Page 1

Installation Instructions

Remote Blowers

READ AND SAVE THESE INSTRUCTIONS

TESTED IN ACCORDANCE WITH THE LATEST EDITION OF ANSI/UL507, STANDARD FOR ELECTRIC FANS, AND

CSA C22.2 NO. 113, STANDARD FOR FANS AND VENTILATORS.

CONVENTIONS USED IN THESE INSTRUCTIONS

WARNINGS:

Must be followed carefully to avoid personal injury or damage.

NOTES:

Contain helpful hints and tips to facilitate the installation.

IMPORTANT

1. Before beginning installation, please thoroughly read and become familiar with these instructions.

2. Installation and service must be completed by a qualified installer or service agency.

3. Installer: Please leave these Installation Instructions with the owner.

4. Owner: Please keep these instructions for local electrical inspector’s use and for future reference.

5. Read the accompanying Use & Care Manual prior to operating this appliance.

TABLE OF STEPS

Installation Planning Pages 2-3

Electrical Connection Pages 3-5

Installing the ILB Page 6

Installing the REMP Page 6

Verifying Proper Operation Page 6

Part No. 65265 Rev. D

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE

FOLLOWING:

a) Installation work and

electrical wiring must be

done by qualified person(s)

in accordance with all

applicable codes and

standards, including fire-rated

construction.

b) Sufficient air is needed

for proper combustion

and exhausting of gases

through the flue (chimney)

of fuel burning equipment

to prevent back drafting.

Follow the heating equipment

manufacturer’s guidelines

and safety standards such

as those published by the

National Fire Protection

Association (NFPA), and

the American Society for

Heating, Refrigeration and

Air Conditioning Engineers

(ASHRAE), and the local code

authorities.

c) When cutting or drilling into

wall or ceiling, do not damage

electrical wiring and other

hidden utilities.

d) Ducted fans must always be

vented outdoors.

e) Use this unit only in the

manner intended by the

manufacturer. If you have

questions, contact the

manufacturer.

f) Before servicing or cleaning

unit, switch power off at

service panel and lock

the service disconnecting

means to prevent power

from being switched on

accidentally. When the service

disconnecting means cannot

be locked, securely fasten a

prominent warning device,

such as a tag, to the service

panel.

g) Blower must not be installed

in a ceiling thermally insulated

to a value greater than R40.

h) Blower must not be installed

in furnace ductwork.

1

WARNING:

TO REDUCE THE RISK OF FIRE,

USE ONLY METAL DUCTWORK.

WARNING:

TO REDUCE THE RISK OF A

RANGE TOP GREASE FIRE:

a) Never leave surface units

unattended at high settings.

Boilovers cause smoking and

greasy spillovers that may

ignite. Heat oils slowly on low

or medium settings.

b) Always turn hood ON when

cooking at high heat or when

flambeing food (i.e. Crepes

Suzette, Cherries Jubilee,

Peppercorn Beef Flambe’).

c) Clean ventilating fans

frequently. Grease should not

be allowed to accumulate on

fan or filter.

d) Use proper pan size. Always

use cookware appropriate

for the size of the surface

element.

WARNING:

TO REDUCE THE RISK OF INJURY

TO PERSONS IN THE EVENT OF

A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

a) SMOTHER FLAMES with a

close-fitting lid, cookie sheet,

or metal tray, then turn off

the burner. BE CAREFUL

TO PREVENT BURNS. If

the flames do not go out

immediately, EVACUATE

AND CALL THE FIRE

DEPARTMENT.

b) NEVER PICK UP A FLAMING

PAN - You may be burned.

c) DO NOT USE WATER,

including wet dishcloths

or towels - a violent steam

explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a Class

ABC extinguisher, and

you already know how to

operate it.

2) The fire is small and

contained in the area where

it started.

3) The fire department is being

called.

4) You can fight the fire with

your back to an exit.

CAUTION:

For General Ventilating Use Only.

Do Not Use To Exhaust Hazardous

Or Explosive Materials And

Vapors.

CAUTION:

To reduce risk of fire and to

properly exhaust air, be sure to

duct air outside – Do not vent

exhaust air into spaces within

walls or ceilings or into attics,

crawl spaces or garages.

NOTES:

1. Consult a licensed ventilation

contractor or qualified

technician for proper

installation of exhaust

ducting.

2. Locate the cooking area for

minimum cross drafts – away

from doors and windows,

when possible.

3. Ducts must be of adequate

size and duct runs should

be as short and straight as

possible. Where turns are

necessary, keep turning

radius as large and smooth as

possible.

4. The ducting must be air tight.

Use a minimum of 2 sheet

metal screws at every duct

joint. Then, seal the duct joints

with a high quality duct tape.

5. In duct runs less than 10

equivalent straight feet, the

remote blower may interfere

with the cooktop burner

performance due to the

high volume of air moved.

An adjustable damper (not

included) should be installed

in the ducting system. The

damper can be adjusted so

that proper ventilation and

cooktop burner performance

is achieved.

6. Installation of duct work

should be carefully planned

if it is to go under a concrete

slab floor. The duct trench

should be boxed to prevent

collapse from the wet cement.

Be sure to allow room to

run the electrical wiring and

conduit.

Page 3

Installation Planning

"A"

"B"

Attachment

Surface

ROTATION

AIRFLOW

120V, 60Hz, 15A POWER SUPPLY

CAUTION: DISCONNECT POWER SUPPLY AT THE FUSE BOX BEFORE SERVICING THIS EQUIPMENT

FAN MOTOR

GR

N

DACOR P/N 85829

WIRING DIAGRAM, ILB-8

M

BK

L

"C"

"D"

Attachment

Surface

Electrical

Access Panel

17 1/8" (435mm)

19" (483mm)

24 1/16"

(611mm)

3 5/8"

(92mm)

9 1/4"

(235mm)

Mounting

Flange

25 1/2"

(648mm)

7 1/2"

(191mm)

9 1/2" (241mm)

Discharge

Cutout

Location

Intake Collar

Power Supply

Conduit

Location

C

L

C

L

CLC

L

5 13/16"

(148mm)

8"

(203mm)

7 13/16"

(198mm)

Discharge

Intake Collar

24" (610mm)

26" (660mm)

31 1/2"

(800mm)

3 1/2"

(89mm)

12 1/4"

(311mm)

Mounting

Flange

33 1/2"

(851mm)

9 1/2"

(241mm)

12 11/16" (322mm)

Discharge

Cutout

Location

Intake Collar

Power Supply

Conduit

Location

C

L

C

L

CLC

L

9 9/16"

(243mm)

10"

(254mm)

11 1/2"

(292mm)

Discharge

Intake Collar

A qualified technician must complete the

installation of this appliance.

Carefully check the location where the remote

blower is to be installed. The remote blower

should be placed for convenient access. Make

certain that electrical power can be provided in

the selected location.

Plan the installation so that all minimum

clearances are met or exceeded. Dimensions

shown provide minimum clearances, unless

otherwise noted.

NOTES:

1. All dimensional tolerances are

+ 1/16”, - 0” unless otherwise

stated.

2. Before commencing

installation, remove the top

cover of the remote blower

(REMP ONLY). Check to see

if the blower wheel turns

freely. Do not replace the top

cover until the installation is

complete.

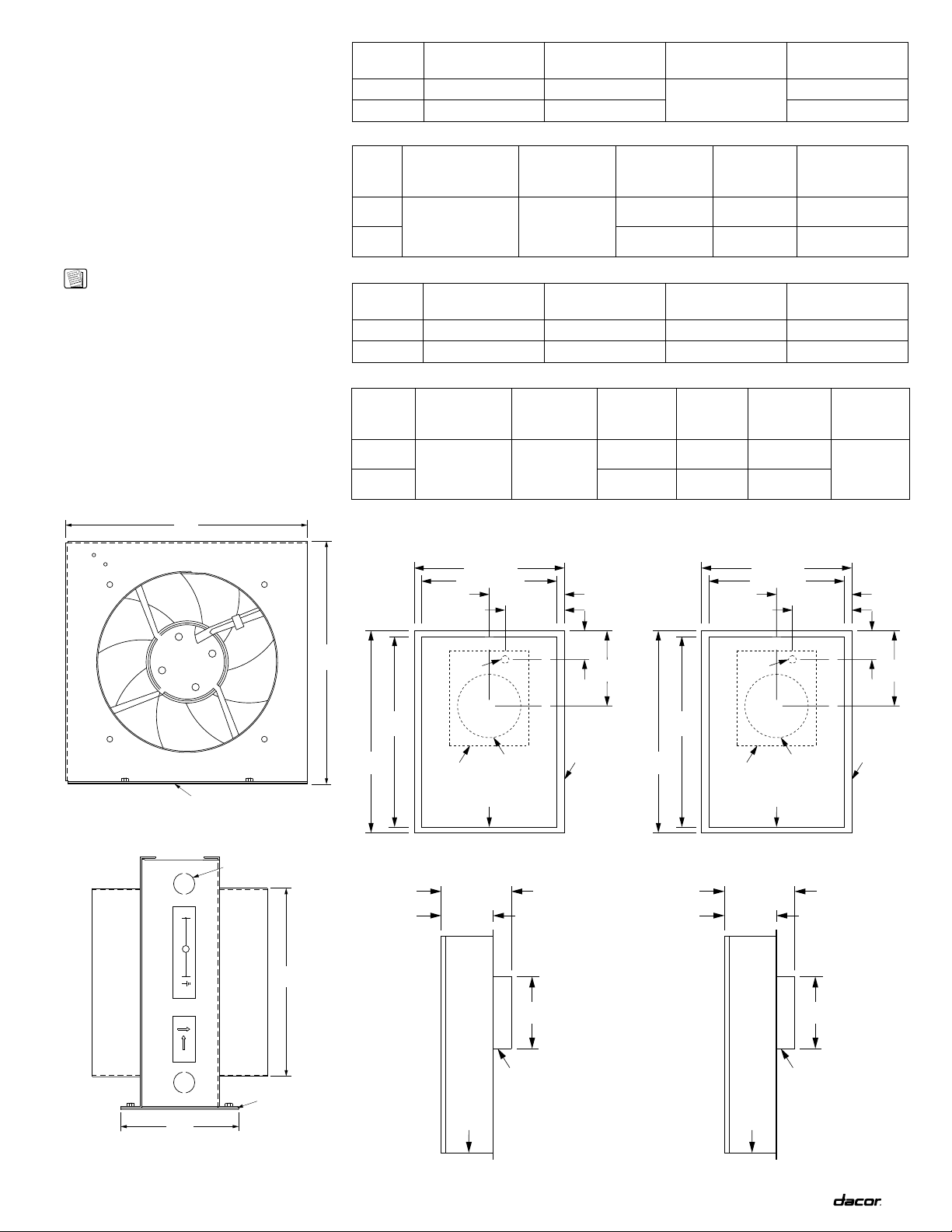

Model

No.

ILB8 10 5/8” (270mm) 10 1/2” (267mm)

ILB10 12 5/8” (321mm) 12 1/2” (318mm) 10” (254mm)

Overall Chassis

Width “A”

Overall Chassis

Height “B”

ILB Overall Dimensions

Overall Chassis

Length “C”

5” (127mm)

Duct Diameter

“D”

8” (203mm)

Total

Model

ILB8

ILB10 0.2kW (2A) 900 CFM 18 lbs.

Electrical Supply

No.

Refer to Ventilator

Model

No.

Requirements

Specifications

Overall Chassis

Width

Maximum

Duct Length

Max. 60

Equivalent

Straight Feet

ILB Specifications

Overall Chassis

Height

Connected

Load

Blower

Rating*

Approximate

Shipping Weight

0.1kW (1A) 500 CFM 15 lbs.

Overall Chassis

Length Duct Diameter

REMP3 19” (483mm) 5 13/16” (148mm) 25 1/2” (648mm) 8” (203mm)

REMP16 26” (660mm) 9 9/16” (243mm) 33 1/2” (851mm) 10” (254mm)

REMP Overall Dimensions

Model

No.

Supply

Requirements

REMP3 Refer to

Ventilator

Specifications

Electrical

Maximum

Duct Length

Max. 60

Equivalent

Straight Feet

Total

Connected

Load

Blower

Rating*

Approx.

Shipping

Weight Finish

0.5kW (4A) 620 CFM 35 lbs. Galvanized

REMP Specifications

(may be

painted)REMP16 0.3kW (3A) 980 CFM 55 lbs.

* All the CFM Blower Ratings are valued at 0” (zero-inch) static pressure.

ILB Overall Dimensions

Front View

ILB Overall Dimensions

Side View

REMP3 Overall Dimensions

Top View

REMP3 Overall Dimensions

Side View

REMP16 Overall Dimensions

Top View

REMP16 Overall Dimensions

Side View

2

Page 4

NOTE:

RV

REMP

Dacor Preference

and Millennia Cooktops

AIR

3 1/4" x 10"

90° Elbow

3 1/4" x 10"

90° Elbow

3 1/4" x 10" to

Round

Transistion

45° Adjustable

Elbow

Air

Discharge

Roof Curb

Sealant

Air

Discharge

Sealant

REMP

Round Duct

45° Adjustable

Elbow

Flange

25 1/2"

(648mm)

2"

(51mm)

19"

(483mm)

23 1/4"

(591mm)

6"

(152mm)

2"

(51mm)

33 1/2"

(851mm)

2"

(51mm)

26"

(660mm)

30 1/2"

(776mm)

6"

(152mm)

2"

(51mm)

The ILB8 & ILB10 inline blowers

are only approved in updraft

(hood) applications.

NOTE:

The REMP must be sealed

between the roof or wall and

the underside of the flange with

mastic to prevent leaks. For

installation on a flat roof, or a

roof with a pitch of less than 2:12,

install the REMP on a curb as

shown below. Position the curb

on flat roofs so that the discharge

(low) end points away from the

prevailing wind.

3

REMP Flat Roof Installation

REMP Sloped Roof Installation

REMP3 Sloped Roof Installation

REMP16 Roof Curb Dimensions

REMP Roof Installation

Side View

Electrical Connection

WARNINGS:

1. Ensure that the power supply

is disconnected before

proceeding.

2. Verify that the power supply

matches the ratings found on

the appliance data plate before

proceeding.

3. The complete appliance must

It is the owner ’s responsibility to ensure that

a qualified electrician performs the electrical

connection of this appliance. The electrical

installation, including minimum supply wire

size, must comply with the latest revision of the

National Electric Code ANSI/NFPA 70* and local

codes and ordinances.

*A copy of this standard may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

NOTES:

be properly grounded at all

times when electrical power is

applied.

4. Do not ground the appliance

with the neutral (white) house

supply wire. A separate

ground wire must be utilized.

5. If aluminum house supply

wiring is used, splice the

1. Make all electrical connections

between the vent and blowers,

then connect power to the

vent as per the wiring diagram

shown.

2. Use wire nuts and electrical

tape to secure all wiring

connections at the blowers.

appliance copper wires to the

aluminum house wiring with

special connectors designed

and agency-certified for this

purpose. Follow the connector

manufacturer’s recommended

procedure carefully. Improper

connection can result in a fire

hazard.

6. Failure to complete electrical

connections properly may

result in a damaged or nonfunctional system. Follow the

wiring diagrams carefully to

ensure a proper installation.

Page 5

N1

L1

N2

BLK

WHT 120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

GRN

WHT

L2

BLK

BLK

WHT

Gnd

GRN

Gnd

GRN

RV

L2

N2

Gnd

GRN

WHT

BLK

CABP3

L2

N2

Gnd

GRN

WHT

BLK

REMP

J-BOX

Wiring of RV with REMP and CABP3

N1

L1

N2

L2

N2

Gnd

BLK

WHT

120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

GRN

WHT

L2

BLK

BLK

WHT

Gnd

GRN

Gnd

GRN

GRN

WHT

BLK

RV

REMP OR CABP3

N1

L1

N2

L2

N2

Gnd

BLK

WHT

120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

GRN

WHT

L2

BLK

BLK

WHT

Gnd

GRN

Gnd

GRN

GRN

WHT

BLK

ERV/PRV

REMP

Wiring of RV with REMP or CABP3

Wiring of ERV/PRV with REMP

4

Page 6

L1

N1

Gnd

L2

N2

Gnd

L2

N2

Gnd

GRN

WHT

BLK

L2

N2

Gnd

GRN

WHT

120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

BLK

GRN

WHT

BLK

GRN

WHT

BLK

GRN

WHT

BLK

ILB

REMP

J-BOX

REMOTE BLOWER/

HOOD

L1

N1

Gnd

L2

N2

Gnd

L2

N2

Gnd

GRN

WHT

120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

BLK

GRN

WHT

BLK

GRN

WHT

BLK

REMP

HOOD

L1

N1

Gnd

L2

N2

Gnd

L2

N2

Gnd

GRN

WHT

BLK

GRN

WHT

120VAC, 60Hz, 15A

Supply power from

dedicated circuit breaker

BLK

GRN

WHT

BLK

HOOD

ILB

GRN

WHT

BLK

Wiring of DACOR Hood with ILB

Wiring of DACOR Hood with REMP

5

Wiring of DACOR Remote Blower/Hood with ILB and REMP

Page 7

Installing the ILB

Mount the ILB using the 4 screws, isolation

grommets and washers provided in the Parts

Bag, included in the Instruction Envelope.

Installing the REMP

Mount the REMP to the wall or roof using

screws, through mounting trim flange.

Verifying Proper Operation

1. Temporarily re-install the remote blower

cover, using 2 screws per side (REMP

ONLY).

2. Turn on the power supply at the circuit

breaker.

3. Refer to Ventilator Installs for further

instructions on verifying the proper

operation.

NOTES:

If the remote blower does not

operate properly, follow these

troubleshooting steps:

1. Verify that power is being

supplied to the Ventilator and

the remote blower.

2. Check the electrical

connections to ensure that

the installation has been

completed correctly.

3. Repeat the above test.

4. If the appliance still does not

work, contact an authorized

DACOR service company.

If you are unable to locate

a DACOR Servicer, please

contact DACOR at (800)

793-0093, or visit us on the

web at www.dacor.com. Do

not attempt to repair the

appliance yourself. DACOR

is not responsible for service

required to correct a faulty

installation.

6

Page 8

Web Site: www.dacor.com

For a Dealer/Service: (800) 772-7778

Corporate Phone: (800) 793-0093

Loading...

Loading...