Page 1

OPERATOR’S MANUAL

CSV 260

CHIPPER-VACUUM

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368023 Cleveland, Ohio 44136-9722.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

CUB CADET CORP. P.O. BO X 368023 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-10053A

(5/99)

Page 2

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMP TING TO O PERATE YOU R CHIPPER -VACUU M. FAILURE TO COMPLY WITH

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS

SYMBOL-HEED ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

DANGER: Your chipper-vacuu m was buil t to be ope rated acc ordin g to the rules for safe ope ratio n

in this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This unit is capable of amputating fingers and hands and

throwing objects. Fai lure to observe the fol lowing safety ins tructions could re sult in serious in jury or

death.

1. GENERAL OPERATION

• Read this operator's manual carefully in its entirety

before attempting to assemble this machine. Read,

understand, and follow all instructions on the

machine and in the manual(s) before operation. Be

completely familiar with the controls and the proper

use of the machine before operating it. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

• Your chipper-vacuum is a powerful tool, not a

plaything. Therefore, exercise extreme caution at

all times. Your unit has been designed to perform

two jobs; to chip and vacuum vegetation found in a

normal yard. Do not us e it for any other purpose.

• Never allow children under 16 to operate the unit.

Children 16 years and older should only operate

under close parental supervision. Only responsible

individuals who are familiar with these rules of safe

operation should be allowed to use your unit.

• Keep the area of operation clear of all persons,

particularly small children and pets. Stop the

engine when they are in the vicinity of the unit.

• When feeding material into this equipment, be

extremely careful that pieces of metal, rocks,

bottles, cans or other foreign objects are not

included. Personal injury or damage to the machine

could result.

• Always wear safety glasses or safety goggles,

during operation and while performing an

adjustment or repair, to protect eyes from foreign

objects that may be thrown from the machine.

• Wear sturdy, rough-soled work shoes and close

fitting sla cks and shirt. Shirt and slacks that cover

the arms and legs and steel-toed shoes are

recommended. Do not wear loose fitting clothes or

jewelry, and secure hair above shoulder length.

They can be caught in moving parts. Never operate

a unit in bare feet, sandals or sneakers. Wear

gloves when feeding material in the chipper chute.

• Do not operate the unit while under the influence of

alcohol or drugs.

• Do not overreach. Keep proper footing and balance

at all times.

• Never place your hands or any part of your body or

clothing near or under rotating parts. Keep clear of

the discharge opening at all times Never insert

your hands or any part of your body or clothing into

the nozzle, chipper chute or discharge opening as

the rotating impeller can cause serious injury.

• If it is necessary for any reason to unclog the feed

intake or discharge openings or to inspect or repair

any part of the machine where a moving part can

come in contact with your body or clothing, stop the

machine, allow it to cool, disconnect the spark plug

wire from the spark plug and move it away from the

spark plug before attempting to unclog, inspect or

repair.

• Never operate unit without vacuum bag and

discharge chute properly affixed to unit. Large

zippered end of bag must be closed to prevent

objects from being blown out.

• Never operate unit without either the inlet nozzle or

optional hose attachment properly affixed to unit.

These devi ces shield the operat or from accidental

contact with the rotating impeller. Never attempt to

convert the unit from nozzle to hose mode or vice

versa with the engine running.

• Never attempt to remove or empty vacuum bag

when engine is running. Shut the engine off and

wait for the impeller to come to a complete stop

before removing the bag. The impeller continues to

rotate for a few seconds after the engine is shut off.

Never place any part of the body in the impeller

area until you are sure the impeller has stopped

rotating.

• Keep all guards and safety devices in place and

operating properly.

2

Page 3

• Do not allow an accumulation of processed

material to build up in the discharge area as this

will prevent proper discharge and can result in

kickback from the chipper chute.

• Keep your face and body back from chipper chute

to avoid accidental bounce back of any material.

• If the cutting mechanism strikes a foreign object or

if your machine should start making an unusual

noise or vibration, immediately stop the engine,

disconnect the spark plug wire and move the wire

away from the spark plug. Allow the machine to

stop and take the following steps.

• Inspect for damage

• Repair or replace any damaged parts.

• Check for any loose parts and tighten to

assure continued safe operation.

• Muffler and engine become hot and can cause a

burn. Do not touch.

• Do not allow leaves or other debris to build up on

engine’s muffler. The debris could ignite and cause

a fire.

• Do not operate engine if air cleaner or cover over

carburetor air intake is removed, except for

adjustment. Removal of such parts could create a

fire hazard.

2. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of small children. Children are often attracted to

the chipping and vacuuming activity. Never assume that

children will remain where you last saw them.

• Keep children out of the work area and under the

watchful eye of a responsible adult other than the

operator.

• Be alert and turn the unit off if a child enters the

area.

• Never allow children under the age of 16 to operate

the chipper-vacuum.

3. SERVICE

• Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

• Store fuel and oil in approved containers, away

from heat and open flame, and out of the reach of

children.

WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

• Check and add fuel before starting the engine.

Never remove gas cap or add fuel while the engine

is running. Allow engine to cool at least two

minutes before refueling.

• Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it may

cause a fire or explosion.

• Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

• Never refuel unit indoors because flammable

vapors will accumulate in the area.

• Never store the machine or fuel container inside

where there is an open flame or spark such as a

gas hot water heater, clothes dryer or furnace.

• Never run your machine in an enclosed area as the

exhaust from the engine contains carbon

monoxide, which is a odorless, tasteless and

deadly poisonous gas.

• To reduce fire hazard, keep engine and muffler free

of leaves, grass, and other debris build-up. Clean

up fuel and oil spillage. Allow unit to cool at least 5

minutes before storing.

• Before cleaning, repairing, or inspecting, make

certain the impeller and all moving parts have

stopped. Disconnect the s park plug wire and keep

wire away from spark plug to prevent accidental

starting. Do not use flammable solutions to clean

air filter.

• Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly.

• After striking a foreign object, immediately stop the

engine, disconnect the spark plug wire from the

spark plug, and thoroughly inspect the unit for any

damage. Repair damage before starting and

operating unit.

• Do not alter or tamper with the engine’s governor

setting. The governor controls the maximum safe

operating speed of the engine. Overspeeding the

engine is dangerous and will cause damage to the

engine and to other moving parts of the machine.

• Check the vacuum bag frequently for wear.

Replace if worn or damaged.

• Keep vacuum bag free of debris when not in use.

3

Page 4

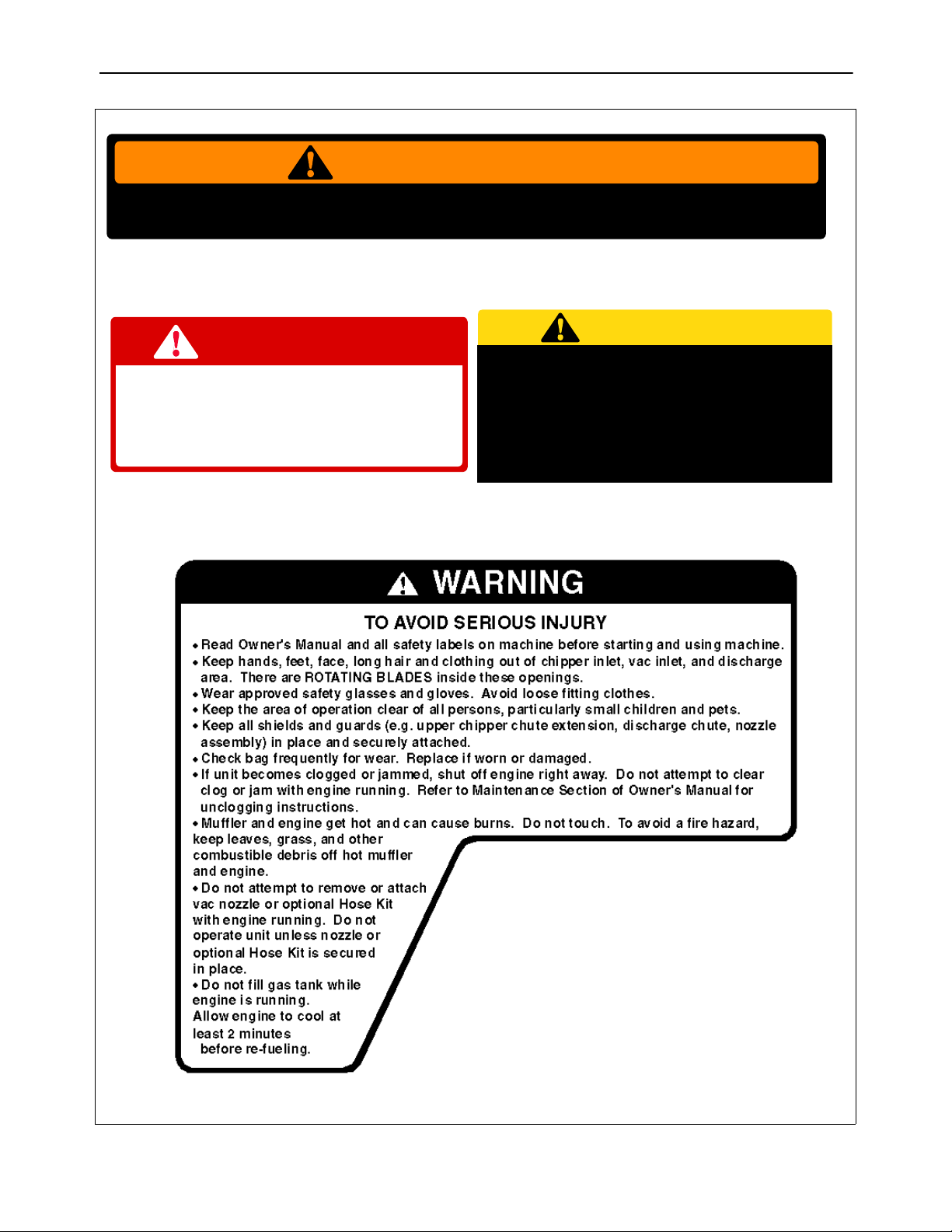

SECTION 2: SAFETY LABELS FOUND ON YOUR UNIT.

WARNING

ROTATING BLADES INSIDE. KEEP HANDS AWAY FROM ALL OPENINGS. DO NOT

REMOVE OR ATTACH NOZZLE OR OPTIONAL HOSE KIT WHEN ENGINE IS RUNNING!

CAUTION

DANGER

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

IS RUNNING.

S30181

DO NOT OPERATE THIS UNIT WITHOUT

ENTIRE BAG AND DISCHARGE CHUTE

IN PLACE. TURN THE ENGINE OFF AND

ALLOW THE IMPELLER TO COME TO A

COMPLETE STOP BEFORE REMOVING

THE BAG.

S30183

S30131

4

Page 5

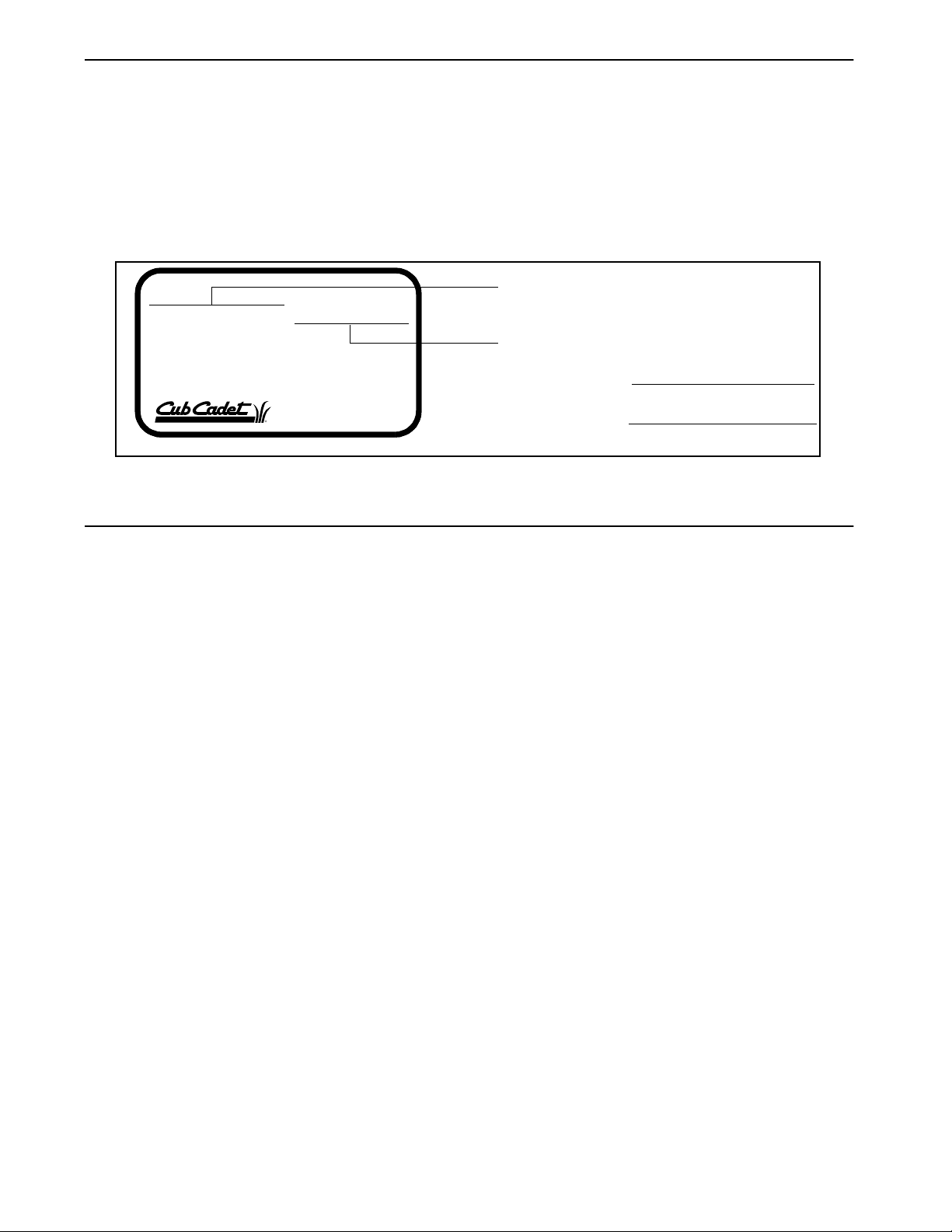

SECTION 3: FINDING YOUR MODEL NUMBER

This Operator’s Ma nua l i s an important part of y ou r new ch ipp er -vac uu m. I t wi ll hel p y ou ass emb le, prepare and

maintain your chipper-vacuum. Please read and understand what it says.

Before you prepare y our c hip per -va cu um fo r it s fir s t use, pl ea se l oc ate the m ode l pl ate and c op y th e in for ma tio n

from it in this Operator’ s Manual. The information on the model pl ate is very important if you need help from

your dealer or Customer Support Department.

• Every chipper-vacuum has a model p late. You can locate it by standi ng behind the unit in the operatin g

position and looking down at the frame just below the engine.

• The model plate will look like this.

This is where your model number will be.

XXX-X-XXX-X-XXX XXXXXXXXXXX

This is where your serial number will be.

Copy the model number here:

CUB CADET CORP .

P. O. BOX 368023

CLEVELAND, OHIO 44136

Copy the serial number here:

SECTION 4: CALLING WARRANTY SERVICE

If you are having d ifficult y assembl ing this product o r if yo u have a ny ques tion reg arding t he controls , opera tion

or maintenance of th is chipper-v accum, pleas e call the Cus tomer Deale r Referral Lin e. You can re ach them by

calling:

1-800-528-1009

Before calling your local dealer , make sure that you have your model an d serial numbe rs ready. By havin g the

model and serial num bers ready, you help your local d ealer give you faster servic e. To find your units model

and serial number, see SECTION 3: FINDING YOUR MODEL NUMBER.

5

Page 6

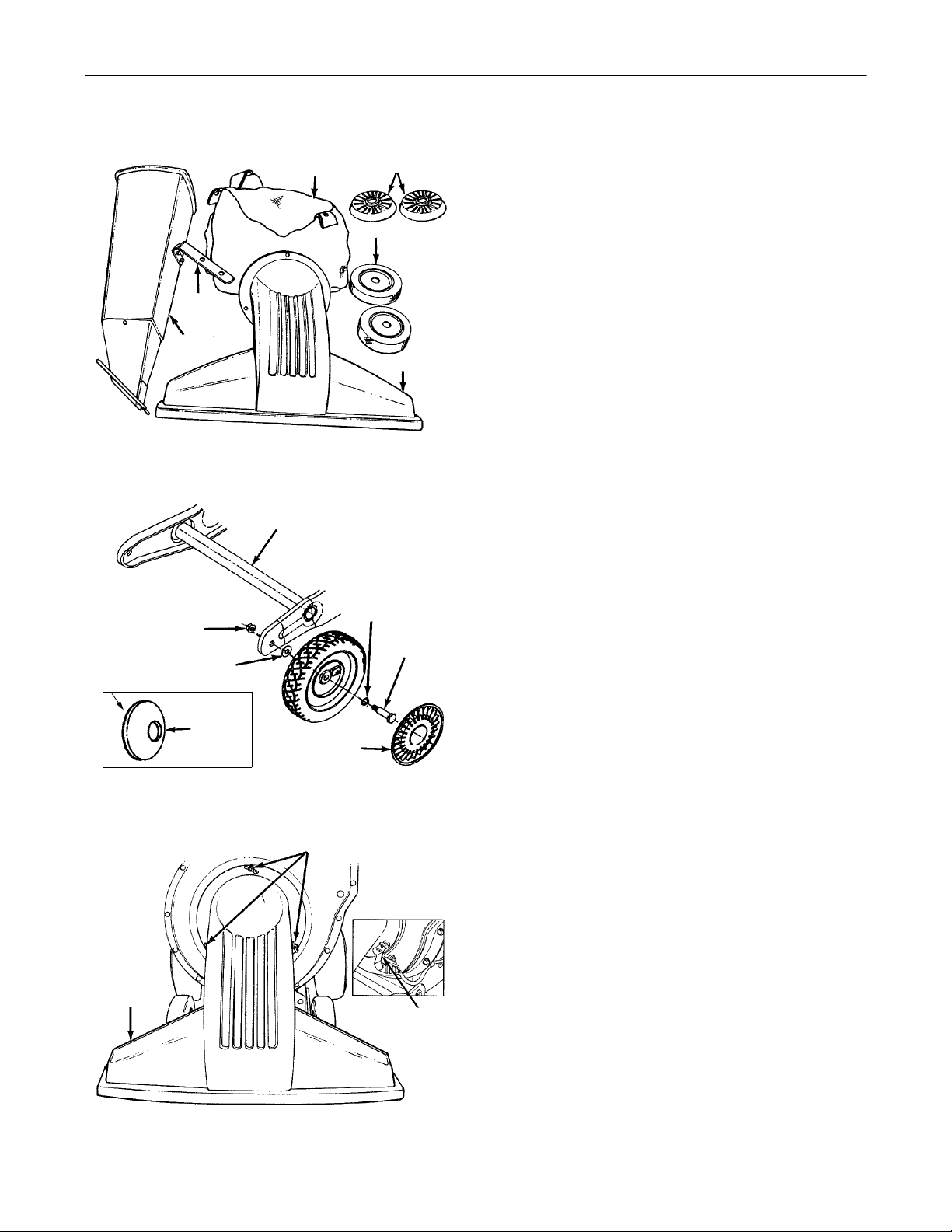

SECTION 5: ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL in the engine. After assembly,

see separate engine manual for proper fuel and

engine oil recommendations.

NOTE: To det ermine right and left hand side s of your

chipper-vacuum, stand behind and face the unit.

TO REMOVE CHIPPER-VACUUM FROM

CARTON

1. Remove staples, break glue on top flaps, or cut

2. Remove loose parts if included with unit (i.e.,

3. Cut corner’s and lay carton down flat.

4. Remove packing material.

5. Push down on handle to lift the front of the

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/4" Open End Wrench* (2) 1/2" Wrenches*

(1) Funnel (1) 9/16" Wrench*

(1) Set of Pliers (2) 7/16" Wrenches*

*Adjustable wrenches may be used.

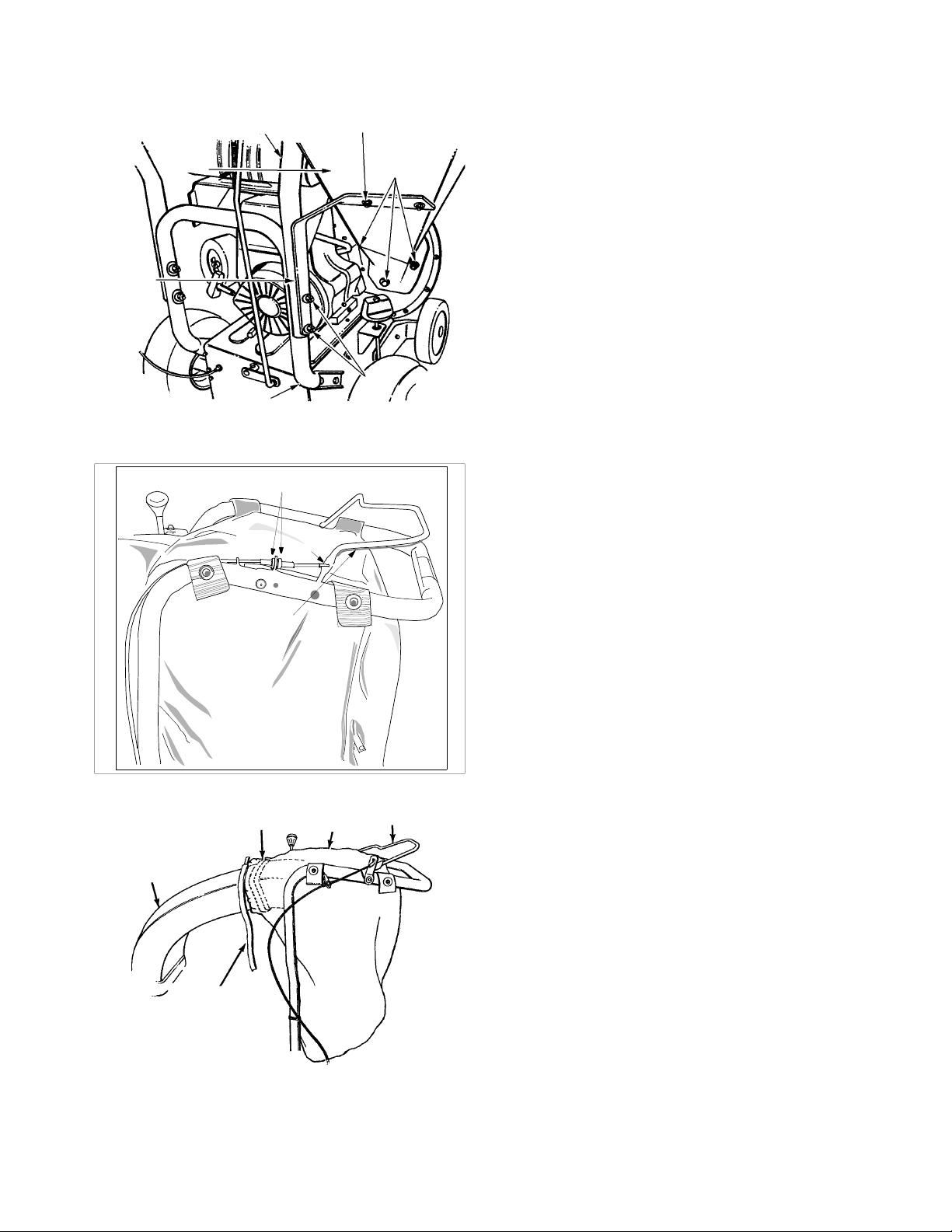

LOOSE PARTS IN CARTON (See Figure 1)

(2) Front Wheels (1) Bag

(2) Hub Caps (1) Shift Knob†

(1) Nozzle (1) Tamper Plug† (Opt.)

(1) Chipper Chute (1) Safety Glasses†

(1) Support Bracket

†Not Shown

ATTACHING THE FRONT WHEELS

1. Tilt unit backward so that it rests on the handle

2. Remove the hex lock nuts and s houlder bolts from

3. Place wave washer on shoulder bolt. Insert

4. Place cupped washer on shoulder bolt (crowned

5. Assemble wheel to outside of wheel bracket.

6. Attach hub caps to wheels by placing in position

ATT ACHING THE NOZZLE (See Figure 3)

1. Remove three wing nuts from the front of the

NOTE: The metal tab on the nozzle must depress the

safety switch on the front of th e chipper-vacuum or the

engine will not start.

2. Set unit in upright position.

Cupped

Side

Nozzle

Support

Bracket

Chipper

Chute

Hex Lock

Nut

Cupped

Washer

Crowned

Side

Bag

Figure 1

Wheel Bracket

Figure 2

Wing Nuts

Figure 3

Hub Caps

Front Wheels

Nozzle

Wave

Washer

Shoulder

Bolt

Hub

Cap

Metal Tab

tape at carton end and peel along top flap to open

carton.

operator’s manual, etc.).

chipper-vacuum, a nd roll unit ou t of carton. Check

carton thoroughly for loose parts.

(place a piece of th e carton under h andle to avoid

scratches). Remove the cardboard packing

material around the wheel brackets.

the front of the wheel brackets. See Figure 2.

shoulder bolt through wh eel, with the head of the

shoulder bolt through the flat side of the wheel.

side of washer goes against the wheel).

Secure hex lock nut. Tighten.

against the inner hub of the wheel. Press firmly

around the center portion of hub cap in a c ircular

motion, similar t o ins talli ng a l id on a round, pla stic

container. The hub caps ar e flexible and will snap

over the wheel hubs.

chipper-vacuum. Plac e nozzle in position ov er the

three studs. Secure with wing nuts just removed.

6

Page 7

Support

Bracket

Discharge

Chute

Chipper

Chute

Drawstring

Upper Handle

Lower

Handle

Figure 4

Hex Nuts

Drive Clutch

Handle

Figure 5

Rib

Hex Bolts, Flat

Washers and Nuts

Hex Nuts

and Cupped

Washers

Hex

Lock

Nuts

“Z”

End

Drive

Clutch Handle

Bag

ATTACHING THE CHIPPER CHUTE AND

SUPPORT BRACKET

1. Remove the two hex bo lts , fl at was hers a nd n uts

which are attached to the support bracket.

2. Attach the support brac ket to the bottom of the

chipper chute loosely using the hardware

removed previous ly. Heads of the hex bo lts and

washers go to the inside of the chipper chute.

3. Remove the two hex lock nuts from the hex bolts

which secure the right side of the upper handle to

the lower handle. Leave bolts and washers in

place.

4. Remove three cupped washers and 5/16" hex

nuts from the weld st uds beside the opening o n

the right side of the chipper-vacuum.

5. Place the chipper ch ute in po siti on over the weld

studs (slot goes at the bottom). Secure with

cupped washers and hex nuts just removed.

Only tighten the three nuts one or two threads

for ease of further assembly.

(See Figure 4)

NOTE: Cupped side of the washer goes against

the chipper chute. See Figure 2 to identify cupped

side of washer.

6. Place the support bracket over the two bolts in

the handle. Pushing UP on the chipper chute will

aid the alignment of the holes in the support

bracket with the bolts in the handle.

7. Tighten all hardware securely on the chipper

chute, support bracket and handle.

ATTACHING THE CLUTCH CABLE

The clutch cable has been p artia lly asse mbled at the

factory. You will have to attach the clutch cable, to

the handle.

1. Loosen the hex nuts at the cable bracket and

back the bottom hex nut all the way down.

2. Holding the drive c lutch handle up, hook the “Z”

end of the cable into the drive cl utc h han dle from

the outside to the inside. See Figure 5. Pliers will

aid in assembly.

CLUTCH CABLE ADJUSTMENT

Adjust the hex nuts at the c able bracket so there is

no slack in the cable, but the cable is NOT tight. Do

not overtighten the cable. See Figure 5.

To check the clutch adjustment, proceed as follows.

1. Push the chipper-v acuum ba ckward and fo rward

with the drive clutch handle released. It should

move freely.

2. If it does not, loosen bot h hex nuts at the cable

bracket. See Figure 5. Turn bottom nut

clockwise to loosen the cable.

3. Engage the drive clutch handle (hold against

upper handle), and try to push chipper-vacuum

backward and forward. The wheels should lock

up.

4. If the wheels do not lock up, loosen both hex

nuts at the cable bracket. Turn bottom nut

counterclockwise to tighten the cable.

5. Recheck adjustment. Tighten both hex nuts

when correct adjustment is reached.

Figure 6

7

Page 8

Straps on

Bag

Shift Knob

Straps on

Bag

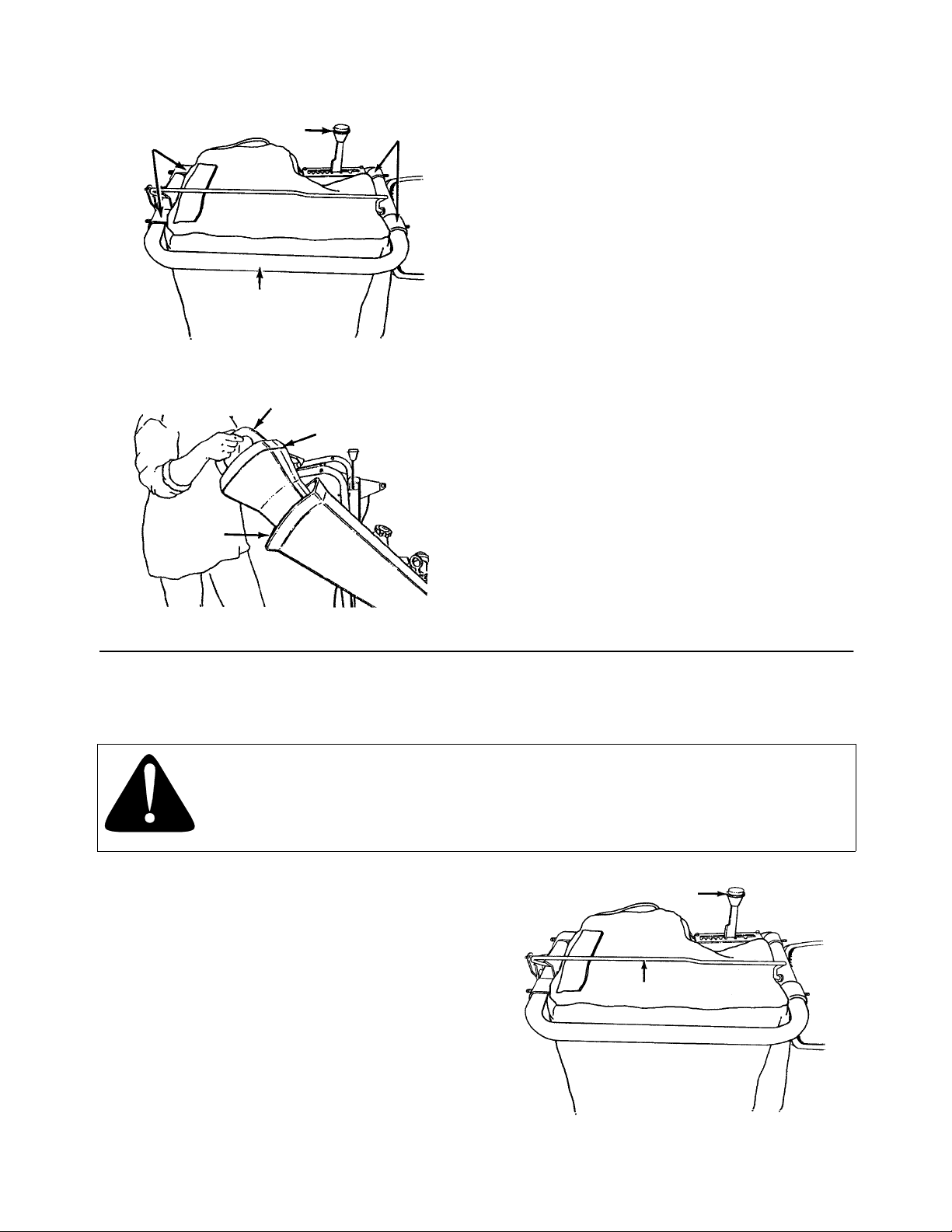

ATTAC HING THE BAG

1. Place bag inside of handle assembly. Slip the

opening on the bag over the discharge chute,

making certain it is over the rib on the disc harge

chute. See Figure 6.

2. Place the four straps on the top of the bag over

upper handle, hooking them on studs. See

Figure 7. Be sure the bag go es under the drive

clutch handle.

3. Squeeze the clamp on the drawstring, and pull

the drawstring tight. Release the clamp.

Upper Handle

Figure 7

Handle

Tamper Plug

Chipper

Chute

Figure 8

INSTALLING THE SHIFT KNOB

Thread the shift knob onto the end of the shift lever.

TAMPER PLUG (IF EQUIPPED)

The handle on the tamper plug must be in the

vertical positio n as shown in Figure 8. To determine

which side of the tamper plug is up, match the an gle

of the tamper plu g to the angle of the chipp er chute.

Insert the tamper plug into the chipper chute.

NOTE: Tamper plug should remain in the chipper

chute whenever the chipper chute is not in use.

SECTION 6: OPER ATIO N

BEFORE USING YOUR CHIPPER-VACUUM, REFER TO THE ‘‘SAFETY RULES’ ’ AS SHOWN ON PAGES

2 AND 3 OF THIS MANUAL. ALWAYS BE CAREFUL.

The operation of any c hi ppe r-v ac uum ca n r esu lt i n fo re ign obj ects b e ing th ro wn in to th e ey es ,

which can damage your ey es s ev erel y. Al ways w ea r th e sa fet y glas ses p r ovided wi th t his

unit or eye shields before chipping, or while performing any adjustments or repairs.

We recommend Wide Vision Safety Mask for over spectacles or standard glasses.

CONTROLS (See Figure 9)

SHIFT LEVER—The shift lever determines ground

speed of your unit. It may be placed in one of eight

positions. Of these eight, six positions are to go

forward, and two positions are to go in reverse.

Forward—one of six speeds. Position number one

(1) is the slowest. Position number six (6) is the

fastest.

Reverse—two reverse (R) speeds. “R” (all the way

to the right) is the faster of the two.

DRIVE CLUTCH HANDLE

Squeezing the drive clutch handle a gainst the upper

handle engages the wheel drive. Release the drive

clutch handle to stop the wheel drive.

Shift Lever

Drive Clutch Handle

Figure 9

8

Page 9

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as

instructed in the separate engine manual packed

with your chipper-vacuum. Read instructions

carefully.

NOTE: Your chipper -va cu um is s hipped without oil;

however, a small amount of oil m ay be presen t from

the factory. Do not overfill.

WARNING: Never fill fuel tank indoors,

with engine running or whil e engine is hot.

Do not smoke when filling fuel tank.

TO START ENGINE

8. Repeat instructions 6 and 7 until engine fires.

When engine starts, move choke control (if so

equipped) gradually to RUN position.

TO STOP ENGINE

1. To stop engine, move throttle control lever to

OFF position.

2. Disconnect spark plug wire and ground to

prevent accidental starting while equipment is

unattended.

TO EMPTY BAG

Open the large zipper on the bag to empty the bag.

See Figure 10. Be certain the zipper is closed

when operating the unit.

IMPORTANT:

with the clutch handle disengaged, shut engine off

immediately. Readjust as instructed in the “Clutch

Cable Adjustment” section of the Assembly

Instructions.

If unit shows any sign of motion

WARNING: Be sure no one other than

the operator is standi ng near the chippervacuum while star ting or operating . Do not

operate this chipper-vacuum unless the

nozzle, discharge chute and bag have

been properly installed.

NOTE: Your chipper-vacuum unit has a safety

switch at the front of the housing. The nozzle or

optional hose attachment must be in place on the

chipper-vacuum before the engine can be started.

1. Attach spark plug wire to spark plug.

2. Make certain drive clutch handle is in the

disengaged (released ) posit ion .

3. Engines with choke lever: Move choke lever

on engine to CHOKE position. (A warm engine

may not require choking.)

Engines with primer: Prime engine as

instructed in separate engine manual.

4. Move throttle control lever on engine to FAST

position.

5. Place one foot on th e left rear wheel to preven t

the unit from skidding while starting.

6. Grasp starter handle and pull rope out slowly

until engine reaches start of compression cycle

(rope will pull slightly harder at this point). Let

the rope rewind slowly.

NOTE: A noise will be heard wh en finding the star t

of the compression cycle. This noise is caused by

the flails and fingers whi ch are part of the shredd ing

mechanism falling into place, and should be

expected. In addition, the flails and fingers will be

noisy after the engine is started, until the impeller

reaches full speed.

7. Pull rope with a rapid, continuous, full arm

stroke. Keep a firm grip on starter handle. Let

rope rewind slowly. Do not let starter handle

snap back against starter.

Large

Zipper

Closed

Figure 10

TO ENGAGE DRIVE

IMPORTANT: Always release the drive clutch

handle before moving the shift lever.

With the engine running at top speed, move shift

lever into one of the six FORW ARD positions or two

REVERSE positions. Se lect a speed appropriate for

the conditions that ex ist. Use th e slow er sp eeds un til

you are familiar with the operation of the chippervacuum.

To engage the wheel drive, hold the drive clutch

handle against the chipper-vacuum handle.

Releasing the dri ve clutch handle stops the wheels

from driving. Rele ase the dr ive clutc h handle to slow

down when negotiating an obstacle, making a turn or

stopping. Engage slowly to prevent front wheels

from lifting up.

HOW TO USE THE CHIPPER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (i.e.,

branches, leaves, twigs, etc.). Material such as

stalks or heavy branches up to 3" in dia meter may

be fed into the chipper chute. See Figure 11.

9

Page 10

WARNING: Material up to a

maximum of 3" in diameter may be fed

into the chipper chute. Do not attempt

to shred or chip any material larger

than 3" in diameter. Personal injury or

damage to the machine could result.

Use the tamper plug (if so equipped) to push

material into the chipper chute. See Figure 8.

NEVER PLACE HANDS INSIDE CHIPPER CHUTE.

Place tamper plug inside chipper chute w hen not in

use to deaden the sound.

IMPORTANT: There is a flail screen located

inside the housin g in the discharge area. If the flail

screen becomes clogged, remove and clean as

instructed in the Maintenance section on page 11.

For best performance, it is important to keep the

chipper blades sh arp. Refer to Maintenance section ,

page 11. If the composition of the material being

discharged changes (be comes stringy, etc.) or if the

rate at which the material is di scharged slows down

considerably, it is likely that the chipper blades are

dull and need to be sharpened or replaced.

Figure 11

SECTION 7: ADJUSTMENTS

WARNING: Do not at any time make

any adjustment to the unit without first

stopping engine and disconnecting spark

plug wire.

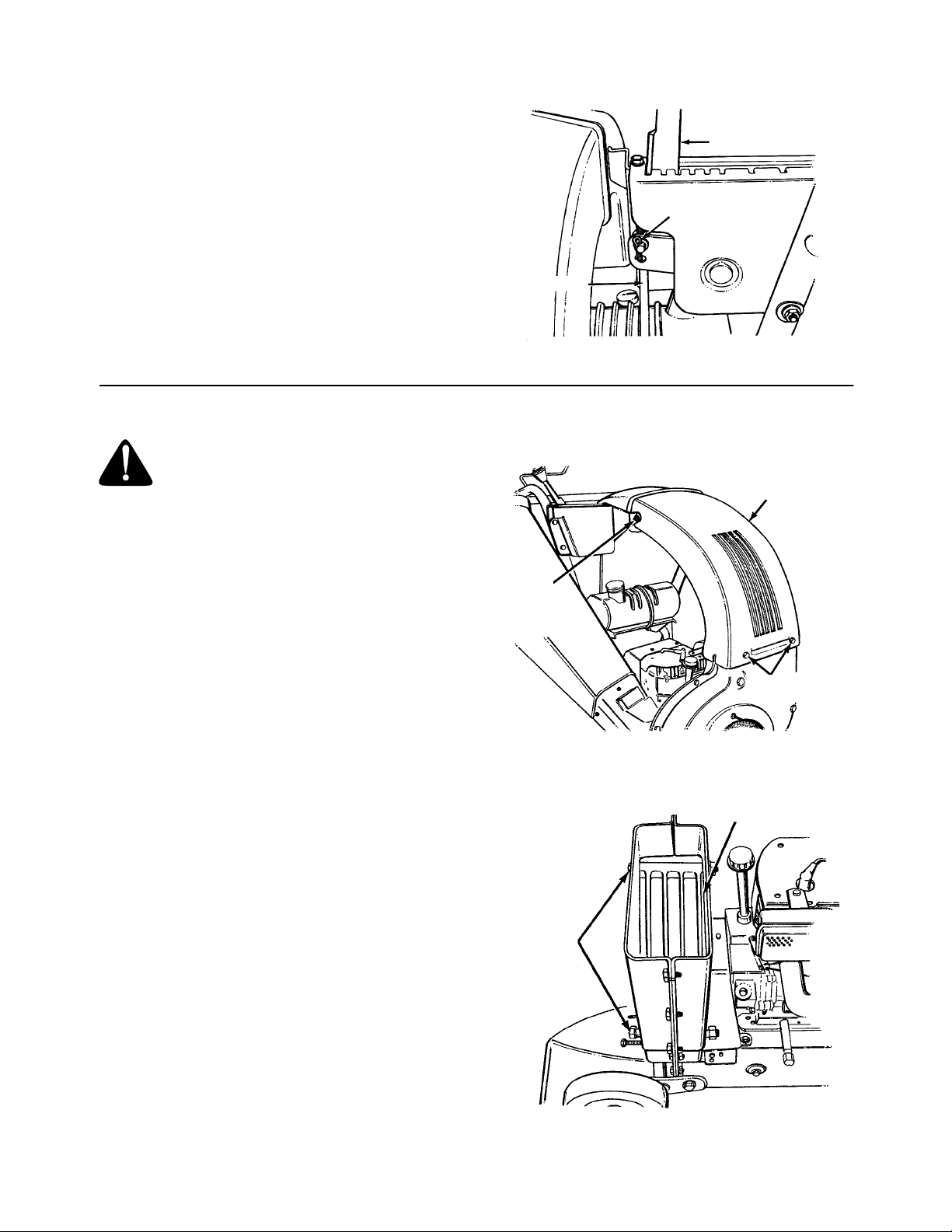

HEIGHT ADJUSTMENT

The height adjustment knob is located on the right

hand side of the chipper-vacuum. See figure 12.

Turn the knob clockwise to raise the nozzle. Turn the

knob counterclockwise to lower. (Be careful not to

turn knob too far—rod could come out of ferrule.)

The best height for the nozzle will v ary according to

the conditions. Adjust the height of th e nozzle to fin d

the setting which g ives the best p erformance for th e

operating conditio ns. In general, raise the nozzle to

vacuum a thick layer of leaves; lower the nozzle for

smooth surfaces.

Height

Adjustment

Knob

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are

made to the engine while the engine is

running (e.g., carburetor), keep clear of

all moving parts. Be careful of heated

surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude or load. Do not make unnecessary

adjustments. Factory settings are satisfactory for

most applications and conditions. If adjustment is

needed, refer to the s eparate eng ine ma nual p acked

with your chip per-vacuum.

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

CLUTCH CABLE ADJUSTMENT

To adjust the clutch cable, refer to the “Clutch Cable

Adjustment” section of Assembly Instructions.

Ferrule

Figure 12

10

Page 11

SHIFT ROD ADJUSTMENT

If the shift rod needs adj ustment to o btain forwar d or

reverse correctly, proceed as follows. See Figure 13.

1. Remove the bag from the unit.

2. Remove the hairpin clip a nd flat wa sher from the

upper end of the sh ift rod. Pull the ferrule o ut of

the hole in the shift lever. (Make certain wave

washer remains in place on the ferrule.)

3. Place the shift lever in 6th position (all the way to

the left).

4. Push down on the shift rod. Thread the ferrule

up or down the shift rod until the ferrule lines up

with the upper hole in the shift lever.

5. Secure ferrule to shift leve r with flat washer and

hairpin clip.

SECTION 8: MAINTENANCE

Shift Lever

6th Position

Hairpin Clip

Flat Washer

Shift Rod

Figure 13

WARNING: Always stop engine and

disconnect spark plug wire before

cleaning, lubricating or performing any

repairs or maintenance.

LUBRICATION

Wheels—Rear wheels are provided with light oil

bearings. Place a fe w drops of SAE 30 oil on each

bearing once a season.

Height Adjustment Mechanism—Lubricate the

pivot points on the height adjustment mechanism

once a season using a light oil.

CLEANING

Clean the chipper-vacuum thoroughly after each

use. Wash the bag per iodically with water. Allow to

dry thoroughly in the shade. Do not use heat.

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

REMOVING THE FLAIL SCREEN

If the discharge area become s clogged, remove the

flail screen and clean area as follows.

1. Stop the engine. Make certain the chippervacuum has come to a complete stop.

Disconnect the spark plug wire before

unclogging the discharge chute.

2. Remove the vacuum bag from the unit.

3. Remove the four self-tapping screws from the

bottom of the discharge chute, and the hex bol t,

flat washer and hex nut from the top. Remove

the discharge chute assembly. See Figure 14.

4. Remove the two hex bolts and hex nuts which

extend through the housin g. Lift the flail screen

from inside the housing. See Figure 15.

5. Clean the screen by scraping or washing with

water. Reinstall the screen.

NOTE: Be certain to reassemble the flail screen

with the curved side down as shown in Figure 15.

Discharge

Chute

Assembly

Hex Bolt

Flat Washer

Hex Nut

Self-Tapping

Screws

Figure 14

Flail Screen

Hex Bolts

and Nuts

Figure 15

11

Page 12

SHARPENING OR REPLACING CHIPPER

BLADES

1. Disconnect the spark plu g wire and move away

from the spark plug.

2. Remove the flail screen as instructed in the

previous section.

3. Remove the plastic belt cov er on the front of the

engine by removing t he two self -tapping scr ews.

See Figure 16.

Belt

Cover

Self-Tapping

Screws

Figure 16

4. Remove the access plate by removing two hex

lock nuts. See Figure 17.

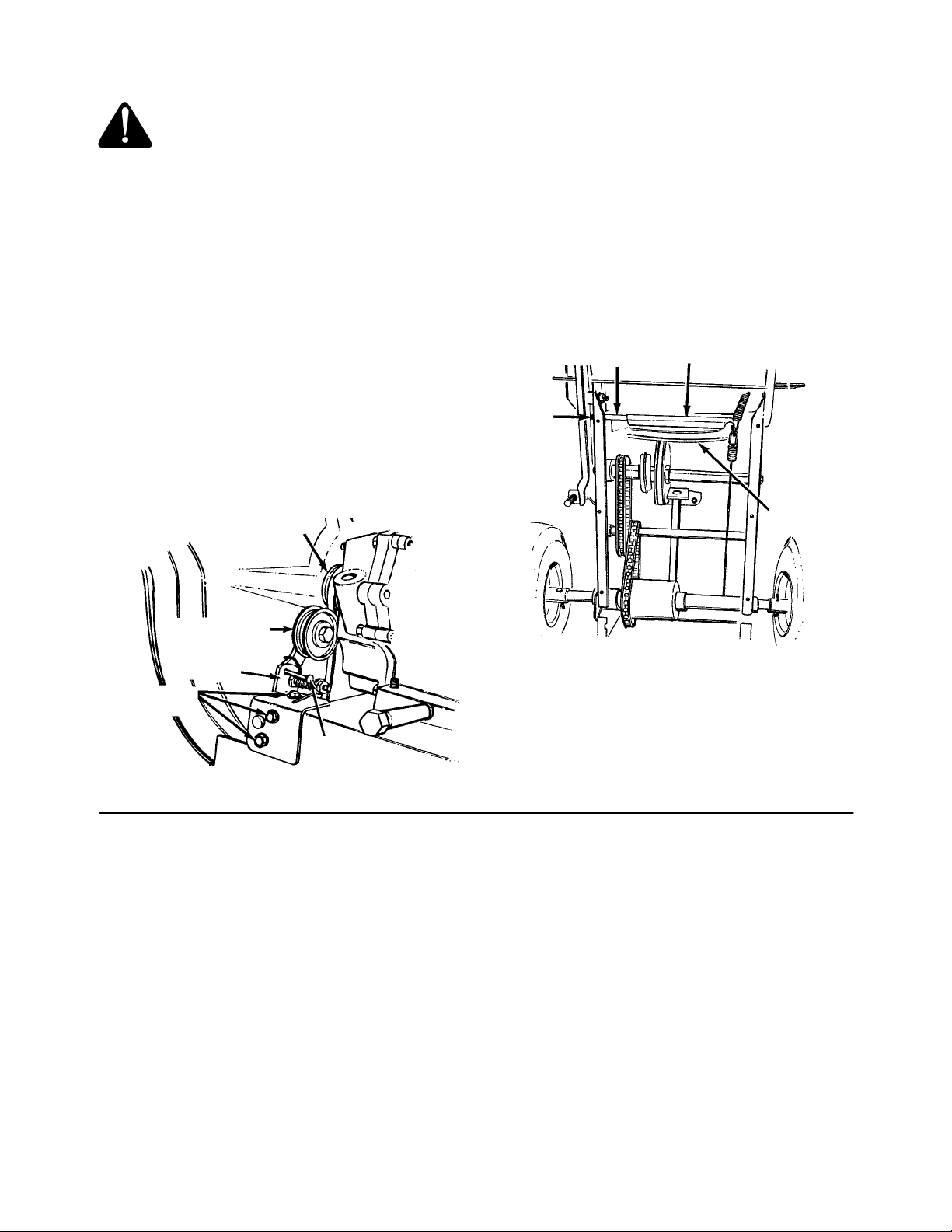

CHANGING THE FRICTION WHEEL

RUBBER

The rubber on the friction wheel is subject to wear

and should be checke d after 50 hours of operation,

and periodically thereafter. Replace friction wheel

rubber if any signs of wear or cracking are found.

1. Drain the gasoline and oil from the chippervacuum.

2. Tip the unit backward so it rests on the handles.

3. Remove the frame cov er by removing eight selftapping screws from underneath the chippervacuum. See Figure 18.

4. Remove the hex shaft from the uni t by removing

the hex bolts, lock washers and flat washers

from each side of the frame. See Figure 19. Hold

the friction wheel assembly, and slide the hex

shaft out of the unit toward the right side.

5. Remove the six screws from the friction wheel

assembly (three from each side). Remove the

friction wheel rubber from between the friction

wheel plate.

6. Reassemble new friction wheel rubber to the

friction wheel assembly, tightening the six

screws in rotation and with equal force.

7. Slide the friction wheel assembly up onto the

shift mechanism, then slide the hex shaft back

into the unit. Reassemble in reverse order.

8. Readjust the clutch cable. Refer to adjustment

section.

Hex

Lock Nuts

Access

Plate

Figure 17

5. Locate one of the chipper blade s in the access

plate opening by rot ating the impeller assembly

by hand. Remove the blad e using a 3/16" allen

wrench on the outside of the blade and 1/2"

wrench on the impeller assembly, inside the

housing. Torque hardware to 250-300 inch

pounds.

6. Remove the other blade in the same manner.

Replace or sharpen blades. If s harpening, make

certain to remove an equal amount from each

blade. Reassemble in reverse order.

NOTE: Make certain blades are r eassembled with

the sharp edge facing upward, as viewed from the

access plate opening.

Friction

Wheel

Self-Tapping

Screws

Frame Cover

Figure 18

Hex

Shaft

Figure 19

Hex Bolt

Lock Washer

Flat Washer

12

Page 13

BELT REMOVAL AND REPLACEMENT

WARNING:

wire and move away from the spark

plug.

1. Remove the plastic belt cov er on the front of the

engine by removing two self-tapping screws.

Refer to Figure 16.

2. Drain the gasoline and oil from the chippervacuum.

3. Tip the unit backward so that it rests on the

handles.

4. Remove the frame cov er by removing eight selftapping screws from underneath the chippervacuum. Refer to Figure 18.

5. Remove the idler pulley br acket as follows. ( See

Figure 20.)

a. Take the tension off the belt by pivoting the

idler pulley towar d you, and li ne up the holes

in the idler bracket asse mbly. Insert a nail or

similar object through the holes to hold the

idler pulley in this position.

b. Remove three self-tappi ng screws , and lift off

the idler bracket assembly.

Disconnect the spark plug

Engine

Pulley

6. Remove the hex bolt and lock washe r from the

engine pulley. See Figure 20. Slip the engine

pulley off the engine shaf t, and remove the belt

from the pulley.

7. Loosen the nut on the stop bolt until there is

clearance between the sup port bracket and the

friction wheel disc. See Figure 21.

8. Slip the belt between the friction wheel and

friction wheel disc. Remove and replace belt.

Reassemble following instruction in reverse

order.

NOTE: The support bracket must rest on the stop

bolt after the new belt has been assembled.

Support

Stop Bolt

Loosen

Nut

Bracket

Friction

Wheel Disc

Idler

Pulley

Idler

Bracket

Assembly

Self-Tapping

Screws

Nail

Figure 20

SECTION 9: OFF-SEASON STORAGE

The following steps s hould be taken to prepare your

chipper-vacuum for storage .

1. Remove all dirt from exterior of engine and

equipment.

2. Refer to engine manual for correct engine

storage instructions.

3. Wipe unit with an oiled rag to preve nt rust (us e a

light oil or silicone), especially if storing in an

unventilated or metal storage shed.

4. Store in a dry, clean a rea. Do not store next to

corrosive materials, such as fertilizer.

Figure 21

13

Page 14

SECTION 10: TROUBLE SHOOTING GUIDE

T rouble Possible Cause(s) Corrective Action

Engine fails to start Dirty aircleaner.

Fuel tank empty or stale fuel.

Spark plug wire

disconnected.

Cannot pull recoil cord.

Choke not in ON position.

Faulty spark plug.

Nozzle safety switch not

depressed.

Loss of power; operation

erratic

Engine overheats Carburetor not adjusted

Too much vibration Loose parts or damaged

Unit does not discharge Discharge chute clogged.

Rate of discharge slows

considerably or

composition of discharged

material changes

Spark plug wire loose.

Unit running on CHOKE.

Blocked f uel line or stale fuel.

Water or dirt in fuel system.

Carburetor out of adjustment.

Low engine RPM.

Dirty air cleaner.

properly.

Dirty aircleaner.

Engine oil level low.

impeller.

Foreign object lodged in

impeller.

Low engine RPM.

Vacuum bag is full.

Low engine RPM.

Chipper blades dull.

Refer to the engine manual packed with your unit.

Fill tank with clean, fresh gasoline. Fuel will not last over

thirty days unless a fuel stabilizer is added.

Connect wire to spark plug.

Obstruction lodged in impeller. Stop immediately and disconnect spark plug wire. Re move lodged object.

Move switch to ON position.

Clean, adjust gap or replace.

Adjust metal tab so it depresses the safety switch.

Connect and tighten spark plug wire.

Move choke lever to OFF position.

Clean fuel line; fill tank with clean fresh gasoline. Fuel will

not last over thirty days unless a fuel stabilizer is used.

Disconnect fuel line at carburetor to drain fuel tank. Refill

with fresh fuel.

Refer to the engine manual packed with your unit.

Always run engine at full throttle.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Stop engine immediately and disconnect spark plug wire.

Have unit serviced by a an authorized service dealer.

Stop engine immediately and disconnect spark plug wire.

Clean flail screen and inside of blower housing. See

Maintenance section of this manual.

Stop engine immediately and disconnect spark plug wire.

Remove lodged object.

Always run engine at full throttle.

Empty bag.

Always run engine at full throttle.

Replace chipper bl ades or see your authorized service

dealer.

Note: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

14

Page 15

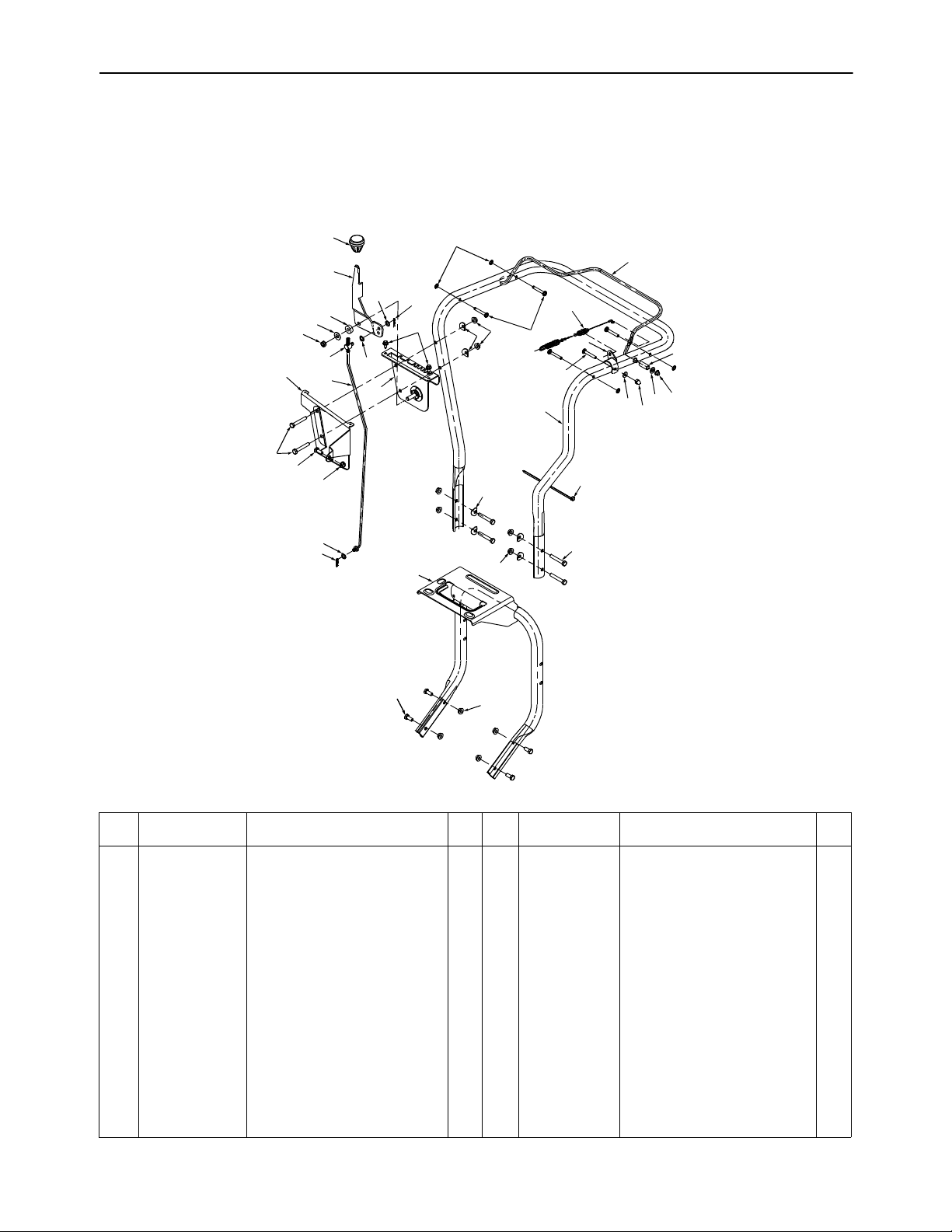

SECTION 11: ILLUSTRATED PARTS

CSV 260

14

27

17

16

18

11

9

26

6

8

12

13

19

25

19

5

1

2

13

7

4

12

20

20

12

24

10

28

21

3

6

29

15

22

23

31

30

8

REF.

PART

NO.

NUMBER DESCRIPTION QTY

1 1539-019 Nut, Push, .25 4 18 736-0300

12

REF.

PART

NO.

NUMBER DESCRIPTION QTY

Washer, Flat, .406 x .875x

.059

2 747-1133-0498 Control Assembly, Clutch 1 19 736-0413 Washer, Spring, .390 x .62 2

3 749-1083-0498 Handle Assembly, Upper 1 20 736-0451 Washer, Saddle, .320 x .93 6

4 649-0012-0498 Handle Assembly, Lower 1 21 710-0495 Carr. Bolt 1/4-20 x 1.75” Lg. 1

5 681-0076-0498 Bracket Assembly, Shift 1 22 750-1185 Spacer 1

6 710-3103 Screw, Hex Cap, 5/16-18 x 2.0 6 23 726-0135 Nut, Cap Speed 1

7 710-0896 Screw,Hex Wash Hd,4-14x 2 24 746-1080 Cable, Clutch 1

8 710-3008 Screw, Hex Cap 5/16-18 x .75 5 25 747-0626 Rod, Shift 1

9 711-0677 Ferrule 1 26 781-0626-0498 Cover, Shift 1

10 711-0737 Pin, Stud, .250 x 1.75 4 27 784-0297A Handle, Shift 1

11 712-0116 Nut, Hx Ins Jam Lk 3/8-24 Thd. 1 28 781-0157 Bracket, Cable Mtg. 1

12 712-3004A Nut, Hex Flange Lock 5/16-18 11 29 736-3020 Washet, Flat .271 x .63 x .65 1

13 714-0104 Pin, Internal Cotter 2 30 712-0442 Nut, Lock, Acorn 1/4-20 1

14 720-0232 Knob, Shift 1 31 736-0275 Washer, Flat 5/16 1

15 725-0157 Cable Tie 1

16 735-0126 Rubber Washer 1

17 736-0117 Washer, Flat .385 x .62 x .6 1

1

15

Page 16

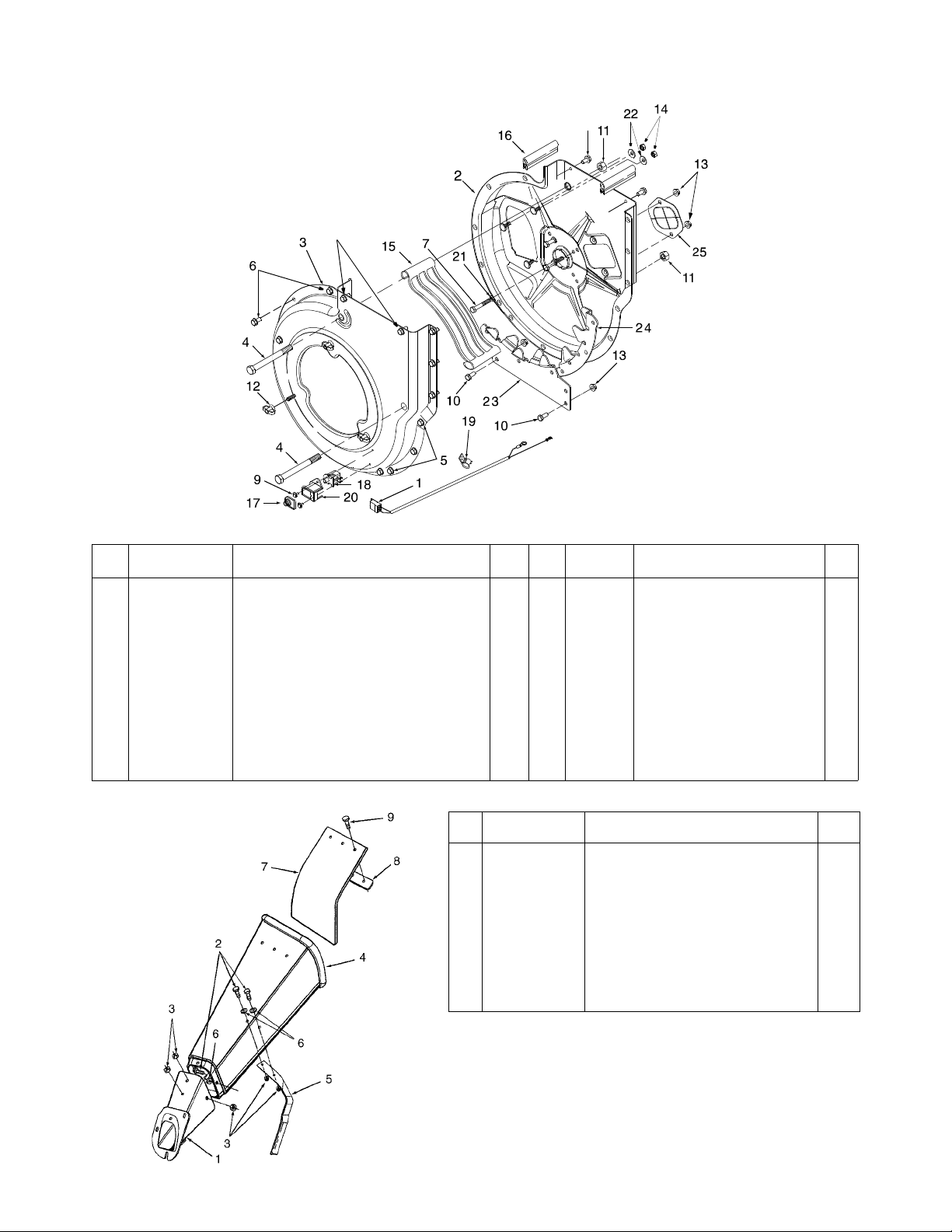

CSV 260

5

5

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 629-0241 Harness, Wire 1 14 712-3010 Nut, Hex, 5/16-18 3

2 681-0059-0498 Housing Ass’y, Inner Flail 1 15 719-0326 Screen, Discharge 1

3 681-0060-0498 Housing Ass’y, Outer Flail 1 16 723-0438 Rubber Seal 2

4 710-0382 Screw, Hex Cap, 1/2-13 x 5.0 2 17 725-1700 Cover, Switch 1

5 710-0604 Screw, Hex Wash Hd Tapp 5/16-18 x .62 10 18 725-3166 Switch, Snap Mount 1

6 710-0607 Screw, Hex Wash Hd Tapp 5/16-18 x .50 8 19 726-0272 Clamp 1

7 710-0772 Screw, Hex Cap, 5/16-24 x 2 GR5 3 20 731-1613 Cover, Safety Switch Mtg. 1

9 710-1268 Screw, Hex Wash Hd Tapp #10-16 x .38 21 736-0119 Washer, Lock, 5/16 3

10 710-3008 Screw, Hex Cap, 5/16-18 x .75 GR5 2 22 736-0242 Washer, Bell, .345 x .88 x .06 3

11 712-0384 Nut, Hex Center Lock, 1/2-13 2 23 781-0598 Blade, Lower Shredder 1

12 712-0421 Knob, 5/16-18 2 24 781-0599 Blade, Upper Shredder 1

13 712-3004A Nut, Hex Flange Lock, 5/16-18 3 25 781-0627 Cover, Chipper Blade 1

REF.

NO.

1 681-0068-0498 Chute Assembly, Chipper 1

2 710-0751 Screw, Hex Cap, 1/4-20 x .625 5

3 712-3027 Nut, Hex Flange Lock, 1/4-20 5

4 731-1574 Chute, Chipper 1

5 781-0625-0498 Bracket, Chipper Chute Support 1

6 736-0173 Washer, Flat, .28 x .74 x .63 5

7 735-0249 Flap, Chipper Chute 1

8 781-0633 Strip, Chute Flap 1

9 728-0175 Rivet, Pop, .156 x .504 3

— 731-1617 Tamper Plug (Optional - Not Shown) 1

REF.

PART

NO.

NUMBER DESCRIPTION QTY

PART

NUMBER DESCRIPTION QTY.

16

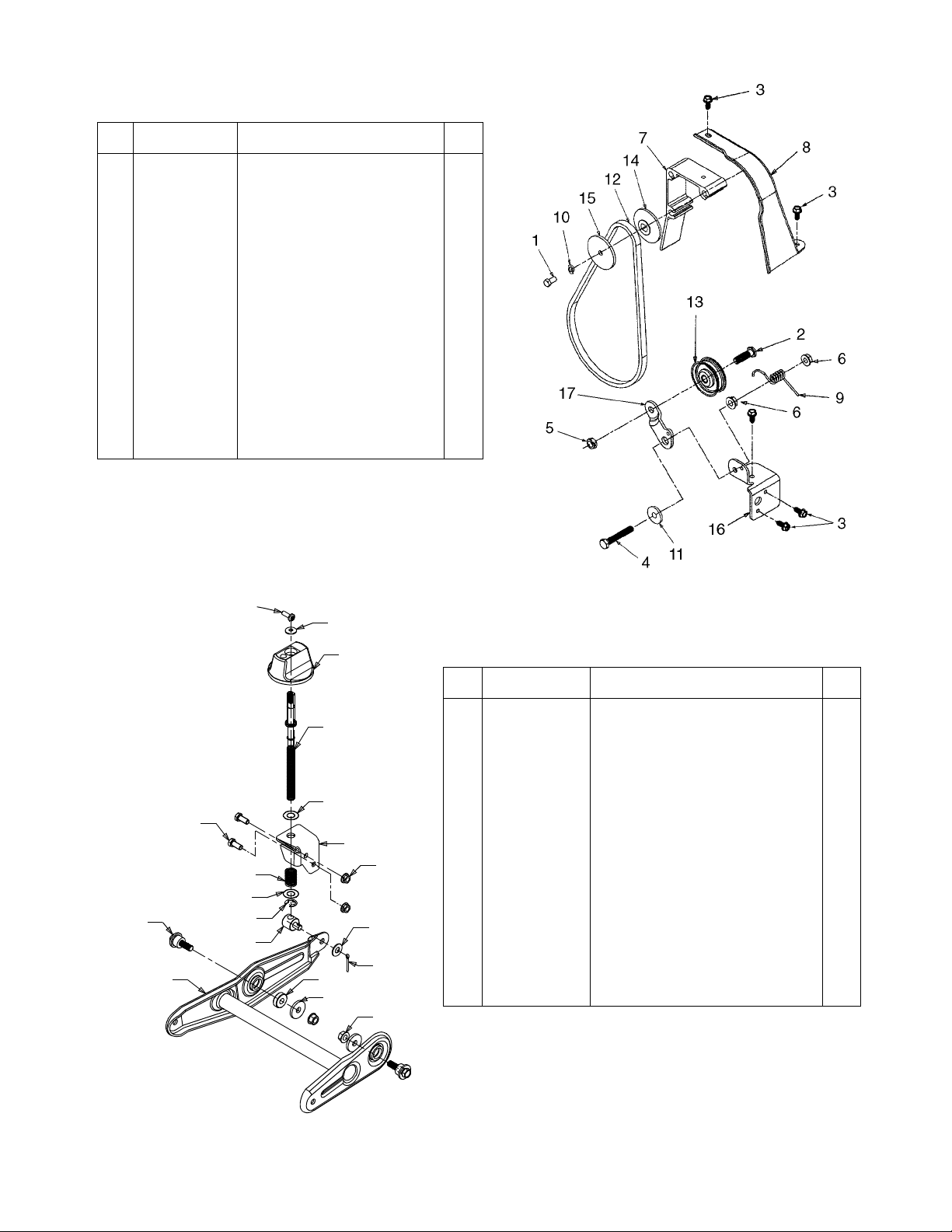

Page 17

CSV 260

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 710-0230 Screw, Hex Cap, 1/4-28 x .50 1

2 710-0723 Screw, Hex Cap, 3/8-16 x 1 .25 1

3 710-08 96 Screw, Hex Wash Hd Tapp. 1/4-

4 710-0646 Screw, Hex Cap, 5/16-18 x 2.0 1

5 712-0266 Nut, Hex Cent-L Jam, 3/8-16 1

6 712-3004A Nut, Hex Flange Lock, 5/16-18 2

7 719-0330A Adapter, Engine Mt g 1

8 731-1584 Belt Cover 1

9 732-07 45 Spring, Torsion, .54 x 1.0 1

10 736-0329 Washer, Lock, 1/4 1

11 748-0234 Shoulder Spacer, .50 ID x .27 Lg 1

12 754-0256 V-Belt, 3/8 x 29.0 Lg 1

13 756-0313 Pulley, Flat Idler 1

14 756-0987 Pulley Half, 2.0 Dia 1

15 756-0986 Pulley Half, 2.0 Dia 1

16 781-0611-0498 Bracket, Idler Pivot 1

17 781-0614 Bracket, Idler 1

14 x .625

5

16

3

13

10

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 681-0096-0498 B racket Ass’y, Wheel Pivot 1

17

15

4

19

11

15

9

5

1

18

12

7

14

8

6

3 710-0924 Screw, Pan Hd Mach, 1/4-20 x .75 1

4 710-3008 Screw, Hex Cap, 5/16-18 x .75 GR5 2

5 711-1041 Ferrule, Adjustment 1

6 712-0431 Nut, Hex Flange Lock, 3/8-16 2

7 712-3004A Nut, Hex Flange Lock, 5/16-18 2

8 714-0115 Pin, Cotter, 1/8 x 1.0 1

9 716-0104 E-Ring, .50 Dia 1

10 720-0236 Knob 1

11 732-0645 Spring, Compression 1

12 736-0247 Washer, Flat, .406 x 1-1/4 2

13 736-0270 Washer, Bell, .265 x .75 x .062 1

14 736-0300 Washer, Flat, .406 x .875 x .059 1

15 736-0369 Washer, Flat, . 508 x 1.0 x .020 2

16 738-0955 Shoulder Bolt, .75 x .43: 3/8-16 2

17 747-0631 Rod, Height Adj ustment 1

18 711-0242 Spacer, .380 ID x 1.0 OD x .32 Lg 1

19 781-0605-0498 Bracket, Height Adj 1

17

Page 18

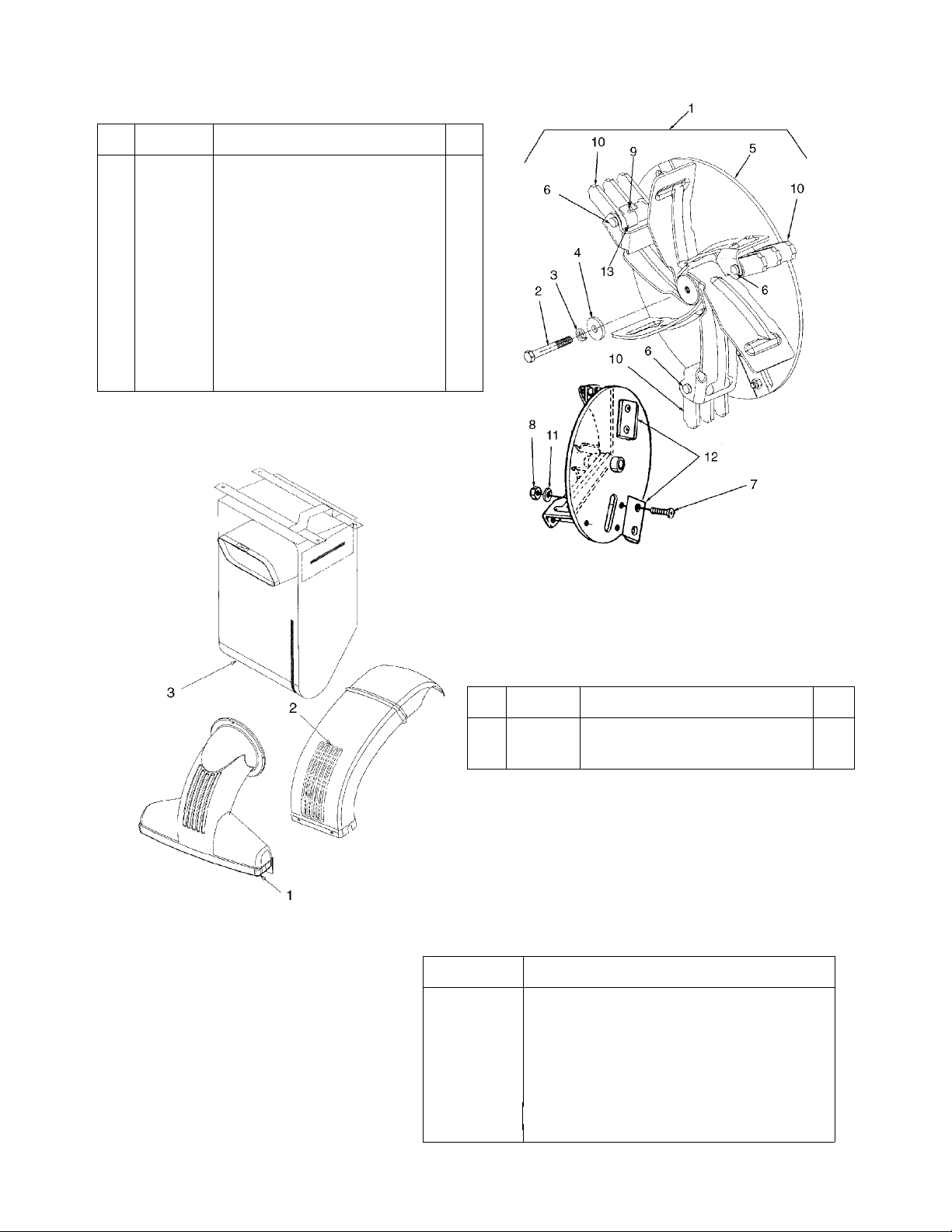

CSV 260

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 681-0078 Impeller Ass’y, Complete Includes

2 710-1273 Screw, Hex Cap, 3/8-24 x 2.75 GR5 1

3 736-0217 Washer, Lock, 3/8 Heavy Duty 1 1

4 736-0247 Washer, Flat, .406 x 1-1/4 HD1 1

5 681-0052 Impeller Assembly 1

6 711-0833B Pin, Clevis 3

7 710-1054 Screw, Flat Hd. Cap, 5/16-24 x 1.0 4

8 712-0411 Nut, Hex Insert Lock, 5/16-24 4

9 715-0166 Pin, Spirol, 5/32 x 1.125 3

10 719-0329 Blade, Flail 3

11 736-0119 Washer, Lock, 5/16 4

12 742-0544 Blade, Chipper 2

13 781-0735 Pin Retaining Clip 3

Ref. Nos. 5 thru 13

1

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 631-0029 Nozzle Assembly, Vacuum 1

2 731-1616 Chute, Discharge 1

3 764-0474 Bag, Vacuum 1

Labels found on your unit.

PART

NUMBER DESCRIPTION

777S30181 Label—Danger Top of Chipper Chute

777I20350 Label—Squeeze Bail

777I20351 Label—Raise, Lower

777S30183 Label—Warning Top Flail Housing

777S30041 Label—Warning Back Flail Housing

777I20353 Label—6 Speed

777D00543 Label—Hubcaps

777D03044 Label—CSV 260

777D03045 Label—9 HP Cub Cadet

18

Page 19

CSV 260

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 618-0168 Differential Ass’y Complete 1

2 710-1206 Screw, Hex Wash Hd Tapp 1/4-20

3 711-1035 Cross Shaft 1

4 711-1037 Axle Shaft, .75 x 10.95 1

5 711-1038 Axle Shaft, .75 x 9.82 1

6 713-0445 Spocket, 22T 1

7 716-0232 Ring, Retaining 4

8 717-1358 Gear, Differential, 14T 2

9 717-1437 Gear, Differential, 10T 2

10 719-0333 Housing, Differential RH 1

11 719-0334 Housing, Differential LH 1

12 748-0383 Bearing, Flange, .75 ID x 1.0 OD 2

13 737-0300 Grease, Benalene 1 oz

14 721-0328 Sealant, Ultra Grey Loctite 5699 1

x 2-5/16

4

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 710-0751 Screw, Hex Cap, 1/4-20 x .62 2

2 712-3027 Nut, Hex Flange Lock, 1/4-20 2

3 726-0209 Cable Tie, 30.66 Lg 1

4 726-0205 Clamp, Hose, 1/2 Inch 2

5 73 6 -0173 Washer, Flat, .28 x .74 x .063 2

6 751-0535 Hose, Fuel Line 9 Inch 9 In.

7 751-0603 Cap, Fuel 1

8 751-0610 Tank, Fuel 1

19

Page 20

CSV 260

20

Page 21

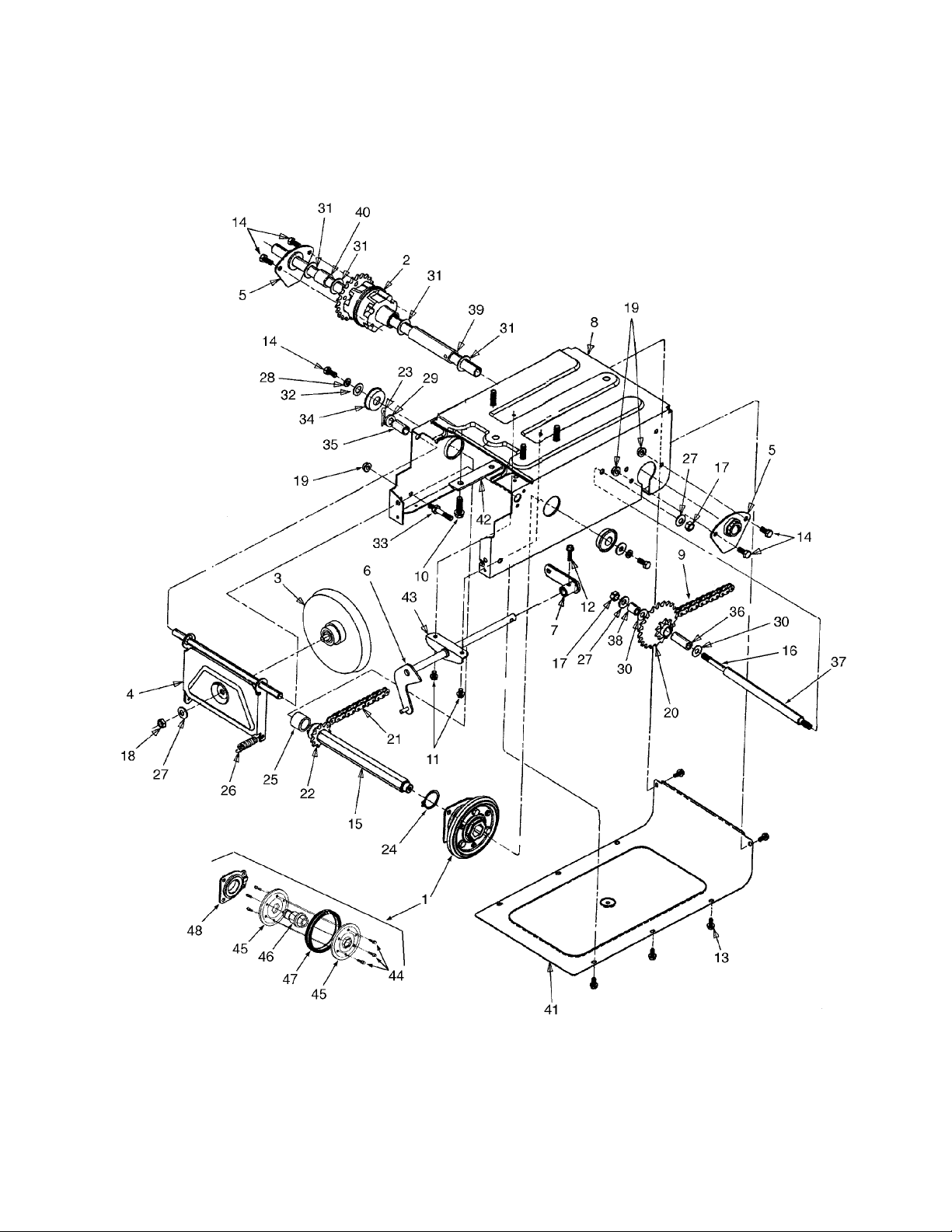

CSV 260

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 684-0042B Friction Wheel Ass’y Complete 1 25 750-0998 Spacer, .675 x 1.0 x 1.53 1

2 618- 0168 Differential Ass’y Complete 1 26 732-0209 Spring, Extension 2

3 656-0012A Friction Disc Assembly 1 27 736-0105 Washer, Bell, .406 x .870 x .063 3

4 681-0055 Bracket Ass’y, Frctn Wheel Supt 1 28 736-0119 Washer, Lock, 5/16 2

5 681-0058 Bracket Ass’y, Axle 2 29 736-0160 Washer, Flat, .536 x .930 x .05 1

6 681- 0082 Shaft Ass’y, Shift 1 30 736-0267 Washer, Flat, .385 x .87 x .06 2

7 681-0072 Arm Ass’y, Shift 1 31 736-0287 Washer, Flat, .793 x 1.24 x .06 4

8 681-0081-0498 Frame Assembly 1 32 736-3089 Washer, Flat, .345 x 1.0 x .100 2

9 713-0374 Chain, #420 x 36 Lnks 1 33 738-0908 Bolt, Idler 1

10 710-0502A Screw, Hex Wash Hd Tapp 3/8-16

11 710-0653 Screw, Hex Was h Hd Tapp 1/4-20

12 710-0788 Screw, Hex Was h Hd Tapp 1/4-20

13 710-0896 Screw, Hex Was h Hd Tapp 1/4-14

14 710-3008 Screw, Hex Cap, 5/16-18 x .75

15 711-1073 Hex Shaft 1 39 750-0980 Spacer, .782 x 1.0 x 4.11 1

16 711-1028 Jack Shaft 1 40 750-0981 Spacer, .782 x 1.0 x .99 1

17 712-0241 Nut, Hex, 3/8-24 2 41 781-0612A-0498 Cov er, Frame Bottom 1

18 712-0711 Nut, Hex Jam, 3/8-2 4 1 42 781-0 638 A Plate, Frame Reinforcement 2

19 712-3004A Nut, Hex Flange Lock, 5/16-18

20 713-0330 Sprocket Ass’y, 9T & 22T 1 44 710-0599 Screw, Hex Wash Hd Tapp 1/4- 20 6

21 713-0284 Chain, #41 x 36 Lnks 1 45 784-5617A Plate, Friction Wheel 2

22 713-0413 Sprocket, 10T 1 46 718-0301A Hub, Friction Wheel 1

23 714-0111 Pin, Cotter, 3/32 x 1.0 1 47 735-0243 Wheel, Rubber Friction 1

24 716-0102 Ring, Snap, 1.0 Dia 1 48 618-0063 Bearing Ass’y, Friction Wheel 1

x 1.25

x .375

x 1.0

x .625

GR5

GR5

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

4 34 741-0563 Bearing, Ball 2

2 35 748-0382 Spacer, .508 x .75 x .94 1

1 36 750-0351 Sleeve, .380 x .623 x 1.5 1

8 37 750-0978 Spacer, .407 x .625 x 7.86 1

6 38 750-0979 Spacer, .407 x .625 x .71 1

5 43 784-5590-0498 Bracket, Frame Shift 1

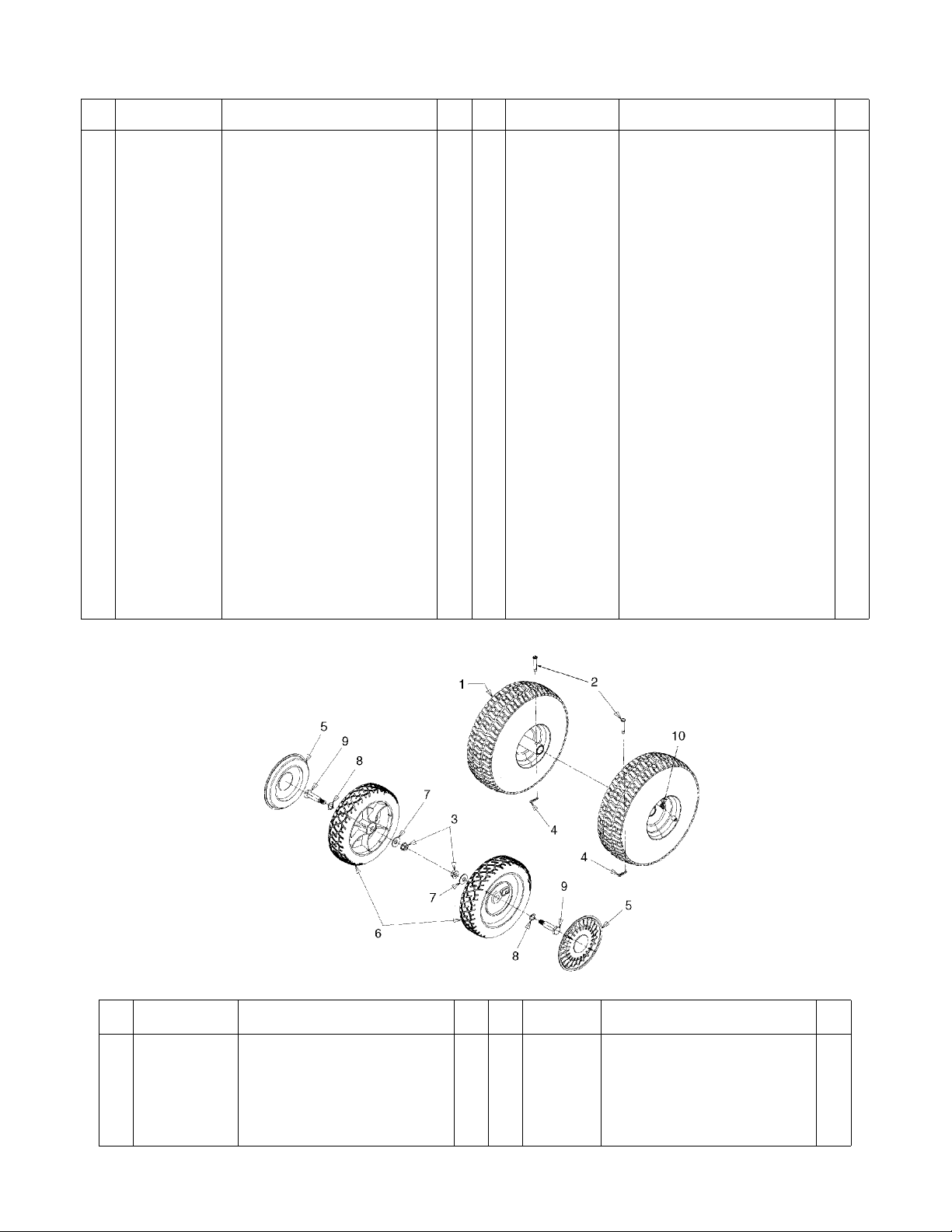

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

1 634-0100

634-0101-0499

734-1598

2 711-1017 Pin, Clevis, .25 x 1.53 2 7 736-0105 Washer, Bell, .401 x .870 x .06 2

3 712-0431 Nut, Hex Flange Lock, 3/8-16 2 8 736-0232 Washer, Wave, .53 x .78 x .013 2

4 714-0104 Pin, Internal Cotter 2 9 738-0213 Shoulder Bolt 2

5 731-0982A Hubcap, Beige 2 10 734-0255 Valve, Tubeless Air 2

Wheel Ass’y Complete

Rim Assembly

Tire, Pneumatic, 10 x 4

REF.

PART

NO.

NUMBER DESCRIPTION QTY.

2

6 734-1517B Wheel Ass’y Complete, 8 x 2.0 2

2

2

21

Page 22

Notes

Page 23

Notes

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR:

TWO-YEAR RESIDENTIAL

ONE-YEAR COMMERCIAL

Proper maintenance of your Cub Cad et equi pm ent is the own er’s responsibility. Follow the instructions in your

operator’s manual for correct lubricants and maintenance schedule. Your Cub Cadet dealer carries a

complete line of quality lubricants and filters for your equipment’s engine, transmission, chassis and

attachments.

Riding mowers, lawn tractors, garden tractors, Cub Cadet

attachments and home maintenance products

This limited warra nty for residential users, covers a ny defect in mater ials or workmansh ip in your Cub Cadet

equipment for two years from the dat e of purchase for the firs t user purchase r. We will replace or repa ir any

part or parts without charge through your authorized Cub Cadet dealer.

Batteries have a one-year prorated limited warranty with 100% replacement during the first three months.

V-belts for either the traction drive or any attachments are covered for one year only.

Cub Cadet equipment used commercially is warranted for one year only.

(Commercial use is defined as either having hired operators or used for income producing purposes.)

Items not covered

The warranty doe s not c over rout ine ma intena nce i tems suc h as lubri cants, f ilt ers (o il, fue l, air a nd h ydraul ic),

cleaning, tune-ups, br ake and/or clutch inspection, a djustments made as part of normal maintenance, blade

sharpening, set-up, a bus e, a ccid ent s and normal wear. It doe s n ot c ov er incidental costs s uch as tr ansporting

your equipment to and from the dealer, telephone charges or renting a product temporarily to replace a

warranted product.

There is no other express warranty.

How to obtain service

Contact your autho riz ed Cub Ca det s ervi cing de ale r who s old you your Cub Ca det eq uip men t. I f this dealer is

not available, see the Consumer Yellow Pages under “lawn mowers” for the name of a dealer near you.

If you need further assistance in finding an authorized Cub Cadet servicing dealer, contact:

Cub Cadet Corporation

Post Office Box 368023

Cleveland, Ohio 44136

How does state law apply?

This limited warranty gi ves y ou spec ific lega l rig hts, and you m ay als o have ot her right s which va ry from s tate

to state.

Loading...

Loading...