Daikin ARYN-L, ATYN-L User manual

INSTALLATION

MANUAL

WALL MOUNTED

R410A SPLIT TYPE AIR CONDITIONER

MODELS

ATYN20LV1 ARYN20LV1

ATYN25LV1 ARYN25LV1

ATYN35LV1 ARYN35LV1

ATYN50LV1 ARYN50LV1

ATYN60LV1 ARYN60LV1

Installation Manual

R410A Split Type Air Conditioner

Руководство по установке

R410A разделить Кондиционер

воздуха типа

English

Русский

IM-5WMJR-0515(0)-DAIKIN SIESTA

Part No.: R08019043338

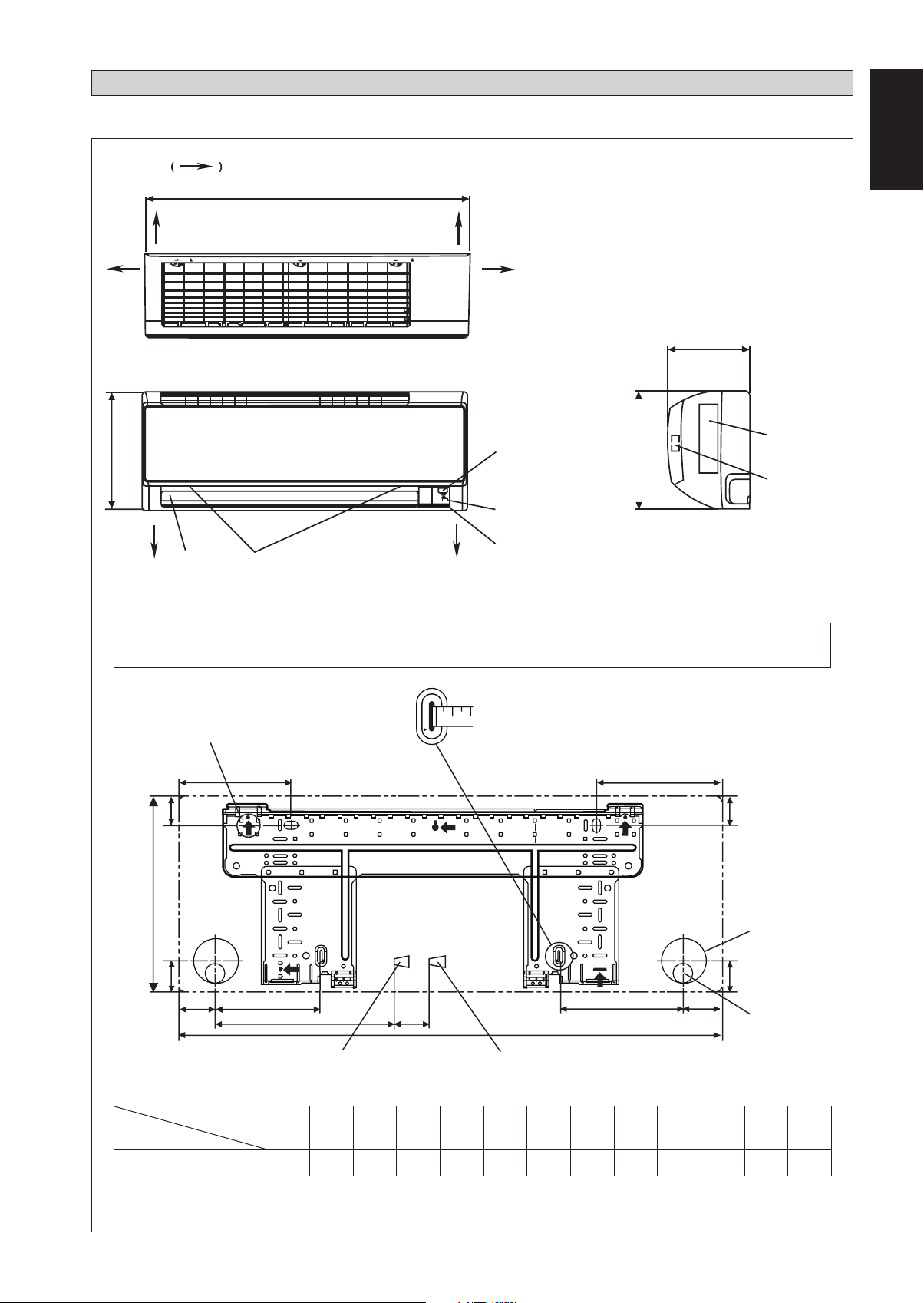

Indoor Unit [ATYN]

OUTLINE AND DIMENSIONS

THE MARK SHOWS PIPING DIRECTION

A

LEFT

B

BOTTOM

REAR REAR

TOP VIEW

LOUVER

FRONT GRILLE FIXED SCREWS

(INSIDE)

BOTTOM

FRONT VIEW

RIGHT

SIGNAL RECEIVER

INDOOR UNIT

ON/OFF SWITCH

ROOM TEMPERATURE

THERMISTOR (INSIDE)

B

C

SIDE VIEW

English

Original Instruction

NAME PLATE

TERMINAL

BLOCK

WITH EARTH

TERMINAL

NOTE: PLEASE BASED ON ACTUAL INSTALLATION PLATE DESIGN IN THE UNIT FOR INSTALLATION PLATE

20/25/35J DIMENSION REFERENCE AT PAGE 1&2.

«

Recommended mounting plate retention spots

(5 spots in all)

D

F

B

G

H

J

L

Liquid pipe end

M

Use tape measure as shown.

Position the end of a tape measure at

A

Gas pipe end

Ñ

E

F

Through the wall

hole Ø 65mm

G

K

I

Drain hose position

INSTALLATION PLATE 20/25/35J

Dimension

Model

ABCDE FGHI J KLM

20/25/35J 800 288 206 166 184 42 46 55 56 154 182 263 52

All dimensions are in mm

1-1

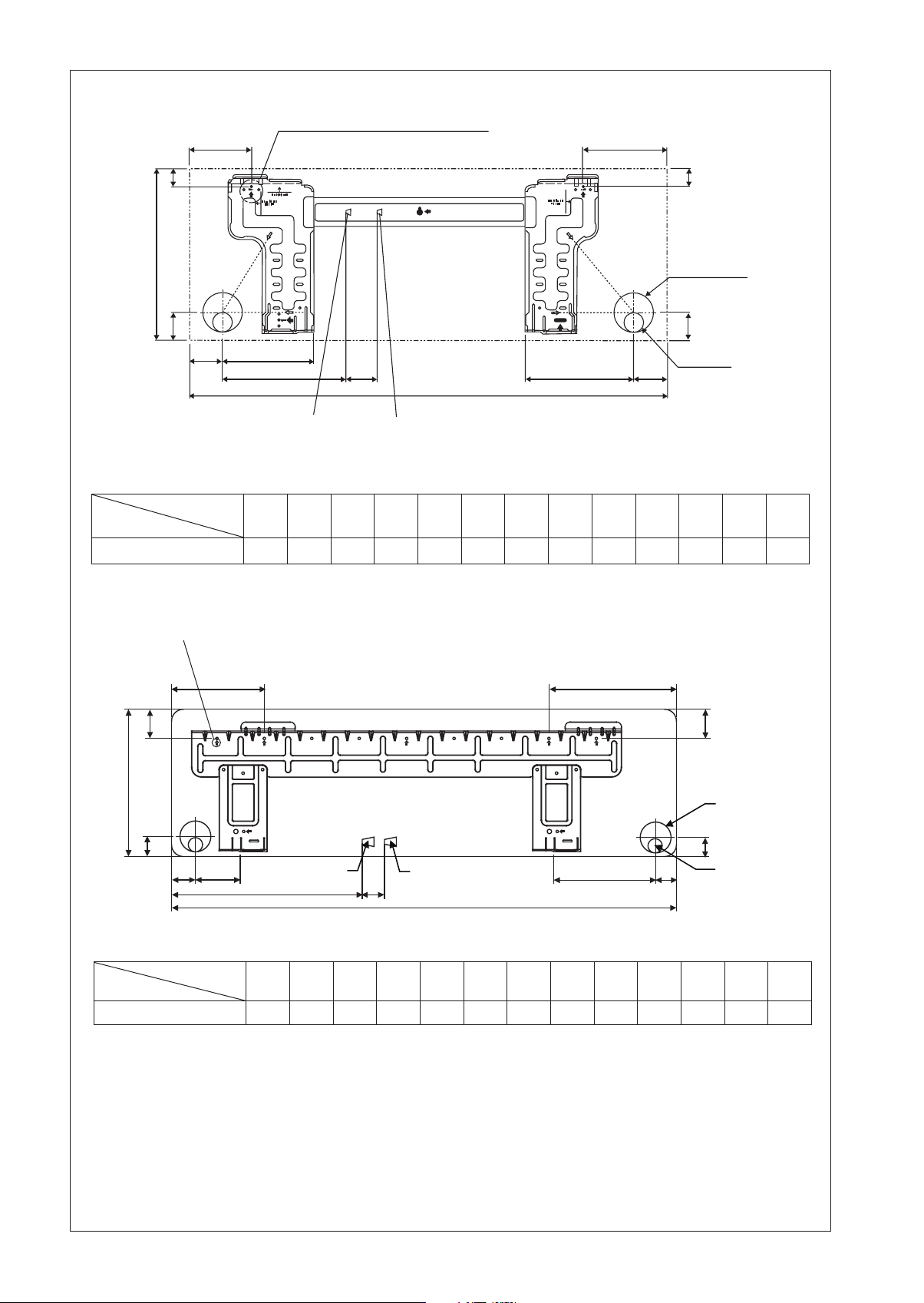

« Recommended mounting plate retention spots

(5 spots in all)

D

E

F

Through the wall

hole Ø 65mm

G

Drain hose position

IK

Model

F

B

G

Dimension

JH

ML

Liquid pipe end

ALTERNATIVE INSTALLATION PLATE 20/25/35J

A

Gas pipe end

ABCDE FGHI J KLM

20/25/35J 800 288 206 104 141 30 46 55 56 153 181 207 52

«

Recommended mounting plate retention spots

(7 spots in all)

E

F

Through the wall

hole Ø 65mm

G

K

I

Drain hose position

B

Model

F

G

Dimension

D

H

J

Liquid pipe end Gas pipe end

L

M

A

INSTALLATION PLATE 50/60J

ABCDE FGHI J KLM

50/60J 1065 310 224 190 173 61 40 45 48 91 219 580 45

1-2

All dimensions are in mm

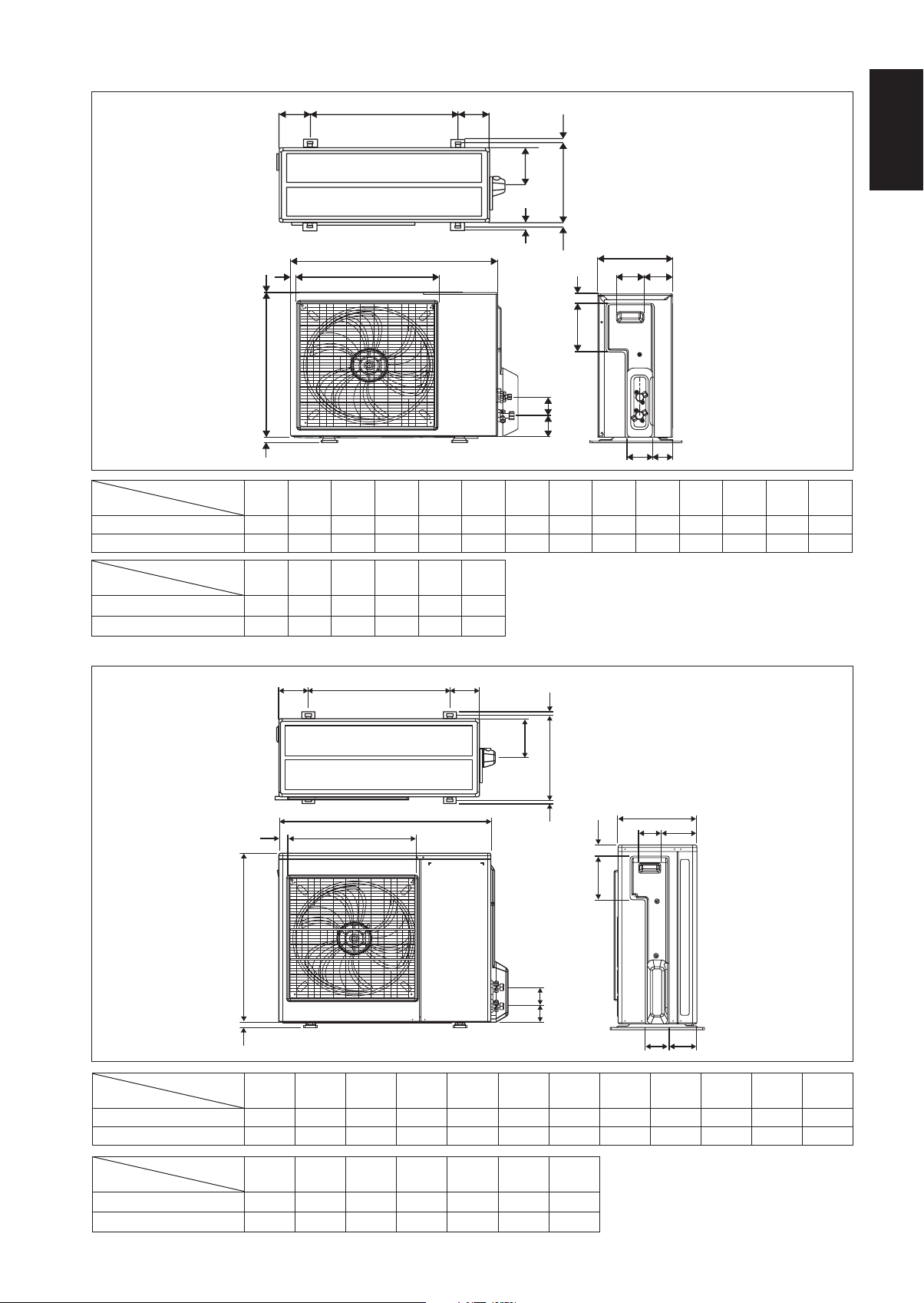

Outdoor Unit [ARYN]

KLL

N

All dimensions are in mm

English

M

C

T

A

O

PQ

B

D

N

FE

SR

C

GH

I

J

Mode

Dimension

l

ABCDE FGHI J KLMN

20C 600 475 245 418 177 35 93 81 83 55 398 101 97 17

25/35C 700 521 250 485 175 36 95 93 86 68 441 130 111 15

Mode

Dimension

l

OPQRST

20C 22 3 19658030

25/35C 18 3 19658030

Outdoor Unit [ARYN]

KLL

N

M

Q

A

O

B

D

N

F

E

All dimensions are in mm

C

H

G

S

R

IJ

Model

Dimension

P

ABCDE FGHI J KL

50C 855 628 328 520 179 46 93 149 101 113 603 126

60C 855 730 328 520 179 46 93 149 101 113 603 126

Model

Dimension

MNO P Q R S

50C 164 15 34 23 362 73 75

60C 164 15 34 23 362 73 75

1-3

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air

conditioner unit.

Special adjustment may be necessary to suit local requirement.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for

commercial use by lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

! WARNING ! CAUTION

Installation and maintenance should be performed by

•

qualified persons who are familiar with local code

and regulation, and experienced with this type of

appliance.

All field wiring must be installed in accordance with the

•

national wiring regulation.

Ensure that the rated voltage of the unit corresponds to

•

that of the name plate before commencing wiring work

according to the wiring diagram.

The unit must be GROUNDED to prevent possible

•

hazard due to insulation failure.

All electrical wiring must not touch the water piping or

•

any moving parts of the fan motors.

Confirm that the unit has been switched OFF before

•

installing or servicing the unit.

Risk of electric shock, can cause injury or death.

•

Disconnect all remain electric power supplies before

servicing.

DO NOT pull out the power cord when the power is

•

ON. This may cause serious electrical shocks which

may result in the fire hazards.

Keep the indoor and outdoor units, power cable and

•

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending on

the type and source of the electrical waves, static may

be heard even when more than 1m away}.

Please take note of the following important points when

installing.

Do not install the unit where leakage of flammable gas

•

may occur.

If gas leaks and accumulates around the unit, it may

cause fire ignition.

Ensure that drainage piping is connected properly.

•

If the drainage piping is not connected properly, it may

cause water leakage which will dampen the furniture.

Do not overcharge the unit.

•

This unit is factory pre-charged. Overcharge will cause

over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service or

•

installation.

Unsecured panels will cause the unit to operate

noisily.

Sharp edges and coil surfaces are potential locations which

•

may cause injury hazards. Avoid from being in contact with

these places.

Before turning off the power supply set the remote controller’s

•

ON/OFF switch to the “OFF” position to prevent the nuisance

tripping of the unit. If this is not done, the unit’s fans will start

turning automatically when power resumes, posing a hazard to

service personnel or the user.

Do not install the units at or near doorway.

•

Do not operate any heating apparatus too close to the air

•

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or deform

as a result of excessive heat or chemical reaction.

When the unit is used in kitchen, keep flour away from going

•

into suction of the unit.

This unit is not suitable for factory used where cutting oil mist

•

or iron powder exist or voltage fluctuates greatly.

Do not install the units at area like hot spring or oil refinery

•

plant where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the terminal

•

markings are same to the indoors respectively.

IMPORTANT : DO NOT INSTALL OR USE THE AIR

•

CONDITIONER UNIT IN A LAUNDRY ROOM.

Don’t use joined and twisted wires for incoming power

•

supply.

The equipment is not intended for use in a potentially explosive

•

atmosphere.

1-4

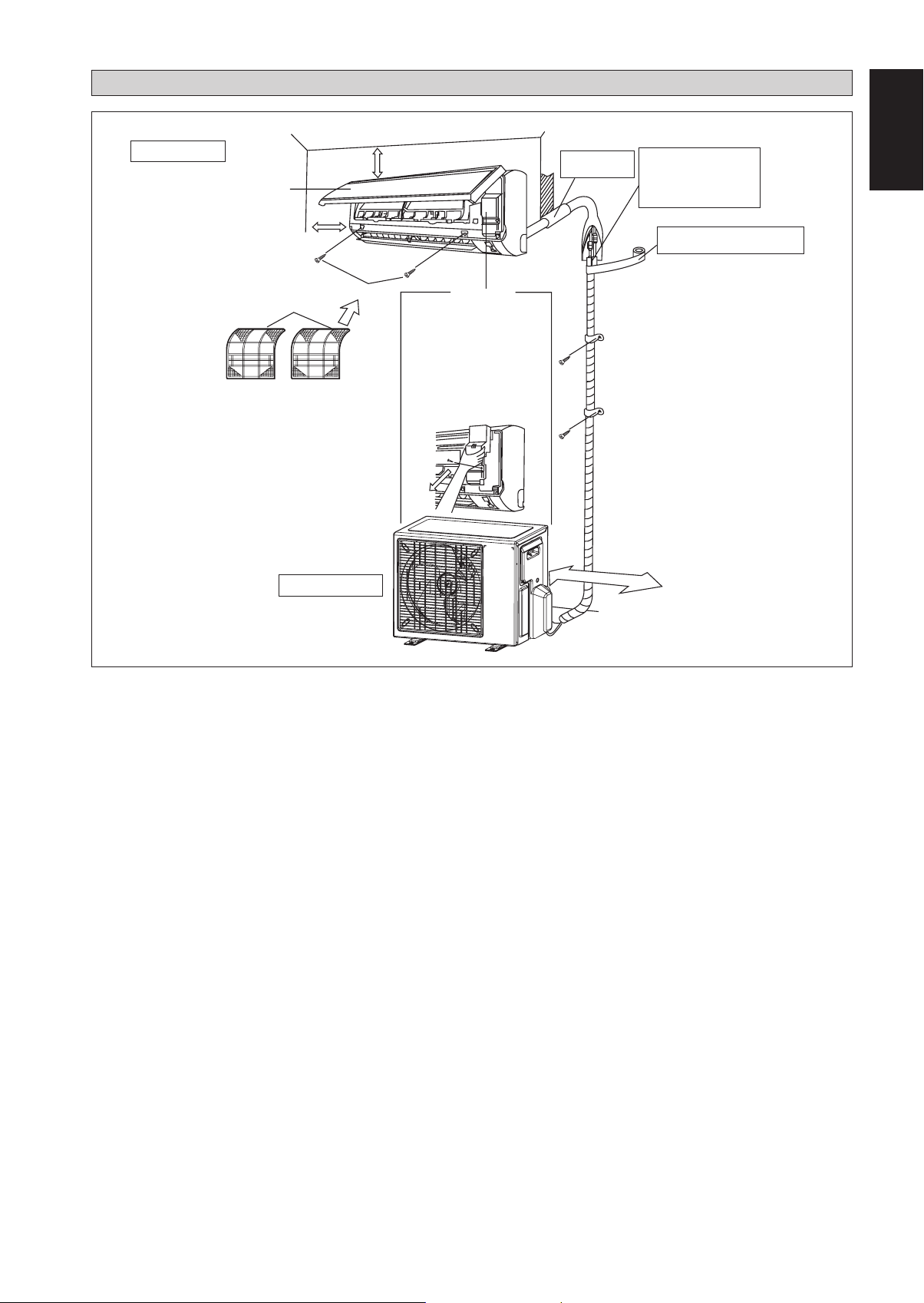

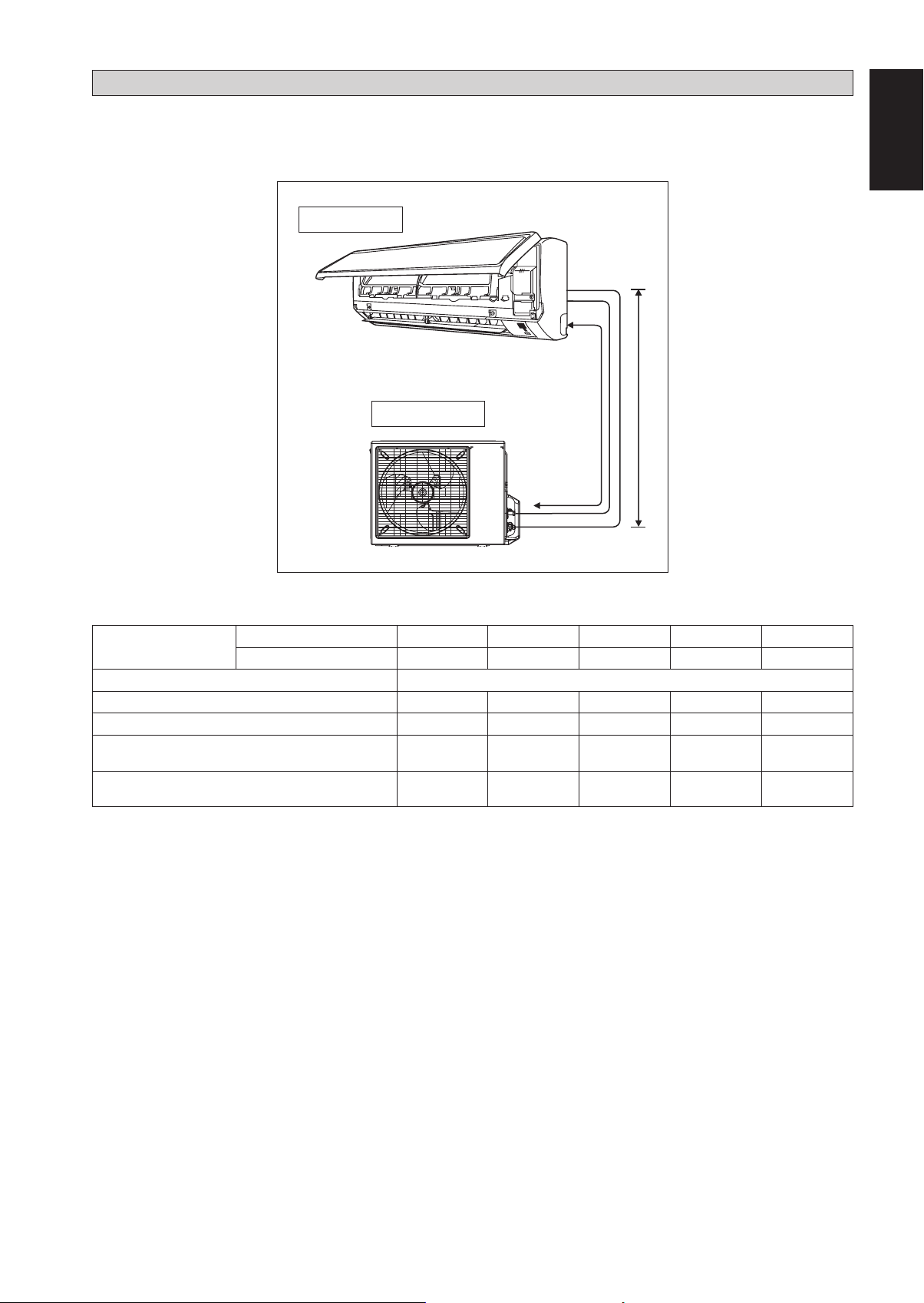

INSTALLATION DIAGRAM

Indoor unit

Front panel

50mm or more from walls

(on both sides)

Air filter

Outdoor Unit

M4 x 12L

75mm or more from ceiling

Service lid

Opening service lid

¢

Service lid is opening/closing

type.

Opening method

¢

1) Remove the service lid screws.

2) Pull out the service lid

diagonally down in the

direction of the arrow.

3) Pull down.

Caulk pipe hole

gap with putty.

500mm from wall

Cut thermal insulation pipe

to an appropriate length and

wrap it with tape, making

sure that no gap is left in the

insulation pipe’s cut line.

Wrap the insulation pipe with the

finishing tape from bottom to top.

English

1-5

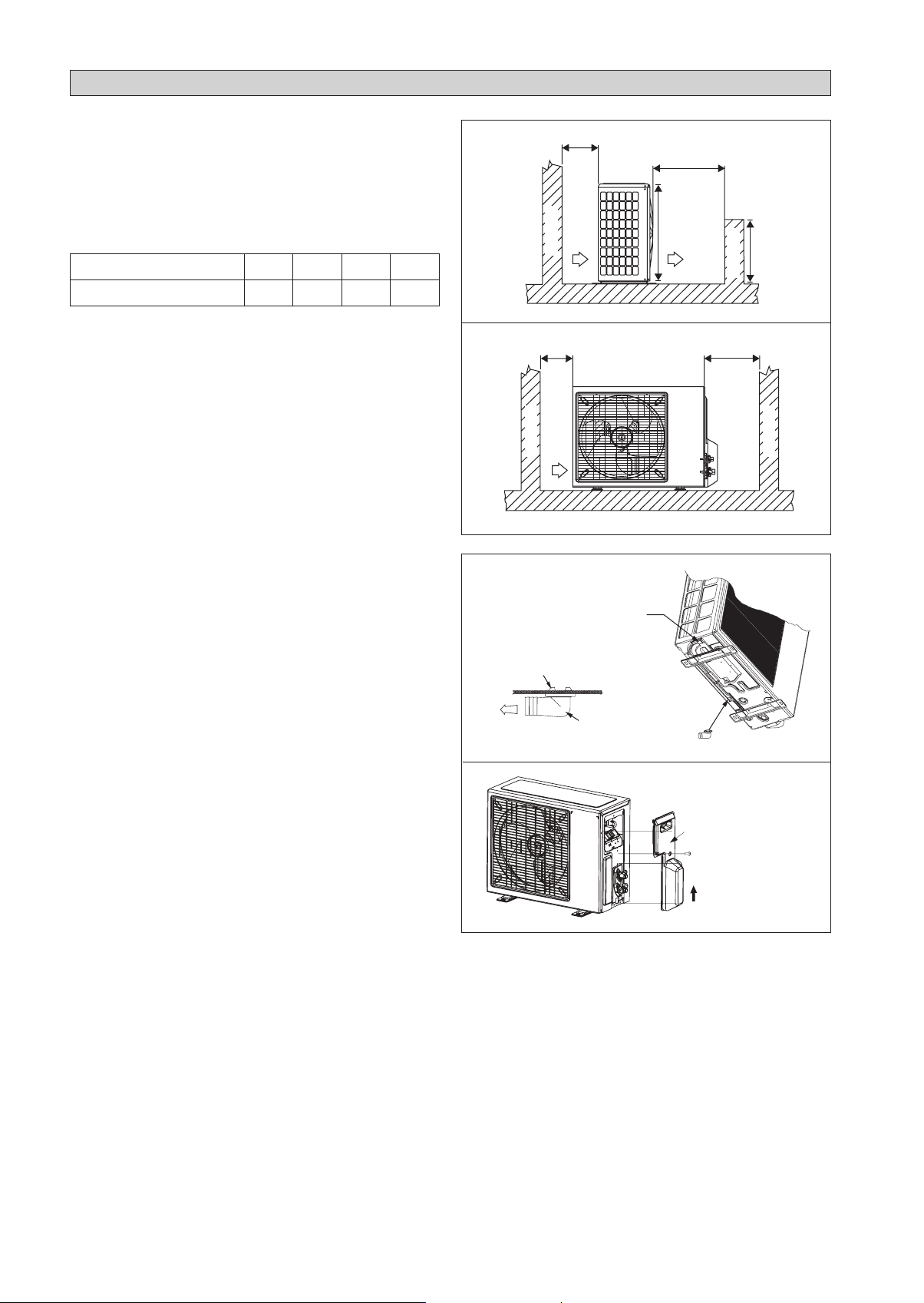

INSTALLATION OF THE OUTDOOR UNIT

The outdoor unit must be installed in such a way, so as to

prevent short circuit of the hot discharged air or obstruction to

the smooth air flow. Please follow the installation clearances

shown in the figure. Select the coolest possible place where

intake air temperature is not greater than the outside air

temperature (please refer operating range).

Installation clearances

Dimension

ABCD

Minimum Distance, mm 300 1000 300 500

Note: If there is any obstacle higher than half, of the unit’s

height (H), please allow more space than the figure indicated

in the above table.

Condensed Water Disposal Of Outdoor Unit

(Heat Pump Unit Only)

There are 2 holes on the base of Outdoor Unit for condensed

•

water to flow out. Insert the drain elbow to one of the

holes.

To install the drain elbow, first insert one portion of the

•

hook to the base (portion A), then pull the drain elbow in

the direction shown by the arrow while inserting the other

portion to the base. After installation, check to ensure that

the drain elbow clings to base firmly.

If the unit is installed in a snowy and chilly area, condensed

•

water may freeze in the base. In such case, please remove

plug at the bottom of unit to smooth the drainage.

BASE

Obstacle

C

Obstacle

Return air

A

A

Return air

PLUG

DRAIN ELBOW

DRAIN ELBOW

B

H

Discharge air

H/2

Obstacle

D

Obstacle

Service access

1-6

Please remove side

plate when connecting

the piping and

connecting cord

PUSH & PULL UP

INSTALLATION OF THE INDOOR UNIT

The indoor unit must be installed in such a way so as to prevent

short circuit of the cool discharged air with the hot return air.

Please follow the installation clearance shown in the figure. Do

not place the indoor unit where there could be direct sunlight

shining on it. Also, this location must be suitable for piping

and drainage, and be away from doors or windows.

Return Air

Air flow

(Indoor)

min. 75

(Space for

performance)

min. 50

(Space for

maintenance)

Required space

min. 50

(Space for

maintenance)

All dimensions are in mm

The refrigerant piping can be routed to the unit in a number

of ways (left or right from the back of the unit), by using the

cut-out holes on the casing of the unit (see figure). Bend the

pipes carefully to the required position in order to align it with

the holes. For the side and bottom out, hold the bottom of the

piping and then position it to the required direction (see figure).

The condensation drain hose can be taped to the pipes.

Right-Side, Right-Back or Right-Bottom Piping

Right-side piping

Remove pipe port cover

here for right-side piping

Remove pipe port cover

here for right-bottom piping

Right-bottom

piping

Right-back piping

Bind coolant pipe

and drain hose

together with

insulating tape.

Left-Side, Left-Back or Left-Bottom Piping

Remove pipe port

cover here for

left-side piping

English

Mounting Installation Plate

Ensure that the wall is strong enough to withstand the weight

of the unit. Otherwise, it is necessary to reinforce the wall

with plates, beams or pillars.

Use the level gauge for horizontal mounting, fix it with

5 suitable screws for 20/25/35J and 7 suitable screws for

50/60J.

In case the rear piping draws out, drill a hole 65mm in

diameter with a cone drill, slightly lower on the outside wall

(see figure).

Mounting plate

Left-side piping

Remove pipe port cover

here for left-bottom piping

Left-bottom piping

20/25/35J (ALTERNATIVE INSTALLATION PLATE)

Mounting plate

Mounting plate

fixing screw

50/60J20/25/35J

Mounting plate

Left-back piping

Mounting plate fi xing screw

Mounting plate

fixing screw

1-7

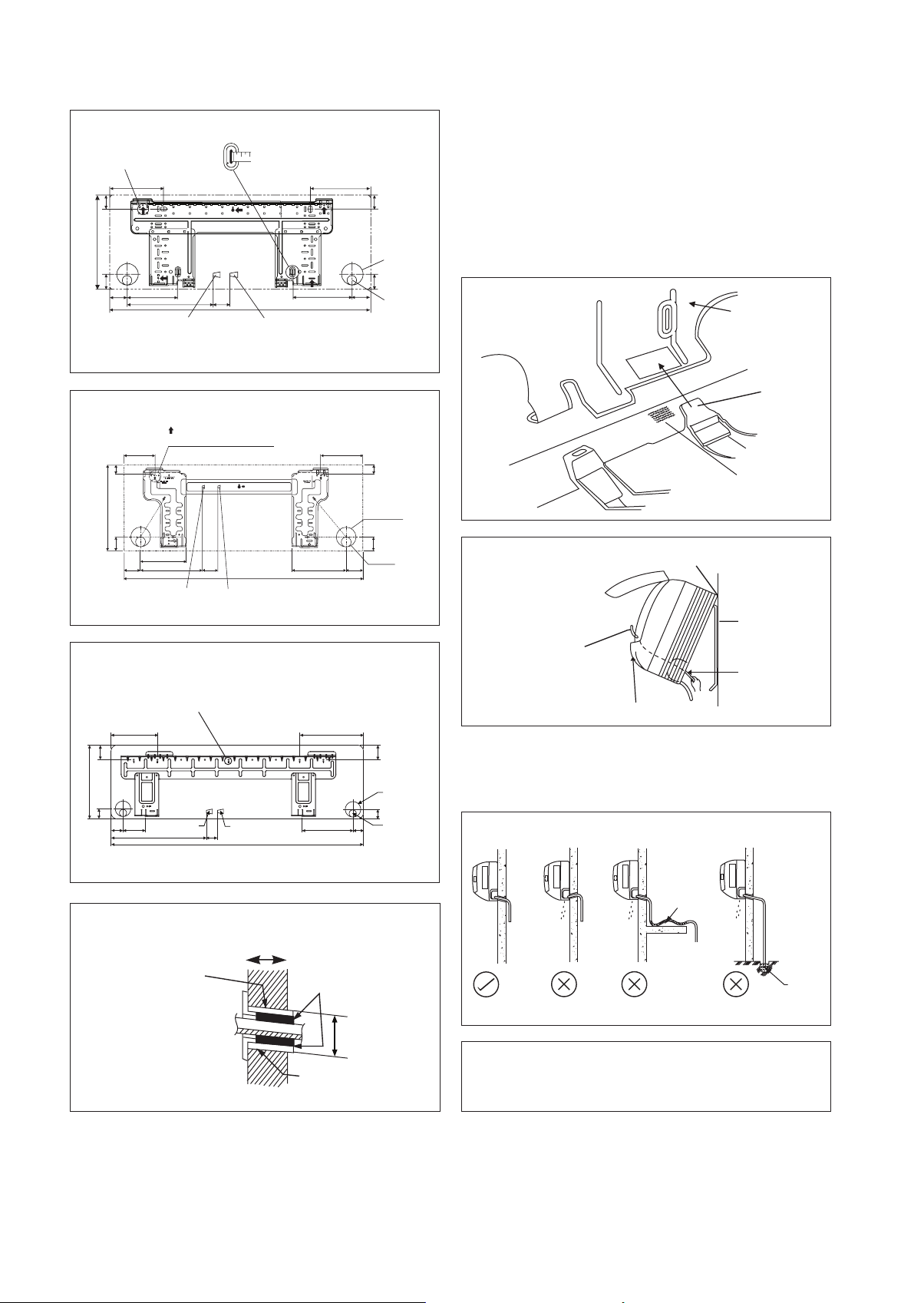

Recommended Mounting Plate Retention Spots And

Dimensions

20/25/35J

«

Recommended mounting plate

retention spots (5 spots in all)

166

42.2

288

45.9

54.5 153.8

20/25/35J

30

288

263 51.9

(ALTERNATIVE INSTALLATION PLATE)

Recommended mounting plate retention spots

(5 spots in all)

104

Use tape measure as shown.

Position the end of a tape measure at

184

800

Gas pipe endLiquid pipe end

181.7 55.5

All dimensions are in mm

141

42.2

Through the

wall hole

Ø 65mm

45.9

Drain hose

position

30

Through the

wall hole

Ø 65mm

Ñ

Mount The Unit Onto The Installation Plate

Hook the indoor unit onto the upper portion of the installation

plate (Engage the two hooks at the rear top of the indoor unit

with the upper edge of the installation plate). Ensure that the

hooks are properly seated on the installation plate by moving

it to the left and right.

How To Attach The Indoor Unit

Hook the claws of the bottom frame to the mounting plate.

How To Remove The Indoor Unit

Push up the marked area (at the lower part of the front grille)

to release the claws.

Mounting plate

Clip

Bottom frame

Front grille

Mark (rear side)

46

55

Liquid pipe end

153

52

207

800

Gas pipe end

50/60J

«

Recommended mounting plate retention spots

(7 spots in all)

190 173

61

310

40

45

Liquid pipe end

91

580

45

1065

Gas pipe end

Hole With Cone Drill

Wall embedded pipe

(Field supply)

Inside

46

Drain hose

position

56181

All dimensions are in mm

61

Through the

wall hole

Ø 65mm

40

48

219

Drain hose

position

All dimensions are in mm

Outside

Caulking

Hang indoor unit’s hook here.

When stripping the

Mounting plate

ends of interconnecting

wires in advance, bind

right ends of wires with

insulating tape.

Interconnecting

wires

Wire guide

Water Drainage Piping

The indoor drain pipe must be in a downward gradient for

smooth drainage. Avoid situations that are likely to cause

water to leak.

Water Drainage

Water

Retention

Water

leaking

Wrong

End dipped

into water

Drain

Correct

Water

leaking

Wrong

Water

leaking

Wrong

Wall hole cover

(Field supply)

Ø 65

Wall embedded pipe

(Field supply)

! CAUTION

• Do not install the unit at altitude over 2000m for both

indoor and outdoor.

1-8

REFRIGERANT PIPING

If the pipe is too long, both the capacity and reliability of the unit will drop. As the number of bends increases, resistance to

the flow of refrigerant system increases, thus lowering cooling capacity. As a result, the compressor may become defective.

Always choose the shortest path and follow the recommendations as tabulated below:

Indoor unit

English

Outdoor Unit

LE

Heat Pump Model

Model

Min. Allowable Length (L), m 3

Max. Allowable Length (L), m 12 12 12 20 20

Max. Allowable Elevation (E), m 5 5 5 15 15

Gas Pipe Size, mm/(in) 9.52

Liquid Pipe Size, mm/(in) 6.35

*Be sure to add the proper amount of additional refrigerant. Failure to do so may result in reduced performance.

Remark: The refrigerant pre-charged in the outdoor unit is for piping length up to 7.5m.

Indoor (ATYN) 20J 25J 35J 50J 60J

Outdoor (ARYN) 20C 25C 35C 50C 60C

(3/8")

(1/4")

9.52

(3/8")

6.35

(1/4")

12.70

(1/2")

6.35

(1/4")

12.70

(1/2")

6.35

(1/4")

15.88

(5/8")

6.35

(1/4")

1-9

Equivalent length for various fitting (meter)

Pipe Size L joint

Trap bend

3/8" (OD9.52mm) 0.18 1.3

1/2" (OD12.7mm) 0.20 1.5

5/8" (OD15.9mm) 0.25 2

3/4" (OD19.1mm) 0.35 2.4

7/8" (OD22.2mm) 0.40 3

1" (OD25.4mm) 0.45 3.4

1 1/8" (OD28.6mm) 0.50 3.7

1 3/8" (OD34.9mm) 0.60 4.4

Notes:

1. Equivalent piping length is obtained with actual length of gas piping.

2. 90° bend of piping is equivalent to L joint.

Bending must be carefully made so as not to crush the pipe. Use a pipe bender to bend a pipe where possible.

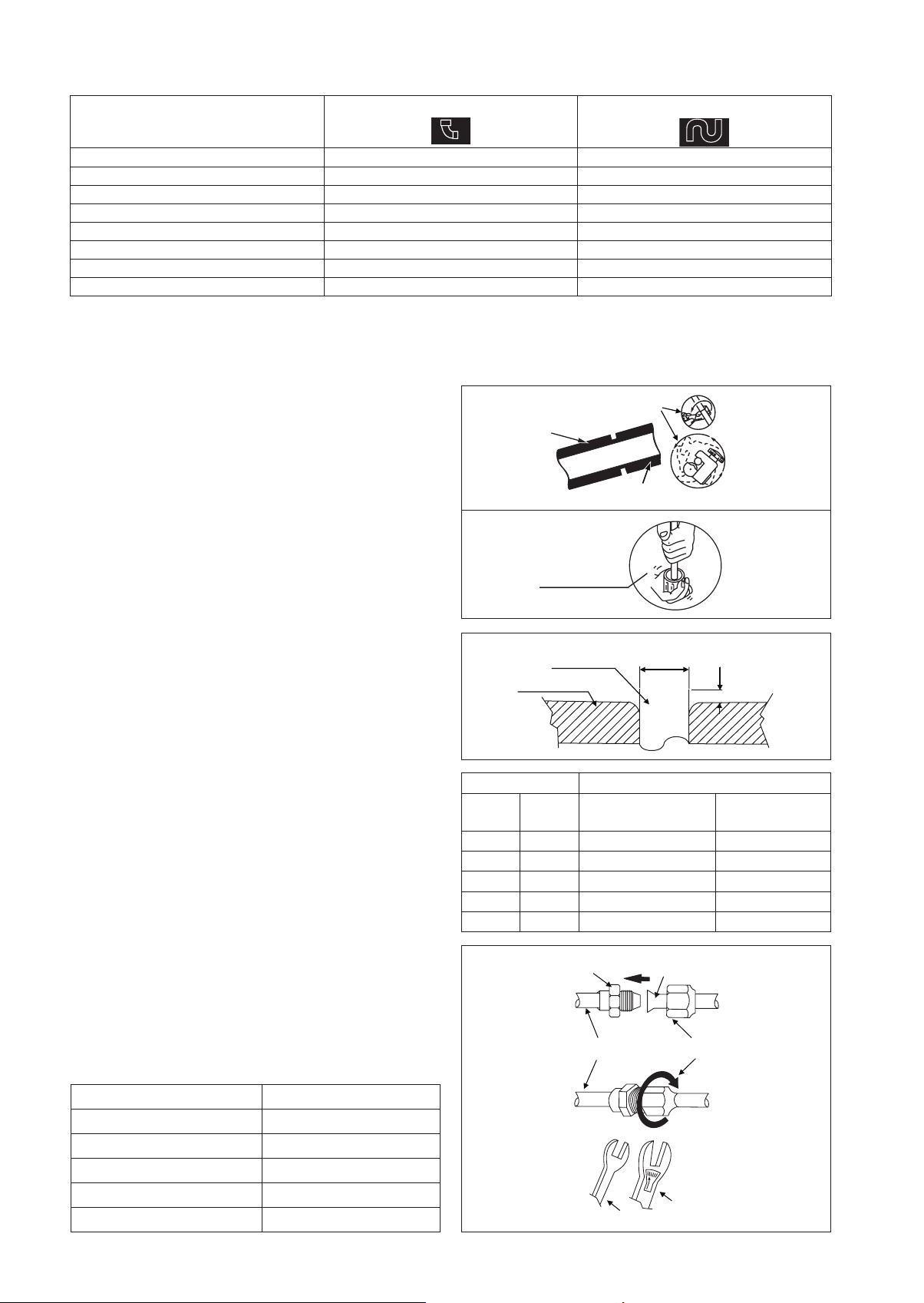

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If

•

any piping, evaporator or condenser had been exposed or

had been opened for 15 seconds or more, the system must

be vacuumed. Generally do not remove plastic, rubber

plugs and brass nuts from the valves, fittings, tubing and

coils until it is ready to connect suction or liquid line into

valves or fittings.

If any brazing work is required, ensure that nitrogen gas

•

is passed through coil and joints while the brazing work

is being done. This will eliminate soot formation on the

inside wall of copper tubings.

Cut the pipe stages by stages, advancing the blade of pipe

•

cutter slowly. Extra force and a deep cut will cause more

distortion of pipe and therefore extra burr. See Figure I.

Remove burrs from cut edges of the pipes with remover. See

•

Figure II. Hold the pipe on top position and burr remover

at lower position to prevent metal chips from entering the

pipe. This will avoid unevenness on the flare faces which

will cause gas leak.

Insert the flare nuts, mounted on the connection parts

•

of both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface

•

of the swaging block is determined by the flaring tool.

See Figure III.

Fix the pipe firmly on the swaging block. Match the centers

•

of both the swaging block and the flaring punch, then

tighten the flaring punch fully.

Piping Connection To The Units

Align the center of the piping and tighten the flare nut

•

sufficiently with fingers. See Figure IV.

Finally, tighten the flare nut with torque wrench until the

•

wrench clicks.

•

When tightening the flare nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

•

The refrigerant pipe connection are insulated by closed

cell polyurethane.

Figure I

Figure II

Figure III

Cutting Copper Tube

1/4t

Remove Burr

Copper Tube

Swaging Block

Copper Tube

D

A

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Figure IV

Flare Joint

Flared Tube

Flare NutIndoor Piping

Pipe Size (mm/in) Torque, Nm/(ft-lb)

6.35 (1/4") 18 (13.3)

9.52 (3/8") 42 (31.0)

12.70 (1/2") 55 (40.6)

15.88 (5/8") 65 (48.0)

19.05 (3/4") 78 (57.6)

1-10

Spanner

Torque Wrench

Loading...

Loading...