Daewoo DWD-L100. Service Manual

S/M No. :

DWDLD14004

Service Manual

Drum Washing Machine

Model: DWD-L100 Series

✔ Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information, please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

May. 2011

DRUM WASHING MACHINE

SERVICE MANUAL

1. WHAT IS DRUM WASHING MACHINE? ......................................1

2. WASHER SPECIFICATION ..........................................................3

3. PARTS LIST BY ASS'Y .................................................................4

4. CONTROL PART FUNCTION SPECIFICATION ........................21

5. ELECTRONIC FIELD PARTS LIST AND SPECIFICATION .......33

6. WIRING DIAGRAM .....................................................................34

1. WHAT IS DRUM WASHING MACHINE?

1. Drum Washing Machine

Water consumption is reduced by using the power of the laundry falling (free-fall) created when rotating

the drum. With temperature control system, this drum washing machine saves energy and improves

washing performance at the same time.

2. Key Features

◈ Waist Care

Designed by the waist, and the most comfortable

angle eject into the laundry is convenient and easy to

manipulate.

◈ Star Drum

Using Star Drum is able to show users higher

Washing Performance and Minimal damage of

laundry, water consumption.

◈ Luxury Audio Dial

Using the advanced Audio Dial is luxury design of

exterior.

◈ DD inverter motor

The direct-drive type of which motor is directly

connected to drum without an interim clutch,

significantly reduces noise and vibration.

◈ Self-Cleaning Course of Drum.

Enables the machine to do Self-Cleaning of Drum.

◈ Digital Condensing Dry System.

Condensing Dry System with saveing energy.

1

3. Power System

LAUNDRY

Pump Drainage

• DD Control: Direct drive type of direct connection between drum and motor

• Rotation by powerful high-performance BLDC motor

BLDC

2

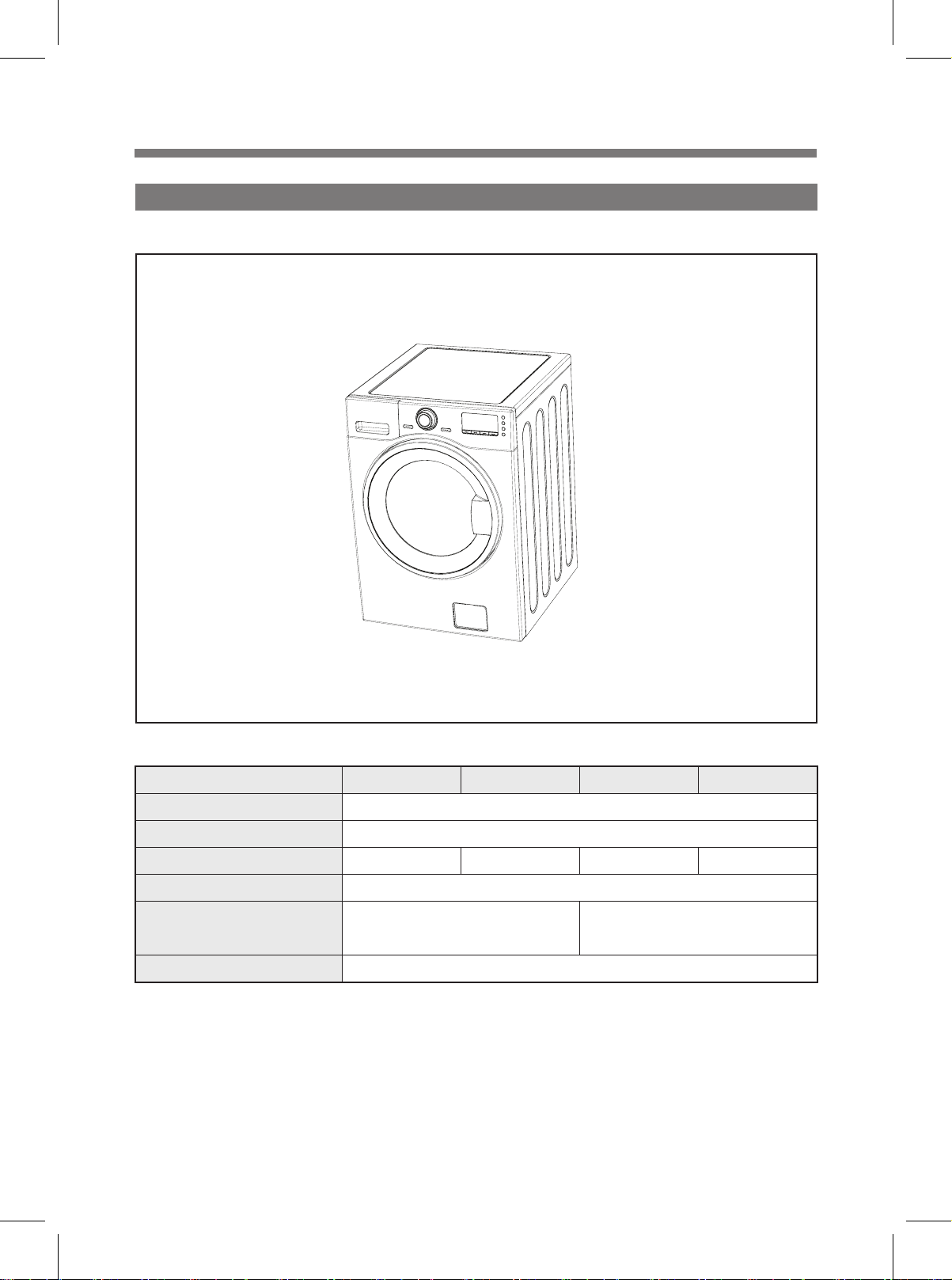

2. WASHER SPECIFICATION

1. Product Specification

■ 2st Model

MODEL DWC-LU1011/1211 DWD-LU1011/1211 DWC-LD1411/1611 DWD-LD1411/1611

Dimension (mm) 600 X 645 X 850

Maximum mass of textile (kg) 9 Kg

Unit Weight (net/gross) 78/82 71/75 76/80 69/73

Standard Water Consumption 65 ℓ

Spin Speed (RPM)

Operating Water Pressure 0.03MPa ~ 0.8MPa (0.3kgf/cm2 ~ 8kgf/cm2)

DWC(DWD)-LU10XX : MAX 1000

DWC(DWD)-LU12XX : MAX 1200

33

DWC(DWD)-LD14XX : MAX 1400

DWC(DWD)-LD16XX : MAX 1600

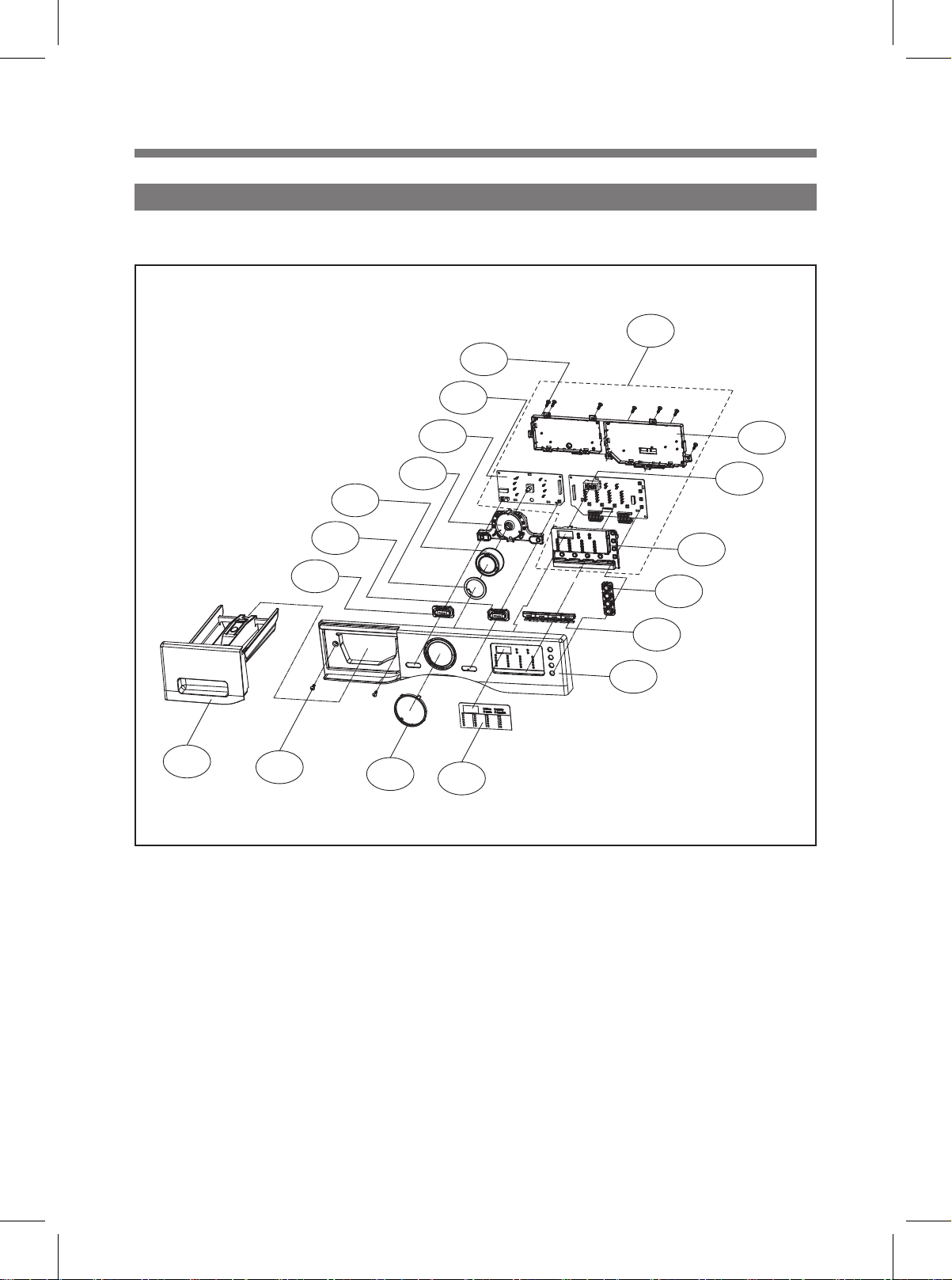

3. PARTS LIST BY ASS'Y

1. PANEL F AS

■

2st Model

A04

A04-2

A04-3

A12

A11

A07

A08

A06

A10

A04-4

A05

A04-1

A04-0

A04-5

A03

A02

A01

A09

4

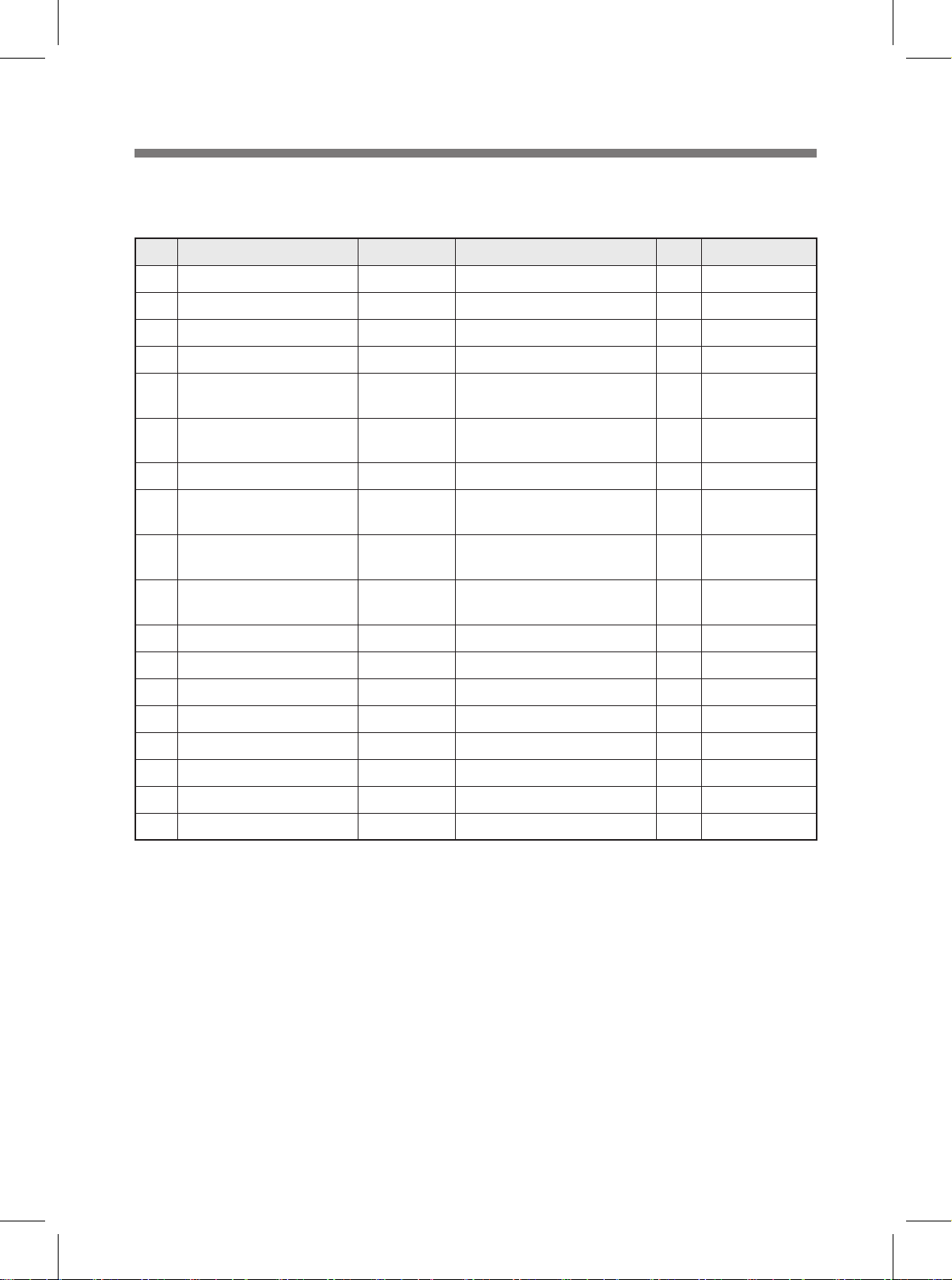

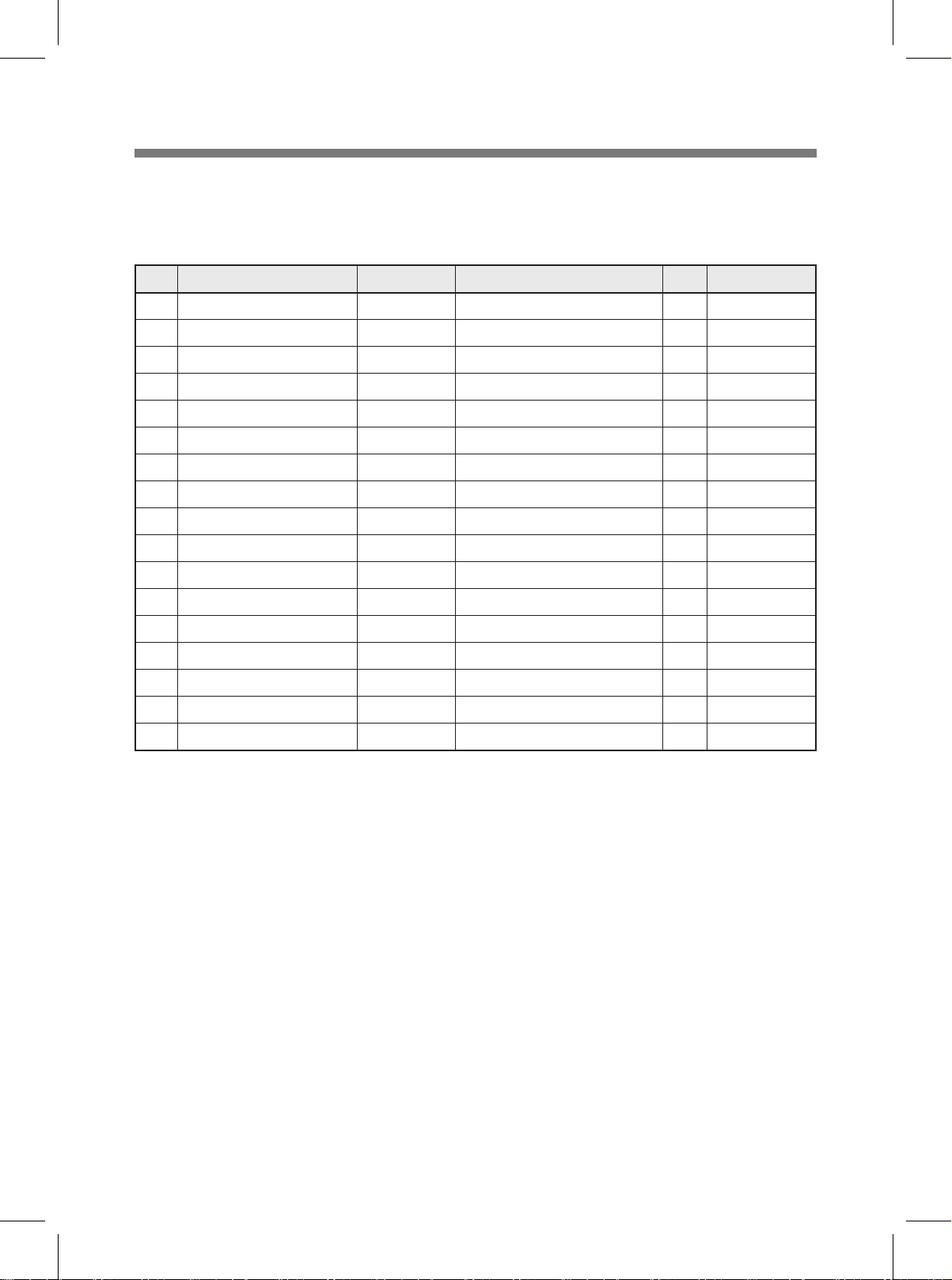

No. PARTS NAME CODE SPECIFICATIONS Q’TY REMARK

A01 PANEL *F 36142T2100 ABS 2 4x16 SUS 430

A02 BUTTON FUNCTION 3616644400 ABS 1

A03 BUTTON OPTION 3616644700 ABS 1

A04 PCB AS PRPSSWL052

A04-0 HOLDER LED DISPLAY 3613058600 ABS 1

A04-1 CASE PCB F 36111T1R00 HIPS 1

A04-2 SCREW TAPPING 7122401611 T2S TRS 1 4x16 MFZN

A04-3 PCB BOARD F 3614348500 FR-1 1

HOLDER LED COURSE 3613058400 HIPS 1

A04-4

A04-5 HOLDER LED FUNCTION 3613058500 HIPS 1

A05 KNOB DIAL 3616644300 ABS 1

A06 DECORATOR BUTTON DIAL 3611696400 ABS 1

A07 BUTTON START 3616644600 ABS 1

A08 BUTTON POWER 3616644500 ABS 1

A9 DECORATOR FILM 3611696500 P.C FILM 1

A10 WINDOW COURSE 3615509400 TR-ABS 1

A11 SCREW TAPPING 7122401608 T2S TRS 1

L'S 2ND FRONT PCB AS (LD14,STANDBY 1W)

1 stand by

Not being supplied

for replacement

Not being supplied

for replacement

Not being supplied

for replacement

Not being supplied

for replacement

Not being supplied

for replacement

CHROMIUM CILDING

CASE DETERGENT AS 36111T1P10 PP 1

A12

5

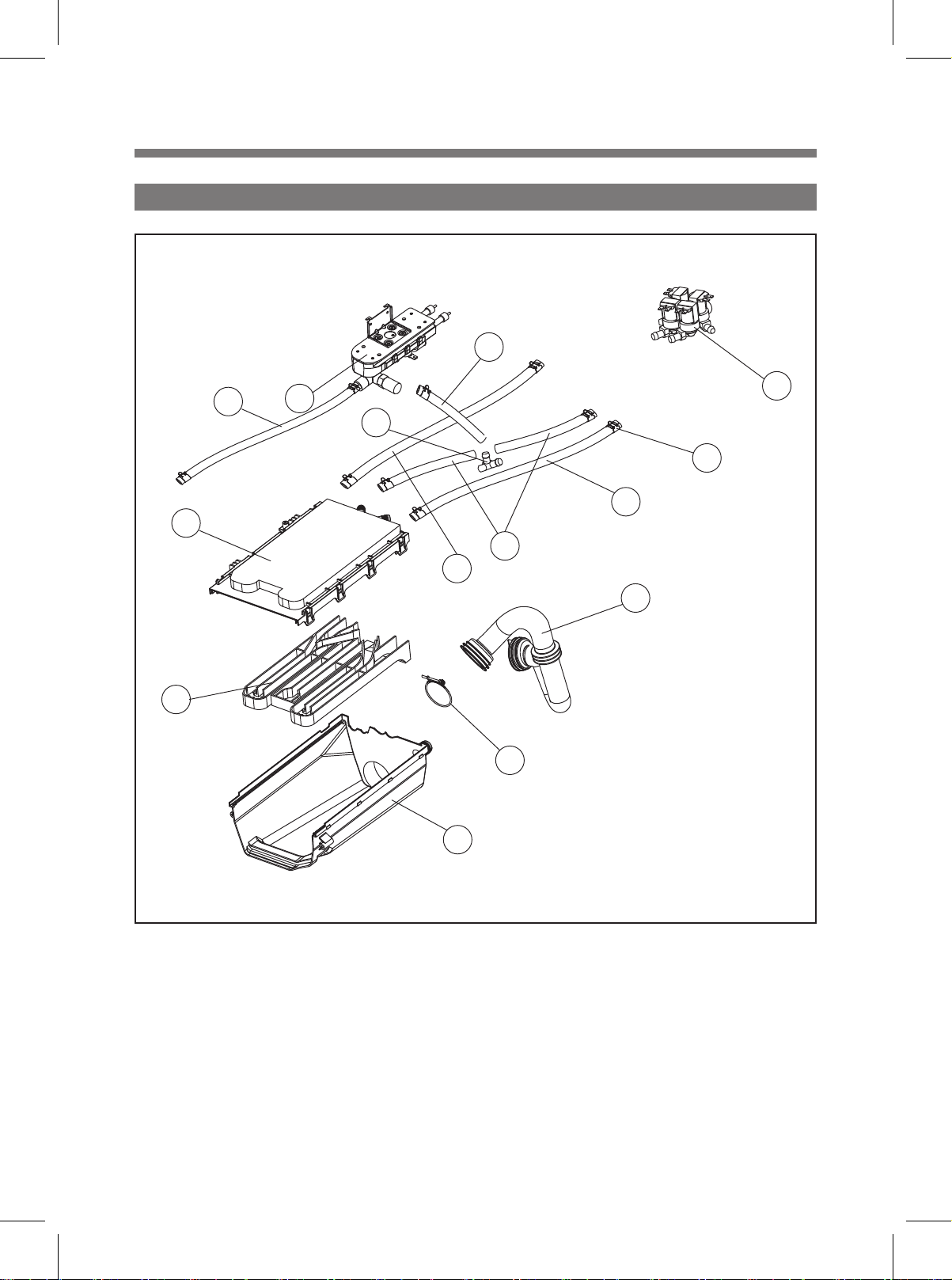

2. INLET BOX AS

B11

B02

B01

B14

B13

B06

B12

B09

B07

B08

B10

B04

B05

B03

6

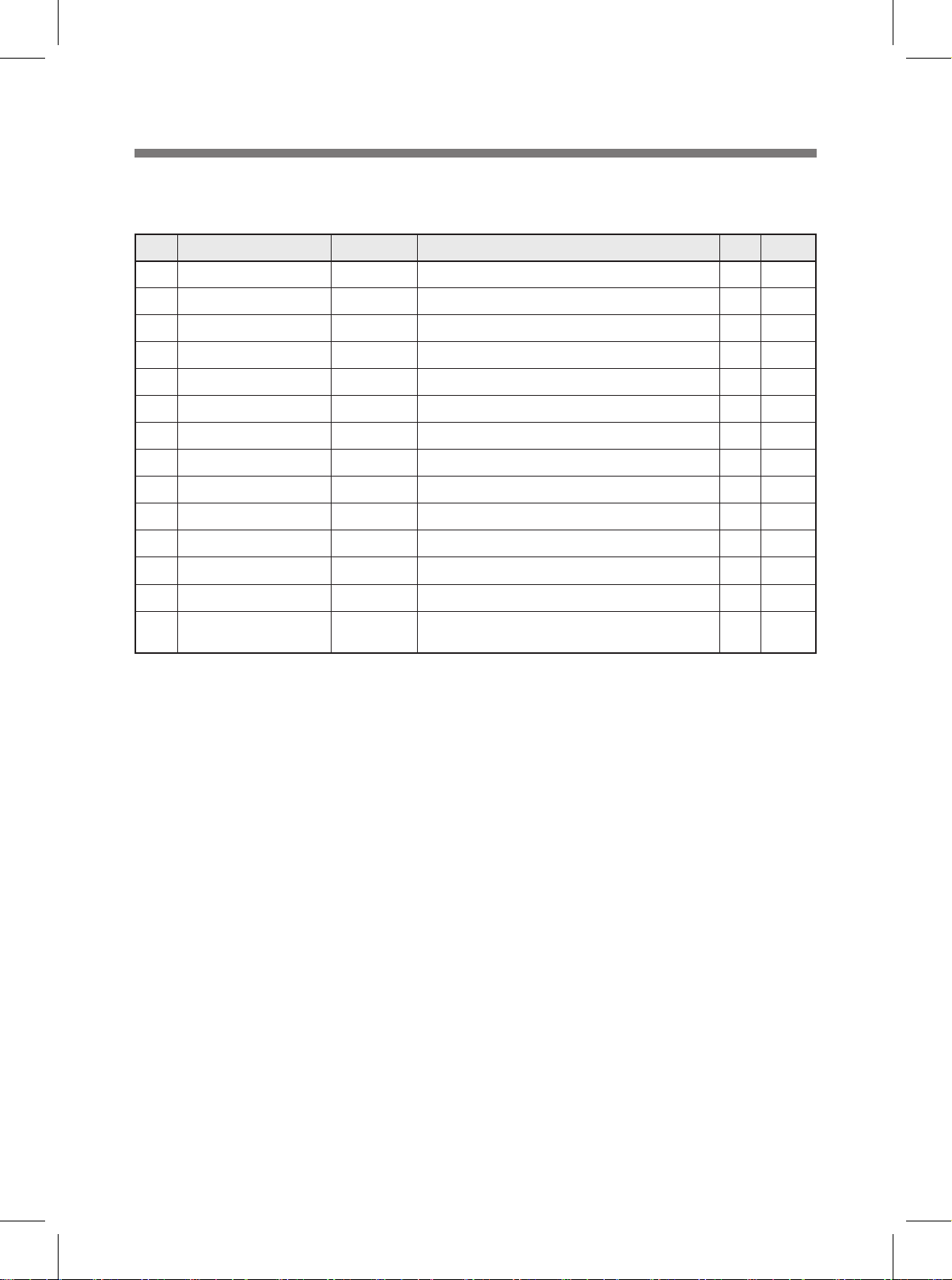

No. PARTS NAME CODE SPECIFICATIONS Q’TY

B01 NOZZLE *T 3618111100 PP 1

B02 NOZZLE *U 3618111000 PP 1

B03 BOX INLET 3610526500 PP 1

B04 HOSE INLET 3613274600 EPDM 1

B05 CLAMP AS 3611203200 ID=60, WIRE+GUIDE+BOLT+NUT 1

B06 VALVE INLET 36154L3A00 220-240V.VDE.BITRON.4WAY V1:DRY V2:STEAM 1

B07 HOSE WATER SUPPLY 3613270900 EPDM ID9.5 OD14.5, WASHING 1

HOSE WATER SUPPLY 3613270900 EPDM ID9.5 OD14.5, PRE.WASH 2

B08

B09 CLAMP HOSE 3611205800 100H, ID=13.8 W=10.0 0.9T 10

B10 HOSE WATER SUPPLY 3613270900 EPDM ID9.5 OD14.5, HOT 1

B11 HOSE WATER SUPPLY 3613270900 EPDM ID9.5 OD14.5, STEAM 1

B12

PIPE JOINT(HOSE INLET)

B13 UNIT STEAM AS 36189M2U00 L-SERIES STEAM UNIT 900W 1 option

B14 HOSE WATER SUPPLY 3613270900

3614413300 PP , T-type 1

EPDM ID9.5 OD14.5, connecting UNIT STEAM AS

and NOZZLE SHOWER

REMARK

1

7

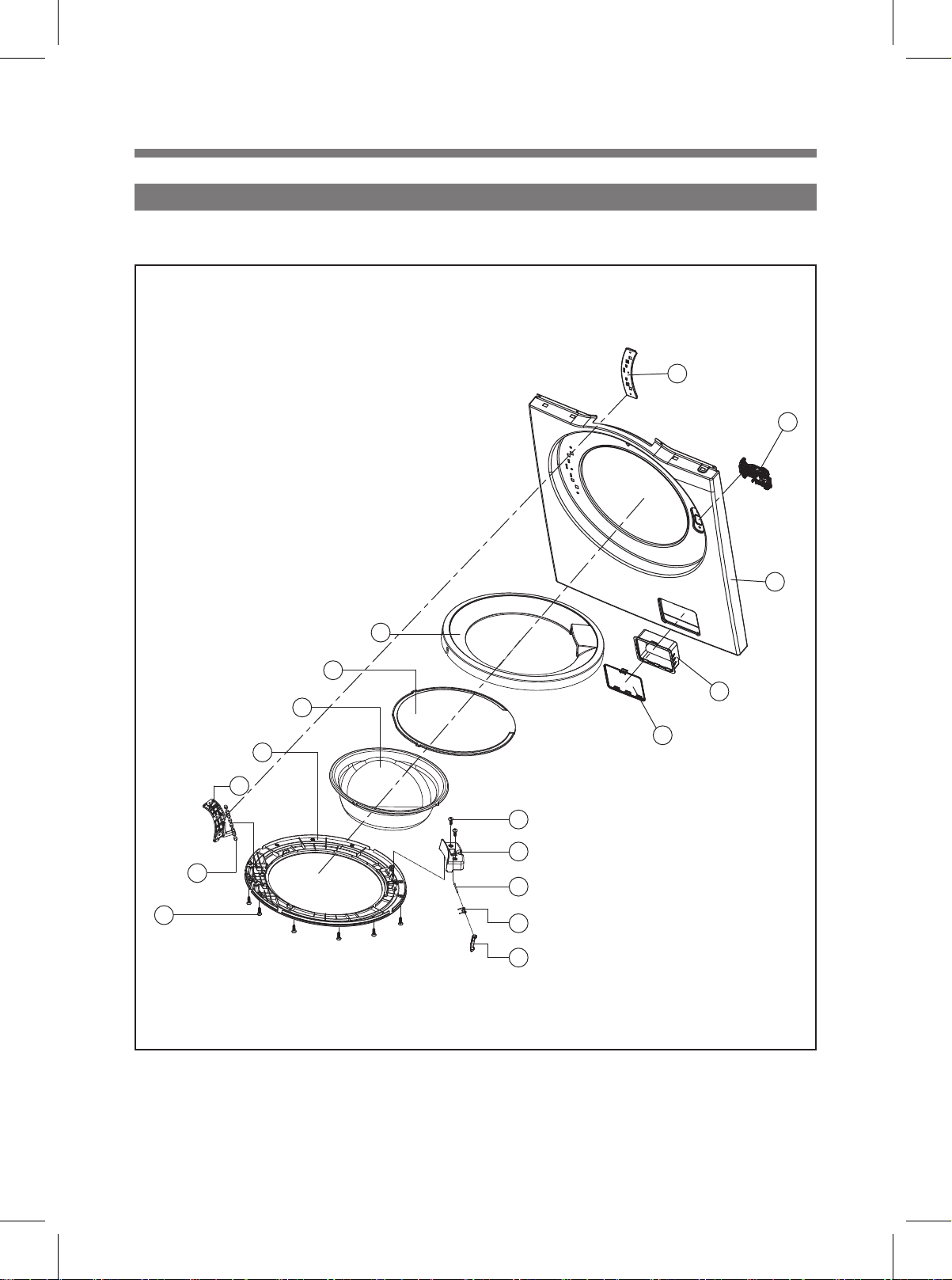

3. CABINET F ASSY

■

2nd Model

C03

C02

C01

C12

C06

C07

C04

C08

C05

C09

C10

C17

C16

C11

C15

C14

C13

8

No. PARTS NAME CODE SPECIFICATIONS Q’TY REMARK

C01 CABINET *F 3610814000 SECD 0.8T 1

C02 SWITCH DOOR LOCK 3619047230 DL-S2.250V16A.BITRON 1

C03 PLATE HINGE SUPPORT 3614539800 SPG 0.8T, DWD-T110R 1

C04 CASE PUMP AS 36111T1K10 CASE PUMP(PP)+PAD 1

C05 COVER PUMP 3611431500 ABS 1

C06 FRAME DOOR *0 36122UDC00 ABS 1

C07 PROTECTOR GLASS 3618345600 TR-ABS 1

C08 DOOR GLASS 361A113300 GLASS 1

C09 FRAME DOOR *I 36122UDD00 PP 1

C10 HINGE DOOR 3612903800 ALDC 1

C11 CAP HINGE DOOR 3610916500 POM 4

C12 SCREW TAPPING 7115402029 T1S FLT 14

C13 HOOK DOOR 3613100900 ZNDC 1

C14 SPRING HOOK 3615115400 SUS 1

C15 HOOK SHAFT 36131010001 SUS 1

C16 CASE SPRING DOOR 3611149300 ABS 1

C17 SCREW TAPPING 7122401611 T2STRS 2 4*6 MFZN

4*20 STS430 NATURE

9

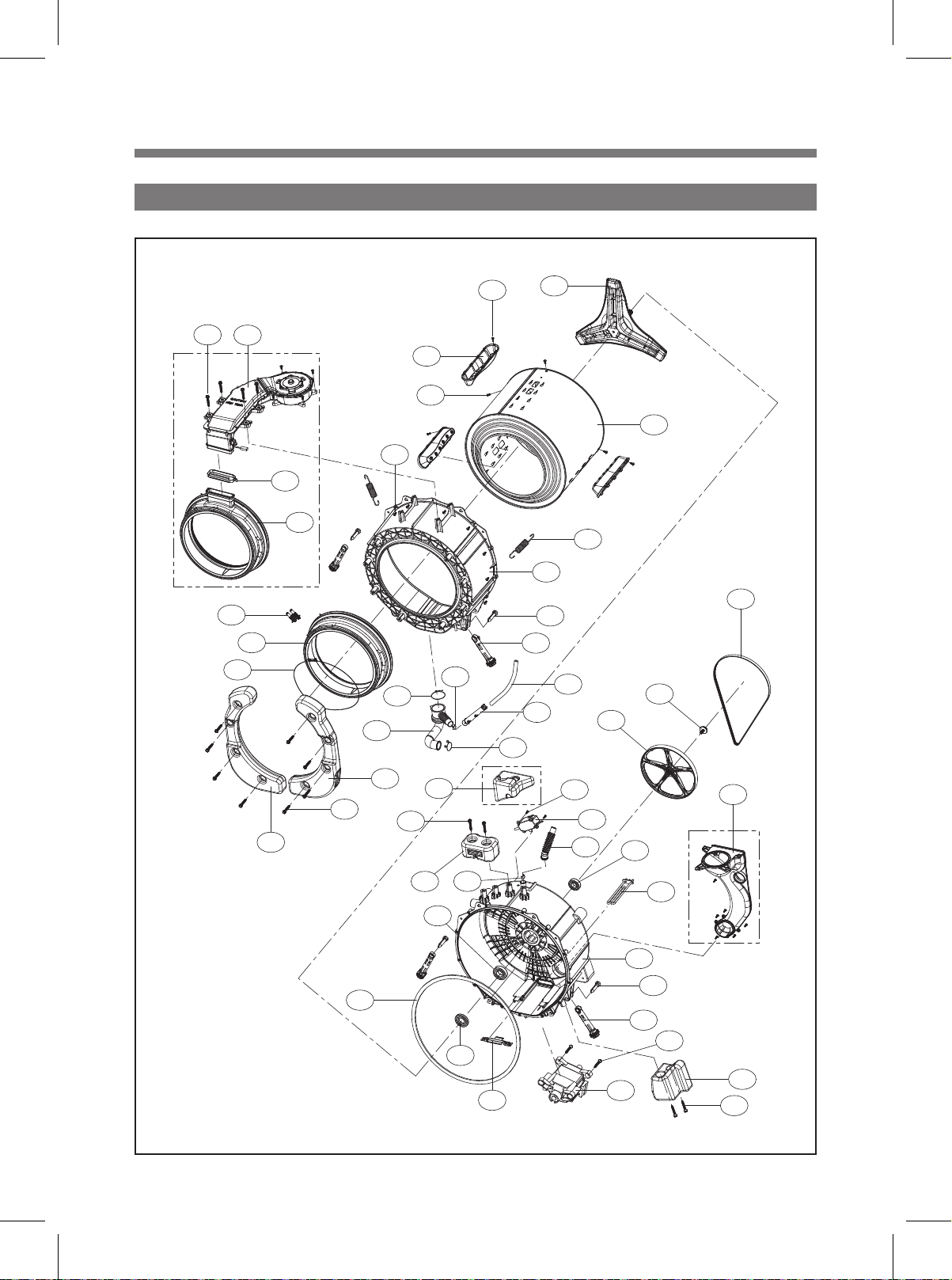

4. TUB ASSY(UNIVERSAL)

D09

D07

D04

D10

D05

D08

D06

D11

D21

D12

D23

D22

D14

D24

D13

D19

D17

D15

D26

D18

D16

D25

D20

D50

D49

D48

D01

D02

D28

D03

D40

D38

D39

D30

D41

D27

10

D29

D42

D44

D43

D31

D47

D45

D46

D37

D36

D35

D34

D32

D33

Loading...

Loading...