Page 1

Service Manual

LCD PROJECTION TV

(HDTV MONITOR)

CHASSIS : SJ-210

Model : DSJ-6000LN

S/M No. : DSJ210BEF0

Nov. 2002

DAEWOO ELECTRONICS Corp.

http : //svc.dwe .co.kr

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

Page 2

- 1 -

1. Safety precautions 2

2. Product specification 4

3. Remocon specification 5

4. Adjustment 7

5. Circuit Manual 11

6. Trouble shooting 27

7. Block diagram 35

8. Exploded View 36

9. Connection diagram 37

Page 3

- 2 -

1. Safety precautions

CAUTION : Do not attempt to modify this product in any way. Unauthorized

modifications will not only void the warranty, but may lead to your being liable for any resulting property damage or

user injury.

Service work should be performed only after you are thoroughly familiar with all of the following safety checks and

servicing guide-lines. To do otherwise, increases the risk of potential hazards and

injury to the user.

SAFETY CHECKS

After the original service problem has been corrected, a check should be made of the following:

SUBJECT : FIRE & SHOCK HAZARD

1. Be sure that all components are positioned in such a way as to avoid possibility of adjacent component shorts. This

is especially important on those chassis which are transported to and from the repair shop.

2. Never release a repair unless all protective devices such as insulators, barriers, covers, shields, strain relief, and

other hardware have been reinstalled per original design.

3. Soldering must be inspected to discover possible cold solder joints, frayed leads, damaged insulation (including

A.C. cord), solder splashes or sharp solder points. Be certain to remove all loose foreign particals.

4. Check for physical evidence of damage or deterioration to parts and components, and replace if necessary follow

original layout, lead length and dress.

5. No leads or components should touch a receiving tube or a resistor rated at 1 watt or more. Lead tension around

protruding metal surfaces must be avoided.

6. All critical components such as fuses, flameproof resistors, capacitors, etc. must be replaced with exact factory

types. Do not use replacement components other than those specified or make unrecommended circuit modifications.

7. After re-assembly of the set always perform an A.C. leakage test on all exposed metallic parts of the cabinet, (the

channel selector knob, antenna terminals, handle and screws) to be sure the set is safe to operate without danger of

electrical shock. Do not use a line isolation transformer during this test. Use an A.C. voltmeter, having 5000 ohms per

volt or more sensitivity, in the following manner : connect a 1500 ohm 10 watt resistor, paralleled by a 15 mfd. 150V

A.C. type capacitor between a known good earth ground (9water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the A.C. voltage across the combination of 1500 ohm resistor and 0.15 MFD capacitor.

Reverse the A.C. plug

and repeat A.C. voltage measurements for each exposed metallic part. Voltage measured must not exceed 0.75 volts

R.M.S. This corresponds to 0.5 milliamp A.C. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

Page 4

- 3 -

Safety precautions

GRAPHIC SYMBOLS :

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert the service

personnel to the presence of uninsu-lated" dangerous voltage" that may be of suffi-cienty magnitude to

constitute a risk of electric shock.

The exclamation point within an equilateral tri-angle is intended to alert the service personnel to the

presence of important safety information in service literature.

Fuse symbol is printed on pcb adjacent to the fuse, with " RISK OF FIRE REPLACE FUSE AS

MARKED". The symbol is explained in the ser-vice manual with the following wording or equiv-alent

CAUTION : FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH SAME

TYPE (6.3A, 125V)" and

" ATTENTION: AFIN D’ ASSU UNE PROTECTION PERMANENTE CONTRE LES RISQUES D’ INCENDIE,

REMPLACER UNIQUE-MENT PAR UN FUSIBLE DE MEME TYPE ET DE " 6.3A, 125V" .

SUBJECT : TIPS ON PROPER INSTALLATION

1. Never install any receiver in closed-in recess, cubbyhole or Closely fitting shelf space over, or close to heat duct,

or in the path of heated air flow.

2. Avoid conditions of high humidity such as : Outdoor patio Installations where dew is a factor. Near steam radiators

where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct rear venting. The customer should also avoid the use of decorative

scarves or other coverings which might obstruct ventilation.

4. Wall and shelf mounted installations using a commercial mounting kit, must follow the factory approved mounting

instructions. A receiver mounted to a shelf or platform must retain its original feet (or the equivalent thickness in

spacers) to provide adequate are flow across the bottom, bolts or screws used for fasteners must not touch and

parts or wiring. Perform leakage test on customized installations.

5. Caution customers against the mounting of a receiver on sloping shelf or a tilted position, unless the receiver is

properly secured.

6. A receiver on a roll-about cart should be stable on its mounting to the cart. Caution the customer on the hazards of

trying to roll a cart with small casters across thresholds or deep pile carpets.

7. Caution customers against the use of a cart or stand which has not been listed by underwriters laboratories, inc.

For use with their specific model of television receiver or generically approved for use with T.V.’ s of the same or

larger screen size.

Caution for servicing

When the general troubles happen, Remove the back cover of the TV set. But , however if the components (the Air

filter, Lamp, Lamp detect switch, or LCD Engine driver PCB, etc) in the front of TV set is out of order, Remove the

speaker grill and the front panel of the TV set.

Specially, First you have to plug out socket , for exchanging the Fuse of TV set,.

When Lamp driver is operated, the high voltage(13~20kV) is generated from the Lamp. Therefore the person only

who has the enough knowledge for the high voltage must handle it with care.

Page 5

- 4 -

Page 6

- 5 -

Page 7

- 6 -

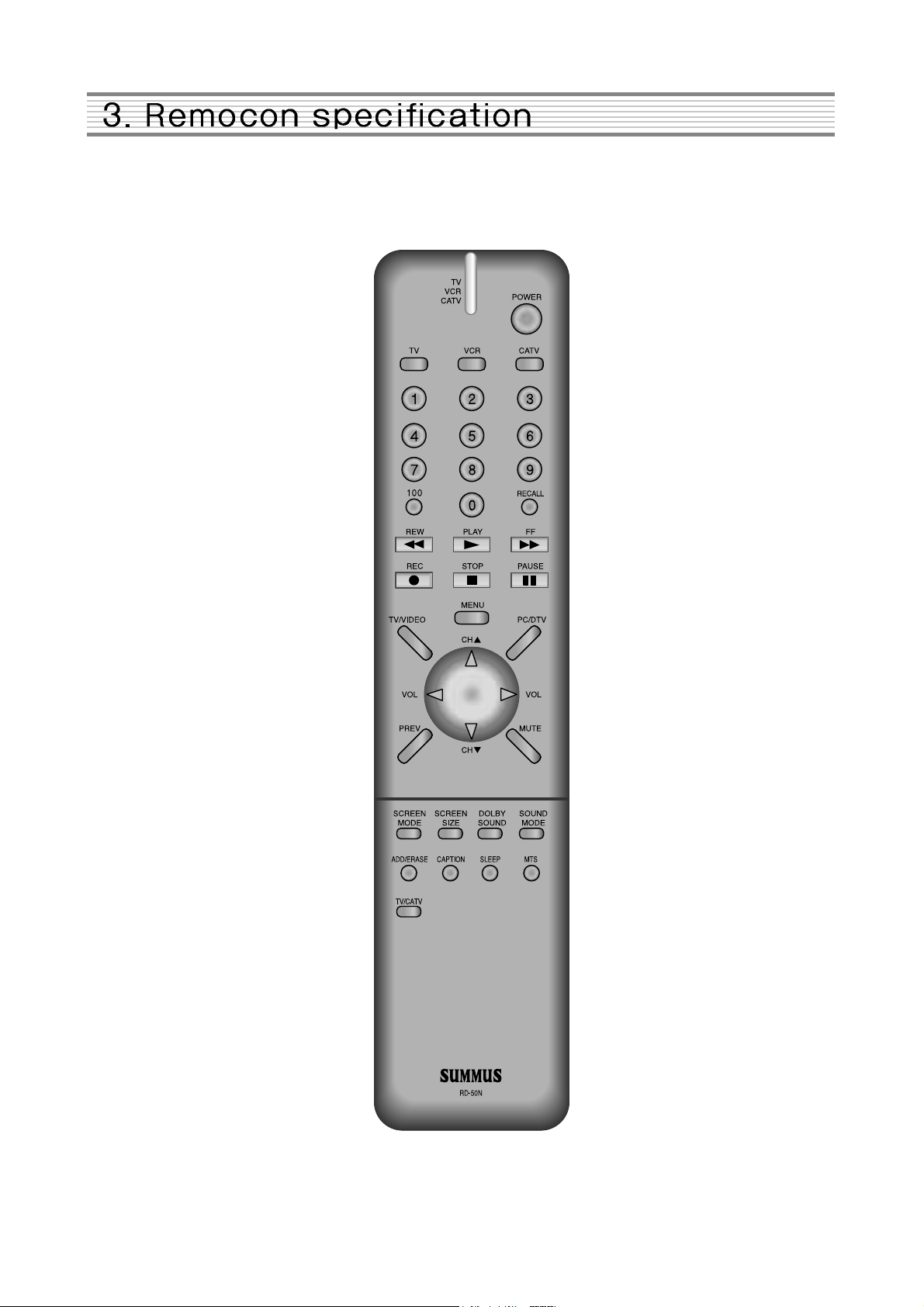

KEY Button and Function

KEY BUTTON FUNCTION

Remote controller Green - TV in use

Lamp Orange - VCR in use

Red - CATV in use

POWER Use turning on, turning off TV

TV/VCR/CATV TV / Video / Cable Converter

Use to select Use to select channel directly 0~9

channel directly

100 Button Use it when selecting a channel number of over 100

RECALL It displays currently watching TV channel and its input signal.

VCR Function REW, PLAY, FF, STOP, REC, PAUSE.

MENU Use it to make picture adjustment, screen format, sound adjustment, input

selection, and utilities.

TV/ VIDEO Use this function to make video input selection.

It changes in the fallowing sequence

TV VIDEO 1 VIDOE 2 VIDEO 3 DVD TV

PC/DTV PC DTV can be selected alternately.

Use it when selecting either PC or DTV.

Channel/ Volume Use this function to select the channel / to adjust the volume.

PREV It returns to previous channel.

MUTE Use to mute.

SCREEN MODE This feature converts the screen mode each time you press the button

from Normal Bright Soft User

SCREEN SIZE This feature converts the screen size by changing its aspect ratio. Each

time you press the button, it will be change from

Normal Wide Panorama Enlarge(LB) Enlarge(LBS)

DOLBY SOUND This button allows you to choose one of the Pro-logic modes.

Normal Off 3-stereo Wide

SOUND MODE This feature allows you to choose the mode, Each time the button is pressed,

it rotates from Normal Music Movie News User

ADD/ERASE This feature either momorizes the current channel or erases a channel that

has previously memorized.

CAPTION This feature allows you choose the caption. Each time the button is pressed it

rotates from CC1 CC2 CC3 CC4 off

SLEEP This feature is use to set up the time out of automatic turn off..

MTS This feature allows you to select the language while broadcasting.

TV/CATV This button allows you to select the broadcasting alternately.

Page 8

- 7 -

4-1. Adjustment in Production

1) How to Fix Engine.

You measure the range of screen s shifting after assembling set.

But, in case of the range is over spec ( H : 7mm, V: 3mm, Tilt : 2mm), adjust again in Local CH 8(RETMA) of

the factory.

2) Adjustment H/V Position.

You select PC Mode to receive reference signal of VG-828 (Program #. 954 : 720p Pattern. 990 : Display

Position Pattern)

Note : LCD Panel is 720p.

You can adjust screen size and position in operating User Menu ( Horizontal Size & Position, Vertical Size &

Position).

3) White balance adjustment

Input the signal of VG-828 (Program #. 946(NTSC) White Window Pattern.(20 20)) to Video 1.

Confirm the initial data of PW364 Mode in SVC Menu.

Adjust the White Balance changing R/G/B Gain after setting signal level 100IRE( 255).

How to adjust temperature of color. : X = 0.265 0.01 0.270 0.01.

You can set Luminance level .

Adjust the White Balance changing R/G/B Bias after setting signal level 40IRE( 102).

Input the signal of VG-828 (Program #. 972(1080i) White Window Pattern.(20

20)) to DTV.

Adjust the White Balance changing AD9884 s Register Value(CXA1315A, CXA1315B, CXA1315C) after

setting signal level 40IRE( 102).

Adjust the White Balance changing CXA2101

s Register Value(R-Drive, G-Drive, B-Drive) after setting

signal level 40 IRE( 102).

Confirm the range of White Balance being in limit and measure Luminance value

Set all adjustment after about 5 Min s heatruning

Note : Lamp wattage converted automatically from 160W to 130W after 3 min.

Heatrun must be operated after inputing White_Pattern, (no concerned ‘No Signal’)

Note : You select ‘White_Pattern’ in ‘Test Pattern’ of SVC Menu.

You select Screen Size is ‘Wide’ and Screen Mode is ‘Normal’.

Page 9

- 8 -

4-2. SERVICE MODE

To operate Service : Press the USER Remote controller in order starting with CH Up Mute RECALL

Mute (You can operate in case INPUT is TV mode, or being input signal)

Service Mode

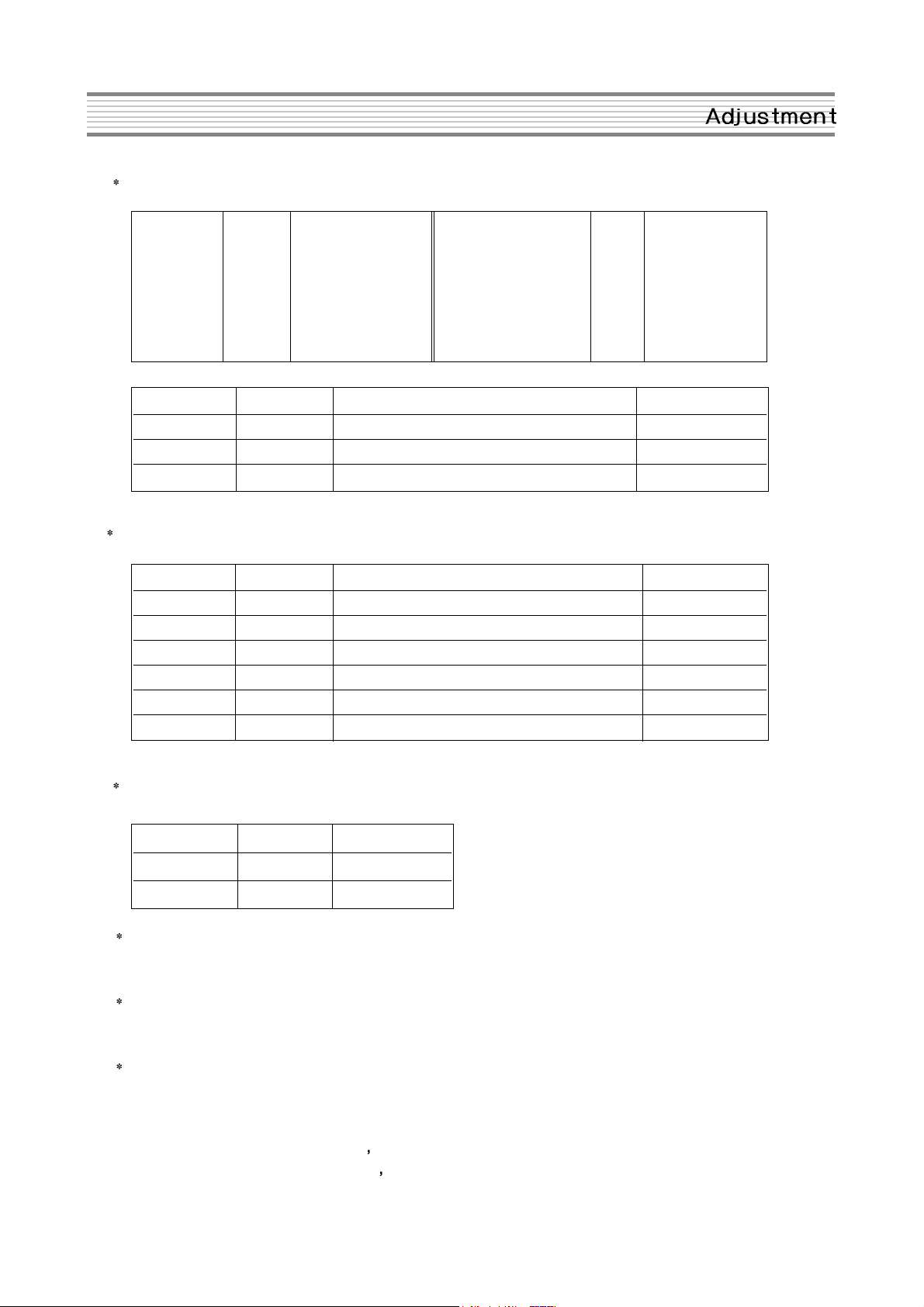

* PW364 (Adjusting Brightness Contrast and White Balance of full Iinput)

Item Initial Value Description

S Bright 64 Screen Brightness Fixing Value

S Contrast 64 Screen Contrast Fixing Value

R Bias 63 Red Color of Low level signal Adjusting Value

G Bias 63 Green Color of Low level signal Adjusting Value

B Bias 63 Blue Color of Low level signal Adjusting Value

R Gain 63 Red Color of Low High signal Adjusting Value

G Gain 63 Green Color of Low High signal Adjusting Value

B Gain 63 Blue Color of Low High signal Adjusting Value

SVC MAIN (Initial Data of the Service mode)

PW364 (Adjusting Brightness Contrast and White Balance of full input)

AD9884 (Adjusting Brightness Contrast of DTV/ PC input)

CXA2101 (Adjusting Brightness Contrast and White Balance of DTV input)

VPC3230 (Adjusting Brightness Contrast of TV / VIDEO/DVD input)

Test Pattern (Displaying in order R

G B W BLK

Lamp Watt (Adjusting Lamp Wattage 160W or 130W)

ENG Control (Adjusting LCD ENGINE UNIT)

Use Time (Total usage time of LCD panel)

Factory Set (operating Initalization)

DSJ6000LW200209181500 (Model name, micom version)

Page 10

- 9 -

AD9884 (Adjusting Brightness Contrast of DTV/ PC input )

CXA2101 (Adjusting Brightness Contrast and White Balance of DTV input)

R Gain 148 Fixing Value RED MIN 148

G Gain 148 Fixing Value RED MAX 148 Reading velue

B Gain 148 Fixing Value GRN MIN 148 automatirally

CLP PL 4 Fixing Value GRN MAX 148 accorling to

CLP DR 4 Fixing Value BLU MIN 148 adjustment state

Phase 15 Fixing Value BLU MAX 148

ITEM Initial Value Description

CXA1315A 42 Adjusting Red Color of Low level signal Adjusting Value

CXA1315B 40 Adjusting Green Color of Low levelsignal Adjusting Value

CXA1315C 40 Adjusting Blue Color of Low level signal Adjusting Value

ITEM Initial Value Description

Picture 63 Contrast Fixing Value

Bright 8 Brightness Adjusting Value

R Drive 22 Adjusting Red Color of High level signal Adjusting Value

G Drive 18 Adjusting Green Color of high levelsignal Adjusting Value

B Drive 16 Adjusting Blue Color of high level signal Adjusting Value

BLK BTM 15 Fixing Value

VPC3230 (Adjusting Brightness Contrast of TV / VIDEO / DVD input)

ITEM Initial Value

Sub Bright 0 Adjusting Value

Sub Contrast 20 Adjusting Value

Test Pattern

R => G => B => W => BLK

Lamp Watt (160W is 25% brighter than 130W but lifetime of Lamp is shorter)

160W

130W

ENG Control (Adjusting LCD ENGINE UNIT )

GAMMA (NORMAL, Natural1, Natural2) : NORMAL(NO GAMMA compensation ),

NATURAL1=NATURAL2

ROTATION Scren Rotation (0, 90, 180, 270)

COLOR Screen

s color compensation

sub CPU sub CPU

s initalization in Engine Unit

Page 11

- 10 -

TEMP Detecting the femperature in the inside of ENGINE

V-T Engine V-T compensation

*Use Time : Total usage time of LCD panel

*Factory Set (Operating Initalization)

Page 12

- 11 -

1. Specification / Feature

1-1. Product Specification

1-2. Product Feature

1-3. General Block Diagram

2. Power Supply

2-1. Summery

2-2. Block Diagram

2-3. Power structure

2-4. Power Action manual

3. Sound & Audio Amp

3-1. Summery

3-2. I/O Specification

3-3. Block Diagram

3-4. Action Manual

4. Video

4-1. Summery

4-2. Block Diiagram

4-3. Video Circuit Manual

4-4. *IF and Video Manual

5. Engine Drive

5-1. Summery

5-2. Block Diagram

5-3. Action Manual

Page 13

- 12 -

1.Specification / Feature

1-1.Product Specification

Page 14

- 13 -

1-2.Product Feature

TV Turn on/ off : The Lamp feature

When the main power lamp flickers on green, the screen will gradually turn on. During this instance, the power

button will not operate. When the process is completed, the main power lamp lights on green.

It is LCD-Projection TV characteristics that it takes a little while for the video to be displayed on the screen

when it is turned on. This is not malfunctioning; thus, please be patient and wait for a moment.

The degree of brightness will decrease insignificantly after 3 minutes is passed. This is not a breakdown; it is

only using a power saving process to maximize the lamp

s lifetime. (Lamp watt : 160W -> 130W)

When the power buttons are pressed, the main power lamp may flicker in green, but the secondary power lamp

may flicker in red and orange alternately. In this case, the TV

s main power has been erroneously pressed, or

has been turned off improperly by a power stoppage or by any other reason. However, please wait for an

instant, and the TV will be back on (the latest 1min. 30sec.) since this is not a malfunctioning of the product.

Turning off the TV set.

Press the power button on the remote controller or that of the TV set. Audio and Video will be turned off and

the main power lamp will flash. In green at this time. This is not malfunctioning nor an error; it is just a process

of cooling the lamp off. During this time, the power button will not operate. A red light will light up after a

minute.

1-3. General Block Diagram

Page 15

- 14 -

2. Power Supply

2-1. Introduction

The POWER PCB is composed of 140W Power for 60

LCD PTV(DSJ-6000LN) as well as

the Power that makes 380V and 18V primary voltage for Ballast.

2-2. Block Diagram(attach)

2-3. Power Supply Component

(1) Input Power : 100V ~ 240VAC, 50/60Hz

(2) Consumption Power : 270W

(3) Power Supply for the secondary side : See the table below.

No. location voltage Function Current remarks

1 T802 D5V Main and Video/Engine Power 1,000mA F/B Line

2 T802 33V Tuning B+ 3mA

3 T802 A5V Main and Video Power 1,000mA

4 T802 12V Main and Video Power 300mA

5 T802 9V Main and Video Power 80mA

6 T802 18V Ballast and PFC Control Power 150mA Primary

7 L805 380V Ballast Power 470mA Primary

8 T802 17.5V Engine Power 300mA

9 T803 7V/10V Engine Fan Power 1,000mA 10V (more than 45 degree

of Engine temperature

10 T803 +15V Audio Power 3,000mA

11 T803 -15V Audio Power 3,000mA

12 T801 ST5V Stand-By Power 600mA

2-4. Description of Operation

(1)Power Supply and Stand-by Power

(1-1) The voltage coming through Bipolar Power Code (PC801) passes through the

Line Filter composed of EMI Filter (L801, L802), X-Capacitor (C801, C803,

C806), and Y-Capacitor (C822, C823) and is rectified and smoothed in the Bridge

Diode (D803, D806, D831, D832) through the Mimetal that is the P303E

Temperature Sensor (Power OFF when Lamp Temperature 125 ~ 135).

(1-2) The smoothed voltage is supplied to the TOP232P that is STAND-BY POWER

IC(1804), and the TRANS secondary winding supplies STAND-BY Power (5V)

for U-COM.

Page 16

- 15 -

(2) MAIN Power Operation

(2-1) PWR SWITCH ON(HIGH) Signal is supplied from U-COM to the Base of Q804 via

P805M CONNECTOR, Positive Terminal Relay(Y801) is activated, then Starting

Voltage is supplied to the No.4 pin (Vin) of STR-F6656(IC802, IC803) via R836 and

R844.

(2-2) AC Power is rectified in the Bridge Diode(D801), and is applied to P winding of the

TRANS, and reaches 16V of TRANS Auxiliary Winding (No.7 pin), then Control

Circuit is active by the operation of Start Circuit.

(2-3) The winding voltage of the Auxiliary Winding (No.6 pin) is rectified, 18 V is upplied

to 1601(FA5332M) No. 3/16 pins, and the phase of Voltage/Current is compensated,

No.13 Pin Reference Voltage/No. 15 Pin OSC Timing C/R oscillates internally, and

mixed to AND Gate, passes to No.13 pin, and its voltage is elevated to DC380V

from L805 by FET Switching via Debias Stabilization Circuit (Q801/802). The

elevated 380V

is smoothed through Diode(D802), and is supplied to the Ballast via P804B.

(3) Specification of STR-F6656

STR-F6656 is the Hybrid IC for the power of Flyback Converter-type Switching where

Power MOSFET and IC for Control is installed. The characteristics of this IC are parts to

be added are just a few, and various protection functions such as Transient Current

Protection, Transient Voltage Protection, Overheat Protection), and has the QuasiResonance function proper for miniaturization and standardization.

The detailed specifications of this IC is as follows.

Pin Number Symbol Name Function

1 OCP/F.B OCP/F.B OCP detection input and Feed Back

2 S Source MOS FET Source

3 D Drain MOS FET Drain

4 Vin Vin Control circuit voltage Input

5 GND GND Ground

Symbol Function

OVP Over voltage protect

TSD Over temperature protect

<Extra Function>

Page 17

- 16 -

(3-1) Power Supply for Vin

When Vin Terminal (No.4 pin) voltage that is charged to C821, C830 through the Starting

Resistance reaches 16V(Typ), the Control Circuit inside the F6656 starts to operate. Here,

the Circuit Current is limited to 100

A(MAX) before F6656 operates, so the high Starting

Resistance (47K

,2W) is used. After F6656 operated, the voltage coming out of D

winding of TRANS (T802, T803) is rectified and smoothed, supplying the stable voltage

to the Vin terminal. Here,

dl winding is rectified and smoothed via D812, D816, C821,

and C830, and about 16V is supplied to the Vin terminal (No.4 pin) of F6656.

(3-2) OCP/F.B Terminal (Oscillator, Electrostatic Voltage Control Circuit)

Inside the F6656, there is the Oscillator that generates Pulse signal for controlling

electrostatic voltage in the secondary side by turning ON/OFF the MOSFET using the

charging/discharging of

C . When AC input is high or Load Current is low, the inflow of

the current of F/B terminal increases, and ON time decreases. The Oscillator has the

Transient Current Protection Circuit (O.C.P. circuit) of Pulse by Pulse type that controls

the oscillator

s output by detecting MOSFET Drain current s peak value per every pulse.

(3-3) D/S Terminal (Driver Circuit)

This Circuit is the circuit that charges/discharges the capacity between Gate-Sources of

Power MOSFET by receiving Pulse signal.

(3-4) Latch Circuit

This Circuit is the circuit that stops Power Circuit by keeping the output of the Oscillator

to LOW when the Over Voltage Protection Circuit (OVP) and Overheat Protection Circuit

(TSD) operate. The Sustaining Current of the Latch Circuit is 400

A(MAX) when Vin

terminal voltage is 8.5V, so if the current over 400

A is made to flow to the Vin terminal,

the Power Circuit keeps normal. This circuit activates the Latch Circuit only when OVP,

TSD Circuit operates or when external signal input is kept over 10

sec, by setting the

delay time in accordance with

C inside F6656 in order to prevent erroneous operation

due to Noise, etc. Besides, even though Latch Circuit operates, it is operated in

electrostatic power circuit in the Control Circuit so the Circuit Current gets elevated,

decreasing the Vin terminal voltage dramatically. When Vin terminal voltage gets below

Termination Voltage (10V TYP), the Circuit Current increases again, so Vin terminal

oltage decreases. That is, Vin terminal voltage increases or decreases between 10V and 6V

when Latch Circuit operates, it is possible to prevent Vin terminal voltage rising

bnormally. To cancel the Latch Circuit, Vin terminal voltage should be decreased to below

6.5V. Generally, it can be cancelled by turning off the AC power.

(3-5) Overheat Protection Circuit (TSD)

This Circuit is the circuit that operates the Latch Circuit when the Frame

temperature exceeds 150 degrees (TYP). In this circuit, the real temperature detection is

Page 18

- 17 -

carried out in the Control System, but MOSFET as well as Control Circuit element is on

the Frame, so the circuit operates same for the overheat of MOSFET.

(3-6) Transient Voltage Protection Circuit (OVP)

This Circuit is the circuit that operates the Latch Circuit when the Vin terminal voltage

exceeds 22V (TYP). Basically, this circuit protects Transient Voltage, but the Vin

erminal is supplied from the TRANS Auxiliary Winding, and this voltage is roportional

to the output voltage, so it operates when the secondary side out is transient voltage such

as when Control Circuit is open.

Page 19

- 18 -

Partition NAME DESCRIPTION

SIF SIF Signal from TV TUNER

Sound NTSC L/R The Selected Audio signal of 3 input Video

INPUT DVD L/R, DTV L/R The Audio signal of the DVD & DTV

PC L/R The Audio signal of the PC

I2C SCL, SDA

The controlling I2C signal of SOUND IC & DOLBY IC

MAIN L/R The Audio signal L/R

C The Audio signal Center

Sound W The Audio signal Woofer

SL/SR The Audio signal SURROUND L/R

HP L/R The Audio signal HEAD_PHONE

MON L/R The Audio signal MONITOR

OUTPUT

VOL L/R Volume control L/R SPEAKER

VOL C Volume control CENTER SPEAKER

Control VOL W Volume control WOOFER SPEAKER

VOL SL/SR Volume control SURROUND L/R SPEAKER

A_MUTE AUDIO MUTE

3. Sound & Audio Amp

3-1. Introduction

Sound Processor is composed of Switching that selects signal proper to the Select Mode among

Sound Signal of the Video Input (SIF, DVD, Input 1/2/3) and the Sound Signal of Graphic

(DTV, PC); and Signal Processor that generates Sound Signal (C, W, SL, SR) which is Dolby

decoded through MAIN L/R Sound Signal and IIC(SCL/SDA) Interface. Besides, it is composed

of Amplifier that amplifies the signal generated by Volume Control Block to the sound signal

proper for speaker capacity.

3-2. I/O Description

(1) Sound Processor

Page 20

- 19 -

3-4. Description of Operation

Sound Processor is composed of Switching that selects signal proper to the Select Mode

mong Sound Signal of the Video Input (SIF, DVD, Input 1/2/3) and the Sound Signal of

Graphic (DTV, PC); and Signal Processor that generates Dolby Prologic Sound Signal via

Sound DSP. In the VIDEO the SIF signal is received from TUNER in MSP3440G (SOUND

PROCESSOR IC) generates sound signal L/R. Besides, Among the Sound Signal (NTSC

L/R: VIDEO_1/2/3 Sound Signal L/R selected from the TUNER Sound Signal L/R,

CXA1855 (VIDEO SWITCHING IC), and DVD Sound Signal, a proper sound signal is

selected, then it is outputted to MAIN L/R. In the GRAPHIC, a proper signal is selected in

DPL3519A among the sound signal of DTV and PC, and outputs to MSP3440G, so MAIN

L/R can be selected. Also, D/A converted Sound Digital signal is generated to SERIAL

ATA(IS2_DA, 12S_CL, 12S_WS, I2S_OUT), so Central Sound signal (C) which is DOLBY

PROLOGIC Sound Signal, Woofer Sound Signal (W), and Surround Sound signal(SL/SR) is

generated.

Partition NAME DESCRIPTION

INPUT SOUND PROCESSOR Audio signal (the excepted HP L/R, MON L/R)

L/R Output L/R SPEAKER

OUTPUT

C Output CENTER SPEAKER

W Output WOOFER SPEAKER

SL/SR Output SURROUND L/R

3-3. Block Diagram

Page 21

- 20 -

In the AMPLIFIERM, the signal component that passed Volume Control Block is amplified

to the respective GAIN (MAIN L/R, C, W, SL, SR). L/R SOUND and SURROUND L/R

Sound are adjusted simultaneously, besides L/R Volume Balance can be adjusted. The Sound

of Center and Woofer is adjusted independently, and Volume Balance cannot be adjusted. The

Sound Signal decreased by Internal Volume Control of MS3440G and DPL3519A is

amplified through TDA7265 (25W+25W STEREO AMPLIFIER with MUTE). Main Sound

L/R and Central Sound Signal is connected to each Speaker via connectors, and the Sound

Signal from Woofer and surround is connected to external Jack, then is outputted when

additional Speaker is connected.

Page 22

- 21 -

4. Video

4.1 Introduction

The VIDEO Signal Processing Circuit of DSJ-6000LN converts PC signal(VGA~UXGA),

DTV signal (Y, Pb, Pr 1080i, 720P, 480P@60Hz), DVD signal (Y, Cb, Cr@60 Hz), Y/C

signal (60 Hz) as well as Image Processor PW364, to HD Video signal (1280 x 720 :

Progressive) proper to LCD Projection TV device of this appliance type. It is composed of

Video Processor, Digital TV Processor, Graphic Video Processor, Image Resizing Part

(PW364), LVDS Output, CPU Circuit for System Control.

4-2. Block Diagram

4-3.

Circuit Manual

(1) Video Processor Circuit

Video Processor receives Video signal whose Y/C Color Difference is separated, then

converts A/D in VPC3230 that is Video Decoder, and processes Component Video Signal

(Y/UV), and converts the Interlaced Video signal received from Line Doubler SDA9400 to

Progress Video signal. Also, DVD signal that is entered in Component Video signal enters

to another terminal, and processed likewise.

Page 23

- 22 -

(2) Digital TV Signal Processor Circuit

The Digital TV signal entering to the Component type is processed in CXA2101A that is IC

for processing TV Video Signal, and is outputted to Analog RGB signal, then is switched

according to the RGB signal of OC.

(3) Graphic Video Signal Processor Circuit

The RGB signal selected in the Digital TV signal and PC signal is converted to two channel

48bit digital RGB signal in AD9884D which is high speed A/D converter.

(4) Image Resizing Circuit

The Digital Video signal and Digital Graphic signal that enter to PW364 from the previous

part are selected, and Image Resizing is done that converts those signals in the proper form,

then the signal is outputted in 24bit RGB signal.

(5) LVDS Output Circuit

The Video signal and Synchronizing signal (H,V sync) converted to the display format of this

appliance system is converted to LVDS signal in the TH63LVDM83A that is the LVDS

Transmitter in order to transfer to LCD Engine.

(6) System Control Circuit

This system is composed of two U-COM, and the overall system control is done in the Main

U-COM, the signal is sent that controls all IC except Engine Block, and the System Control

controls regarding image resizing, and process the key entered from the Front Key, then

controls the front-display LED.

4-4. IF Circuit & Video Circuit Structure

This IF Circuit and Video Circuit receives NTSC broadcasting signal and its corresponding

external video signal, DVD, DTV, PC signal via I set of Antenna Input in the terminal board and

6 set of external video jacks including 3 set of NTSC video jacks, then video processing is done

properly.

(1)IF Circuit

IF Signal Processing is as follows.

(1-1) NTSC TV RF Signal received from the Antenna Input of the Terminal Board enters to

TUNER (TU601).

5V, 9V : TUNER Main Power

33V : Voltage for Tuning (Vt Voltage)

(1-2) A desired broadcasting channel is selected from the TV broadcasting signal selected by

Remote Control or Switch in such a way that the data

sent from pins of SDA and SCL of

-COM are routed to Pin 4 and 5 of DATA/CLK of

Page 24

- 23 -

TUNER, and those data are converted to TUNER (IF) signal in the PLL inside the Tuner and

Tuner IC.

(1-3) The carrier of the selected broadcasting signal is converted to PIP frequency (P:

45.75MHz, S: 41.25MHz, C: 42.17MHz), and modulated to IF signal of TU. The

modulated IF signals are converted to Composite Video and SIF signal in the internal IF

Module, then are sent to each Video_Out Port(#16) and Audio_Out Port (#13).

(2) NTSC Video Signal Switching Circuit

Signal Processing of Video Signal Switching Circuit is as follows.

(2-1) In the case of NTSC ANT Input, the Composite Video Signal sent from Tuner

Video_Out Port (#16) is sent to TV Pin 41 of Video Switching IC CXA1855(U101) via

Tr Buffer(Q101), and 3 set of external Video Jack Input 1, 2, 3 are, respectively, sent to

Switching 1,2,3 Input Port of CXA1855.

(2-2) The 4 set of NTSC Video signal sent to CXA1855 is switched to the inside and is

outputted in the Video_Out 2 terminal. At this time, one of the Composite signal

coming from Vout Pin 23 and Yout2, Cout2 Pin (19, 21) is selected via Switching IC

MM1232(U104).

(2-3) The selected Composite or Y/C signal is sent to 3D Comb Filter IC uPD4082(U105) via

Filter, and is processed. This IC is three dimensional Y/C Separate IC, and has the

external AD Converter and 4M bit EDO Memory, and process Y/C separation and

YCNR (YC Noise Reduction) when Composite and Y/C signals are coming.

(2-4) The Y/C signal processed in D Module is routed to Video Board via TR Buffer (Q106,

Q107), respectively.

(2-5) In the case of Monitor Out, 3D Module Input Composite signal and 3D Module Output

Y/C signal are outputted via Buffer (Q102, U102, U103).

(3) DVD, HDTV, PC SIGNAL PROCESSING Circuit

Input of DVD, DTV, and PC signals are sent to A/V Board and Side Board Jacks, then sent to

Video Board directly.

Page 25

- 24 -

Page 26

- 25 -

5. Engine Drive

5.1 Introduction

The Engine Drive Signal Processing Circuit of this DSJ-600LN is the circuit for

generating and supplying Video Signal and Driving Signal to activate 3 LCD Panels. It is

composed of RGB Video Processing, Panel Driving Signal Generating, and Panel

Auxiliary Signal Generating sectors.

5.2 Description of Operation

5-3.

Circuit Manual

(1) RGB Video Signal Processing Circuit

RGB 10 bit of Digital Video signal (3.3 Vpp) processed by G/A for LCD Panel and

IC(SLA550TH) for compensating Unit is outputted along the LCD Panel connected to LCD

driving board in such a way that 10 bit digital data are converted to the Video Signal for

driving LCD of 2x6 channel their levels are adjusted (10.0Vpp; 2.0V~12.0V) by Serial D/A

Converting IC(M62393).

(2) Panel Driving Signal Generating Circuit

The Panel Driving Timing Signal (3.3Vpp) developed from IC(SLA550TH) for processing

Panel Signal is supplied to the LCD Panel by Level Shifter IC (ET1030F0A) by doing level

shift to Level(15.5Vpp) necessary for driving the Shift Register inside the LCD Panel.

Page 27

- 26 -

(3) Panel Auxiliary Signal Generating Circuit

The Panel Driving Auxiliary Signal developed from IC(SLA550TH) for processing Panel

Signal is supplied to Panel through 4 each composite Transistor(XN4051) by doing level shift

to the Level(10.0Vpp; 2.5V~ 7.5V) necessary for free-charging the Video Line inside the

Panel by the Level Shifter IC(ET1030F0A).

Page 28

- 27 -

No “Power On”

(Timer on/off and the main

power lamp lighting in red)

Check fixing state of air filter

(Power On after removing air filter and

pressing Detect S/W by hand or tape)

Check Fixing state of lamp Door side

(After pulling up Door side, Power On

when pressing Detect S/W on the left

side of engine by hand or tape)

Check whether Sensor (DETECT S/W)is

wrong or not, and fix air filter correctly

After checking Detect S/W is wrong or

not, pull down and fix Door slide

correctly

Replace VIDEO PCB ASSY

Replace POWER PCB ASSY

Check voltage of pin 14 (PWR-CTL) in

P612V at Main PCB

Check voltage of pin 1 (PWR) in P605 at

Main PCB

When turning set on, the voltage is more

than 1V in a short time, then it goes to 0V

Check whether all 4 Pins in P619L and

P621L at Main PCB are short

Replace CONNECTOR

OK

OK

0V

0V

Contact badness of P619L, P621L CONNECTOR

NG

NG

Page 29

- 28 -

No “Power On”

(Timer on/off and the main power lamp

flickering in red and orange alternately)

Remove lamp and then fix it again Check normal operation

OK

Check output voltage of P804(POWER)

(380V / 18V)

Replace Power PCB

Less than 2V

Check voltage of pin 1 (Lamp_On) in

P626C at Main PCB

Replace Main PCB

Check voltage of pin 3 (Error) in P626C

at Main PCB

Check voltage of pin 3(32PIN) in

P612V at Main PCB

Replace MAN PCB Replace VIDEO PCB

Replace lamp and then

check mormal operation

Replace LCD ENGINE

Page 30

- 29 -

No “Power On”

(Timer on/off and the main power lamp

lighting in orange)

Check if Engine Fan acts for a moment and stops

(Check if air blows to center ventilation hole on

backside of product)

Check voltage of pin 7(7V/10V)

in P806M at Power PCB

Replace Power PCB

Check “Short” between output

voltages at Power PCB and GND

Replace

LCD ENGINE

Replace

SHORT PCB

Replace MAIN PCB Replace VIDEO PCB

Contact badness

of Connector

Check voltage of pin 5 (ID_1)

in P626C at Main PCB

Check voltage of pin 3 (32Pin) in P612V

at Main PCB

Remove Engine Unit, Check if it’s

short between pin 3 (Red wire) in

P922E at interior PCB (1x3cm) in

Eugire and Pin 5 in P626C at main

PCB

The voltage is mane

Then DC 5V in a short

Time, then it goes to 0V

POWER ON

NO

0V

More than 0.5V

NO SHORT

SHORT

NO YES

Less than 2V More than 2V

0V

Page 31

- 30 -

No “Power On”

(The main power lamp is

not red)

If DRAIN and SOURCE Impedance value approach

0 ohm, replace I804 because it is broken

The main power lamp is not red

FUSE CHECK

I821 CHECK

(POTO COUPLER CHECK)

Check if ST5V is correct.

When pressing Power button, check if

The main power lamp is red

END

I804 CHECK (TOP232P)

R895, R896 SHORT CHECK

D803, D806, D830, D831 DIODE CHECK

D836 CHECK

Check always because it’s part of feed back

Page 32

- 31 -

No “Power on”

(the main power lamp is red.

stand-by Power is on)

Check I802 18V Regulator Replace

Replace 5332 Module END

END

When part is destroyed by lightning and shock, D801, Q803, FUSE is easily damaged

I802 is often destroyed by shock of the primary and the secondary

Check normal voltage

END

Check voltage waveform of Q803

SPEC.3.3V, (if it is more than 1.5V:Normal

operation), if less than 1.5V:Check path of

MAIN. VIDEO Circuit

Check P805M WAFER Power ON/OFF

Check Q804 Tr, D829 SHORT TEST

Check if POWER CORD is OPEN

Check D801

Check Q803

Page 33

- 32 -

No Display

(DTV / PC Input)

When pressing Menu

button, is OSD displayed?

check LVDS of IC225E

#2,3 #5,6 #8,9 #11,12

Check output of CLK in IC213

Check Sync Output in IC216

ClK : #3, H_sync : #6, V_sync: #3

Check CLK output and Sync in IC217

CLK : IC213 of #2

H_sync : IC216 #5, V_sync : IC216 #2

Check R,G,B output of IC226

R : #35, G : #37, B : #39

Check signal output of DTV of

PC and Set Connection

Check sync output in IC227

H_sync : #3, V_sync : #6

Check DTV/PC_SEL signal

#9, 10 of IC224

DTV(high), PC(low)

Check H_sync output of IC236 #7 &

sync output of IC228

h_sync : #7, V_sync : #3

Check P211M DTV input

Y : #17, Pb : #19, Pr : #21

Checkconnectionbetween#17,19,

21 of P211M and #1(Y), #2(Pb)

#3(Pr) of J108

Is ‘No Signal’ displayed?

If pressing “recall” key, does

correct resolution to input signal ?

Check R,G,B output of IC227

R: #14, G:#15, B:#4

Check DTV/PC_SEL signal

#9,10,11, of IC230

DTV(high), PC (low)

Check PC input of P211M

H_sync: #29, V_sync : #31

R : #23, G : #25, B : #27

Check Y, Pb, Pr, SCP input of P226

Y : #5. Pb : #4, Pr : #3, SCP : #31

Checkconnectionbetween#23,25,27,29,31

of P211M and #1,3,5,7,9 of P913M (side

jack)

Does Power LED operate

normally in green?

Lamp, Fan,

Abnormal Power

1

END END

IC216 abnormal

1

Page 34

- 33 -

No Display

(RF / VIDEO / DVD)

LAMP, FAN, Power abnormal

Does Power LED operate normally in green?

When pressing Menu button, is OSD

displayed normally?

RF signal is off RF, VIDEO Screen is off

Check U101 (1855) output

(#19-C, #21-Y, #23-V)

Check after Q106, Q107 Repair

(#E-C, #E-Y)

Is IC219 (3230) output correct?

(#Y0~#Y7, #C0~#7)

Check after IC218 (9400) repair

(#VPT00~#VPT20)

Check after

repair

Check after

connection

Check after

connection

Check Input signal

(480i)

Check after

connection

Only DVD Screen is off

Check IC219 (3230) input

(#4-B, #5-G, #6-R)

Check after IC219 Repair

(#Y0~#Y7, #C0~#C7)

Repair Engine BOARD

CheckIC217 (PW364) output

(#DPT00~#DPT23)

Check IC220 (LVDS IC) output

(#LVDS00~#LVDS09)

Check U104 (1232) output

(#5-Y/V,#6-C)

Check connection of antenna

Check TU601 (TUNER output)

repair

Check after Q101 repair (#E)

Is all Screens not displayed?

(RF / VIDEO / DVD)

Page 35

- 34 -

No SOUND

Check SOUND MUTE

Check each input CABLE

Check input signal

AUDIO AMP

Check input/output

END

MAIN L/R : IC601(#27,28) CENTER : IC602(#28)

WOOFER : IC601(#30) SURROUND L/R : IC602(#24,25)

HEADPHONE : IC601(#36,37)

RF

Check TU101 SIF input Check IC601 (#67) Signal

External Input 1/2/3 Check U101 (#20,22) output Check IC601 (#47,48) Signal

DVD

Check P610A (#10,11) path Check IC601 (#50,51) Signal

HDTV

Check P610A (#15,16) path Check IC602 (#50,51) Signal

MAIN N/R INPUT : IC604(#7, 11) OUTPUT : IC604(#2, 4)

CENTER/WOOFER INPUT : IC605(#7, 11) OUTPUT : IC604(#2, 4)

SURROUND L/R INPUT : IC606(#7, 11) OUTPUT : IC604(#2, 4)

PC

Check P613S (#11,13) path Check IC602 (#53,54) Signal

Check SPEAKER CONNECTOR

Check IC601 & IC602 output

Page 36

-35-

Z86129

(caption/rating)

Page 37

-36-

131

7172401412

1

SCREW TAPTITE

TT2 TRS MFZN 4X14 BK

93

2

4

3

123 5

7 8

10 12

11

129

127

126

124

1

82 83

79 80 81

77

117

78

118

113

6463

76

69 70

67

65

68

107106

61 62

116

55

115

56

66

105

100

75

113

16 17

19 20

18

1514

13

72

73 74

119

90

103

60

102

71

133

96

95

5857 59

98

97

32

3938

363337

EXPLODED VIEW

PART NAME

DSJ-6000LN

4X14 MFZN BK

TT2 WAS MFZN 3X12 BK

4X20 WAS MFZN BK

TT2 BIN MFZN 3X10 ZINC

TT2 TRS MFZN 4X14 BK

HIPS BK + JERSEY

DIGITAL TV RESEARCH CENTER

DAEWOO ELECTRONICS CO., LTD.

REFERENCE

NAME

MODEL

127

2

BOX BOTTOM

4958002102

129

121

No.

120

118

119

125

122

123

124

130

128

126

127

2

CLOTH BLACK

4957800600

SHIELD DOOR

BUTTON COTROL

PART NAME

SPEAKER

PART CODE

4957204000

4954800600

Q’TY

1

8

4

BAG P.E

DETECT SW AS

BOX CARTON

BOX UPPER

MARK BRAND

4958002101

4958002100

4955600200

4958200602

4958101100

4958102100

PAD

PAD

1

1

1

2

2

1

133

128

132

130

131

125

CLAMP WIRE

CLOTH BLACK

BAG INSTRUCTION

CLAMP WIRE

4957800600

4856815400

4858213800

4956801000

1

2

1

2

DW-4

3

SCREW TAPTITE

7172401412

12

4857818503

4957904700

4953802501

4952301101

4857818503

4952001800

4952002000

7171301011

4953901700

4952001900

4952001700

PART CODE

0.7T 40X120

4

MATERIAL

SPONGE 8T 10X115

ABS (AL)

REMARKS

No.

N/S

mm

SCALE

UNITS

3

2

1

FOAM T0.5X1900X1550

DW-4

AL T=1.0 DIA-CUTTING

DW-4

E.P.S

E.P.S

8

7

5

6

10

9

11

16

SCREW TAPTITE

INSPECTED BY

MASK FRONT L

MASK FRONT T

BRKT CLAMP B

PART NAME

CHECKED BY

DESIGNED BY

.. ...

Q’TY

APPROVED BY

..

.

2

1

1

CLOTH BLACK

PANEL CONTROL

FRAME NET

SCREEN

MASK FRONT B

MASK FRONT R

CLOTH BLACK

1

8

1

1

4

2

1

4956000700

4952300901

4953903000

4955901300

4956000600

4952301001

4952800301

4952200300

7178301212

4955000301

4856716000

4954800501

7173301011

4955700501

4955700601

4953501101

L.D.P.E T0.05X250X400

0.7T 40X120

NYLON 6/6

NYLON 6/6

16

15

14

13

20

19

17

18

24

22

21

23

25

26

27

28

SPRING

SCREW TAPTITE

DECO CONTROL

BUTTON POWER

SCREW TAPTITE

HOLDER CONTROL

DECO LED POWER

DECO LED

1

1

1

2

1

1

4

1

SCREW WOOD

DECO PANEL AV

BRKT WOOD S

PANEL AV

CABINET WOOD

PANEL FRONT

DOOR LAMP

SCREW WOOD

1

1

1

5

1

3

1

2

49500026

T

/

D

TT2 BIN 3X10

1 OF 1

PAGE OF DRAWING

REMARKS

MATERIAL

AL 6063

AL 6063

AL

T=0.5 20X300

AL 6063

AL 6063

T=0.5 20X300

HIPS WH-081A

HIPS BK

PMMA

PMMA

SWPA PIE0.5

ACRYLE T=3

ABS BK

MDF T=15

HIPS BK

HIPS BK

HIPS BK

PVC T=0.25

SECC T=1.6

4X20 WAS MFZN BK

4X20 WAS MFZN BK

TT2 WAS MFZN 3X12 BK

TT2 BIN MFZN 3X10 ZINC

TT2 BIN MFZN 3X10 ZINC

TT2 BIN MFZN 3X10 ZINC

M-WAS 3X10 MFZN

M-WAS 3X10 MFZN

M-WAS 3X10 MFZN

TT2 BIN MFZN 3X10 ZINC

M-WAS 3X10 MFZN

TT2 WAS MFZN 3X12 BK

TT2 TRS MFZN 4X14 BK

TT2 TRS MFZN 4X14 BK

TT2 TRS 4X14 MFZN BK

TT2 BIN MFZN 3X10 ZINC

TT2 TRS MFZN 4X14 BK

TT2 TRS MFZN 4X14 BK

TT2 TRS MFZN 4X14 BK

TT2 TRS MFZN 4X14 BK

NYLON 66 BLK 5280N

4X14 MFZN BK

FOMEX 80PPI

M-WAS 3X10 MFZN

PVC T=1 + SPONGE T=15

4X20 WAS MFZN BK

1

COVER BALLAST

4957502601

61

21

22 23

84

120

8786

122

85

88

89

94

24

7172401412

7173301011

7172401412

7172401412

7172401412

7172401412

4956000600

4956000600

4953802400

4953600701

4953501200

4953902500

4953902801

4953902701

4953902900

4953902600

31

29

30

32

36

35

34

33

38

39

40

37

41

43

44

42

SCREW TAPTITE

SCREW TAPTITE

SCREW WOOD

SCREW WOOD

BRKT MIRROR R

BRKT MIRROR L

BRKT MIRROR B

BRKT WOOD C

8

6

2

1

2

4

11

1

SCREW TAPTITE

SCREW TAPTITE

SCREW TAPTITE

SCREW TAPTITE

TERMINAL ANT

FRAME MAIN PCB

BRKT MIRROR T

HOLDER PCB

6

2

1

1

9

3

1

1

7178301212

7172401412

7172401412

4956000600

4957903801

4957501900

7008301011

4957700400

4957501800

4957701000

4952101501

4957701100

4957502001

4957904300

4955901100

4953903701

45

47

46

48

49

52

50

51

57

53

56

55

54

60

59

58

SCREW TAPTITE

SCREW TAPTITE

SCREW WOOD

COVER BACK

CUSHION MIRROR T

COVER REAR

MESH STEEL

DECO TERM

6

1

1

1

4

17

1

7

SCREW TAPTITE

DUCT OUT R

CASE ENGINE

CUSHION P-LENS

SCREW MACHINE

COVER ENGINE T

CUSHION MIRROR B

DUCT OUT L

1

2

1

1

2

6

1

1

2625

27

121

91

3130

28 29

40 41

42

112 114

43 44

1

BRKT SCREEN T

4953901800

77

7008301011

7008301011

7008301011

7173301011

7008301011

4952800500

4957300600

4956900200

4952301100

4956800600

4957502100

4953802701

4957203100

4953802601

4953903601

69

65

63

62

64

68

67

66

73

72

70

71

75

74

76

1

FRAME DOOR SLIDE

SCREW MACHINE

SCREW TAPTITE

SCREW MACHINE

CLAMP BALLAST

COVER ENGINE F

SHI CASE BALLAST

FRAME BALLAST

1

4

6

1

4

1

1

SCREW MACHINE

SCREW MACHINE

DOOR SLIDE

SU

PP

O

R

T C

O

N

N

E

C

TIO

N

BUSHING TERMINAL

BUSHING LVDS

DUCT ENGINE INLET

1

6

1

2

4

2

1

7178301212

7173301011

7173301011

7173301011

4957700100

97P4602700

4952600100

4953903501

4953903101

4956000700

4953901600

4957903800

4952800401

4953902000

4953902100

85

81

78

80

79

82

83

84

89

87

86

88

90

91

92

1

FILTER DUST

BRKT CLAMP A

SCREW TAPTITE

DOOR FILTER

BRKT SCREEN L

BRKT SCREEN R

SCREW TAPTITE

SCREW TAPTITE

10

8

1

1

2

18

1

SCREW TAPTITE

CUSHION DUST

HANDLE CABINET

CLAMP CORD

DUCT IN T

DUCT IN B

SCREW WOOD

4

8

1

1

1

2

1

HIPS BK

FR HIPS BK

SECC T=1.6

HIPS BK

HIPS BK

FR HIPS BK

SECC T=1.6

FR HIPS BK

HIPS BK

HIPS BK

SECC T=0.8

PVC T=0.25

CR

HIPS BK

HIPS BK

SECC T=1.6

CR

SECC T=1.6

HIPS BK

AL 6063

PC ABS

HIPS BK

SECC T=1

FR HIPS BK

SECC T=1.6

FR HIPS BK

CR

CR

PC ABS

NYLON

AL 6063

AL 6063

HIPS BK

AL

HIPS BK

HIPS BK

SPONGE T=40

HIPS BK

9

66

132

54

53

52

108

34 35

99

111110

51 50

TRS 4X24 MFZN BK

-------------

ADDA AD0512ME-D70

M4 PAN 4X12 MFZN

101

109

45

4649 48 47

93

92

4953901900

4957701200

7001401211

97P2316600

4952700050

4956900300

4957904600

4957700800

4957700500

4956900100

4957700600

4957700700

97

94

95

96

101

98

99

100

103

104

105

102

108

107

106

109

HOLDER AC CORD

BUSHING FAN

MIRROR

CUSHION SOUND B

CUSHION SOUND R

RUBBER BUSHING

CUSHION SOUND L

CUSHION SOUND T

2

12

1

1

1

1

1

2

A/V PCB AS

CUSHION MIRROR S

DETECT SW AS

CONNECTION PCB

BRKT SCREEN B

CONNECTION PCB

SCREW MACHIINE

LCD ENGINE AS

1

1

7

1

2

1

1

1

7122402412

4957800400

--------

4957904400

4957700300

112

111

110

113

114

117

116

115

CLOTH BLACK

SCREW TAPTITE

SHIELD CASE

DC FAN

VIDEO PCB AS

MAIN PCB AS

POWER PCB AS

CUSHION CASE ENGINE

1

1

8

1

4

3

1

1

NYLON66 UL/CSA

SPONGE 10T

SPONGE 10T

SPONGE 10T

CR

SPONGE 10T

T=5

CR

AL6063

40X14

DEK-1

SPONGE 10T

40X50

CR

INOAC F-9L T=10

0.7T 10X125

Page 38

-37-

Page 39

Loading...

Loading...