Page 1

S/M No. : VK580NTEF0

Service Manual

TIME LAPSE VCR

Model: DV-K580NZ-T

DAEWOO ELECTRONICS CO., LTD.

http : //svc.dwe.co.kr

Jan. 2000

Page 2

TABLE OF CONTENTS

SAFETY&PRECAUTIONS ............................................................................................... 2

EXTERNAL VIEWS ........................................................................................................ 4

FRONT VIEWS FUNCTION ...................................................................................................................4

REAR VIEWS FUNCTION .....................................................................................................................5

ELECTRICAL ADJUSTMENT ........................................................................................... 6

SPECIFICATIONS ....................................................................................................... 14

TIMELAPSE REC/PB SPEED CHART ................................................................................ 15

CIRCUIT OPERATION .................................................................................................. 16

TROUBLE SHOOTING FLOW CHART ............................................................................. 24

POWER CIRCUIT ................................................................................................................................24

SERVO-SYSCON CIRCUIT ...................................................................................................................26

VIDEO CIRCUIT .................................................................................................................................34

AUDIO CIRCUIT .................................................................................................................................38

u-COM PORT DESCRIPTION ....................................................................................... 41

VOLTAGE CHART ....................................................................................................... 44

CIRCUIT DIAGRAM ..................................................................................................... 50

CONNECTION DIAGRAM ..................................................................................................................50

POWER CIRCUIT DIAGRAM ................................................................................................................51

SYSCON CIRCUIT DIAGRAM ..............................................................................................................52

VIDEO CIRCUIT DIAGRAM .................................................................................................................53

HEADAMP CIRCUIT DIAGRAM ............................................................................................................54

OSD CIRCUIT DIAGRAM ....................................................................................................................55

Y/C SEPARATION CIRCUIT DIAGRAM ..................................................................................................56

AUDIO CIRCUIT DIAGRAM .................................................................................................................57

LOGIC CIRCUIT DIAGRAM .................................................................................................................58

TERMINAL CIRCUIT DIAGRAM ............................................................................................................59

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW ........................................... 60

PCB MAIN .........................................................................................................................................60

PCB UNION .......................................................................................................................................61

DISASSEMBLY ............................................................................................................. 62

PANEL FRONT ASS’Y ...........................................................................................................................62

SET TOTAL ASS’Y .................................................................................................................................63

PACKING ASS’Y .................................................................................................................................64

ELECTRICAL PARTS LIST ............................................................................................... 65

1

Page 3

SAFETY&PRECAUTIONS

SAFETY CHECK AFTER SERVING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screw, parts and wires

have been returned to original positions. Afterwards, perform the following tests and conform the specified values in order

to verify compliance whit safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance between power cord plug prong and externally exposed parts of the set

(RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

isgreater than values given in table 1 below.

2. Dielectric strengthen test

Confirm specified dielectric strengthen between power cord

plug prongs and exposed accessible parts of the set

(RF terminals, antenna terminals, video and audio input output

terminals, microphone jack, ear phone jacks, etc.)

is greater than values given table 1.

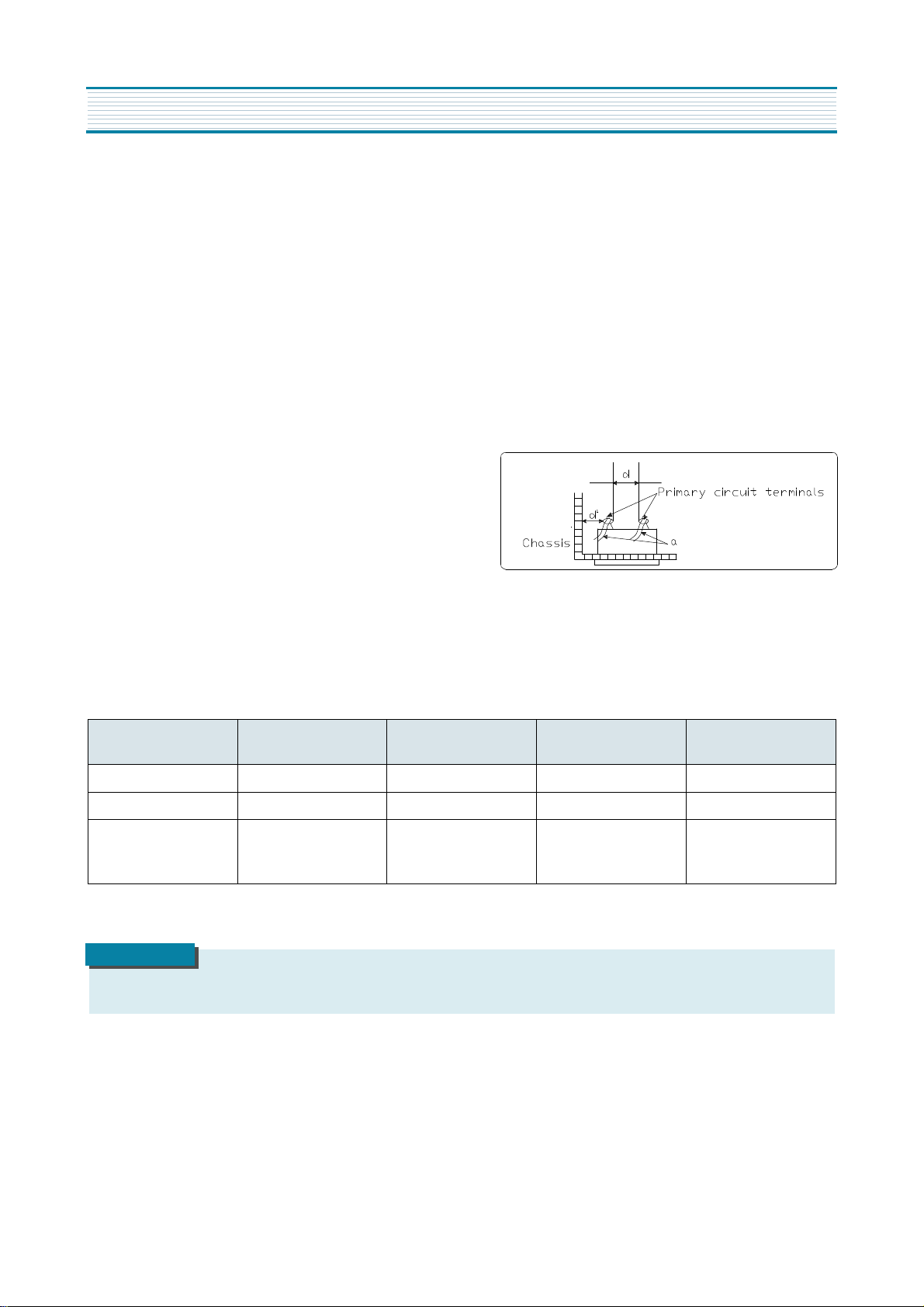

3. Clearance distance

When replacing primary circuit component, confirm specified clearance distance (d), (d

’

) between soldered terminals,

and between terminals and surrounding metallic parts. See table below.

Rating for selected areas

AC Line Voltage Region

100V Japan

110 to 130V

* 110 to 130V

200 to 240V

* : Class model only

USA & Canada

Latin America

Europe

Australia

Insulation

Resistance

]

1MΩ/500V DC

- 900V AC 1min.

]

10MΩ/500V DC 4kV AC 1min.

Dielectric

Strength

1kV AC 1min.

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Clearance

Distance(d),(d)

]

3

]

3.2

]

6(d)

]

8(d')

(a :Power cord)

2

Page 4

SAFETY&PRECAUTIONS

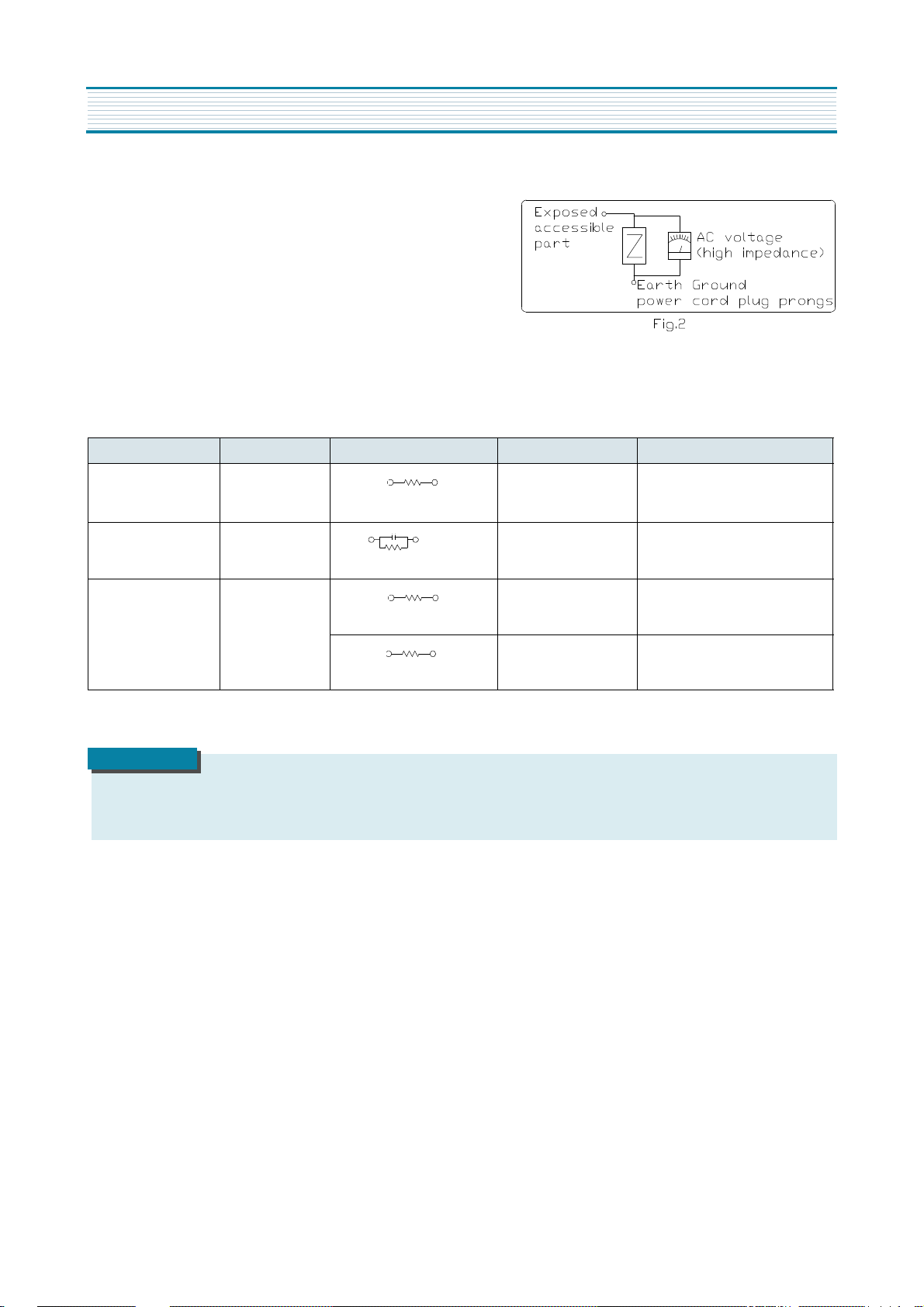

4. Leakage current test

Confirm specified or lower leakage current between B(earth

ground, power cord plug prongs) and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input

output terminals, microphone jacks, earphone jacks, etc.)

Measuring method:(Power ON) Insert load Z between B(earth

ground, power cord plug prongs) and exposed accessible parts.

Use on AC voltmeter to measure across both terminals of load Z.

See figure2 and following table.

Leakage current ratings for selected are as

AC Line Voltage Region Load Z Leakage Current(i) Clearance Distance(d),(d’)

100V Japan

1k

Ω

110 to 130V USA &Canada

110 to 130V

200 to 240V

Europe

Australia

1k

2k

50k

15kµF

Ω

Ω

Ω

NOTE

This table is unofficial and for reference only. Be sure to confirm the precise values

for your particular country and locality.

i*

1mArms

i*

0.5mArms Exposed accessible parts

i*

0.7mA peak

i*

2mAdc

i*

0.7mA peak

i*

1mAdc

Exposed accessible parts

Antenna earth terminals

Other terminals

3

Page 5

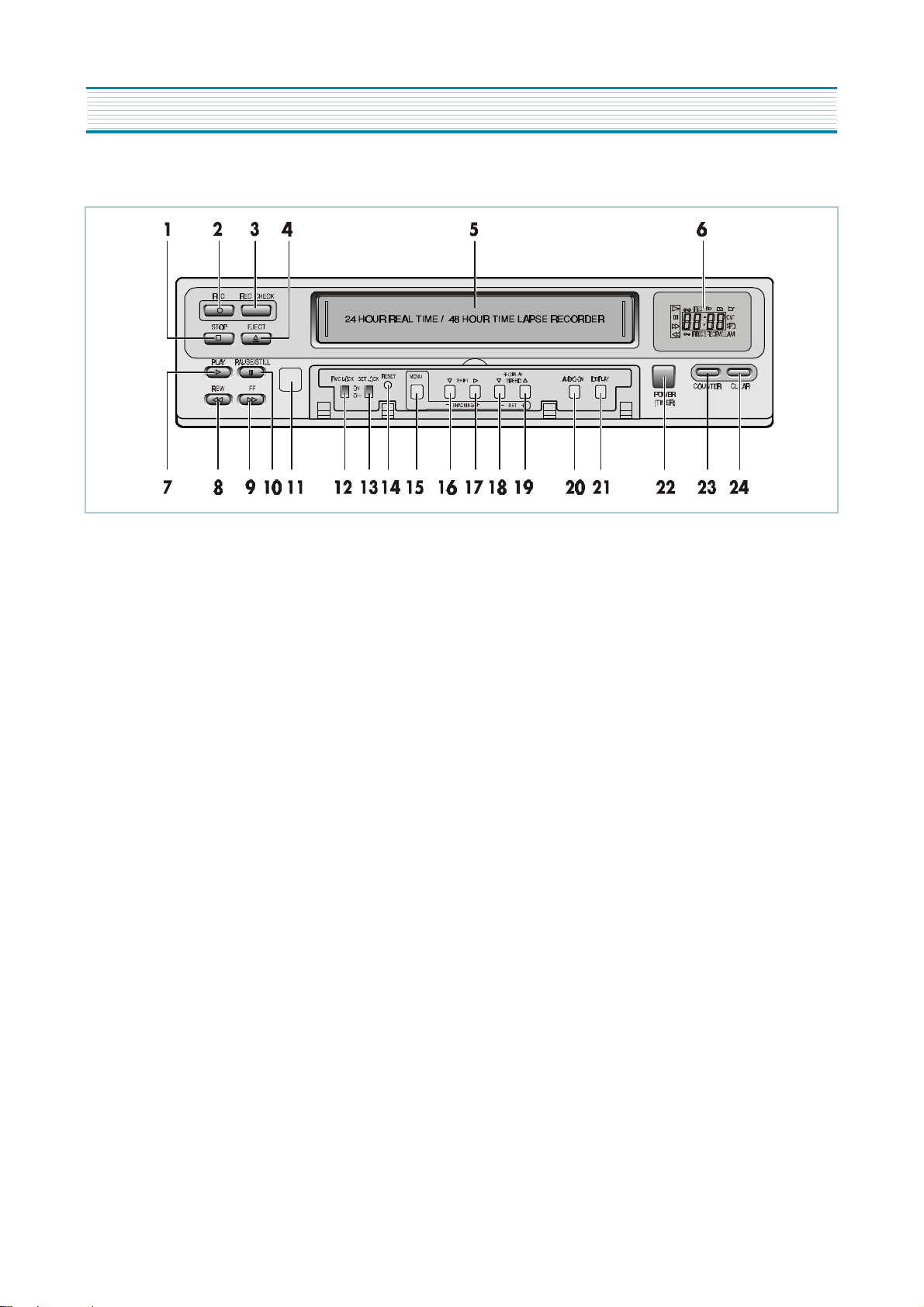

EXTERNAL VIEWS

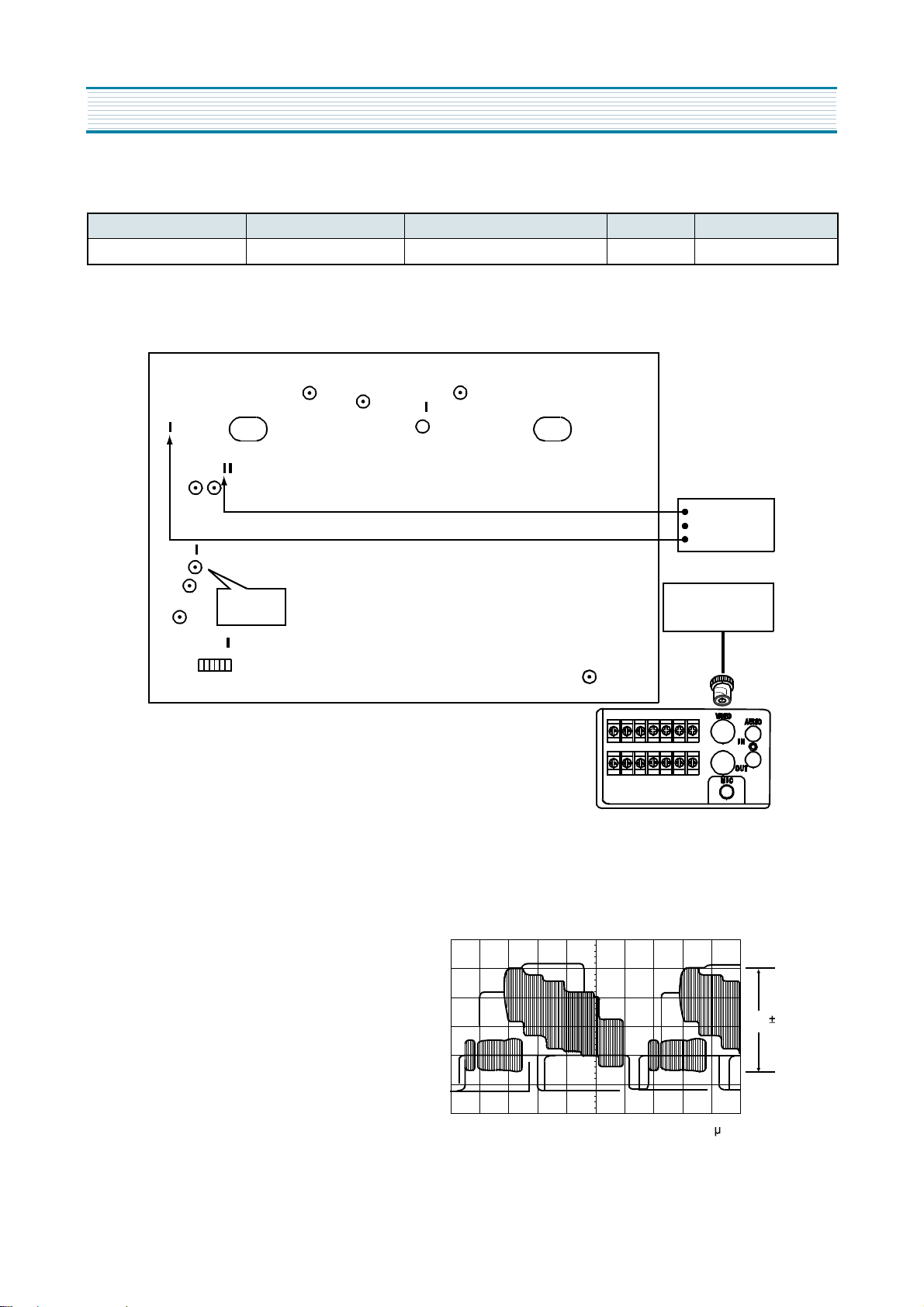

1. FRONT VIEWS FUNCTION

1) STOP button

2) REC button

3) REC CHECK button

4) EJECT button

5) CASSETTE LOADING DOOR

6) DISPLAY PANEL

7) PLAY button

8) REW button

9) FF button

10)PAUSE/STILL button

11)REMOTE SENSOR

12)REMOCON LOCK SWITCH

13)SET LOCK SWITCH

14)RESET button

15)MENU button

16)SHIFT( t ) / TRACKING (-) button

17)SHIFT( U ) / TRACKING (-) button

18)REC/PLAY SPEED (-) button (SET - button)

19)REC/PLAY SPEED (+) button (SET + button)

20)AUDIO ON button

21)DISPLAY button

22)POWER (TIMER ) button

23)COUNTER button

24)CLEAR button

4

Page 6

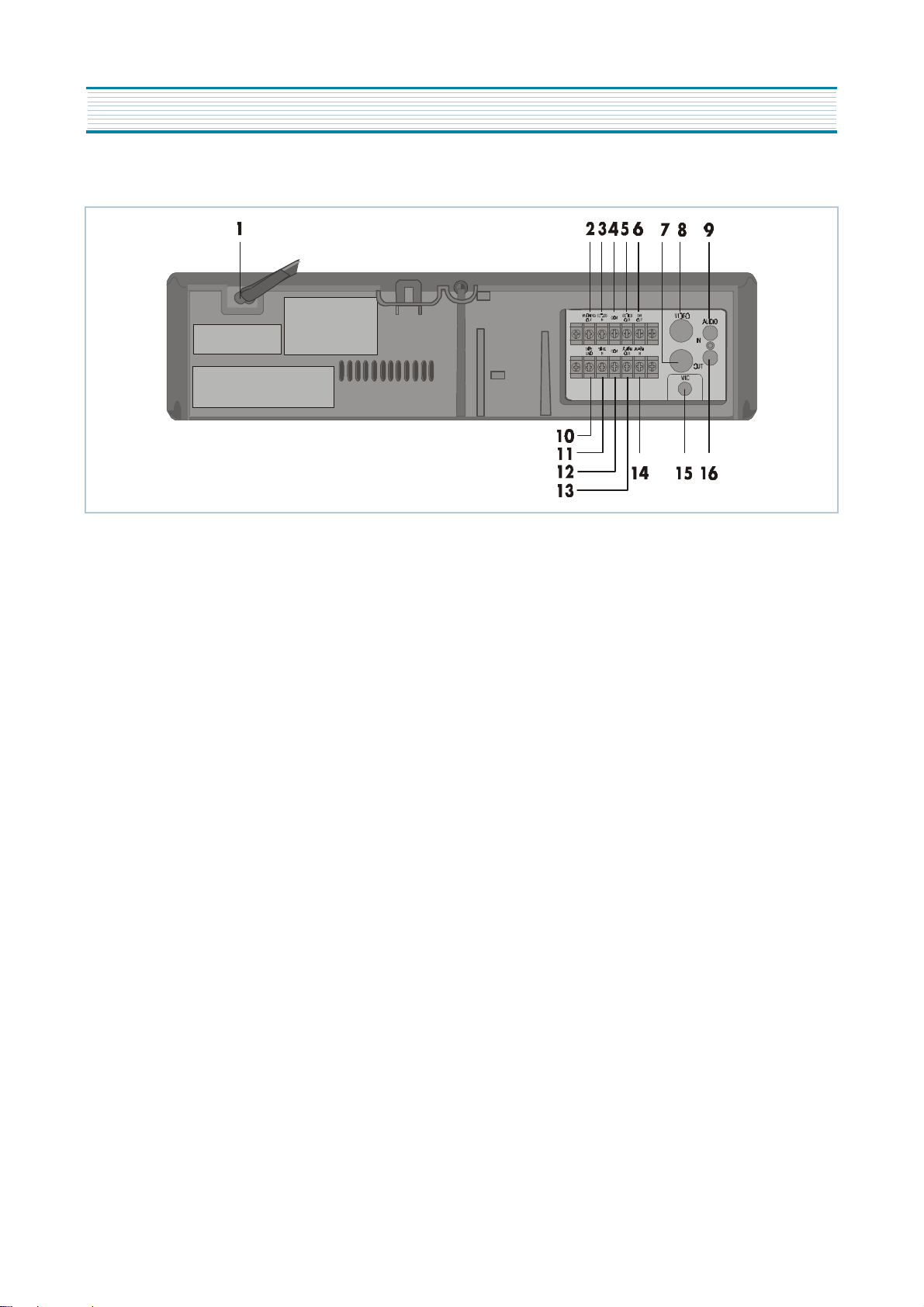

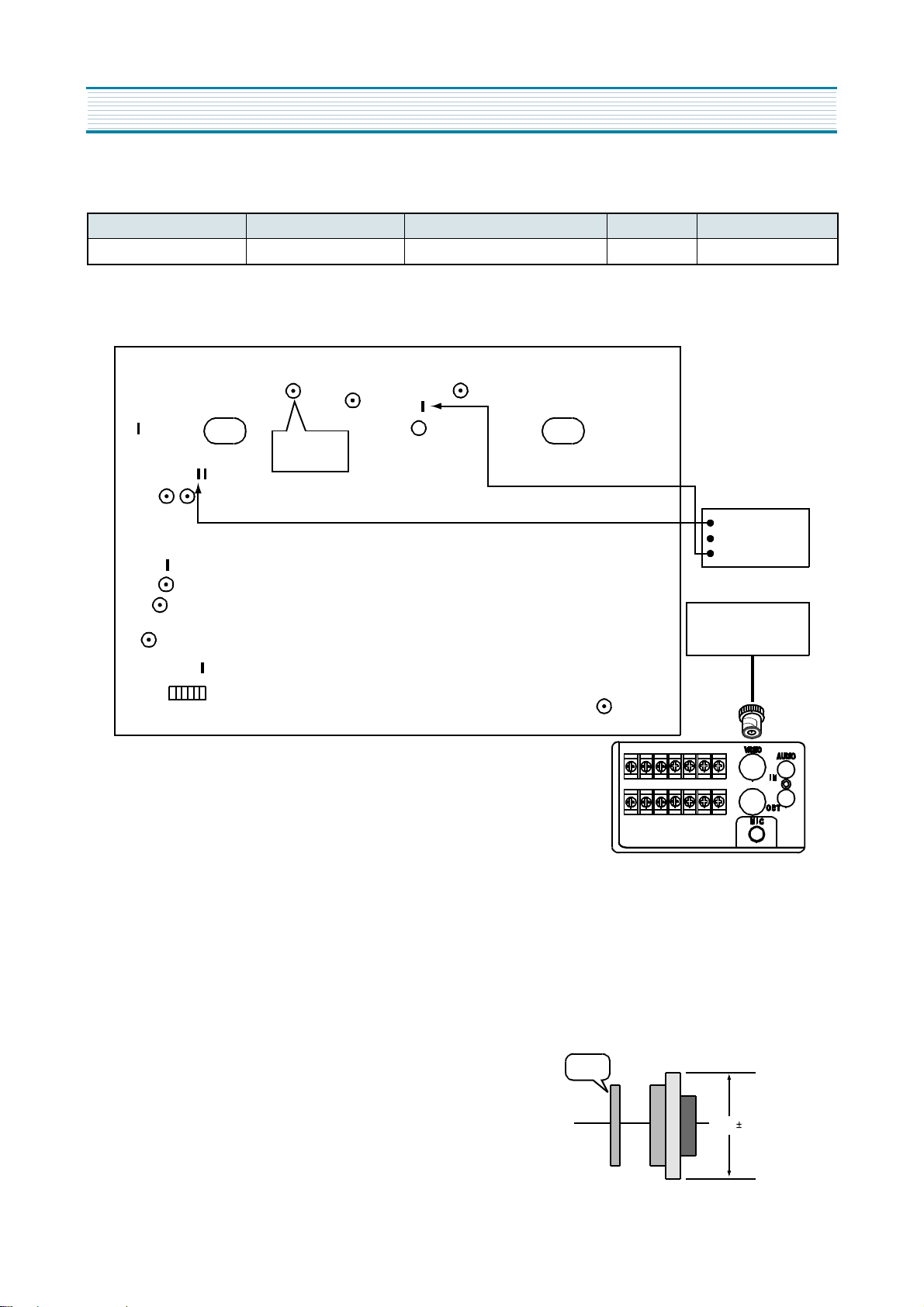

2. REAR VIEWS FUNCTION

EXTERNAL VIEWS

1) AC POWER CORD

2) WARNING OUT terminal

3) SERIES IN terminal

4) COM terminal

5) SERIES OUT terminal

6) SW OUT terminal

7) VIDEO OUT jack

8) VIDEO IN jack

9) AUDIO IN jack

10)TAPE END terminal

11)PANIC IN terminal

12)COM terminal

13)ALARM OUT terminal

14)ALARM IN terminal

15)MIC (microphone input) jack

16)AUDIO OUT jack

5

Page 7

ELECTRICAL ADJUSTMENT

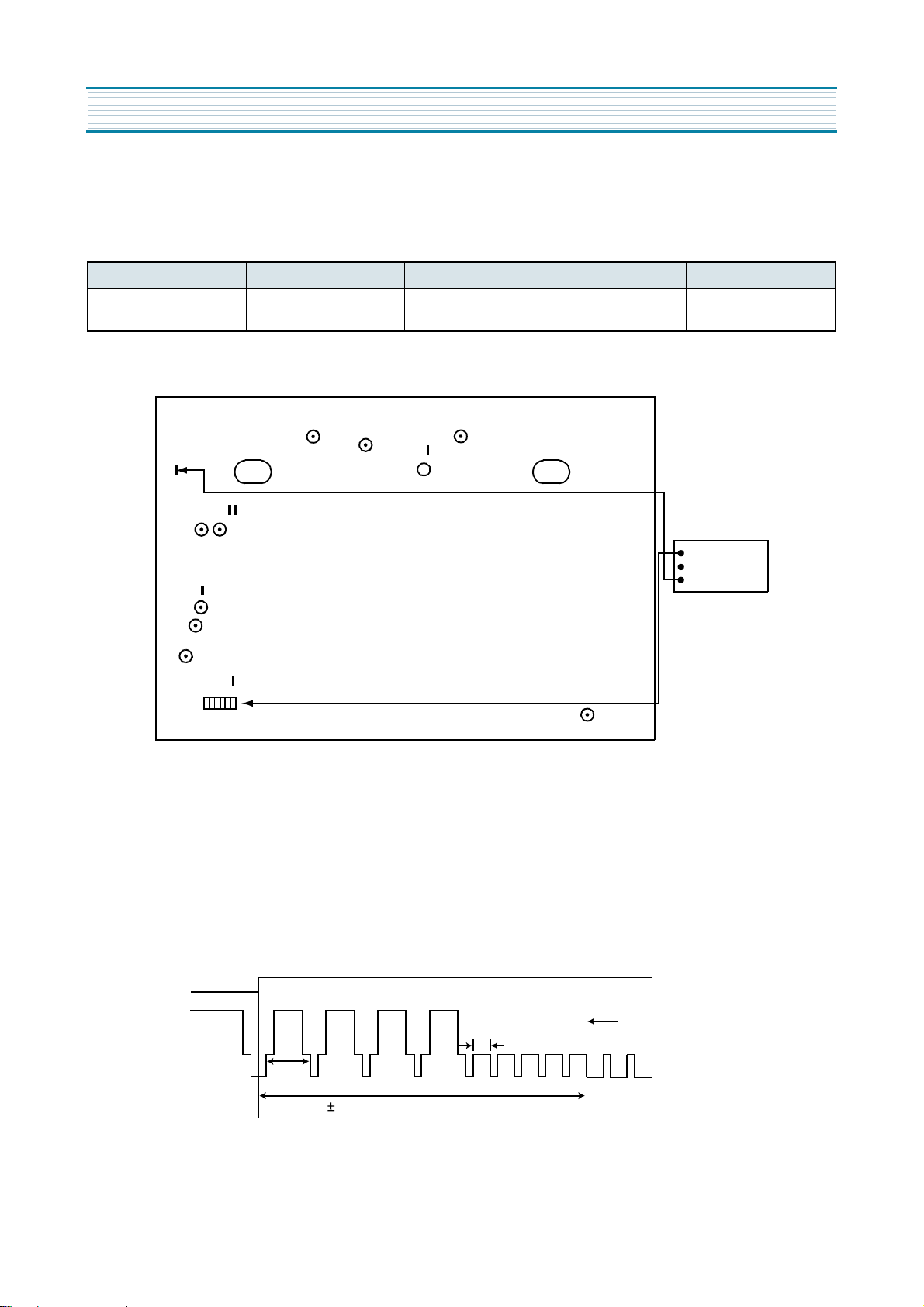

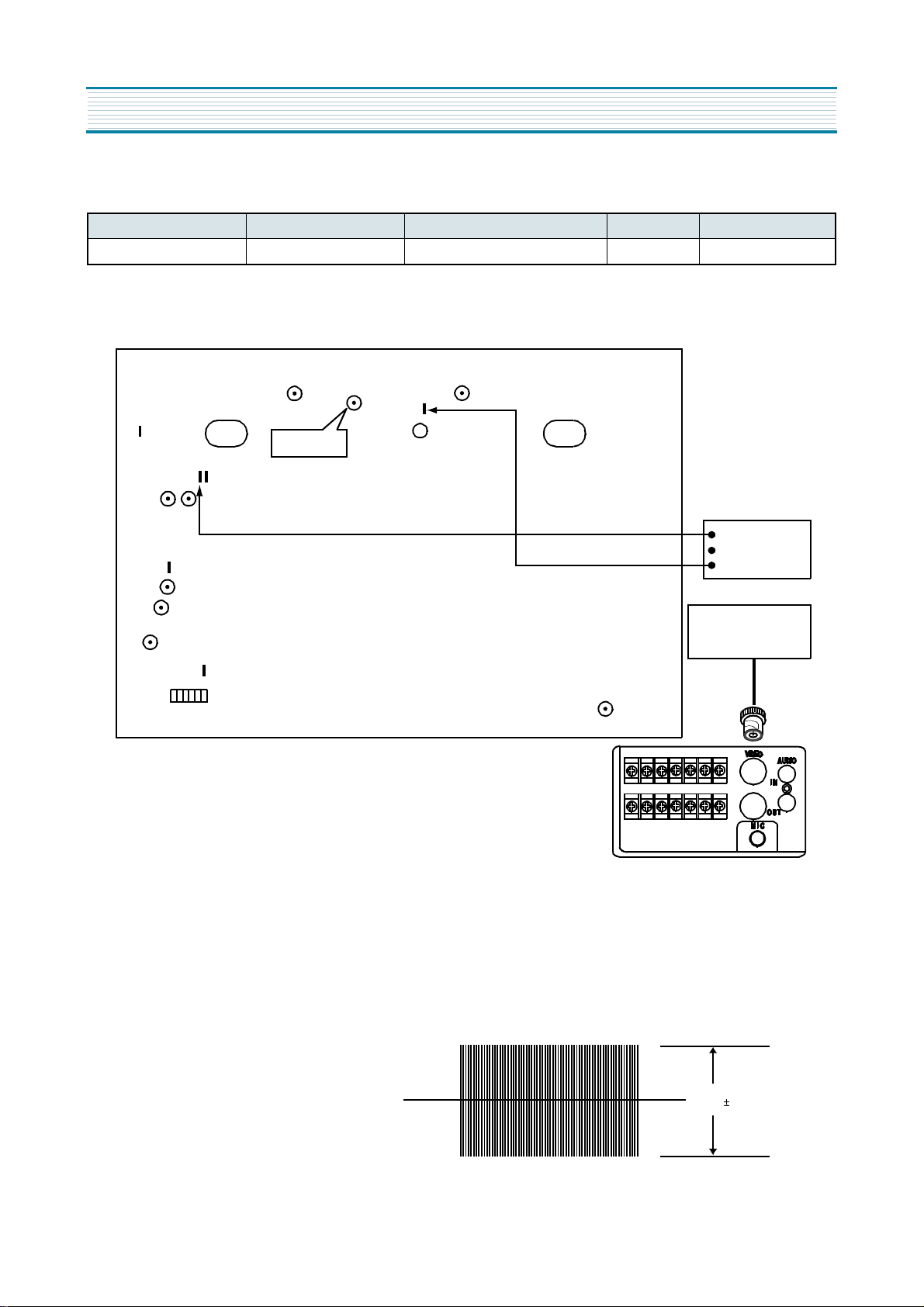

1. SERVO/SYSCON CIRCUIT ADJUSTMENT METHOD

v

VIDEO HEAD SWITCHING POSITION

Adjustment Part Checking Point Measuring Equipment Mode Test Tape

R595

v

CONNECTION METHOD

TJ396

TJ396

PT501 PIN3

OSCILLOSCOPE Play DN-1 (Color Bar)

CH-1

Oscilloscope

CH-2

PT501

v

ADJUSTMENT PROCEDURE

R595

1) Play back the test tape.

2) Set the oscilloscope in the chop mode connect the CH1 to SW pulse(PT501 (r)PIN), the CH2 to TJ396(video out) with

CH1 triggering.

3) Adjust R595 for the positive trigger until 6.5 ± 0.5H cycle before the vertical SYNC pulse.

CH1

Vertical SYNC Signal

1H

6.5H 0.5H

Trigger Position

SW PULSE

(PT501 3PIN)

VIDEO OUT

(TJ396)

6

Page 8

ELECTRICAL ADJUSTMENT

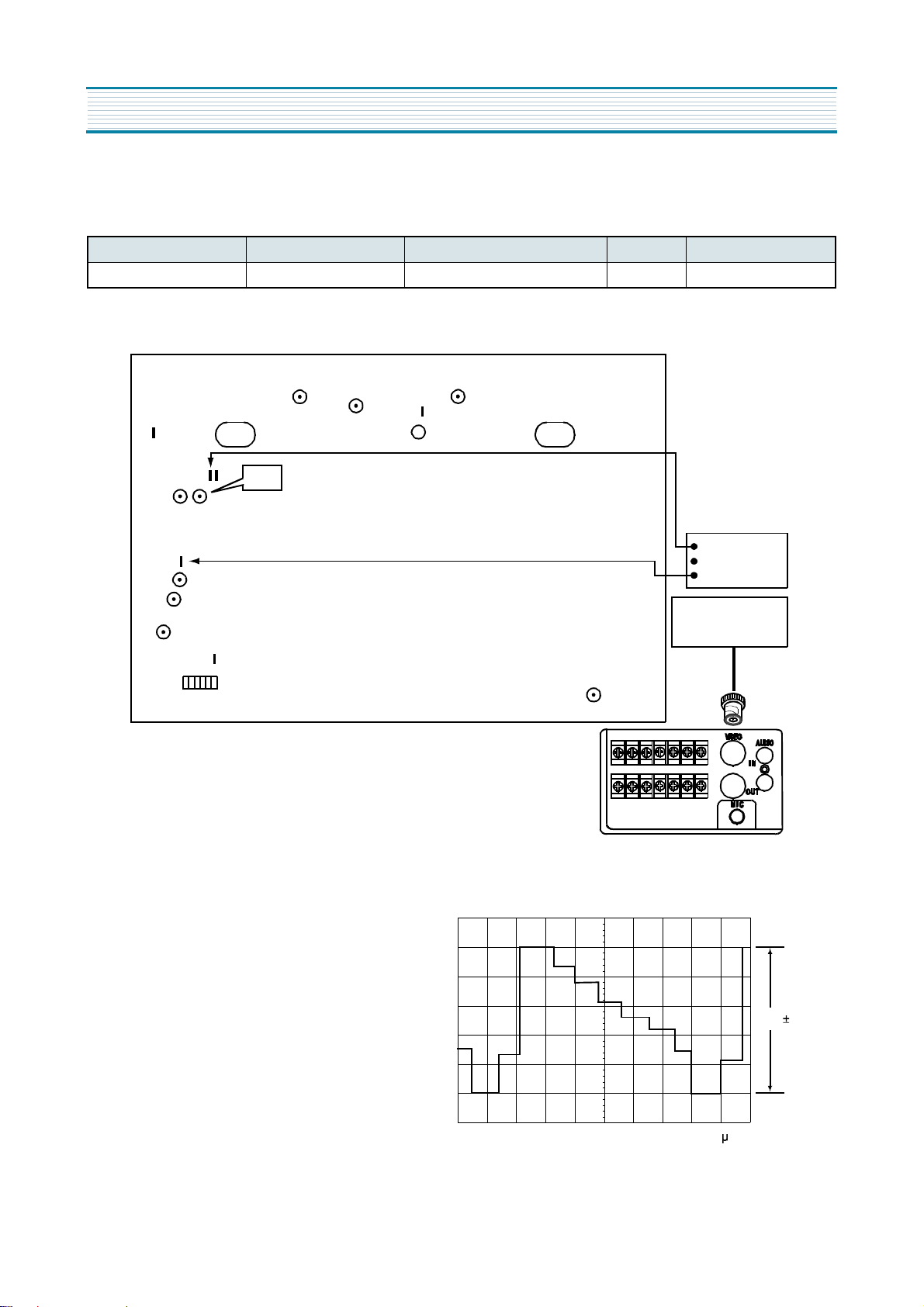

2. VIDEO CIRCUIT ADJUSTMENT METHOD

(1) EE LEVEL

Adjustment Parts Checking Point Measuring Equipment Test Tape Input Signal

R395 TJ396 Signal Gen. Oscilloscope - Color Bar

v

CONNECTION METHOD

TJ302

R395

TJ396

v

ADJUSTMENT PROCEDURE

EE

CH-1

Oscilloscope

CH-2

SIGNAL

GENERATOR

1) Supply the Color Bar Signal to the VIDEO IN

JACK, and set the VCR to the STOP mode.

2) Connect the oscilloscope to TJ396 and trigger the

scope with a composite sync signal at TJ302.

3) Adjust R395 to obtain 2.0Vp-p ± 0.2Vp-p

between the SYNC Tip and 100% white level

TJ395

2.0V 0.2Vp-p

Horizontal :10 s/div

Vertical :0.1V/div

7

Page 9

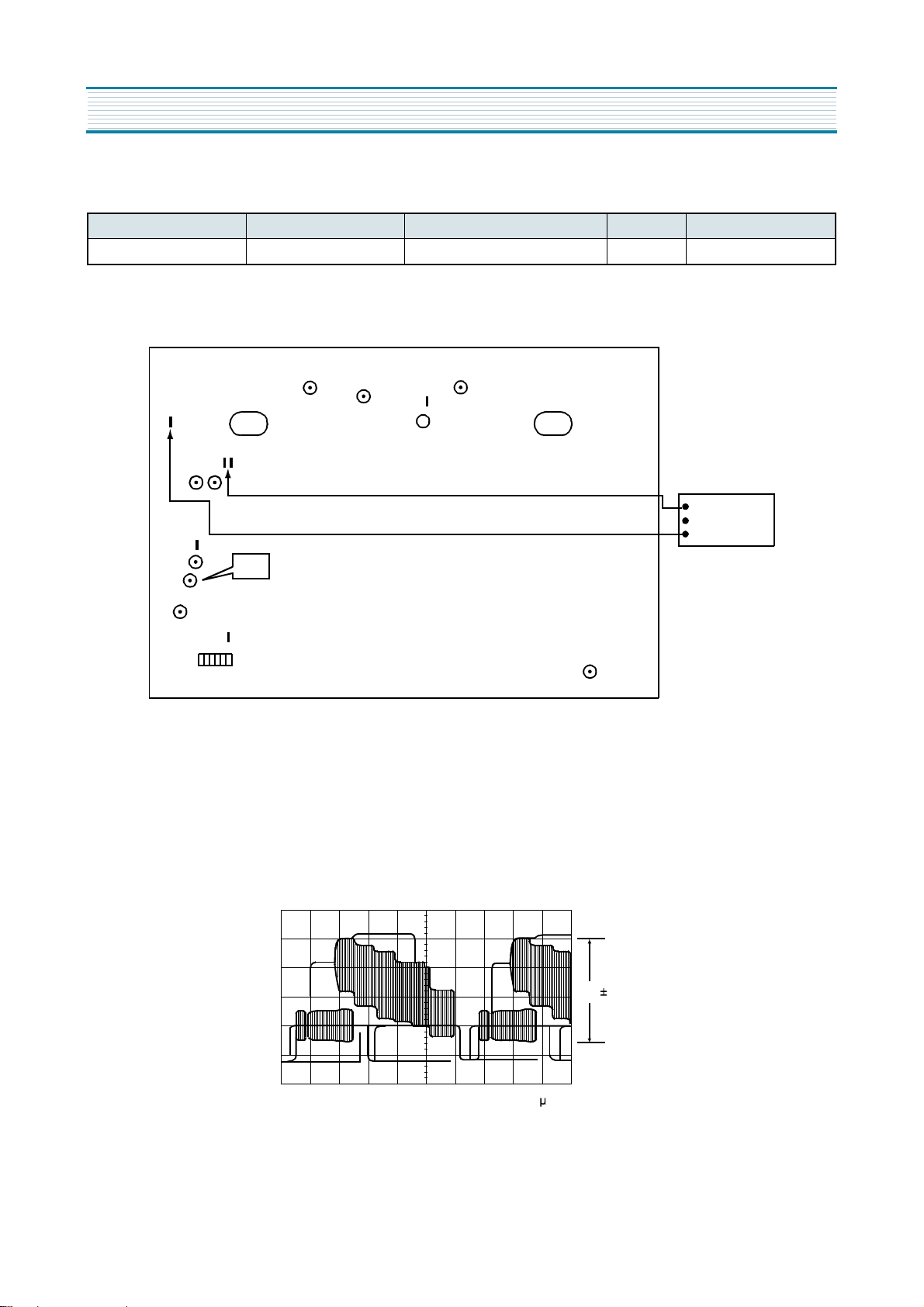

ELECTRICAL ADJUSTMENT

(2) PLAYBACK Y-SIGNAL OUTPUT LEVEL

Adjustment Parts Checking Point Measuring Equipment Test Tape Input Signal

R396 TJ396 Oscilloscope DN-1 -

v

CONNECTION METHOD

TJ396

TJ302

CH-1

Oscilloscope

CH-2

PB-Y

R396

v

ADJUSTMENT PROCEDURE

1) Playback the COLOR BAR Test tape (DN-1).

2) Connect the oscilloscope to TJ396 and trigger the scope with a composite sync signal at TJ302.

3) Adjust R396 to obtain 2.0 ± 0.2Vp-p between the SYNC TIP and 100% white peak level.

TJ396

2.0V 0.2Vp-p

Horizontal :10 s/div

Vertical :0.5V/div

8

Page 10

ELECTRICAL ADJUSTMENT

(3) SYNC TIP FREQUENCY

Adjustment Parts Check Point Measuring Equipment Test Tape Input Signal

R391 TJ391 Frequency Counter - -

v

CONNECTION METHOD

R391

VIDEO IN is shorted with Ground

TJ391

SYNC TIP

CH-1

Oscilloscope

CH-2

v

ADJUSTMENT PROCEDURE

1) Set the VCR to STOP mode without Video Signal.(VIDEO IN JACK is shorted with Ground)

2) Connect the frequency counter TJ391.

3) After Inserting Rec Tape REC in SP Mode

4) Adjust R391 to obtain 4.20 ± 0.1 MHz.

9

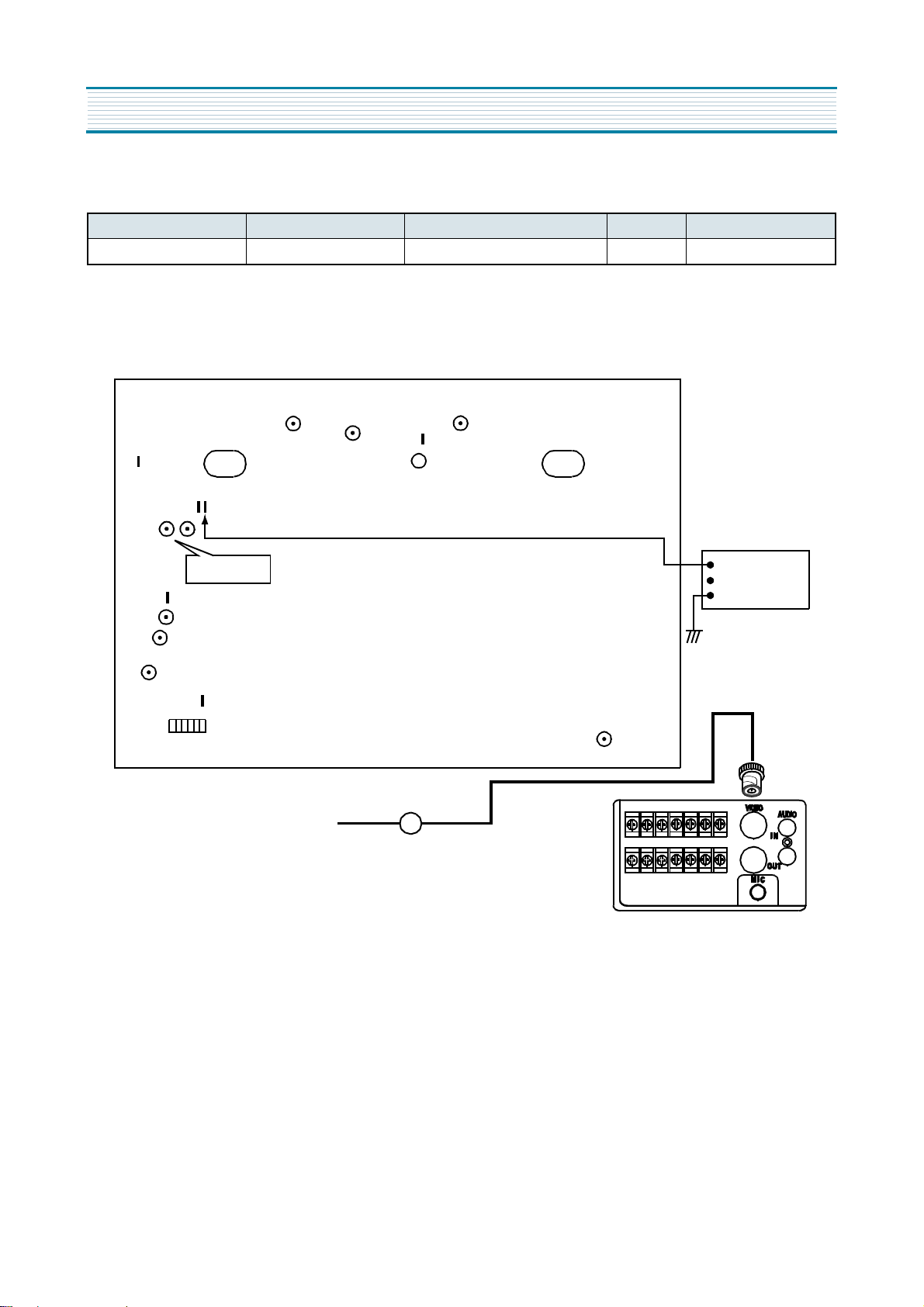

Page 11

ELECTRICAL ADJUSTMENT

(4) FM DEVIATION

Adjustment Parts Check Point Measuring Equipment Test Tape Input Signal

R392 TJ396 Signal Gen. Oscilloscope Blank Tape Color Bar

v

CONNECTION METHOD

TJ396

TJ302

CH-1

Oscilloscope

CH-2

R392

FM DEV

v

ADJUSTMENT PROCEDURE

1) Supply the Color Bar Signal to the VIDEO IN JACK, and set the VCR to the REC mode.

2) Connect the oscilloscope to TJ396 and trigger scope with a composite sync signal at TJ302.

3) Record the Color Bar Signal for a few minute and

playback it. Then confirm that the playback video

output level (TJ396) is 2.0 ± 0.2Vp-p.

4) Adjust as follows if the playback video output level

is not 2.0 ± 0.2Vp-p.

4-1) Adjust R392 a little.

4-2) Record the Color Bar Signal for a few minute

and playback it.

4-3) Confirm the playback video output level.

4-4) Repeat the procedure of 4-1) to 4-3) until

the playback video output level becomes 2.0

( 0.2Vp-p between sync tip and 100% white

level.

SIGNAL

GENERATOR

TJ396

2.0V 0.2Vp-p

Horizontal :10 s/div

Vertical :0.5V/div

10

Page 12

ELECTRICAL ADJUSTMENT

(5) C RECORD CURRENT

Adjustment Parts Check Point Measuring Equipment Test Tape Input Signal

R492 TJ491 Signal Gen. Oscilloscope Blank Tape Color Bar

v

CONNECTION METHOD

TJ302

R492

REC-C

R491

TJ491

CH-1

Oscilloscope

CH-2

SIGNAL

GENERATOR

v

ADJUSTMENT PROCEDURE

1) Supply the Color Bar Signal to the VIDEO IN JACK, and set the VCR to the REC mode.

2) Connect the oscilloscope to TJ491 and trigger the scope with a composite sync signal at TJ302.

3) Adjust R491 until Y-FM record current is minimized.

4) Adjust R492 until color record current is 130 ± 10mVp-p.

Burst

TJ491

11

130 10mVp-p

Page 13

ELECTRICAL ADJUSTMENT

(6) Y RECORD CURRENT

Adjustment Parts Checking Point Measuring Equipment Test Tape Input Signal

R491 TJ491 Signal Gen. Oscilloscope Blank Tape Color Bar

v

CONNECTION METHOD

TJ302

REC-Y

R491

TJ491

CH-1

Oscilloscope

CH-2

SIGNAL

GENERATOR

v

ADJUSTMENT PROCEDURE

1) Supply the Color Bar Signal to the VIDEO IN JACK.

2) After Inserting a Rec Tape, Rec in SP MODE.

3) Connect the oscilloscope to TJ491

and trigger the scope with a composite sync signal at TJ302.

4) Adjust R491 until Y-FM record current

is 500 ± 10mVp-p. (Standard SYNC

Tip)

TJ491

500V 10mVp-p

12

Page 14

ELECTRICAL ADJUSTMENT

3. AUDIO CIRCUIT ADJUSTMENT METHOD

(1) AUDIO RECORD BIAS

Adjustment Parts Checking Point Measuring Equipment Condition of Adj. Test Tape

R292 - Audio Level Meter REC mode Blank Tape

v

CONNECTION METHOD

R292

REC BIAS

(+)

Audio

(-)

Level Meter

v

ADJUSTMENT PROCEDURE

1) Supply the signal in the OPEN mode.

2) Connect the Audio Level Meter to R01 at the Deck AC Head.

3) After inserting a blank tape, record in SP mode.

4) Adjust R292 to obtain 3 m Vrms .

13

Page 15

SPECIFICATIONS

Video Signal system NTSC

REC/PB System Helical scanning system

Tape Width 12.65mm (1/2 inch), VHS

Record system of Luminance Signal Frequency modulation record

Record system of Color Signal Down converted subcarrier phase shift system

Tape Speed (T-120)

Record/Play Time (T-120) SP : 2H/24H/36H, EP : 6H/18H/24H (PLAY)

FF/REW Time (T-120) Within 3 minutes

Video Signal Input 1.0Vp-p 75Ω, unbalanced

Video Signal Output 1.0Vp-p 75Ω, unbalanced

Luminance Signal to Noise ratio SP : Minimum 45dB, EP : Minimum 41dB

Horizontal resolution Mimimum 350 Lines (B/W), Minimum 300 Lines (Color)

Audio Signal Input Line Input -8.8dBm (1KHz), 47K

Audio Signal Output Line Output -7.8dBm (1KHz), 1K

Audio Signal to Noise Ratio (A.Weighted) SP : 42dB minimum VHS, EP : 40dB minimum VHS

Audio Frequency Range SP : 0+3, -6dB [100Hz~10KHz] VHS, EP : 0+3, -6dB [100Hz~5KHz] VHS

Distortion SP : 4% maximum VHS, EP : 5% maximum VHS

WOW Flutter SP : 0.3% maximum VHS, EP : 0.4% maximum VHS

Alarm input DC 4~5V (open), DC 0~0.8V (closed) / 5.7k

Alarm output DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Panic input DC 4~5V (open), DC 0~0.8V (closed) / 5.7k

2H : 33.35mm/s (SP), 6H : 11.12mm/s(EP),

18H : 3.71mm/s, 36H : 1.85mm/s

Ω

minimum

Ω

maximum

Ω

Ω

Ω

End output DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Warning output DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Series input DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Series output DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Switch output DC 4~5V (High), DC 0~0.8V (Low) / 5.7k

Common GND

Microphone Input -60dBs 3.5mm mini Jack 10k ohm, unbalanced

Accuracy of Timer Within 2 seconds per day

Compensate Time for Power Fail About 1 Month

Power Supply AC 120V, 60Hz

Power Consumption 17W

Operation Temperature

Storage Temperature

Dimension (W x H x D) 360 x 90 x 300 (mm)

Weight Approximate 4.3 Kg (NET)

5°C ~ 35°C (Humidity : under 80%)

-20°C ~ 60°C

Ω

Ω

Ω

Ω

Ω

14

Page 16

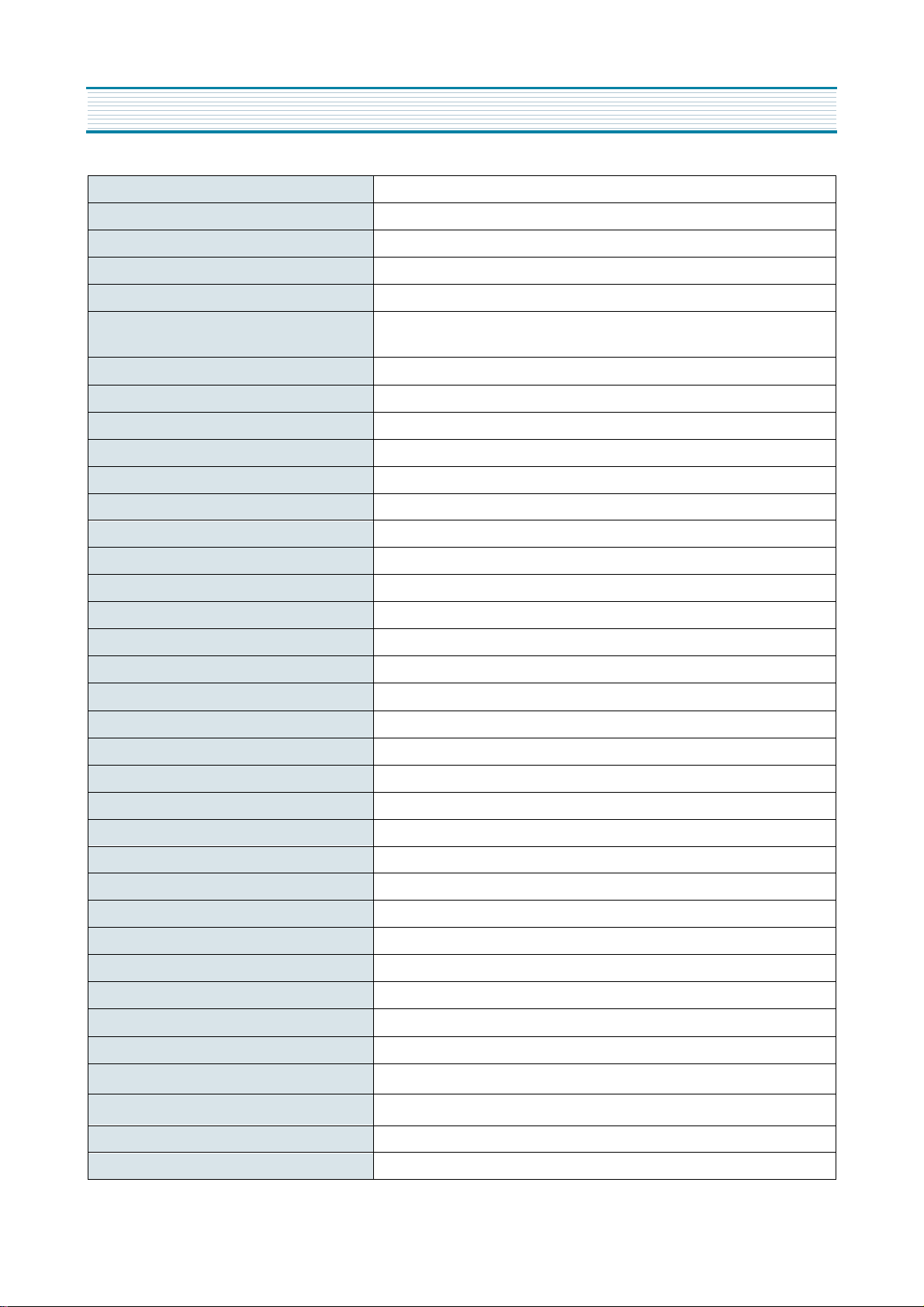

TIMELAPSE REC/PB SPEED CHART

TAPE MODE TAPE SPEED REMARK

SP 2H 24H 36H

T-120

EP 6H 18H

REC MODE

SP 2.7H 32H 49.5H

T-160

EP 8H 24H

SP 2H 24H 36H

T-120

EP 6H 18H 24H

PLAY

MODE

SP 2.7H 32H 49.5H

T-160

EP 8H 24H

EP 24H MODE

IS POSSIBLE

IN PLAY

MODE.

AUDIO POSSIBLE NOT POSSIBLE

15

Page 17

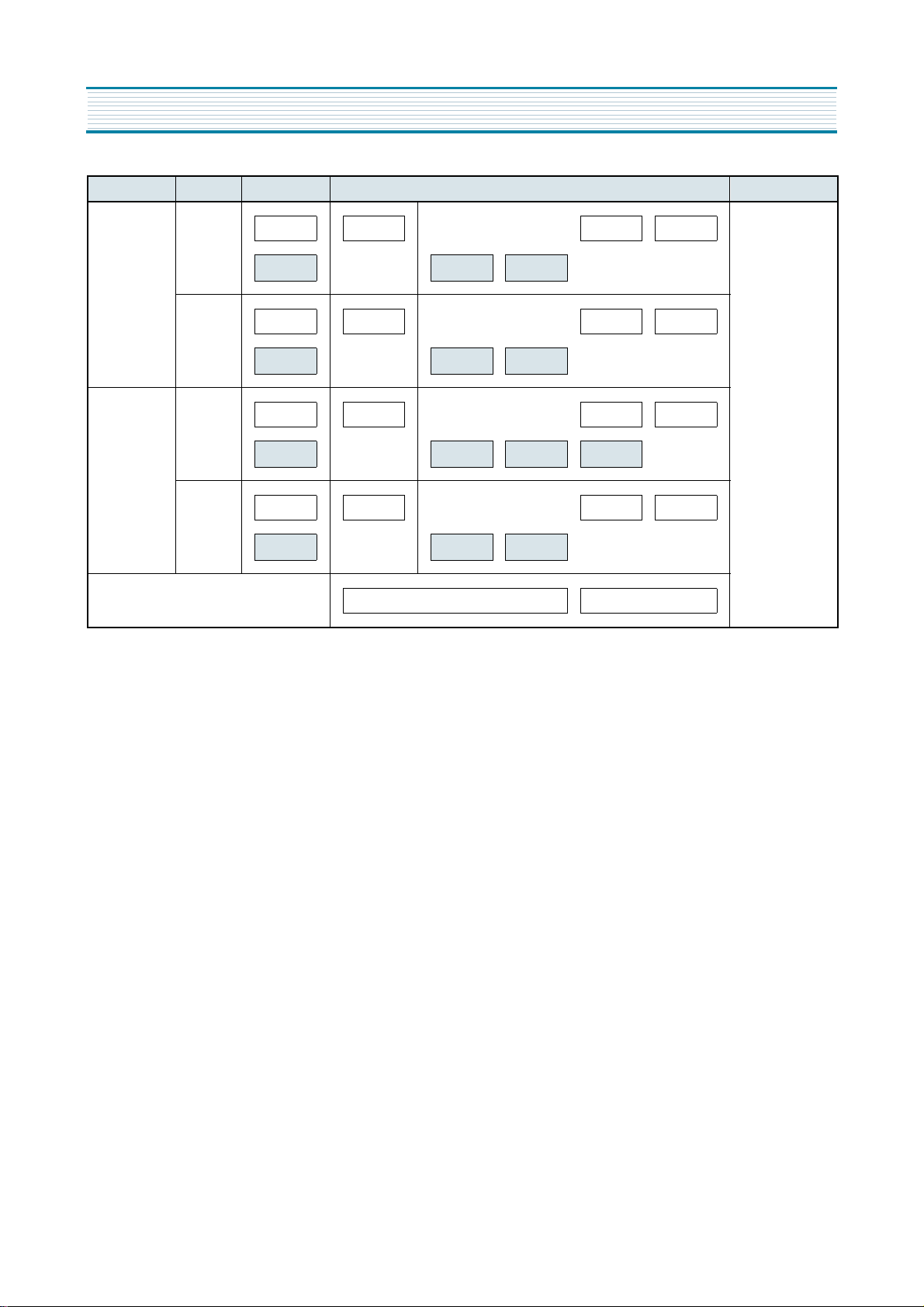

CIRCUIT OPERATION

1. VIDEO PART

1-1) EE MODE

Video Signal which is output from RL902 is input to pin 37 of IC301 through OSD IC. It is amplified 6dB by AGC, then it is

output to pin 34. This output signal is output to Video Jack through RL902 of RELAY IC.

1-2) REC MODE

The signal which is input to pin 37 of IC301 is output to pin 3 through IC internal AGC AMP. If this output signal has burst,

it is input to X303 then it separates color signal. If it has not burst, it will pass Y-Emphasis circuit. Each signal is input to

pin 4 then passes 3.5M LPF. Luminance signal is output from pin 40 after FM modulator through MAIN-Emphasis and

color signal is output from pin 15 after low-converted. Each signal is input to pin 12 of IC401 through REC-EQ, then it is

recorded on the tape through HEAD after passing out MIX AMP.

VIDEO IN

IC001

OSD IC

V.IN

REC Y

REC EQ

IC401 HEAD AMP

VIDEO OUT

IC301

VIDEO IC

REC C

WITH

BURST

X303

Y/C

COMB

Y-EMPA

CIRCUIT

16

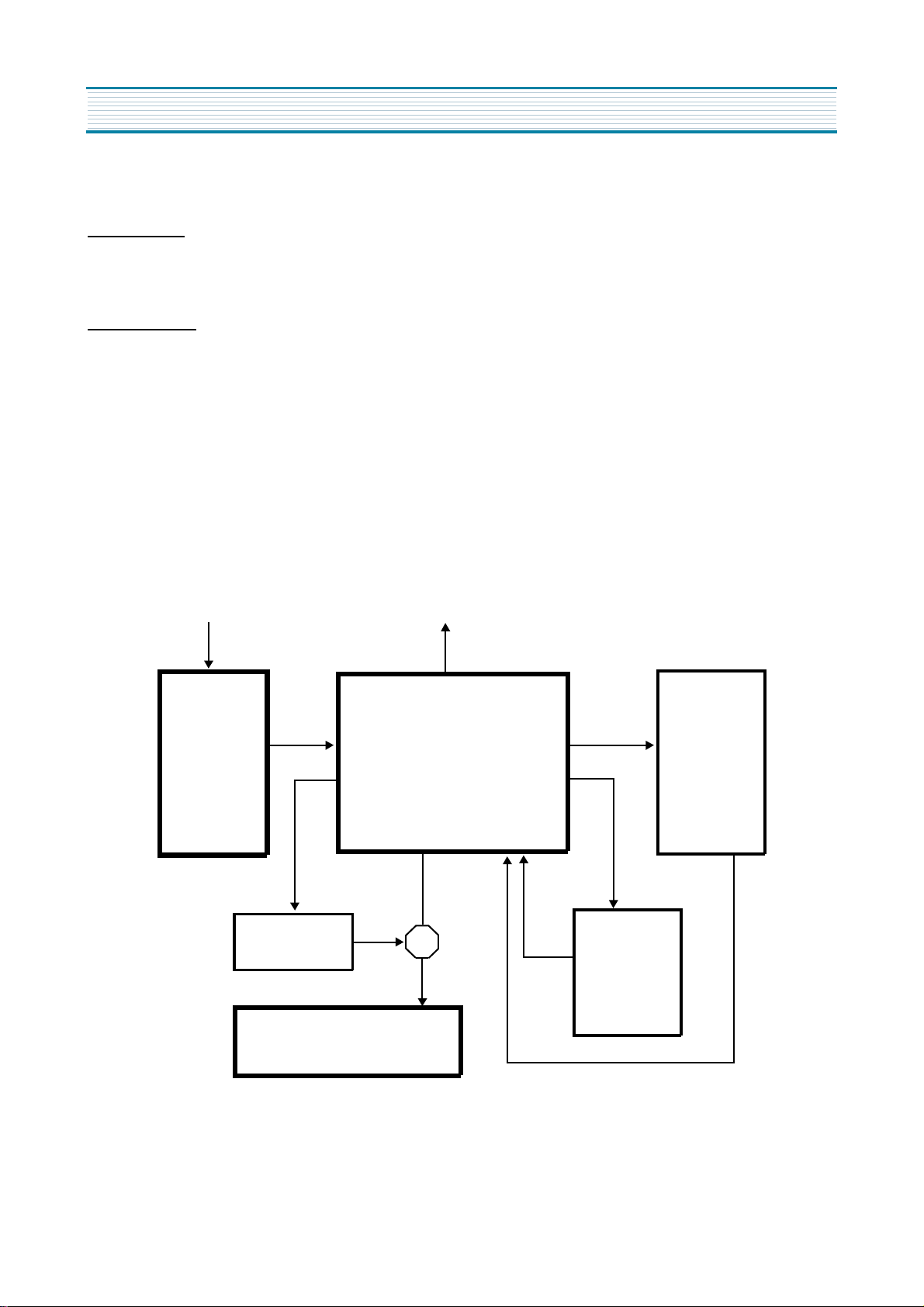

Page 18

CIRCUIT OPERATION

1-3) PB MODE

When playing the tape, the signal which is picked up from the tape is amplified 50 dB. Then luminance signal goes to pin

11 and color signal goes to pin 7 through AGC. Luminance signal of pin 11 is input to pin 39 of IC301 through PB EQ circuit in order to match playback characteristic. Color signal which is output from pin 7 of IC401 is input to pin 15 of IC301.

PB FM signal is demodulated by IC internal demodulator then it is input to pin 3 after MAIN DE-Emphasis process. If this

output signal has burst, color component will be separated by X303. If it has burst, it is input to pin 4 of IC301 through Yemphasis circuit. The signal which is input to pin 4 is output from pin 12 through 3.5M LPF, then it is input to pin 10

through 1H CCD. Color signal which is input to pin 15 passes ACC in order to stabilize level, then 3.58H components will

be extracted by 3.58M BPF through Main Converter.

This 3.58M color signal is input to pin 25 of IC301 in order to eliminate crosstalk, then it will be mixed with luminance signal after passing CNR circuit. Finally Y/C composite video signal is output from pin 34.

V.IN

V-OUT

PB EQ

IC401

HEAD AMP

IC301

VIDEO IC

IC302

IH CCD

X302 IH DLY

Y-EMPH

X303

Y/C

COMB

17

Page 19

CIRCUIT OPERATION

2. AUDIO PART

2-1) EE MODE

External AUDIO signal which is input to pin 16 of IC201 is output from pin 22 of IC201 after being amplified through ALC

and Line Amp.

2-2) REC MODE

It will be the REC mode when REC 5V is input to pin 24 of IC201. Input signal will be replaced on the tape through R/P

HEAD after being amplified and modulated with Bias Frequency. Input signal is amplified and frequency compensated by

REC AMP, ie. it means high band compensation in order to match AUDIO HEAD characteristic. Each mode’s peaking frequency will be determined by BIAS element (R, L, C) of REC AMP. OSC oscillation frequency is 70KHz sinewave, it will

be used for tape’s full erasing and AUDIO TRACK erasing.

2-3) PB MODE

It will be the PB mode when PB 5V is input to pin 11 of IC201. The signal which is picked up from AUDIO HEAD is input

to EQ AMP, then constant Audio Level will be output by PB LEVEL fixed resistor after each mode is amplified and frequency is compensated.18H AUDIO output level will be compensated with receiving Audio 24H(H) control of u-COM.

Finally this output signal is output through 20KHz LPF.

18

Page 20

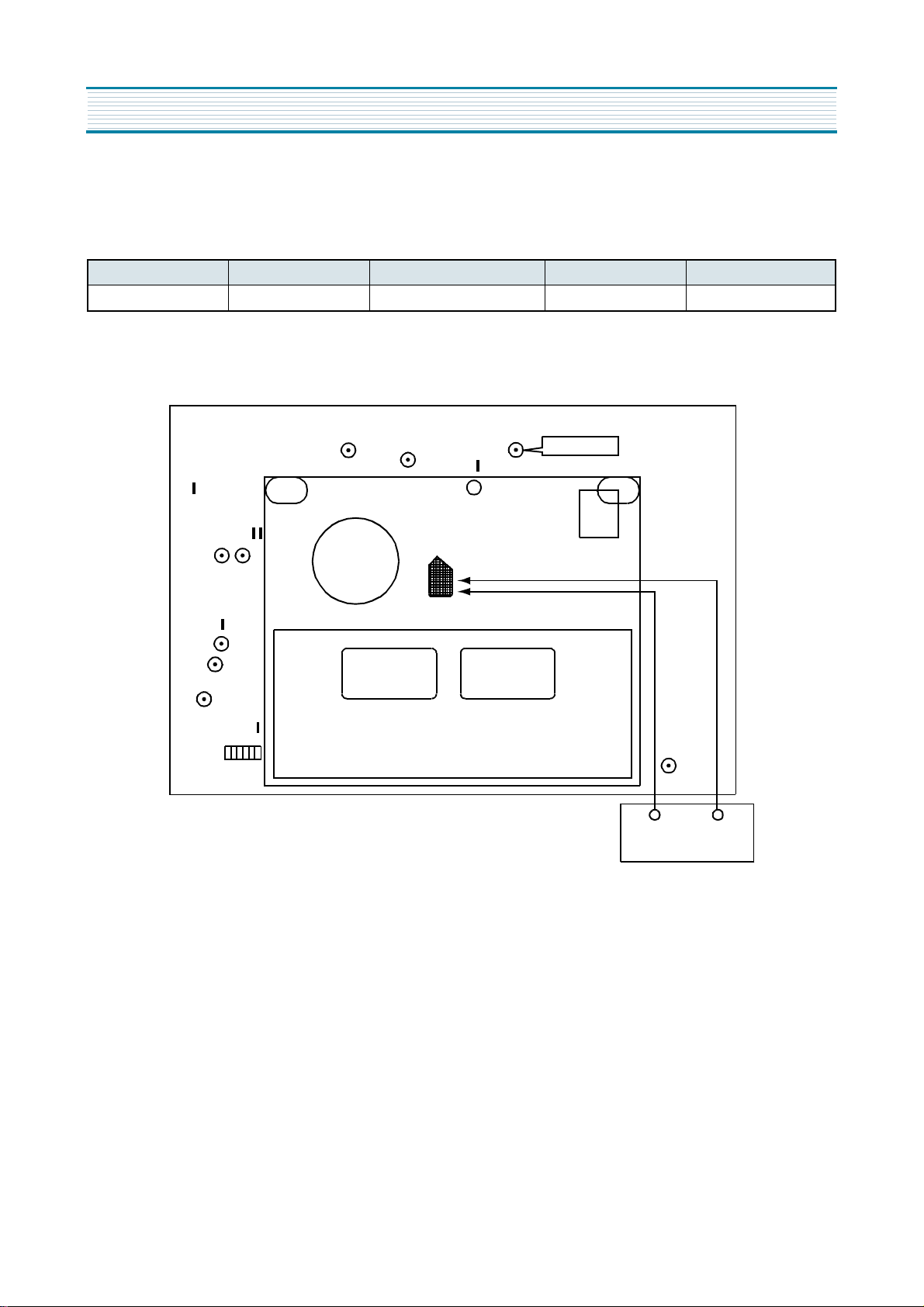

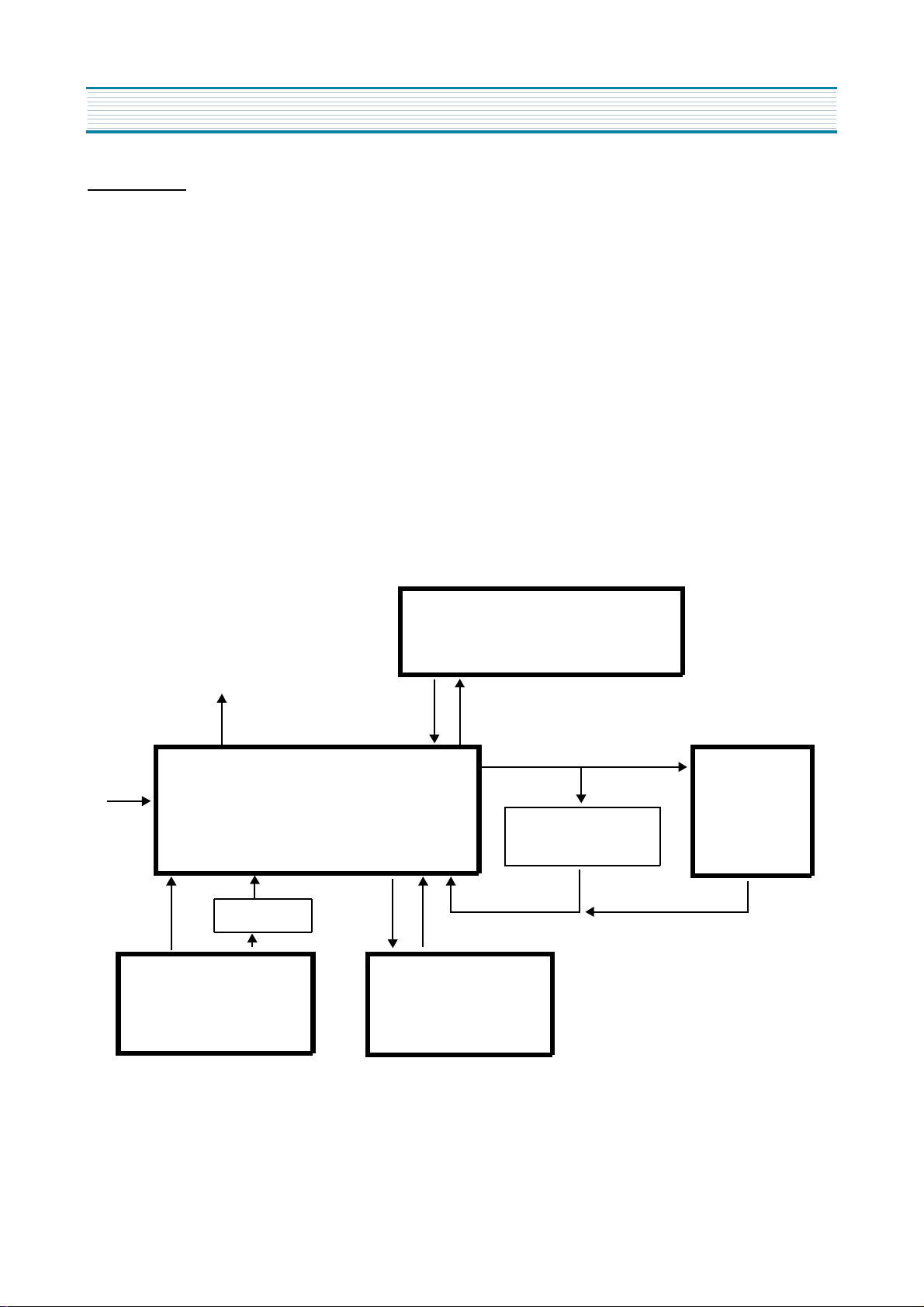

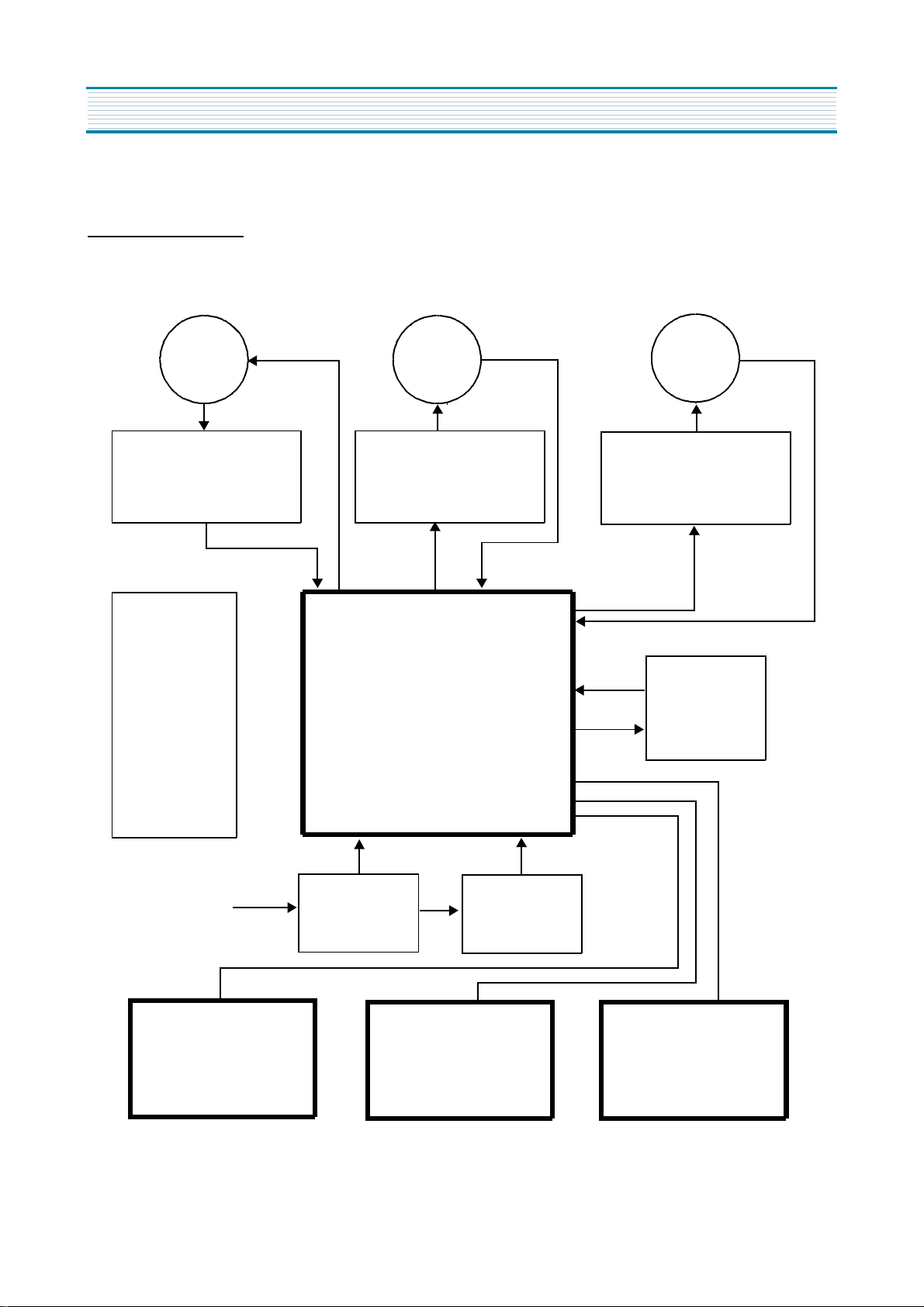

3. SERVO SYSCON PART

3-1) BLOCK DIAGRAM

CIRCUIT OPERATION

DRUM

PG FG AMP

Start end

SENSOR

&

REEL

SENSOR

Vcc

BACK

UP BATT

CAPSTAN

SPEED CTL

IC501

M37775M5H

u-COM

PROCESSOR

LOADING

CAM DRIVE

CTL

AMP

OSC&

RESET

VIDEO

BLOCK

AUDIO

BLOCK

<K580N-T SERVO SYSCON BLOCK>

19

TERMINAL

BLOCK

Page 21

CIRCUIT OPERATION

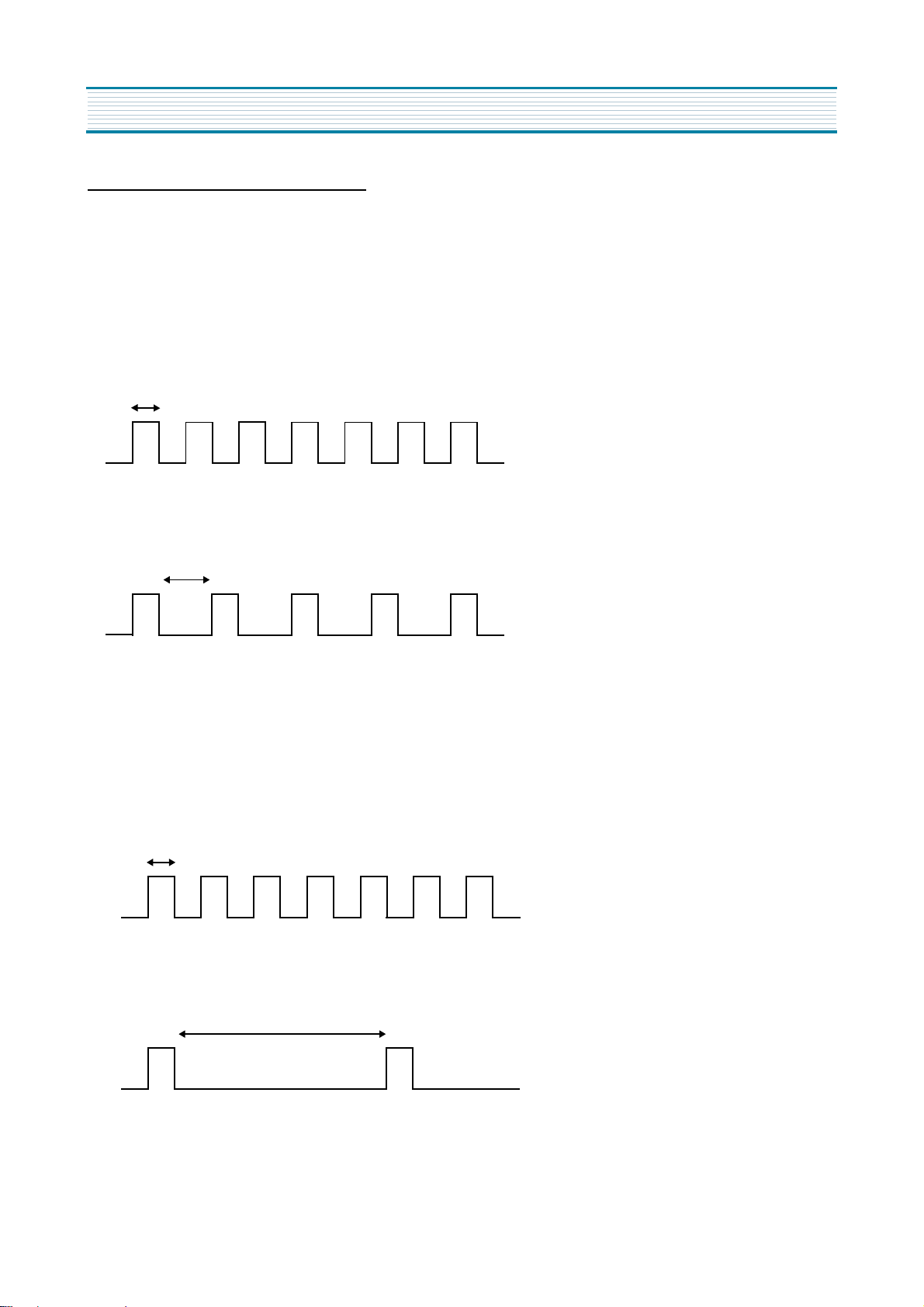

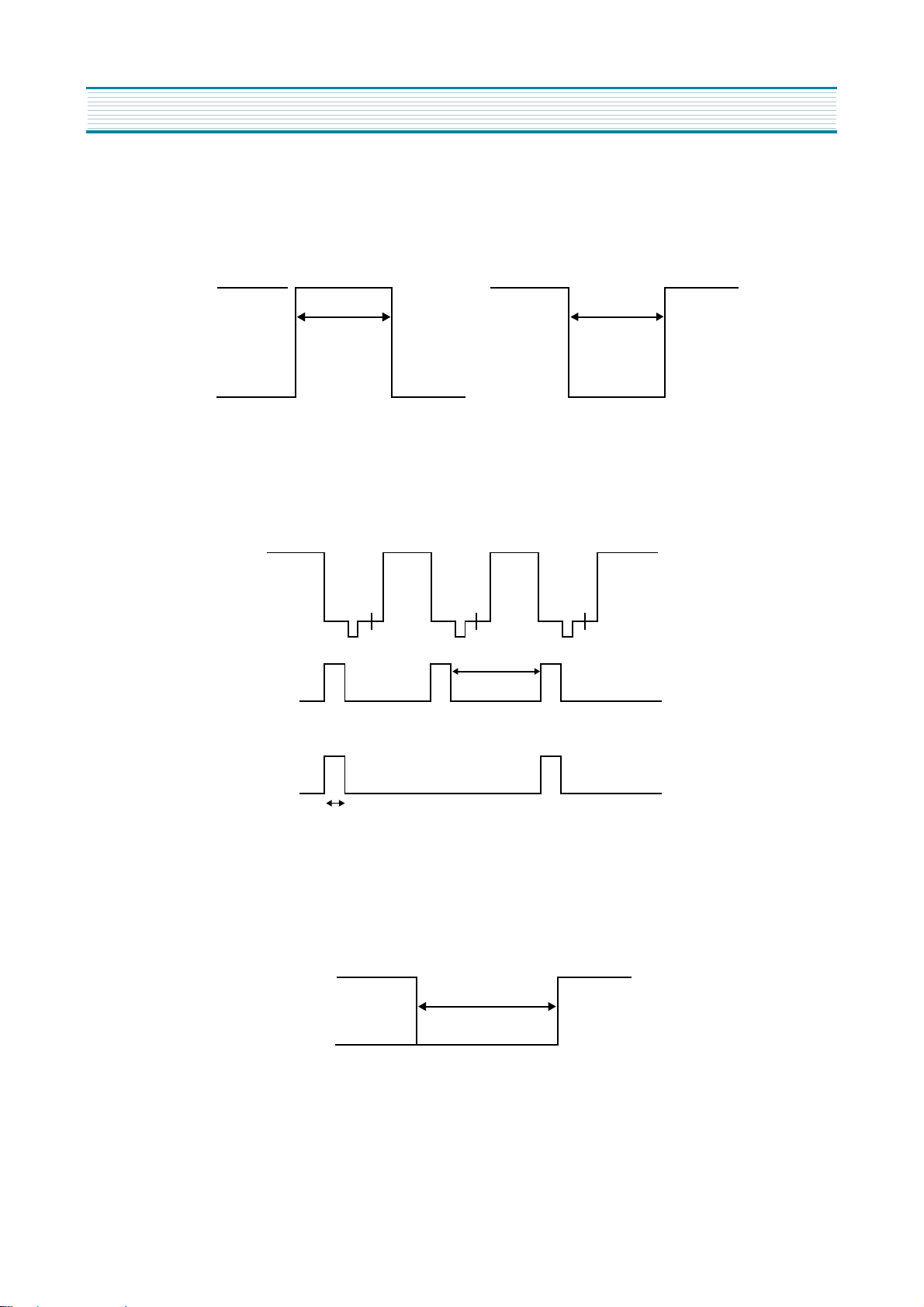

3-2) TIME LAPSE RECORDING METHOD

The numbers of VHS 2HOUR (SP), 6HOUR (EP) REC FIELD are 60 field/sec, then it will be 1FRAME = 33.3Ms, 1FIELD

= 16.65Ms.

CAPSTAN MOTOR FG numbers for Time Lapse are 6HOUR(EP) = 720 numbers/sec, 2HOUR(SP) = 720*3=2160 numbers/sec.

18H(EP) RECORDING (20FIELD/SEC)

2H & 6H (60FIELD/SEC)

16.65ms

L R L R L R L R L R L R L

(Capstan FG numbers are ; 1SEC:720=16.65ms:X X=12)

18H (20FIELD/SEC) : Recording 1 field per 3 fields

33.3ms

L R L R L

(Capstan FG numbers are ; 1SEC:720=33.3ms:X X=24)

u

u-COM controls capstan motor (C I LIMIT) with capstan motor FG numbers. DRUM HEAD ON/OFF controlled by

HEAD AMP SW & REC mute signal.

24H(SP) RECORDING (5FIELD/SEC)

: recording 1 field per 12 fields

16.65ms

L R L R L R L R L R L R L

(Capstan FG numbers are ; 1SEC:720=16.65ms:X X=12)

18H (20FIELD/SEC) : Recording 1 field per 3 fields

16.65ms*10=166.6ms

L R

(Capstan FG numbers are ; 1SEC:2160=166.6ms:X X=36)

u

u-COM controls capstan motor (C I LIMIT) with capstan motor FG numbers. DRUM HEAD ON/OFF controlled by

HEAD AMP SW & REC mute signal.

20

Page 22

CIRCUIT OPERATION

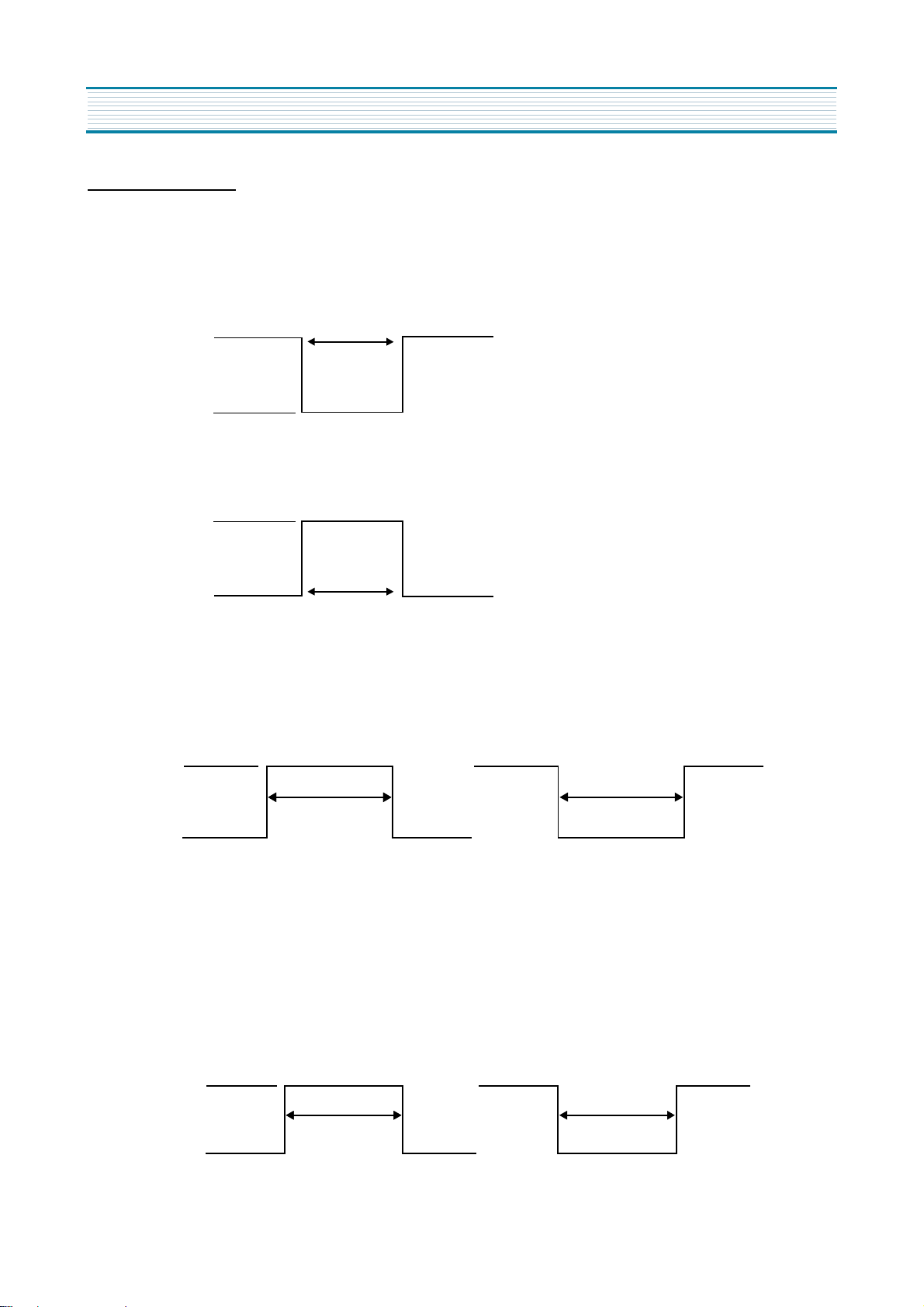

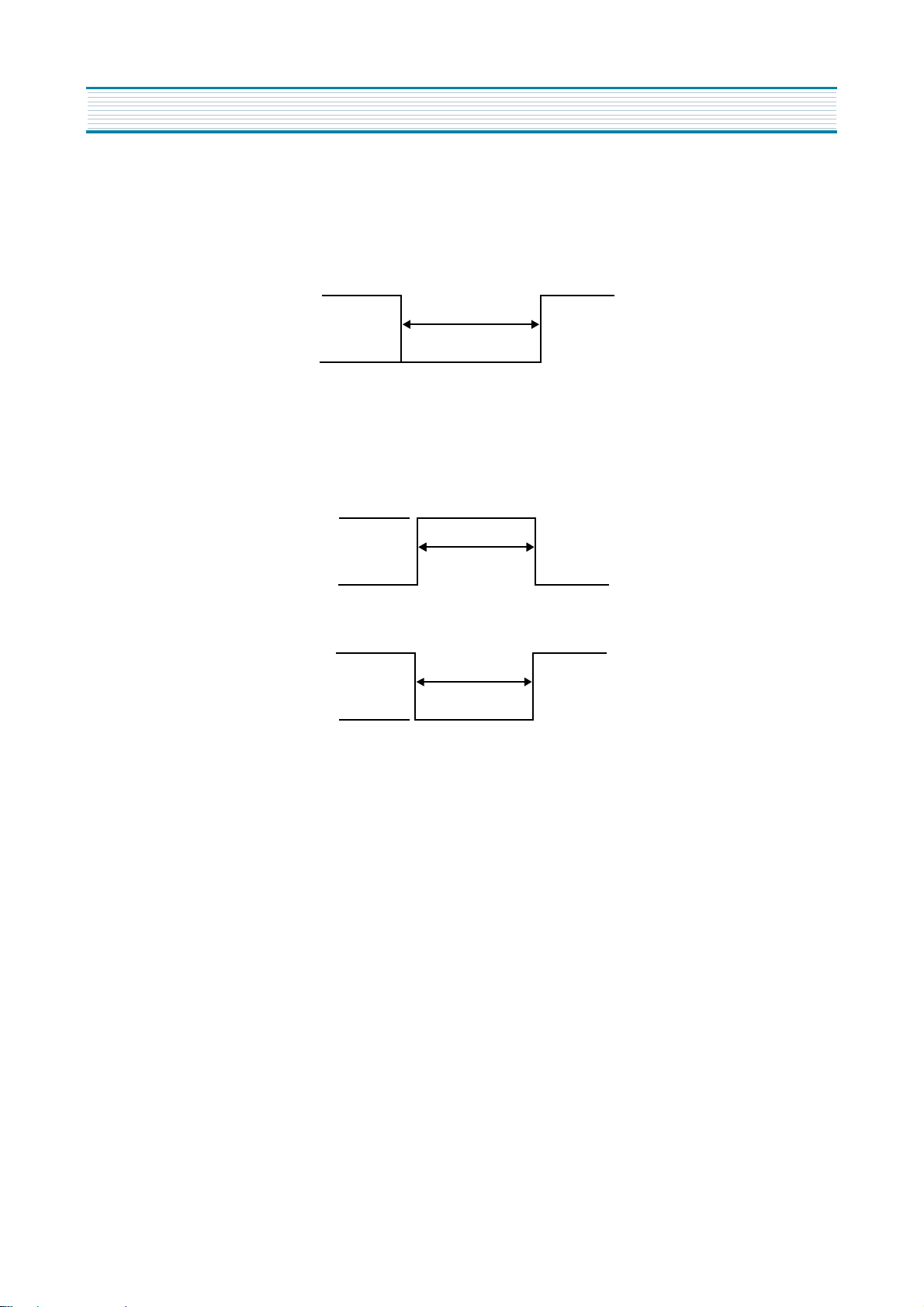

3-3) TERMINAL PART

ALARM INPUT

Connect DOOR SW&SENSOR etc and this port will be used for emergency recording by using open/close status.

N/O(NORMALY OPEN)

5V

500ms

0V

N/C(NORMALY CLOSED)

5V

500ms

0V

ALARM OUTPUT

This port is always triggered during ALARM REC, which is used to inform the outside that time lapse VCR is now performing Alarm Recording.

5V

Minimum 2mins.

Minimum 2mins.

0V

HIGH

u

Trigger Time will be the set time on MENU, it will be approximately 2 minutes at least.

PANIC INPUT

This is the first priority REC, then operation is similar as Alarm Rec. But if Panic Recording is triggered, the set stops all

kinds of Recording then starts recording with 2H(SP) mode at the end of tape.

LOW

5V

0V

500ms

N/CLOSED

500ms

N/OPEN

21

Page 23

CIRCUIT OPERATION

TAPE END OUT

When the recording tape ends during recording, end sensor will be detected. This port is used Alarm to outsider until

release the end sensor detecting.

5V

END Detect END Detect

0V

HIGH

SW OUTPUT

This port is used triggering video signal with external equipment during recording.

VIDEO

SIGNAL

SW

OUT

1FIELD

SW

OUT

2FIELD

4ms

SERIES OUTPUT

When the series recording proceeds after setting the series recording to “on”, this port is used to output the control signal

to the set which will be recorded continuously after pre-recording set.

16.67ms

LOW

5V

0V

250ms

22

Page 24

CIRCUIT OPERATION

SERIES INPUT

When the series recording proceeds after setting the series recording to “on”, this port is used to receive the control signal

to the set which will be recorded continuously after pre-recording set.

5V

200ms

0V

WARNING OUTPUT

This port is used to inform emergency status of Time Lapse VCR Set to outsider.

5V

0V

5V

0V

EMER

status term

HIGH

500ms

LOW

23

Page 25

TROUBLE SHOOTING FLOW CHART

1. POWER CIRCUIT

When changing the parts which are broken first, remove the power plug from the socket and then discharge the voltage

across the terminals of C806. (Use an external K

When check the primary circuit , use the oscilloscope isolated properly (Use the isolated transformer) and connect

GND to the primary GND, however it is not necessary to isolate the oscilloscope when check the secondary circuit.

A. CHECKING THE PRIMARY CIRCUIT

No output Voltage.

YES

Prepare the oscilloscope

connected the isolated

Transformer.

YES

Ω

resistance)

Check F801 Fuse.

YES

Is voltage applied to D801?

YES

Is voltage applied to the

terminals of C806?

YES

Check the Secondary circuit

NO

NO

Check L801.

Check M801 Power Module,

D801

24

Page 26

B. CHECKING THE SECONDARY CIRCUIT

TROUBLESHOOTING FLOW CHART

Check each output voltage

Check M801.

Check any diode which

causes no power

Check any COIL, or capacitor

which causes no power

END

25

Page 27

TROUBLESHOOTING FLOW CHART

2. SERVO-SYSCON CIRCUIT

A.

Playback picture

is not good

Noise appears

although

adjusting tracking.

YES

Is CTL pulse output

at pin 25 of IC501?

YES

The voltage of pin 89

of IC501 not changing?

YES

Adjust tracking.

NO

NO NO

NO

Noise appears

although change

cassette tape.

CTL HEAD height

is normal and

there is not dust?

Check R527, C514.

YES

YES

Check and re-adjust

the path of Deck.

Adjust the HEAD

height and

remove dust.

Check circuit

adjacent to Ic501 & IC502.

Playback picture

Check IC501

is not good

26

Page 28

B.

TROUBLESHOOTING FLOW CHART

Playback picture

is not good.

Noise appears on the

screen on the whole.

YES

Is SW-pulse applied to

video IC?

YES

Is Enve. waveform

supplied to pin 4

of P T501?

NO NO

NO NO

NO NO

Noise appears on the

screen at the bottom

YES

Is sw pulse supplied

from pin 18 of IC501?

YES

Check connector,

and Head dust.

Check flow A.

Check the PG

Adjustment.

Check D.PG input

and connector.

Check pattern

Change Drum Ass'y

YES

Check video circuit.

27

Page 29

TROUBLESHOOTING FLOW CHART

C.

Auto-stop during

playback.

Is reel pulse applied to

pin 5 and 6 of IC501?

YES

Is D. FG applied to

pin 24 of IC501?

YES

Check IC501.

NO

NO

Check reel sensor.

Check connector and

D. FG circuits.

28

Page 30

D.

TROUBLESHOOTING FLOW CHART

Drum M/T loading stops.

Is motor 12V supplied

from Ic504 pin7, 8?

YES

Is 5.2V supplied from

POWER CIRCUIT?

YES

Check connector

and motor.

NO

NO

Check circuit adjacent

EVER +12.4V.

NO

Check power module.

Check D814.

29

Page 31

TROUBLESHOOTING FLOW CHART

E.

Capstan M/T

loading stops.

Is motor 12V supplied?

YES

Is the input of pin 6

of P501 2.5V~3.5V?

YES

Is pin 4 of P501 2.5V?

YES

Does pin 3 of IC501

supply C.PWM?

YES

NO

NO

NO

NO

Check power Module.

Check circuit of R516,

R517, R520, C509, C511.

Check R525, R526.

Check IC501.

Check connector

and motor.

30

Page 32

F.

TROUBLESHOOTING FLOW CHART

Drum M/T and capstan M/T

rotate at regular speed.

(IN REC MODE)

G.

Is C. sync applied to

pin 93 of IC501?

YES

Check motor

Emergency mode when

plugging (power cord)

Is ever 5V applied? Check power Module.

YES

Does X501 crystal

oscillate?

NO

NO

NO

Check C. sync of video

IC and pattern.

Check IC501 and X501.

YES

Is CAM SW DATA correct?

YES

Check IC501.

31

NO

Recheck connector and

CAM SW contact.

Page 33

TROUBLESHOOTING FLOW CHART

H.

Cassette is not inserted.

Is motor 12V supplied?

CAM DATA is changed

Check IC501.

YES

when CST IN?

YES

Is 5V supplied at

pin 31 of IC501?

YES NO

Check pattern

and R572.

NO

NO

Check power Module.

Check connector.

NO

Check Deck part.

32

Page 34

TROUBLESHOOTING FLOW CHART

I.

Power compensation

does not operate.

When mains is unplugged,

is 3.6V at pin 26,pin 81 of IC501?

YES

Is (sine) signal applied to

pin 42 and 43 of IC501?

YES

Is 5V at pin 37 of IC501?

YES

NO

NO

NO

Check C548, C523,

C547, C524.

Check X502.

Check reset circuit

Of IC503.

Check IC501.

33

Page 35

TROUBLESHOOTING FLOW CHART

3. VIDEO CIRCUIT

A. EE MODE N.G.

Is VIDEO signal input

Into pin 2 of RL 902?

YES

Is E9V supplied at

Pin 1 of RL 902?

YES

Is signal output from

pin 8 of RL 902?

YES

Is signal input into

pin 18 of IC 001?

YES

Is signal input into

pin 37 of IC 301?

YES

Is signal output from

pin 34 of IC 301?

YES

NO

NO

NO

NO

NO

NO

Check terminal.

Check EVRE 9V.

Check pin 3 input signal

of RL902.

Is signal output from pin 3

of IC 002?

Check IC 001.

Check pin 35 Vcc of IC 301.

YES

Check pin 5 EE(L)/PB(H)

of IC 301.

NO

NO

NO

Is signal input into pin 1

of IC 002?

Check Power Circuit.

Check pin 44 of IC 601.

Is signal input into

Base of Q317?

YES

Is signal output from

TJ 396?

YES

Is signal output into

pin 4 of RL 902?

YES

Is signal output from

pin 3 of RL 902?

YES

Is signal output into

pin 8 of P902?

YES

TERMINAL OUT.

NO

NO

NO

NO

NO

Check PATTERN.

Check Q317.

Check PATTERN.

Check RL 902.

Check PATTERN.

34

Page 36

B. REC SIGNAL N.G.

Check EE mode.

TROUBLESHOOTING FLOW CHART

Is REC-Y signal output

From pin 40 of IC 301?

YES

Is REC-Y signal input

into pin 12 of IC 401?

YES

Is REC-C signal input

into pin 12 of IC 401?

YES

INPUT VIDEO HEAD.

NO NO

NO

NO NO

Is signal input into

pin 37 of IC 301?

YES

Check Q402, Q403,

Q404, Q405.

Is 5V supplied at

pin 28 of IC 301?

YES

Is color signal output

from pin 15 of IC 301?

YES

Check Q402, Q420.

NO

Check method A.

Check Power Circuit.

Change IC 301.

35

Page 37

TROUBLESHOOTING FLOW CHART

C. PB-Y SIGNAL N.G.

Is envelope output

from pin 7,11 of IC 401?

YES

Q409, 410, 411.

Is signal input at

pin 39 of IC 301?

YES

Is signal output from

pin 3 of IC 301?

YES

Is signal input into

pin 4 of IC 301?

YES

Check

NO

NO

NO

NO

NO

Check PCB PATTERN

Check pin 5 EE(L)/PB(H)

Is 5V supplied at

pin 1, 2 of IC 401?.

YES

Is SW pulse input at

pin 6 of IC 401?.

YES

and Q408.

Check pin 35 Vcc

of IC301.

YES

of IC 301?.

YES

Is signal output from

pin 8 of IC 303?

YES

NO

NO

NO

NO

NO

Check power circuit.

Check pin 18 of IC 601.

Clean head or change head.

Check pin 44 of IC 601.

Check Q301, Q302, Q305.

Check power.

Change IC 301.

Is signal input into

pin 10 of IC 301?

YES

Is signal output from

pin 34 of IC 301?

YES

Is signal input into

pin 4 of RL 902?

YES

TERMINAL OUT.

NO

NO

NO

Check Q303.

Check IC 302 and

Q311, Q313.

Is supplied at

pin 35 Vcc?.

YES

Check PCB PATTERN.

36

NO

Check power.

Change IC 301.

Page 38

D. PB-C SIGNAL N.G.

TROUBLESHOOTING FLOW CHART

Is color signal output

from pin7 of IC 401?

YES

Is color signal input into

pin 15 of IC 301?

YES

Is color signal output from

pin 27 of IC 301?

YES

Is color signal input into

pin 25 of IC 301?

YES

Check oscillation of

pin 18, 19 of IC 301.

YES

Is composite video signal

output from pin 3 of IC 301?

YES

NO

NO

NO

NO

NO

NO

Is C-ROTARY input into

Check pin 35 Vcc of IC 301.

Is +5V supplied at

pin 1, 2 of IC 401?.

YES

Check Q409,

Q414, Q415.

pin 41 of IC 301?

YES

Is 5V supplied at

pin 28 of IC 301?

YES

Check X 301.

NO

NO

NO

Check power circuit.

Clean head or change head.

Check pin 15 of IC 601.

Change IC 301.

Check power.

Check X 302.

Is V composite signal input

into pin 4 of IC 301?

YES

Is composite V-signal output

from pin 34 of IC 301?

YES

NO

NO

Is signal output from

pin 8 of IC 303?

NO

Is signal input

into pin 4 of X301?

YES

Is signal output

into pin 1 of X303?

YES

Is signal input

into pin 6 of IC 303?

YES

Is B/W(H) signal input

into pin 4 of IC 303?

YES

Change IC 301.

Change IC 301.

YES

NO

NO

NO

NO

Check Q303.

Check PATTERN.

Check X303.

Check Q370, 371, 372,

373, 374, 375, 378.

Check pin100 of IC 601.

TERMINAL OUT.

37

Page 39

TROUBLESHOOTING FLOW CHART

4. AUDIO CIRCUIT

A. TROUBLESHOOTING OF PB MODE

No sound in the

playback mode.

Is signal input pin 2 of IC 201?

YES

Is 9V applied to

pin 7 of IC 201?

YES

Is signal output

pin 22 of IC 201?

YES

Is signal output

pin 3 of RL 901?

YES

NO

NO

NO

NO

Check PJ 201

&

Check C207, R208.

Check Q801 & POWER.

Check IC 201 adjacent circuit.

Check RL 901.

Check P902

& Audio JACK.

38

Page 40

B. TROUBLESHOOTING OF REC MODE

No sound in the playback

mode after recording.

YES

TROUBLESHOOTING FLOW CHART

Is signal input pin 16

of IC 201?

YES

Is 9V applied to

pin 7 of IC 201?

YES

Is the voltage above 4V

at "REC H"?

YES

Does pin 6 of T201

oscillate?

YES

NO

NO

NO

NO

Check RL 901 & P 902.

Check Q801 & POWER.

Check SERVO SYSCON.

Check T201 adjacent circuit.

AC signal put on 70KHz

at Base of Q201.

YES

Clean Head.

39

Page 41

TROUBLESHOOTING FLOW CHART

C. TROUBLESHOOTING OF EE MODE

No sound in

the EE modes.

YES

Is 9V applied to pin 7

of IC 201?

YES

Is signal input

pin 16 of IC 201?

YES

Is signal output

pin 22 of IC 201?

YES

NO

NO

NO

Check Q 801 & POWER.

Check RL 901, P902,

AudioJACK.

Check EE(L), IC 201.

40

Page 42

u-COM PORT DESCRIPTION

NO PORT SET PORT NAME DESCRIPTION

1 I/O OUT S OUTPUT Series record output

2 I/O IN S INPUT Series record input

3 I/O OUT C PWM Capstan control

4 I/O OUT D PWM Drum control

5 I/O IN S REEL Supply reel

6 I/O IN T REEL Take up reel

7 I/O OUT SP (H) SP HIGH

8 I/O OUT BUZ SIG Buzzer sound signal

9 I/O OUT AUDIO 24H (H) Audio 24H Output level control

10 I/O OUT REC MUTE Record mute

11 I/O IN REMOCON IN Remocon input

12 I/O OUT C I LIMIT Capstan current limit

13 I/O OUT C F/R Capstan F(-) / R(+)

14 I/O OUT SLOW STEP CTL Schmidt level select for slow playback

15 I/O OUT C ROTARY Color rotary

16 I/O OUT H.A SW Head Amp switching

17 I/O IN ENVE COMP Enve compare

18 I/O OUT PB SW Video switching

19 I/O OUT Q V SYNC Q V Sync

20 I/O OUT SW OUT Field/Frame switching output

21 I/O OUT REC CTL Record control

22 I/O IN C FG Capstan FG

23 I/O IN D PG Drum PG

24 I/O IN D FG Drum FG

25 I/O OUT PB CTL PB Control

26 Vcc Vcc Vcc Vcc

27 I/O IN CAM A CAM Data A

28 I/O IN CAM B CAM Data B

29 I/O IN CAM C CAM Data C

30 I/O IN CAM D CAM Data D

31 I/O OUT LM FWD Loading forward

32 I/O OUT LM REV Loading reverse

33 I/O IN SOFT RESET Reset except running time

34 I/O OUT REC (H) Record HIGH

35 NUB N.C GND

36 NUA N.C GND

37 RESET IN HARD RESET All Reset

38 Xin Xin Xin 16MHz in

41

Page 43

u-COM PORT DESCRIPTION

NO PORT SET PORT NAME DESCRIPTION

39 Xout Xout Xout 16MHz out

40 CLKSET N.C N.C GND

41 Vss N.C N.C GND

42 Xcin Xcin Xcin 32MHz in

43 Xcout Xcout Xcout 32MHz out

44 I/O OUT EE(L) EE LOW

45 I/O OUT TRICK (H) Trick HIGH

46 I/O OUT A MUTE (H) Audio Mute HIGH

47 I/O OUT PB (L) PB LOW

48 I/O IN D SEL Drum select (2H’D / 4H’D)

49 I/O IN KEY4 Key IN 4

50 I/O IN KEY3 Key IN 3

51 I/O IN KEY2 Key IN 2

52 I/O IN KEY1 Key IN 1

53 I/O GND GND GND

54 I/O N.C N.C

55 I/O IN SET LOCK Set Lock

56 I/O IN RMC LOCK Remocon Lock

57 I/O OUT S8 LED Array segment data output

58 I/O OUT S7 LED Array segment data output

59 I/O OUT S6 LED Array segment data output

60 I/O OUT S5 LED Array segment data output

61 I/O OUT S4 LED Array segment data output

62 I/O OUT S3 LED Array segment data output

63 I/O OUT S2 LED Array segment data output

64 I/O OUT S1 LED Array segment data output

65 OUT N.C S14 GND

66 OUT N.C S15 GND

67 OUT N.C S16 GND

68 OUT N.C N.C

69 OUT OUT G6 LED Array grid data output

70 OUT OUT G5 LED Array grid data output

71 OUT OUT G4 LED Array grid data output

72 OUT OUT G3 LED Array grid data output

73 OUT OUT G2 LED Array grid data output

74 OUT OUT G1 LED Array grid data output

75 V

76 Vcc Vcc Vcc Vcc

EE

V

EE

V

EE

GND

42

Page 44

u-COM PORT DESCRIPTION

NO PORT SET PORT NAME DESCRIPTION

77 I/O OUT OSD DATA OSD Data

78 I/O OUT OSD STB OSD Strobe

79 I/O OUT OSD CLK OSD Clock

80 I/O OUT EP (H) EP HIGH

81 Vcc Vcc Vcc Vcc

82 V

83 I/O OUT WARNING OUTPUT Warning output

84 IN IN REC SAFETY Record protect

85 I/O IN END SENSOR End sensor A/D IN

86 I/O IN START SENSOR Start sensor A/D IN

87 I/O IN PWR FAIL (L) Power fail A/D IN

88 I/O OUT CUE REV (H) Cue/Review control

89 I/O IN PATH ADJUST Tracking adjust A/D IN

90 I/O IN PG DELAY PG adjust A/D IN

91 I/O IN KILLER V Burst or not voltage

92 I/O IN DC ENVE Video ENVE A/D IN

93 C

94 I/O IN ALARM INPUT Alarm record input

95 I/O OUT IR ON/OFF IR LED ON/OFF

96 I/O OUT ALARM OUTPUT Alarm record output

97 I/O OUT POWER ON (L) Power ON Low

98 I/O IN PANIC INPUT Panic record input

99 I/O OUT TAPE END Tape end signal output

100 I/O OUT B/W (H) High in Black & White (without burst)

REF

SYNCIN

V

REF

V

REF

V

REF

IN C SYNC Composite sync input

43

Page 45

VOLTAGE CHART

IC OP AMP (KA4558 IC502)

REC PB REC PB

1

2

3

4

IC RESET (MN1380L IC503)

1

2

3

2.9 3.4

3.0 3.2

3.0 3.2

0.0 0.0

REC PB

0.0 0.0

5.3 5.3

5.3 5.3

5

6

7

8

3.0 3.2

3.0 3.2

3.0 3.0

5.8 5.8

IC MOTOR DRIVE (BA6209 IC504)

REC PB REC PB

1

2

3

4

5

0.0 0.0

0.5 0.5

0.9 0.9

6.2 6.2

0.0 0.0

IC OP AMP (KA4558 IC505)

REC PB REC PB

1

2

3

4

3.3 3.3

2.5 2.5

2.5 2.5

0.0 0.0

IC MOTOR DRIVE (BA6209 IC504)

10

6

7

8

9

5

6

7

8

0.0 0.0

13.6 13.4

13.6 13.4

0.9 0.9

0.5 0.5

2.6 2.6

1.2 1.2

4.2 4.2

5.8 5.8

REC PB REC PB

1

2

3

4

0.0 0.0

3.6 3.5

0.0 0.0

0.0 0.0

13

14

15

16

3.2 3.2

0.0 0.0

4.3 4.3

4.2 4.2

44

Page 46

REC PB REC PB

5

6

7

8

9

10

11

12

9.1 9.1

3.6 3.6

9.2 9.2

3.6 3.6

0.0 0.0

3.6 3.6

0.0 5.2

4.2 4.2

IC OP AMP (KA4558 IC901)

REC PB REC PB

1

2

3

4

9.1 8.8

2.0 2.0

2.1 2.2

0.0 0.0

17

18

19

20

21

22

23

24

VOLTAGE CHART

0.5 0.5

0.0 0.0

4.3 4.3

0.0 0.0

4.3 4.3

4.3 4.2

0.0 0.0

4.9 0.5

5

6

7

8

4.6 4.6

4.6 4.6

4.6 4.6

9.3 9.3

IC RELAY (A9W-K RL901)

REC PB REC PB

1

2

3

4

5

8.8 8.8

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

IC RELAY (A9W-K RL902)

REC PB REC PB

1

2

3

4

5

8.7 8.7

0.1 0.1

0.0 0.0

0.0 0.0

0.0 0.0

10

10

6

7

8

9

6

7

8

9

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.1 0.1

0.1 0.1

0.0 0.0

0.0 0.0

45

Page 47

VOLTAGE CHART

IC VIDEO (LA7391A IC301)

REC PB REC PB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

0.0 0.0

1.25 2.3

2.4 2.3

2.7 2.5

2.6 4.7

2.6 4.7

4.8 4.8

2.3 2.4

2.2 3.3

2.1 2.1

0.0 0.0

2.0 2.0

2.5 2.5

1.7 0.9

2.9 2.9

2.5 2.2

2.2 2.2

3.7 3.7

3.2 2.4

2.4 2.4

4.5 4.5

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

4.2 4.2

3.7 3.4

3.4 3.4

2.4 2.0

1.9 2.0

2.0 2.0

4.9 4.9

0.0 0.0

4.2 4.2

2.6 2.6

0.5 0.5

0.0 0.0

2.2 2.2

4.9 4.9

1.8 1.8

3.2 3.2

1.6 1.4

3.3 3.3

3.0 3.6

0.0 0.8

2.4 0.0

IC CCD (LC89962 IC302)

REC PB REC PB

1

2

3

4

0.1 2.3

0.0 0.0

0.0 1.3

0.0 0.0

IC HEAD AMP (LA7374 IC401)

REC PB REC PB

1

2

3

4.9 4.9

4.9 4.9

0.0 4.5

46

16

17

18

5

6

7

8

2.3 0.9

0.0 2.2

0.0 0.0

0.0 4.8

0.0 0.0

4.1 0.0

0.0 0.6

Page 48

10

11

12

13

14

15

VOLTAGE CHART

REC PB REC PB

4

5

6

7

8

9

0.0 0.0

0.0 0.0

1.4 1.4

4.3 1.4

0.0 0.0

3.5 3.5

0.0 0.8

3.8 2.4

1.6 2.5

2.1 0.3

1.8 1.6

1.6 1.6

19

20

21

22

23

24

25

26

27

28

29

30

0.3 0.2

4.1 0.0

4.1 0.0

0.1 0.6

0.0 0.0

0.1 0.1

0.0 0.0

0.0 0.0

0.1 1.0

0.1 0.1

0.0 0.0

0.0 0.0

IC VIDEO SW (LA7152 IC303)

REC PB REC PB

1

2

3

4

5

0.0 0.0

0.0 0.0

2.7 2.7

0.0 0.0

0.0 0.0

IC OSD (LA74763 IC001)

REC PB REC PB

1

2

3

4

5

6

7

8

9

10

11

12

13

0.0 0.0

2.4 2.4

2.5 2.5

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

2.9 2.9

2.3 2.3

2.3 2.3

0.0 0.0

0.0 0.0

0.0 0.0

16

17

18

19

20

21

22

23

24

25

26

27

28

6

7

8

9

2.7 2.7

0.0 0.0

1.3 1.2

5.0 5.0

1.7 1.7

4.9 4.9

1.7 1.7

1.4 1.8

2.8 2.8

0.0 1.9

0.0 0.0

2.6 2.6

2.6 2.6

3.3 3.3

3.3 3.3

2.5 2.5

2.5 2.5

47

Page 49

VOLTAGE CHART

REC PB REC PB

14

15

0.0 0.0

4.3 4.3

29

30

0.0 0.0

4.9 4.9

IC VIDEO AMP (NJM2267 IC002)

REC PB REC PB

1

2

3

4

2.2 2.2

0.0 0.0

2.4 2.4

2.5 2.5

5

6

7

8

1.5 1.5

1.6 1.6

4.9 4.9

1.9 1.9

TRANSISTER

REC PB

E B C E B C

Q201 0.1 0.5 4.7 0.0 0.5 0.5

Q202 0.0 0.0 0.0 0.0 0.0 0.0

Q203 0.0 0.2 0.0 0.0 0.2 0.0

Q301 1.8 2.4 3.8 1.7 2.3 3.8

Q302 1.1 1.8 5.0 1.0 1.7 4.9

Q303 1.9 1.3 0.0 1.7 2.0 0.0

Q304 0.0 0.0 2.4 0.0 1.2 0.0

Q305 0.0 1.2 0.0 1.7 1.1 0.0

Q306 1.8 2.4 4.9 1.7 2.3 4.9

Q307 1.2 4.9 1.2 0.5 0.5 1.0

Q311 0.7 0.0 0.0 1.3 0.7 0.0

Q313 0.0 0.0 0.0 0.7 1.3 4.8

Q315 2.2 2.8 4.9 1.2 2.8 4.9

Q316 0.0 0.0 2.8 0.0 0.0 0.9

Q317 3.2 2.4 0.0 3.1 2.4 0.0

Q320 2.5 3.1 5.0 1.7 2.3 5.0

Q371 2.4 1.7 0.0 2.4 2.7 0.0

Q372 1.0 1.6 3.7 1.0 1.6 3.7

Q373 1.7 2.4 4.9 1.7 2.4 4.9

Q374 1.4 1.8 0.0 2.4 1.8 0.0

Q375 1.4 0.7 0.0 1.4 0.7 0.0

Q376 0.0 0.0 2.4 0.0 5.2 0.0

Q378 4.3 3.7 0.7 4.3 3.7 0.7

Q401 0.7 0.0 4.9 4.0 4.5 4.9

48

Page 50

VOLTAGE CHART

REC PB

E B C E B C

Q402 2.4 1.7 4.9 1.7 2.3 4.9

Q403 2.5 1.8 0.0 2.5 1.8 0.0

Q404 1.8 1.4 4.9 1.8 2.4 4.9

Q405 2.7 1.8 4.9 2.7 1.8 4.9

Q406 2.7 3.3 4.9 2.7 3.3 4.9

Q407 0.0 0.0 3.3 0.0 0.0 3.3

Q408 3.1 3.8 4.9 1.8 2.4 4.9

Q409 0.0 4.3 0.0 1.1 1.4 0.0

Q370 1.7 2.3 3.8 1.7 2.4 3.8

Q410 0.0 0.0 0.0 1.8 1.4 3.1

Q411 0.0 0.0 0.0 1.1 1.8 4.3

Q412 0.0 0.0 0.0 0.0 0.0 0.8

Q413 0.0 0.0 0.0 0.0 5.2 0.0

Q414 0.0 0.0 0.0 1.7 2.3 4.0

Q415 0.0 0.0 0.0 3.6 4.0 4.8

Q416 0.0 0.0 0.0 0.0 0.0 0.0

Q420 0.0 0.7 0.0 0.7 0.0 0.0

Q501 5.0 0.0 4.9 5.1 0.0 5.0

Q502 5.0 5.1 0.0 5.0 4.2 4.9

Q503 5.0 4.3 4.9 5.0 5.0 0.4

Q504 0.0 5.2 0.0 0.0 0.0 5.0

Q801 9.3 9.9 13.6 9.3 9.9 13.5

Q802 0.0 0.0 9.9 0.0 0.0 9.9

Q803 0.0 0.0 5.8 0.0 0.0 5.6

Q901 0.0 0.6 0.0 0.0 0.6 0.0

Q902 5.1 5.1 0.0 5.2 5.1 0.0

Q903 0.0 0.0 5.1 0.0 0.0 5.1

Q904 0.0 0.5 1.1 0.0 0.6 0.0

Q905 0.6 0.0 0.0 0.0 0.6 0.0

Q906 5.1 5.1 0.0 5.2 0.0 5.1

Q907 0.0 0.6 0.0 0.0 0.6 0.0

Q908 5.1 5.1 0.0 5.2 5.1 0.0

49

Page 51

CIRCUIT DIAGRAM

1. CONNECTION DIAGRAM

50

Page 52

CIRCUIT DIAGRAM

2. POWER CIRCUIT DIAGRAM

51

Page 53

3. SYSCON CIRCUIT DIAGRAM

CIRCUIT DIAGRAM

52

Page 54

CIRCUIT DIAGRAM

4. VIDEO CIRCUIT DIAGRAM

53

Page 55

5. HEADAMP CIRCUIT DIAGRAM

CIRCUIT DIAGRAM

54

Page 56

CIRCUIT DIAGRAM

6. OSD CIRCUIT DIAGRAM

55

Page 57

7. Y/C SEPARATION CIRCUIT DIAGRAM

CIRCUIT DIAGRAM

56

Page 58

CIRCUIT DIAGRAM

8. AUDIO CIRCUIT DIAGRAM

57

Page 59

9. LOGIC CIRCUIT DIAGRAM

CIRCUIT DIAGRAM

58

Page 60

CIRCUIT DIAGRAM

10. TERMINAL CIRCUIT DIAGRAM

59

Page 61

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW

1. PCB MAIN

60

Page 62

COMPONENTS LOCATION GUIDE ON PCB BOTTOM VIEW

2. PCB UNION

61

Page 63

DISASSEMBLY

1. PANEL FRONT ASS’Y

62

Page 64

DISASSEMBLY

2. SET TOTAL ASS’Y

63

Page 65

3. PACKING ASS’Y

DISASSEMBLY

64

Page 66

ELECTRICAL PARTS LIST

“ 2 ” is a recommendable part for stock.

DEL : DV-K580NZ-T

LOC PART-CODE PART-NAME PART-DESC

1 97PC0252A- ACCESSORY AS DV-K580NZ-T

D001 97P9560000 MANUAL OWNERS ALL MODEL

2 97PC0022P- PACKING AS DV-K444DY-AQ

C001 97P4923200 PAD LEFT/RIGHT EPS

C002 97P4803100 POLY BAG FOR SET P.E FOAM

C003 97P5043800 BOX CARTON SW-4

C004 47P4502200 LABEL SERIAL A ART PAPER STICKER

C005 6520010020 STAPPLE M20

3 97PC0252C- CHASSIS MAIN AS DV-K580NZ-T

A001 97P0610110 CHASSIS MAIN HI-PS(V0)

A0011 97P0800600 LEG SBR 80 BLK

A002 97P9340000 LABEL SPEC PE FILM (ALL MODEL)

A003 7173401211 SCREW TAPPTITE TT2 BIN 4X12 MFZN

A014 97P4217600 CUSHION T/PLATE EVA T1.2 BLACK

A017 7173401211 SCREW TAPPTITE TT2 BIN 4X12 MFZN

A018 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

A040 97P0475000 COVER TOP P.C.M T0.625

A041 7173401012 SCREW TAPPTITE TT2 BIN 4X10 BK MFZN

A050 2233030000 LOCK PAINT NO-2

A060 97P0468610 COVER BOTTOM SECC T0.4(UL)

A061 7174301011 SCREW TAPPTITE TT2 RND 3X10 MFZN

2

D00197P1R2B500 REMOCON HANDSET AS VR-F2B5

2

F8015F1GB1521L FUSE GLASS TUBE UL/CSA TL 1.5A 125V MF51

M01 97PP321710 PANEL FRONT AS DV-K580NZ-T

B001 97P0321710 PANEL FRONT HI-PS(V0)

B002 97P1822410 DOOR FRONT HI-PS(V0)

B003 97P1625400 WINDOW FRONT SAN

B004 97P1625500 WINDOW R/S SAN

B005 97P1367300 KNOB REC ABS

B006 97P1367400 KNOB S/E ABS

B007 97P1367500 KNOB PLAY ABS

B008 97P1367600 KNOB POWER ABS

B010 97P0984400 PLATE FUNCTION PVC T0.5

B011 97P3022200 SPRING DR SUS 304 CSP T0.2 (6050N)

B012 97P1820500 DOOR F/L ABS

B013 97P3040000 SPRING F/L DOOR SWPB

M1000 97PC0268D- DECK TOTAL AS DRN-9439A

AC001 97SA381500 HEAD CLEANER AS FM,K-MECHA

B5810 97S2601200 LEVER HEAD CLEANER F20-03 NATURAL

B5820 97S4100600 FELT CLEANER URETHAN UNIJEHF 60PPI

AD001 97PA269841 DRUM PRICE AS CYN-KT413T

AF001 97SA251400 F/L AS K-MECHA

LOC PART-CODE PART-NAME PART-DESC

A5000 97S0902000 PLATE TOP SECC T1.0

A5100 97S2400900 BRKT F/L R SECC T1.0

A5200 97SA311400 CST HOLDER AS K-MECHA

B5200 97SA410100 HOLDER AS K-MECHA

C5200 97S0902100 PLATE CST HOLDER SECC T1.2

C5210 97S3505100 POST HOLDER SWRC MFZN-II-C

C5220 97S3504500 POST HOLDER L SWRC MFZN-II-C

C5230 97S3504600 POST HOLDER R SWRC MFZN-II-C

C5240 97S3004500 SPG UPPER SUS304CSP T0.25

B5210 97S2601500 LEVER SAFETY SECC T1.0

B5230 97S2605400 LEVER RELEASE DURACON M90-02 NATURAL

B5240 97S3004700 SPG RELEASE SUS304WPB D0.23

B5250 97S2605500 LEVER SAFETY R SUS304CSP T0.5

B5260 97S3101600 WASHER POLY D6.5XD3.6XT0.5

A5300 97SA311500 LOADING LEVER AS K-MECHA

B5300 97S2614600 LEVER FL L DURACON M90-02 BLACK

B5310 97S2614700 LEVER FL R DURACON M90-02 BLACK

B5320 97S3600200 SHAFT LOADING SUM32 MFZN-II-C

B5330 97S3004800 SPG FL LEVER SWPB D1.0

B5350 97S3505400 POST LEVER-R SWRC MFZN-II-C

A5400 97S2602210 LINK PRISM L PMMA(HI-855M)NATURAL

A5500 97S2602110 LINK PRISM R PMMA(HI-855M)NATURAL

A5700 97S1800400 OPENER DOOR DURACON M90-02 BLACK

A5800 7278260611 SCREW TAPPTITE TT3 WAS 2.6X6 MFZN

A5900 7278300611 SCREW TAPPTITE TT3 WAS 3X6 MFZN

AM001 97SA267900 DECK AS K-MECHA(TIME LAPSE)

A0100 97SA309700 MAIN BASE AS K-MECHA

B0100 97S1401900 BASE OUTSERT SECC T1.6+F20-03

B0110 97S3504200 POST REEL TABLE SUS303

B0120 97SA408000 REEL GEAR POST AS SUS303+C3604

C0120 97S3504100 POST REEL GEAR SUS303

C0130 97S4000600 BUSH REEL GEAR C3604

B0130 97S3504000 POST PINCH LEVER SWRC MFNI

B0140 97S3503900 POST AC HEAD SWRC MFZN-II-C

B0150 97S3503800 POST CAM GEAR SWRC MFZN-II-C

B0160 97S3503700 POST LOADING LEVER SUS303

B0180 97S3503500 POST T GUIDE SUS303

B0190 97S3504300 POST UNLOCKING SWRC MFZN-II-C

B0200 97S3505200 POST VERTICAL SUS303

B0210 97S2604200 LINK PRISM LED PMMA(IF-850) NATURAL

A0200 97S0901400 PLATE CONNECT SECC T1.0

A0300 97S2701800 RACK F/L PBT (KP213G30) NATURAL

65

Page 67

ELECTRICAL PARTS LIST

LOC PART-CODE PART-NAME PART-DESC

A0400 97SA310900 S SLANT POLE AS G,FM,K-MECHA

B0400 97SA409900 S POLE BASE AS G,FM,K-MECHA

C0400 97S1402600 BASE S POLE ZDC-2

C0410 97S3513200 POLE SLANT SUS303

B0410 97SA411300 GUIDE ROLLER AS VW-32, LEE

B0420 97S3102800 SCREW MACHINE PAN M2X0.4 MFZN(BK)

B0430 97S3100500 RING-O RUBBER(NBR 65)

A0500 97SA311000 T SLANT POLE AS G,FM,K-MECHA

B0500 97SA410000 T POLE BASE AS G,FM,K-MECHA

C0500 97S1402400 BASE T POLE ZDC-2

C0510 97S3513200 POLE SLANT SUS303

B0510 97SA411300 GUIDE ROLLER AS VW-32, LEE

B0520 97S3102800 SCREW MACHINE PAN M2X0.4 MFZN(BK)

B0530 97S3100500 RING-O RUBBER(NBR 65)

A0600 97SA308500 L LOADING AS K-MECHA

B0600 97S2702600 GEAR L LOADING DURACON M90-02 NATURAL

B0610 97S2605000 LEVER L LOADING SECC T1.0

B0620 97S2605200 LEVER L LOADNIG SUB SECC T1.0

B0630 97S3003800 SPG LOADING SWPB D0.6

B0640 97S3401300 RIVET LOADING LEVER SWRC MFZN-II-C

A0700 97SA308600 R LOADING AS K-MECHA

B0700 97S2702500 GEAR R LOADING DURACON M90-02 BLACK

B0710 97S2605300 LEVER R LOADING SECC T1.0

B0720 97S2605100 LEVER R LOADNIG SUB SECC T1.0

B0730 97S3003800 SPG LOADING SWPB D0.6

B0740 97S3401300 RIVET LOADING LEVER SWRC MFZN-II-C

A0800 97SA308400 LODING RACK AS K-MECHA

B0800 97S2701300 RACK LOADING SECC T1.6

B0810 97S3503300 POST LOADING RACK SWRC MFZN-II-C

A0900 97S3101800 WASHER POLY D3.1XD8XT0.5

A1000 97S8101400 CAP M/T (TIME LAPSE) DMVCMC061R/M

A1100 97S3102000 SCREW TAPPTITE TT2 BIN-P 2.6X7 MFZN

A1200 97S3004000 SPG AC HEAD SUS304WPB D1.2

A1300 97S8020600 HEAD A/C HVMXB1010AK(LG)

A1400 7391300211 NUT HEX 6N-1-5 MFZN

A1500 97S2604100 LEVER RELAY ZDC-2

A1600 97S2701400 GEAR CAM DELIN 500 NATURAL

A1700 97SA310700 PINCH LEVER TOT AS K-MECHA

B1700 97SA409010 PINCH LEVER AS K-MECHA

C1700 97S2604010 LEVER PINCH SECC T1.6

C1710 97S3500900 SHAFT PINCH ROLLER SWRC MFZN-II-C

B1710 97SA481000 PINCH ROLLER AS D15(730)

C0622 97SA518200 PINCH ROLLER SUB AS NBR60+A2011

D0623 97S2811700 SLEEVE PINCH ROLLER A2011

LOC PART-CODE PART-NAME PART-DESC

C0624 97S5300800 BEARING BALL NMB(L-730ZZ SD 204H)

C0626 97S4005800 BUSH PINCH ROLLER GR-20

B1720 97S0448400 CAP PINCH ROLLER F20-03 NATURAL

B1730 97S3032000 SPG PINCH ROLLER SWPB D0.7

A1800 97S3117300 WASHER POLY D3.6XD8XT0.5

A1900 97SA310400 L/C BRKT TOT AS K-MECHA

B1900 97SA414100 L/C BRKT AS K-MECHA

C1900 97S2400700 BRKT L/C F20-03 NATURAL

C1910 97S3503200 POST WORM WHEEL SUS303

B1910 97SA409200 L/C MOTOR AS K-MECHA

C1900 97S8103600 L/C MOTOR MDH2B70

C1910 97S2702000 WORM DURANEX 2002 NATURAL

B1920 97P6538222 PCB L/C MOTOR PHENOL T1.6

B1930 97P6271500 CONN WAFER (ANGLE) 00-8283-0711-00000

B1940 5SSF1DKM10 SW CAM MMS00320ZMBO

B1960 97S2901500 WHEEL WORM DERLIN 100 NATURAL

B1970 97S3601600 SHAFT WORM SUS304

A2000 7274300611 SCREW TAPPTITE TT3 RND 3X6 MFZN

A2100 97SA311600 IDLER PLATE AS K-MECHA

B2100 97S2701500 GEAR IDLER NYLON12-1724KH NATURAL

B2110 97S4103500 FELT IDLER GEAR B-BUFF D15XD20XT0.5

B2120 97S0901500 PLATE IDLER SECC T0.5

B2130 97S3502700 POST IDLER SWRC MFNI

B2140 97S3002900 SPG IDLER SUS304WPB D0.3

A2200 97S3108200 POLYWASHER D2.6XD6.0XT0.5

A2300 97S2901600 TABLE REEL F20 BLACK

A2400 97S3903600 POLY SLIDER D3.1XD6XT0.5

A2500 97SA310800 TENSION BAND AS K-MECHA

B2500 97SA409800 TENSION LEVER AS K-MECHA

C2500 97S2602800 LEVER TENSION SECC T1.2

C2510 97S3503000 POLE TENSION SUS303

C2520 97S3503100 POST TENSION SUM32 MFZN-II-C

B2510 97SA409700 BAND BRAKE AS K-MECHA

C2540 97S4300200 BRAKE BAND FILM T0.188+A-BUFF T0.5

C2550 97S2301100 HOLDER BAND BRAKE A F20-02 NATURAL

C2560 97S2301200 HOLDER BAND BRAKE B F20-02 BLACK

B2520 97S0400700 CAP BAND BRAKE POM

A2600 97S3003500 SPG TENSION SWPB D0.4

A2700 97SA309300 S SUB BRAKE AS K-MECHA

B2700 97S2603200 LEVER S SUB BRAKE F20-03 NATURAL

B2710 97S3003100 SPG S SUB BRAKE SUS304WPB D0.4

A2800 97SA309400 T SUB BRAKE AS K-MECHA

B2800 97S2603300 LEVER T SUB BRAKE F20-03 NATURAL

B2810 97S4102500 FELT T SUB BRAKE B-BUFF 13.5X2.0XT1.0

66

Page 68

ELECTRICAL PARTS LIST

LOC PART-CODE PART-NAME PART-DESC

B2820 97S3003000 SPG T SUB BRAKE SUS304WPB D0.5

A2900 97SA309110 MAIN BRAKE AS K-MECHA

B2900 97S2603010 LEVER S MAIN BRAKE KP213G30 NATURAL

B2910 97S2603110 LEVER T MAIN BRAKE KP213G30 GREEN

B2920 97S3003010 SPG MAIN BRAKE SUS304WPB D0.35

B2930 97S4102610 FELT MAIN BRAKE CLARINO 3611 8X4XT1.0

A3100 97S8012900 HEAD FE HVFHF0004AK(LG)

A3200 97S3102100 SCREW TAPPTITE TT2 BIN-P 2.6X10 MFZN

A3300 97SA309000 REEL GEAR TOT AS K-MECHA

B3300 97SA408700 REEL GEAR SUB AS K-MECHA

C3300 97S2701900 GEAR REEL F20-03 NATURAL

C3310 97S3003400 SPG CLUTCH WHEEL SUS304WPB D0.45

C3320 97S2301000 HOLDER REEL GEAR F20-03 NATURAL

C3330 97S0901800 PLATE CLUTCH SUS304CSP T0.2

C3340 97S2901700 WHEEL CLUTCH F20-03 NATURAL

C3350 97S2602900 LEVER CLUTCH DELIN 500 NATURAL

B3305 97SA408710 REEL BASE AS K-MECHA

C3300 97S1402010 BASE REEL F20-03 NATURAL

C3310 97S4000410 BUSH REEL SUS304

C3320 97S4103610 FELT REEL BASE B-BUFF D20XD29XT0.5

B3350 97S3700410 PULLEY REEL DURACON AW-01 NATURAL

B3390 97S3003210 SPG REEL GEAR SUS304WPB D0.55

A3400 97S3108200 POLYWASHER D2.6XD6.0XT0.5

A3500 97S5500400 BELT REEL CR68

A3600 97S2603500 LEVER RECORD SAFETY F20-03 NATURAL

A3700 97SB381100 EARTH BRACKET AS G,FM,K-MECHA

B3700 97S2431000 BRKT EARTH SECC T1.0

B3710 97SA411800 SPRING LEAF AS G,FM,K-MECHA

C5021 97S3001600 SPRING LEAF PBSP T0.15

C5023 97S6000200 CONTACT AG22P

C5025 97S4200300 RUBBER CR65

A3800 7274301011 SCREW TAPPTITE TT3 RND 3X10 MFZN

A3900 7274301211 SCREW TAPPTITE TT3 RND 3X12 MFZN

A4000 7274300611 SCREW TAPPTITE TT3 RND 3X6 MFZN

A4100 2291129004 OIL LUBRICANT OA-305P

A4200 2291131304 GREASE DELUXE 5221G(NAM-YOUNG)

PW01 97PA4E2211 CORD POWER AS KKP-419C 0.75MM 2100MM

P502A 97P88F0714 CABLE FFC 1.25K 7P 140MM

31 97PE106500 PCB MAIN AS DV-K580NZ-T

BA01 97P0474200 CASE SHIELD PREAMP ET T0.4

BA02 97P0983400 PLATE SHIELD PREAMP ET T0.4

2

C501 97P7801300 BATTERY 3/V 15H 3.6V (NI-MH)

C801 CL1UE3104M C LINE ACROSS AC275V 0.1MF M 1.40 WORLD

C804 CH1CEE332M C CERA AC 2.5KV 3300PF M DE AC250V

LOC PART-CODE PART-NAME PART-DESC

C805 CH1CEE332M C CERA AC 2.5KV 3300PF M DE AC250V

C806 CEXF2E680V C ELECTRO 250V RSS 68MF 16X25(SG)

C810 CEXF1E331F C ELECTRO 25V RX 330MF 10X20

C814 CEXF1A102F C ELECTRO 10V RX 1000MF 10X20

D501 DS1R481T-- LED IR SIR-48IT(P-RANK)

D501A 97P2339600 HOLDER IR ABS

2

IC001 12BKK81NAL IC OSD LC74763-9778

2

IC201 1BA7790LSK IC AUDIO BA7790LS

2

IC301 1LA7391--- IC LA7391

2

IC302 1LC89962-- IC VIDEO LC89962

IC303 1LA7152--- IC SWITCH LA7152

2

IC401 1LA7374--- IC VIDEO LA7374

IC502 1MC4558C-- IC OP AMP MC4558C(KA4558)

IC503 1MN1380L--

2

IC504 1BA6209--- IC BA6209

IC505 1MC4558C-- IC OP AMP MC4558C(KA4558)

2

IC801 1PQ05RF11- IC REGULATOR PQ05RF11

IC901 1MC4558C-- IC OP AMP MC4558C(KA4558)

L801 5PLFSF2120 FILTER LINE SF-2120 40MH

M802 97P0974300 PLATE EARTH-P ET T=0.4

PJ201 97P885X101 CONN AS 6H/2H-8S 160/350(TUBE)MM

PJ501 97P8810712 CONN AS (Y10712) 7H-7S, 120MM

PT501 97P6269000 CONN WAFER 00-8283-0612-00000

P401 97P62G06D7 CONN HOUSING GF120 FPC 1.25MM 7P

P501 97P62T112A CONN B/B (PLUG) TKC-GP PLUG 10P

P502 97P62G06D7 CONN HOUSING GF120 FPC 1.25MM 7P

P503 97P62G05CB CONN HOUSING2 GB150 RECEP 1.5MM 11P

P504 97P62G05CM CONN HOUSING2 GB150 RECEP 1.5MM 21P

P801 97P62Y04X4 CONN WAFER YW396 4P NC

P901 97P62G02BD CONN B/B GB200 PLUG 2.0MM 13P

P902 97P62G02BA CONN B/B GB200 PLUG 2.0MM 10P

2

Q801 TKSD2058Y- TR KSD2058-Y

Q804 TKSD2058Y- TR KSD2058-Y

RL901 5SC0204001 SW RELAY A9W-K 9V DPDT

RL902 5SC0204001 SW RELAY A9W-K 9V DPDT

R570 RS02F339J- R M-OXIDE FILM 2W 3.3 OHM J

R811 RS02F330JS R M-OXIDE FILM 2W 33 OHM J(SMALL)

SW501 5SN0101Z20 SW DETECT JDS1105-6X

S501 97P0S01900 SENSOR REEL SG-258S

S502 97P0S01900 SENSOR REEL SG-258S

S503 TST5811--- TR PHOTO ST-5811(D-RANK)

S503A 97P2338200 HOLDER TR ABS

S504 TST5811--- TR PHOTO ST-5811(D-RANK)

IC COMPARATOR

(RESET)

MN1380-L(RESET IC)

67

Page 69

ELECTRICAL PARTS LIST

LOC PART-CODE PART-NAME PART-DESC

S504A 97P2338200 HOLDER TR ABS

T201 560202L697 COIL OSC DEO-010(BIAS)

U001 97P65246MA PCB MAIN 330*247*1.6T(K580NZ-N)

VA801 DSVC471D14 VARISTOR SVC471D14A

X001 5XJ14R31AE CRYSTAL QUARTZ HC-49/S 14.31818MHZ 30PPM

2

X302 97P7005100 DELAY LINE 1H ADL-FN2038Y

X303 5PUGL349KN FILTER COMB UGL-349KNT

X501 5XJ16R0LAE CRYSTAL QUARTZ HC-49/S 16.00000MHZ 30PPM

X502 5XZR03276G CRYSTAL QUARTZ SO-26 32.768000KHZ 10PPM

031C 97PB242900 PCB MAIN CHIP AS DV-K580N-T

C001 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012

C002 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012

C003 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C004 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C005 HCLK221JCA C CHIP CERA 50V SL 220PF J 2012

C008 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C011 HCBK682KCA C CHIP CERA 50V X7R 6800PF K 2012

C012 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C013 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012

C014 HCQK240JCA C CHIP CERA 50V CH 24PF J 2012

C015 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C017 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

C020 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C205 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C206 HCLK821JCA C CHIP CERA 50V SL 820PF J 2012

C301 HCLK201JCA C CHIP CERA 50V SL 200PF J 2012

C302 HCLK510JCA C CHIP CERA 50V SL 51PF J 2012

C303 HCLK300JCA C CHIP CERA 50V SL 30PF J 2012

C304 HCLK330JCA C CHIP CERA 50V SL 33PF J 2012

C305 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C307 HCLK150JCA C CHIP CERA 50V SL 15PF J 2012

C308 HCLK391JCA C CHIP CERA 50V SL 390PF J 2012

C309 HCLK470JCA C CHIP CERA 50V SL 47PF J 2012

C310 HCLK150JCA C CHIP CERA 50V SL 15PF J 2012

C311 HCLK120JCA C CHIP CERA 50V SL 12PF J 2012

C312 HCLK509CCA C CHIP CERA 50V SL 5PF C 2012

C315 HCLK120JCA C CHIP CERA 50V SL 12PF J 2012

C317 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C318 HCLK150JCA C CHIP CERA 50V SL 15PF J 2012

C321 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C328 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C329 HCLK100DCA C CHIP CERA 50V SL 10PF D 2012

C330 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C331 HCLK390JCA C CHIP CERA 50V SL 39PF J 2012

LOC PART-CODE PART-NAME PART-DESC

C334 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C338 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C340 HCLK390JCA C CHIP CERA 50V SL 39PF J 2012

C341 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C345 HCFK473ZCA C CHIP CERA 50V Y5V 0.047MF Z 2012

C358 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C360 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C361 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C363 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C372 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C374 HCLK330JCA C CHIP CERA 50V SL 33PF J 2012

C375 HCLK220JCA C CHIP CERA 50V SL 22PF J 2012

C379 HCLK220JCA C CHIP CERA 50V SL 22PF J 2012

C392 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C396 HCLK390JCA C CHIP CERA 50V SL 39PF J 2012

C402 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C404 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C405 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C406 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C407 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C409 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C410 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C411 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C412 HCFK473ZCA C CHIP CERA 50V Y5V 0.047MF Z 2012

C413 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C415 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C416 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C417 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C418 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C419 HCLK220JCA C CHIP CERA 50V SL 22PF J 2012

C420 HCLK100DCA C CHIP CERA 50V SL 10PF D 2012

C421 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C422 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C423 HCLK220JCA C CHIP CERA 50V SL 22PF J 2012

C424 HCLK151JCA C CHIP CERA 50V SL 150PF J 2012

C427 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C428 HCLK181JCA C CHIP CERA 50V SL 180PF J 2012

C429 HCLK220JCA C CHIP CERA 50V SL 22PF J 2012

C430 HCLK470JCA C CHIP CERA 50V SL 47PF J 2012

C432 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C433 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C434 HCLK330JCA C CHIP CERA 50V SL 33PF J 2012

C435 HCLK330JCA C CHIP CERA 50V SL 33PF J 2012

C436 HCLK560JCA C CHIP CERA 50V SL 56PF J 2012

68

Page 70

ELECTRICAL PARTS LIST

LOC PART-CODE PART-NAME PART-DESC

C437 HCLK681JCA C CHIP CERA 50V SL 680PF J 2012

C438 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C439 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C440 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C441 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C442 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C443 HCLK680JCA C CHIP CERA 50V SL 68PF J 2012

C450 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C451 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C452 HCLK391JCA C CHIP CERA 50V SL 390PF J 2012

C455 HCFK473ZCA C CHIP CERA 50V Y5V 0.047MF Z 2012

C458 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C459 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C470 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C472 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C480 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C502 HCLK471JCA C CHIP CERA 50V SL 470PF J 2012

C503 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C505 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C506 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C507 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C508 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C509 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C510 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C511 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C512 HCFK223ZCA C CHIP CERA 50V Y5V 0.022MF Z 2012

C514 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C515 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

C516 HCBK122KCA C CHIP CERA 50V X7R 1200PF K 2012

C517 HCLK101JCA C CHIP CERA 50V SL 100PF J 2012

C518 HCBK102KCA C CHIP CERA 50V X7R 1000PF K 2012

C522 HCBK222KCA C CHIP CERA 50V X7R 2200PF K 2012

C524 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C525 HCQK130JCA C CHIP CERA 50V CH 13PF J 2012

C526 HCQK150JCA C CHIP CERA 50V CH 15PF J 2012

C527 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

C528 HCQK180JCA C CHIP CERA 50V CH 18PF J 2012

C529 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C531 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C532 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C534 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C535 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C536 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C537 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

LOC PART-CODE PART-NAME PART-DESC

C538 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C539 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C540 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C541 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C542 HCLK471JCA C CHIP CERA 50V SL 470PF J 2012

C543 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C544 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C545 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C546 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C552 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C556 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C557 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C812 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C818 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C901 HCFK103ZCA C CHIP CERA 50V Y5V 0.01MF Z 2012

C904 HCLK561JCA C CHIP CERA 50V SL 560PF J 2012

C905 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

C907 HCFK104ZCA C CHIP CERA 50V Y5V 0.1MF Z 2012

2

D801 DS1WBA60-C DIODE BRIDGE S1WBA60 4072 CHIP

IC002 1NJM2267M- IC NJM2267M

RJ001~

HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ029

RJ031~

HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ040

RJ042 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ044 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ045 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ046 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ047 HRFT000-CA R CHIP 1/10 0 OHM 2012

RJ048~

HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ053

RJ055 HRF8000-EA R CHIP 1/8 0 OHM 3216

RJ056 HRF8000-EA R CHIP 1/8 0 OHM 3216

R001 HRFT204JCA R CHIP 1/10 200K OHM J 2012

R002 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

R003 HRFT682JCA R CHIP 1/10 6.8K OHM J 2012

R004 HRFT121JCA R CHIP 1/10 120 OHM J 2012

R005 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R006 HRFT202JCA R CHIP 1/10 2K OHM J 2012

R007 HRFT512JCA R CHIP 1/10 5.1K OHM J 2012

R008 HRFT272JCA R CHIP 1/10 2.7K OHM J 2012

R201 HRFT223JCA R CHIP 1/10 22K OHM J 2012

R202 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R203 HRFT243JCA R CHIP 1/10 24K OHM J 2012

R204 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

69

Page 71

ELECTRICAL PARTS LIST

LOC PART-CODE PART-NAME PART-DESC

R205 HRFT562JCA R CHIP 1/10 5.6K OHM J 2012

R206 HRFT183JCA R CHIP 1/10 18K OHM J 2012

R207 HRFT220JCA R CHIP 1/10 22 OHM J 2012

R208 HRFT333JCA R CHIP 1/10 33K OHM J 2012

R209 HRFT151JCA R CHIP 1/10 150 OHM J 2012

R210 HRFT334JCA R CHIP 1/10 330K OHM J 2012

R211 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012

R213 HRFT104JCA R CHIP 1/10 100K OHM J 2012

R214 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

R217 HRFT229JCA R CHIP 1/10 2.2 OHM J 2012

R218 HRFT229JCA R CHIP 1/10 2.2 OHM J 2012

R219 HRFT470JCA R CHIP 1/10 47 OHM J 2012

R222 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012

R223 HRFT473JCA R CHIP 1/10 47K OHM J 2012

R224 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

R225 HRFT622JCA R CHIP 1/10 6.2K OHM J 2012

R226 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

R227 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

R228 HRFT621JCA R CHIP 1/10 620 OHM J 2012

R229 HRFT912JCA R CHIP 1/10 9.1K OHM J 2012

R302 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

R303 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012

R304 HRFT472JCA R CHIP 1/10 4.7K OHM J 2012

R305 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R306 HRFT272JCA R CHIP 1/10 2.7K OHM J 2012

R307 HRFT681JCA R CHIP 1/10 680 OHM J 2012

R308 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R309 HRFT362JCA R CHIP 1/10 3.6K OHM J 2012

R310 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R311 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R312 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

R313 HRFT332JCA R CHIP 1/10 3.3K OHM J 2012

R314 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R315 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R316 HRFT391JCA R CHIP 1/10 390 OHM J 2012

R317 HRFT821JCA R CHIP 1/10 820 OHM J 2012

R318 HRFT123JCA R CHIP 1/10 12K OHM J 2012

R319 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R320 HRFT202JCA R CHIP 1/10 2K OHM J 2012

R321 HRFT681JCA R CHIP 1/10 680 OHM J 2012

R322 HRFT122JCA R CHIP 1/10 1.2K OHM J 2012

R323 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R324 HRFT123JCA R CHIP 1/10 12K OHM J 2012

R326 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012

LOC PART-CODE PART-NAME PART-DESC

R329 HRFT124JCA R CHIP 1/10 120K OHM J 2012

R330 HRFT105JCA R CHIP 1/10 1M OHM J 2012

R331 HRFT822JCA R CHIP 1/10 8.2K OHM J 2012

R332 HRFT750JCA R CHIP 1/10 75 OHM J 2012

R334 HRFT392JCA R CHIP 1/10 3.9K OHM J 2012

R337 HRFT391JCA R CHIP 1/10 390 OHM J 2012

R339 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R341 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R343 HRFT824JCA R CHIP 1/10 820K OHM J 2012

R348 HRFT271JCA R CHIP 1/10 270 OHM J 2012

R349 HRFT122JCA R CHIP 1/10 1.2K OHM J 2012

R350 HRFT223JCA R CHIP 1/10 22K OHM J 2012

R351 HRFT333JCA R CHIP 1/10 33K OHM J 2012

R353 HRFT103JCA R CHIP 1/10 10K OHM J 2012

R354 HRFT473JCA R CHIP 1/10 47K OHM J 2012

R355 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R358 HRFT103JCA R CHIP 1/10 10K OHM J 2012

R359 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

R371 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R372 HRFT333JCA R CHIP 1/10 33K OHM J 2012

R373 HRFT333JCA R CHIP 1/10 33K OHM J 2012

R374 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R375 HRFT152JCA R CHIP 1/10 1.5K OHM J 2012

R376 HRFT222JCA R CHIP 1/10 2.2K OHM J 2012

R377 HRFT681JCA R CHIP 1/10 680 OHM J 2012

R378 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R379 HRFT362JCA R CHIP 1/10 3.6K OHM J 2012

R380 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

R381 HRFT222JCA R CHIP 1/10 2.2K OHM J 2012

R382 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

R383 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R385 HRFT102JCA R CHIP 1/10 1K OHM J 2012

R386 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012

R387 HRFT182JCA R CHIP 1/10 1.8K OHM J 2012