Page 1

Page 2

TABLE OF CONTENTS

SAFETY&PRECAUTIONS ...............................................................................................2

EXTERNAL VIEWS

1. FRONT VIEWS FUNCTION ............................................................................................................... 4

2. REAR VIEWS FUNCTION ................................................................................................................. 5

GENERAL ADJUSTMENT ............................................................................................. .6

SPECIFICATIONS .......................................................................................................7

PRINTED CIRCUIT BOARD ............................................................................................ 8

1. PCB MAIN ..................................................................................................................................... 8

2. PCB POWER(SMPS) ........................................................................................................................ 9

CIRCUIT DIAGRAM ..................................................................................................... 10

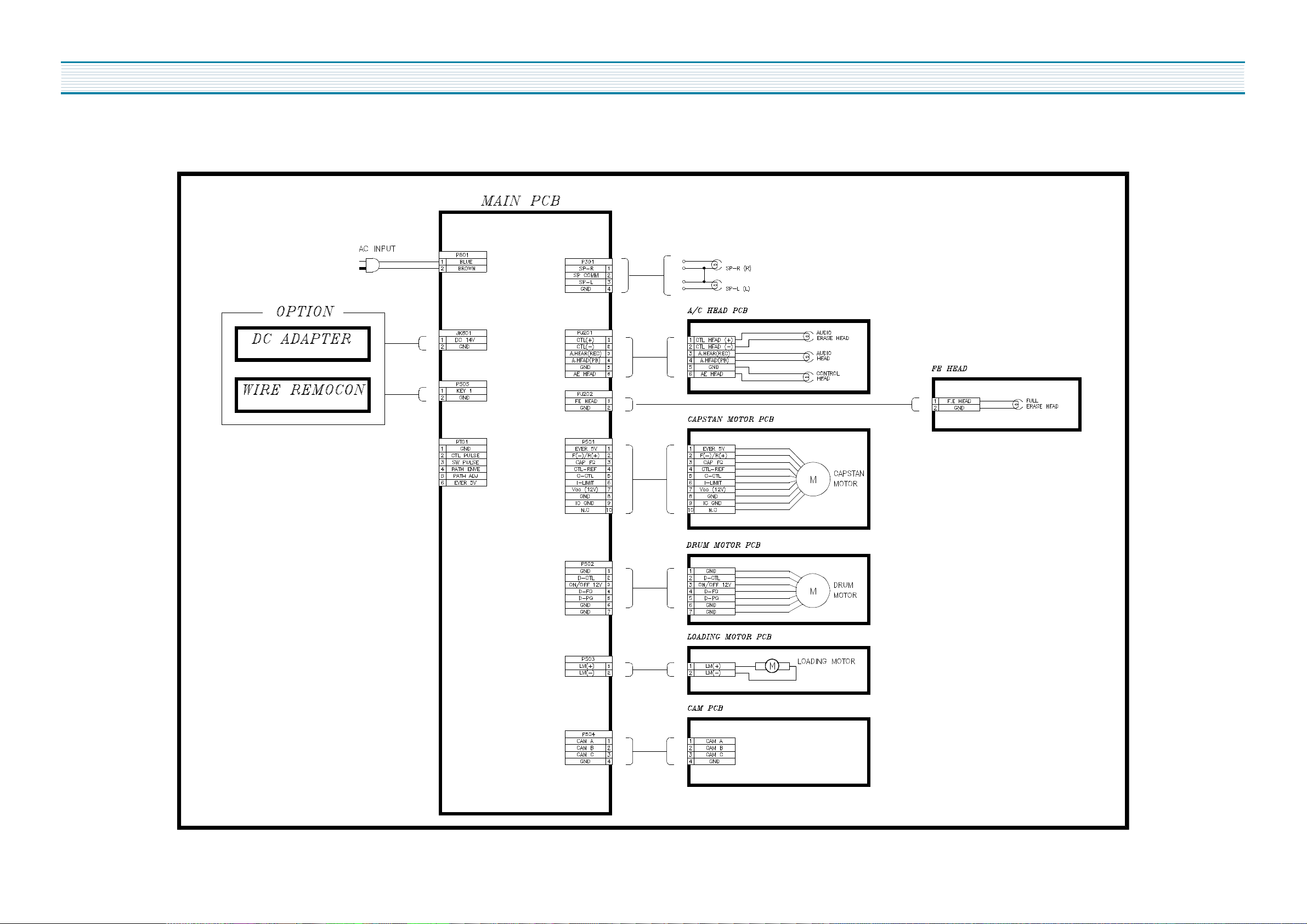

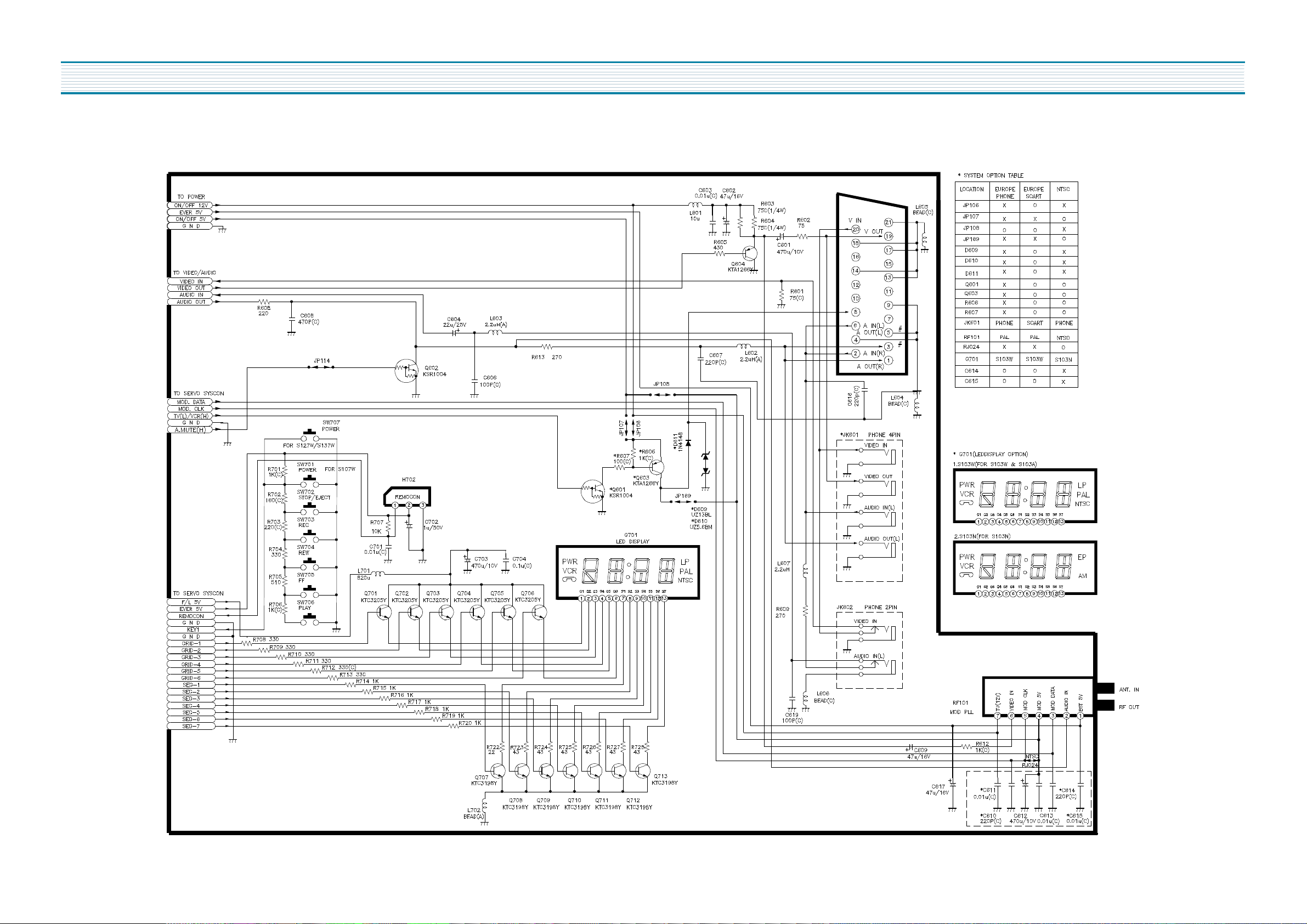

1. CONNECTION DIAGRAM .............................................................................................................. 10

2. POWER CIRCUIT ............................................................................................................................ 11

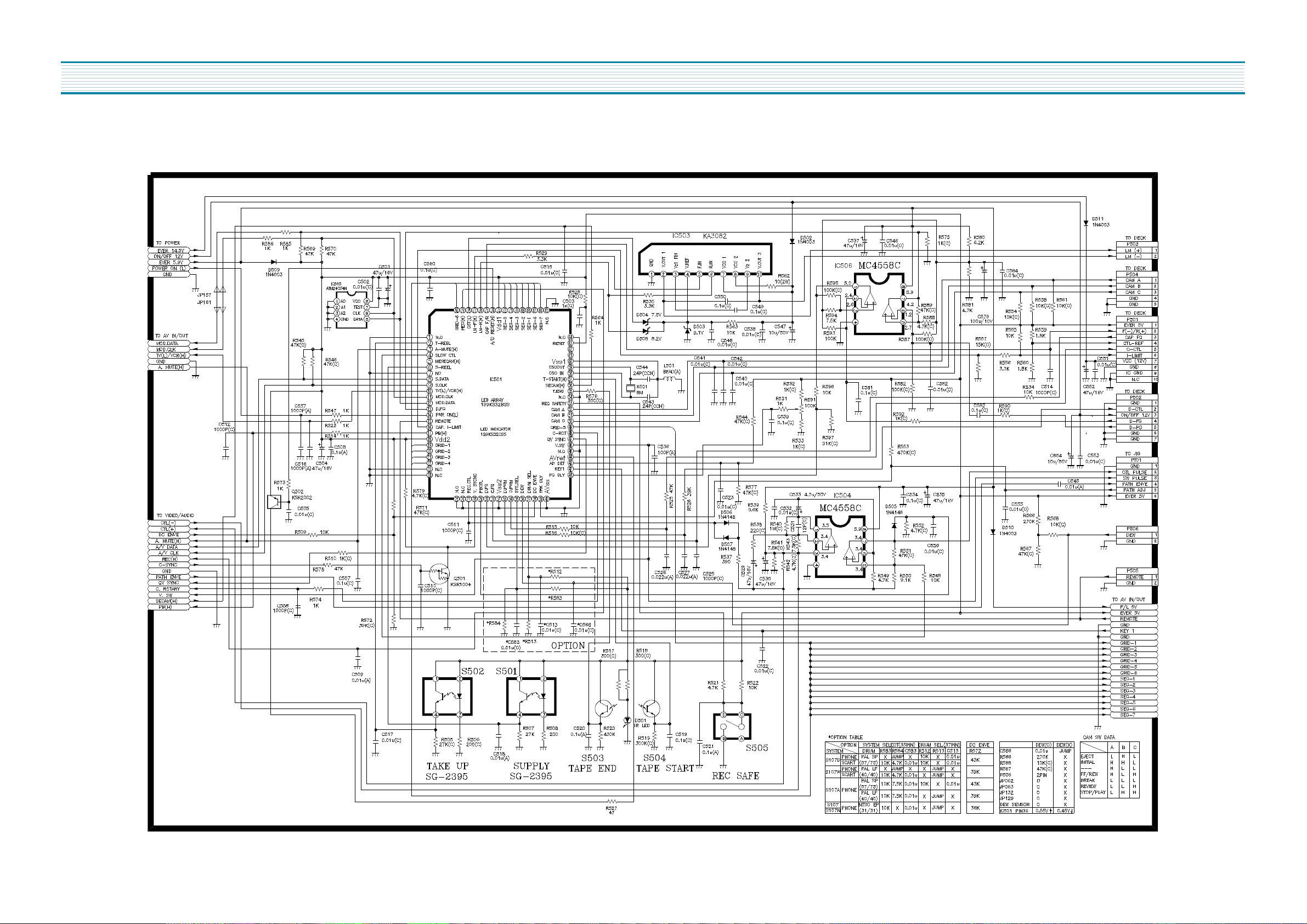

3. SERVO SYSCON CIRCUIT ............................................................................................................... 12

4. AV INPUT OUTPUT CIRCUIT .............................................................................................................. 13

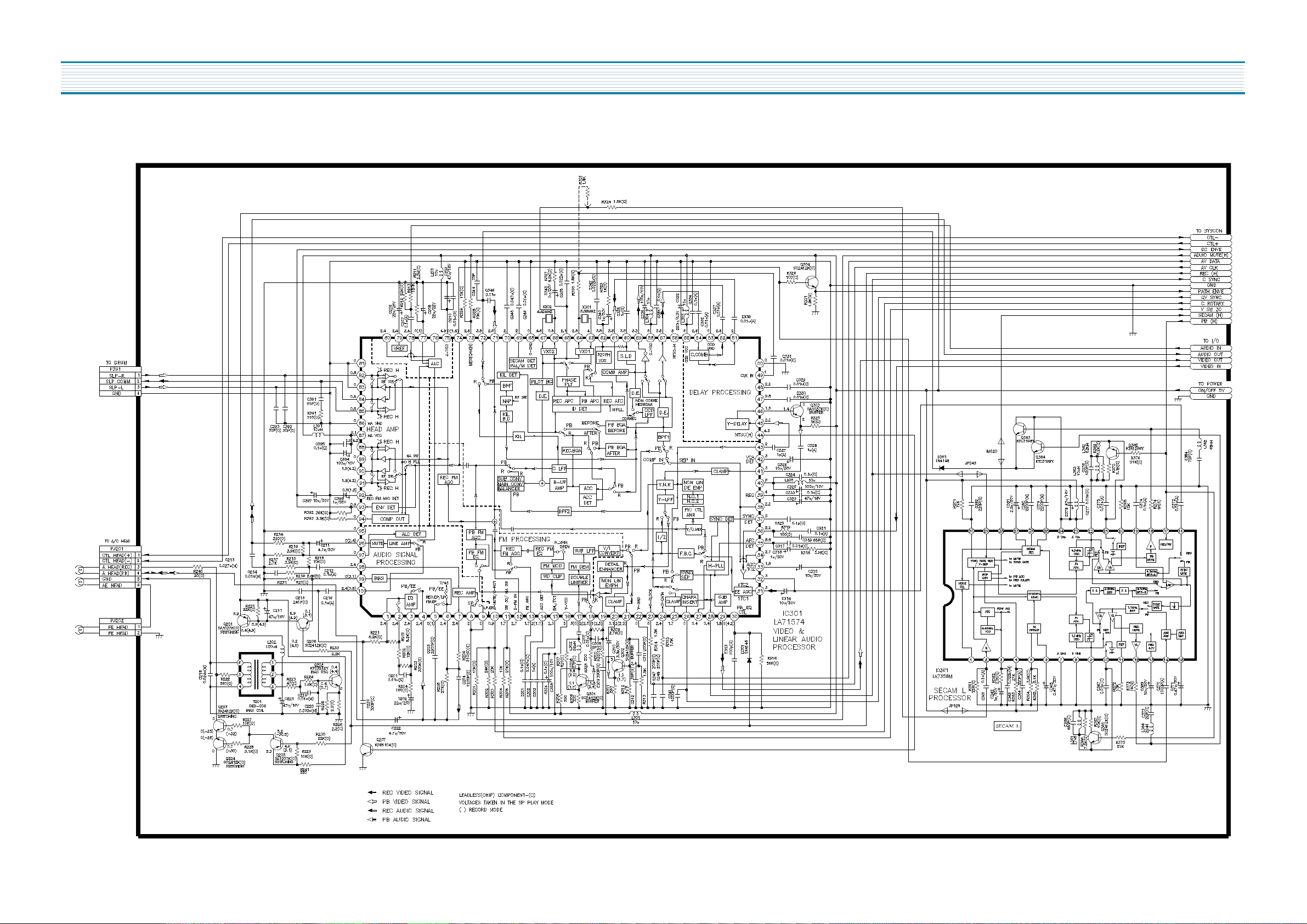

5. VIDEO AUDIO CIRCUIT .................................................................................................................. 14

EXPLODING VIEWS & PARTS LIST

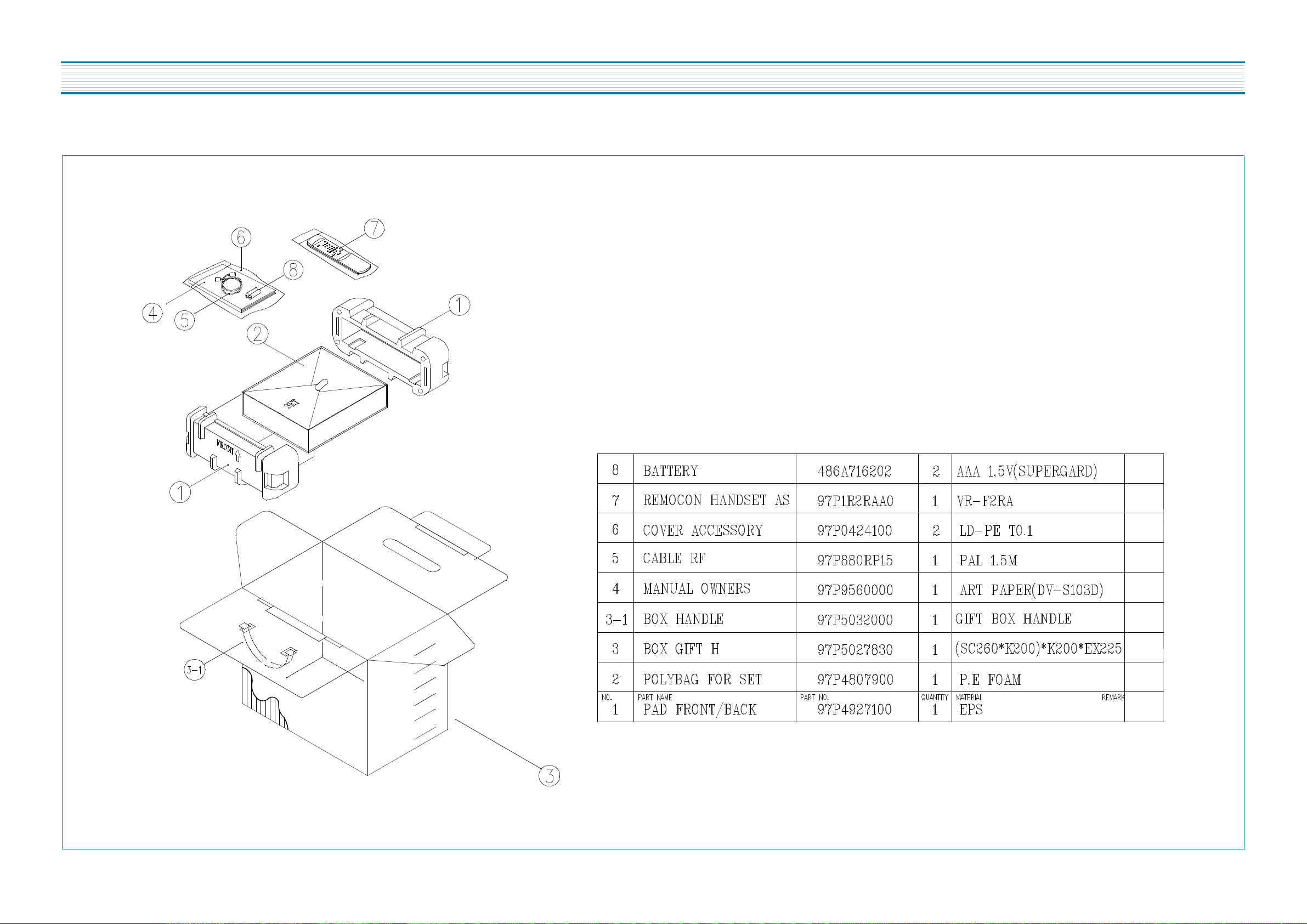

1. PACKING AS ................................................................................................................................. 15

2. SET TOTAL ASSEMBLY ..................................................................................................................... 16

3. FRONT PANEL ASSEMBLY ............................................................................................................... 17

ELECTRICAL PARTS LIST ............................................................................................... 18

1. PCB MAIN AS ................................................................................................................................ 18

2. PCB AUTO VOLT REGULATOR AS ................................................................................................. 24

3. DIFFERNCE PARTS LIST ................................................................................................................... 26

APPENDIX

(Appendix is provided only by internet http:\\svc.dwe.co.kr)

TROUBLE SHOOTING GUIDE ........................................................................................1

1. TROUBLE SHOOTING FLOW CHART ................................................................................................ 1

2. WAVEFORMS ON VIDEO CIRCUIT .................................................................................................. 18

3. µ-COM PIN ASSIGNMENT............................................................................................................... 21

1

Page 3

SAFETY&PRECAUTIONS

SAFETY CHECK AFTER SERVING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screw, parts and wires

have been returned to original positions. Afterwards, perform the following tests and conform the specified values in order

to verify compliance whit safety standards.

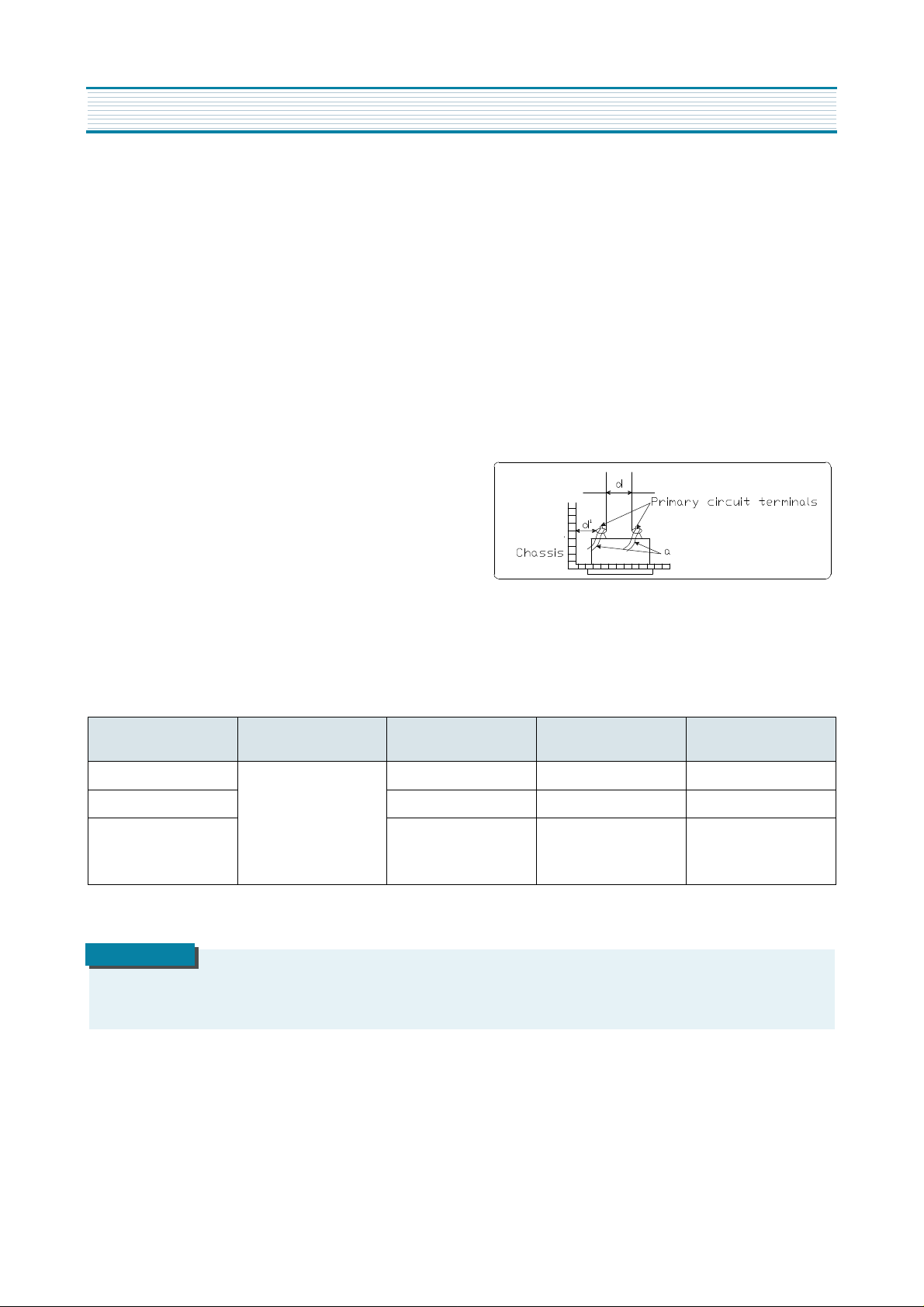

1. Insulation resistance test

Confirm the specified insulation resistance between power cord plug prong and externally exposed parts of the set

(RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

is greater than values given in table 1 below.

2. Dielectric strengthen test

Confirm specified dielectric strengthen between power

cord plug prongs and exposed accessible parts of the set

(RF terminals, antenna terminals, video and audio input

output terminals, microphone jack, ear phone jacks, etc.)

is greater than values given table 1.

3. Clearance distance

When replacing primary circuit component, confirm specified clearance distance (d), (d’) between soldered terminals,

and between terminals and surrounding metallic parts. See table below.

Rating for selected areas

AC Line Voltage Region

100V

110 to 130V - 900V AC 1min.

* 110 to 130V

200 to 240V

* : Class model only

Africa

the middle east

Southeast Asia

Insulation

Resistance

¡Ã1§Û

/500V DC 1

¡Ã10§Û

/500V DC 4§Ç AC 1min.

Dielectric

Strength

§Ç

AC 1min.

Clearance

Distance(d),(d)

¡Ã

3m

¡Ã

3.2mm

¡Ã

6mm(d)

¡Ã

8mm(d’)

(a :Power cord)

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values for your

particular country and locality

2

Page 4

SAFETY&PRECAUTIONS

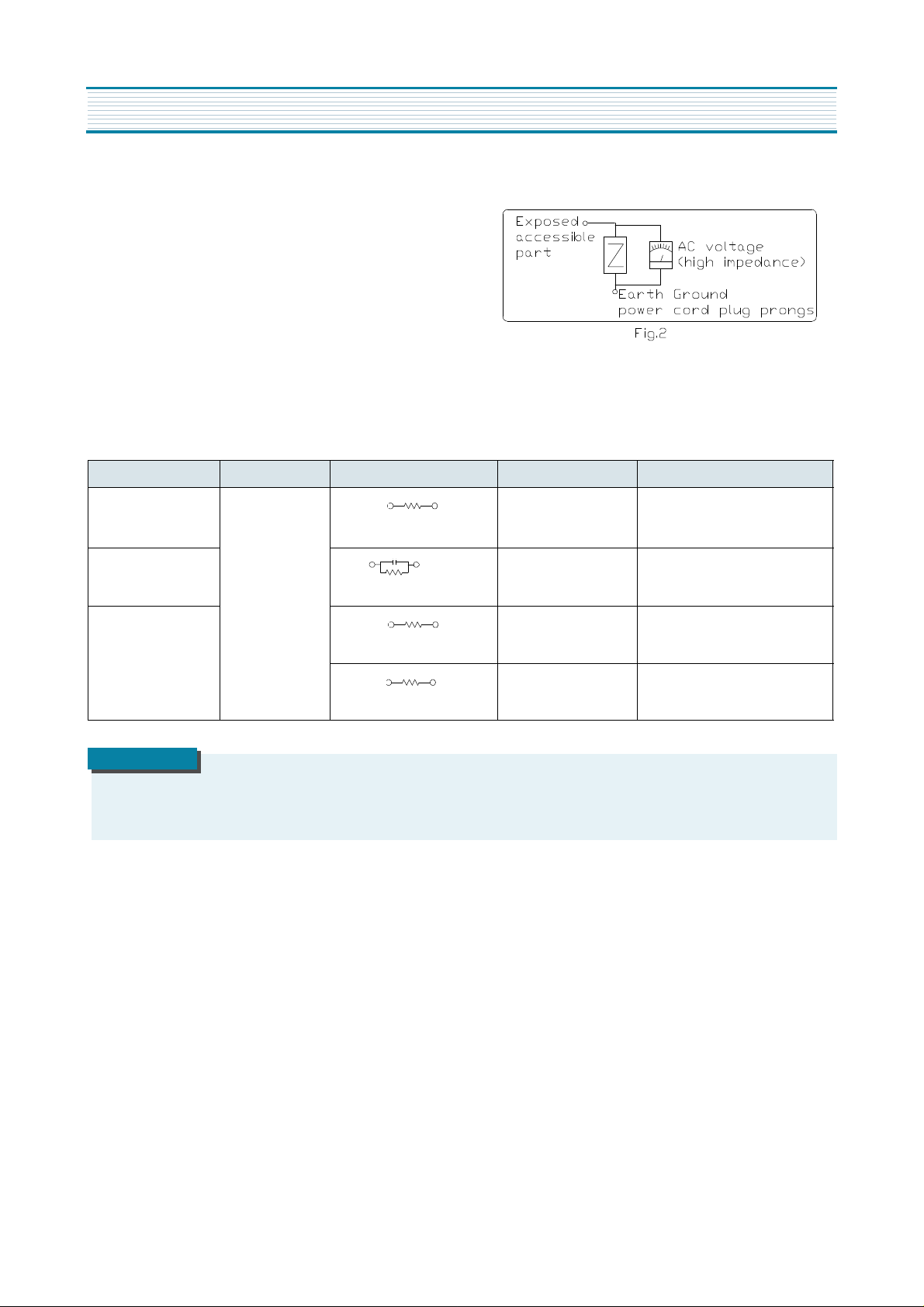

4. Leakage current test

Confirm specified or lower leakage current between

B(earth ground, power cord plug prongs) and externally

exposed accessible parts (RF terminals, antenna terminals, video and audio input output terminals, microphone

jacks, earphone jacks, etc.)

Measuring method:(Power ON) Insert load Z between

B(earth ground, power cord plug prongs) and exposed

accessible parts. Use on AC voltmeter to measure across

both terminals of load Z. See figure2 and following table.

Leakage current ratings for selected are as

AC Line Voltage Region Load Z Leakage Current(i) Clearance Distance(d),(d’)

100V

1

§Ú

110 to 130V

110 to 130V

200 to 240V

Africa

the middle east

Southeast Asia

50

15k

§Þ

1

§Ú

2

§Ú

§Ú

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values

for your particular country and locality.

i ¡Â1§Ì

i ¡Â

i ¡Â

i ¡Â2§Ì

i ¡Â

i ¡Â1§Ì

rms

0.5§Ìrms

0.7§Ìpeak

dc

0.7§Ì peak

dc

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

3

Page 5

EXTERNAL VIEWS

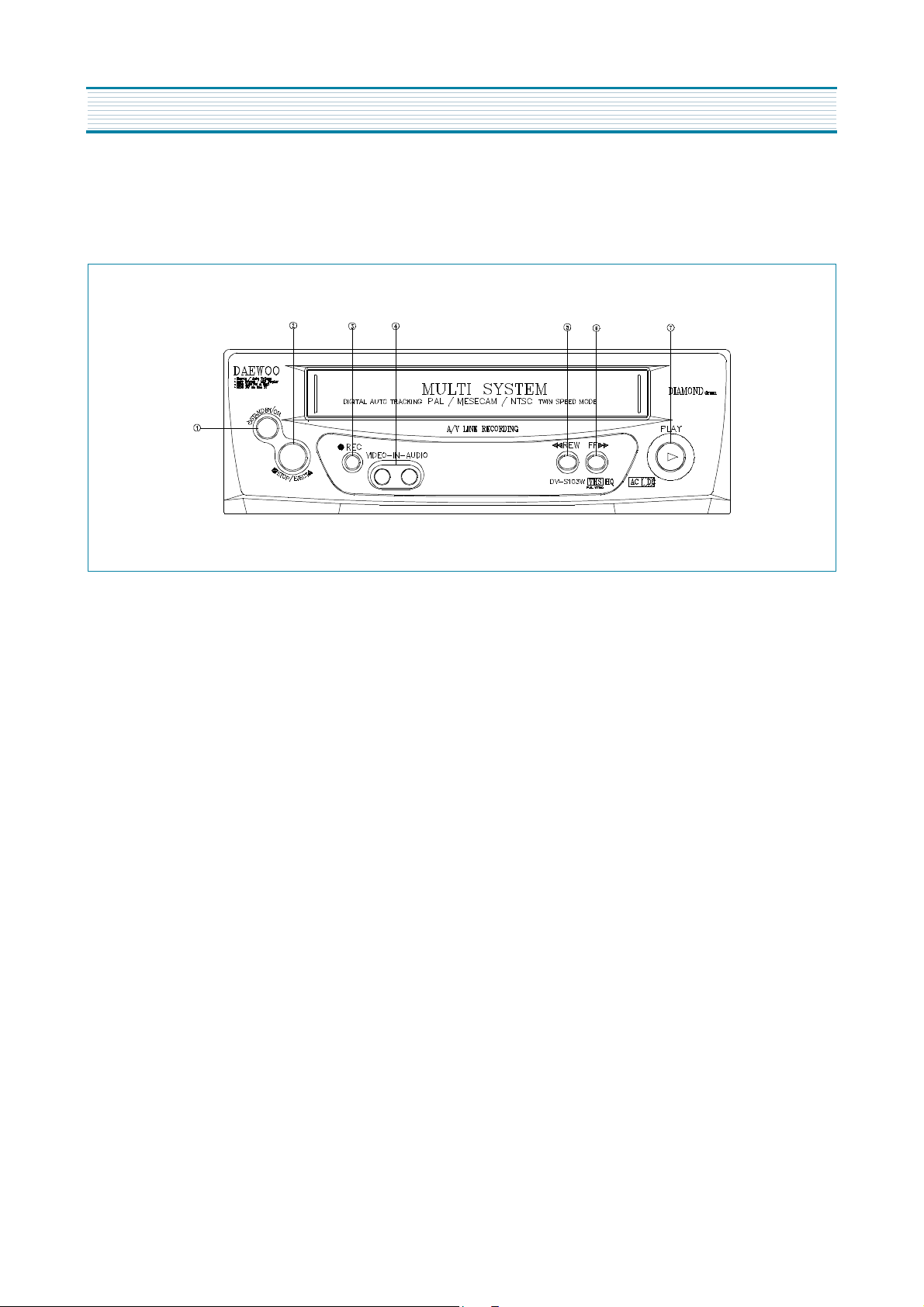

1. FRONT VIEWS FUNCTION

DV-S107W FRONT VIEW

<

STAND BY /ON

=

STOP / EJECT

>

RECORD

?

FRONT VIDEO AUDIO INPUT JACK

@

REWIND / REVIEW

A

FAST FORWARD / CUE

B

PLAY BACK

4

Page 6

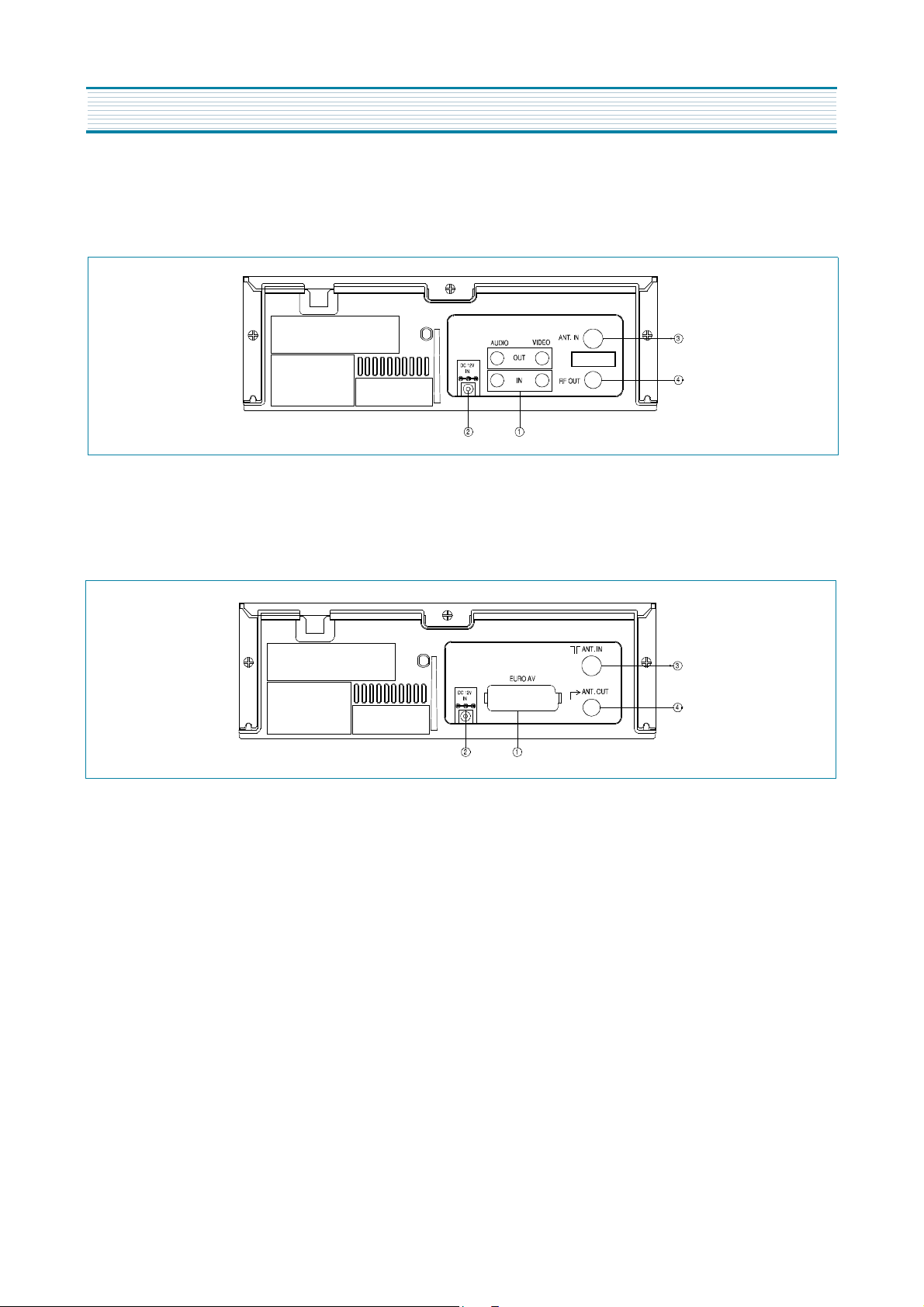

2. REAR VIEWS FUNCTION

DV-S107W PHONE JACK TYPE REAR VIEW

<

AUDIO/ VIDEO IN/OUT JACK

=

DC12V INPUT JACK

>

ANT INPUT

?

RF OUTPUT

EXTERNAL VIEWS

DV-S107W SCART JACK TYPE REAR VIEW

<

EURO AUDIO / VIDEO IN/OUT JACK

=

DC12V INPUT JACK

>

ANT INPUT

?

RF OUTPUT

5

Page 7

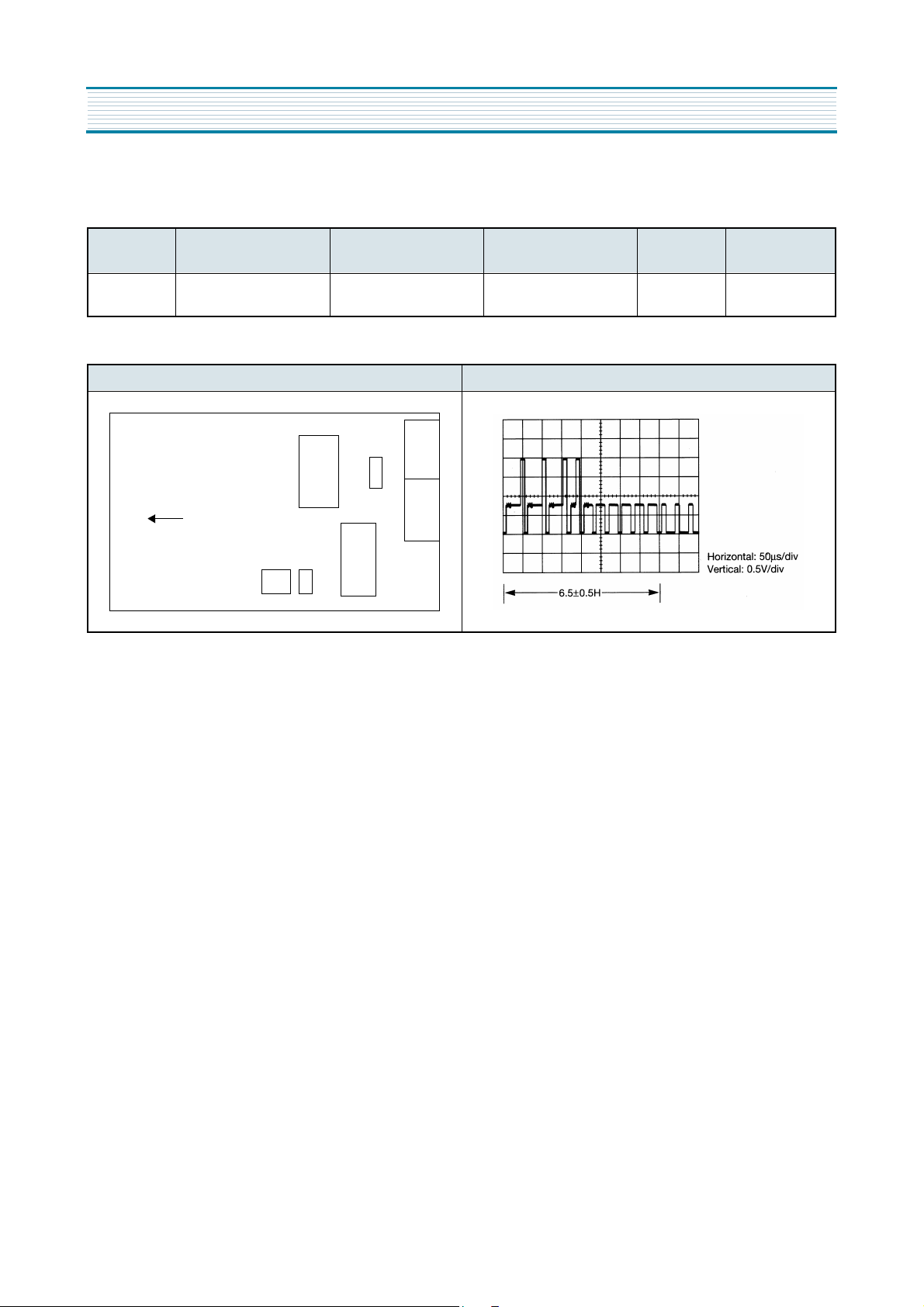

GENERAL ADJUSTMENT

M

SERVO CIRCUIT

ITEM

Playback

Phase

ADJUSTMENT

PARTS

R591

LOCATION OF ADJUSTMENT PARTS OBSERVATION WAVEFORM

F

R

O

N

T

R59

ADJUSTMENT PROCEDURE

TJ591

(V. SW)R591

CHECK POINT TEST EQUIPMENTS MODE TEST TAPE

TJ591(V.SW)

TJ391(VIDEO OUT)

TJ391

PRE-AMP

(VIDEO OUT)

SMPS

Oscilloscope Play DP-2

OD

A/V JACK

1. Preparation

Playback the test tape (DP-2).

Set the oscilloscope to the CHOP mode. Connect CH1 to the V.SW PULSE (TJ591) and CH2 to the VIDEO OUT

(TJ391) and trigger the scope with the signal from CH1.

2. Adjustment

Adjust R591 to the positive rising edge of V.SW PULSE at 6.5H ±0.5H from the V-SYNC.

3. Adjustment Inspection Standard

6.5H ± 0.5H

4. REMARKS

6

Page 8

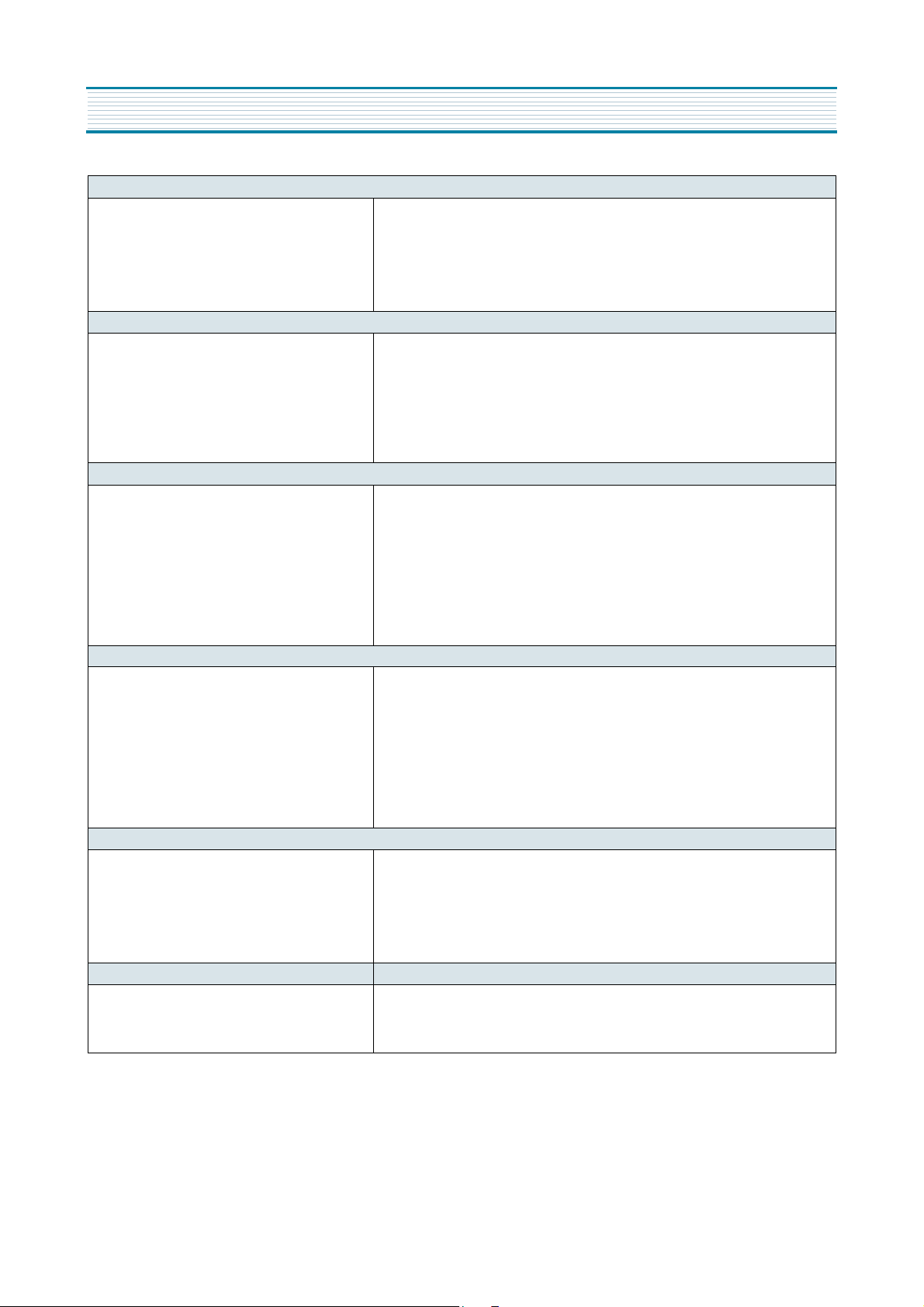

SPECIFICATIONS

SYSTEM

Video signal

RF Output

VIDEO

Input : Video line in

Output : Video line out

Recording system

Signal to Noise ratio

Horizontal Resolution

AUDIO

Input : Audio line in

Output : Audio line out

Frequency Response

Signal to Noise Ratio

Audio Distortion

TAPE TRANSPORT

Format

Tape Width

Tape Speed

Maximum Recording Time

FF/REW time

GENERAL

Power Requirements

Power Consumption

Temperature

Operating position

DIMENSIONS

Carton size (W x H x D)

Set size (W x H x D)

Weight

PAL/MESECAM/NTSC colour (for DV-S107W Series)

PAL-N/NTSC colour (for DV-S107A Series)

NTSC colour (for DV-S107N Series)

PAL-G/K/I UHF CH22 ~ CH40

(for DV-S107W & DV-S107S Series)

NTSC-M VHF CH3 OR CH4

(for DV-S107A & DV-S107N Series)

75 ohms unbalanced, sync.

75 ohms unbalanced, sync. Negative

Rotary two-head helical scan

More than 45dB (PAL-SP)

More than 43dB (NTSC-SP)

240 Lines (PAL-SP)

210 Lines (NTSC-SP)

-8dBm, (CENELEC standard),

more than 47, unbalanced

-6dBm, (CENELEC standard),

less than 1, unbalanced

100Hz ~ 8KHz ( for PAL-SP)

100Hz ~10KHz (for NTSC-SP)

More than 38dB (for PAL-SP)

More than 40dB (for NTSC-SP)

Less than 3% (SP)

VHS standard

12.65 (1/2)

PAL SP : 23.39mm/sec

PAL LP :11.70mm/sec

NTSC-SP : 33.35/sec.

NTSC-EP : 11.12/sec.

480min, with E-240 tape (PAL-LP)

540min, with T-180 tape (NTSC-EP)

about 5min, with T-120 tape

AC 90V ~ 260V, 50/60Hz

DC12V ~ 16V (2A)

Max. 14W (in REC mode)

5°C ~ 35°C (Operating)

-20°C ~ 60°C (Storage)

Horizontal only

417 x 172 x 369 mm

280 x 91 x 347 mm

3.5 Kg

7

Page 9

PRINTED CIRCUIT BOARD

1. PCB MAIN

8

Page 10

PRINTED CIRCUIT BOARD

2. PCB POWER(SMPS)

9

Page 11

CIRCUIT DIAGRAM

1. CONNECTION DIAGRAM

10

Page 12

CIRCUIT DIAGRAM

2. POWER CIRCUIT

11

Page 13

3. SERVO SYSCON CIRCUIT

CIRCUIT DIAGRAM

12

Page 14

CIRCUIT DIAGRAM

4. AV INPUT OUTPUT CIRCUIT

13

Page 15

5. VIDEO AUDIO CIRCUIT

CIRCUIT DIAGRAM

14

Page 16

EXPLODING VIEWS & PARTS LIST

1. PACKING AS

15

Page 17

2. SET TOTAL ASSEMBLY

EXPLODING VIEWS & PARTS LIST

16

Page 18

EXPLODING VIEWS & PARTS LIST

3. FRONT PANEL ASSEMBLY

DV-S107W FRONT PANEL ASSEMBLY

17

Page 19

ELECTRICAL PARTS LIST

“ 2 ” is a recommendable part for stock.

1. PCB MAIN AS

REF. PART CODE PART NAME PART DESCRIPTION

C201 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 AUDIO

C202 CEXF1E220A C ELECTRO 25V RSM 22MF 6.3X7 AUDIO

C203 HCBK332KCA C CHIP CERA 50V X7R 3300PF K 2012 AUDIO

C204 HCBK122KCA C CHIP CERA 50V X7R 1200PF K 2012 AUDIO

C206 CEXF1E220A C ELECTRO 25V RSM 22MF 6.3X7 AUDIO

C207 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL AUDIO

C208 CEXF1E220A C ELECTRO 25V RSM 22MF 6.3X7 AUDIO

C209 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) AUDIO

C210 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 AUDIO

C211 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7 AUDIO

C212 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL AUDIO

C213 CMXM2A273J C MYLAR 100V 0.027MF J (TP) AUDIO

C214 CMXM2A103J C MYLAR 100V 0.01MF J (TP) AUDIO

C215 HCLK241JCA C CHIP CERA 50V SL 240PF J 2012 AUDIO

C216 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL AUDIO

C217 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) AUDIO

C218 CMXM2A243J C MYLAR 100V 0.024MF J (TP) AUDIO

C219 CMXM2A103J C MYLAR 100V 0.01MF J (TP) AUDIO

C220 CMXM2A333J C MYLAR 100V 0.033MF J (TP) AUDIO

C221 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) AUDIO

C222 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7 AUDIO

C223 HCBK332KCA C CHIP CERA 50V X7R 3300PF K 2012 AUDIO

C301 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C302 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012 VIDEO

C303 CCZF1H105Z C CERA AXIAL 50V F 1MF Z VIDEO

C304 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C305 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7 VIDEO

C306 HCLK270JCA C CHIP CERA 50V SL 27PF J 2012 VIDEO

C307 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C308 HCLK509CCA C CHIP CERA 50V SL 5PF C 2012 VIDEO

C309 HCLK391JCA C CHIP CERA 50V SL 390PF J 2012 VIDEO

C310 CEXF1H339A C ELECTRO 50V RSM 3.3MF 4X7 VIDEO

C311 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012 VIDEO

C312 HCLK390JCA C CHIP CERA 50V SL 39PF J 2012 VIDEO

C313 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012 VIDEO

C314 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) VIDEO

C315 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) VIDEO

C317 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C318 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) VIDEO

C319 HCLK680JCA C CHIP CERA 50V SL 68PF J 2012 VIDEO

C320 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C321 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL VIDEO

C322 CEXF1A221V C ELECTRO 10V RSS 220MF 6.3X11 VIDEO

C323 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) VIDEO

REMARK

REF. PART CODE PART NAME PART DESCRIPTION REMARK

C324 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C325 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7 VIDEO

C326 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) VIDEO

C327 CCZF1H105Z C CERA AXIAL 50V F 1MF Z VIDEO

C328 CCZF1H105Z C CERA AXIAL 50V F 1MF Z VIDEO

C329 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C330 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C331 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C332 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL VIDEO

C333 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C334 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL VIDEO

C335 HCBK223KCA C CHIP CERA 50V X7R 0.022MF K 2012 VIDEO

C336 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7 VIDEO

C337 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL VIDEO

C338 HCBF105KEA C CHIP CERA 16V X7R 1MF K 3216 VIDEO

C339 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL VIDEO

C340 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) VIDEO

C341 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 VIDEO

C342 HCBK223KCA C CHIP CERA 50V X7R 0.022MF K 2012 VIDEO

C343 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) VIDEO

C344 HCLK750JCA C CHIP CERA 50V SL 75PF J 2012 VIDEO

C345 HCBK473KCA C CHIP CERA 50V X7R 0.047MF K 2012 VIDEO

C346 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C347 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012 VIDEO

C348 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012 VIDEO

C349 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 VIDEO

C350 HCLK330JCA C CHIP CERA 50V SL 33PF J 2012 VIDEO

C351 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C391 HCLK510JCA C CHIP CERA 50V SL 51PF J 2012 VIDEO

C392 HCLK300JCA C CHIP CERA 50V SL 30PF J 2012 VIDEO

C393 HCLK300JCA C CHIP CERA 50V SL 30PF J 2012 VIDEO

C394 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7 VIDEO

C395 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 VIDEO

C396 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7) VIDEO

C397 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) VIDEO

C501 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C502 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C503 HCBF105KEA C CHIP CERA 16V X7R 1MF K 3216 SERVO

C504 CEXF1C470A

C505 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C507 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 SERVO

C508 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL SERVO

C509 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL SERVO

C510 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C ELECTRO

16V RSM 47MF (5X7)

SERVO2

18

Page 20

ELECTRICAL PARTS LIST

REF. PART CODE PART NAME PART DESCRIPTION REMARK

C511 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C512 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C514 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C515 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C517 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C518 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL SERVO

C519 HCBK104KCA C CHIP CERA 50V X7R 0.1MF K 2012 SERVO

C520 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL SERVO

C521 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL SERVO

C522 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C523 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C525 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C526 CCZB1H223K C CERA HIBK 50V 0.022MF K AXL SERVO

C527 CCZB1H223K C CERA HIBK 50V 0.022MF K AXL SERVO

C529 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C530 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C531 HCQK120JCA C CHIP CERA 50V CH 12PF J 2012 SERVO

C532 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C533 CEXF1H479A C ELECTRO 50V RSM 4.7MF 4X7 SERVO

C534 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C535 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C536 CCZB1H101K C CERA 50V B 100PF K AXL SERVO

C537 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C538 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C539 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C540 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C541 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C542 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C543 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012 SERVO

C544 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012 SERVO

C545 CCZB1H103K C CERA HIKB 50V 0.01MF K AXIAL SERVO

C546 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C547 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) SERVO

C548 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C549 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C550 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C551 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C552 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) SERVO

C553 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C554 CEXF1H100A C ELECTRO 50V RSM 10MF (5X7) SERVO

C555 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C556 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C557 CCZB1H102K C CERA 50V B 1000PF K SERVO

C558 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012 SERVO

C560 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C564 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C566 HRFT000-CA R CHIP 1/10 0 OHM 2012 SERVO

REF. PART CODE PART NAME PART DESCRIPTION REMARK

C579 CEXF1A101A C ELECTRO 10V RSM 100MF 6.3X7 SERVO

C580 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C581 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 SERVO

C582 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012 SERVO

C601 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5

C602 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7)

C603 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

C604 CEXF1E220A C ELECTRO 25V RSM 22MF 6.3X7

C606 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C607 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C608 HCLK471JCA C CHIP CERA 50V SL 470PF J 2012

C609 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7)

C610 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C611 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

C612 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5

C613 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

C614 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C615 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

C616 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C617 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7)

C619 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C701 HCBK103KCA C CHIP CERA 50V X7R 0.01MF K 2012

C702 CEXF1H109A C ELECTRO 50V RSM 1MF (4X7)

C703 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5

C704 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C801 CL1EE3104M

C LINE ACROSS

C802 CH1CEE472M C CERA AC

AC275V 0.1MF M PCX2 335 W

2.5KV 4700PF M DE AC250V

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

POWER

POWER

C803 CEXN2G820P C ELECTRO 400V LHS 82MF 22X25 POWER

C804 CH1TFB101K

C CERA AC

C805 CH1TFE222M C CERA AC

C806 CEXF1E331V

C ELECTRO

4.0KV 100PF K AD

AC250V

4.0KV 2200PF M AD AC250V

25V RSS 330MF

(10X12.5)

POWER

POWER

POWER

C807 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL POWER

C808 CEXF1A102V C ELECTRO 10V RSS 1000MF (10X16) POWER

C809 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL POWER

C810 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) POWER

C811 CEXF1A471V C ELECTRO 10V RSS 470MF 8X11.5 POWER

C812 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 POWER

C813 CEXF1V101V C ELECTRO 35V RSS 100MF (8X11.5) POWER

C814 CEXF1C470A C ELECTRO 16V RSM 47MF (5X7) POWER

C815 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012 POWER

C816 CCZB1H104K C CERA HIBK 50V 0.1MF K AXL POWER

D301 DZN4148--- DIODE 1N4148 AUTO VIDEO

D501 DS1R481T-- LED IR SIR-48IT(P-RANK) SERVO

D501A

97S2302200 HOLDER LED ABS SERVO

D502 DZN4003--- DIODE IN4003(DAEBO)

SERVO2

D503 DZUZ9R1BSC DIODE ZENER UZ-9.1BSC(8.89-9.29V) SERVO

19

Page 21

ELECTRICAL PARTS LIST

REF. PART CODE PART NAME PART DESCRIPTION REMARK

D504 DZUZ7R5BSC DIODE ZENER UZ-7.5BSC(7.33-7.64) SERVO

D505 DZN4148--- DIODE 1N4148 AUTO SERVO

D506 DZN4148--- DIODE 1N4148 AUTO SERVO

D507 DZN4148--- DIODE 1N4148 AUTO SERVO

D508 DZUZ8R2BSC

DIODE ZENER

UZ-8.2BSC(8.07-8.41) SERVO2

D509 DZN4003--- DIODE IN4003(DAEBO) SERVO

D510 DZN4003--- DIODE IN4003(DAEBO) SERVO

D511 DZN4003--- DIODE IN4003(DAEBO) SERVO

D801 DS1WBA60-C DIODE BRIDGE S1WBA60 4072 CHIP

POWER2

D803 DZUZ18BSC- DIODE ZENER UZ-18BSC(17.51-18.30) POWER

D804 DUG2D-----

DIODE

UG2D 200V 2A POWER2

D805 DZN4148--- DIODE 1N4148 AUTO POWER

D807 DZN4003--- DIODE IN4003(DAEBO) POWER

D808 DZN4148--- DIODE 1N4148 AUTO POWER

D809 DZN4148--- DIODE 1N4148 AUTO POWER

D810 DZN4003--- DIODE IN4003(DAEBO) POWER

F801A

97P460170P CLIP FUSE PFC5000-0702 POWER

F801B

97P460170P CLIP FUSE PFC5000-0702 POWER

G701 DS103W---- LED DISPLAY S103W 13P ANGLE

H702 1GP1U291U- R/RECEIVER GP1U291U(38KHZ)

IC301 1LA71578-IC501 199KS32BSS

IC503 1KA3082---

IC AV

IC MICOM

IC DRIVER

LA71578 VIDEO2

KS88C8016-29D(S107W) SERVO2

KA3082B SERVO2

AV IN/OUT

AV IN/OUT

IC504 1KA4558D-- IC OP AMP KA4558D(8 SOP) SERVO

IC505 14ATM24D04 IC EEPROM ATM24C04N(8 SOP) SERVO

IC506 1KA4558D-- IC OP AMP KA4558D(8 SOP) SERVO

IC801 1KA78R12-- IC REGULATOR KA78R12

IC802 1KA78R05TU

IC REGULATOR

KA78R05TU (5V) POWER2

POWER2

IC803 1KA350---- IC REGULATOR KA350 TO-220 POWER2

JK601

97P6313600 JACK PIN (4P) DPAM-9640

JK602

97P6314700 JACK PIN DPAS-9224

JK801

97P6310800 JACK DC YSC-1535 POWER

AV IN/OUT

AV IN/OUT

L201 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) AUDIO

L202 5CPX101J2T COIL PEAKING 100UH(BRN-BRN) AUDIO

L301 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) VIDEO

L302 5CPX560J-- COIL PEAKING 56UH J (RADIAL) VIDEO

L303 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) VIDEO

L304 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) VIDEO

L305 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) VIDEO

L391 5CPX100J2T COIL PEAKING 10UH(BRN-BLK) VIDEO

L501 5PB13857-- COIL BEAD BI3857(AXIAL) SERVO

L601 5CPX100J2T COIL PEAKING 10UH(BRN-BLK)

L602 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L603 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L604 HLX1210001

BEAD CHIP

TB201209Z121

L605 HLX1210001 BEAD CHIP TB201209Z121

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/

OUT2

AV IN/OUT

REF. PART CODE PART NAME PART DESCRIPTION REMARK

L606 HLX1210001 BEAD CHIP TB201209Z121

L607 5CPZ229K02 COIL PEAKING 2.2UH K(AXIAL 3.5MM)

L701 56C821K700 COIL CHOKE 820MF TAPPING

L702 5PB13857-- COIL BEAD BI3857(AXIAL)

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

L802 5PLFSF212A FILTER LINE SF-2120A POWER

M401 97P0478800 CASE SHI ET T0.4 VIDEO

PVPWSWW063

M801

P391 97P62G06D4

AUTO VOLT

CONN HOUSING

S103WY-QB/D(F13-S,M-IN)

POWER

GF120R FPC 1.25MM 4P VIDEO

P501 97P62J012A CONN B/B JE612 PLUG 2.0 10P . SERVO

P502 97P62G06D7

P503 97P62T13B2

CONN HOUSING

CONN B/B

GF120 FPC 1.25MM 7P SERVO

TMC-

A,S0CKET,2.0MM,2P

SERVO

P504 97P62T12A5 CONN B/B TAS-X,RECEP2.5MM,5P SERVO

P801 97P62Y02X2 CONN WAFER YFW800 STR 10MM 2P POWER

PJ201

97P8811614 CONN AS 6H-6S 140MM SHIELD AUDIO

PJ202

97P8851210 CONN AS 2H-2S 100MM AUDIO

PT01 97P6269000 CONN WAFER 00-8283-0612-00000 SERVO

Q201 T2SA1037KB TR CHIP 2SA1037K-T146-R AUDIO

Q202 TZTC3202Y- TR

KTC3202Y (AUTO)(1959Y)

AUDIO

Q203 T2SC2412KB TR CHIP 2SC2412K-T146-BR AUDIO

Q204 T2SC2412KB

Q205 T2SA1037KB

Q206 T2SC2412KB

TR CHIP

TR CHIP

TR CHIP

2SC2412K-T146-BR AUDIO2

2SA1037K-T146-R AUDIO2

2SC2412K-T146-BR VIDEO2

Q207 TKSR1104-B TR CHIP KSR1104 AUDIO

Q301 T2SC2412KB TR CHIP 2SC2412K-T146-BR VIDEO

Q302 T2SC2412KB TR CHIP 2SC2412K-T146-BR VIDEO

Q303 T2SA1037KB TR CHIP 2SA1037K-T146-R VIDEO

Q304 T2SC2412KB TR CHIP 2SC2412K-T146-BR VIDEO

Q501 TZSR1004-- TR KSR1004 (AUTO) SERVO

Q502 TZSR2002-- TR KSR2002 (AUTO) SERVO

Q604 TZTA1266Y- TR

Q701 TZTC3205Y-

TR

KTA1266Y- (AUTO)(1015Y)

KTC3205Y (2236Y)

Q702 TZTC3205Y- TR KTC3205Y (2236Y)

Q703 TZTC3205Y- TR KTC3205Y (2236Y)

Q704 TZTC3205Y- TR KTC3205Y (2236Y)

Q705 TZTC3205Y- TR KTC3205Y (2236Y)

Q706 TZTC3205Y- TR KTC3205Y (2236Y)

Q707 TZTC3198Y-

Q708 TZTC3198Y- TR

Q709 TZTC3198Y- TR

Q710 TZTC3198Y- TR

Q711 TZTC3198Y- TR

Q712 TZTC3198Y- TR

Q713 TZTC3198Y- TR

Q801 TZSR1004-Q802 TZSR1001--

TR

TR

TR

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KTC3198Y-(1815Y) (AUTO)

KSR1004 (AUTO)

KSR1001 (AUTO) POWER2

AV IN/OUT

AV IN/

OUT2

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/

OUT2

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

POWER2

20

Page 22

ELECTRICAL PARTS LIST

REF. PART CODE PART NAME PART DESCRIPTION REMARK

R201 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012 AUDIO

R202 HRFT123JCA R CHIP 1/10 12K OHM J 2012 AUDIO

R203 HRFT334JCA R CHIP 1/10 330K OHM J 2012 AUDIO

R204 HRFT161JCA R CHIP 1/10 160 OHM J 2012 AUDIO

R205 HRFT273JCA R CHIP 1/10 27K OHM J 2012 AUDIO

R206 HRFT911GCA R CHIP 1/10 910 OHM G AUDIO

R211 HRFT225JCA R CHIP 1/10 2.2M OHM J 2012 AUDIO

R212 HRFT223JCA R CHIP 1/10 22K OHM J 2012 AUDIO

R213 RD-AZ184J- R CARBON

FILM

1/6 180K OHM J AUDIO

R214 HRFT221JCA R CHIP 1/10 220 OHM J 2012 AUDIO

R215 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012 AUDIO

R216 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012 AUDIO

R217 RD-AZ272J-

R CARBON FILM

1/6 2.7K OHM J AUDIO

R218 HRFT103JCA R CHIP 1/10 10K OHM J 2012 AUDIO

R219 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012 AUDIO

R220 HRFT223JCA R CHIP 1/10 22K OHM J 2012 AUDIO

R221 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012 AUDIO

R222 HRFT561JCA R CHIP 1/10 560 OHM J 2012 AUDIO

R223 HRFT470JCA R CHIP 1/10 47 OHM J 2012 AUDIO

R224 HRFT162JCA R CHIP 1/10 1.6K OHM J 2012 AUDIO

R225 HRFT229JCA R CHIP 1/10 2.2 OHM J 2012 AUDIO

R226 HRFT229JCA R CHIP 1/10 2.2 OHM J 2012 AUDIO

R227 HRFT103JCA R CHIP 1/10 10K OHM J 2012 AUDIO

R228 HRFT512JCA R CHIP 1/10 5.1K OHM J 2012 AUDIO

R229 HRFT103JCA R CHIP 1/10 10K OHM J 2012 AUDIO

R230 HRFT223JCA R CHIP 1/10 22K OHM J 2012 AUDIO

R231 HRFT821JCA R CHIP 1/10 820 OHM J 2012 AUDIO

R233 RD-AZ222J- R CARBON FILM 1/6 2.2K OHM J AUDIO

R240 HRFT200JCA R CHIP 1/10 20 OHM J 2012 AUDIO

R241 RD-AZ241J-

R CARBON FILM

1/6 240 OHM J AUDIO

R301 HRFT103JCA R CHIP 1/10 10K OHM J 2012 VIDEO

R302 HRFT243JCA R CHIP 1/10 24K OHM J 2012 VIDEO

R303 RD-AZ203JR304 RD-AZ203J-

R CARBON FILM

R CARBON FILM

1/6 20K OHM J VIDEO

1/6 20K OHM J VIDEO

R305 HRFT103JCA R CHIP 1/10 10K OHM J 2012 VIDEO

R306 RD-AZ331J- R CARBON FILM 1/6 330 OHM J VIDEO

R307 HRFT821JCA R CHIP 1/10 820 OHM J 2012 VIDEO

R308 RD-AZ331J-

R CARBON FILM

1/6 330 OHM J VIDEO

R309 HRFT272JCA R CHIP 1/10 2.7K OHM J 2012 VIDEO

R310 HRFT621JCA R CHIP 1/10 620 OHM J 2012 VIDEO

R311 RD-AZ561JR312 RD-AZ472JR313 RD-AZ152JR314 RD-AZ152JR315 RD-AZ152J-

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

1/6 560 OHM J VIDEO

1/6 4.7K OHM J VIDEO

1/6 1.5K OHM J VIDEO

1/6 1.5K OHM J VIDEO

1/6 1.5K OHM J VIDEO

R316 HRFT563JCA R CHIP 1/10 56K OHM J 2012 VIDEO

REF. PART CODE PART NAME PART DESCRIPTION REMARK

R318 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012 VIDEO

R319 HRFT101JCA R CHIP 1/10 100 OHM J 2012 VIDEO

R320 HRFT102JCA R CHIP 1/10 1K OHM J 2012 VIDEO

R321 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012 VIDEO

R323 HRFT102JCA R CHIP 1/10 1K OHM J 2012 VIDEO

R325 RD-AZ201J-

R CARBON FILM

1/6 200 OHM J VIDEO

R326 HRFT101JCA R CHIP 1/10 100 OHM J 2012 VIDEO

R327 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012 VIDEO

R328 HRFT103JCA R CHIP 1/10 10K OHM J 2012 VIDEO

R329 HRFT103JCA R CHIP 1/10 10K OHM J 2012 VIDEO

R330 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012 VIDEO

R391 HRFT511JCA R CHIP 1/10 510 OHM J 2012 VIDEO

R392 HRFT363JCA R CHIP 1/10 36K OHM J 2012 VIDEO

R393 HRFT332JCA R CHIP 1/10 3.3K OHM J 2012 VIDEO

R505 HRFT273JCA R CHIP 1/10 27K OHM J 2012 SERVO

R506 HRFT201JCA R CHIP 1/10 200 OHM J 2012 SERVO

R507 RD-AZ273JR508 RD-AZ201JR509 RD-AZ103J-

R CARBON FILM

R CARBON FILM

R CARBON FILM

1/6 27K OHM J SERVO

1/6 200 OHM J SERVO

1/6 10K OHM J SERVO

R510 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R513 HRFT000-CA R CHIP 1/10 0 OHM J 2012 SERVO

R514 RD-AZ102JR515 RD-AZ103J-

R CARBON FILM

R CARBON FILM

1/6 1K OHM J SERVO

1/6 10K OHM J SERVO

R516 HRFT103JCA R CHIP 1/10 10K OHM J 2012 SERVO

R517 HRFT301JCA R CHIP 1/10 300 OHM J 2012 SERVO

R518 HRFT301JCA R CHIP 1/10 300 OHM J 2012 SERVO

R519 HRFT304JCA R CHIP 1/10 300K OHM J 2012 SERVO

R520 RD-AZ434J-

R CARBON FILM

1/6 430K OHM J SERVO

R521 RD-AZ472J- R CARBON FILM 1/6 4.7K OHM J SERVO

R522 RD-AZ103JR525 RD-AZ473JR526 RD-AZ393J-

R CARBON FILM

R CARBON FILM

R CARBON FILM

1/6 10K OHM J SERVO

1/6 47K OHM J SERVO

1/6 39K OHM J SERVO

R527 RD-AZ470J- R CARBON FILM 1/6 47 OHM J SERVO

R528 HRFT103JCA

R529 RD-AZ332JR530 RD-AZ332J-

R CHIP

R CARBON FILM

R CARBON FILM

1/10 10K OHM J 2012 SERVO

1/6 3.3K OHM J SERVO

1/6 3.3K OHM J SERVO

R531 RD-AZ102J- R CARBON FILM 1/6 1K OHM J SERVO

R532 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R533 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R534 RD-AZ103JR537 RD-AZ391J-

R CARBON FILM

R CARBON FILM

1/6 10K OHM J SERVO

1/6 390 OHM J SERVO

R538 HRFT221JCA R CHIP 1/10 220 OHM J 2012 SERVO

R539 RD-AZ562J-

R CARBON FILM

1/6 5.6K OHM J SERVO

R540 HRFT105JCA R CHIP 1/10 1M OHM J 2012 SERVO

R541 HRFT752JCA R CHIP 1/10 7.5K OHM J 2012 SERVO

R542 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012 SERVO

R543 HRFT752JCA R CHIP 1/10 7.5K OHM J 2012 SERVO

21

Page 23

ELECTRICAL PARTS LIST

REF. PART CODE PART NAME PART DESCRIPTION REMARK

R544 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R545 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R546 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R547 RD-AZ102JR548 RD-AZ103JR549 RD-AZ472JR550 RD-AZ912J-

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

1/6 1K OHM J SERVO

1/6 10K OHM J SERVO

1/6 4.7K OHM J SERVO

1/6 9.1K OHM J SERVO

R551 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R552 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012 SERVO

R553 HRFT474JCA R CHIP 1/10 470K OHM J 2012 SERVO

R554 HRFT103JCA R CHIP 1/10 10K OHM J 2012 SERVO

R555 RD-AZ103J- R CARBON FILM 1/6 10K OHM J SERVO

R556 RD-AZ332J-

R CARBON FILM

1/6 3.3K OHM J SERVO

R557 HRFT153JCA R CHIP 1/10 15K OHM J 2012 SERVO

R558 HRFT103JCA R CHIP 1/10 10K OHM J 2012 SERVO

R559 RD-AZ182J- R CARBON FILM 1/6 1.8K OHM J SERVO

R560 RD-AZ182J-

R CARBON FILM

1/6 1.8K OHM J SERVO

R561 HRFT103JCA R CHIP 1/10 10K OHM J 2012 SERVO

R562 RS02B100JR563 RD-AZ103JR564 RD-AZ102JR569 RD-AZ473JR570 RD-AZ473J-

R M-OXIDEFILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

2W 10 OHM J (BULK) SERVO

1/6 10K OHM J SERVO

1/6 1K OHM J SERVO

1/6 47K OHM J SERVO

1/6 47K OHM J SERVO

R571 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R572 HRFT393JCA R CHIP 1/10 39K OHM J 2012 SERVO

R573 RD-AZ102JR574 RD-AZ102J-

R CARBON FILM

R CARBON FILM

1/6 1K OHM J SERVO

1/6 1K OHM J SERVO

R575 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R576 HRFT301JCA R CHIP 1/10 300 OHM J 2012 SERVO

R577 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R578 RD-AZ473J-

R CARBON FILM

1/6 47K OHM J SERVO

R579 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012 SERVO

R580 RD-AZ622J- R CARBON FILM 1/6 6.2K OHM J SERVO

R581 RD-AZ472J-

R CARBON FILM

1/6 4.7K OHM J SERVO

R582 HRFT104JCA R CHIP 1/10 100K OHM J 2012 SERVO

R584 HRFT000-CA R CHIP 1/10 0 OHM 2012 SERVO

R585 RD-AZ102J- R CARBON FILM 1/6 1K OHM J SERVO

R586 RD-AZ102J-

R CARBON FILM

1/6 1K OHM J SERVO

R587 HRFT104JCA R CHIP 1/10 100K OHM J 2012 SERVO

R588 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012 SERVO

R589 HRFT473JCA R CHIP 1/10 47K OHM J 2012 SERVO

R590 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R591 RV5426104M R SEMI FIXED H100K-5X3-6Y-PC-MS SERVO

R592 HRFT102JCA R CHIP 1/10 1K OHM J 2012 SERVO

R593 RD-AZ104JR594 RD-AZ752J-

R CARBON FILM

R CARBON FILM

1/6 100K OHM J SERVO

1/6 7.5K OHM J SERVO

R595 HRFT104JCA R CHIP 1/10 100K OHM J 2012 SERVO

REF. PART CODE PART NAME PART DESCRIPTION REMARK

R596 RD-AZ103JR597 HRFT513JCA R CHIP 1/10 51K OHM J 2012

R601 HRFT750JCA R CHIP 1/10 75 OHM J 2012

R602 RD-AZ750JR603 RD-4Z751JR604 RD-4Z751JR605 RD-AZ431JR608 85801065GY WIRE COPPER

R609 RD-AZ271JR612 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R613 RD-AZ271JR701 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R702 HRFT161JCA R CHIP 1/10 160 OHM J 2012

R703 HRFT221JCA R CHIP 1/10 220 OHM J 2012

R704 RD-AZ331JR705 RD-AZ511J- R CARBON FILM 1/6 510 OHM J

R706 HRFT102JCA

R707 RD-AZ103JR708 RD-AZ331JR709 RD-AZ331JR710 RD-AZ331JR711 RD-AZ331JR712 HRFT331JCA

R713 RD-AZ331JR714 RD-AZ102JR715 RD-AZ102JR716 RD-AZ102JR717 RD-AZ102JR718 RD-AZ102J- R CARBON FILM 1/6 1K OHM J

R719 RD-AZ102JR720 RD-AZ102JR722 RD-AZ220JR723 RD-AZ430J- R CARBON FILM 1/6 43 OHM J

R724 RD-AZ430JR725 RD-AZ430JR726 RD-AZ430JR727 RD-AZ430J- R CARBON FILM 1/6 43 OHM J

R728 RD-AZ430JR801 RW02B229JR802 RC-2Z565KP

R803 RC-2Z565KP

R804 RD-AZ472J-

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CHIP

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CHIP

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R CARBON FILM

R WIRE WOUND

R CARBON COMP

R CARBON COMP

R CARBON FILM

1/6 10K OHM J SERVO

AV IN/OUT

AV IN/OUT

1/6 75 OHM J

1/4 750 OHM J

1/4 750 OHM J

1/6 430 OHM J

AWG22 1/0.65 TIN COATING

1/6 270 OHM J

1/6 270 OHM J

1/6 330 OHM J

1/10 1K OHM J 2012

1/6 10K OHM J

1/6 330 OHM J

1/6 330 OHM J

1/6 330 OHM J

1/6 330 OHM J

1/10 330 OHM J 2012

1/6 330 OHM J

1/6 1K OHM J

1/6 1K OHM J

1/6 1K OHM J

1/6 1K OHM J

1/6 1K OHM J

1/6 1K OHM J

1/6 22 OHM J

1/6 43 OHM J

1/6 43 OHM J

1/6 43 OHM J

1/6 43 OHM J

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

2W 2.2 OHM J POWER

1/2 5.6M OHM K POWER

1/2 5.6MOHM K POWER

1/6 4.7K OHM J POWER

R805 HRFT241JCA R CHIP 1/10 240 OHM J 2012 POWER

R806 RD-AZ271J-

R CARBON FILM

1/6 270 OHM J POWER

R807 HRFT751JCA R CHIP 1/10 750 OHM J 2012 POWER

R808 RS02F621JS

R M-OXIDE FILM

2W 620 OHM J SMALL POWER

22

Page 24

ELECTRICAL PARTS LIST

REF. PART CODE PART NAME PART DESCRIPTION REMARK

RF101 97P7213400

MODULATOR RF

KCR104PSV AV IN/

OUT

S501 97P0S01900 SENSOR REEL SG-258S SERVO

S502 97P0S01900 SENSOR REEL SG-258S SERVO

S503 TST5811--- TR PHOTO ST-5811(D-RANK) VIDEO

S503A 97P2342101 HOLDER P/T ABS(HF-06601) SERVO

S504 TST5811--- TR PHOTO ST-5811(D-RANK) SERVO

S504A

97P2342101 HOLDER P/T ABS(HF-06601) SERVO

S505

5SN0101Z20 SW DETECT JDS1105-6X SERVO

SW701

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

SW702

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

SW703

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

SW704

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

AV IN/OUT

AV IN/OUT

AV IN/OUT

AV IN/OUT

REF. PART CODE PART NAME PART DESCRIPTION REMARK

SW705

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

SW706

5S50101Z97 SW TACT SKHV10914B 9.5M AUTO

AV IN/OUT

AV IN/OUT

T201 560202L692 COIL OSC DEO-006 AUDIO

TJ391

85801065GY

TJ591

85801065GY

U101

97P65255MA PCB MAIN 330X246X1.6T(S107W)

X301 5XJ3R579UC

X302 5XJ4R433UC

X501 5XJ8R000AE

WIRE COPPER

WIRE COPPER

CRISTAL QUARTZ

CRYSTAL

QUARTZ

CRYSTAL

QUARTZ

AWG22 1/0.65 TIN COAT

ING

AWG22 1/0.65 TIN COAT

ING

HC-49/S 3.579545MHZ

20PPM

HC-49/S 4.433619MHZ

20PPM

HC-49/S 8.000000MHZ

30PPM

-

-

VIDEO

SERVO

AV IN/OUT

VIDEO

VIDEO

SERVO

23

Page 25

ELECTRICAL PARTS LIST

2. PCB AUTO VOLT REGULATOR AS

REF. PART CODE PART NAME PART DESCRIPTION CIRCUIT

0M801 PVPWSWW063 AUTO VOLT REGULATOR S103WY-QB/D(F13-S,M-IN)

C11 HCBK223KCA C CHIP CERA 50V X7R 0.022MF K 2012 POWER

C13 CEXF1H220F C ELECTRO 50V RX 22MF 6.3X11 POWER

C19 RS02F104JS R M-OXIDE FILM 2W 100K OHM J SMALL POWER

C20 CBXB3A470J C CERA SEMI 1KV SL 47PF J HR POWER

C21 CEXF1A102F C ELECTRO 10V RX 1000MF 10X20 POWER

C22 CEXF1A101F C ELECTRO 10V RX 100MF 6.3X11 POWER

C23 CEXF1E471F C ELECTRO 25V RX 470MF 10X20 POWER

C24 CEXF1E101F C ELECTRO 25V RX 100MF 8X11.5 POWER

C25 HCBK104KCA C CVHIP CERA 50V X7R 0.1MF K 2012 POWER

CN11 97P6284000 CONN WAFER YFAW025-105 ANGLE 3.5X4.5 POWER

CN21 97P6284000 CONN WAFER YFAW025-105 ANGLE 3.5X4.5 POWER

D11 DZEG01C--- DIODE EG01C POWER

D12 DZEU01Z--- DIODE EU01Z POWER

D21 D31DQ09--F DIODE SCHOTTKY 31DQ09-FC5 POWER

D21A 56X0000008 COIL BEAD OP5*5*2.5H POWER

D22 DS2L20U--F DIODE S2L20U 4004 P15 POWER 2

D22A 56X0000008 COIL BEAD OP5*5*2.5H POWER

IC11 1KA1L0380R IC POWER SW KA1L0380RB-YDTU POWER2

IC21 1KA431AZ-- IC REGULATOR KA431AZ POWER2

L12 56X0000007 COIL BEAD BI-4865(5TS) BASE POWER

L21 56C220K695 COIL CHOKE(CAP TYPE) 22UH K (CAP TYPE) 9X11.1 POWER

L22 56C220K686 COIL CHOKE(CAP TYPE) 22UH K 27.5X0.4D POWER

M801A 97PC316600 COVER SHI SMPS AS DV-S103 POWER

M801B 97P0970501 PLATE SHI SMPS ET T=0.5 POWER

M801C 97P5603700 INSULATION SMPS PC T0.5 POWER

PC11 1PC123FY8- IC PHOTO PC123FY8 CTR100-200 POWER

R11 RD-4Z100JS R CARBON FILM 1/4 10 OHM J SMALL POWER

R13 CMXL2J104K C MYLAR 630V MEU 0.1MF K POWER

R14 RD-2Z124JS R CARBON FILM 1/2 120K OHM J SMALL POWER

R15 RD-2Z124JS R CARBON FILM 1/2 120K OHM J SMALL POWER

R21 RS02F122JS R M-OXIDEFILM 2W 1.2K OHM J SMALL POWER

R22 HRFT391JCA R CHIP 1/10 390 OHM J 2012 POWER

R23 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012 POWER

R24 HRFT122GCA R CHIP 1/10W 1.2K OHM G 2012 POWER

R25 HRFT181GCA R CHIP 1/10 180 OHM G 2012 POWER

R26 HRFT102GCA R CHIP 1/10 1K OHM G 2012 POWER

RJ01 HRF8000-EA R CHIP 1/8 0 OHM 3216 POWER

RJ02 HRF8000-EA R CHIP 1/8 0 OHM 3216 POWER

RJ03 HRF8000-EA R CHIP 1/8 0 OHM 3216 POWER

RJ04 HRF8000-EA R CHIP 1/8 0 OHM 3216 POWER

RJ05 HRF8000-EA R CHIP 1/8 0 OHM 3216 POWER

T11 57M8282202 TRANS POWER TSW-S103 POWER

U801 97P65211PA PCB POWER 197X197X1.6T/6(S103) POWER

24

Page 26

ELECTRICAL PARTS LIST

DV-S107N-QD/A DV-S107A-QB

- - 97P7213700 HSM-3460MV1 97P7213700 HSM-3460MV1

LOC PART-NAME PART-CORD PART-DESC PART-CORD PART-DESC PART-CORD PART-DESC

FEATURE MODEL DV-S107WY-QB/D

01 ACCESSORY AS PVACPSD340 F342DY(BT:AAA) - S107N-QD/A S107A-QB

D001 MANUAL OWNERS 97P95600W0 MULT MODEL 97P95600N0 ALL MODEL 97P95600A0 N-PAL/NTSC

3.DIFFERNCE PARTS LIST

D002 CABLE RF 97P881RP10 PAL 1.0M 97P880RN10 NTSC 1.0M 97P880RD15 NTSC-PAL 1.5M

2

D006 ADAPTOR AC PLUG - - 97P7702900 HPA-2V 15A 4.0 - -

03 CHASSIS MAIN AS PVMCASW083 DV-S107WY-QB/D - S107N-QD/A S107A-QB

D100 REMOCON HANDSET AS 97P1R2RAA0 VR-F2RAA0 97P1R2RAB0 VR-F2BA0 97P1R2RAB0 VR-F2RBA0

PW01 CORD POWER AS 97P69DB900 EUROPEAN - - 97P69NB900 ARGENTIAN

M1000 DECK TOTAL AS 97PC0292D- S3-MECHA(PAL 2HD LP DLC) 97PC0369D- S3-M(NTSC 2HD EP NON-DLC) 97PC0370D- S3-M(PAL 2HD LP NON-DLC)

001 PCB MAIN MANUAL AS PVMPMSW083 DV-S107WY-QB/D - S107N-QD/A S107A-QB

C803 C ELECTRO CEXN2G820P 400V LHS 82MF 22X25 CEXF2G470V 400V RSS 47MF 16X25 CEXF2G470V 400V RSS 47MF 16X25

G701 LED DISPLAY DS103W---- S103W 13P ANGLE DS103N---- S103N 13P ANGLE - -

M601 BOARD ANT 97P0722400 HI-PS(HB) 97P0722300 HI-PS(HB) 97P0722300 HI-PS(HB)

RF101 MODULATOR RF 97P7213300 RMUP74055WA 97P7213800 KCR101NSV 97P7213800 KCR101NSV

X302 CRYSTAL QUARTZ 5XE4R433BB HC-49/U 4.433619MHZ 15PPM - - 5XE3R582BB HC-49/U 3.582056MHZ 15PPM

0011 PCB MAIN CHIP AS PVMPJ1W083 DV-S107WY-QB/D - S107N-QD/A - S107A-QB

C203 C CHIP CERA HCBK332KCA B 50V 3300PF K 2012 HCBK222KCA B 50V 2200PF K 2012 HCBK102KCA B 50V 1000PF K 2012

C223 C CHIP CERA HCBK332KCA B 50V 3300PF K 2012 HCBK182KCA B 50V 1800PF K 2012 - -

C502 C CHIP CERA HCBK103KCA B 50V 0.01MF K 2012 - - HCBK103KCA B 50V 0.01MF K 2012

C583 C CHIP CERA - - HCBK103KCA B 50V 0.01MF K 2012 - -

C610 C CHIP CERA HCLK221JCA SL 50V 220PF J 2012 - - - -

C611 C CHIP CERA HCBK103KCA B 50V 0.01MF K 2012 - - - -

C614 C CHIP CERA HCLK221JCA SL 50V 220PF J 2012 - - - -

C615 C CHIP CERA HCBK103KCA B 50V 0.01MF K 2012 - - - -

IC505 IC EEPROM 14ATM24D04 ATM24C04N(8 SOP) - - HRFT132JCA 1/10 1.3K OHM J 2012

R393 R CHIP HRFT561JCA 1/10 560 OHM J 2012 - - HRFT511JCA 1/10 510 OHM J 2012

R201 R CHIP HRFT822JCA 1/10 8.2K OHM J 2012 HRFT103JCA 1/10 10K OHM J 2012 - -

R204 R CHIP HRFT161JCA 1/10 220 OHM J 2012 HRFT221JCA 1/10 220 OHM J 2012 - -

R212 R CHIP HRFT223JCA 1/10 22K OHM J 2012 HRFT243JCA 1/10 24K OHM J 2012 - -

R215 R CHIP HRFT392JCA 1/10 3.9K OHM J 2012 HRFT622JCA 1/10 6.2K OHM J 2012 - -

25

Page 27

ELECTRICAL PARTS LIST

DV-S107N-QD/A DV-S107A-QB

LOC PART-NAME PART-CORD PART-DESC PART-CORD PART-DESC PART-CORD PART-DESC

FEATURE MODEL DV-S107WY-QB/D

R219 R CHIP HRFT562JCA 1/10 5.6K OHM J 2012 HRFT392JCA 1/10 3.9K OHM J 2012 - -

R584 R CHIP HRFT000-CA 1/10 0 OHM J 2012 - - HRFT752JCA 1/10 7.5K OHM J 201

R606 R CHIP - - HRFT102JCA 1/10 1K OHM J 2012 HRFT102JCA 1/10 1K OHM J 2012

R607 R CHIP - - HRFT101JCA 1/10 100 OHM J 2012 HRFT101JCA 1/10 100 OHM J 2012

RJ005 R CHIP - - HRFT000-CA 1/10 0 OHM J 2012 HRFT000-CA 1/10 0 OHM J 2012

0012 PCB MAIN RADIAL AS PVMPJRW083 DV-S107WY-QB/D S107N-QD/A S107A-QB

C214 C MYLAR CMXM2A103J 100V 0.01MF J CMXM2A123J 100V 0.012MF J

C501 C ELECTRO CEXF1C470A RSM 16V 47MF (SRA.S - - - -

C617 C ELECTRO CEXF1C470A RSM 16V 47MF (SRA.S - - - -

Q601 TR - - TZSR1004-- KSR1004 (AUTO) TZSR1004-- KSR1004 (AUTO)

Q603 TR - - TZTA1266Y- KTA1266Y- (AUTO)(1015Y) TZTA1266Y- KTA1266Y- (AUTO)(1015Y)

0013 PCB MAIN AXIAL AS PVMPJAW083 DV-S107WY-QB/D S107N-QD/A S107A-QB

C516 C CERA SEMI - - CBZP1C103M 16V Y5S 0.01MF M CBZP1C103M 16V Y5S 0.01MF M

JP001 WIRE COPPER - - 85801060TA 0.6X52MM TAPING 85801060TA 0.6X52MM TAPING

JP107 WIRE COPPER - - 85801060TA 0.6X52MM TAPING 85801060TA 0.6X52MM TAPING

JP169 WIRE COPPER - - 85801060TA 0.6X52MM TAPING 85801060TA 0.6X52MM TAPING

R523 R CARBON FILM - - RD-AZ102J- 1/6 1K OHM J RD-AZ102J- 1/6 1K OHM J

R569 R CARBON FILM RD-AZ473J- 1/6 47K OHM J - - - -

R570 R CARBON FILM RD-AZ473J- 1/6 47K OHM J - - - -

R583 R CARBON FILM - - RD-AZ103J- 1/6 10K OHM J RD-AZ103J- 1/6 10K OHM J

R585 R CARBON FILM RD-AZ102J- 1/6 1K OHM J - - - -

R586 R CARBON FILM RD-AZ102J- 1/6 1K OHM J - - - -

0014 PCB MAIN J/V ONLY AS PVMPJVW081 DV-S107WY-QB/E S107A-QB S107A-QB

JP019 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP020 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP108 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP117 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP118 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP157 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP161 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

JP165 WIRE COPPER 85801065GY AWG22 1/0.60 TIN CO - - - -

26

Page 28

DAEWOO ELECTRONICS CO., LTD

686, AHYEON-DONG MAPO-GU

SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX : DWELEC K28177-8

CABLE : "DAEWOOELEC"

E-mail : leesk@web.dwe.co.kr

TEL : 82-2-360-7802

FAX : 82-2-360-7877

Page 29

TROUBLE SHOOTING GUIDE

1. TROUBLE SHOOTING FLOW CHART

A. POWER CIRCUIT

When changing the parts which are out of order, first, remove the power plug from the socket and then discharge the

voltage across between both terminals of C803. (Use an external approximately 20 resistance)

When check the primary circuit by using the oscilloscopes insulate the oscilloscope properly (Use the insulating transformer)and GND must be connected GND into the primary GND (But there is no connection when checking the secaondary circuit.

When changing M801, check FUSE and ceramic resistor properly.

A-1. CHECKING THE PRIMARY CIRCUIT.

No output voltage

YES

Is the voltage applied to

CN11?

YES YES

Is the voltage +15V at pin3

of IC11?

YES YES YES

Check the secondary

circuit

NO

NO

NO

Check F801, L801, L802

C803, D801, R801

Is the voltage above 10V

at pin3 of IC11?

( A )

NO

NO

A-2. CHECKING THE SECONDARY CIRCUIT.(Before secondary circuit open).

(A)

YES

Check each output voltage

YES

NO

NO

Check transformer of no

output stages

Check the diode of no

output stages

Is the voltage 0V at pin3

of IC11?

Check R14, R15, T11

R13, D11, L12

YES

Check the CN11

YES

Check the coil, condensor

of no output stages

1

Page 30

A-3. CHECKING THE DC - INPUT CIRCUIT.

Do not turn on the front

DISPLAY

YES

TROUBLE SHOOTING GUIDE

Check the polarity of

DC adaptor

YES

Is Vcc input at pin1 of

IC803?

YES

Is 6.5V output at pin2 of

IC803?

YES

Check SERVO/SYSCON

circuit

B. LED DISPLAY CIRCUIT.

LED does not operate

properly.

YES

NO

NO

NO

NO

Change the DC adaptor

Check JK801 and pattern

Is 1.25V input at pin4 of

Is +5.1V supplied from

D510 cathod to L701?

IC803?

NO

NO

Check R805, R806 and

R807

Check power module

Is +5.1V supplied to the

collectors of Q701~Q706?

YES

Are the signals supplied

from u-com to the bases

of Q701~Q706?

YES

Are the signals supplied

from u-com to the bases

of Q707~Q713?

YES

Are the signals supplied

to the LED(G701)?

YES

Check G701 and pattern

NO

NO

NO

NO

Check L701

Check u-com

Check u-com

Check Q701~ Q713 and

patterns

2

Page 31

TROUBLE SHOOTING GUIDE

C. SERVO/SYSCON CIRCUIT

C-1. FRONT KEYS

Front keys do not operate

correctly

YES

Is +5.1V supplied to pin18

of IC501?

YES

Is +5.1V supplied to the

emitter of Q502?

YES

Is +5.1V input at pin44 of

IC501?

YES

Check IC501

C-2. PICTURE IN PB MODE

PB picture is not good

YES

Noise appears although

adjusting tracking?

NO

NO

NO

NO

NO

Check power module

Check u-com, JP044 and

JP059

Check Q502 and circuit

Adjust tracking

Noise appears although

Change cassette tape

YES

Check and re-adiust the

path of DECK

YES

Is CTL pulse output at

NO

pin1 of IC504?

YES YES

Is CTL pulse input at

NO

pin29 of IC501?

YES

The voltage of IC501's

NO

pin18 is not changing?

YES

Check IC501

AC HEAD's height is

normal and there is not

dust?

Check C556, C533, D505

and adjacent circuit.

Check power module

3

NO

Adjust the head height

and remove dust

Check IC504 and adjacent

YES

circuit

Page 32

C-3. PICTURE IN PB MODE

PB picture is not good

YES

TROUBLE SHOOTING GUIDE

Noise appears on the

screen on the whole?

YES YES

Is V-SW puls applied to

PREAMP circuit?

YES

Is DC-ENVE waveform

input at pin38 of IC501?

YES

Check video circuit

C-4. AUTOSTOP IN PB MODE

Autostop during playback

NO

Noise appears on the

screen at the bottom?

NO

Is V-SW pulse supplied

From pin46 of IC501?

NO

NO

Is DC-ENVE waveform

output at pin93 of IC 301?

YES

Check pattern

NO

Check flow C-2

Adjust the PG delay

Check D.PG input at pin13

of IC501 and P502

NO

Check video circuit

(R591)

YES

YES

Are S&T pulses input at

pin1 and pin7 of IC501?

YES

Is D.FG input at pin30 of

NO

NO

Check Reel sensors

Is D.PWM output at pin33

IC501?

YES

Check IC501 Check P502 and R592

of IC501?

YES

NO

Check IC501

4

Page 33

TROUBLE SHOOTING GUIDE

C-5. CASSETTE IS NOT INSERTED

Cassette is not inserted

YES

Is ON/OFF 12V supplied

NO

at pin7 of IC503?

YES

CAM data are changed

NO

when CST IN?

YES

Is +5V applied to pin5

NO

of IC503 when CST IN?

YES YES

Is 9.1V supplied to pin4

NO

of IC503?

YES

Are control signals output

NO

at pin2 and 10 of IC503

Check power module

Check P504

Is control signal output

at pin77 of IC501?

Check pattern and R529

Are control signals output

at pin76 and 78 of IC501?

YES

Check IC503

NO

NO

NO

Check DECK

Check IC501

Check IC503

YES

Check D504, D508 and

D503

YES

Check P503 and L/C

Motor.

5

Page 34

C-6. CAPSTAN MOTOR

Capstan M/T loading stops

YES

TROUBLE SHOOTING GUIDE

Is +12V supplied to pin7

NO

of P501?

YES

Is the input of P501's pin6

NO

2.5 ~ 3.5V?

YES

Is pin4 of P501 2.5V?

YES

Is C.PWM output at pin34

NO

NO

of IC501?

YES

Check P501, R515, R525

and C526

C-7. DRUM & CAPSTAN M/T IN REC MODE

Drum M/T and capstan

M/T rotate at regular

speed (IN REC MODE)

Check power module

Check circuit of R555,

R556 and R557

Check R559 and R560

Check IC501

YES

Is C.SYNC applied to the

base of Q501?

YES

Is V.SYNC input at pin28

of IC501?

YES

Check motors

NO

NO

Check C.SYNC of IC301

and pattern

Check Q501 and R578

6

Page 35

TROUBLE SHOOTING GUIDE

C-8. EMERGENCY

Emergency mode when

plugging (power cord)

YES

Is +5.1V applied to pin18

of IC501?

YES

Does X501 crystal

oscillate?

YES

Are CAM SW data cor-

rect?

YES

NO

NO

NO

Check power module

Check IC501 and crystal

circuit

Recheck P504 and CAM

SW contact

Check IC503 and IC501

C-9. VCP DOES NOT OPERATE (ALTHOUGH POWER CIRCUIT IS NORMAL.)

VCP does not operate after

power cord plugging

YES

Is +5V input at pin63 of

IC501?

NO

Check R528 and pattern

YES

Check flow C-8

7

Page 36

D. AUDIO CIRCUIT

D-1. PB MODE

No sound in the PB mode

YES

TROUBLE SHOOTING GUIDE

NO

Is the output at pin96 of

Is +5V supplied to pin95 of

IC301?

YES YES

Check R214, R216,

R218,L602

Is voltage less than 0.2V

and pattern

Is collector of Q204 GND?

IC301 and to pin2 of

T201?

at base of Q206?

YES

YES

Check pattern and AC

Head

NO

Check IC802 and adjacent

NO

Are CLK and DATA

applied to pin23 and 24 of

YES NO

Check IC501

NO

Check Q202, Q204 and

circuit

IC301?

Q205

8

Page 37

TROUBLE SHOOTING GUIDE

D-2. NO SOUND IN THE PB MODE AFTER RECORDING

IN REC MODE

Is signal audio input into

pin78 of IC301?

YES

Is +5V applied to pin58

and 75 of IC301?

YES

Is the voltage above 4V at

base of Q206?

YES

Is audio signal input into

pin98 of IC301?

YES

Does pin6 of T201

Oscillate?

YES

NO

Check C604,

C606,C619,R609,L607

NO

Check IC802 and adjacent

NO

Is CLK and DATA applied

to pin23 and 24 of

NO

Check C211, C212, R216

NO

Is the volatge from 0.7V

to 3.0V at pin99 of IC301?

and JK603

circuit

IC301?

and R218

YES

YES

NO

NO

Check IC501

YES

AC signal is put on the

DC voltage at pin99 of

IC301?

YES

AC signal put on 70KHz

at base of Q201?

YES

Clean Audio head

Check T201's circuit

Is the voltage from 2.4V

at pin6 of IC301?

YES

Check Q205

NO

Check AC head

Check IC301

9

Page 38

TROUBLE SHOOTING GUIDE

D-3. EE MODE

No sound in the EE mode

Is signal input into pin78

Is signal output at pin96 of

Check C212, R217, R218

YES

Is video signal input at

pin36 of IC301?

YES

of IC301?

YES

IC301?

YES

C213 and L602

NO

NO

TO VIDEO EE MODE

Check C604,C606,

C619,R609,L607 and

NO

Is +5V applied to pin58

and 75 of IC301?

Are CLK and DATA input

at pin23 and 24 of IC301?

JK602

YES

YES

NO

NO

Check IC802 and

adjacent circuit

Check SERVO/SYSCON

Check IC301

10

Page 39

TROUBLE SHOOTING GUIDE

E. VIDEO CIRCUIT

E-1. EE MODE

No output at pin19 of

JK603 or JK601?

YES

Is ON/OFF 12V supplied

to R603 and R604?

YES

Is video signal output at

pin29 of IC301?

YES

Check R312, Q604 and

Adjacent circuit

NO

Check IC801 and adjacent

NO

Is video signal input at

pin36 of IC301?

Are CLK & DATA signals

input at pin23 and 24 of

Is ON/OFF 5V supplied at

pin58 and 75 of IC301?

Do X301 and X302

circuit

YES

IC301?

YES

YES

oscillate?

YES

Check IC301

NO

NO

Check JK603 and pattern

Check SERVO/SYSCON

circuit and pattern

NO

Check IC802 and adjacent

NO

Check X301 and X302

circuit

11

Page 40

E-2. PREAMP IN THE PLAYBACK MODE

TROUBLE SHOOTING GUIDE

Is signal from heads fed to

pin1 and 3 of P391?

YES

Is ON/OFF5V supplied to

pin87 of IC301?

YES

Is REC(H) from pin79 of

IC501 supplied to base of

Q206(LOW)?

YES

Is V.SW pulse from pin46

of IC501 supplied to

pin11 of IC301?

YES

Is the signal from pin1 and

3 of P391 fed to pin82

or 85 of IC301?

YES

NO

Check the DRUM and

DECK mechanism

NO

NO

Check the ON/OFF 5V

Check Pattern, IC501 and

adjacent circuit

NO

Check SERVO/SYSCON

NO

Check P391and IC301

TO LUMINANCE

SIGNAL IN THE REC

NOTE : 1) REC(H) : "HIGH" in the REC mode.

"LOW" in the EE and PB mode

12

Page 41

TROUBLE SHOOTING GUIDE

E-3. LUMINANCE IN THE PALYBACK MODE

Is the signal from head

fed to pin82 of IC301?

YES

Is ON/OFF 5V supplied to

pin16 and 58 of IC301?

YES

Is the luminance signal

from pin18 fed to pin17

YES

Is the luminance signal

from 21 fed to pin20

of IC301?

YES

Is the luminance signal

from 43 fed to pin45 of

IC301?

YES

Is the luminance signal

from 46 fed to pin41 of

IC301?

NO

NO

NO

NO

Check P391 and DRUM

Check the ON/OFF 5V

Check Q301 and adjacent

Check Q302 and IC301

NO

NO

Check Q303 and IC301

and adjacent circuit

Circuit

Check IC301

YES

To output buffer circuit

( Check Q604 and

adjacent circuit )

13

Page 42

E-4. COLOUR IN THE PLAYBACK MODE

TROUBLE SHOOTING GUIDE

Is the signal from heads

fed to pin82 and 85 of IC

301?

YES

Is ON/OFF 5V supplied to

Pin 16 and 58 of IC301?

YES

Is the colour signal form

Pin57 of IC301 fed to

Pin54 of IC301?

YES

Is the colour signal from

pin51 of IC301 fed to

pin61 of IC301?

YES

Is the colour sinal from

pin72 of IC301

fed to pin71 of IC301?

YES

NO

Check P391 and DRUM

NO

NO

NO

Check the ON/OFF 5V

Check IC301

NO

Check C344, C346, and

IC302 and adjacent circuit

Check IC301

Is the colour signal from

pin129 of IC302 fed to

buffer circuit?

NO

Check Q604 and

adjacent circuit

14

Page 43

TROUBLE SHOOTING GUIDE

E-5. PREAMP CIRCUIT IN THE RECORD MODE

Is there the signal at

pin20 and pin71 of IC301?

YES

Is ON/OFF 5V supplied to

pin87 of IC301?

YES

Is REC(H) from pin79 of

IC501 supplied to

base of Q206?

YES

Is V.SW pulse from pin46

of IC501 supplied to pin11

of IC301?

YES

Is the signal from pin84 of

IC301 fed to pin2 of P391?

NO

Check the luminance and

colour circuit in REC mode

NO

NO

Check ON/OFF 5V

Check pattern, IC501 and

adjacent circuit

NO

Check SERVO/SYSCON

NO

Check P391 and DRUM

NOTE : 1) REC(H) : "HIGH" in the REC mode.

"LOW" in the EE and PB mode

15

Page 44

E-6. LUMINANCE SIGNAL IN THE RECORD MODE

TROUBLE SHOOTING GUIDE

Is ON/OFF 5V supplied

to pin16 and 58 of IC301?

YES

Is the obtained from pin36

of IC301?

YES

Is the signal from pin32 of

IC301 fed to pin31 of

IC301?

YES

Is the luminance signal

from pin21 fed to pin20 of

IC301?

YES

Is the modulated lumi-

nance signal from pin84

of IC301 fed to P391?

YES

NO

NO

NO

Check the ON/OFF 5V

TO EE MODE

Check IC301

NO

Check Q302 and adjacent

NO

Check IC301

YES

circuit

Check P391 and DRUM

16

Page 45

TROUBLE SHOOTING GUIDE

E-7. COLOUR SIGNAL IN THE RECORD MODE

Is ON/OFF 5V supplied to

pin15 and 58 of IC301?

YES

Is the obtained from pin34

of IC301?

YES

Is the colour signal from

pin32 of IC301 fed to

Pin31

YES

Is the down converted

colour signal from pin14

of IC301 fed to pin10 of

IC401 through C406?

YES

Is the modulated lumi-

nance signal from Pin84 of

IC301 fed to P391?

YES

NO

NO

NO

NO

NO

Check the ON/OFF 5V

TO EE MODE

Check IC302 .and

C314

Check IC302

Check IC301

Check P391 and DRUM

F. MODULATOR CIRCUIT

F-1. NO MODULATOR OUTPUT

Check the output channel

of VCP and input

channel of TV?

YES

Are +5V & ON/OFF 5V

applied to pin1 and 4 of

RF101?

YES

Is ON/OFF 12V applied to

pin7 of RF101?

YES

Are video and audio signal

input into pin2 and 6 of

RF101?

YES

Are CLK & DATA signal

input into pin3 and 5 of

RF101?

YES

Check RF101

NO Set the output channel of

VCP reference to owners

Mannual

NO

NO

NO

NO

Check ON/OFF 5V and

the option circuit

according to the option table

Check RJ013 and IC801

Check A/V circuit

Check SERVO/SYSCON

circuit

17

Page 46

TROUBLE SHOOTING GUIDE

2. WAVEFORMS ON VIDEO CIRCUIT

WAVEFORMS IN THE EE MODE(colour BAR INPUT)

1 Pin 31 of IC301

(SECAM color bar input :

1.0Vp-p

2 Pin 36 of IC301

(PAL color bar input :

1.0Vp-p)

3 Pin 29 of IC301

(PAL color bar output :

2.0Vp-p)

WAVEFORMS OF THE LUMINANCE IN THE RECORD MODE(colour BAR INPUT)

4 Pin 84 of IC301(PAL)

(REC luminance :

300mVp-p)

6 Pin 20 of IC301

(0.5Vp-p)

7 Pin 21 of IC301

(0.5Vp-p)

8 Pin 31 of IC301

(Color bar input :

1.0Vp-p)

9 Pin 41 of IC301

(0.4Vp-p)

10

Pin 43 of IC301

(0.4Vp-p)

18

Page 47

WAVEFORM OF THE PAL colour IN THE RECORD MODE(colour BAR INPUT)

12

Pin 36 of IC301

(PAL color input :

1.0Vp-p)

Pin 51 and 50 of IC301

13 14

(300mVp-p)

TROUBLE SHOOTING GUIDE

Pin 52 of IC301

(400mVp-p)

Pin 28 of IC301

(C.SYNC : 2Vp-p)

Pin 61 of IC301

1615

(300mVp-p)

WAVEFORMS OF THE LUMINANCE IN THE PB MODE (DP-1 TEST TAPE)

23

UP : Pin 10 of IC301(color

Rotary : 1Vp-p

DOWN : Pin 74 of IC301

(ENVE : 0.5Vp-p)

Pin 20 of IC301

24 25

(0.5Vp-p)

17

Pin 59 of IC401

(REC PAL color :

300mVp-p)

Pin 21 of IC301

(0.5Vp-p)

26

Pin 29 of IC301

(Video out : 2.0Vp-p)

Pin 41 of IC301

27

(400mVp-p)

19

Pin 43 of IC301

28

(300mVp-p)

Page 48

TROUBLE SHOOTING GUIDE

WAVEFORMS OF THE LUMINANCE IN THE PB MODE (DP-1 TEST TAPE)

UP : Pin 10 of IC301(color)

29

rotary : 0.5Vp-p)

DOWN : Pin 74 of IC301

(500mVp-p)

Pin 51 of IC301

(300mVp-p)

Pin 29 of IC301

30

(Video out : 2.0Vp-p)

Pin 72 of IC301

(500mVp-p)

Pin 71 of IC301

343332

(500mVp-p)

20

Page 49

TROUBLE SHOOTING GUIDE

3. ¥ì-COM PIN ASSIGNMENT

P : Pulse H : High L : Low

No. NAME I/O ASSIGNMENT ACTIVE CN

1 N.C GND

2 T_ REEL I TAKE-UP REEL PULSE P DECK(REEL)

3 A_MUTE(H) O AUDIO MUTE(H) OUTPUT H A/V

4 SLOW CTL O SLOW CONTROL

5 N.C

6 S_REEL I SUPPLY REEL PULSE P DECK(REEL)

7 N.C O H GND

8 S_DATA O A/V SERIAL DATA OUTPUT P A/V

9 S_CLK O A/V SERIAL CLK OUTPUT P A/V

TV/VCR MODE SWITCHING

10 TV(L)/VCR(H) O

11 MOD_CLK O MODULATOR CLK OUTPUT P RF101, IC505

12 MOD_DATA O MODULATOR DATA OUTPUT P RF101, IC505

13 D_PG I DRUM PG INPUT P DECK(DRUM)

14 PWR ON(L) O POWER ON/OFF CONTROL L POWER

15 REMOTE I REMOTE DATA INPUT P R_RECEIVER

16 CAP_I-LIMIT O

17 PB(H) O A/V CONTROL IN PLAYBACK H A/V

18 Vdd2 Vcc = +5V Vcc

19 GRID_1 O LED GRID_1 OUTPUT P LDISPLAY

20 GRID_2 O LED GRID_2 OUTPUT P L-DISPLAY

21 GRID_3 O LED GRID_3 OUTPUT P L-DISPLAY

22 GRID_4 O LED GRID_4 OUTPUT P L-DISPLAY

23 N.C GND GND

24 N.C GND GND

25 N.C GND GND

26 N.C GND GND

27 REC_CTL O CTL PULSE OUT IN REC MODE P DECK(CTL)

28 V_SYNC I V_SYNC DATA INPUT P A/V

29 PB_CTL I CTL INPUT IN PB MODE P IC501

30 D_FG I DRUM FG INPUT P DECK(DRUM)

31 C_FG I CAPSTAN FG INPUT P DECK(CAPSTAN)

32 Vss2 GND

33 D_PWM O DRUM M/T CONTROL PWM P DECK(DRUM)

ON TV

TV : L VCR : H

THIS PORT IS USUALLY OPEN BUT

OUPUTS FOR FRAME ADVANCE

H/L

L/P

SYSTEM

OPTION

DECK

(CAPSTAN)

21

Page 50

TROUBLE SHOOTING GUIDE

No. NAME I/O ASSIGNMENT ACTIVE CN

34 C.PWM O CAPSTAN M/T CONTROL PWM P DECK(CAPSTAN)

35 SYSSEL1 I DON’T CARE

36 DEW I DC P506

37 DRUM SELECT GND GND

38 DC_ENVE I DC_ENVE INPUT IN PB MODE PRE-AMP

39 TRKDLY I

40 AVss GND GND

41 PG_DLY I PG DELAY INPUT TO ADJUST 6.5H DC DECK & R591

42 KEY1 I FRONT PANNEL KEY’S DATA INPUT DC A/V IN/OUT

43 AD_DET I TO DETECT +5V LEVEL DC +5V

44 AVref I Vcc FOR u-COMS AD BLOCK

45 N.C GND

46 V_SWP O VIDEO SWITCHING PULSE OUTPUT P PREAMP

47 QV_SYNC O OUPUT DURING TRICK MODE P/L A/V

48 C_ROT O INVERTED V_SW PULSE P A/V

49 GRID_5 O LED GRID_5 OUTPUT P L-DISPLAY

TRACKING DELAY IN

MANUAL TRACKING

DC PATH JIG

50 CAM_C

51 CAM_B

52

53 REC_SAFETY(L) I

54 N.C GND GND

55 T_END(H) I TAPE END SENSOR INPUT H DECK

56 SECAM(H) I SECAM MODE INPUT H SECAM-L

57 T_START(H) I TAPE START SENSOR INPUT H DECK

58 OSC_IN I 8MHz OSC INPUT

59 OSC_OUT O 8MHz OSC OUTPUT

60 Vss1 CRYSTAL GND

61 N.C OPEN

62 N.C OPEN

63 RESET(L) RESET INPUT L

CAM_A

I DECK (CAM SW)

CAM_A CAM_B CAM_C MODE

H H H CAM OFF

L H L EJECT

H H L STAND-BY

H L H FF/REW

L L L BRAKE

L L H REV

L H H STOP/PLAY/CUE

REC SAFETY TAB IS DETECTED L

STATE SO THAT RECORDING IS

INHIBITED

L REC SAFETY SW

22

Page 51

No. NAME I/O ASSIGNMENT ACTIVE CN

64 N.C GND GND

65 N.C GND GND

66 SEG_7 O LED SEGMENT_7 OUTPUT P L-DISPLAY

67 SEG_6 O LED SEGMENT_6 OUTPUT P L-DISPLAY

68 SEG_1 O LED SEGMENT_1 OUTPUT P L-DISPLAY

69 SEG_2 O LED SEGMENT_2 OUTPUT P L-DISPLAY

70 SEG_3 O LED SEGMENT_3 OUTPUT P L-DISPLAY

71 SEG_4 O LED SEGMENT_4 OUTPUT P L-DISPLAY

72 SEG_5 O LED SEGMENT_5 OUTPUT P L-DISPLAY

73 Vdd1 Vcc

74 A/D RESET(H) O TO RESET AVref H

75 CAP_F/R O CAP-M/T FORWARD(L)/REVERSE(H) L/H DECK CAP.

76 LM_R

77 LM_F

78 CST IN(L) O

O

H/L

DECK LM M/T

(IC503)

O

TO OUTPUT L STATE IN CASSETTE

IN MODE ( PLAY, FF/REW, CUE/REV,

SLOW, STILL AND STOP ETC. )

L

DECK LM M/T

( IC503 )

79 REC(H) O TO OUTPUT DURING RECORDING H A/V, PREAMP

80 GRID_6 O LED GRID_6 OUTPUT P L-DISPLAY

23

Loading...

Loading...