Page 1

Installation Instructions

Renaissance® Downdraft Vent

Models ERV3015, ERV36-ER, ERV3615, ERV48,

ERV48-ER, PRV30, PRV36 and PRV46

Includes installation instructions for cabinet blower (Dacor model CABP3) which is

an option for models ERV3015 and ERV3615.

Part No. 107736 Rev. B

Use these downdraft vents only with approved Dacor ® appliances. See the

installation instructions for the particular appliance model being installed to

determine suitability.

Page 2

Table of Contents

Important Safety Instructions .......................................... 1

Important Information About Safety Instructions .............. 1

Safety Symbols and Labels ............................................. 1

General Safety Precautions ............................................. 2

Product Specifications ..................................................... 2

Electrical Specifications ................................................... 2

Product Dimensions - ERV3015 and ERV3615 ............... 3

Product Dimensions - ERV48 and PRV Series ............... 4

Product Dimensions - ERV36-ER and ERV48-ER .......... 5

Installation Specifications ................................................ 6

Planning the Installation ................................................... 6

Planning the Duct Work ................................................... 8

Installation Instructions .................................................. 12

Installation Preparation .................................................. 12

Installing the Downdraft Vent in the Cutout ................... 13

Verifying Proper Operation ............................................. 16

Installation Checklist ...................................................... 16

Wiring Diagram - All Models .......................................... 17

CABP3 Cabinet Blower Ratings ..................................... 17

Before You Begin...

Important:

• Installer: In the interest of safety and to minimize problems, read these installation instructions completely and care-

fully before you begin the installation process. Leave these installation instructions with the customer.

• Customer: Keep these installation instructions for future reference and the local electrical inspector’s use.

Customer Service Information

If You Need Help...

Model Identification

If you have questions or problems with installation, contact

your Dacor ® dealer or the Dacor Customer Service Team.

For repairs to Dacor appliances under warranty call the Dacor

Distinctive Service line. Whenever you call, have the model

and serial number of the appliance ready. The model and serial number are printed on the product data label on the front of

the unit. The product data label also specifies the power supply requirements.

Dacor Customer Service

Phone: ((800) 793-0093 ex. 2813 (U.S.A. and Canada)

Monday - Friday 6:00

Web site: www.dacor.com

Dacor Distinctive Service (for repairs under warranty only)

Phone: 793-0093 ex. 2822 (U.S.A. and Canada)

Monday - Friday 6:00

a.m. to 5:00 p.m. Pacific Time

a.m. to 5:00 p.m. Pacific Time

ERV3015 = 30-inch wide downdraft vent with ERV

style top cap. For use with approved

Dacor cooktops and ranges.

ERV3615 = 36-inch wide downdraft vent with ERV

style top cap. For use with approved

Dacor cooktops and ranges.

ERV36-ER = 36-inch wide downdraft vent with ERV

style top cap. For use with approved

Dacor ranges.

ERV48 = wide downdraft vent with ERV style

top cap. For use with approved Dacor

cooktops and ranges.

ERV48-ER = 48-inch wide downdraft vent with ERV

style top cap. For use with approved

Dacor ranges.

PRV30 = wide downdraft vent with PRV style

top cap. For use with approved Dacor

cooktops and ranges.

PRV36 = 36-inch wide downdraft vent, PRV

style top cap. For use with approved

Dacor cooktops and ranges.

PRV46 = 46-inch wide downdraft vent, PRV

style top cap. For use with approved

Dacor cooktops.

All specifications subject to change without notice.

Dacor

assumes no liability for changes to specifications.

© 2013 Dacor, all rights reserved.

Page 3

Important Safety Instructions

Important Information About

Safety Instructions

• The Important Safety Instructions and warnings in

these instructions are not meant to cover all possible

problems and conditions that can occur. Use common

sense and caution when installing, maintaining or operating this or any other appliance.

• Always contact the Dacor Customer Service Team

about problems and conditions that you don’t understand. See Customer Service Information.

DANGER

IMPORTANT: Do not store or use combustible,

flammable or explosive vapors and liquids (such as

gasoline) inside or in the vicinity of this or any other

appliance. Also keep items that could explode, such

as aerosol cans, away from the range or cooktop. Do

not store flammable or explosive materials in adjacent

cabinets or areas.

WARNING

WARNING – TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Installation work and electrical wiring must be

done by qualified person(s) in accordance with

all applicable codes and standards, including

fire-rated construction.

b) Sufficient air is needed for proper combustion

and exhausting of gases through the

flue(chimney) of fuel burning equipment to

prevent back drafting. Follow the heating

equipment manufacturer’s guideline and safety

standards such as those published by the

National Fire Protection Association (NFPA), and

the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and

the local code authorities.

c) When cutting or drilling into wall or ceiling, do

not damage electrical wiring and other hidden

utilities.

d) Ducted fans must always be vented to the

outdoors.

Safety Symbols and Labels

DANGER

Immediate hazards that WILL result in severe personal

injury or death.

WARNING

Hazards or unsafe practices that COULD result in severe

personal injury or death.

CAUTION

Hazards or unsafe practices that COULD result in minor

personal injury or property damage.

WARNING

This appliance is equipped with a three prong grounding

plug for your protection against possible electric shock

hazards. It must be plugged into a dedicated, grounded

electrical outlet. Where a standard two prong electrical

outlet is encountered, it is the personal responsibility

and obligation of the customer to have it replaced with a

dedicated, properly grounded three prong electrical outlet.

Do not under any circumstances:

♦ Cut or remove the third (ground) prong from the

power cord.

♦ Use an adapter plug.

♦ Use an extension cord.

♦ Use a power cord that is frayed or damaged.

♦ Use of a ground fault interrupter (GFI) is not

recommended.

Grounding

type

electrical

outlet

Three prong

grounding plug

READ AND SAVE THESE INSTRUCTIONS

1

Page 4

Important Safety Instructions

General Safety Precautions

To reduce the risk of fire, electric shock, serious injury or death when using your appliance, follow basic safety precautions, including the following:

WARNING

• Do not install or operate a damaged appliance. If you

receive a damaged appliance, contact your dealer or

builder.

• Observe all governing codes and ordinances during

planning and installation. Contact your local building

department for further information.

• The electric outlet for the downdraft vent should be

installed only by a licensed electrician

• For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and vapors.

• Use this downdraft vent only for its intended purpose

as outlined in the use and care manual. This appliance is not intended for commercial use.

• The customer should not install, repair or replace

any part of this unit unless specifically recommended

in the literature accompanying it. A qualified service

technician should perform all other service. Contact

the Dacor Customer Service Team for examination,

repair or adjustment.

• Keep all packaging materials away from children.

Plastic bags can cause suffocation.

• For proper operation, this unit must be installed with a

cabinet, in-line or remote blower. Use only one of the

models specified. Only one blower shall be installed.

• Before installing or servicing the downdraft vent, disconnect the power plug from the electrical outlet.

WARNING

• The installer must show the customer the location of

the electrical outlet so that the customer knows where

and how to disconnect power.

• Install or locate this appliance only in accordance

with these installation instructions, the Dacor range/

cooktop installation instructions and the blower installation instructions. Improper installation, adjustment,

alteration, service or maintenance can cause serious

personal injury or property damage.

• Read the use and care manual completely before

operating this appliance.

• Do not tamper with the controls.

• Never allow the filters or vent openings to become

blocked or clogged. Do not allow foreign objects, such

as cigarettes or napkins, to be sucked into the vent

holes.

• Clean the filters and all grease-laden surfaces often

to prevent grease fires and maintain performance.

Clean this appliance only as specified in the use and

care manual.

• Do not leave children or pets alone or unattended in

the area around the range or cooktop when it is in

use. Never allow children to sit or stand on an appliance. Do not let children play with a range, cooktop

or the downdraft vent. Do not store items of interest to

children above or around the appliance.

Product Specifications

Electrical Specifications

The downdraft vent is supplied with a 28” (71.1 cm) power

cord with a three prong plug. Plug it directly into a three

prong electrical outlet meeting the requirements below. Do

not use an extension cord.

The correct voltage, frequency and amperage must be supplied as specified below. The circuit must be protected by a

properly sized circuit breaker or time-delay fuse.

Electrical Supply Requirements

A three prong electrical outlet connected to a 120 Vac,

60 Hz, 15 Amp. grounded, dedicated, single phase circuit

is required.

• The above specifications are for reference only. If they

do not agree with those listed on the product data label,

use the ratings on the label.

2

• The customer must supply 3 conductor wiring/conduit

with minimum current carrying capacity of 8 Amps. to

supply power to the blower from the downdraft vent.

See Installation Specifications for further details.

• It is the owner’s responsibility to ensure that the electrical outlet is installed by a licensed electrician. The electrical installation must comply with the latest revision of

the National Electric Code ANSI/NFPA 70* (latest revision) and local codes and ordinances.

*A copy of this standard may be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

• Locate the electrical outlet in an accessible location,

so that the power plug can be disconnected for service

without removing the appliances from the cabinet.

Page 5

Product Specifications

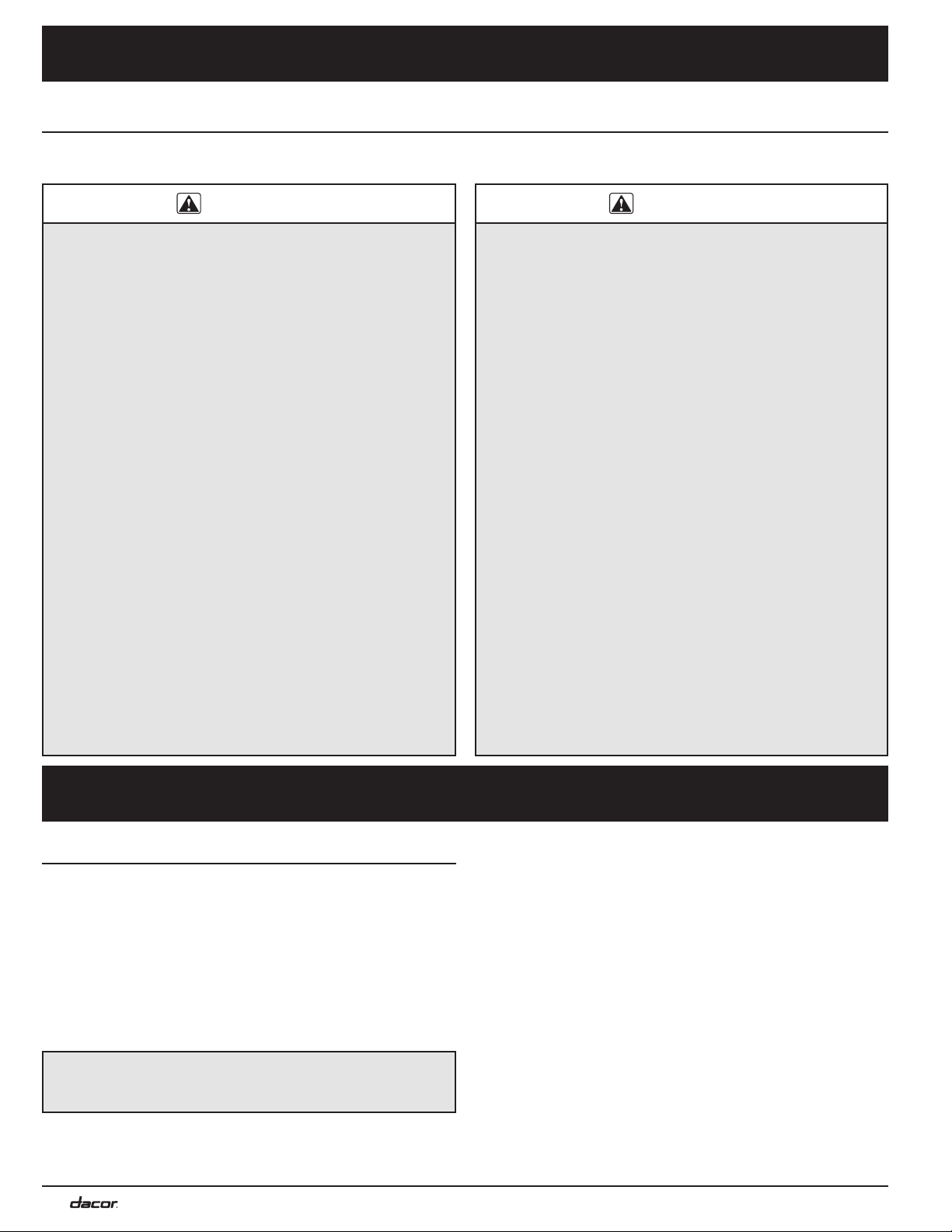

Product Dimensions - ERV3015 and ERV3615

Tolerances: ±1/16” (±1.6 mm) unless otherwise stated

2 3/16”

5/16” (8 mm)

thick stiffener

across back

3”

(7.6 cm)

”

1 15/16

(4.9 cm)

(5.6 cm)

2 1/8

(5.4 cm)

3/16”

(5 mm)

2 9/16”

(6.5 cm)

”

Top cap with

vent down

9/16”

(1.4 cm)

*

Model

Number

ERV3015 30” (76.2 cm) 27 3/8” (69.5 cm)

ERV3615 36” (91.4 cm) 33 3/8” (84.8 cm)

2 1/8" (5.4 cm)

ERV top cap - side view

A

A - Top Cap

Width

B - Chassis

Width

3/8"

(1.0 cm)

20”

(50.8 cm)

3 3/4”

(9.5 cm)

1 1/8”

(2.9 cm)

Vent shown

in raised

position

15"

(38.1 cm)

See pages 9 and

B

Product

data label

10 for exhaust

locations and

dimensions.

30 1/4”

(76.8 cm)

to

37 1/4”

(94.6 cm)

(76.2 cm)

**

30"

6”

(15.2 cm)

Motor

cover

Front of unit

Adjustable

anchor legs

28" 3 prong

grounded

power cord

* Total chassis depth with optional CABP3 blower installed is 10 3/8” (26.3 cm).

** Maximum height of downdraft vent must not exceed maximum specified counter

height for cooking appliance. See installation instructions for cooking appliance.

3

Page 6

Product Specifications

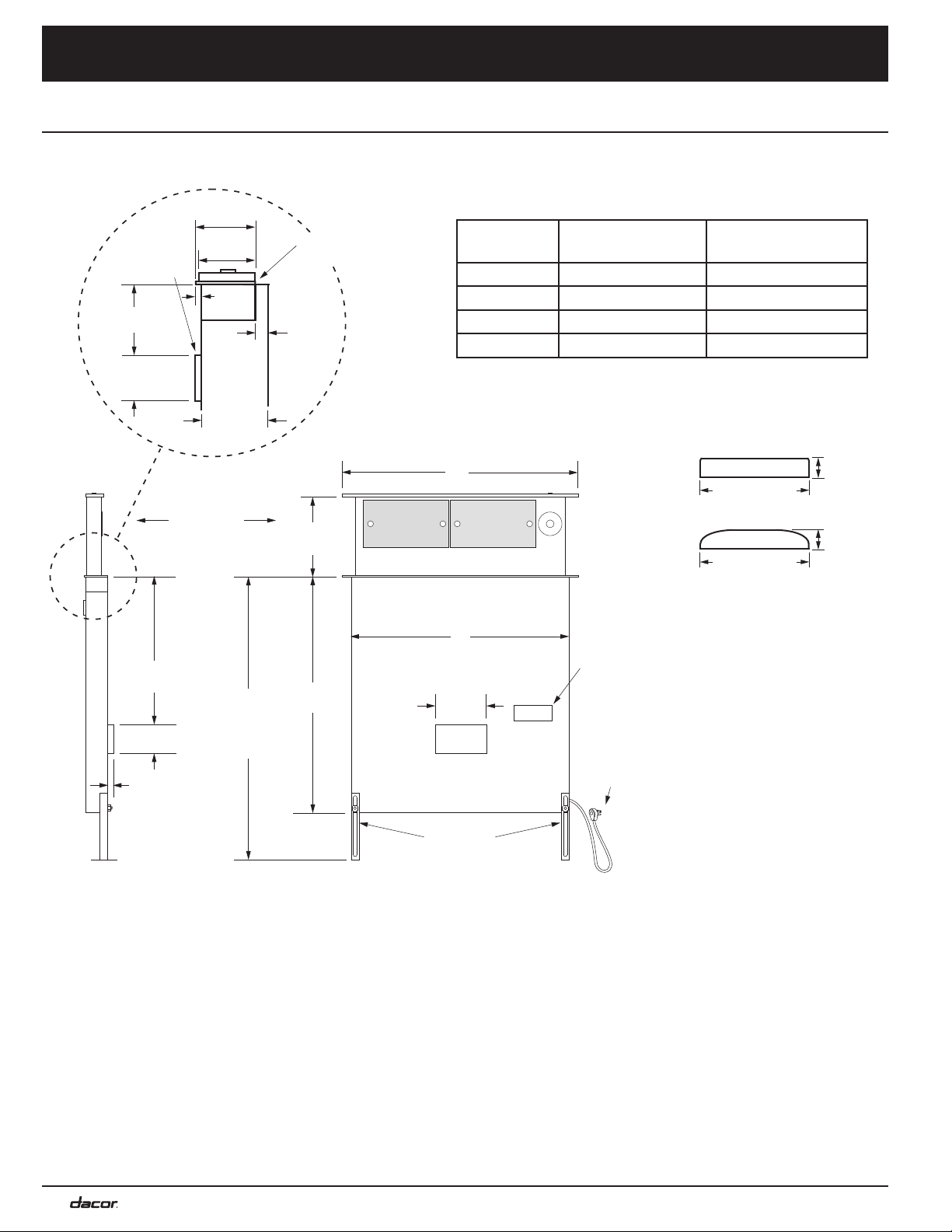

Product Dimensions - ERV48 and PRV Series

5/16” (8 mm)

thick stiffener

across back

2 1/2"

(6.4 cm)

1 15/16"

(4.9 cm)

18 5/8”

(47.3 cm)

3 3/4"

(9.5 cm)

1"

(2.5 cm)

2 3/16"

(5.6 cm)

2 1/8"

(5.4 cm)

3/16"

(5 mm)

2 9/16"

(6.5 cm)

Vent shown

in raised

position

(76.8 cm)

(94.6 cm)

30 1/4"

to

37 1/4"

9/16"

(1.4 cm)

(25.4 cm)

(76.2 cm)

*

Top cap with

vent down

10"

30"

Tolerances: ±1/16” (±1.6 mm) unless otherwise stated

Model

Number

ERV48 48” (121.9 cm) 43 3/8” (110.2 cm)

PRV30 30” (76.2 cm) 27 3/8” (69.5 cm)

PRV36 36” (91.4 cm) 33 3/8” (84.8 cm)

PRV46 46” (116.8 cm) 43 3/8” (110.2 cm)

A

B

6"

(15.2 cm)

Motor

cover

Front of unit

A - Top Cap

Width

Product

data label

28" 3-prong

grounded

power cord

B - Chassis

Width

3/8"

(1.0 cm)

2 1/8" (5.4 cm)

ERV top cap - side view

7/16"

(1.1 cm)

2 1/8" (5.4 cm)

PRV top cap - side view

See page 9 for exhaust

locations and dimensions.

* Maximum height of

downdraft vent must

not exceed maximum

specified counter height

for cooking appliance. See

installation instructions for

cooking appliance.

Adjustable

anchor legs

4

Page 7

Product Specifications

Product Dimensions - ERV36-ER and ERV48-ER

1/4"

5/16” (8 mm)

thick stiffener

across back

2 1/2"

(6.4 cm)

1 15/16"

(4.9 cm)

(6 mm)

2 13/16"

(7.1 cm)

Top cap with

vent down

2 9/16"

(6.5 cm)

Model

Number

ERV36-ER 36” (91.4 cm) 33 3/8” (84.8 cm)

ERV48-ER 48” (121.9 cm) 43 3/8” (110.2 cm)

Tolerances: ±1/16”, (±1.6 mm) unless otherwise stated

A

Top Cap

Width (A)

Chassis

Width (B)

18 5/8”

(47.3 cm)

3 3/4"

(9.5 cm)

1"

(2.5 cm)

Vent shown

in raised

position

30 1/4"

(76.8 cm)

37 1/4"

(94.6 cm)

to

(25.4 cm)

(76.2 cm)

*

10"

30"

B

6"

(15.2 cm)

Motor

cover

Front of unit

Adjustable

anchor legs

Product

data label

28" 3 prong

grounded

power cord

See page 9 for

exhaust locations and

dimensions

* Maximum height of

downdraft vent must not

exceed maximum specified counter height for

cooking appliance. See

installation instructions for

cooking appliance.

5

Page 8

Installation Specifications

Planning the Installation

General System Layout

The vent system consists of the downdraft vent itself and a

single Dacor approved cabinet blower (models ERV3015 and

ERV3615), remote blower or in-line blower (see facing page

for examples).

WARNING

• Failure to install an approved blower or proper duct

work will result in a back draft and/or the insufficient

venting of smoke and fumes.

• To reduce the risk of personal injury caused by reaching over a hot appliance, cabinet storage space

located directly above the range/cooktop should be

avoided.

• Follow the instructions and diagrams for minimum safe

clearances and installation location in these instructions, the appliance installation instructions and the

blower installation instructions. Failure to do so may

result in a fire or safety hazard.

• Plan the installation so that all minimum dimensions

are met or exceeded. All contact surfaces between the

downdraft vent and any cabinets or walls must be solid

and at right angles.

• The downdraft vent is equipped with adjustable anchor

legs to accommodate various cabinet heights.

• Install the downdraft vent and range/cooktop so that

they can be removed if service is required.

• When installing the downdraft vent with a cooktop,

access from the front of the cabinet to the chassis and

the electrical/gas supplies of both appliances must

be provided for inspection and service. Any drawers

or shelves must be easy to remove for access to the

cooktop, downdraft vent and utilities.

• There are 7/8” access holes in the bottom and side of

the downdraft vent for connecting the blower wiring and

strain relief. Wire the blower to turn on when the downdraft vent is turned on. When installing a remote or inline blower, run the blower wiring/conduit parallel to the

duct work, connecting it to the downdraft vent on one

end and the blower on the other.

• Allow room for the exhaust duct coming out of the unit.

See Planning the Duct Work for further details.

• The maximum allowable duct run must be taken

into consideration when determining the layout. See

Planning the Duct Work for further details.

• Refer to the range/cooktop installation instructions for

the minimum cutout dimensions specific to the particular downdraft vent model being installed.

Backsplash

Countertop

overhang

non-combustible

surface rear wall

Notches required for some downdraft vent

installations, see cooktop

installation instructions

See the cooktop installation

instructions for exact countertop

and cabinet dimensions

Flush with back side

of cabinet front

Vertical

Cooktop Cabinet/Countertop Cutout - Top View

Backsplash

Countertop

Vertical

non-combustible

surface rear wall

Notches required for some downdraft vent

installations, see range

installation instructions

Notches for self-rimming

style installations, see range

installation instructions

See the range installation

instructions for exact countertop

and cabinet dimensions

overhang

Range Cabinet/Countertop Cutout - Top View

6

Page 9

Installation Specifications

Blower wiring

Front of unit

Cabinet blower -

option on ERV3015,

and ERV3615 only

Backsplash

Cooktop

Downdraft vent

3 ¼ x 10 to

round transition

and 45°

adjustable elbow

Wall board

Connection to

cabinet blower

Connection to

remote/in-line

blower

Electrical Layout

REMP series

remote blower

Duct work between

downdraft and

remote blower

Backsplash

access hole

Blower wiring

access hole

Cabinet blower,

option on

ERV3015 and

ERV3615

only

Floor

3 1/4 x 10

90° elbow

Wall

Wall cap

12” min.

(30.5 cm)

Example of Layout with Cabinet

Blower Configuration, Exhaust Through Wall

Cabinet back

Outside wall

Downdraft vent

Cooktop

Floor

Downdraft vent

Downdraft vent

configured for

rear exhaust

Wiring/conduit

from downdraft

to remote blower

Example of Layout with Cooktop

and Rear Exhaust

Range

Wiring/conduit

from downdraft to

in-line blower

Downdraft vent

configured for

bottom exhaust

3 ¼ x 10 to

round transition

Duct work Duct work

Floor

Wall cap on

outside wall

ILHSF series

in-line blower

Example of Layout with Range

and Bottom Exhaust

7

Page 10

Installation Specifications

Planning the Duct Work

WARNING

• To reduce the risk of fire and to properly exhaust air,

be sure to duct air outside the house or building. Do

not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces or garages.

• TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCT WORK.

• DO NOT install more than one blower to increase the

length of the duct run. Even small differences between

blower air flow rates can greatly reduce the air draw

by the downdraft vent.

Local building codes may require the use of makeup air

systems with ventilation systems that move air greater than

the specified movement rate (CFM). The specified rate varies based on locale. Consult a qualified HVAC specialist

when designing the system for the requirements in your

area and to assure optimal performance.

You must install one of the Dacor blower models listed

below for the downdraft vent to operate properly. See the

blower installation instructions for directions. For model

CABP3, see the instructions later in this manual.

Installations with ILHSF and REMP series blowers:

With ILHSF and REMP blowers, the downdraft vent can

be configured to exhaust through the back, the bottom or

either side by removing the appropriate exhaust knock-out

shown on the facing page.

• When connecting the duct work to the back of the unit,

the customer must supply a 3 ¼ x 10 rectangular transition to make the connection.

• For side and bottom exhaust connections, use the supplied transition to connect the duct work to the unit. It

transitions between the 1

unit and a 3 ¼ x 10 rectangular duct connection. On

bottom exhaust installations cut a hole in the floor to

allow the transition and/or duct work to pass through

the floor (see page 13).

5"

(12.7 cm)

1"

(2.5 cm)

5

/8 x 16 exhaust outlet on the

2 x 16, connects to

side or bottom exhaust

on downdraft

APPROVED DACOR BLOWERS FOR USE WITH

MODEL ERV-PRV SERIES DOWNDRAFT VENTS

Dacor Blower

Model Number

CABP3

ILHSF8 600 CFM

ILHSF10 1100 CFM

REMP3 600 CFM

REMP16 1000 CFM

1

IMPORTANT: Due to a lack of clearance, do not use a

CABP3 blower if a range or wall oven is to be installed in

front of the downdraft vent.

2

Nominal rating at zero inches static pressure, see the

CABP3 blower ratings on page 17 for actual rating.

3

Revision B and later units only.

4

Nominal rating at zero inches static pressure. See blower

installation instructions for actual ratings.

For installations with CABP3 blowers:

• Installation with a CABP3 blower requires Dacor adapt-

er kit # AERVCAB.

• The blower assembly is mounted to the front of the

downdraft vent with the exhaust pointing in the desired

direction. See page 10.

• The CABP3 blower output connects directly to 3 ¼ x 10

rectangular duct.

1

Rating

600 CFM

2

4

4

Compatible with

Vent Models

ERV3015

ERV3615

4

4

3

3

ALL

ALL

ALL

ALL

3 ¼ x 10 to duct work

1 5/8 x 16 Duct Transition

• On side exhaust installations, allow five inches of space

on the side for the 2 x 16 to 3 ¼ x 10 transition plus

additional space for the duct attached to it (X).

X

5”

1 5/8 x 16 duct

transistion

8

Page 11

1 1/8"

(2.9 cm)

Installation Specifications

6 1/4"

(15.9 cm)

C

L

Front of unit

Motor

cover

C

L

26" (66.0 cm)

Rear Exhaust Knock Out (3 ¼ x 10)

Vertical center line of rear exhaust knock out lines up with vertical

center line of chassis

Bottom Exhaust Knock Out (1 5/8 x 16)

On 46” and 48” wide models, the vertical center line of bottom knock out lines up with vertical center line of chassis

On 30” and 36” wide models, the vertical center line of bottom knock out is offset 3”

Side Exhaust Knock Outs (1 5/8 x 16)

Exhaust Knock-out Locations for Use with

REMP and ILHSF Series Blowers

Duct installation requirements for all blowers:

• All duct work materials (including screws and duct tape)

must be purchased separately by the customer.

• When planning new duct work, always look for the

shortest, most direct route to the outside. See page

7 for examples.

• You can increase the duct size over the duct run if

desired. To prevent a back draft, never decrease the

duct size over the run.

• Do not rely on duct tape alone to seal duct joints.

Fasten all connections with sheet metal screws and

tape all joints with certified silver tape or duct tape.

3”

C

L

• Use sheet metal screws as required to support the duct

weight.

• To prevent back-drafts, a damper at the duct outlet may

also be required.

• Make sure duct work does not interfere with floor joists

or wall studs.

• With concrete slab construction, “box-in” the duct work

and blower wiring to prevent collapsing or other damage when the wet concrete is poured.

• Cross-drafts or air currents from adjacent open windows or doors, heating/air conditioning outlets, ceiling

fans and recessed ceiling lights reduce vent efficiency.

• System exhaust location (see page 8) must take

into account accumulated snowfall, where applicable.

9

Page 12

Installation Specifications

Exhaust Locations and Dimensions

for CABP3 Cabinet Blower Installations

(ERV3015, ERV3615 only)

Cooktop

ERV

CABP3

C

L

8 7/8" (22.5 cm)

from back of ERV

cutout to center

ADAPTER

DUCT

line of CABP3

exhaust in any

orientation

Bottom exhaust

configuration shown

Exhaust Locations and Side Dimensions

for CABP3 Cabinet blower

Model A B C

ERV3015

ERV3615

Countertop

26 1/4”

(66.7 cm)

Duct connection

center line

12 1/8”

(30.7 cm)

9 3/4”

(24.8 cm)

5 5/8”

(14.4 cm)

8”

(20.3 cm)

A

3 1/4 x 10

duct

connection

(4.4 cm)

(10.8 cm)

Downdraft vent

center line

Front Exhaust Dimensions

CABP3 Blower - Left Exhaust

1 3/4”

4 1/4”

Downdraft vent

center line

10

Countertop

B

3 1/4 x 10

Duct connection

duct

connection

Front Exhaust Dimensions

CABP3 Blower - Right Exhaust

15 3/8”

(39.1 cm)

center line

Countertop

29 1/4”

(74.3 cm)

Downdraft vent

Duct connection

center line

C

3 1/4 x 10

duct connection

Front Exhaust Dimensions

CABP3 Blower - Bottom Exhaust

center line

Page 13

Installation Specifications

Calculating the Maximum Duct Run Length

• For optimal performance, consult a qualified HVAC

specialist when designing the duct system.

• Do not use duct work that is smaller in cross-sectional

area than the required duct sizes in the tables below.

• Keep the duct run as short as possible for best performance and never exceed the maximums stated in the

table below right.

• The maximum duct length for the downdraft vent system depends on the blower model used and the number of elbows and transitions. The Equivalent Number

of Feet for each elbow and transition (see table below)

must be subtracted from the maximum straight length

to compensate for wind resistance. To determine the

maximum allowable length of the duct work, subtract all

of the equivalent lengths of the elbows and transitions

listed below from the Blower Maximum Duct Straight

Length (see table right).

For example, for a downdraft vent system using 3 ¼ x 10

rectangular duct, two (2) 3 ¼ x 10 90° elbows, a 3 ¼ x 10

rectangular to 10” round transition, and a REMP16 remote

blower:

• From the Blower Maximum Duct Straight Length

table below, the maximum length without transitions

and elbows is 60 feet.

• The equivalent length of each 90° elbow is 15 feet.

• The equivalent length of 45° elbow is 2 feet.

• The equivalent length of the transition is 4 feet.

• The total equivalent length of the above components is:

15 feet + 15 feet + 4 feet + 2 feet = 36 feet.

• The maximum amount of straight duct that can be used

with a REMP16 and the above components is: 60 feet 34 feet = 24 feet.

Duct Work Design Tips

• Wherever possible, reduce the number of transitions

and turns to as few sharp angles as possible. Two

staggered 45° angles are better than one 90°. Keep

turns as far away from the hood exhaust as possible,

with as much space between each bend as possible.

• For best performance, use round duct instead of rectangular when possible, especially when elbows are

required.

• If multiple elbows are used, try to keep a minimum of

24” of straight duct between them. Avoid “S” or “back to

back” configurations of adjacent elbows.

• Do not use flexible metal duct.

Blower

Used

CABP3

ILHSF8

ILHSF10

REMP3

REMP16

Blower Maximum Duct Straight Length

8 Inch Duct 10 Inch Duct

40 feet

(12.2 m)

50 feet

(15.2 m)

60 feet

(18.3 m)

50 feet

(15.2 m)

60 feet

(18.3 m)

30 feet

(9.2 m)

40 feet

(12.2 m)

70 feet

(21.3 m)

40 feet

(12.2 m)

70 feet

(21.3 m)

3 ¼ x 10

Duct

30 feet

(9.2 m)

40 feet

(12.2 m)

60 feet

(18.3 m)

40 feet

(12.2 m)

60 feet

(18.3 m)

Equivalent Number of Feet (Nominal) -

Duct Elbows and Transitions

45° elbow

8 inch

45° elbow

10 inch

90° elbow

8 inch

90° elbow

10 inch

90° 3 ¼ x 10

to 8” round

transition

Roof cap * Wall cap** *

* The equivalent lengths of roof and wall caps vary with

model and configuration. For equivalent length, contact the

manufacturer or a qualified HVAC specialist.

** Not applicable for REMP series blowers.

3 feet

2 feet

7 feet

5 feet

25 feet

3 ¼ x 10

45° elbow

3 ¼ x 10

90° elbow

3 ¼ x 10

90° flat elbow

3 ¼ x 10

to 8” round

transition

3 ¼ x 10

to 10” round

transition

7 feet

15 feet

20 feet

4 feet

4 feet

11

Page 14

Installation Instructions

Installation Preparation

Verify Package Contents

1. Unpack the unit and verify that all required parts have

been provided. If any item is missing or damaged,

please contact your dealer immediately. Do not install a

damaged or incomplete appliance. The customer must

report cosmetic issues within 30 days of installation.

Parts List

• Product literature

• Anchoring legs (left - PN 36861, right - PN 36862)

• 2 wood screws, #14 x 2 1/2 (PN 83047)

• 3 wire nuts

5

• 1

• 2 sheet metal screws, #10 x 1/2 (PN 83022)

• 2 keps nuts, 1/4-20 (PN 83049)

• 2 flat washers, 1/4-20 (PN 83203)

• Insulation foam (tape)

Installation with CABP3 blower requires Dacor adapter kit

# AERVCAB. Kit includes adapter, wiring diagram label

(PN 106770), 3 wing nuts (PN 83035), 3 flat washers (PN

83008) and 6 lock washers (PN83340).

/8 x 16 to 3 ¼ x 10 duct transition (PN 13768)

Installation Preparation for Downdraft Vent

with ILHSF or REMP Series Blower:

NOTE: For units using the CABP3 cabinet blower, skip to

Installation Preparation for Downdraft Vent with CABP3

Cabinet Blower, on facing page.

1. Remove the appropriate side, back or bottom exhaust

knockout, depending on the desired exhaust configuration, from the downdraft vent chassis by cutting the

metal cross overs and removing the insert (see below).

Back of unit

Side

knock-out

Rear knock-out with

metal cross overs

shown

Side

knock-out

WARNING

• If the electrical service (electrical outlet) does not meet

the Electrical Specifications on page 2, do not

proceed with the installation. Call a licensed electrician

and have an electrical outlet installed that meets the

specifications.

• Install the vent only in a vertical orientation. Do not

mount the vent on a slant or angle.

• Do not enlarge or modify the exhaust knock-outs or

cut an exhaust hole in a location on the chassis other

than those shown. Doing so may cause an increase in

noise and decrease performance.

NOTE: The downdraft vent installs in the back of the cutout, separate from the range or cooktop. Install the downdraft vent before installing the range or cooktop.

2. Start by loosely attaching the anchoring legs to the

studs on the left and right sides of the downdraft vent

using the provided Keps nuts and washers.

Anchor leg

Front of unit

Bottom knock-out

2. Cut and remove the foil material inside the knock-out

hole. If you fail to remove the foil, the vent will not work.

• If the unit will vent through the bottom or side,

install the suppled 1

to the exhaust location. Before installing, peel the

protective backing off the foam tape and apply it to

the transition flanges. Attach the transition with the

provided sheet metal screws (see below).

Transition bottom

installation

5

/8 x 16 to 3 ¼ x 10 transition

Transition side

installation

Attach sealing

foam

12

Put nuts/

washers on

studs

• If the unit will exhaust air from the back, attach a

3 ¼ x 10 duct to the vent hole created by removing

the knock-out on the back of the unit.

3. Skip to Installing the Downdraft Vent in the Cutout

on page 13.

Page 15

Installation Instructions

Adapter Installation for CABP3 Blower:

(optional, ERV3015 and ERV3615 only)

1. Remove the front cover so that the AERVCAB cabinet

blower adapter can be installed. To do so, remove and

retain the three (3) wing nuts and three (3) flat washers

on the front of the unit. Discard the three (3) lock washers (they will be replaced). Tilt the cover out and pull

up. to remove it.

Front of unit

Cover

Installing the Downdraft Vent in

the Cutout

1. Cut a hole in the cabinet to allow the duct work to pass

through to the floor or wall for the planned duct system

layout. Use the dimensions on pages 9 and 10 to

determine the hole center line locations. If using the 2” x

16” to 3 1/4” x 10” transition (REMP and ILHSF blower

installations), the hole may need to be enlarged slightly.

Rear corner of cutout

(back of downdraft vent)

plumbed down

2. Peel the backing off of some of the foam tape included

with the adapter. Attach it to the right and left flanges.

3. Hold the adapter in front of the opening on the front

of the unit with the adapter’s studs on top and all the

flanges closest to the downdraft vent chassis.

4. Slide the bottom flange on the adapter into the bottom

retainer bracket on the downdraft vent at an angle.

Attach the adapter using the three (3) wing nuts and

flat washers removed in

step 1 and three (3) of

the lock washers from the

adapter kit.

Front of unit

Studs

Adapter

Bottom retainer bracket

Attach foam

to right/left

flanges

Insert bottom

flange into

bottom retainer

bracket

2. Gently slide the vent into the rear of the countertop cutout with the electrical access panel toward the front.

3. Adjust the anchoring leg height so that the top of the

downdraft vent rests on the counter, then tighten the

hex nuts. Secure the anchoring legs to the cabinet floor

with the provided wood screws.

Top of vent resting

on countertop

Front of unit

Anchor leg

Floor

Exhaust: size and location

varies with installation type

Electrical access

panel

13

Page 16

Installation Instructions

Cabinet Blower Installation:

(optional, ERV3015 and ERV3615 only)

1. Locate the wiring diagram label included with the

adapter kit. Peel the protective backing off and place it

over the existing label on the CABP3 blower as shown.

New label

Existing

label

2. Locate the foam tape supplied with the downdraft vent.

Place the blower on the floor in the orientation it will be

mounted on the front of the downdraft vent. Peel the

backing off the included foam tape and attach it to the

right and left flanges of the blower base plate.

3. With the exhaust in the desired orientation, slide the

bottom flange of the CABP3 blower base plate behind

the tab on the bottom of the adapter mounted to the

front of the downdraft vent.

4. Cover the opening on the adapter by pushing the

blower against it. Make sure that the foam tape creates a good seal on the right and left side of the opening. Center the blower base plate horizontally over the

opening on the front of the adapter.

5. Install the adapter top retainer bracket over the blower

base plate flange. Secure it in place with the three (3)

wing nuts, lock washers and flat washers included with

the adapter.

Top retainer

bracket

Attach foam

to right/left

flanges

Adapter

CABP3

ILHSF or REMP Series Blower Installation

If using a ILHSF or REMP series blower, install it according

to the blower installation instructions.

Duct Work Installation

WARNING

Tape all duct joints securely to prevent combustion

by-products, smoke or odors from entering the home.

Doing so will also improve system efficiency.

Install the duct work according to the Installation

Specifications section. Use sheet metal screws and duct

tape to connect and seal all of the pieces. Support the duct

weight as necessary to ensure sealed joints.

Electrical Installation

WARNING

• ELECTRIC SHOCK HAZARD - Do not connect the

downdraft vent power plug to the electrical outlet until

installation is complete.

• Failure to complete electrical connections properly

may result in an electric shock hazard or a damaged

or non-functional system. Follow the wiring diagrams

carefully to ensure a proper installation. Do not

change the factory wired terminal connections inside

the electrical access panel for the downdraft vent or

the blower.

• To avoid an electric shock hazard and to prevent damage route all wiring away from hot surfaces.

1. For ILHSF and REMP blower installations, run the wiring/conduit line used to supply power from the downdraft vent to the blower parallel to the duct work.

2. Remove the cover from the downdraft vent electrical

access panel.

3. Connect the wiring/conduit to the blower as shown in

the wiring diagrams below and the facing page according to local codes and ordinances. Make sure all terminal connections, including the factory wired connections, are tight. Replace the electrical access panel.

Range/Cooktop Installation

Install the range or cooktop according to its installation

instructions.

14

Insert bottom flange into

tab at bottom of adapter

Page 17

Installation Instructions

Front of unit

CABP3 cabinet

blower

Electrical connection

from downdraft vent,

match Wire Colors

Electrical access

panel

Downdraft vent

blower wiring

access hole

Electrical Installation - CABP3 Cabinet Blower

Match wire colors to

terminals as shown.

Blower

Output

Input

Power

Ground

GREEN

Attach ground wire

as shown

Wire Colors : Black = Line (L), White = Neutral (N),

Green = Ground (Gnd)

Blower power wiring/conduit.

Connect other end of wires

Wires to power plug.

Pre-wired at factory.

Do not modify.

BLACK

WHITE

to blower terminal block.

Downdraft Vent Electrical Access Panel

Downdraft vent

Range

REMP16

remote blower

Connect wires/conduit

according to remote

blower installation

instructions

Example of Electrical Installation

with ILHSF or REMP Series Blower

(Side View)

See Downdraft Vent

Electrical Access

Panel, above

Wiring/conduit from

downdraft vent to remote

(or in-line) blower

Floor

15

Page 18

Installation Instructions

Verifying Proper Operation

WARNING

• Read the downdraft vent use and care manual completely before operation.

• Install all of the front filters prior to operating the

downdraft vent. Refer to the use and care manual for

filter installation instructions.

CAUTION

To prevent damage to the downdraft vent power cord,

route it away from the surfaces of the range or cooktop

before connecting it.

1. Make sure the power switch on the top of the downdraft

vent is in the up position.

2. Plug the downdraft vent power plug into the electrical

outlet.

3. Press the power switch once to raise the vent to its

operating position.

4. Once in the up position the vent should begin to draw

air. Turn the variable speed control switch in both directions to verify that the system is operating correctly.

5. Press the top cap up/down switch once to lower the

vent.

6. Make sure that the top cap on the downdraft vent

intake does not catch on the back edge of the cooktop

or range when the intake is lowered. If interference

occurs, adjust the position of the cooktop or range.

Failure to eliminate any interference may result in permanent damage to the vent.

If the downdraft vent is not operational after installation:

• Make sure that power is being supplied to the unit.

• Make sure that power is being supplied to the blower

from the downdraft vent.

• If the vent will not raise properly or makes a scraping

sound check for obstructions interfering with the raising

of the unit.

If the downdraft vent still does not function after performing the above checks, do not attempt to repair it yourself.

Contact Dacor Distinctive Service at 793-0093 ex. 2822. Be

sure to have all model and serial numbers from the product

data labels for the downdraft vent and the blower available

when you call.

Dacor is not responsible for the cost of correcting problems

caused by a faulty installation.

Installation Checklist

Are the anchor legs extended down to make contact

□

with the floor and tightened into place? Are the anchor

legs fastened to the floor? Is the unit level?

□ Is the duct work completely installed? Are all joints

attached with sheet metal screws and wrapped with

duct tape?

□ Are both ends of the blower power cable connected (to

the downdraft vent and to the blower itself)?

□ Are the vent filters installed according to the use and

care manual instructions?

□ Is the power cord routed away from the hot surfaces of

the range or cooktop.

□ Is the unit connected to an electrical outlet that meets

the electrical specifications in these instructions?

□ Has proper operation been verified?

□ Has the warranty been activated on-line or the warranty

card been filled out completely and mailed?

16

Page 19

Technical Data

CABP3 Blower Performance

Wiring Diagram - All Models

DOWN

LIMIT SWITCH

COM

NO

NC

WHT

BLUE

UP

LIMIT SWITCH

COM

NO

NC

RED

BLK

REMOTE POT

YEL

YEL

WHT

RELAY

COMNNO

L

SNORKEL SWITCH

COM NCNO

RED

BLUE

CHASSIS

GROUND

STUD

WHT

GNDL2 N1L1N2 GND

SPEED CONTROL

BLK

ORNG

ORNG

CABP3 Cabinet Blower Ratings

CABP3 Cabinet blower Airflow*

Nominal 600 CFM

Actual 585.6 CFM

* At zero inches static pressure. Performance varies based

on duct system configuration.

Electrical Rating: 4 Amps. @ 120 Vac, 60 Hz.

For ILHSF or REMP series blower ratings, see the blower

installation instructions.

RED

BLK

5.0

4.0

3.0

2.0

1.0

BLOWER

OUTPUT

GROUNDPOWER

INPUT

Static pressure - inches of water

0

100 200 300 400 500 600

Airflow CFM (Cubic feet/minute)

17

Page 20

Dacor●14425ClarkAvenue,CityofIndustry,CA91745●Phone:(800)793-0093●Fax:(626)403-3130●www.dacor.com

Loading...

Loading...