Page 1

S/M No. : TSP110AEF0

Service Manual

Model : DSP-4210GM

CHASSIS : SP-110

DAEWOO ELECTRONICS CO., LTD

http : //svc.dwe.co.kr May.2001

Page 2

TABLE OF CONTENTS

1. Safety precautions........................................................................................................................... 2

2. Product specification ...................................................................................................................... 4

3. Block diagram .................................................................................................................................. 6

4. Adjustment (How to use service remote controller)..................................................................... 7

5. When changing the new board....................................................................................................... 9

6. Trouble shooting..............................................................................................................................10

7. Assembly list ....................................................................................................................................30

8. Circuit diagram.................................................................................................................................31

9. Exploded view..................................................................................................................................35

- 1 -

Page 3

Service manual SP-110

1. SAFETY & PRECAUTIONS

S

AFETY CHECK AFTER SERVING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screw,

parts and wires have been r eturned to original positions. Afterwards, perform the following tests and

conform the specified values in order to v erify compliance with safety standards.

1-1. Insulation resistance test

Confirm the specif ied insulation resistance between po wer cord plug prong and externally e xposed

parts of the set (video and audio input terminals, speaker out terminals etc) is greater than v alues

given in table 1 below.

1-2. Dielectric strengthen test

Confirm specified dielectr ic strengthen between

power cord plug prongs and exposed accessible

parts of the set (video and audio input terminals,

speaker out, etc) is greater than v alues gi ven

table 1 below.

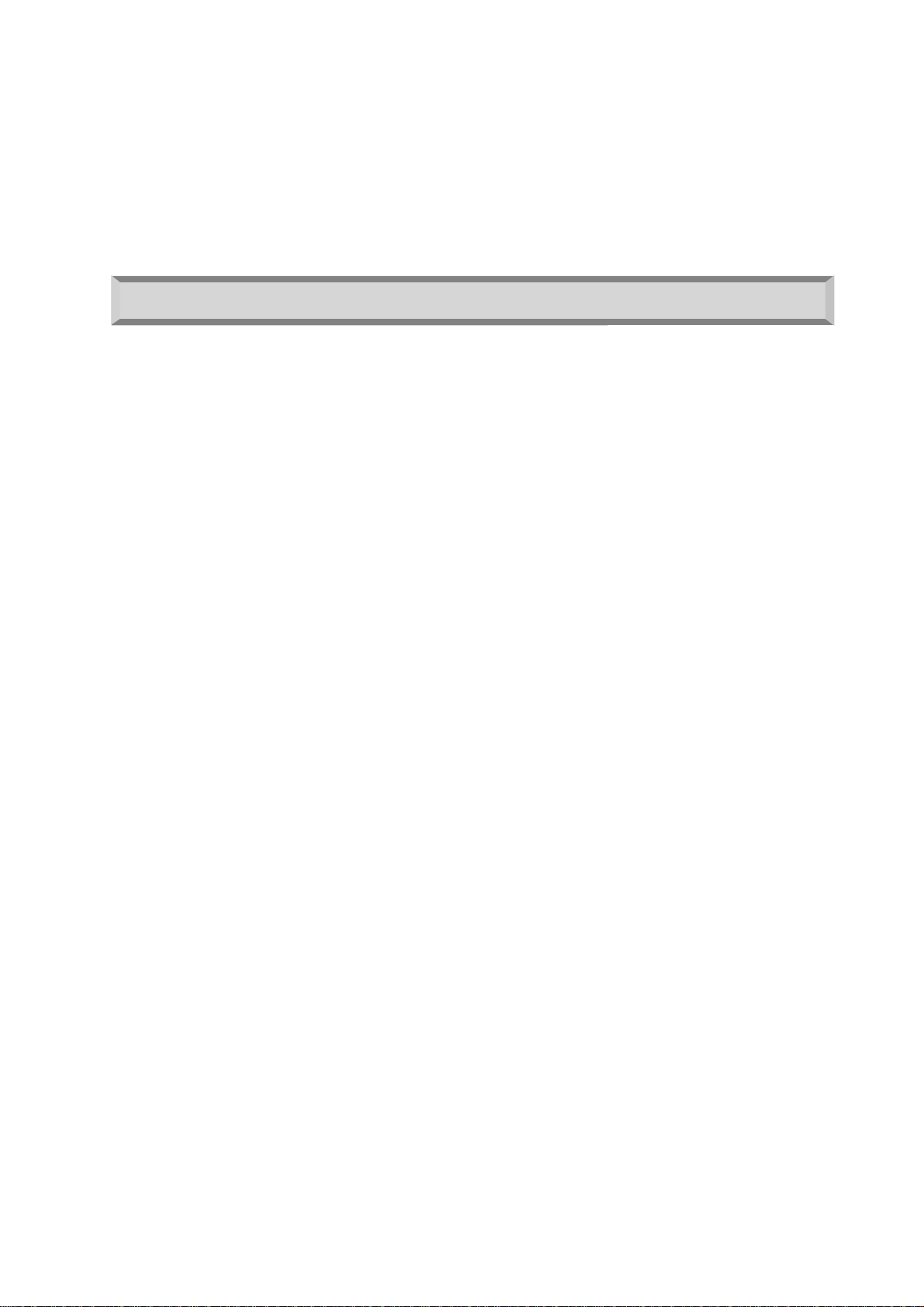

1-3. Clearance distance

When replacing primary circuit component, confirm specified clearance distance (d), (d’) betw een

soldered terminals (see Fig1), and between terminals and surrounding metallic parts. See table 1

below.

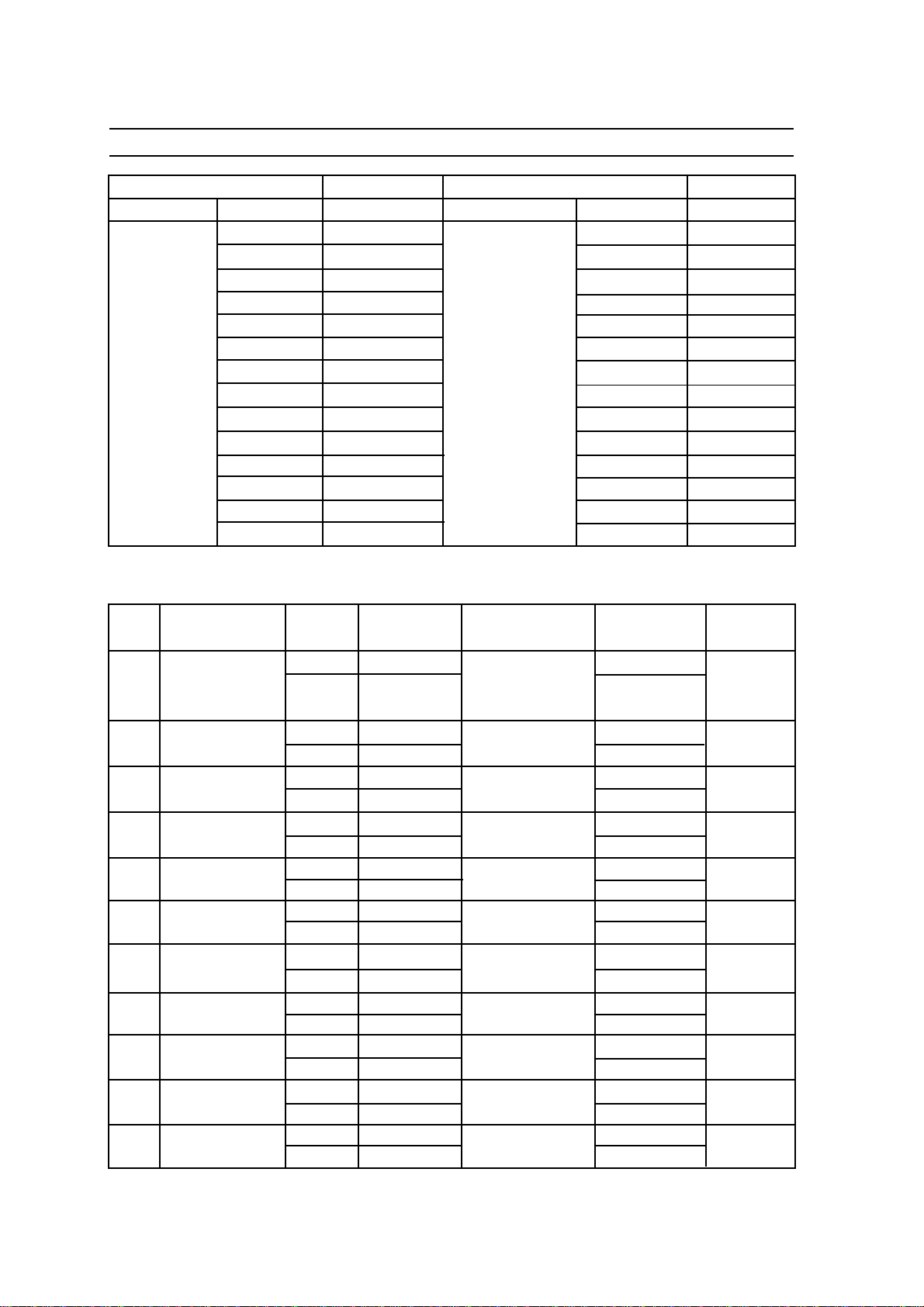

Rating for selected areas (table 1)

AC Line Voltage

100V Japan 3

110 to 130V USA &Canada - 900V A C 1min 3.2

110 to 130V

200 to 240V

Class model only

*

Region

Europe 6(d)

Australia 8(d)

Latin America (a : Power cord)

Insulation Dielectric Clearance

Resistance Strength Distance(d),(d’)

1M / 500V DC

10M / 500V DC

1kV AC 1min

4kV AC 1min.

.

NOTE

This table is unoff icial and for reference only. Be sure to confirm the precise values for your particular.

- 2 -

Page 4

Service manual SP-110

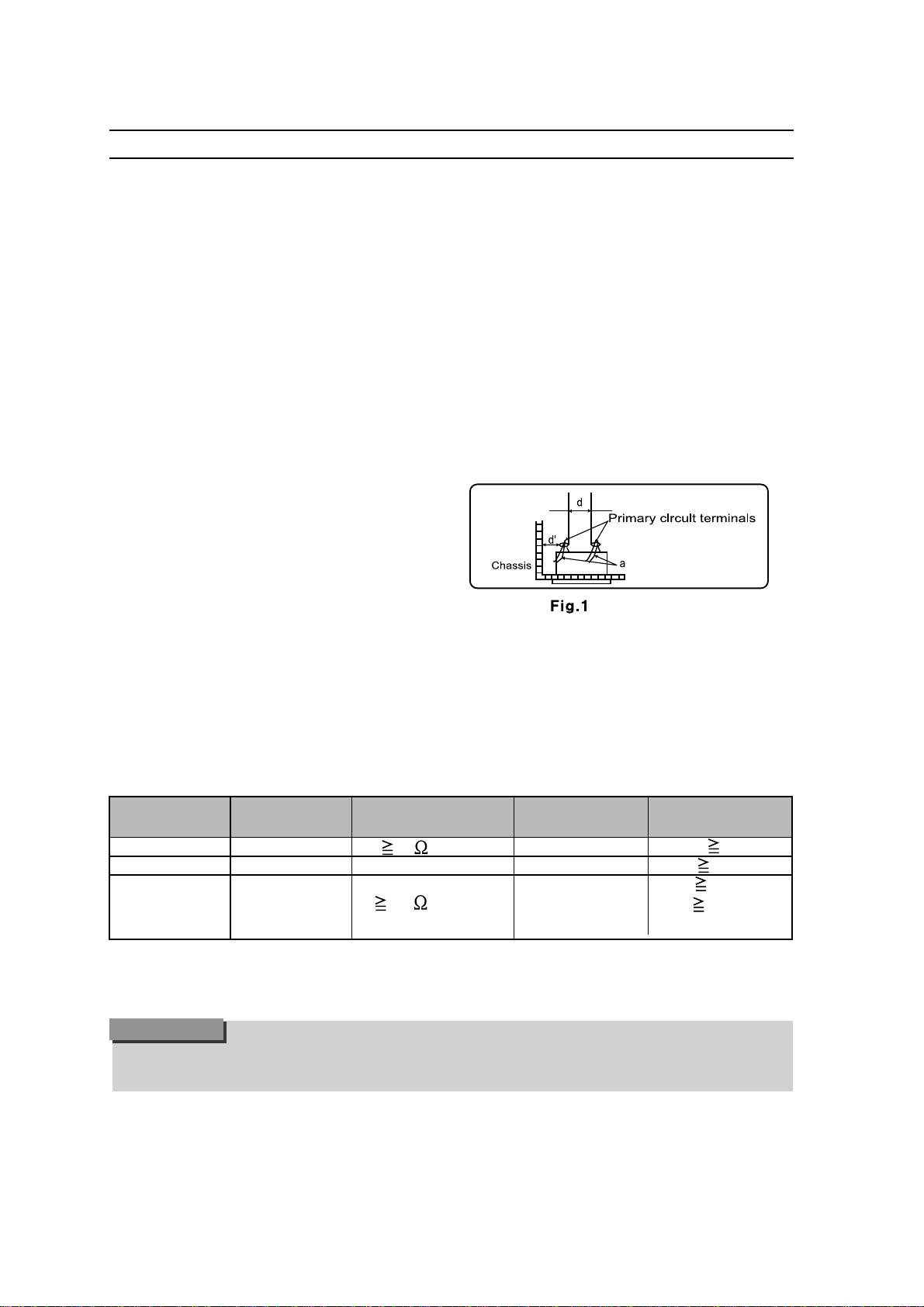

1-4. Leakage current test

Confirm specified or lo wer leakage current between

B(earth ground, power cord plug prongs) and externally

exposed accessible parts (video and audio input terminals, speaker out, etc.)

Measuring method:(Power ON) lnsert load Z between

B(earth ground, power cord plug prongs) and exposed

accessible parts. Use AC voltmeter to measure AC voltage across both terminals of load Z. See Fig.2 and

following table.

Leakage current ratings for selected are as

Ac Line Voltage Region Load Z Leakage Current( i )Clearance Distance(d),(d’)

100V

110 to 130V

110 to 130V

200 to 240V

Japan

USA & Can-

ada

Europe

Australia

1

1

2

50

15 F

i 0.5mArms.

i 0.7mA peak

i 2mAdc

i 0.7mA peak

i 1mAdc

i 1mArms.

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values

for your particular country and locality.

Other terminals

- 3 -

Page 5

Service manual SP-110

2. PRODUCT SPECIFICATION

[ DSP-4210GM ]

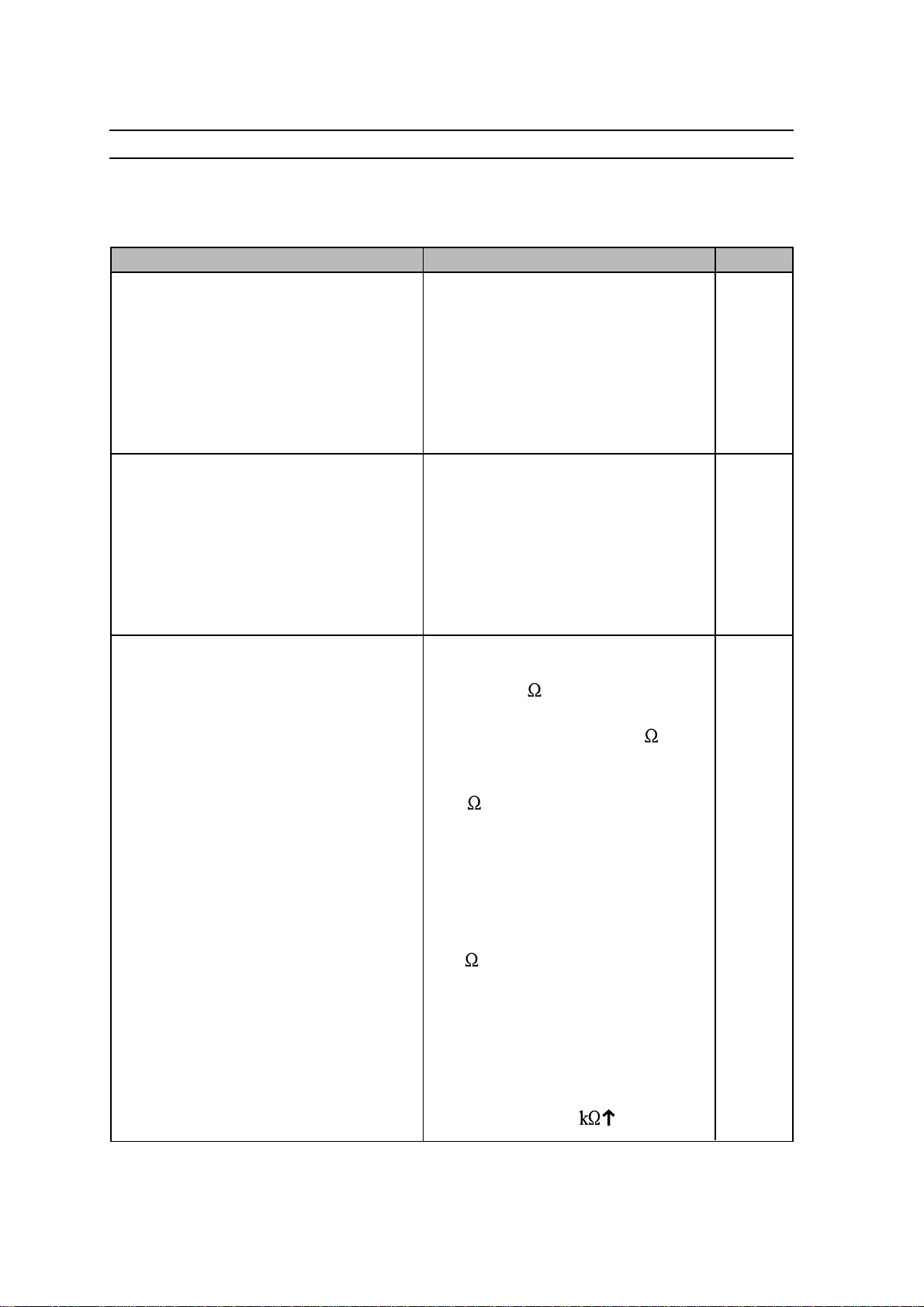

ITEM SPECIFICATION REMARK

1. GENERAL

1-1. MODEL NO DSP-4210GM

1-2. CHASSIS NO SP-110

1-3. SCREEN SIZE 42” (16:9)

1-4. COUNTRY WORLD WIDE

1-5. RESOLUTION 853(W) X 480(H)

1-6. REMOCON TRANSMITTER TYPE R-V2A(ENGLISH), R-V2AK(KOREAN)

1-7. SAFETY STANDARD UL, CSA, CE, KE

2. MECHANICAL

2-1. DIMENSION

1) WITHOUT STAND W X H X D = 1055 X 652 X 85

2) WITH STAND W X H X D = 1055 X 730 X 85

3) BOX W X H X D = 1190 X 870 X 480

2-2. WEIGHT

1) WITHOUT STAND 33kg

2) WITH STAND 39kg

3. ELECTRICAL & OPTICAL

3-1. COMPOSITE VIDEO INPUT SIGNAL NTSC,PAL,SECAM,PAL-M/N,NTSC4.43

1 INPUT ( 75 , 1Vp-p )

3-2. Y/C INPUT SIGNAL 50/60Hz, Super Jack 1 Input( 75 ,1Vp-p )

3-3. DTV/DVD INPUT SIGNAL Y,Pb/Cb,Pr/Cr 1 Input

( 75 ,1Vp-p )

DTV Resolution Mode ( Y, Pb, Pr ) :

*

1920X1080i, 1280X720p,

640X480p

DVD ( Y,Cb,Cr ) : 50/60Hz

*

3-4. PC SIGNAL R,G,B,H,V 15Pin D-sub jack 1 Input

( 75 ,1Vp-p )

* Resolution Mode : VGA - UXGA

3-5. SOUND INPUT SINAL Composite, Y/C : L/R Phone Jack 1Pair

DTV/DVD : L/R Phone Jack 1Pair

PC : L/R Phone Jack 1Pair

Input Impedance 47

*

- 4 -

Page 6

Service manual SP-110

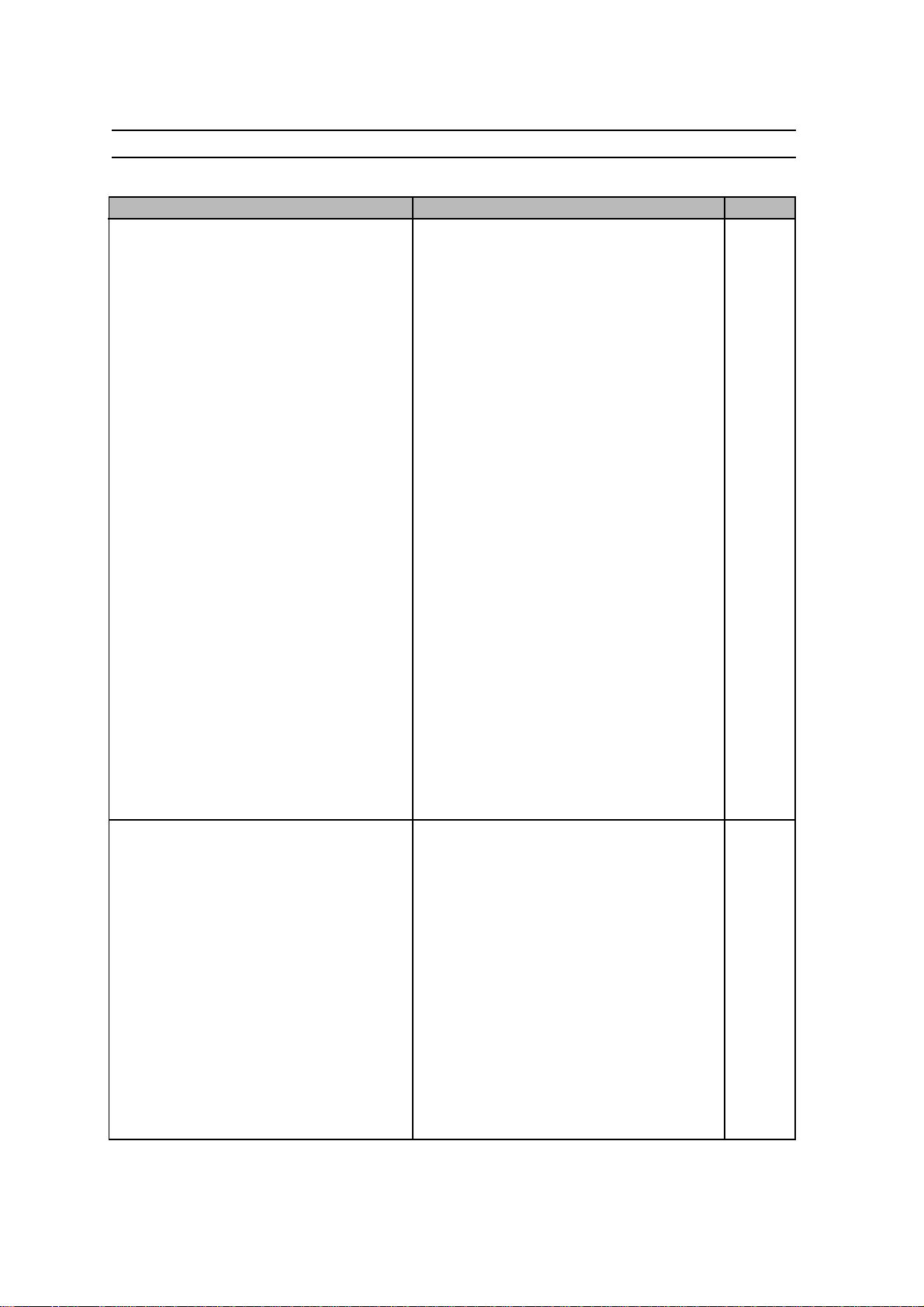

ITEM SPECIFICATION REMARK

3-6. Optical Chracteristics

1) Display Resolution 16:9 Wide 853 X 480

2) Peak Luminance 160cd/ m

3) Contrast Ratio 500:1

4) Color Temperature 8000o K

3-7. Scaling <Scaling Mode>

PC, DTV : Fill to Aspect Ratio,

DVD, VIDEO : Normal, Wide, Panaroma,

Letter Box, Letter Box with Sub Title

<Scaling Adjust>

PC,DTV (User Control) : H-Size, V-Size

3-8. Zoom Zoom

3-9. PIP Video Window in DTV/PC Picture

PIP Size, Position Changeable

3-10.OSD 8Language

KOREAN,ENGLISH,NETHERLAND,

FRENCH,SPANISH,GERMAN,

PORTUGUESE,ITALIAN

3-11. AC Power AC 90V-264V, 50/60Hz

3-12. Power Consumption 350 WATTS

3-13. Sound Output L : 8Watts, R : 8Watts

3-14. LAN Interface Option

3-15. Settop Box Interface Option

3-16. Others Freeze Picture, Video Rotation

2

Fill to Screen

H-Position, V-Position

+

, 4Direction Paning Avaiable

4. USER CONTROL & ACCESSORIES

4-1.CONTROL

1) SET AC POWER, MENU, INPUT SELECT, UP,

DOWN, LEFT, RIGHT

2) REMOCON TRANSMITTER INPUT SELECT,POWER,RECALL, ZOOM-,

ZOOM+,MENU,UP,DOWN,LEFT,RIGHT,

PICTURE MODE,FREEZE,SCREEN MODE,

MUTE

4-2. ACCESSORIES 1) REMOCON : R-V2A, R-V2AK

2) BATTERY : “AAA” 2EA

3) INSTRUCTION MANUA L

4) STAND (OPTION)

5) WALL HANGER (OPTION)

6) SPEAKER UNIT 2ASS’Y (OPTION)

- 5 -

Page 7

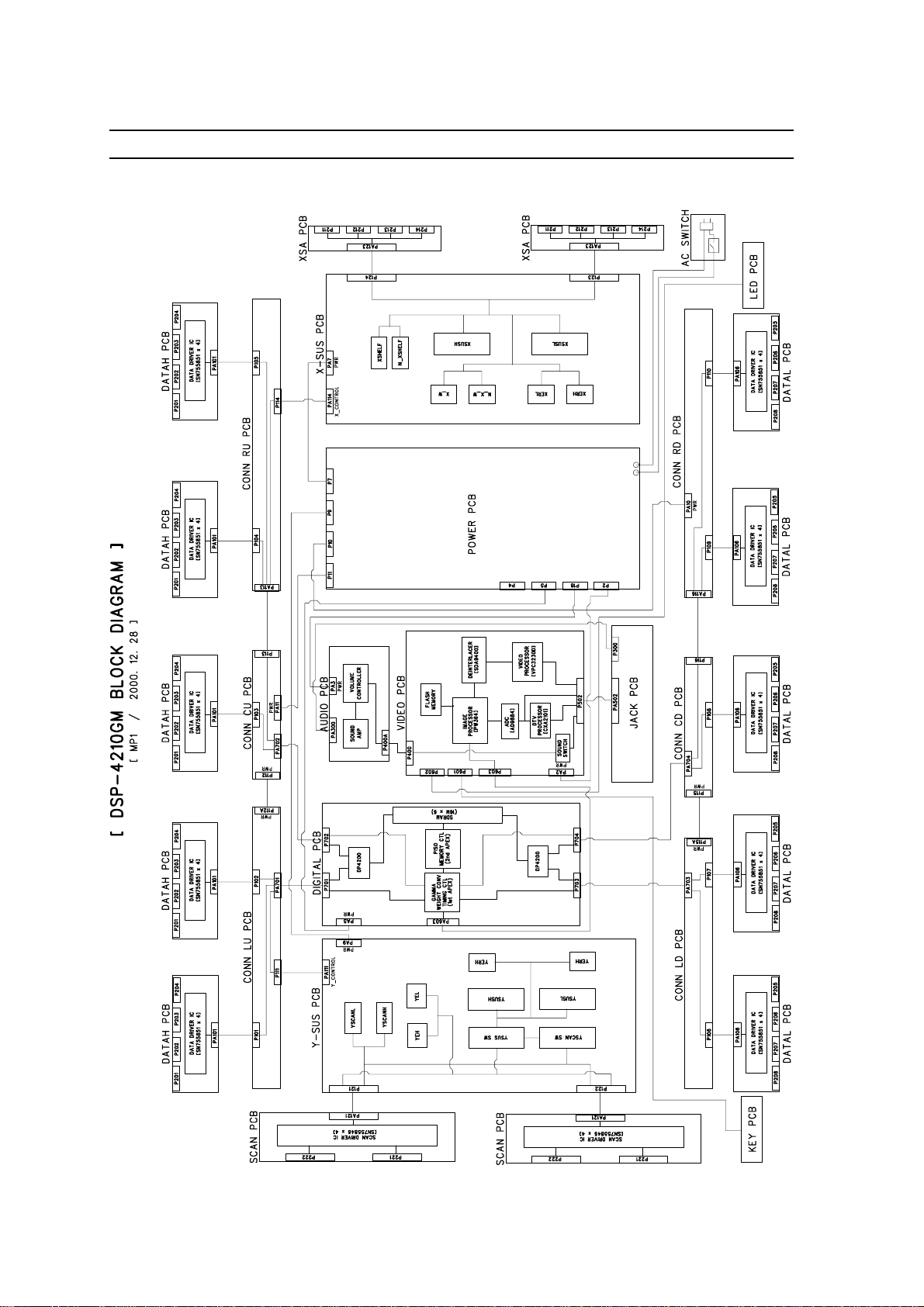

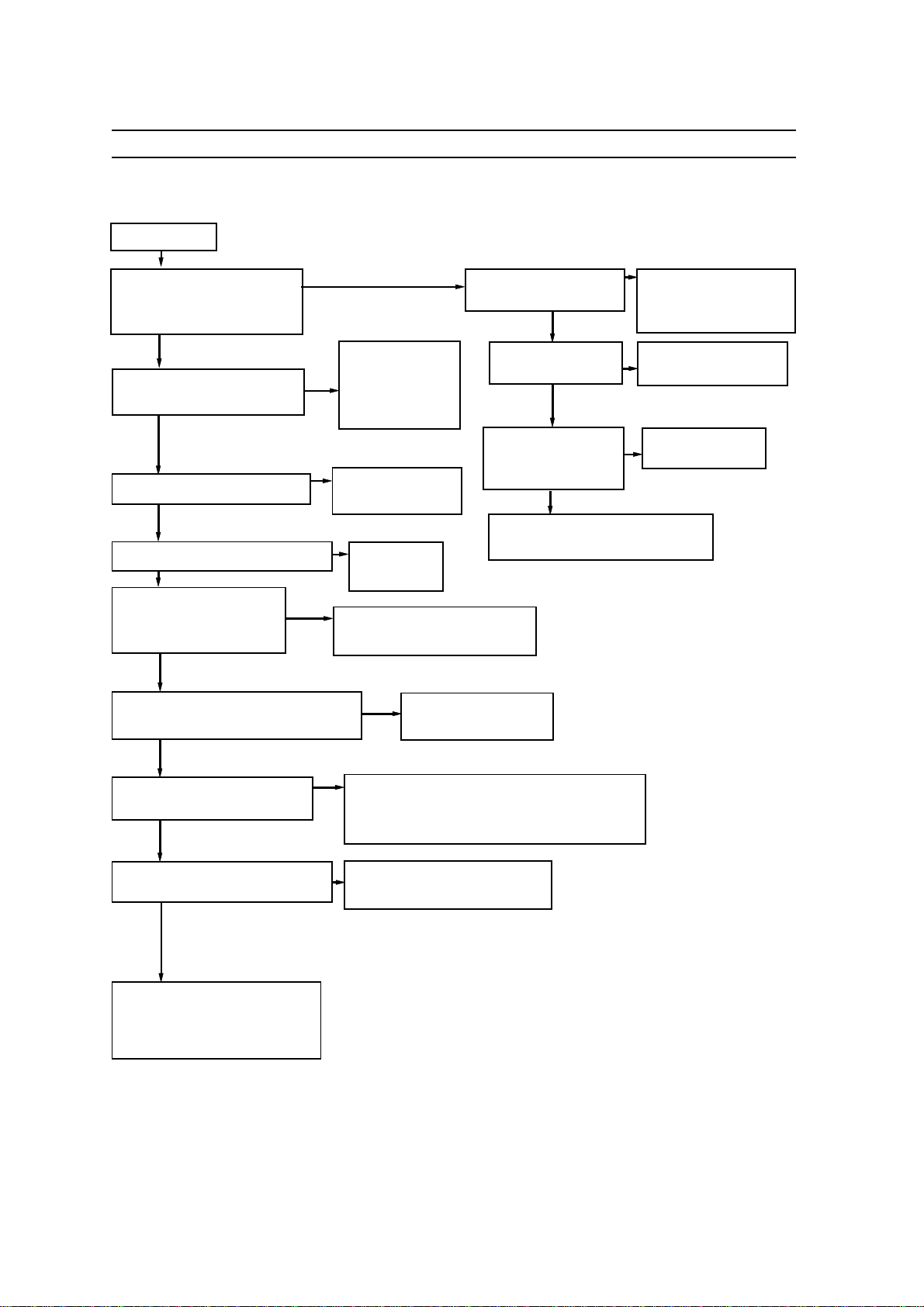

3. BLOCK DIAGRAM

Service manual SP-110

- 6 -

Page 8

4. Adjustment

4-1. How to conf irm the origianl data of VIDEO PCB

(1) Input selection : You select video mode

(2) You confirm the original data of user control

- Brightness : 36 ( :20 in case of DTV/PC input mode )

- Contrast : 60

- Sharpness : 2

- Colour : 32

- T int : 0 ( Center )

(3) You confirm the original data of SERVICE MODE (PW364)

( See 4-4 )

- Sub-Brightness : 60

- Sub-Contrast : 70

- R-Bias : 63

- G-Bias : 63

- B-Bias : 68

- R-Gain : 53

- G-Gain : 57

- B-Gain : 76

Service manual SP-110

4-2. How to adjust POWER PCB

(1) Devices for measurement : Digital volt meter, Pattern generator

(2) Conditions : You adjust as follows after assembling set and inputting WHITE PATTERN.

(Sustain voltage) : Voltage sustaining electronic discharge

1) V

SUS

TP : P12

Adjustment control : RV600

Standard voltage : 166V

2) V

(Scan voltage) : Scan voltage when recording D ATA

SCAN

TP : PA9 #6 PIN of Y PCB

Adjustment control : RV14

Standard voltage : -160V

3) V

(ADDRESS voltage) : Voltage recording DAT A

ADD

TP : P14

Adjustment control : VRS1

Standard voltage : 80V

4-3. X/Y PCB adjustment

(1) Devices for measurement : Digital volt meter, Pattern generator

(2) Previous adjustment voltage : You adjust as follows after assembling set and inputting BLUE

PATTERN.

- 7 -

Page 9

Service manual SP-110

1) V

(SHELF voltage) : X-electrode sustain voltage when recording D ATA

SHELF

TP : RCU25

Adjustment control : RU5

Standard voltage : +60V

(SCAN VH voltage) : VH voltage of SCAN IC when scanning

2) V

VH

TP : RY7 voltage each side

Adjustment control : RY6

Standard voltage : -70V

(3) The final operation adjustment

1) Input a monochrome pattern of R,G,B. And then you check if there are a bnormal OFF-state

pixels (which must be in ON-state but are in OFF-state).

If any, increase V

voltage slowly from 166V to remo v e abnormal OFF state pix els in that

SUS

pattern.

2) If there is no abnormal OFF-state pixel in monochrome pattern of R,G,B, make sure if there is

abnormal OFF-state in Magenta, Cyan, Yellow or not. If any, increase V

slowly in that

SUS

pattern.

3) Increase V

, which is set as above, by 1V.

SUS

4) Make sure if there are abnormal ON-state pixels(which must be on OFF-state but are in ONstate, for example, R or G) in Blue pattern after aging Blue pattern 5 minutes. If any, set V

slowly from - 160V to - 150V and decrease V

slowly to remo v e wrong electronic

SHELF

discharge.

SCAN

4-4. White balance adjustment

(1) Feed grey scale signal to video input terminal.

(2) Confirm the original data of user control (See 4-1).

(3) Press Remote controller in order starting with UP => MUTE => RECALL => MUTE BUTTON

to access Service adjustment mode and select PW364. And then confirm the original data of

the Service mode PW364 register. (See 4-1).

(4) Make sure you can’t recognize an y grey scale errors in the form of colour tint in this darker bands.

(5) You attach the sensor of a White balance meter to the white part on the upper end of this grey

scale pattern.

(6) Set White balance changing R,G,B-Gain.

• You make sure that R,G,B-Gain must be set within the limit of 63 20. If it is over the limit, it

is N.G.

• How to adjust temperature of colour

X = 0.290 0.01, Y = 0.310 0.01

o

Temperature of colour : 8,300

K

(7) You can set Luminance level changing Sub-contrast.

• If the set data of Sub-contrast is over the limit of 80, it is N.G.

(8) Press Menu button, to escape from Service mode.

- 8 -

Page 10

5. When fitting a new board

5-1. V ideo

(1) Check the related adjustments are correctly set as per previous page.

5-2. X-Sustain

Service manual SP-110

(1) Set the V

voltage according to the list of adjustments.

SHELF

(2) The data of adjustment v oltage is on the label, which is attached on the metal part under

Y-Sustain board.

5-3. Y -Sustain

(1) Set the Vvh v oltage according to the list of adjustments.

(2) The data of adjustment voltage is on label, which is attached on the metal part under Y-Sustain

board.

5-4. Power module

(1) You set each voltage according to the list of adjustments.

(2) The data of adjustment v oltage is on the label, which is attached on the metal part under

Y -Sustain board.

- 9 -

Page 11

6. Trouble shooting

6-1. Audio/video

6-2. Digital

6-3. X-SUSTAIN

6-4. Y-SUSTAIN

6-5. SCAN Board

6-6. DATA H/L, Connection(LU,CU,RU,LD,CD,RD)

6-7. Power

Service manual SP-110

- 10 -

Page 12

6-1. Audio/V ideo

Service manual SP-110

- 11 -

Page 13

* IMAGE PROCESSOR PART BLOCK DIAGRAM

Service manual SP-110

- 12 -

Page 14

Service manual SP-110

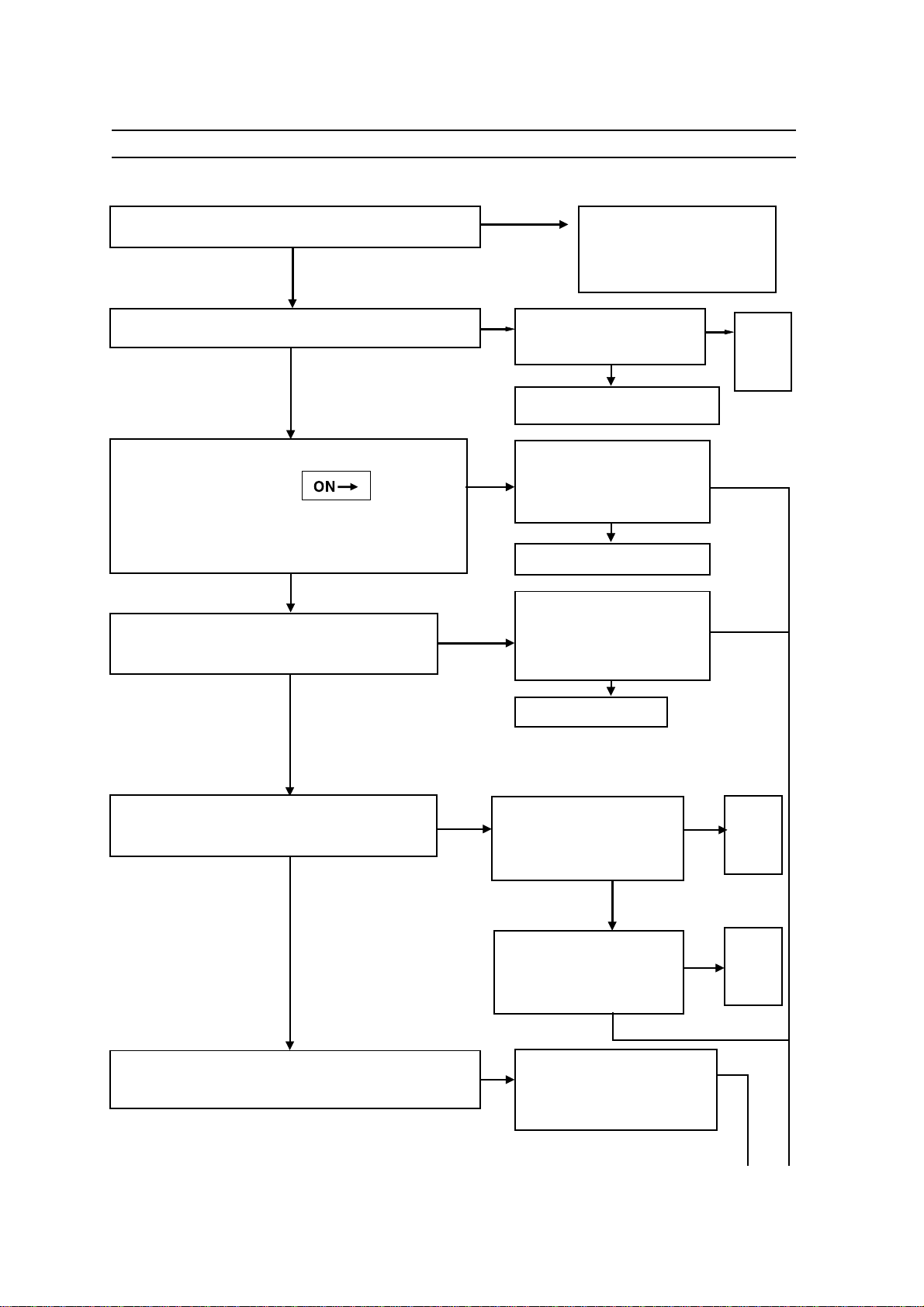

NO Video screen ( Composite input

Check start

Does the ‘Please check input Is there a weak electronic 1.Confirm AC connection

signal or press “input” key.’ discharge on the screen? 2.Confirm Power S/W on

message appear? Y 3.Inspect Digital and X,Y

Y

Is the signal input jack

correctly connected?

Y

Does the input source operate?

Y

Is input selection in Video mode?

Y

Does the ‘DTV, PC’ screen

appear after inputting signal 1. Video signal processing is N.G

to DTV or PC jack? 2. Change video PCB

N

1.Make sure of is PA603 properly Confirm Video to digital

connection of connected? Connector PA603

N

Jack(PDP Monitor

& A/V de vice)

is DVS,DHS,DCLK Video PCB is N.G

of Video PCB P603 Change PCB

N

Operate A/V device, being outputted?

Which is used.

N

Confirm

input selection

)

NN

N

Y

N

Y

1.Confirm other PCBs Video PCB than

2.Change PA603

Y

Can you see input to P502 No.43 V1 1. Inspect jack PCB

of Video PCB? 2. Inspect input jack

Y

Can you see input to TP Y0, V0? 1. Video S/W and 3D COMB filter

(IC402) are N.G

2. Change video PCB

Can you output Sync of TP V2 : 60Hz/ 1. Confirm if IC400 and IC401

50Hz H2 : 31.5KHz/KHz? are N.G

2. Change video PCB

1. Video signal processing is N.G

2. Change Video PCB

Y

Y

N

N

N

CAUTION : 1.You must only remove PA603 after confirming

that you switch off the power.

2. You must thoroughly understand instruction manual

before removing Back cover.

- 13 -

Page 15

Service manual SP-110

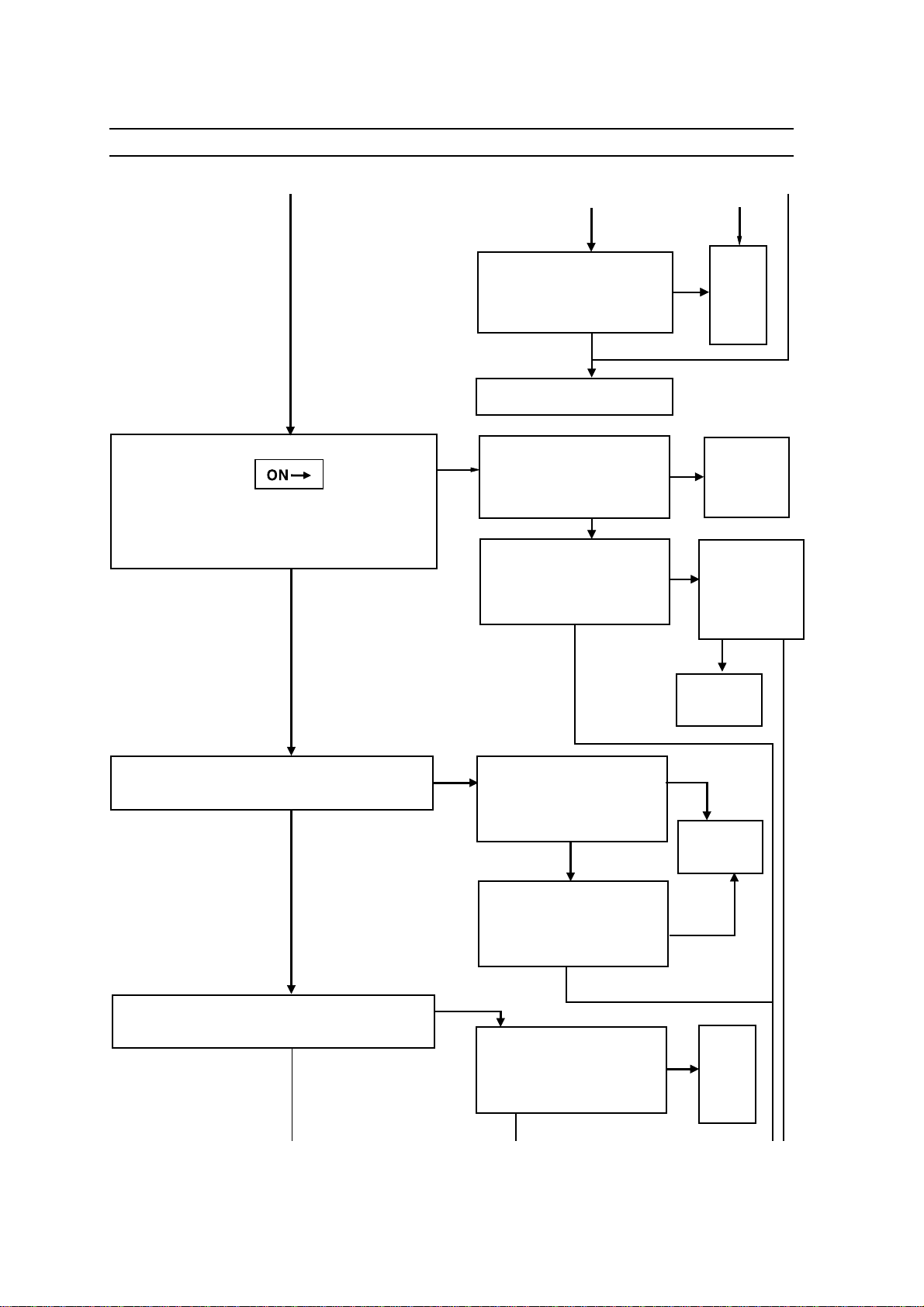

NO DTV screen (1080I, 720P, 480P)

Check start

NN

Does the ‘Please check input Is there a weak electronic 1.Confirm A C connection

signal or press “input” key.’ discharge on the screen? 2.Confirm Power S/W on

message appear? Y 3.Inspect Digital and X,Y

Y

Is the signal input jack

correctly connected?

Y

Does the input source operate?

Y

Is input selection in DTV/DVD mode?

Y

Does the ‘V ideo’ screen

appear after inputting signal 1. DTV signal processing is N.G

to Video jack? 2. Change video PCB

N

1.Make sure of is PA603 properly Confirm Video to digital

connection of connected? Connector PA603

N

Jack(PDP Monitor

& A/V de vice)

is DVS,DHS,DCLK Video PCB is N.G

of Video PCB P603 Change PCB

N

Operate A/V device, being output?

Which is used.

N

Confirm

input selection

1.Confirm other PCBs than Video PCBs

2.Change PA603

Y

Y

N

N

Y

Can you see input to P502 No.10 1. Inspect jack PCB

YD1 of Video jack? 2. Inspect input jack

Y

Can you output DTV signal in 1. DTV S/W and DTV processor(IC505) circuit are N.G

TP R,G,B? 2. DTV H/V Sync processing part is N.G

3. Change video PCB

Can you output Sync of TP V1:Hz/ 1. DTV S/W and DTV processor

H1 : KHz/ Hz? (IC505) circiuit are N.G

2. Change video PCB

1. Video signal processing is N.G

2. AD Converter(IC500) is N.G

3. Change Video PCB

Y

Y

N

N

N

- 14 -

Page 16

Service manual SP-110

NO PC screen

Check start

NN

Does the ‘Please check input Is there a weak electronic 1.Confirm AC connection

signal or press “input” key.’ discharge on the screen? 2.Confirm Power S/W on

message appear? Y 3.Inspect Digital and X,Y

Y

Is the signal input jack

correctly connected?

Y

Does the input source operate?

Y

Is input selection in PC mode?

Y

Does the ‘V ideo’ screen

appear after inputting signal 1. PC signal processing is N.G

to Video jack? 2. Change video PCB

Y

Can you see input to P502 No.9,8,31,32,33 1. Inspect jack PCB

R,G,B,Hsync,Vsync of Video PCB? 2. Inspect input jack

Y

Can you output PC signal in 1. PC S/W and DTV processor(IC505) are N.G

TP R,G,B? 2. PC H/V Sync processing part is N.G

3. Change video PCB

Can you output Sync of TP V1 : Hz/ 1. PC S/W is N.G

H1 : KHz/ Hz? 2.Change video PCB

Y

N

1.Make sure of is PA603 properly Confirm Video to digital

connection of connected? Connector PA603

N

Jack(PDP Monitor

& PC)

Does DVS,DHS,DCLK Video PCB is N.G

of Video PCB P603 Change PCB

N

Operate A/V device, being output?

Which is used.

N

Confirm

input selection

N

N

N

1.Confirm other PCBs than Video PCB

2.Change PA603

Y

Y

N

N

Y

1. PC signal processing is N.G

2. A/D Converter is N.G

3. Change Video PCB

- 15 -

Page 17

NO Sound

Check start

Service manual SP-110

Does the screen appear?

Y

is the sound signal input jack

correctly connected?

Y

is the speaker properly connected?

Y

Is sound signal output from P502?

Y

is sound signal on P400 No.2,3

of audio PCB?

Y

is sound signal on PA400 No.2,4 1. PA400 connector is N.G

of audio PCB? 2. Change audio PCB

N

N

1. Confirm AC connection

2. Confirm po wer S/W on

3. Inspect video PCB and other blocks

N

1.Make sure of connection of jack(PDP monitor & A/V device)

N

Connect speaker

N

1. Jack PCB is N.G

2. Video connection to

jack PCB is N.G

1. Sound S/W is N.G

2. Confirm IC404

3. Change video PCB

N

See: Siganl composition of P502 sound

1. RSPC, LSPC => PC sound

2. RSD1, LSD1 => DTV/DVD sound

3. RSV1, LSV1 => VIDEO, S-VHS sound

Y

is sound AMP on PA300 No.1,4 of Is power fed to PA3 of 1. Confirm if PA3 connector is N.G

audio PCB processing an output? audio PCB? 2. Change power board

Y

Does sound AMP on PA300 No.1,4 and

JP659 of audio PCB produce an output?

Y

1. Speaker or sound cable is N.G

2. Change speaker or sound cable

N N

Y

N

1. PA300 is N.G (Change audio PCB)

or JP659 is N.G (Change jack PCB)

- 16 -

Page 18

NO Remote Controller operation

Check start

N

Is red LED next to PO WER S/W

on?

Y

Service manual SP-110

1. Confirm AC connection

2. Confirm po wer S/W on

3. Inspect video PCB, LED PCB and other

blocks

Does Remote Controller operate?

Y

Is screen on with key input?

Y

Is there waveform when pressing remocon

in IR NO.2 of P602

1. IR receipt block of video PCB is N.G

2. Inspect video PCB and other PCBs

N

1. Confirm Remote Controller operation and battery

N

1. Connection with video PCB is N.G or video PCB N.G

2. Inspect video PCB and other blocks

N

1. LED PCB is N.G

2. Change LED PCB

- 17 -

Page 19

NO Key operation

Check start

Is red LED on next to POWER S/W

on?

Y

N

1. Confirm AC connection

2. Confirm po wer S/W on

3. Inspect video PCB, LED PCB and other

blocks

Service manual SP-110

Does power come on with

remocon?

Y

Is connection between PA601 of key PCB

and video PCB good?

Y

1. Inspect video PCB and other PCBs

N

1. Connection with video PCB is N.G or

V ideo PCB is N.G

2. Inspect video PCB and other blocks

N

1. PA601 connector is N.G

2. Change key PCB

- 18 -

Page 20

Service manual SP-110

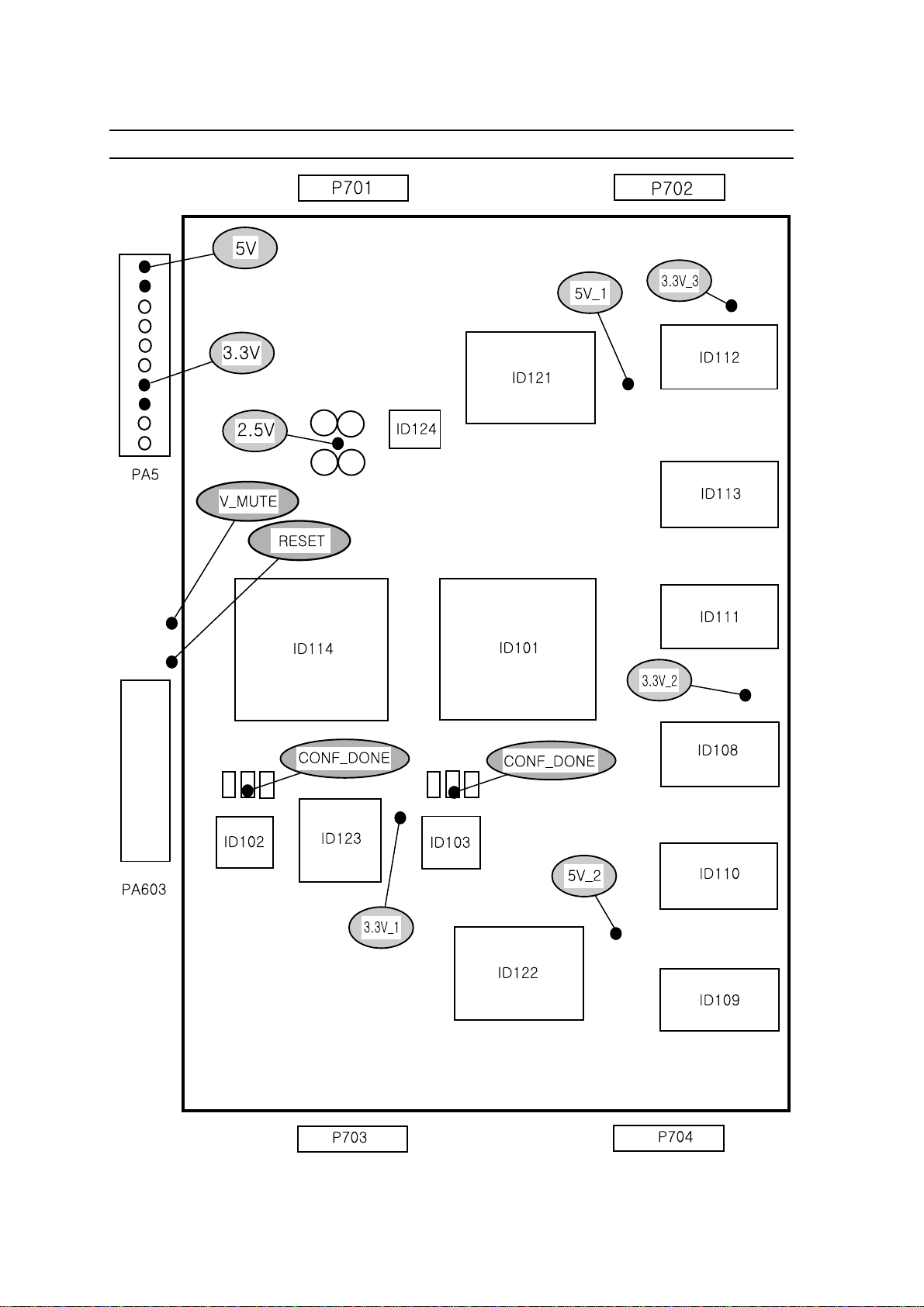

6-2. DIGITAL

Checking Order for normal operation of Digital Board and Check Points

( * Measure RMS voltage with a multi-meter , refer to the attached picture for position of

check points )

1. After make sure that the set turns off, turn off the High Voltage ON/OFF Switch of the Power

Board and then turn on the set

2. Confirm whether there is an input of 5V, 3.3V into Power Connector ( PA5 ).

- 5V input (pin No.1,2) : If 4.5V ~ 5.2V, O.K.

- 3.3V input (pin No.7,8) : If 3.0V ~ 3.5V, O.K.

3. Confirm whether Power 2.5V, 3.3V_1, 3.3V_2, 3V_3, 5V_1, 5V_2

- 2.5V : If 2.2V ~ 2.7V, O.K.

- 3.3V : If 3.0V ~ 3.5V, O.K.

- 5V : If 4.5V ~ 5.2V, O,K.

4. Confirm Reset and V_MUTE

- Reset : If 3.0V ~ 3.5V, O.K.

- V_MUTE :If 3.0V ~ 3.5V, O .K.

5. Confirm CONF_DONE ( ID102, ID103 )

- CONF_DONE : If 3.0V ~ 3.5V, O.K.

- 19 -

Page 21

Service manual SP-110

- 20 -

Page 22

Service manual SP-110

6-3. X-SUSTAIN BOARD

1. Separate PA7 and PA114 connector

2. Check the remaining electrical voltage of PA7

(1) Check the Voltage of Terminal 170V : If maintained beyond 10 volt, discharge (belo w 5 v olt)

with resistance of beyond 1K ohm 5 Watt

3. Confirm the v alue of series and parallel resistance of RU10//RU13-R U11//RU14-RU12//R U15

(1) Each value of resistance : 6.8 ohm 5 Watt

(2) The total value of resistance : 10.2 +/- 0.5 ohm

(3) In case of wrong value of resistance, replace (open) board and conf irm each connector

: the state of insertion ( installation )

4. In case of normal value of resistance, measure the v alue as follo wing table1.

(1) Use a Diode Tester

(2) If abnormal part is found, replace the board

(3) In case of normal state, Inspect connectors and other boards

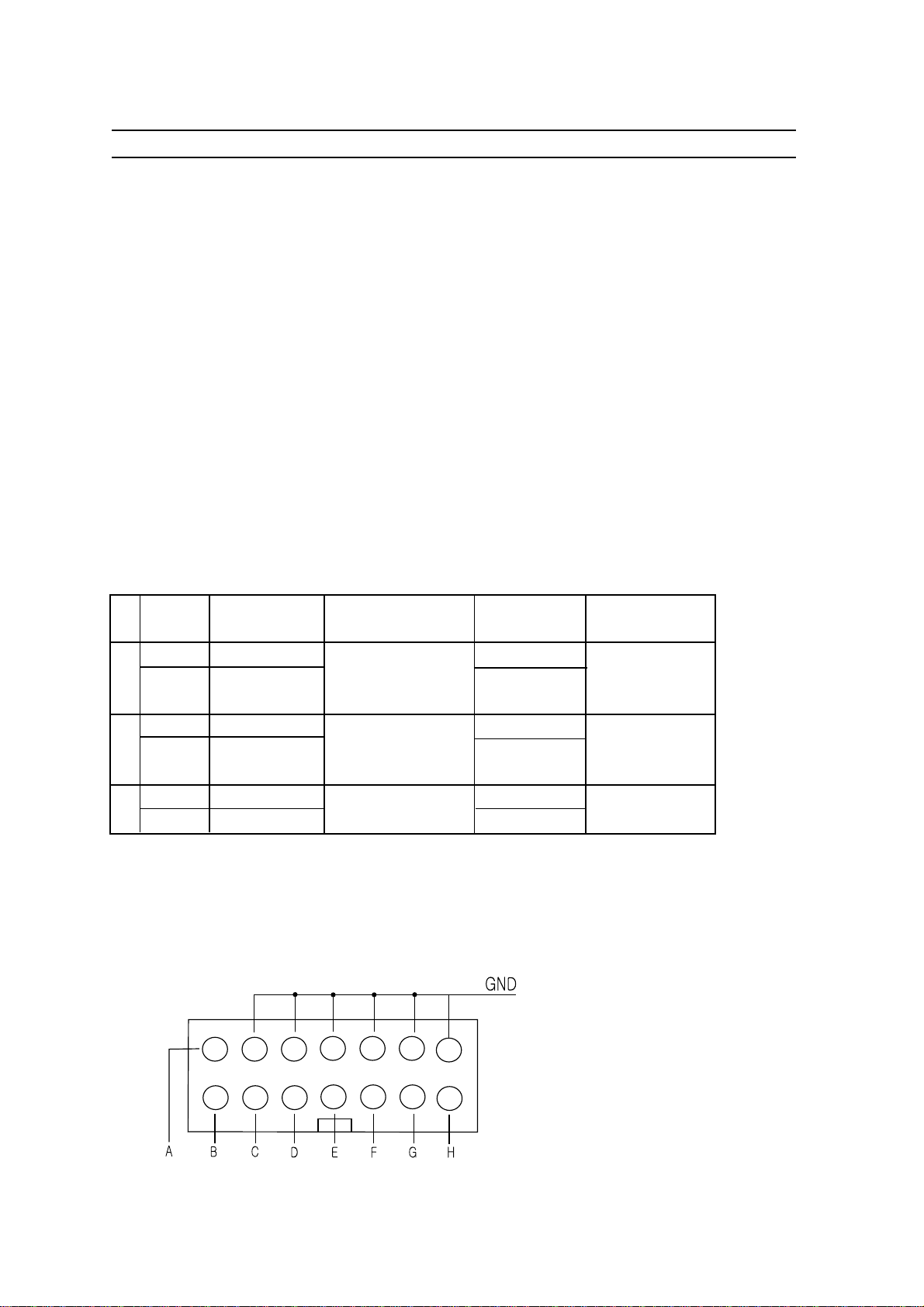

Table 1. P A7 The value of Diode Tester of each terminal

+ : red, - : black

*

NAME DIODE MEASURE DIODE MEASURE

TESTER TESTER

1 170V + About 5 sec. - 0.49

GND - Later, +

Open

2 15V + About 3 sec. - 0.47

GND - Later, +

Open beyond 2V

3 CU1(5V) + Beyond 1.43 - 0.48

GND - +

Table 2. PA114 The v alue of Diode Tester of each terminal

+ : red, - : black

*

The configuration of terminal ( top view, components side )

- 21 -

Page 23

Service manual SP-110

DIODE TESTER MEASURE DIODE TESTER MEASURE

- + + -

GND A 0.6 GND A 0.5

B 0.6 B 0.5

C 0.6 C 0.5

D 0.6 D 0.5

E 0.6 E 0.5

F 0.6 F 0.5

G 0.6 G 0.5

H 0.6 H 0.5

Table 3. The value of Diode Tester of each Semiconductor

+ : red, - : black

*

NAME DIODE MEASURE DIODE MEASURE

TESTER TESTER

1 QU5/QU6 D + ABOUT 5 - 0.48

S - SEC. LATER, +

OPEN

2 QU7/QU8 D + Open - 0.48

S- +

3 QU17/QU18 D + Open - 0.45

S- +

4 QU15/QU16 D + Open - 0.45

S - +

5 QU23~QU26 D + Open - 0.4

S- +

6 QU19~QU22 D + Open - 0.4

S- +

7 QU12 D + Open - 0.49

S- +

8 QU11 D + Beyond 2.3 - 0.49

S- +

9 QU9 D + ABOUT 5 - 0.5

S - SEC.LATER, +

OPEN

10 QU4 D + Open - 0.5

S- +

11 QU13/QU14 D + Open - 0.48

S- +

- 22 -

Page 24

Service manual SP-110

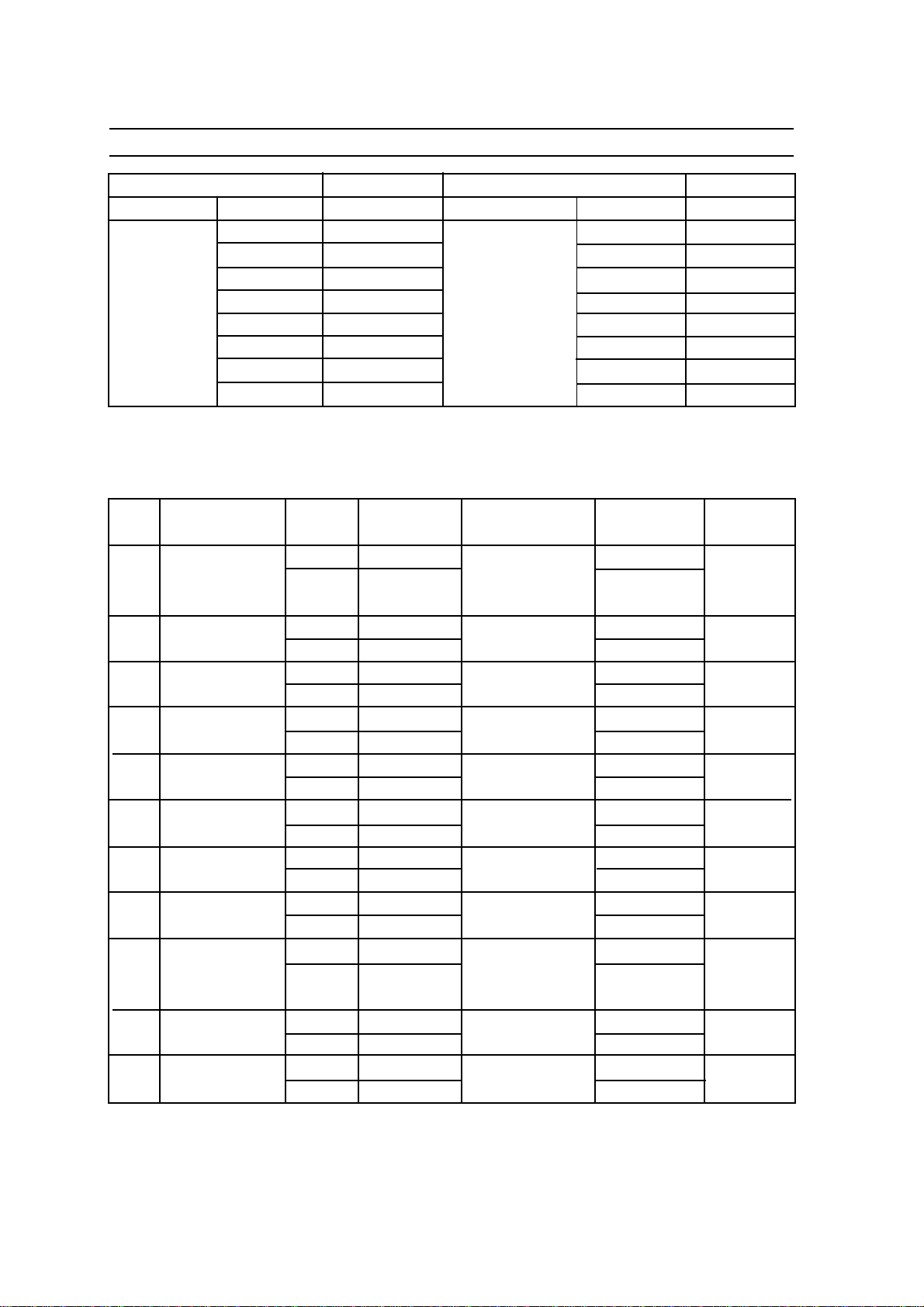

6-3. Y -SUST AIN BOARD

1. Separate PA9, PA111 connector

2. Confirm the remaining electrical Voltage of PA9

(1) Confirm the Voltage of T erminal 170V : If maintained be yond 10 v olt, dischar ge(below 5 volt)

with resistance of beyond 1K ohm 5 Watt

(2) Confirm the Voltage of T erminal -155V : If maintained be yond -10 v olt, dischar ge(belo w -5

volt) with resistance of beyond 1K ohm 5Watt

3. Confirm the resistance of RY2 ( 470 ohm 5W att )

(1) In case of wrong value, replace board and conf irm each connector

4. In case of normal value of resistance, measure the value as following Table 1.

(1) Use a Diode Tester

(2) If abnormal part is found, replace the board

(3) In case of normal state, Inspect connectors and other boards

Table 1. PA9 The value of Diode Tester of each terminal

+ : red, - : black

*

NAME DIODE MEASURE DIODE MEASURE

TESTER TESTER

1 170V + About 3 Sec. Later, - Beyond 0.8

GND - Open +

2 -155V + Beyond 0.7 - Open

GND - +

3 ON/OFF + Open - Beyond 2.4

GND - +

4 15V + Beyon 0.7 - About 5 Sec. Later, beyond 0.4

GND - +

Table 2. PA111 The v alue of Diode Tester of each terminal

+ : red, -: black

*

The configuration of terminal (top view, components side)

- 23 -

Page 25

Service manual SP-110

DIODE TESTER MEASURE DIODE TESTER MEASURE

- + + -

GND A 1.2 GND A 0.5

B 0.6 B 0.5

C 0.6 C 0.5

D 0.6 D 0.5

E 1.2 E 0.5

F 1.2 F 0.5

G 0.6 G 0.5

H 0.6 H 0.5

I 0.6 I 0.5

J 0.6 J 0.5

K 1.2 K 0.5

L 0.6 L 0.5

M 0.6 M 0.5

P 1.2 P 0.5

Table 3. The value of Diode Tester of each Semiconductor

+ : red, - : black

*

NAME DIODE MEASURE DIODE MEASURE

TEST TEST

1 QY5~QY8 D + ABOUT 3 - 0.4

S - SEC. LATER, +

OPEN

2 QY9~QY12 D + Open - 0.4

S- +

3 QY1~QY2 D + Open - 0.4

S- +

4 QY3~QY4 D + Open - 0.4

S- +

5 QY25~QY28 D + Open - 0.4

S- +

6 QY20~QY23 D + Open - 0.4

S- +

7 QY15~QY16 D + Open - 0.4

S- +

8 QY19 D + Open - 0.4

S- +

9 QY14 D + Open - 0.4

S- +

10 QY13 D + Beyond 1 - Open

S- +

11 QY2 D + Open - 0.4

S- +

- 24 -

Page 26

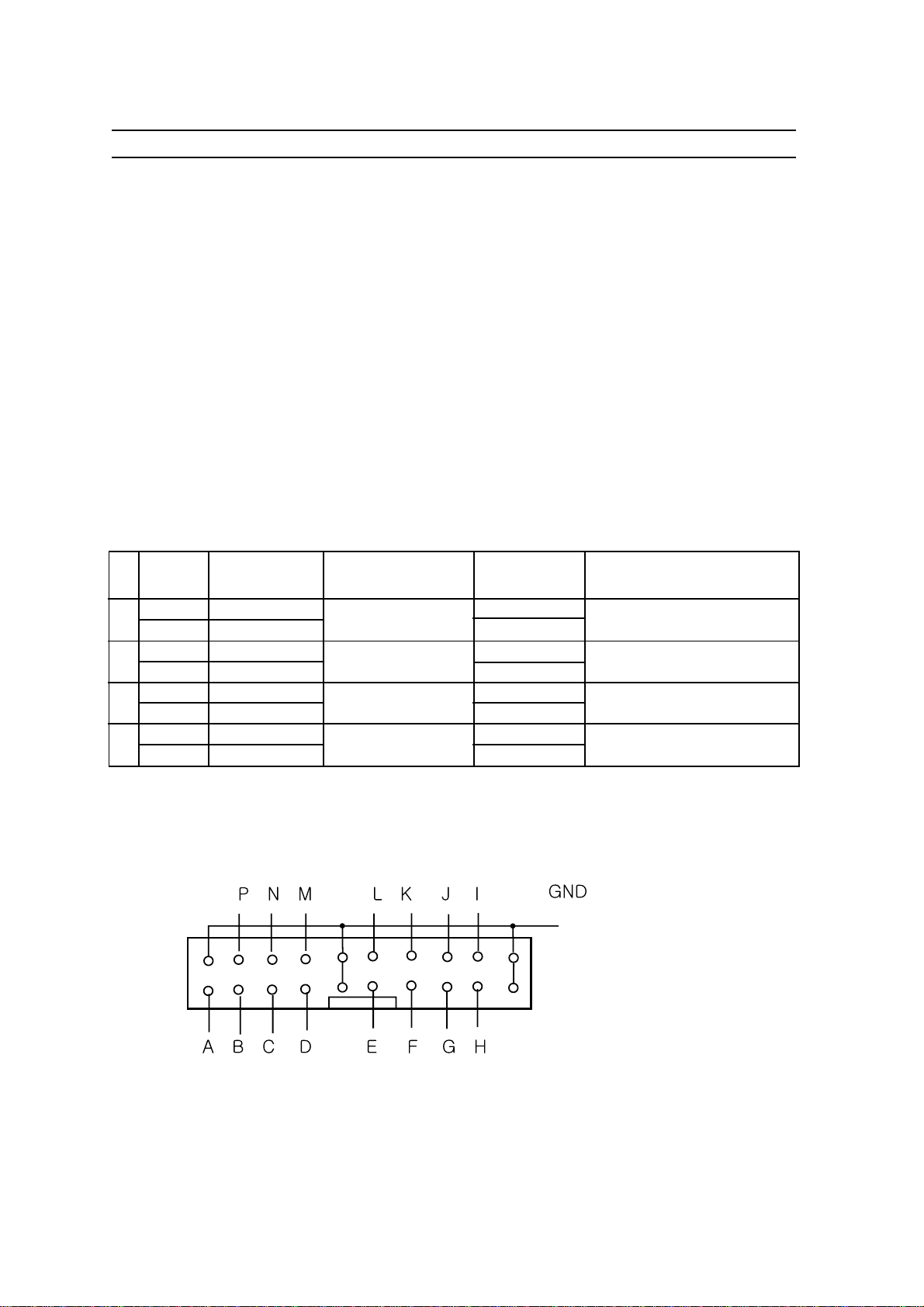

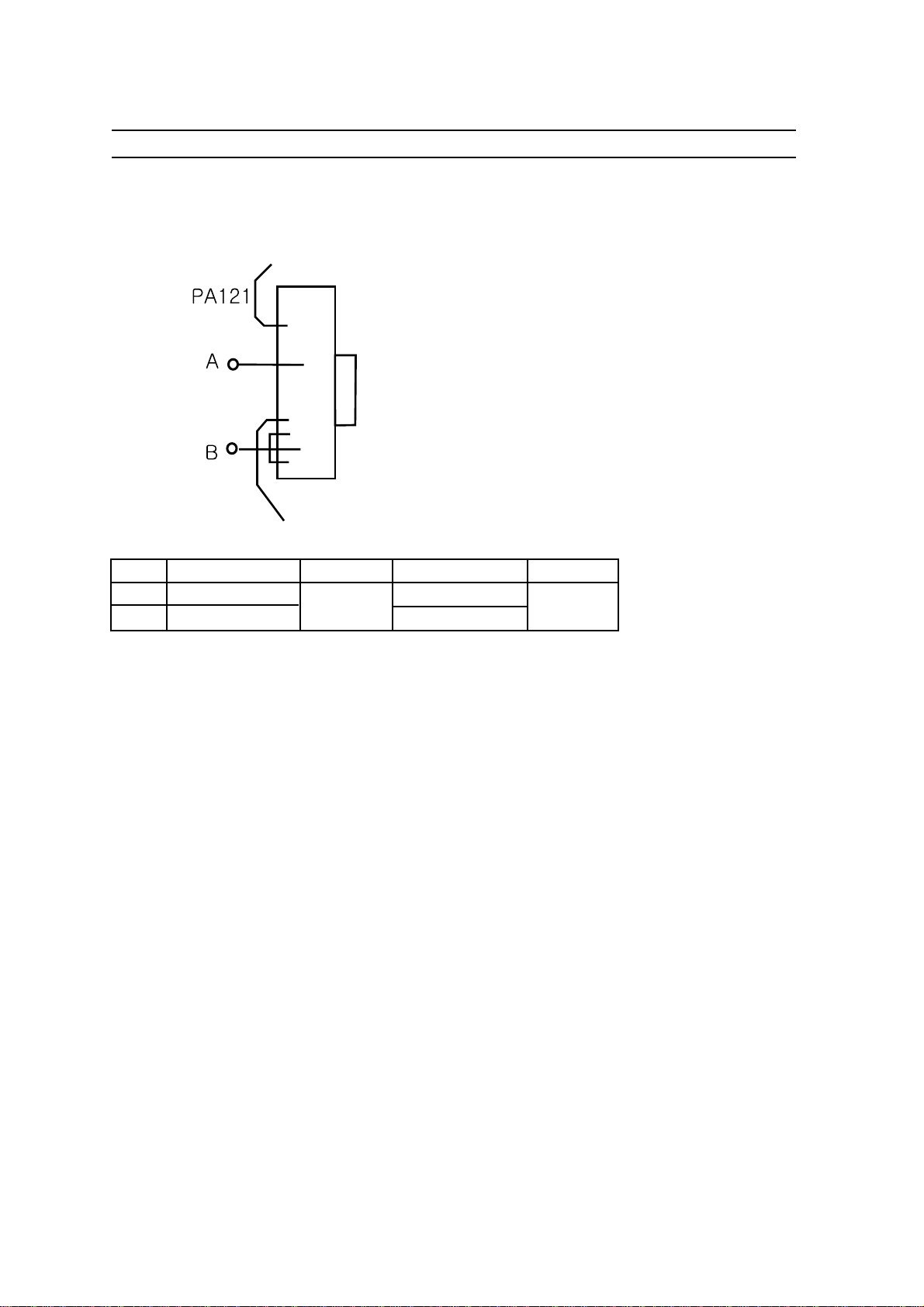

6-5. SCAN BOARD

1. Confirm the DIOED TESTER, PCB separately

2. The configuration

(1) The Voltage Terminal of Scan (top view, components side)

DIODE TESTER MEASURE DIODE TESTER MEASURE

A + Beyond 0.6 - Open

B- +

Service manual SP-110

- 25 -

Page 27

6-6. D ATA H/L, CONNECTION(RU,CU,LU,RD,CD,LD)

1. Confirm the upper part and the lo wer part

(1) Separate PA10 and PA11

(2) Confirm DIODE TESTER

2. Separate P112

(1) Confirm LU and two DATA H boards

3. Separate PA113

(1) Confirm CU and DATA H board

(2) Confirm RU and two DATA H boards

4. Separate P115

(1) Confirm LD and two DATA L boards

5. Separate P116

(1) Confirm CD and DATA L board

(2) Confirm RD and two DATA L boards

Table 1. The value of Diode Tester of each terminal

+ : red, - : black

*

NAME DIODE TESTER MEASURE DIODE TESTER MEASURE

1 Vadd + Open - 0.6

GND - +

2 5V + Beyond - 0.5

GND - 1.3 +

Service manual SP-110

- 26 -

Page 28

Service manual SP-110

6-7. POWER CHECK

NO

When the set is switched on, the power LED turns red? 1. Check Fuse F1 open

2. Check RC 1(Bridge Diode)

YES

open/short

NO

NO

When remote controller is switched on, LED turns green? Is 7PIN of CONNECTOR P2 Check

0 V? VIDEO

PCB?

YES

Check R20, R21, R22 open

Push the SW1 (Slide switch) of POWER MODULE After P3 CONNECTOR is

NO

NO

in the opposite direction of separated, is each voltage

Then, check LOW B+. (30V, 12V, 5V) correct?

Is each voltage (30V, 12V, 5V) of CONNECTOR P3

YES

correct? Check Audio AMP PCB

YES

After P5 CONNECTOR is

Is each voltage(5V, 3.3V) of CONNECTOR P5 separated, is each voltage

NO

NO

correct? (5V, 3.3V) correct?

YES

Check Digital PCB

YES

Is 1 pin voltage of CONNECTOR P7 and P9

correct at 15V?

YES

Is 1 pin voltage of CONNECTOR P10 and P11 correct

at 15V?

NO

- 27 -

After P7 CONNCETOR is

Separated, 15V

present?

NO

After P9 CONNCETOR is

Separated, 15V

present?

NO

NO

After P10 CONNCETOR is

Separated, 15V

present?

YES

YES

Check

X-sus

PCB

Check

Y-sus

PCB

YES

Page 29

Service manual SP-110

YES

Push the SW1(Slide Switch) POWER Module

in the direction of

Then, check High Voltage

And turn on the Power,

Can Vsus(170V) be produced?

YES

After P11 CONNECTOR is

Separated, is 15V

produced?

Replace Power Module

Without Connector P7

NO

Can Vsus(170V) be

producde?

Without Connector P9

Can Vsus(170V) be

produced?

NO

NO

NO

Check

YES

CONNECTION

PCB

Check

YES

X-sus PCB

Is the

YES

Vol ta ge

Of Conncetor

P7,5PIN 0V?

Check

Y-sus PCB

YES

YES

NO

Turn on the POWER. Can Vadd(70V) be

produced?

YES

Turn on the POWER. Can Vscan(-155V) be

produced?

YES

NO

NO

- 28 -

Without Connector P10

Can Vadd(70V) be

produced?

NO

Without Connector P11

Can Vadd(70V) be

produced?

NO

Without Connector P9

Can Vscan(-155V) be

produced?

YES

Check

Y-sus PCB

YES

Check

YES

Y-sus

PCB

Page 30

E N D

Service manual SP-110

NO

Replace

POWER

Module

- 29 -

Page 31

7. Assembly List

NO

PCB ASS’Y NAME

WORKING PR OCESS ASSEMBLY

ASS’Y NAME CODE

1 A CCESSOR Y AS PEACPWD011

2 PACKING AS PEPKCPD011

3 CABINET AS PECACAD011

4 MASK FRONT AS PEFMSJD011

5 VIDEO PCB AS

6 PCB VIDEO MANUAL A PEVDMSD011

7 PCB VIDEO CHIP B AS PEVDJ2D011

8 PCB VIDEO CHIP A AS PEVDJ1D011

9 DIGITAL PCB AS

10 PCB DIGITAL MANUAL PEDGMSD011

11 PCB DIITAL CHIP B PEDGJ2D011

12 PCB DIGIT AL CHIP A A PEDGJ1D011

13 DATA_H PCB AS PCB DATA H AS PED1MSD011

14 PCB DATA H CHIP A A PED1J1D011

15 DATA_L PCB AS

16 PCB DATA L MANUAL PED2MSD011

17 PCB DATA L CHIP A A PED2J1D011

18 SCAN PCB AS

19 PCB SCAN MANUAL A PES1MSD011

20 PCB SCAN CHIP A AS PES1J1D011

21 X-SUS PCB AS

22 PCB X-SUS MANUAL A PEXSMSD011

23 PCB X-SUS RHU AS PEXSJ0D011

24 PCB X-SUS M-10 AS PEXSJBD011

25 PCB X-SUS RADIAL AS PEXSJRD011

26 PCB X-SUS CHIP A AS PEXSJ1D011

27 Y-SUS PCB AS

28 PCB Y -SUS MANUAL A PEYSMSD011

29 PCB Y -SUS RHU AS PEYSJ0D011

30 PCB Y -SUS M-10 AS PEYSJBD011

31 PCB Y -SUS RADIAL AS PEYSJRD011

32 PCB Y-SUS CHIP A AS PEYSJ1D011

33 AUDIO PCB AS

34 PCB AUDIO MANU AL A PEAUMSD011

35 PCB AUDIO RADIAL AS PEA UJRD011

36 PCB AUDIO AXIAL AS PEA UJ AD011

37 JACK PCB AS

38 PCB JACK MANUAL AS PEJAMSD011

39 XSA PCB AS

40 PCB XSA MANUAL AS PEXAMSD011

41 CONN UNION

42 PCB AS PCB UNION CHIP A AS PEUNJ1D011

43 PCB UNION AS PEUNSWD011

44 PCB RIGHT-DO MANU PERWMSD011

45 PCB RIGHT-DO A AS PERWJ1D011

- 30 -

Service manual SP-110

Page 32

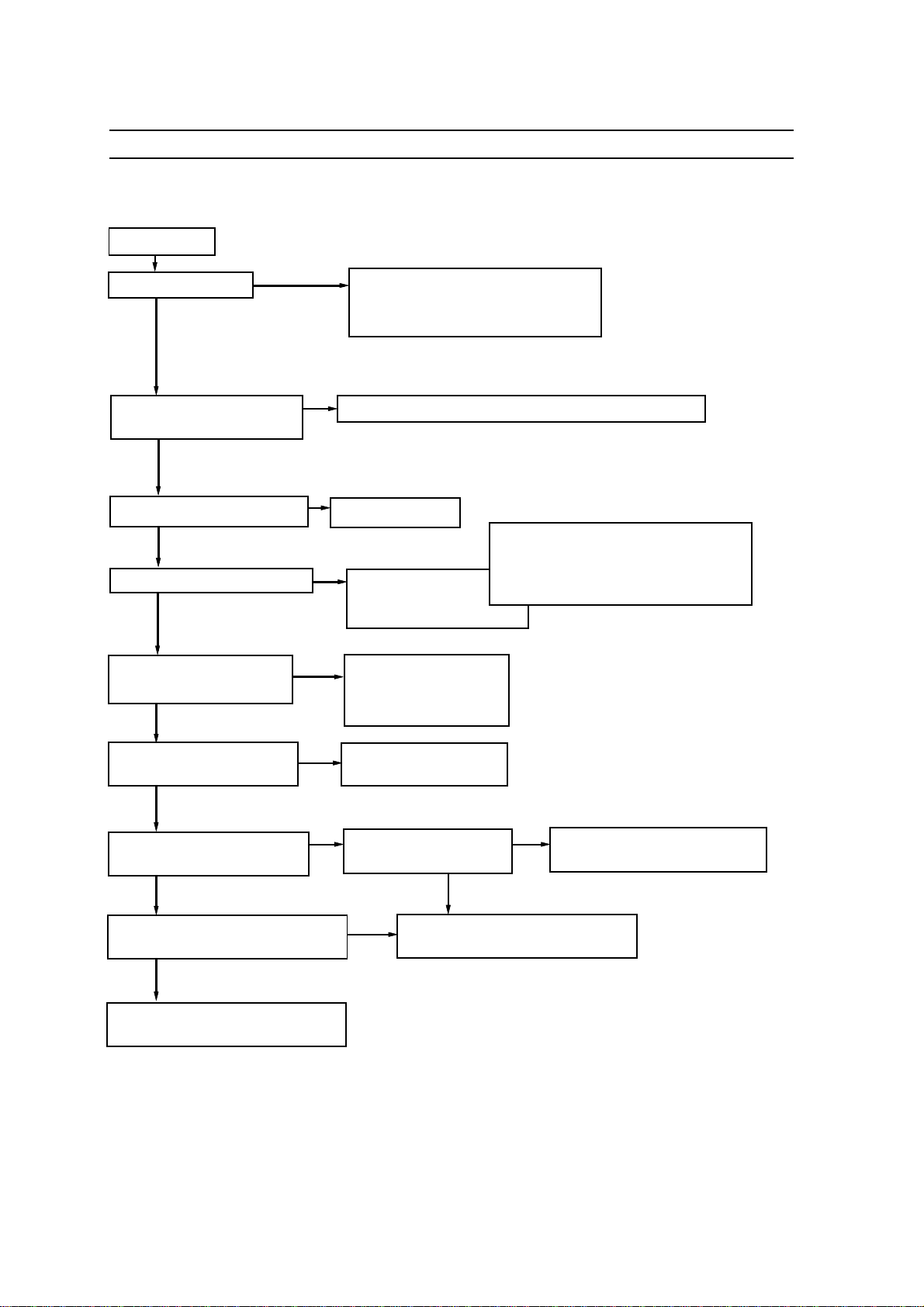

8. Block Diagram

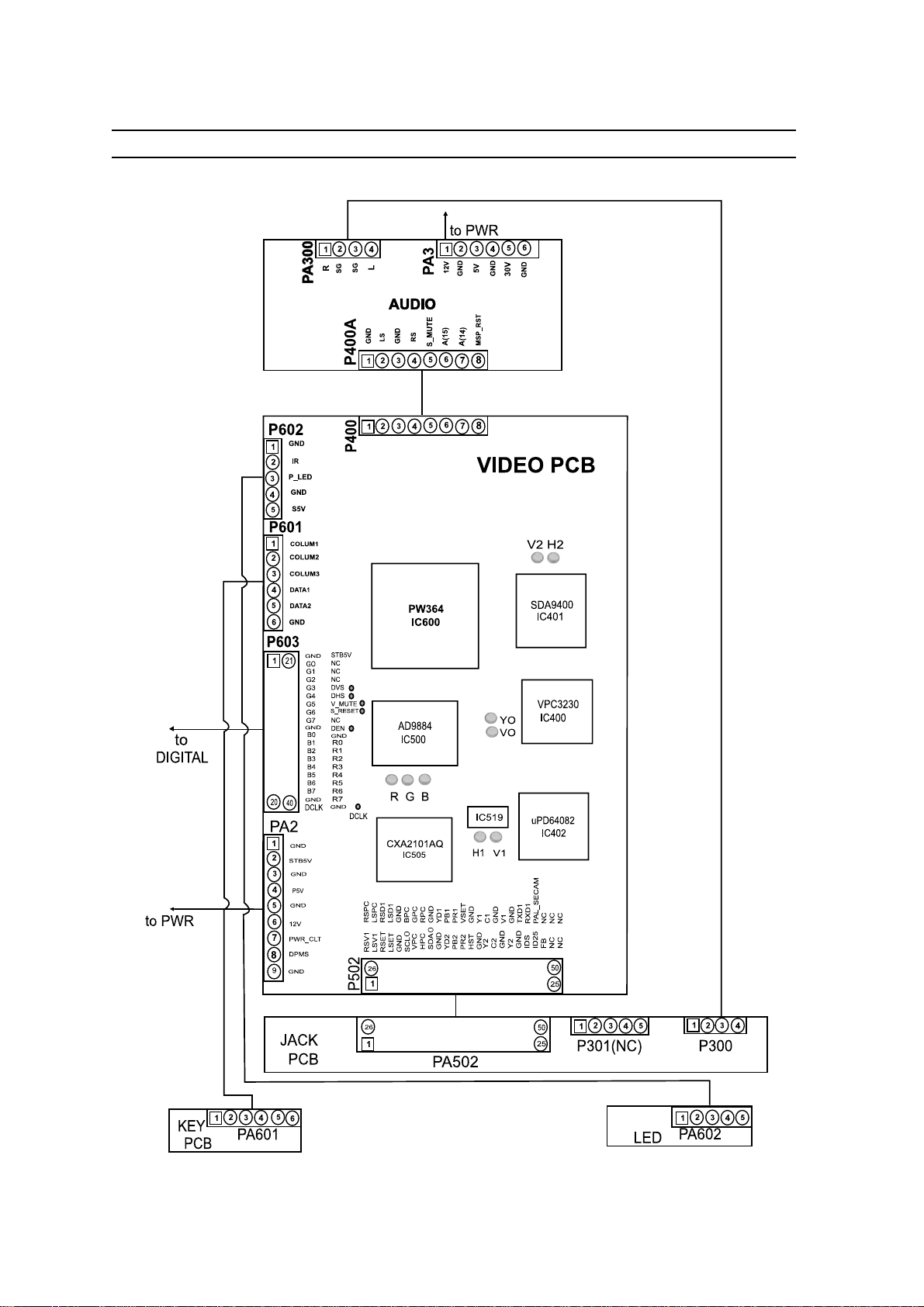

8-1. VIDEO / A UDIO

Service manual SP-110

- 31 -

Page 33

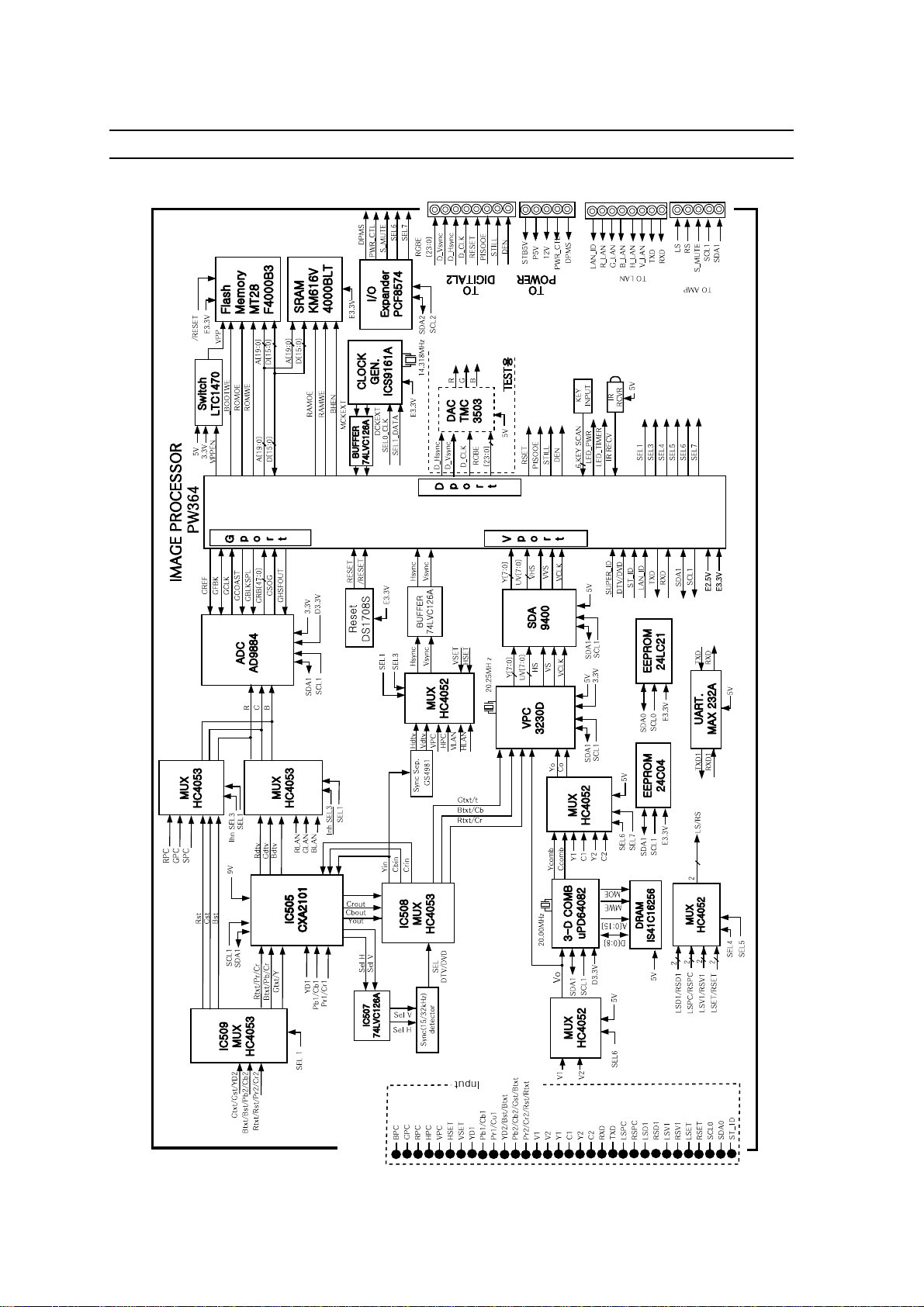

8-2. Digital

Service manual SP-110

- 32 -

Page 34

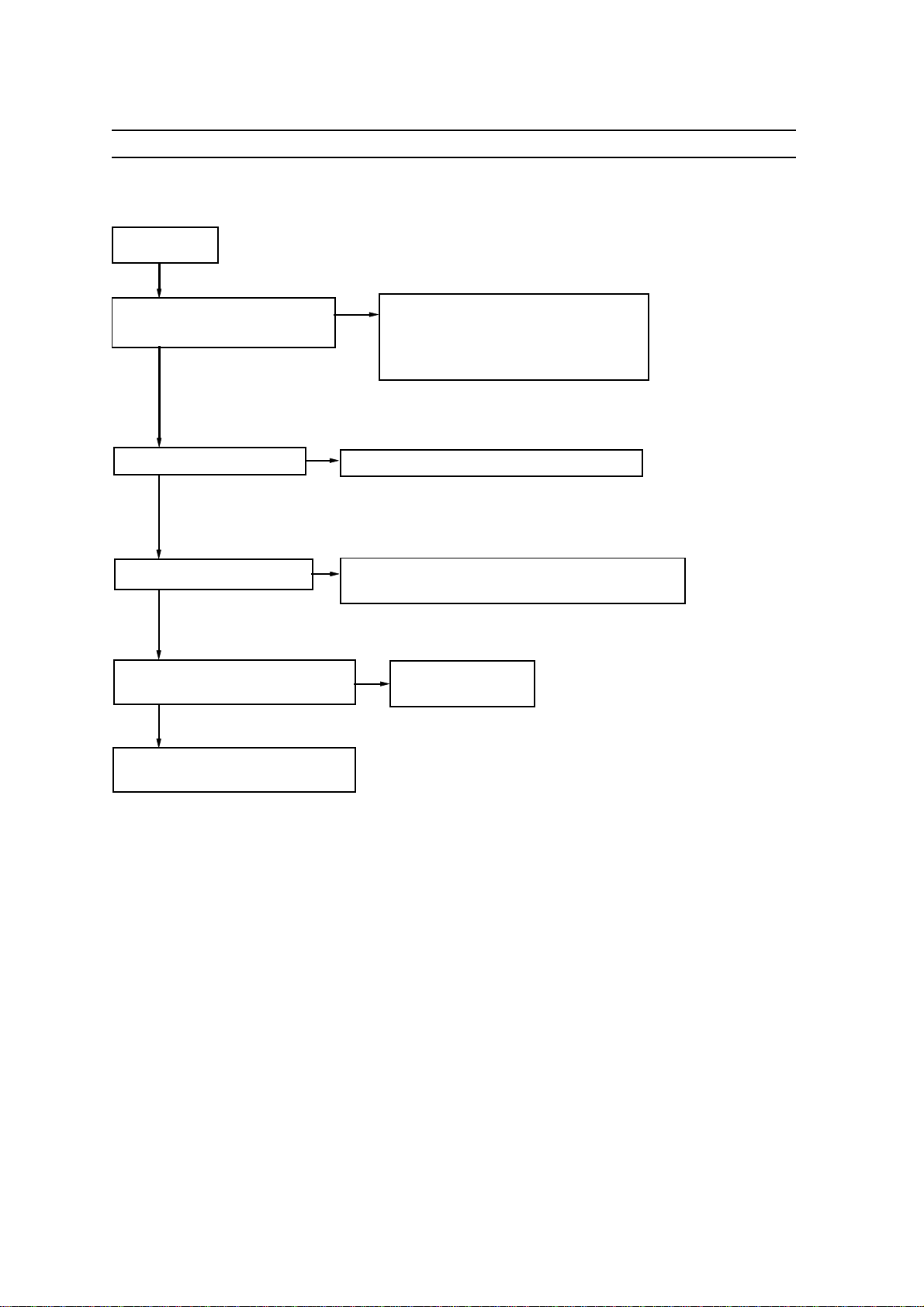

8-3. Y -Sustain

Y-Sustain Block Diagram

Service manual SP-110

- 33 -

Page 35

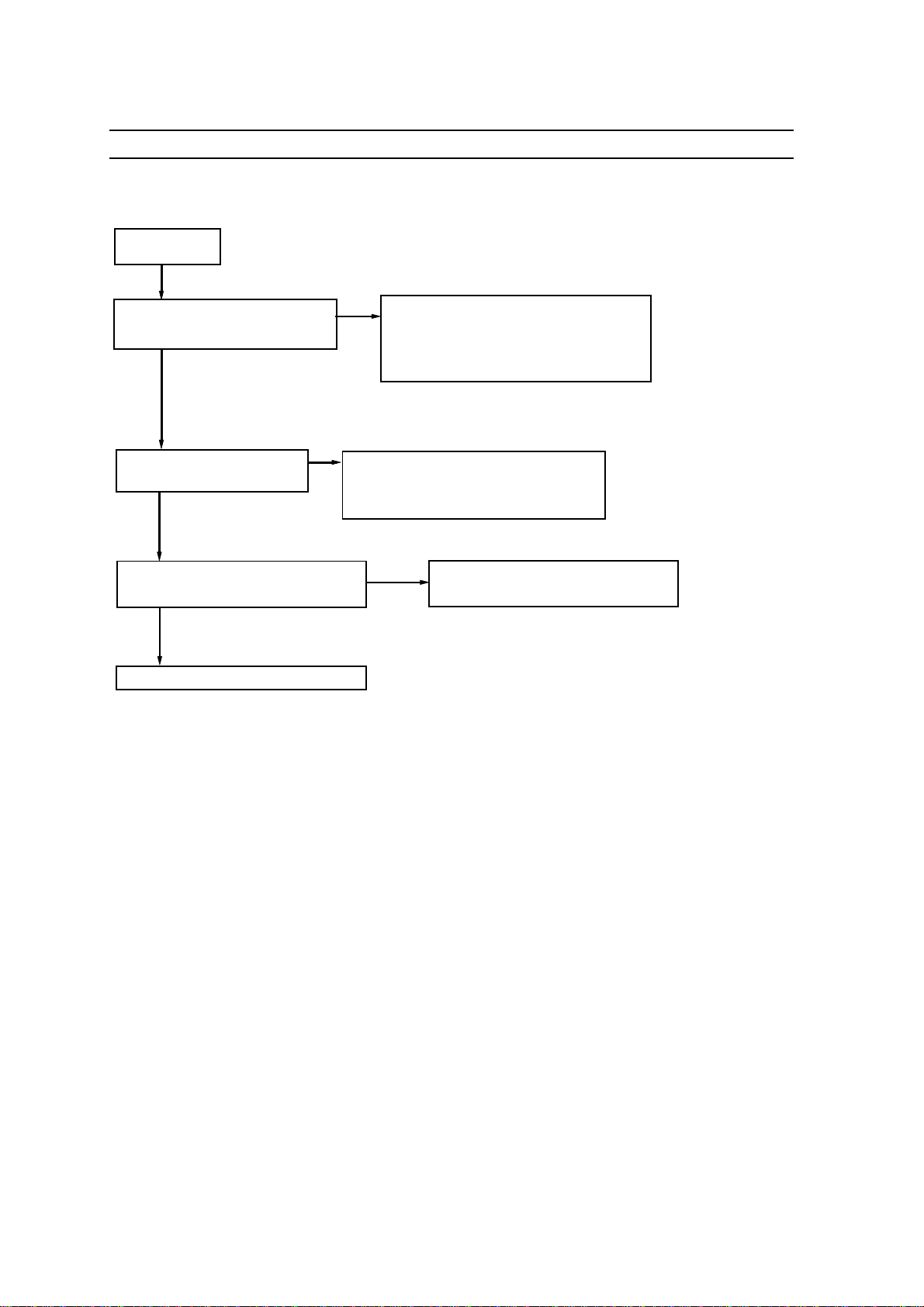

8-4. X-Sustain

·

·

·

·

·

·

X-Sustain Block Diagram

Service manual SP-110

- 34 -

Page 36

Page 37

686, AHYEON-DONG MAPO-GU

SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX : DWELEC K28177-8

CABLE : “DAEWOOELEC”

E-mail :djkoo@web.dwe.co.kr

TEL : 82-2-360-7806

FAX : 82-2-360-7877

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

DSP-4210GM

Data-board change procedure

Daewoo Electronics

Page 45

Step 1.

Un-screw the following locations.

This is backside of PDP. The circled locations are where the screws in

order to take off the back panel.

Page 46

Step 2

Inside look of PDP

This is inside look of PDP. The upper data board is different from bottom.

Upper: “Data High”, Lower: “Data Low”. You can read these on the board.

Page 47

Step 3

Page 48

Step 4

Testing. Find out the exact location of the line by pictures.

Connect any video source and display. This is normal picture.

Page 49

Step 5

Testing. Unhook the data connector.

Find out exact location of the line and unhook the connector right above

that position.

Page 50

Step 6

Picture of opened hook.

Page 51

Step 7

Take out the connect strip.

Page 52

Step 8

Exam the picture.

You will see some thin dead lines vertically.

Page 53

Step 9

Close look of the picture

If you still see the problem line in between these dead lines, then you have

to change the “Data Low (Lower)” board.

If you cannot see the problem line between these dead lines, you have to

change the “Data High (Upper)” board.

Page 54

Step 10

Changing Data High. Unhook all the connectors.

Page 55

Step 11

Unscrew

Page 56

Step 12

Pull the data board and replace with new one.

Page 57

Step 13

Slide in the new board

Page 58

Page 59

Step 14

1. Push in the connector

2. Push down the clip.

**** Caution ****

At the tip of the connector, there is a little hook. So lift a little and push in

all the way, and then clip down.

Page 60

Step 15

Screw in.

Step 16

Same technic is applied if you have to change the “Data Low

(Lower)”

Page 61

Page 62

Step 17

Put back the back cover.

Page 63

Please send back the Defected parts to the following address.

Daewoo Electronics DTV Service.

120 Chubb Ave.

Lyndhurst, NJ 07071

If you have any question?

Call 1-800-Daewoo-8 (1-800- 323-9668) or,

Email: service@daewoodigital.com

Page 64

DSP-4210GM

Horizontal Data-board change procedure

Daewoo Electronics

Page 65

Step 1.

Un-screw the following locations.

This is backside of PDP. The circled locations are where the screws in

order to take off the back panel.

Page 66

Step 2

Inside look of PDP

Page 67

Step 3

Horizontal Data board (Showing bottom one for example)

Page 68

Step 4

Pull out the 2 connectors.

Page 69

Step 5

Unscrew 2 positions

Page 70

Step 6

Slide and disconnect the board from main unit.

Page 71

Step 7

Slide in the new board.

Page 72

Step 8

Screw in the 2 screws in the position

Page 73

Step 9

Put in the data connector.

Page 74

Step 10

Cover the back panel and screw in those positions.

Page 75

Step 11

Please send back to us the unused and defected part.

Please mark which one is unused and defected.

Address:

Daewoo Electronics Research Center

120 Chubb Ave.

Lyndhurst, NJ 07071

Phone Number

201-964-9349

Page 76

DSP-4210GM

Data board change procedure

(When multiple thin lines occur in-group)

Daewoo Electronics

Page 77

Step 1.

Un-screw the following locations.

This is backside of PDP. The circled locations are where the screws in

order to take off the back panel.

Page 78

Step 2

Look for the position of the lines occur.

Close Look

Page 79

If the lines occur in the middle of screen, disassemble the connecter part.

Step 3.

Unscrew those positions.

Page 80

Step 4

Take out the wires and the connector.

Page 81

Step 5.

Slide out the input connector consol.

** Note **

Input connecting consol is still connected with power cable. Therefore, Do

not pull the consol to get completely separate from the main unit.

Page 82

Step 6.

Picture after input connecting consol is detached.

Page 83

Step 7.

Check if any connection is loosed.

Close Look

Page 84

If there is no connector that is loosed, change data-board.

Step 7.

Change Data-board.

See Data-board Change procedure.

Step 8.

Changing Data-board controller. (Step 8 ~ Step ??)

Location of Data-board Controller

Page 85

Page 86

How To Access Service Mode for Screen Control

1. Turn on the PDP.

2. Set up the PDP and a picture source. E.g. PDP and DVD are connected with component or

composite connection.

3. Play any DVD and select a picture scene and pause it. When you select a picture scene, try to

find a scene has bright (light source) spot and dark (shadow) spot in the same picture. (e.g. A

little dark room with bright light comes through a window.)

4. Go into the “service menu” mode using your remote control.

(Press following order on your remote: Up -> Mute -> Recall -> Mute)

5. You will see the Following option on the center of the screen.

CXA2101AQ

VPC3230D

PW364

MSP3405P

PICTURE

Test Pattern

Factory

6. Highlight the option “PW364” by pressing “down” arrow.

7. Select the option by pressing “right” arrow.

8. You will see the following option.

S Brt

S Cont

R Bias

G Bias

B Bias

R Gain

G Gain

B Gain

9. “S Brt” is the Brightness and “S Cont ” is the Contras.

10. Write down all the values on that screen and use this as a reference.

11. Highlight S Brt.

12. Change its value to “0” by press left arrow.

13. Highlight S Cont.

14. Change its value to “0” by press left arrow. (You will see almost nothing)

Page 87

15. Increase “S Cont ” value using “Right” arrow until you see the bright spot of the picture.

You still don’t see the dark (shadow) spot of the screen but it is ok.

16. Highlight “S Brt” by pressing “up” arrow once.

17. Increase its value using “right” arrow until you see the dark (shadow) spot of the screen.

18. Exit the service menu by pressing “Exit” button twice.

19. Turn off the PDP and Turn on again.

20. Enjoy your PDP.

Page 88

INSTRUCTION MANUAL

DSP-4210GM

Page 89

Important safety instructions

FCC regulations state that any

unauthorized changes or

modifications to this equipment many

void the user's authority to operate it.

To prevent electric shock, use a 3-wire

grounding-type plug, and fully insert

the plug.

To prevent damage which may result in fire or

electric shock hazard, do not expose this

appliance to rain or moisture.

Important safety information

Always be careful when using your monitor. To

reduce the risk of fire, electrical shock, and

other injuries, keep these safety precautions in

mind when installing, using, and maintaining

your machine.

Read all safety and operating instructions

before operating the PDP monitor.

Retain the safety and operating instructions

for future reference.

Heed all warnings on the monitor and in the

operating instructions.

Follow all operating and use instructions.

Unplug this monitor from the wall outlet

before cleaning. Use a damp cloth; do not

use liquid or aerosol cleaners.

Never add any attachments and/or equipment

without approval of the manufacturer. Such

additions may result in the risk of fire,

electric shock, or other personal injury.

Do not use the monitor where contact with or

immersion in water is a possibility, such

as near bath tubs, sinks, washing machines,

swimming pool, etc.

Provided ventilation for the monitor. The

unit is designed with slots in the cabinet for

ventilation to protect it from overheating. Do

not block these openings with any object. On

not place it near a radiator or heat register.

Operate your monitor only from the type of

power source indicated the marking label. If

you are sure of the type of power supplied to

your home, consult your monitor dealer or

local power company.

This plug will fit into a grounding-type

power outlet only one way. If you are unable

to insert the plug into the outlet, contact your

electrician to replace your outlet. Do not

defeat the purpose of the grounding-type

plug.

This monitor is equipped with a 3-wire

grounding-type plug. That is, a plug having a

third (grounding) pin.

Protect the power cord. Power supply cords

should be routed so that they are unlikely to

be walked on or pinched by items placed on

or against them. Pay particular attention to

cords at plugs, convenience receptacles, and

the point where they exit from the unit.

CAUTION

TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT

REMOVE COVER ( OR BACK )

NO USER SERVICEABLE PART INSIDE REFER

SERVICING TO QUALIFIED SERVICE PERSONNEL

Page 90

Unplug the monitor from the wall outlet and

disconnect the interfacing cable system

during a lightning storm or when left

unattended and unused for long periods of

time. This will prevent damage to the unit

due to lightning and power-line surges.

Avoid overhead power lines. An external

connection cables should not be placed in the

vicinity of overhead power lines or other

electric light or power circuits. When

installing an external connection cables be

careful to keep from touching the power

lines or circuits. Contact with such lines can

be fatal.

Do not overhead the wall outlet or extension

cords. Overloading can result in fire or

electric shock.

Do not insert foreign objects through

openings in the units, as they may tough

dangerous voltage points or damage parts.

Never spill liquid of any kind on the monitor.

Do not attempt to service this monitor

yourself. Refer all servicing to qualified

service personnel. Unplug the unit from the

wall outlet and refer servicing to qualified

service personnel under the following

conditions :

when the power-supply cord or plug is

damaged

if liquid has been spilled on or objects

have fallen into the unit

if the monitor has been exposed to rain or

water

if the monitor does not operate normally

by following the operating instructions

if the monitor has been dropped or the

cabinet has been damaged

when the monitor exhibits a distinct

change in performance

If you make adjustments yourself, adjust

only those controls that are covered by the

operating instructions. Adjusting other

controls may result in damage and will often

require extensive work by a qualified

technician to restore the monitor to normal.

When replacement parts are required, be sure

the service technician uses replacement parts

specified by the manufacturer or those that

have the same characteristics as the original

part. Unauthorized substitutions may result

in additional damage to the unit.

Upon completion of any service or repairs to

this monitor, ask the service technician to

perform safety checks to determine that the

monitor is in a safe operating condition.

Page 91

R

E

C

A

L

L

M

E

N

U

P

I

C

T

U

R

E

M

O

D

E

S

C

R

E

E

N

M

O

D

E

F

R

E

E

Z

E

M

U

T

E

R

-

V

2

A

Z

O

O

M

–

Z

O

O

M

+

P

O

W

E

R

I

N

P

U

T

S

E

L

E

C

T

V

O

L

V

O

L

The Daewoo Plasma Monitor is a high definition and high resolution big

screen, true flat monitor.

The Daewoo Plasma Monitor displays clear and precise high quality

pictures using a high resolution PDP panel of 400,000 pixels that produces

picture quality far superior to current analog TV’s.

The Daewoo Plasma Monitor with its slim depth (83 mm) and light weight

(only 33 kg) allows a greater possibility of placement and movement.

The Daewoo Plasma Monitor supports a wide range of PC inputs

(VGA/SVGA/XGA/SXGA/UXGA), that are adaptable to various

multimedia components.

The Daewoo Plasma Monitor with its wide screen supports both the 16:9

and 4:3 format, while also providing Zoom and PIP functions as well.

HIGHLIGHTS OF THE DAEWOO PLASMA MONITOR

ACCESSORIES

Please read all instructions completely before operating your new

Daewoo Plasma Monitor and equipment. Please follow all warnings and

instructions written in this manual. Please keep this manual for future

reference.

CAUTION :

To reduce the risk of electric shock, DO NOT remove its cover.

No user-serviceable parts inside. Refer servicing to qualified

service personnel.

Remote control Batteries for the remote

control (AAA type)

Connection cable for

video/audio

Power cable

▼

▼▼▼▼

Page 92

Table of Contents

Preparation

Important safety instructions…………………… .......................................................................2

Safety precautions…………………….......................................................................................3

Panel Description

Front Side………… ....................................................................................................................4

Rear Side …………....................................................................................................................4

Remote Control Key Function………........................................................................................5

Basics (Settings)

VCR Connection…………..........................................................................................................6

DVD Connection……….. ...........................................................................................................7

DTV Connection…………..........................................................................................................8

PC Connection…………............................................................................................................9

Menu Operation (PC or DTV)

How to adjust picture quality…….............................................................................................10

How to adjust sound quality………..........................................................................................11

How to adjust screen mode, zoom, or screen size and position……....................................13

How to select input signal………….........................................................................................16

How to use utility functions for OSD language, reset to factory defaults or

operate graphic resolution or video systems………………….. .............................................17

How to operate the PIP function…… ......................................................................................19

Menu Operation (Video, S-VHS, or DVD)

How to adjust video picture…….. ............................................................................................21

How to adjust screen mode and rotation………….................................................................22

How to operate hot keys from remote control or front panel

How to power the unit on/off………….....................................................................................24

How to adjust the volume……………......................................................................................24

How to adjust screen size………….........................................................................................25

How to select inputs using the hot key………….....................................................................26

How to select a picture mode……….......................................................................................26

How to zoom…….. ...................................................................................................................27

How to directly check the video system or graphic resolution……………............................27

How to freeze/pause the picture frame……………................................................................27

Other OSDs related to auto progress

When auto progressing……………......................................................................................... 28

When there is no signal after auto detection….......................................................................28

When there is an unacceptable signal after auto detection……............................................28

Troubleshooting

Before requesting technical support…… ................................................................................29

Plasma display panel …………………. ..................................................................................29

Specifications................................................................................................30

Page 93

2

• When a problem occurs,

immediately stop all operations.

•

Do not place any liquid container on top

of the Plasma Monitor. If water spills

into the Plasma Monitor, a short-circuit

may occur which could result in fire or

electric shock.

• Do not place any objects on top of the

Plasma Monitor. If any foreign objects

get inside, it can cause damage to or

premature failure of the unit.

•

When installing this unit on a wall or

ceiling, please consult an Authorized

Service Center. Improper mounting

can result in personal injury or

damage to the unit.

•

During a lightning storm, do not

touch the unit. Doing so may result

to an electric shock.

•

Do not place the Plasma Monitor on

sloped or unstable surfaces. The

unit may fall off or tip over causing

injury and damage.

•

Do not do anything that might

damage the power cable.

Damaging the power cable may

result in fire or electric shock.

•

Do not handle the power cord with

wet hands. Doing so may cause

electric shocks.

•

Do not overload wall outlets and

extension cords. Doing so may

result in power failure.

•

Do not make any modifications.

(Never attempt to disassemble this

unit yourself) The internal

components of this unit is high

voltage which may cause electric

shocks.

•

Do not place the Plasma Monitor in

sunlight or near heating units. Doing

so may cause damage to or cause

premature failure of the unit.

•

Do not cover the ventilation holes.

Doing so may cause the Plasma

Monitor to overheat, which can cause

fire or damage to the internal

components.

Preparation

IMPORTANT SAFETY INSTRUCTIONS

Page 94

3

PREPARATION

•

Do not pull or hang the connecting

cable. Any damage to the cable can

result in electric shocks or fire.

•

Do not rest the Plasma Monitor on top

of other objects.

•

Do not place the Plasma Monitor in a

humid or dusty place or any place near

oil, smoke or steam. Built-up dust can

increase humidity which might damage

the insulation and cause fire.

•

Do not pull the power cord to

remove the power plug from the wall

outlet. Doing so can cause fire or

electric shock.

•

If the Plasma Monitor is not in use

for a long period of time, unplug the

power cord from the wall outlet. It

will conserve electricity.

•

Do not place any heavy objects on

the unit. If any foreign objects get

inside, please consult an Authorized

Service Center.

•

When inserting batteries, to ensure

proper installation, check the

polarity.

•

Do not lean or step on the Plasma

Monitor.

•

Be sure to disconnect all cables

before moving the Plasma Monitor.

Moving the unit with its cables

attached might damage the cables

which, in turn, can cause fire or

electric shock.

•

Do not combine a used battery with

a new one. Batteries should always

be replaced as a pair. Always use

new batteries when replacing the old

set.

SAFETY PRECAUTIONS

PREPARATION

Page 95

4

Panel Description

REAR SIDE

FRONT SIDE

Press the MENU button to display the menu

and use MOVE/CH buttons to select and

adjust items

PC Input Connection

VIDEO Input Connection

DTV Settop Box (Y, Pb, Pr * 1080i, 720p, 480p,

60Hz) or DVD (Y, Cr, Cb * 50/60Hz) Connection

Power Cord

Connection

External Speaker Connection

Remote controller receiver

Power ON/OFF Button

LED Display - Red: Standby

Green: Operating state

Press VOLUME Up/Down button to

adjust sound level

Press INPUT SELECT

button to switch between

Video/S-Video/DTV or

DVD inputs

DTV/DVD INPUT

R

Y Pb/Cb Pr/Cr

S-VIDEO VIDEO

L

AUDIO

PC INPUT

R

L

AUDIO

VIDEO INPUT

EXTERNAL INPUT LAN ~ACIN

SPEAKER(8Ω)

RL

R

L

AUDIO

AC IN

POWER STAND-BY/

OPERATE

MOVE/CH VOLUME MENU INPUT

–

+

SELECT

Page 96

RECALL

MENU

PICTURE

MODE

SCREEN

MODE

FREEZE

MUTE

R-V2A

ZOOM– ZOOM+

POWERINPUT

SELECT

VOL VOL

5

PANEL

DESCRIPTION

REMOTE CONTROL KEY FUNCTION

INPUT SELECT KEY:

Direct input select

function

ZOOM –

ARROW UP / DOWN

POWER KEY:

To switch to standby or

on again

PICTURE MODE KEY

MUTE KEY

Temporarily mute the

sound or restore it

RECALL KEY

ZOOM +

MENU KEY

To switch the menu on/off

VOLUME– / +KEY

Press -/+ to adjust the

volume

SCREEN MODE KEY

to switch between a 4:3 or a

16:9 picture format

FREEZE KEY

Still picture

Note

• Use 1.5V “AAA” batteries.

Inserting batteries

• Insert batteries properly by

matching polarity, then close lid.

Page 97

6

INPUT SELECTION

• Press the INPUT SELECT button on the front

panel or on your remote control to select Video or

S-Video.

Input mode rotates in the following sequence

each time you press the INPUT SELECT button.

• You can watch TV by selecting TV mode on your VCR and tuning to your TV

channel.

• You can watch NTSC or PAL / SECAM signals.

Basics(settings)

VCR CONNECTION

VIDEO

NOTE

An afterimage may appear on the plasma panel when a still image has been

displayed for a long duration (i.e. when playing video games.)

S-VIDEO DTV/DVD PC

POWER

INPUT

SELECT

S-VIDEO VIDEO

VIDEO INPUT

R

L

AUDIO

VIDEO

VCR

S-Video

Jack

Video/Audio

SELECT

RECALL

ZOOM– ZOOM+

MENU

VOL VOL

PICTURE

MODE

FREEZE

MUTE

R-V2A

POWERINPUT

SCREEN

MODE

Page 98

S-VIDEO VIDEO

VIDEO INPUT

R

L

AUDIO

DTV/DVD INPUT

R

Y Pb/Cb Pr/Cr

L

AUDIO

DVD DVD

INPUT SELECTION (REMOTE CONTROL)

• Press INPUT SELECT button on the front panel or on your Remote Control to

select Video, S-Video, or DTV/DVD according to your connection type.

Input mode rotates in the following sequence each time you press the

INPUT SELECT button.

7

DVD CONNECTION

VIDEO S-VIDEO DTV/DVD PC

POWER

INPUT

SELECT

BASICS

(SETTINGS)

(Using Y, Cb, Cr Connection)

Y, Cb, Cr Connection

S-Video Connection (using 4 pin mini DIN Connection)

RCA Video

(Without Y, Cb, Cr Connection)

Video

Audio

Video/AudioS-Video

Page 99

8

INPUT SELECTION (REMOTE CONTROL)

• Press INPUT SELECT button on the front panel or

on your Remote Control to select DTV/DVD

Input mode rotates in the following sequence

each time you press the INPUT SELECT button

DTV FORMA TS SUPPORTED

• 1080i(60Hz), 710p(60Hz), 480p(60Hz)

DTV CONNECTION

VIDEO

NOTE

If your DTV Settop Box is equipped with a 15pin D-Sub connector, you can

also watch DTV via PC input.

S-VIDEO DTV/DVD PC

POWER

INPUT

SELECT

DTV SETTOP BOX

DTV/DVD INPUT

R

Y Pb/Cb Pr/Cr

L

AUDIO

Video

DTV SET -TOP BOX

Audio

SELECT

RECALL

ZOOM– ZOOM+

MENU

VOL VOL

PICTURE

MODE

FREEZE

MUTE

R-V2A

POWERINPUT

SCREEN

MODE

Page 100

9

INPUT SELECTION (REMOTE CONTROL)

• Press INPUT SELECT button on the front panel or on your Remote Control

to select PC.

Input mode rotates in the following sequence each time you press the

INPUT SELECT button.

RESOLUTIONS SUPPORTED

• VGA - SVGA - XGA - SXGA - UXGA

PC CONNECTION

VIDEO S-VIDEO DTV/DVD PC

PC INPUT

R

L

AUDIO

POWER

INPUT

SELECT

BASICS

(SETTINGS)

Audio

15 PIN D-Sub

Use appropriate connector

to match your PC output

connector.

Loading...

Loading...