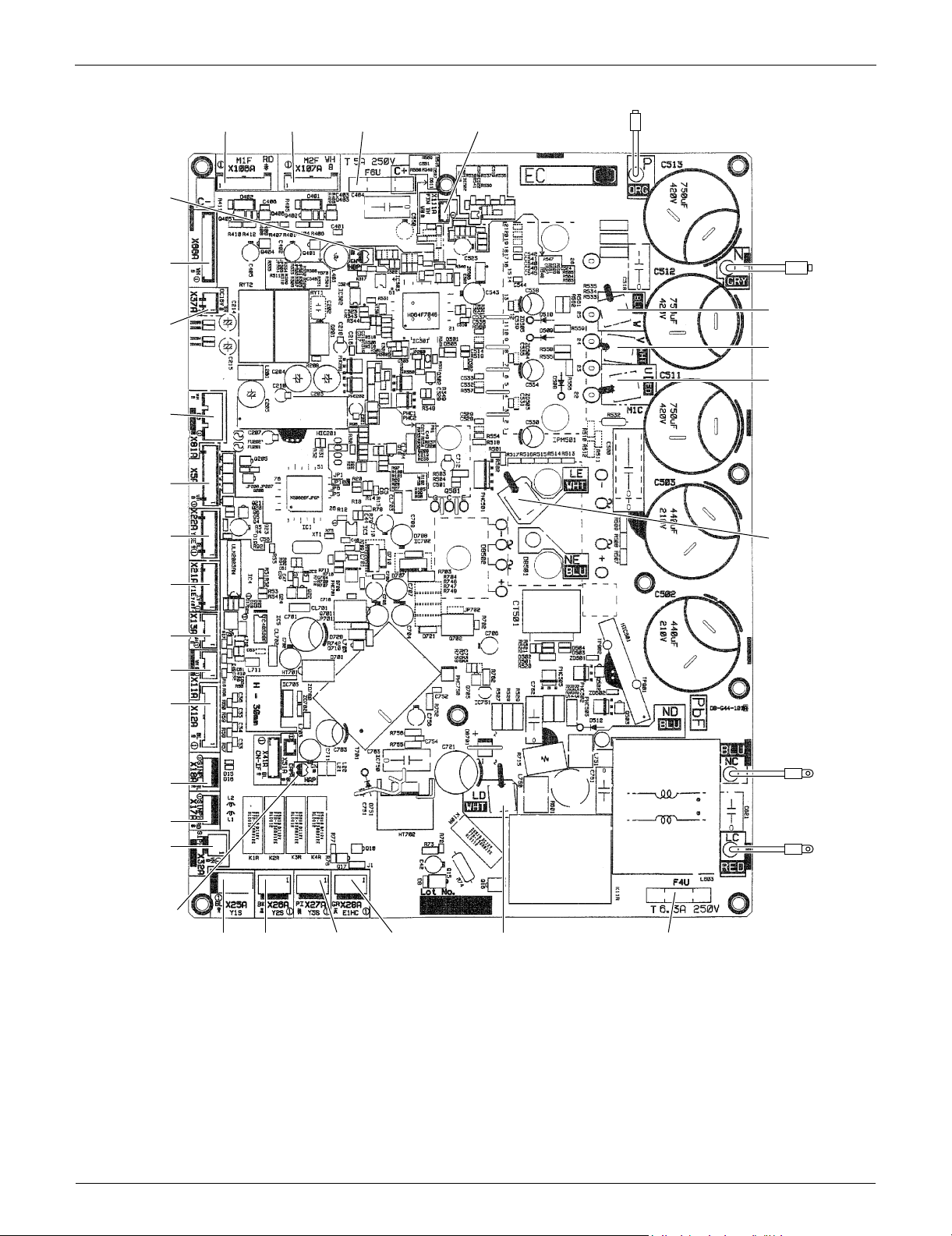

1. Outdoor Unit

1.1 RMXS48LVJU

A1P: Main PCB

1) X5A Connector to service PCB (A2P)

2) X11A Connector for outdoor temperature thermistor

3) X12A Connector for thermistors

(suction pipe 1, suction pipe 2, outdoor heat exchanger,

discharge pipe)

4) X13A Connector for thermistors (subcooling outlet, liquid pipe)

5) X17A Connector for high pressure sensor

6) X18A Connector for low pressure sensor

7) X21A Connector for electronic expansion valve coil (main)

8) X22A Connector for electronic expansion valve coil (subcooling)

9) X25A Connector for solenoid valve coil (four-way valve)

10)X26A Connector for solenoid valve coil (hot gas bypass valve)

11)X27A Connector for solenoid valve coil (unloading)

12)X28A Connector for crankcase heater

13)X32A Connector for high pressure switch

14)X37A Connector for power supply for optional PCB (16 VDC)

15)X66A Connector for cool / heat selector PCB (A4P)

16)X81A Connector for terminal board (inter-unit wiring)

17)X106A Connector for fan motor (upper)

18)X107A Connector for fan motor (lower)

19)X111A Connector for radiation fin thermistor

20)LD, LE Connector for reactor

21)LC, NC Terminal for noise filter PCB (A3P)

22)P Connector for capacitor C4 +

23)N Connector for capacitor C4 –

24)U, V, W Connector for compressor

25)F4U Fuse (6.3 A / 250 V)

26)F6U Fuse (5.0 A / 250 V)

27)HAP Operation pilot lamp (LED for service monitor: green)

28)HBP Inverter pilot lamp (LED for service monitor: green)

Printed Circuit Board Connector Wiring Diagram 14

Outdoor Unit SiUS181305E

LC

NC

LE

W

V

U

N

P

X111AF6UX107AX106A

HBP

X66A

X37A

X81A

X5A

X22A

X21A

X13A

X11A

X12A

X18A

X17A

X32A

HAP

X25A

X26A X27A X28A LD F4U

2P294944-17

15 Printed Circuit Board Connector Wiring Diagram

SiUS181305E Outdoor Unit

DS1

BS5

H1P

H2P

H3P

H4P

H5P

H6P

H7P H8P

X205A

BS4

BS3

BS2

BS1

2P174185-1

NBF1U

NA

LA

E

LB

2P174186-3

X1M

X1A

2P174187-1

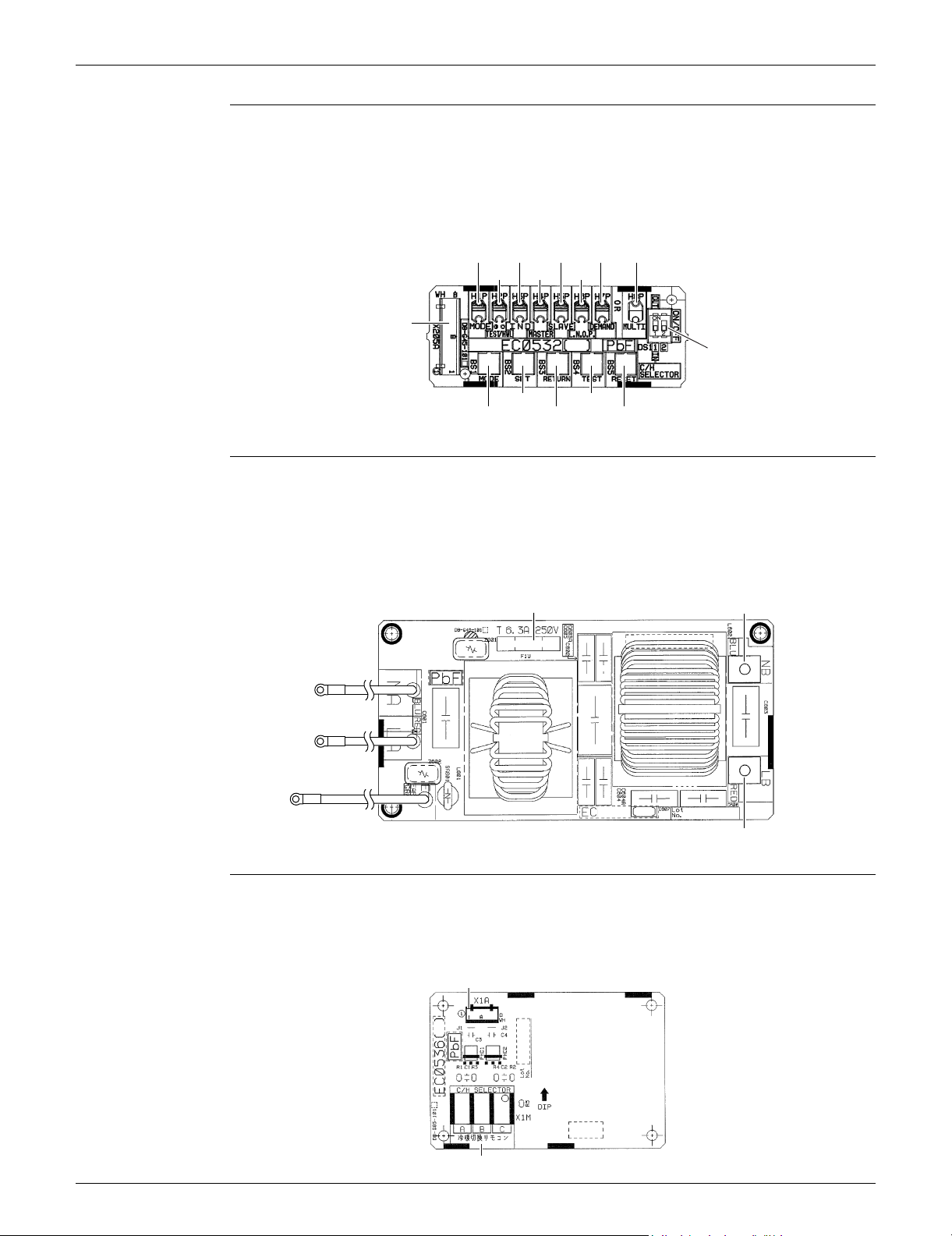

A2P: Service PCB

1) X205A Connector for main PCB (A1P)

2) H1P - H8P LED for service monitor (orange)

3) BS1 - BS5 Push button switch (mode, set, return, test, reset)

4) DS1 DIP switch for cool / heat selector

A3P: Noise Filter

PCB

1) LA, NA Terminal for terminal board (power supply)

2) LB, NB Terminal for main PCB (A1P)

3) E Terminal for ground

4) F1U Fuse (6.3 A / 250 V)

A4P: Cool / Heat

Selector PCB

1) X1A Connector for main PCB (A1P)

2) X1M Terminal for cool / heat selector

Printed Circuit Board Connector Wiring Diagram 16

Branch Provider (BP) Unit SiUS181305E

X3M

X4M

X5M

F2U

E1

X22A

X21A

X20A

F2

X6M

X1M

F1

L2

L1

X90ADS2

X23A

H1P (LED A)

H2P (LED 1)

H3P (LED 2)

H4P (LED 3)

H5P (LED 4)

N2L2N1L1

3P326842-1

3P326842-2

2. Branch Provider (BP) Unit

2.1 BPMKS048A2U, BPMKS049A3U

PCB Detail

1) X20A Connector for bypass electronic expansion valve

2) X21A - X23A Connector for electronic expansion valve for room A, B, C

3) X90A Connector for thermistors

4) F2U Fuse (3.15 A / 250 V)

5) X3M Terminal for inter-connecting wire to room A

6) X4M Terminal for inter-connecting wire to room B

7) X5M Terminal for inter-connecting wire to room C

8) F1, F2 (on X6M) Terminal for transmission to outdoor unit or other BP units

9) L1, L2 (on X1M) Terminal for power supply (60 Hz, 208 ~ 230 V)

10)E1 Terminal for ground

11)H1P (LED A) LED for service monitor (green)

12)H2P - H5P LED for error indication (red)

(LED 1 - 4)

13)DS2 Dip switch

Note: X23A and X5M are not used for BPMKS048A2U.

17 Printed Circuit Board Connector Wiring Diagram

SiUS181305E Indoor Unit

V1

FU1

S1S41

S21

S47

JBJAJC

S46

S25

LED A

S32

FG

H1

H2H3

2P206687-4

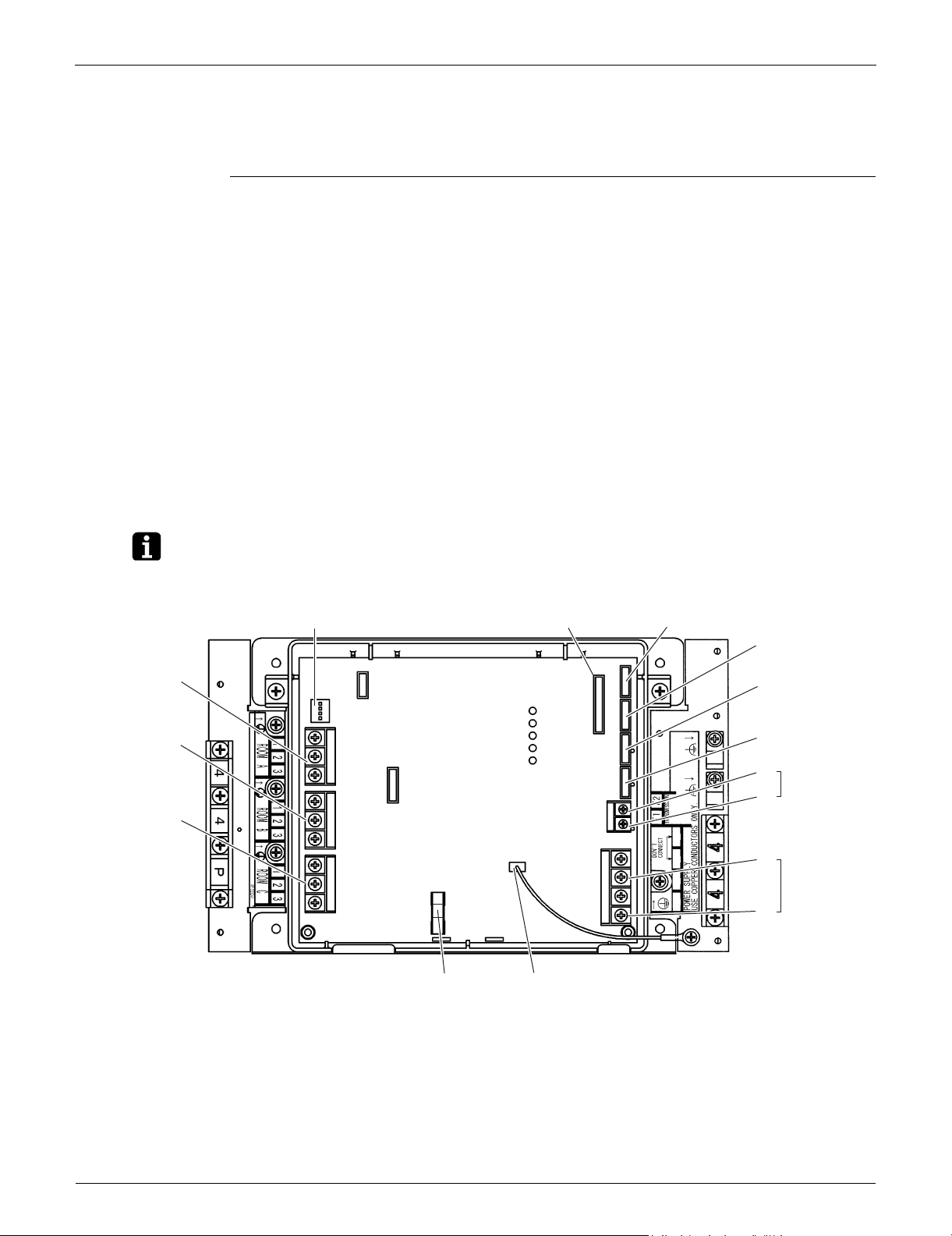

3. Indoor Unit

3.1 CTXS07LVJU

Control PCB

1) S1 Connector for DC fan motor

2) S21 Connector for centralized control (HA)

3) S25 Connector for INTELLIGENT EYE sensor PCB

4) S32 Indoor heat exchanger thermistor

5) S41 Connector for swing motors

6) S46 Connector for display PCB

7) S47 Connector for signal receiver PCB

8) H1, H2, H3, FG Connector for terminal board

9) JA Address setting jumper

Refer to page 111 for detail.

10)JB Fan speed setting when compressor stops for thermostat OFF

JC Power failure recovery function (auto-restart)

Refer to page 112 for detail.

11)LED A LED for service monitor (green)

12)FU1 (F1U) Fuse (3.15 A, 250 V)

13)V1 Varistor

Caution Replace the PCB if you accidentally cut the jumpers other than JA, JB, and JC.

Jumpers are necessary for electronic circuit. Improper operation may occur if you cut any of them.

Printed Circuit Board Connector Wiring Diagram 18

Indoor Unit SiUS181305E

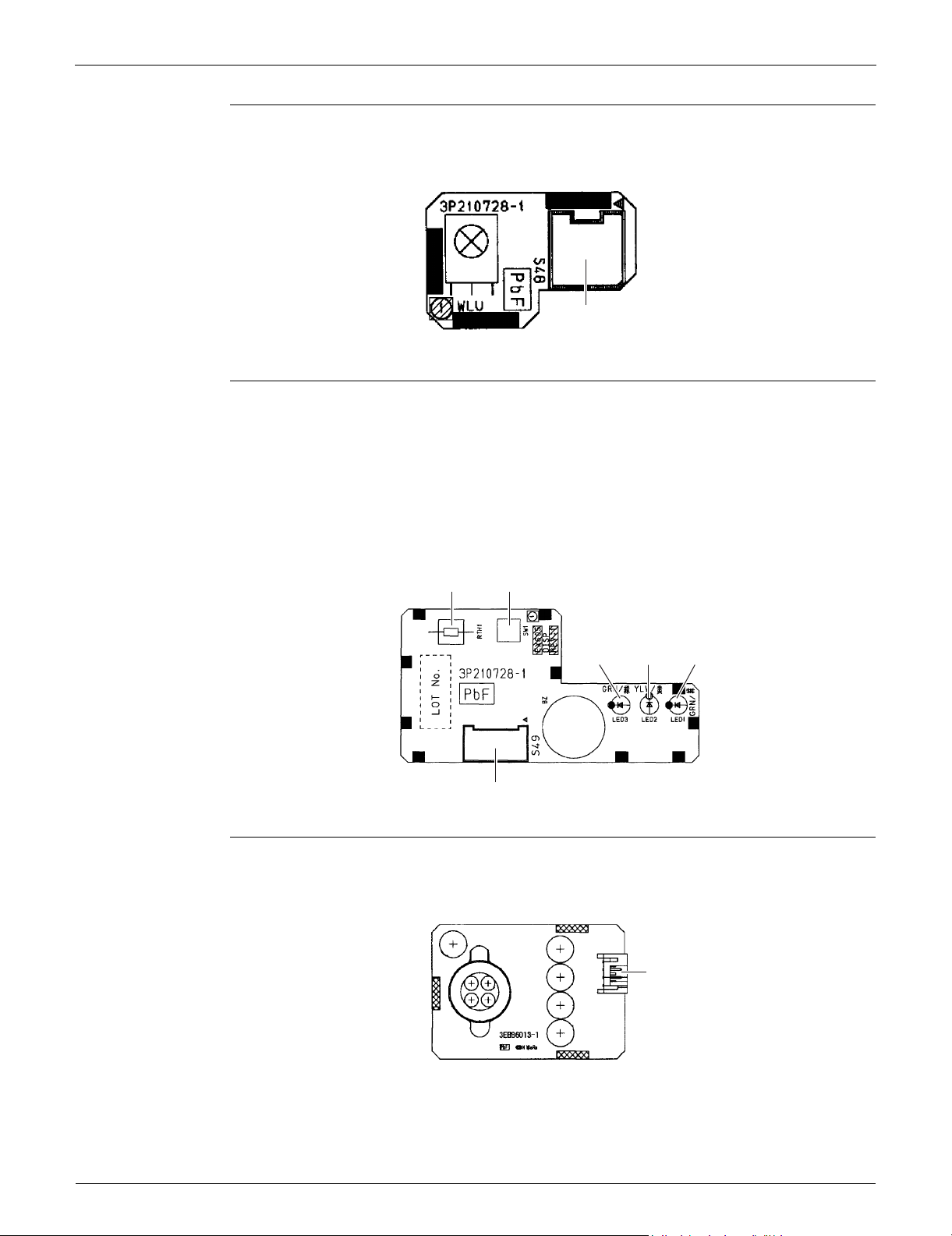

3P210728-1

S48

3P210728-1

RTH1

SW1

S49

LED3 LED2 LED1

3EB86013-1

S26

Signal Receiver

PCB

1) S48 Connector for control PCB

Display PCB

1) S49 Connector for control PCB

2) SW1 Forced operation ON/OFF button

3) LED1 (H1P) LED for operation (green)

4) LED2 (H2P) LED for timer (yellow)

5) LED3 (H3P) LED for INTELLIGENT EYE (green)

6) RTH1 (R1T) Room temperature thermistor

INTELLIGENT

EYE Sensor PCB

19 Printed Circuit Board Connector Wiring Diagram

1) S26 Connector for control PCB

SiUS181305E Indoor Unit

S1

V1

FU1

S6

S8

2P099167-1

JCJBJALED A

S21

S35

H1

S26

S28

H2

H3

FG

S32

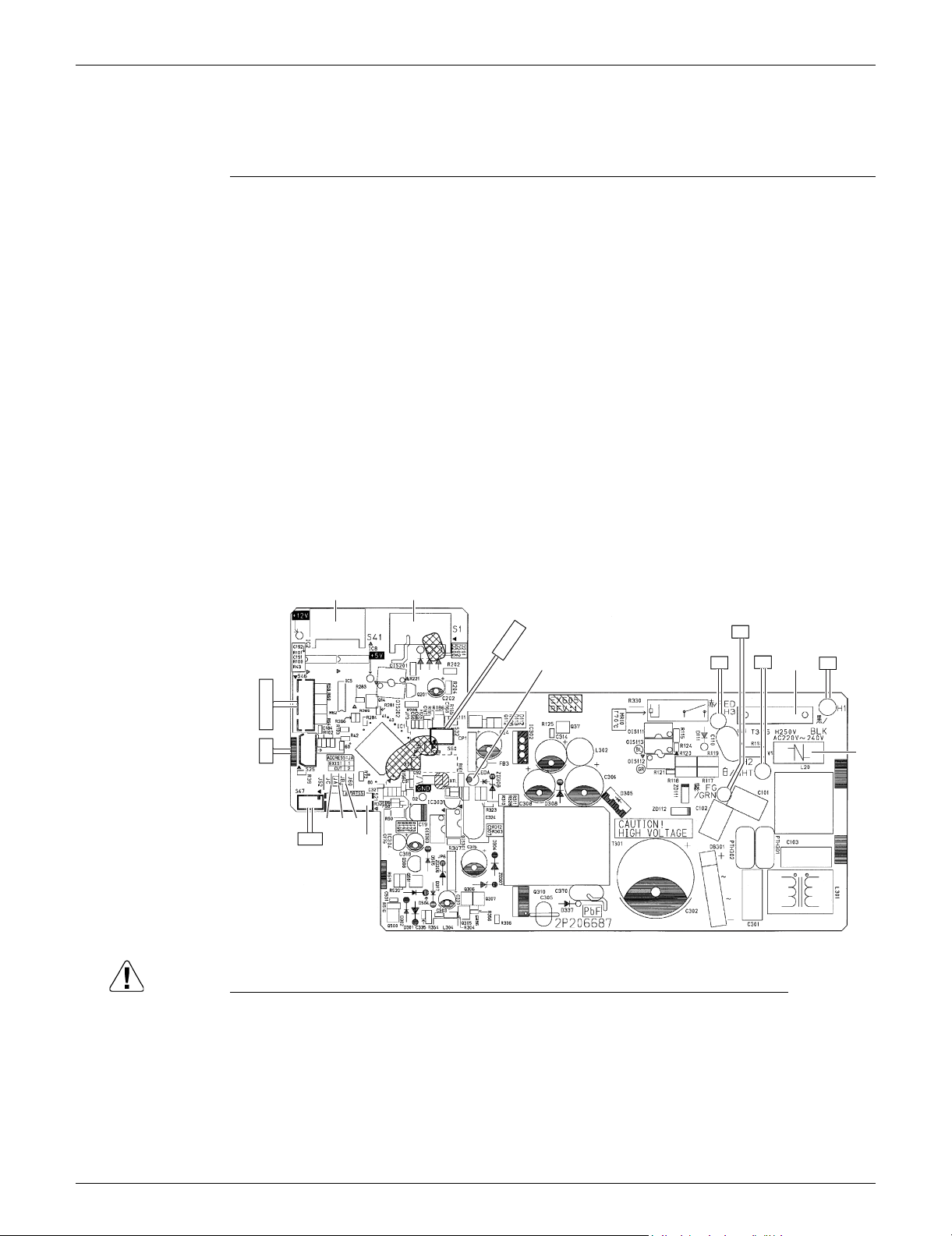

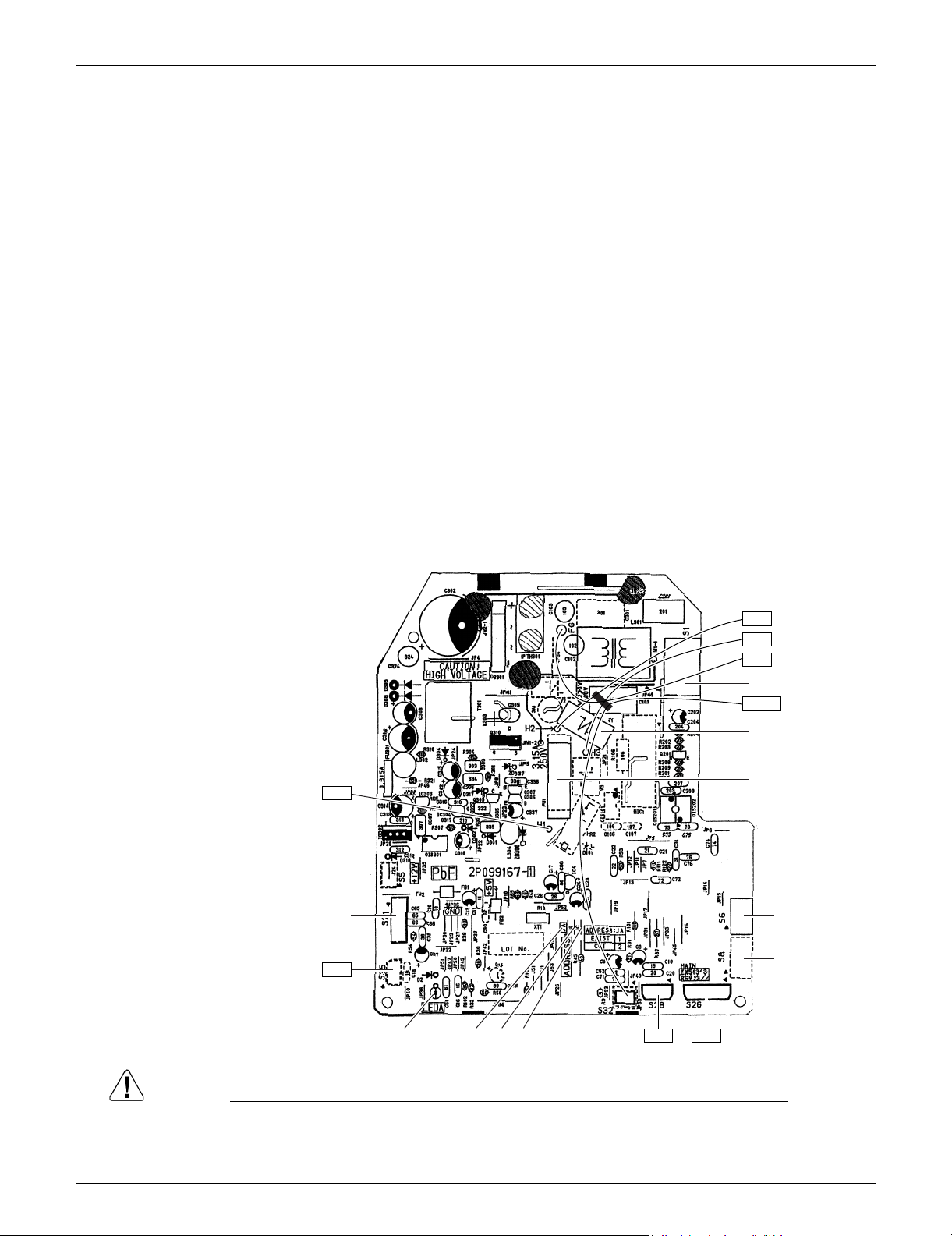

3.2 CTXS07JVJU, CTXS09/12HVJU

Control PCB

1) S1 Connector for DC fan motor

2) S6 Connector for swing motor (horizontal blades)

3) S8 Connector for swing motor (vertical blades)

4) S21 Connector for centralized control (HA)

5) S26 Connector for buzzer PCB

6) S28 Connector for signal receiver PCB

7) S32 Indoor heat exchanger thermistor

8) S35 Connector for INTELLIGENT EYE sensor PCB

9) H1, H2, H3, FG Connector for terminal board

10)JA Address setting jumper

Refer to page 111 for detail.

11)JB Fan speed setting when compressor stops for thermostat OFF

JC Power failure recovery function (auto-restart)

Refer to page 112 for detail.

12)LED A LED for service monitor (green)

13)FU1 Fuse (3.15 A, 250 V)

14)V1 Varistor

Caution Replace the PCB if you accidentally cut the jumpers other than JA, JB, and JC.

Jumpers are necessary for electronic circuit. Improper operation may occur if you cut any of them.

Printed Circuit Board Connector Wiring Diagram 20

Loading...

Loading...