Page 1

S/M NO. : DSL150TP00

Service Manual

19”,20”,22” LCD TV

CHASSIS: SL-150T/150P

Model: DLT-19W4 / DLP-19W4

DLT-22W4 / DLP-22W4

DLT-20J1 / DLP-20J1M

DLT-20J3 / DLP-20J3M

DLT-20J9 / DLP-20J9M

DLT-19L1 / DLP-19L1

DLT-19L2 / DLP-19L2

DLT-22L1 / DLP-22L1

DLT-22L2 / DLP-22L2

Caution:

In this manual some parts can be changed for improving. Their

performance without notice in the parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service

Information Center.

JAN. 2008

Page 2

Contents

I. Parts with the exception of MODULE

1. Safety Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4. Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5. PCB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6. Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7. Service Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8. Different part list for models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10. Out Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

11. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

12. Software Install & Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

13. SVC keys function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

* Remarks

Points from 3 show data for DLT models.

For DLP models diffrent part list for models (point 8) must be used.

1

Page 3

1. Safety Precautions

(1) When moving or laying down a LCD Set, at least two people must work together. Avoid any

impact towards the LCD Set.

(2) Do not leave a broken LCD Set on for a long time. To prevent any further damages, after

checking the condition of the broken Set, make sure to turn the power (AC) off.

(3) When opening the BACK COVER, you must turn off power (AC) to prevent any electric

shock.

(4) When loosening screws, check the position and type of the screw. Sort out the screws and

store them separately for reassembling. Because screws holding PCBs are working as electric circuit grounding, make sure to check if any screw is missing when assembling / reassembling. Do not leave any screws inside the set.

(5) A LCD Set contains different kinds of connector cables. When connecting or disconnecting

cables, check the direction and position of the cable beforehand.

(6) Connect/disconnect the connectors slowly with care especially FFC (film) cables and FPC

cables. Do not connect or disconnect connectors instantaneously with force, and handle

them carefully for reassembling.

(7) Connectors are designed so that if the number of pins or the direction does not match,

connectors will not fit. When having problem in plugging the connectors, check their kind,

position, and direction.

2

Page 4

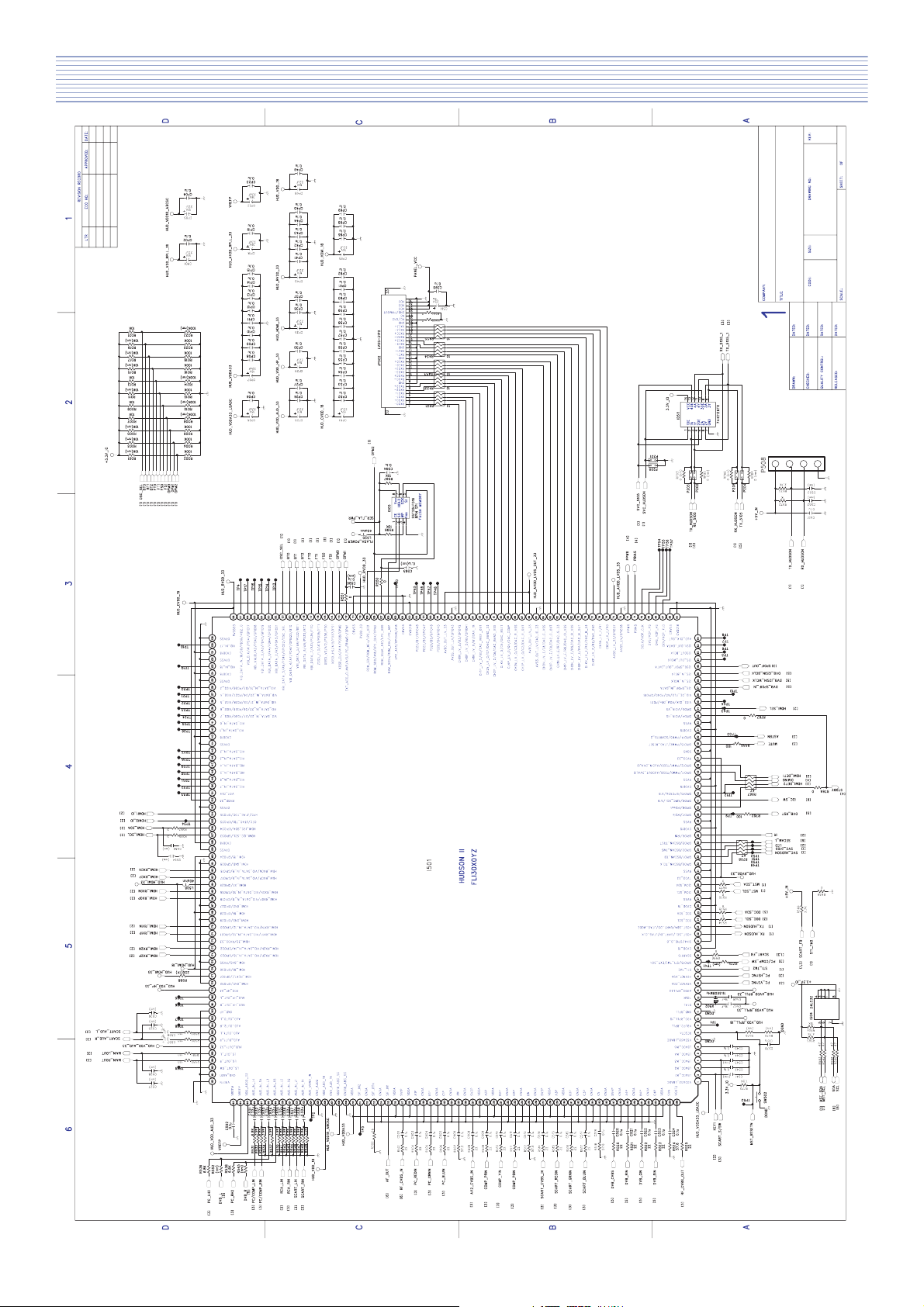

2. Product Specifications

Model DLT-19W4 / DLP-19W4 DLT-20Jx / DLP-20JxM DLT-22W4 / DLP-22W4

Screen Size 480mm (diagonal) 510.54mm (diagonal) 558.673mm (diagonal)

Display Colour 16.7 M

Aspect Ratio 16:10 4:3 16:10

Resolution 1440 x 900 (WXGA+) 640 x 480 (VGA) 1680 x 1050 (WSXGA+)

Pixel Pitch 0.2835 x 0.2835 0.6375 x 0.6375 0.2835 x 0.2835

Contrast Ratio 1000:1 350:1 1000:1

Appearance

(W x H x D)

Weight

(Net)

Power Consumption 42W / 39W 52W / 49W 50W / 46W

Sound Output 2.0W + 2.0W

Terminals

Reception Channel

Power Source AC 220 ~ 240V, 50Hz

The following picture

formats is

available:

w/o stand

with stand

w/o stand

with stand

RF, AV1, AV2

MODE

COMPONENT,

HDMI, PC

DVB-T MODE

476.3 x 346 x 80 514 x 460 x 85 545.4 x 400 x 81

476.3 x 401.5 x 190 514 x 498 x 239 545.4 x 426 x 190

4.9 Kg 7.0 Kg 5.6 Kg

5.2 Kg 8.0 Kg 5.9 Kg

AV IN : SCART, COMPOSITE VIDEO, AUDIO L/R,

COMPONENT, PC, HDMI

HEADPHONE : 3.5mm STEREO MINI-JACK

DIGITAL AUDIO OUT: Coaxial

ANT. IN : COAXIAL-TYPE

VHF BAND I : CH2-CH4

BAND II : CH5-CH12

UHF HYPER BAND : SI’-S3’, S1-S20

BAND IV, V : CH21-CH68

PAL-B/G, D/K, SECAM-L/L’, NTSC(AV input only)

WIDE, FULL SCREEN

4:3, FULL SCREEN

FULL SCREEN

WIDE, FULL SCREEN

4:3, FULL SCREEN

PC Input resolution in LCD

Resolution V-Freq

640 x 480 60Hz o o o o

800 x 600 60Hz o o x x

1024x768 60Hz o o x x

1280x768 60Hz o x x x

1440 x 900 60Hz o x x x

DLT/P-19W4, 22W4 DLT/P-20J1, 20J3, 20J9

PC(D-Sub) HDMI PC(D-Sub) HDMI

Multimedia input resolution table in LCD

Resolution V-freq

720 x 480i 60Hz oxox

720 x 480p 60Hz o o o o

720 x 576i 60Hz oxox

720 x 576p 60Hz o o o o

1280 x 720p

1920 x 1080i

50Hz o o o o

60Hz o o o o

50Hz o o o o

60Hz o o o o

DLT/P-19W4, 22W4 DLT/P-20J1, 20J3, 20J9

Component HDMI Component HDMI

Remark

Remark

3

Page 5

p\WX

o|kzvuGpp

mspZW]WYo

oktpGX

oktpGY

Ovw{pvuP

oktp

z~

OP

{|uly

{k{nTzXW[kG

zpm

ymj}iz

wjG

kTz

yVnViVoV}

yVs

yVs

zjhy{

yVnVi

j}iz

yVs

j}iz

j

yVs

VwVw

yjhGq

j}iz

yVs

h

htw

y

s

oVw

s}kzGOX`”~SYY”~

P

sjk

whuls

p\W\

z

mshzo

p\W[

llwyvt

hGpYj

pjkXZ

jvmkt

z{}WZ]Y

pkWY

z{\XW\

jp

{z

kh{h

kGpYj

pkWZ

zkyht

pkX_

m

j

zwkpm

yVnViVj}iz

zwkpm

pkWY

llwyvt

kGpYj

zpmGpu

ymGj}izGpu

oktpGpu

jvtwvulu{

pu

wjGpu

yni

j}izGpu

j}izGv|{

h|kpvGpu

h|kpvGv|{

zjhy{Gpu

jvtwGhGpu

h}YGj}izGpu

h}GhGpu

zwkpmGv|{

{{sOYWUX”P

wjGh

pkXW

pYjGz~

hGGpYj

kGpYj

pkX[

X]Y[[

pkW^

X]Y[[

pkX^

ojXY]

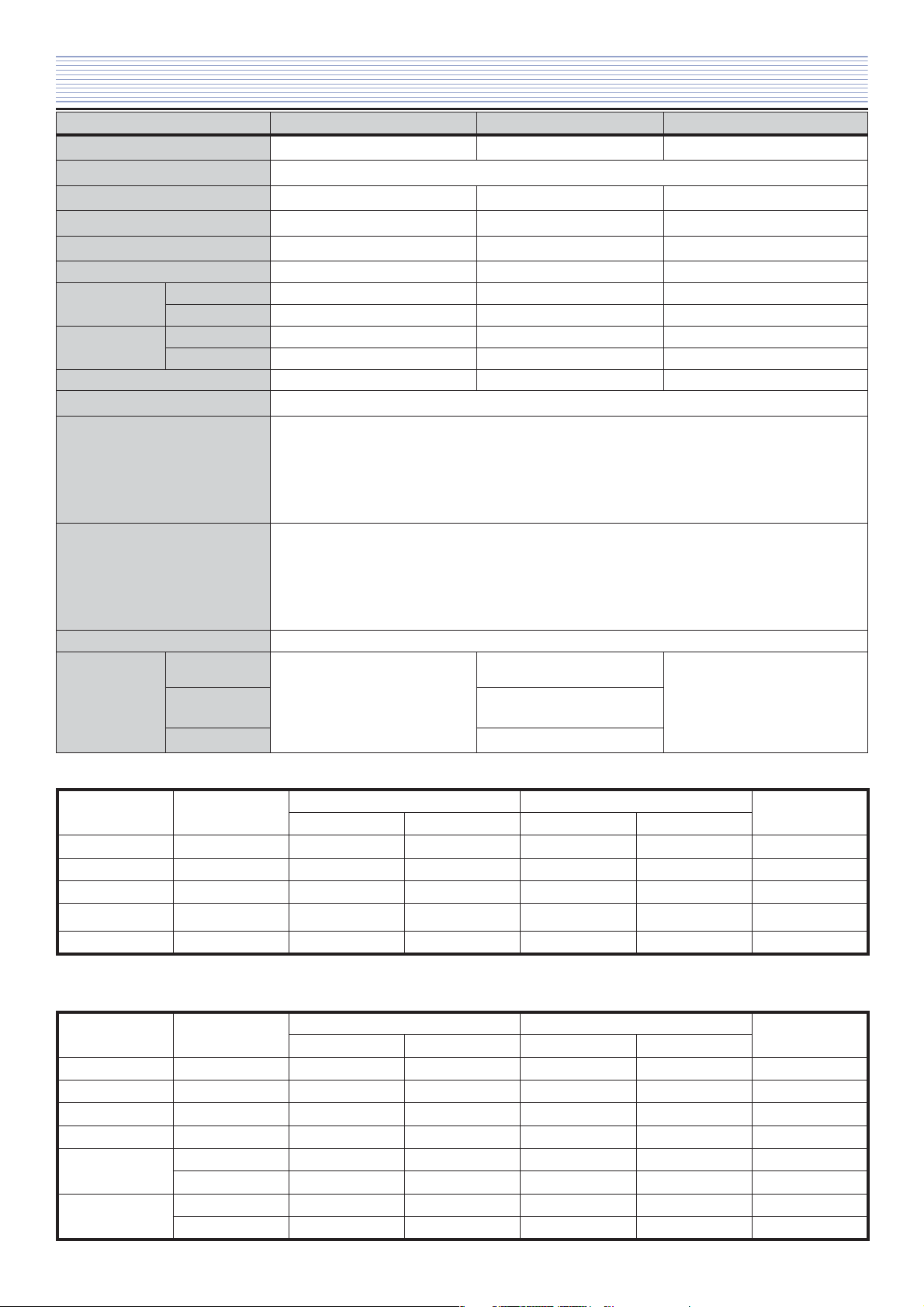

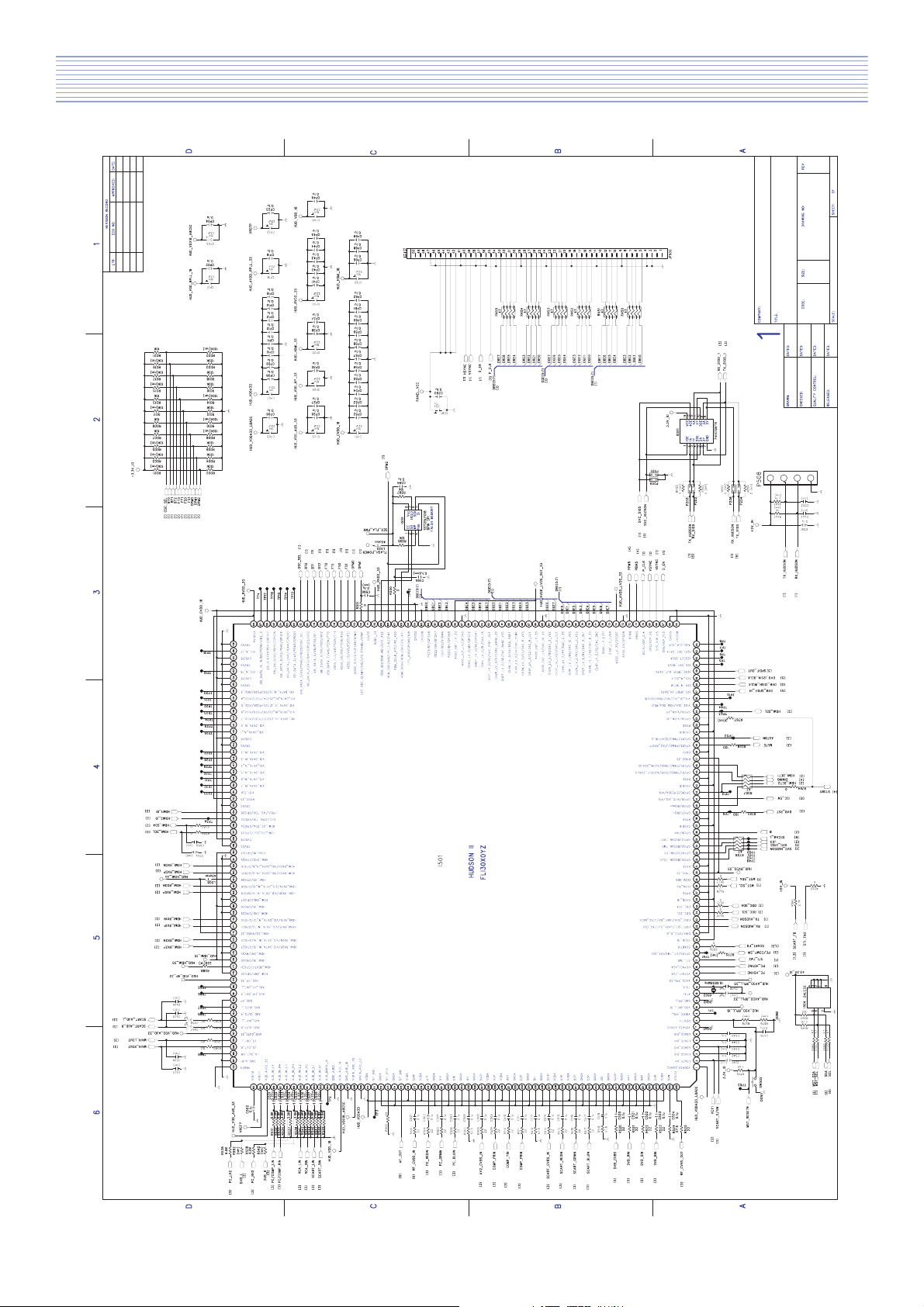

3. Block Diagram (Main)

* DLT model only

4

Page 6

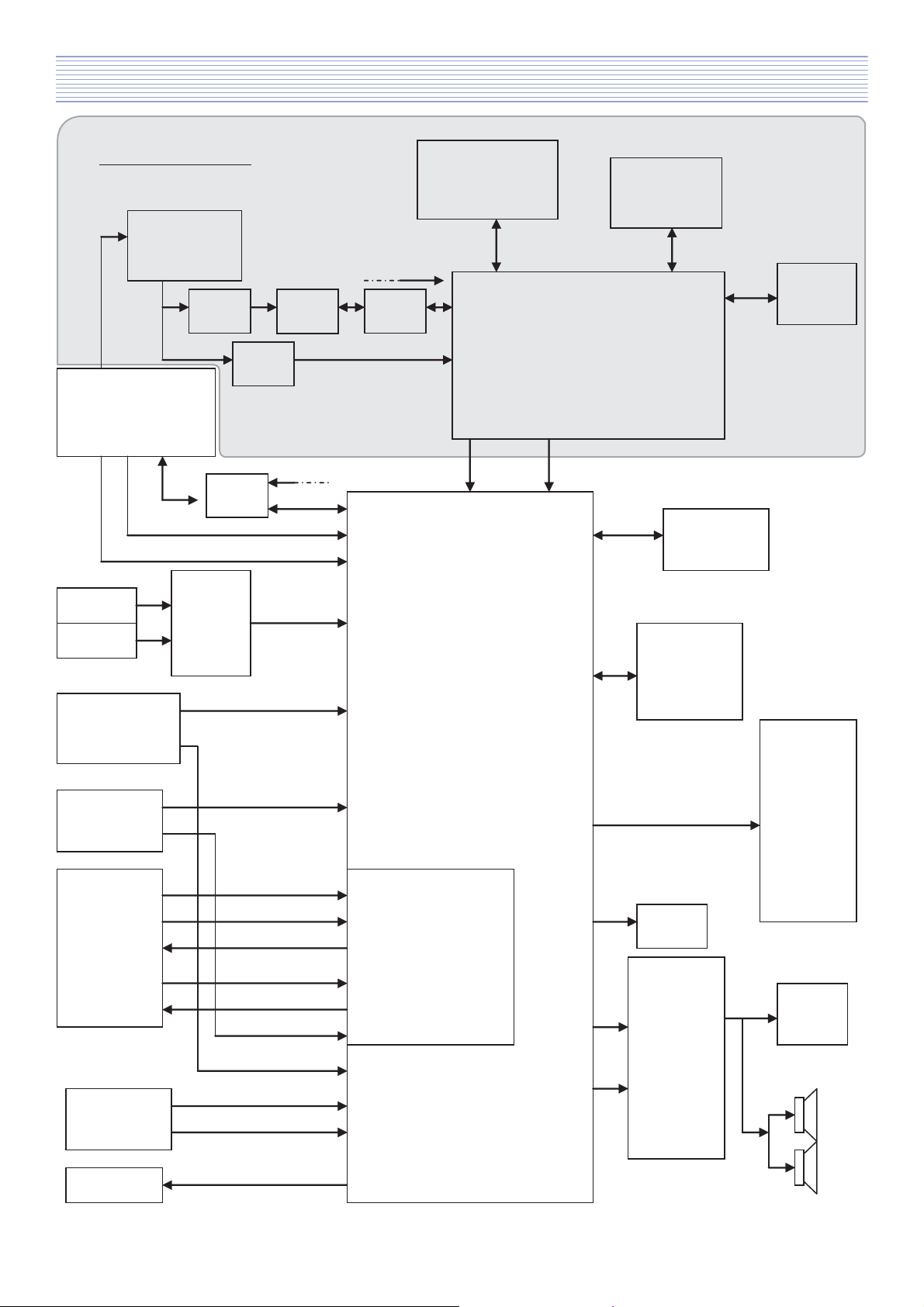

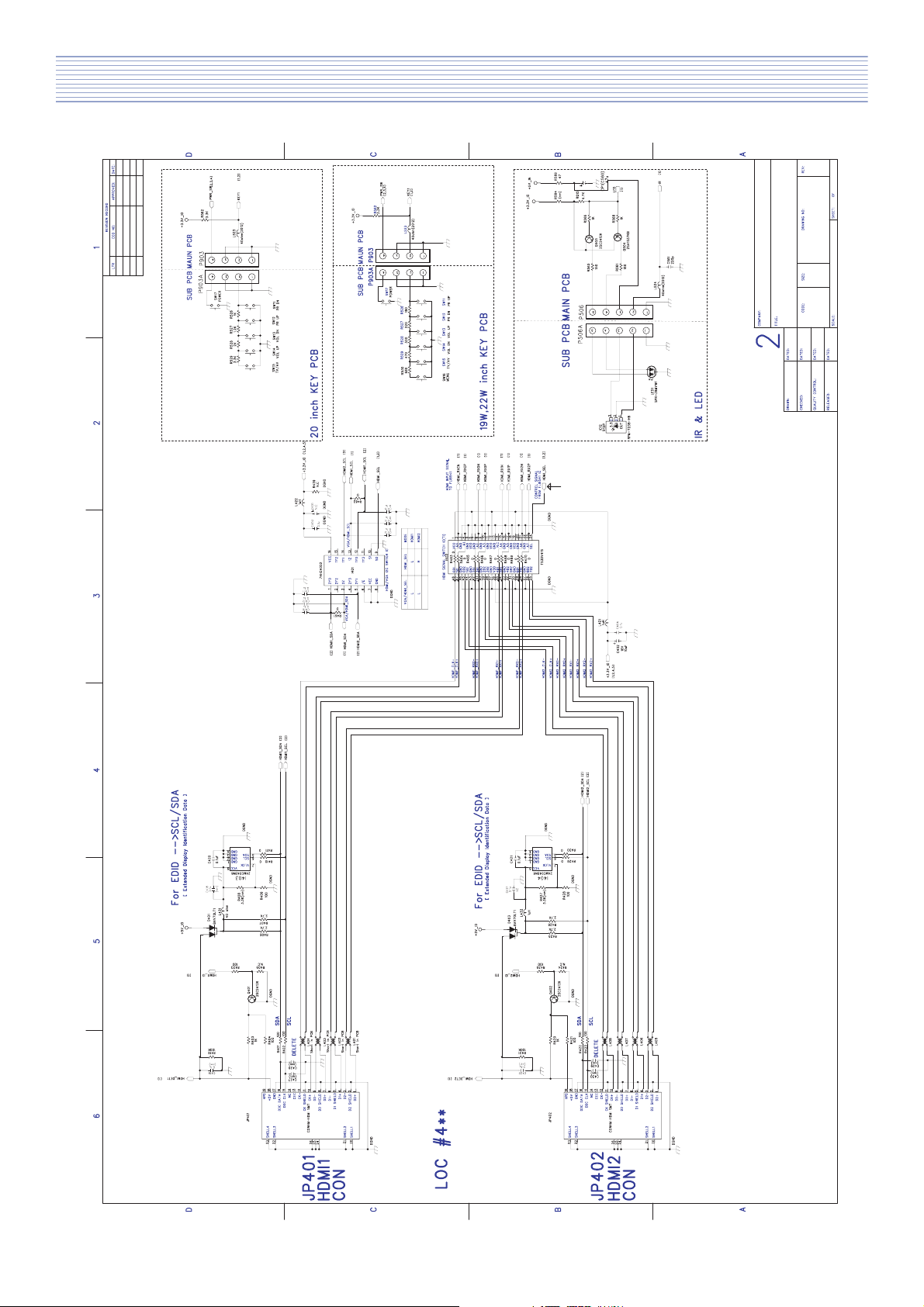

Block Diagram (Power Lips)

{|uly

h|kpvGhtw

pkWYOz{\XW\P

\}{|

pkWZOzkyhtP

YU\}

pkX_OmshzoP

pkX\OllwyvtP

ZUZ}

pkXZOjvmktP

wkWZ

w\W_G

pkXWGOGpYjGz~GP

pjXYGOpjGwylhtwP

whulsOzVzSh|vP

qkWY

wjtjph

p`YX

ylnU\}

ZUZ}SYU\}SXUY}

ZUZ}SYU\}SXUW}

ZUZ}

k}iT{

p\W\GOzGmshzoP

ZUZ}

kjTkjGjU

p\W[GOllwyvtP

p`XZ

XU_}

kjTkjGjU

X[U\}OX\}Pz~

ml{

p`X\

p`WY

ylnUZUZ}

\}z~

p`XX

ylnUYU\}

p`X[

p`X]

ylnUXUY}

ylnUXUW}

\}jp

p`W^

mspZW]WYoP

p\WXOo|kzvuGpp

\}

kjTkjGjU

p`XY

isluSishkq

X[U\}OX\}P

\}

_U\}

spwz

wv~ly

5

Page 7

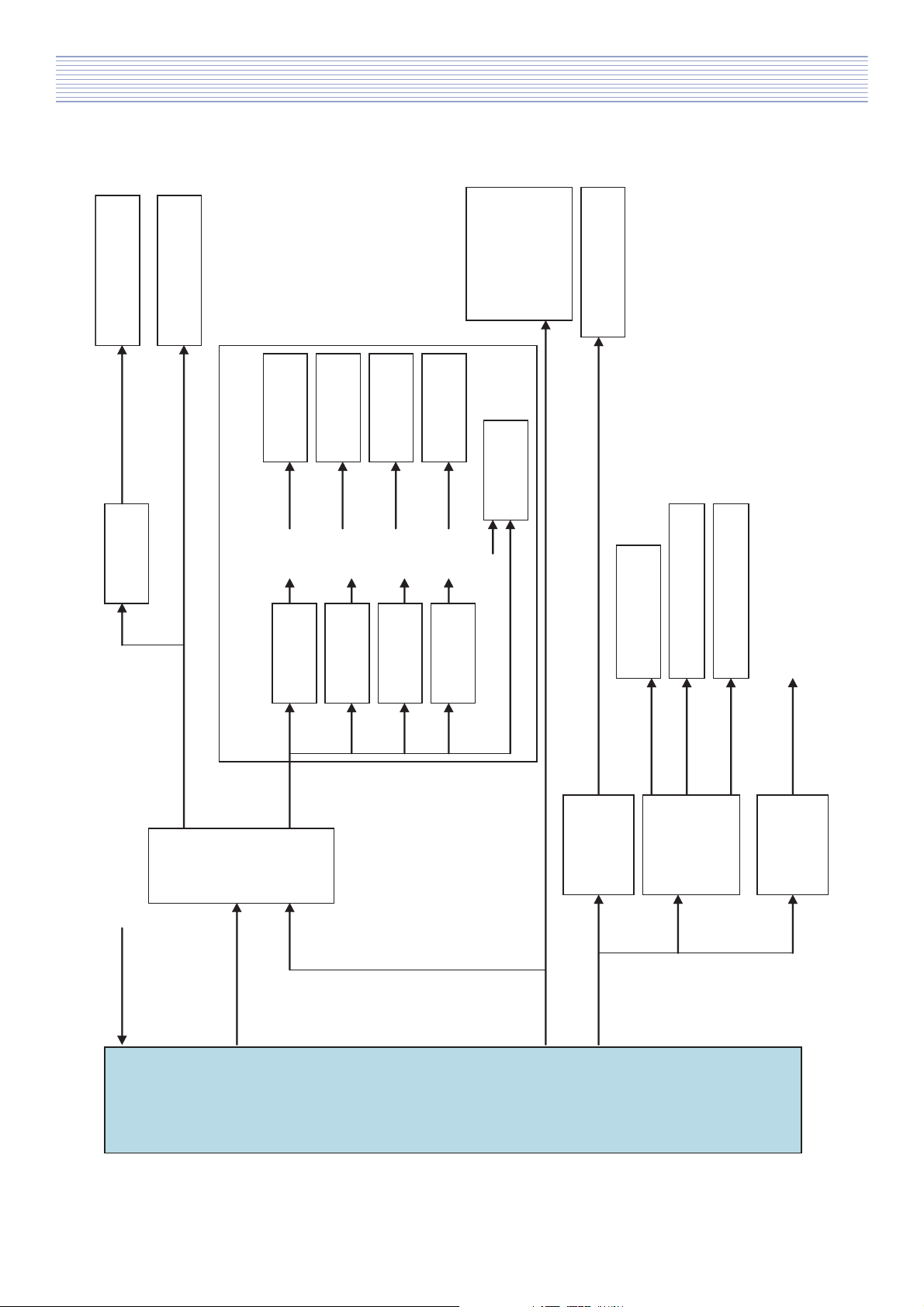

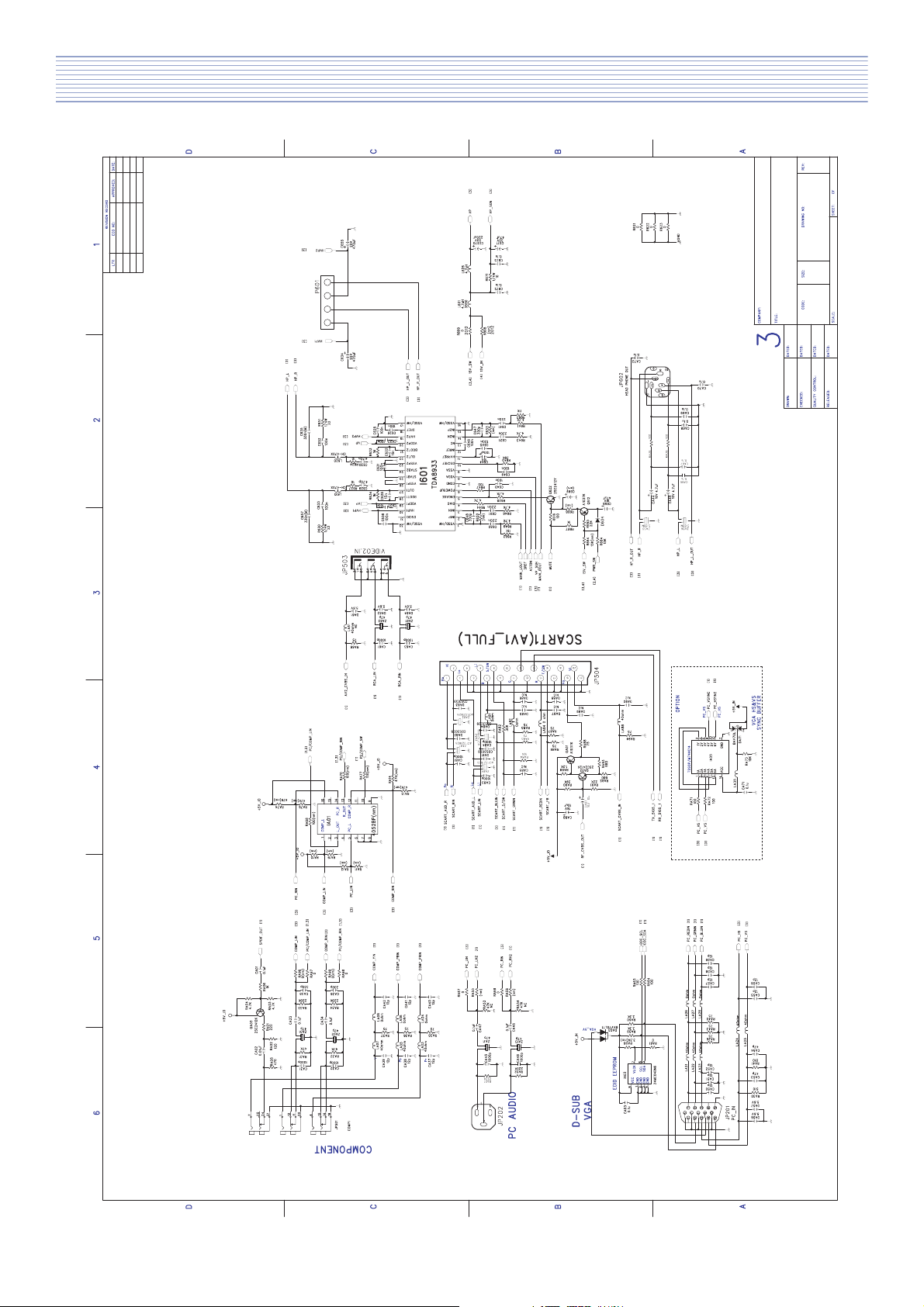

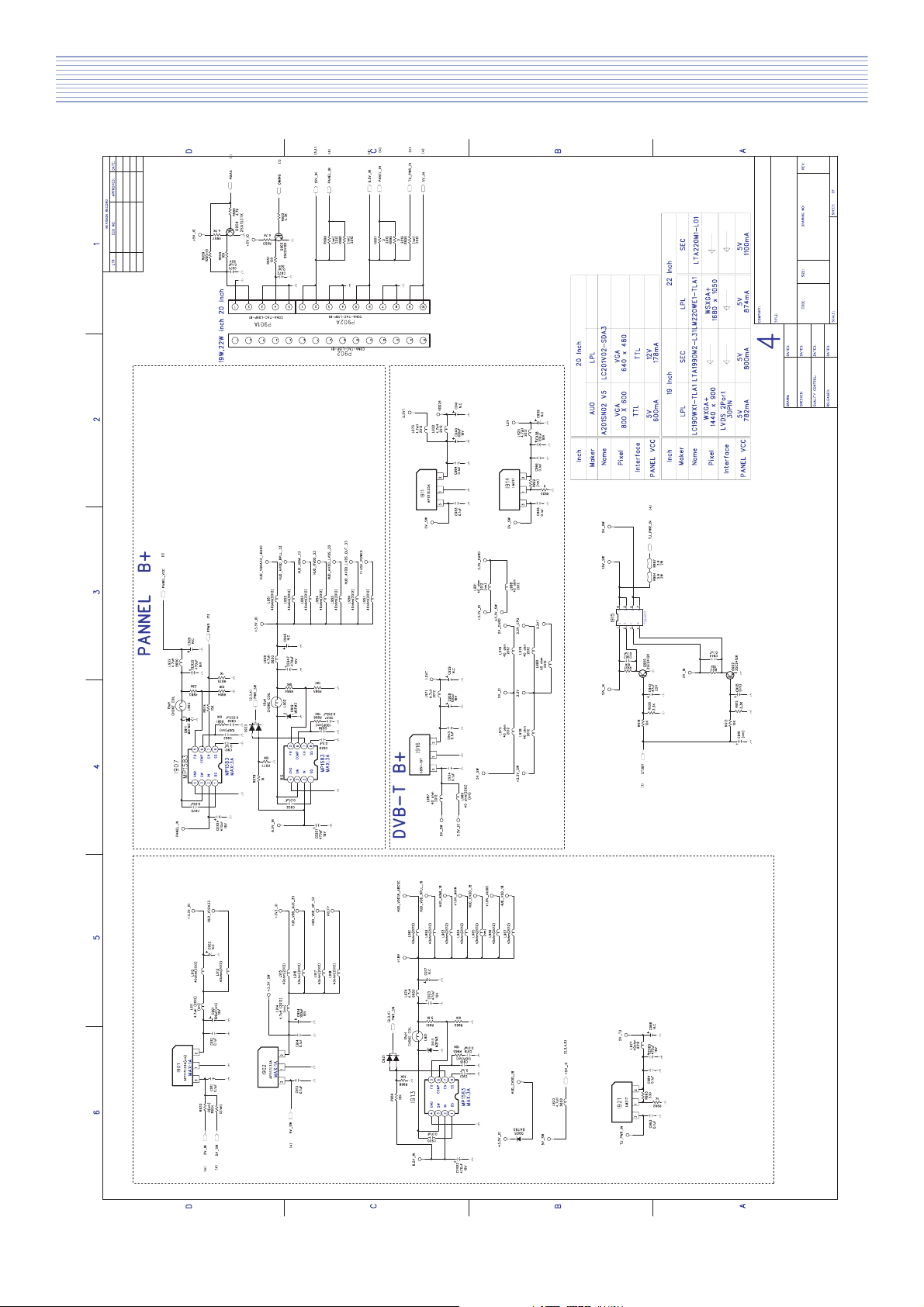

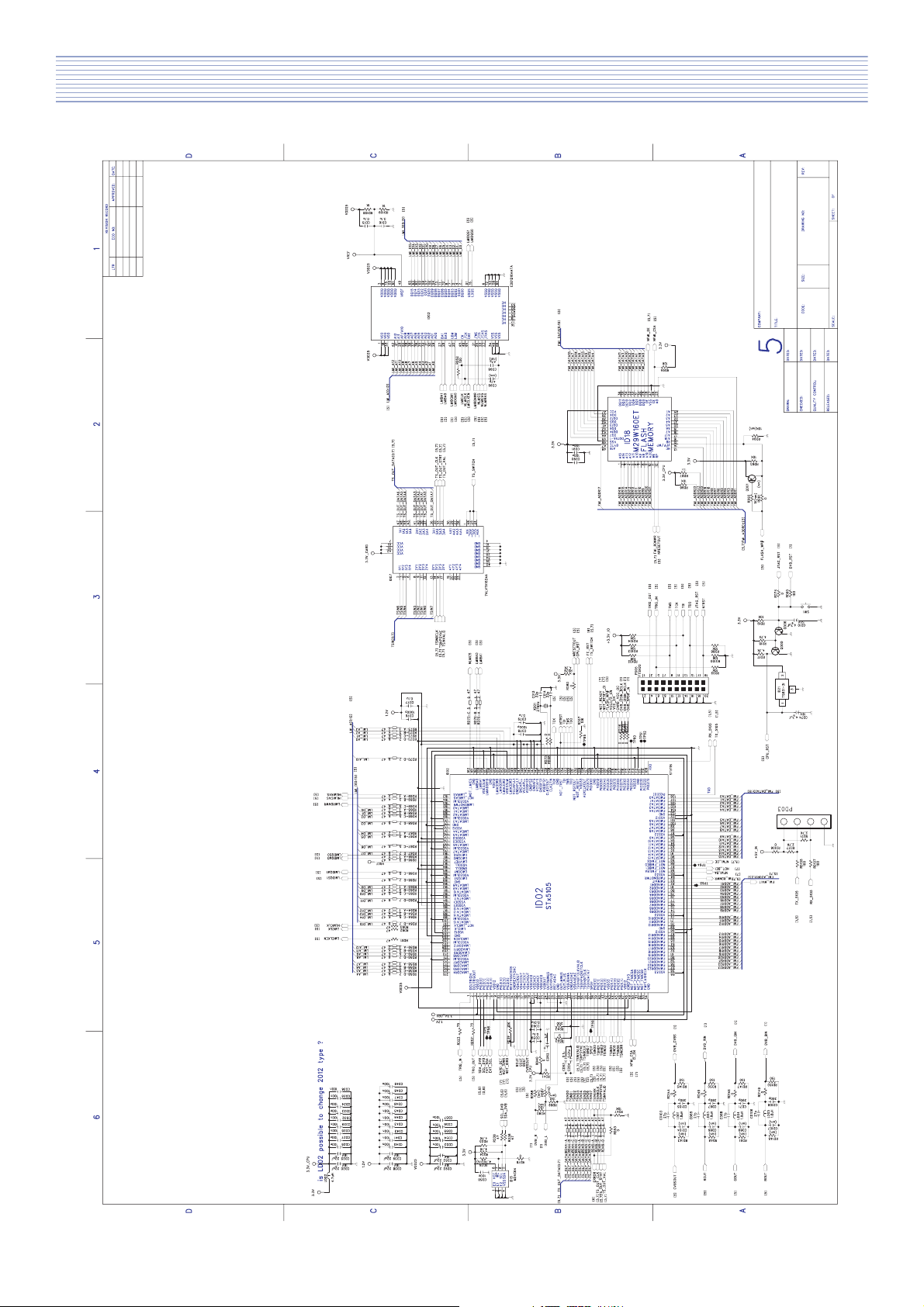

4. Schematic Diagram (DLT-19W4, DLT-22W4)

6

Page 8

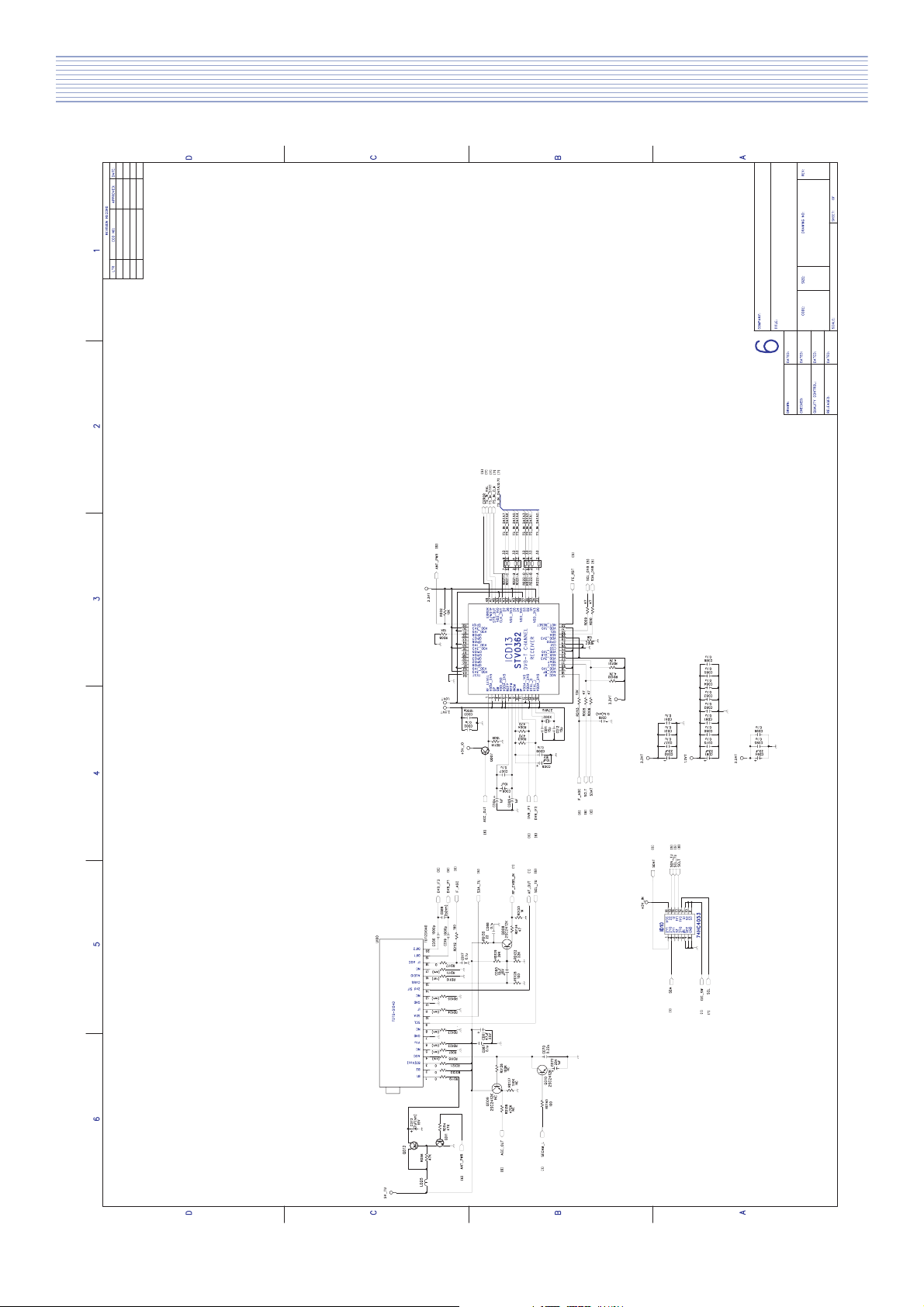

Schematic Diagram (DLT-20J1, DLT-20J3)

7

Page 9

Schematic Diagram

8

Page 10

Schematic Diagram

9

Page 11

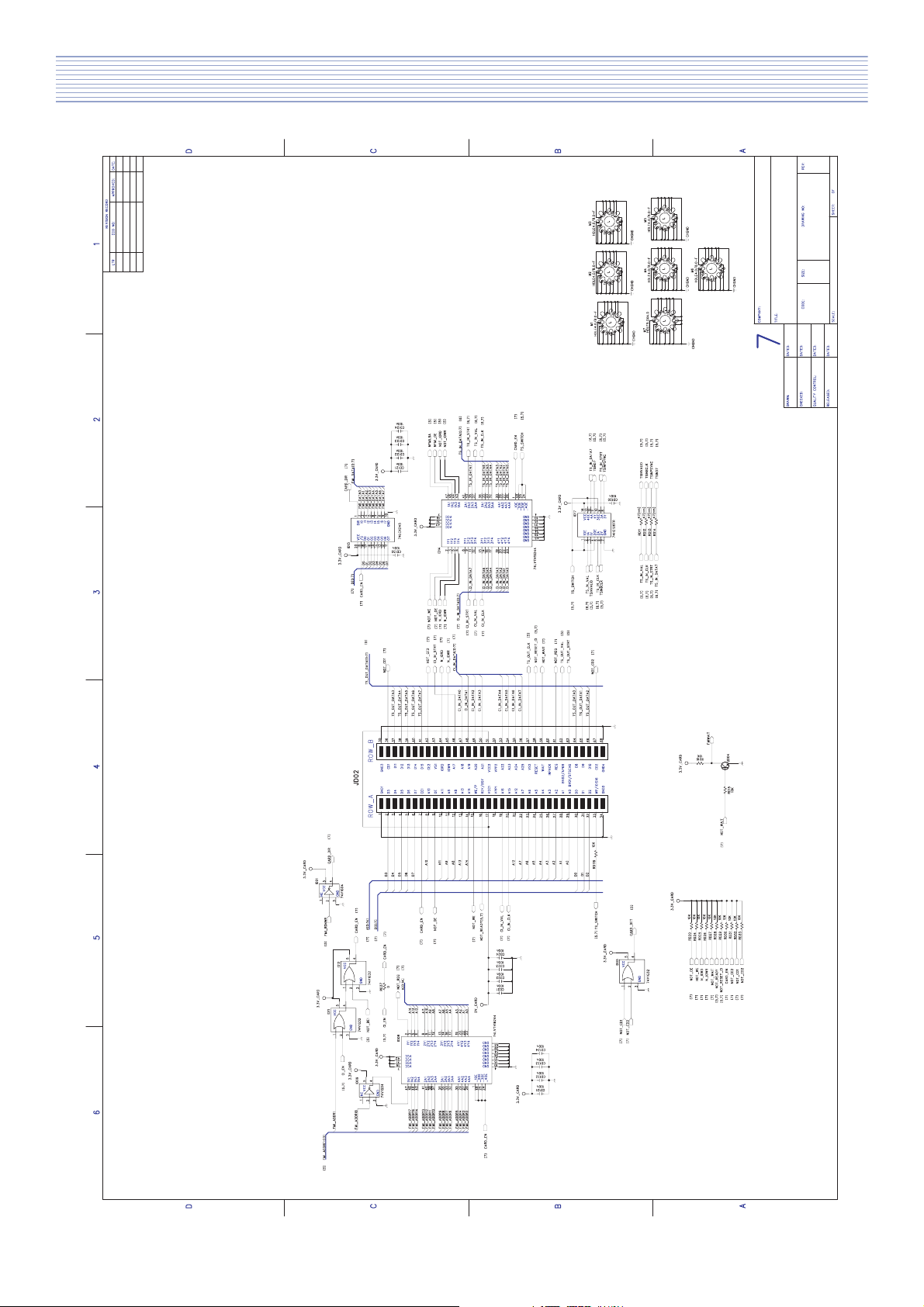

Schematic Diagram

10

Page 12

Schematic Diagram

This page can be used only for DLT models

11

Page 13

Schematic Diagram

12

Page 14

Schematic Diagram

13

Page 15

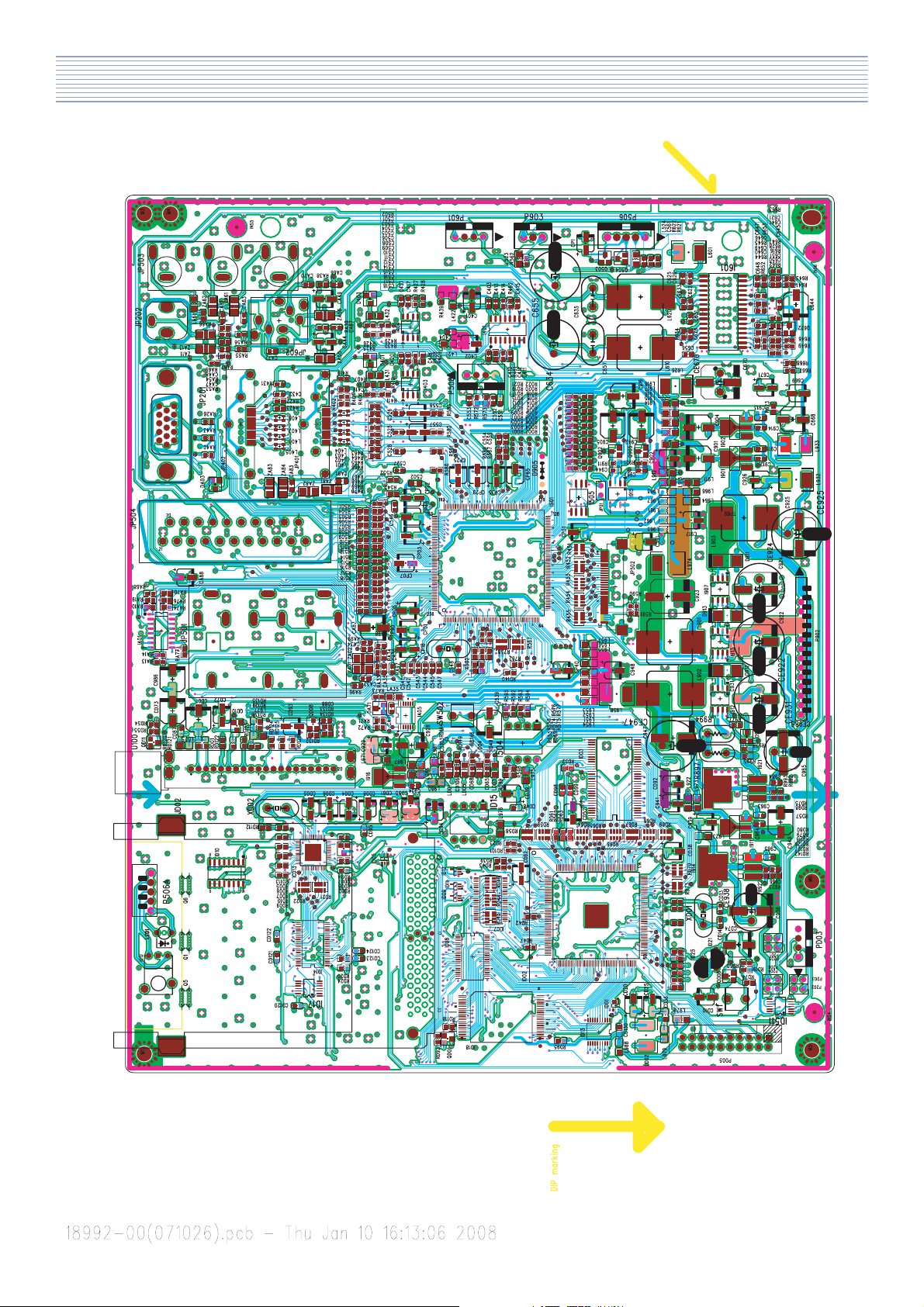

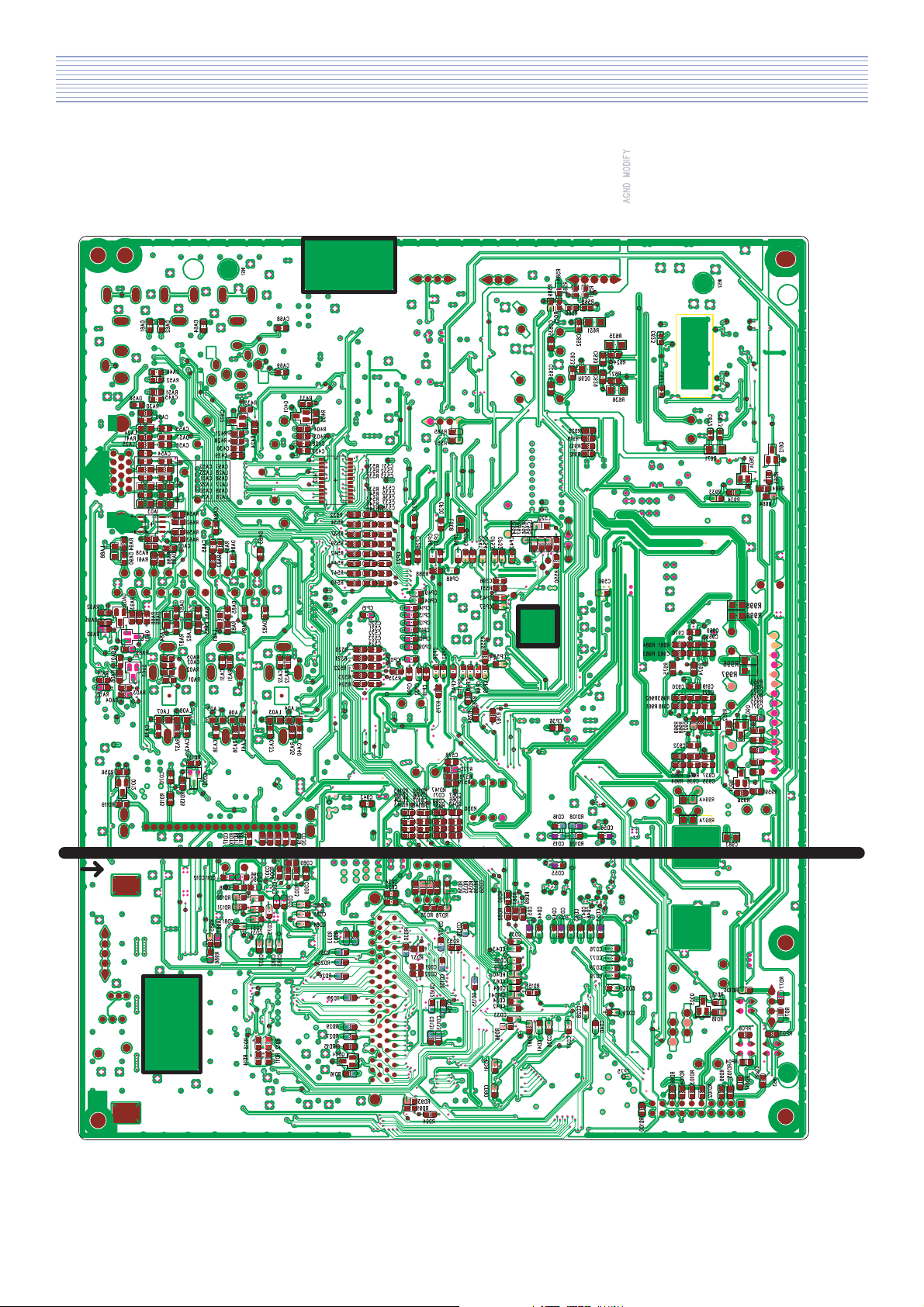

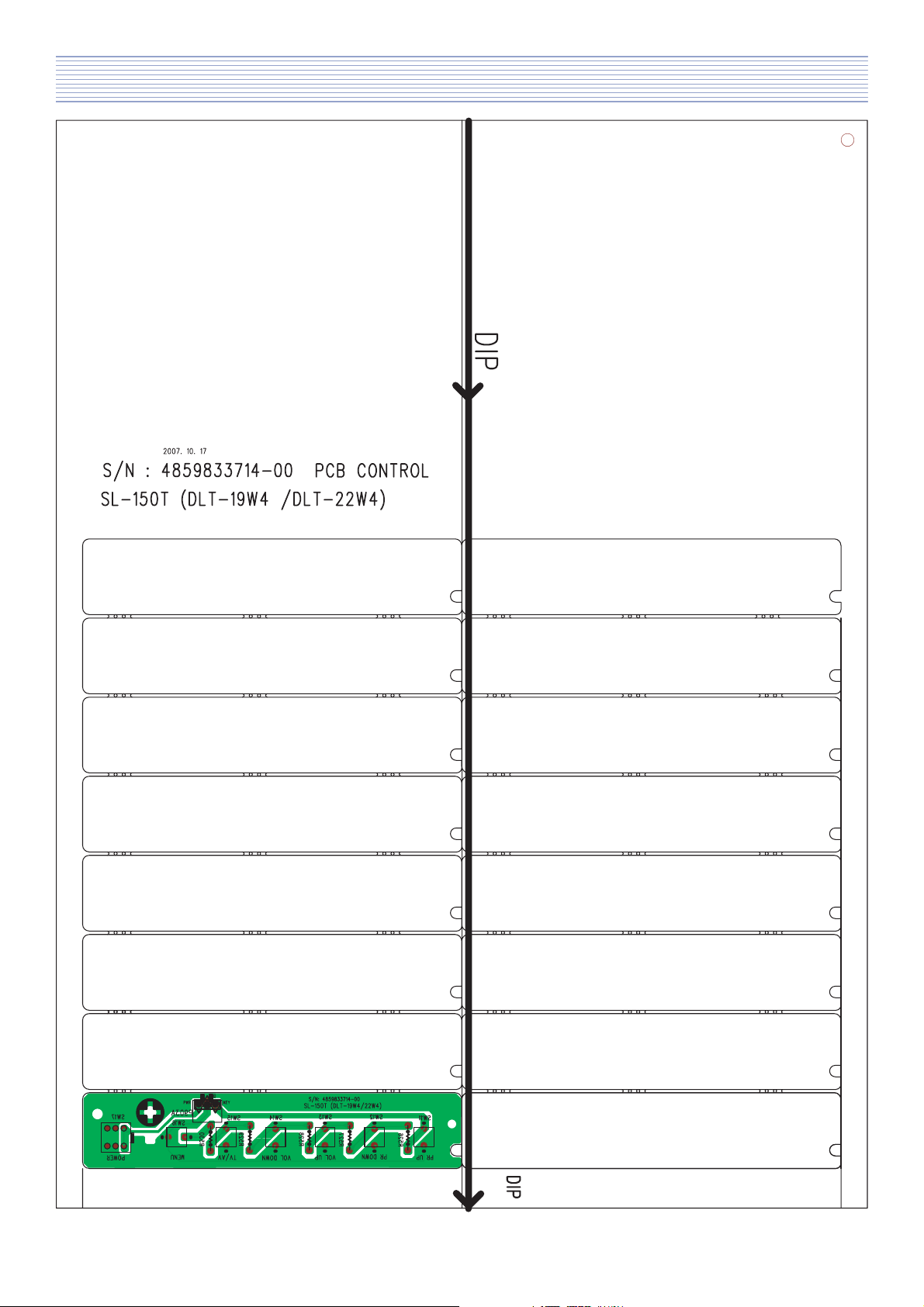

5. PCB Data (DLT-19W4, DLT-22W4 - TOP)

14

Page 16

PCB Data (DLT-19W4, DLT-22W4 - BOTTOM)

15

Page 17

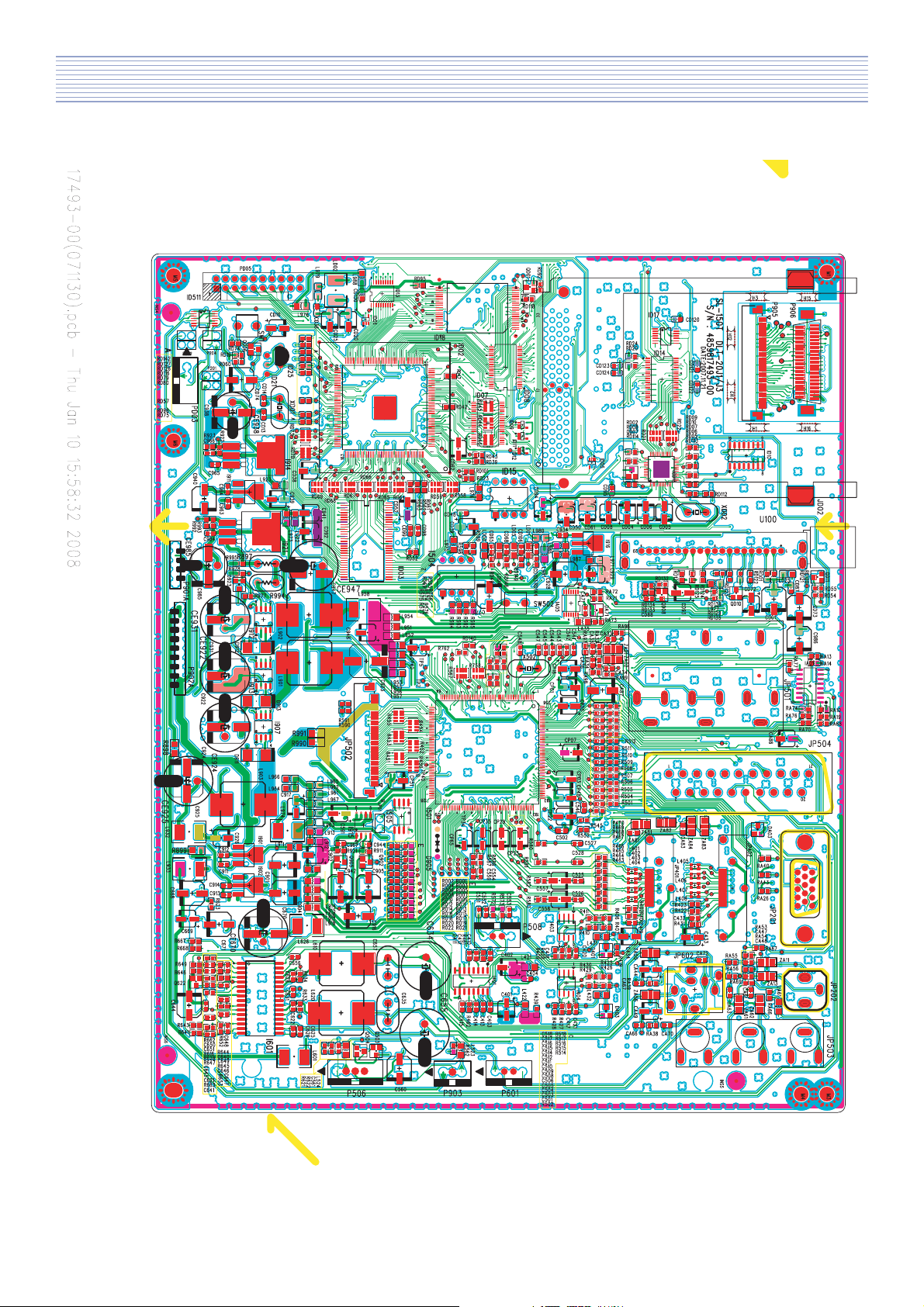

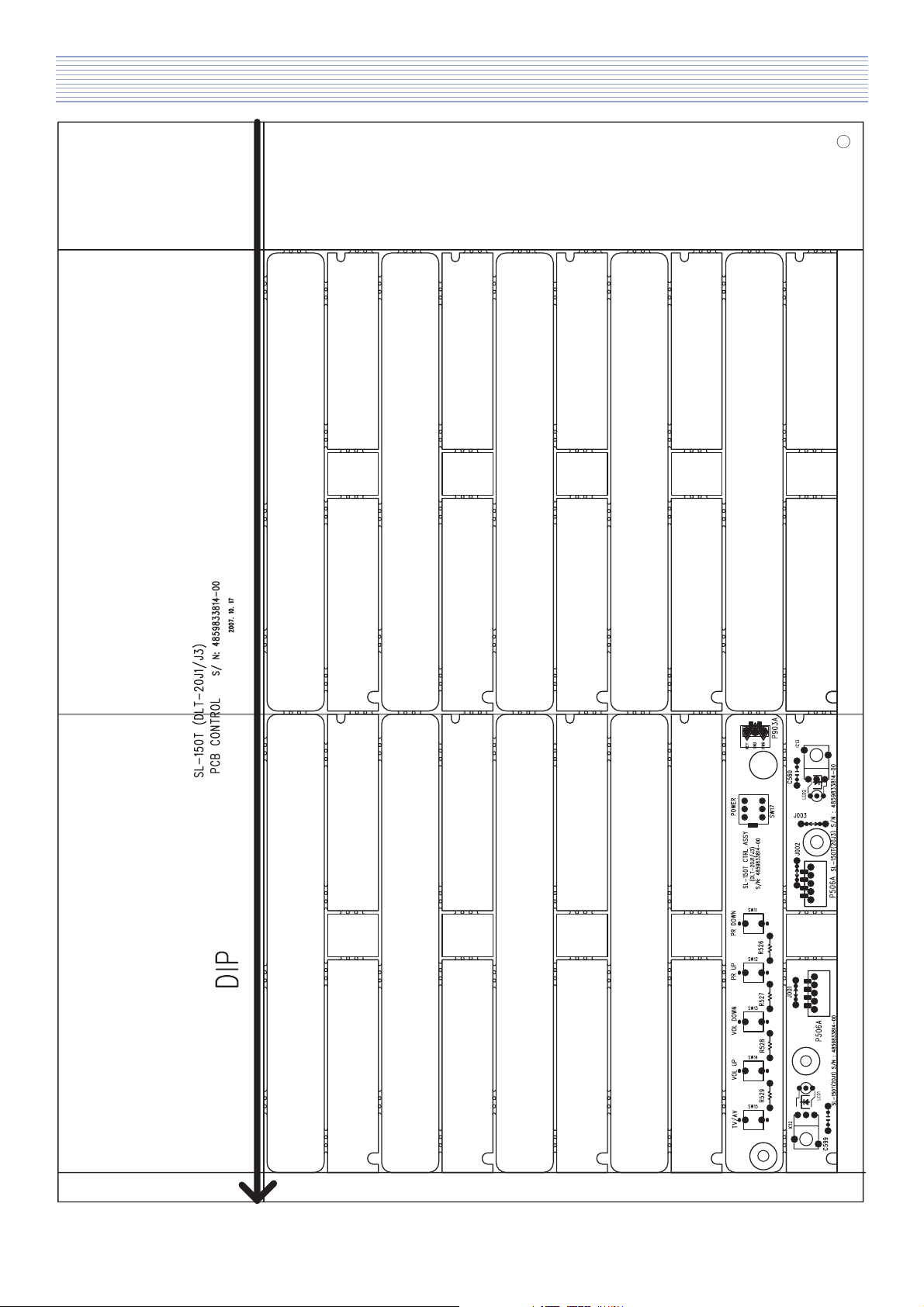

PCB Data (DLT-20J1, DLT-20J3 - TOP)

16

Page 18

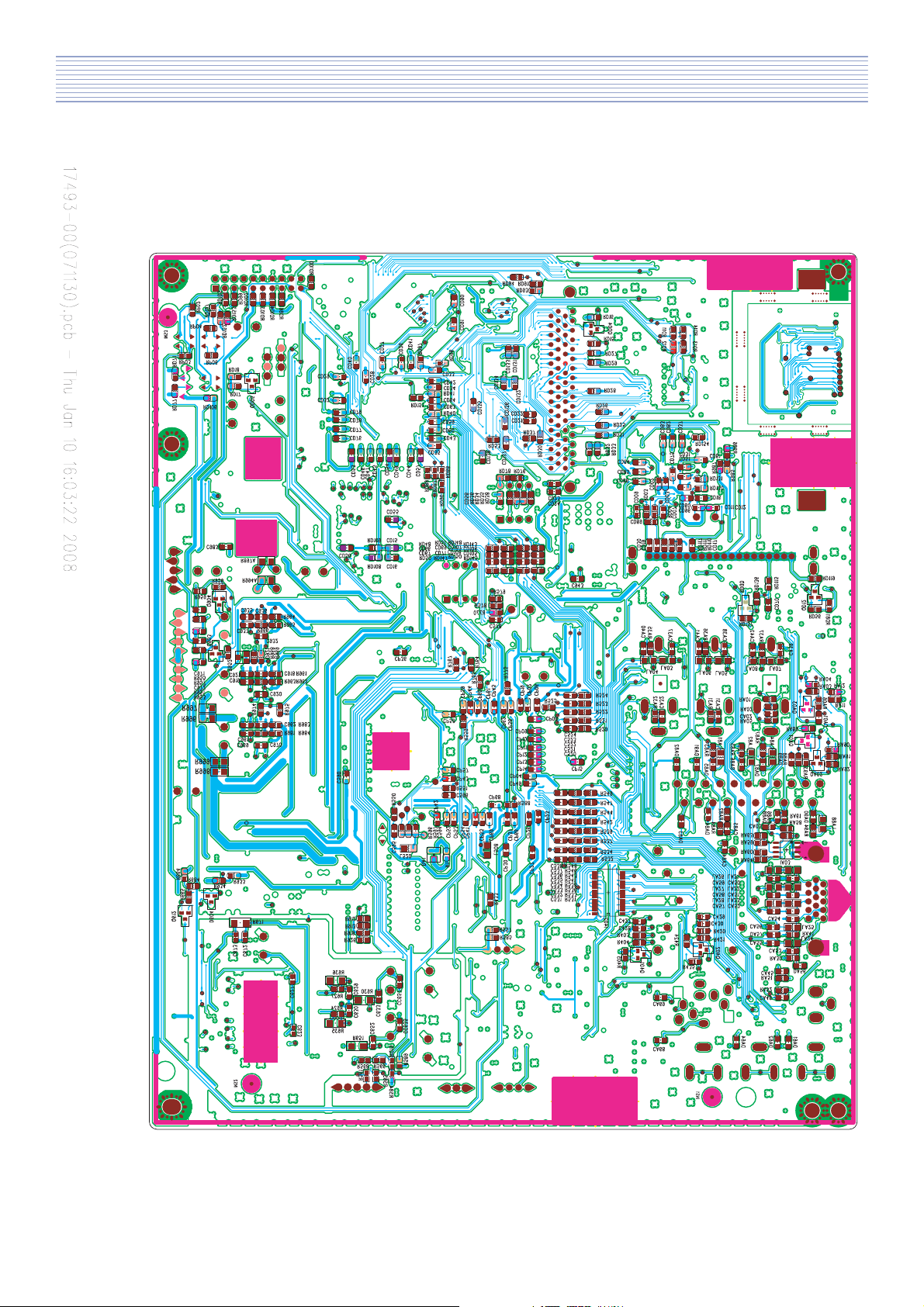

PCB Data (DLT-20J1, DLT-20J3 - BOTTOM)

17

Page 19

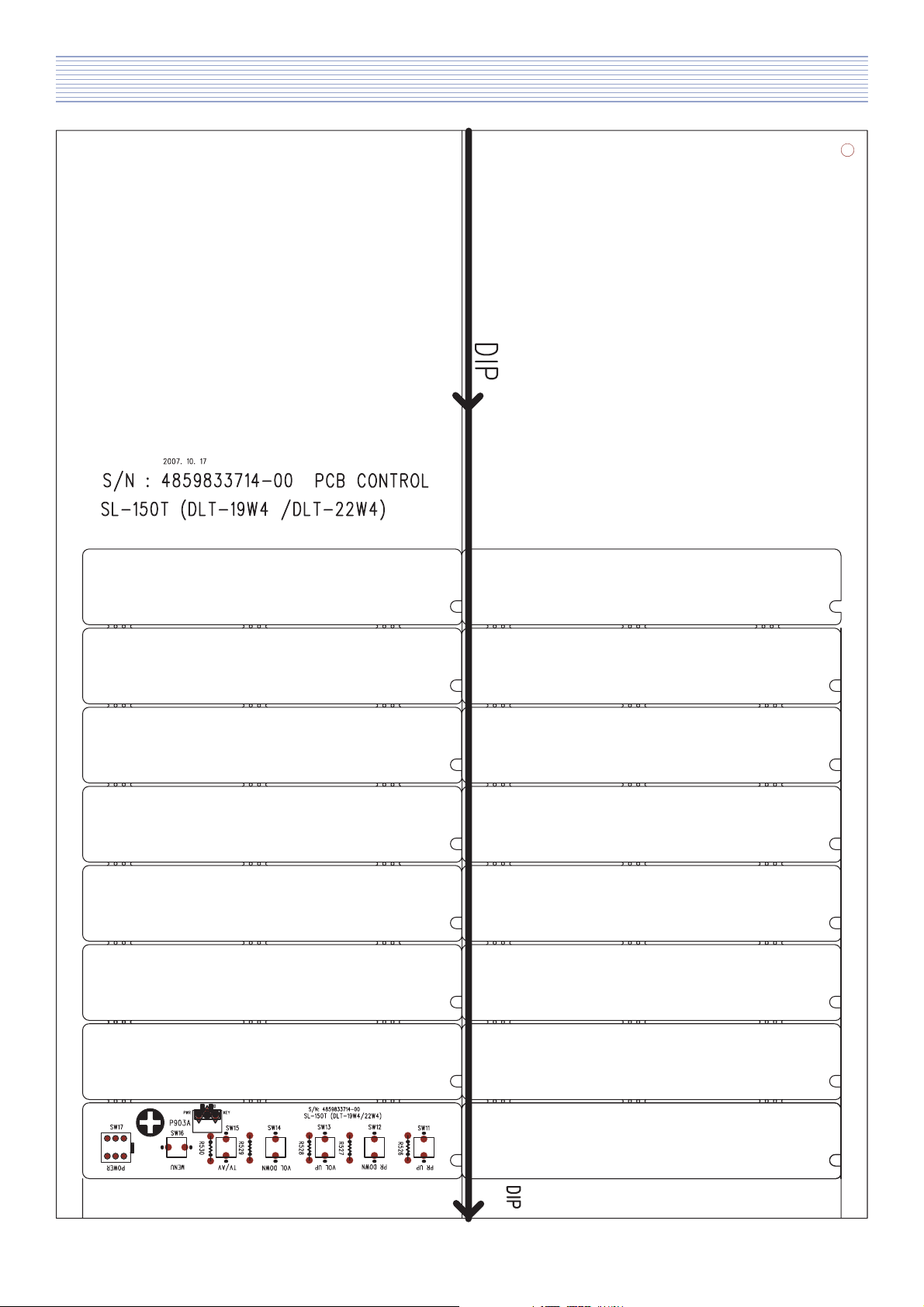

PCB Data (DLT-19W4, DLT-22W4 - Control PCB - TOP)

18

Page 20

PCB Data (DLT-19W4, DLT-22W4 - Control PCB - BOTTOM)

19

Page 21

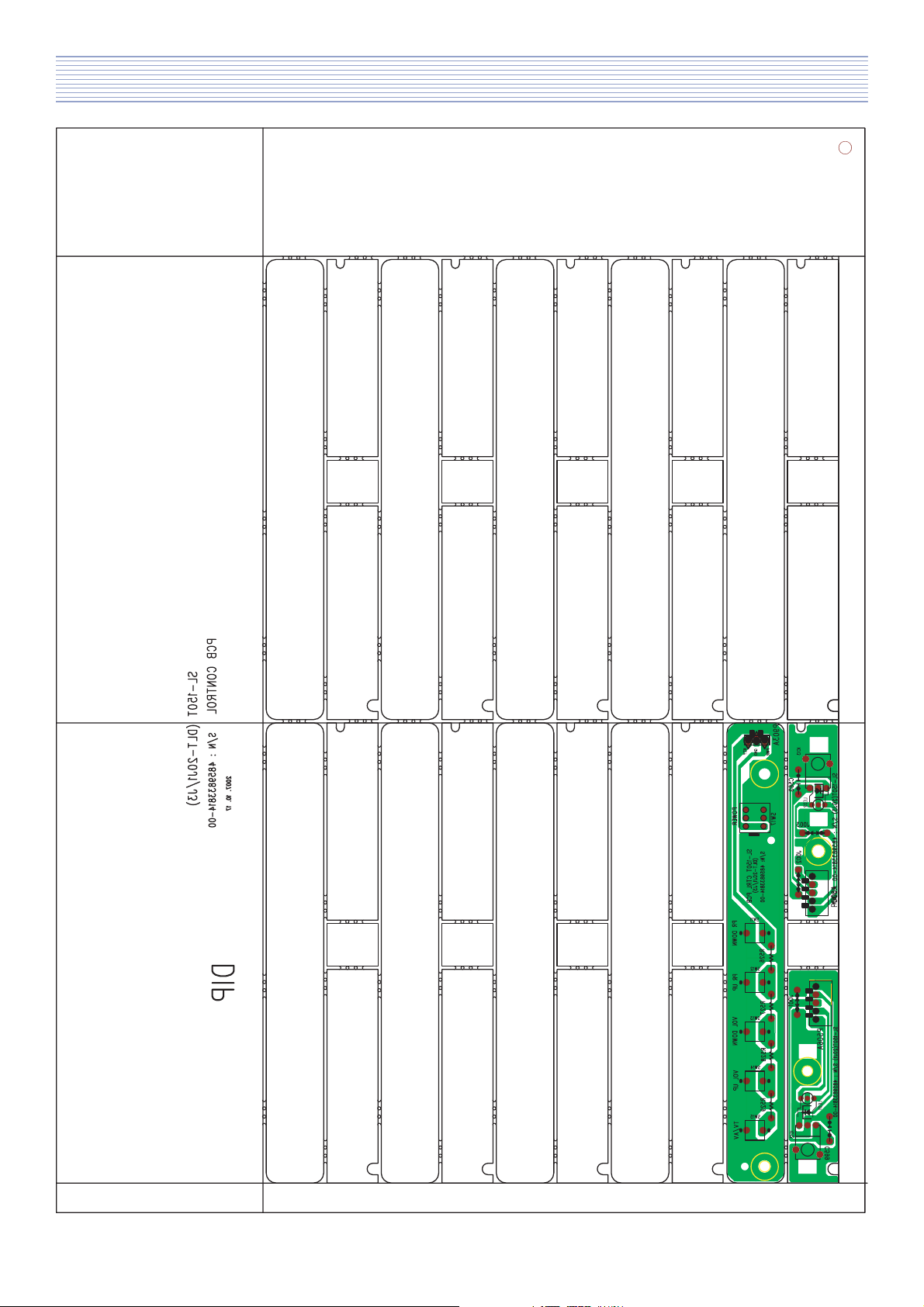

PCB Data (DLT-20J1, DLT-20J3 - Control PCB - TOP )

20

Page 22

PCB Data (DLT-20J1, DLT-20J3 - Control PCB - BOTTOM)

21

Page 23

6. Trouble Shooting

* Facts you must know at trouble diagnosis or repairing

(1) The trouble diagnosis and repairing of set means Module .

In other words, find out which PCB modules are not working and replace them with normal PCB

modules.

(2) This TROUBLE SHOOTING list only contains representative and simple PCB trouble diagnosis and

Module Exchange method. Therefore, if you find Sets which are difficult to diagnose or to repair,

contact Daewoo Electronics.

(3) Basic TROUBLE SHOOTING procedure :

Check Trouble Symptoms Detach Back Cover Trouble Diagnosis Replace broken PCB module

Adjust ADC Function Check Repair Complete.

(4) Required equipments for trouble diagnosis

- Digital Multi-meter (measure Dc voltage, measure Diode Voltage, Short-Open test)

- Screwdriver (or electric screwdriver), plastic adjusting tool

(5) Before assemble/disassemble PCBs, check to see if AC Switch is OFF.

(6) After Back cover is closed, redo Heat-run for at least one hour by inputting Full white pattern.

Symptoms of power, inverter, panel Trouble

<Symptom.1> Not even weak discharge (luminescence) shows on screen.

<Symptom.2> Discharge (luminescence) on screen is unstable

<Symptom.3> Set is producing unusual noise Symptoms of VIDEO or JACK PCB Trouble

<Symptom.1> Only weak discharge (luminescence) shows on screen, but No Data is on screen

<Symptom.2> Screen DATA is abnormal

<Symptom.3> Particular input signal (Video, etc.) does not operate

<Symptom.4> No SOUND

<Symptom.5> Remote Control or KEY does not operate

22

Page 24

Trouble Shooting

6-1. When LED doesn’t lit.

Check start

Y

Is the AC power cord

correctly connected?

Y

Is power S/W ON?

Y

N

N

Confirm power cord

connection.

Confirm Power S/W ON.

Is output voltage of

Power LIPS correct?

Y

Check the Main PCB.

N

23

Check the power connection.

Exchange the power LIPS.

Page 25

Trouble Shooting

6-2. When TV doesn’t turn on in red LED.

Check start

Y

Does TV turn on

pushing the CH key?

Y

Check the connection to IR PCB.

Check the operation of Remote

Controller.

N

6-3. When “white screen”.

Check start

Y

Is output voltage of

Power module correct?

(or LIPS)

Y

Confirm Power S/W ON.

N

Check the power connection.

Exchange the Power module.

Is correctly

connected?

Y

Is normal?

Y

Check the connector or Main PCB

N

N

Check the connection

Of Panel

Check the Main PCB

24

Page 26

Trouble Shooting

6-4. When “No picture” in TV mode.

Check start

Y

Does LED turn on in

GREEN?

Y

Does raster appear?

Y

Does auto - tuning

Function operate

normally?

N

N

Go to chap 7 - 2

Is this weak discharge

On the screen?

Y

Check I501

Confirm AC connection.

N

Confirm Power SW ON.

Check the power,

Inverter and panel

Y

Tune the channel

Check the tuner

N

25

Page 27

Trouble Shooting

6-5. When “No picture” in External input mode.

Check start

Y

Does OSD menu

Screen appear?

Y

Is the signal jack

Correctly connected?

Y

Does input source

operate?

Y

Confirm AC connection.

N

N

N

Is this weak discharge

On the screen?

Check the

Connection of Jack

Operate AV device

N

Y

Confirm Power SW ON.

Check the power,

Inverter and panel

Go to 7 - 4

Is input selection

In used mode?

Y

Check the main PCB

and sub - JACK PCB

N

Confirm input selection

26

Page 28

Trouble Shooting

6-6. When No Sound in External input mode.

Check start

Y

Does Screen appear?

Y

Is the sound input jack

Correctly connected?

Y

Is the speaker jack

Correctly connected?

N

N

Connection of sound Jack

N

Connection of speaker

Go to 7-5

Check the

Check the

Y

Is the I601 output

Normal?

Y

Exchange speaker or

speak cable

N

27

Check the AUDIO AMP(I601)

And I501

Page 29

Trouble Shooting

6-7. When Key does not operate.

Check start

Y

Does remote

Controller operate?

Y

Is 2th PIN of P903A

Correctly operate?

Y

Check Key cable and I501

N

N

Check the I501

Exchange Key PCB

28

Page 30

Trouble Shooting

6-8. When Remote Controller does not operate.

Check start

Y

Does input of key

operate?

Y

Does remote

Controller operate?

Y

Whenever push the button of

Remote controller, does the 2nd pin

Of P506A output normal?

Y

N

N

N

Check the I501

Check the battery of

remote controller

Exchange the Key PCB

Check IR cable and I501

Output of 2nd pin of P501A (IR) : PCB for Remote Control EX) Push “PR DOWN” button.

29

Page 31

7. Service part list (DLT-19W4)

LOC PART CODE

ZZ110 PTACPWG105

10 4850Q00910

20 7178301251

M382A 7172401452

M382B DMP2505200

M821 4858213801

ZZ100 48B5655H1101

ZZ120 PTBCSHG105

M211 4852181401

M211A 4857823900

M211B 4857823900

M321 4853298800

ZZ130 PTPKCPG105B

M191 485819E500

M212 485218151101

M212A 4852716201

M382 485383321101

M801 DMP5030700

M822 DMP2504300

ZZ140 PTCACAG108B

M191 4851959800

M191A 7172401452

M211B 2TF01612CL

M351 4853535500

M361 4853636301

M362 485363530101

M362A 7178301052

M381C 4956800200

M381D 7172401252

M381E 7008300651

M381F 4856815910

P502A 4859000260

PWC1 48599DL002

V901 485LD16191

ZZ200 PTFMSJG105B

PART NAME PART DESCRIPTION

ACCESSORY AS DLT-19W4LMBSCF

BATTERY AAA R03 SUPERGARD/ROCKET

SCREW TAPPTITE TT2 WAS 3X12 MFZN 3CR

SCREW TAPPTITE TT2 TRS 4X14 MFZN BK 3CR

BAG P.E. P.E 40X60 DLT-19/22W4

BAG INSTRUC-

L. D. P. E. T0. 05X250X400

TION

TRANSMITTER

R-55H11 (AAA)

REMOCON

COVER BACK AS DLT-19W4LMBSCF

COVER BACK 19W4 HIPS BK

CLOTH BLACK FELT 240X12XT1.0

CLOTH BLACK FELT 240X12XT1.0

BRKT VESA 19/22W4 SECC T=1.0

PACKING AS

DLT-19W4SMB-CF

PACKING

PAD 19W4 EPS

COVER STAND

19/22W4 HIPS BK9604BP

BASE

LEG BOTTOM CR (14V5)

FRAME STAND 19/22W4 HIPS BK9604

BOX DLT-19W4TB

BAG P.E. PE FOAM T0.5X700X650

CABINET AS AS-

DLT-19W4SMB-CF

SEMBLY

HINGE AS 19/22W4

SCREW TAPPTITE TT2 TRS 4X14 MFZN BK 3CR

TAPE FILAMENT 12MMX55ME CLEAR

HOLDER AC

14A5 NYLON66 UL/CSA

CORD

TERMINAL JACK 19/22W4 HIPS BK

TERMINAL COVER HIPS BK

SCREW TAPPTITE TT2 WAS 3X10 MFZN BK 3CR

CLAMP WIRE WS-A-2-19

SCREW TAPPTITE TT2 TRS 4X12 MFZN BK 3CR

SCREW MACHINE WAS 3X6 MFZN 3CR

CLAMP WIRE EGI T0.4+TUBE+PIE 4.2

CABLE LVDS FMW1214A-31+FH10001-

30+UL1571#30=250MM

CORD POWER W/F 6-LO (LOMAX) YH396-43V

LCD PANEL LTM190M2-L31

MASK FRONT AS DLT-19W4SMB-CF

LOC PART CODE

M201 4852098411

M201A 4857818506

M201D 2233039604

M201E 48558000A02T

M561 48556192SD02

M591 485594900001

ZZ210 PTSPPWG105

P601A 4850704S41

SP01 4858319910

SP01A 4853956801

SP01B 7178301051

SP01C 4857818705

SP01D 4857818705

SP02 4858319910

SP02A 4853956801

SP02B 7178301051

SP02C 4857818705

SP02D 4857818705

ZZ280 PTCTMSG105

M231 4852335301

M481 4854873411

M491 4854965611

M491A 7178301051

P903A 4850703S70

SW17 5S40101009

ZZ200 PTCTJRG105

SW11 5S50101Z90

SW12 5S50101Z90

SW13 5S50101Z90

SW14 5S50101Z90

SW15 5S50101Z90

SW16 5S50101Z90

ZZ200 PTCTJAG105

A002 4859833714

R526 RD-AZ102J-

R527 RD-AZ122J-

R528 RD-AZ202J-

R529 RD-AZ332J-

R530 RD-AZ822J-

ZZ290 PTMPMSG108

10 2193110032

20 2193011612

30 2291050620

40 2291050314

C634 CEXF1E471V

PART NAME PART DESCRIPTION

MASK FRONT 19W4 HIPS BK

CLOTH BLACK CLOTH 240X8XT0.5

PAINT WATER BK9604BP CETELON

LABEL POP GLOSSY PET

MARK BRAND DAEWOO 68MM (20”21”)

DECO PLATE 19W4 PC T2.0

SPEAKER AS DLT-19W4LMBSCF

CONNECTOR YH025-04+YRT205+ULW=300

SPEAKER SP-5090F24C

BRKT SPKR 19/22W4 HIPS BK

SCREW TAPPTITE TT2 WAS 3X10 MFZN 3CR

CLOTH BLACK FELT T0.7 L=110 W=15

CLOTH BLACK FELT T0.7 L=110 W=15

SPEAKER SP-5090F24C

BRKT SPKR 19/22W4 HIPS BK

SCREW TAPPTITE TT2 WAS 3X10 MFZN 3CR

CLOTH BLACK FELT T0.7 L=110 W=15

CLOTH BLACK FELT T0.7 L=110 W=15

PCB CTRL

DLT-19W4LMBSCF

MANUAL AS

PANEL CTRL 19/22W4 HIPS BK

BUTTON POWER 19/22W4 ABS

GY340A+SV2405BP

BUTTON CH 19/22W4 ABS

GY340A+SV2405BP

SCREW TAPPTITE TT2 WAS 3X10 MFZN 3CR

CONNECTOR YH025-03+YBH250-

03+ULW=400

SW PUSH PS-22E06

PCB CTRL RADIAL ASDLT-19W4LMBSCF

SW TACT SKHV10910A

SW TACT SKHV10910A

SW TACT SKHV10910A

SW TACT SKHV10910A

SW TACT SKHV10910A

SW TACT SKHV10910A

PCB CTRL AXIAL ASDLT-19W4LMBSCF

PCB CONTROL SL-150T 115X23(246X330/

2X8)D1B

R CARBON FILM 1/6 1K OHM J

R CARBON FILM 1/6 1.2K OHM J

R CARBON FILM 1/6 2K OHM J

R CARBON FILM 1/6 3.3K OHM J

R CARBON FILM 1/6 8.2K OHM J

PCB MAIN

DLT-19W4SMBSCF

MANUAL AS

SOLDER WIRE SP001 PHI 3.0MM (LFCO-W3.0)

SOLDER WIRE LFC-107 (1.6MM)

FLUX SOLDER DF-2810U (0.810)

FLUX SOLVENT IM-1000

C ELECTRO 25V RSS 470MF (10X16) TP

30

Page 32

Service part list (DLT-19W4)

LOC PART CODE

C635

C655

C657

CE670

CE922

CE924

CE925

CE931

CE947

CE985

D905

I504

IC12

ID15

ID25

JD02

JP01

JP201

JP202

JP501

JP503

JP504

JP602

LED1

M381

M381A

M381B

P201

P202

P202A

P202B

P204

P204A

P204B

P506

P506A

P508

P601

P902A

P903

PD03

R897

R994

S101

S102

SW1

SW502

U100

V902

CMXL1J334J C MYLAR 63V 0.33MF J MEU TP

CEXF1E471V C ELECTRO 25V RSS 470MF (10X16) TP

CMXL1J334J C MYLAR 63V 0.33MF J MEU TP

CEXF1H221V C ELECTRO 50V RSS 220MF (10X16) TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

CEXF1C471V C ELECTRO 16V RSS 470MF (10X12.5)TP

DBAT85---- DIODE BAT85 (TAPPING)

1M24C32BN6 IC EEPROM M24C32WRNG

1R24FH1B-- IC PREAMP R24FH1B

14C64WBN6- IC EEPROM M24C64-WBN6

1K1A7025AP IC RESET KIA7025AP

4859200440 CONN PCMCIA PC68PRA5513XZ

4859295520 CONN WAFER 4602-02MV2-60-1 PLUG 2P ST

4959200160 CONN D-SUB SHF-015-B111-22/BR2-J0.6

4959102340 JACK PHONE YKB21-5157

4859117750 JACK PIN TPSE-9612-6

4859112850 JACK PIN DPSS-0173 3PIN STR

4859112950 JACK SCART DSSM-0378 STR

97P6316100 JACK HEAD

DSPR39MVW- LED SPR-39MVW (DUAL)

4853833301 FRAME MAIN PCB 19W4 SECC T0.8 (SEC)

7178300852 SCREW TAPTITE TT2 WAS 3X8 MFZN BK 3CR

7178300852 SCREW TAPTITE TT2 WAS 3X8 MFZN BK 3CR

4859295420 CONN WAFER 4602-04MV2-1 PLUG 4P ST

4859295420 CONN WAFER 4602-04MV2-1 PLUG 4P ST

4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

4859295420 CONN WAFER 4602-04MV2-1 PLUG 4P ST

4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

4859295620 CONN WAFER 4602-2FV2-1 JUMPER 2P 2.54

4859231820 CONN WAFER Y W025-05

4850705S32 CONNECTOR YH025-05+YBH250-

485923172S CONN WAFER YW025-04 (STICK )

485923172S CONN WAFER YW025-04 (STICK )

4850715N09 CONNECTOR YH025-15+YBNH250-

4859231620 CONN WAFER Y W025-03

485923172S CONN WAFER YW025-04 (STICK )

RN02B399JS R METAL FILM 2W 3.9 OHM J SMALL

RN02B399JS R METAL FILM 2W 3.9 OHM J SMALL

485A115170 SHIELDRON 12X20X10(H)

485A115170 SHIELDRON 12X20X10(H)

5S50101Z90 SW TACT SKHV10910A

5S50101Z90 SW TACT SKHV10910A

4859732130 TUNER DIGITAL TDTG-S154D

485AS003PL POWER LIPS IPB-6012M01

PART NAME PART DESCRIPTION

DHSE-9959

PHONE

05+ULW=350

15+ULW=100

LOC PART CODE

PART NAME PART DESCRIPTION

X502 5XJX19R6JE CRYSTAL QUARTZ HC-49/S 19.6608MHZ 18PF

30PPM

XD01 5XJ27R00AC CRYSTAL QUARTZ HC-49/S 27.000MHZ 15PF

20PPM

XD02 5XJ27R00AC CRYSTAL QUARTZ HC-49/S 27.000MHZ 15PF

20PPM

ZZ200 PTMPJ2G105 PCB CHIP MOUNT

DLT-19W4LMBSCF

B AS

C520 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C521 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C522 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C523 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C524 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C531 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C532 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C533 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C534 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C535 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C536 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C537 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C538 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C578 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C590 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C594 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C623 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C627 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C629 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

C630 HCQK471JBA C CHIP CERA 50V CH 470PF J 1608

C633 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C652 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C672 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C673 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C919 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C920 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C921 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C932 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C935 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C937 HCBK153KBA C CHIP CERA 50V X7R 0.015MF K 1608

C943 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C961 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C969 HCBK223KBA C CHIP CERA 50V X7R 0.022MF K 1608

C970 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

C971 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C972 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C983 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA01 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA02 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CA03 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA31 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA32 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA37 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA38 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA39 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

31

Page 33

Service part list (DLT-19W4)

LOC PART CODE

CA40 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA41 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA42 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA45 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA46 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA50 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA51 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA52 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA53 HCQK470JBA C CHIP CERA 50V CH 47PF J 1608

CA54 HCQK470JBA C CHIP CERA 50V CH 47PF J 1608

CA55 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA56 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA57 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA58 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA59 HCQK120JBA C CHIP CERA 50V CH 12PF J 1608

CA68 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA69 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA84 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD02 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD03 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD07 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD09 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD105 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CD108 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CD11 HCQK150JBA C CHIP CERA 50V CH 15PF J 1608

CD12 HCQK150JBA C CHIP CERA 50V CH 15PF J 1608

CD131 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD132 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD133 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD134 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD135 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD136 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD137 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD138 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD15 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD16 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD17 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD19 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD21 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD22 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD23 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD24 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD26 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD27 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD28 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD29 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD30 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD31 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD32 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD33 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD34 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD35 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

PART NAME PART DESCRIPTION

LOC PART CODE

CD37 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD40 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD41 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD42 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD43 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD44 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD45 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD46 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD47 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD49 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD51 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD53 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD54 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD55 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD56 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD57 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD58 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD59 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD60 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CD63 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD64 HCBK103KBA C CHIP CERA 50V X7R 0.01MF K 1608

CD67 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CD70 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

CD71 HCQK391JBA C CHIP CERA 50V CH 390PF J 1608

CD75 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD76 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD77 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD78 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CD79 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD80 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD81 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD82 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD83 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD84 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD85 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD86 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD90 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD91 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD96 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP02 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP04 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP06 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP08 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP09 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP10 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP11 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP12 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP13 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP14 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP15 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP19 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP23 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

PART NAME PART DESCRIPTION

32

Page 34

Service part list (DLT-19W4)

LOC PART CODE

R550 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R551 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R557 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R559 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R561 HRFT181JBA R CHIP 1/10 180 OHM J 1608

R566 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R568 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R584 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R585 HRFT272JBA R CHIP 1/10 2.7K OHM J 1608

R588 HRT2490FBA R CHIP 1/10 249 OHM F 1608

R596 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R597 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R630 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

R635 HRF4100JEA R CHIP 1/4W 10 OHM J 3216

R636 HRF4100JEA R CHIP 1/4W 10 OHM J 3216

R651 HRF4220JEA R CHIP 1/4W 22 OHM J 3216

R665 HRFT223JBA R CHIP 1/10 22K OHM J 1608

R671 HRF4100JEA R CHIP 1/4W 10 OHM J 3216

R684 HRFT153JBA R CHIP 1/10 15K OHM J 1608

R764 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R770 HRFT752JBA R CHIP 1/10 7.5K OHM J 1608

R912 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R913 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R919 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R926 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

R934 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R951 HRFT104JBA R CHIP 1/10 100K OHM J 1608

R952 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R953 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R955 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R956 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R957 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

R961 HRFT512JBA R CHIP 1/10 5.1K OHM J 1608

R962 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R963 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R964 HRFT183JBA R CHIP 1/10 18K OHM J 1608

R965 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R966 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R968 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R969 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R974 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R975 HRFT102JBA R CHIP 1/10 1K OHM J 1608

R981 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R983 HRFT333JBA R CHIP 1/10 33K OHM J 1608

R984 HRFT103JBA R CHIP 1/10 10K OHM J 1608

R985 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R996 HRFT000-CA R CHIP 1/10 0 OHM 2012

R997 HRFT000-CA R CHIP 1/10 0 OHM 2012

RA01 HRFT221JBA R CHIP 1/10 220 OHM J 1608

RA02 HRFT121JBA R CHIP 1/10 120 OHM J 1608

RA03 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RA04 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

PART NAME PART DESCRIPTION

LOC PART CODE

RA05 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RA06 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RA30 HRFT511JBA R CHIP 1/10 510 OHM J 1608

RA31 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RA32 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RA35 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA36 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA37 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA41 HRFT511JBA R CHIP 1/10 510 OHM J 1608

RA51 HRFT224JBA R CHIP 1/10 220K OHM J 1608

RA52 HRFT224JBA R CHIP 1/10 220K OHM J 1608

RA59 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

RA60 HRFT332JBA R CHIP 1/10 3.3K OHM J 1608

RA61 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RA63 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RA64 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RA82 HRFT303JBA R CHIP 1/10 30K OHM J 1608

RA83 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA84 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RA85 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA86 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA87 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA88 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA89 HRFT122JBA R CHIP 1/10 1.2K OHM J 1608

RA90 HRFT393JBA R CHIP 1/10 39K OHM J 1608

RA91 HRFT223JBA R CHIP 1/10 22K OHM J 1608

RA92 HRFT681JBA R CHIP 1/10 680 OHM J 1608

RA93 HRFT681JBA R CHIP 1/10 680 OHM J 1608

RA94 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RD03 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RD04 HRFT471JBA R CHIP 1/10 470 OHM J 1608

RD100 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD102 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD103 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD104 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD105 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RD106 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD107 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RD108 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RD109 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RD117 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD119 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD130 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD131 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD145 HRFT151JBA R CHIP 1/10 150 OHM J 1608

RD147 HRFT151JBA R CHIP 1/10 150 OHM J 1608

RD15 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD150 HRFT151JBA R CHIP 1/10 150 OHM J 1608

RD16 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD17 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD18 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD25 HRFT103JBA R CHIP 1/10 10K OHM J 1608

PART NAME PART DESCRIPTION

33

Page 35

Service part list (DLT-19W4)

LOC PART CODE

RD26 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD27 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD28 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD29 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD30 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD31 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD32 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD33 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD34 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD35 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD36 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD37 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD38 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD40 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD41 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD50 HRFT151JBA R CHIP 1/10 150 OHM J 1608

RD53 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD56 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RD76 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD91 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD93 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD96 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD97 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD99 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RQ15 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

ZZ200 PTMPJ1G105 PCB CHIP MOUNT

100 2193220009 SOLDER CREAM PJ790-G0061

A001 4859818992 PCB MAIN SL-150T 234X189 K4V (WIDE)

C402 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

C403 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C404 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C420 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C501 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C502 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C503 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C504 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C505 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C506 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C508 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C509 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C510 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C511 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C512 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C514 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C515 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C516 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C517 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C518 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C541 HCFK103ZBA C CHIP CERA 50V Y5V 0.01MF Z 1608

C542 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C543 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

PART NAME PART DESCRIPTION

DLT-19W4LMBSCF

A AS

LOC PART CODE

C544 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C545 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C547 HCQK180JBA C CHIP CERA 50V CH 18PF J 1608

C548 HCQK180JBA C CHIP CERA 50V CH 18PF J 1608

C551 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C557 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

C558 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

C561 HCQK221JBA C CHIP CERA 50V CH 220PF J 1608

C591 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

C621 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C622 HCBK153KBA C CHIP CERA 50V X7R 0.015MF K 1608

C625 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C626 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C628 HCBK153KBA C CHIP CERA 50V X7R 0.015MF K 1608

C631 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C640 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C641 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C644 HCEEF101MC C CHIP ELECTRO MV 16V 100MF 6.3DX5.7H

C645 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C646 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C647 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C648 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

C649 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C650 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C651 HCBF224KBA C CHIP CERA 16V X7R 0.22MF K 1608

C656 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C668 HCEJF470MC C CHIP ELECTRO 16V 47MF CS 6352

C671 HCELH100MC C CHIP ELECTRO 25V 10MF CM 4052

C904 HCEEF101MC C CHIP ELECTRO MV 16V 100MF 6.3DX5.7H

C911 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C912 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C913 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C914 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C923 HCELF471ME C CHIP ELECTRO 16V 470MF CM 8010

C928 HCEEF101MC C CHIP ELECTRO MV 16V 100MF 6.3DX5.7H

C934 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C938 HCEEF101MC C CHIP ELECTRO MV 16V 100MF 6.3DX5.7H

C940 HCEEF101MC C CHIP ELECTRO MV 16V 100MF 6.3DX5.7H

C942 HCEJF470MC C CHIP ELECTRO 16V 47MF CS 6352

C944 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C963 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C964 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C965 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C966 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C967 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

C984 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA33 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA34 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA35 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

CA36 HCQK331JBA C CHIP CERA 50V CH 330PF J 1608

CA44 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

CA47 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

PART NAME PART DESCRIPTION

34

Page 36

Service part list (DLT-19W4)

LOC PART CODE

CA48 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA49 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

CA61 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA63 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA66 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA67 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA70 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA71 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA72 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CA81 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA83 HCBK102KBA C CHIP CERA 50V X7R 1000PF K 1608

CA87 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

CA88 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

CD01 HCEJF470MC C CHIP ELECTRO 16V 47MF CS 6352

CD04 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

CD05 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

CD06 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

CD08 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

CD10 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

CD103 HCQK270JBA C CHIP CERA 50V CH 27PF J 1608

CD106 HCQK270JBA C CHIP CERA 50V CH 27PF J 1608

CD120 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD121 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD122 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD123 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD124 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD13 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

CD130 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD14 HCQK220JBA C CHIP CERA 50V CH 22PF J 1608

CD20 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD25 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD36 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD38 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD39 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD48 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD50 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD52 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD61 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD62 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

CD65 HCQK270JBA C CHIP CERA 50V CH 27PF J 1608

CD68 HCQK270JBA C CHIP CERA 50V CH 27PF J 1608

CD72 HCEJK109MC C CHIP ELECTRO MV 50V 1MF 4.0DX5.3H

CD74 HCELK479MC C CHIP ELECTRO 50V 4.7MF CM 4052

CD87 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CD88 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

PART NAME PART DESCRIPTION

LOC PART CODE

CD92 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD93 HCEJF100MC C CHIP ELECTRO 16V 10MF MV 4052

CD94 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CD95 HCBK104KBA C CHIP CERA 50V X7R 0.1MF K 1608

CP01 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP03 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP05 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP07 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP1 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP18 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP22 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP25 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP29 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP35 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP40 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP48 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP51 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

CP65 HCELF220MD C CHIP ELECTRO 16V 22MF CM 4052

D401 DBAV70---B DIODE CHIP BAV70

D911 DM2FM3---C

D912 DM2FM3---C

D913 DM2FM3---C

D923 DBAV70---B DIODE CHIP BAV70

DA03 DBAV70---B DIODE CHIP BAV70

DA71 DBAV70---B DIODE CHIP BAV70

I403 124C04MN6D IC CHIP EEPROM M24C04-WMN6T

I501 1FL130602Q

I505 125VF016-Q

I601 1TDA8933-Q IC CHIP AUDIO AMP TDA8933

I902 1G9173363C IC CHIP REGULATOR G9117-33T63U 3.3V

I907 1MP1583--D IC CHIP CONVERTER MP1583DN

I911 1AZ117H25C IC CHIP REGULATOR AZ1117H-2.5TREI 2.5V

I912 1MP1583--D IC CHIP CONVERTER MP1583DN

I913 1MP1583--D IC CHIP CONVERTER MP1583DN

I914 1LM317BD2E IC CHIP REGULATOR

I915 TFDS4953-C FET CHIP FDS4953 SO-8 -30V -5A

I916 1G95110T-C IC CHIP REGULATOR G951-10T65U SOT-223

I921 1LM317BD2E IC CHIP REGULATOR

IA05 1M74HC14TC IC CHIP LOGIC M74HC14TTR

ICD13 1STV0362-Q IC CHIP CHANNEL

ID01 1C1GU04GWD IC CHIP INVERTER 74AHC1GU04GW

ID02 1ST5105--Q

ID03 11216AJTAQ IC CHIP DDR SDRAM EDD1216AJTA-5B-E

ID05 1HC1G32GWD IC CHIP OR GATE 74AHC1G32GW

PART NAME PART DESCRIPTION

DIODE CHIP SCHOTTKY

DIODE CHIP SCHOTTKY

DIODE CHIP SCHOTTKY

IC CHIP VIDEO DECODER

IC CHIP FLASH MEMORY

DECODER

IC CHIP MEDIA PROCESSOR

M2FM3 M2F TYPE

M2FM3 M2F TYPE

M2FM3 M2F TYPE

FLI30602H

SST25VF016

SOT-223

SOT-223

LM317BD2T ADJ 1.2V 37V

1.5A D2PAK

REEL

LM317BD2T ADJ 1.2V

37V 1.5A D2PAK

STV0362

ST5105

35

Page 37

Service part list (DLT-19W4)

LOC PART CODE

ID07 174LVC162D IC CHIP BUFFER 74LVC16244

ID08 174L16244D IC CHIP BUFFER 74LVTH16244

ID09 1C1GU04GWD IC CHIP INVERTER 74AHC1GU04GW

ID10 1HEF4053BD IC CHIP LOGIC HEF4053B

ID11 1HC1G32GWD IC CHIP OR GATE 74AHC1G32GW

ID12 1HC1G32GWD IC CHIP OR GATE 74AHC1G32GW

ID13 1C245APW-D IC CHIP TRANSCEIVER 74LVC245APW

ID14 174LVC162D IC CHIP BUFFER 74LVC16244

ID17 174HC126PD IC CHIP BUFFER 74HC126PW-T

ID18 1160ET70NQ IC CHIP FLASH MEMORY M29W160ET70N6T

ID511 174HC126PD IC CHIP BUFFER 74HC126PW-T

JP401 4859201660 CONN HDMI WF050-21UBR STR.

JP502 4859293820 CONN WAFER GT121-31P-TD-A

L421 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L431 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L432 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L523 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L524 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L601 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L610 HLC470KECE L CHIP COIL 47UH K 1280

L620 HLC470KECE L CHIP COIL 47UH K 1280

L626 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L901 HLC150KECE L CHIP COIL 15UH K 1280

L902 HLC150KECE L CHIP COIL 15UH K 1280

L903 HLC150KECE L CHIP COIL 15UH K 1280

L912 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L913 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L915 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L916 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L917 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L918 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L922 HLC479J00A L CHIP COIL 4.7UH MLF2012

L923 HLC479J00A L CHIP COIL 4.7UH MLF2012

L932 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L933 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L951 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L952 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L953 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L954 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L955 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L956 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L957 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L958 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

PART NAME PART DESCRIPTION

SHEEL REEL TYPE

31P ST

LOC PART CODE

L961 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L962 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L963 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L964 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L965 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L966 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L967 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L971 HLC479J00A L CHIP COIL 4.7UH MLF2012

L973 HLC479J00A L CHIP COIL 4.7UH MLF2012

L974 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

L975 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L976 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L977 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L978 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L979 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L980 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L987 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

L988 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

LA35 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

LA61 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

LD01 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

LD02 HLC479K03C L CHIP COIL 4.7UH K NLC5650T

LD03 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

LD04 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

LD05 HLC189K00A L CHIP COIL 1.8UH K MLF 2012

LD25 HFFMMZ400A F CHIP FERRITE BEAD 40 OHM MMZ 2012S

Q503 T2SC2412KB TR CHIP 2SC2412KB

Q504 T2SA1037KB TR CHIP 2SA1037KB

Q622 T2SC2412KB TR CHIP 2SC2412KB

Q902 T2SC2412KB TR CHIP 2SC2412KB

Q905 T2SC2412KB TR CHIP 2SC2412KB

QD06 T2SC2412KB TR CHIP 2SC2412KB

QD07 T2SC2412KB TR CHIP 2SC2412KB

QD08 T2SC2412KB TR CHIP 2SC2412KB

QD10 T2SC2412KB TR CHIP 2SC2412KB

QD11 T2SC2412KB TR CHIP 2SC2412KB

R401 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R402 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R406 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R407 HRFT473JBA R CHIP 1/10 47K OHM J 1608

R409 HRFT101JBA R CHIP 1/10 100 OHM J 1608

R410 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R411 HRFT000JBA R CHIP 1/10 0 OHM J 1608

R419 HRFT104JBA R CHIP 1/10 100K OHM J

R451 HRTS8E100J R CHIP ARRAY 1/16 8P 10 OHM 3216

PART NAME PART DESCRIPTION

1608

36

Page 38

Service part list (DLT-19W4)

LOC PART CODE

RA66 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RA71 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RA72 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RA73 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RA97 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RA98 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD02 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD05 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD06 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD07 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD08 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD09 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD10 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD101 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RD112 HRFT181JBA R CHIP 1/10 180 OHM J 1608

RD113 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD114 HRFT154JBA R CHIP 1/10 150K OHM J 1608

RD116 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD118 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD120 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD121 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD126 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD127 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD128 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RD129 HRFT393JBA R CHIP 1/10 39K OHM J 1608

RD132 HRFT223JBA R CHIP 1/10 22K OHM J 1608

RD133 HRFT102JBA R CHIP 1/10 1K OHM J 1608

RD134 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD135 HRFT220JBA R CHIP 1/10 22 OHM J 1608

RD140 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RD144 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD146 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD149 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD19 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD20 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD21 HRTS8E330J R CHIP

RD22 HRTS8E330J R CHIP

RD23 HRFT750JBA R CHIP 1/10 75 OHM J 1608

RD24 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD39 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD42 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD43 HRFT201JBA R CHIP 1/10 200 OHM J 1608

RD47 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD49 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD52 HRFT101JBA R CHIP 1/10 100 OHM J 1608

PART NAME

ARRAY

ARRAY

PART DESCRIPTION

1/16 8P 33 OHM J 3216

1/16 8P 33 OHM J 3216

LOC PART CODE

RD54 HRFT473JBA R CHIP 1/10 47K OHM J 1608

RD57 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD58 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD59 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD60 HRFT101JBA R CHIP 1/10 100 OHM J 1608

RD61 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD62 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD63 HRFT470JBA R CHIP 1/10 47 OHM J 1608

RD64 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD65 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD66 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD67 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD68 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD69 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD70 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD73 HRTS8E470J R CHIP ARRAY 1/16 8P 47 OHM 3216

RD74 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD75 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD79 HRFT472JBA R CHIP 1/10 4.7K OHM J 1608

RD80 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RD95 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RD98 HRFT000JBA R CHIP 1/10 0 OHM J 1608

RO02 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO04 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO06 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO07 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RO09 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RO12 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO13 HRFT103JBA R CHIP 1/10 10K OHM J 1608

RO16 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO18 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO20 HRFT104JBA R CHIP 1/10 100K OHM J 1608

RO21 HRFT103JBA R CHIP 1/10 10K OHM J 1608

ZA01 HFEACF470B F CHIP EMI ACF321825 47P

ZA02 HFEACF470B F CHIP EMI ACF321825 47P

ZA11 HFEACF470B F CHIP EMI ACF321825 47P

ZA13 HFEACF470B F CHIP EMI ACF321825 47P

ZA55 HFEACF470B F CHIP EMI ACF321825 47P

ZA56 HFEACF470B F CHIP EMI ACF321825 47P

ZA61 HFEACF470B F CHIP EMI ACF321825 47P

ZA62 HFEACF470B F CHIP EMI ACF321825 47P

ZA81 HFEACF470B F CHIP EMI ACF321825 47P

ZA82 HFEACF470B F CHIP EMI ACF321825 47P

ZA83 HFEACF470B F CHIP EMI ACF321825 47P

ZA84 HFEACF470B F CHIP EMI ACF321825 47P

PART NAME PART DESCRIPTION

37

Page 39

8. Different part list for models

Model: DLT-19W4 DLT-22W4

LOC PART CODE PART NAME (PART DESCRIPTION) PART CODE PART NAME (PART DESCRIPTION)

20 7178301251 SCREW TAPPTITE (TT2 WAS 3X12 MFZN 3CR) 7178301251 SCREW TAPPTITE (TT2 WAS 3X12 MFZN 3CR)

A001 4859818992 PCB MAIN (SL-150T 234X189 K4V (WIDE)) 4859818992 PCB MAIN (SL-150T 234X189 K4V (WIDE))

A002 4859833714 PCB CONTROL (SL-150T 115X23(246X330/2X8)D1B) 4859833714 PCB CONTROL (SL-150T 115X23(246X330/2X8)D1B)

C560

CD30

CD30 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608) HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CP1 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052) HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

IC12 1R24FH1B-- IC PREAMP (R24FH1B) 1R24FH1B-- IC PREAMP (R24FH1B)

IC13

J001

J002

J003

JP502 4859293820 CONN WAFER (GT121-31P-TD-A 31P ST) 4859293820 CONN WAFER (GT121-31P-TD-A 31P ST)

LED1 DSPR39MVW- LED (SPR-39MVW (DUAL)) DSPR39MVW- LED (SPR-39MVW (DUAL))

LED2

M191 485819E500 PAD (19W4 EPS) 485819E600 PAD (22W4 EPS)

M191A 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK 3CR) 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK 3CR)

M1F1A

M201 4852098411 MASK FRONT (19W4 HIPS BK) 4852098511 MASK FRONT (22W4 HIPS BK)

M201A

M201C 2233032405 PAINT WATER (SV 2405BP CETELON)

M201D 2233039604 PAINT WATER (BK9604BP CETELON) 2233039604 PAINT WATER (BK9604BP CETELON)

M211 4852181401 COVER BACK (19W4 HIPS BK) 4852181601 COVER BACK (22W4 HIPS BK)

M211A

M212 485218151101 COVER STAND BASE (19/22W4 HIPS BK9604BP) 4852181511 COVER STAND BASE (19/22W4 HIPS

M212A 4852716201 LEG BOTTOM (CR (14V5)) 4852716201 LEG BOTTOM (CR (14V5))

M213

M213A

M213B

GY340A+SV2405BP)

M231 4852335301 PANEL CTRL (19/22W4 HIPS BK) 4852335301 PANEL CTRL (19/22W4 HIPS BK)

M381 4853833301 FRAME MAIN PCB (19W4 SECC T0.8 (SEC)) 4853833401 FRAME MAIN PCB (22W4 SECC T0.8 (SEC))

M381A 7178300852 SCREW TAPTITE (TT2 WAS 3X8 MFZN BK 3CR) 7178300852 SCREW TAPTITE (TT2 WAS 3X8 MFZN BK 3CR)

M381B 7178300852 SCREW TAPTITE (TT2 WAS 3X8 MFZN BK 3CR) 7178300852 SCREW TAPTITE (TT2 WAS 3X8 MFZN BK 3CR)

M381C 4852937500 RUBBER BOTTOM (CR60 BK PHI 18.0XT3.0)

M381D 7172401252 SCREW TAPPTITE (TT2 TRS 4X12 MFZN BK 3CR) 7172401252 SCREW TAPPTITE (TT2 TRS 4X12 MFZN BK 3CR)

M381E 7008300651 SCREW MACHINE (WAS 3X6 MFZN 3CR) 7008300651 SCREW MACHINE (WAS 3X6 MFZN 3CR)

M381F 4856815910 CLAMP WIRE (EGI T0.4+TUBE+PIE 4.2) 4856815910 CLAMP WIRE (EGI T0.4+TUBE+PIE 4.2)

M382 485383321101 FRAME STAND (19/22W4 HIPS BK9604) 4853833211 FRAME STAND (19/22W4 HIPS GY340A+SV2405BP)

38

Page 40

Different part list for models

Model: DLT-19W4 DLT-22W4

LOC PART CODE PART NAME (PART DESCRIPTION) PART CODE PART NAME (PART DESCRIPTION)

M382A 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK 3CR) 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK 3CR)

M382B DMP2505200 BAG P.E. (P.E 40X60 DLT-19/22W4) DMP2505200 BAG P.E. (P.E 40X60 DLT-19/22W4)

M388A

M481 4854873411 BUTTON POWER (19/22W4 ABS GY340A+SV2405BP) 4854873411 BUTTON POWER (19/22W4 ABS GY340A+SV2405BP)

M491 4854965611 BUTTON CH (19/22W4 ABS GY340A+SV2405BP) 4854965611 BUTTON CH (19/22W4 ABS GY340A+SV2405BP)

M491A

M542

M551

M551A

M561 48556192SD02 MARK BRAND (DAEWOO 68MM (20”21”)) 48556192SD02 MARK BRAND (DAEWOO 68MM (20”21”))

M591 485594900001 DECO PLATE (19W4 PC T2.0) 485594910001 DECO PLATE (22W4 PC T2.0)

M801 DMP5030700 BOX (DLT-19W4TB) DMP5030900 BOX (DLT-22W4)

P502A 4859000260 CABLE LVDS (FMW1214A-31+FH10001-

30+UL1571#30=250MM)

P506A 4850705S32 CONNECTOR (YH025-05+YBH250-05+ULW=350) 4850705S32 CONNECTOR (YH025-05+YBH250-05+ULW=350)

P901A

P902A 4850715N09 CONNECTOR (YH025-15+YBNH250-15+ULW=100) 4850715N09 CONNECTOR (YH025-15+YBNH250-15+ULW=100)

QD12

QD12 T2SA1037KB TR CHIP (2SA1037KB) T2SA1037KB TR CHIP (2SA1037KB)

R450

R530 RD-AZ822J- R CARBON FILM (1/6 8.2K OHM J) RD-AZ822J- R CARBON FILM (1/6 8.2K OHM J)

R899

RD56

RD56 HRFT473JBA R CHIP (1/10 47K OHM J 1608) HRFT473JBA R CHIP (1/10 47K OHM J 1608)

SP01 4858319910 SPEAKER (SP-5090F24C) 4858320010 SPEAKER (SP-5090N03C)

SP01A 4853956801 BRKT SPKR (19/22W4 HIPS BK) 4853956801 BRKT SPKR (19/22W4 HIPS BK)

SP01B 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR) 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

SP01C 4857818705 CLOTH BLACK (FELT T0.7 L=110 W=15) 4857817300 CLOTH BLACK (CLOTH 152X15XT0.5)

SP01D 4857818705 CLOTH BLACK (FELT T0.7 L=110 W=15) 4857817300 CLOTH BLACK (CLOTH 152X15XT0.5)

SP02 4858319910 SPEAKER (SP-5090F24C) 4858320010 SPEAKER (SP-5090N03C)

SP02A 4853956801 BRKT SPKR (19/22W4 HIPS BK) 4853956801 BRKT SPKR (19/22W4 HIPS BK)

SP02B 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR) 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

SP02C 4857818705 CLOTH BLACK (FELT T0.7 L=110 W=15) 4857817300 CLOTH BLACK (CLOTH 152X15XT0.5)

SP02D 4857818705 CLOTH BLACK (FELT T0.7 L=110 W=15) 4857817300 CLOTH BLACK (CLOTH 152X15XT0.5)

SW16 5S50101Z90 SW TACT (SKHV10910A) 5S50101Z90 SW TACT (SKHV10910A)

V901 485LD16191 LCD PANEL (LTM190M2-L31) 485LD16221 LCD PANEL (LTM220M1-L01)

V902 485AS003PL POWER LIPS (IPB-6012M01) 485AS003PL POWER LIPS (IPB-6012M01)

ZZ200 PTMPJ2G105 PCB CHIP MOUNT B AS (DLT-19W4LMBSCF) PTMPJ2G105 PCB CHIP MOUNT B AS (DLT-19W4LMBSCF)

ZZ210 PTSPPWG105 SPEAKER AS (DLT-19W4LMBSCF) PTSPPWG106 SPEAKER AS (DLT-22W4SMBSCF)

ZZ220

ZZ280 PTCTMSG105 PCB CTRL MANUAL AS (DLT-19W4LMBSCF) PTCTMSG105 PCB CTRL MANUAL AS (DLT-19W4LMBSCF)

ZZ290 PTMPMSG108 PCB MAIN MANUAL AS (DLT-19W4SMBSCF) PTMPMSG106 PCB MAIN MANUAL AS (DLT-22W4SMBSCF)

4859000260 CABLE LVDS (FMW1214A-31+FH10001-

30+UL1571#30=250MM)

39

Page 41

Different part list for models

Model: DLT-20J1 DLT-20J3

LOC PART CODE PART NAME (PART DESCRIPTION) PART CODE PART NAME (PART DESCRIPTION)

20

A001 4859817493 PCB MAIN (SL-150T 234X189 K4V) 4859817493 PCB MAIN (SL-150T 234X189 K4V)

A002 4859833814 PCB CONTROL (SL-150T 140 X34(246X330/

2X5)D1B)

C560 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052) HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD30 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608) HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CD30

CP1

IC12 1R24FH1B-- IC PREAMP (R24FH1B)

IC13 1R24FH1B-- IC PREAMP (R24FH1B)

J001 85801050GY WIRE COPPER (1/0.5 TIN COATING)

J002 85801050GY WIRE COPPER (1/0.5 TIN COATING)

J003 85801050GY WIRE COPPER (1/0.5 TIN COATING)

JP502 4859297320 CONN WAFER (05002HR-50A01(G)) 4859297320 CONN WAFER (05002HR-50A01(G))

LED1 DSPR39MVW- LED (SPR-39MVW (DUAL))

LED2 DSPR39MVW- LED (SPR-39MVW (DUAL))

M191 485819CM00 PAD (EPS 20J1) 485819D600 PAD (EPS 20J3)

M191A

M1F1A 7172401652 SCREW TAPPTITE (TT2 TRS 4X16 MFZN BK

3CR)

M201 4852093421 MASK FRONT (DLT-20J1 HIPS BK) 4852094731B MASK FRONT (DLT-20J3 HIPS BK)

M201A 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK

3CR)

M201C 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN

3CR)

M201D 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN

3CR)

M211 4852181701 COVER BACK (DLT-20J1/J3 HIPS BK) 4852181701 COVER BACK (DLT-20J1/J3 HIPS BK)

M211A 7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK

3CR)

M212 4852176401 COVER STAND BASE (20J1 (BK9604BP)) 4852176411B COVER STAND BASE (20J3 BK9604BP)

M212A

M213 4855218800 PLATE BASE STAND (SECC T2.2) 4855218800 PLATE BASE STAND (SECC T2.2)

M213A 4857942702 RUBBER (BK PHI 19X2.0T HRC 70-75) 4857942702 RUBBER (BK PHI 19X2.0T HRC 70-75)

M213B 7115400851 SCREW TAPPING (FLT 4X8 MFZN 3CR) 7115400851 SCREW TAPPING (FLT 4X8 MFZN 3CR)

M231 485233300101 PANEL CTRL (20J1 HIPS BK) 485233300101 PANEL CTRL (20J1 HIPS BK)

M381 4853833501 FRAME MAIN PCB (DLT-20J1/J3 SECC T0.8

(AUO))

M381A 7178300851 SCREW TAPPTITE (TT2 WAS 3X8 MFZN 3CR) 7178300851 SCREW TAPPTITE ( TT2 WAS 3X8 MFZN 3CR)

M381B 7178300851 SCREW TAPPTITE (TT2 WAS 3X8 MFZN 3CR) 7178300851 SCREW TAPPTITE (TT2 WAS 3X8 MFZN 3CR)

M381C

M381D

M381E 7008301451 SCREW MACHINE (M-WAS 3X14 MFZN 3CR) 7008301451 SCREW MACHINE (M-WAS 3X14 MFZN 3CR)

4859833814 PCB CONTROL (SL-150T 140 X34(246X330/2X5)D1B)

7172401652 SCREW TAPPTITE (TT2 TRS 4X16 MFZN BK 3CR)

7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

7172401452 SCREW TAPPTITE (TT2 TRS 4X14 MFZN BK 3CR)

4853833501 FRAME MAIN PCB (DLT-20J1/J3 SECC T0.8 (AUO))

M381F

M382

40

Page 42

Different part list for models

Model: DLT-20J1 DLT-20J3

LOC PART CODE PART NAME (PART DESCRIPTION) PART CODE PART NAME (PART DESCRIPTION)

M382A

M382B

M388A 7005400608 SCREW MACHINE (FLT 4X6 SUS) 7005400608 SCREW MACHINE (FLT 4X6 SUS)

M481 485487201103 BUTTON POWER (20J1 ABS

GY340A+BK9604BP)

M491 485496401103 BUTTON CH (20J1 ABS

GY340A+BK9604BP)

M491A 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN

3CR)

M542 4855800022P1 LABEL SERIAL (ART 90 55X34) 4855800022P1 LABEL SERIAL (ART 90 55X34)

M551 485555650001 DECO SENSOR (20J1 GPPS MILKY) 4855557011 DECO SENSOR (20J3 GPPS MILKY)

M551A 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN

3CR)

M561 48556192SD02 MARK BRAND (DAEWOO 68MM (20”21”)) 48556254SD02 MARK BRAND (SILVER DIA-CUTTING(DOUBLE FACED TYPE))

M591

M801 DMP5031200 BOX (DLT-20J1) DMP5031300 BOX (DLT-20J3)

P502A 4859007960 CABEL FFC (0.50P-50N-300L-T5) 4859007960 CABEL FFC (0.50P-50N-300L-T5)

P506A 4850705S32 CONNECTOR (YH025-05+YBH250-

05+ULW=350)

P901A 4850705S01 CONNECTOR (YH025-

05+YBNH250+ULW=100)

P902A 4850710S03 CONNECTOR (YH025-10+YBNH250-

10+ULW=100)

QD12 T2SA1037KB TR CHIP (2SA1037KB) T2SA1037KB TR CHIP (2SA1037KB)

QD12

R450 HRTS8E100J R CHIP ARRAY (1/16 8P 10 OHM 3216) HRTS8E100J R CHIP ARRAY (1/16 8P 10 OHM 3216)

R530

R899 HRFT000-CA R CHIP (1/10 0 OHM 2012) HRFT000-CA R CHIP (1/10 0 OHM 2012)

RD56 HRFT473JBA R CHIP (1/10 47K OHM J 1608) HRFT473JBA R CHIP (1/10 47K OHM J 1608)

RD56

SP01 4858318310 SPEAKER (SP-5090F01C) 4858318310 SPEAKER (SP-5090F01C)

SP01A

SP01B

SP01C

SP01D

SP02 4858318310 SPEAKER (SP-5090F01C) 4858318310 SPEAKER (SP-5090F01C)

SP02A

SP02B

SP02C

SP02D

SW16

V901 485LD10205 LCD PANEL (A201SN02-V5) 485LD10205 LCD PANEL (A201SN02-V5)

V902 485AS005PL POWER LIPS (IPB-6015NV02(T )) 485AS005PL POWER LIPS (IPB-6015NV02(T))

ZZ200 PTMPJ2G109 PCB CHIP MOUNT B AS (DLT-20J1AMS-CF) PTMPJ2G109 PCB CHIP MOUNT B AS (DLT-20J1AMS-CF)

ZZ210 PTSPPWG109 SPEAKER AS (DLT-20J1AMS-CF) PTSPPWG109 SPEAKER AS (DLT-20J1AMS-CF)

ZZ220 PTSTCAG109B STAND ASSY (DLT-20J1AMB-CF) PTSTCAG110B STAND ASSEMBLY (DLT-20J3AMD-CF)

ZZ280 PTCTMSG109B PCB CTRL MANUAL AS (DLT-20J1AMB-CF) PTCTMSG110B PCB CTRL MANUAL AS (DLT-20J3AMB-CF)

ZZ290 PTMPMSG109B PCB MAIN MANUAL AS (DLT-20J3AMB-CF) PTMPMSG109B PCB MAIN MANUAL AS (DLT-20J3AMB-CF)

485487201103 BUTTON POWER (20J1 ABS GY340A+BK9604BP)

485496401103 BUTTON CH (20J1 ABS GY340A+BK9604BP)

7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

4850705S32 CONNECTOR (YH025-05+YBH250-05+ULW=350)

4850705S01 CONNECTOR (YH025-05+YBNH250+ULW=100)

4850710S03 CONNECTOR (YH025-10+YBNH250-10+ULW=100)

41

Page 43

Different part list for models

Model: DLT-19W4 DLP-19W4

LOC PART CODE PART NAME (PART DESCRIPTION)

C671 HCELH100MC C CHIP ELECTRO (25V 10MF CM 4052)

C904 HCEEF101MC C CHIP ELECTRO (MV 16V 100MF 6.3DX5.7H)

C913 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C914 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C928 HCEEF101MC C CHIP ELECTRO (MV 16V 100MF 6.3DX5.7H)

C934 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C938 HCEEF101MC C CHIP ELECTRO (MV 16V 100MF 6.3DX5.7H)

C940 HCEEF101MC C CHIP ELECTRO (MV 16V 100MF 6.3DX5.7H)

C943 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C963 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C964 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C965 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

C966 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD02 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD03 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CD04 HCEJK109MC C CHIP ELECTRO (MV 50V 1MF 4.0DX5.3H)

CD05 HCEJK109MC C CHIP ELECTRO (MV 50V 1MF 4.0DX5.3H)

CD06 HCEJF100MC C CHIP ELECTRO (16V 10MF MV 4052)

CD07 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD08 HCEJF100MC C CHIP ELECTRO (16V 10MF MV 4052)

CD09 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD10 HCELK479MC C CHIP ELECTRO (50V 4.7MF CM 4052)

CD103 HCQK270JBA C CHIP CERA (50V CH 27PF J 1608)

CD105 HCQK391JBA C CHIP CERA (50V CH 390PF J 1608)

CD106 HCQK270JBA C CHIP CERA (50V CH 27PF J 1608)

CD108 HCQK391JBA C CHIP CERA (50V CH 390PF J 1608)

CD11 HCQK150JBA C CHIP CERA (50V CH 15PF J 1608)

CD12 HCQK150JBA C CHIP CERA (50V CH 15PF J 1608)

CD120 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD121 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD122 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD123 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD124 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD13 HCQK220JBA C CHIP CERA (50V CH 22PF J 1608)

CD130 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD131 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD132 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD133 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD134 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD135 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD136 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD137 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD138 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD14 HCQK220JBA C CHIP CERA (50V CH 22PF J 1608)

CD15 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD16 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD19 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

42

Page 44

Different part list for models

Model: DLT-19W4 DLP-19W4

LOC PART CODE PART NAME (PART DESCRIPTION)

CD20 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD21 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD22 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD23 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD24 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD25 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD26 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD27 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD28 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD29 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD30 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CD31 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD32 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD33 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD34 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD35 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD36 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD37 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD38 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD39 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD40 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD41 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD42 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD43 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD44 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD45 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD46 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD47 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD48 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD49 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD50 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD51 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD52 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD53 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD54 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD55 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD56 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD57 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD58 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD59 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD60 HCBK103KBA C CHIP CERA (50V X7R 0.01MF K 1608)

CD61 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD62 HCEJK109MC C CHIP ELECTRO (MV 50V 1MF 4.0DX5.3H)

CD63 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD64 HCBK103KBA C CHIP CERA (50V X7R 0.01MF K 1608)

CD65 HCQK270JBA C CHIP CERA (50V CH 27PF J 1608)

CD67 HCQK391JBA C CHIP CERA (50V CH 390PF J 1608)

43

Page 45

Different part list for models

Model: DLT-19W4 DLP-19W4

LOC PART CODE PART NAME (PART DESCRIPTION)

CD68 HCQK270JBA C CHIP CERA (50V CH 27PF J 1608)

CD71 HCQK391JBA C CHIP CERA (50V CH 390PF J 1608)

CD74 HCELK479MC C CHIP ELECTRO (50V 4.7MF CM 4052)

CD75 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD76 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CD77 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD78 HCBK102KBA C CHIP CERA (50V X7R 1000PF K 1608)

CD79 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD80 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD81 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD82 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD83 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD84 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD85 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD86 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD90 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD91 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD92 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD94 HCELF220MD C CHIP ELECTRO (16V 22MF CM 4052)

CD95 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

CD96 HCBK104KBA C CHIP CERA (50V X7R 0.1MF K 1608)

DA80 D3C09GTA-- CERA DIODE (CDS3C09GTA)

DA81 D3C09GTA-- CERA DIODE (CDS3C09GTA)

I902 1G9173363C IC CHIP REGULATOR (G9117-33T63U 3.3V

I911 1AZ117H25C IC CHIP REGULATOR (AZ1117H-2.5TREI 2.5V

I914 1LM317BD2E IC CHIP REGULATOR (LM317BD2T ADJ 1.2V

I916 1G95110T-C IC CHIP REGULATOR (G951-10T65U SOT-223)

ICD13 1STV0362-Q IC CHIP CHANNEL DECODER (STV0362)

ID01 1C1GU04GWD IC CHIP INVERTER (74AHC1GU04GW )

ID02 1ST5105--Q IC CHIP MEDIA PROCESSOR (ST5105)

ID03 11216AJTAQ IC CHIP DDR SDRAM (EDD1216AJTA-5B-E)

ID05 1HC1G32GWD IC CHIP OR GATE (74AHC1G32GW)

ID07 174LVC162D IC CHIP BUFFER (74LVC16244)

ID08 174L16244D IC CHIP BUFFER (74LVTH16244)

ID09 1C1GU04GWD IC CHIP INVERTER (74AHC1GU04GW )

ID11 1HC1G32GWD IC CHIP OR GATE (74AHC1G32GW)

ID12 1HC1G32GWD IC CHIP OR GATE (74AHC1G32GW)

ID13 1C245APW-D IC CHIP TRANSCEIVER (74LVC245APW)

ID14 174LVC162D IC CHIP BUFFER (74LVC16244)

ID15 14C64WBN6- IC EEPROM (M24C64-WBN6)

ID17 174HC126PD IC CHIP BUFFER (74HC126PW-T)

ID18 1160ET70NQ IC CHIP FLASH MEMORY

ID25 1K1A7025AP IC RESET (KIA7025AP)

JD02 4859200440 CONN PCMCIA (PC68PRA5513XZ)

SOT-223)

SOT-223)

37V 1.5A D2PAK)

(M29W160ET70N6T)

44

Page 46

Different part list for models

Model: DLT-19W4 DLP-19W4

LOC PART CODE PART NAME (PART DESCRIPTION)

L922 HLC479J00A L CHIP COIL (4.7UH MLF2012)

L923 HLC479J00A L CHIP COIL (4.7UH MLF2012)

L971 HLC479J00A L CHIP COIL (4.7UH MLF2012)

L973 HLC479J00A L CHIP COIL (4.7UH MLF2012)

L975 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

L976 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

L978 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

L979 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

L980 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

L987 HFFMMZ400A F CHIP FERRITE BEAD (40 OHM MMZ 2012S)

LD01 HLC189K00A L CHIP COIL (1.8UH K MLF 2012)

LD02 HLC479K03C L CHIP COIL (4.7UH K NLC5650T)

LD03 HLC189K00A L CHIP COIL (1.8UH K MLF 2012)

LD04 HLC189K00A L CHIP COIL (1.8UH K MLF 2012)

LD05 HLC189K00A L CHIP COIL (1.8UH K MLF 2012)

M004 407-Q31T PLATE (CUTTING PAPER ANGLE PAPER)

M211 4852181401 COVER BACK (19W4 HIPS BK) 4852181421 COVER BACK (DLP-19W4 HIPS BK)

M361 4853636301 TERMINAL JACK (19/22W4 HIPS BK) 4853636321 TERMINAL JACK (DLP-19/22W4 HIPS BK)

M491A 7178301051 SCREW TAPPTITE (TT2 WAS 3X10 MFZN 3CR)

M591 485594900001 DECO PLATE (19W4 PC T2.0) 485594900002 DECO PLATE (19W4 (SL-150P))

PD03 485923172S CONN WAFER (YW025-04 (STICK))

QD04 T2SC2412KB TR CHIP (2SC2412KB)

QD05 T2SC2412KB TR CHIP (2SC2412KB)

QD06 T2SC2412KB TR CHIP (2SC2412KB)

QD07 T2SC2412KB TR CHIP (2SC2412KB)

QD11 T2SC2412KB TR CHIP (2SC2412KB)

QD12 T2SA1037KB TR CHIP (2SA1037KB)

R589 HRFT470JBA R CHIP (1/10 47 OHM J 1608)