Page 1

DAEWOO CP-310

1

General Information

Also Covers:

DVT-1484D, DVT-2084D

Ferguson

FG 14 CB 12V, FG 20 CB 12V

Goodmans

TVC 1400 & TVC 14 VP

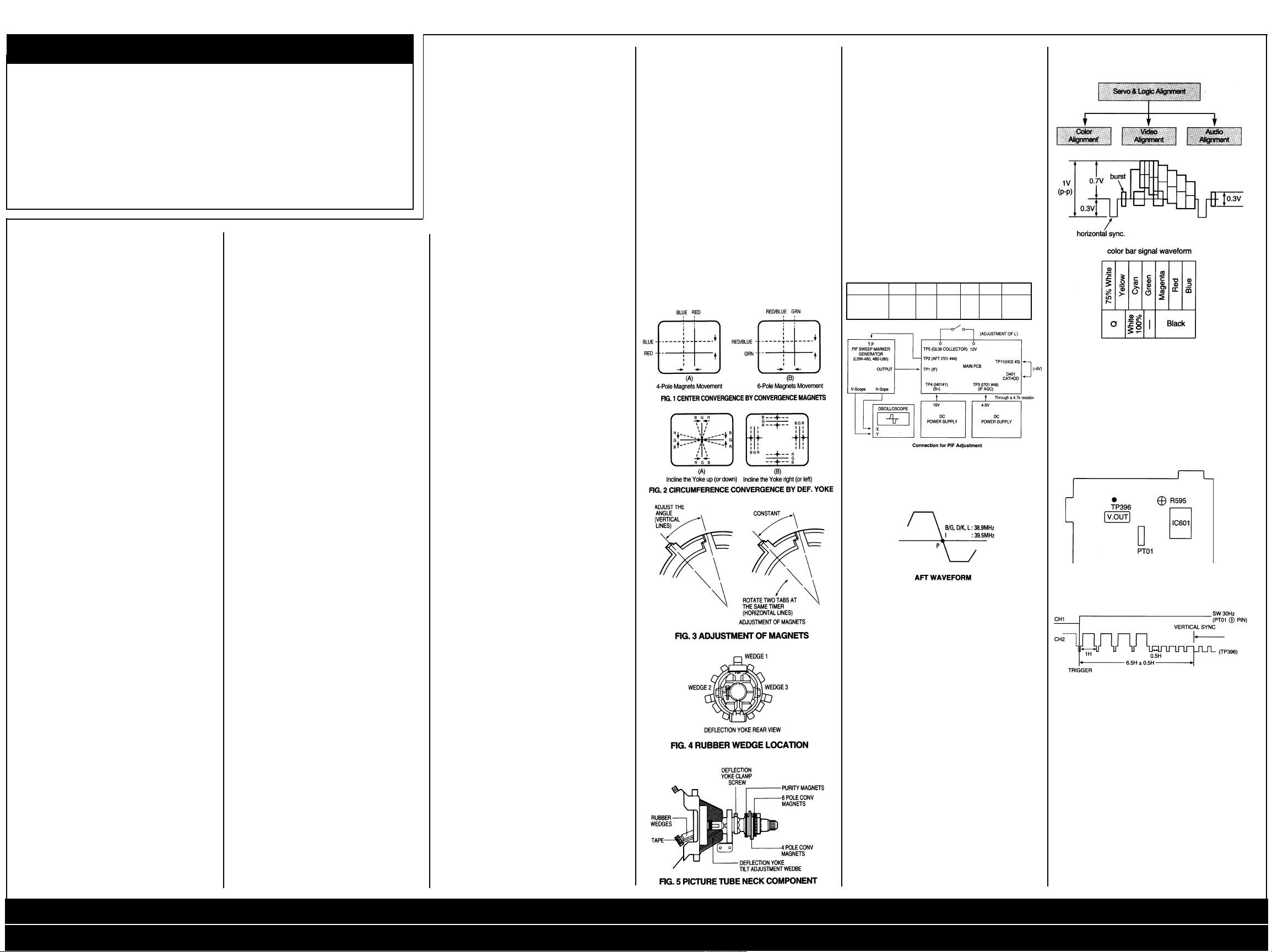

Electrical Adjustments (TV)

GENERAL INFORMATION

All adjustments are throughly checked and

corrected when the receiver leaves the factory.

Therefore the receiver should operate normally

and produce proper colour and B/W pictures

upon installation. But, several minor adjustments may be required depending on the

particular location in which the receiver is

operated. This receiver is shipped completely in

a card-board carton. Carefully draw out the

receiver from the carton and remove all packing

materials.

Plug the power cord into a AC power outlet.

Turn the receiver ON and adjust the FINE

TUNING for the best picture detail. Check and

adjust all the customer controls such as

BRIGHTNESS, CONTRAST and COLOUR

Controls to obtain a natural B/W picture.

PROTECTION CIRCUIT CHECK

1. Turn on the receiver.

2. The receiver must be turned off and changed

in stand-by mode.

HIGH VOLTAGE CHECK

1. Connect an accurate high voltage metre to

the anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS

and CONTRAST controls to minimize (zero

beam current).

3. High voltage should be below 27.5kv

(14:25.0kv, 21”: 29.0kv)

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture

tube so that external degaussing after moving

the receiver is normally unnecessary. Providing

the receiver is properly degaussed upon

installation. The degaussing coil operates for

about 1 second after the power of the receiver is

switched ON. If the set is moved or placed in a

different direction, the power switch must be

switched off for at least 15 minutes in order to

make the automatic degaussing circuit operate

properly.

Should the chassis or parts of the cabinet

become magnetized to cause poor colour purity,

use an external degaussing coil. Slowly move

the degaussing coil around the faceplate of the

picture tube, the sides and front of the receiver

and slowly withdraw the coil to a distance of

about 2m before disconnecting it from the AC

source.

If colour shading still persists, perform the

COLOUR PURITY ADJUSTMENT and CONVERGENCE ADJUSTMENTS procedures, as

mentioned later.

DYNAMIC CONVERGENCE ADJUSTMENT

Dynamic convergence (convergence of the

three colour field at the edges of the CRT

screen) is accomplished by proper insertion and

positioning of three rubber wedges between the

edges of the deflection yoke and the funnel of

the CRT. This is accomplished as follows:

1. Switch the receiver on allow it to warm up for

15 minutes.

2. Apply crosshatch pattern from dot/bar

generator to the receiver. Observe spacing

between lines around edges of the CRT

screen.

3. Tilt the deflection yoke up and down, and

insert tilt adjustment wedges 1 and 2 between

the deflection yoke and the CRT until the misconvergence illustrated in figure. 2 (A) has

been corrected.

4. Tilt the deflection yoke right and left, and

insert tilt adjustment wedge 3 between the

deflection yoke and the CRT until misconvergence illustrated in figure. 2 (B) has

been corrected.

5. Alternately change spacing between, and

depth of the insertion of, the three wedges

until proper dynamic convergence is obtained.

6. Use a strong adhesive tape to firmly secure

latch of the three rubber wedges to the funnel

of the CRT.

7. Check purity and readjust, if necessary.

STATIC (CENTRE) CONVERGENCE

ADJUSTMENT

1. Switch the receiver on and allow it to warm

up for 15 minutes.

2. Connect the output of a crosshatch generator

to the receiver and concentrating on the

centre of the CRT screen, proceed as follows:

a. Locate the pair of 4 pole magnet rings.

Rotate individual rings (Change spacing

between tabs) to converge the vertical red

and blue lines. Rotate the pair of rings

(maintaing spacing between tabs) to converge the horizontal red and blue lines. (Refer

to fig. 1 (A))

b. After completing red and blue centre conver-

gence, locate the pair of 6 pole magnet rings.

Rotage individual rings (change spacing

between tabs) to converge the vertical red

and blue (Magenta) and green lines. Rotate

the pair of rings (maintaining spacing

between tabs) to converge the horizontal red

and blue (Magenta) and green lines. (Refer to

Fig. 1(B))

COLOR PURITY ADJUSTMENT

For the best result, it is recommended that the

purity adjustment is made in final receiver

location. If the receiver will be moved, perform

adjustment with it’s facing east. The receiver

must have been operating 15 minutes prior to

this procedure and the faceplate of the CRT

must be at room temperature. The receiver is

equipped with an automatic degaussing circuit.

But, if the CRT shadow mask has come

excessively magnetized, it may be necessary to

degauss it with manual coil. Do not switch the

coil.

The following procedure is recommended while

using a dot generation.

1. Check for correct location of all neck components (See figure. 5).

2. Rough-in the static convergence at the centre

of the CRT, as explained in the static convergence procedure.

3. Rotate the picture control to centre of its

rotation range, and rotate brightness control

to max. CW position.

4. Apply green color signal to procedure a green

raster.

5. Loosen the deflection yoke tilt adjustment

wedges (3), loosen the deflection yoke clamp

screw and push the deflection yoke as close

as possible to the CRT screen.

6. Begin the following adjustment with the tabs

on the round purity magnet rings set together,

initially move the tabs on the round purity

magnet rings to the side of the CRT neck.

Then, slowly separate the two tabs while at

the same time rotating them to adjust for a

uniform green vertical band at the CRT

screen.

7. Carefully side the deflection yoke backward to

achieve green purity. (uniform green screen)

Centre purity was obtained by adjusting the

tabs on the round purity magnet rings, outer

edge purity was obtained by sliding the

deflection yoke forward. Tighten the deflection

yoke clamp screw.

8. Check for red and blue field purity by applying

red signal and touch up adjustments, if

required.

9. Perform black and white tracking procedure.

SCREEN & WHITE BALANCE ADJUSTMENT

1. This adjustment is to be made only after

warming up at least 15 minutes.

2. Receive B/W pattern signal

3. Set the RGB Bias VR (R522, R512, R502) to

center.

4. Set the G, B Drive VR (R515, R505) to

CENTER.

5. Set the CONTRAST, BRIGHTNESS, COLOR

control to MIN, and Sub-brightness control to

CENTER.

6. Rotate the R, G and B Bias VR of the other

color which did not appear on the screen

clockwise, until a dim white is obtained.

7. Rotate the Screen control gradually anticlockwise until the last horizontal line

disappears on the screen.

8. Set the CONTRAST, BRIGHTNESS, COLOR

control to MAX.

9. Set the G, B Drive VR to obtain the best white

uniformity on the screen.

10.Rotate the CONTRAST, BRIGHTNESS,

COLOR controls until a dim raster is obtained

and touch-up adjustment of RGB Bias VR to

obtain the best white uniformity on the screen.

SUB-BRIGHTNESS ADJUSTMENT

1. White balance adjustment must proceed this

procedure.

2. Set the CONTRAST, BRIGHTNESS, COLOR

control to MIN.

3. Rotate the SUB-BRIGHTNESS VR (VRAO1)

gradually CCW until the last beam disappears

on the screen.

VERTICAL HEIGHT ADJUSTMENT

1. Receive RETMA pattern signal.

2. Set the BRIGHTNESS control and CONTRAST control to Max., and the COLOR

control to centre.

3. Adjust VR301 for the optimum vertical height

and over scanning.

VERTICAL CENTER ADJUSTMENT

1. Receive RETMA pattern signal.

2. Adjust VR302 so that the vertical center of the

picture may be coincident with the mechanical

center of CRT.

HORIZONTAL CENTER ADJUSTMENT

1. Receive RETMA pattern signal.

2. Adjust VR401 so that the horizontal centre of

the picture may be coincident with the

mechanical centre of CRT.

FOCUS VOLTAGE ADJUSTMENT

1. Receive RETMA pattern signal.

2. Adjust the FOCUS VOLUME on the FBT and

make the picture on the screen be finest.

RF AGC ADJUSTMENT

1. Receive PAL COLOR BAR signal in the VHF

high band where the strength of signal can be

60-65 dB.

2. Set the CONTRAST control to Max., the

BRIGHTNESS control to provide adequate

black and grey scales.

3. Maintain the fine tuning on the screen, and

adjust VR601 (AGC DELAY CONTROL VR.)

in order that it may be located on the position

which the picture noise disappear on the

image.

MAIN B+ (+103V) ADJUSTMENT

1. Set the Bright, Contrast and colour to MAX.

2. Connect DC voltage meter to the P405 and

adjust VR801 for +103V DC.

PIF ADJUSTMENT

1. APPARATUS CONNECTION &

PRESETTING

CONNECTION

1. Connect H-out of LSW-480 to X-axis of the

oscilloscope and V-out of LSW-480 to Y-axis

of the oscilloscope.

2. Connect the sweep signal output to TP1.

3. Set ATTENUATOR of LSW-480 to 30dB.

4. Supply 12V D.C. voltage (B+) to TP4.

5. Supply 4-5V D.C. voltage to TP3.

PRESET

1) Oscilloscope Scaling

a) Put the scale of X and Y of the oscilloscope

to D.C level.

b) Set the horizontal time display to X-Y

c) Put the horizontal axis (X) to 1V/div. and the

vertical axis (Y) to 2V/div.

2) LSW-480 MARKER FREQ. SETTING.

fp(n+1) fs fc fp-2 fp fs(n-1)

B/G, D/K, L 31.9 33.4 34.5 36.9 38.9 40.4

31.9 33.5 35.07 37.5 39.5 41

II. ADJUSTMENT OF AFT(B/G, D/K, I, L)

1. Connect the test point of LSW-480 to TP2.

2. Adjust L103 (AFT COIL) so that the P marker

point is located on the reference level.

Electrical Adjustments (VCR)

ALIGNMENT AND ELECTRICAL ADJUSTMENT

For these adjustment, use the equipment

mentioned below The suitable output waveform

of the color-bar singal and proceed by using the

alignment tape and video signal. generator is

shown below.

Instrument and Tools Required

1. Color TV receiver.

2. Oscilloscope having 10 MHz or more

bandwidth.

3. Color-bar generator.

4. Frequency counter.

5. VTVM.

6. VOM (20 kµ/V).

7. Audio oscillator.

8. Audio attenuator.

Signal Level and Input and Output Impedance

Requirement

1. Video input: Negative sync, 1 Vp-p standard

composite video signal, 75Ω.

2. Video output: Same as above.

3. Audio input: Line -5dBm 47KΩ.

4. Audio output: -5dBm, 10KΩ. or less.

Adjustment Sequence

The VCR should be adjusted in the sequence

shown below.

SERVO

1. PLAYBACK PHASE

Mode Play

Adjustment Parts R595

Check Point TP396

Test Equipments Oscilloscope

Test T ape DP-1

Location of Adjustments Parts

MAIN PCB

Observation Waveform

Horizontal Axis: S/DIV

Vertical Axis: CH1: SW30, CH2: V.OUT

Adjustment Procedure

1. Preparation

1) Play back on test tape (COLOR BAR).

2) Set the oscilloscope to the CHOP mode.

Connect CH1 to the SW PULSE (PT01 (3))

and CH2 to the VIDEO OUT (TP396) and

trigger the scope with the signal from CHi.

2. Adjustment

1) Adjust R595 to position the rising edge of SW

PULSE at 6.5H±0.5H from the V-SYNC.

VIDEO

1. EE LEVEL ADJUSTMENT

Mode EE (Stop)

Adjustment Parts R395

Check Point TP395

Test Equipments Oscilloscope Signal gen.

Input Signal Color bar signal with

100% white

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 2

2DAEWOO CP-310

Electrical Adjustments

(VCR) Cont’d

Location of Adjustments Parts

Main PCB

Observation Waveform

Horizontal Axis: 10µS/DIV

Vertical Axis: 0.1 V/DIV

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the COLOR BAR signal with 100%

white to the VIDEO IN JACK.

2. Adjustment

1) Set the VCR to STOP (FE) mode.

2) Connect the oscilloscope to TP395 and

trigger the scope externally with the composite synchronous signal from TP31 3.

3) Adjust R395 to obtain 0.5±0.01 Vp-p between

the SYNC TIP and 100% white level.

2. PLAYBACK OUTPUT LEVEL

Mode PLAY

Adjustment Parts R396

Check Point TP396

Test Equipments Oscilloscope

Test T ape DP-1

Location of Adjustments Parts

Main PCB

Adjustment Procedure

1. Preparation

1) Set the SYSTEM SELECT SWITCH to the

AUTO MODE.

2) Play back the test tape (COLOR BAR).

2. Adjustment

1) Connect the oscilliscope to TP396 and trigger

the scope externally with the C.SYNC signal

from TP313.

2) Adjust R396 to obtain 2.0±0.1 Vp-p between

the SYNC TIP and 100% white level.

3. SYNC TIP FREQUENCY

Mode (STOP)

Adjustment Parts R391, R393

Check Point TP391

Test Equipments Frequency counter

Input Signal No signal

Location of Adjustments Parts

Main PCB

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the input signal in the OPEN state.

2. Adjustment

1) Set the VCR to the FE (STOP) mode.

2) Connect the frequency counter to TP391.

3) Set the SYSTEM SELECT SWITCH to the

PAL mode.

4) Adjust R393 to obtain 3.8 ±0.1 Mhz.

4. FM DEVIATION

Mode REC PLAY

Adjustment Parts R392

Check Point TP396

Test Equipments Oscilloscope

Input Signal Color bar with

100% white

Location of Adjustments Parts

Main PCB

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the COLOR BAR signal to the VIDEO

IN JACK.

2) Connect the oscilloscope to TP396 (VOUT)

and trigger the scope externally with the

C.SYNC signal from TP31 3.

3) Record the signal for about 10 seconds in SP

mode and play back the signal just recorded.

Confirm the playback output level is

2.0±0.2Vp-p.

2. Adjustment

If the playback output level is not 2.0±0.2Vp-p,

adjust as follows.

1) Adjust R392 a little.

2) Record the Color bar signal for about 10

seconds and play back the signal just

recorded.

3) Confirm the playback output level.

4) Repeat the procedure 1) to 4) until the

playback output level becomes 2.0±0.2Vp-p

between the SYNC TIP and 100% white peak.

5. C RECORD CURRENT

Mode EE

Adjustment Parts R399 & R491

Check Point TP399

Test Equipments Oscilloscope

Test Tape Blank T ape

Input Signal Color Bar

Location of Adjustments Parts

Main PCB

Observation Waveform

Horizontal Axis: 10µS/DIV

Vertical Axis: 20 mV/DIV

Test T ape Blank Tape

Input Signal Color Bar

Location of Adjustments Parts

Main PCB

Observation Waveform

Horizontal Axis: 10µS/DIV

Vertical Axis:50 mV/DIV

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the COLOR BAR signal to the VIDEO

IN JACK.

2. Adjustment

1) Set the VCR to the EE mode.

2) Trigger the scope externally with the C.SYNC

signal from TP31 3.

3) Connect the oscilloscope to TP399.

Adjust R399 until Y-FM record current

becomes 300±10 mVp-p.

AUDIO

1. AUDIO PLAYBACK OUTPUT LEVEL

Mode Play

Adjustment Parts R291

Check Point Audio Output

Test Equipments Audio Level Meter

Test T ape DP-1

Location of Adjustments Parts

Main PCB

Location of Adjustments Parts

Main PCB

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the signal in OPEN mode.

3) Connect the AUDIO level meter to both

TP201 and TP202.

4) After inserting a blank tape, record in SP

mode.

2. Adjustment

1) Adjust R292 to obtain 2.4mVrms.

3. Adjustment Inspection Standard

In comfirmation of recording playback

frequency characteristics, compared with 1

KHz recording-playback output level, (8KHz)

recording-playback output level is higher than

the standard, increase the record bias and if

lower, decrease it.

End

Observation Waveform

Horizontal Axis: S/DIV

Vertical Axis: 0.5 V/DIV

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Observation Waveform

Horizontal Axis: 10µS/DIV

Vertical Axis: 0.5V/DIV

Adjustment Procedure

1. Preparation

1) Set the LINE mode.

2) Supply the COLOR BAR signal to the VIDEO

IN JACK.

2. Adjustment

1) Set the VCR to FE mode.

2) Connect the oscilloscope to TP399.

Adjust R399 until Y-FM record current

becomes minimum.

3) Trigger the scope externally with the C.SYNC

signal from TP313.

4) Adjust R491 until Color record current

becomes 80±5 mVp-p.

6. Y RECORD CURRENT

Mode FE

Adjustment Parts R399

Check Point TP399

Test Equipments Oscilloscope

Adjustment Procedure

1. Preparation

1) Connect the AUDIO level meter to the AUDIO

OUTPUT JACK.

2) Play back the test tape (DP-1).

2. Adjustment

1) Adjust R291 until the output level becomes

-5 ±1.5dBm.

2. AUDIO RECORD BIAS

Mode REC

Adjustment Parts R292

Check Point TP201, TP202

Test Equipments Audio Level Meter

Test T ape Blank Tape

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 3

DAEWOO CP-310

Video

Diagram

3

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 4

Audio Diagram

4DAEWOO CP-310

Remote

Control

Diagram

Head Amp

Diagram

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 5

DAEWOO CP-310

5

Connection Diagram

(DVT-1484)

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 6

6DAEWOO CP-310

Connection Diagram

(DVT-2084)

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 7

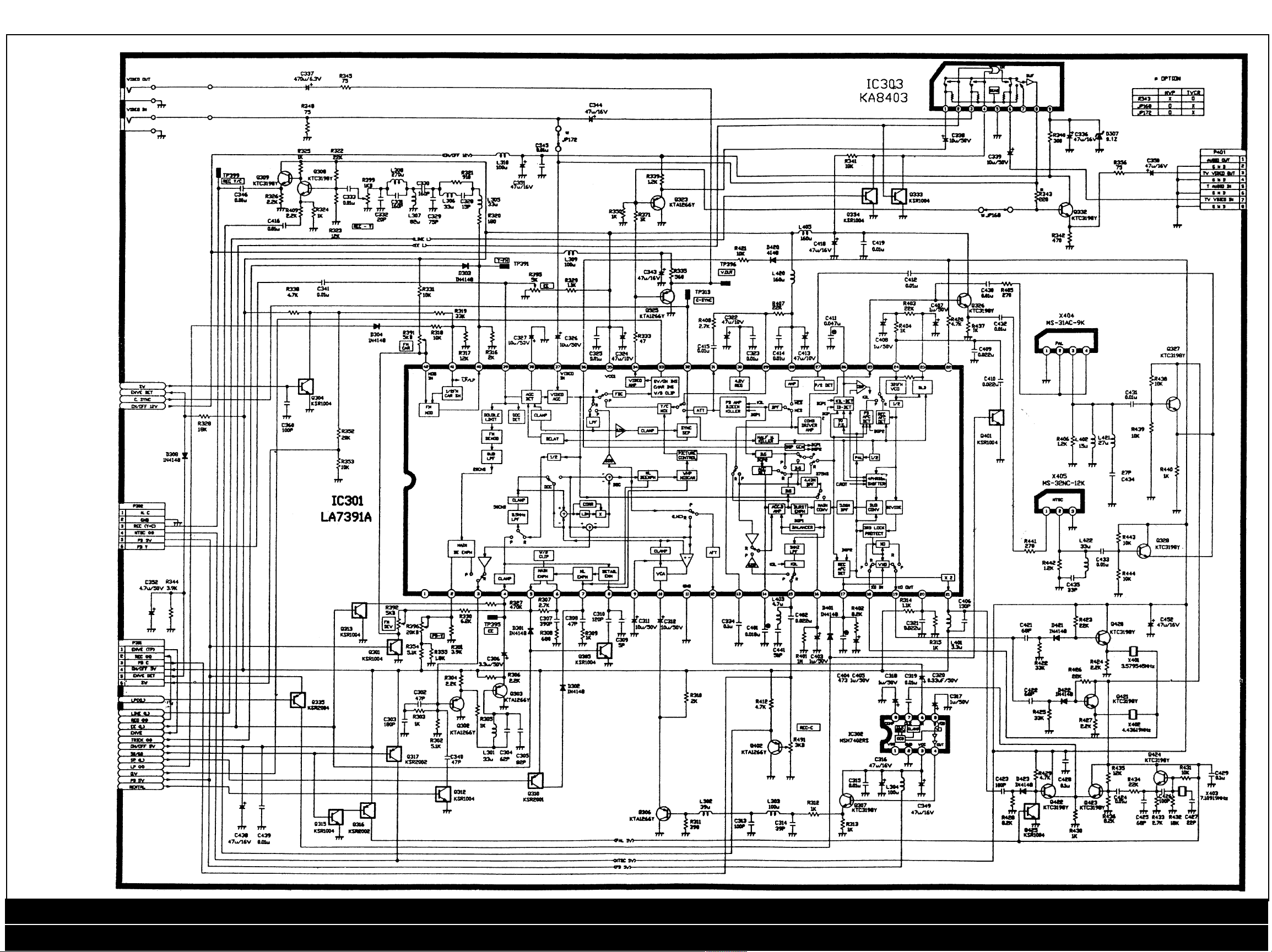

DAEWOO CP-310

Main

Diagram

(TV)

7

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 8

8DAEWOO CP-310

Power Servo Syscon Diagram (DVT 1484P)

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Page 9

DAEWOO CP-310

9

Power Servo Syscon Diagram (DVT 2084P)

Electrical Adjustments (TV) (VCR) / Electrical Adjustments (VCR) Cont’d / Head Amp Diagram / Audio Diagram / Remote Control / Video Diagram

Connection Diagrams (DVT-1484) (DVT-2084) / Main Diagram (TV) / Power Servo Syscon Diagrams (DVT 1484P) (DVT 2084P)

Loading...

Loading...