Daewoo CP-810 Service Manual

¸¬¬°æññ-ª½ò¼©

»

ò½±

òµ®

УЯОфоррр

S/M No: CP810P-010

Service Manual

66 Cm STEREO ColourTelevision

CHASSIS : CP-810

MODEL :DTJ - 28A6F

DTJ - 28A7F

DTJ - 28B1F

DTJ - 28G6F

DTJ - 28G7F

DTJ - 28G8F

ì

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CO., LTD.

МЯЮФЫ СЪ ЭСТМЫТМН

1. Safety Instruction ........................................................................................................................ 2

2. Specifications .............................................................................................................................. 3

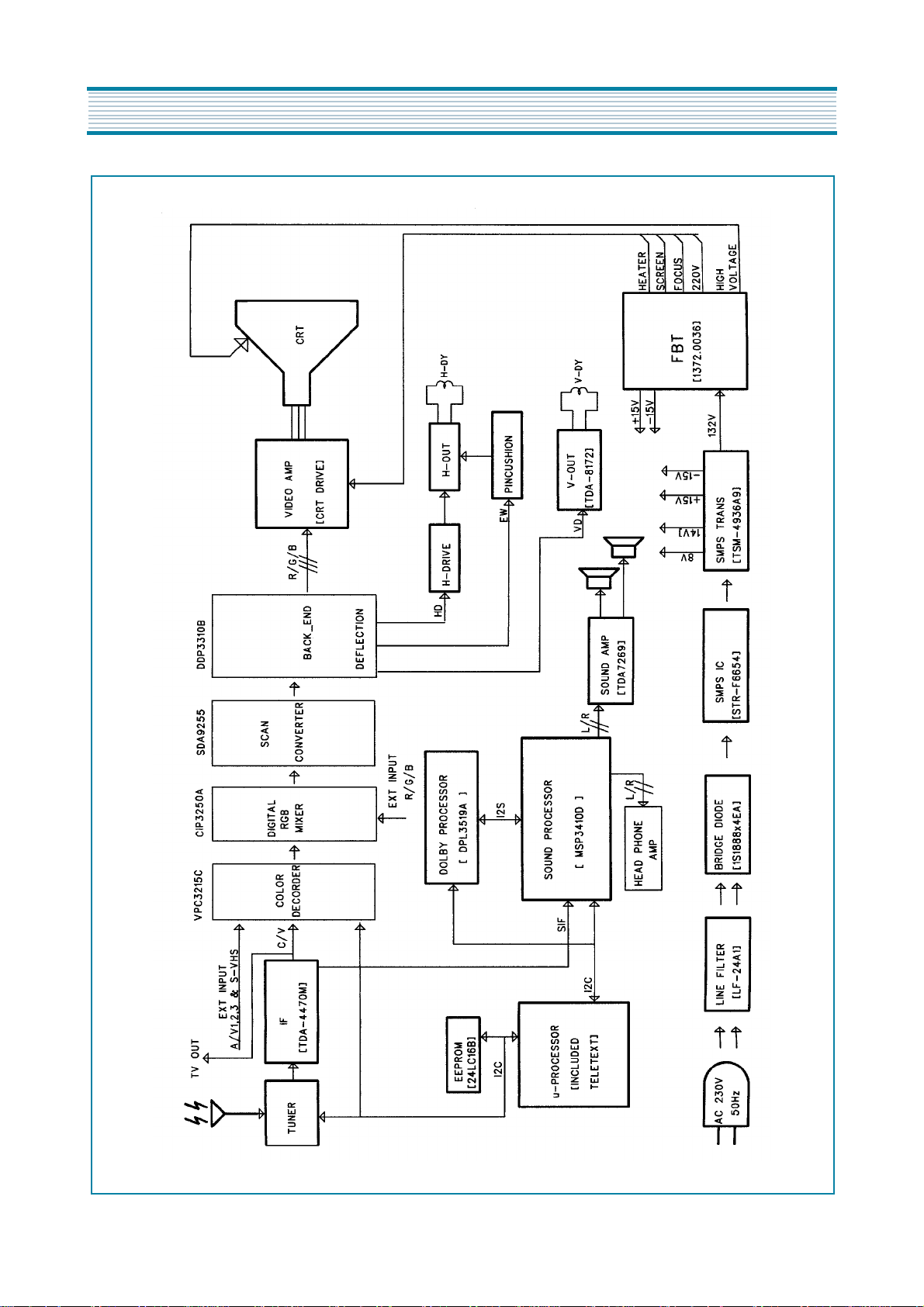

3. Circuit block Diagram ................................................................................................................. 5

4. Alignment Instructions ............................................................................................................... 6

5. IC Description .............................................................................................................................. 12

6. IC DC Voltage Charts .................................................................................................................. 32

7. Service Parts List/Recommendable Spare Parts List .............................................................. 35

8. Mechanical Exploded View ......................................................................................................... 45

9. Printed Circuit Board .................................................................................................................. 51

10. Schematic Diagram ..................................................................................................................... 52

1

1. Safety Instruction

WARNING

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can prodece potentially hazardous X-RAY RADIATION. To avoid such hazards,

the high voltage must not exceed the specified limit.

The nominal value of the high voltage of this receiver is

23-24kv at max beam current. The high voltage must

not, under any circumstances, exceed 30kv.

Each time a receiver require servicing, the high volt-

age should be checked. It is imprortant to use an accurate and reliable high voltage meter.

: Only competent service personnel may carry out work involving the testing or repair of this equipment

2. The only source of X-RAY Radiation in this TV receiver

is the picture tube. For continued X-RAY RADIATION

protection, the replacement tube must be exactly the

same type tube as specified in the parts list.

SAFETY PRECAUTION

1. Potentials of high voltage are present when this

receiver is operating. Operation of the receiver outside

the cabinet or with the back board removed involves a

shock hazard from the receiver.

1) Servicing should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high-voltage equipment.

2) Dischange the high potential of the picture tube

before handling the tube. The picture tube is highly

evacuated and if broken, glass fragments will be

violently expelled.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this have

special safety-related characteristics. These characteristics are often passed unnoticed by a visual

inspection and the X-RAY RADIATION protection

afforded by them cannot necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc. Replacement parts which have

these special safety characteristics are identified in

this manual and its supplements, electrical compo-

2. If any Fuse in this TV receiver is blown, replace it with

the FUSE specified in the Replacement Parts List.

3. When replacing a high wattage resistor ( oxide metal

film resistor ) in circuit board, keep the resistor 10mm

away from circuit board.

4. Keep wires away from high voltage or high temperature components.

5. This receiver must operate under AC230 volts, 50Hz.

NEVER connect to DC supply or any other power or

frequency.

nents having such features are identified designated

symbol on the parts list.

Before replacing any of these components, read the

parts list in this manual carefully. The use of substitute

replacement parts which do not have the same safety

characterisitics as specifide in the parts list may create

X-RAY Radiation.

2

2. Specifications

CRT 28" : A66EAK071X54 ( PHILIPS )

System PAL/SECAM-B/G, D/K, PAL-I/I’, SECAM-L/L’, NTSC-3.58/4.43 (Play back )

Main Voltage 230V AC, 50Hz

Power Consumption Stand-by mode : 2.0 Watts

Normal operating mode : 80 Watts

Sound output 10 + 10 Watts, 10% THD at RF 60% mod. ( 1 kHz )

Speaker 12W 8ohm x 2 EA

Antenna Impedance 75 ohm unbalanced input (Din Standard )

Tuning system Frequency Synthesize(FS) Tuning System

Tuner DT5-BF14D, EL2782-105-B

Number of Program 100 programs

Aux. Terminal 21 pin EURO-SCART jack ( AV input, TV output, RGB input )

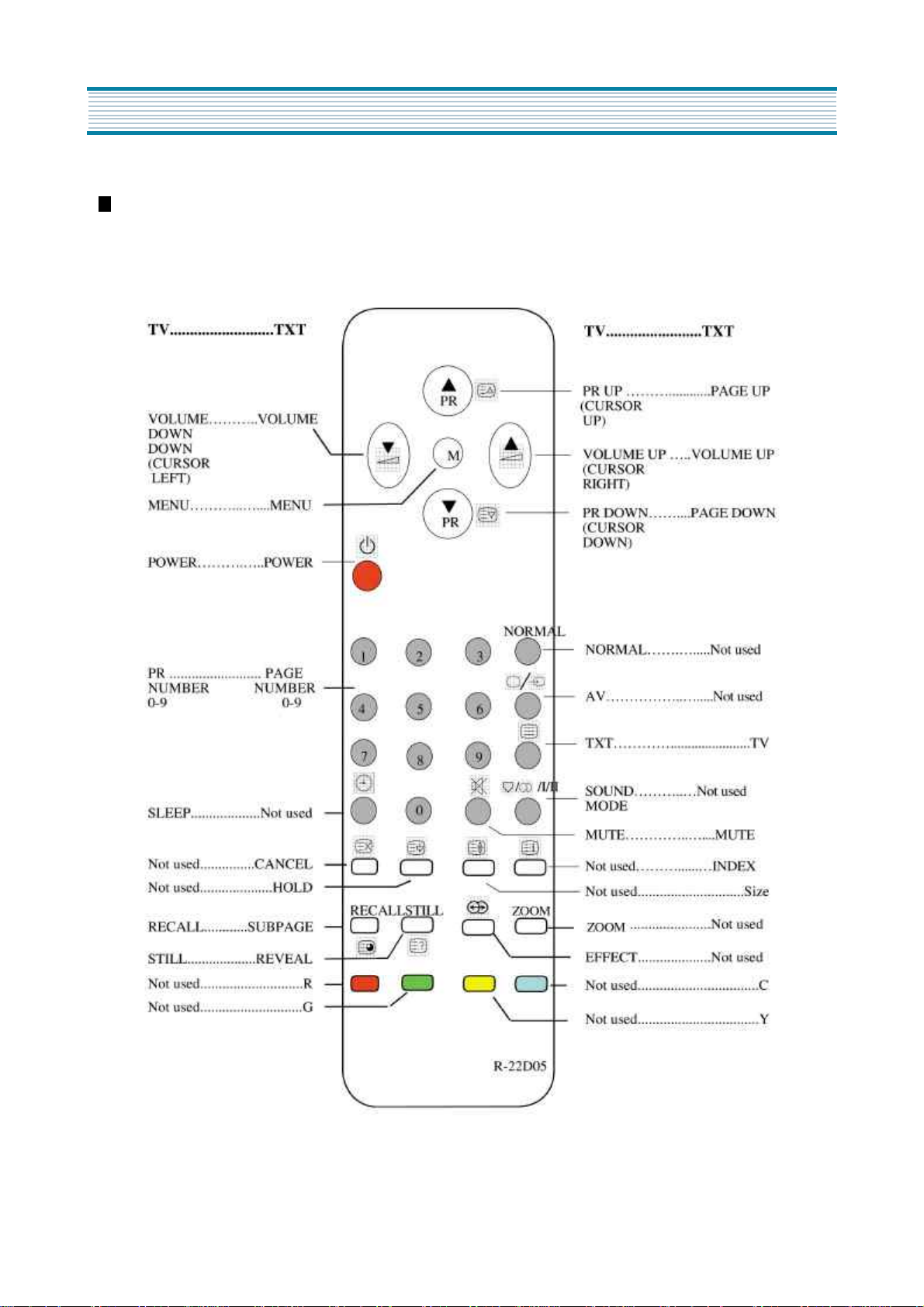

Remote controller R-22D05 with 2 "AAA" type batteries

Teletext TOP(5 Page memory) & FLOF(7 Page memory)

OSD language - West : English, German, French, Italian, Spanish, Nethelands, Swedish

21 pin EURO-SCART jack ( AV input, S-VHS input )

RCA type AV input jack

Headphone jack ( 3.5 mm )

JACK AUDIO TERMINAL (AUDIO OUT L, R)

- West option : English, German/Dutch/Flemish, French, Italian, Spanish/Portuguese,

Swedish/Finnish/Danish, Hungarian, Rumanian, Turkish

- East option : Polish, Czech/Slovak, Rumanian, Servo-croat, German/Dutch/Flemish,

French, Estonian, Lettish

- East : English, Russian, Polish, Rumanian, Czech, Hungarian

O

l

3

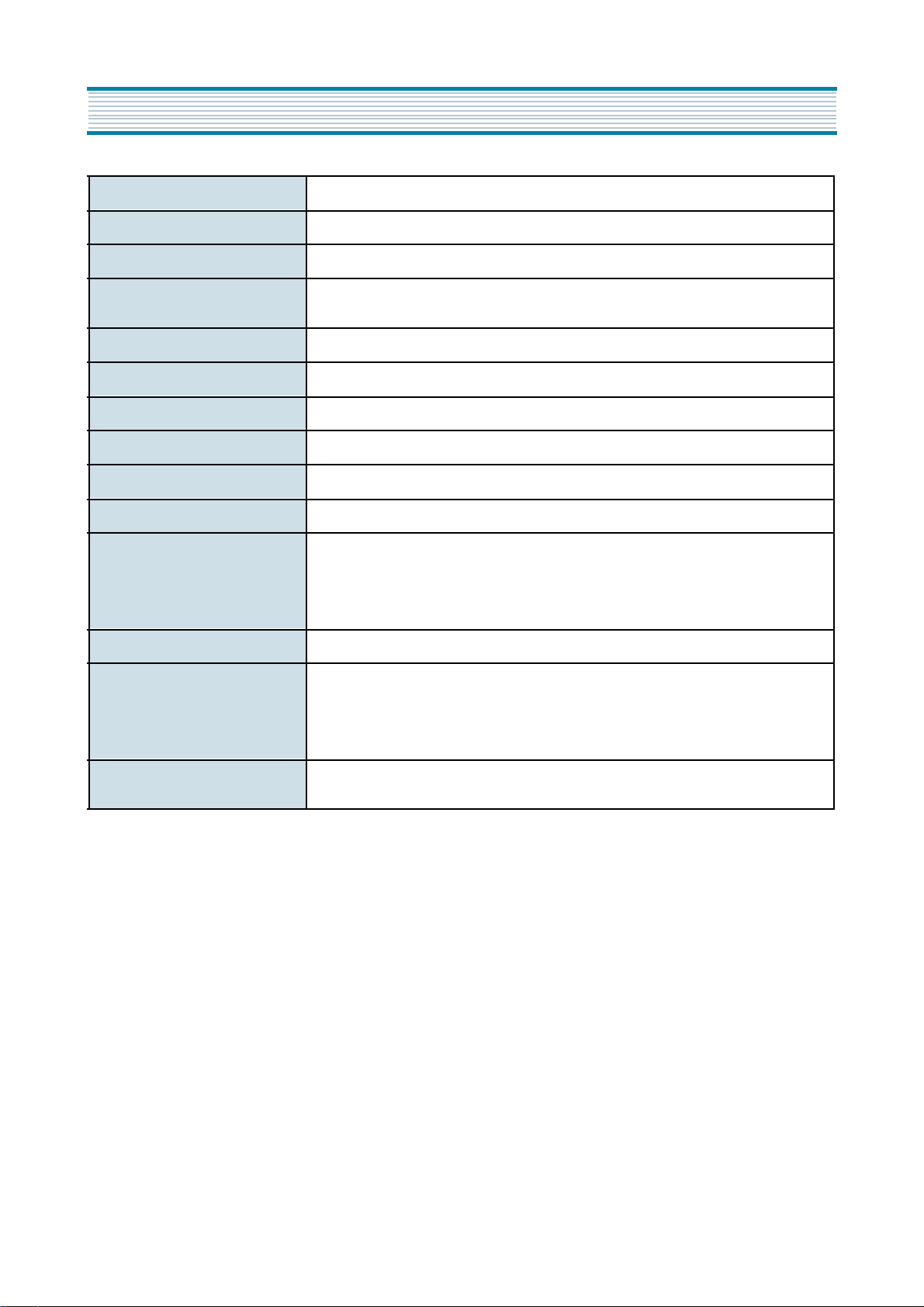

PIN Signal Designation Matching Value

Specifications

1 Audio Out (linked with 3)

2 Audio In (linked with 6)

3 Audio Out (linked with 1)

4 Audio Earth

5 Blue Earth

6 Audio in (linked with 2)

7 Blue in

8 Slow (Function) Switching

9 Green Earth

10 NC

11 Green In

12 NC

13 Red Earth

14 Rapid(Blanking) Switching Earth

15 Red In, C In

16 Rapid(Blanking) switching

0.5Vrms, Imp < 1 k • (RF 60% MOD)

0.5Vrms, Imp < 10 k

0.5Vrms, Imp < 1 k •(RF 60% MOD)

0.5Vrms, Imp < 10 k •(RF 60% MOD)

+

0.7Vpp 2dB, Imp 75

-

TV : 0-2V, PERI : 9.5 - 12V, Imp > 10 k

+

0.7Vpp 2dB, Imp 75

-

+

0.7Vpp 2dB, Imp 75

-

Logic 0 : 0 - 0.4V, Logic 1 : 1 - 3V, Imp 75

17 Video Earth

18 Rapid Blanking Earth

19 Video Out

20 Video In, Y In

21 Common Earth

+

1Vpp 2dB, Imp 75

-

+

1Vpp 2dB, Imp 75

-

4

3. Circuit Block Diagram

5

4. Alignment Instructions

4-1. User Remocon

R-22D05

6

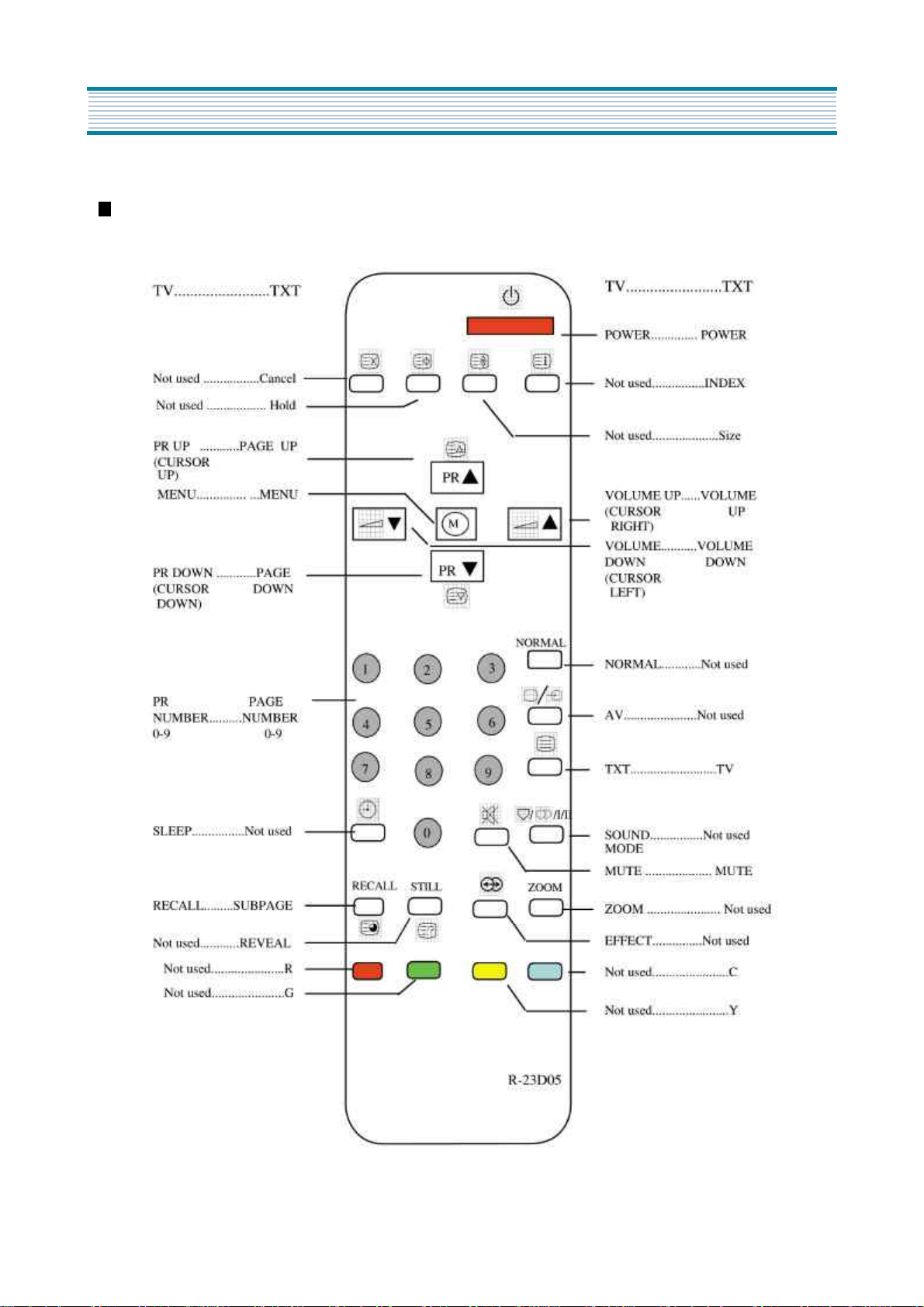

R-23D05

Alignment Instructions

7

Alignment Instructions

* How to Enter the "Service Mode" with user remocon.

1) Set the TV Pr 91

2) Sharpness " MIN " control.

3)Press the Red, Green, Menu buttons in regular sequency within 5 seconds after setting TV power off.

4) You can see the Menu of " Srvice Mode" on the screen.

5) The PR UP/DOWN buttons on the remote controller are used to move the selection bar up or down the Menus.

6) The VOL UP/DOWN buttons on the remote controller are used to adjust levels.

7) If you want to exit from " Service Mode" then power the TV off.

SVC v1

V. Slope

V. Center

V. Size

S. Curve

H. Center

H. Width

EW. Para

EW. Cor T

EW. CB

EW.Sym

R. bias

G. b

B. b

R. drive

G. d

B. d

G2

Sub Bri

DT

005

995

220

019

-190

510

382

028

500

021

370

311

311

330

315

330

330

021

048

- You can see the SVC Menu by OSD in TV set.

8

Alignment Instructions

4-2. AFT

Standard B/G, D/K, I and L

1) Set a Signal Generator with

- RF FREQUENCY = 38.9 MHz,

- RF OUTPUT LEVEL = 80 5dBuV

- Pattern = Color Bar

- System = PAL-B/G

2) Connect the Signal Generator RF Output to TP2 (Tuner IF Output).

There must be no signal input to the tuner.

3) Set the L109 to TP1(I101, #22) with DC Voltage to 2.5V 0.1V

+

-

+

-

4-3. AGC

1) Set a Pattern Generator with RF LEVEL 60 3dBuV, RF Frequency 210. 25MHz(10CH), Pattern Color Bar.

2) Connect a OSCILLOSCOPE PROBE to P101 (TUNER AGC INPUT).

3) Set the RBOI to P101(Tuner AGC Input) with DC Voltage to 2.8V 0.2V

+

-

+

-

4-4. SCREEN (G2)

1) Set a Pattern Generator with - RF Frequency : 210.25MHz (10CH)

- Pattern : RETMA

2) Select the “G2” in Menu

3) And a Horizontal Line will appear on the screen.

4) Adjust the SCREEN VOLUME on FBT barely to see the Horizontal Line.

5) Press the PR UP/DOWN keys to finish the SCREEN adjustment.

4-5. FOCUS

1) Apply a RETMA PATTERN signal.

2) Adjust the FOCUS VOLUME on FBT to obtain optimal resolution.

4-6. GEOMETRY

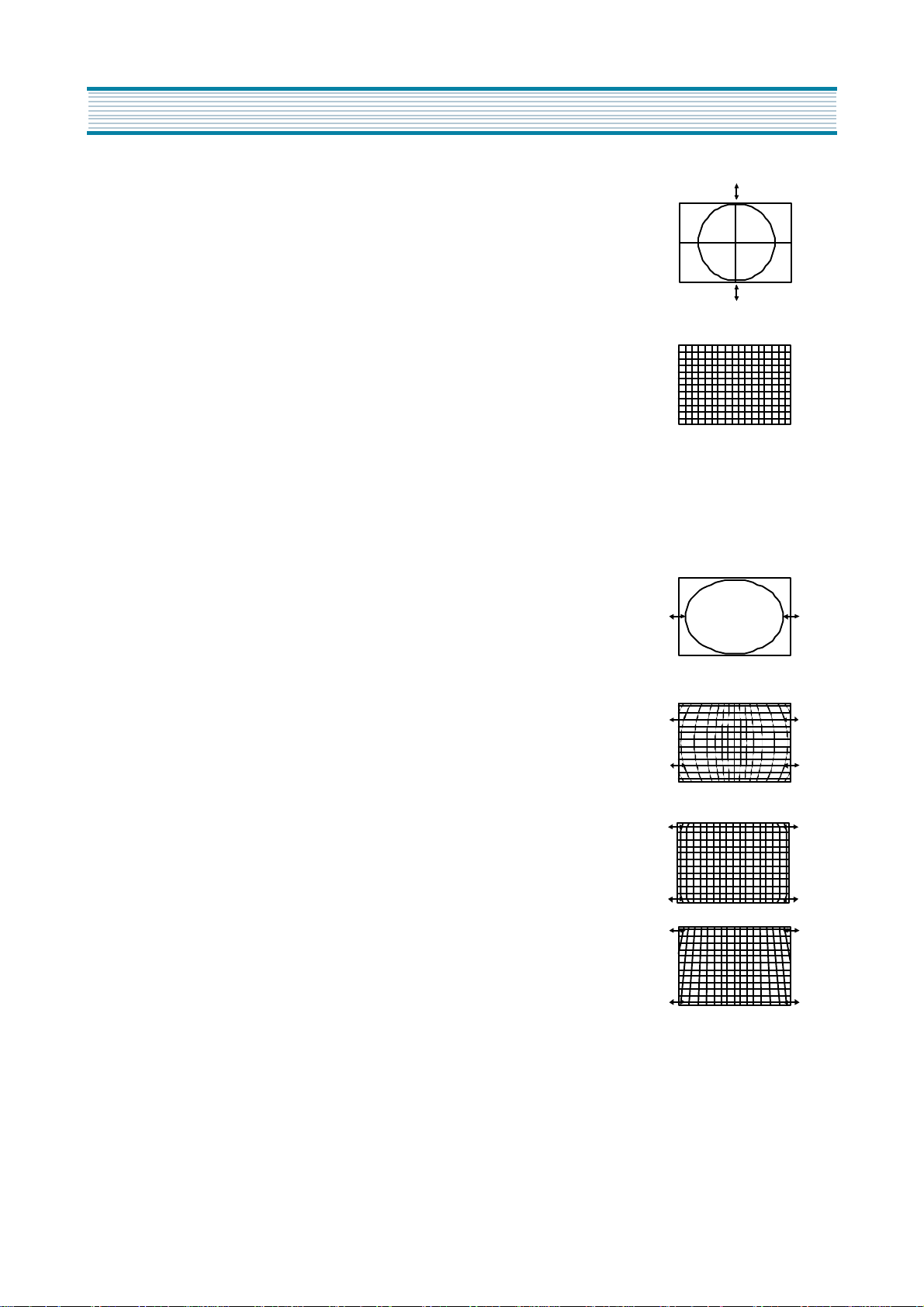

4-6-1 VERTICAL SLOPE ( Fixed : Adjust if need be )

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the higher semicircle and the lower semicircle to be the same, with the V.Slope by volume

Up/Down keys.

4-6-2 VERTICAL CENTER

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the center of the picture with the V.Center by volume Up/Down keys.

9

Alignment Instructions

4-6-3 VERTICAL SIZE

* The VERTICAL CENTER adjustment has to be done in advance.

1) Apply a RETMA PATTERN Signal.

2) Set the TV to Normal I mode.

3) Adjust the VERTICAL SIZE of the picture with the select V.size by

volume UP/DOWN keys.

4-6-4 VERTICAL S-CORRECTION ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the S-CORRECTION to obtain the same distance between

horizontal lines with the S.Curve by volume UP/DOWN keys.

4-6-5 HORIZONTAL CENTER

1) Apply a RETMA PATTERN Signal.

2) Adjust picture centering with the select H.Center by volume UP/DOWN keys.

4-7. EW

4-7-1 WIDTH

1) Apply a RETMA PATTERN Signal.

2) Adjust the horizontal width to make a perfect circle with the select H.Width

by volume UP/DOWN keys.

4-7-2 PARA

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the vertical line to straight with the select E.W Para by volume

UP/DOWN keys.

4-7-3 CORNER ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the vertical line to straight with the select EW.Cor T by volume

UP/DOWN keys.

4-7-4 SYMMETRY ( Fixed : Adjust if need be )

1) Apply a CROSSHATCH PATTERN Signal.

2) Adjust the symmetrical balance to be suitable with the select EW Sym by

volume UP/DOWN keys.

10

4-8. WHITE BALANCE

4-8-1 RGB Reference R

Alignment Instructions

4-8-2 Beam Reference LOW ( 288, 301 : 10Cd/ )

HIGH ( 288, 301 : 10Cd/ )

m

2

2

m

4-8-3 Adjust G, B Gain with select Menu G,B of BIAS, DRIVE of select Menu so that R, G, B Bars

are on the center position of the analog meter. If R Analog meter is not on center, control

the Brightness +/- of user Remocon so as R Analog meter to be on the center position.

4-9. SUB BRIGHT

4-9-1 Pattern : Retma

4-9-2 Adjust the SUB BRIGHT with the select Sub Bri by volume UP/DOWN keys.

so that only H-Center parts of picture can be seen.

4-10. DOUBLE TEXT CENTER

4-10-1 Pattern : Pattern RED

4-10-2 Select Menu

4-10-3 Select DT in SVC menu time to see the Double Text Picture.

( Left : RF Picture, Right : Text Picture )

4-10-4 Change the Double Text control keys volume UP/DOWN keys so that the left edge of text

picture concur with the right edge of RF picture.

11

5. IC description

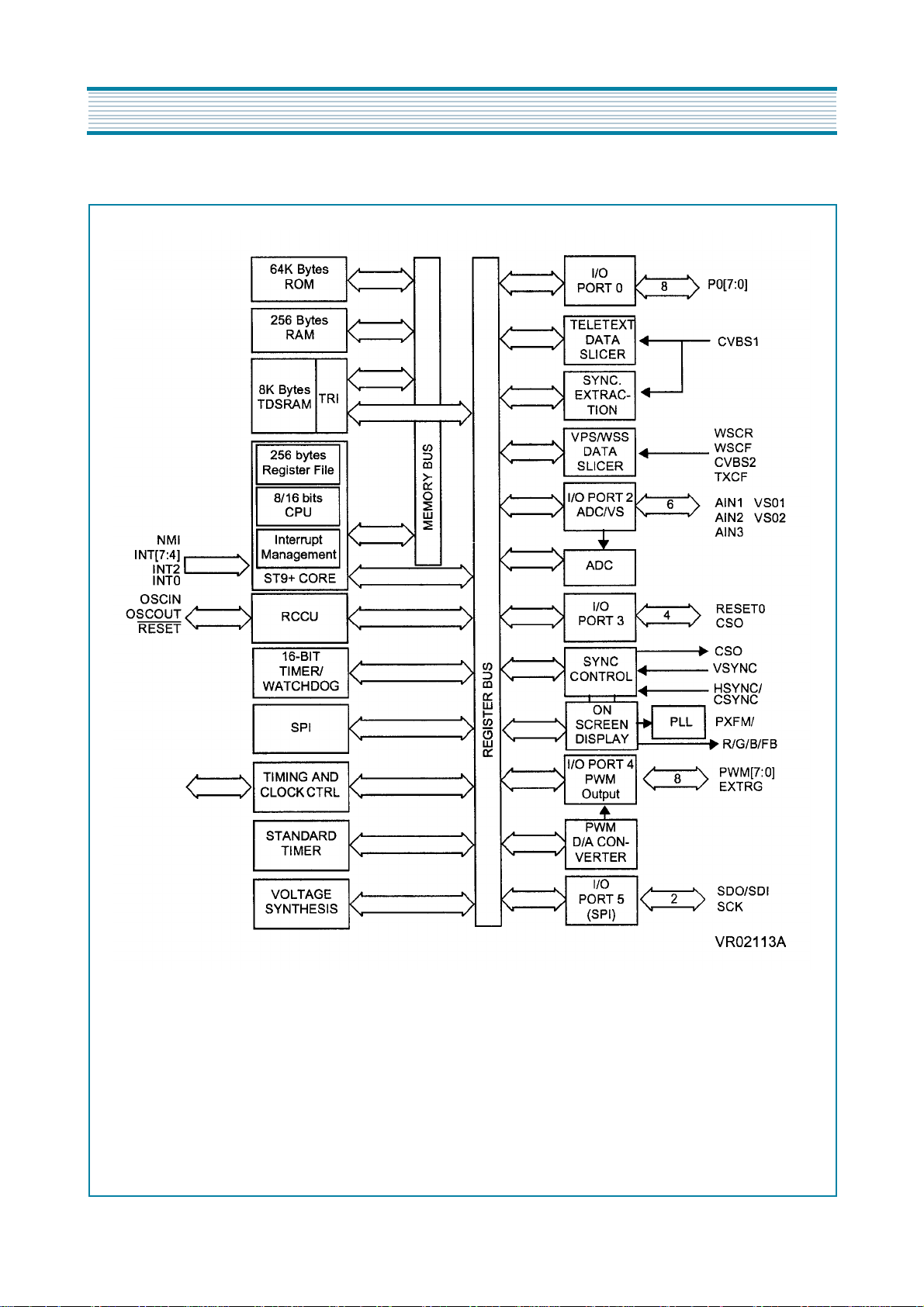

5-1. ST92195

(1) General Description

1.1 INTRODUCTION

The ST92195 microcnontoller is developed and manufactured by STMicroelecrtonics using a proprietary n-well

HCMOS process. Its performance derives from the use of

a flexible 256-register programming model for ultra-fast

context switching and real-time event response. The intelligent onchip peripherals offload the ST9 core from I/O

and data management processing tasks allowing critical

application tasks to get the maximum use off core

resources. The ST92195 MCU supports low power consumption and low voltage operation for power-efficient

and low-cost embedded systems.

1.1.1 ST9+Core

The advanced Core consists of the Central Processing

Unit (CPU), the Register File and the Interrupt controller.

The general-purpose registers can be used as accumulator, Index register, or address pointers. Adjacent register

pairs make up 16-bit registers for addressing or 16-bit

processing. Although the ST9 has an 8-bit ALU, the chip

handles 16-bit operations, including arithmetic, loads/

stores, and memory/register and memory/memory

exchanges. Two basic memory spaces are available :

Program Memory and the Register File, Which includes

the control and status registers of the on-chip peripherals.

1.1.2 Power Saving Modes

To optimize performance versus power consumption, a

range of operating modes can be dynamically selected.

Run Mode.

CPU and peripherals running at the maximum clock

speed delivered by the phase Locked Loop(PLL) of the

Clock Control Unit(CCU).

Wait For Interrupt Mode.

rupt(WFI) instruction suspends program execution until

an interrupt request is acknowledged. During WFI, the

CPU clock is halted while the peripheral and interrupt

controller keep running at a frequency programmable via

the CCU. In this mode, the power consumption of the

device can be reduced by more than 95%(LP WFI).

Wait For Interrupt Mode.

rupt(WFI) instruction, and if the Watchdog is not enable,

the CPU and its peripherals stop operation and the I/O

This is the full speed execution mode with

The Wait For Inter-

The Wait For Inter-

ports enter high impedance mode. A reset is necessary to

exit from Halt mode.

1.1.3 I/O Ports

Up to 28 I/O lines are dedicated to digital Input/Output.

These lines are grouped into up to five I/O Ports and can

be configureed on a bit basis under software control to provide timing, status signals, timer and output, analog inputs,

external interrupts and serial or parallel I/O.

1.1.4 TV Peripherals

A set of on-chip peripherals form a complete system for TV

set and VCR applications:

- Voltage Synthesis

- VPS/WSS Slicer

- Teletext Slicer

- Teletext Display RAM

- OSD

1.1.5 On Screen Display

The human interface is provided by the On Screen Display

module, this can produce up to 26 lines of up to 80 characters from a ROM defined 512 character set. The character

resolution is 10x10 dot. Four character sizes are supported. Serial attributes allow the user to select foreground

and background. Parallel attributes can be used to select

additional foreground and background colors and underline

on a character by character basis.

1.1.6 Teletext and Display RAM

The internal 8k Teletext and Display storage RAM can be

used to store Teletext pages as well as Display parameters.

1.1.7 Teletext, VPS and WSS Data Slicers

The three on-board data slicers using a single external

crystal are used to extract the Teletext, VPS and WSS

information from the video signal. Hardware Hamming

decoding is provided.

1.1.8 Voltage Synthesis Tuning Control

14-bit Voltage Synthesis using the PWM (Pulse Width

Modulation)/BRM (Bit Rate Modulation) technique can be

used to genetate tuning voltages for TV set applications.

The tuning voltage is output on one of two separate output

pins.

12

IC description

1.1.9 PWM Output

Control of TV settings is able to be made with up to eight

8-bit PWM outputs, with a frequency maximum of

lutions with higher frequency operation can be programmed.

1.1.10 Serial Peripheral Interface (SPI)

The SPI bus is used to communicate with external

devices via the SPI, or bus communication standards. The SPI uses one or two lines for serial data and a

synchronous clock signal.

2

I C

1.1.11 Standard Timer (STIM)

The Standard Timer includes a programmable 16-bit

down counter and an associated 8-bit prescaler with Single and Continuous counting modes.

1.1.12 Analog/Digital Converter (ADC)

In addition there is a 3 channel Analog to Digital Converter with integral sample and hold, fast 5.7us conver-

sion timer and 6-bit guaranteed resolution.

(2) Feature

Register File based 8/16 bit Core Architecture with

RUN, WFI, SLOW and HALT modes

to operating temperature range

0 CO70 C

Up to 24 MHz Operation @5V 10%

Minimum instruction cycle time : 375ns at 16MHz internal clock

64K Bytes ROM

256 Bytes RAM of Register file(accumulator or index

registers)

256 Bytes of on-chip static RAM

8K Bytes of TDSRAM(Teletext and Display RAM)

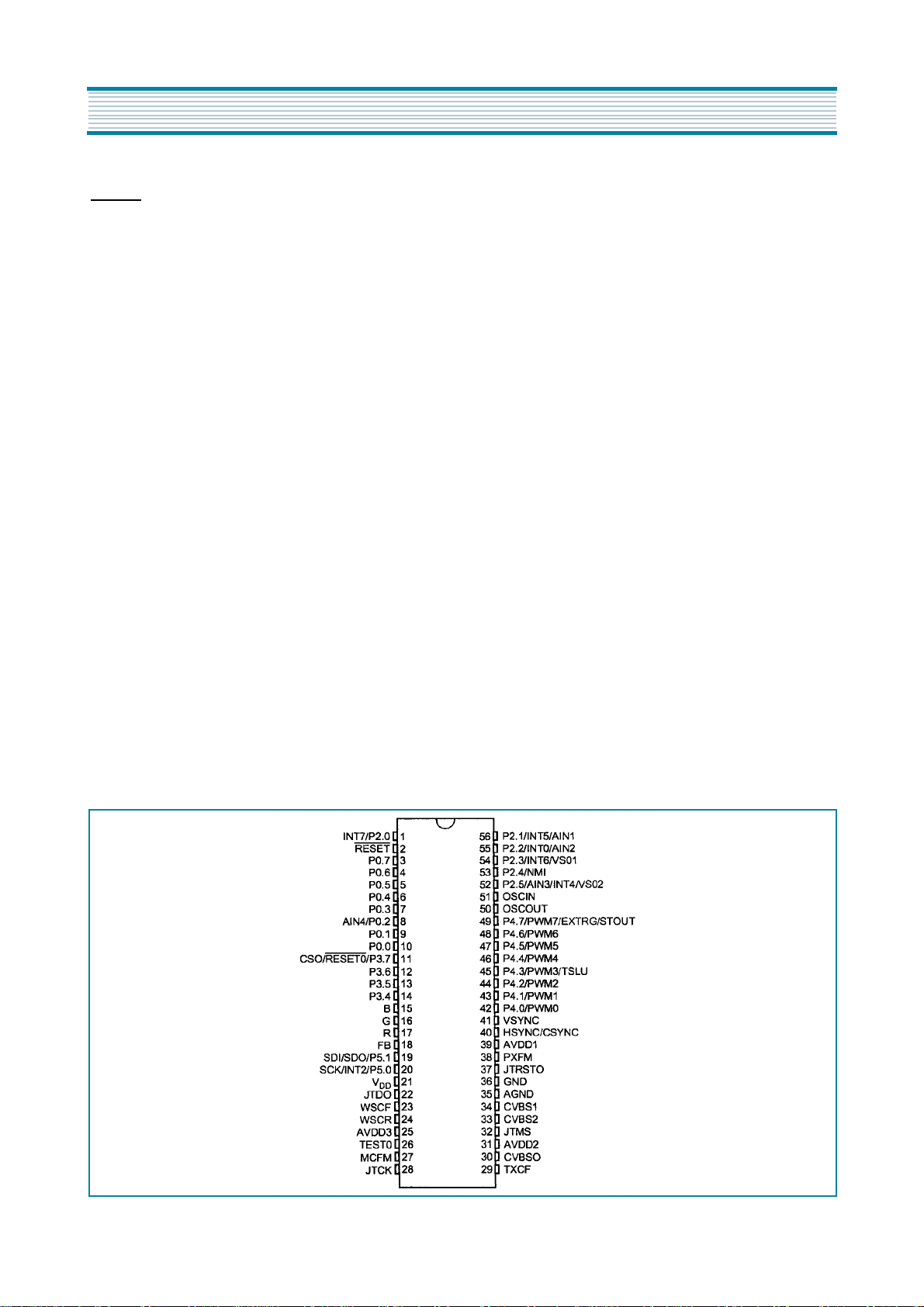

56-lead Shrink DIP package

28 fully programmable I/O pins

Serial Peripheral Interface

Flexible Clock controller for OSD, Data Slicer and Core

clocks running from one single low frequency external

crystal.

Enhanced Display Controller with 26 rows of 40/80

characters

- Serial and Parallel attributes

- 10x10 dot Matrix, 512 ROM characters, definable by

user

- 4/3 and 16/9 supported

O

+_

- Rounding, fringe, double width, double height,

scrolling, cursor, full background colour,

semitransparent mode and reduced intensity colour

supported

Teletext unit, including Data slicer, Acquisition Unit and

up to 8K Bytes RAM for Data Storage

VPS and Wode Screen Signalling slicer

Integrated Sync Extractor and Sync Controller

14-bit Voltage Synthesis for tuning reference voltage

Up to 6 external interrupts plus 1 non-maskable interrupt

8x8-bit programmable PWM outputs with 5V opendrain or push-pull capability

16-bit Watchdog timer with 8-bit prescale

16-bit standard timer with 8-bit prescaler usable as a

Watchdog timer

3-channel Analog-to-Digital converter ; 6-bit guaranteed

Rich instruction set and 14-Addressing modes

Versatile Development Tools, including Assembler,

Linker, C-compiler, Archiver, Source Level Debugger

and Hardware Emulators with Real-Time Operating

System available from third parties

Piggyback board available for prototyping

13

IC description

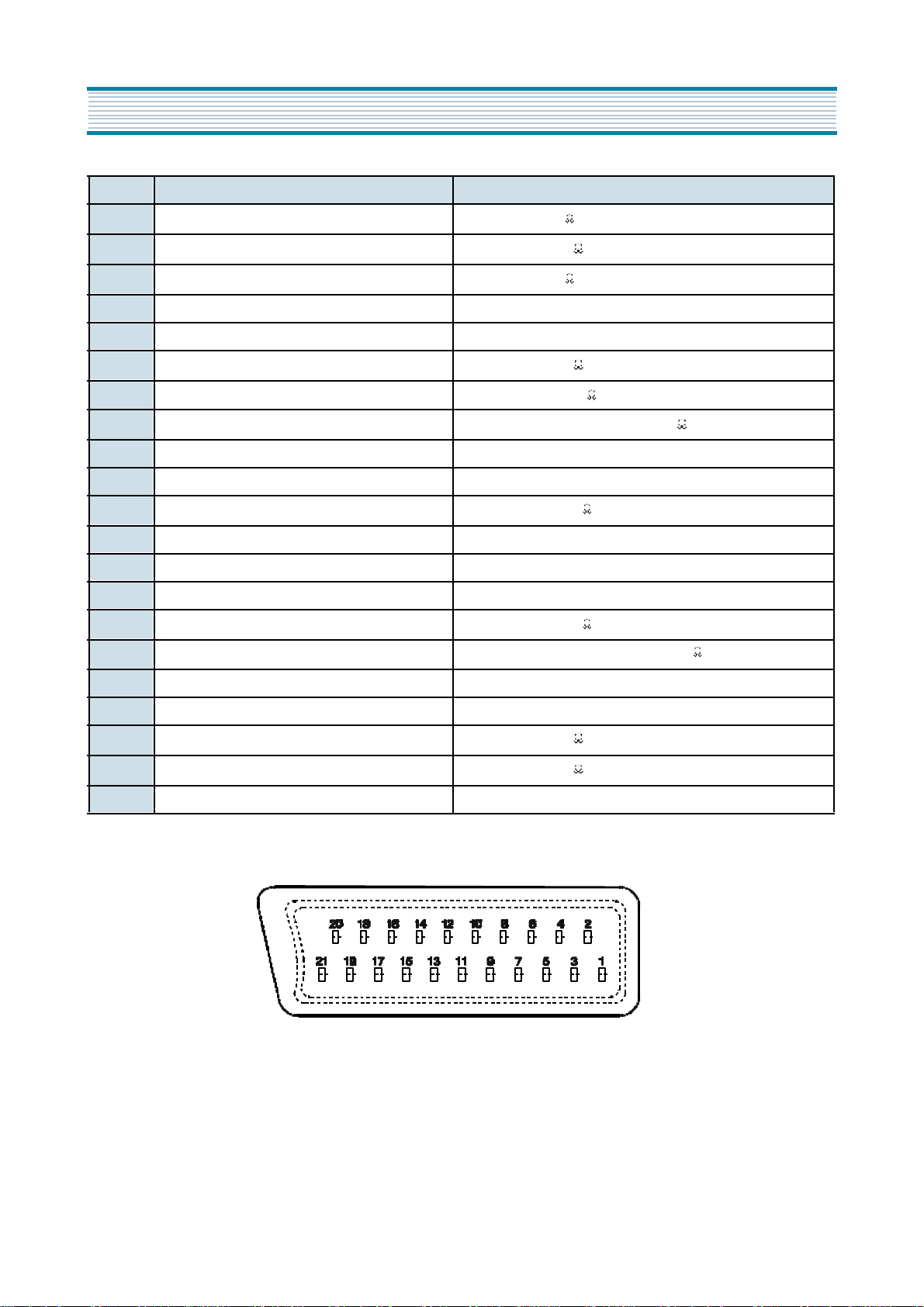

(3) Block Diagram

14

(4) PIN DESCRIPTION

IC description

RESET Reset(input, active low). The ST9+ is initialised

by the Reset signal. With the deactivation of RESET,

program execution begins from the Program memory

location pointed to by the vector contained in program

memory locations 00h and 01h.

R/G/B Red/Green/Blue.Video color analog DAC out-

puts

FB Fast Blanking. Video analog DAC output.

VOD Main power supply voltage(5V 10%, digital)

WSCF, WSCR Analog pins for the VPS/WPP slicer line

PLL.

MCFM Analog pin for the display pixel frequency multiplier.

OSCIN, OSCOUT Oscillator(input and output).

These pins connect a parallel-resonant crystal(24MHz

maximum), or an external source to the on-chip clock

oscillator and buffer. OSCIN is the input of the oscilltor

inverter and internal clock generator; OSCOUT is the

HYNC/CSYNC Horizontal/Composite sync. Horizontal

or composite video synchronisation input to OSD. Positive or negativety.

PXFM Analog pin for the Display Pixel Frequency Multiplier

AVDD Analog VDD of PLL. This pin must be tied to

VDD externally to the ST92195.

GND Digital circuit ground.

AGND Analog circuit ground(must be tied externally to

digital GND).

CVBS1 Composite video input signal for the Teletext

slicer and sync extraction.

CVBS2 Composite video input signal for the VPS/WSS

slicer. Pin AC coupled.

AVDD1, AVDD2 Analog power supplies(must be tied

externally to AVDD).

TXCF Analog pin for the VPS/WSS line PLL.

CVBSO, JTDO, JTCK Test pins : leave floating.

output of the oscillator inverter.

VSYNC Vertical Sync. Vertical video synchronisation

input to OSD. Positive or negative polarity.

Figure 2. Pin Description

JTMS, TEST0 Test pins : must be tied to AVDD2.

JTRST0 Test pin : must be tied to GND.

15

Loading...

Loading...